Method for improving motor torque density and radial and axial magnetic flux parallel-connected permanent magnet motor

A technology of motor torque and axial flux, applied in the direction of magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of hole size and shape limitations, difficulty in achieving results, and insufficient use of rotor space, etc., to achieve improved Effect of torque density and utilization improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

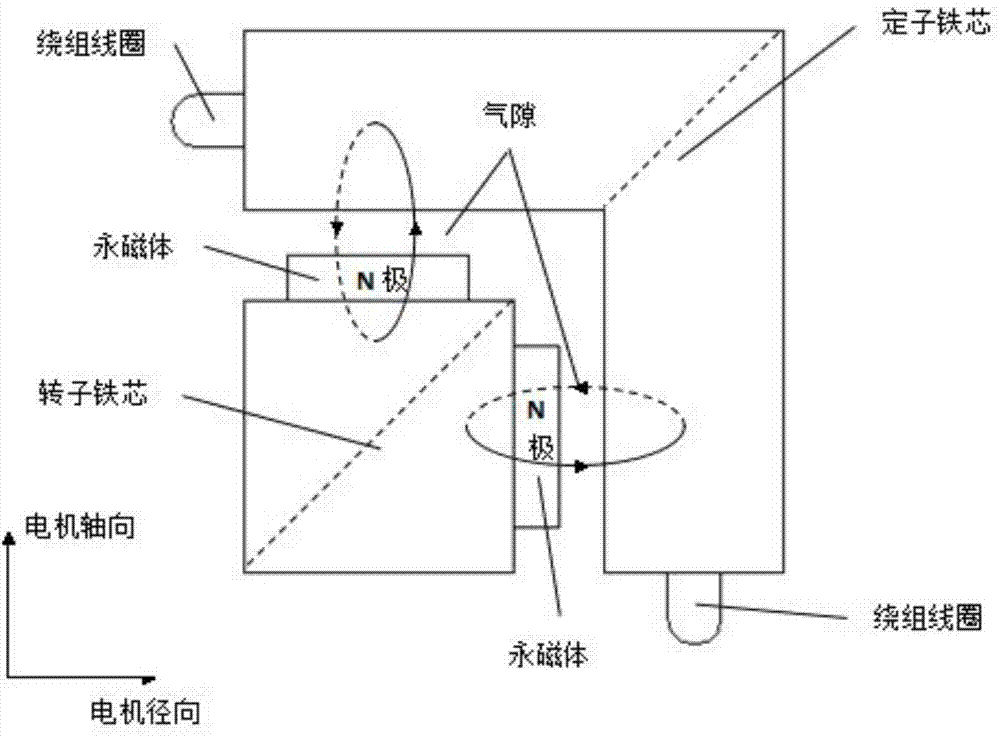

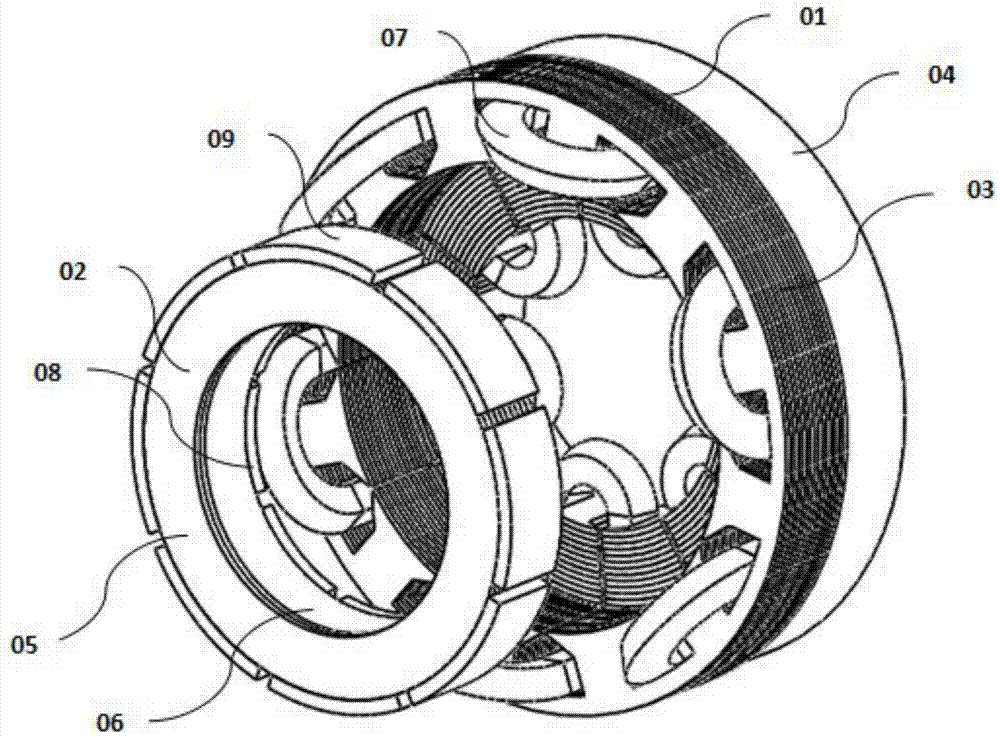

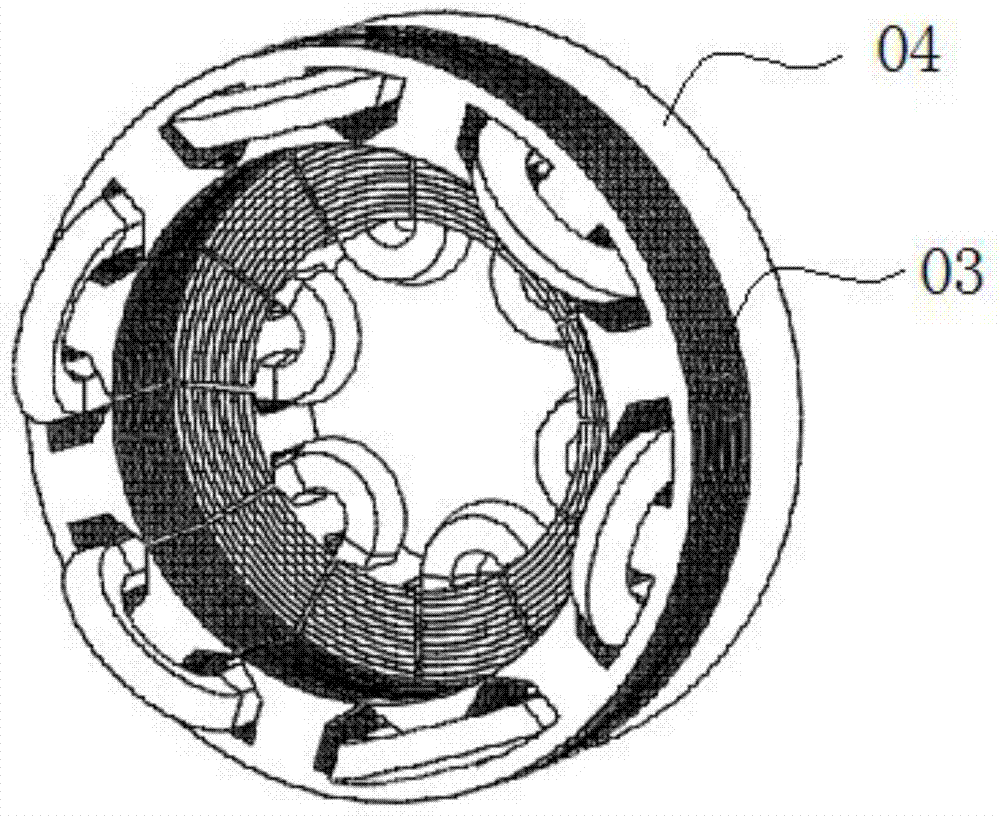

[0029] Principle of the present invention is as follows, as figure 1 As shown, in a method for increasing the torque density of a motor provided in an embodiment of the present invention, the torque density of a motor can be increased based on a combination of radial flux and axial flux. The radial magnetic flux and the axial magnetic flux are connected in parallel, and in the motor rotor, the radial magnetic flux and the axial magnetic flux have independent magnetic flux paths. It effectively improves the utilization rate of the rotor iron core and reduces the limitation of the iron core saturation on the torque density and power density of the motor.

[0030] Among them, the axial magnetic flux passes through the forehead of the rotor, the permanent magnet group on the end face of the rotor, the air gap on the end face of the rotor, and the stator to form a closed loop. The radial magnetic flux passes through the rotor, the permanent magnet group on the circumferential surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com