Rolling vibration test bench for simulating wheel-rail relation in rail transit

A technology of vibration test bench and wheel-rail relationship, which is applied in the field of rail corrugation and can solve problems such as difficulty and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

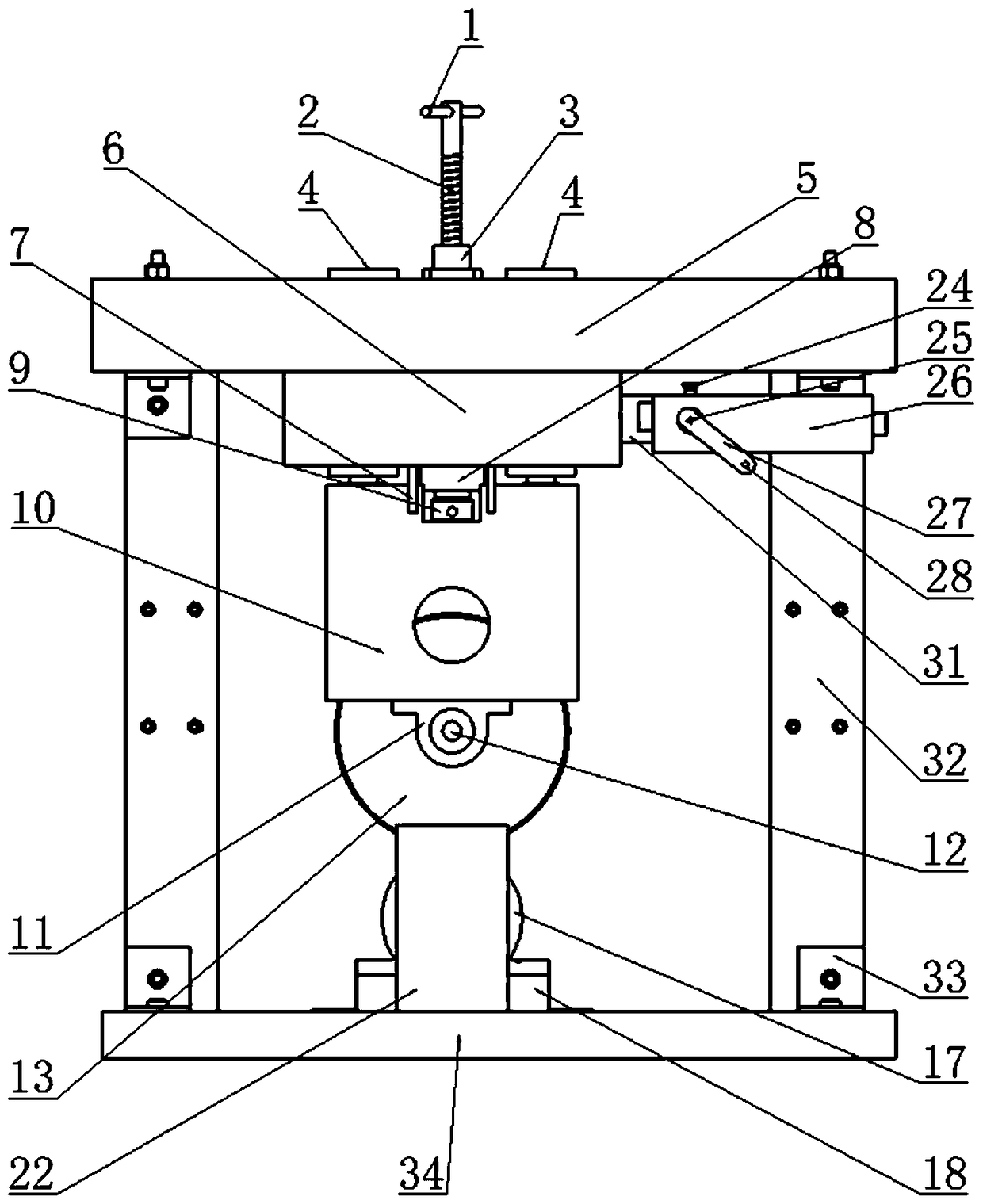

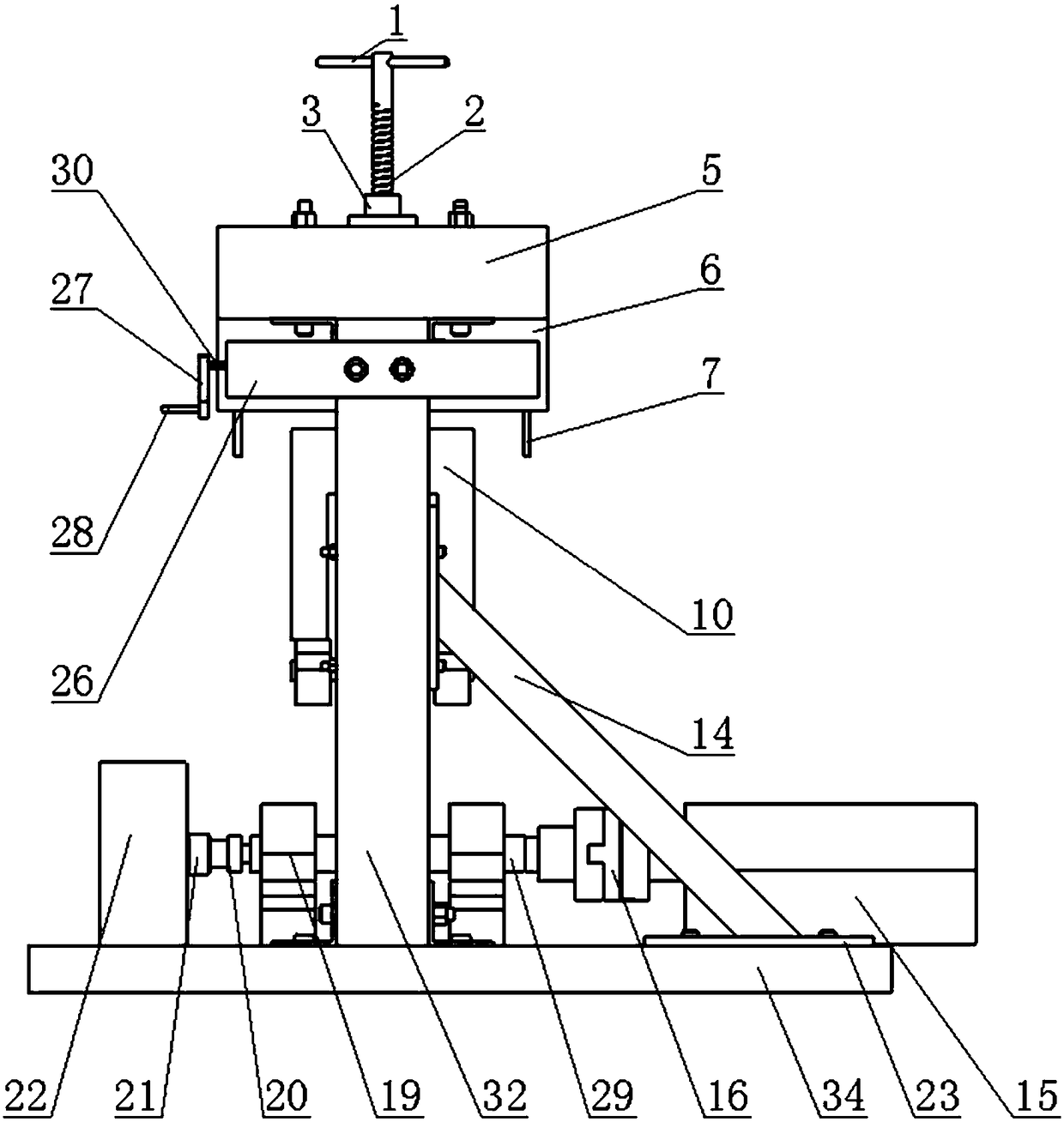

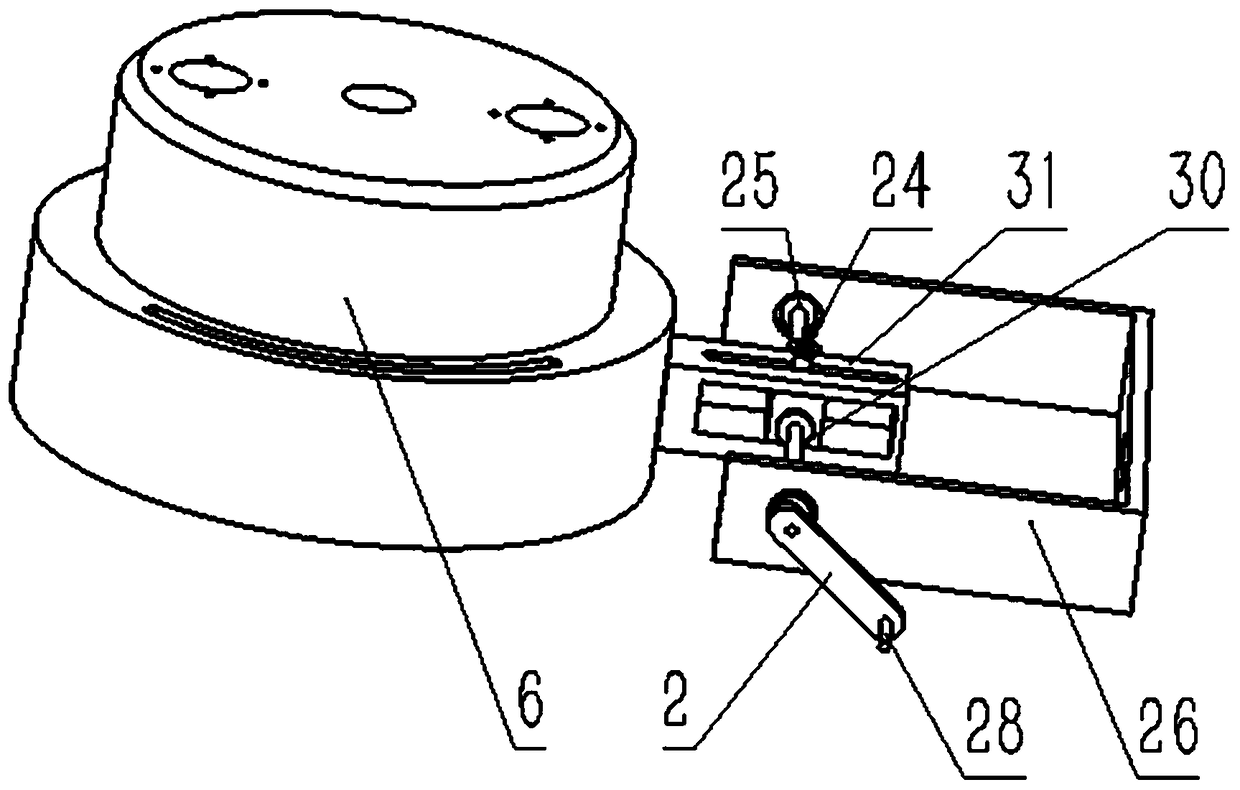

[0037] Such as figure 1 and 2 As shown, the present invention provides a rolling vibration test bench for simulating the relationship between rail transit wheels and rails. acquisition device. Among them, the wheel-rail simulation device is designed according to the ratio of 1:3 according to the geometric dimensions and mechanical characteristics of the subway vehicle wheels and rails. It is the core part and foundation of the entire test bench. The vertical loading device simulates the load on the rail. And the spring controls the vertical loading force of the test bench. The axial drive restraint device simulates the speed of the subway vehicle through the motor-driven rail wheel, and the angle adjustment device is to simulate the wheel-rail attack angle. The rotary motion of the rocker arm is converted into the linear motion of the screw rod, and then the scroll wheel is driven to rotate so that an angle is formed between the rail wheel and the scroll wheel. The main fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com