Patents

Literature

44results about How to "High mechanical efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

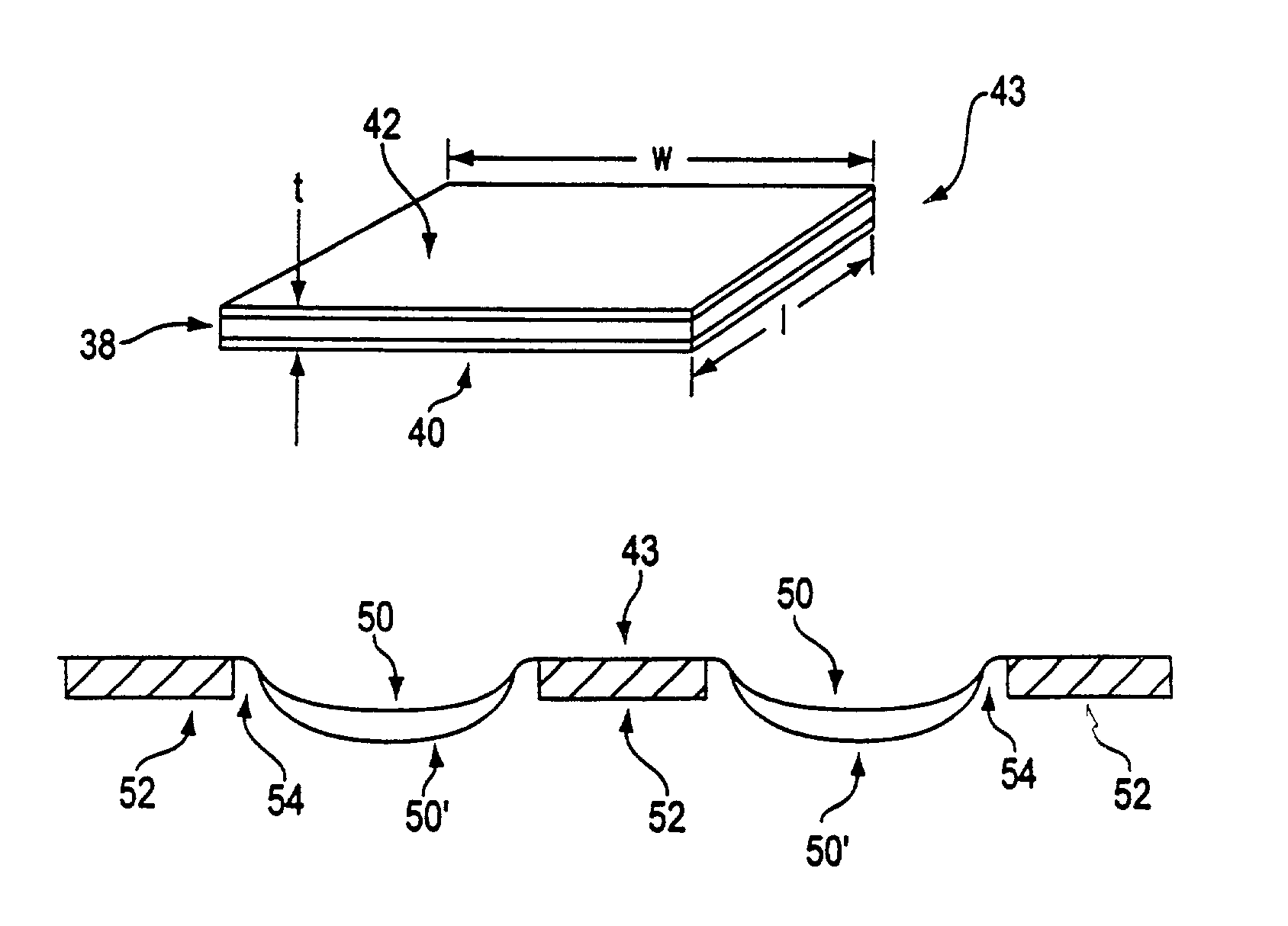

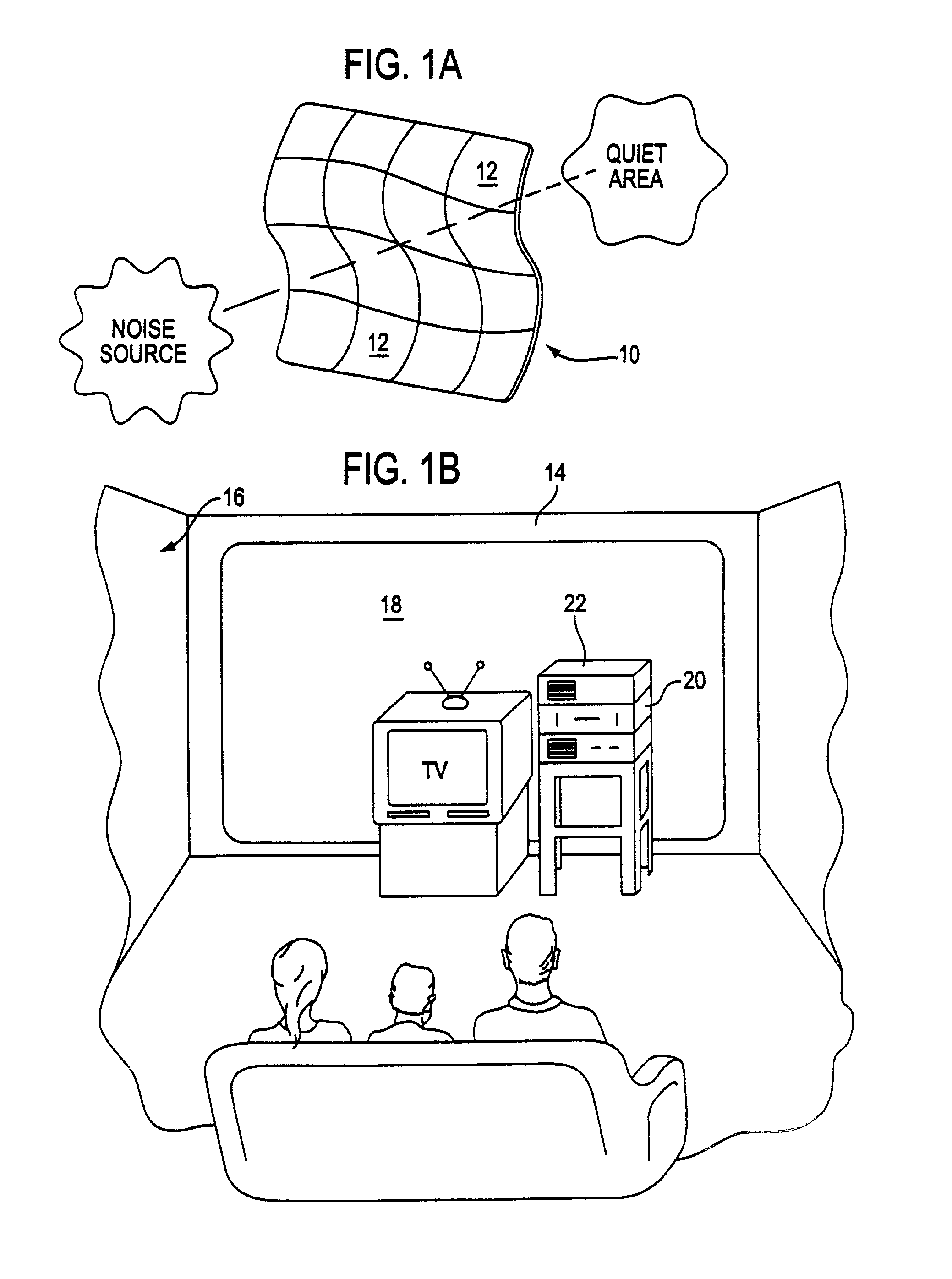

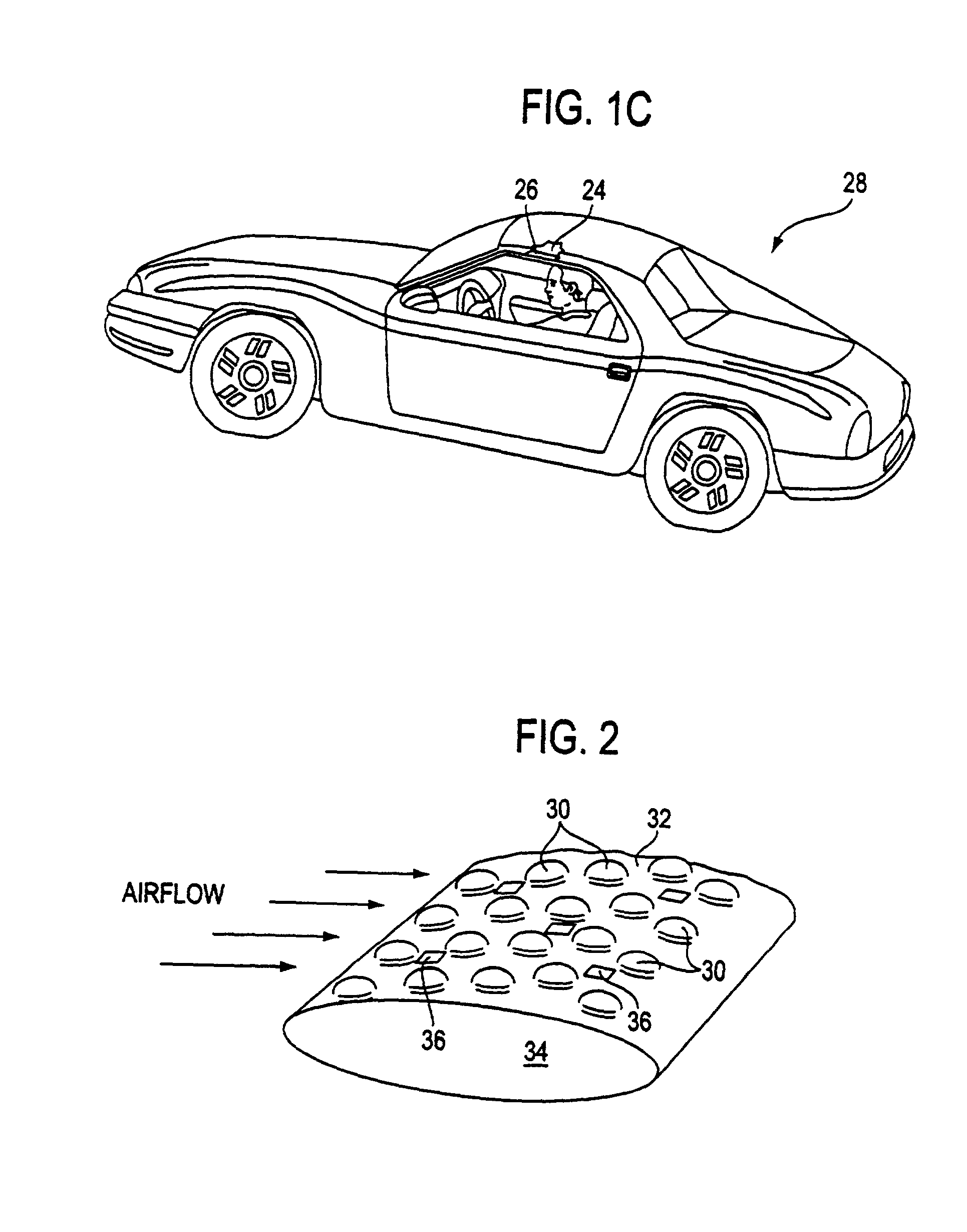

Elastomeric dielectric polymer film sonic actuator

InactiveUS7062055B2Optimize power outputLow working voltagePiezoelectric/electrostrictive gramophone pickupsStirling type enginesDielectricConductive polymer

A sonic actuator including a multi-layer membrane having a non-metallic elastomeric dielectric polymer layer with a first surface and a second surface, a first compliant electrode layer contacting the first surface of the polymer layer, and a second compliant electrode layer contacting the second surface of the polymer layer. The actuator further includes a support structure in contact with the sonic actuator film. Preferably, the non-metallic dielectric polymer is selected from the group consisting essentially of silicone, fluorosilicone, fluoroelastomer, natural rubber, polybutadiene, nitrile rubber, isoprene, and ethylene propylene diene. Also preferably, the compliant electrode layer is made from the group consisting essentially of graphite, carbon, and conductive polymers. The support structure can take the form of grid having a number of circular apertures. When a voltage is applied to the electrodes, portions of the film held at the aperture of the support structure can bulge due to the electrostriction phenomenon. The resultant “bubbles” can be modulated to generate sonic vibrations, or can be used to create a variable surface for airflow control.

Owner:SRI INTERNATIONAL

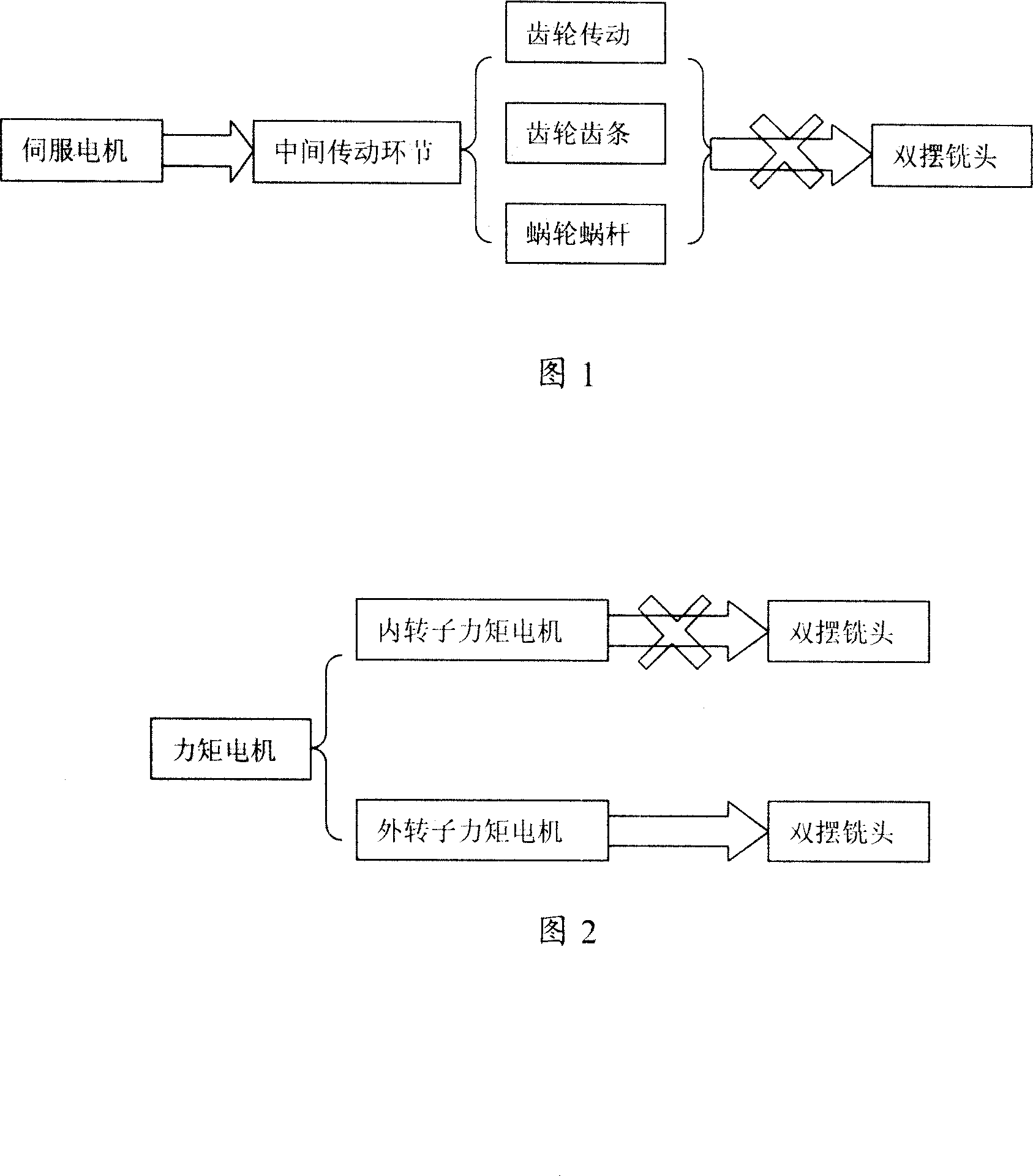

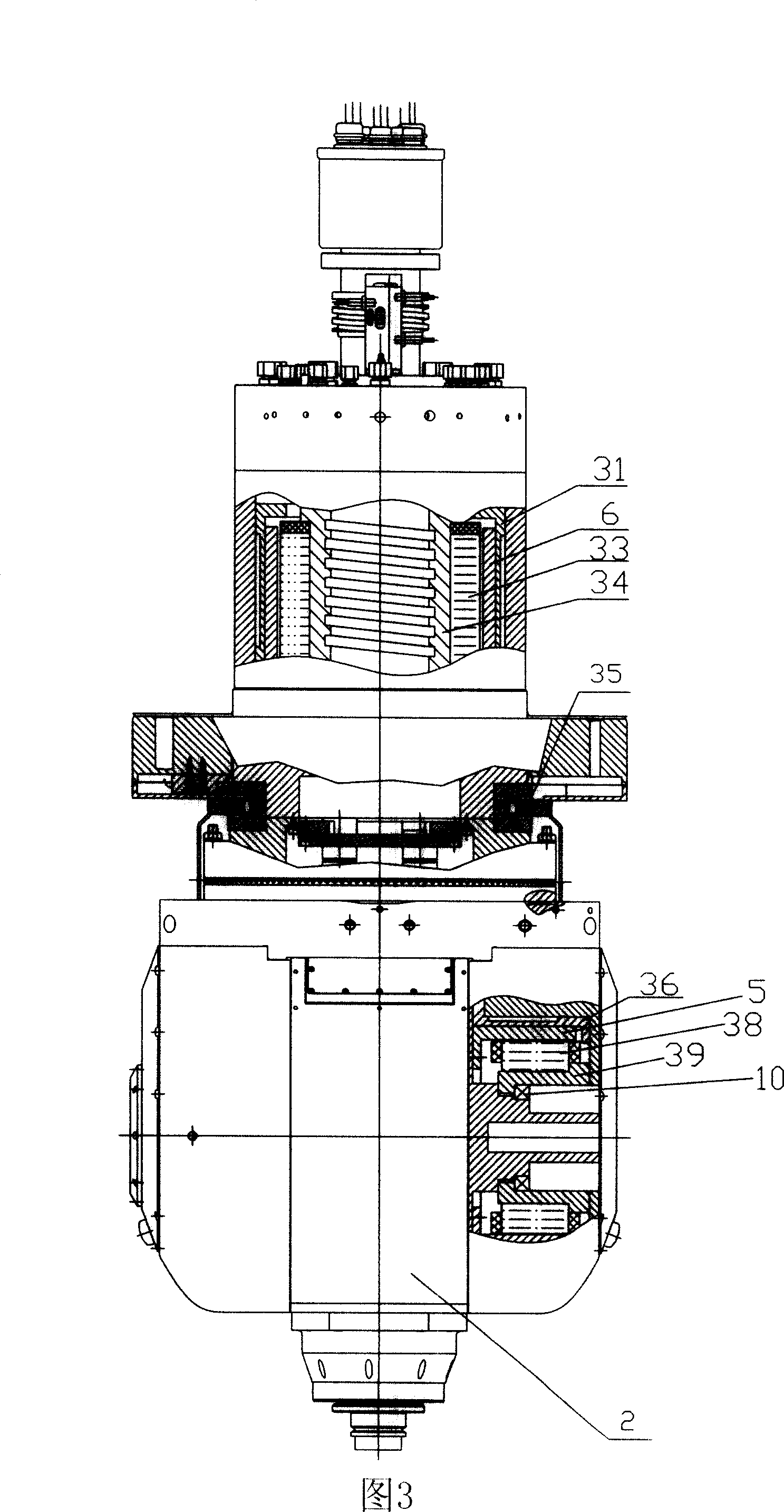

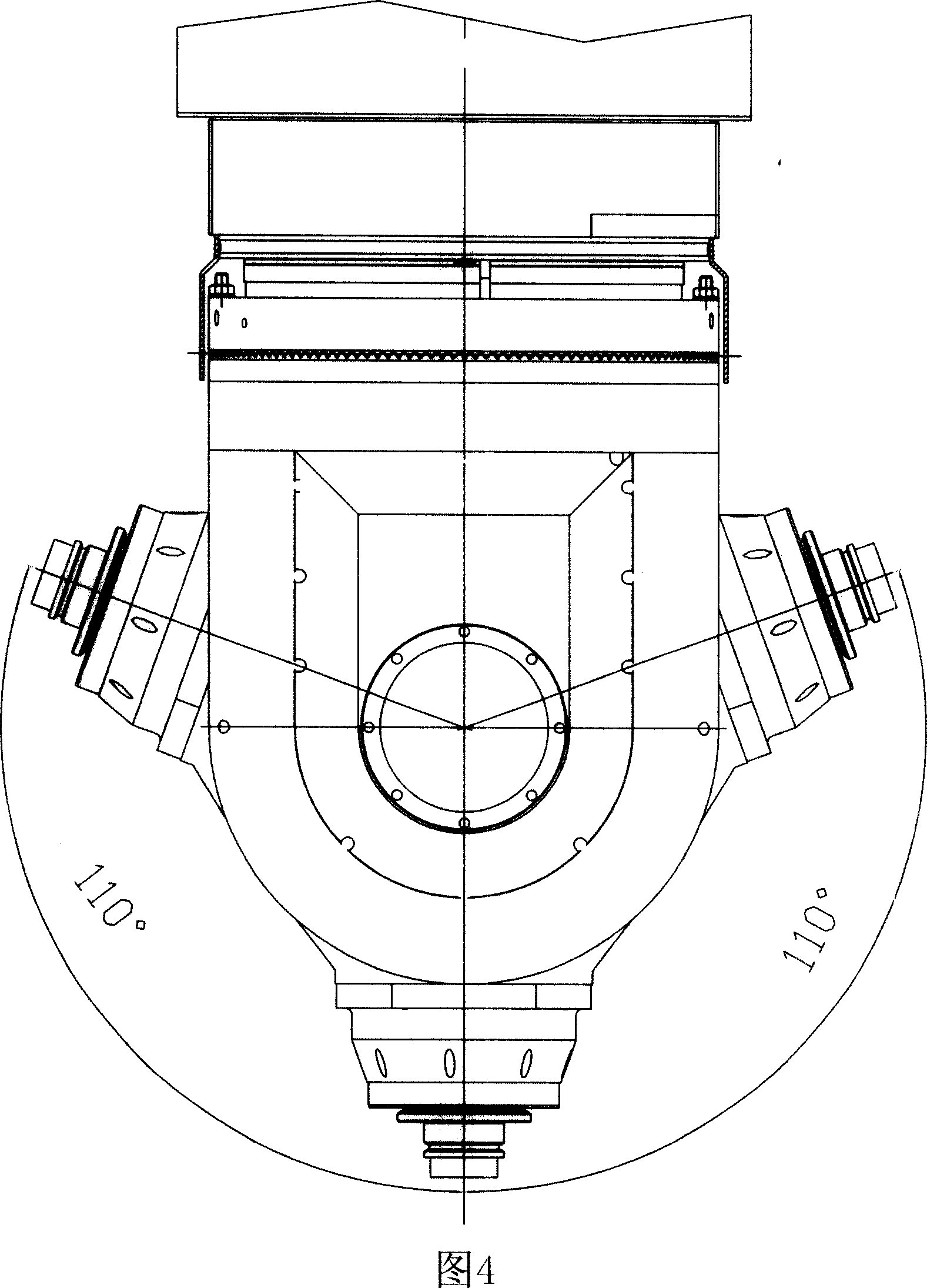

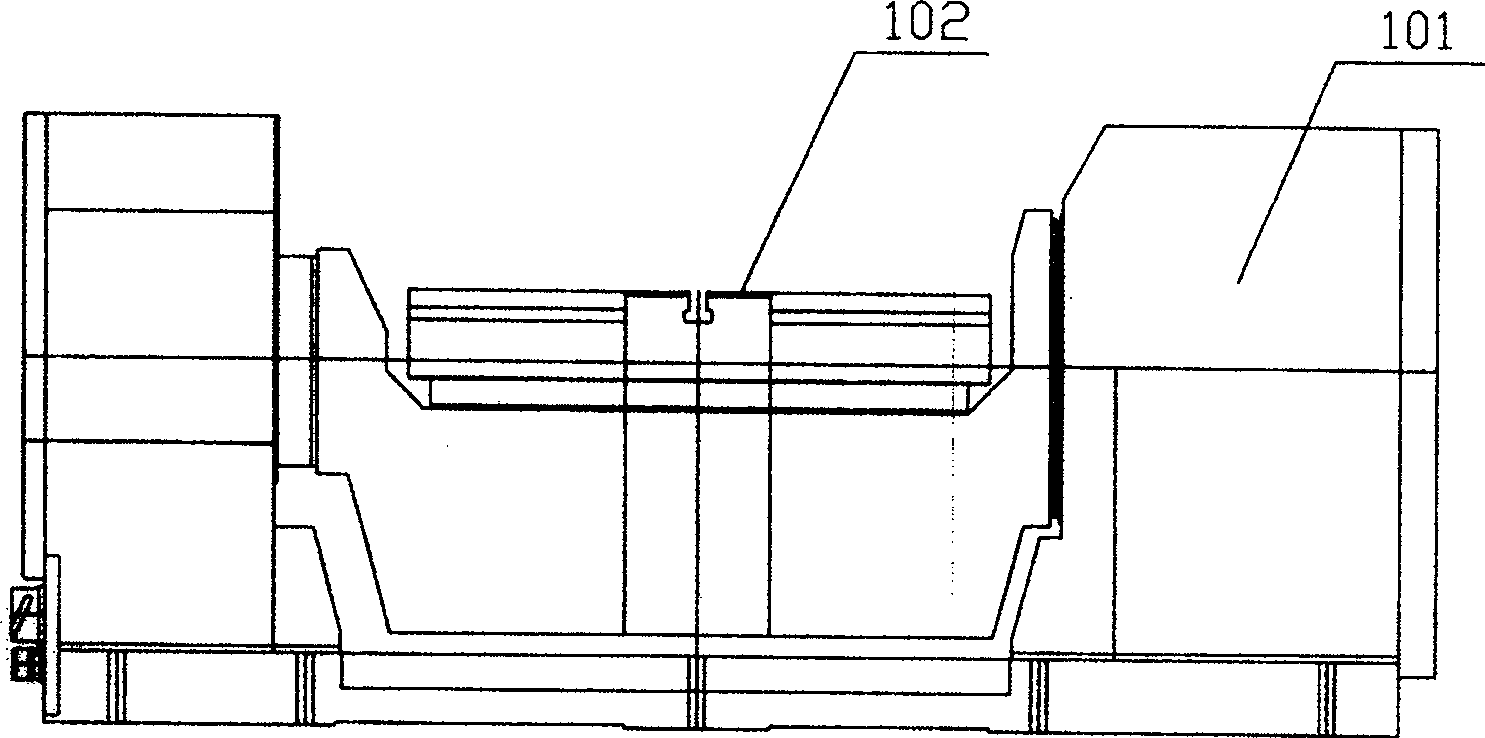

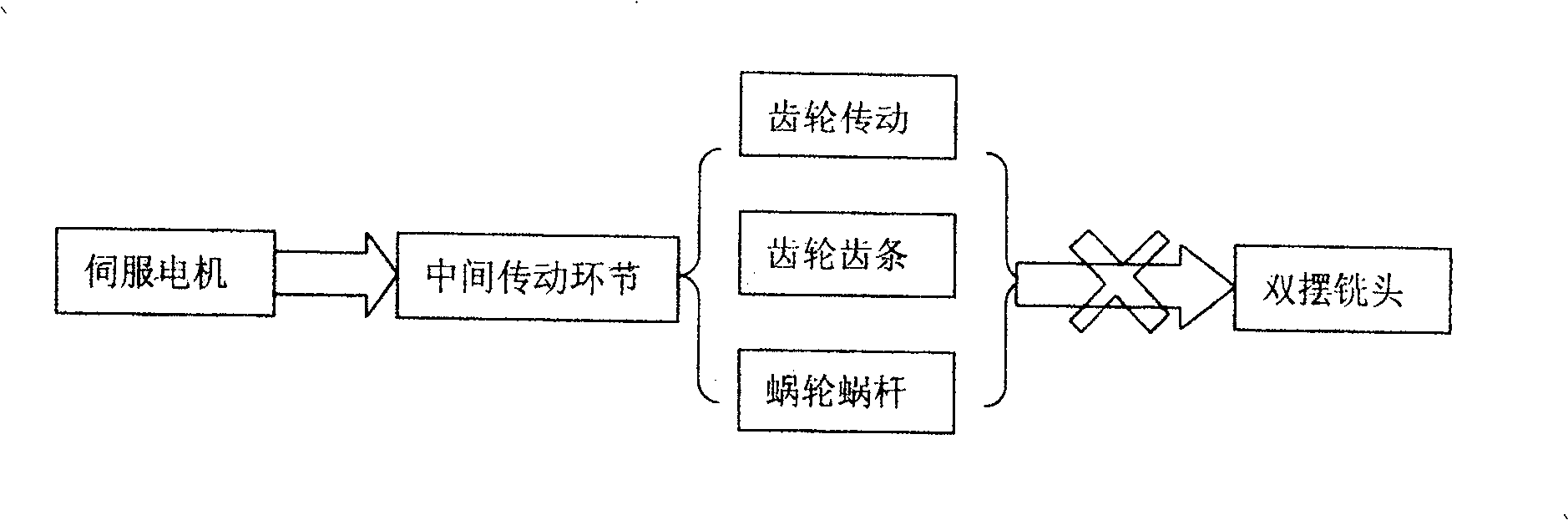

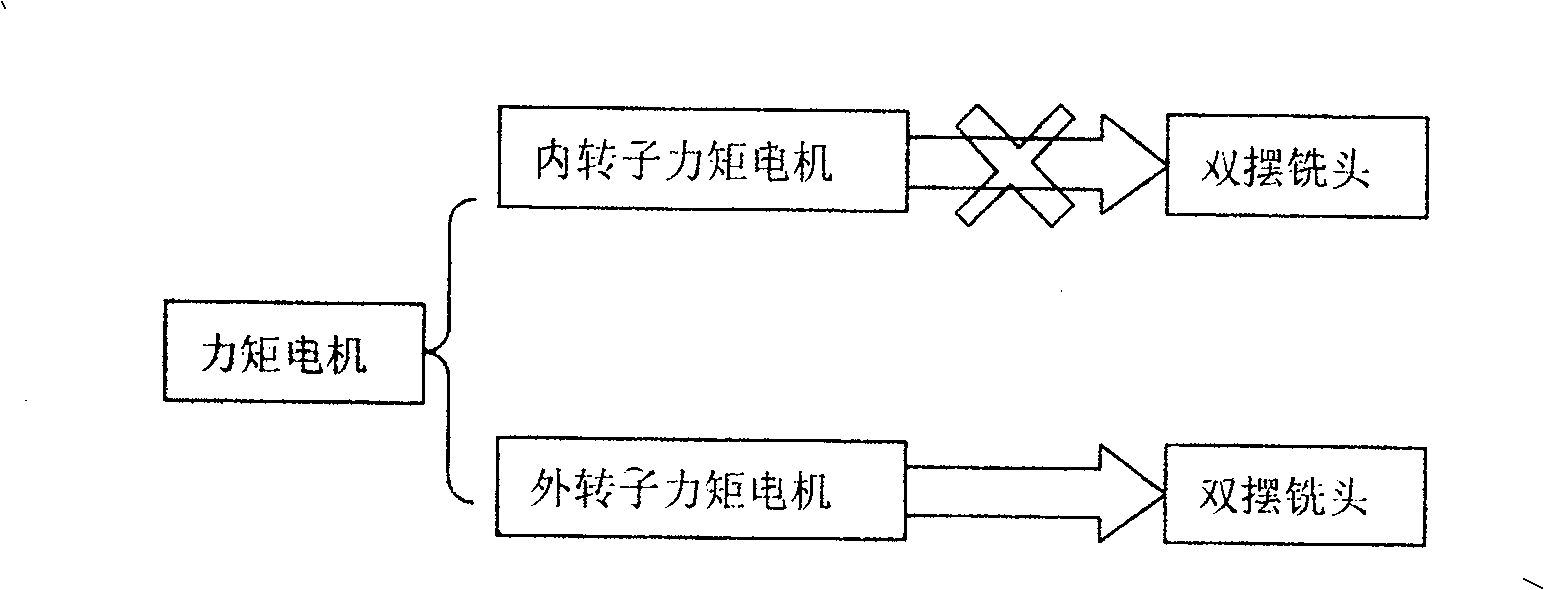

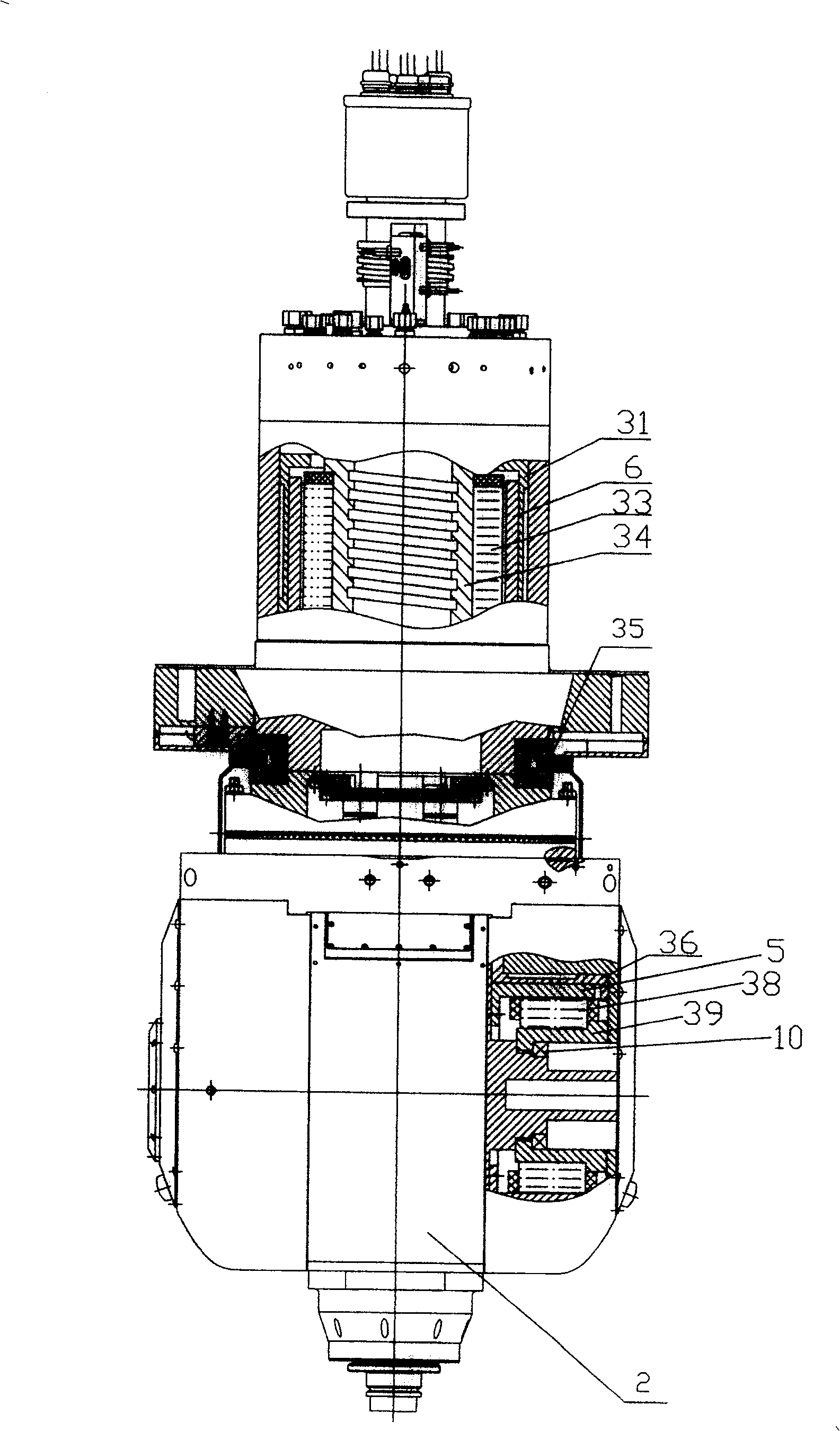

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN101011795AImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

