Patents

Literature

91results about How to "Eliminate the effect of precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

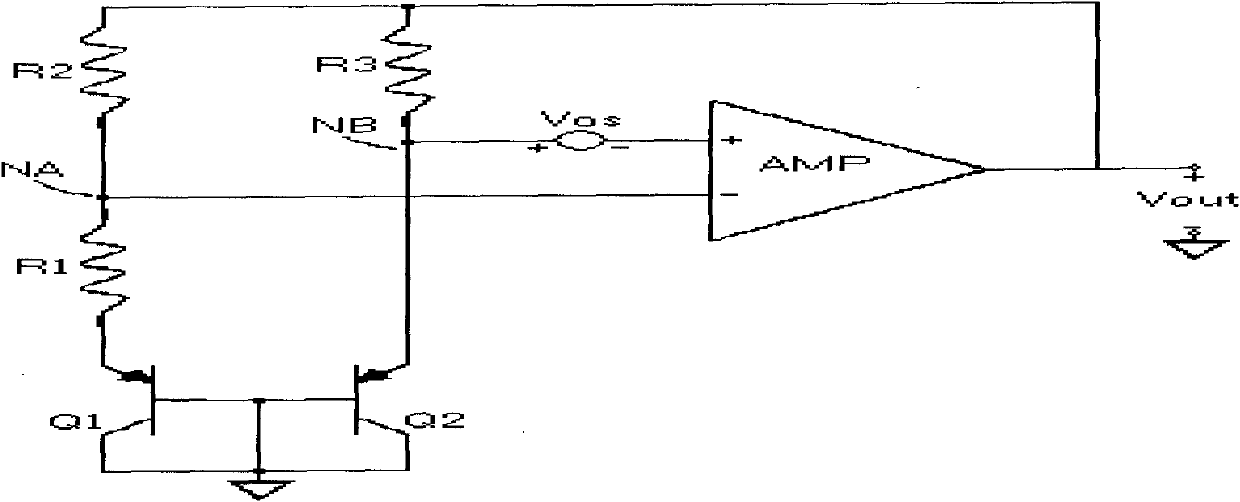

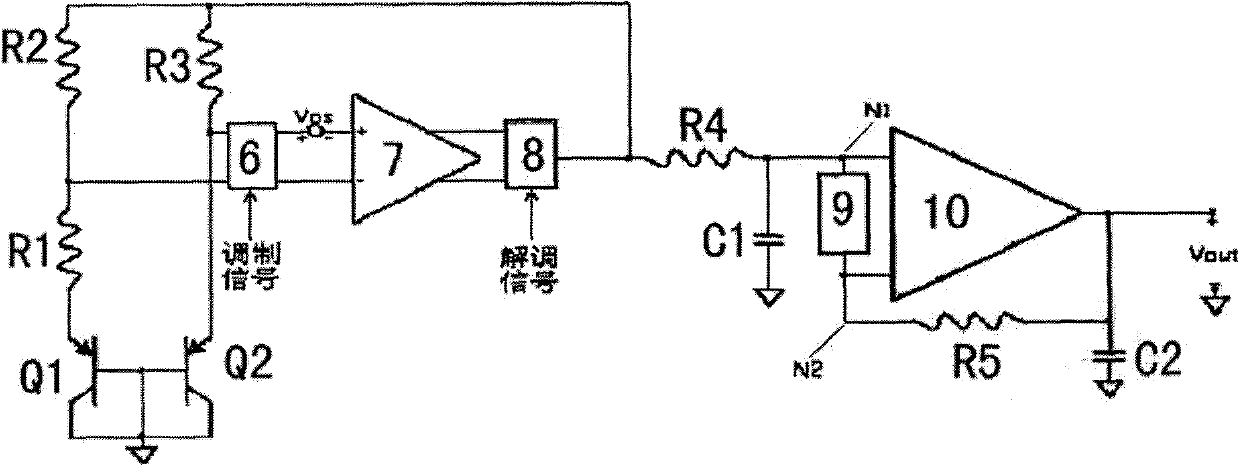

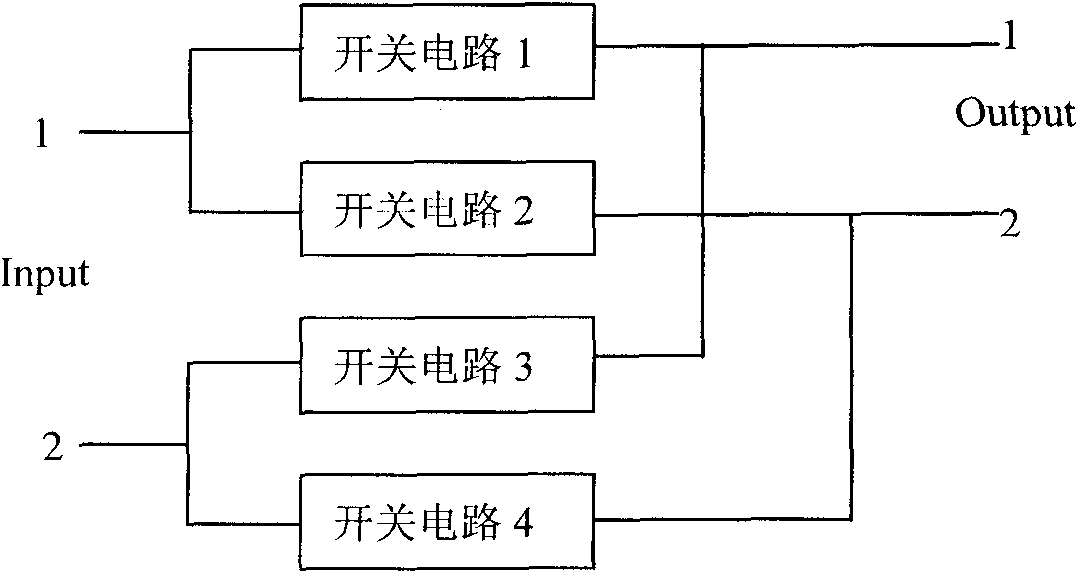

Band-gap reference source circuit with stable low-offset and low-noise noise chopped wave

InactiveCN102200796ASolve the phenomenon of low precisionEliminate the effect of precisionElectric variable regulationLow noiseLow-pass filter

The invention provides a band-gap reference source circuit with a stable low-offset and low-noise noise chopped wave, comprising an operational amplifier, a transistor arranged in the form of a mirror image and a divider resistor, wherein a modulator is connected in front of an input end of the operational amplifier while an output end of the operational amplifier is connected with a demodulator; an output end of the demodulator is connected with an input end of a RC low-pass filter; an output end of the RC low-pass filter is connected with an input end of a buffer; a transmission gate circuit is connected between two input ends of the buffer; another input end of the buffer is connected with an input end of another RC low-pass filter; and an output end of the RC low-pass filter is connected with an output end of the buffer. By using the invention, a signal is modulated at the input end of the operational amplifier and demodulated at the output end. The demodulated input signal is recovered while an equivalent offset voltage and 1 / F noise are modulated to a high frequency and then filtered by the low-pass filter, thereby reducing or even eliminating the influences of the offset voltage and the 1 / F noise on the precision and successfully solving the phenomenon of low output voltage precision caused by the offset voltage of the operational amplifier.

Owner:SHANGHAI SANDHILL MICROELECTRONICS

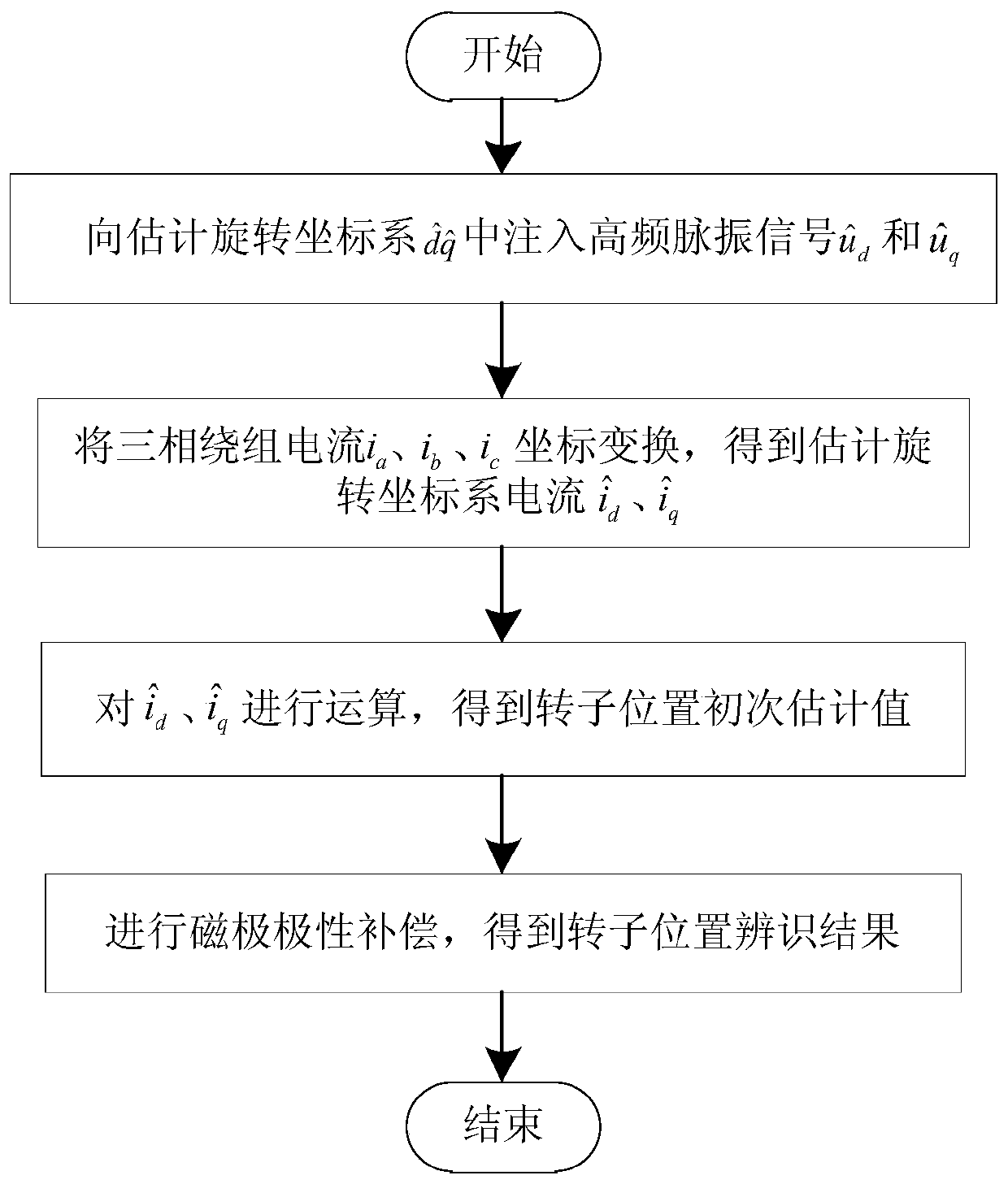

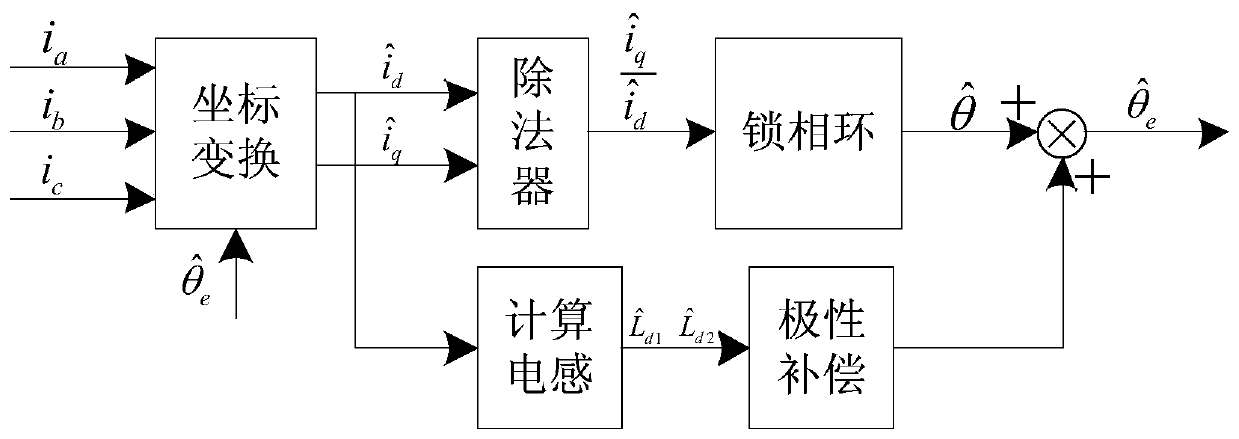

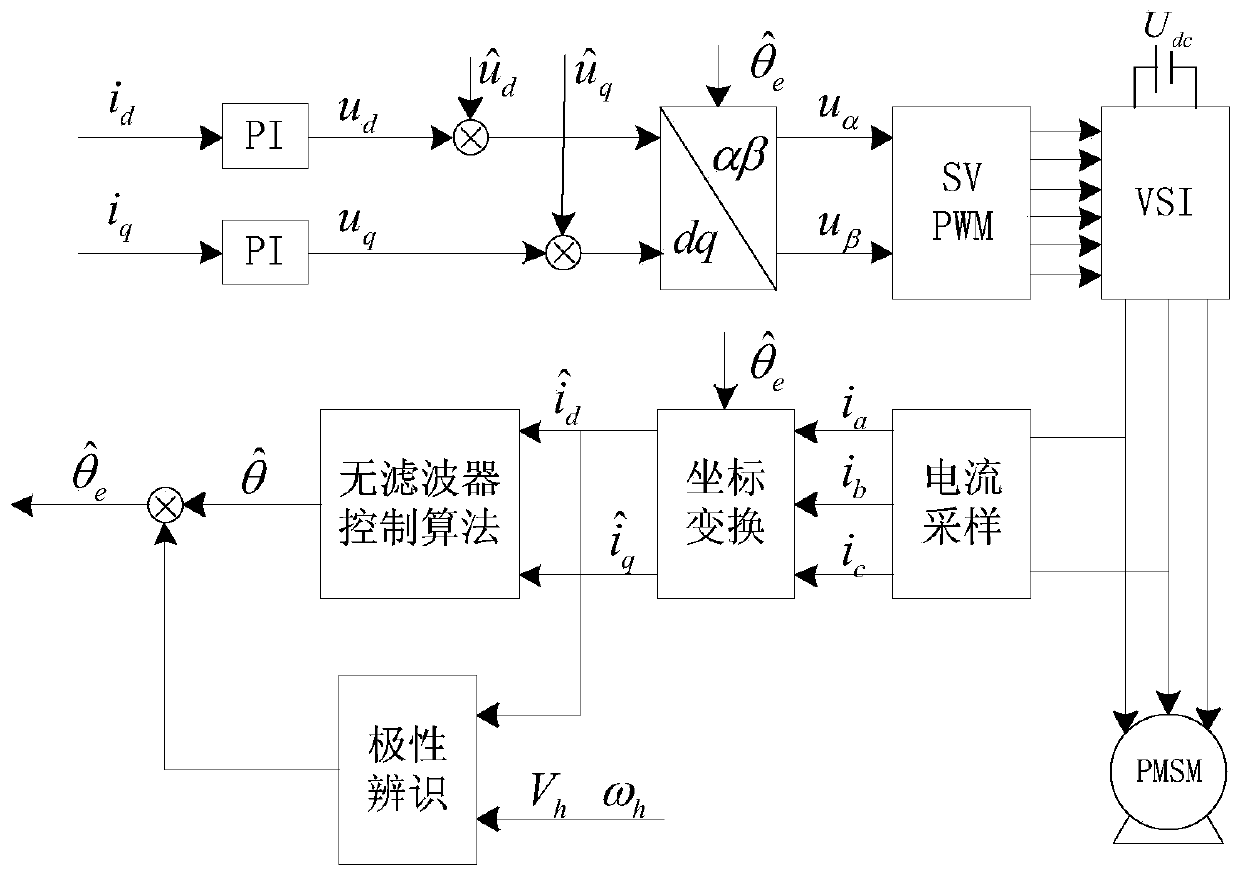

Filter-free permanent magnet synchronous motor rotor initial position identification method

ActiveCN109802618AAvoid filteringImprove dynamic characteristicsElectronic commutation motor controlVector control systemsPower flowPermanent magnet synchronous motor

The invention relates to a filter-free permanent magnet synchronous motor rotor initial position identification method and belonging to the field of motor control to solve the problems that an existing permanent magnet synchronous motor rotor initial position identification process is low in precision and has an identification result affected by the amplitude and the frequency of an input signal and a filter has an influence on the stability of the system. The method of the invention comprises inputting a high-frequency pulse vibration signal into the stator winding of the motor; obtaining a position deviation signal by subjecting a response current to coordinate transformation and signal processing; locking the position deviation signal to obtain a rotor position initial identification result [theta]<^>; determining the polarities of the N and S poles of the rotor by using a magnetic saturation effect so as to obtain a rotor initial position identification value. The filter is removedduring the identification process, which can suppress the influence of the filter on the system bandwidth and stability, and remove the influence of the amplitude and frequency of the input signal onthe identification accuracy. The algorithm is simple and reliable.

