Patents

Literature

220results about How to "Reduce mechanical failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

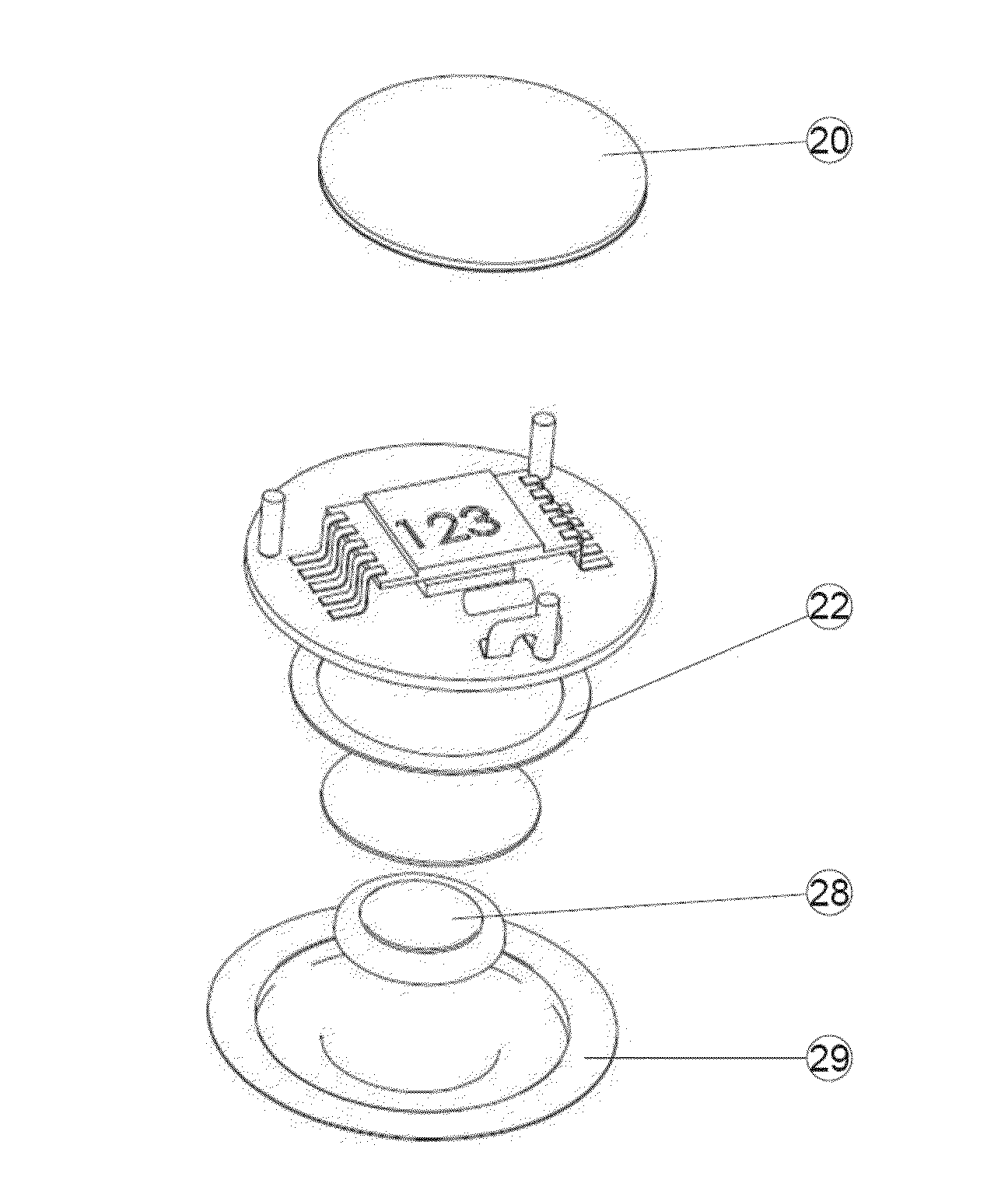

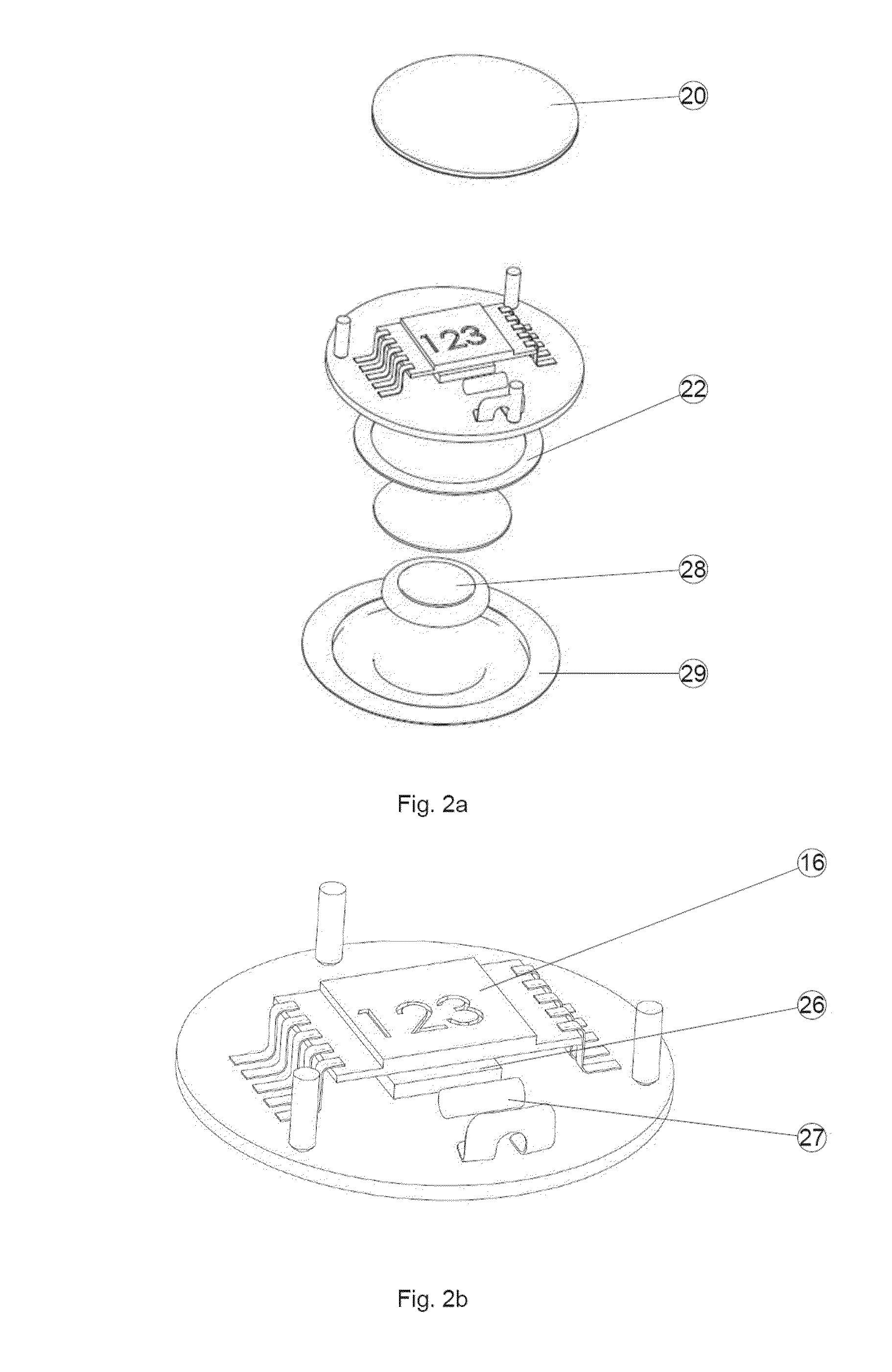

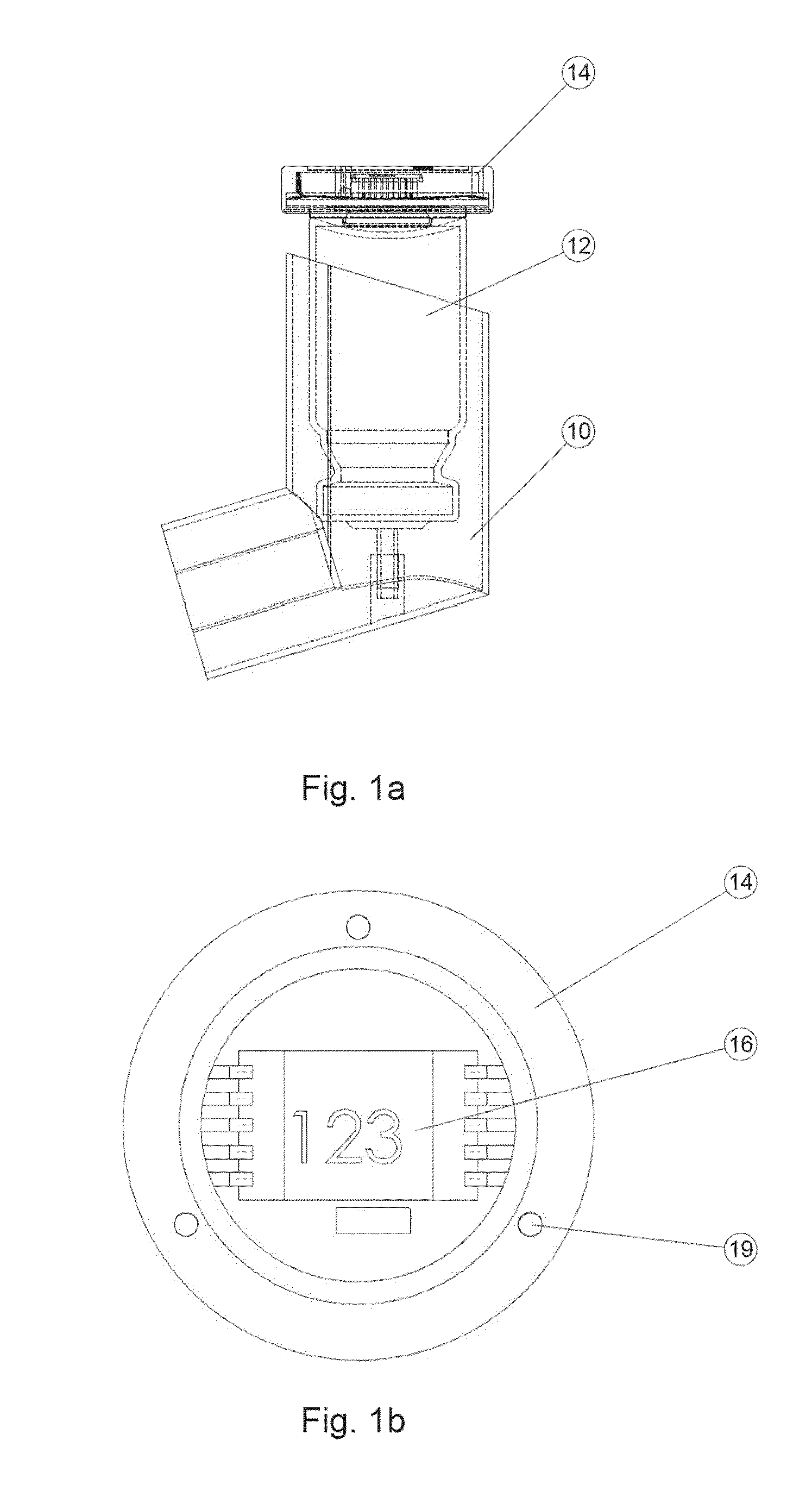

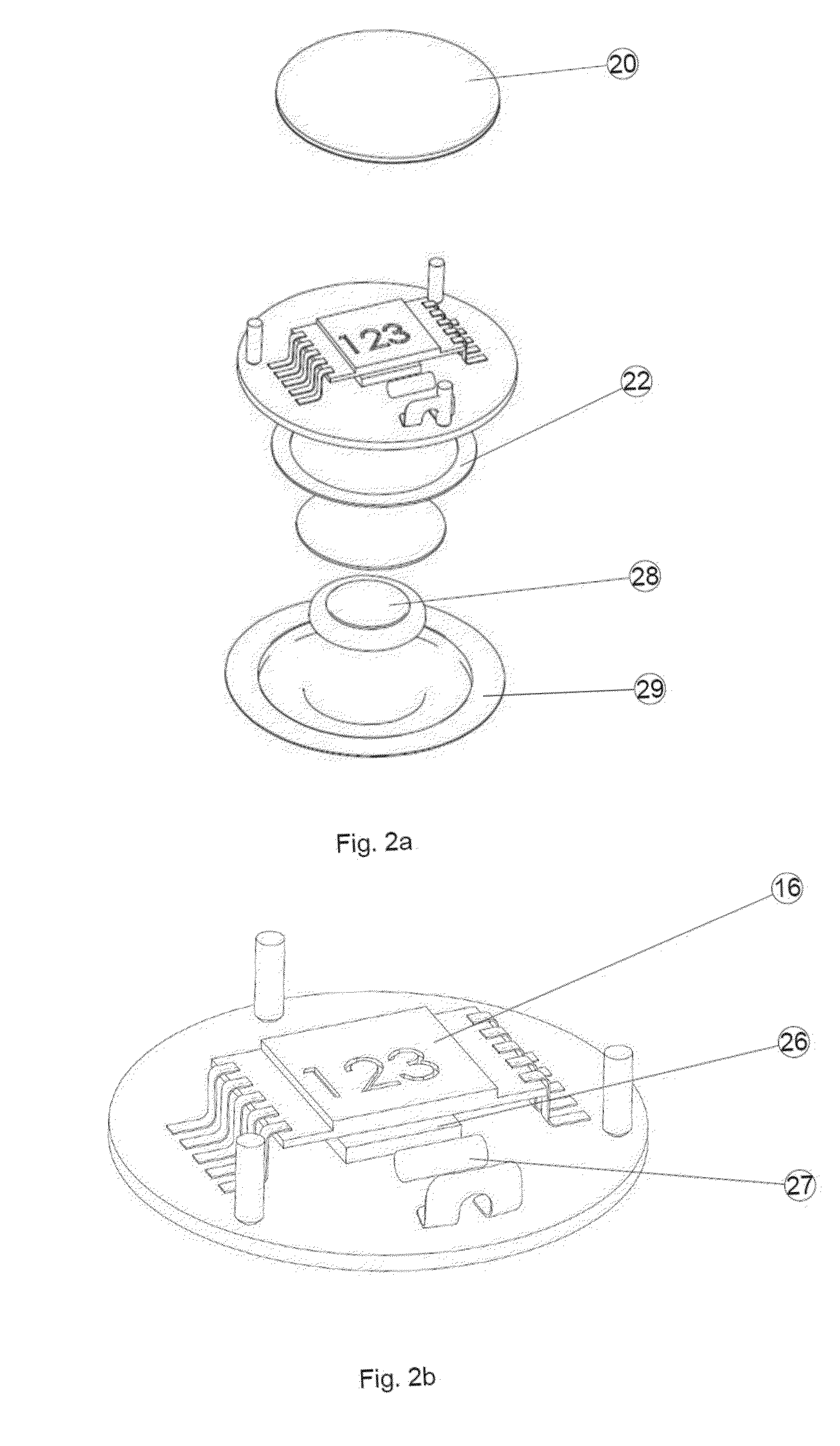

Dose Counter and Recording Method

ActiveUS20110041845A1Potential for errorMinimize doseLiquid surface applicatorsPowdered material dispensingElectronic controllerMedicine

A dose counter for a metered dose inhaler includes a force sensor, an electronic controller, a memory for storing data indicative of a remaining number of doses and an electronic display device coupled to the controller for displaying the remaining number of doses. The dose counter is attached or integrated into a base of a canister containing medicament such that force applied to the base of the canister is registered by the force sensor, the controller being configured to measure force applied to the dose counter when depressing the canister and being responsive to measured force to decrement the remaining number of doses stored in the memory and shown on the display device.

