Patents

Literature

36results about How to "Eliminate thermal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

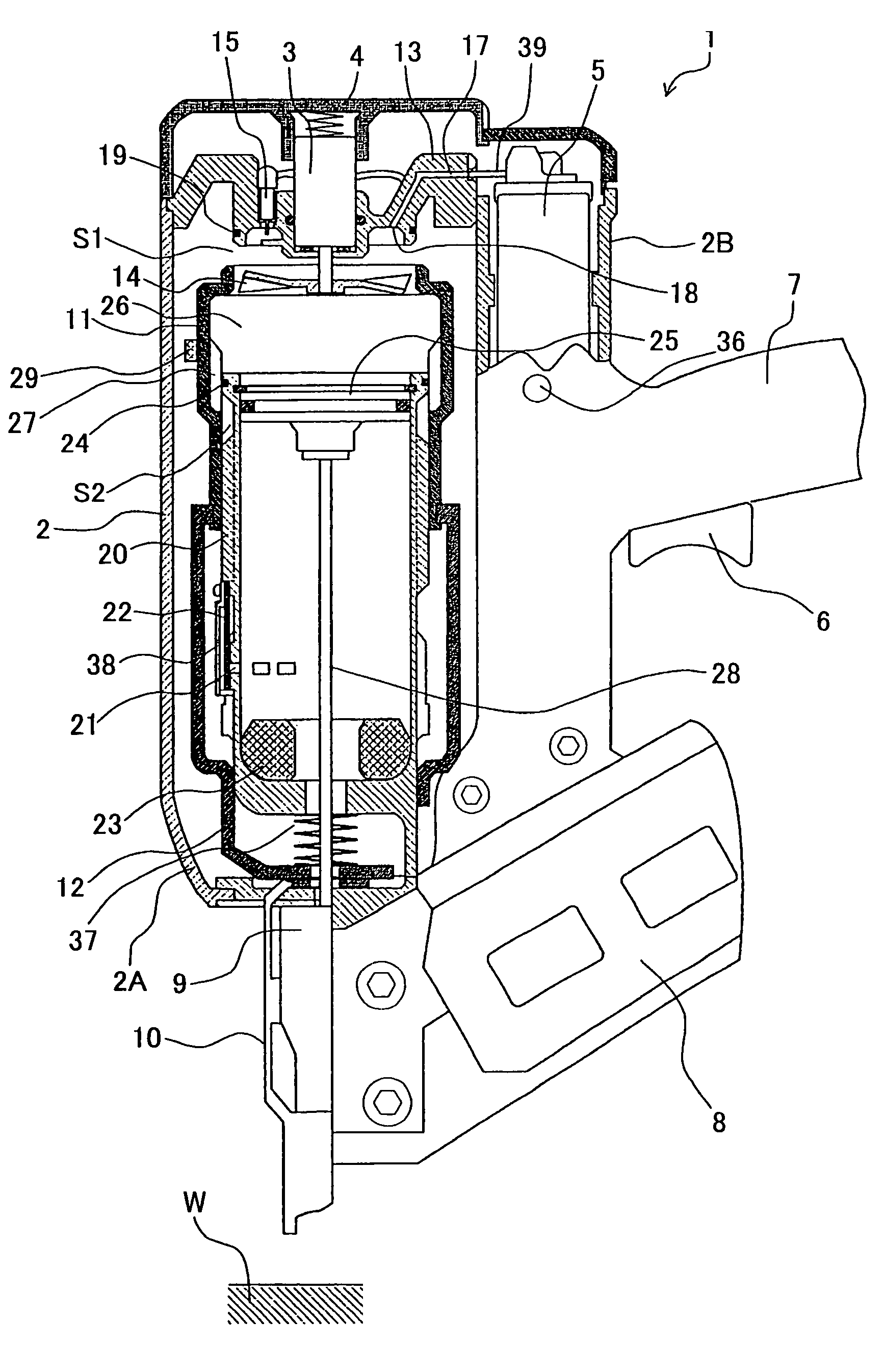

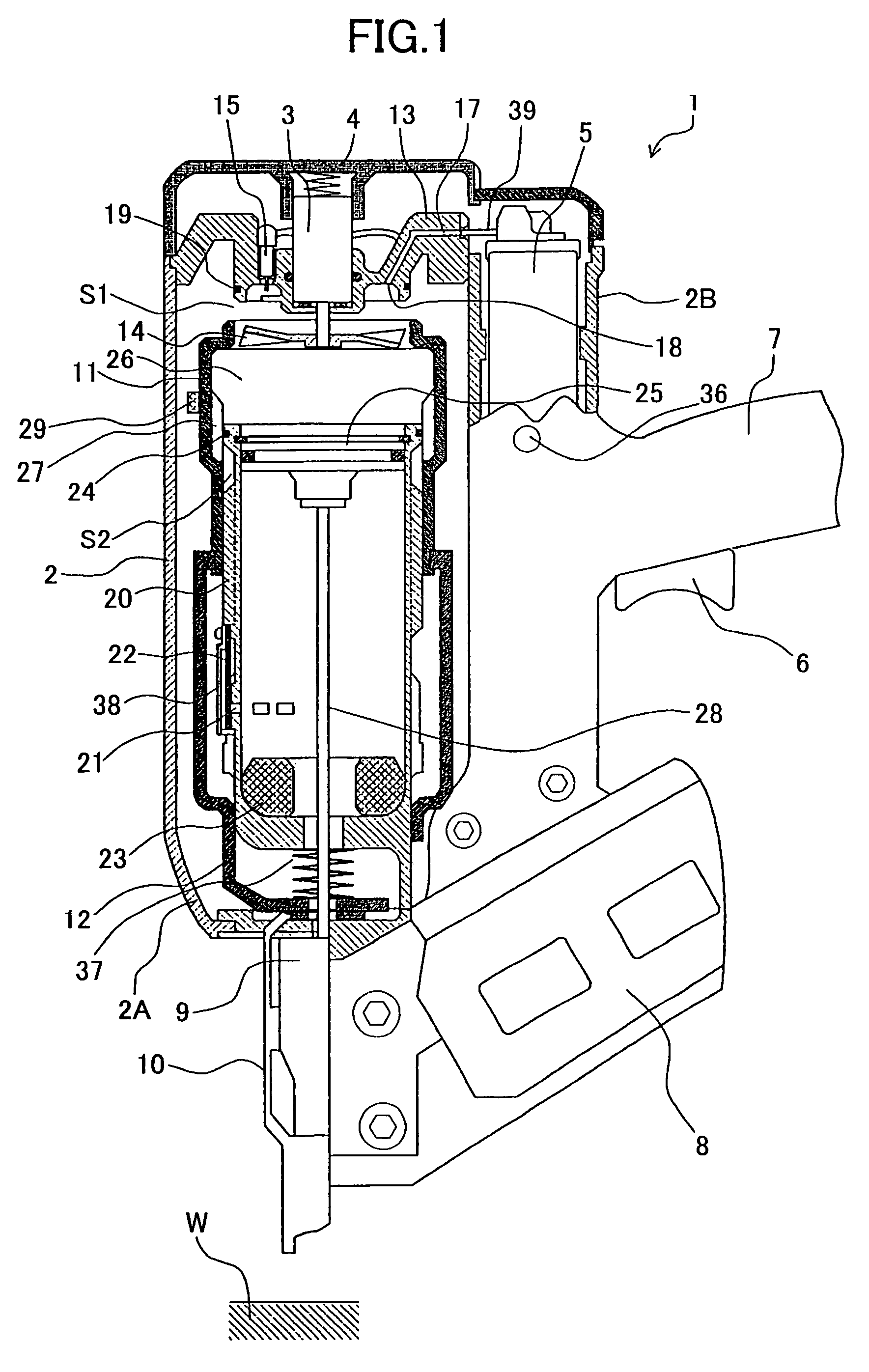

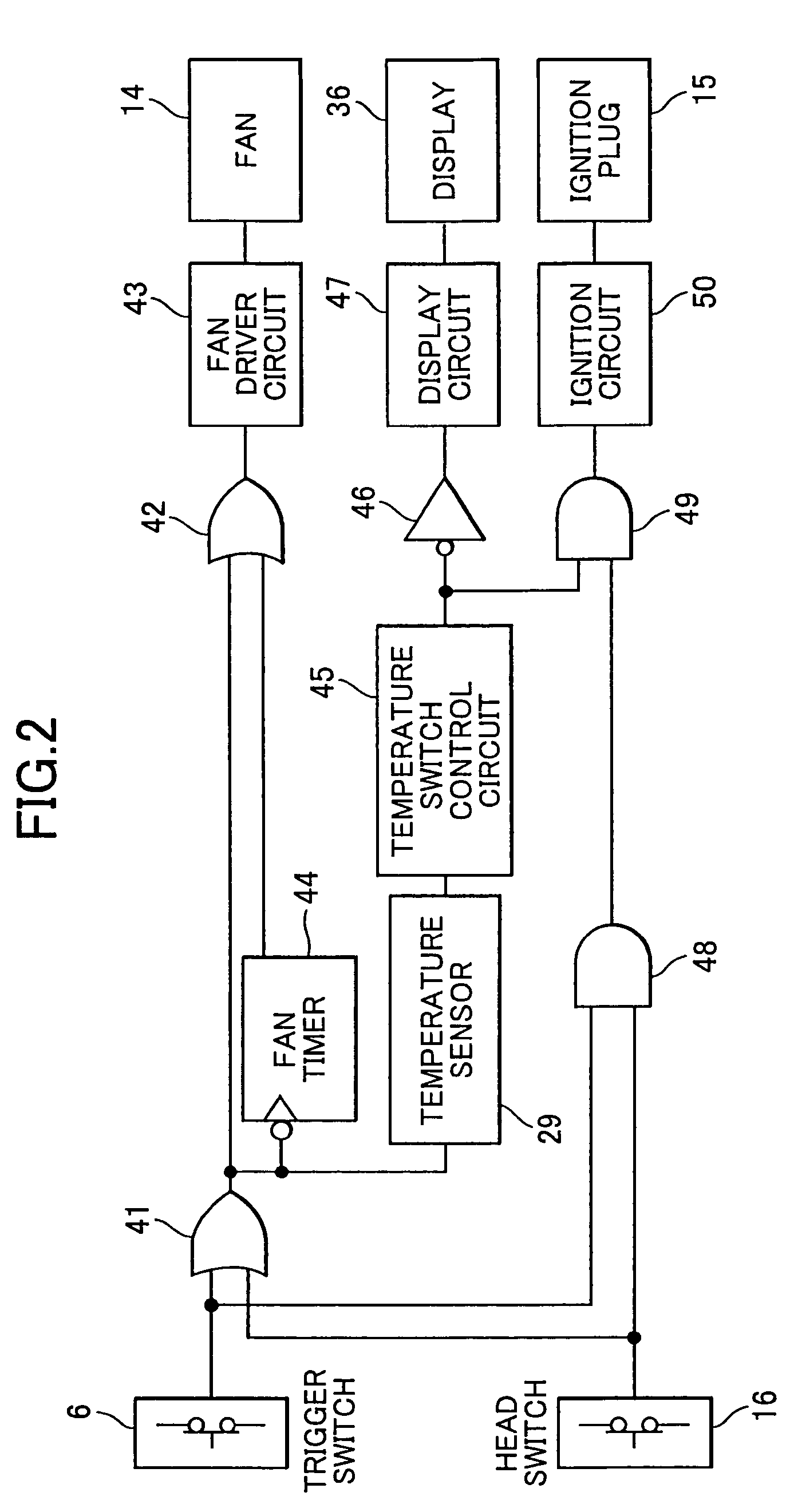

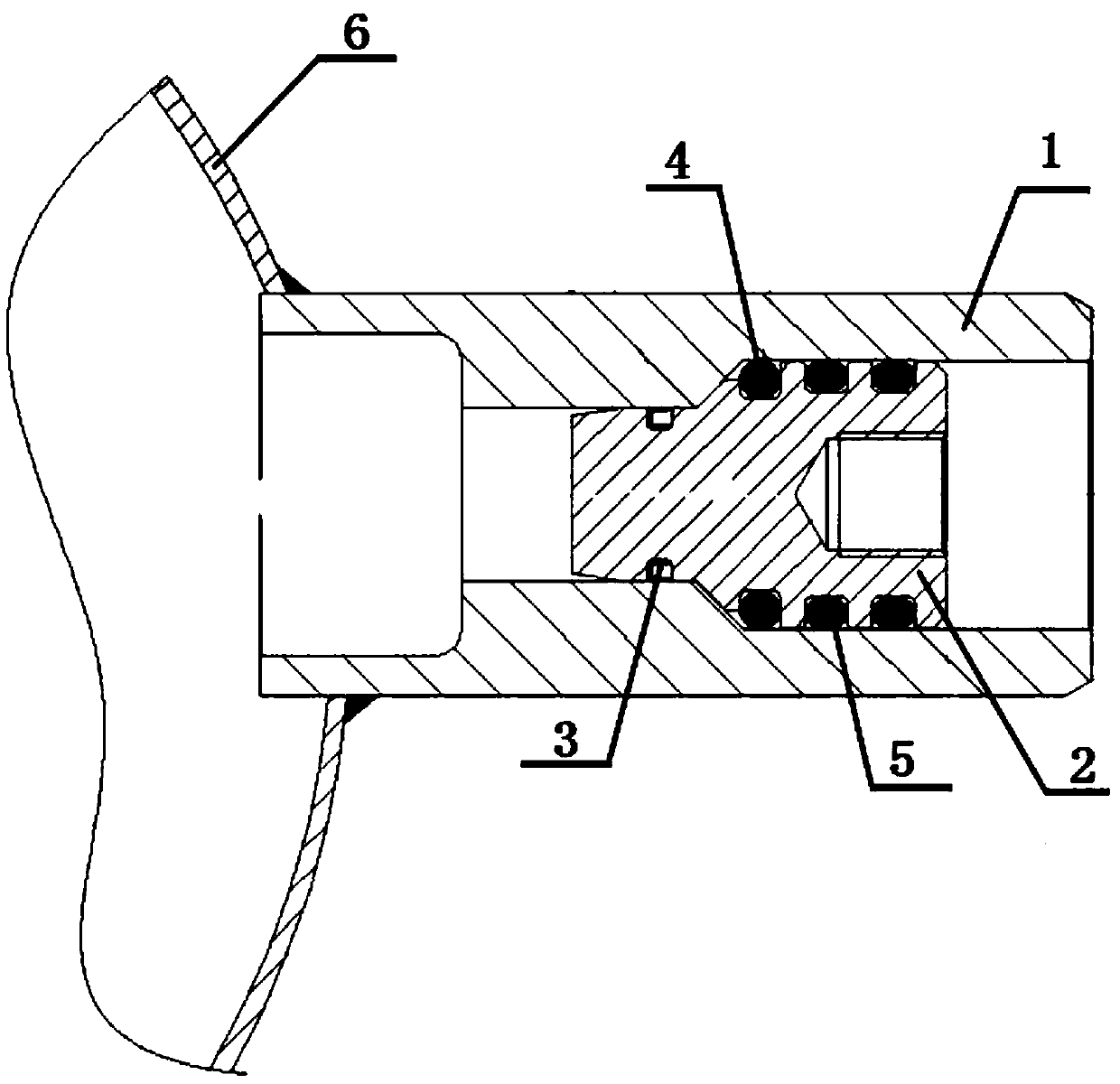

Combustion type power tool having avoiding unit for avoiding overheating to mechanical components in the tool

InactiveUS7021251B2Work lessEliminate thermal deformationFree piston enginesNailing toolsMechanical componentsCombustion chamber

A combustion type power tool capable of avoiding damage to seal members and a housing to prolong a service life, and capable of enhancing operability and workability. Temperature elevation of a combustion chamber frame due to combustion of a mixture of combustible gas and air is detected by a temperature sensor disposed in a housing. If the detected temperature exceeds a preset temperature, ignition of an ignition plug is prohibited by a prohibiting unit in spite of ON operation of a trigger switch. In this state, alarming is performed by a display to notify the user of the inoperable state of the tool. Similar control can be made when the temperature sensor is disposed at a cylinder, an exhaust cover and the housing.

Owner:HITACHI KOKI CO LTD

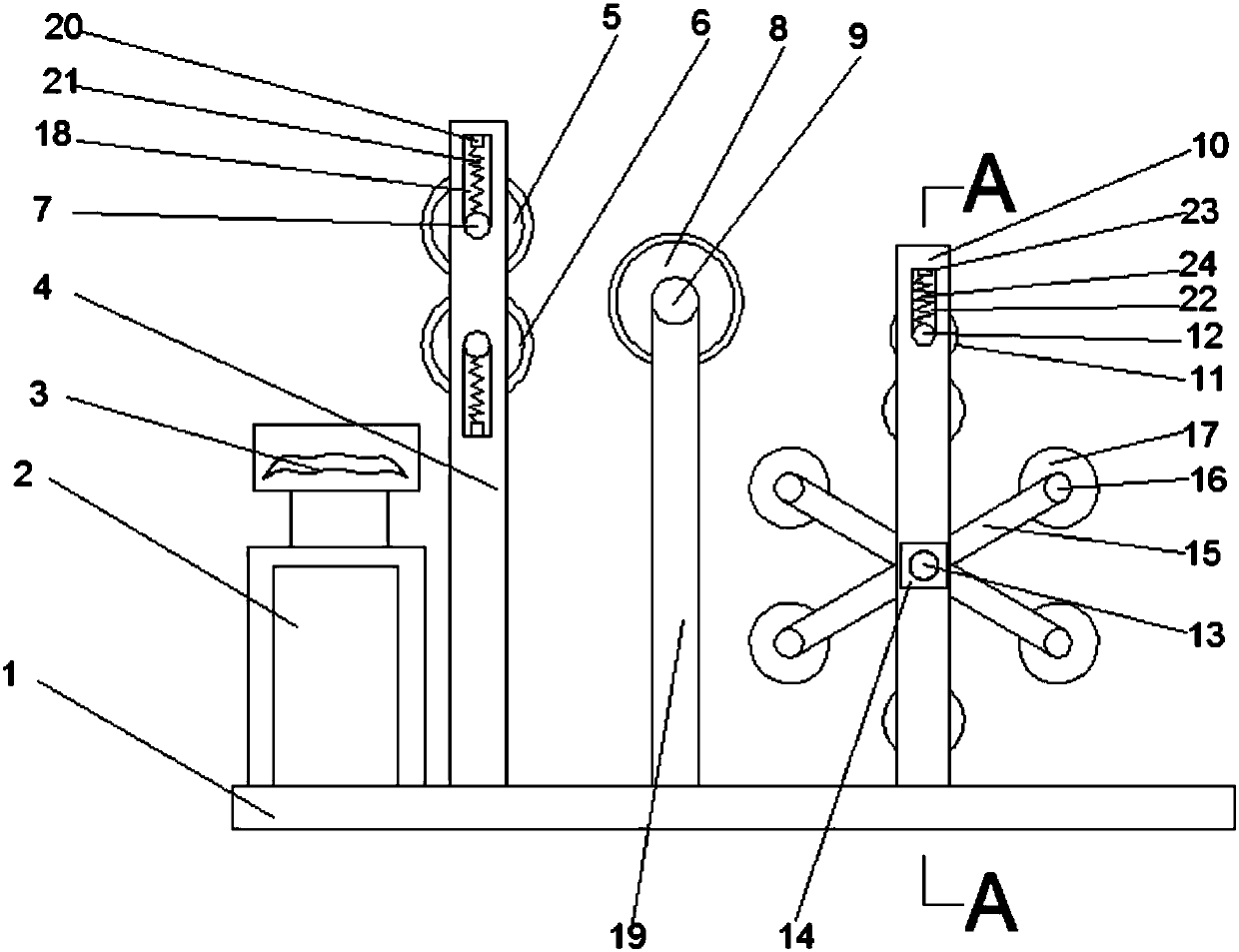

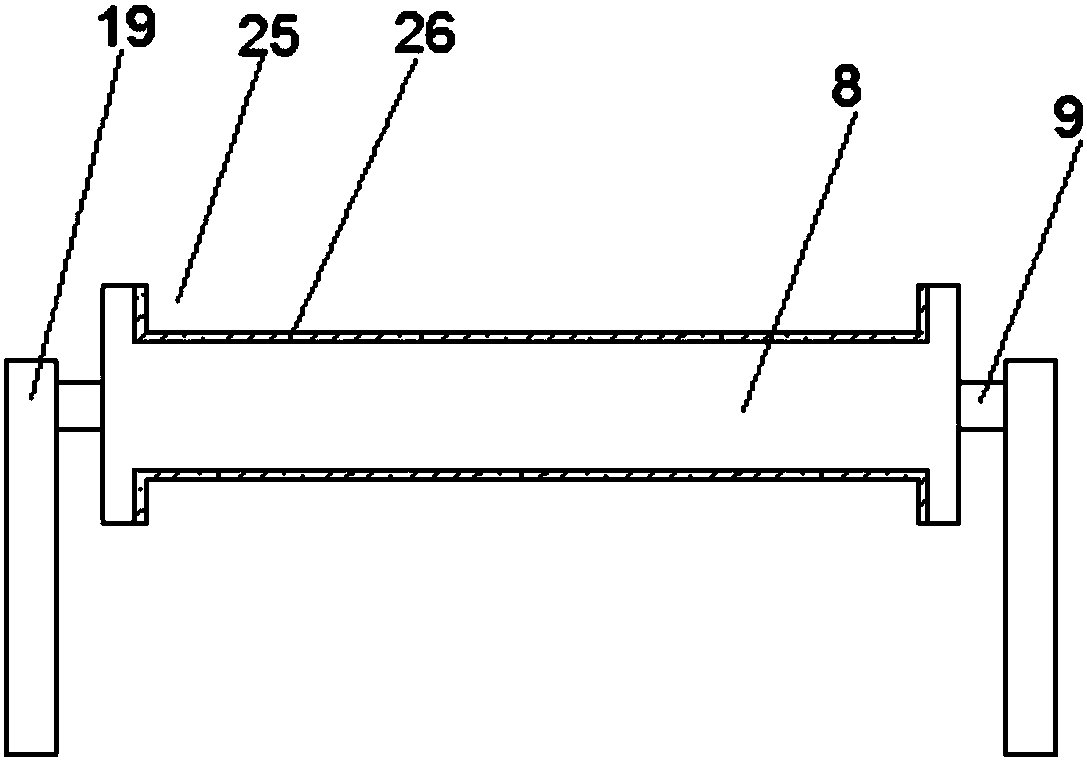

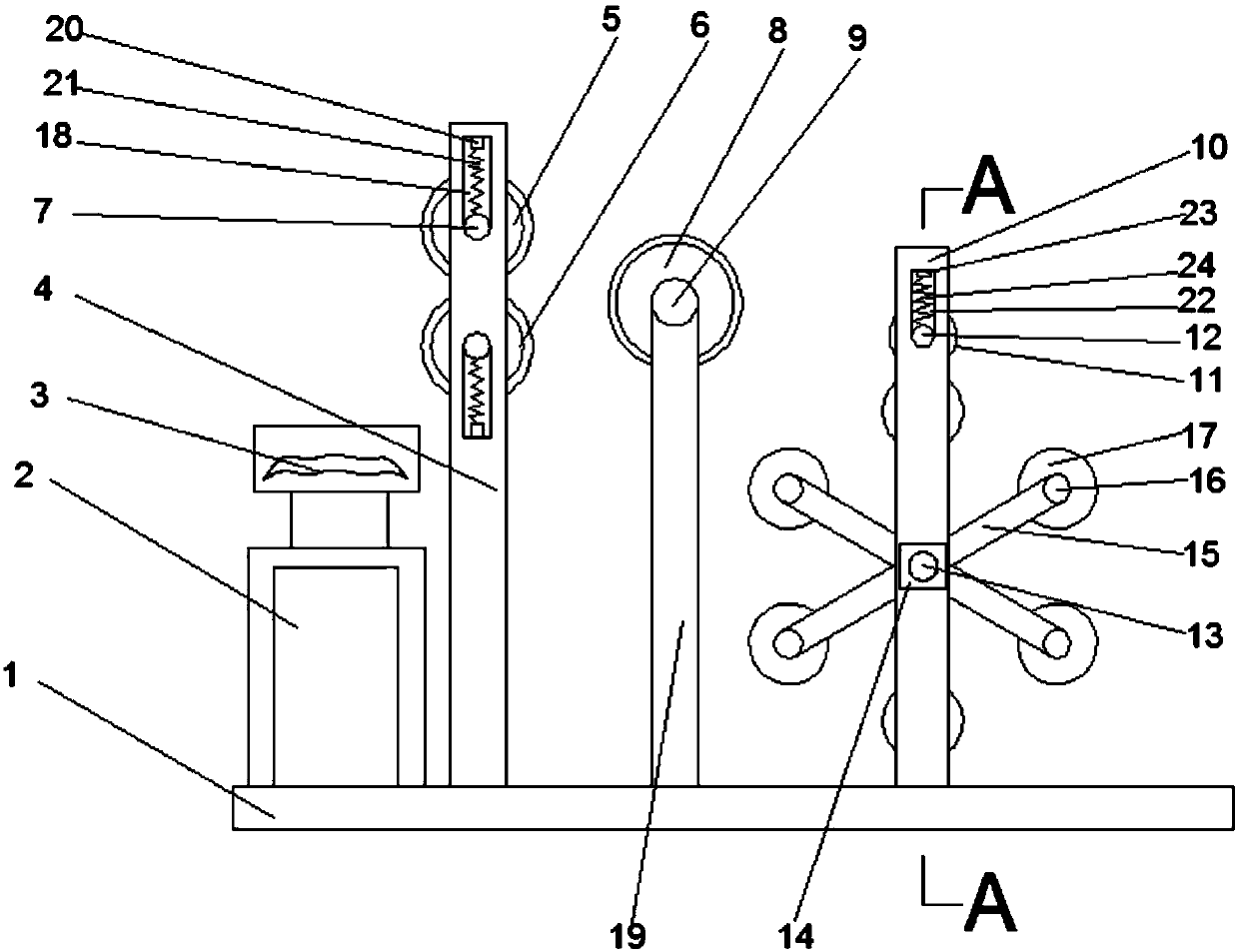

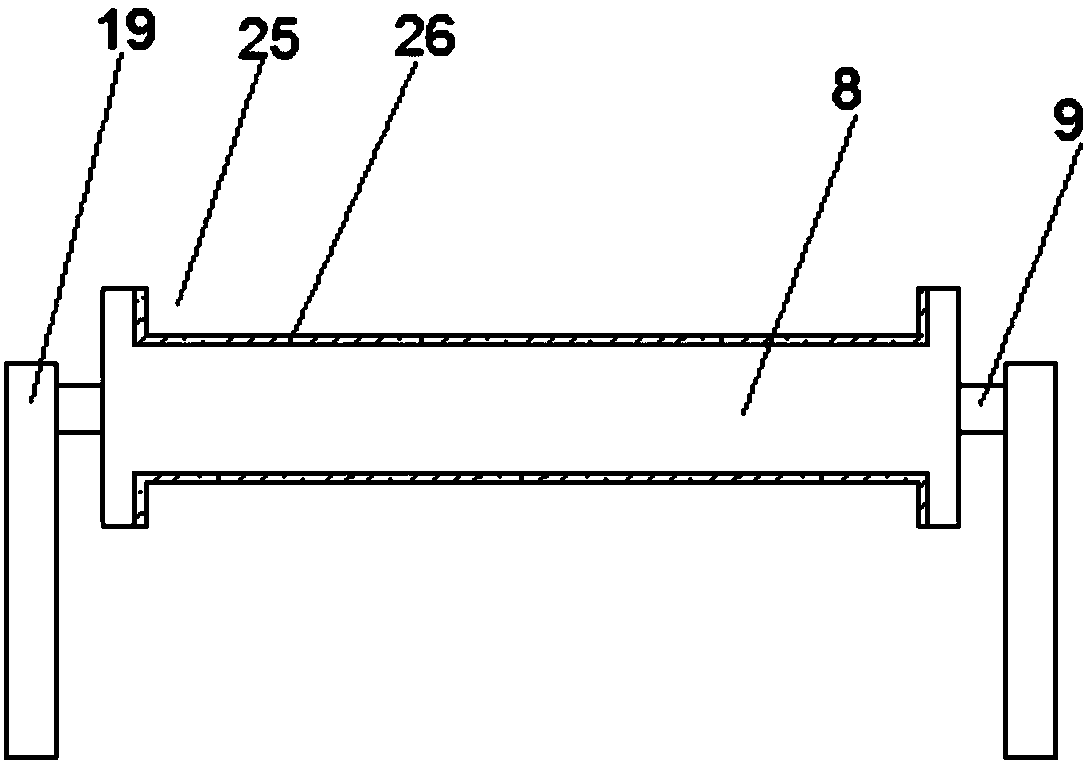

Isolation type non-woven fabric textile winding machine and application method

The invention discloses an isolation type non-woven fabric textile winding machine which belongs to the technical field of textile winding. A cooling fan is arranged at the top of a fixed bracket; anupper flattening roller and a lower flattening roller are arranged at the top of a first bracket in sequence from top to bottom; a tensioning roller is arranged at the top of a third bracket; the tensioning roller is connected onto the third bracket through a second connecting shaft; a second through hole is formed in the top of a side wall of a second bracket; a second fixed block is arranged atthe top of the second through hole; a second rigid spring is arranged at the bottom of the second fixed block; a third connecting shaft is provided with a tracking roller; six groups of winding rollers with the same structure are arranged below the tracking roller; the winding rollers are connected with a connecting frame through a fourth connecting shaft; a ratchet wheel mechanism which is matched with a mounting groove is arranged at the left end of a fifth connecting shaft. The winding machine disclosed by the invention is reasonable in structural design and high in automation degree; simple and convenient textile winding work can be ensured and the winding effect of the fabric is remarkable.