Owner:YANSHAN UNIV

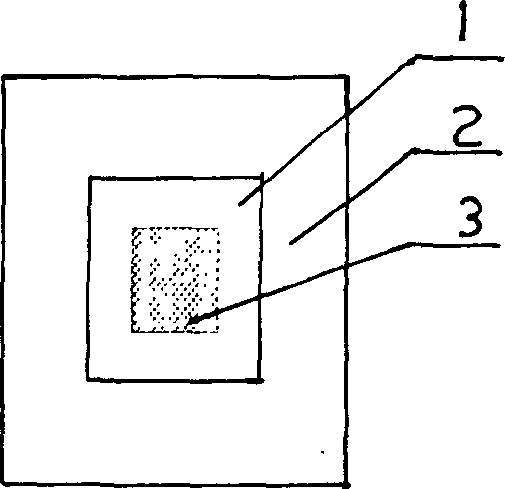

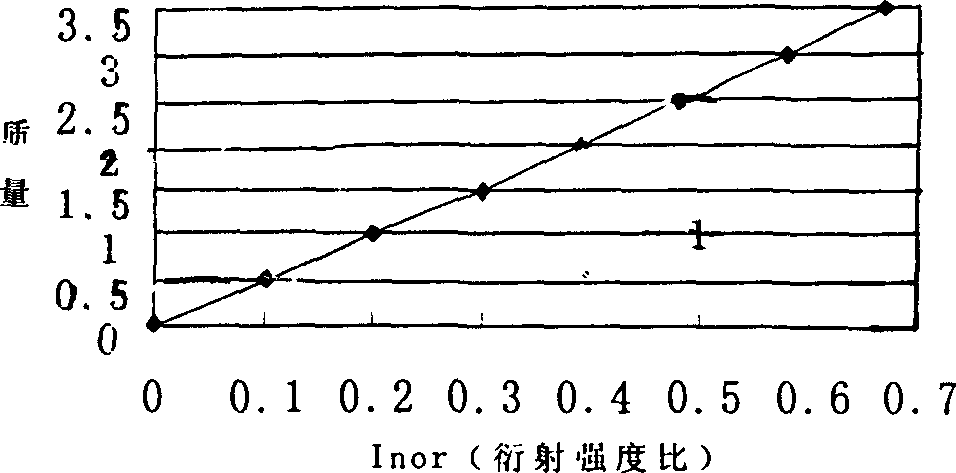

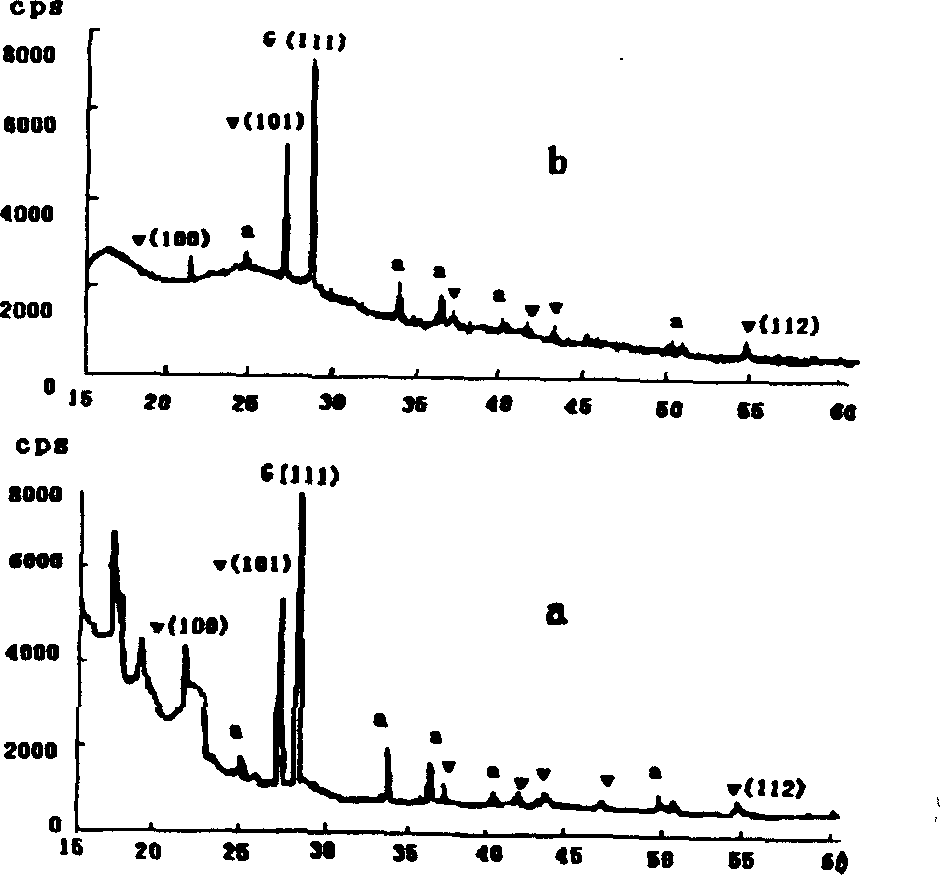

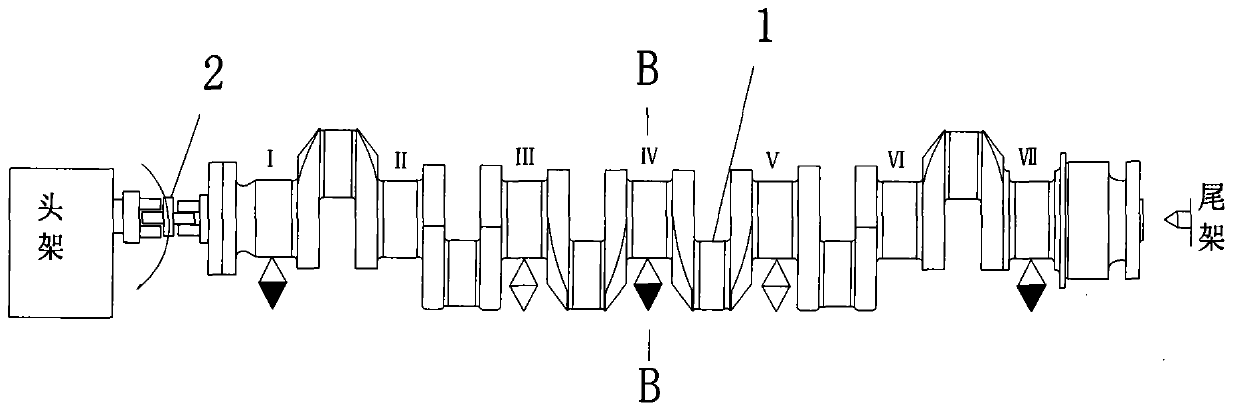

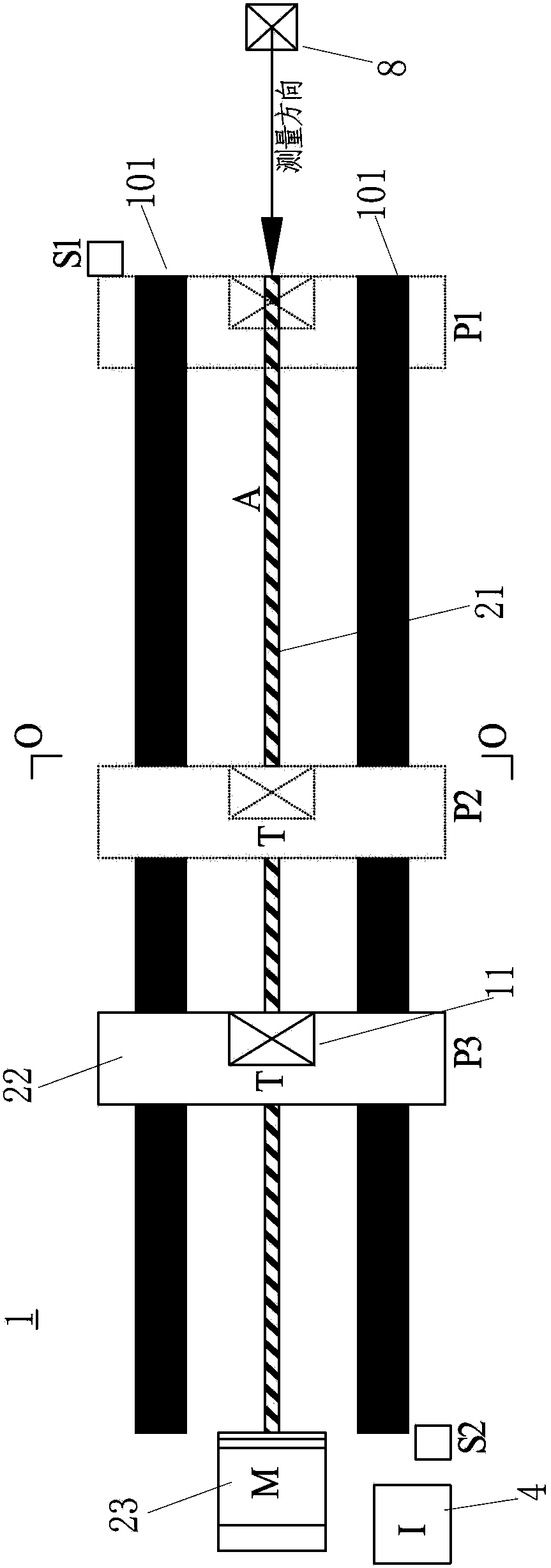

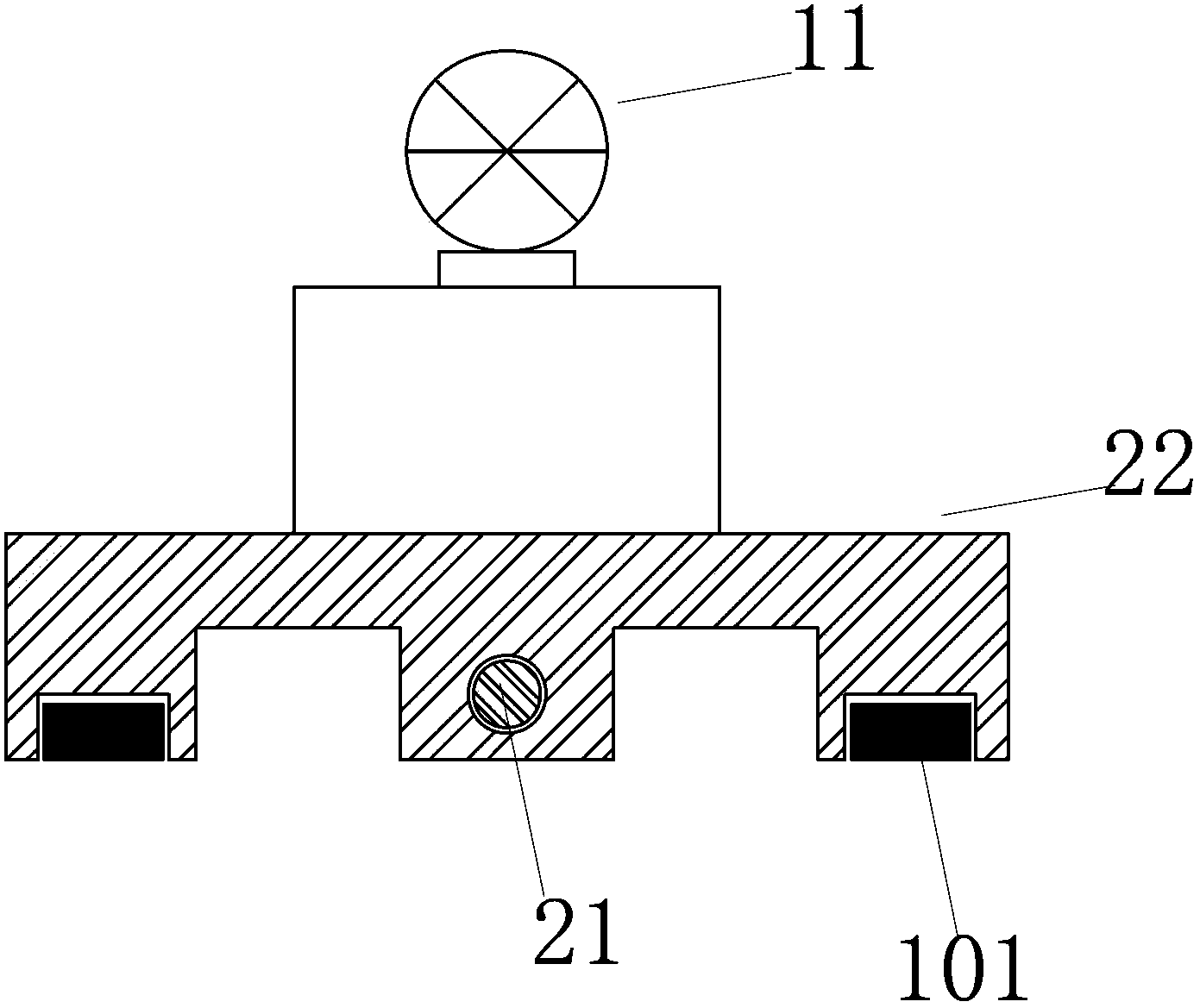

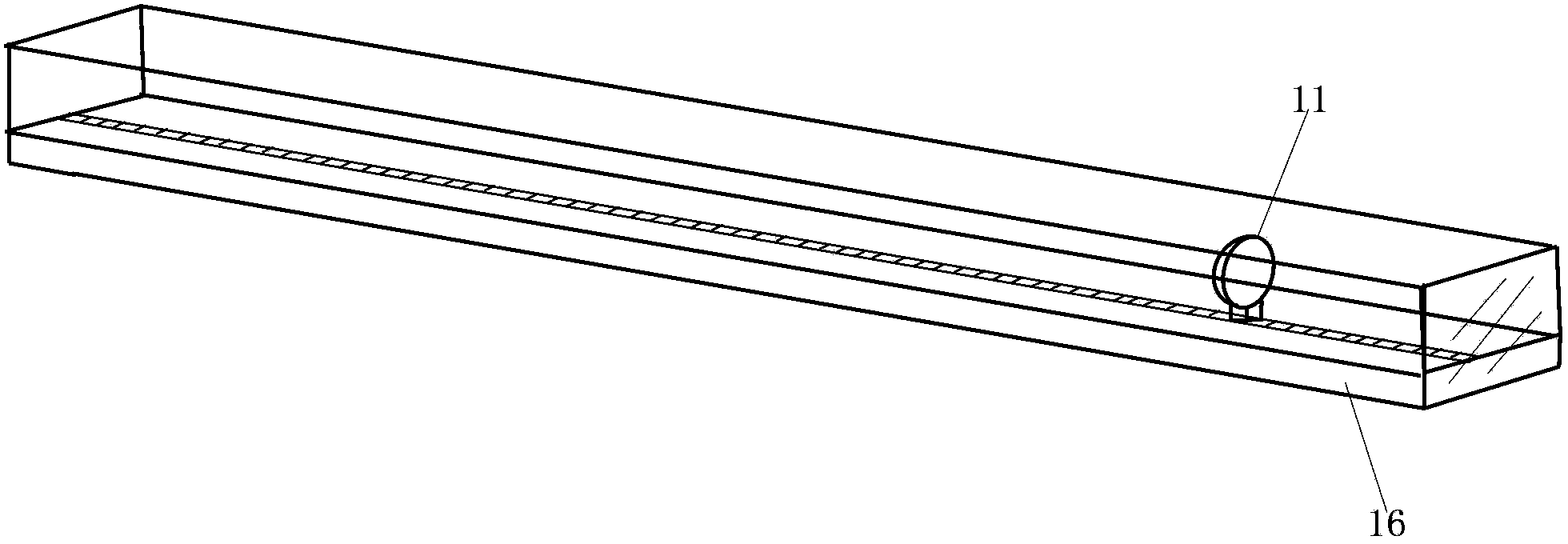

Sample rack for X-ray diffraction phase analysis and analysis method thereof

InactiveCN1800839AEliminate the effect of precisionInter-laboratory versatilityMaterial analysis using radiation diffractionSoft x rayQuantitative phase analysis

The invention relates to qualitative and quantitative analysis for X-ray diffraction mineral. Wherein, the X-ray diffraction phase analysis sample bracket comprises a silicon single-crystal piece in the following base frame, a base frame, and a dust-carry film stuck on said single-piece; the single-crystal piece is single diffraction peak, and is prepared by cutting into pieces along the crystal face 0-12Deg and grinding and polishing. This invention can eliminate the effect to measurement accuracy from device, time and parameter, simplifies operation, and cuts time to improve efficiency.

Owner:MAANSHAN IRON & STEEL CO LTD

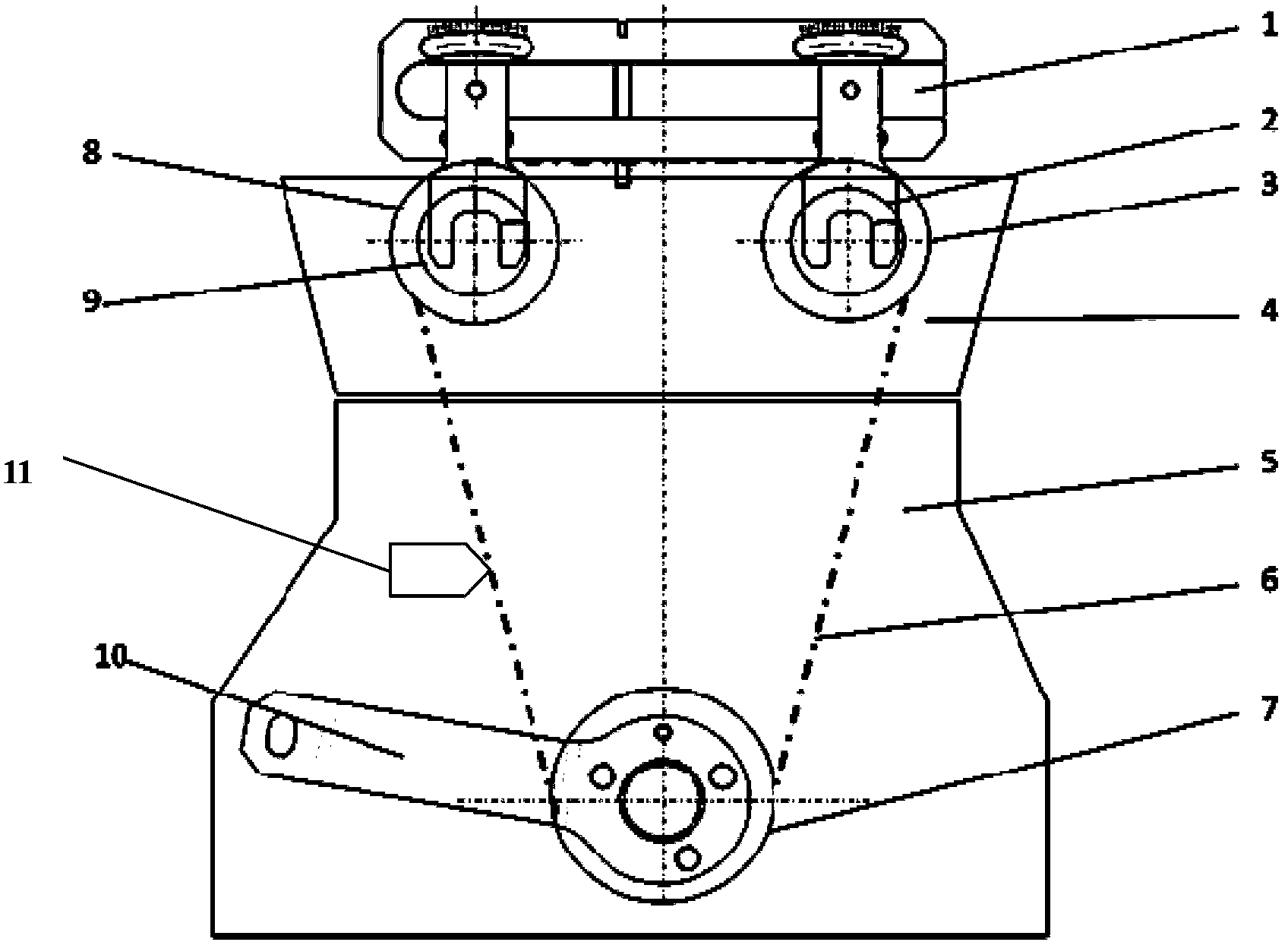

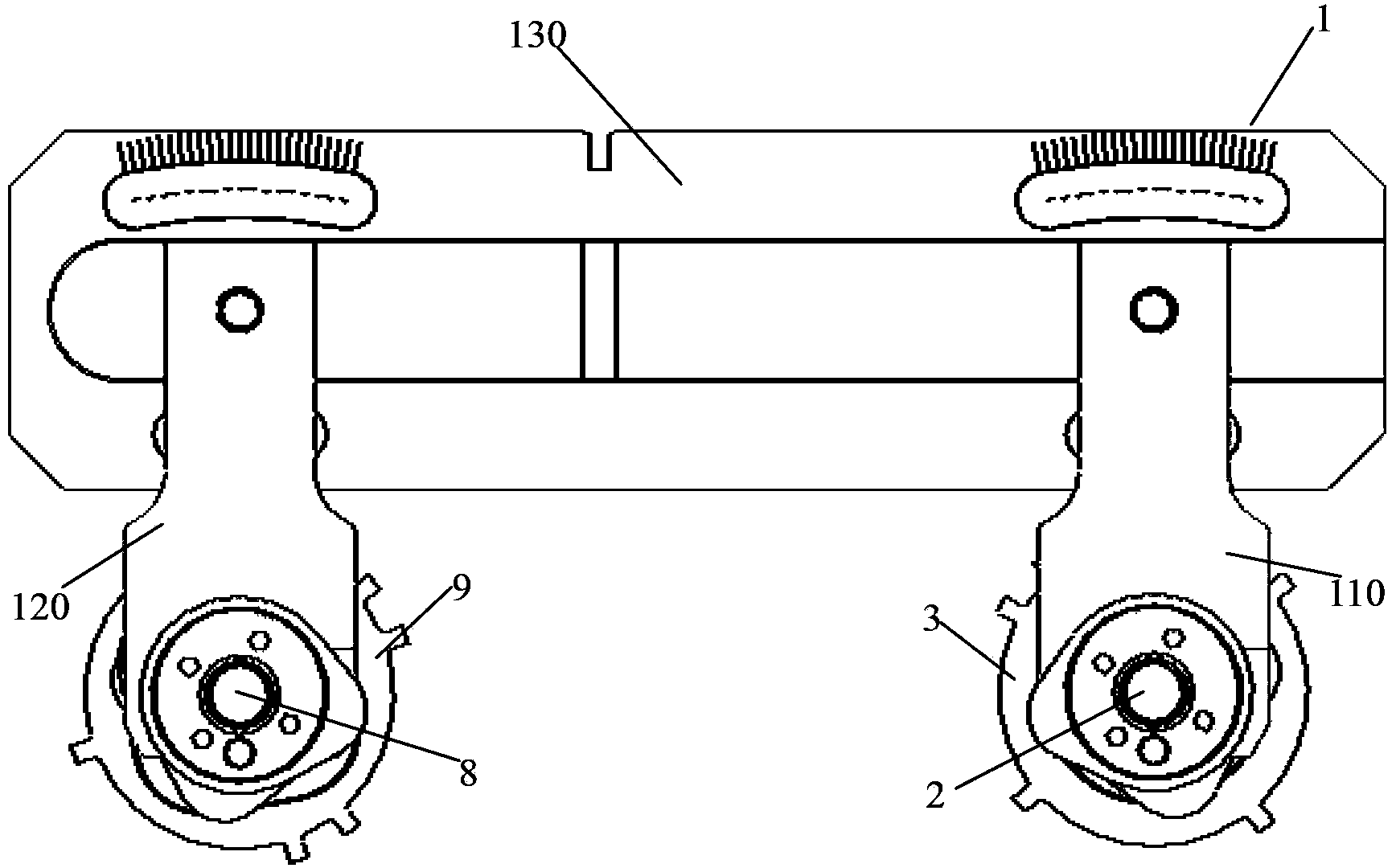

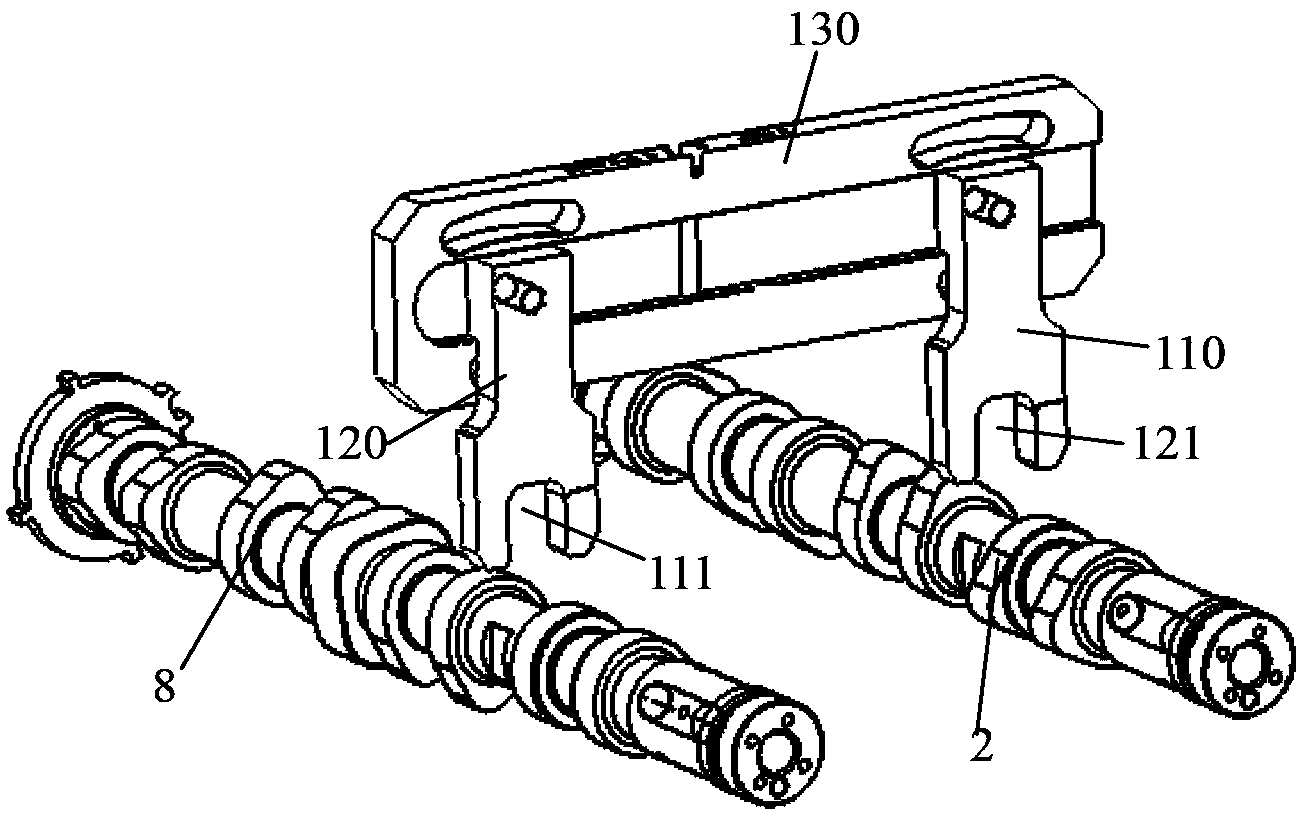

Positioning and mounting system and positioning and mounting method used for engine timing system

InactiveCN104249320AEliminate assembly errorsEliminate the effect of precisionWork holdersMetal-working hand toolsSprocketEngineering

The invention provides a positioning and mounting system and a positioning and mounting method used for an engine timing system. The positioning and mounting system comprises a cam shaft locking device and a crankshaft locking device, wherein the cam shaft locking device is used for locking and fixing a gas inlet cam shaft and a gas inlet cam shaft chain wheel on a first mounting position, and locking and fixing a gas outlet cam shaft and a gas outlet cam shaft chain wheel on a second mounting position; the crankshaft locking device is used for locking and fixing a crankshaft and a crankshaft chain wheel on a third position; a timing chain sleeves around the gas inlet cam shaft chain wheel, the gas outlet cam shaft chain wheel and the crankshaft chain wheel; the first mounting position, the second mounting position and the third mounting position are corresponding; a valve is located on a preset position. According to the positioning and mounting system and the positioning and mounting method used for the engine timing system, the cam shaft locking device, the crankshaft locking device and a chain adjusting device are mutually matched, and the aim of improving the timing assembly precision of an engine is reached.

Owner:北京汽车动力总成有限公司

Manufacture method of door module of integral vehicle main model checking fixture

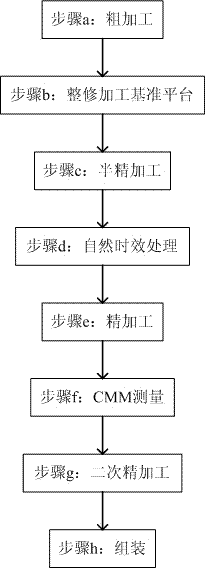

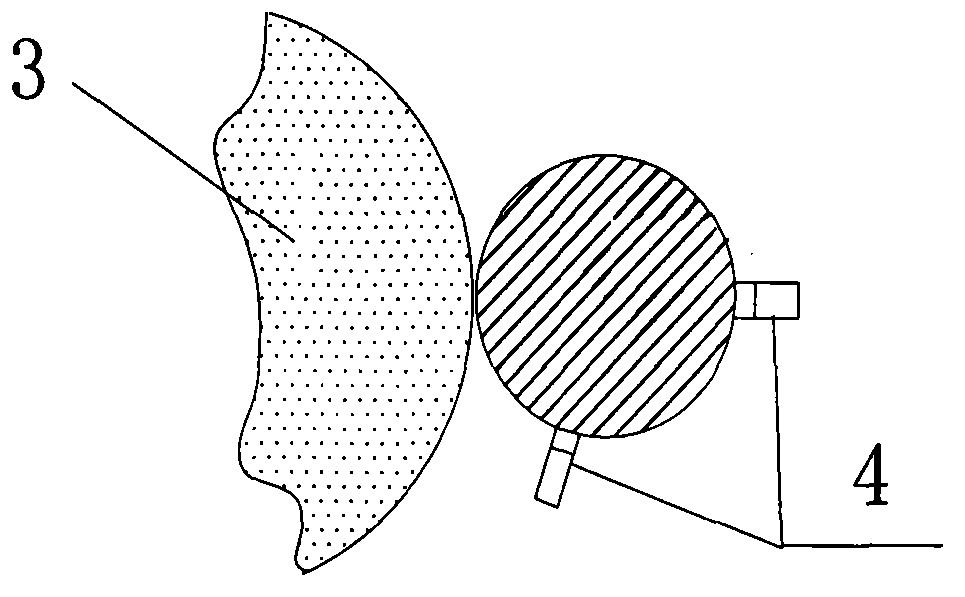

InactiveCN102189388AEliminate the effect of precisionMeet strength requirementsMachining deformationCoordinate-measuring machine

The invention discloses a manufacture method of a door module of an integral vehicle main model checking fixture. The manufacturing method approximately comprises the following steps of: carrying out rough machining on an aluminum alloy blank, then carrying out aging treatment, renovating a corresponding machining reference platform, semifinishing, then carrying out aging treatment, finishing, measuring by using a three-coordinate measuring machine, renovating the corresponding machining reference platform, secondarily finishing, and assembling a workpiece. The method has the advantages of effectively eliminating precision influence of machining deformation to final products through multiple aging treatment and renovation on the machining reference platform, ensuring that the final product reaches the requirement for strength by using the aluminum alloy material with reliable strength, and manufacturing the door module of the integral vehicle main model checking fixture according withrequirements for strength and precision.

Owner:ROYAL GAUGE IND

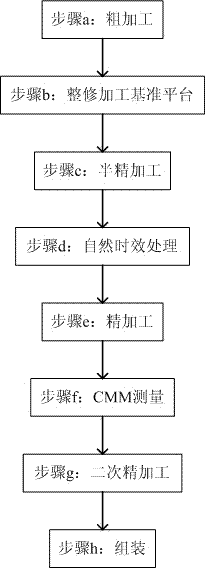

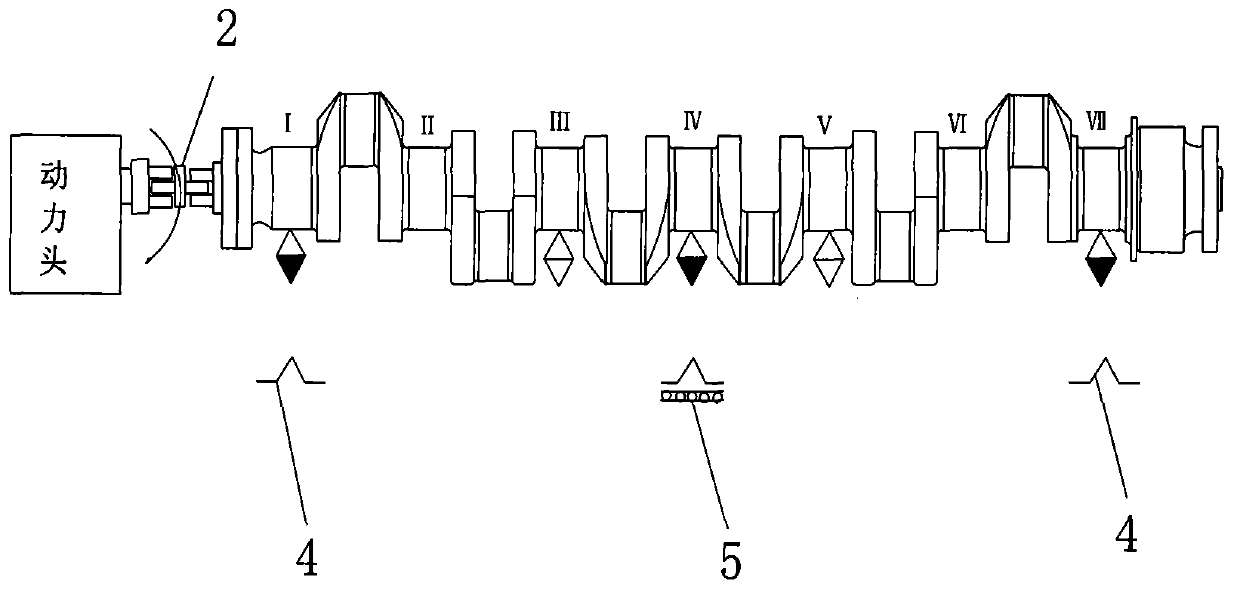

Machining method for grinding main journal of crankshaft in floating mode

InactiveCN103624642AEliminate the effect of precisionEliminate thermal deformationRevolution surface grinding machinesNatural stateEngineering

The invention relates to a machining method for grinding a main journal of a crankshaft in a floating mode. The method sequentially comprises the following steps: S1, clamping; S2, adjusting a bracket support; S3, rough grinding, wherein first rough grinding is conducted on an IV gear main journal through a grinding wheel 3, a bracket at the position corresponding to the IV gear main journal is adjusted while the IV gear main journal is ground, and during adjustment, it is ensured that the bracket is consistent in height, feeding scales of a grinding wheel frame handle are consistent, the practical size of the journal is consistent, and an error of a processing reference supporting gear is within + / -0.005mm; then, rough grinding is conducted on an IIV gear main journal and an I gear main journal, the more three reference supporting gears are ground in a reciprocating mode, the higher the grinding precision of the crankshaft is, and the coaxiality is better; S4, fine grinding, the step of rough grinding is repeated, fine grinding is conducted four to five times, after fine grinding, the main journal D=210mm, and tolerance ranges from 0mm to 0.029mm; S5, the remaining main journal is machined. Floating grinding is adopted in the machining method for grinding the main journal of the crankshaft in the floating mode, namely grinding is conducted on the crankshaft in the natural state, and influence of prestress, heat deformation and precision of a machine tool spindle is eliminated.