Owner:TEVA PHARMA IND LTD

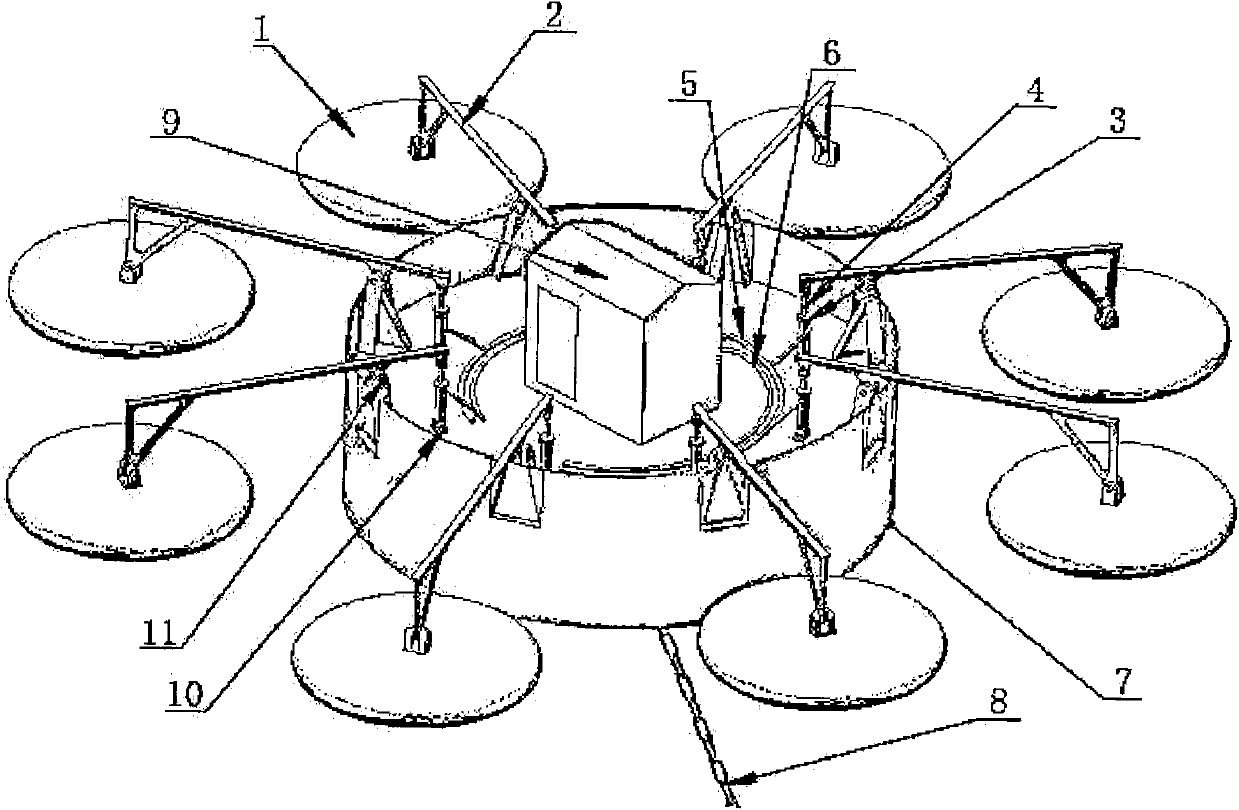

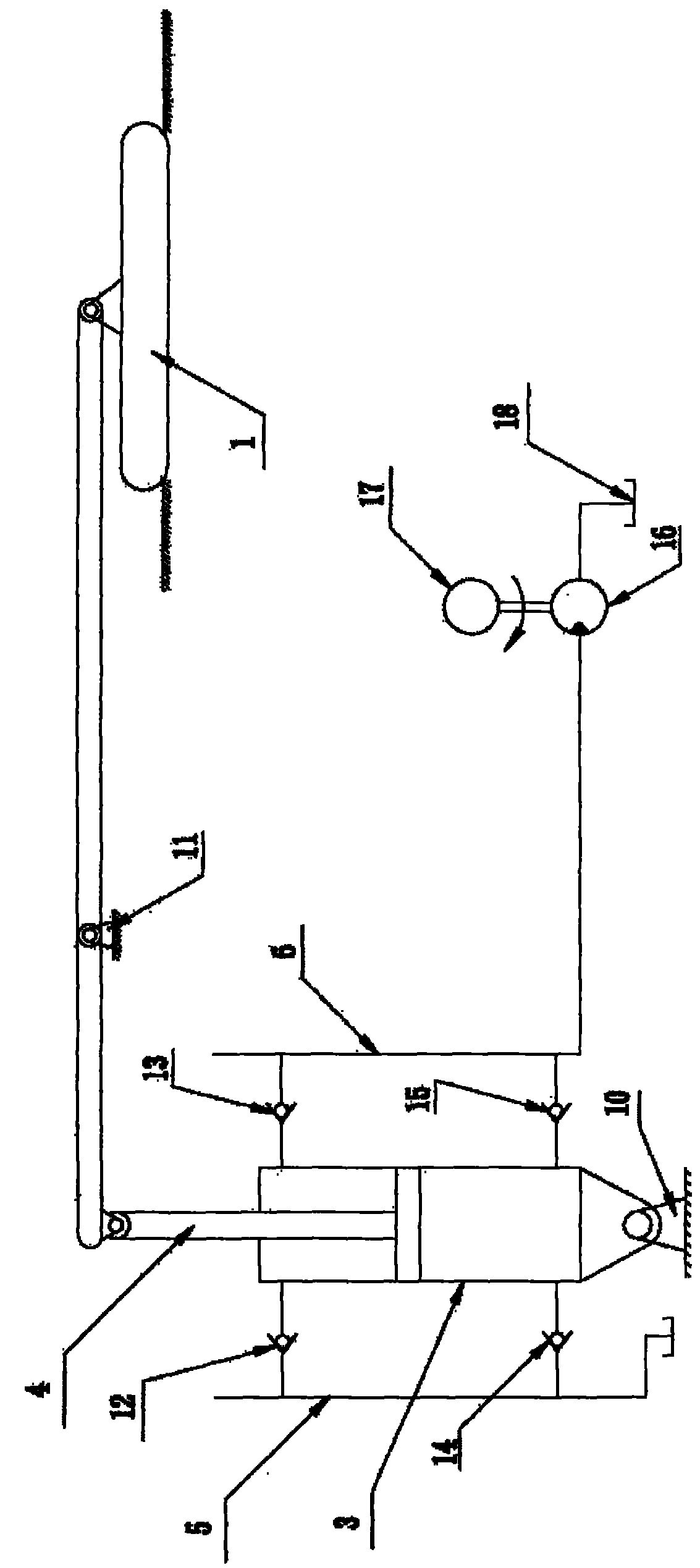

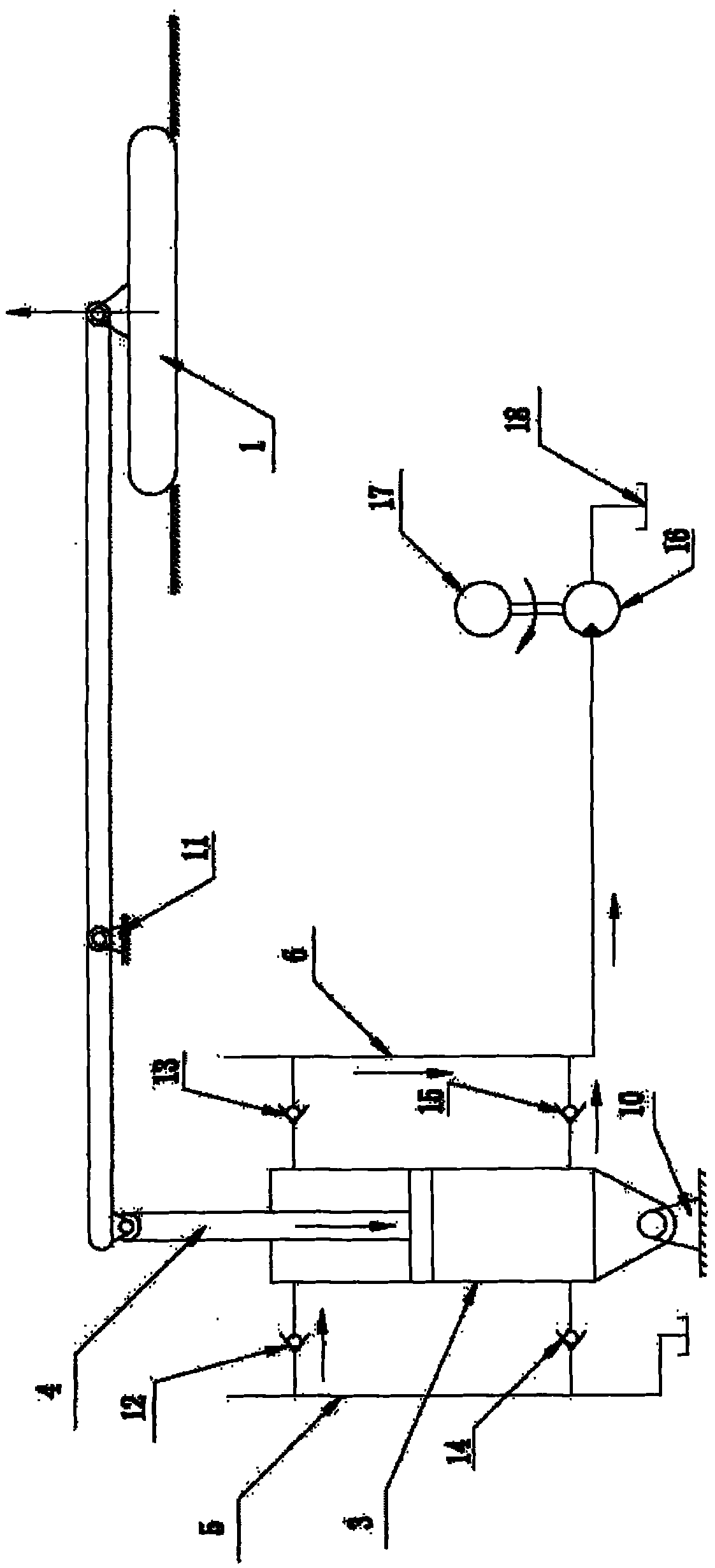

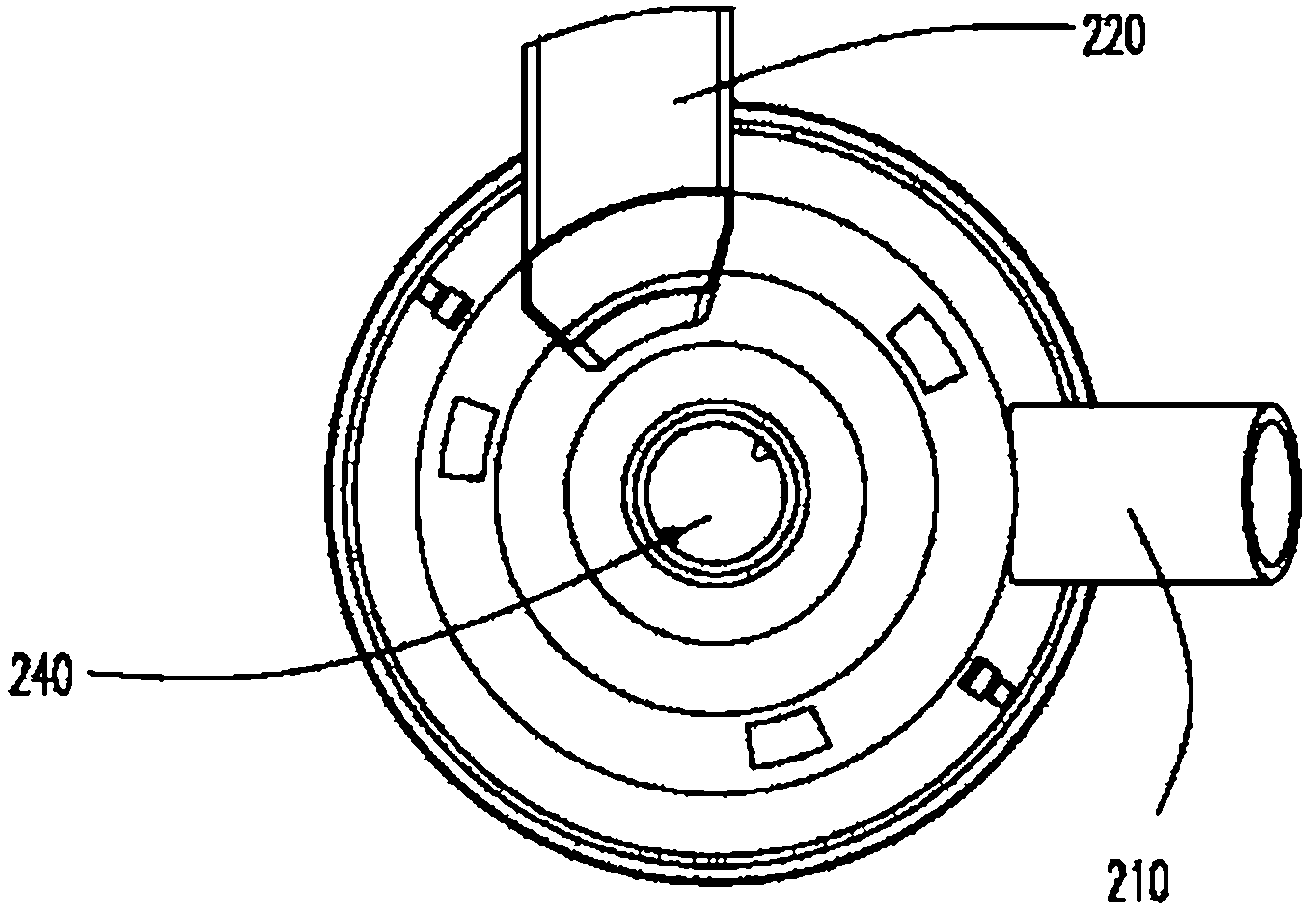

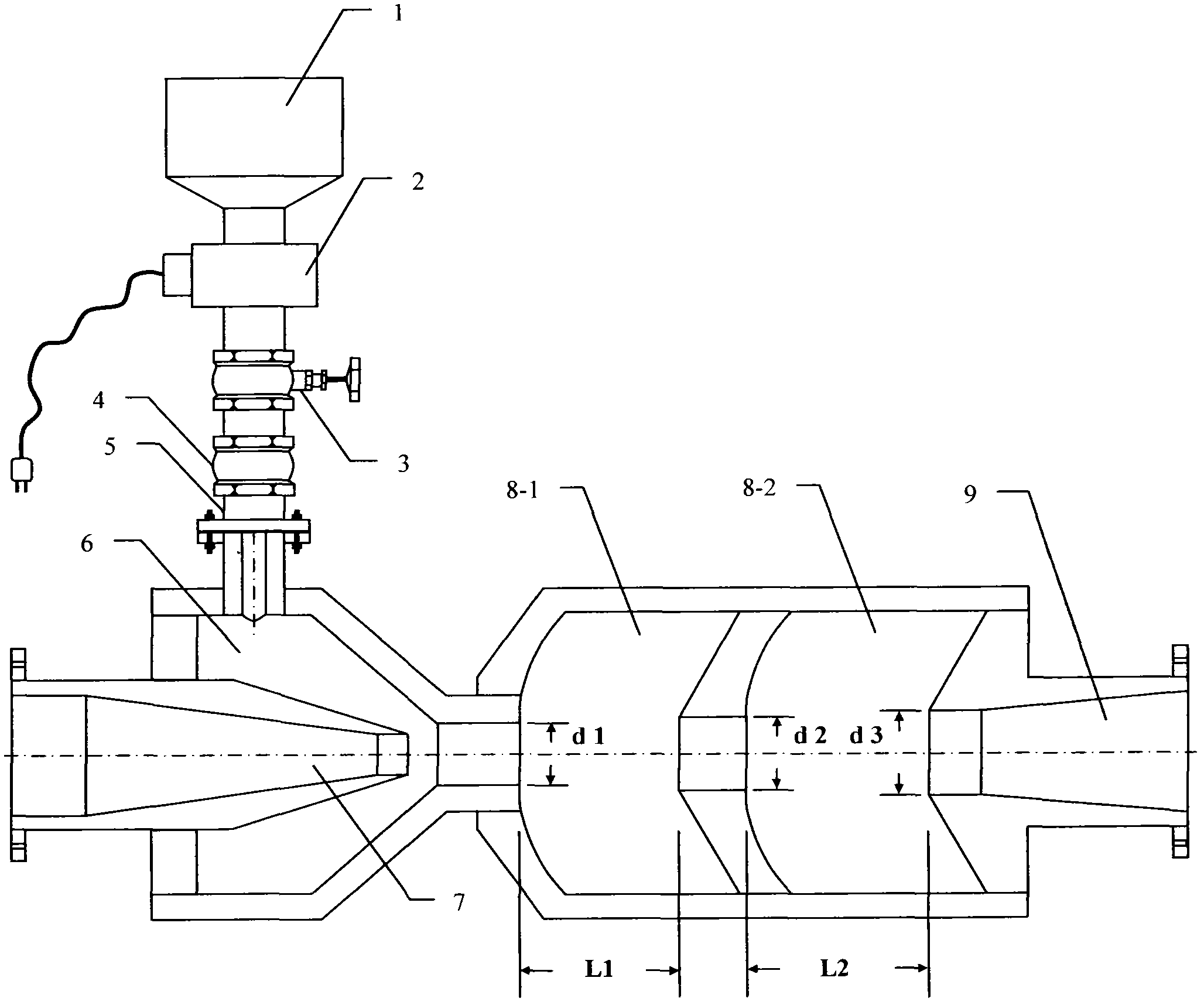

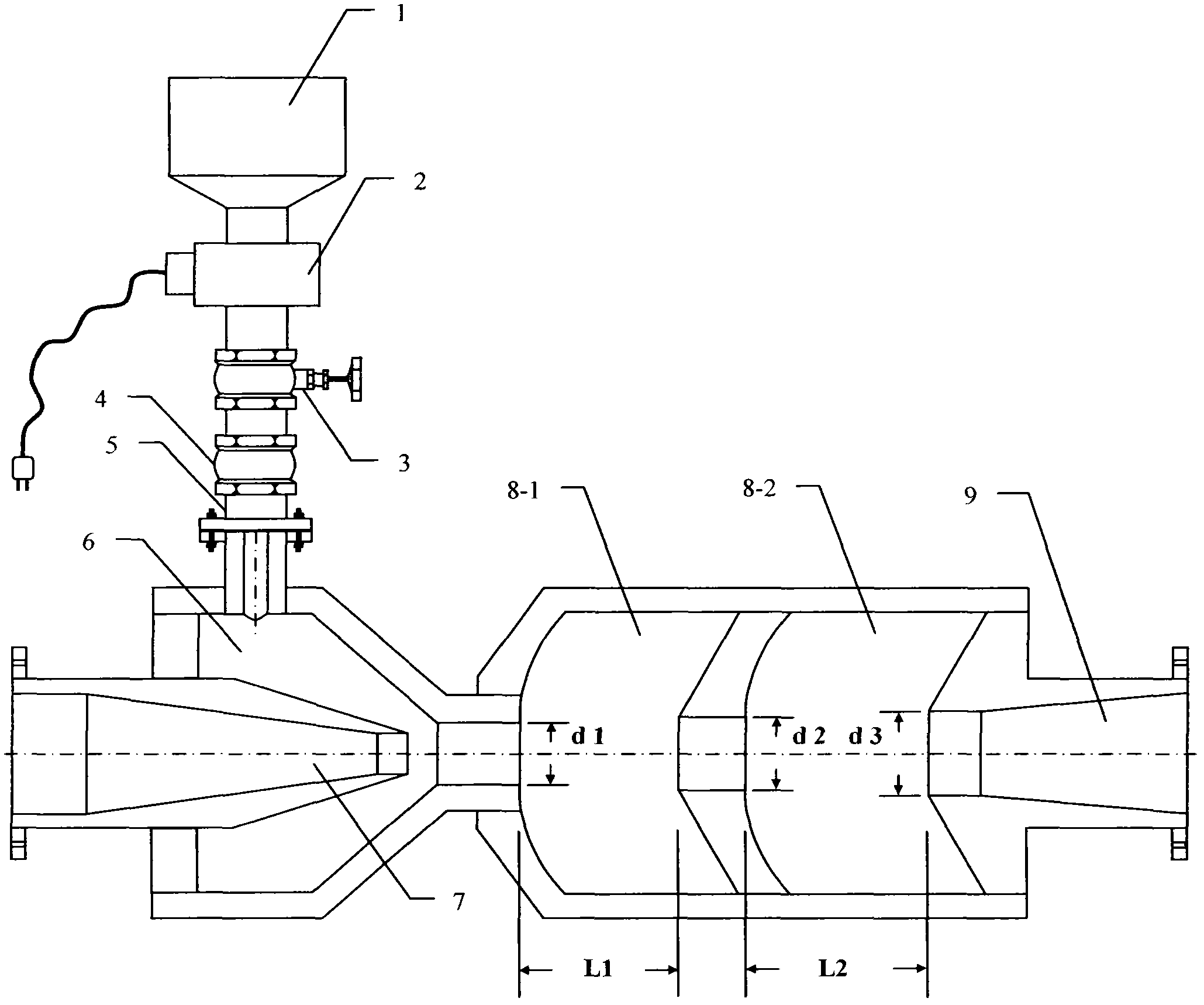

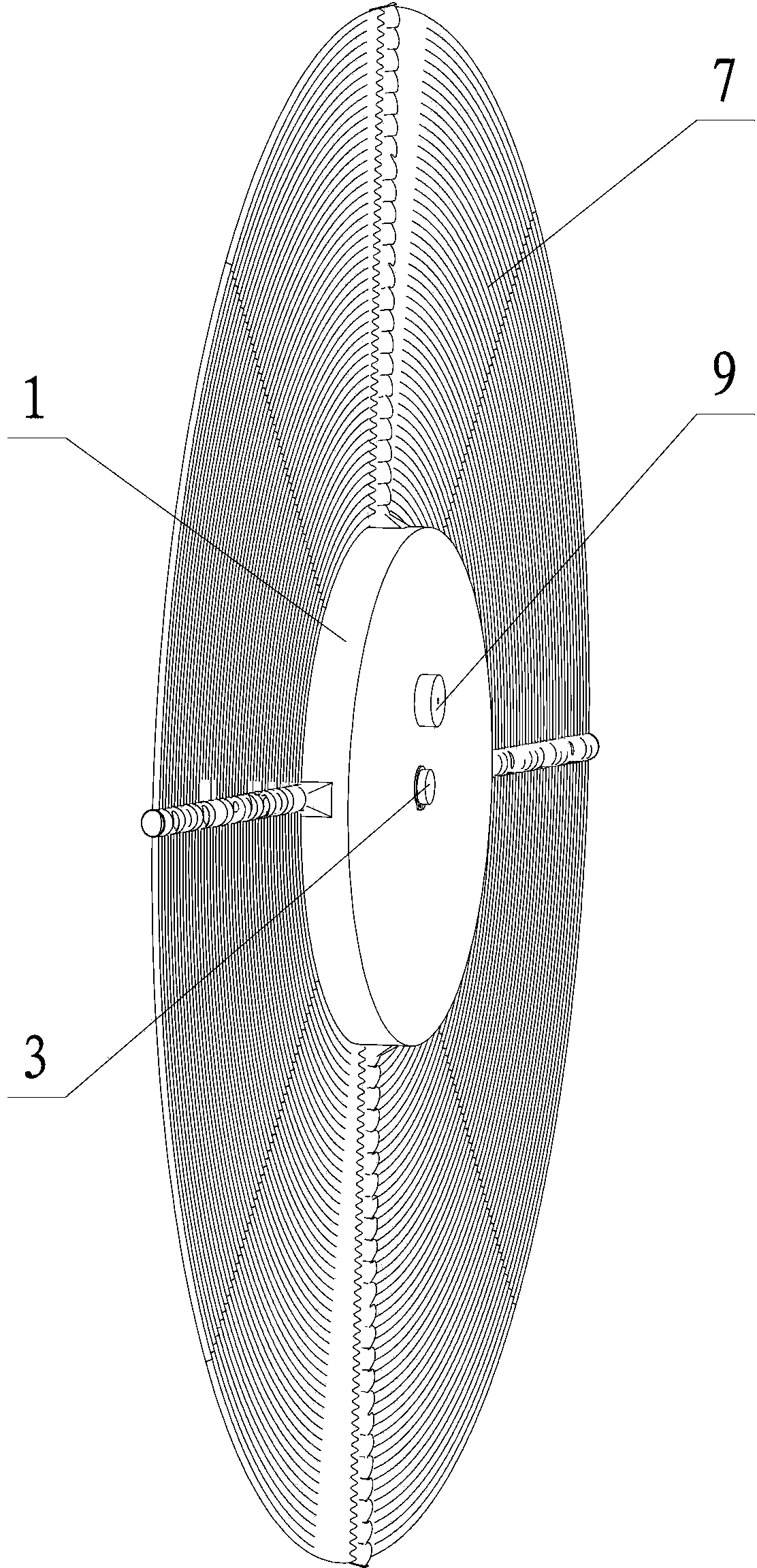

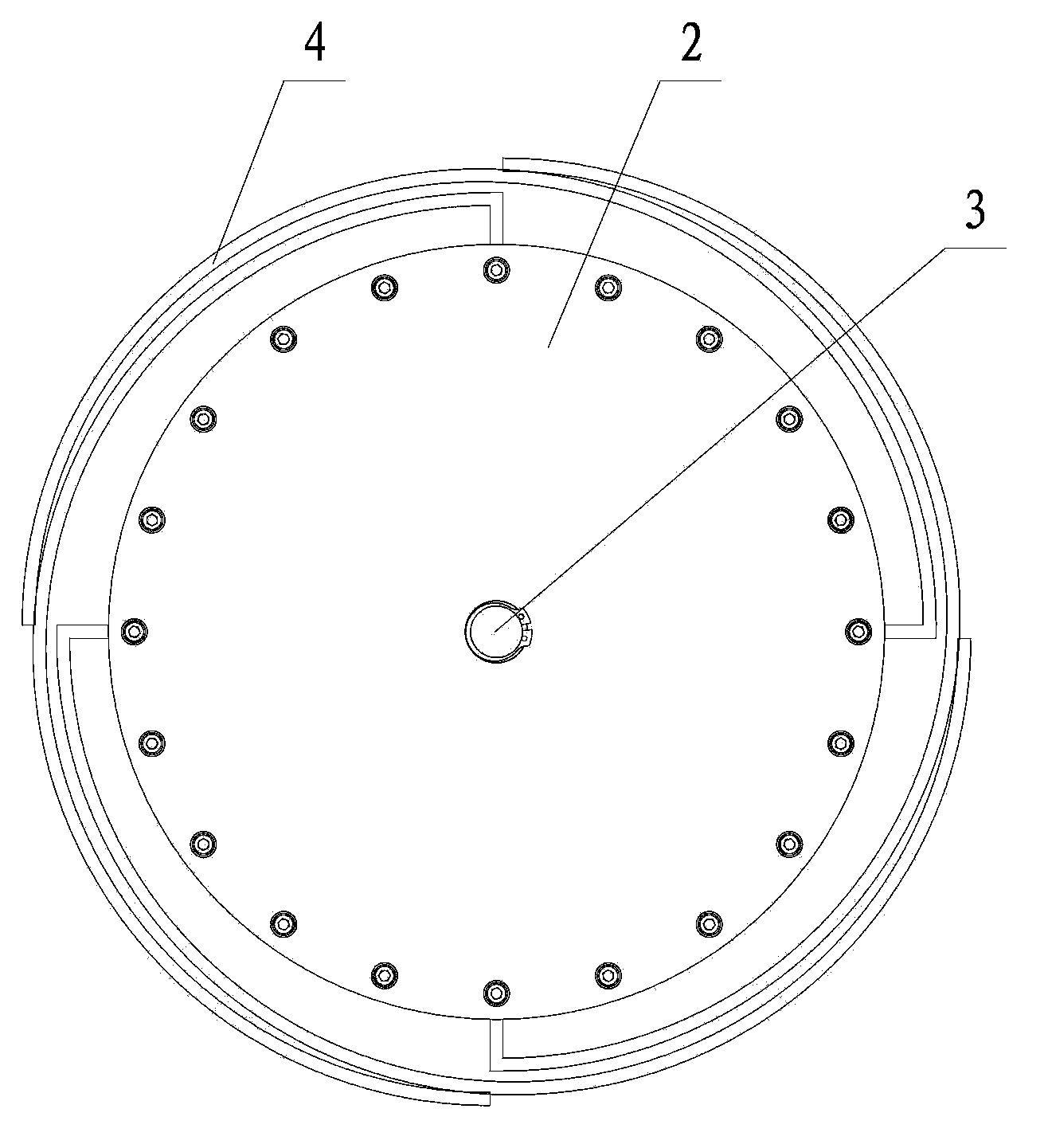

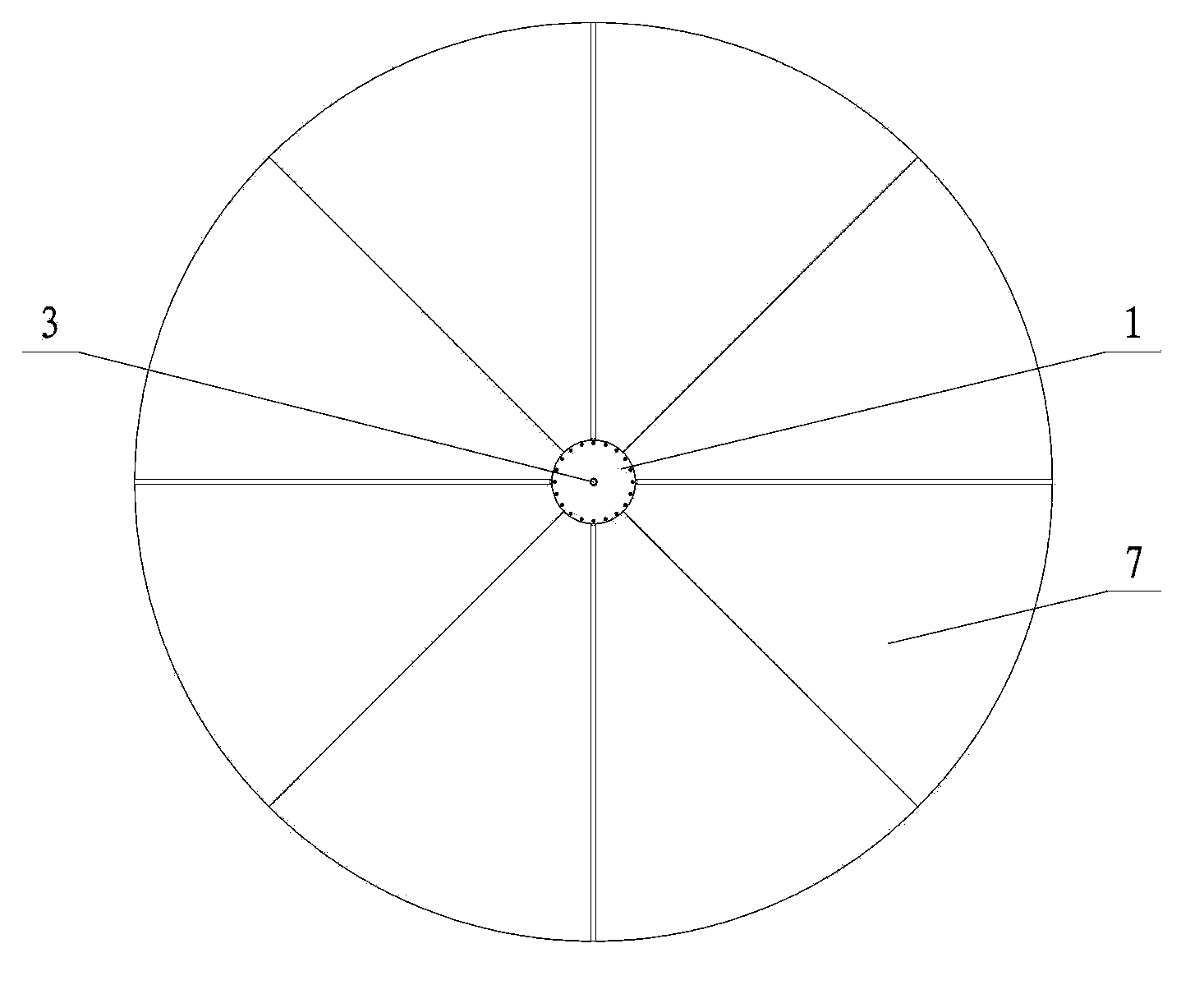

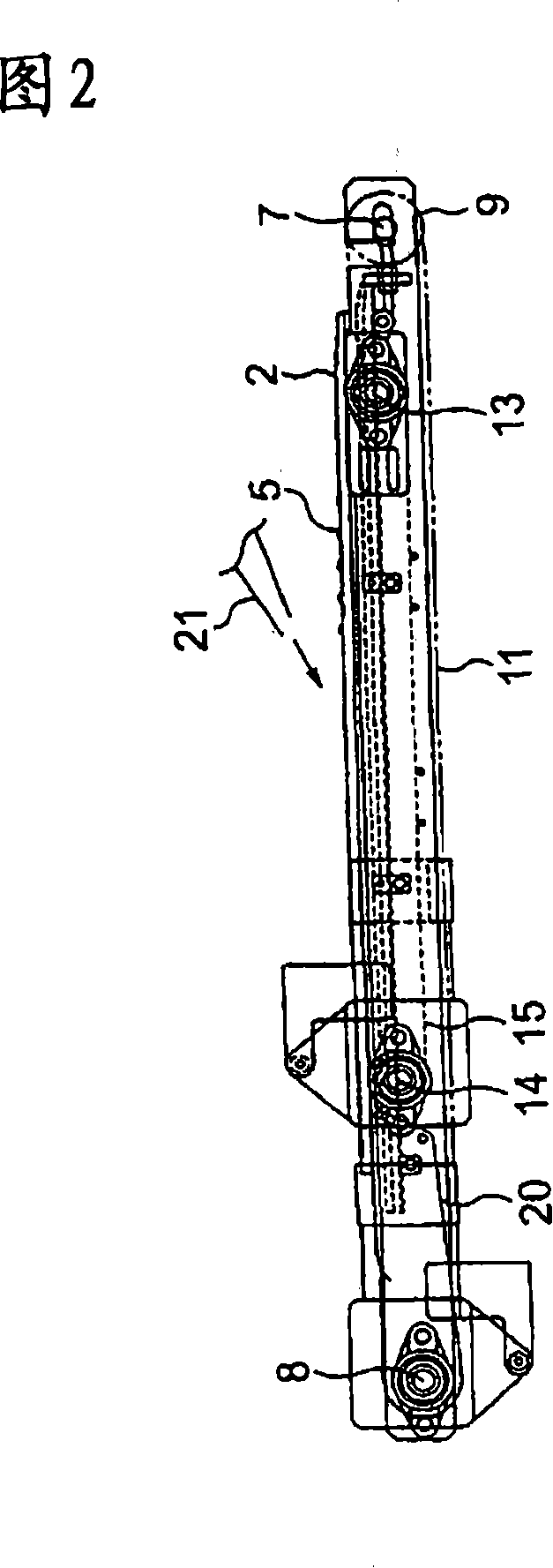

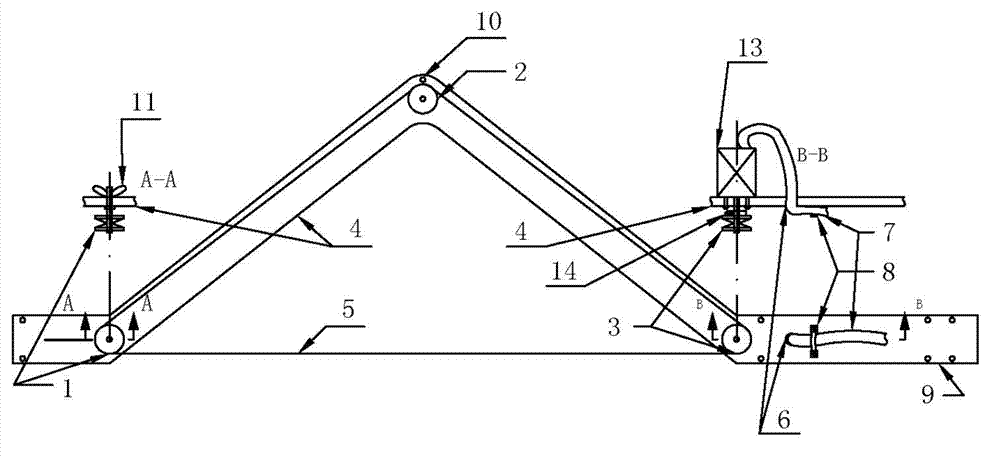

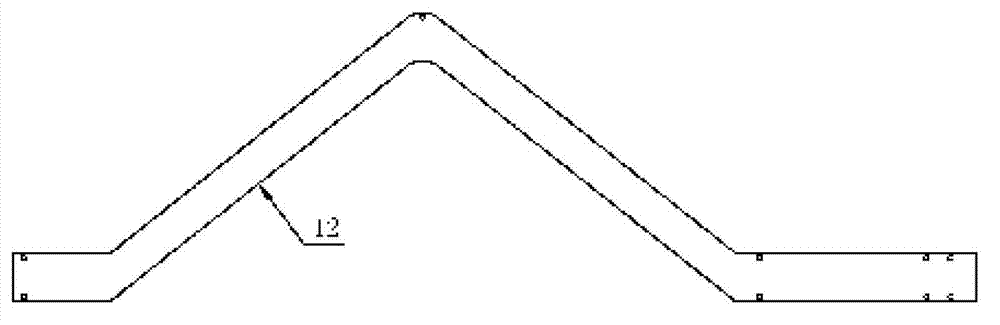

A floating type wave power generation system

InactiveCN102022248AEfficient captureControllable outputMachines/enginesEngine componentsWave power generationMechanical energy

A floating type wave power generation system is characterized in that the system consists of eight sets of lever-type floating bodies and a hydraulic energy accumulation converter with the hydraulic pump function. On a floating workbench 7, eight sets of levers 2 and a floating body 1 are connected through supporting hinge bearers 10 and 11; in this way, the highly undulating displacement caused by waves can be converted to relatively lesser displacement of a piston rod 4, and the minor force that the floating body bears can be converted through the lever to the major force on the piston rod. The piston rod drives a hydraulic tank 3 to switch and transmit the hydraulic energy through a connecting oil pipe5, a high-pressure oil pipe6, a hydraulic oil tank and four no-return valves of each set to a hydraulic motor in a hydraulic power generation control chamber 9; in this way the generator is driven to work. The present system can absorb, convert and accumulate the intermittent unstable wave energy in a highly effective way and can buffer the destructive effect of waves. The floating platform can be suitable to different marine space by adjusting the length of an anchor chain 8. And in various sea conditions, kinetic energy and potential energy possessed by waves in the sea surface can be converted and accumulated as hydraulic mechanical energy by utilization of the wave drop; thus the generator is driven to unremittingly provide electric power.

Owner:杨超

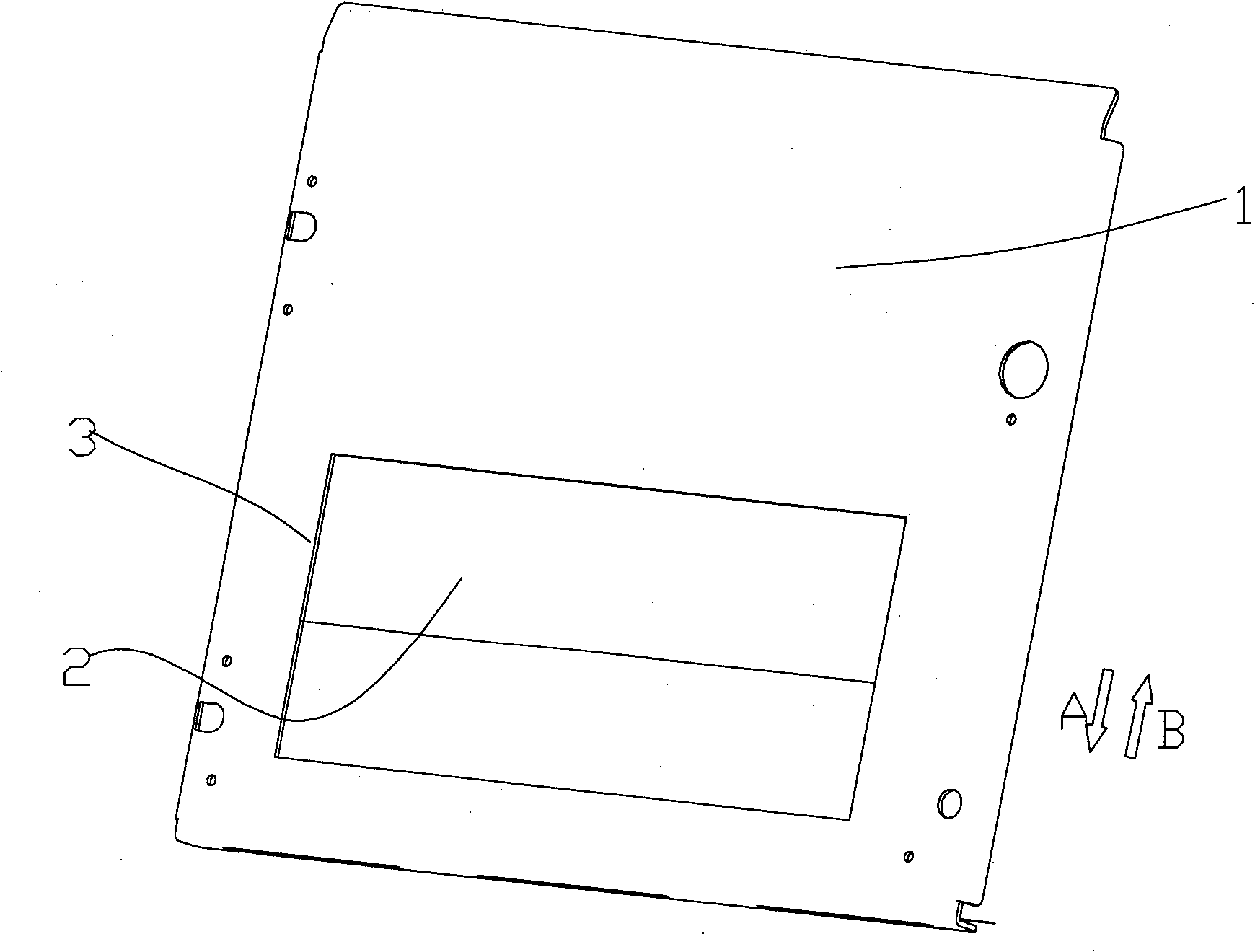

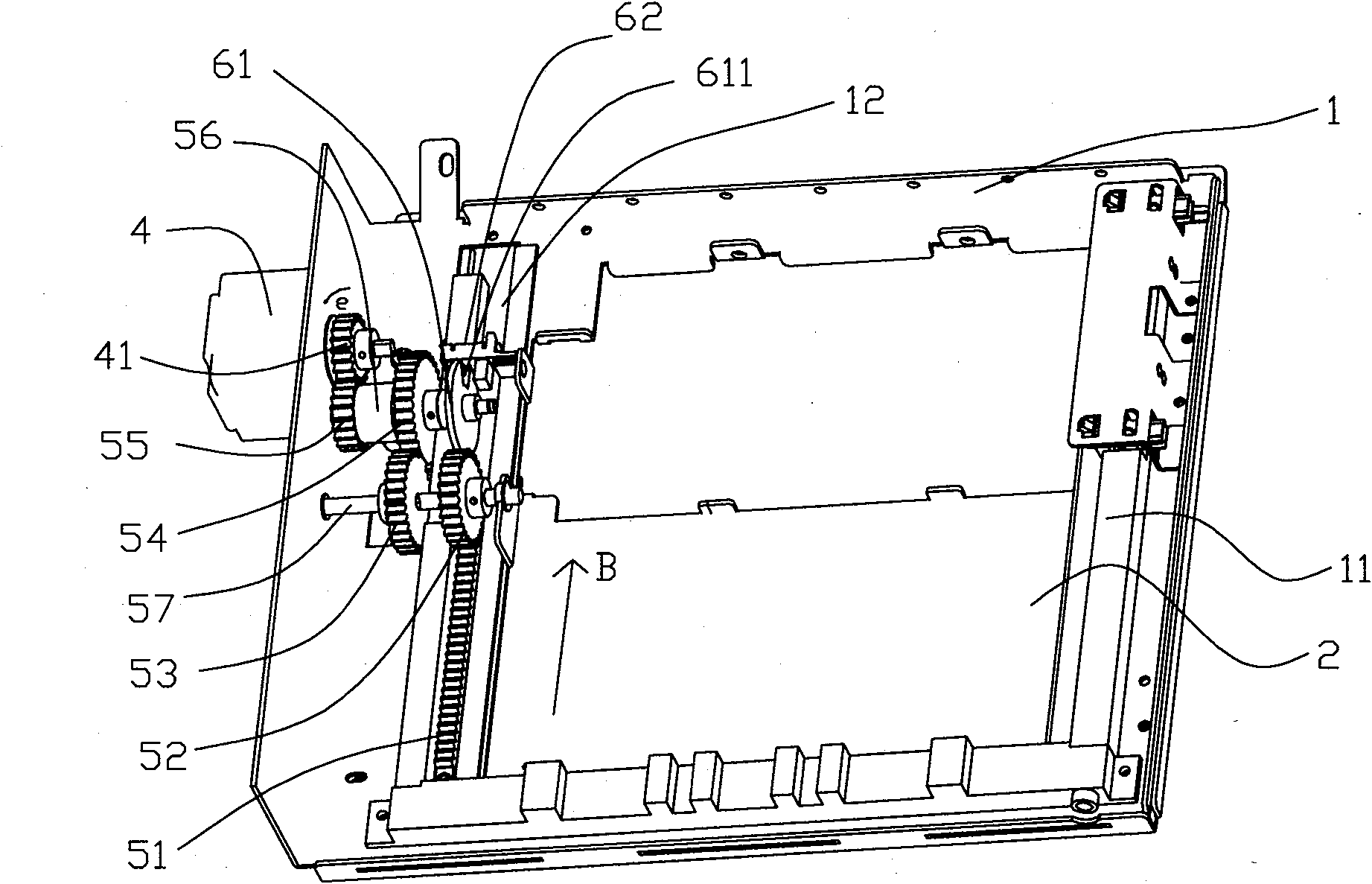

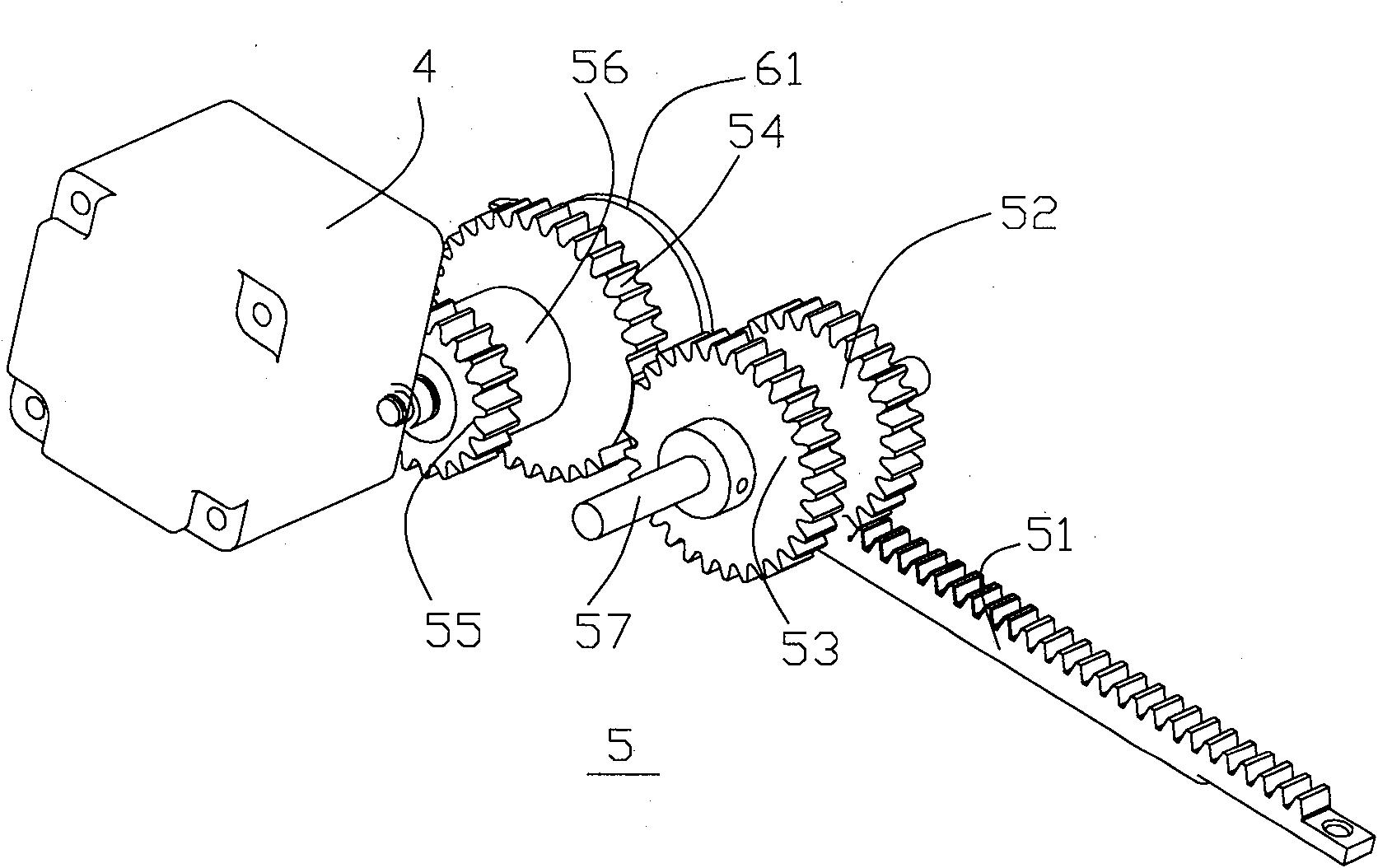

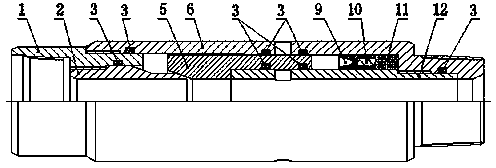

Safety gate device and automatic teller machine provided with same

ActiveCN101684713ALow costReduce mechanical failureComplete banking machinesCoin/currency accepting devicesGear wheelEngineering

The invention relates to a safety door mechanism, in particular to a safety gate device which is used on automatic service equipment and has the function of anti-violence opening. In order to solve the problem that a gate is opened illegally, the invention provides a safety gate device, which comprises a substrate, the gate and a power system driving the gate to slide, wherein the power system comprises a motor capable of rotating positively and reversely, a first transmission gear, a first incomplete gear, a second incomplete gear, a second transmission gear and a rack; the motor is providedwith a power output gear; the first transmission gear is engaged with the power output gear; the first incomplete gear is coaxial with the first transmission gear and provided with an arc surface of aconvex locking arc; the second incomplete gear is engaged with the first incomplete gear and provided with an arc surface of a concave locking arc; the curvature of the concave locking arc is equal to that of the convex locking arc; the second transmission gear is coaxial with the second incomplete gear; and the rack is fixed on the inner side of the gate and engaged with the second transmissiongear.

Owner:GRG BAKING EQUIP CO LTD

Shunt system with coating and flow restricting component exerting a passive and essentially constant resistance to outflow

InactiveUS20070112291A1Reduce as muchReduce infectionWound drainsFlow monitorsCsf shuntBrain Ventricle

The present invention relates to an improved cerebrospinal fluid shunt system comprising a coating covering at least part of the system and a flow restricting component exerting a passive and essentially constant resistance to flow. The present invention also relates to methods for implanting different catheters of a cerebrospinal fluid shunt system into a brain ventricle and the sinus system, respectively, of an individual. The present invention further relates to methods for shunting cerebrospinal fluid from a brain ventricle to the sinus system of an individual.

