Metal spring leaf in electronic product and connecting structure adopting same

A technology of metal reeds and electronic products, applied in the direction of connection, fixed connection, circuits, etc., can solve the problems of PCB board pad pull-up, metal reed bump deformation, PCB board scrapping, etc., to reduce bump deformation, reduce The amount of deformation and the effect of avoiding PCB scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

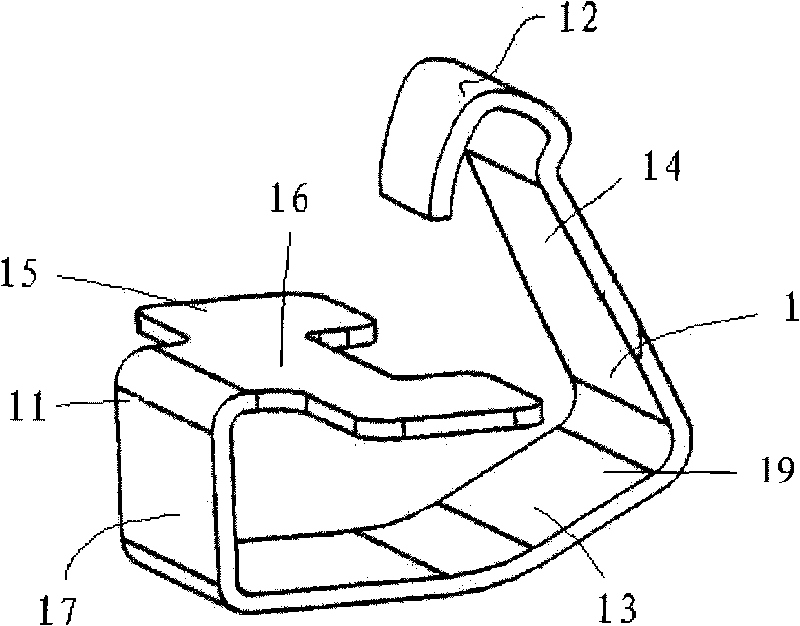

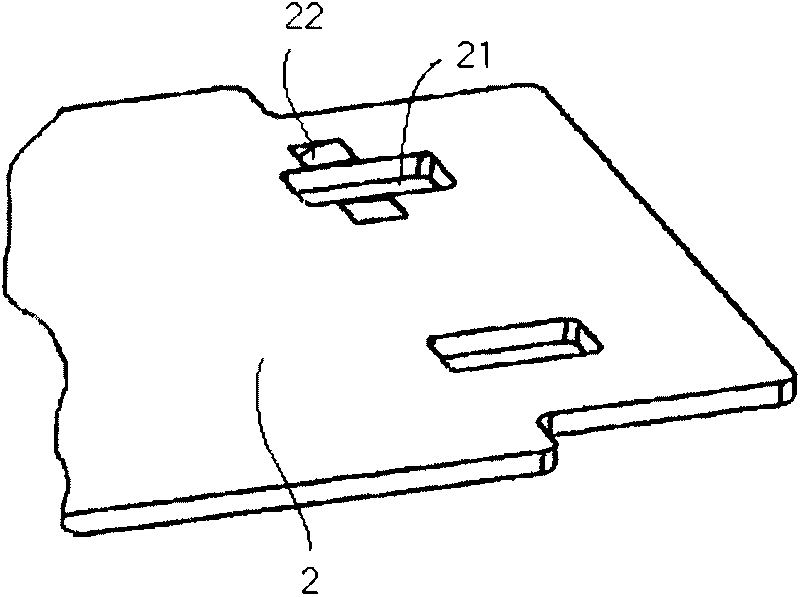

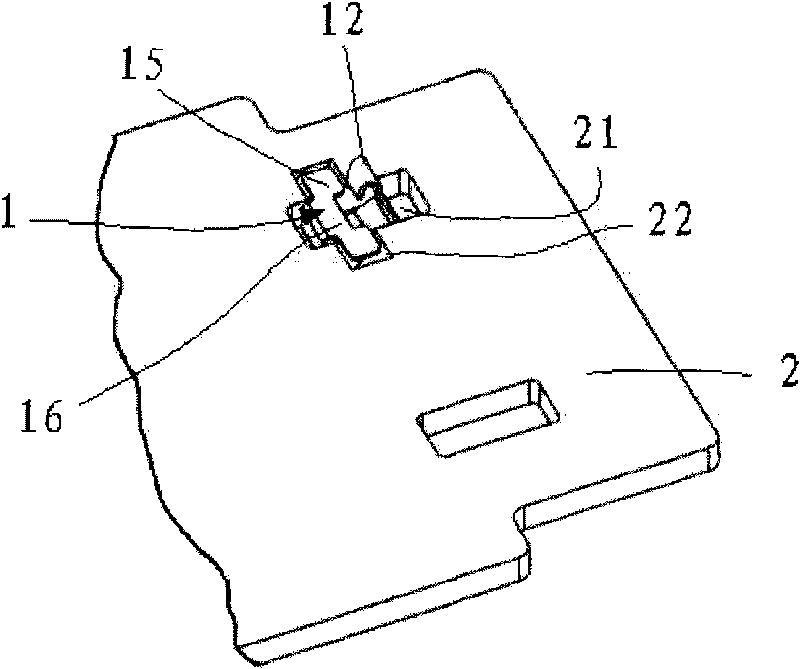

[0028] Such as figure 1 As shown, the metal reed 1 includes a reed body 19 with elastic bending, a contact end 12 and a welding end 11 . The reed body 19 includes a bent portion 13, a first supporting piece 14 is extended from one end of the bent portion 13, and a second supporting piece 17 is extended from the other end. In this embodiment, the bent portion 13 is approximately V-shaped. The first supporting piece portion 14 and the second supporting piece portion 17 are located on the same plane of the bent portion 13, and the first supporting piece portion 14 and the second supporting piece portion 17 have a certain angle, which can be 0° to 90°. In this embodiment, the included angle is 30 degrees. The contact end 12 is arranged at the end of the first support piece 14 , and the soldering end 11 is arranged at the end of the second support piece 17 . The welding end 11 is close to the middle of the reed body 19 , the contact end 12 is located at the upper part of the reed...

Embodiment 2

[0040] The difference from Embodiment 1 is that the shape of the bent portion 13 of the metal reed 1 of this embodiment is approximately L-shaped, such as Figure 4 As shown, the first supporting piece portion 14 and the second supporting piece portion 17 are respectively located on two surfaces of the bent portion 13 . In addition, pins 18 extending perpendicular to the side wing plate 15 are provided on both sides of the side wing plate 15 , and the pins 18 are used to assist in fixing the metal reed 1 to the PCB 2 . In this embodiment, the angle between the first support piece 14 and the second support piece 17 is 60 degrees. All the other structures are the same as in Example 1. The pins 18 , the side panels 15 , the welding platform 16 and the welding end 11 are integrally formed. The pins 18, the side panels 15 and the welding platform 16 are all flat pieces with smooth surfaces.

[0041] The structure in which the metal reed 1 of this embodiment is welded to the PCB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com