Stator permanent-magnetic doubly salient disc-type motor

A disc motor and double salient pole technology, applied in the direction of motor, magnetic circuit shape/style/structure, electric vehicles, etc., can solve the problems of inconvenient use, long axial length, etc., to prevent damage, facilitate installation, and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

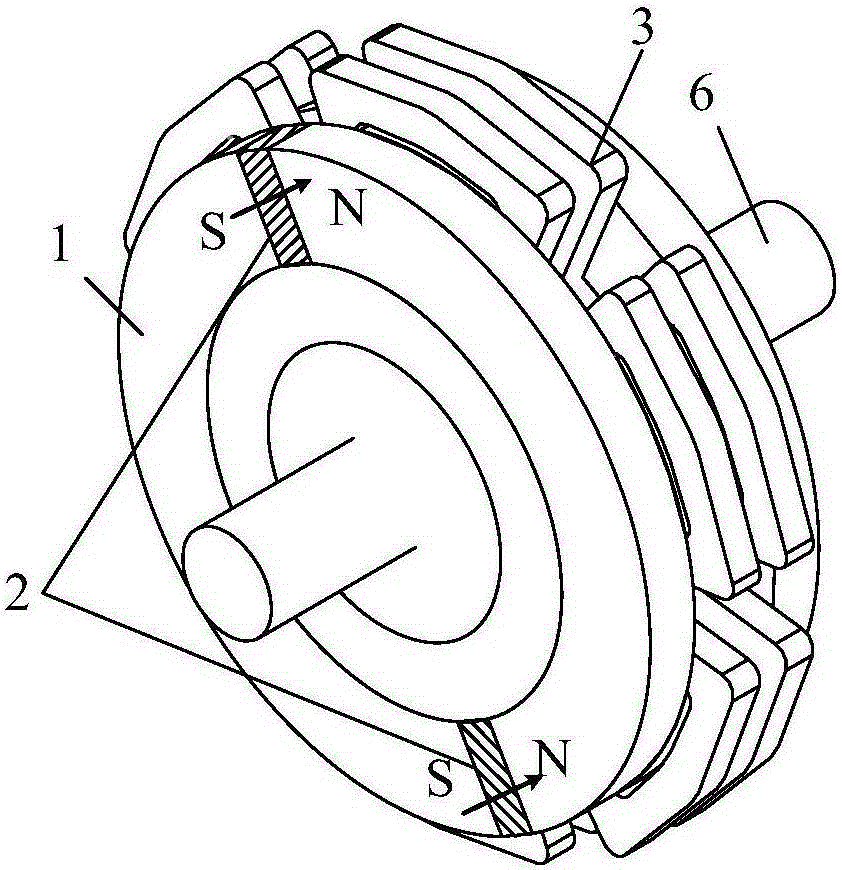

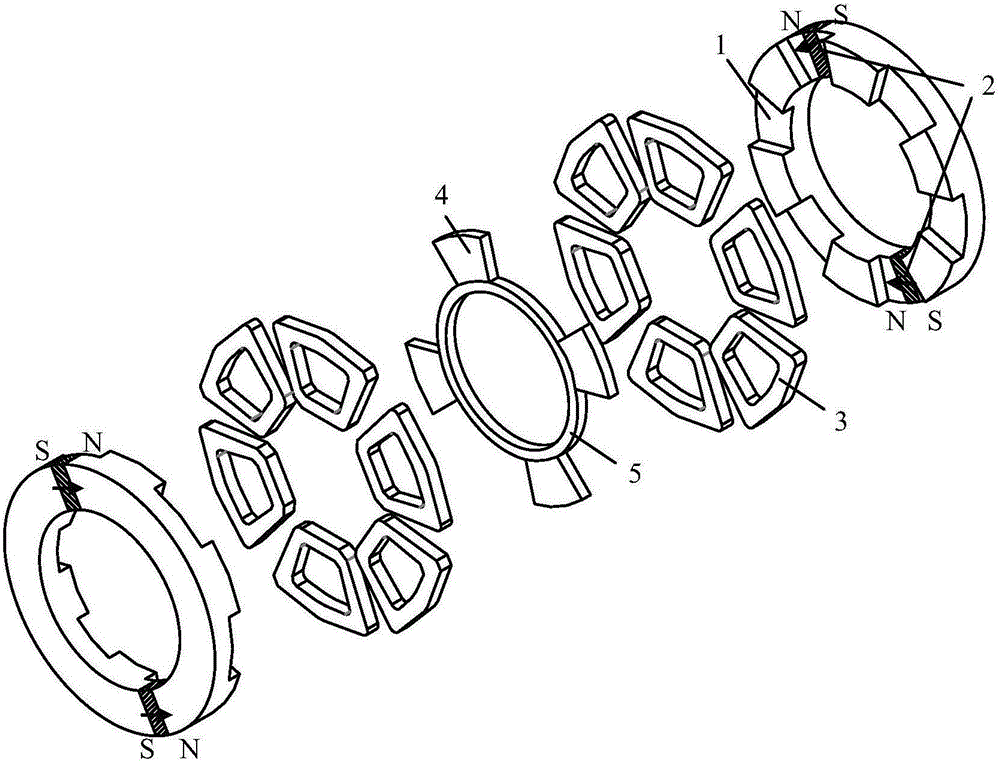

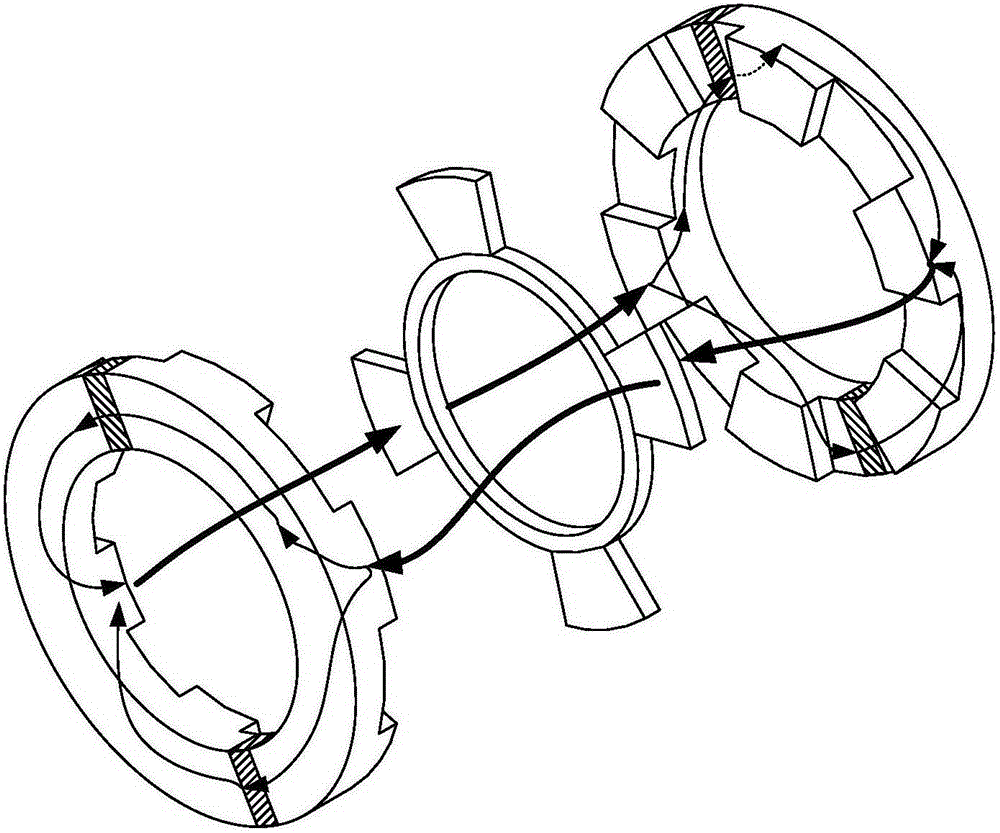

[0024] Taking the three-phase stator permanent magnet double salient pole disc motor as an example

[0025] to combine figure 1 , figure 2 and image 3 , the stator permanent magnet double salient pole disc motor includes a rotor mechanism, a motor shaft 6 and two identical stator mechanisms, the rotor mechanism is placed between the two stator mechanisms, the stator mechanism is connected to the motor shaft 6 through a bearing, and the rotor mechanism is fixed Connected to the motor shaft 6, the stator mechanism includes a stator core 1, two permanent magnets 2 and 6 annular armature windings 3, the stator core 1 is annular, and 6 stator teeth are evenly distributed on the inner wall of the stator core 1, and the stator teeth constitute the stator Salient poles, the slots between two adjacent stator teeth are stator slots, and permanent magnets 2 are respectively arranged in the center of any pair of stator slots on the same diameter, and the permanent magnets 2 are magnet...

Embodiment 2

[0031] Taking the four-phase stator permanent magnet double salient pole disc motor as an example

[0032] to combine figure 1 , figure 2 and image 3 , a stator permanent magnet double salient pole disc motor, comprising a rotor mechanism, a motor shaft 6 and two identical stator mechanisms, the rotor mechanism is placed between the two stator mechanisms, the stator mechanism is connected to the motor shaft 6 through a bearing, The rotor mechanism is fixed on the motor shaft 6. The stator mechanism includes a stator core 1, two permanent magnets 2 and 8 annular armature windings 3. The stator core 1 is ring-shaped, and 8 stator teeth are evenly distributed on the inner wall of the stator core 1. The stator The teeth constitute the salient poles of the stator, and the slots in the middle of two adjacent stator teeth are stator slots. A permanent magnet 2 is respectively arranged in the center of any pair of stator slots located on the same diameter, and the permanent magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com