Patents

Literature

46results about How to "Reduce stress and strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

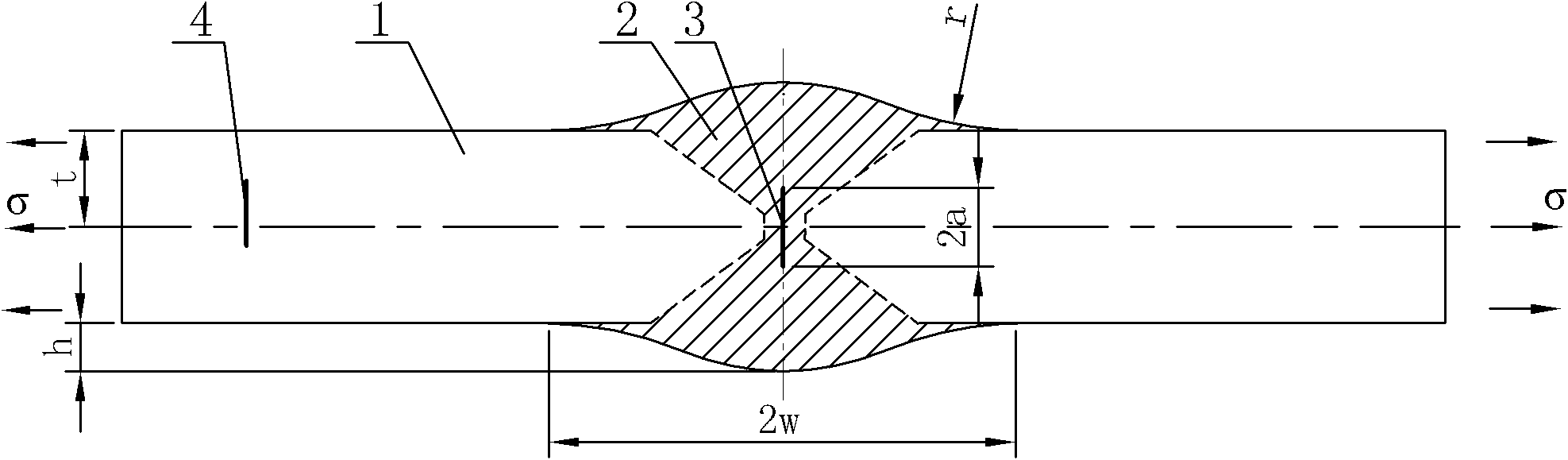

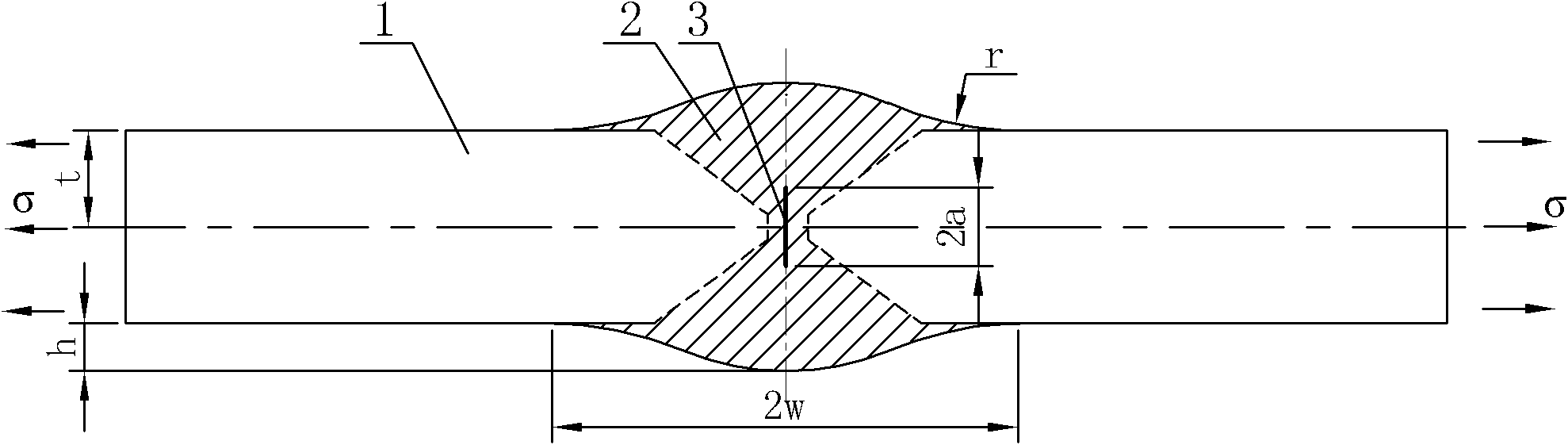

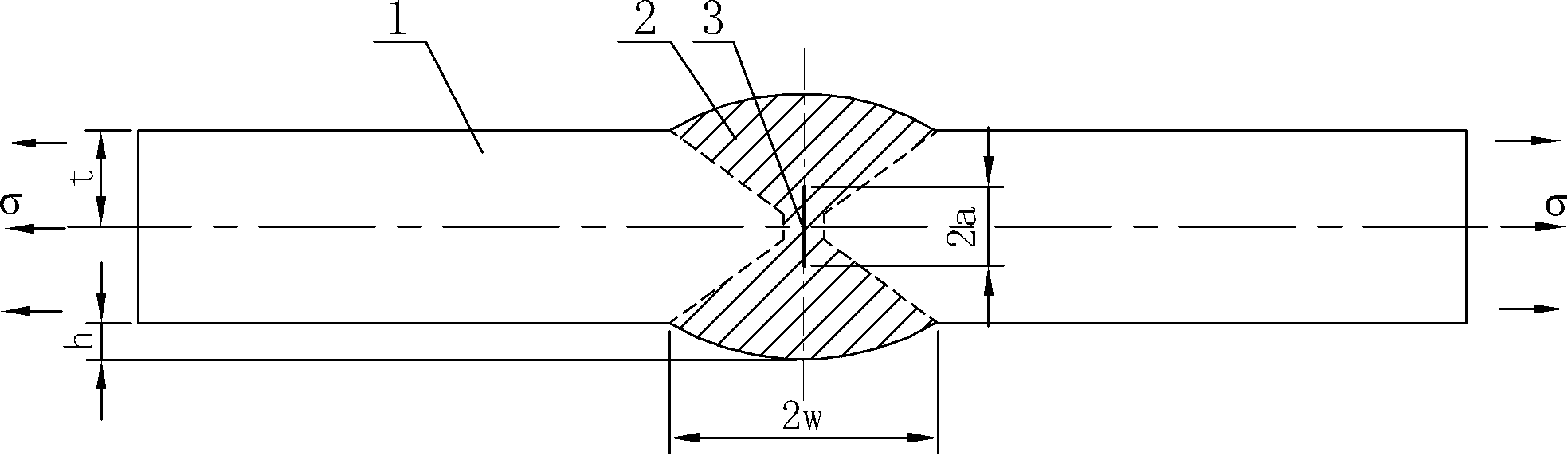

Designing method for realizing equal load-carrying of tension-loaded butt joint with central crack on welding line, and application of K factor

InactiveCN102136018AImprove carrying capacityImprove fatigue strengthSpecial data processing applicationsLoad carryingCarrying capacity

The invention discloses a designing method for realizing the equal load-carrying of a tension-loaded butt joint with a central crack on a welding line, and the application of a K factor, which belong to the field of welding and aim to solve the problem that the load-carrying capacity of the tension-loaded butt joint with the central crack is lower than that of a parent metal. If the parent metal of the tension-loaded joint with the central crack on the welding line also has a crack, the designing method comprises the following steps of: determining equal load-carrying conditions, and the fracture toughness of a weld metal and the parent metal; calculating a stress intensity factor of a parent metal area and the stress intensity factor of a welding line area meeting equal load-carrying; calculating a stress intensity factor formula; and obtaining geometrical parameter values of the welding line. If the parent metal of the tension-loaded joint with the central crack on the welding line is free from defect, the designing method comprises the following steps of: determining the equal load-carrying conditions, and the tensile strength of the parent metal; calculating the stress intensity factor formula; determining a critical stress relational expression, and the fracture toughness of the weld metal; and obtaining the geometrical parameter values of the welding line. The stress intensity factor of the welding line area is applied to the calculation of critical crack size, critical stress and remaining service life of the tension-loaded joint with the central crack. The method and the application are applied to plate butt joints welded on both sides.

Owner:HARBIN INST OF TECH

Method of preventing transverse corner cracks of microalloyed steel continuous casting sheet billet

The invention relates to the technical field of metallurgy steelmaking sheet billet continuous casting, in particular to a method of preventing transverse corner cracks of a microalloyed steel continuous casting sheet billet. After the method is applied in a ladle furnace smelting technology and a continuous casting technology, the mass percent of Ti in microalloyed steel is controlled at 0.018-0.025%, and a specific water flow of secondary cooling water of a continuous casting machine is adjusted to 0.42L / kg. According to the method, the problem of the transverse corner cracks of microalloyed steel continuous casting sheet billet is mainly solved by adopting a technological means; through molten steel micro-Ti treatment, the grain boundary precipitation of NbN and VN in the microalloyed steel and the grain boundary strength are reduced and weakened, a third high-temperature brittleness area of steel is avoided from a cooling procedure, and the stress strain of corners of the casting billet during straightening is reduced; no additional equipment transformation or investment is required; no strict requirement is made on whether electromagnetic stirring equipment is equipped; and the method is low in investment and wide in application range, and has few restrictions.

Owner:ANYANG IRON & STEEL

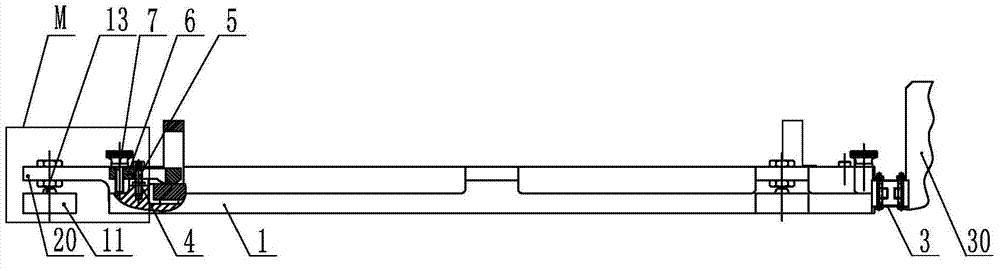

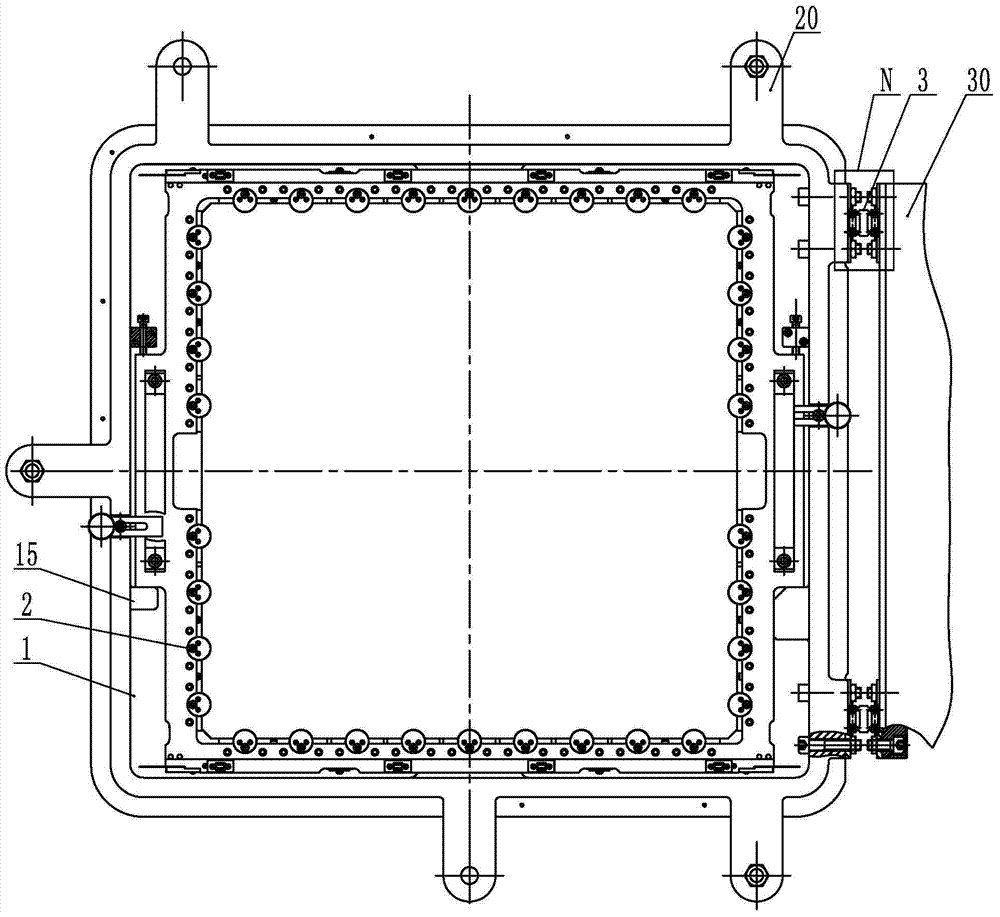

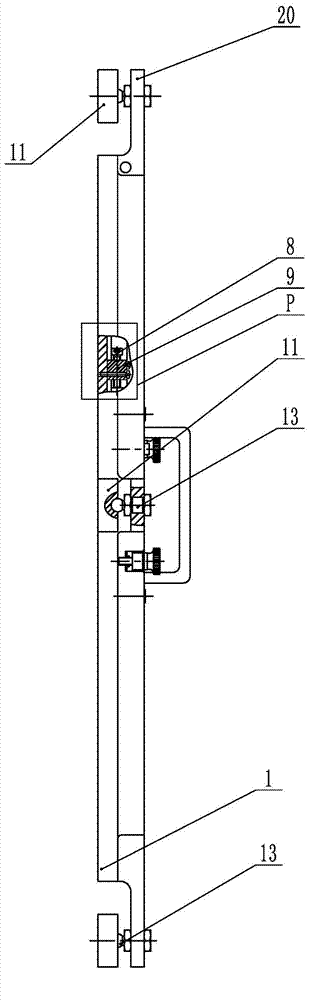

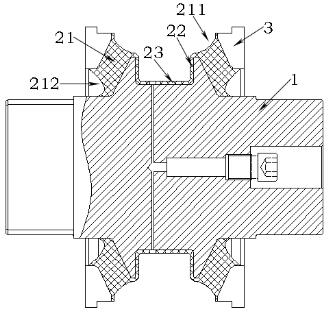

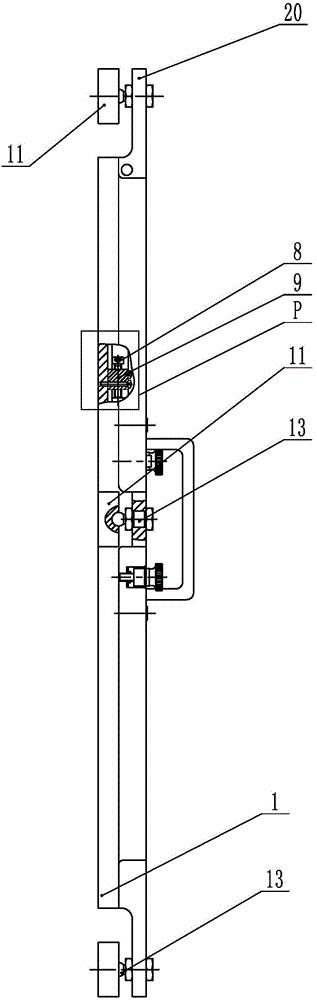

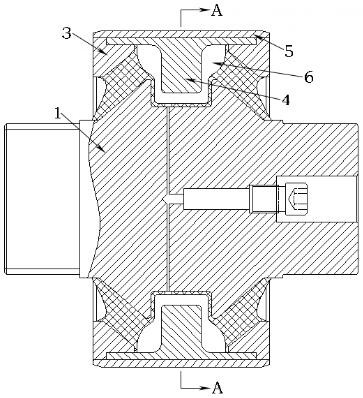

Flexible hinge and floating frame matched clamping and positioning device for optical component

ActiveCN103753449AGuaranteed uptimeMeet the requirements of precision restorationWork holdersEngineeringMechanical engineering

The invention discloses a flexible hinge and floating frame matched clamping and positioning device for an optical component. A flexible hinge and a floating frame are matched to be used for clamping and positioning the optical component, so that a large-caliber optical component is provided with the low-stress-strain reliable clamping capacity in the horizontal plane, moreover, the floating frame and two-dimensional large stroke are in flexible connection, so that the parallelism between the optical element surface and the work table plane is guaranteed. The flexible hinge is fixedly connected with a crystal frame, connection lugs are fixed on the crystal frame, positioning blocks are fixed in the crystal frame, and the optical component is disposed in the crystal frame integrally and positioned through the positioning blocks. Locking blocks are fixed in the crystal frame, first positioning screws are screwed in the locking blocks, and the optical component is pre-clamped and fixed between the first positioning screws and the positioning blocks. Compression blocks are fixedly connected with the crystal frame, and the optical component is compressed and fixed vertically through the compression blocks. Spherical hinge studs are fixedly connected with connection lugs and are in contact with air floating pads. The device is used for clamping and positioning of optical elements during micro-defect rapid searching and repairing.