Owner:SINU SHUNT

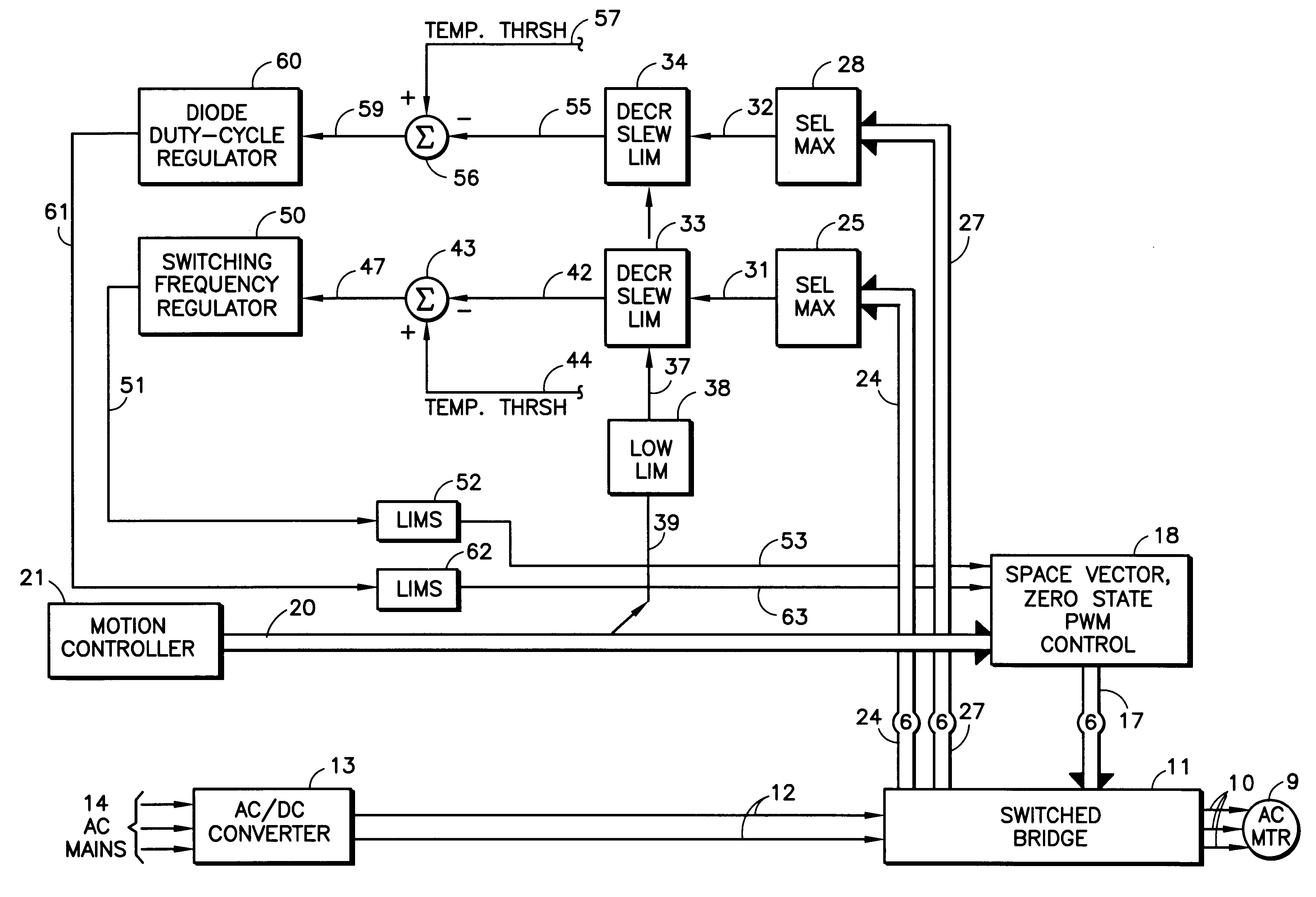

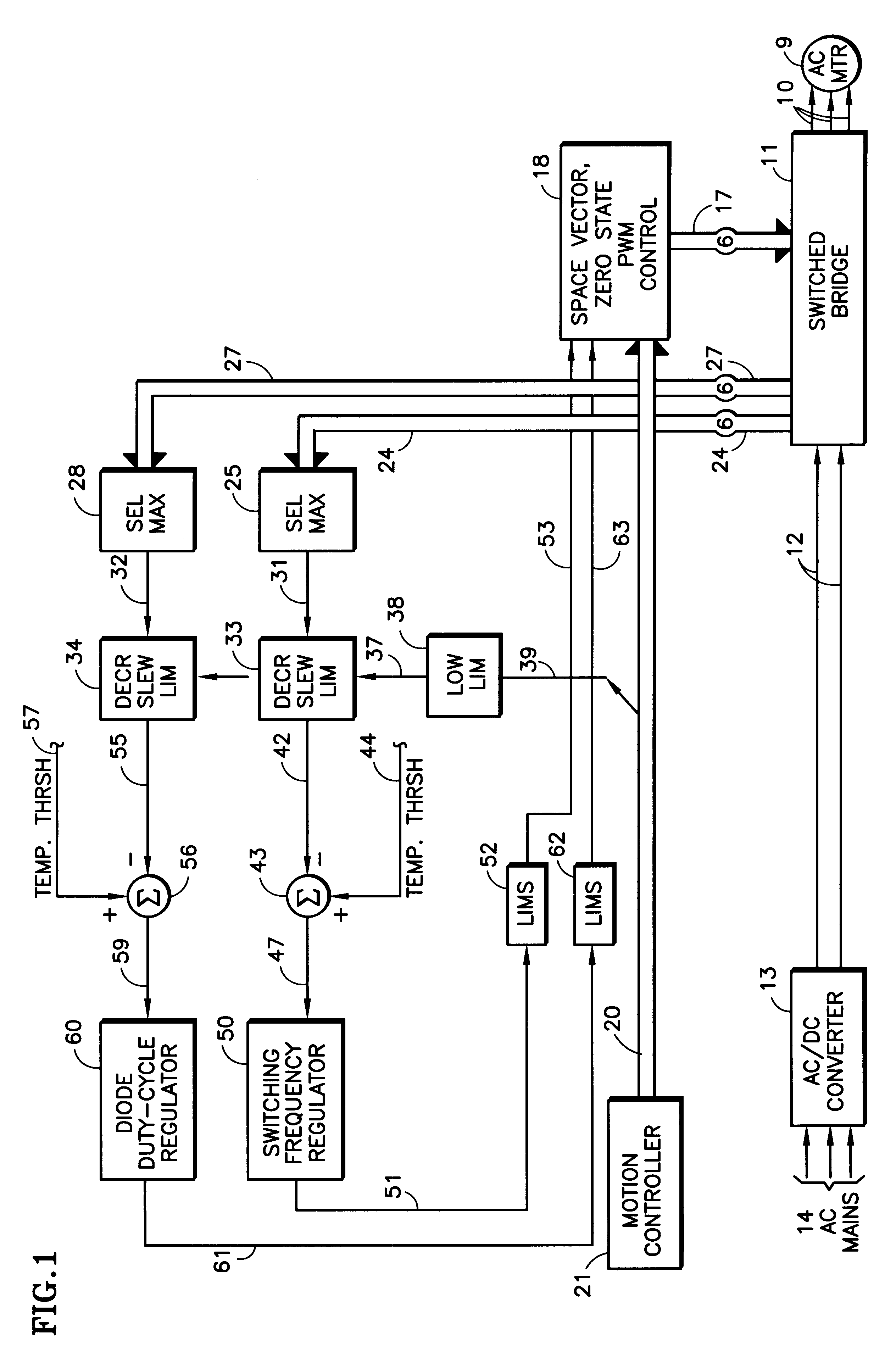

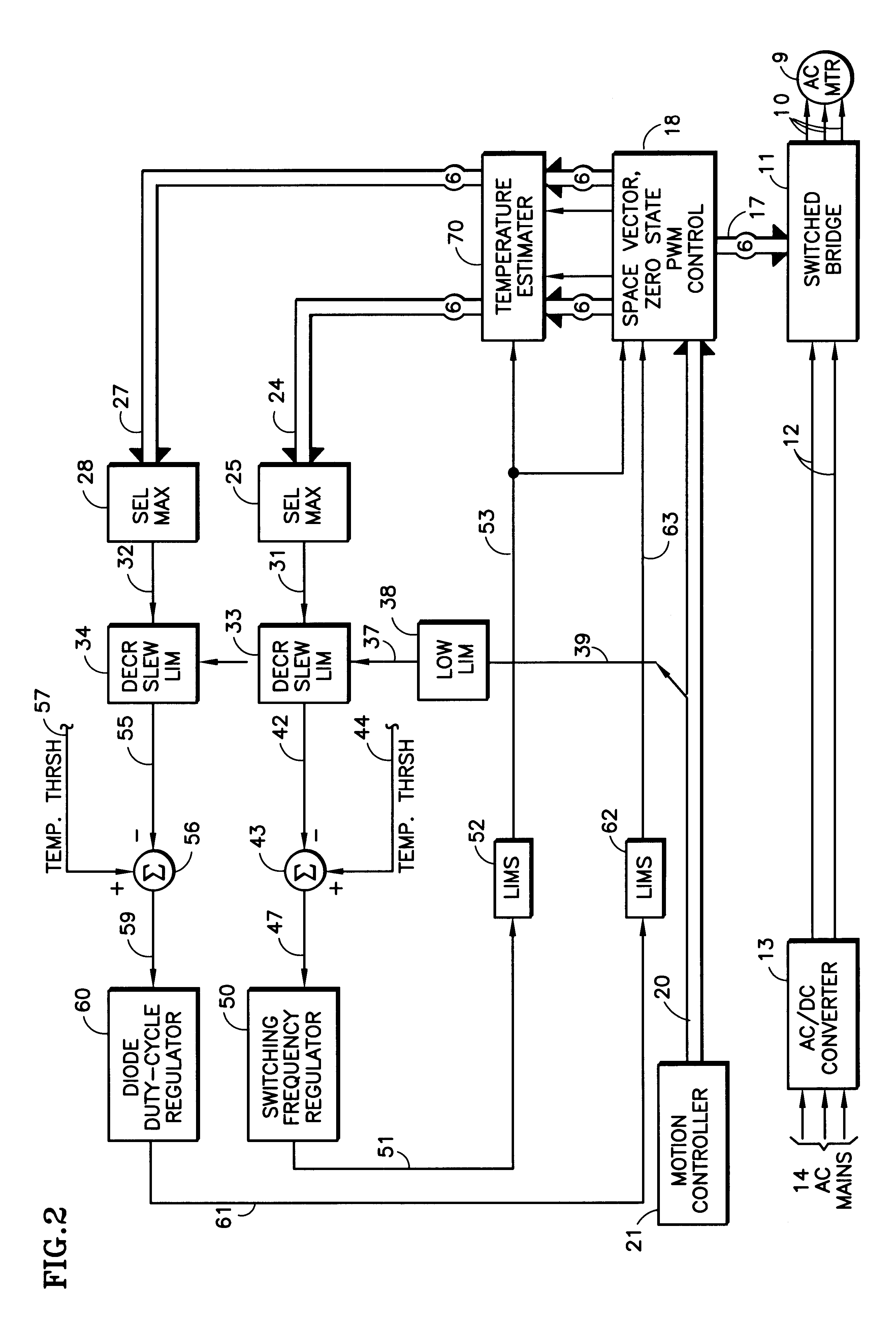

Motor drive parameters

InactiveUS6483271B1More stressReduce mechanical failureSingle-phase induction motor startersAC motor controlMotor speedMotor drive

The temperature (25, 33, 43) of solid state switching devices in variable speed motor drives (11, 18), such as elevator motor drives, are utilized to reduce the load on the drive, by reducing the switching frequency (50) or the commanded load (110). The choice between the preferred non-switching zero state and an alternative zero state is determined (60) by temperature (28, 34, 56) of the switched transistor's anti-parallel diode. The rate of recognizing reduced temperatures is limited (33, 34) to avoid motor speed and / or load variations. The temperature may either be measured (24, 27) or determined (70) from models utilizing manufacturer product specification and normalized thermal transient response from the transistor / diode package to a heat sink.

Owner:OTIS ELEVATOR CO

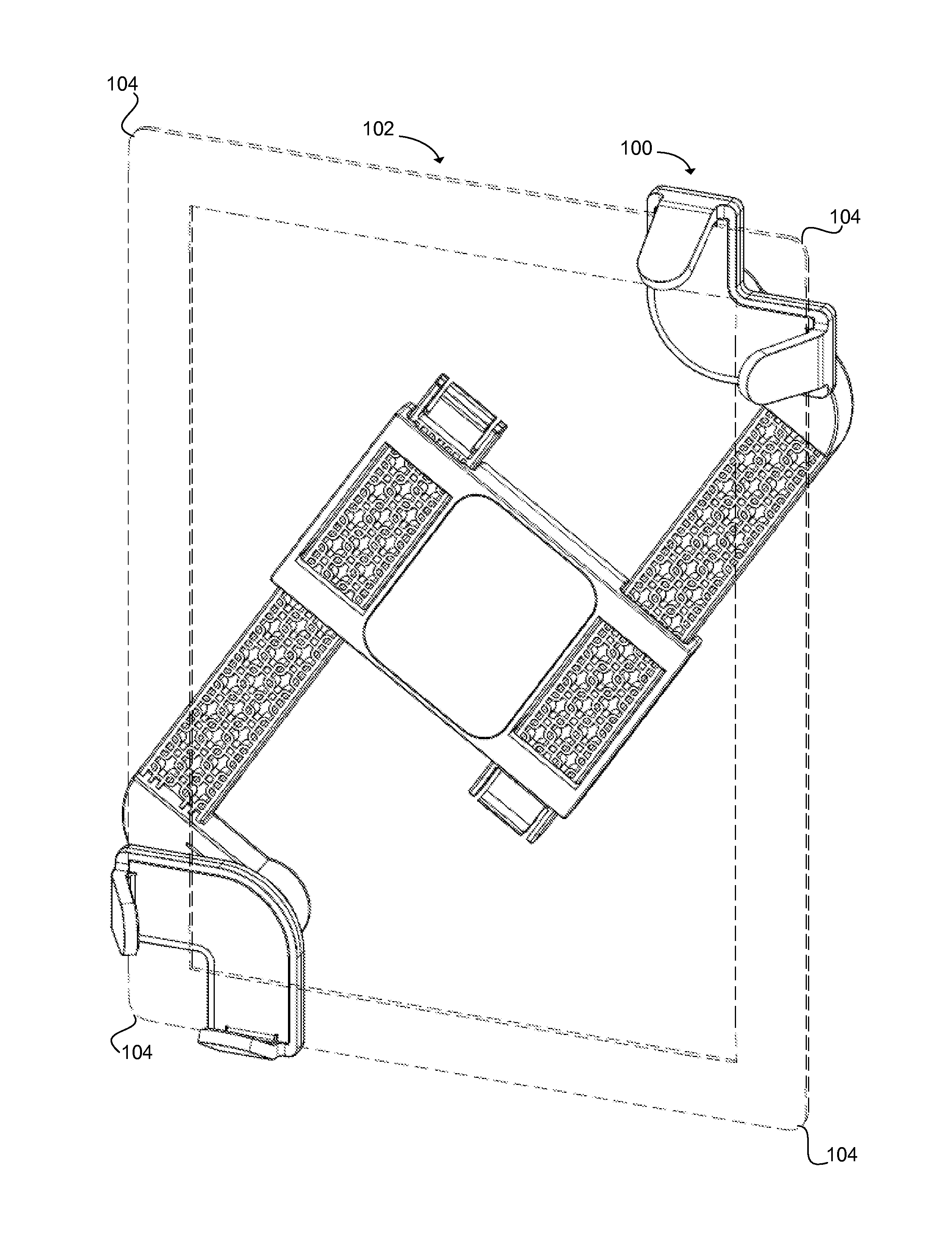

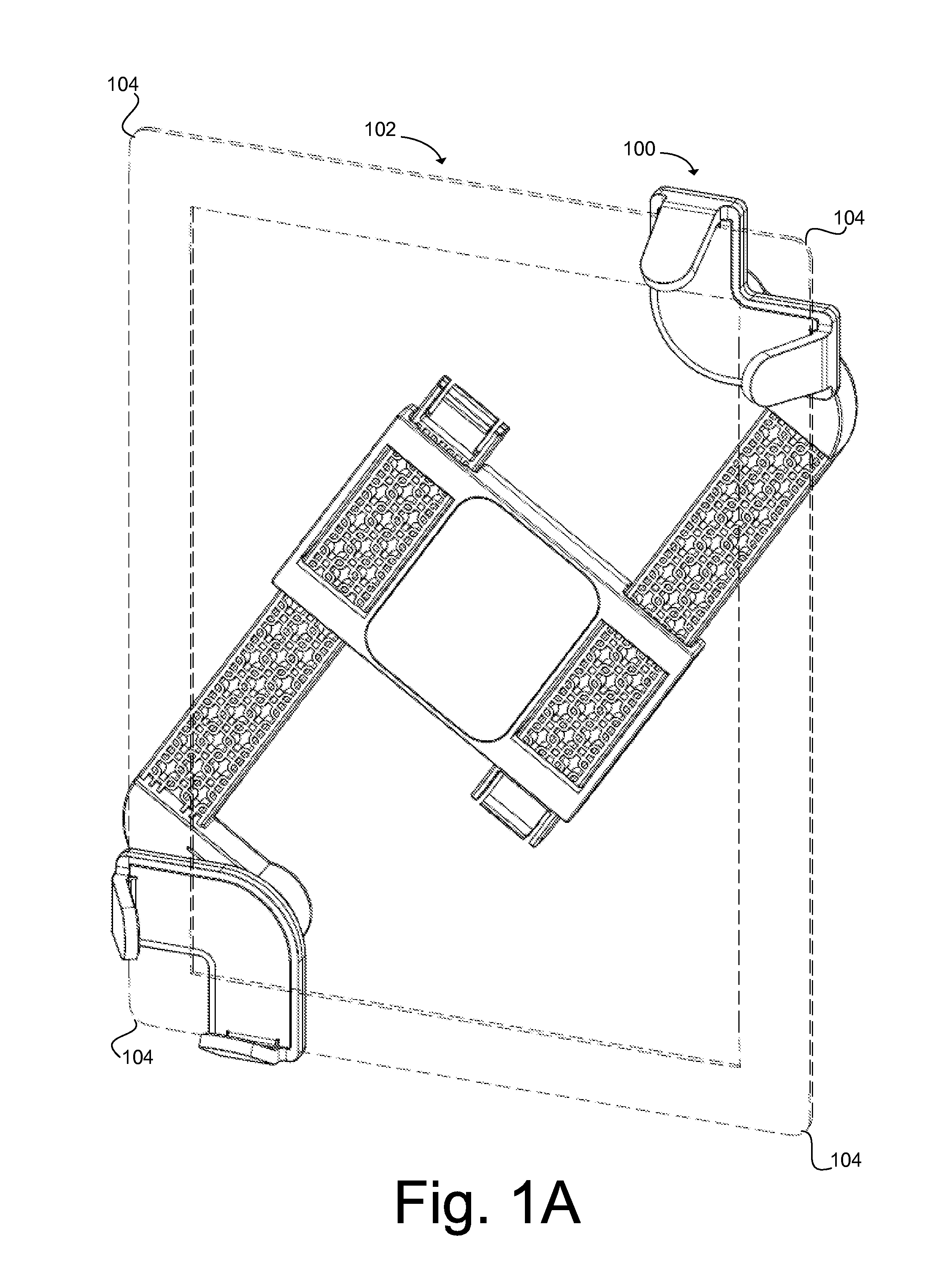

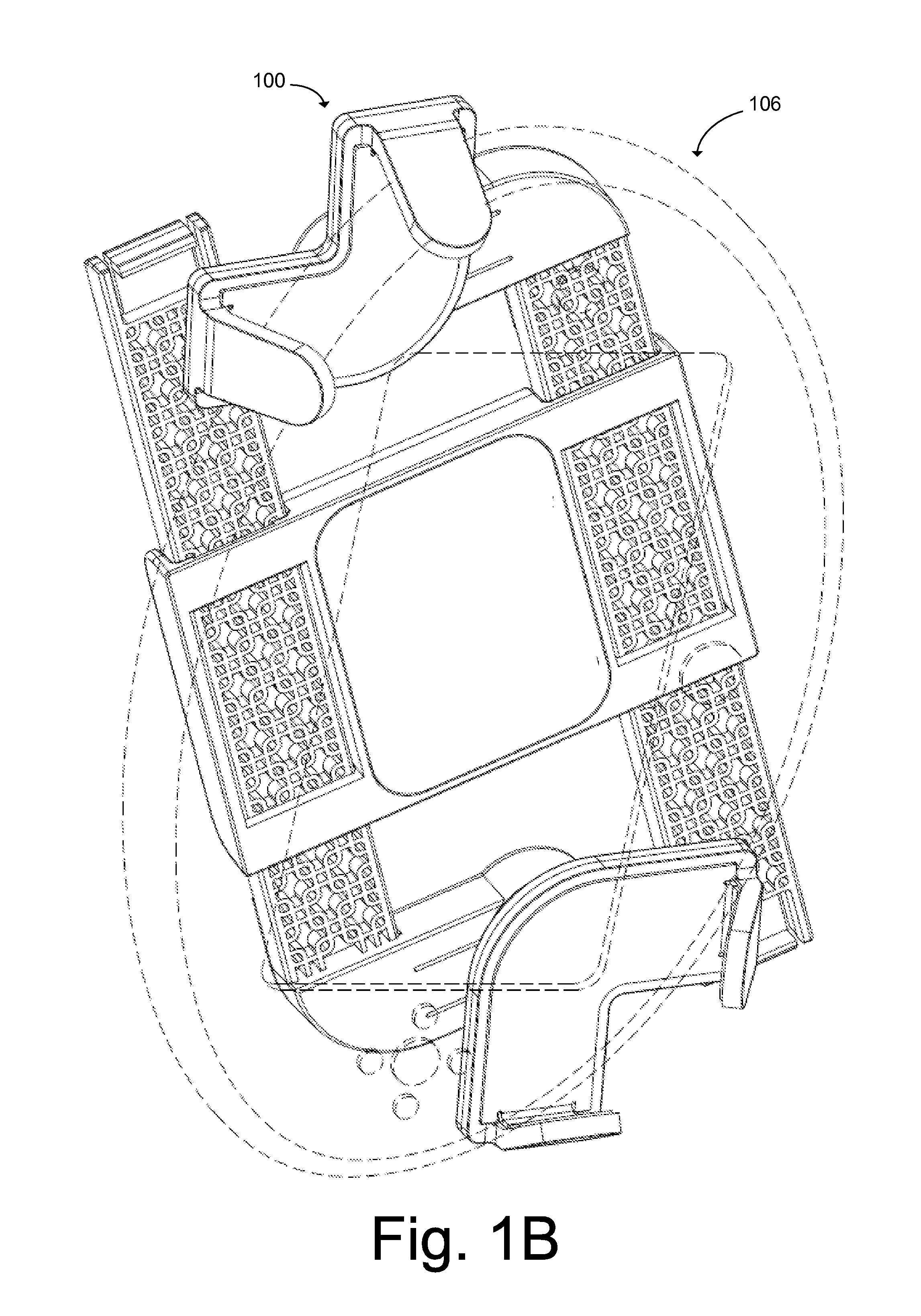

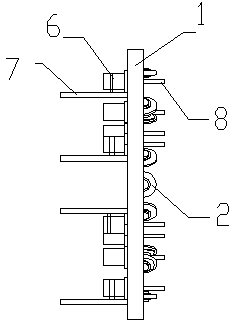

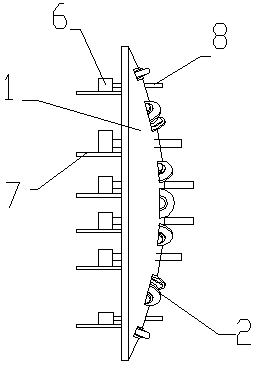

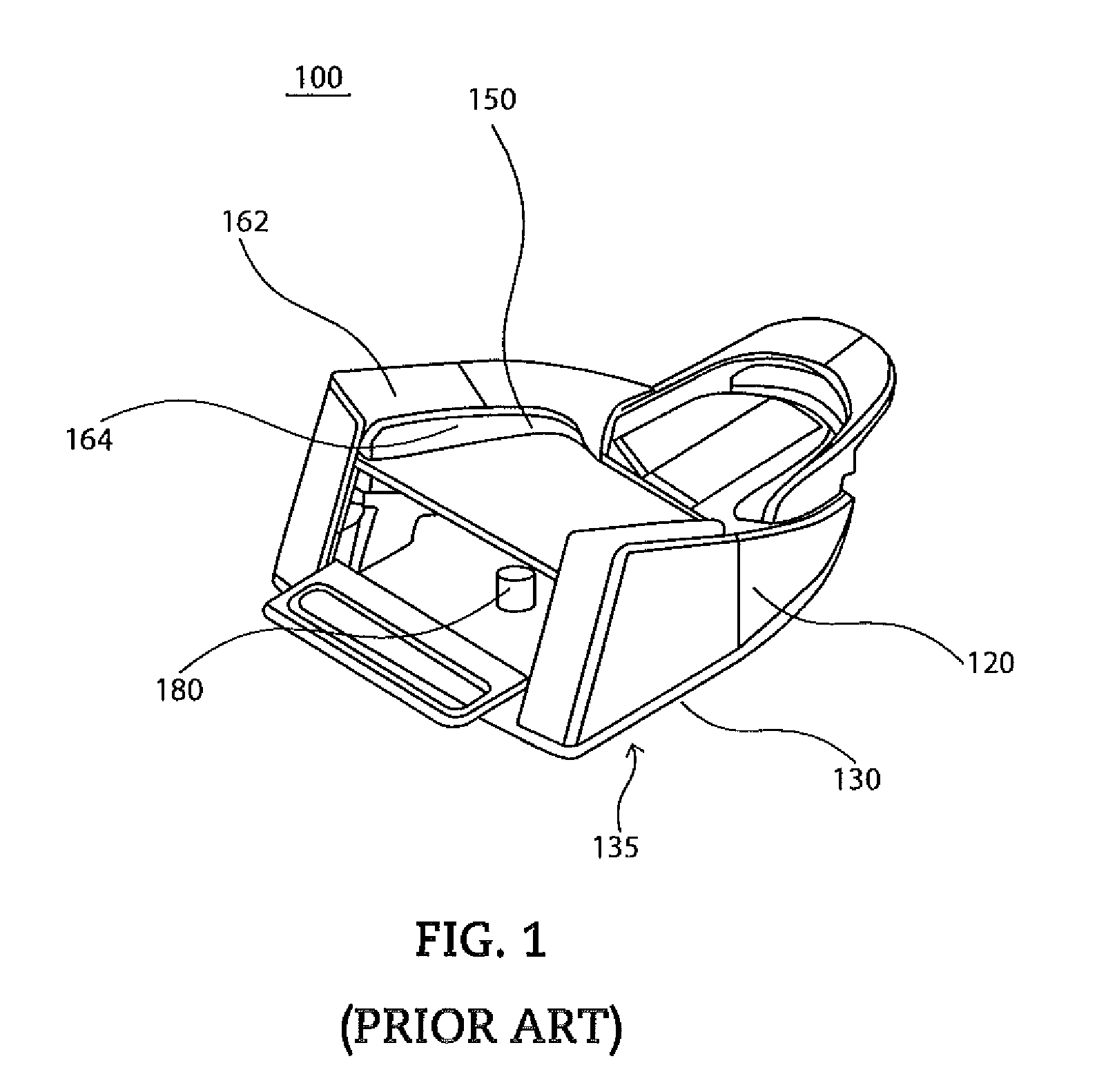

Adjustable holder for devices

InactiveUS20140246551A1Reduce mechanical failureImprove versatilityStands/trestlesKitchen equipmentFixed positionEngineering

Disclosed is an adjustable holder for devices with a simplified design for accommodating devices of various form factors and shapes. The adjustable holder comprises at least a pair of offset, generally parallel arms that are slidable within corresponding openings of a support in order to adjust the arms and fixedly position the arms at varying distances relative to the support. The adjustable holder further comprises a gripping member coupled to a distal end of each of the arms to grip a device at opposing sides of the device. In some embodiments, the arms are adjustable via a two-part ratcheting mechanism. In yet other embodiments, the gripping members are rotatable to accommodate devices of various geometries. The holder can fit onto a stand or structure to hold a device in a fixed position.

