A flexible parallel platform device

A platform device and platform technology, applied in the field of robot micro-operation, can solve problems such as inability to achieve high precision and larger workspace requirements, and achieve the effects of avoiding errors, compact mechanism structure, and eliminating the influence of mechanism accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

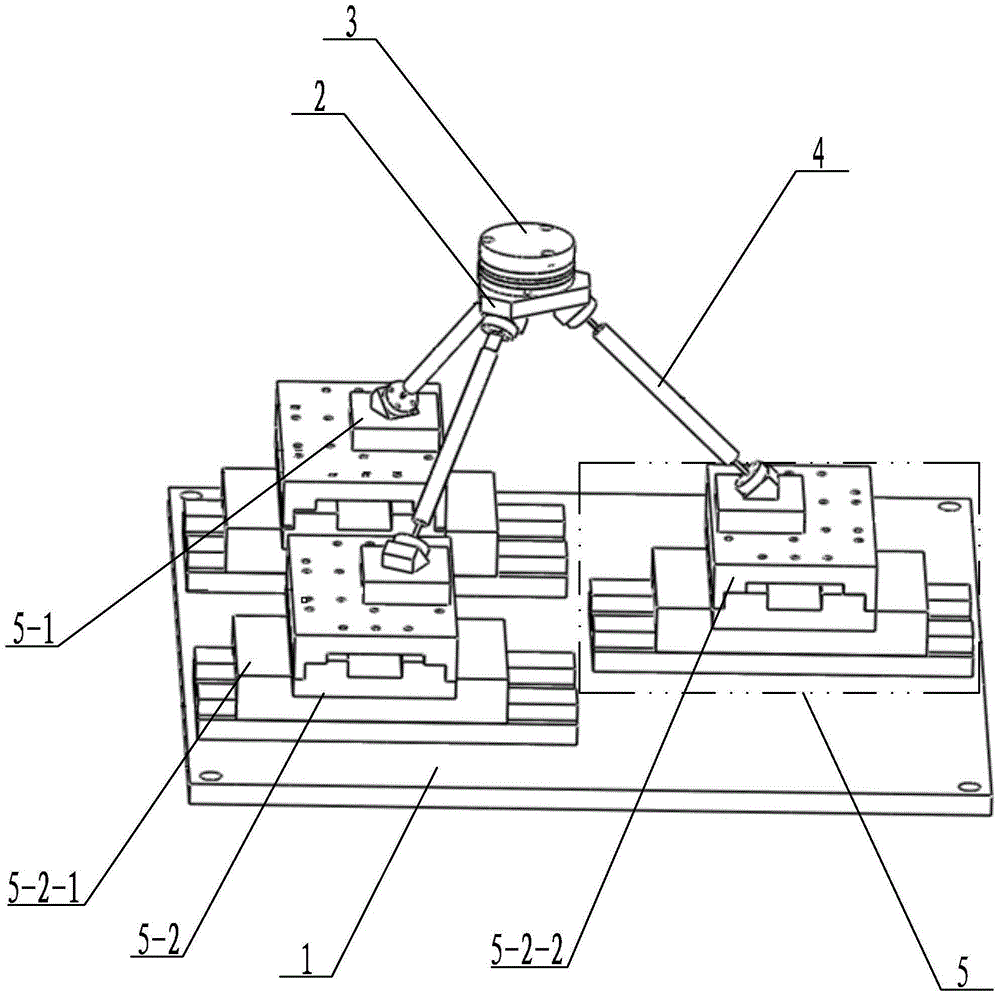

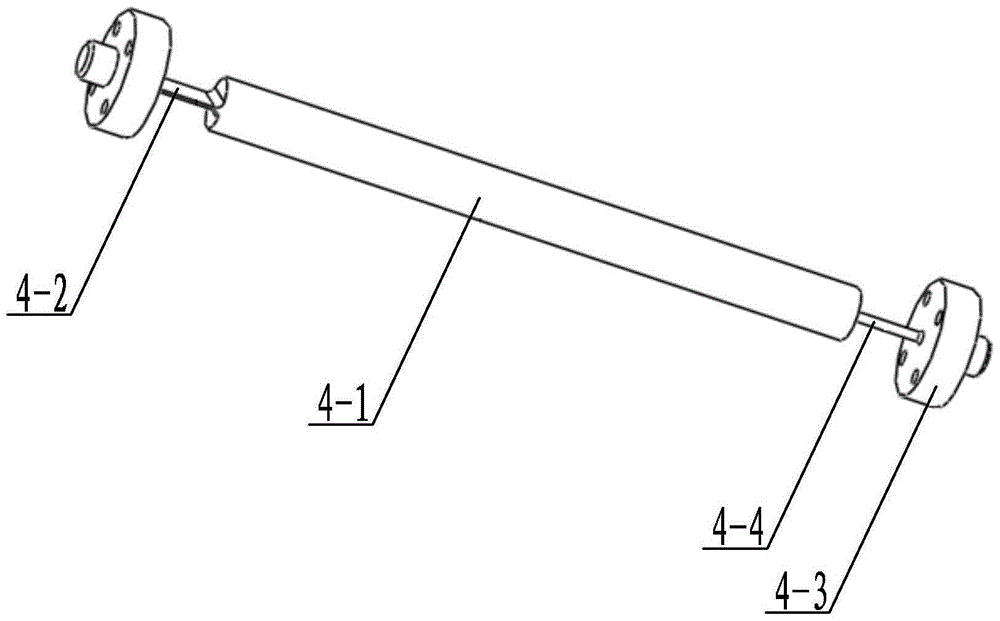

[0012] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a flexible parallel platform device of this embodiment includes a shock-isolation platform 1, an upper platform 2, a six-dimensional force sensor 3, three flexible branch chains 4 and three sets of platform assemblies 5, and the three sets of platform assemblies 5 are installed on On the isolation platform 1, the upper platform 2 is located above the three sets of platform components 5, each set of platform components 5 and the lower end surface of the upper platform 2 are connected by a flexible branch chain 4, and the six-dimensional force sensor 3 is installed on the upper platform 2, each group of platform components 5 includes a base 5-1 and a piezoelectric drive motor 5-2, and the base 5-1 is installed on the upper end of the piezoelectric drive motor 5-2.

[0013] The upper platform 2 of this embodiment is fixed with a six-dimensional force sensor 3, which can detect the c...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 and figure 2 The present embodiment will be described. The piezoelectric drive motor 5 - 2 of the present embodiment is a piezoelectric ceramic drive motor. Such setting is convenient to ensure that the present invention has the advantages of high displacement precision of sub-nanometer level, high frequency response of tens of kHz, high reliability and small mechanism structure. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the included angles between two adjacent flexible branch chains 4 among the three flexible branch chains 4 of this embodiment are both 120°. Such setting can effectively utilize the space, and at the same time make the three branch chains at the same initial position, avoiding the occurrence of singular structures and failures caused by excessive local deformation. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com