Owner:HARBIN INST OF TECH

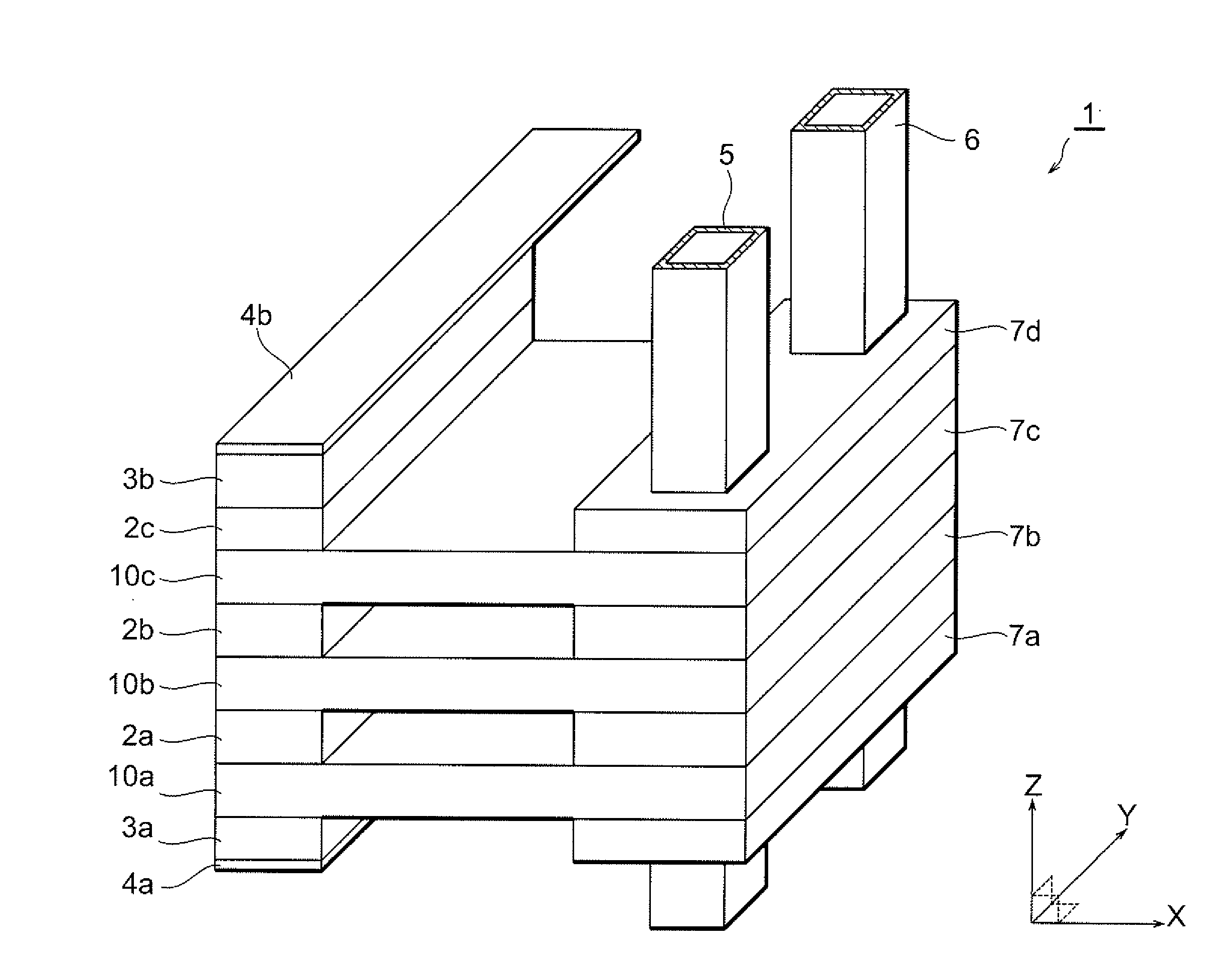

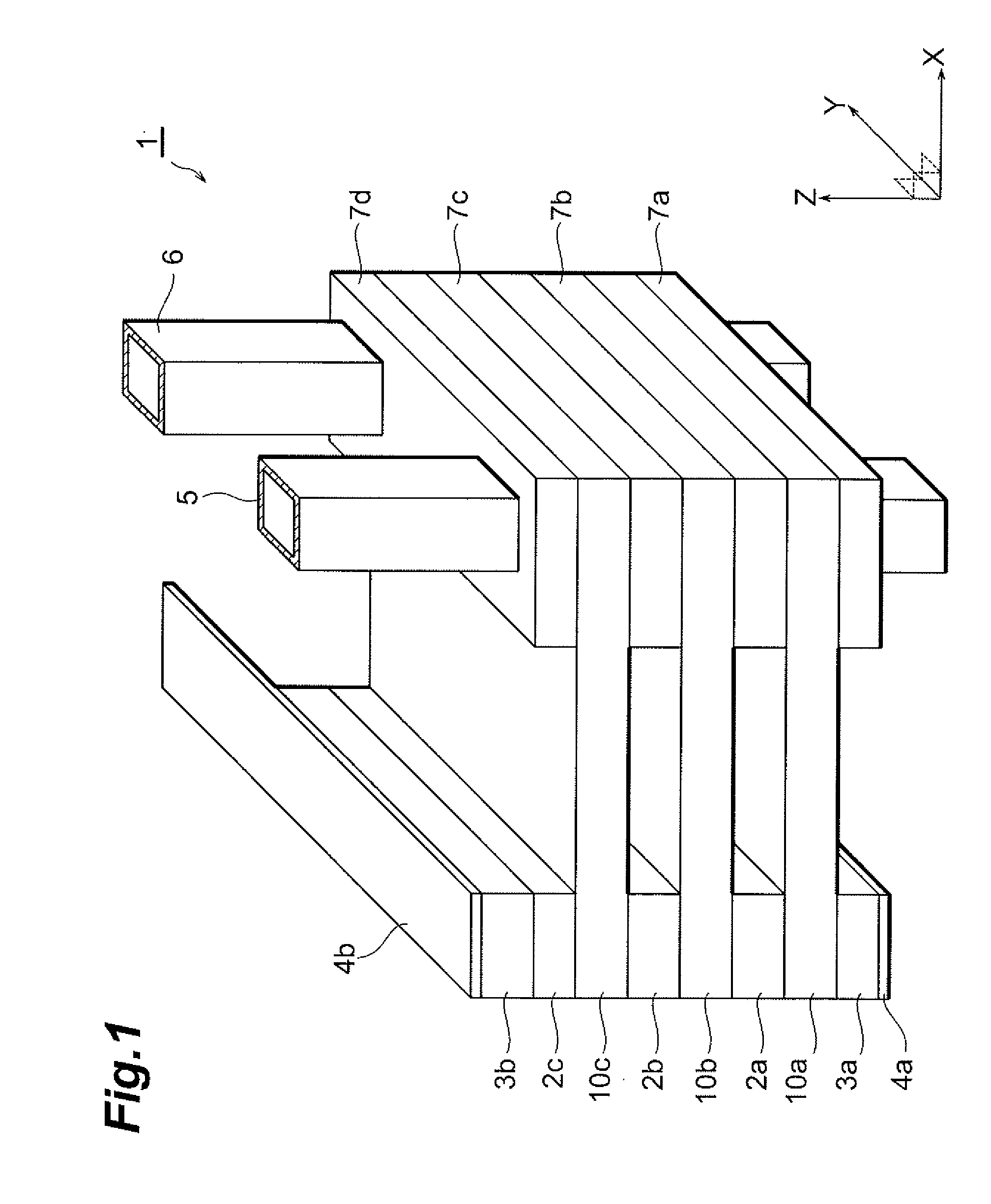

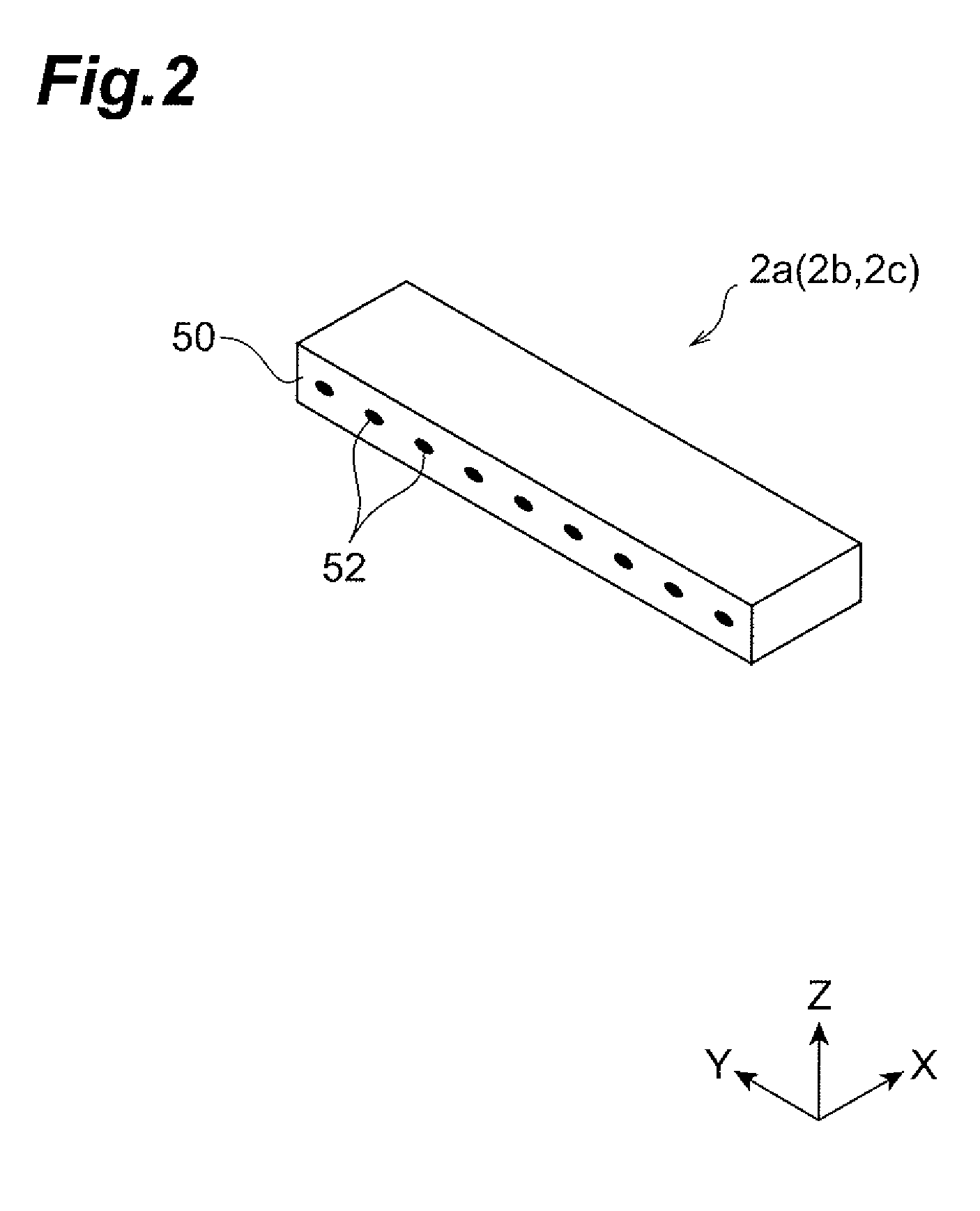

Heat sink, laser apparatus provided with such heat sink, and laser stack apparatus

InactiveUS20100202479A1Reduce stress and strainSemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

A heat sink has a first flat plate, a partition plate, and a second flat plate. The first flat plate has an upper surface in which a first recess is formed. The second flat plate has a lower surface in which a second recess is formed, and an upper surface on which a semiconductor laser element is mounted. These recesses form a part of a refrigerant channel. The partition plate has a lower surface covering the first recess, an upper surface covering the second recess, and at least one through hole having the first recess communicated with the second recess. The first flat plate and the second flat plate both have a first coefficient of thermal expansion. The partition plate has a second coefficient of thermal expansion lower than the first coefficient of thermal expansion.

Owner:HAMAMATSU PHOTONICS KK

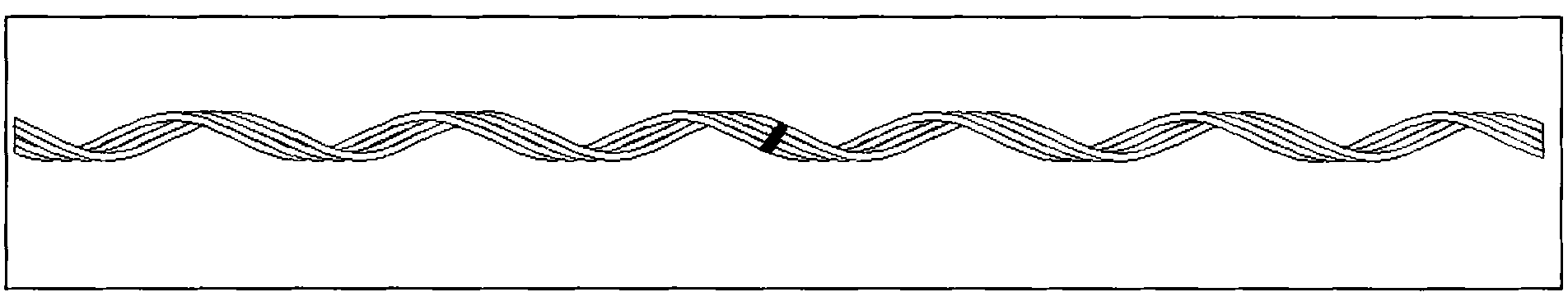

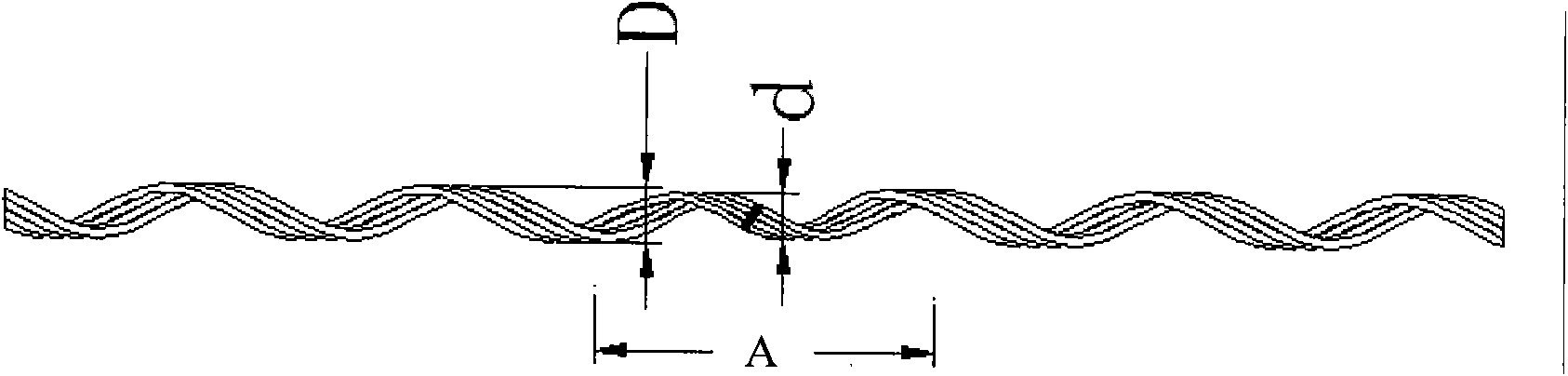

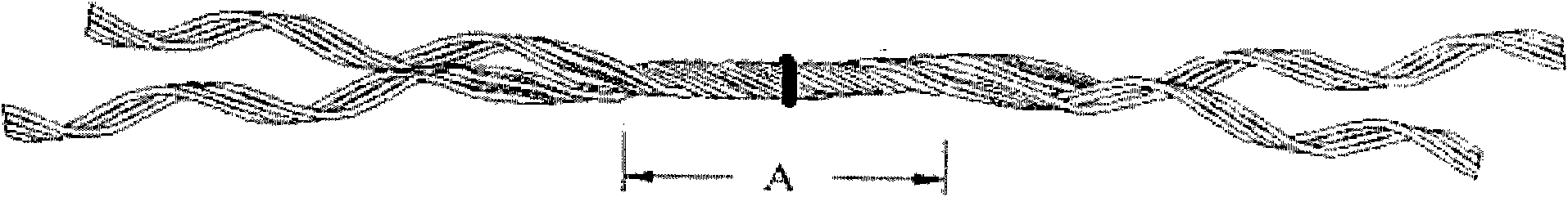

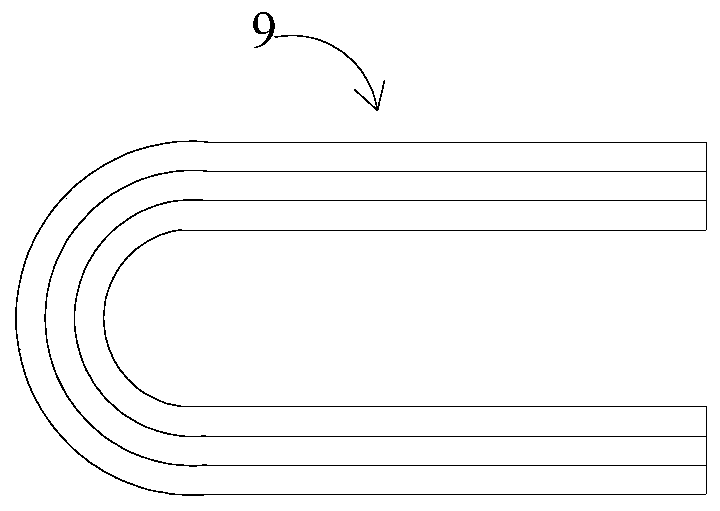

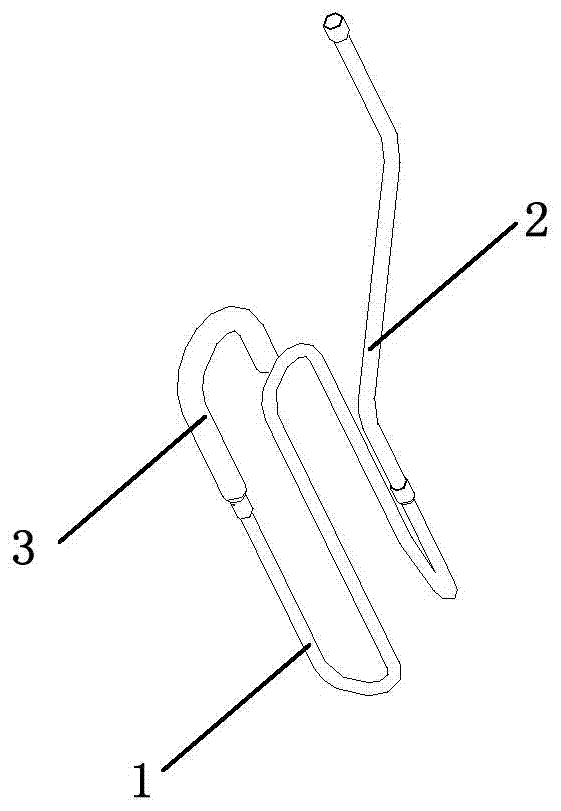

Anti-fatigue pre-twisted protective bar

InactiveCN102398533AIncrease stiffnessReduce stress and strainTrolley linesStress concentrationFatigue damage

The invention discloses an anti-fatigue pre-twisted protective bar. The protective bar comprises two spiral pre-twisted wire sheets; and the centers of the two pre-twisted wire sheets are twisted to form an enclosed circular tube. The anti-fatigue pre-twisted protective bar uniformly disperses pressure borne by a bearing seat to two sides without stress concentration; the stress strain of a lead at the position is reduced, the anti-fatigue property is improved, and the fatigue damage of the lead is effectively avoided; in addition, the invention has the advantages that the anti-fatigue pre-twisted protective bar can be installed manually, and is easy and quick to operate.

