Patents

Literature

203results about How to "Improve running accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

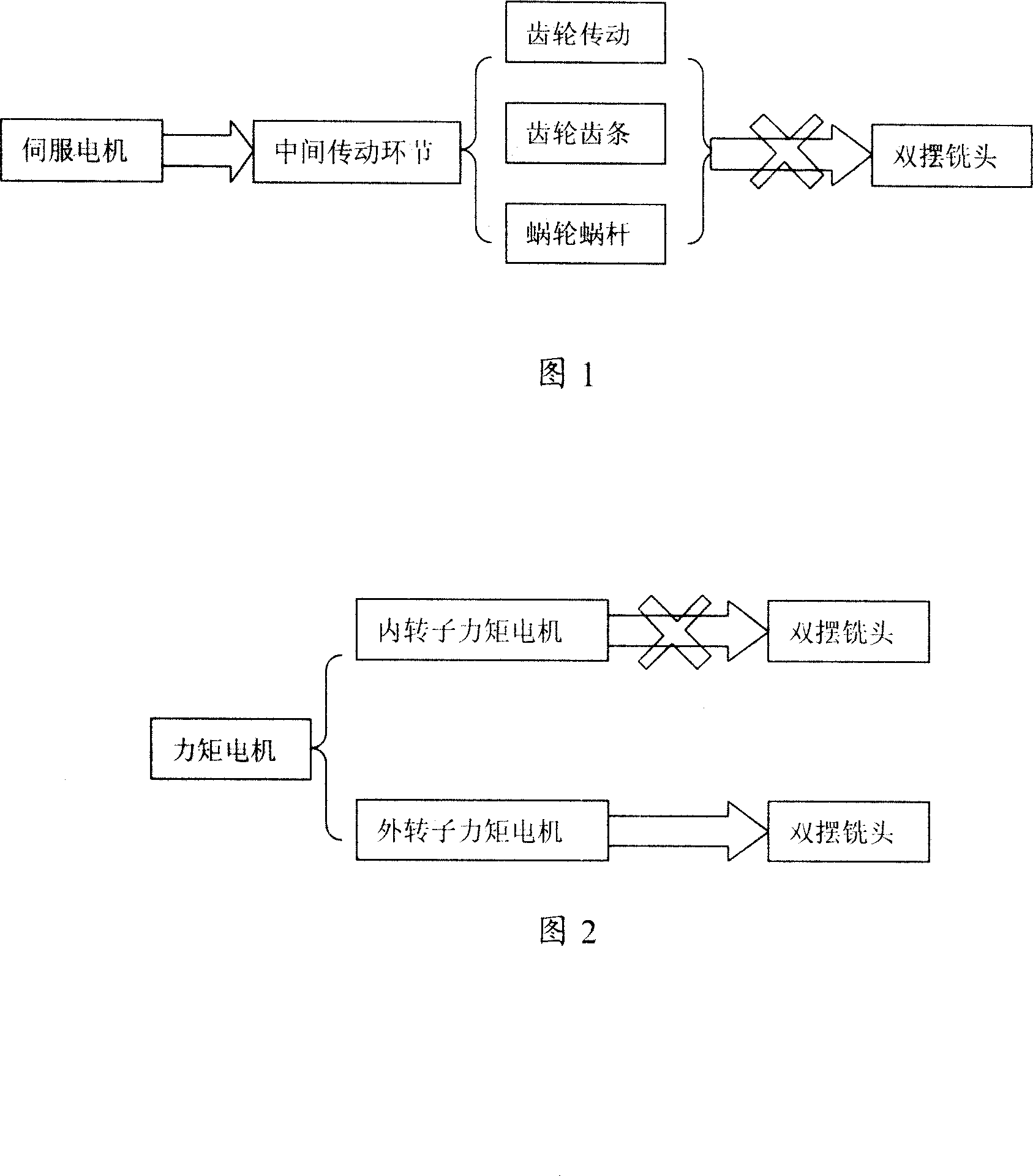

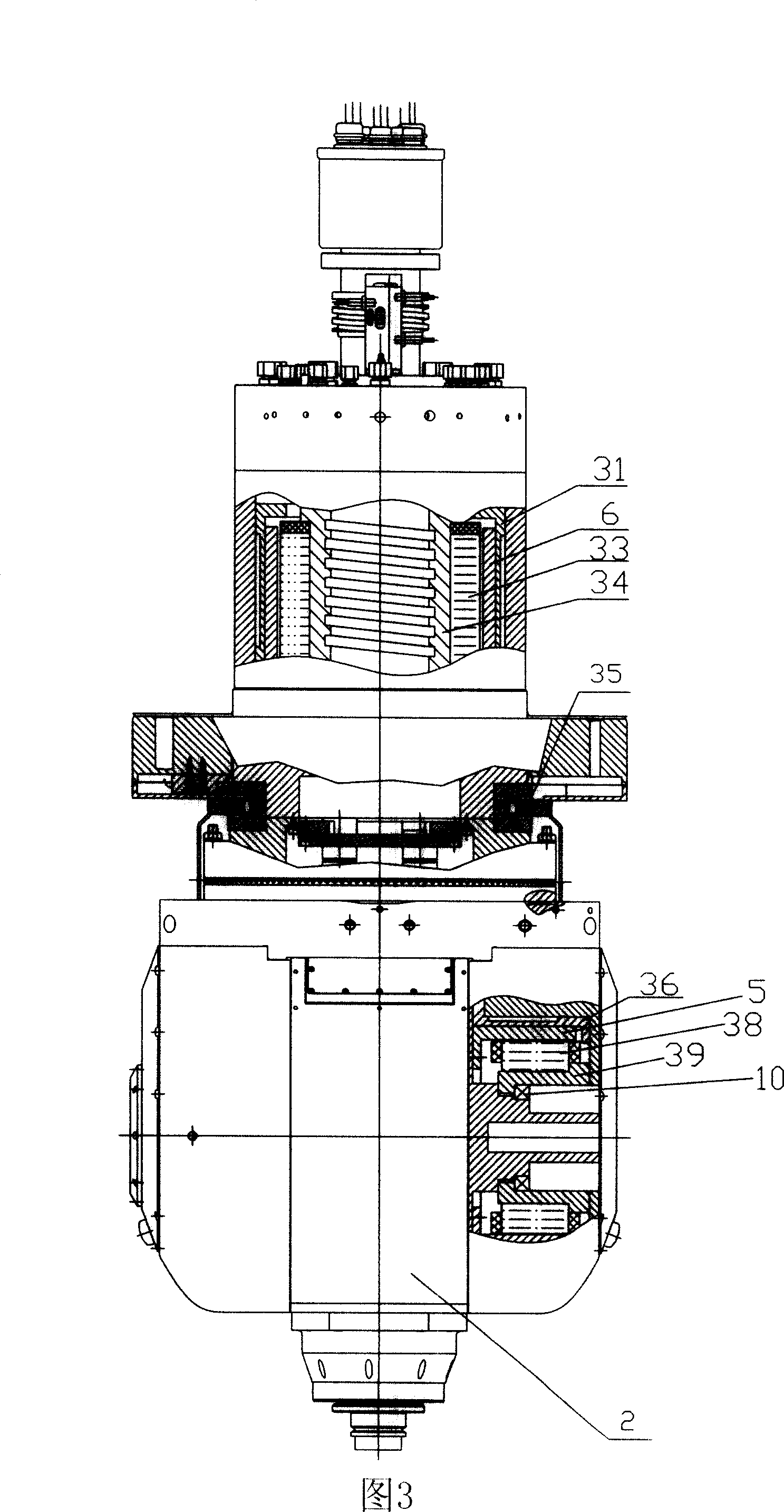

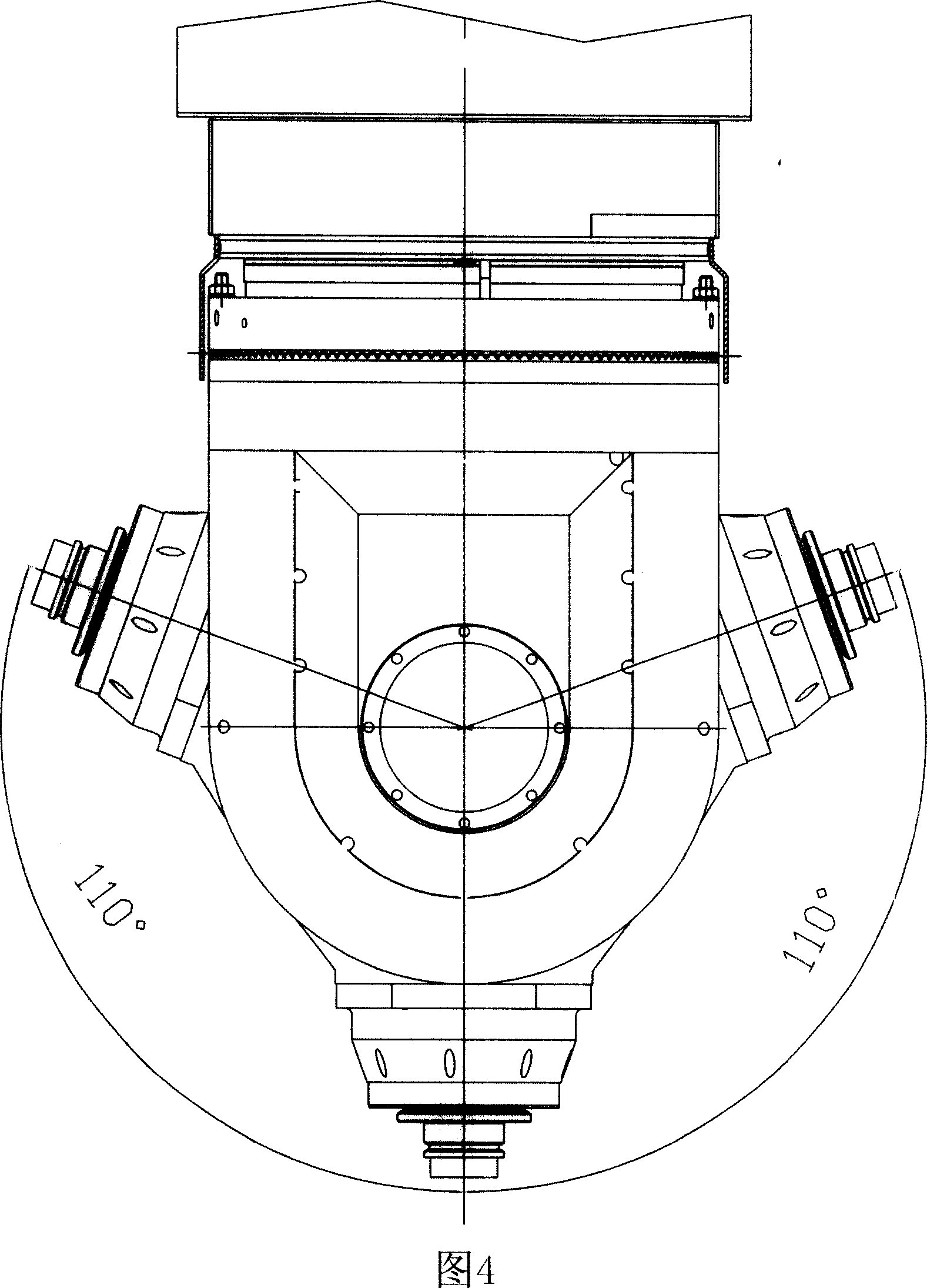

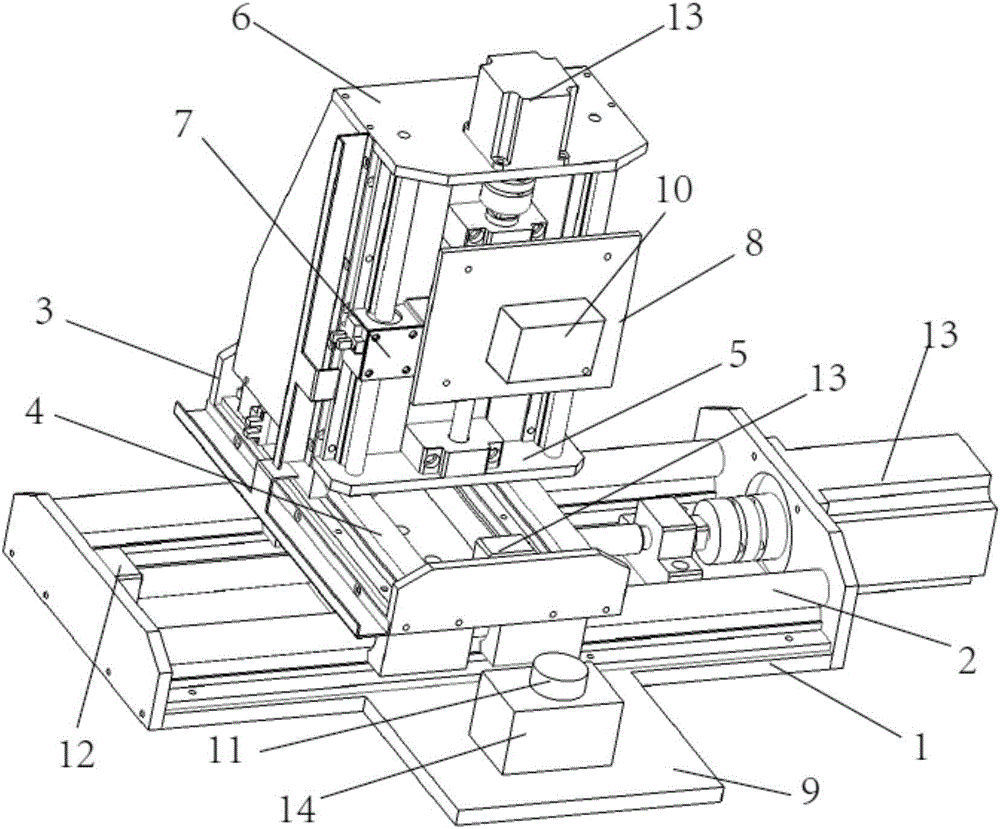

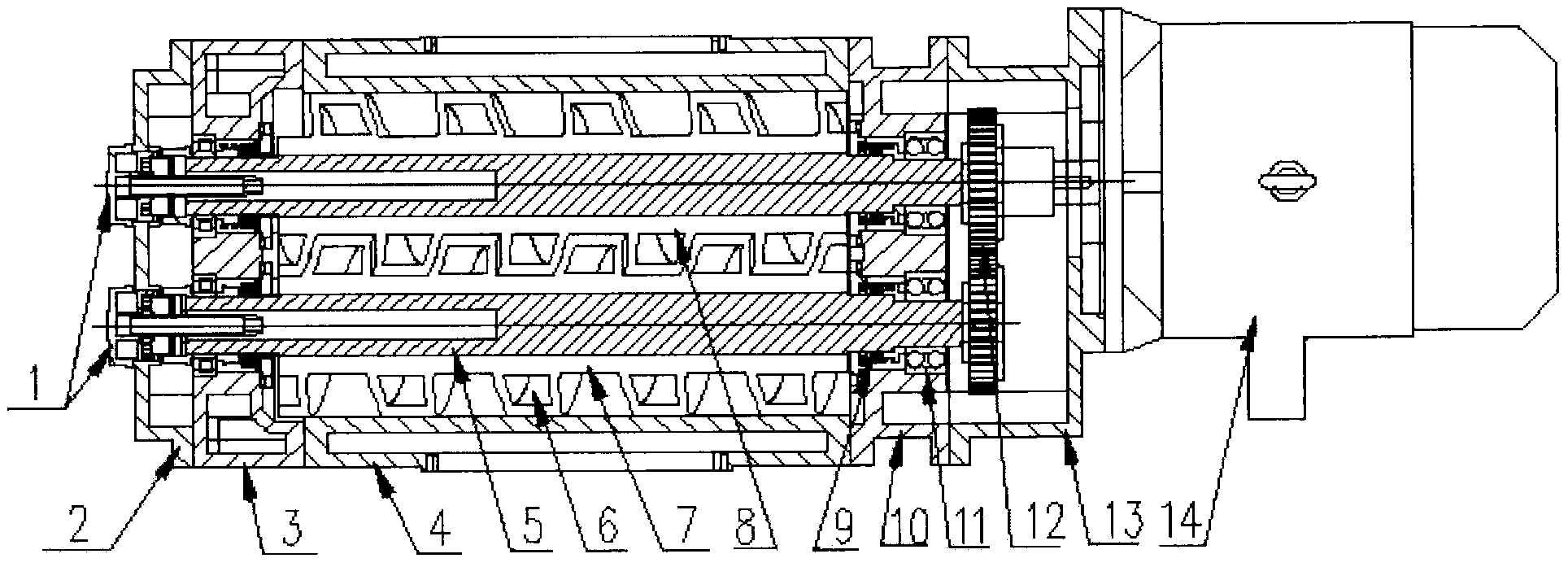

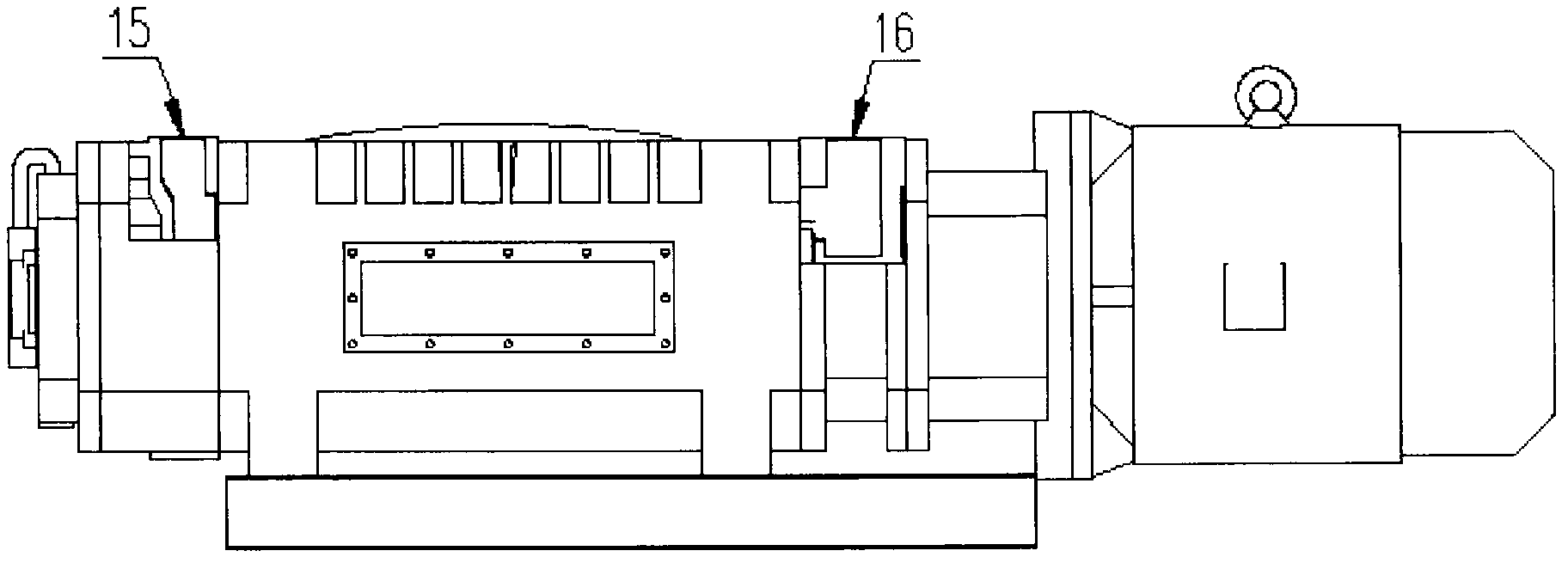

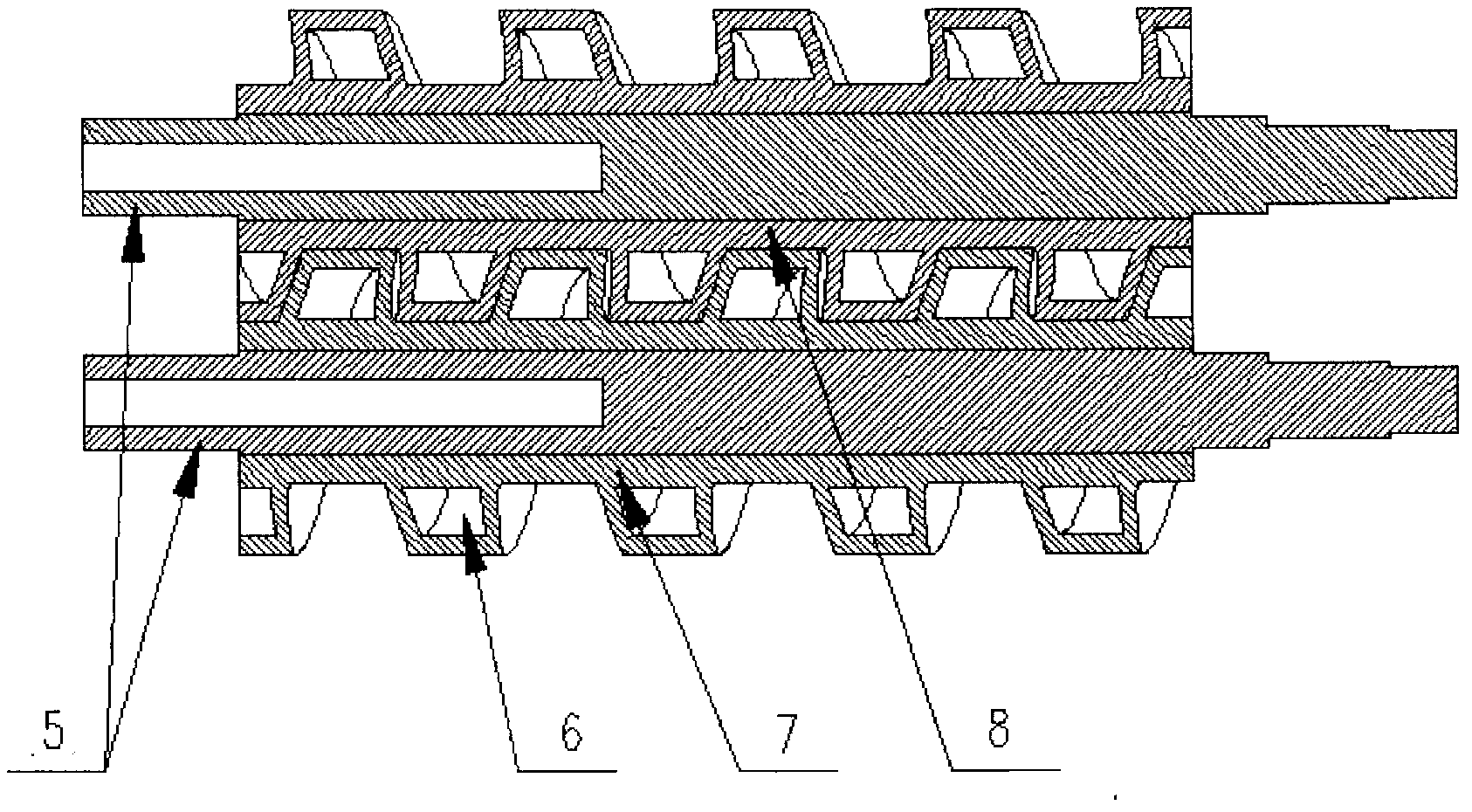

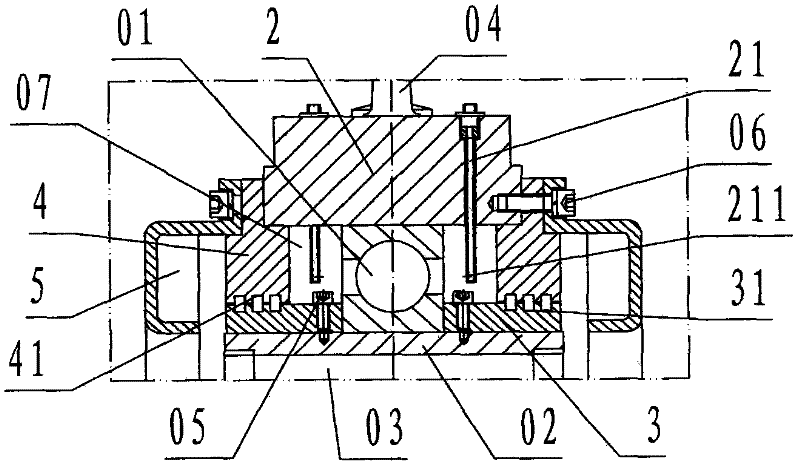

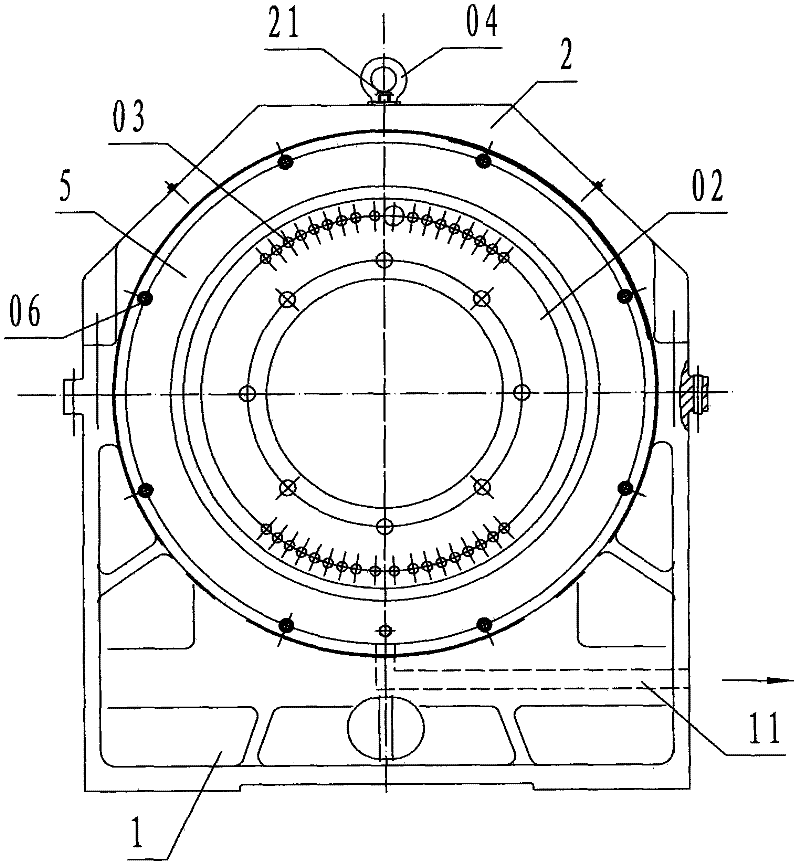

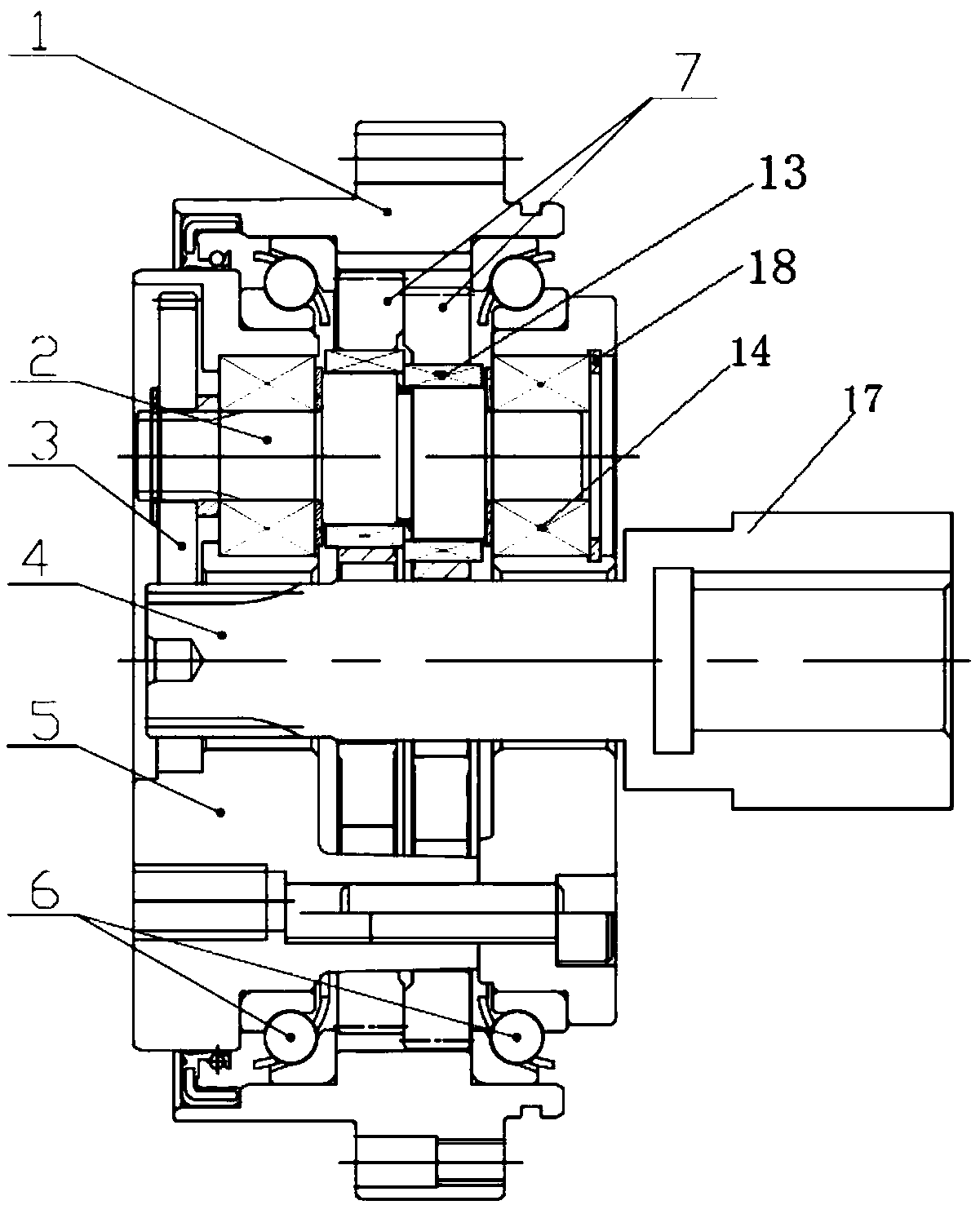

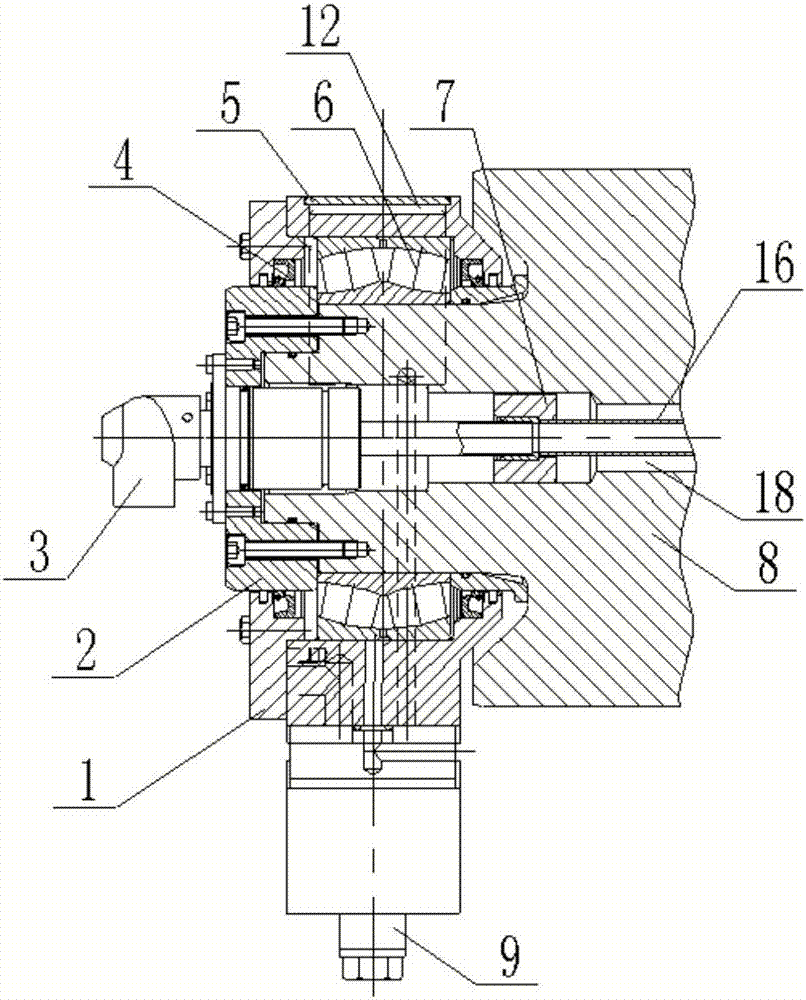

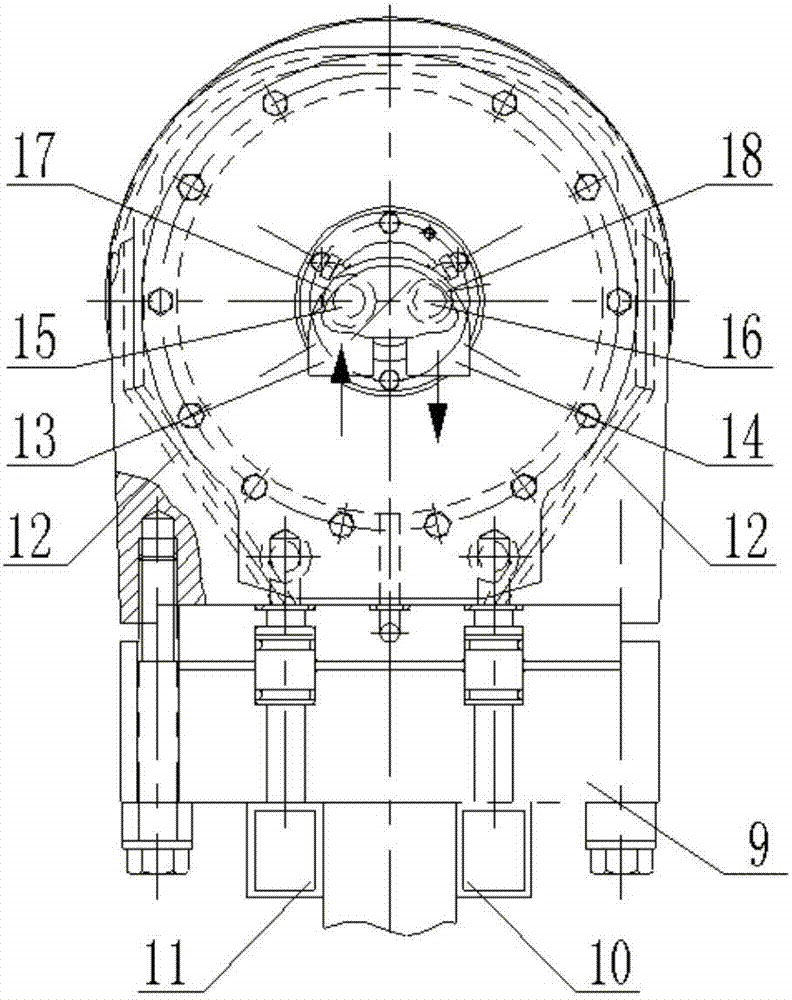

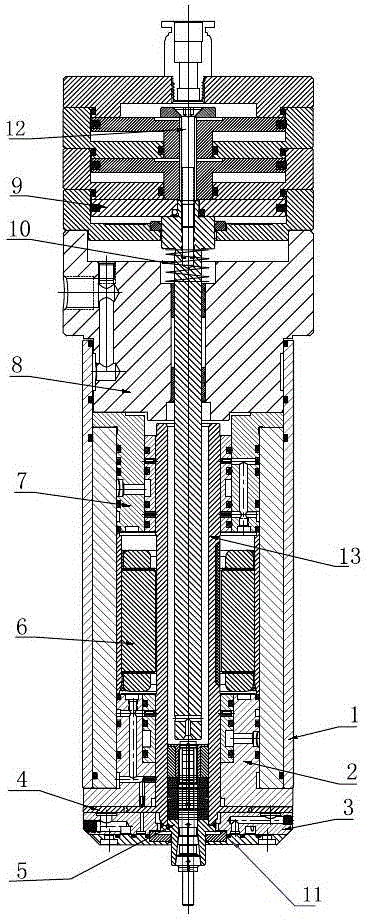

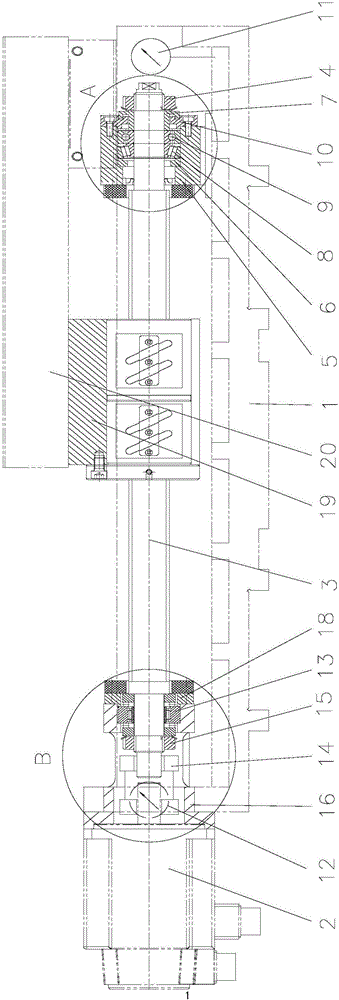

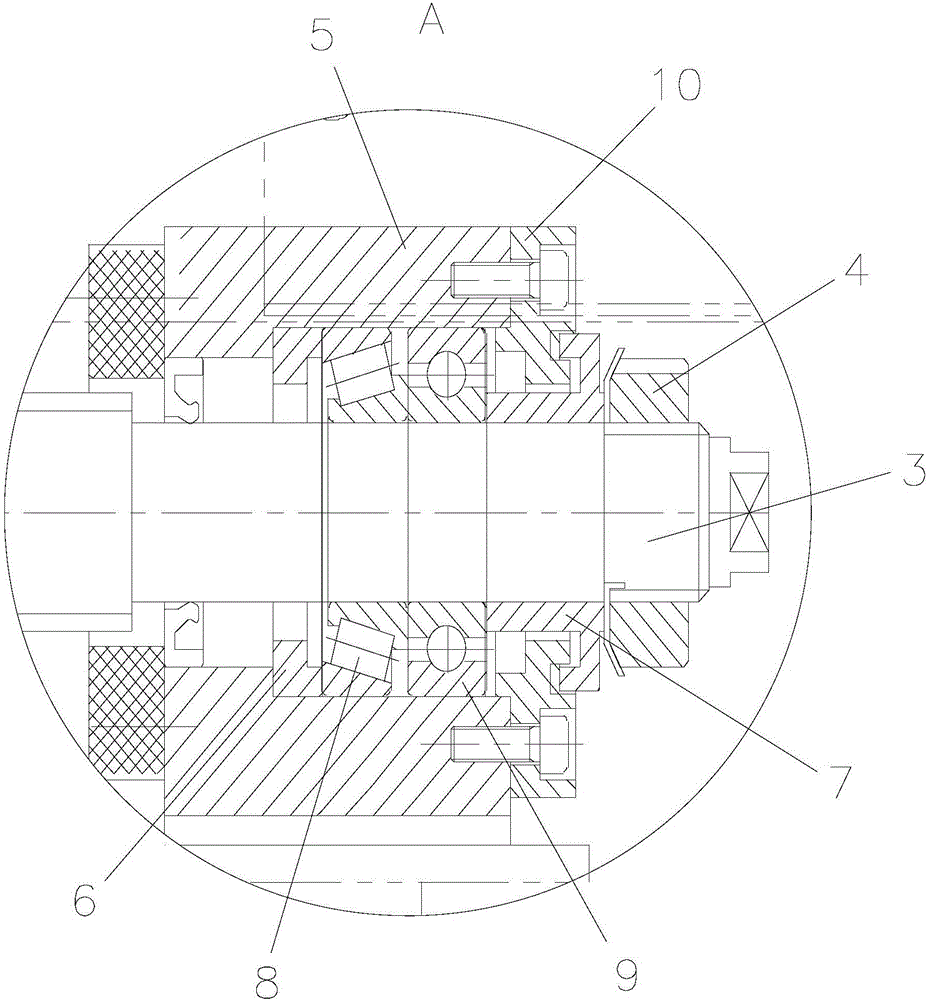

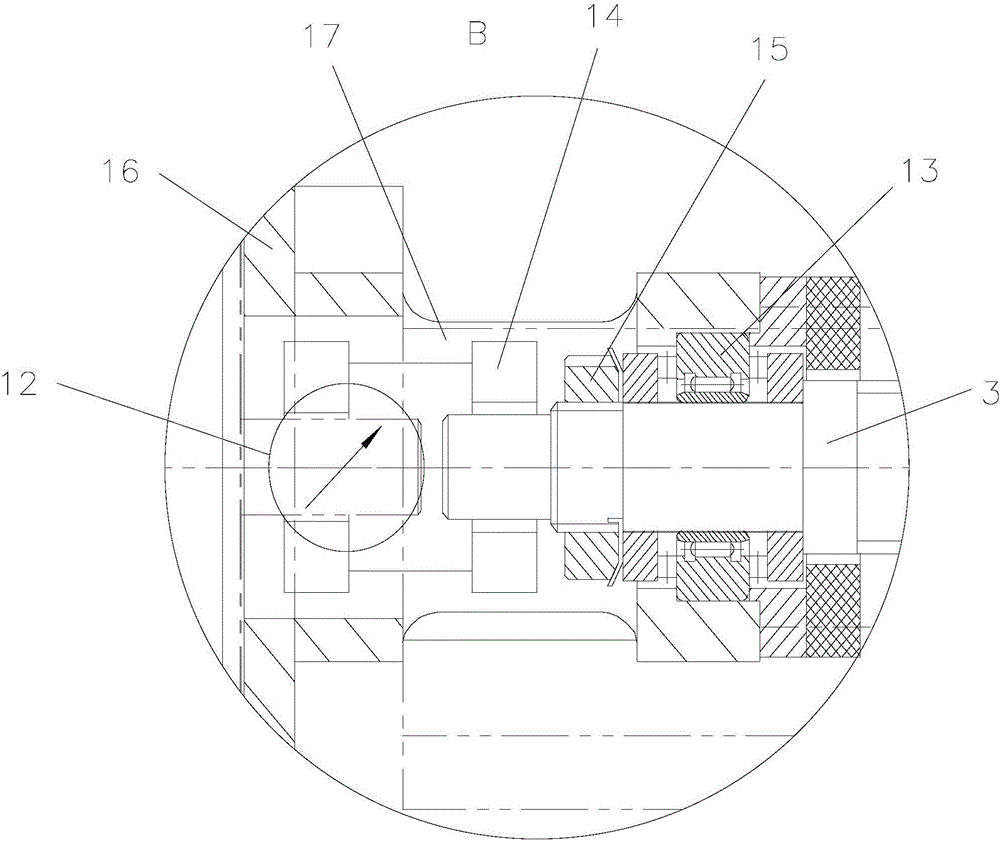

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN101011795AImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

Telemedicine service system and realizing method thereof based on cloud technology

InactiveCN103150469ALow input costAvoid restrictionsDiagnosticsSurgeryThe InternetCustomer-premises equipment

The invention discloses a telemedicine service system based on a cloud technology, which comprises CPE (customer premise equipment) controlled by a patient, a remote cloud server communicated with the CPE through a remote communication network, and medical end equipment which is controlled by medical staff and communicated with the remote cloud server through the remote communication network or the internet, wherein each of the CPE and the medical end equipment comprises personal portable medical equipment or family medical equipment. The invention further discloses a realizing method for the telemedicine service system. Through the system and the method, excellent medical staff around the world can be gathered for reasonable distribution and application of the human resources, and teletherapy can be realized truly. Therefore, the system and the method have high utility value and popularization value.

Owner:SICHUAN XUKANG MEDICAL ELECTRICAL EQUIPCO

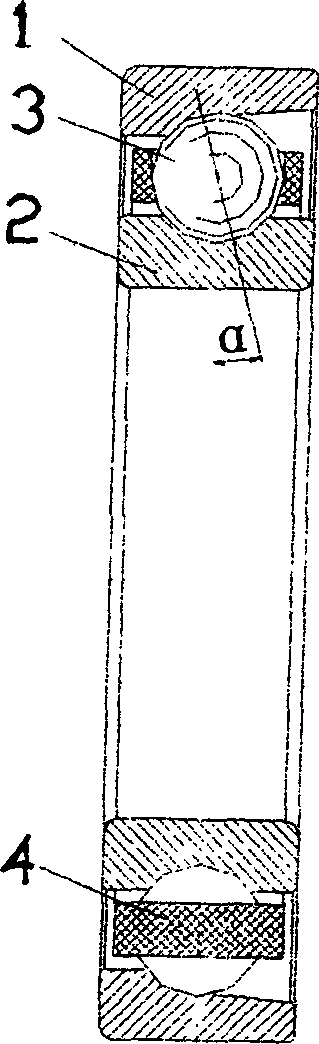

High precision hot press silicon nitride ceramic ball bearing and its manufacturing method

ActiveCN1619171AHigh limit speedImprove running accuracySpherical surface grinding machinesBall bearingsNumerical controlManufacturing technology

