Patents

Literature

151results about How to "Guaranteed transmission effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

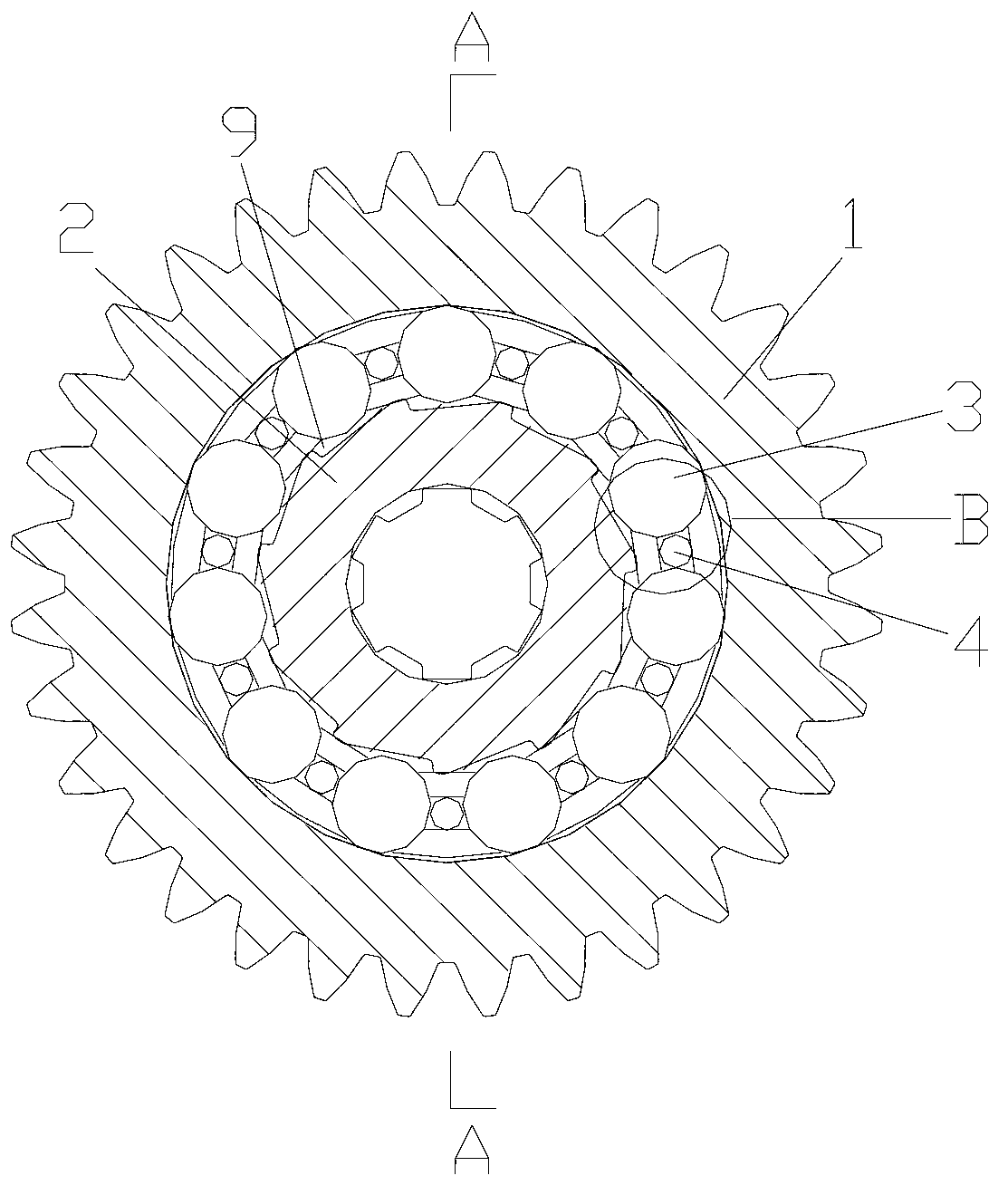

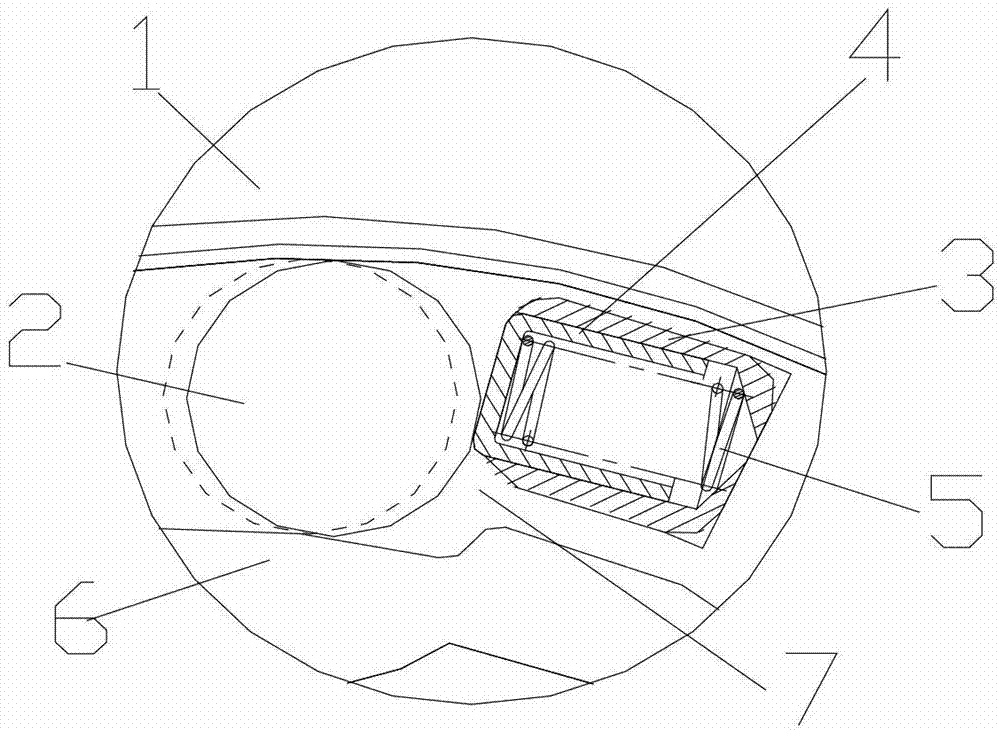

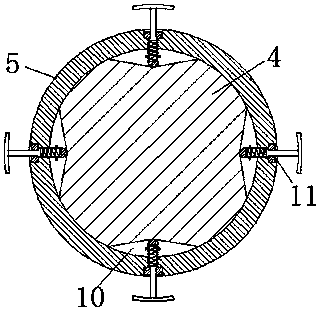

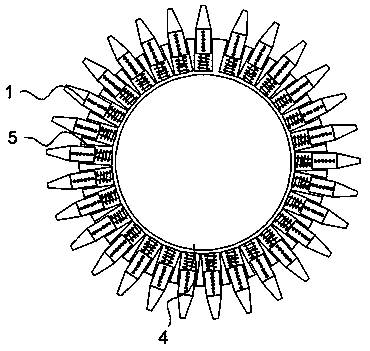

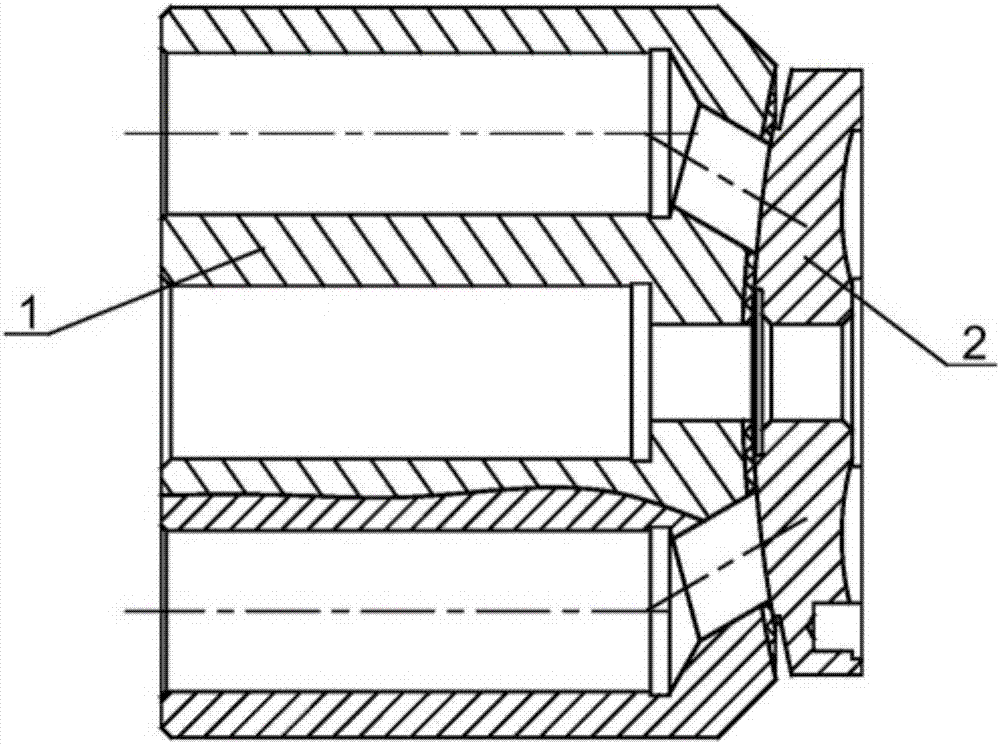

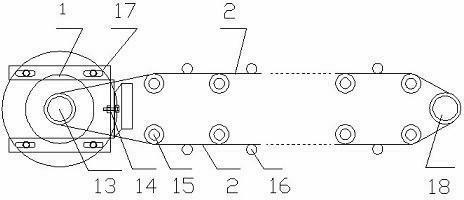

Floating auxiliary roller type overrun clutch

InactiveCN103307140AIncrease axial lengthIncrease the lengthFreewheel clutchesEngineeringMachining process

The invention discloses a floating auxiliary roller type overrun clutch which comprises an outer ring, an inner ring, rolling bodies and auxiliary rollers, wherein engagement spaces used for being engaged with or separated from the rolling bodies are formed between the outer ring and the inner ring; the auxiliary rollers are parallel to an axial line of the overrun clutch and are spaced from the rolling bodies; and the auxiliary rollers are arranged between the rolling bodies in such a way that the auxiliary rollers can move in a circumferential direction of the overrun clutch. According to the floating auxiliary roller type overrun clutch, the processing of a limiting seat is avoided, the processing process is simplified, the working efficiency is improved, and the processing cost is reduced; as the auxiliary roller structure is adopted, the axial length of the overrun clutch and the rolling bodies can be theoretically infinitely prolonged, the engagement length is prolonged, the bearing capacity of the overrun clutch is increased, the radial size of the overrun clutch under higher bearing capacity is reduced, and the service life of the overrun clutch is prolonged; and meanwhile, the probability of imbalance caused by application of a pretension force to point contact of each roller in the prior art is removed, thereby enabling each roller to keep parallel to the axial line of the inner ring.