Owner:北京盈电电气有限公司

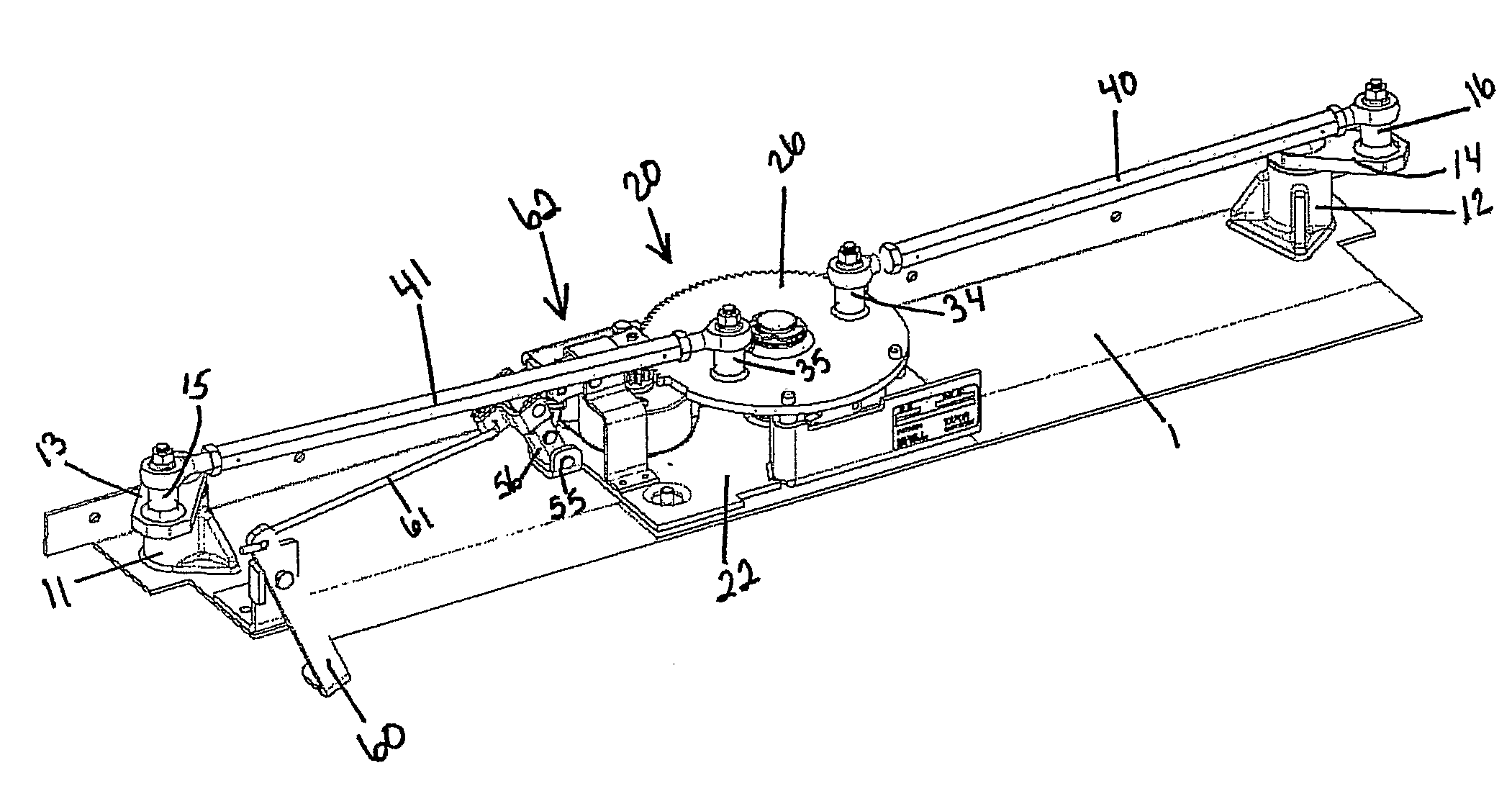

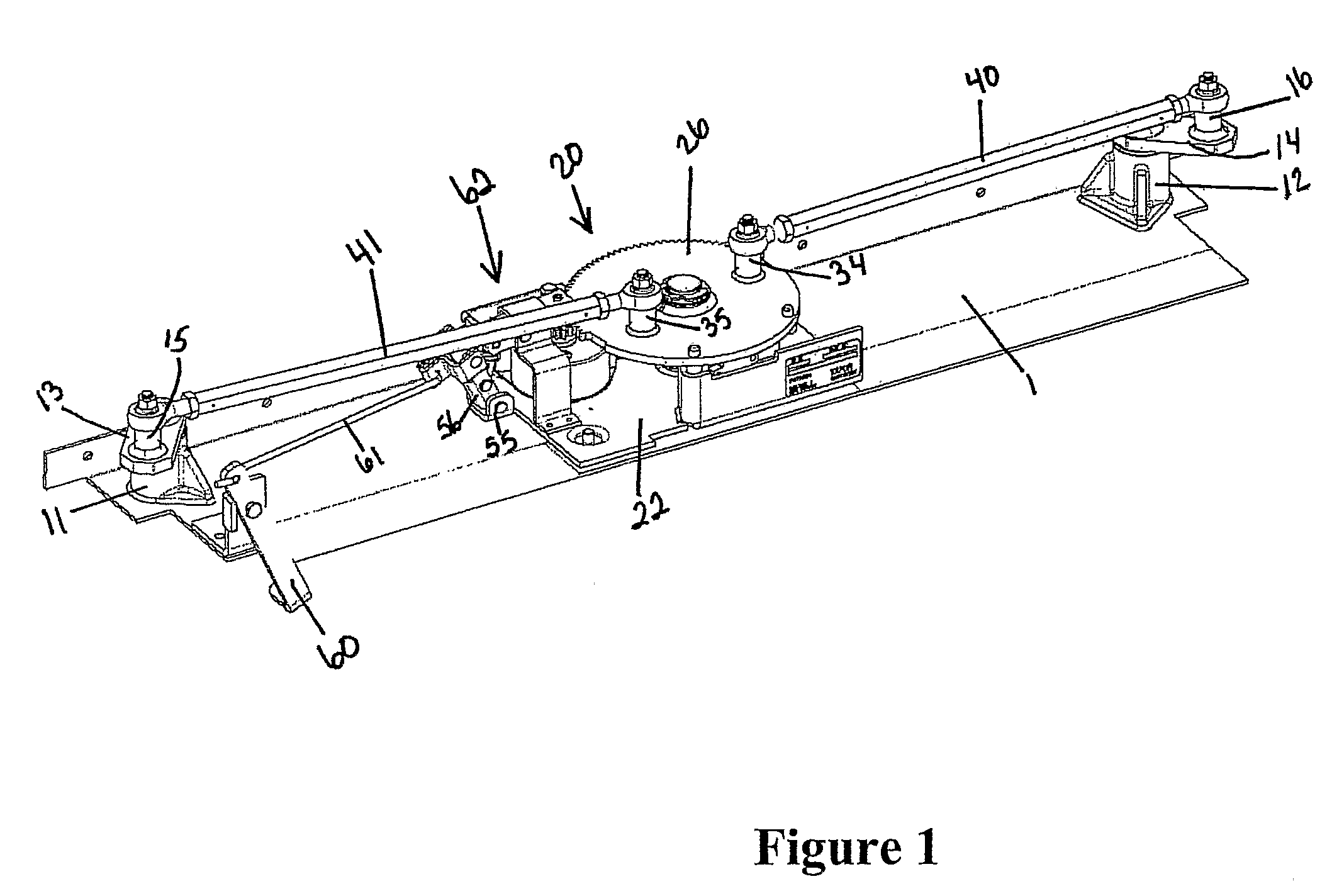

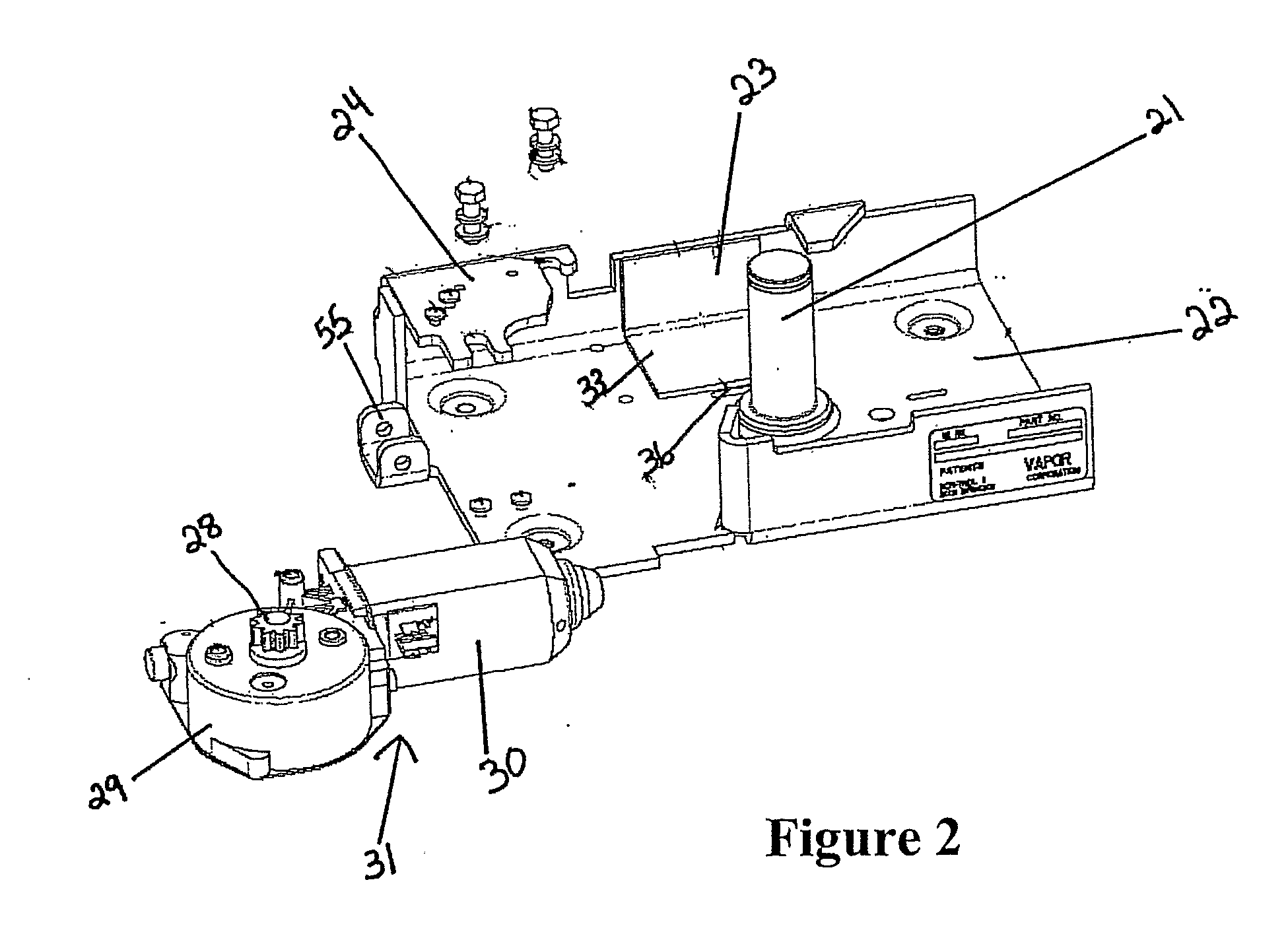

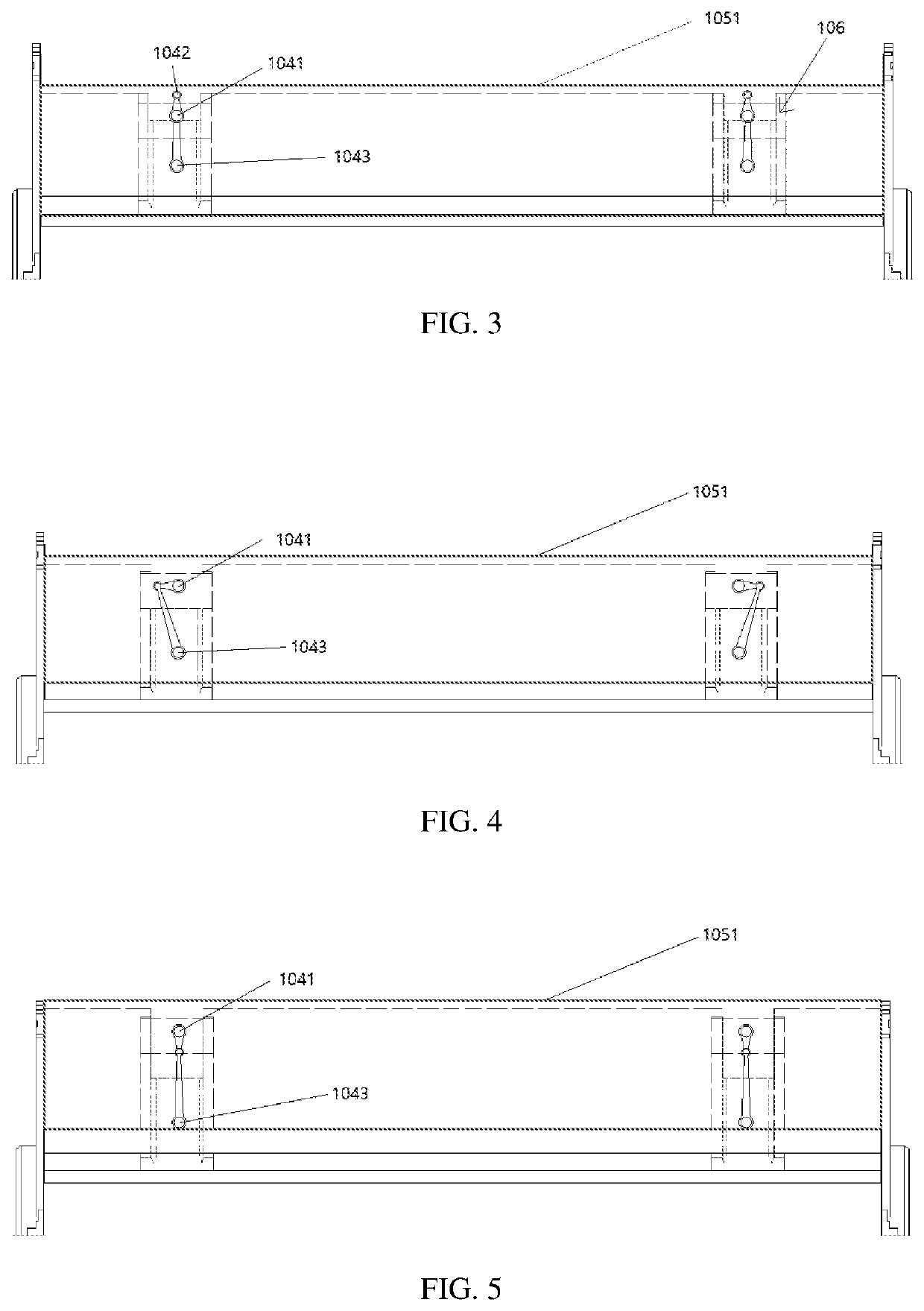

Electrically Driven Entryway Actuation System

InactiveUS20080196312A1Reduces inefficiencyReduce stress and strainWing fastenersPower-operated mechanismElectricityEngineering

An electrically driven entryway activation system for opening and closing two spaced swinging doors hung on spaced rotating parallel door posts comprises a base plate extending between the door posts. Levers attached to each door post rotate in a plane parallel to the base plate. A low profile actuation system spaced between the levers comprises a center post, a sector gear journaled on the center post for rotation parallel to the base plate, and a low profile gearmotor mounted between the base plate and the sector gear. A low profile emergency manual mechanism is provided for unclutching the output pinion gear of the gearmotor.

Owner:WABTEC HLDG CORP

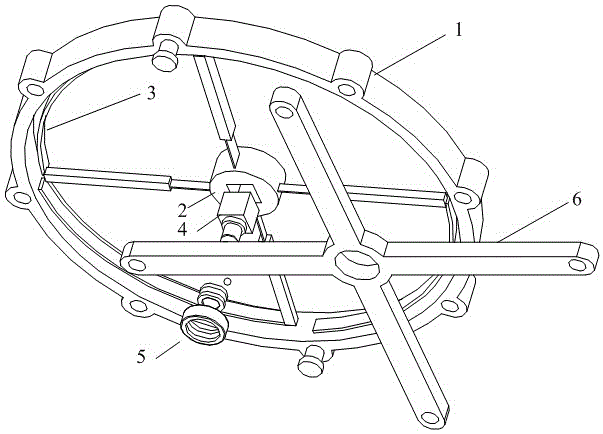

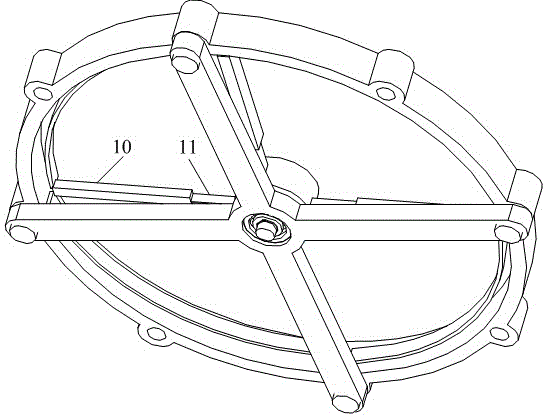

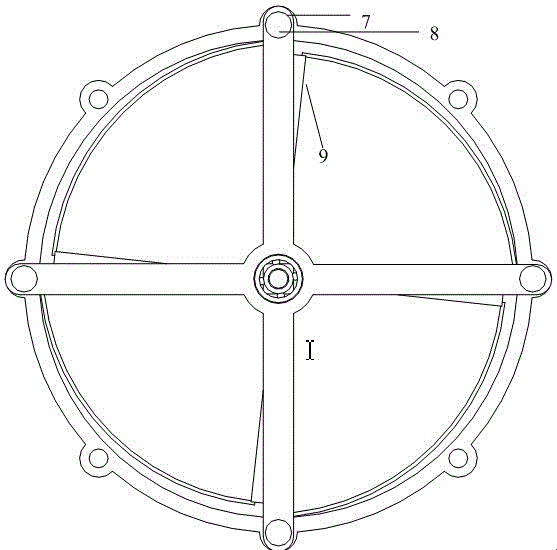

Large-travel flexible rotary hinge based on four-link mechanisms

ActiveCN106224480AIncrease the range of motionReduce stress and strainShaftsGearingHinge angleEngineering

A flexible rotary hinge based on four-link mechanisms is formed in such a way that an inner ring and an outer ring are connected with each other through the uniformly distributed four-link mechanisms and are connected with an outer ring support frame. In each four-link mechanism, one end of each side link is connected with the inner wall of the outer ring, the other ends of the side links are connected with rigid links, and the other ends of the rigid links are connected with the inner ring, so that a four-link rotation magnification structure is formed. The flexible rotary hinge provided by the invention is a flexible rotary hinge based on driving of the four-link rotation magnification mechanisms, has the characteristics of large travel and high precision and is suitable for a large-travel precise control mechanism.

Owner:TAIYUAN UNIV OF TECH

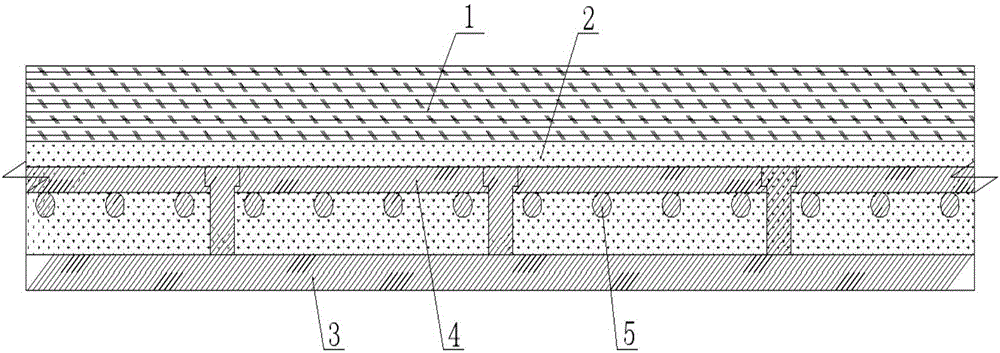

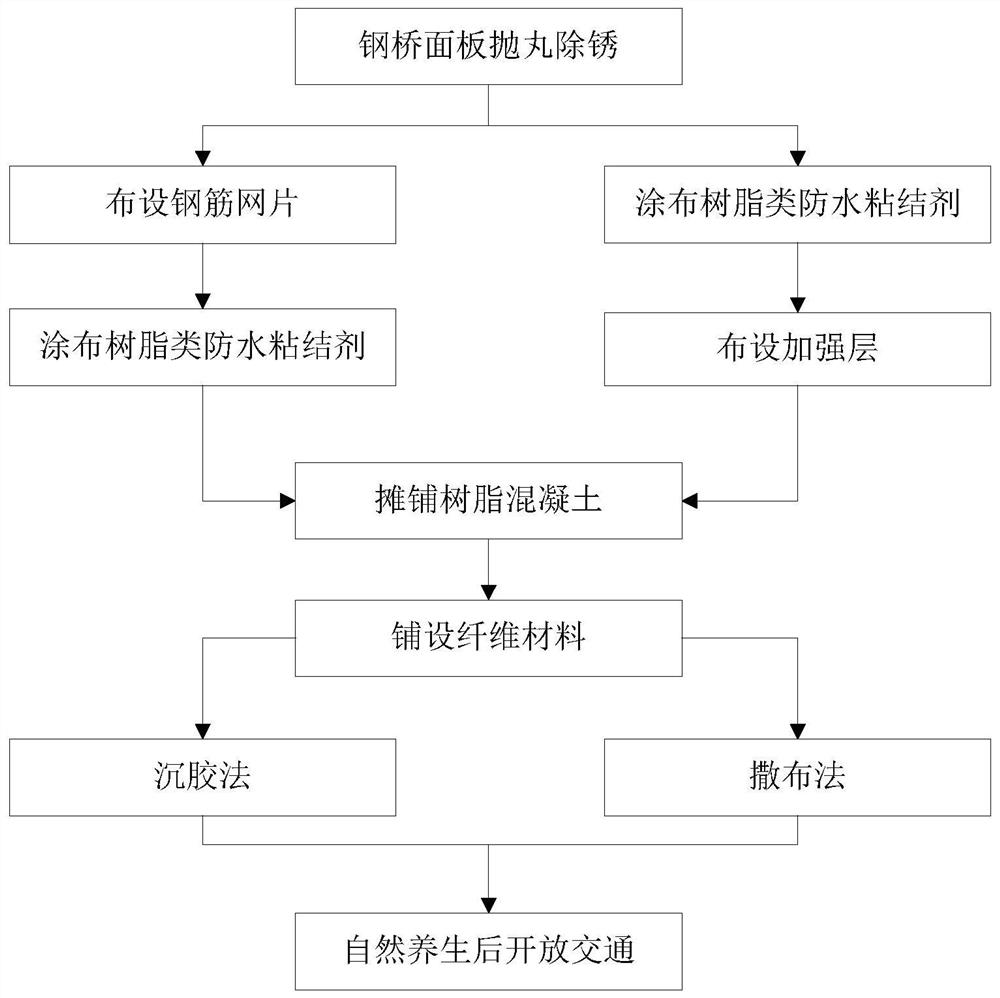

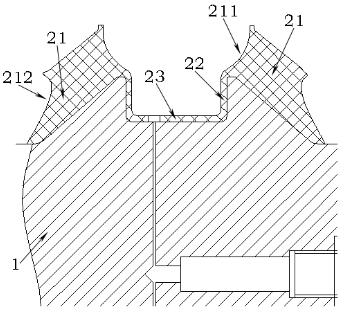

Reinforcing method of orthotropic steel box girder bridge deck slab

InactiveCN106758878AIncreased bending stiffnessReduce stress and strainBridge erection/assemblyBridge strengtheningRebarFlexural rigidity

The invention relates to a reinforcing method of an orthotropic steel box girder bridge deck slab. The reinforcing method is characterized by including the following operation steps that (1) derusting is performed; (2) a steel box girder top plate is detected; (3) an anti-corrosion layer is sprayed; (4) shear nails are welded; (5) a reinforcing mesh is mounted; (6) a high-tenacity concrete layer is poured; (7) high-temperature steam curing is performed; (8) coating with a water-proof bonding layer is performed; and (9) an asphalt layer is laid. The reinforcing method of the orthotropic steel box girder bridge deck slab is scientific and reasonable in design; the flexural rigidity of the orthotropic steel box girder bridge deck slab is improved, the stress strain of the orthotropic steel box girder bridge deck slab is effectively reduced, and the cracking risk is reduced; and the stability of the whole structure is improved, the cooperative stress of the whole structure after reinforcing is ensured, and the driving comfort and the braking performance are improved.

Owner:天津市交通科学研究院

Multi-mold cold-rotary-swaging and cold-drawing machining method for AgSnO2 wire rods

ActiveCN107052075AReduce stress and strainReduce stress gradientMetal-working apparatusProduction rateSwaging

The invention relates to a machining technology for an electric-contact composite material, and aims to provide a multi-mold cold-rotary-swaging and cold-drawing machining method for AgSnO2 wire rods. The method comprises the steps of carrying out annealing treatment on raw materials of the AgSnO2 wire rods, then placing the raw materials of the AgSnO2 wire rods in a pay-off spool and continuously feeding the raw materials of the AgSnO2 wire rods into a rotary swaging mold for rotary swaging treatment; repeating the operation twice, and replacing the rotary swaging mold with a slightly smaller rotary swaging mold; coiling wires and then carrying out annealing and acid-pickling treatment; carrying out cold-drawing machining by using a wire drawing mold with the first deformation amount less than 10% and selecting the wires with the diameter 0.05-0.1mm greater than the diameter of finished products to be machined for softening annealing and acid-pickling treatment; and selecting a wire drawing machining mold matched with the specification of the finished products for wire drawing treatment and cleaning the wires obtained from by wire drawing with an ethanol solution. According to the method, a cold machining technology combining rotary swaging and drawing is provided, the machining advantages of low stress strain and small stress gradient of rotary forging machining are utilized, and therefore the machining purposes that other technologies, such as extruding, rolling and drawing are difficult to complete can be achieved. The technological method is simple to operate and high in productivity and product yield.

Owner:ZHEJIANG UNIV

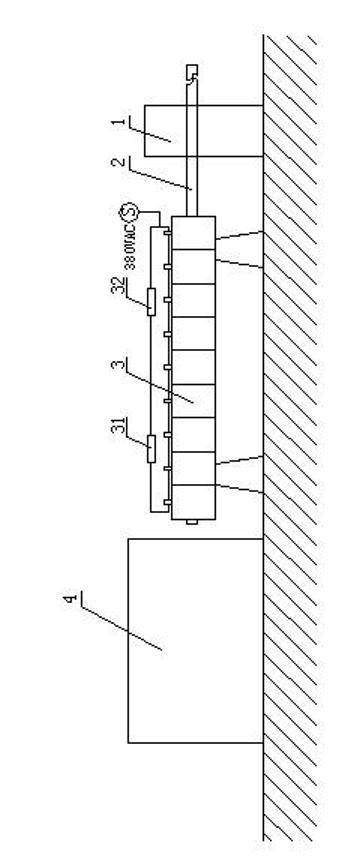

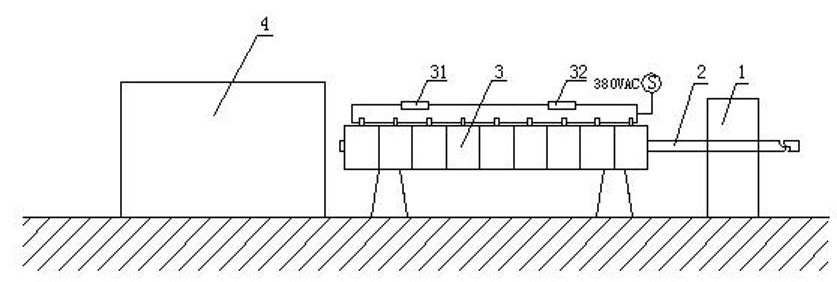

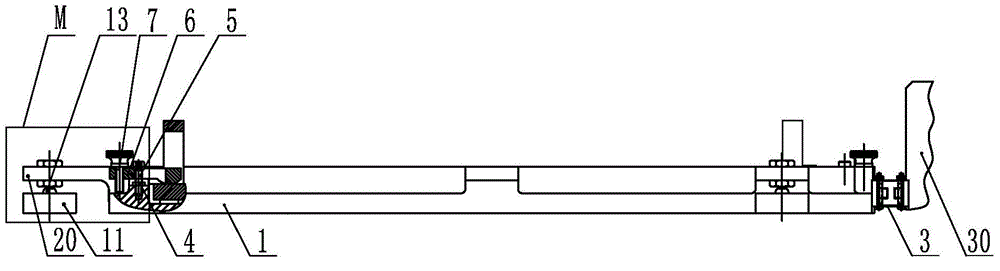

Armored cable preheated-type cold rotary forging device and forging method thereof

ActiveCN102314973ASmall amount of reboundReduce stress and strainCable/conductor manufactureEngineeringElectric cables

The invention discloses an armored cable preheated-type cold rotary forging device and a forging method thereof. The forging device comprises a reducing rotary forging machine which is provided with a clamping and feeding device; a cylindrical temperature controllable heater is arranged between a host machine of the reducing rotary forging machine and the clamping and feeding device. The method for carrying out armored cable preheated-type cold rotary forging by utilizing the armored cable preheated-type cold rotary forging device comprises the following steps of: a) straightening; b) clamping; c) feeding; d) heating; and e) rotary forging. According to the invention, the springback quantity of materials in the rotary forging process can be reduced obviously; and by preheating a work piece continuously in the rotary forging process, the stress strain of a work piece inner region is reduced and the plastic deformation capability of work piece materials is improved. A result shows that when the armored cable rotary forging is carried out by adopting the rotary forging technology, the springback quantity of the materials is reduced by 50% in the rotary forging process, the finishing size of the rotary forging piece is ensured, and the tolerance grade of the rotary forging piece is improved effectively.