A high-precision hot-pressed silicon nitride ceramic ball bearing and its manufacturing method belong to bearing manufacturing technology and are suitable for installation on high-precision, high-speed, high-end CNC machine tools and machining center spindles. The high-precision hot-pressed ball bearing provided by the invention Silicon nitride ceramic ball bearings include: an inner ring and an outer ring made of steel. The inner ring and the outer ring respectively have ball bearing arc raceways; they are arranged between and in contact with the inner and outer ring ball bearing raceways. Ceramic ball rolling elements; a rolling element isolation ring, that is, a cage, arranged between the inner and outer rings to hold the ceramic balls; its characteristic is that the ceramic ball rolling elements are obtained by conical grinding processing technology and technical equipment, and its accuracy is Reached G5 and G3 levels. The characteristics of the invention are: high limit operating speed; high operating accuracy; high temperature resistance and can operate without lubrication; light weight; long-term stable operation in some highly corrosive media; high degree of standardization, easy maintenance and interchange.

Owner:SHENYANG JIANZHU UNIVERSITY

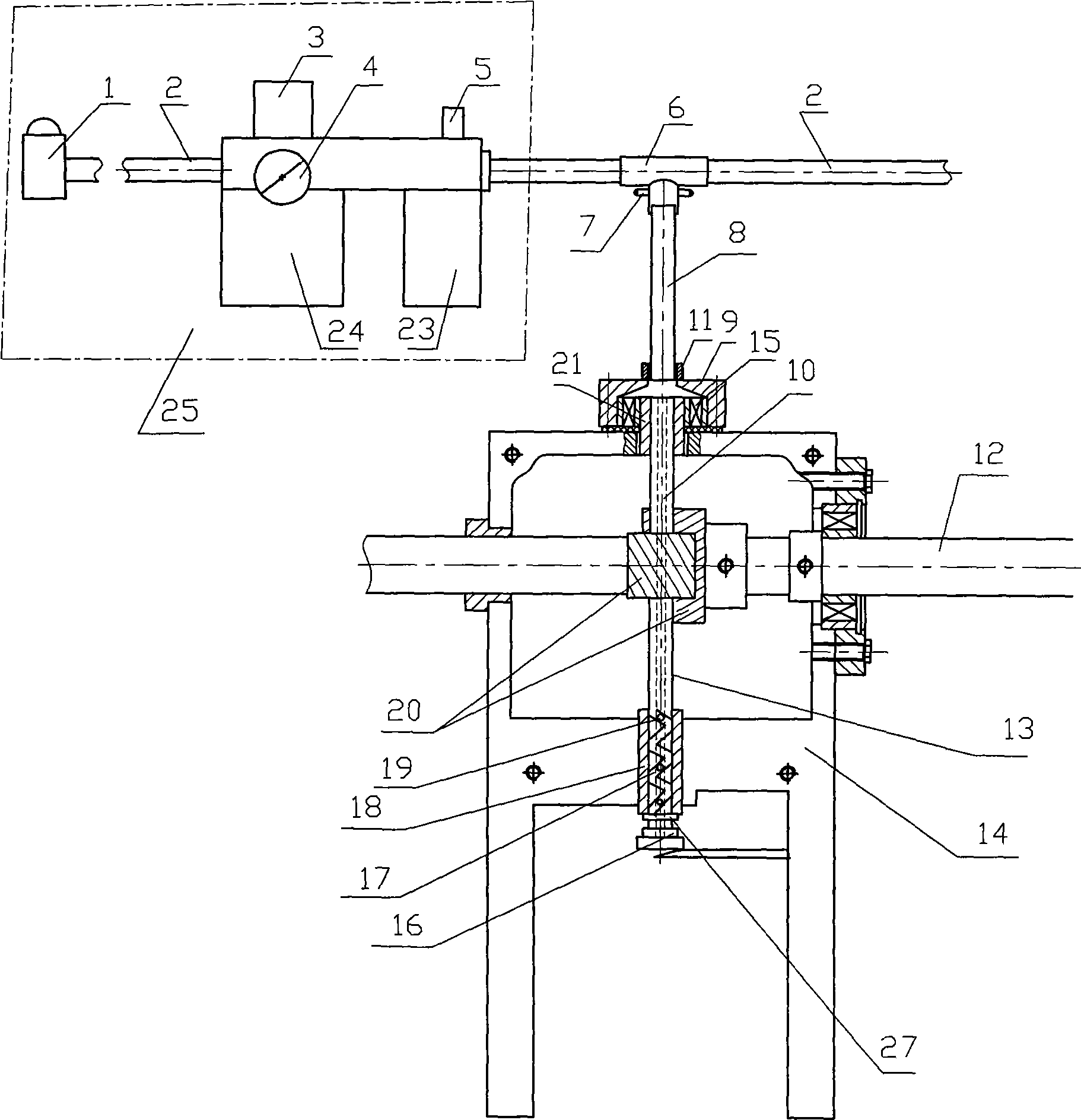

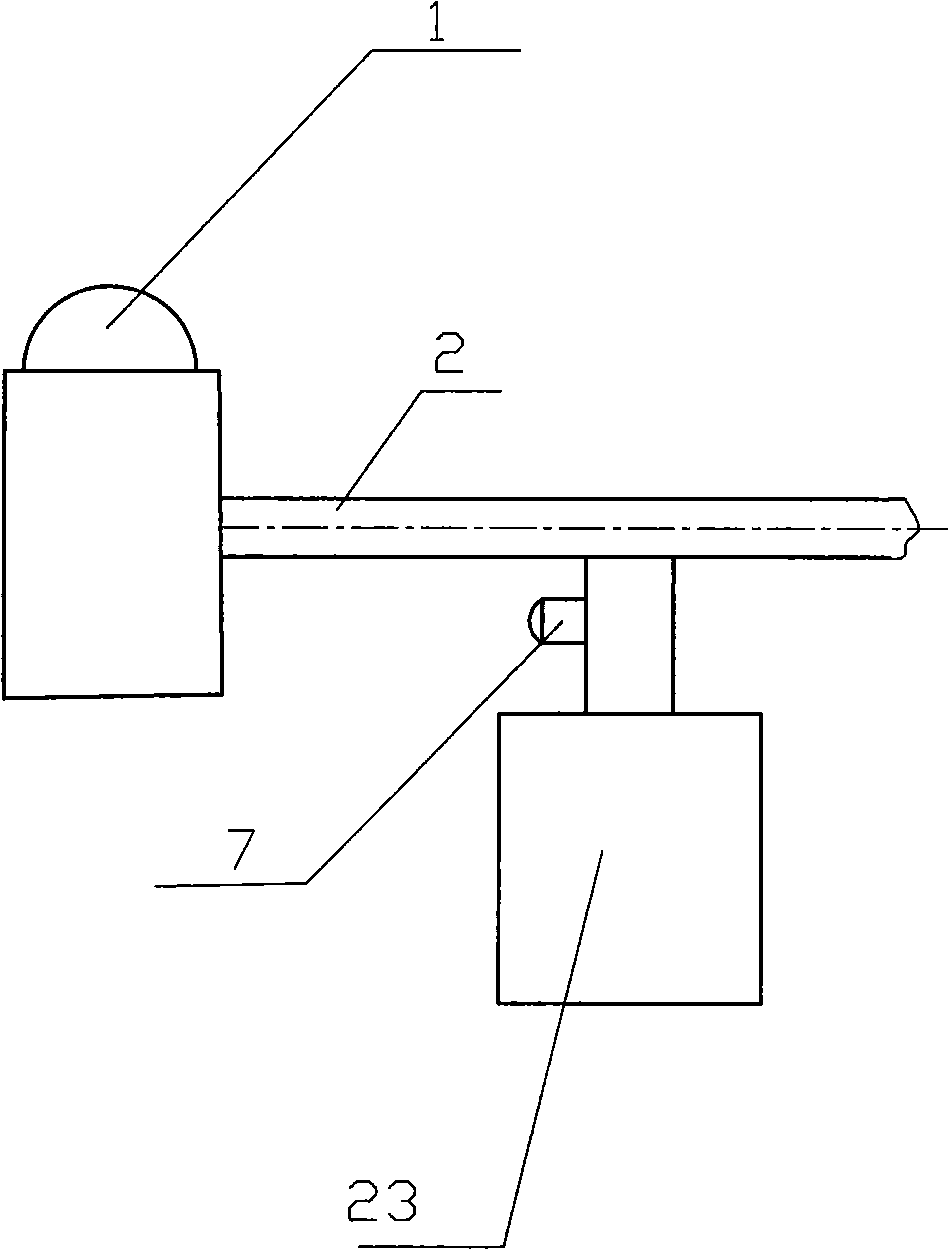

Test-bed for testing performance of vibration damping belt pulley wheel

InactiveCN1601248ASmooth runningImprove running accuracyEngine testingVehicle suspension/damping testingAxial displacementComputerized system

The invention relates to a vibration-damping belt pulley performance test table. It includes table frame, motor and vibration-damping belt pulley to be tested on its motor shaft, load and its belt pulley on its shaft and tension pulley; on the side walls of external ring and internal ring of the vibration-damping belt pulley to be tested the marks are respectively set; and on the table frame the mark sensors for sensing marks, laser displacement sensor for measuring radial displacement of the vibration-damping belt pully and laser displacement sensor for measuring axial displacement of the vibration-damping belt pulley; the output end of every sensor is connected with computer system. Besides, said invention also provides the application and action of said test table.

