Patents

Literature

246 results about "Textile mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A textile mill is a manufacturing facility where textiles, or types of cloth, are produced or processed into finished products, such as clothing.

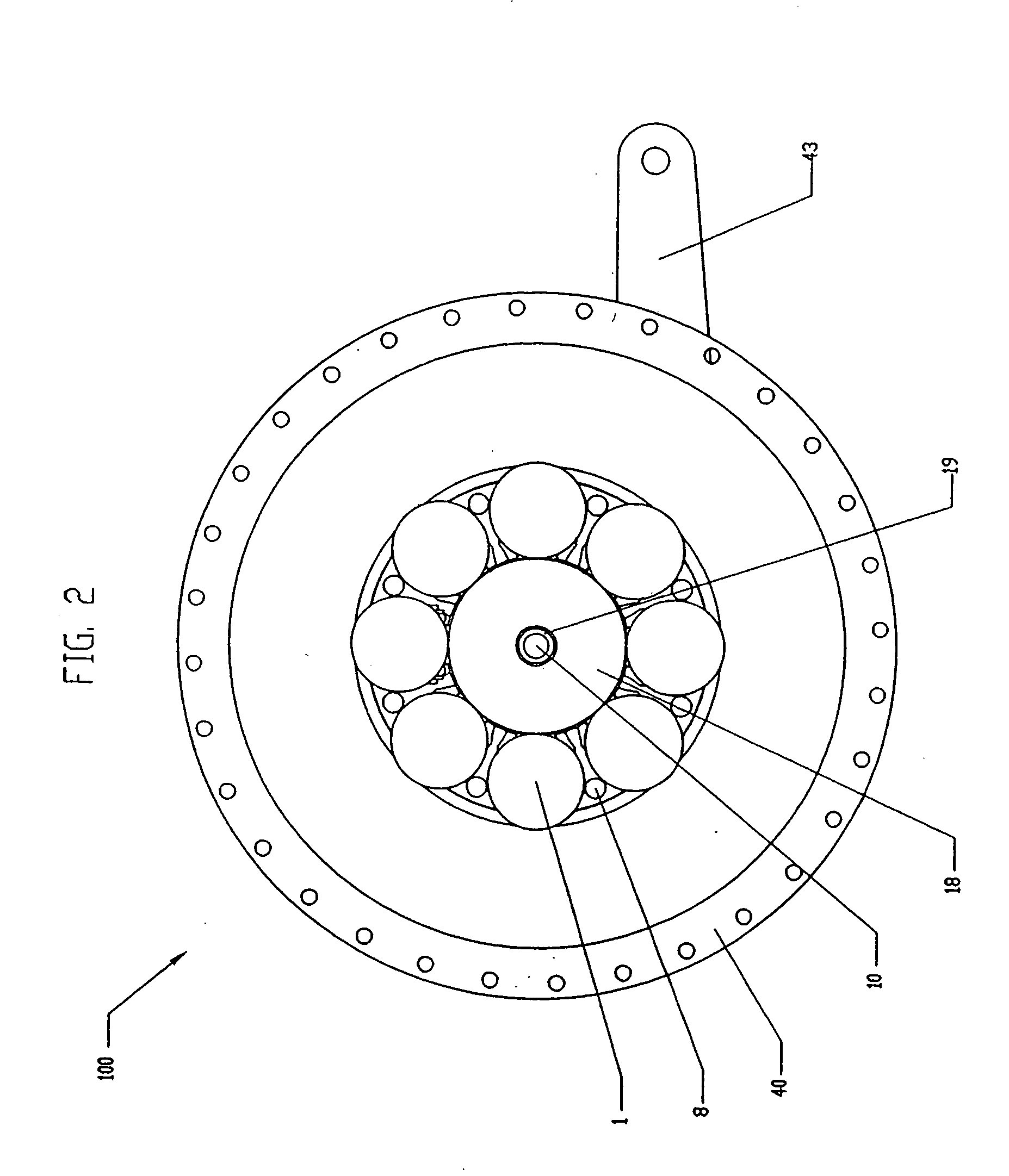

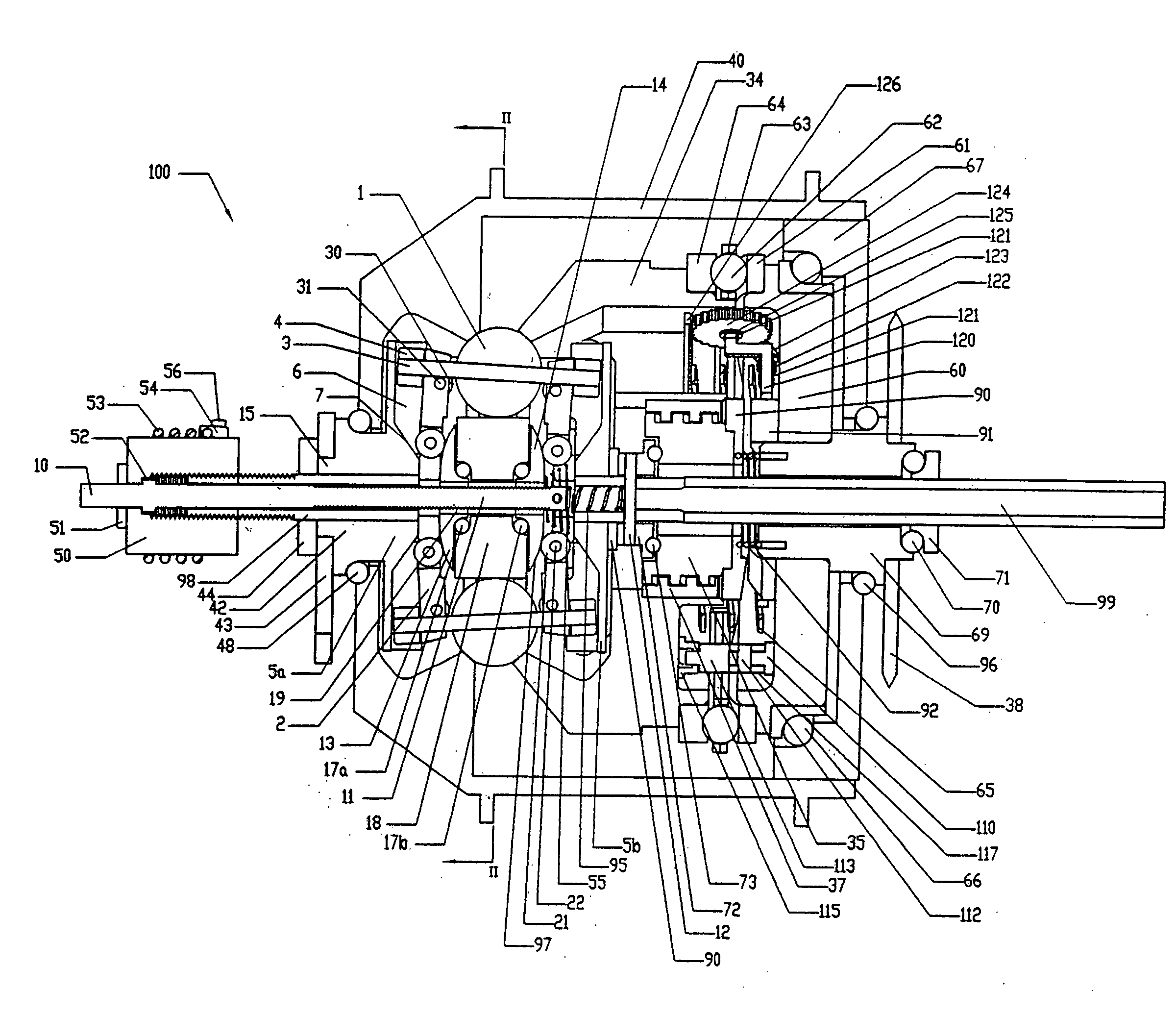

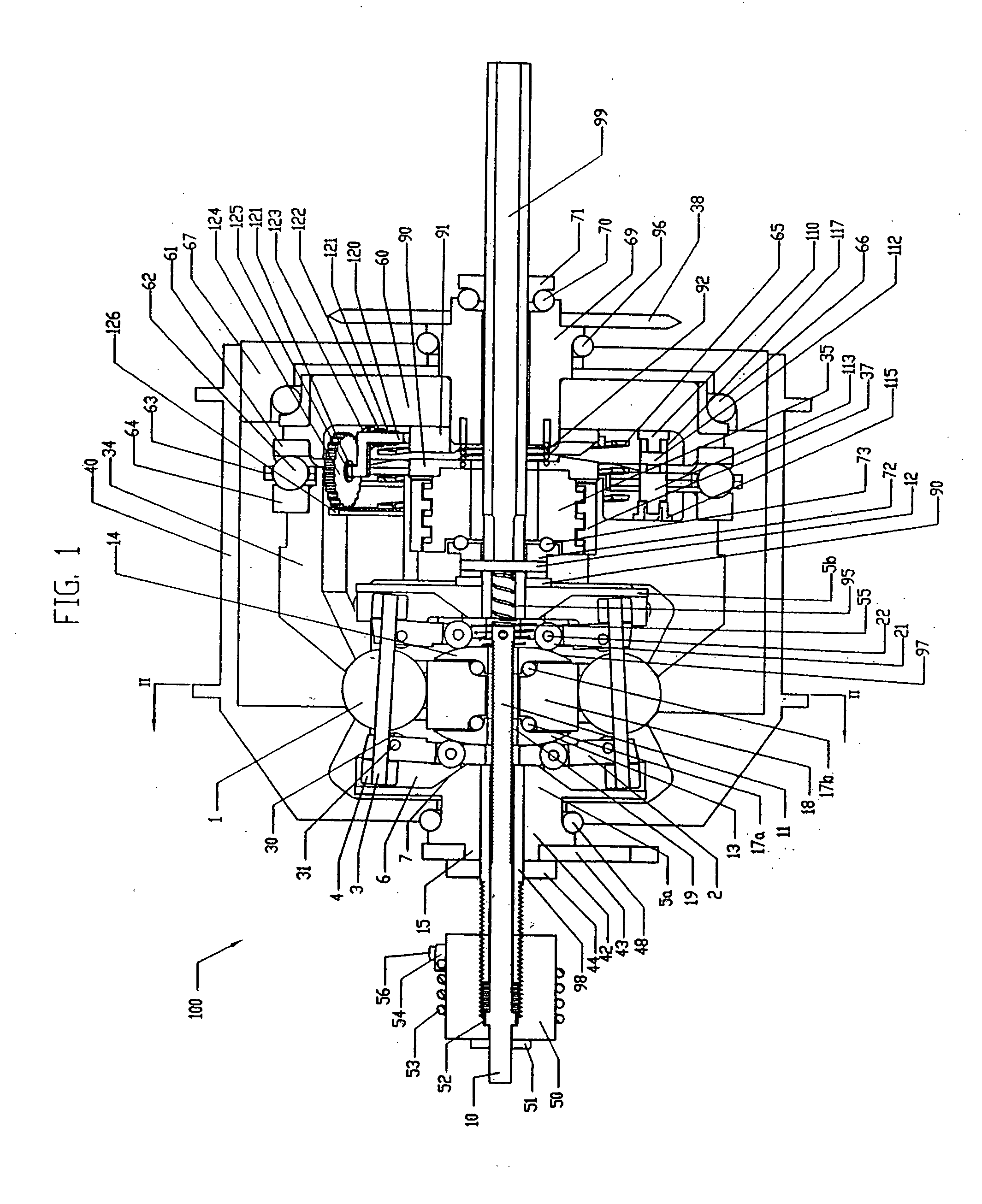

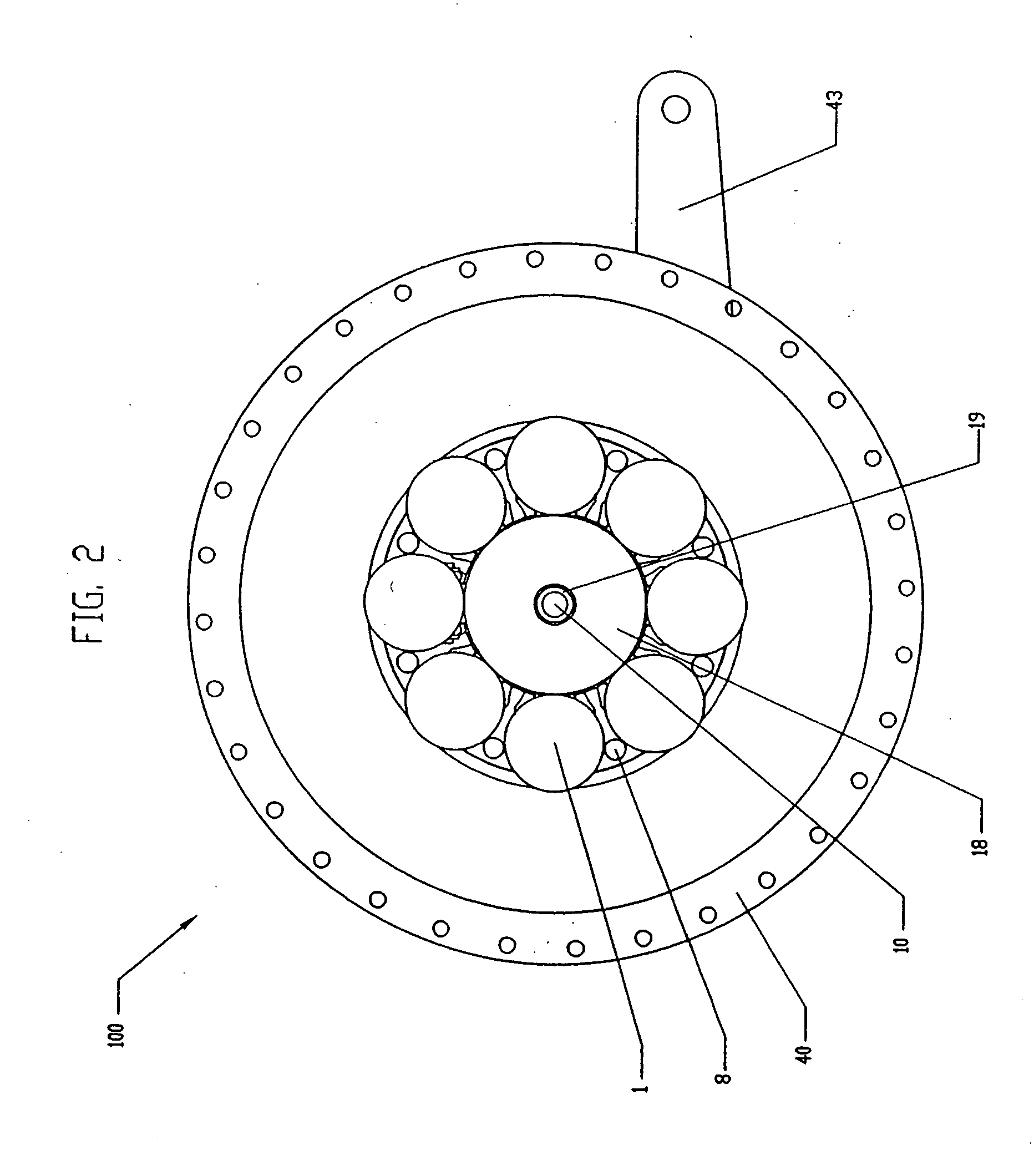

Continuously variable transmission

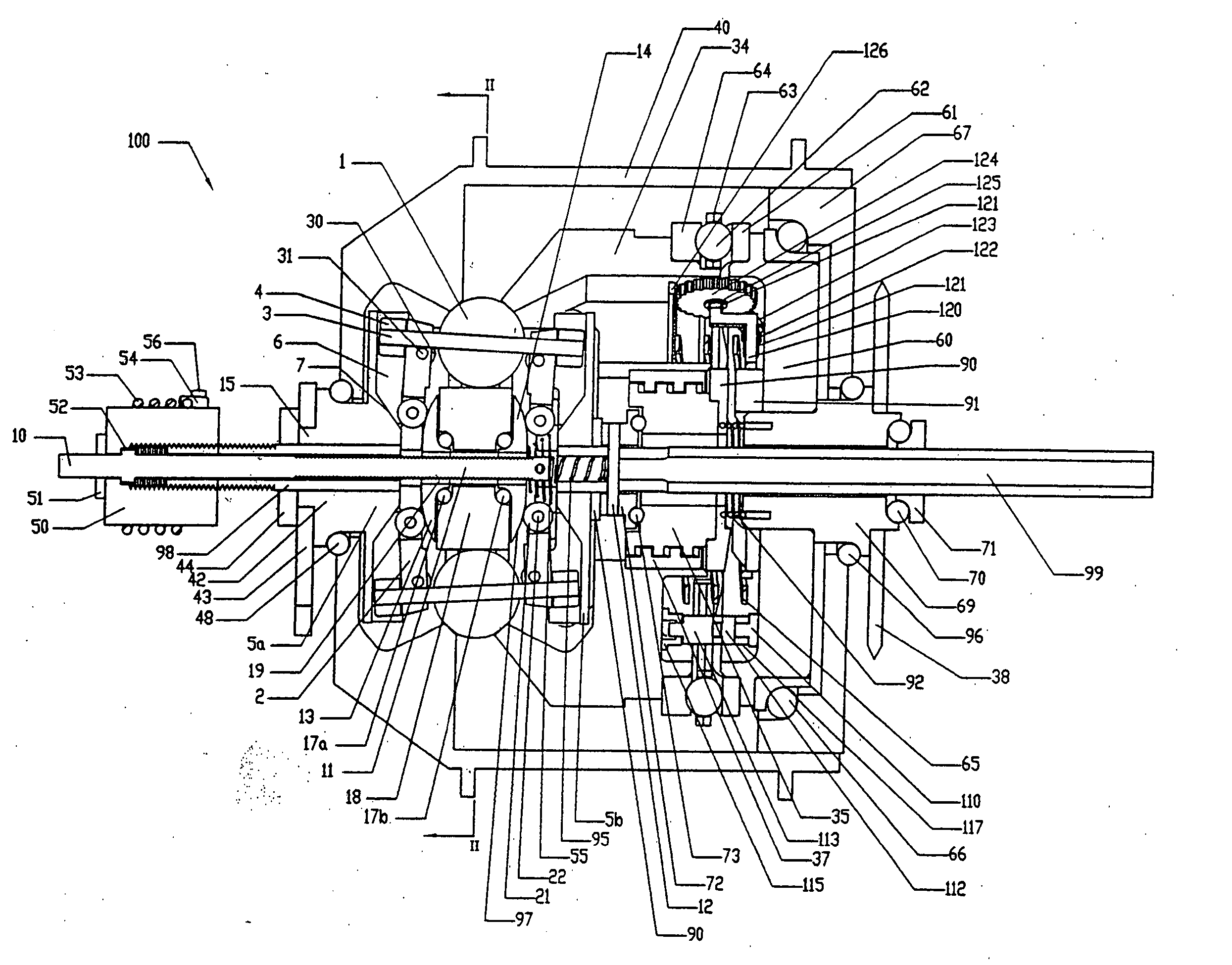

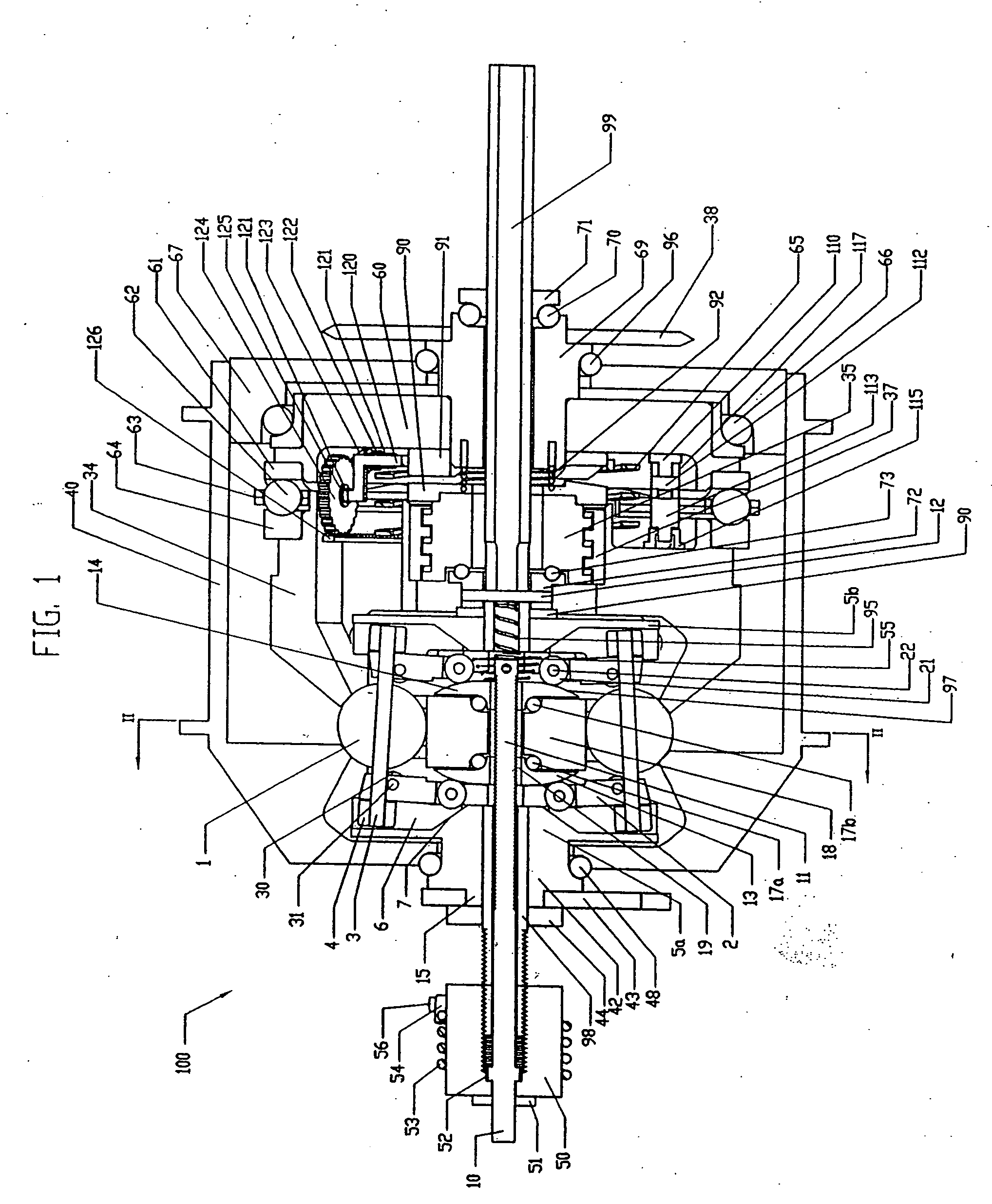

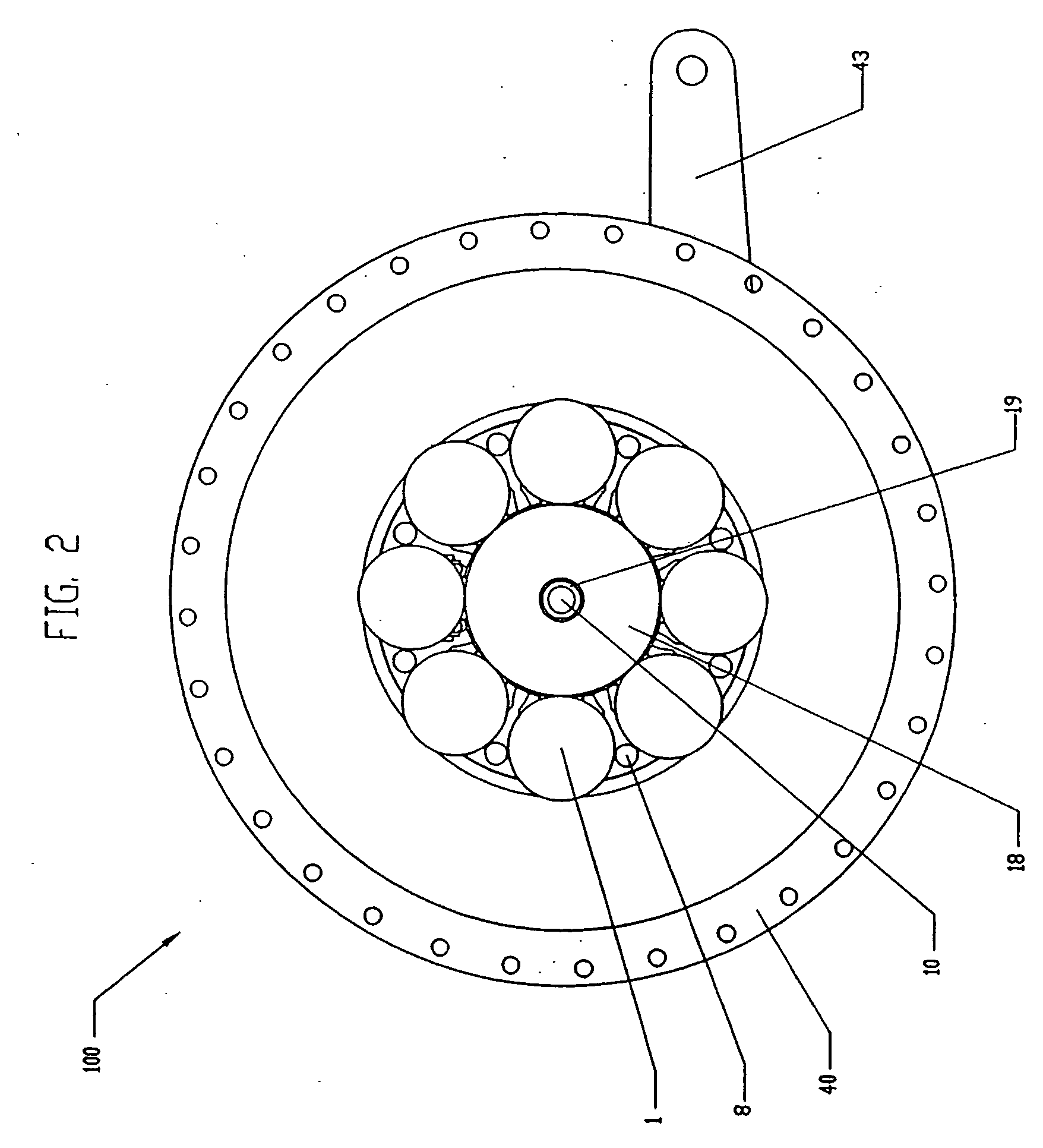

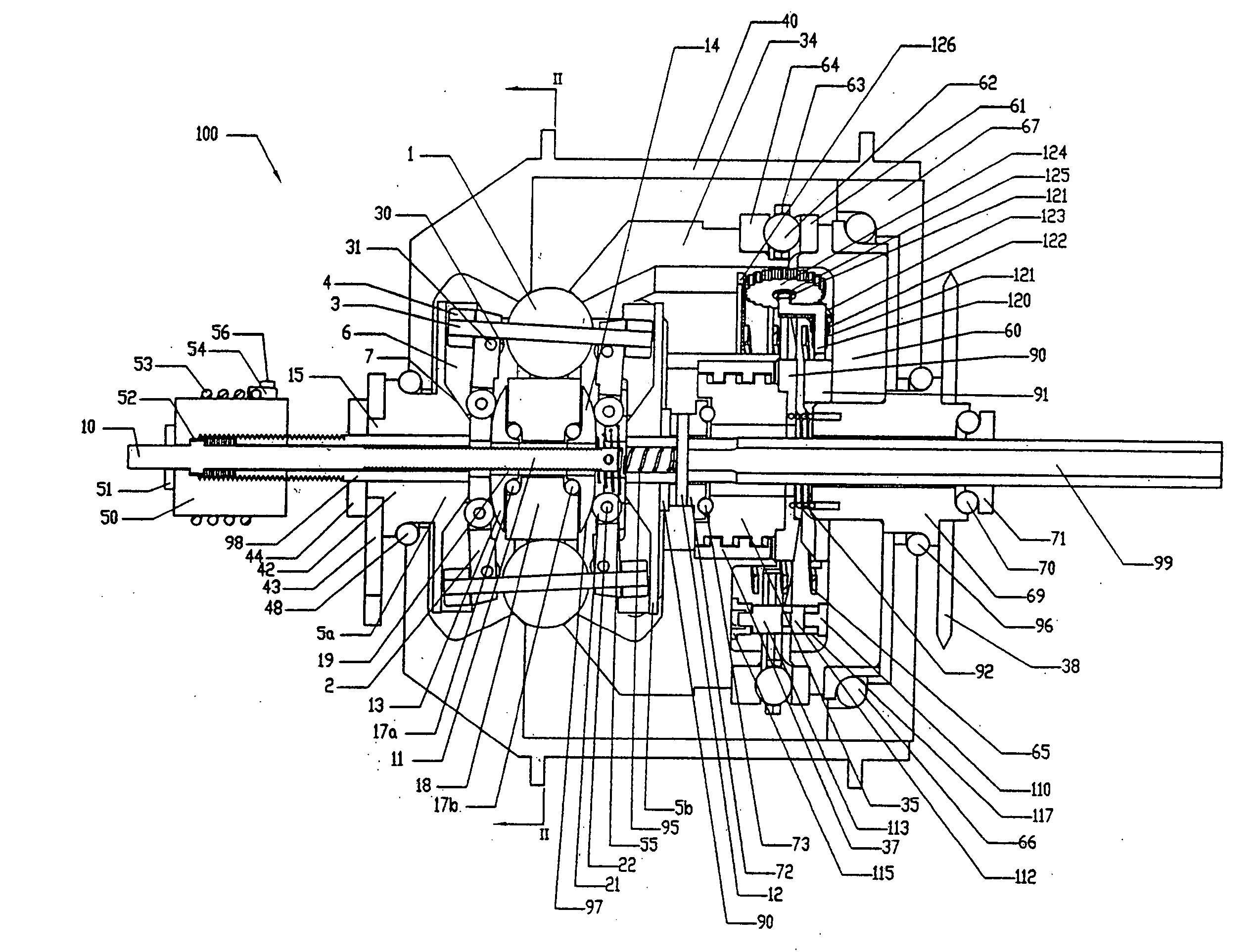

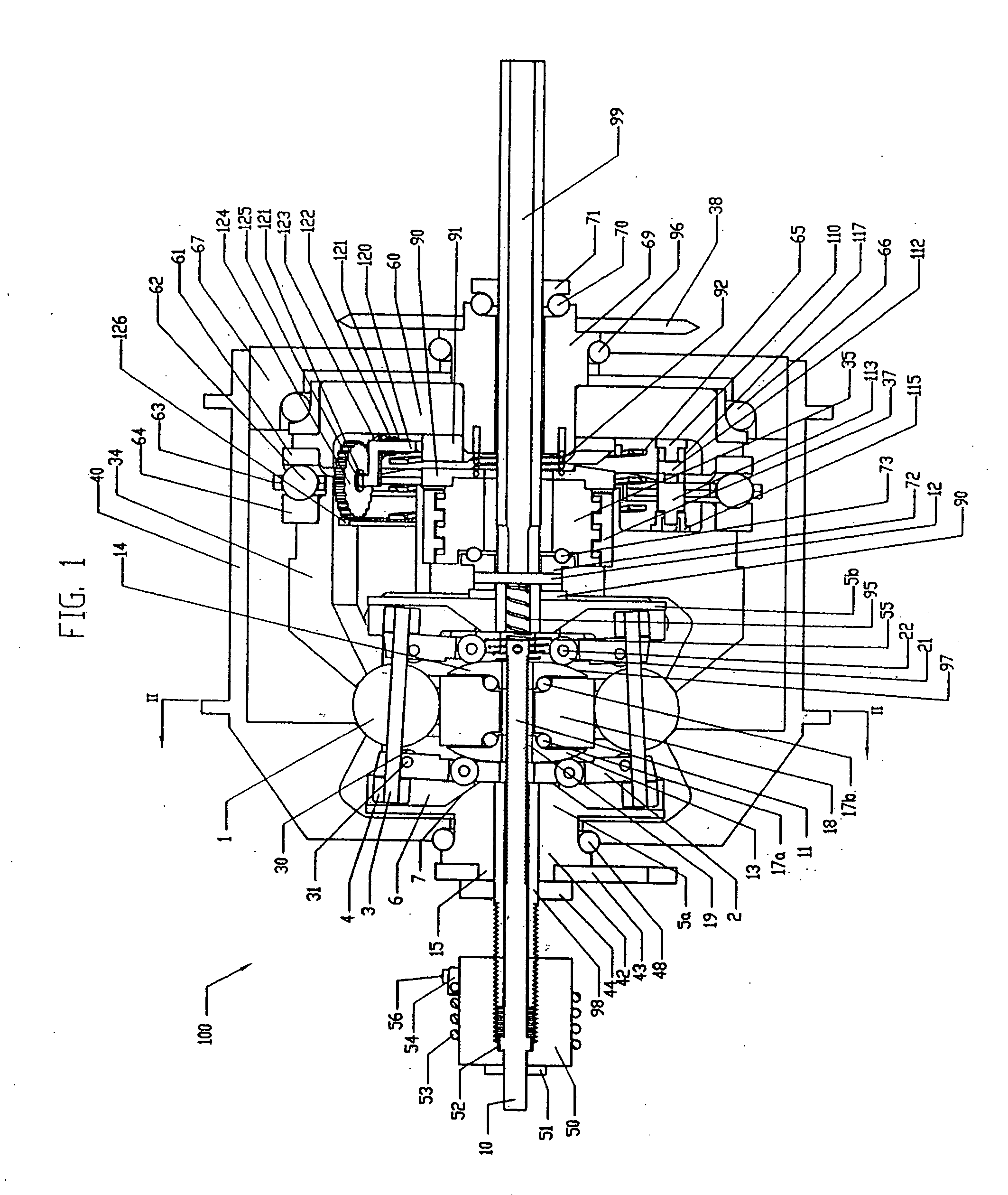

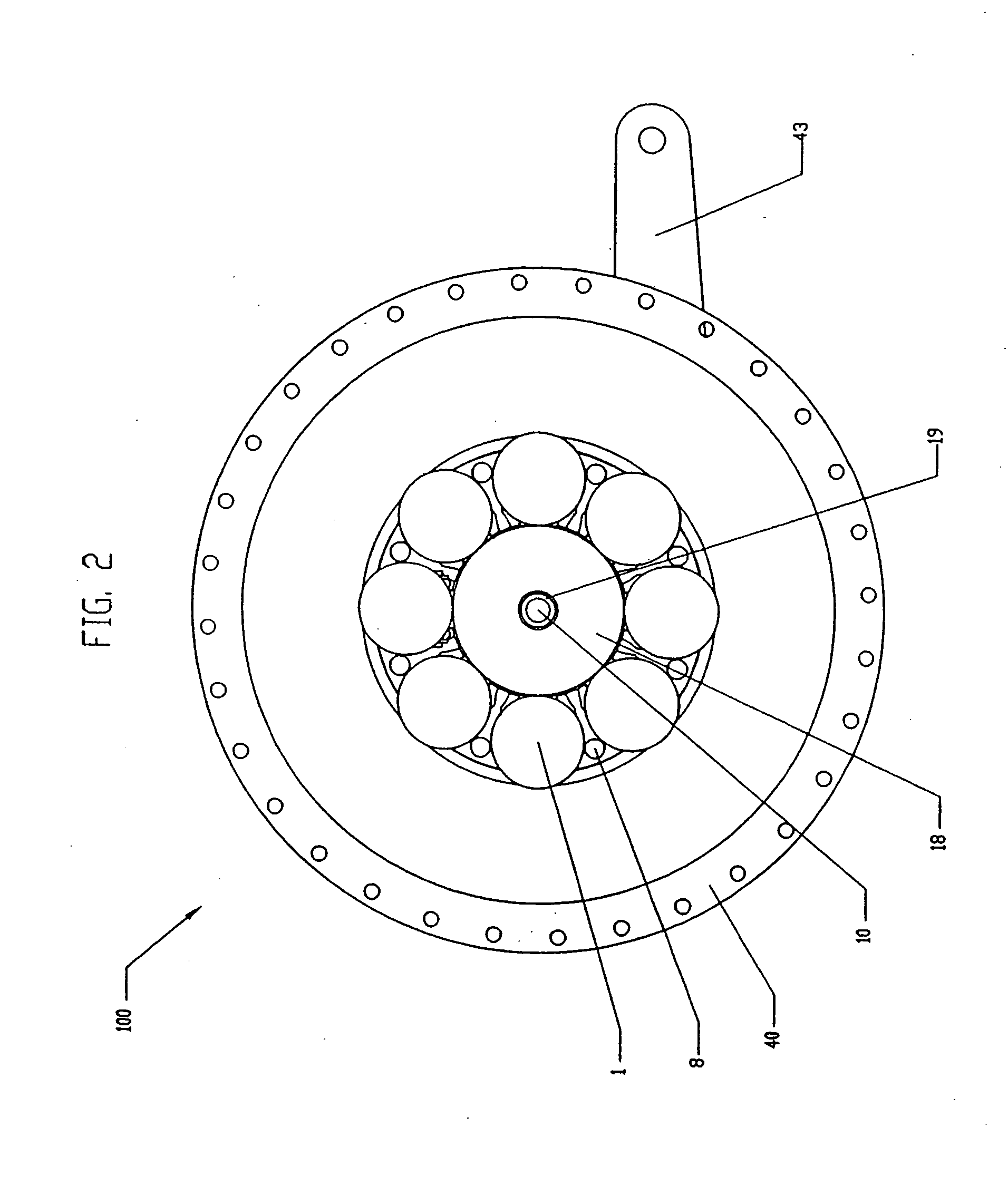

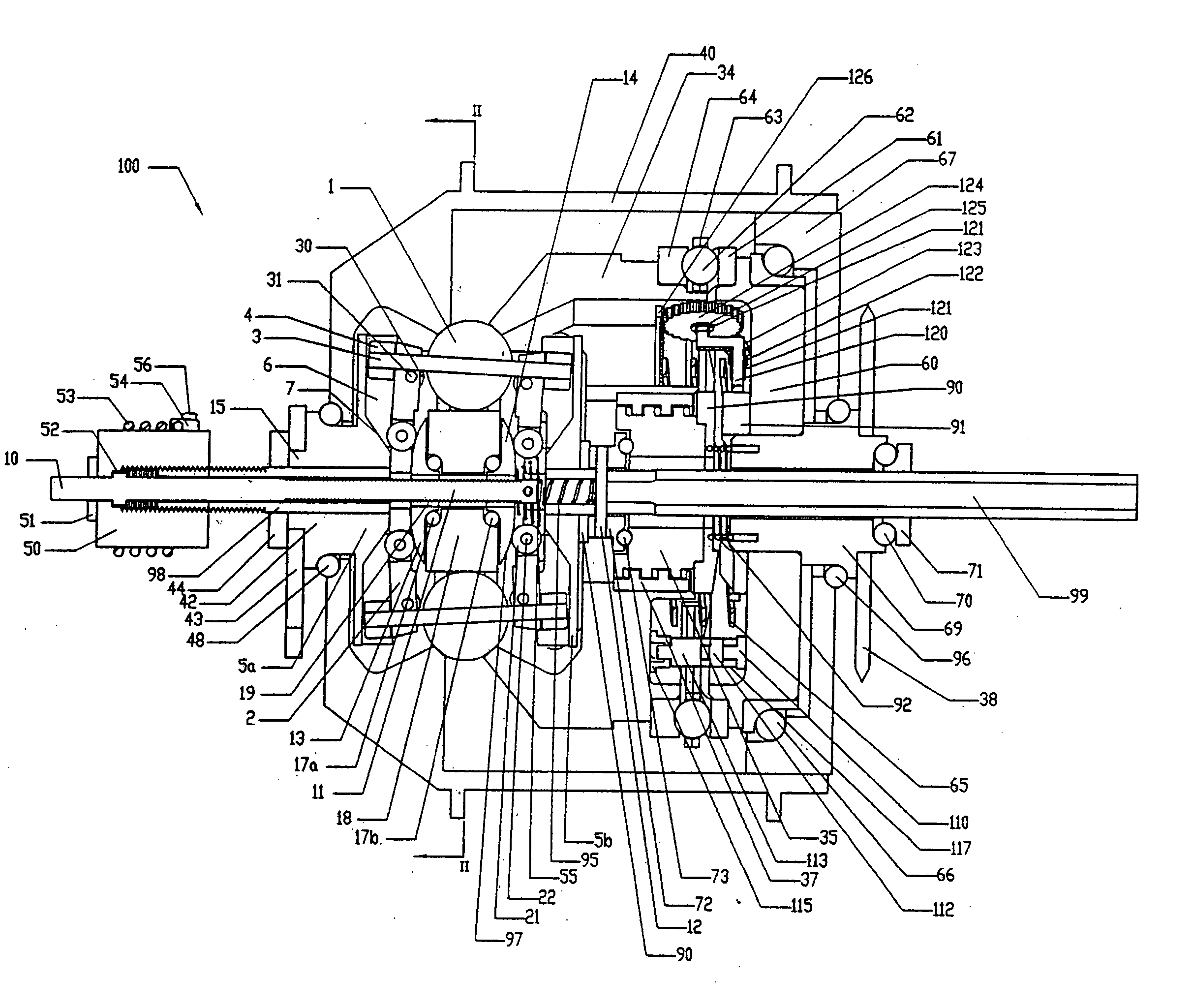

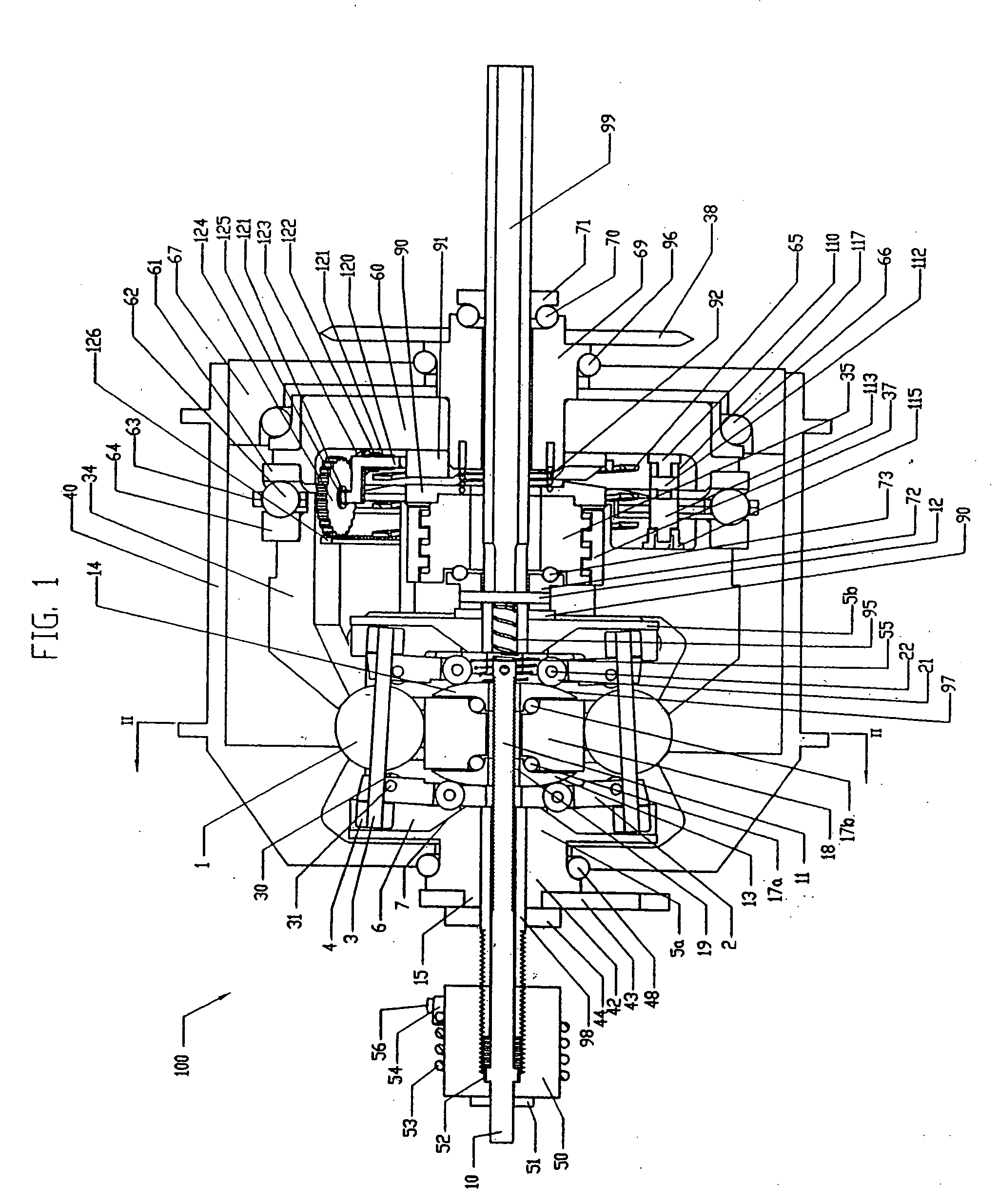

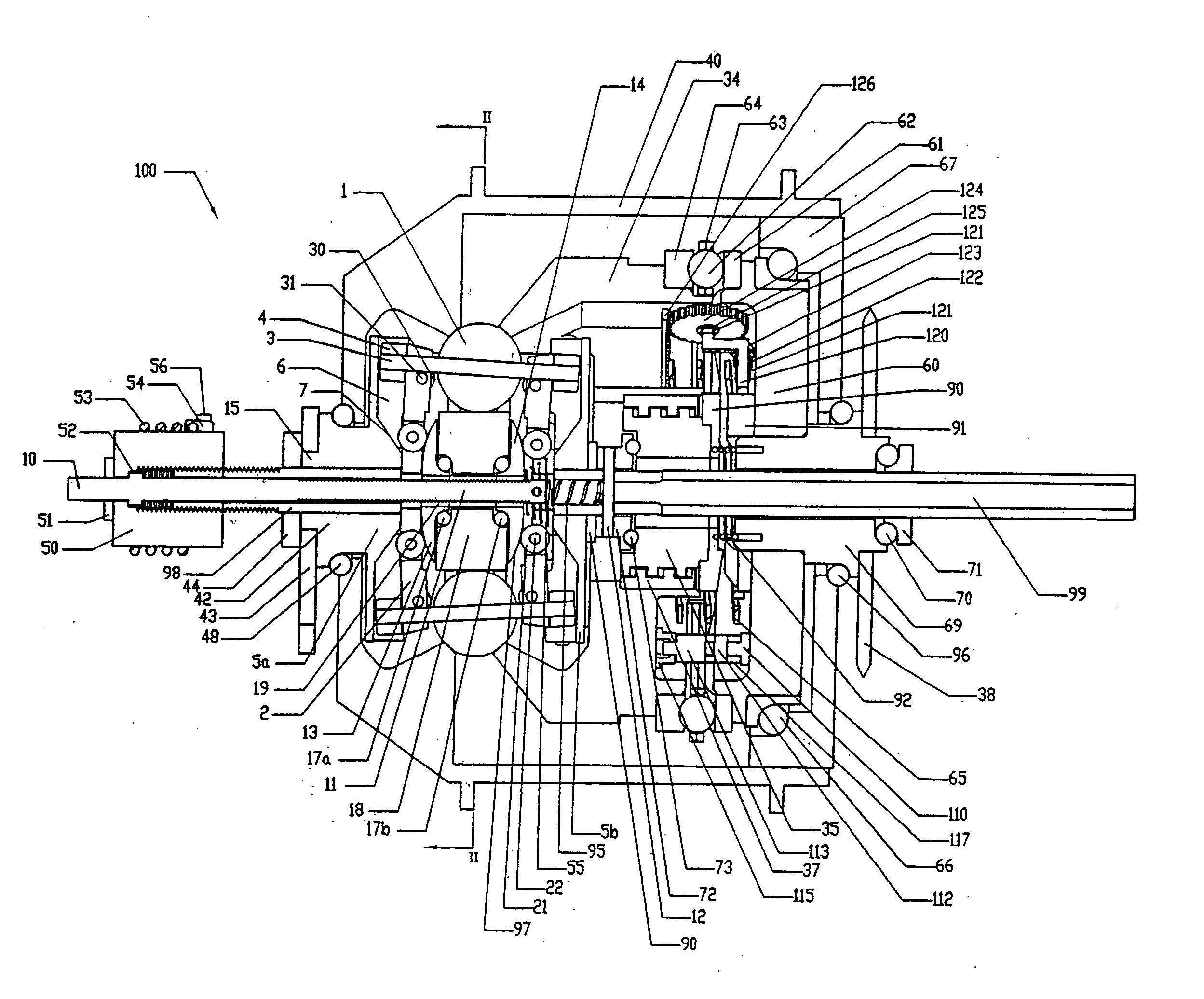

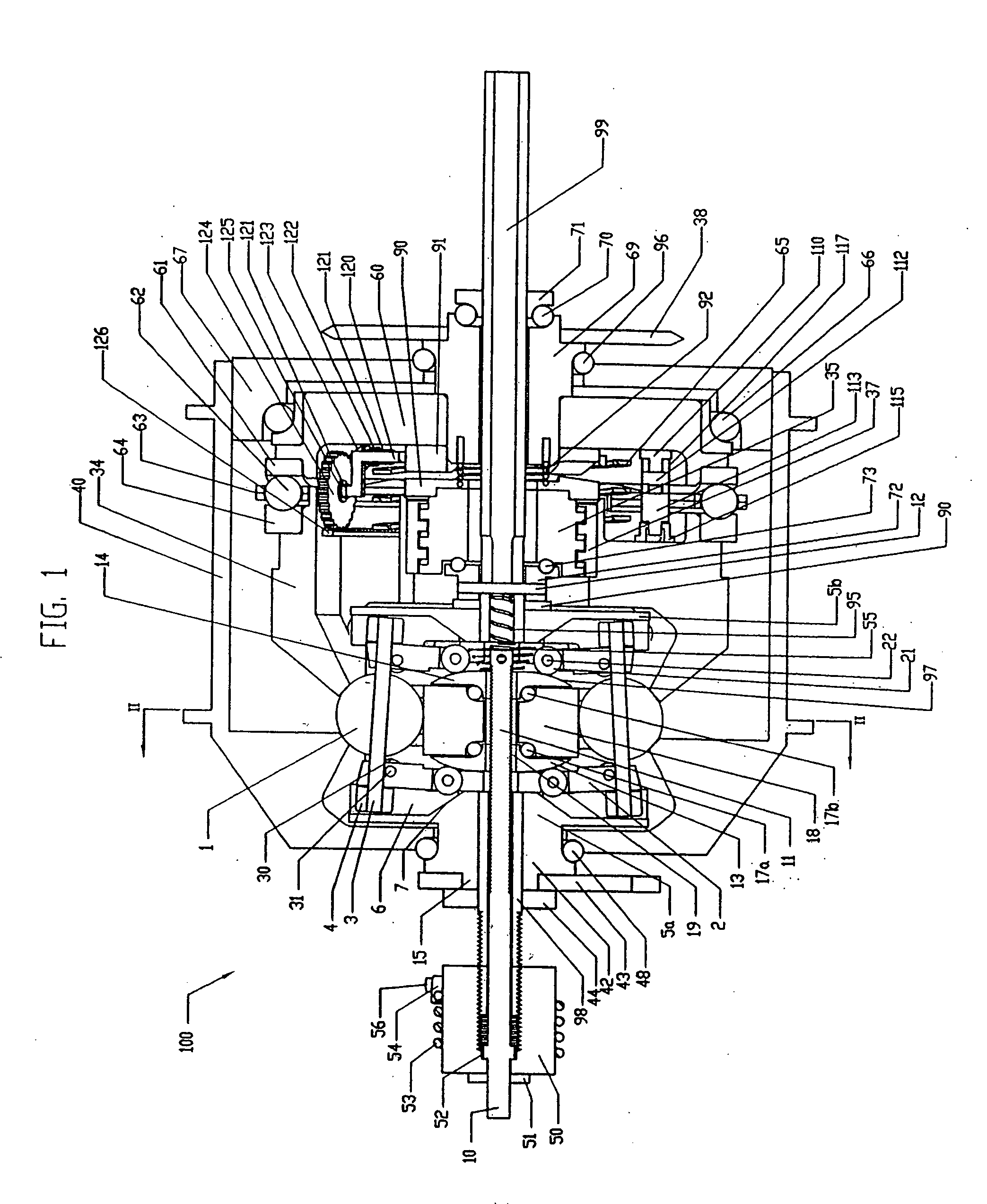

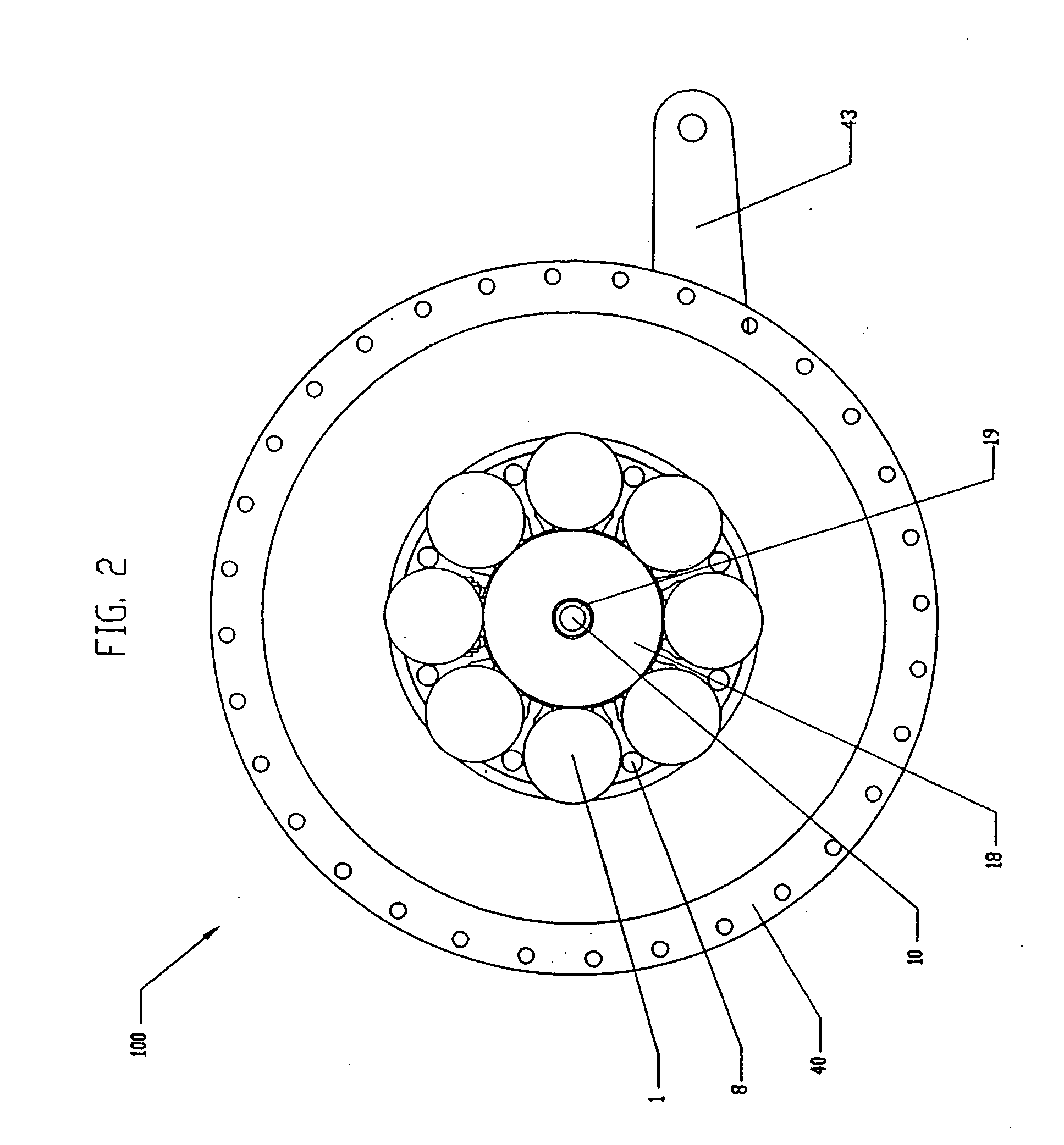

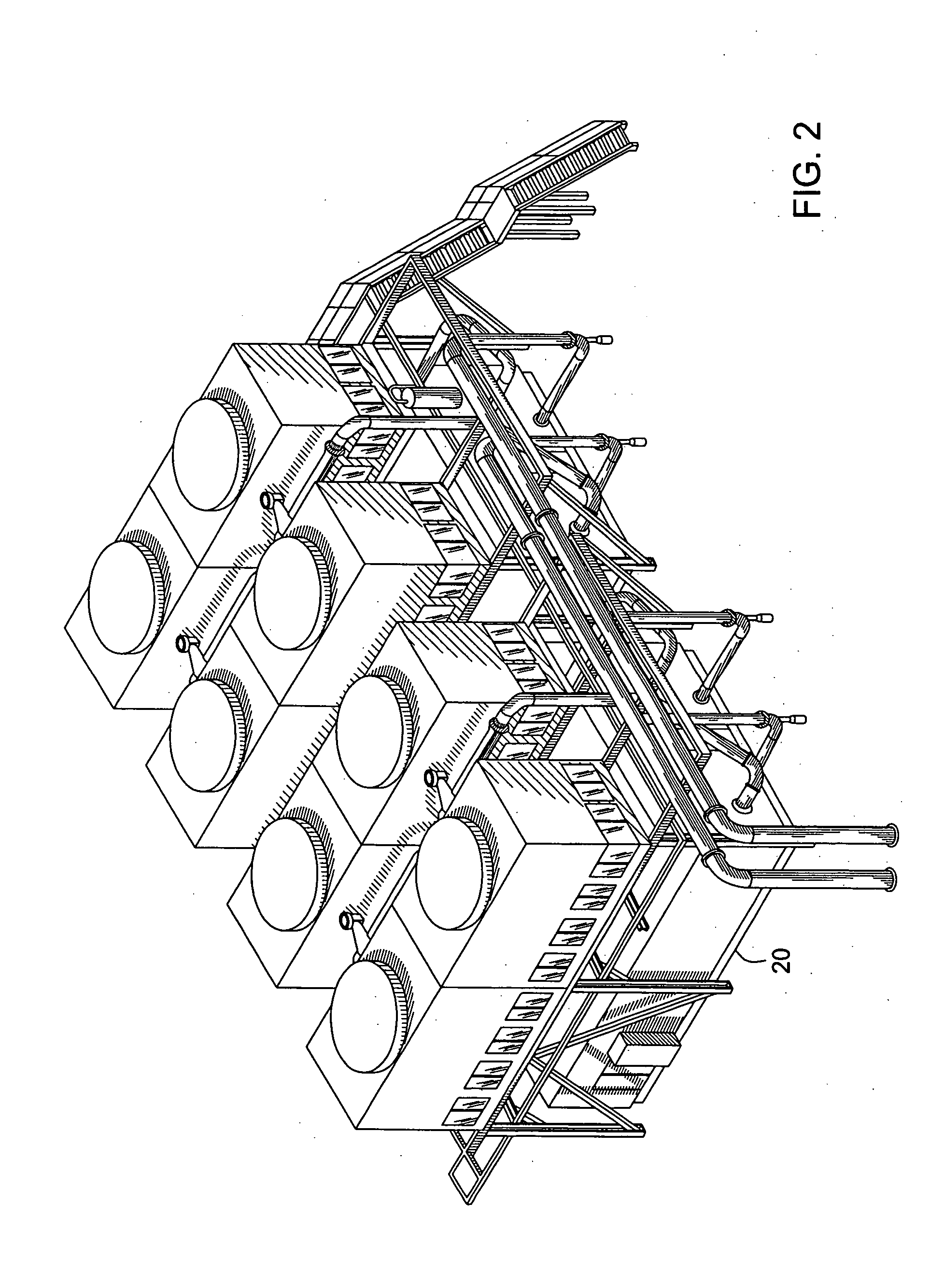

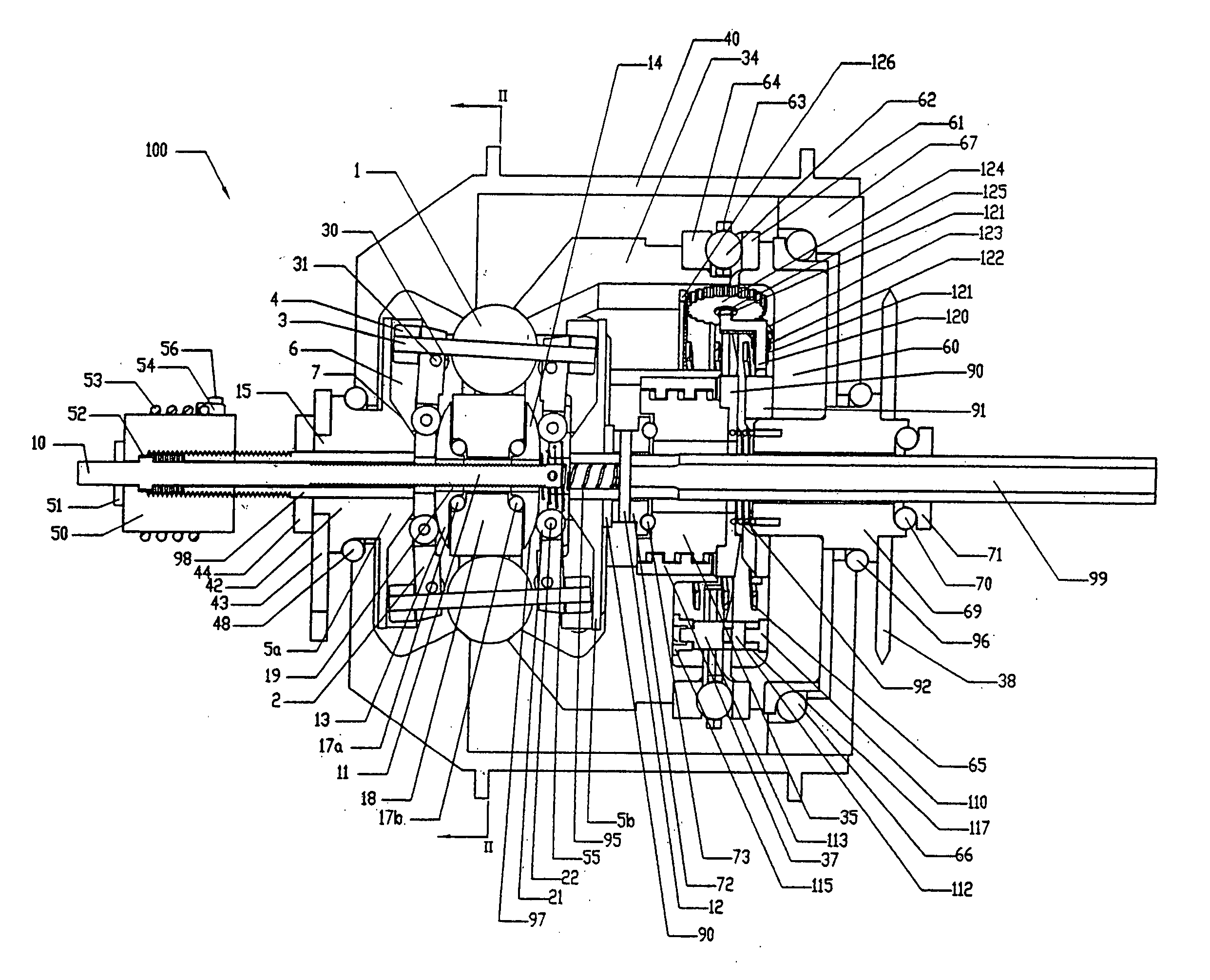

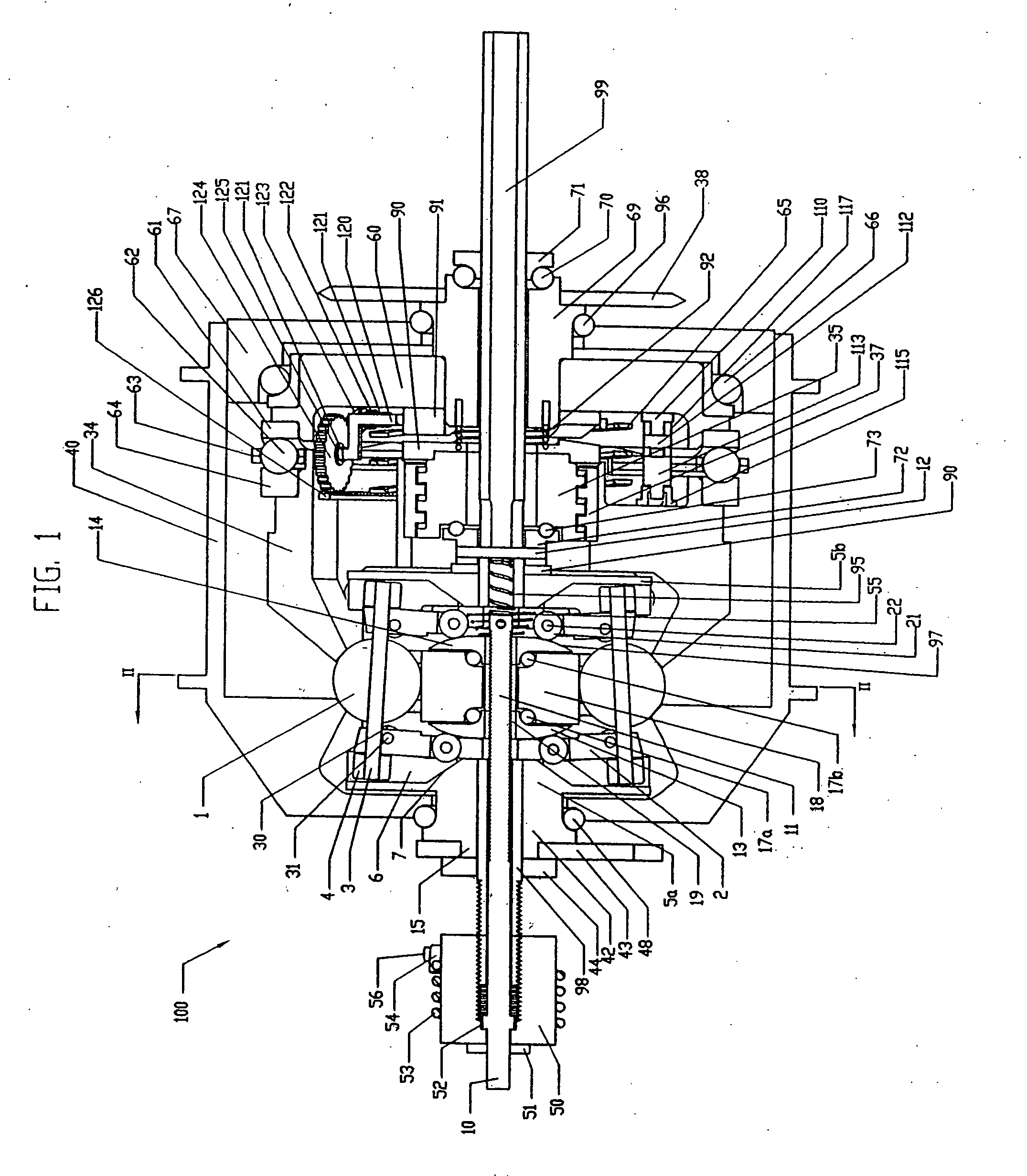

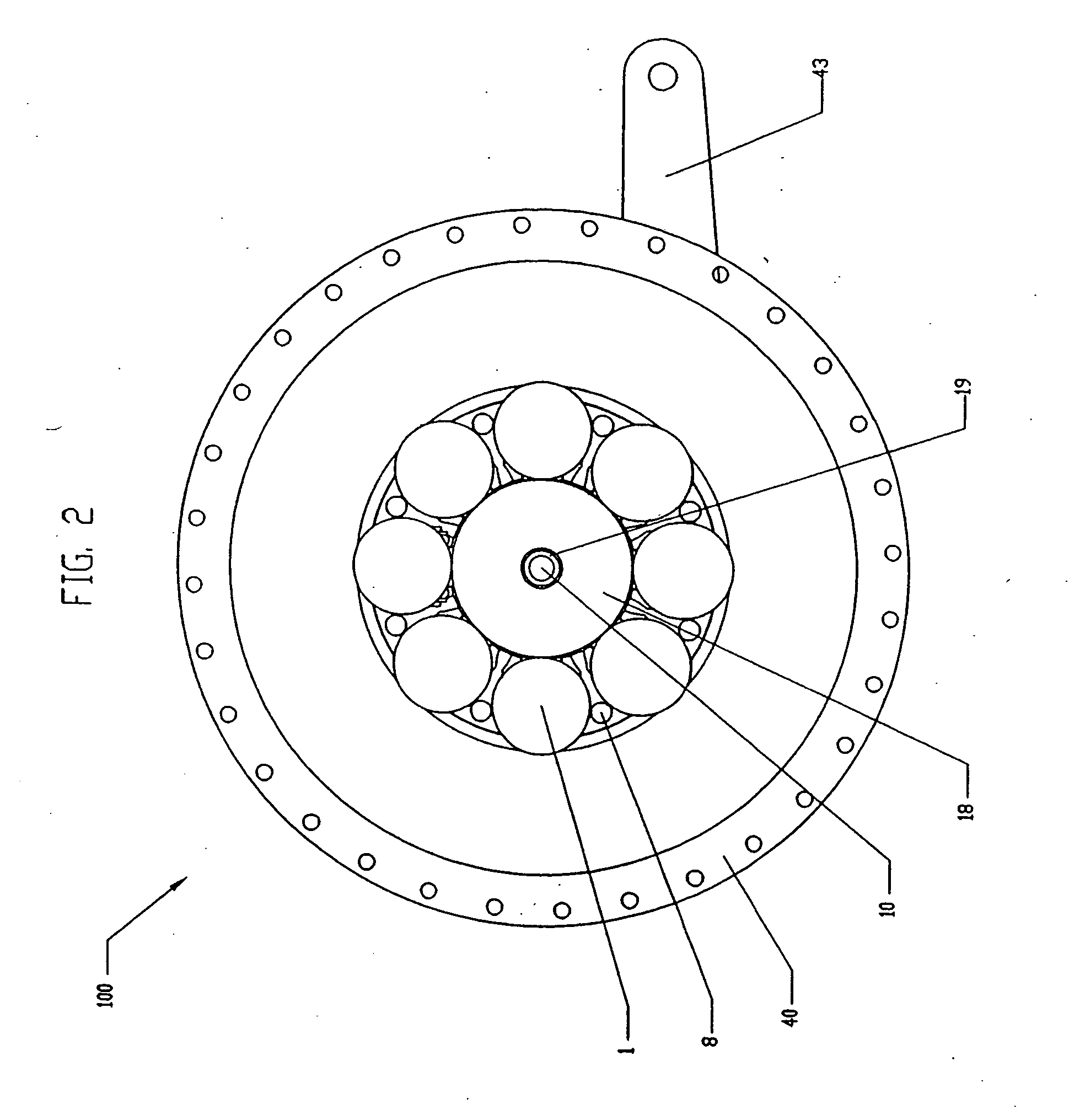

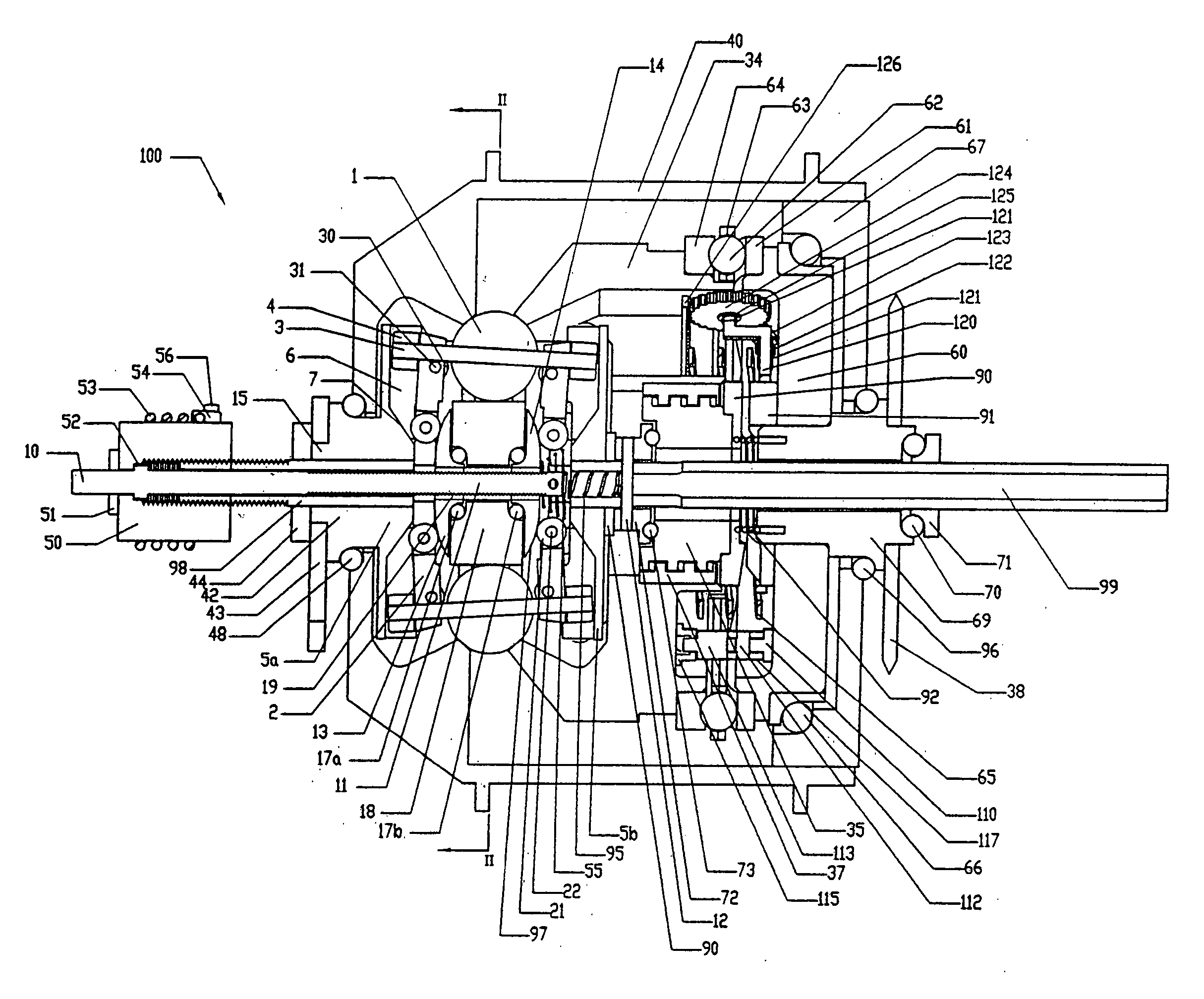

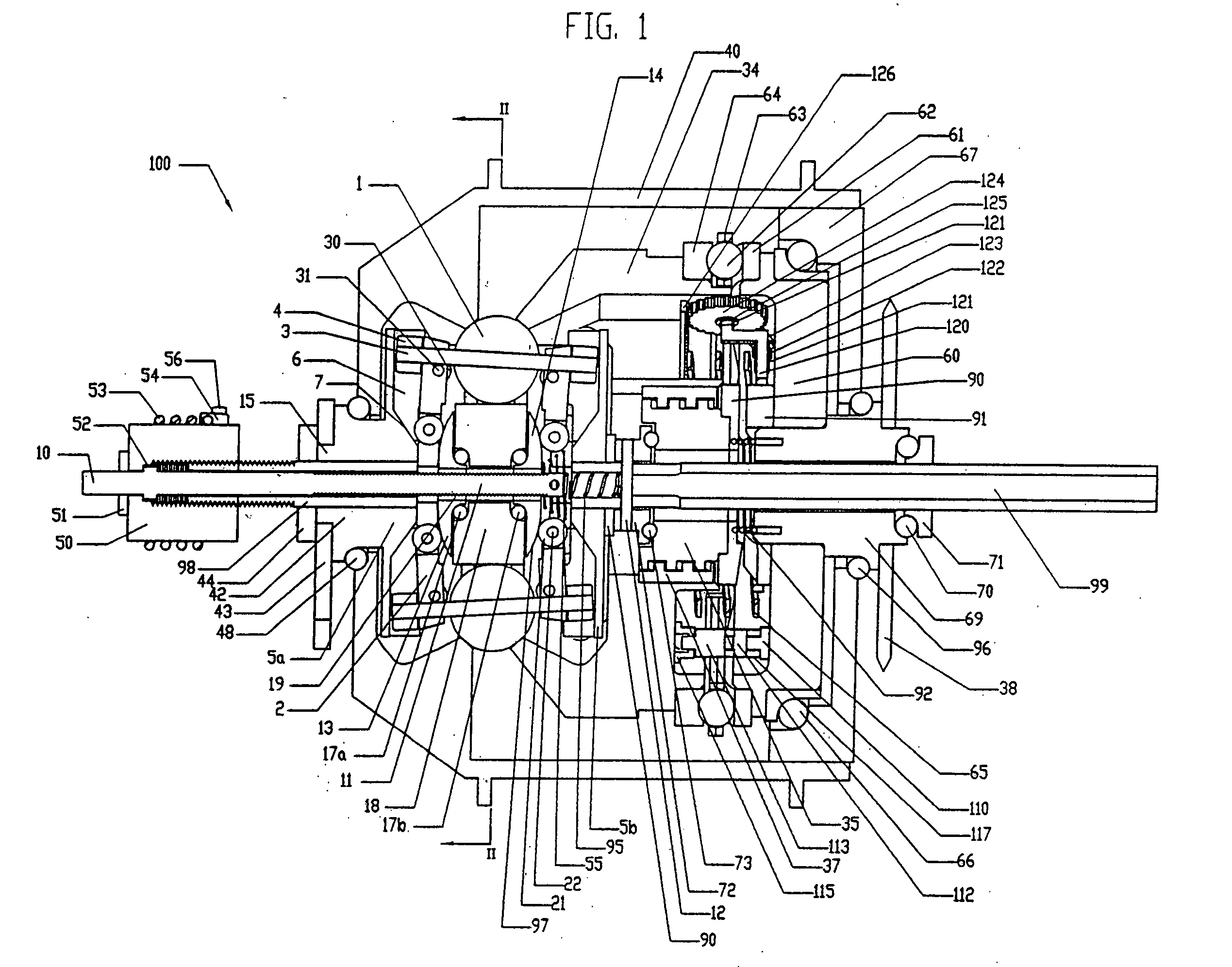

A continuously variable transmission is disclosed for use in rotationally or linearly powered machines and vehicles. The transmission provides a simple manual shifting method for the user. Further, the practical commercialization of traction roller transmissions requires improvements in the reliability, ease of shifting, function and simplicity of the transmission. The present invention includes a continuously variable transmission that may be employed in connection with any type of machine that is in need of a transmission. For example, the transmission may be used in (i) a motorized vehicle such as an automobile, motorcycle, or watercraft, (ii) a non-motorized vehicle such as a bicycle, tricycle, scooter, exercise equipment or (iii) industrial equipment, such as a drill press, power generating equipment, or textile mill.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmission