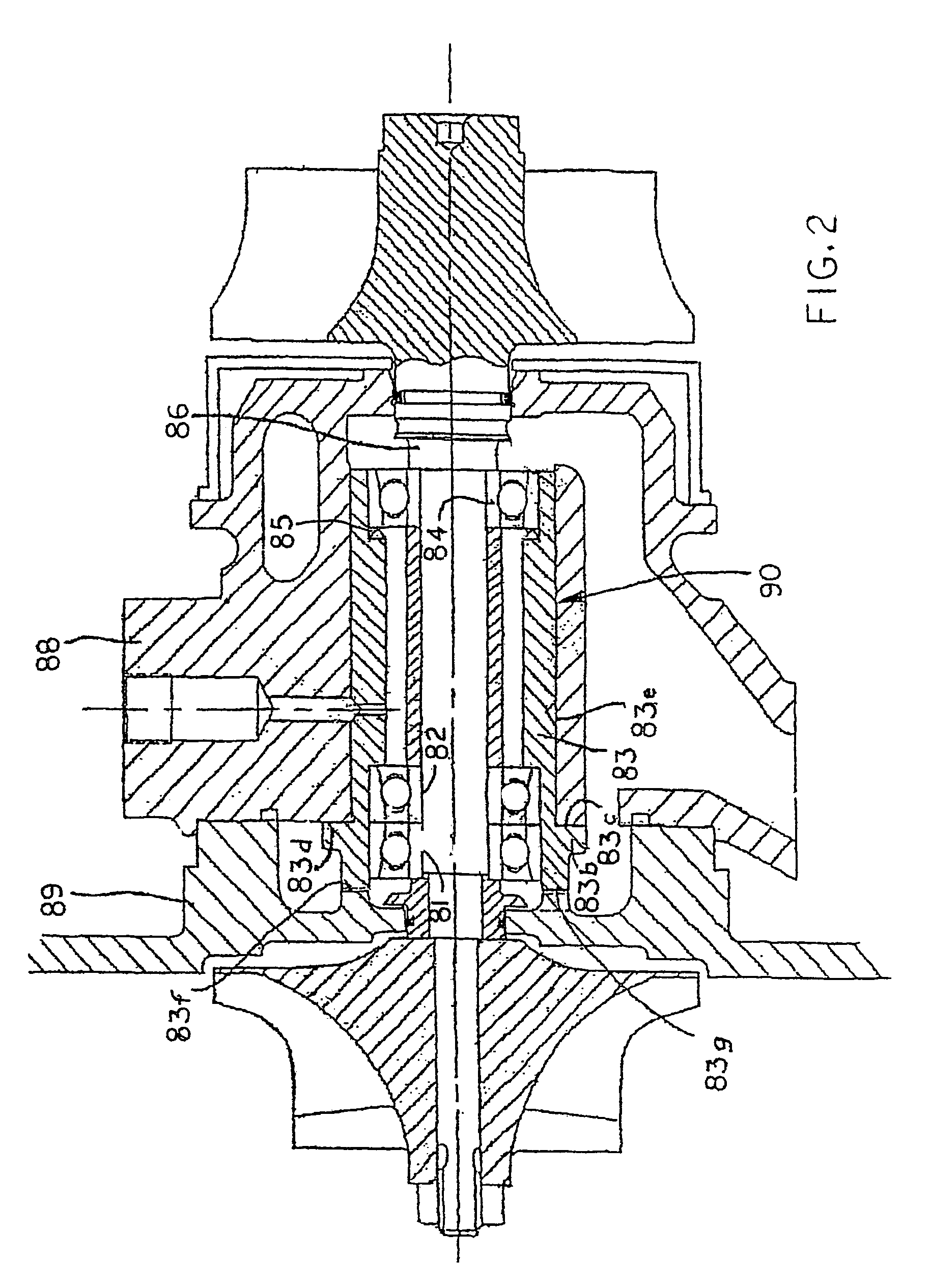

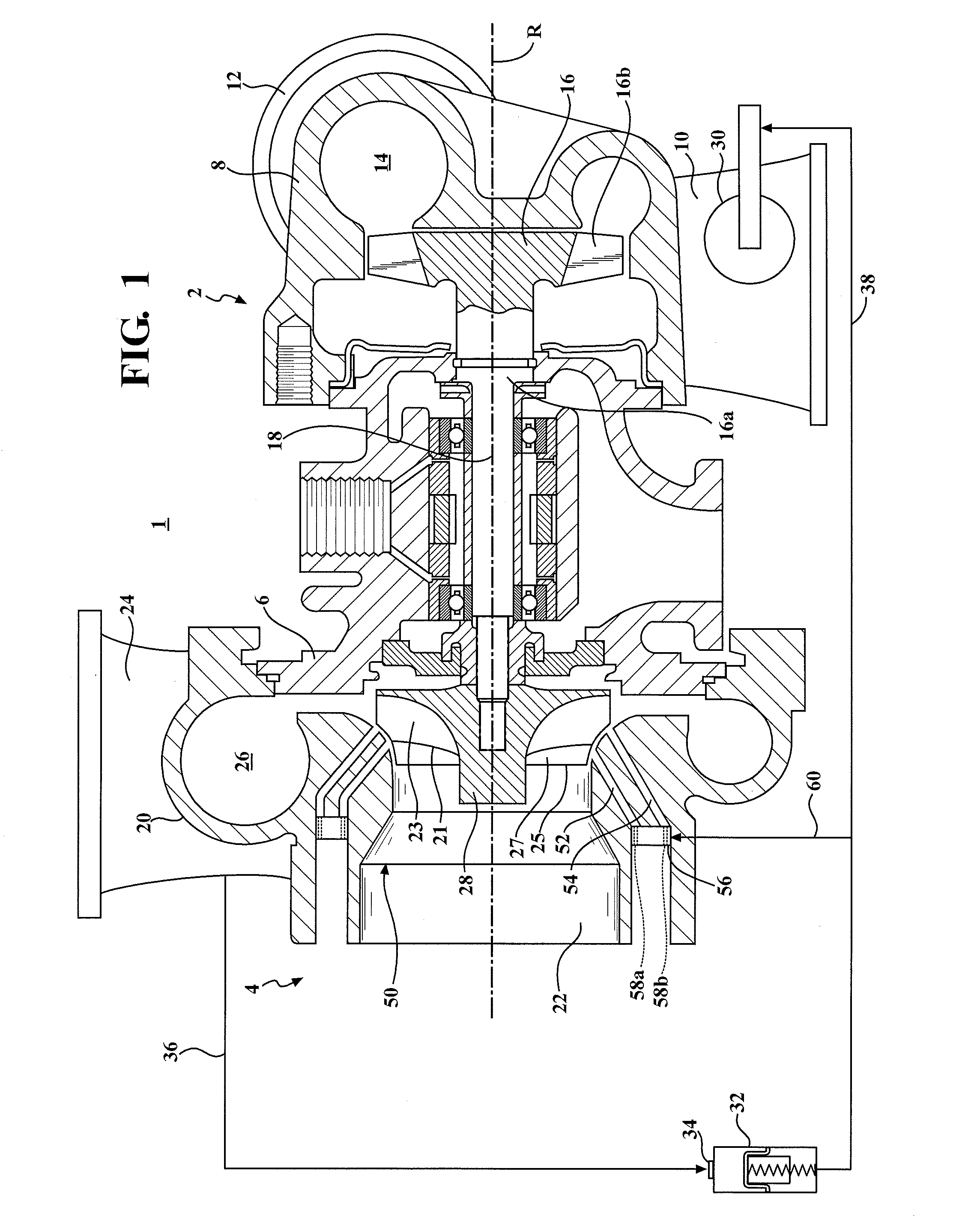

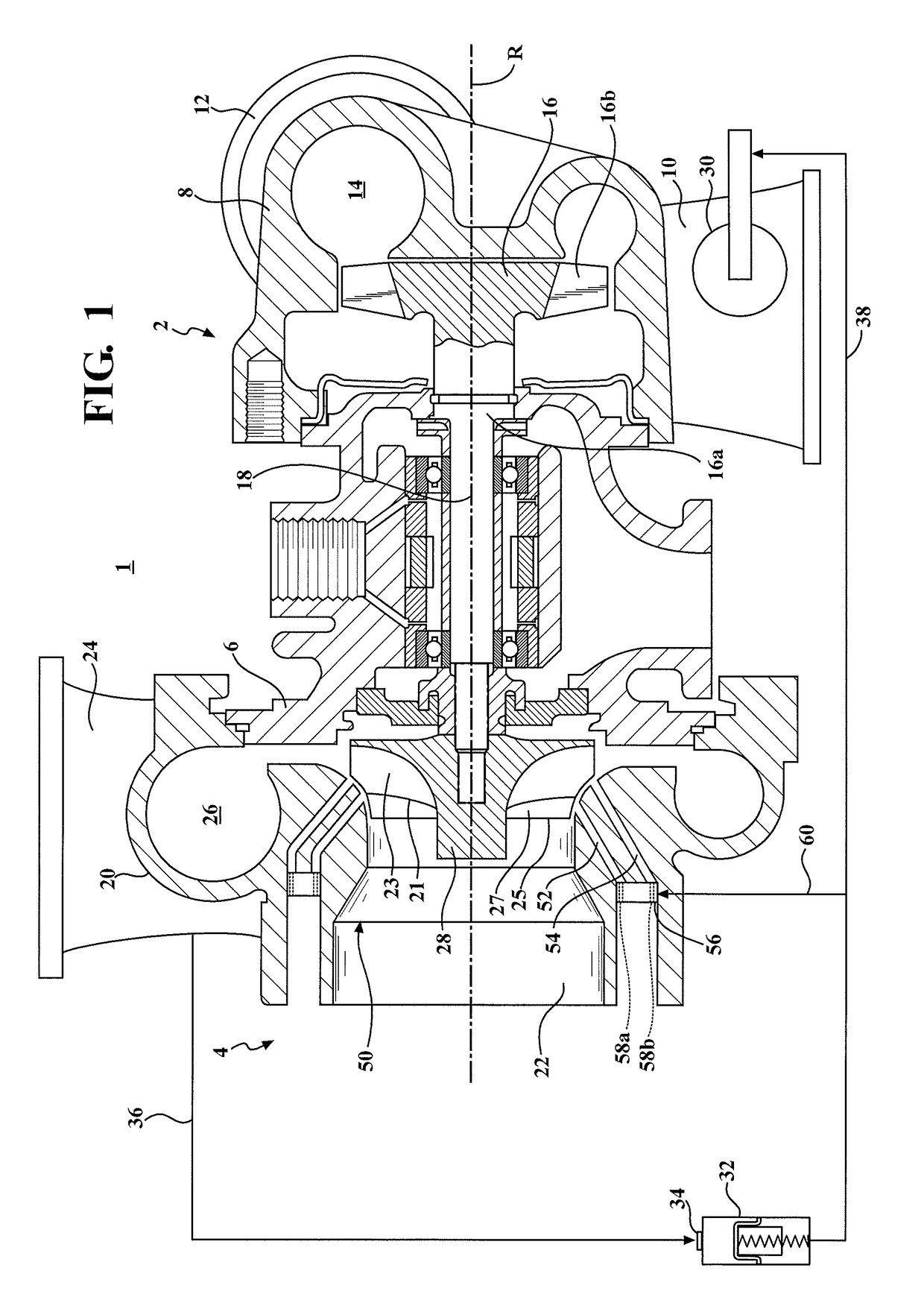

Bearing systems for high-speed rotating machinery

InactiveUS7677041B2Improve performanceMaintain integrityRolling contact bearingsShaftsBall bearingTurbocharger

Bearing systems for high speed rotating shafts, such as turbocharger shafts, include a first ball bearing in one end of an elongated cylinder capable of carrying axial thrust in both directions and a second ball bearing in the opposite end of the elongated cylinder with its outer race slideably mounted in the cylinder against the biasing force of a preload spring. The second ball bearing is free to move axially with the shaft upon axial expansion of the shaft when exposed to high temperature. The inner races of the ball bearings are clamped to and rotate with the shaft as part of the rotating assembly.

Owner:DELGADO LAUREN N

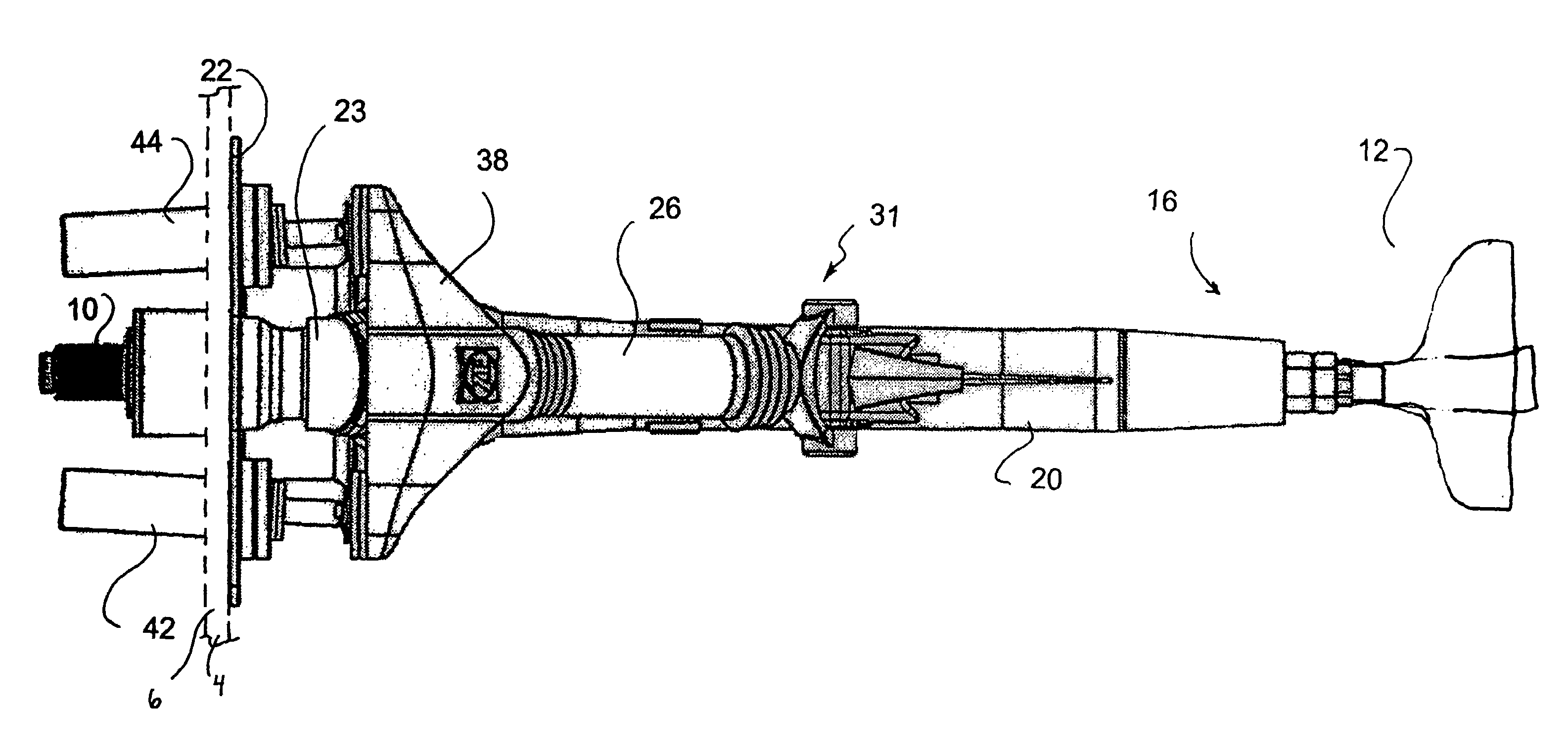

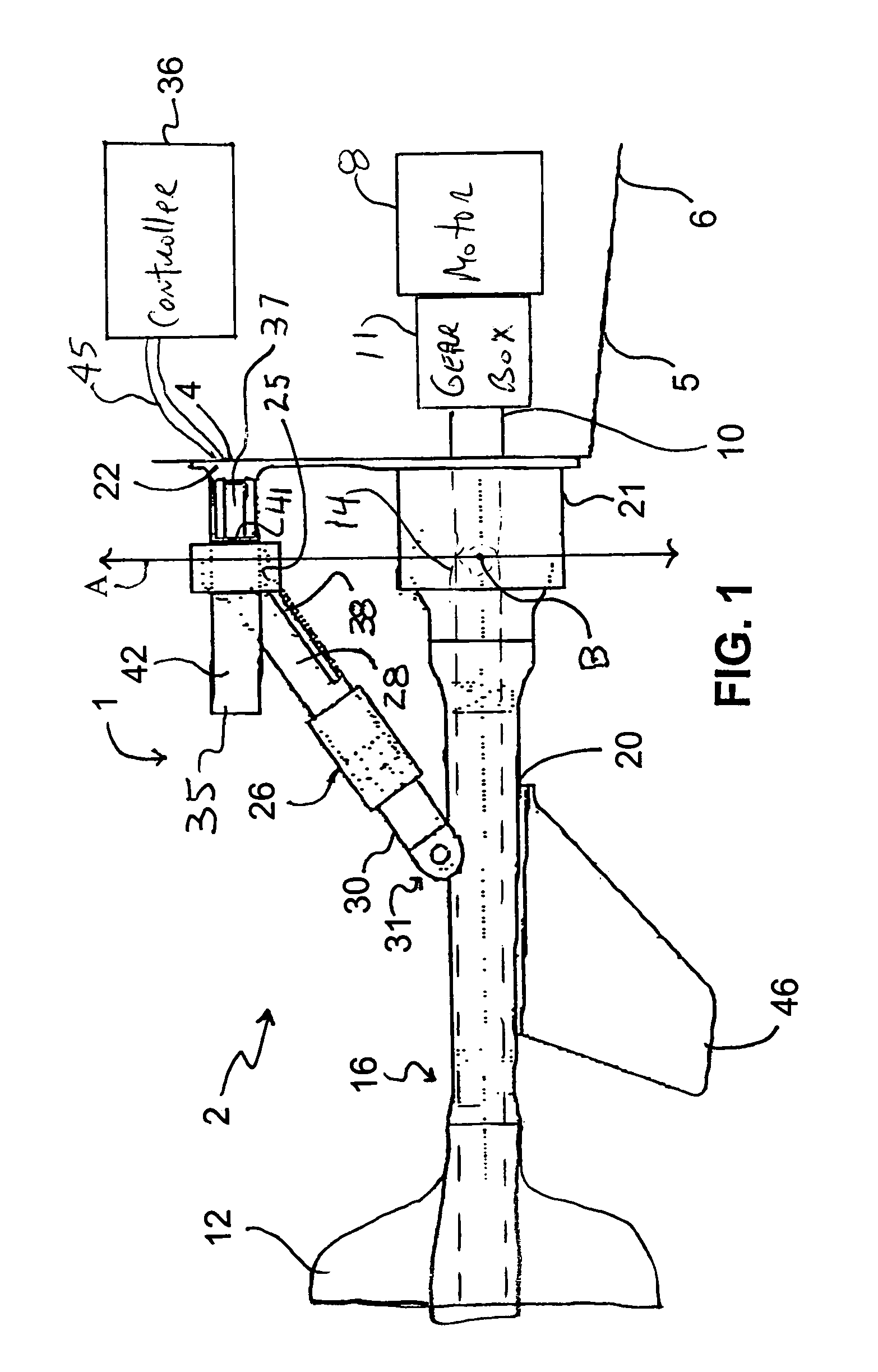

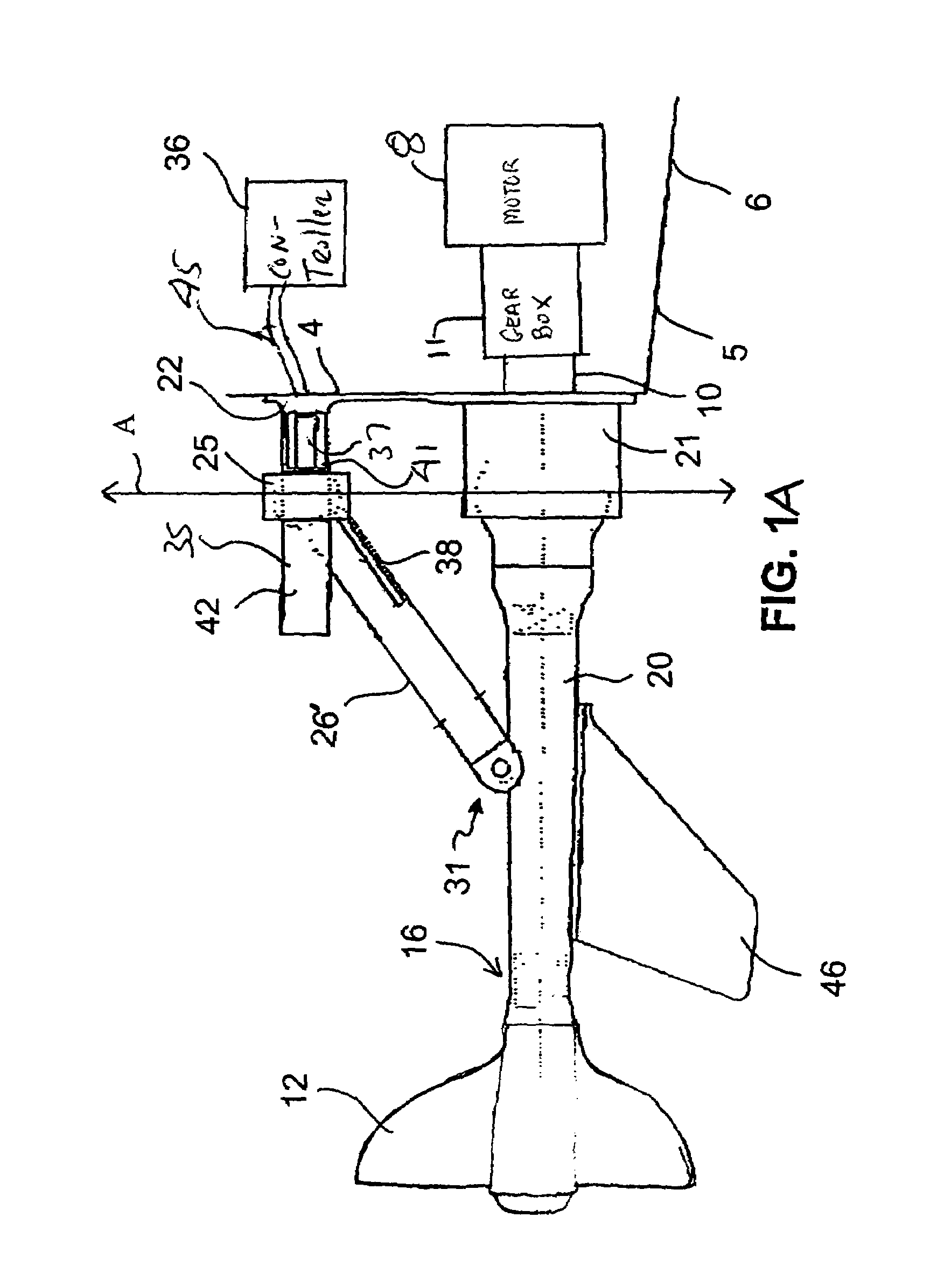

Trim apparatus for marine outdrive with steering capability

ActiveUS6908350B1High mechanical efficiencyCompact and light in weightRotary propellersPropulsion power plantsPropellerActuator

A marine outdrive (2) steering and trim system comprising a support linkage (26) which is either of fixed length (non-trimmable) or of an adjustable telescoping length (trimmable) and having a first end (28) pivotally mounted to the transom (4) and a second opposed end (30) attached to a propeller end (16) of the marine outdrive (2). A pair of steering actuators (42, 44) are connected between a steering yoke (38), secured to the support linkage (26), and a stationary pivot point on the transom (4) for providing a pure force couple to facilitating steering of the marine outdrive (2).