Owner:宁夏中恒创越新材料科技有限公司

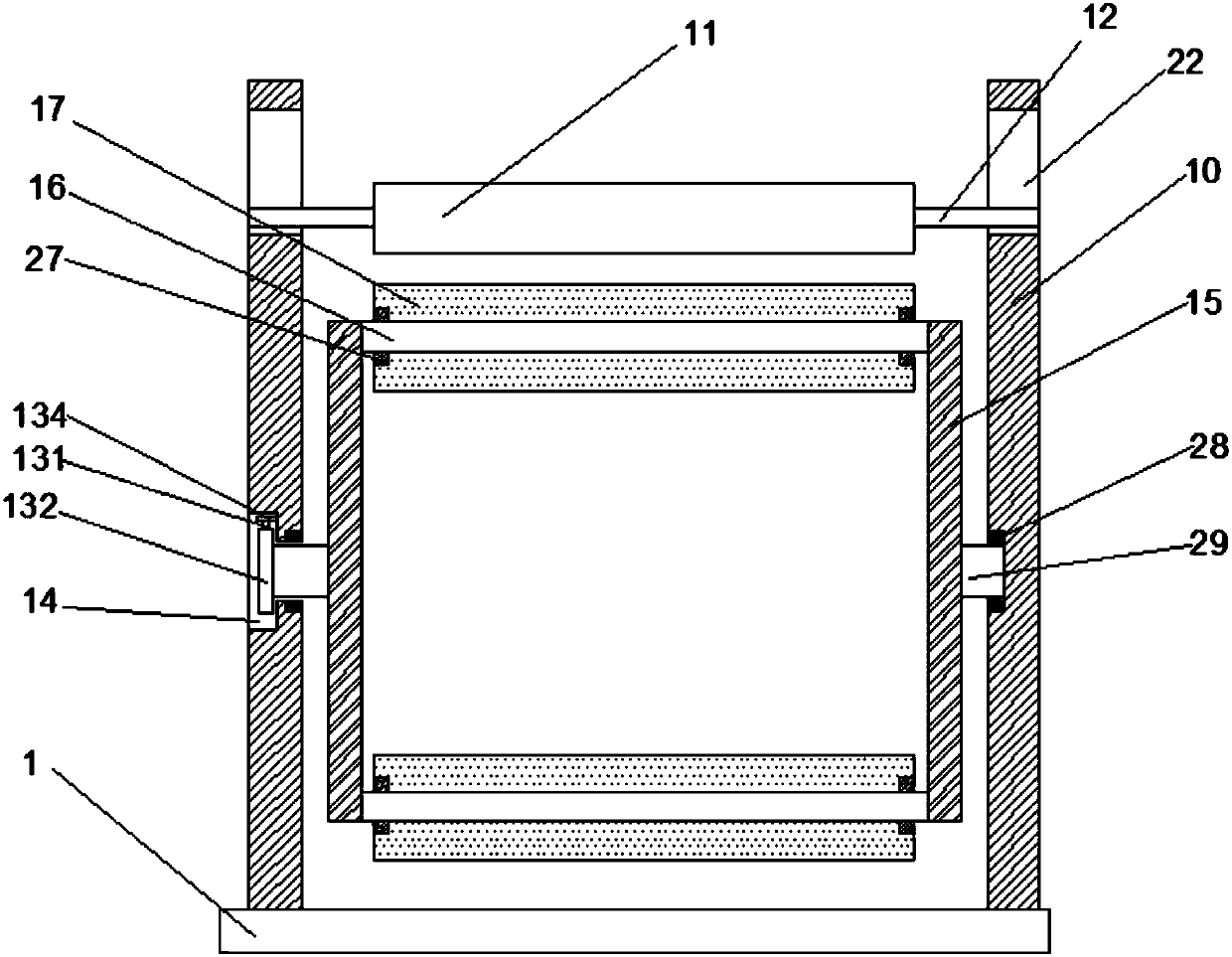

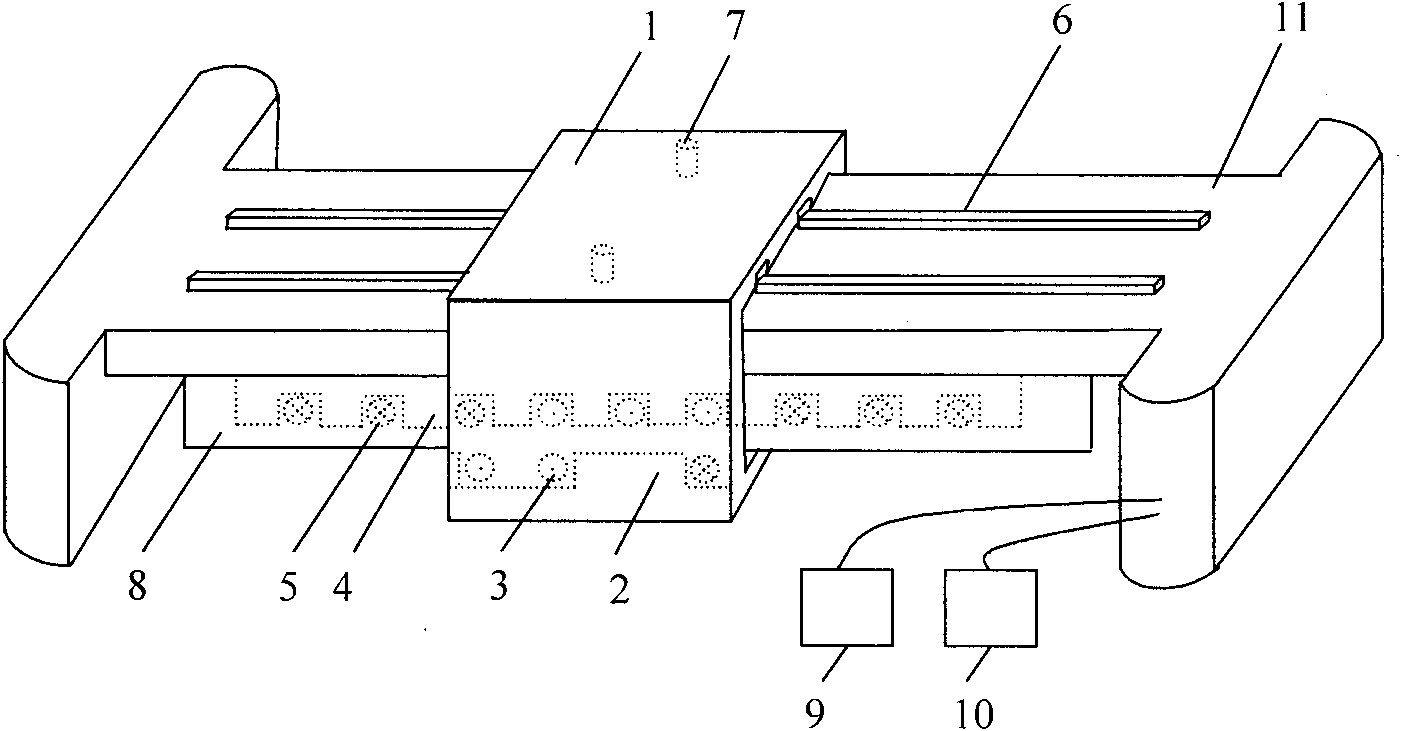

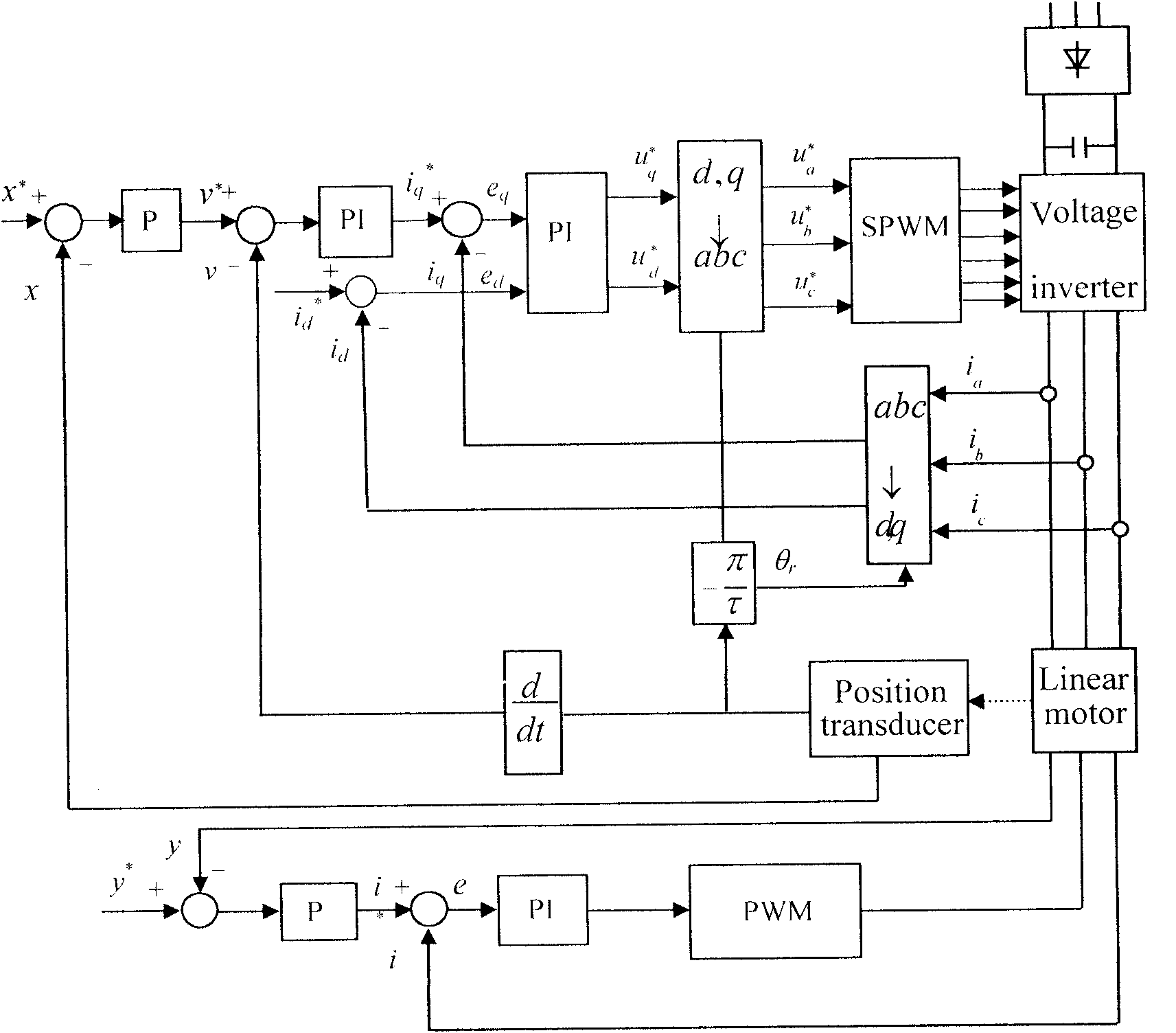

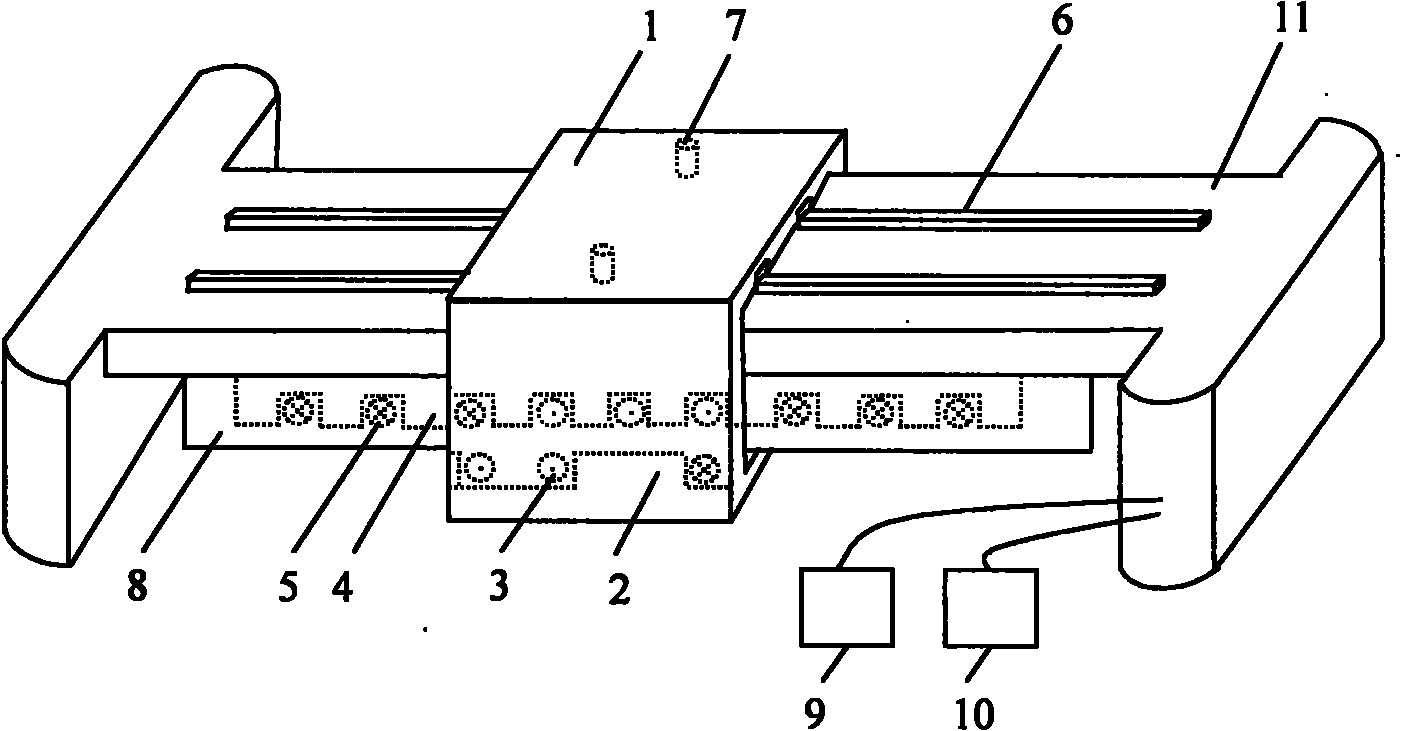

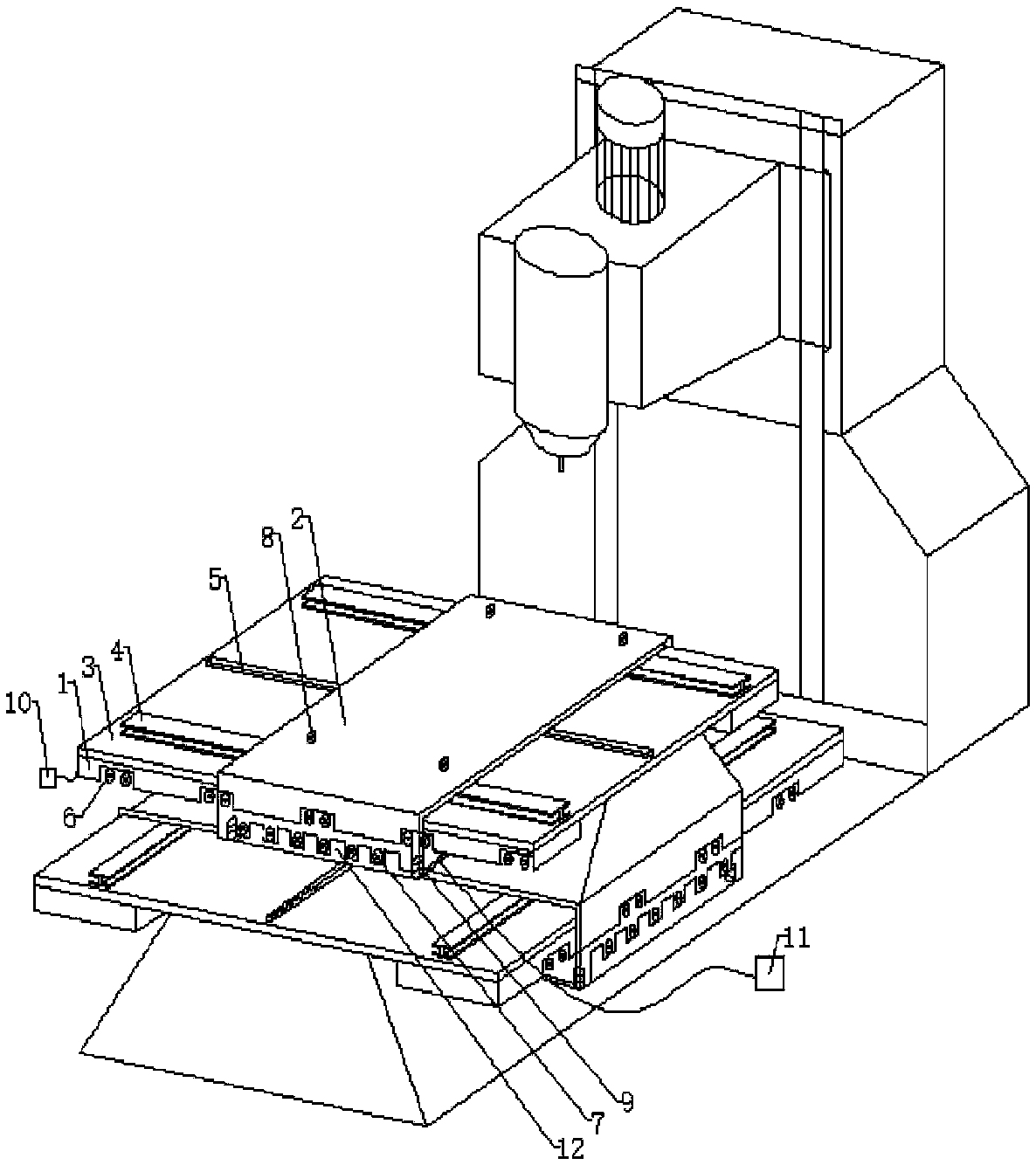

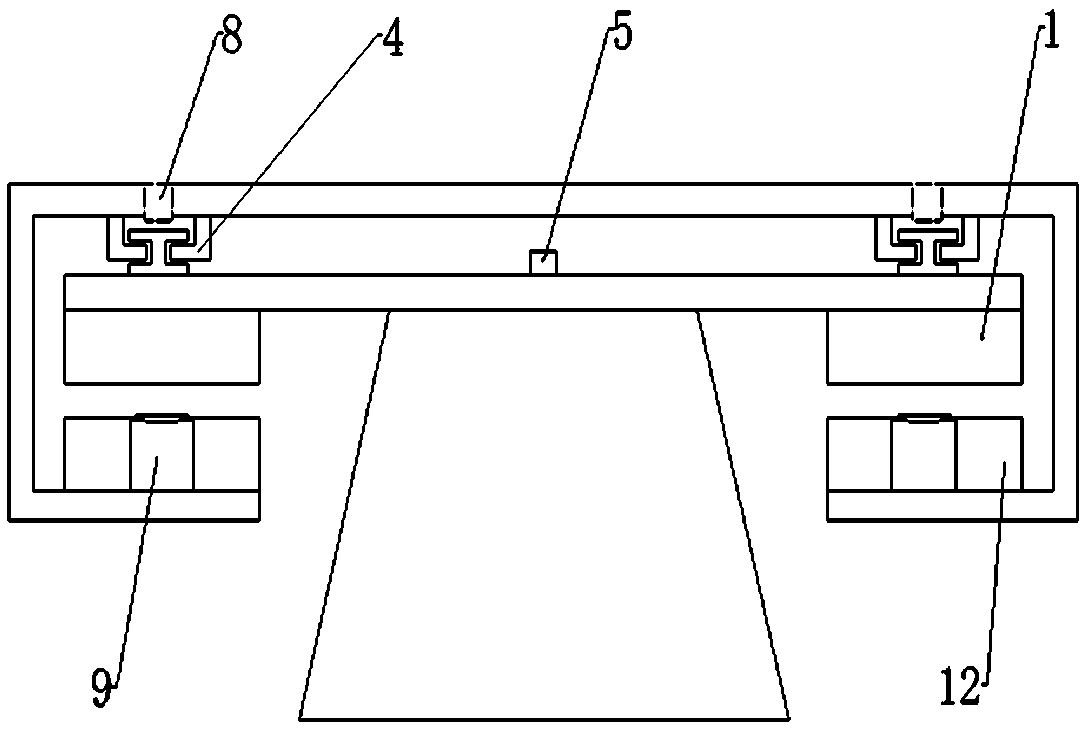

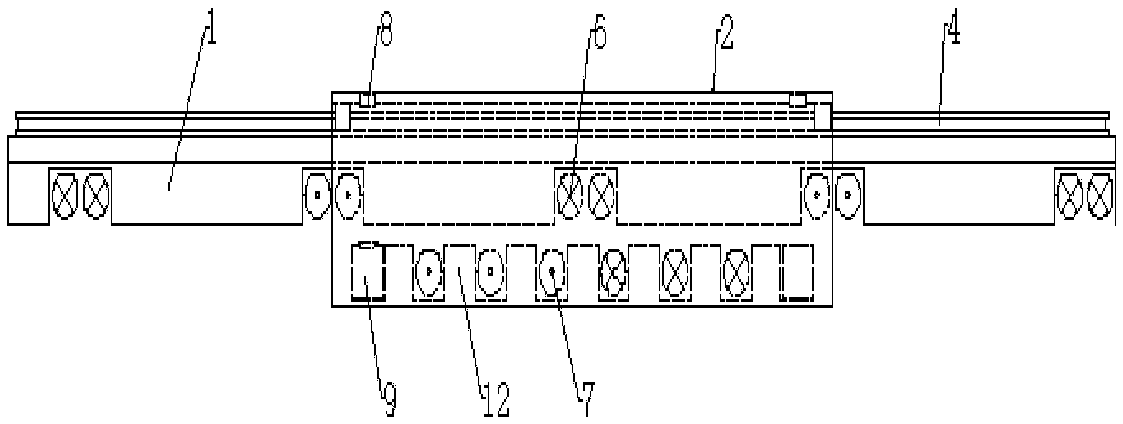

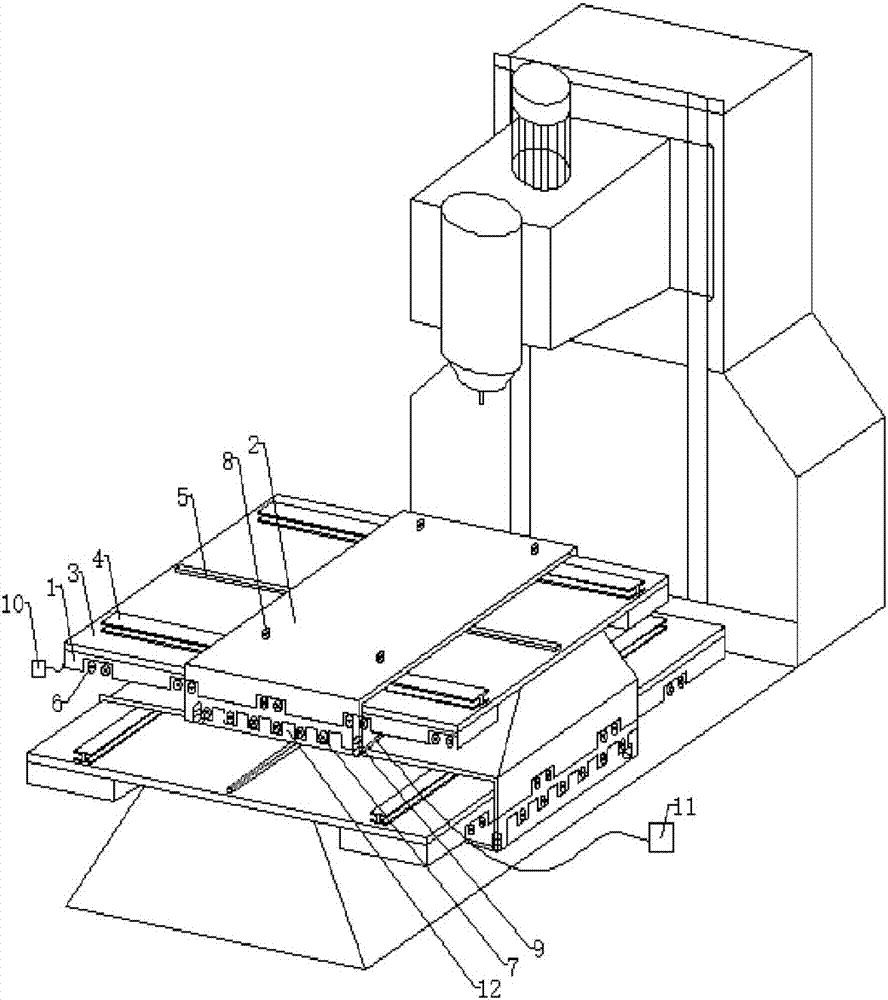

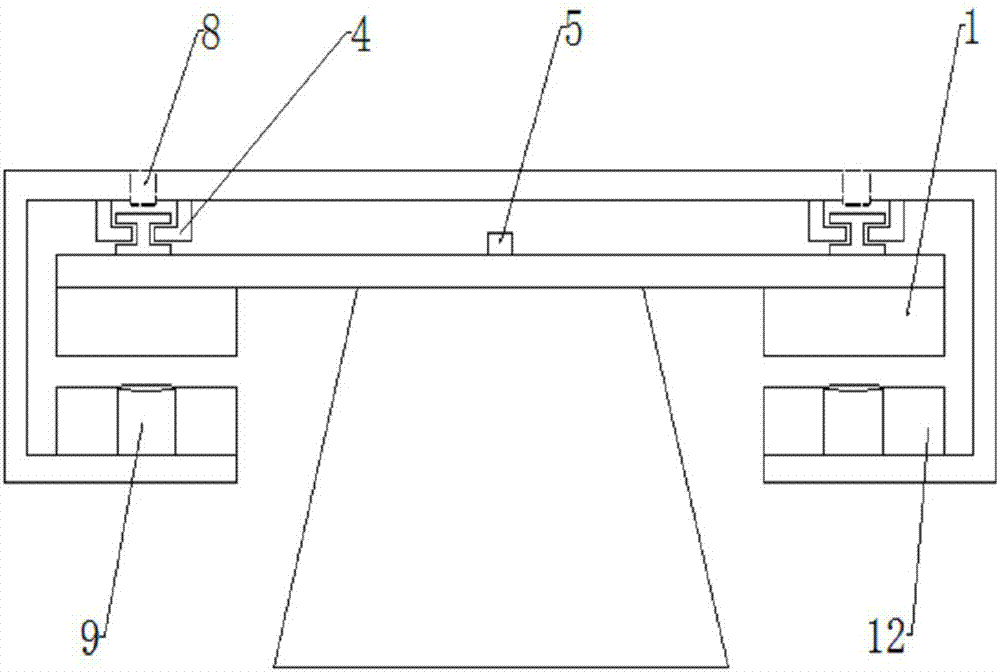

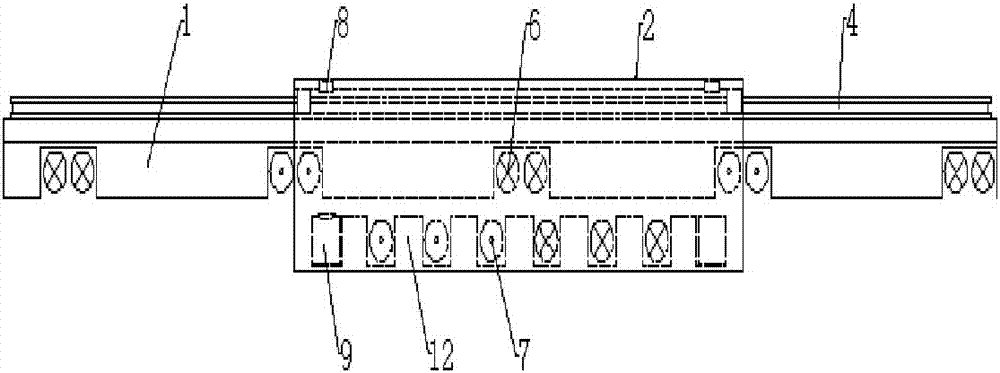

Magnetic suspension feeding platform of liner synchronous motor of digital control machine tool

InactiveCN101850523ASimple structureImprove reliabilityFeeding apparatusPropulsion systemsNumerical controlSynchronous motor

The invention provides a magnetic suspension feeding platform of a liner synchronous motor of a digital control machine tool, comprising a feeding platform and a long stator linear synchronous motor, wherein the long stator linear synchronous motor mainly comprises a stator iron core and a rotor iron core capable of making motion relative to the stator iron core. The invention is characterized in that the feeding platform is installed on the rotor iron core; an excitation winding is arranged in the rotor iron core, and a thrust winding is arranged in the stator iron core; the feeding platform is provided with an eddy current sensor; the stator iron core is provided with a long grating sensor; the excitation winding and the eddy current sensor are connected to a magnetic suspension control system; and thrust winding and the long grating sensor are connected to a feeding control system. The invention adopts the normal magnetic tensile force of the electro-magnetic liner synchronous motor to suspend the feeding platform in order to eliminate friction, thereby having significant meaning for further improving the processing accuracy of the feeding platform of the digital control machine tool.

Owner:SHENYANG POLYTECHNIC UNIV

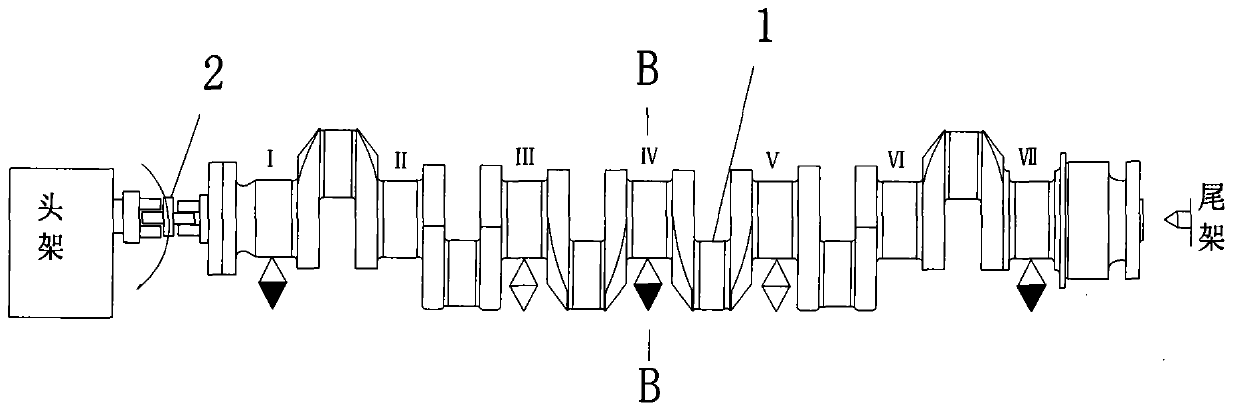

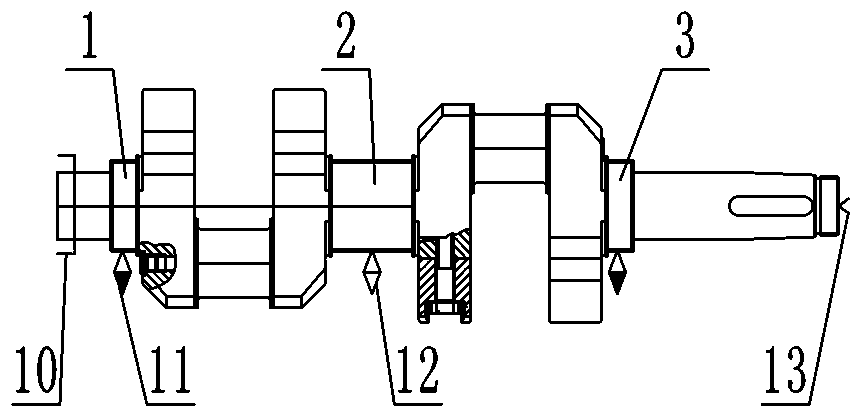

Machining method for grinding main journal of crankshaft in floating mode

InactiveCN103624642AEliminate the effect of precisionEliminate thermal deformationRevolution surface grinding machinesNatural stateEngineering

The invention relates to a machining method for grinding a main journal of a crankshaft in a floating mode. The method sequentially comprises the following steps: S1, clamping; S2, adjusting a bracket support; S3, rough grinding, wherein first rough grinding is conducted on an IV gear main journal through a grinding wheel 3, a bracket at the position corresponding to the IV gear main journal is adjusted while the IV gear main journal is ground, and during adjustment, it is ensured that the bracket is consistent in height, feeding scales of a grinding wheel frame handle are consistent, the practical size of the journal is consistent, and an error of a processing reference supporting gear is within + / -0.005mm; then, rough grinding is conducted on an IIV gear main journal and an I gear main journal, the more three reference supporting gears are ground in a reciprocating mode, the higher the grinding precision of the crankshaft is, and the coaxiality is better; S4, fine grinding, the step of rough grinding is repeated, fine grinding is conducted four to five times, after fine grinding, the main journal D=210mm, and tolerance ranges from 0mm to 0.029mm; S5, the remaining main journal is machined. Floating grinding is adopted in the machining method for grinding the main journal of the crankshaft in the floating mode, namely grinding is conducted on the crankshaft in the natural state, and influence of prestress, heat deformation and precision of a machine tool spindle is eliminated.

Owner:LIYANG CITY RICHWAY MEDIUM SPEED DIESEL ENGINE PARTS

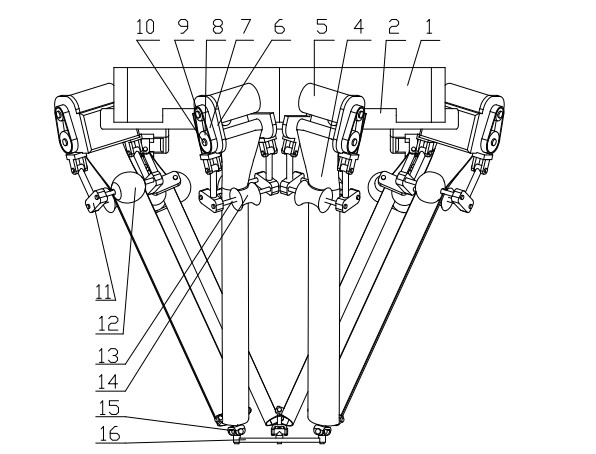