Owner:CHONGQING MATERIALS RES INST

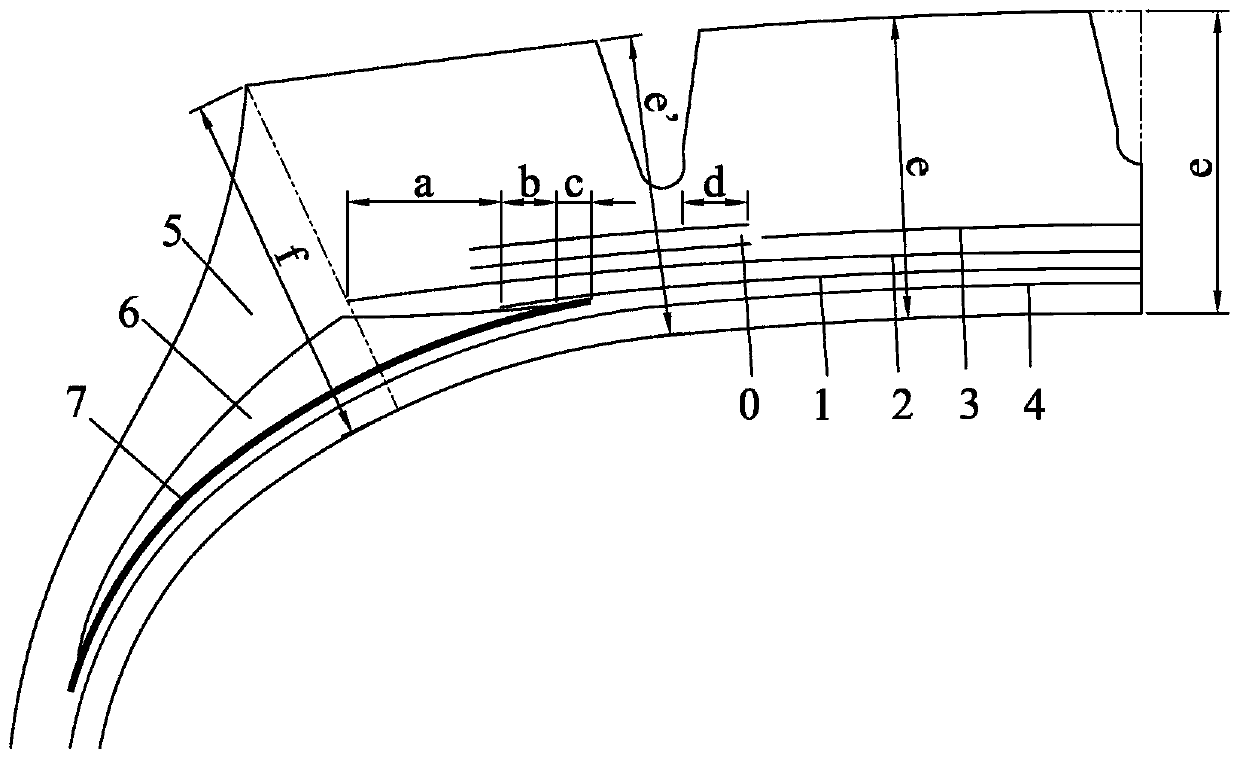

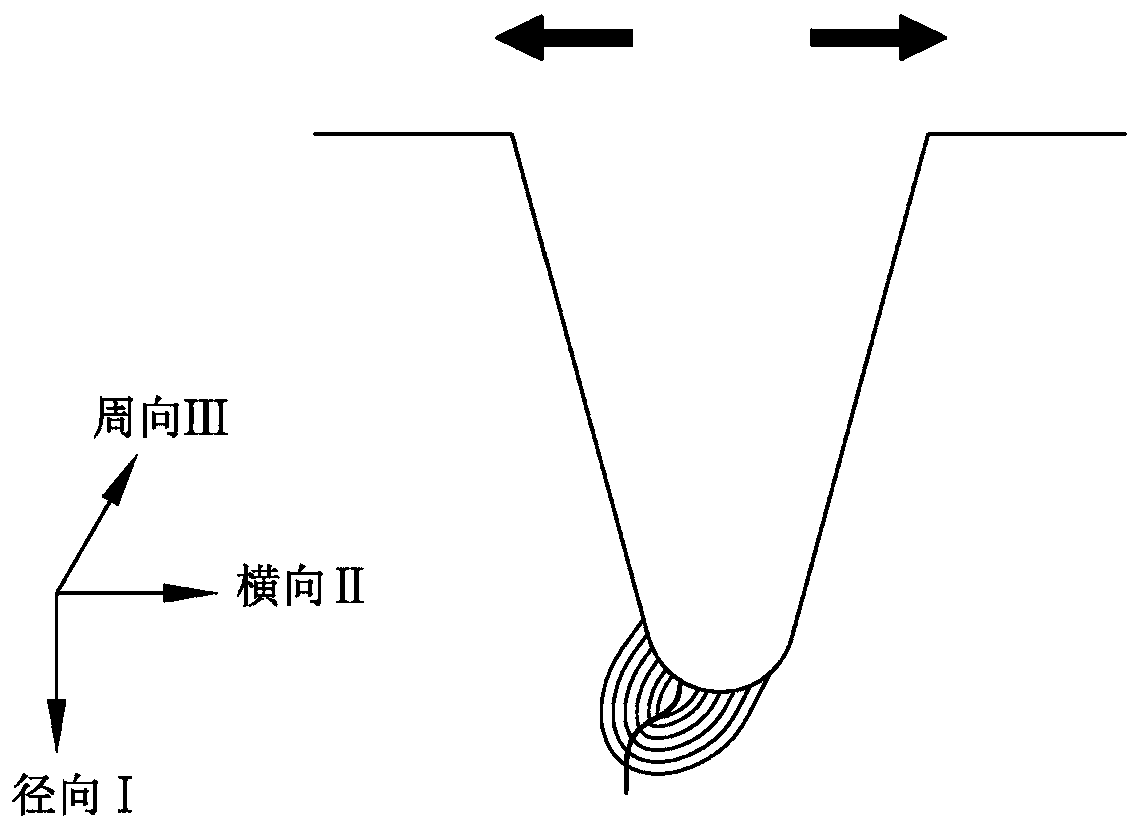

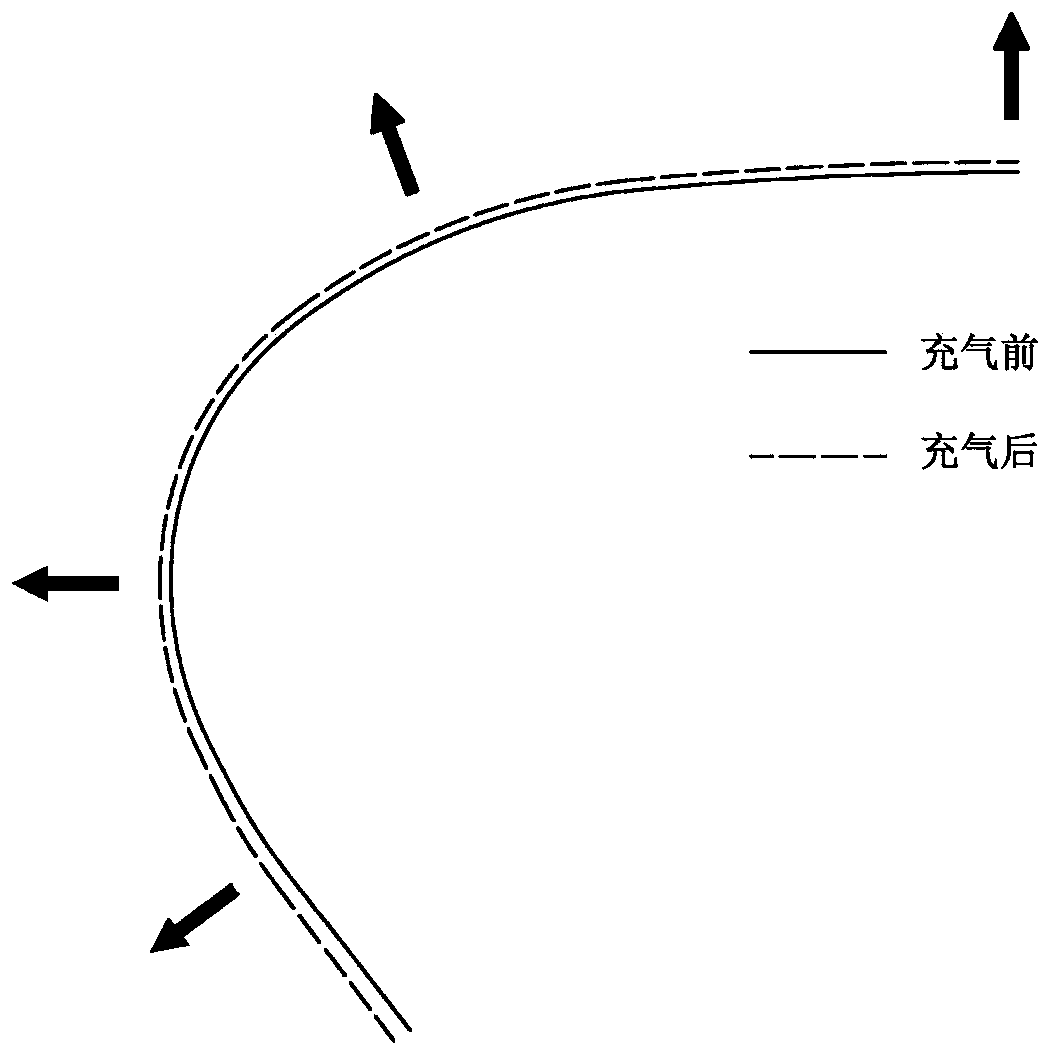

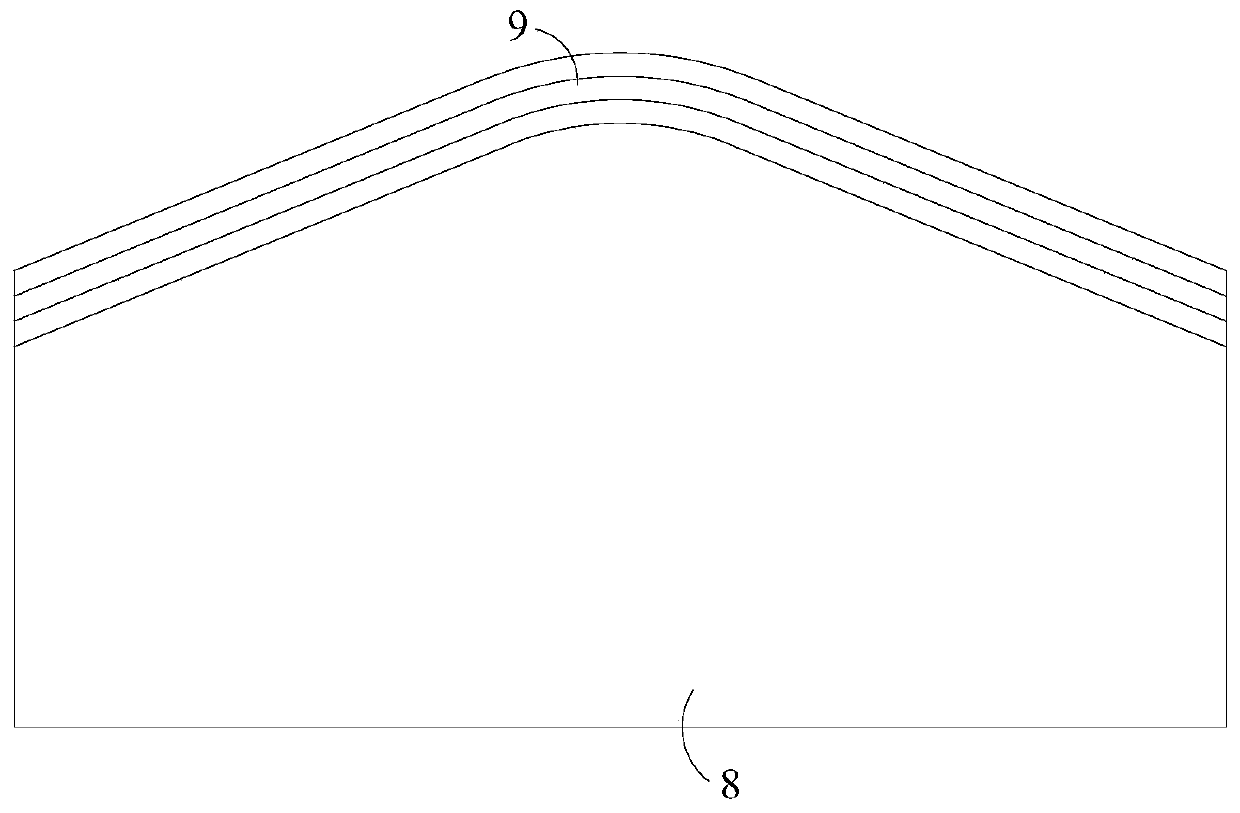

Truck tyre with groove bottom crack resistance

PendingCN110588248AReduce distortionReduce stress and strainPneumatic tyre reinforcementsEngineeringCrack resistance

The invention relates to a truck tyre, in particular to a truck tyre with groove bottom crack resistance. According to the truck tyre with groove bottom crack resistance, a tyre crown part of the tyrecomprises a tread, a first belted layer, a second belted layer, a third belted layer, two zero-degree belted layers, a tyre body and a rubber tyre shoulder pad; at least three pattern grooves are formed on the surface of the tread; the tyre shoulder pad is arranged between the belted layers and the tyre body; the tyre crown part also comprises a tyre body rubber sheet; the tyre body rubber sheetis arranged between the tyre body and the rubber tyre shoulder pad; the distance b between the endpoint of the first belted layer and the inner endpoint of the rubber tyre shoulder pad is 5 to 10 mm;the distance c between the inner endpoint of the rubber tyre shoulder pad and the endpoint of the tyre body rubber sheet is 5 to 10 mm; the edge covering rubber of the first belted layer is 24 to 28 mm in width and 0.5 to 0.8 mm in thickness; and the tyre body rubber sheet is 100 to 110 mm in width and 0.5 to 0.8 mm in thickness. From the angle of the tyre structure design, the tear resistance ofthe tyre groove bottom is improved and the service life of the tyre is prolonged.