Owner:STAND FOR STUFF

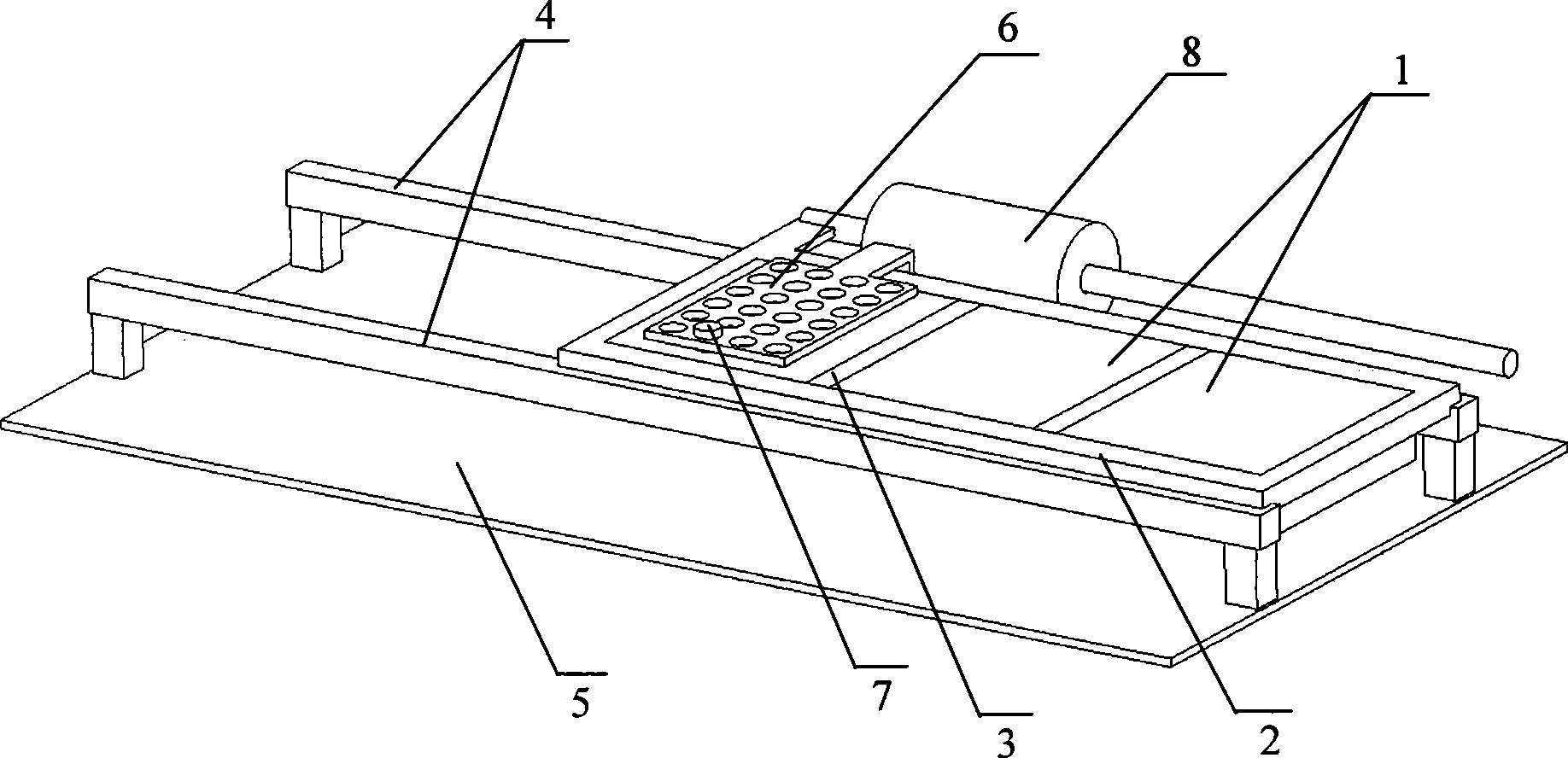

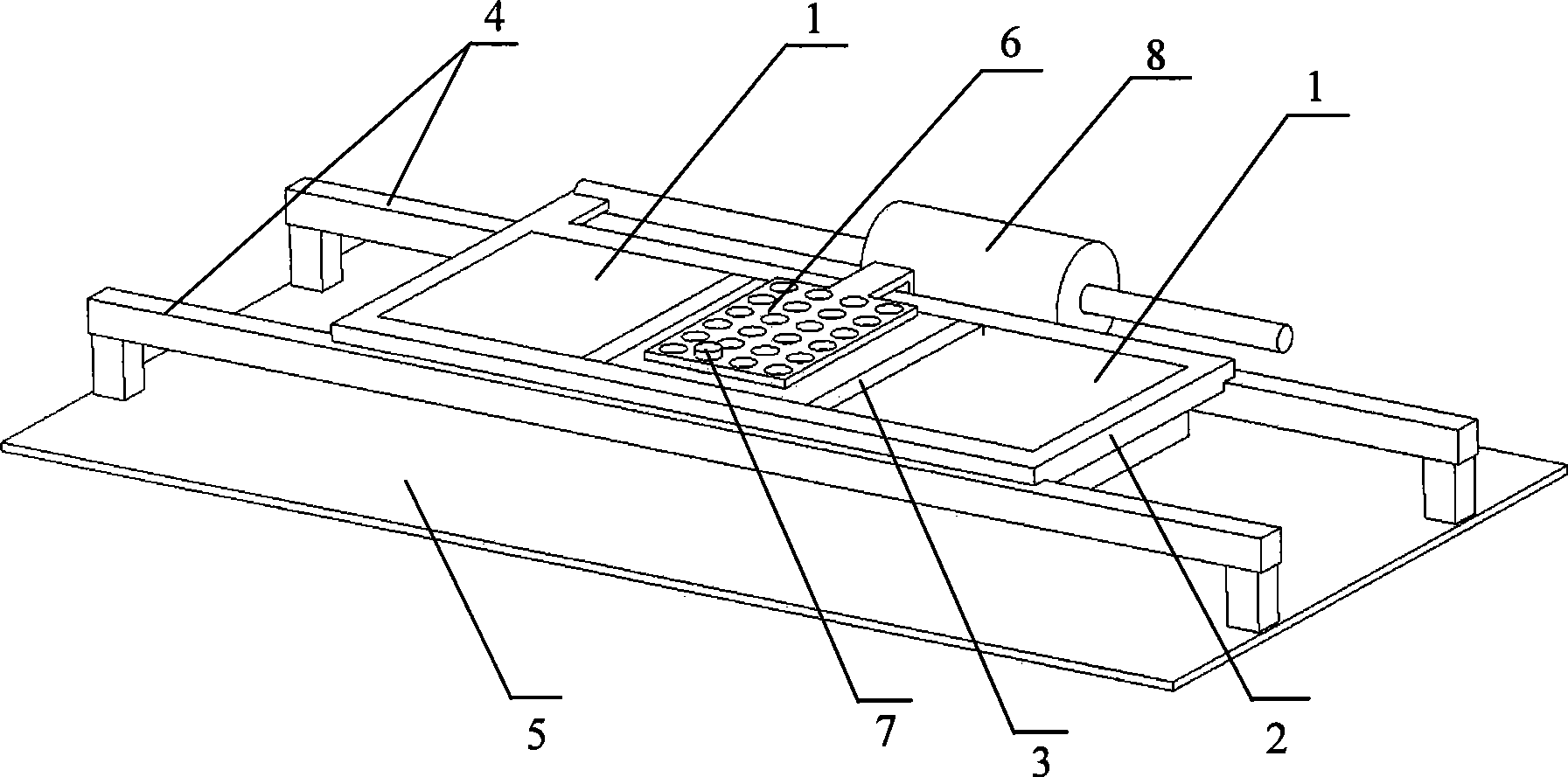

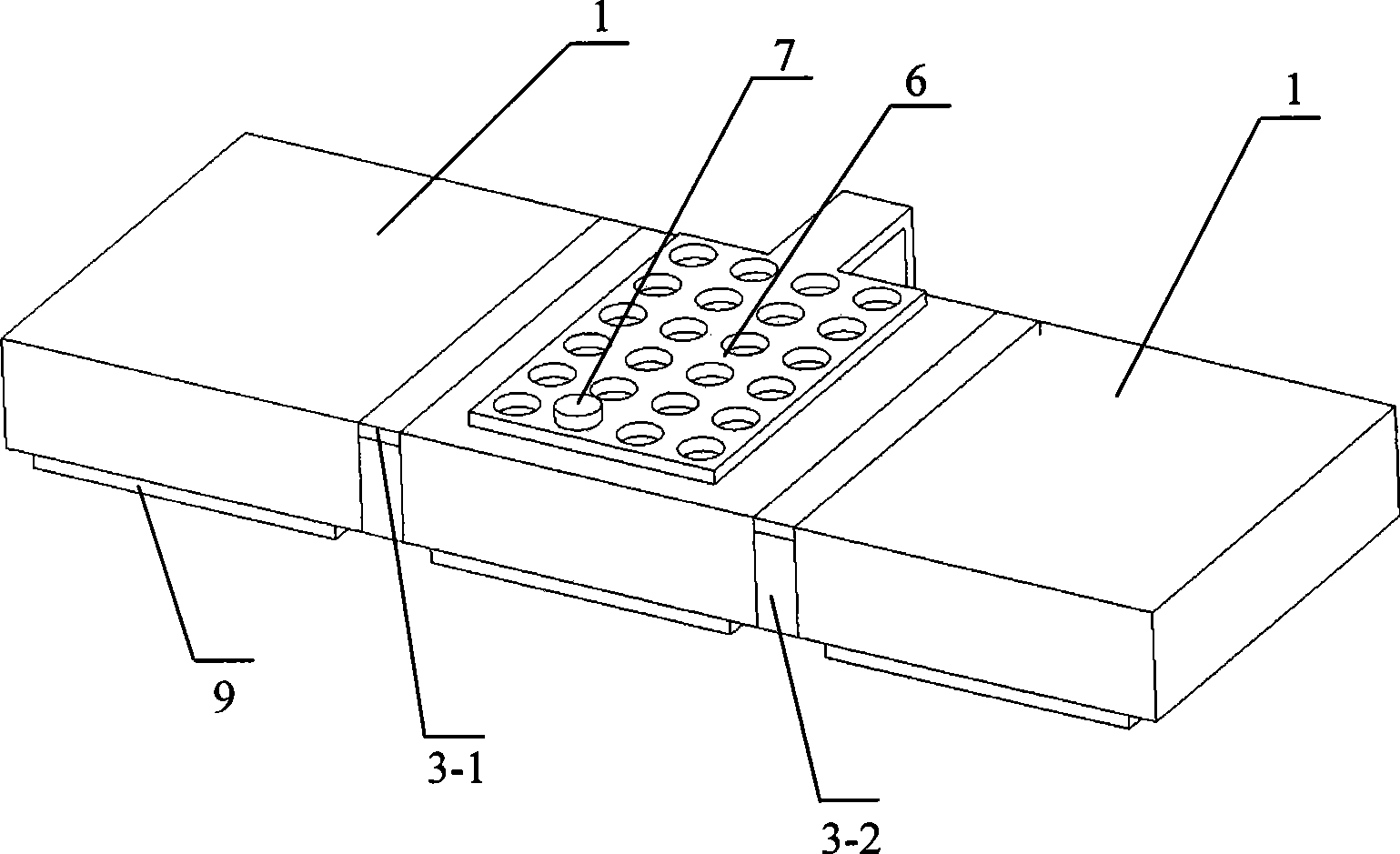

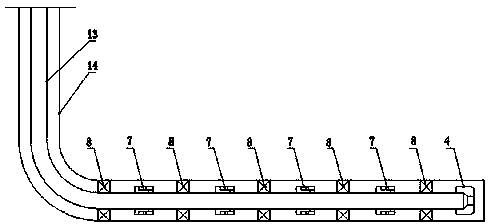

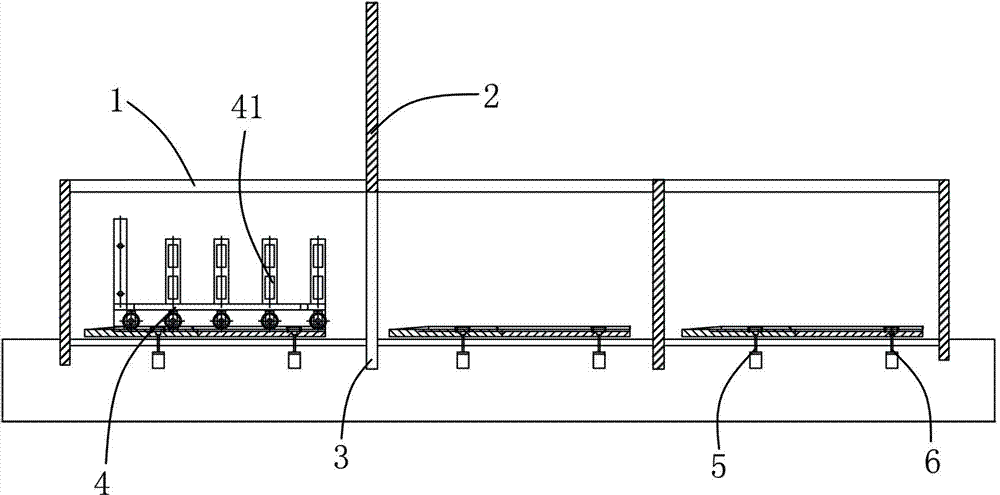

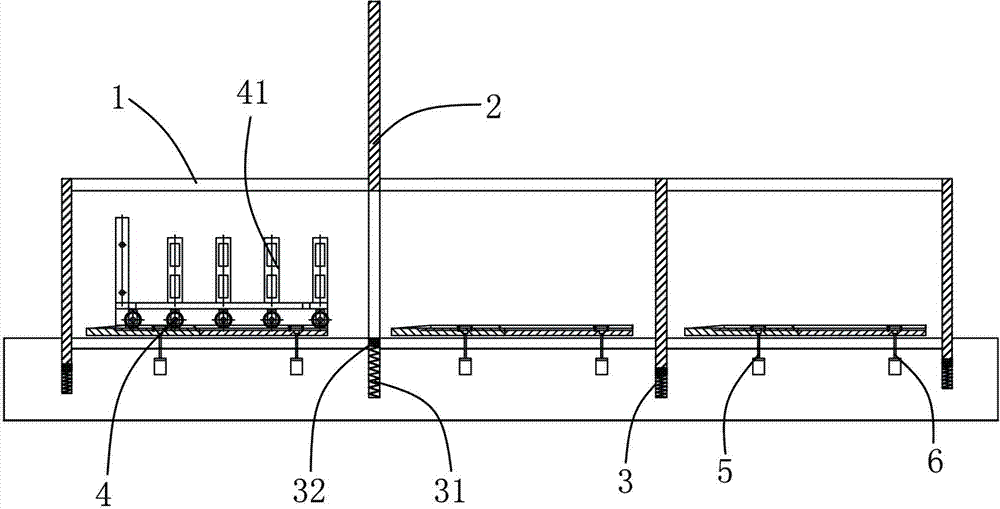

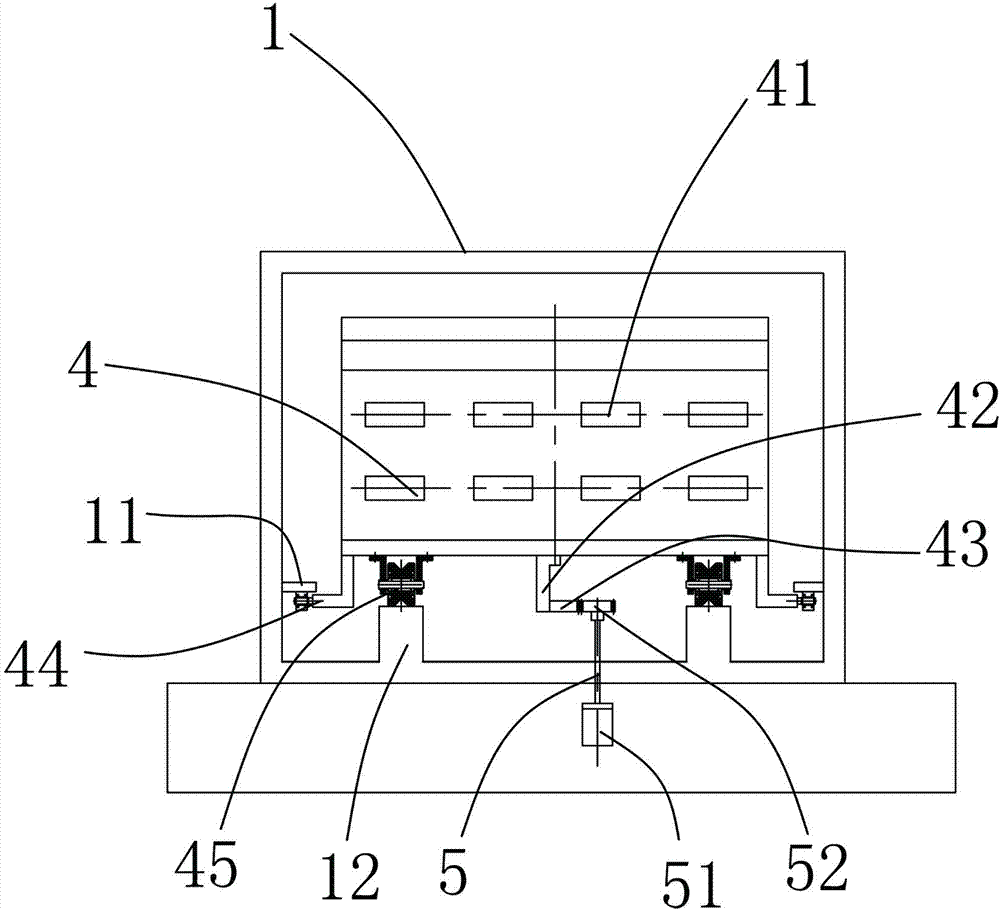

Sliding mode heat transfer media plate PCR instrument

InactiveCN101363001APlacement omittedAvoid excessive coolingBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMobile device

The invention discloses a sliding type heat transfer media plate PCR instrument, comprising a machine shell, a plurality of heat transfer media plates which can set the temperature in advance and a sample holder for placing a sample tube, wherein, a plurality of heat transfer media plates are arranged below the sample holder, the vertical distances between the upper surfaces of the heat transfer media plates to the sample holder are equal, the heat transfer media plates and the sample holder can be correspondingly slid under the action of a transmission device, the sliding trajectory is on the same plane, and the sample tube is indirectly or directly contacted with the upper surfaces of the different heat transfer media plates which set the different temperatures in advance according to a certain procedure during the sliding process. The PCR instrument can avoid the plugging-in and pulling-out operations of the sample tube, thereby simplifying a mechanical mobile device, simplifying a control circuit and a structure, reducing the size of the instrument, reducing the mechanical faults, reducing the cost and avoiding the harmful excessive temperature decrease of a sample caused by being exposed in air.

Owner:GINGKO BIOTECH BEIJING

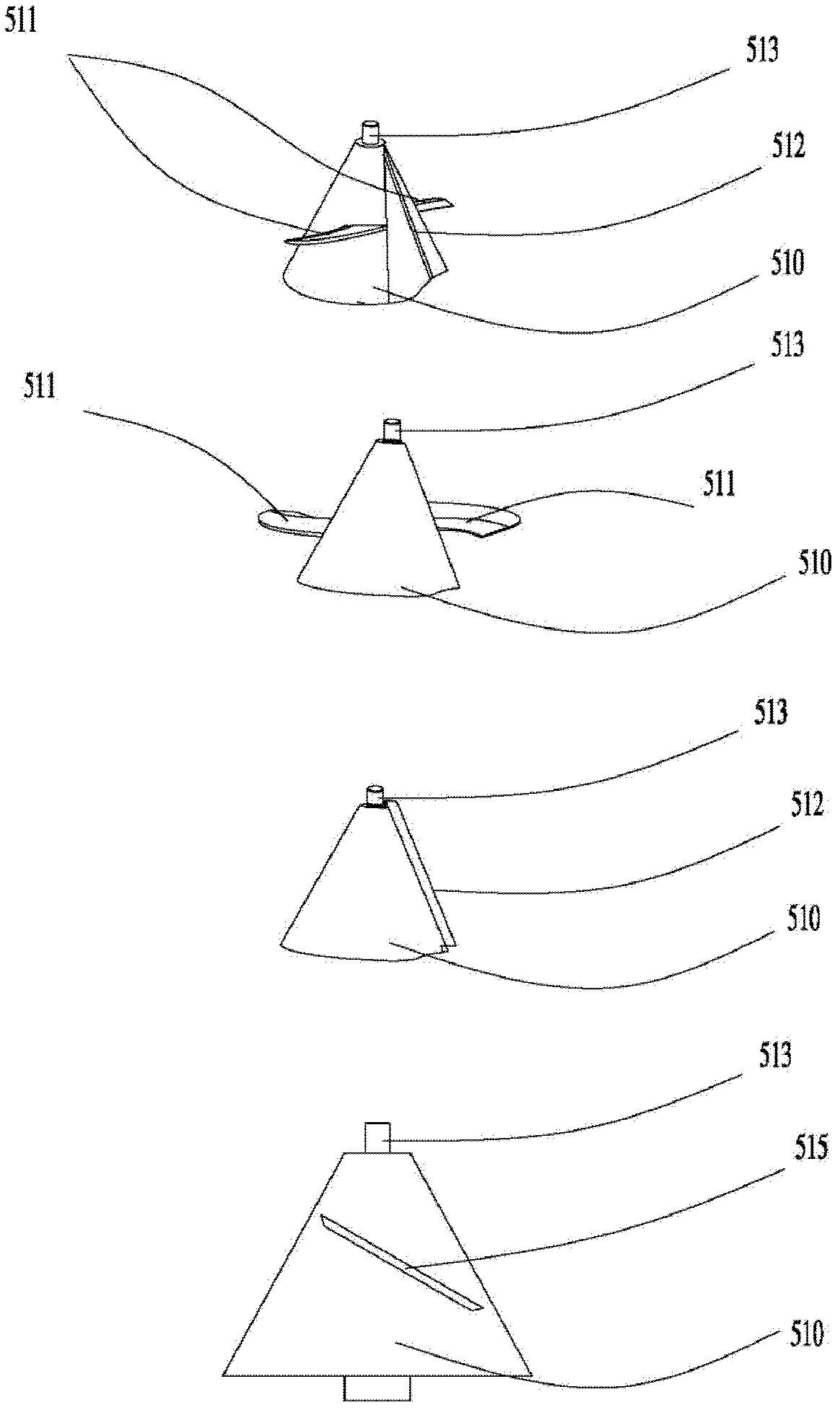

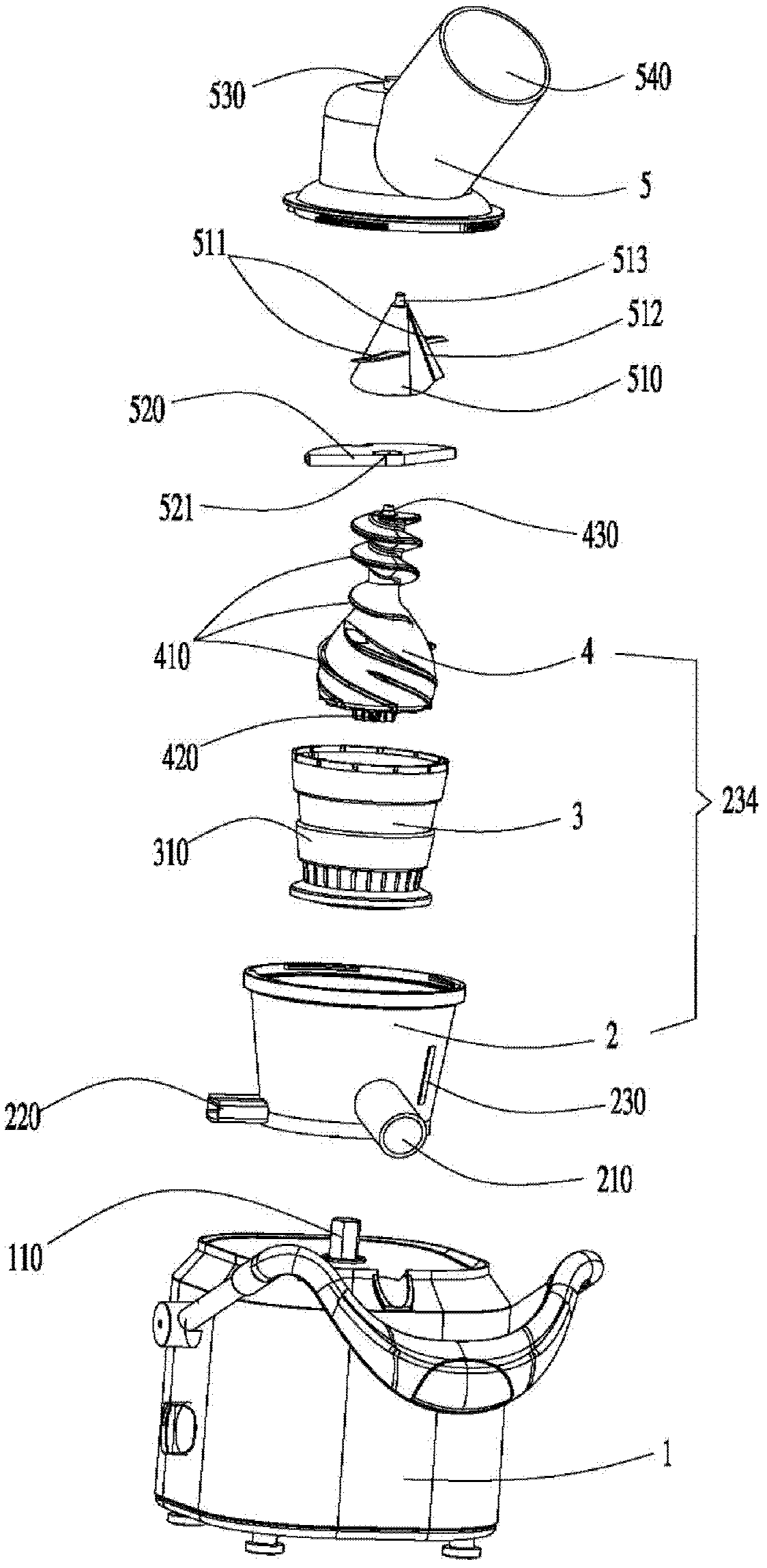

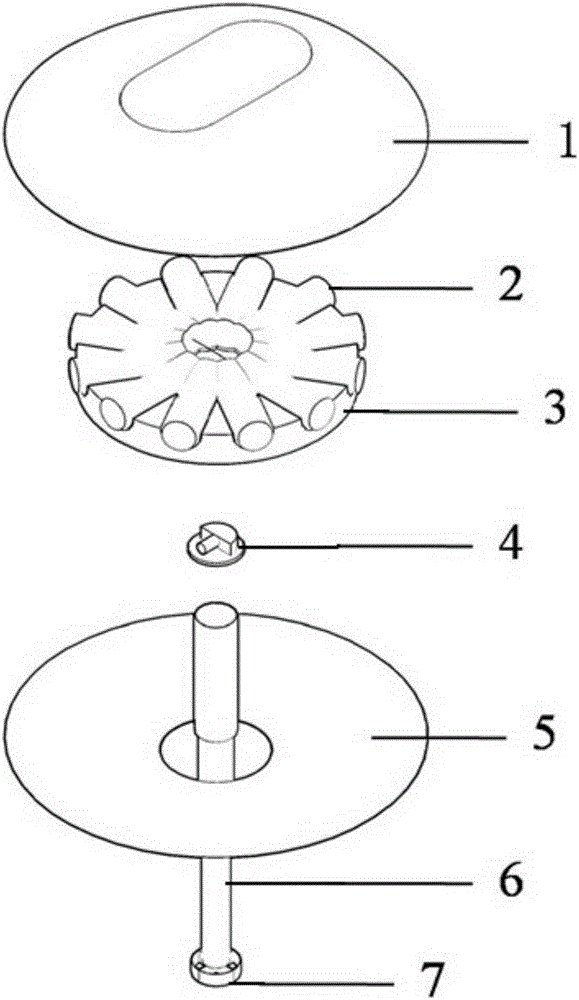

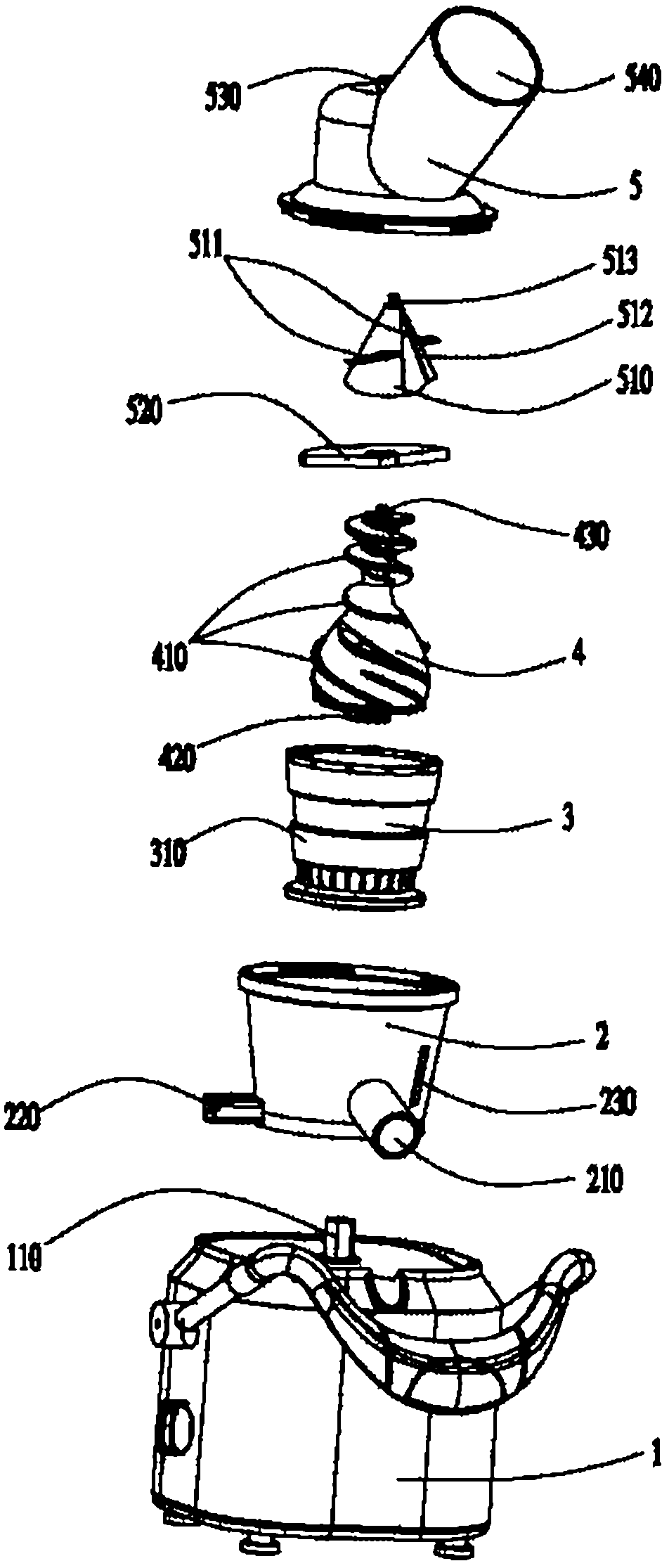

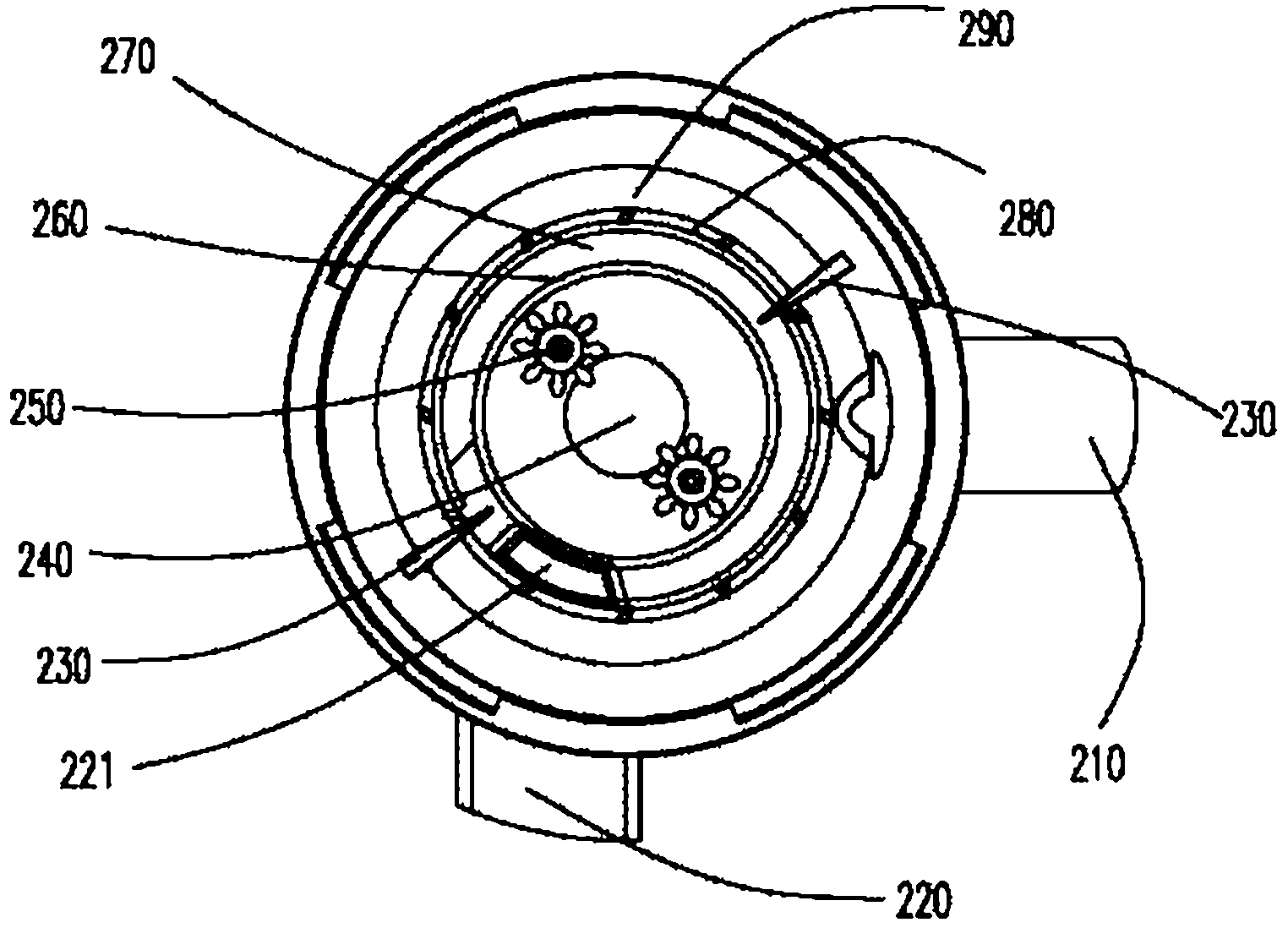

Pre-smashing device for food treating machine and juice extractor applying same

ActiveCN103202653AGuaranteed tasteGuaranteed nutritionJuice extractionStrainersPulp and paper industryFood material

The invention provides a pre-smashing device for a food treating machine, aiming to solve the problem that inconvenience is brought to a user as foods need pre-treating in the prior art. Aiming at the technical problem, the pre-smashing device is mounted behind the food treating machine, the food treating machine is connected with a shaft hole or a connecting shaft in the bottom center of the pre-smashing device through a transmission rotation shaft or a rotation hole of the food treating machine, with the pre-smashing process, the process of pre-treating on food materials is eliminated when an operator carries out food treating, thus the food treating is more convenient and rapid, meanwhile since the pre-smashing process is carried out on the food materials, load of a stirring device is lightened, the service life of a machine is prolonged, and the efficiency of stirring or juice extracting is promoted.

