Elastic wheel for rail traffic vehicle and assembling method and rigidity design method thereof

A rail transit vehicle and elastic wheel technology, which is applied in the direction of wheels, wheels, vehicle parts, etc. characterized by rail running parts, can solve the problem of poor radial lightening effect of the unsprung part of the vehicle, and improve structural stability and Reliability, reduced diameter-to-axis stiffness ratio, reduced maintenance cost and low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

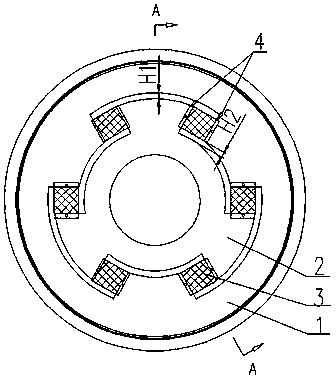

[0041]An elastic wheel for a rail transit vehicle, comprising a tire 1, a wheel core 2 concentrically arranged in the tire 1, and a rectangular parallelepiped elastic body 3 detachably connected between the tire 1 and the wheel core 2, characterized in that The tire 1 and the wheel core 2 are spaced radially to form a radial gap A, and separated along the circumferential direction to form a circumferential gap B, and the circumferential gap B is evenly distributed along the circumferential direction N×2 and N≥3, each An elastic body 3 is compressed in each of the circumferential gaps B, and the elastic body 3 is separated from the tire 1 and the wheel core 2 in the radial direction without contact.

[0042] As shown in the figure, the elastic body 3 is compressed in the circumferential gap B in the circumferential direction, and is separated from the tire 1 and the wheel core 2 in the radial direction without contact. When the elastic wheel is subjected to a vertical force, the...

Embodiment 2

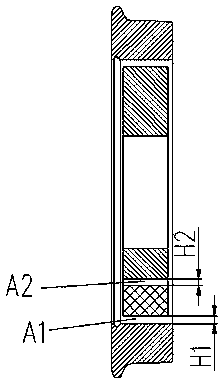

[0047] The difference from Embodiment 1 is that the elastic body 3 is a metal rubber pad composed of multi-layer metal plates and rubber vulcanized between the metal plates, and the metal plates at the end of the elastic body 3 are arranged in parallel with the tire 1 or the wheel core 2 are detachably connected. Such as Figure 6 As shown, the elastic body is composed of a metal plate and rubber vulcanized between the metal plates. The stiffness of the elastic body is increased by adding the metal plate, so that the thickness of the metal plate and rubber in the elastic body 3 can be adjusted according to the rigidity requirements of the elastic wheel. The ratio and the structure of the metal plate adjust the radial stiffness and axial stiffness of the elastic body, thereby adjusting the radial stiffness, axial stiffness and diameter-axis stiffness ratio of the elastic wheel, so that the radial-axis stiffness of the elastic wheel is equal to 1 or greater than 1, To meet the ...

Embodiment 3

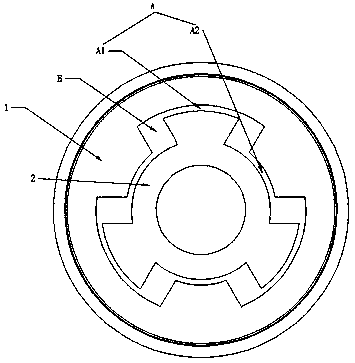

[0049] The difference from Embodiment 1 is that the elastic body 3 includes two end plates 31 , multiple outer partitions 32 and a middle plate 33 , and the partitions 32 and the middle plate 33 are arranged between the two end plates 31 The separators 32 are symmetrically arranged on both sides of the middle plate 33, the end plates 31 and the separators 32, the adjacent separators 32, and the middle plate 33 and the separators 32 are bonded by rubber vulcanization, and the bonding of the middle plate 33 The surface is two mirror-symmetrical V-shaped surfaces 33.1, the separator 32 is a V-shaped plate parallel to the V-shaped surface 33.1, the bonding surface of the end plate 31 is V-shaped parallel to the V-shaped surface 33.1, and the V-shaped surface 33.1 The V-shaped angle β is 0~60 degrees. Such as Figure 7 As shown, the bonding surface of the middle plate 33 is V-shaped. After the elastic body 3 is compressed in the circumferential gap B, the radial thickness of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com