A continuously variable transmission is disclosed for use in rotationally or linearly powered machines and vehicles. The transmission provides a simple manual shifting method for the user. Further, the practical commercialization of traction roller transmissions requires improvements in the reliability, ease of shifting, function and simplicity of the transmission. The present invention includes a continuously variable transmission that may be employed in connection with any type of machine that is in need of a transmission. For example, the transmission may be used in (i) a motorized vehicle such as an automobile, motorcycle, or watercraft, (ii) a non-motorized vehicle such as a bicycle, tricycle, scooter, exercise equipment or (iii) industrial equipment, such as a drill press, power generating equipment, or textile mill.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmission

A continuously variable transmission is disclosed for use in rotationally or linearly powered machines and vehicles. The transmission provides a simple manual shifting method for the user. Further, the practical commercialization of traction roller transmissions requires improvements in the reliability, ease of shifting, function and simplicity of the transmission. The present invention includes a continuously variable transmission that may be employed in connection with any type of machine that is in need of a transmission. For example, the transmission may be used in (i) a motorized vehicle such as an automobile, motorcycle, or watercraft, (ii) a non-motorized vehicle such as a bicycle, tricycle, scooter, exercise equipment or (iii) industrial equipment, such as a drill press, power generating equipment, or textile mill.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmission

A continuously variable transmission is disclosed for use in rotationally or linearly powered machines and vehicles. The transmission provides a simple manual shifting method for the user. Further, the practical commercialization of traction roller transmissions requires improvements in the reliability, ease of shifting, function and simplicity of the transmission. The present invention includes a continuously variable transmission that may be employed in connection with any type of machine that is in need of a transmission. For example, the transmission may be used in (i) a motorized vehicle such as an automobile, motorcycle, or watercraft, (ii) a non-motorized vehicle such as a bicycle, tricycle, scooter, exercise equipment or (iii) industrial equipment, such as a drill press, power generating equipment, or textile mill.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmission

A continuously variable transmission is disclosed for use in rotationally or linearly powered machines and vehicles. The transmission provides a simple manual shifting method for the user. Further, the practical commercialization of traction roller transmissions requires improvements in the reliability, ease of shifting, function and simplicity of the transmission. The present invention includes a continuously variable transmission that may be employed in connection with any type of machine that is in need of a transmission. For example, the transmission may be used in (i) a motorized vehicle such as an automobile, motorcycle, or watercraft, (ii) a non-motorized vehicle such as a bicycle, tricycle, scooter, exercise equipment or (iii) industrial equipment, such as a drill press, power generating equipment, or textile mill.