Owner:ZF FRIEDRICHSHAFEN AG

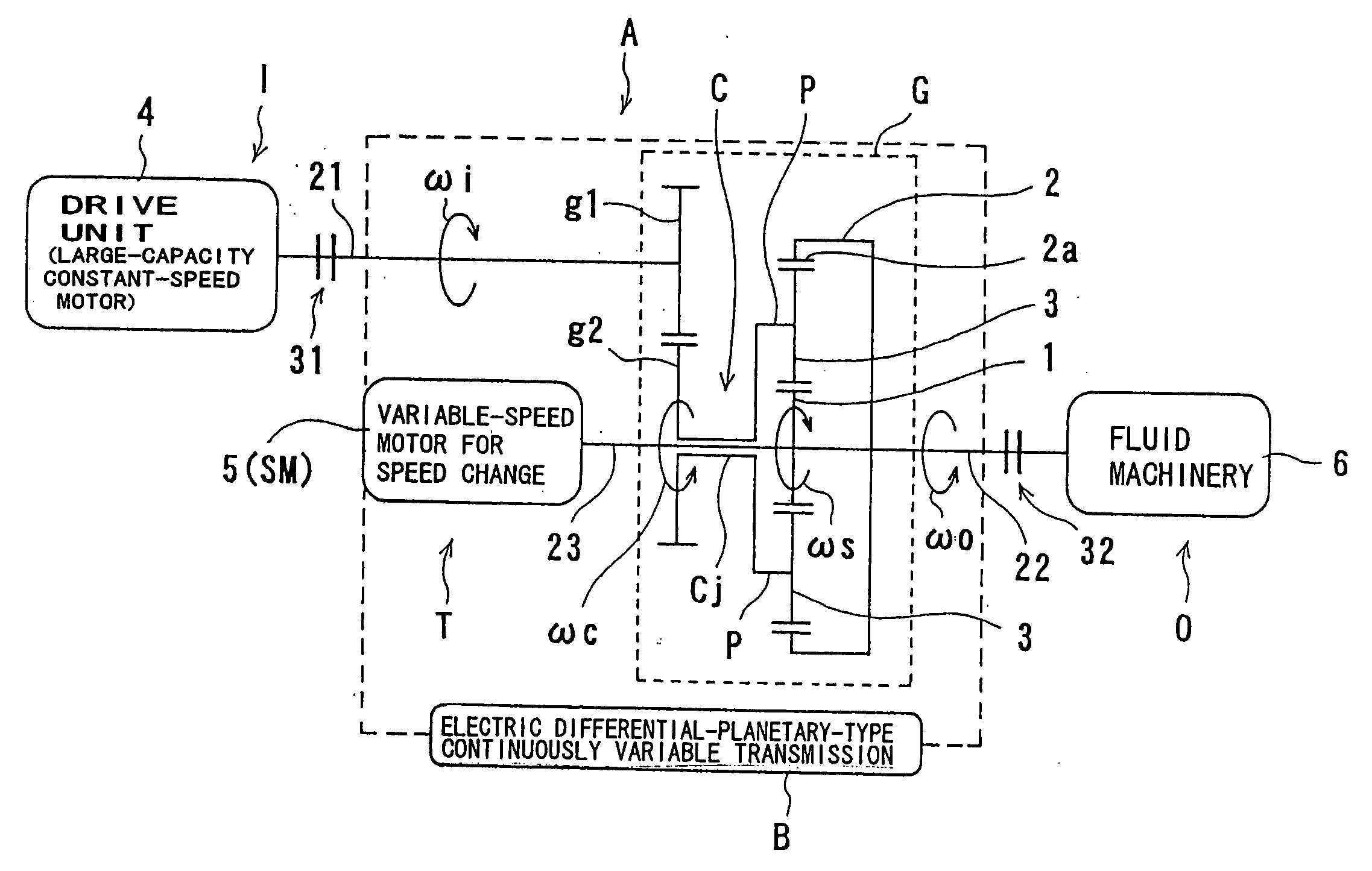

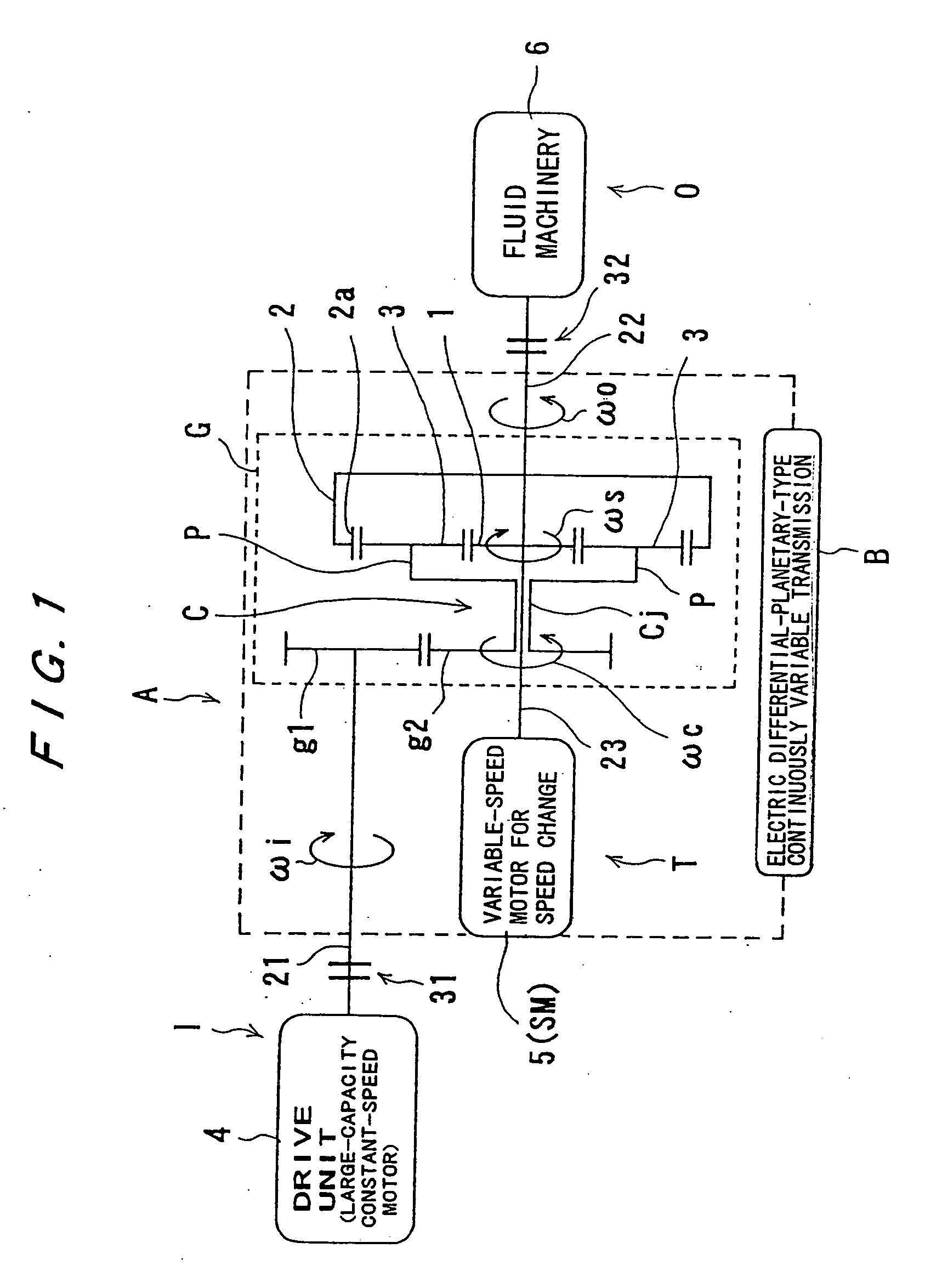

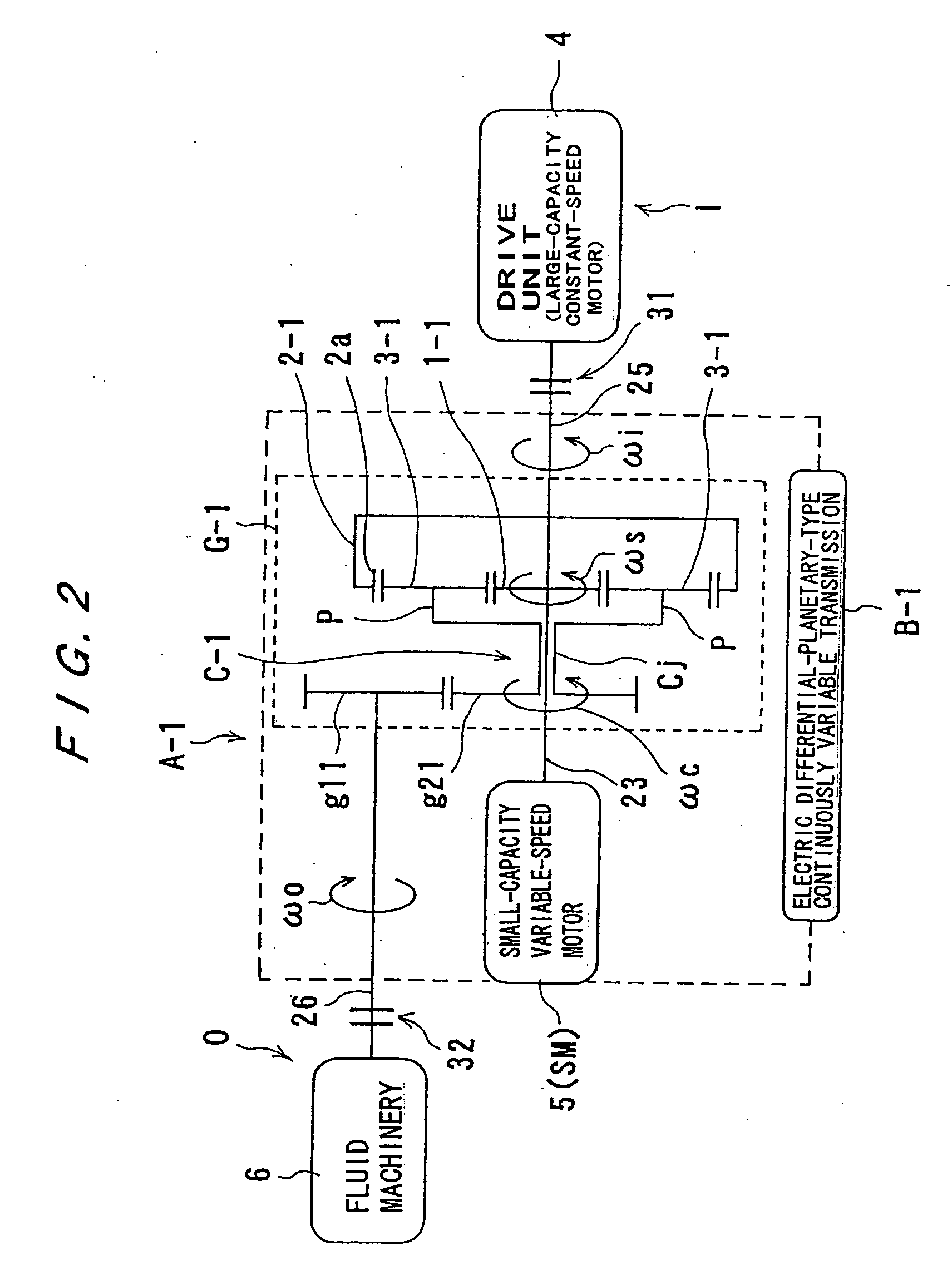

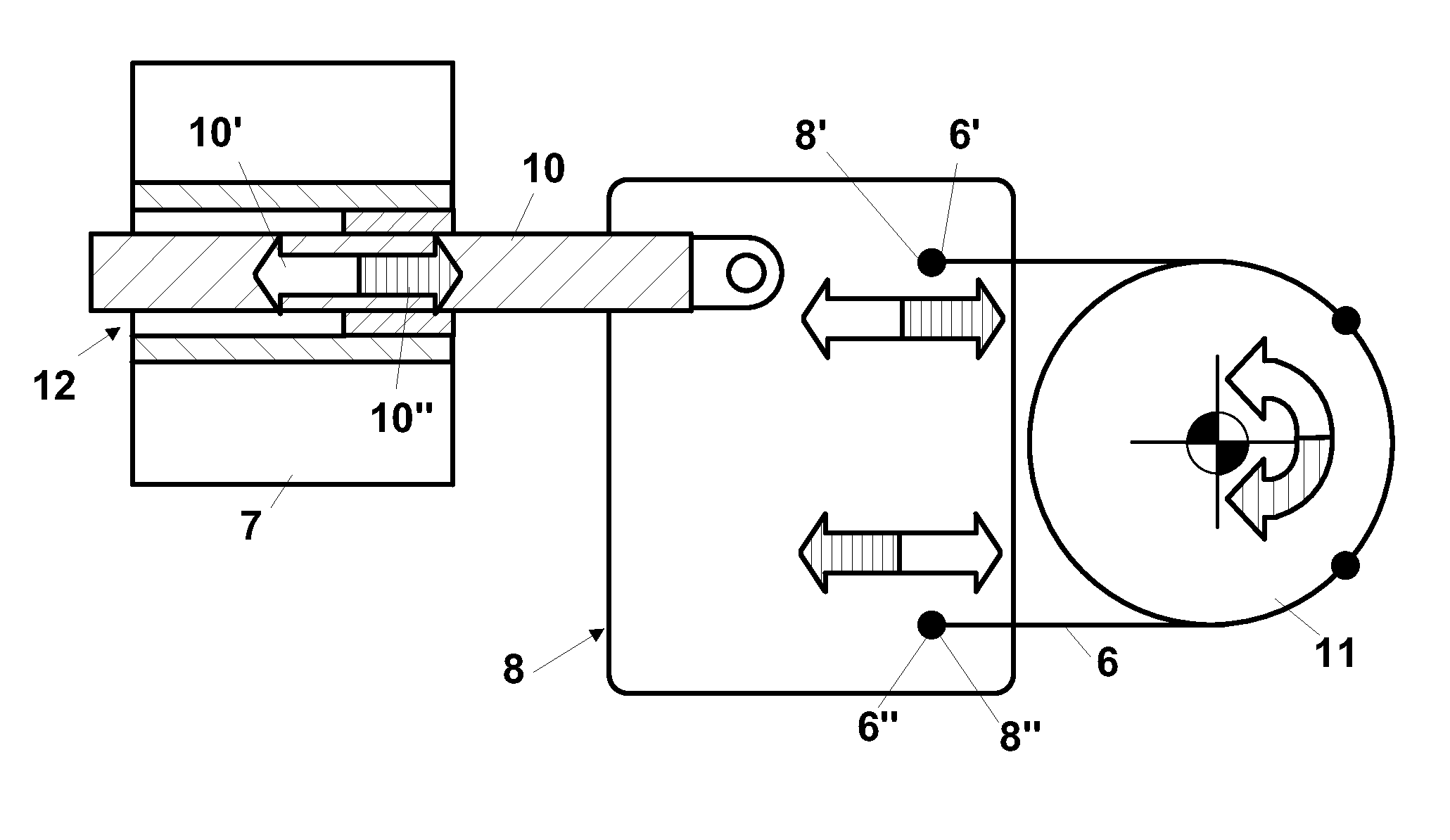

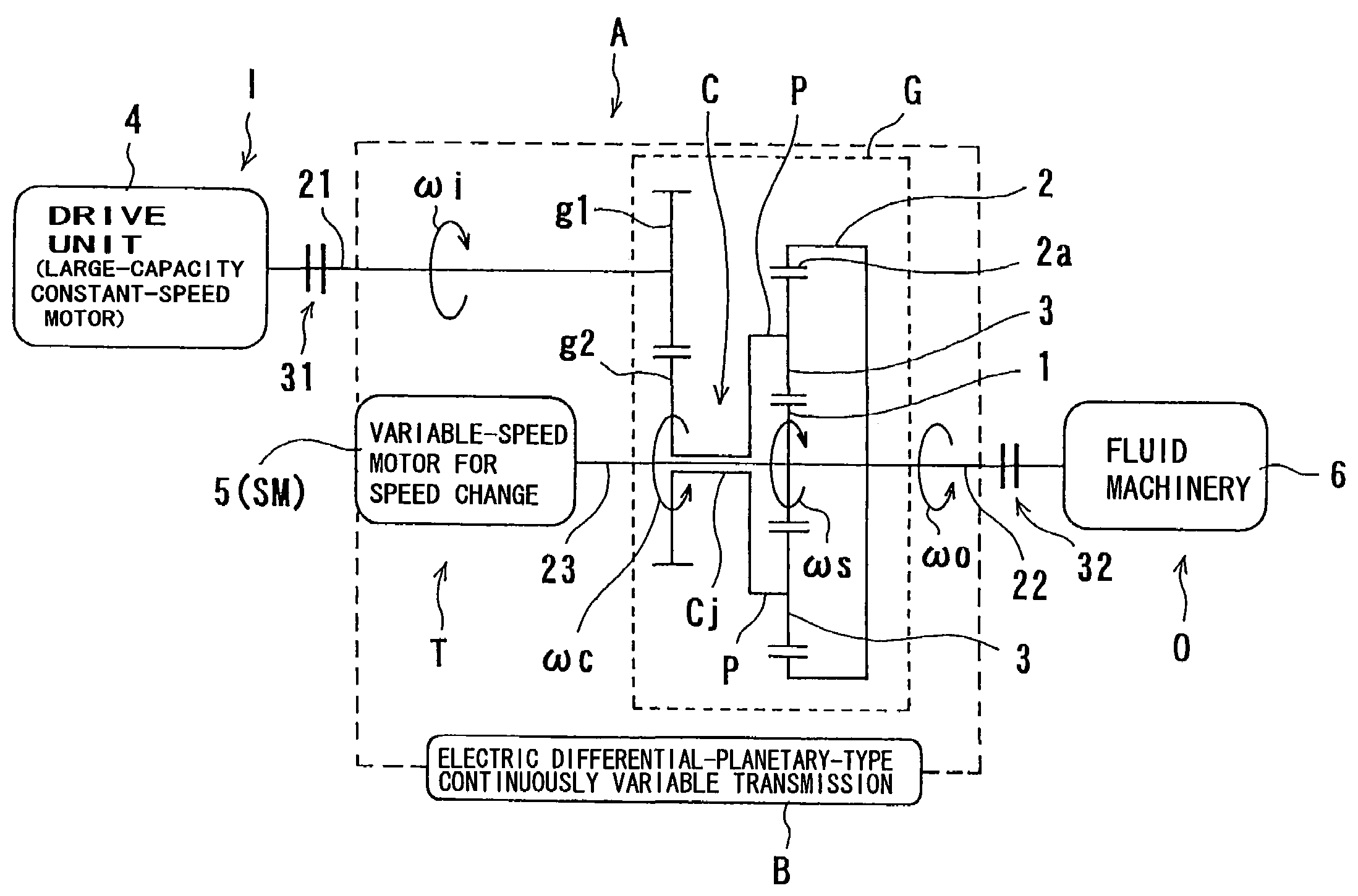

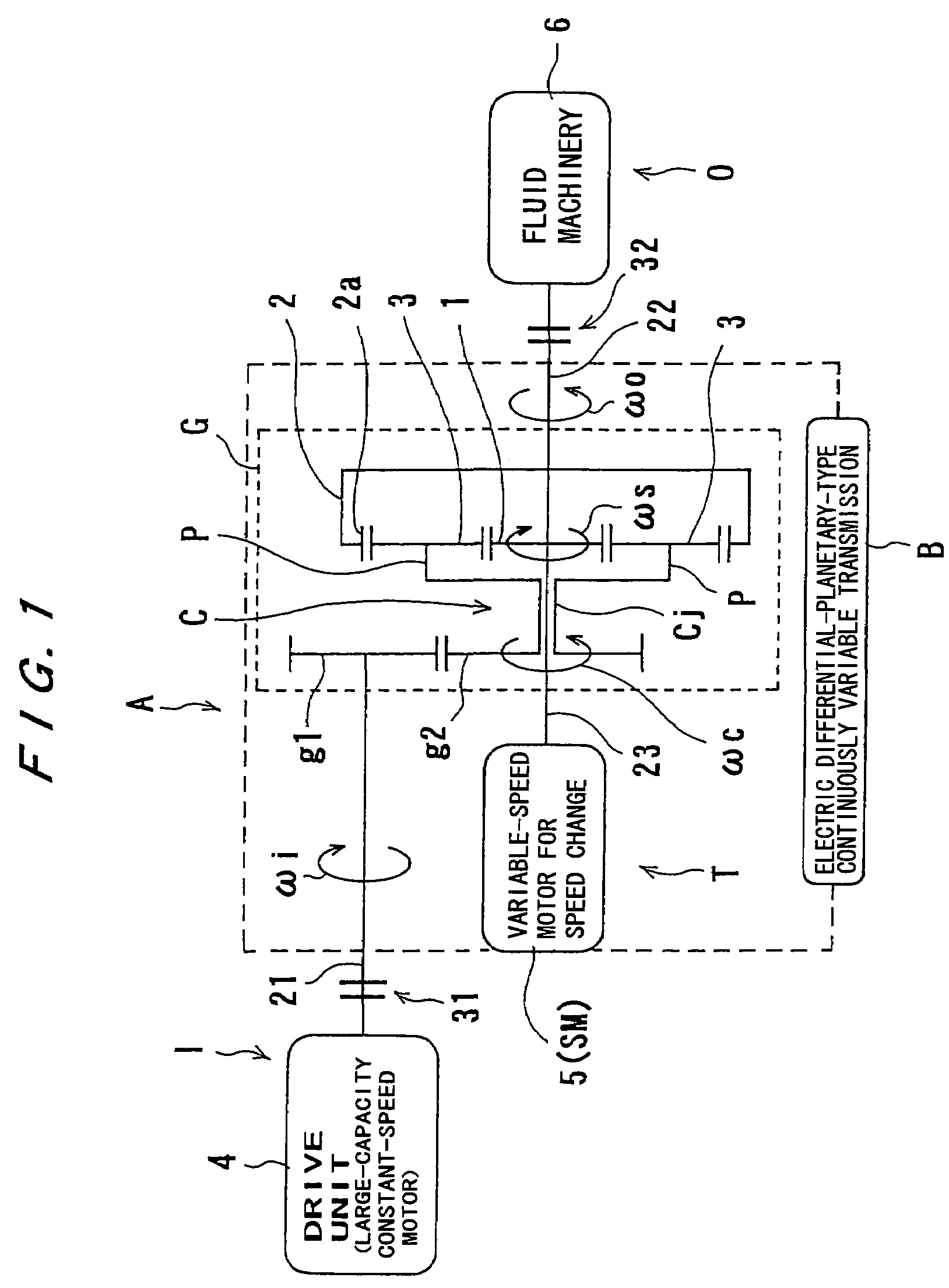

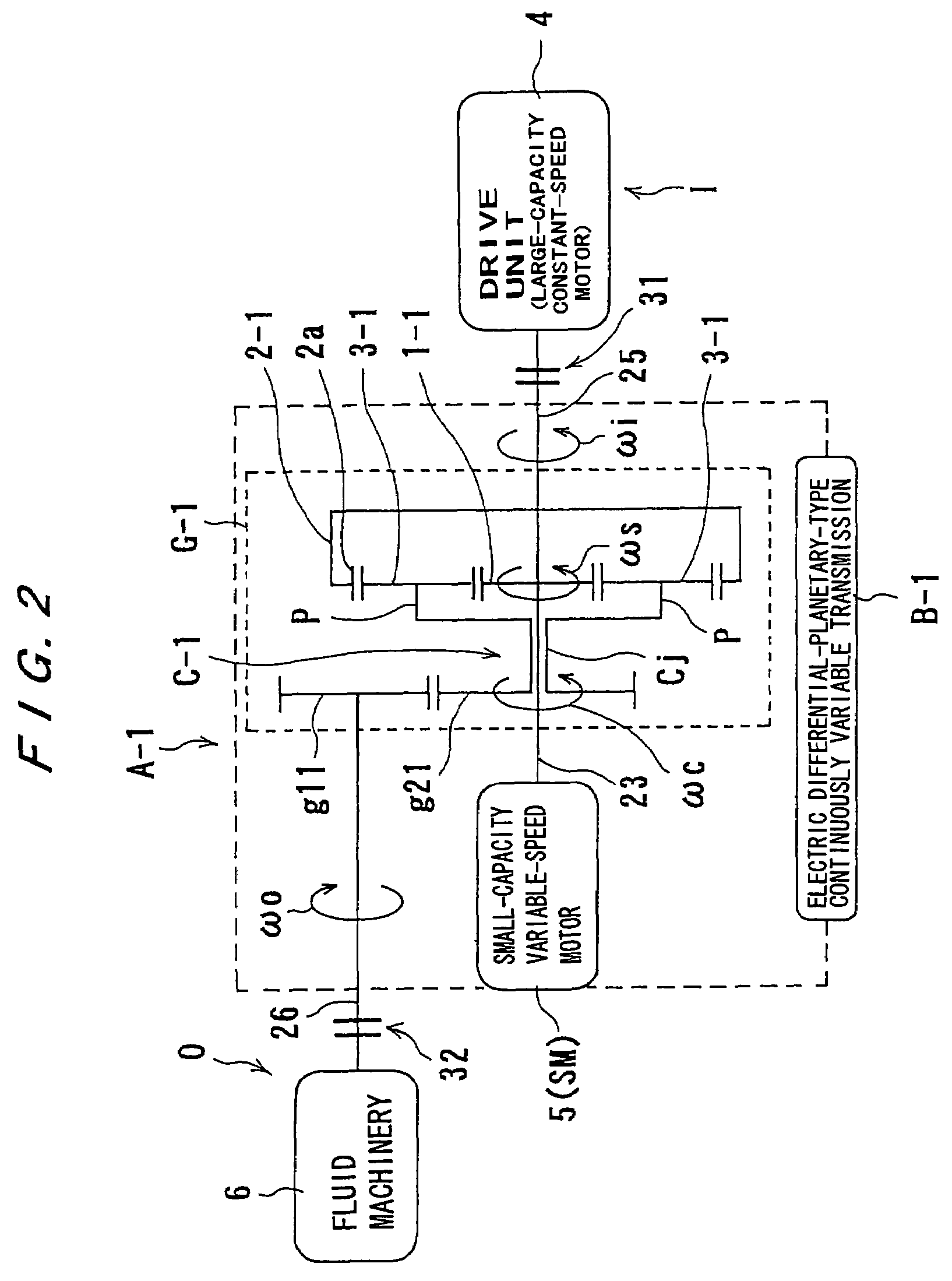

Differential planetary gear apparatus and starting apparatus and method for differential planetary gear apparatus

InactiveUS20070155570A1High mechanical efficiencyReduce loadToothed gearingsDifferential gearingsGear wheelPinion

A differential planetary gear apparatus has a single-pinion-type structure in which one planetary gear (3) is arranged in a radial direction and one or more planetary gears (3) are arranged in a circumferential direction in a region between a sun gear (1) and a ring gear (2), a drive source (4), a speed-change motive source (5), and a driven unit (6) are disposed at any one of an input side (I), an output side (O), and a speed-change side (T), respectively, and the speed-change motive source (5) includes an electric motor.

Owner:EBARA CORP

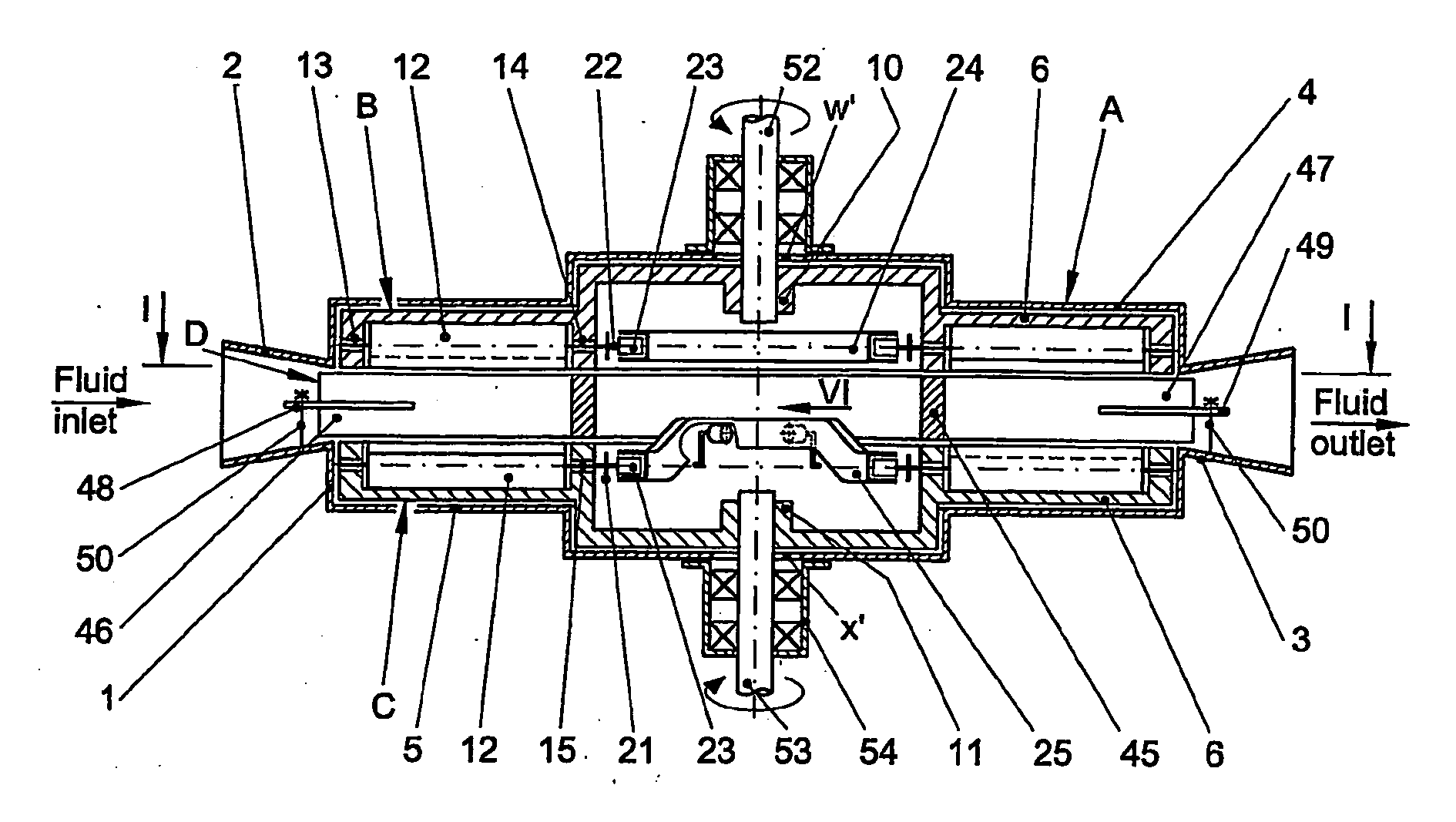

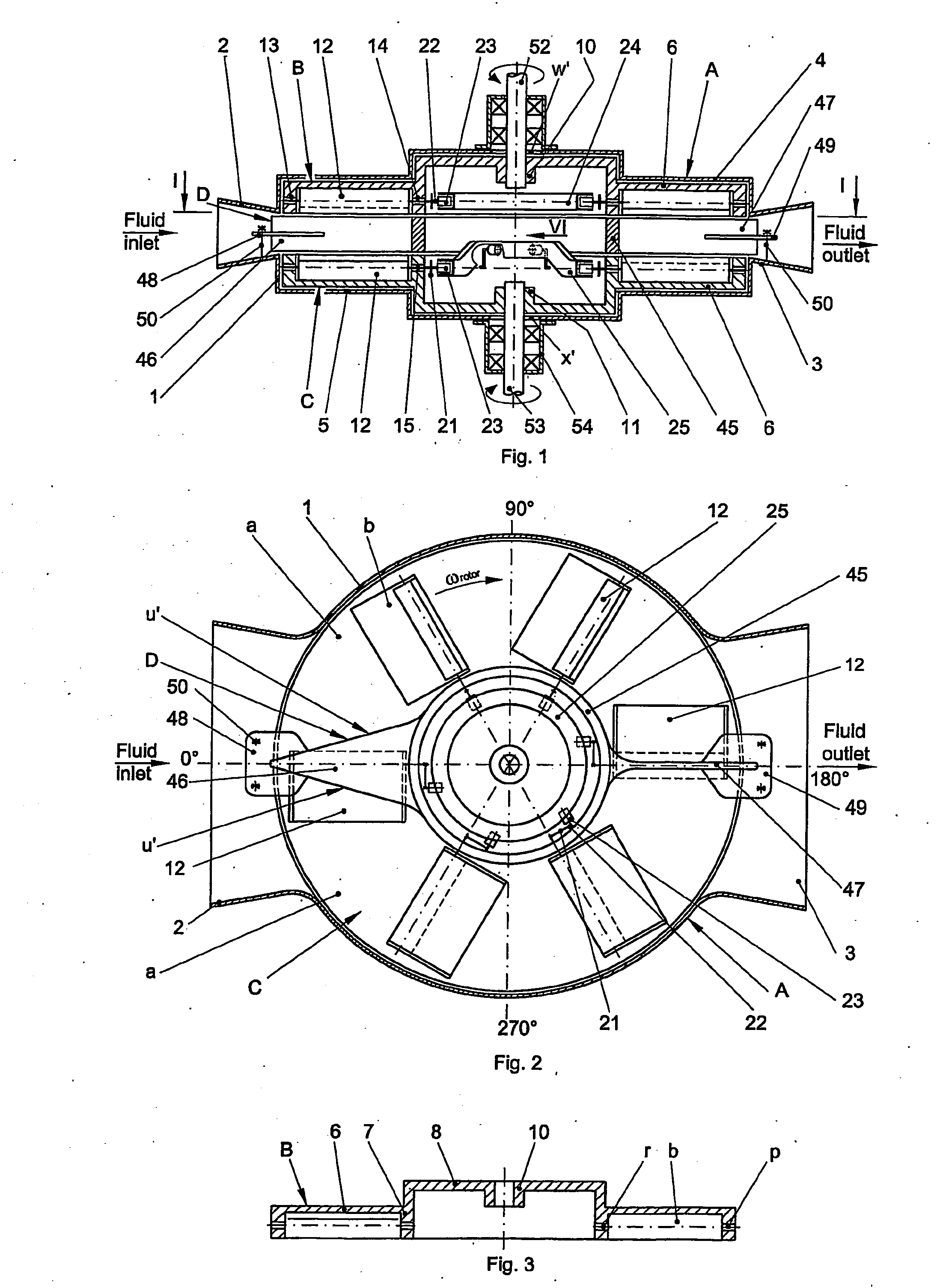

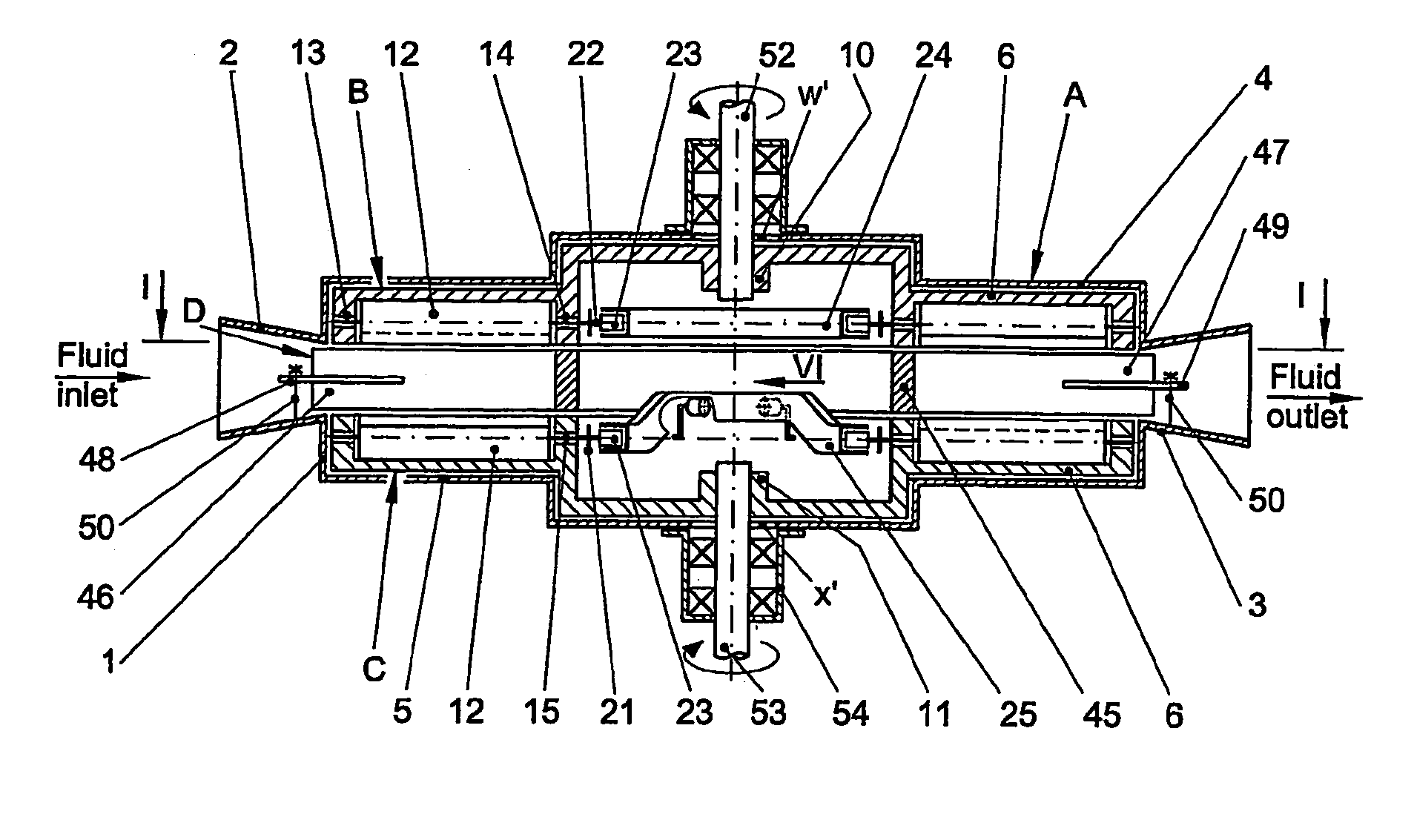

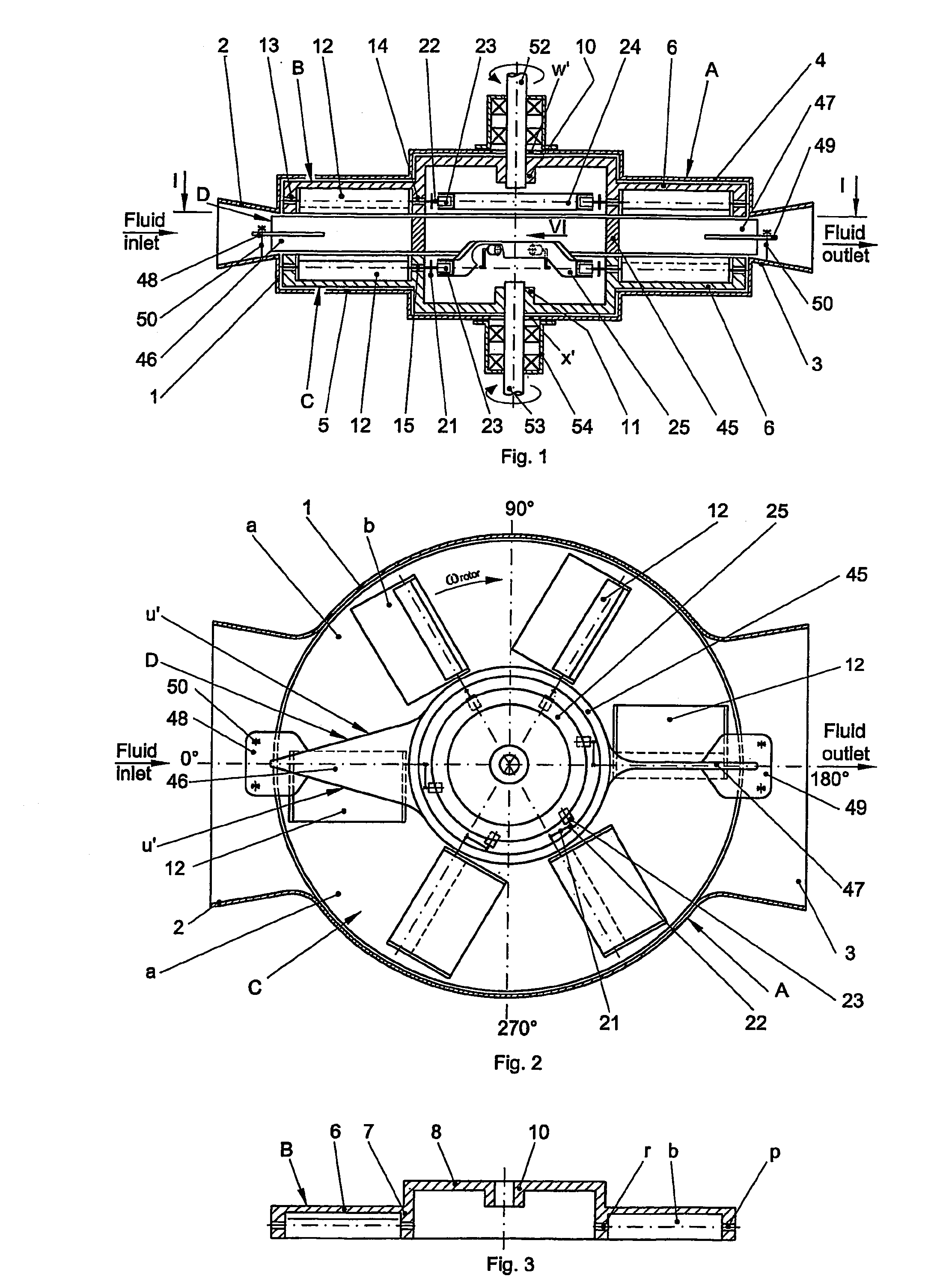

Hydraulic or pneumatic machine with tilting blades

InactiveUS20060083618A1Reduce stressReduce loss valuePropellersPump componentsMechanical engineeringHydraulic pressure

This invention refers to a hydraulic or pneumatic machine with tilting blades, running either as an engine on a fluid flow or on pressure fluid or as a pump or a compressor. The hydraulic or pneumatic machine on a fluid flow according to the invention consists of a cylindrical casing with inlet and outlet openings, radially arranged, diametrically oposed, along the fluid flowing direction, some disk like rotors with tilting blades, hinged over their front faces and provided with driving mechanisms of their own, and some fixed drums located between the rotors, concentrically to them, making inside the machine some channels, symetrically arranged on one or several stages. Flowing through the channels, the fluid drives the tilting blades causing the movement of the rotors, all the rotors moving to one sense being coupled to the same outlet shaft of the machine. The tilting blades of the hydraulic or pneumatic machine operating according to the invention with pressure fluid, run in variable depth grooves located in the rings between the front faces of the rotors and connected to the fluid circuit, the operation conditions of the machine—motor or pump—being determined by the moving sense of the blade in the groove.