Owner:LIYANG CITY RICHWAY MEDIUM SPEED DIESEL ENGINE PARTS

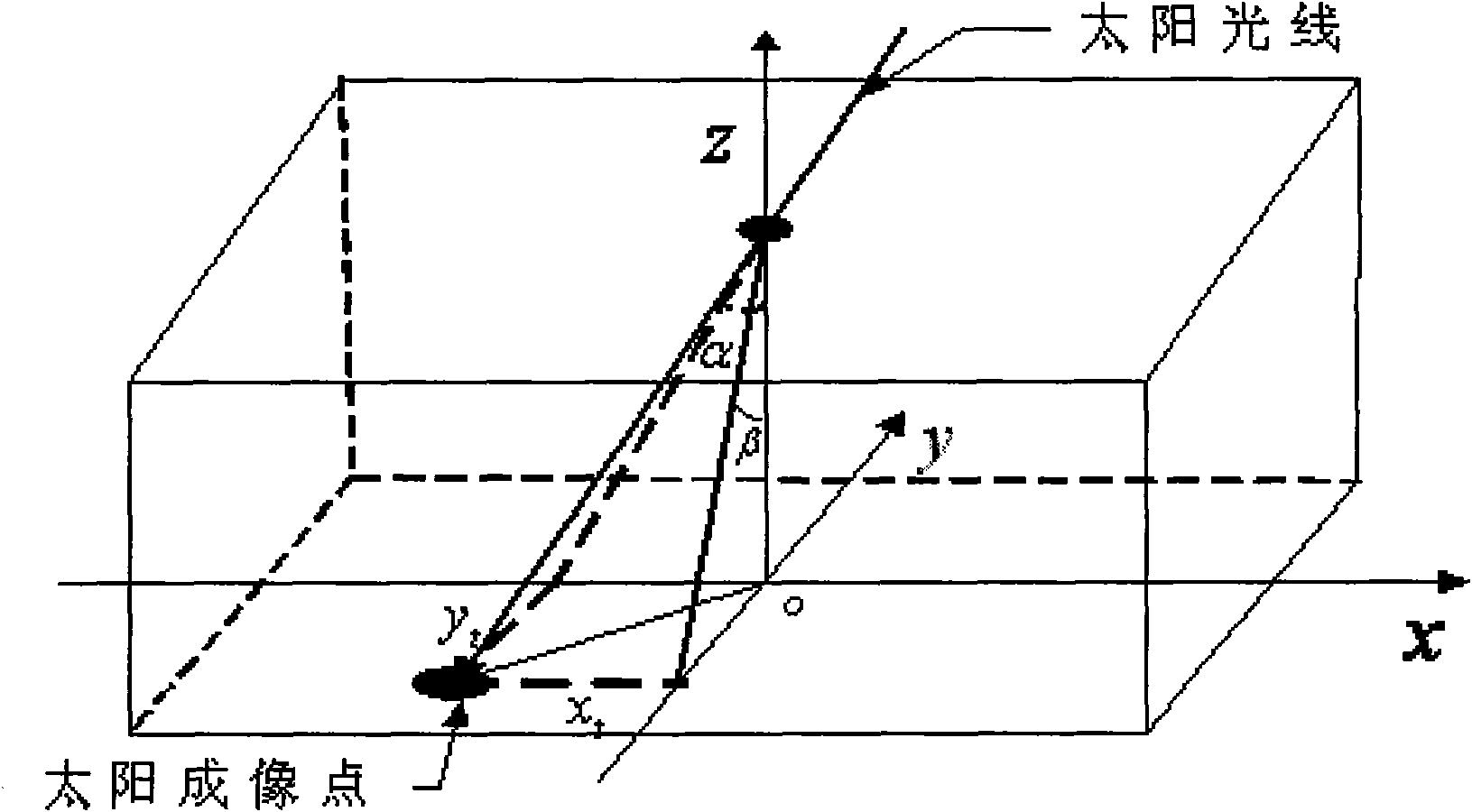

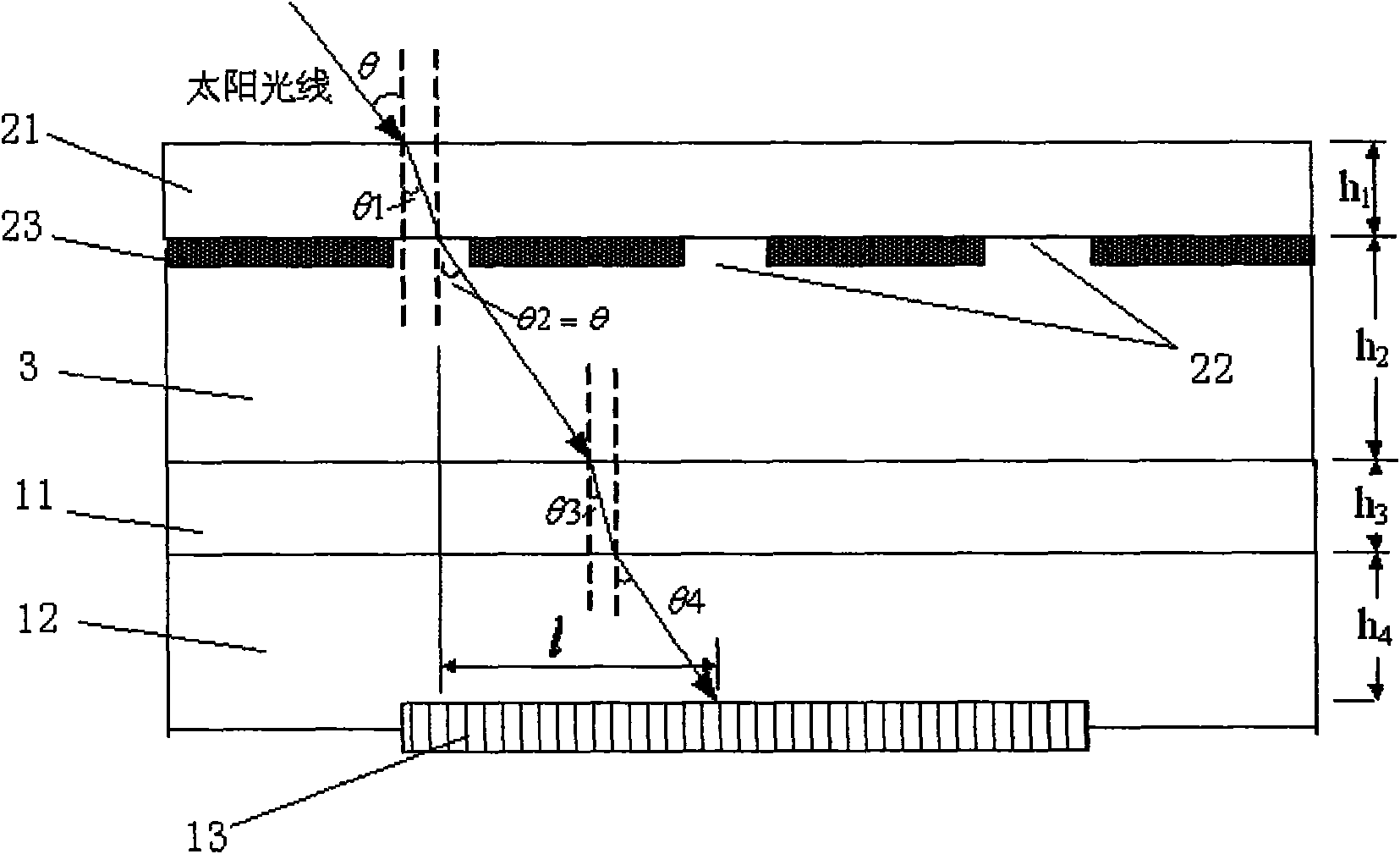

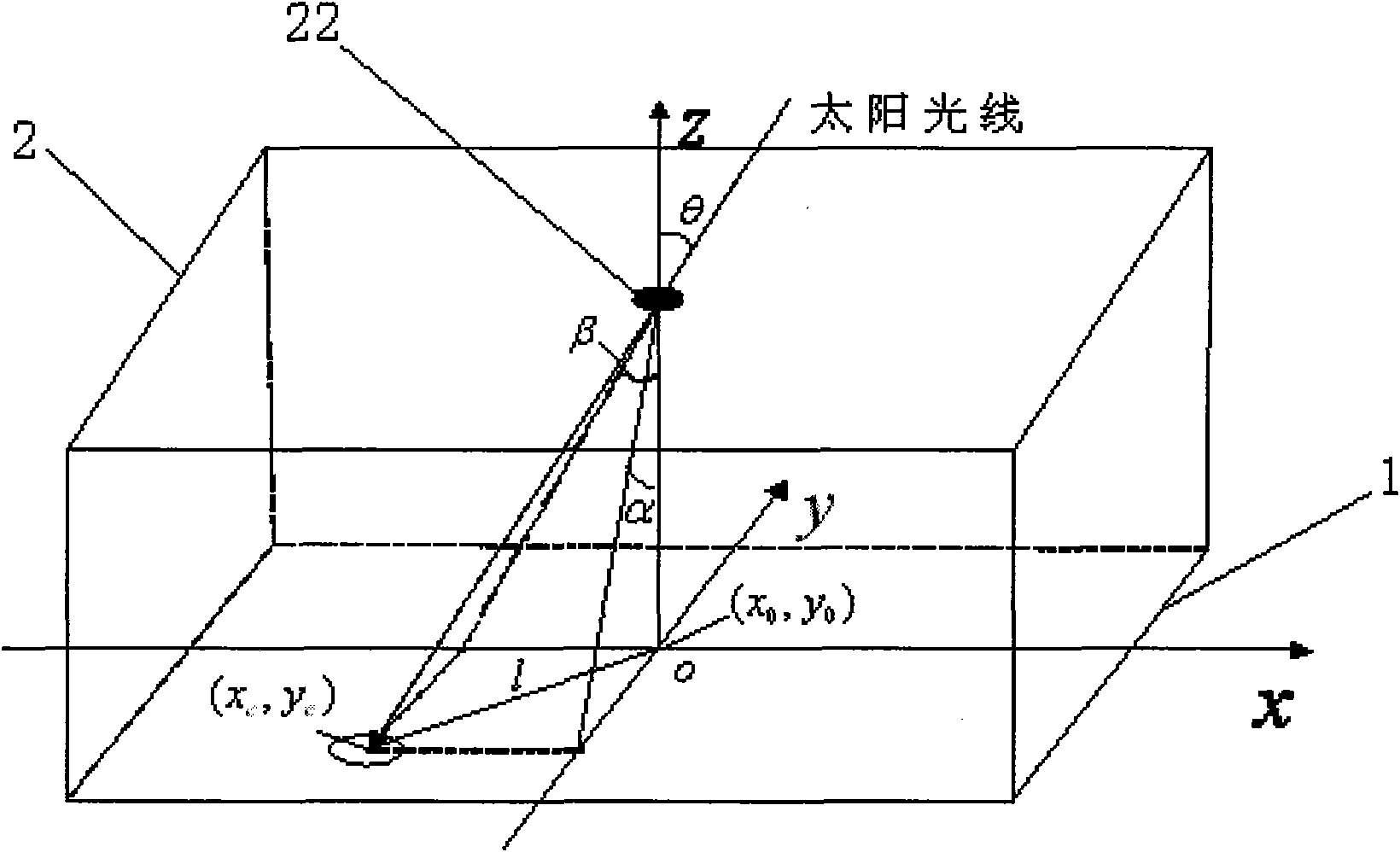

Method and device for measuring angle of incidence of sunlight on basis of APS technology

ActiveCN101598546ASmall amount of calculationImprove reliabilityAngle measurementSpacecraft guiding apparatusCMOS sensorProtective glasses

The invention relates to a method and a device for measuring the angle of incidence of sunlight on the basis of APS (Active Pixels Sensor) technology. The method is characterized by comprising the following steps: fitting the data acquired by simulation in a laboratory to acquire the parameters in the polynomial equation for the tangent value of the angle of incidence of sunlight; pre-setting the parameters in a storage device. In the practical operation of the device of the invention, the related data acquired on a real-time basis is only needed to insert into the polynomial equation to acquire the tangent of the angle of incidence of the sunlight and working out the angle of incidence of the sunlight. Therefore, the measuring method of the invention has the characteristics of low calculated quantity and convenient use. The device of the invention comprises a photo-detector, a light introducer and a cavity between the photo-detector and the light introducer; wherein, the photo-detector comprises protective glasses, a gas-filled cavity and photosensitive pixels; the protective glasses, the gas-filled cavity and the photosensitive pixels are packaged inside the photo-detector. The method and the device of the invention for measuring the angle of incidence of sunlight are widely applicable to the attitude measurement and control system of a spacecraft.

Owner:北京天银星际科技有限责任公司

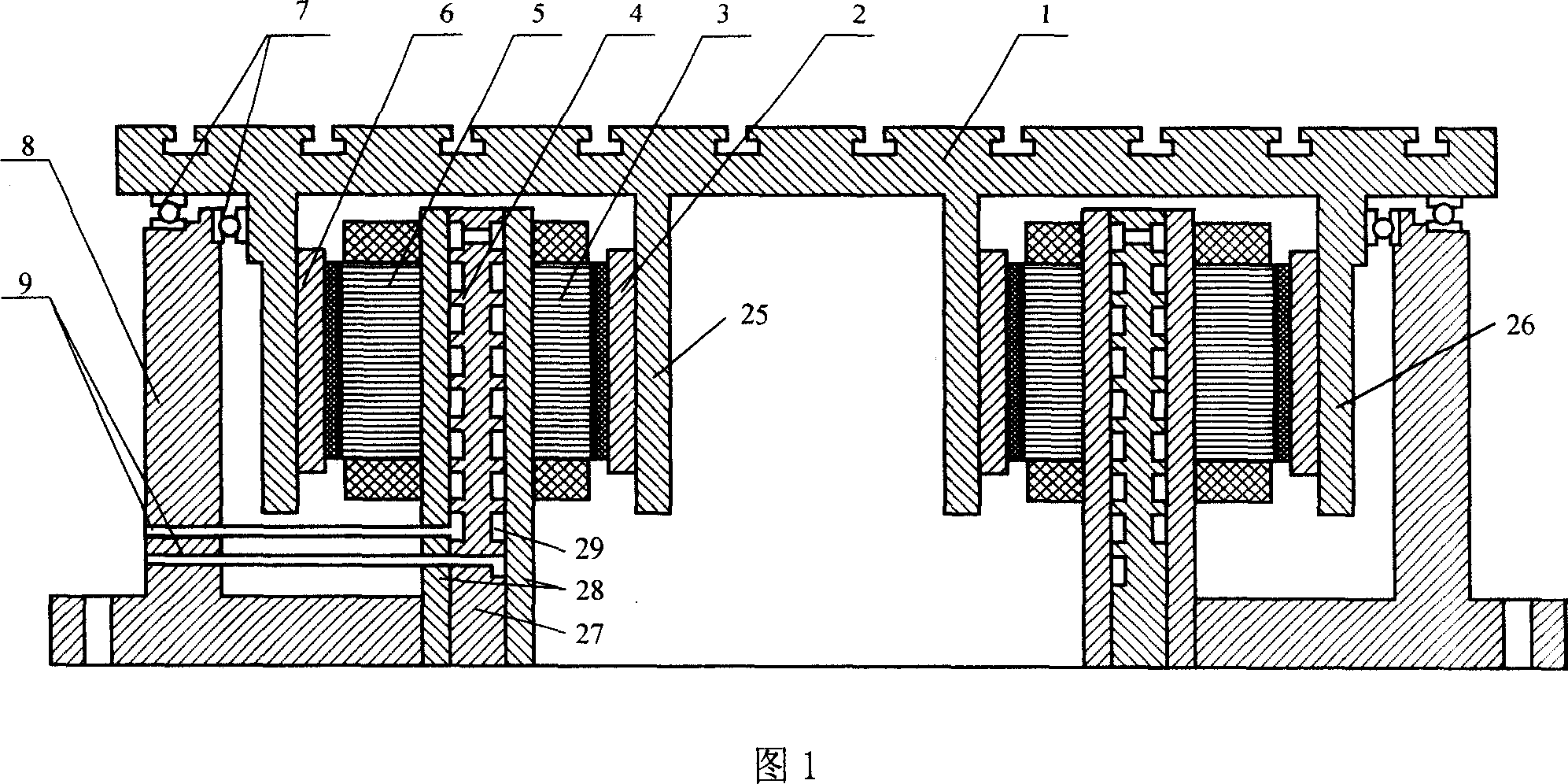

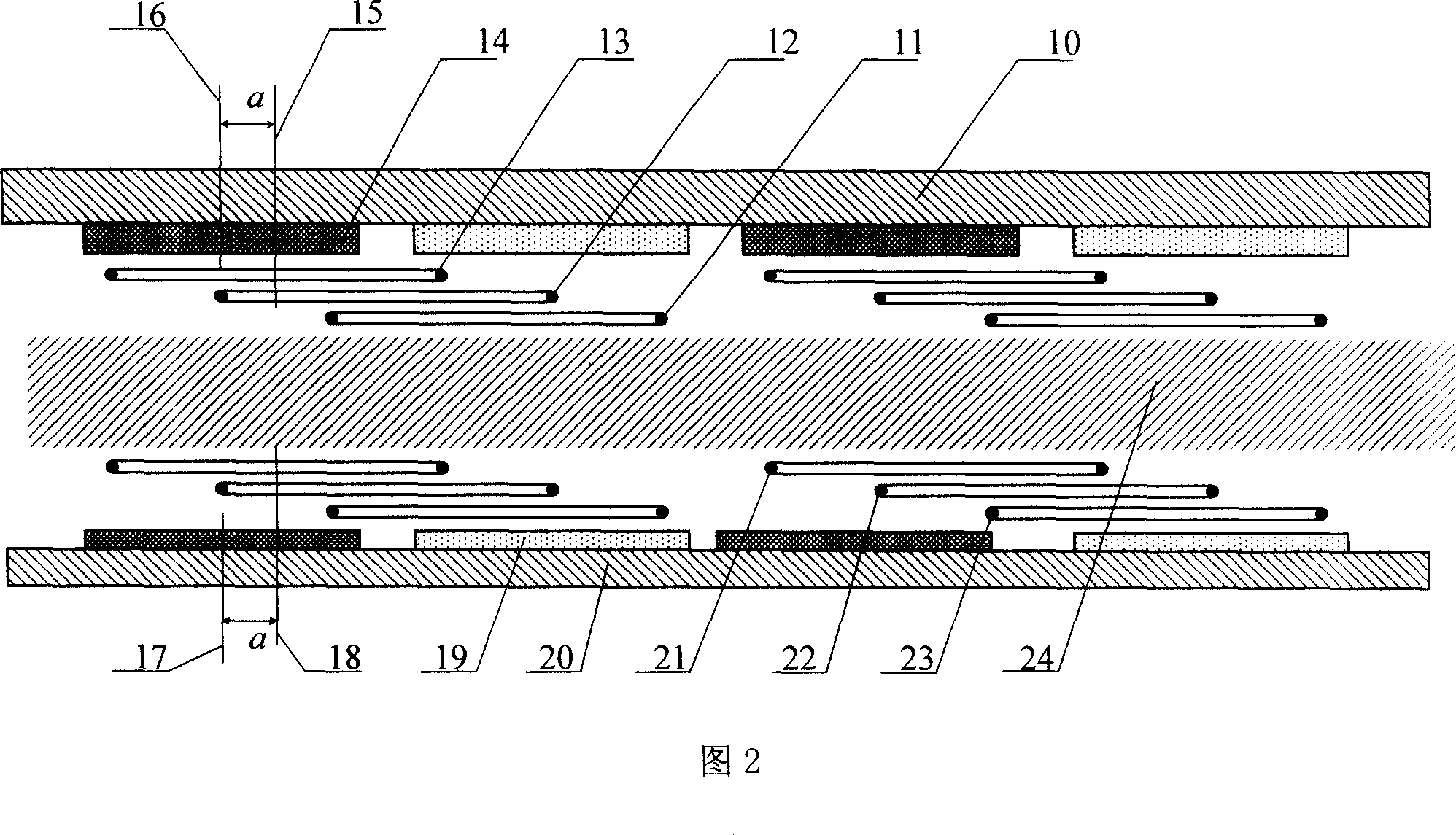

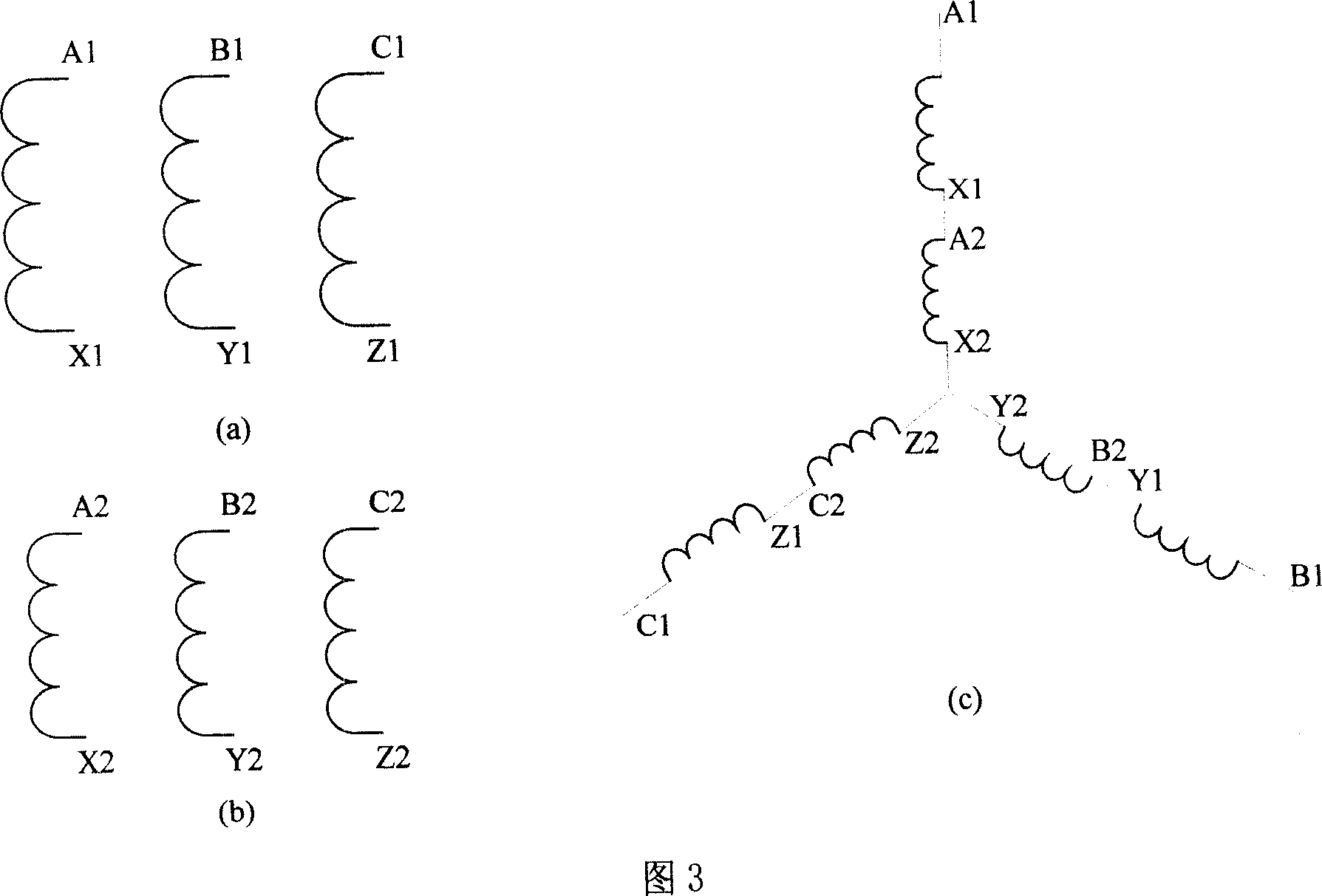

Precise digital control rotation platform based on direct driving of serial dual synchronous torque motor

InactiveCN101034863AIncreased torque densityIncrease rotational accelerationMagnetic circuit rotating partsMultiple ac dynamo-electric motors controlNumerical controlElectric machinery

The invention relates to a precise numerical control turnplate which based on he double synchronized moment of force electrical motor series direct drive, belongs to the electrical machine application technology area. Including the turnplate foundation, the turnplate working surface, the electrical machinery cooling structure, the outer rotor permanent magnetism synchronization ring-like moment motor and internal rotor permanent magnetism synchronization ring-like moment motor, the invention has better radiation effect, has solved the big torque turnplate radiation problem, enhanced the numerical control turnplate torque density and the electrical motor service life; also enhanced the turnplate turning acceleration, the response speed and the system dynamic rigidity, the control precision.

