Patents

Literature

209results about How to "Avoid Scrap Situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

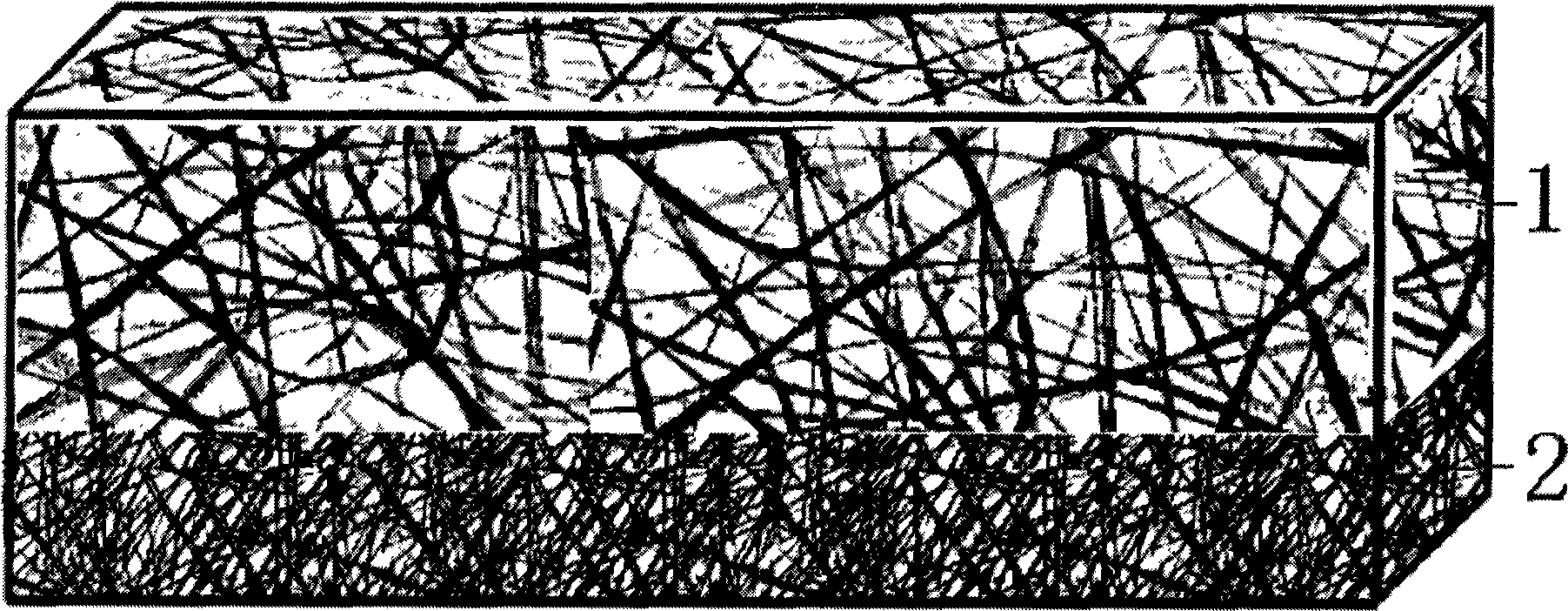

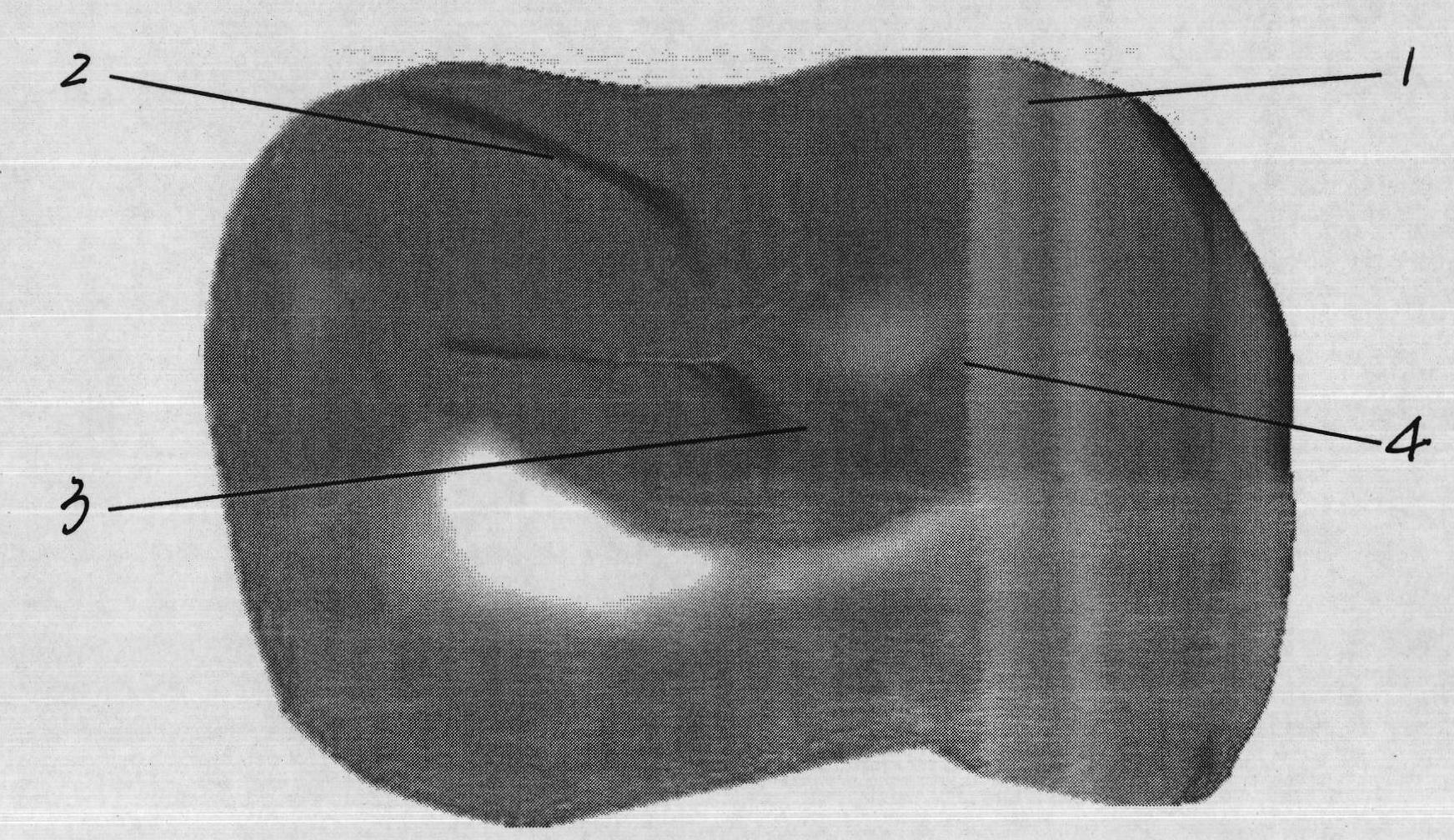

Nano artificial dura mater with multi functional-layers and preparation method thereof

ActiveCN101507661AReliable strengthGood flexibilityFilament/thread formingProsthesisHydrophobic polymerDura mater

The invention provides a nano artificial dura mater with a plurality of functional layers, which comprises a structure with at least two layers; the layer facing the brain is a hydrophobic anti-adhesion electrospun layer; and the layer back to the brain is a hydrophilic nano cytoskeletal layer. The invention also provides a method for preparing the nano artificial dura mater, which comprises the following steps: preparing an electrospun solution of a hydrophobic polymer; preparing an electrospun solution of a hydrophilic polymer; preparing the prepared electrospun solution of the hydrophobic polymer into the hydrophobic anti-adhesion electrospun layer through static spinning; and preparing the hydrophilic nano cytoskeletal layer on the anti-adhesion electrospun layer from the prepared electrospun solution of the hydrophilic polymer through static spinning, receiving a membrane structure, and obtaining the nano artificial dura mater. The mechanical features of the nano artificial dura mater can meet the requirements on tensile strength and flexibility of adaptation diseases; and the nano artificial dura mater can be freely cut as required, and has wide application prospect.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

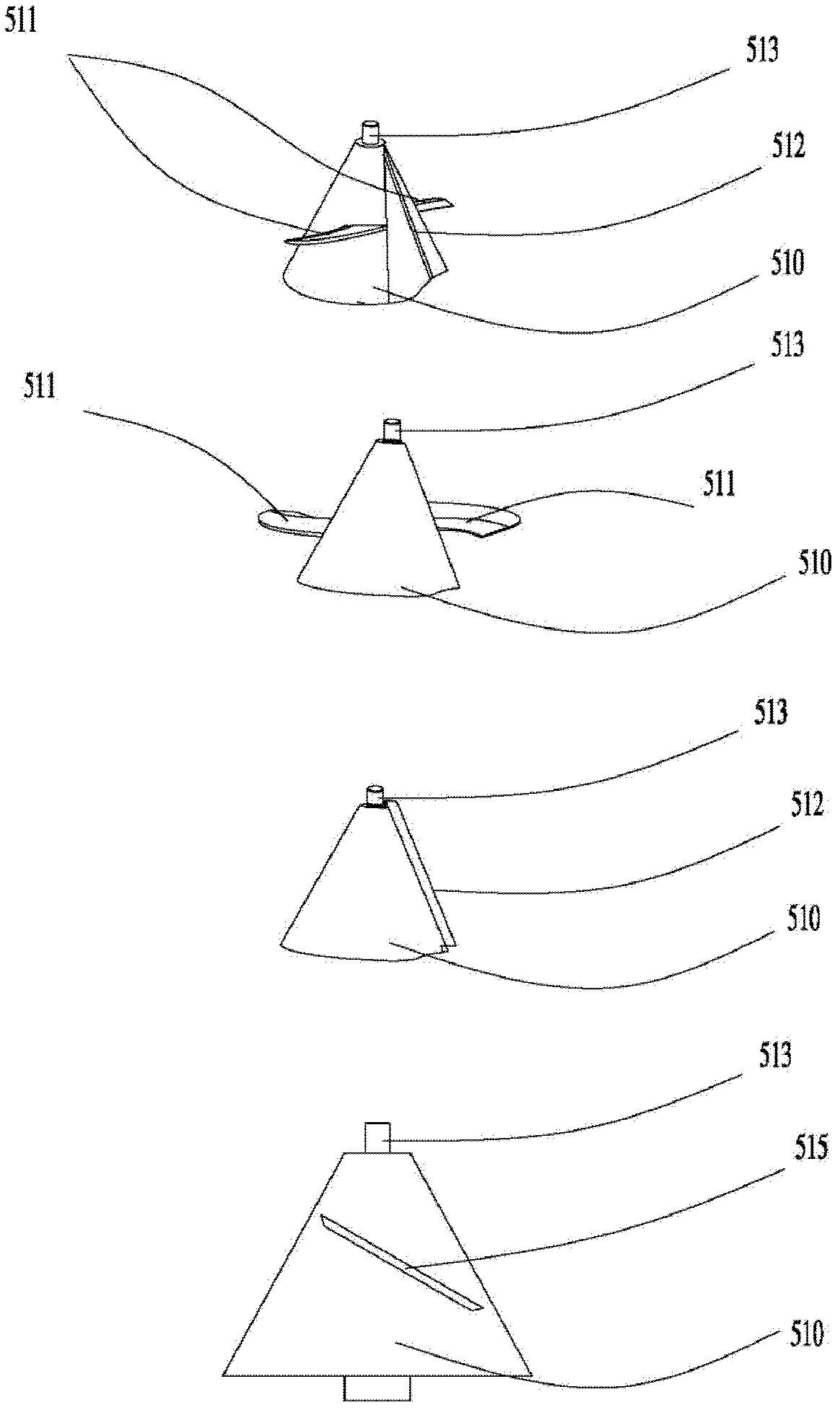

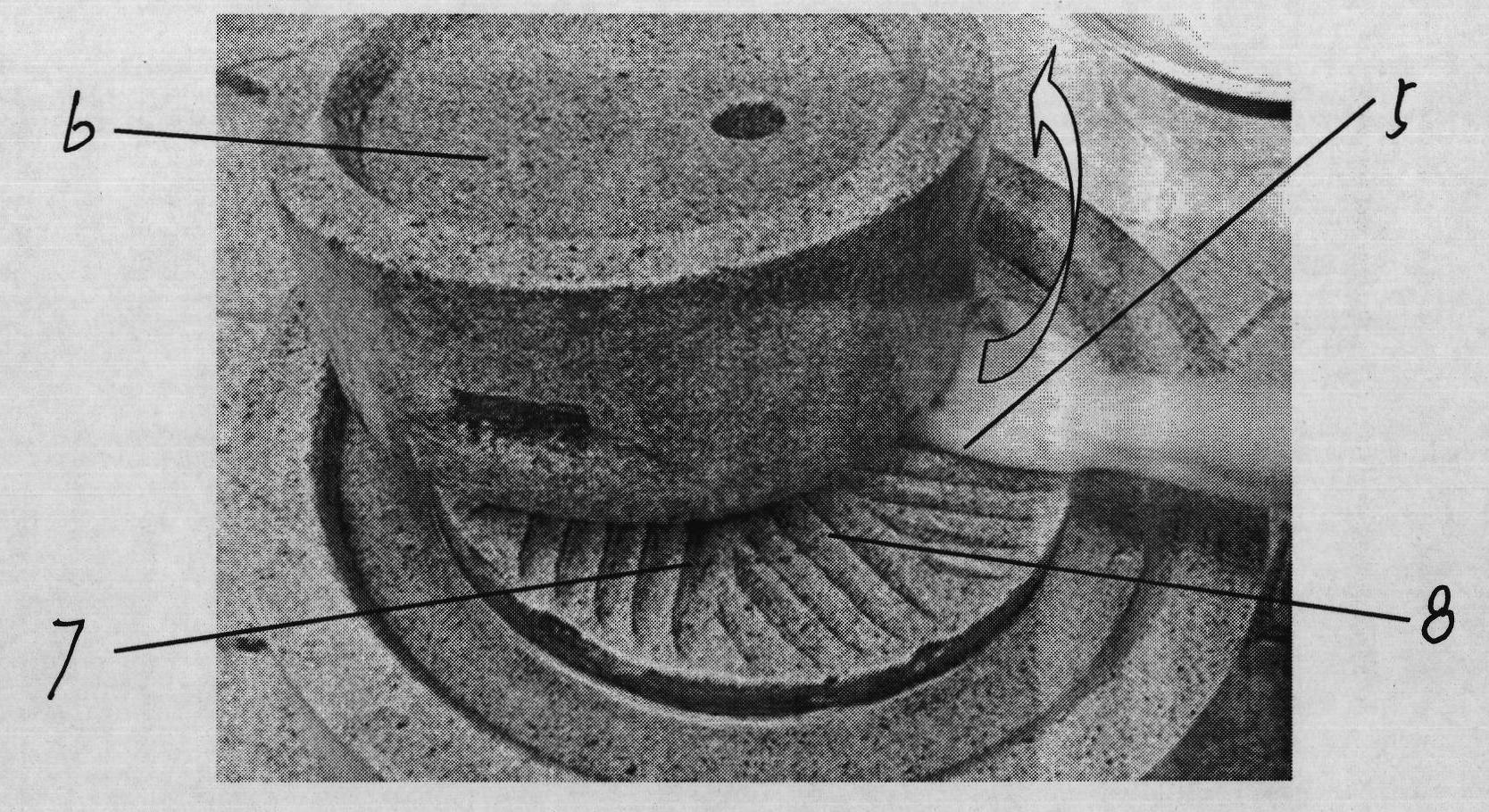

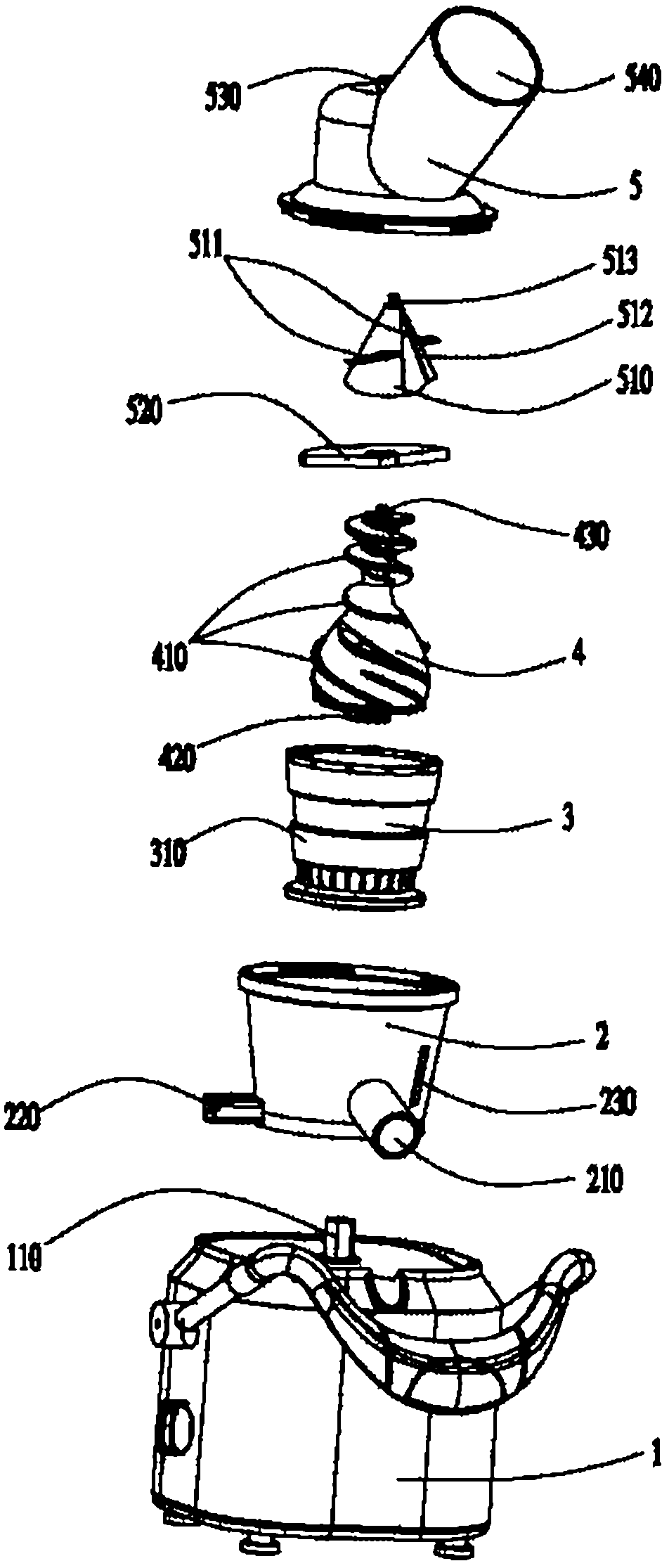

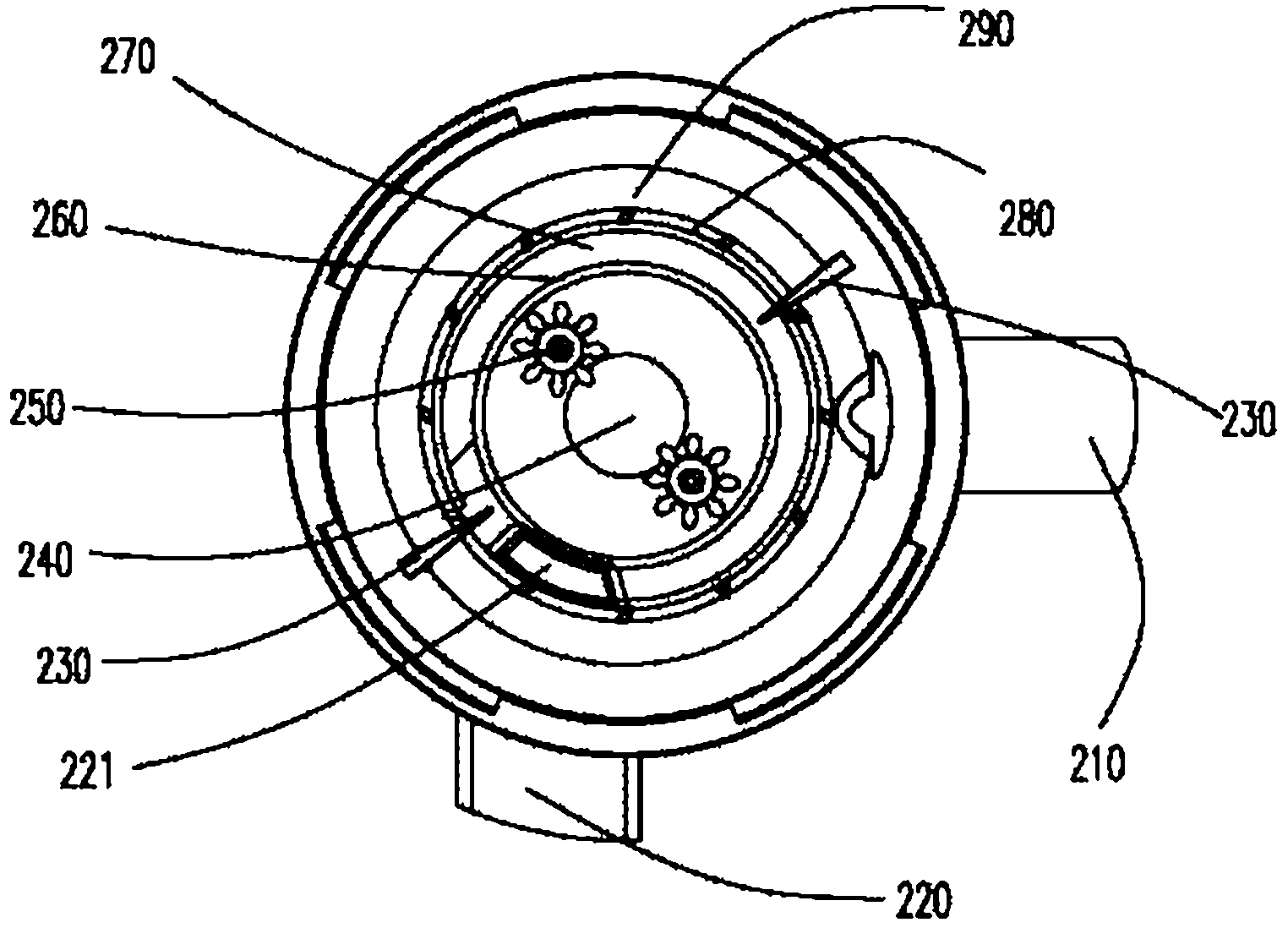

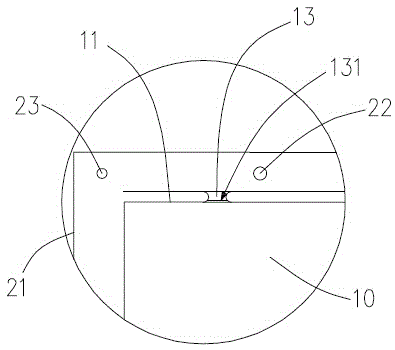

Pre-smashing device for food treating machine and juice extractor applying same

ActiveCN103202653AGuaranteed tasteGuaranteed nutritionJuice extractionStrainersPulp and paper industryFood material

The invention provides a pre-smashing device for a food treating machine, aiming to solve the problem that inconvenience is brought to a user as foods need pre-treating in the prior art. Aiming at the technical problem, the pre-smashing device is mounted behind the food treating machine, the food treating machine is connected with a shaft hole or a connecting shaft in the bottom center of the pre-smashing device through a transmission rotation shaft or a rotation hole of the food treating machine, with the pre-smashing process, the process of pre-treating on food materials is eliminated when an operator carries out food treating, thus the food treating is more convenient and rapid, meanwhile since the pre-smashing process is carried out on the food materials, load of a stirring device is lightened, the service life of a machine is prolonged, and the efficiency of stirring or juice extracting is promoted.

Owner:T F ELECTRICAL TECH SHENZHEN

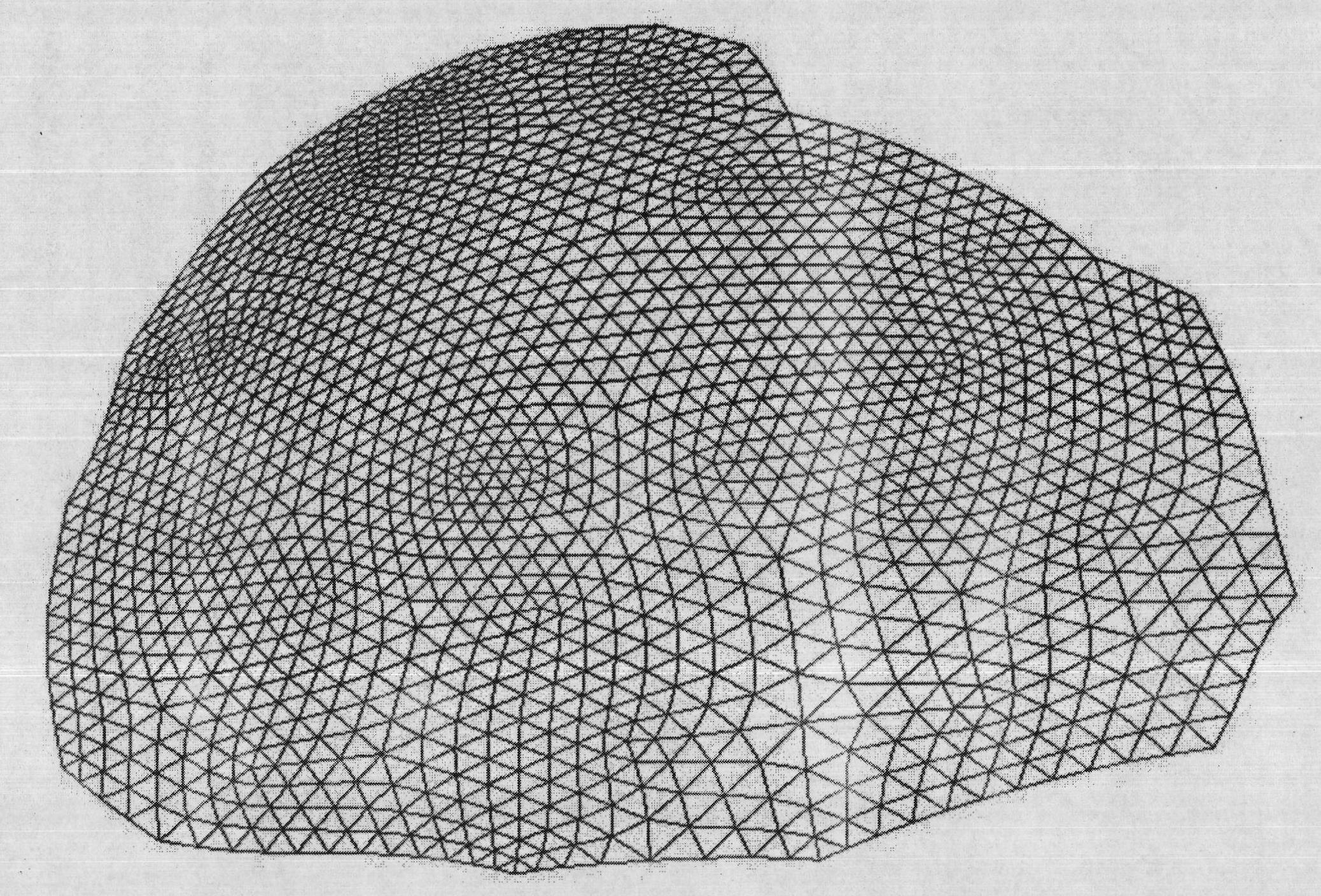

Five-axis linkage simulation machining method of dental prosthesis

InactiveCN101829801AConsistent shapeHigh precisionMilling equipment detailsProcessing accuracyOral Prosthesis

