Patents

Literature

421results about How to "Reduce lateral force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

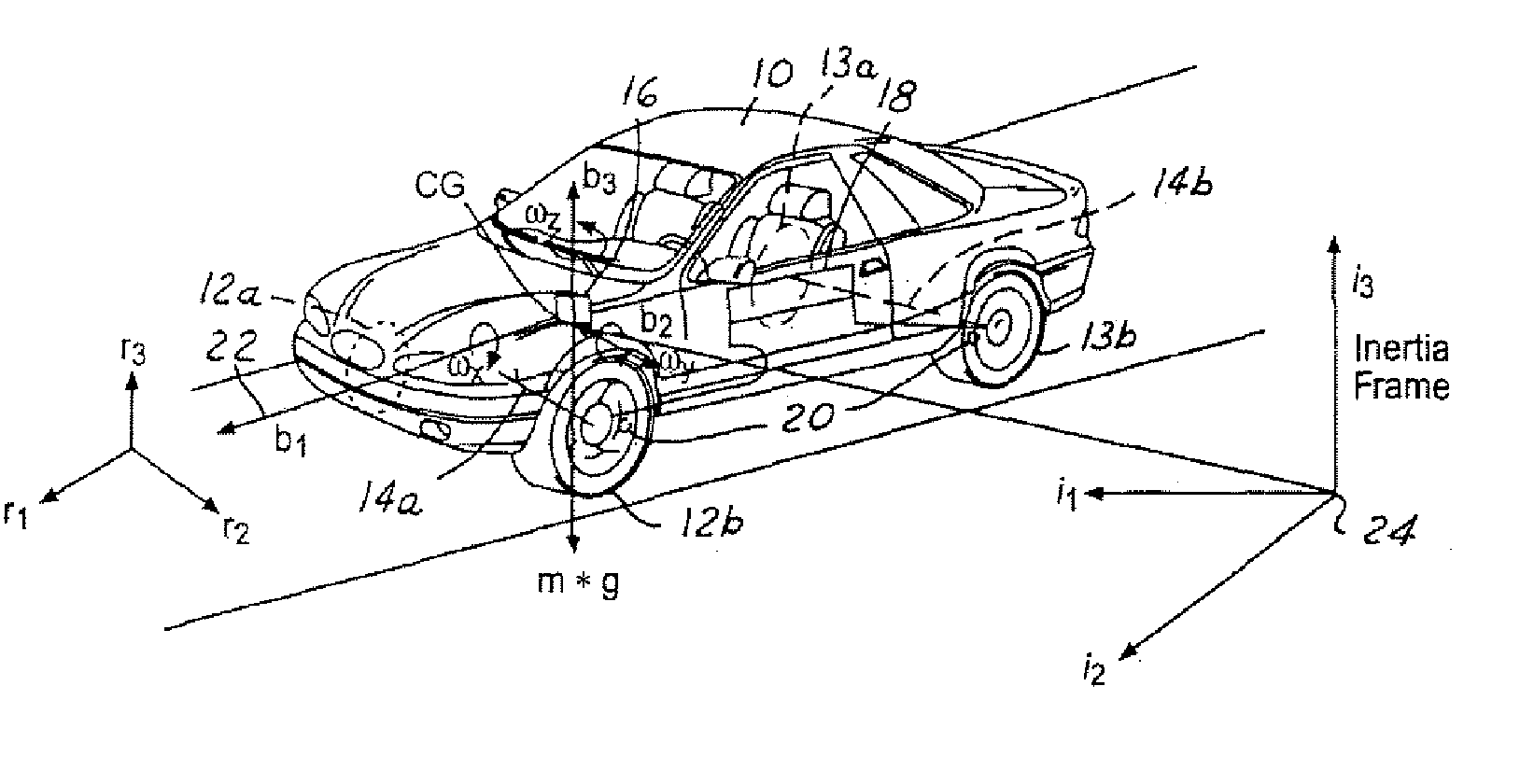

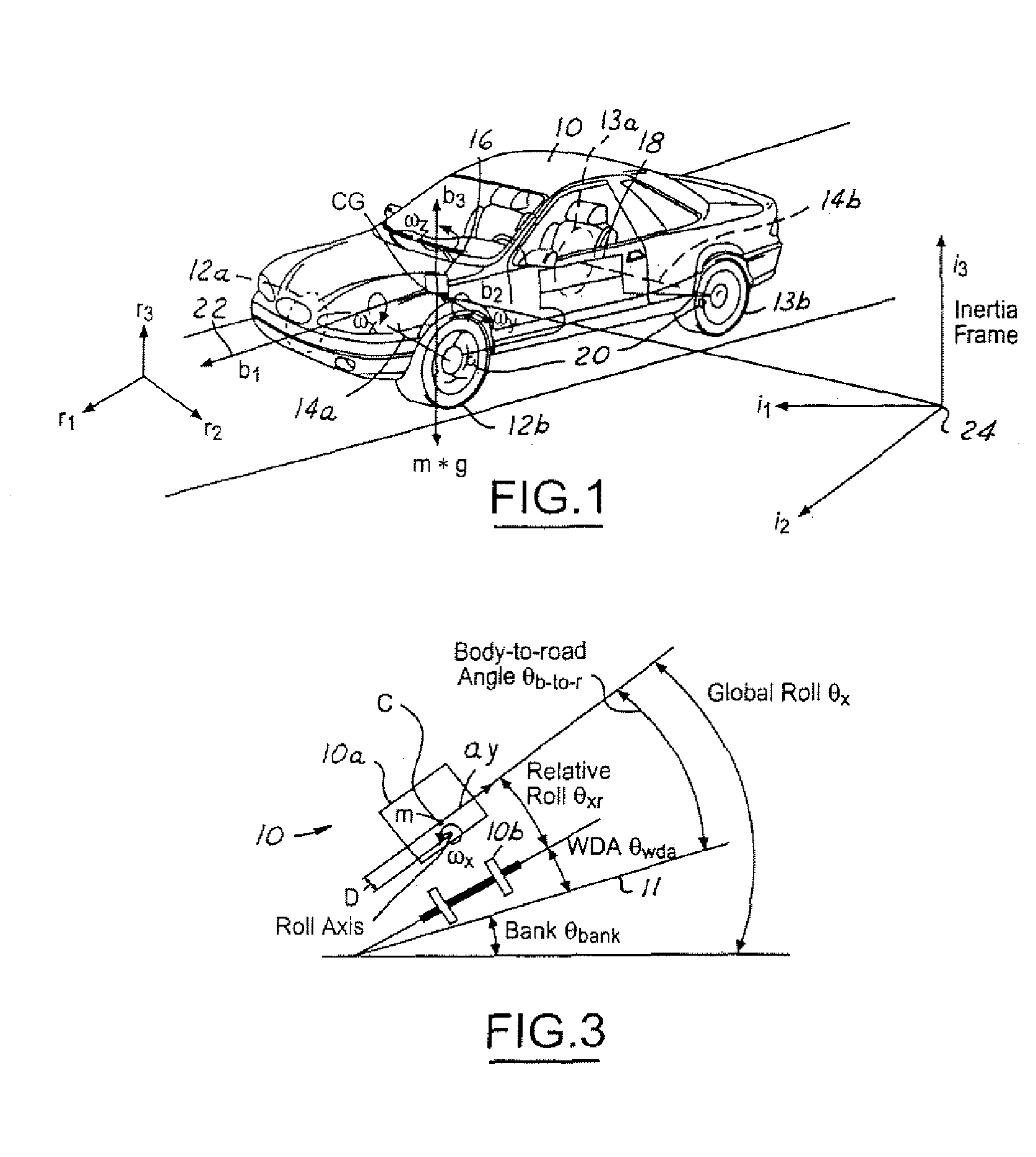

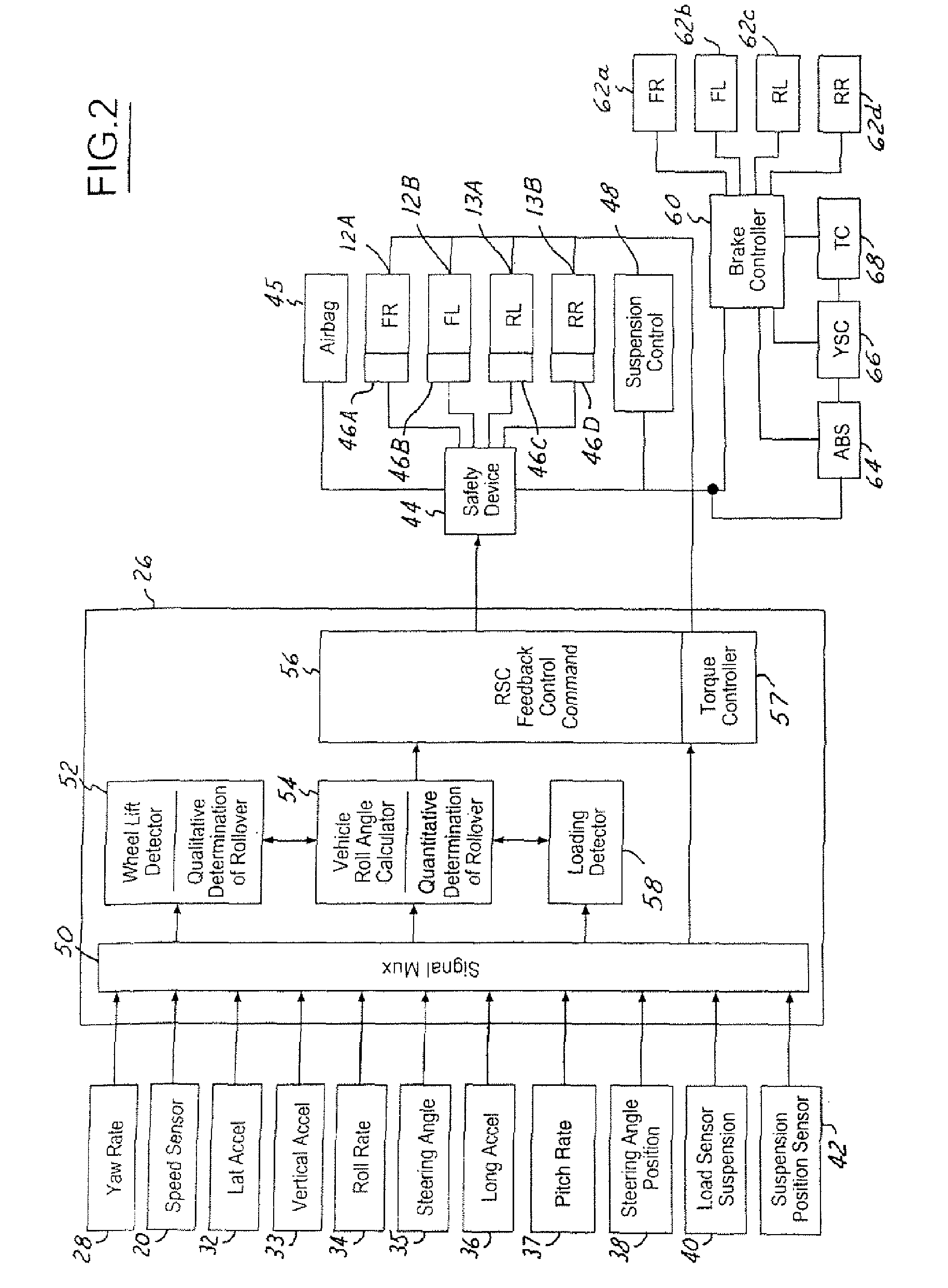

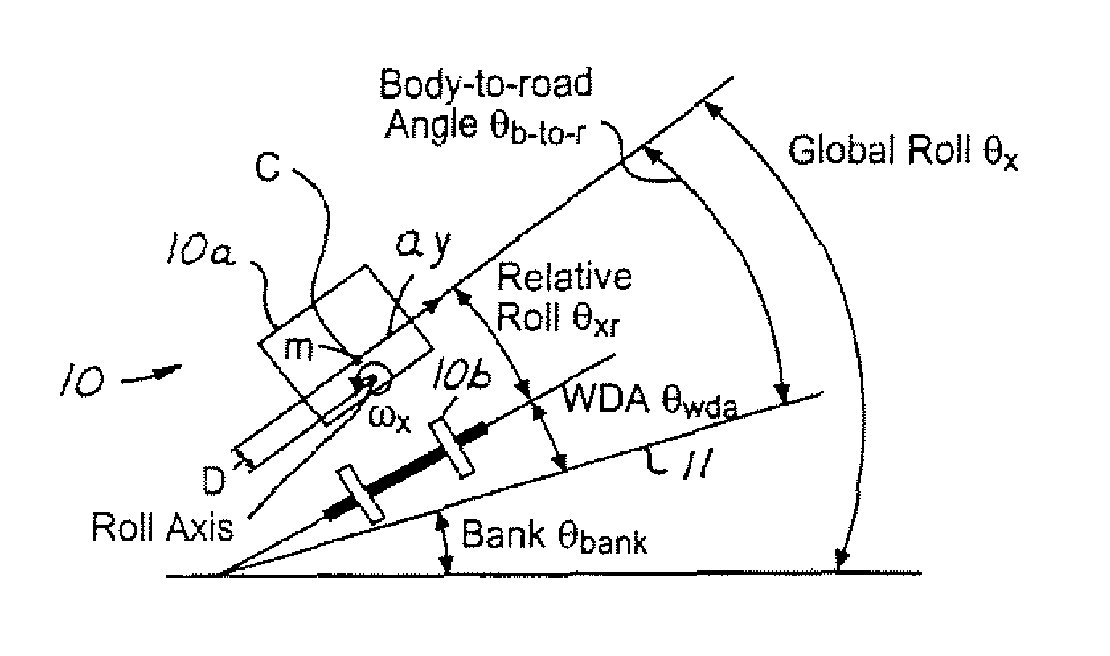

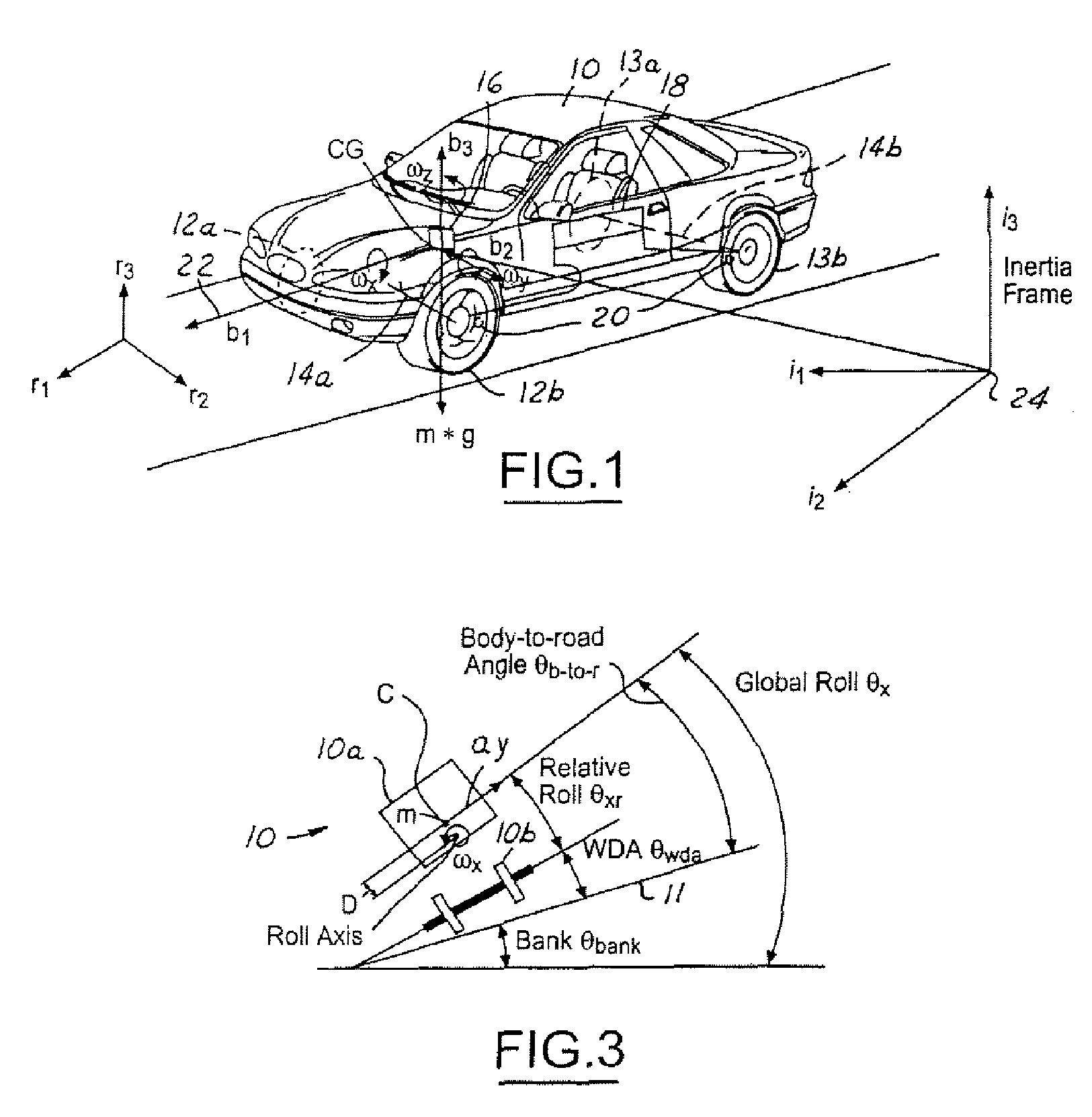

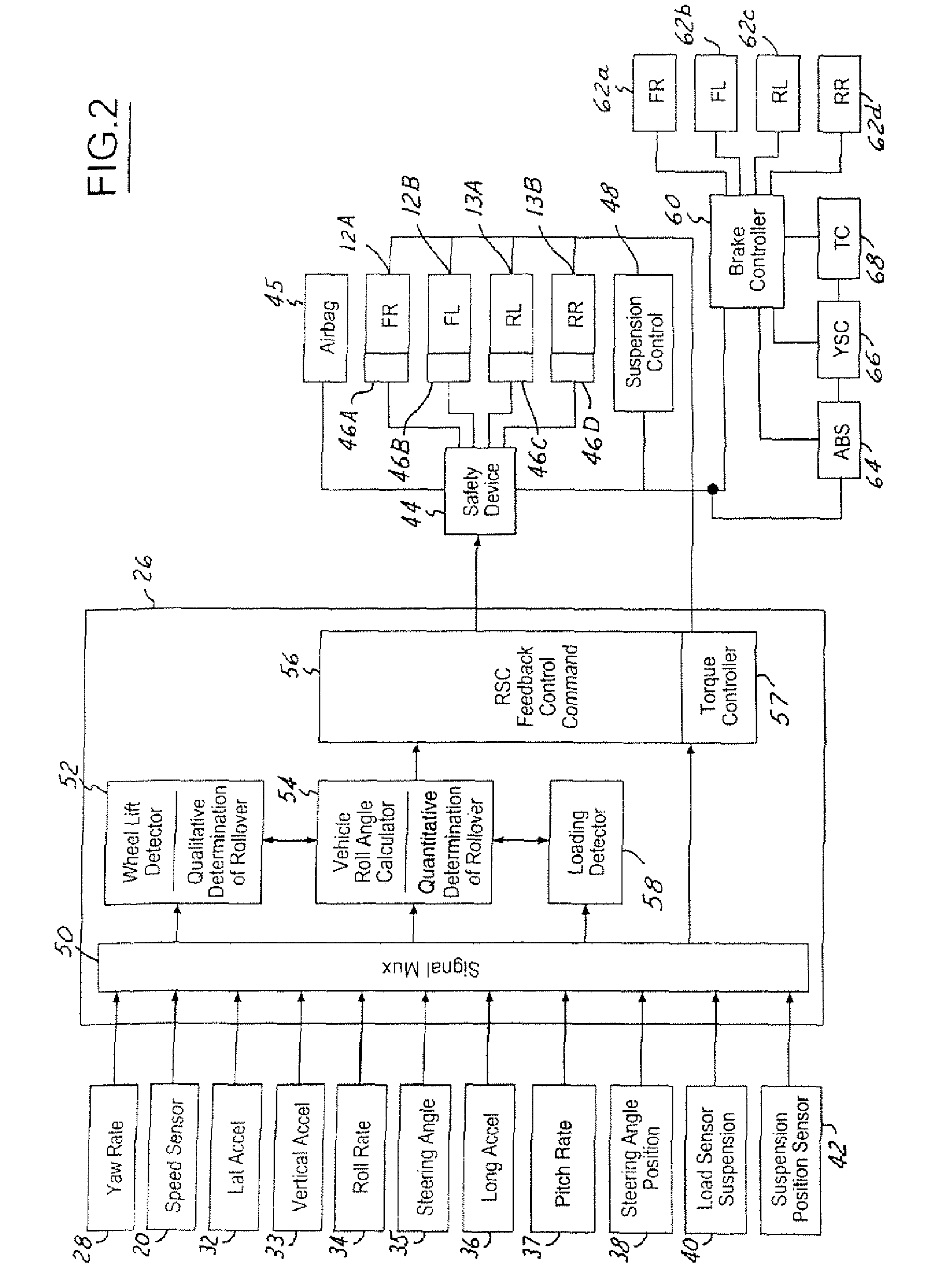

Roll stability control using four-wheel drive

ActiveUS20060074530A1Increase driving torque of drivenSimple torque controlHand manipulated computer devicesDigital data processing detailsRolloverControl system

A control system (18) and method for controlling an automotive vehicle (10) includes a number of sensors that are used to generate a potential rollover signal. In response to the potential rollover, active differentials (112, 114, 116) may be used alone or in addition to braking to prevent the vehicle from rolling over.

Owner:FORD GLOBAL TECH LLC

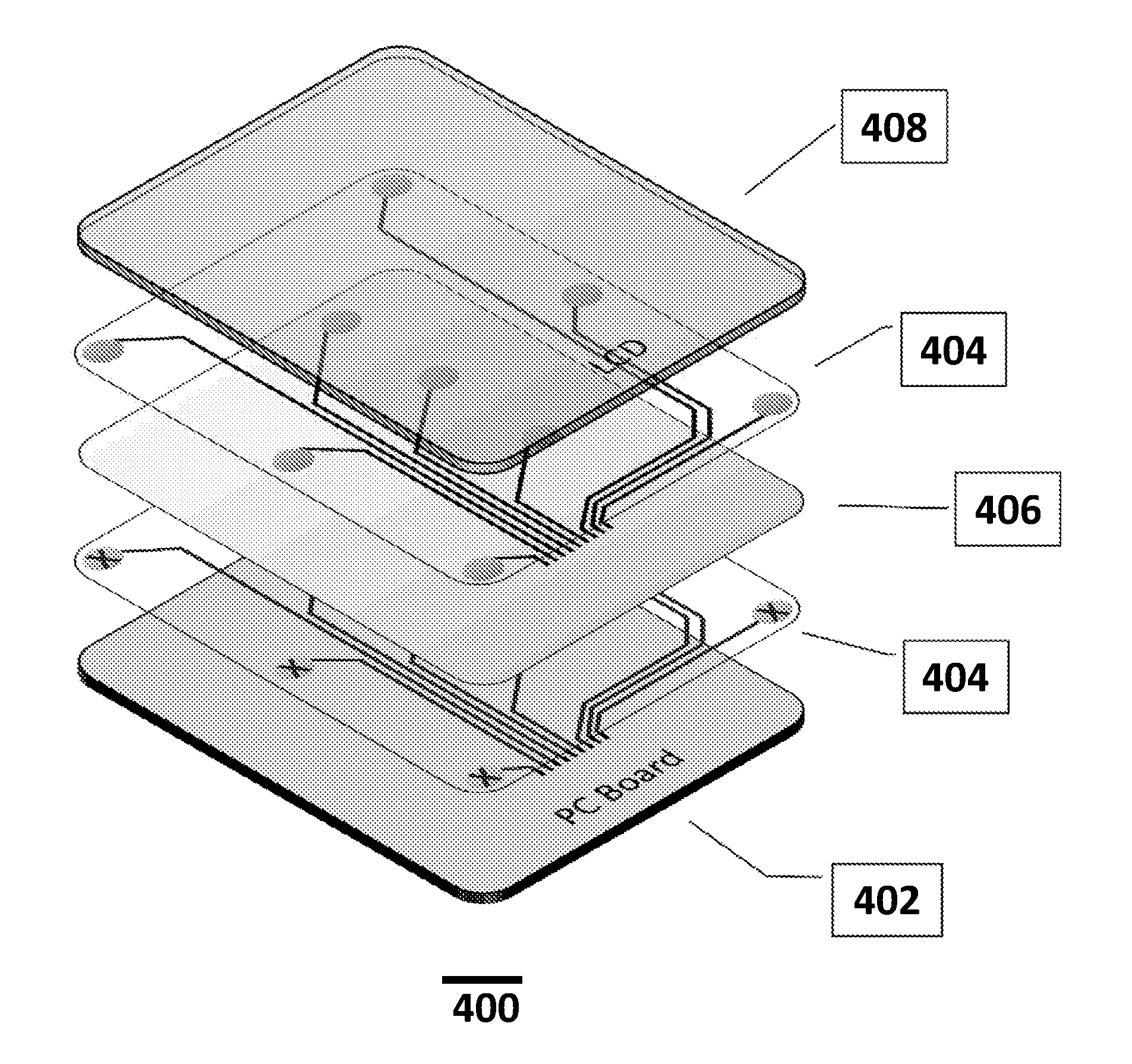