Owner:HOLT CORNELIU

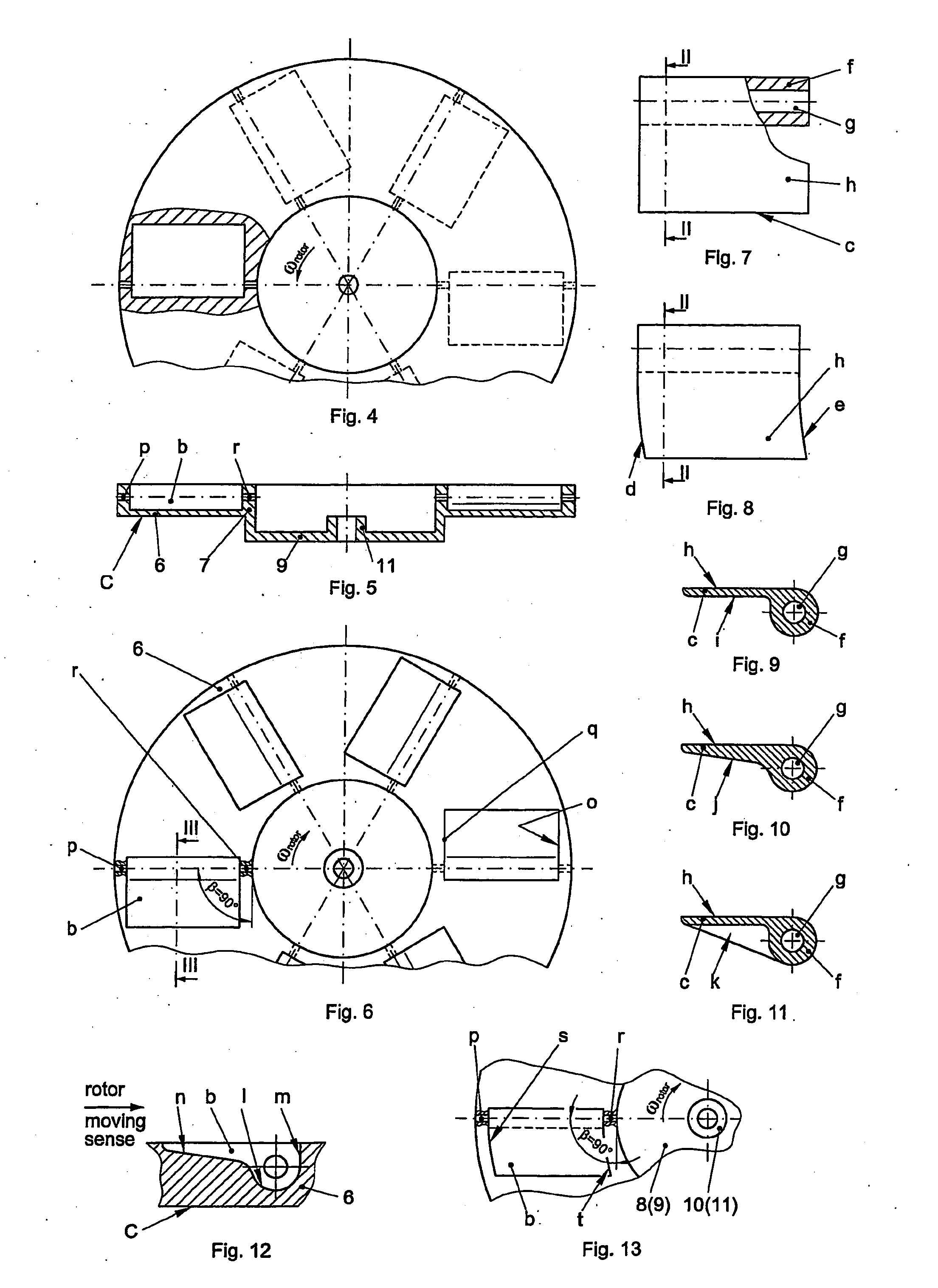

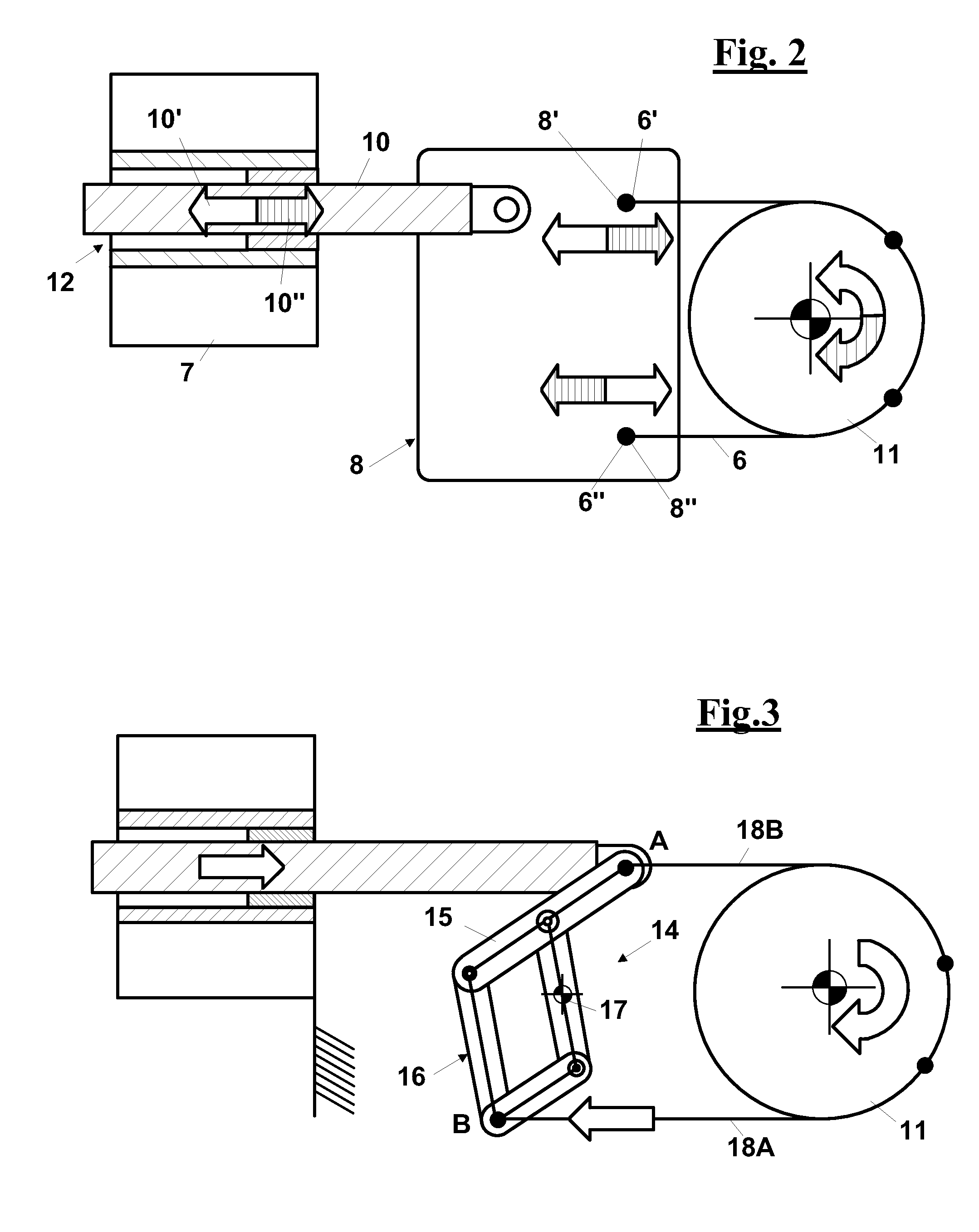

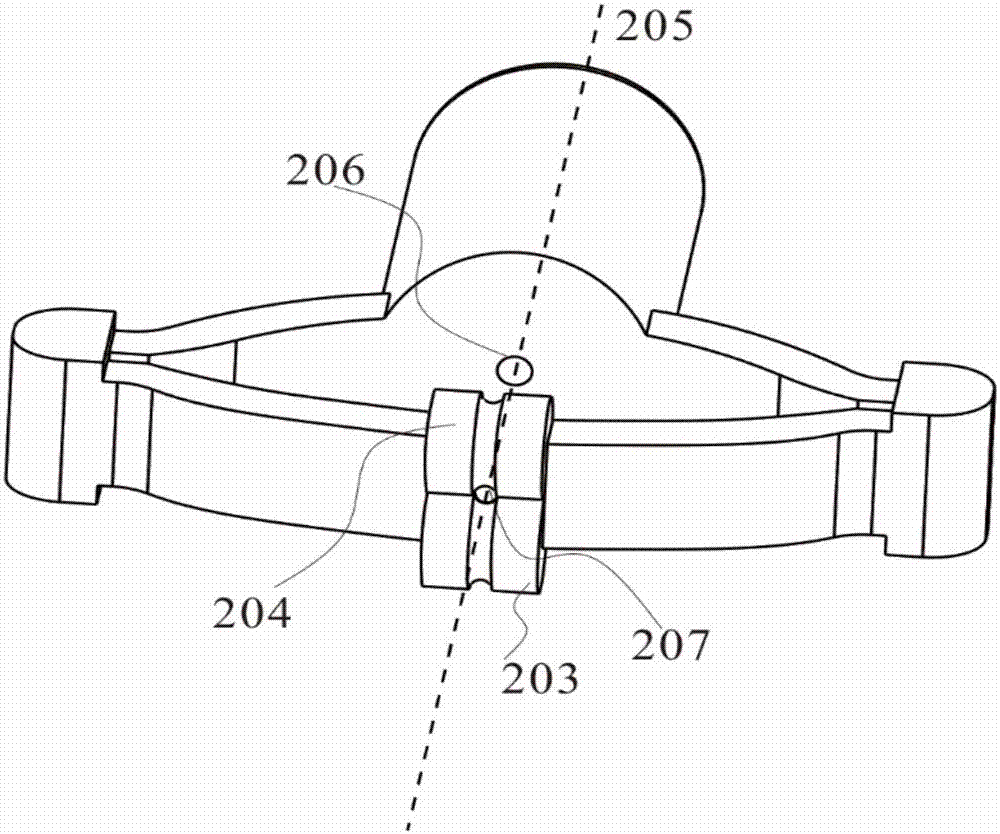

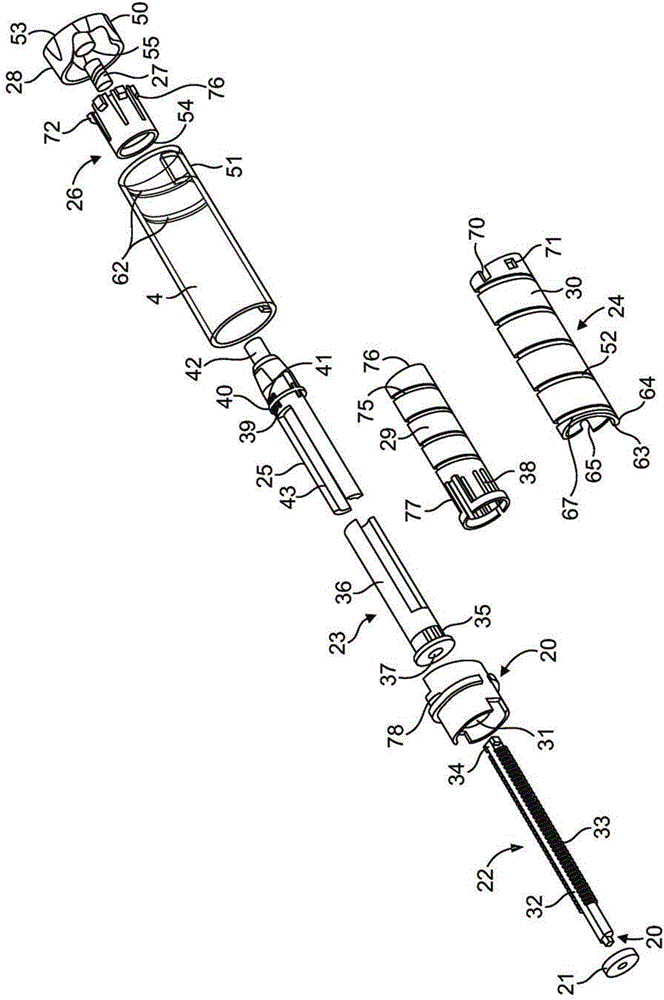

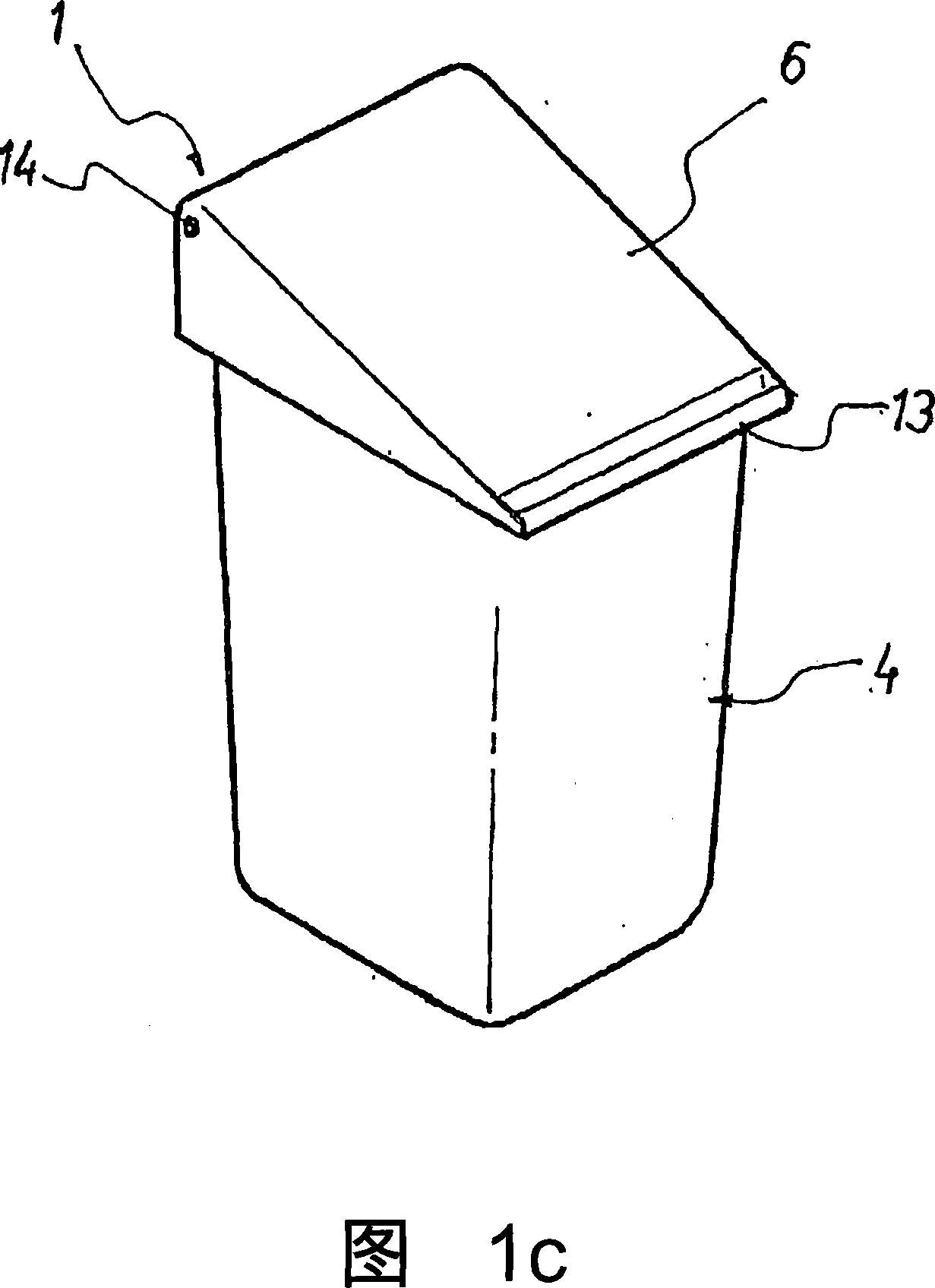

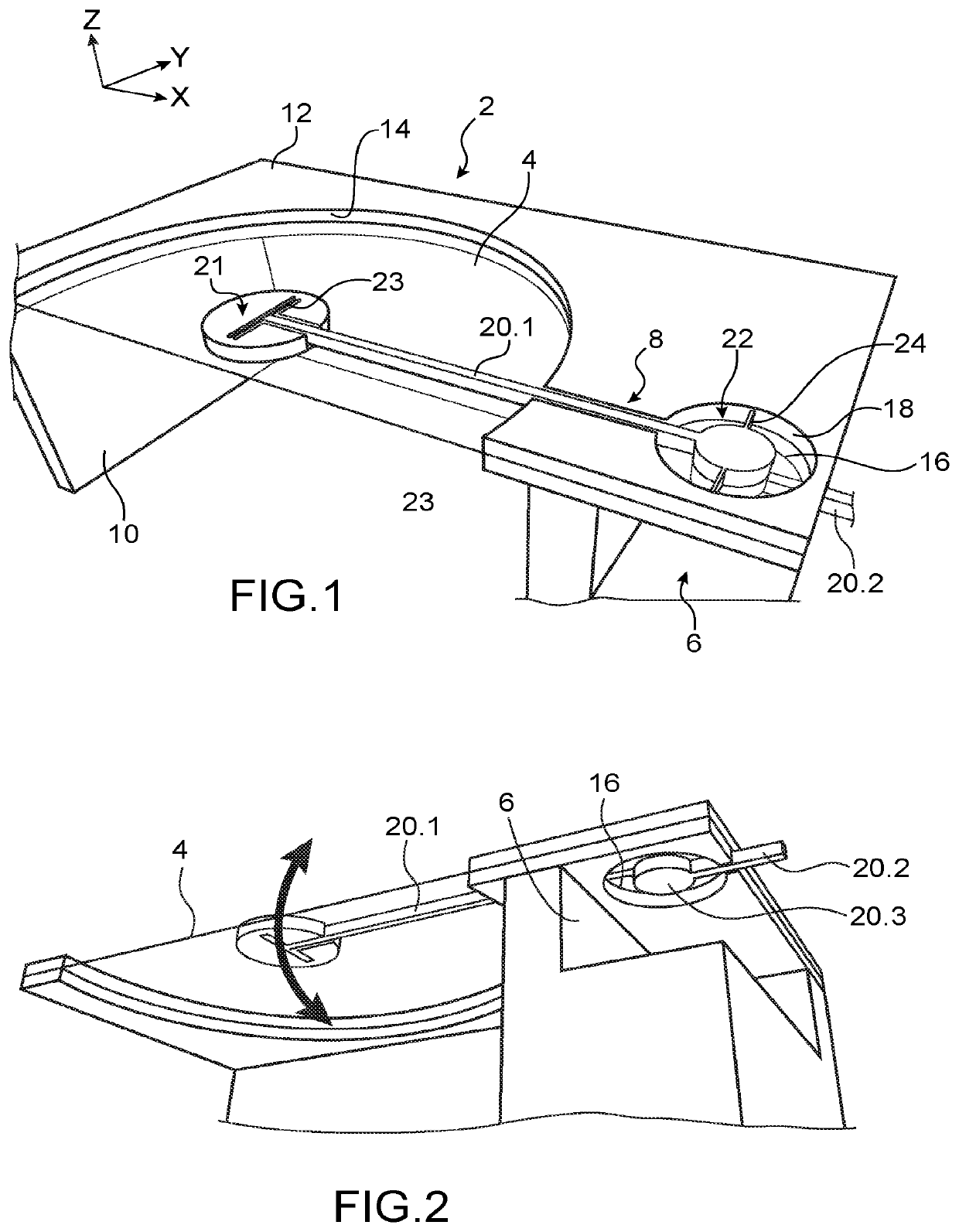

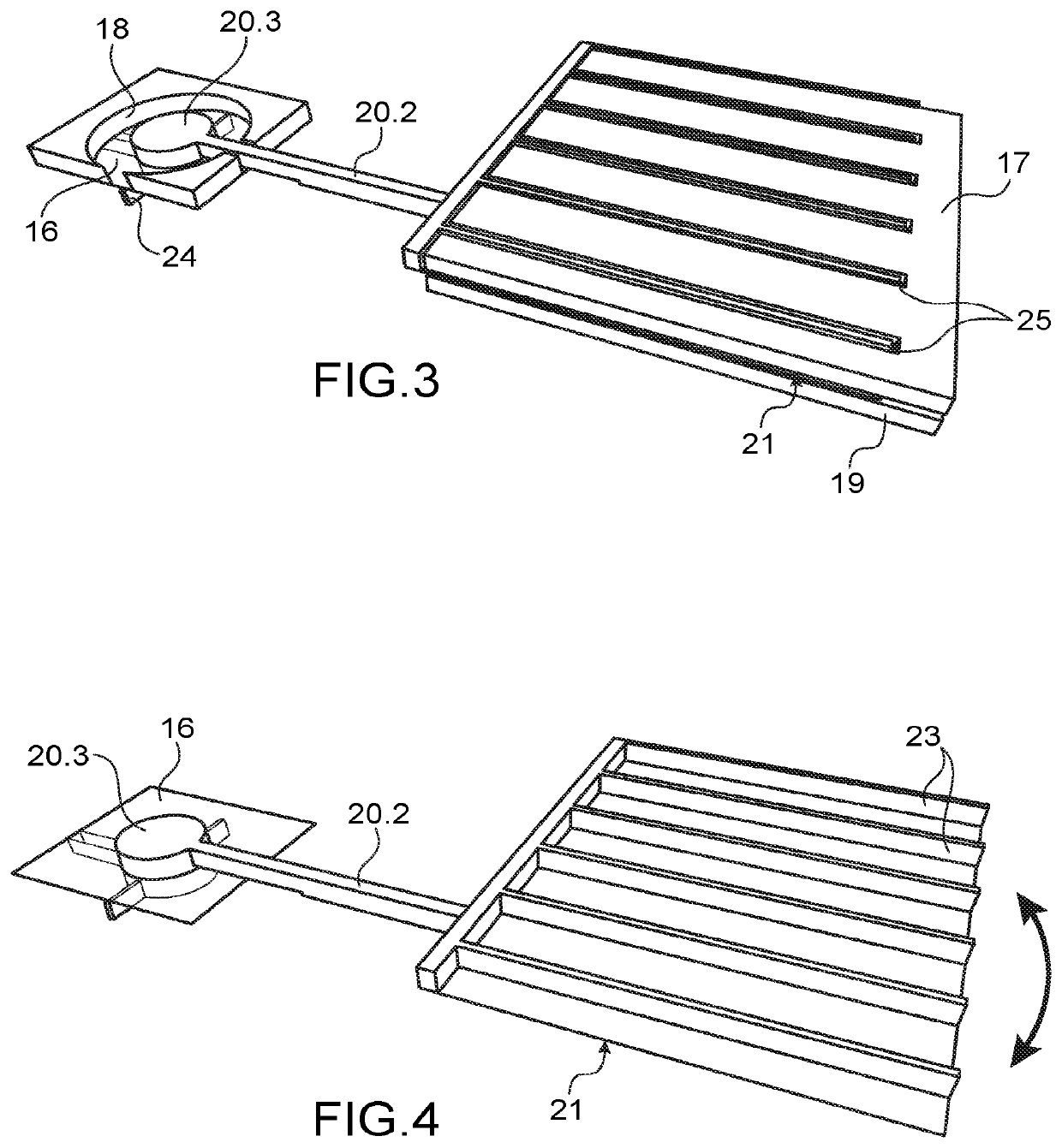

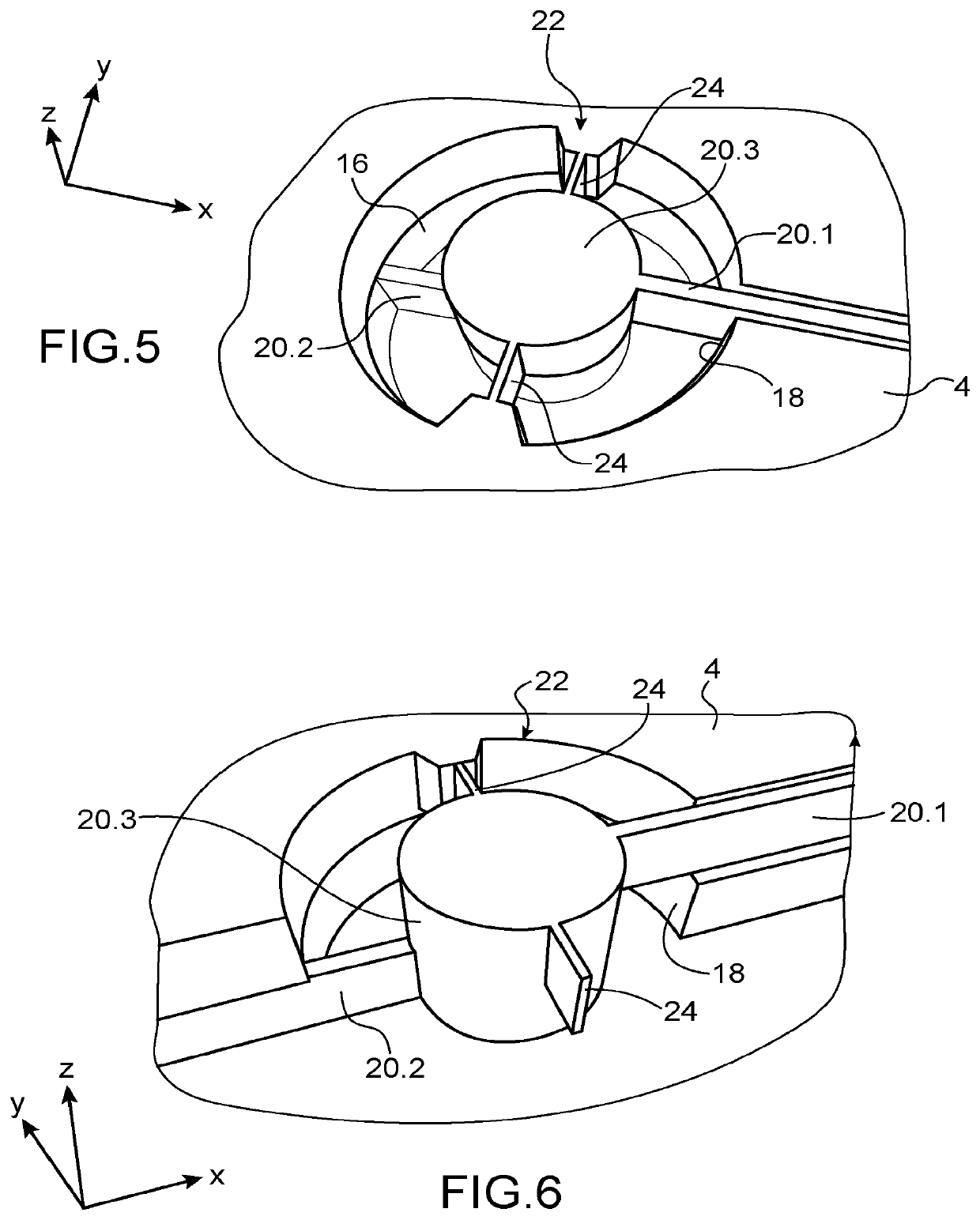

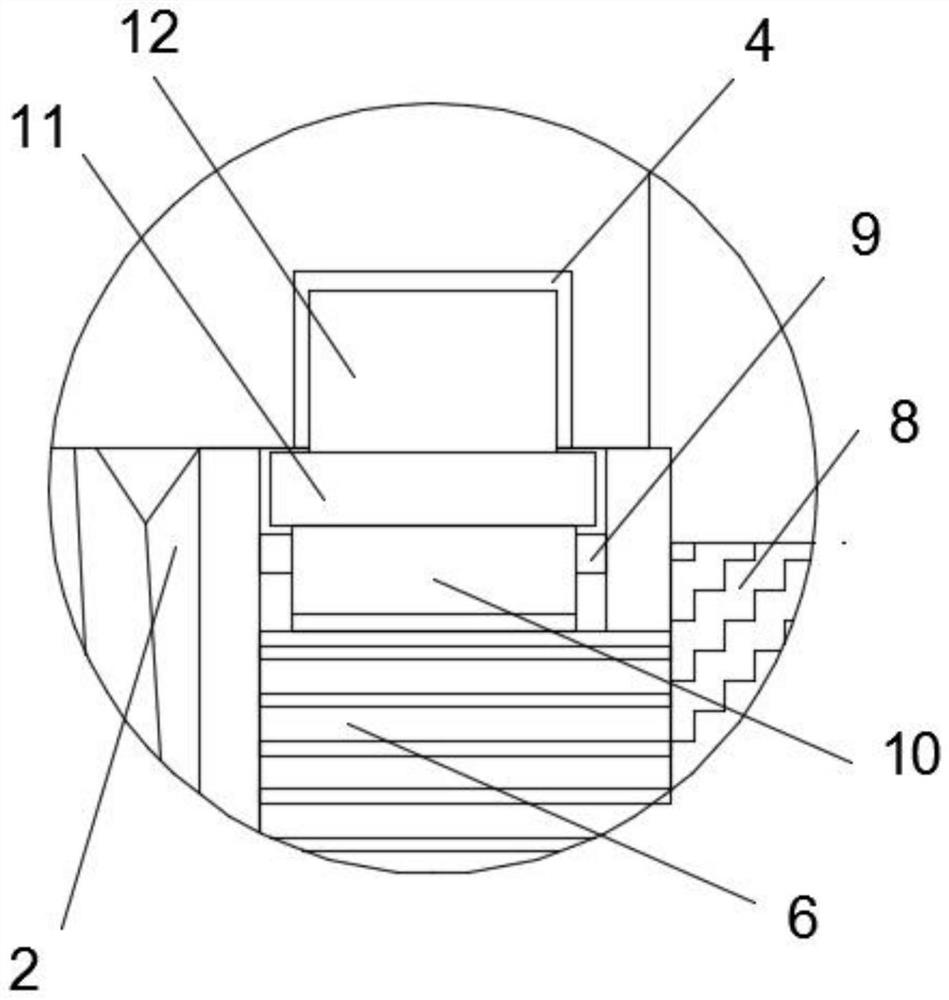

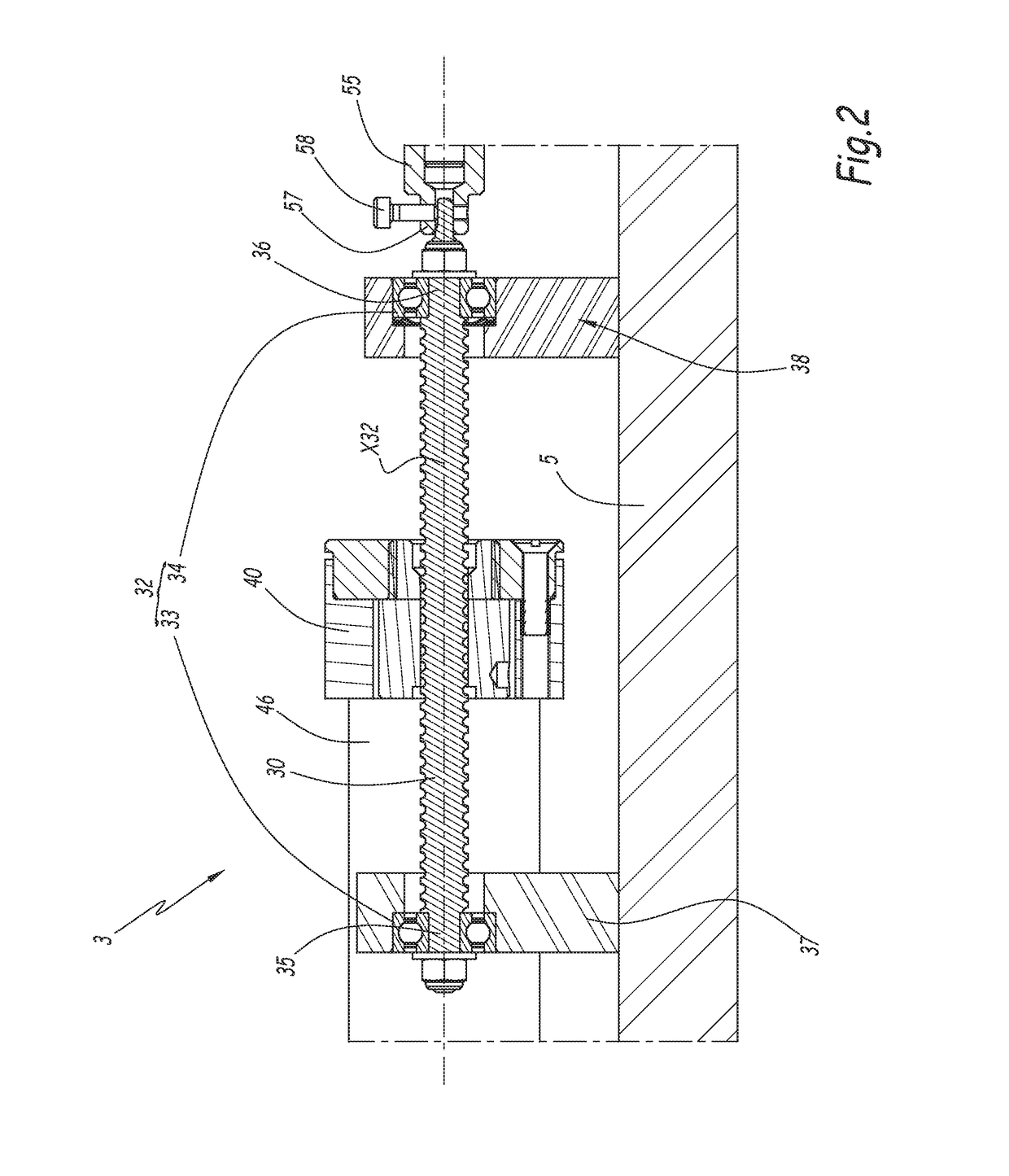

High torque limited angle compact and lightweight actuator

InactiveUS20110174097A1Raise the ratioHigh mechanical efficiencyFriction gearingsLinear motionHigh torque

A high torque limited angle compact and lightweight actuator that comprises a driven pulley (11), a flexible tie-member (6), which is wound about the driven pulley (11), a linear actuator (7) and an inversion mechanism (8). In particular, the linear actuator (7), which is located with respect to the driven pulley (11) such that the direction is substantially tangent to it, comprises a movable element (10) that carries out a linear movement along a line according to two opposite directions (10′), (10″). The inversion mechanism is such that when an input portion (8′) moves along a line (first straight line), tangential to the driven pulley, of a certain an amount a output portion (8″) moves along another line (second straight line), which is also tangential to the driven pulley, for a same movement amount, such that the total length of the tie-member (6) is unchanged. (FIG. 2)

Owner:SCUOLA SUPERIORE DI STUDI UNIVERSITARI E DI PERFEZIONAMENTO SANTANNA

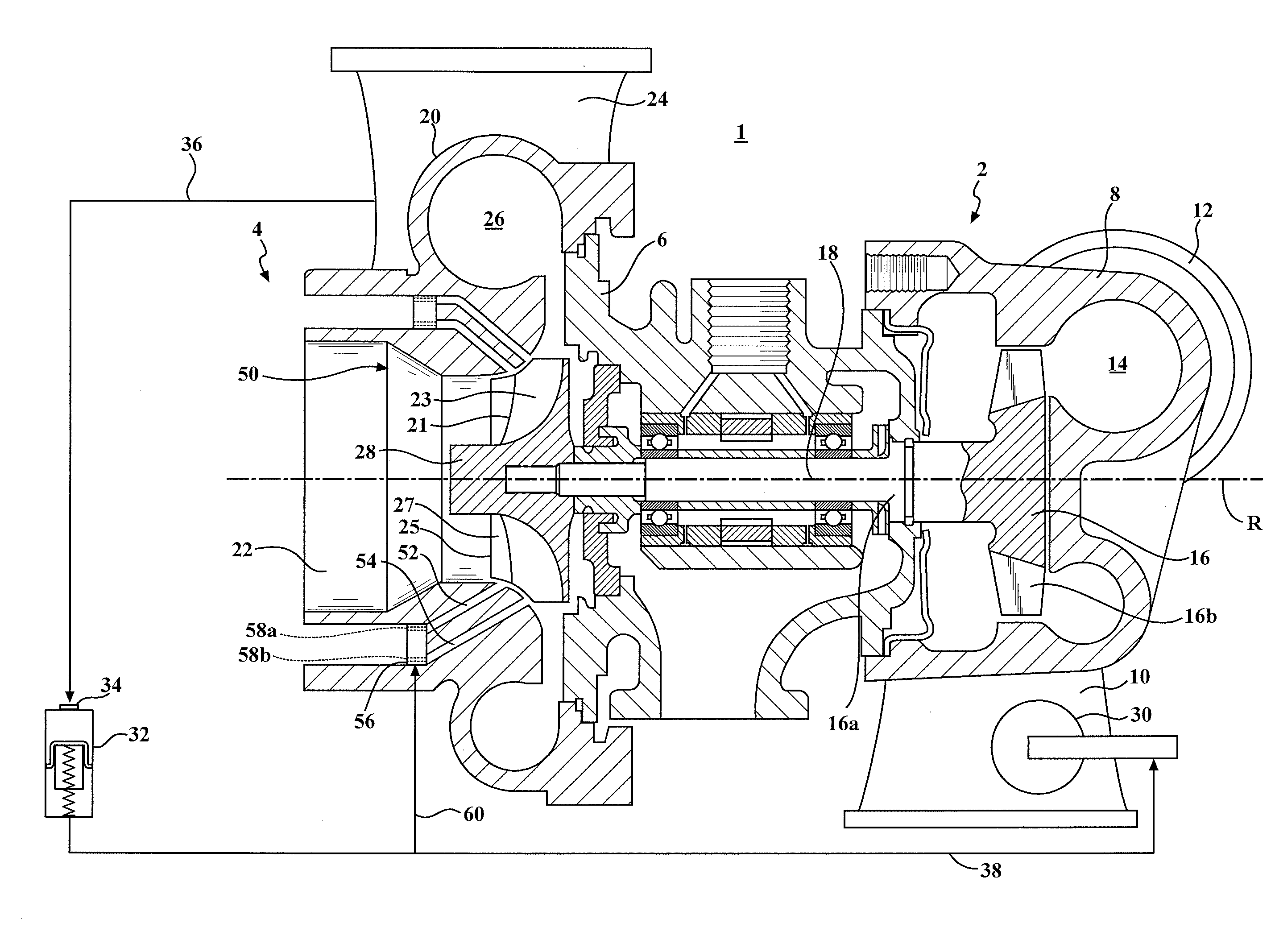

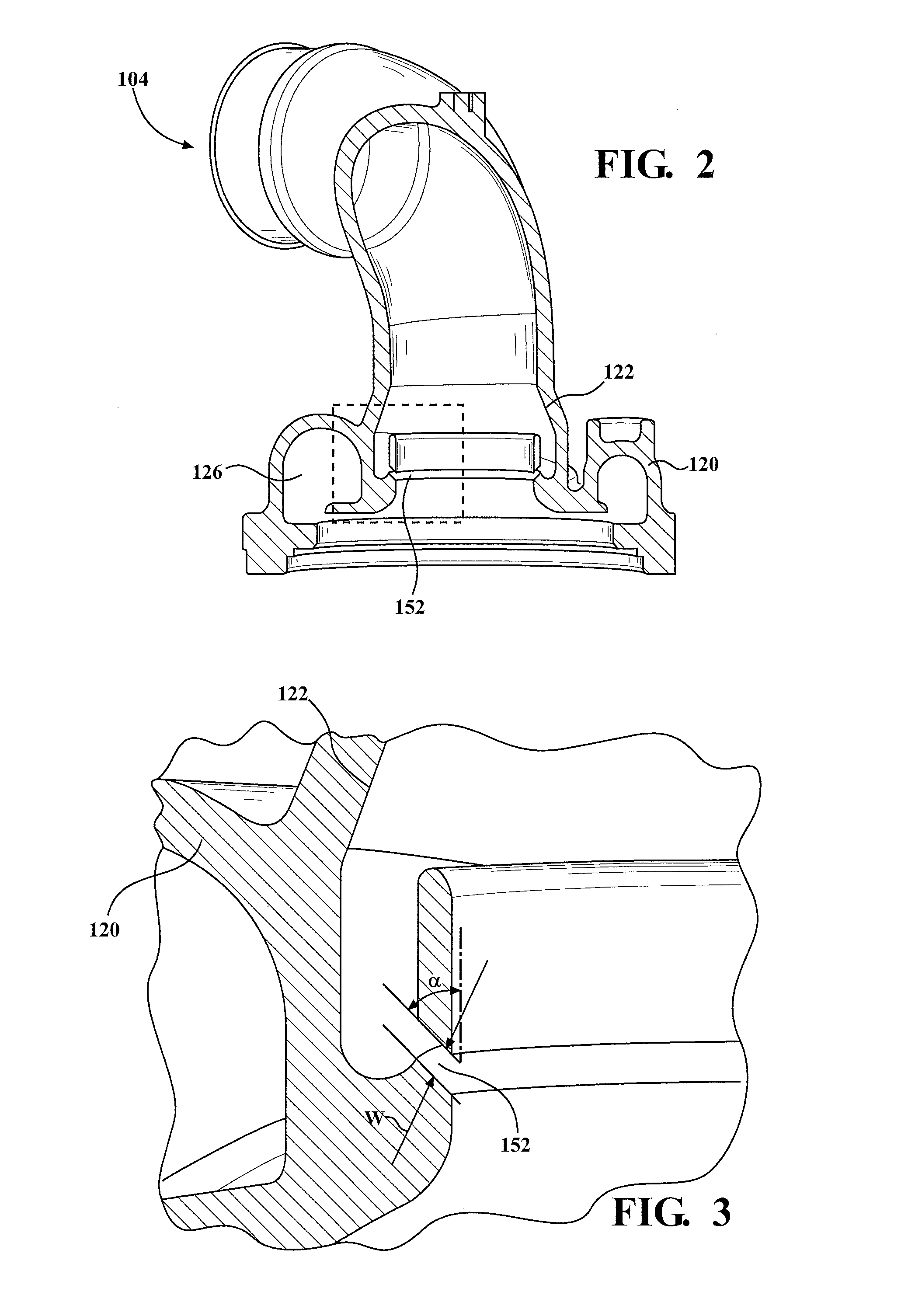

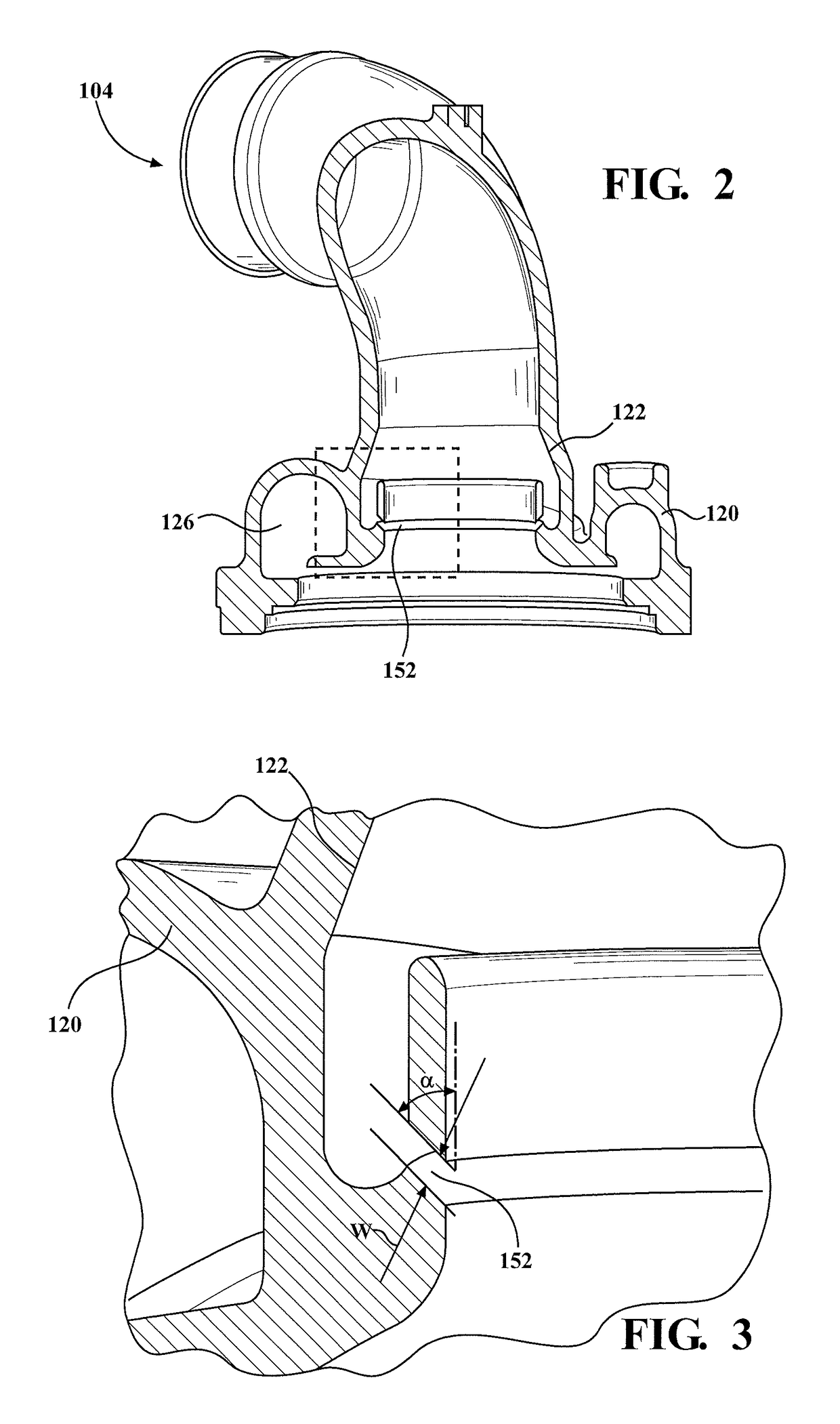

Turbocharger combining axial flow turbine with a compressor stage utilizing active casing treatment