Owner:SOUTHWEST UNIVERSITY

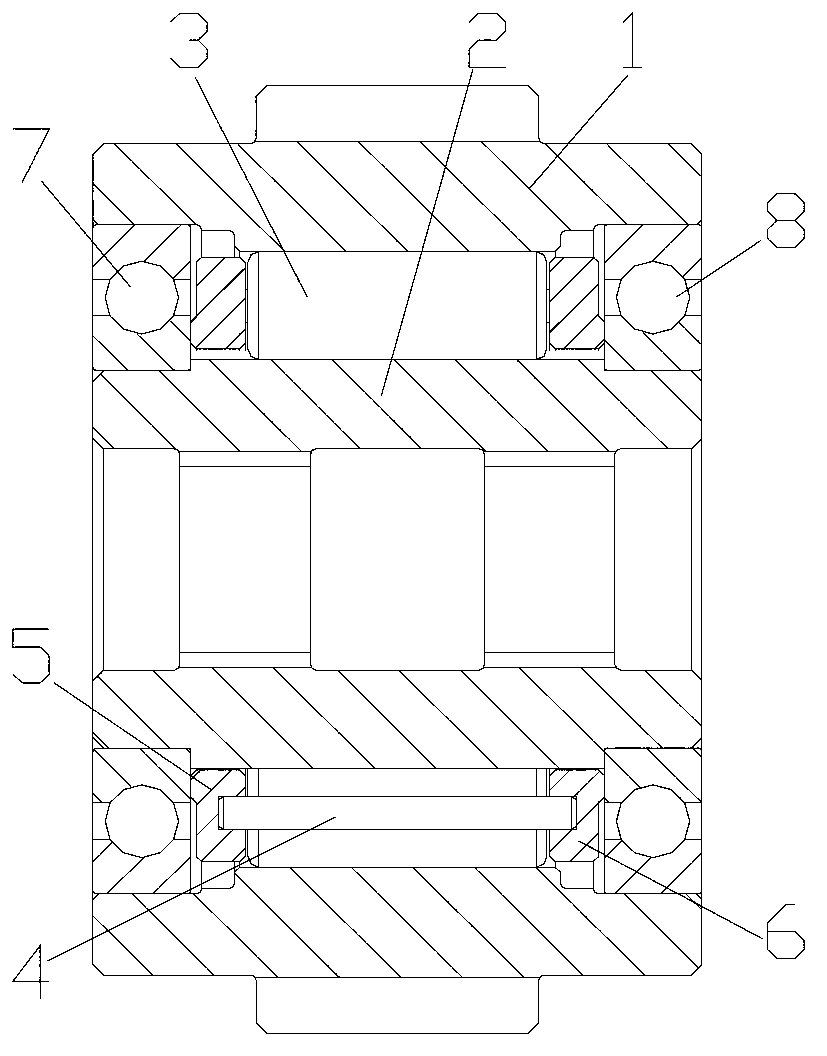

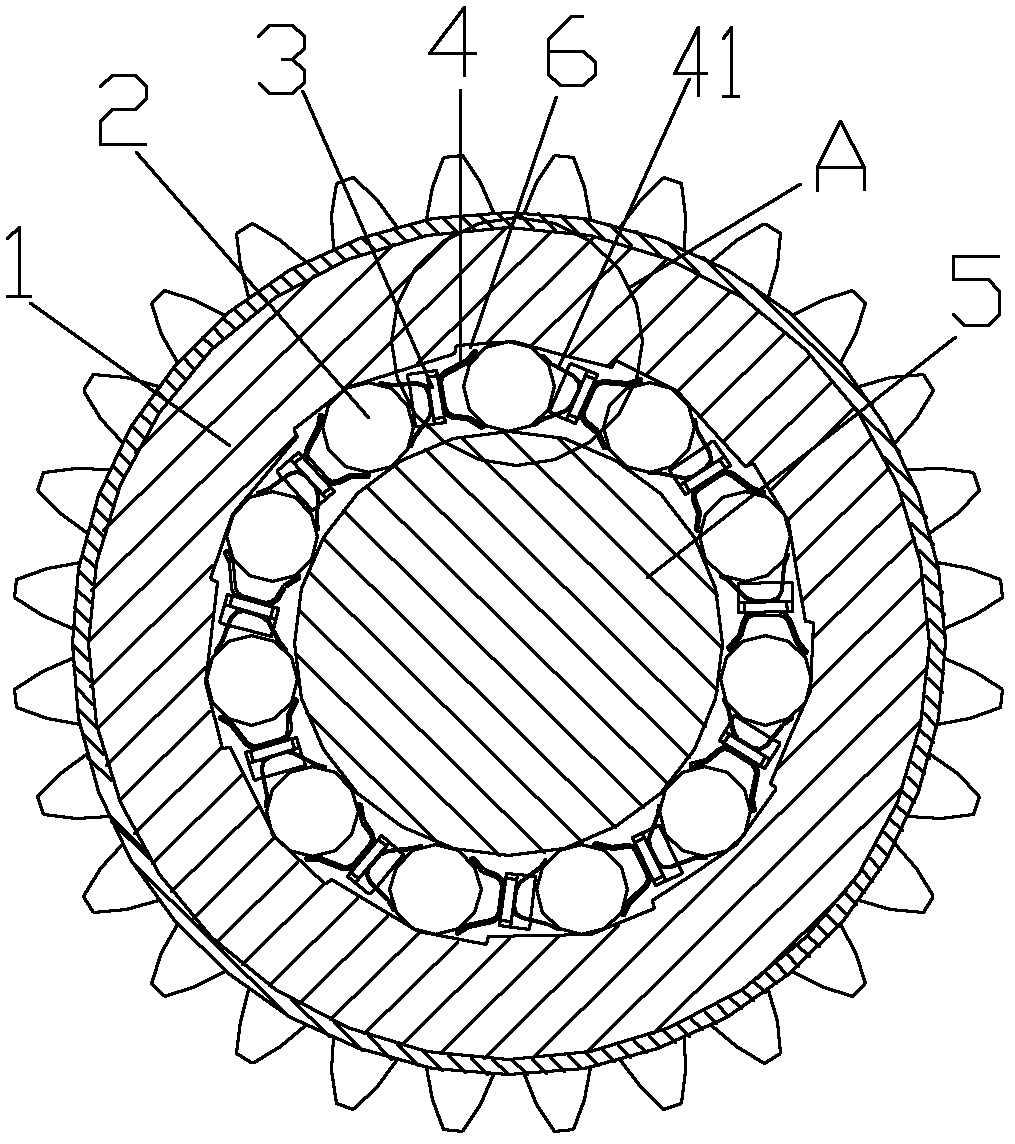

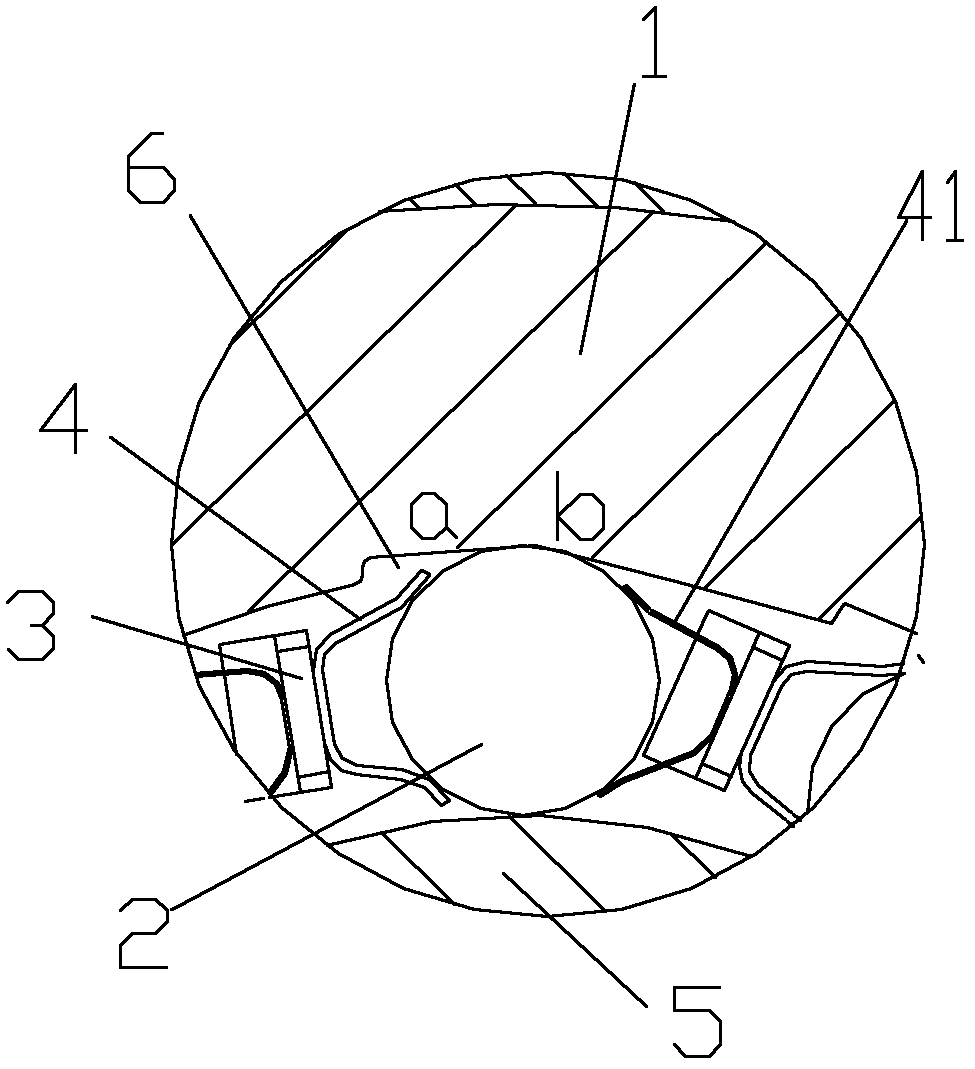

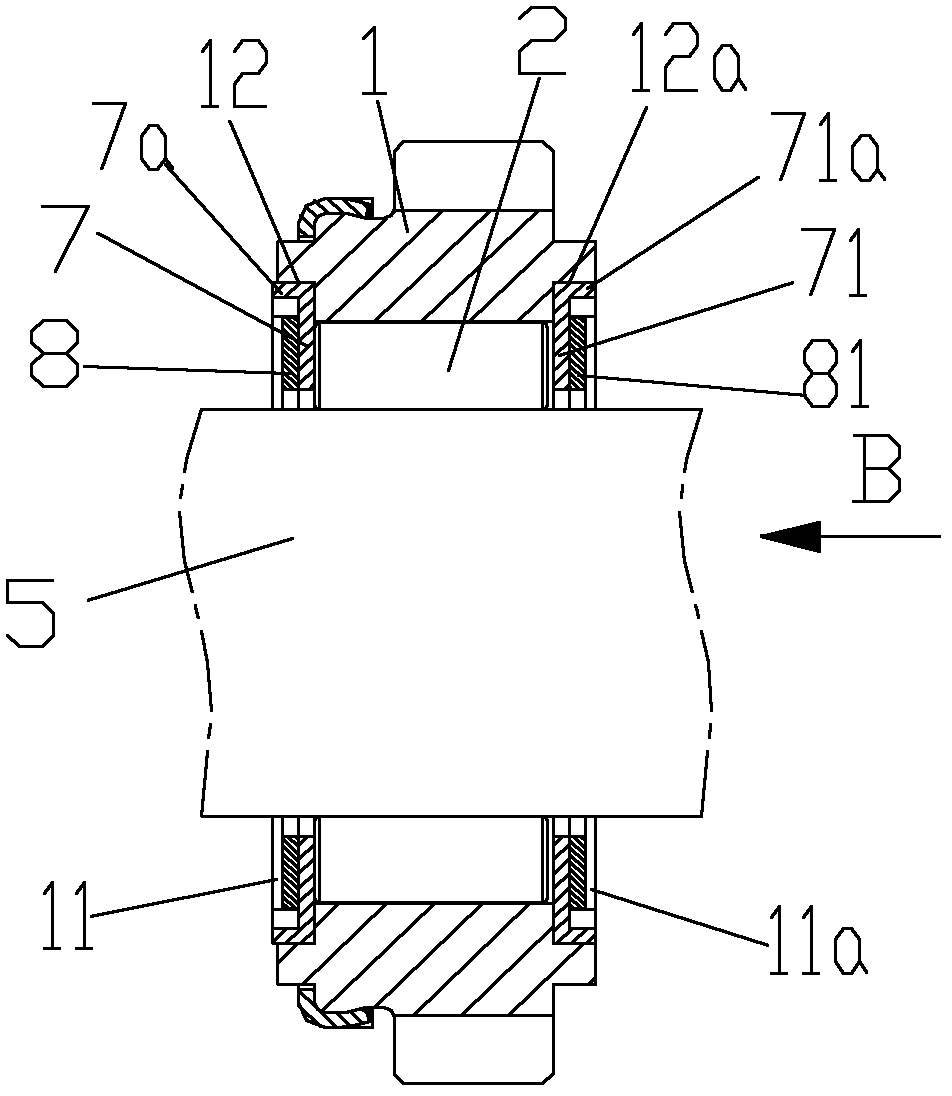

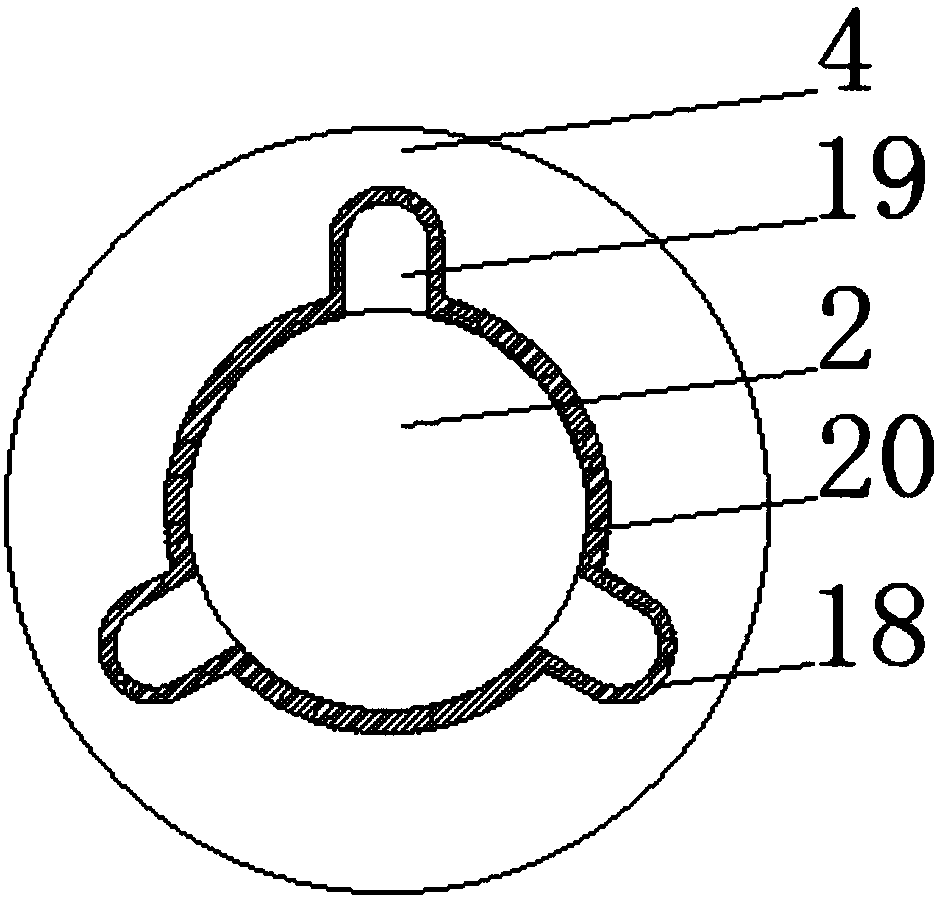

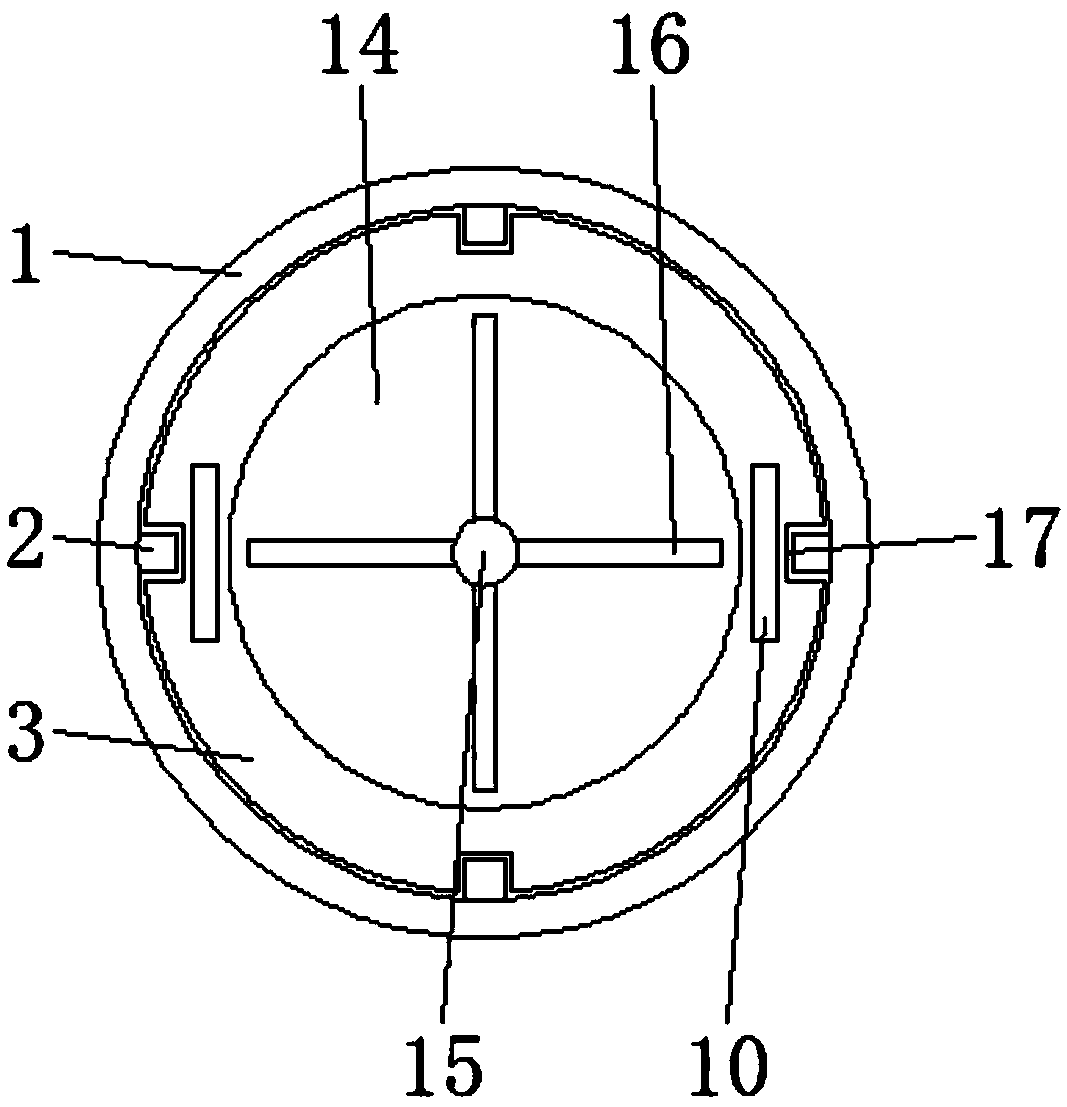

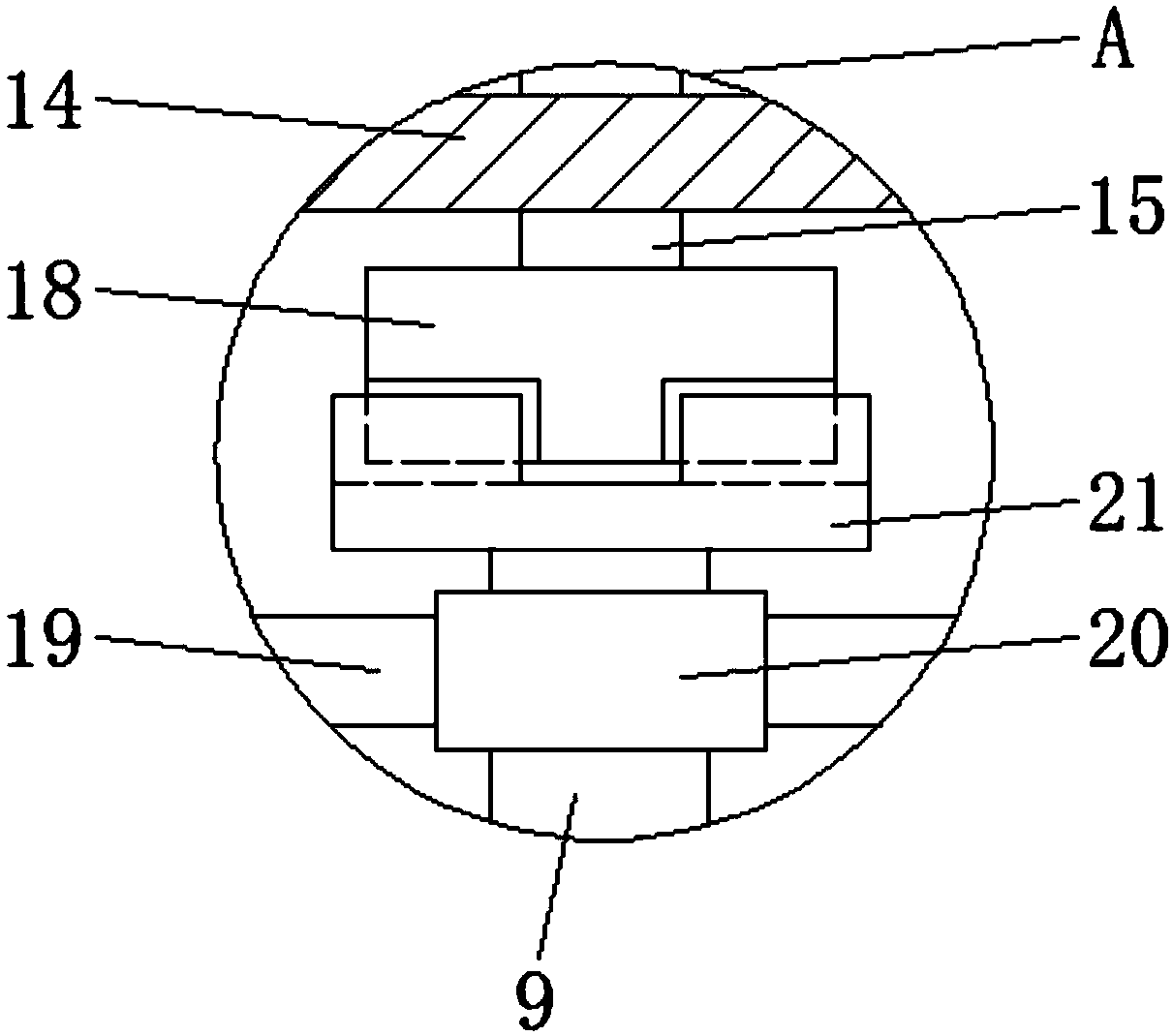

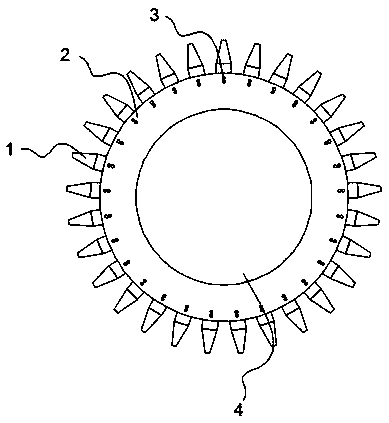

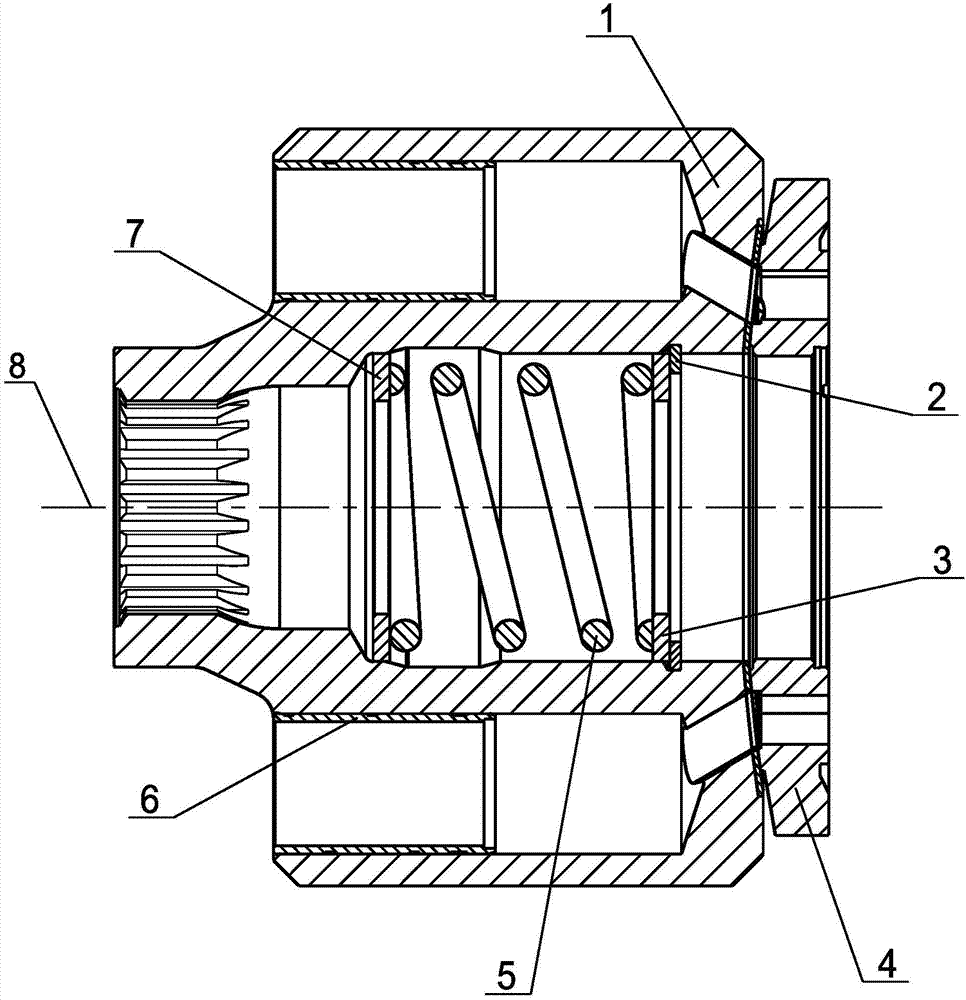

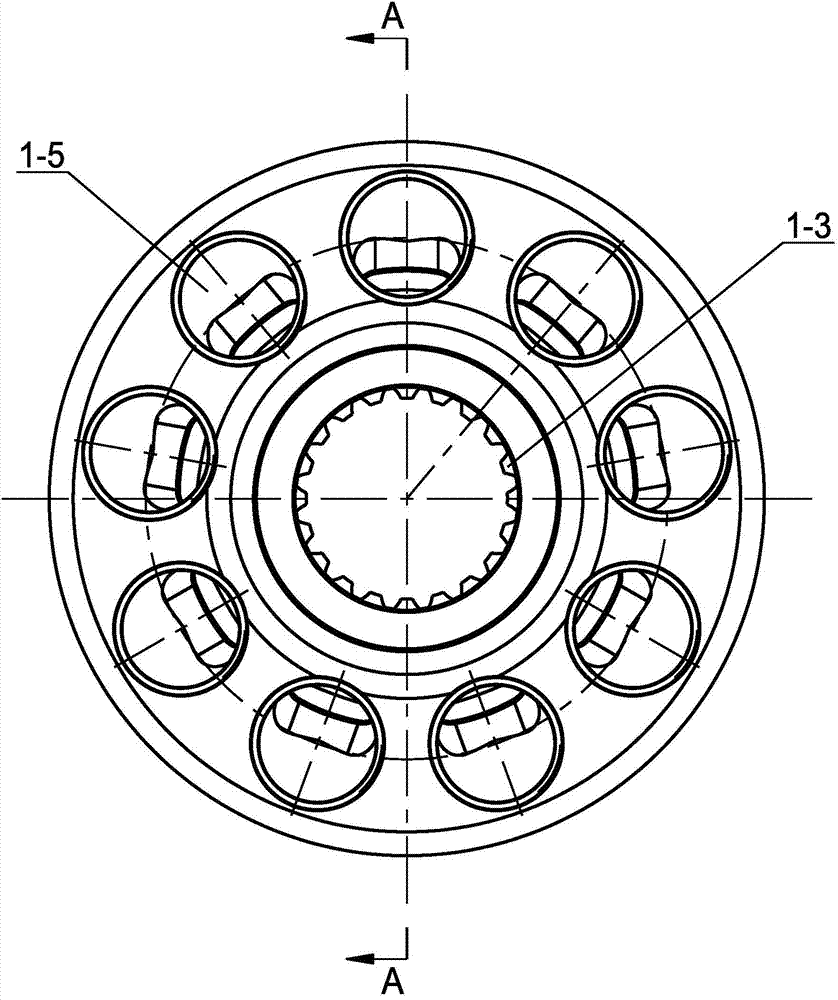

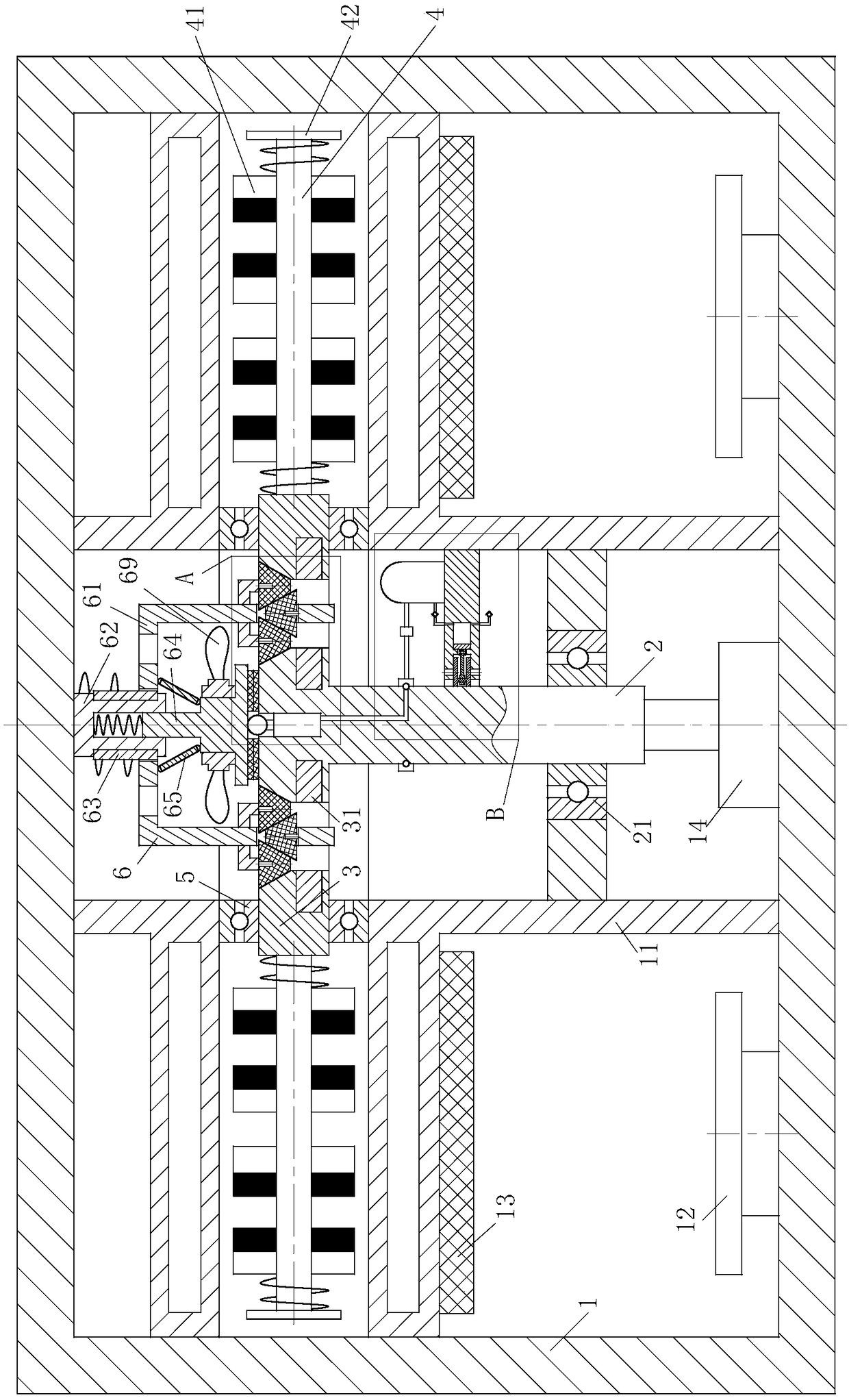

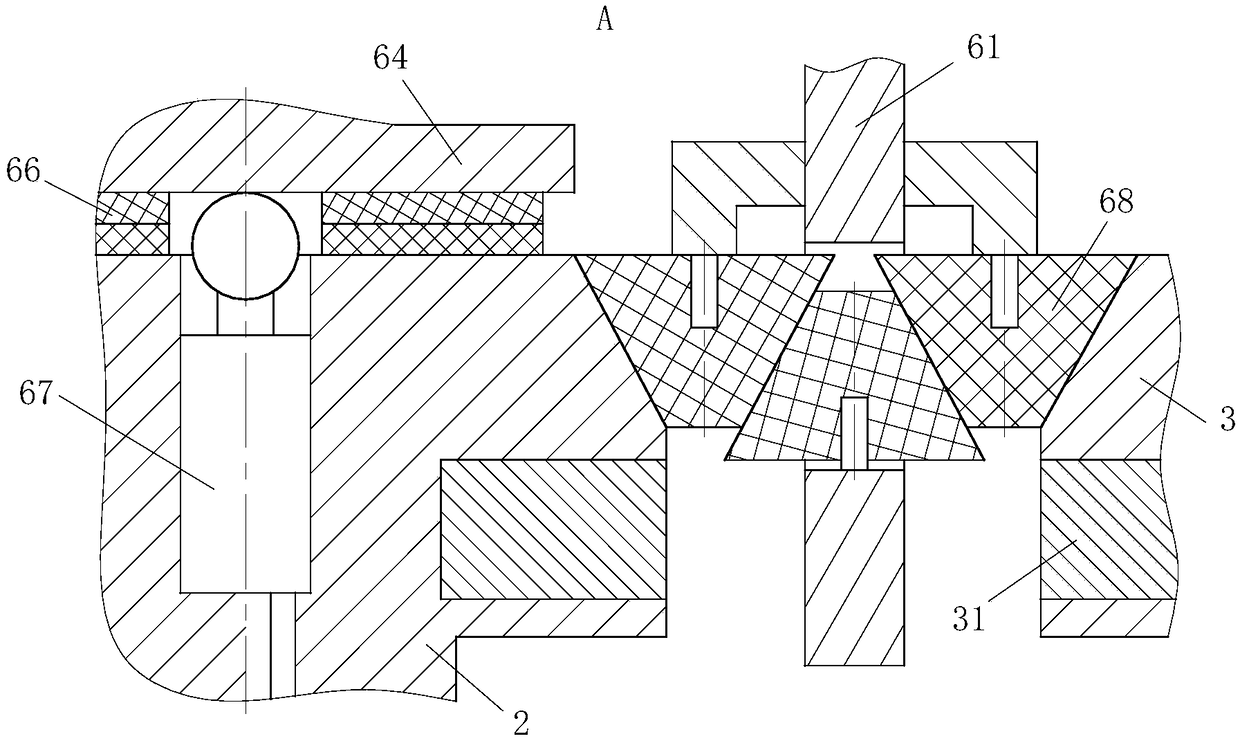

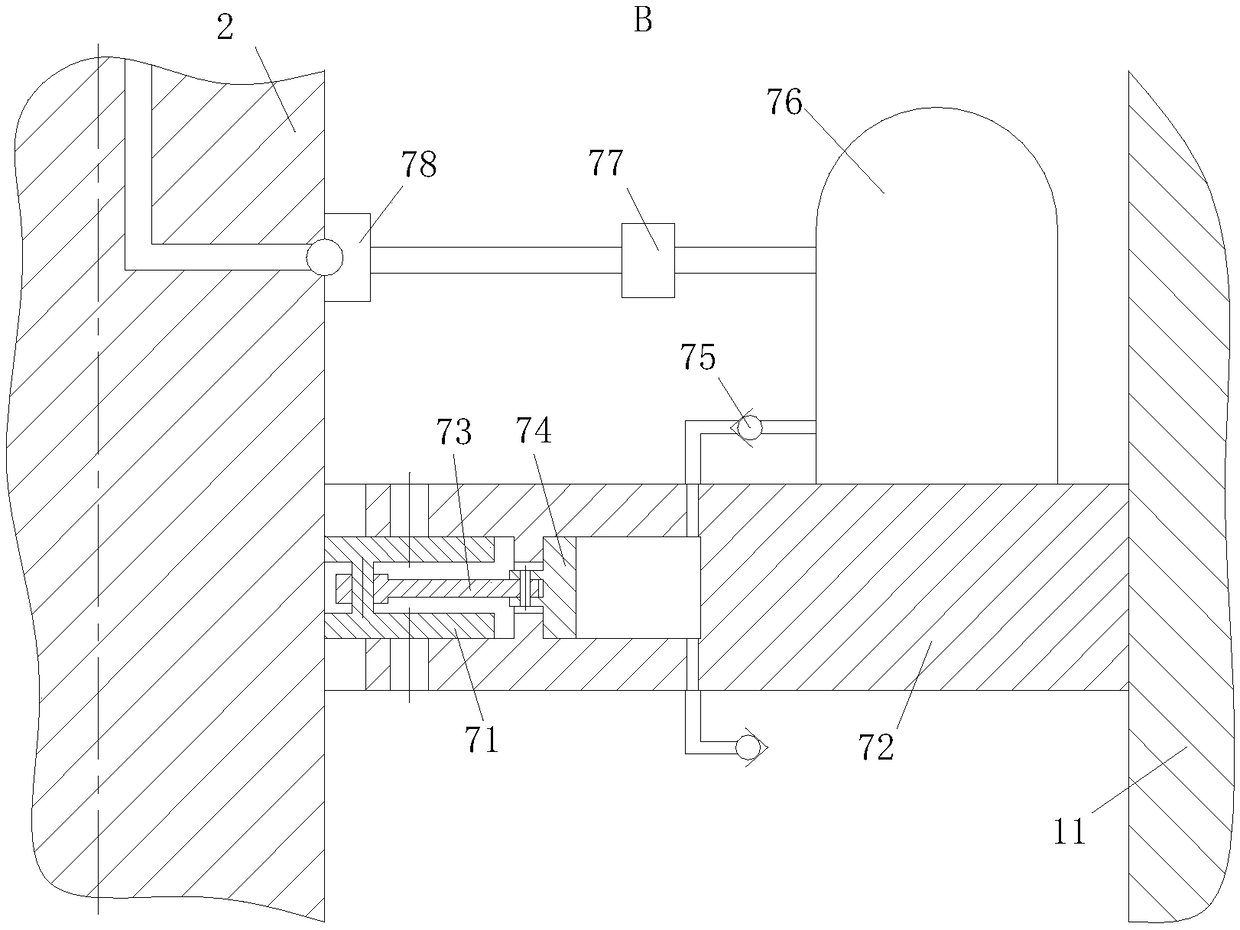

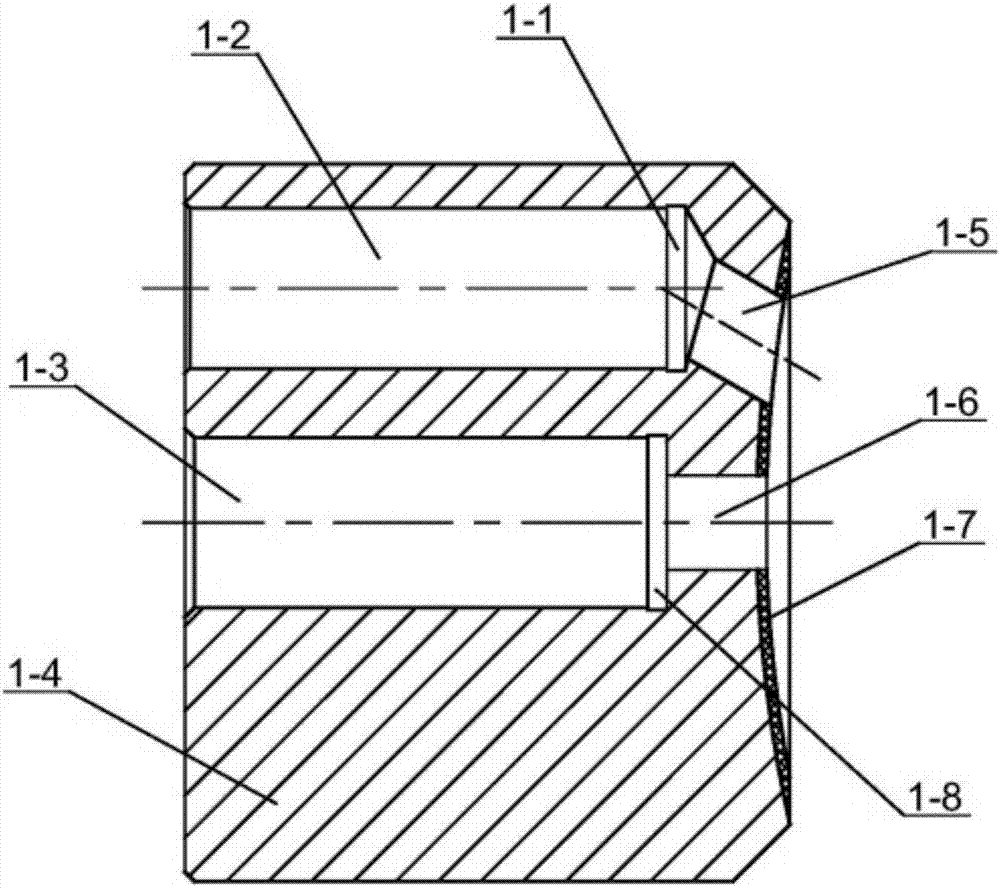

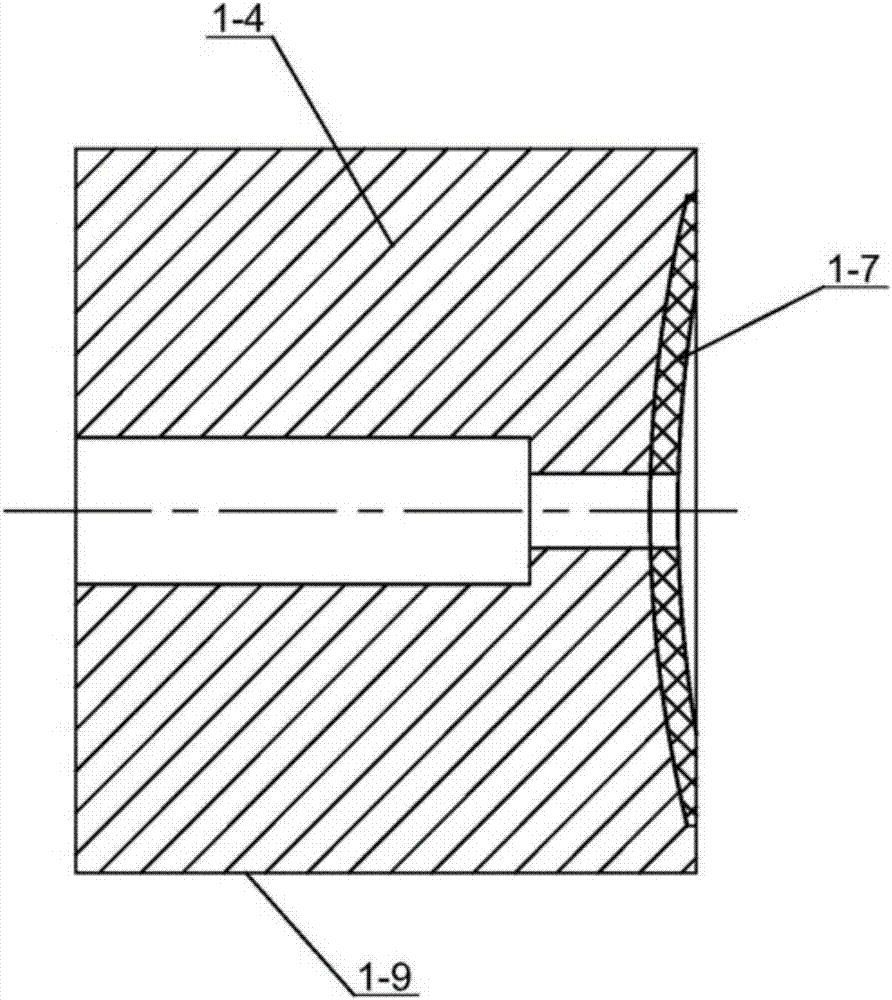

Internal star wheel overrun clutch

The invention discloses an internal star wheel overrun clutch. The internal star wheel overrun clutch comprises an outer ring, an inner ring and rolling columns, wherein wedge grooves are arranged on an outer circle of the inner ring, and meshing spaces used for meshing or separating the rolling columns are jointly formed by the wedge grooves and the inner circle of the outer ring. The internal star wheel overrun clutch further comprises supporting shafts, and the supporting shafts are arranged correspondingly to the rolling columns one by one in the circumferential direction, are detachably fixed relative to the inner ring and at least in the circumferential direction and provided with elastic pieces used for applying pretightening force towards to the meshing direction to the rolling columns. Since the supporting shafts which are detachably fixed relative to the inner ring and at least in the circumferential direction are utilized to apply the pretightening force to the rolling columns, and the wedge grooves used for forming the meshing spaces are arranged on an internal star wheel, the internal star wheel overrun clutch is directly shaped from forging, processing process is simplified, working efficiency is improved, and processing cost is lowered; adjustment to the rolling columns in the circumferential direction during processing is possible, processing and assembling accuracy is guaranteed, service life is prolonged, and transmission effect is guaranteed; and radial size of the internal star wheel overrun clutch in above structure is not limited, and bearing capability is improved.