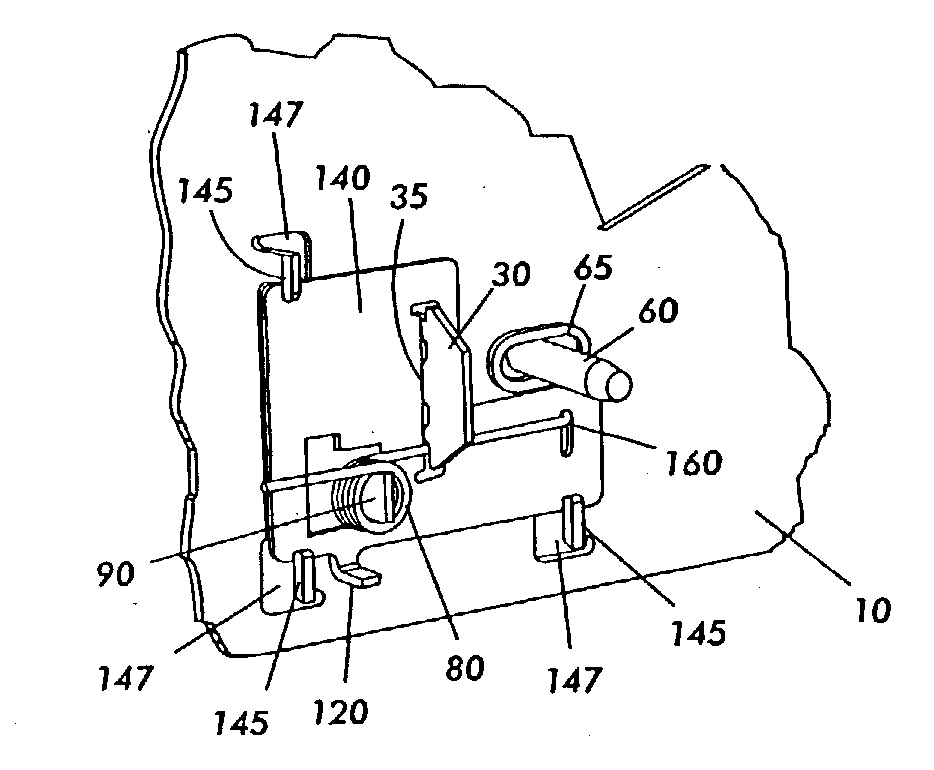

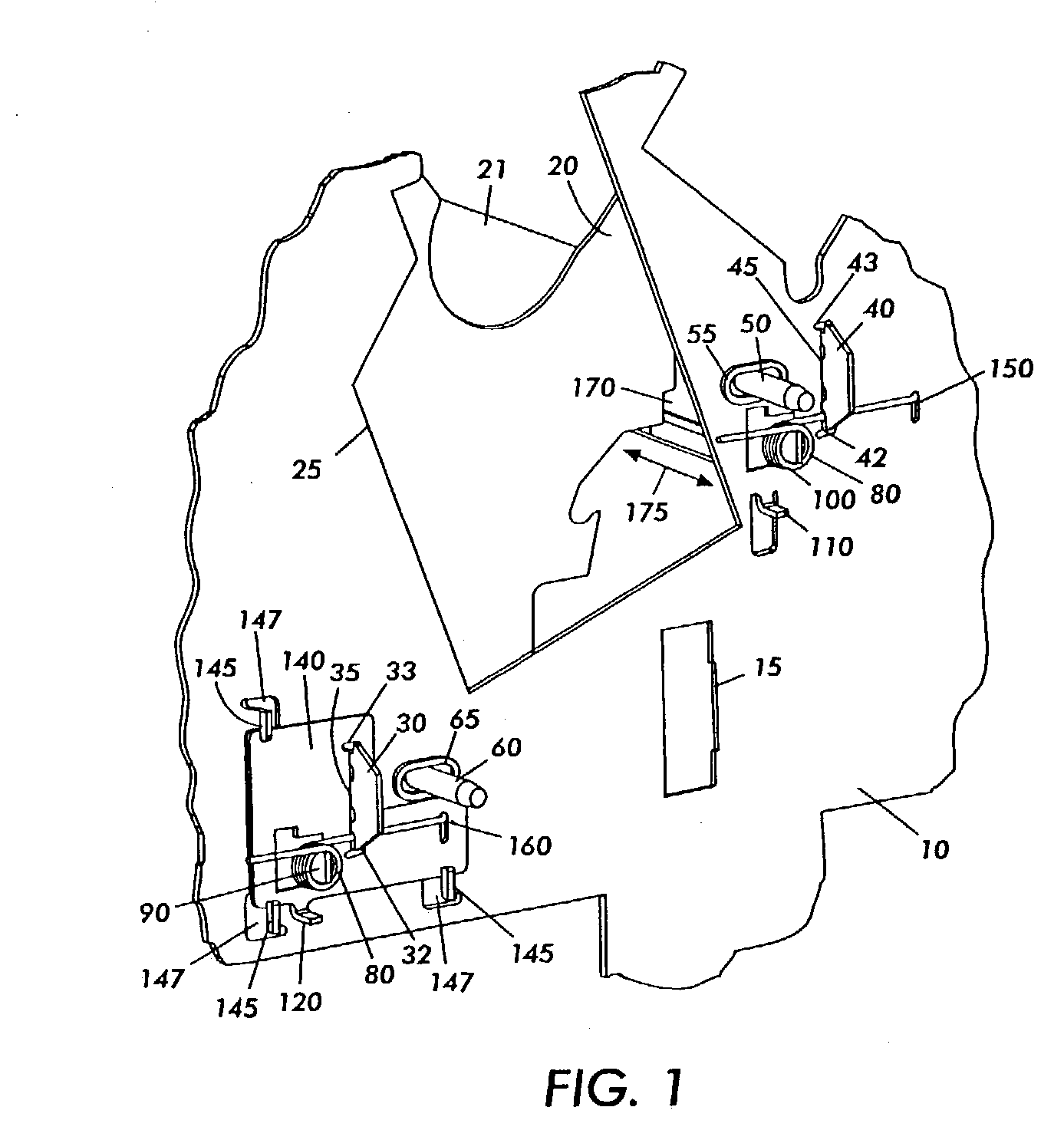

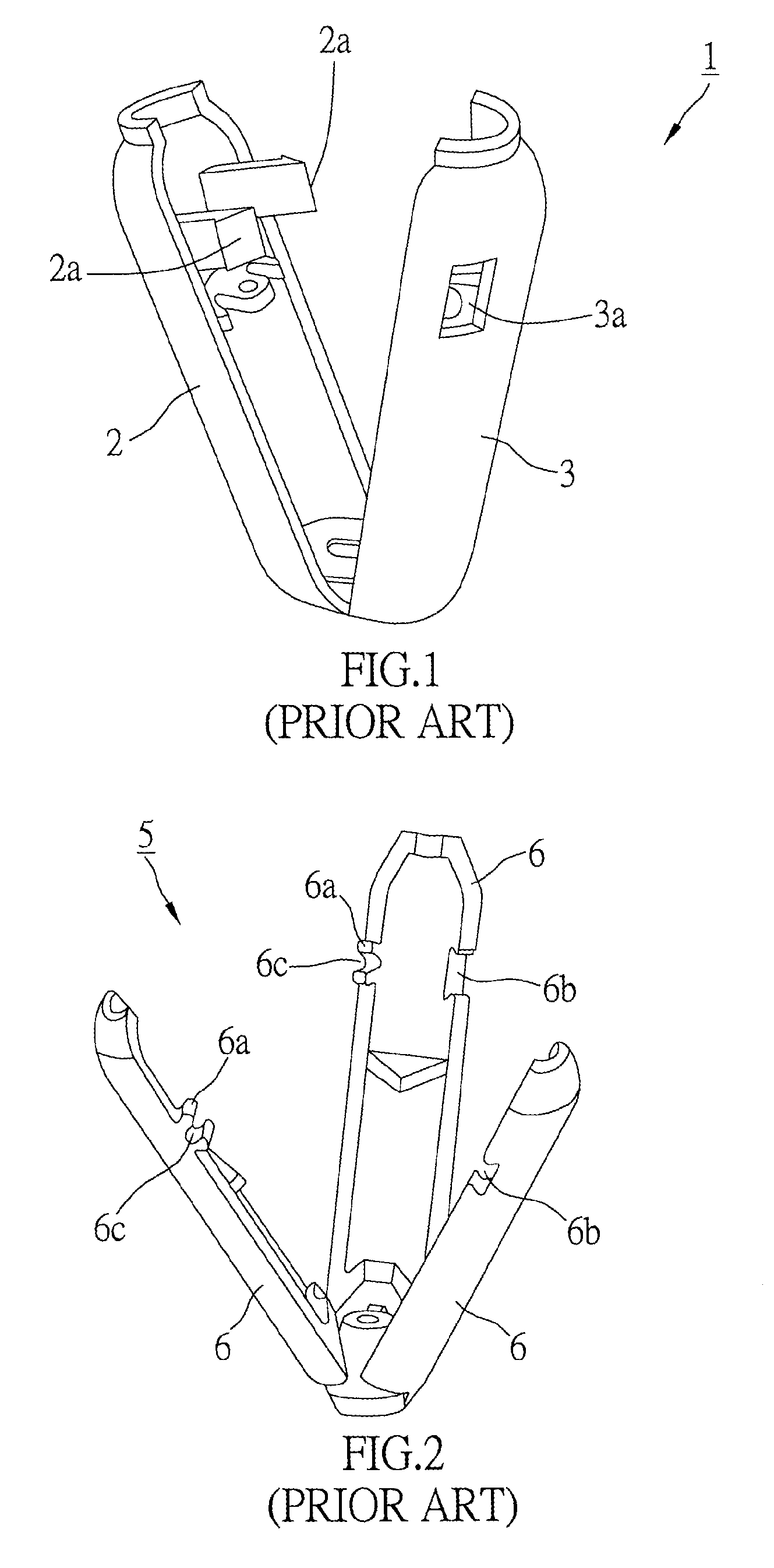

Floating plane touch input device and method

InactiveUS20120038577A1Easy to detectAvoid mechanical complexityTransmission systemsStands/trestlesDisplay deviceTouchscreen

A touch input device and method for manufacturing a touch input device are described. Each embodiment includes a touch surface, a mounting fixture, a sensing-suspension system, and a locating system. The touch surface may be an integral component of a host system, such as a display, which would result in a touch screen, or a touchpad input device. The touch surface is a floating plane, where the suspension positions, attaches and motion-enables the touch surface within the host system, and where the force exerted on the touch surface causes displacement of the touch surface, which motion is interpreted to calculate a touch location.