ActiveUS20160160756A1Improve efficiencySmall sizeInternal combustion piston enginesWind motor controlWastegateChoked flow

A turbocharger (1) with an axial flow turbine (2) includes a compressor stage (4) using active casing treatment (50) for choke flow improvement. With switchable slots (52, 54), one of the slots (52) may be between the compressors full and splitter blades (27, 23) and one of the slots (54) can be located downstream of the compressors splitter blades (23) to maximize choke flow capacity. In turbochargers with a wastegate assembly, an actuator (32) may control both a wastegate control valve (30) and an active casing treatment slot selection valve (56).

Owner:BORGWARNER INC

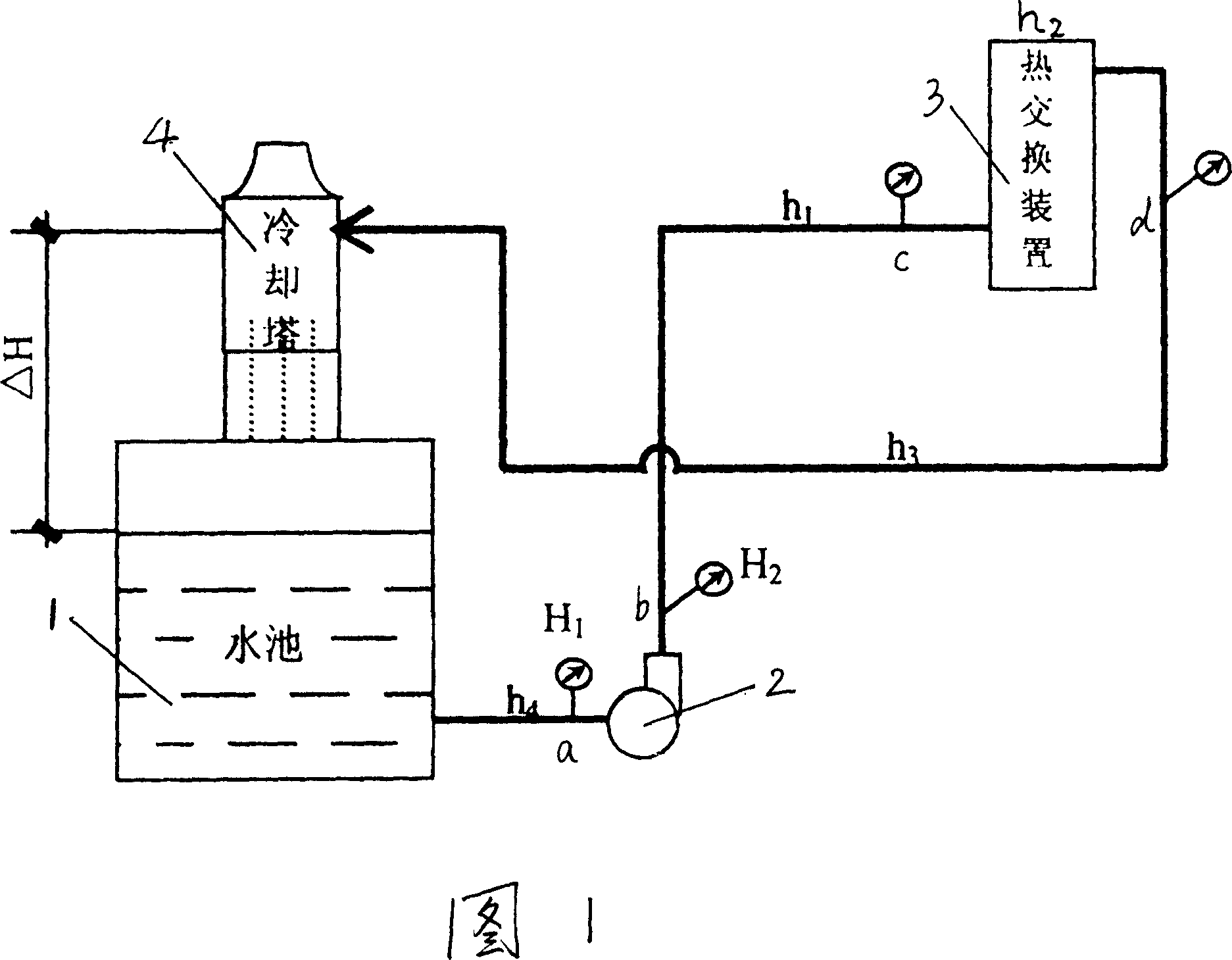

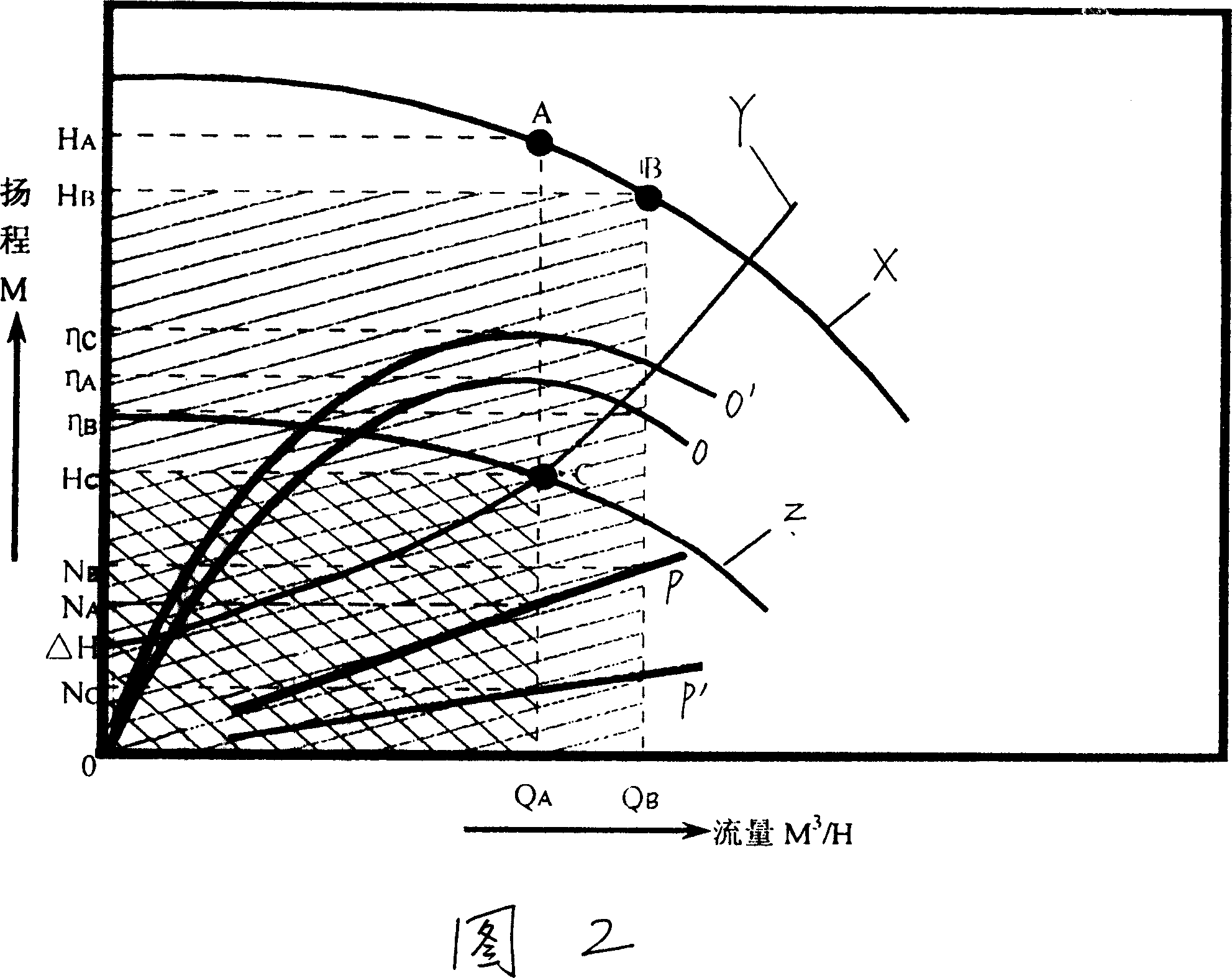

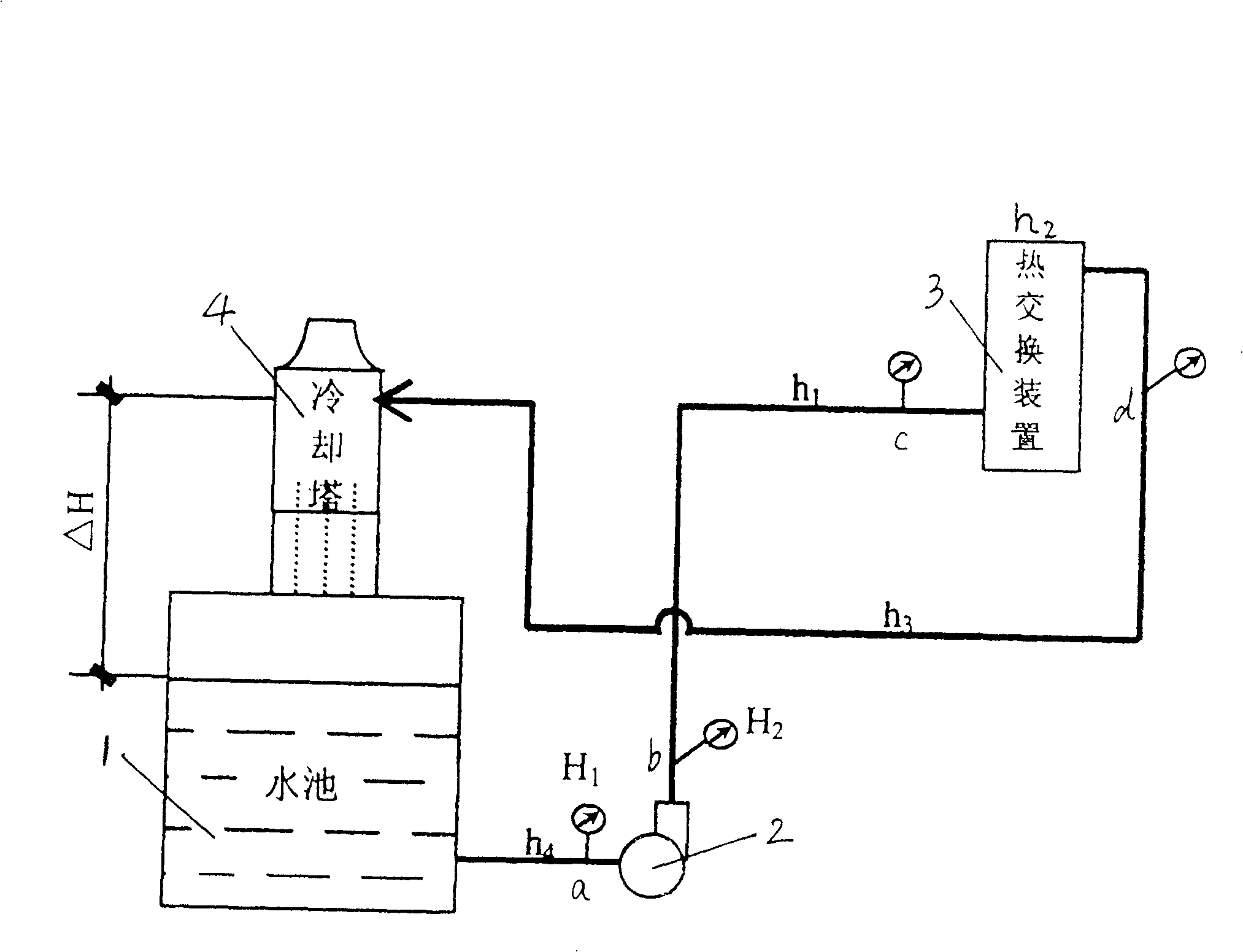

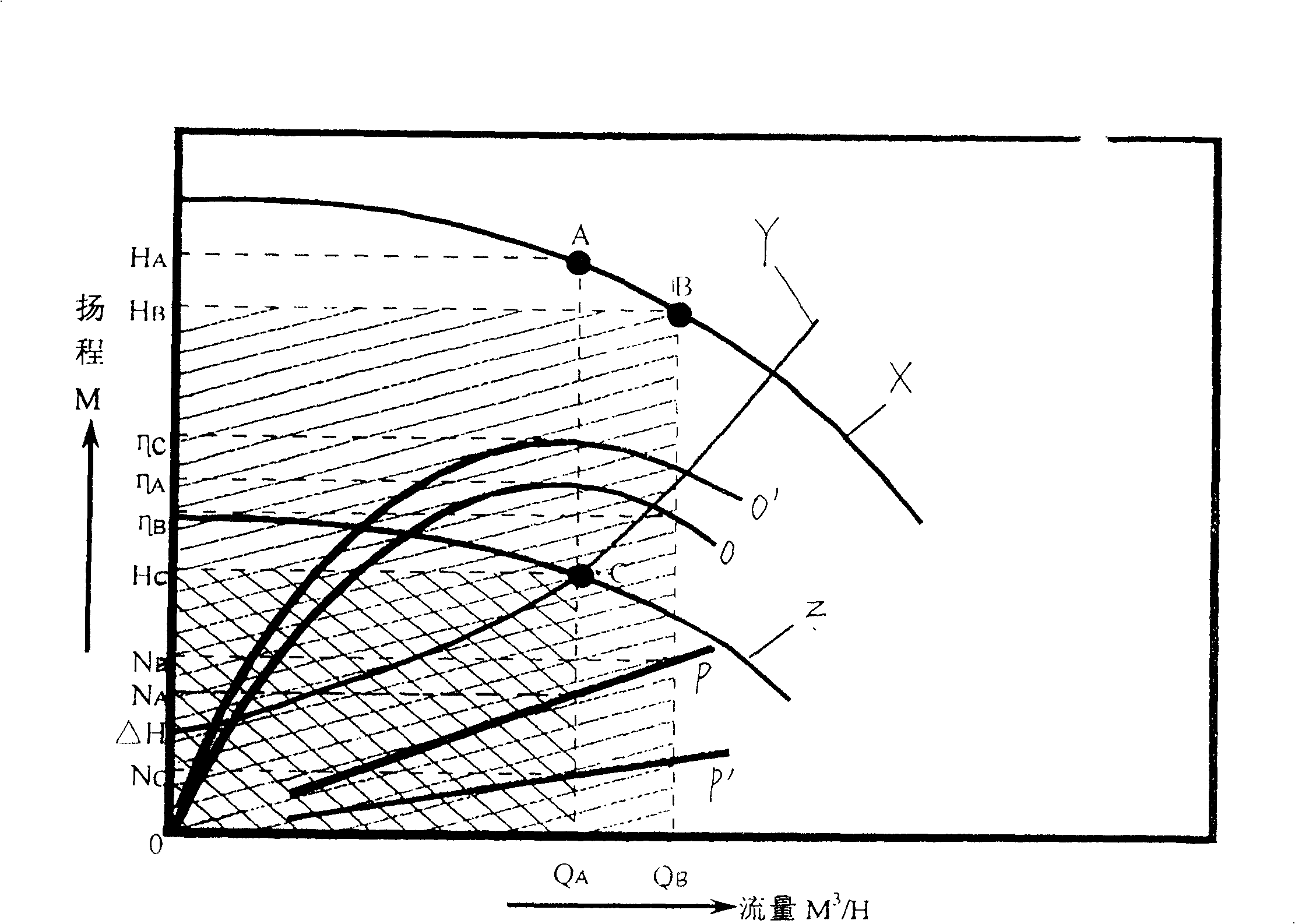

Correction methods of online fluid system

The invention relates to a method for correcting the online fluid system, comprises that 1, selecting the node of online fluid system, measuring the fluid pressure; 2, measuring the power of power device; 3, checking the tube of system; 4, measuring the character of tubes; 5, replacing the power device. The invention can improve the efficiency of power device 10% higher than general condition, reduce energy consumption more than 40%, and prolong the service life of fluid transmitter.

Owner:QINGDAO CHUTIAN ENERGY SAVING TECH

Differential planetary gear apparatus

InactiveUS7211018B2High mechanical efficiencyReduce loadToothed gearingsDifferential gearingsGear wheelEngineering

Owner:EBARA CORP

Hydraulic or pneumatic machine with tilting blades

InactiveUS7198460B2Small sizeImprove efficiencyPropellersPump componentsEngineeringOperant conditioning

Owner:HOLT CORNELIU

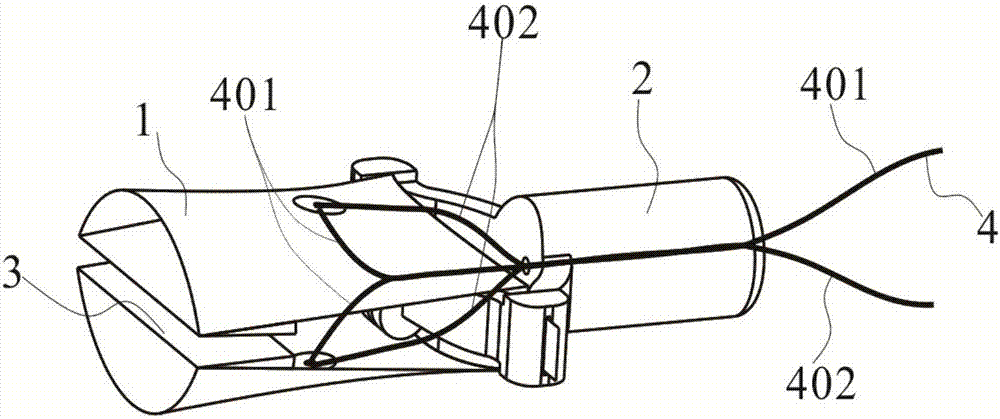

Foldable and extendable minimally invasive operating forceps having bistable state performance

ActiveCN107095704ANo need to overcome frictionReduce force lossSurgical forcepsLess invasive surgeryFiber

The invention relates to the technical field of medical minimally invasive equipment, in particular to foldable and extendable minimally invasive operating forceps having the bistable state performance. The foldable minimally invasive operating forceps comprise a clamping body unit, and further comprise a handle unit, a forceps end unit and a traction fiber unit; the handle unit supports the clamping body unit and guides the deformation of the clamping body; the forceps end unit provides a parallel clamping surface for the operating forceps; the traction fiber unit comprises the two parts of a clamping control line and a relaxing control line. The foldable and extendable minimally invasive operating forceps can achieve the bistable state performance during clamping and extending, compared with traditional operating forceps, the operating forceps do not need to overcome the friction force of a traditional hinge, and accordingly the force wastage is reduced, and the mechanical advantage is improved.

Owner:TIANJIN UNIV

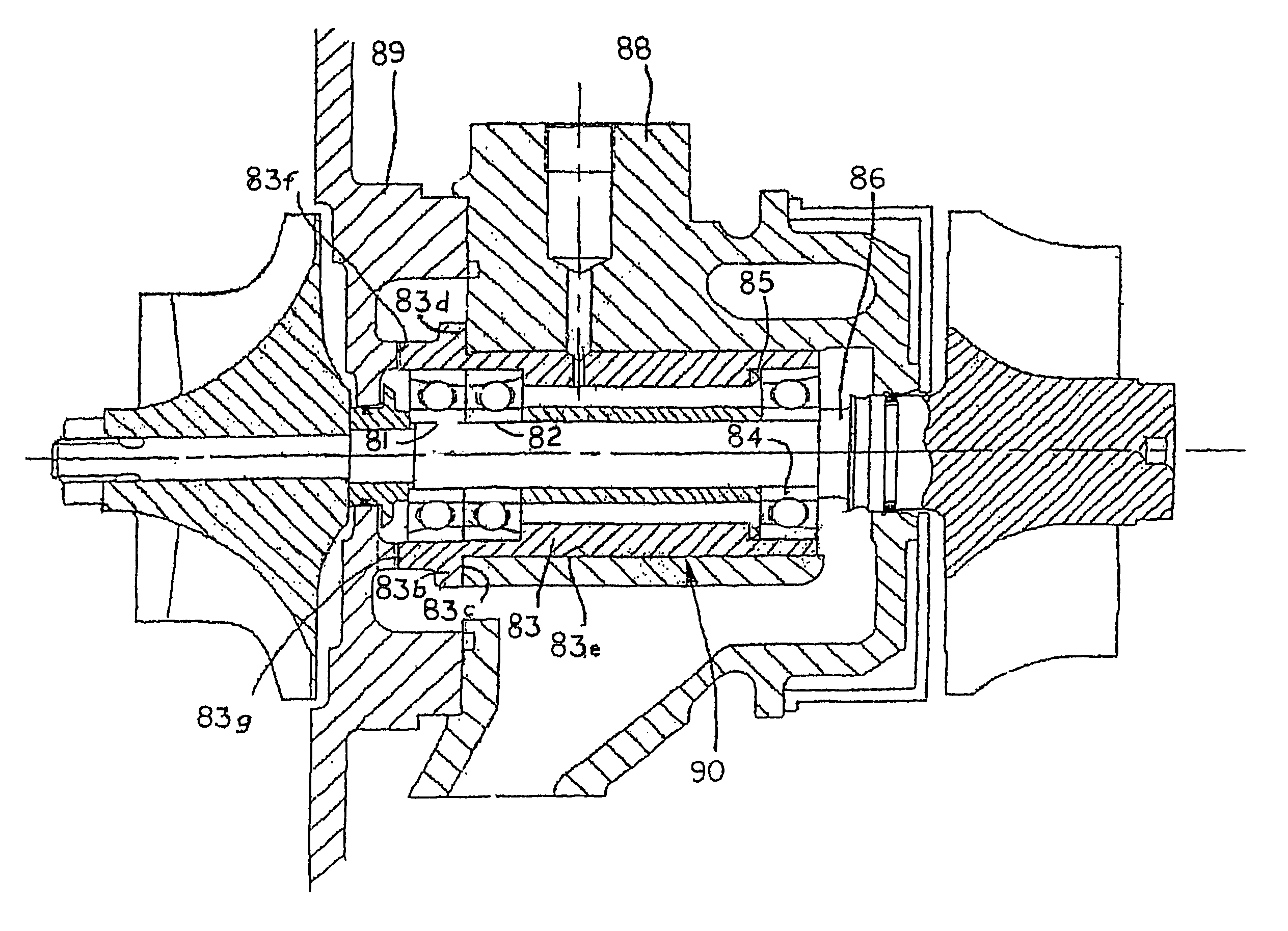

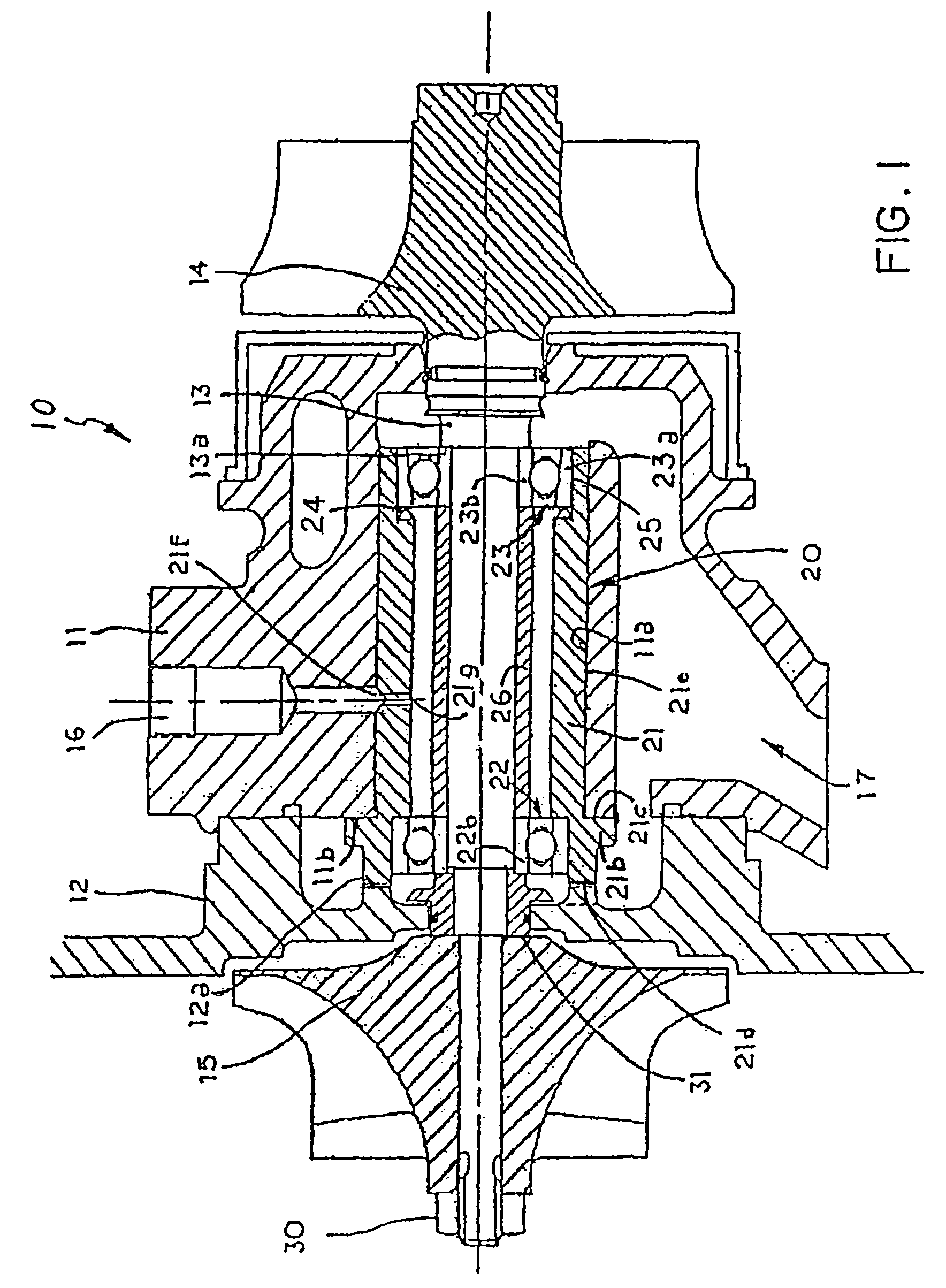

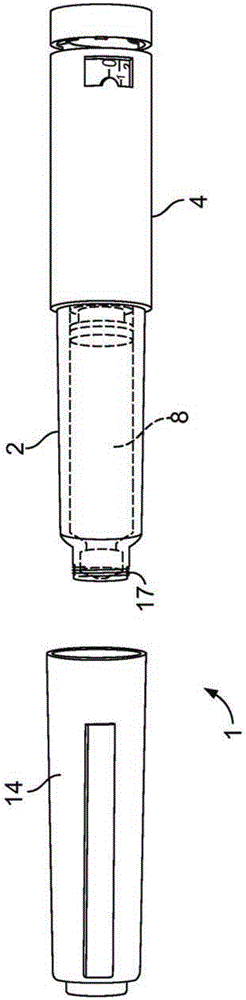

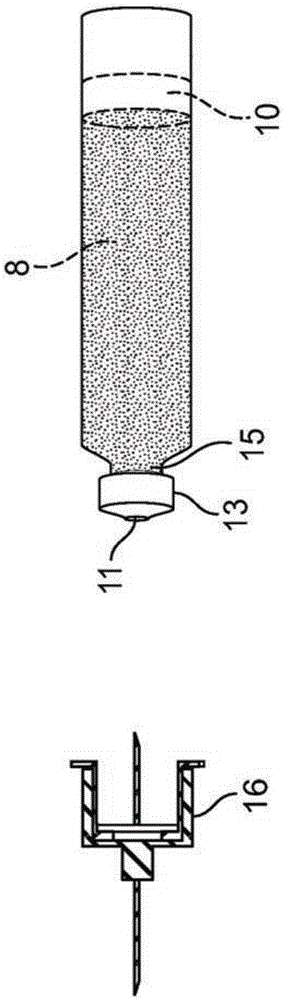

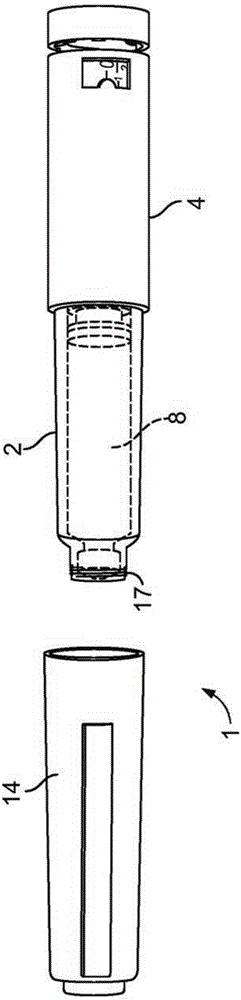

Spring assisted drug delivery device

ActiveCN105764545ADial range of motion reducedReduce user powerAutomatic syringesIntravenous devicesDose deliveryEngineering

A spring assisted drug delivery device (80, 90, 100) is provided comprising a housing (4) and a lead screw (22) having a longitudinal axis, a distal end and a proximal end that is rotatably fixed during dose setting and dose delivery and axially moveable in a distal direction relative to the housing. The device further comprises a drive nut (23) threadedly engaged and screwable along the lead screw threaded shaft and a number sleeve (24) threadedly engaged with the housing (4) to be screwable relative to the housing (4). A dial link (25) is connected with the drive nut (23) and axially moveable and rotatably fixed relative to the drive nut (23) and an inner sleeve (29) is threadedly engaged with the number sleeve (24), the inner sleeve (2) being axially moveable and rotatably fixed relative to the housing (4). A mid-body (20) is axially fixed inside of the housing (4). A spring (82, 92, 102) is provided that assists a user of the device during a dose administration step.