Owner:FALLBROOK INTPROP COMPANY

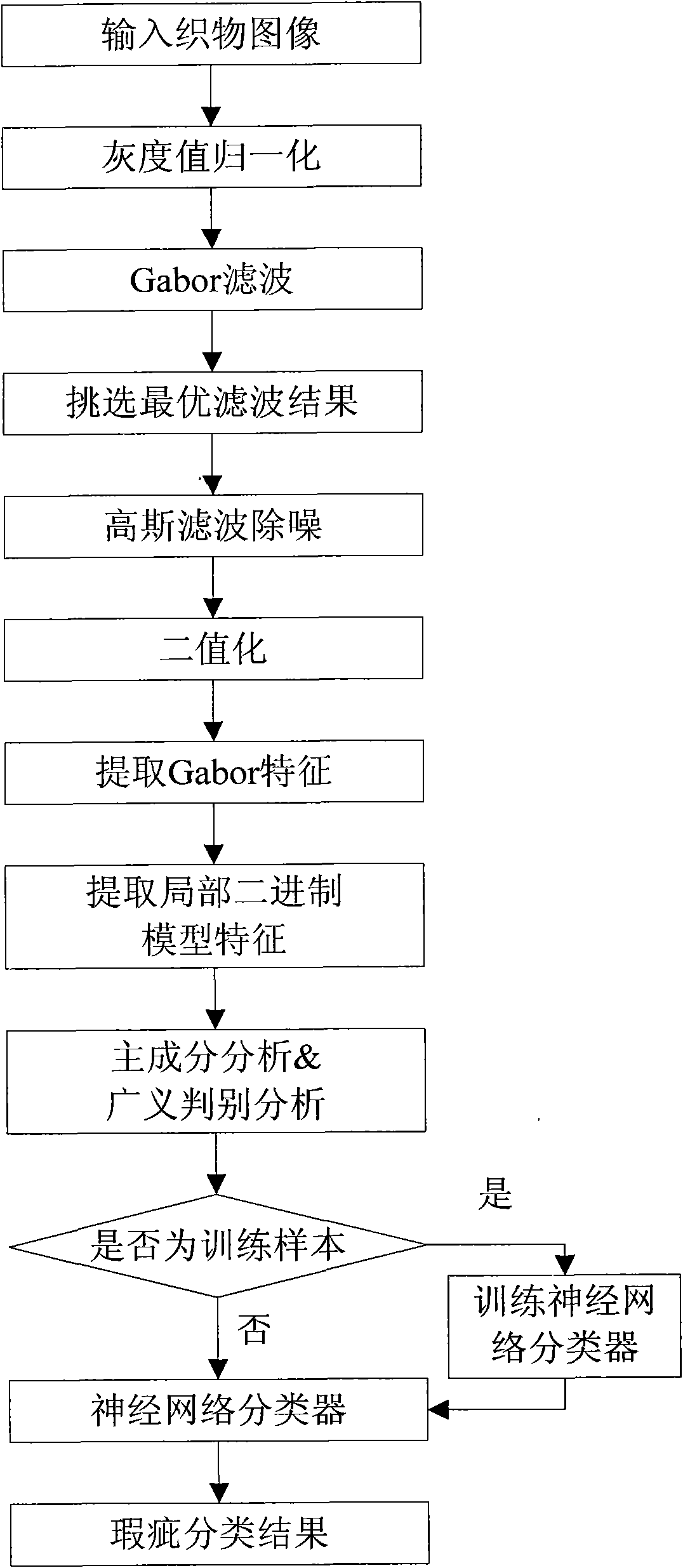

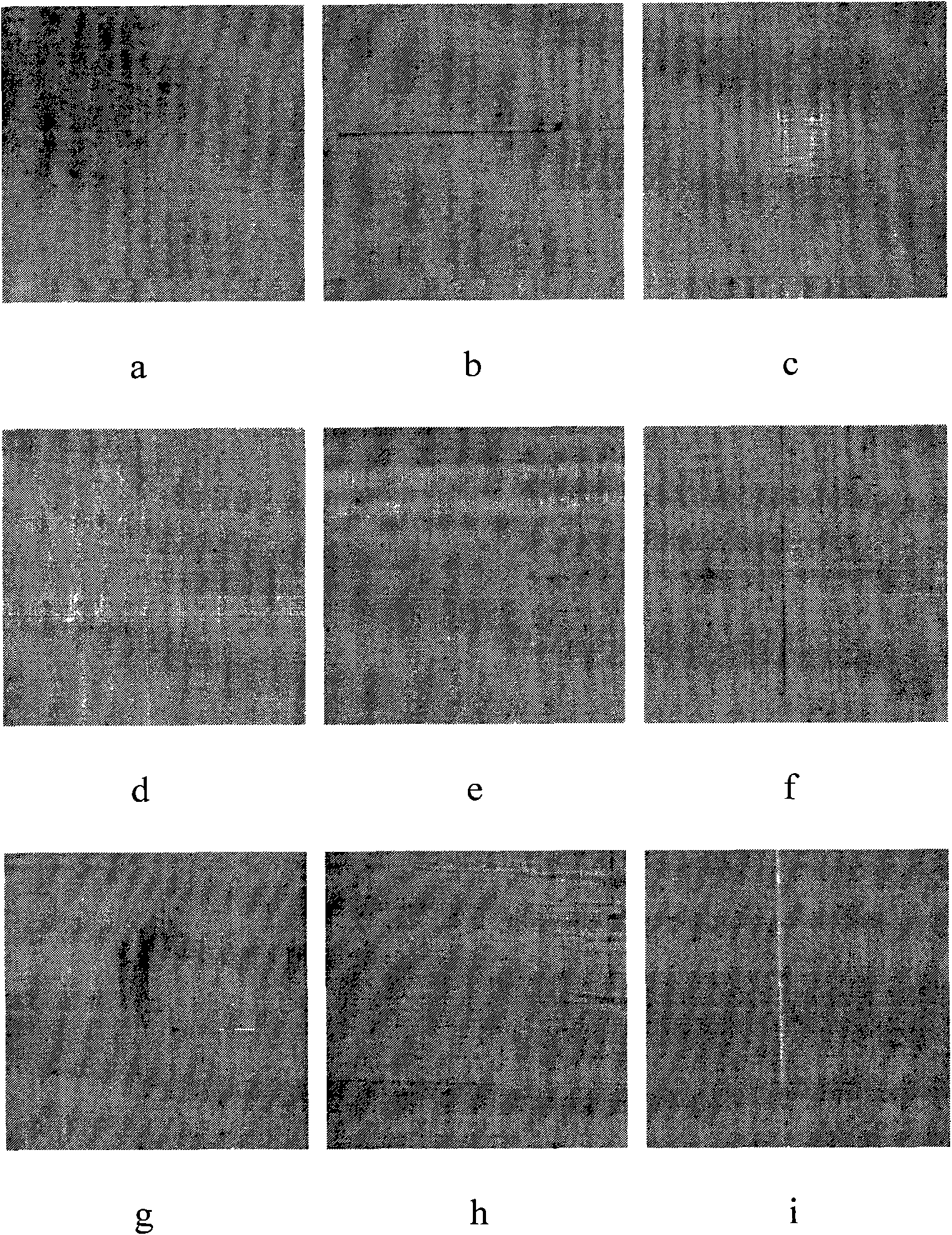

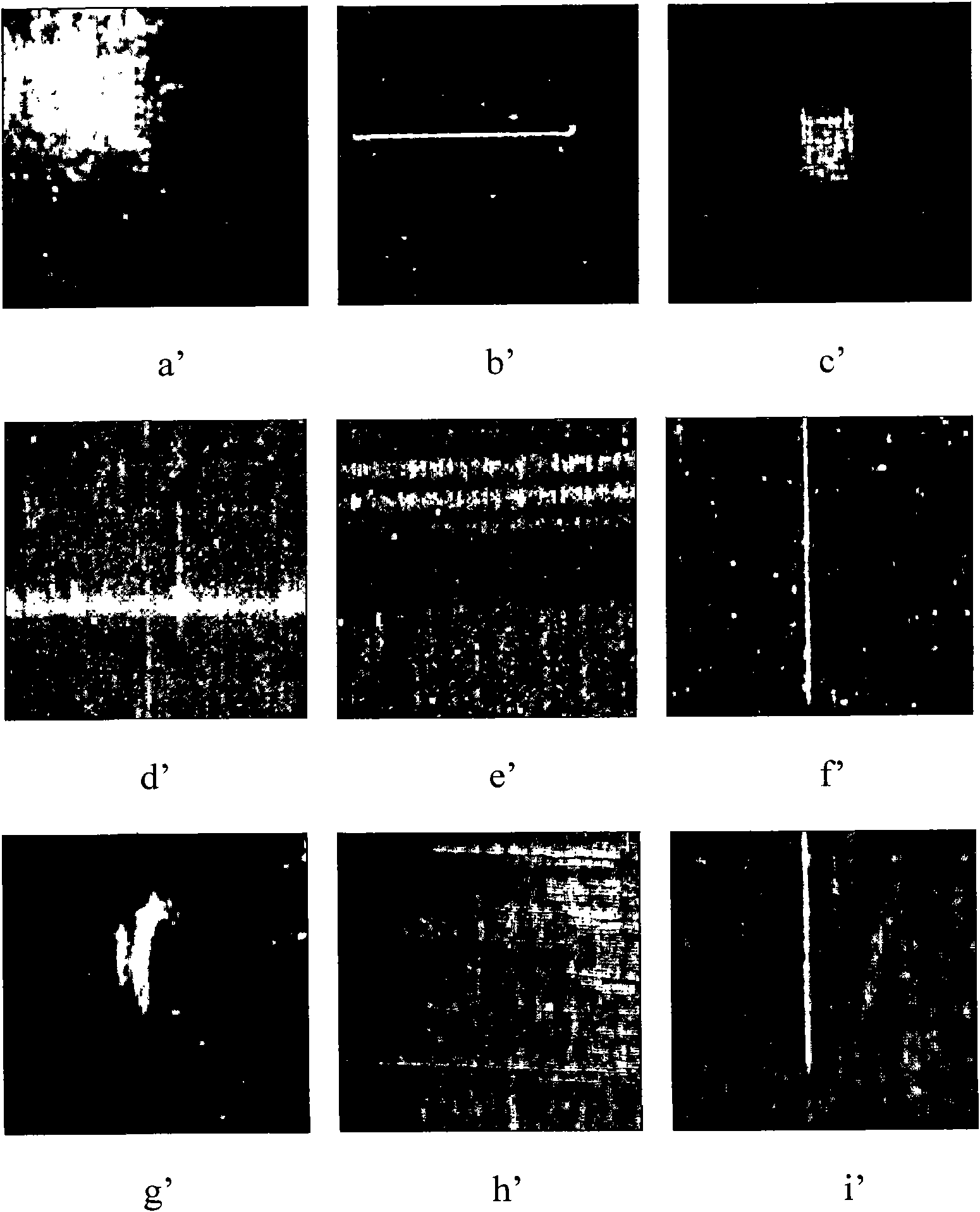

Method for detecting and classifying fabric defects

InactiveCN101866427APrecise positioningFully reflect the difference of flawsCharacter and pattern recognitionTextile millPrincipal component analysis

The invention discloses a method for detecting and classifying fabric defects and mainly aims to solve the problem of automatic detection and classification of fabric defects. The method comprises the following steps of: firstly, detecting a picture of the fabric defects, filtering the picture by using a Gabor filter group, selecting an optimal filtering result and performing binaryzation on the optimal filtering result by using a reference picture so as to position the positions of the defects in the picture; secondly, extracting a compound characteristic consisting of a Gabor characteristic and a partial binary model characteristic according to the positions of the defects; thirdly, performing pre-treatment on the compound characteristic by main constituent analysis and generalized discriminant analysis algorithm; fourthly, training a neural network classifier by using a pre-treated defect characteristic; and lastly, realizing accurate classification of a fabric defect characteristic by using a trained classifier. The method has the advantages of accurate defect positioning and high classification accuracy and can be used for detecting and classifying the fabric defects in a textile mill.

Owner:XIDIAN UNIV

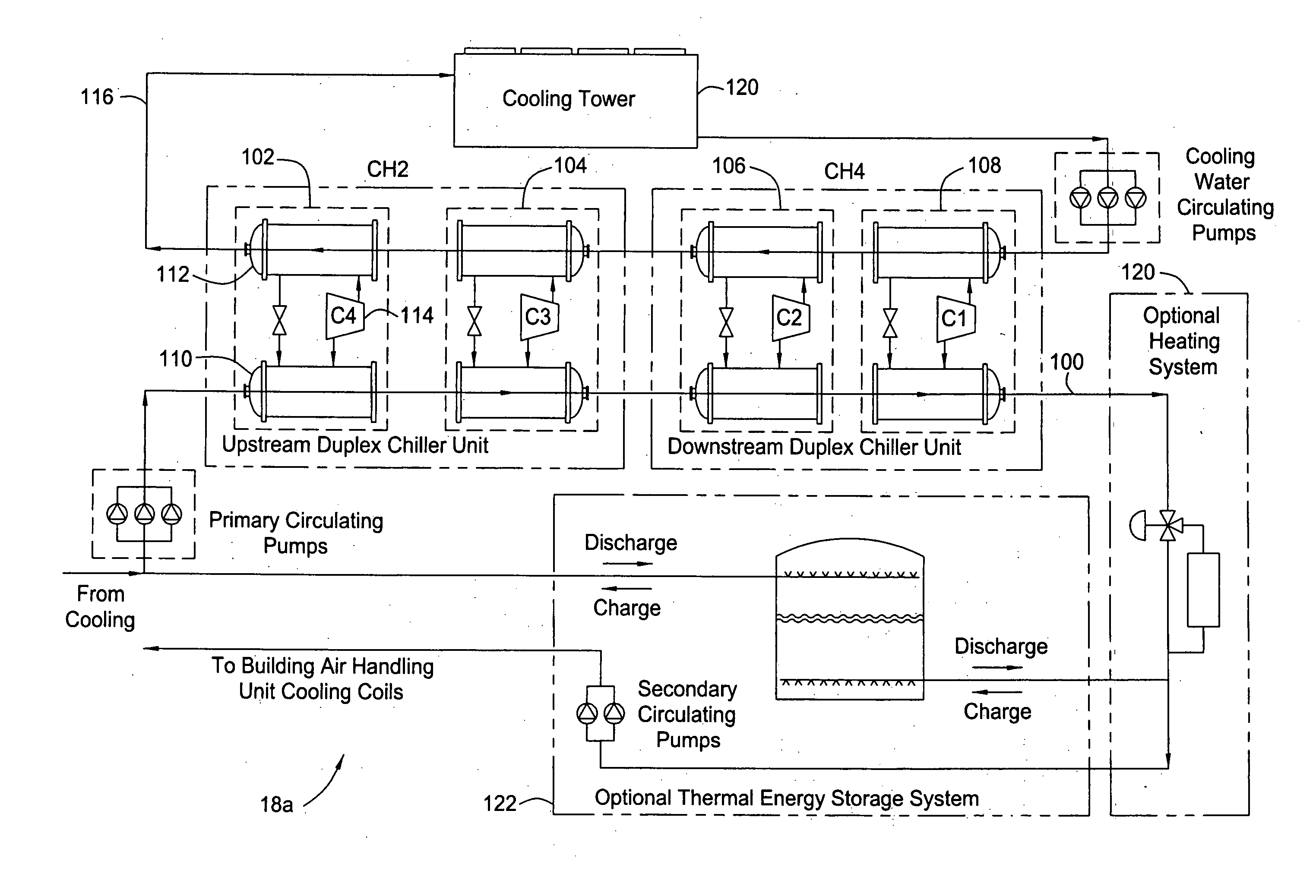

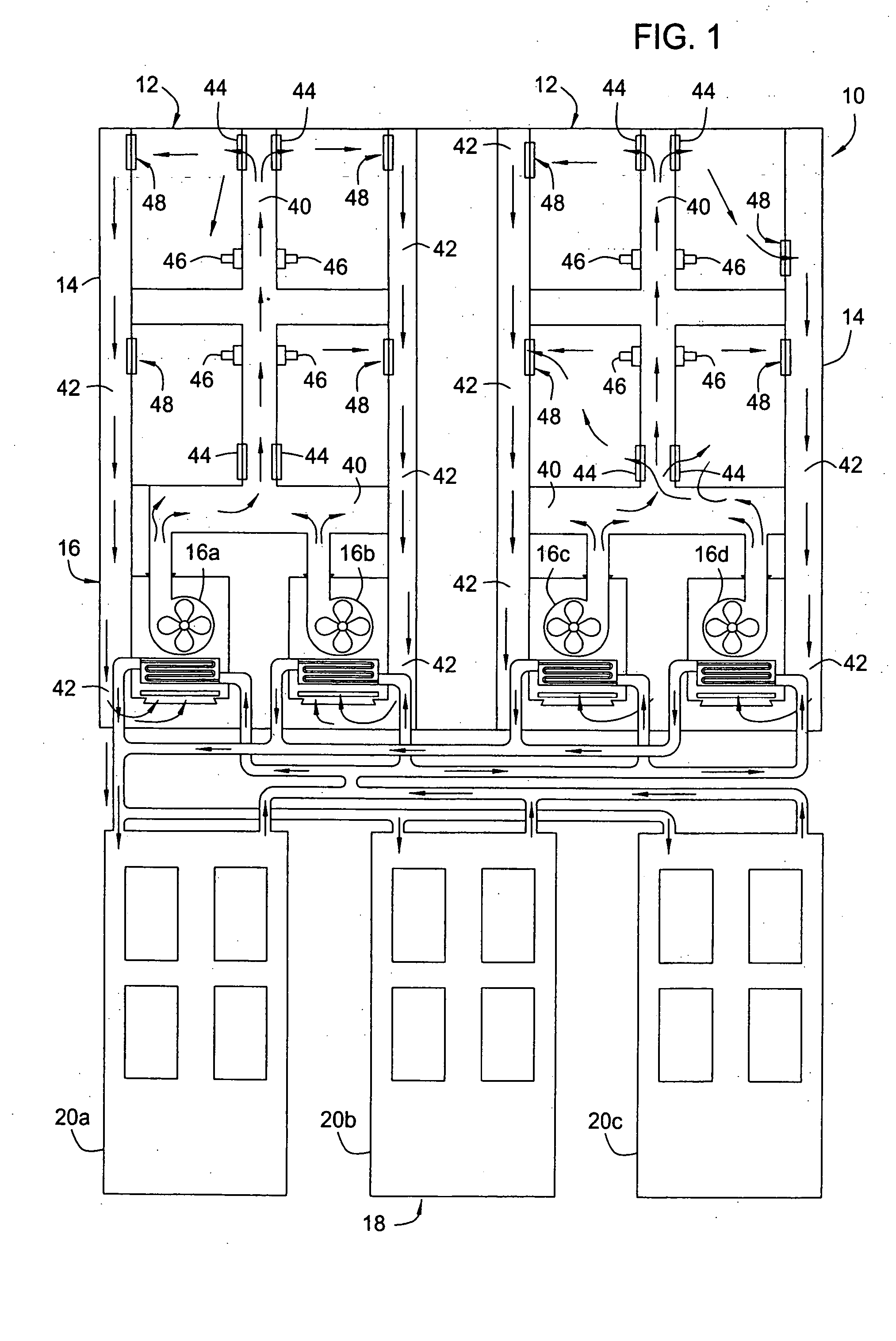

Packaged chilling systems for building air conditioning and process cooling

InactiveUS20050103032A1Domestic cooling apparatusClimate change adaptationChilled waterHandling system

Disclosed is a packaged chilling system for providing chilled water to an air conditioning system for a building that includes: a duct system; an air handling system; and a water chilling system; wherein: the duct system is in operable communication with a building that has a plurality of rooms, at least one of the rooms having a sensor for detecting the room air temperature in the room, the duct system comprising at least one supply duct for directing low temperature air from the air handling system to the building and at least one return duct for directing high temperature air from the building to the air handling system; the air handling system includes a plurality of air handling units, each air handling unit comprising an air inlet for receiving high temperature air from the building, a cooling coil that includes at least one conduit through which chilled water flows, the cooling coil having multiple passes and positioned for heat transfer contact with the high temperature air, and a fan for increasing the velocity of air in the air handling unit; the water chilling system is installed at a location proximate the building, and is operably connected to the air handling system; and the water chilling system includes a moveable support structure comprising a support base on which a plurality of water chilling system components are affixed, the components including at least one water chiller for lowering the temperature of water from a high temperature to a low temperature. This packaged chilling system may also be used to provide chilled water to industrial processes such as chemical plants, automotive plants, textile mills, paper mills, computer cooling, and factory air-conditioning.

Owner:TAS LTD

Continuously variable transmission

A continuously variable transmission is disclosed for use in rotationally or linearly powered machines and vehicles. The transmission provides a simple manual shifting method for the user. Further, the practical commercialization of traction roller transmissions requires improvements in the reliability, ease of shifting, function and simplicity of the transmission. The present invention includes a continuously variable transmission that may be employed in connection with any type of machine that is in need of a transmission. For example, the transmission may be used in (i) a motorized vehicle such as an automobile, motorcycle, or watercraft, (ii) a non-motorized vehicle such as a bicycle, tricycle, scooter, exercise equipment or (iii) industrial equipment, such as a drill press, power generating equipment, or textile mill.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmission

A continuously variable transmission is disclosed for use in rotationally or linearly powered machines and vehicles. The transmission provides a simple manual shifting method for the user. Further, the practical commercialization of traction roller transmissions requires improvements in the reliability, ease of shifting, function and simplicity of the transmission. The present invention includes a continuously variable transmission that may be employed in connection with any type of machine that is in need of a transmission. For example, the transmission may be used in (i) a motorized vehicle such as an automobile, motorcycle, or watercraft, (ii) a non-motorized vehicle such as a bicycle, tricycle, scooter, exercise equipment or (iii) industrial equipment, such as a drill press, power generating equipment, or textile mill.

Owner:FALLBROOK INTPROP COMPANY

Chlorine collecting agent and its prepn and application

ActiveCN1973965AImprove hydrophobicityGood water repellencyDispersed particle separationCalcium hydroxideTextile mill

The present invention discloses one kind of chlorine collecting agent and its preparation process. The chlorine collecting agent is prepared with calcium hydroxide, surfactant, filming drier, diluent and sodium silicate. It has high chlorine eliminating efficiency, waterproof and moistureproof property, no caking, high air permeability and other advantages. It is used in absorbing and eliminating chlorine in various kinds of production fields, such as chloralkali plant, papermaking mill, textile mill, sewage treating yard, etc.

Owner:夏元超 +1

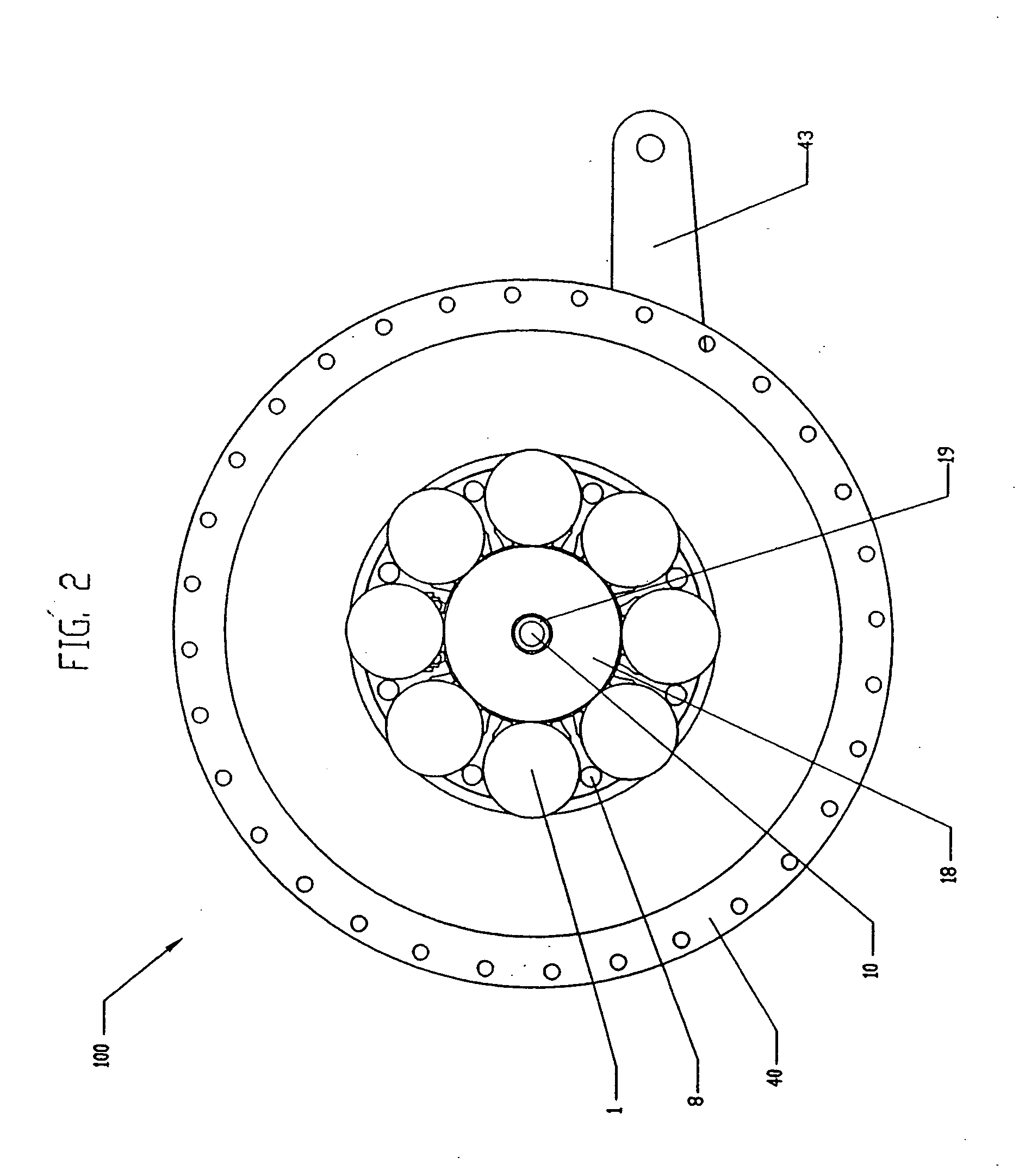

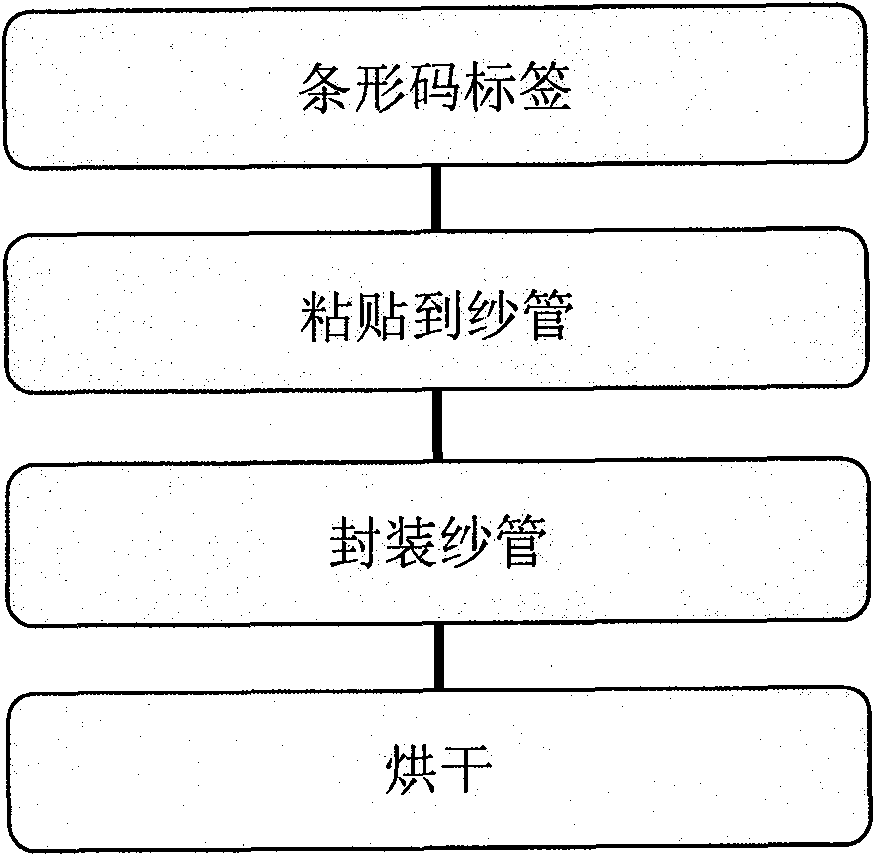

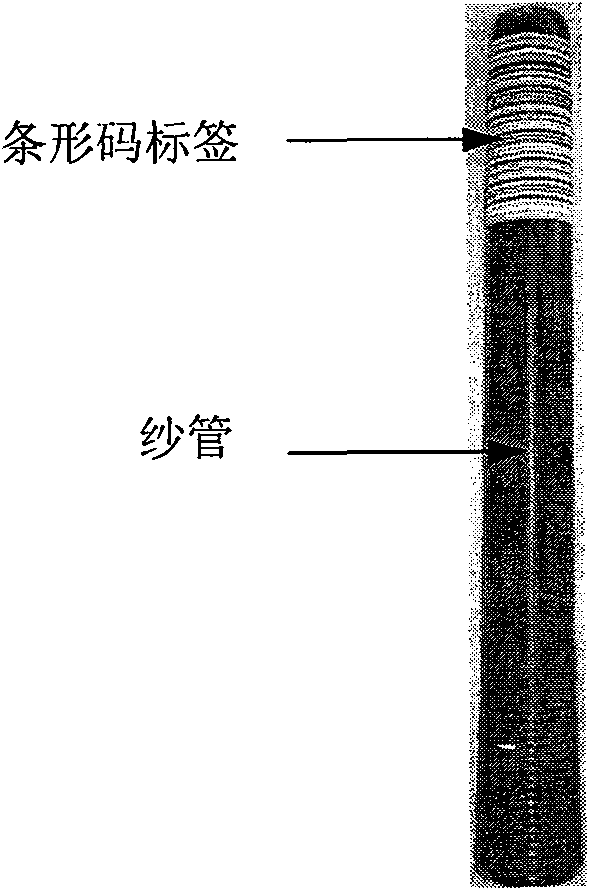

Bar code yarn tube for quality management of spun yarn

The invention relates to a bar code yarn tube for quality management of spun yarn, belonging to the field of novel textile machinery. Because a textile mill has many spinning machines and each spinning machine is provided with a plurality of spindles, which spindle of which spinning machine is each yarn tube from can not be analyzed in the subsequent spinning processes. In order to solve the technical problem, the invention adopts a means of adding a bar code on each yarn tube as the unique identification mark of each yarn tube, and the information of the spindles installed on each yarn tube in the production process of spun yarn is recorded to provide the basis for subsequently checking the spindle on which the yarn tube is positioned. The bar code yarn tube is used for quality tracking of a single spindle of spinning machines, and is used for quality tracing of defective yarn tubes.