Owner:WUHAN UNIV OF TECH

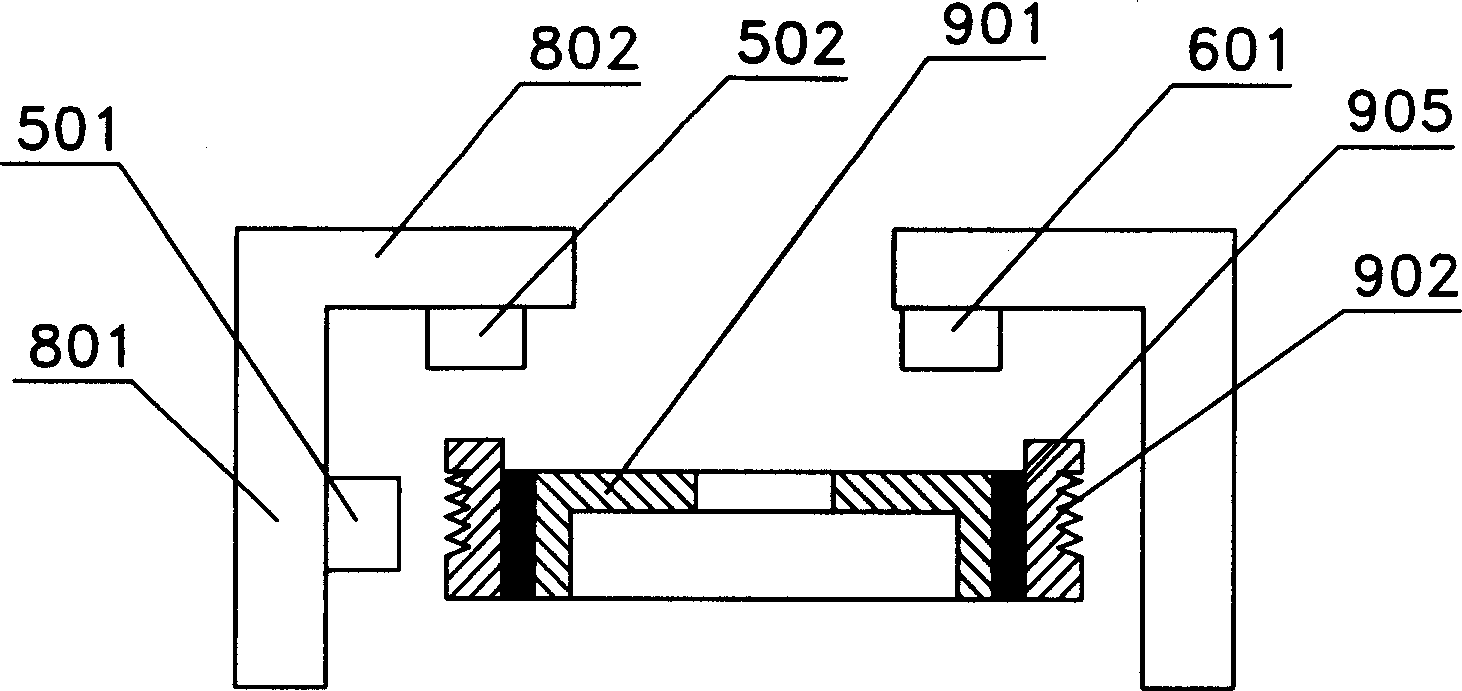

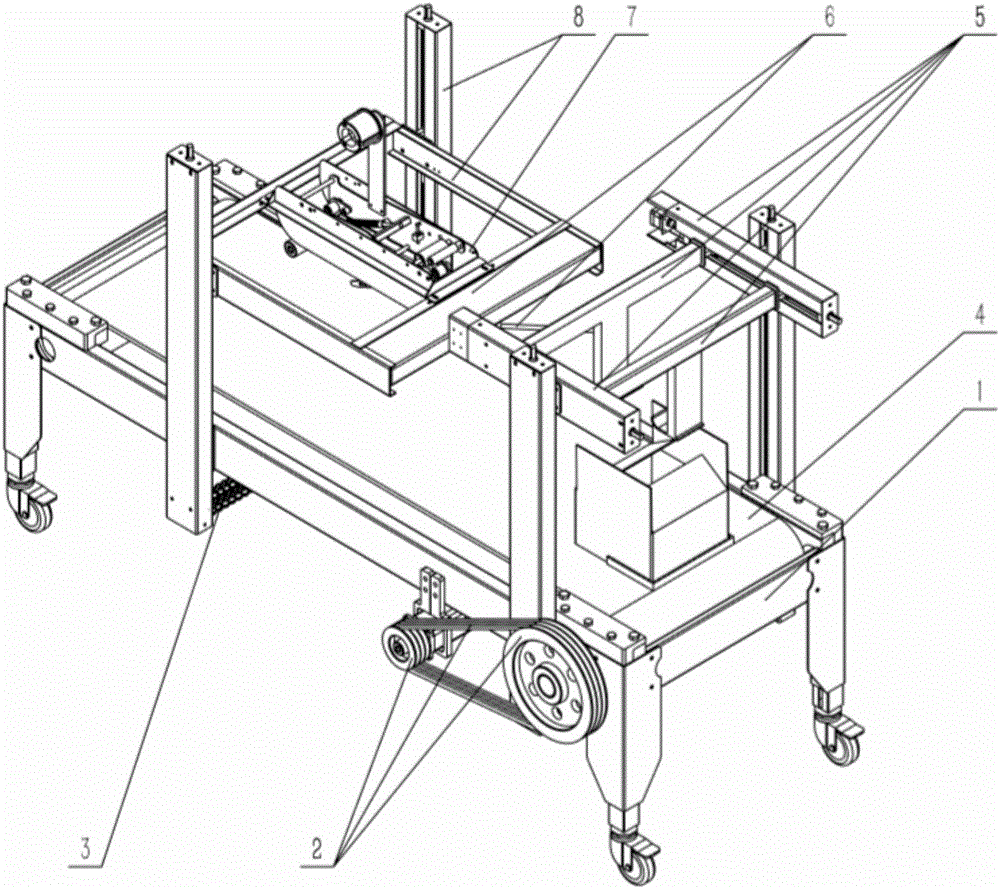

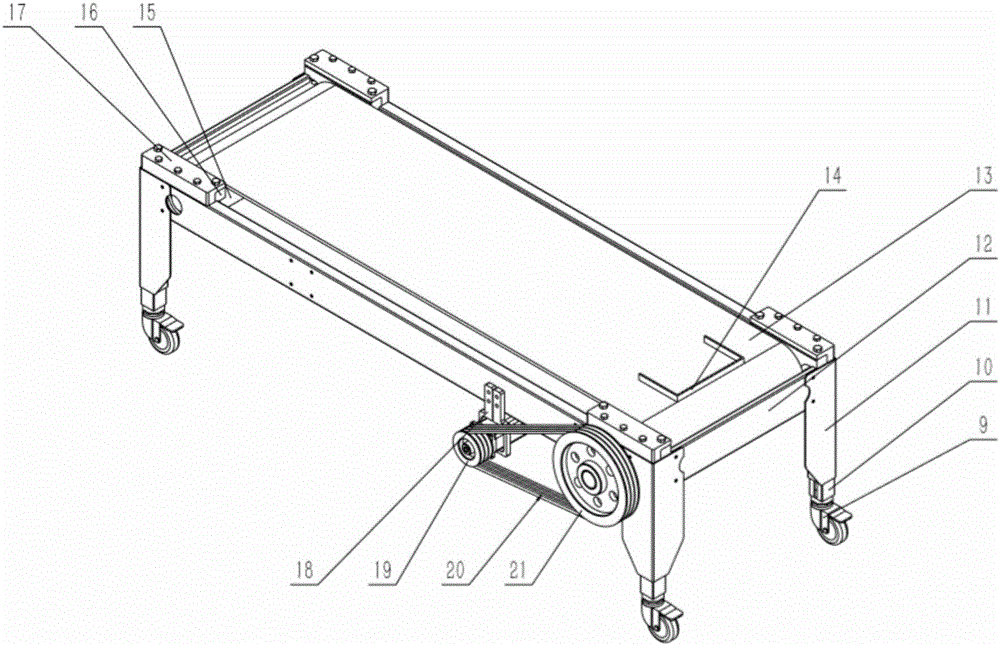

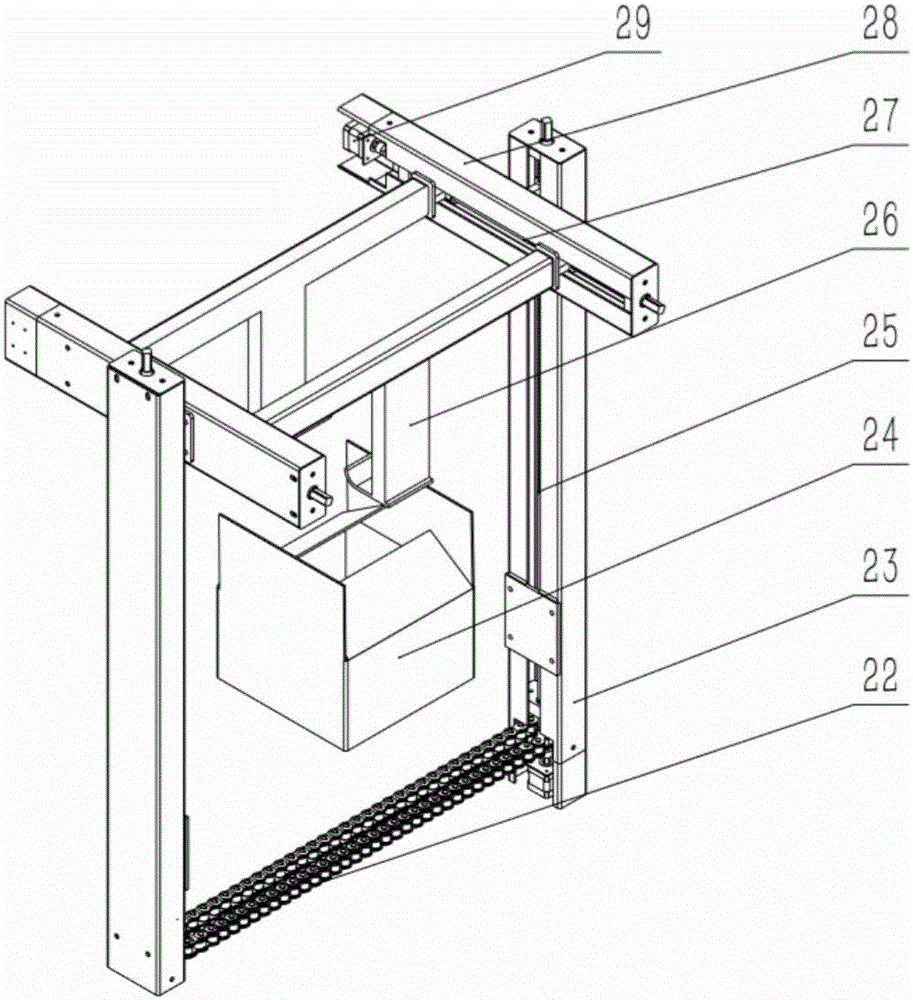

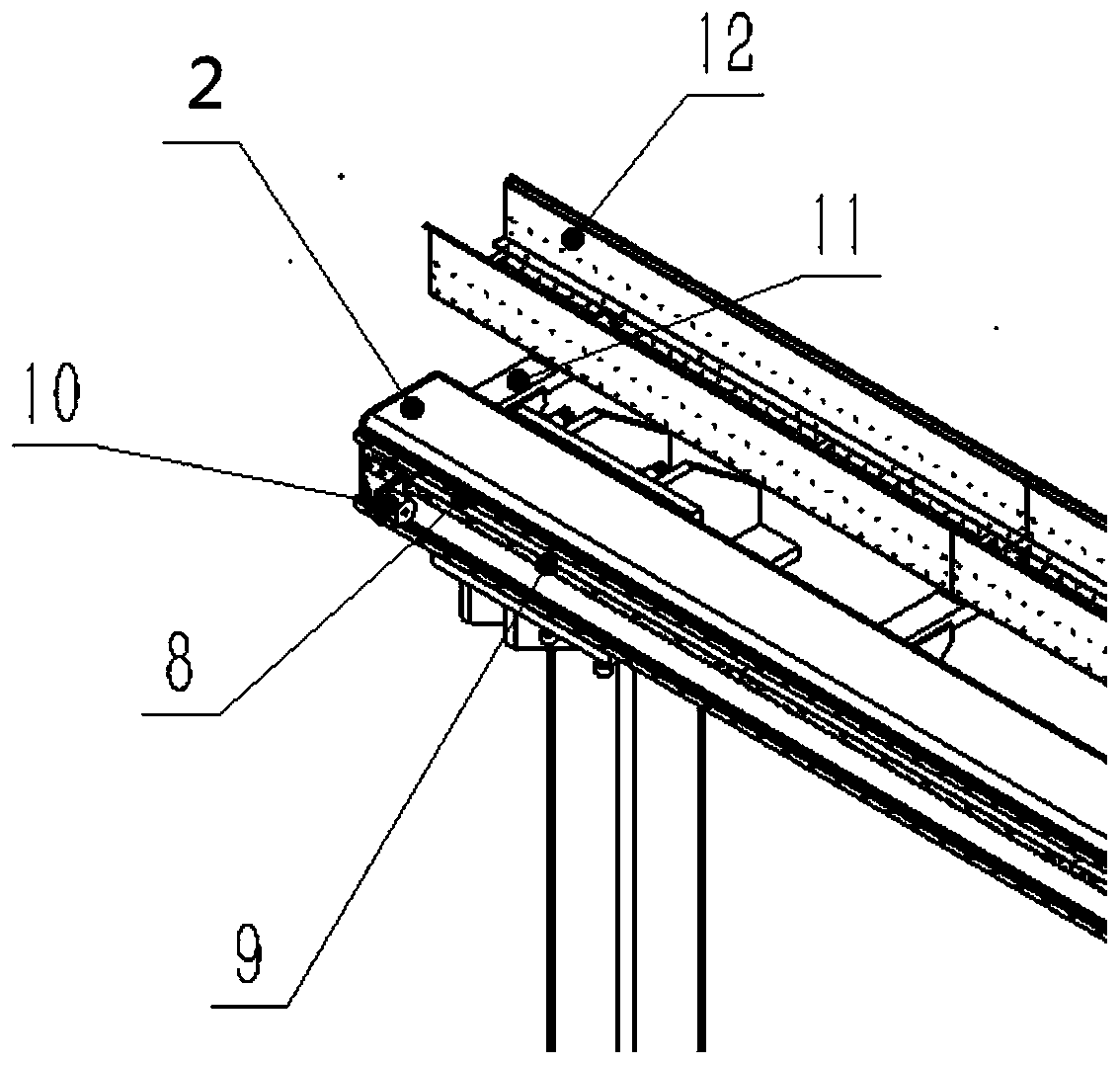

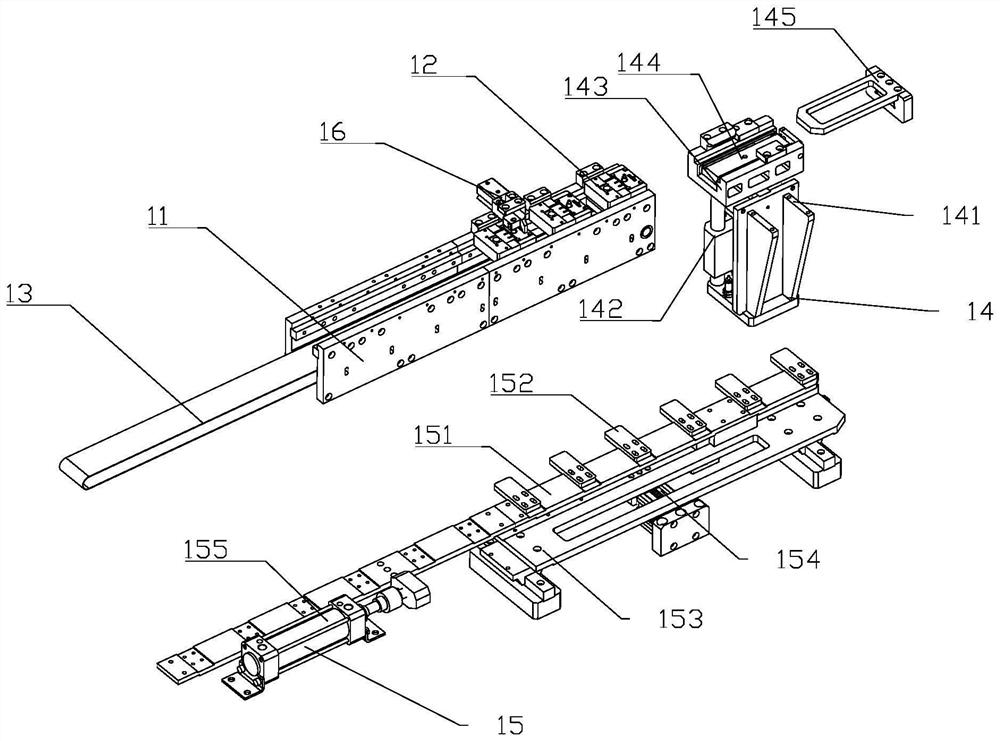

Automatic cover folding carton sealer

Owner:ZHEJIANG SCI-TECH UNIV

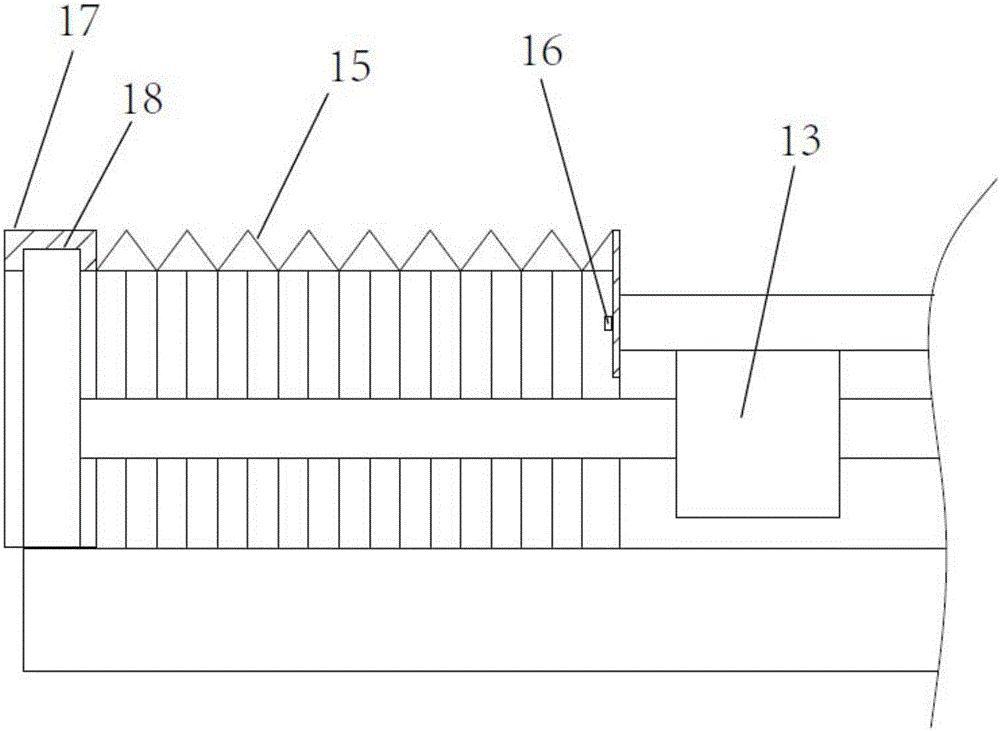

Automatic calibration equipment for light intensity of DLP (Digital Light Processing) printing equipment projector and calibration method

ActiveCN106273487AHigh guiding precisionImprove stabilityAdditive manufacturing apparatusGray levelEngineering

The invention discloses automatic calibration equipment for the light intensity of a DLP (Digital Light Processing) printing equipment projector. The automatic calibration equipment comprises a base; the base is provided with a first cylindrical linear guide rail which moves along the X-axis direction, a first sliding platform, a second cylindrical linear guide rail which moves along the Y-axis direction, a second sliding platform, a mounting platform, a third cylindrical linear guide rail which moves along the Z-axis direction and a third sliding platform in sequence from bottom to top; an extending platform is arranged at a side edge of the base in front of the third sliding platform; the third sliding platform and the extending platform are provided with a projector and a light intensity sensor respectively; the projector and the light intensity sensor are connected with a system control board; a calibration method comprises the following steps: step (1) focusing and adjusting; step (2) determining calibration reference light intensity; step (3) collecting compensation mask gray level numerical value of the projector; step (4) generating a compensation mask; step (5) carrying out calibration. The automatic calibration equipment provided by the invention is reasonable in design, compact in structure, convenient to operate and good in stability and can effectively obtain the light intensity of the projector.

Owner:SUZHOU BC TECH

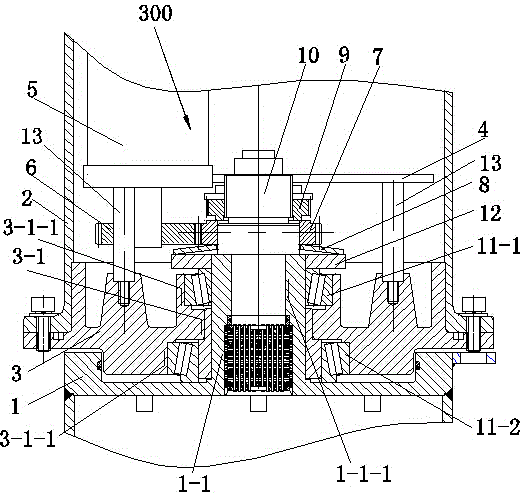

A precision dynamic and static pressure ceramic spindle device

InactiveCN102266951AIncrease speedIncreased operating lifeMaintainance and safety accessoriesThrust bearingEngineering

The invention discloses a precise type dynamic and static pressure ceramic main shaft device. A front radial-bidirectional thrust bearing is mounted at the front end of a main shaft, and a back radial bearing is mounted at the back end of the main shaft. The front radial-bidirectional thrust bearing comprises a front main shaft lining. A front ceramic right shaft sleeve, a thrust ceramic shaft sleeve, a front ceramic left shaft sleeve and a front shaft sleeve end cover are assembled at the external part of the front main shaft lining. A thrust shaft sleeve lining is assembled at the externalpart of the thrust ceramic shaft sleeve. A radial ceramic bearing bush, a left thrust ceramic bearing brush, a right thrust ceramic bearing brush, a front bearing brush lining and a front bearing brush end cover are mounted on a stand. The back radial bearing comprises a back main shaft lining. A back ceramic shaft sleeve and a back shaft sleeve end cover are assembled on the back main shaft lining. A back bearing brush end cover, a back ceramic bearing brush and a back bearing brush lining are mounted on the stand. The edge of a ceramic part can be protected by the precise type dynamic and static pressure ceramic main shaft device, so that the impact resistance is enhanced; the strength of a radial-thrust combined bearing is enhanced; the processibility of the ceramic part is enhanced, and the finished product ratio is increased; and the sealing property of the main shaft is enhanced.