Owner:ZHONGCE RUBBER GRP CO LTD

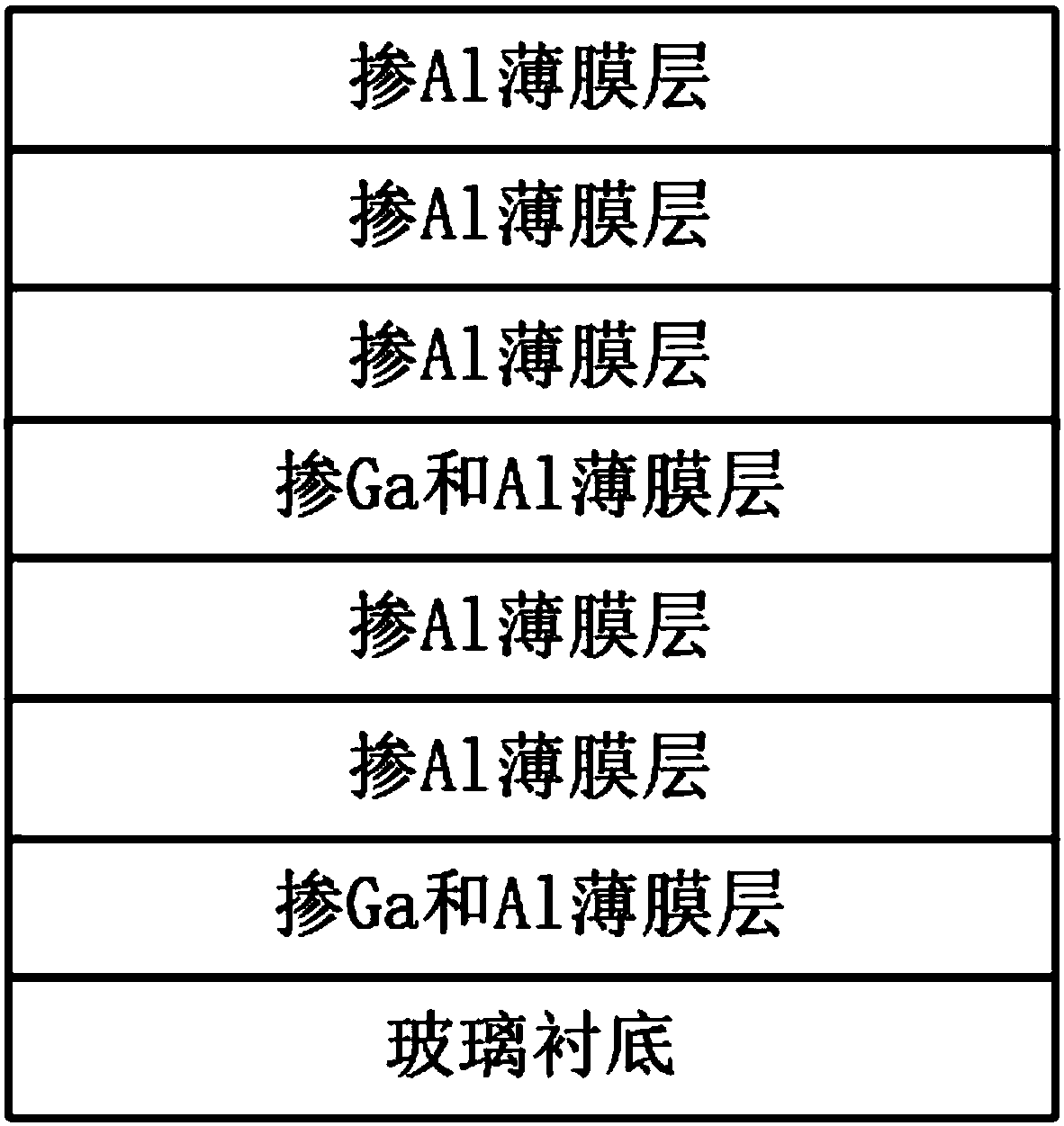

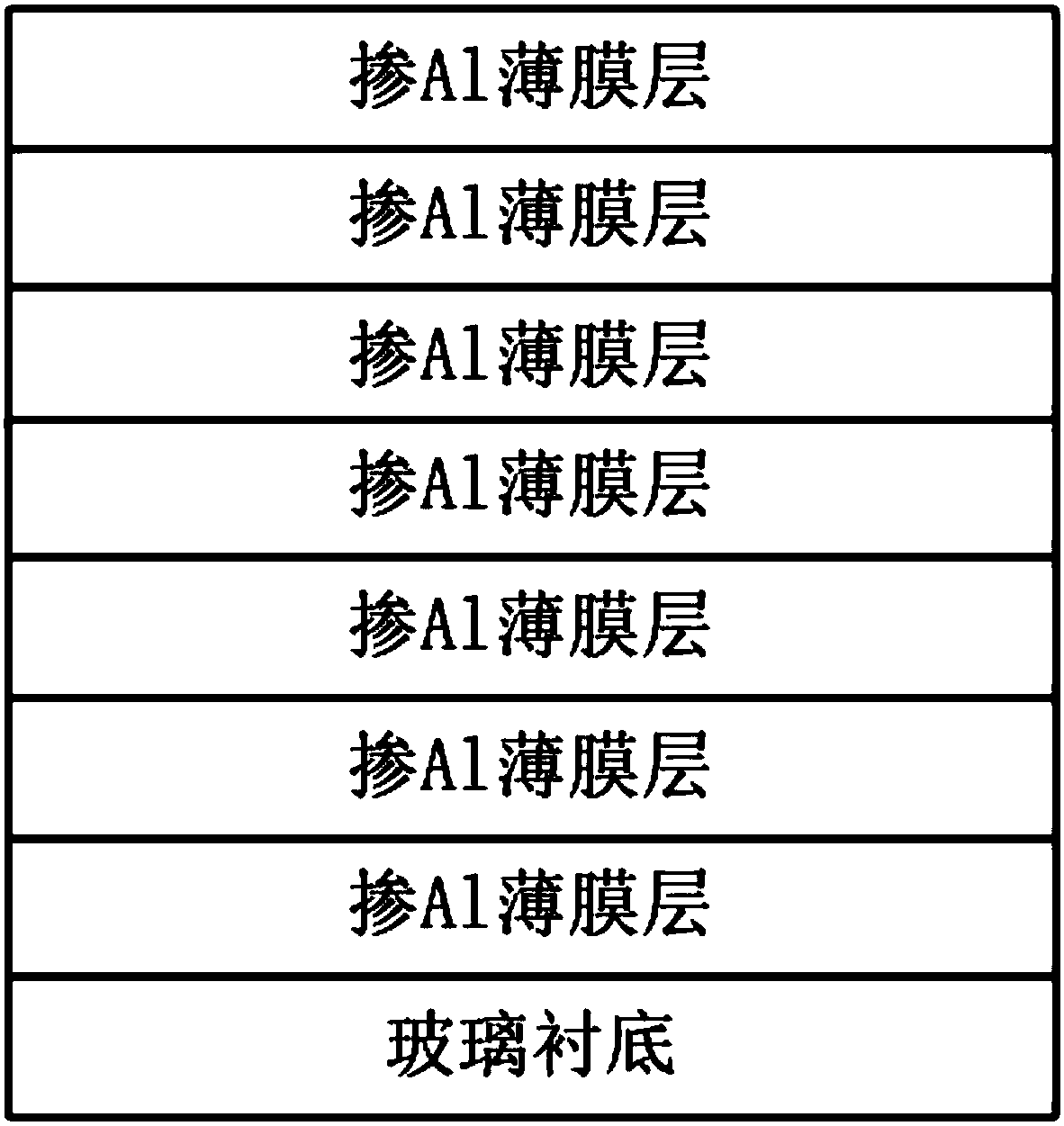

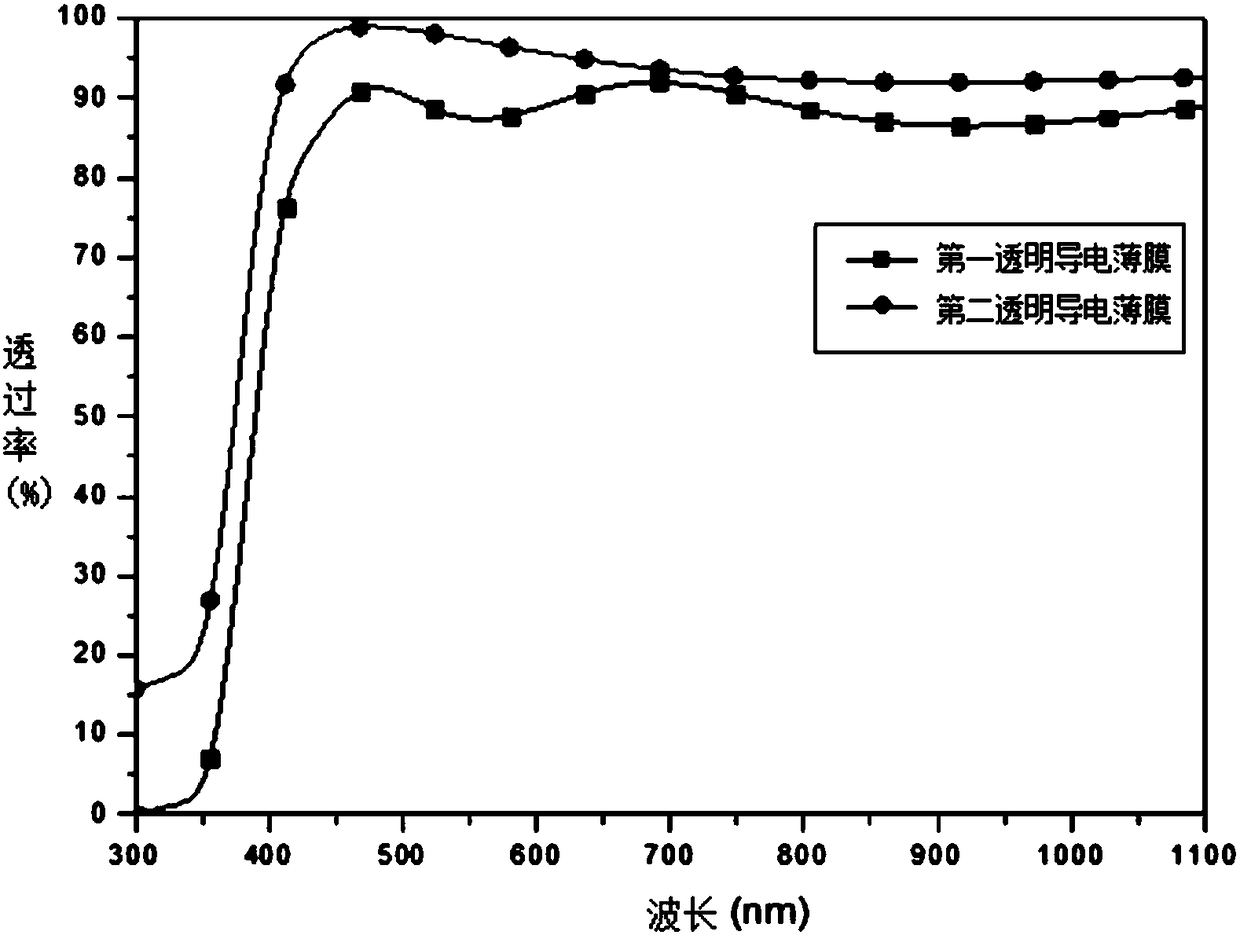

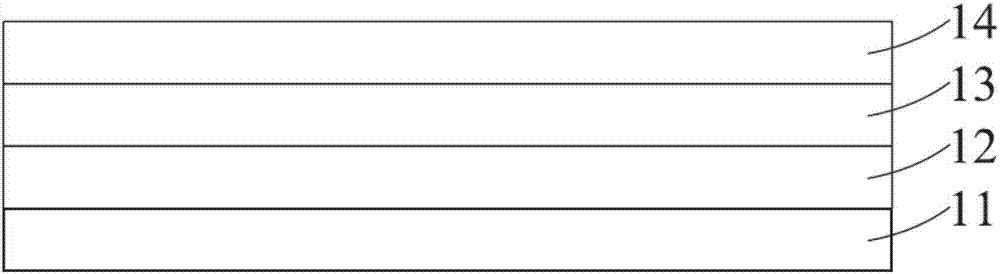

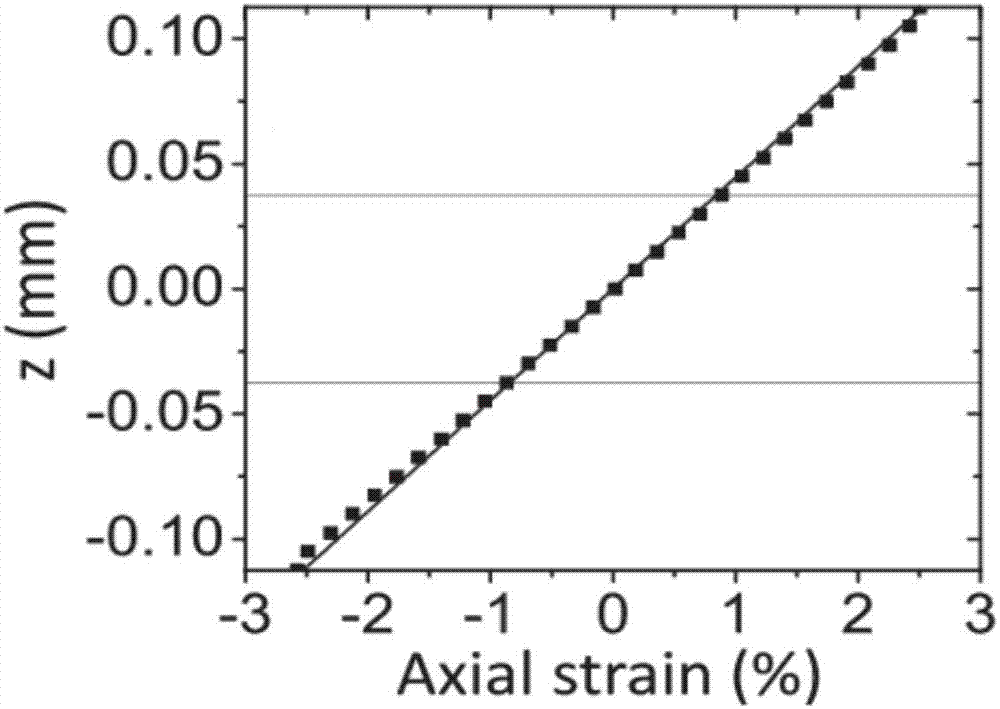

Preparation method of aluminum-doped zinc oxide transparent conductive film

ActiveCN108374162AImprove photoelectric performanceReduce mismatch effectsLiquid/solution decomposition chemical coatingLattice mismatchAluminum doped zinc oxide

The invention particularly relates to a preparation method of an aluminum-doped zinc oxide transparent conductive film. Compared with the prior art, Ga-doped sol A is not prone to acting with components in air during heat treatment so that the sol A can grow a transparent and uniform thin film layer on a substrate as a buffer layer of an aluminum-doped zinc oxide thin film layer, the transparencyis high, and in the thin film doped with Ga, the lattice constant of crystal is closer to the lattice constant of wurtzite ZnO, thus the lattice mismatch effect is effectively reduced and a good lattice buffering effect is achieved, and the aluminum-doped zinc oxide transparent conductive film with better photoelectric performance is prepared.

Owner:SOUTH CHINA NORMAL UNIVERSITY

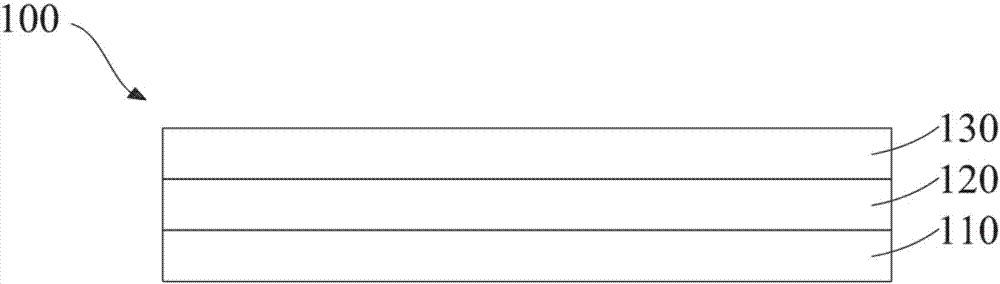

Packaging structure for packaging OLED device, and display device

InactiveCN107994131AReduce thicknessReduce stress and strainSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a packaging structure for packaging an OLED device. The packaging structure comprises a packaging unit. The packaging unit comprises an optical adhesive layer; an inorganic packaging layer arranged on the optical adhesive layer; and an organic packaging layer arranged on the inorganic packaging layer. According to the invention, the optical adhesive layer is introduced intothe packaging structure. The stress strain of the inorganic packaging layer during bending is reduced, so that the cracking risk of the inorganic packaging layer is reduced. In addition, compared with the prior art, the packaging structure provided by the invention saves a barrier layer on the outermost layer of the structure. Therefore, the thickness of the packaging structure can be reduced, and the equipment thinning development can be facilitated.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

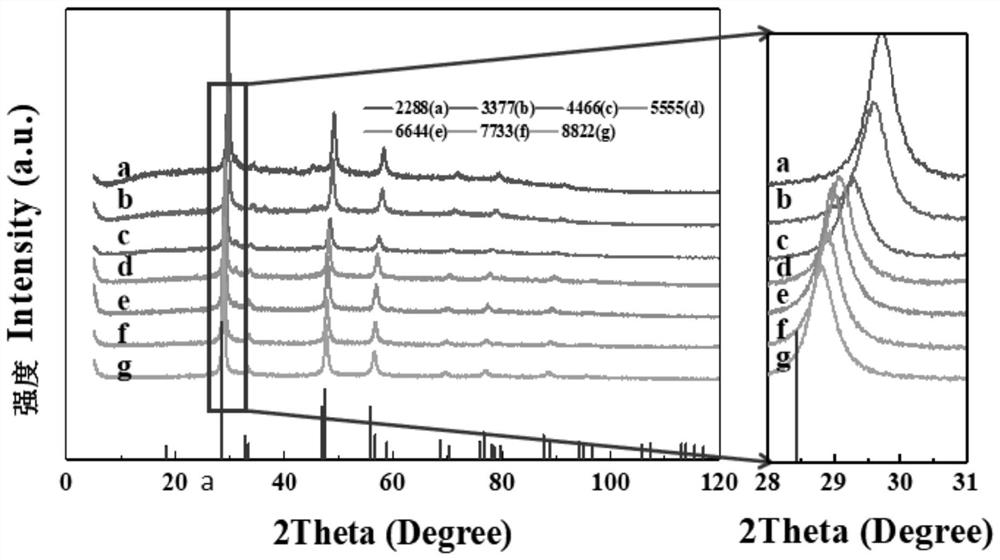

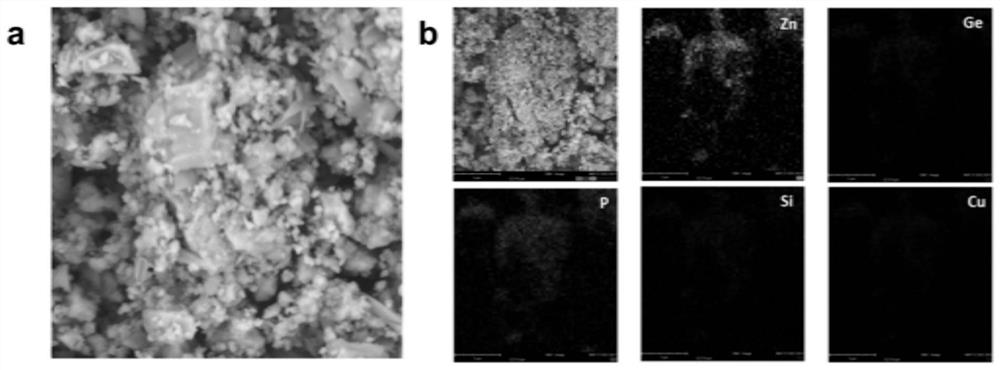

Zn-Ge-Cu-Si-P high-entropy alloy material used as negative electrode of lithium ion battery and preparation method for Zn-Ge-Cu-Si-P high-entropy alloy material

ActiveCN113846258ASimple processLow costNegative electrodesSecondary cellsP2 compoundHigh entropy alloys

The invention provides a Zn-Ge-Cu-Si-P high-entropy alloy material used as a negative electrode of a lithium ion battery and a preparation method for the Zn-Ge-Cu-Si-P high-entropy alloy material. The preparation method comprises the steps that zinc powder, germanium powder, copper powder, silicon powder and red phosphorus are weighed according to a target proportion with a molar ratio of the zinc powder to the germanium powder to the copper powder to the silicon powder to the red phosphorus being x: x: (1-x): (1-x): 2, and a high-entropy ZnxGexCu (1-x)Si (1-x)P2 compound formed by Zn, Ge, Cu, Si and P elements is obtained after ball milling, wherein x is larger than 0 and smaller than 1; and the high-entropy ZnxGexCu (1-x)Si (1-x)P2 compound is mixed with a carbon material, and ball milling is conducted to obtain a ZnxGexCu (1-x) Si (1-x) P2 / C composite. The material has the advantages of large specific discharge capacity, high initial coulombic efficiency, good reversibility, excellent electrochemical performance, low cost and the like.

Owner:HAINAN UNIVERSITY

Scroll compressor and air conditioner with same

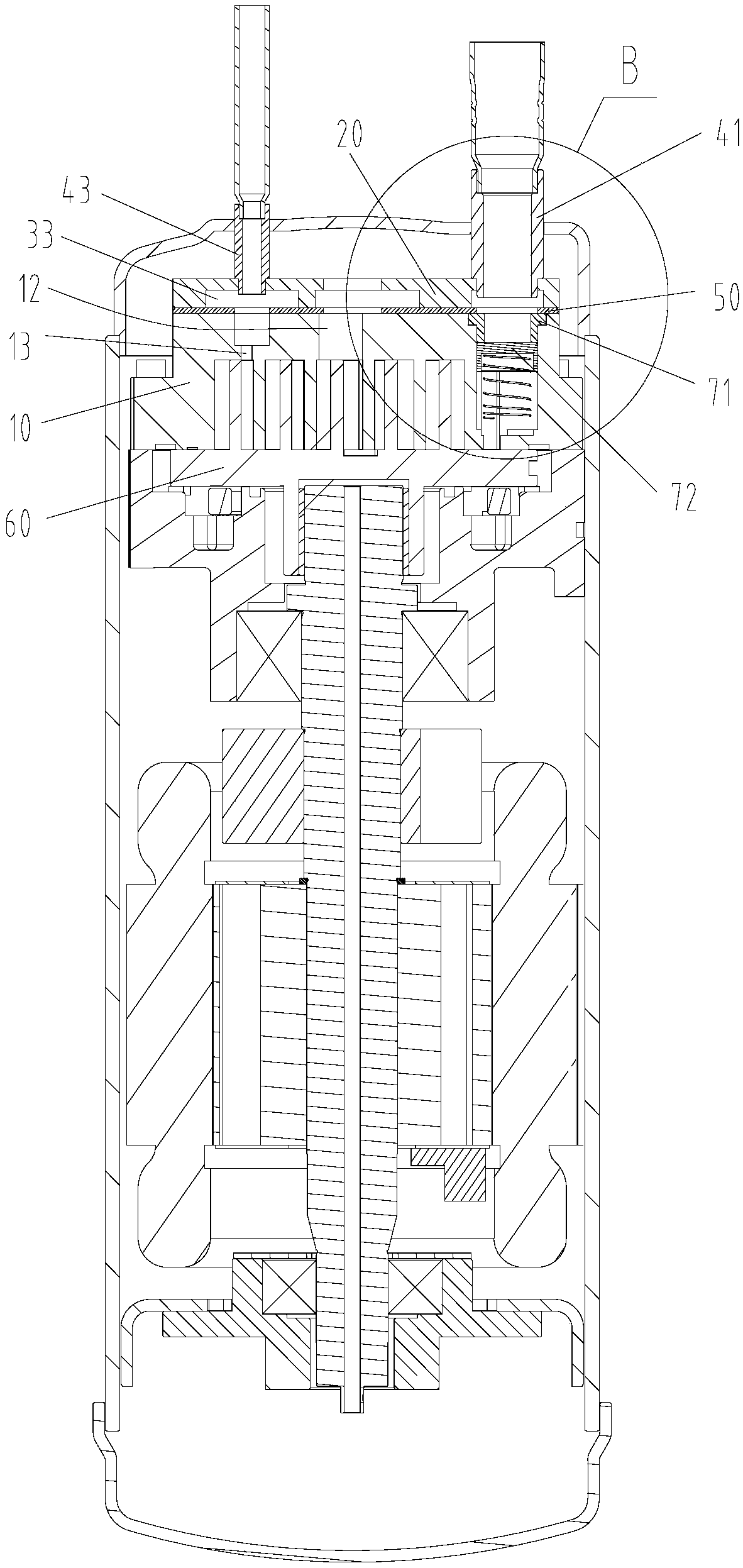

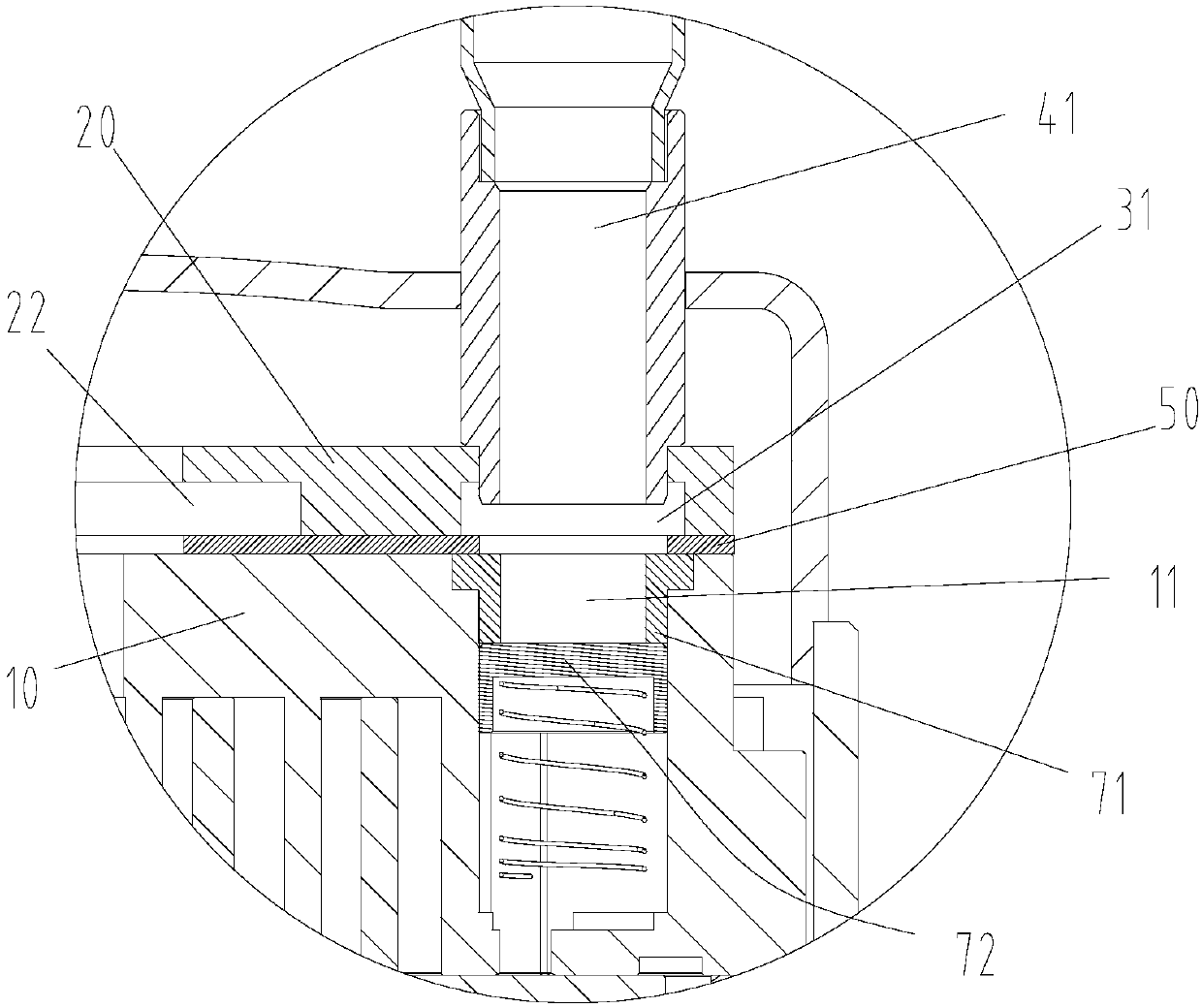

InactiveCN107893760AReduce vibrationReduce stress and strainRotary piston pumpsRotary piston liquid enginesEngineeringAir conditioning