Owner:T F ELECTRICAL TECH SHENZHEN

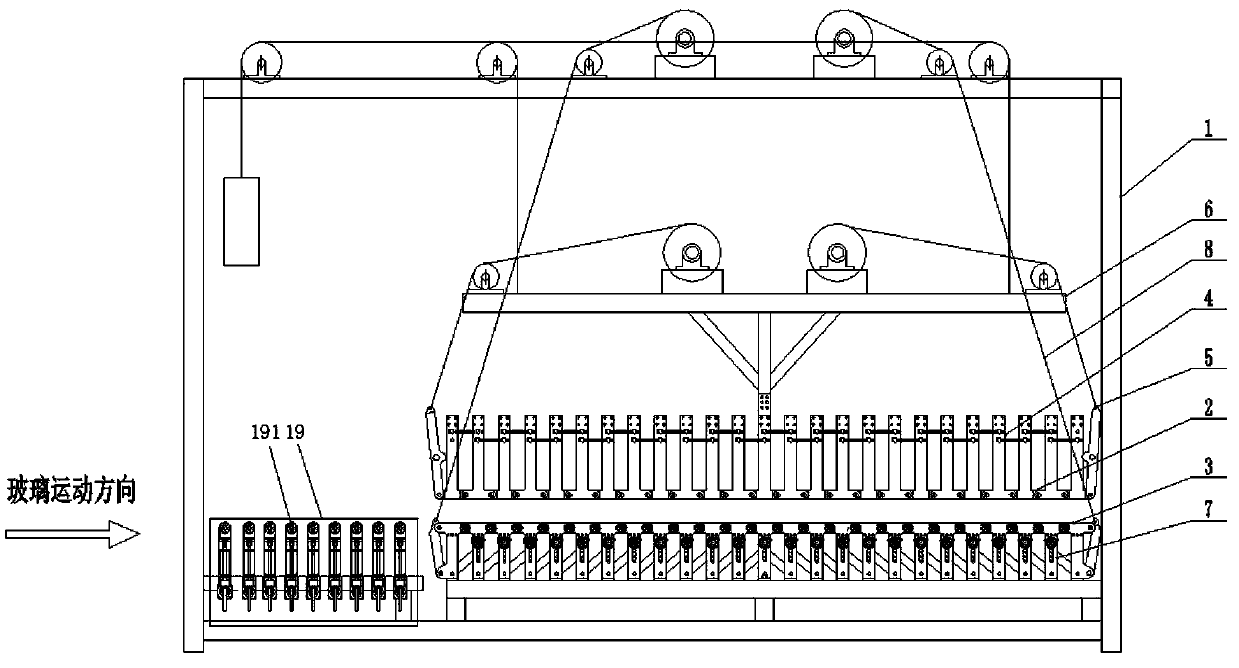

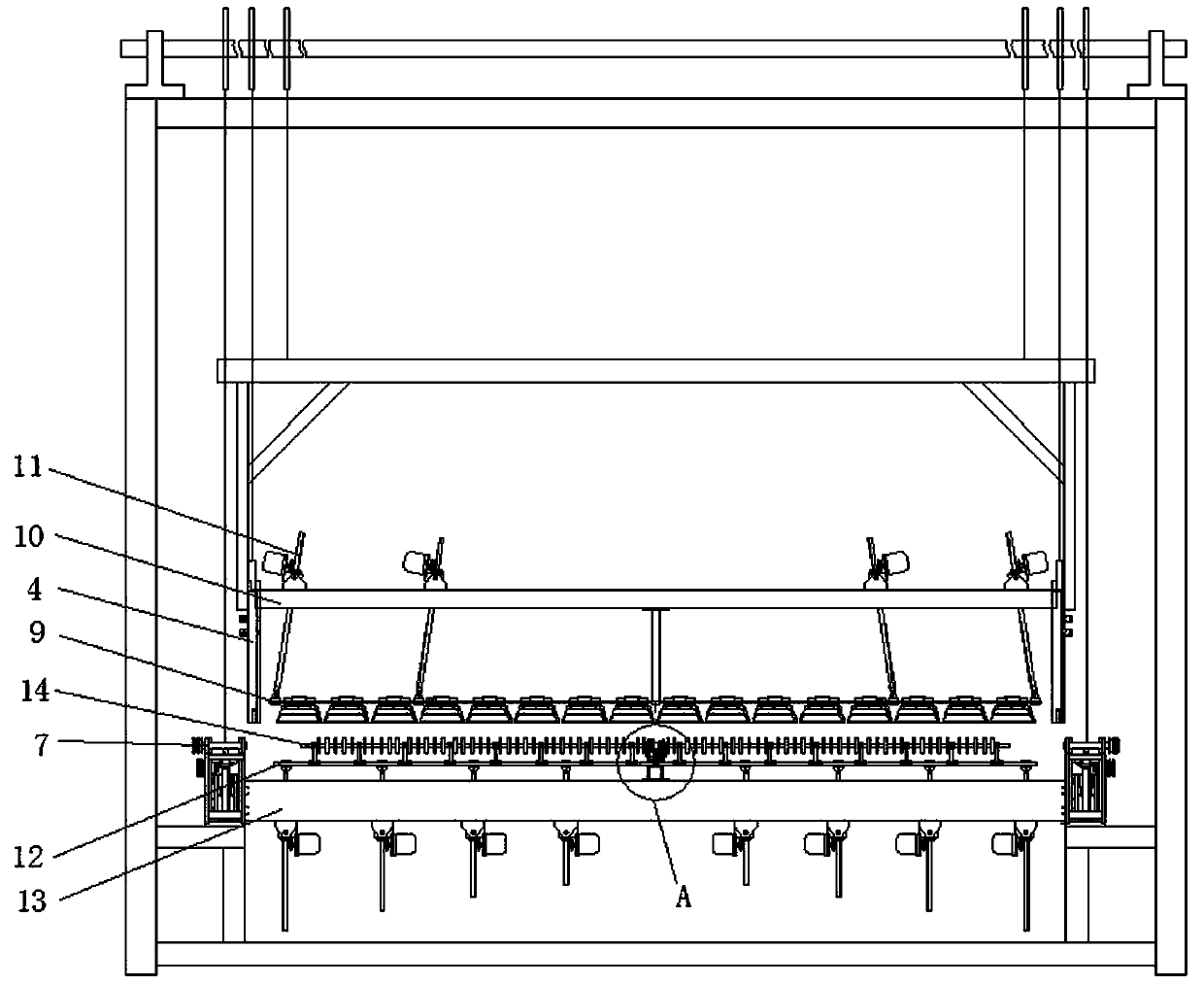

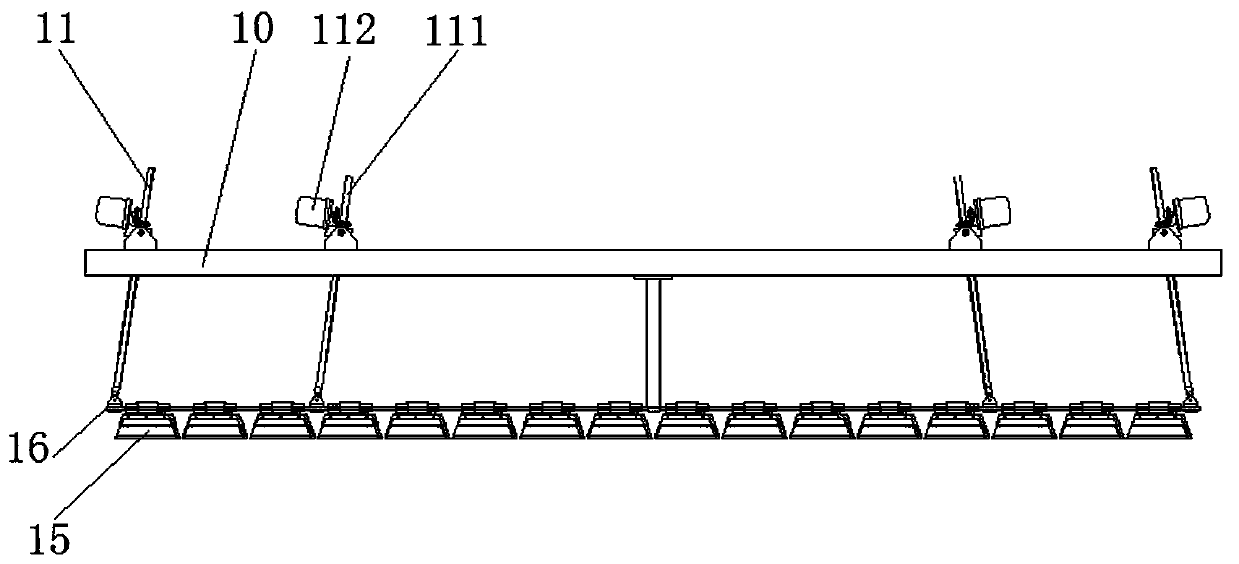

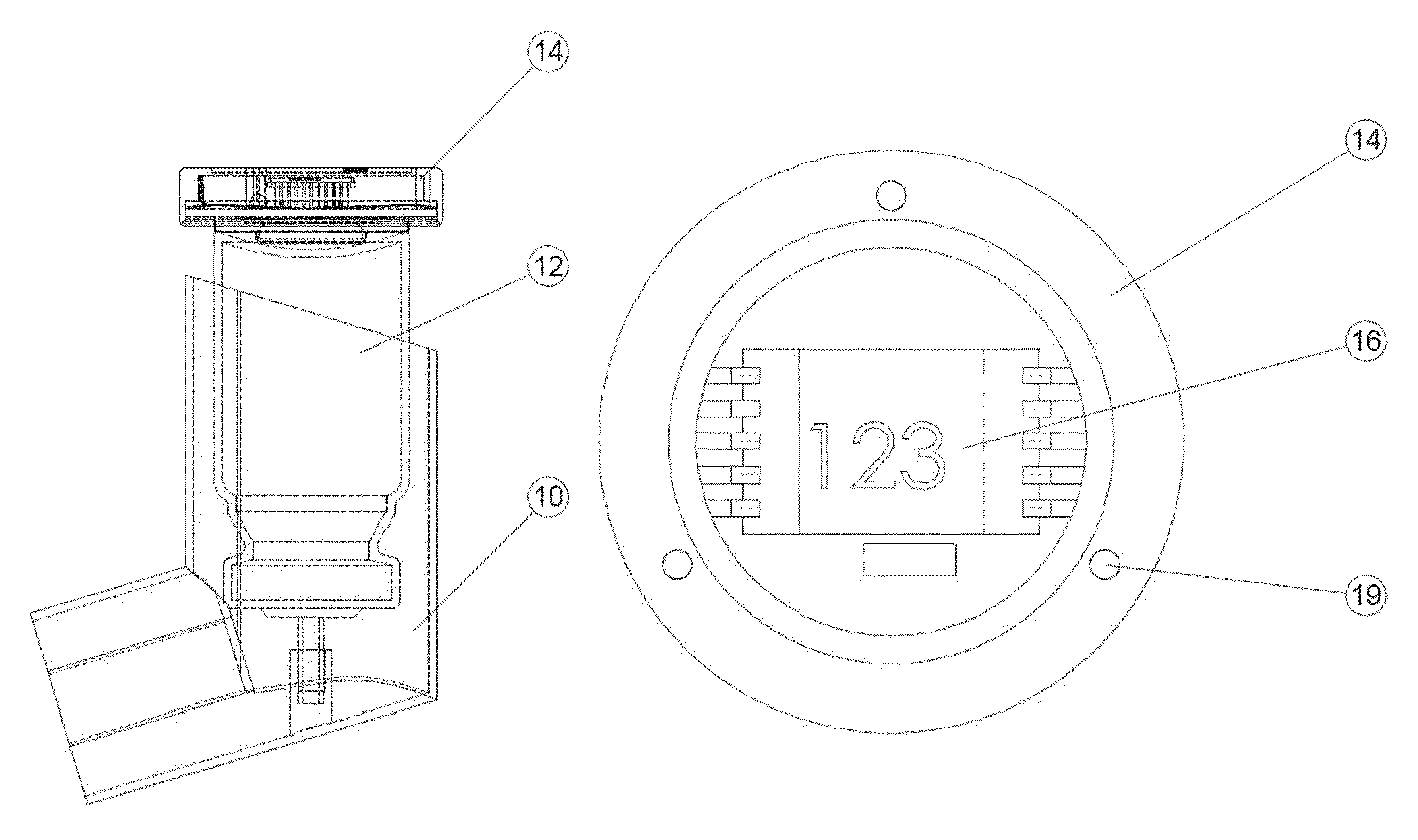

Bent toughened glass forming equipment and method

ActiveCN109748486AImprove general performanceQuick and easy molding adjustmentGlass transportation apparatusGlass reforming apparatusEngineeringToughened glass

The invention discloses bent toughened glass forming equipment. The bent toughed glass forming equipment comprises a rack, an air grid system and a forming system, wherein the air grid system comprises a plurality of upper air grids and a plurality of lower air grids; the upper air grids are mounted on the upper portion of the rack through a hoisting mechanism; the lower air grids are mounted in the forming system on the lower portion of the rack; a gradual transition section is arranged on the inlet side of the forming system, so that a glass plate is gradually changed into an arc in the transverse direction, and the glass plate which has been gradually changed into the arc is fed into the forming system; the forming system comprises two longitudinal forming arc-changing mechanisms and aplurality of transverse forming arc-changing mechanisms arranged in the conveying direction of the glass plate; the longitudinal forming arc-changing mechanism longitudinally bends and forms the glassplate; and the transverse forming arc-changing mechanisms are connected with the longitudinal forming arc-changing mechanisms through lower support cross beams, and the glass plate is transversely bent and formed. The equipment and the forming method provided by the invention can be used for processing various bent toughened glass without manufacturing a special mold, and have the advantages of rapid and convenient forming adjustment, stability, reliability, difficulty in deformation and high production efficiency.

Owner:LUOYANG LANDGLASS TECH CO LTD

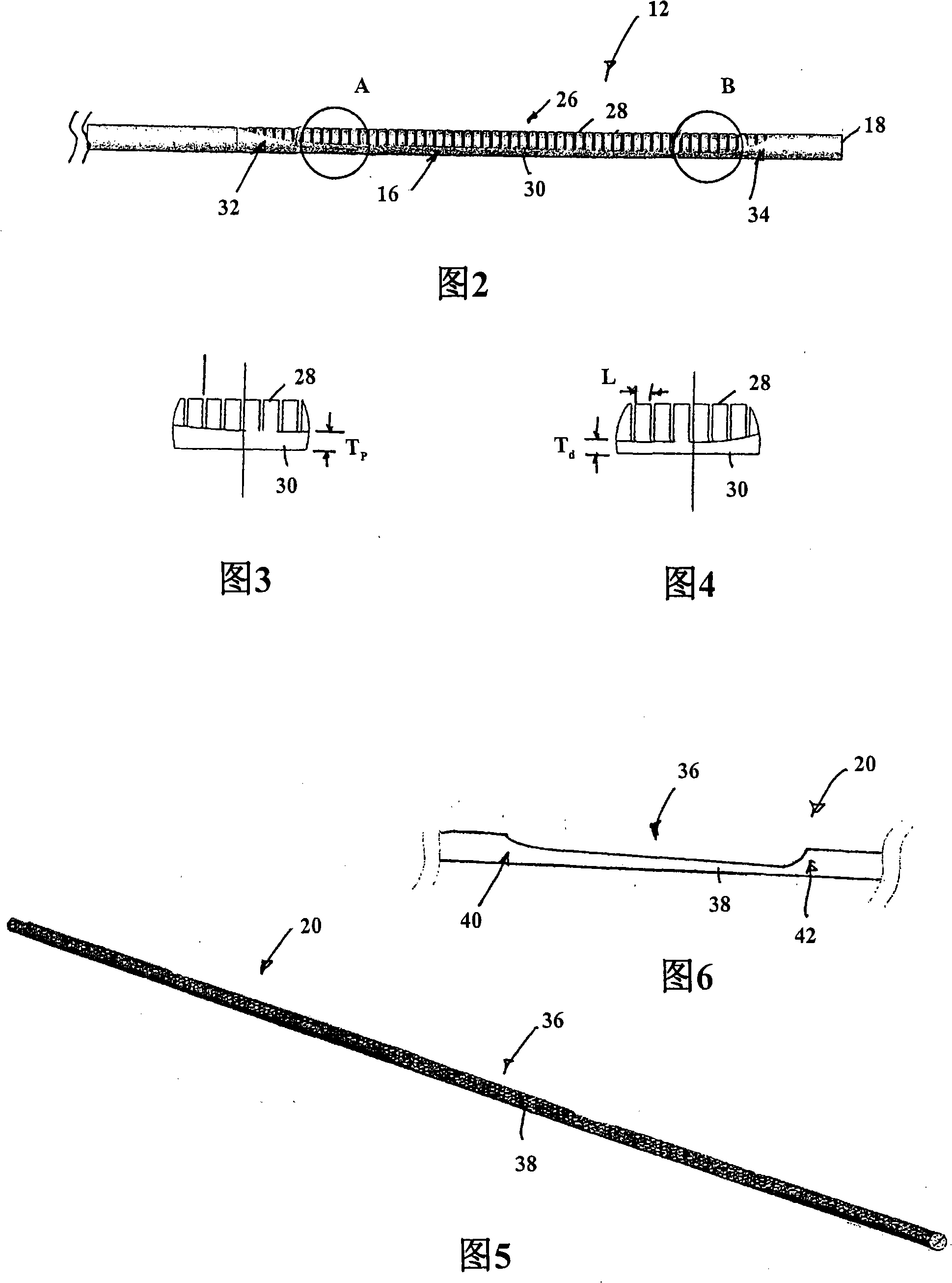

Dose counter and recording method

ActiveUS8539945B2Potential for errorMinimize doseLiquid surface applicatorsPowdered material dispensingElectronic controllerMedicine

A dose counter for a metered dose inhaler includes a force sensor, an electronic controller, a memory for storing data indicative of a remaining number of doses and an electronic display device coupled to the controller for displaying the remaining number of doses. The dose counter is attached or integrated into a base of a canister containing medicament such that force applied to the base of the canister is registered by the force sensor, the controller being configured to measure force applied to the dose counter when depressing the canister and being responsive to measured force to decrement the remaining number of doses stored in the memory and shown on the display device.

Owner:TEVA PHARMA IND LTD

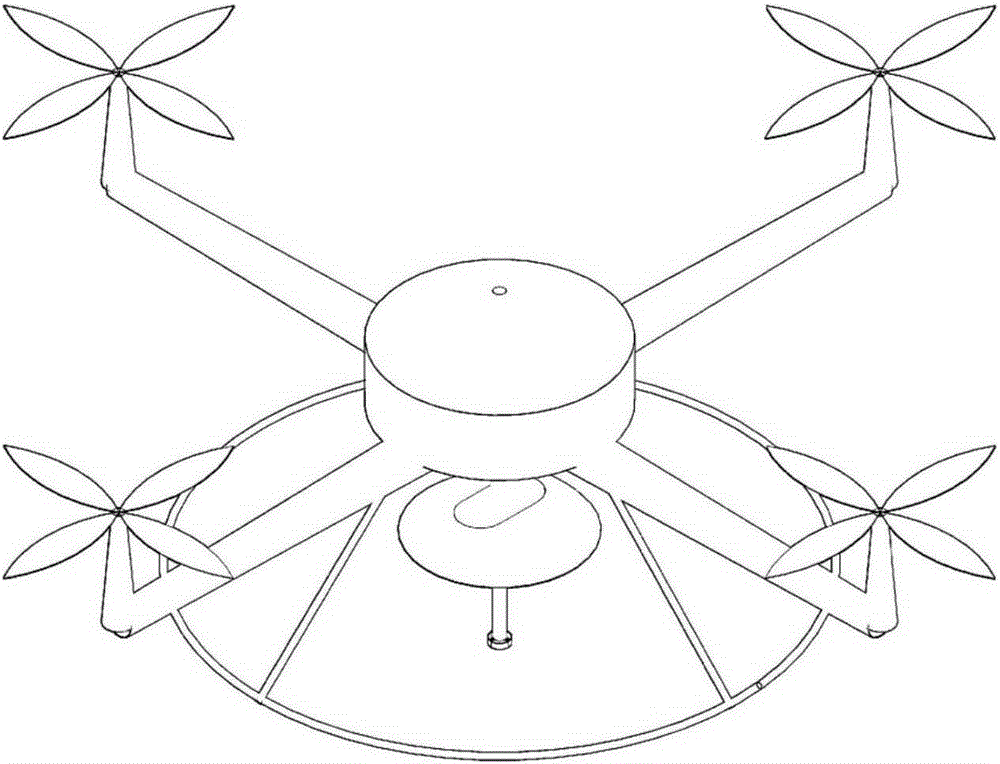

Unmanned aerial vehicle pod for environmental sample collection and collection method

InactiveCN105258978AReduce loadImplement samplingWithdrawing sample devicesControl systemUncrewed vehicle

The invention discloses an unmanned aerial vehicle pod for environmental sample collection and a collection method. The unmanned aerial vehicle pod comprises an unmanned aerial vehicle control system and a sample collection device hung on an unmanned aerial vehicle. The sample collection device comprises a pod shell and a negative pressure sampler arranged in the pod shell. The negative pressure sampler is provided with a collection arm stretching out of the pod shell. Under the negative pressure effect of the negative pressure sampler, samples are pumped into a negative pressure sampling pipe through the collection arm. The unmanned aerial vehicle pod has the advantages of being simple in structure, light, convenient and flexible to control and the like; a plurality of identical or different samples can be collected through one time of flight of the unmanned aerial vehicle; the defects that the power of an existing sampler is supplied by a sampling pump, and the existing sampler is complicated in structure and inflexible in control are overcome; mechanical faults are greatly reduced, the load borne by the unmanned aerial vehicle is lowered, and sample collection is more accurate, more economical and easier.

Owner:SOUTH CHINA UNIV OF TECH

Horizontal well stage-unlimited sectional reconstruction method

ActiveCN103437747AReach the smart selection open functionRealize infinite transformationFluid removalWell/borehole valve arrangementsSand blastingControl signal

The invention discloses a horizontal well stage-unlimited sectional reconstruction method. The method comprises the following steps that: a, a signal receiver on a sliding sleeve sends a search signal within a set range; b, a signal projector is put into the well, when the signal projector enters into the set range, the signal projector receives the search signal and sends a control signal to the signal receiver; c, the signal receiver stimulates a power mechanism after receiving the control signal, the power mechanism pushes a piston to move upwards and open a sand blasting hole, inner and outer communicated channels of an oil pipe are opened, and under the action of the piston, a ball seat generation tube of the sliding sleeve generates a ball seat, and the first section reconstruction is implemented; d, after the first section reconstruction is finished, a ball is added to block the first section reservoir, and the inner and outer communicated channels of the oil pipe are closed; e, the steps above are repeated for orderly performing reconstruction of subsequent sections. By the horizontal well stage-unlimited sectional reconstruction method, stage difference is avoided, the number of stages of sections is not limited by the inner diameter of the well bore, and stage-unlimited large-scale sectional fracturing reconstruction can be realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

