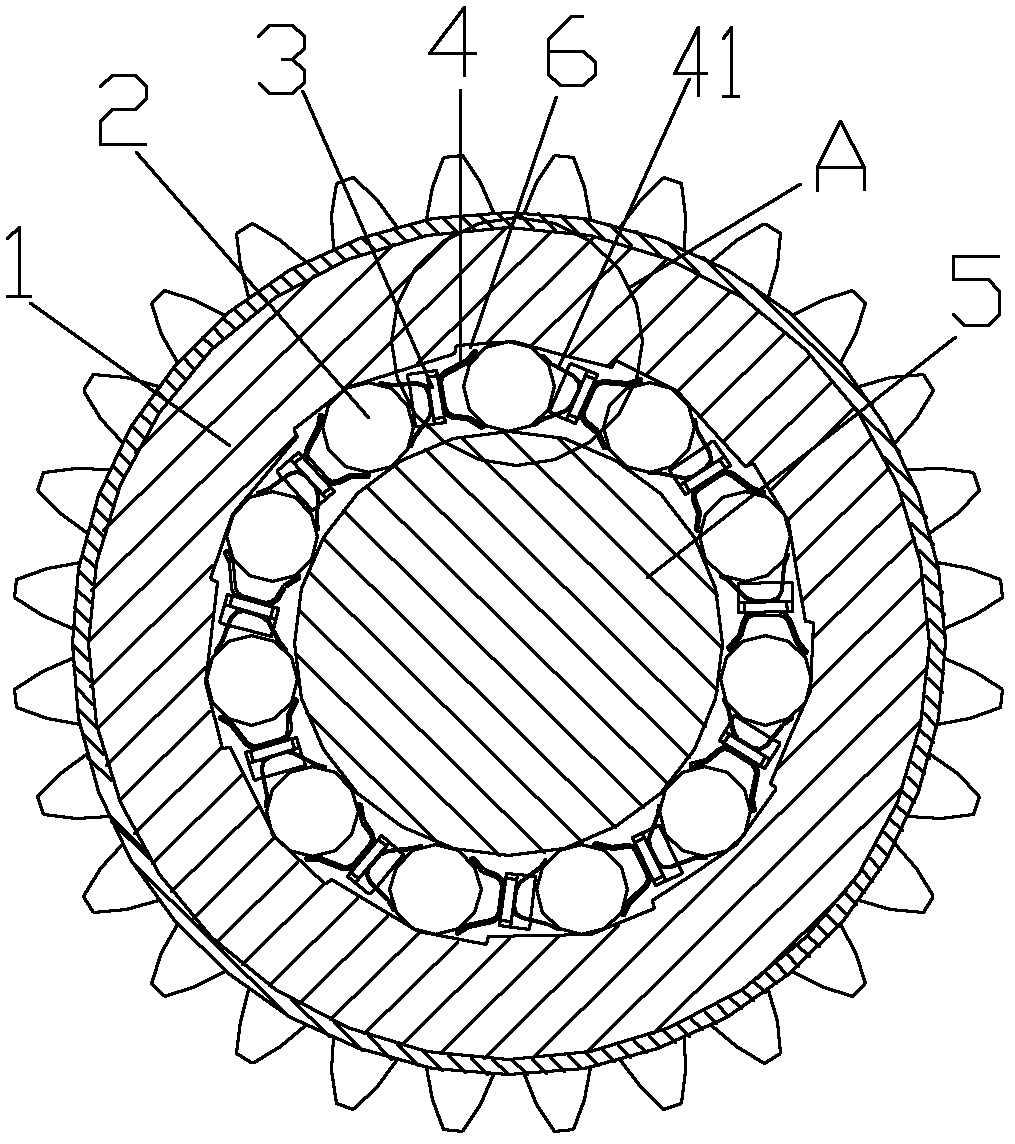

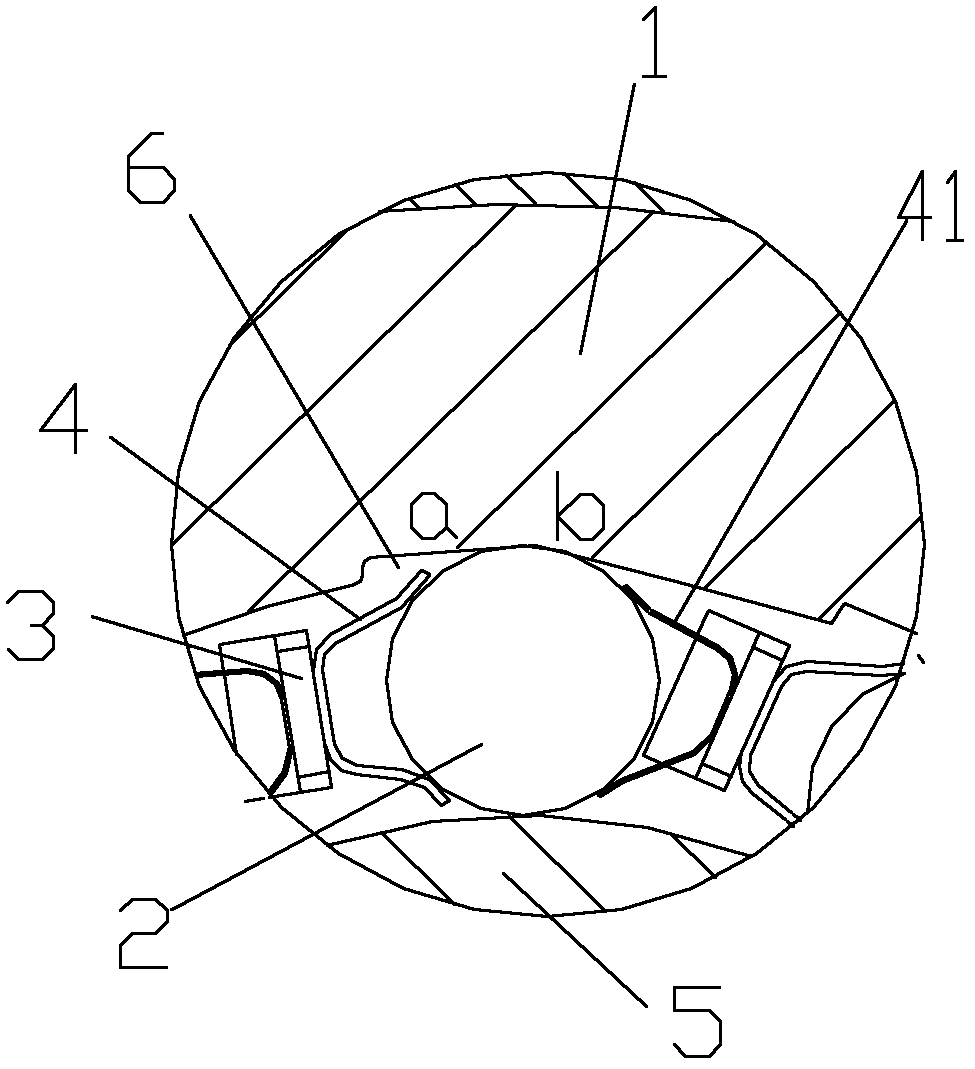

Bearing Overrunning Clutch

A technology of overrunning clutches and bearings, which is applied in the direction of clutches, one-way clutches, bearings, etc., can solve problems such as easy deflection of rollers, large space positions, complex processing processes, etc., to ensure processing and assembly accuracy, improve bearing capacity, Guarantee the effect of the transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