The invention provides a scroll compressor and an air conditioner with the same. The scroll compressor comprises a static scroll disc, at least one pipeline piece and at least one vibration isolationstructure, wherein the at least one pipeline piece is connected with the static scroll disc through the vibration isolation structure. The scroll compressor effectively solves the problem of influenceon the reliability of an air conditioning system pipeline due to overproof stress strain of the air conditioning system pipeline caused by direct transfer of vibration of the static scroll disc to anair sucking pipe or an enthalpy adding pipe in the prior art.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

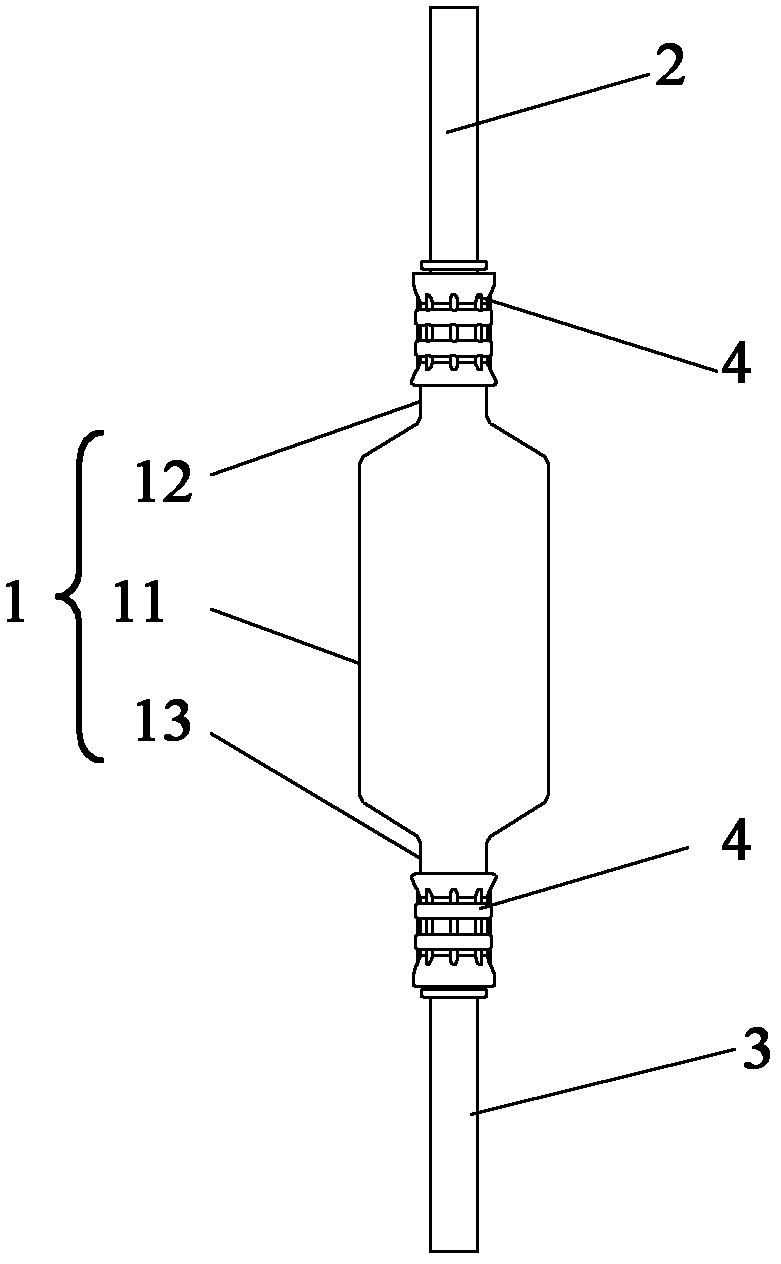

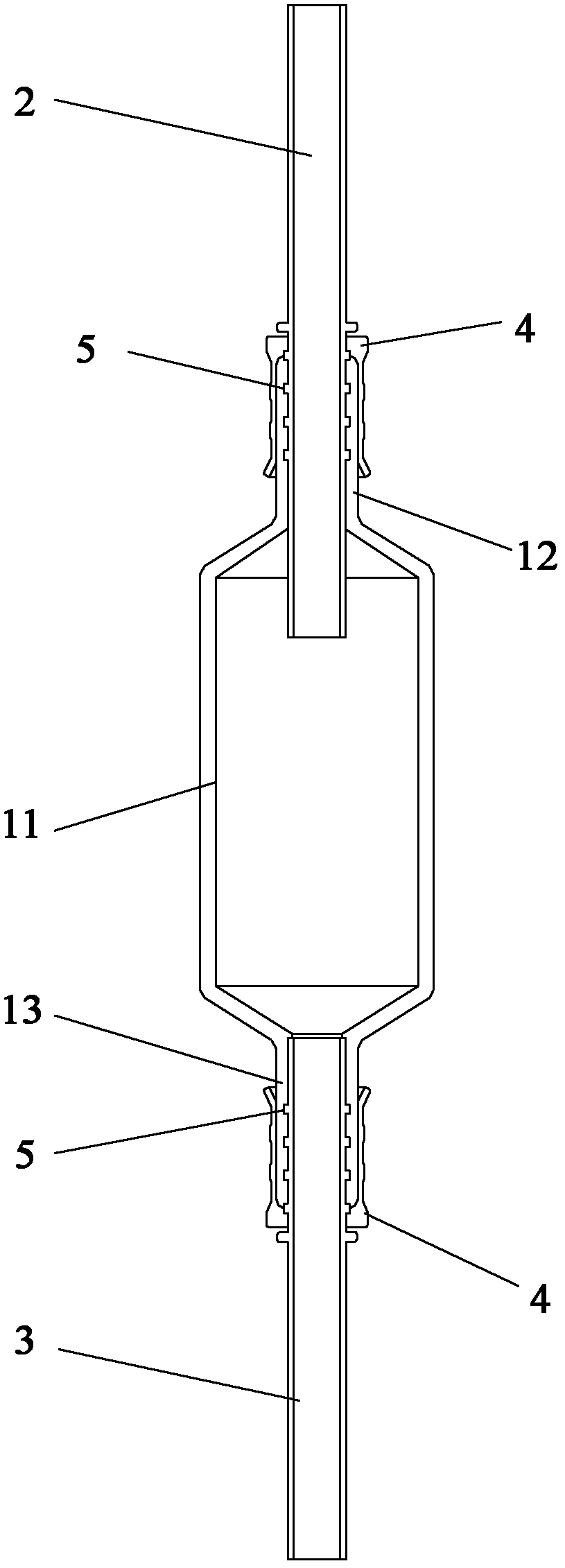

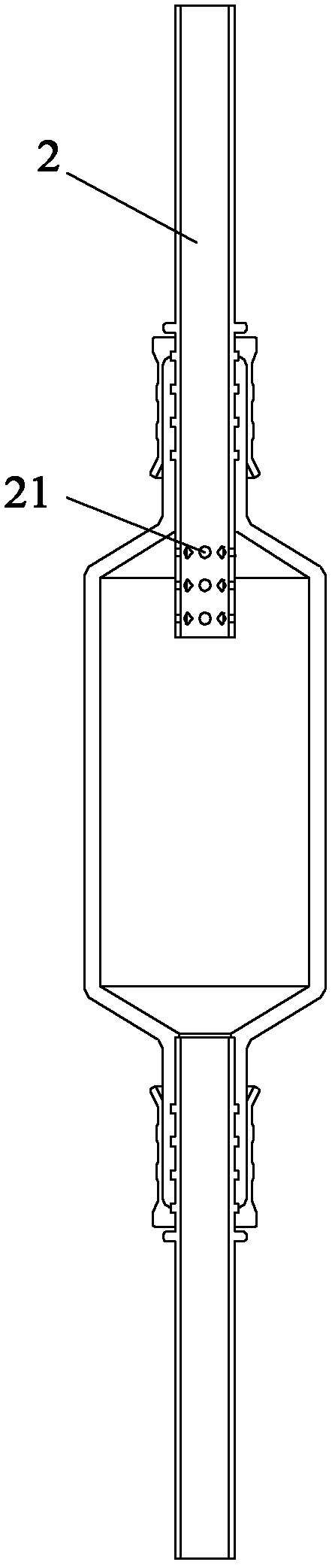

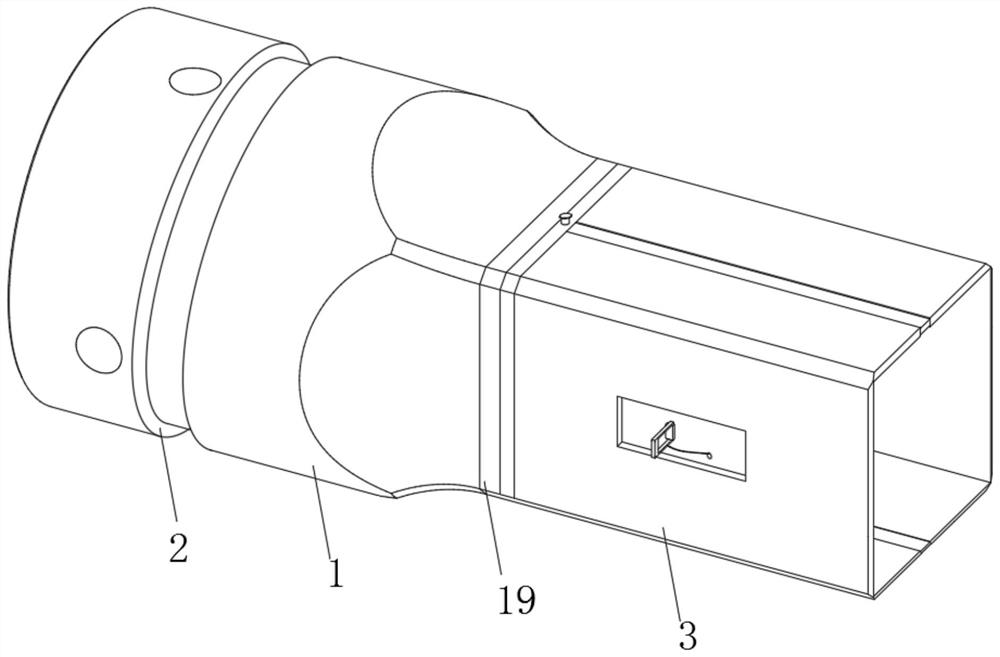

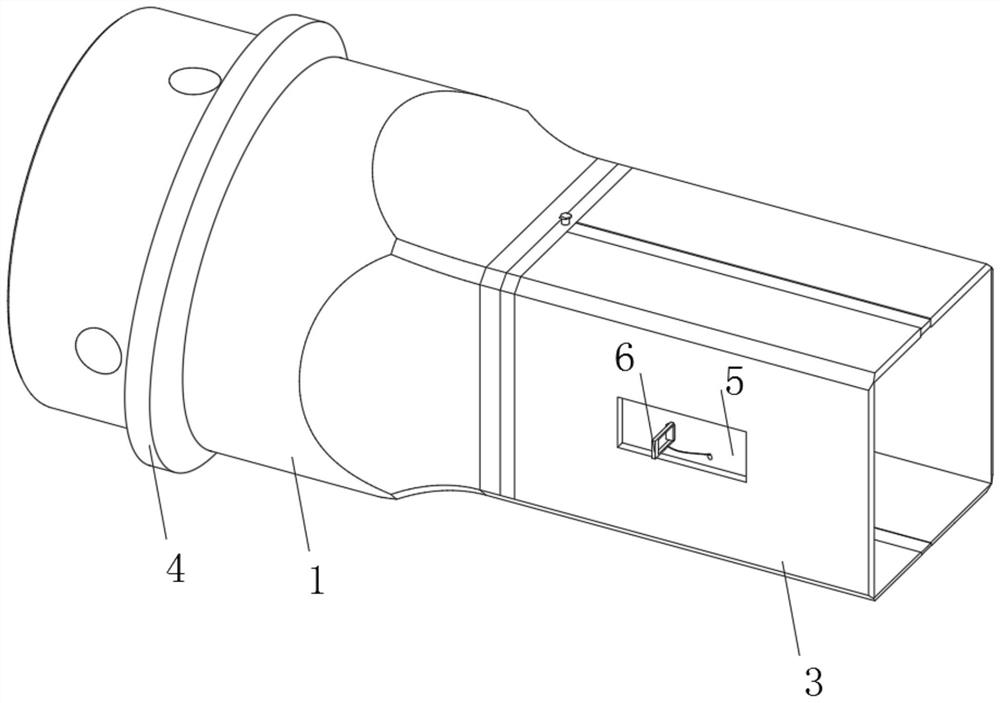

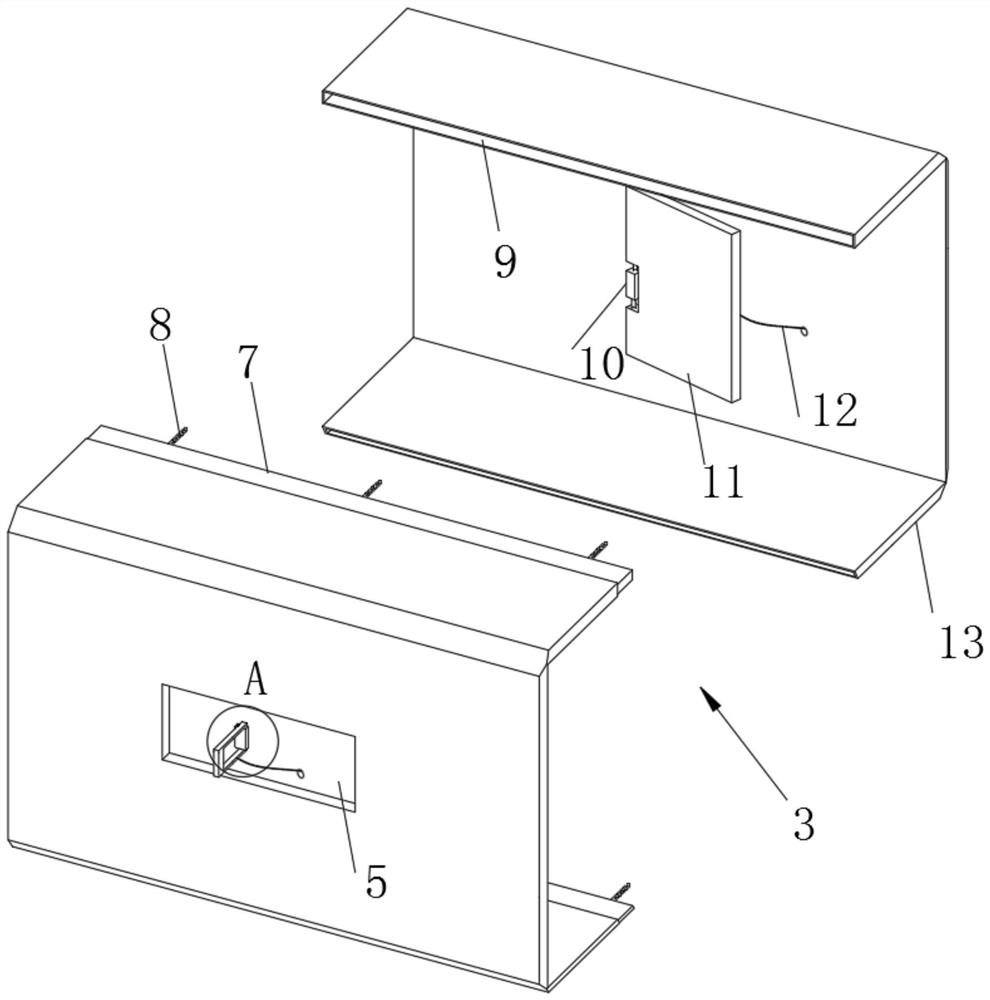

Silencer and air conditioner comprising same

The invention provides a silencer and an air conditioner comprising the same. The silencer comprises a barrel body, an air inlet connecting pipe and an air outlet connecting pipe, wherein the interior of the barrel body is wholly through, a barrel body part is arranged in the middle, an air inlet and an air outlet are formed in two ends respectively, and sectional areas of the air inlet and the air outlet are smaller than the sectional area of an inner cavity of the barrel body part; the sectional area of the air inlet connecting pipe is smaller than that of the inner cavity of the barrel body part, and the air inlet connecting pipe is connected with the air inlet; the sectional area of the air outlet connecting pipe is smaller than that of the inner cavity of the barrel body part, and the air outlet connecting pipe is connected with the air outlet; and the barrel body is made of an elastic material. According to the silencer and the air conditioner comprising the same, the elastic material such as composite rubber or plastic and the like is adopted to prepare the barrel body, so that not only is the cost reduced, but also the barrel body has great elasticity and a buffer performance, and then the silencer can perform an effect of eliminating noise, and can reduce stress strain of a pipeline and pipeline vibration of the device, as well as noise caused by vibration.

