Metal pipe fitting machining fixing device used for numerical control machine tool

A technology of metal pipe fittings and fixing devices, which is applied in the direction of metal processing, metal processing equipment, grinding machine parts, etc., can solve the problems of error, uneven processing degree, unstable clamping of pipe fittings, etc., and achieve good fixing firmness, Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

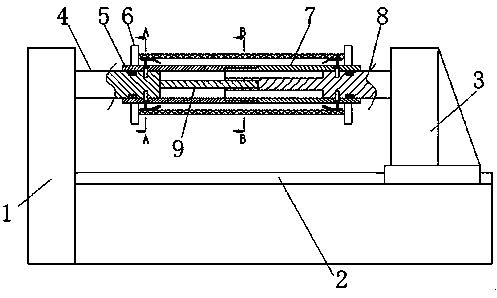

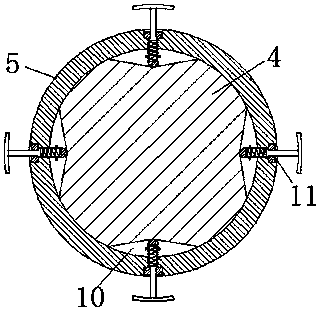

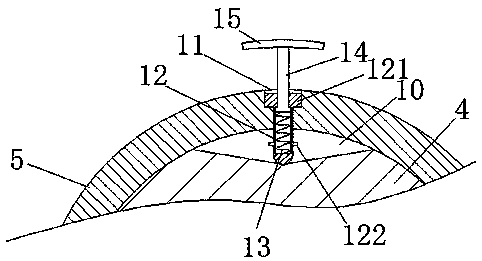

[0027] Such as Figure 1-2 As shown, a metal pipe fitting processing and fixing device for a CNC machine tool includes a machine tool body 1, a slide rail 2 is fixed on the machine tool body 1, a tailstock 3 is slidably connected to the slide rail 2, and a fixed-axis rotation connection is connected to the machine tool body 1. There is a main shaft 4, and the fixed axis rotation on the tailstock 3 is connected with the auxiliary shaft 8 sharing the central axis with the main shaft 4. When processing metal pipe fittings, one end of the metal pipe fittings is inserted and sleeved on the main shaft 4 and the sleeve along the axis of the main shaft 4. 5 on the tensioning mechanism, and buckle the baffle plate 6 on the contact sleeve 5. When the metal pipe is inserted on the main shaft 4, it first contacts the tapered plate, and as the metal pipe advances to the arc The pressing plate 15 exerts an extrusion force pointing to the center of the main shaft 4. The arc-shaped pressing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com