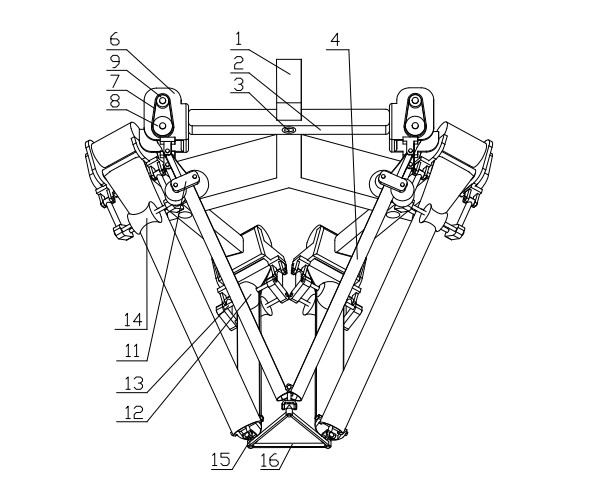

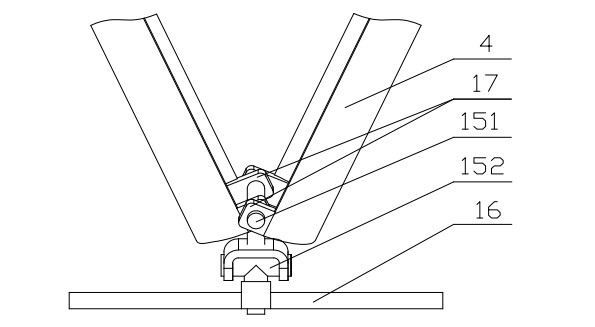

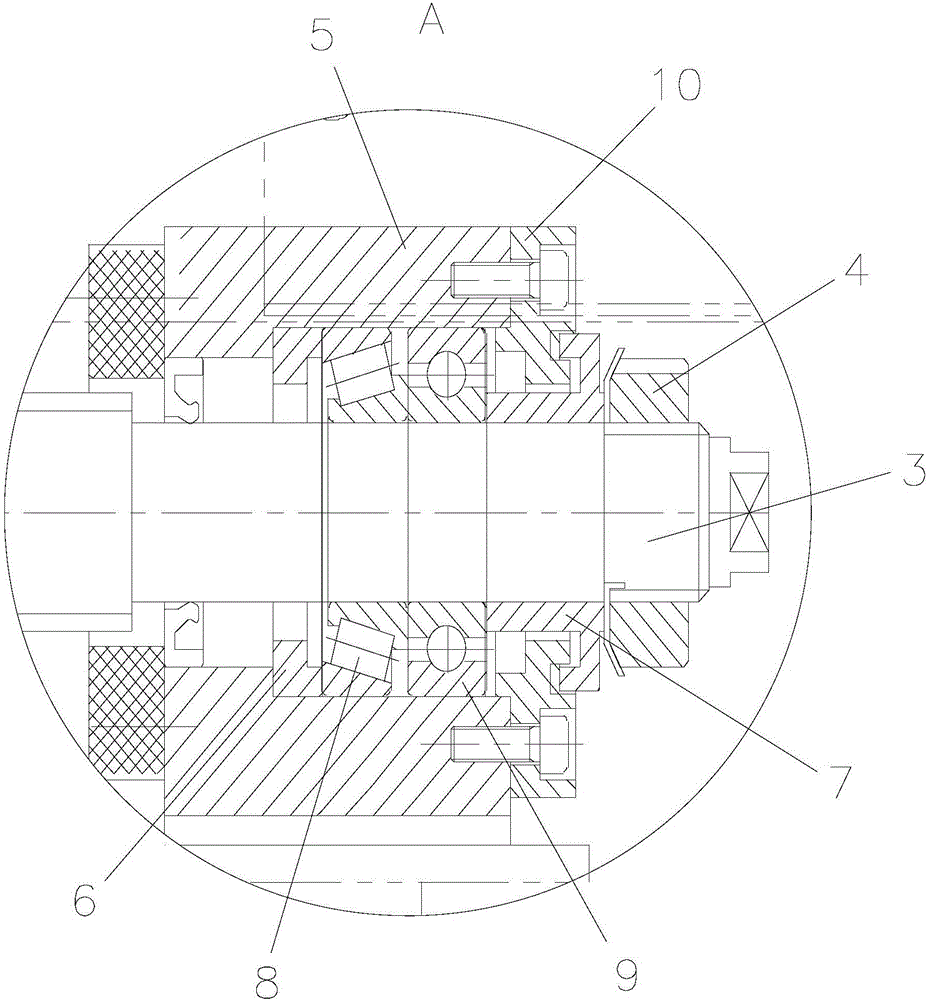

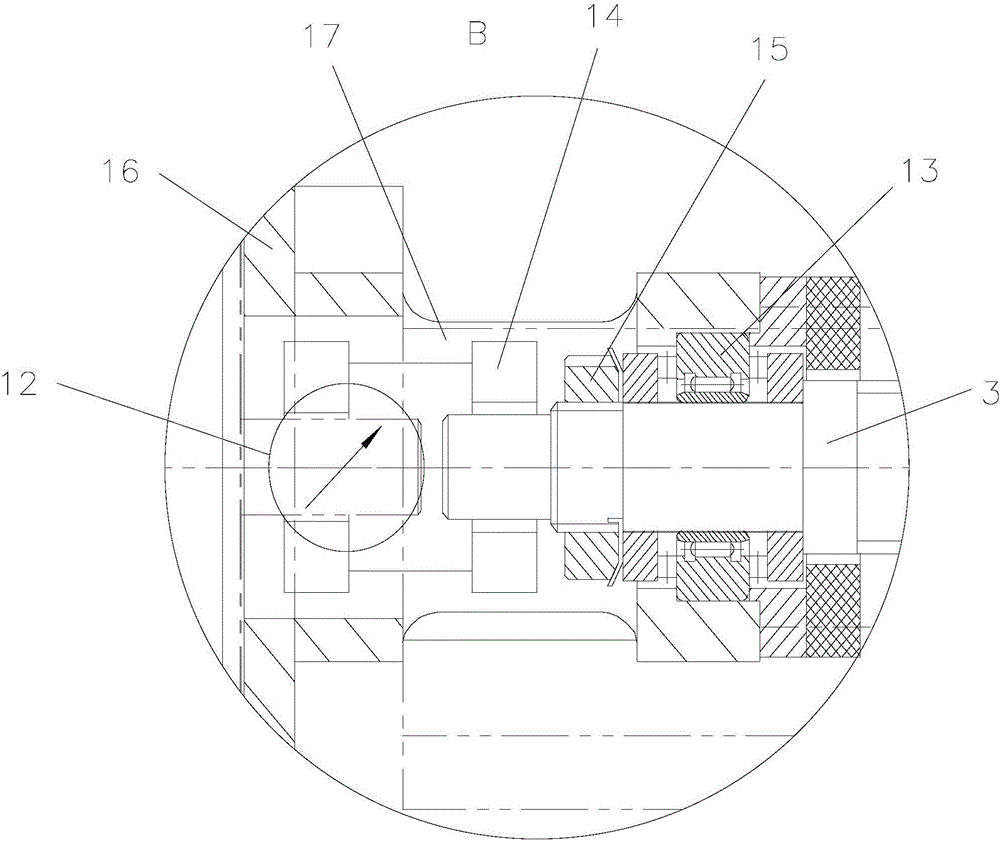

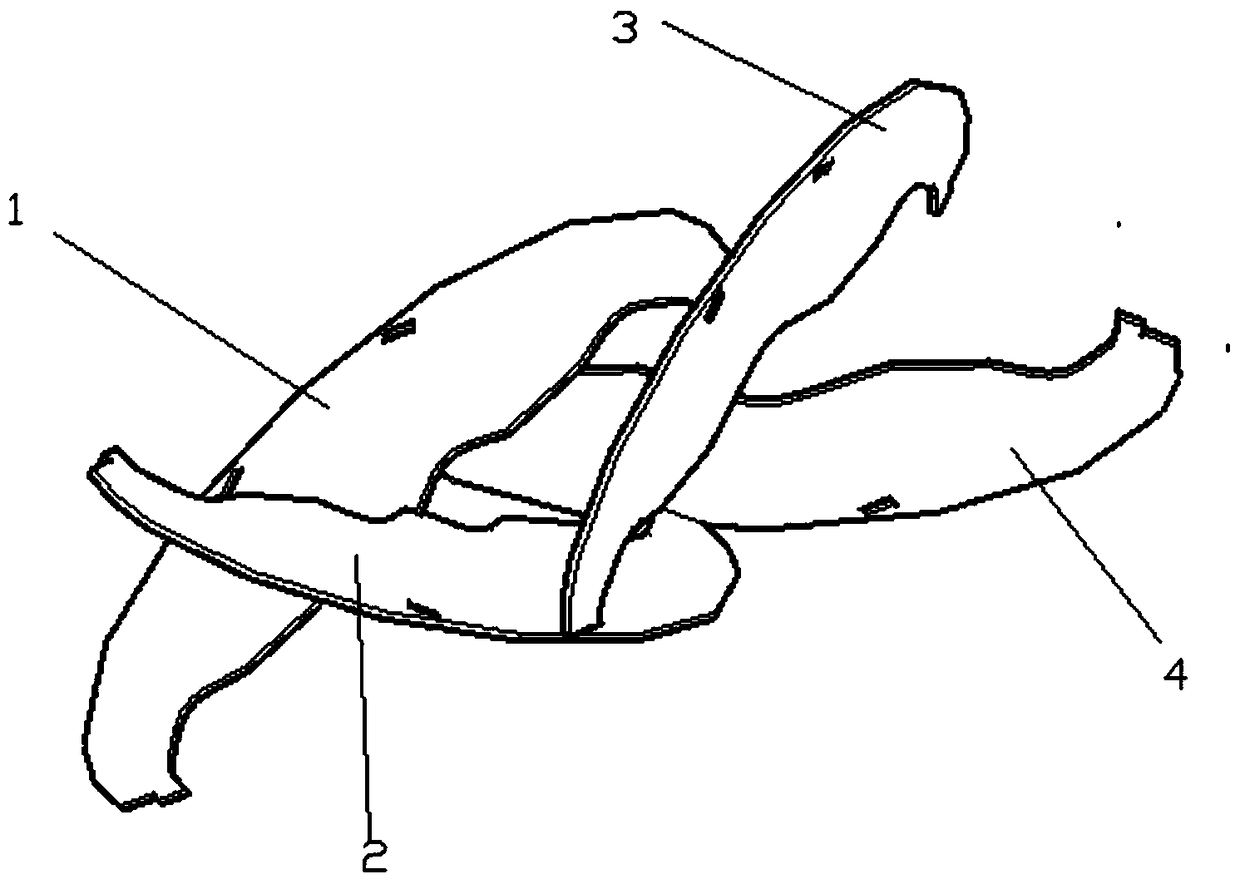

Six-freedom-degree parallel steel belt robot mechanism with roller device

InactiveCN102152301ALarge working spaceEasy to controlProgramme-controlled manipulatorCamMechanical engineering

The invention provides a six-freedom-degree parallel steel belt robot mechanism with a roller device, which comprises a rack. The rack comprises a base, three cross rods are arranged on the base, and the two ends of the cross rods are all connected with movement branch chains. Each of the movement branch chains comprises a motor base connected to the cross rod, the inner side of an end cover of the motor base is provided with a servo motor, a first belt wheel is connected to a rotor of the servo motor, a reel is hinged on the motor base, one end of the reel, which extends out of the motor base, is connected with a second belt wheel, the first belt wheel and the second belt wheel are connected through a belt, a steel belt capable of rotating around the reel is connected to the reel, the lower end of the steel belt is hinged with a composite spherical hinge, and the composite spherical hinge is hinged to a movable platform. A roller device is arranged on the upper end of the steel belt, the roller device comprises a T-shaped bracket connected to the motor base, a convex wheel and a concave wheel are connected to the T-shaped bracket, and the steel belt is extruded and molded through the matching of the convex wheel and the concave wheel which are arranged on the two sides of the steel belt.

Owner:ZHEJIANG UNIV OF TECH

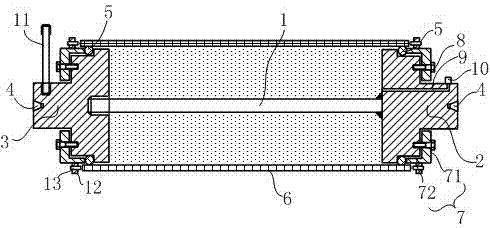

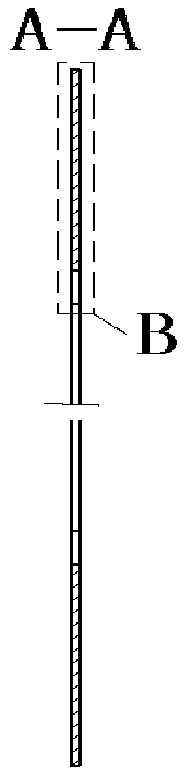

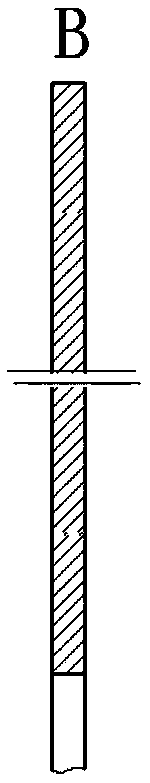

Ultrathin shaft part finish turning clamp

InactiveCN105690125AImprove rigidityAvoid deformationWork clamping meansPositioning apparatusRubber ringThermal deformation

The invention relates to an ultrathin shaft part finish turning clamp which comprises a mandrel. A first flange is fixedly connected with one end of the mandrel, and the other end of the mandrel is in threaded fit with a second flange. Each of the first flange and the second flange comprises three steps of circular truncated cones. A center hole is formed in the end surface of each first step of circular truncated cone. A rubber ring sleeves the circumferential excircle of each second step of circular truncated cone. More than three threaded holes are uniformly formed in the end surface of each second step of circular truncated cone. The external diameter of the circumferential excircle of each third step of circular truncated cone is 1-2 mm smaller than the internal diameter of an ultrathin shaft part. A press plate sleeves each second step of circular truncated cone. Center holes of the press plates sleeve the first steps of circular truncated cones. More than three through holes are uniformly formed in the side wall of each press plate. Bolts pass through the through holes and then are matched with the threaded holes in the end surfaces of the second steps of circular truncated cones so as to enable the outer edges of the side walls of the press plates to be propped against the outer sides of the rubber rings. An oil circuit used for communicating the inner end of the first flange with a nozzle arranged on the circumferential excircle of the first step of circular truncated cone is arranged on the first flange. A shift rod is arranged on the first step of circular truncated cone of the second flange. Compared with the prior art, the ultrathin shaft part finish turning clamp has the advantages that the rigidity of the ultrathin shaft part is enhanced, and the thermal deformation is eliminated.