The invention discloses a five-axis linkage simulation machining method of a dental prosthesis, which comprises the following steps: firstly, carrying out automatic identification and extraction on the characteristic surfaces of the tips, iliac crests, nests and grooves of the dental prosthesis; then, determining the machining tool path of five-axis linkage high-speed milling according to the original appearance of the occlusal surface of an offending tooth and the changing rule of the normal vectors of all points on each characteristic surface; and finally moving a micro-diameter ball-head cutter under the command of spline interpolation machining numerical control codes along the machining tool path to obtain the dental prosthesis by milling. The simulation machining method of the invention solves the problems of low machining accuracy, poor machining pattern, long manufacturing period, poor occlusion function and easy detention of meal residue of the existing dental prosthesis, improves the machining speed and accuracy of the dental prosthesis, and effectively reduces the manufacturing cost.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

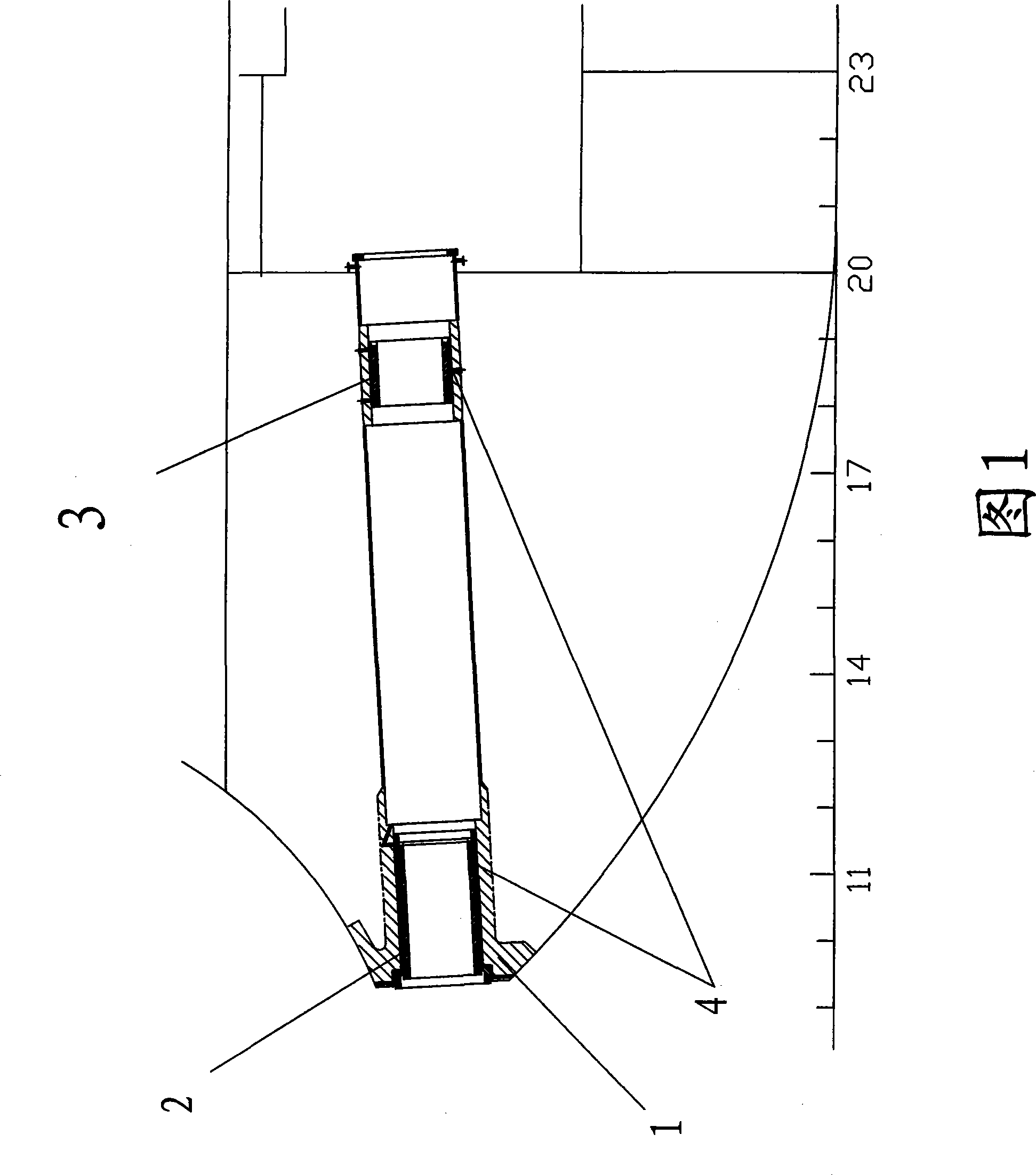

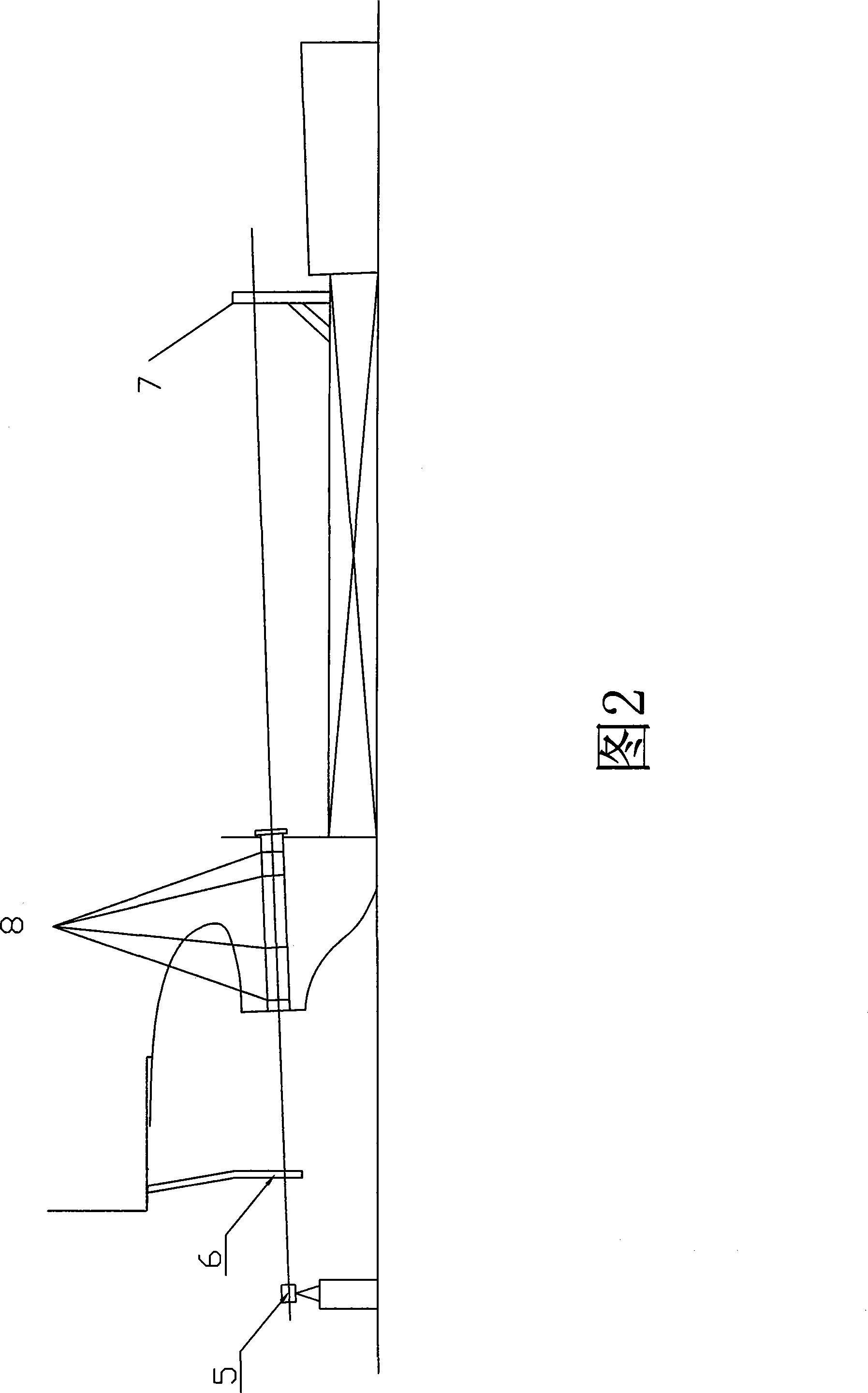

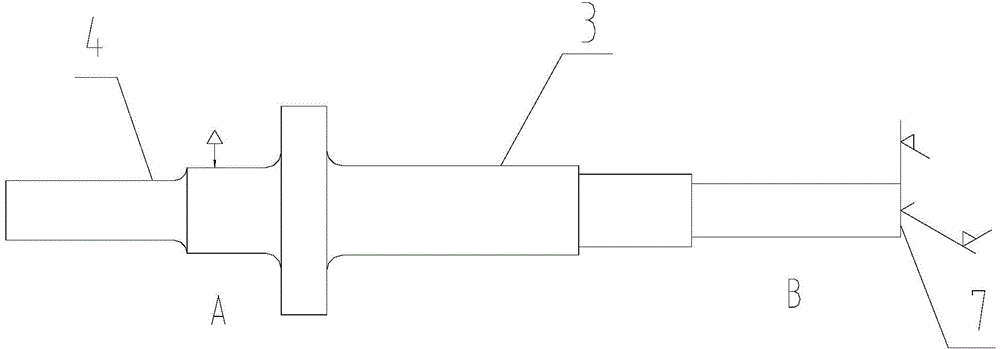

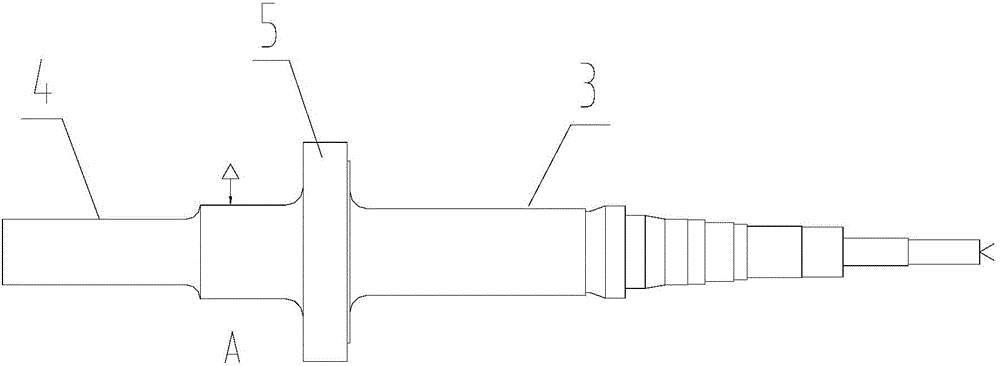

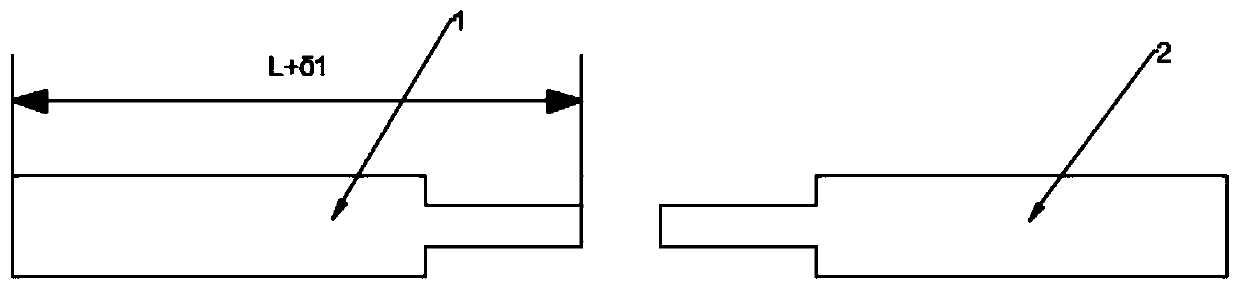

Method for mounting shipping stern shaft tube lining

ActiveCN101239649AShorten the timeGuaranteed Alignment AccuracyVessel partsEngineeringUltimate tensile strength

The present invention provides a method for mounting shipping stern tube bushing, the bushing mounting position of the shipping stern tube processes to an epoxide resin plug hole, inner diameter of stern shaft tube is smaller than outer diameter of bush which is placed in lining mounting position of stern shaft tube, the bush is adjusted to location and gap between outer edge of two ends of lining and stern shaft tube is sealed, filling liquid epoxide resin in chamber betwwen lining and stern shaft tube by epoxide resin plug hole, the lining is exactly fixed in the stern shaft tube by solified epoxide resin. The mounting method of shipping stern tube lining has safe, credible characteristics, and shortens mounting cycle, reduces power strength.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

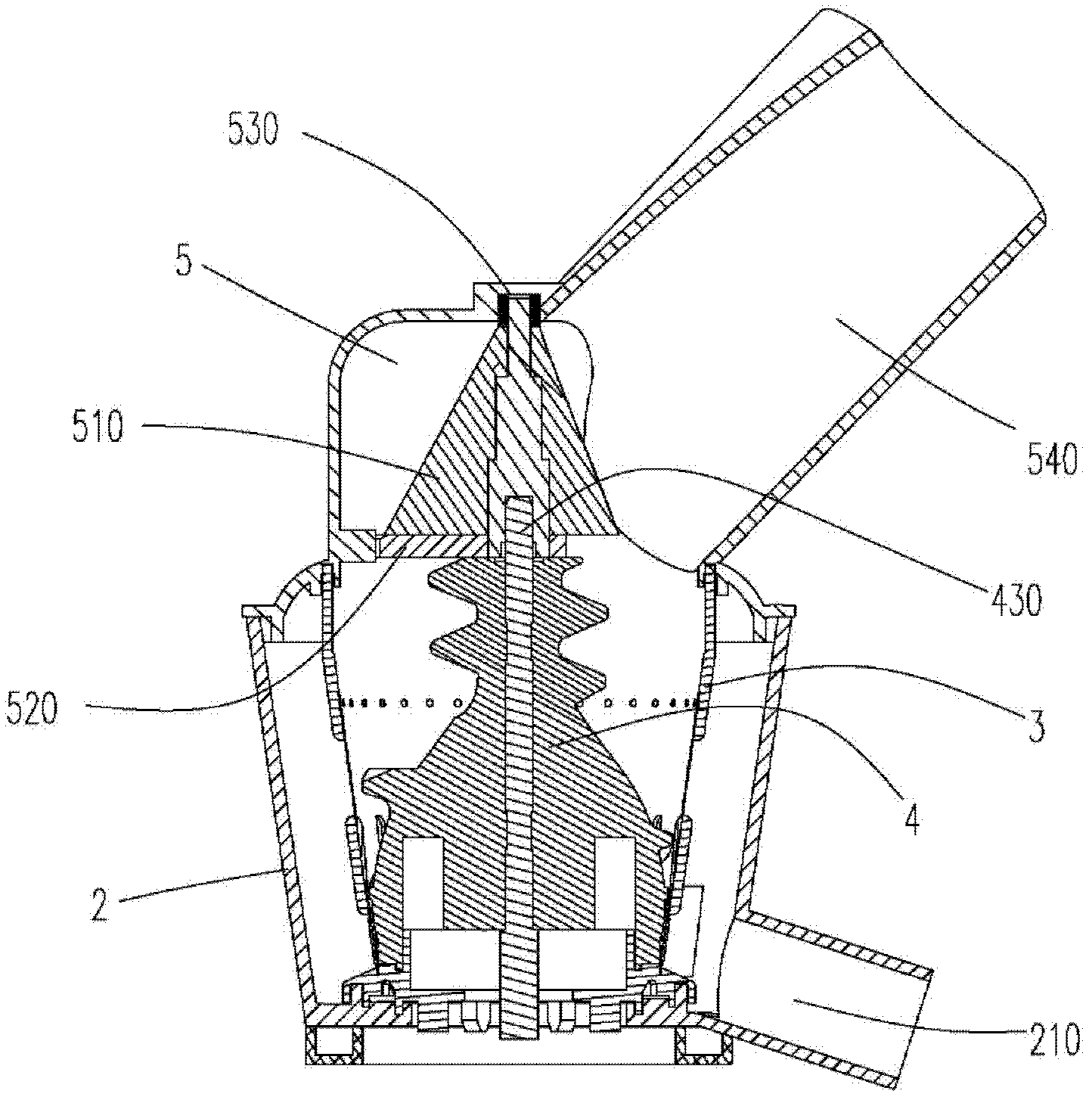

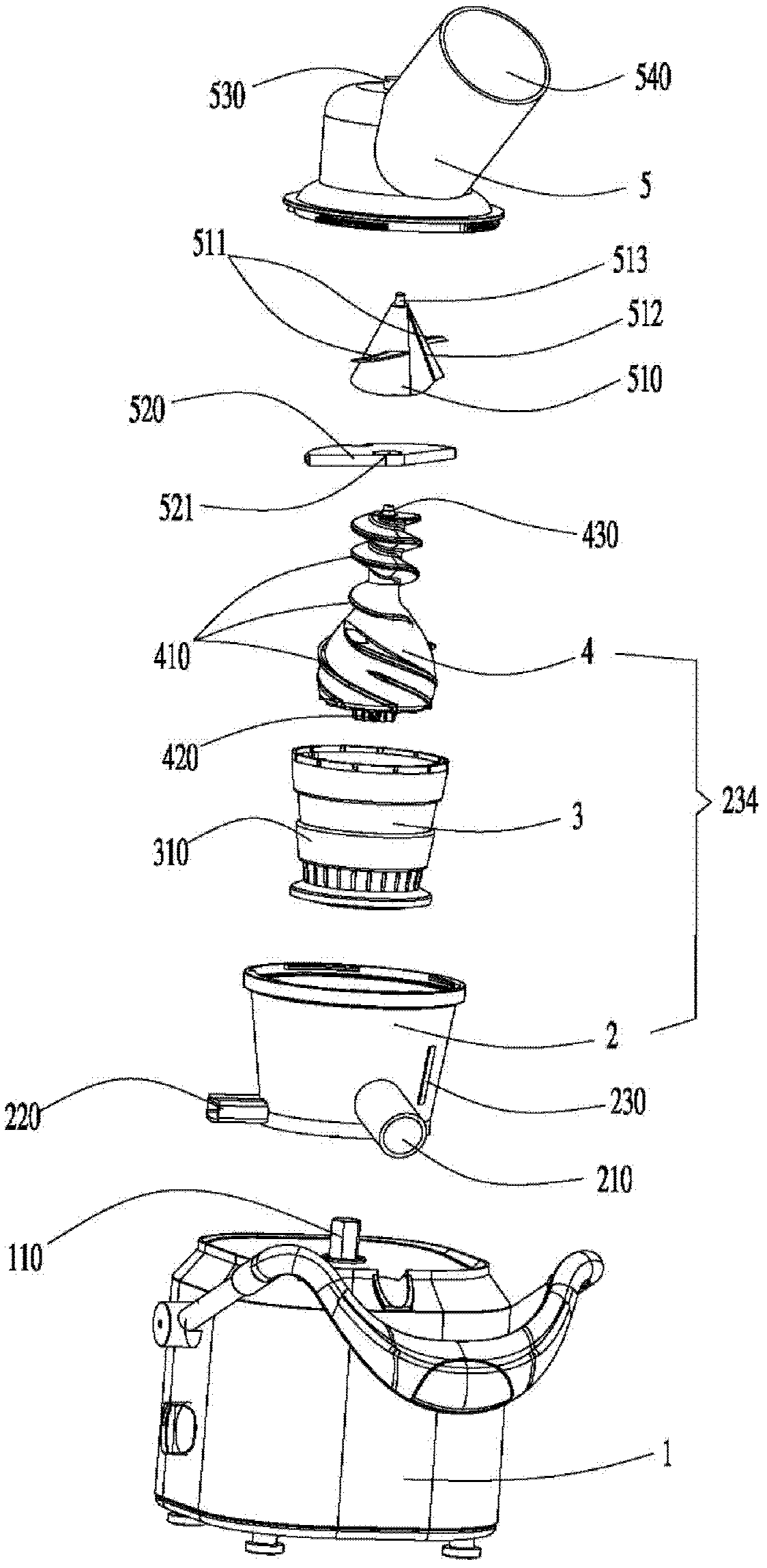

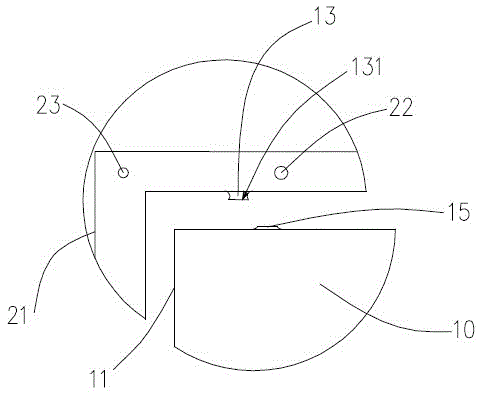

Juicer

ActiveCN103202654AGuaranteed tasteGuaranteed nutritionJuice extractionStrainersMechanical engineering

The invention provides a juicer, which comprises a machine base with a driving mechanism, a squeezing device located above the engine seat, and an upper cover placed above the squeezing device, and is characterized in that the squeezing device is formed by a separator for discharging juice and residual of squeezed food respectively, a filter screen for filtering the residual of the squeezed food, and a rotary head for spirally squeezing the to-be-squeezed food; the separator is provided with a juice outlet at the side wall and a residual outlet at the bottom, the bottom of the filter screen is provided with a residual discharge port movably communicated with the residual outlet, the rotary head is provided with a spiral sheet and arranged in the separator, the filter screen is sleeved between the rotary head and the separator, a first driving end of the driving mechanism of the engine seat is connected with the center of the lower end of the rotary head, the rotary head reversely rotates relative to the filter screen, and the cost is reduced as the assembled parts are reduced.

Owner:T F ELECTRICAL TECH SHENZHEN

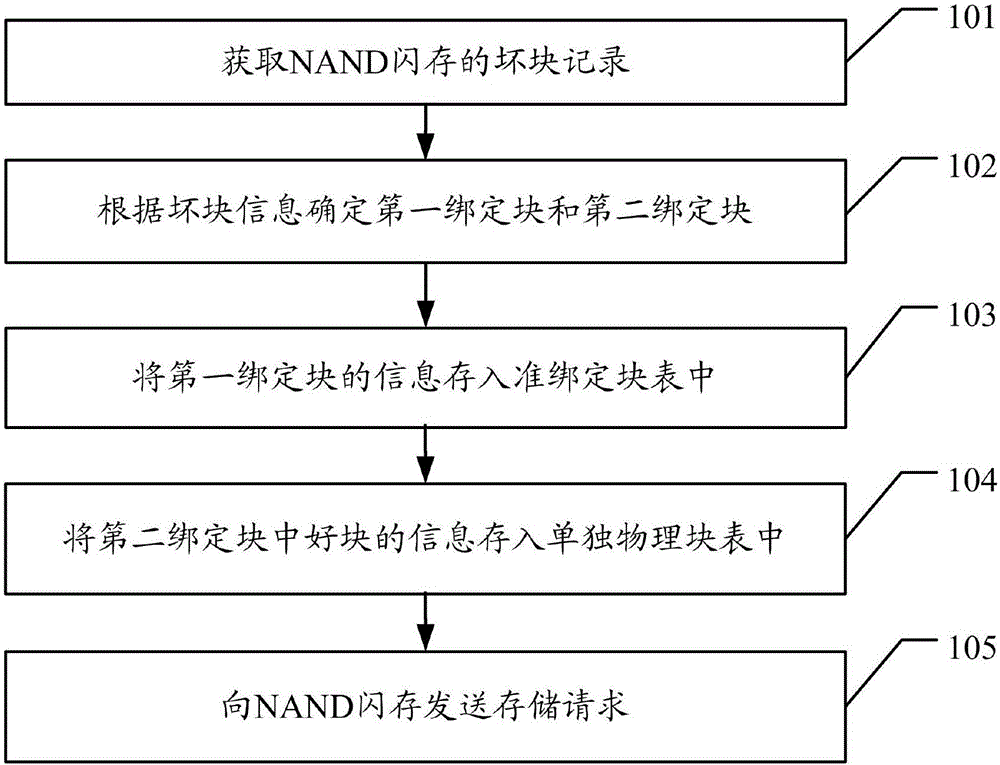

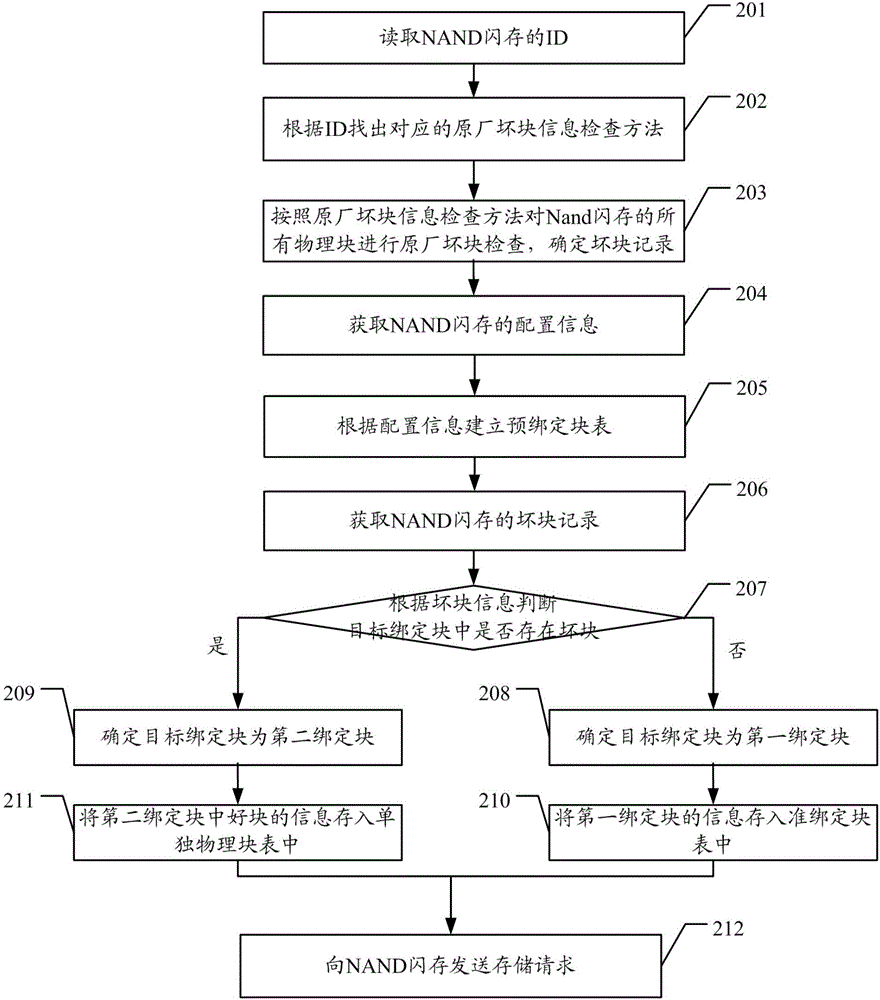

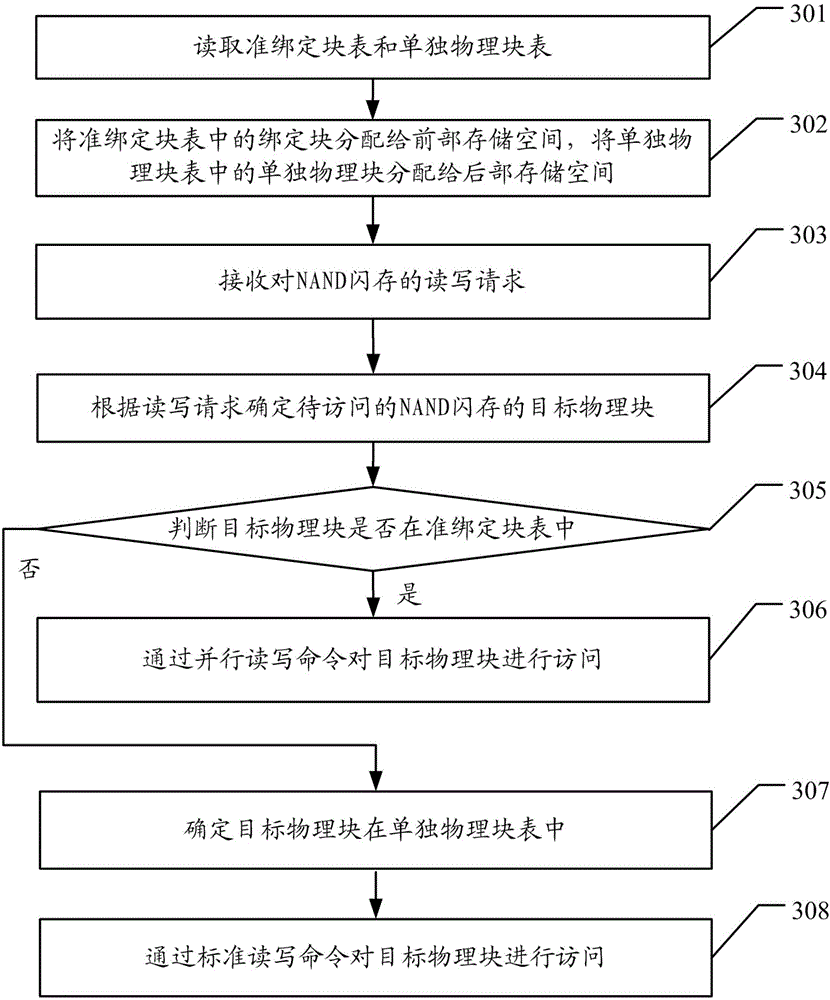

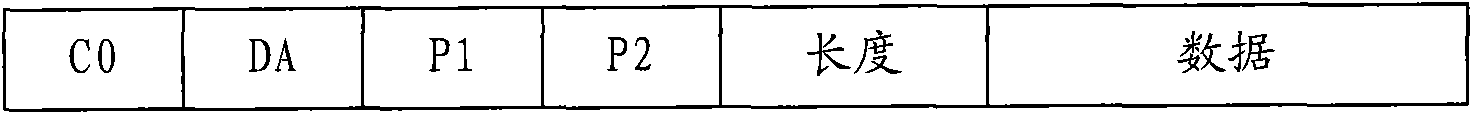

NAND flash memory management method, host, NAND flash memory reading and writing method, and NAND flash memory controller

InactiveCN106445408AReduce usageIncrease usable capacityInput/output to record carriersLarge capacityNand flash memory

The embodiment of the invention discloses an NAND flash memory management method, a host, an NAND flash memory reading and writing method, and an NAND flash memory controller. The NAND flash memory management method provided by the embodiment of the invention comprises the steps of acquiring bad block information of an NAND flash memory; determining a first binding block and a second binding block according to the bad block information, wherein mutually bound physical blocks in the first binding block are all good blocks, and mutually bound physical blocks in the second binding block comprise bad blocks; storing the information of the first binding block into a future binding block list, and storing the information of the good blocks in the second binding block into an independent physical block list in the NAND flash memory; and sending a storage request to the NAND flash memory, wherein the storage request comprises the future binding block list and the independent physical block list, thus allowing the NAND flash memory controller to store the future binding block list and the independent physical block list into the NAND flash memory, access the first binding block via a parallel reading-writing command, and access the good blocks in the second binding block via a standard reading-writing command. According to the method provided by the invention, both high speed and high capacity of the NAND flash memory can be achieved.