Owner:SHENYANG POLYTECHNIC UNIV

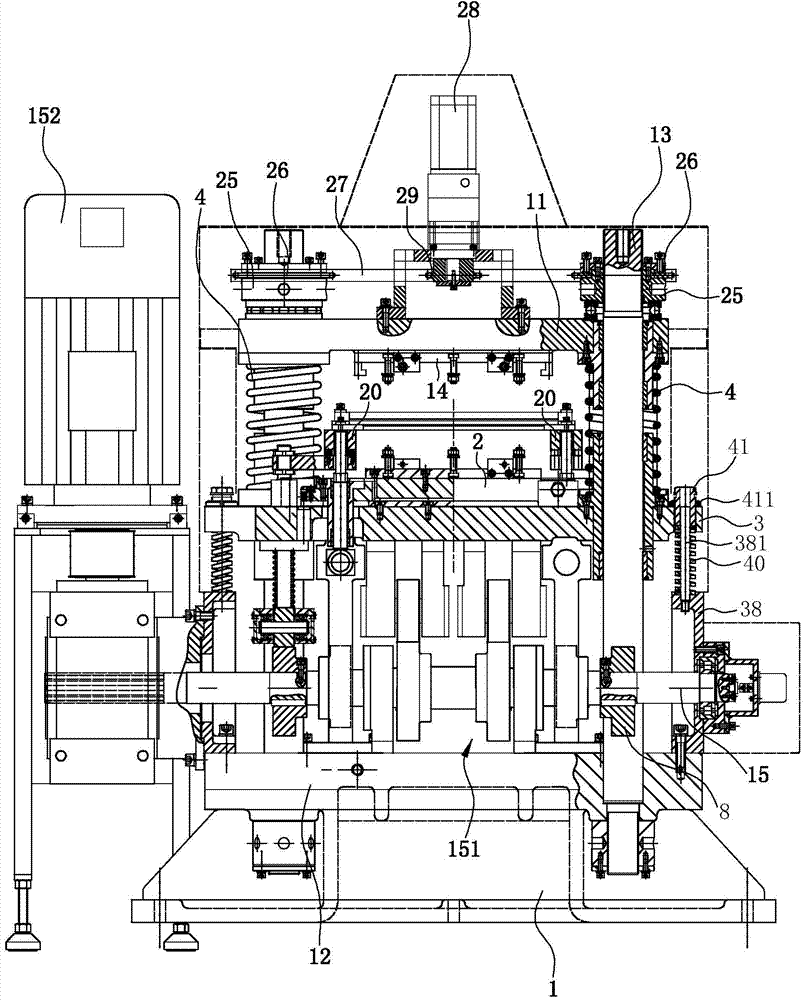

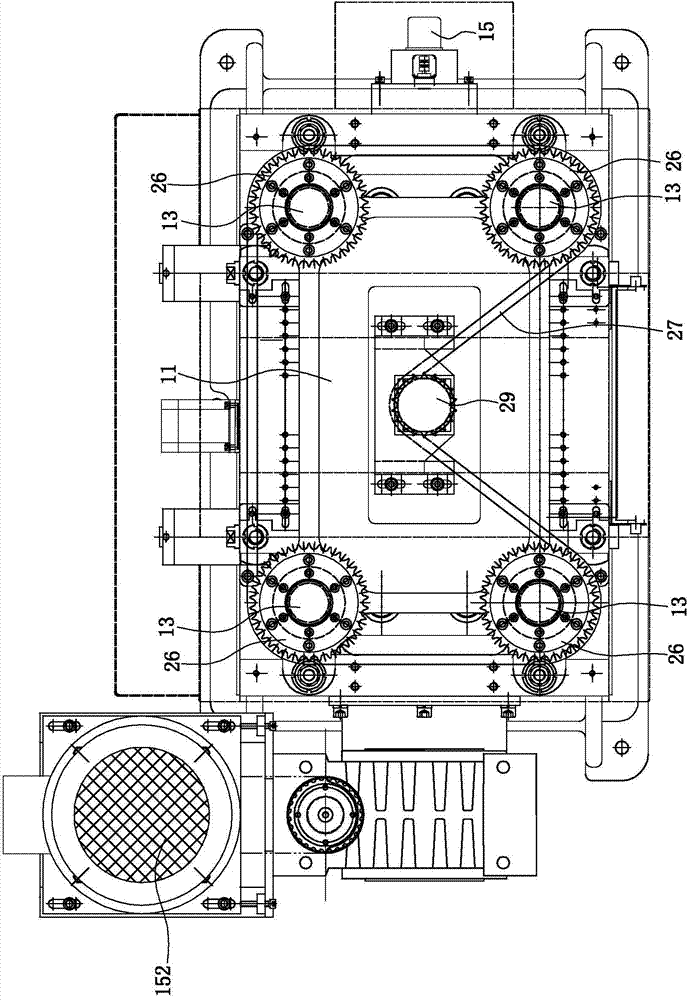

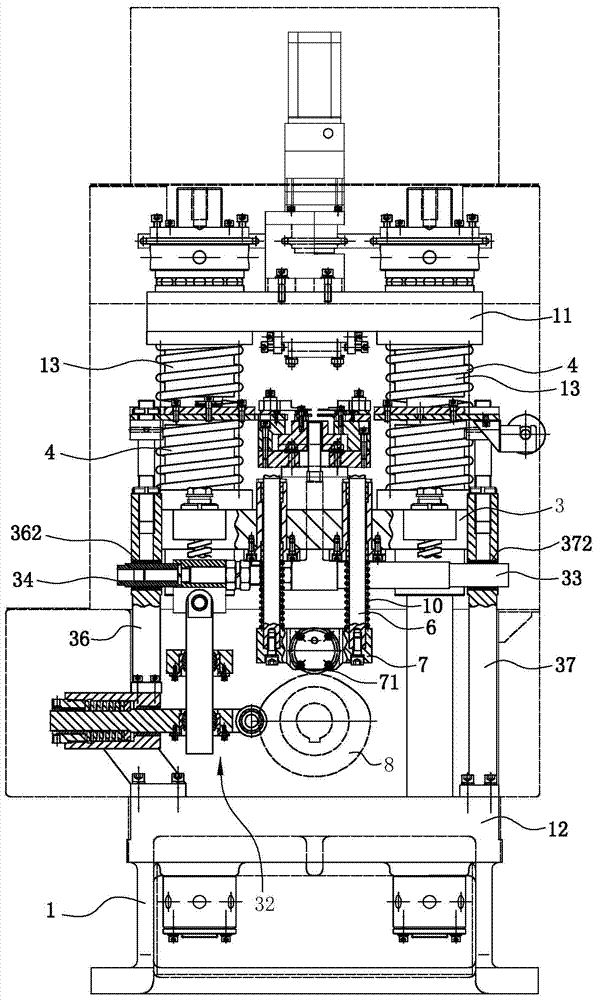

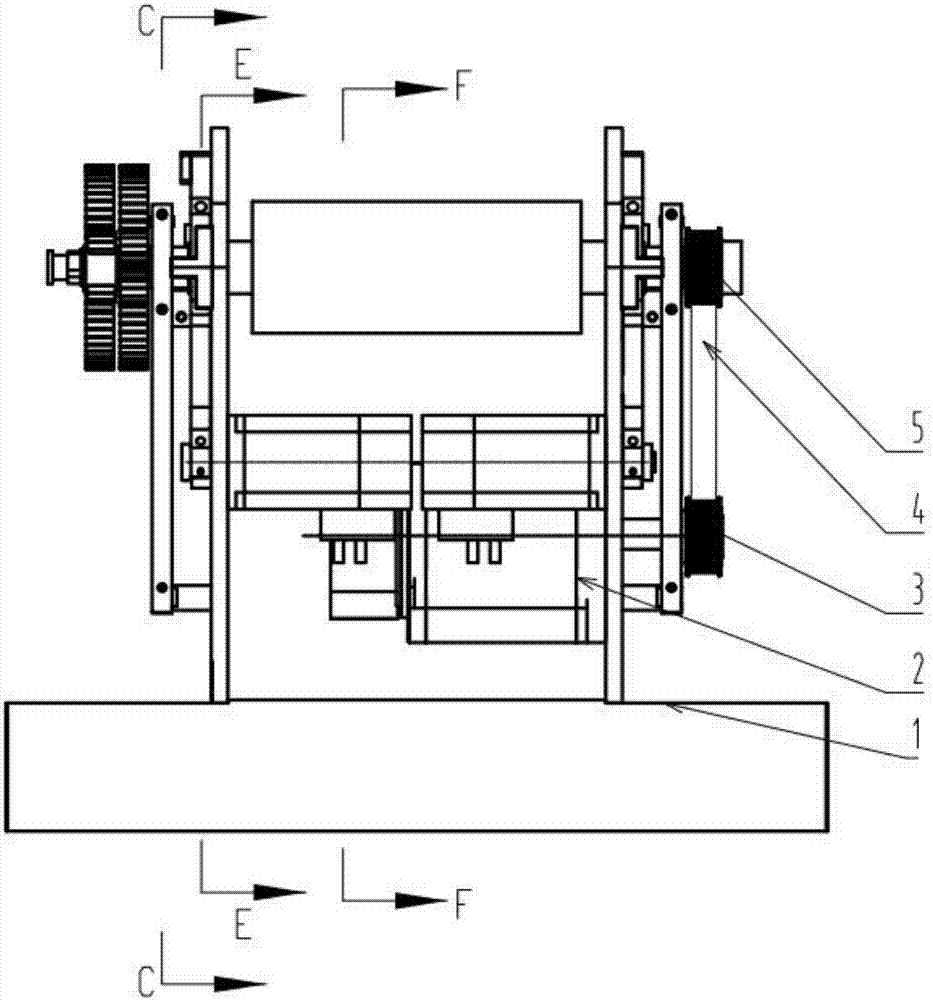

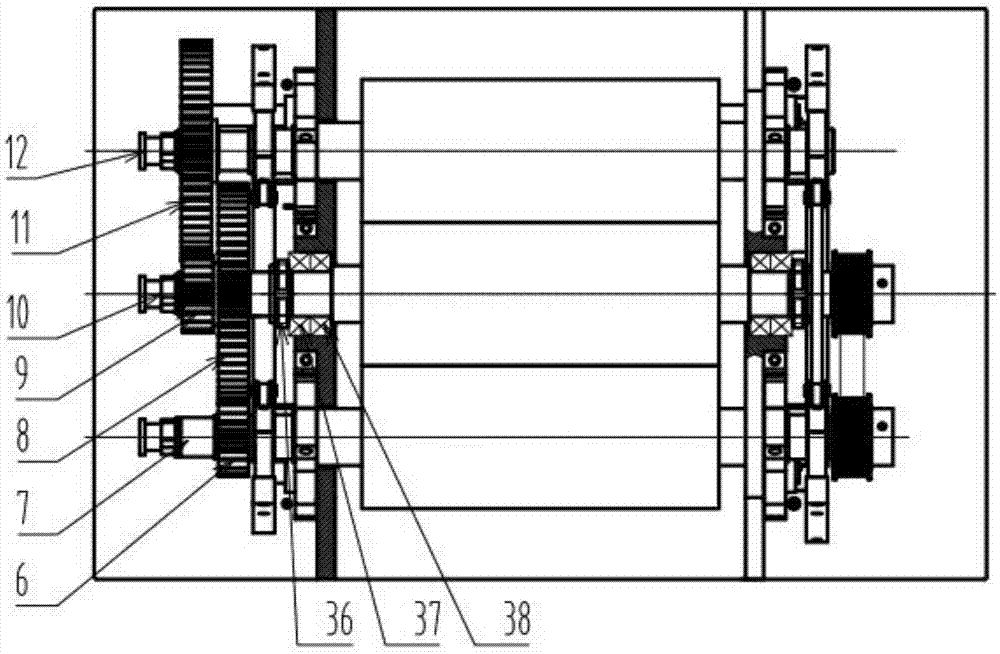

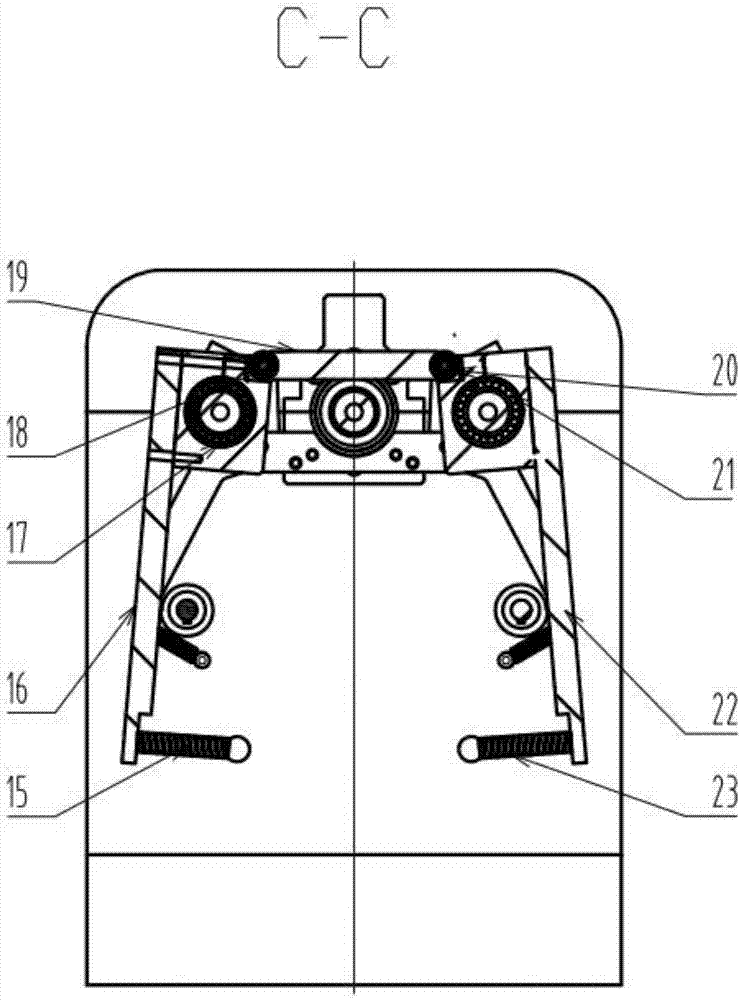

Upper die fixed type fin forming machine

ActiveCN104722679AEliminate the effect of precisionShaping toolsMetal-working feeding devicesCouplingDrive shaft

The invention relates to an upper die fixed type fin forming machine. The upper die fixed type fin forming machine is characterized by comprising a machine frame, a lower die plate, a retaining spring, two shifting rods, a transmission shaft, a cam driving structure and a stripping structure, wherein the machine frame is composed of an upper machine plate, a lower machine plate and a guiding column, an upper die installation plate is installed on the upper machine plate, the lower die plate is arranged on the lower portion inside the machine frame and can slip up and down along the guiding column, a lower die installation sliding plate is arranged above the lower die plate, the guiding column is sleeved with the retaining spring which is supported between the upper machine plate and the lower die plate, the left and right shifting rods are arranged vertically in a spaced mode, penetrate through the lower die plate upwards and then are connected with the lower die installation sliding plate, the transmission shaft is driven by a motor to rotate, the cam driving structure is arranged inside the machine frame, located below the lower die plate and arranged between the transmission shaft and the lower die plate, and the stripping structure is arranged between the lower die plate and the upper machine plate. Due to the fact that the upper die does not need to do the vertical stamping action, an upper driving shaft, an upper die plate and a cam driving structure between the upper driving shaft and the upper die plate in the prior art can be eliminated, and the precision influence generated by abrasion of a universal coupler in an existing structure is eliminated.

Owner:NINGBO RONGZHI AUTOMATION TECH

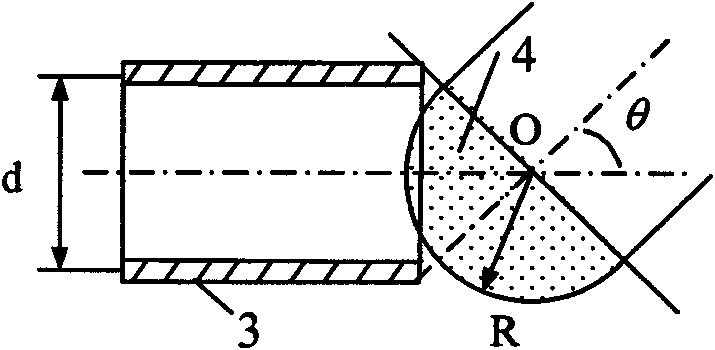

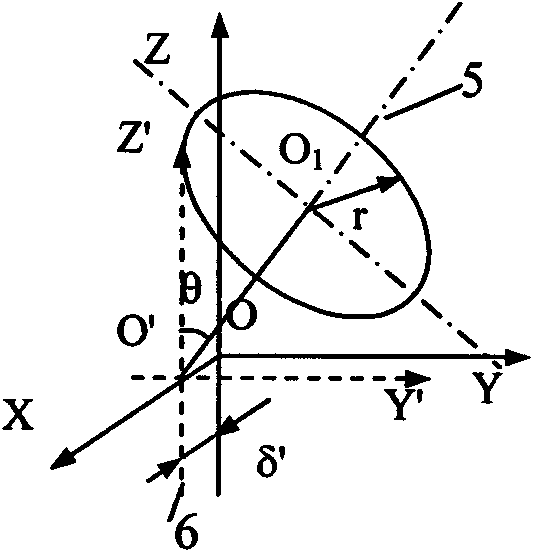

Diamond ball head grinding wheel electric sparkle dressing cutter adjustment method based on two-time cutter adjustment process

InactiveCN101623847AImprove surface accuracyMeet the surface accuracy requirementsAbrasive surface conditioning devicesGrinding wheelFace shape

The invention discloses a diamond ball head grinding wheel electric sparkle dressing cutter adjustment method based on two-time cutting tool process, and relates to a ball head grinding wheel electric sparkle dressing cutter adjustment method. The purpose of the invention is to improve the accuracy of cutter adjustment in dressing a grinding wheel, so as to improve the surface shape accuracy of the diamond ball head grinding wheel which is dressed. The main technical core of the invention is: firstly, the relative mounting positions of a grinding wheel spindle and a electrode spindle are precisely adjusted before grinding wheel dressing, so that the axial lines of the grinding wheel spindle and the electrode spindle form an angle of to 45 degrees and intersect at a point; secondly, first-time cutter adjustment is performed on a small-diameter diamond ball head grinding wheel, and the grinding wheel is dressed for the first time; finally, two newly formed edge feature points of the grinding wheel are selected to realize the second cutter adjustment of the small-diameter diamond ball head grinding wheel. The second cutter adjustment after the first cutter adjustment can effectively eliminate the influence of manufacturing errors of the grinding wheel and judgment errors of the edge feature points on the cutting tool accuracy; under the same conditions, the two-time cutter adjustment process can reduce cutter adjustment errors by 30% to 70%.

Owner:HARBIN INST OF TECH

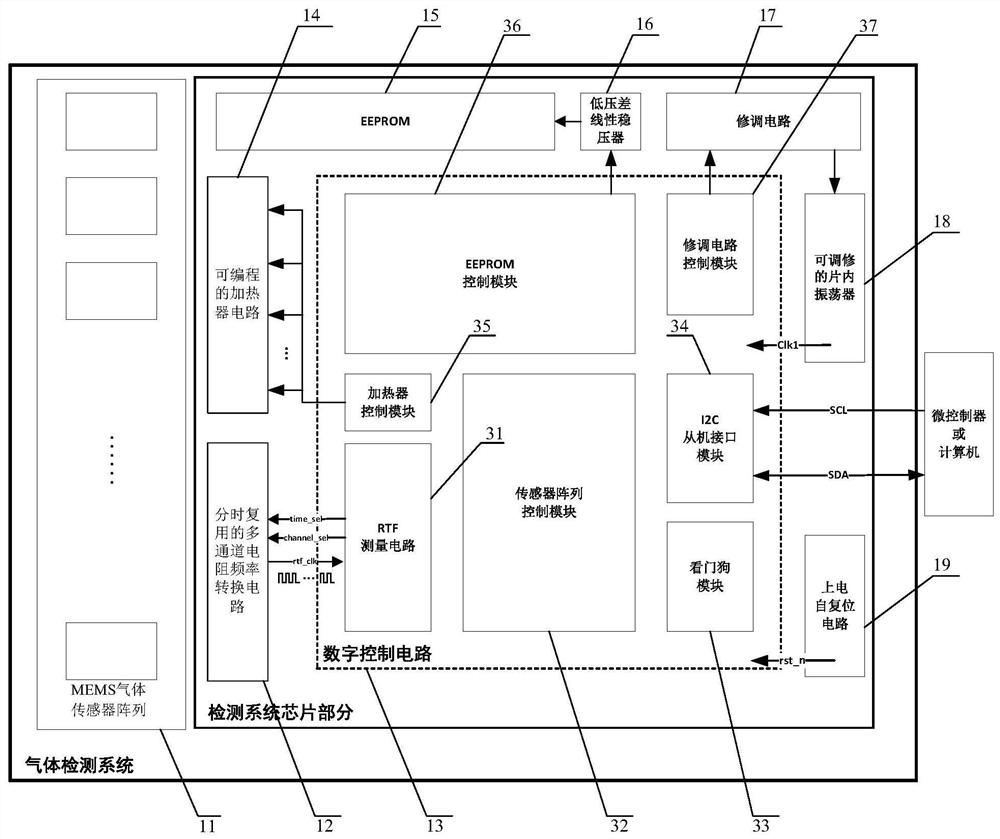

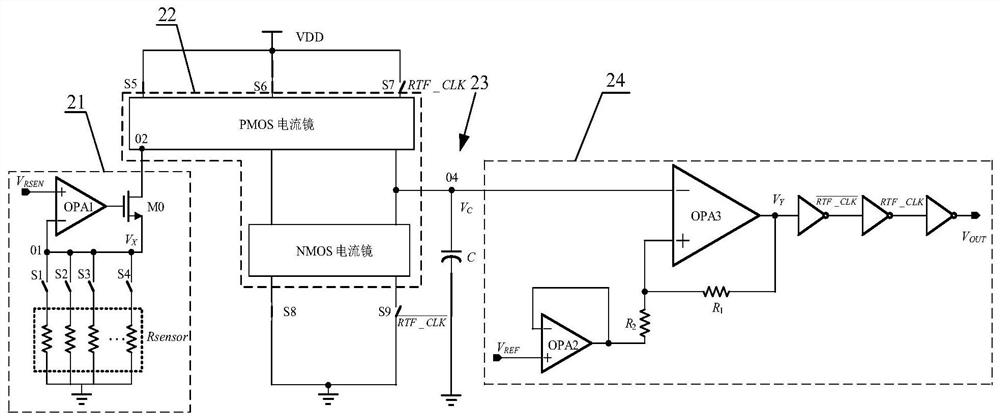

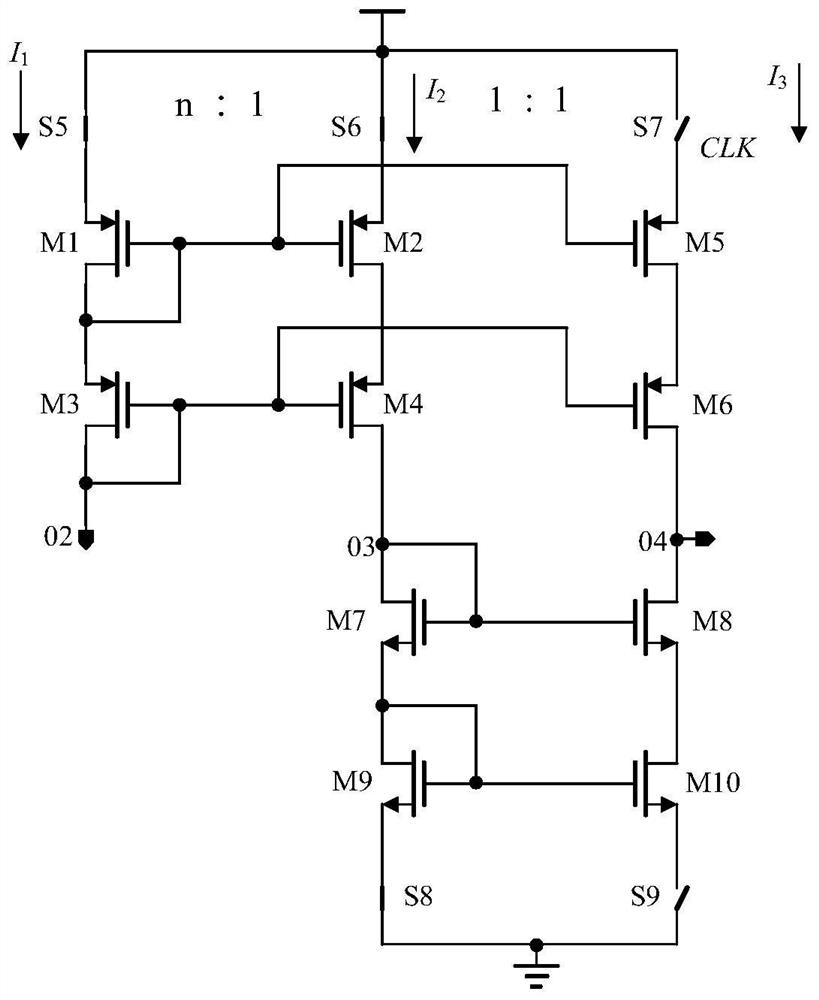

Gas detection system based on MEMS gas sensor array

ActiveCN112730527AEliminate the effect of precisionHigh selectivityMaterial resistanceSensor arrayHemt circuits

The invention discloses a gas detection system based on an MEMS gas sensor array. The gas detection system comprises the MEMS gas sensor array, a time division multiplexing multi-channel resistance frequency conversion circuit, a programmable heater circuit, an EEPROM, a trimmable on-chip oscillator, a power-on self-reset circuit and a digital control circuit. The MEMS gas sensor array comprises a plurality of gas sensors; the gas sensor comprises a heater resistor and a gas sensitive material resistor; the MEMS gas sensor array is used for converting gas information in the environment into resistance change of the gas sensitive material; the multi-channel resistance frequency conversion circuit is used for converting the resistance value of the gas sensitive material of the selected channel into a square wave signal with a corresponding frequency; and the on-chip oscillator is used for generating a stable clock signal required by the system. By applying the technical scheme provided by the invention, the working voltage and the circuit power consumption can be reduced, and the detection range and the detection precision of the gas sensitive material resistor in the gas sensor are improved.