Owner:YANTAI NANSHAN UNIV

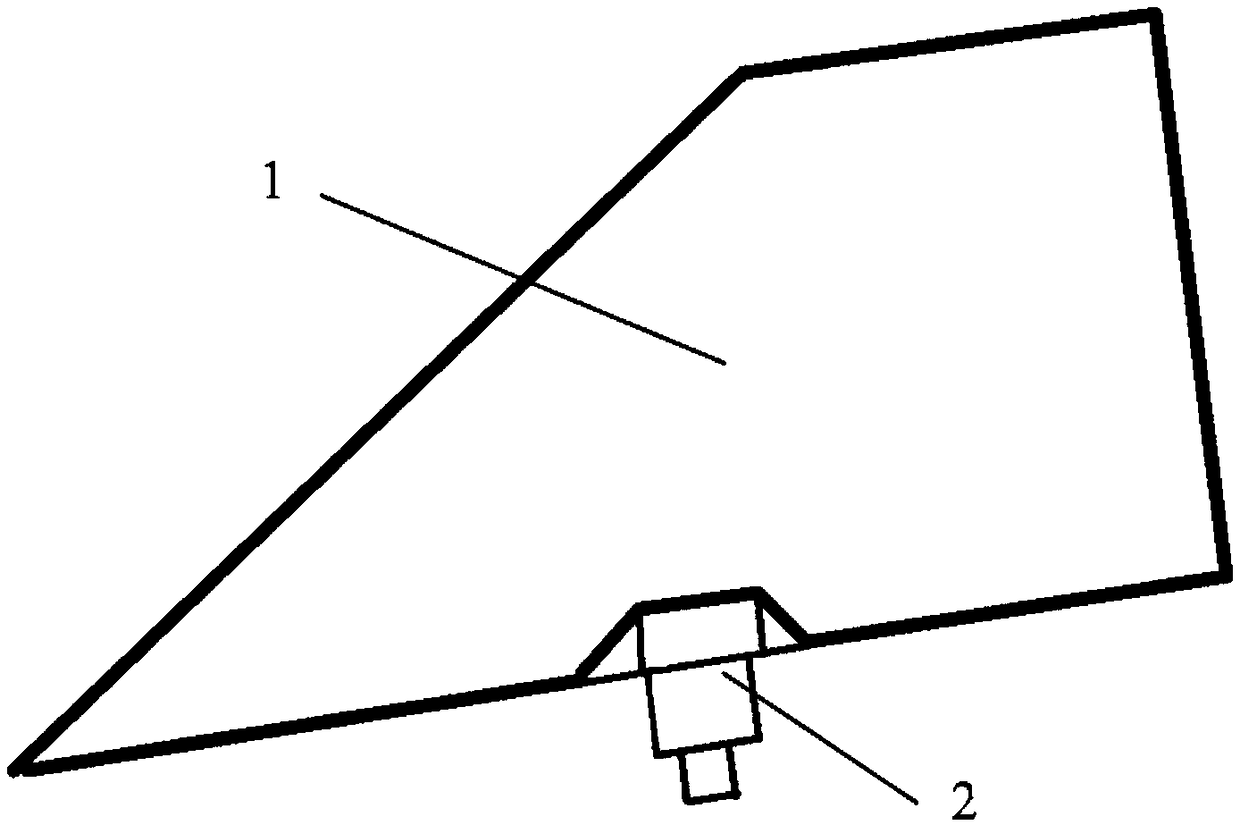

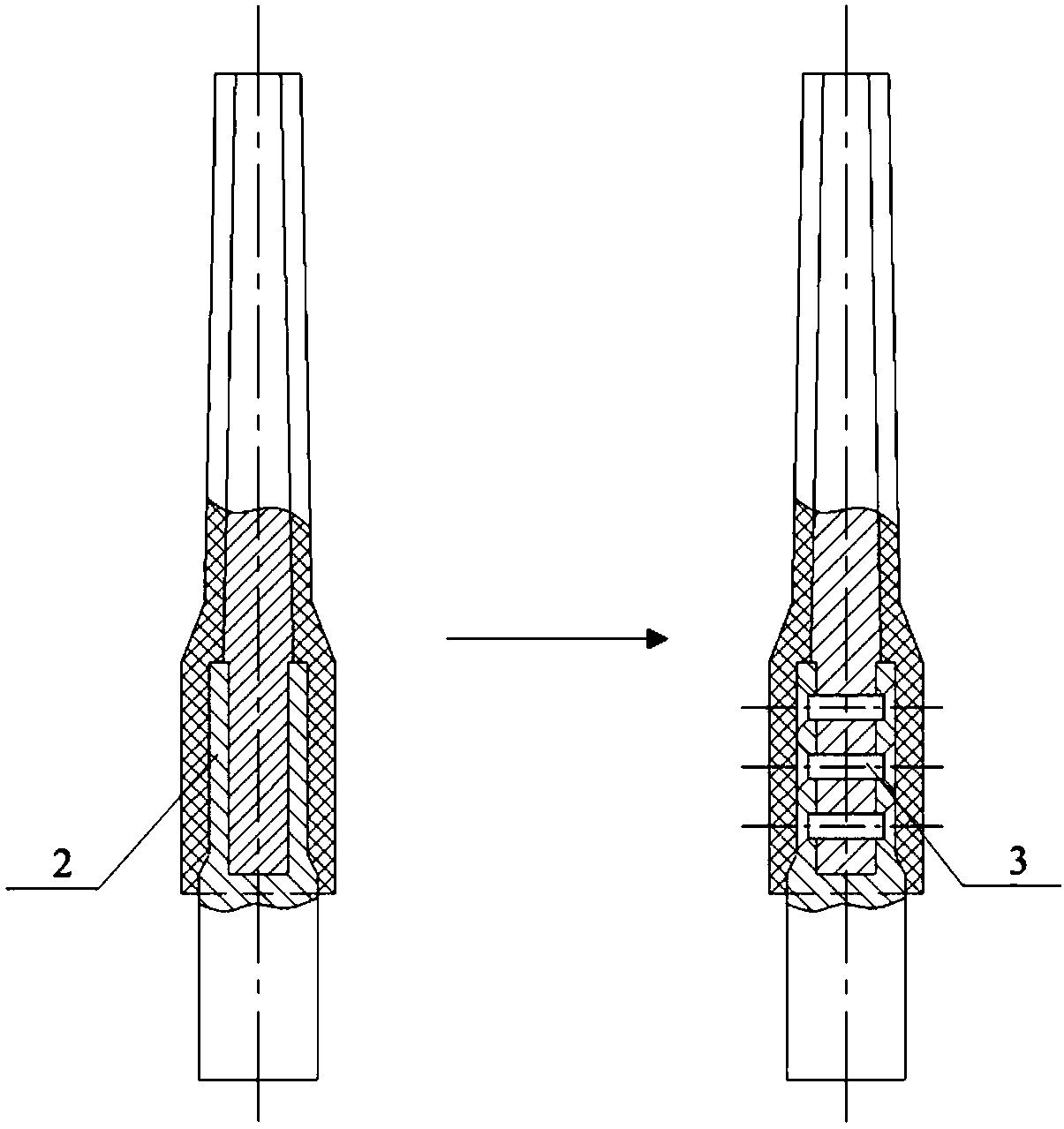

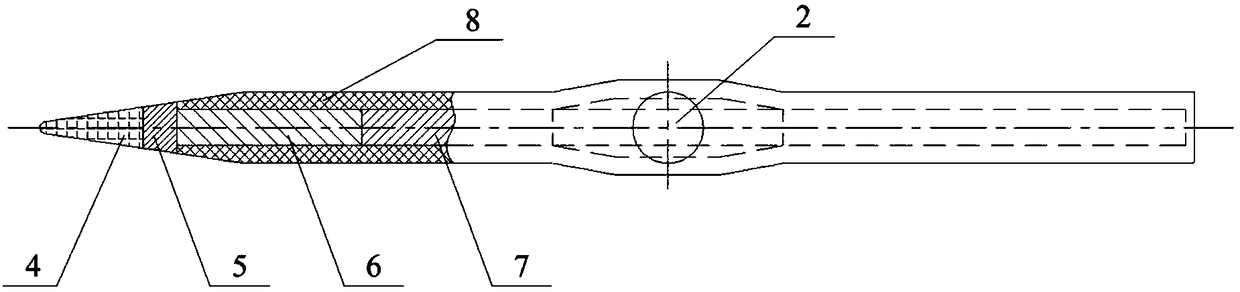

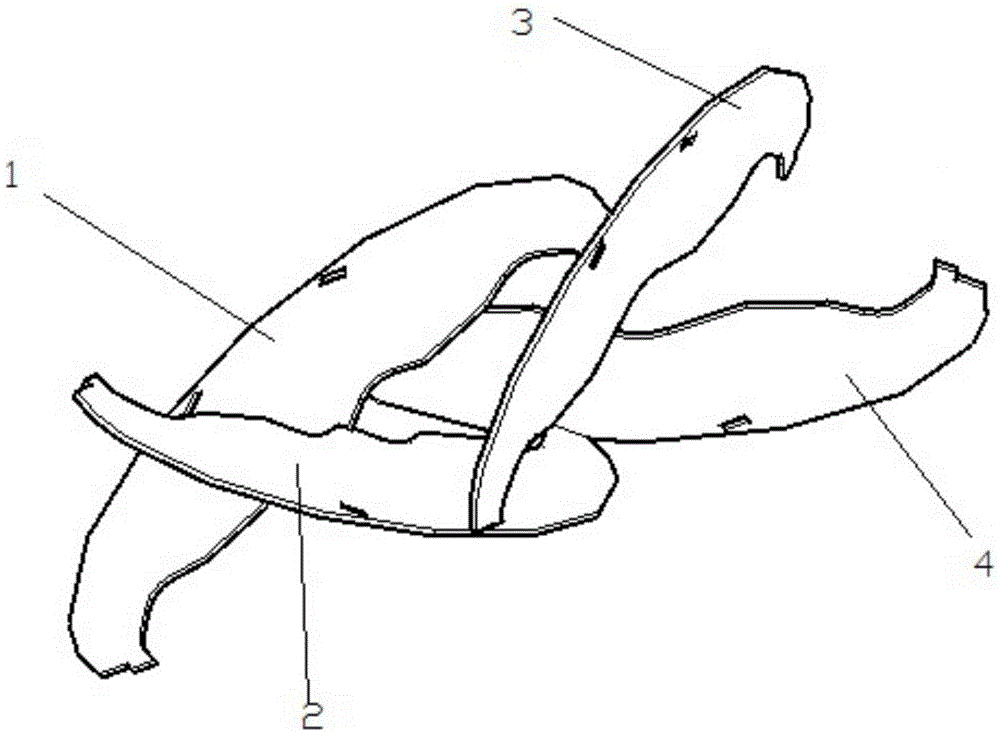

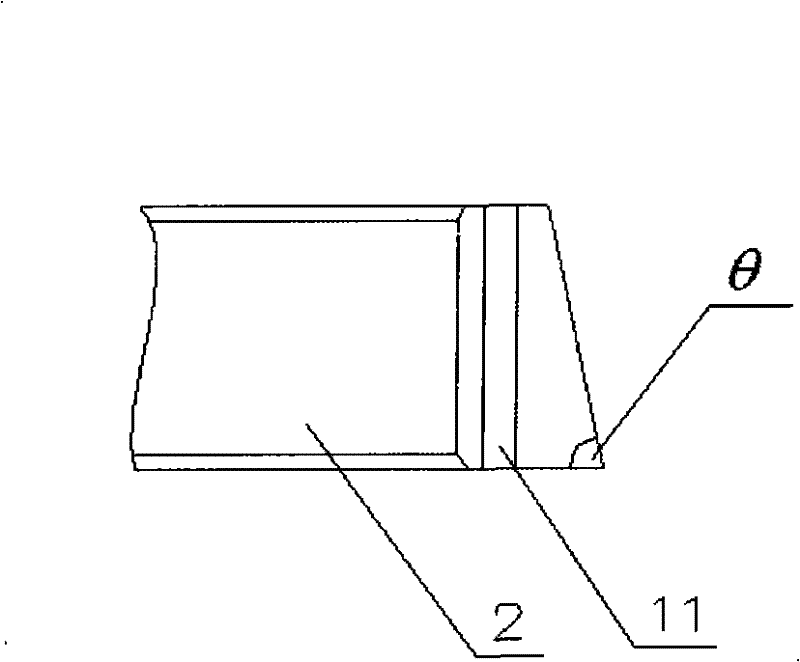

Air steering for a composite structure-

The invention provides an air rudder with a composite structure, which comprises a rudder surface (1) and a rudder shaft (2), wherein the rudder surface (1) and the rudder shaft (2) are connected witheach other through a fastener (3); Wherein the rudder surface (1) comprises a leading edge (4), a rudder core and a heat shield sleeve (8), the rudder core comprises a transition structure, a main structure (7), the transition structure comprises a transition strip (5) and an intermediate (6); The leading edge (4), the transition strip (5), the intermediate body (6) and the main body structure (7) are connected in turn, and the rudder surface (1) is connected with the rudder shaft (2) through the main body structure (7), wherein the intermediate body (6), the main body structure (7) are coated with a heat shield (8), the leading edge (4), the transition strip (5) and the heat shield (8) together constitute the aerodynamic shape of the air rudder. The invention has reasonable structure, adopts a plurality of low-density composite materials, and ensures the structural integrity and reliability of the air rudder under the condition of high-speed and large heat flux flight.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

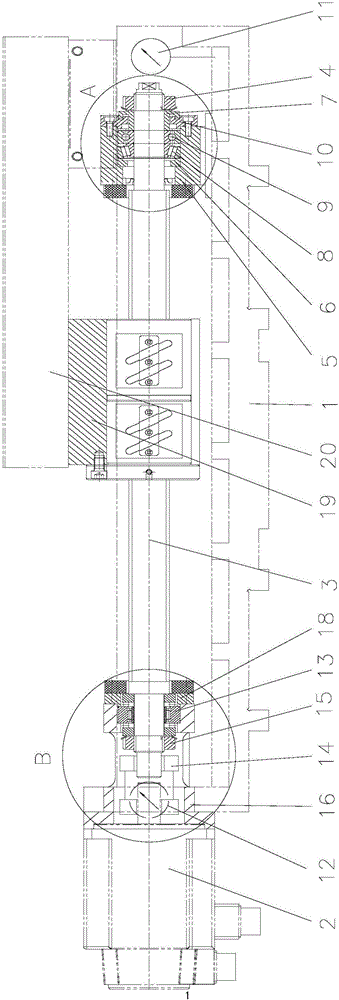

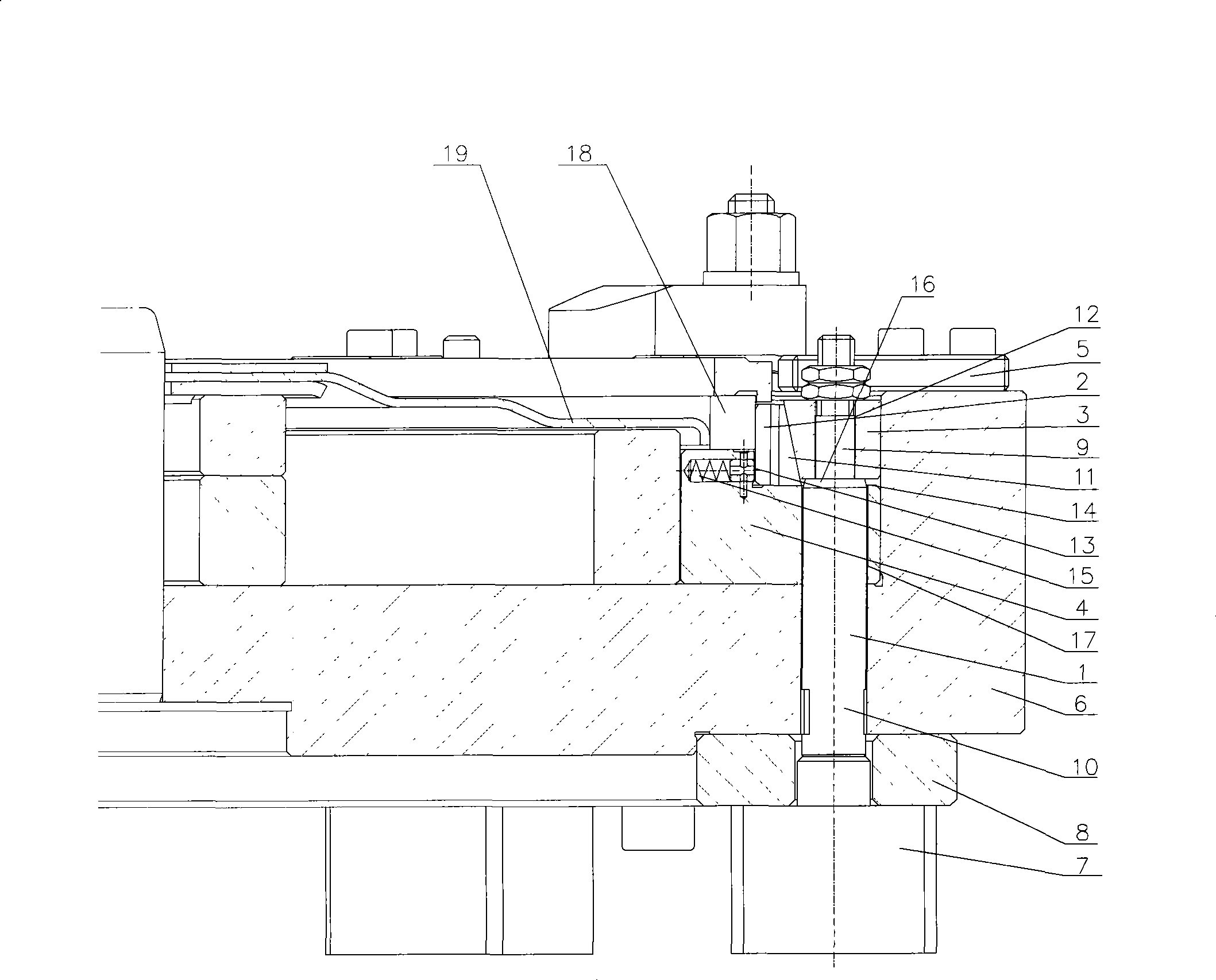

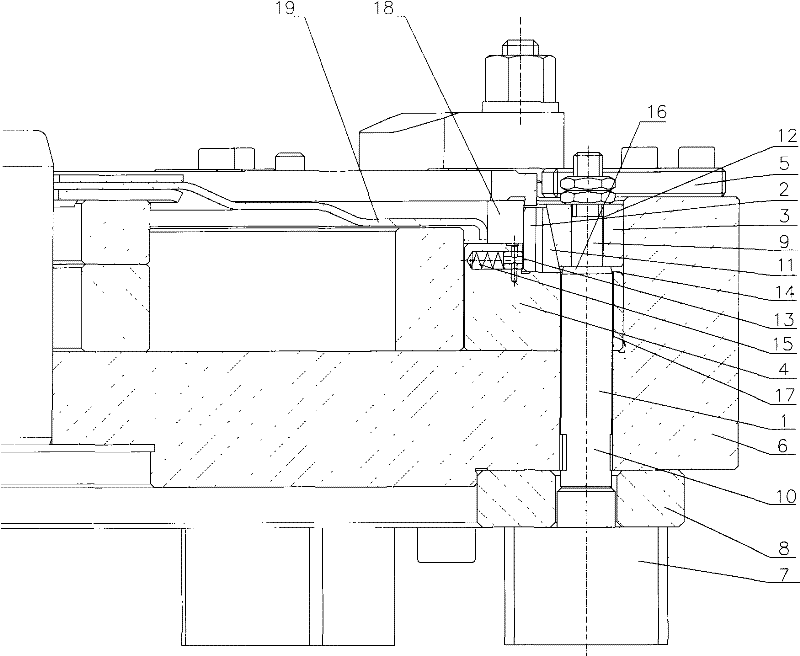

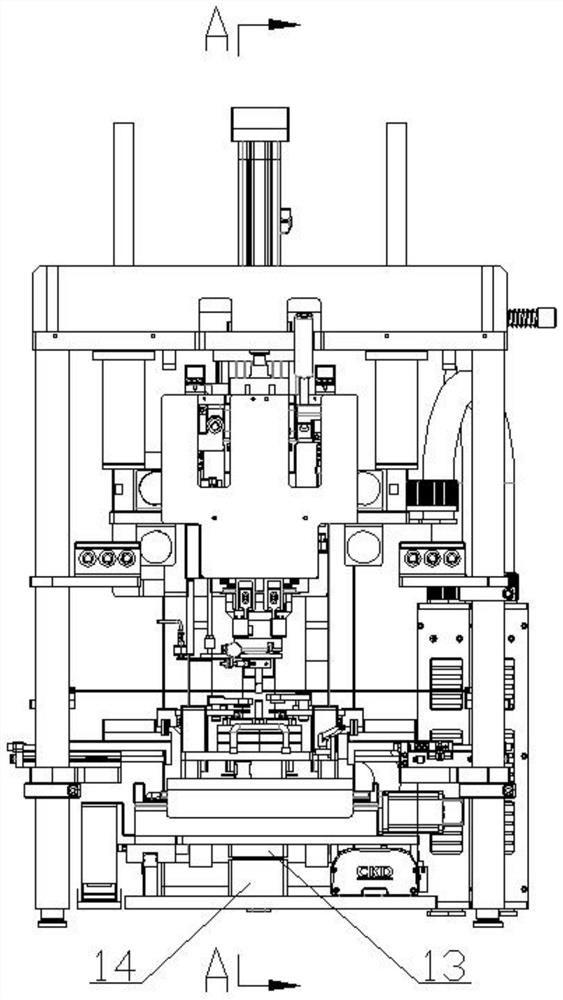

Prestretching structure of numerical control machine tool ball screw pair and method

ActiveCN106624953AEliminate thermal deformationReduce and eliminate impactFeeding apparatusMetal working apparatusNumerical controlBall bearing

The invention relates to a prestretching structure of a numerical control machine tool ball screw pair and a method. A servo feeding motor end ZARN combination bearing is a fixed end; a conical roller bearing and a deep groove ball bearing at the other end form a stretching end; the ball screw pair is prestretched through rotating a nut; the stretching quantity is equal to the difference between the reading number of a dial indicator at the stretching end and a dial indicator at the fixed end, so that the heat deformation of a lead screw in operation is eliminated beforehand, and the influence on the precision of a machine tool by the heat deformation of the machine tool is reduced and eliminated; and as the support rigidity of a ball screw mechanism is improved, the operation precision, the stability of a transmission system and the vibration resistance are improved, and the life is prolonged.

Owner:常州铸鼎机械有限公司

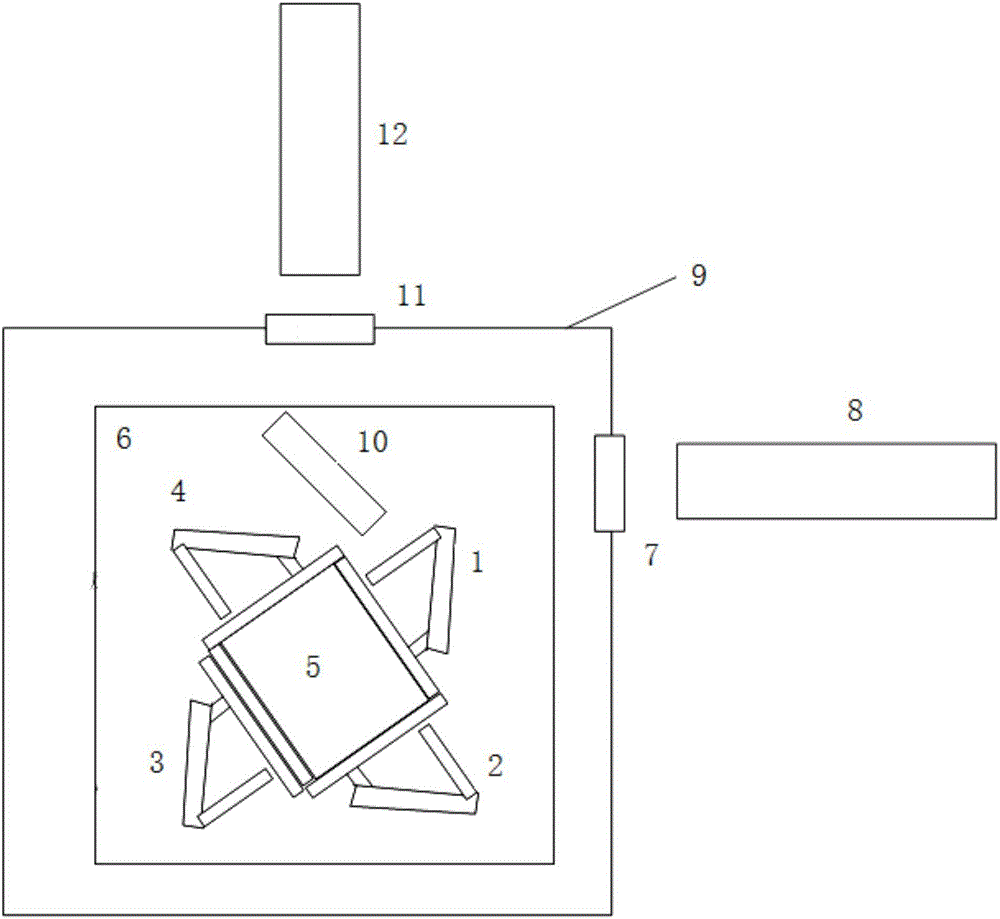

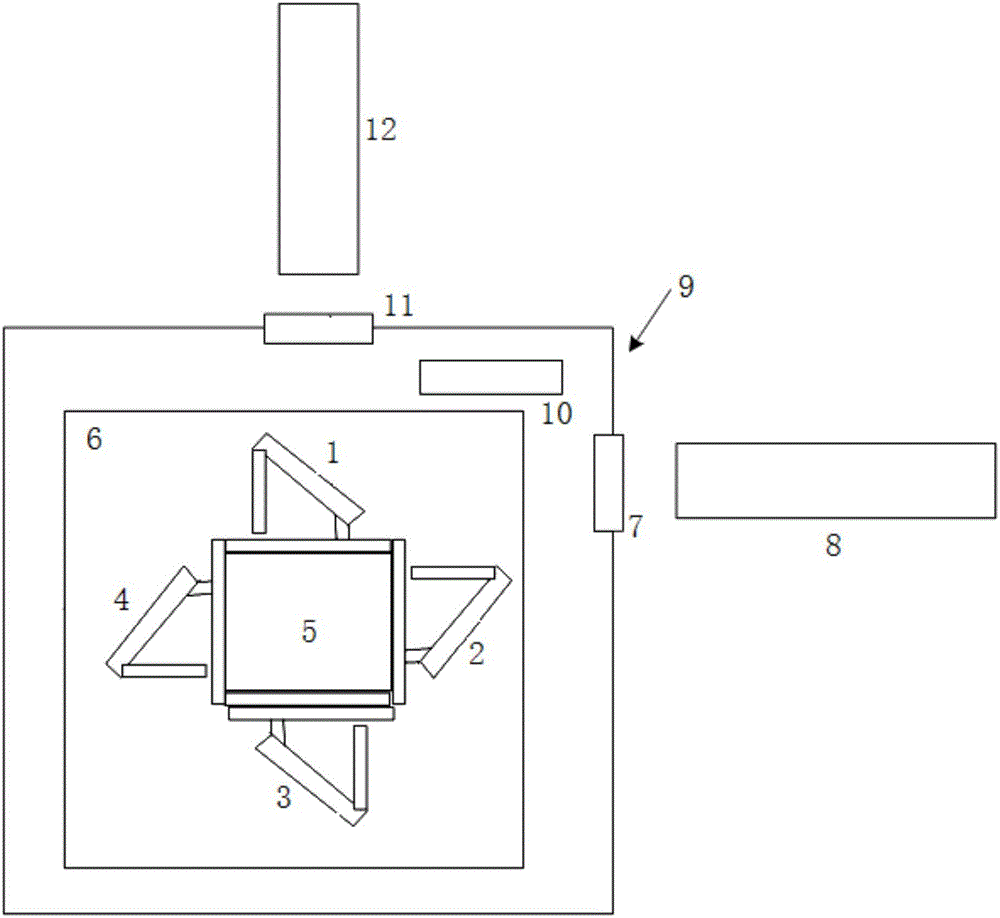

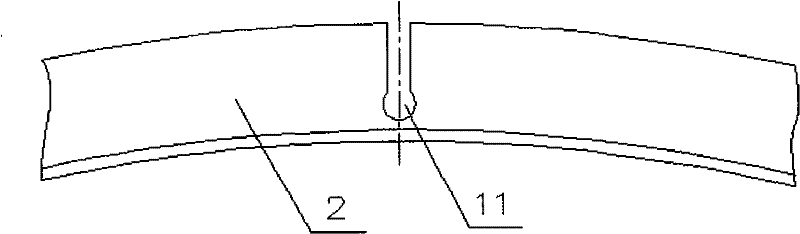

Device and method for testing resolution of reflector

ActiveCN106768885AConsistent temperatureEliminate thermal deformationReflective surface testingTesting optical propertiesImage resolutionThermal deformation

The invention relates to a device and method for testing resolution of a reflector. The tested reflector is placed in a high-and-low-temperature box, and is heated or cooled to a target temperature, parallel light which is transmitted by a collimator penetrates through a light window of the high-and-low-temperature box, the measured reflector and an optical window and enters a front mirror, the front mirror is used for observing a resolution ratio target plate image of the collimator, and the resolution ratio of the reflector is measured at different temperatures. In addition, a surface of the optical window is positioned in the high-and-low-temperature box while another surface of the optical window is positioned out of the high-and-low-temperature box, when the high-and-low-temperature box works at different temperatures, the temperatures of the inner surface and the outer surface of the optical window are not consistent, parameter thermal deformation can be caused, measurement precision can be affected, and even the high-and-low-temperature box cannot be used completely. In order to guarantee measurement precision, heating films are plated on the inner surface and the outer surface of the optical window, the temperatures of the two surfaces of the optical window are consistent, and the thermal deformation is eliminated.