Owner:SHENZHEN CHIPSBANK TECH

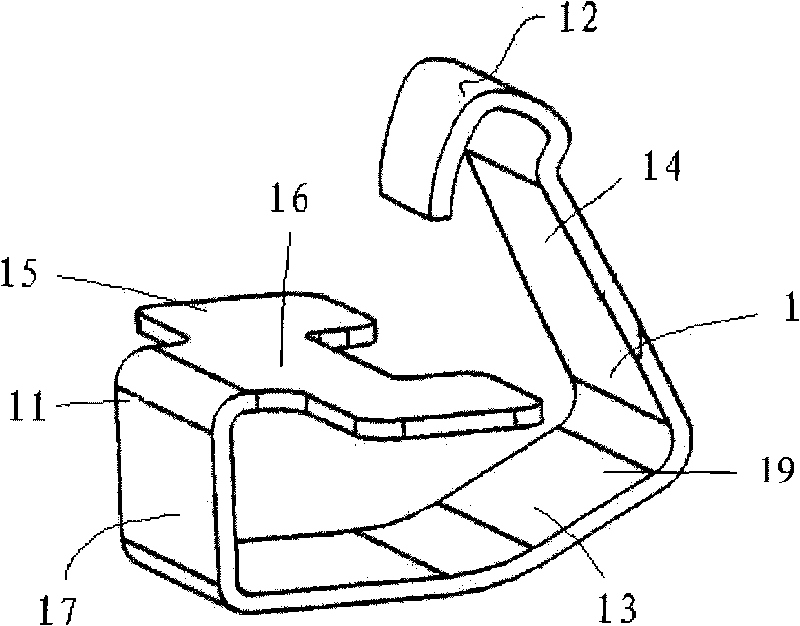

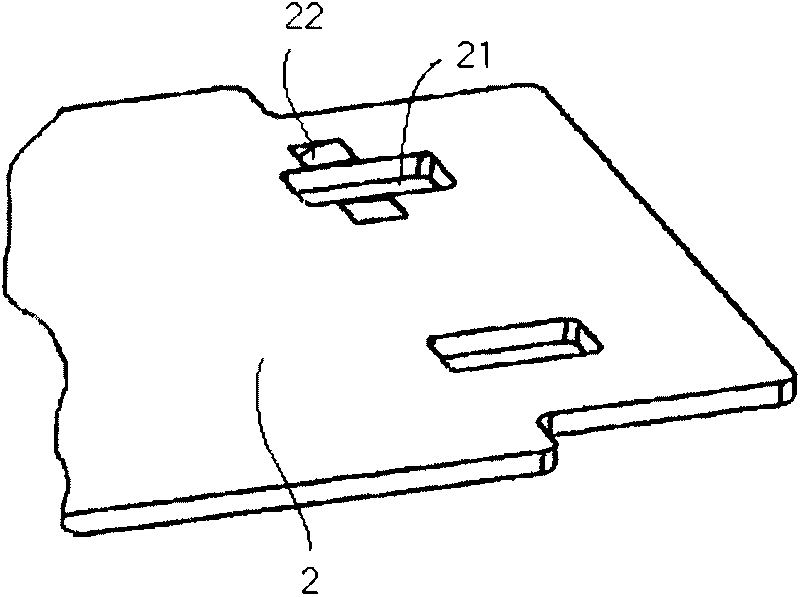

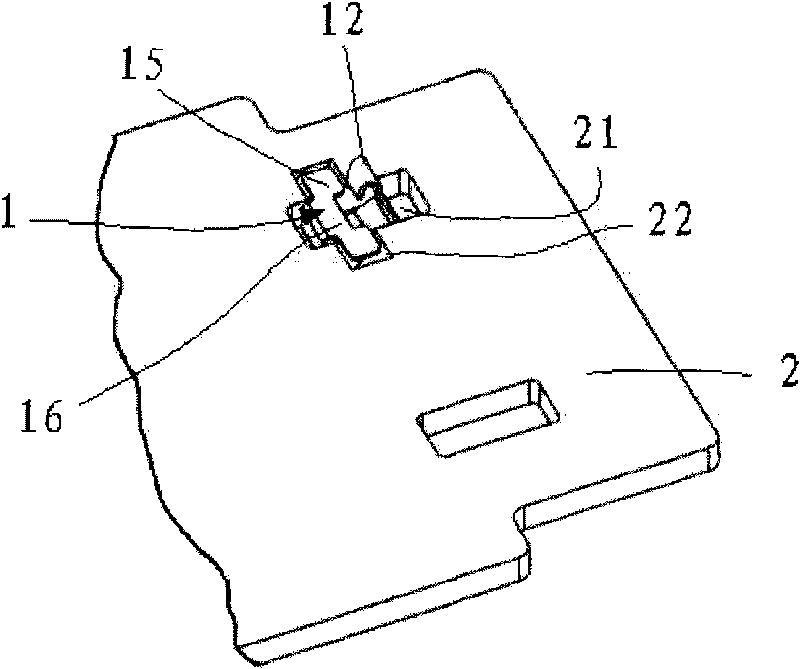

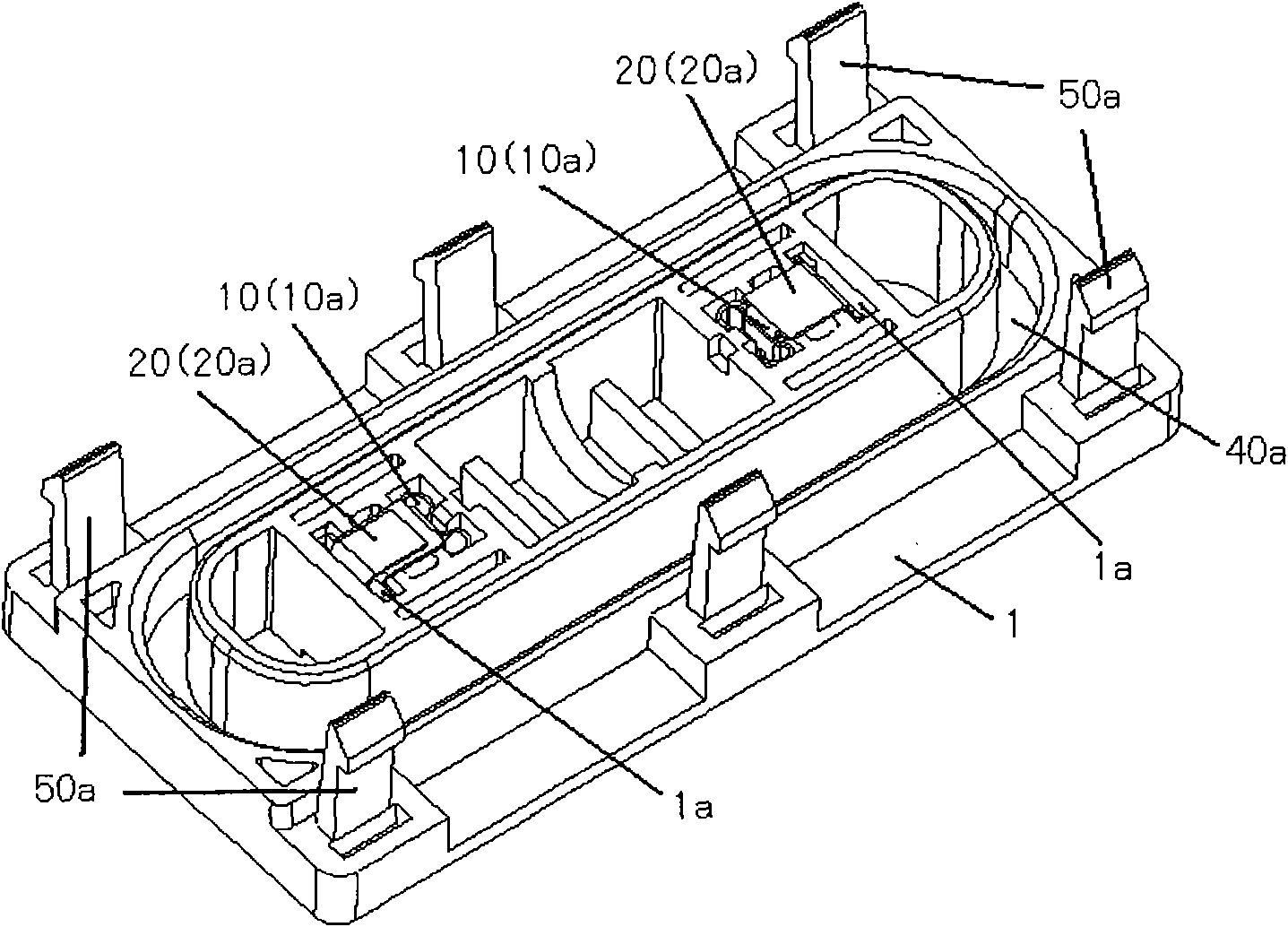

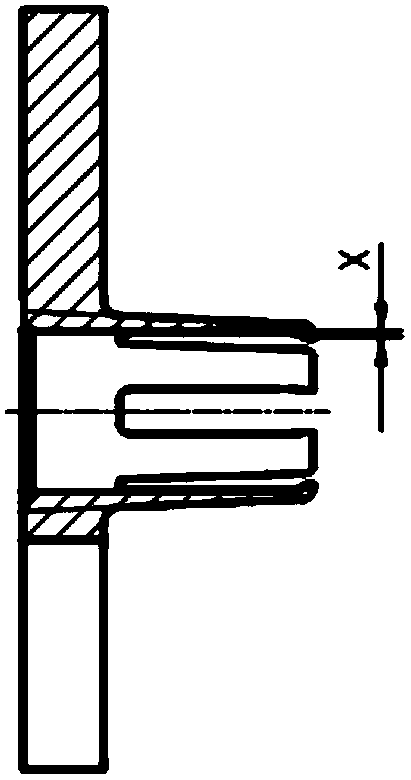

Metal spring leaf in electronic product and connecting structure adopting same

ActiveCN101707301ASmall sizeSmall amount of deformationCoupling contact membersFixed connectionsEngineeringMetal

The invention provides a metal spring leaf in an electronic product and a connecting structure adopting the metal spring leaf, which comprises a metal spring leaf and a PCB. The metal spring leaf comprises a spring leaf body with an elastic back bending structure; a contact end and a welding end are arranged at both ends of the spring leaf body; the welding end is near to the middle part of the spring leaf body; a hole groove is arranged on the PCB; and the metal spring leaf is arranged in the hole groove and welded on the PCB bard through the welding end. As the metal spring leaf has the elastic back bending structure, and the welding end is arranged at the middle part of the elastic back bending structure, the dimension of the metal spring leaf is greatly reduced, and the deformation of the metal spring leaf is reduced. As the metal spring leaf is arranged in the hole groove on the PCB, the exposed part of the metal spring leaf is reduced; therefore, the metal spring leaf can be elastically compressed in the hole groove, and the probability of deformation failure caused by unexpected collision of the metal spring leaf is reduced.

Owner:ZTE CORP

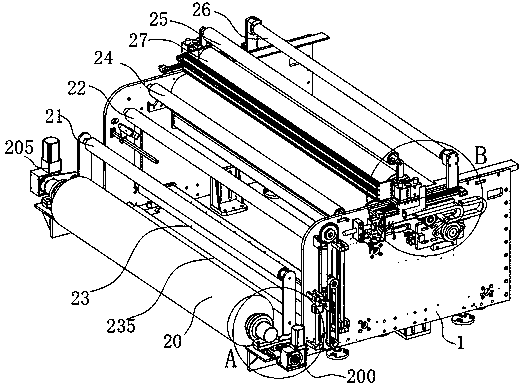

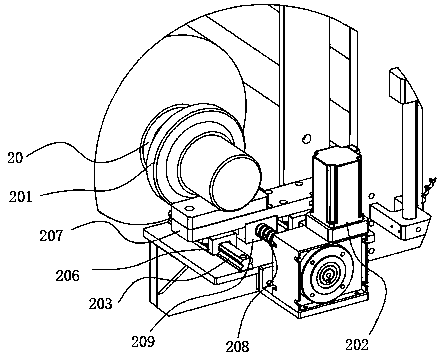

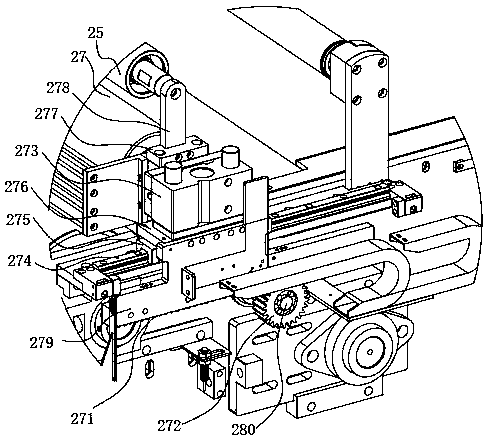

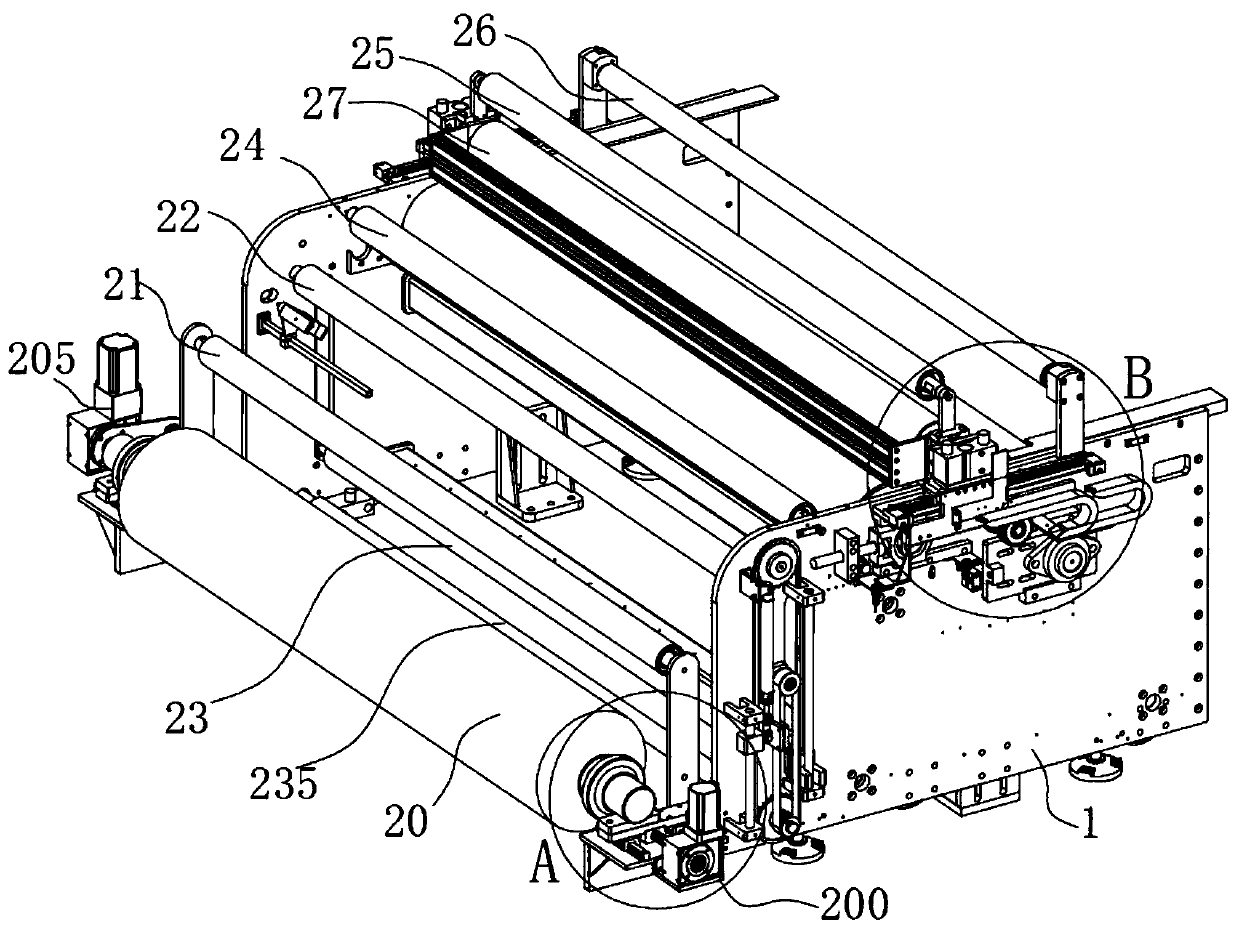

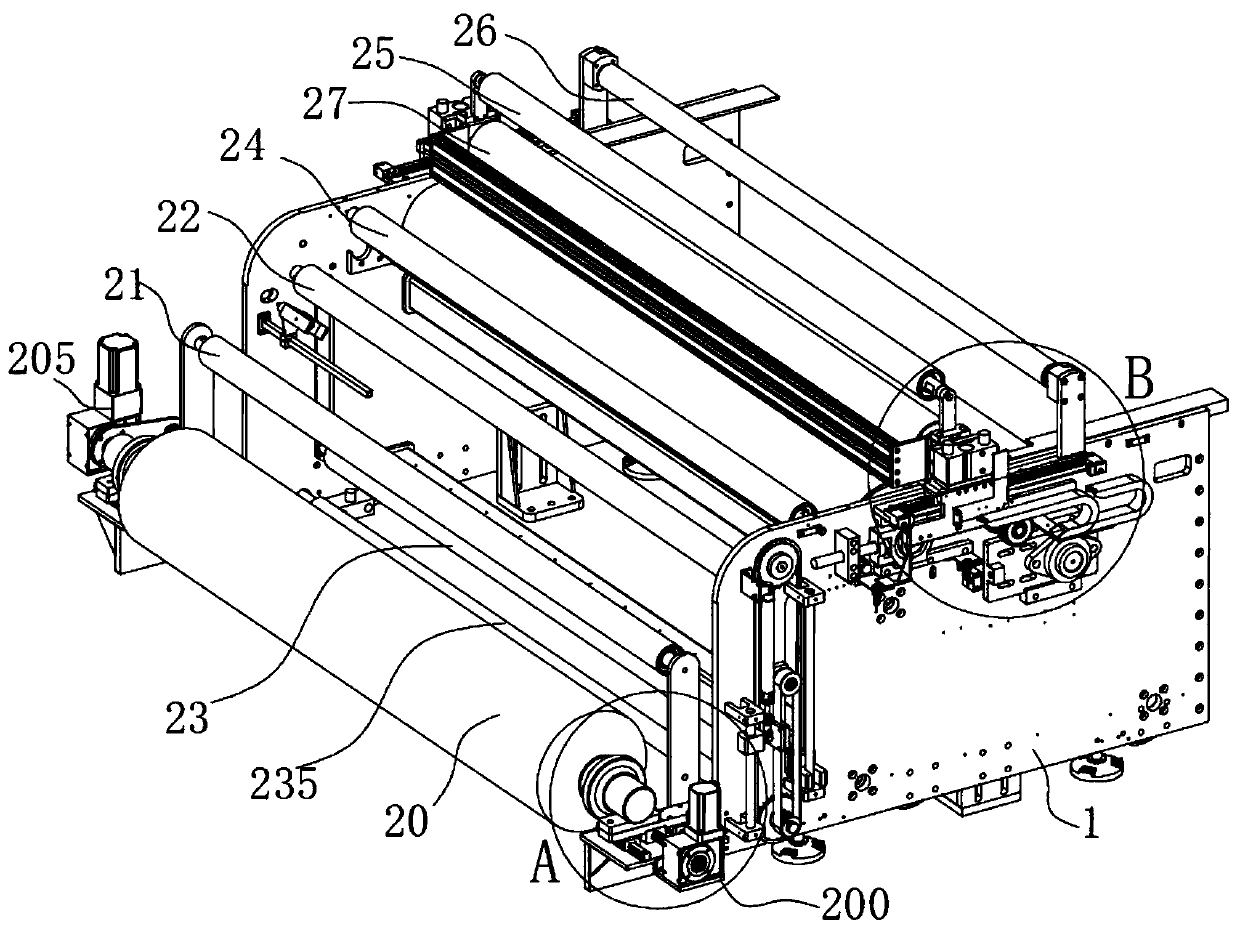

Cloth feeding mechanism of digital printing machine

The invention discloses a cloth feeding mechanism of a digital printing machine. The cloth feeding mechanism of the digital printing machine comprises a machine frame, an air expansion shaft, a largeroll corner wrapping roller, a cloth passing roller a, a constant-tension floating roller, a cloth passing roller b, a cloth passing roller c, a moving roller and a width increase corner wrapping roller. The air expansion shaft, the large roll corner wrapping roller, the cloth passing roller a, the constant-tension floating roller, the cloth passing roller b, the cloth passing roller c, the movingroller and the width increase corner wrapping roller are arranged on the machine frame. An unwinding driving device is arranged at one end of the air expansion shaft. Lifting guide mechanisms and a floating lifting driving device are arranged on the machine frame and drive the constant-tension floating roller to move. A horizontal movement driving device for front-and-rear sliding mechanisms which allow the moving roller to horizontally move is arranged on the machine frame. An unwinding deviation correcting system which conducts position correction on a piece of cloth is arranged on the machine frame. The cloth feeding mechanism of the digital printing machine has the advantages that the cloth feeding mechanism is matched with large rolls of cloth and small rolls of cloth, a cloth framedoes not need to be independently arranged, and the cost is saved; the cloth feeding mechanism has the function that the deviation correction and the edge alignment are automatically conducted on thecloth in real time; the cloth can be closely attached to a conveying belt, few press marks exist, no fold exists, a spray nozzle is protected, and the printing quality is improved; a single air cylinder is adopted so that the control over the value of the constant tension of the constant-tension floating roller can be achieved; and the jam phenomenon is avoided.