Owner:FLOATINGTOUCH

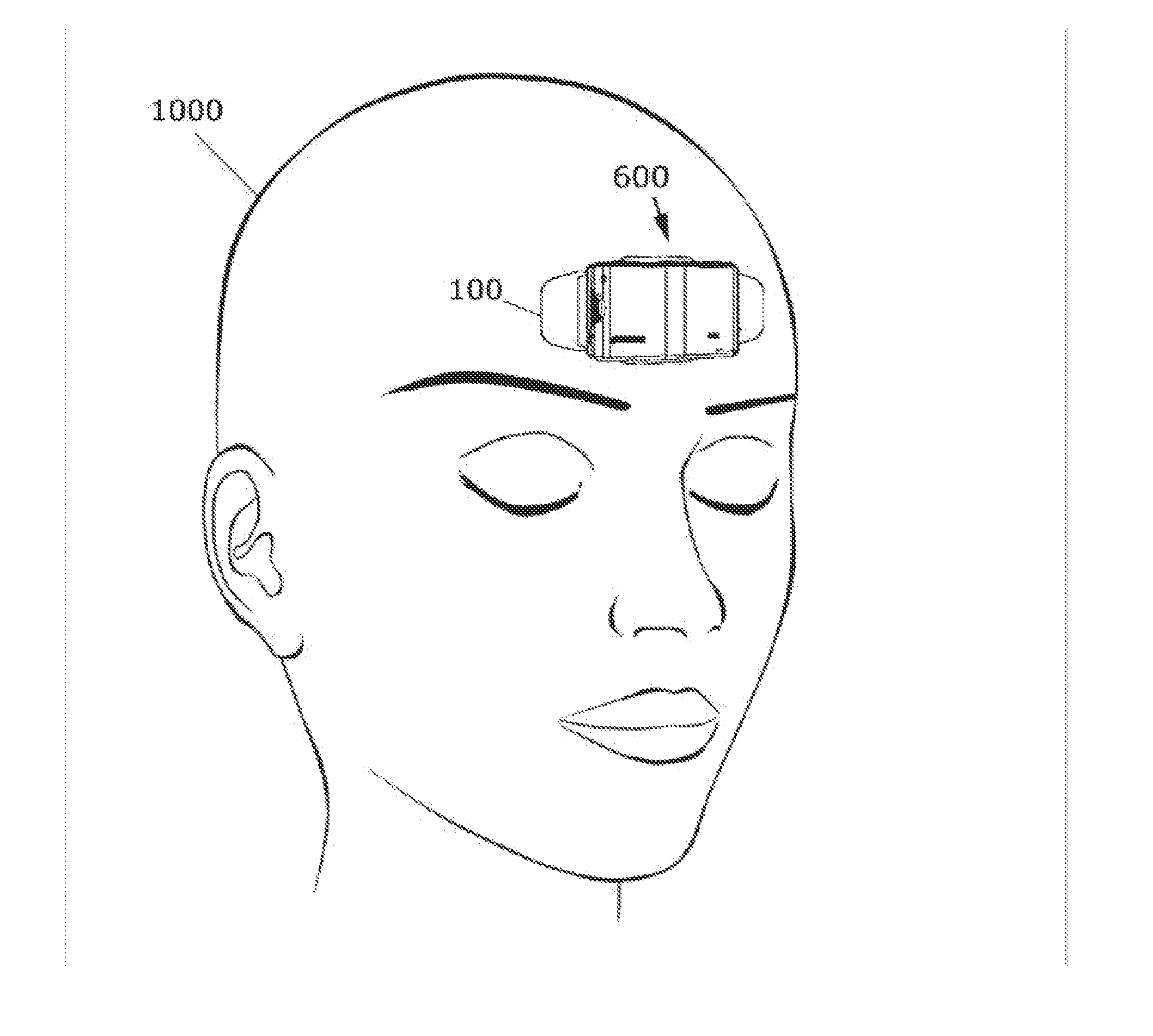

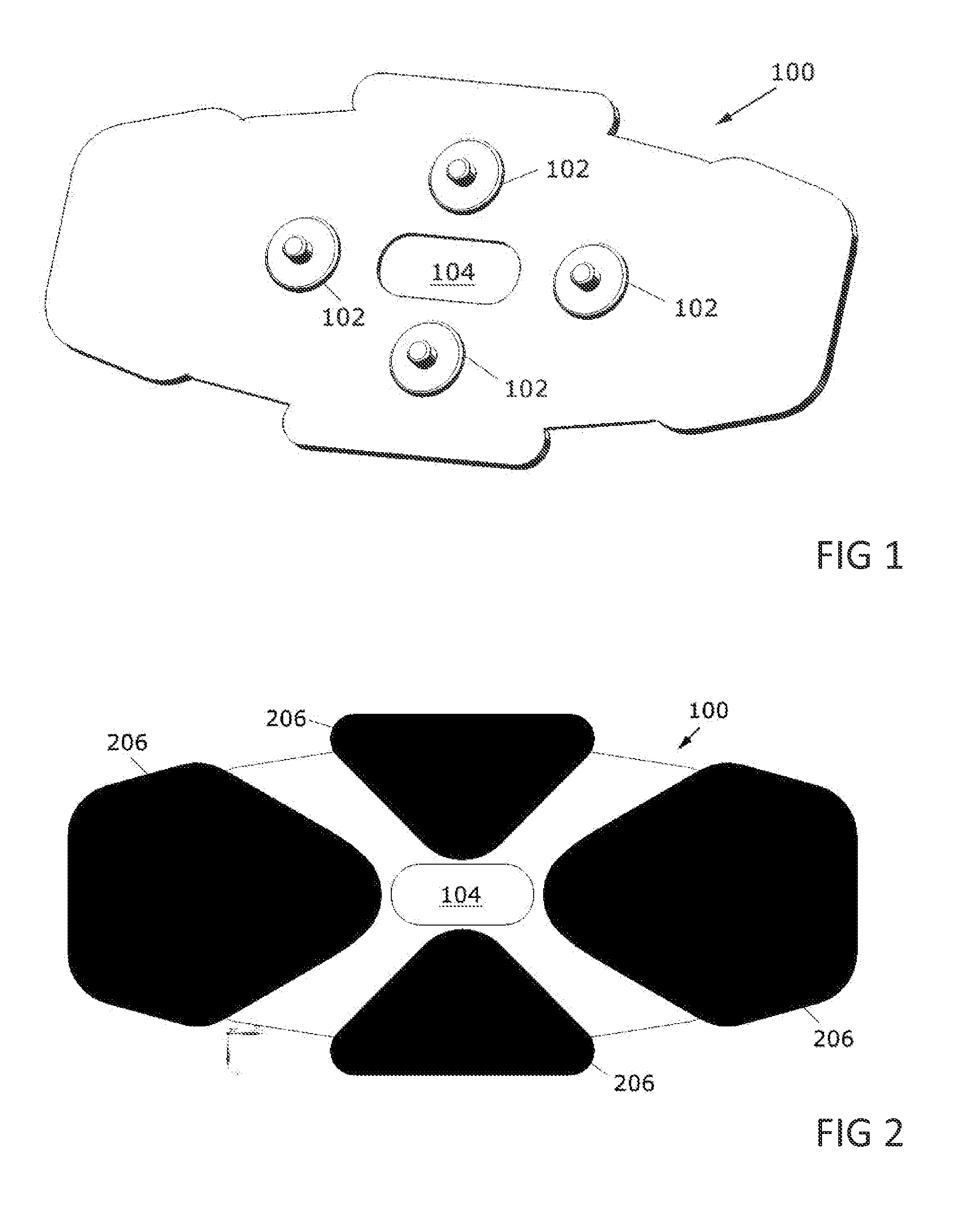

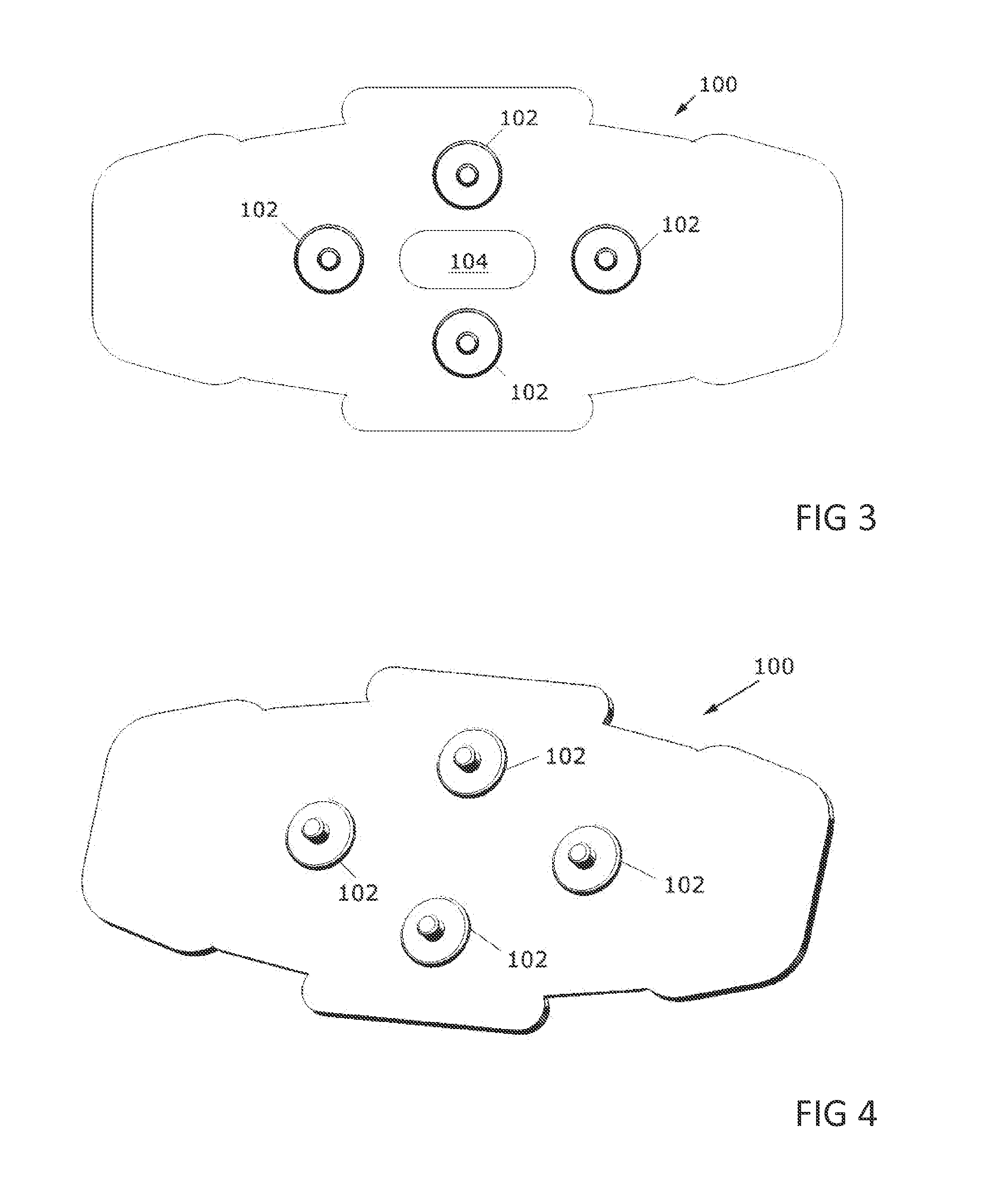

Adhesive-Mountable Head-Wearable EEG Apparatus

InactiveUS20150374255A1Good conditionHigh degree of miniaturizationElectroencephalographySensorsEngineeringWearable eeg

An adhesive-mountable head-wearable EEG apparatus is disclosed. The apparatus includes an EEG sensor for acquiring an EEG signal of a wearer, a central processing unit for receiving the EEG signal, a small circuit board including the EEG sensor and the central processing unit, and a compact enclosing shell for enclosing the small circuit board, the EEG sensor, and the central processing unit. An adhesive electrode assembly attaches to the compact enclosing shell, or to the small circuit board within the enclosing shell, via snaps or magnets. The adhesive electrode assembly includes two or more gel electrodes for acquiring an EEG signal, and for adhering to the forehead so as to wearably support the EEG apparatus on the forehead. The compact enclosing shell includes chamfered edges, and is sized so as to reduce lateral forces on the compact shell that would tend to detach the EEG apparatus from the wearer's forehead.