Owner:SOUTHWEST UNIV +1

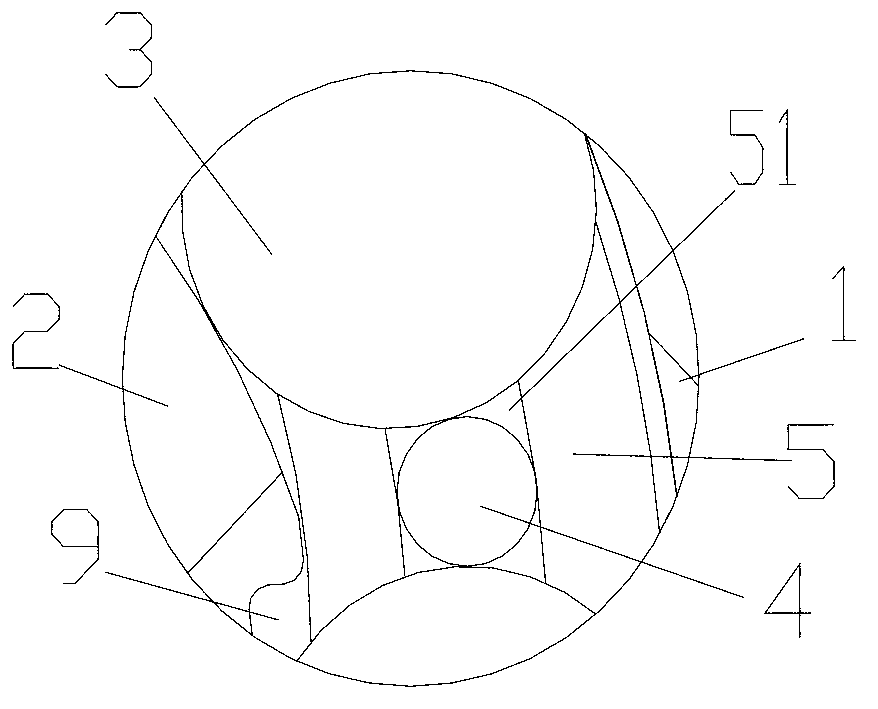

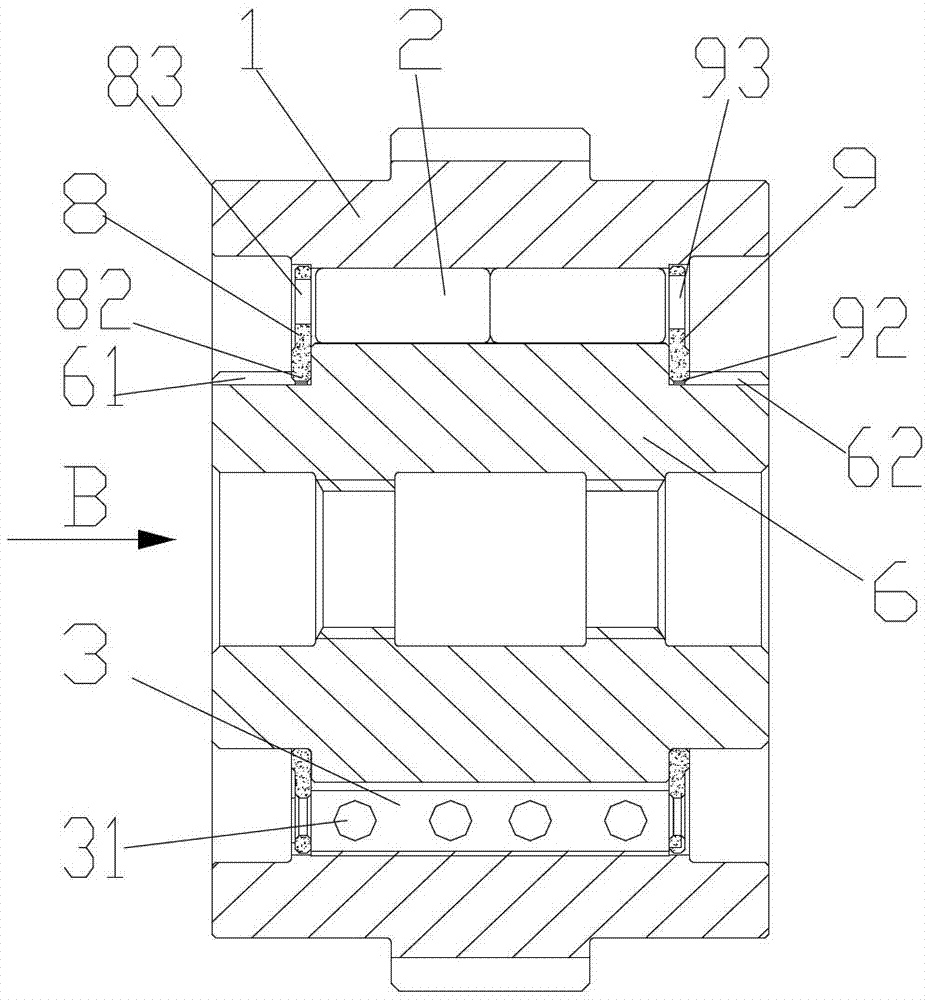

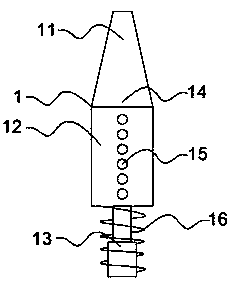

Bearing Overrunning Clutch

ActiveCN102278394ASmall sizeAvoid mechanical failureBearingsFreewheel clutchesEngineeringMachining process

The invention discloses a bearing type overrunning clutch, which is provided with retaining brackets which are arranged corresponding to rollers one to one. A wedge slot for engagement consists of arc segments concentric to an inner ring in transition, and a V-shaped opening of an elastic supporting claw of each retaining bracket is opposite to an engaged part of a wedged engagement space to support each roller along a circumferential direction. By the overrunning clutch, a bearing can be replaced, the cost is saved, the volume of a transmission system is reduced, a limiting seat is prevented from being directly machined on the inner ring or an outer ring, the machining process is simplified, the working efficiency is improved, and the machining cost is reduced; the positions of the rollers can be flexibly adjusted in the circumferential direction according to the need, and the machining and assembling precision is guaranteed; more rollers can be distributed in the circumferential direction, the bearing capacity is improved, and the dimension of the overrunning clutch can be reduced under the condition of higher bearing capacity; meanwhile, due to the elastic supporting claw, line contact limiting is formed, and a condition that the rollers deviate an axis due to imbalanced limiting is avoided; therefore, a mechanical failure caused by instable operation of the overrunning clutch is avoided.

