Truck tyre with groove bottom crack resistance

A technology for tires and carcasses, used in tire parts, reinforcement layers of pneumatic tires, transportation and packaging to achieve the effects of extending service life, improving tear resistance and reducing stress and strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

comparative example 1

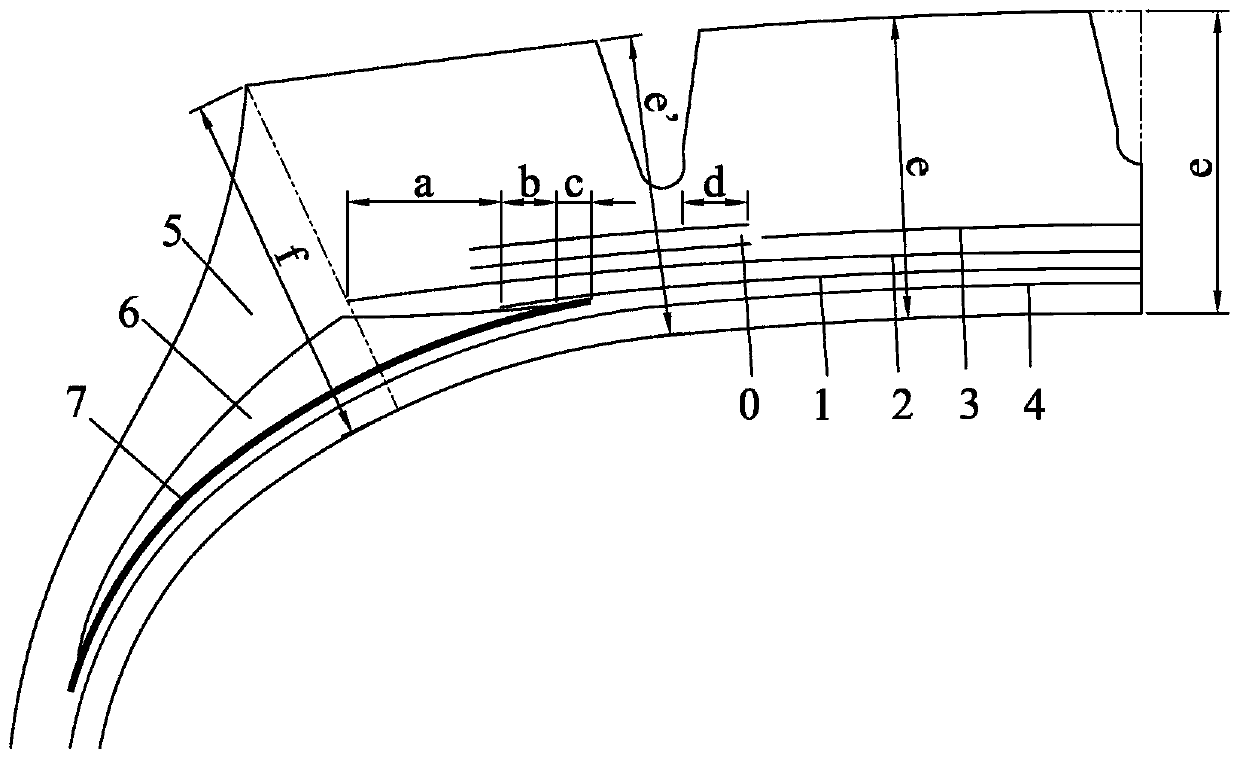

[0032] Set the distance b between the end point of the 1# belt and the inner end point of the shoulder pad rubber 6 as 20mm, and adjust the corresponding value of c to 20mm. Carcass film 71# belt wrapping rubber is set to a width of 30mm and a thickness of 1mm. Carcass 4 puts film and is set to be wide 105mm, thick 1.0mm, and all the other are all identical with this application example.

comparative example 2

[0034] Add a 45*2.0 film under the shoulder pad rubber 6 and on the carcass rubber 7, control the ratio of the shoulder thickness f to the middle thickness value e of the crown to 1.3, and the difference between the added film and the inner end of the shoulder pad rubber 6 The grade is 5-10 mm, and the rest are the same as in this application example.