Owner:UNIV OF SCI & TECH OF CHINA

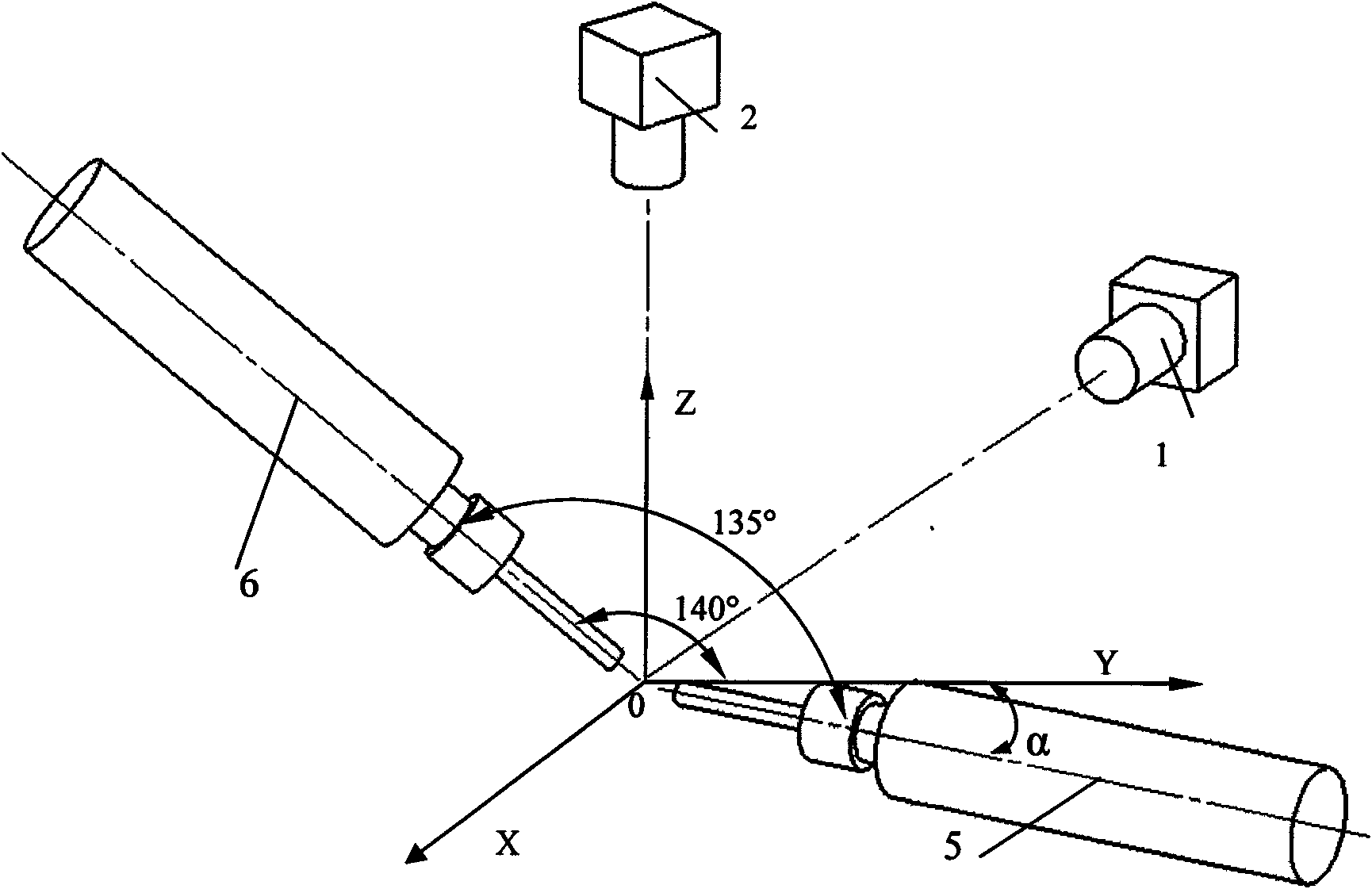

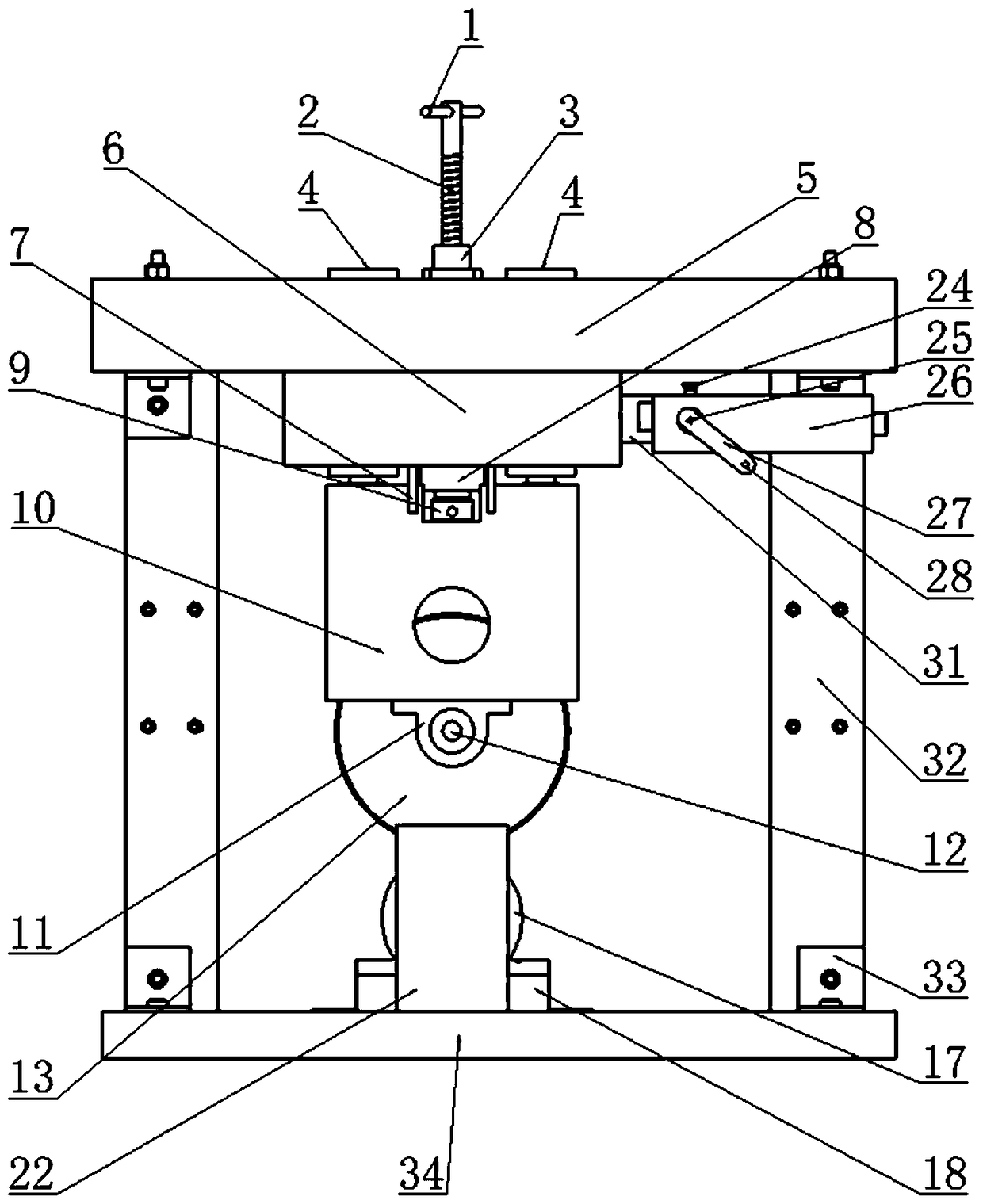

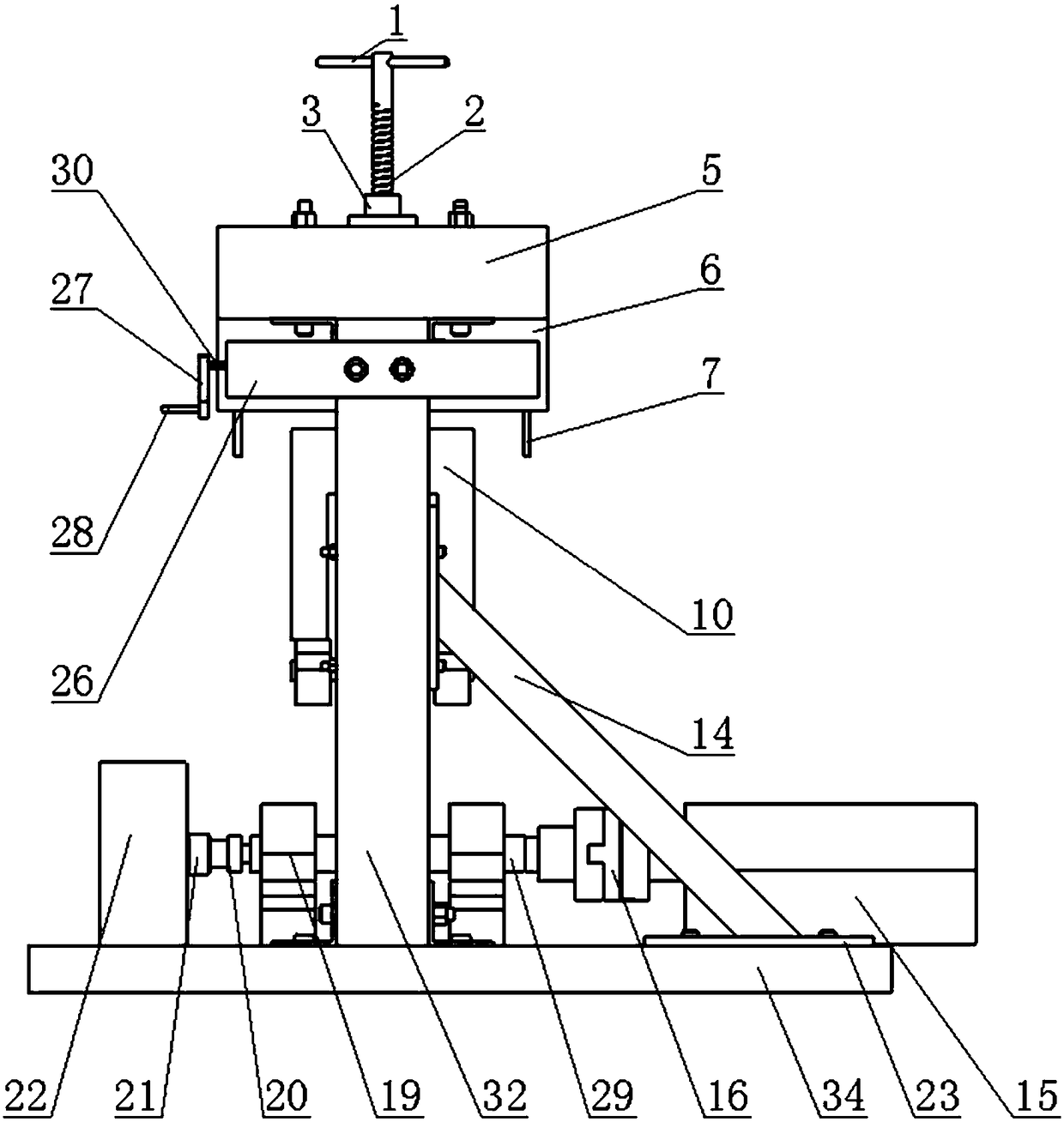

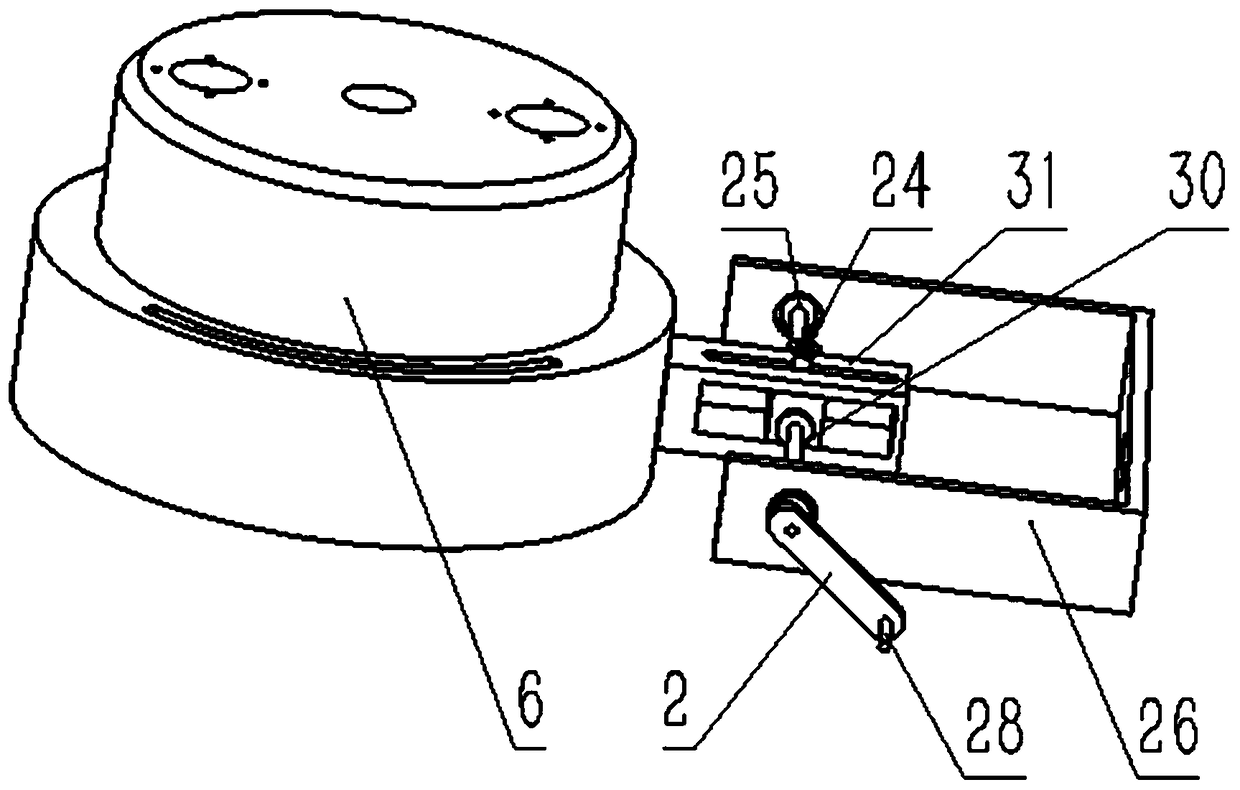

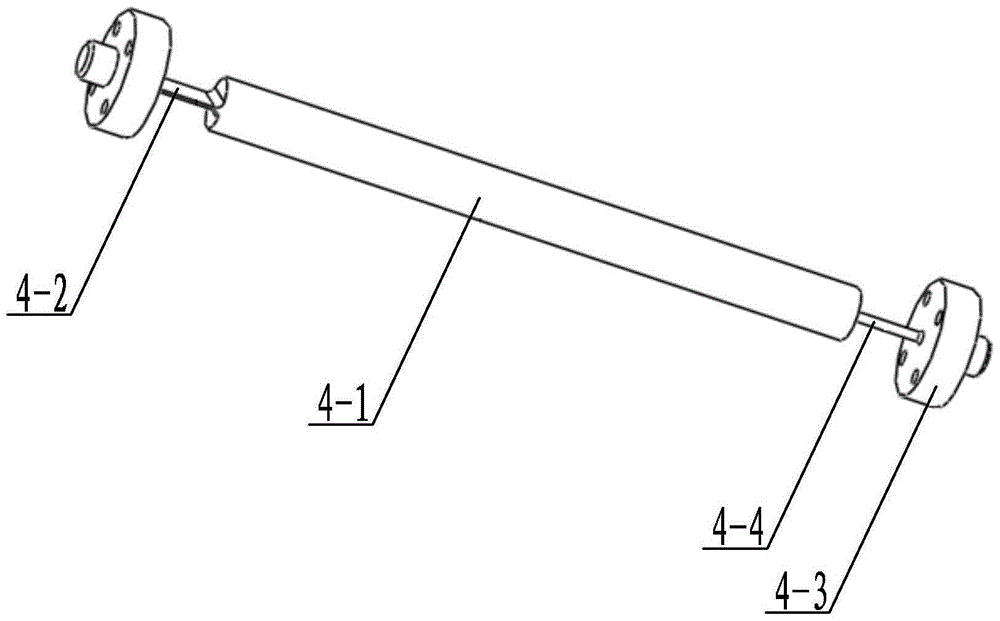

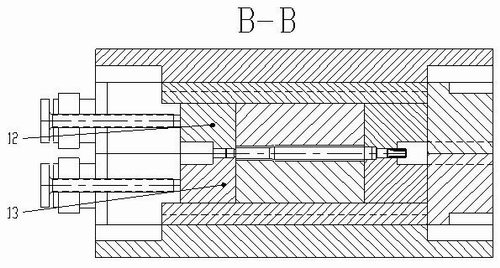

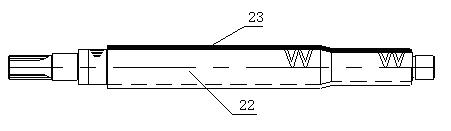

Rolling vibration test bench for simulating wheel-rail relation in rail transit

ActiveCN108956067AObserve creep force-creep rate characteristic curveStable deliveryMachine part testingRailway vehicle testingInterference fitCoupling

The invention relates to a rolling vibration test bench for simulating the wheel-rail relation in rail transit, which is used for simulating wheel-rail vertical loading and wheel-rail attack angle adjustment. The rolling vibration test bench comprises an overall framework supporting device, a wheel-rail simulation device, a driving shaft rotation driving device, a vertical loading device and an angle adjustment device, wherein the overall framework supporting device includes a bottom plate, a top plate, framework square steel connecting the bottom plate and the top plate and inclined square steel used for fixing the framework square steel and the bottom plate; the wheel-rail simulation device includes a lower end cover, a rolling wheel connected with the lower end cover through a driven shaft and a steel rail wheel which is in interference fit with the rolling wheel; the driving shaft rotation driving device includes a motor, a cross coupling and a driving shaft which are sequentiallyconnected, and the driving shaft is in transmission connection with the steel rail wheel; the vertical loading device is connected with the top plate and used for loading a vertical load to the rolling wheel; and the angle adjustment device is connected with the vertical loading device and used for adjusting the wheel-rail attack angle. Compared with the prior art, the rolling vibration test benchhas the advantages of tangential and transverse creep detection, high detection accuracy, ability of being economic and quick, low operation cost and the like.

Owner:SHANGHAI UNIV OF ENG SCI

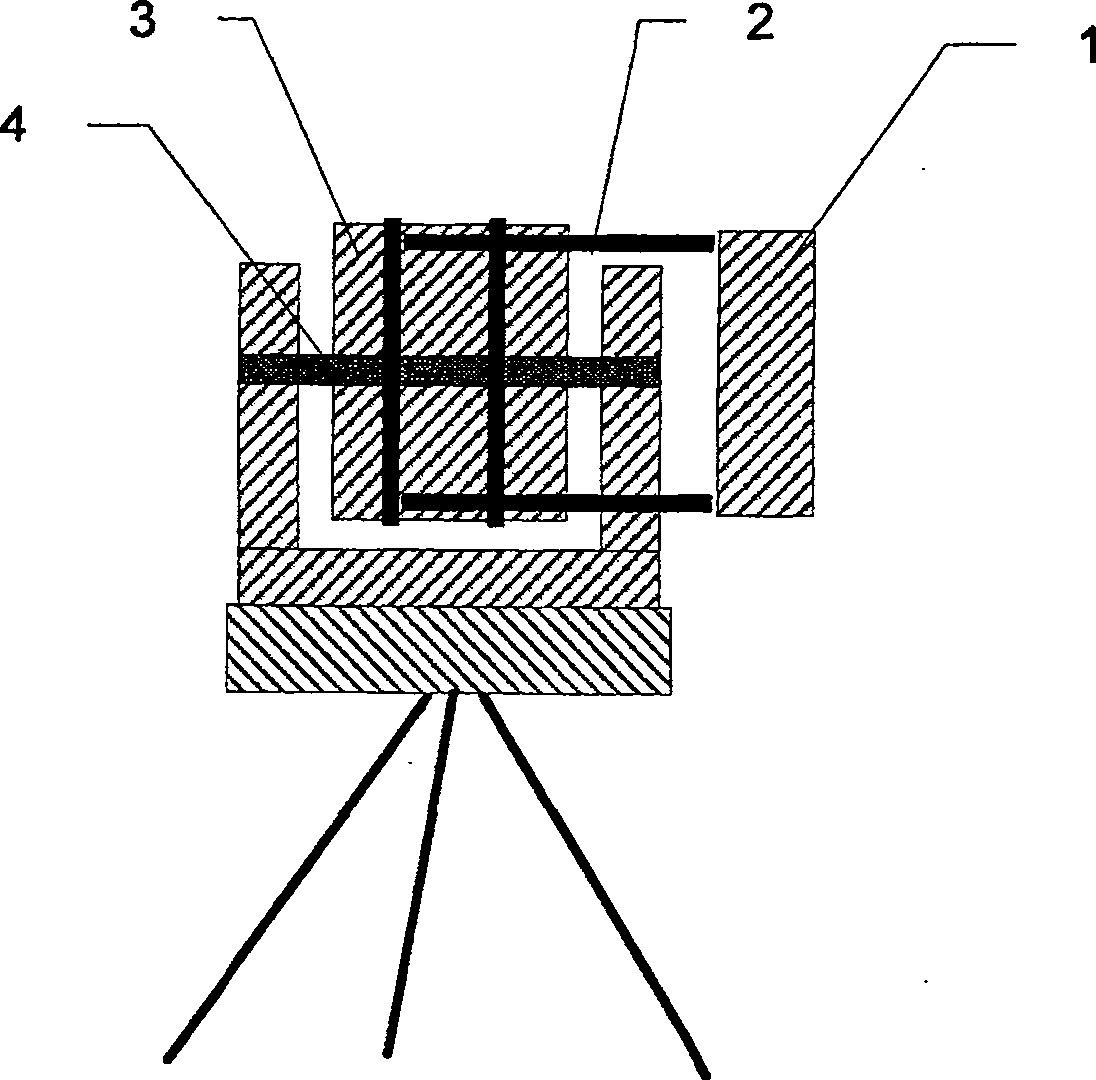

Automatic guide measuring target and measuring system for shield machine

InactiveCN103471569ASimple structureReduce manufacturing costAngle measurementSurveying instrumentsTotal stationEngineering

Provided is an automatic guide measuring target and system for a shield machine. The measuring target is a target prism which is arranged in the shield machine and can move along a fixed rectilinear coordinate. The spatial relationship between the rectilinear coordinate and the axis of the shield machine is known, and the target prism can remain at any position of the straight line. The system comprises the target and a total station which is arranged at the back of the shield machine and havs an automatic recognition function. The target prism moves along a rectilinear track and remains at different positions successively, the prism at the different positions is observed through the total station, spatial position information of a plurality of different remaining points is obtained, a rolling angle and a pitch angle are measured through a double-axis inclinometer INCL, and measurement results are transmitted back to the system. The automatic guide measuring target and system for the shield machine can be suitable for tunnel shield construction of various conditions, influence of angle-measuring errors of the total station on the measurement result precision can be greatly reduced or even eliminated, and the automatic guide measuring target and system for the shield machine can have self-check and correction capabilities.

Owner:北京申江工程技术咨询有限公司 +1

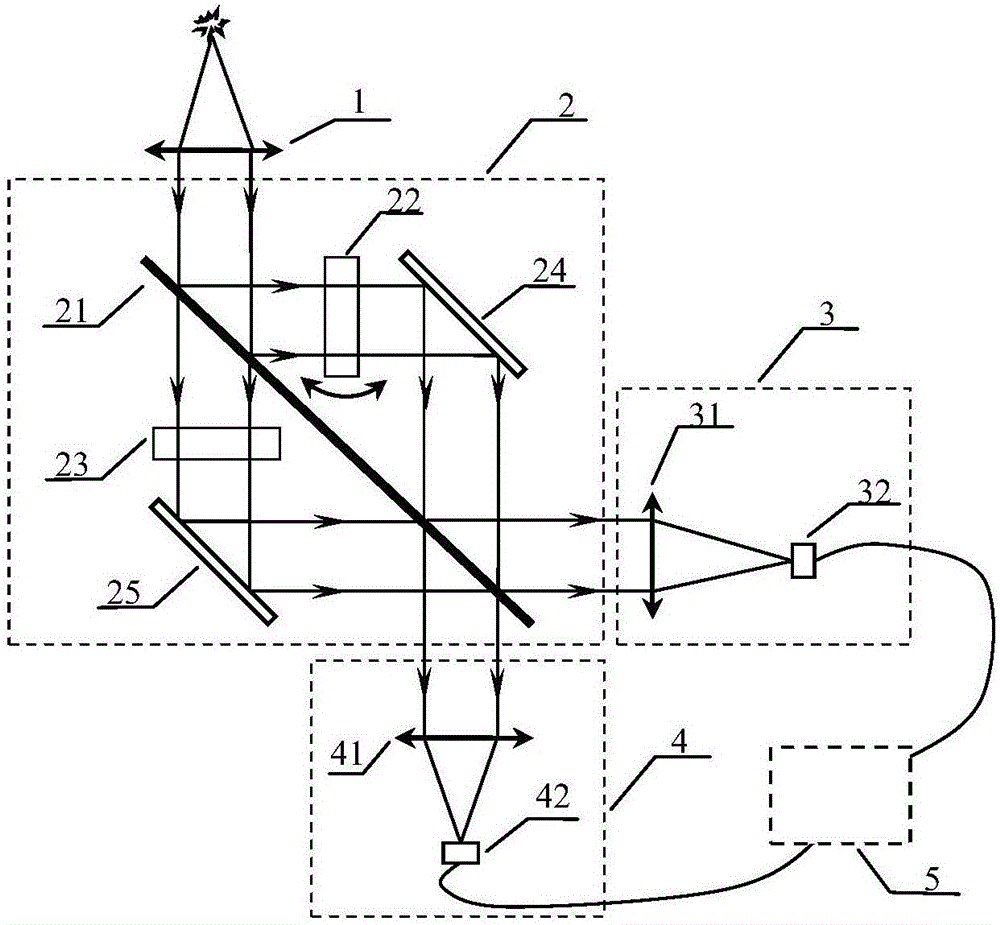

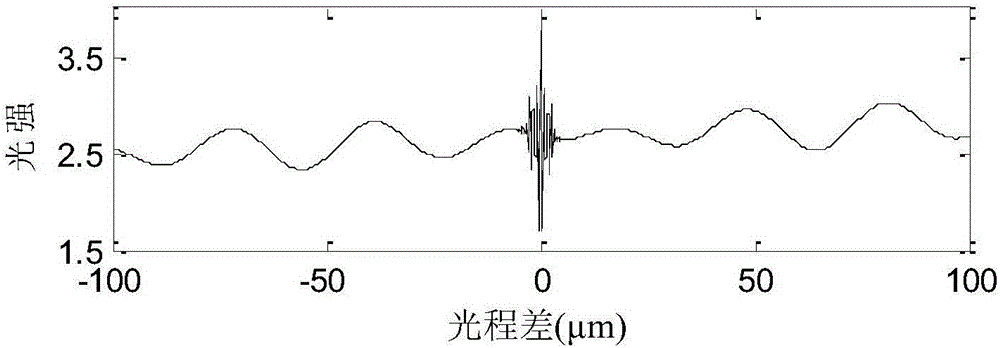

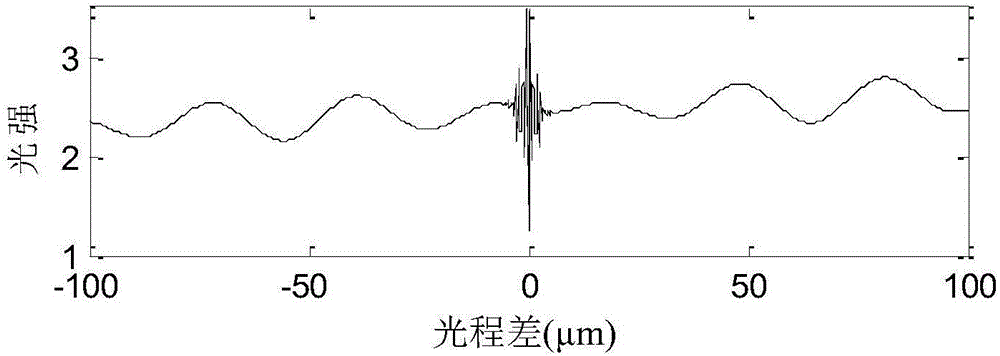

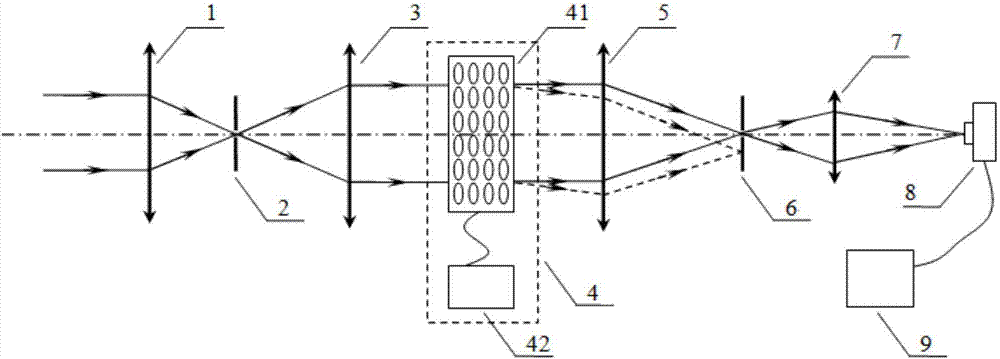

Dual-channel Fourier spectrograph and detection method

InactiveCN106546335AEliminate the effects ofEliminate the effect of precisionInterferometric spectrometryOptical pathPrism

The present invention discloses a dual-channel Fourier spectrograph and a detection method. The dual-channel Fourier spectrograph includes a collimating objective lens, a dual-channel interferometer, a first detection module, a second detection module and a data processing system which are all arranged sequentially along the direction of an optical path; the first detection module and the second detection module are both connected with the data processing system; the dual-channel interferometer comprises a beam splitter, a first prism, a first reflector, a second reflector and a second prism which share one optical axis and are arranged sequentially clockwise; a 45-degree angle is formed between the beam splitter and an incoming optical axis; the first reflector and the second reflector are parallel to the beam splitter; and the first prism can rotate or swing around an axis of which the prism center is perpendicular to a paper surface. With the dual-channel Fourier spectrograph and the detection method adopted, two paths of interference information of a light beam emitted from a detection point (a target) can be obtained simultaneously, the amount of the change of the light intensity of the detection point with time can be demodulated out from the interference information, and therefore, influence on the interference information caused by the change of the light intensity of the detection point can be effectively eliminated, and the accurate spectral information of the detection point can be restored.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

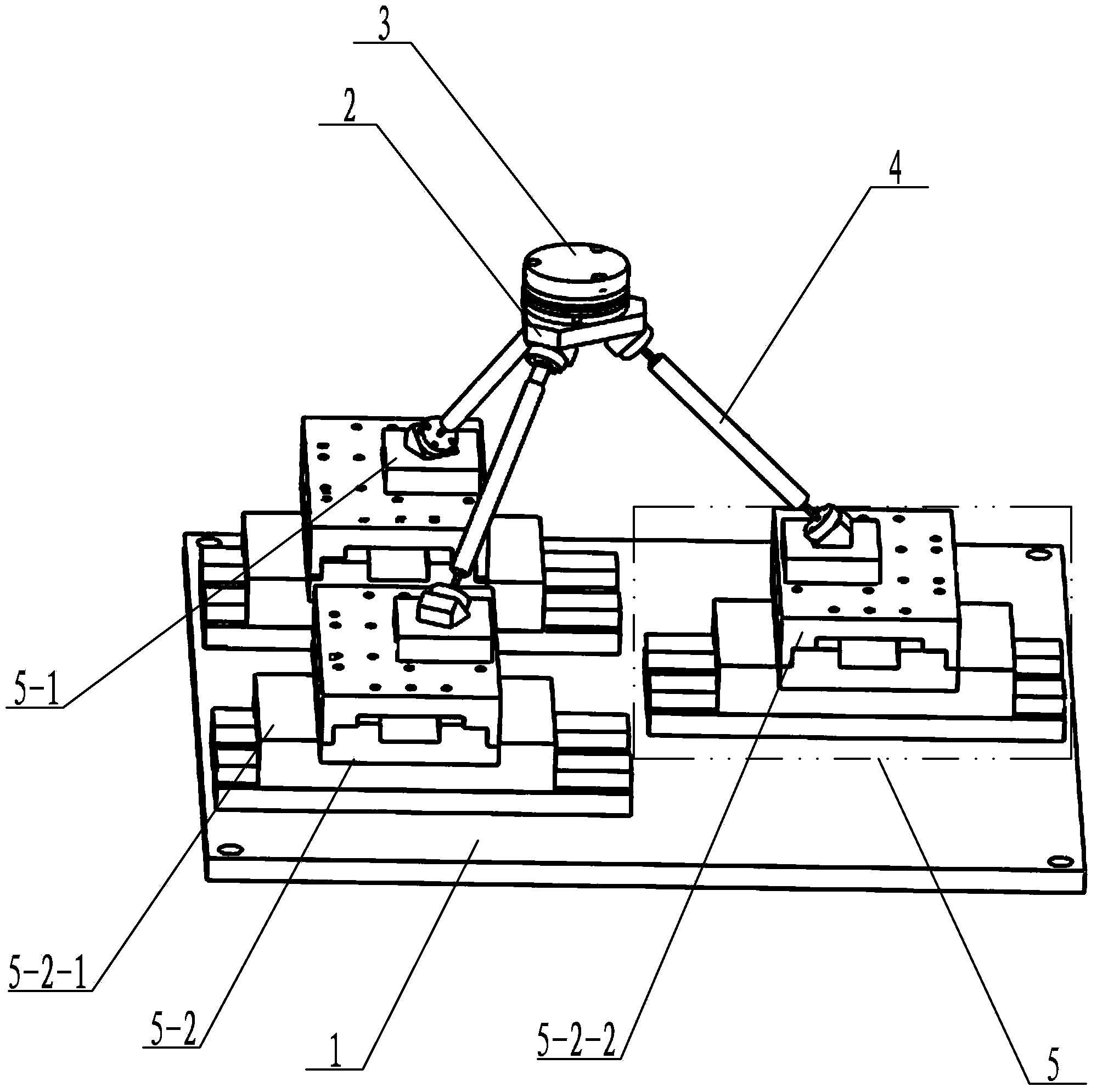

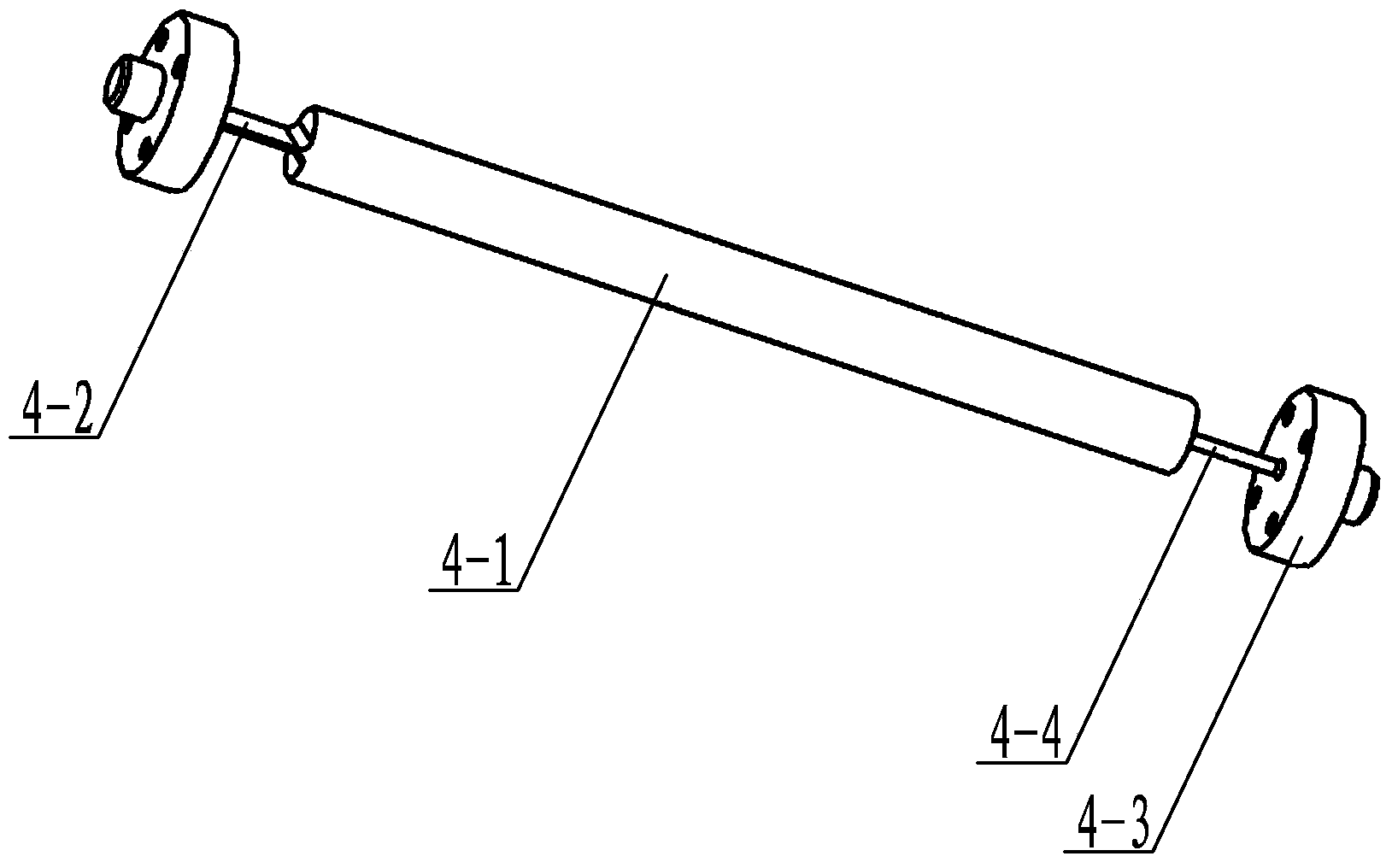

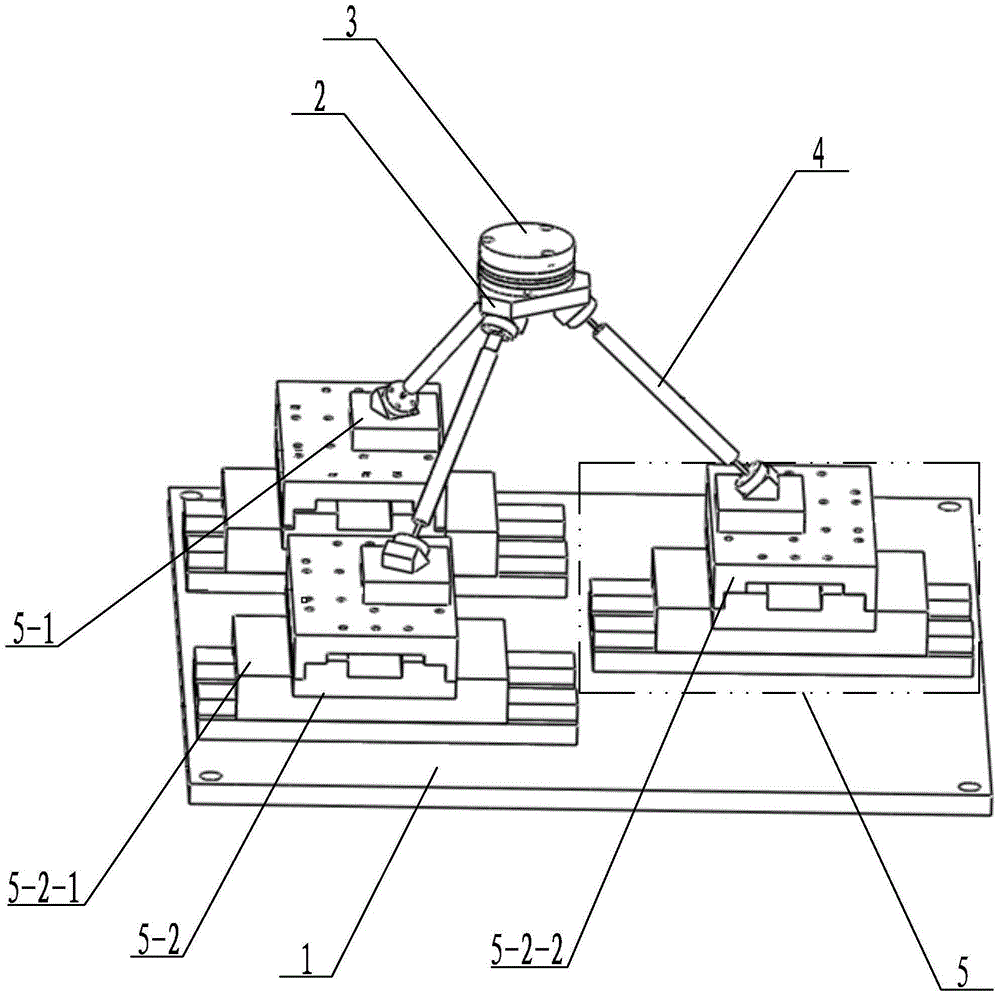

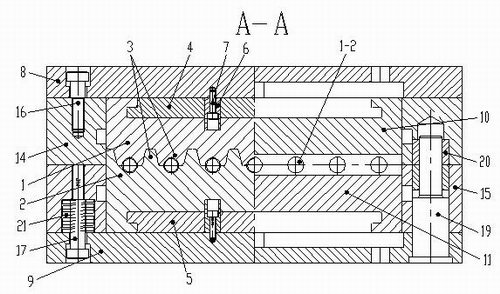

Flexible parallel platform device

ActiveCN104325458ALarge working spaceRealize the hinge functionProgramme-controlled manipulatorElectricityMicro-operation

The invention discloses a flexible parallel platform device, relates to a parallel platform device, and aims to solve the problem of incapability of meeting the requirements of high precision and larger working space in a micro operation environment in the conventional flexible hinge. The flexible parallel platform device comprises a shock isolation platform (1), an upper platform (2), a six-dimensional force sensor (3), three flexible branch chains (4) and three groups of platform assemblies (5), wherein the three groups of platform assemblies (5) are arranged on the shock isolation platform (1); the upper platform (2) is positioned above the three groups of platform assemblies (5); each group of platform assemblies (5) is connected with the lower end face of the upper platform (2) through one flexible branch chain (4); the six-dimensional force sensor (3) is arranged at the upper end of the upper platform (2); each group of platform assemblies (5) comprises a base (5-1) and a piezoelectric driving motor (5-2); the bases (5-1) are arranged at the upper ends of the piezoelectric driving motors (5-2). The flexible parallel platform device is applied to micro-operation of robots.