Owner:SOUTHWEST UNIVERSITY

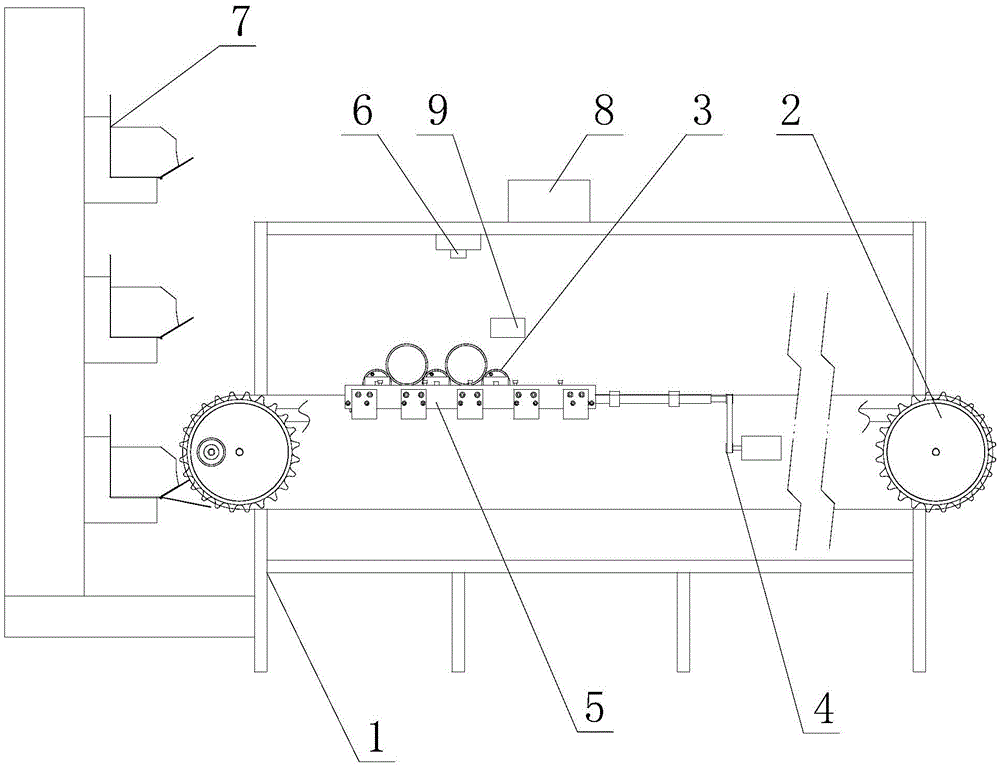

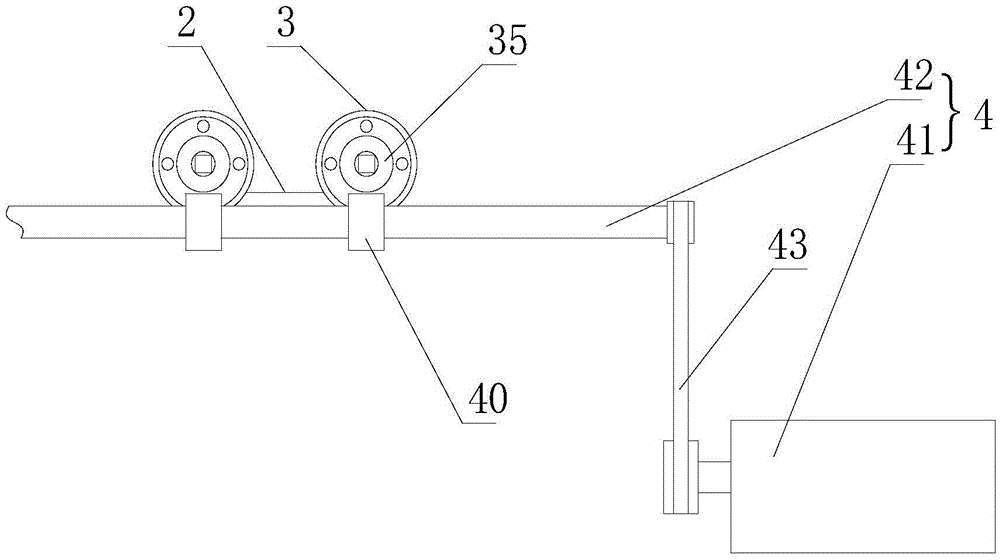

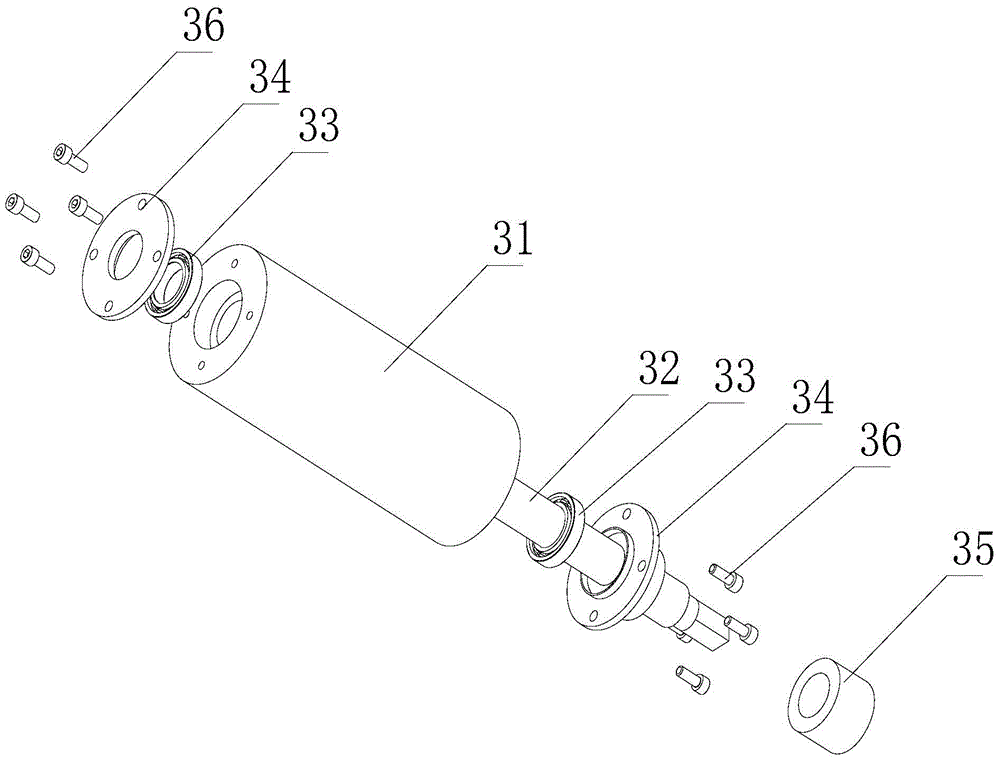

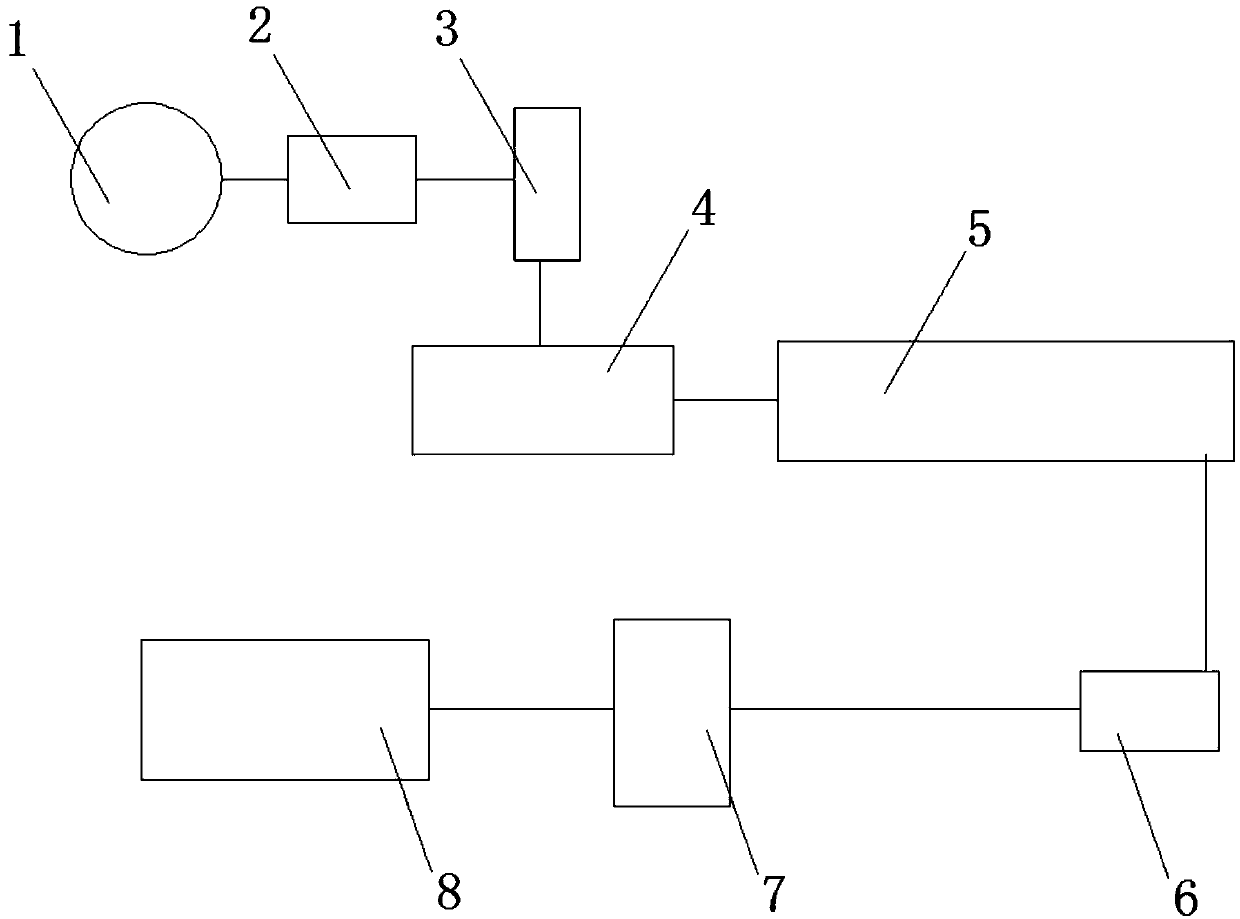

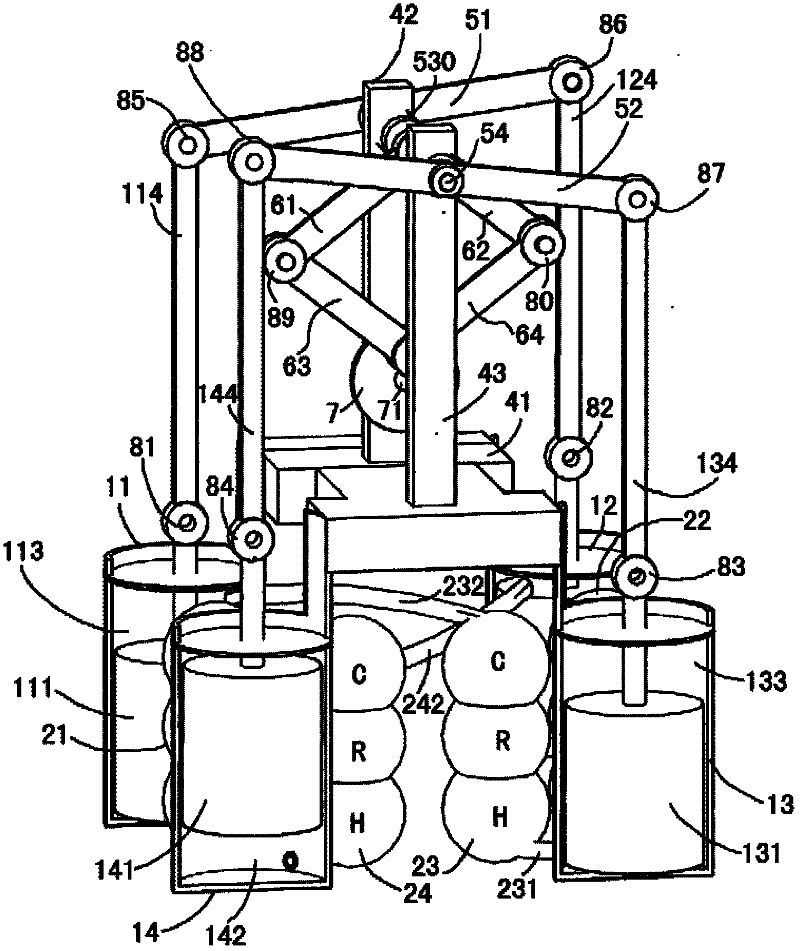

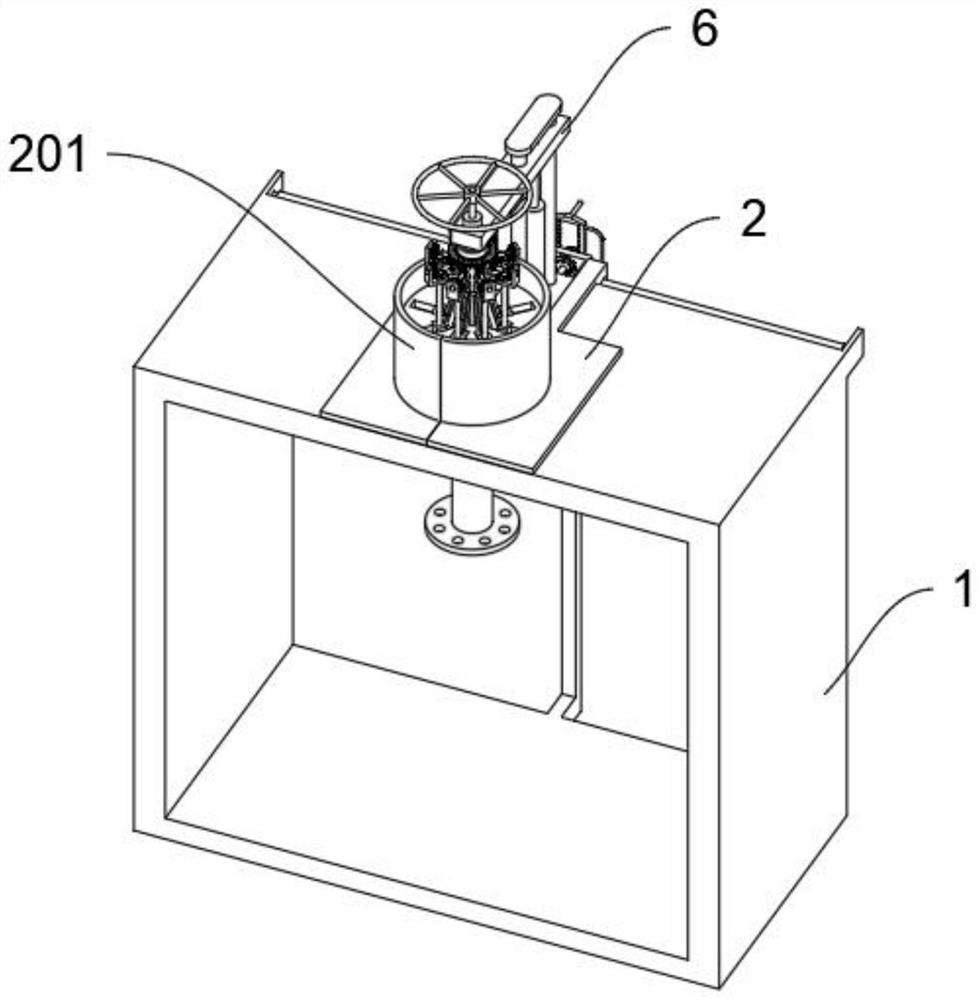

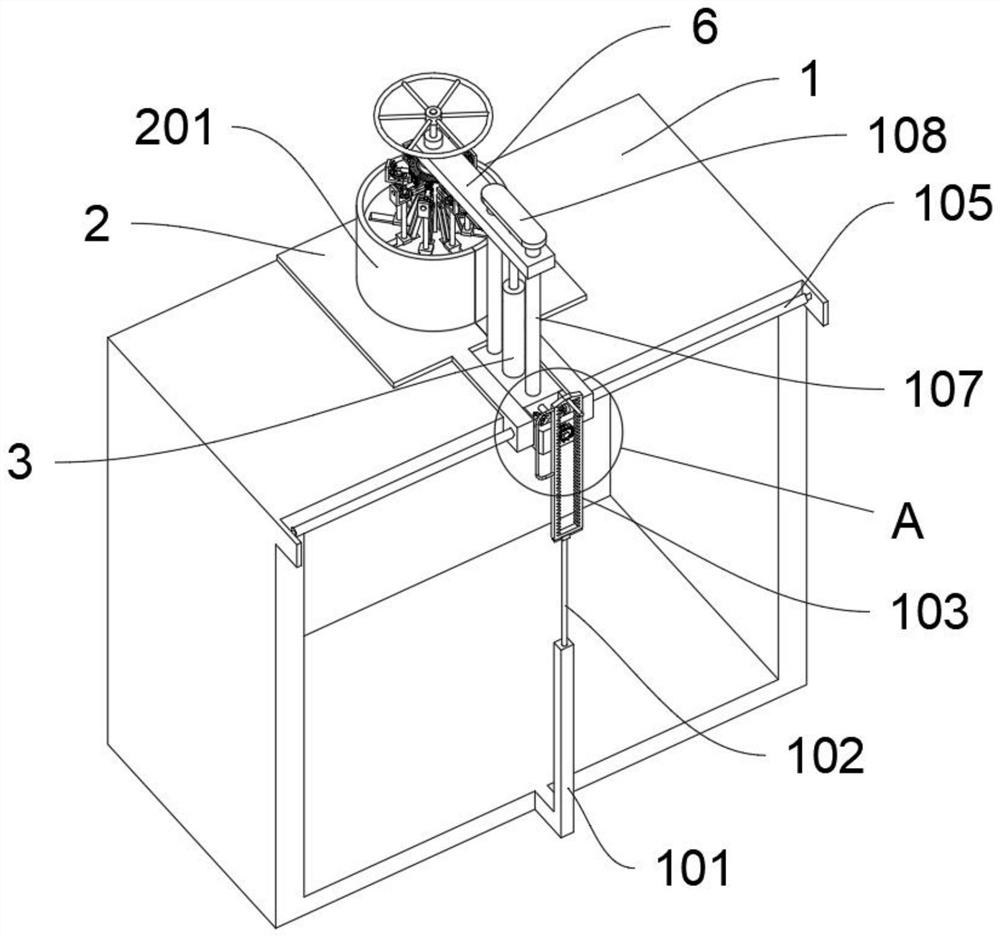

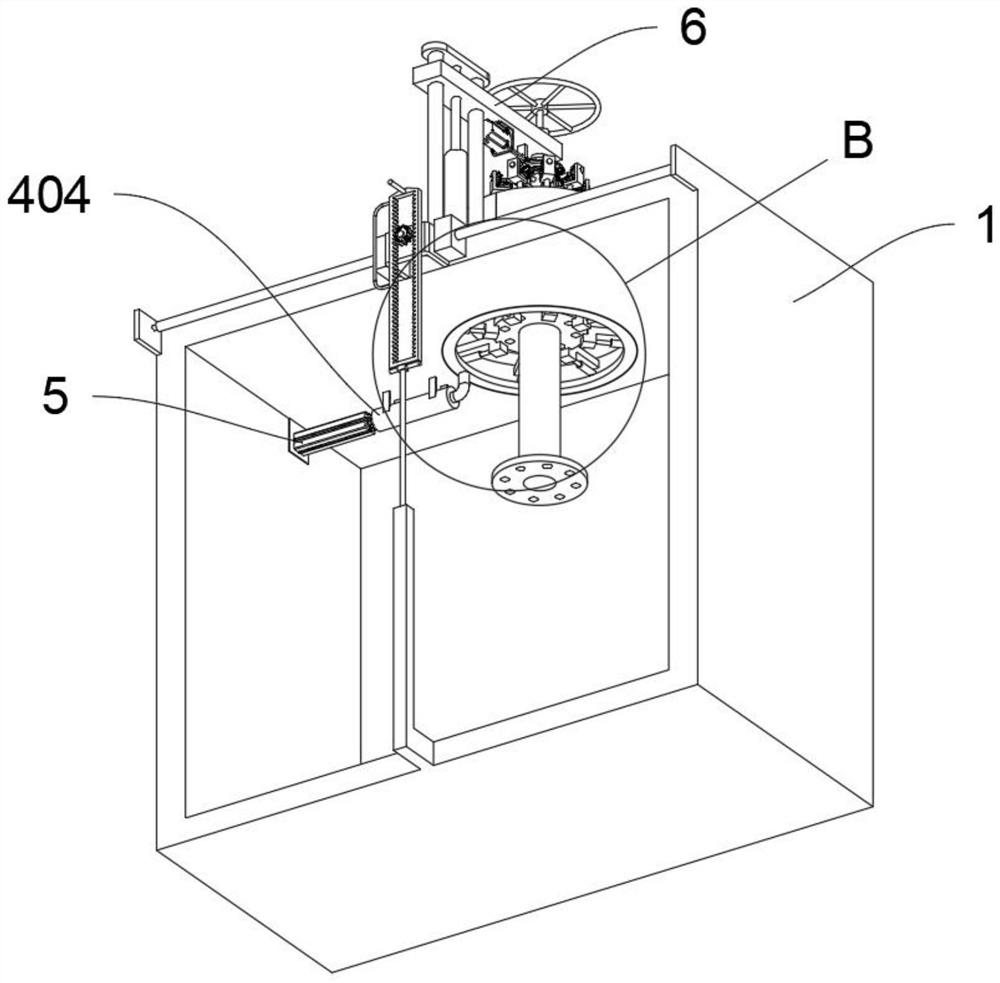

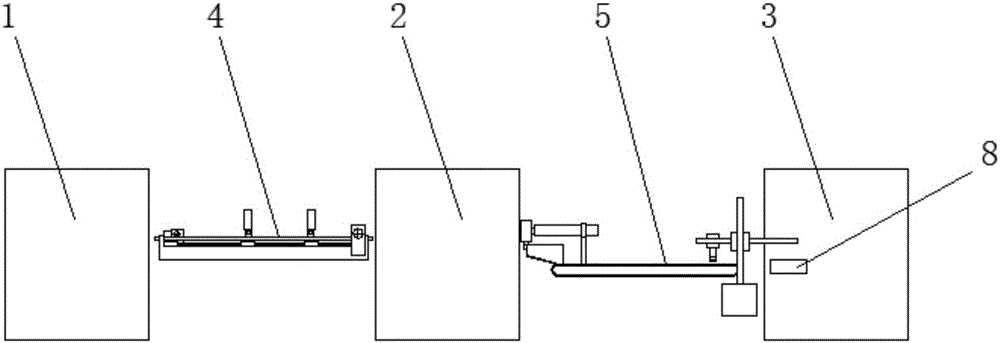

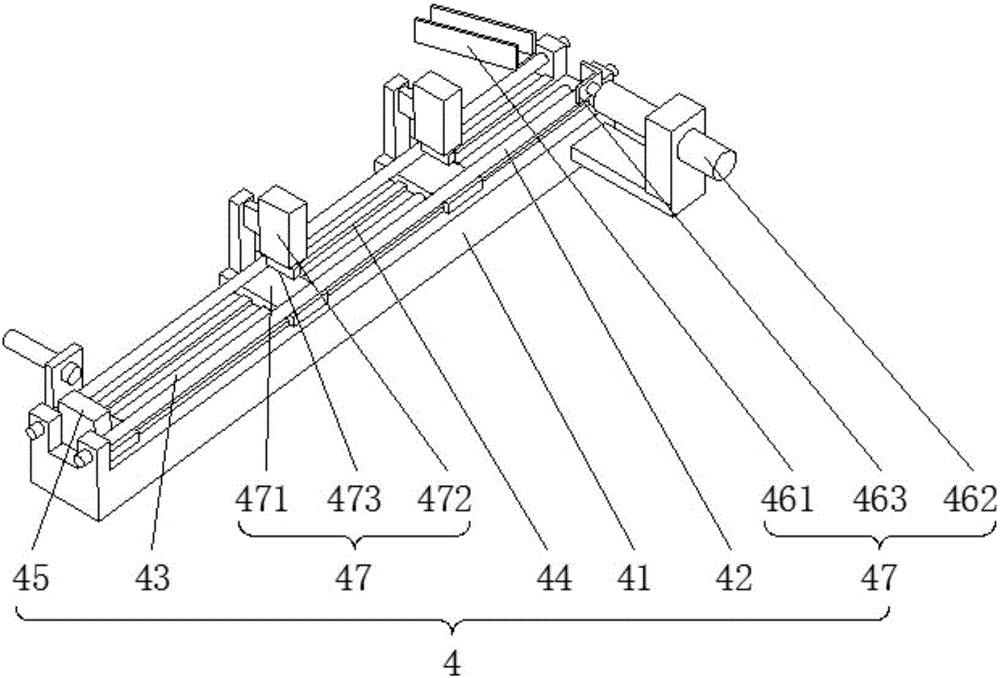

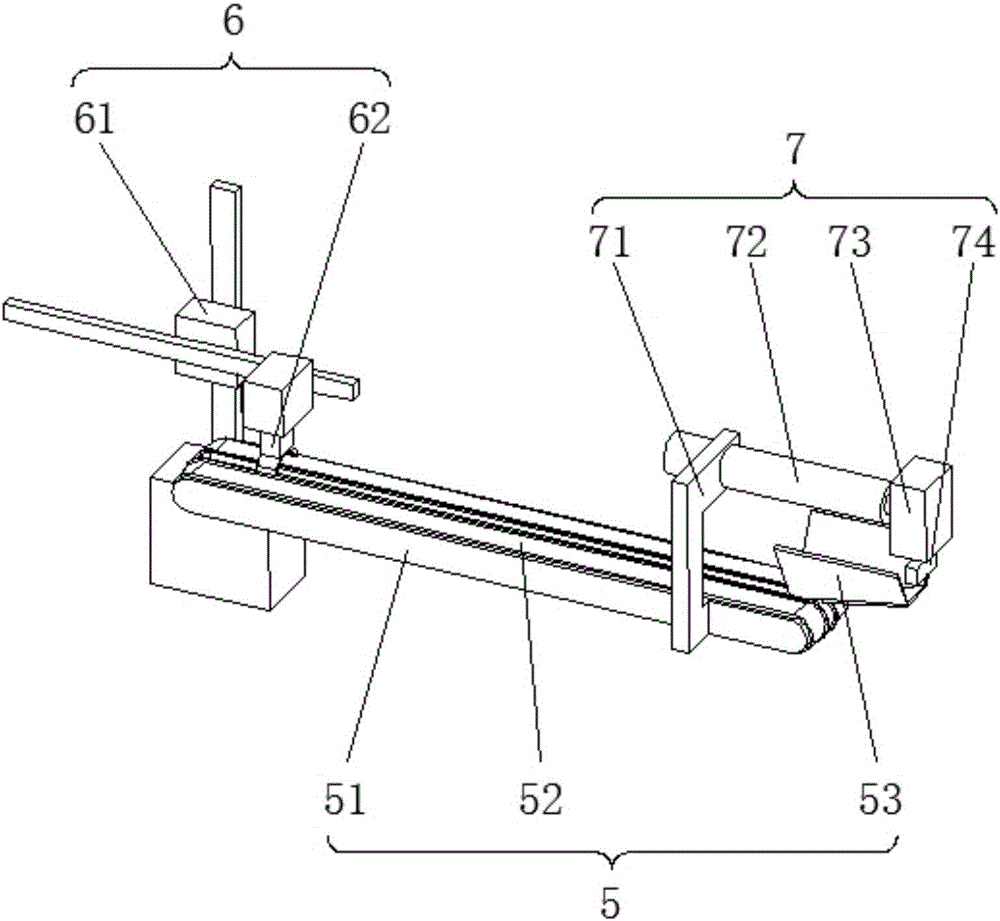

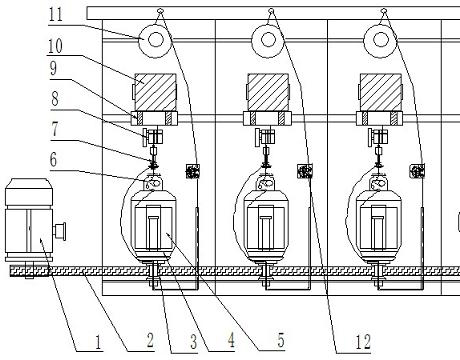

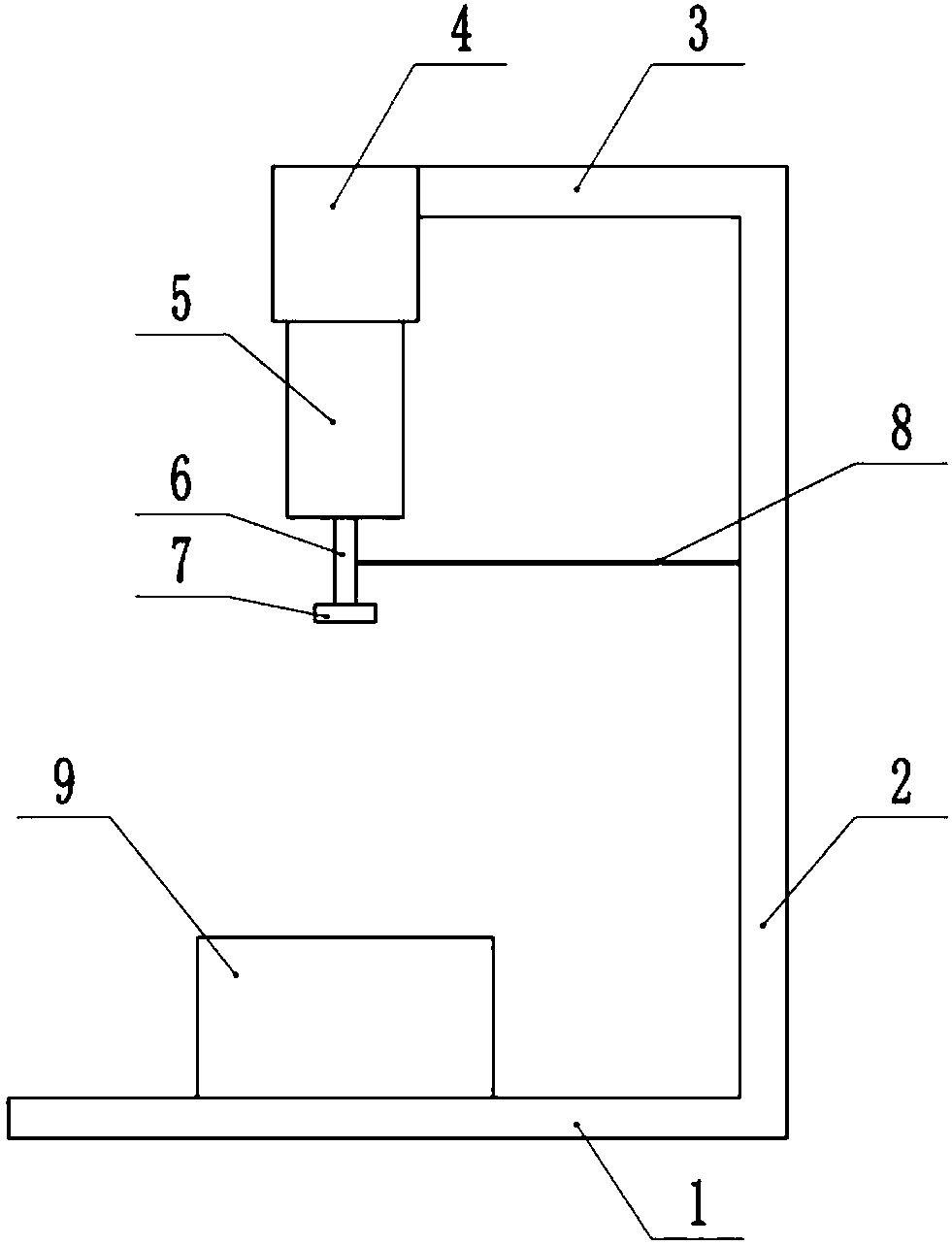

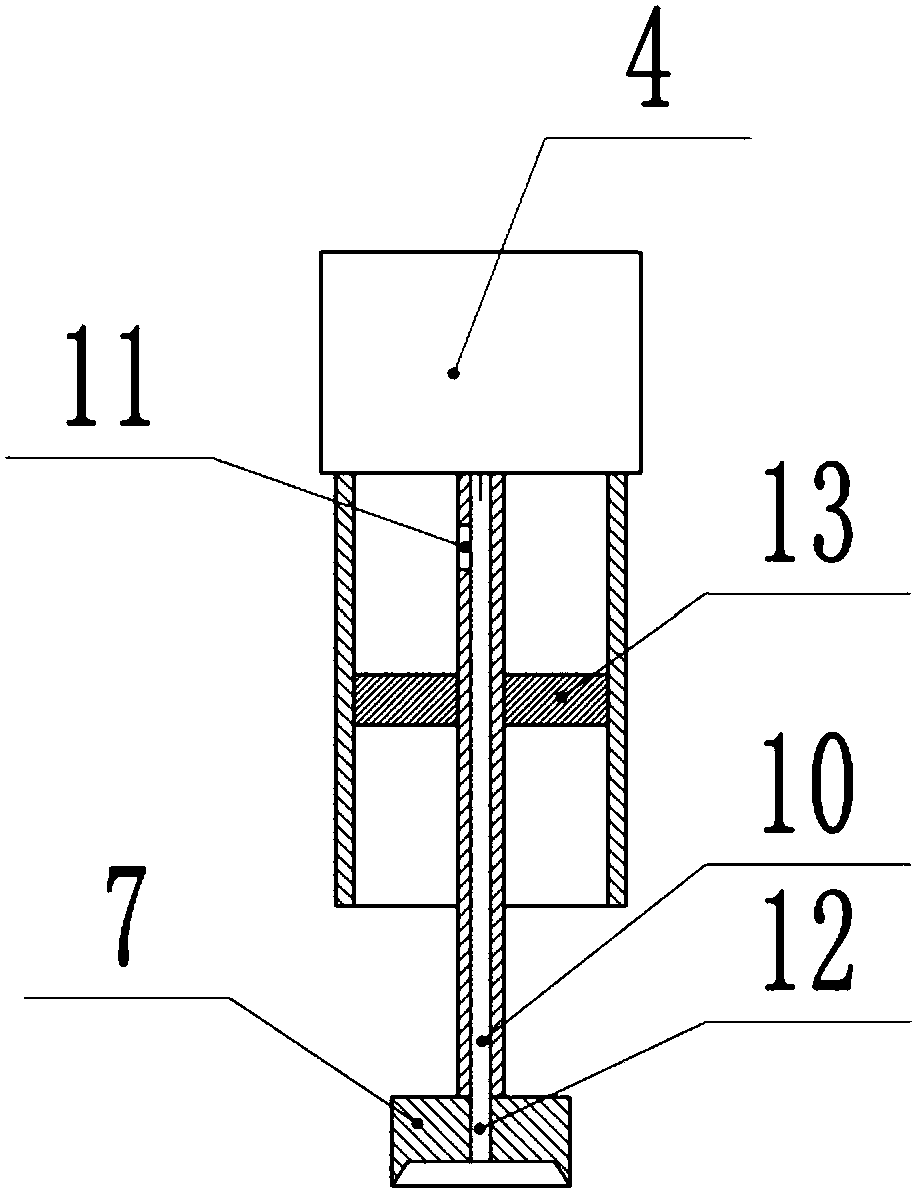

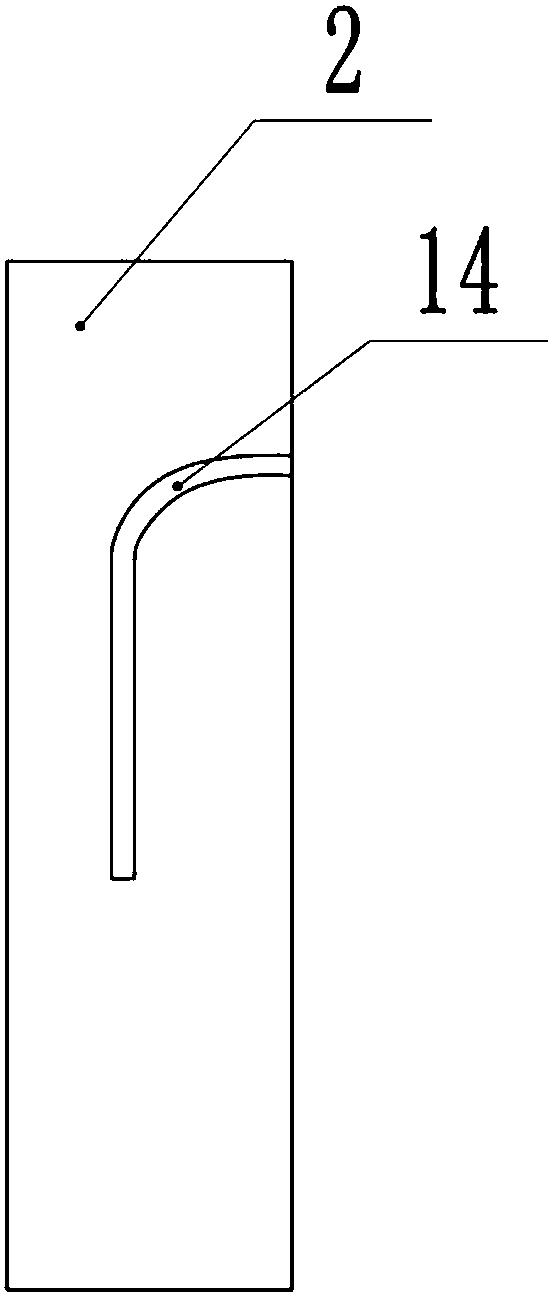

Paper tube detection device

ActiveCN105572141AAchieve level adjustmentPrevent saggingOptically investigating flaws/contaminationConveyor partsDrive shaftPulp and paper industry

The invention relates to a paper tube detection device which comprises a rack and a transmission device, wherein a transmission shaft is arranged on the transmission device, a drive assembly is connected onto the transmission shaft, a support assembly is arranged on the rack, a first camera and a second camera are arranged on the rack, and a PC computer is connected onto the rack. The paper tube detection device has the advantages that the rotation of the transmission shaft is realized through the drive assembly, the rotation of the transmission shaft is realized under the effect of revolution of the transmission device through the drive assembly, so paper tubes are subjected to feed detection in a rotation mode of the transmission shaft, the cost for rotating the paper tubes through the existing equipment is greatly reduced, the detection efficiency is improved, the phenomenon of dropping of the transmission device in the transmission process due to gravity is effectively prevented through the support assembly, the transmission effect of the transmission device is ensured and damage of the transmission device is avoided. The first camera and the second camera shoot the paper tubes and judge the quality of the paper tubes through the PC computer, so the detection is convenient and the qualification rate of paper tube detection can be ensured.

Owner:浙江三信智能机械股份有限公司

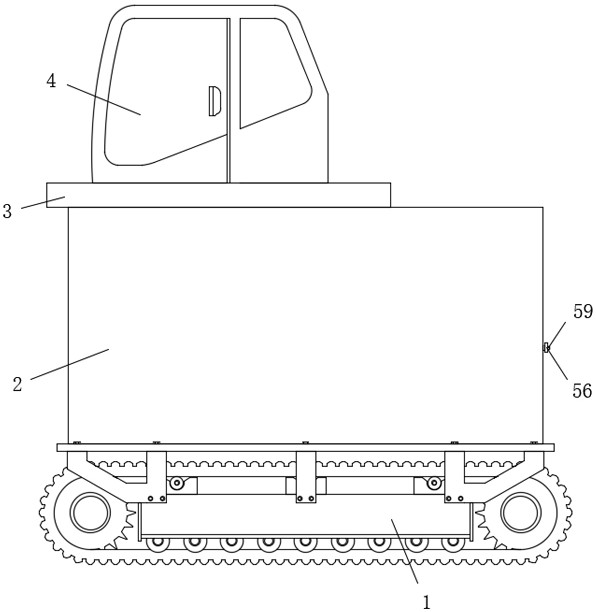

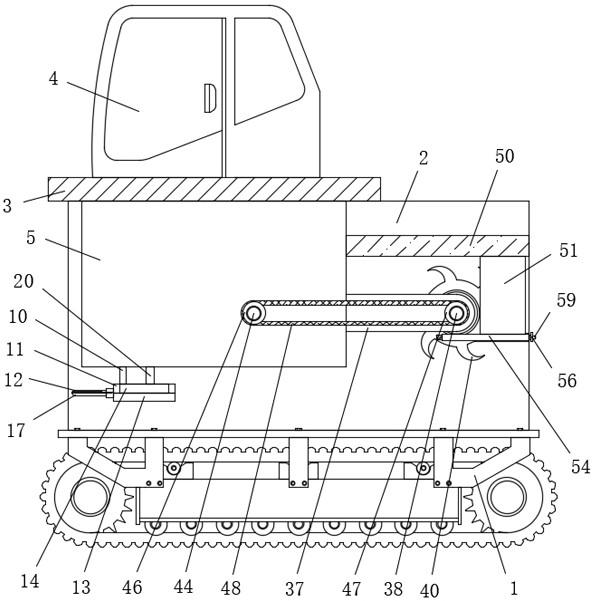

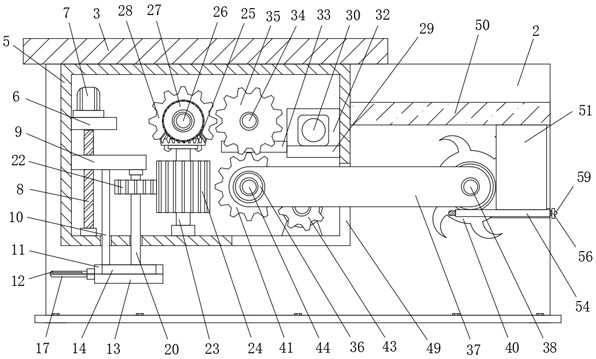

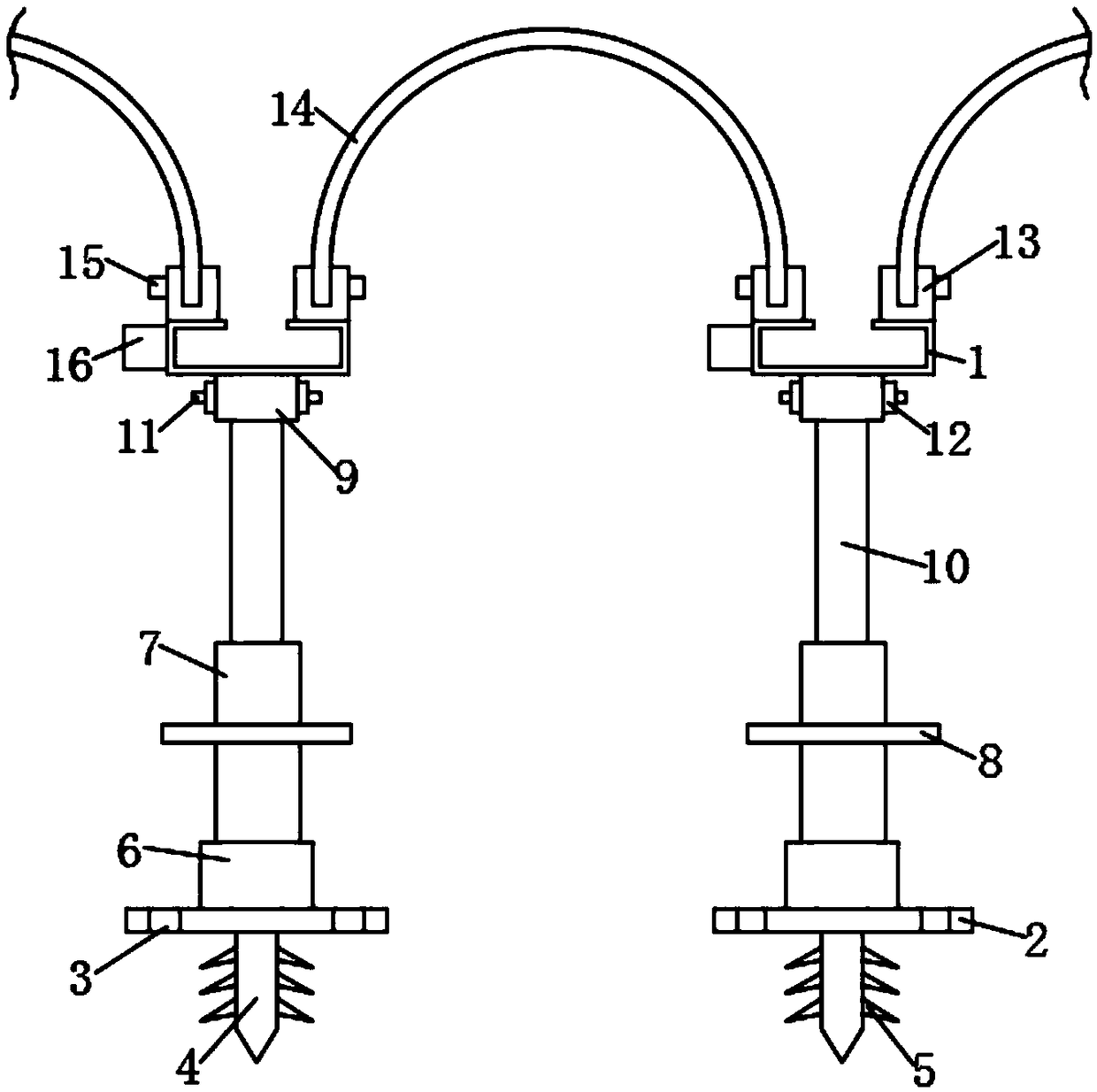

Tea tree heavy pruning and soil turning integrated device and using method thereof

ActiveCN112772195AEasy to moveRealize synchronous up and down movementSpadesBio-organic fraction processingAgricultural scienceAgricultural engineering

The invention belongs to the technical field of agricultural mechanical equipment, and particularly relates to a tea tree heavy pruning and soil turning integrated device which comprises two crawler chassis and vertical plates fixedly connected to the two crawler chassis respectively, one sides of the tops of the two vertical plates are fixedly connected with one top plate, and a cab is arranged at the top of the top plate; and the bottom of the top plate is fixedly connected with a mounting box located between the two vertical plates. The invention further discloses a using method. According to the tea tree heavy pruning and soil turning integrated device, an operator performs operation in the cab, intelligent operation can be realized, the working labor intensity can be reduced, the working efficiency is greatly improved, and the versatility of the whole device is improved through integrated arrangement of trimming and soil turning, so that the operation range is greatly expanded, and the practicability is enhanced; and meanwhile, a power source can be provided for pruning operation and soil turning operation through movement of a rotating motor, operation flexibility is improved, and the manufacturing cost is saved.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

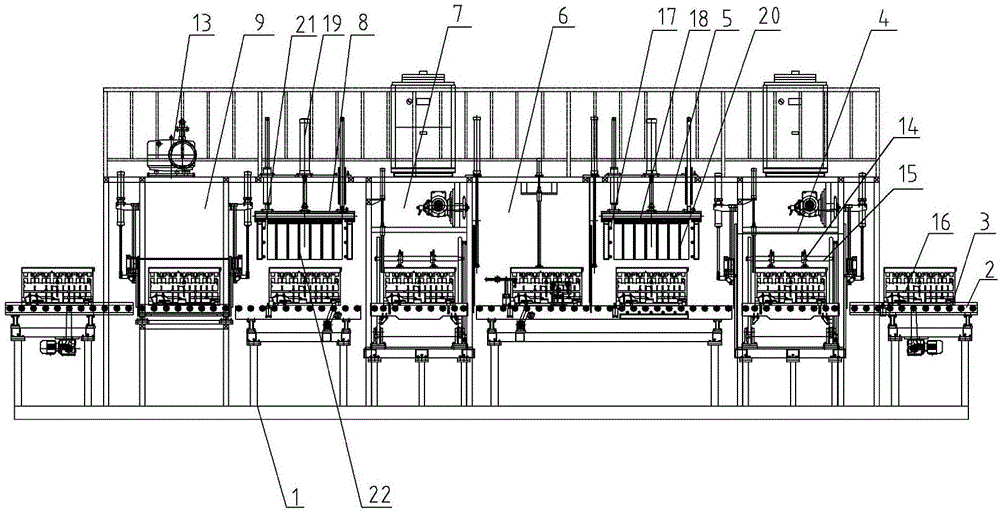

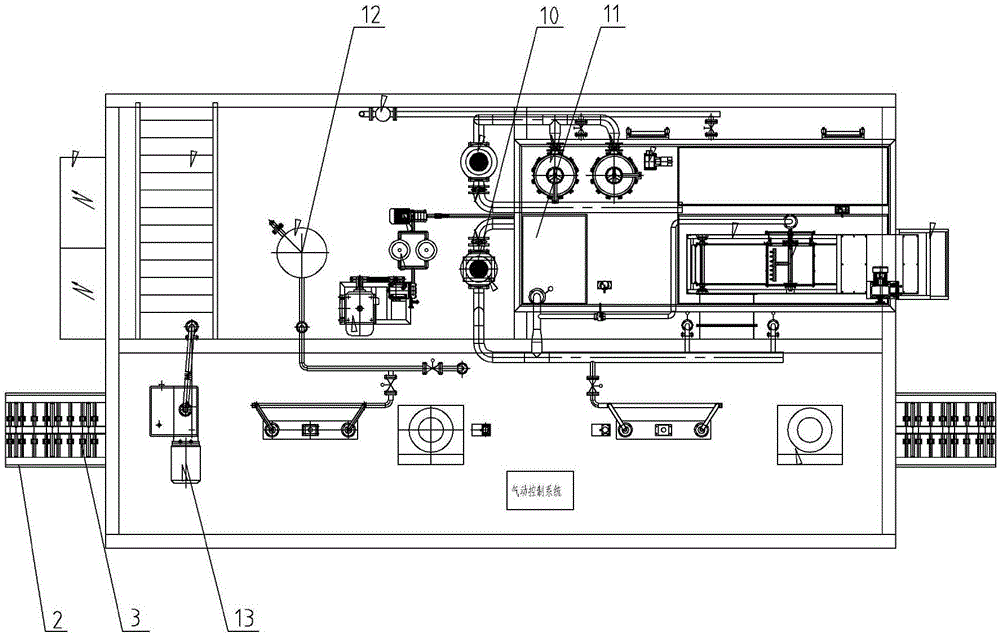

Cylinder body cleaning machine and cleaning method thereof

InactiveCN106513400AGuaranteed service lifeGuaranteed transmission effectDrying solid materials without heatHollow article cleaningSpray nozzleEngineering

The invention discloses a cylinder body cleaning machine comprising a machine frame. A guide rail is installed at the middle position of the machine frame. A vortex cleaning chamber, an alignment cleaning chamber, a high-pressure cleaning chamber, a rotating water pouring chamber, an alignment water blowing chamber and a vacuum drying chamber which are located above a cylinder body conveying mechanism are sequentially arranged on the machine frame. The vortex cleaning chamber, the alignment cleaning chamber, the high-pressure cleaning chamber, the rotating water pouring chamber, the alignment water blowing chamber and the vacuum drying chamber are each provided with a limiting structure, a put-in-place detection system and a pressing mechanism. A rotation mechanism used for rotation of a cylinder body and a side face air knife are arranged in the rotating water pouring chamber. Multiple venturi nozzles are arranged on the top face of the vortex cleaning chamber. The alignment cleaning chamber and the alignment water blowing chamber are each internally provided with multiple angle-adjustable spray nozzles. By means of the cylinder body cleaning machine, comprehensive cleaning of cylinder bodies of various shapes and all hole systems in the cylinder bodies is achieved, and impurities and dust in various corners, grooves and holes in the special-shaped cylinder bodies can be completely and thoroughly removed; and cleanness of the cylinder bodies is ensured, and it is avoided that whole machines frequently break down.