Owner:TIANJIN UNIV

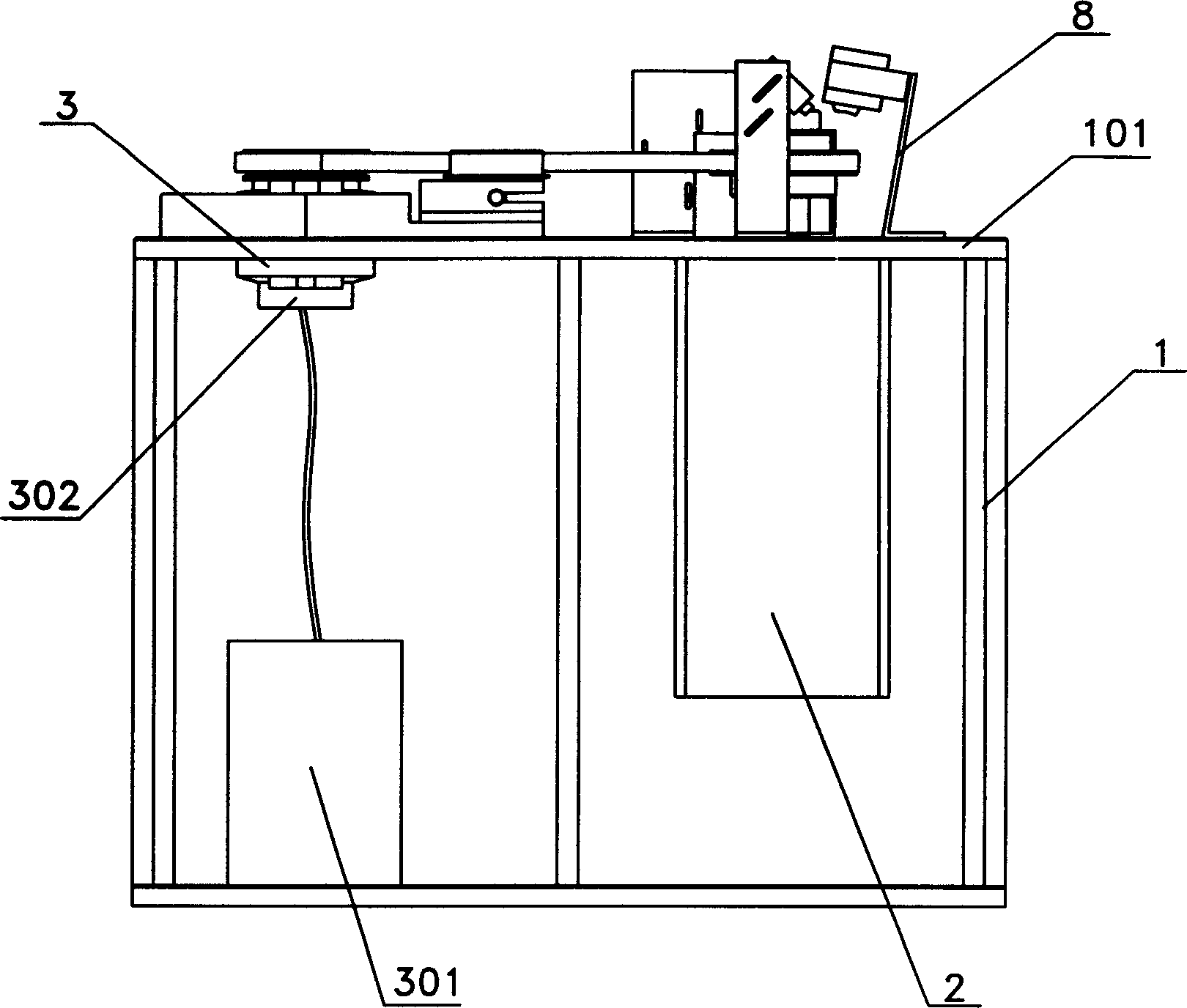

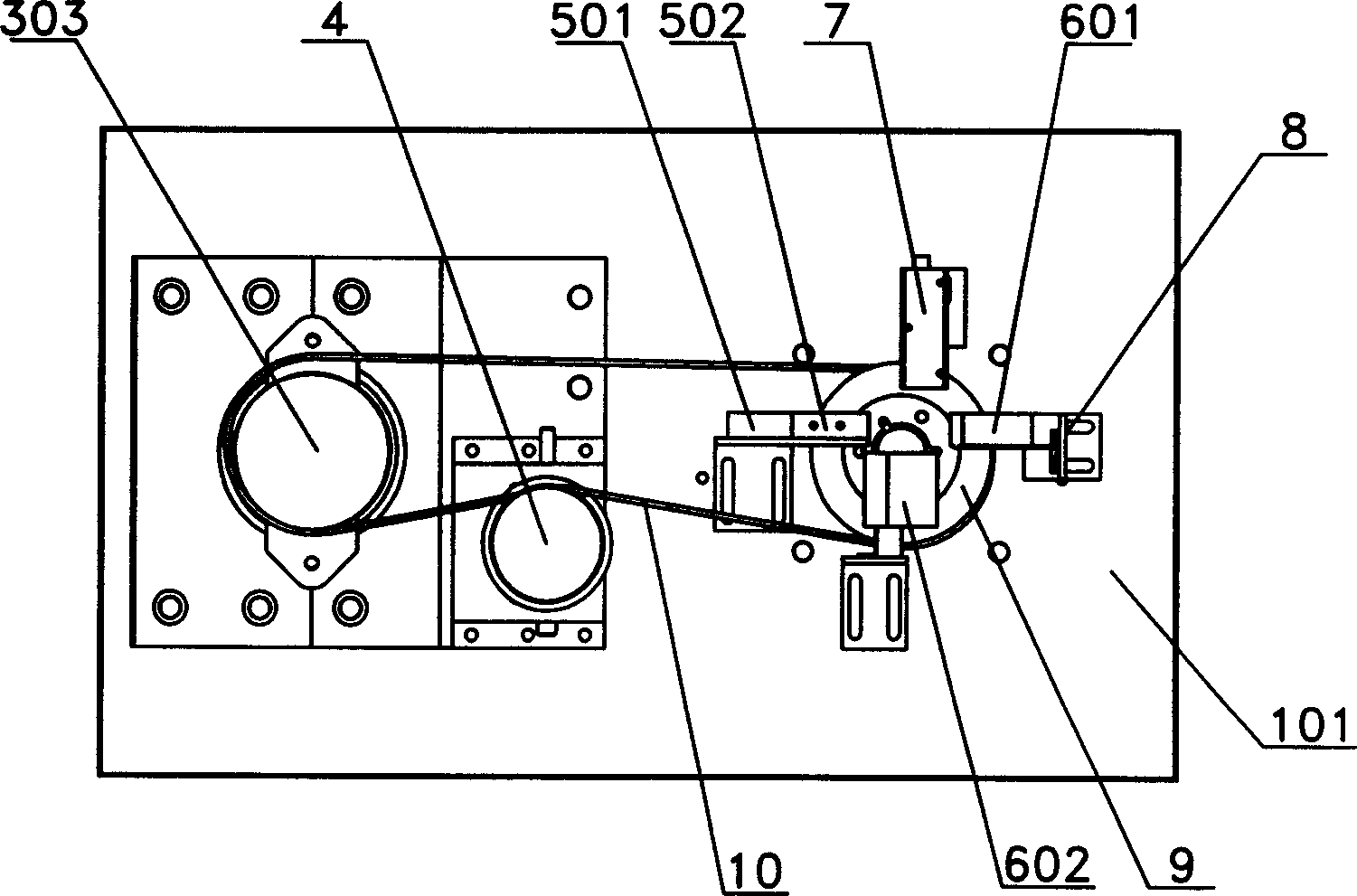

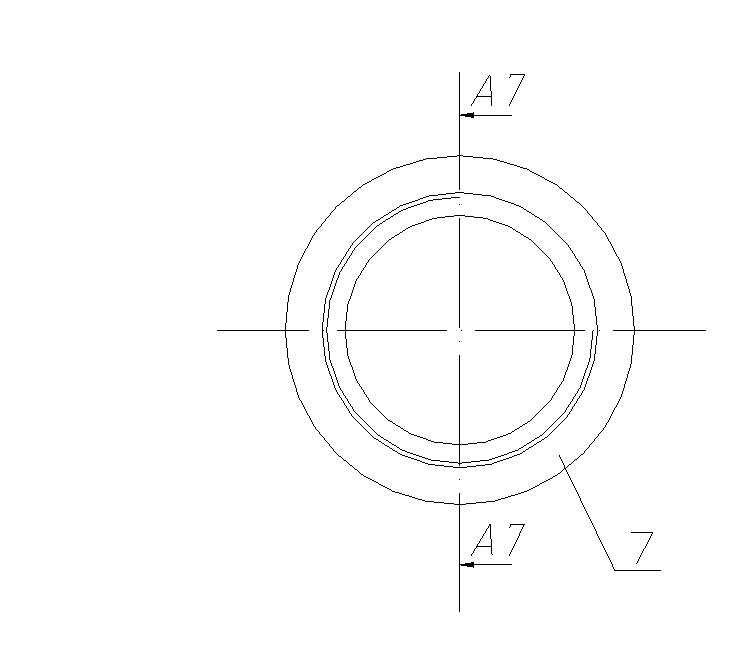

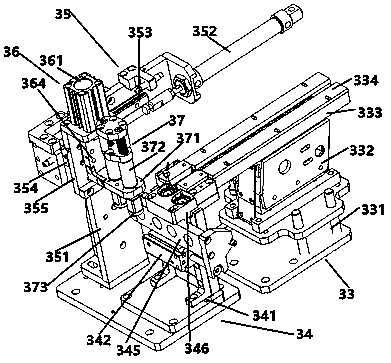

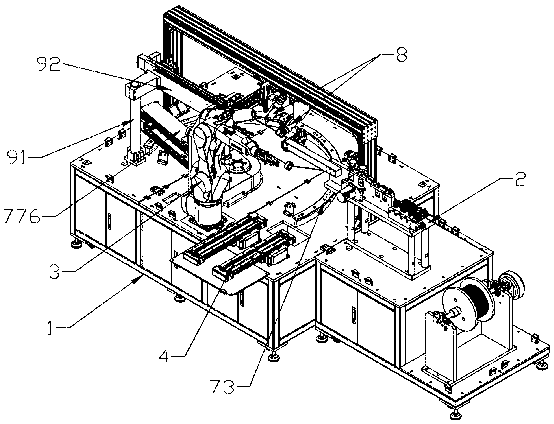

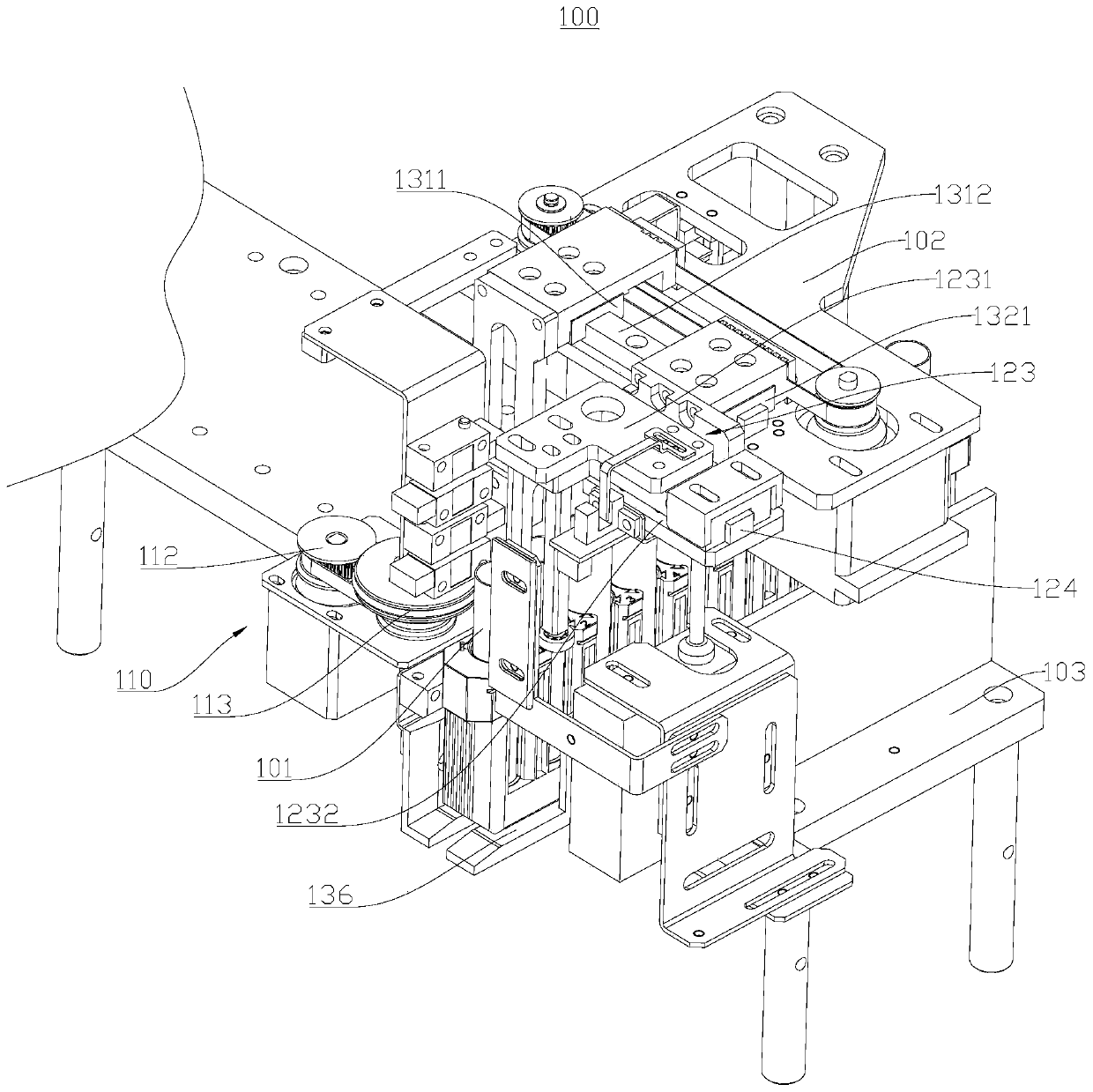

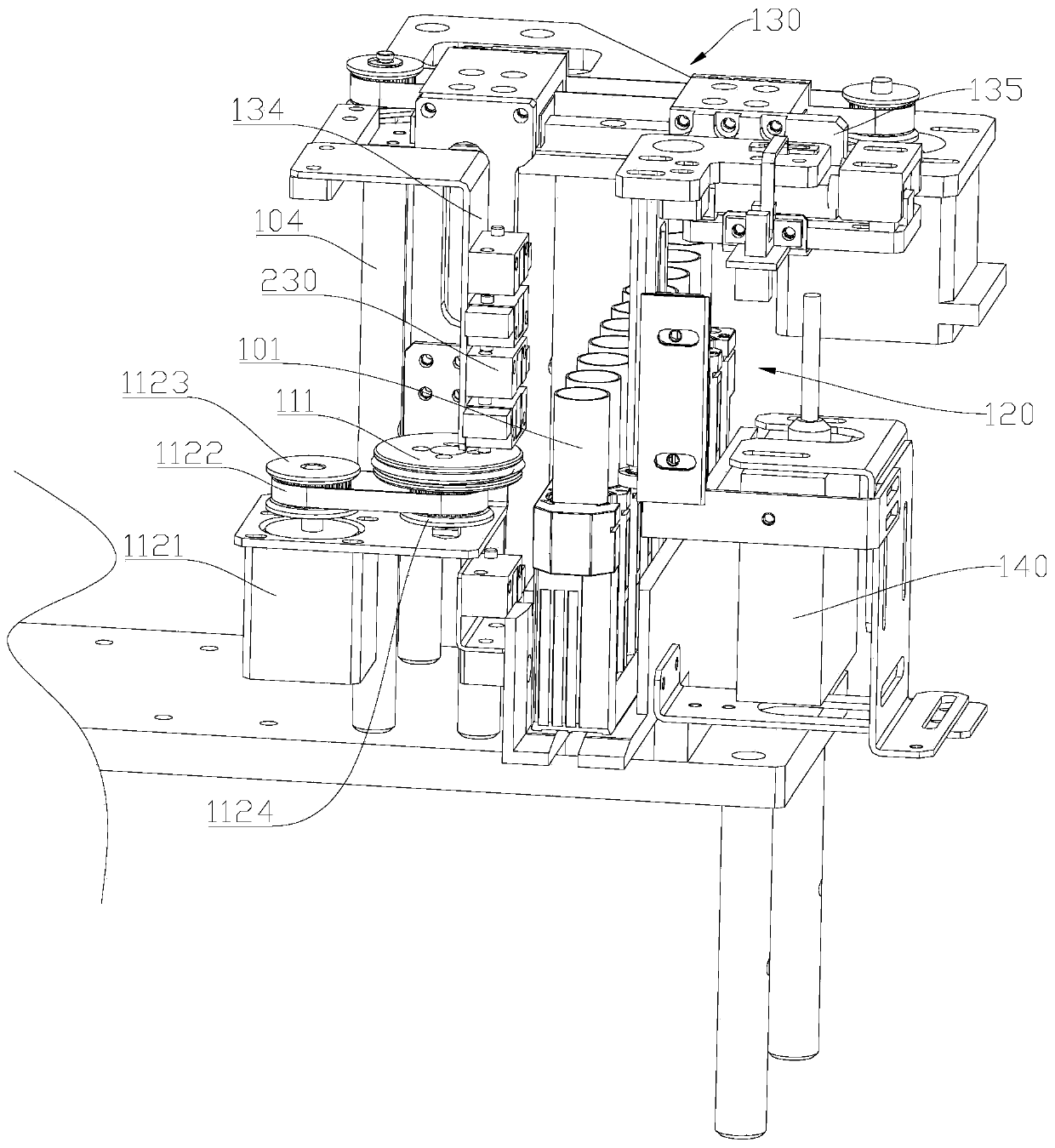

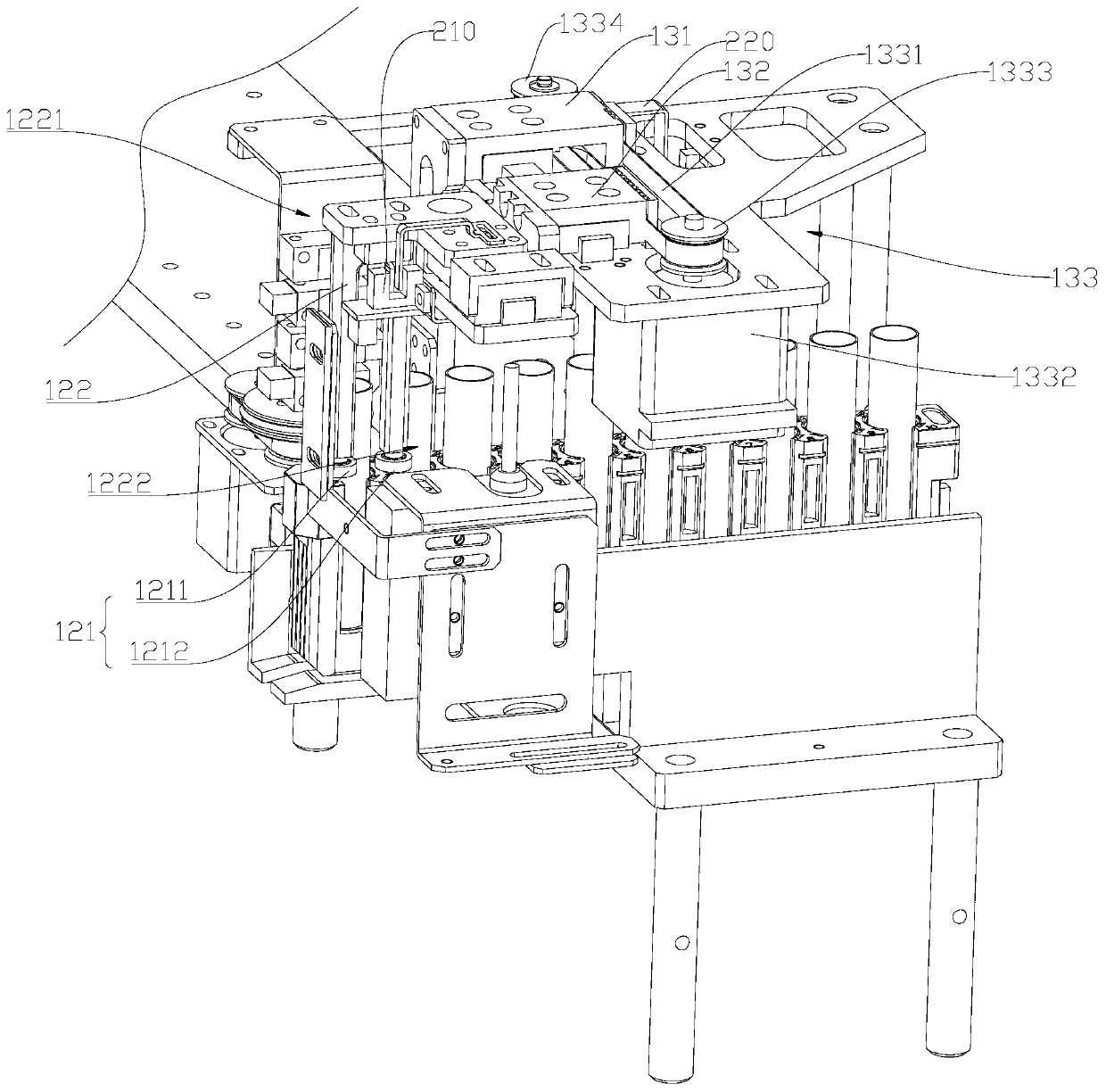

Full-automatic game currency assembling and welding all-in-one machine

ActiveCN108407317AImprove running accuracyHigh speedMetal working apparatusNon-electric welding apparatusEngineeringWelding

The invention discloses a full-automatic game currency assembling and welding all-in-one machine. The full-automatic game currency assembling and welding all-in-one machine comprises an assembling andwelding base, an index plate device, a lower cover feeding device, an upper cover feeding device, a riveting device, a welding device, a control device and a discharging device, wherein the index plate device, the lower cover feeding device, the upper cover feeding device, the riveting device, the welding device, the control device and the discharging device are fixed to the assembling and welding base. The lower cover feeding device is arranged in front of the index plate device. The upper cover feeding device is arranged on the left side of the index plate device. The structure of the uppercover feeding device is the same as the structure of the lower cover feeding device. The riveting device is arranged behind the index plate device. The welding device is arranged behind the right side of the index plate device. The control device is arranged in front of the left side of the index plate device. The discharging device is arranged on the right side of the index plate device. The full-automatic game currency assembling and welding all-in-one machine has the beneficial effects that automatic feeding, automatic riveting, automatic welding and automatic discharging can be achieved,the universality of the all-in-one machine is high, only clamps need to be replaced by adjusting a rail, using is easy and fast, the cost is reduced, and the time is saved.

Owner:NANLING WANGKE INTPROP MANAGEMENT CO LTD

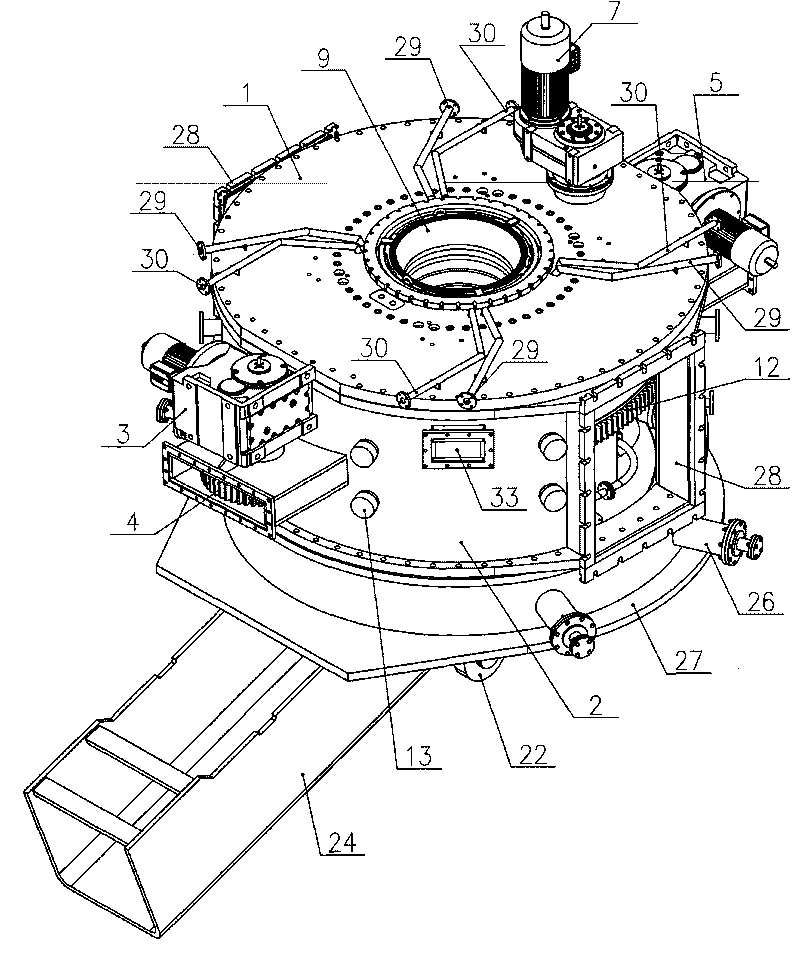

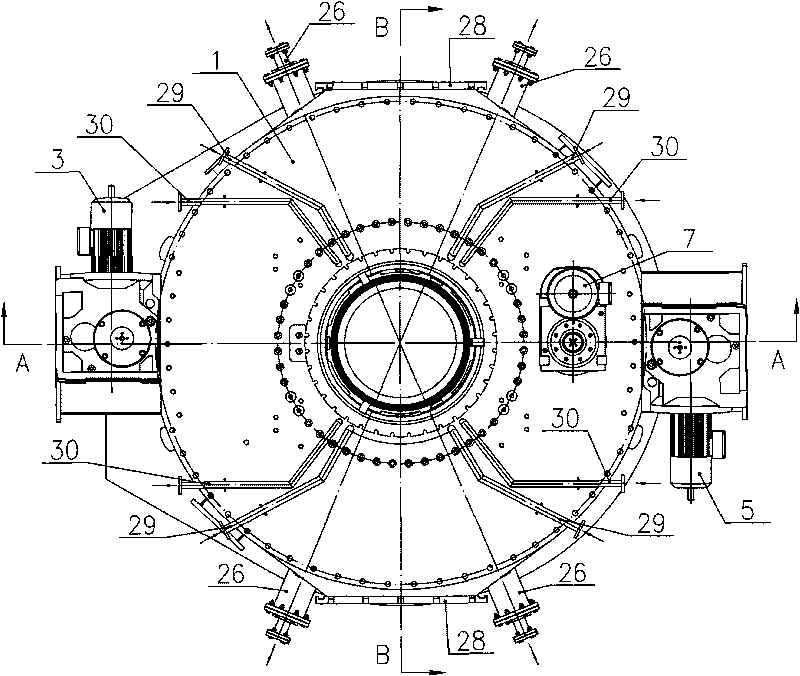

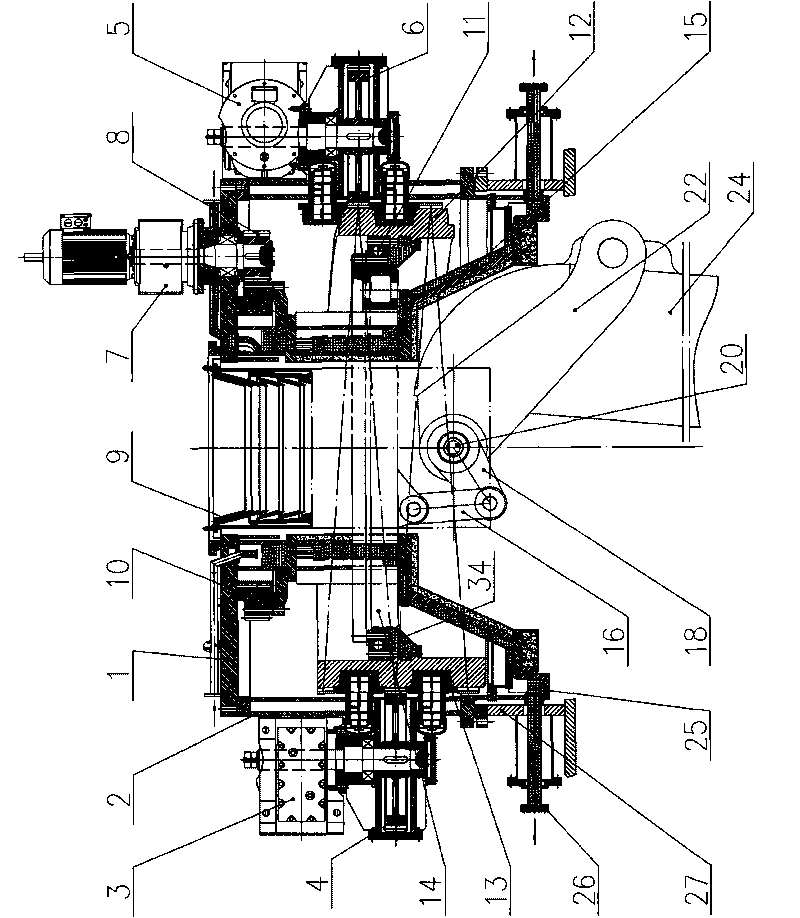

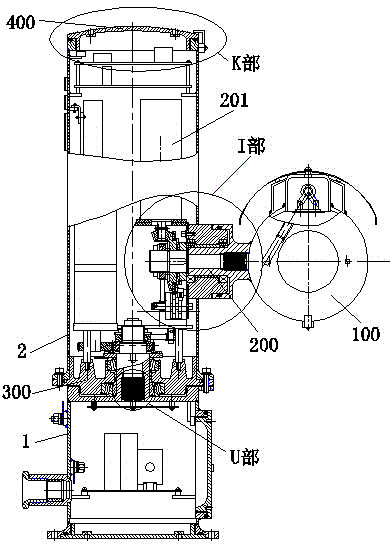

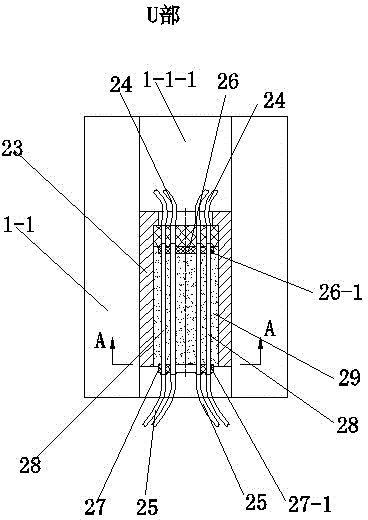

Blast furnace roof material distributing device

ActiveCN101701271AThe principle of mechanical transmission is simpleFabric flexibleBell-and-hopper arrangementEngineeringMechanical drive

The invention relates to a blast furnace roof material distributing device which is characterized by comprising a top cover, a shell, a center throat pipe, a left suspension shaft, a right suspension shaft, a left movable arm, a right movable arm, a chute, a rotating mechanism and a tilting mechanism, wherein the shell is fixedly connected with a steel ring of a furnace roof, and the top cover is fixedly connected with the shell; an output opening at the lower end of the center throat pipe is arranged above an input opening at the upper end part of the chute; the left end at the upper part of the chute is clamped on the left movable arm, and the right end at the upper part of the chute is clamped on the right movable arm; the left movable arm is fixedly connected with the left suspension shaft by a spline, and the right movable arm is fixedly connected with the right suspension shaft by a spline; the left suspension shaft and the right suspension shaft are respectively connected with a rotating cylinder of the rotating mechanism by bearings; the left suspension shaft is fixedly connected with a left crank of the tilting mechanism, and the right suspension shaft is fixedly connected with a right crank of the tilting mechanism. The invention has the characteristics of simple mechanical drive principle, flexible material distribution, high running precision, reliable operation, convenient use and maintenance and long service life.

Owner:WISDRI ENG & RES INC LTD

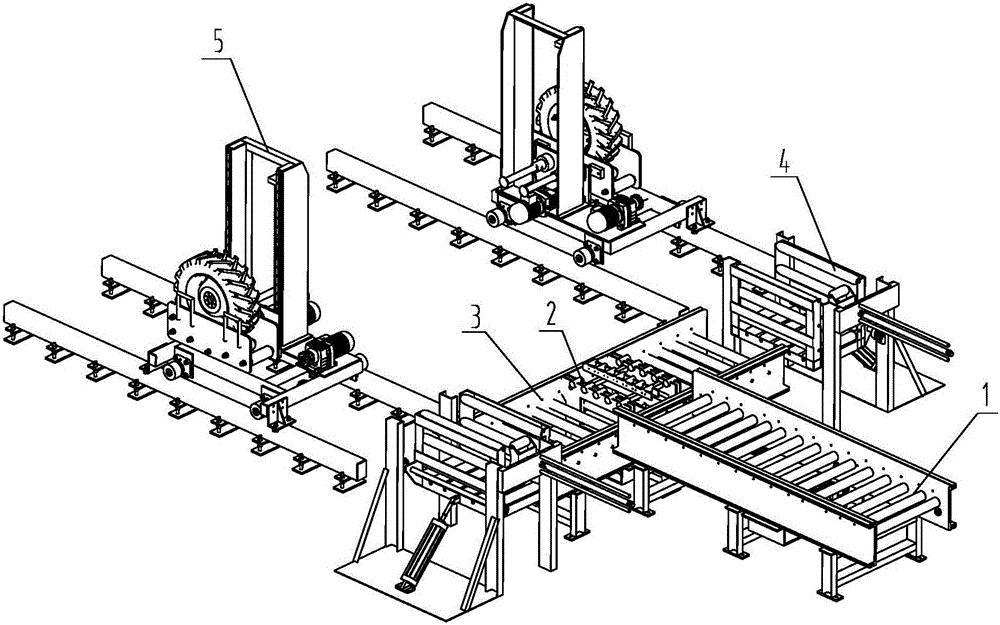

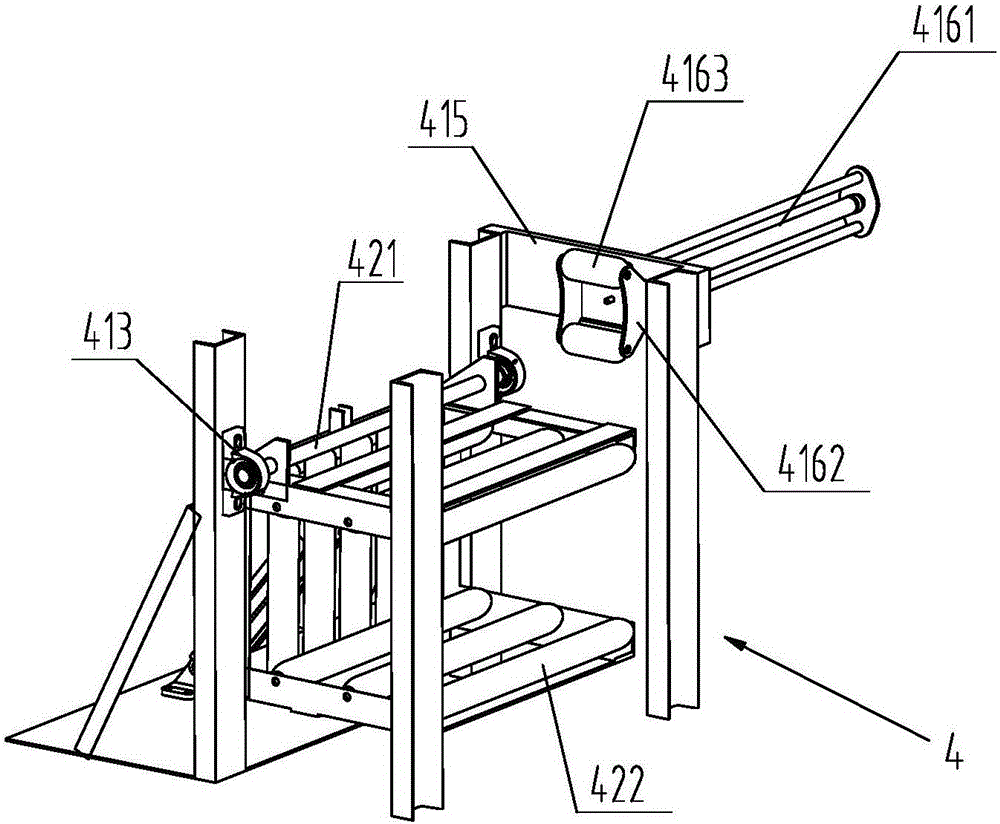

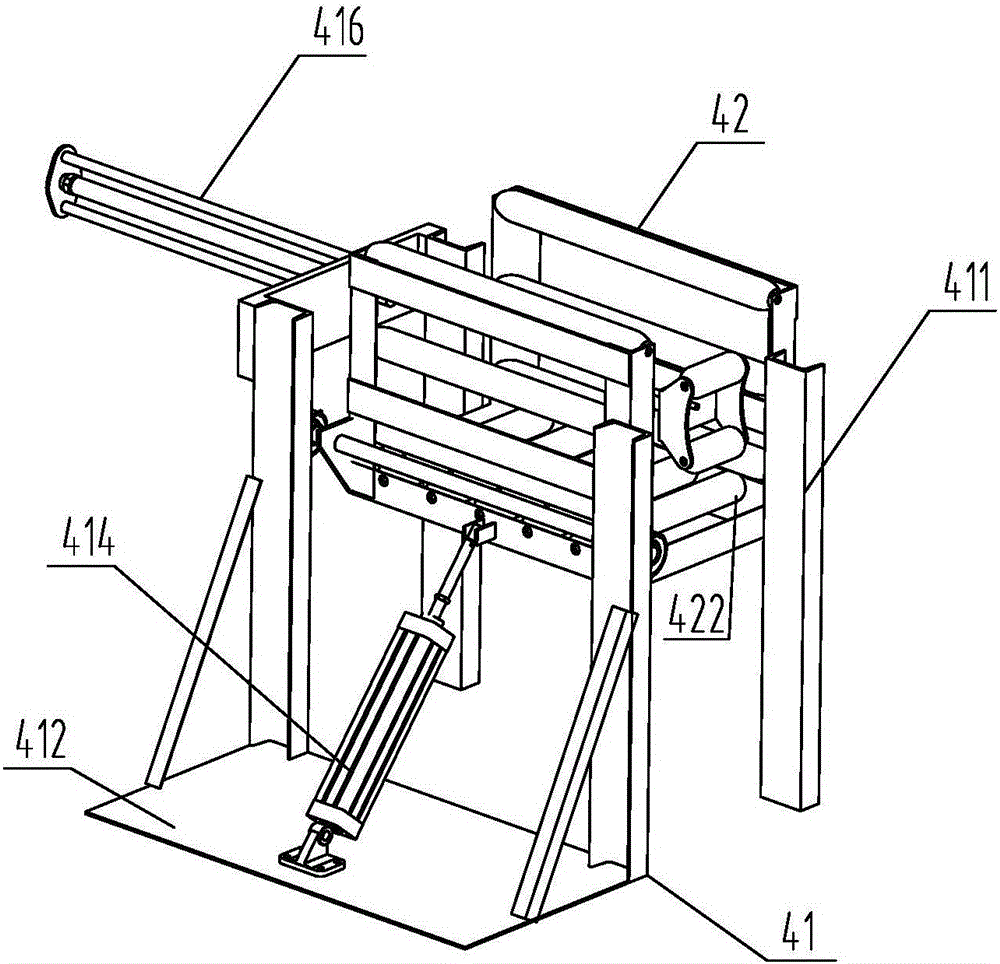

Tire assembling and supplying system

The invention belongs to the field of mechanical conveying of general assembly workshops of automobiles, and particularly relates to a tire assembling and supplying system. The tire assembling and supplying system comprises a conveying roller bed for conveying horizontally arranged tires, a jacking transfer machine and a flow division roller bed, and a pair of turning push devices which are arranged at two ends of the flow division roller bed and connected in a bearing manner front and back, and a follow lifting device, wherein the conveying surface of the flow division roller bed is lower than the conveying roller bed and can operate in two directions; the conveying roller bed and the flow division roller bed are in T-shaped arrangement, and an intersection is transitionally connected in a bearing manner through the jacking transfer machine positioned below the flow division roller bed; the turning push devices receive the tires on the flow division roller bed, roll the tires over and convey the tires to the follow lifting device; the follow lifting device and a vehicle body move synchronously, and the follow lifting device jacks the vertically arranged tires to mounting positions. The tire assembling and supplying system occupies a smaller space, is relatively low in manufacturing cost and high in operation precision, and is convenient to mount and debug; the automation level of tire assembling can be greatly increased.