Owner:中航洛阳光电技术有限公司

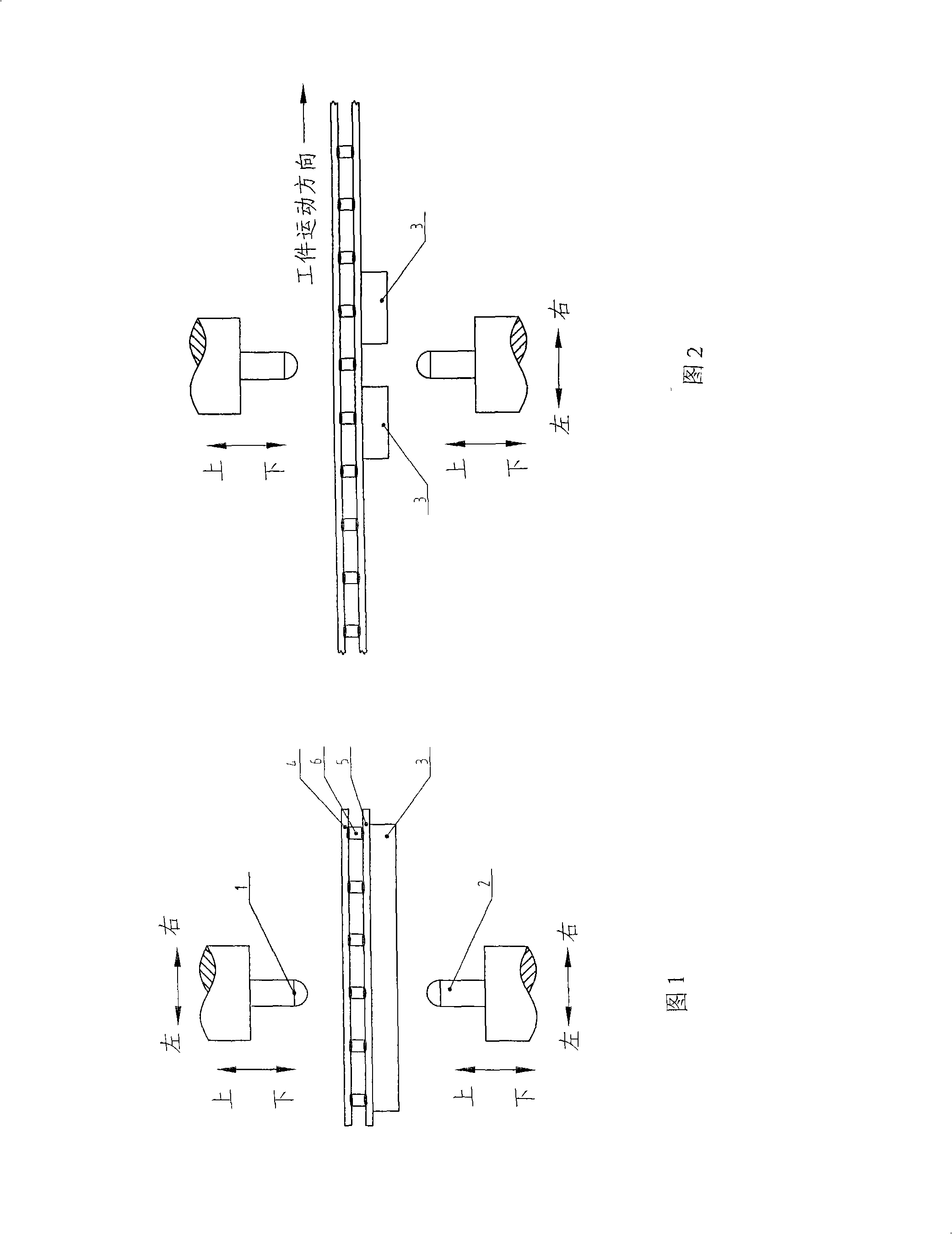

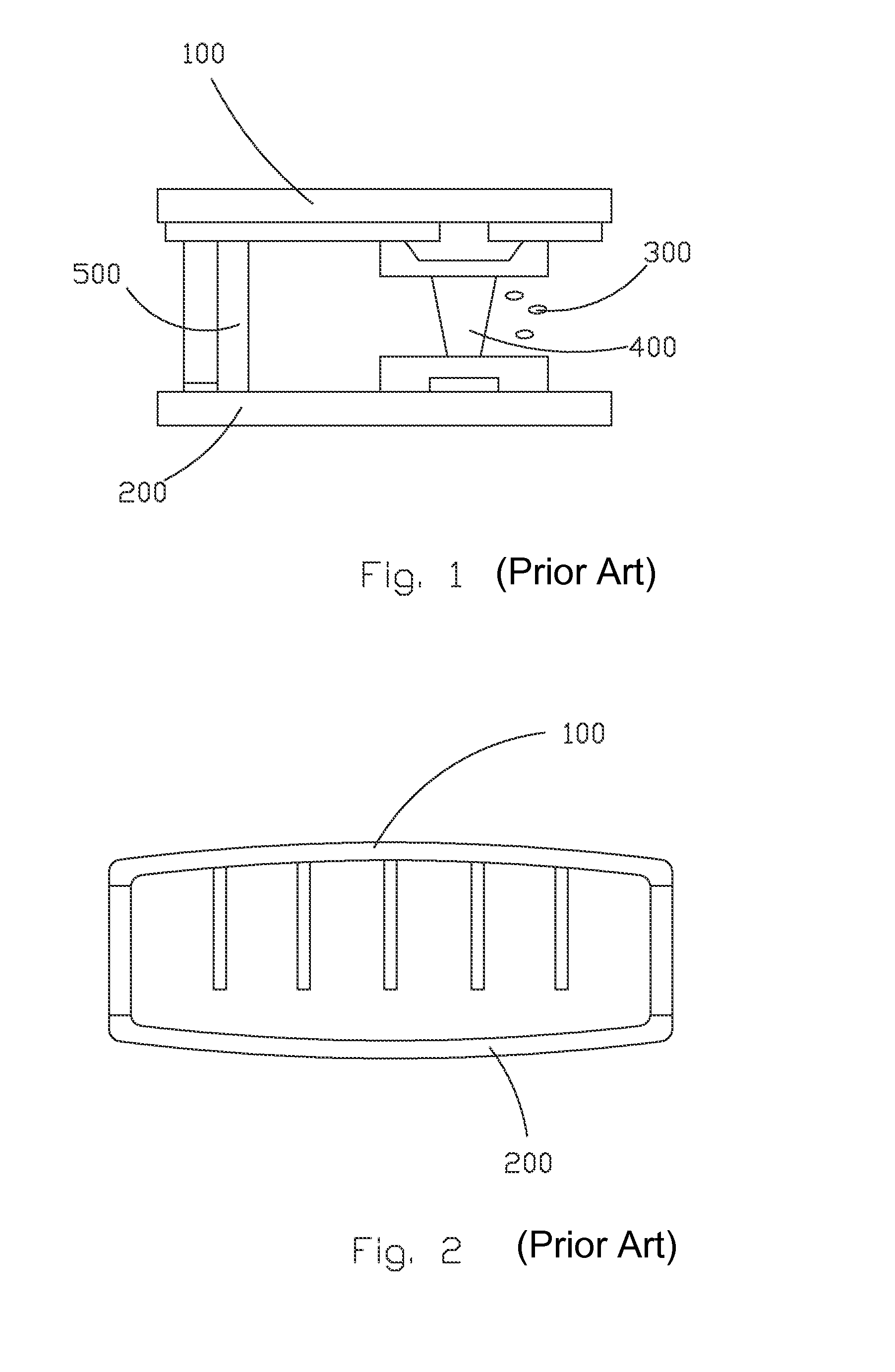

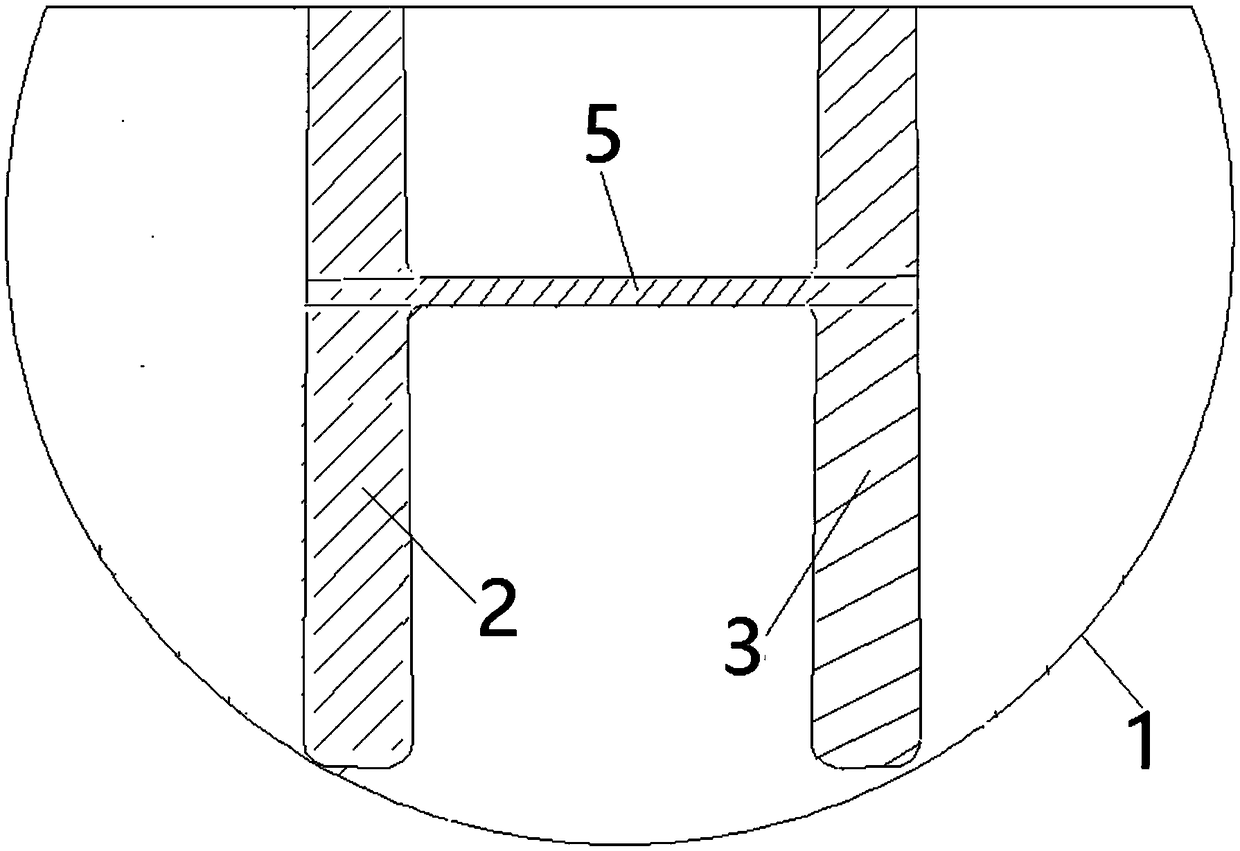

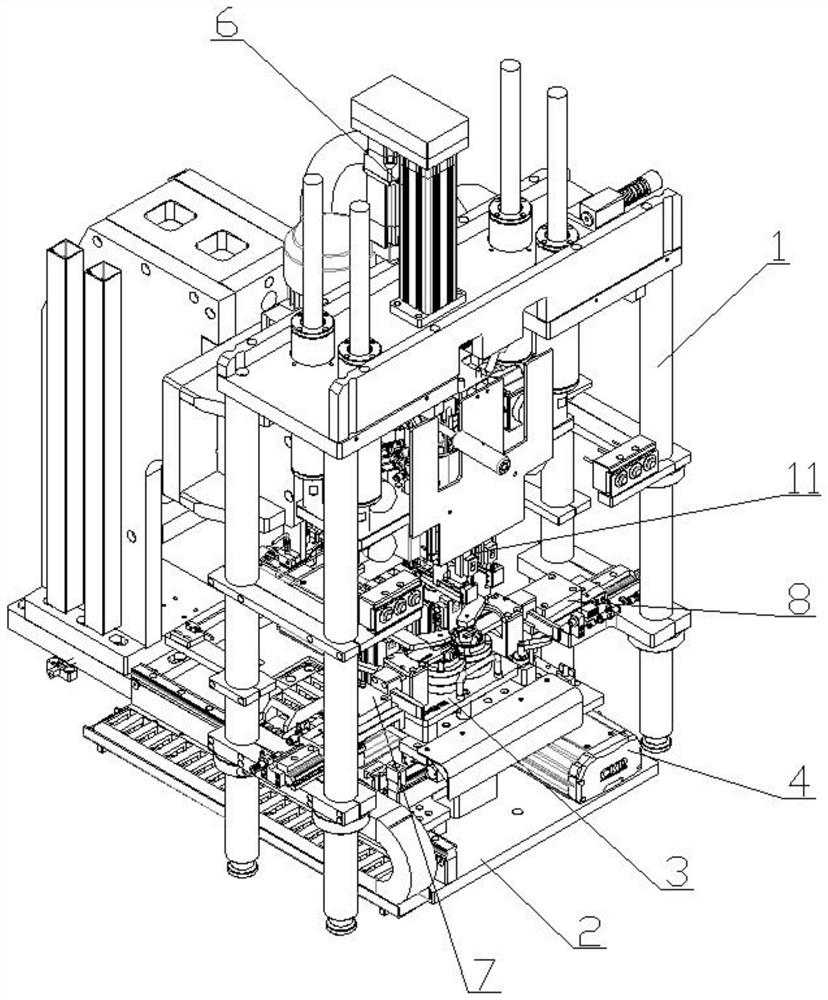

Apparatus for welding and positioning flywheel assembly

ActiveCN101474735AEliminate thermal deformationReduce the overall heightWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyEngineering

The invention relates to a welding and positioning device for a flywheel assembly in the technical field of motorcar part manufacture, comprising air cylinder connecting pieces, a limit piece, a clamp base, an inner gripping sleeve, an outer gripping sleeve and a positioning ring, wherein the inner gripping sleeve and the outer gripping sleeve are respectively arranged on the upper brim of the positioning ring, the limit piece is sheathed on the inner brim of the clamp base, and a plurality of the air cylinder connecting pieces respectively run through the outer gripping sleeve, the positioning ring and the clamp base in order; and the upper and the lower ends of the air cylinder connecting pieces are respectively fixedly connected with the limit piece and a welding air cylinder, and the outer brim of the inner gripping sleeve is matched with the inner brim of the outer gripping sleeve. Aiming at solving the disadvantages of the prior art, the device changes the mode of clamping positioning to greatly eliminate the thermal distortion of a gear ring and effectively reduce the outside diameter jumpiness height and the end face jumpiness height of the flywheel assembly which needs to be welded, thus compared with the prior art, the welding efficiency is increased by 11 percent.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

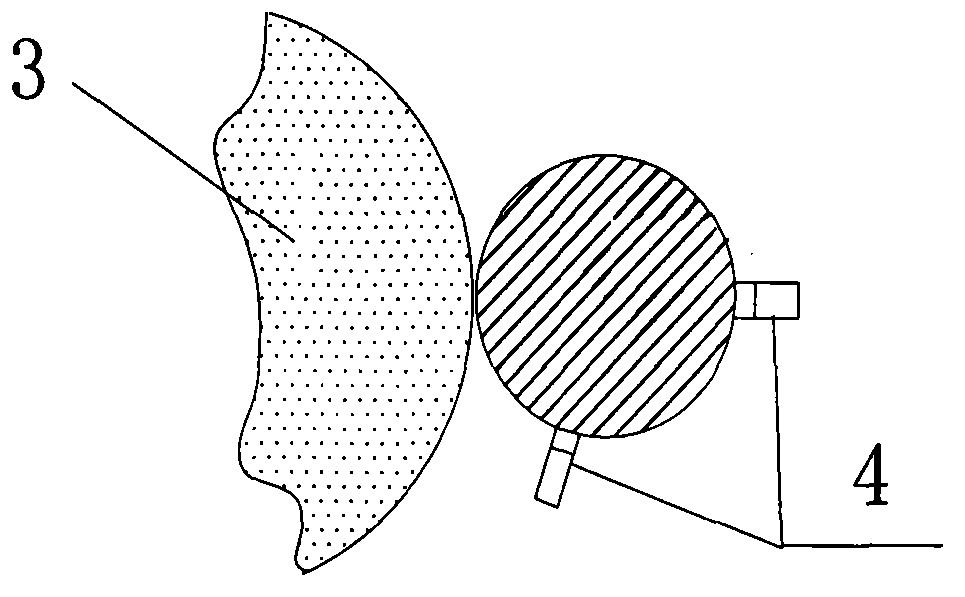

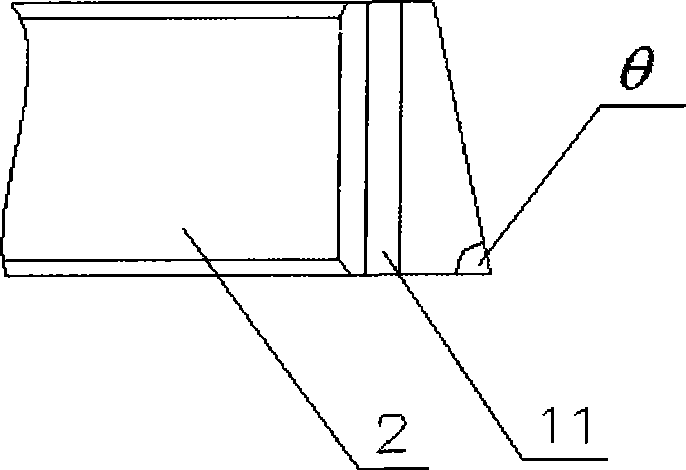

Face-down bonding technique capable of preventing electric resistance welding parts from deforming

InactiveCN101337304AEliminate thermal and mechanical distortionImprove product qualityResistance welding apparatusElectricityThermal deformation

The invention discloses a reverse welding technology for preventing the deformation of a resistance welding workpiece, which comprises the following steps: first, a workpiece platform (3) is mounted under the workpiece; then plank stuff (4 and 5) is arranged on the plane of the platform (3); after a welding pin (6) is mounted and positioned, an upper electrode (1) is pressed first to press the plank stuff (4 and 5) on the workpiece platform; then a lower electrode (2) rises to support the workpiece tightly; the electrodes (1 and 2) discharge electricity to perform welding; during the discharge of electricity, the welding pin (6) in the formed return circuit serves as both a workpiece and an electrode; during welding, the wind direction of axial blowers arranged in advance on the upper and the lower surfaces of the plank stuff (4 and 5) is aimed at the welding position and the direction of the welded plank stuff; the wind, which is mainly aimed at the welding position, is blown constantly to perform wind cooling to the welding point. The reserve welding technology for preventing the deformation of the resistance welding workpiece is mainly used for solving the problem of the deformation of workpieces with relatively large areas when resistance welding is used, thus eradicating the thermal deformation and the mechanical deformation of the workpieces, ensuring the planeness of the workpieces and improving product quality.

Owner:瞿虹

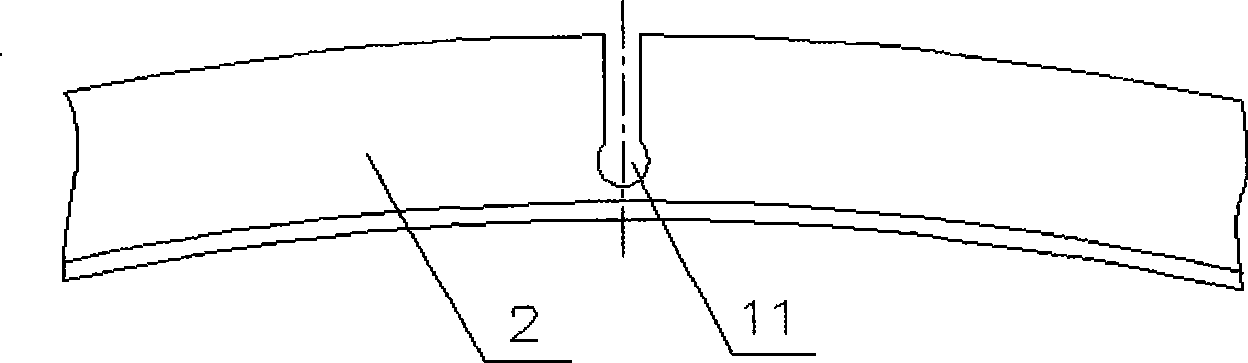

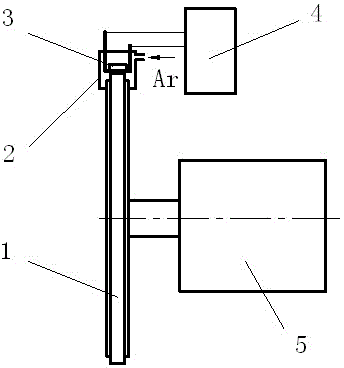

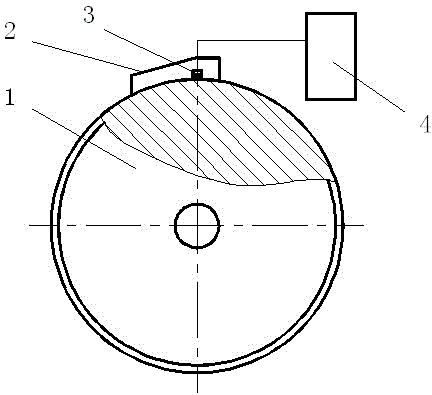

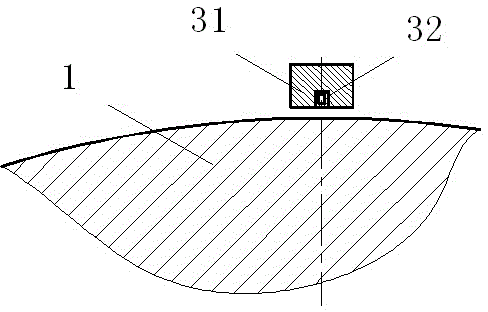

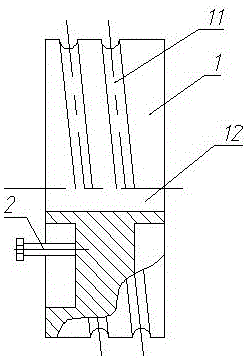

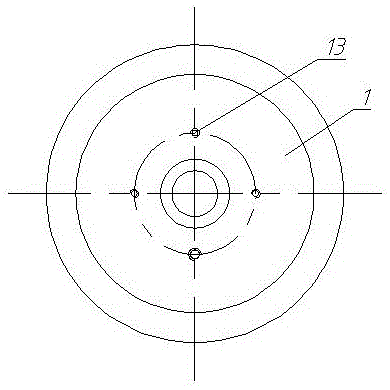

Diamond grinding wheel induction brazing device and brazing method

ActiveCN102974910BFast heatingShort manufacturing cycleMetal working apparatusSoldering auxillary devicesSurface layerThermal deformation

The invention discloses a diamond grinding wheel sensing brazing device and a brazing method. The brazing device comprises a sensing power source and a sensing coil which is electrically connected with the sensing power source. The brazing device further comprises a grinding turning wheel which fixes a diamond grinding wheel base body, the sensing coil is arranged on the outer periphery of the diamond grinding wheel base body and distributed in point shape, and a gas protective cover is arranged outside the sensing coil. The gas protective cover is connected with an inert gas source. The diamond grinding wheel sensing brazing solves the problems that brazing technology in an existing vacuum furnace is long in brazing period, thermal deformation of the grinding wheel base body is large and the like. A heating area is concentrated on the surface layer of the grinding wheel base body, so that the diamond grinding wheel sensing brazing device can effectively eliminate thermal deformation of the grinding wheel base body, and is beneficial to being applied to high-efficiency precise grinding machining of a single-layer brazing diamond grinding wheel. Secondly, temperature of the surface of the base body can quickly rise to brazing temperature. Finally, manufacturing period of a diamond grinding wheel is shortened greatly, and brazing efficiency is improved.