Owner:CHONGQING KEBEN TECH

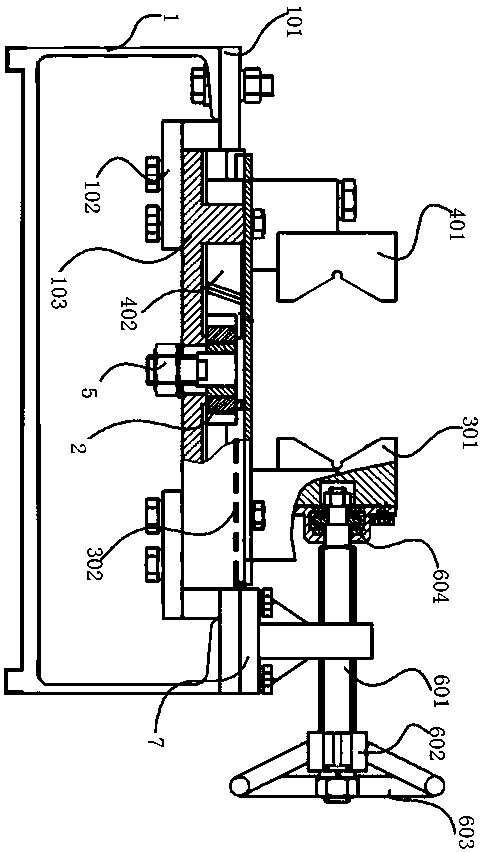

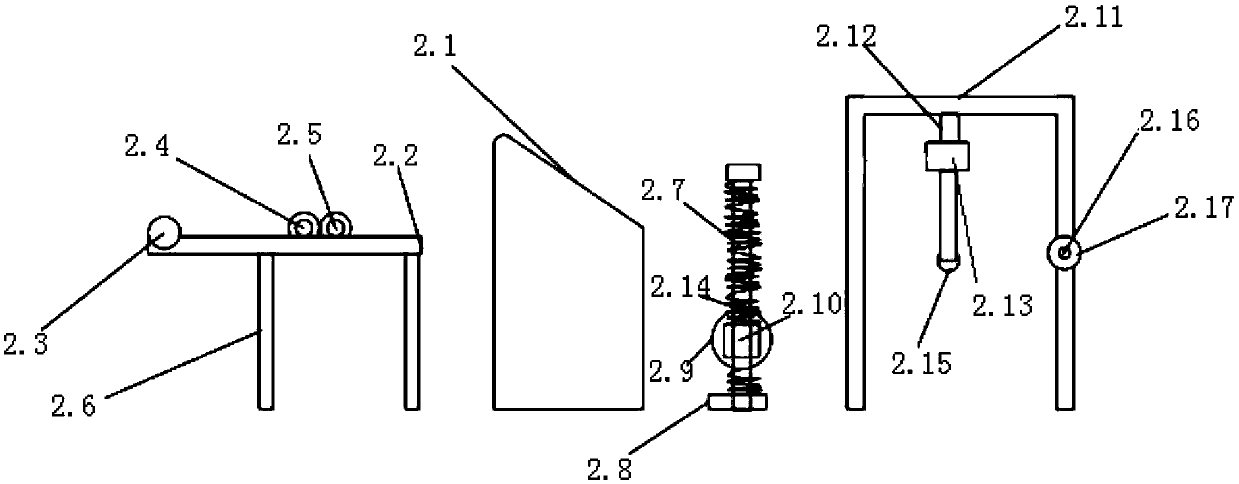

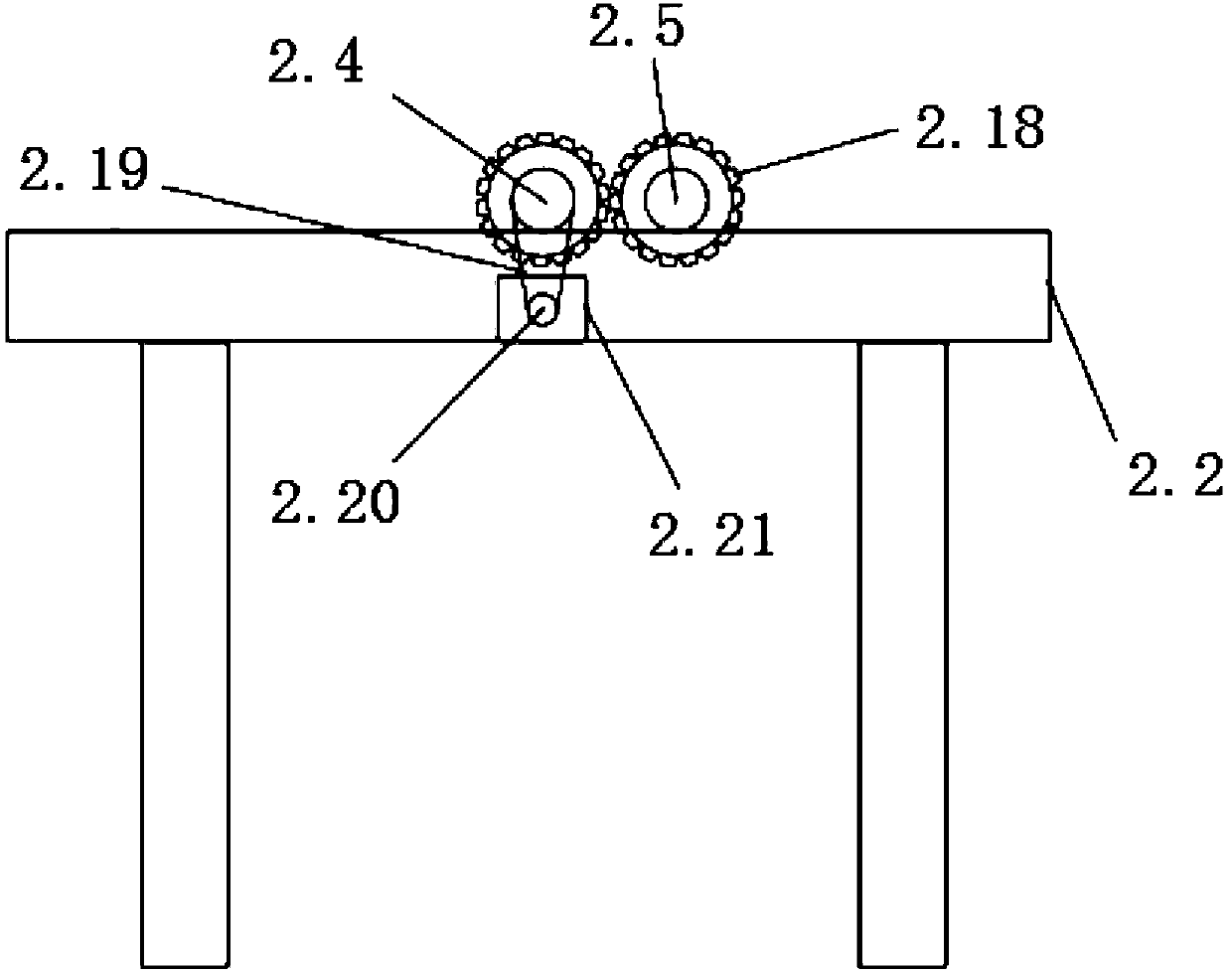

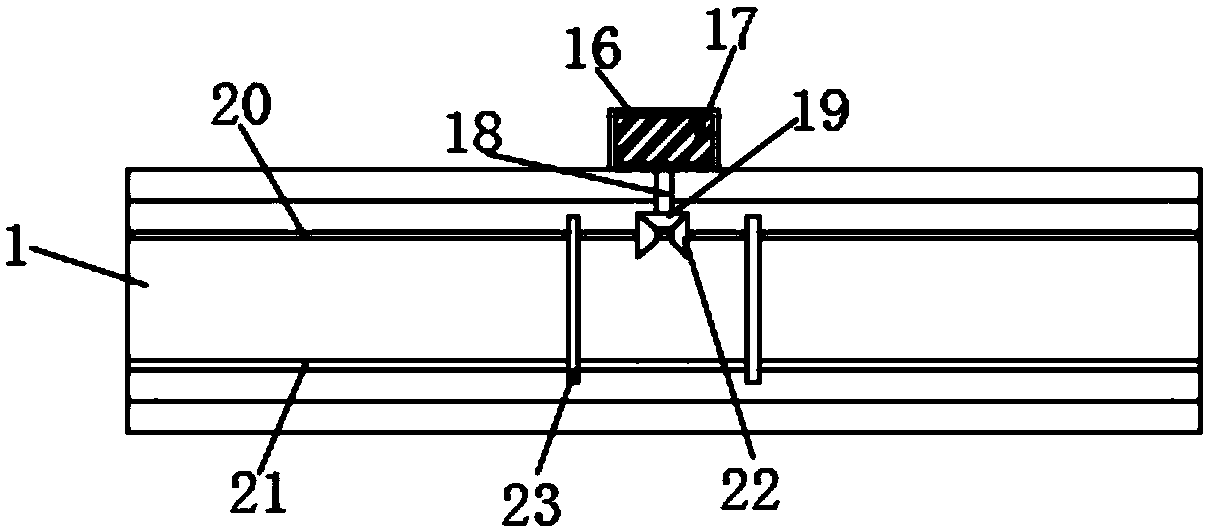

Tube locating device

InactiveCN109382670AReasonable structural designMeet the requirementsPositioning apparatusMetal-working holdersGear wheelElectric machinery

The invention discloses a tube locating device. The tube locating device comprises a support, a regulating gear, a driven unit and a drive unit both arranged on the support, and a power device adaptedto the drive unit; the drive unit comprises a drive V-shaped clamping block, a drive rack fixedly connected with the drive V-shaped clamping block, and a regulating gear adapted to the drive rack; the driven unit comprises a driven V-shaped clamping block, a driven rack fixedly connected with the driven V-shaped clamping block, and a regulating gear adapted to the driven rack; the drive unit drives the driven unit through the regulating gear to move; the power device is in transmission connection with the drive V-shaped clamping block; and the power device comprises a manual regulating screwstructure or a motor power device. The tube locating device is reasonable in structure design, the drive V-shaped clamping block is driven by the power device to move, and the drive V-shaped clampingblock drives the drive rack to drive the regulating gear to rotate, so that the driven rack is driven to move, and the distance of the driven V-shaped clamping block relatively to the drive V-shaped clamping block is driven to be increased to reduced.

Owner:陈振清

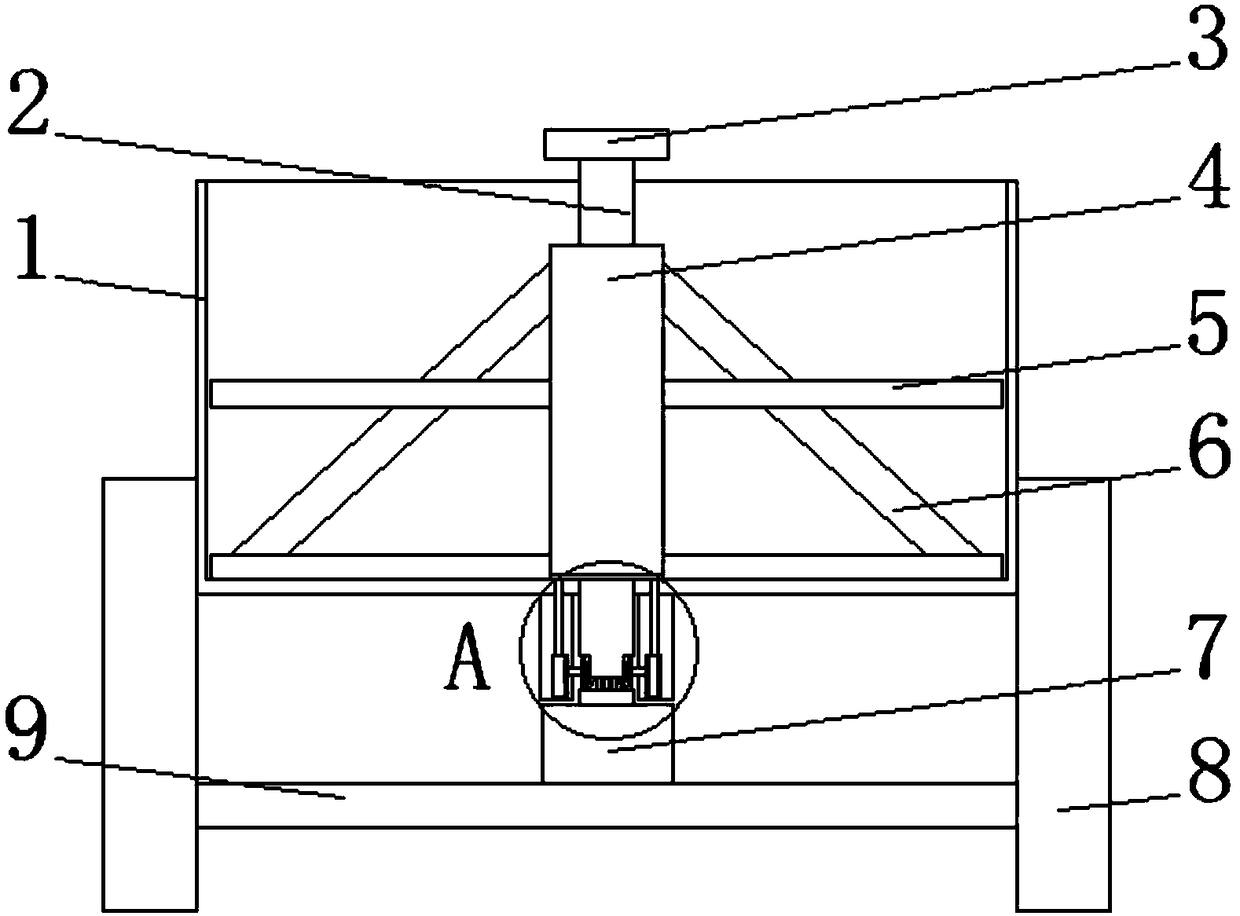

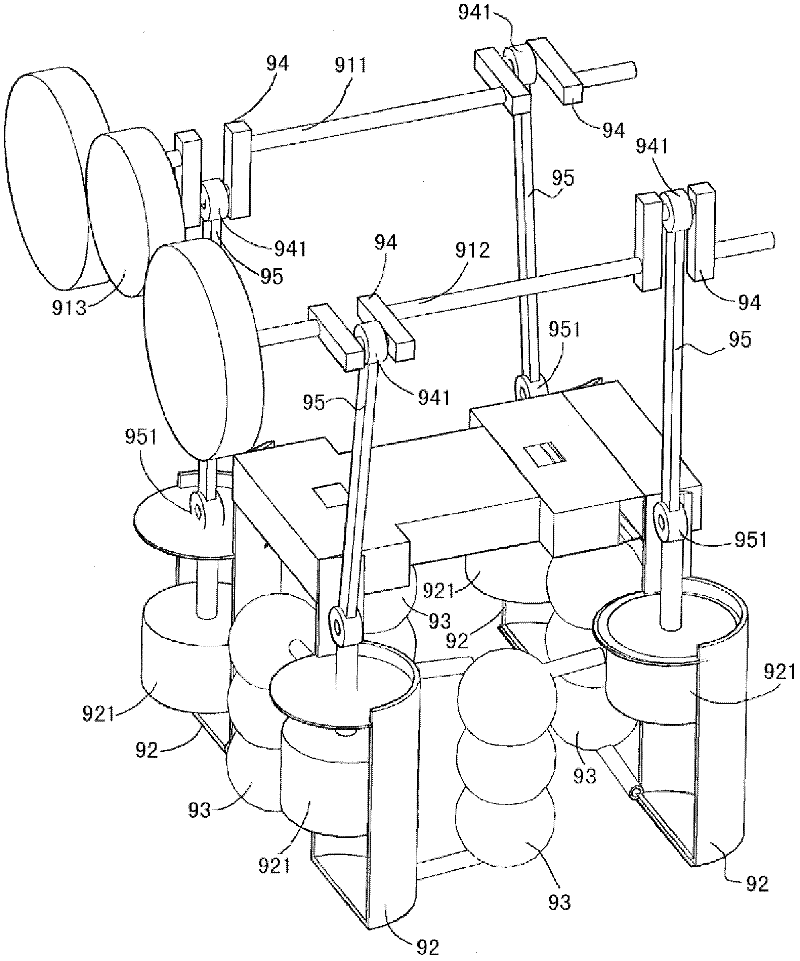

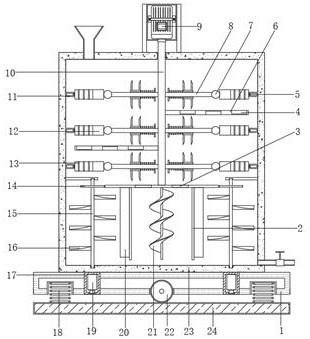

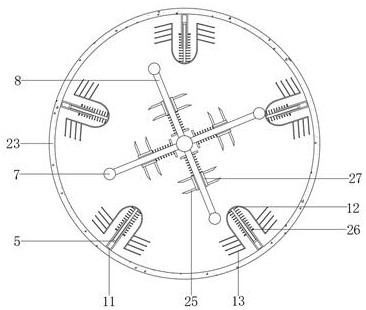

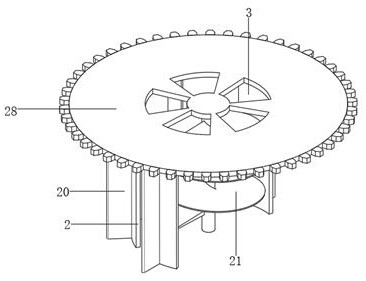

Device for improving stability of moon cake filling raw material stirring equipment

InactiveCN108465409AGuaranteed transmission effectEffective positioningShaking/oscillating/vibrating mixersRotary stirring mixersPulp and paper industryCam

The invention discloses a device for improving the stability of moon cake filling raw material stirring equipment. The device comprises a stirring tank, fixing racks, a stirring shaft, stirring rods and a stirring motor, wherein the rotating shaft is arranged in the middle of the stirring tank; the stirring shaft is arranged on the rotating shaft in a clamped manner; the stirring motor is arrangedat the bottom of the rotating shaft; a plurality of uniformly distributed stirring rods are arranged on the stirring shaft; a first steering gear is arranged on the rotating shaft; a plurality of second steering gears are arranged on the first steering gear; connecting shafts are arranged on the second steering gears; second adjusting troughs are arranged at the bottom of the stirring tank; camsare arranged at the bottoms of the second adjusting troughs; one sides of the cams are fixedly connected with the connecting shafts; adjusting rods are arranged at the upper ends of the cams; upper ends of the adjusting rods penetrate through the bottom of the stirring tank through communicating grooves and are connected with an adjusting ring at the bottom of the stirring shaft; and positioning grooves matched with the bottoms of the adjusting rods are formed in the cams. The device adopting the design is simple to operate, high in comprehensive practicability and easy to popularize and use.

Owner:蚌埠市好味佳食品有限公司

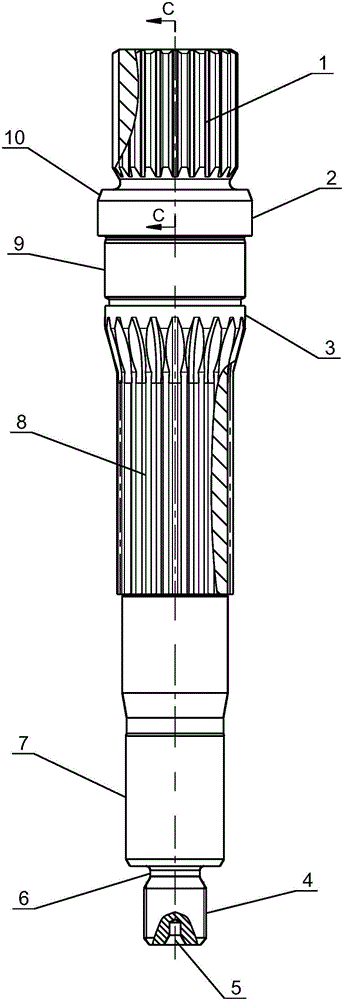

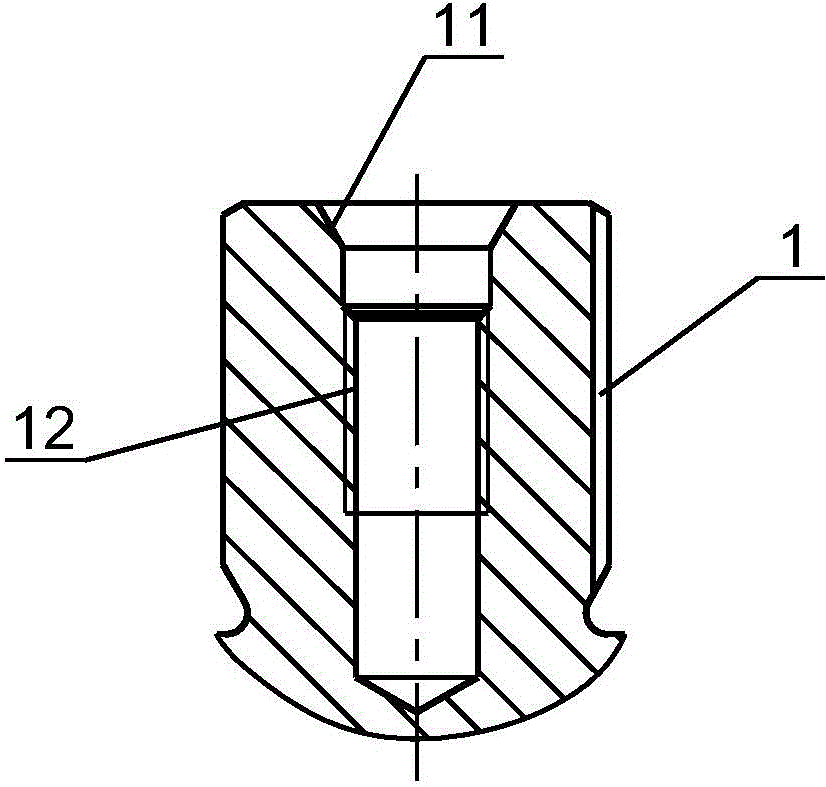

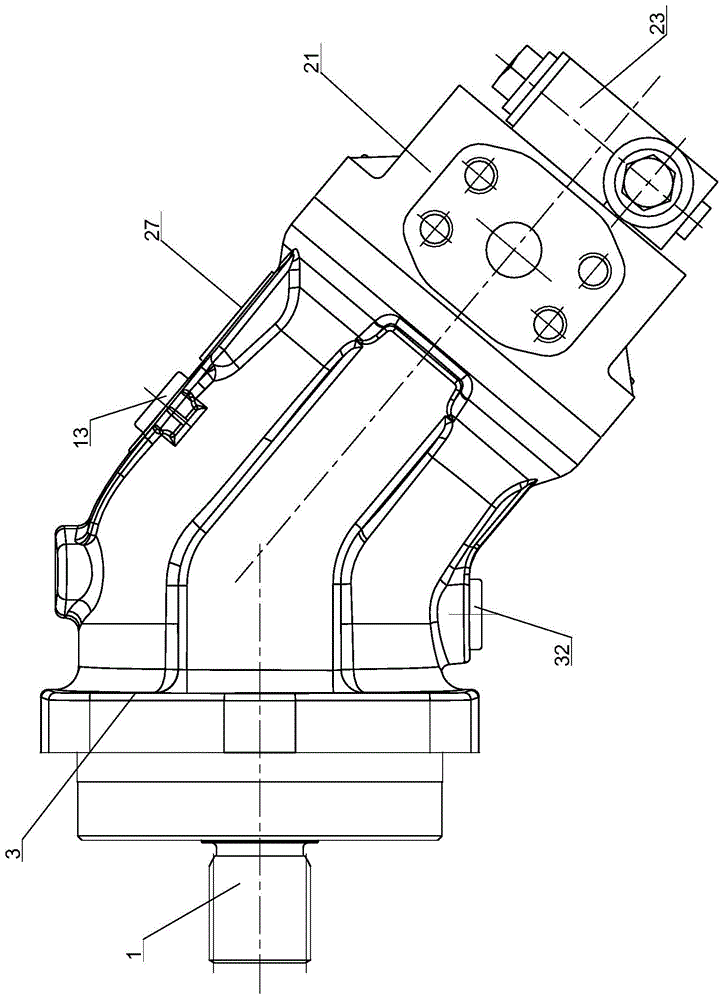

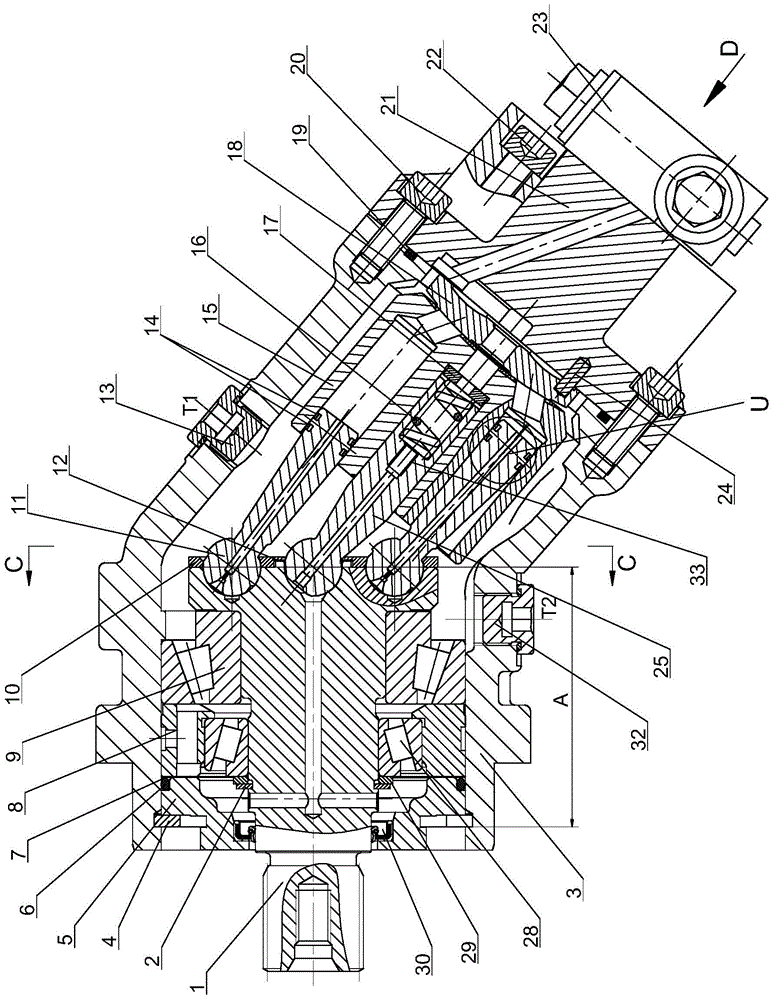

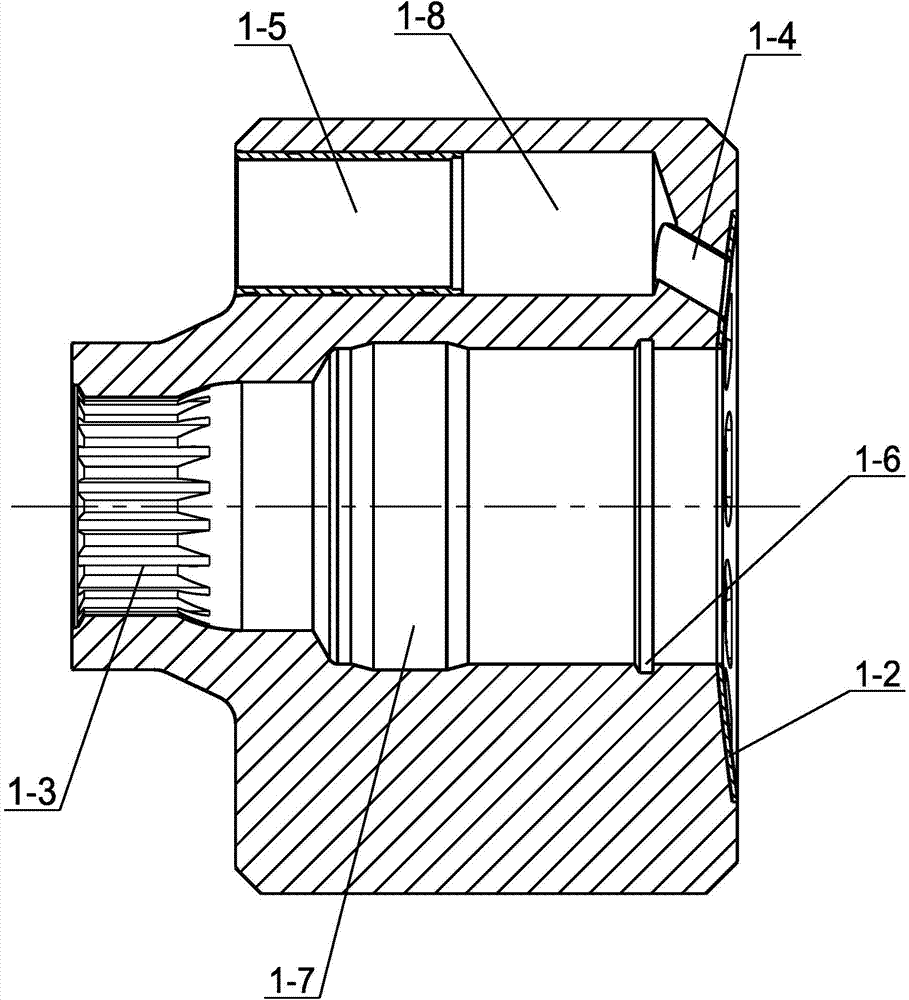

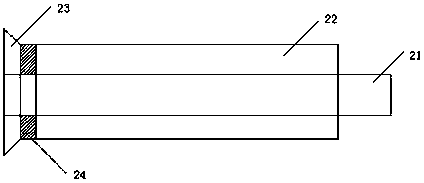

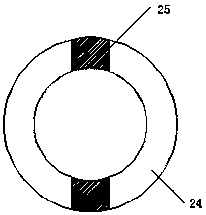

Driving shaft of hydraulic pump and machining method thereof

ActiveCN104625638AGuaranteed machining accuracyControl scrap ratePositive displacement pump componentsShaftsDrive shaftTransmitted power