Owner:JIANGNAN UNIV

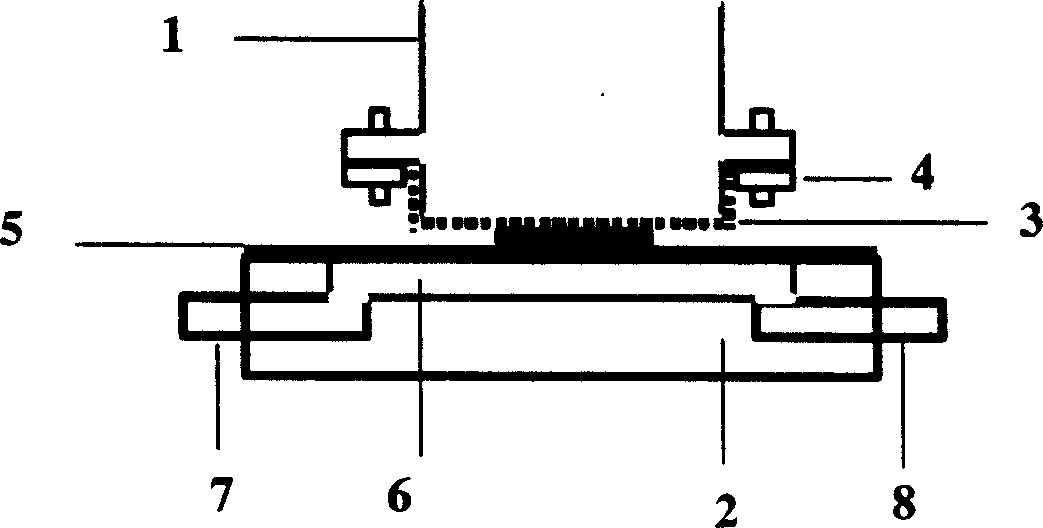

Fabric moisture-penetrability testing device and testing method

InactiveCN1975416AReduce precisionReduce sensitivityInspecting textilesSurface/boundary effectTextile millSaturated water vapor

The invention relates to a testing device and the method for the fabric moisture-penetrability. The device is made up of the column canister, the base, the waterproof moisture film, the pressure ring and the testing board. The shallow groove is set on the base which the two ends are connected with the air inlet and the air outlet carved on the base two sides. The waterproof moisture film is the bottom of the column canister to form the saturate water vapor resource; the dry quick flowing N2 is the carrier to carry the water vapor through the fabric away. So it can measure the relative humidity of the N2 flow to get the moisture content of the fabric. The invention has the high precision and good repetition, the testing time is short and the cost is low; so the device can be used in the textile mill to control the product moisture-penetrability quality.

Owner:WUHAN TEXTILE UNIV

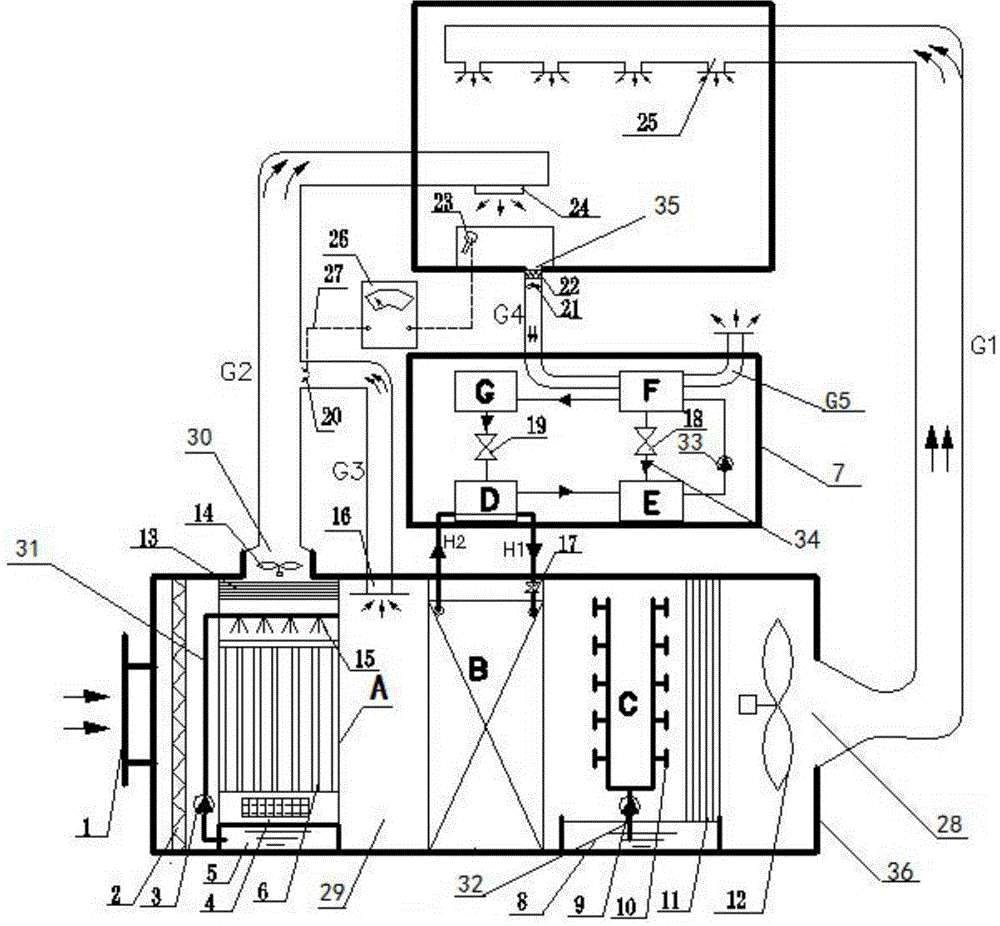

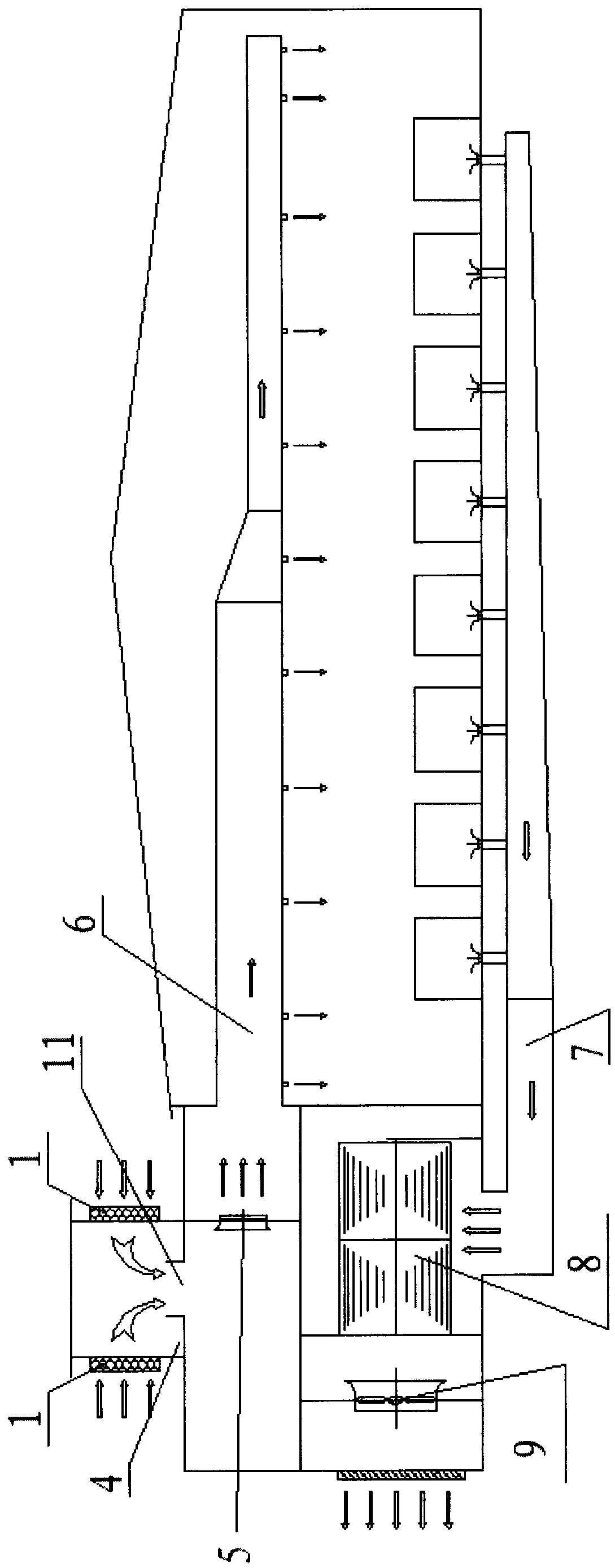

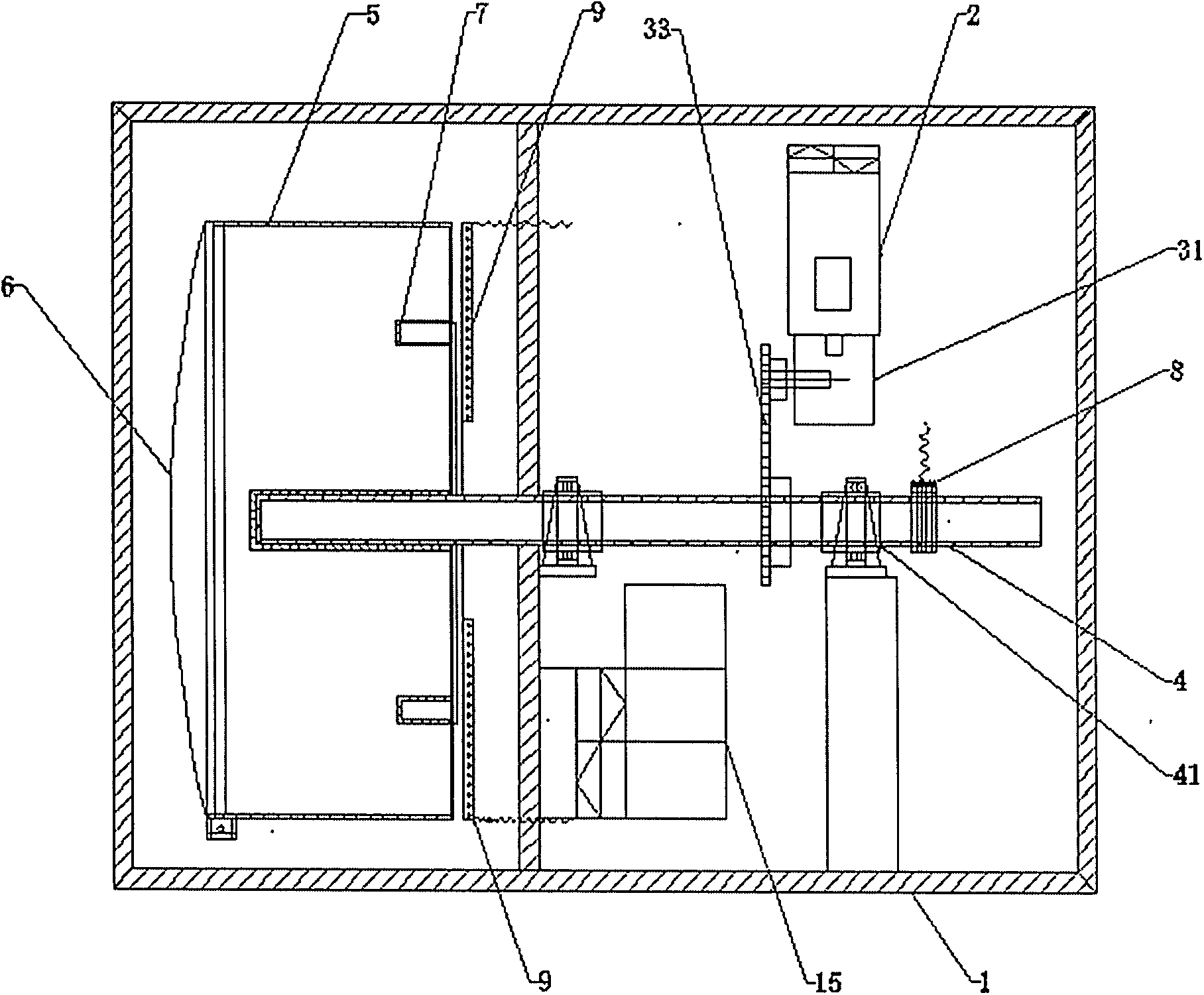

Large and small textile mill environment self-adaptation air conditioner with absorption refrigeration and evaporation cooling combined

InactiveCN104456792AExtended use timeEffective recovery of exhaust air heatMechanical apparatusSpace heating and ventilation safety systemsTextile millEvaporation

The invention discloses a large and small textile mill environment self-adaptation air conditioner with absorption refrigeration and evaporation cooling combined. The self-adaptation air conditioner comprises a combined evaporation cooling air conditioner unit and a lithium bromide absorption type water chilling unit which are connected and communicated with the large textile mill environment and the small textile mill environment respectively. According to the textile mill large and small environment self-adaptation air conditioner with absorption refrigeration and evaporation cooling combined, air is supplied to the large environment and the small environment, a good airflow organization can be formed, the heat of weaving machine equipment can be effectively discharged, the technology exhaust air with the high temperature can serve as a driving heat source of lithium bromide absorption type refrigeration, and the energy utilization efficiency is improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Preparation and application of flax adsorbent

InactiveCN103464115AGood physical and chemical stabilityHigh mechanical strengthOther chemical processesWater/sewage treatment by sorptionFiberEpoxy

The invention discloses a preparation method and application technology of an epoxy chloropropane modified flax adsorbent. The preparation method is characterized by washing waste short fiber flax of a flax textile factory by using water, drying and crushing; processing by using NaOH and OP water solution and drying to obtain degummed flax; adding the following components in percentage by mass in a reactor: 22-40% of epoxy chloropropane, 12-25% of degummed flax, 4-8% of NaOH, 5-10% of isopropyl alcohol and 32-55% of water, wherein the sum of all the components is 100%; stirring at the constant temperature of 55-65 DEG C, carrying out backflow reaction for 1.0-4h, cooling, washing by using de-ionized water, carrying out suction extracting and filtering until the filtrate is neutral, washing by using a small amount of ethanol, drying in a 50-55 DEG C vacuum drying box, so as to obtain the epoxy chloropropane modified flax. The adsorbent has very high adsorbing capacity to basic dye, has high regeneration property, can be used repeatedly for several times, and is low in cost and environment-friendly.

Owner:UNIV OF JINAN

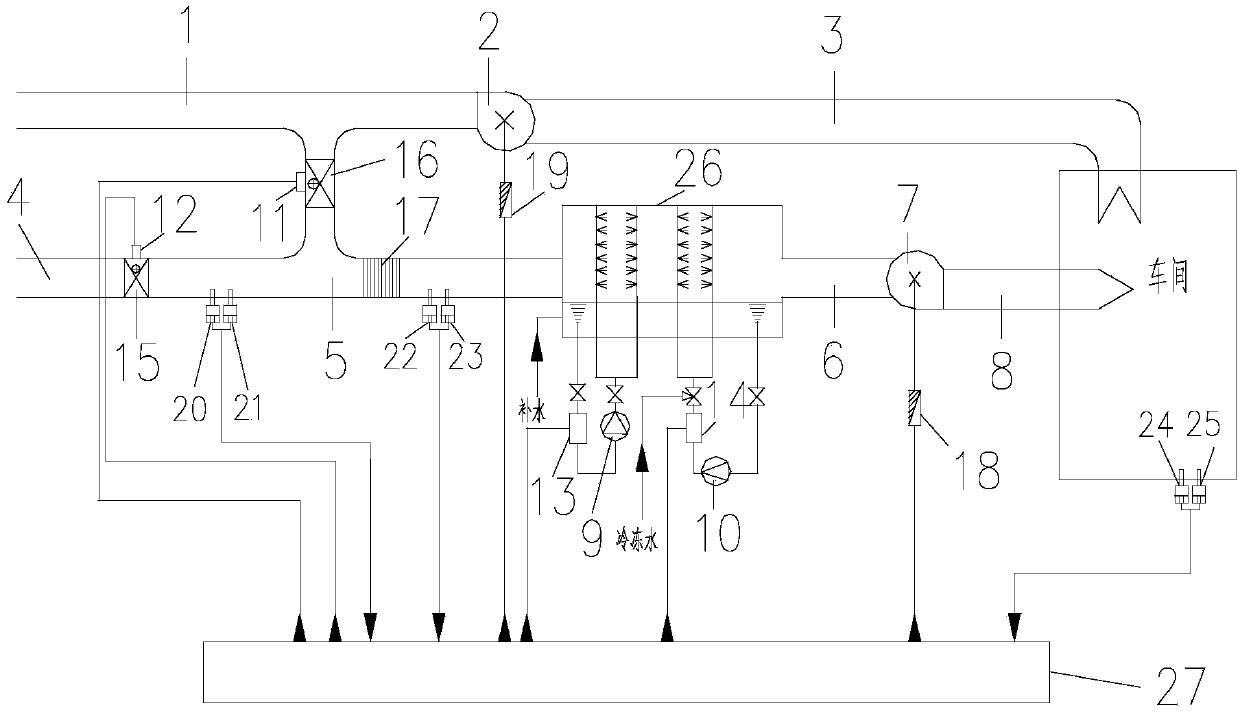

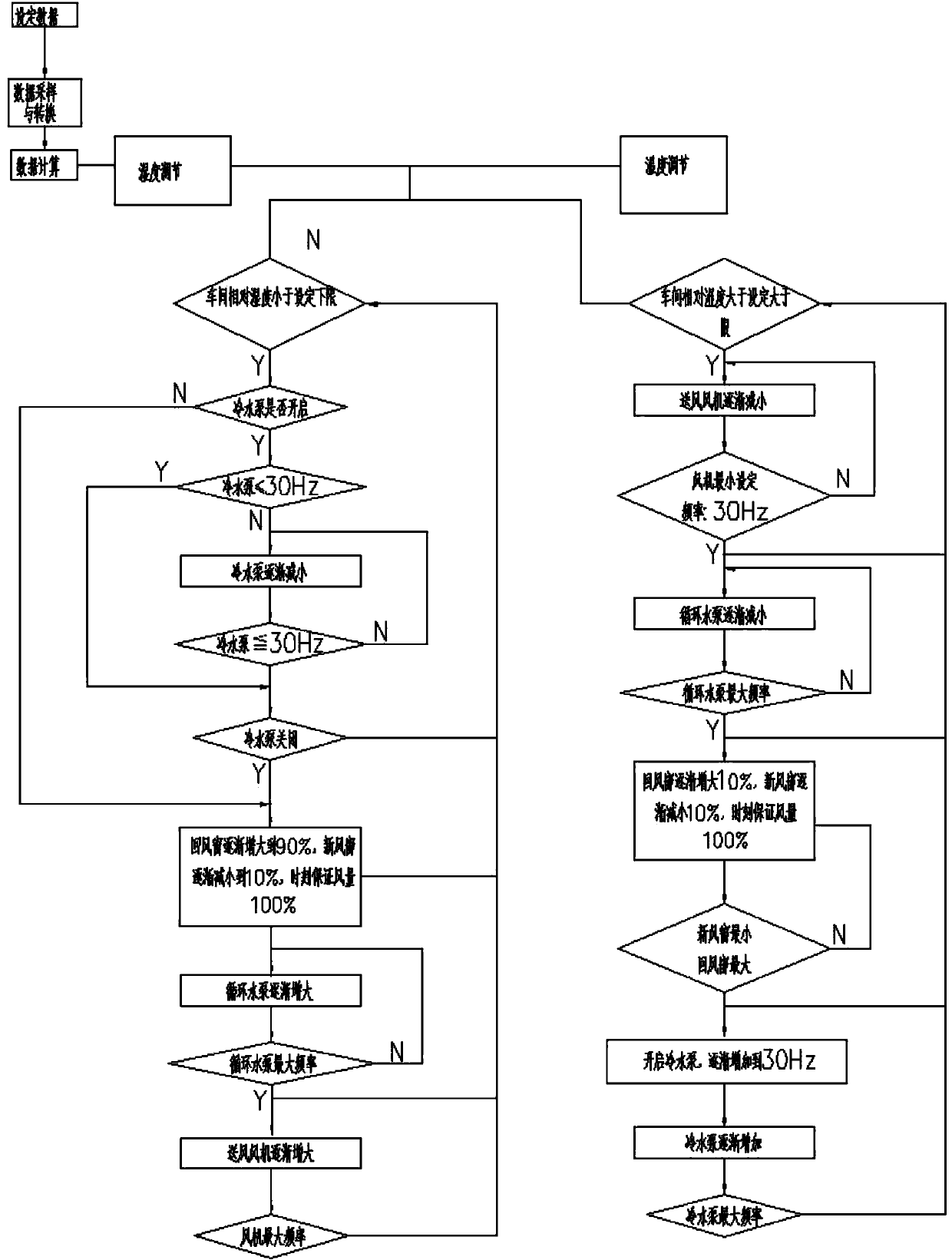

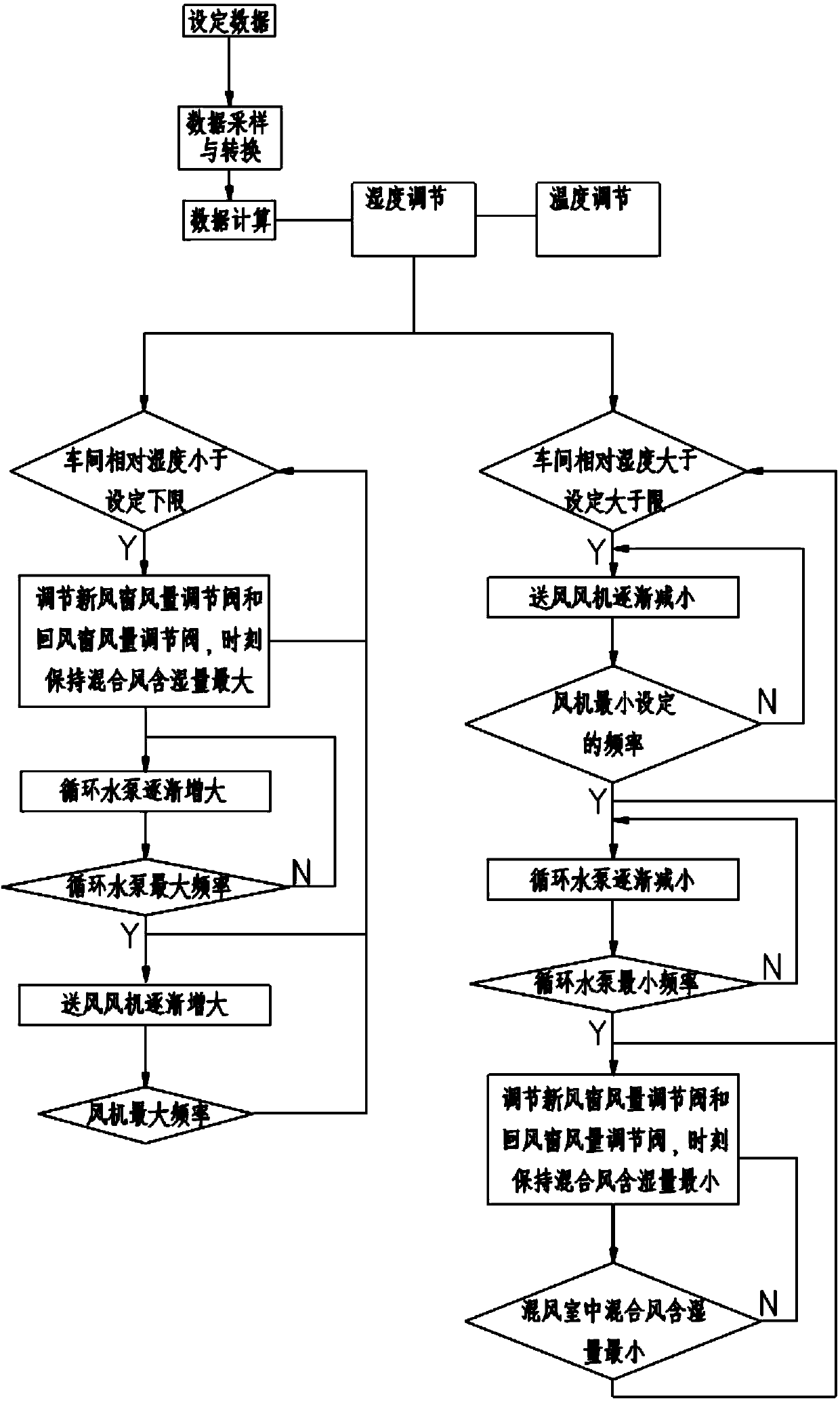

Control method of compound PLC (programmable logic controller) air conditioning automatic control system in textile mill

InactiveCN104214911AGuarantee production process requirementsReduce energy consumptionSpace heating and ventilation safety systemsLighting and heating apparatusHysteresisAutomatic control

The invention discloses a control method of a compound PLC (programmable logic controller) air conditioning automatic control system in a textile mill. The method is based on the compound PLC air conditioning automatic system in the textile mill; adjustment is performed by taking the humidity of shop air as a primary object according to a principle of humidity priority; according to a principle of 'increasing low and reducing high' adjustment is performed by sequentially increasing the frequency of equipment with low power consumption to meet production requirements when the humidity of the shop air is lower than a set standard, and adjustment is performed by sequentially reducing the frequency of equipment with high consumption to meet the production requirements when the shop humidity is higher than a set standard. The control method of the compound PLC air conditioning automatic control system in the textile mill further reduces the operation energy consumption of an air conditioning system on the basis that temperature and humidity requirements of a production shop are met, solves the problems of hysteresis quality and high energy consumption of the existing control method, guarantees production technological requirements of the shop, greatly reduces the operation energy consumption of the air conditioning system, and achieves the purposes of high efficiency and energy conservation.