Owner:VASAPOLLO CURZIO

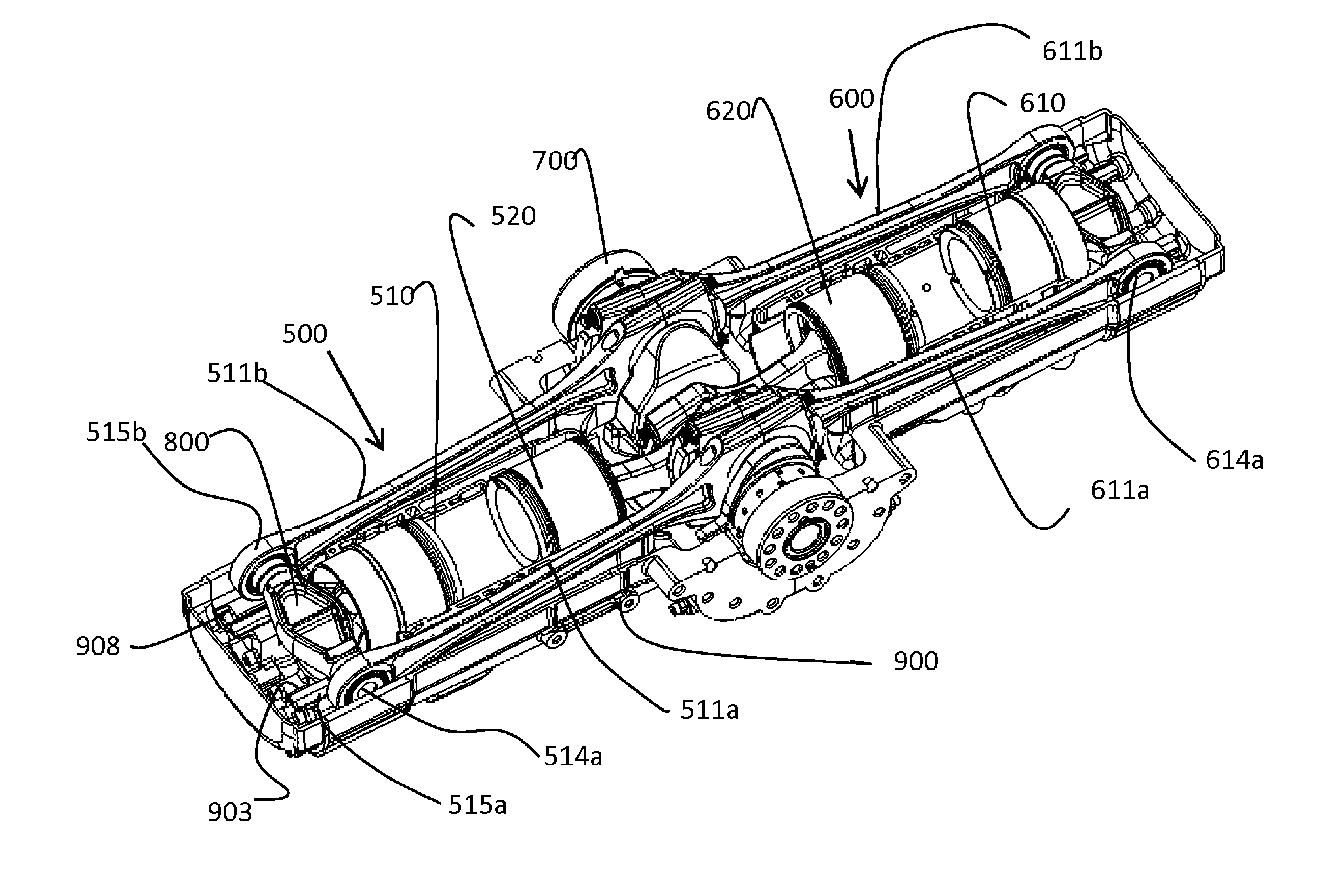

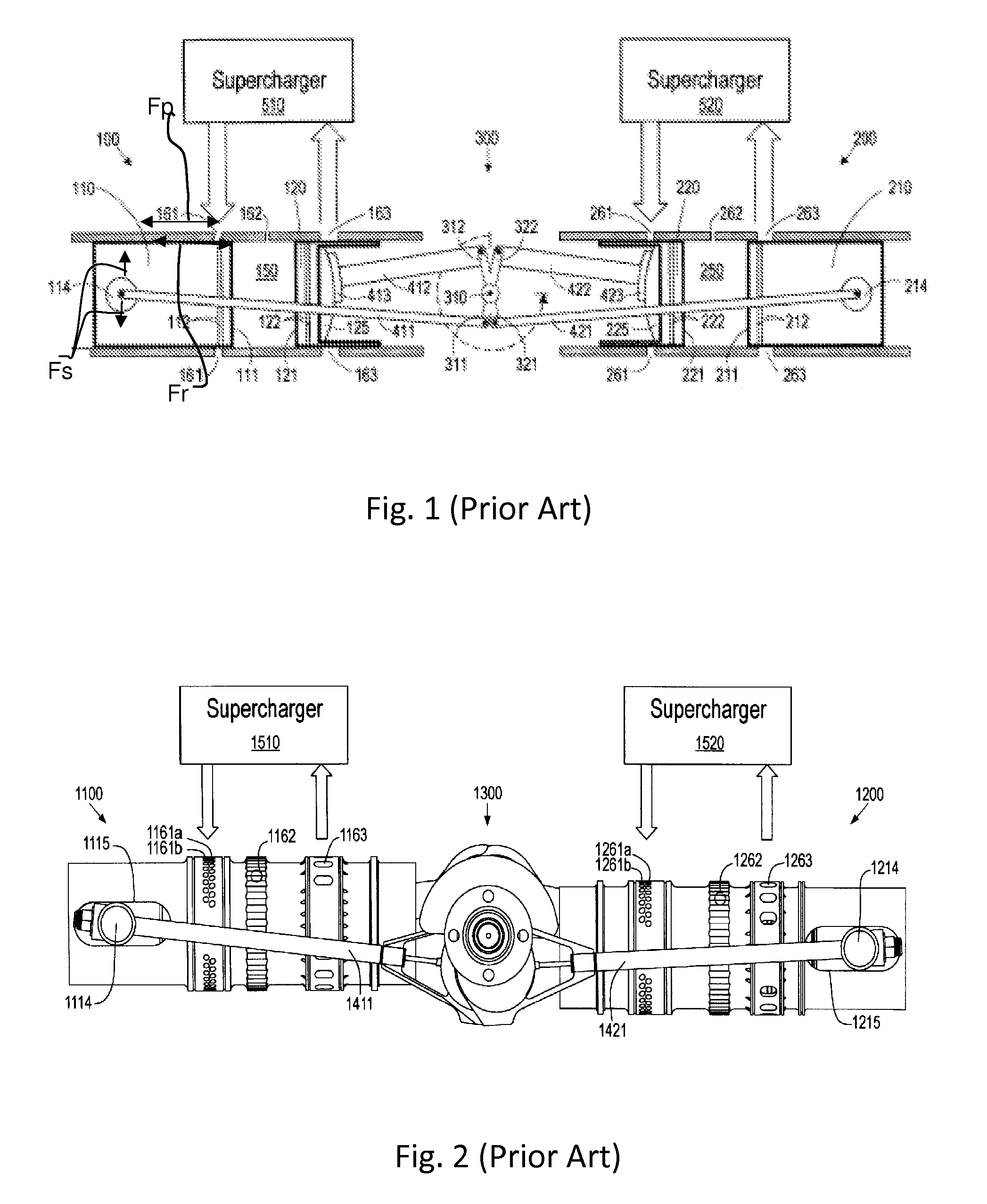

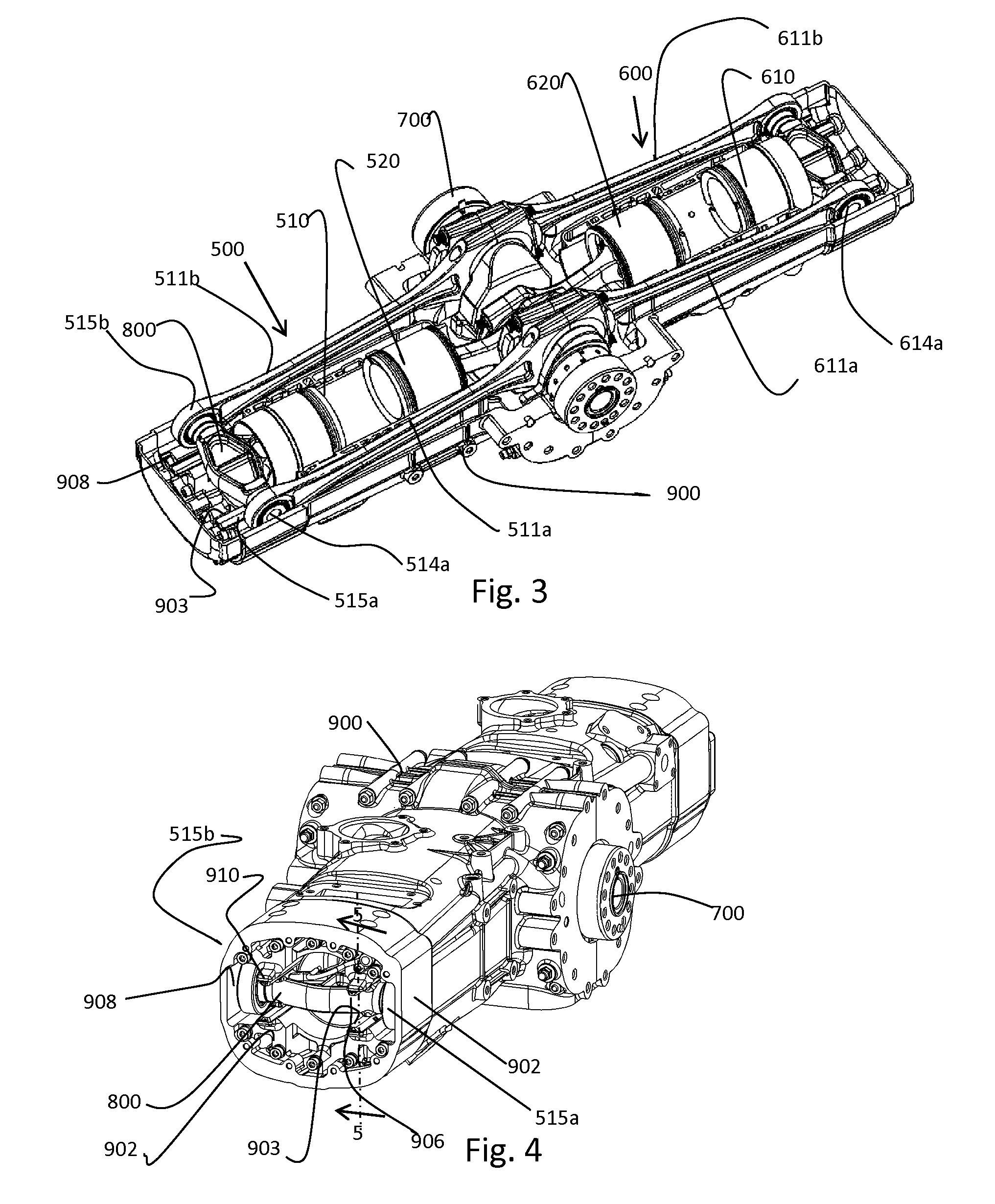

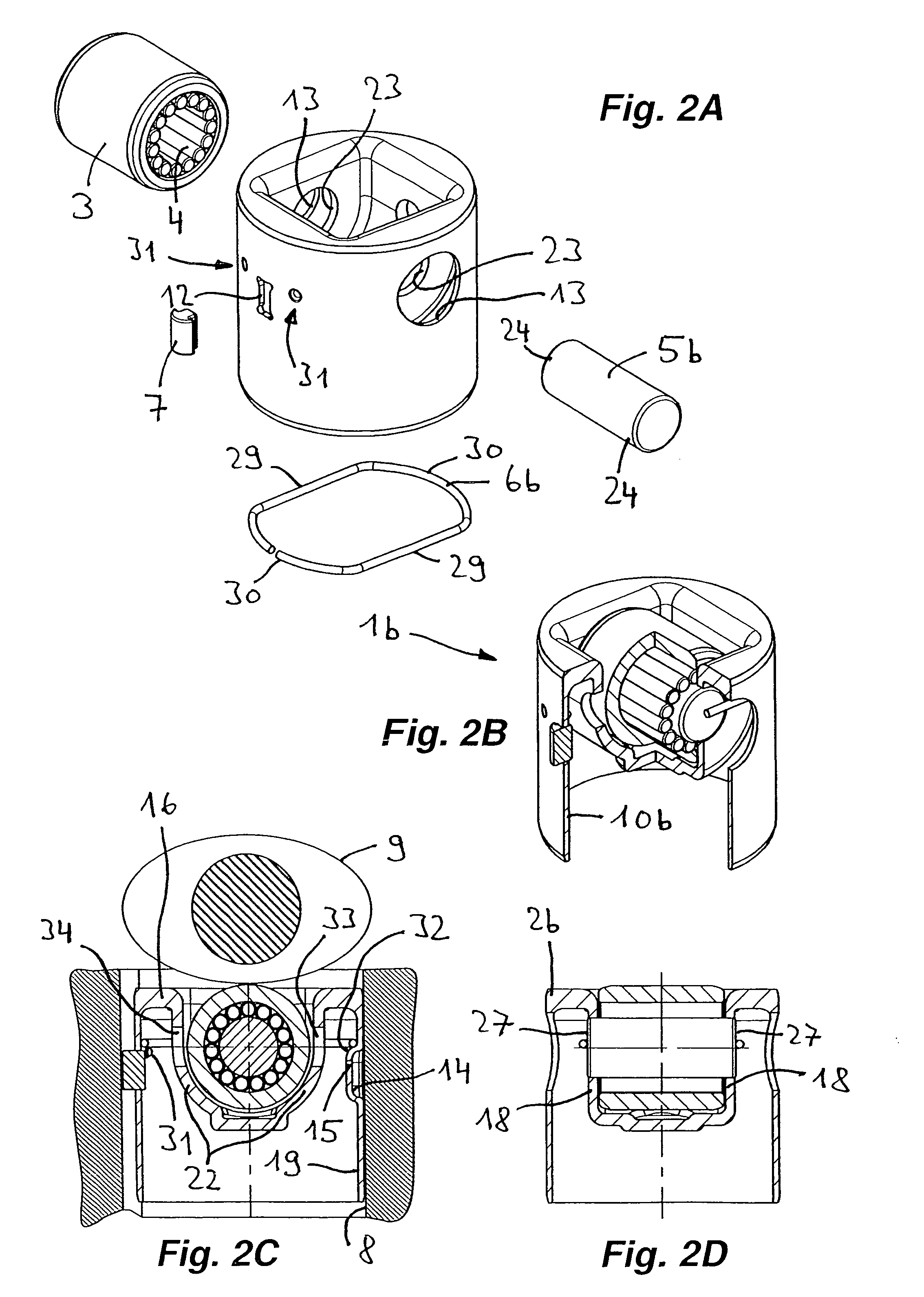

Guided bridge for a piston in an internal combustion engine

InactiveUS20100229836A1Reduce frictionImprove efficiencyPistonsReciprocating piston enginesPistonEngine cycle

An improved configuration for internal combustion engine that reduces side forces on pistons during the engine cycle. The improvement is an intermediate and guided bridge element located between pull rods and pistons with articulated connections that allow side forces to be dissipated away from the pistons.

Owner:ECOMOTORS INT +1

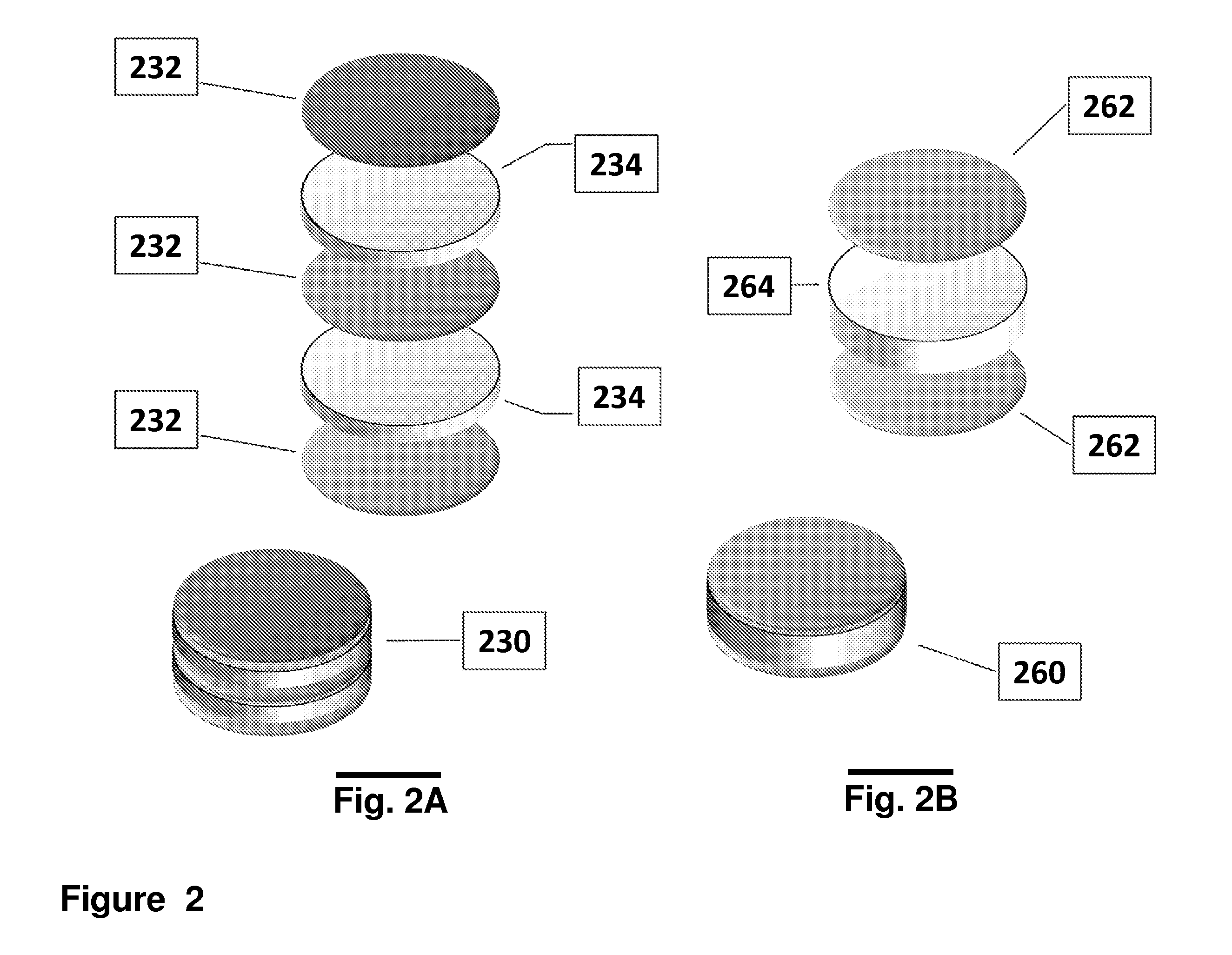

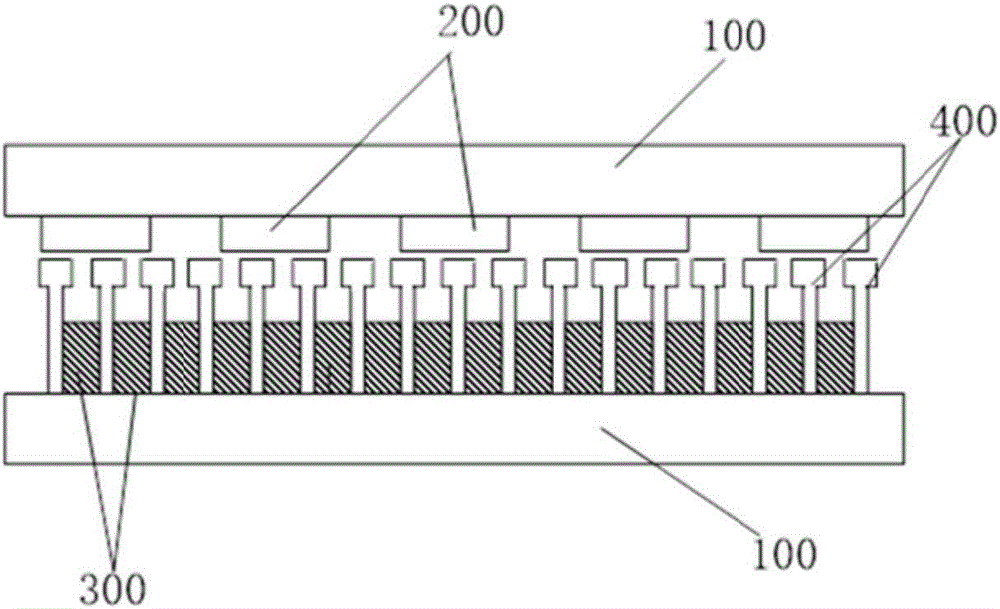

Method of forming an article

ActiveUS20090202378A1Reduce lateral forceAvoid layeringAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceParallel channel

From one aspect, a method of forming a support for use in a selective sintering or melting process includes forming a body on a platen having a plurality of generally parallel channels each channel being open at least one end. The base of the channels may be formed by the platen. Preferably the support is formed by a selective sintering or melting process.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