Owner:SANOFI AVENTIS DEUT GMBH

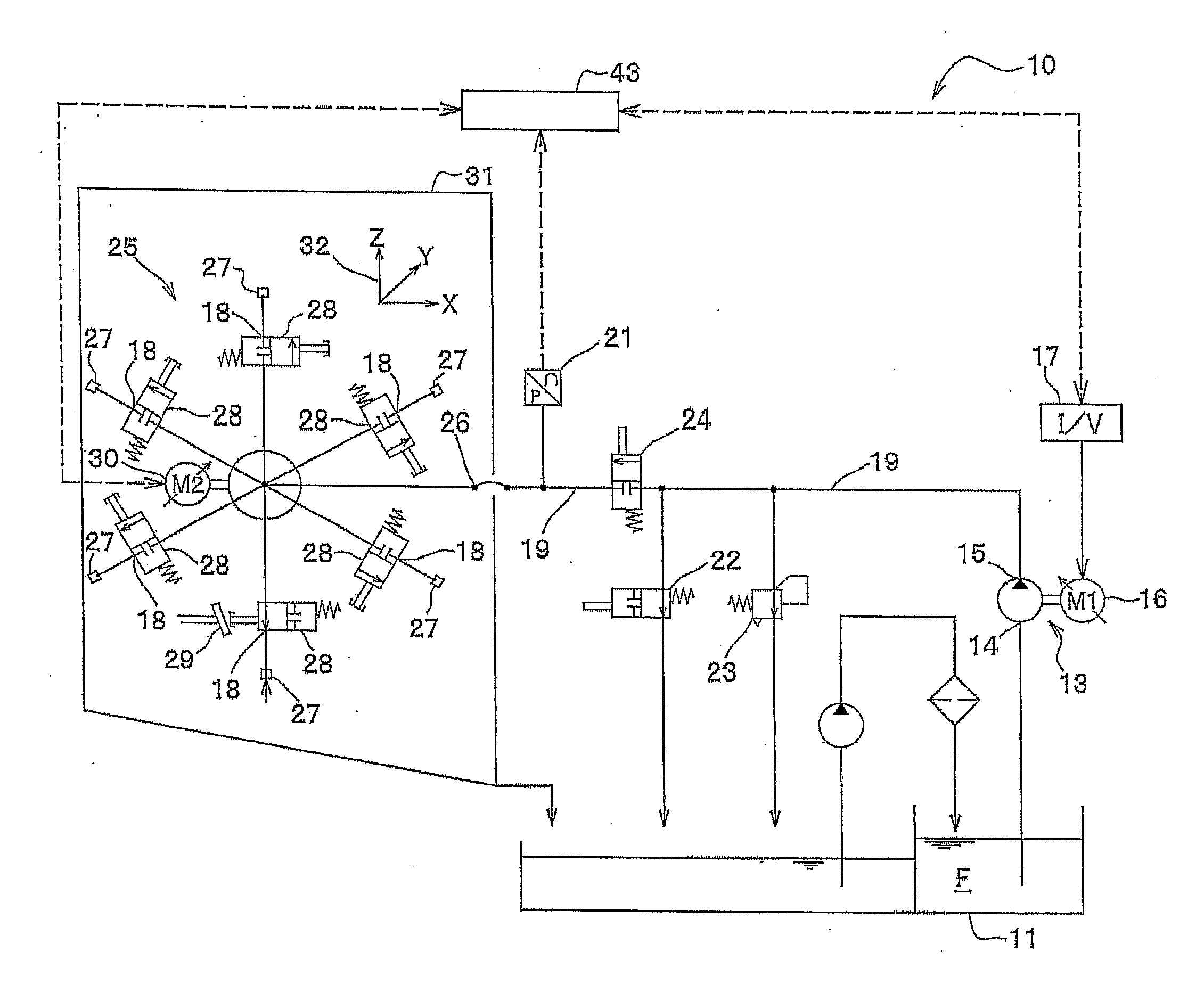

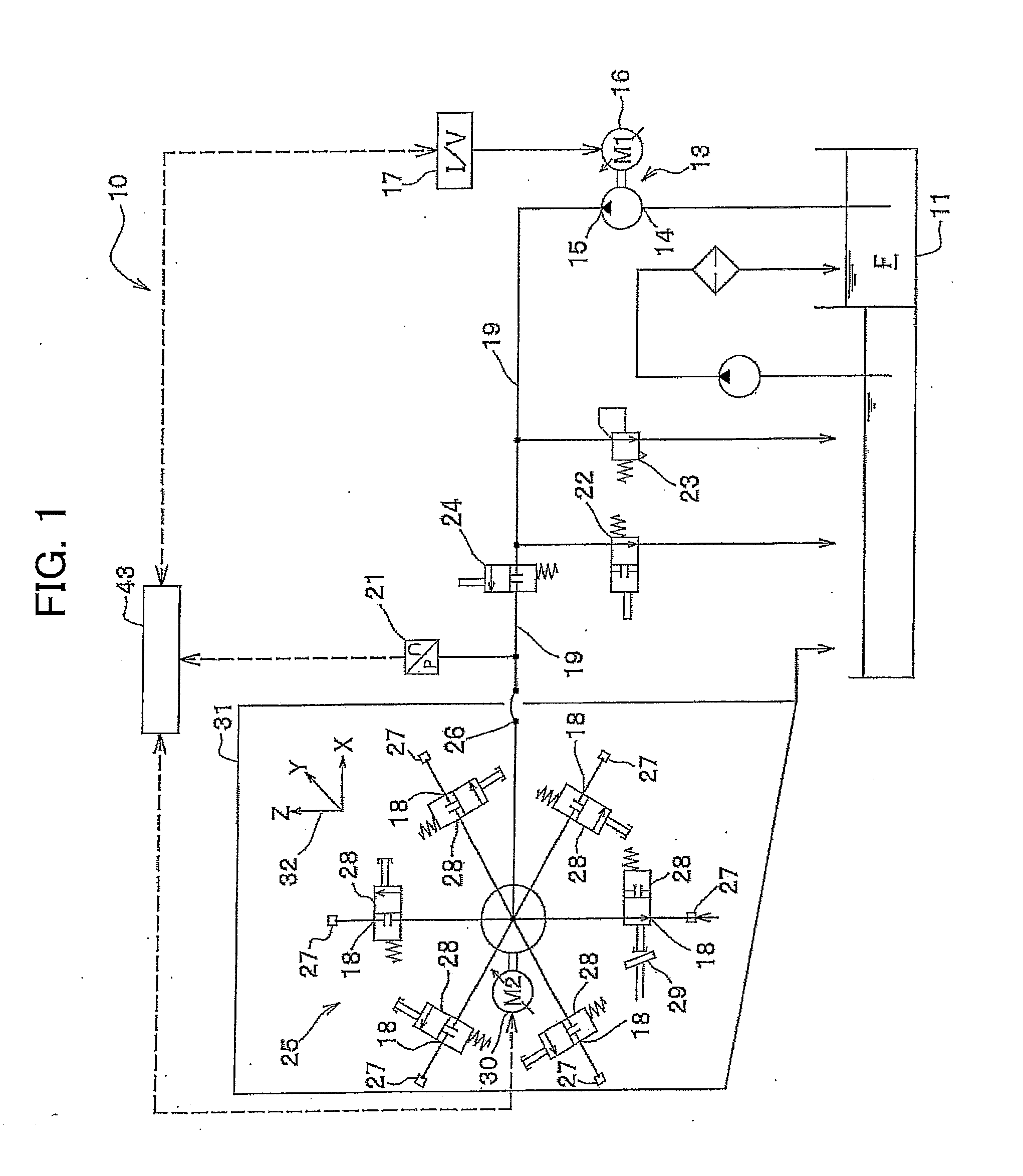

Pumping system

ActiveUS20160222950A1Eliminate delaysIncrease powerFluid parameterSpray nozzlesSynchronous motorDischarge pressure

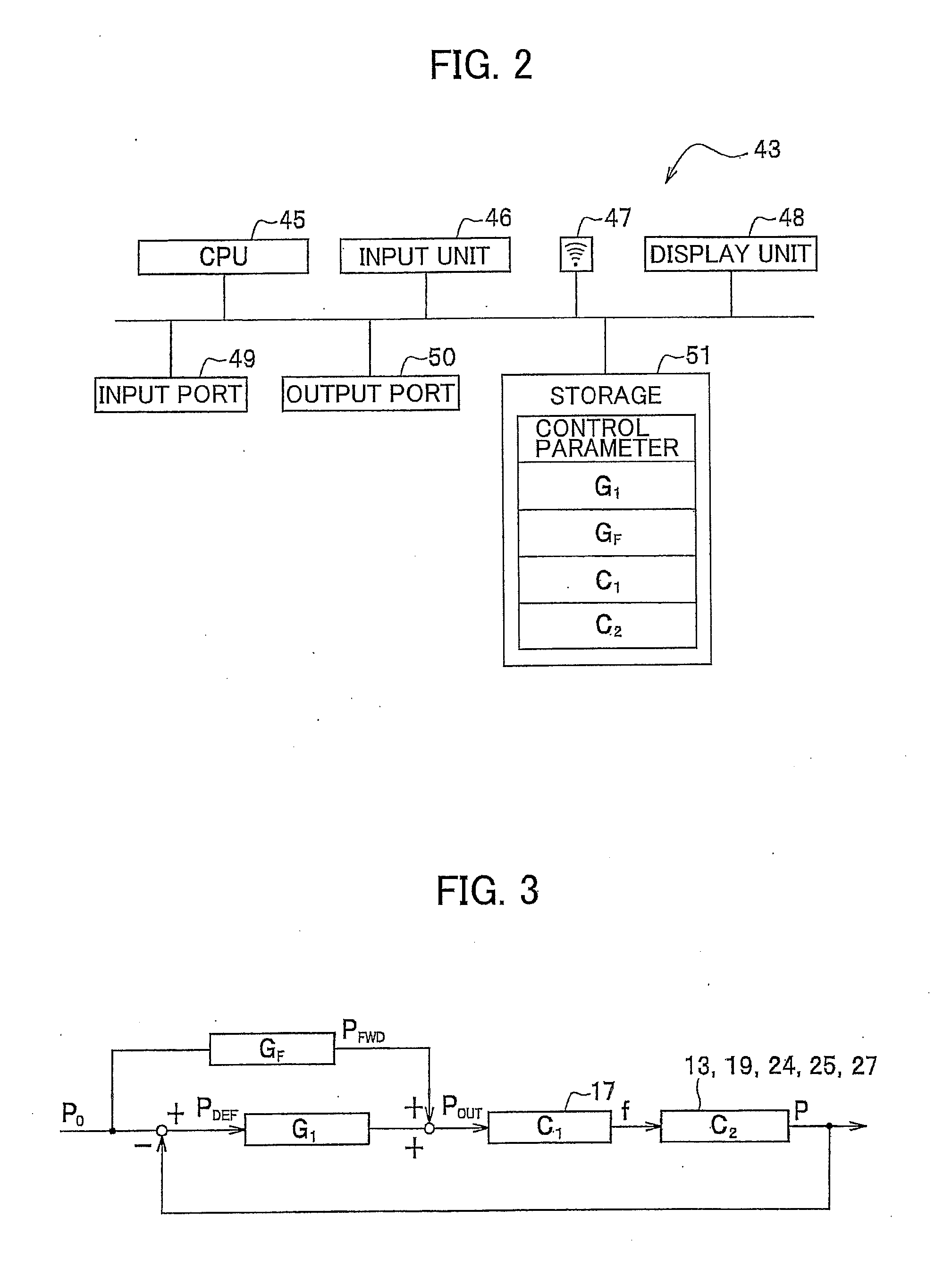

To keep a discharge pressure or a discharge flow rate of a pumping system that jets a fluid from a nozzle selected from a plurality of nozzles a set value every selected nozzle. A pumping system that jets the fluid from the nozzle selected from the plurality of nozzles is provided with: a piston pump as a positive-displacement pump; a permanent-magnet type synchronous motor as a rotational speed variable drive unit; a turret device as selecting arrangement; a discharge pipe; the nozzle; a controller that controls the rotational speed of the drive unit; a storage that stores control parameters and a target value of the discharge pressure corresponding to each nozzle; and a pressure sensor, wherein the controller controls the rotational speed of the drive unit by feeding back the discharge pressure using the control parameters corresponding to the selected nozzle to match the discharge pressure with the target value.

Owner:SUGINO MACHINE

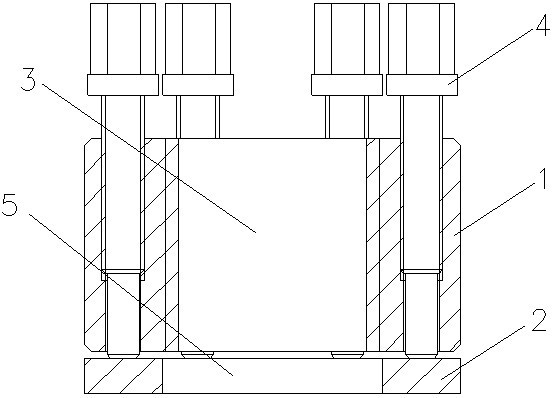

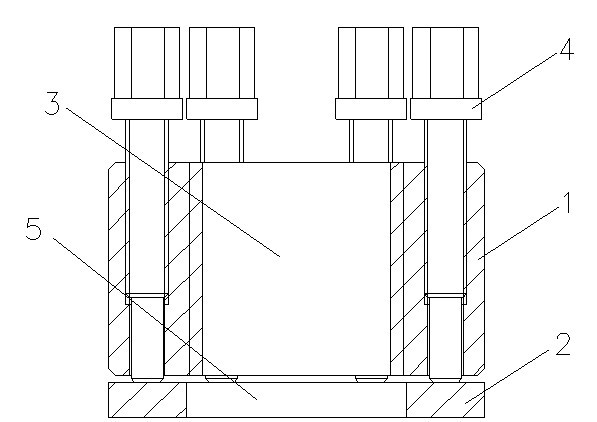

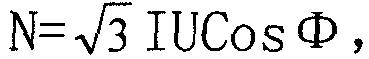

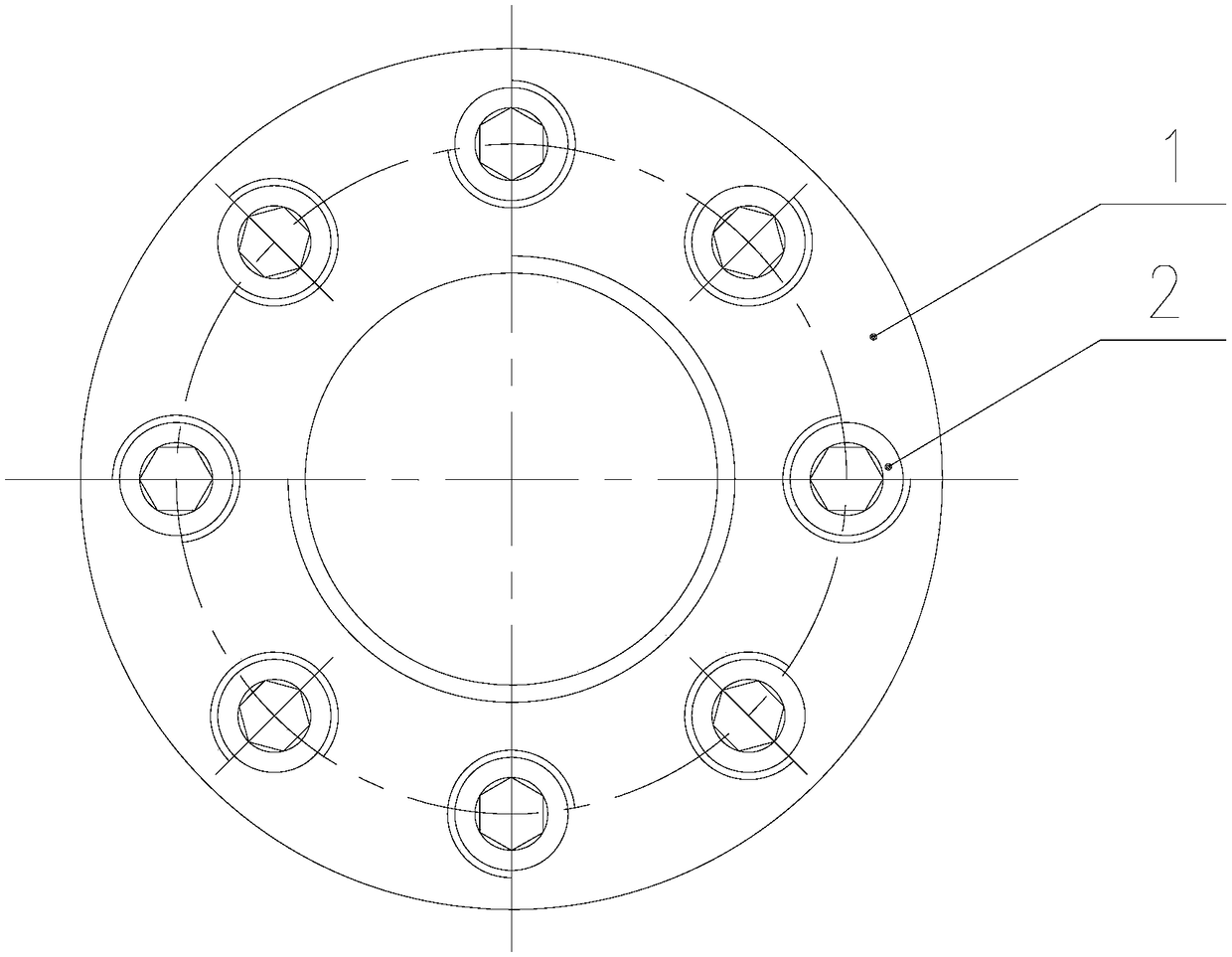

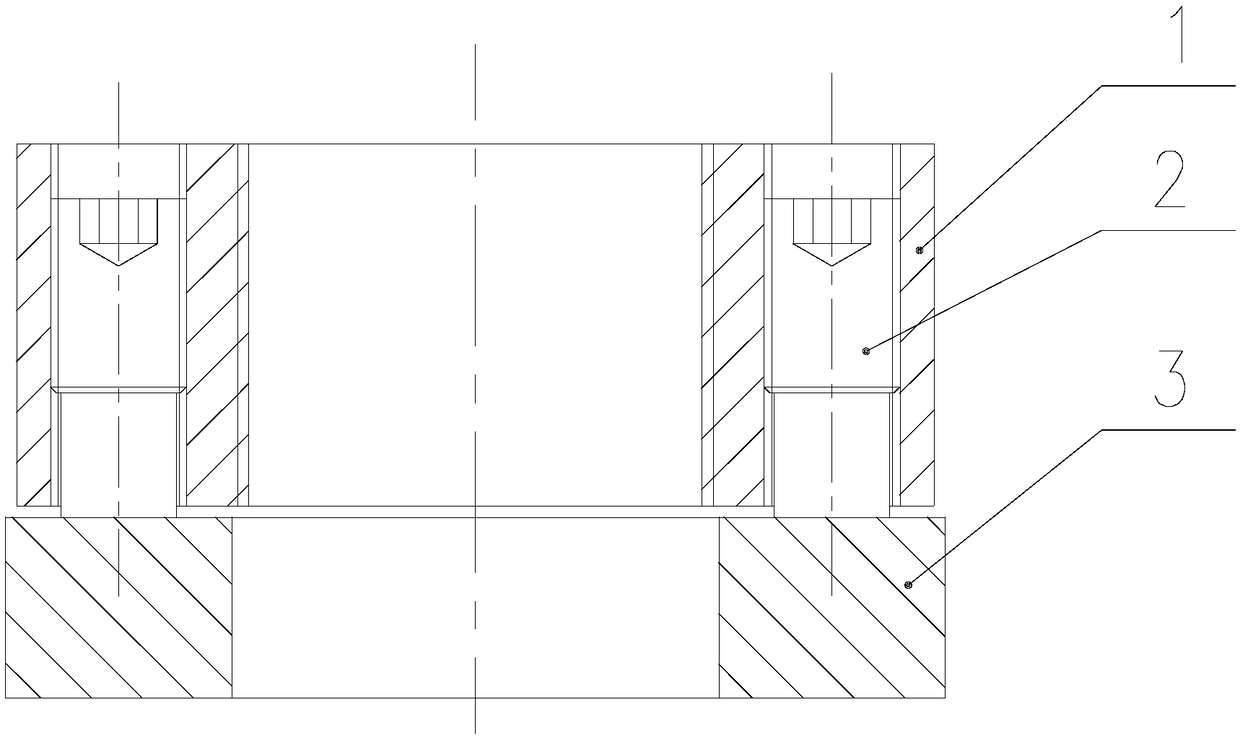

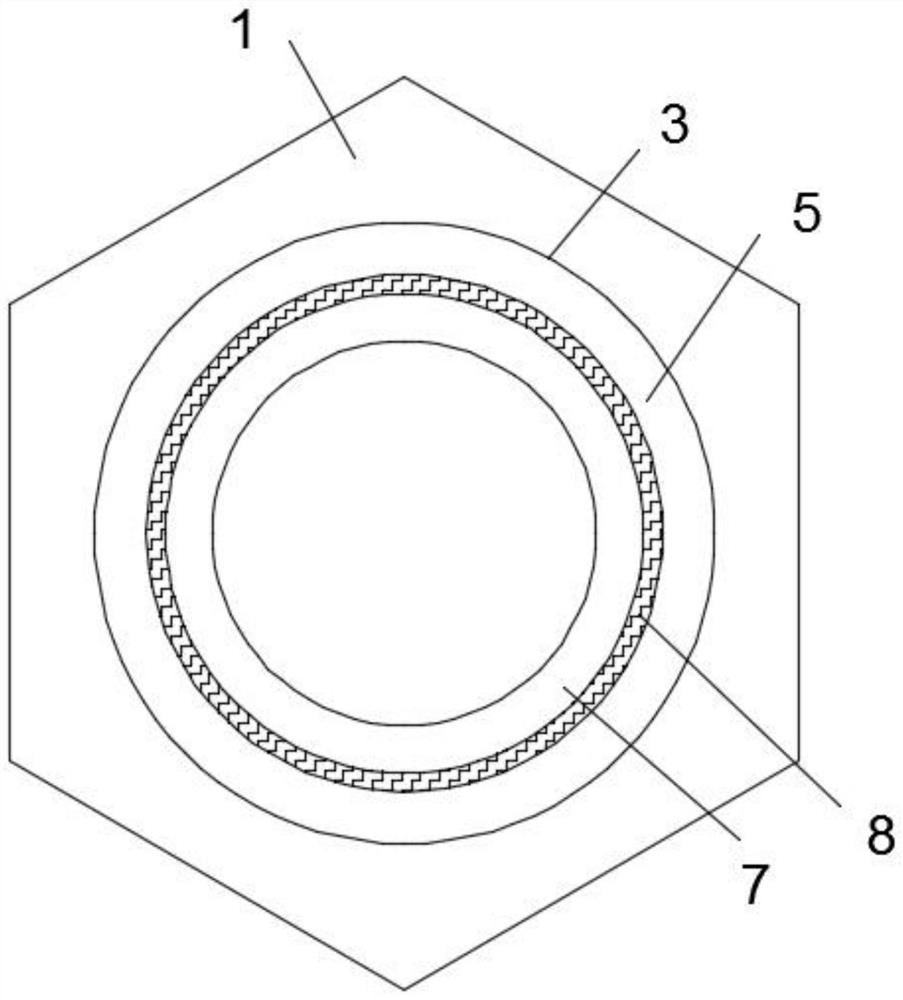

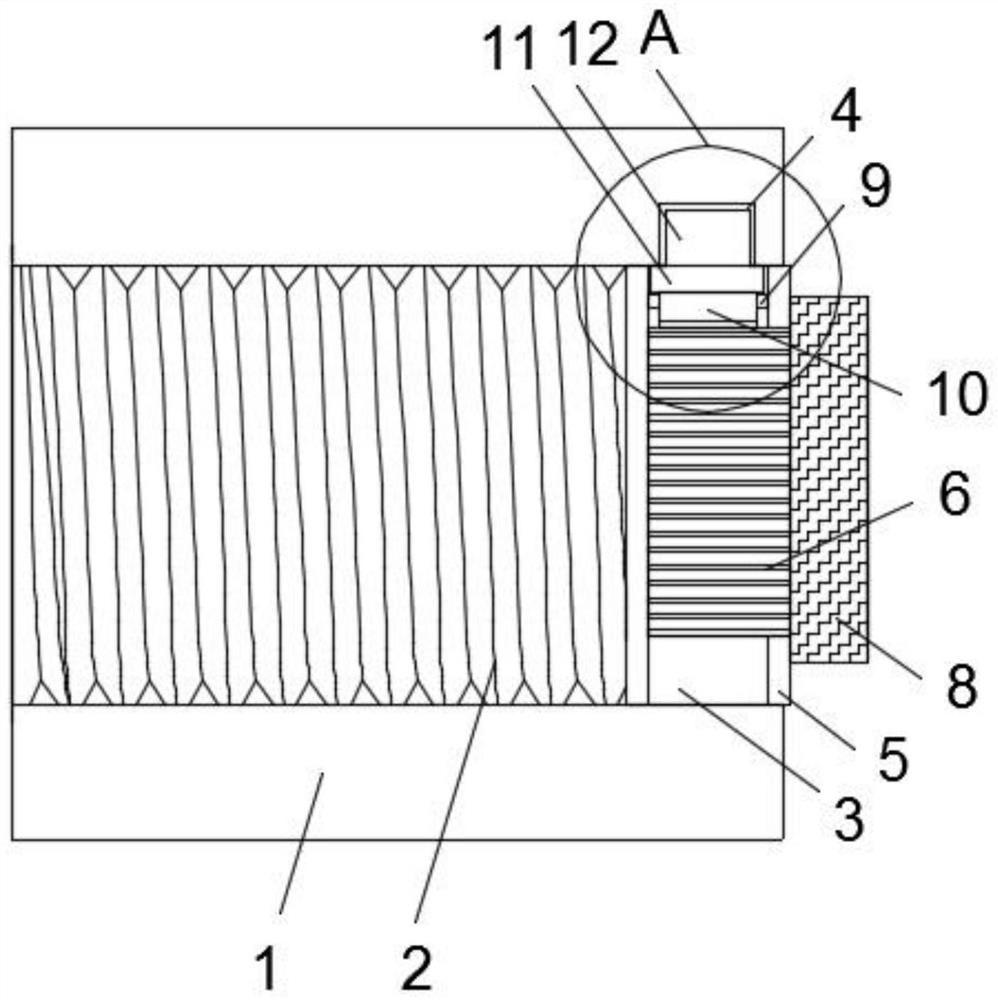

Pushing tension device

The invention discloses a pushing tension device which comprises a cylindrical nut body, wherein the bottom of the nut body is provided with a gasket, the middle of the gasket is provided with a round hole, the middle of the nut body is provided with a central hole penetrating through the nut body, the inner wall of the central hole is provided with an internal thread, the round hole and the central hole are correspondingly arranged, a plurality of through holes are uniformly formed around the central hole, a pushing bolt is connected in the through hole, and the bottom of the pushing bolt is pressed against the gasket. The pushing tension device disclosed by the invention has higher mechanical efficiency and can generates powerful pre-stressing force between connecting components, therefore, the pushing tension device is good in fastening effect and persistent in fastening, saves the fastening time and greatly improves the operating efficiency.

Owner:常州轩达液压机电设备有限公司

Vertical milling lathe complex machining center

ActiveCN101722419BIncrease productivityReduce wearOther manufacturing equipments/toolsLarge fixed membersTorque motorElectric machinery

The invention discloses a vertical milling lathe complex machining center which comprises a horizontally arranged lathe body (6) and a vertically arranged upright post (7). The lathe body (6) is provided with an X-axis lateral supporting line track (2) and an X-axis guide screw (5) and configured with a uniaxial rotating table (1) which reciprocates and is driven by a first outer rotor torque motor in a direct driven mode. The upright post (7) is vertically provided with a Z-axis lateral supporting line track (10) and a Z-axis guide screw (9) and configured with a crossbeam which reciprocatesup and down. The crossbeam (11) is provided with a transverse Y-axis line track (13) and a Y-axis guide screw (12) and configured with a single pendulum milling head seat frame which can reciprocate along the Y-axis guide screw (12); and a single pendulum milling head is driven by a second outer rotor torque motor at the rear part in the direct driven mode. Since a direct driven technology is applied to a B axis and a C axis, the motor torque is greatly increased and a functional part can stably operate; therefore the integral rigidity and the stability of a lathe are improved.