Owner:XI'AN POLYTECHNIC UNIVERSITY

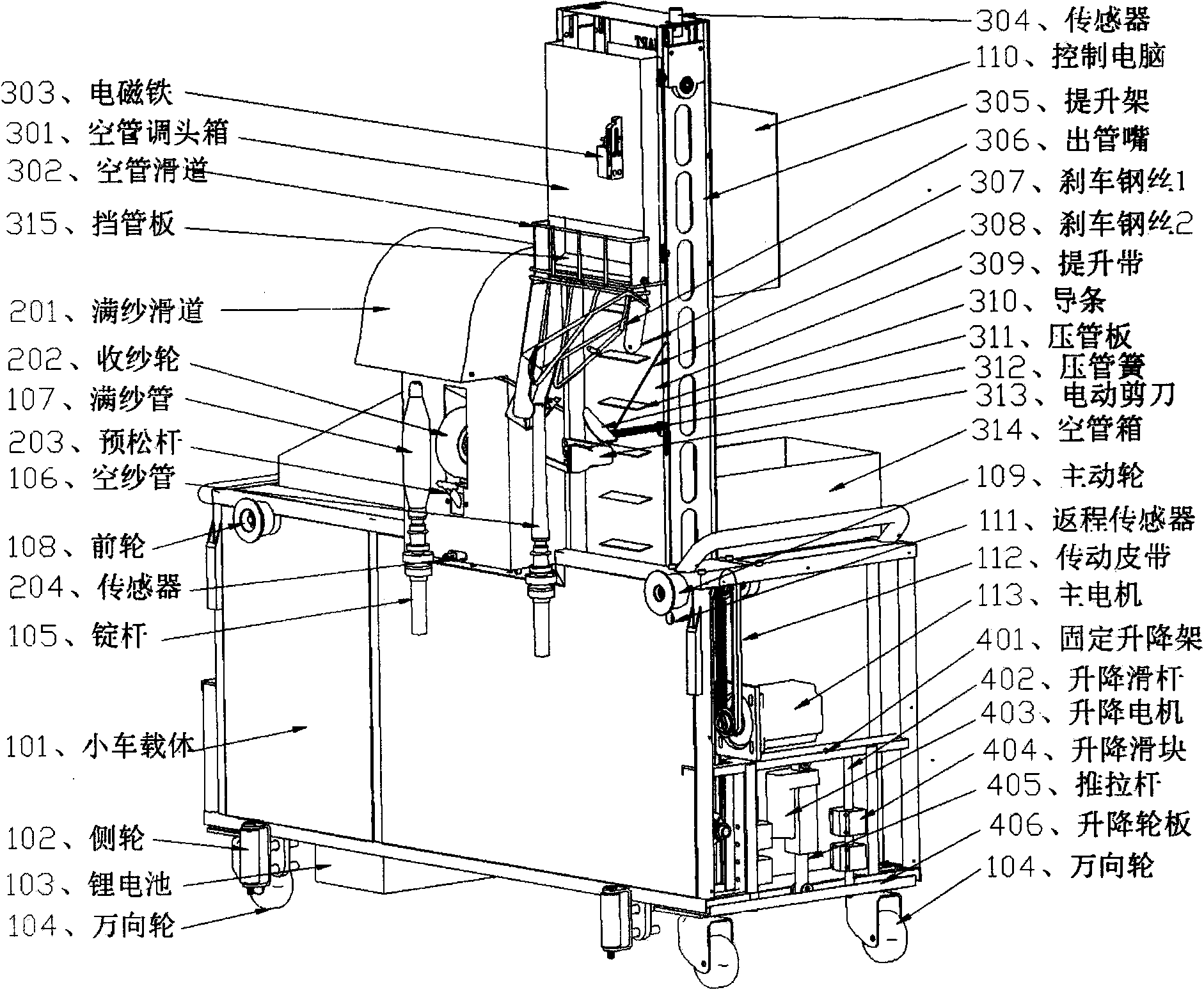

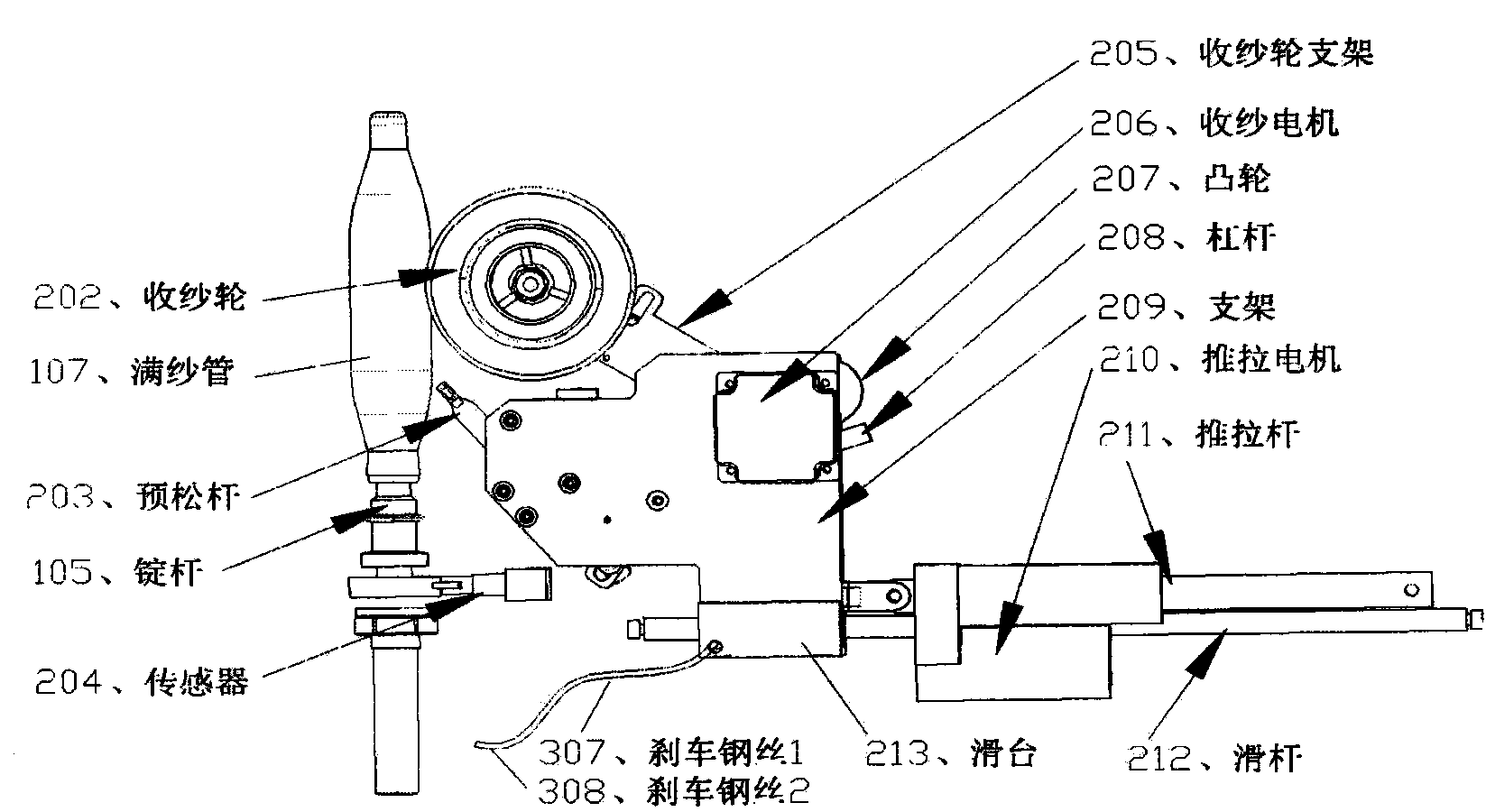

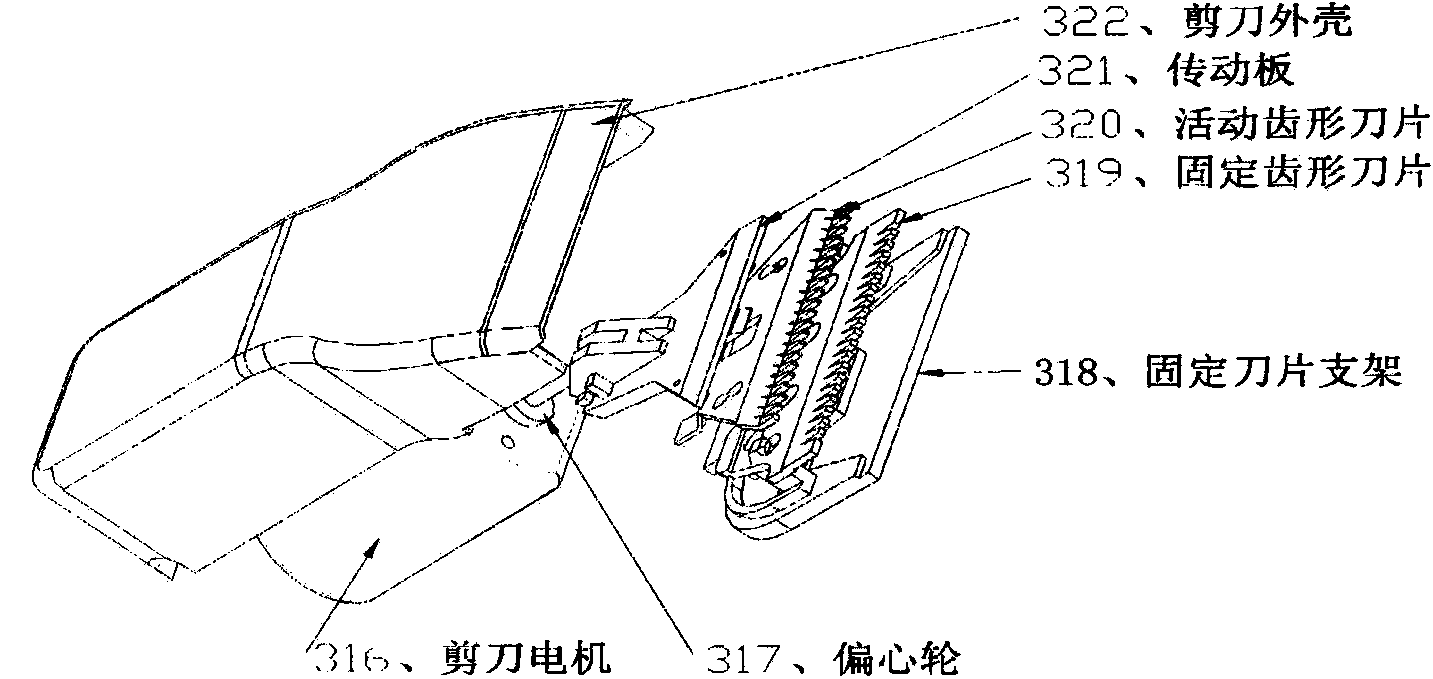

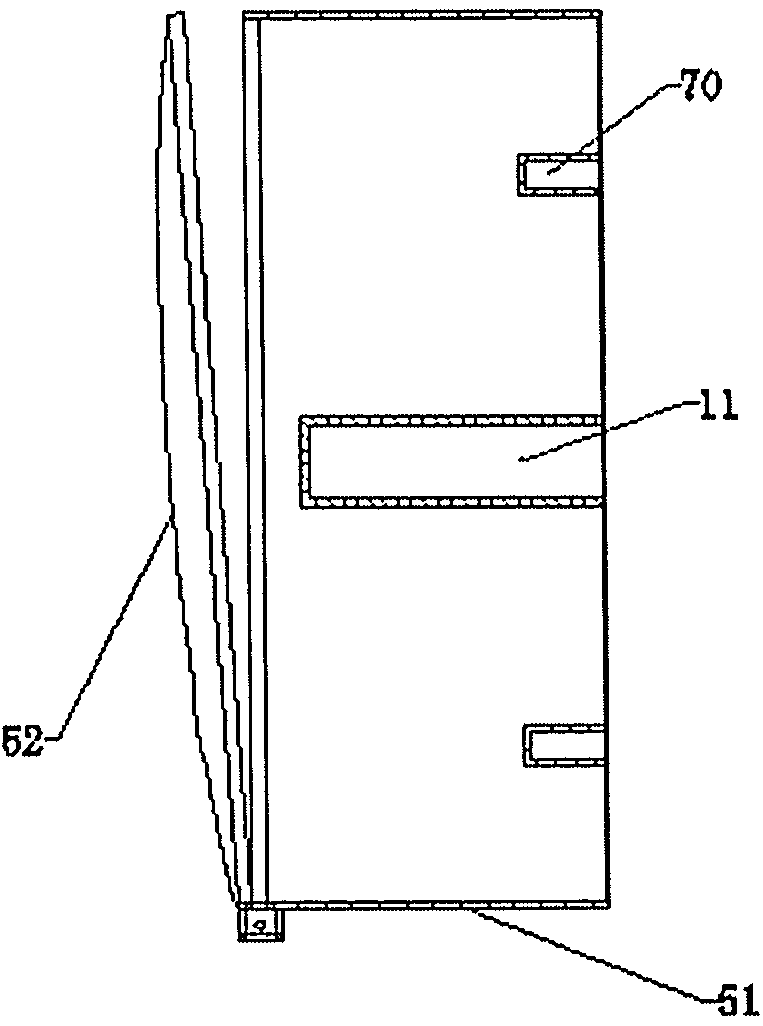

Bobbin exchanger

InactiveCN103866440AImprove the level of automated continuous productionReduce labor costsTextiles and paperComputer control systemTextile mill

The invention relates to a bobbin exchanger, and belongs to the technical field of spinning frames of spinning equipment. The bobbin exchanger is independent and comprises a trolley carrier, a computer control system, a power device, a trolley body lifting and attaching device, a bobbin collecting device, an electric scissor device, a bare bobbin box, a bare bobbin lifting device, a bare bobbin turning device, a sliding way bobbin inserting device, a bobbin pressing device, an accumulator power supply device, an auxiliary transmission mechanism and the like. The working procedures of pulling out full bobbins and inserting bare bobbins are automatically achieved. The working procedures of manually pulling out the full bobbins and inserting the bare bobbins can be replaced. The bobbin exchanger is simple and reliable in structure and high in bobbin pulling out and inserting speed and automation degree, one bobbin exchanger can serve multiple spinning frames, labor intensity and needed workers in the manual doffing process are effectively relieved and reduced respectively, and production efficiency of a textile mill is improved.

