Rapid harmless biological degradation method against waxy oil sludge

A waxy oil sludge and biodegradation technology, applied in sludge treatment, biological sludge treatment, mining wastewater treatment, etc., can solve the problems of non-recyclable resources and slow degradation, and achieve short treatment time, accelerated degradation, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a kind of rapid and harmless biodegradation method for waxy oil sludge, and this method comprises the following steps:

[0051] Step 1, prepare seed solution:

[0052] Pseudomonas aeruginosa NY3 of the present application is an existing strain, see literature: Maiqian Nie, Xihou Yin, Chunyan Ren, Yang Wang, Feng Xu, Qirong Shen.Novel rhamnolipid biosurfactants produced by a polycyclic aromatic hydrocarbon-degrading bacterium Pseudomonas aeruginosa strain NY3. Biotechnology Advances., 2010, 28:635–643.

[0053] Pseudomonas stutzeri N2 in this application is an existing strain, see literature: Fan Yu, Nie Maiqian, Ge Bizhou, Wan Yi, Zi Jing, Zhao Jing, Shen Xiaojuan, Chen Xingdu. High-concentration phenol-resistant strains Screening and research on its degradation characteristics. Journal of Environment and Safety. 2012,12(4):113-117.

[0054] Activation of strains: Transfer NY3 bacterial seed solution and N2 bacterial seed solution to beef extr...

Embodiment 2

[0088] Embodiment 2: Replacement of sawdust particle size

[0089] The difference between this comparative example and Example 1 is that the particle size of the sawdust was changed from the original 0.3mm to 0.56mm and 1mm respectively, and the other processes were the same as in Example 1. On a shaker, the aerobic cultivation was carried out at a constant temperature at 30°C. 6d, complete the degradation of waxy oil sludge.

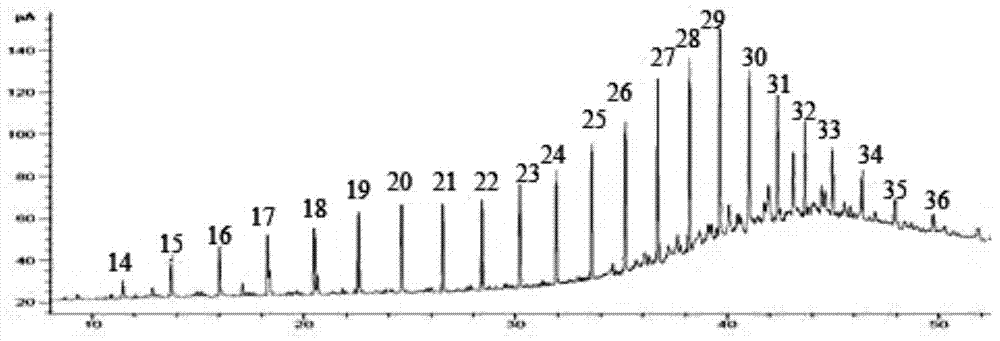

[0090] The degradation result is: the degradation result of linear n-alkane is shown in image 3 , the degradation rate of each straight-chain n-alkane in petroleum hydrocarbons is significantly lower than that of wood chips in Example 1 when the particle size is 0.3 mm, and the degradation rates of phenanthrene and pyrene are also reduced.

Embodiment 3

[0092] This embodiment is the same as the other process of embodiment 1, the only difference is that in the biodegradation process of step 4, step 1 is added to the degradation system obtained in step 3 to obtain 7ml of Pseudomonas aeruginosa NY3 seed solution, and 3ml of the seed solution of Monascus N2 was cultured on a shaker at a constant temperature and aerobic at 30°C for 6 days to complete the degradation of waxy oily sludge.

[0093] Results Test Characterization:

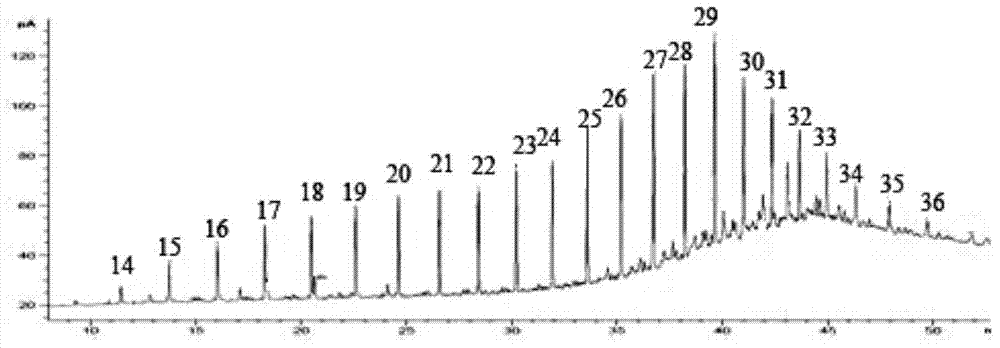

[0094] The removal rates of C14-C18 in waxy oily sludge all reached over 80%, the removal rates of C19-C30 were between 70%-83%, the removal rates of C31-C38 were between 53%-66%, and the removal rates of phenanthrene and pyrene The rates can reach 30.9% and 28.1% respectively.

[0095] In the waxy oil sludge, the output of the conversion product is that every gram of the waxy oil sludge produces 0.23g of the conversion product, and it is characterized. The characterization result is the same as that in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com