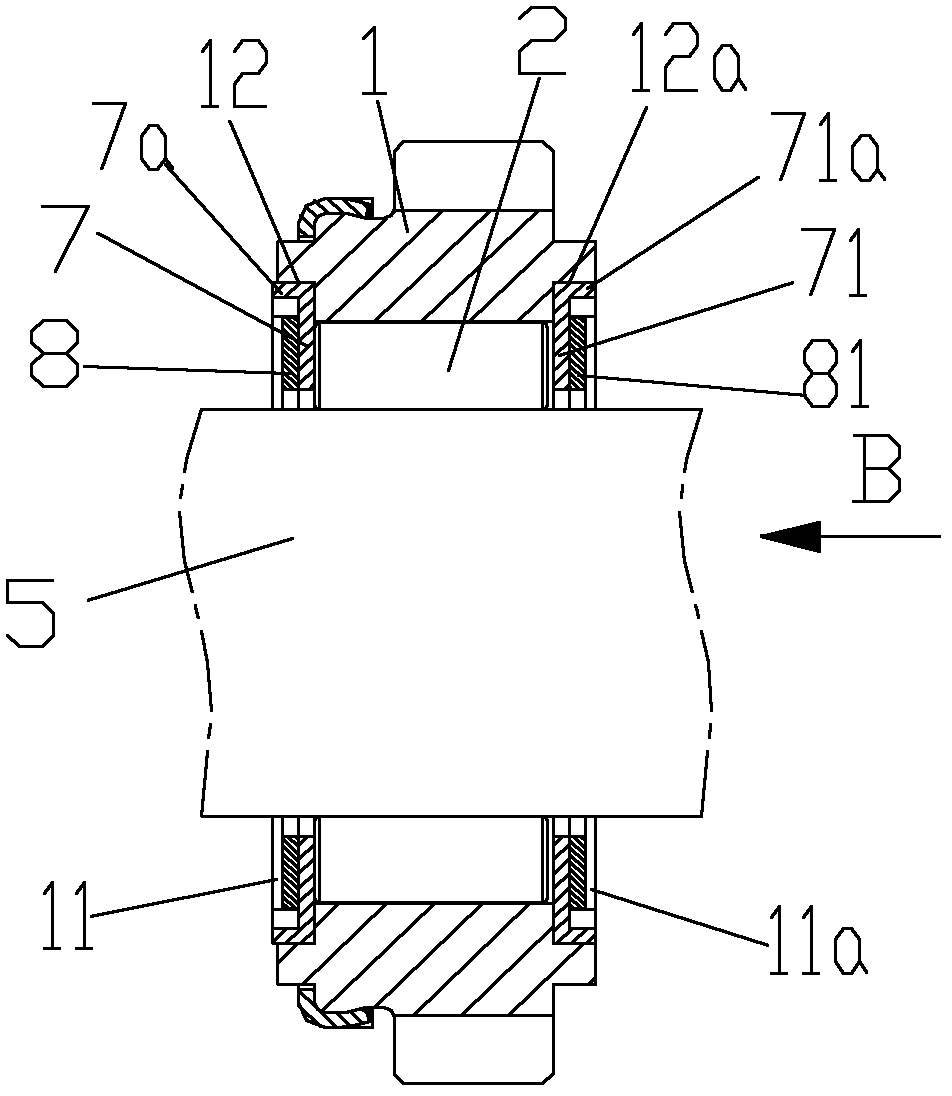

Embodiment 2

[0037] Figure 5 It is an axial sectional view of Embodiment 2 of the present invention, Image 6 for Figure 5 The sectional view along C-C direction, as shown in the figure, the difference between this embodiment and Embodiment 1 is that in this embodiment, the outer diameter of the retaining ring I72 is smaller than the inner diameter of the outer ring 1, and the outer circle of the retaining ring II71 is folded outward. The axial bosses 71a are curved and distributed along the circumferential direction. In this embodiment, six axial bosses 71a are evenly distributed along the circumferential direction; the two axial ends of the outer ring 1 are respectively provided with sinking grooves (sinking grooves 11 and sinking groove 11a), the inner circle of the sinking groove (sinking groove 11a) corresponding to the retaining ring II71 is provided with an axial groove 12a, and the retaining ring I72, rolling body 2 and retaining bracket axially penetrate the inner circle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com