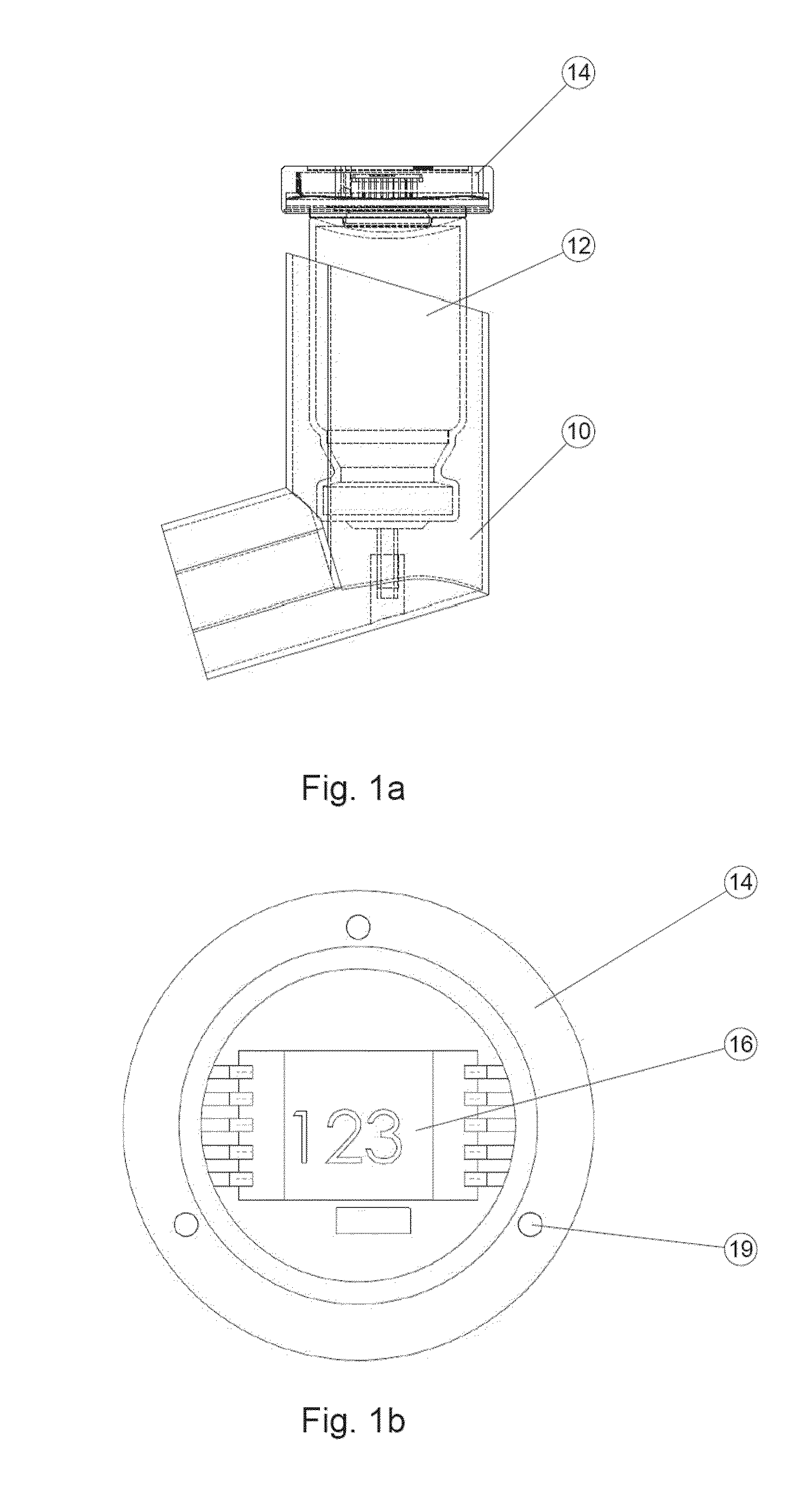

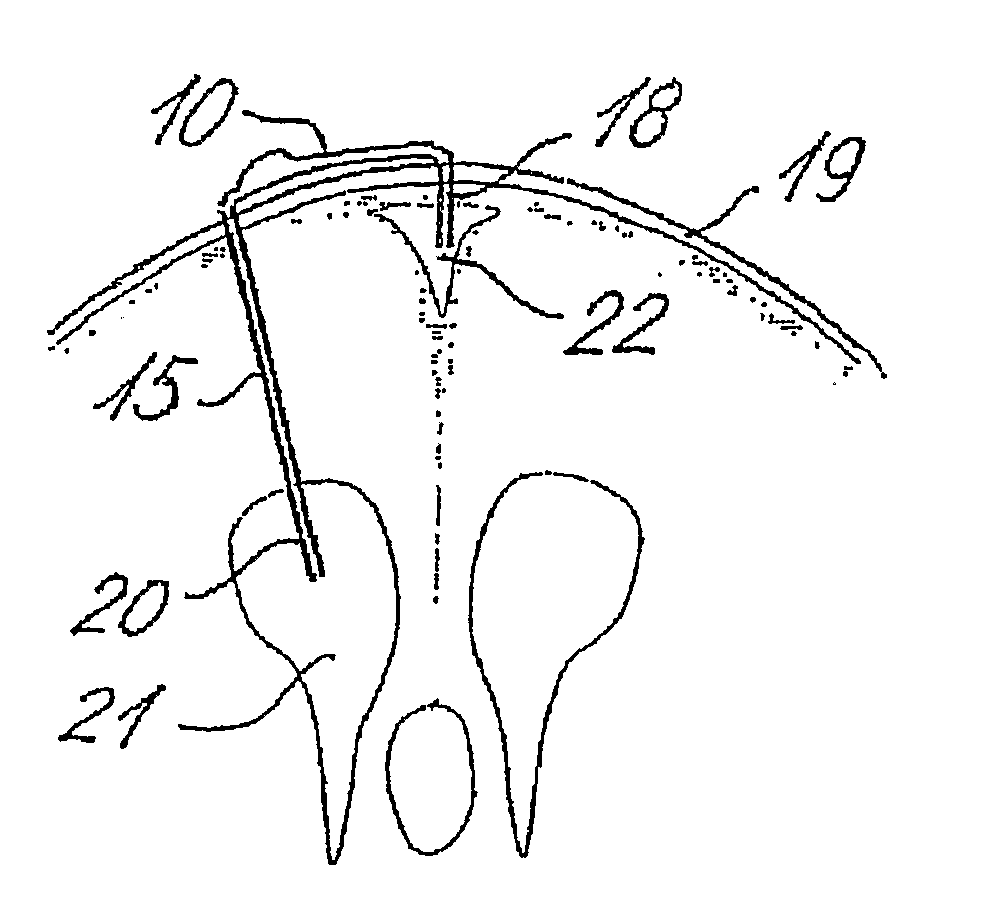

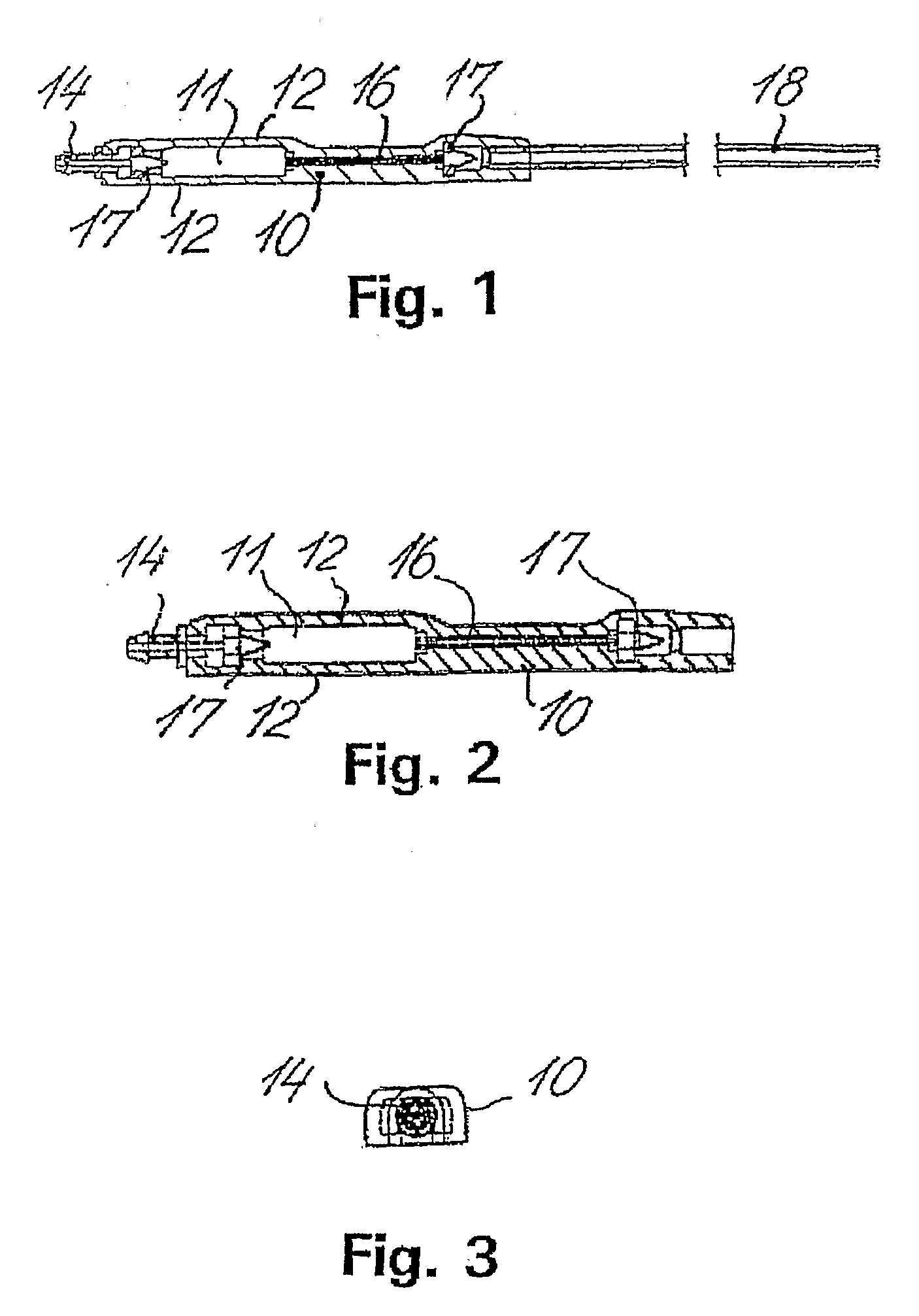

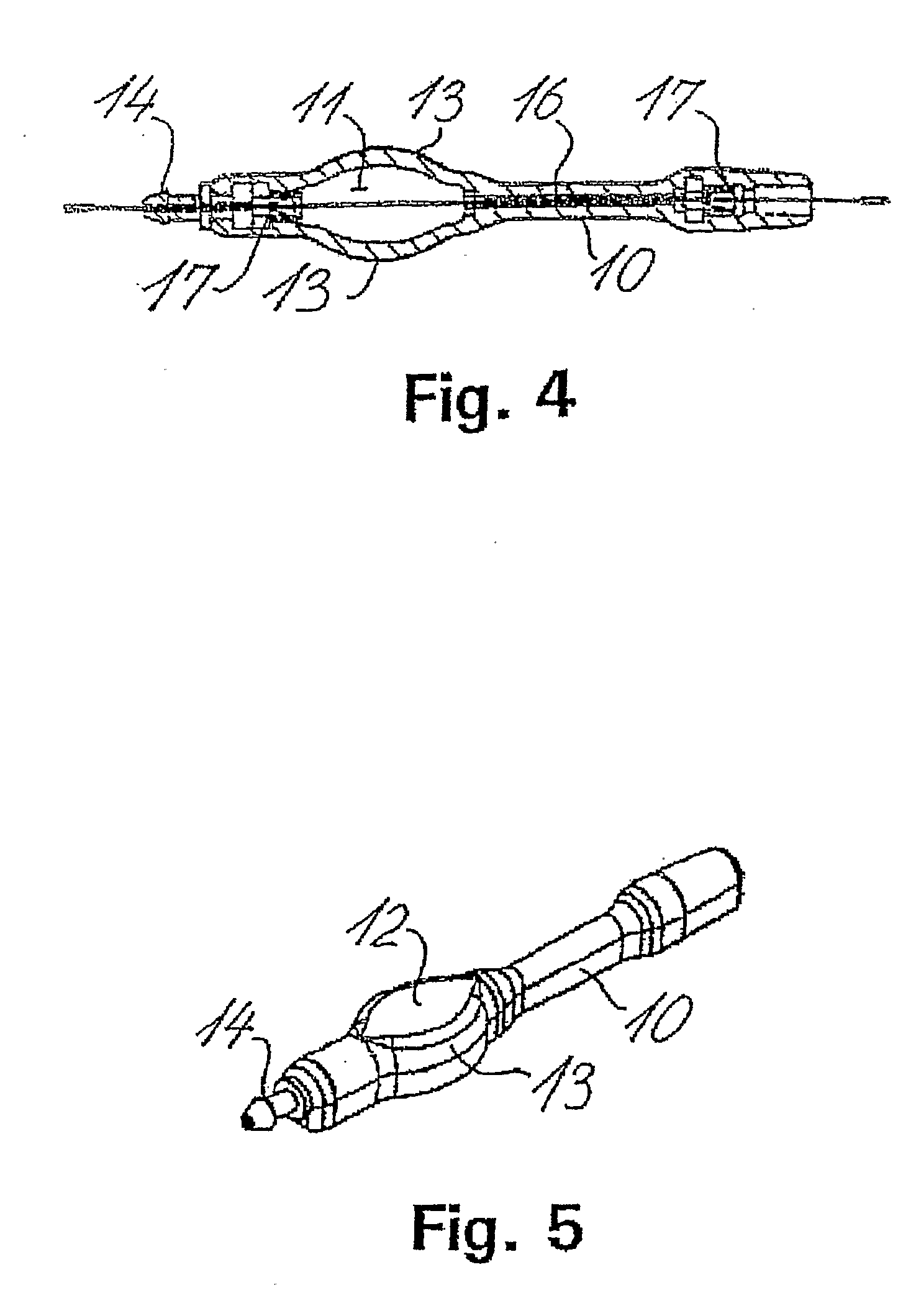

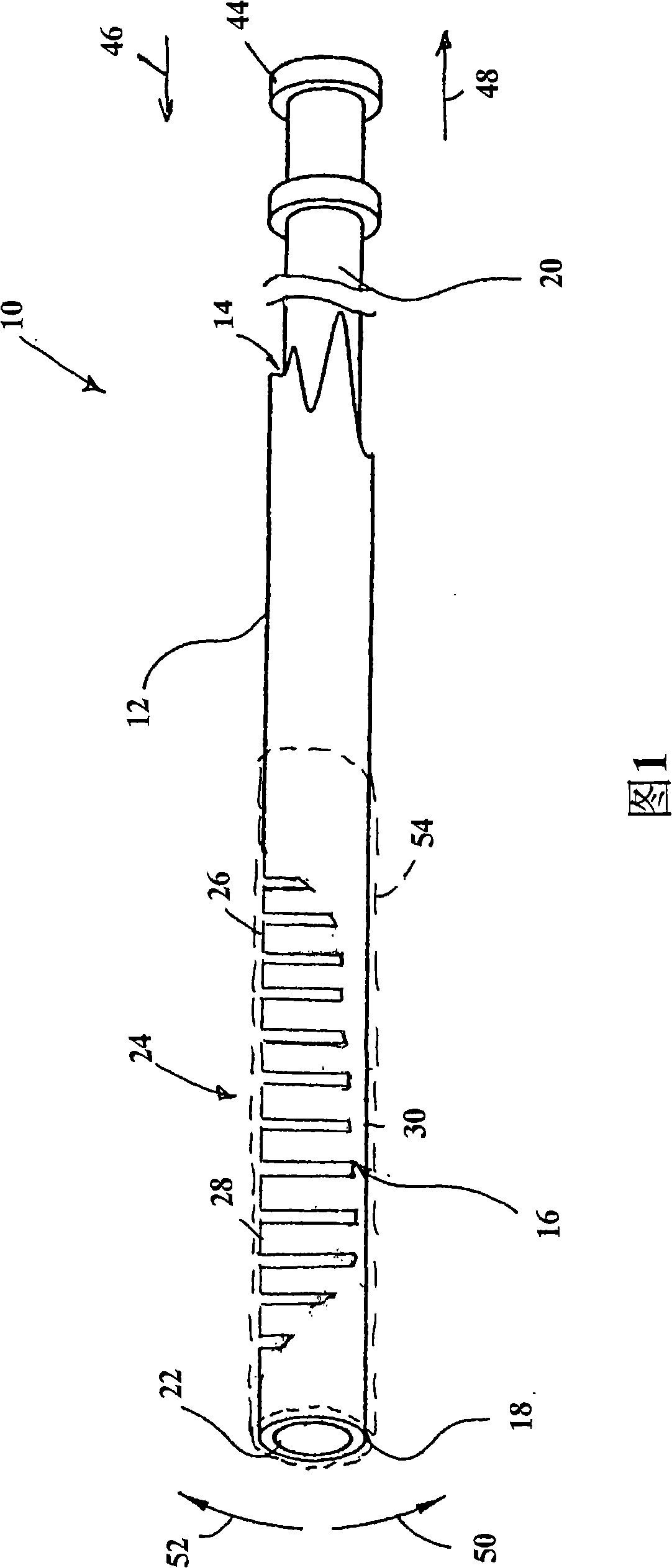

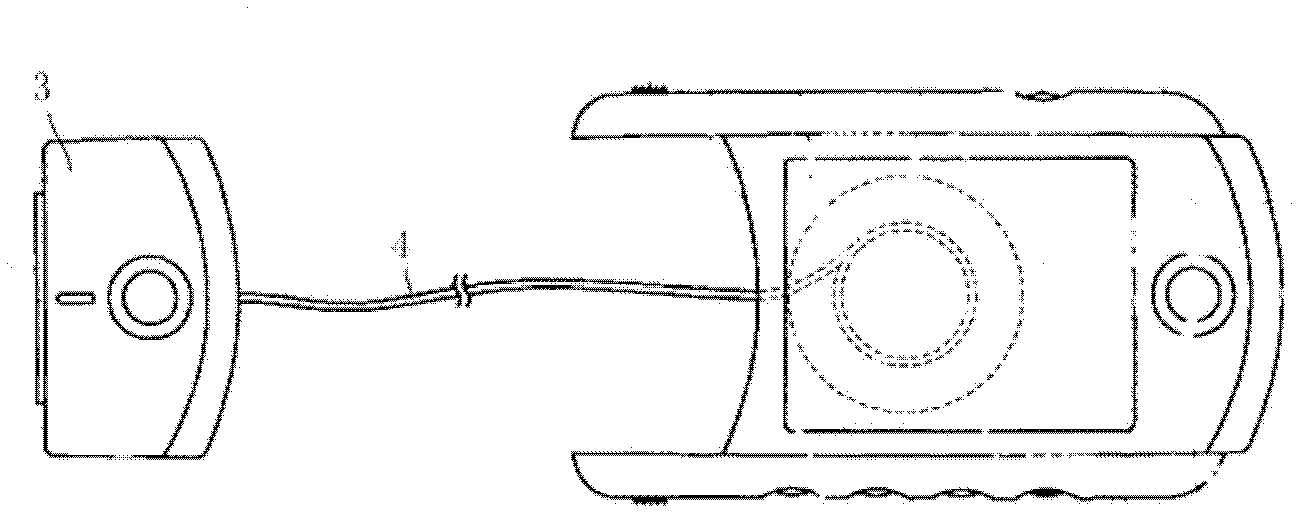

A catheter steering system

InactiveCN101259014AHigh strengthIncreased durabilityCatheterDiagnostic recording/measuringEngineeringActuator

A catheter steering mechanism 10 includes a tubular member 12 defining a passage 14 . The tubular member 12 has a longitudinally extending, cutaway portion 16 defining a bend-enhancing region formed at a predetermined location along a length of the tubular member 12 . An actuator 20 is received in the passage 14 of the tubular member 12 , a distal part 22 of the actuator 20 being fast with a distal part of the tubular member 12 . A restraining arrangement 24 is defined by the tubular member 12 , the restraining arrangement 24 comprising a structure 26 arranged at the bend-enhancing region to retain the actuator 20 substantially within the confines of the tubular member 12 during bending.

Owner:CATHRX LTD

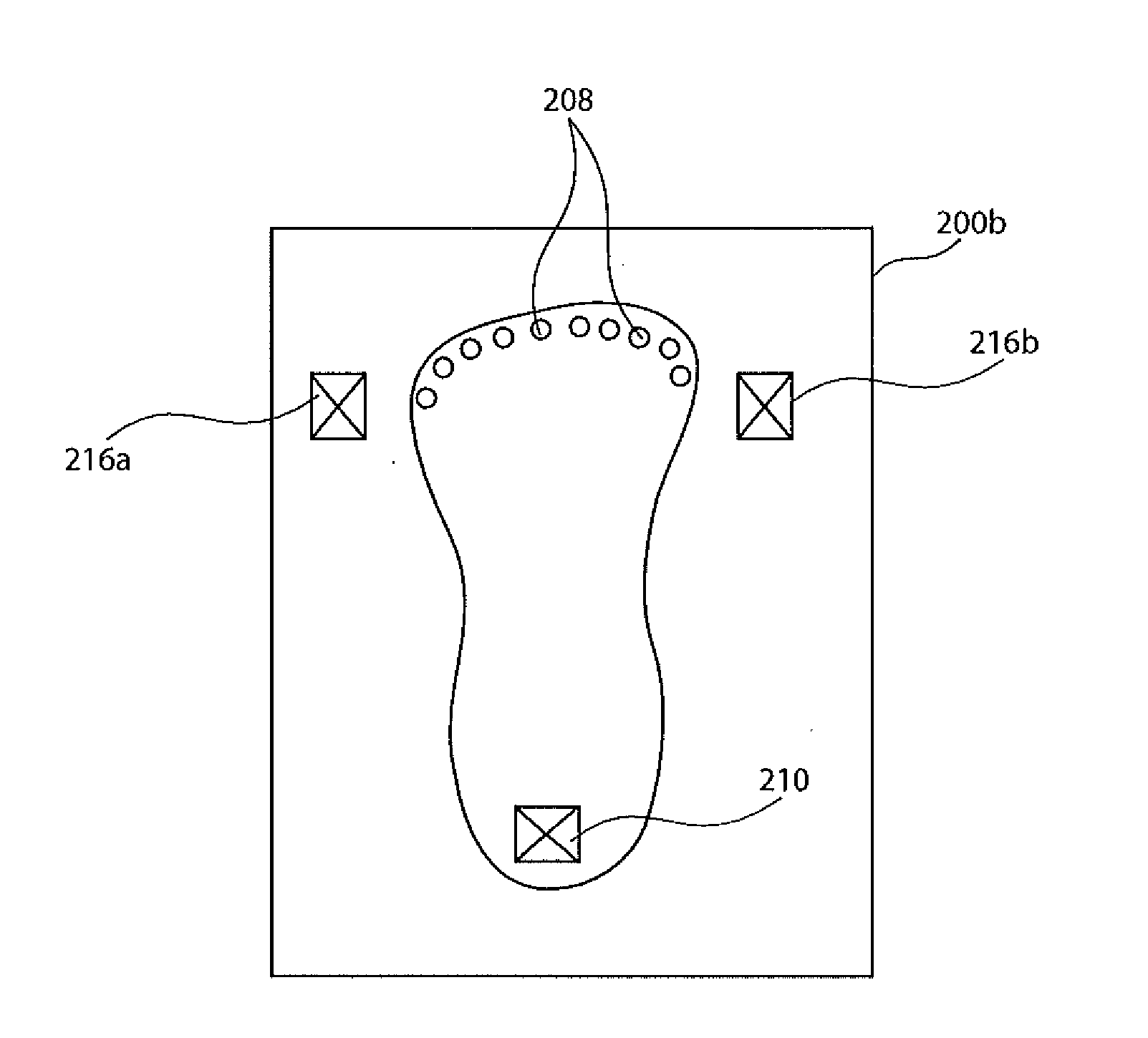

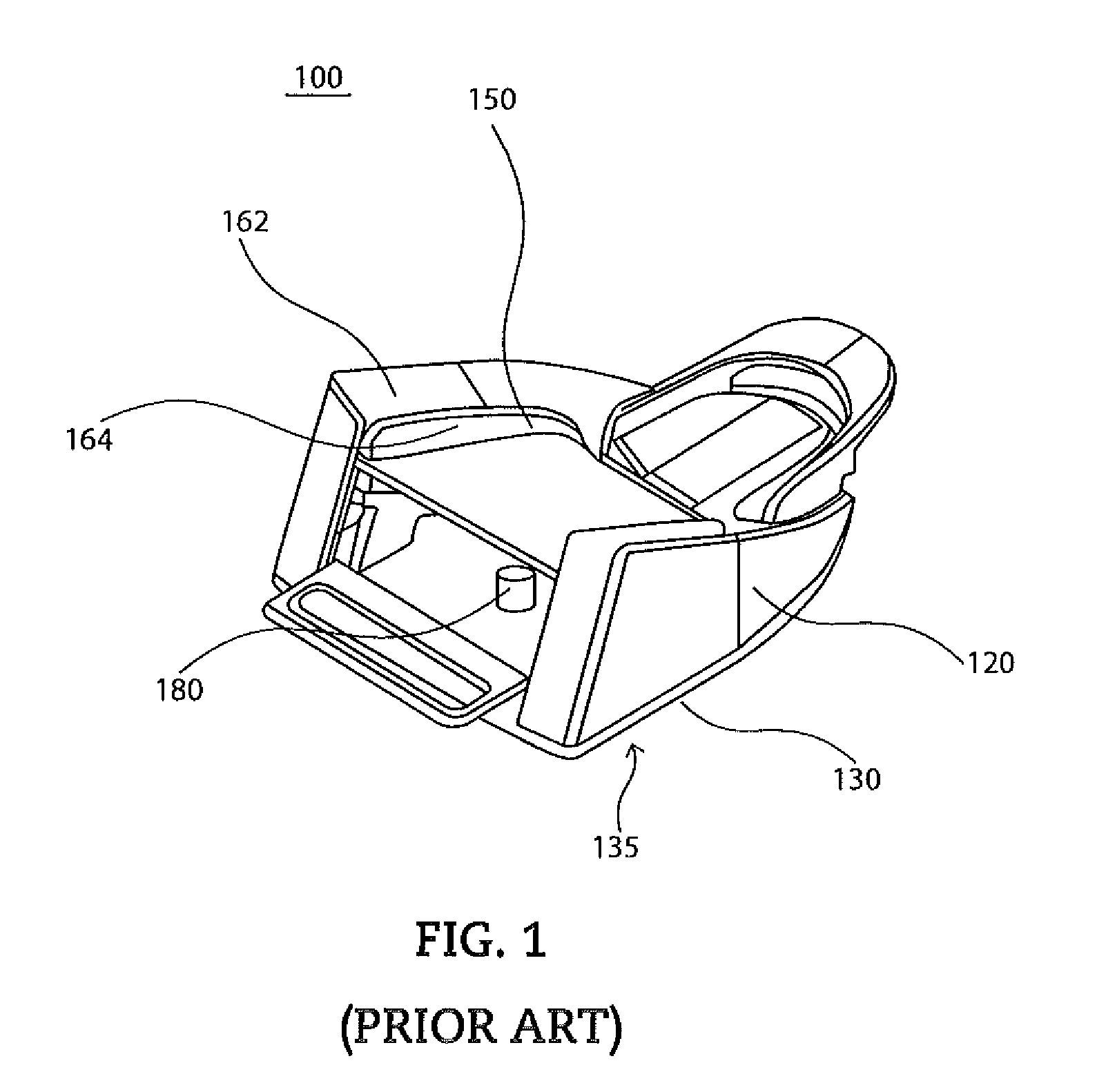

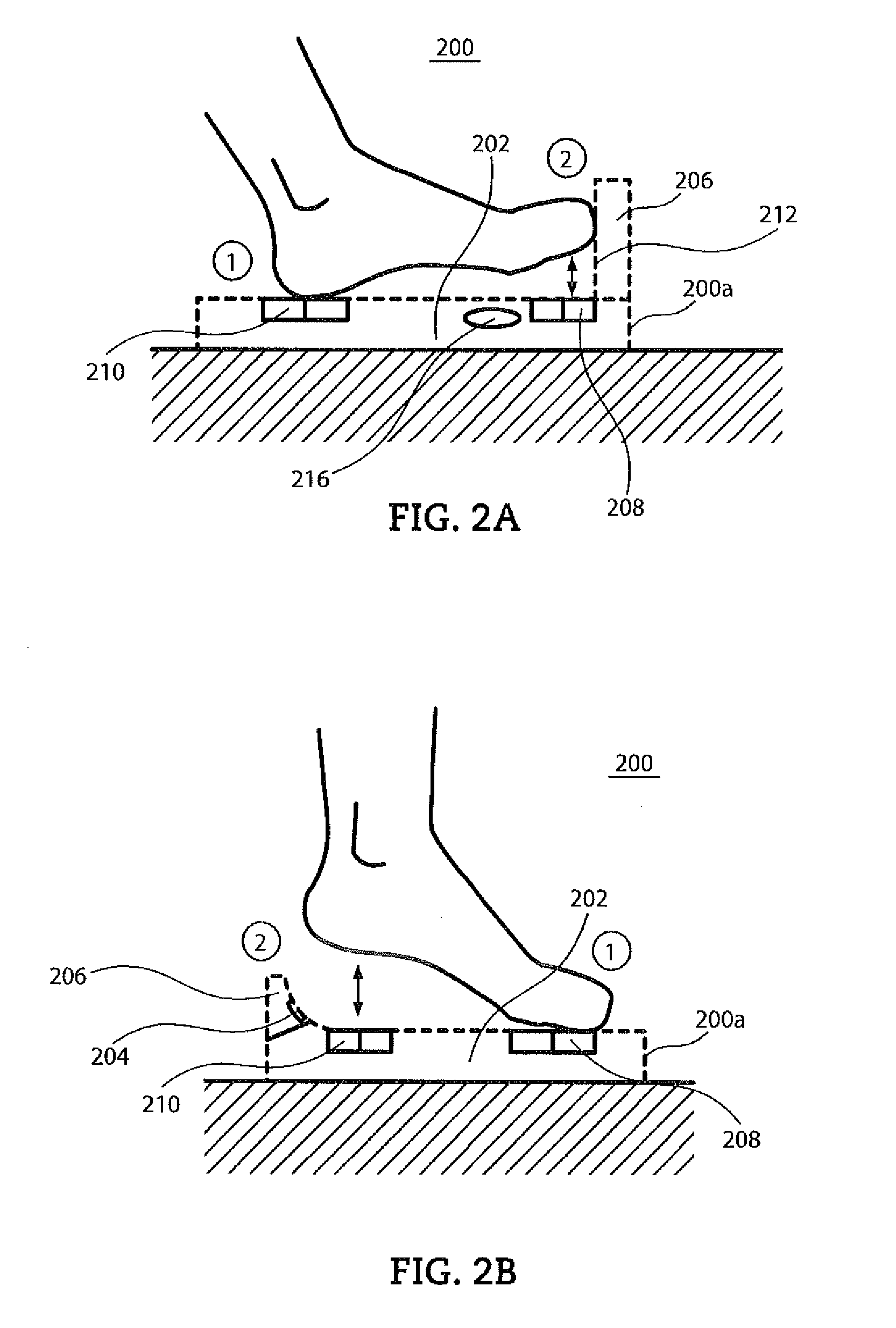

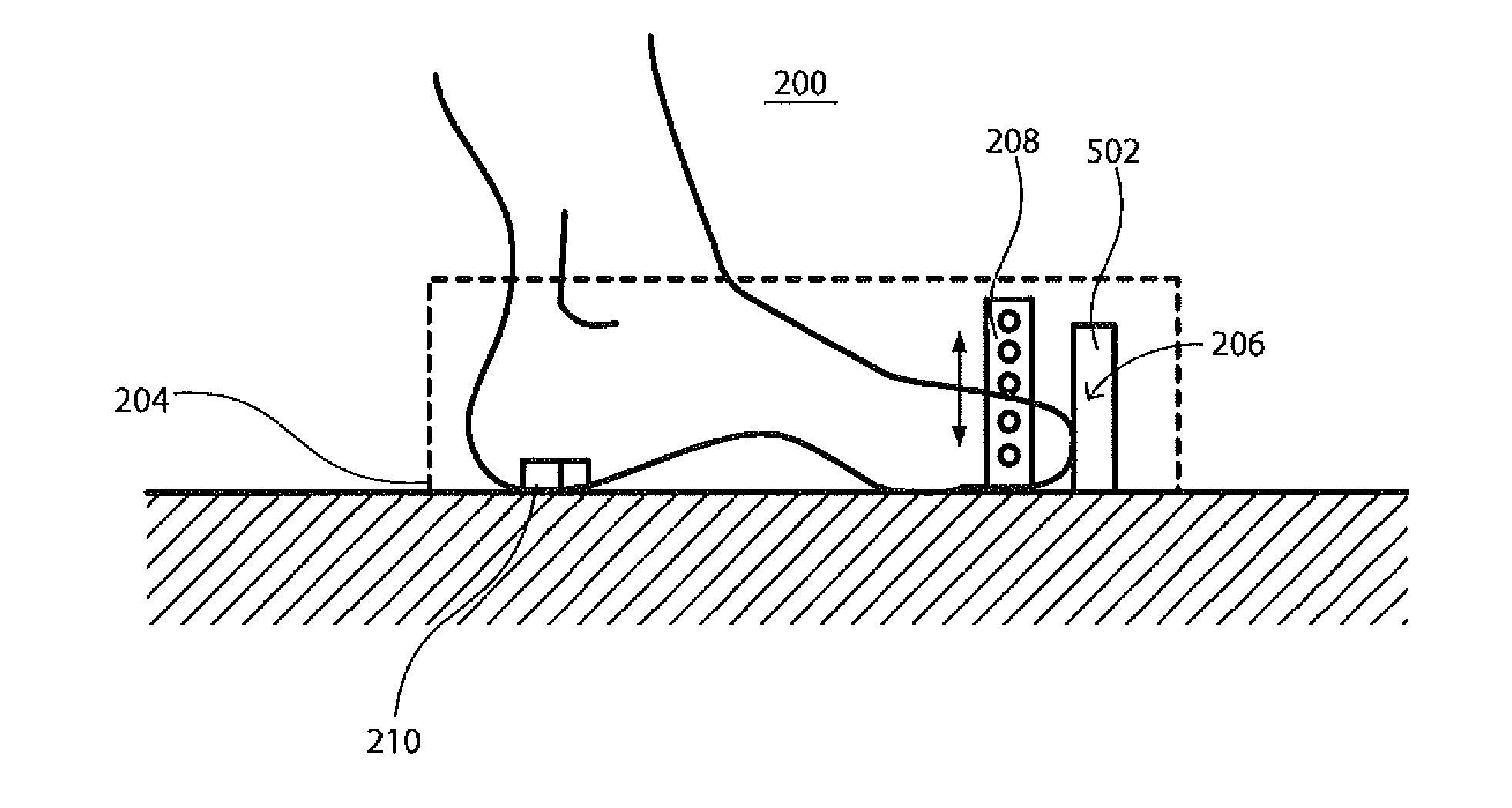

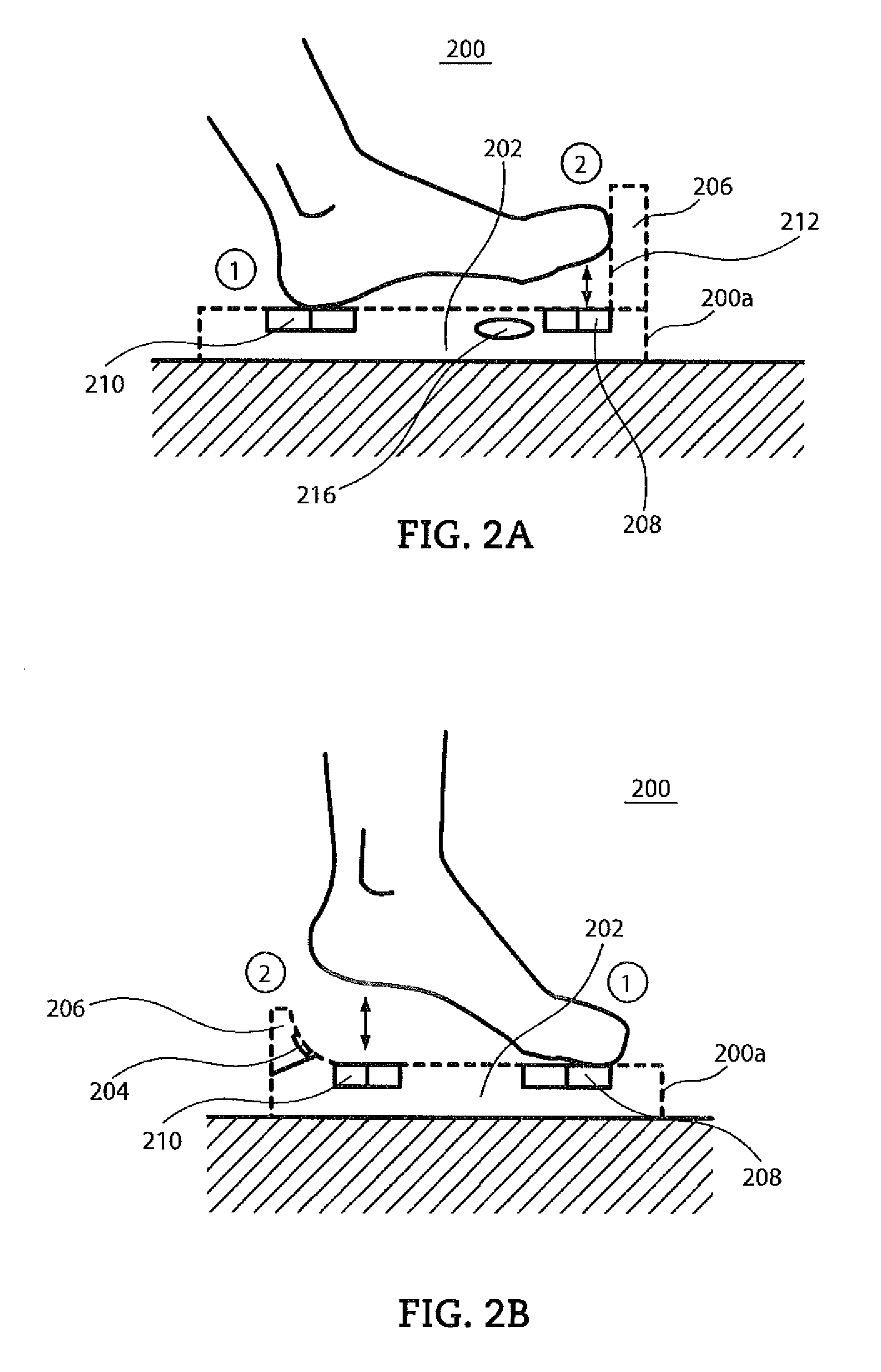

Foot pedal system and apparatus

InactiveUS20140378986A1Reduce mechanical failureImprove ergonomicsEye surgerySurgical manipulatorsEngineeringSurgical instrument

A phacoemulsification system and method, and a foot pedal device, system and method. The devices, systems and methods may include a console comprising a plurality of modes for at least one physically associated surgical instrument, and a foot pedal communicatively associated with said console and suitable for varying ones of the plurality of modes. The foot pedal may include a foot pedal base, and at least two electronically actuated sensors physically associated with the foot pedal base, communicatively connected to the console, and suitable for receiving physical indications of variations in ones of the plurality of modes.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

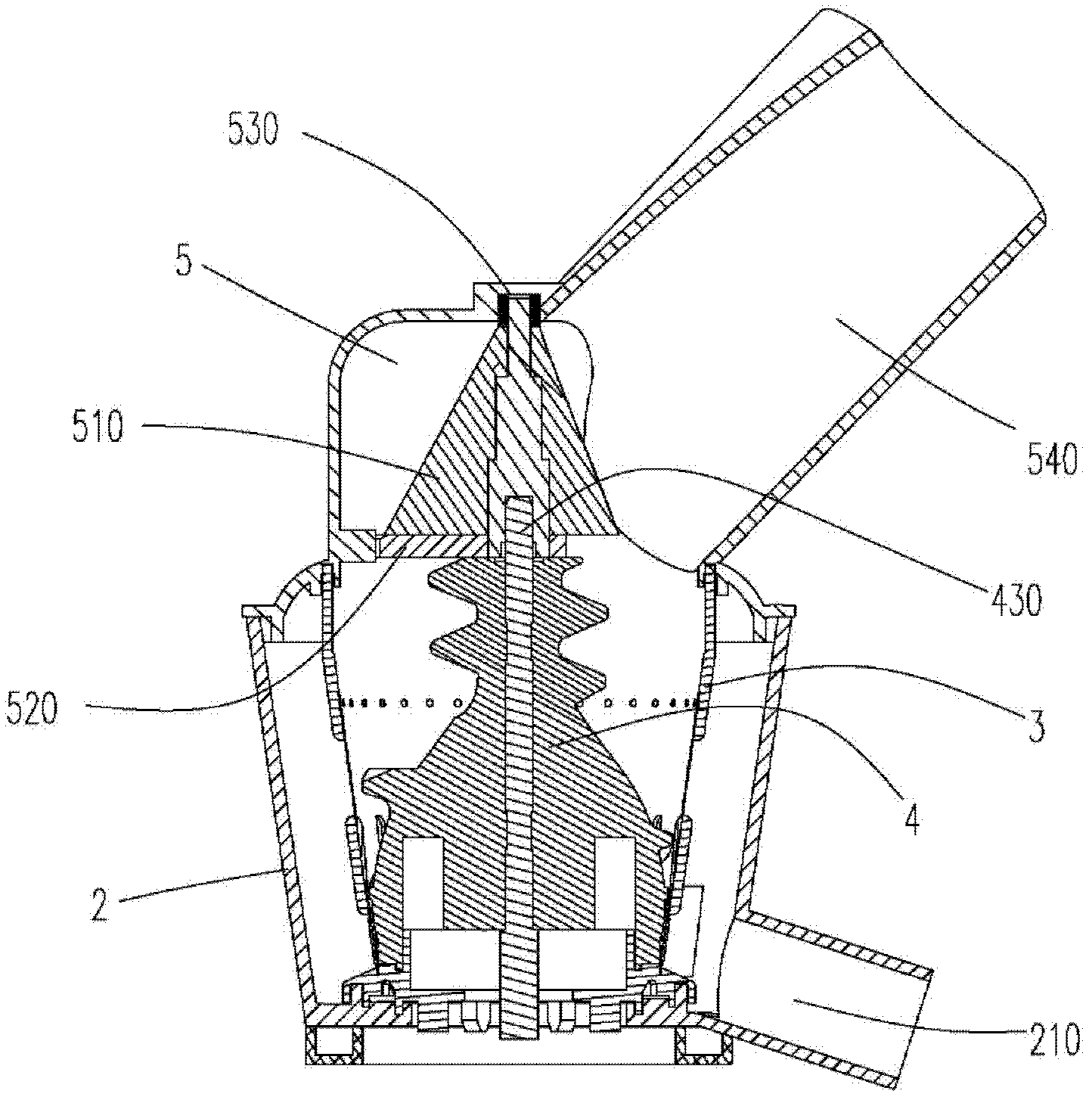

Juicer

ActiveCN103202654AGuaranteed tasteGuaranteed nutritionJuice extractionStrainersMechanical engineering

The invention provides a juicer, which comprises a machine base with a driving mechanism, a squeezing device located above the engine seat, and an upper cover placed above the squeezing device, and is characterized in that the squeezing device is formed by a separator for discharging juice and residual of squeezed food respectively, a filter screen for filtering the residual of the squeezed food, and a rotary head for spirally squeezing the to-be-squeezed food; the separator is provided with a juice outlet at the side wall and a residual outlet at the bottom, the bottom of the filter screen is provided with a residual discharge port movably communicated with the residual outlet, the rotary head is provided with a spiral sheet and arranged in the separator, the filter screen is sleeved between the rotary head and the separator, a first driving end of the driving mechanism of the engine seat is connected with the center of the lower end of the rotary head, the rotary head reversely rotates relative to the filter screen, and the cost is reduced as the assembled parts are reduced.

Owner:T F ELECTRICAL TECH SHENZHEN

Reflective wrist oximeter with electrocardiograph function

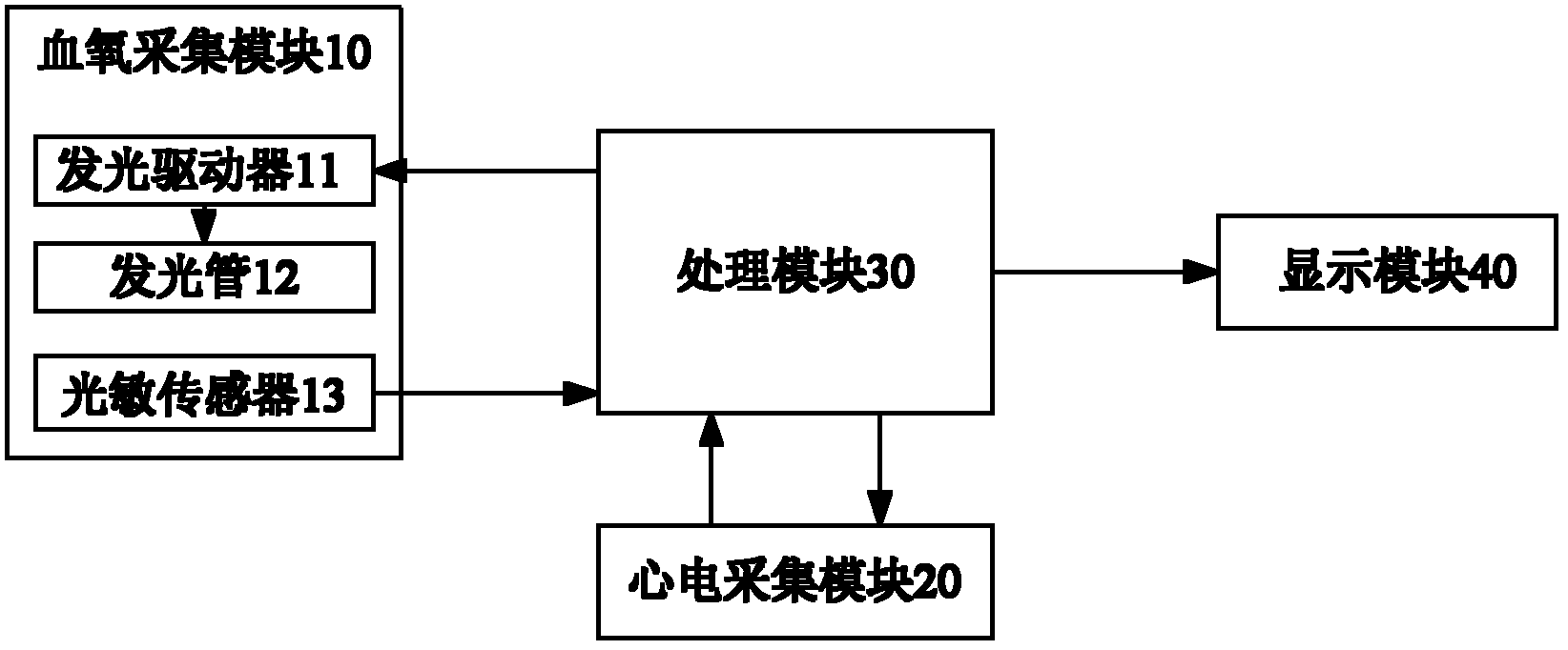

InactiveCN102198005AImprove signal-to-noise ratioReduce external distractionsSensorsMeasuring/recording heart/pulse rateEcg signalEngineering

The invention relates to a reflective wrist oximeter with an electrocardiograph function, which comprises a blood oxygen acquisition module, an electrocardiosignal acquisition module, a processing module, a display module, a shell and wrist bands, wherein the blood oxygen acquisition module comprises a light-emitting driver, a light-emitting tube and a photosensor; the light-emitting tube and the photosensor are arranged at the same side of a position to be detected, and an included angle having preset degrees is formed between the light-emitting tube and the photosensor; the electrocardiosignal acquisition module comprises a first electrode and a second electrode and is used for acquiring electrocardiosignals; the processing module is used for processing pulse blood oxygen data acquired by the acquisition module and the electrocardiosignals acquired by the electrocardiosignal acquisition module; the display module is used for displaying information processed by the processing module to a user; the wrist bands are connected to both sides of the shell; the first electrode is arranged at one side of the shell, which is in contact with the wrist; the display module is arranged at the other side of the shell, which is opposite to the first electrode; the second electrode is arranged outside the display module; and the blood oxygen acquisition module is arranged inside or outside the second electrode. The reflective wrist oximeter delicately combines the reflective blood oxygen technology and the electrocardiograph technology, and is convenient to operate.