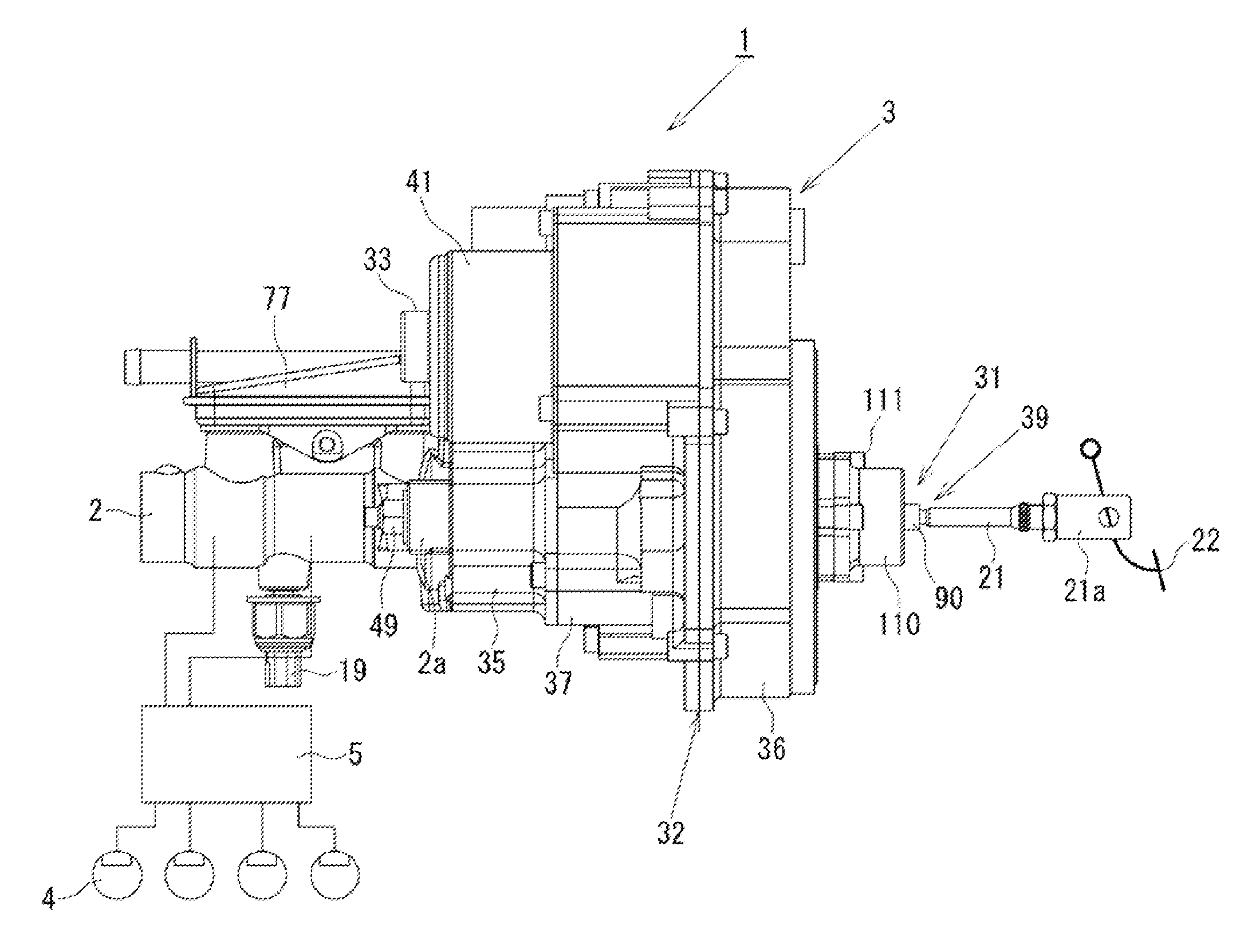

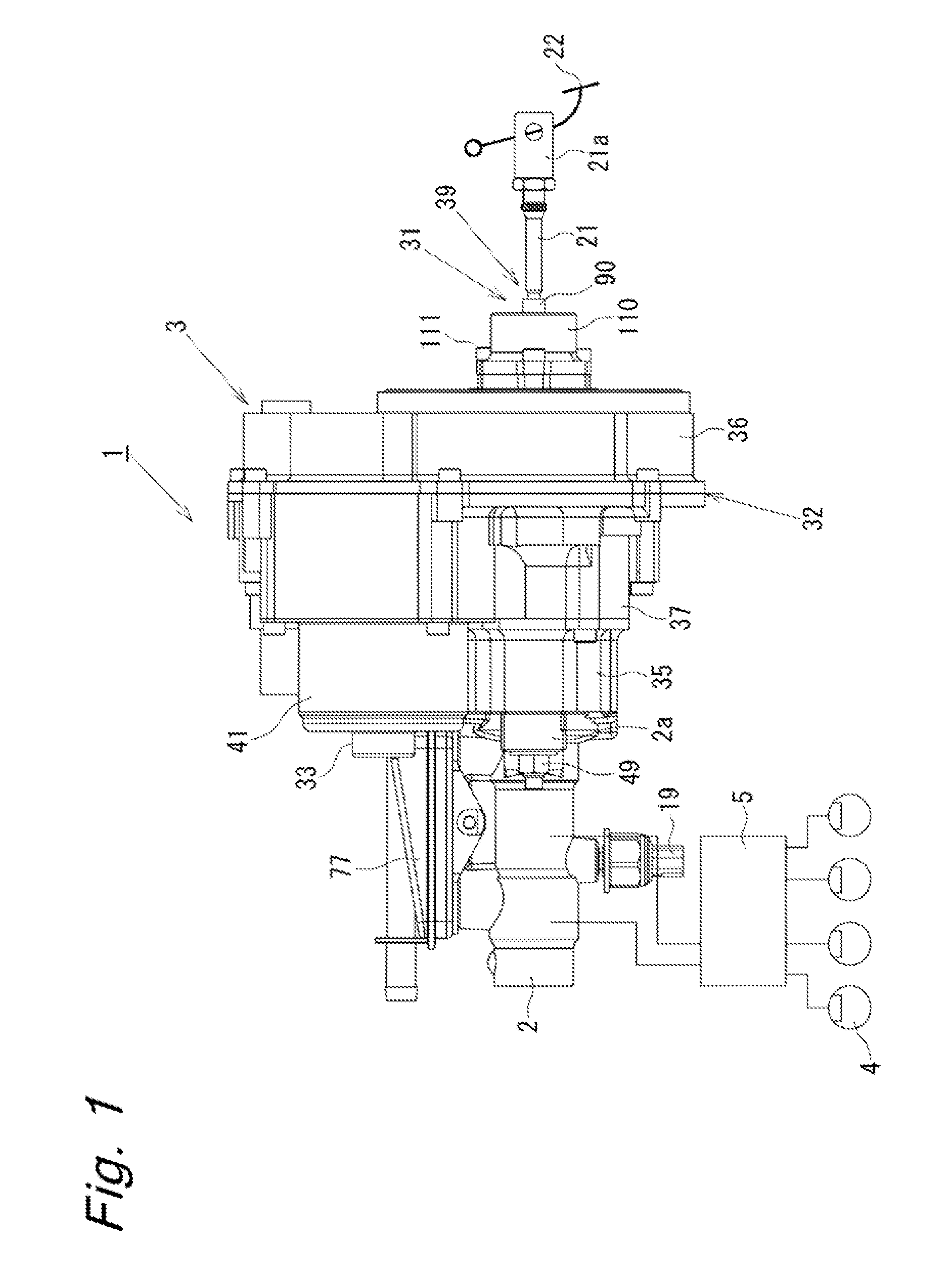

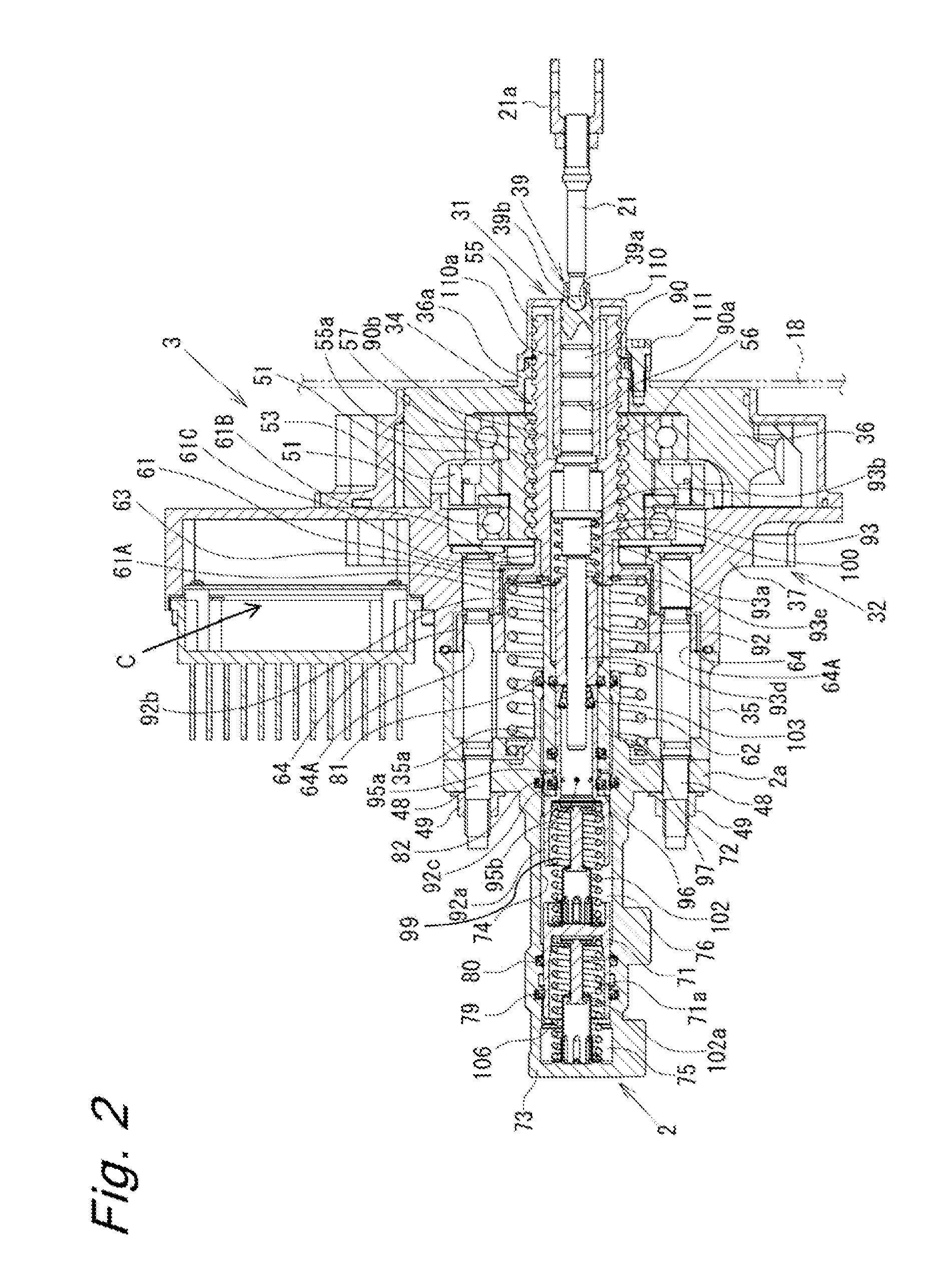

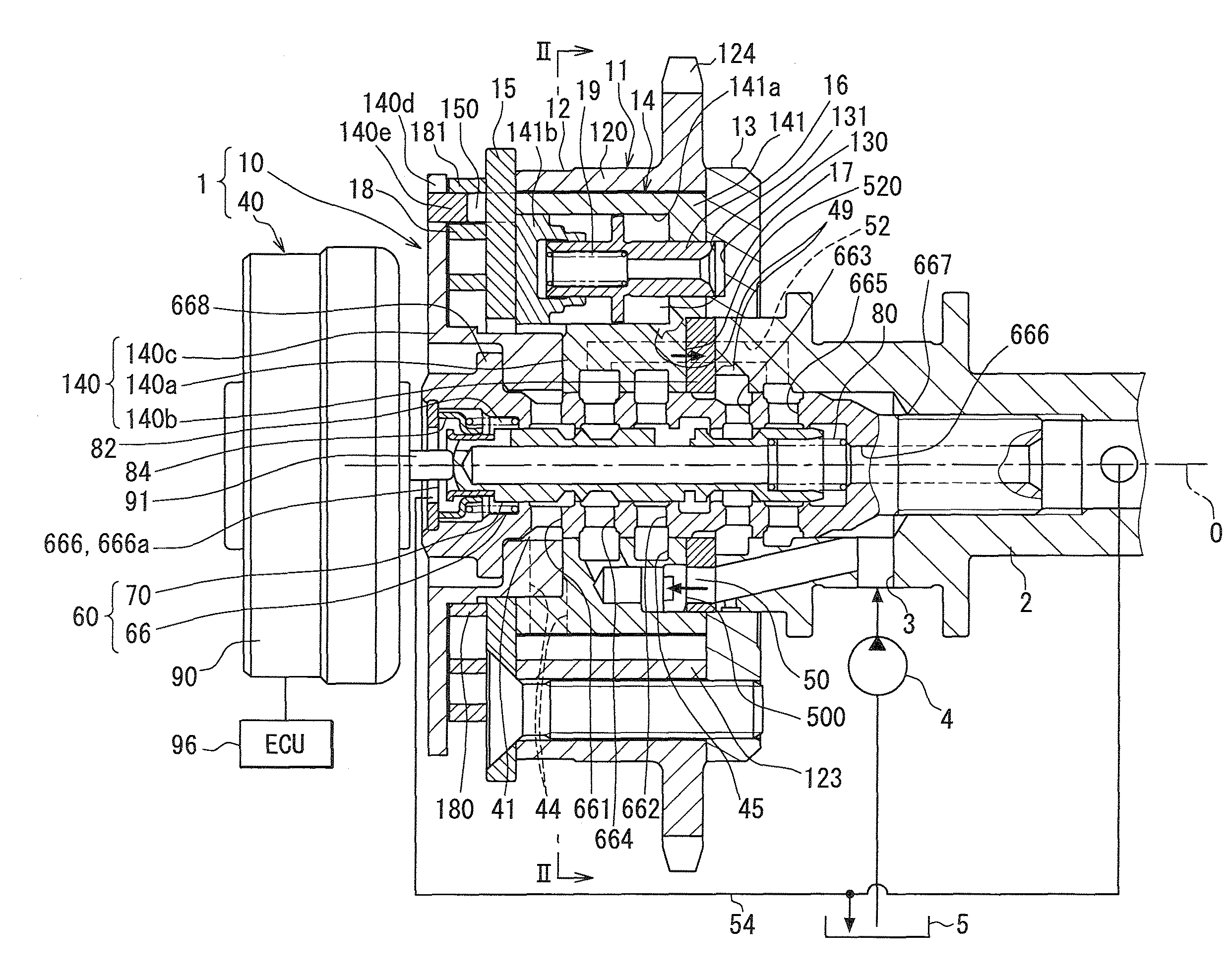

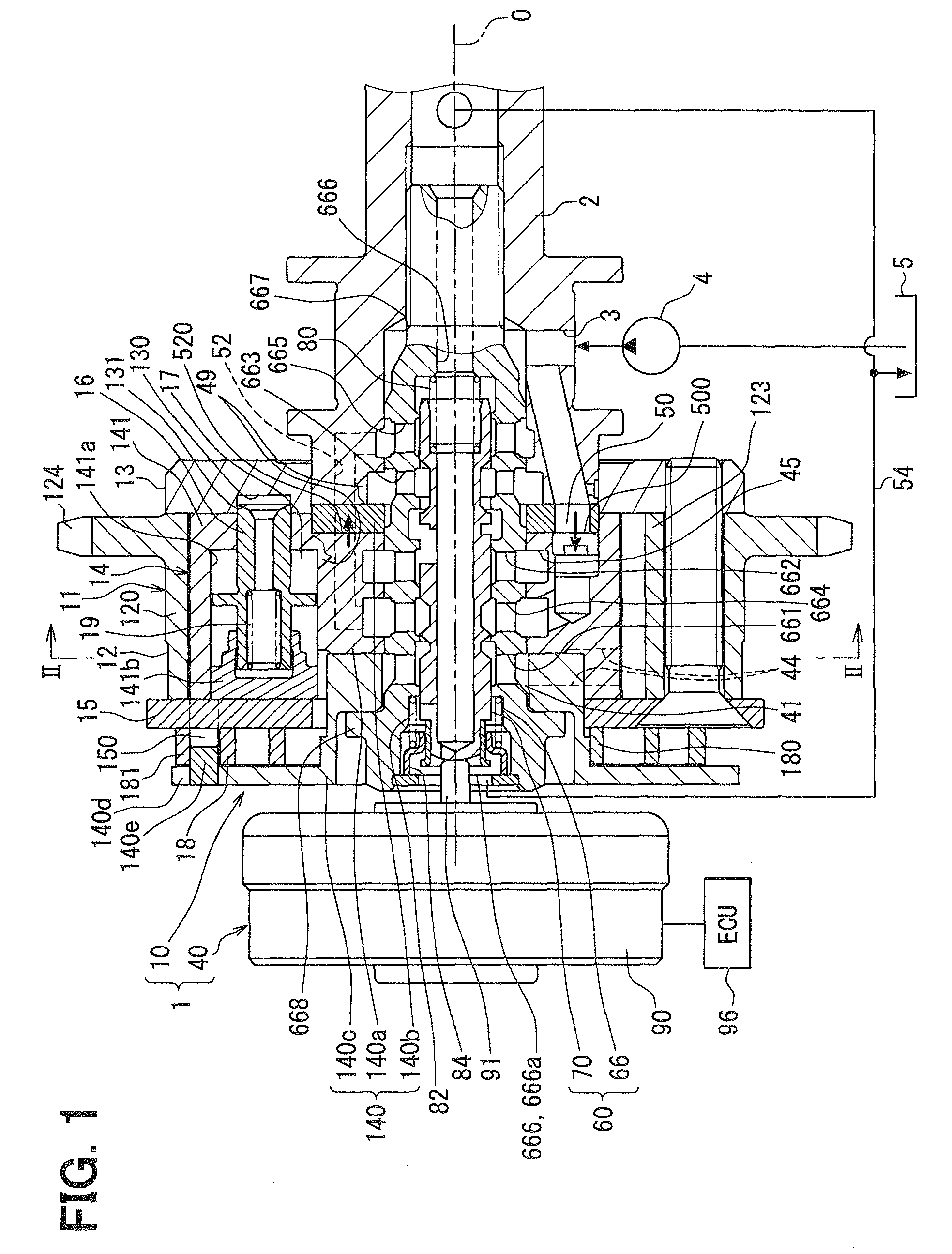

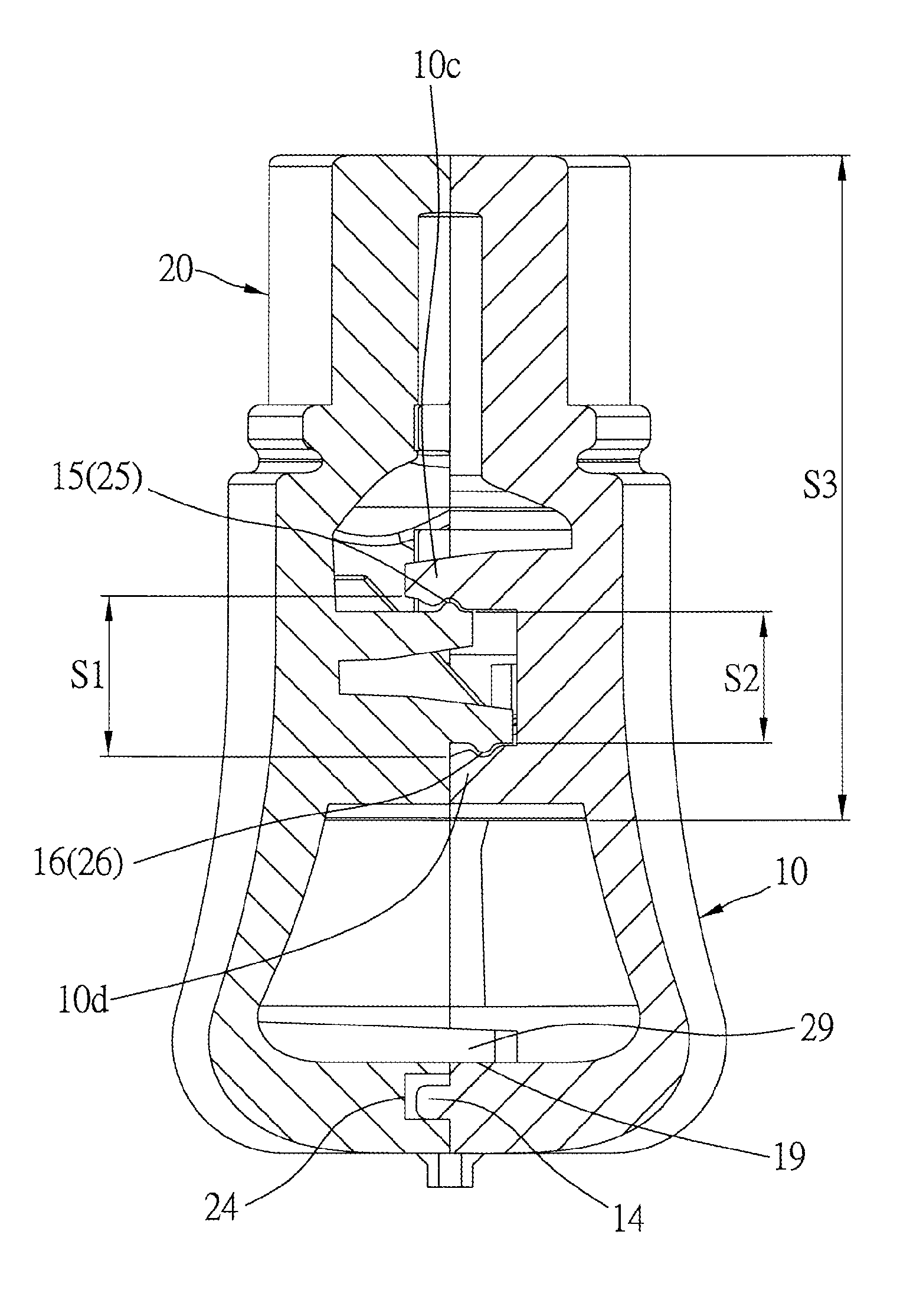

Electric motor-driven booster

An electric motor is controlled according to an operation of a brake pedal connected to an input rod to drive a ball-screw mechanism through a transmission mechanism, thereby propelling a primary piston and a subpiston to generate brake hydraulic pressure in a master cylinder. The brake hydraulic pressure in the master cylinder is received with an input piston and transmitted to the brake pedal through a plunger rod and the input rod. The input rod and the plunger rod are tiltably connected, through a ball joint, and the plunger rod is axially slidably guided by a guide part of a rear cover. Thus, a lateral force acting on the primary piston or the subpiston is reduced to prevent an increase in sliding resistance and degradation of sealing performance.