Owner:广东希望高科数字技术有限公司

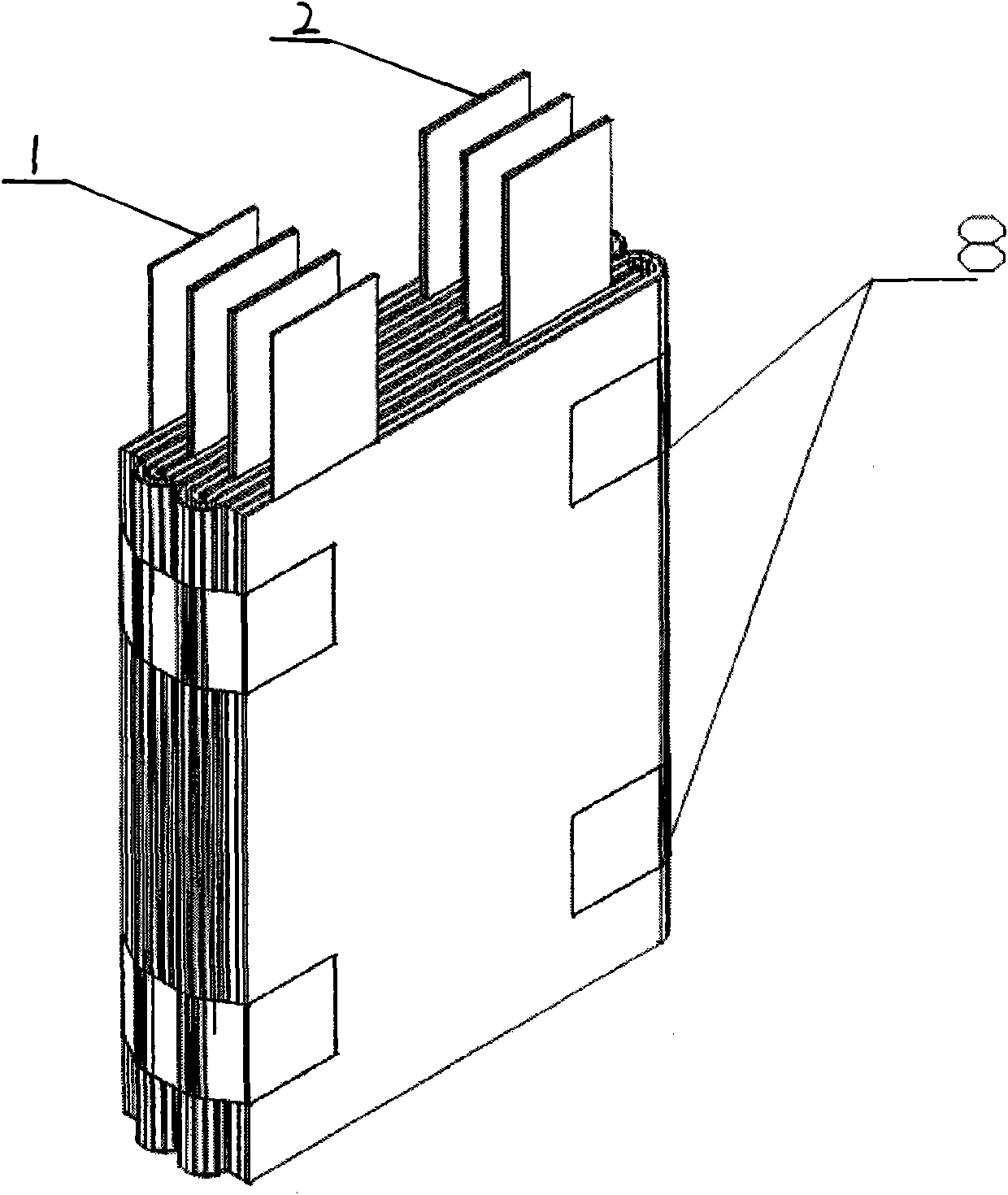

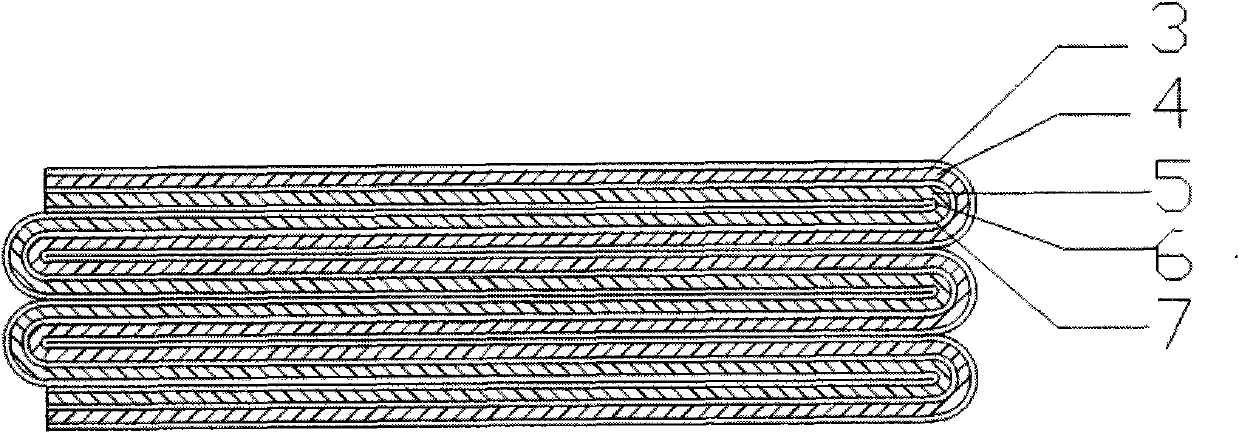

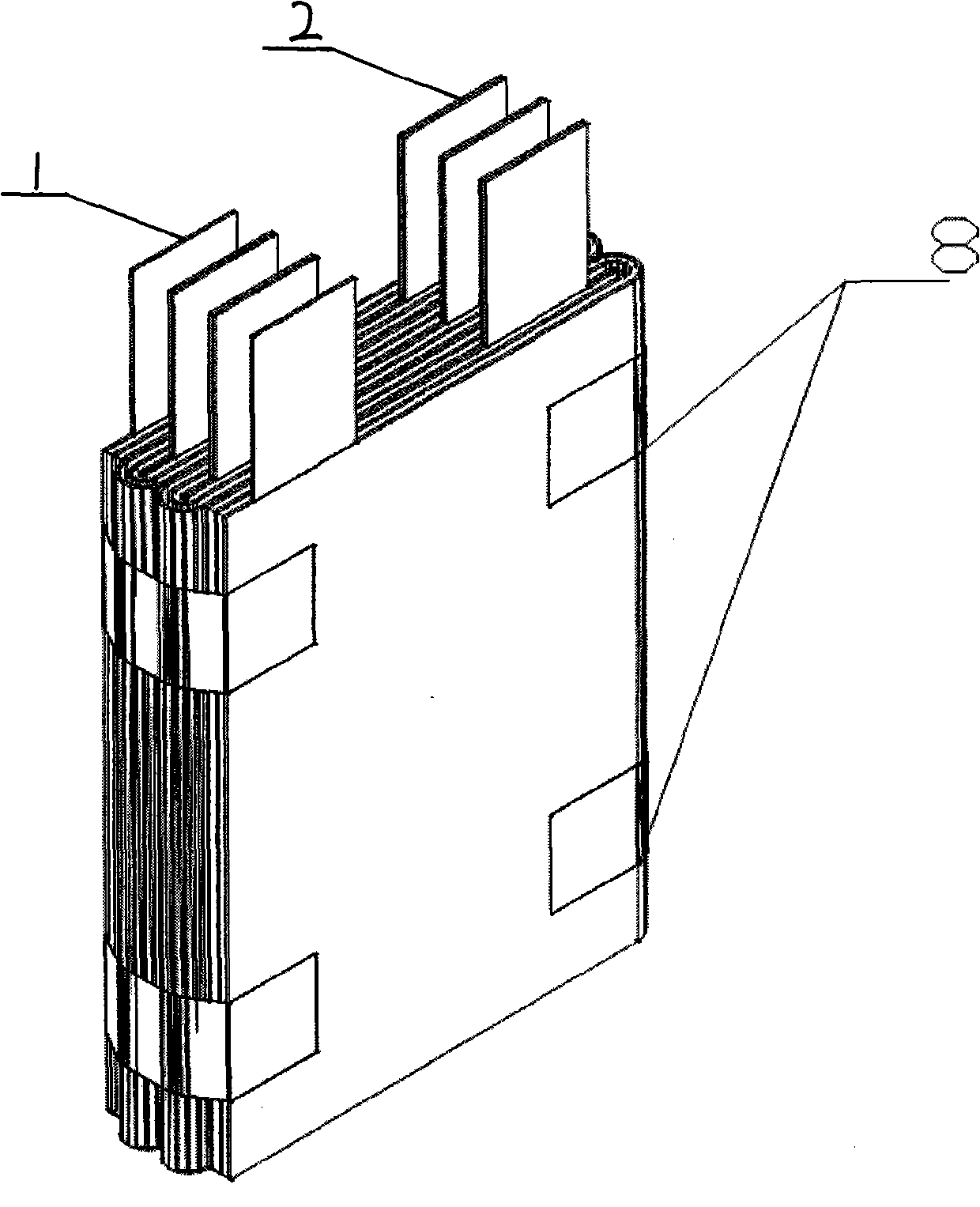

Method for manufacturing cells of power lithium ion batteries

InactiveCN102024990AImprove consistencyHigh density dischargeFinal product manufactureCell electrodesInternal resistanceElectrical battery

The invention discloses a method for manufacturing cells of power lithium ion batteries. The method is characterized in that active substances of the cathode and anode are respectively coated on single surfaces of cathode and anode current collectors to form anode and cathode coils; the coils are rolled and split to prepare anode and cathode pieces; a plurality of tabs are reserved on the anode and cathode pieces; the surfaces of the anode and cathode pieces, which are coated with the active substances, are opposite and are separated by a diaphragm; the tabs respectively coincide after S-shaped folding; and finally gummed paper is used for fixing the four corners of the folded semi-finished batteries. The method has the advantages of good manufacturability and high production efficiency, and the cells manufactured by the method have high consistency and low internal resistance, therefore, the method is especially suitable for manufacturing the power lithium ion batteries.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

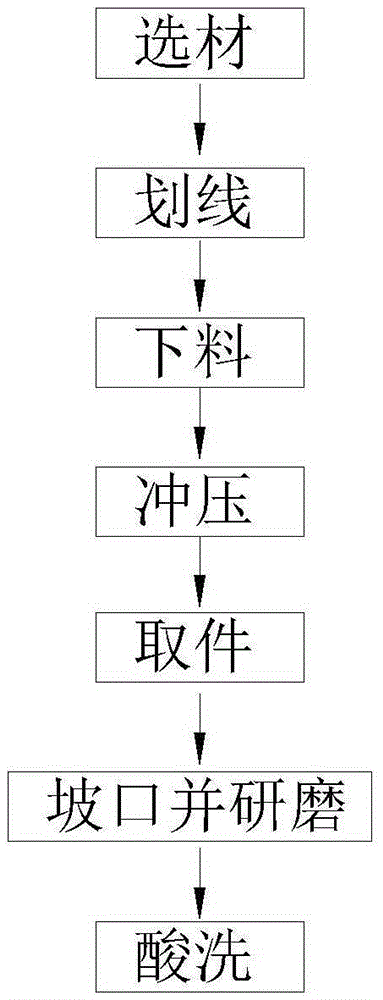

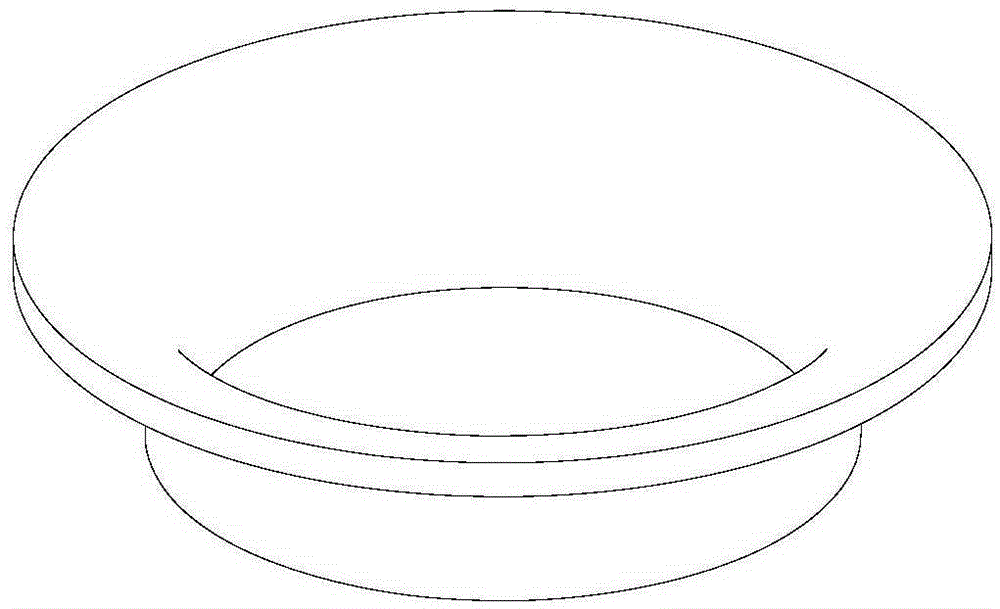

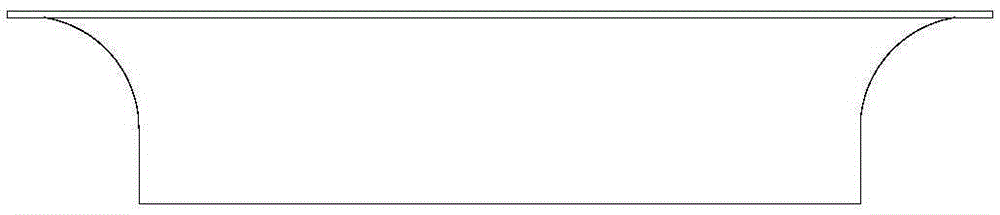

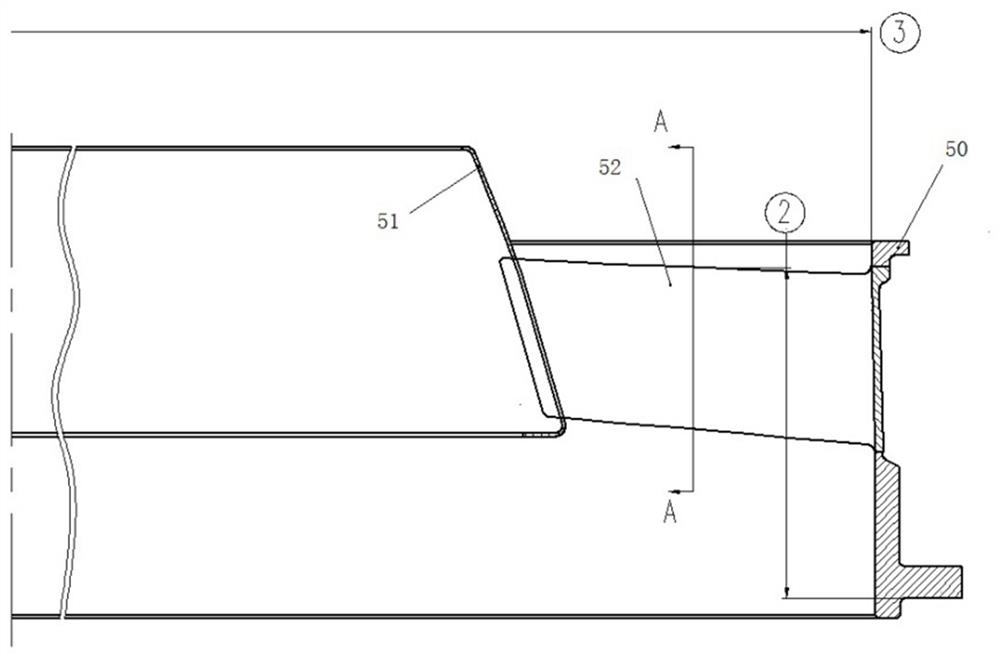

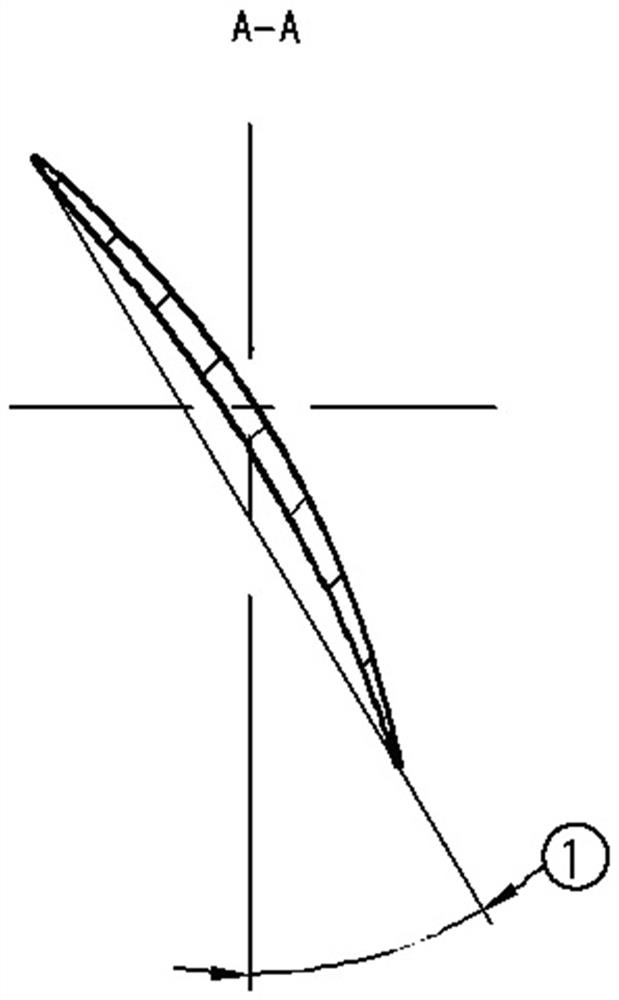

Machining method of horn-shaped seal head

ActiveCN105344872AGood shape consistencyAvoid Scrap SituationsHollow articlesEngineeringMachining process

The invention provides a machining method of a horn-shaped seal head. The machining method comprises machining steps including material selection, scribing, blanking, stamping, part taking, groove machining and grinding and acid pickling. The overall cold stamping is realized through preset clearance cooperation of an existing stamping machine and a stamping die, the machined seal head has good size and shape consistency, the accuracy requirement of a foreign power spinning machine is met, a curved surface machined through the stamping die is smooth, the curved surface of the seal head and the round section of a lower straight barrel are in smooth transition, the condition of scrapping caused by edges and marks and even cracking of the seal head in the machining process of the strong spinning machine is avoided, and the scrappage is very low; meanwhile, an ordinary operator of the stamping machine can master the machining method after a little training, the technical requirements for the operator are lower, the production efficiency is remarkably improved, and the delivery term is greatly shortened.

Owner:CHANGZHOU KUANGDA WEIDE MACHINERY

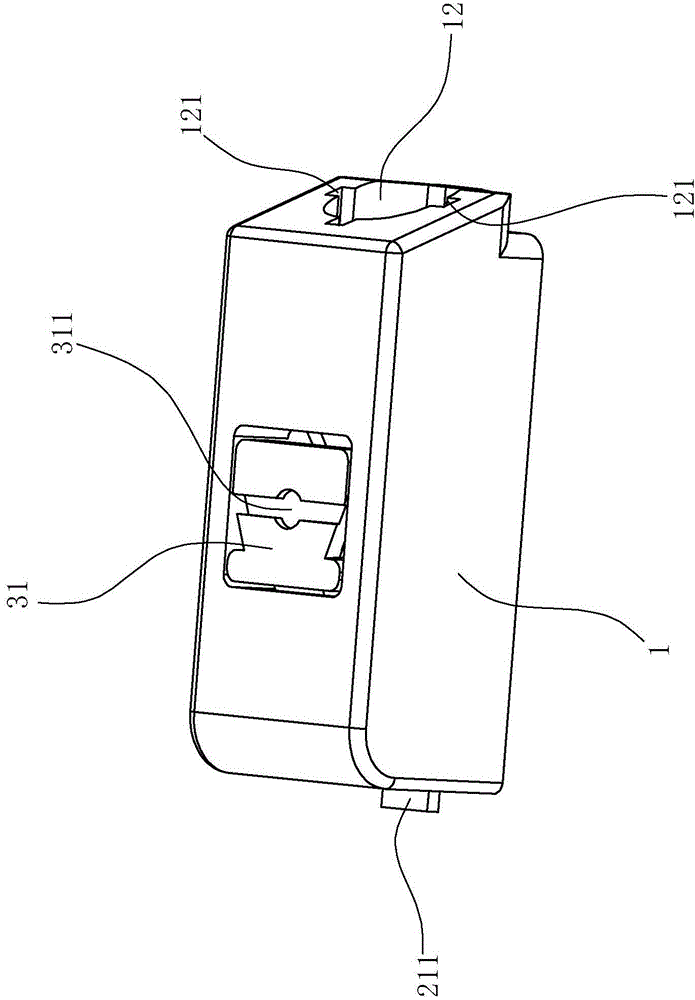

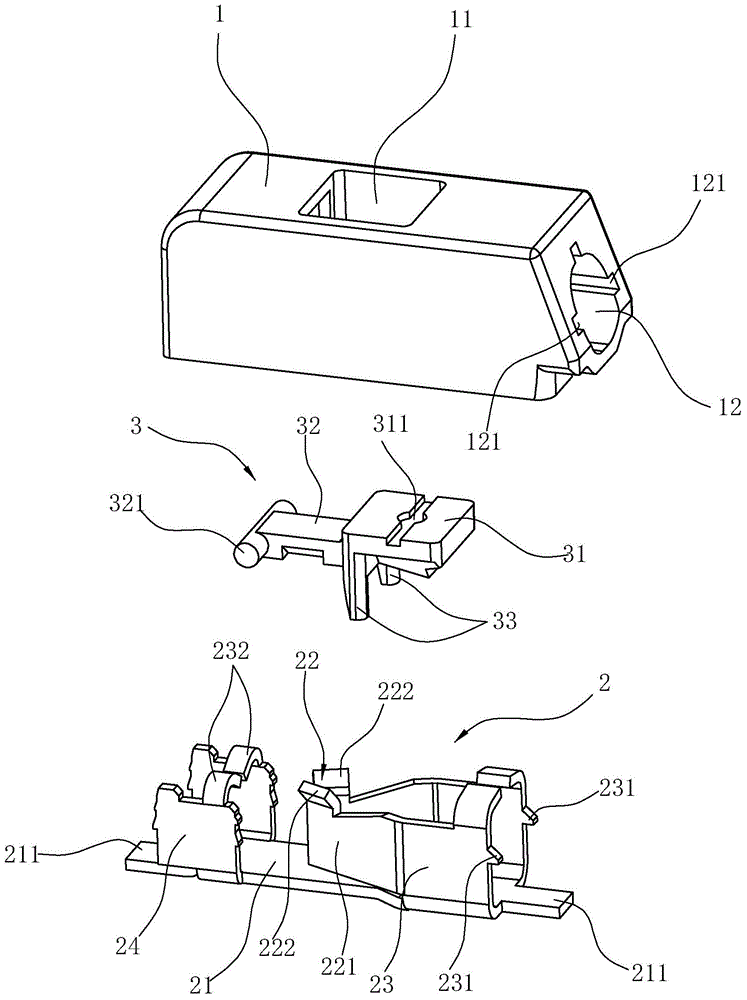

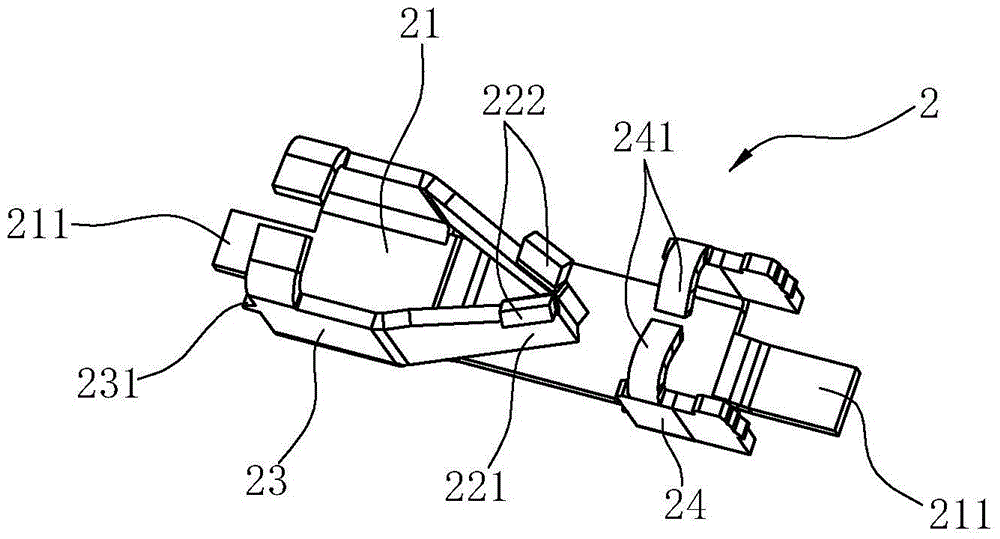

SMT wiring terminal convenient to operate

ActiveCN104916929AEasy clamping and looseningExtended Life and ReusabilityElectric connection basesClamped/spring connectionsEngineeringElectrical conductor

The invention relates to an SMT wiring terminal convenient to operate, which comprises an insulating shell body and an electric conductor arranged inside the insulating shell body, and is characterized in that a body of the electric conductor is provided with a clamping part for clamping a lead wire, a through hole is formed in the top part of the shell body, and a button which can make the clamping part of the electric conductor open and can reset elastically is arranged inside the through hole. Compared with the prior art, the SMT wiring terminal has the advantages that the single button which can be pressed downward for operation is additionally arranged, so that the clamping and loosening of the lead wire is more convenient and simpler, the SMT wiring terminal can realize the assembly and disassembly of the lead wire quickly when compared with the traditional wiring terminal without the button structure; in addition, the button is an independent part and can be replaced separately in case of damage after repeated use, the situation that the entire wiring terminal is scrapped due to the integral structure of the button and the shell body is avoided, the service life of the entire terminal is prolonged, the repeated utilization rate of the entire terminal is increased, and the SMT wiring terminal has higher practicality.

Owner:NINGBO DEGSON ELECTRICAL CO LTD

Manufacturing method of printed circuit board

ActiveCN106034380APrecise positioningPositioning does not shiftPrinted circuit manufactureEngineeringCopper

The invention relates to a manufacturing method of a printed circuit board. The manufacturing method is applicable to the printed circuit board with no positioning hole designed in the inner side of a technological side or only with non-electroplate-copper hole with the diameter smaller than or equal to 1.5 mm. The manufacturing method comprises the steps that V-cut production is carried out, the technological edge, close to the peripheral edge, of each unit of the printed circuit board is provided with at least two connection places with the length of 1-2 mm, the V-cut line of each connection place exceeds the technological edge by 0.1-0.2 mm, the remaining thickness of each connection place is 0.15-0.25 mm, and peripheral positioning holes are drilled near the connection places. According to the method, V-cut production is carried out on the PCB at first, the technological edge, close to the peripheral edge, of the PCB is provided with the connection places, the peripheral positioning holes are formed in the outer sides of the connection places and used for carrying out cutting operation, and it can be ensured that positioning is accurate and displacement is avoided.

Owner:AOSHIKANG TECH CO LTD

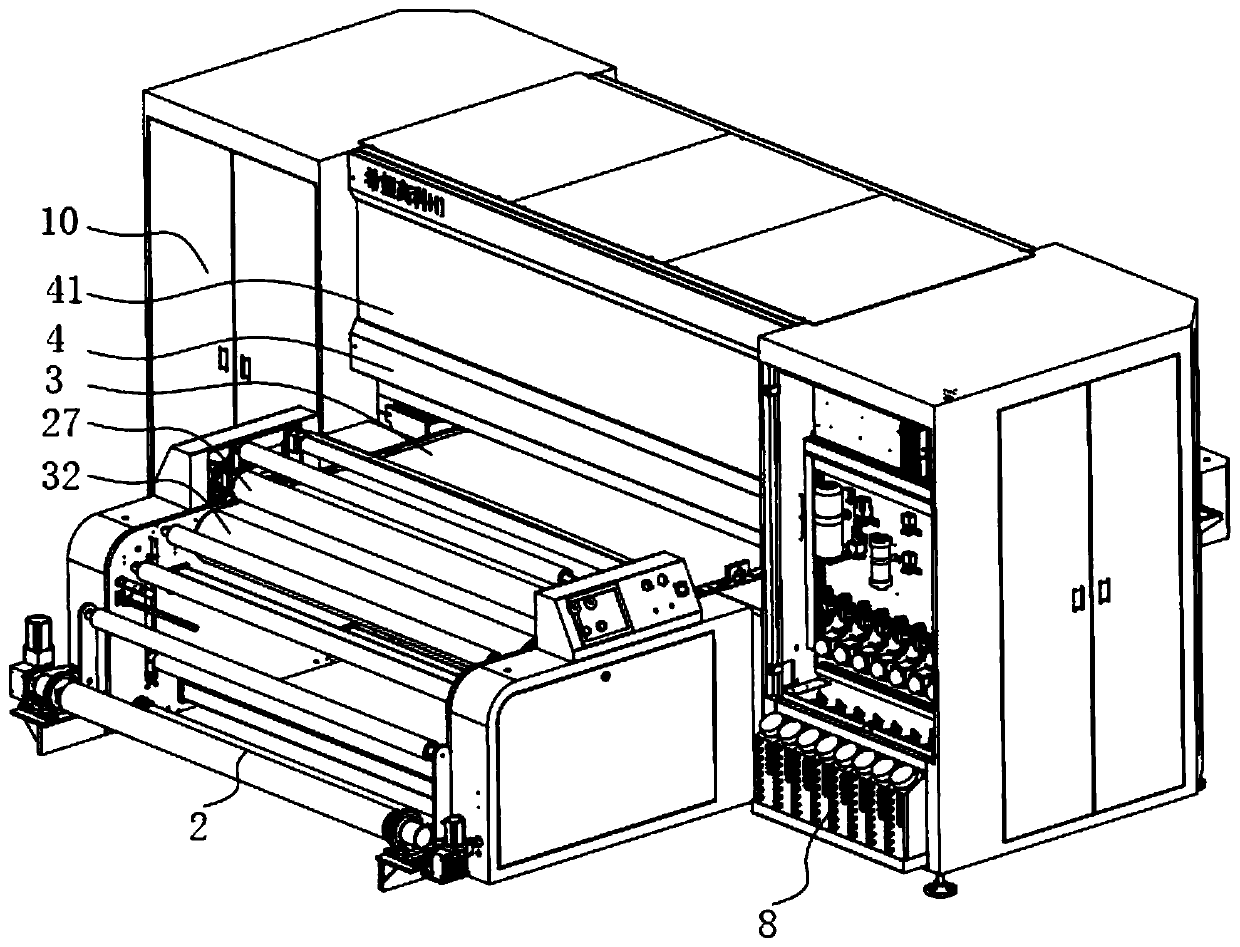

Scanning type textile digital printing equipment

ActiveCN111114130AReduce creasesAvoid wrinklesOther printing apparatusTextile printerProcess engineering

The invention discloses scanning type textile digital printing equipment. The scanning type textile digital printing equipment comprises a cloth feeding mechanism, a printing conveying belt mechanism,a gantry sliding frame, a printing scanning vehicle, a belt glue distributing and removing device, a belt cleaning device, a printing control cabinet and an ink supply system; the printing conveyingbelt mechanism is arranged at the top of the rack, the gantry sliding frame stretches across the printing conveying belt mechanism, the printing scanning vehicle is arranged on the gantry sliding frame in a sliding mode, the belt glue distributing and removing device stretches across the front portion of the printing conveying belt mechanism, and the cloth feeding mechanism is arranged behind theprinting conveying belt mechanism, and the belt cleaning device is arranged below the printing conveying belt mechanism. The printing equipment has the advantages that the cloth feeding mechanism adapts to large and small rolls of cloth; automatic online real-time deviation correction and edge alignment of the cloth are achieved; the printing quality is high; the glue distributing function and theglue removing function are integrated; the belt cleaning device adopts the combination of a composite cleaning mode and composite drying, so that the cleaning effect is improved; water consumption islow, and energy conservation and environmental protection are achieved; and the ink supply system is fast to start and high in production efficiency.