Owner:江苏华燕集团有限公司 +1

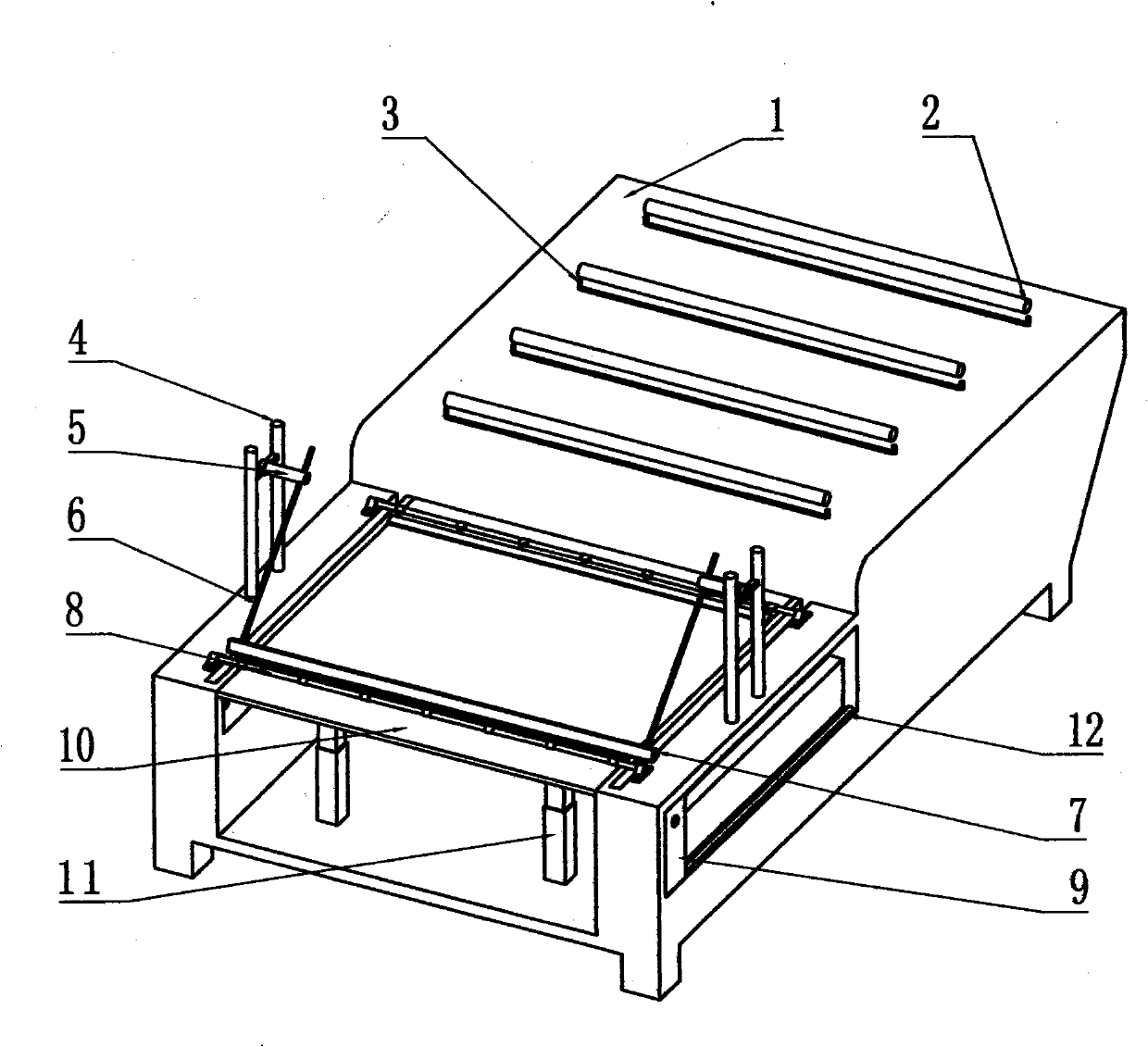

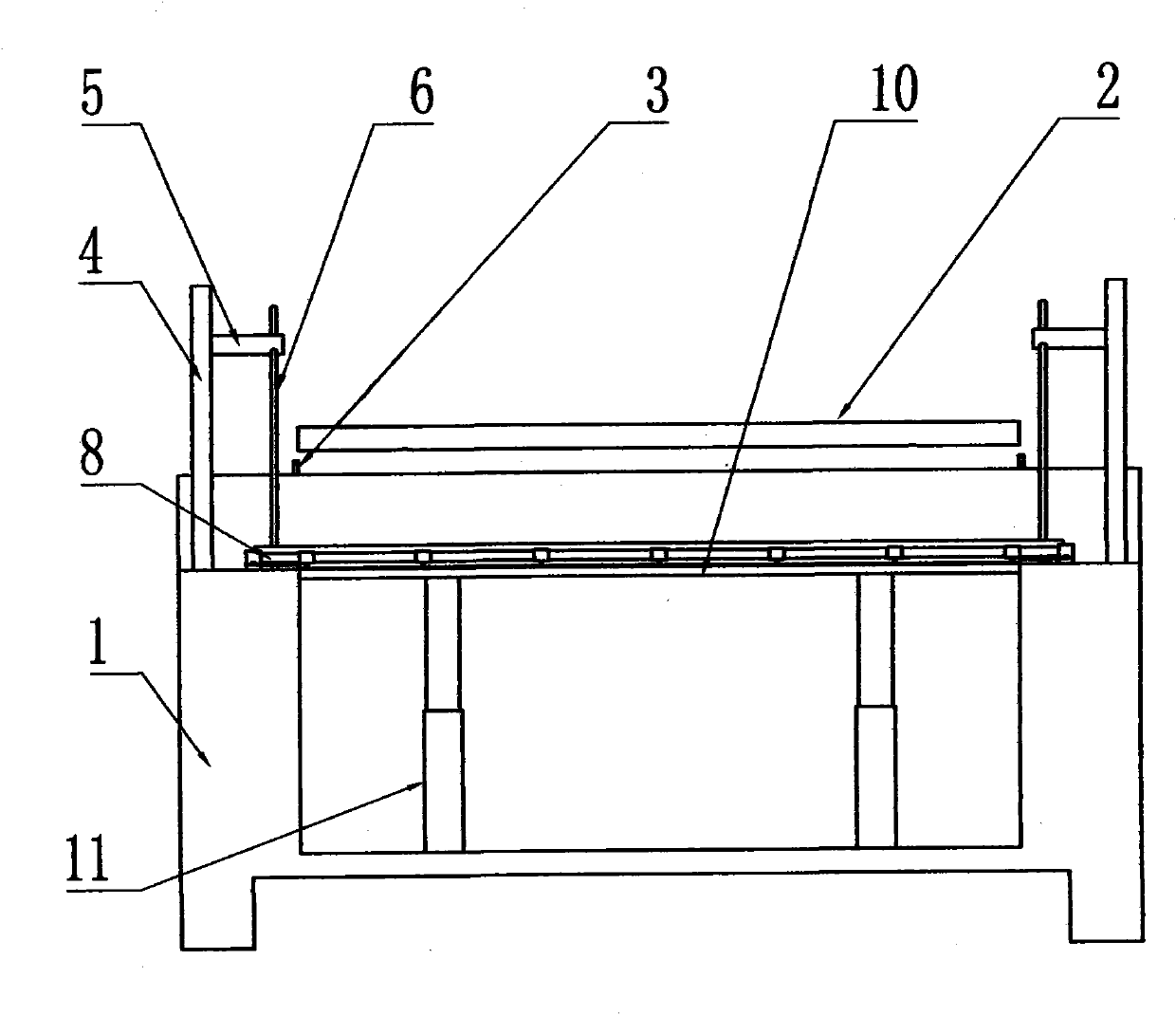

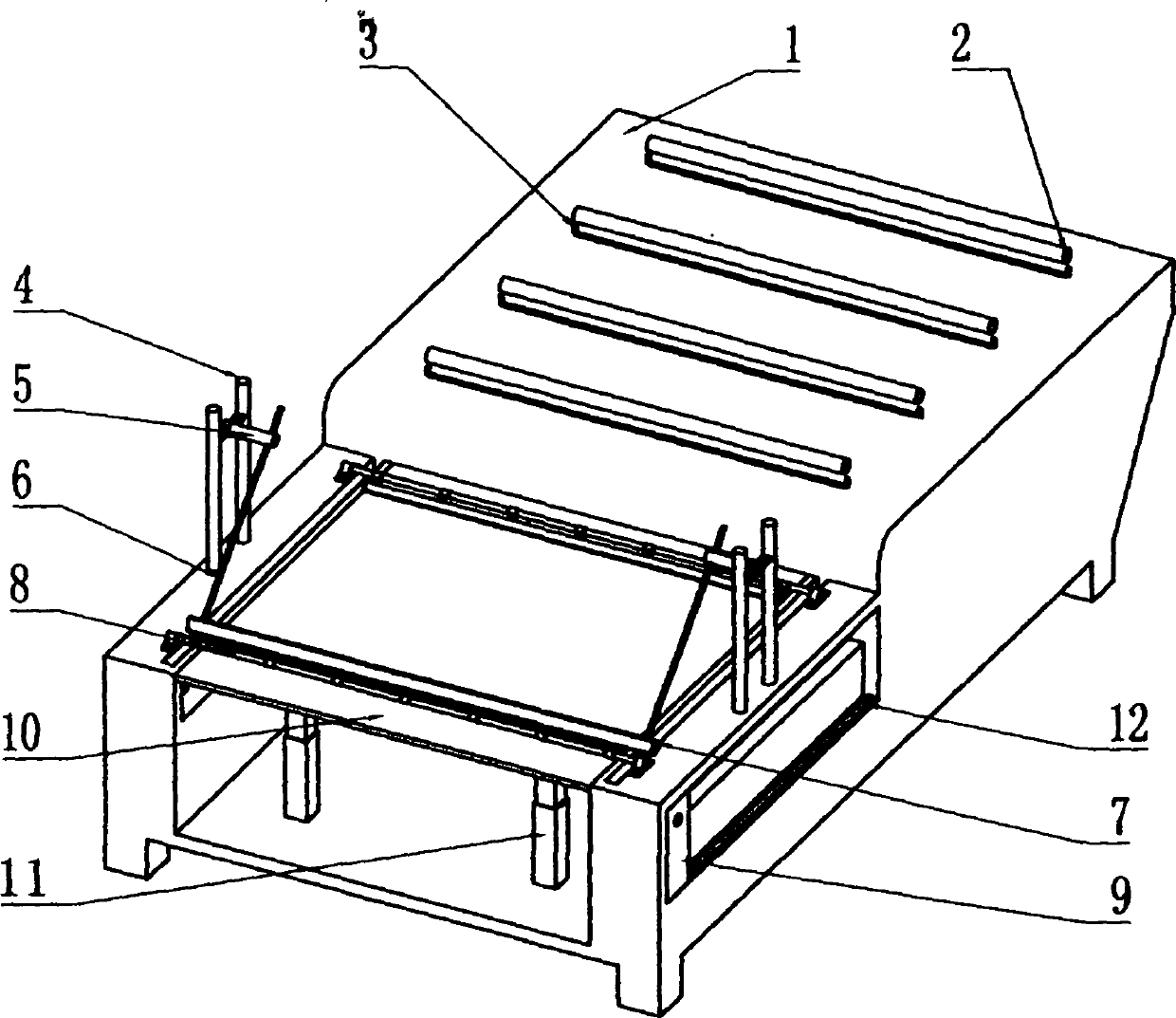

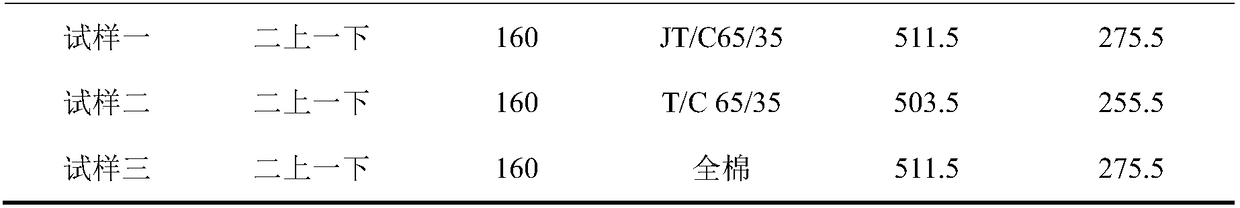

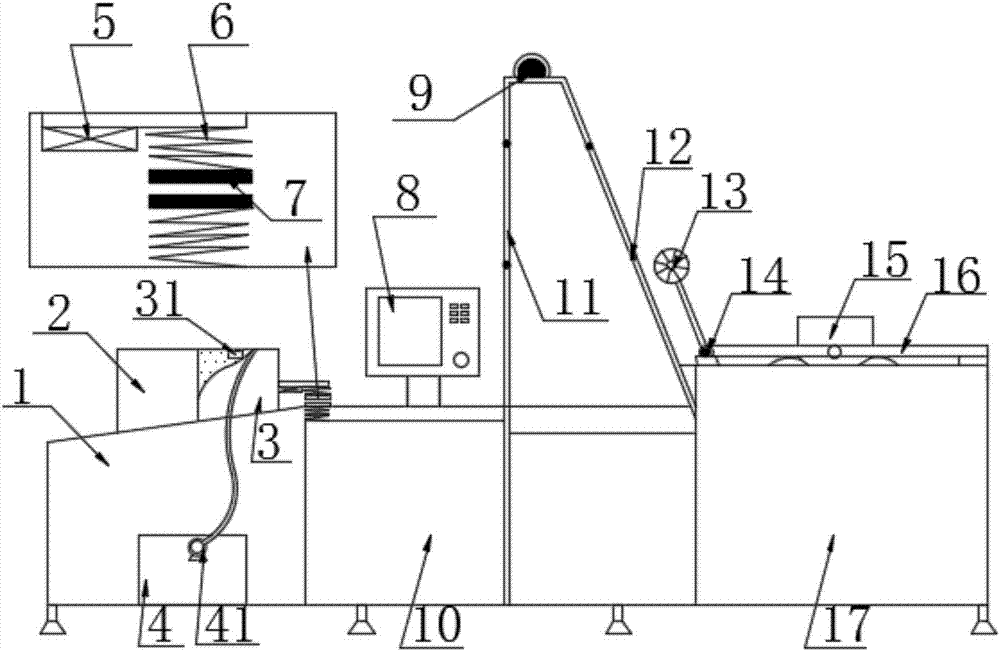

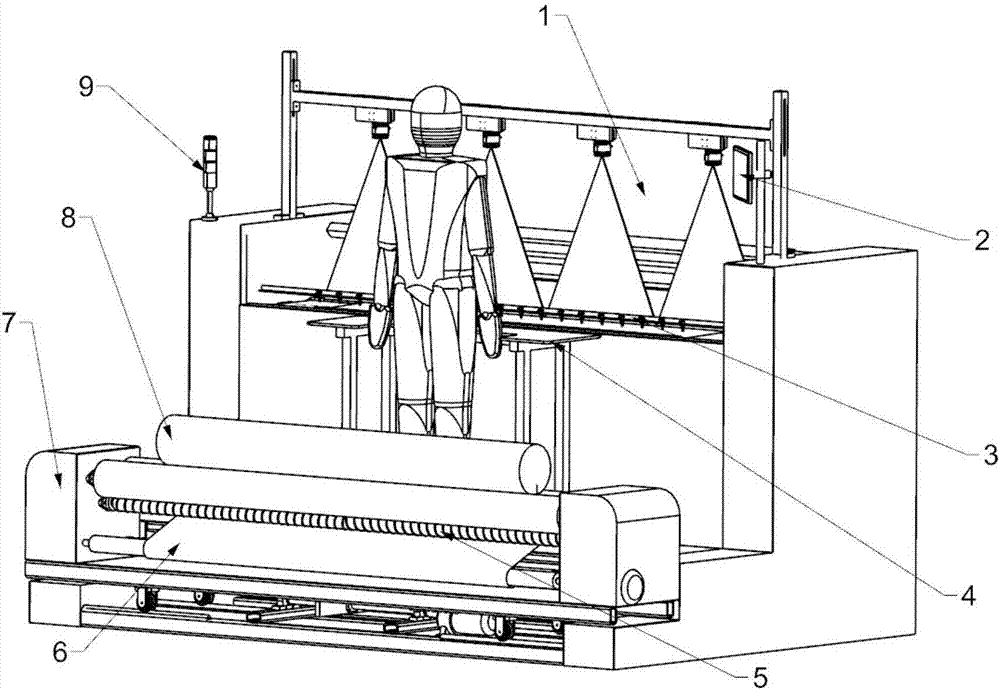

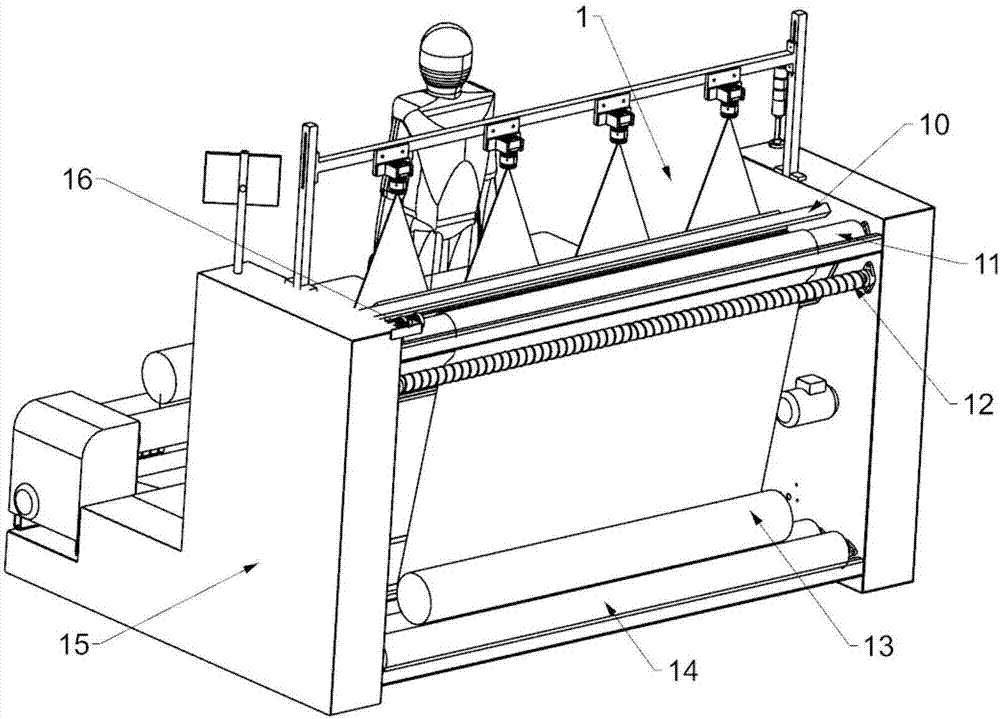

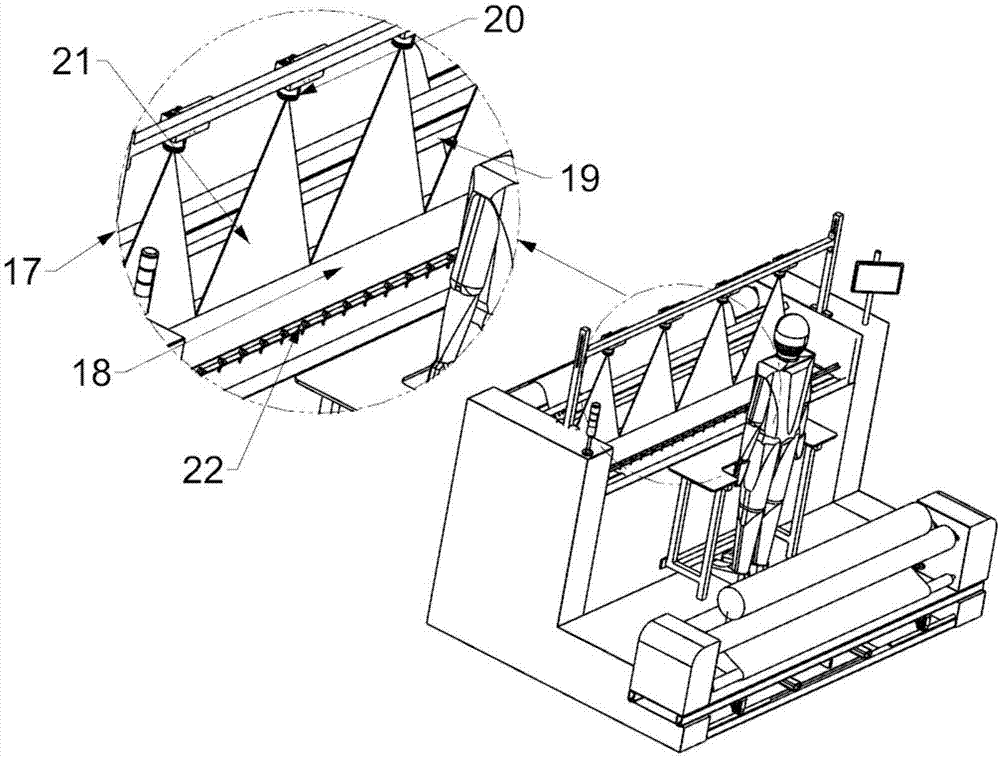

Intelligent plaiting machine

The invention relates to an intelligent plaiting machine, in particular to an intelligent plaiting machine for folding grey cloth or printed and dyed cloth into webs according to scales in a textile mill, a cloth plant or a dyeing and printing finishing workshop. The plaiting machine comprises a machine tool, a cloth drawing device and a plaiting device, wherein the cloth drawing device and the plaiting device comprise four groups of air tubes arranged on the machine tool and provided with pores, limit controllers arranged at two ends of the air tubes, a servo motor, a mesa, two rotary bar frames on two sides of the mesa, rotary bars fixed on the rotary bar frame, two connecting rods on the two sides of the mesa and with one end connected to the rotary bar and the other end connected with the servo motor, a slide bar connected with the two connecting rods, two buckling bars on the mesa, four pneumatic brackets below the mesa for supporting the mesa, and a slipway for arranging the servo motor. The plaiting machine has the characteristics of high intellectualization, low noise, reduced labor intensity, cost saving and the like.

Owner:杭州青菱自动化技术有限公司

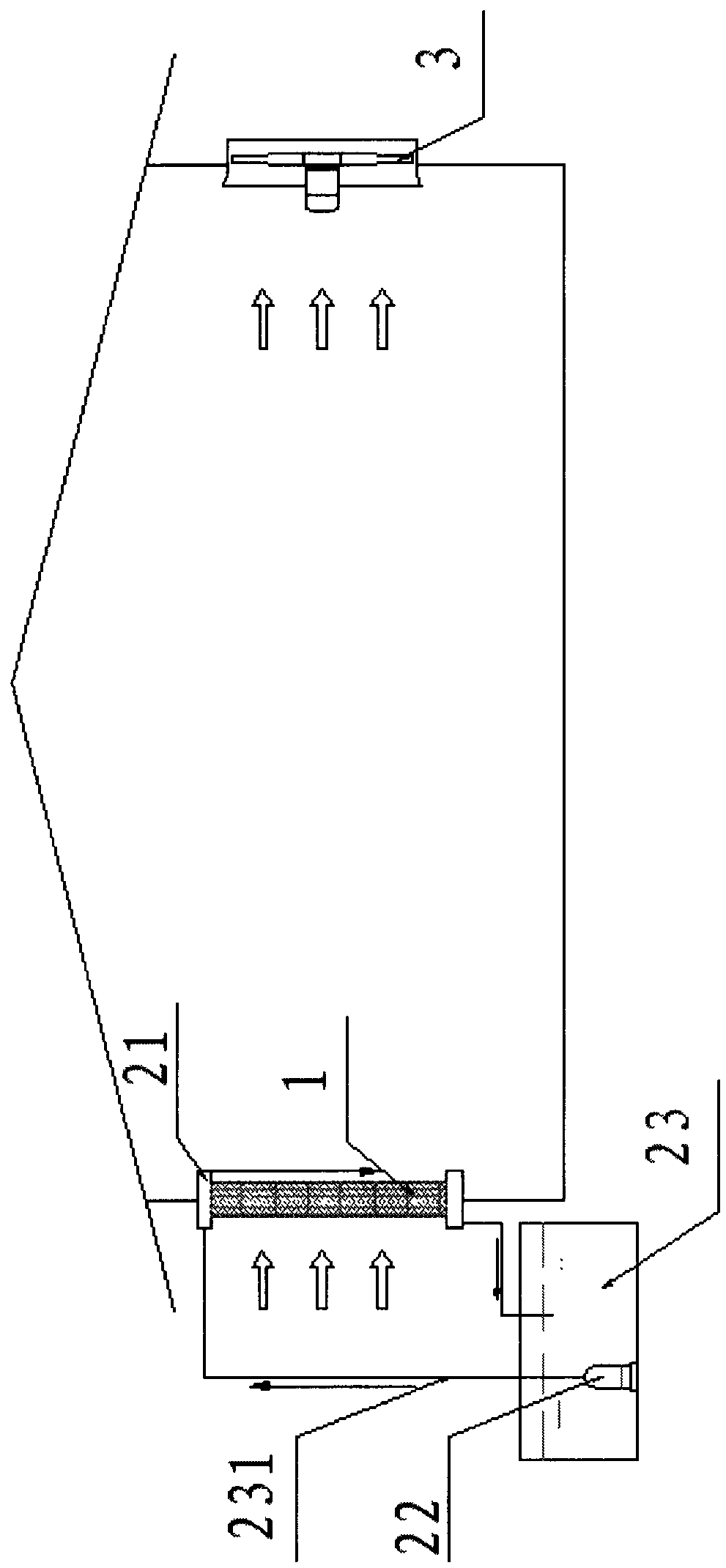

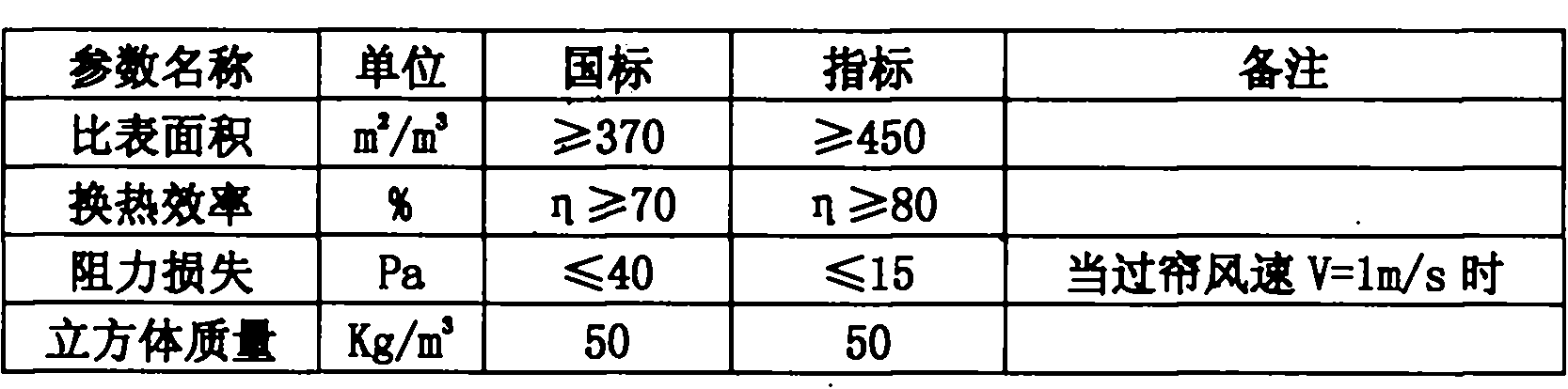

Novel wet curtain energy-saving textile mill air-conditioning system

InactiveCN104235974ASummer cooling controlTemperature and Humidity ControlLighting and heating apparatusAir conditioning systemsTextile millAir conditioning

The invention provides a novel wet curtain energy-saving textile mill air-conditioning system which comprises wet curtains, a main air duct, a wet curtain clerestory, a forced draft blower, an air feeding duct, an exhausting duct and a dust filter unit. The wet curtains are of honeycomb structures formed by stacking corrugated paper layers and are respectively arranged on two sides of the wet curtain clerestory, the wet curtain clerestory is arranged above the main air duct, the main air duct is communicated with the wet curtains and horizontally communicated with the air feeding duct, the forced draft blower is arranged at the position of an air inlet of the air feeding duct, the air feeding duct is arranged at the upper portion of a production workshop, the exhausting duct is arranged at the lower portion of the production workshop, and the dust filter unit is arranged at the air outlet end position of the exhausting duct. A 'side feeding and side exhausting' air supplying mode of the system is changed into an 'upward supplying and downward exhausting' mode, is combined with a textile mill air conditioner, and accordingly temperature reduction in summer, humidification in winter and temperature and humidity control of the workshop can be achieved well.

Owner:无锡市河埒空调设备有限公司

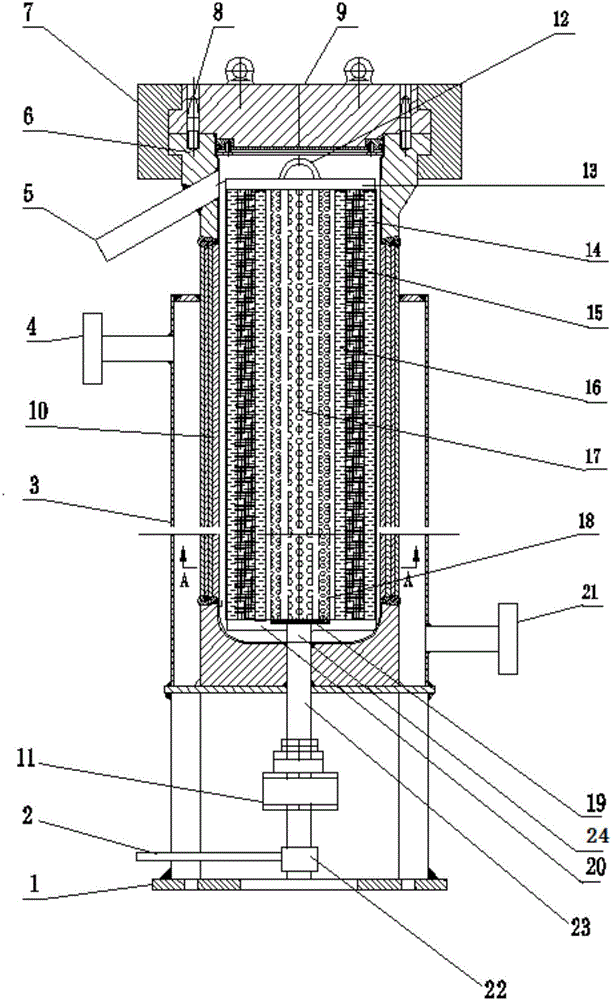

Supercritical carbon dioxide beam dyeing frame, dyeing kettle and dyeing method

ActiveCN105040317AIncrease profitReduce lossTextile treatment containersTextile solvent-dyeingCircular discYarn

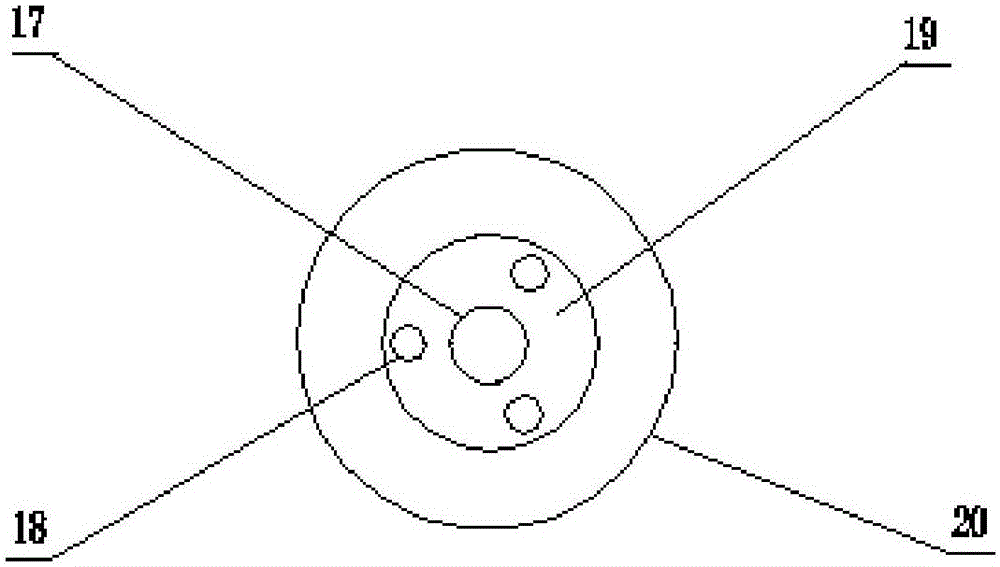

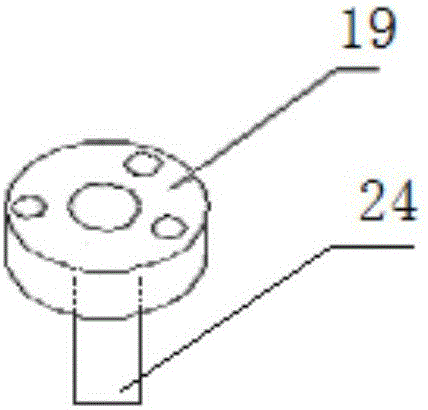

The invention discloses a supercritical carbon dioxide beam dyeing frame, dyeing kettle and dyeing method. The dyeing frame comprises a central supporting pipe (17) and a rotating disc (19), the rotating disc (19) is of a hollow cylinder structure, four holes are formed in the upper portion of the rotating disc, a short shaft (24) is arranged on the lower portion of the rotating disc in a communicated mode, and the beam dyeing frame comprises the central supporting pipe (17), a three-arm shaft (18), a beam supporting shaft (16), a beam (15) and a porous cover in sequence from inside to outside with the central supporting pipe (17) as the center; the bottom of the hollow rotating shaft is connected with a carbon dioxide fluid pipe through a rotary sealing device. According to the beam dyeing frame, dyeing kettle and dyeing method, the central supporting pipe and the three-arm shaft rotate in the circumferential direction, large impact force is generated by the carbon dioxide fluid by means of the centrifugal force, dye passes through yarn rapidly, and the dye permeability is improved. According to the steam heating type supercritical carbon dioxide beam dyeing kettle, high-temperature steam inside a textile mill is utilized, a steam heating mode is adopted, and the heat utilization rate is high.

Owner:晋江国盛新材料科技有限公司

Sewage treating agent

InactiveCN1344688AImprove precipitation effectImprove water qualitySedimentation separationWater/sewage treatment by flocculation/precipitationWater qualityTreated water

The present invention relates to environment protection technology. The sewage treating agent contains Al iron, Fe ion, Mg iron, Mn ion and lithopone, and is compounded by mixing water, aluminium sulfate, ferric sulfate, magnesium sulfate, manganese sulfate and lithopone through stirring for complete dissolving. It has the advantages of wide use range, high deposit rate, good quality of treated water, low cost, no corrosion to steel structure, no toxicity, no pollution and relatively high safety, and it may be widely used for effluent treatment in oil field, coal mine, textile mill, printing and dyeing mill, etc. and city sewage treatment.

Owner:SHENYANG ZHONGLU WATER BUSINESS

Textile mini-type dyeing machine

InactiveCN103668834ASimple heatingSave materialTextile treatment dyeing devicesTextile millSmall sample

The invention discloses a textile mini-type dyeing machine, relates to a dyeing machine and provides a dyeing machine used for dyeing small samples or medium samples. Heat-conduction media are not needed, materials are saved, and the heating efficiency is high. The textile mini-type dyeing machine is provided with a machine frame, a motor, a transmission device, a rotating shaft, a dyeing roller, a temperature sensor, an electric slip ring, an electric heater and a control circuit; an electric control chamber and a dyeing chamber are formed in the machine frame, the motor is arranged in the electric control chamber of the machine frame, the motor is connected with the transmission device, the transmission device is connected with the rotating shaft, the rotating shaft is connected with the machine frame in a rotating mode, the dyeing roller comprises a roller body and a roller cover, the dyeing roller is a closed pressure container, the dyeing roller is arranged in the dyeing chamber of the machine frame, a thermometer hole is formed in the roller body of the dyeing roller, the temperature sensor is arranged in the thermometer hole formed in the dyeing roller, one end of the rotating shaft extends into the dyeing chamber and is connected with the dyeing roller, the electric slip ring is arranged on the rotating shaft, a temperature sensor lead is electrically connected with the control circuit through the electric slip ring, and the electric heater is arranged at the outer side of the roller body of the dyeing roller and electrically connected with the control circuit.

Owner:赢世科技(厦门)有限公司

Basic catalase high-yield strain and basic catalase prepared by fermentation method using same

InactiveCN1966671AChange the dyeing and finishing processImprove the environmentBacteriaBiochemical fibre treatmentTextile millHydrogen

A bacterium with high yield of alkaline hydrogen peroxidase and method for producing hydrogen peroxidase through fermenting the bacterium belongs to the field of bioengineering technique. The bacterium of the invention is Bacillus subtilis (CCTCC NO:M206062) screened from effluent water of textile mill workshop through air bubble generation conditions by dropping 5% H2O2 on the plate. Alkaline hydrogen peroxidase with 3200u / ml enzyme activity is obtained by fermenting the bacterium through shaking flasks for deep liquid fermentation. The alkaline hydrogen peroxidase can be used for treating texture dying.