Owner:GREE ELECTRIC APPLIANCES INC

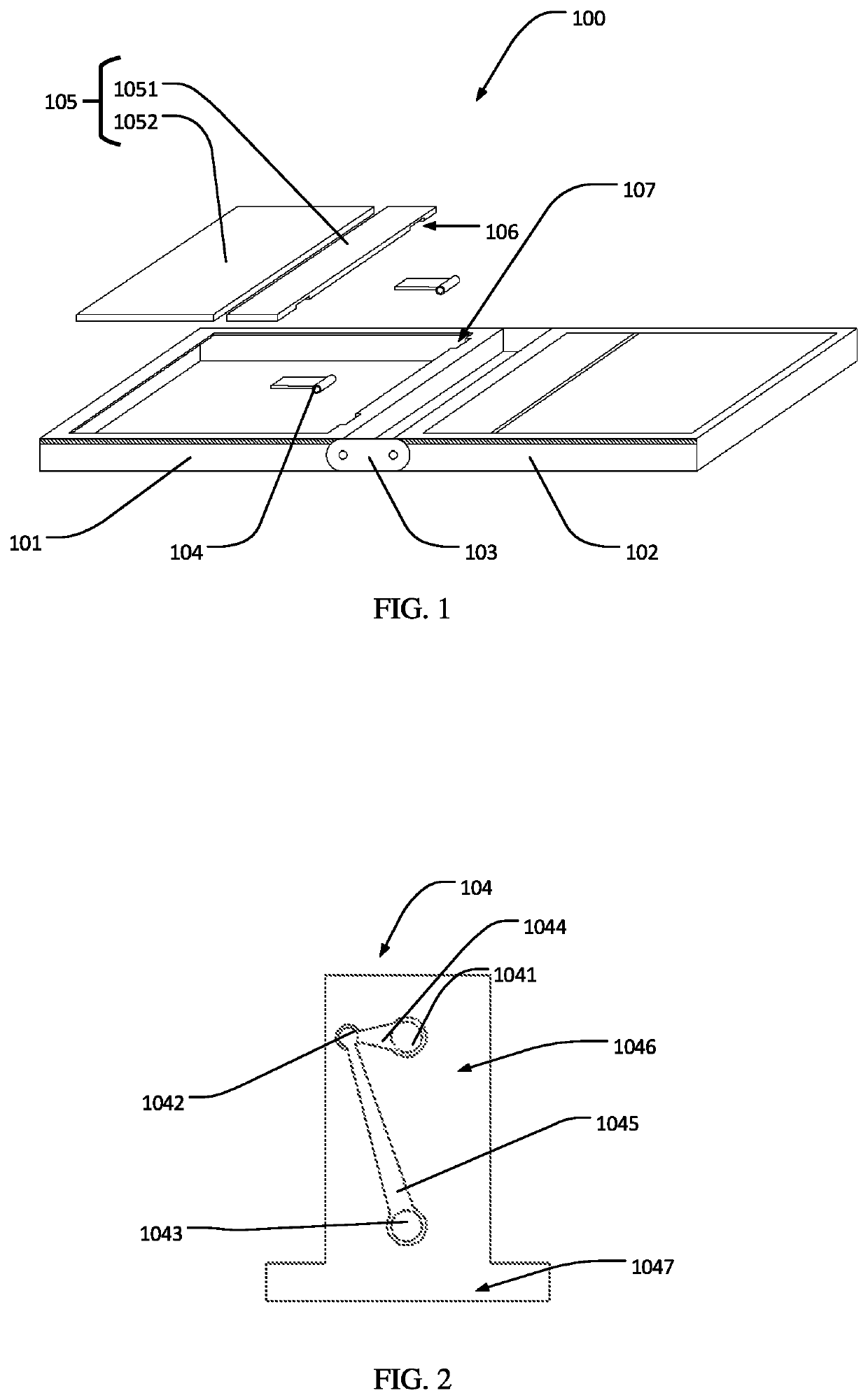

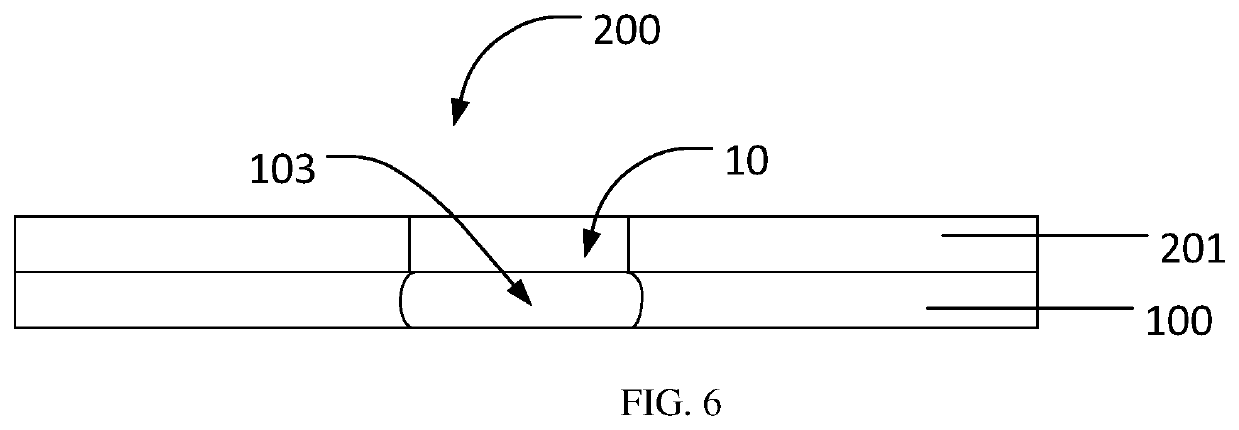

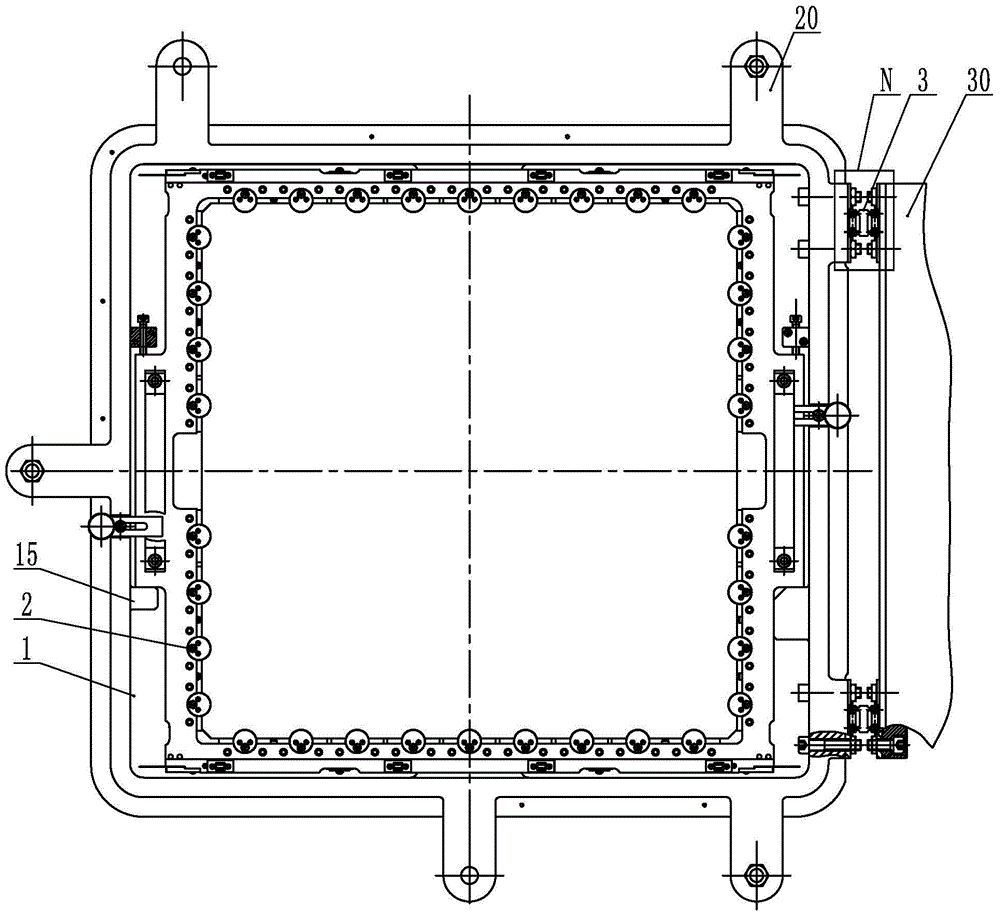

Flexible screen attaching jig and flexible screen attaching method

PendingCN111532009ASmall amount of deformationReduce stress and strainLamination ancillary operationsLaminationEngineeringMaterial resources

The invention relates to the technical field of flexible screens, and provides a flexible screen attaching jig and a flexible screen attaching method. The attaching jig comprises a carrying table, wherein the carrying table comprises a first attaching plate, a second attaching plate, an angle adjusting mechanism and a flattening plate assembly; the first attaching plate is provided with a first attaching surface; the second attaching plate is provided with a second attaching surface, and the second attaching surface and the first attaching surface are coplanar or form a preset included angle;the angle adjusting mechanism is connected between the first attaching plate and the second attaching plate; the flattening plate assembly is arranged on the first attaching face, the angle adjustingmechanism and the second attaching face. The angle adjusting mechanism is used for adjusting the included angle between the first attaching face and the second attaching face, so that the flattening plate assembly forms an arc face, and the radius and the arc length of the arc face are changed. By means of the attaching jig, the stress strain of the flexible screen in the limit state is reduced, arc surfaces with various radiuses and arc lengths can be formed when the flexible screen is attached through one attaching jig, frequent replacement of the attaching jig is not needed, and manpower and material resources are saved.

Owner:BOE TECH GRP CO LTD

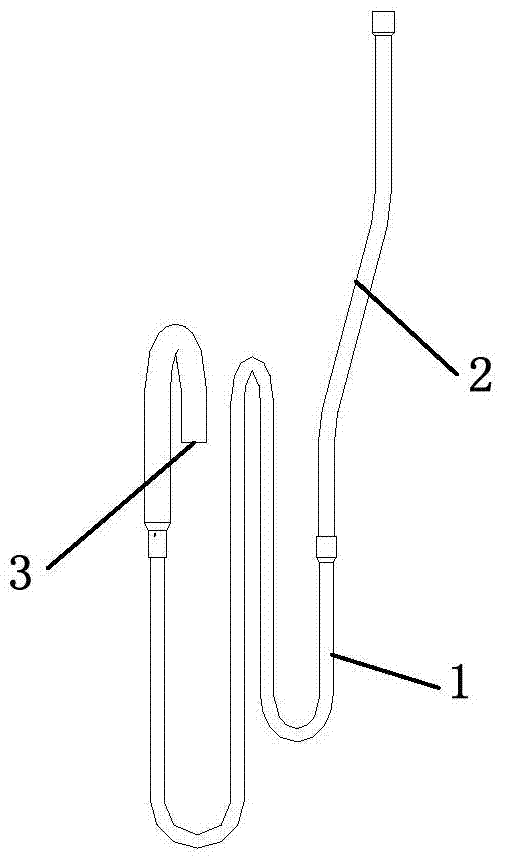

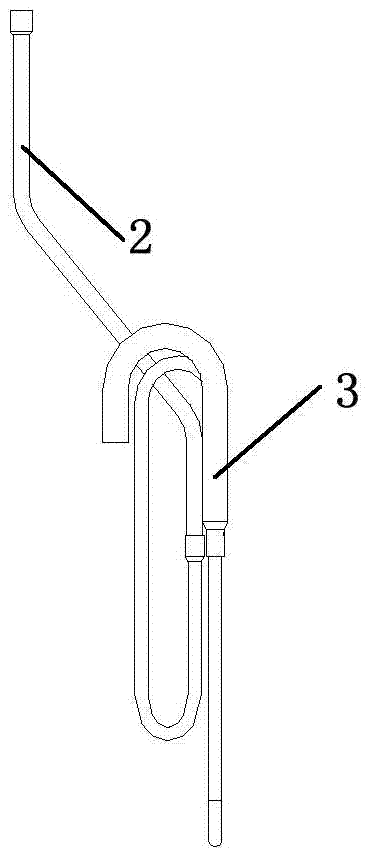

Auxiliary suction pipe, suction structure, household appliance and dehumidifier

ActiveCN104501379ASmall sizeReduce noiseDucting arrangementsLighting and heating apparatusEngineering

The invention discloses an auxiliary suction pipe, a suction structure, a household appliance and a dehumidifier for lowering noise produced by the auxiliary suction pipe and relates to the field of household appliances. The auxiliary suction pipe comprises a first suction pipe and a connecting pipe, one end of the connecting pipe is communicated with the other end of the first suction pipe, and the ratio between the outer diameter of the first suction pipe and the outer diameter of the connecting pipe is less than 63%. Different form the existing auxiliary suction pipe formed by pipes with the outer diameter more than 63% of the size of the connecting pipe, the auxiliary suction pipe applies the first suction pipe with small outer diameter, noise caused by vibration of the pipe is lowered by the aid of flexibility of the pipe, and noise of the complete appliance is lowered to the uttermost degree; meanwhile, pipe stress is released better, and stress-strain is lowered.

Owner:GREE ELECTRIC APPLIANCES INC

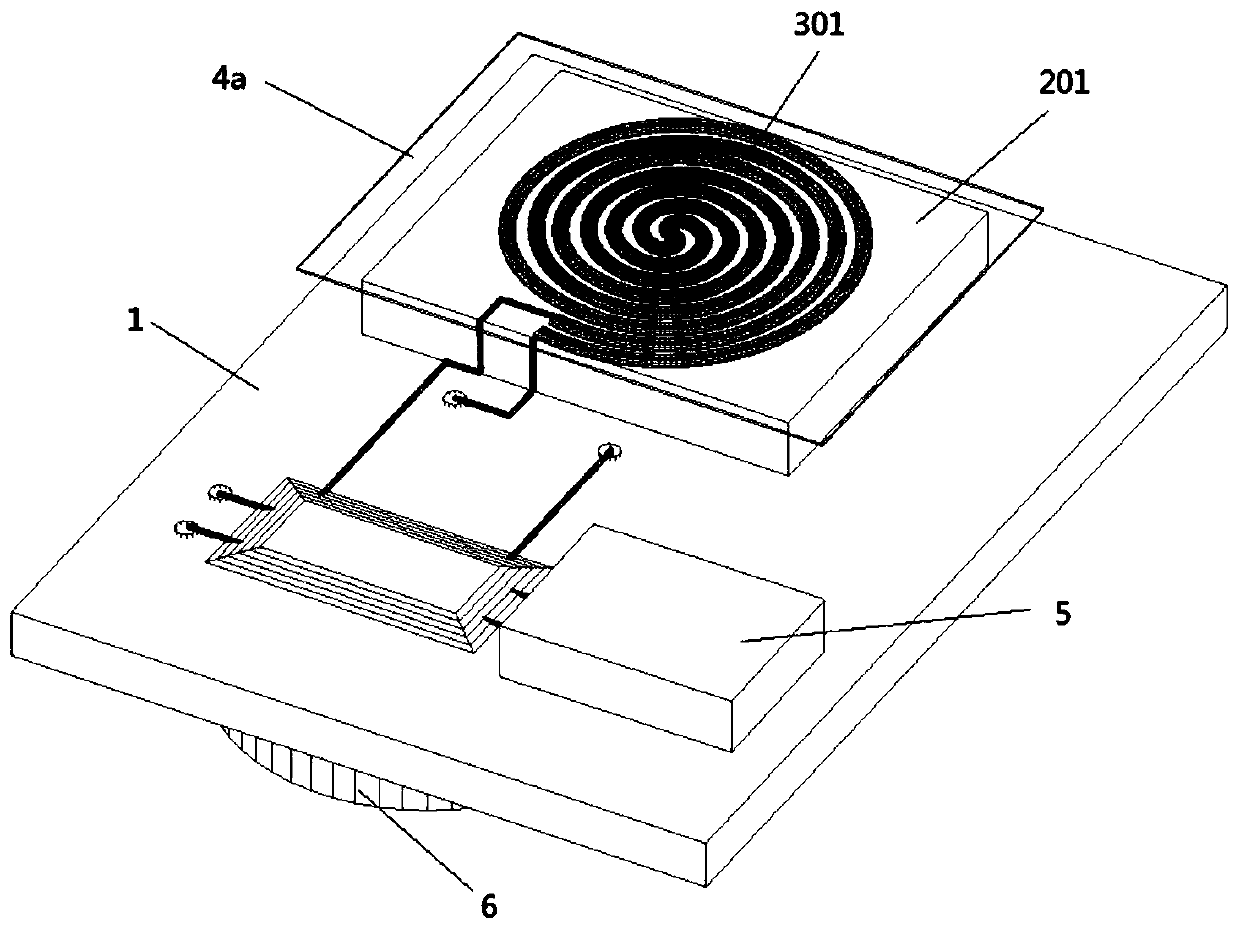

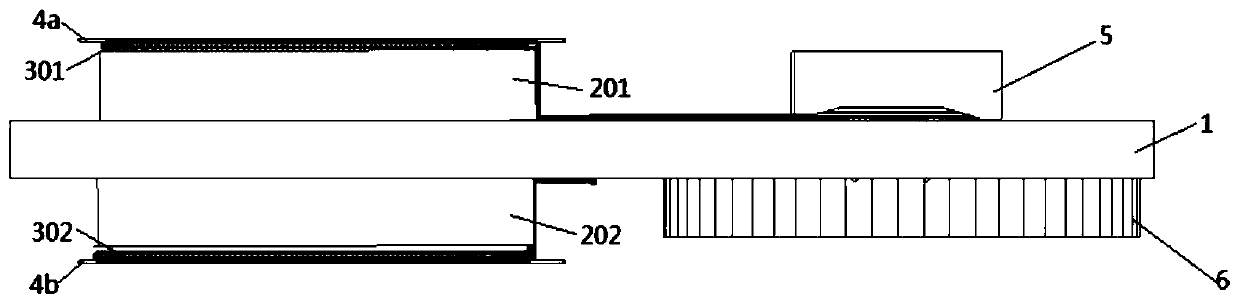

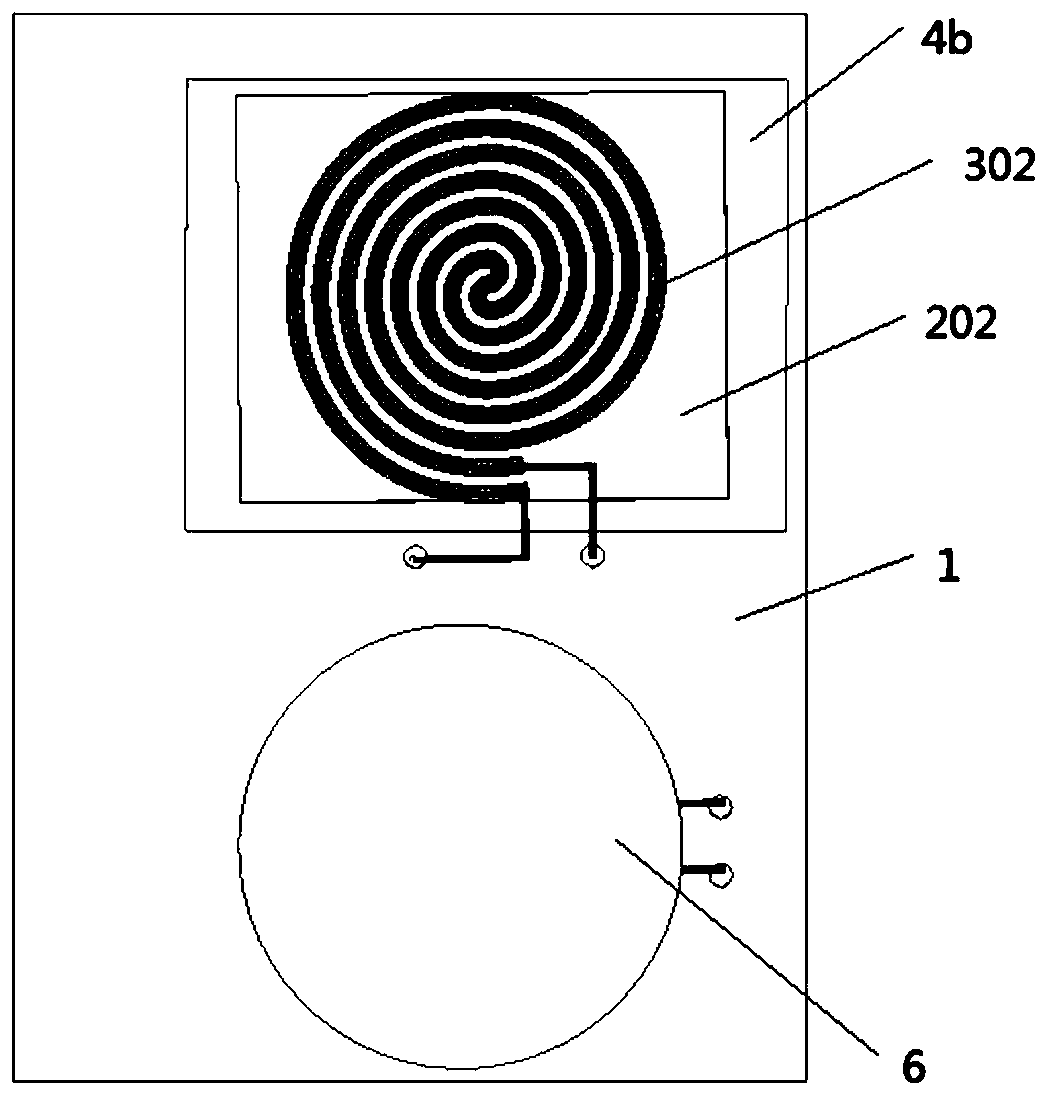

Integrated high-precision flexible temperature sensor and preparation method thereof

ActiveCN109827674AReduce stress and strainImprove performanceThermometers using electric/magnetic elementsUsing electrical meansEngineeringTemperature sensitive

The invention, which belongs to the field of flexible sensors, discloses an integrated high-precision flexible temperature sensor comprising a flexible substrate. Bosses are arranged on the upper surface and the lower surface of the flexible substrate symmetrically, wherein the height of each boss is 25 to 35 microns. Temperature sensitive units are arranged on the bosses on the upper surface of the flexible substrate and temperature compensation units are arranged on the bosses on the lower surface of the flexible substrate; and the temperature sensitive units and the temperature compensationunits are connected in series. Therefore, the influence caused by the deformation of the flexible substrate is reduced effectively; and the accuracy of the flexible sensor is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Thick slab corner crack control process

PendingCN113042695AReduce stress and strainReduce corner cracksUltimate tensile strengthMechanical engineering

The invention discloses a thick slab corner crack control process, which relates to the technical field of steel production, and comprises the following steps: comprehensively optimizing steel microalloy element components, selecting casting powder with proper alkalinity and viscosity, adjusting the cooling system of a crystallizer, optimizing secondary cooling strength, optimizing the vibration parameter and taper of the crystallizer, and improving the precision control of casting machine equipment, or measures such as a chamfering crystallizer and a surface structure control SSC technology are adopted, so that the occurrence of transverse cracks at the corners of a casting blank can be effectively controlled.

Owner:NANJING IRON & STEEL CO LTD

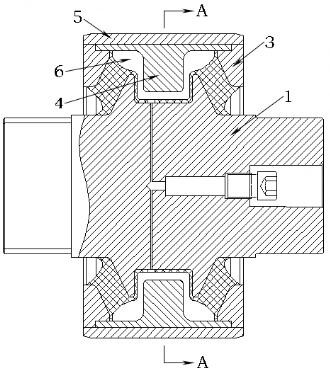

Rear drive transmission shaft supporting piece of integrated bidirectionally-vulcanized structure and machining method thereof

InactiveCN104924899AGood stiffness characteristicsReduce stress and strainControl devicesDrive shaftEngineering

The invention discloses a rear drive transmission shaft supporting piece of an integrated bidirectionally-vulcanized structure. The rear drive transmission shaft supporting piece of the integrated bidirectionally-vulcanized structure comprises a middle supporting installation support, a middle supporting bearing and middle supporting main springs. The two middle supporting main springs are in the same shape and are symmetrically arranged, each middle supporting main spring is of a rotary body structure, and the radial section of each middle supporting main spring is of a C-shaped structure. Each middle supporting main spring comprises an edge side and a bent side. The edge sides of the two middle supporting main springs are arranged oppositely. An inner side portion and an outer side portion which are both of an annular structure are arranged between the edge side and the bent side of each middle supporting main spring. Connecting portions used for connecting the inner side portions with the outer side portions are arranged on the bent sides of the middle supporting main springs. Radial protrusions of annular structures are arranged on the edge sides of the inner side portions towards the outer side portions. The rear drive transmission shaft supporting piece of the integrated bidirectionally-vulcanized structure can overcome the defects of the prior art and meet actual use requirements. The invention further discloses a machining method of the rear drive transmission shaft supporting piece of the integrated bidirectionally-vulcanized structure.

