Precise digital control rotation platform based on direct driving of serial dual synchronous torque motor

A torque motor, precision numerical control technology, applied to synchronous motors with static armatures and rotating magnets, control of multiple AC motors, multiple motor speed adjustments, etc. Density and motor operating life, beneficial to heat dissipation, and the effect of improving rotational acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

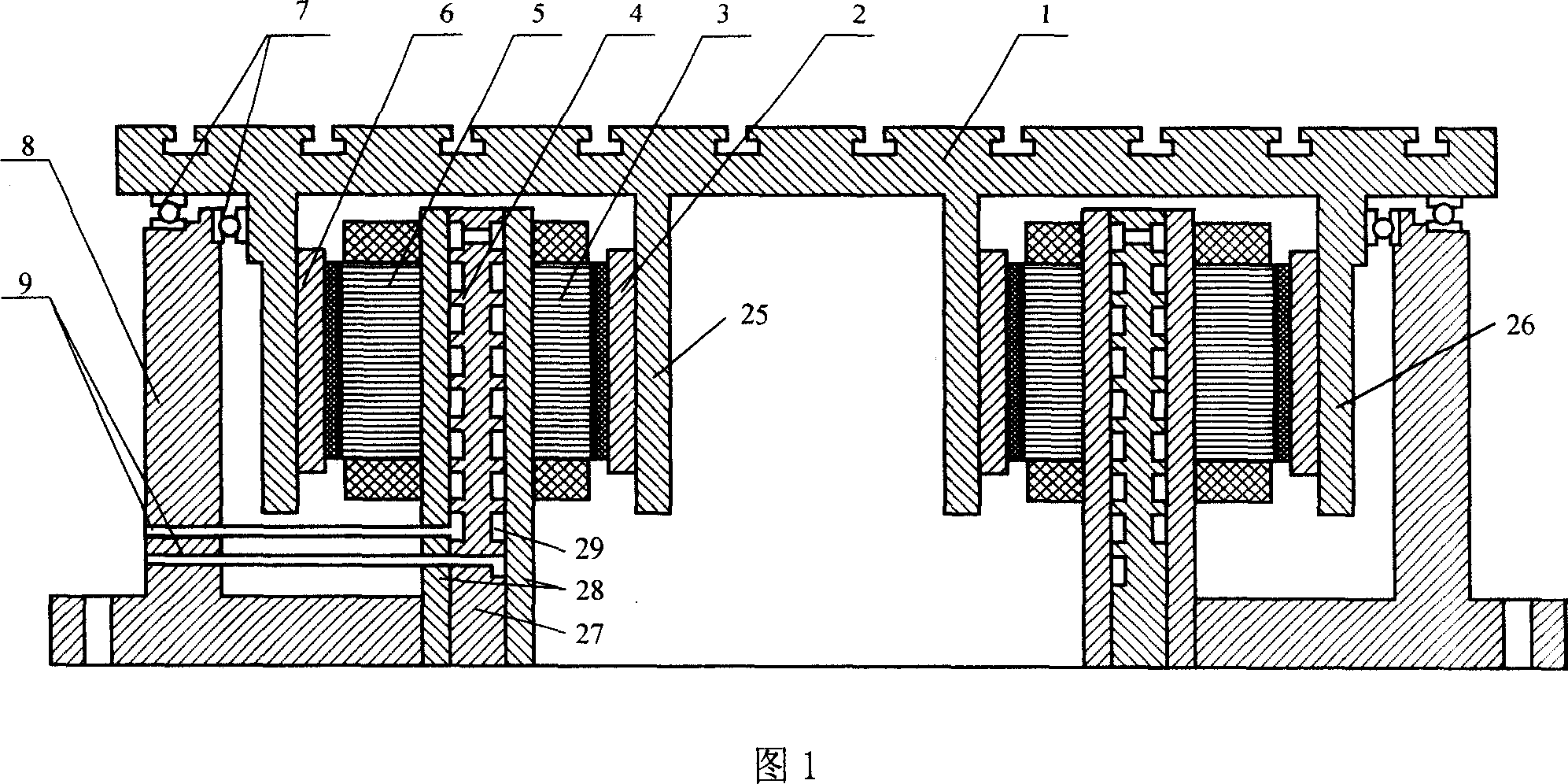

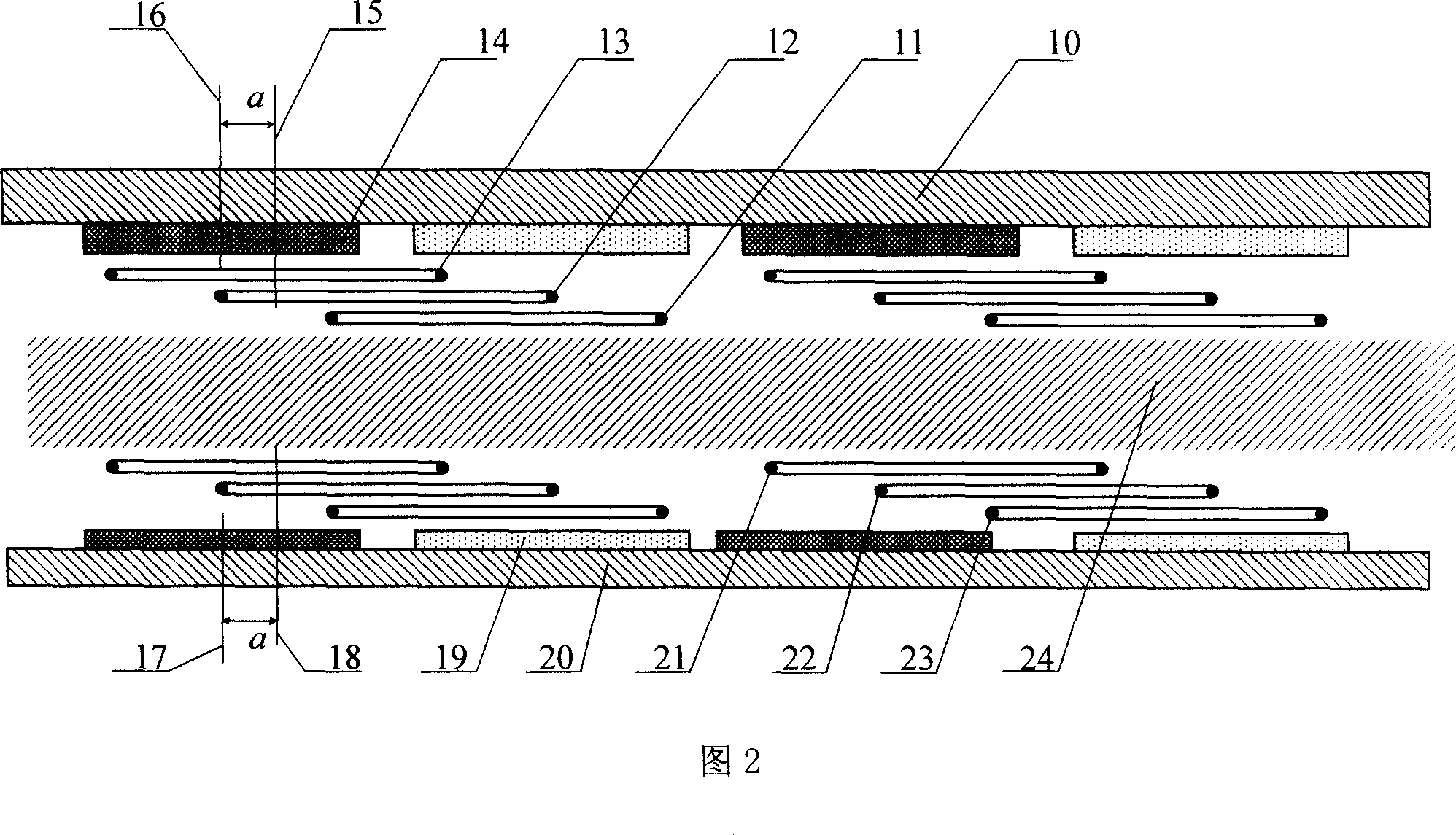