Owner:KEDE NUMERICAL CONTROL CO LTD

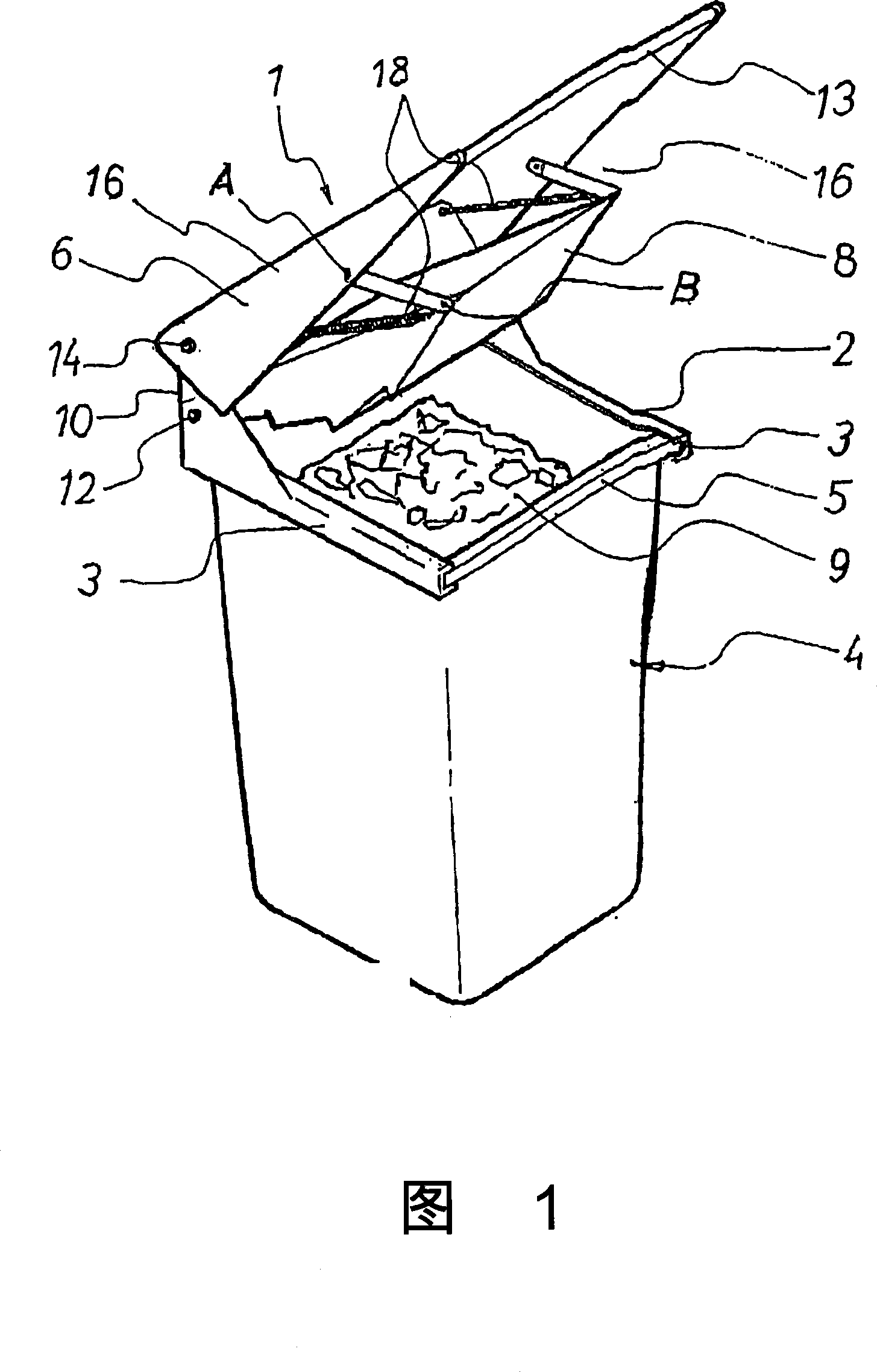

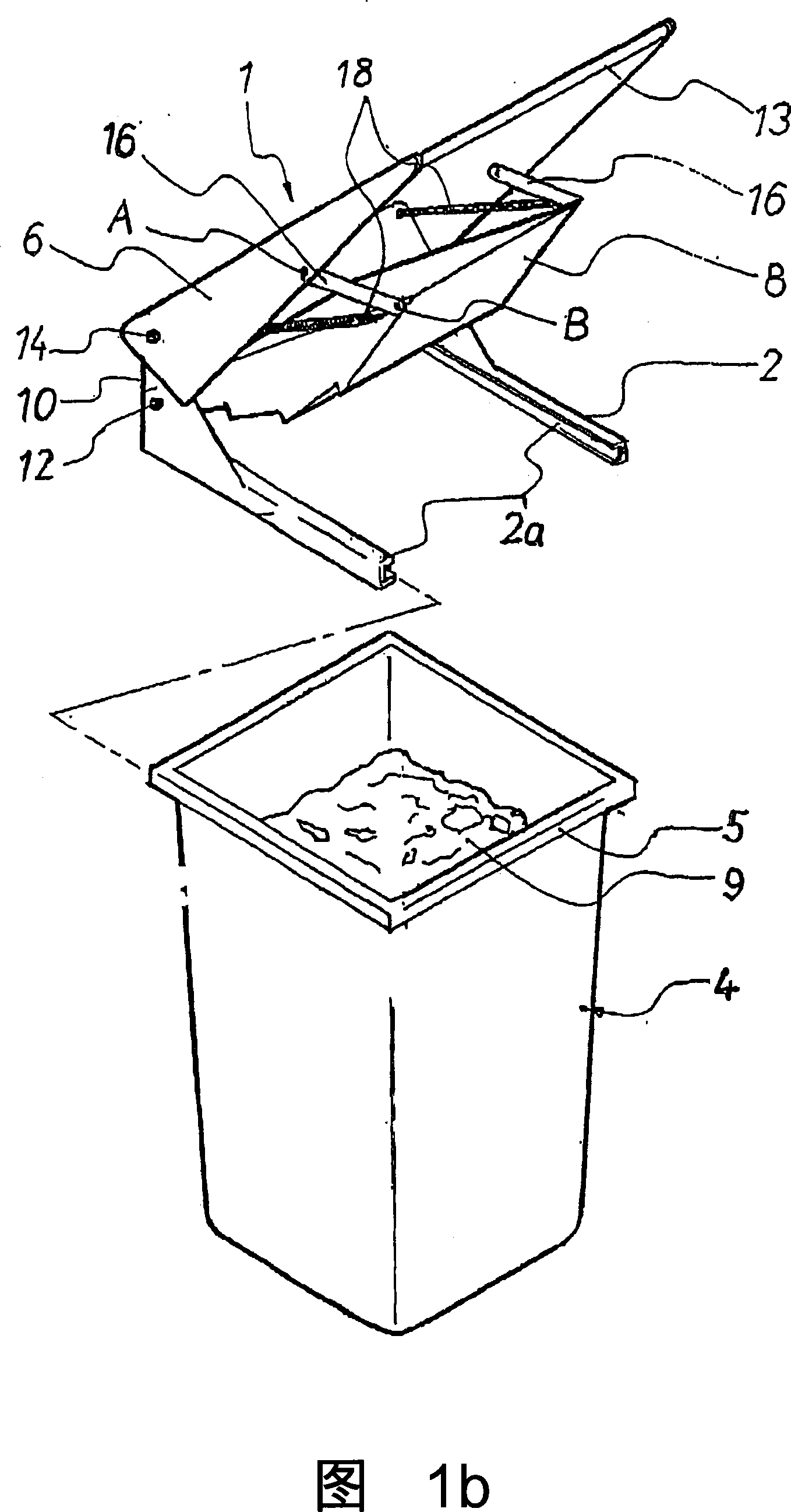

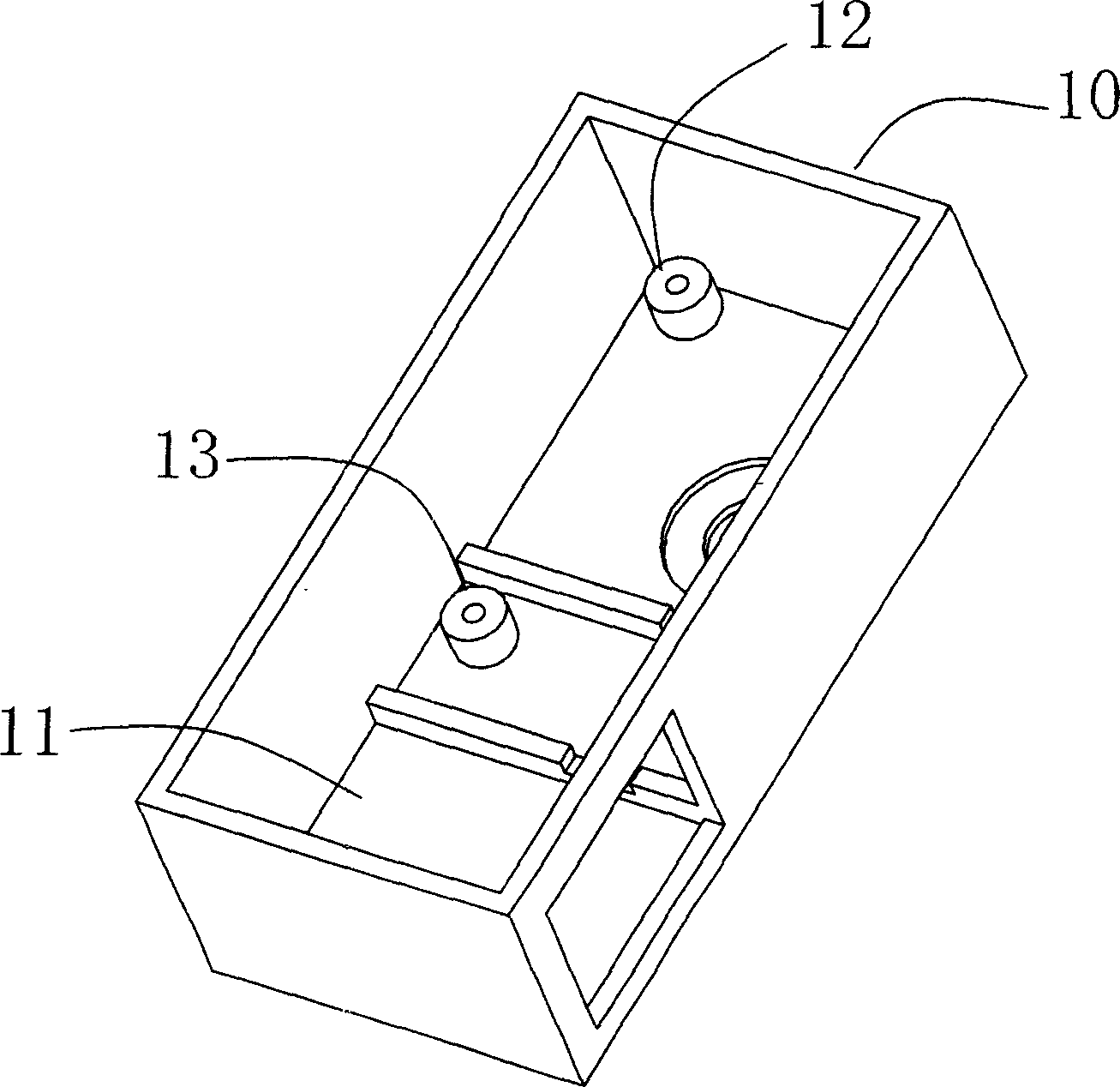

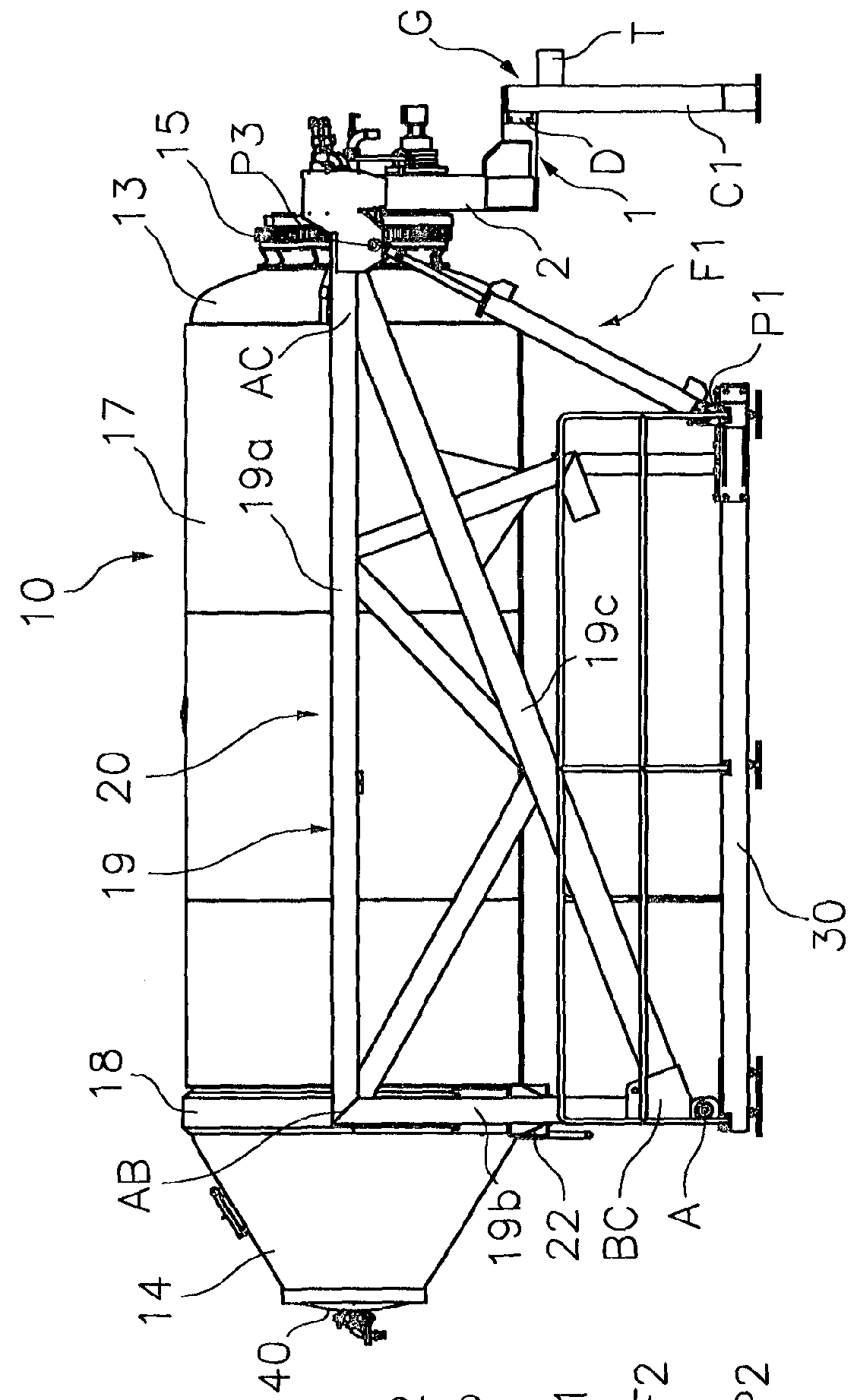

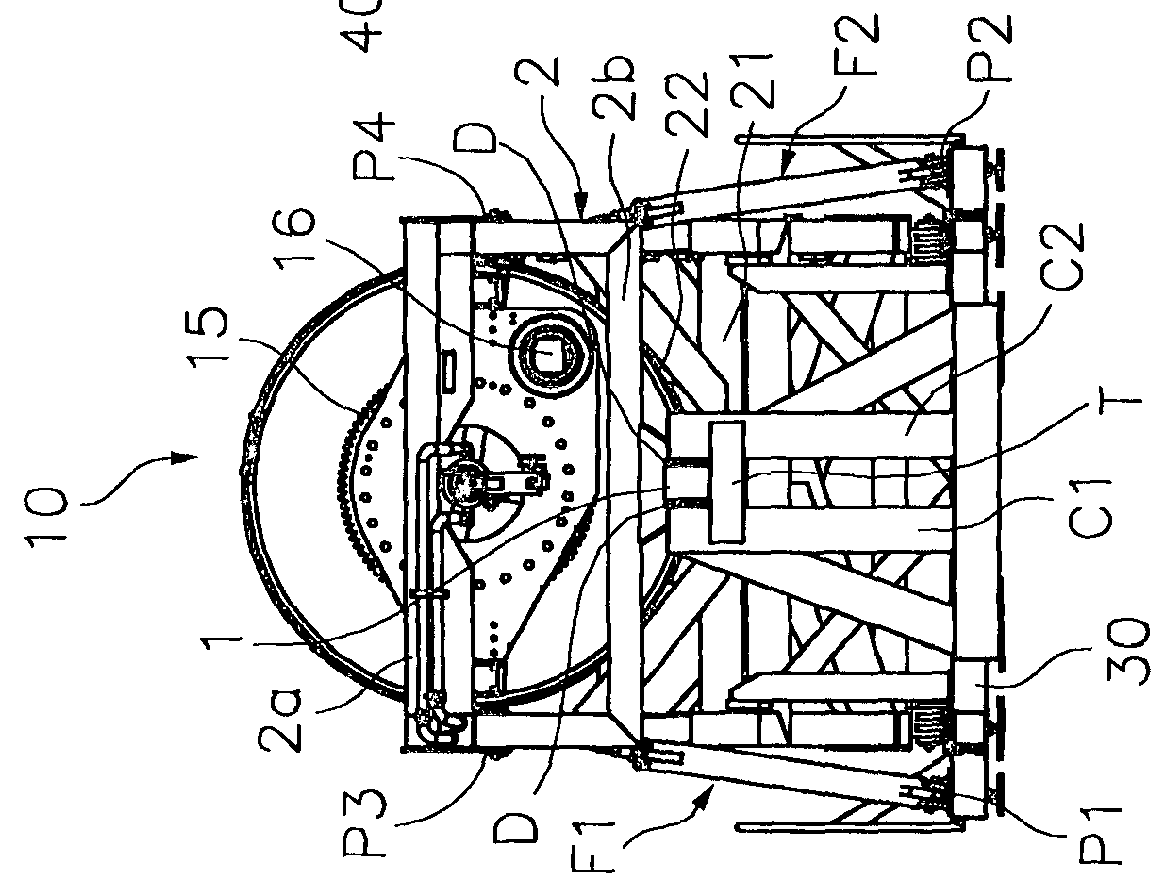

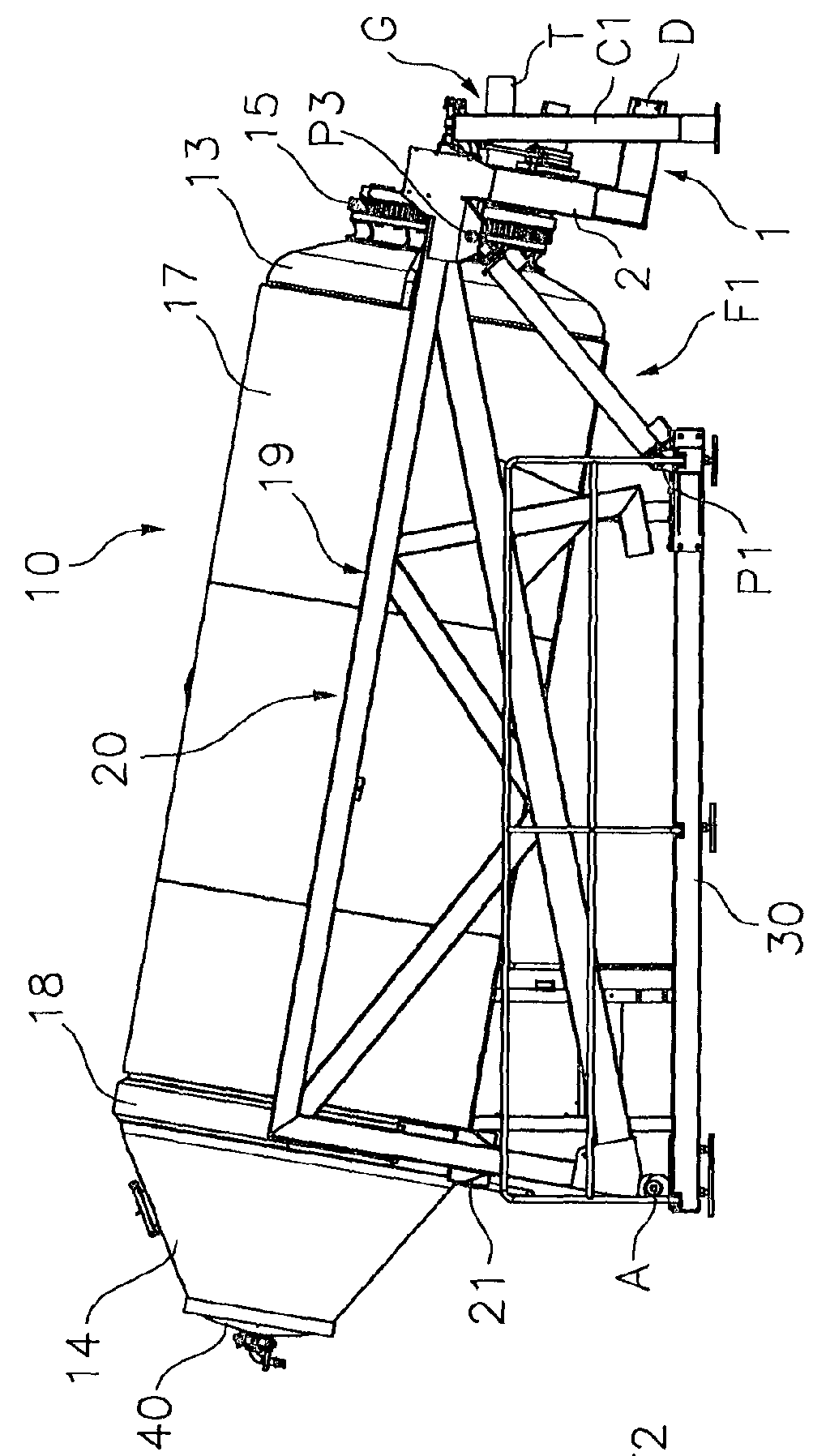

A bin compactor

InactiveCN1972852ASuppressiveHigh mechanical efficiencyRefuse receptaclesPressesEngineeringMechanical engineering

Owner:盖伊·威廉·皮尔斯 +1

Device for transmitting a movement and a force between two zones that are insulated from one another

A device transmits a movement and a force between a first zone and a second zone which are insulated from one another in a sealed manner. The device includes a planar support, a transmission element that is rotatably movable with respect to the support by a pivot joint having an axis of rotation that is parallel to a plane of the support, an opening in the support through which the transmission element passes and level with which the pivot joint is positioned. The transmission element includes at least one first transmission arm on one side of the plane of the support and one second transmission arm on the other side of the plane of the support, and sealed insulation positioned in the opening, such that it insulates the first zone from the second zone in a sealed manner and allows the rotational movement of the transmission element.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

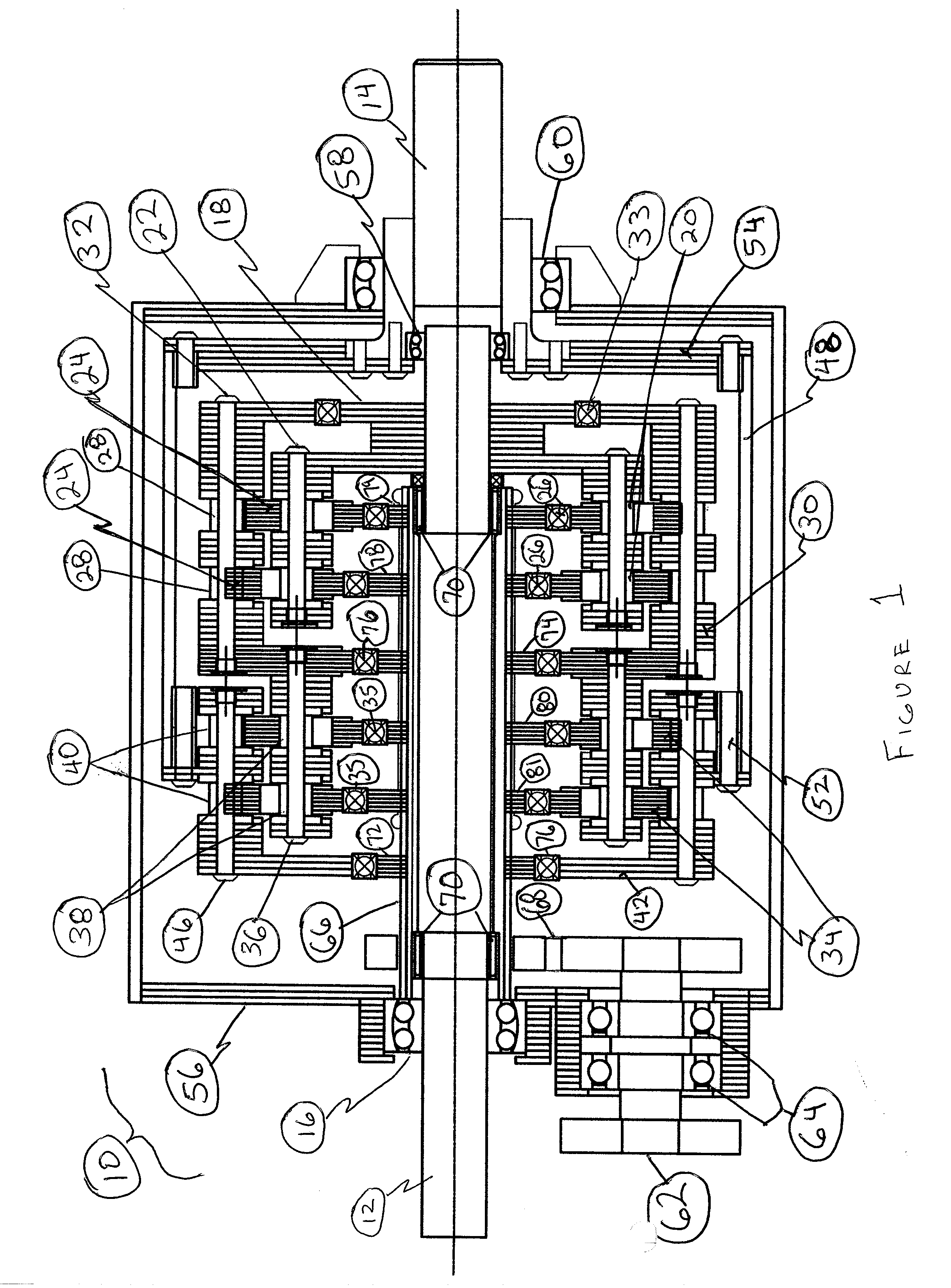

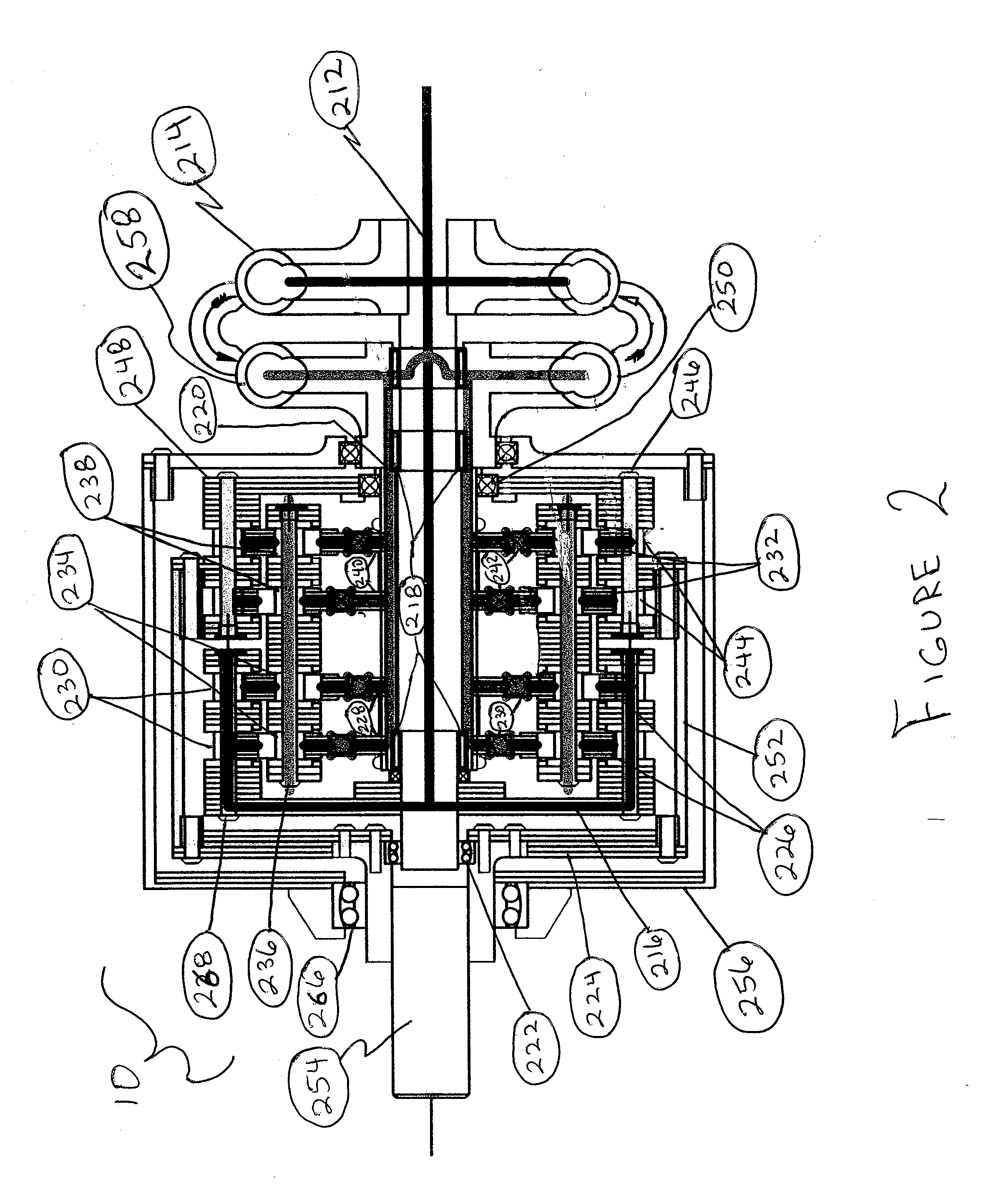

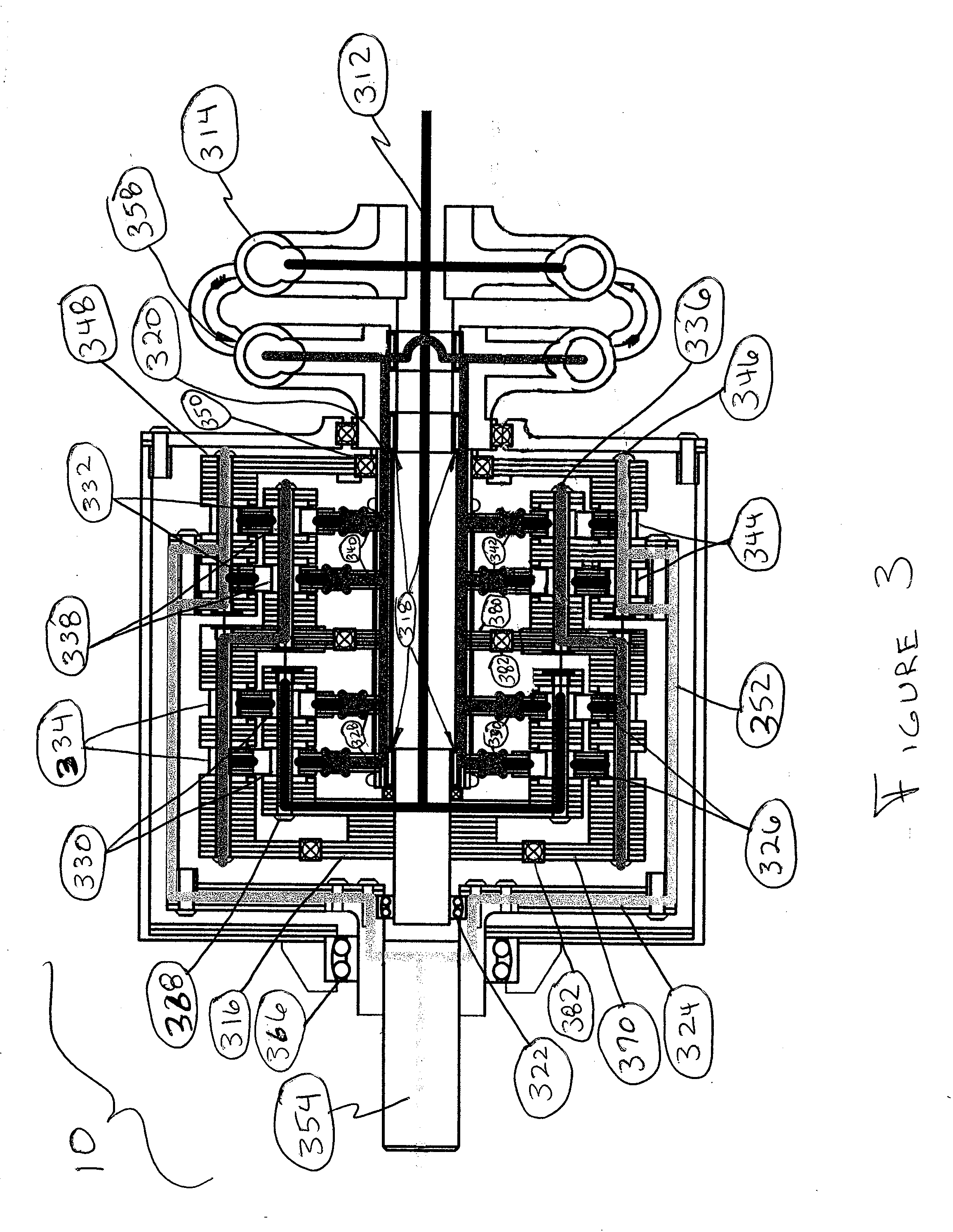

Power transmission system with continuously variable speed control

InactiveUS20080090695A1High torque transmissionMaximum fuel economyToothed gearingsPortable liftingDrivetrainControl theory

The present invention is directed toward an apparatus for continuous speed variation of an output member with respect to a primary input member. In particular, the present invention provides a device having an output that rotates at reduced speed and increased torque relative to its prime input through the low friction, rolling engagement of its members, or alternatively, at increased speed and reduced torque for overdrive applications. Furthermore, the speed of the output member may be varied continuously and infinitely between the apparatus's lowest and highest ratio via a secondary input member and its low friction, rolling engagement with the device's members.

Owner:EPI ENERGY LTD A TEXAS

Turbocharger combining axial flow turbine with a compressor stage utilizing active casing treatment

ActiveUS10233834B2Reduce resistanceReduce stressInternal combustion piston enginesPump componentsWastegateChoked flow

A turbocharger (1) with an axial flow turbine stage (2) includes a compressor stage (4) using active casing treatment (50) for choke flow improvement. With switchable slots (52, 54), one of the slots (52) may be between the compressor's full and splitter blades (27, 23) and one of the slots (54) can be located downstream of the compressor's splitter blades (23) to maximize choke flow capacity. In turbochargers with a wastegate assembly, a pneumatic actuator (32) may control both a wastegate control valve (30) and an active casing treatment slot selection valve (56).

Owner:BORGWARNER INC

Correction methods of online fluid system

InactiveCN100453888CImprove efficiencyImprove or eliminate unfavorable conditionsPipeline systemsEngineeringLife time

The invention relates to a method for correcting the online fluid system, comprises that 1, selecting the node of online fluid system, measuring the fluid pressure; 2, measuring the power of power device; 3, checking the tube of system; 4, measuring the character of tubes; 5, replacing the power device. The invention can improve the efficiency of power device 10% higher than general condition, reduce energy consumption more than 40%, and prolong the service life of fluid transmitter.

Owner:QINGDAO CHUTIAN ENERGY SAVING TECH

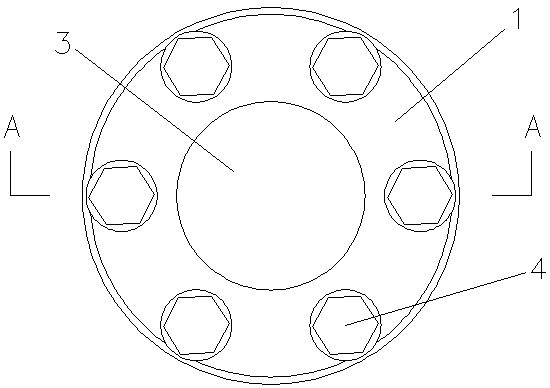

Compact multi-pushing-bolt pre-tightening device

The invention relates to a compact multi-pushing-bolt pre-tightening device. A superhard gasket is arranged under a nut body. The middle portion of the superhard gasket is provided with a circular through hole. The center of the nut body is provided with a threaded hole which is through in the nut body. The circular through hole of the superhard gasket corresponds to the threaded hole of the center of the nut body. The threaded end of a screw rod is sleeved with the through hole of the superhard gasket. The lower end face of the superhard gasket makes contact with a connected part. The threaded hole of the center of the nut body is connected with an external thread of the threaded end of the screw end in a screw-thread fit mode. A plurality of threaded through holes are uniformly distributed on the periphery of the threaded hole of the center of the nut body. Pushing bolts are in threaded connection with the interiors of the threaded through holes. The bottoms of the pushing bolts abutagainst the upper end face of the superhard gasket. Compared with a traditional bolt fastener, the compact multi-pushing-bolt pre-tightening device has the advantages that the main screw rod and thehead of the nut are separated; axial force of the screw rod is uniformly distributed on the pushing bolts; the axial tensile force of the screw rod is acquired by tightening the pushing bolts; and thecompact multi-pushing-bolt pre-tightening device has the higher mechanical benefits.