Owner:广东希望高科数字技术有限公司

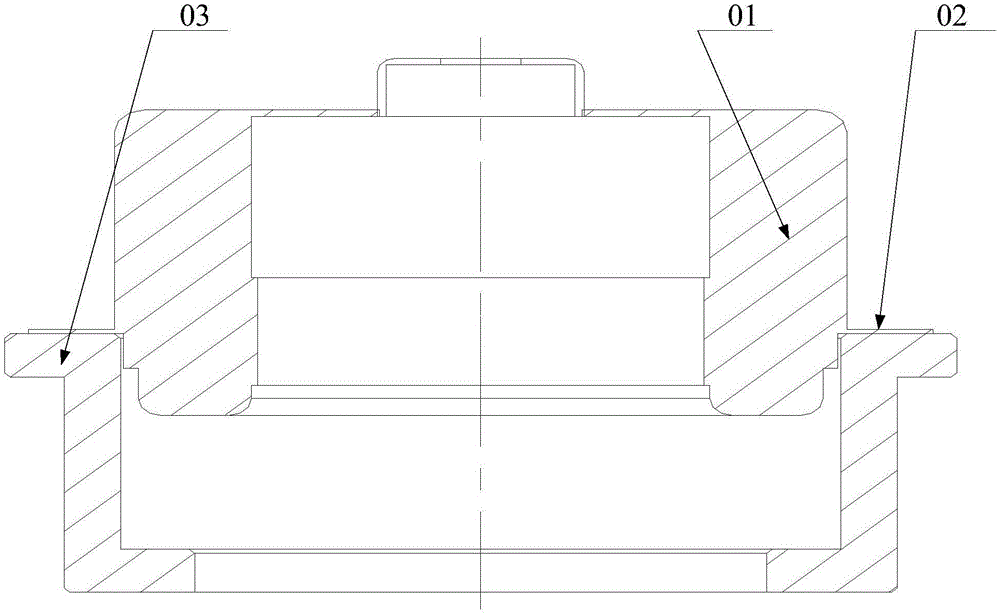

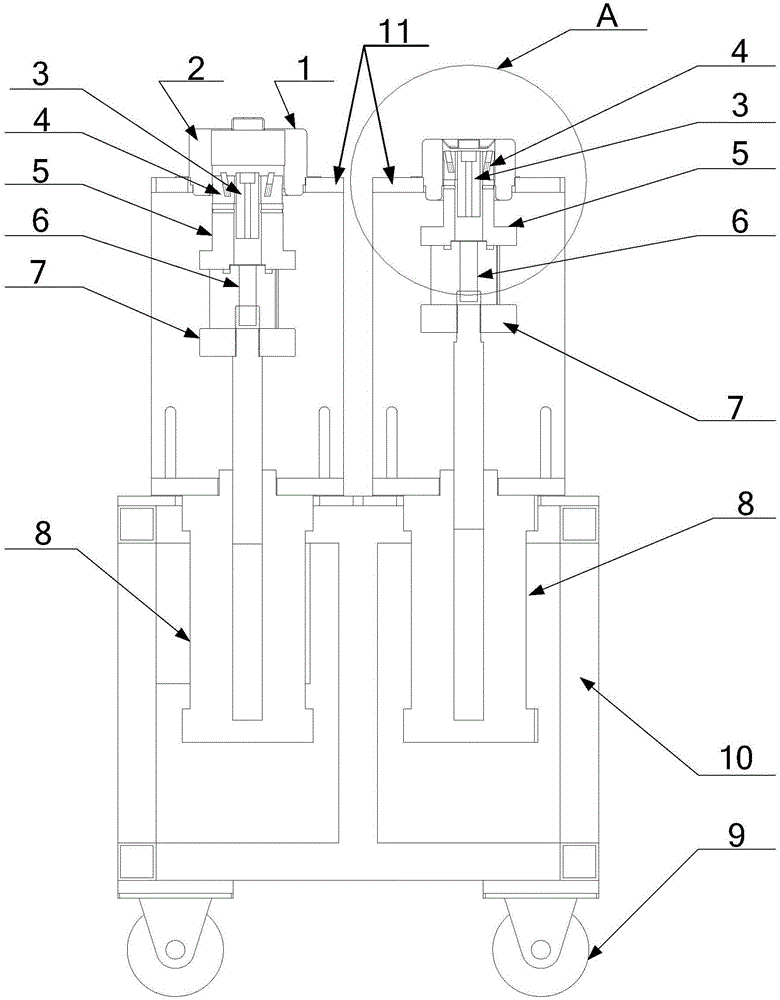

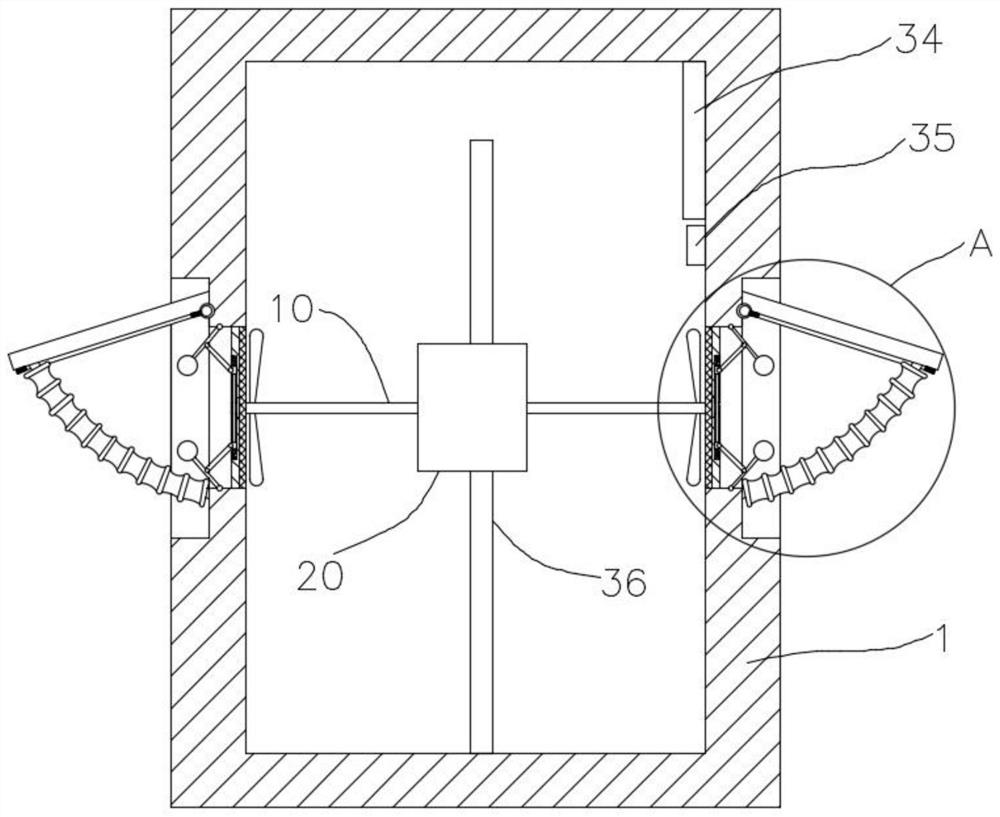

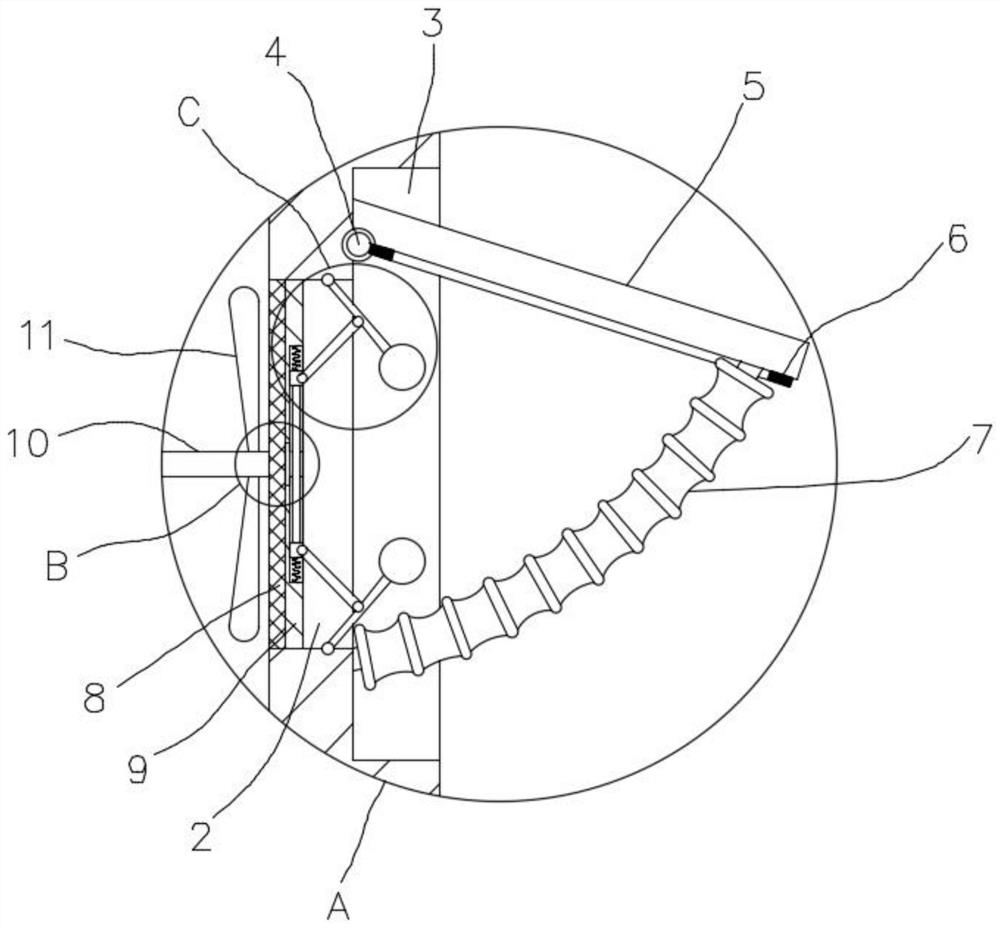

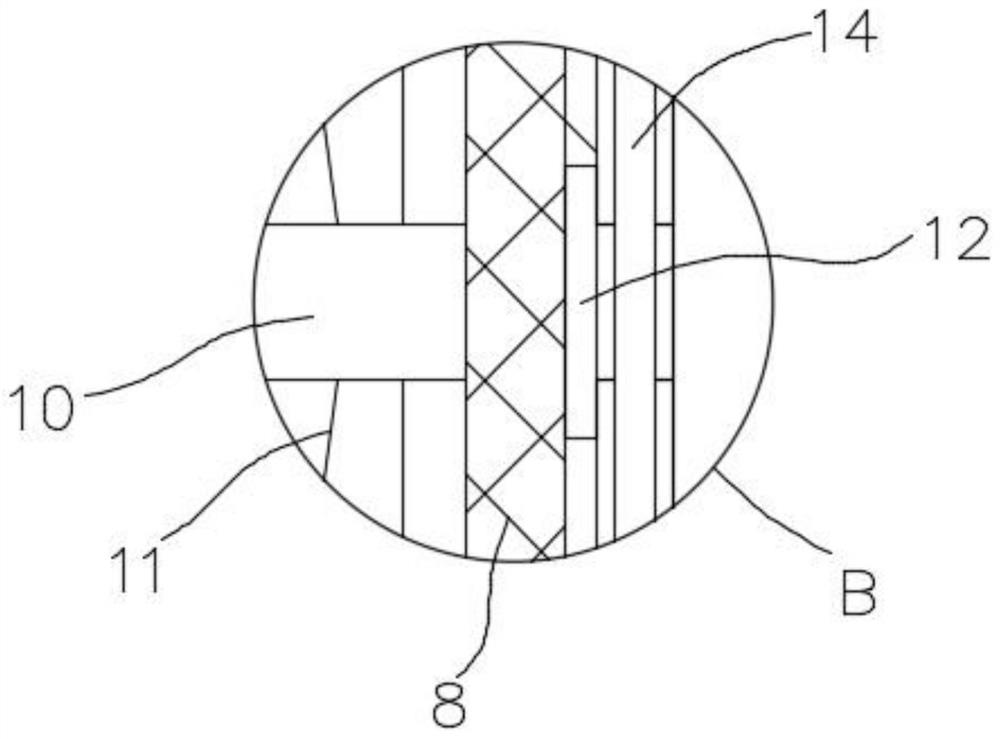

Separating device for motor end covers and stators

ActiveCN105099098AAvoid Scrap SituationsAchieve separationManufacturing dynamo-electric machinesEngineeringDriven element

The invention discloses a separating device for motor end covers and stators. The separating device comprises a bracket and a disassembly assembly, wherein the disassembly assembly is arranged on the bracket, and comprises locating plates, separating assemblies and first drive elements; each locating plate is fixed on the bracket and comprises a locating hole; the stators located in the locating holes; the flanged sides of the end covers are propped against the upper end surfaces of the locating plates; the separating assemblies are located below the locating plates, can extend to the upper parts of the stators and are clamped with the upper end surfaces of the stators; and the first drive elements are arranged on the bracket and can drive the separating assemblies to move up and down. According to the structural design of the separating device for the motor end covers and the stators, the problems of time and energy waste and low efficiency when the motor end covers and the stators are dismantled can be effectively solved.

Owner:ZHUHAI KAIBANG MOTOR MFR +2

Power distribution cabinet with heat dissipation and fire extinguishing functions

InactiveCN112968371AAffect heat dissipationAvoid affecting the air intakeSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringFan blade

A power distribution cabinet with heat dissipation and fire extinguishing functions disclosed by the present invention comprises a cabinet body, stepped ventilation openings are symmetrically formed in the two sides of the cabinet body, each ventilation opening is composed of an inner ventilation opening and an outer ventilation opening which are communicated from inside to outside, and a flashing board is rotatably mounted on the inner wall of the upper end of the side, away from the inner ventilation opening, of the outer ventilation opening through a rotating shaft. The flashing board and the inner wall of the lower end of one side of the outer ventilation opening are jointly connected with an arc-shaped corrugated pipe in a sealed mode, the side, close to the inner ventilation opening, of the flashing board is fixedly connected with a frame-shaped sealing gasket in a glued mode, the sealing gasket is larger than the inner ventilation opening in shape and size, the arc-shaped corrugated pipe is connected with a deflation pipe, and an electromagnetic valve is installed on the deflation pipe. The power distribution cabinet has the advantages that one power source has multiple purposes, heat dissipation and vibration removal of impurities on meshes are separately carried out by flexibly utilizing the arrangement direction of the fan blades and the one-way bearing, in addition, the flashing board is opened through an arc-shaped corrugated pipe for heat dissipation or closed through the arc-shaped corrugated pipe for fire extinguishing, and creativity is high.

Owner:谢满英

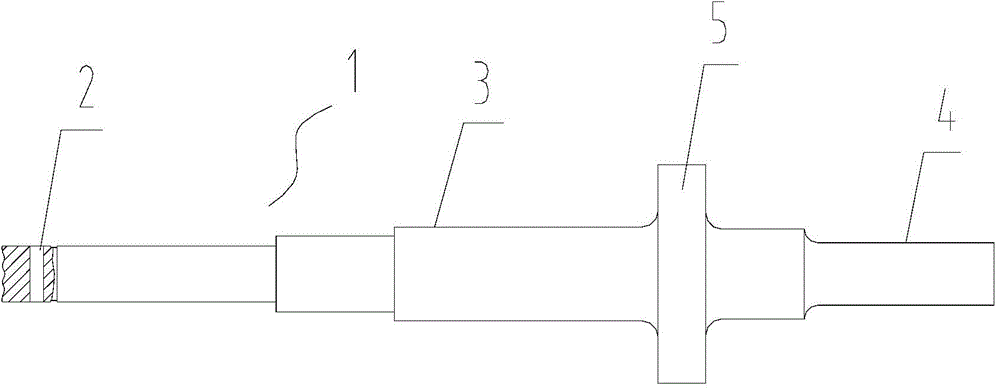

Machining method of turbine rotor

A machining method of a turbine rotor comprises the following processes of step a, performing rough turning on a pressure air end, a turbine disk and a turbine end of a turbine shaft; step b, performing drilling and heat treatment on a lifting hole; step c, performing heat treatment on the turbine shaft; step d, performing half-finished turning on the pressure air end, the turbine disk and the turbine end of the turbine shaft; step e, grinding outer circles and an end surfaces; step f, aligning the ground outer circles and end surfaces and performing finish turning on the pressure air end, the turbine disk and the turbine end of the turbine shaft; step g, grinding a tongue groove positioning circle and a key groove positioning circle; step h, aligning the tongue groove positioning circle and broaching a tongue groove; step i, aligning the key groove positioning circle and milling a key groove, an air guide wheel key groove and a pressure air impeller key groove; step j, performing finish turning an air sealing groove, an oil sealing groove and a center hole; step k, grinding stages of outer circles and end surfaces; step l, performing rounding on the key groove and performing deburring and chamfering on the tongue groove; step m, installing an air sealing ring on the turbine shaft; step n, performing finish turning on the end surface of the total length of the pressure air end and performing smooth transfer and polishing on the outer circles; step o, performing finish turning on the air sealing ring and performing smooth transfer and polishing on the outer circles; step p, performing appearance inspection. According to the machining method of the turbine rotor, the rotary accuracy of the turbine rotor is improved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

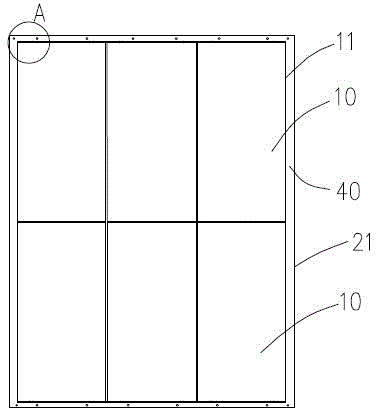

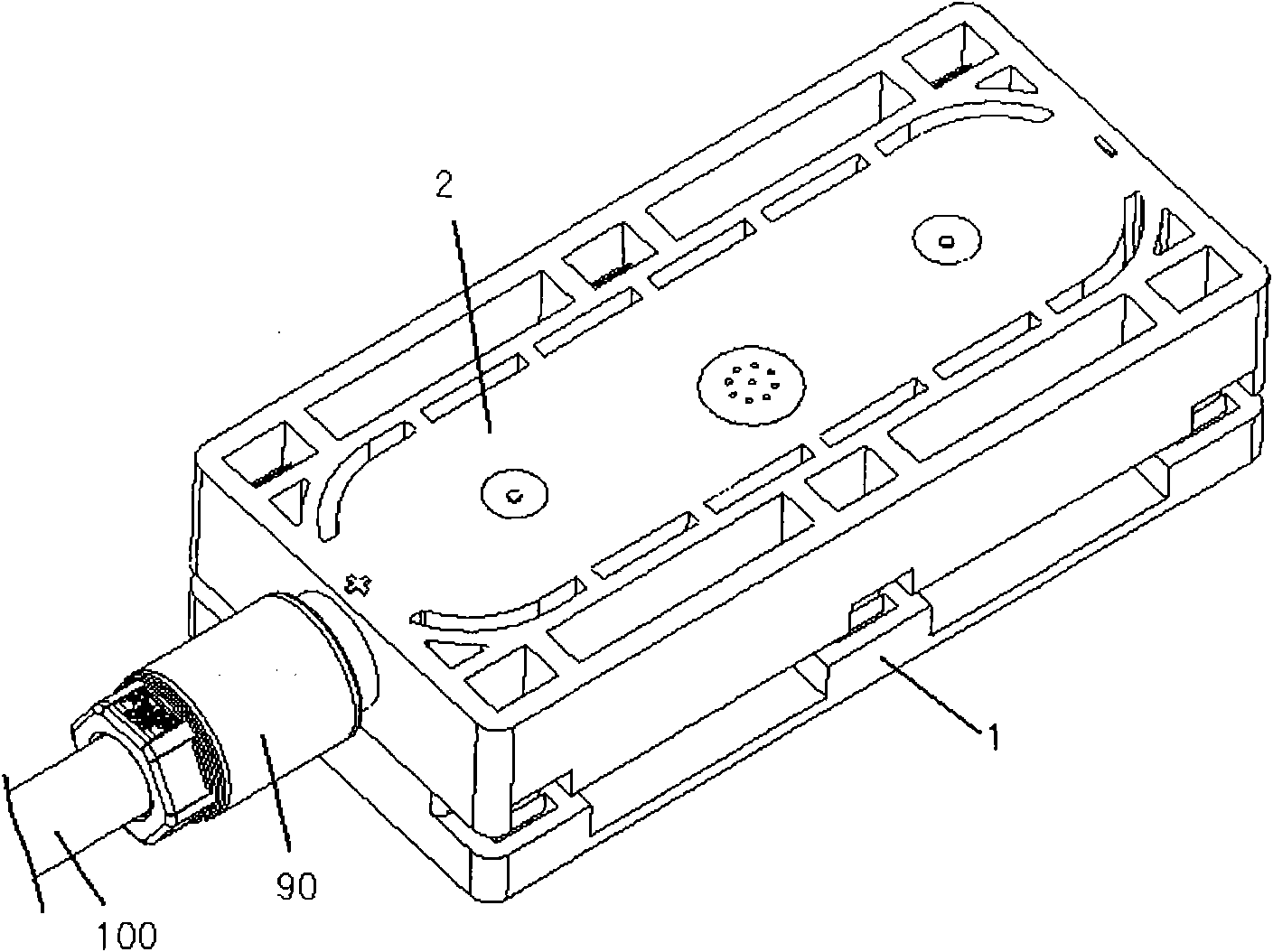

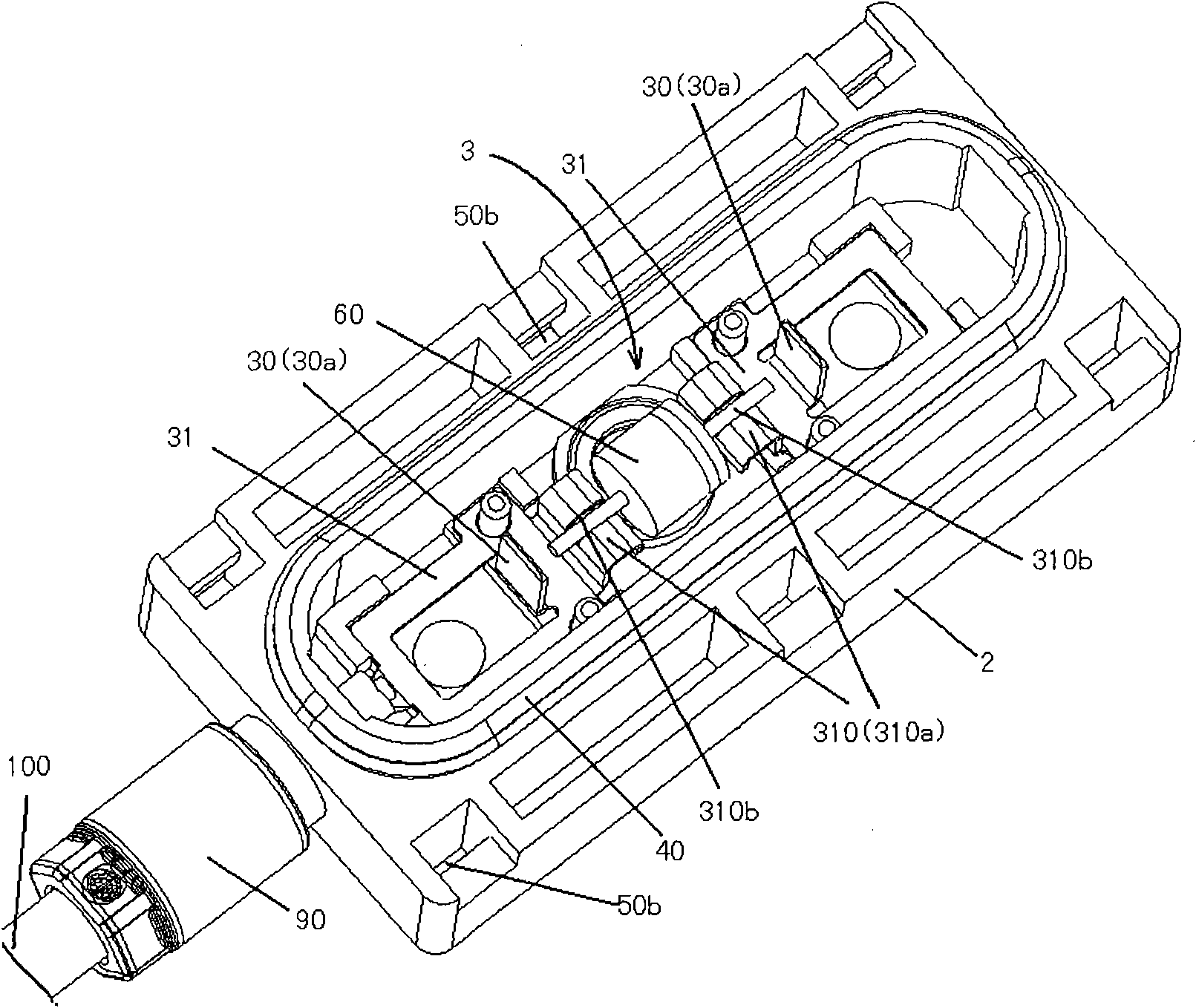

Junction box for solar photovoltaic module

InactiveCN102044571AAvoid scrappingReduce use costPhotovoltaicsPhotovoltaic energy generationElectricityEngineering

The invention relates to the field of electric connectors. A junction box for a solar photovoltaic module comprises a base, an upper cover in sealing fit with the base, and a wiring component, wherein the wiring component is arranged in the upper cover; the base is provided with a first connection terminal; an opening through which a metal sheet connected with positive and negative electrodes of a solar panel passes is formed on the base; the wiring component comprises a second connection terminal; and the second connection terminal is electrically connected with the first connection terminal when the base and the upper cover are closed. In the junction box for the solar photovoltaic module provided by the invention, important parts and components in the junction box are mainly arranged in the upper cover, and the upper cover and the base of the junction box which is fixed on the solar panel are assembled in an inserting way, so that the defects of the prior art are overcome.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

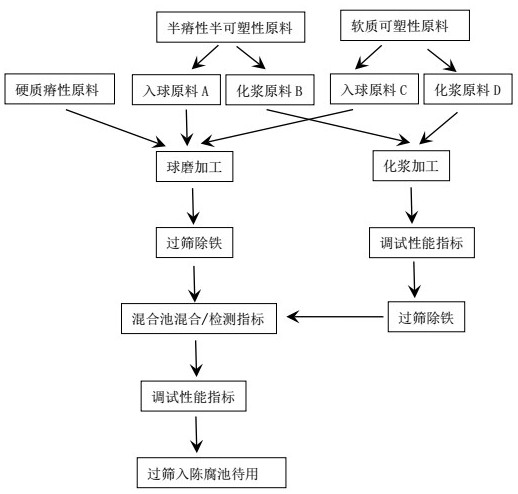

High-efficiency ceramic slurry preparation process

The invention discloses a high-efficiency ceramic slurry preparation process. The process comprises the following steps of classifying ceramic slurry raw materials into a hard barren raw material, a semi-barren semi-plastic raw material and a soft plastic raw material, wherein the semi-barren semi-plastic raw materials comprise a ball feeding raw material A and a slurrying raw material B, and thesoft plastic raw materials comprise a ball feeding raw material C and a slurrying raw material D, jointly puting the hard barren raw material, the ball feeding raw material A and the ball feeding rawmaterial C into a ball mill for ball milling, and acquiring ball-milled slurry, jointly puting the slurrying raw material B and the slurrying raw material D into a slurrying pool, adding water, stirring, and acquiring slurrying, and transferring the ball-milled slurry and the slurrying slurry to a mixing tank, and uniformly mixing to obtain mixed slurry. A large amount of ball milling time is saved in the whole preparation process, energy consumption is effectively reduced, and the production efficiency is greatly improved. And in the preparation process, multiple times of detection and debugging are carried out, so that the debugging difficulty of the slurry is reduced, and the slurry with accurate indexes can be obtained more easily.