Owner:DONGFENG DESIGN INST

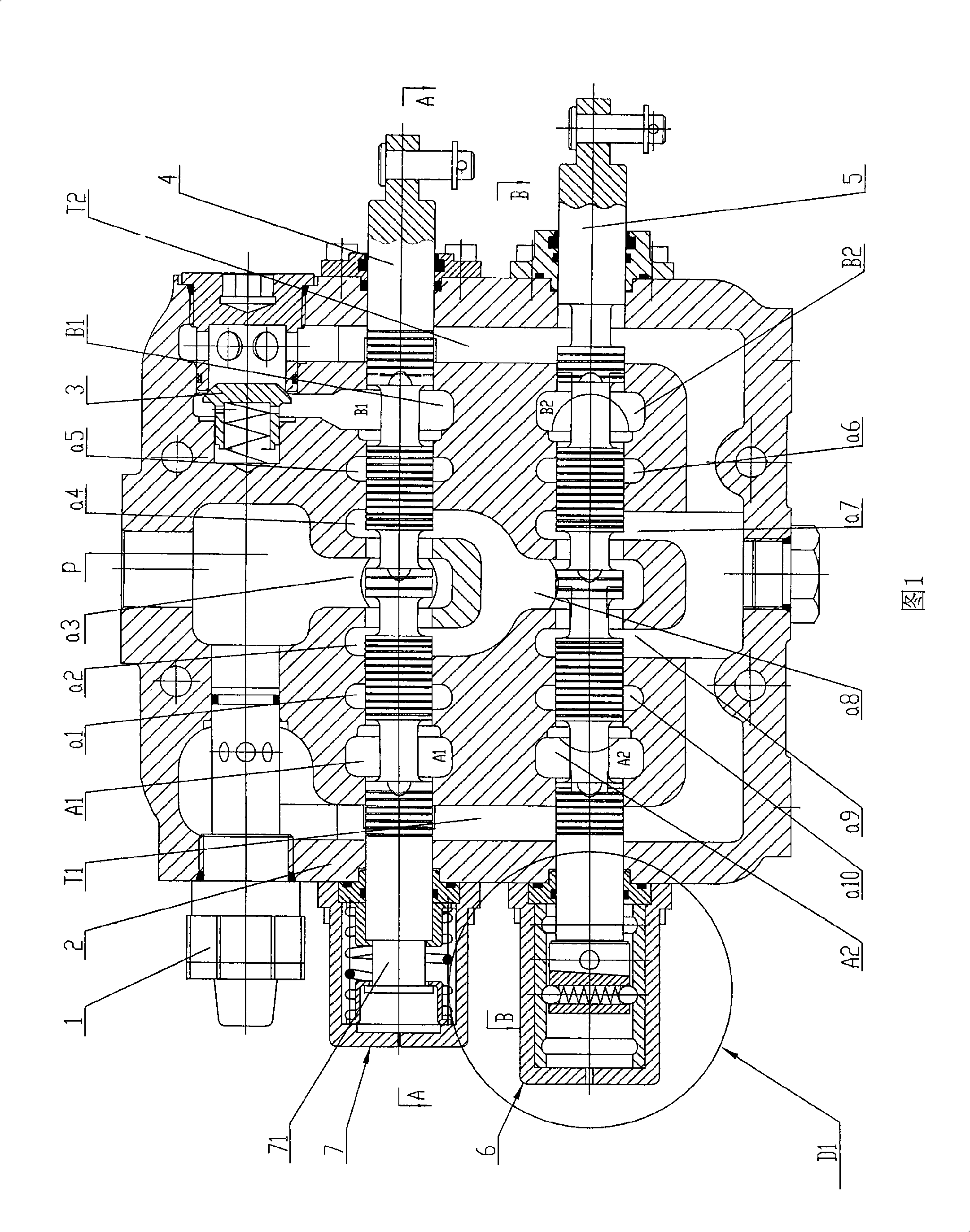

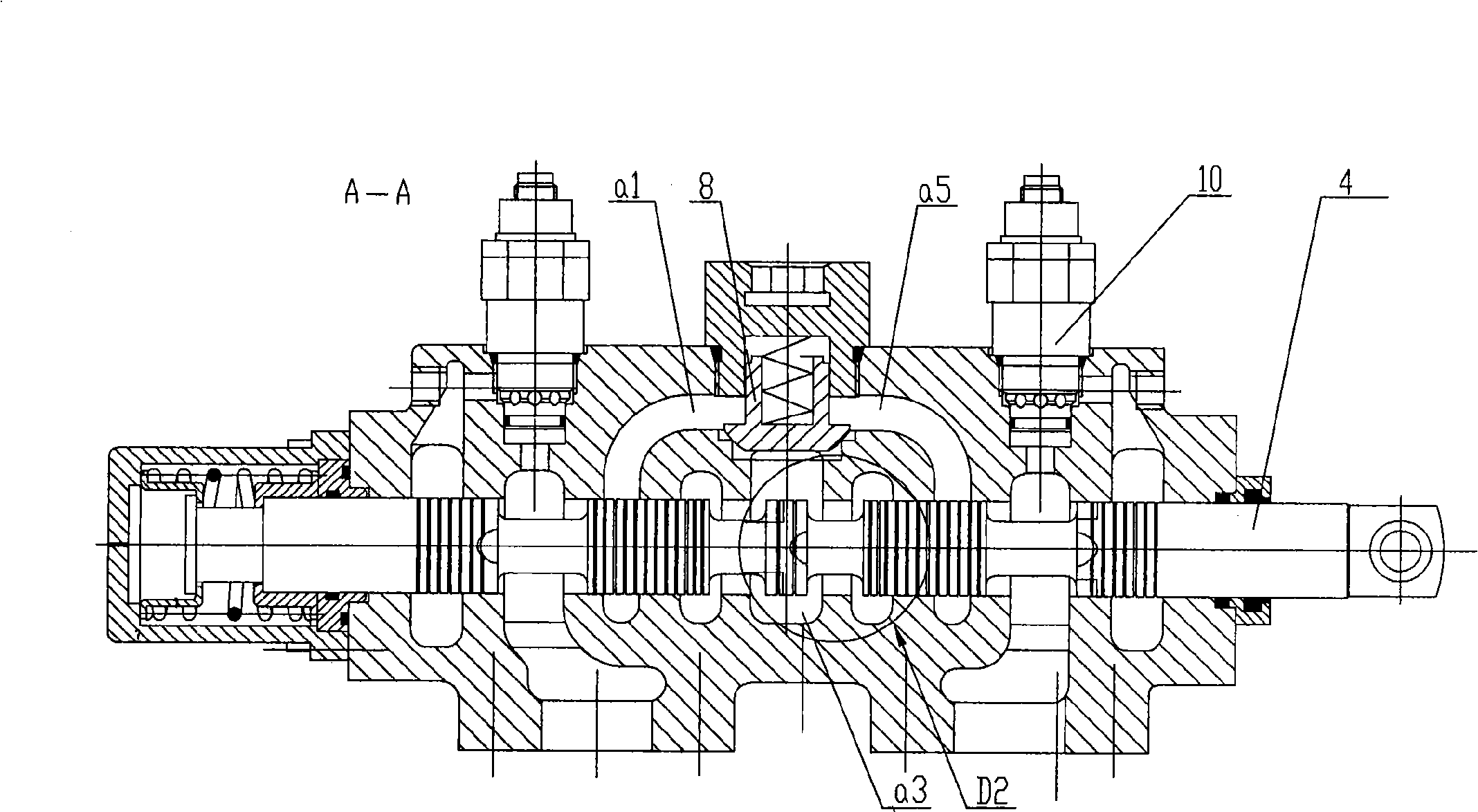

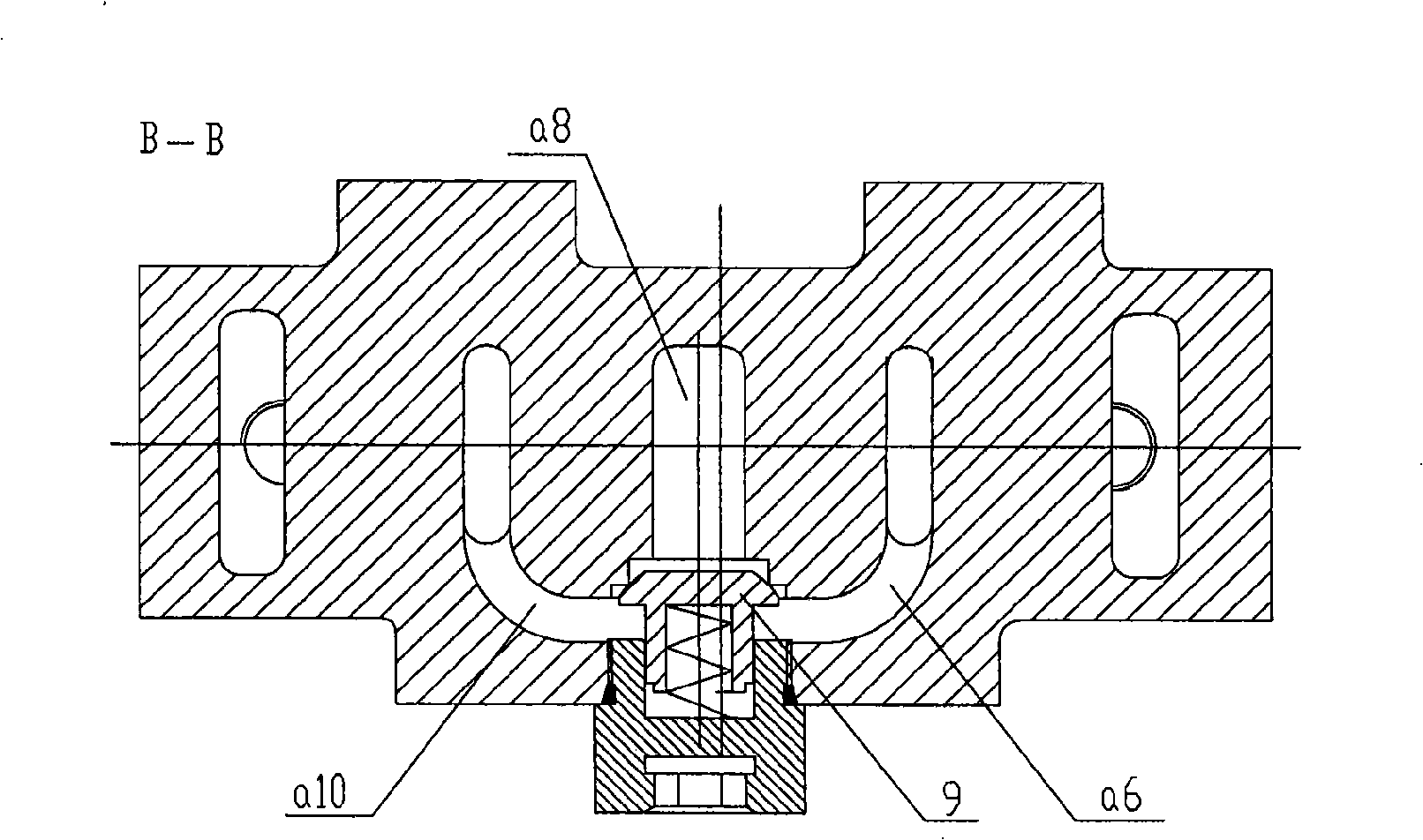

Multipath hydraulic change-over valve

InactiveCN101338829AIncrease the bearing surfaceHigh running accuracyOperating means/releasing devices for valvesServomotor componentsSteel ballEngineering

The present invention relates to a multi-path hydraulic reversing valve, which comprises a valve body, a turning bucket valve rod, a movable arm valve rod, a main safety valve, an overload valve, a turning bucket load-retaining one-way valve, a movable arm load-retaining one-way valve, an oil-supplementing valve, a turning bucket valve rod-positioning unit and a movable arm valve rod-positioning unit. The tail ends of the valve rods in the positioning units are provided with stepped holes, wherein, the deep holes are connected with the front ends of positioning blocks by threads, and the shallow holes serve as positioning holes to be tightly fitted with the middle cylindrical surfaces of the positioning blocks. The bodies of the turning bucket valve rod and the movable arm valve rod are provided with longitudinal throttling grooves and multiple annular compensating grooves, and the throttling groove is intersected with at least one annular compensating groove. Valve rod holes on the valve body, through which the valve rods pass, are stepped, wherein, the deep holes are fitted with the valve rods, and the shallow holes serve as positioning holes to be tightly fitted with the cylindrical surface of the flange part of a pressing plate. The inner wall of a lining is provided with three arc-shaped steel ball-positioning ring grooves. The present invention can reduce the operating force of the hydraulic valve, resolve the jamming problem of the hydraulic valve, reduce the abrasion of the related parts of the hydraulic valve and prolong the service life of the hydraulic valve, and the multi-path hydraulic reversing valve is characterized by simple structure and reliable operation.

Owner:浙江海克力液压有限公司

Lubrication system for rotating shuttle components of embroidery machines

ActiveCN101545184AExtend your lifeIncrease rotation speedLubrication/cooling devicesAuxillary devicesEngineeringGuide tube

The invention relates to a lubrication system for rotating shuttle components of embroidery machines, in particular to a rotating-shuttle-component lubrication system consisting of a rotating shuttle, a rotating-shuttle shaft and a rotating-shuttle shaft sleeve, wherein the inside of the rotating-shuttle shaft is provided with a through hole coaxial with the rotating-shuttle shaft; one end of the through hole is a lubricating oil inlet communicated with a rotating-shuttle oil supply device through a duct, and the other end of the through hole is a lubricating oil outlet communicated with an inner cavity of the rotating shuttle; and the surface of the rotating-shuttle shaft is provided with an oil spray hole communicated with the through hole. The lubrication system not only can continue oiling the rotating shuttle, the rotating-shuttle shaft and the rotating-shuttle shaft sleeve, but also can cool and clean the components.

Owner:杭州大云自动化科技有限公司

Heat pipe internal cooling dry type screw rods vavuum pump

InactiveCN103267015AImprove cooling effectReduce surface temperatureRotary piston pumpsRotary piston liquid enginesCooling chamberEngineering

The invention relates to a vacuum obtaining apparatus, namely a dry type screw rods vavuum pump that designs two screw rods into hollow and employs the heat pipe internal cooling method. In the heat pipe internal cooling dry type screw rods vacuum pump provided by the invention, the screw rods are made into hollow; the internal of the screw rods are cooling chambers, which is convenient for cooling the screw rods, taking away the heat generated by the screw rods, therefore the surface temperature of the screw rods is reduced, the problem of medium solidification carbon formation generated in the process of pumping the medium by the screw pump is solved, and service life of the screw rods are greatly improved.

