Integrated high-precision flexible temperature sensor and preparation method thereof

A temperature sensor and high-precision technology, applied in the field of sensors, can solve the problems of low measurement accuracy and large deformation of flexible substrates, and achieve the effect of digital temperature signal output, weakening the influence of deformation, and improving the temperature output signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A method for preparing an integrated high-precision flexible temperature sensor, comprising the following steps:

[0047] Step 1: Prepare a double-sided flexible substrate 1 with square bosses by casting multiple times on a mold with grooves;

[0048] Step 2: preparing a metal film on the square boss, and using a stripping process to obtain a temperature sensitive unit 301 and a temperature compensation unit 302 for the metal film;

[0049] Step 3: Prepare a protective layer 4 on the upper surface of the temperature sensitive unit 301 and the lower surface of the temperature compensation unit 302 by using a spin coating process;

[0050]Step 4: Paste the microcircuit chip 5 and the power supply unit 6 on the non-square boss area of the flexible substrate 1, and realize the microcircuit chip 5, the power supply unit 6, the temperature sensitive The electrical connection between the unit 301 and the temperature compensation unit 302.

Embodiment 1

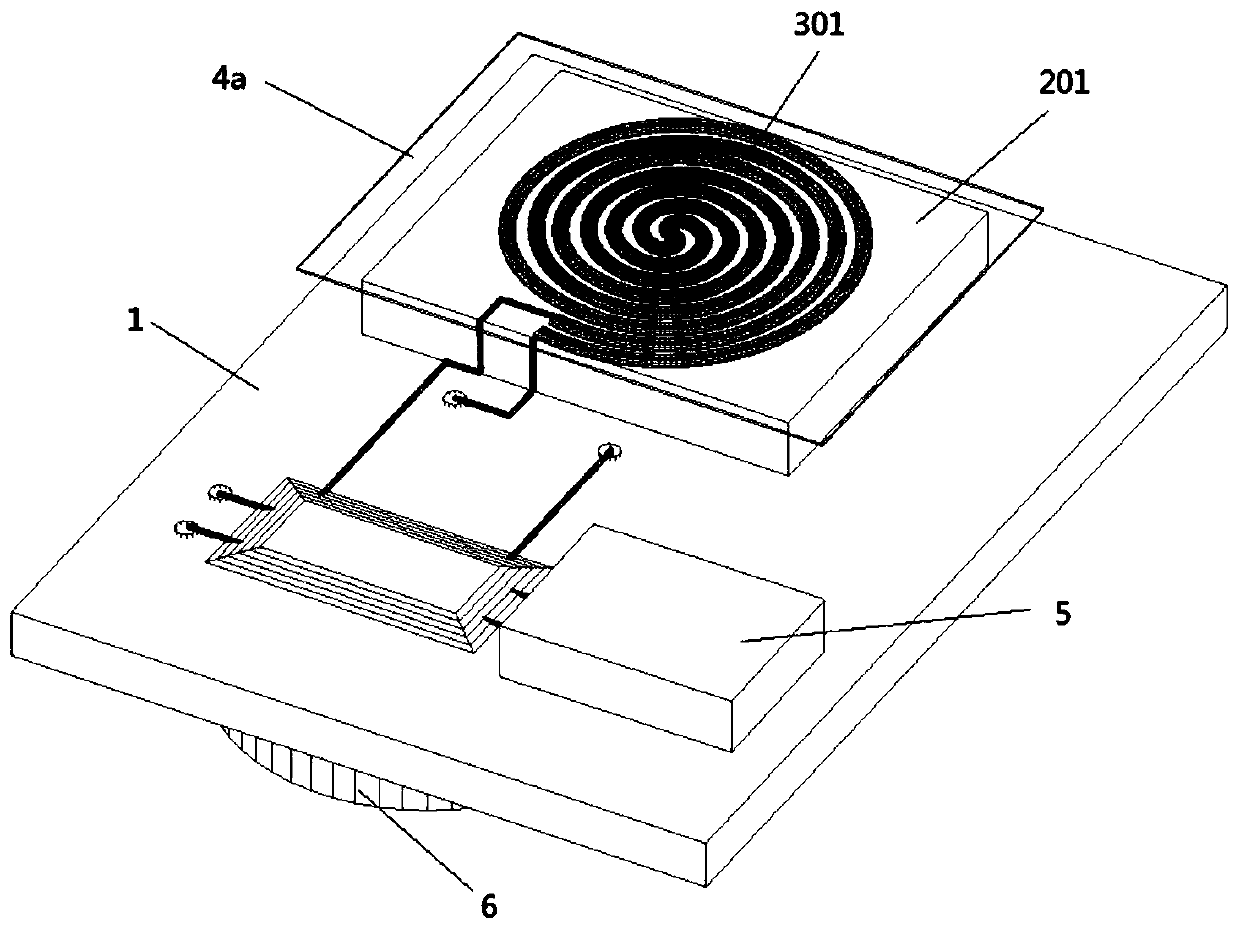

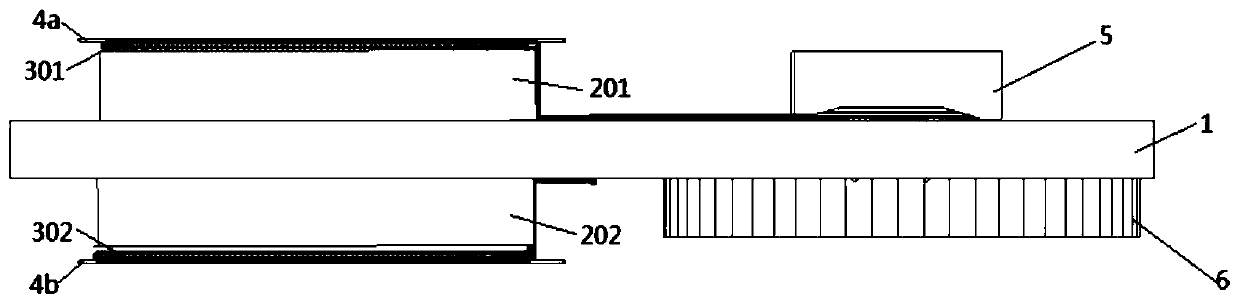

[0053] An integrated high-precision flexible temperature sensor provided by a preferred embodiment of the present invention includes a flexible substrate 1, the thickness of the flexible substrate 1 can be conventional, and bosses are symmetrically arranged on the upper and lower surfaces of the flexible substrate 1 , that is, the upper surface of the flexible substrate 1 is provided with a boss A201, and the lower surface of the flexible substrate 1 is provided with a boss B202 symmetrically arranged with the boss A201. The boss and the flexible substrate 1 are integrally formed and are square , it is convenient for the temperature sensitive unit 301 and the temperature compensating unit 302 to be pasted together. When the height of the boss is 30 μm, it is most beneficial to reduce the influence of deformation on the measurement signal of the flexible temperature sensor. A temperature sensitive unit 301 is pasted on the upper surface of the boss A201, a temperature compensati...

Embodiment 2

[0056] Based on Embodiment 1, this embodiment is used to describe the structures of the temperature sensitive unit and the temperature compensation unit.