Owner:江门市东鹏智能家居有限公司 +1

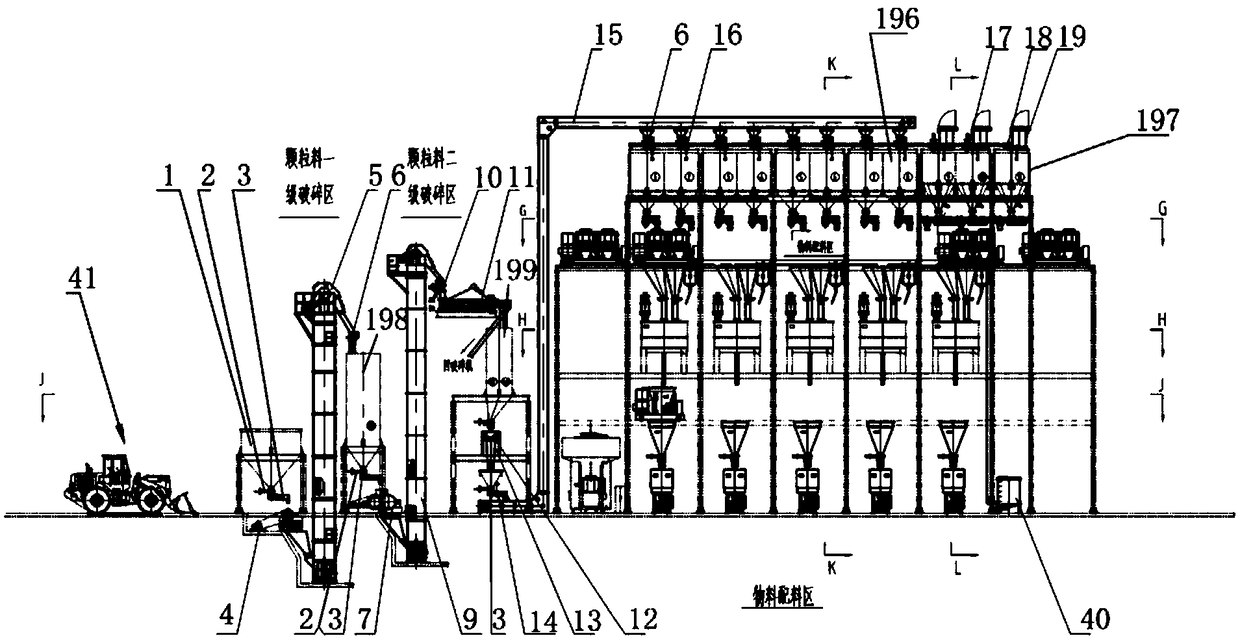

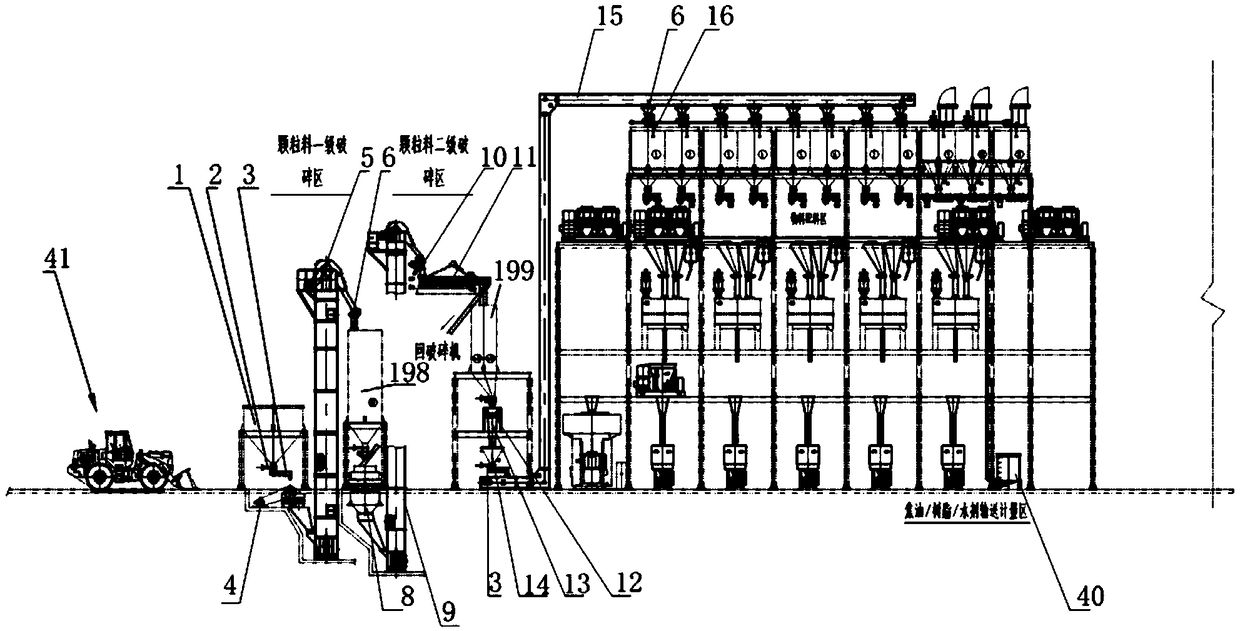

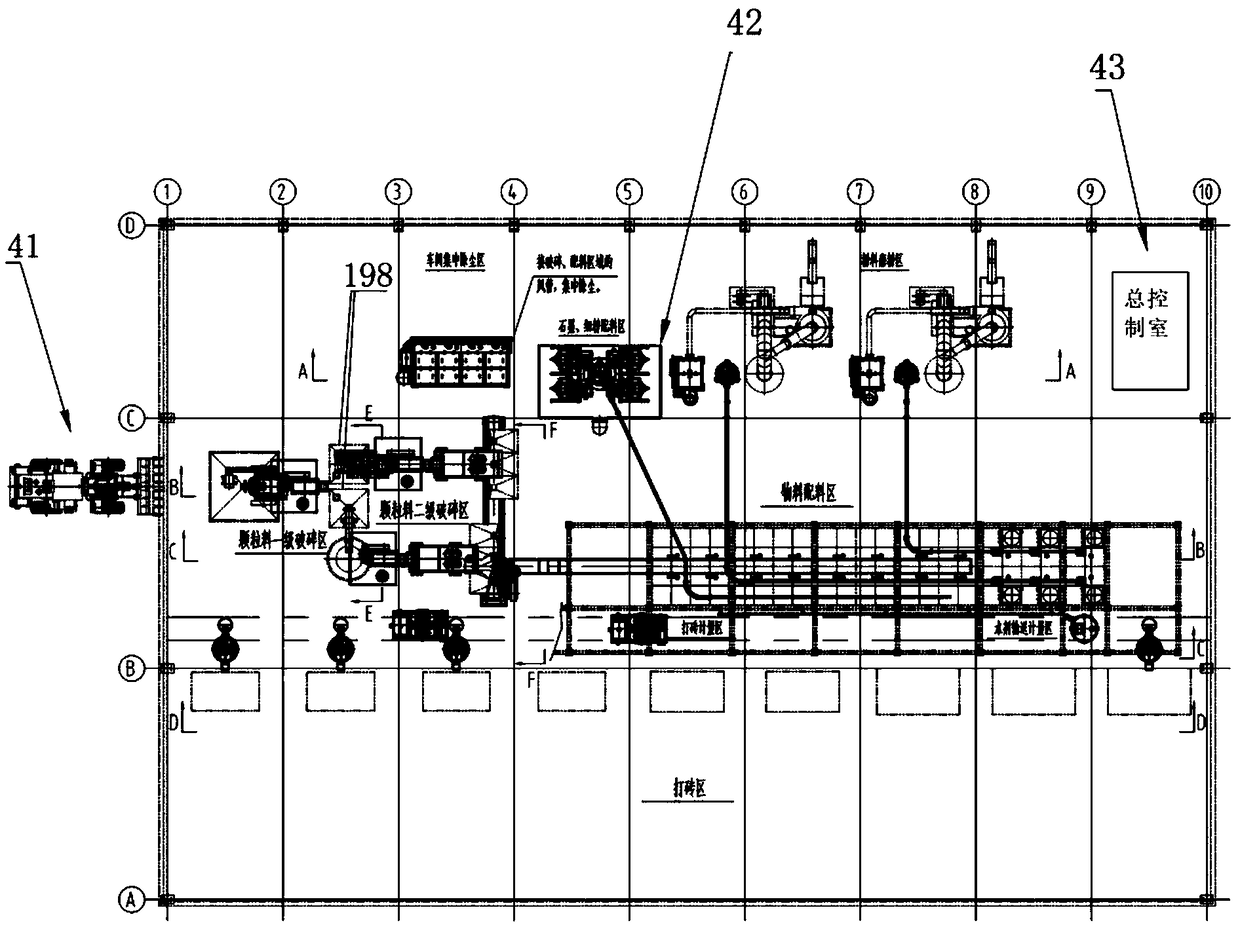

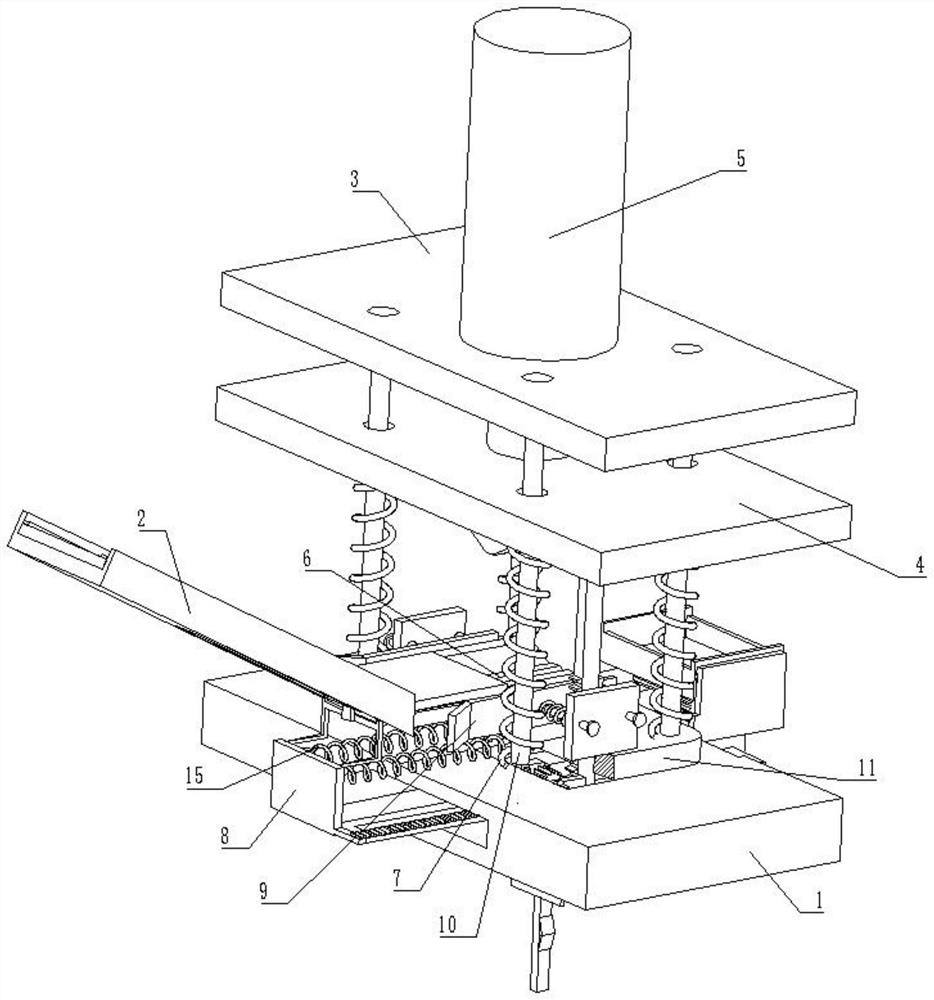

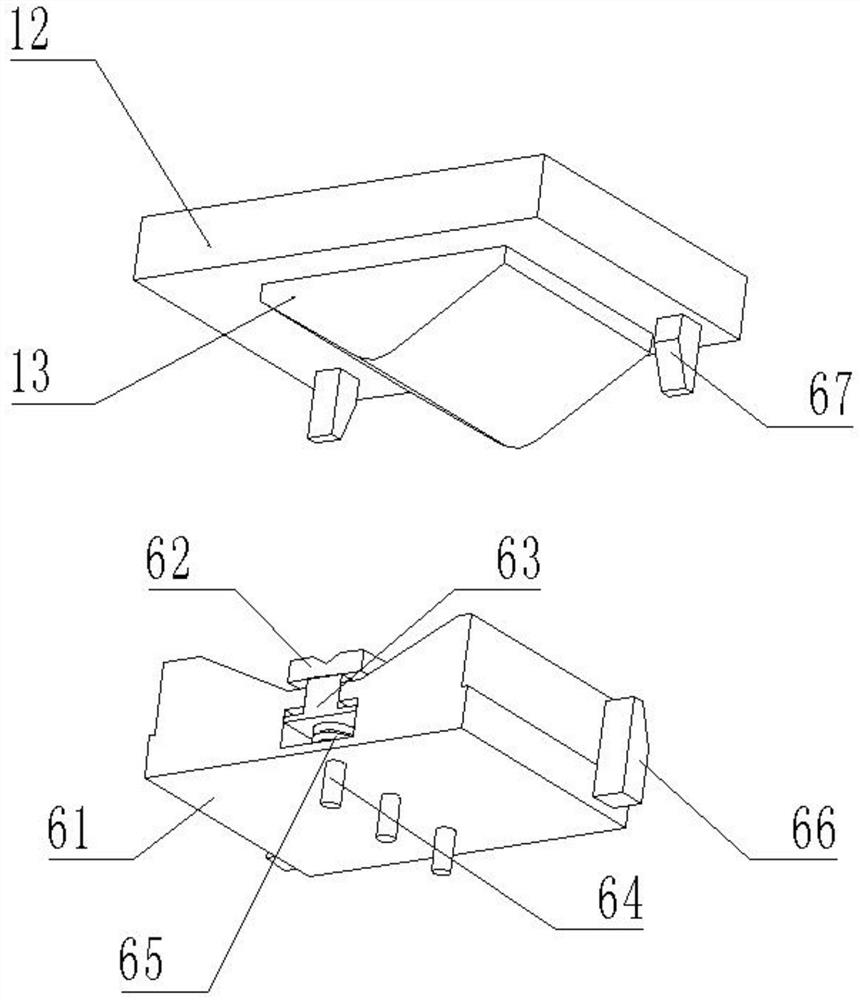

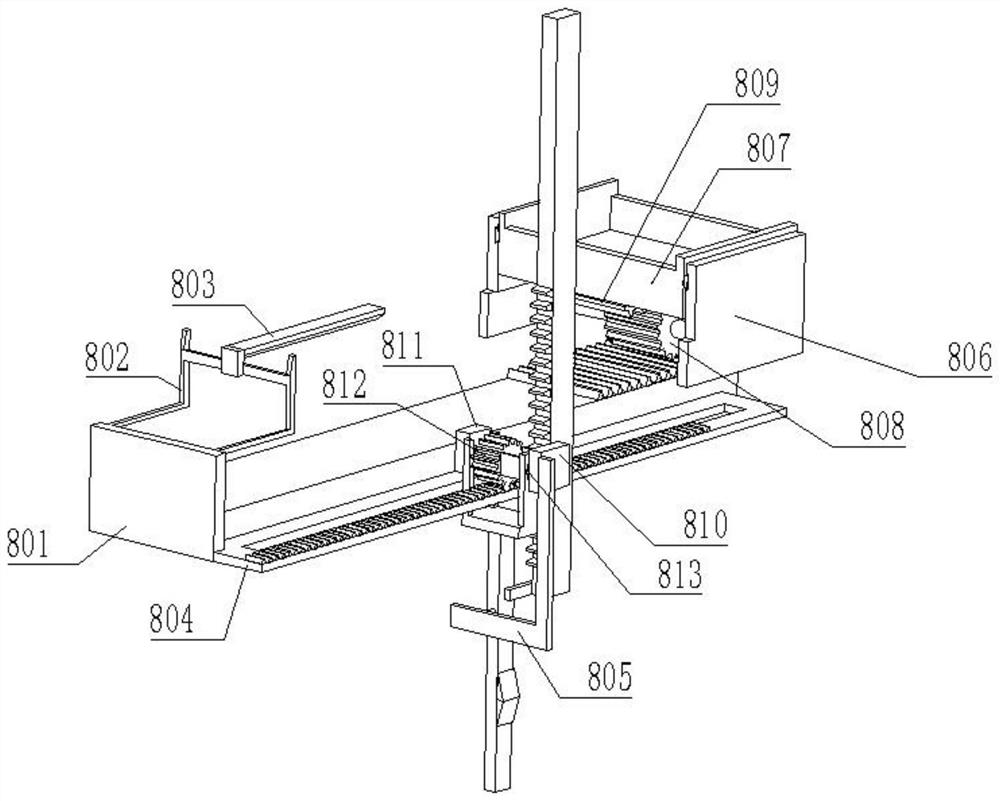

Production line used for magnesia carbon brick products and technology thereof

PendingCN108858722ARealize automatic deliveryOptimize layoutCeramic shaping plantsFeeding arrangmentsProduction lineBrick

The invention relates to a production line used for magnesia carbon brick products and a technology thereof. The production line comprises a granule crushing unit, a plurality of powder grinding units, a graphite or fine powder automatic burden charging and conveying system and a liquid metering and conveying unit, and further comprises a material burden charging unit, a material mixing unit and abrickmaking metering unit. Burden charging carriages are arranged between the material burden charging unit and the mixing unit and between the mixing unit and the brickmaking metering unit. By meansof the production line, the whole set of automatic procedures including automatic feeding treatment, automatic burden charging, automatic mixing, automatic weighing and calculating and automatic brickmaking of granules, powder, graphite and fine powder raw materials and liquid raw materials can be achieved, automatic conveying, burden charging and dust recovery of the powder industry are achieved, the whole working process conforms to environment-friendly requirements, the workshop internal environment and an operating environment of workers are effectively guaranteed, and safe production isachieved.

Owner:江苏万衡智能科技有限公司

Full-automatic plate bending method

ActiveCN112642887AFit closelyAvoid misalignmentShaping toolsMetal-working feeding devicesIndustrial engineeringBolt connection

The invention relates to the technical field of bending dies, and discloses a full-automatic plate bending method which is based on a plate bending die. The plate bending die comprises a base, wherein the upper surface of the base is connected with a lower die plate through bolts, the front portion of the lower die plate is fixedly connected with a material frame, a guide column is fixedly connected to the upper surface of the lower die plate, a fixing plate is fixedly connected to the top of the guide column, an upper die plate is fixedly connected to the output end of an oil cylinder, the surface of the guide column is slidably connected to the surface of the upper die plate, a feeding and discharging mechanism is arranged in the base, and an anti-rebound mechanism is arranged on the upper surface of the lower die plate. Two upper guide blocks and two lower guide blocks are oppositely contacted and aligned, so that the die is automatically corrected in the pressing process, the dislocation condition of an upper die and a lower die can be well avoided, the upper die and the lower die can be well matched, and the percent of pass of products is improved.

Owner:沈阳圣泽丰交通设施有限公司

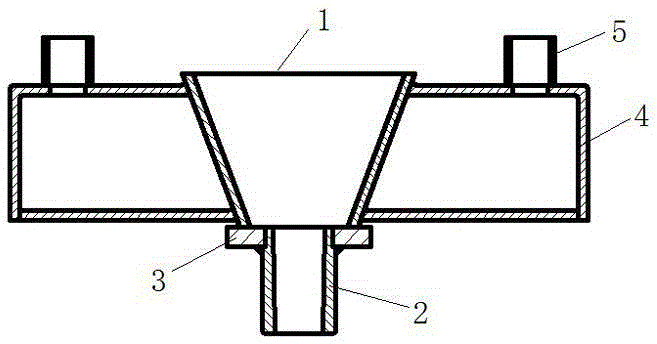

Mold gate for pouring insulating cylinder

The invention relates to a mold gate for pouring an insulating cylinder. The mold gate comprises a gate body, wherein a storage hopper is arranged at the lower part of the gate body, and a pouring nozzle communicated with the storage hopper is arranged at the lower part. When the mold gate is used, the storage hopper can store enough materials; in the curing process of the insulating cylinder, the storage hopper can continuously replenish the materials into a molding cavity of a mold, and a curing furnace is not needed to open to add the materials in the pouring nozzle; and meanwhile, when the insulating cylinder is cured to shrink, the materials in the storage hopper can be timely supplied into the molding cavity of the mold to prevent the condition of waste products due to generation of sucking holes in the insulating cylinder, so that te production cost is saved, and the economic benefit is improved.

Owner:HENAN PINGGAO ELECTRIC +2

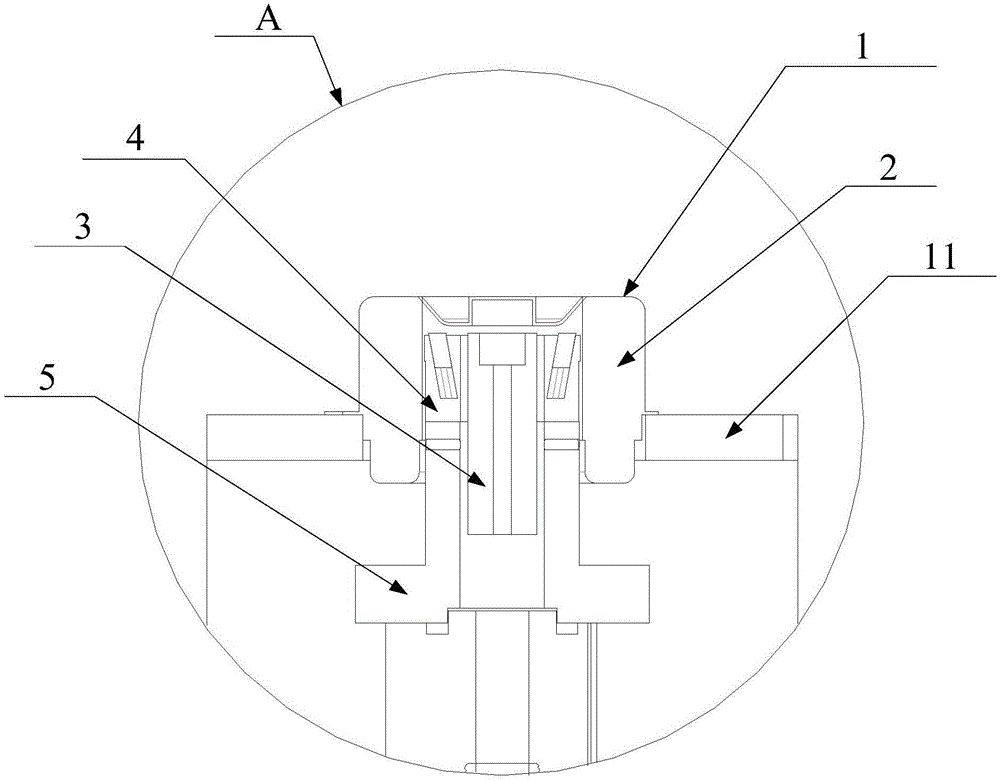

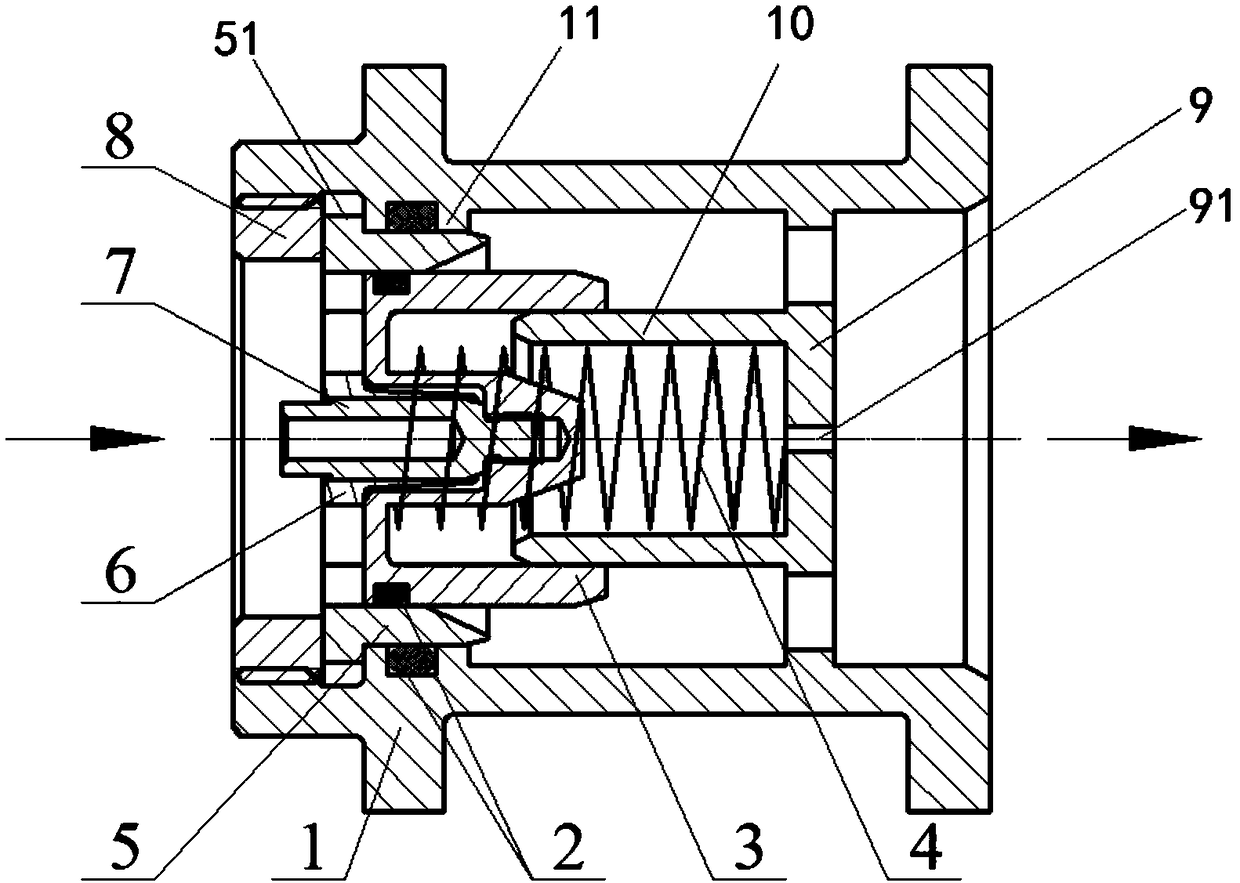

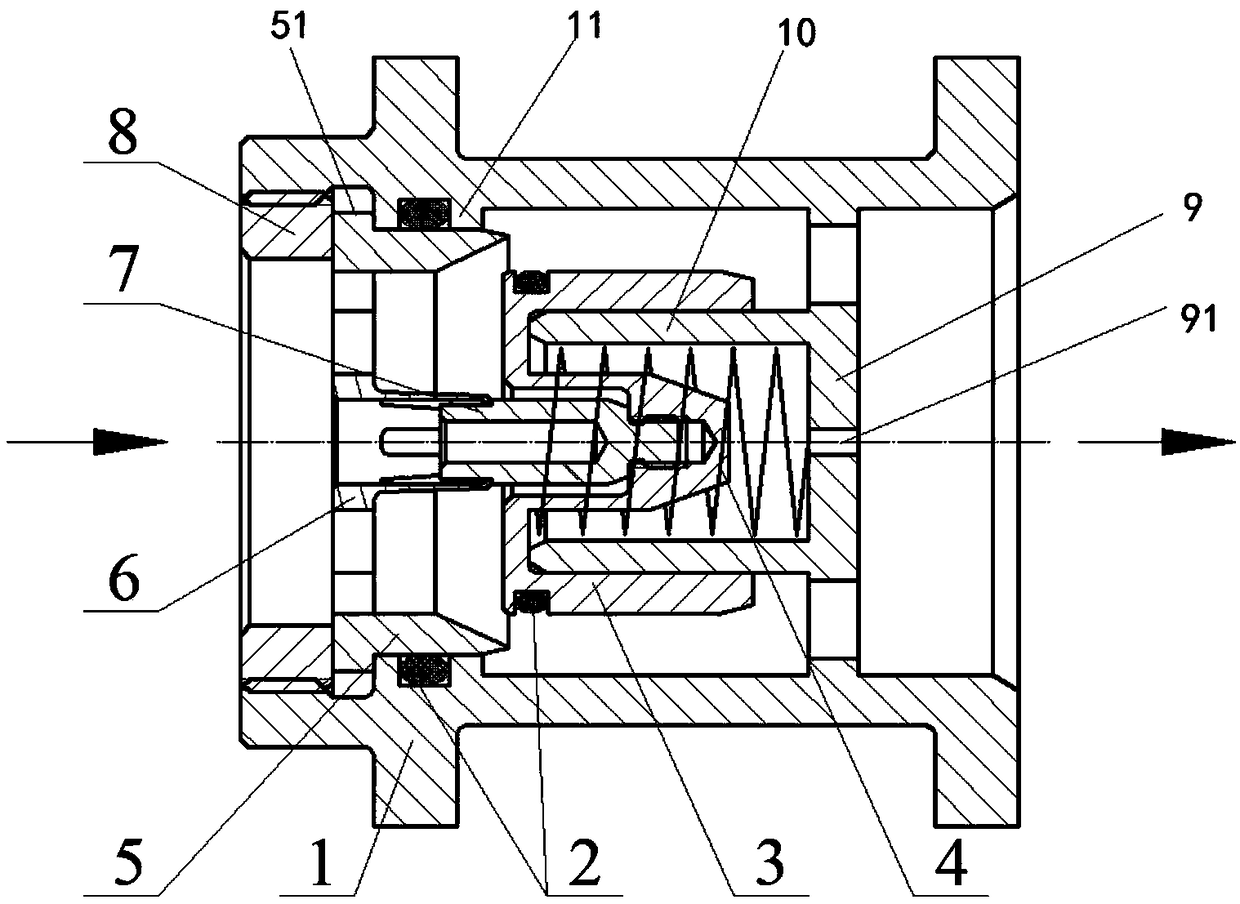

One-way valve with self-locking function

ActiveCN109357050AAvoid Scrap SituationsPlay a guiding roleCheck valvesLift valveSelf lockingEngineering