Owner:威海智德真空科技有限公司

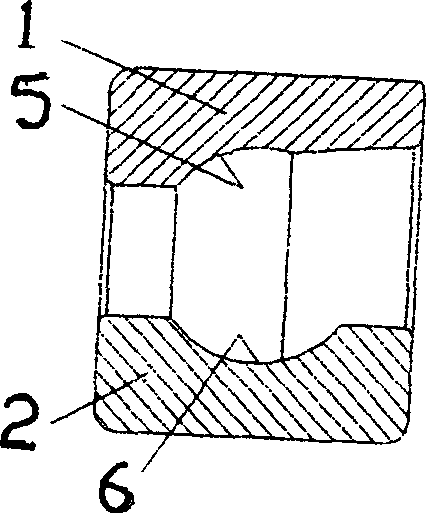

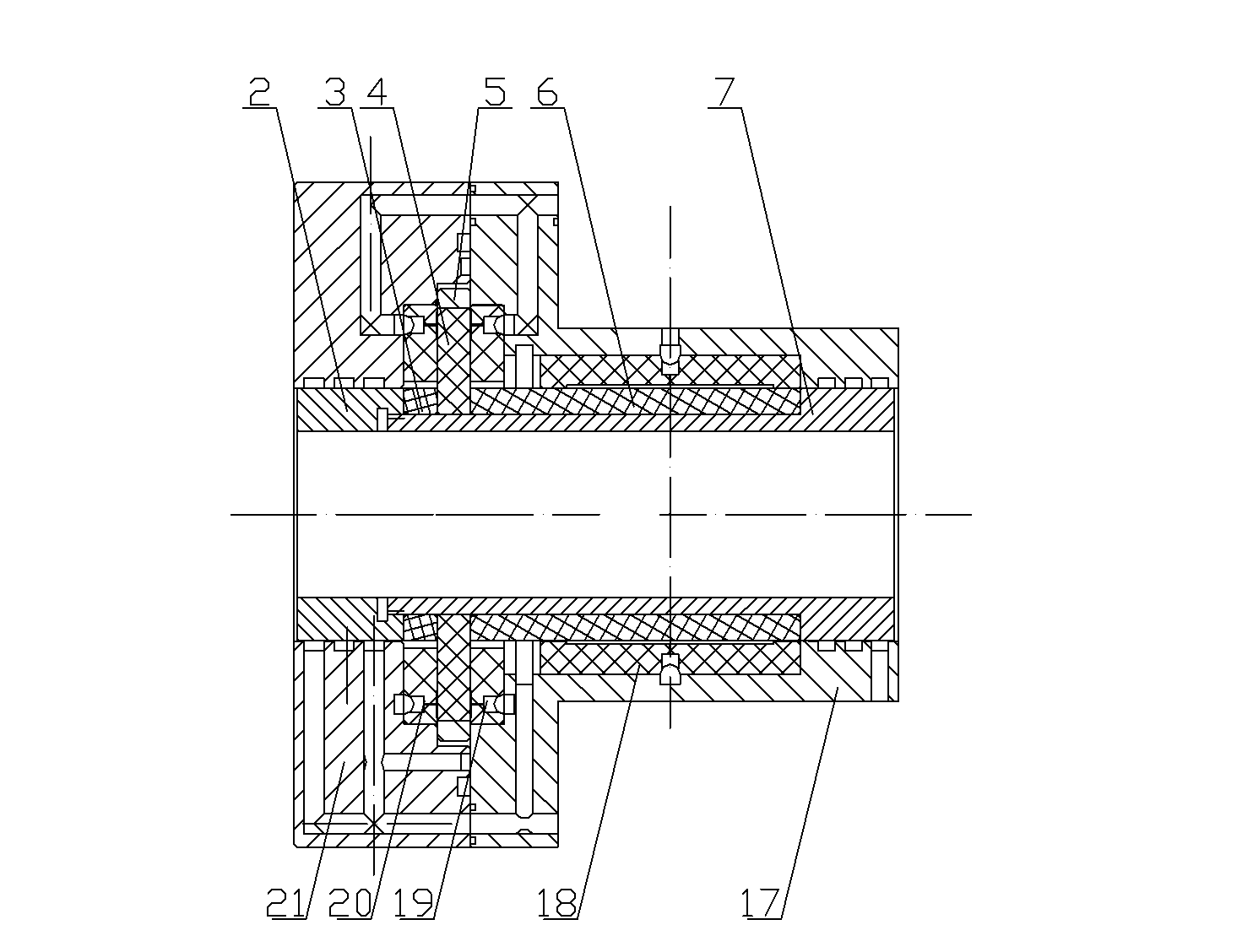

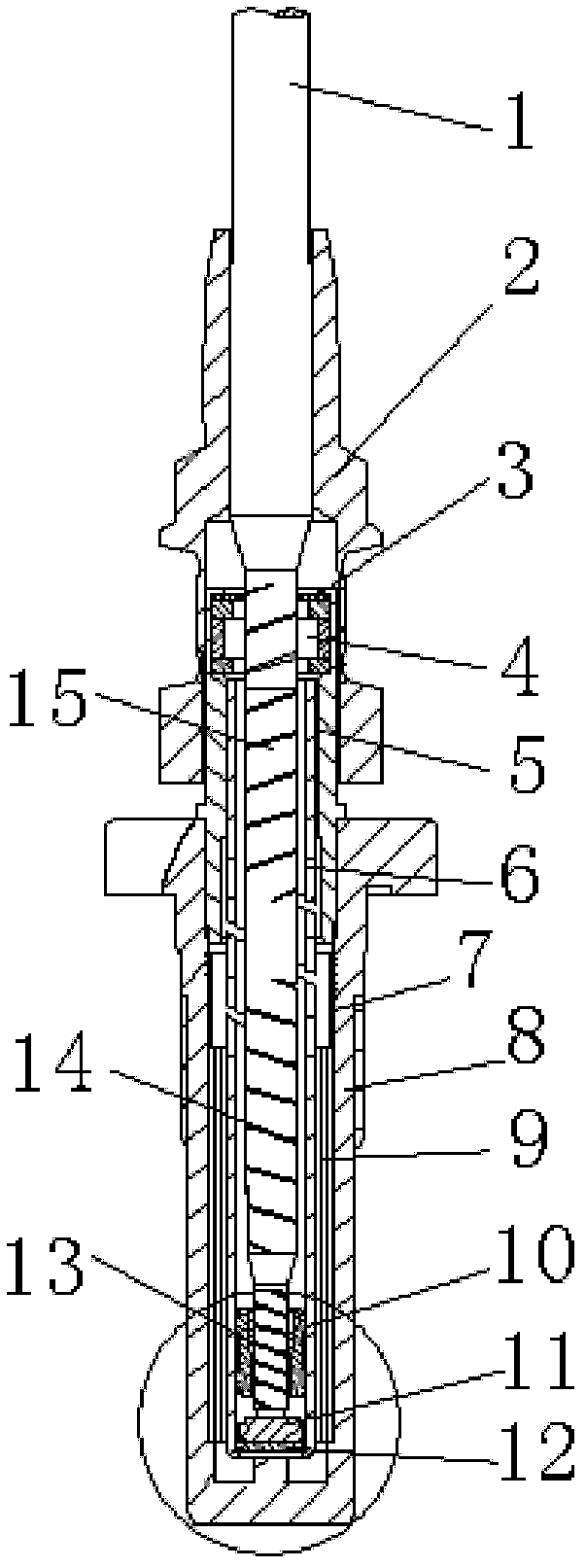

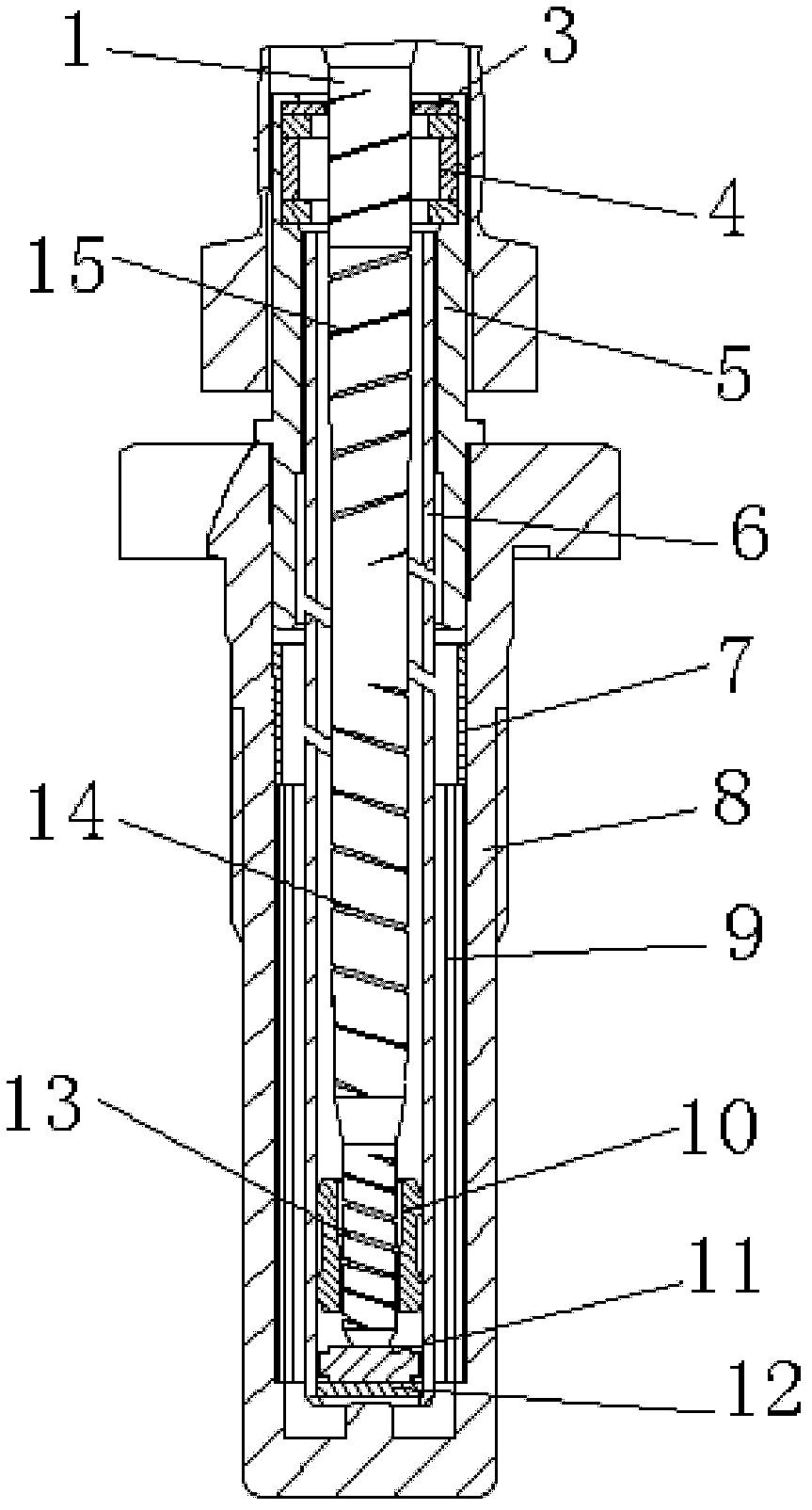

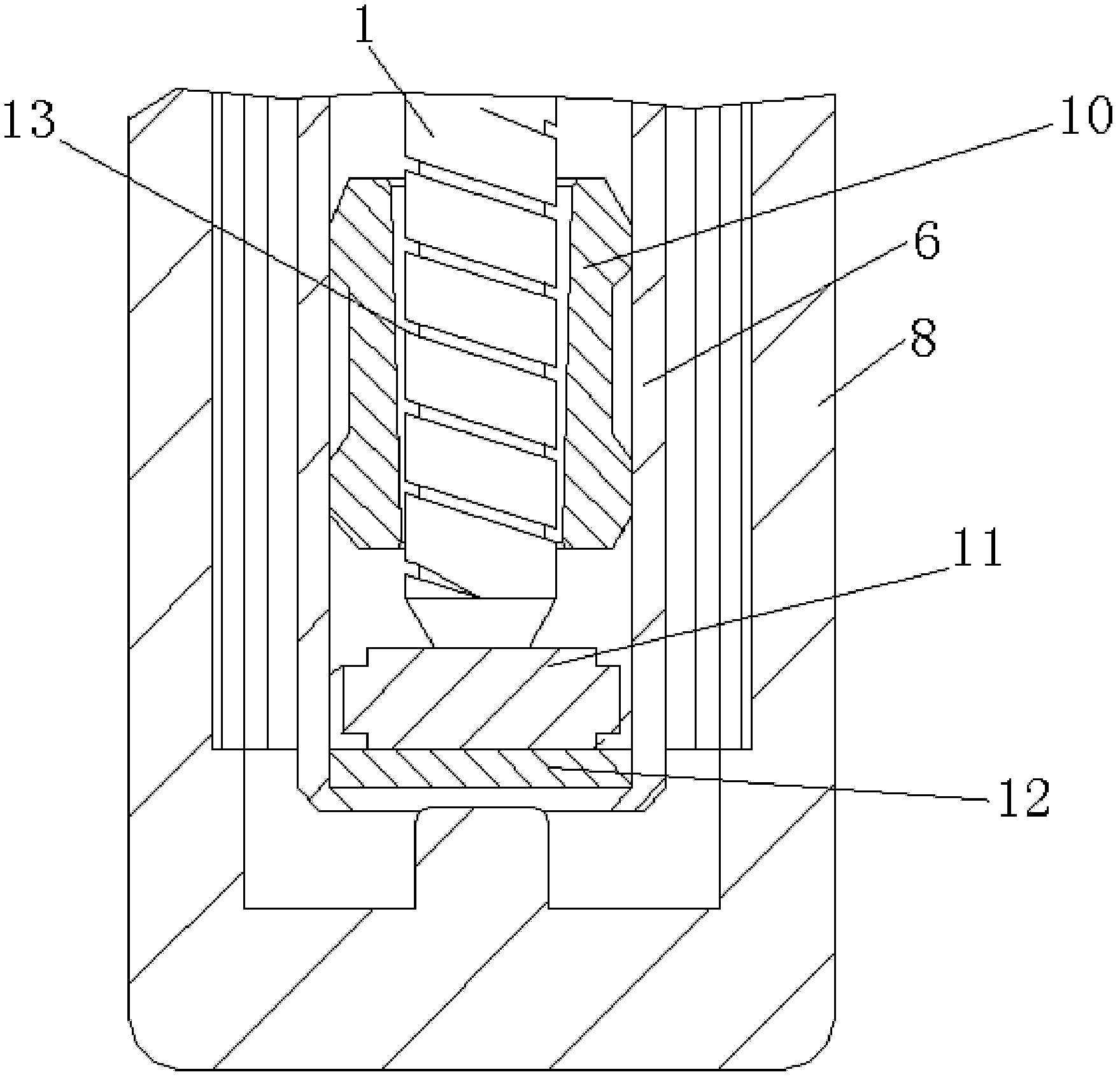

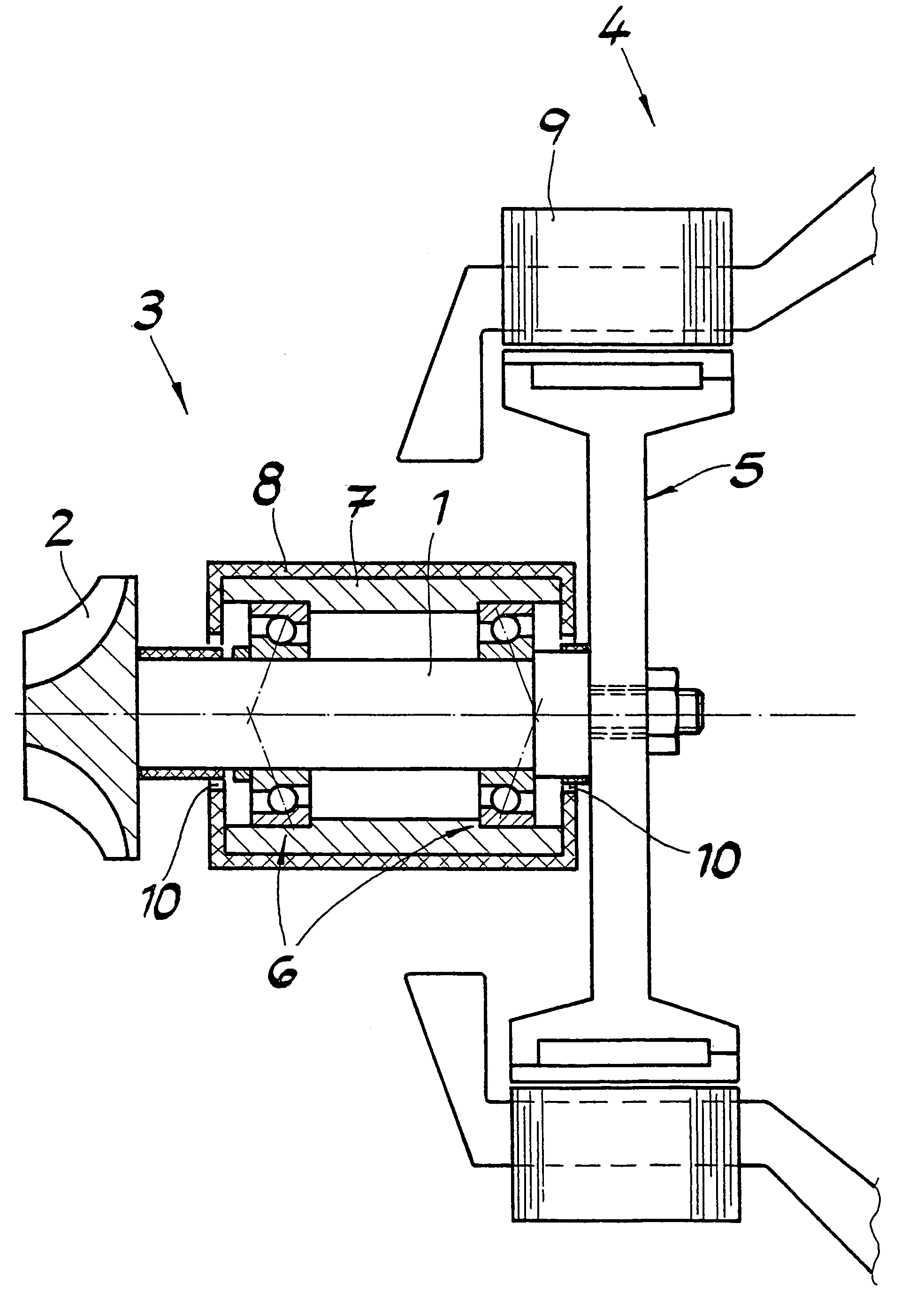

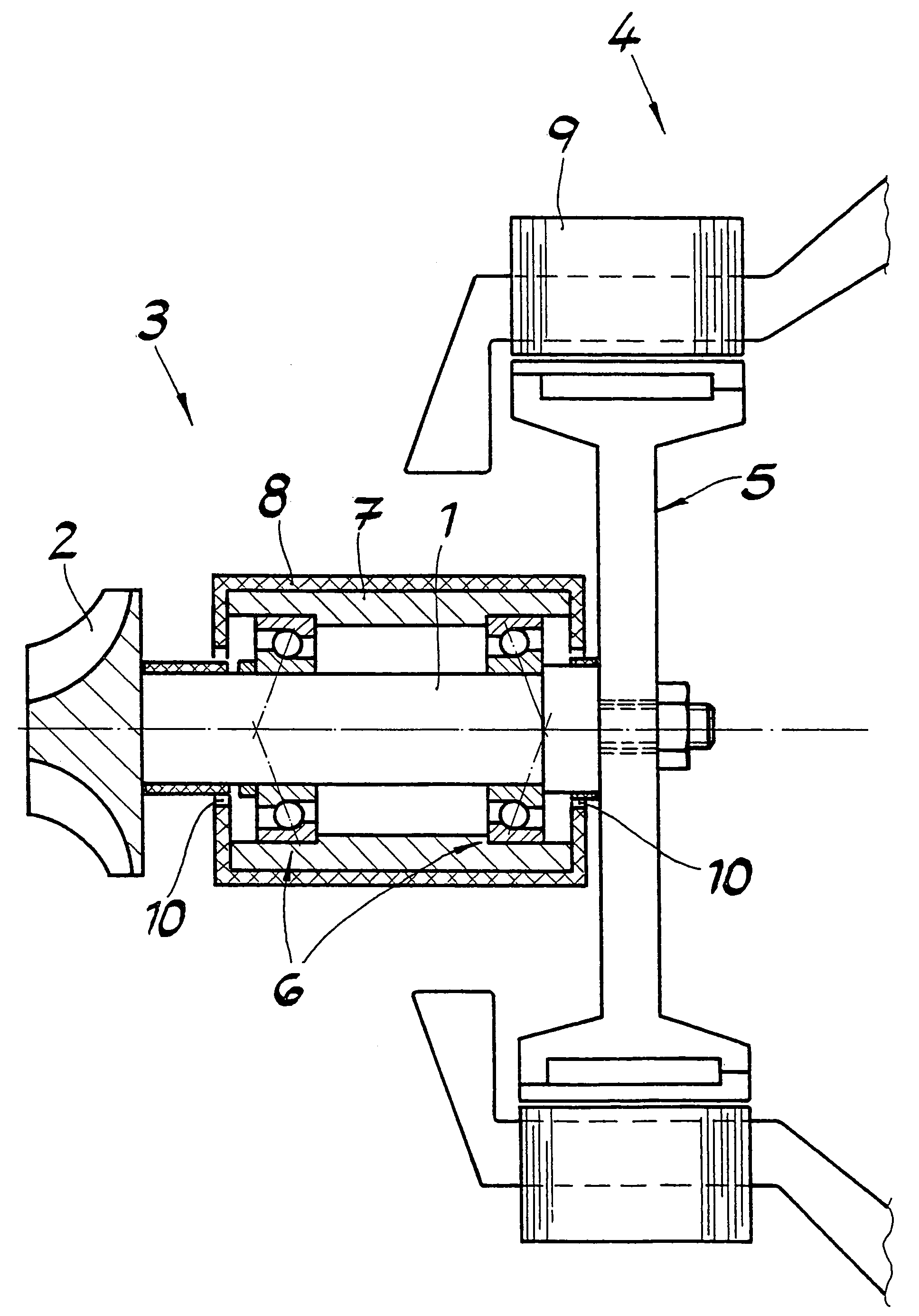

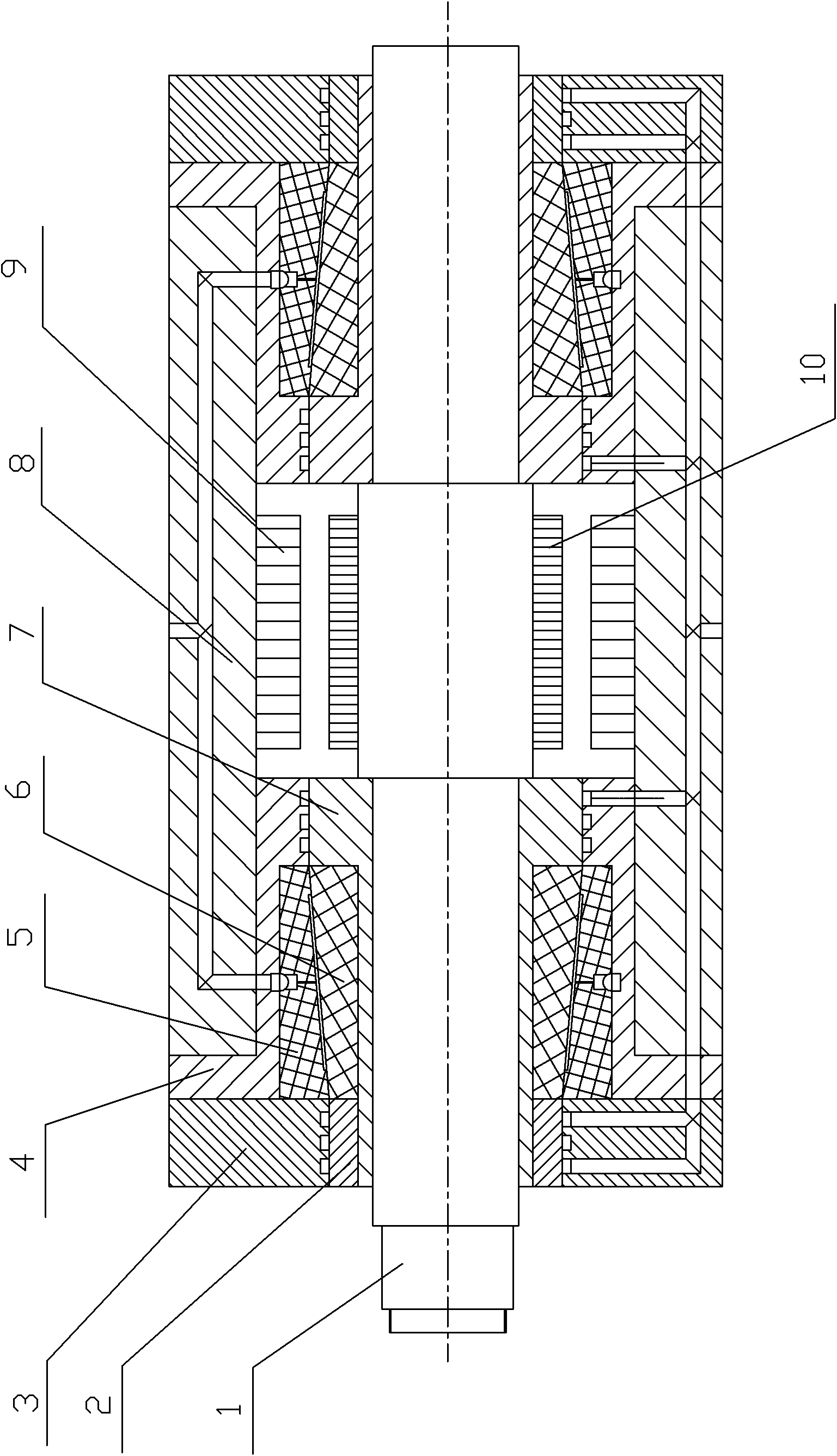

Bearing Block Device of Pulse Liquid Grease Circulation Lubrication Mode for Steel Wire Rope Stranding Machine

InactiveCN102297205AImprove running accuracyReduce noiseRope making machinesBearing coolingPulse injectionLubrication

The invention discloses a bearing seat device of pulse liquid grease circulation lubrication mode for a wire rope stranding machine, which is characterized in that it comprises a base (1), an upper cover (2), a thrust ring (3), an end cover (4), Anti-leakage cover (5). The present invention adopts the metal oil pipe that pulse-sprays lubricating oil to the rolling bearing on the upper cover; the main oil return passage is arranged on the base; the outer labyrinth groove is arranged on the thrust ring, and the inner labyrinth groove is arranged on the end cover; The lower part of the cover is provided with an auxiliary oil return channel; in application, it is collected and recovered through pulse jet oil injection, labyrinth dynamic damping seal and anti-leakage cover, which overcomes the difficulty in controlling the leakage and splash of liquid lubricating oil in the existing technology and recycles liquid lubrication The problem and shortage of oil make the wire rope stranding machine suitable for the pulse injection liquid lubricating oil circulation cooling lubrication method, which prevents the leakage and splashing of the liquid lubricating oil and recycles the lubricating oil, thereby further improving the operating speed of the tubular stranding machine the goal of.

Owner:NINGBO KAITE MACHINERY

Digitization sampling time delay frequency conversion measuring method and measuring system

ActiveCN103812731AImprove running accuracyRun accuratelyData switching networksSmart substationTime delays

The invention discloses a digitization sampling time delay frequency conversion measuring method, and the method measures the non integer period time delay to the different frequency steady state analog quantity signals from an electronic transformer or analog inputting and merging unit to obtain the inertial time delay to all frequency signals from the digitization sampling process, including the non integer period time delay and integer period time delay, compensates the sending time difference for SV message based on the transmit frequency of the phaselock technique tracking SV message, reduces the influence caused by the sending time difference for SV message, and raises the digitization sampling time delay measuring precision. The invention also discloses a test system based on the method for ensuring the reliable application of the electronic transformer and the analog inputting and merging unit in the intelligent substation, eliminating the potential safety hazard of the electronic transformer and the analog inputting and merging unit on engineering application, raising the second-order system running veracity for the intelligent substation and having significance to the safe and reliable operation for the intelligent substation.

Owner:STATE GRID CORP OF CHINA +2

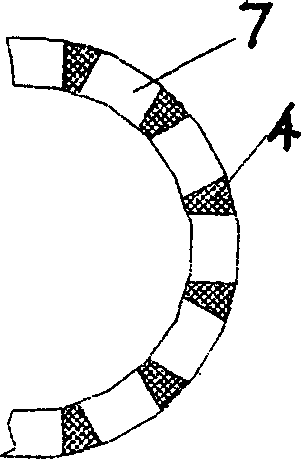

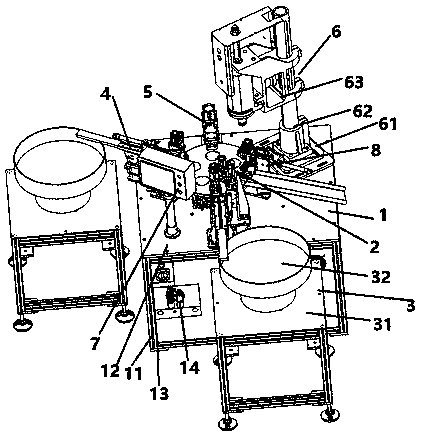

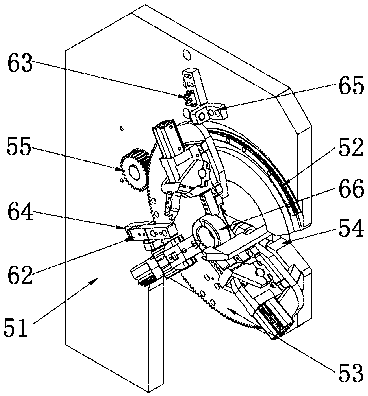

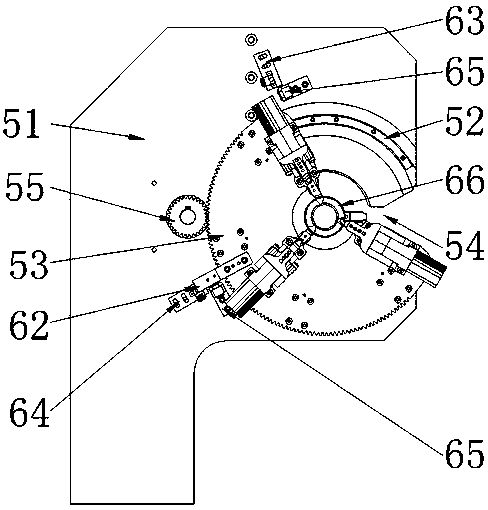

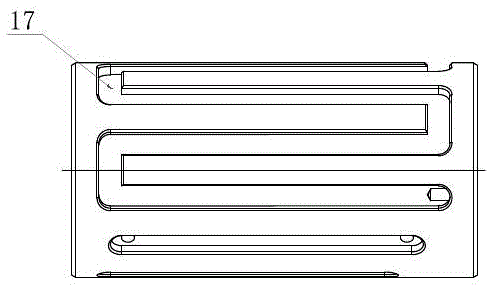

A thick-diameter magnetic loop automatic winding machine and a winding method thereof

ActiveCN109036838AHigh cable work reliabilitySmooth linesCoils manufactureWinding machineEngineering

The invention discloses a thick wire diameter magnetic loop automatic winding machine and a winding method thereof, which have high working efficiency, low labor cost, high working precision, uniformwire arrangement and stable clamping. The automatic winding machine for thick wire diameter magnetic loop coil in the invention comprises a machine table and wire feeder respectively arranged on the machine table, Manipulator, magnetic clip ring indexing device, Cable-clamping device for that first time, wire winding and pulling device, A line cut and clamping arm and a unloading table, the manipulator is arranged between the wire feeder and the magnetic clip ring indexing device, the first cable clamping and pulling device is arranged behind the magnetic clamping ring indexing device, The wire winding and pulling device is arranged at the rear of the magnetic clip ring indexing device and under the first wire clip and pulling device, the wire clipping arm is arranged in front of the magnetic clip ring indexing device, and the unloading table is arranged at one side of the magnetic clip ring indexing device. The invention is applicable to the field of magnetized winding.

Owner:ZHUHAI KLES MACHINE TECH

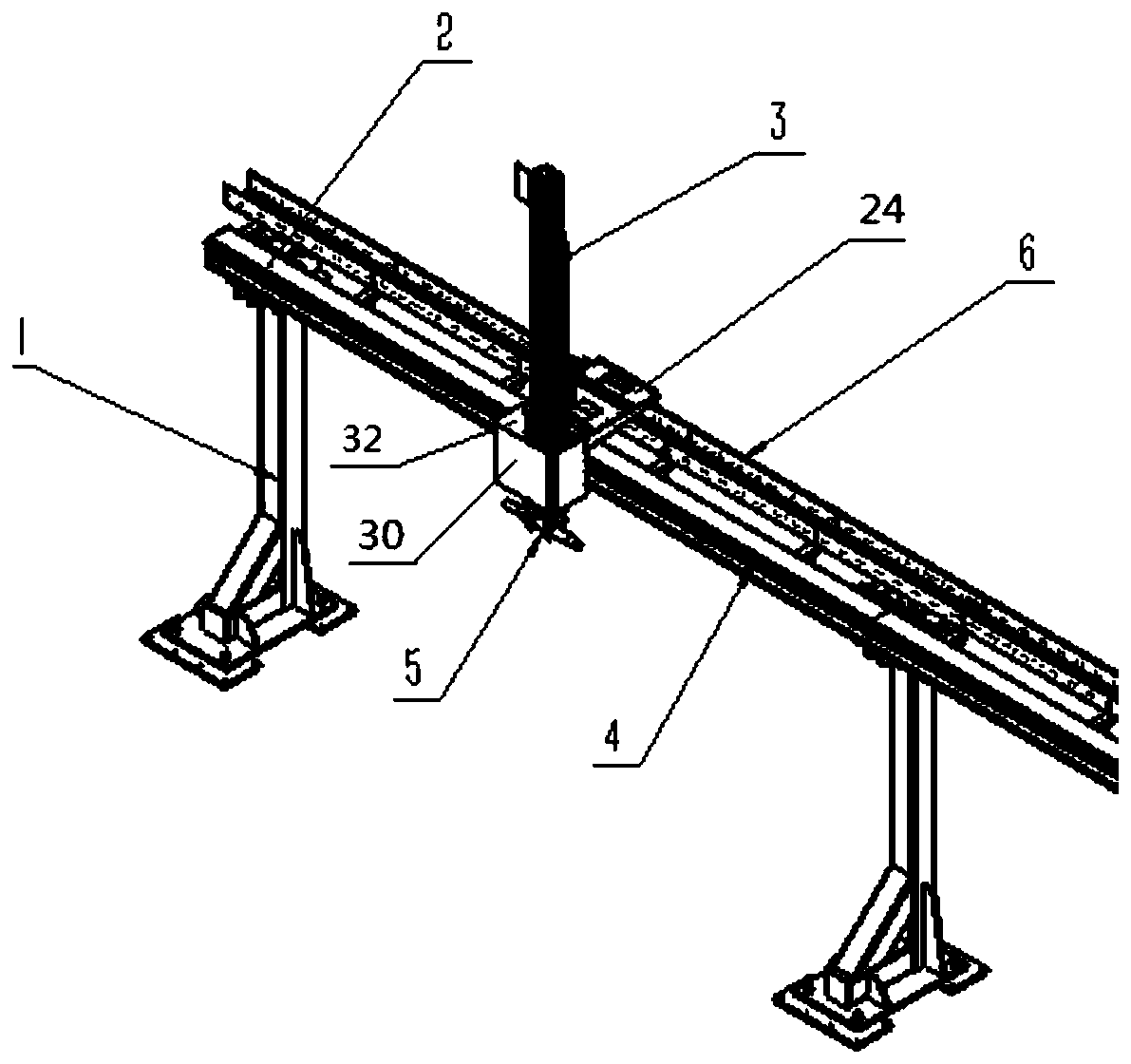

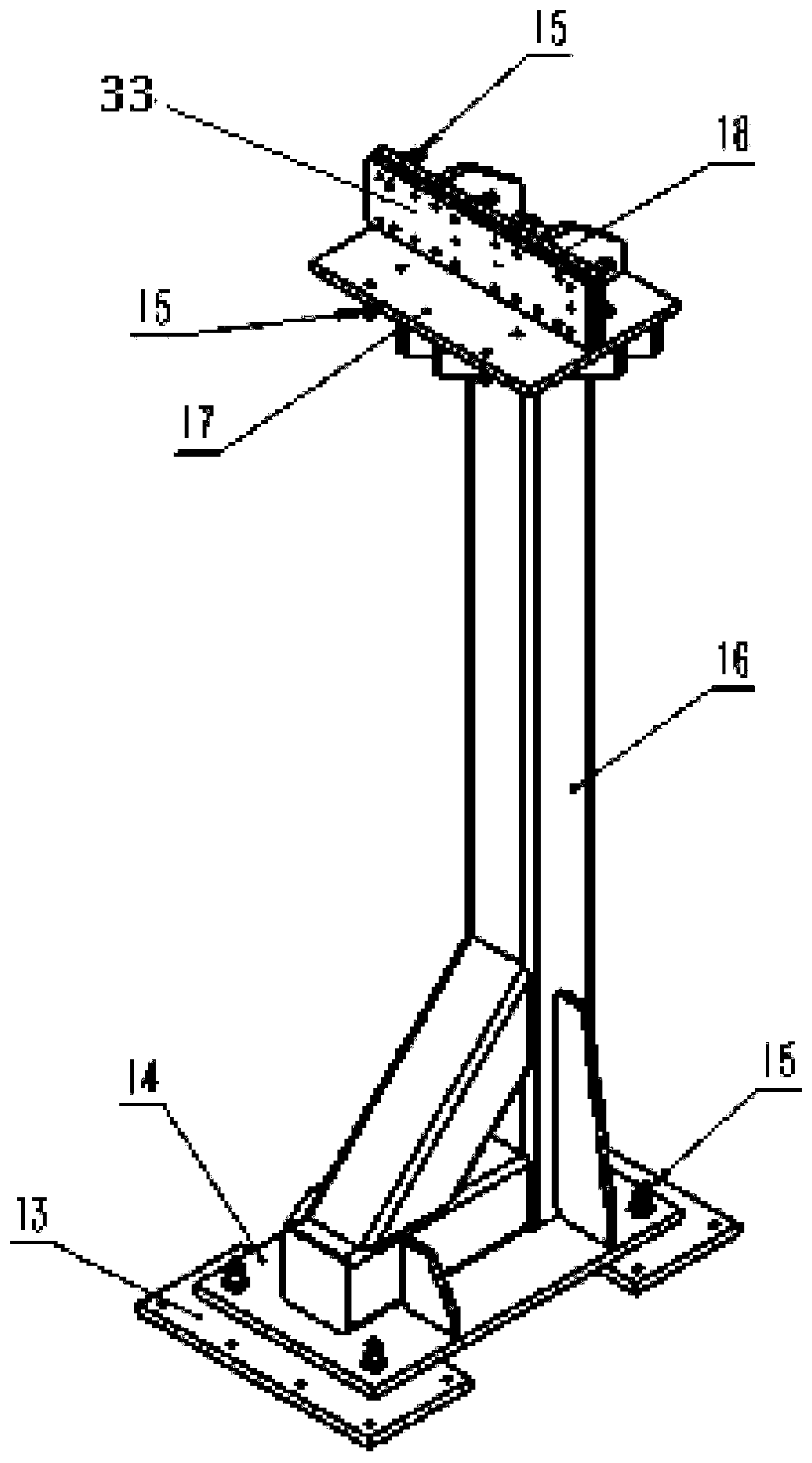

Truss mechanical arm device for intelligent production line

PendingCN109773765AImprove operational efficiencyFlexible operationProgramme-controlled manipulatorMetal working apparatusProduction lineEngineering

The invention discloses a truss mechanical arm device for an intelligent production line. The truss mechanical arm device comprises a transverse beam main body, wherein at least two supporting stand columns are mounted at the bottom end of the transverse beam main body; an X-axis horizontal movement unit is arranged along the axial direction of the transverse beam main body; the X-axis horizontalmovement unit is provided with a sliding seat which can move horizontally; a Z-axis movement unit which can move vertically is mounted at the outer side of the sliding seat; the Z-axis movement unit comprises a Z-axis main body; and a grasping mechanism for grasping materials is mounted at the lower end of the Z-axis main body. The truss mechanical arm device provided by the invention aims at replacing manual operation with efficient and rapid automatic machines and conveniently improving the running precision and the running efficiency.