Owner:SHANGHAI MARINE EQUIP RES INST

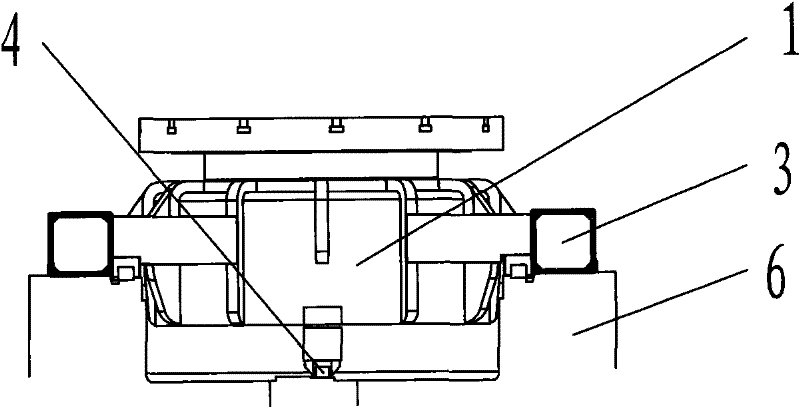

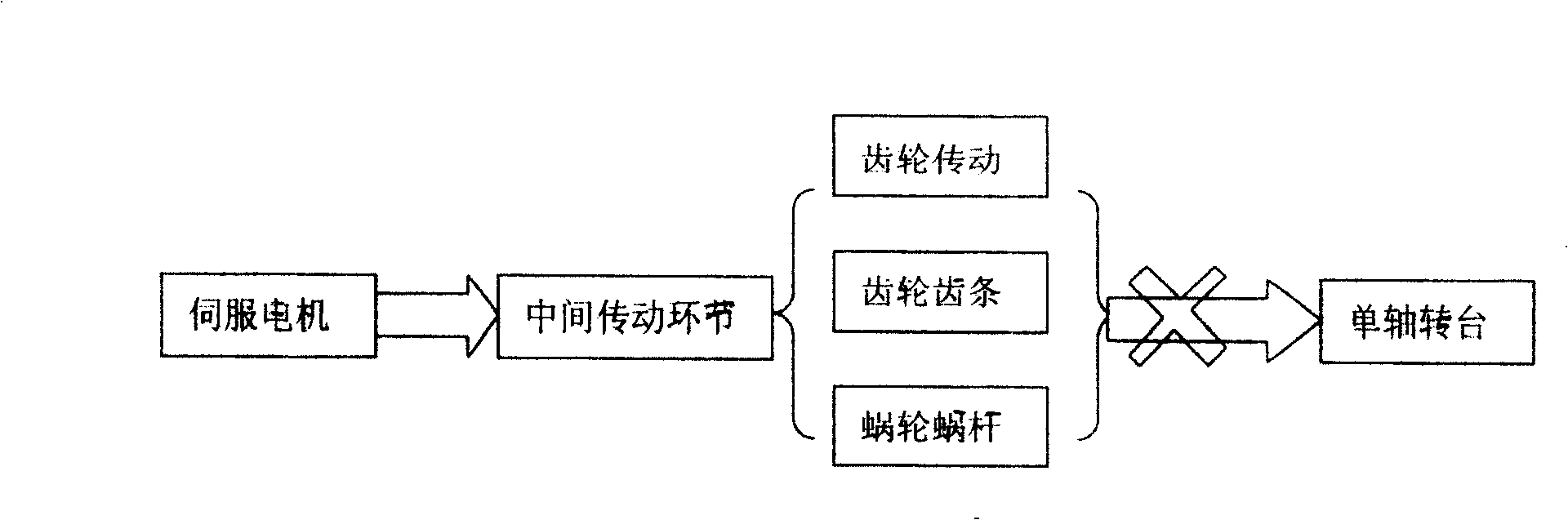

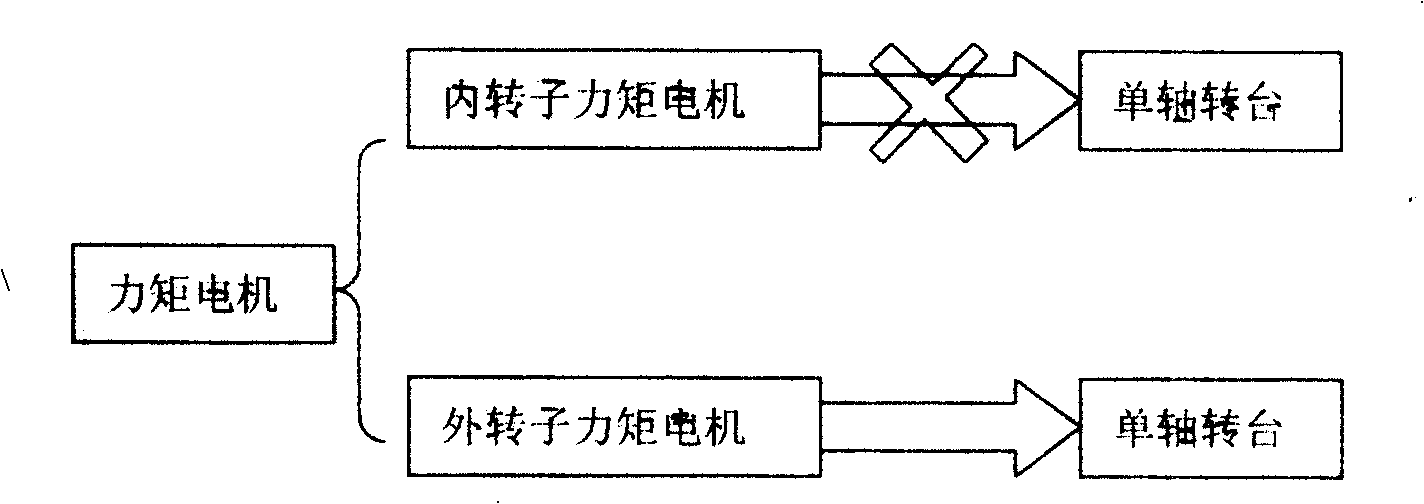

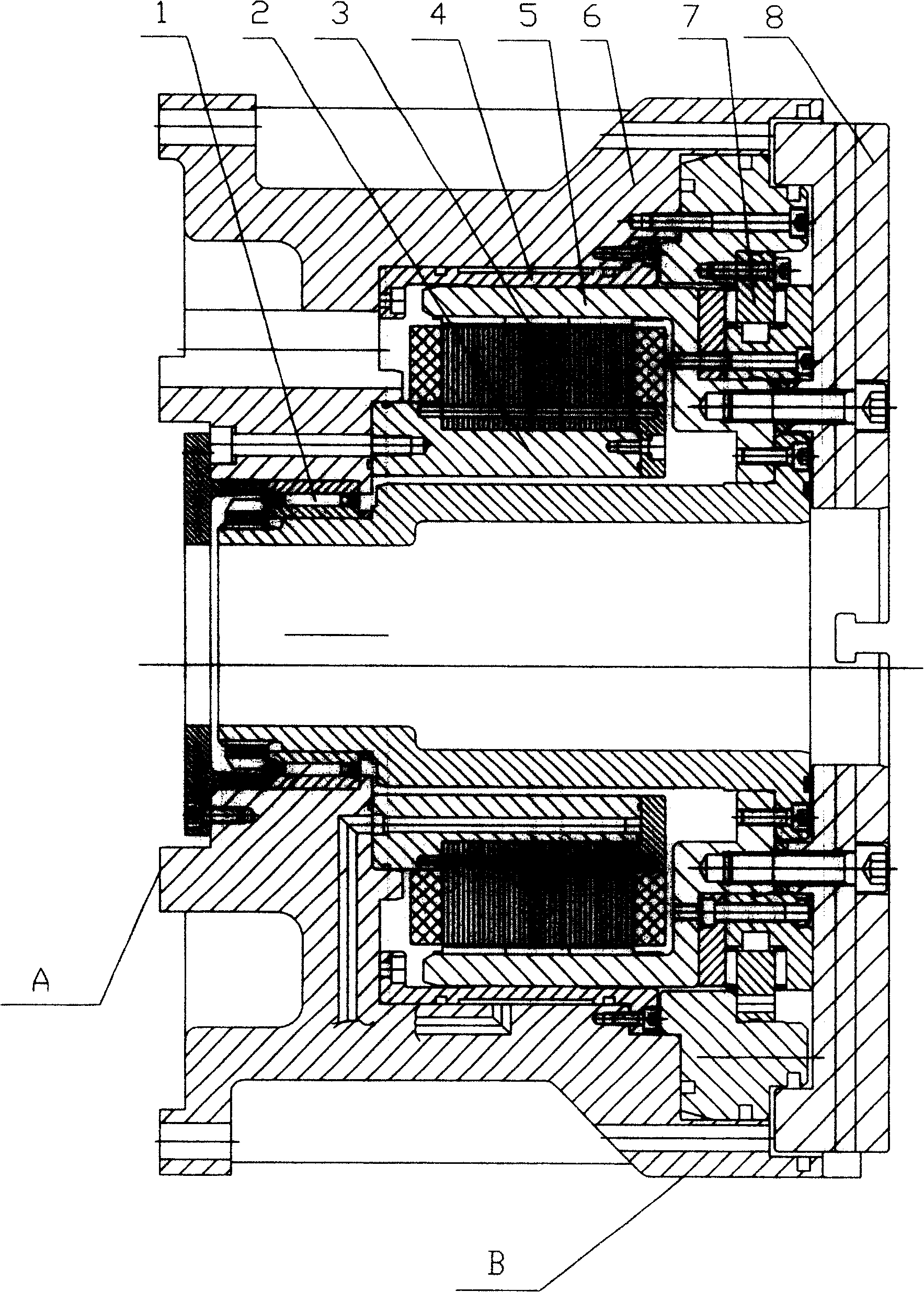

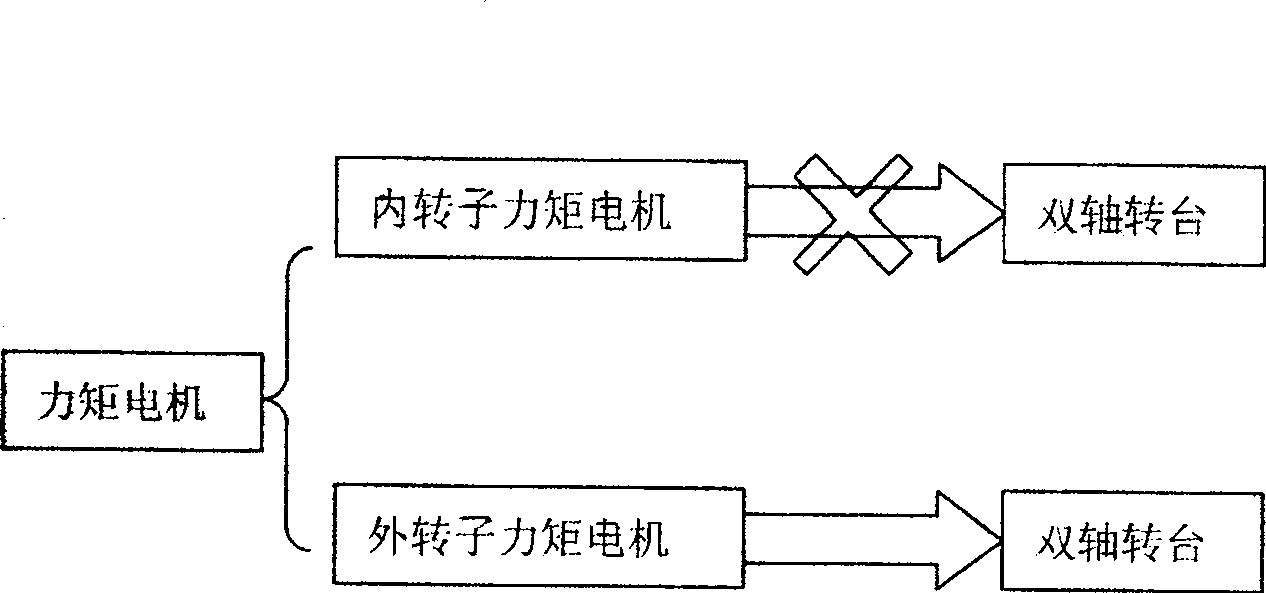

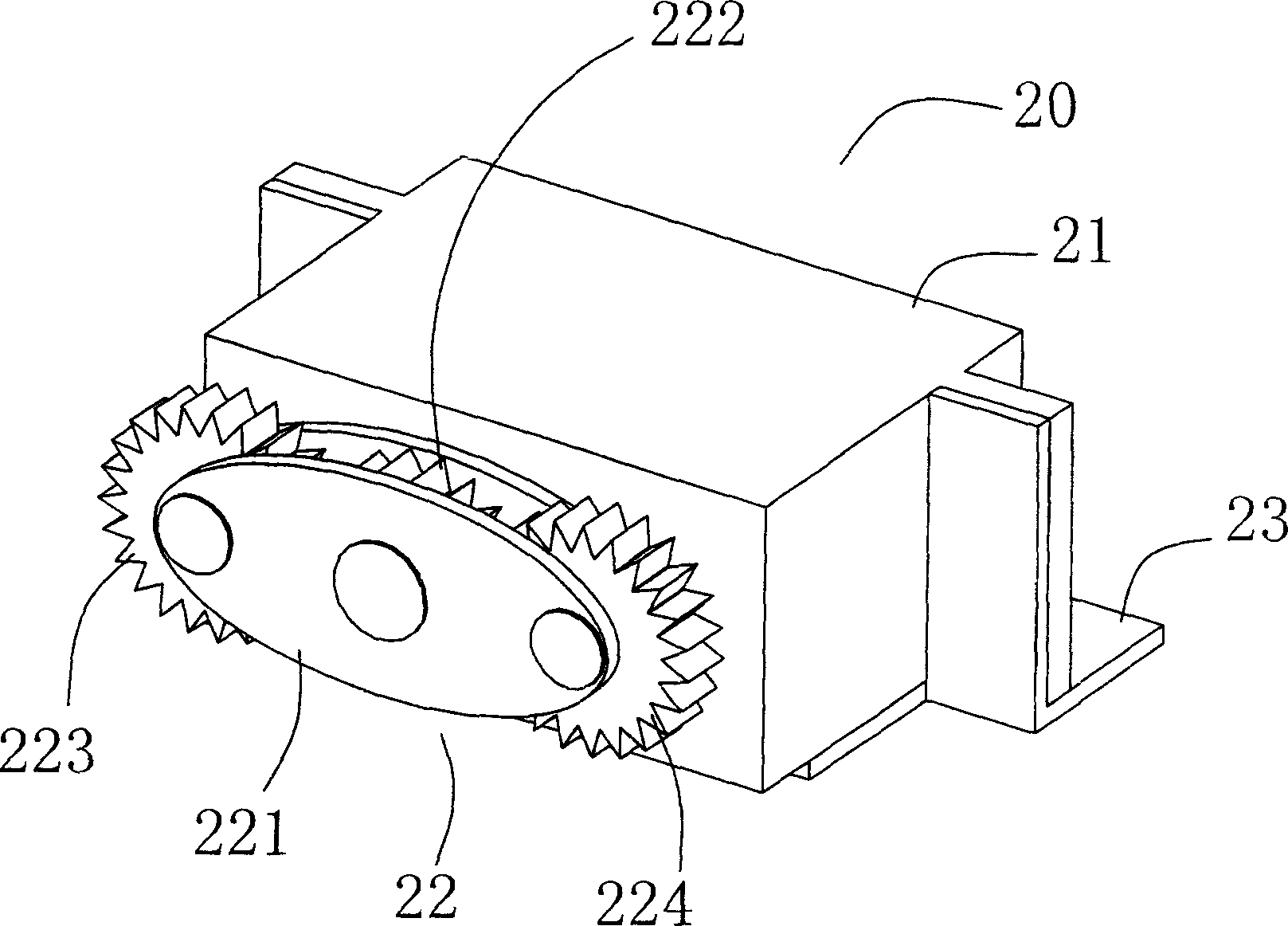

Vertical and horizontal dual-purpose single axle table of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN100421874CImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsMotor driveTorque motor

The invention relates to the vertical and horizontal single shaft rotary bench driven by an alternate permanent syntactic outside rotor torque motor. It directly fixes the bench on the end of the said torque motor rotor, connecting the shell with the inner cold bushing of the stator and the stator of the torque motor, with reduced middle drive linkages, improves the running precision and stability of the rotary bench, with bigger output torque and improved mechanical effect. It simplifies the braking mechanism with bigger clamping area, less drive effect with less size of the outside rotor torque motor under same performance conditions.

Owner:KEDE NUMERICAL CONTROL CO LTD

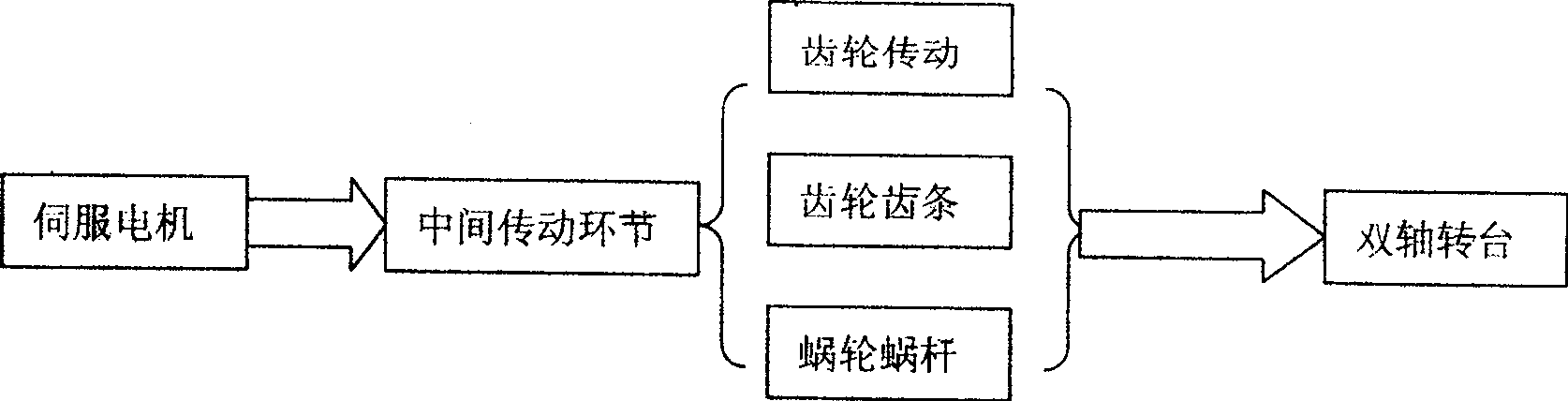

Double axle table driven by AC permanent magnetic synchronization external-rotor-type force moment motor

ActiveCN100467208CImprove running accuracyImprove stabilityEngine sealsMagnetic circuit stationary partsTorque motorEngineering

The biax turntable of an AC permanent magnet syntactic outside rotor torque motor comprises a turntable in the middle with vertical main shaft, turntable at one side of the said turntable with horizontal main shaft connecting with horizontal torque motor and vertical torque motor, oscillating driven by the horizontal torque motor, rotating driven the vertical motor. Saving a lot of middle drive linkage, it improves the running precision and stability of the turntable, with bigger output torque, and improved mechanical returns. It simplifies the braking structure with enlarged clamping area, less effect to the drive and system, smaller size of the outside rotor torque motor.

Owner:KEDE NUMERICAL CONTROL CO LTD

Integrated self-locking nut

The invention discloses an integrated self-locking nut, and particularly relates to the technical field of self-locking nuts, the integrated self-locking nut comprises a body, a threaded hole is formed in the body, a limiting groove is formed in the right end of the body, five clamping grooves are formed in the right part of the body at equal intervals, and two mounting rings are fixedly connected in the left end and the right end of the limiting groove. By rotating a rotary knob, when a threaded hole is in threaded fastening connection with a bolt or a screw rod, a stepped barrel is driven to rotate, so that a gear barrel rotates, the outer wall of the gear barrel is in meshing transmission with five sector gears, the sector gears rotate around a fulcrum shaft, a support rotationally extends out of the space between two mounting rings, a clamping block extends out, and the clamping block is in sliding clamping connection with a clamping groove; the anti-loosening nut has the advantages of being simple in structure, low in machining cost, convenient to operate, good in anti-loosening and anti-vibration effect, suitable for batch production and high in practicability, and rotation of the body is limited, so that when the nut is affected by external vibration and other factors, the nut cannot be separated from a bolt or rotation of a screw rod, and the nut is prevented from loosening.

Owner:苏州特耐五金有限公司

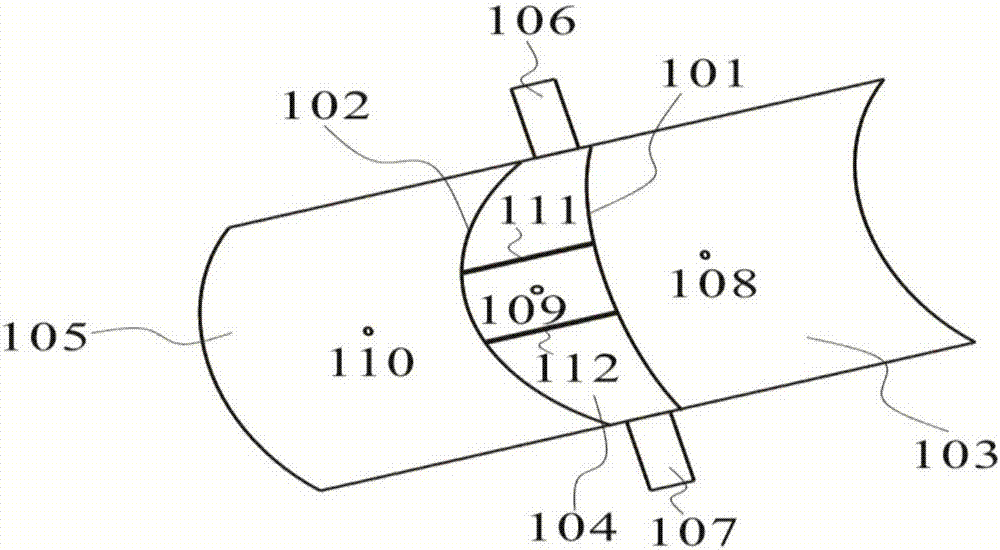

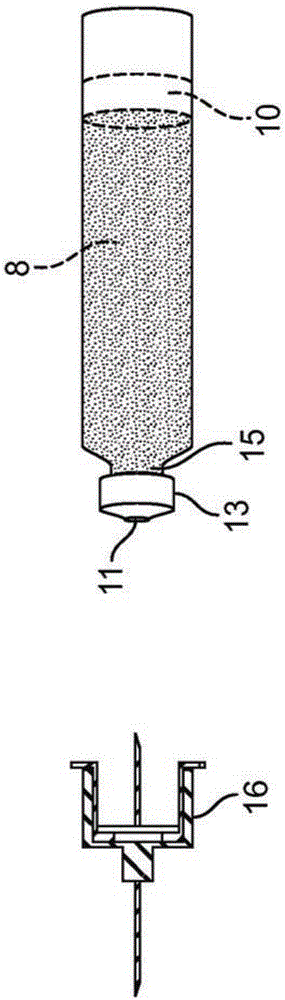

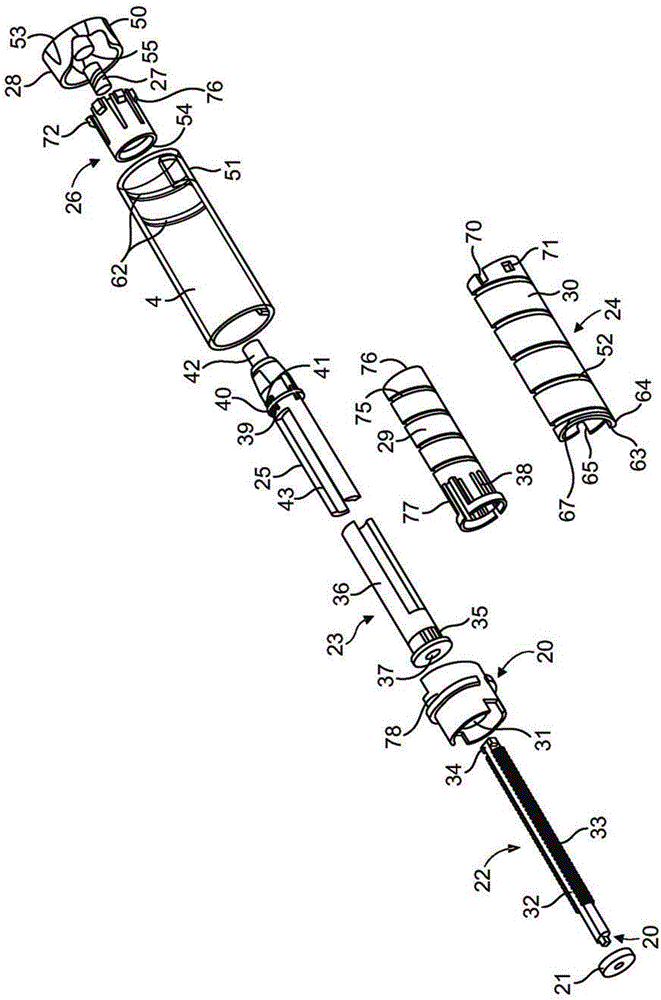

Drug delivery device

ActiveCN105744974AHigh mechanical efficiencyReduce deliveryAmpoule syringesMedical devicesEngineeringPiston rod

The present disclosure provides for a drive assembly for a drug delivery device. The drive assembly comprises a housing (4); a piston rod having a longitudinal axis, a distal end and a proximal end and being axially movable in a distal direction relative to the housing and a mid-body (20) axially fixed inside of the housing (4) and coupled to the piston rod. The mid-body (20) comprises at least one metal ratchet arm (81 ) configured to prevent the piston rod from moving in the proximal direction. Moreover, a drug delivery device with such a drive assembly is presented.

Owner:SANOFI AVENTIS DEUT GMBH

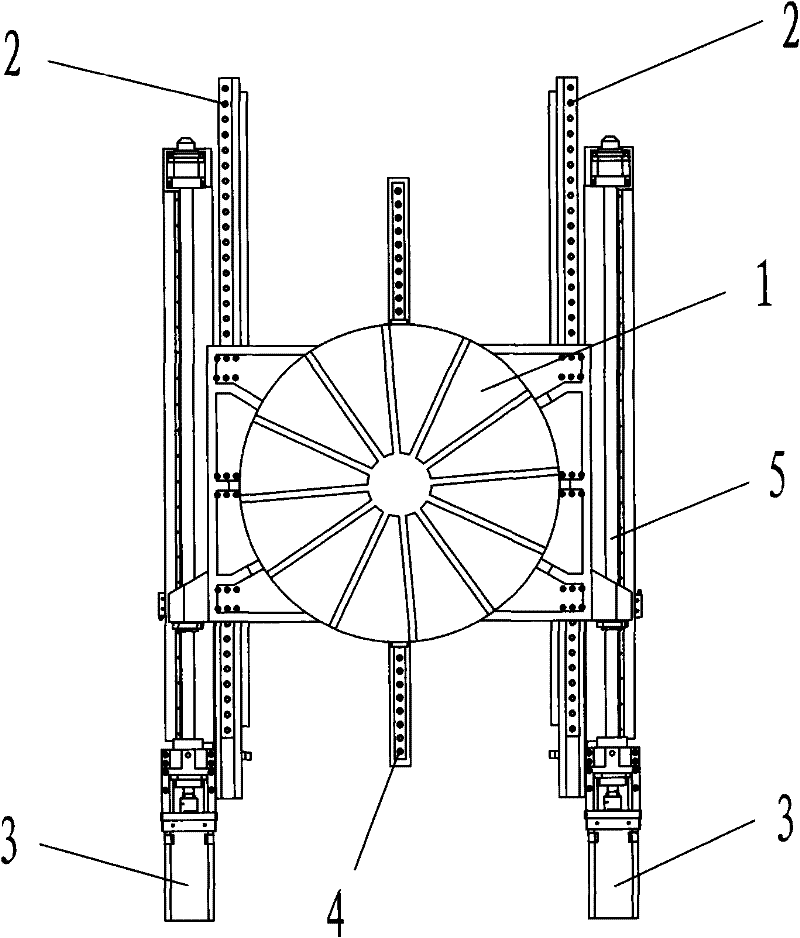

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN100475437CImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

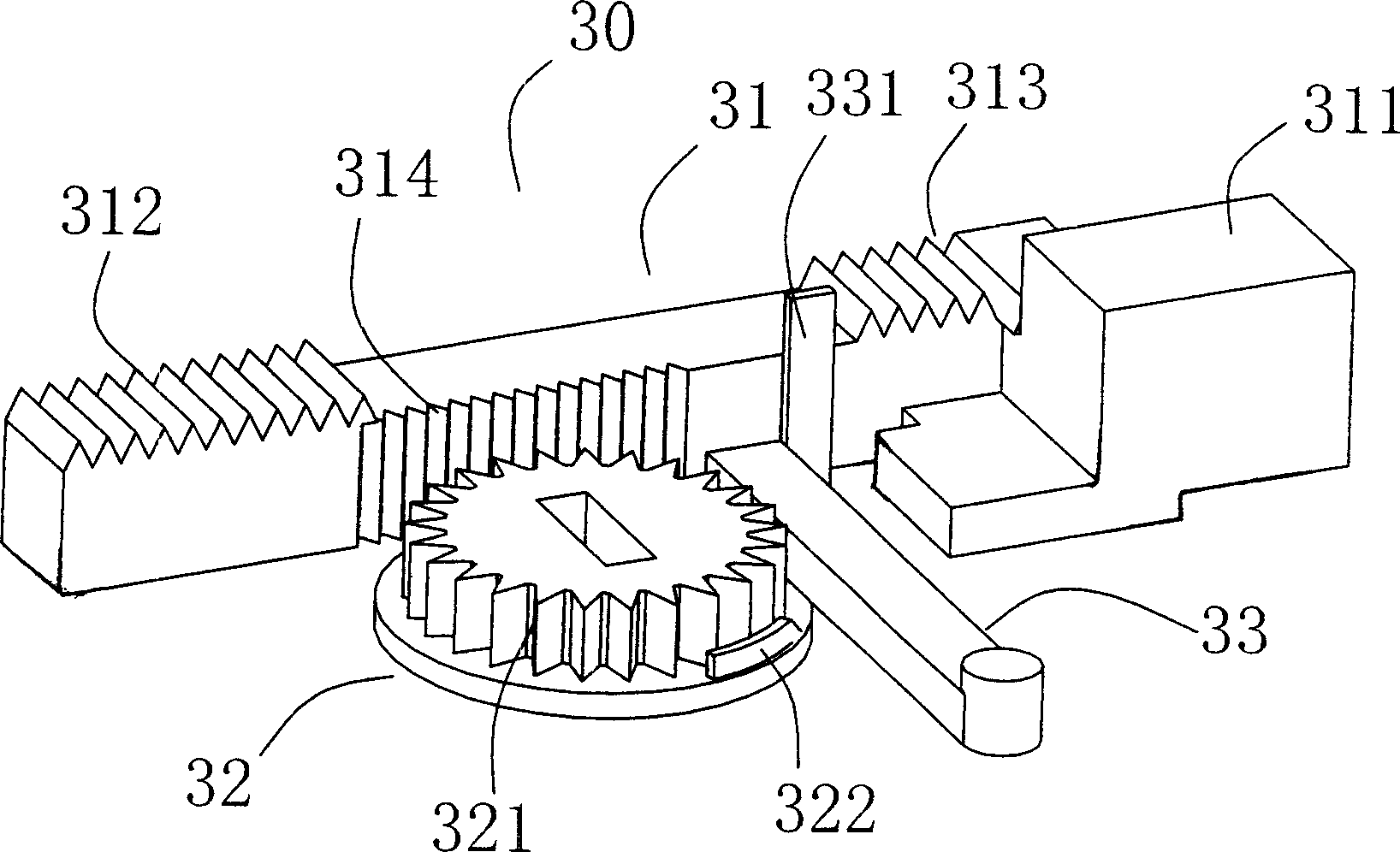

Minitype electronic lock

The present invention relates to a miniature electronic lock, including the control mechanism in lock box and the lock bolt controlled by driving mechanism. There through equips a lock stopping hole for the pull rod head of the driving mechanism at the side of the lock bolt bracket. The middle of one surface of the driving mechanism pull rod and both ends of its near and vertical surface respectively equip racks. The racks at both ends of driving mechanism pull rod mesh on the gear wheel group fixed on the output axis of the control mechanism electromotor of the external electrical source. The gear wheel group includes two elliptic plywood to clip the main gear wheel of the gemel and the driven gear wheel respectively meshed with the main gear wheel from two ends gemel of the two elliptic plywood. When driven by the electromotor, the main gear wheel turns to the direction of driven gear wheel, which automatically meshs with the pull rod gear wheel through running outside force, to drive the pull rod move forward to the edental strip segment to achieve the separating and jointing state. Whereas when the main gear wheel turns from the direction of driven gear wheel, which automatically meshs with the pull rod gear wheel through running outside force, to drive the pull rod move backward to the edental strip segment to achieve the separating and jointing state.

Owner:吴斐

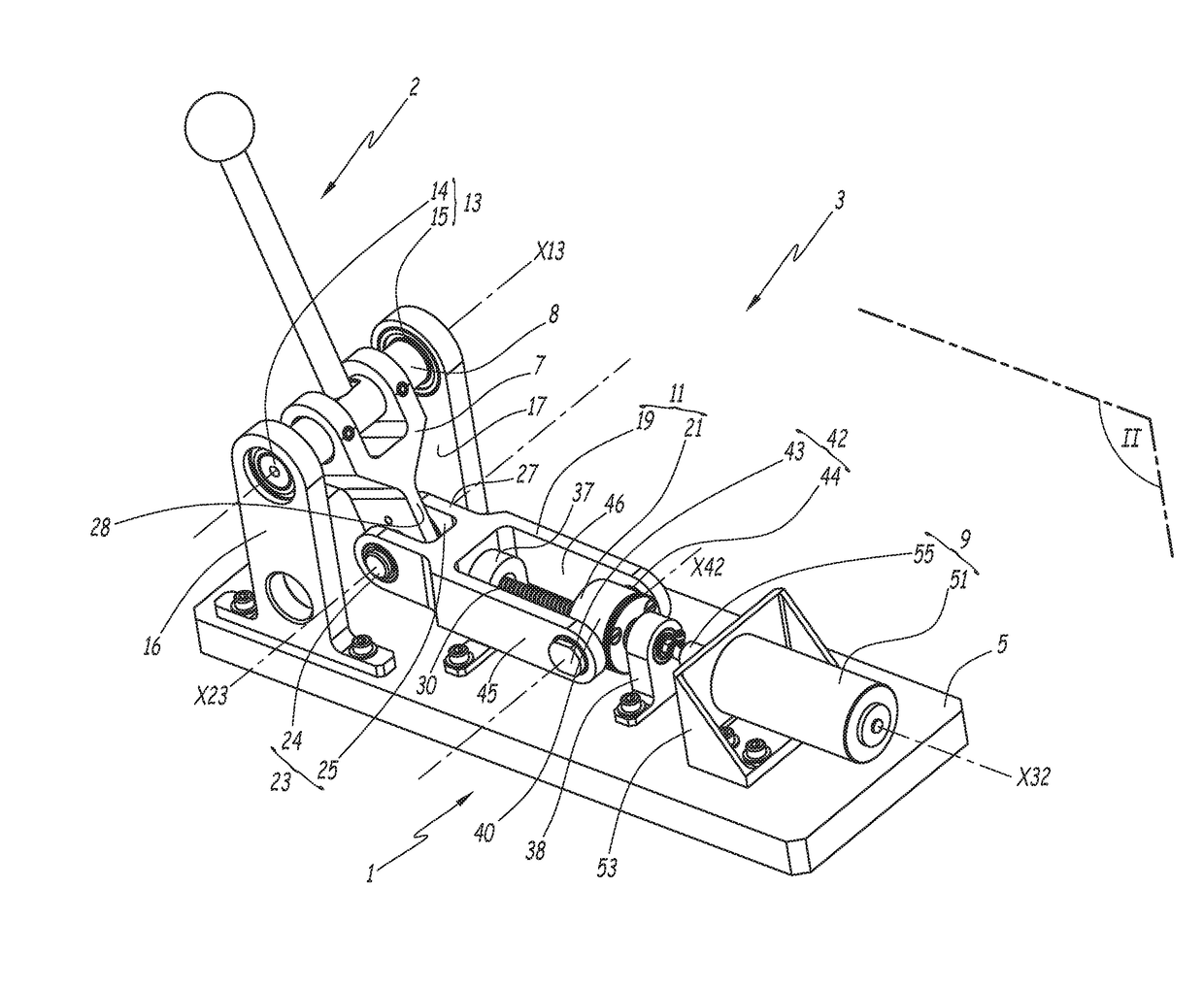

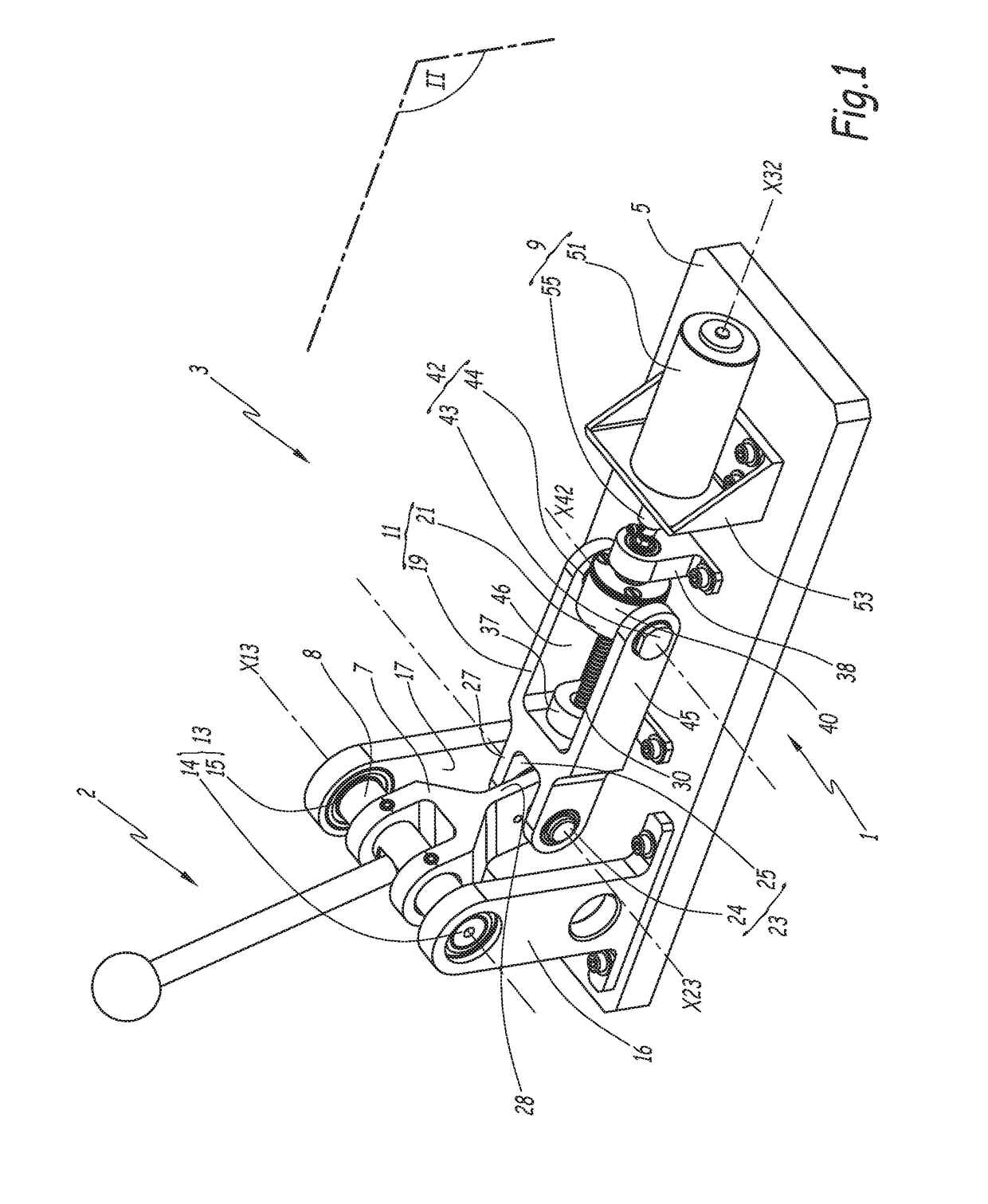

Force Sending Device and A Flight Control Device Comprising Such A Force Sensing Device

ActiveUS20180251208A1High mechanical efficiencyReduce frictionGearingActuated personallyReduction ratioMechanical engineering

A flight control device of an aircraft including a support, an action member attached to the support rotating freely around a primary axis, a rotary device including a stator, rotatably connected to the support around a secondary axis, and a rotor rotating freely relative to the stator around the secondary axis, the rotary device applying a force sensing torque on the rotor relative to the stator around the secondary axis, and a mechanical reducing gear, which connects, with a reduction ratio, rotation of the action member with rotation of the rotor, the mechanical reducing gear including a screw-nut system with rolling elements, including a screw, attached to the rotor, connected in rotation to the rotor around the secondary axis, and a nut fixed in rotation around the secondary axis relative to the stator and helically connected with the screw around and along the secondary axis via the rolling elements.

Owner:FLY BY WIRE SYST FRANCE

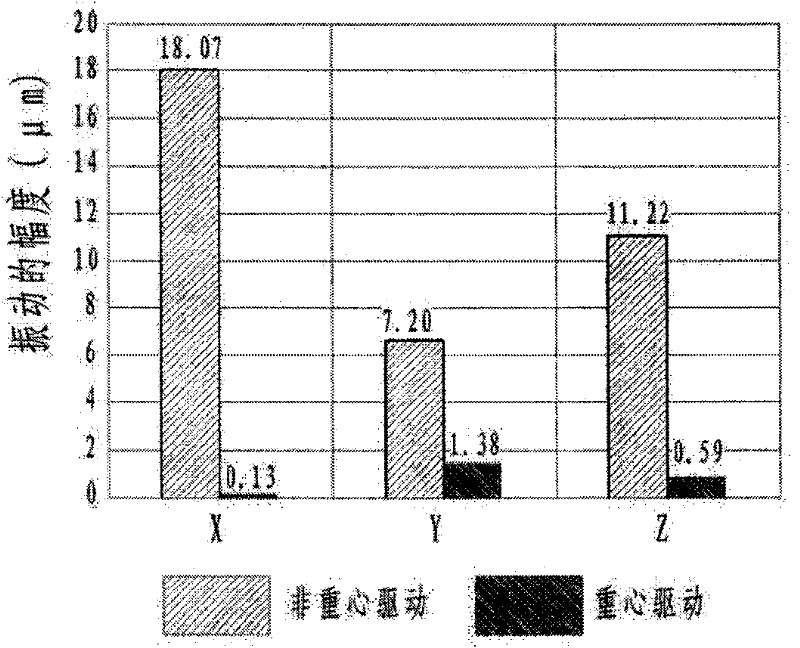

Machine for processing a meat mass

ActiveUS9380792B2Increase speedHigh speed machiningMassaging-based meat tenderisingEngineeringVibration damper

Owner:METALQUIMIA SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com