Pre-smashing device for food treating machine and juice extractor applying same

A food processor and pre-crushing technology, applied in food science, household machinery for filtering food, applications, etc., can solve problems such as user inconvenience and food need to be pre-processed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

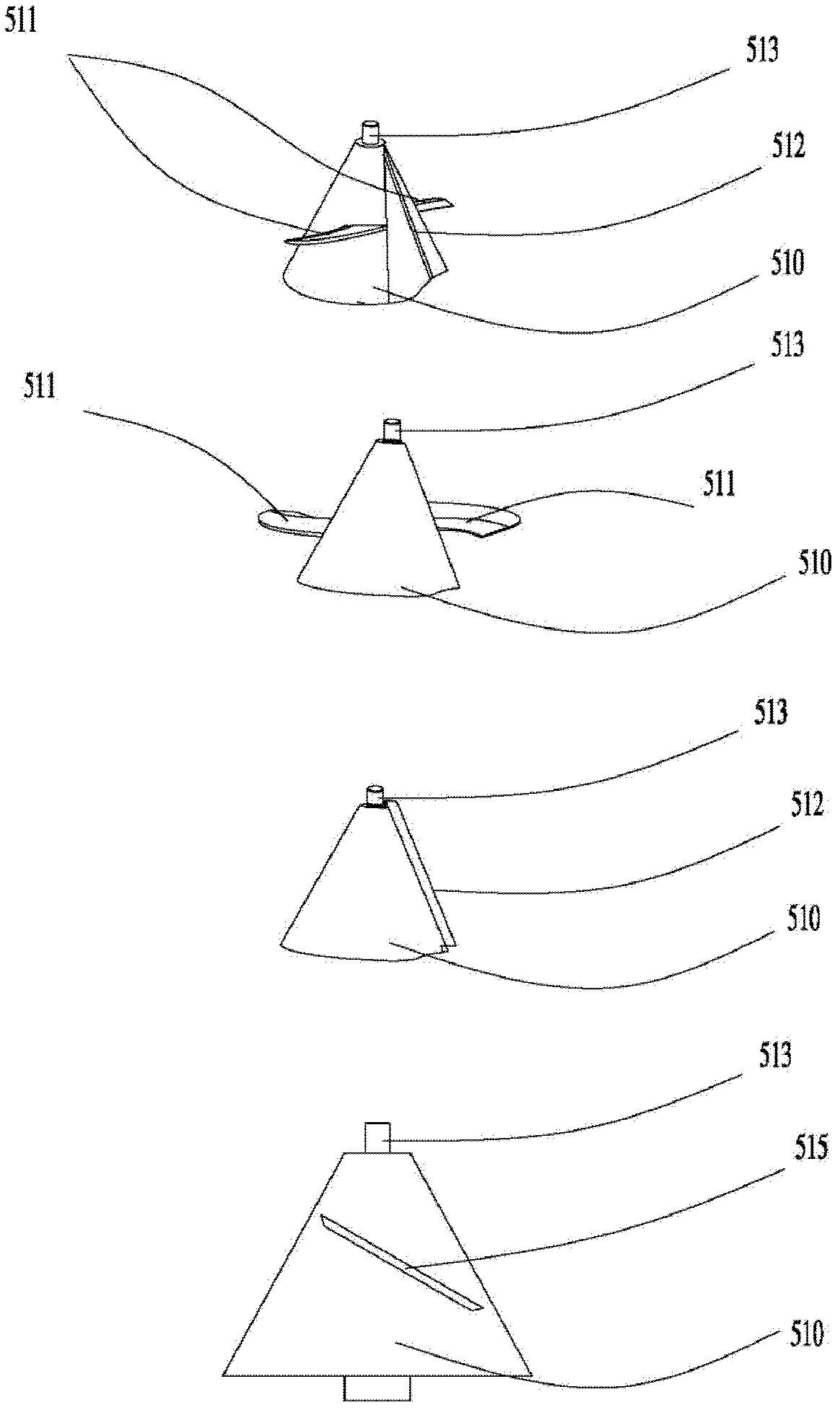

[0035] refer to figure 1 , figure 2 As shown, the embodiment of the present invention provides a food processor pre-crushing device 510, the pre-crushing device 510 is conical, the conical surface of the pre-crushing device 510 is provided with at least one blade, the A connection shaft 513 or a shaft hole (not shown) that can be matched with a food processor is provided on the cone tip and the center of the bottom surface respectively.

[0036]According to the above technical problems, after the pre-crushing device 510 provided by the present invention is installed in the food processor, the drive shaft 430 or the rotating hole of the food processor is connected to the shaft hole or the connecting shaft at the center of the bottom surface of the pre-crushing device 510. connected to drive the pre-crushing device 510 to rotate, while the cone tip of the pre-crushing device 510 is fixed to the top 530 of the food processor to form a fulcrum, ensuring that the pre-crushing dev...

