Double axle table driven by AC permanent magnetic synchronization external-rotor-type force moment motor

A technology of torque motor and two-axis turntable, applied in synchronous motor with static armature and rotating magnet, sealing of engine, shape/style/structure of magnetic circuit, etc. Problems such as small output torque, to achieve the effect of large clamping area, improved braking effect, and large braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

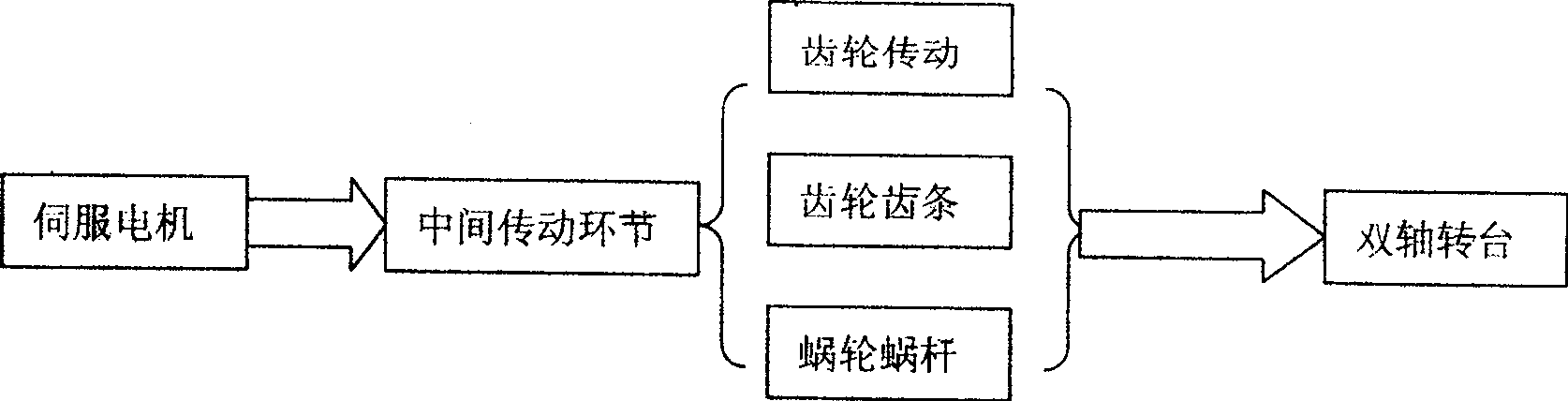

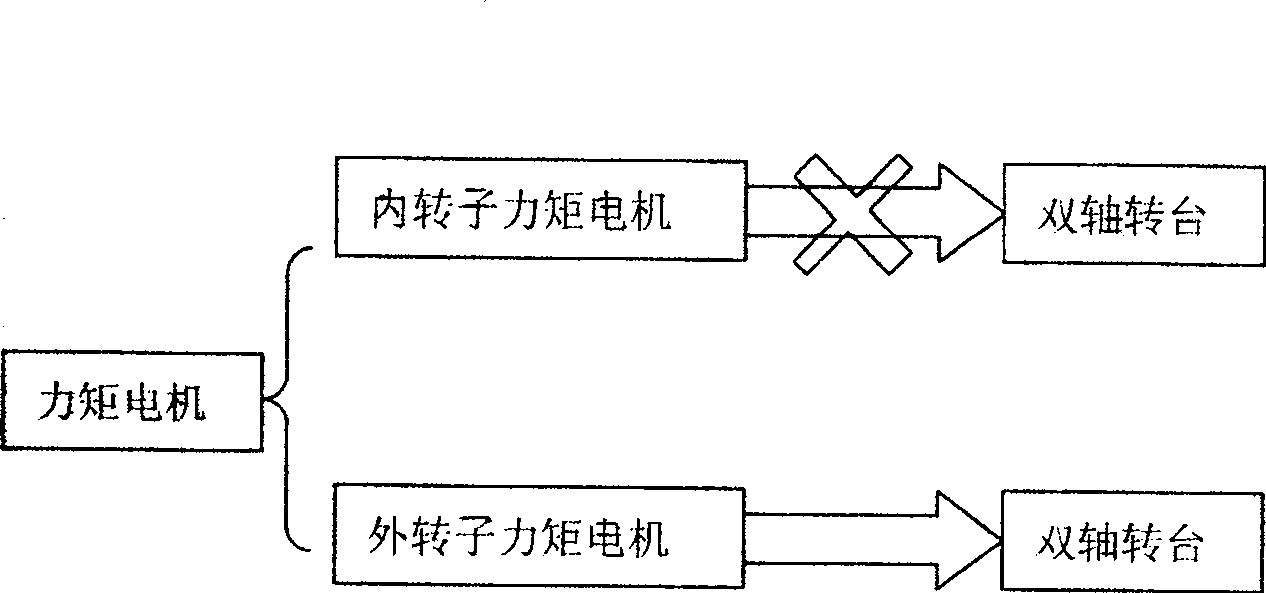

Problems solved by technology

Method used

Image

Examples

Embodiment 1

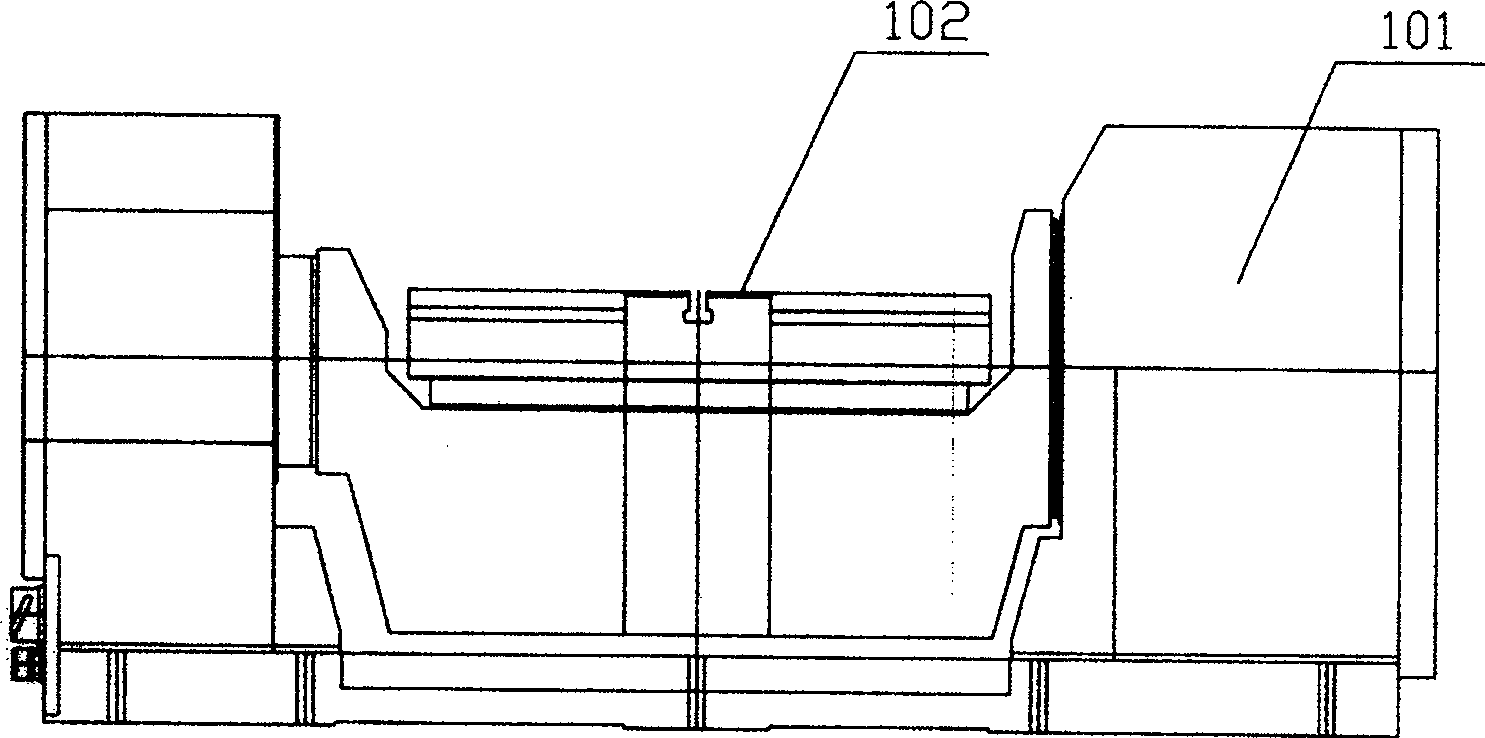

[0021] As shown in Figure 5, in the figure, 1 indicates a double-row short cylindrical roller bearing; 2 indicates an outer rotor rotary joint; 3 indicates the outer shell of the C-axis torque motor; 4 indicates the C-axis hydraulic clamping sleeve; 5 indicates C The rotor of the axial torque motor; 6 represents the stator of the C-axis torque motor; 7 represents the inner cooling sleeve (or cooling sleeve) of the stator of the C-axis torque motor; 8 represents the axial / radial bearing; 9 represents the axial / radial bearing; 10 represents the rotor of the A-axis torque motor; 11 represents the stator of the A-axis torque motor; 12 represents the hydraulic clamping sleeve of the A-axis; 13 represents the inner cooling sleeve (or cooling jacket) of the stator of the A-axis torque motor; 14 represents the encoder for the A-axis. The internal structure of the single-axis turntable 102 in the middle is the same as the single-axis turntable directly driven by the above-mentioned torq...

Embodiment 2

[0024] Since the shell of the horizontal turntable is type structure, the other end can also be symmetrically clamped on a turntable with the main axis transverse and the table vertical. And a horizontal torque motor is set for the turntable, and its correlation mode is exactly the same as that of the above-mentioned turntable 101 and its torque motor, but it needs to be set in a form corresponding to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com