A driving shaft of a hydraulic pump comprises a shaft body. A first external spline used for receiving external power to drive the driving shaft to rotate is arranged at the upper end of the shaft body, and a guiding conical surface where a frame oil seal is installed is arranged below the first external spline; a second external spline used for bearing a plunger type cylinder body and driving the plunger type cylinder body to rotate is arranged in the middle of the shaft body, and a first supporting outer circle used for bearing a bearing and playing a role in supporting the entire driving shaft is arranged above the second external spline; a second supporting outer circle and a third external spline are arranged at the lower end of the shaft body, the second supporting outer circle is used for bearing a bearing and playing a role in supporting the entire driving shaft, the third external spline is used for transmitting power to an oil supplementing pump, and the first supporting outer circle and the second supporting outer circle are used for reducing abrasion of the driving shaft of the hydraulic pump; meanwhile, a first ejector pin conical surface and a second ejector pin conical surface which are used for machining positioning of the shaft body are arranged on the two end surfaces of the shaft body. The machining accuracy of the shaft body is improved beneficially, and further transmission performance among assemblies is guaranteed.

Owner:SUZHOU SABO IND DESIGN

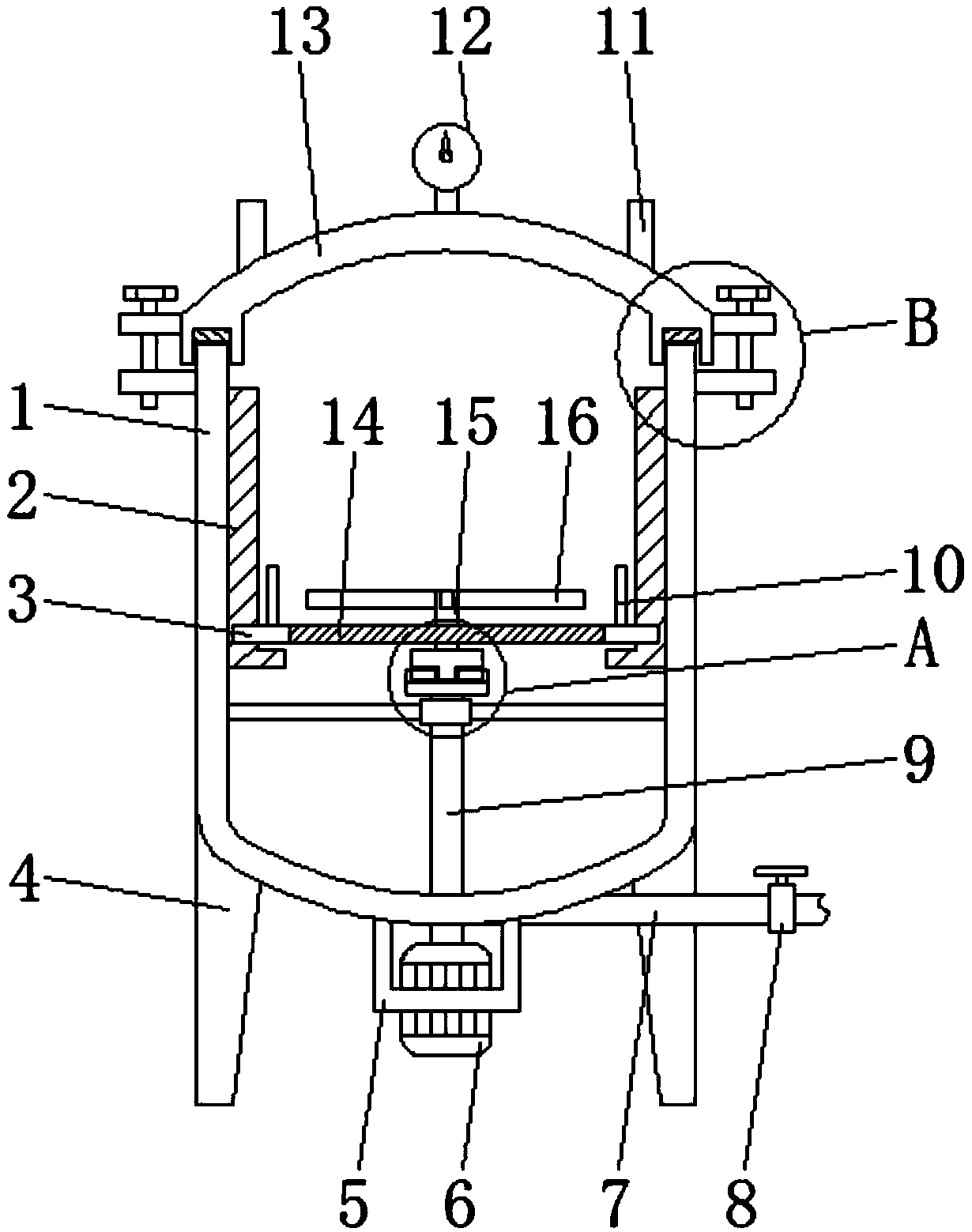

Device specially used for fermentation treatment of biological products

InactiveCN108531379AImprove mixing uniformityWell mixedBioreactor/fermenter combinationsBiological substance pretreatmentsFixed frameEngineering

The invention discloses a device specially used for fermentation treatment of biological products. The device comprises a tank, a fixing plate, a motor, a tank cover, a stirring shaft and a second chimeric block, wherein the fixing plate is movably installed in the tank, and clamping grooves are formed in the outer wall of the fixing plate; limiting strips are movably engaged in the clamping grooves; a filter screen is installed in the fixing plate; the stirring shaft is connected with the middle position of the filter screen in an inserting way; stirring rods are fixed on the outer wall of the upper end of the stirring shaft; a first chimeric block is fixed at the lower end of the stirring shaft; the motor is installed on the lower surface of the tank by means of a motor fixing frame; a motor shaft, passing through the lower surface of the tank, is rotatably installed on the upper surface of the motor; the second chimeric block is fixed at the upper end of the motor shaft. The devicespecially used for the fermentation treatment of the biological products is provided with the fixing plate which can be flexibly taken out, so that residues obtained after fermentation can be conveniently taken out; furthermore, the stirring rods are driven to stir fermentation raw materials by means of the motor, so that the fermentation raw materials are enabled to be fully mixed with added zymocytes well, and the fermentation effect is improved.

Owner:佛山市尚柏科技有限公司

Improved hydraulic motor and assembly test method thereof

InactiveCN104405575AGood for heat dissipationImprove efficiencyReciprocating piston enginesRotary piston enginesIntermediate pressureDrive shaft

The invention discloses an improved hydraulic motor, a front end tapered roller bearing, a rear end tapered roller bearing and a driving shaft are installed by interference fit, an intermediate pressure ring is installed on the front end tapered roller bearing by interference fit, an oil groove radial channel arranged on the driving shaft is extended to the driving shaft front end to prompt the driving shaft to generate centrifugal force to improve the hydraulic energy to transform into mechanical energy efficiency; the intermediate pressure ring and an outer ring of the rear end tapered roller bearing are in interference fit with an inner hole of a motor casing; a bearing pressure cover is mounted in the motor casing, a plunger ring shrinks and sheathes a plunger, the plunger and a ball head end of a center connecting rod are respectively installed in the driving shaft, a cylindrical spring is installed in the center connecting rod for prevention of locking of the center connecting rod, the cylindrical spring and the axially uniformly distributed plunger are filled into a cylinder body, an oil distributing plate and the cylinder body spherical surface are fit, a spring seat is arranged in the end part of the center connecting rod; a rear end cover is installed in the motor casing end part, a positioning pin is inserted into the oil distributing plate, and a flush valve is tightly installed on the rear end cover end part in order to realize the automatic control of cooling.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Efficient production line for clothes

InactiveCN109527685AEasy to storeReduce work proceduresClothes making applicancesYarnProduction line

The invention discloses an efficient production line for clothes, which sequentially comprises a knitting machine, a cloth inspecting device, a loosening machine, a fabric placing frame, a cutting machine, a sewing machine, an ironing device and a finishing system from front to back, wherein yarns are knitted into a fabric by the knitting machine, after being rolled into a cloth roll, the fabric is sent to the cloth inspecting device for cloth inspecting operation; after the fabric passes through the cloth inspecting device, the fabric is directly sent to the cloth loosening machine for clothloosening; after the cloth loosening is finished, the fabric is placed on the fabric placing frame; after the fabric is stored on the fabric placing frame, when the fabric needs to be cut, the fabricis pushed to the front of the cutting machine, and after the fabric is cut, the fabric is sent to a sewing machine to be sewed to form clothes, then is sent to an ironing device to be ironed, and thenis sent to a finishing system to be finished to finally form the finished clothes. The efficient production line for the clothes can avoid cloth wrinkles and improve the smoothness of the cloth, thefabric placing frame has a larger capacity of, and the cloth is smoothly distributed and conveyed on the cutting machine, the cutting speed is high.

Owner:江阴嘉美针织制衣有限公司

Flower greenhouse bracket

InactiveCN108934612APrevent collapseAdjust lift heightClimate change adaptationGreenhouse cultivationGreenhouseAgricultural engineering

The invention discloses a flower greenhouse bracket, and relates to the technical field of flower greenhouses. The bracket comprises drainage channel steel and bases; a bearing base is fixedly mountedin the middle of the top of each base, a rotating drum is fixedly connected to the top of each bearing base, a mounting sleeve is arranged in the middle of the bottom of the drainage channel steel, and a retractable rod is inserted in the bottom of each mounting sleeve. By means of the flower greenhouse bracket, a worker conveniently operates the bracket to adjust the lifting height of the bracket, the convenience of the bracket is improved, the labor intensity of the worker is greatly reduced, the bracket is conveniently mounted and dismounted, the later maintenance is facilitated, the function of lifting adjustment is achieved, the worker can change different heights according to the demands of actual situations, the later storage of the greenhouse bracket is facilitated, supporting plates different in specification and size are conveniently mounted, the rigidity and toughness are improved, the collapse of a greenhouse is prevented, the clamping effect is good, and the connection tightness and stability are improved.

Owner:安吉富民生态农业开发有限公司

Metal pipe fitting machining fixing device used for numerical control machine tool

ActiveCN110814807AEasy to fixNo damageGrinding drivesMetal working apparatusNumerical controlPipe fitting

The invention discloses a metal pipe fitting machining fixing device used for a numerical control machine tool. The metal pipe fitting machining fixing device comprises a machine tool body, a slidingrail is fixed to the machine tool body, a tail base is in sliding connection to the sliding rail, a transversely-arranged fixed shaft on the machine tool body is rotatably connected with a spindle, afixed shaft on the tail base is rotatably connected with an auxiliary shaft, the outer side of the spindle is sleeved with a first sleeve through a bearing, the outer side of the auxiliary shaft is sleeved with a second sleeve sharing the center axis with the first sleeve through a bearing, a tensioning mechanism is arranged between the first sleeve and the spindle, and comprises a V-shaped groovein the outer side wall of the spindle, a ladder through hole corresponding to the groove is formed in the first sleeve, a guide cylinder is sleeved with the ladder through hole, an ejector rod is sleeved with the guide cylinder in a sliding mode, one end of the ejector rod is connected with the interior of the guide cylinder through a spring, the other end of the ejector rod penetrates through the outer portion of the guide cylinder, and the end is fixedly connected with an arc pressing plate. The metal pipe fitting machining fixing device used for the numerical control machine tool firmly fixes a metal pipe fitting, the use range is wide, and safety is high.

Owner:屈伟斌

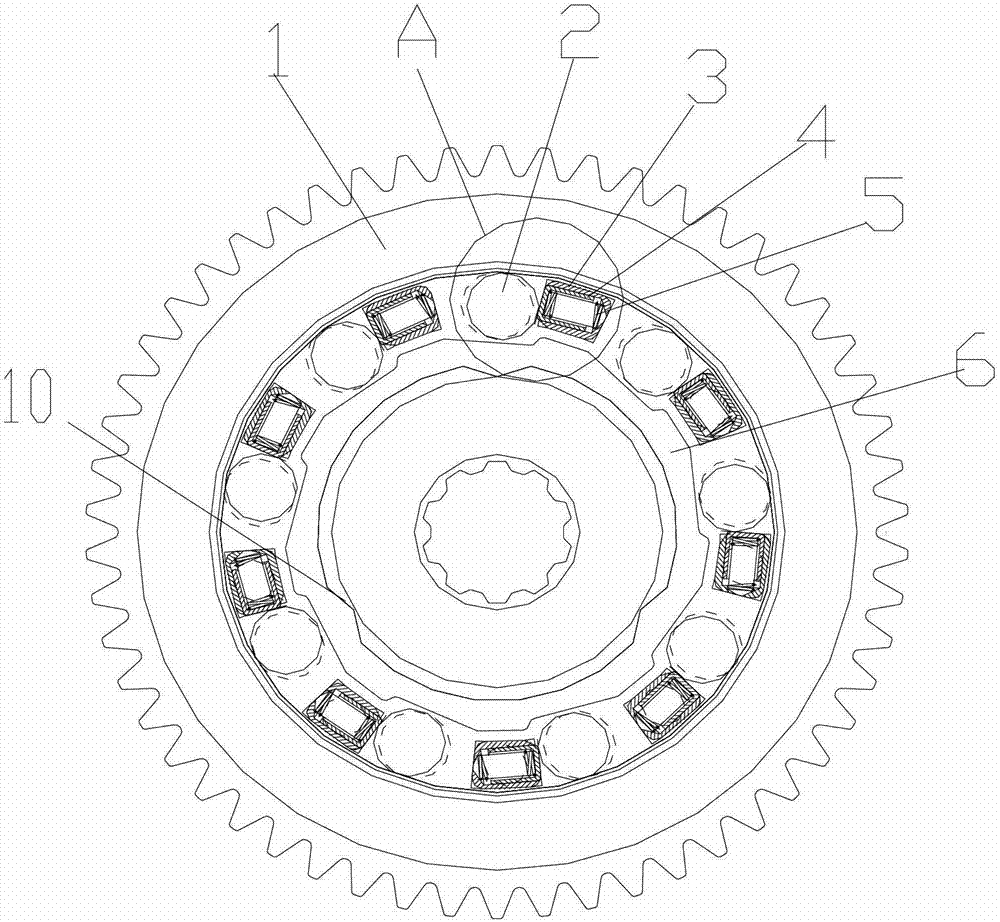

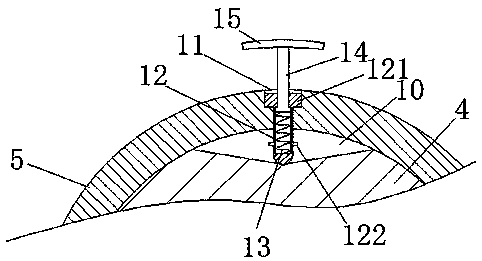

Wheel tooth length-adjustable mechanical transmission rotating wheel

PendingCN109681610AGuaranteed transmission effectPrevent slippingPortable liftingGearing elementsTooth lengthTransmission belt

The invention relates to a mechanical transmission rotating wheel, in particular to a wheel tooth length-adjustable mechanical transmission rotating wheel. The wheel tooth length-adjustable mechanicaltransmission rotating wheel comprises an outer adjusting ring and an inner rotating wheel main body; the outer adjusting ring is arranged at the external of the inner rotating wheel main body; extension wheel teeth are mounted on the outer adjusting ring in an annular array mode; and the extension wheel teeth are adjusted, limited and fixed through fixed pins. The lengths of the extension wheel teeth in the outer adjusting ring can be adjusted and limited through the fixed pins, so that the extension lengths of the extension wheel teeth are adjusted, the transmission effect is guaranteed, andthe slippage phenomenon caused by long-time transmission wear is prevented; and two fixed pins are provided to improve the limiting stability of the extension wheel teeth, so that the slippage phenomenon easily caused by long-time transmission wear of the wheel teeth with chains or other wheel teeth in a large transmission rotating wheel applying some transmission belts and mechanical conveying equipment in the material conveying field is solved.

Owner:HUNAN UNIV OF SCI & ENG

External combustion engine and transmission mechanism thereof

InactiveCN102251877AGuaranteed transmission effectLow costGearingEngine componentsExternal combustion engineEngineering

The invention discloses an external combustion engine and a transmission mechanism thereof. The external combustion engine comprises a hot gas assembly, the transmission mechanism and a crankshaft; the hot gas assembly comprises four groups of heaters, heat regenerators and coolers and four cylinders arranged in a rectangle; disconnected cold and hot cavities are formed in each cylinder; each hot cavity is communicated with a cold cavity gas circuit of a group of heater, heat regenerator and cooler and the other cylinder to form a gas passage; the transmission mechanism comprises a swinging rod group and a connecting rod group; the swinging rod group comprises a first swinging rod and a second swinging rod, the swinging planes of which are mutually parallel; the connecting rod group comprises four connecting rods, namely a first connecting rod and a second connecting rod with equal length, and a third connecting rod and a fourth connecting rod which are extended downwards from a second pivot and a first pivot respectively and have equal length; and the upper ends of the third connecting rod and the fourth connecting rod are hinged with the first connecting rod and the second connecting rod respectively, and the lower ends of the third connecting rod and the fourth connecting rod are hinged with a connecting rod neck of the crankshaft. The external combustion engine has low cost, and is convenient to manufacture.

Owner:杨永顺

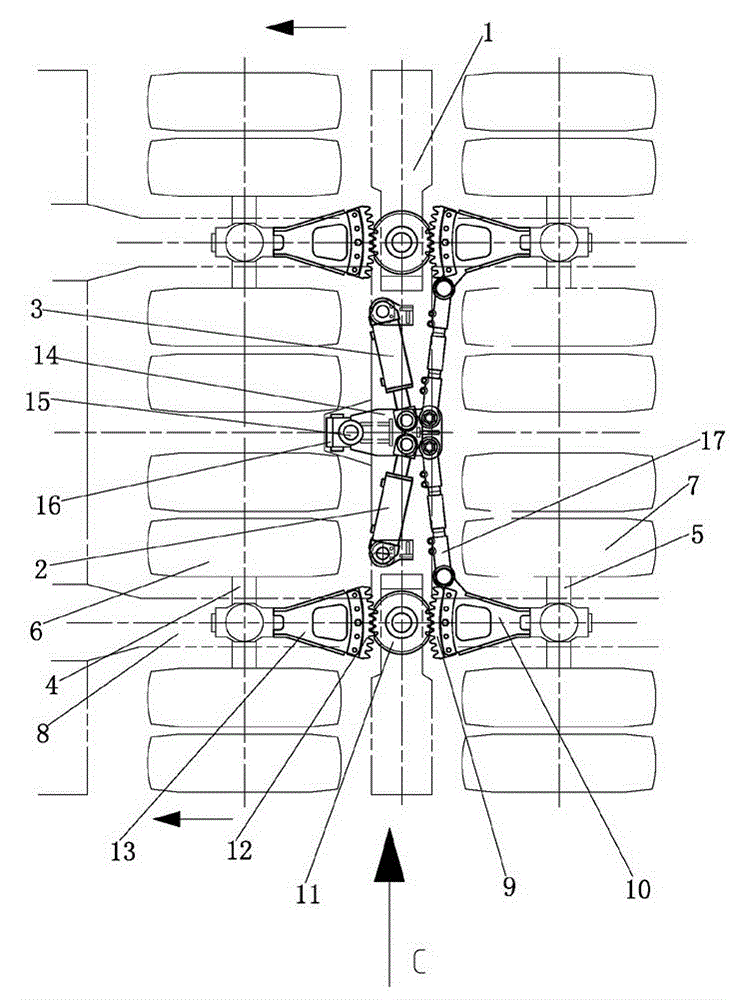

Semi-trailer with accurate steering function

ActiveCN105059387ARealize synchronous rotationLow costSteering linkagesMechanical steering gearsVehicle frameEngineering

The invention belongs to the technical field of transport vehicles, and discloses a semi-trailer with an accurate steering function. The torque of a front-row wheel group and a back-row wheel group which are at the back part of a vehicle frame is transmitted in a gear transmission manner, synchronous rotation of the front-row wheel group and the back-row wheel group is realized, the synchronicity of the rotation of the front-row wheel group and the rotation of the back-row wheel group is ensured through the smoothness and the reliability of gear transmission and the accuracy of the torque, and the passing rate of steering is greatly increased; a driving arc rack and a driven arc rack are arranged, so that the semi-trailer is convenient to manufacture, the transmission effect can be ensured through rack structures, besides material cost can be reduced, a cumbersome gear structure is omitted, and the practicality is greatly improved.

