A method for predicting the milling force of end face milling cutter combined with SVM

A prediction method and face milling cutter technology, applied in the direction of instrumentation, calculation, design optimization/simulation, etc., can solve the problems of large cutting force error, decreased cutting force calculation accuracy, long calculation time, etc., to improve efficiency and shorten simulation time , the effect of reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

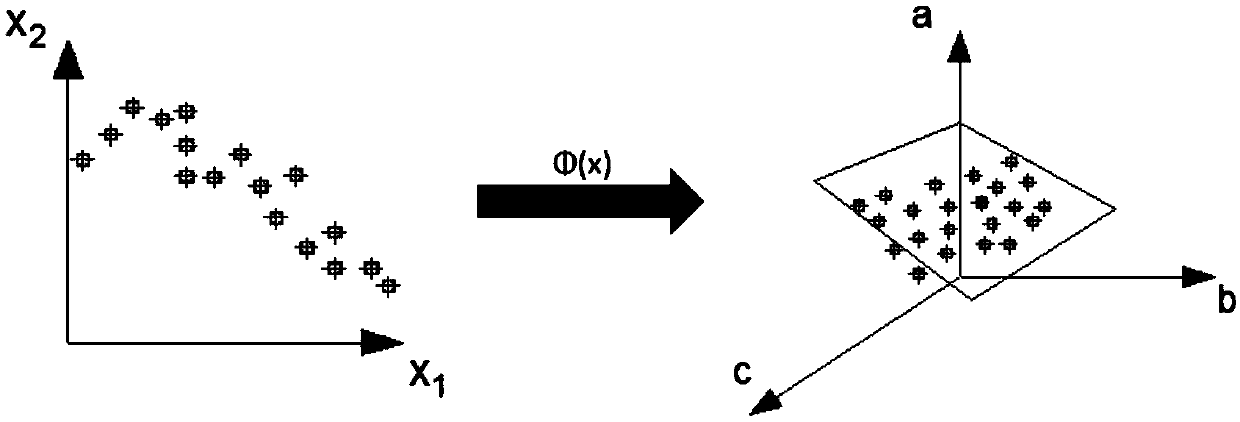

[0026] The technical difficulties of the present invention mainly lie in the geometric modeling of the blade finite element model and the solution of the cutting force model and the tool tip kinematics model fitted by the hybrid kernel function SVM method. The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings. The specific measures are as follows:

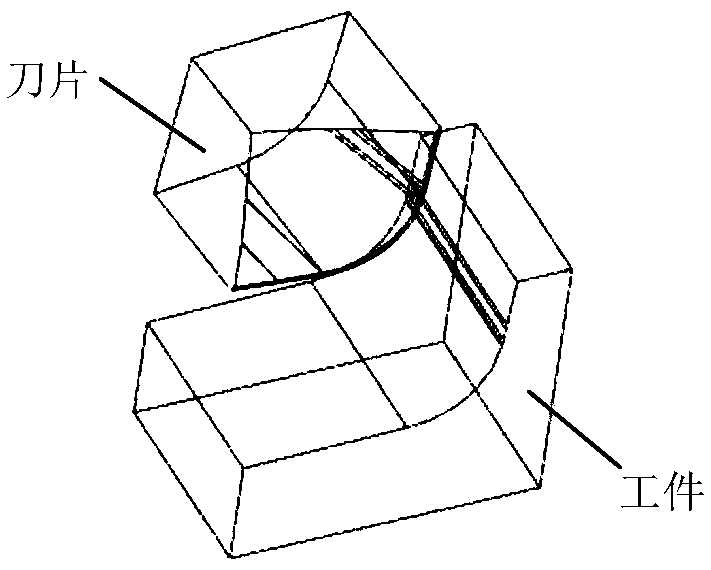

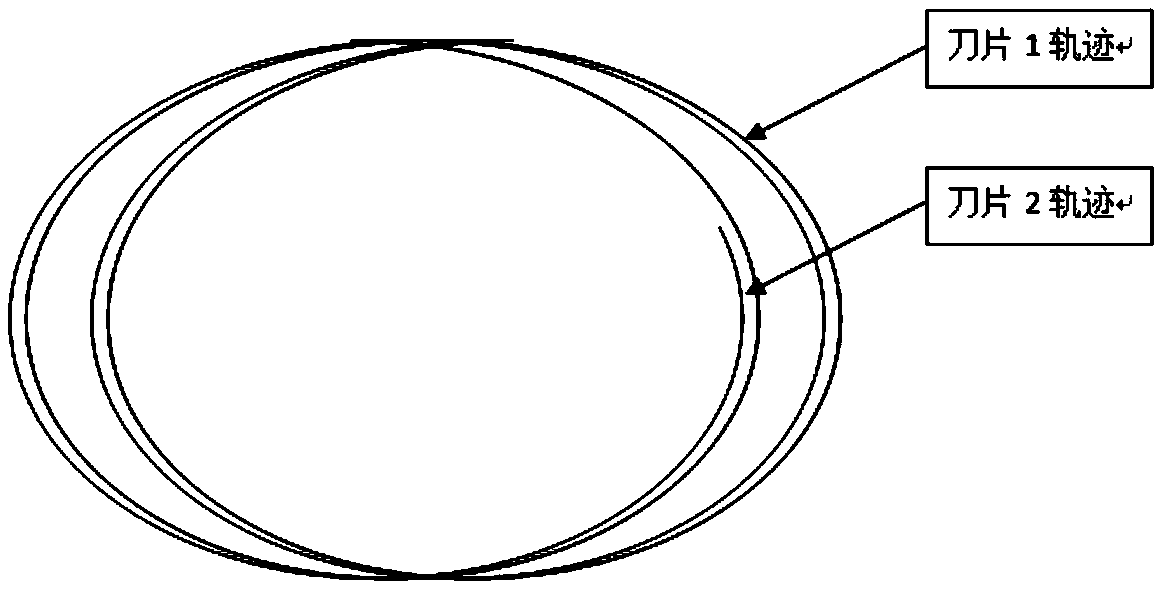

[0027] 1) Design 100 sets of simulation parameters with different depths of cut and different radial back cuts (5 sets of different parameters for depth of cut and radial depth of cut), and establish a geometric model. The geometric model is as follows: figure 1 As shown, the position of the cutting edge of the insert needs to be rounded, and the insert only takes the part of the tip that is in contact with the workpiece, reducing the number of grids and improving the accuracy of the grid, so that the grid can combine the shape of the tiny structure on the blade. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com