Owner:JIANGNAN UNIV

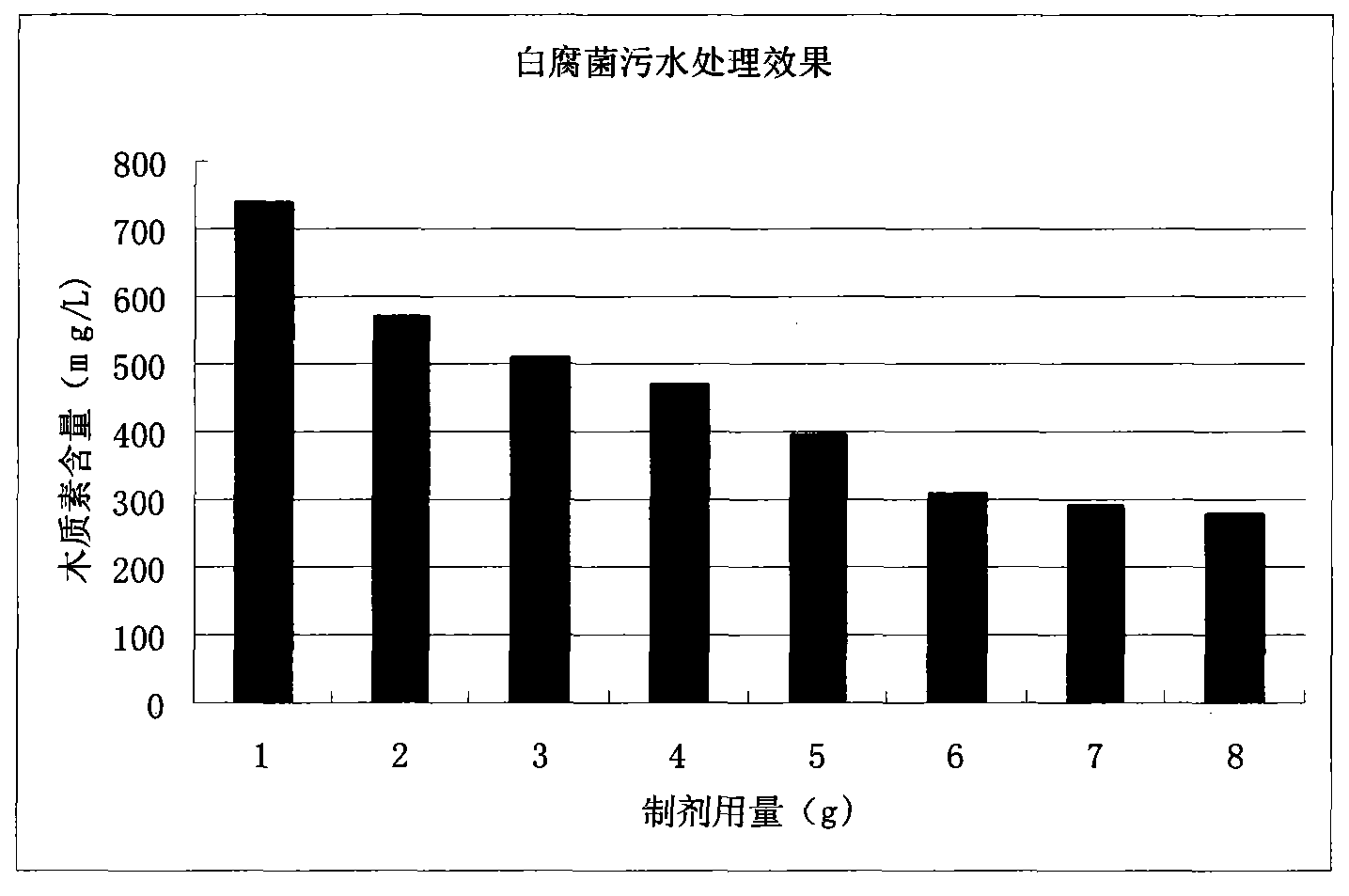

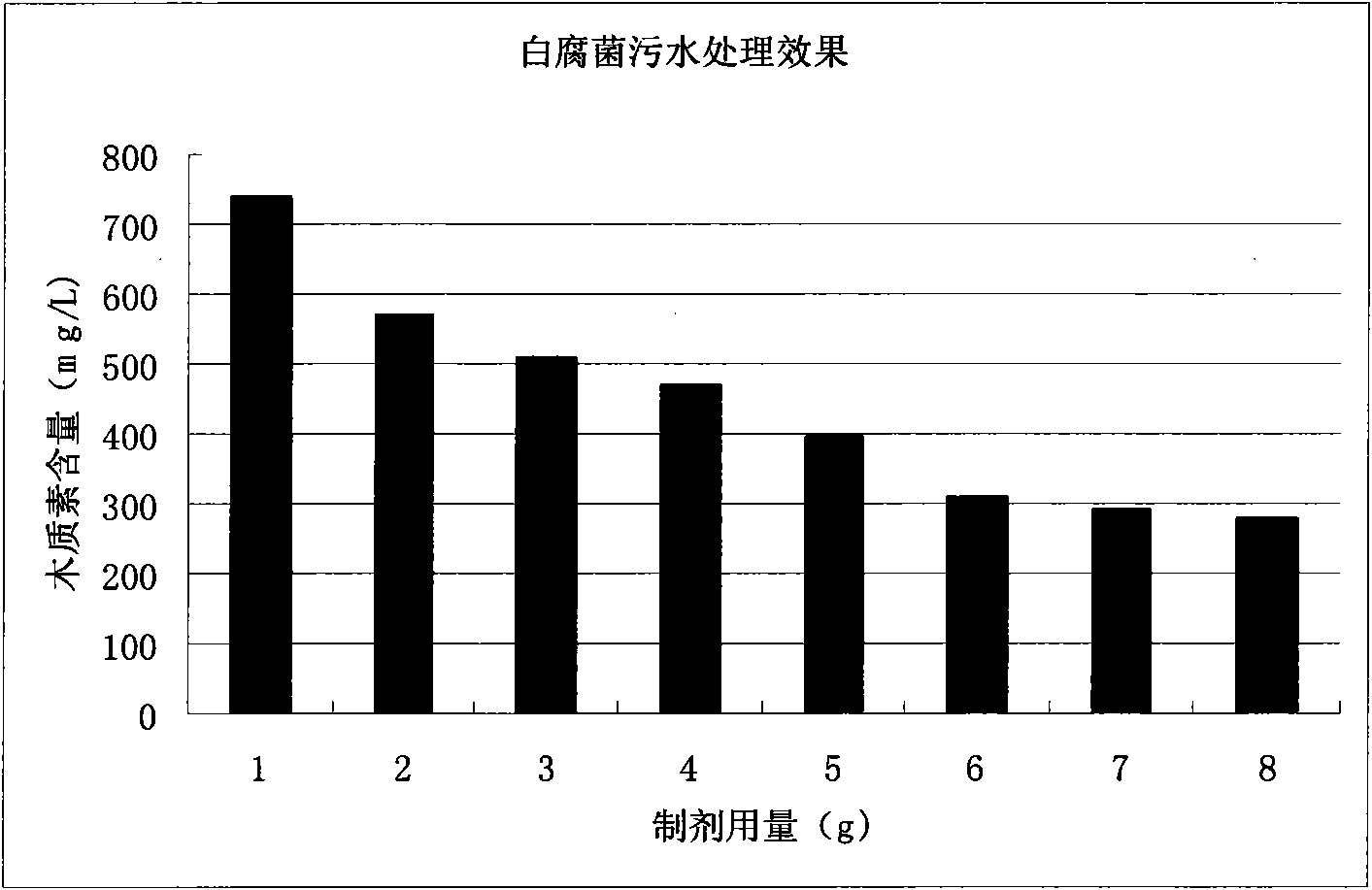

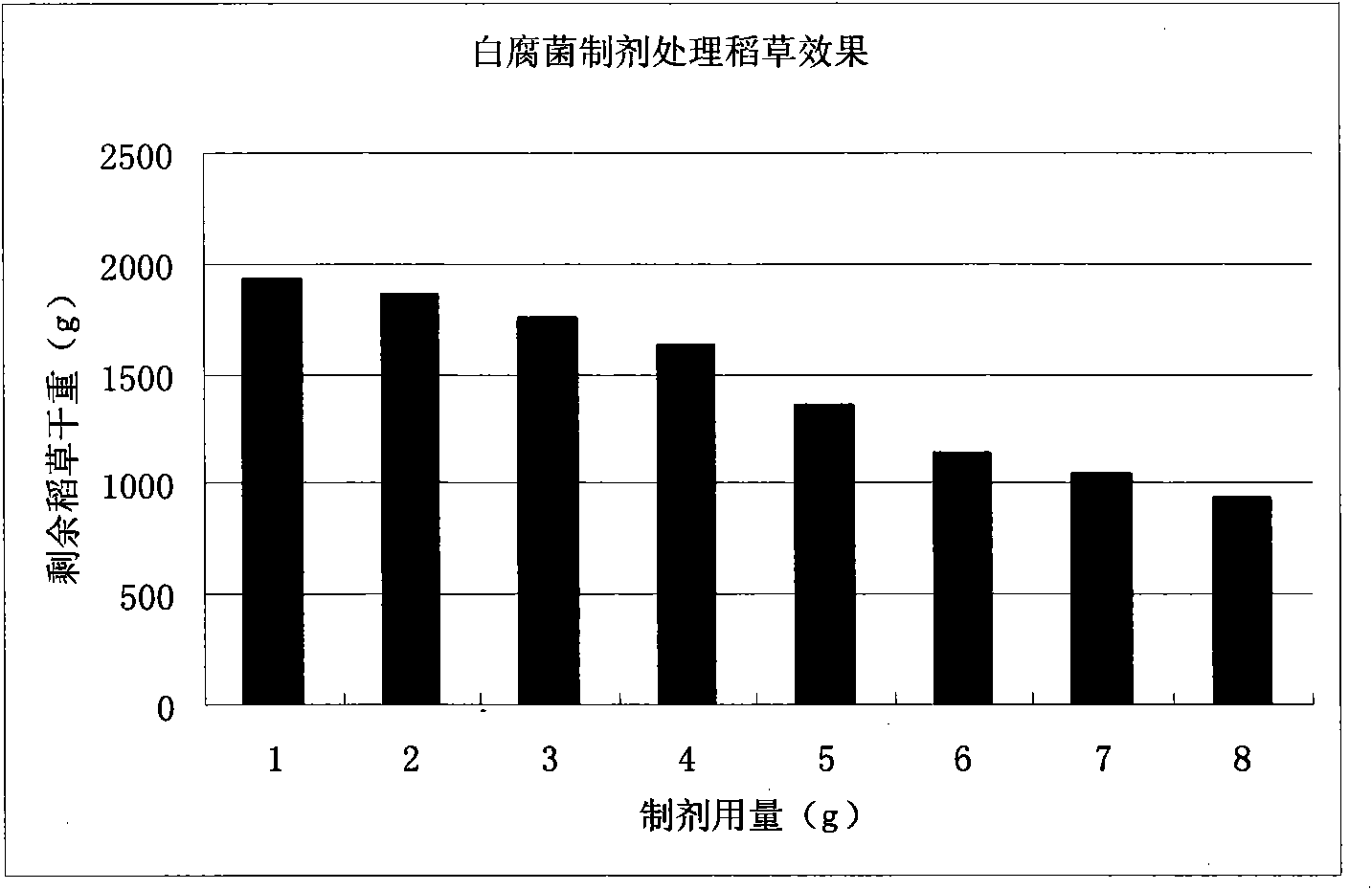

White rot fungus rot agent and method for producing organic pollutant rot agent by using white rot fungi

InactiveCN101811781APromote sustainable developmentImprove balanceWaste water treatment from animal husbandryWaste water treatment from food industryBiotechnologyFeces

The invention provides a white rot fungus rot agent and a method for producing an organic pollutant rot agent by using white rot fungi. In the method, the white rot fungi are obtained in a large quantity through industrial production and used as a treating agent for waste water, sewages and excrements of paper mills, textile mills, printing and dyeing mills, food factories, livestock and poultry factories, and the like, can also be used as a quick rot agent of composts prepared from farmland straws applied to farmlands and straw pollutions and has higher economic values and good application prospects. The invention also provides an application of the white rot fungi used as a waste water treating agent. The production method of the white rot fungi comprises the following steps of: putting a culture medium in a culture container; after sterilization at a proper temperature, inoculating the white rot fungi to the culture medium and controlling the temperature, the humidity, the pressure and the pH condition of the culture medium; introducing sterile air; adsorbing by using attapulgite, peat, kaolin, and the like after culturing; drying by air or drying in the shade; and pulverizing to prepare into a solid or powdered finished product.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

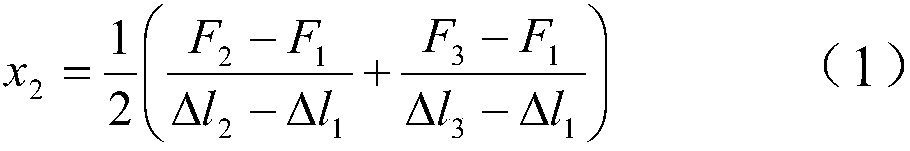

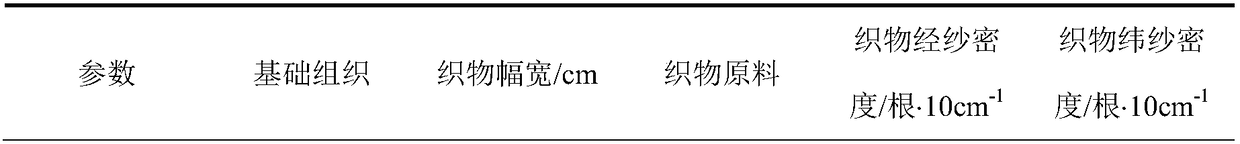

Construction and application of least square method-based woven fabric woven fabric elongation predicting model

ActiveCN108152153AImprove product qualityReduce commissioning productionInvestigating material ductilityTextile millEngineering

The invention discloses a construction and application of a least square method-based woven fabric woven fabric elongation predicting model, and aims to provide a convenient and quick method for predicting elongation of woven fabric in an elasticity range. The construction of the model comprises the following steps: performing performance test on a woven fabric sample under the condition of the industrial standard; performing a scientific and rational analysis on the test data; establishing a multiple linear regression model with a good fitting result in combination with the least square method. The fabric elongation predicting method disclosed by the invention comprises the following steps: measuring the performance of the woven fabric sample according to the textile industrial standard;in combination with the model, quickly predicting corresponding theoretical elongation when different loads are applied within the elasticity range of the woven fabric. The method disclosed by the invention is simple and can obviously shorten the time of calculating the elastic elongation of the woven fabric, and provides a direct theoretical basis and guidance for the design for a textile mill, the application of twill woven fabric, the development of relevant products as well as reasonable utilization of raw materials.

Owner:HENAN INST OF ENG

Cloth rolling machine with flaw detection and treatment functions

InactiveCN106915645AAvoid wrinklesNeatly coiledOptically investigating flaws/contaminationCleaning using liquidsEngineeringHigh pressure

The invention discloses a cloth rolling machine with flaw detection and treatment functions. The cloth rolling machine comprises a cloth conveying platform, a detection mechanism, a CCD (Charge Coupled Device) camera, a cleaning mechanism, a high-pressure nozzle, a cleaning liquid tank, a high-pressure pump, a fan, a spring, an electric iron, a PLC (Programmable Logic Controller) control box, a display screen, an audible and visual alarm, a cloth guide roller, a processor, an image acquisition card, an optical imaging module, an image processor, an encoder, a support column, a tension roller, a friction shaft, a support rod, a clamping plate, a connecting rod, a cloth rolling mechanism, a servo motor, a speed reducer, a cloth roller and a winding roller. The cloth rolling machine has the beneficial effects that the cloth roller is driven to roll and store cloth by the winding roller, so that the replacing times of the winding roller is reduced, and the cloth roll forming speed of a textile mill is increased; the detection mechanism is additionally arranged and is used for detecting flaws and stains of cloth in time and on line and reminding, and the stains of the cloth can be directly cleaned by the cleaning mechanism, so that the cloth roll forming quality of the textile mill is increased.

Owner:扬州市嘉鑫织造实业有限公司

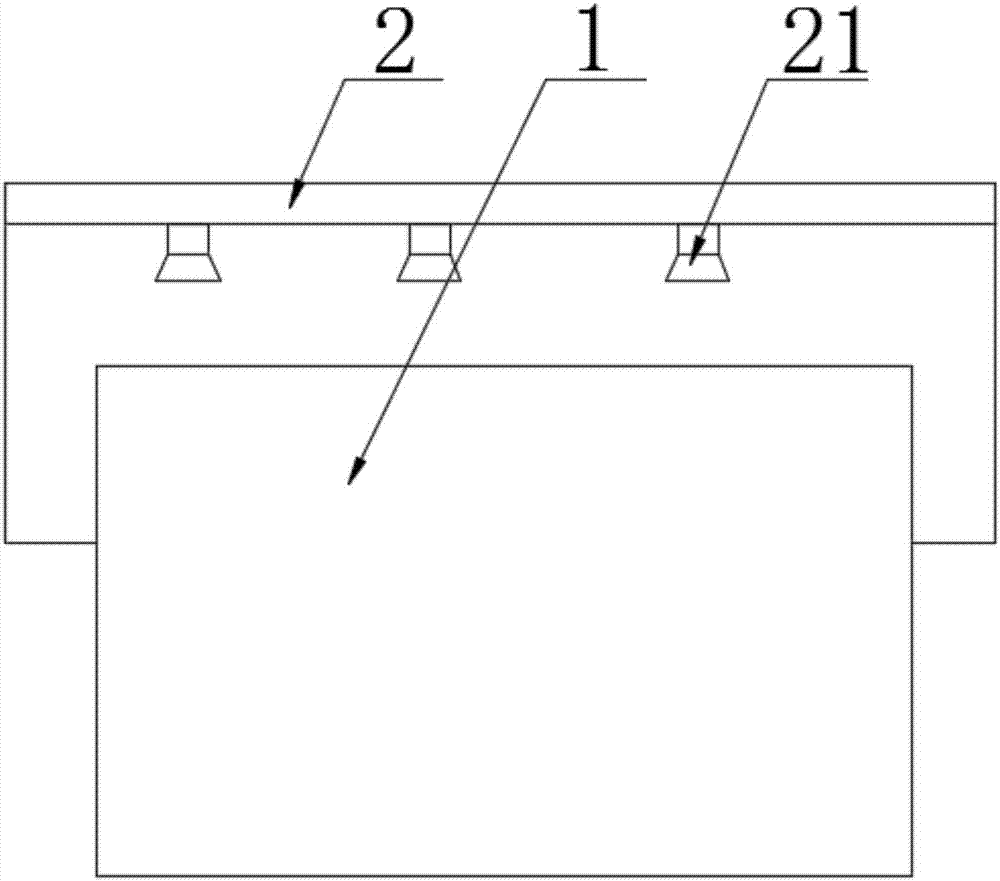

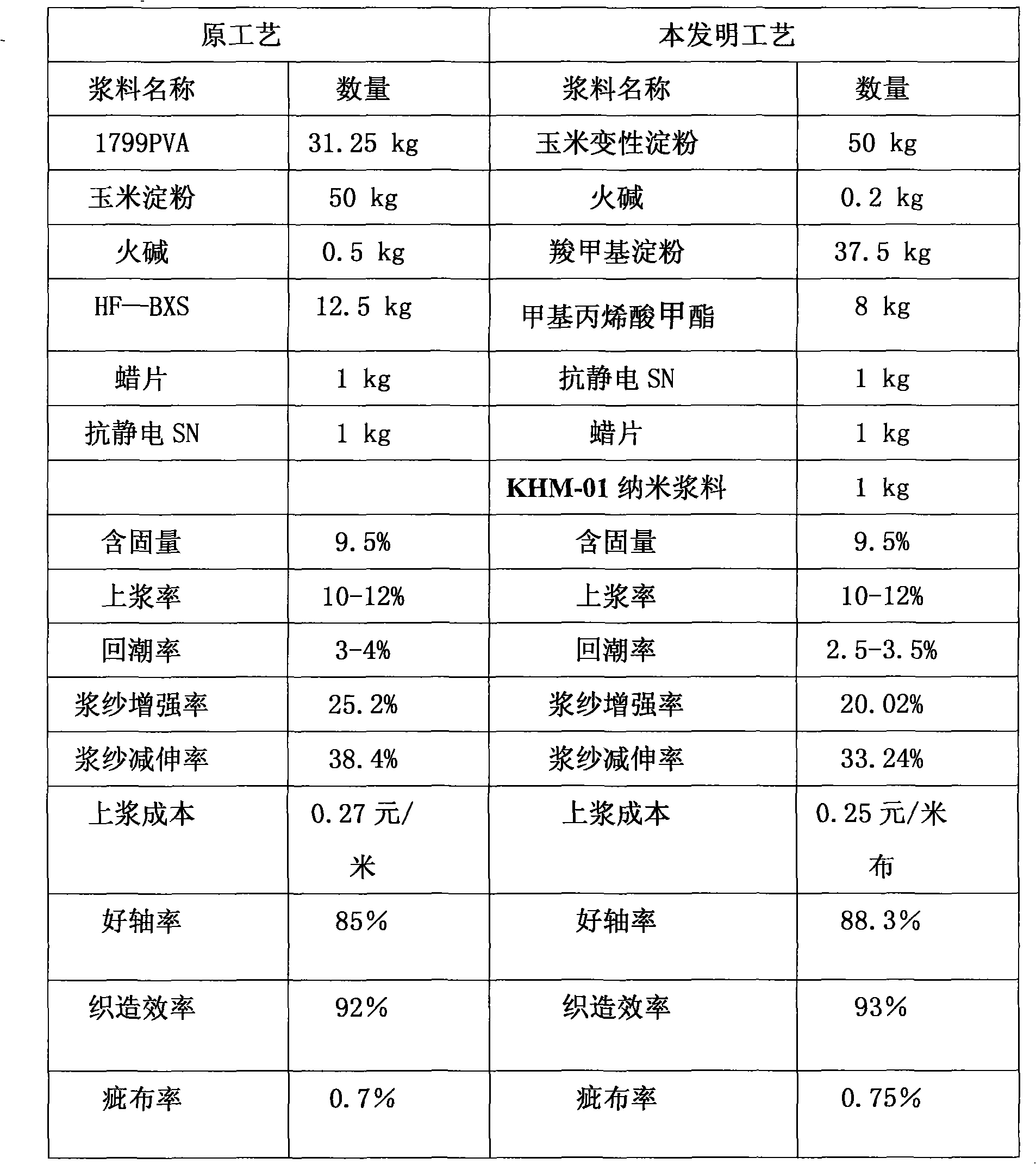

Environment-friendly pulp material for fabric twill face fabric and size mixing technology

The invention relates to a polyester-cotton and khaki fabric environment-friendly finishing mixture, which is made from the following raw materials: modified corn starch 50kg, sodium hydroxide 0.2 kg, carboxymethyl starch 37.5kg, methyl methacrylate 8kg, wax scale 1kg, antistatic agent 1kg, and KHM-01 nano-slurry 1kg. The invention also provides the size mixing process of the finishing mixture. The invention creatively solves the PVA conventional mode which is required to be used on polyester-cotton variety and troubles the prior textile industry, not only the sizing procedure of production in a textile mill is clean, but also the clean production of upstream and downstream enterprises is driven. The performance advantages of various green slurries are utilized for complementation, the function of the original used PVA slurry formula is reserved, thereby not only satisfying the sizing requirement of the polyester-cotton variety, but also lowering the cost of production, guaranteeing the original characteristic for fabrics which is comfortable to wear and is noble and quietly elegant, and satisfying the public requirement for healthy, comfortable, and fashionable life.

Owner:SHANDONG QISAI TEXTILE

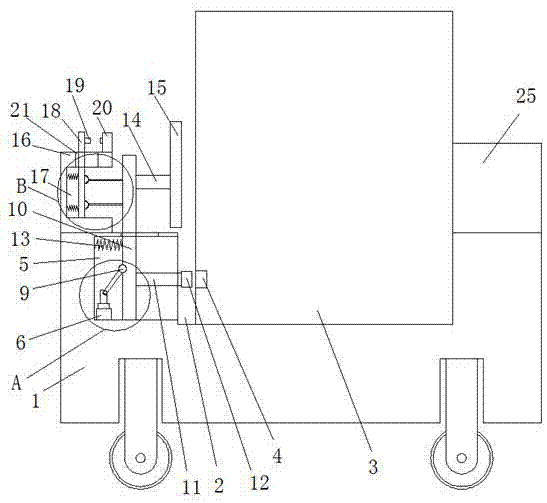

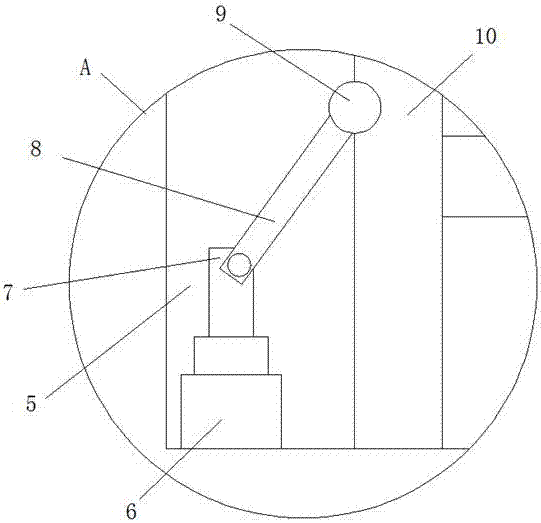

Air purifying equipment applied to textile mill

InactiveCN107965852AEasy to moveEasy to fixLighting and heating apparatusSpace heating and ventilation detailsTextile millControl engineering

The invention discloses an air purification device used in textile mills, which comprises a base and an air purification device body movably installed on the base. The inner walls of the bottom are in contact, and an installation groove is opened on the inner wall of one side of the placement groove. A telescopic motor is fixedly installed on the inner wall of the bottom of the installation groove, and a push block is fixedly installed on the output shaft of the telescopic motor. There is a push plate, and the push plate is located above the telescopic motor. The side of the push plate away from the push block is rotated and installed with a rotating shaft. A moving plate slidingly connected to the side wall of the installation groove is fixedly installed on the rotating shaft. The top of the moving plate extends to the base above. The invention increases the stability of itself when moving, and can control the fixing strength when fixing, and has simple structure and convenient use.

Owner:刘丽影

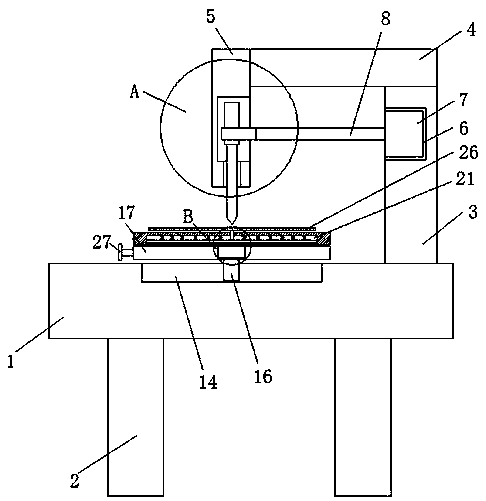

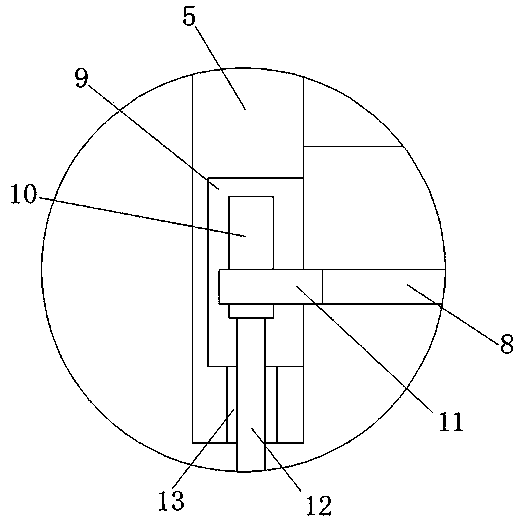

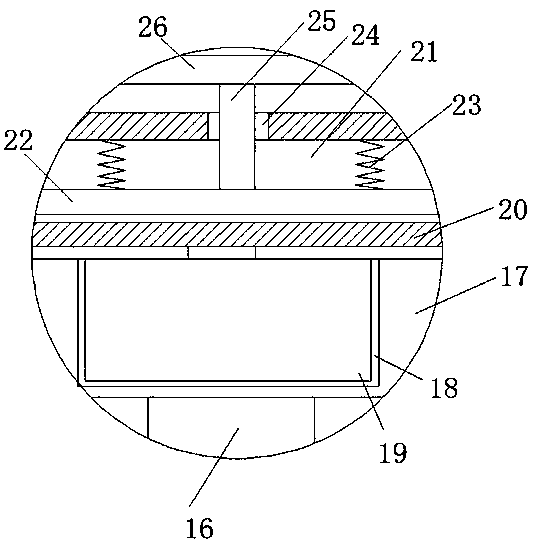

Gray cloth defect visual inspection equipment and method

PendingCN106970090AIncrease productivityReduce labor costsOptically investigating flaws/contaminationCombined useVisual inspection

Aiming at the deficiency of the conventional inspection technology in combination with the demands of various textile factories, the invention provides gray cloth defect visual inspection equipment. The equipment at least comprises a visual inspection platform and an ink jet marking mechanism, a multithreaded gray cloth quality inspection algorithm is adopted through a visual detection platform to perform defect inspection and identification, and the ink jet marking mechanism is used for marking. The equipment can automatically realize gray cloth defect inspection and stores defect data into a local database, and the inspection speed and inspection rate thereof are greatly higher than that of manual inspection, therefore, the production efficiency of the textile factories is improved, the manual labor intensity is lowered greatly, and the labor expenses in terms of quality inspection of the textile factories are reduced.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST

Portable sewing machine used in textile mill

InactiveCN107904788AEasy height adjustmentEasy to sewWork-feeding meansSewing-machine control devicesTextile millElectric machinery

The invention discloses a portable sewing machine used in textile mills, which comprises a sewing machine base, two symmetrically arranged support plates are welded on the bottom of the sewing machine base, and a first vertical plate is welded on one side of the top of the sewing machine base, The top of the first vertical plate is welded with a horizontal plate, and the side of the horizontal plate away from the first vertical plate is welded with a second vertical plate, and the side of the first vertical plate close to the second vertical plate has a The first installation groove, and the first drive motor is installed in the first installation groove, the output shaft of the first drive motor is welded with a rotating shaft, and the second vertical plate is provided with a first rectangular groove on the side close to the first vertical plate . The present invention has high practicability, and it is convenient to adjust the height of the needle of the sewing machine through the screw rod and the nut, so as to facilitate the sewing of clothes; through the spring and the clothes board, it is convenient to rotate and move the clothes holding board, and further facilitates the sewing of clothes. Reduce the work intensity of the staff and improve the work efficiency of the staff.

Owner:刘丽影

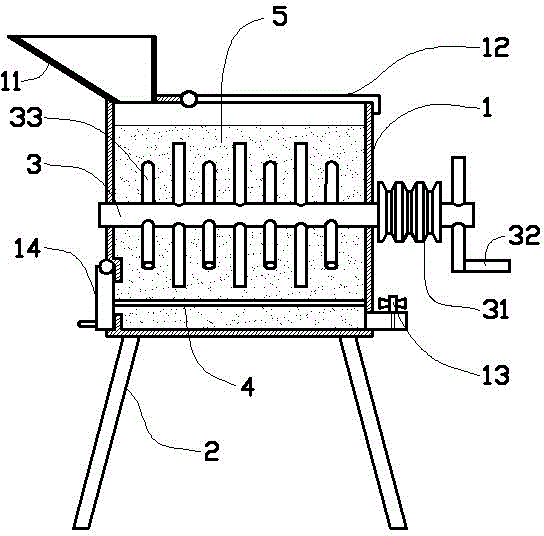

Wool processing device

ActiveCN103334160AIncrease added valueEasy to processWool fibre washing/scouringTextile millEngineering

The invention provides a wool processing device, and belongs to the technical field of textile machinery. The wool processing device comprises a box body, a support leg rack and a stirring shaft, wherein the support leg rack is assembled at the lower part of the box body; a feed hopper is fixed at the upper part of the box body; a lid is hinged to the upper part of the box body; the stirring shaft penetrates through the box body horizontally, and can be assembled with the box body in a rotating manner; a collecting net is mounted at the lower part of the inner cavity of the box body; a valve for communicating the inner cavity of the box body with the outside is mounted at the lower part of the collecting net; a material fetching door is hinged to the side wall of the box body corresponding to the collecting net. According to the invention, the device has simple structure and smaller size, is lower in cost and easy to carry, is suitable for being used in a household or an individual workshop, can be used for processing raw wool in time, increases the additional value of the wool fiber, and facilitates the follow-up processing of a textile mill.

Owner:吴江市恒帛纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com