Owner:YANG ZHOU VULCAN MACHINERY MFG CO LTD

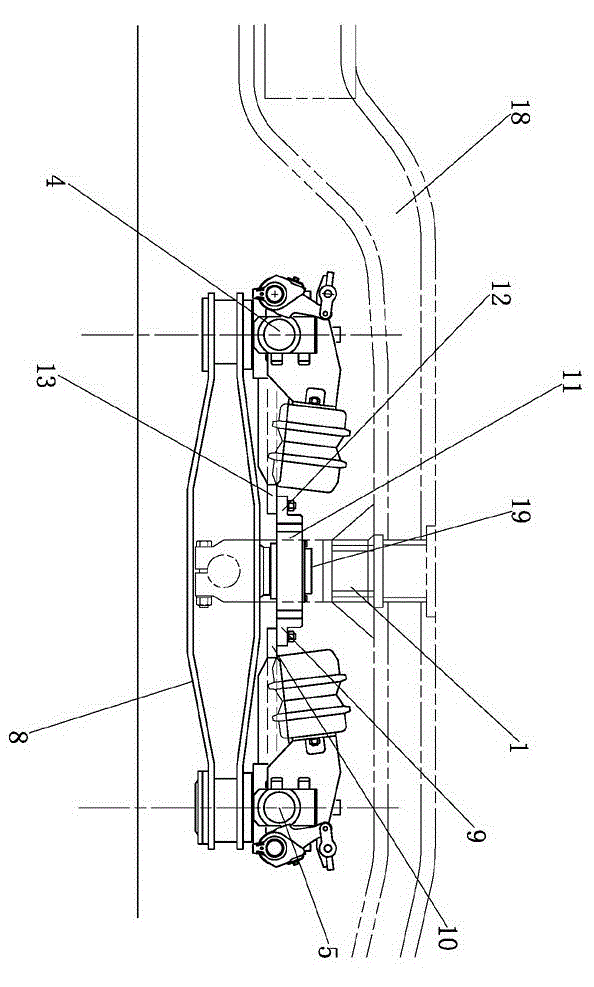

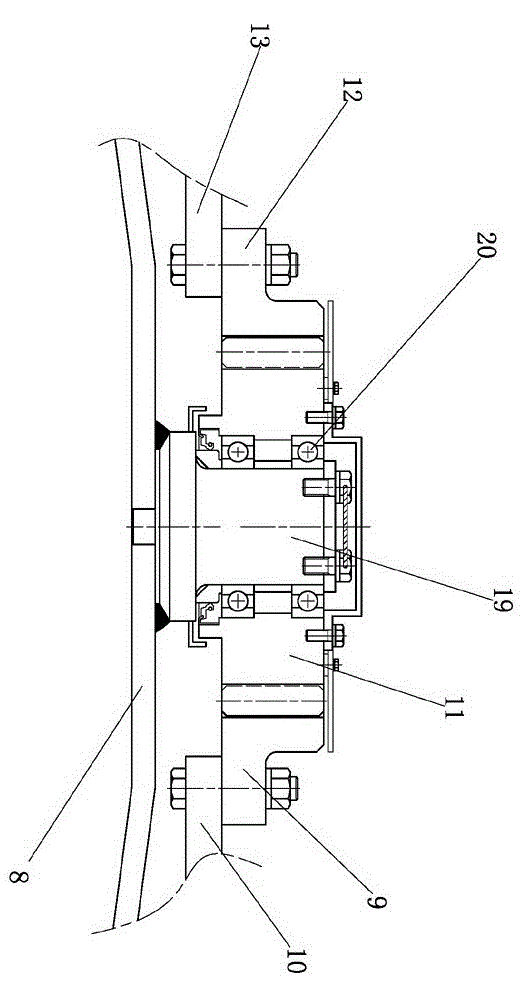

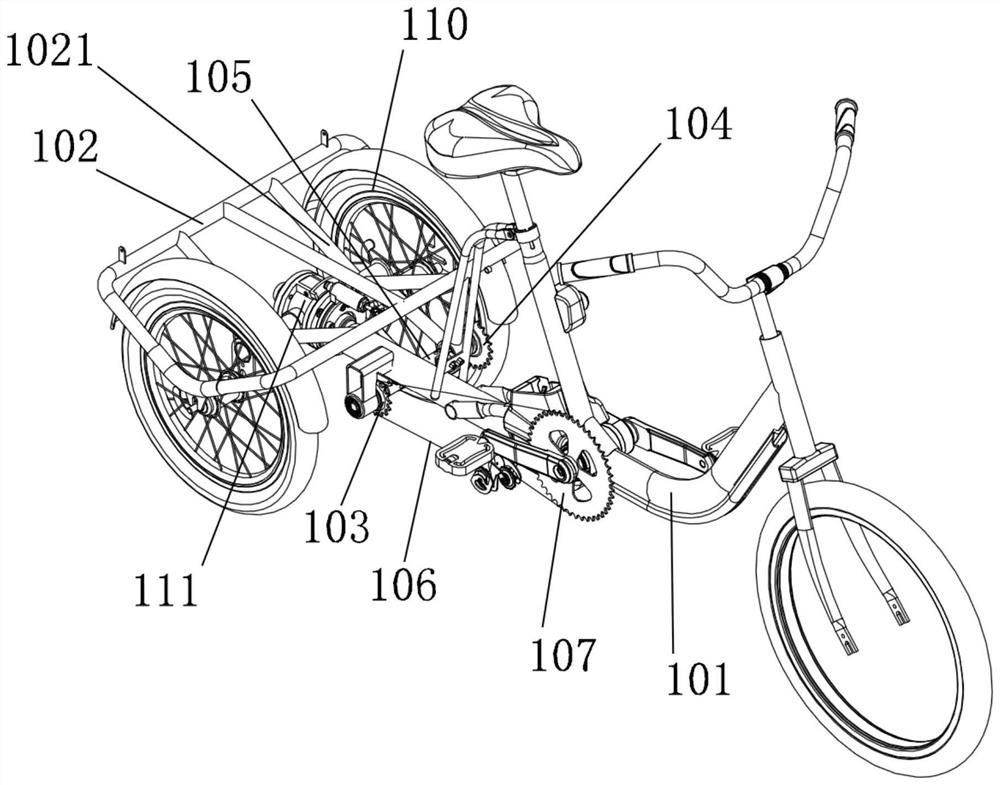

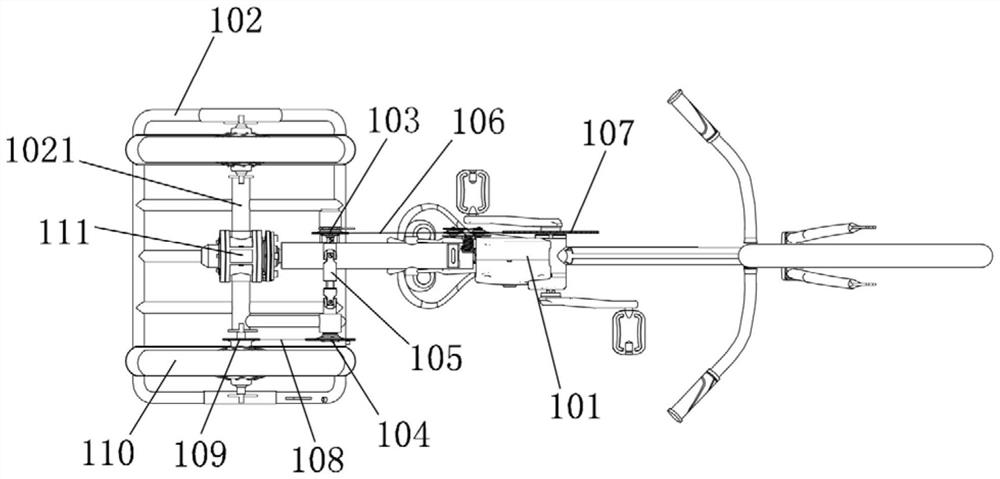

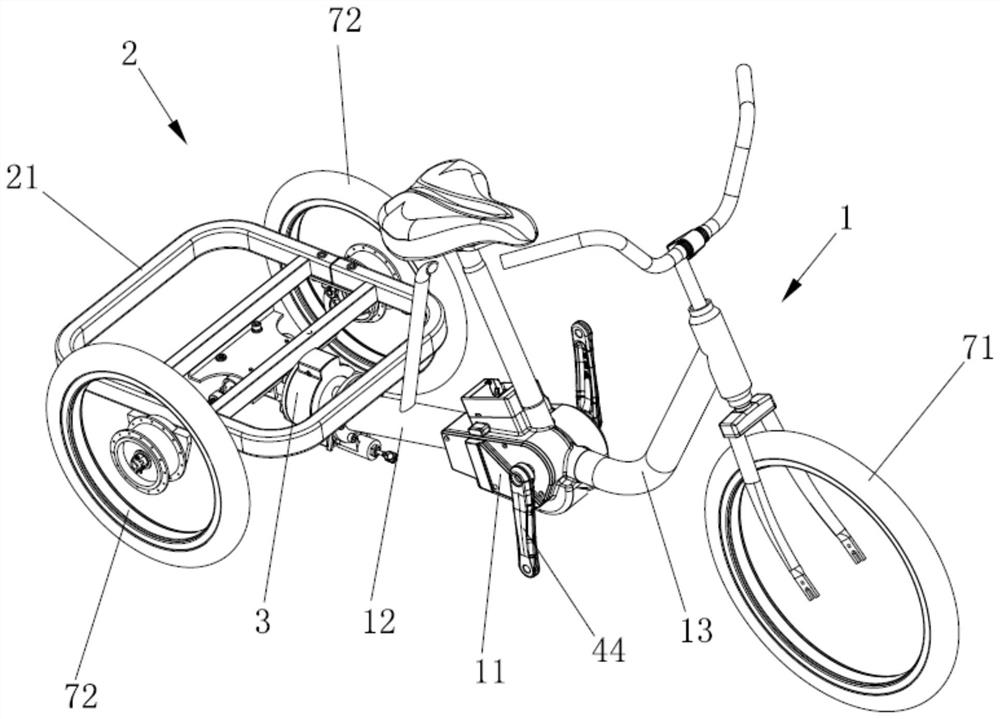

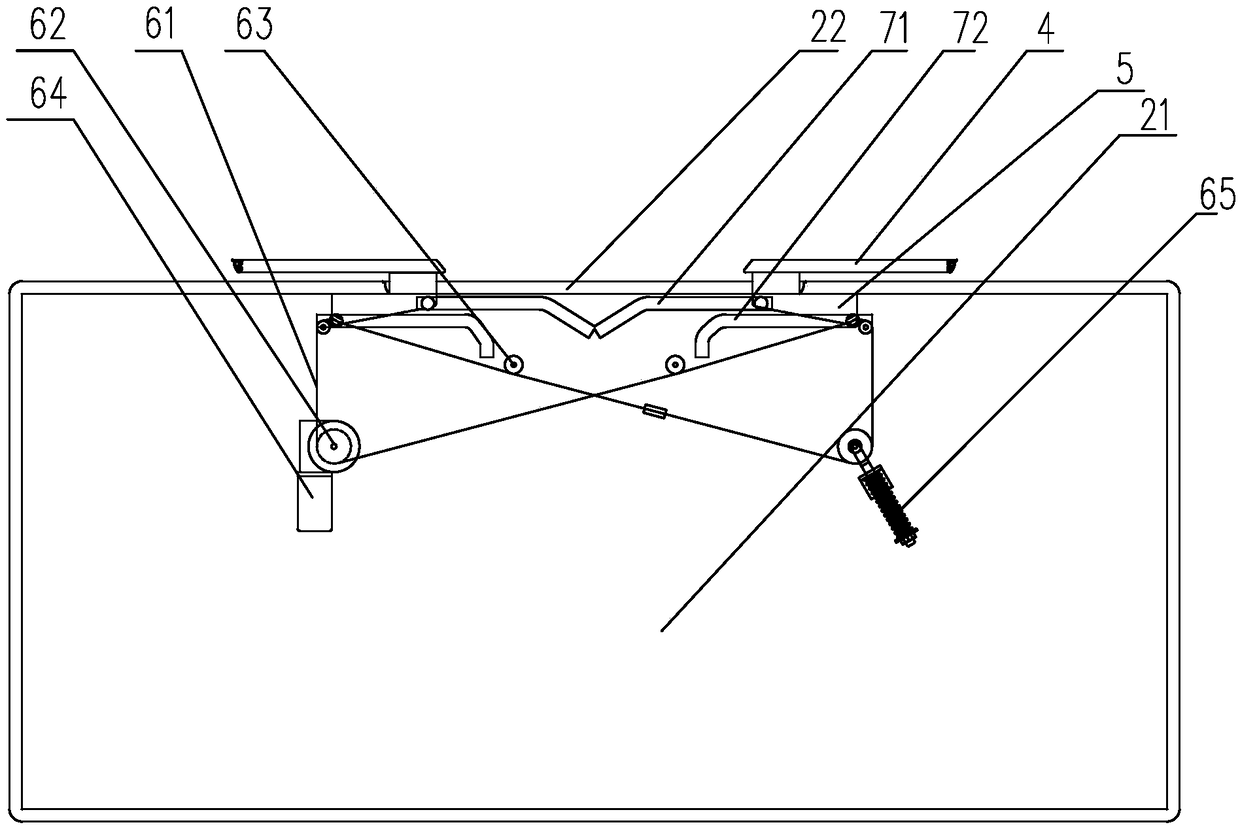

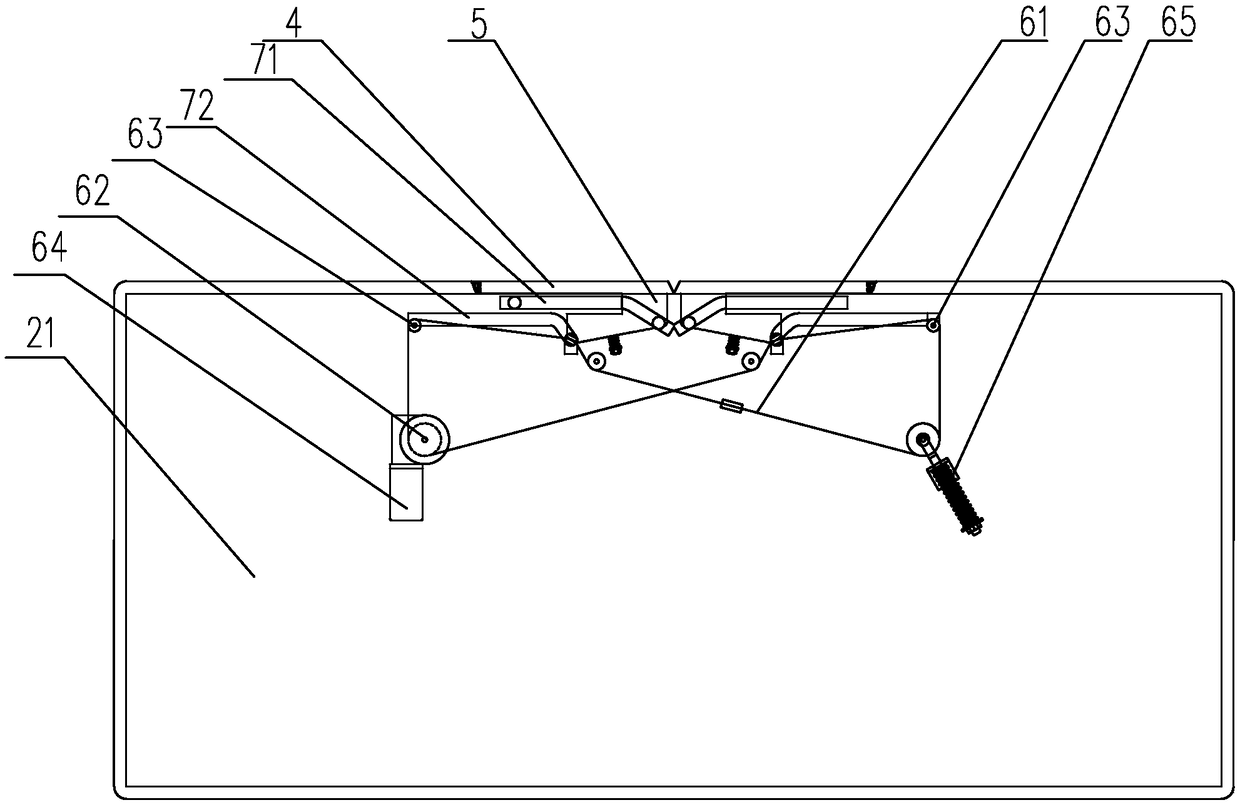

Shaft transmission tricycle capable of swinging

PendingCN113799909AGuaranteed transmission performanceSimple structureCyclesRotary transmissionsVehicle frameThree-Wheeler Vehicles

The invention provides a shaft transmission tricycle capable of swinging. The shaft transmission tricycle comprises a front tricycle frame, a rear tricycle frame and a transmission mechanism, the front tricycle frame is connected with the rear tricycle frame through a swinging mechanism, and the transmission mechanism comprises a first torque output assembly arranged on the front tricycle frame and a second torque output assembly arranged on the rear tricycle frame. The first torque output assembly transmits torque to the second torque output assembly through a transmission shaft. The second torque output assembly is in linkage fit with at least one of the two rear wheels. Compared with the prior art, the shaft transmission tricycle capable of swinging has the following advantages that the problem that in the prior art, when the front tricycle frame and the rear tricycle frame swing, the transmission system needs to swing along with the tricycle frames, and consequently the transmission reliability is poor is solved; and secondly, the problems that in the prior art, the chain is prone to falling off due to bumping and vibration, the riding experience is affected, and even the safety is affected are solved.

Owner:宁波兴隆巨创机电科技有限公司

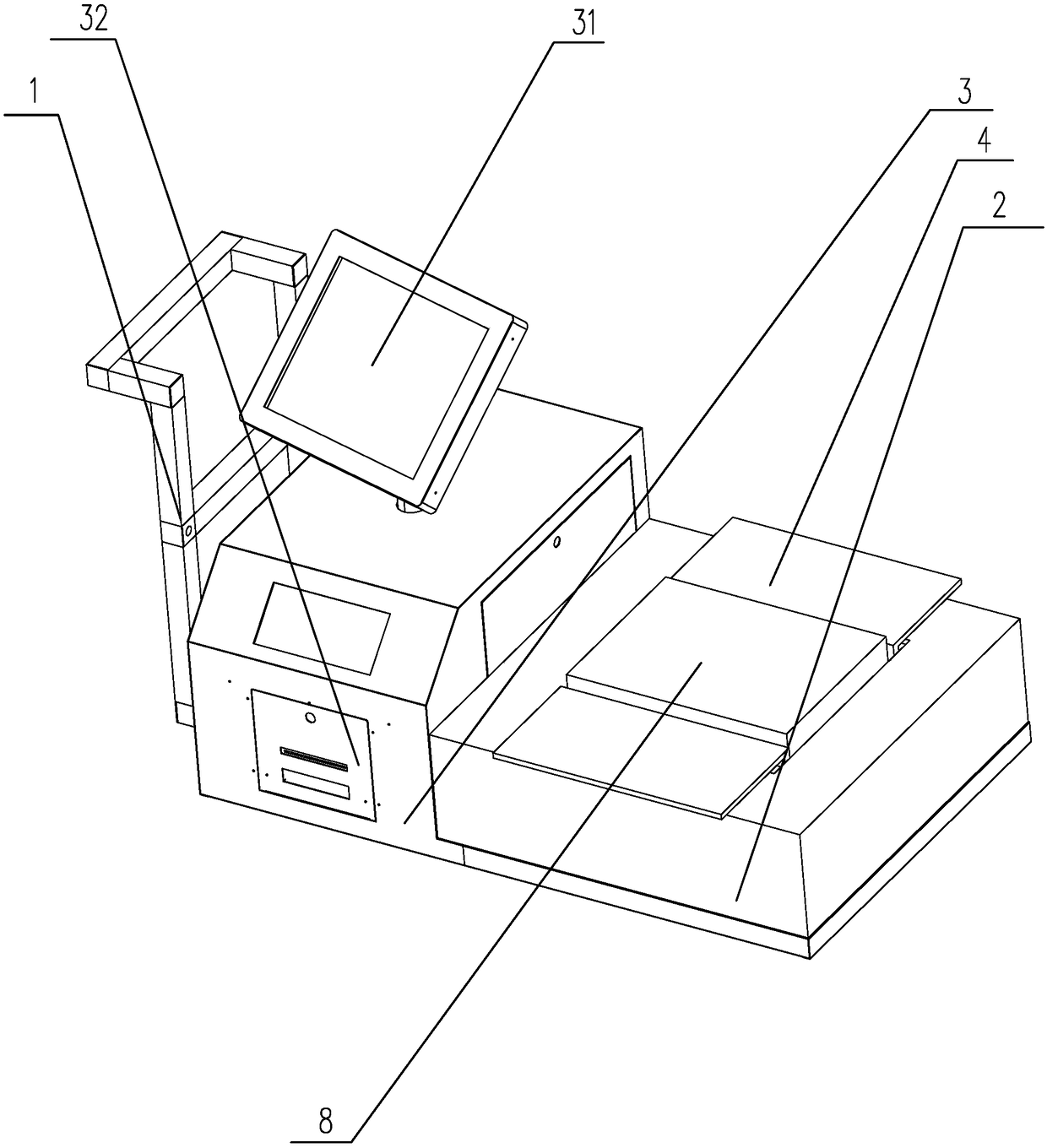

Multifunctional transfer vehicle

PendingCN108860261AEasy to transportValid countHand carts with multiple axesSpecial purpose weighing apparatusEngineeringFruits and vegetables

The invention discloses a multifunctional transfer vehicle, comprising a vehicle body, wherein the vehicle body is provided with a weighing scale and a computer for recording weighing data, the weighing scale is electrically connected with the computer, the vehicle body comprises a bearing portion and a mounting portion, the computer is mounted at the position of the mounting portion, the mountingportion is further provided with a printer for printing a goods document, the printer is electrically connected with the computer, and the weighing scale is arranged on the carrying portion. The multifunctional transfer vehicle has the advantages of simple structure, convenient transportation of fruits and vegetables, and simultaneous weighing operation.

