Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

An external rotor motor, permanent magnet synchronous technology, applied in the direction of magnetic circuit rotating parts, drive devices, electric components, etc., can solve the problems of large torque motor, complex braking mechanism, small output torque, etc., and achieve clamping action area. Large, improve the braking effect, the effect of large braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

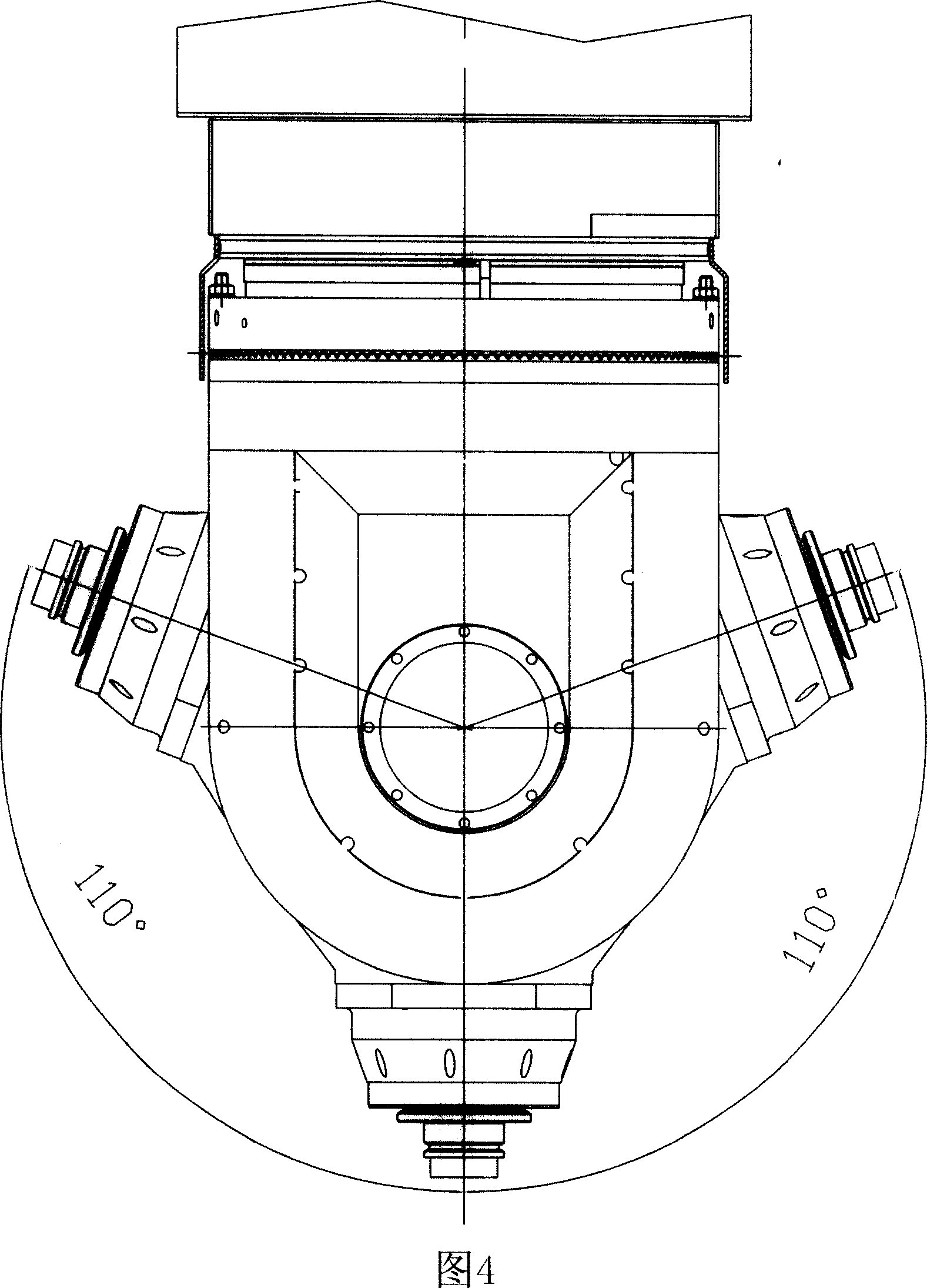

[0028] In order to illustrate the double pendulum milling head of the present invention, a single-axis turntable driven by an AC permanent magnet synchronous outer rotor torque motor is illustrated with reference to FIG. The description of the motor structure is helpful for understanding the driving structure of the double pendulum milling head of the present invention. As shown in Figure 16, the rotor 5' of the motor is directly connected to the turntable table 2', and usually the table 2' is fixed to the end of the rotor 5' by bolts. Simultaneously, the stator 6' positioned at the inner ring of the rotor 5' is connected with the fixed casing 9' of the turntable by bolts. The rotation angle of the turntable is 360°×n (n represents the number of revolutions).

[0029] Permanent magnets are arranged on the inner wall of the rotor 5', and a braking mechanism 4' is arranged outside the rotor. In addition, in order to effectively cool the stator coil windings of the heat source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com