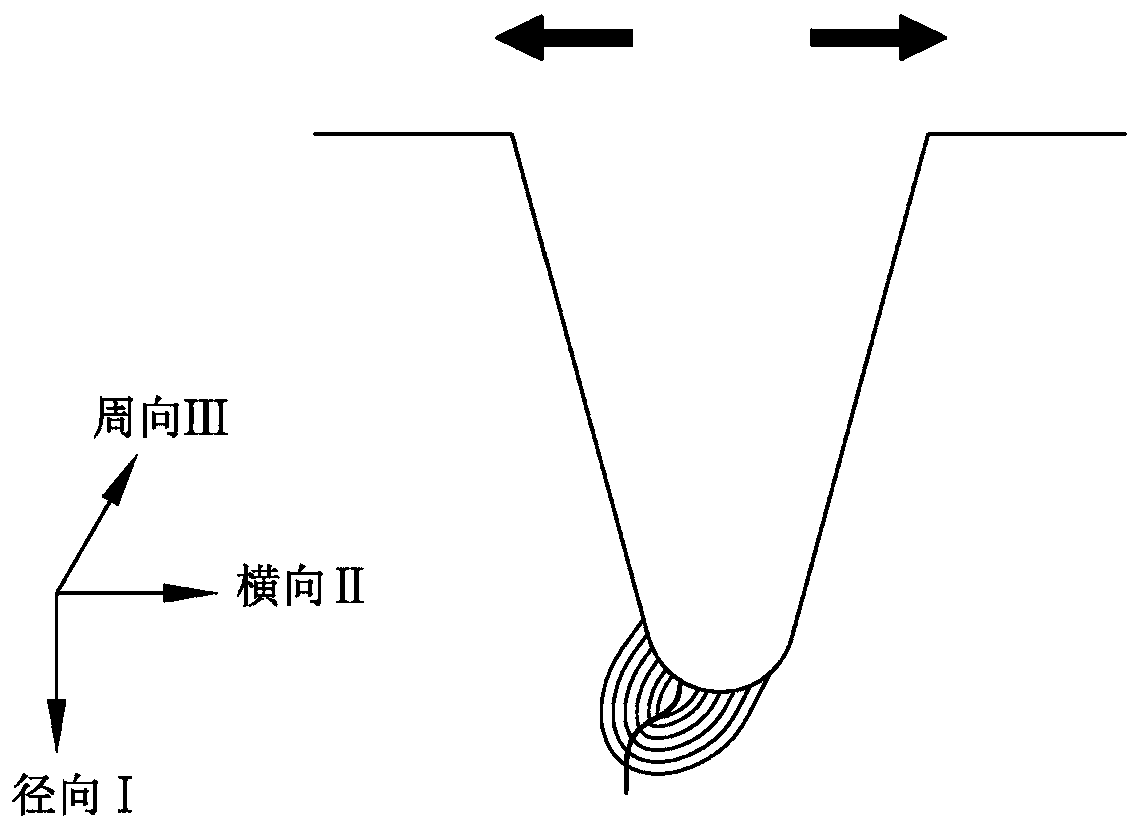

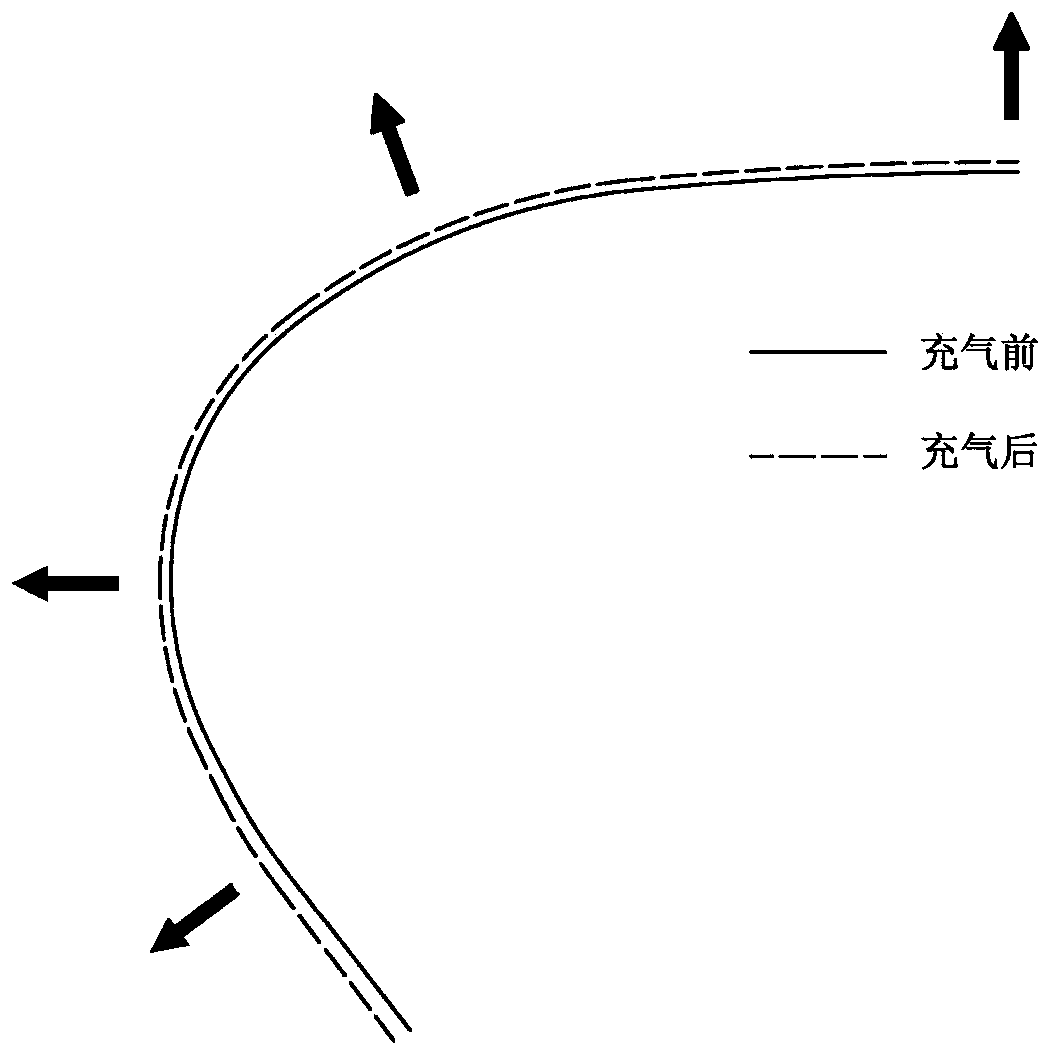

[0035] figure 2 is the growth diagram of the crack at the bottom of the pattern groove. The occurrence of tire groove bottom cracks is mainly affected by the stress and strain in these three directions. Among them, the groove cracks (usually occurring in side grooves) caused by the expansion force in the transverse direction can be detected by measuring the change in groove width after the tire is inflated. pre-assessment. The cracks caused by circumferential shear force and radial stress generally need to be judged by observing the shape of the groove after actual use. Therefore, by reducing the variation of the groove wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com