Owner:HARBIN INST OF TECH

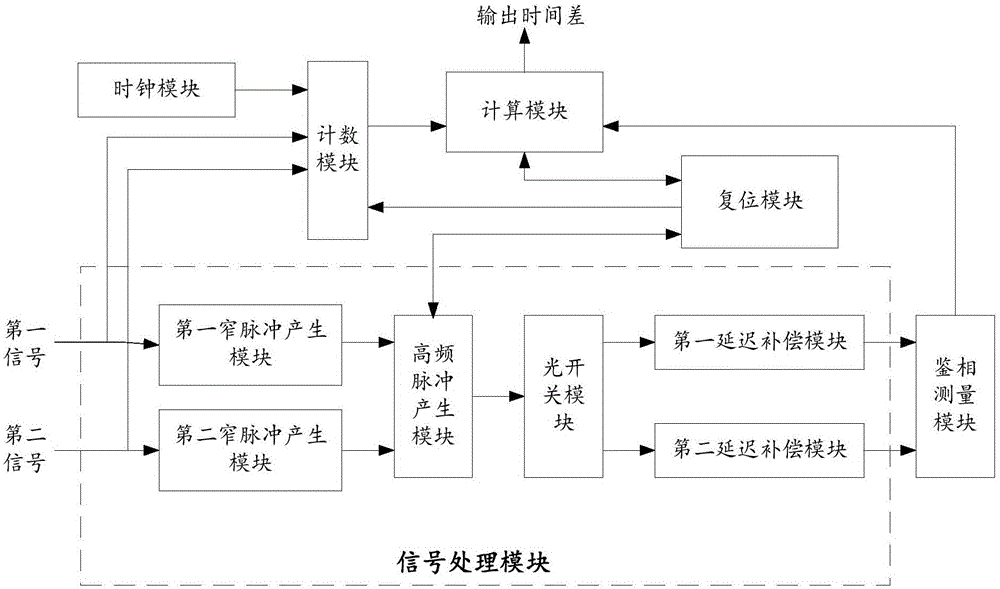

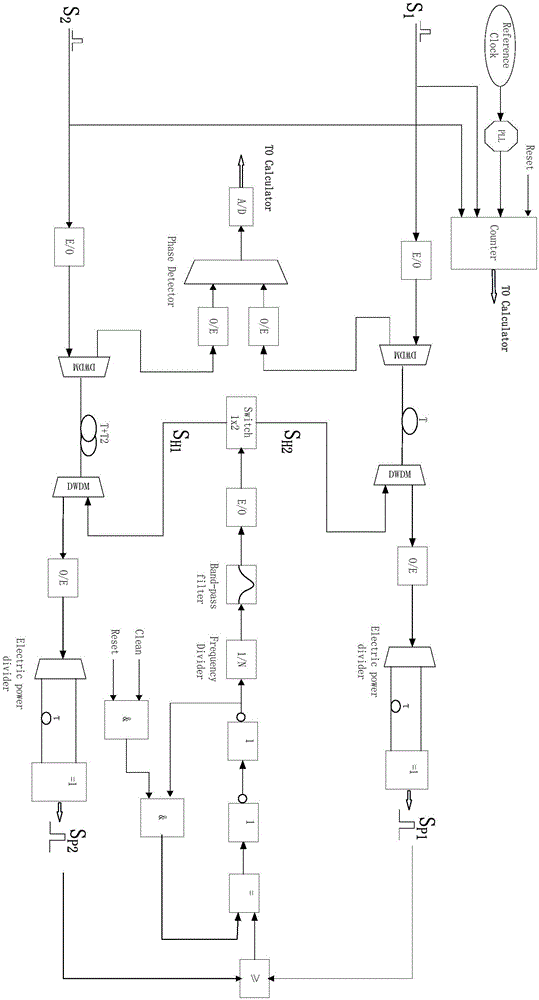

High-precision pulse signal time difference measurement device and method

InactiveCN107436383AEliminate the effect of precisionHigh precisionPulse characteristics measurementsDiscriminatorMeasurement device

The invention provides a high-precision pulse signal time difference measurement device, and the device comprises a signal processing module which is used for generating a high-frequency sinusoidal observed quantity signal, a clock module which is used for generating a signal with the same period as the high-frequency sinusoidal observed quantity signal, a counting module which is used for obtaining integral-multiple period time difference, a phase discrimination measurement module for obtaining the phase difference, a calculation module for calculating the time difference between a first signal and a second signal, and a resetting module which is used for enabling the device to be in an initial state. The invention also provides a method employing the above device. The method employs the optical signal and electric signal processing technology to process two input signals into two high-frequency sinusoidal observed quantity signals, and the two sinusoidal observed quantity signals are inputted to a phase discriminator for direct phase discrimination, so as to obtain the time difference which is less than one counting cycle, thereby eliminating the precision impact from a reference clock signal. When the counting clock with the same period with the high-frequency sinusoidal observed quantity signal is used for the timing of the integral-multiple periods, the precision of the signal time difference counting period is improved, and a problem that the high-precision testing of pulse signal time difference is difficult to achieve is solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Precision control type three-roller grinding machine

The invention discloses a precision control type three-roller grinding machine. The precision control type three-roller grinding machine comprises a machine frame, vertical plates, and a front roller, a middle roller, a rear roller, a roller transmission part, a roller spacing control part and a roller floating gap eliminating part which are arranged on the machine frame and the vertical plates, wherein the roller spacing control part comprises a front power source, a front spacing adjusting cam, a second front bearing, a front spacing adjusting swinging arm, a front spacing adjusting rotating pin, a front adjusting screw and a front tension spring; the front spacing adjusting rotating pin and the front spacing adjusting swinging arm form a rotating pair; the front adjusting screw and the front spacing adjusting swinging arm form a screw thread pair; and the front power source drives the front spacing adjusting cam to rotate to push the front spacing adjusting swinging arm to rotate so as to adjust roller spacing. The precision control type three-roller grinding machine is precise in spacing adjustment and is time-saving and labour-saving by utilizing the roller spacing control part with a lever and the roller floating gap eliminating part.

Owner:SHENZHEN ZYE TECH LTD

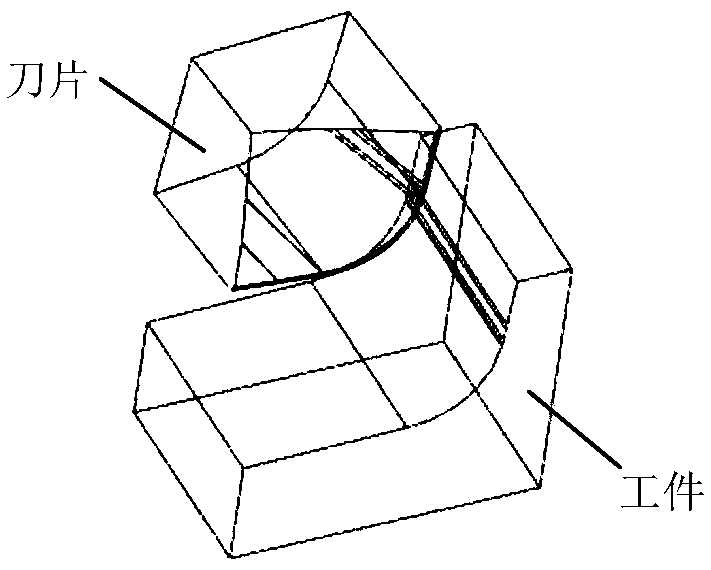

A method for predicting the milling force of end face milling cutter combined with SVM

ActiveCN109543329ASmall amount of calculationReduced simulation timeDesign optimisation/simulationSpecial data processing applicationsMicro structureMilling cutter

The invention relates to a method for predicting the milling force of an end face milling cutter combined with SVM, which relates to an ultra-precision machining technology. The simulation parametersof different cutting depth and different radial feed back are designed, and the geometric model is established. The round corners are arranged at the cutting edge position of the insert, and the insert only takes the tip part which is in contact with the workpiece, so that the mesh can combine the shape of the micro-structure on the insert. After getting the simulation value, the mixed kernel function SVM algorithm is used to fit the simulation value. the tool tip kinematics model is computed. According to the kinematics model, At that current phase angle, the cut forces of each insert are calculated by substituting the cutting force model into the cutting force model. The cutting forces are divided into three directions: axial force, radial force and tangential force, which are convertedinto tool axial force Fz, feed direction force Fy and perpendicular feed direction force Fx, and the cutting forces are directly superposed and solved.

Owner:XIAMEN UNIV +1

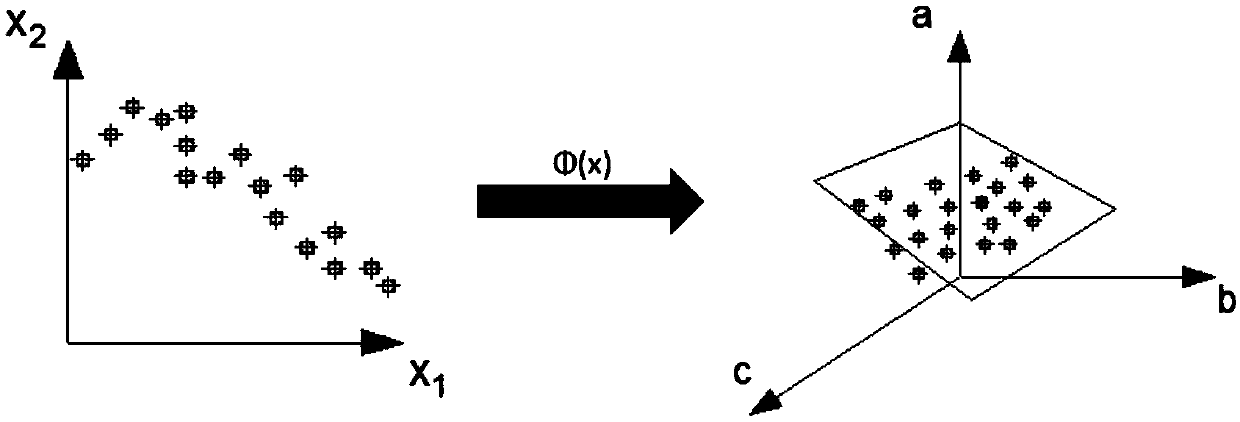

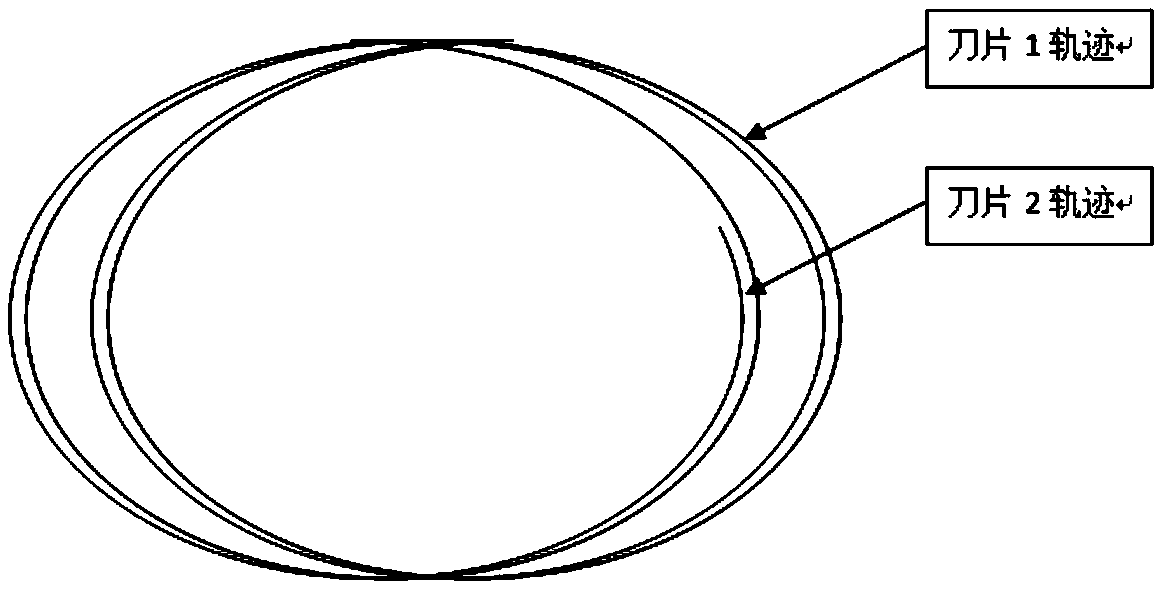

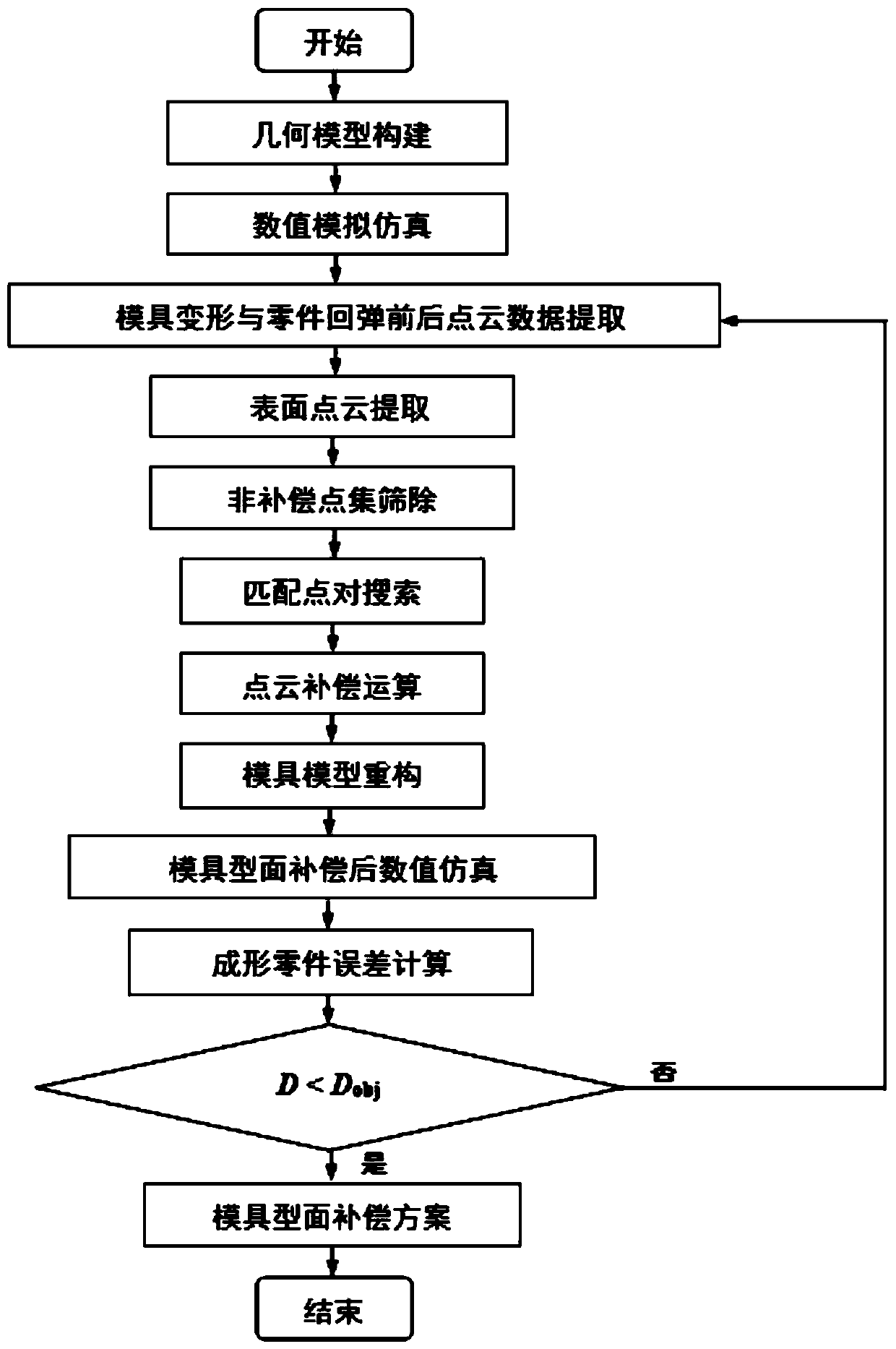

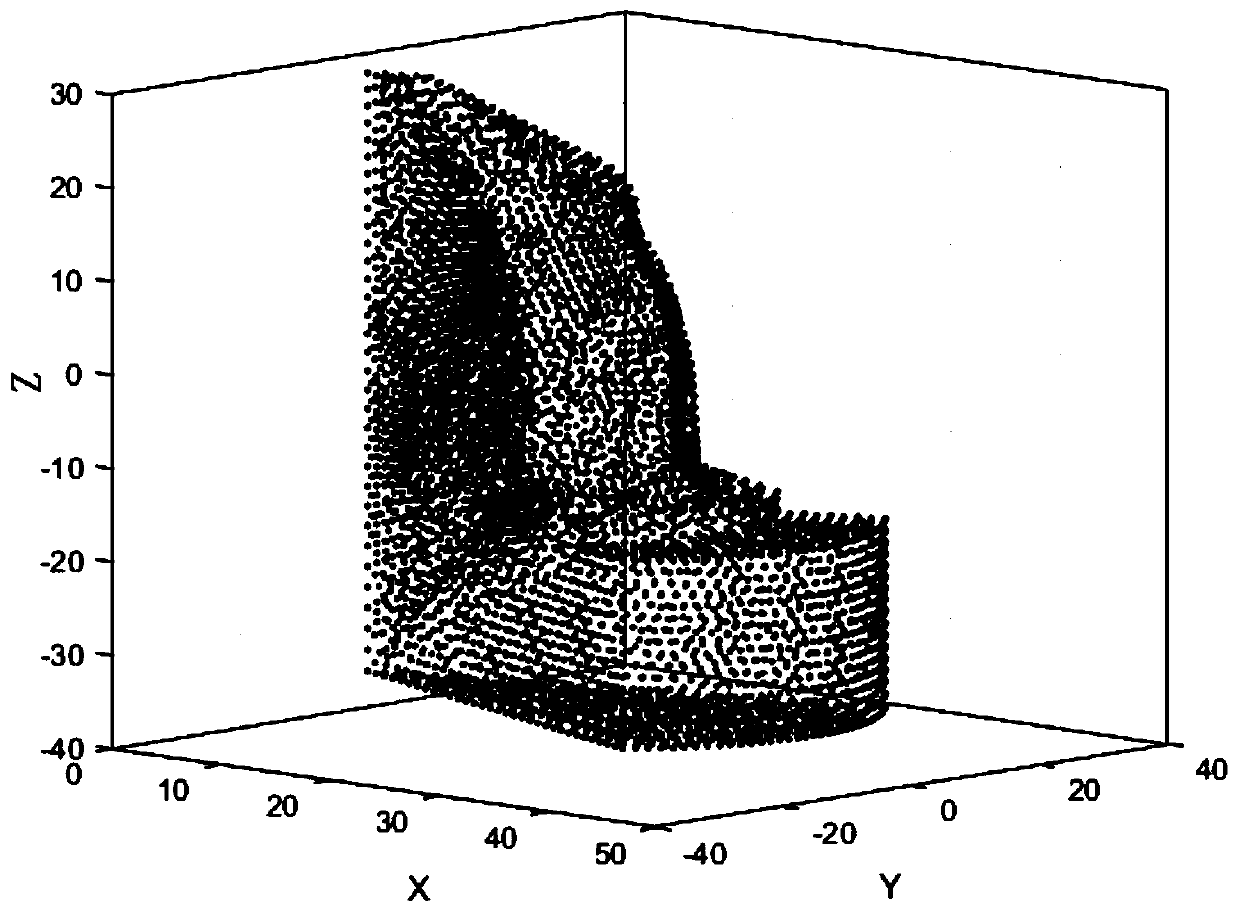

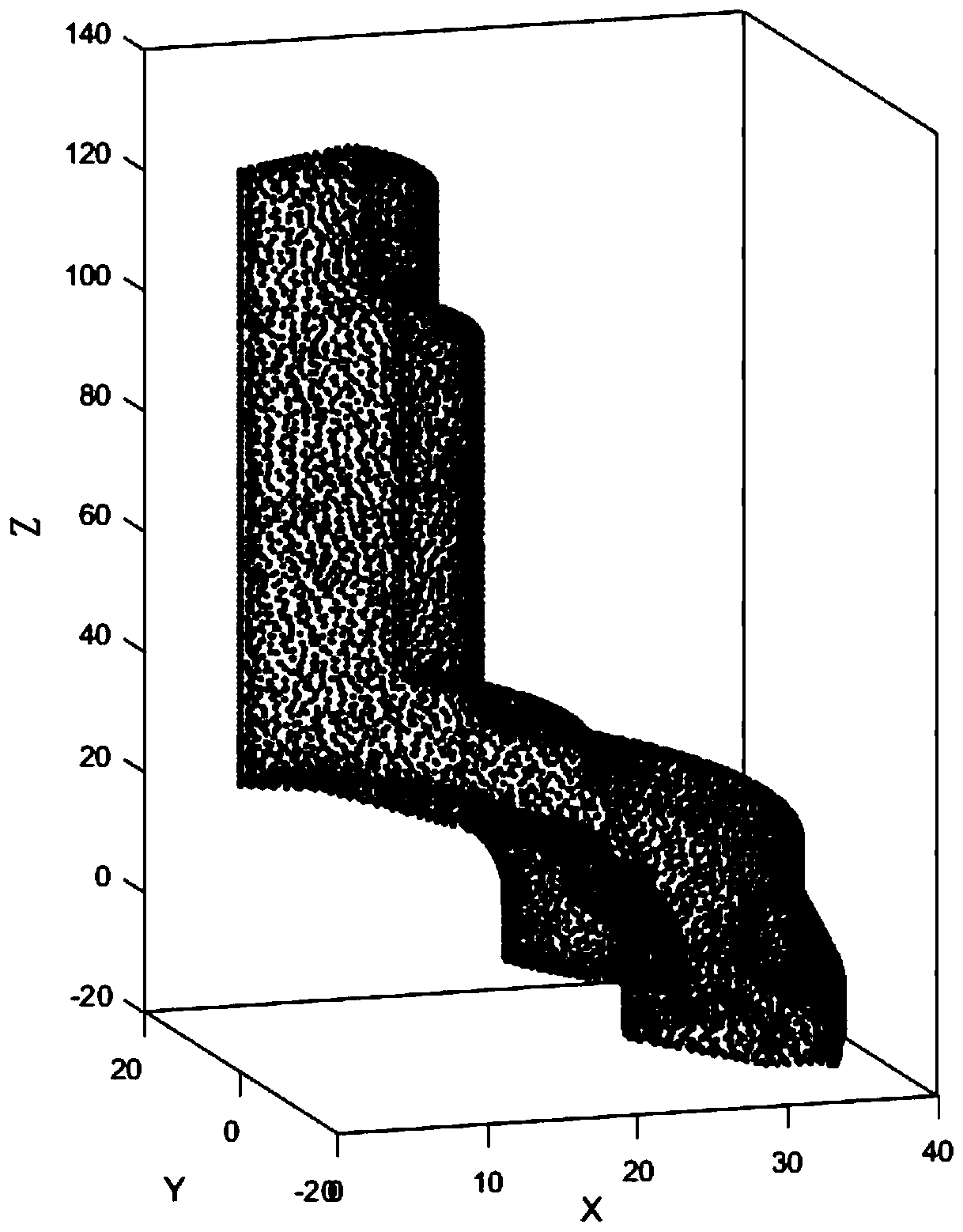

Discretized mold profile accurate compensation method

ActiveCN111177906AAvoid errorsImprove accuracy and efficiencyGeometric CADDesign optimisation/simulationProcess engineeringSurface fitting

The invention belongs to the field of metal forging extrusion precision forming, in particular to a discretized mold profile accurate compensation method. The method is a profile compensation method based on point-to-point operation, analog simulation is carried out according to a novel profile of a mold after mold deformation and part springback compensation are completed by utilizing the method,and iterative compensation can be repeated if the forming precision does not meet the design requirement, so that accurate compensation for mold deformation and part springback is realized. The method is based on a profile reverse compensation principle; point cloud matching of the mold profile and the part profile is completed by utilizing a nearest point pair technical thought; therefore, all point clouds of the mold profile are compensated, the influence of mold deformation and part springback on the forming precision can be effectively reduced, meanwhile, the technology of directly generating the STL model through the point clouds is provided, point-line-surface fitting errors of a traditional profile are avoided, and the compensation precision of the complex mold profile is improved.The influence of mold deformation and part springback on the forming precision can be reasonably controlled, precise design of die products is facilitated, and the development efficiency is improved.