Embodiment 2

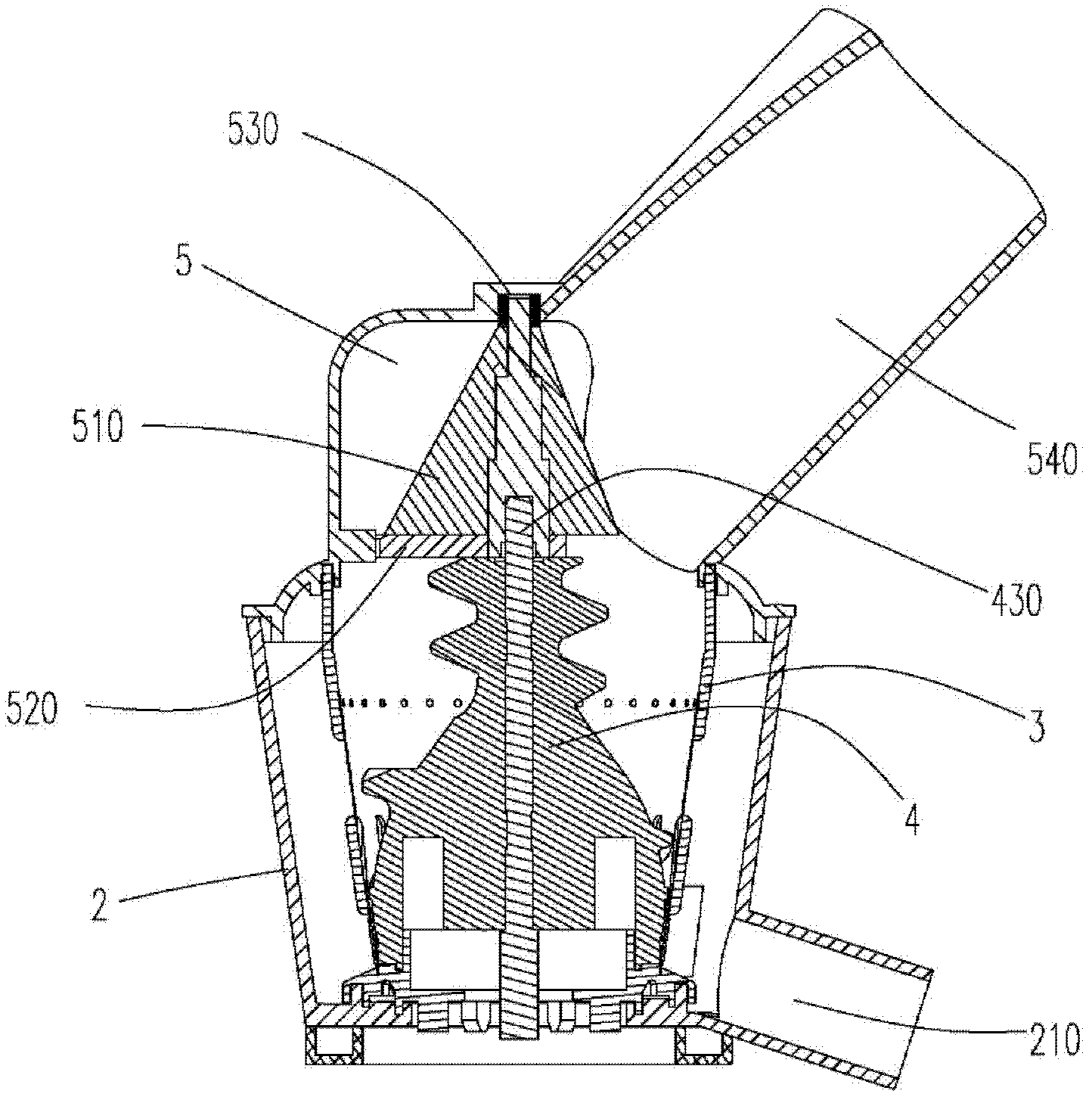

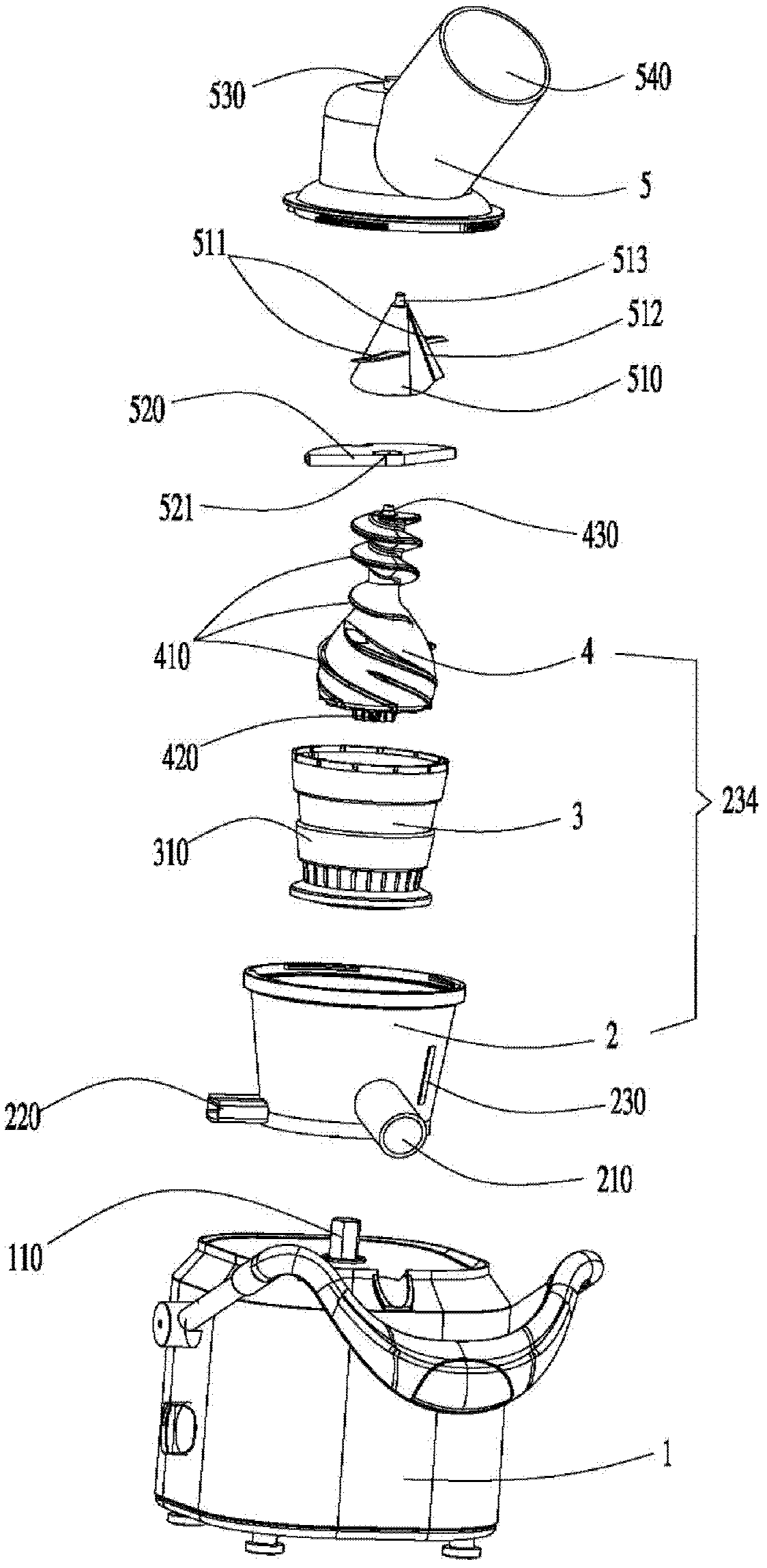

[0039] refer to Figure 1 to Figure 7 As shown, the present embodiment provides a juice extractor, including a machine base 1 with a transmission mechanism, a squeezing device 234 located above the machine base 1 , and a material inlet 540 placed above the squeezing device 234 The upper cover 5 of the upper cover 5, the food processor pre-crushing device 510 described in the first embodiment is provided between the pressing device 234 and the upper cover 5, after the food enters the upper cover 5 through the feeding port 540, it is crushed After the pre-crushing device 510 rotates and cuts, it falls down into the squeezing device 234 to perform squeezing work. The squeezing device 234 receives the pretreated food material, which can improve efficiency and process the food material more finely. The squeezing device 234 can be The blender for stirring and beating the ingredients may also be a juice extractor for squeezing the ingredients through a juicer knife, or a juice extrac...

Embodiment 3

[0047] refer to Figure 8 , Figure 9 , Figure 10 As shown, the embodiment of the present invention provides a juice extractor, the main difference from the second embodiment above is that the base 1 is also provided with a through hole 240 through which the second driving end 120 passes through the separator 2 and The lower end of the filter screen 3 is connected to drive the filter screen 3 to rotate in the same direction or in the opposite direction to the rotating head 4 to achieve a greater extrusion force, and it can also perform corresponding compression when the food is stuck. Movement in the same direction avoids damage to the juice extractor. At the same time, when there is a problem with the driving end 110 or the second driving end 120, the other driving end can continue to complete the work. Further, the bottom of the filter screen 3 is provided with a End 110 or the through hole 320 through the center of the lower end of the rotating head 4, a transmission 331...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com