The invention provides a one-way valve with a self-locking function. The problems that in the prior art, the sealing performance of a conventional one-way valve in the long-term storage process is poor, stability in the small flow condition becomes poor, and oil supply of a system is likely to be oscillated are solved. A sealing part, a locking assembly and an elastic assembly are arranged in thevalve, and the structure is compact, small and exquisite; a lock ring and a guide rod have a guiding effect on a valve element, the valve element is not subjected to any lateral acting force, motion is flexible, high reliability is achieved in locking, and the clamping stagnation problem is not likely to happen; the valve element can be opened at a time, a medium circulation channel is gotten through; and in addition, machining and assembling processes are simple, and repeated use can be achieved after disassembling and reset assembling.

Owner:XIAN AEROSPACE PROPULSION INST

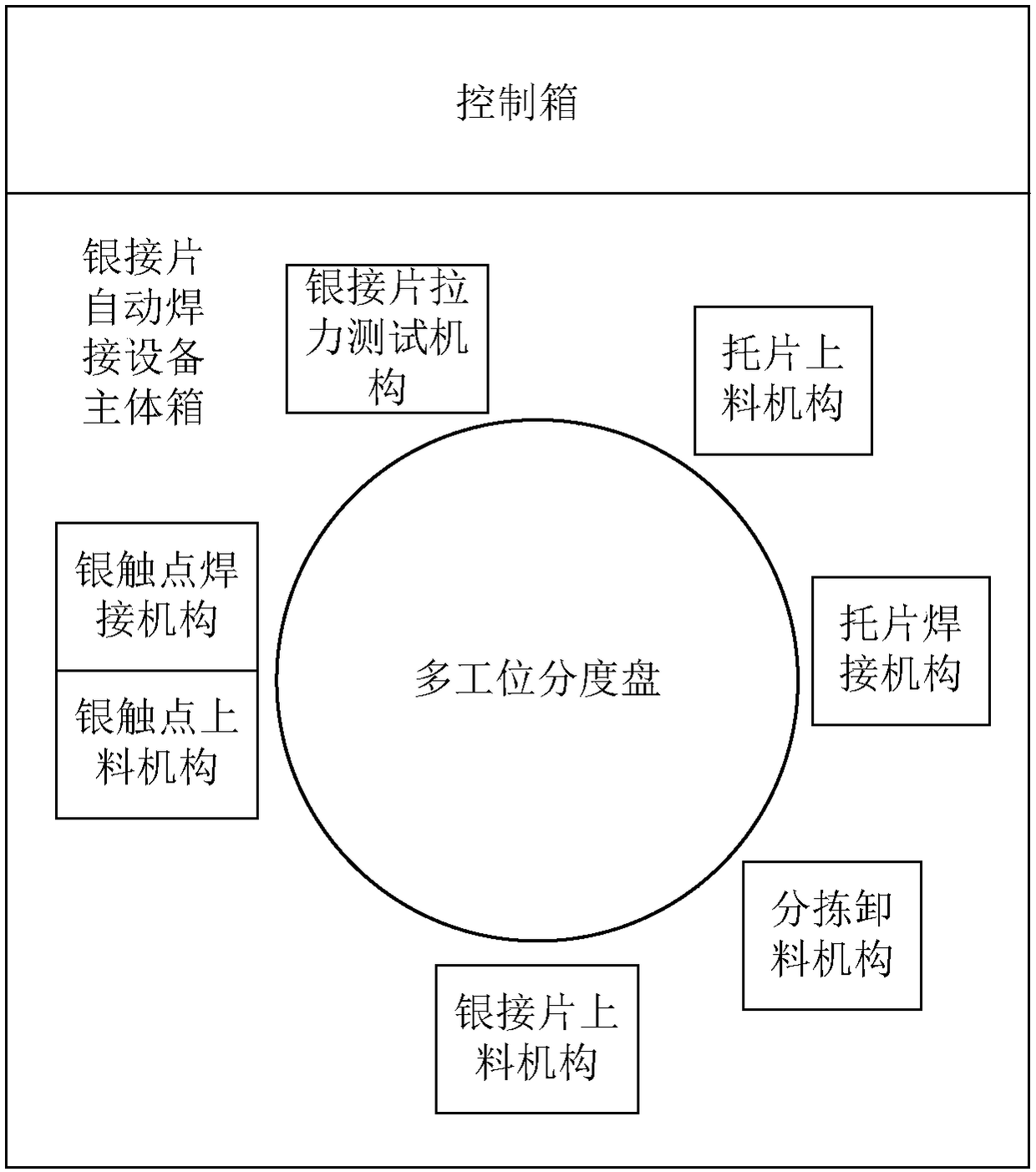

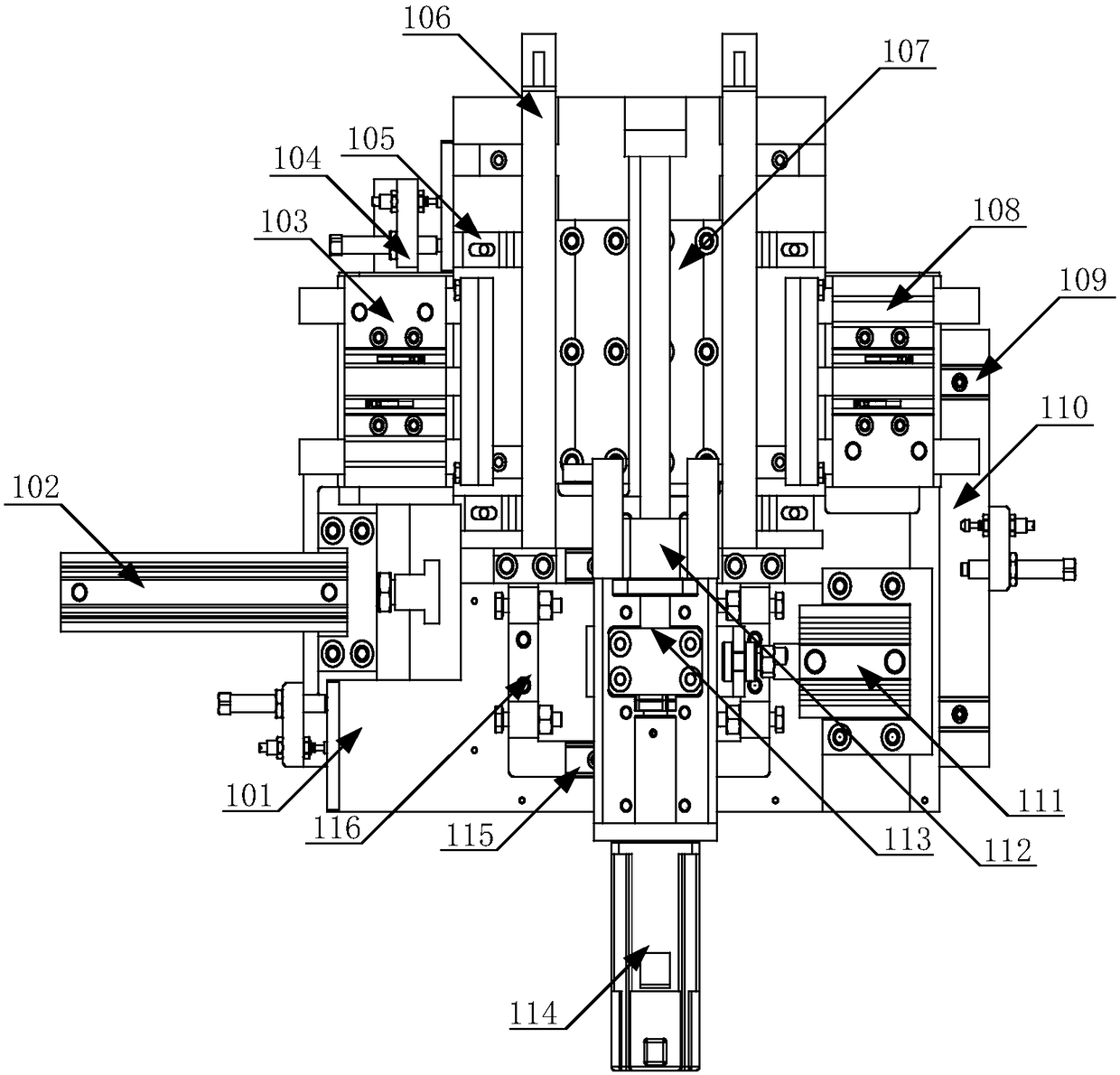

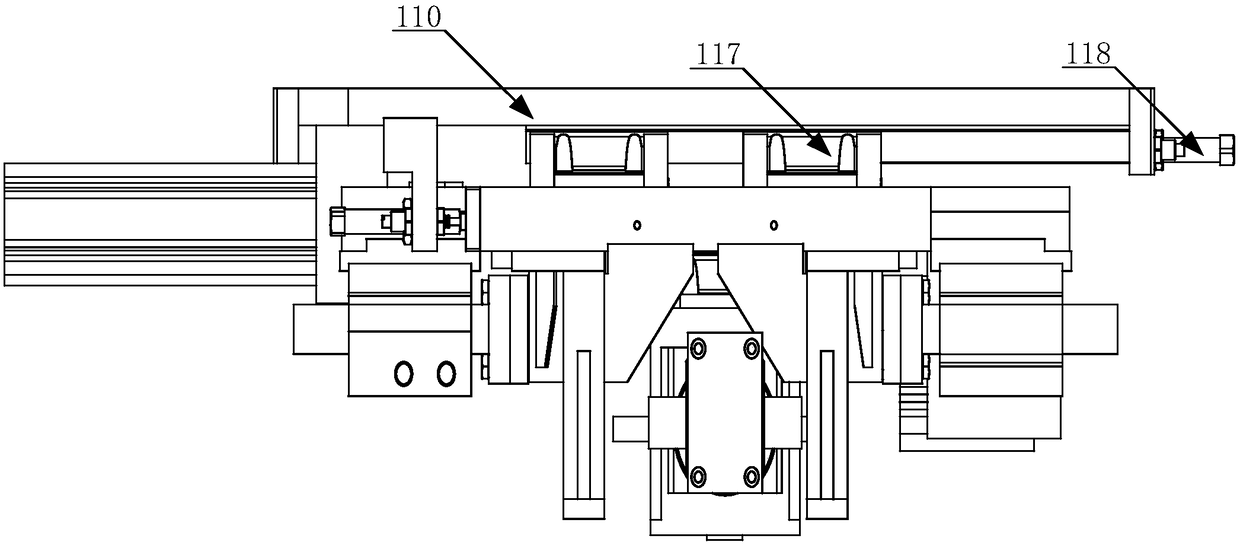

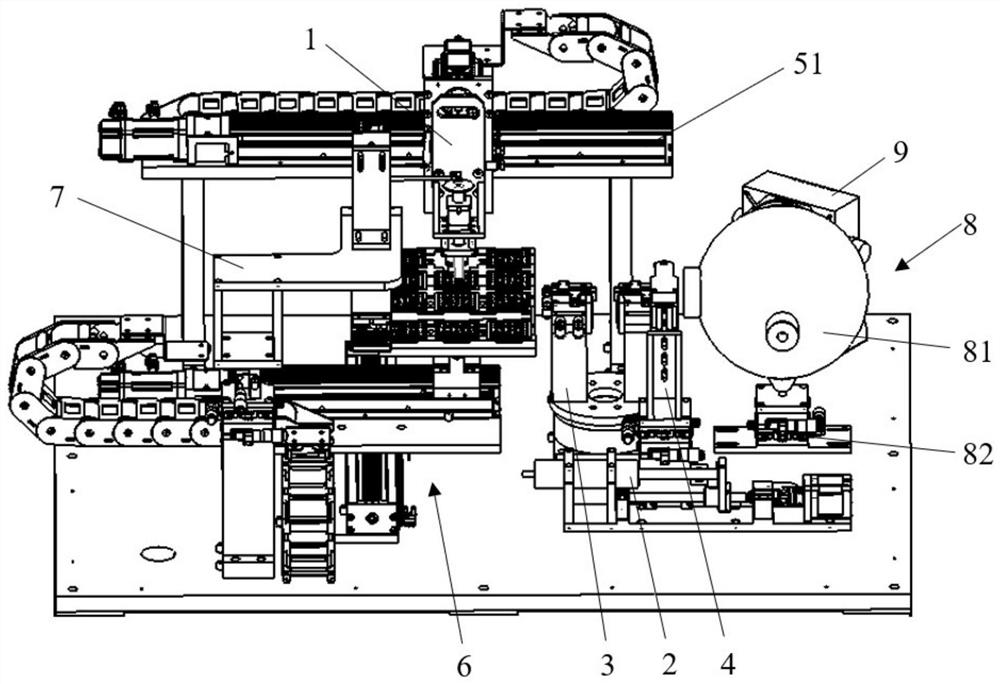

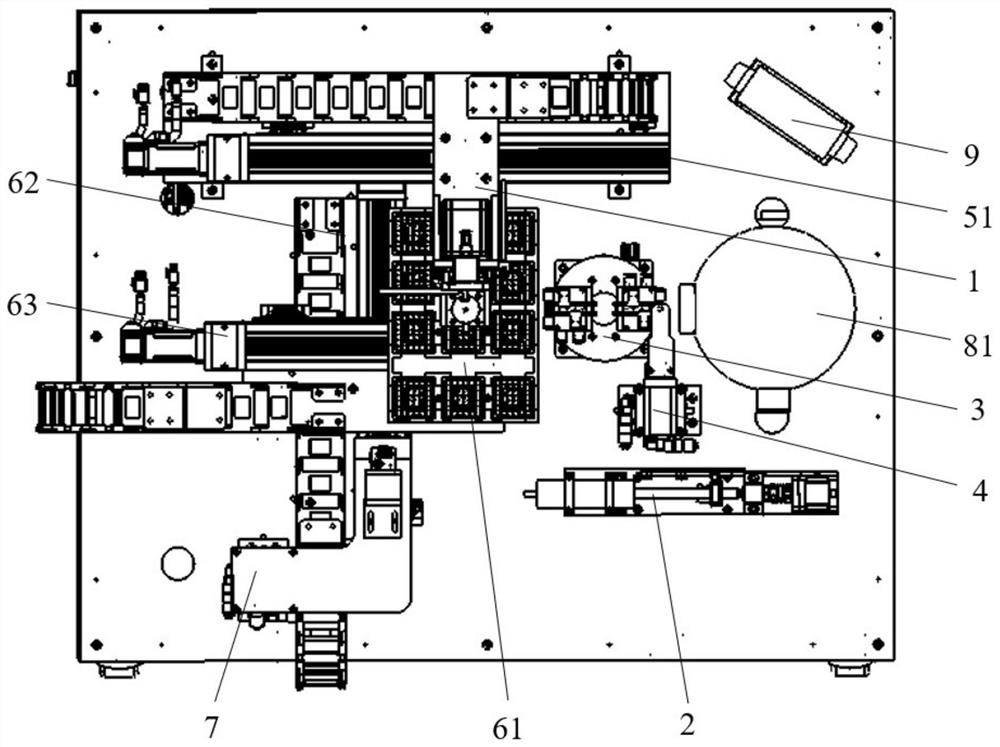

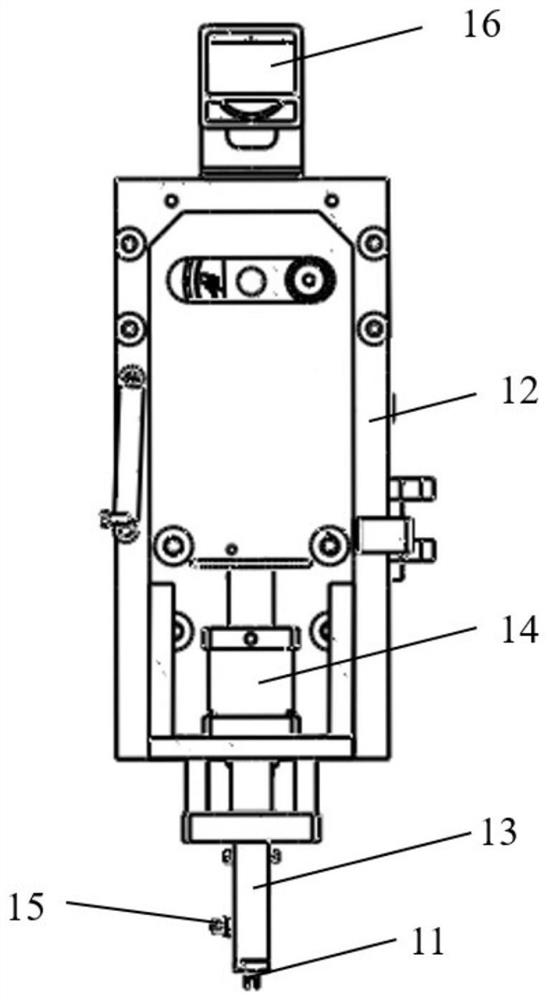

Silver contact chip automatic-welding equipment

ActiveCN108422072AImprove running accuracyWon't wear outWelding/cutting auxillary devicesAuxillary welding devicesEngineeringProduction risk

The invention discloses silver contact chip automatic-welding equipment which comprises a main box of the silver contact chip automatic-welding equipment and a control box, wherein the control box isconnected with the main box of the silver contact chip automatic-welding equipment; the main box of the silver contact chip automatic-welding equipment is instituted by a multi-station indexing plateas well as a silver contact chip feeding mechanism, a silver contact point feeding mechanism, a silver contact point welding mechanism, a silver contact chip tension testing mechanism, a support sheetfeeding mechanism, a support sheet welding mechanism and a sorting-discharging mechanism which are positioned around the multi-station indexing plate and sequentially arranged according to the clockwise direction; one and the same feeding mechanism is selected as the silver contact chip feeding mechanism and the support sheet welding mechanism; and one and the same electrode rotation welding mechanism is selected as the silver contact point welding mechanism and the support sheet welding mechanism. By adoption of the silver contact chip automatic-welding equipment provided by the invention, the production of silver contact chips can be automatically completed; the automation degree of the silver contact chip automatic-welding equipment can be greatly improved; the product quality and theproduction efficiency can be improved; and the production risk of an enterprise can be further reduced.

Owner:成都成焊焊接设备有限公司

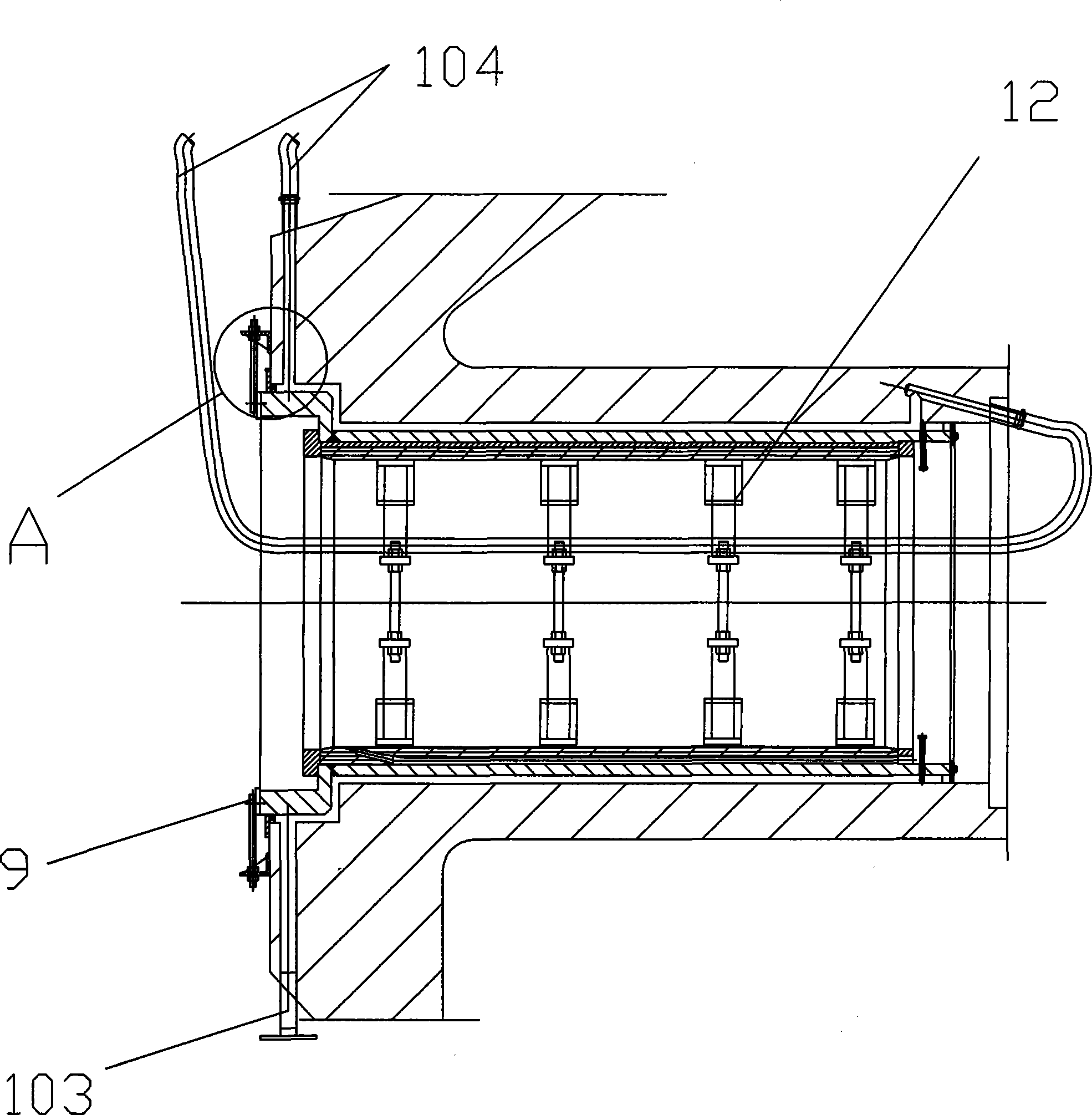

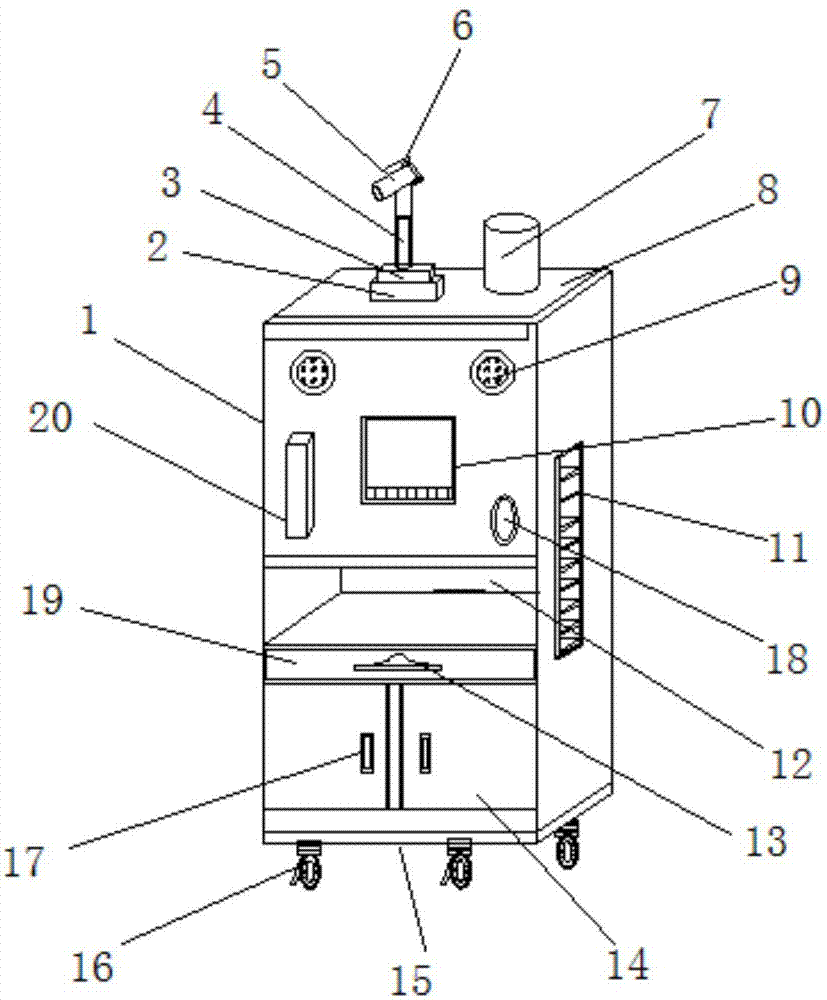

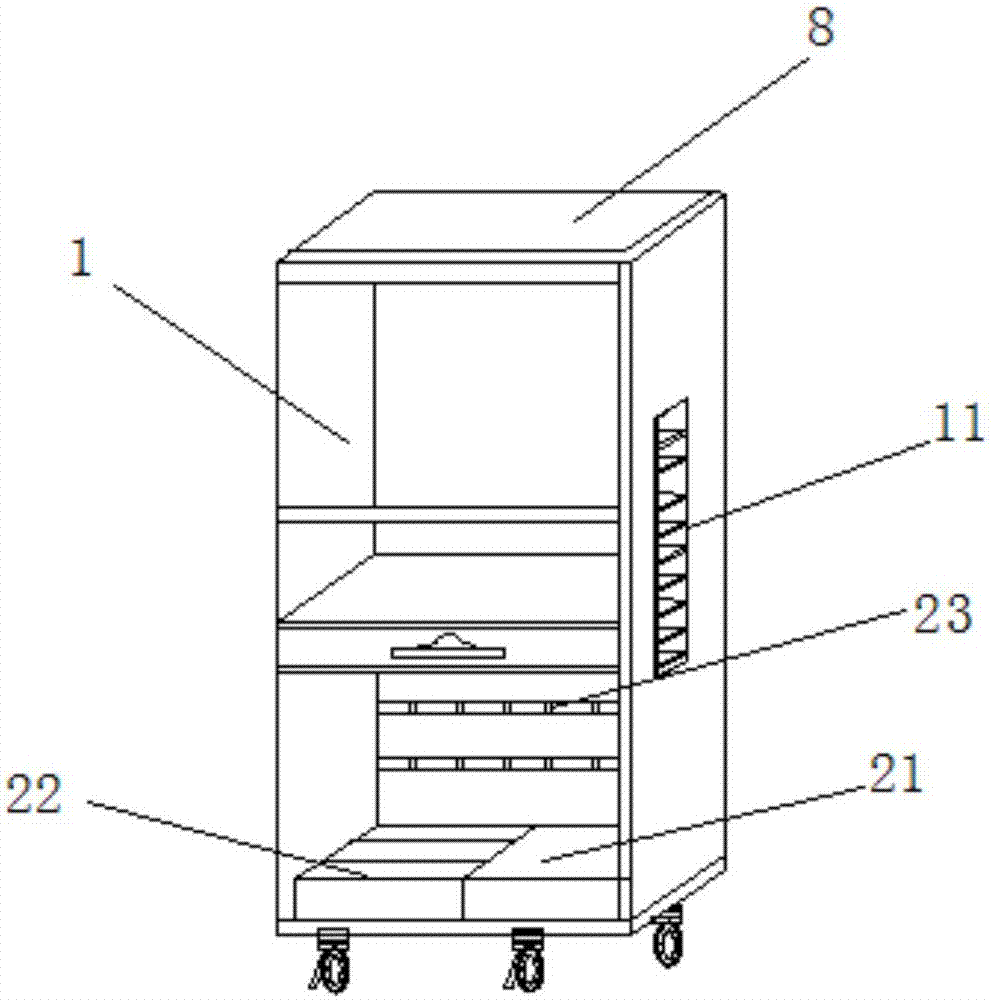

Chip temperature control equipment

PendingCN111948513AAvoid Scrap SituationsImprove test efficiencyTesting optical propertiesContactless circuit testingTemperature controlProcess engineering