Owner:SHANDONG UNIV

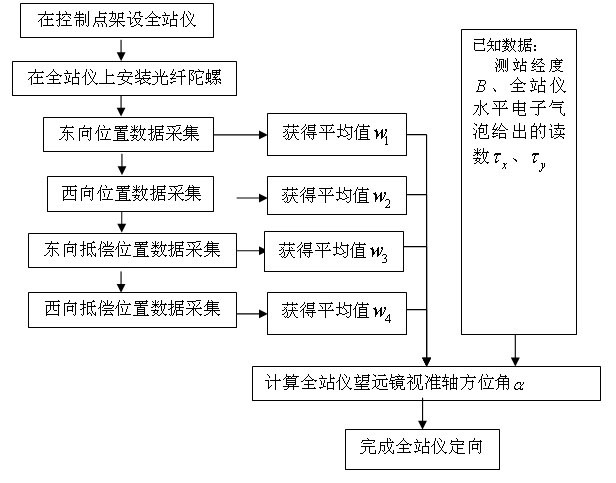

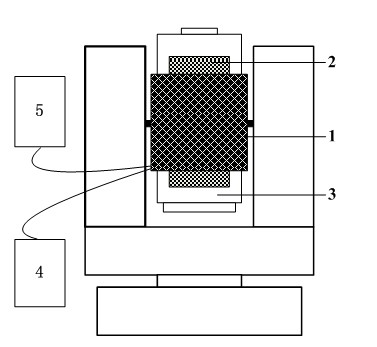

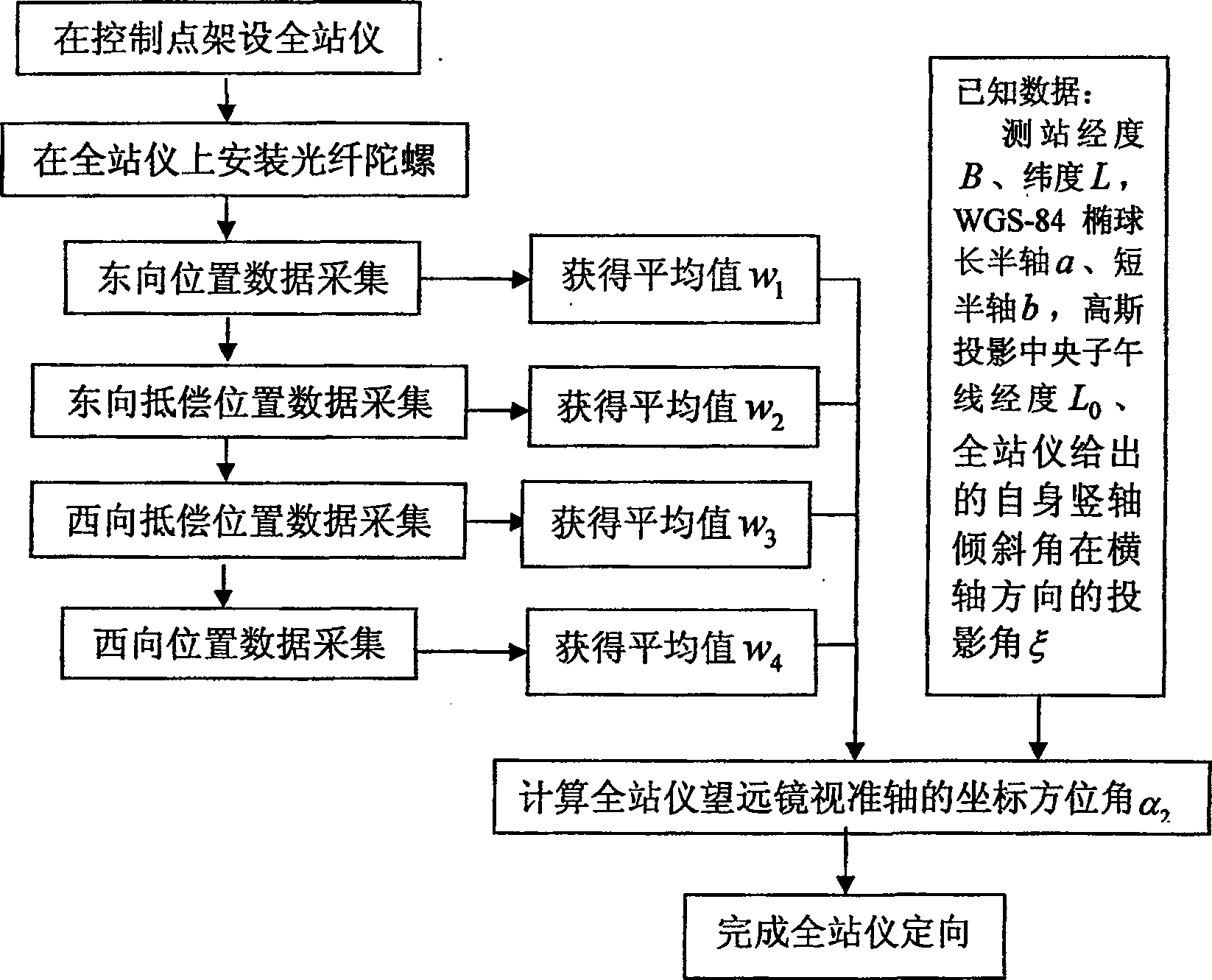

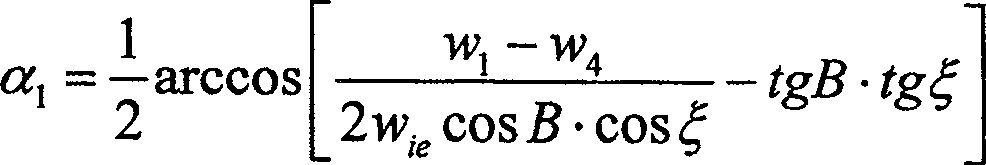

Plug and play optical fiber gyro and total station combination orientation method

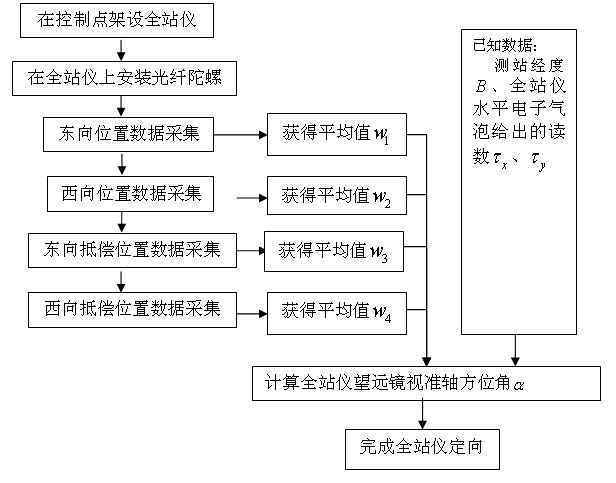

ActiveCN102095402AEasy to manufactureEasy to operateAngle measurementSagnac effect gyrometersEarth's rotationAlidade

The invention discloses a plug and play optical fiber gyro and total station combination orientation method, which is a hardware combination method, an operation flow and a calculation formula applied to surveying and mapping work. The method comprises the following steps of: leveling and centering the total station on a control point of a known point position longitude B; fixedly connecting the optical fiber gyro to a telescope of the total station by using a locking device; connecting a power supply and computer equipment with the optical fiber gyro; horizontally rotating an alidade of the total station to drive the telescope of the total station to an east orientation position and a west orientation position which have an included angle of 180 degrees respectively; vertically rotating the telescope of the total station 180 degrees at the east orientation position and the west orientation position respectively to drive the optical fiber gyro to an east orientation compensation position and a west orientation compensation position; measuring the rotational angular velocities of the earth by using the optical fiber gyro at the four positions respectively; and calculating a true azimuth of a collimation axis of the total station at the east orientation position by using measurement data. In the method, the structure is simple, connection error calibration is not needed to be performed, and the orientation of the total station can be realized under the condition of only one control point by performing simple operation.

Owner:SOUTHEAST UNIV

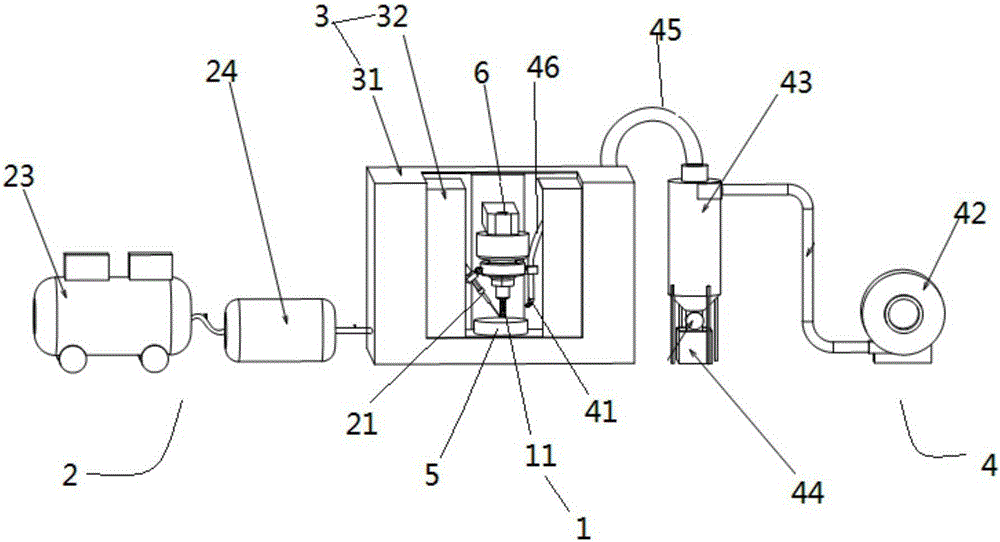

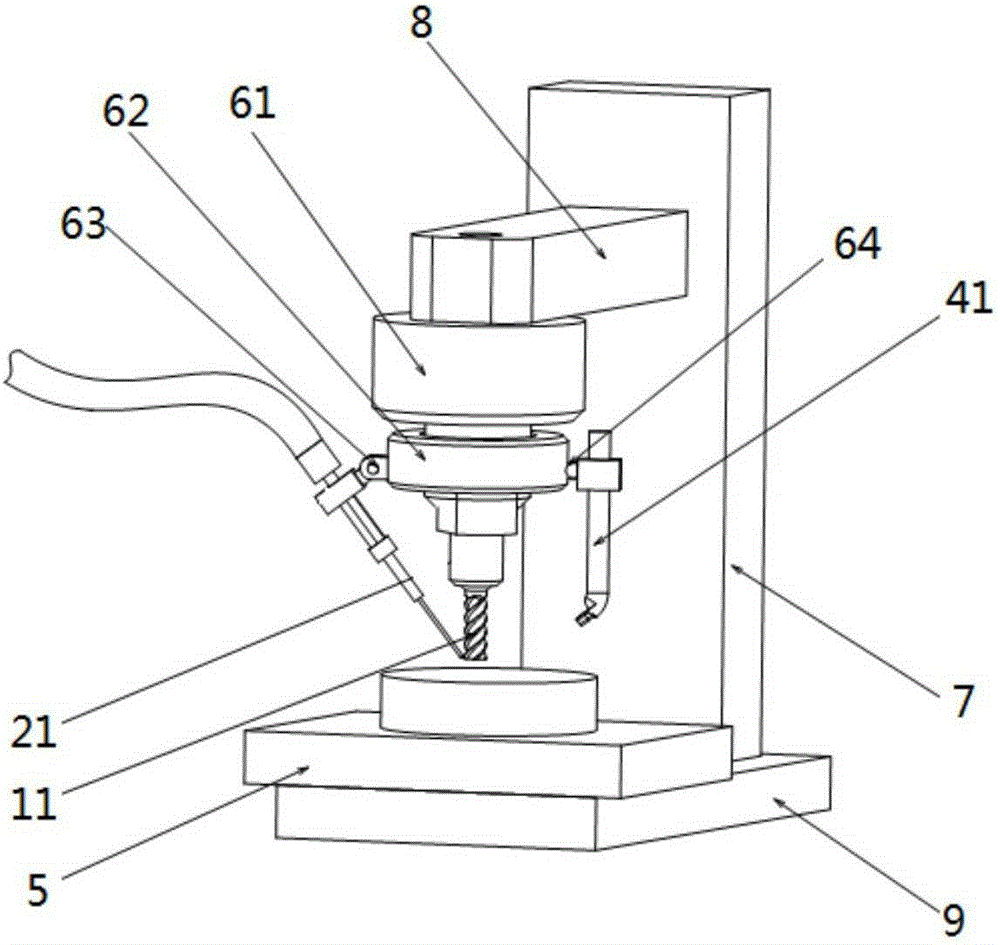

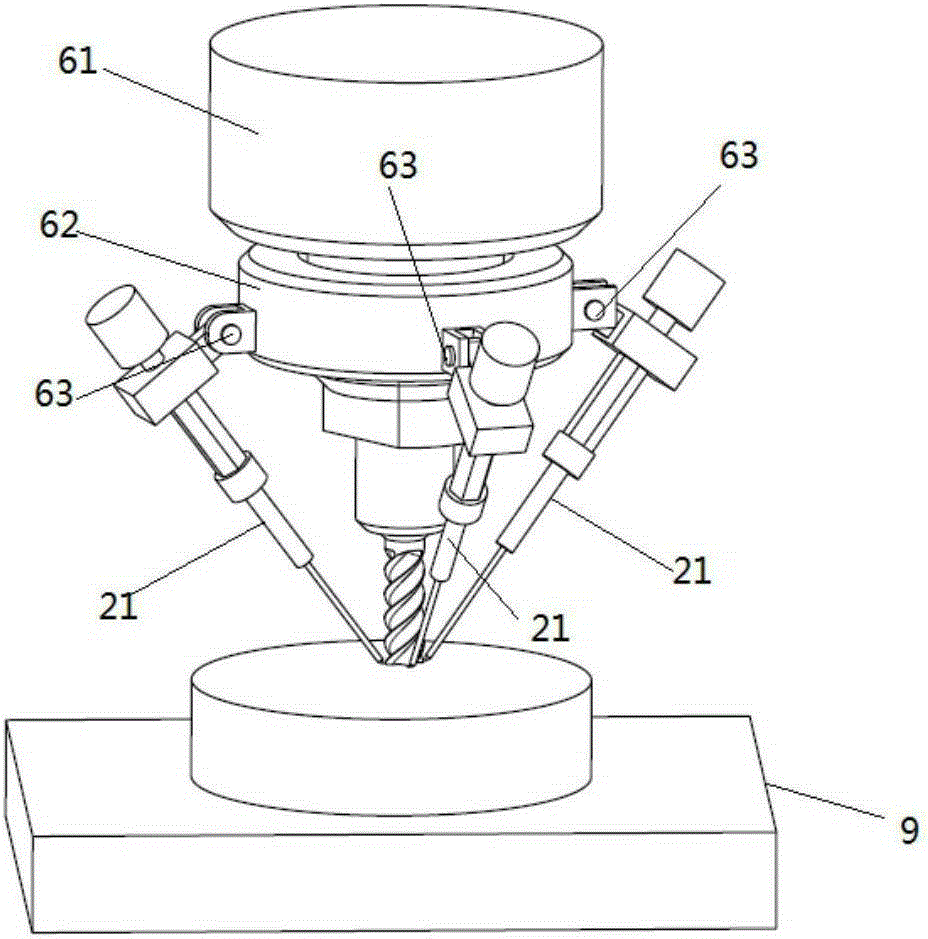

Combined machining equipment for micro parts

InactiveCN105171426AImprove machining accuracyImprove processing efficiencyOther manufacturing equipments/toolsMetal machiningEngineering

The invention discloses combined machining equipment for micro parts. The combined machining equipment for micro parts comprises a milling and grinding device, an abrasive material jet machining device, a machine cover and a dust sucking device. A workbench used for clamping parts to be machined and an installation base opposite to the workbench are arranged inside the machine cover. The milling and grinding device comprises a milling and grinding tool. The abrasive material jet machining device comprises jet nozzles. The dust sucking device comprises a suction nozzle. In this way, micro parts clamped on the workbench can be milled or ground through the milling and grinding tool for the first time, burrs and turnup generated by first-time machining are removed through the jet nozzles under the condition that secondary clamping is not conducted, and secondary machining similar to shot peening strengthening and the like is conducted on the surfaces of workpieces similar to groove bottoms and the like. Therefore, influence of micro burrs on precision of micro parts can be eliminated, machining errors generated by secondary clamping can also be avoided, and the machining precision and efficiency of micro parts are effectively improved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

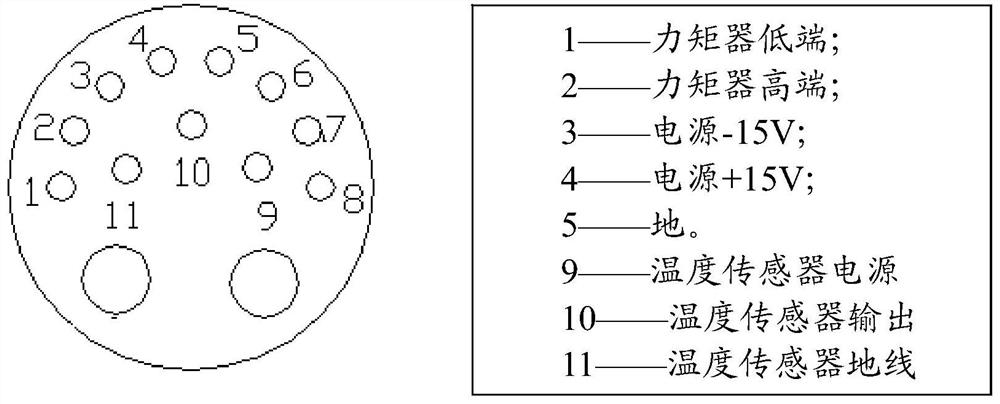

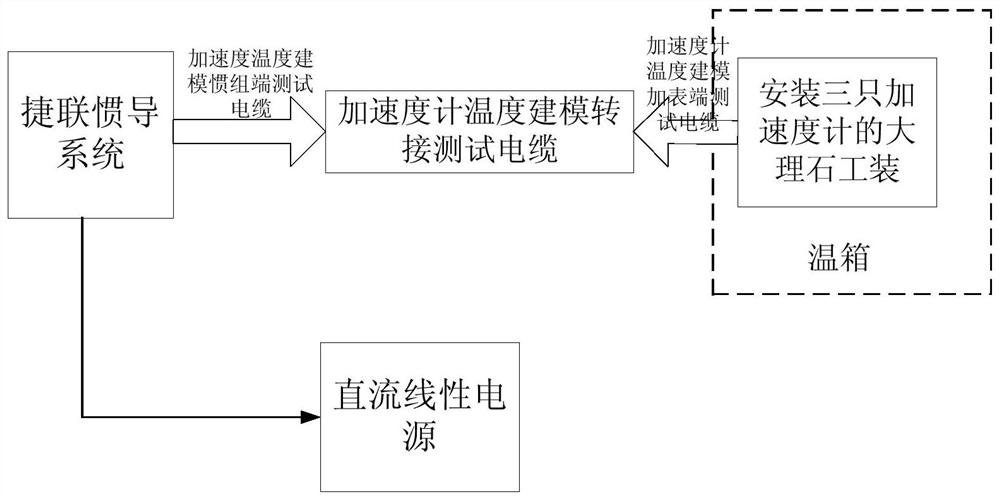

High-precision accelerometer temperature compensation method

ActiveCN111679097AHigh outputHigh precisionAcceleration measurement using interia forcesSpeed/acceleration/shock instrument detailsAccelerometerHemt circuits

The invention discloses a high-precision accelerometer temperature compensation method, and belongs to the field of inertial measurement. The quartz flexible accelerometer is composed of a gauge outfit assembly and a servo circuit assembly. The change of the ambient temperature enables the physical parameters of various materials in the quartz flexible accelerometer to change, thereby generating an influence on the output of the accelerometer. According to the marble tool single-meter-level two-way variable temperature modeling method, the influence of deformation of a strapdown inertial navigation combination body and a test tool on the precision of an accelerometer in the previous temperature modeling process is eliminated, and the precision that the zero-bias stability 3sigma of the accelerometer is smaller than or equal to 0.05 mg under the full-temperature condition is achieved.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