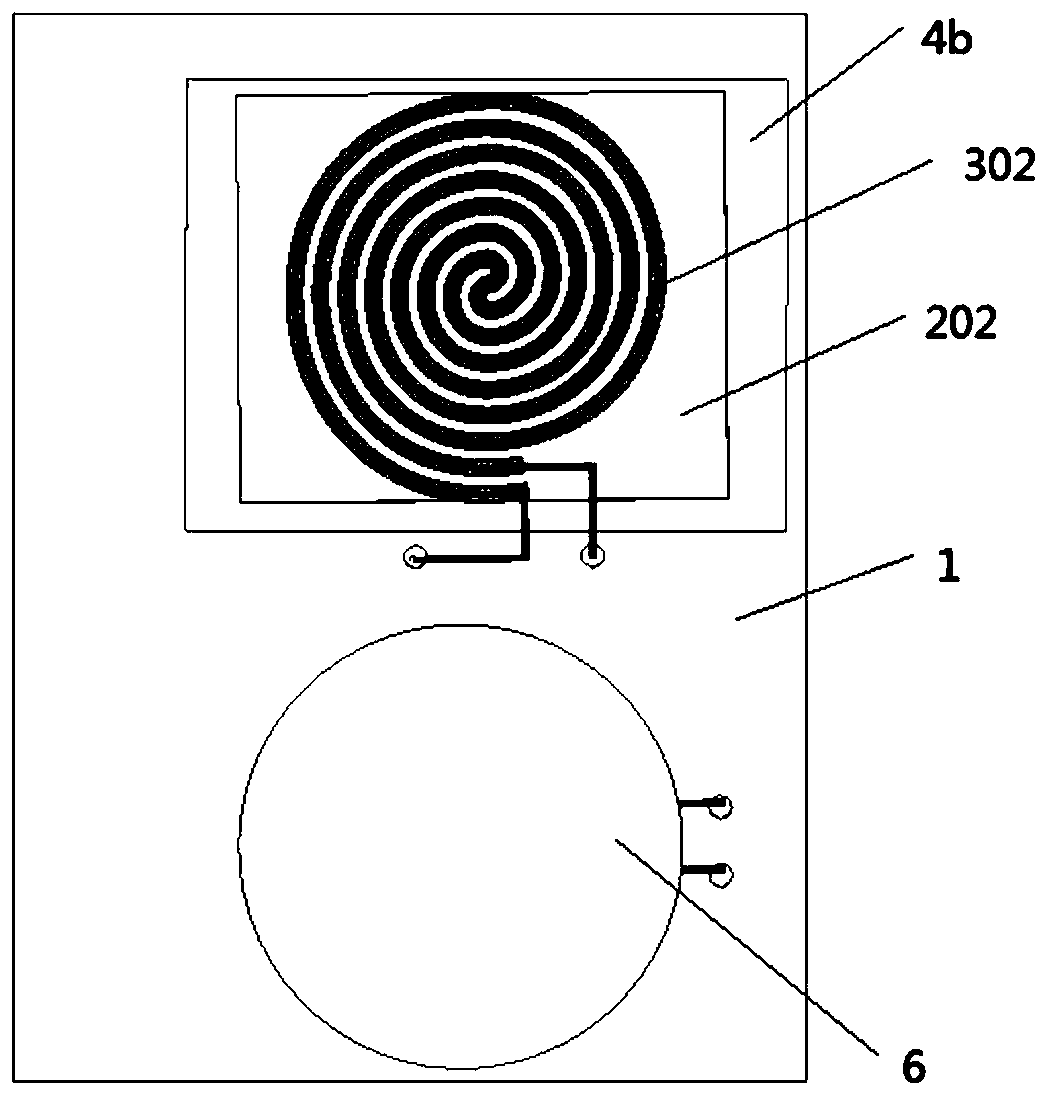

[0057] Both the temperature sensitive unit 301 and the temperature compensation unit 302 are Pt metal resistors, a temperature sensitive resistor with a common structure can be used, but a double helix structure is more optimal, and the double helix structure is Figure 5 As shown, the double helix structure can effectively eliminate the influence of deformation in any direction in the horizontal plane. The principle is as follows:

[0058] According to the definition of strain and Poisson's law, from Figure 5 It is easy to know that the isolated segment dI of the circular metal strip (temperature sensitive unit or temperature compensation unit) and the horizontal direction angle θ is strained in the horizontal direction ε x The relative change in resistance is:

[0059]

[0060] Then the relative resistance change of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com