Owner:CONTEC MEDICAL SYST

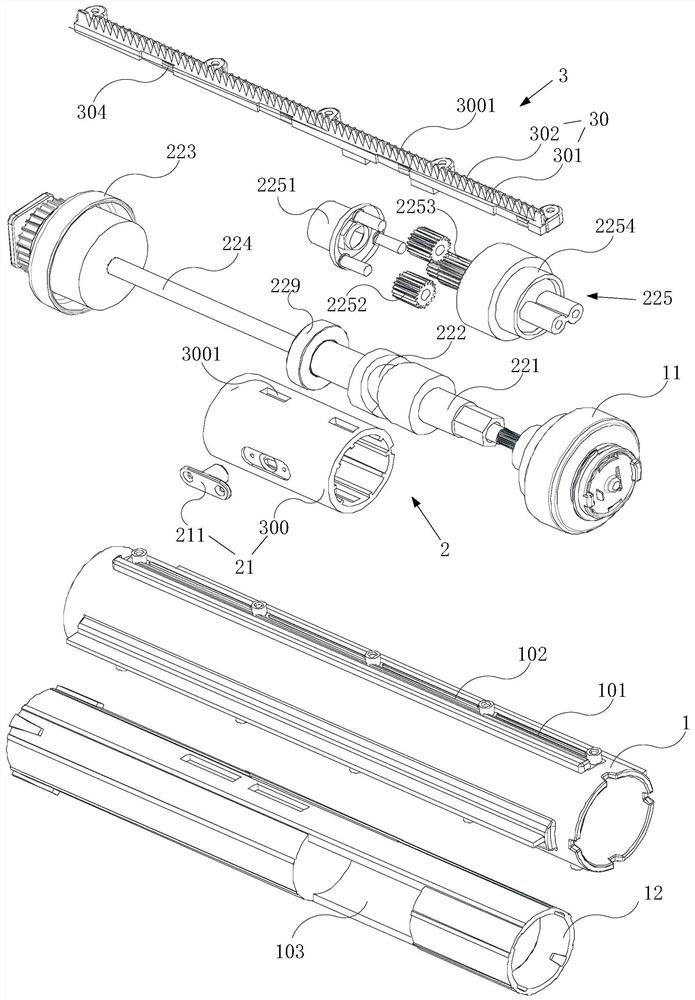

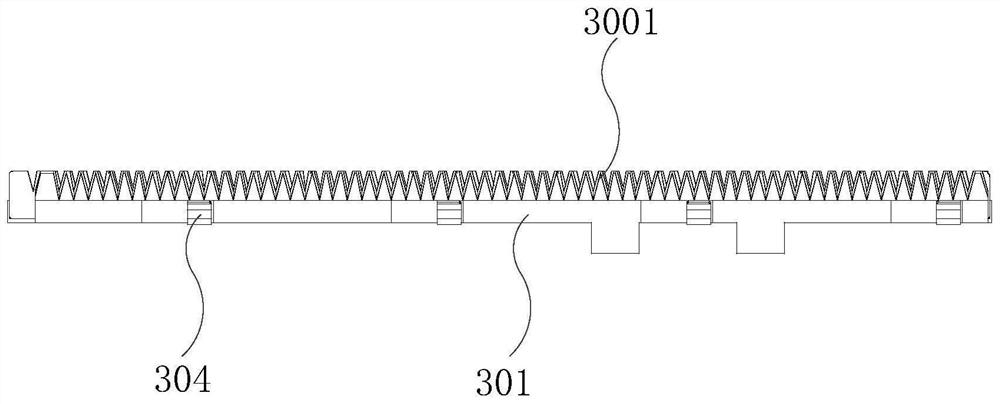

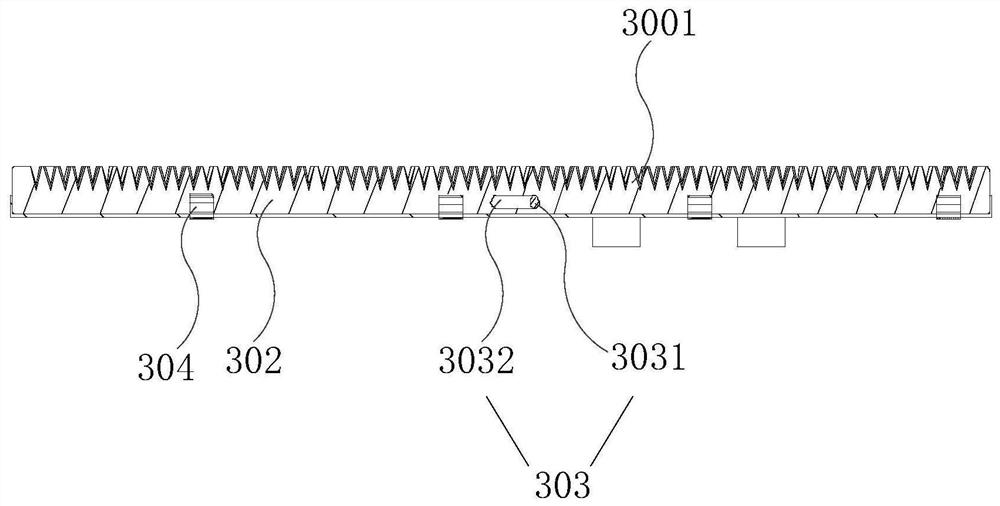

Rolling brush assembly, floor brush mechanism and cleaning device

ActiveCN112674642AImprove cleanlinessReduce mechanical failureMachine detailsSuction nozzlesReciprocating motionEngineering

The invention discloses a rolling brush assembly which comprises a first rolling brush, a reciprocating mechanism and a cutting piece. The cutting piece is connected with the reciprocating mechanism so that the cutting piece can be driven by the reciprocating mechanism to do reciprocating motion in the direction parallel to the axial direction of the first rolling brush, and the cutting piece applies cutting force to an object wound on the first rolling brush. According to the technical scheme provided by the invention, attachments wound on the rolling brush can be cut.

Owner:TIANKE INTELLIGENT TECH CO LTD

Anti-biological blocking device for drip irrigation system

InactiveCN102283080ANo residueNo troubleClimate change adaptationWatering devicesAir filterHazardous substance

The invention relates to an anti-biological clogging device for a drip-irrigation system. The drip-irrigation system is started, an air intake brake valve is opened, an ozone generator is started, and compressed water which comes from the head part of the drip-irrigation system is sprayed at high speed from a jet orifice of a jet nozzle so as to form the negative pressure in a gas injection cavity; and under the action of the negative pressure, the ozone generator ensures that ozone generated through air ionization enters the gas injection cavity through the air intake brake valve, a check valve and an air inlet pipe along with the air filtered by an air filter, and enters an oscillating cavity for vortex oscillation, stirring and aerification along with the high-speed water flow sprayed by the jet nozzle so as to form 'ozone water' of which gas and liquid are distributed uniformly, and the 'ozone water' enters the drip-irrigation system to kill microorganisms in flow channels and cansynchronously inhibit crop root systems from growing toward the direction of a water outlet of a drip irrigation emitter in an underground drip-irrigation system, so that the aim of biological clogging resistance of the drip-irrigation system is fulfilled. Compared with a method of injecting a chemical agent into irrigation water, the invention has the advantages that: the residue of harmful substances which can pollute the environment is not produced, and the risk of using dangerous chemical agents is avoided.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

Distributed-driven electric automobile and control method thereof

PendingCN106945562AReduce dependenceAchieve strategic transformationSpeed controllerCharging stationsSupply managementDrive wheel

The invention relates to a distributed-driven electric automobile and a control method thereof. The distributed-driven electric automobile comprises a main controller, four driving wheels with hub motors correspondingly and motor drivers used for driving all the hub motors, and braking systems are arranged in all the driving wheels. When an accelerator pedal is triggered, the main controller assigns the corresponding motor rotating speeds and rotating torque through all the motor drivers to drive all the hub motors to enable the driving wheels to rotate; and when a braking pedal is triggered, the main controller is suitable for braking the hub motors through the braking systems. According to the distributed-driven electric automobile, a power supply management system is utilized to drive the four hub motors through the motor drivers correspondingly, and the driving wheels are driven to work, so that dependence on oil chemical energy of diesel is effectively reduced, energy strategy transformation is realized, the working noise is reduced, pollution emissions are reduced, the environment is effectively protected, and the market prospects are wide.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Space unfolding structure

ActiveCN103662099ASimple structureDoes not take up spaceCosmonautic power supply systemsStructural reliabilityAlloy

The invention relates to a foldable structure, in particular to a space unfolding structure which can be unfolded without needing a driving device. The space unfolding structure comprises a cylinder, a heater, memory alloys and films. The heater is installed in the cylinder, a plurality of memory alloys are evenly distributed on the periphery of the cylinder in the circumferential direction, one end of every memory alloy penetrates through the cylinder and is connected with the heater, the other end of every memory alloy is a free end, the memory alloys are sleeved with the films in a stacked mode through the free ends of the memory alloys, the films are in sealed connection with the cylinder, the free ends of the memory alloys sleeved with the films are sequentially bent in the clockwise direction and coiled around the cylindrical surface of the cylinder, and an inflation nozzle capable of inflating the cylinder is installed on the cylinder. The space unfolding structure does not need to be driven by a motor, is simple in structure and easy to install and does not occupy too much space, and reliability of the space unfolding structure is greatly improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

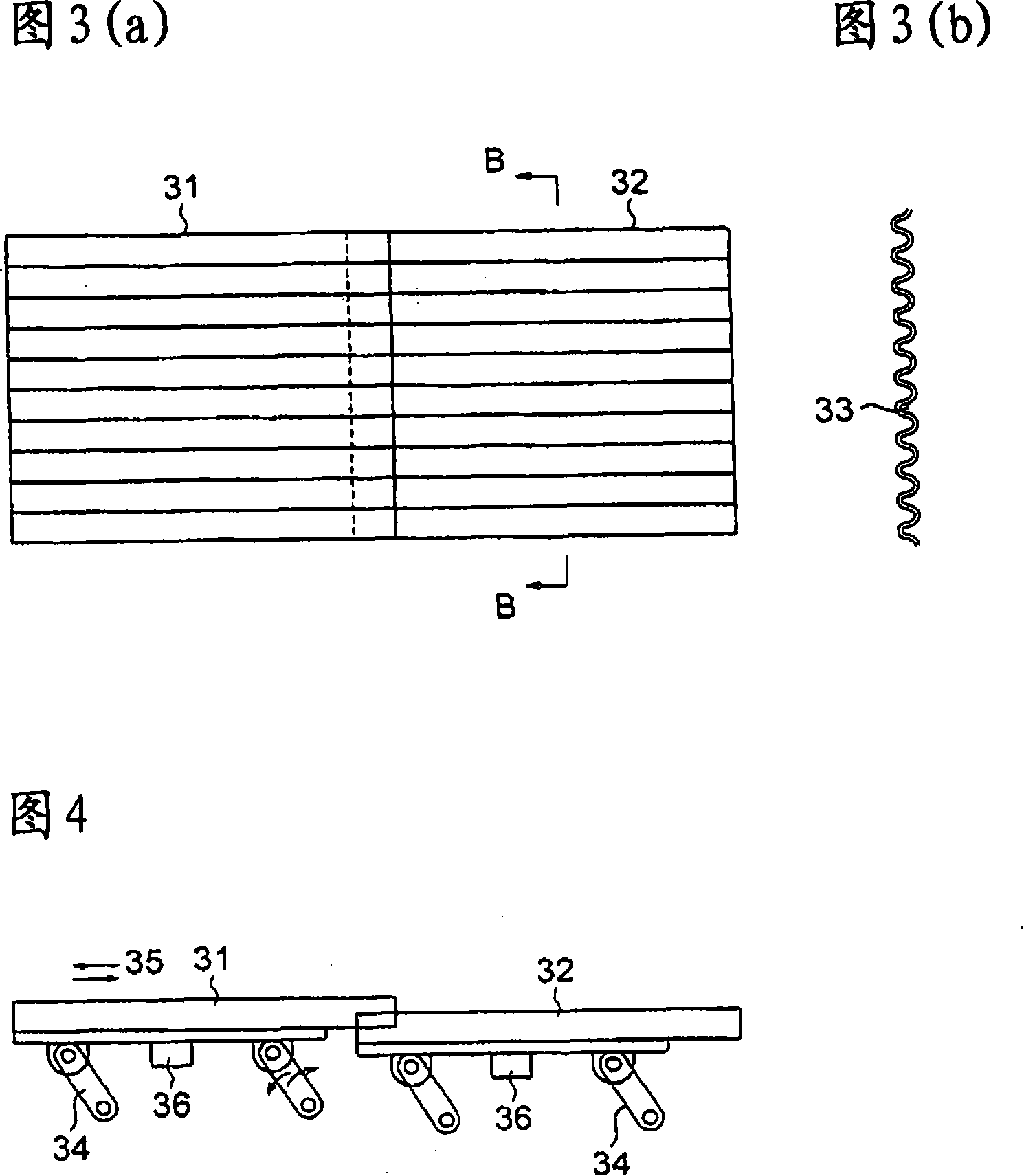

Bean sprout both end portions removing method and bean sprouts treating devices therefor

InactiveCN101103836AReduce mechanical failureConvenient ArrangementFood treatmentKnife bladesSprouting

Method for removing bean sprout both end portions and treating devices therefor. The method comprises a bean sprouts separating step, a bean sprouts arraying step during which bean sprouts supplied onto a grooved plate (31,32) are moved into longitudinal grooves (33) and have their lengthwise directions arrayed and a bean sprout both end portions cutting and removing step to cut and remove both end portions of the bean sprouts by a bean sprout both end portions cutting and removing device comprising a cutting conveyor (62) and a transfer conveyor (68) provided with transfer bars (67) and arranged above the cutting conveyor (62) to be continuously moved at a velocity lower than a velocity of the cutting conveyor (62). By a relative movement between the both conveyors (62,68), the bean sprouts have their root portions and sprouting portions cut off by the cutters.

Owner:DAISEY MASCH CO LTD

Electric wire-cutting fruit tree pruning machine

The invention discloses an electric wire-cutting fruit tree pruning machine, which comprises a bracket mechanism, a transmission mechanism and a wire saw. The bracket mechanism includes a bottom bracket, a bracket cover and an extending handle, wherein the bracket cover is in press fitting with the bottom bracket through bolts and fixing holes, and the extending handle is disposed at one side of the bottom bracket. The transmission mechanism comprises a tension wheel, a guide wheel, a power wheel and a motor, wherein the motor is fixed at the back surface of the bottom bracket, and the tension wheel, the guide wheel and the power wheel are distributed at three corners of the bottom bracket. The annular wire saw is fitted over the tension wheel, the guide wheel and the power wheel, and the bottom edge of the wire saw is a cut edge. By using a steel wire for cutting, the inventive machine has small ineffective cutting frictional area, reduces power consumption, is light in overall weight and low in noise, can easily cut off the thick branches which cannot be cut off by the conventional pruning machine, is flexible to use, and can replace the large-sized machine such as chain saw and electric saw.

Owner:SOUTH CHINA AGRI UNIV

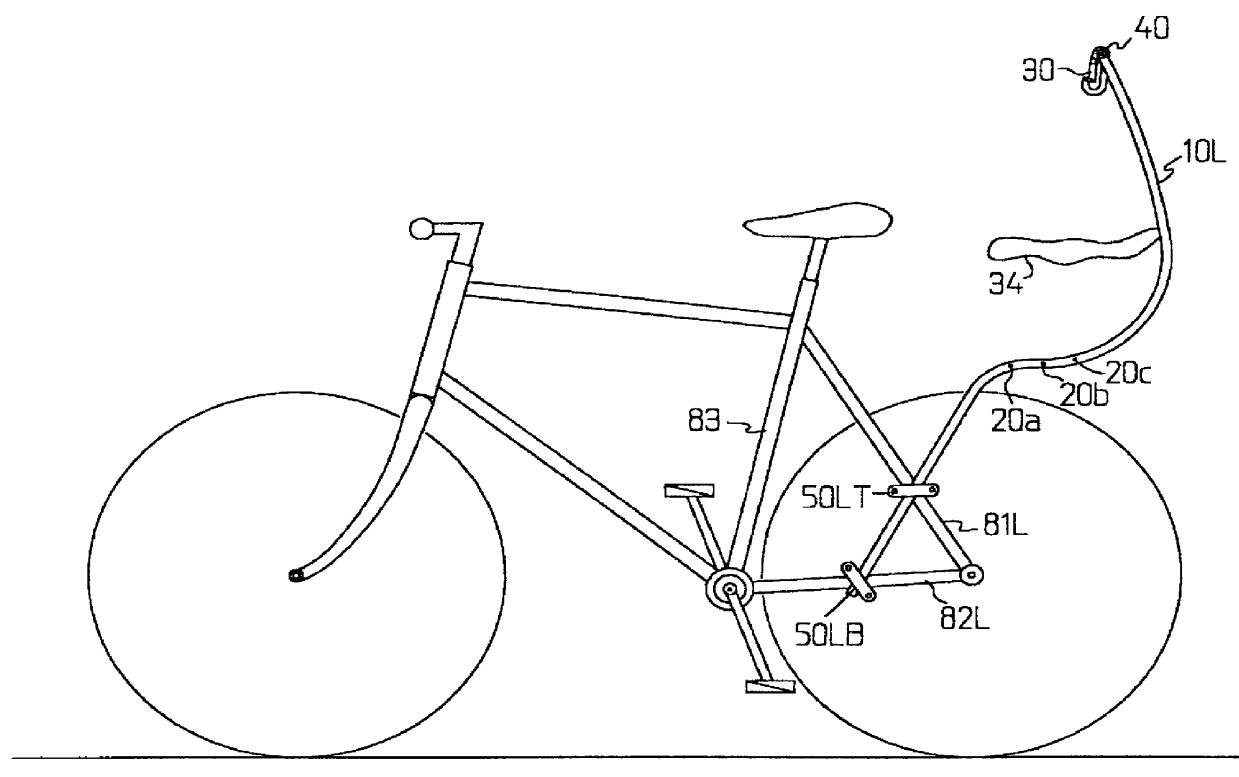

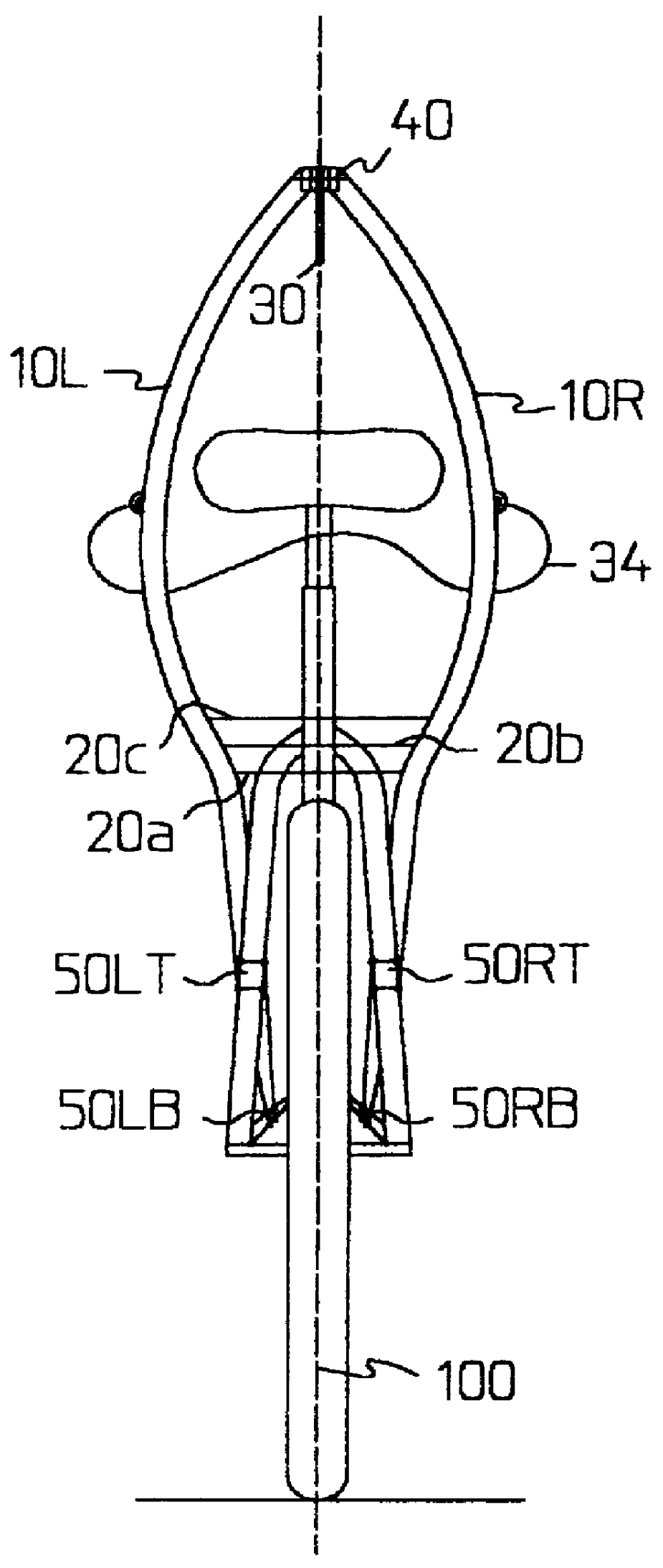

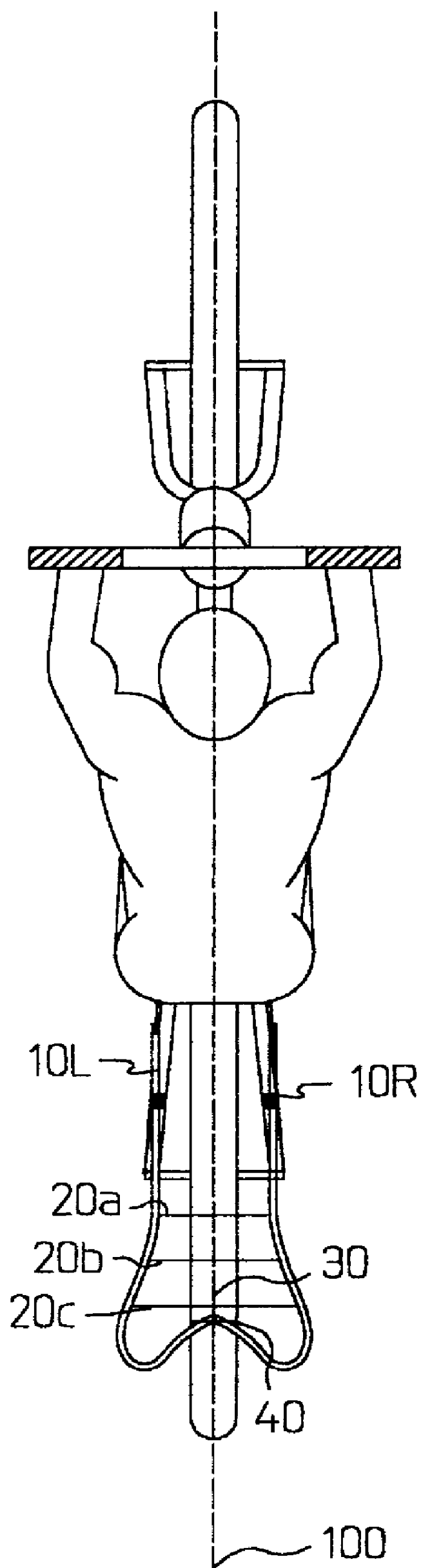

Article carrier for bicycles with centrally suspended hook

InactiveUS6045021AStrong mountingMinimizing peak forceLuggage carriersArticle supporting devicesSagittal planeVehicle frame

A load carrier for use on bicycles incorporating a load-suspending hook. The hook is affixed atop two support tubes that are mounted directly to the rear triangle of a standard bicycle frame. Four mounting sites near the rear wheel axle provide secure mounting. The hook is located on the central, sagittal plane of the bicycle approximately 50-60 centimeters directly above the rear wheel. A restraining strap, such as an elastic bungee-type cord, secures the suspended load against the support tubes to prevent swinging and maintain the central, sagittal position. The forces of the load, which can comprise any handled bag including backpacks, remain centered during riding and do not adversely affect balance of the bicycle.

Owner:STITES WILLIAM J

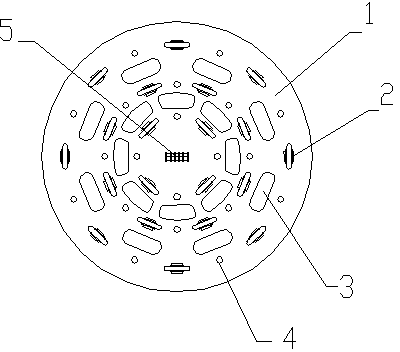

Drilling and rolling combination cutter disc structure for TBM (tunnel boring machine)

Disclosed is a drilling and rolling combination cutter disc structure for a TBM (tunnel boring machine). The drilling and rolling combination cutter disc structure for the TBM is characterized in that a working face of the drilling and rolling combination cutter disc structure is a spherical face which is protruded outwards, a plurality of hob sets different in radius are arranged on the working face and around the center of a cutter disc body, each hob set comprises a plurality of disc type hobs, drilling machine operation holes are formed between each two adjacent disc type hobs, a rail and a rock drilling machine which slides along the rail are arranged on one side of the cutter disc body and along the direction opposite to the TBM work direction, drill bits of the rock drilling machine can stretch out or retract through the drilling machine operation holes, soil and stone discharge holes are located between each two adjacent hob sets and used to discharge excavated soil and stone from the soil and stone discharge holes, and the other rock drilling machine is arranged at the center of the cutter disc body in the same mode. According to the drilling and rolling combination cutter disc structure for the TBM, the rock drilling machines are added on the cutter disc body, and therefore a combination of the drilling machines and the hobs is achieved, rock breaking efficiency is improved, torque of the cutter disc body and the disc type hobs is reduced, and the excavation area of a cutter disc is increased by improving the structure of the cutter disc body and optimizing the arrangement mode of the hobs.

Owner:LUOYANG INST OF SCI & TECH

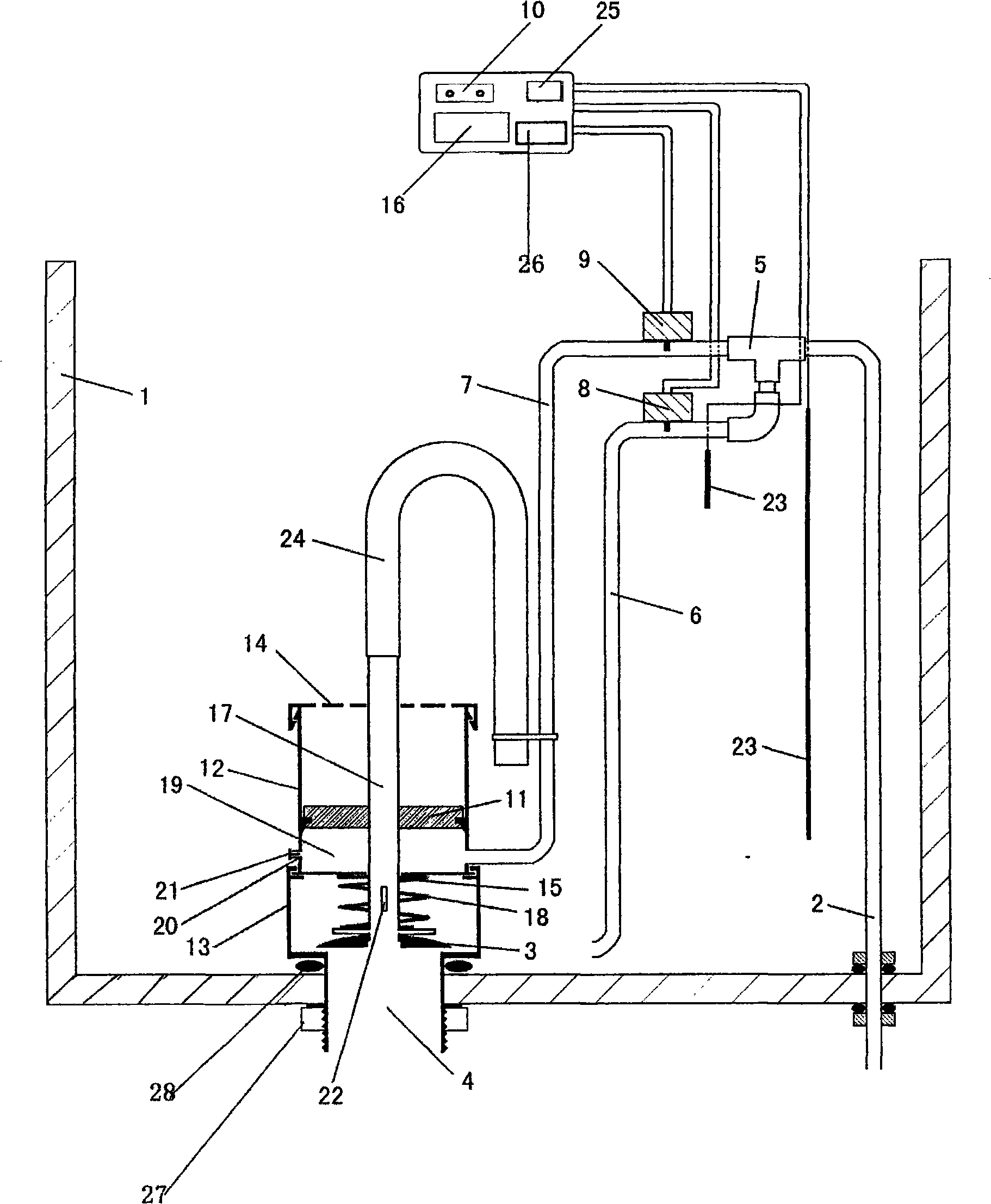

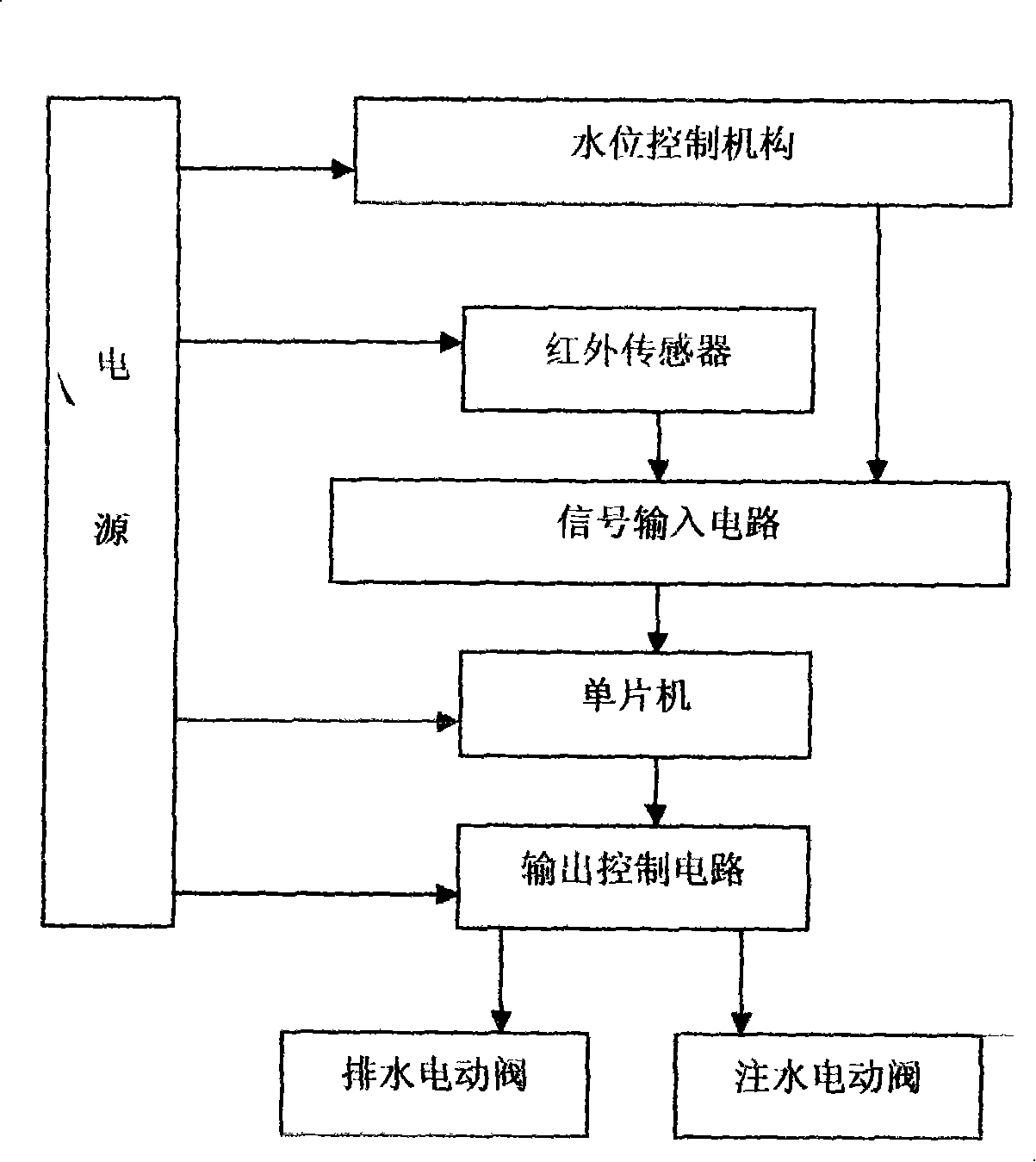

Intelligent water saving toilet and intelligent flushing control method

InactiveCN101289874AGuaranteed water savingPrevent water leakageFlushing devicesWater leakageAutomatic control

The invention discloses an intelligent water-saving closestool and an intelligent toilet-flushing control method to overcome the problems that the prior closestool has water leakage and great randomness of manual operation and can not automatically control flushing time and flushing quantity. The intelligent water-saving closestool comprises a water tank as well as a water inlet pipe, a drain valve and a drain opening arranged inside the water tank, wherein the water inlet pipe is connected with a water injection pipe and a pressure pipe through a teejunction; a hydraulic cylinder which is used to open and close the drain valve is arranged between the pressure pipe and the drain valve; the water injection pipe and the pressure pipe are respectively provided with a water injection electric valve and a drain electric valve, and are in electrical connection with an infrared sensor through a signal input / output circuit and an output control circuit. The intelligent water-saving closestool and the intelligent toilet-flushing control method not only can completely solve the water leakage phenomenon of a closestool, but also can realize automatic toilet flushing according to required water quantity; moreover, the closestool and the method can keep the water tank in a seeper-free state when the closestool is not used.