Owner:江苏航浦国创复材研究院有限公司

Winding length counter wheel of winding machine

InactiveCN105070415AAvoid mutual contactEliminate thermal deformationUsing optical meansCable/conductor manufactureWinding machineEngineering

The invention discloses a winding length counter wheel of a winding machine. The winding length counter wheel comprises a counter wheel and a screw; the outer cylindrical surface of the counter wheel is provided with a spiral groove; the spiral groove is semicircular; the radius of the spiral groove ranges from 3 to 8mm; the axial spacing of the spiral groove ranges from 15 to 20mm; the lead angle of the spiral groove ranges from 6 degrees to 8 degrees; a bearing hole is formed in the counter wheel; four screw holes which are separated from each other by the same angle are formed in a side surface at one end of the counter wheel; and the screw is arranged in one of the screw holes. With the winding length counter wheel of the winding machine of the invention adopted, various kinds of defects brought about by the unreasonable structure of an existing counter wheel can be eliminated.

Owner:潘琴丽

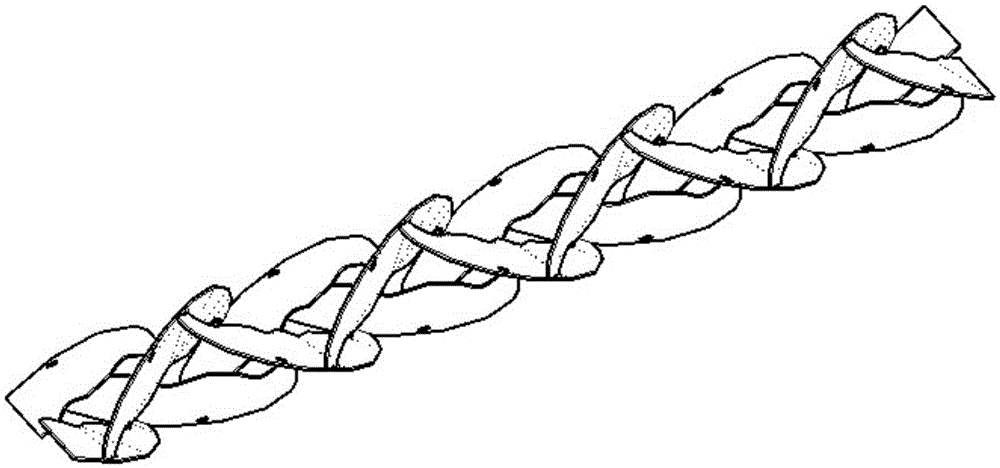

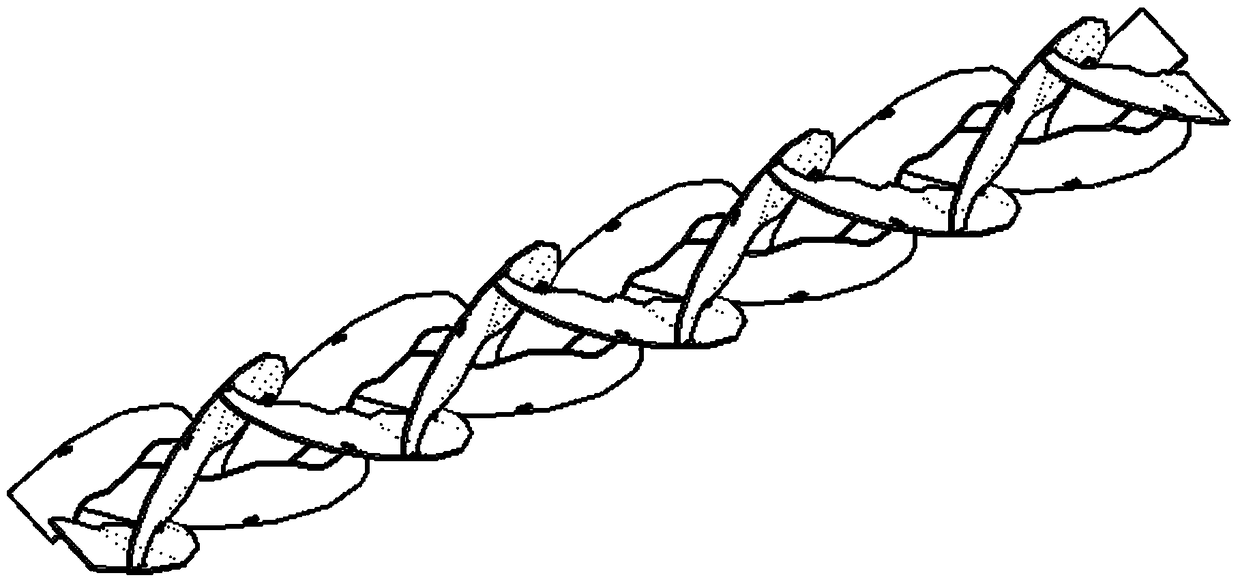

Large-sized static mixer

ActiveCN105642145AImprove mixing efficiencyAdd spoilersFlow mixersTransportation and packagingEngineeringStatic mixer

The invention provides a large-sized static mixer. The large-sized static mixer comprises a pipeline and a mixing unit arranged in the pipeline, wherein openings are formed in two ends of the pipeline; the mixing unit comprises a first blade, a second blade, a third blade and a fourth blade which are of a circular arc sheet shape; the first blade and the second blade are arranged in an opposite crossing manner, the axis of the crossing point is level, the first blade forms a downward deflection angle around the axis of the crossing point, and the second blade forms an upward deflection angle around the axis of the crossing point; the third blade and the fourth blade are arranged in an opposite crossing manner, the axis of the crossing point is vertical, the third blade forms a right deflection angle around the axis of the crossing point, and the fourth blade forms a left deflection angle around the axis of the crossing point; the rear end of the first blade is connected with the plate surface of the third blade, the rear end of the second blade is connected with the plate surface of the fourth blade, the front end of the third blade is connected with the plate surface of the second blade, and the front end of the fourth blade is connected with the plate surface of the first blade. By virtue of a special blade combination manner, the integral structural strength of the mixer is enhanced, and by virtue of a reasonable integral structure, the mixer has excellent mixing efficiency.

Owner:GUANGZHOU BATONG MIXER CO LTD

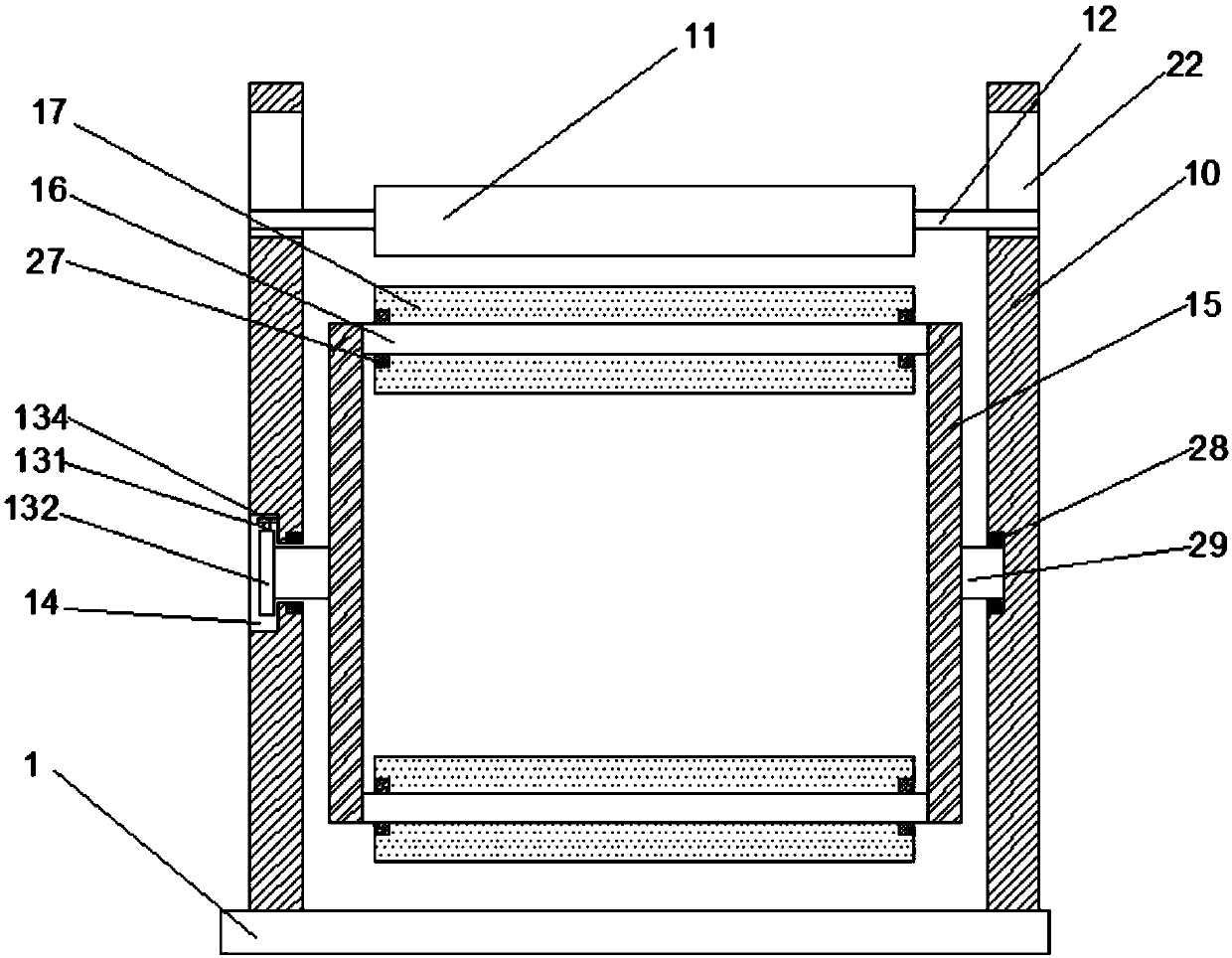

Magnetic levitation motion stage provided with controllable excitation linear synchronous motors and used for vertical machining center

InactiveCN105500032ASimple platform structureImprove reliabilityFeeding apparatusLarge fixed membersStatorControl system

The invention provides a magnetic levitation motion stage provided with controllable excitation linear synchronous motors and used for a vertical machining center. The magnetic levitation motion stage is characterized in that the magnetic levitation motion stage comprises a motion stage, a base, the controllable excitation linear synchronous motors, a levitation control system and a motion control system. The magnetic levitation motion stage has the advantages and effects that the electromagnetic thrust force is changed by adjusting the current of armature windings; the magnetic levitation forces are the unilateral magnetic pull generated between excitation magnetic poles on stators and rotor iron cores of the linear synchronous motors and are adjusted by adjusting the exciting current; the motion stage depends on the magnetic levitation forces generated by the two motors to operate and has the capacity of direct automatic levitation.

Owner:SHENYANG POLYTECHNIC UNIV

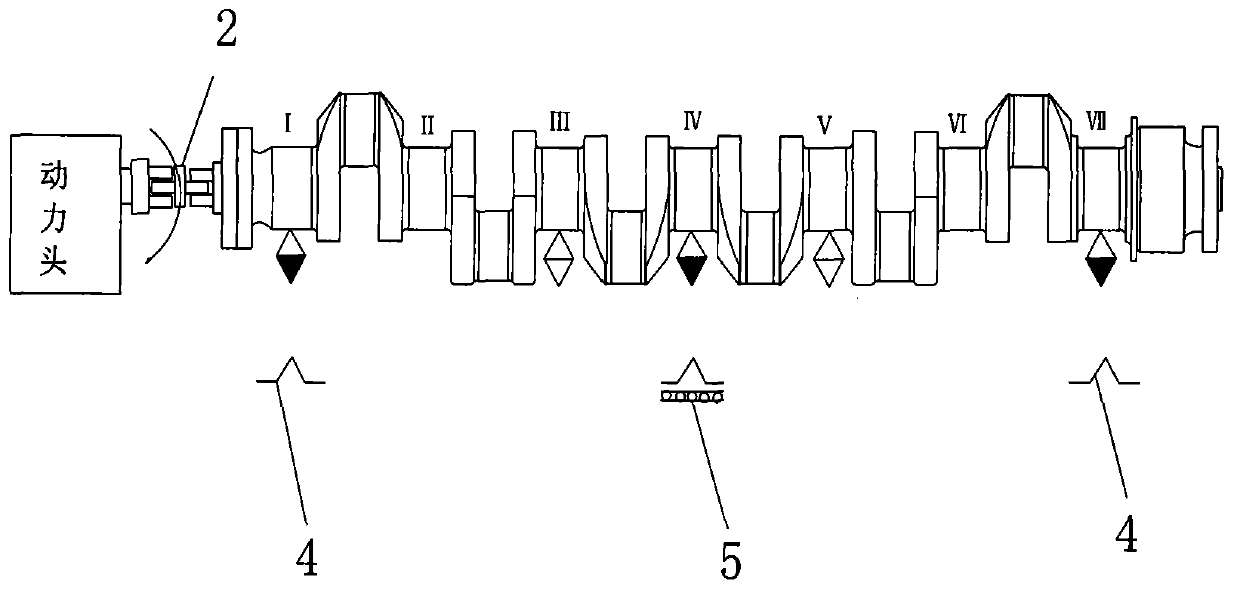

Crankshaft and main shaft neck grinding method

InactiveCN107617931AEliminate the impact of jacking force and thermal deformation and the accuracy of the machine tool spindleImprove machining accuracyGrinding machinesEngineeringMachine tool

The invention discloses a crankshaft and main shaft neck grinding method. The method comprises the following steps: (A) firstly, a tip hole is grinded; (B) a main shaft of a machine tool is flexibly connected with a crankshaft through a universal coupling; and the other end of the crankshaft butts against the tip of a tail frame of the machine tool; (C) a middle main shaft neck is used as a reference support position; and after adjustment, the tail frame is loosened; (D) the middle main shaft neck is roughly grinded by using a grinding wheel, so that a grinding quantity of 0.1-0.12 mm is formed between the size of the middle main shaft neck in the reference support position and the middle main shaft neck of a finished crankshaft; (E) the step (D) is repeated; multiple times of fine grinding are repeated; and the middle main shaft neck is grinded to the size of the middle main shaft neck of the finished crankshaft; and (F) main shaft necks in two bearing positions are grinded to reach the size of the main shaft neck in the bearing position of the finished crankshaft to finish the operation; and when the main shaft necks in the two bearing positions are grinded, a bracket is used onthe middle main shaft neck. Compared with the prior art, the method can solve the problem of weak fine grinding of traditional crankshaft and main shaft neck coaxiality.

Owner:卢丽

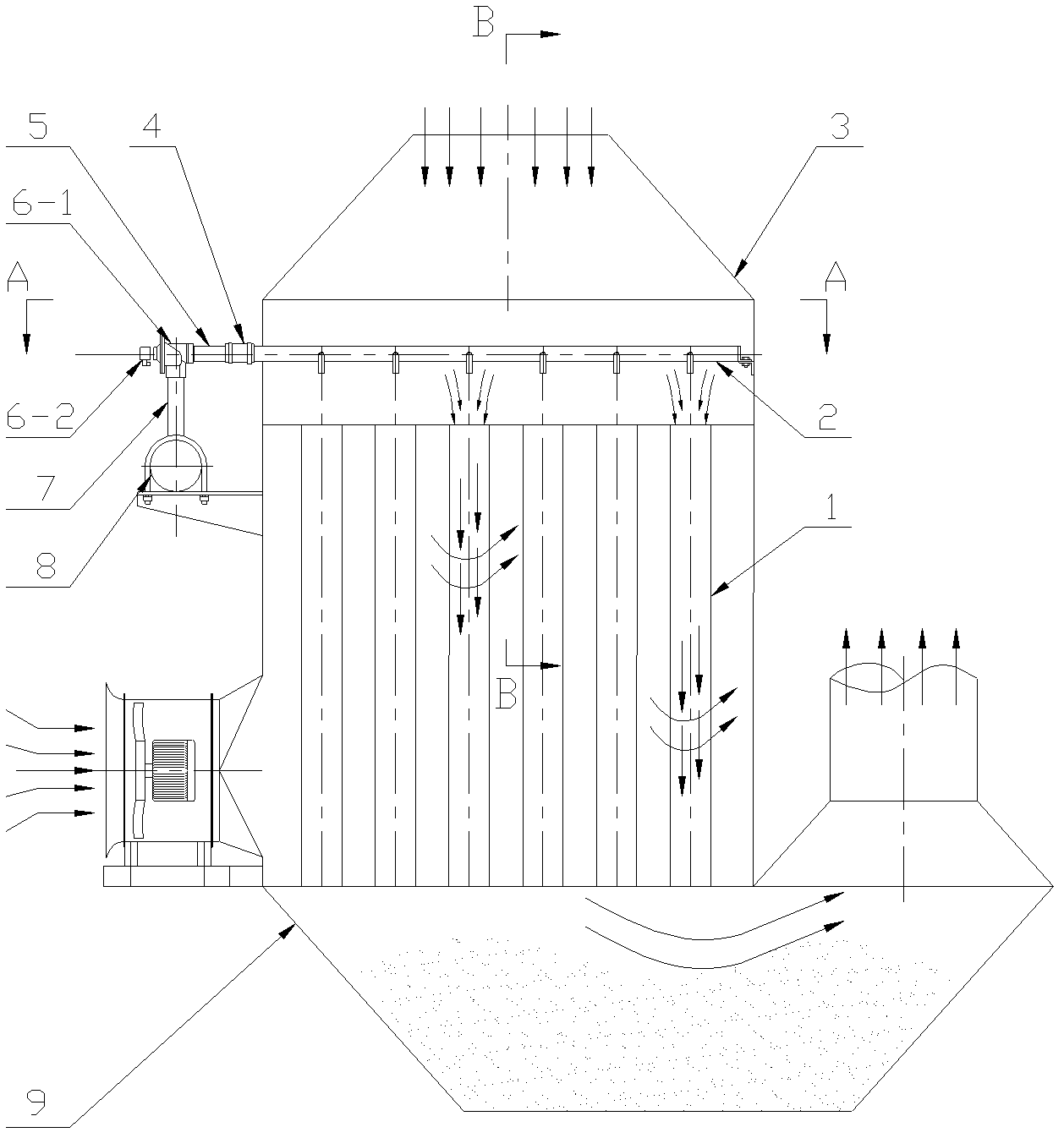

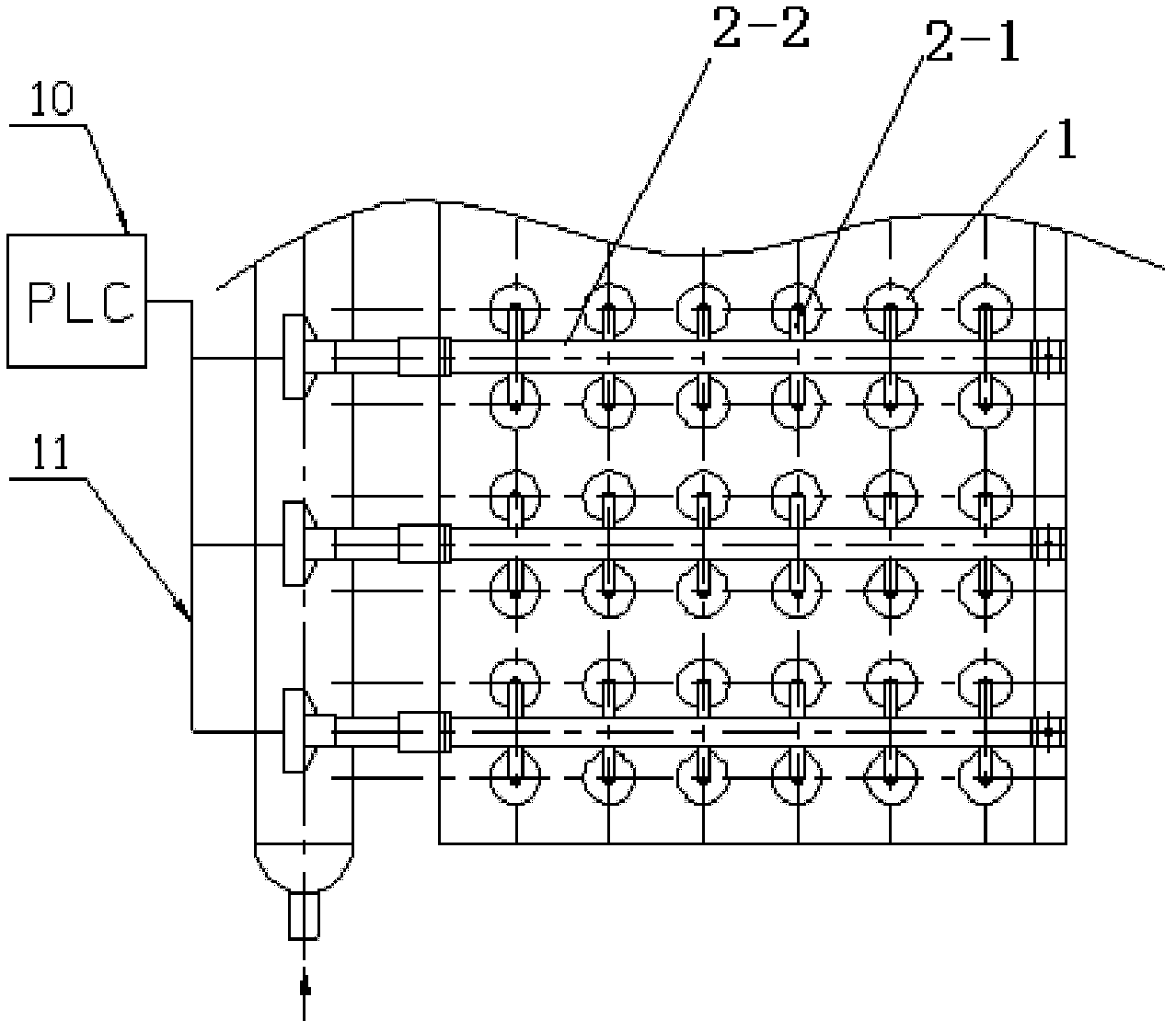

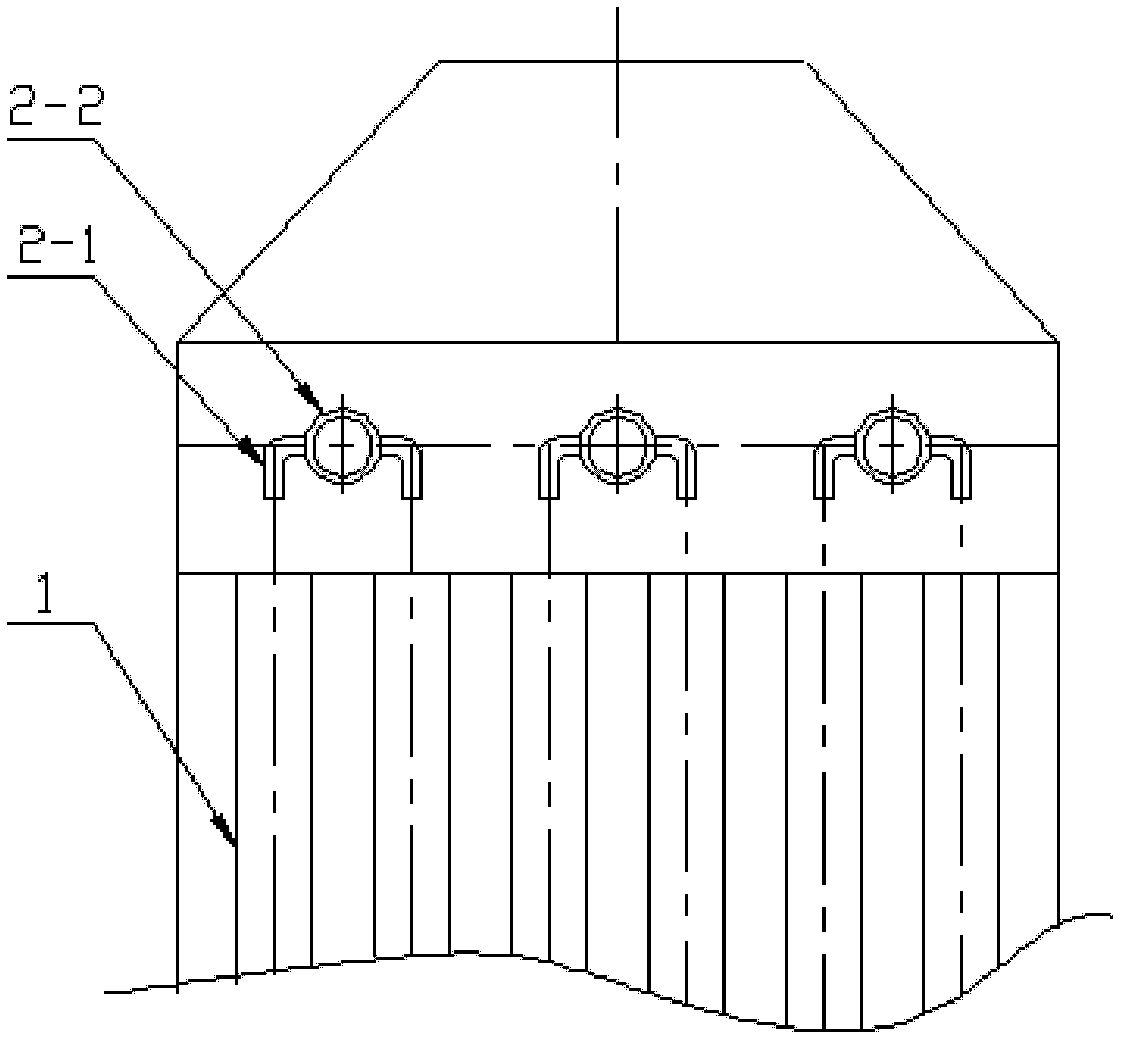

Tube bundle type cooler soot deposit cleaning device

The invention discloses a tube bundle type cooler soot deposit cleaning device which comprises a cooler machine body, wherein a plurality of rows of cooling tubes are arranged in the cooler machine body; a jetting tube is fixed above a space between the two rows of cooling tubes; each jetting tube is provided with a nozzle which is corresponding to the position of the tube mouth on the top of the corresponding cooling tube one by one; and one end of the jetting tube extends out of the cooler machine body and is communicated with an air supply system. The tube bundle type cooler soot deposit cleaning device has the advantages of simple structure, small energy consumption and low cost, is convenient to install and use and is convenient to operate and maintain, and instant expansion generated when air is compressed is used for impacting the soot deposit, raise the dust and take away the dust so as to prevent generation of scales.