Owner:秦川机床工具集团股份公司

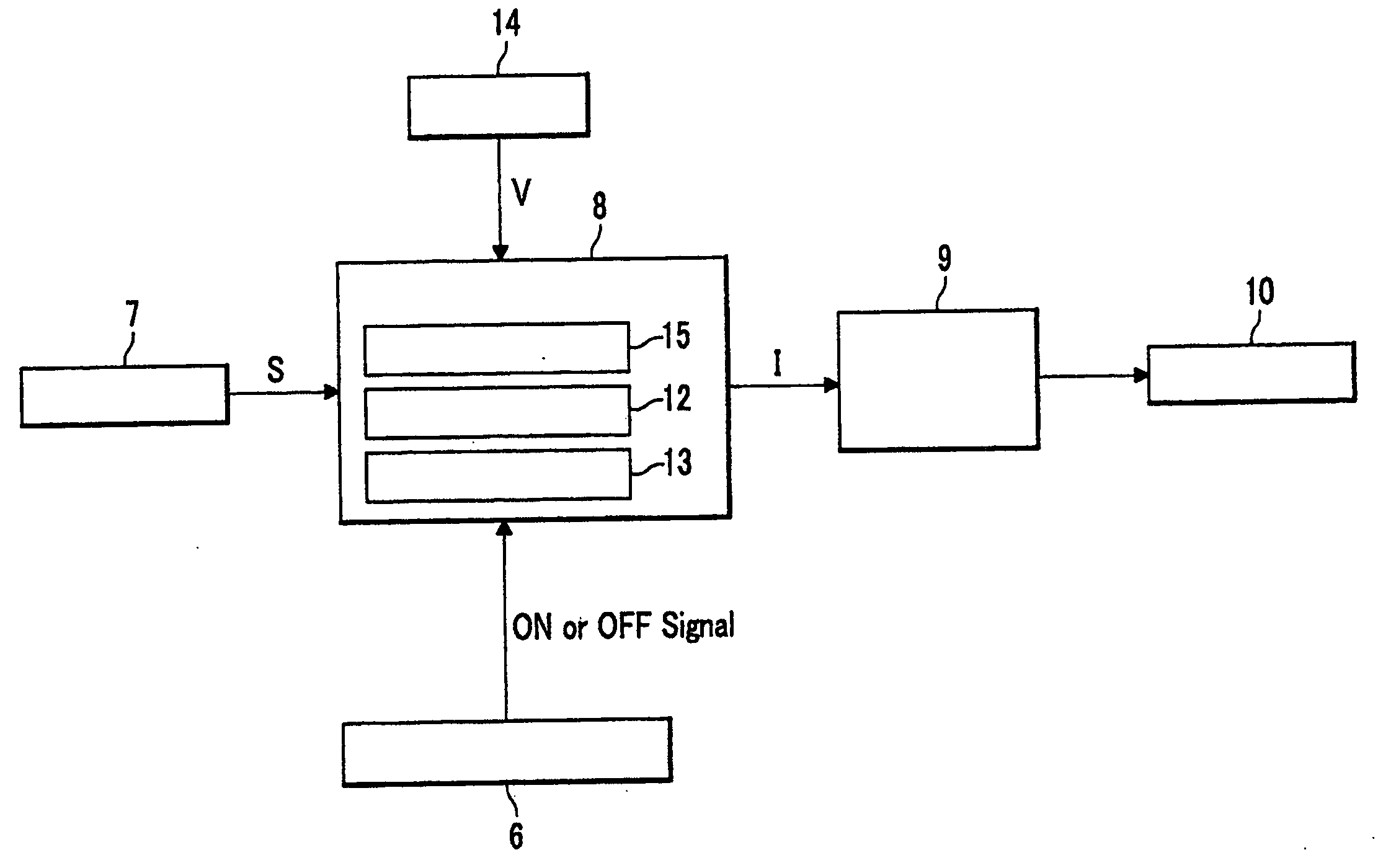

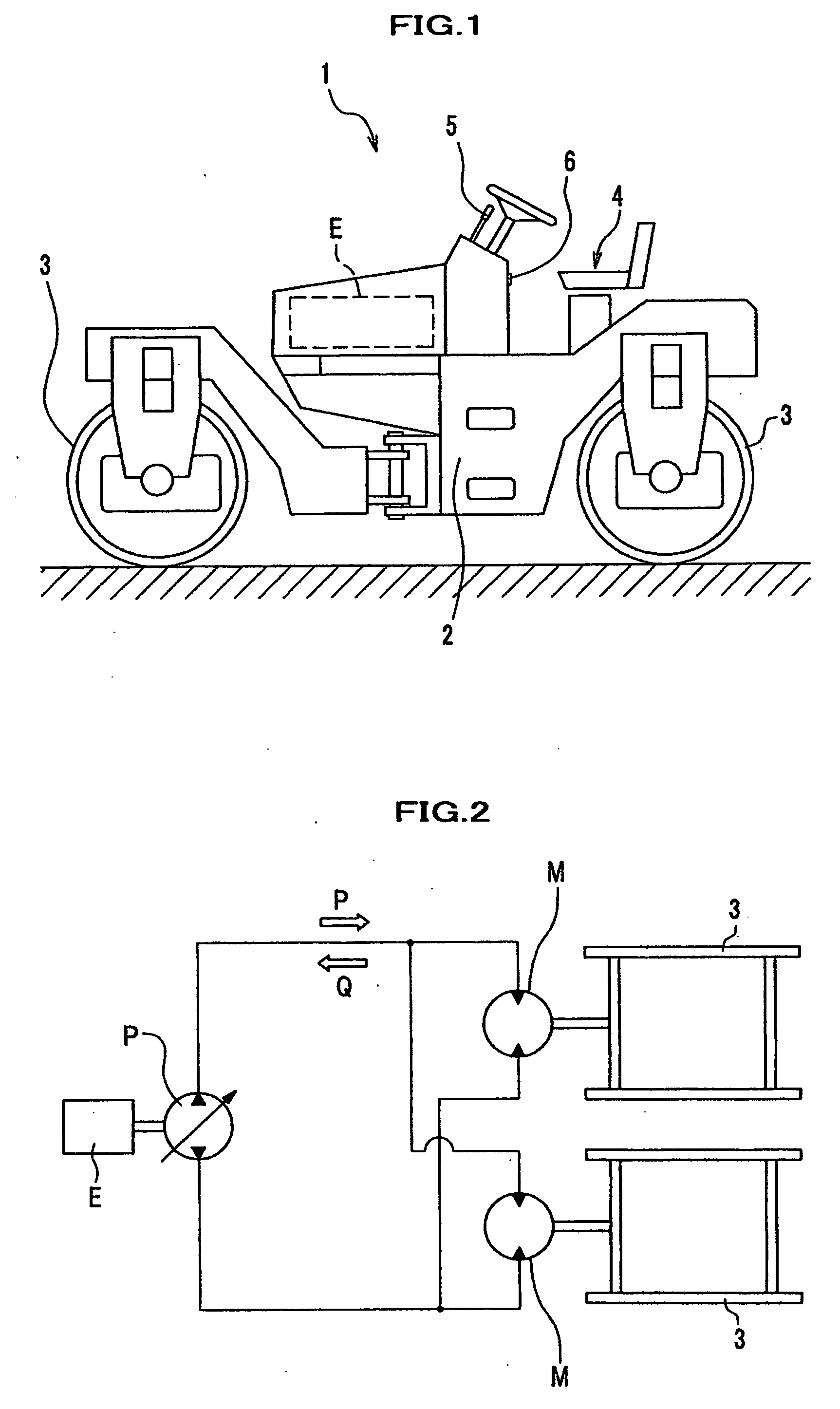

Compaction vehicle

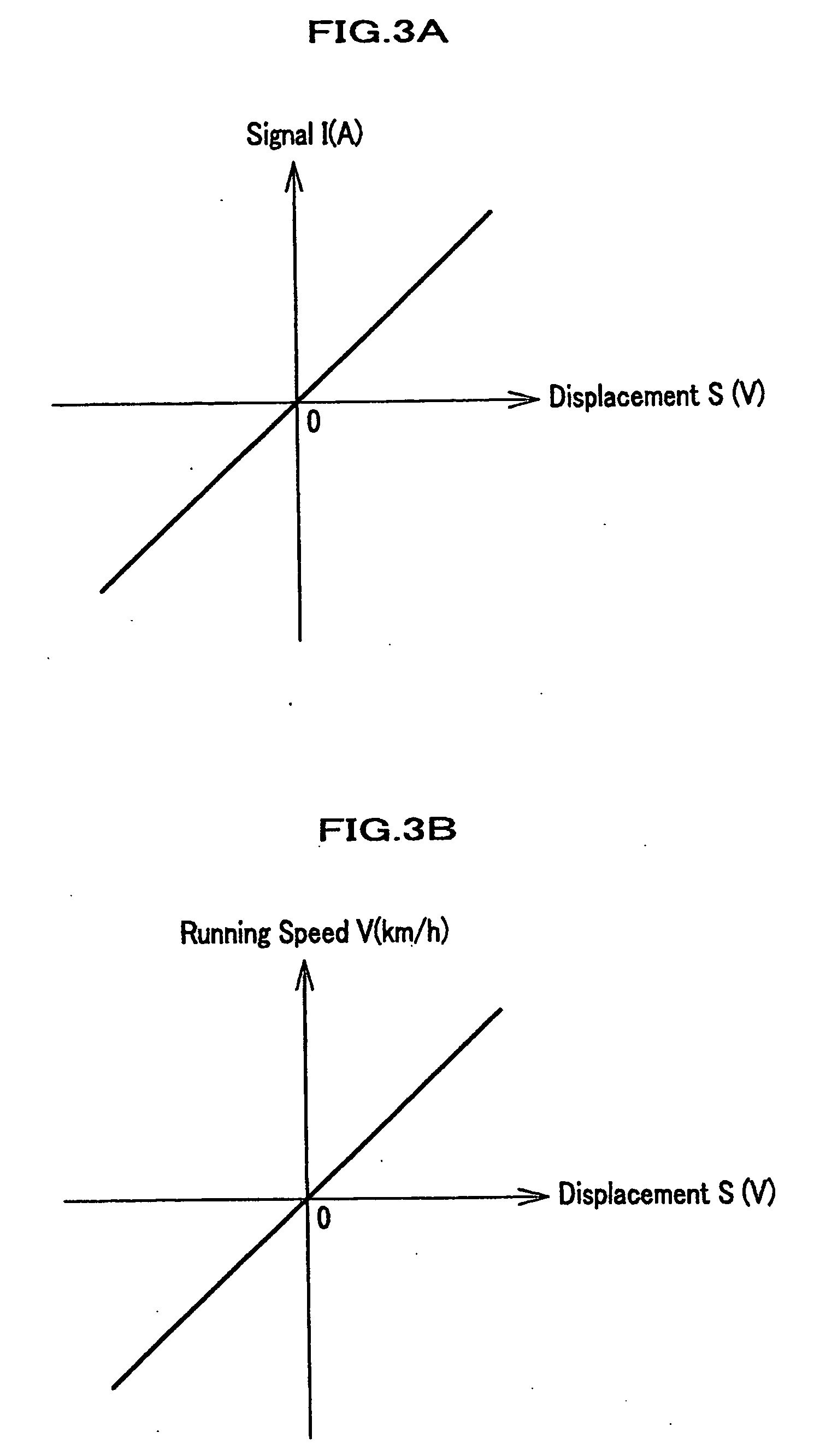

ActiveUS20070032934A1Improve running accuracyHigh maintenance accuracyVehicle fittingsAnalogue computers for trafficControl signalControl theory

The compaction vehicle having a speed adjustment member, a displacement detector, and a drive source controller further includes a calculation device between the displacement detector and the drive source controller, receiving the displacement S, and outputting a signal I calculated to the controller; a running speed setting switch for the operator operating ON at a desired running speed; a control signal memory device provided inside the calculation device and memorizing a signal I1 to the controller, wherein in a normal operation the calculation device outputs the signal I to the controller so that a running speed increases or decreases according to the displacement S, and wherein when the switch is operated to ON, the calculation device maintains the ON state, and the displacement S is not less than a predetermined value, the calculation device outputs the signal I1 memorized in the memory device so as to run the vehicle at a constant speed.

Owner:SAKAI HEAVY INDS

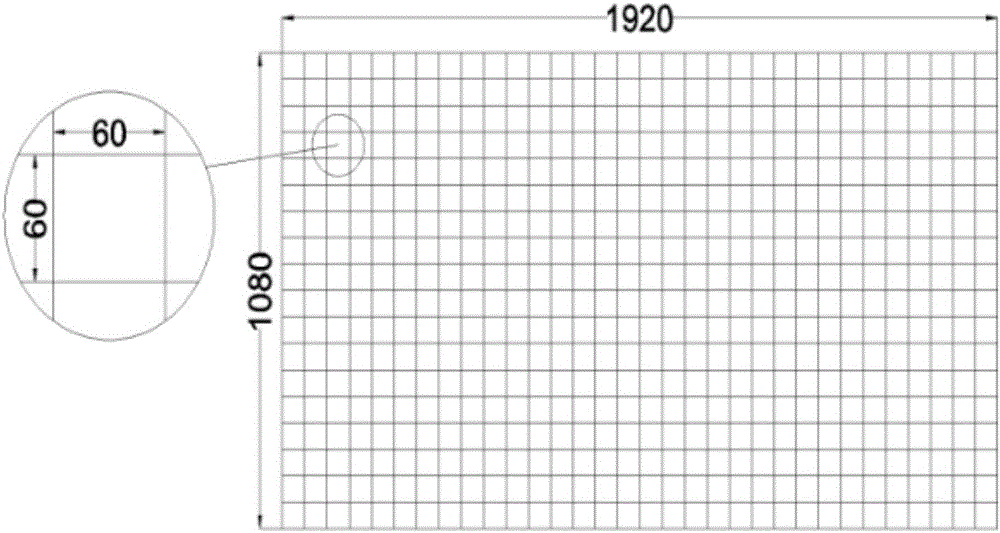

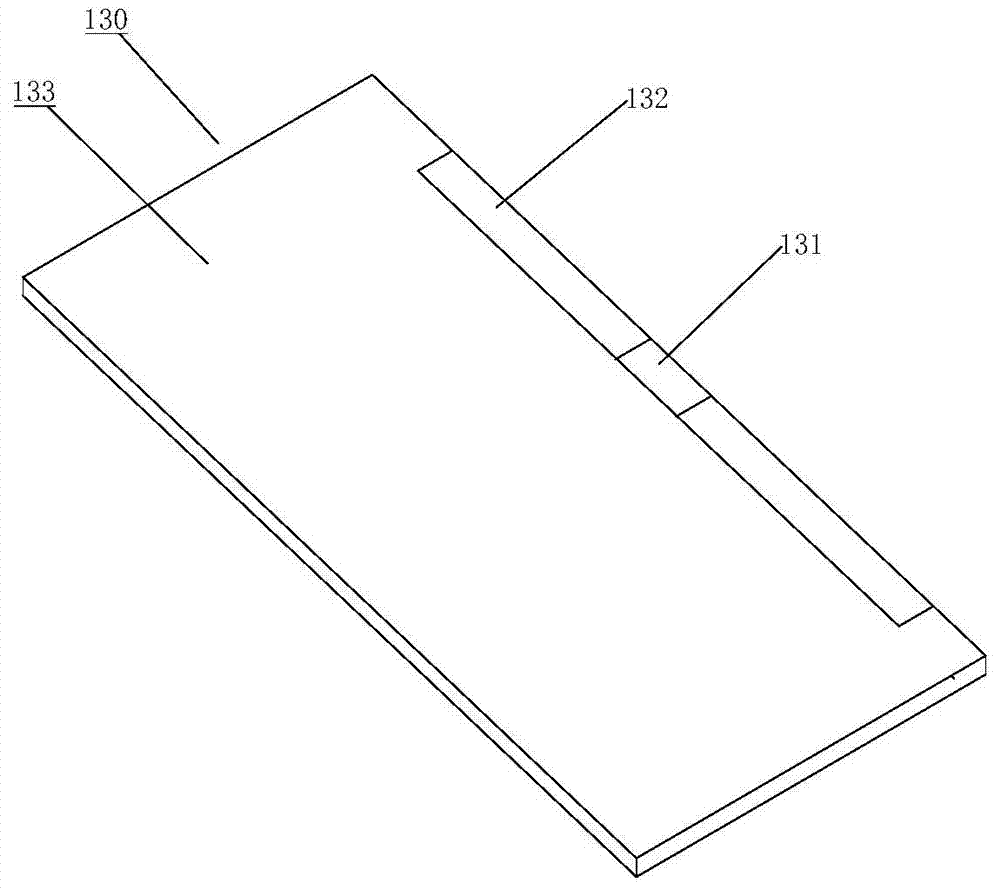

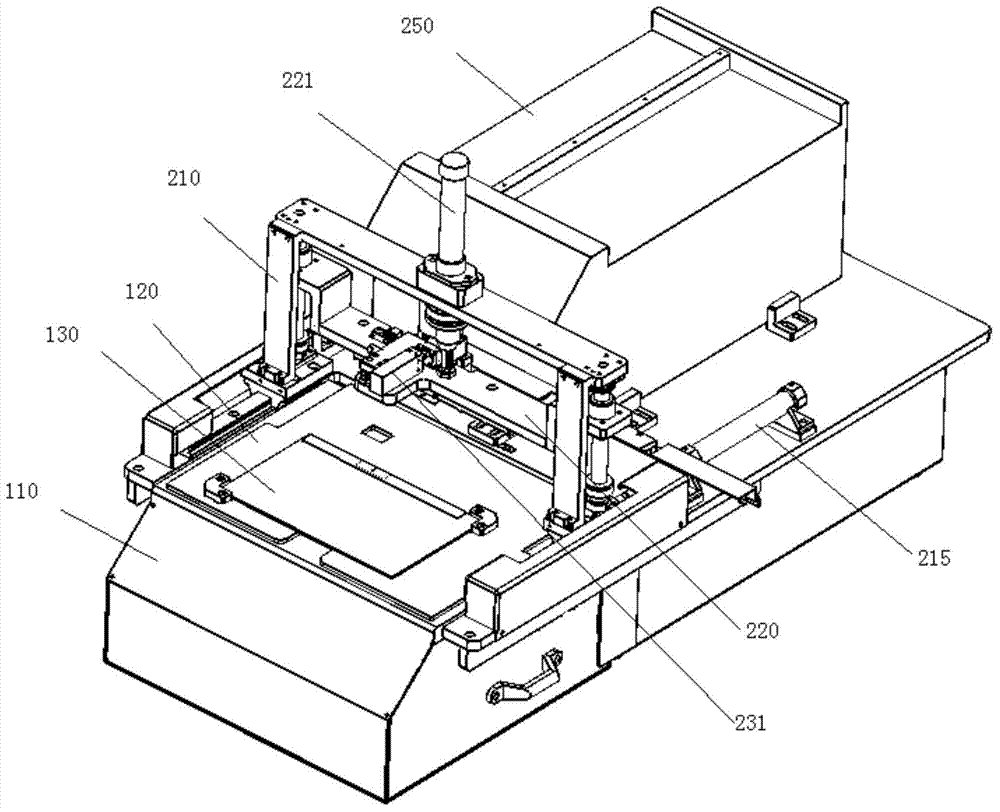

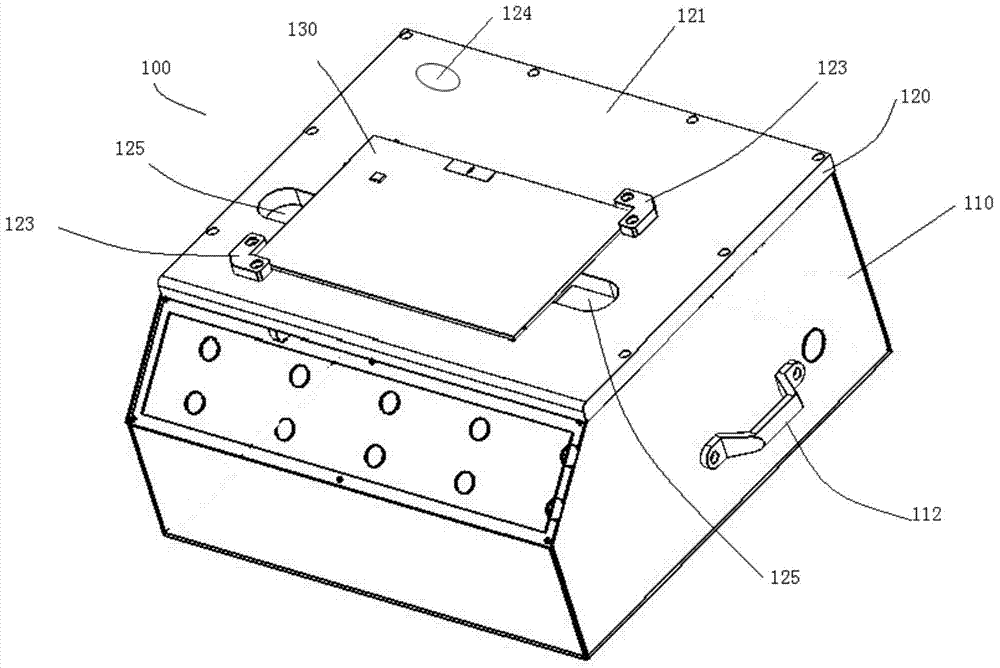

Liquid crystal display screen detecting and assembling device

The invention discloses a liquid crystal display screen detecting and assembling device. The liquid crystal display screen detecting and assembling device is characterized by comprising a fixing device, a liquid crystal display screen detecting device and a liquid crystal display screen detecting and assembling device body, wherein the liquid crystal display screen detecting device is arranged below the fixing device, and the liquid crystal display screen detecting and assembling device body is arranged above the fixing device. The liquid crystal display screen detecting and assembling device can be used for detecting the performance of the front face of a liquid crystal display screen, pasting a label to the back face of the liquid crystal display screen and pressing a circuit board in an attaching mode to enable the circuit board to be tightly attached to the liquid crystal display screen; detection, pasting of the label and pressing attachment of the circuit board can be conducted at the same time, in this way, the production time of the liquid crystal display screen is shortened, and the production efficiency is improved.

Owner:苏州华星光电显示有限公司 +1

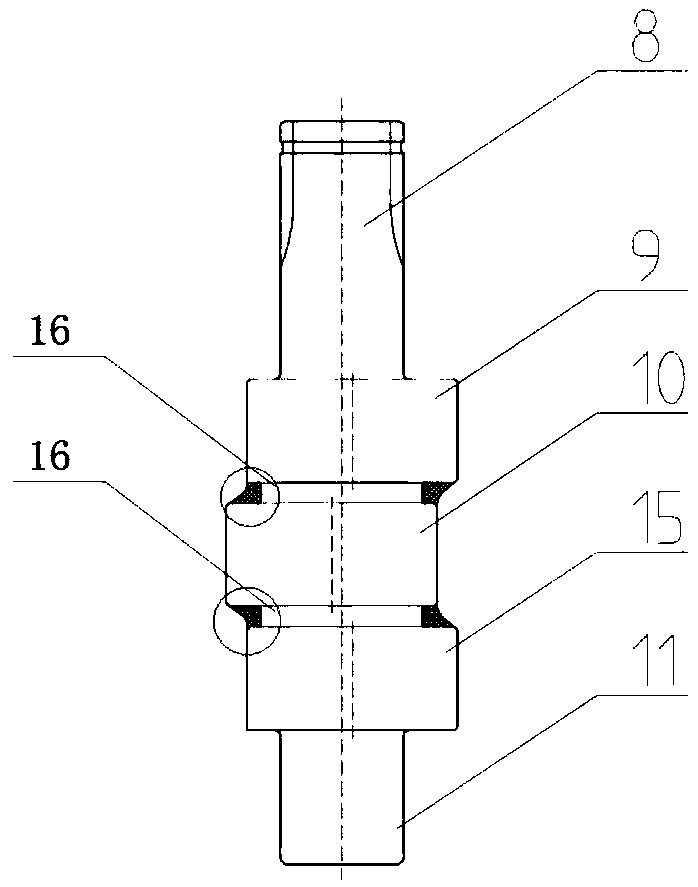

RV precise speed reducer eccentric shaft and precise speed reducer

ActiveCN108799316AIncrease load capacityImprove impact resistanceEccentric-shaftsToothed gearingsBall bearingAgricultural engineering

The invention provides a RV precise speed reducer eccentric shaft and a precise speed reducer. An annular reinforcement block is arranged in a sunken groove between two adjacent cams of the eccentricshaft; the precise speed reducer comprises a pin wheel housing, the eccentric shaft, a planet wheel, an input shaft, an output plate rack, an angular contact ball bearing and a cycloidal wheel; the planet wheel is arranged at one end of the eccentric shaft; the input shaft is located in the center of the pin wheel housing; one end of the input shaft is connected with a motor; a center gear is arranged at the other end of the input shaft; the center gear and the planet wheel are in mesh connection on the same rotation plane so as to form a first-stage planet speed reduction mechanism; and the angular contact ball bearing is arranged between the pin wheel housing and the output plate rack. According to the RV precise speed reducer provided by the invention, through increasing the diameter ofa cam connecting part, the impact resistance of the RV precise speed reducer eccentric shaft is greatly improved, the fatigue life of the RV precise speed reducer eccentric shaft is greatly prolonged, and the carrying capacity, the impact resistance, the service life and the running precision of the RV speed reducer are further improved.

Owner:NANTONG ZHENKANG WELDING ELECTROMACHINERY +1

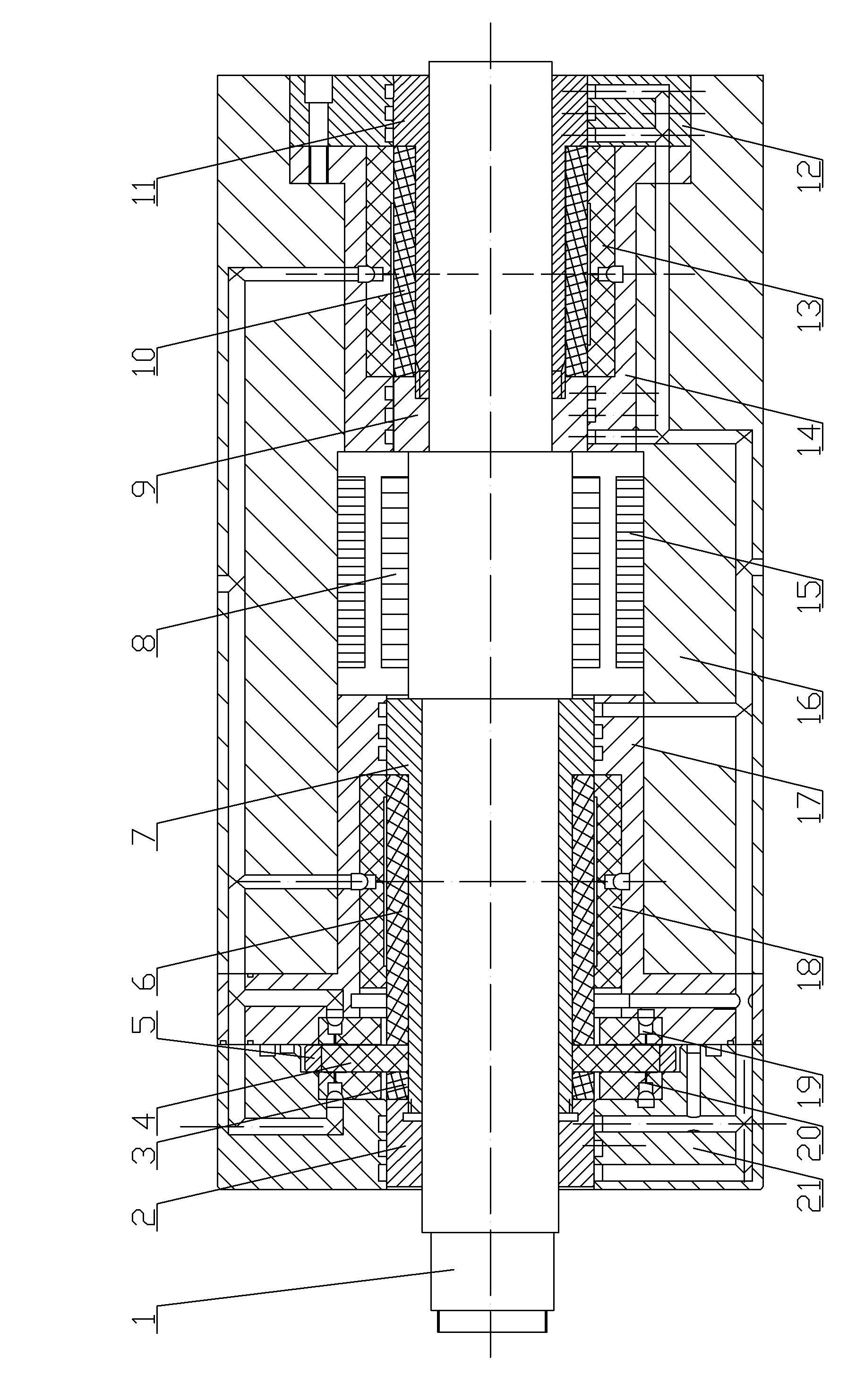

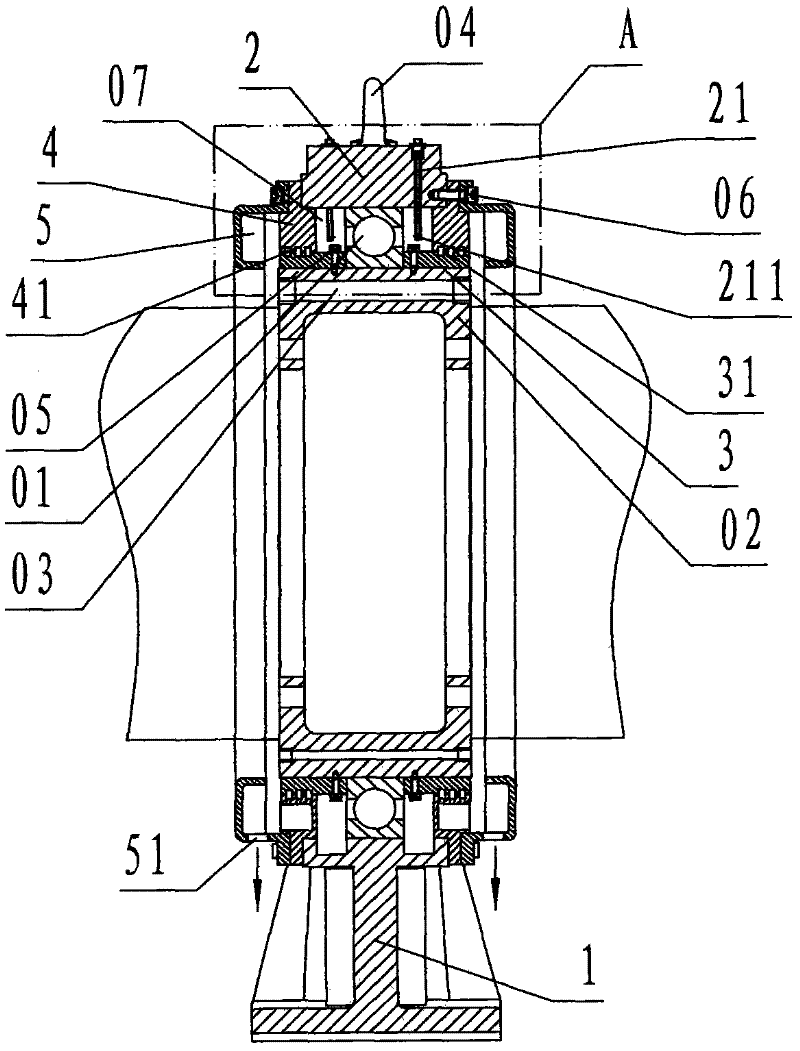

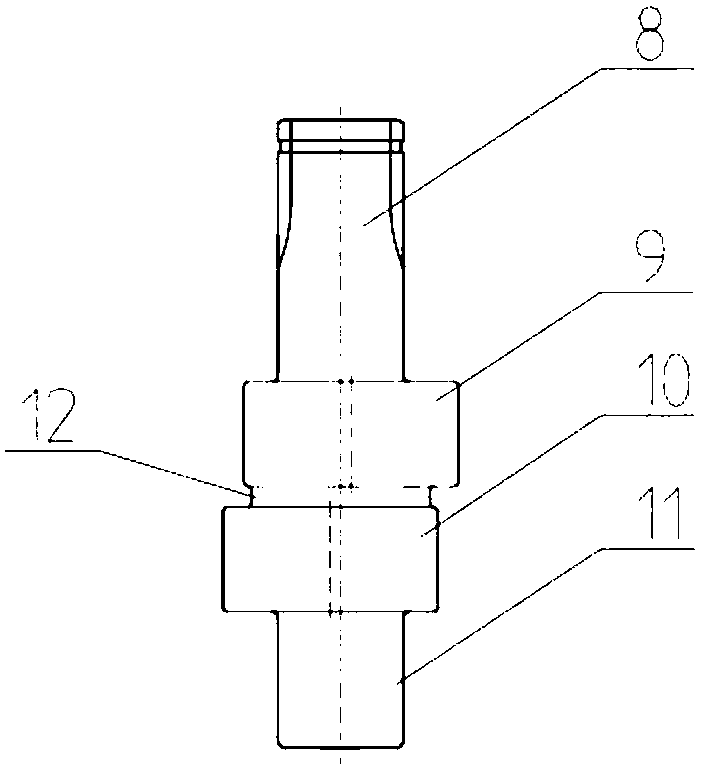

High-speed spindle for spinning frame

ActiveCN102634888AHigh centering accuracyImprove running accuracyTextiles and paperAgricultural engineeringBearing capacity

The invention discloses a high-speed spindle for a spinning frame. The high-speed spindle comprises a spindle blade, wherein an upper bearing is arranged at the upper part of the spindle blade and a bearing seat is arranged outside the upper bearing; an elastic tube is arranged at the lower part of the spindle blade; a lower bearing is arranged at the lower end of the spindle blade in the elastic tube; spiral linear grooves are formed on the surface of the spindle blade and comprise a first spiral linear groove, a second spiral linear groove and a third spiral linear groove; the first spiral linear groove is arranged at the lower part on which the lower bearing is arranged, of the spindle blade; the third spiral linear groove is arranged at the upper par on which the upper bearing is arranged, of the spindle blade; and the second spiral linear groove is arranged between the first spiral linear groove and the second spiral linear groove on the spindle blade. The high-speed spindle for the spinning frame is strong in bearing capacity, high in centering precision and good in high-speed stability, and the service life of the spindle can be prolonged effectively.