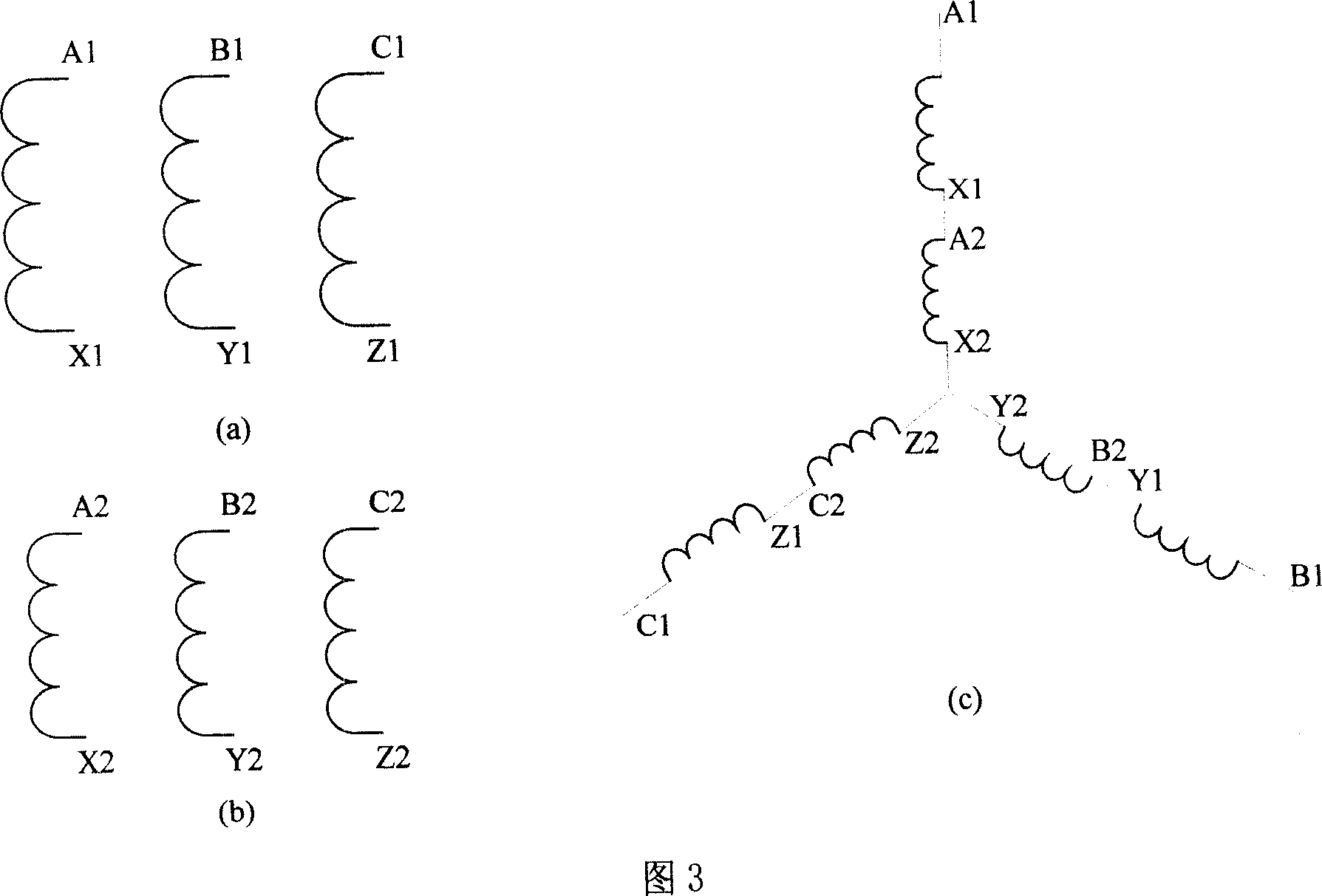

[0036] Embodiment: As shown in Figure 1, the present invention includes a turntable base 8, a turntable working surface 1, a motor cooling structure, an outer rotor and an inner rotor permanent magnet synchronous ring torque motor, and the turntable base 8 is an annular structure with an inverted T-shaped cross section. The turntable base 8 and the turntable working surface 1 are respectively connected by bearings in the horizontal and vertical directions. The turntable working surface 1 is a table with an inner ring 25 and an outer ring 26. An annular stainless steel motor cooling structure is installed on the inner ring side of the turntable base 8. The motor cooling structure includes a cooling ring 27 and a cooling jacket 28. On the inside and outside surfaces of the cooling ring 27, there are spiral cooling liquid passages 29, and there are through holes between the two spiral cooling liquid passages at the top. Cooling jackets 28 are installed on both sides of 27; an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com