Owner:合肥中亚环保科技有限公司

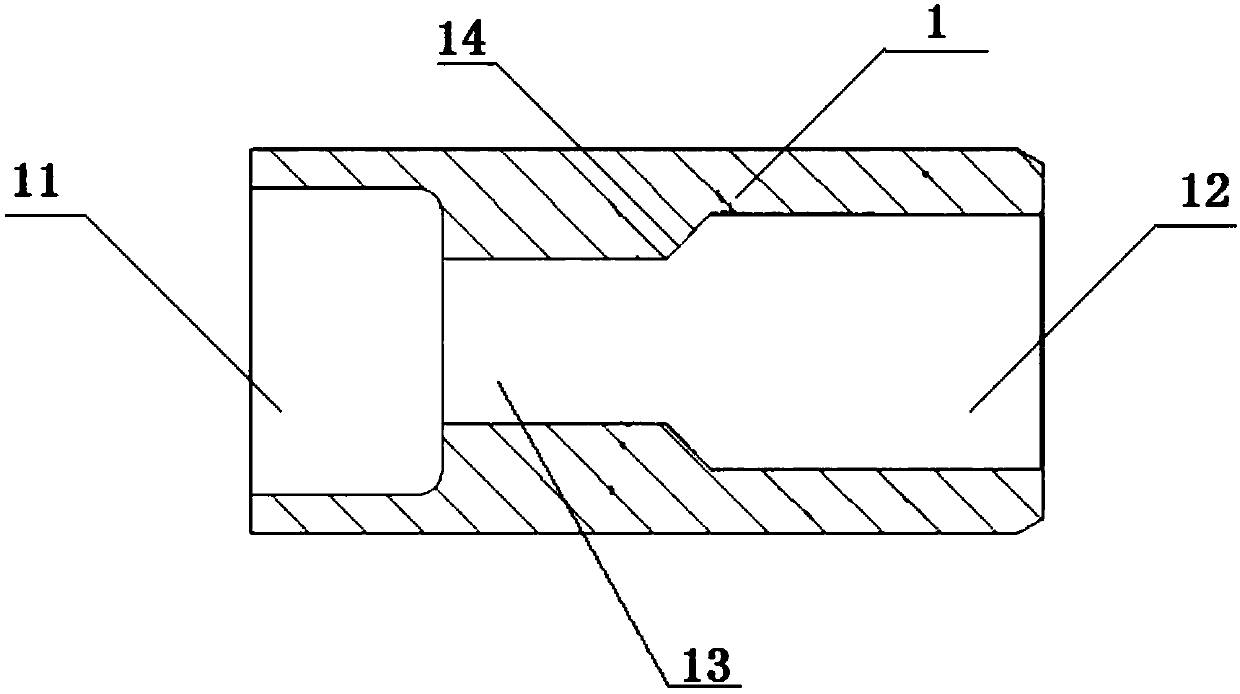

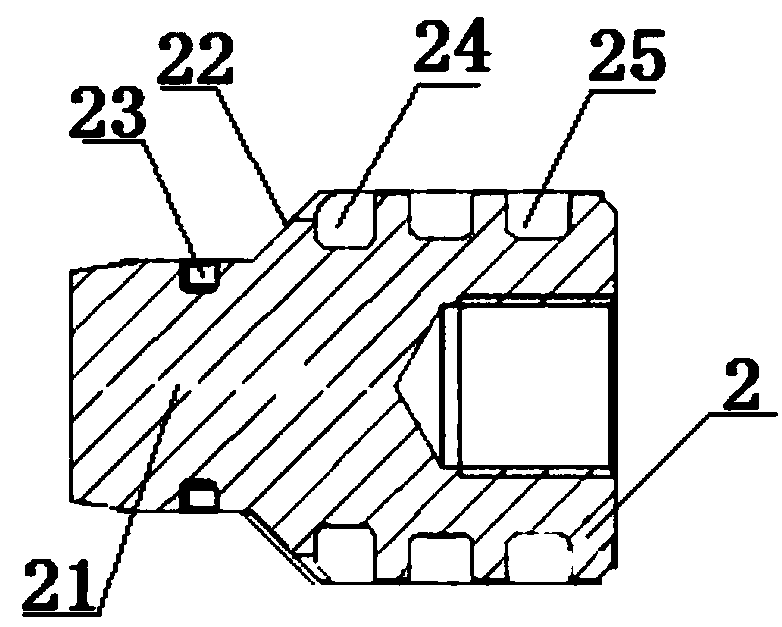

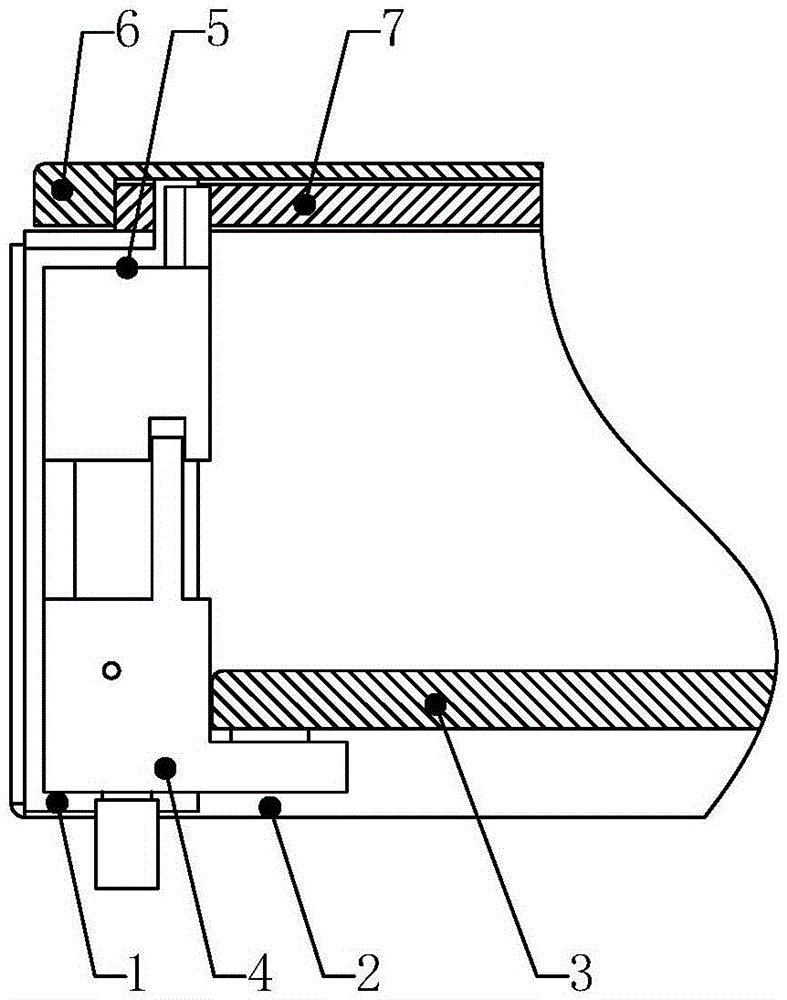

Vacuum stopper applicable to LNG (liquefied natural gas) cylinder

InactiveCN107726047AEliminate thermal deformationImprove the one-time pass rateVessel mounting detailsVessel geometry/arrangement/sizeEngineeringBottle

The invention discloses a vacuum plug for LNG liquefied natural gas bottle, relates to the technical field of liquefied natural gas equipment, and comprises a C-shaped sealing ring, a first O-shaped sealing ring and several second O-shaped sealing rings; the plug seat is hollow Cylindrical structure, the inside is divided into a first opening chamber, a connecting chamber and a second opening chamber from inside to outside, and the diameters of the first opening chamber and the second opening chamber are larger than the diameter of the connecting chamber; the plug The body is a cylindrical structure, and the diameter of the plug body is adapted to the diameter of the second opening chamber; a first annular groove and several second annular grooves are opened on the plug body; a column is also arranged inside the plug body Plug body, the diameter of the plunger body matches the diameter of the connecting chamber; a third annular groove is opened on the plunger body; the C-shaped sealing ring is clamped in the third annular groove; the first O-shaped sealing ring It is clamped in the first annular groove; each second O-ring is clamped in a corresponding second annular groove.

Owner:HUBEI YINLILAI CONTAINER

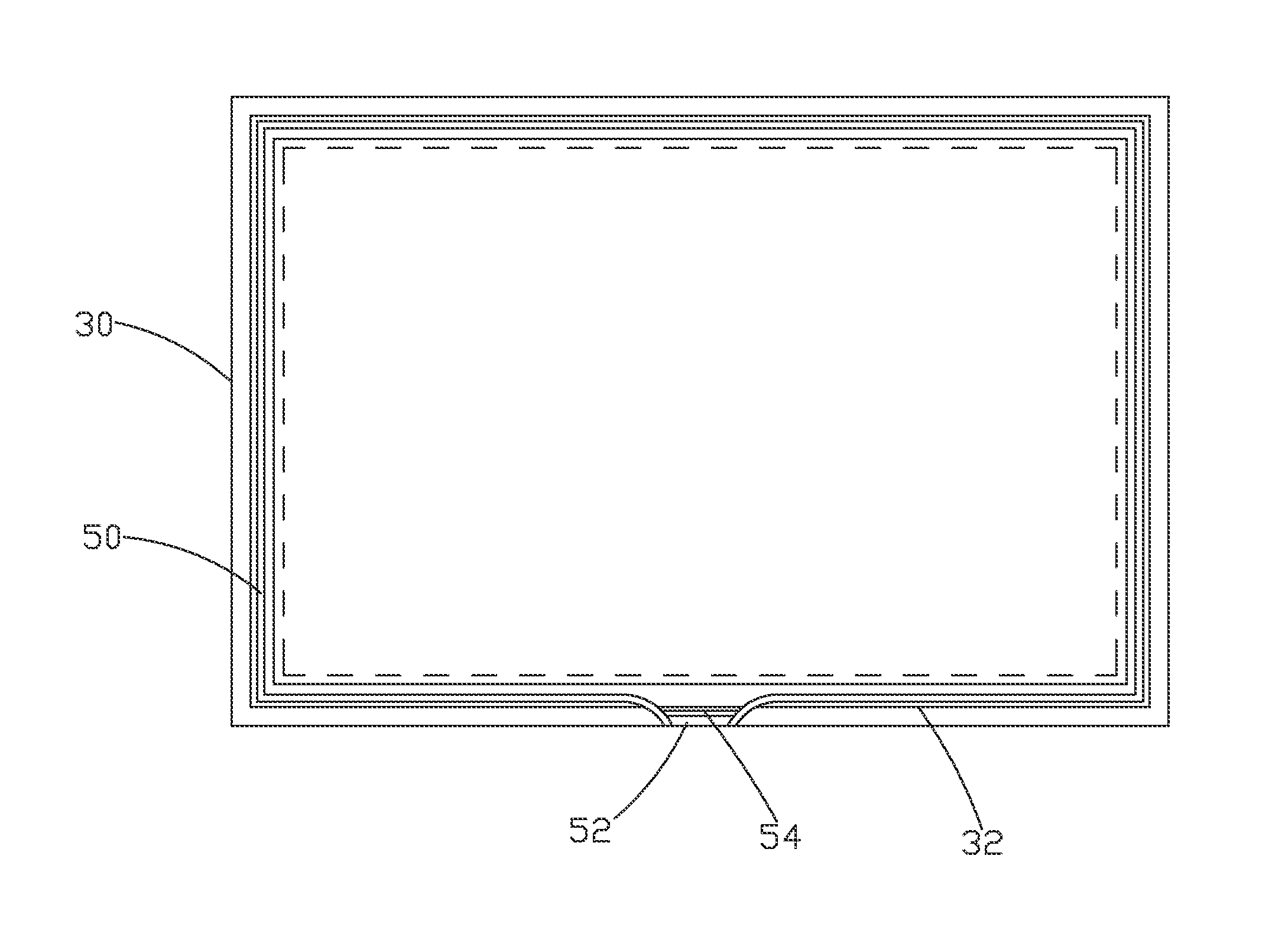

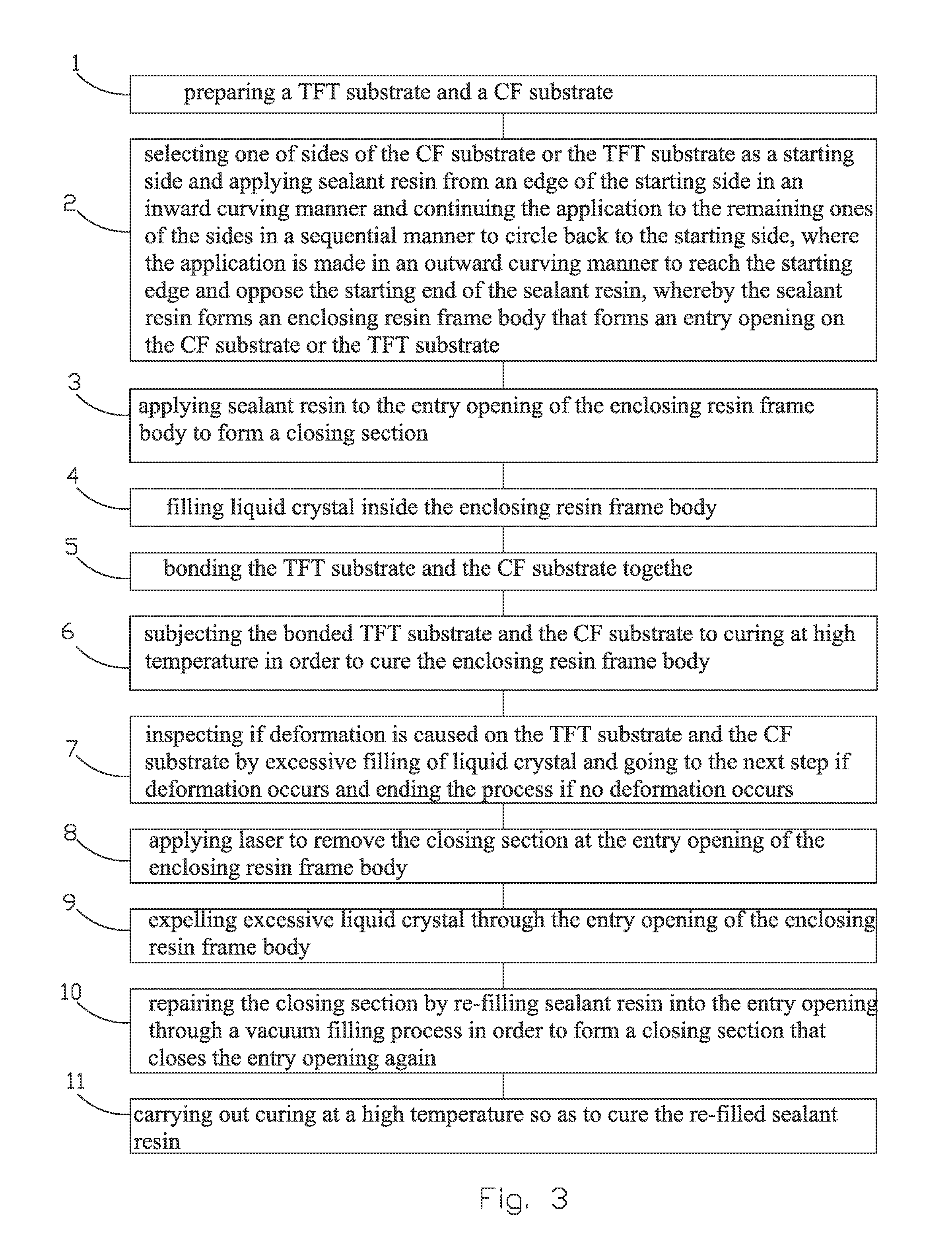

Method for Manufacturing Liquid Crystal Display Device and Liquid Crystal Display Device

ActiveUS20130300971A1Eliminate the problemEliminate thermal deformationSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayEngineering

The present invention provides a method for manufacturing a liquid crystal display device and a liquid crystal display device. The method includes (1) preparing a TFT substrate and a CF substrate; (2) applying sealant resin to the TFT substrate or CF substrate to form an enclosing resin frame body that forms an entry opening on the CF substrate or the TFT substrate; (3) applying sealant resin to the entry opening of the enclosing resin frame body to form a closing section; (4) filling liquid crystal inside the enclosing resin frame body; (5) bonding the TFT substrate and the CF substrate together; and (6) subjecting the bonded TFT substrate and the CF substrate to curing at high temperature in order to cure the enclosing resin frame body.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

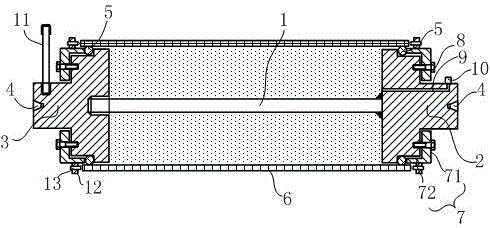

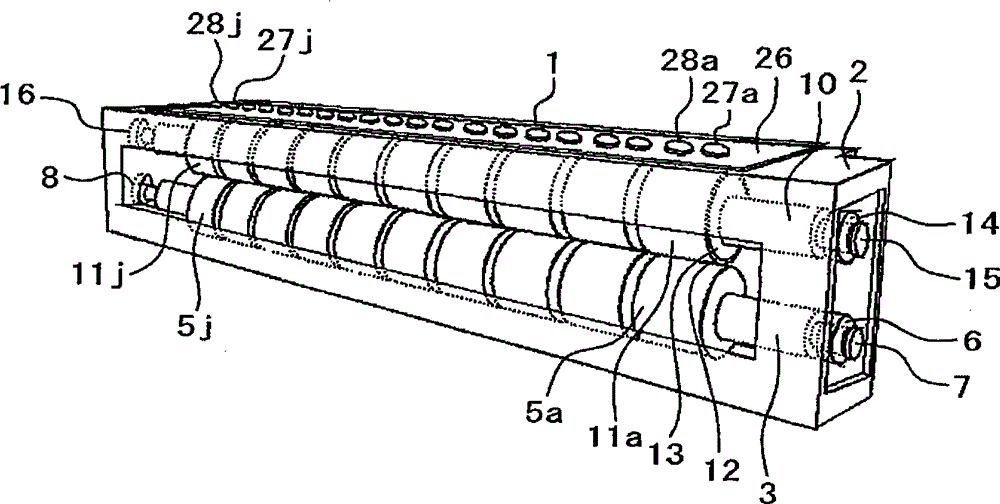

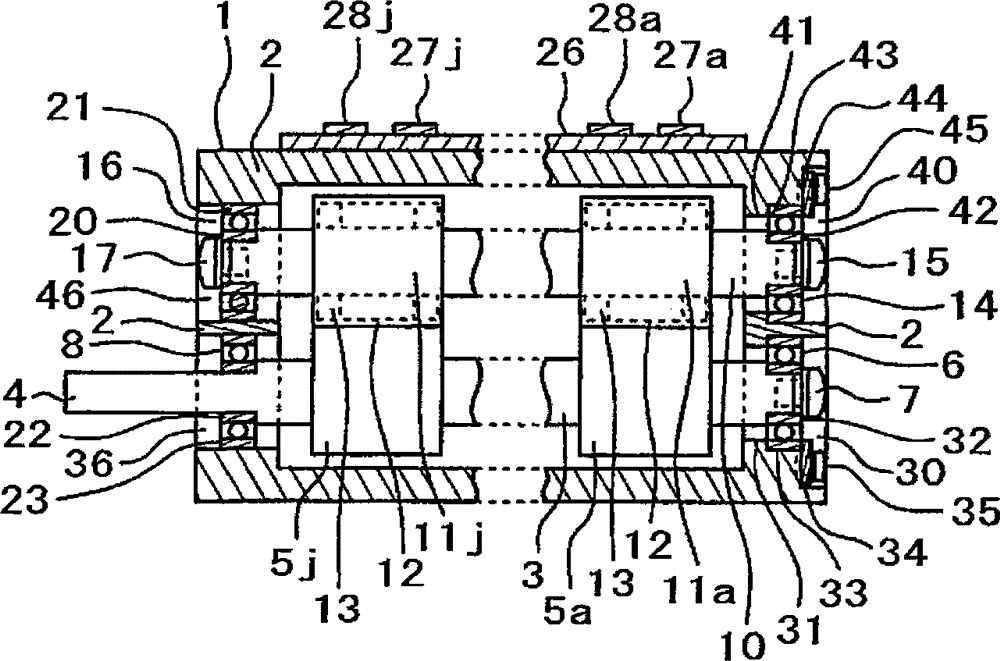

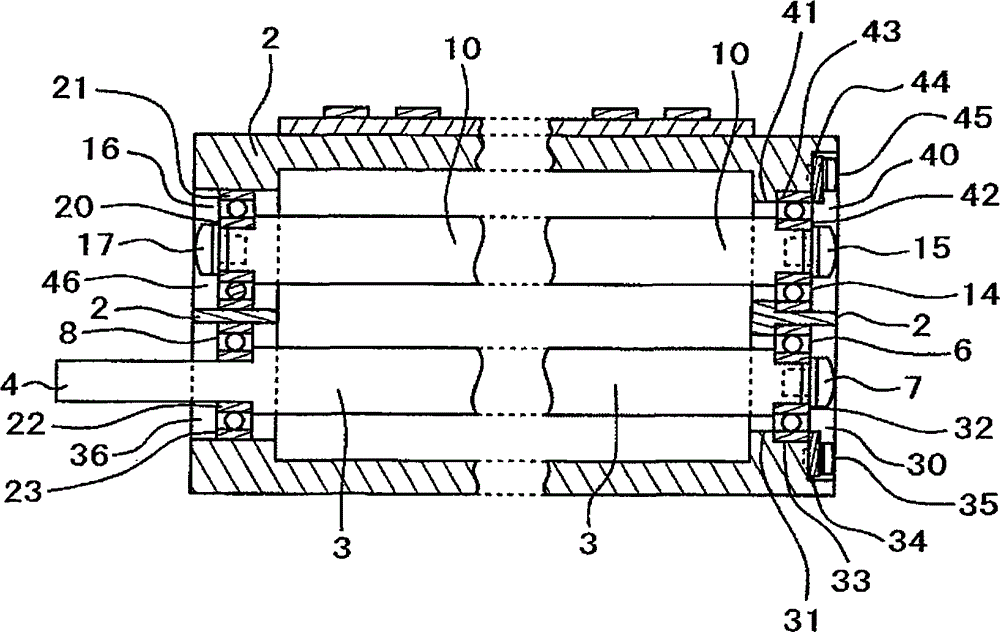

A paper sheet thickness detection device and a note processing device

ActiveCN102968847BEliminate thermal deformationAccurate detectionPaper-money testing devicesBall bearingEngineering

The invention provides a paper sheet thickness detection device which can be disposed on an automatic note processing device and accurately detect altered notes bound with tapes. The paper sheet thickness detection device comprises a housing supporting detection rollers and reference rollers in a rotary manner, and a plurality of displacement detection sensors disposed on the upper surface, which is opposite to the detection rollers, of the housing and used for detecting displacements of the detection rollers. The paper sheet thickness detection device is used for detecting the thicknesses of paper sheets conveyed through contact parts between the reference rollers and the detection rollers. Inner rings of ball bearings are fixed to the both ends of a rotating shaft of the reference rollers and a rotating shaft of the detection rollers; outer rings of the ball bearings fixed to the ends of one of the rotating shafts of the reference rollers and the detection rollers are fixed to installation holes of the housing; and the outer rings of the ball bearings installed on the ends of the other rotating shaft of the reference rollers and the detections rollers are inserted in the installation holes of the housing.

Owner:HITACHI OMRON TERMINAL SOLUTIONS CORP

Vertical machining center controllable excitation linear synchronous motor magnetic levitation motion platform

InactiveCN105500032BSimple structureImprove reliabilityFeeding apparatusLarge fixed membersLinear motionSynchronous motor

A controllable excitation linear synchronous motor magnetic levitation motion platform for a vertical machining center, characterized in that: the magnetic levitation motion platform includes a motion platform, a base, a controllable excitation linear synchronous motor, a suspension control system and a motion control system; Adjust the current of the armature winding to change the electromagnetic thrust; the magnetic levitation force is the unilateral magnetic pull generated between the excitation pole on the stator and the mover core of the linear synchronous motor. The magnetic levitation force is adjusted by adjusting the excitation current. The motion platform relies on two The magnetic levitation force generated by the motor itself operates, and has the ability of direct automatic levitation.

Owner:SHENYANG POLYTECHNIC UNIV

A jig for finishing machining of ultra-thin shaft parts

InactiveCN105690125BImprove rigidityAvoid deformationWork clamping meansPositioning apparatusRubber ringThermal deformation

The invention relates to an ultrathin shaft part finish turning clamp which comprises a mandrel. A first flange is fixedly connected with one end of the mandrel, and the other end of the mandrel is in threaded fit with a second flange. Each of the first flange and the second flange comprises three steps of circular truncated cones. A center hole is formed in the end surface of each first step of circular truncated cone. A rubber ring sleeves the circumferential excircle of each second step of circular truncated cone. More than three threaded holes are uniformly formed in the end surface of each second step of circular truncated cone. The external diameter of the circumferential excircle of each third step of circular truncated cone is 1-2 mm smaller than the internal diameter of an ultrathin shaft part. A press plate sleeves each second step of circular truncated cone. Center holes of the press plates sleeve the first steps of circular truncated cones. More than three through holes are uniformly formed in the side wall of each press plate. Bolts pass through the through holes and then are matched with the threaded holes in the end surfaces of the second steps of circular truncated cones so as to enable the outer edges of the side walls of the press plates to be propped against the outer sides of the rubber rings. An oil circuit used for communicating the inner end of the first flange with a nozzle arranged on the circumferential excircle of the first step of circular truncated cone is arranged on the first flange. A shift rod is arranged on the first step of circular truncated cone of the second flange. Compared with the prior art, the ultrathin shaft part finish turning clamp has the advantages that the rigidity of the ultrathin shaft part is enhanced, and the thermal deformation is eliminated.