Owner:温州菜篮子农副产品配送有限公司

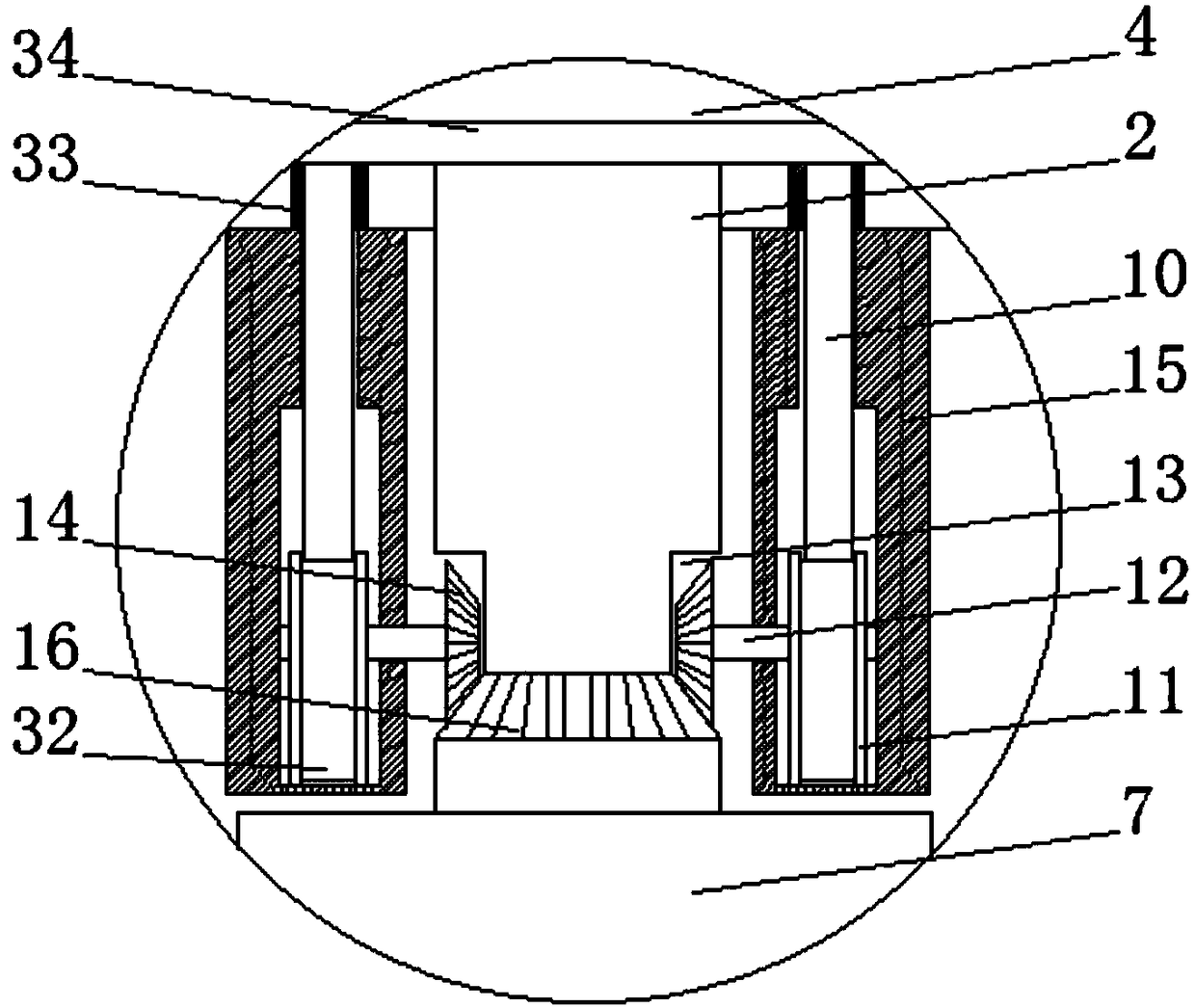

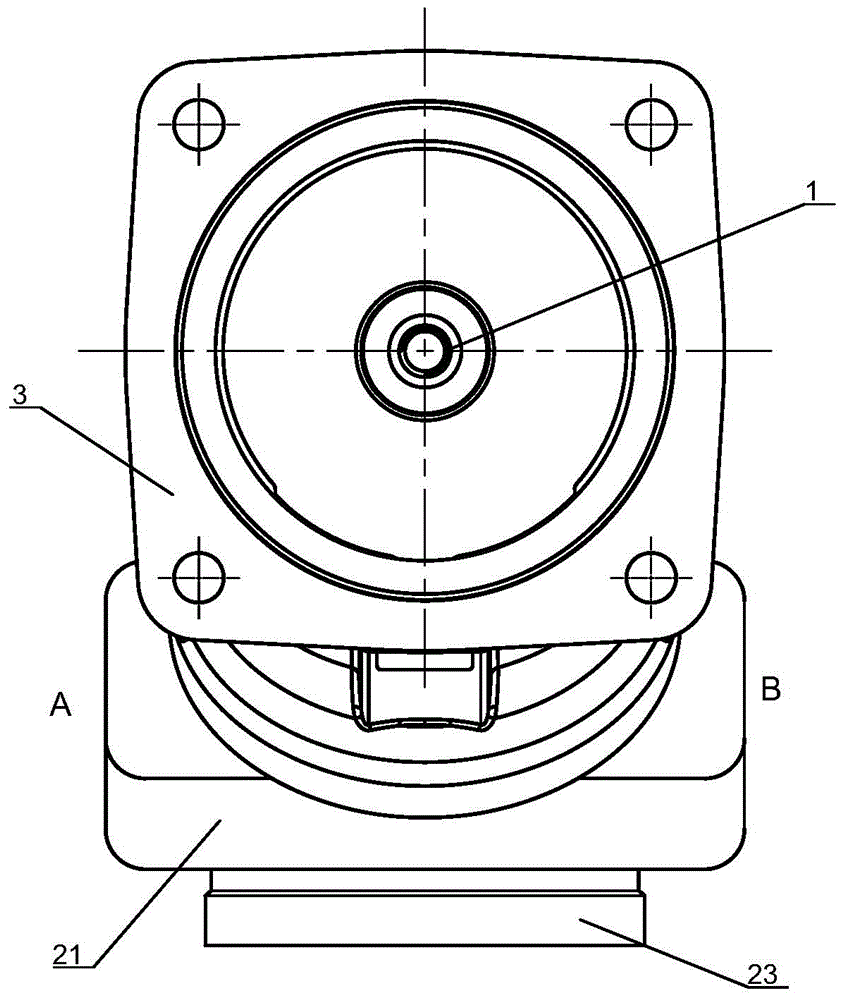

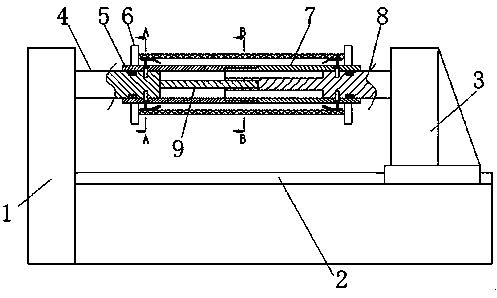

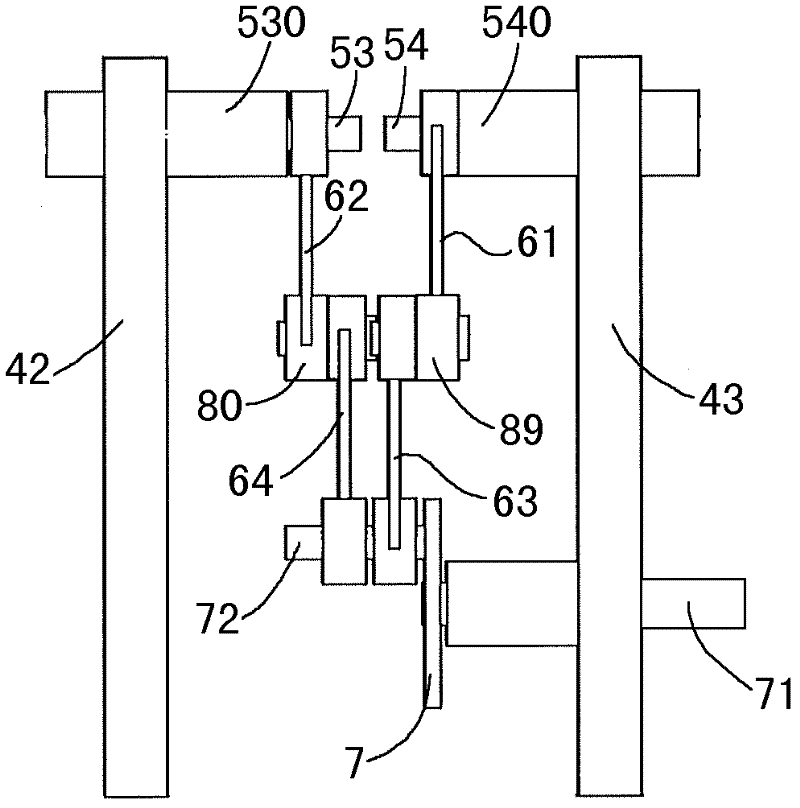

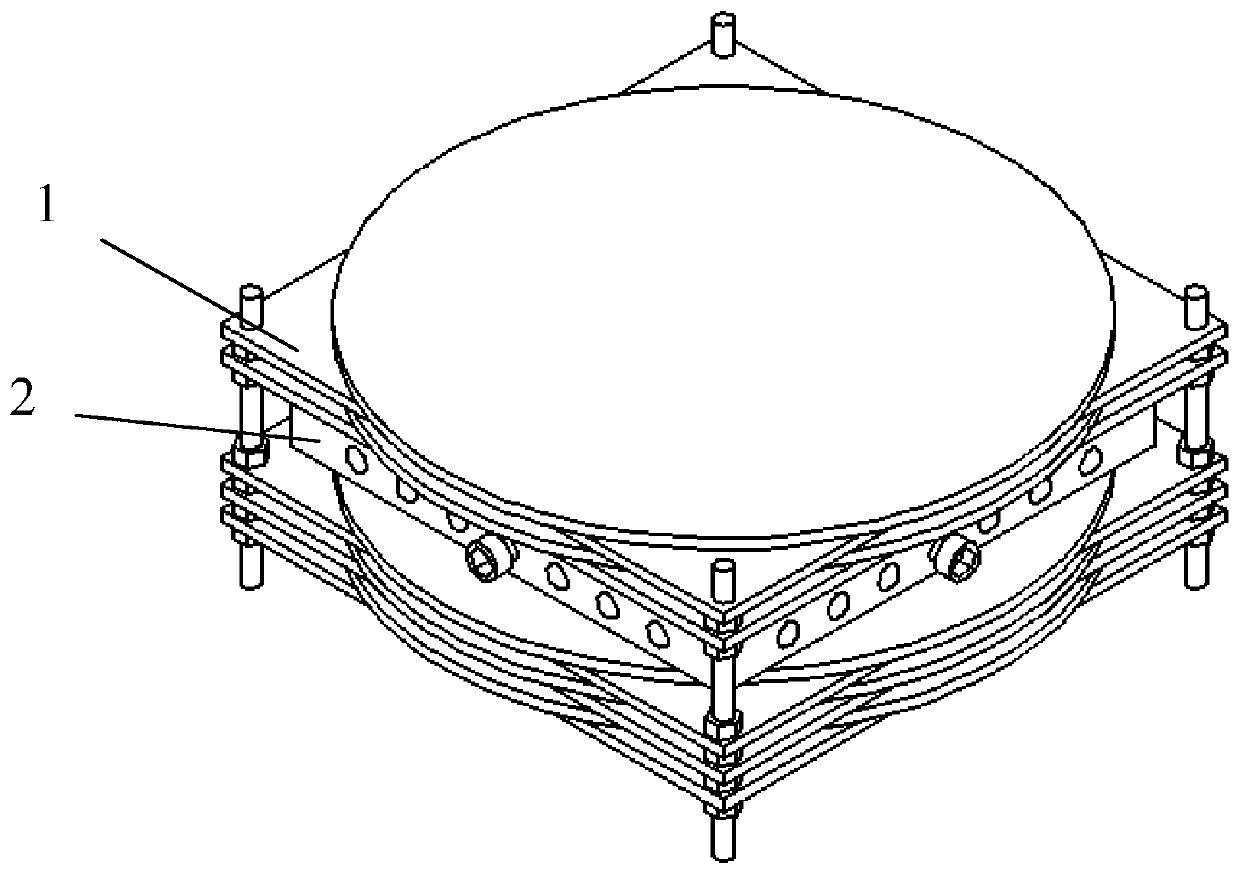

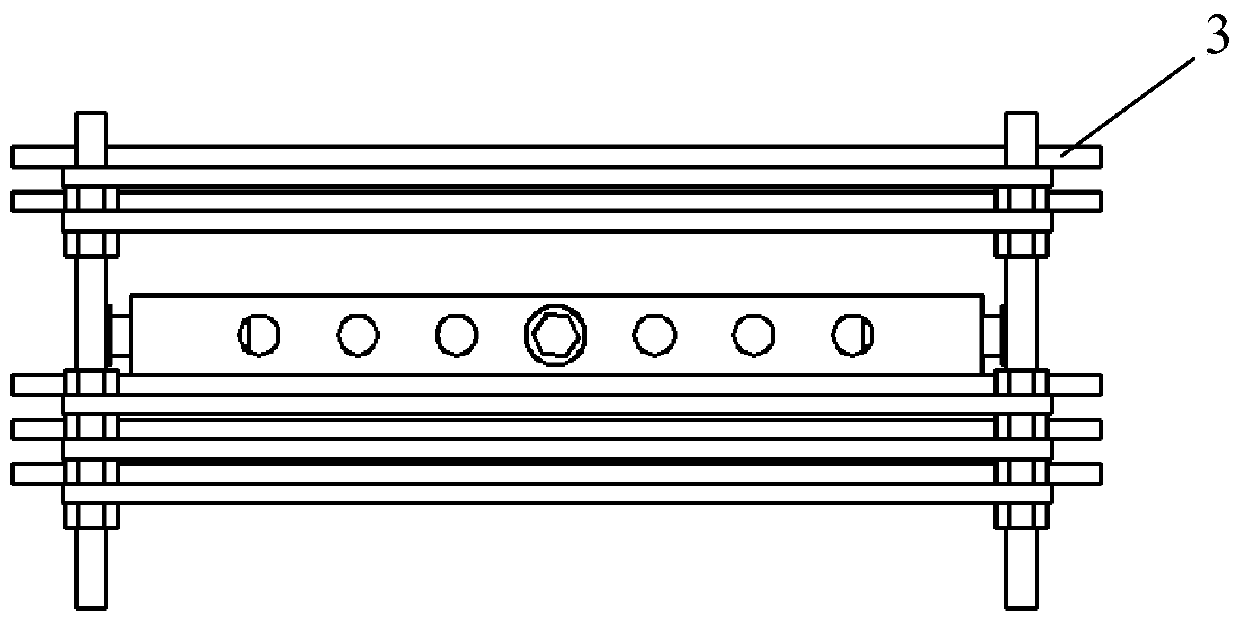

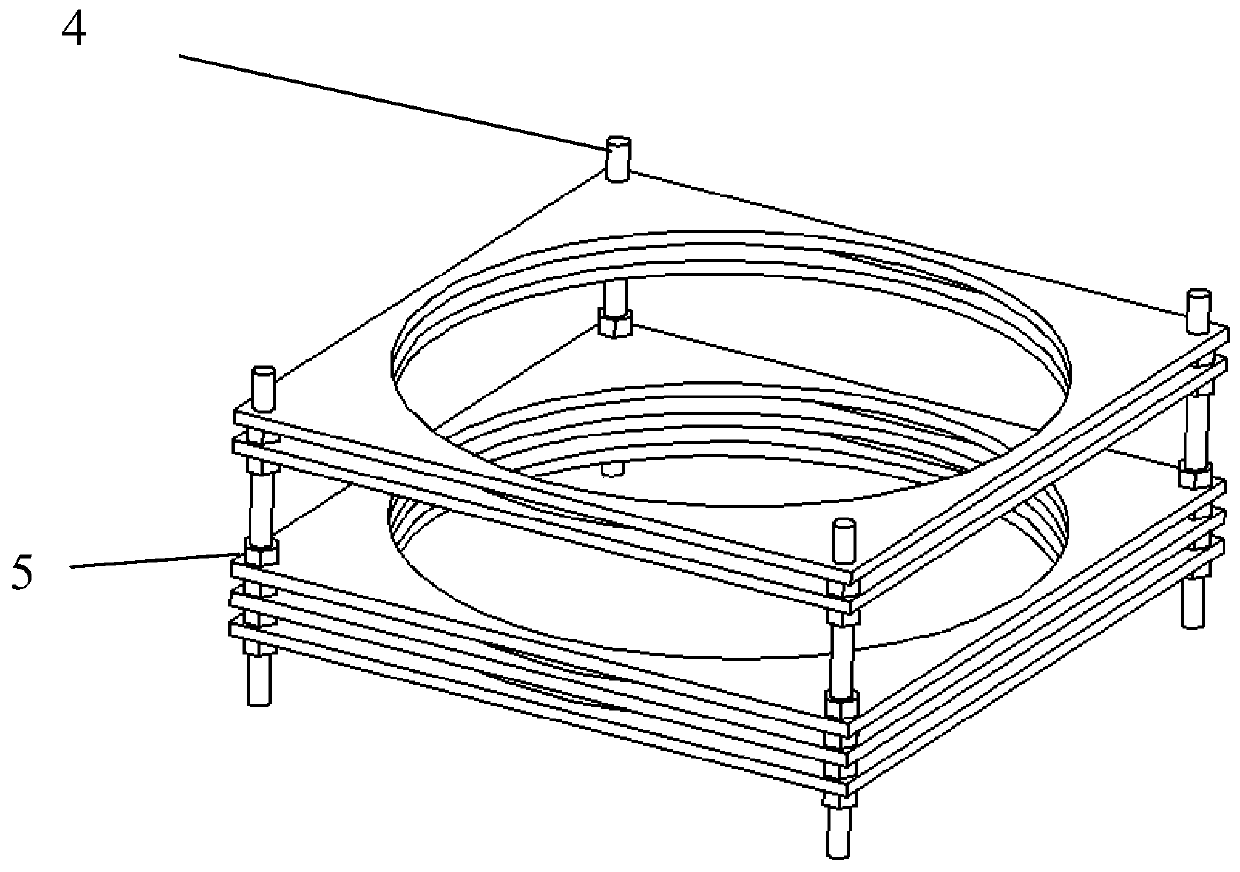

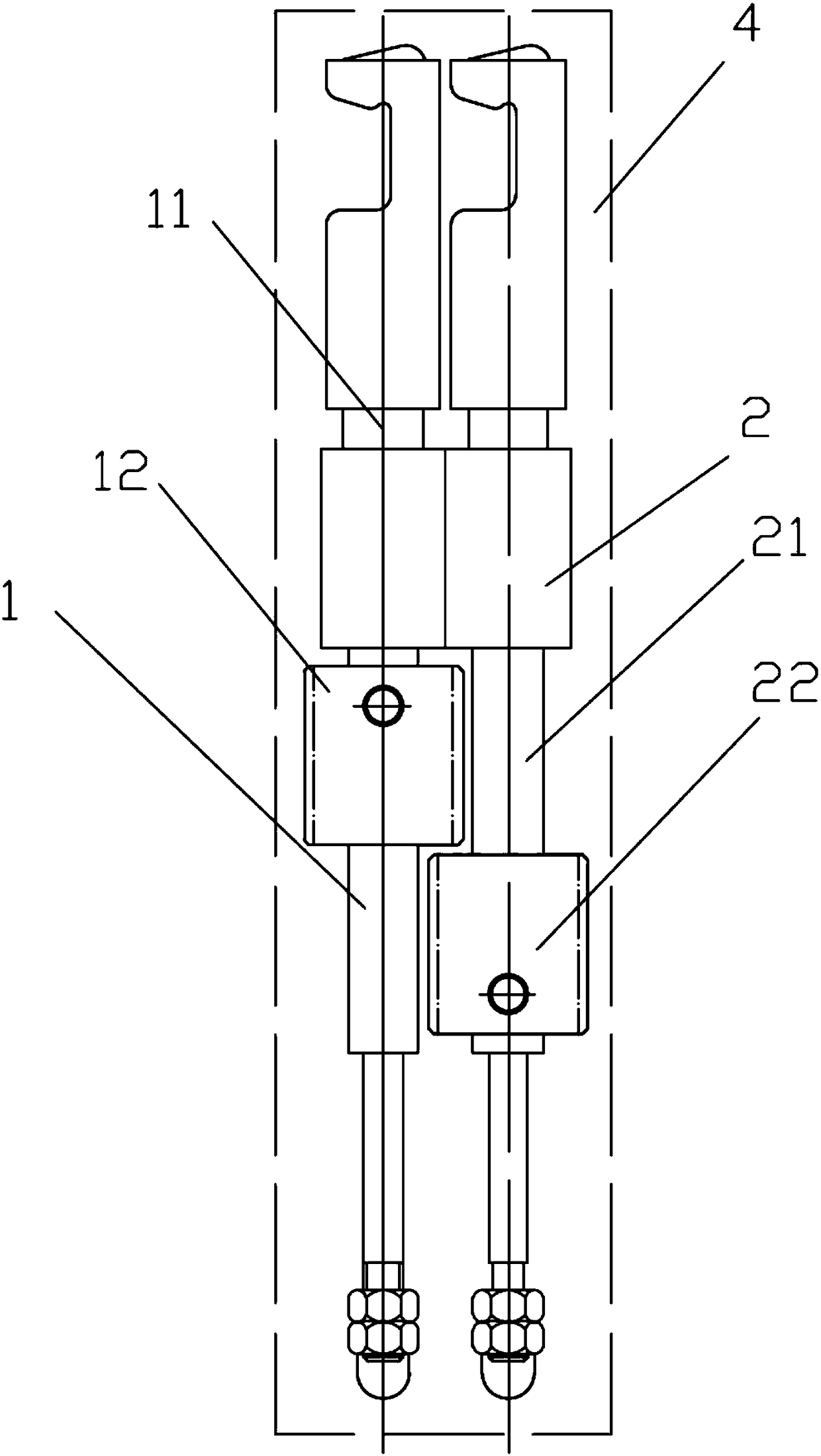

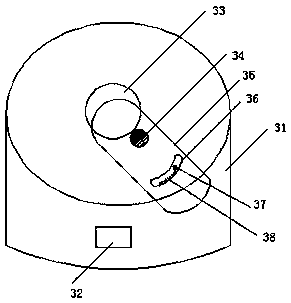

Transmission-type photo-elastic instrument

PendingCN110186601ASimple structureEasy to useForce measurement by measuring optical property variationEngineeringSolid of revolution

The invention relates to a transmission-type photo-elastic instrument comprising a support (1) and a rotation assembly; the rotation assembly is rotationally arranged in the support and comprises a plurality of rotary bodies (3), a plurality of optical elements and a fixing device (2); the rotating bodies are laminated from top to bottom and are arranged at intervals; the plurality of optical elements are fixedly arranged on the rotating bodies (3); and the fixing device (2) is used for fixing a sample (8) and enabling the sample (8) to generate stress and is arranged in the middle of the rotation assembly. Compared with the prior art, the transmission-type photo-elastic instrument in the invention has the advantages of being simple in structure, convenient to use, small in size and convenient to carry, and the cost can be greatly reduced.

Owner:TONGJI UNIV

Reaming device with synchronous adjusting function and for flange structure machining

The invention discloses a reaming device with a synchronous adjusting function and for flange structure machining, and relates to the technical field of flange machining. The problem that a currently-used reaming device is mainly used for reaming a single hole after a flange is positioned and does not have the function of quickly adjusting the reaming position according to different pipeline diameters are solved. The reaming device with the synchronous adjusting function and for flange structure machining comprises a frame seat. Two sets of buckle seats are arranged on the rear side of the top of the frame seat in a sliding manner. A mounting hole is formed in the front side of the top of the frame seat. A U-shaped frame is fixedly arranged in the middle of the rear side of the frame seat, and two sets of side lead screws are rotationally arranged on the two sides of the U-shaped frame. An octagonal nut, a connecting rod and a drill rod sliding seat are arranged, the function of quickly adjusting the reaming position is provided for the reaming device, a drill rod, an L-shaped frame and a hexagonal telescopic shaft synchronously stretch out and draw back to move while the drill rod sliding seat moves, and the drilling position of the reaming device is adjusted, so that quick adjustment can be carried out according to different types of flanges.

Owner:訾坤

Pesticide mixing equipment for agricultural technology development

InactiveCN112121668AEffective toggleRealize the mixing effectShaking/oscillating/vibrating mixersRotary stirring mixersAgricultural scienceReciprocating motion

The invention belongs to the technical field of agricultural technology development, particularly relates to pesticide mixing equipment for agricultural technology development. In view of the problemthat a pesticide diluting device in traditional agriculture is relatively simple in design and relatively single in mode, so that the diluting and mixing effect is relatively common, the following scheme is provided. The equipment comprises a cavity plate, a medicine mixing tank is fixed to the outer wall of the top of the cavity plate through bolts, a rotating motor is fixed to the outer wall ofthe top of the medicine mixing tank through bolts, and an output shaft of the rotating motor is connected with a rotating column through a coupler. According to the invention, through the arrangementof the rotating motor, a driving rod and an abutting ball can be driven to rotate, in the movement process of the abutting ball, an arc-shaped end plate is abutted, the arc-shaped end plate is enabledto horizontally reciprocate back and forth under the action of a reset spring, and under the action of an inclined stirring plate, liquid is effectively stirred, so that a mixing effect is realized;and through the arrangement of a sliding block, under the action of centrifugal force and the reset spring, the sliding block can also move back and forth, and a further mixing effect is achieved through movement of a liquid stirring disc.

Owner:刘哲

Oil distribution disc and cylinder block assembly of hydraulic pump and machining method thereof

InactiveCN104514710AFit tightlyAchieve circumferential limitPositive displacement pump componentsLiquid fuel engine componentsBodies oilHydraulic pump

The invention discloses an oil distribution disc and cylinder body assembly of a hydraulic pump. The oil distribution disc and cylinder body assembly includes a cylinder body and an oil distribution disc, wherein the cylinder body is sintered on a main body workblank by welding copper, and an internal transmission spline is arranged at the center of the cylinder body; the cylinder body is matched with the oil distribution disc by spherical surfaces, for improving work efficiency of the oil distribution disc; meanwhile, a cylinder body rotating cavity is arranged in the cylinder body, a spring is installed in the cylinder body rotating cavity, thus being beneficial to form fitting of the cylinder body and the oil distribution disc; a plunger oil pressing cavity is arranged at the periphery of the cylinder body rotating cavity, a cylinder sleeve is installed in the plunger oil pressing cavity in a pressing manner, and a plunger is installed in the hole of the cylinder sleeve; the oil distribution disc is cooperatively installed on the valve body of the hydraulic pump, and an inner circle tool relief groove is arranged on the oil distribution disc; in addition, the oil distribution plate is provided with a first kidney-shaped oil sucking and pressing hole and a second kidney-shaped oil sucking and pressing hole, a vibration damping groove is arranged on the side of each of the first and second kidney-shaped oil sucking and pressing holes, for cooperatively sucking and pressing oil, and reducing vibration; the plunger oil pressing cavity is communicated with the first and second kidney-shaped oil sucking and pressing holes by cylinder body oil paths.

Owner:HUNAN AGRICULTURAL UNIV

Equipment for bombarding surface of workpiece through energetic plasma and forming smooth plating layer

ActiveCN109055909AEven consumptionAvoid wastingVacuum evaporation coatingSputtering coatingReciprocating motionThrust bearing

The invention belongs to the technical field of film plating, and particularly relates to equipment for bombarding the surface of a workpiece through energetic plasma and forming a smooth plating layer. The equipment comprises an outer shell, inner shells, workbenches, target materials, a motor, a rotary shaft, a first bearing, a fixing ring, permanent magnets, a rotary rod, thrust bearings, annular magnets, springs, a baffle and a magnetic isolation module. According to the equipment, the cylindrical surface of the upper end of the rotary shaft is provided with one permanent magnet, the upperend and the lower end of the fixing ring are provided with thrust bearings correspondingly, the cylindrical surface of the inner side of the fixing ring is provided with one permanent magnet, the magnetic isolation module is arranged between the upper end of the rotary shaft and the fixing ring, the annular magnets on the rotary rod can do reciprocating motion continuously through the magnetic isolation module, accordingly, magnetic fields loaded on the target materials are uniform, the effect that target material consumption is uniform is ensured, target material wasting is avoided, meanwhile, the plating layer of the to-be-plated workpiece is uniform, and accordingly, the plated workpiece quality is ensured.

Owner:广东腾胜科技创新有限公司

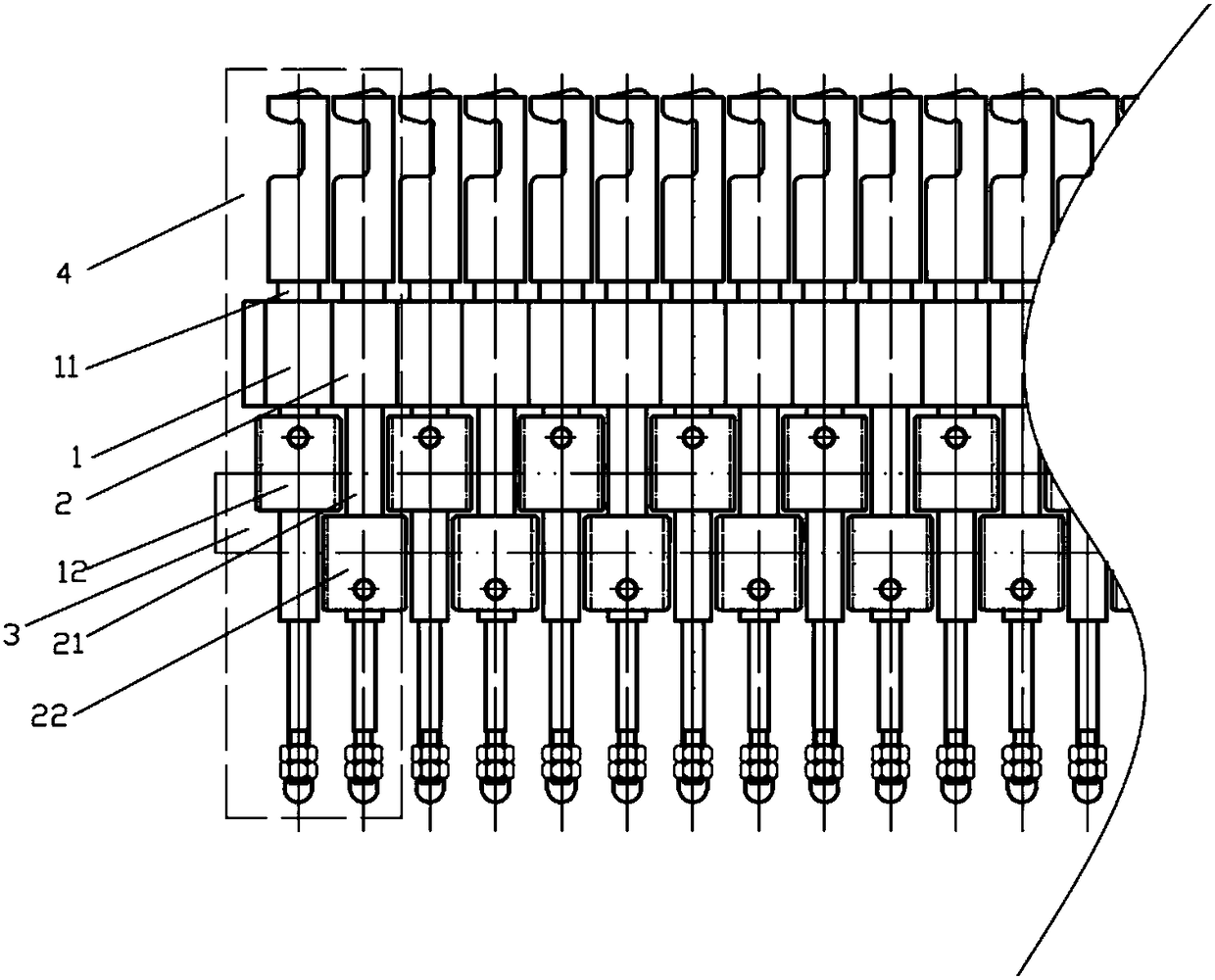

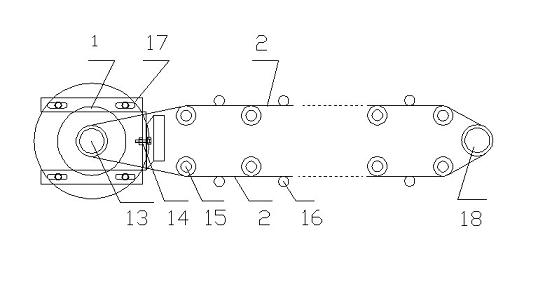

Novel gear and gear rack drive mechanism used for rope twisting knotting machine

The invention relates to the field of application of rope twisting knotting machines, in particular to a novel gear and gear rack drive mechanism used for a rope twisting knotting machine. The novel gear and gear rack drive mechanism makes knotting spacing smaller, and is simpler in structure, more convenient to assemble and more stable in mechanical drive. The novel gear and gear rack drive mechanism comprises first knotting claws, second knotting claws and gear racks, the first knotting claws comprise first claw rods and first gears, the first gears are arranged on the first claw rods, the second knotting claws comprise second claw rods and second gears, and the second gears are also arranged on the second claw rods. The novel gear and gear rack drive mechanism is characterized in that the horizontal height of the first gears is larger than that of the second gears, part of the second gears are contained in the gaps between the first gears and the first claw rods, the first knottingclaws and the second knotting claws form multiple knotting units, and the gear racks are meshed with the first gears and the second gears in all the knotting units.

Owner:WUXI XIANGHONG IND & TRADE CO LTD

Minitype water pump

InactiveCN107630824APrevent deviationAffect the transmission effectPump componentsPump controlImpellerDrive shaft

The invention relates to a minitype water pump. The minitype water pump comprises a pump body, a transmission device and a pump cover; the transmission device is arranged in the pump body, and the pump body is movably connected with the pump cover; an adjusting plate is arranged on the pump cover, an arc-shaped adjusting hole is formed in the adjusting plate, and a plurality of convex ribs distributed equidistantly are arranged on one inner side of the arc-shaped adjusting hole; an adjusting rod vertical to a pump cover body is arranged on the upper end face of the pump cover body, and the adjusting rod is positioned in the arc-shaped adjusting hole; the transmission device comprises an annular magnetic ring, and grooves A are symmetrically formed in the end face of the end, near an impeller, of the annular magnetic ring; a channel for a transmission shaft to pass through is formed in the pump body; and a heat-dissipating channel is formed in the channel along the long-axis extending direction. The minitype water pump has the advantages of effectively controlling the quantity of water flowing out from a water outlet of the pump cover according to the pressure of the water pump, avoiding dry burning phenomenon and prolonging the service life of the water pump.

Owner:如皋千骏工具有限公司

Piston processing production line

InactiveCN106625157AIncrease productivityReduce manufacturing costGrinding machinesGrinding feedersProduction lineEngineering

The invention relates to a piston processing production line. The piston processing production line includes a hole honing machine, a coreless rough grinding machine, and a coreless fine grinding machine; a first transmission unit for sending a work piece to the coreless rough grinding machine is arranged between the hole honing machine and the coreless rough grinding machine; and a second transmission unit for sending the work piece to the coreless fine grinding machine is arranged between the coreless rough grinding machine and the coreless fine grinding machine. According to the invention, multiple work stations are integrated into one production line, the processing efficiency of pistons can be greatly improved, and the production cost can be effectively reduced.

Owner:JIANGSU HENGHAO ELECTROMECHANICAL MFG

Hydraulic motor cylinder block oil distribution disc assembly and machining method thereof

InactiveCN107953085AGuaranteed transmission effectReduce noiseServomotor componentsHydraulic motorOil distribution

The invention relates to the technical field of hydraulic system executive components, and discloses a hydraulic motor cylinder oil distribution plate assembly and a processing method thereof, including a plunger cylinder and an oil distribution plate. The plunger cylinder includes a cylinder body and sintered copper. Sintered copper is sintered on the main body of the cylinder body. A connecting rod cavity is set in the center of the plunger cylinder body, and a plunger cavity is set on the periphery of the connecting rod cavity. The oil channel is connected, and the oil discharge channel is provided with a vibration-reducing groove; the oil distribution plate is provided with a positioning pin hole of the oil distribution plate and the flushing oil circuit of the oil distribution plate; Oil pan right craft cone. The invention has the characteristics of wear resistance, corrosion resistance and impact resistance, and has high processing precision; it not only reduces the noise generated when the hydraulic motor is running, but also can ensure the transmission performance of each component, and is equipped with assembly guides to avoid damage to assembly parts and effectively prolong the life of the hydraulic motor. Component life.

Owner:SICHUAN QIXING ELECTRONICS

Direct twisting machine

InactiveCN102586961AImprove energy savingGuaranteed tensionContinuous wound-up machinesEngineeringPulley

The invention relates to a direct twisting machine. On the basis of an existing direct twisting machine, a motor and a belt pulley are mounted at two ends of a frame respectively, a motor transmission belt pulley is mounted on an output shaft of the motor, a transmission belt is mounted between the motor transmission belt pulley and the belt pulley positioned at the other end of the frame, and wharve shafts fixedly mounted at the lower ends of spindles are driven by means of friction or meshing. The wharve shafts positioned at the lower ends of the spindles on the same row are simultaneously driven by the motor and the transmission belt, the spindles are driven to simultaneously rotate, and an energy saving effect is obvious. By the aid of a sliding tension device and a tension pulley structure, the transmission belt is ensured to keep a certain tension during operation, and a transmission effect is ensured.

Owner:JIANGSU HAIYANG CHEM FIBERS

Cutting device

ActiveCN108330223AAchieve improvementAchieve transferLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusAnnular cutterEngineering

The invention belongs to the technical field of cutting equipment and particularly discloses a cutting device. The cutting device comprises a base. The base is provided with a support column and a cross beam, wherein the support column and the cross beam are connected in sequence. The cross beam is provided with an air cylinder. A piston rod is provided with an annular cutter. The base is providedwith a workbench. The support column is provided with a sliding rail, the upper portion of the sliding rail is inclined towards one side. The piston rod is provided with an empty cavity structure, and the annular cutter is provided with an air sucking hole. A sleeve is arranged between the annular cutter and the air cylinder. The sleeve and the air cylinder are connected in a sealed manner. The middle of the piston rod is provided with a push plate fixedly connected with the piston rod, the upper portion of the piston rod is provided with an air discharging hole communicating with the empty cavity structure. A cross rod is connected between the piston rod and the sliding rail, the cross rod and the sliding rail are connected in a sliding manner. The air cylinder is inclined when the crossrod is located on the upper portion of the sliding rail. The cutting device is mainly used for cutting annular leather, and the problem that the cutting effect is poor in the leather cutting processis solved.

Owner:宁波隆锐机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com