Owner:HITACHI AUTOMOTIVE SYST LTD

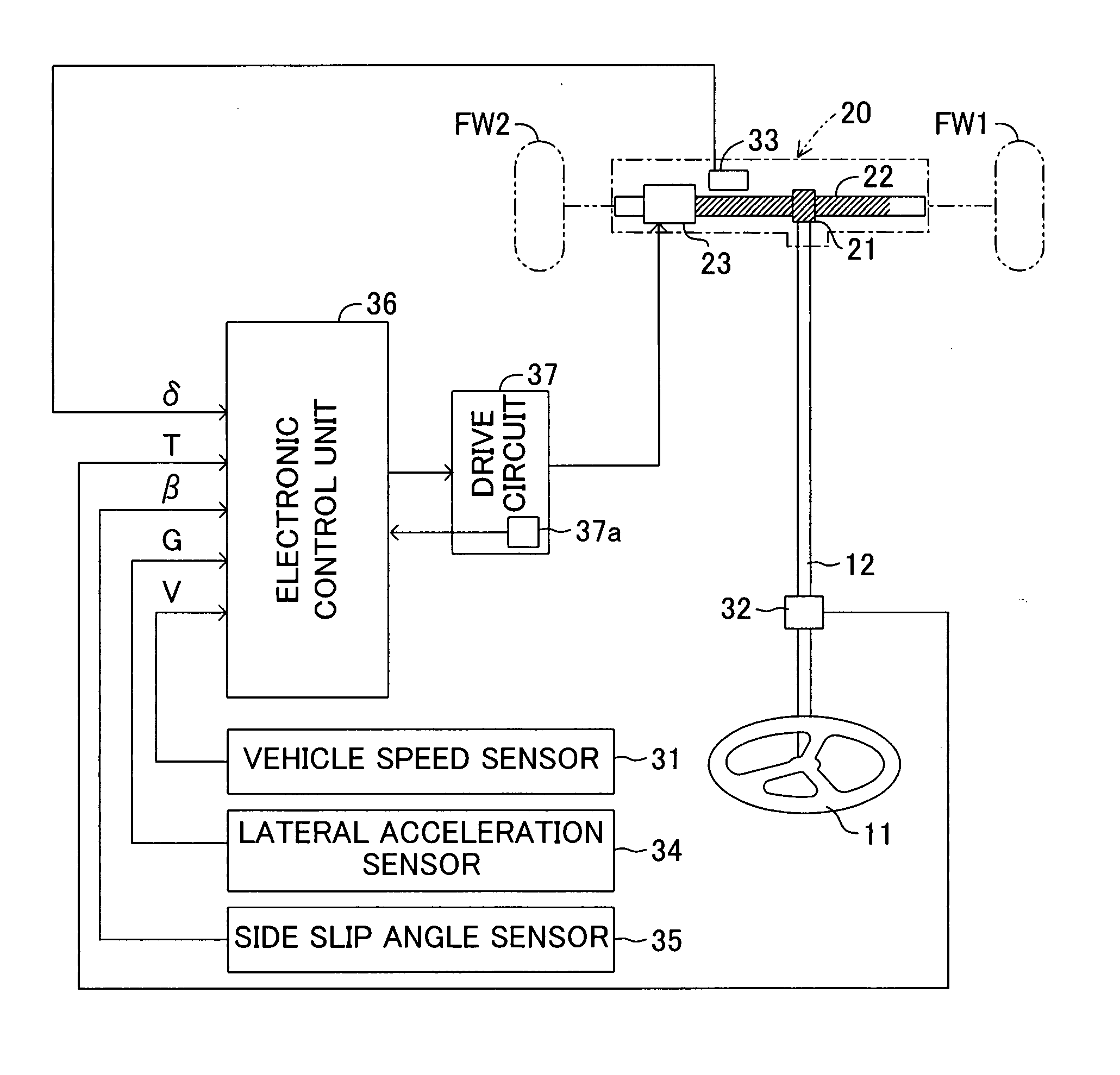

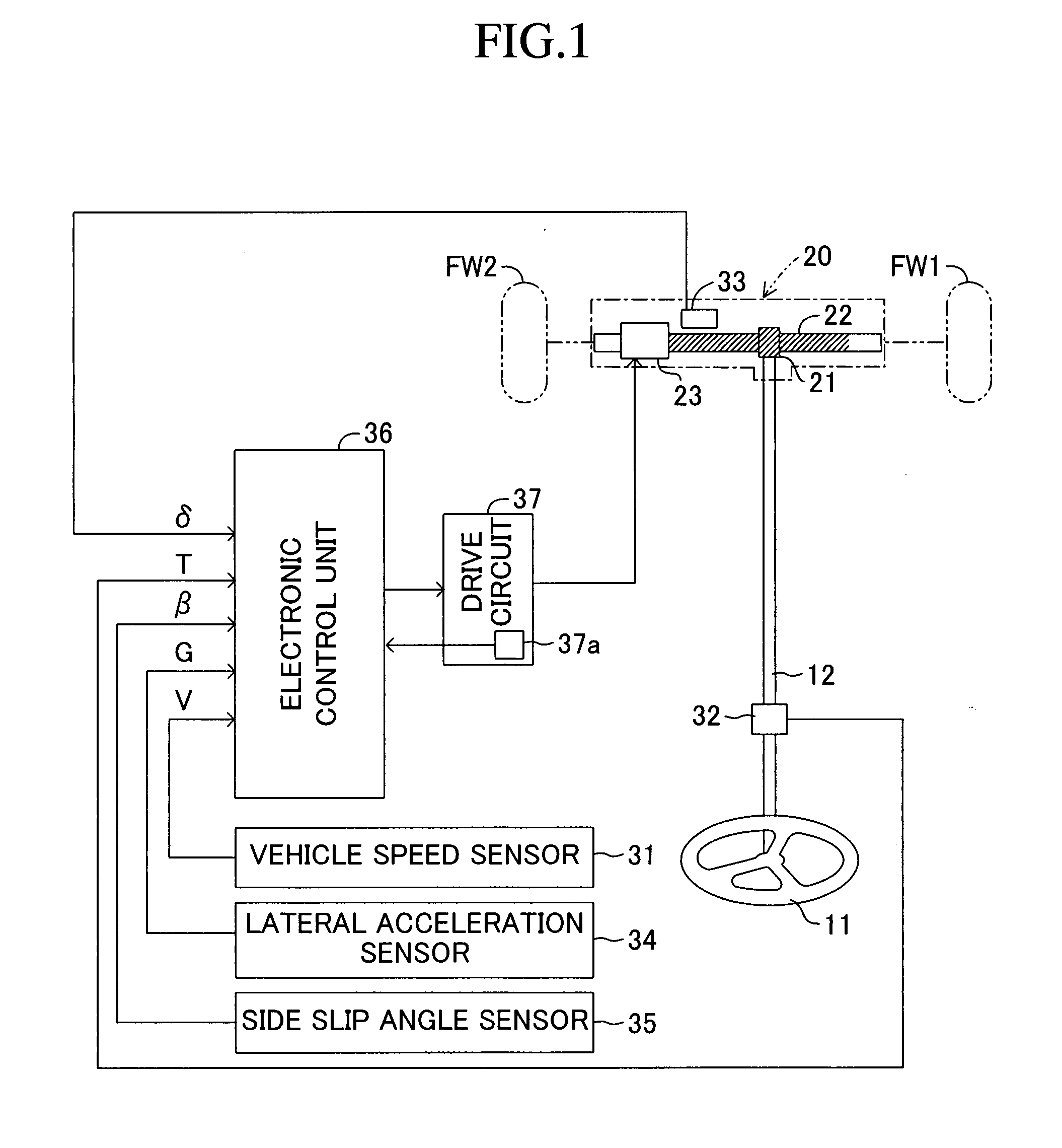

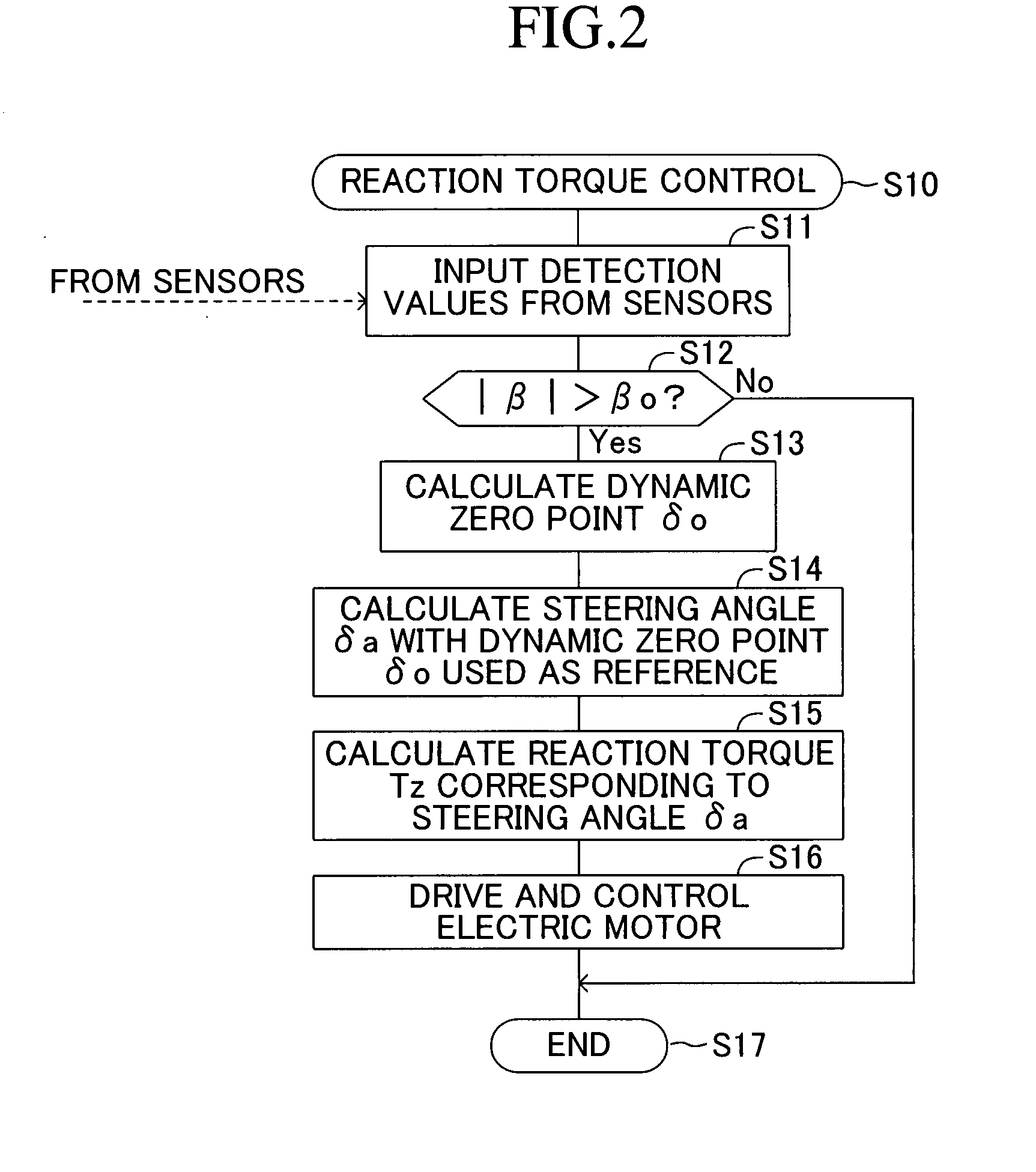

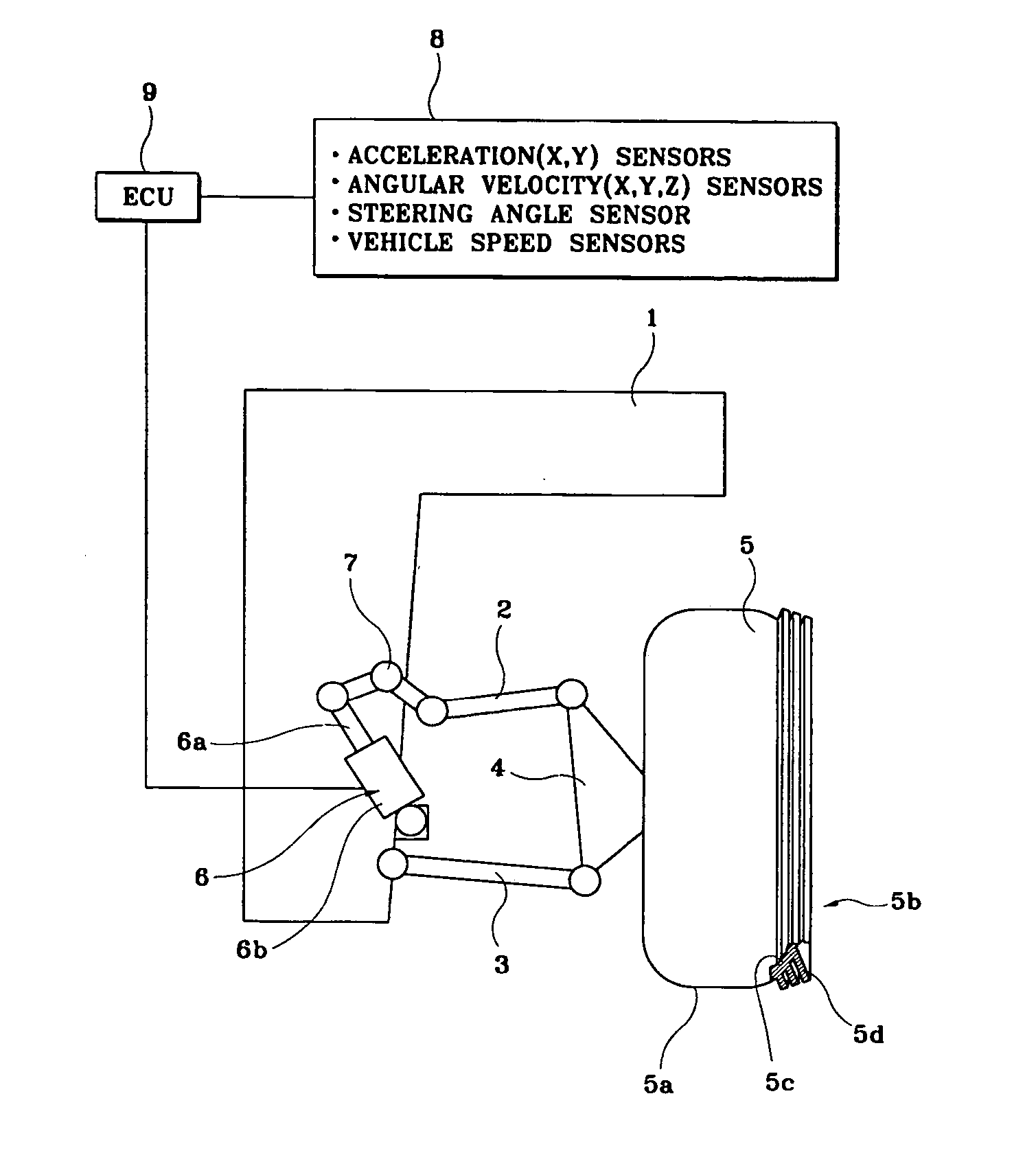

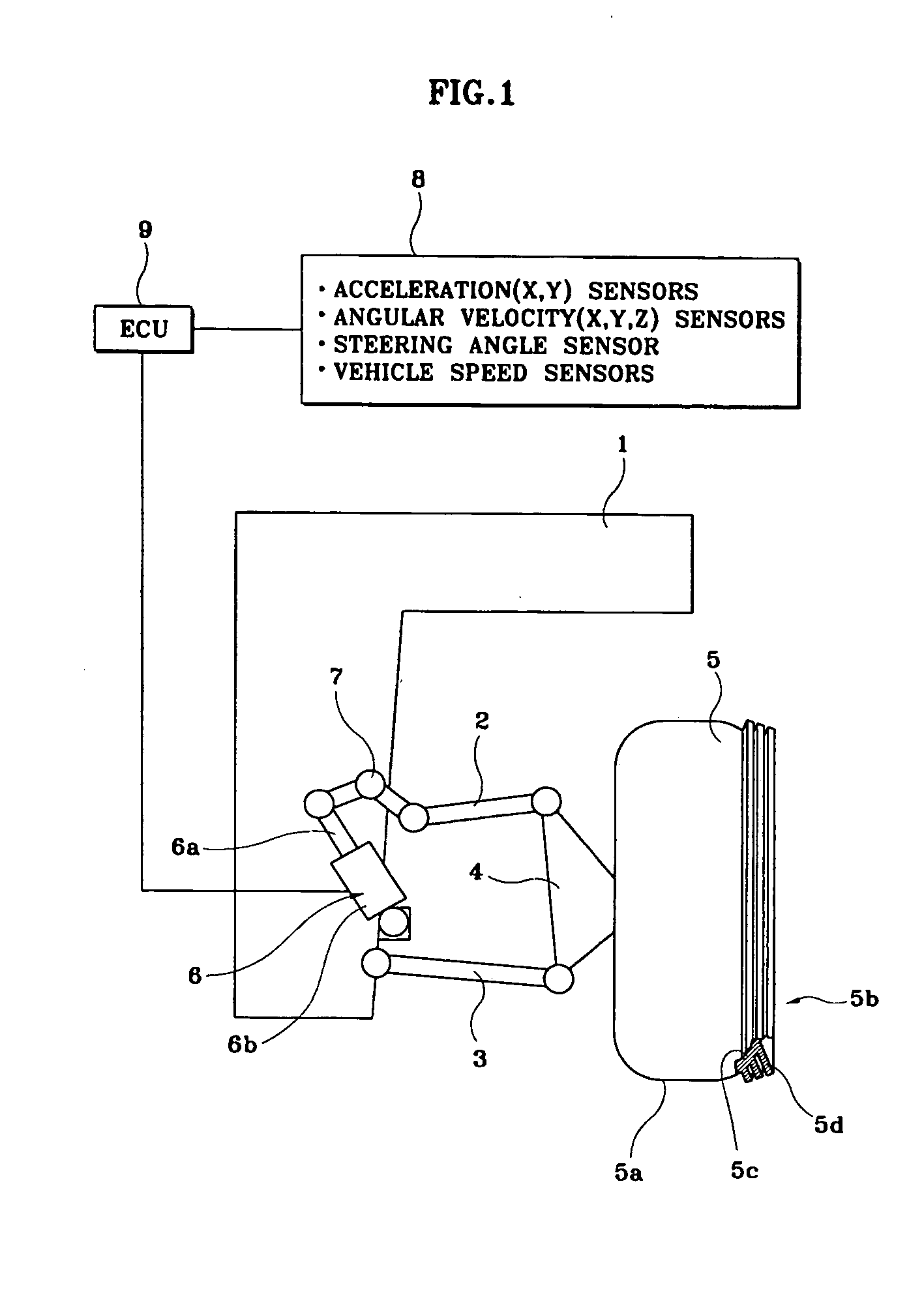

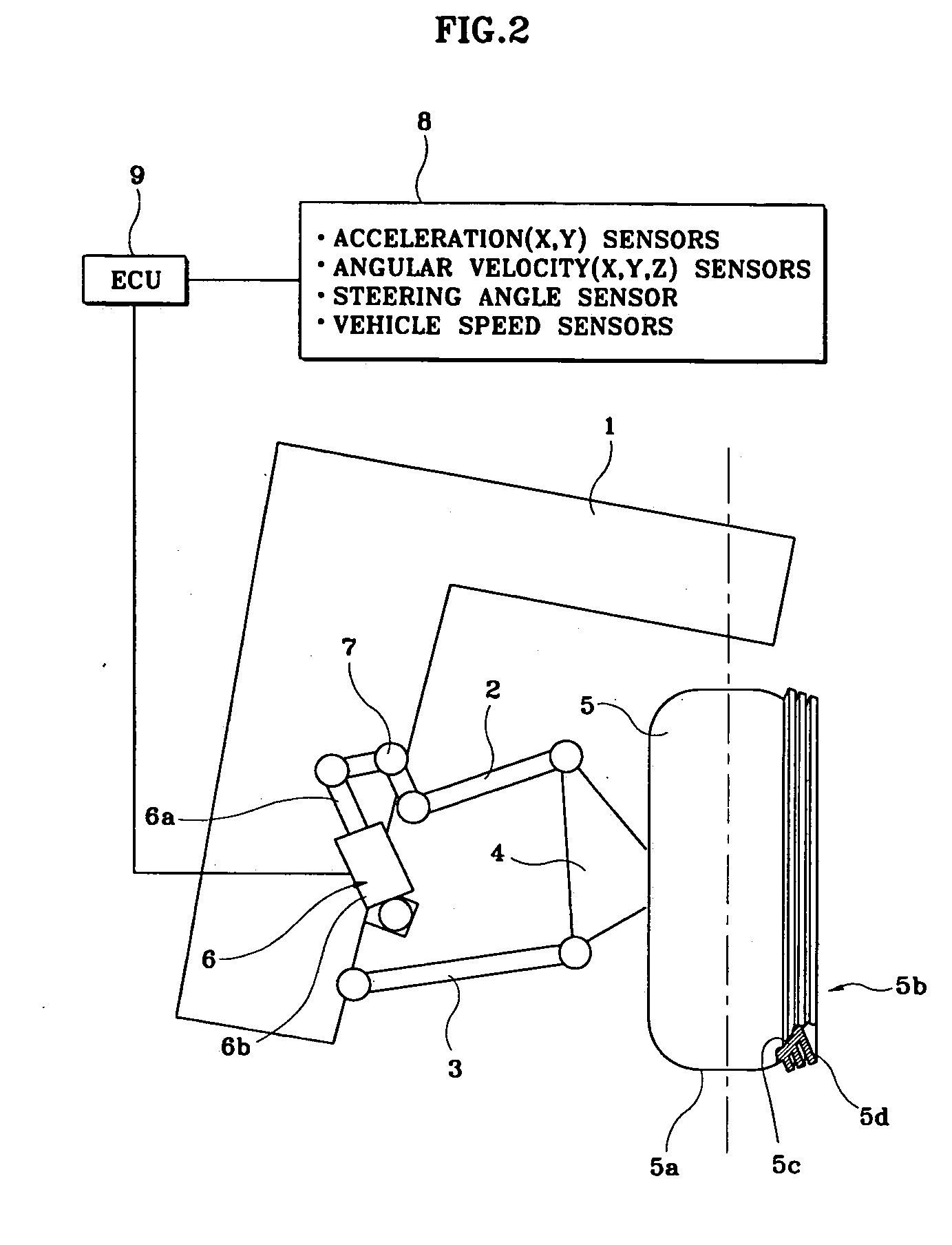

Steering Apparatus for Vehicle

InactiveUS20080142293A1Accurate calculationReduce lateral forceDigital data processing detailsSteering initiationsElectronic control unitSteering angle

An electronic control unit inputs a side slip angle β of a vehicle body in step S11. Next, in step S13, the unit calculates, while using the side slip angle β of the vehicle body, a dynamic zero point δo for reducing a lateral force generated in the vehicle due to the side slip angle β of the vehicle body. Next, in step S14, the unit calculates a steering angle δa, which is represented by the difference between the dynamic zero point δo and a steering angle δ detected by a steering angle sensor. Next, in step S15, the unit calculates a reaction torque Tz having a predetermined relation with the steering angle δa. Subsequently, in step S16, the unit drives and controls an electric motor to generate the calculated reaction torque Tz. Thus, the unit guides a driver to a proper steering-wheel rotating direction.

Owner:TOYOTA JIDOSHA KK

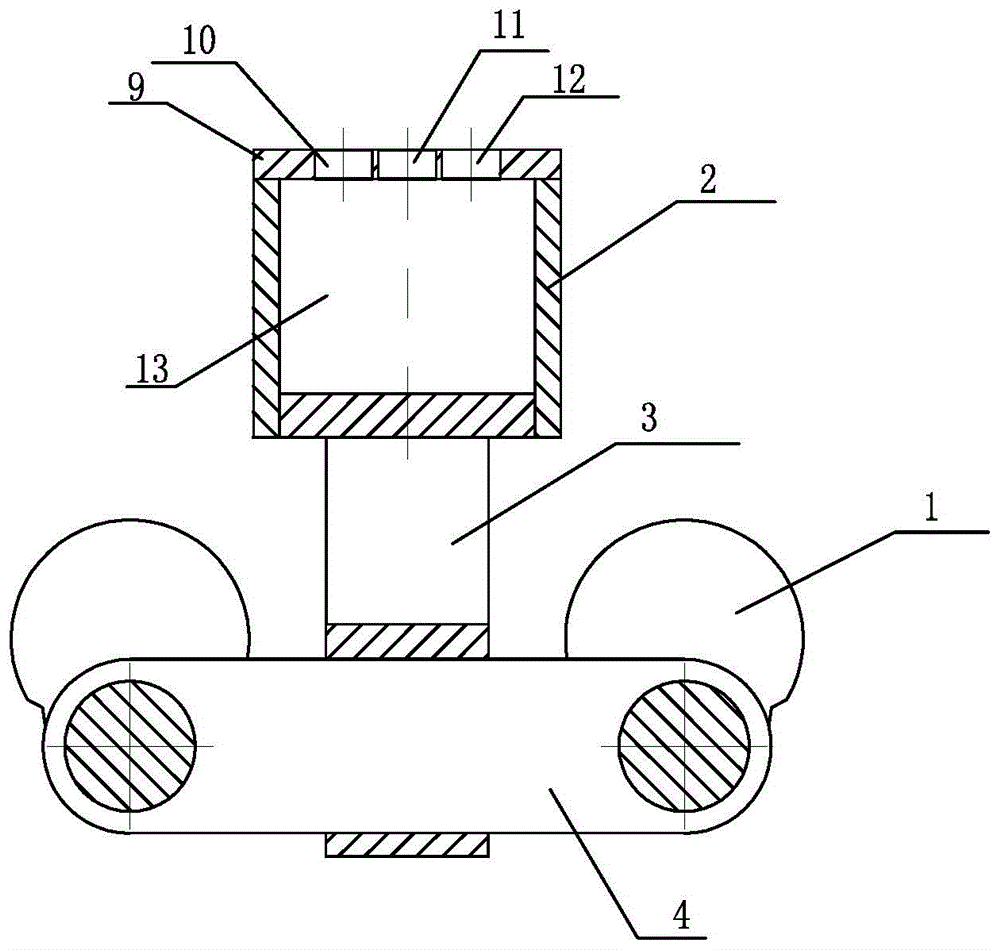

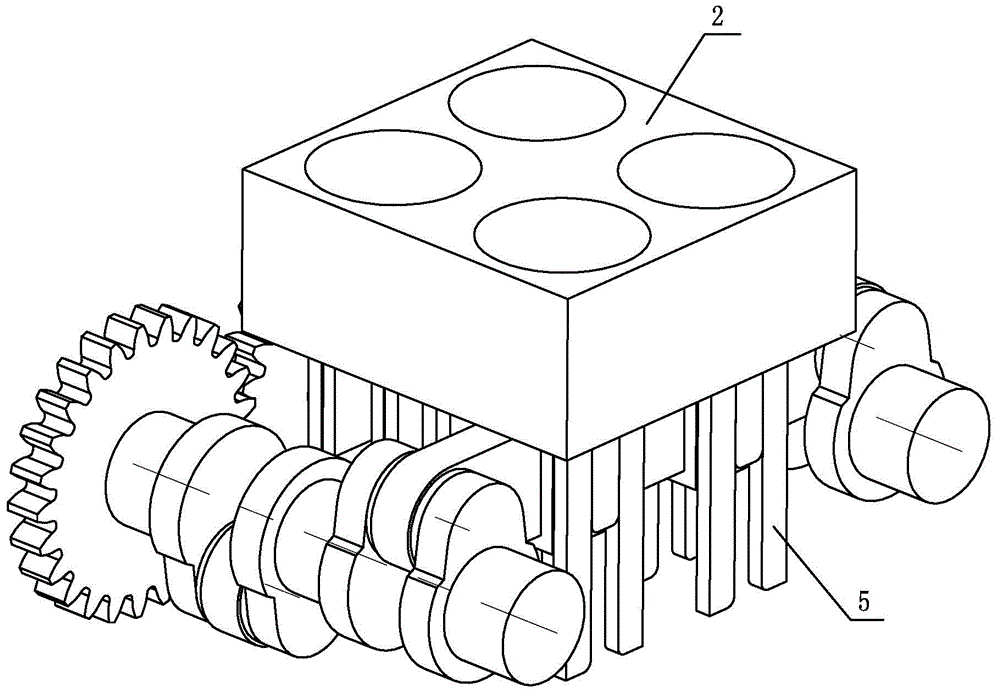