Owner:赵丕君

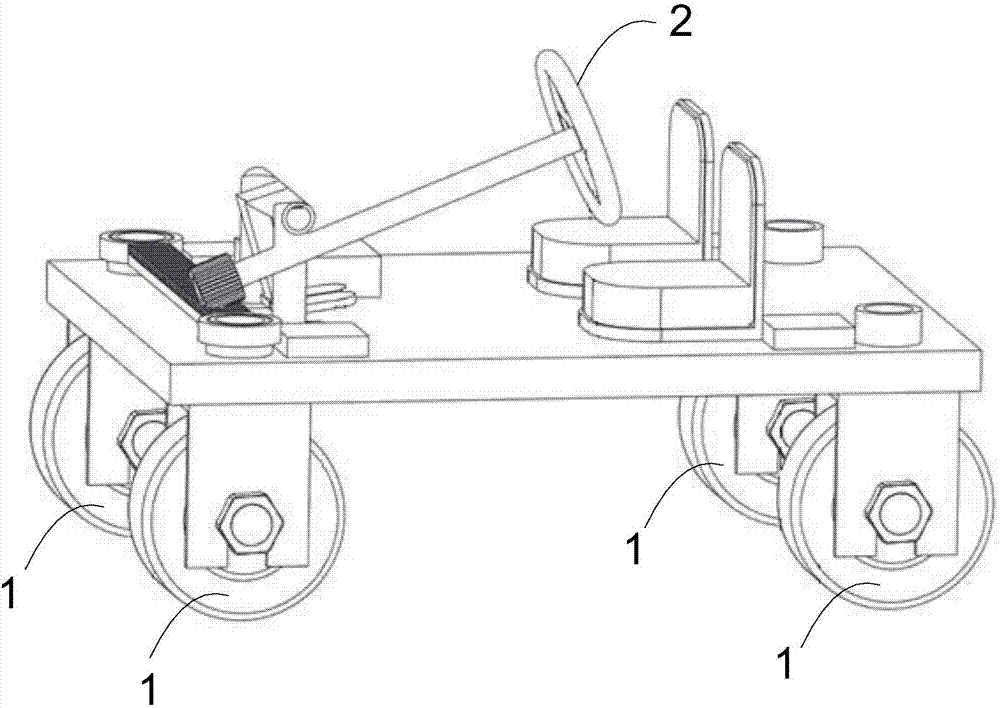

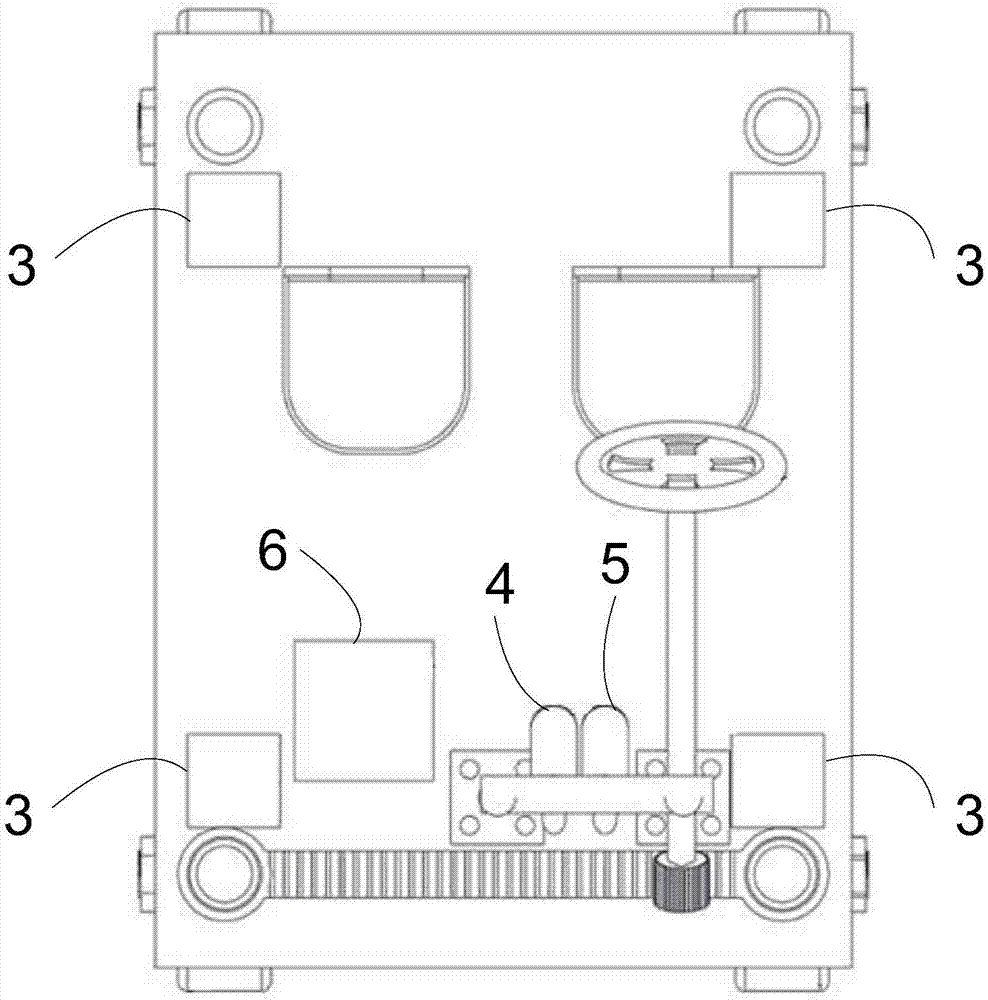

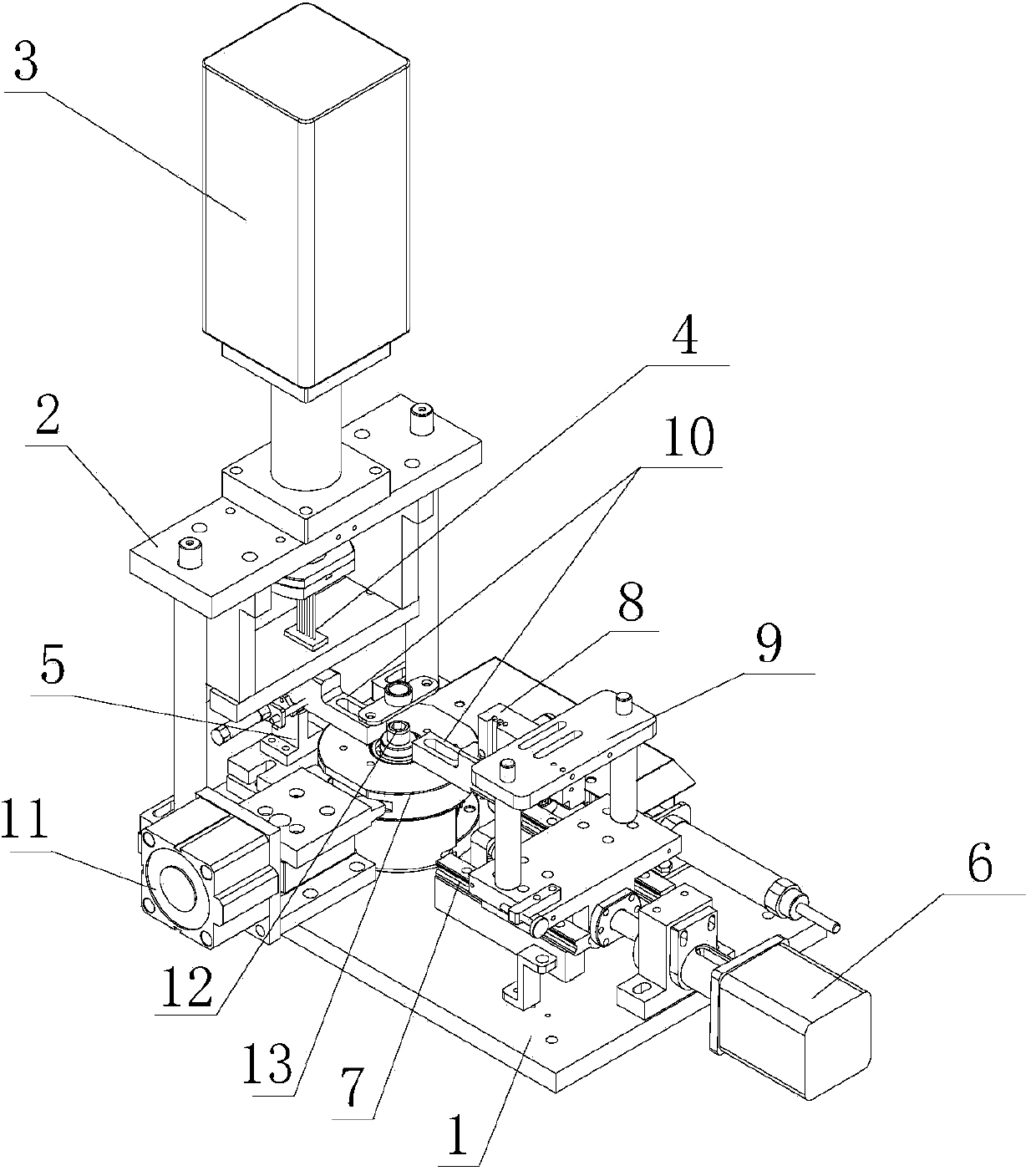

Assembling equipment for spring and billiard sealer on spring lock

ActiveCN103465018AAccuracy controllableImprove processing efficiencyAssembly machinesPunchingMachining

The invention relates to assembling equipment for a spring lockset, in particular to assembling equipment for a spring and a billiard sealer on a spring lock, which comprises a substrate, a punching device and a feeding device, wherein the punching device and the feeding device are installed on the substrate, the punching device comprises a punching frame, a punching cylinder, a punching-pin mould handle and a lockset clamp, the feeding device comprises a stepping motor, a linear guide rail, a spring billiard-sealer discharging device, an installing frame and a feeding cylinder, the feeding device also comprises a rotating mechanism and two rotary material-storing devices with the same structures, and the two rotary material-storing devices with the same structures are installed on a rotary disk; the two rotary material-storing devices with the same structures on the rotary disk are driven by a driving piece through a rotating shaft to rotate for 180 degrees and mutually replace positions. The assembling equipment for the spring and the billiard sealer on the spring lock has the advantages of novel structure and high machining efficiency and assembling precision.

Owner:JINHUA KETE PRECISION MACHINERY

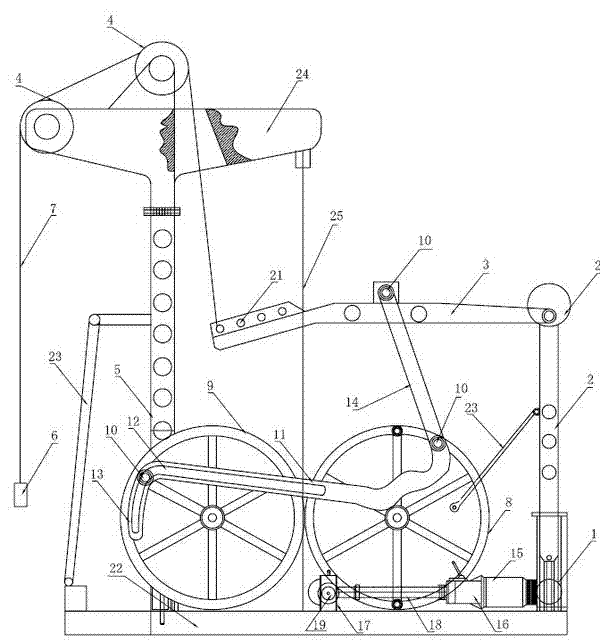

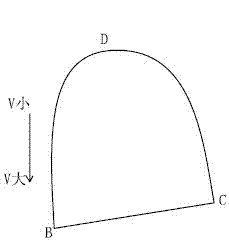

Automatic speed-changing wide-swing-angle oil pumping machine

InactiveCN102808602ASolve the oil spill problemImprove oil pumping efficiencyGearingFluid removalCrankshaftPulley

The invention relates to the technical field of oil extraction machinery, in particular to an automatic speed-changing wide-swing-angle oil pumping machine. The automatic speed-changing wide-swing-angle oil pumping machine comprises an electric motor, a speed changing mechanism, a swing arm support, a swing arm arranged on the swing arm support, a support provided with a fixed pulley and a wellhead oil pumping device, wherein the speed changing mechanism is connected with a driving crankshaft wheel, the driving crankshaft wheel is meshed with a driven crankshaft wheel, the driving crankshaft wheel is connected with a connecting piece through a bearing, one end of the connecting piece is connected with the driven crankshaft wheel, the other end of the connecting piece is connected with the swing arm through a connecting rod, a sliding chute is arranged on the connecting piece of which one end is connected with the driven crankshaft wheel, and a bearing on the driven crankshaft wheel is sleeved in the sliding chute. The automatic speed-changing wide-swing-angle oil pumping machine disclosed by the invention has the advantages that when the two crankshaft wheels are in rotation, since the position of the bearing of a driven pulley is changed, the position of the connecting piece can be also correspondingly changed, a motion trail of the connecting rod is affected by the motion of the connecting piece, the speed of the wellhead oil pumping device in the up-stroke is higher than that in the down-stroke, the oil leakage problem existing in an oil pumping process is avoided, and the oil pumping efficiency is increased.

Owner:德阳振华机械设备制造有限公司

Foot pedal system and apparatus

InactiveUS9439806B2Improve concentrationReduce mechanical failureEye surgerySurgical manipulatorsEngineeringSurgical instrument

A phacoemulsification system and method, and a foot pedal device, system and method. The devices, systems and methods may include a console comprising a plurality of modes for at least one physically associated surgical instrument, and a foot pedal communicatively associated with said console and suitable for varying ones of the plurality of modes. The foot pedal may include a foot pedal base, and at least two electronically actuated sensors physically associated with the foot pedal base, communicatively connected to the console, and suitable for receiving physical indications of variations in ones of the plurality of modes.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

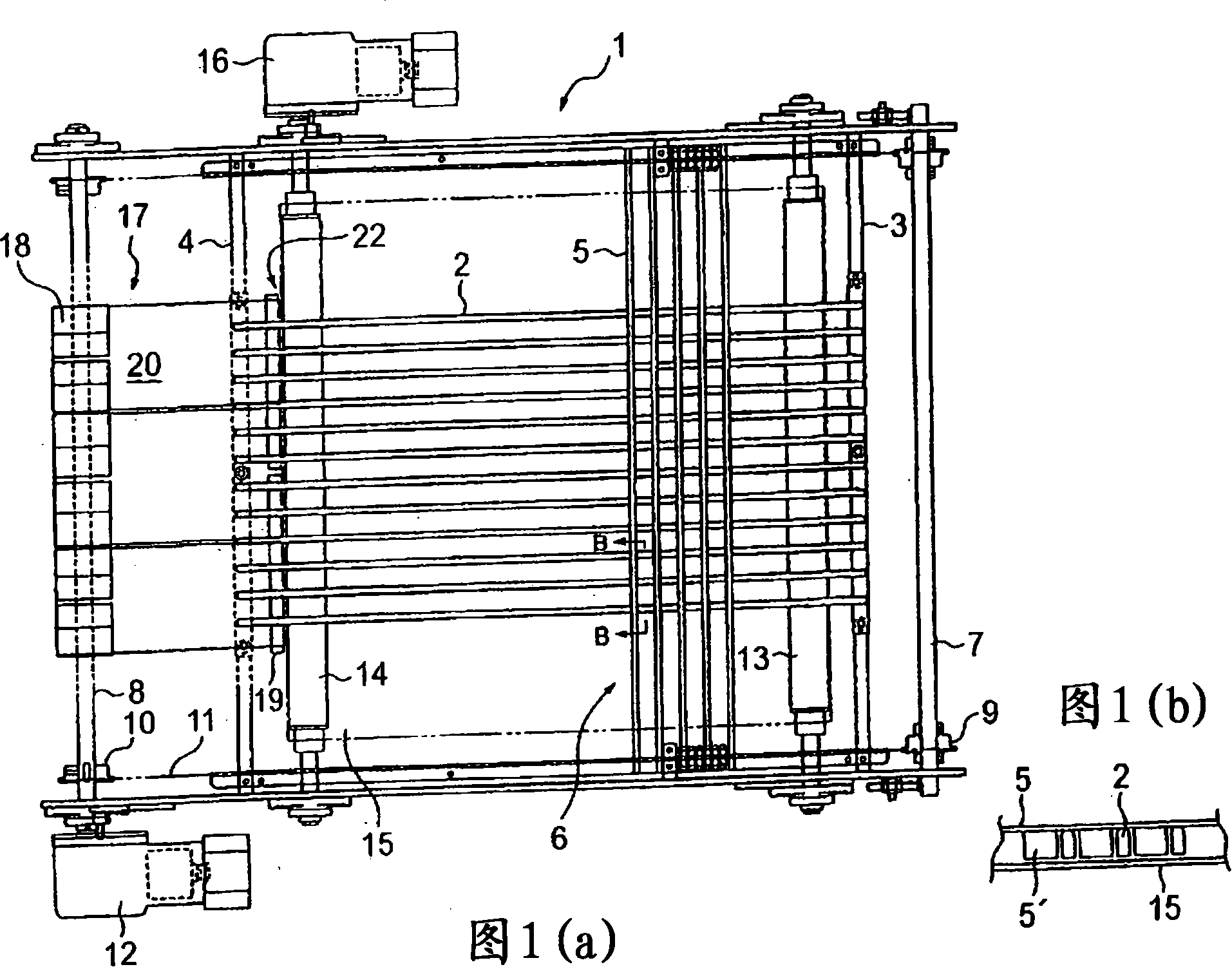

Tunnel baking line material conveying method and device

ActiveCN104729258AGuaranteed tightnessAchieve continuous bakingDrying machines with progressive movementsDrying solid materialsCooking & bakingFailure rate

The invention discloses a tunnel baking line material conveying method and device. The tunnel baking line material conveying device comprises a material bearing device, a main driving device and at least one standby driving device. The main driving device and the standby driving devices comprise a main driving structure and standby driving structures respectively. The material bearing device is provided with a driven driving structure matched with the main driving structure and the standby driving structures. The main driving structure or the standby driving structures drive the material bearing device to move in a sealable functional box through the driven driving structure. Due to the fact that each sealable functional box is internally provided with at least one independent tunnel baking line material conveying device which comprises the main driving device and the standby driving devices, during material conveying, the main driving device or the standby driving devices work, mechanical failures can be effectively reduced, tooth jumping or tooth clamping is prevented, and the tunnel baking line material conveying method and device have the advantages that the failure rate is low, the structure is simple, the production efficiency is improved, and the product percent of pass is increased.

Owner:SHENZHEN XINYUREN TECH

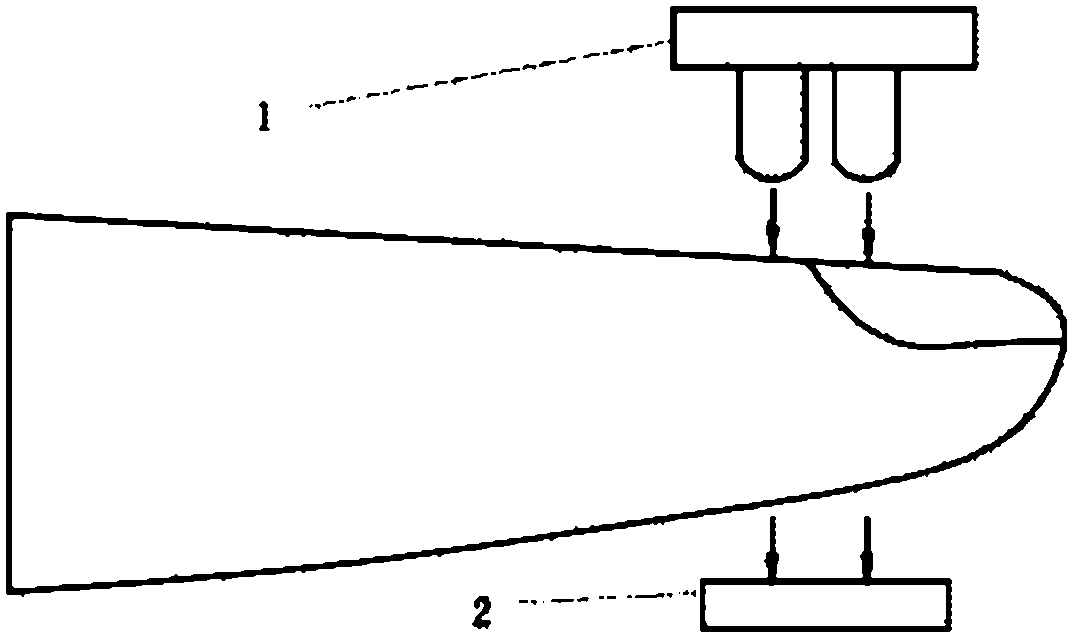

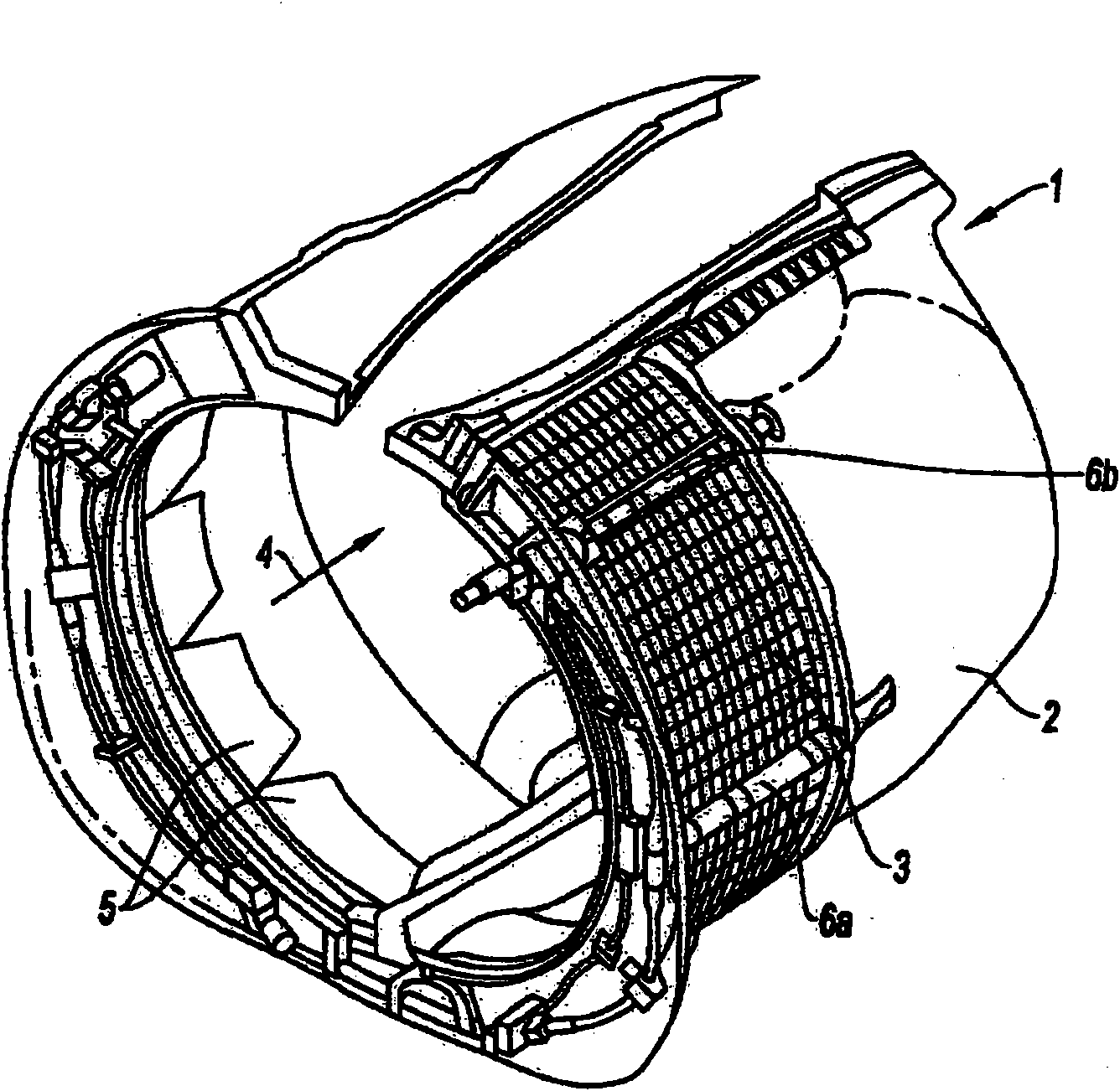

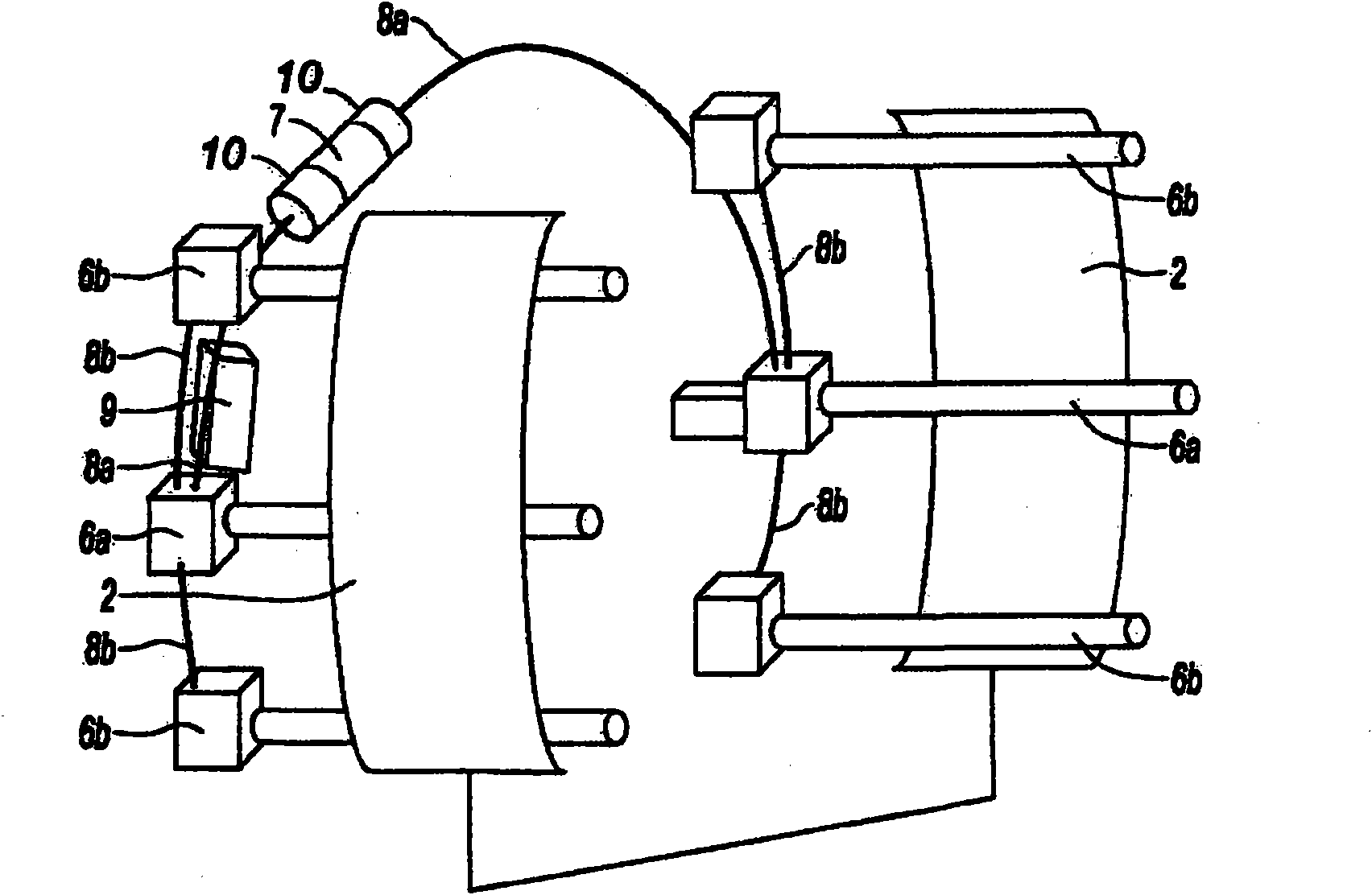

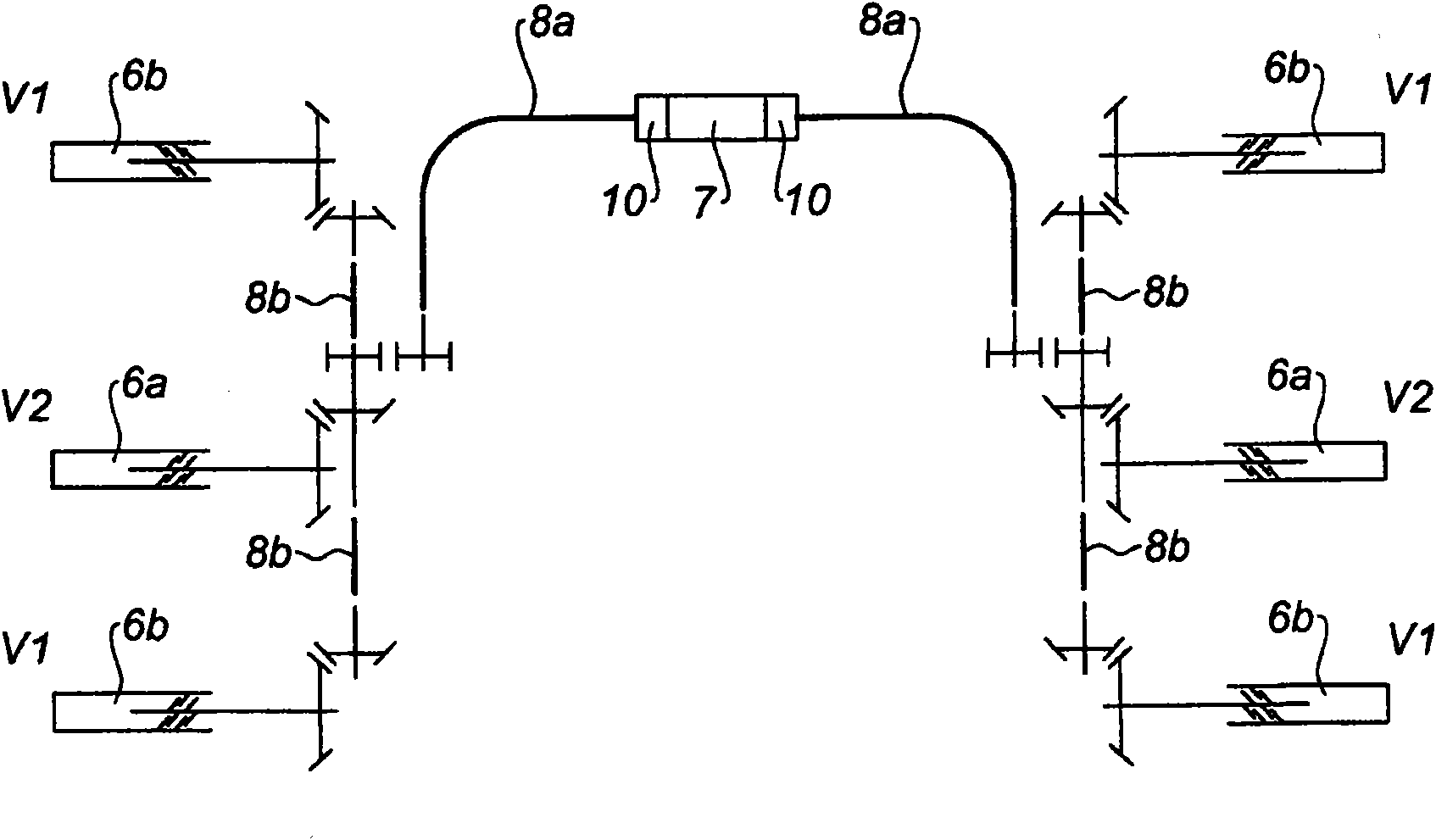

Thrust reverser with a system for braking the actuators

InactiveCN101784781AReduce mechanical failureImprove vibrationJet propulsion plantsNacelleJet engine

The present invention relates to a thrust reverser for a jet engine nacelle comprising at least one movable cowl (2) mounted on a fixed reverser structure between a closed position, in which they provide the nacelle with aerodynamic continuity and deactivate means for deflecting at least part of the air flow, and an open position in which they open a passage in the nacelle and activate said deflection means, each movable cowl being able to be moved between these two positions by at least one actuating means (6a, 6b), characterized in that the actuating means are combined with at least one means (10) for mechanically braking said actuating means.

Owner:AIRCELLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com