The invention relates to the technical field of chip testing, and discloses chip temperature control equipment, which comprises a test positioning mechanism, a power-up mechanism, a water injection mechanism and a temperature control mechanism which are arranged on a test bench; the power-up mechanism is located at one side of the test positioning mechanism and is used for powering up a chip on the test positioning mechanism; the temperature control mechanism is located on the test positioning mechanism and is used for carrying out temperature control on the chip on the test positioning mechanism; and the water injection mechanism is connected with the test positioning mechanism and is used for carrying out rapid heat dissipation and cooling on the chip located on the test positioning mechanism. According to the chip temperature control equipment provided by the invention, the temperature control mechanism is used for carrying out temperature control on the chip under test, and the water injection mechanism is used for carrying out rapid heat dissipation and cooling treatment on the chip under test, so that the situation that the chip is scrapped due to overheating is avoided to acertain extent.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

Self-hardening core for precision casting and manufacturing method thereof

InactiveCN102764851AHigh temperature strengthReduce scrap rateFoundry mouldsFoundry coresMulliteRejection rate

The invention relates to a self-hardening core for precision casting and a manufacturing method thereof and particularly relates to a self-hardening core which is used for casting workpieces with complex shapes or narrow cavities and a manufacturing method thereof. The manufacturing method of the self-hardening core for precision casting comprises the steps of mixing raw materials such as silica sol, mullite powder, mullite sand and lime, casting, unshelling and the like. By use of the self-hardening core for precision casting, workpieces with complex cavities and narrow cavities can be cast, the rejection rate of castings can be reduced, and the quality of castings can be improved.

Owner:WUXI UNIVERSAL PRECISION CASTING

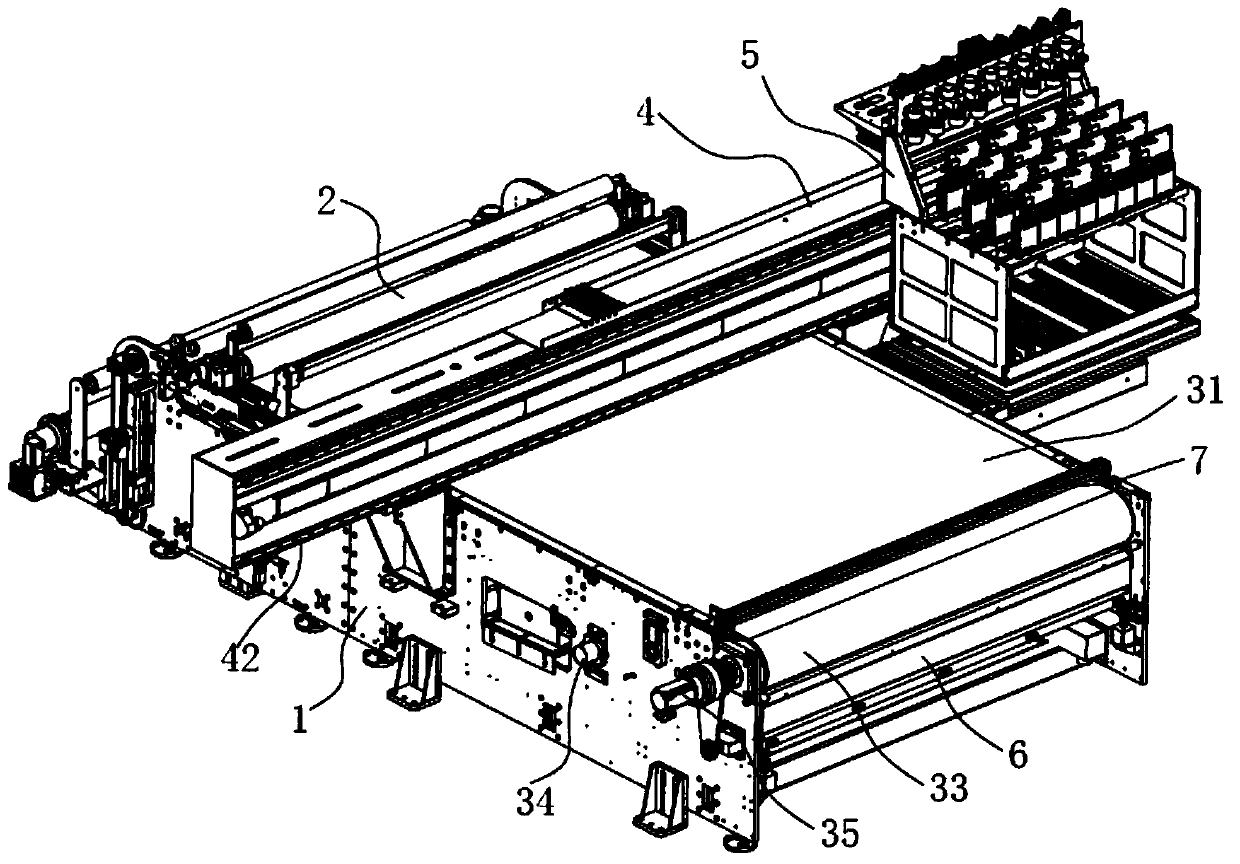

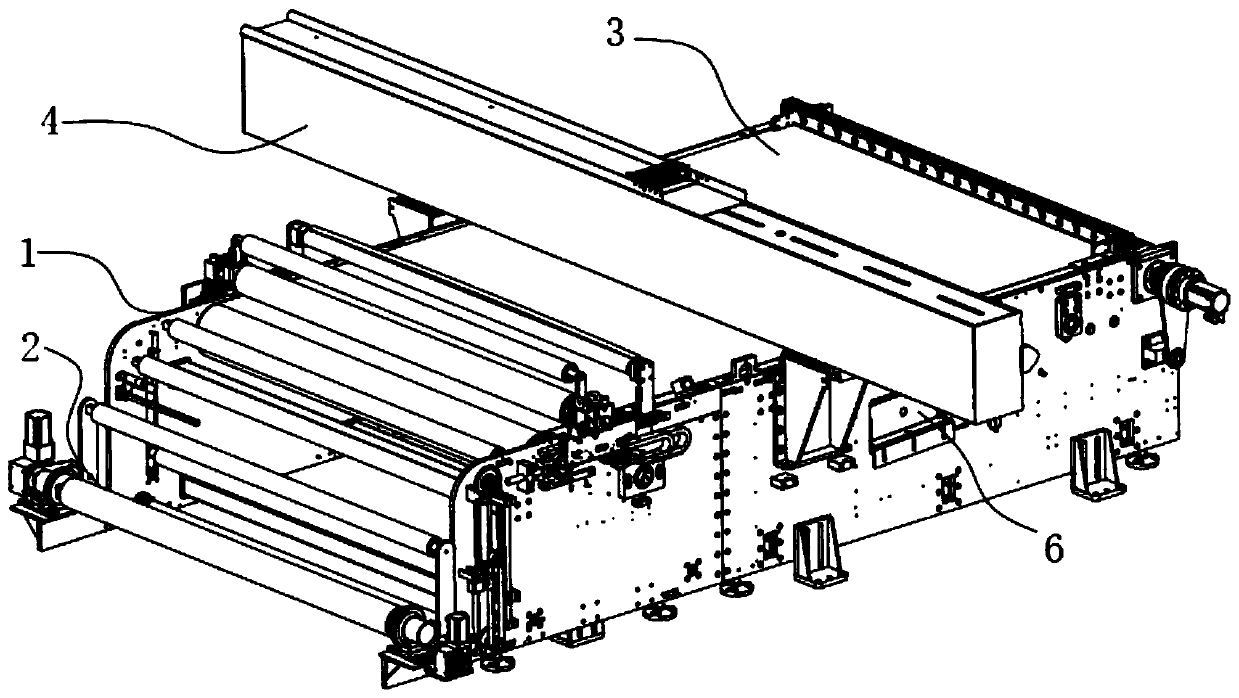

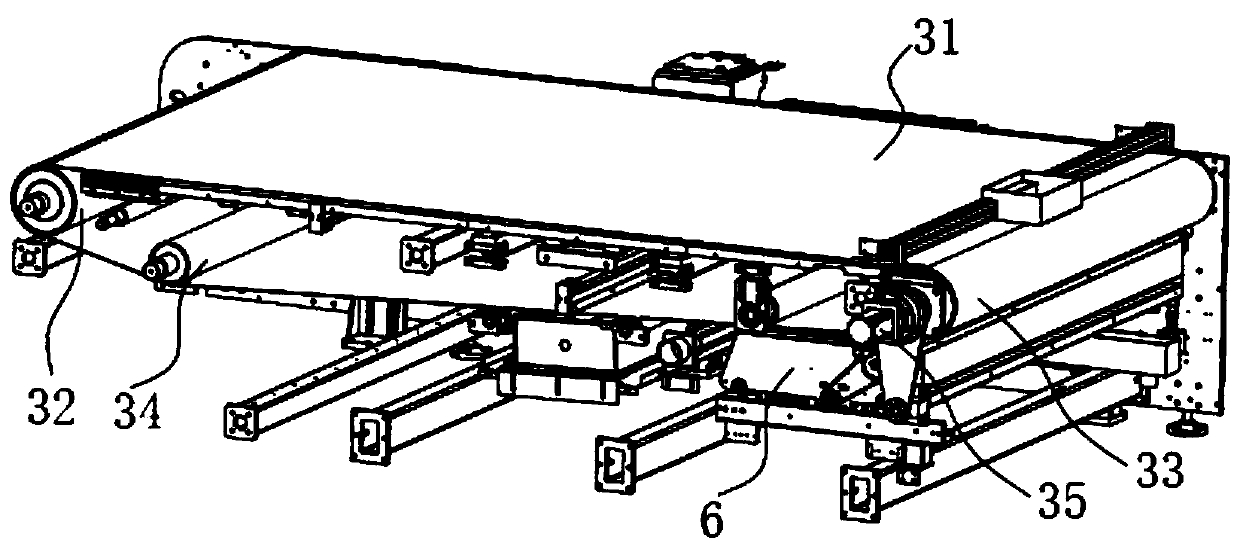

Rack system of digital printing machine

ActiveCN111055599AReduce creasesAvoid wrinklesOther printing apparatusStationary filtering element filtersTextile printerEngineering

The invention discloses a rack system of a digital printing machine. The system comprises a rack, a printing conveying belt mechanism is arranged at the top of the rack, a gantry sliding frame stretches across the upper portion of the printing conveying belt mechanism, a cloth feeding mechanism is arranged behind the printing conveying belt mechanism, and a belt cleaning device is arranged below the printing conveying belt mechanism; the cloth feeding mechanism comprises an inflatable shaft, a large roll wrap angle roller, a cloth passing roller a, a constant-tension floating roller, a cloth passing roller b, a cloth passing roller c, a moving roller and an expanding wrap angle roller which are all arranged on the rack; a lifting guide mechanism for driving the constant-tension floating roller to act is arranged; and an unwinding deviation correcting system for correcting the position of cloth is arranged. The system has the advantages that the cloth feeding mechanism simultaneously adapts to large and small rolls of cloth, so that the cost is saved; automatic online real-time deviation rectification and edge alignment of the cloth are realized; the printing quality is high; the belt cleaning device combines a composite cleaning mode and a composite drying mode, so that the cleaning effect is improved; the system is small in water consumption, energy-saving and environmentallyfriendly; and the production efficiency is improved.

Owner:广东希望高科数字技术有限公司

Monitoring robot convenient to move

The invention provides a monitoring robot that is easy to move, including a legal robot body, a hydraulic lift, a rotating table, a telescopic rod, a camera, an LED light, a GPS locator, an end cover, an alarm, a computer display screen, a connection line interface, and an opening stopper. , handle slot, two-door storage cabinet, base, universal wheels, handle, voice sensor, retractable desktop, information memory, battery, processor and block, voice sensor is installed on one side of the connection line interface, computer display An information memory is installed on the right side of the device. The present invention has the characteristics of simple structure, reasonable design, complete functions and wide applicability. The information collected by the camera and the voice sensor can be stored and recorded through the set information memory, which improves the review. , increase transparency and openness, and improve the efficiency of staff.

Owner:SHAANXI LAIFU TECH DEV CO LTD

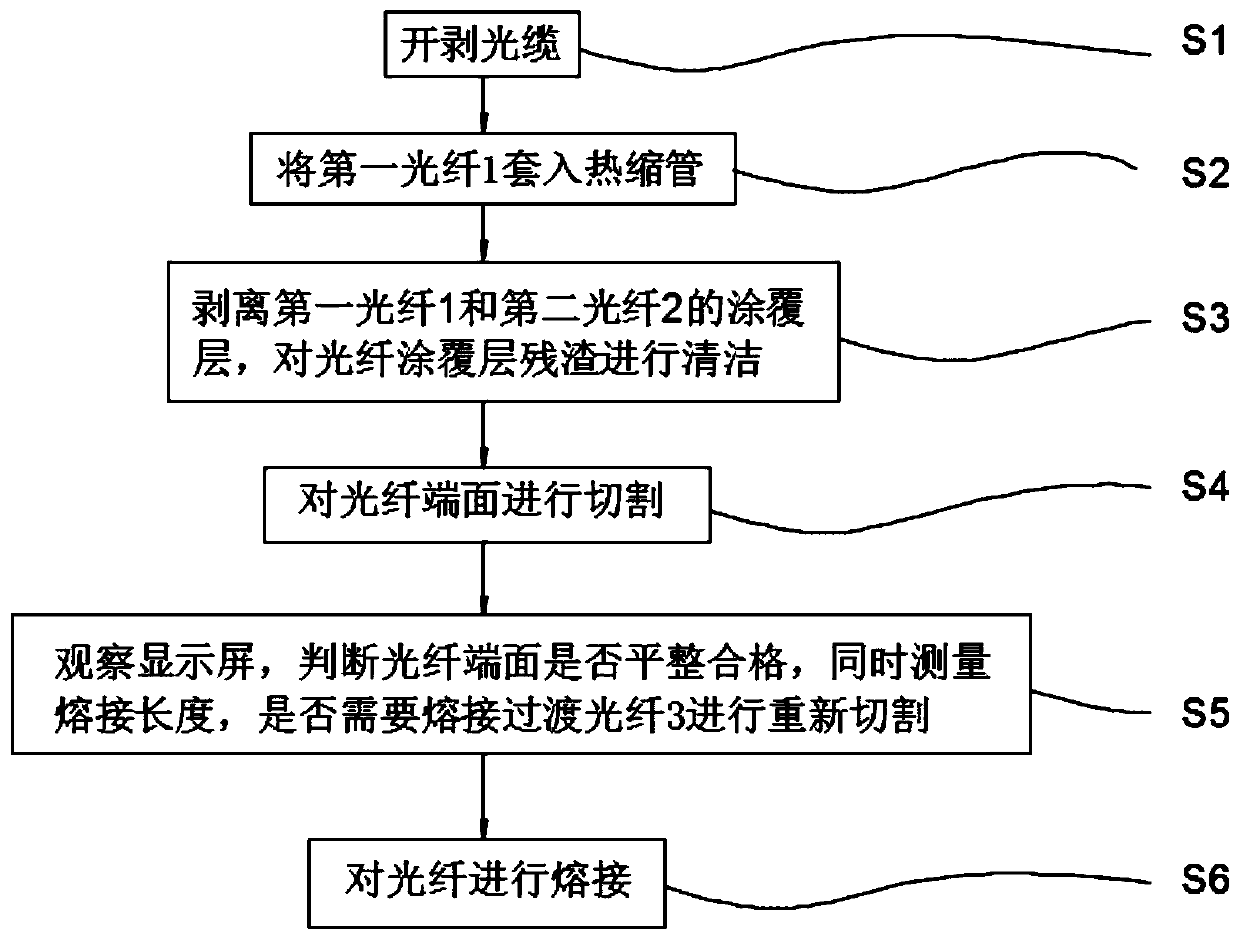

Method for accurately controlling and repairing cutting length in optical fiber welding process

The invention particularly discloses a method for accurately controlling and repairing a cutting length in an optical fiber welding process. The invention belongs to the technical field of optical fiber cutting and welding. The method is scientific and reasonable, safe and convenient use. for the problems that after the optical fiber is cut by using an optical fiber cutting machine, the length ofan optical fiber is larger than a designed length and smaller than the designed length, the cutting surface of the optical is not even and the welding requirements are not met, a section of transitionoptical fiber is welded on the optical fiber, then cutting is performed, and the original optical fiber is welded, so that the scrapping condition of the original optical fiber and the original optical fiber connecting device is avoided, when the optical fiber cutting knife is used for cutting the optical fiber, the cutting length of the optical fiber is accurately measured, the optical fiber isfixed through an optical fiber guide groove, a small pressing plate and a pressing rod on the optical fiber cutting knife and carefully operated, the error phenomenon generated when the optical fibercutting knife cuts the optical fiber is avoided, equipment scrapping caused by misoperation in the actual operation process is avoided, losses are reduced, and the effect is good.

Owner:青岛自贸激光科技有限公司

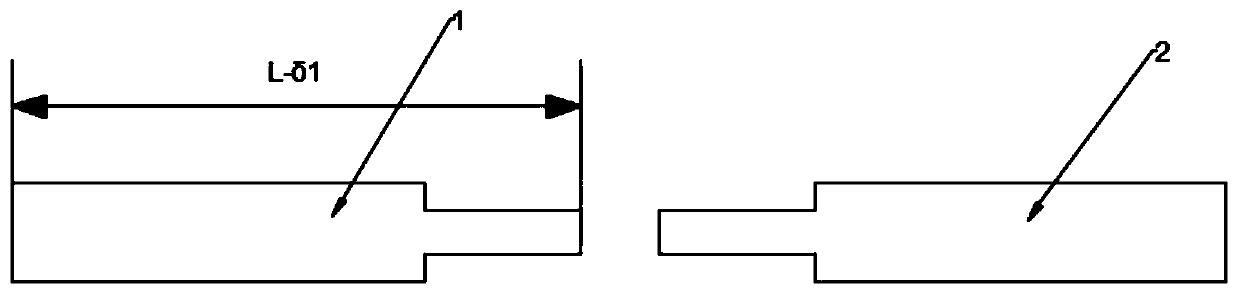

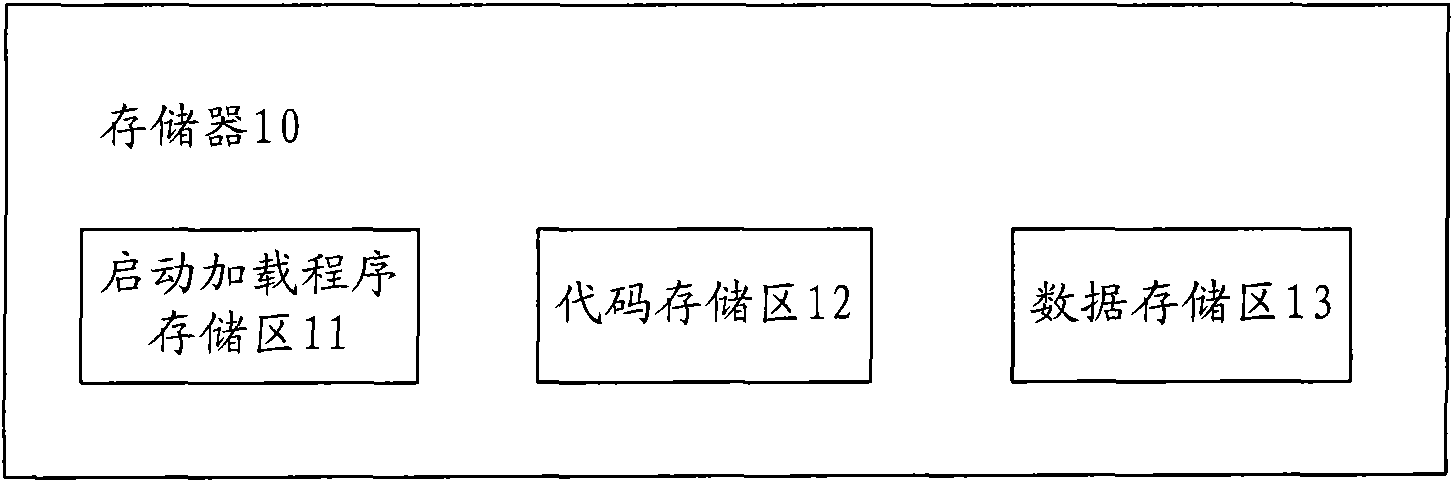

Method for improving production efficiency of telecommunication smart card

ActiveCN101571808AAvoid Scrap SituationsImprove accuracyProgram loading/initiatingRecord carriers used with machinesMaster CardOperational system

The invention provides a method for improving the production efficiency of a telecommunication smart card. The telecommunication smart card is provided with a storing device comprising a code storage area and a data storage area. The method comprises the following: a step of making a master card, which comprises: writing an operating system program into the code storage area of the storing deviceof a blank telecommunication smart card, and creating a file system and updating data in the data storage area when the operating system is operated; a step of making an image file, which comprises: reading out and copying the data stored in the data storage area of the master card to form the image file; and a step of making the telecommunication smart card, which comprises: writing the operatingsystem into the code storage area of the storing device of each telecommunication smart card, and writing the image file into the data storage area of the storing device of the telecommunication smart card. The method can reduce the time of creating a file system and updating data so as to shorten the time of generating each telecommunication smart card and improve the production efficiency of the telecommunication smart card.

Owner:EASTCOMPEACE TECH

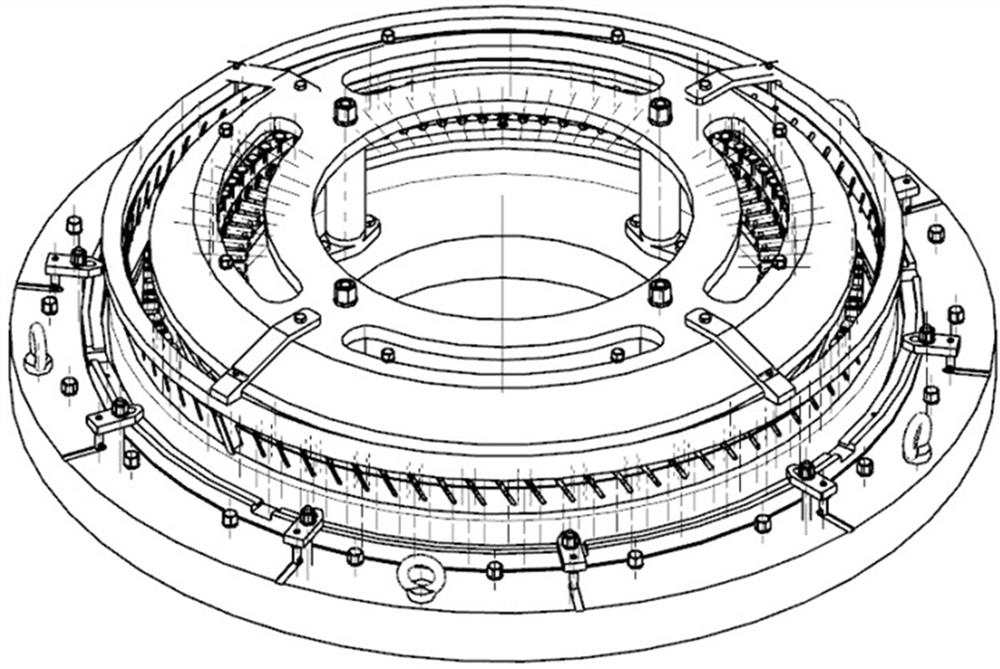

Special fixture for welding multi-weld blade ring parts and welding deformation control method

ActiveCN113681183AControl welding deformationWon't hurtWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention discloses a special fixture for welding a multi-weld blade ring part and a welding deformation control method. The fixture ensures that an outer casing, an inner ring and blades meet drawing requirements after being assembled; the height positions of the outer casing and the inner ring are ensured by controlling the distance and tolerance between the bottom surface of a positioning ring and the bottom surface of an inner positioning ring; the axial position and the radial position of the outer casing are controlled through the positioning ring and an upper support ring; the outer casing is attached to the positioning ring through pressing of a movable pressing plate, and the upper support ring is attached to the outer casing through a baffle; the axial position and the radial position of the inner ring are controlled through the inner positioning ring and a compression ring; the inner ring is compressed by the compression ring through a hexagonal head compression screw; the position of an upper positioning ring is limited through the end surface position of a large support column; and through the technological processes of part assembly, argon arc positioned welding, three-coordinate measurement, electron beam welding, nondestructive inspection, vacuum heat treatment, size inspection and the like, welding deformation is effectively reduced, and the dimensional accuracy and the use performance of parts are improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com