Owner:TONGXIN TEXTILE MACHINERY WUHU

Cooling water circulating device for continuous casting roller set

InactiveCN107511466AAvoid overall overheatingExtended service lifeMechanical engineeringCooling pipe

The invention discloses a cooling water circulation device for a continuous casting roll group, which comprises a bearing seat, a bearing cover, a rolling bearing and a mandrel, one end of the mandrel is provided with a press ring, and a rotary joint is connected to the outer side of the press ring , the outer side of the rotary joint is provided with a first water inlet and a first water outlet, and the inside of the mandrel is provided with a first through hole and a second through hole in the axial direction, and the first through hole and the second A first cooling pipe and a second cooling pipe are correspondingly arranged in the through hole, the first water inlet is connected to the first cooling pipe, and the first water outlet is connected to the second cooling pipe; the bearing seat The lower end of the valve block is provided with a valve block, the lower end of the valve block is provided with a second water inlet and a second water outlet, and the inner ring of the bearing seat is provided with a cooling water tank. The invention improves the effect of cooling and crystallization of the continuous casting roll group, reduces the occurrence of secondary faults, improves the operation stability and prolongs the service life.

Owner:黄石市火炬科技实业有限责任公司

Turbomachine

ActiveUS7077626B2Convenient thermal protectionImprove the protective effectPump componentsBlade accessoriesEngineeringCantilever

A turbomachine has a turborotor made up of a shaft and a rotor disk, and an electric machine having an electric rotor. The rotor disk is arranged at one end of the shaft, in overhung manner, and the electric rotor is connected with the shaft of the turborotor. The electric rotor is arranged on the other end of the shaft, also in overhung manner, and the shaft is mounted on shaft bearings in a bearing housing that thermally separates the shaft bearings from the electric machine.

Owner:ATLAS COPCO ENERGAS

Rotary test tube code scanning device and system and test tube code scanning assembly line

PendingCN110866414AImprove accuracyIncrease productivitySensing by electromagnetic radiationTest tube stands/holdersEngineeringApparatus instruments

The invention relates to the field of medical instruments, in particular to a rotary test tube code scanning device and system and a test tube code scanning assembly line. The moving mechanism of thedevice drives a rotating part and the abutting part to get close to each other and abut against the test tube, and the rotating mechanism drives the rotating part to rotate so as to drive the test tube to rotate. As the bar code of the test tube is attached to the test tube wall, the bar code on the test tube wall can be rotated by rotating the test tube. Furthermore, the code scanner is arrangedat the notch of the containing space, and when the rotating part drives the test tube to rotate to the notch, the code scanner can scan the bar code on the test tube. Therefore, even if the bar code on the test tube initially arranged in the test tube rack does not face the code scanner, the bar code on each test tube can be scanned by the code scanner by rotating the test tube. According to the rotary test tube code scanning device, the accuracy is greatly improved, the manual error rate is reduced, and the production efficiency is improved.

Owner:GETEIN BIOTECH

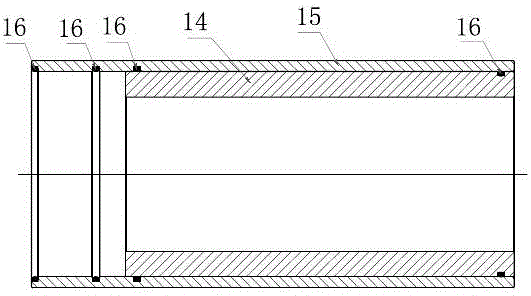

Motorized spindle of aerostatic bearing

InactiveCN104368829APrecise suspensionImprove running accuracyLarge fixed membersMaintainance and safety accessoriesThrust bearingMachining

The invention belongs to the field of machining, relates to a machining device and discloses a motorized spindle of an aerostatic bearing. The motorized spindle comprises a main component, a front bearing component, a rear bearing component, a thrust bearing, a stator component, a rotor component, a water / gas circuit sleeve component and an air cylinder component; the front bearing component is arranged at the front end of the main component and extend into the same to be flush with the outer edge of the main component, the front end of the front bearing component is connected with the rotor component which is externally connected with the thrush component, and a thrust clearance ring is arranged between the thrust bearing and the front bearing component; the front bearing component is backwardly connected with the stator component in a main component cavity, the rear end of the stator component is connected with the rear bearing component in the main component cavity, the narrower front part of the water / gas circuit sleeve component extends into the main component cavity to be connected with the rear bearing component while the rear end of the water / gas circuit sleeve component is connected with the air cylinder component, and the rear end of the air cylinder component is provided with a screw penetratingly connected with the air cylinder component. The motorized spindle is high in rotation speed, good in stability and high in machining precision.

Owner:东莞市科隆电机有限公司

Prestretching structure of numerical control machine tool ball screw pair and method

ActiveCN106624953AEliminate thermal deformationReduce and eliminate impactFeeding apparatusMetal working apparatusNumerical controlBall bearing

The invention relates to a prestretching structure of a numerical control machine tool ball screw pair and a method. A servo feeding motor end ZARN combination bearing is a fixed end; a conical roller bearing and a deep groove ball bearing at the other end form a stretching end; the ball screw pair is prestretched through rotating a nut; the stretching quantity is equal to the difference between the reading number of a dial indicator at the stretching end and a dial indicator at the fixed end, so that the heat deformation of a lead screw in operation is eliminated beforehand, and the influence on the precision of a machine tool by the heat deformation of the machine tool is reduced and eliminated; and as the support rigidity of a ball screw mechanism is improved, the operation precision, the stability of a transmission system and the vibration resistance are improved, and the life is prolonged.

Owner:常州铸鼎机械有限公司

Hydro-hybrid ceramic main shaft device

InactiveCN102151852AImprove the problem of small carrying capacityImprove carrying capacityMetal-working apparatusStress concentrationMetallurgy

The invention discloses a hydro-hybrid ceramic main shaft device which adopts a symmetrically arranged cone bearing structure and a structure of which a ceramic rubbing pair is totally wrapped by metal simultaneously in the aspect of structural design, and avoids shape mutation of all ceramic parts. The hydro-hybrid ceramic main shaft device disclosed by the invention adopts a ceramic hydro-hybrid bearing as the supporting bearing and cone hydro-hybrid bearings as the front bearing and the rear bearing, has the radial pressure bearing function and axial thrust function simultaneously, has a simple structure, and is provided with a conveniently adjusted axial gap; the hydro-hybrid ceramic main shaft device adopts the structure of which the ceramic rubbing pair is totally wrapped by metal, thus breaking of the ceramic parts caused by powerful stretching or higher force applied on the edges of parts is prevented; and all the ceramic parts avoid shape mutation when being designed, thus stress concentration inside the ceramic parts is reduced, and breaking of the ceramic parts caused by self design defects is prevented.

Owner:TIANJIN UNIV

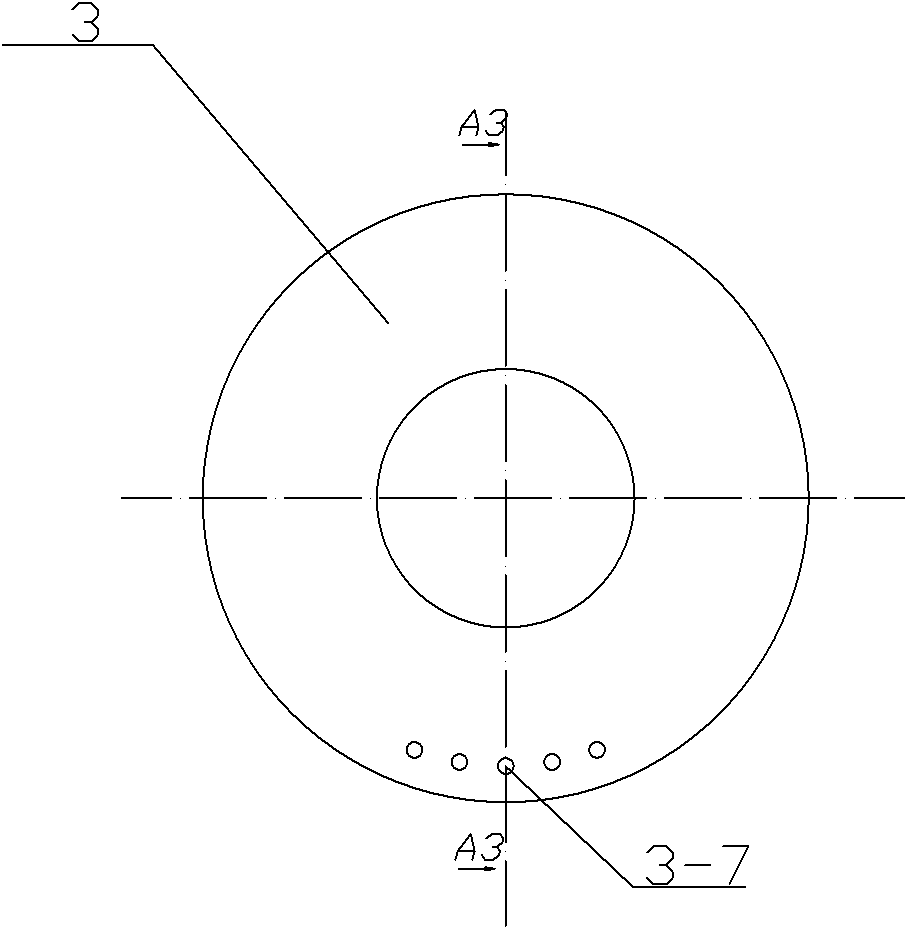

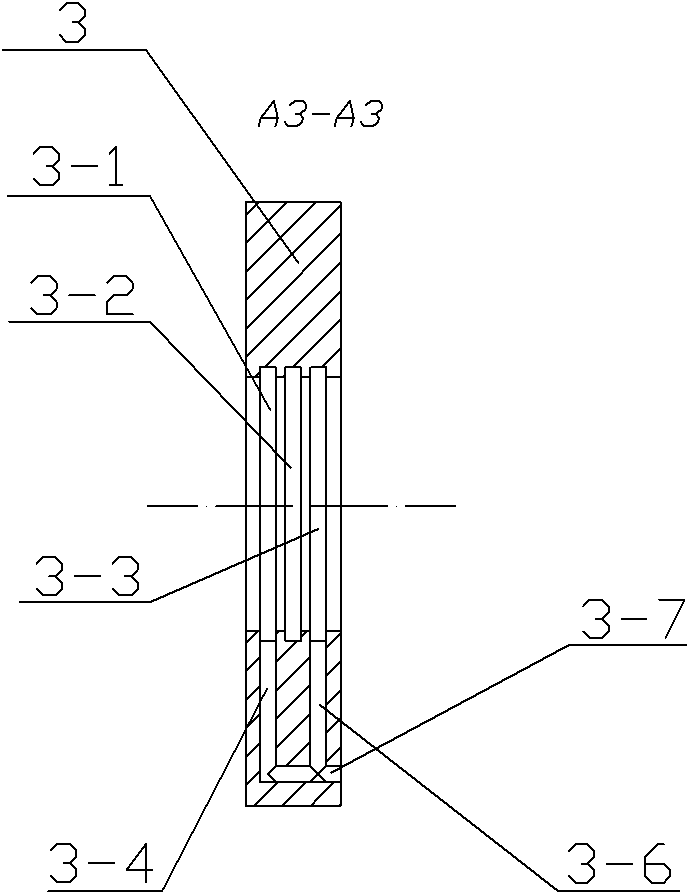

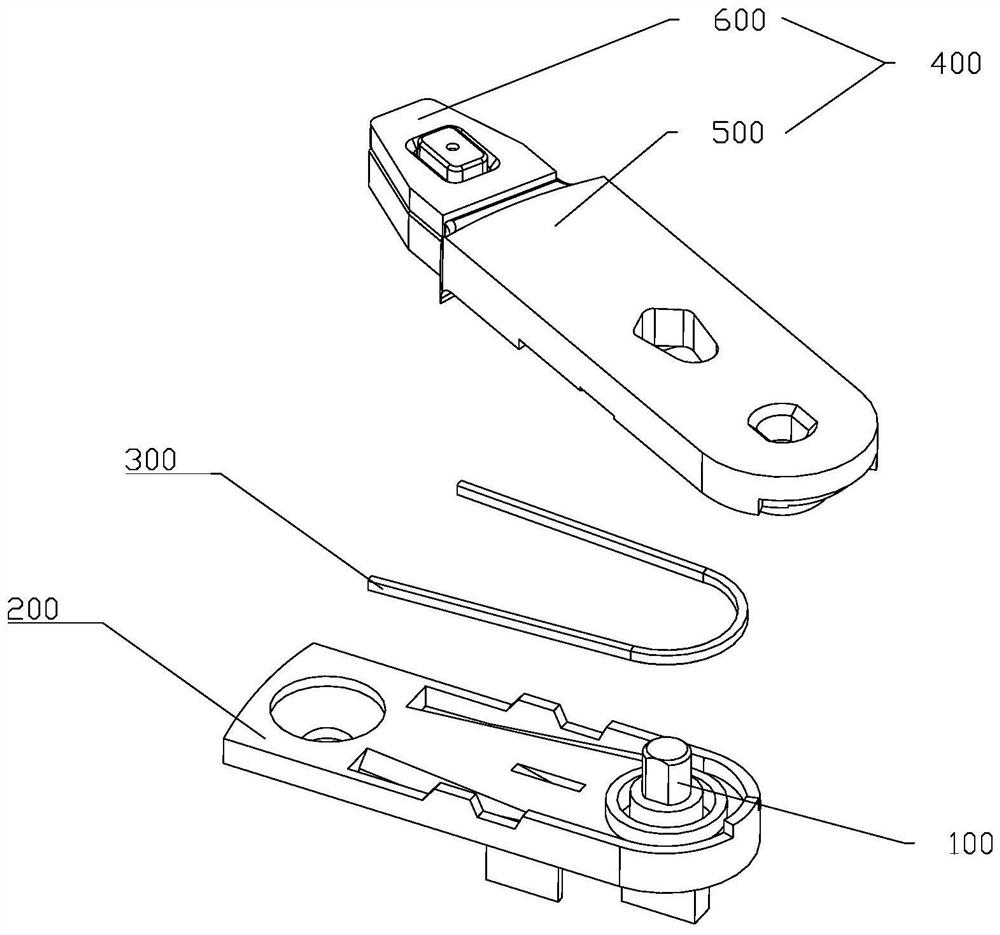

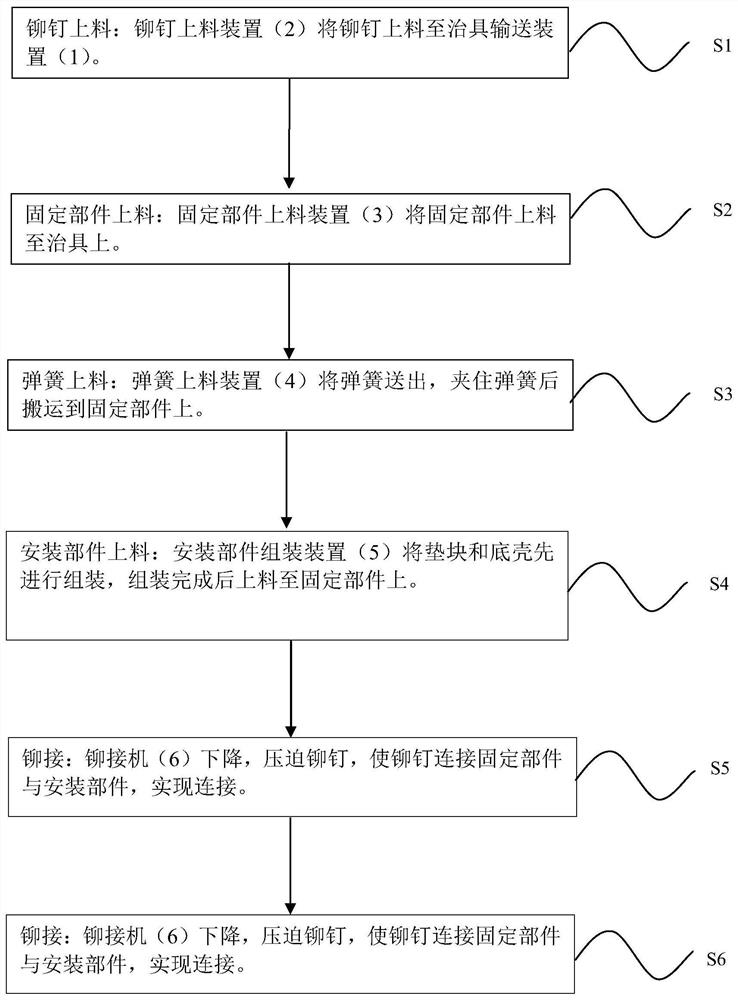

Hinge spring feeding device and feeding method thereof

InactiveCN112338473AImprove running accuracyEasy to separateControl devices for conveyorsMetal working apparatusGear wheelAgitator

The invention relates to the technical field of hinge production, in particular to a hinge spring feeding device and a feeding method thereof. The hinge spring feeding device comprises a spring carrying mechanism, a third material agitator, a spring material rail, a rotary material receiving base, a gear, a rack, a material distributing air cylinder, an arc-shaped material passing block and a rotary base, wherein the third material agitator is connected to the rack, the spring material rail is arranged at the upper end of the third material agitator, the arc-shaped material passing block is connected with the spring material rail, and an arc-shaped material passing rail is arranged in the arc-shaped material passing block; the rotary base is fixed on the rack, the rotary material receivingbase is rotatably connected into the rotary base, the rotary material receiving base is connected with the lower end face of the arc-shaped material passing block, the gear is fixed on a rotary shaftof the rotary material receiving base, the rack is arranged at the telescopic end of the material distributing air cylinder, the gear is meshed with the rack, and the material distributing air cylinder is horizontally fixed on the rack. The hinge spring feeding device has the advantages of being high in spring feeding efficiency and feeding stability.

Owner:陈娅萍

Anti-explosion image pickup instrument

ActiveCN104683670AImprove controllabilityIncrease speedTelevision system detailsColor television detailsGratingClosed loop

The invention discloses an anti-explosion image pickup instrument, which comprises a base, a rotating tube body, an image pickup instrument and an image pickup instrument rotating device, wherein the image pickup instrument is connected with the rotating tube body through the image pickup instrument rotating device, the anti-explosion image pickup instrument also comprises a tube body rotating device, the tube body rotating device comprises a transmission base plate, a motor installing frame, a motor, a driving gear, a driven gear, a spring, a spring press ring, a transmission shaft, a first bearing, a second bearing and a bearing press ring, the anti-explosion image pickup instrument also comprises a closed loop servo control device, the closed loop servo control device comprises a detecting mechanism and a servo control mechanism, and the detecting mechanism comprises an optical grating installing shaft, an optical grating disc, a signal receiver and an optical grating installing element. The anti-explosion image pickup instrument has the advantages that when the motor is overloaded, a transmission gear can automatically slip, so that the normal operation of equipment is protected, the transmission line connection is safe and reliable, the service life of the equipment is prolonged, the control precision is high, and in addition, the effect is good.

Owner:CHANGZHOU SHENGHE ELECTRONICS

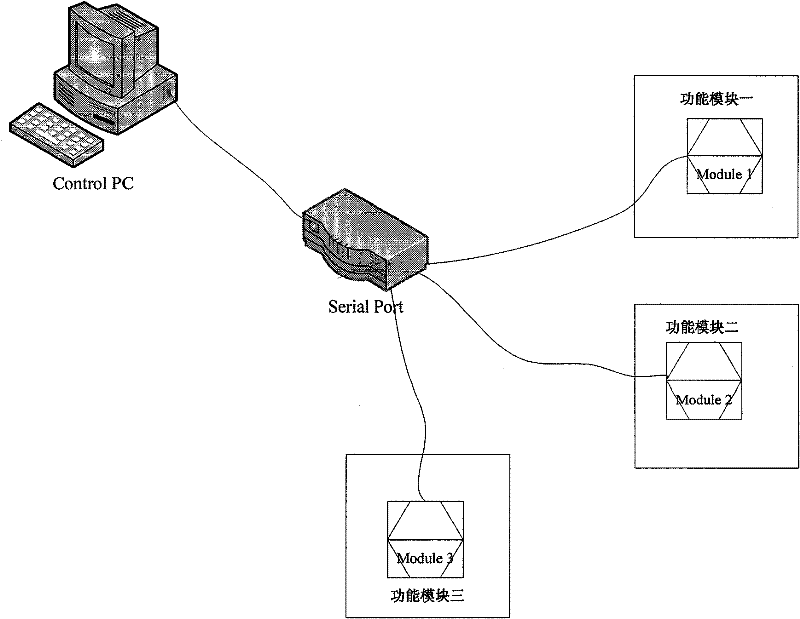

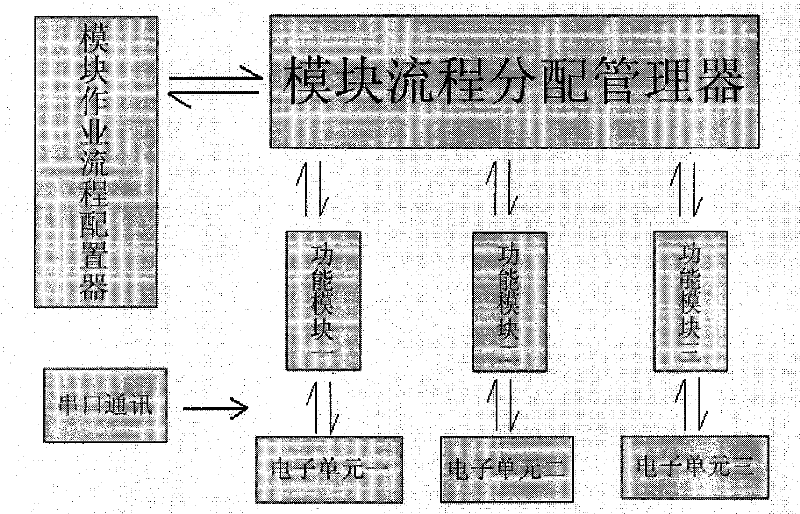

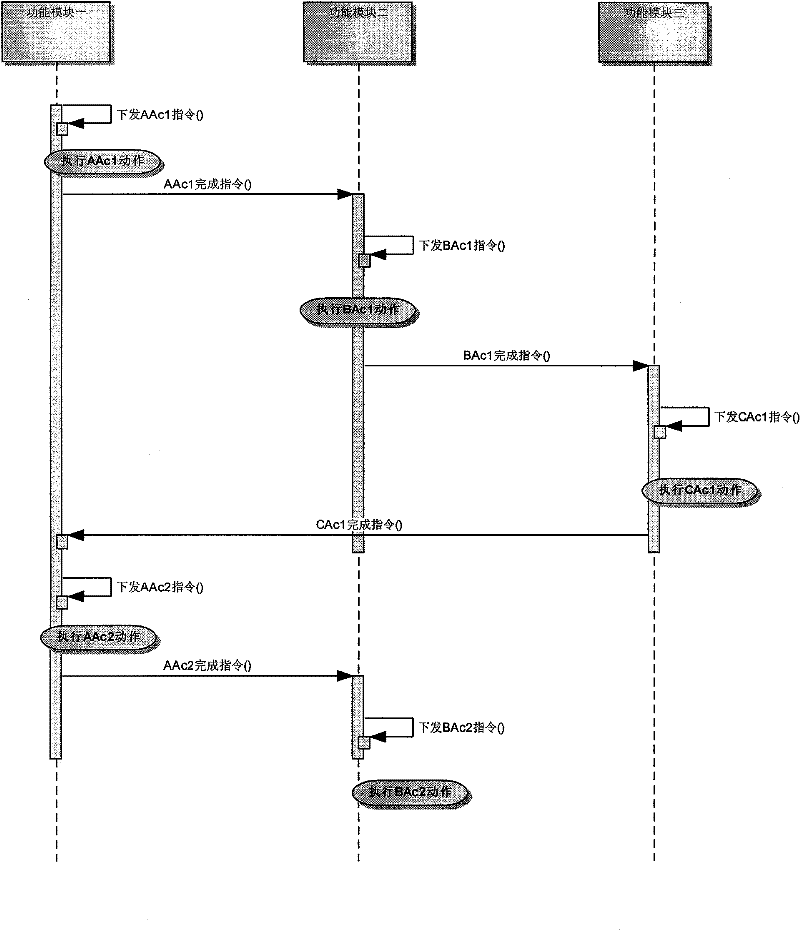

Control method of system realizing multi-module combined work

ActiveCN102183927AClear missionFine control and securityTotal factory controlProgramme total factory controlCapability managementComputer module

The invention discloses a control method of a system realizing multi-module combined work. The system comprises electronic units and a control section, wherein the control section comprises a module work flow configurator and a module flow distribution manager. The system, according to to-be-performed functions, is divided into different functional modules corresponding to the operations that theelectronic units will execute; the module flow distribution manager, based on currently requested work, distributes the work read from the module work flow configurator to the different functional modules according to a functional module list, and the electronic units receive the instruction information transmitted by the corresponding functional modules and having unique identifications; the functional modules receive uploaded information uploaded by the electronic units and having the unique identifications; the module flow distribution manager analyzes and processes the information uploaded to the functional modules by the electronic units; and the module flow distribution manager informs the corresponding functional modules of the analysis results and the functional modules manage andcontrol the operations and executions of the electronic units according to the analysis results.

Owner:BEIJING LEADMAN BIOCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com