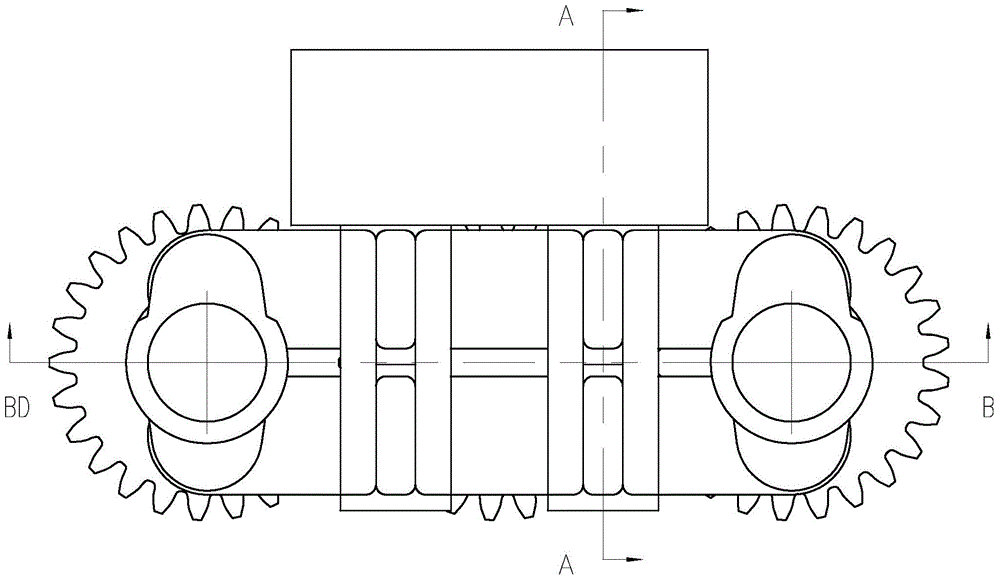

Double-crank mechanism engine

ActiveCN104481689AReduce toughnessReduce manufacturing costCylinder headsCylindersGas cylinderReciprocating motion

The invention discloses a double-crank mechanism engine, belonging to the technical field of engines. The double-crank mechanism engine comprises a gas cylinder and a piston capable of performing straight reciprocating motion in the gas cylinder, wherein two parallel crankshafts are arranged at the two sides of the gas cylinder; a connecting rod is hinged between corresponding crankshaft pins of the two crankshafts to form a double-crank mechanism; a connecting rod insertion slot and a slide block are arranged on a piston rod on the rear end of the piston, the connecting rod is inserted to the connecting rod insertion slot in a sliding manner, a guide block is fixed in the engine; a guide rail for sliding the slide block is formed on the guide block; the slide block is inserted to the guide rail; transmission gears are arranged on the end parts of the crankshafts; an output gear is engaged between the two transmission gears; and an output shaft is arranged on the output gear. The double-crank mechanism engine can be used for effectively lowering the abrasion and the impact of the piston and a cylinder sleeve, improving the reliability of the ceramic material applied to the engine and improving the practical heating efficiency.