Owner:ANHUI ZHONGDING NVH

Display panel support frame and display device

ActiveUS10932381B1Reduce stress and strainGood protectionCasings with display/control unitsCasings/cabinets/drawers detailsComputer graphics (images)Display device

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

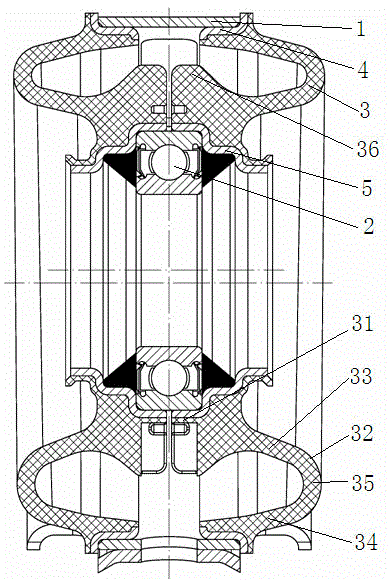

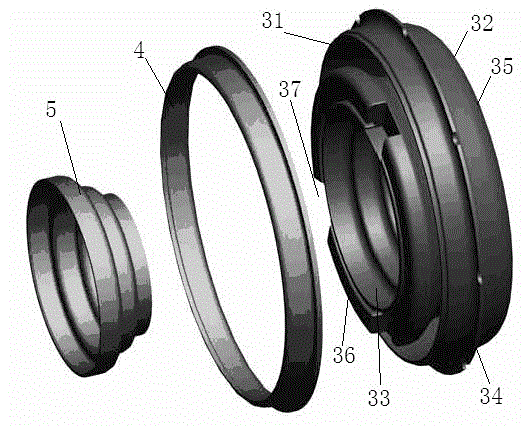

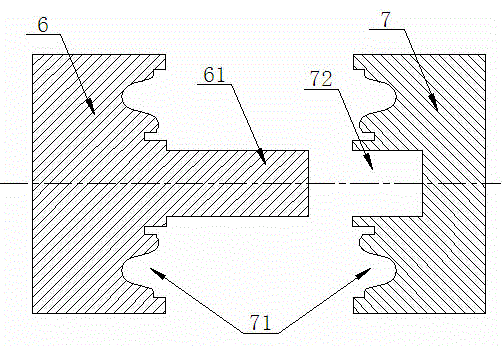

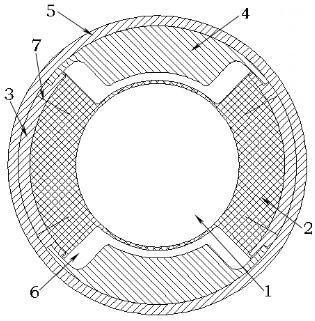

Split type liquid rubber composite joint with low diameter-axial ratio

PendingCN113928361AReduce radial stiffnessImprove axial stiffnessBogie-underframe connectionsWheel axle self-adjustmentsVulcanizationEngineering

The invention discloses a split type liquid rubber composite joint with a low diameter-axial ratio and an adjusting method, the split type liquid rubber composite joint comprises a core shaft, a rubber body, vulcanizing body outer sleeves, a stop block and an integral outer sleeve, the vulcanizing body outer sleeves are split type outer sleeves, a gap is formed between every two adjacent vulcanizing body outer sleeves, the rubber body is vulcanized between the vulcanizing body outer sleeves and the core shaft, a gap between the vulcanizing body outer sleeves extends into the rubber body; a hydraulic cavity with an opening in the outer side is defined by the mandrel, the rubber body and the vulcanizing body outer sleeve, a stop block is arranged in the hydraulic cavity and covers the vulcanizing body outer sleeve, and the outer sides of the stop block and the vulcanizing body outer sleeve are sleeved with an integral outer sleeve. The mandrel is provided with a concave pit which is concave towards the inner side of the mandrel, bosses are arranged on the two sides of the concave pit, the inner side of the stopping block is embedded in the concave pit of the mandrel, and when the stopping block and the mandrel move relatively in the axial direction, the bosses of the mandrel can stop the axial movement of the stopping block. Abrasion of a wheel track can be reduced, meanwhile, large axial rigidity is provided, and the running stability of a vehicle is guaranteed.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

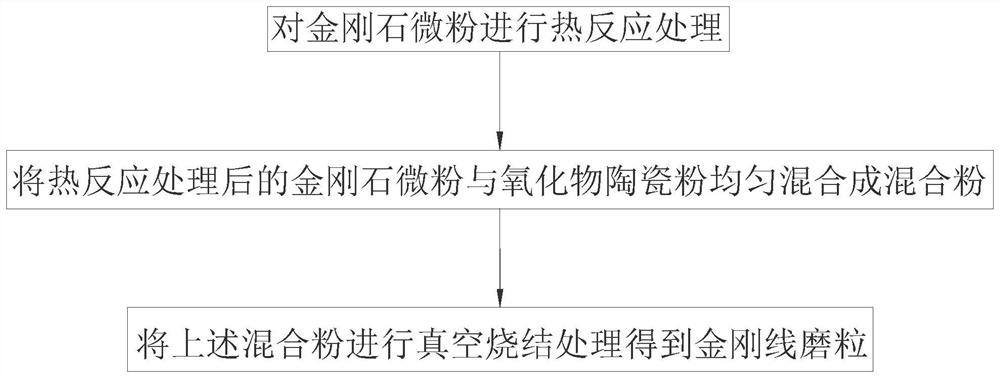

Electroplated diamond wire saw, diamond wire abrasive particle and preparation method of diamond wire abrasive particle

The invention discloses an electroplated diamond wire saw, diamond wire abrasive particles and a preparation method of the diamond wire abrasive particles, and the preparation method of the diamond wire abrasive particles comprises the following steps: carrying out thermal reaction treatment on diamond micro-powder to obtain the diamond micro-powder with roughened surface and structure defects; uniformly mixing the diamond micro-powder with the roughened surface and the structure defects with oxide ceramic powder to obtain mixed powder; and the mixed powder is placed in a vacuum environment to be sintered, and the diamond wire abrasive particles are obtained. According to the method, diamond micro-powder is sequentially subjected to thermal reaction treatment, physical mixing treatment with oxide ceramic powder and sintering treatment, the diamond wire abrasive particles are obtained, the self-sharpening performance of the diamond abrasive particles is improved, and the holding strength of a plating layer on the diamond abrasive particles is improved; the cutting efficiency, the machining effect and the service life of the electroplated diamond fretsaw are further improved. The invention further provides the electroplated diamond fretsaw comprising the base wire, the electroplated layer and the diamond wire abrasive particles embedded in the electroplated layer.

Owner:高景太阳能股份有限公司

Flexible hinge and floating frame matched clamping and positioning device for optical component

The invention discloses a flexible hinge and floating frame matched clamping and positioning device for an optical component. A flexible hinge and a floating frame are matched to be used for clamping and positioning the optical component, so that a large-caliber optical component is provided with the low-stress-strain reliable clamping capacity in the horizontal plane, moreover, the floating frame and two-dimensional large stroke are in flexible connection, so that the parallelism between the optical element surface and the work table plane is guaranteed. The flexible hinge is fixedly connected with a crystal frame, connection lugs are fixed on the crystal frame, positioning blocks are fixed in the crystal frame, and the optical component is disposed in the crystal frame integrally and positioned through the positioning blocks. Locking blocks are fixed in the crystal frame, first positioning screws are screwed in the locking blocks, and the optical component is pre-clamped and fixed between the first positioning screws and the positioning blocks. Compression blocks are fixedly connected with the crystal frame, and the optical component is compressed and fixed vertically through the compression blocks. Spherical hinge studs are fixedly connected with connection lugs and are in contact with air floating pads. The device is used for clamping and positioning of optical elements during micro-defect rapid searching and repairing.

Owner:HARBIN INST OF TECH

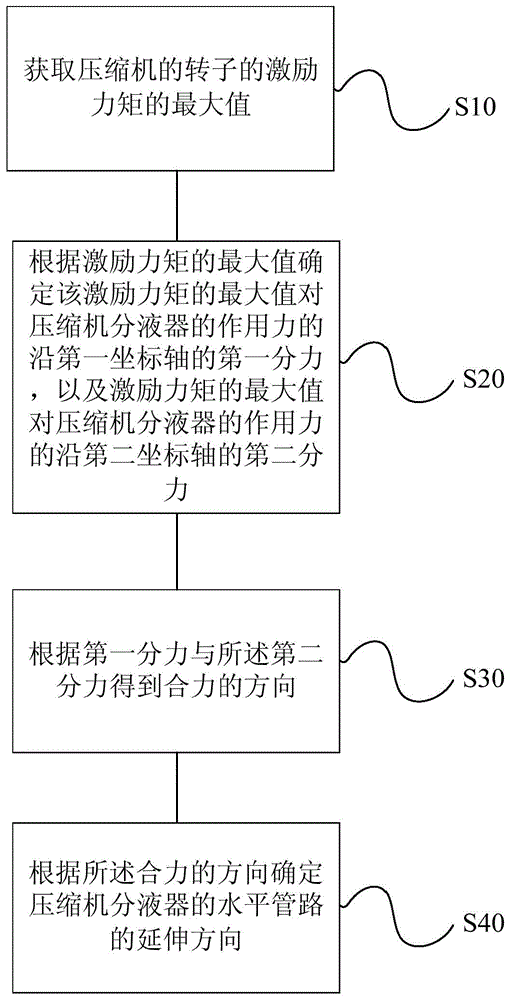

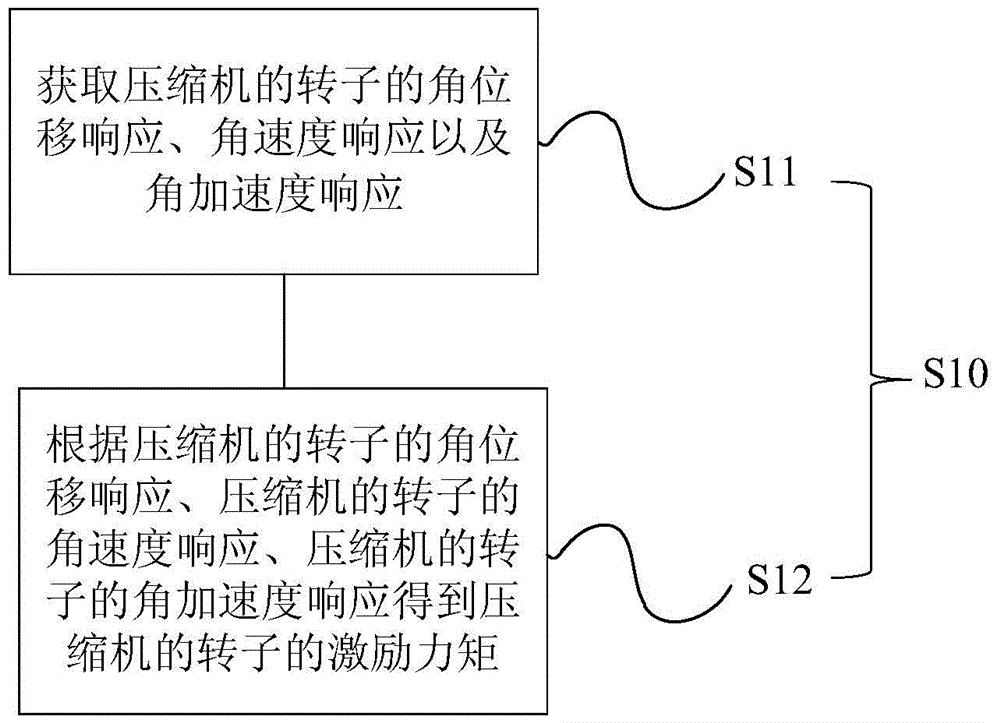

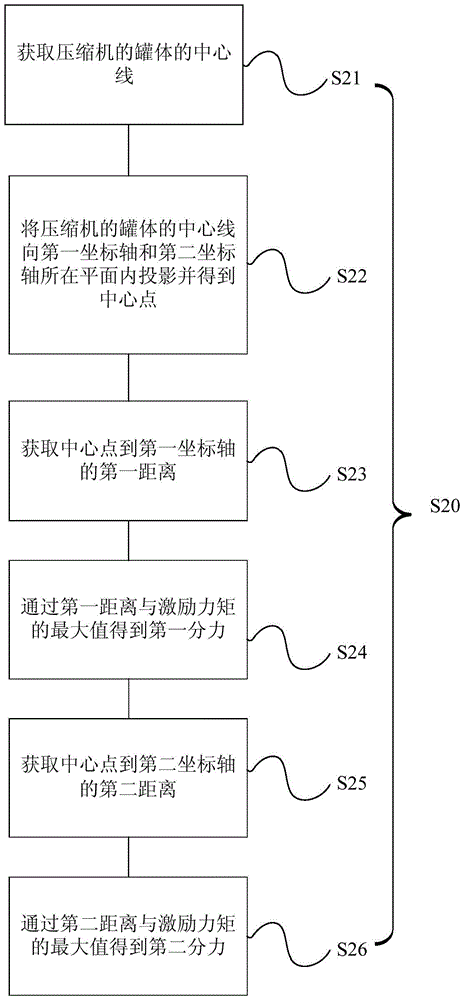

The method for determining the horizontal pipeline and its parameters of the liquid separator of the compressor

InactiveCN105042961BReduce stress and strainReduce vibrationRefrigeration safety arrangementEngineeringResultant force

The invention provides a horizontal pipeline of a compressor liquid separator and a method of determining parameters of the horizontal pipeline. The compressor liquid separator is arranged at one side of a compressor and is connected to the compressor. The method of determining the parameters of the horizontal pipeline comprises the following steps: step 10. obtaining the maximum value of excitation torque of a rotor of the compressor; step 20. determining a first component force, which is along a first coordinate axis, of the acting force of the maximum value of the excitation torque on the compressor liquid separator and a second component force, which is along a second coordinate axis, of the acting force of the maximum value of the excitation torque on the compressor liquid separator according to the maximum value of the excitation torque; step 30. obtaining a direction of a resultant force according to the first component force and the second component force; and step 40. determining an extension direction of the horizontal pipeline of the compressor liquid separator according to the direction of the resultant force. Due to adoption of the technical scheme of the invention, the stress strain of the horizontal pipeline of the compressor liquid separator is decreased, and the vibration of an air conditioner is reduced.

Owner:ZHUHAI LANDA COMPRESSOR +1

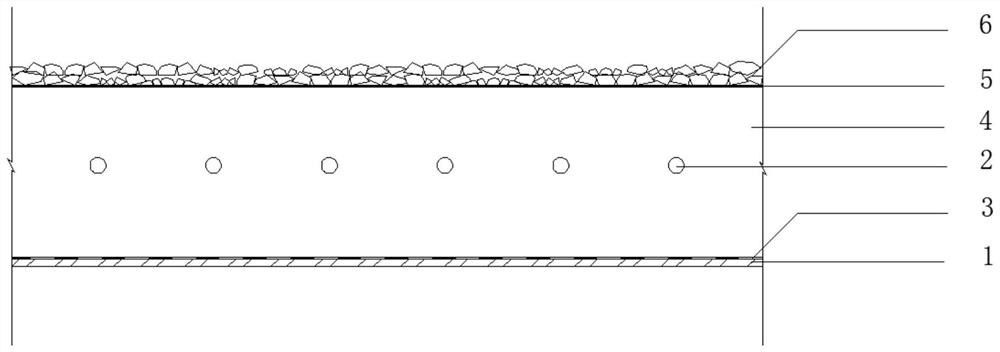

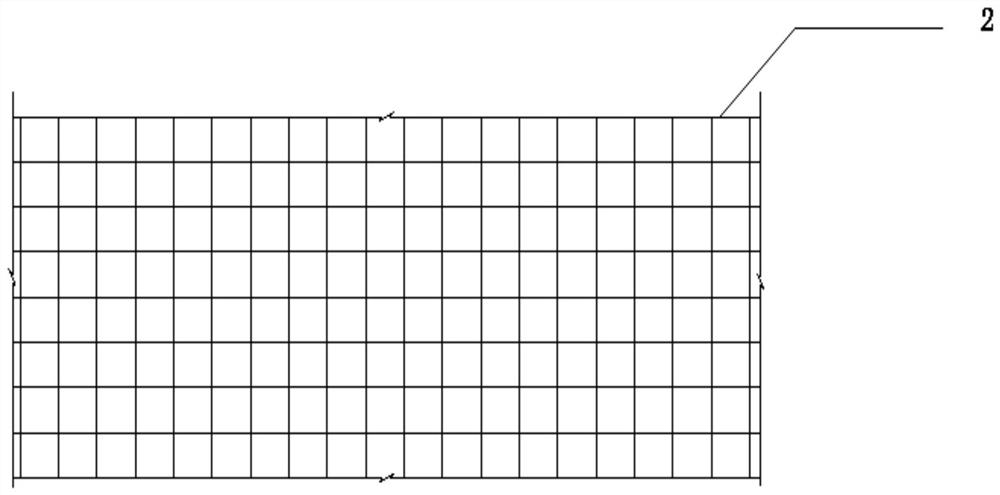

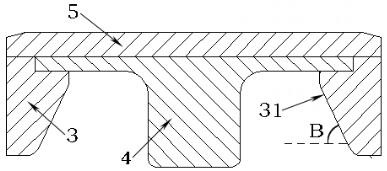

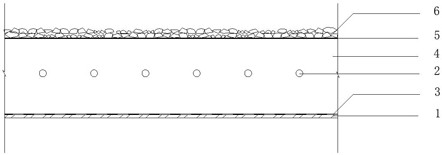

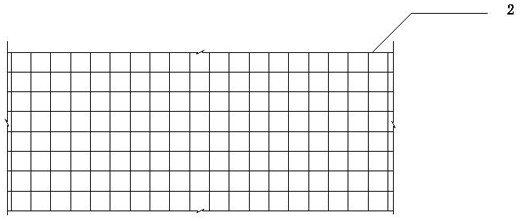

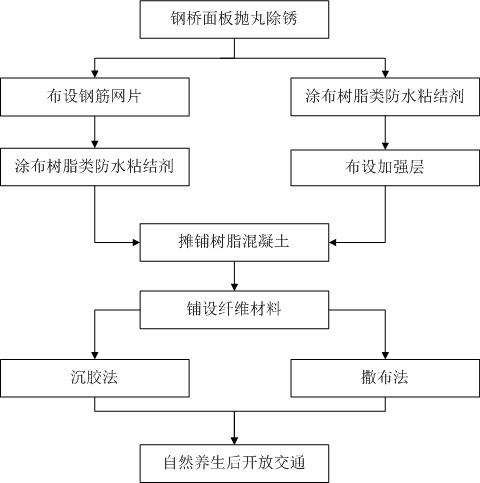

Composite resin concrete steel bridge deck pavement structure and construction method thereof

InactiveCN113668376AImprove toughnessCancel noiseBridge structural detailsBridge erection/assemblyFiberMesh reinforcement

The invention provides a composite resin concrete steel bridge deck pavement structure and a construction method thereof. The steel bridge deck pavement structure comprises a steel bridge deck slab, a resin waterproof bonding layer and a resin concrete layer. A reinforcing layer is laid in the resin concrete layer. The reinforcing layer is a reinforcing mesh, and / or a fiber material, and / or gravel particles. According to the technical scheme provided by the invention, the reinforcing layer is additionally arranged in the resin concrete, so that the overall strength is improved; meanwhile, the steel bridge deck slab and the resin concrete layer are connected through the resin waterproof bonding layer, so that the bonding strength of the steel bridge deck slab and the resin concrete layer is higher, and the shear resistance of the steel bridge deck slab and the resin concrete layer is remarkably improved.

Owner:徐斌

Integral liquid rubber composite joint with small-diameter axial ratio and rigidity adjusting method

PendingCN114060450AReduce radial stiffnessImprove reliabilitySpringsShock absorbersVulcanizationMechanical engineering

The invention discloses an integral liquid rubber composite joint with a small-diameter axial ratio and an adjusting method. The liquid rubber composite joint comprises a core shaft, a rubber body, a vulcanizing body outer sleeve, a stop block and an integral outer sleeve. The rubber body is vulcanized between the vulcanizing body outer sleeve and the core shaft, so that the rubber body generates composite deformation of shearing and extruding when the rubber body bears radial pressure, and the radial rigidity of the liquid rubber composite joint is reduced; and a pit recessed towards the inner side of the mandrel is formed in the core shaft, bosses are arranged on the two sides of the pit, the stop block is arranged at the position of the pit, the maximum outer diameter of the bosses of the core shaft is set to be larger than the minimum inner diameter of the stop block, and when the stop block and the core shaft move relatively in the axial direction, the bosses of the core shaft can stop the axial movement of the stop block. Therefore, the axial rigidity of the liquid rubber composite joint is increased, and the small-diameter axial ratio of the rigidity of the liquid rubber composite joint is achieved. Abrasion of wheels and rails of a vehicle can be reduced, meanwhile, large axial rigidity is provided, and the running stability of the vehicle is guaranteed.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Composite resin concrete steel bridge deck pavement structure and construction method thereof

InactiveCN114277680AImprove toughnessCancel noiseBridge structural detailsBridge erection/assemblyFiberMesh reinforcement

The invention provides a composite resin concrete steel bridge deck pavement structure and a construction method thereof. The steel bridge deck pavement structure comprises a steel bridge deck slab, a resin waterproof bonding layer and a resin concrete layer. Wherein a reinforcing layer is laid in the resin concrete layer. And the reinforcing layer is a reinforcing mesh, and / or a fiber material, and / or gravel particles. According to the technical scheme provided by the invention, the reinforcing layer is additionally arranged in the resin concrete, so that the overall strength is improved; meanwhile, the steel bridge deck slab and the resin concrete layer are connected through the resin waterproof bonding layer, so that the bonding strength of the steel bridge deck slab and the resin concrete layer is higher, and the shear resistance of the steel bridge deck slab and the resin concrete layer is remarkably improved.

Owner:NINGBO ROABY TECH INDAL GROUP

Welding method for manually welding small groove of T-shaped welding seam and matched welding gun nozzle

ActiveCN113579423AImprove welding efficiencyReduce welding costsElectrode supporting devicesWeld seamMechanical equipment

The invention relates to the field of steel welding, and particularly discloses a welding method for manually welding a small groove of a T-shaped welding seam and a matched welding gun nozzle. The welding method comprises the following steps: 1, manufacturing a groove of steel plates to be welded, and forming the groove on the lower portion of any one welding end part of the two steel plates to be welded; 2, enabling the groove forming angle of one steel plate welding end to be 20 degrees, and the distance between the bottom end of the groove and the bottom of the other steel plate welding end to be 6-8 mm; and 3, welding the end of the groove of the steel plates prepared in the first step and the second step through carbon dioxide welding equipment by adopting the matched welding gun nozzle. Mechanical equipment for finish machining of the groove and corresponding welding equipment are not needed, so that the welding cost is reduced, the sectional area of a welding seam is reduced, the welding efficiency is improved, the labor intensity of workers is reduced, the stress strain of a welding joint is reduced, and the comprehensive performance of the welding seam is improved.

Owner:CHANGJIANG & JINGGONG STEEL STRUCTURE GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com