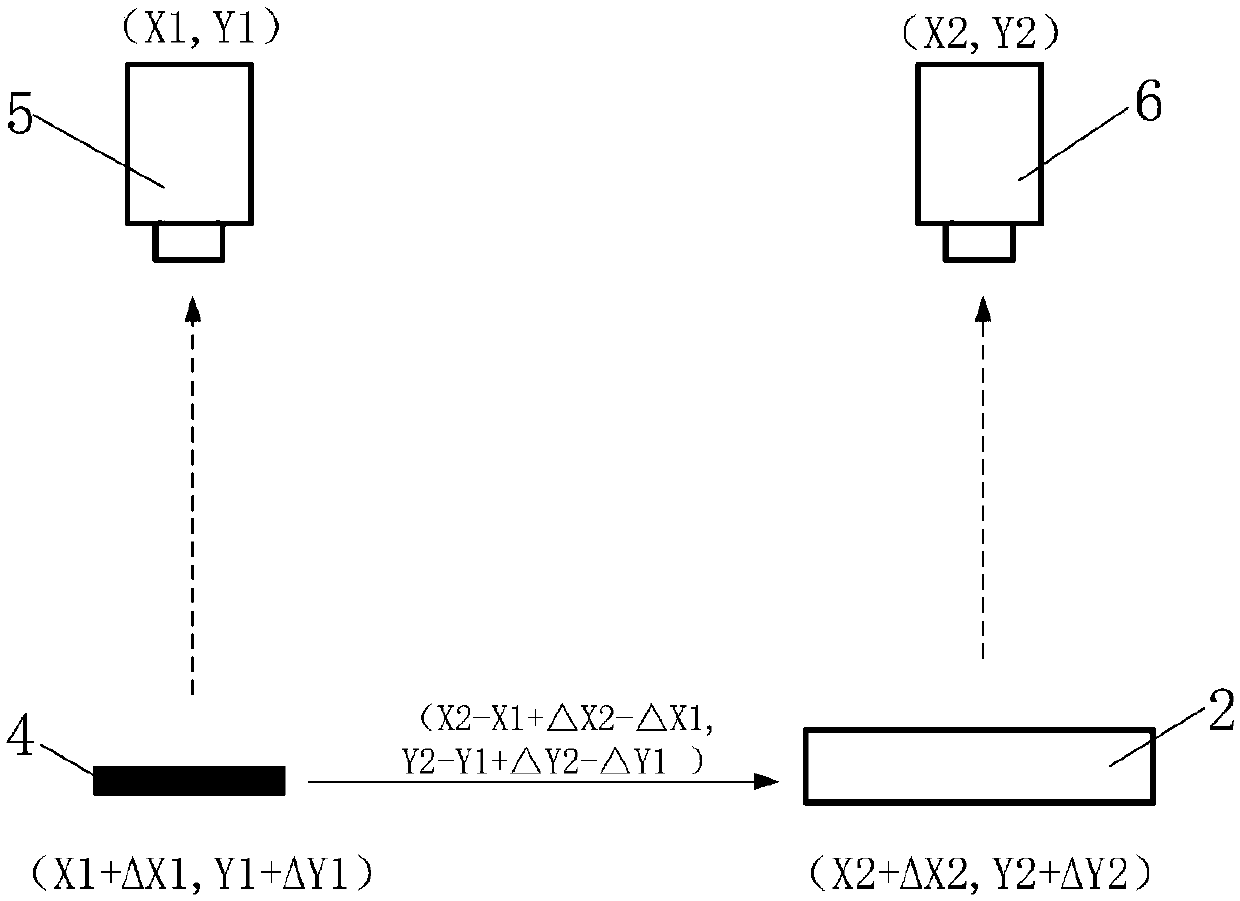

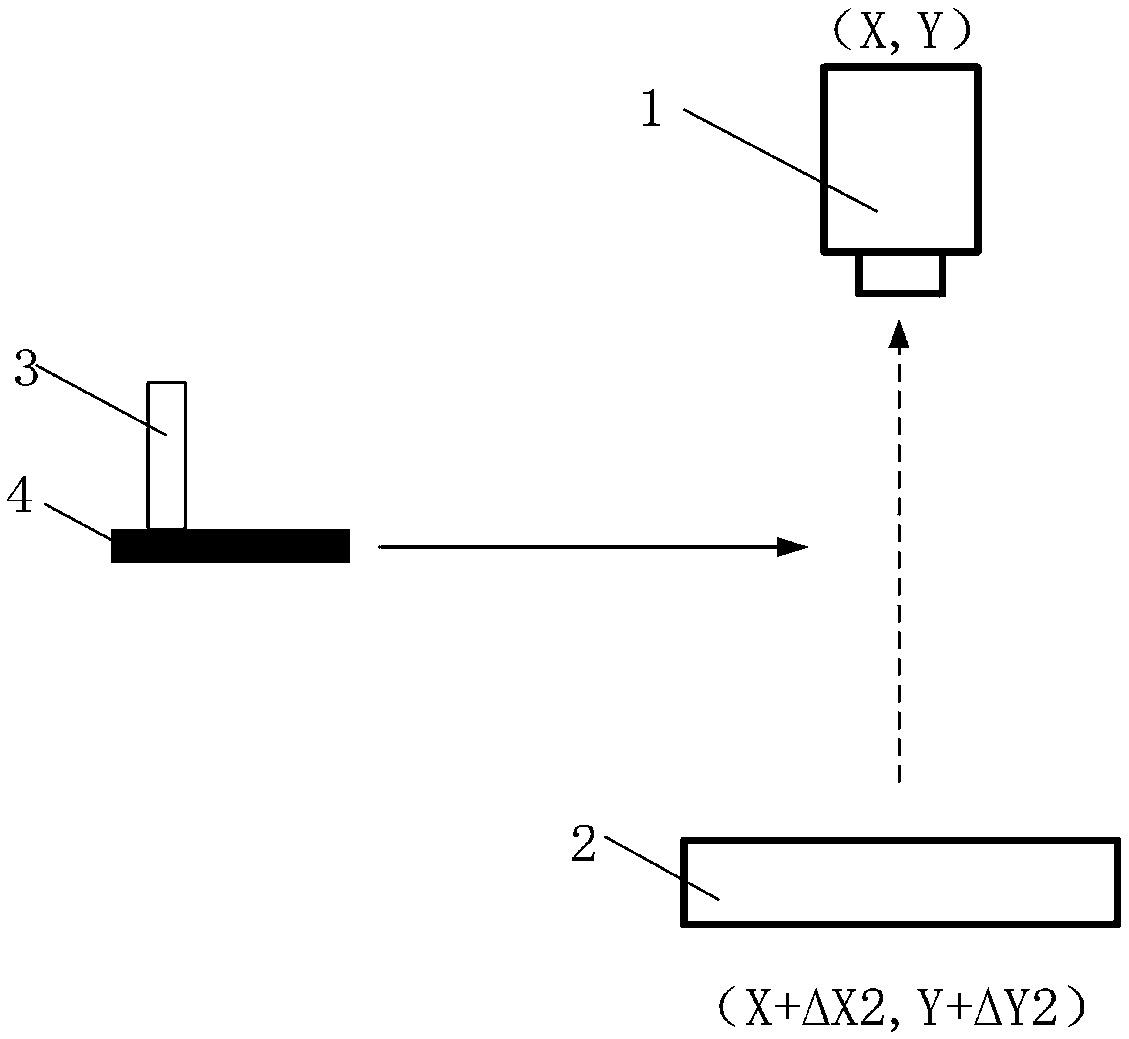

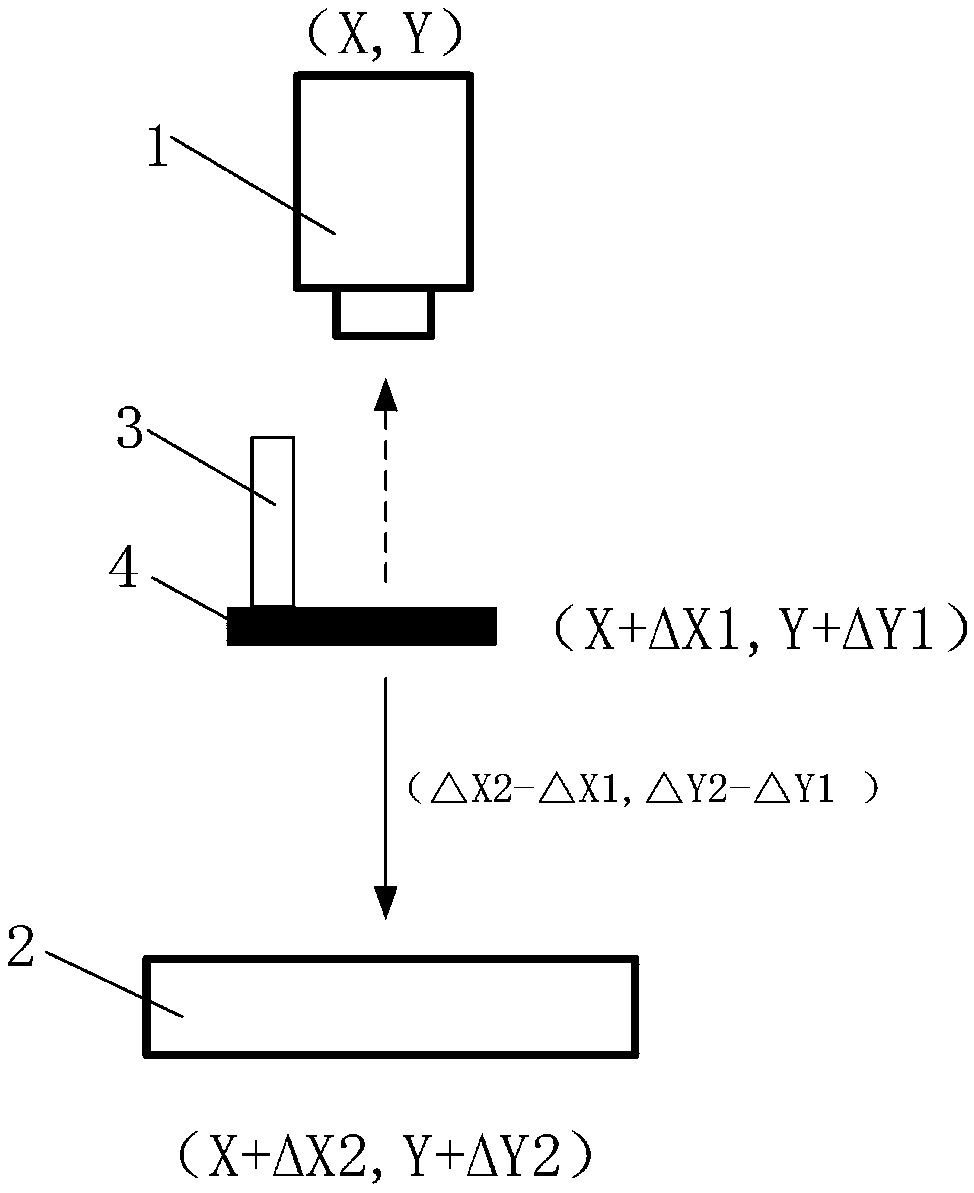

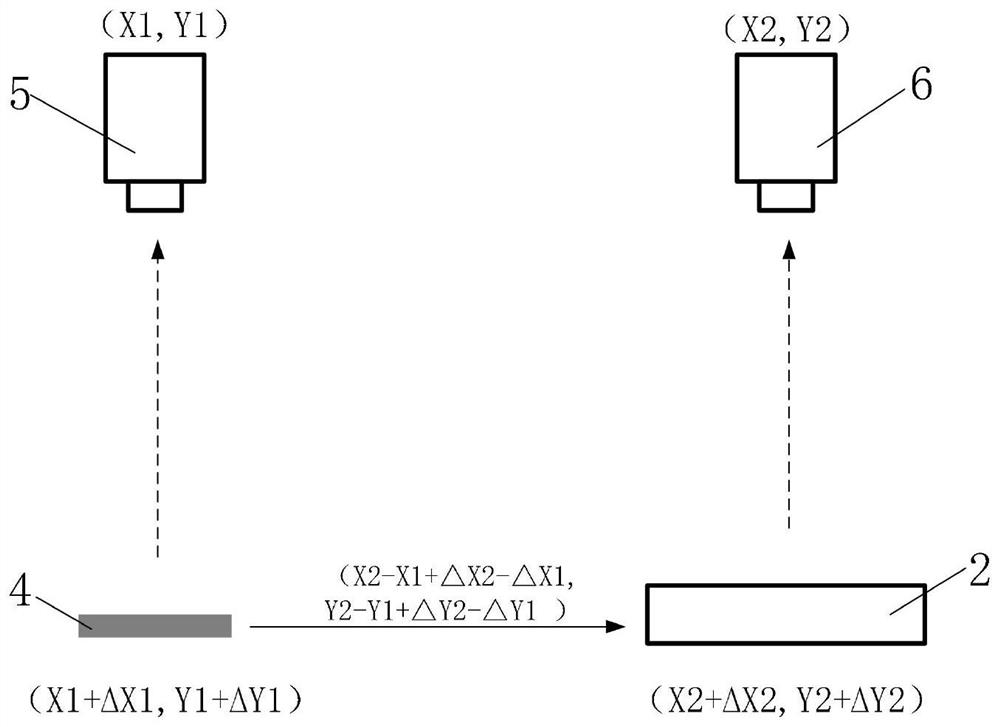

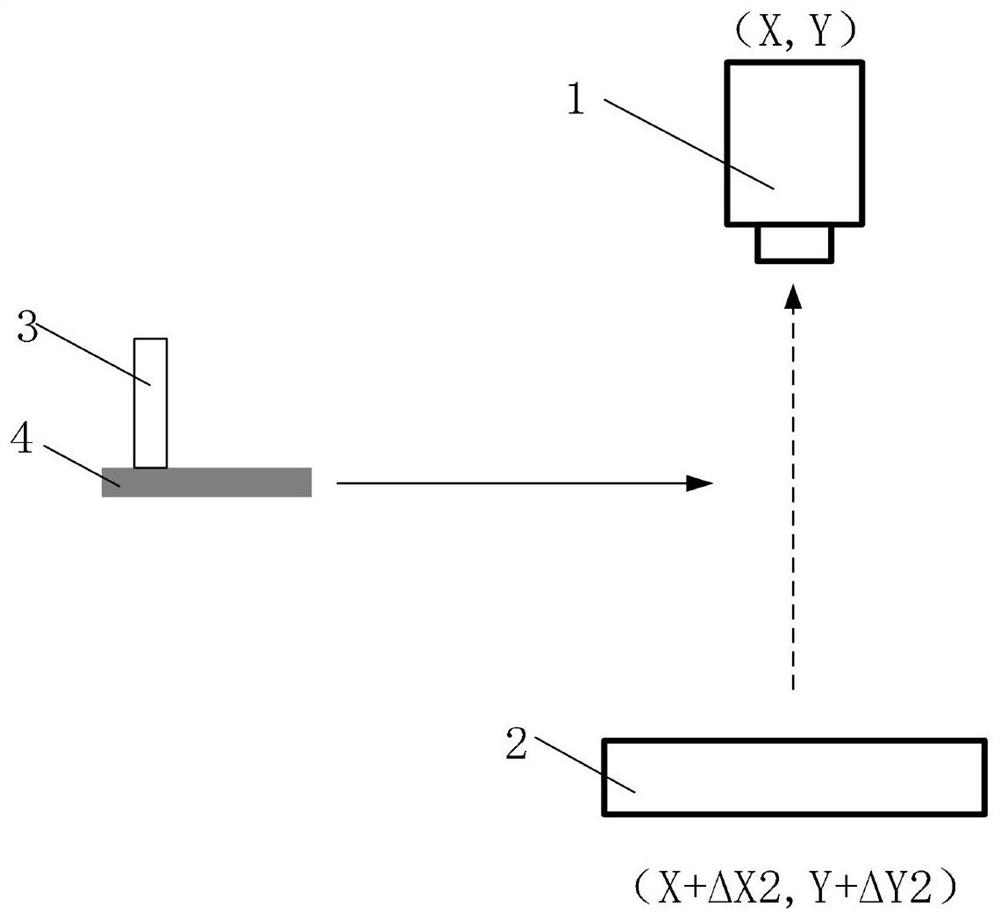

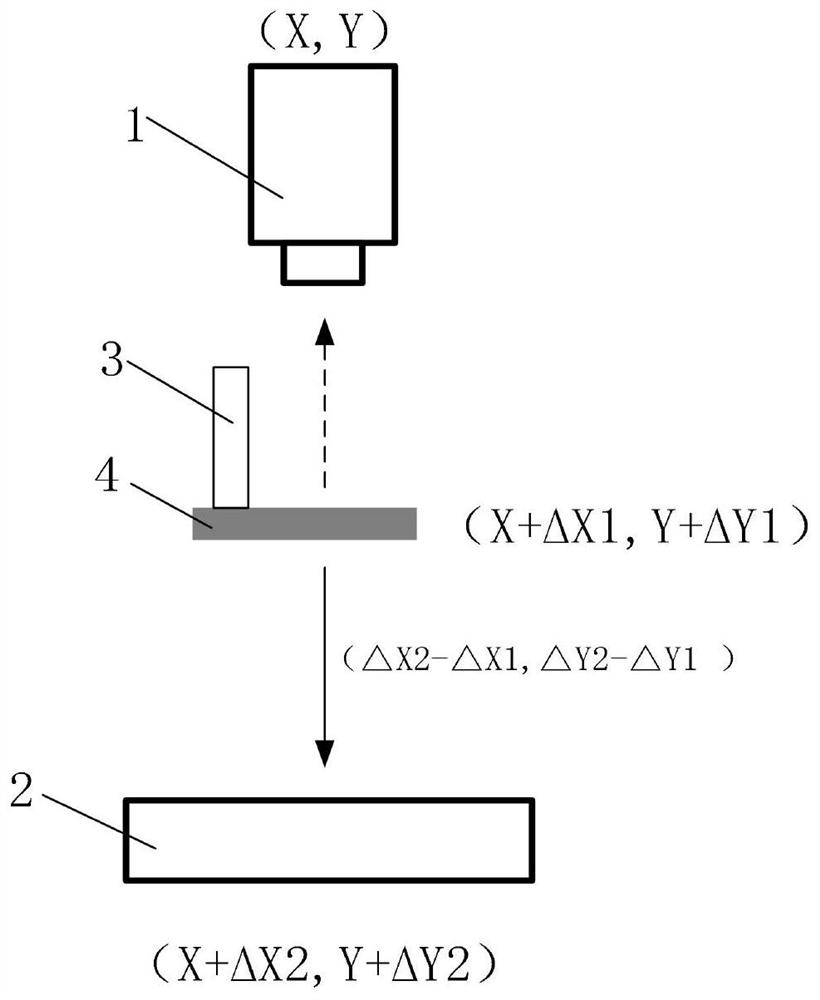

Chip surface-mounting identification system and method

ActiveCN109616430AEliminate the influence of position deviation on placement accuracySlow travel becomes shorterSemiconductor/solid-state device manufacturingInstallation ErrorOptical communication

The invention relates to the technical field of optical communication, and provides a chip surface-mounting identifying system and method. The system comprises a shooting device, a substrate and an absorption device, wherein the shooting device is arranged on the substrate, the substrate is used for surface-mounting a chip, the absorption device is used for absorbing the chip and moving the chip to a part below the shooting device, the shooting device is used for identifying a position of the substrate and a position of the chip by shooting, an identification region is arranged on a surface ofthe chip, and the identification region is exposed when the absorption device absorbs the chip so that the chip is moved to the part below the shooting device, and the shooting device is used for identifying the position of the chip by shooting the identification region. By the system, the identification region of the surface can be exposed when the chip is absorbed by using the special absorption device; identification and positioning of the chip and the substrate are completed by a camera, the system cost is low, the influence of an installation error of different cameras on surface-mounting accuracy is eliminated, moreover, the chip position is identified after the chip is absorbed, and the surface-mounting accuracy and the surface-mounting efficiency are improved.

Owner:WUHAN TELECOMM DEVICES

A chip mounting recognition system and method

ActiveCN109616430BEliminate the effect of precisionEliminate the effects ofSemiconductor/solid-state device manufacturingComputer hardwareOptical communication

The invention relates to the technical field of optical communication, and provides a chip surface-mounting identifying system and method. The system comprises a shooting device, a substrate and an absorption device, wherein the shooting device is arranged on the substrate, the substrate is used for surface-mounting a chip, the absorption device is used for absorbing the chip and moving the chip to a part below the shooting device, the shooting device is used for identifying a position of the substrate and a position of the chip by shooting, an identification region is arranged on a surface ofthe chip, and the identification region is exposed when the absorption device absorbs the chip so that the chip is moved to the part below the shooting device, and the shooting device is used for identifying the position of the chip by shooting the identification region. By the system, the identification region of the surface can be exposed when the chip is absorbed by using the special absorption device; identification and positioning of the chip and the substrate are completed by a camera, the system cost is low, the influence of an installation error of different cameras on surface-mounting accuracy is eliminated, moreover, the chip position is identified after the chip is absorbed, and the surface-mounting accuracy and the surface-mounting efficiency are improved.

Owner:WUHAN TELECOMM DEVICES

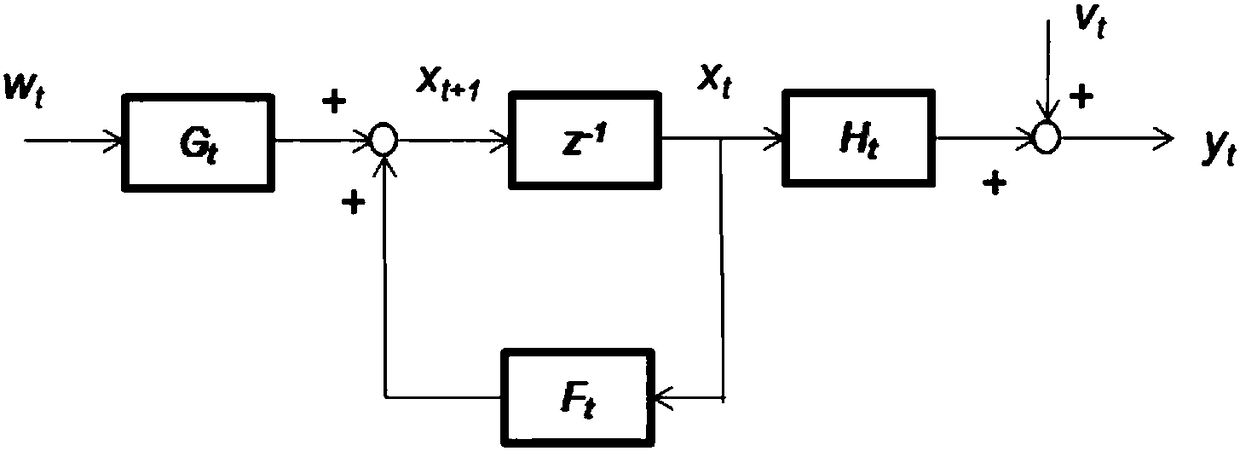

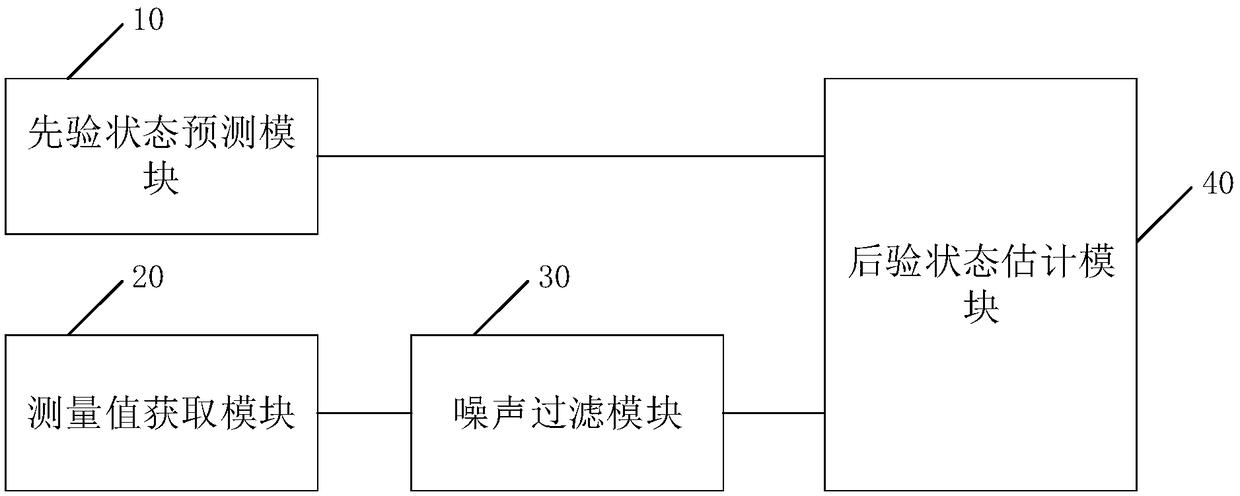

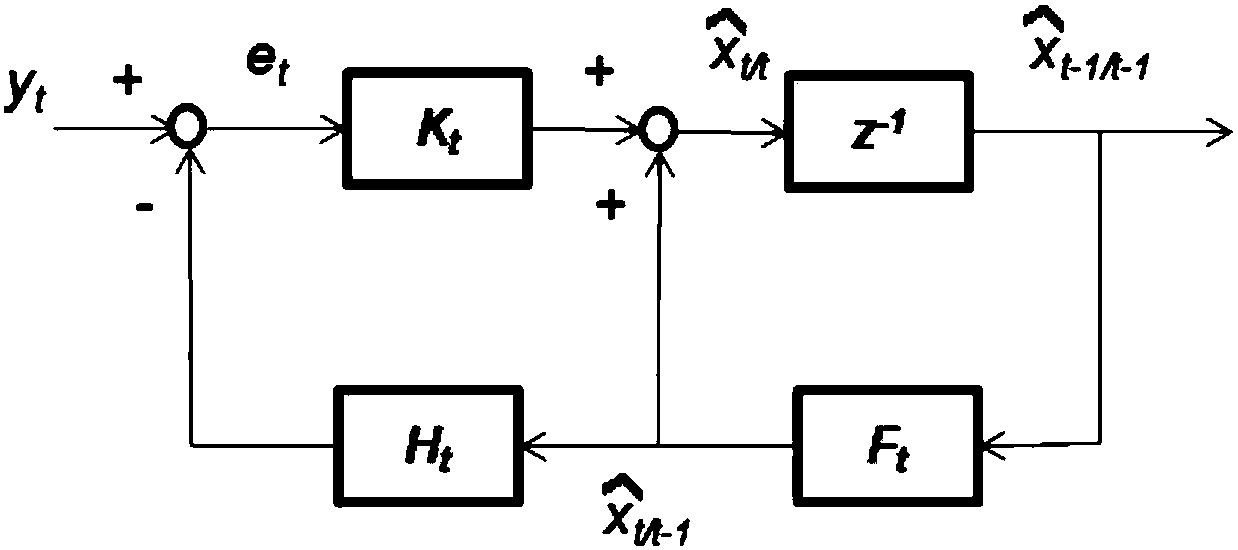

System state prediction device and method based on Kalman filter

ActiveCN109117965AEliminate the effect of precisionAccurate predictionReservationsComplex mathematical operationsKaiman filterState prediction

The invention provides a system state prediction device and method based on a Kalman filter which relate to the technical field of engineering and can accurately predict system states. The system state prediction device based on the Kalman filter includes a priori state prediction module used for predicting a priori state estimation value at time t according to a measured value at time 1 to t-1; ameasured value acquiring module used for acquiring a measured value at the time t; a noise filtering module used for filtering non-Gaussian noise in the measured value obtained at the time t; and a posteriori state estimation module used for estimating a posterior state estimation value at the time based on the priori state estimation value predicted at the time t and the measured value at the time t after the non-Gaussian noise is filtered.

Owner:毫末智行科技有限公司

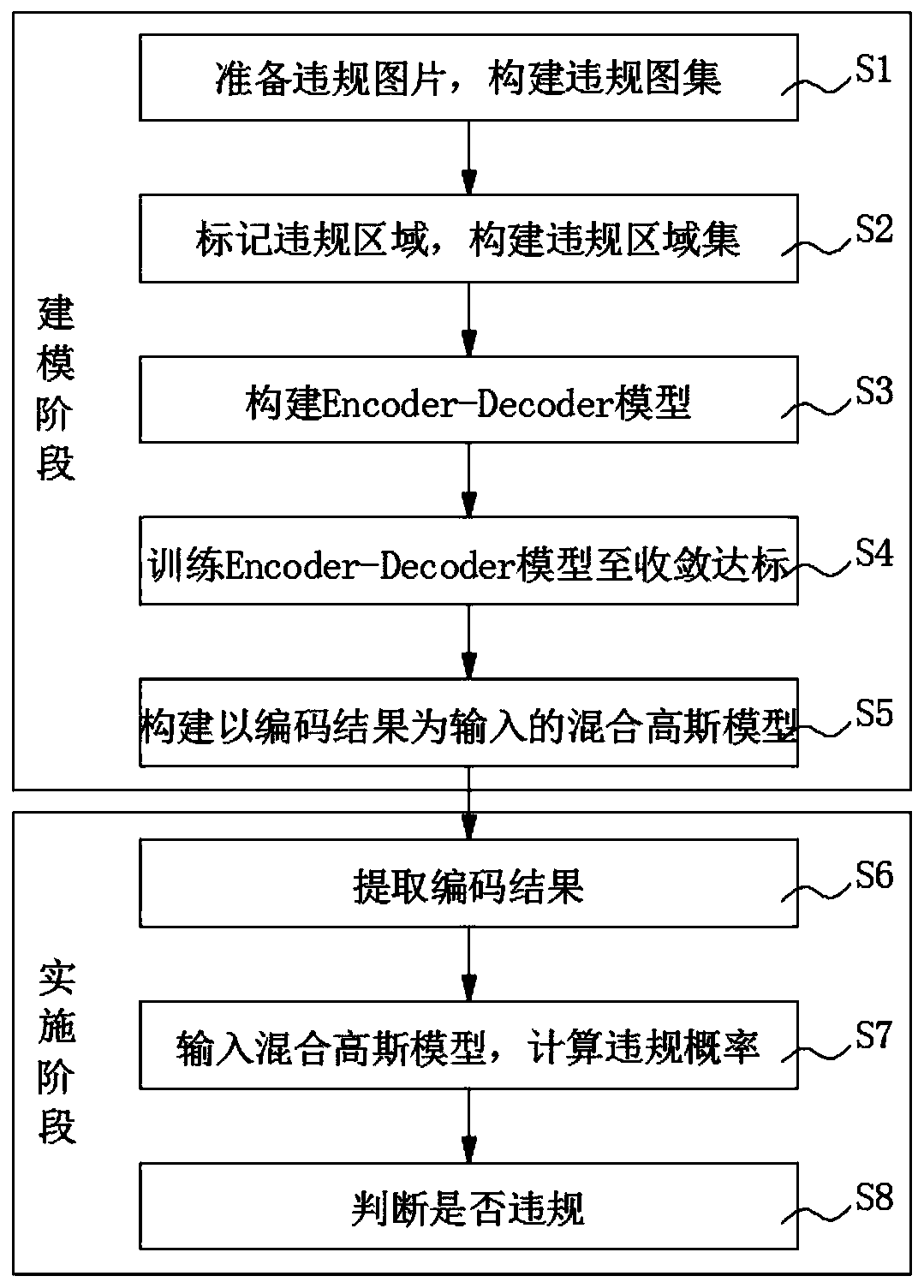

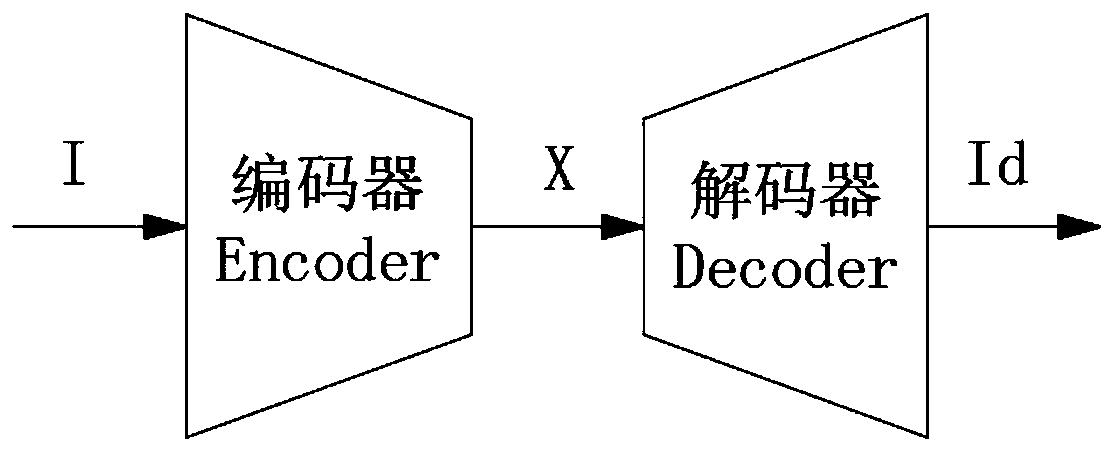

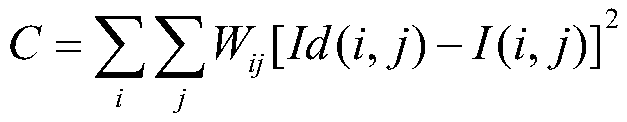

Catering kitchen violation judgment method based on Encoder-Decoder model and Gaussian mixture model

InactiveCN110378311AEliminate the effect of precisionViolation identification generalization performance is goodBiometric pattern recognitionEncoder decoderImaging processing

The invention discloses a catering kitchen violation judgment method based on an Encoder-Decoder model and a Gaussian mixture model, and relates to the technical field of image processing. The methodcomprises a modeling stage: preparing violation pictures, and constructing a violation picture set; marking violation regions in the violation picture, and constructing a violation region set; constructing an Encoder-Decoder model, wherein the Encoder-Decoder model comprises an encoder Encoder and a decoder Decoder; training an Encoder-Decoder model by taking the violation graph set as a sample until the convergence of a cost function reaches the standard; and constructing a Gaussian mixture model by taking the coding result of the trained encoder Encoder as input, and taking the output resultas the violation probability. An implementation stage: extracting an encoding result of the picture to be detected by using the trained encoder; inputting a coding result into the Gaussian mixture model, and calculating the violation probability; and judging whether a violation behavior exists in the to-be-detected picture or not according to the violation probability. According to the method, violation visual features can be accurately extracted. The method is not limited by kitchen scenes, and violation identification generalization performance for different catering stores is good.

Owner:杭州视在科技有限公司

A flexible parallel platform device

ActiveCN104325458BLarge working spaceRealize the hinge functionProgramme-controlled manipulatorElectricityMicro-operation

Owner:HARBIN INST OF TECH

Compression mould with trapezoidal longitudinal guide lock structure

The invention relates to a compression mould with a trapezoidal longitudinal guide lock structure. The compression mould comprises an upper die and a lower die, and is characterized in that: the upper die and the lower die are provided with trapezoidal longitudinal guide locks which are interlocked and matched with each other in favor of longitudinal guiding and positioning between the upper die and the lower die respectively; the upper end of the upper die is arranged on an upper chute plate; the lower end of the lower die is arranged on a lower chute plate; the upper chute plate and the lower chute plate are fixed to an upper bed plate and a lower bed plate through positioning blocks and bolts respectively; the front sides of both the upper die and the lower die are provided with a front upper positioning plate and a front lower positioning plate; the rear sides of both the upper die and the lower die are provided with a rear upper positioning plate and a rear lower positioning plate; the left and right sides of the upper die and the lower die are positioned by an upper die frame and a lower die frame respectively; the upper die frame is fixed to the upper bed plate through the bolts; and the lower die frame is fixed to the lower bed plate through distance bolts. The compression mould has the advantages of improving the positioning accuracy of moulds, prolonging the service life of the moulds and reducing the reject rate of products in turn.

Owner:福州冠锋模具技术有限公司

Liquid crystal modulation optical phase control array type spectrometer and detection method

InactiveCN107084792AHigh resolutionEliminate the effect of precisionSpectrum investigationObject pointData treatment

The invention relates to a liquid crystal modulation optical phase control array type spectrometer and a detection method. The spectrometer comprises a light dividing system, an optical detector and a data processing system. The light dividing system comprises a liquid crystal modulation optical phase control array unit and used for decomposing light beams given out by a to-be-detected point according to different wavelengths. The optical detector detects the decomposed light beams and coverts optical signals into electrical signals. The data processing system is connected with the optical detector and used for obtaining spectrum curves of the to-be-detected point. According to the invention, high-resolution spectrum information of an object point can be acquired without pushing and scanning of movement parts, so compared with the prior art, effects on restoration of spectrum precision imposed by vibration caused by movement can be eliminated.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Total station instrument combined orientation method based on optical fiber gyro

InactiveCN100504296CSimple hardware installation requirementsEasy to operateRotary gyroscopesFiberHorizontal axis

The combined orientation method of the total station based on the fiber optic gyroscope is a combined orientation method of the total station based on the fiber optic gyroscope used in surveying and mapping. The instrument telescope (3) is fixedly connected, so that the fiber optic gyroscope (1) can rotate 180 degrees synchronously with the total station telescope (3) around the transverse axis (4) of the total station instrument, and the difference between the east and west directions of the gyro axis is 180 degrees. Position, each horizontal position is 2×2 position gyro data acquisition at two vertical positions with a difference of 180 degrees in the vertical plate of the total station; use the formula to calculate the true azimuth of the collimation axis of the total station and the convergence angle of the meridian of the station, namely The coordinate azimuth of the collimation axis of the total station can be further obtained to realize the orientation of the total station. The invention has a simple structure, does not need to perform installation error calibration, and can realize the orientation of the total station with only one control point through simple operations, and can be used for surveying and mapping work in towns, forests, mountainous areas and other areas where visibility is difficult.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com