Owner:YANTAI NANSHAN UNIV

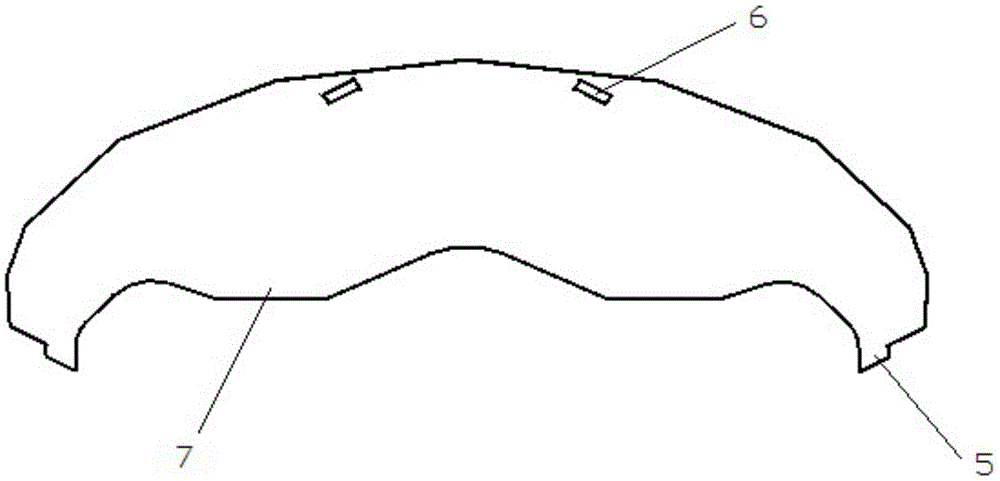

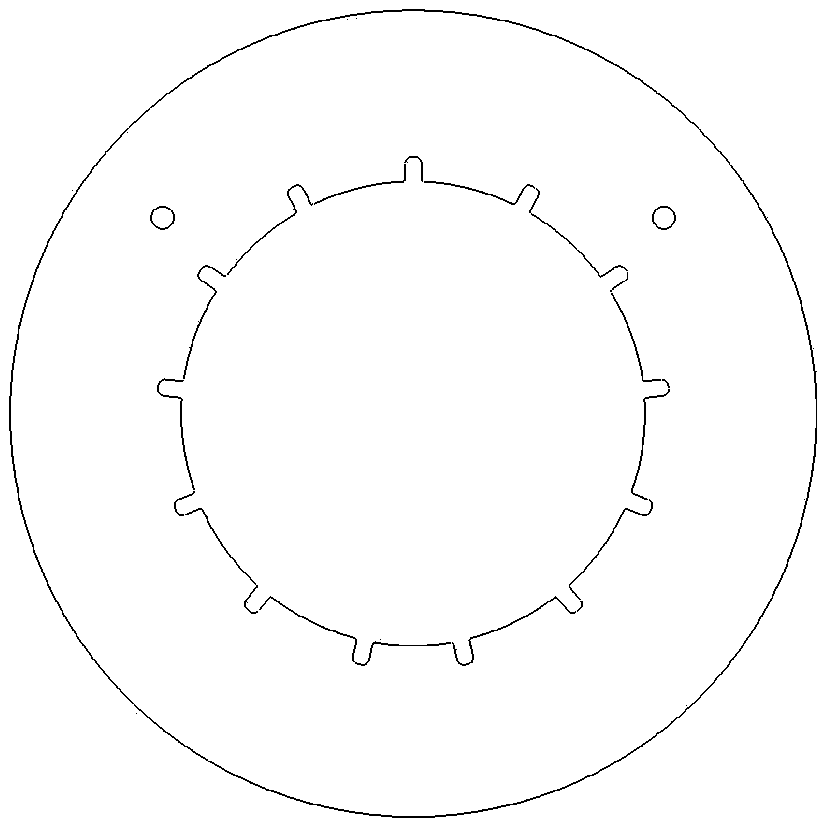

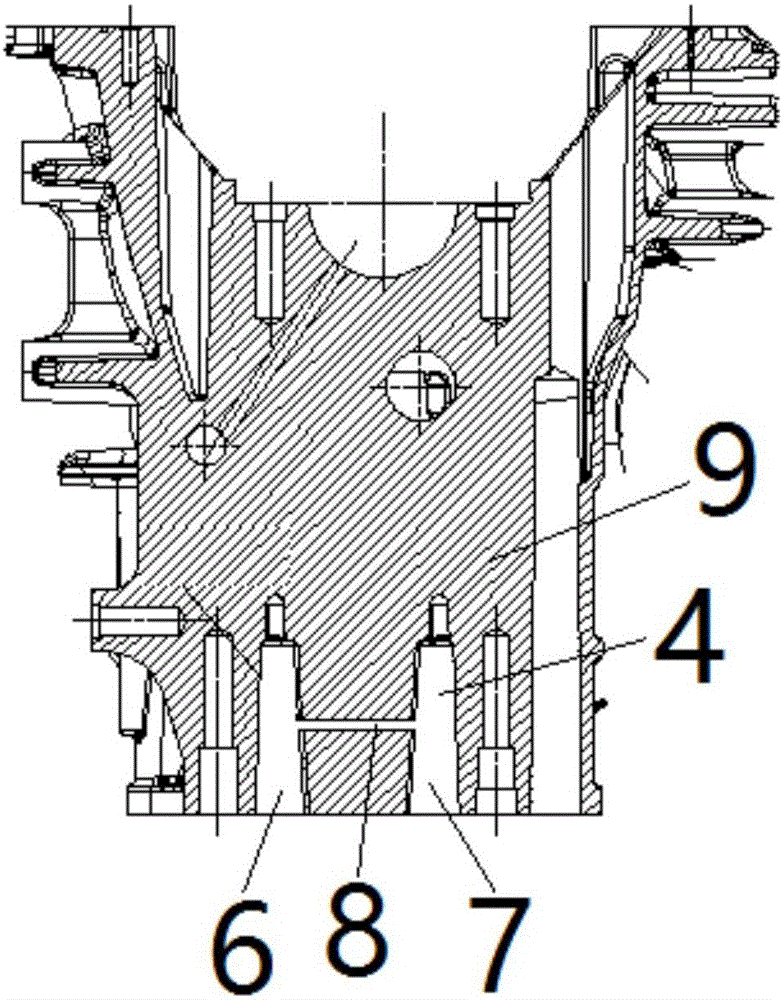

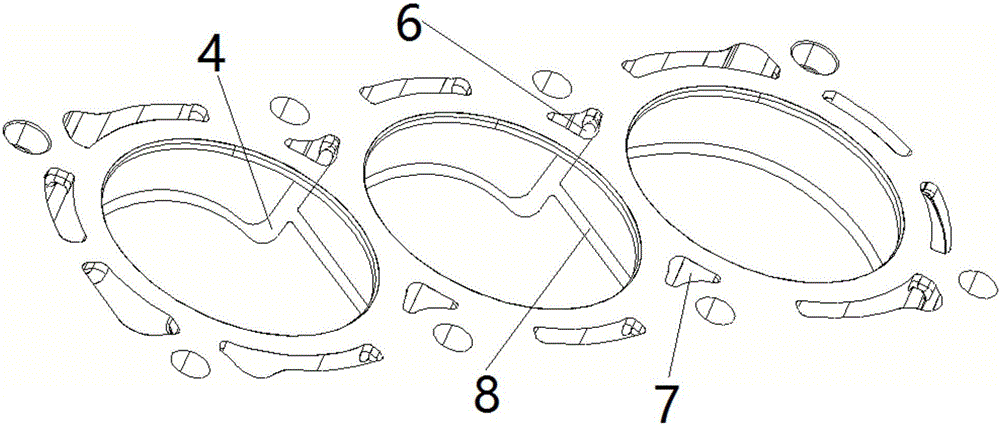

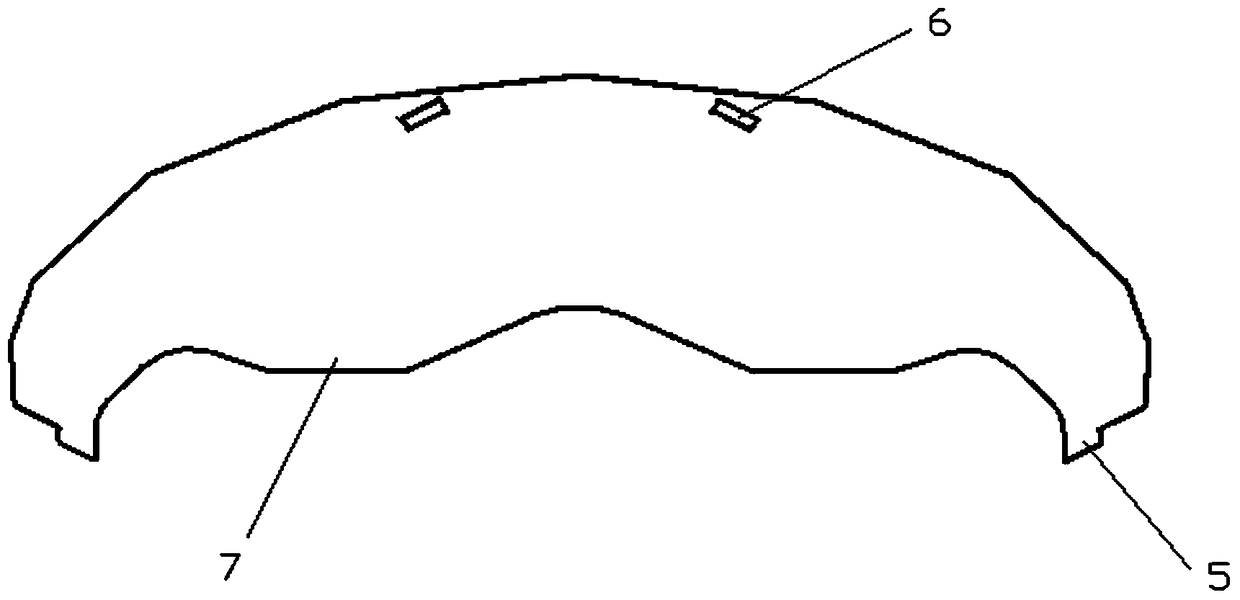

Combined type pallet for brake wheel

ActiveCN109340282AEliminate distortion factorsEliminates the risk of breakingThermal insulationBraking discsThermal deformationEngineering

The invention relates to a combined type pallet for a brake wheel. The combined type pallet for the brake wheel comprises a welding assembly and a plurality of gasket groups. Each gasket group is composed of an inner gasket and an outer gasket. The gasket groups are separately arranged in gasket mounting holes on the surface of a circular disk of the welding assembly. The inner gaskets in the gasket groups are positioned on the side, where a heat insulation piece is arranged, of the welding assembly, and the outer gaskets are positioned on the other side of the welding assembly, and the innergaskets are riveted with the outer gaskets. When the gasket groups are assembled with the welding assembly, the gasket groups and the welding assembly are combined into the combined type pallet. According to the combined type pallet for the brake wheel, the factors that pressure affects the deformation of the pallet welding assembly and the thermal deformation of materials caused by the heat transfer of a high-temperature brake disc after the brake are eliminated; and meanwhile, the heat insulation piece is additionally arranged, so that the heat insulation effect is greatly strengthened, anda cylinder seat assembly composed of non-high-temperature resistant materials is protected.

Owner:XIAN AVIATION BRAKE TECH

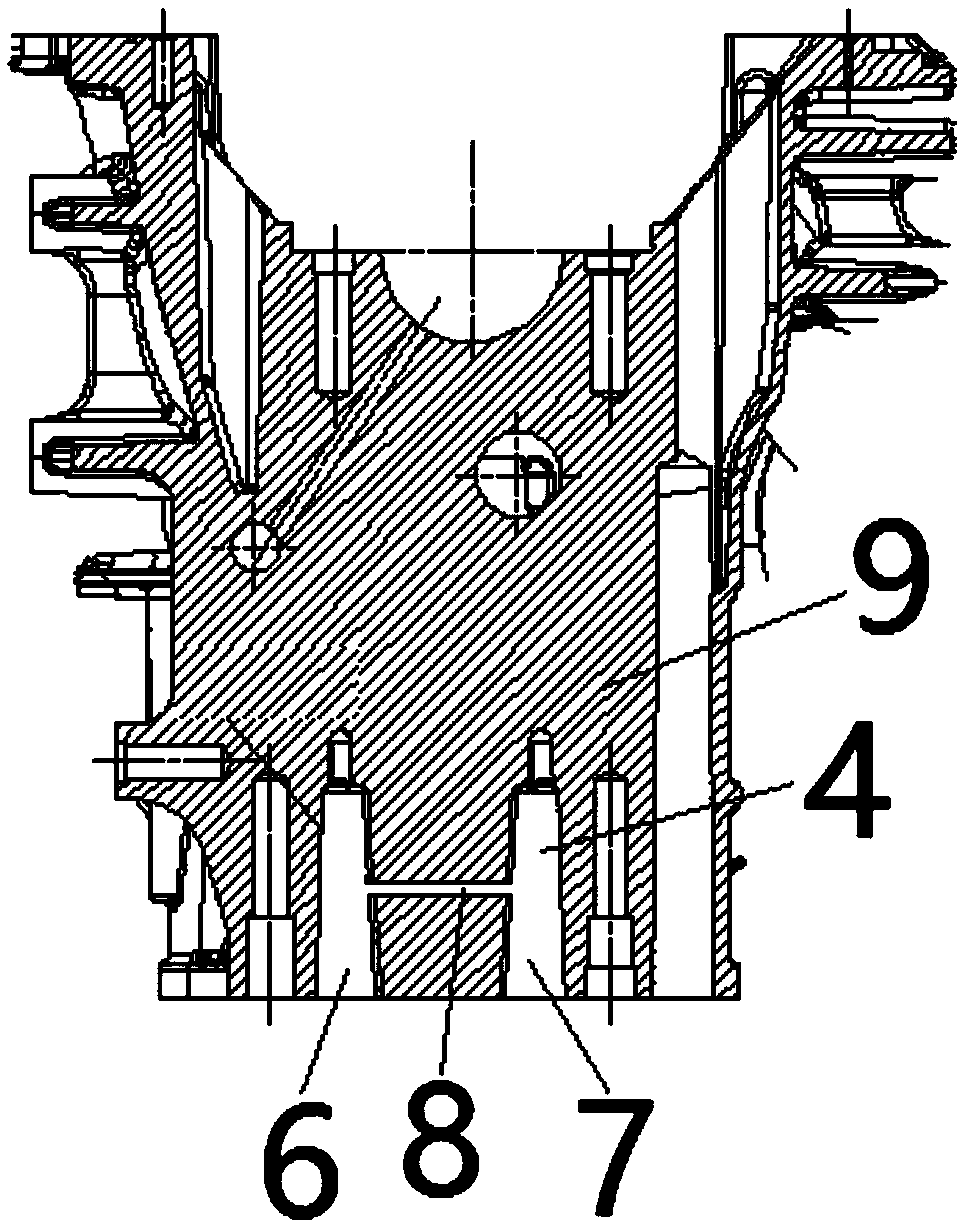

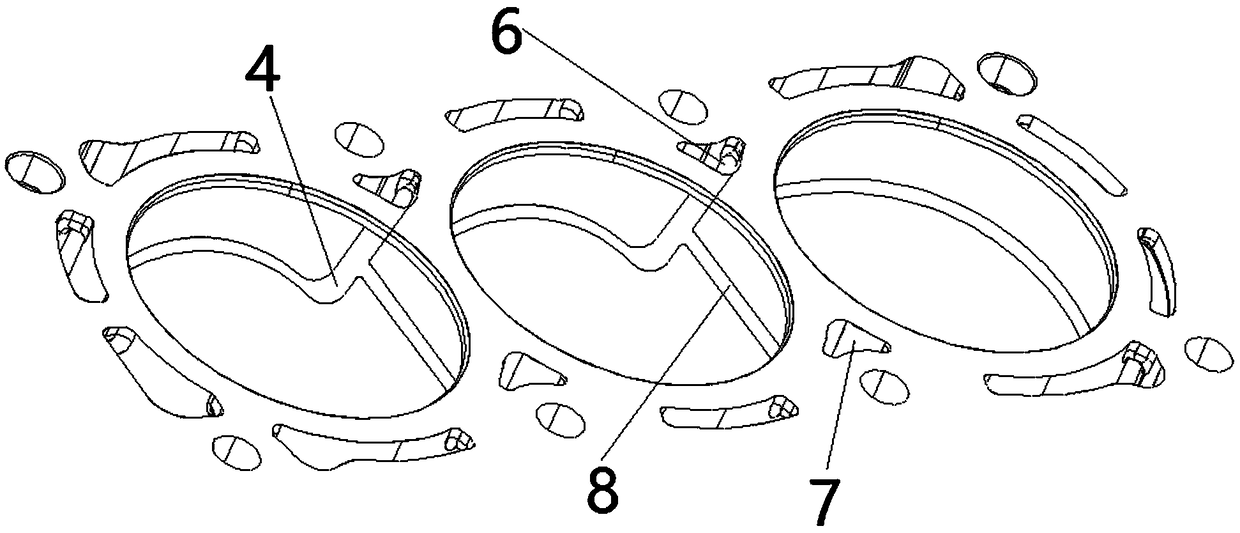

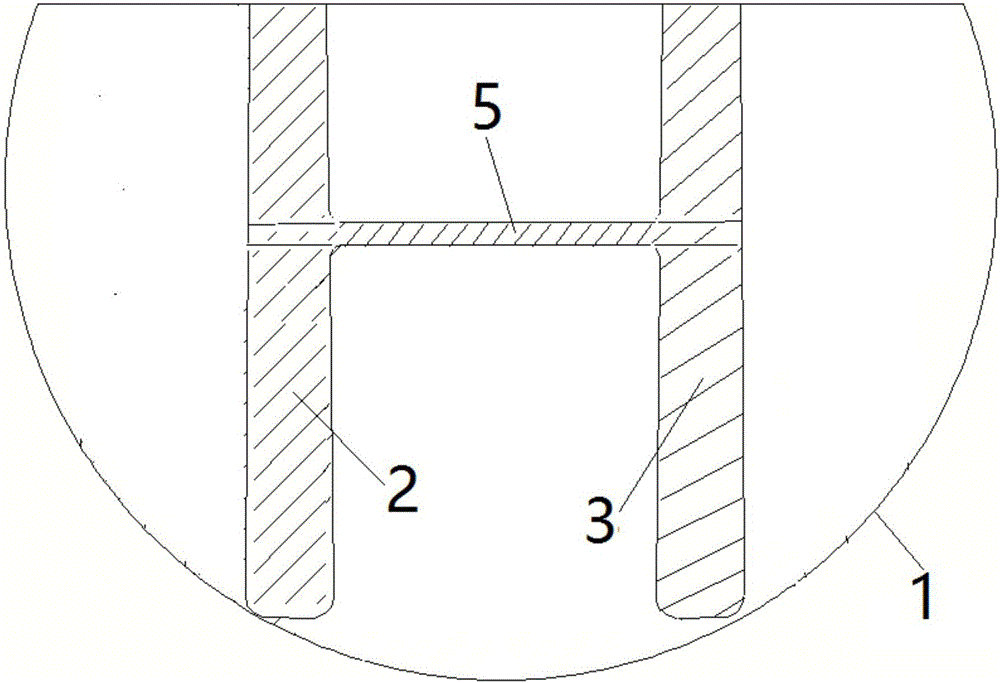

Casting sand core for engine cylinder and method for casting cylinder using said casting sand core

ActiveCN106583658BEliminate thermal deformationEliminate differences in thermal deformationFoundry mouldsFoundry coresWater channelTemperature difference

The invention provides an engine cylinder body casting sand core applied to the field of automobile engine manufacturing auxiliary equipment, and further relates to a method for casting a cylinder body through the casting sand core. Mounting holes of a rubber bar (5) are formed in an air inlet side water channel machining component (2) and an exhaust side water channel machining component (3) of a cylinder body water jacket sand core (1) of the engine cylinder body casting sand core. One end of the rubber bar (5) is mounted on the air inlet side water channel machining component (2), and the other end of the rubber bar (5) is mounted on the exhaust side water channel machining component (3). According to the engine cylinder body casting sand core and the method for casting the cylinder body through the casting sand core, a channel for enabling an air inlet side water channel to communicate with an exhaust side water channel can be machined conveniently and reliably, cooling water between the air inlet side water channel and the exhaust side water channel of an engine freely flows, the temperature difference between an air inlet side water jacket and an exhaust side water jacket is reduced, the overall performance of the engine is improved, and the emission of the engine is reduced.

Owner:JIANGXI TENHLE POWER CO LTD

Assembled high protection photovoltaic combiner box

ActiveCN104201581BReduce direct contactReduce the range of protection areaSubstation/switching arrangement detailsSpecial designStructural engineering

The invention discloses an assembled high-protection photovoltaic combiner box, which includes a box body, a mounting plate and a door panel. The box body is a rectangular frame structure with openings on both sides. The mounting plate and door panels are respectively installed on both sides of the box body, and sealing corner pads are also included. , rear gussets and front gussets, the four corners of the box are respectively provided with sealing corner pads, and the rear gussets and front gussets are installed in the sealing corner pads; the invention also discloses an assembled high-protection photovoltaic combiner box The installation method; this product adopts the special design and manufacturing process of integrated box body and internal sealing, which completely solves the impact of the harsh external environment on the internal components, and the protection level is as high as IP65; all the parts that make up the box body adopt standard modularization , without any welding, completely reduce the impact of thermal stress caused by welding on its shell, improve efficiency, save energy and reduce consumption.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

An isolated non-woven fabric winding machine and its use method

ActiveCN107804733BReasonable structural designHigh degree of automationWebs handlingWinding machineEngineering

The invention discloses an isolation type non-woven fabric textile winding machine which belongs to the technical field of textile winding. A cooling fan is arranged at the top of a fixed bracket; anupper flattening roller and a lower flattening roller are arranged at the top of a first bracket in sequence from top to bottom; a tensioning roller is arranged at the top of a third bracket; the tensioning roller is connected onto the third bracket through a second connecting shaft; a second through hole is formed in the top of a side wall of a second bracket; a second fixed block is arranged atthe top of the second through hole; a second rigid spring is arranged at the bottom of the second fixed block; a third connecting shaft is provided with a tracking roller; six groups of winding rollers with the same structure are arranged below the tracking roller; the winding rollers are connected with a connecting frame through a fourth connecting shaft; a ratchet wheel mechanism which is matched with a mounting groove is arranged at the left end of a fifth connecting shaft. The winding machine disclosed by the invention is reasonable in structural design and high in automation degree; simple and convenient textile winding work can be ensured and the winding effect of the fabric is remarkable.

Owner:宁夏中恒创越新材料科技有限公司

Engine cylinder body casting sand core and method for casting cylinder body through casting sand core

ActiveCN106583658ASmall temperature differenceEliminate thermal deformationFoundry mouldsFoundry coresCylinder blockBody water

The invention provides an engine cylinder body casting sand core applied to the field of automobile engine manufacturing auxiliary equipment, and further relates to a method for casting a cylinder body through the casting sand core. Mounting holes of a rubber bar (5) are formed in an air inlet side water channel machining component (2) and an exhaust side water channel machining component (3) of a cylinder body water jacket sand core (1) of the engine cylinder body casting sand core. One end of the rubber bar (5) is mounted on the air inlet side water channel machining component (2), and the other end of the rubber bar (5) is mounted on the exhaust side water channel machining component (3). According to the engine cylinder body casting sand core and the method for casting the cylinder body through the casting sand core, a channel for enabling an air inlet side water channel to communicate with an exhaust side water channel can be machined conveniently and reliably, cooling water between the air inlet side water channel and the exhaust side water channel of an engine freely flows, the temperature difference between an air inlet side water jacket and an exhaust side water jacket is reduced, the overall performance of the engine is improved, and the emission of the engine is reduced.

Owner:JIANGXI TENHLE POWER CO LTD

Apparatus for welding and positioning flywheel assembly

ActiveCN101474735BEliminate thermal deformationReduce the overall heightWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyEngineering

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

A large static mixer

ActiveCN105642145BGuaranteed structural strengthEliminate thermal deformationFlow mixersTransportation and packagingEngineeringStatic mixer

Owner:GUANGZHOU BATONG MIXER CO LTD

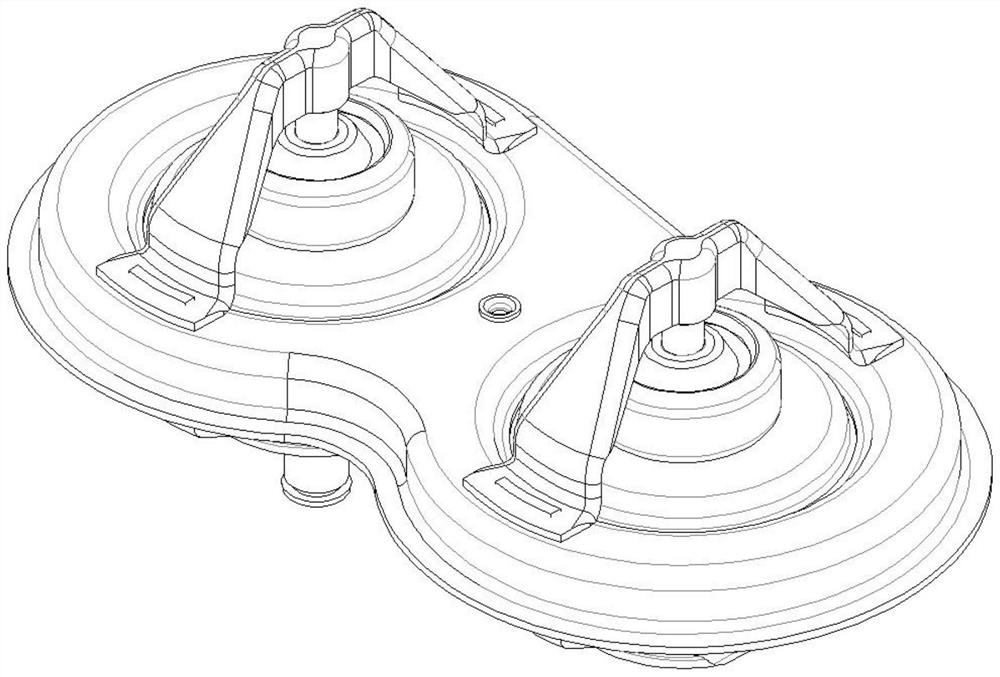

Spin riveting equipment suitable for automobile temperature regulator

PendingCN112439843AEliminate thermal deformationWon't breakMetal-working feeding devicesHeat exchange apparatusPhysicsEngineering

The invention relates to spin riveting equipment suitable for an automobile temperature regulator. A spin riveting jig is jointly driven by a first driving unit and a second driving unit, and a downward pressing unit is driven by a third driving unit. When a support for inserting the automobile temperature regulator is inserted in place in an inserting positioning table of the spin riveting jig, avalve, a push rod, a temperature sensor and a spring of the automobile temperature regulator are arranged in the support, the downward pressing unit tightly presses the support under the action of the third driving unit, a left arranged limiting unit and a right arranged limiting unit act so as to tightly press the support of the automobile temperature regulator into the inserting positioning table, the downward pressing unit moves upwards under the action of the third driving unit so as to be separated from the support by a preset distance, after a valve seat of the automobile temperature regulator is aligned relative to the support, a left arranged material pressing unit and a right arranged material pressing unit act to press down and pre-tighten the valve seat so as to enable the valve seat to cling to the support, and a spin riveting head acts to finish spin riveting combination of the support and the valve seat.

Owner:SUZHOU LING AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com