Integral liquid rubber composite joint with small-diameter axial ratio and rigidity adjusting method

A technology of liquid rubber and adjustment methods, which is applied in the field of rail transit, can solve the problems of small ratio of radial stiffness to axial stiffness, difficulty in realizing the stiffness of liquid rubber composite nodes, and reducing the radial stiffness of liquid rubber composite nodes, etc., to achieve Improves reliability, contributes to fatigue resistance, and improves dynamic stiffness characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

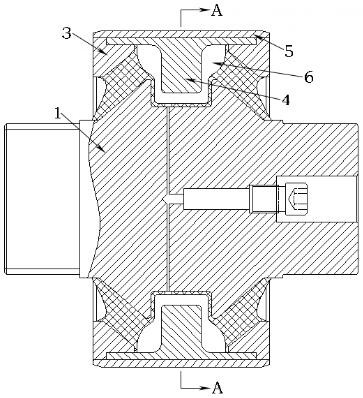

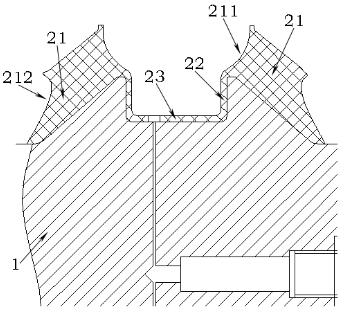

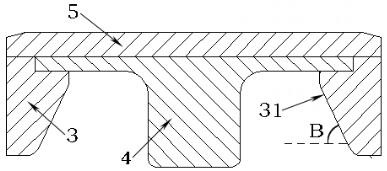

[0030] like figure 1 , Figure 4 and Figure 5 As shown, the integral liquid rubber composite node is vulcanized rubber body 2 between vulcanized body jacket 3 and mandrel 1, so that mandrel 1, rubber body 2 and vulcanized body jacket 3 form a whole. And the mandrel 1, the rubber body 2 and the vulcanized body jacket 3 together form a hydraulic cavity 6 with an outer opening. The hydraulic cavity 6 is provided with a stop block 4, and the longitudinal section of the stop block 4 is T-shaped. The upper end of the stop block 4 is closed on the vulcanized body jacket 3, sealing the hydraulic chamber 6 into a closed cavity, and liquid can be injected into the closed hydraulic chamber 6, thereby forming a joint between liquid and rubber. The overall casing 5 is a hollow circular tube, and the stop block 4 and the vulcanized body casing 3 are installed in the overall casing 5 in a pre-compressed manner, so that the overall casing 5 constrains and compresses the stop block 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com