Environment-friendly pulp material for fabric twill face fabric and size mixing technology

A fabric and yarn card technology, which is applied in the proportioning and pulping process of green and environmentally friendly pulp, can solve the problems of not meeting the quality requirements of blended yarns, affecting production, and single pulp, so as to achieve strength improvement and pulp Membrane integrity, guaranteed recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

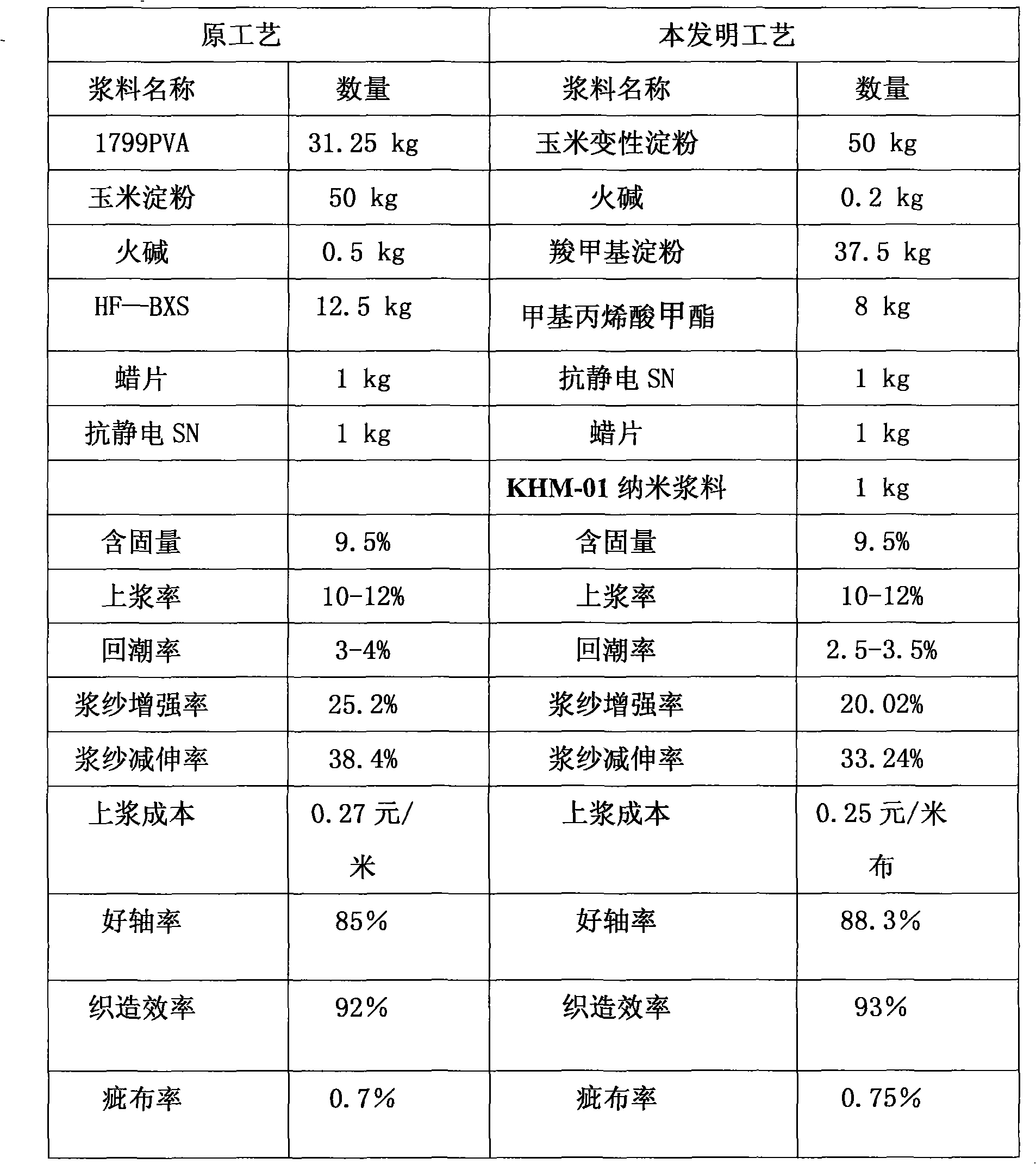

[0020] According to the wearing requirements of polyester-cotton blended clothing fabrics, the use of unclean size "PVA" is not allowed in the fabric sizing, and the residual amount of PVA must be measured after the product is dyed. Therefore, PVA must not be used in the production of gray fabrics. C60 / T4020 ×12×109×48×70″3 / 1 is taken as an example to illustrate the content of the present invention.

[0021] Warp and weft:

[0022] Cotton fiber 55-65% (weight percent)

[0023] Polyester fiber 35-45%.

[0024] Slurry formula: 50kg of corn modified starch, 0.2kg of caustic soda, 37.5kg of carboxymethyl starch, 8kg of methyl methacrylate, 1kg of wax sheet, 1kg of antistatic agent and 1kg of KHM-01 nano slurry (Suzhou Kehaimeng Textile Co., Ltd. New Material Co., Ltd.).

[0025] SG921 type atmospheric pressure mixing tank (diameter 1 meter) is used for slurry mixing. The slurry mixing process is as follows: put in 60cm high clear water, put in KHM-01 nano slurry at high speed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com