Owner:王蓬波

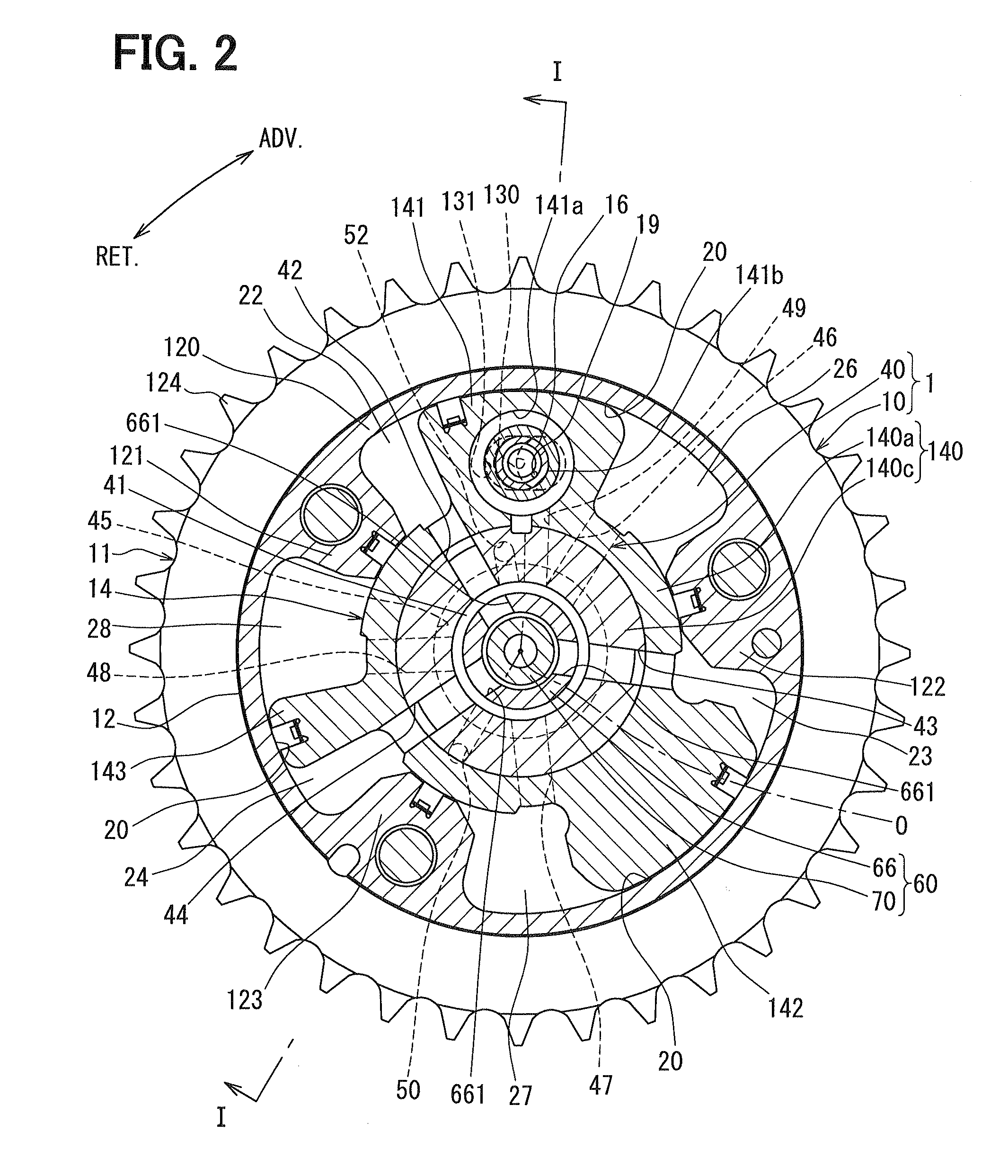

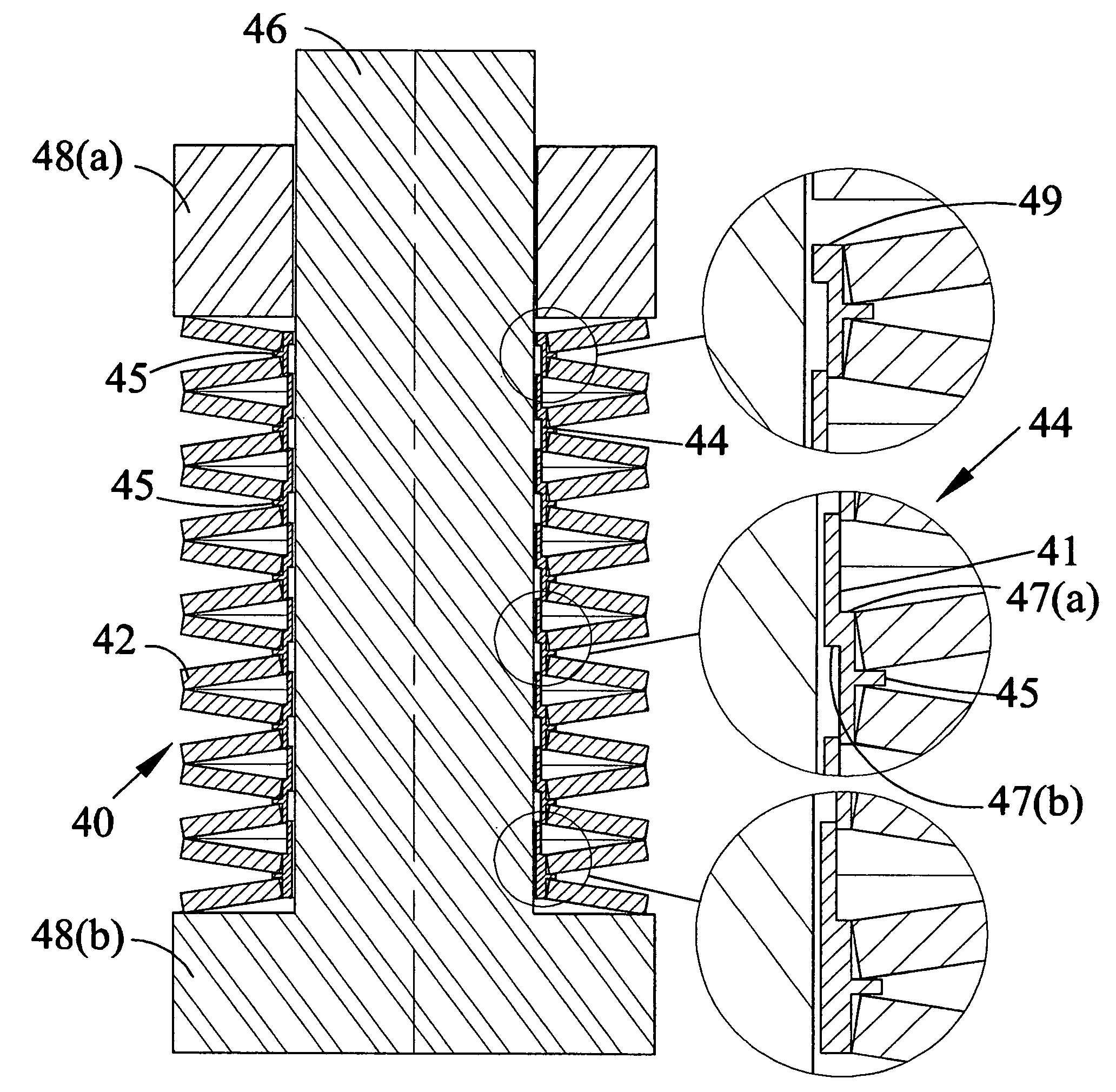

Variable valve timing device

ActiveUS20120186547A1Moving resistance becomes smallImprove the immunityValve arrangementsMachines/enginesVariable valve timingControl valves

A variable valve timing device includes a control valve for switching fluid communication among ports. The control valve includes a sleeve, a spool, a movable member, and resilient members. A first resilient member pushes the spool in both of the regions. A second resilient member acts on the spool via the movable member engaged with the spool in an advancing region. In a lock region, the movable member rests on the sleeve to enable the spool to move freely from the second resilient member. As a result, force acting on the spool can be restricted in the lock region. The movable member is supported from a radial inside by the spool and is radially distanced from the sleeve. As a result, it is possible to reduce a sliding resistance acting on the movable member.

Owner:DENSO CORP

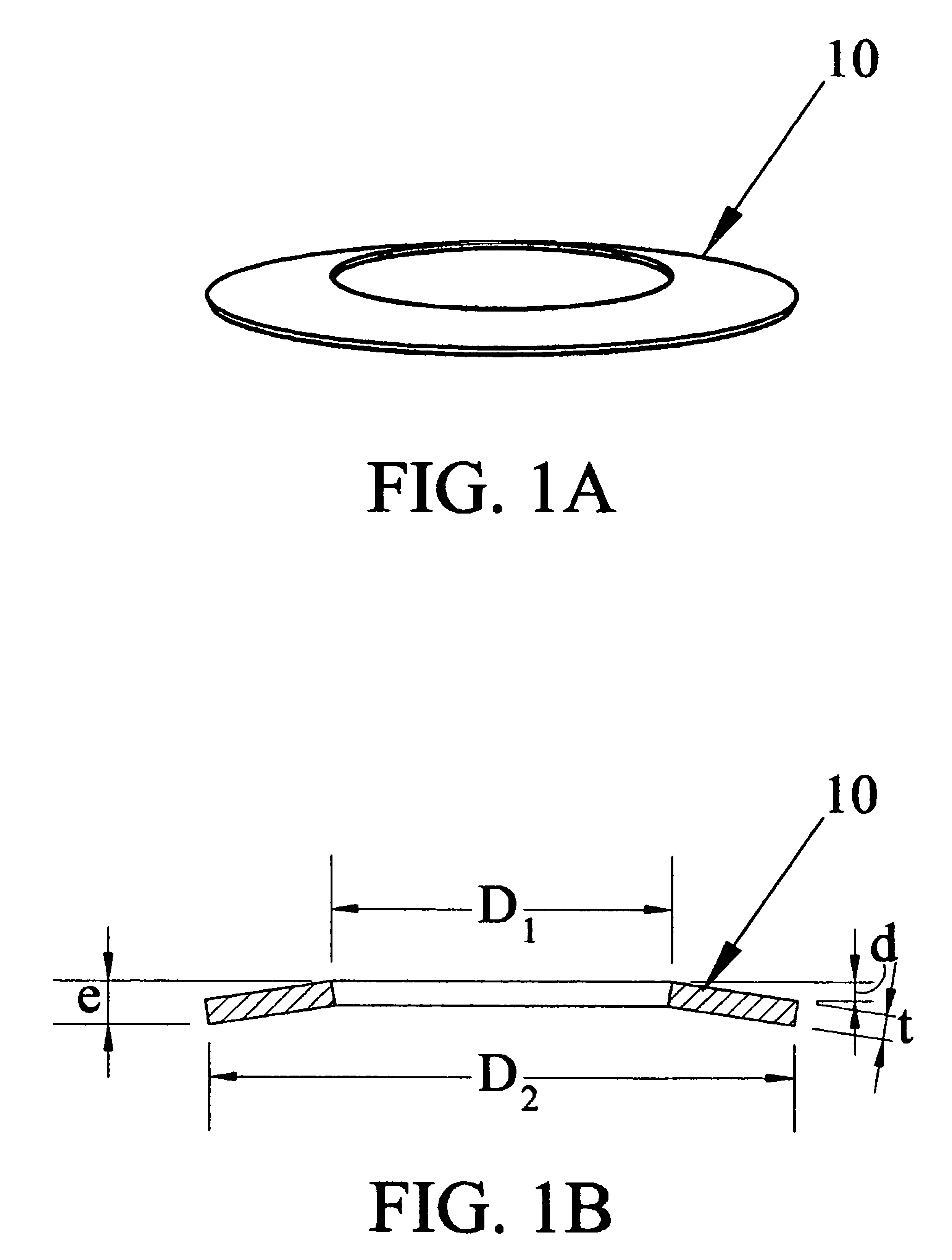

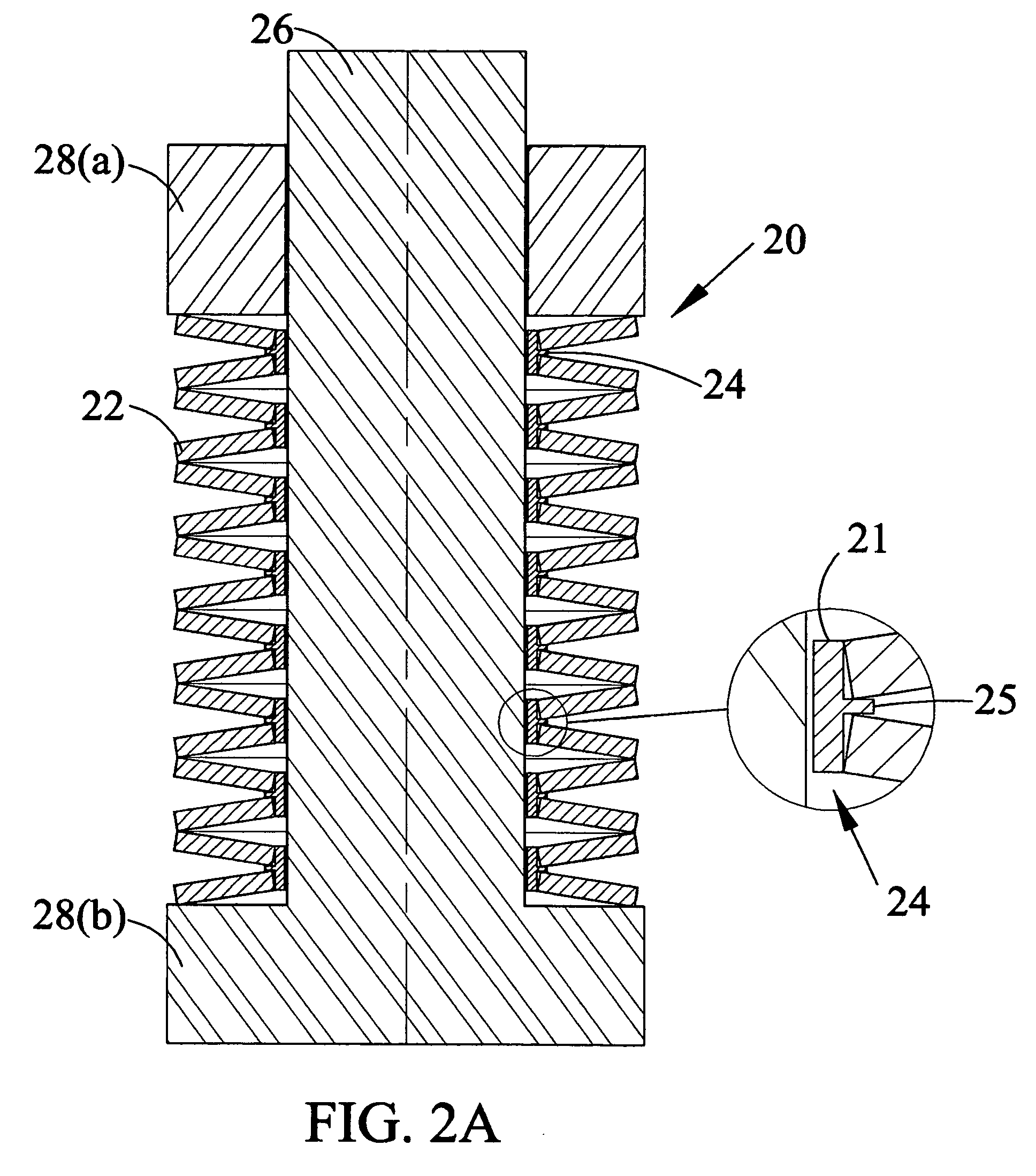

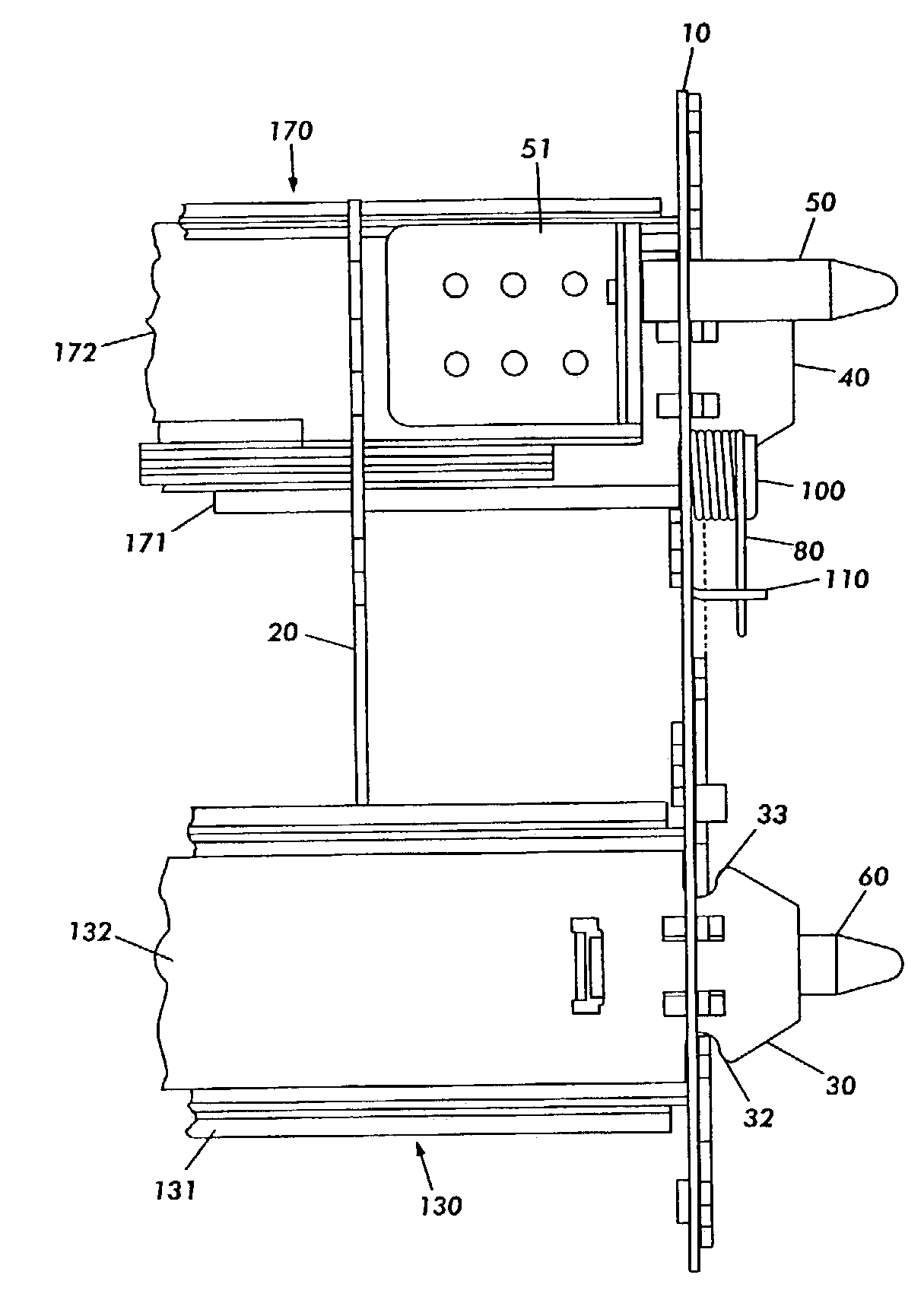

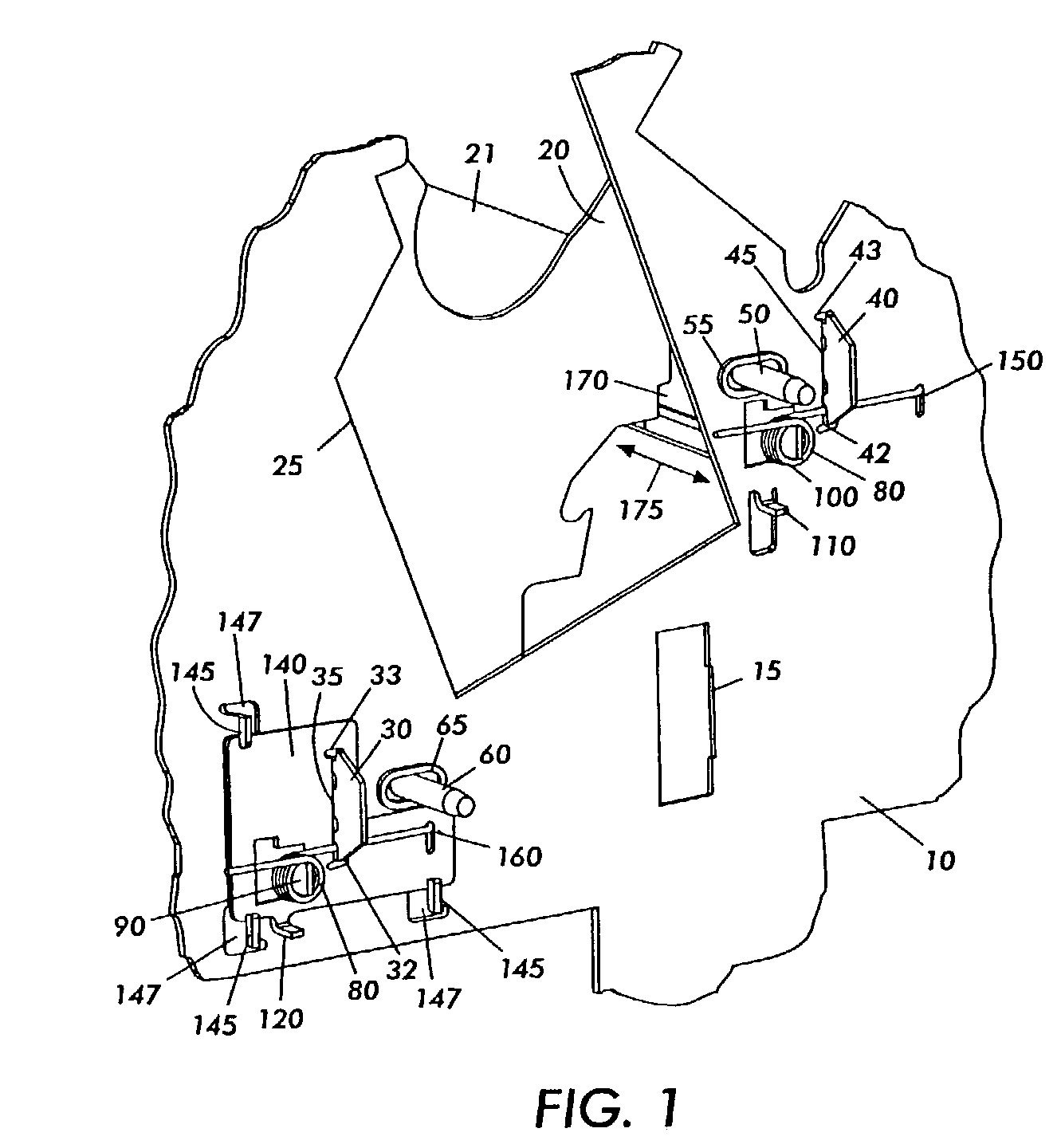

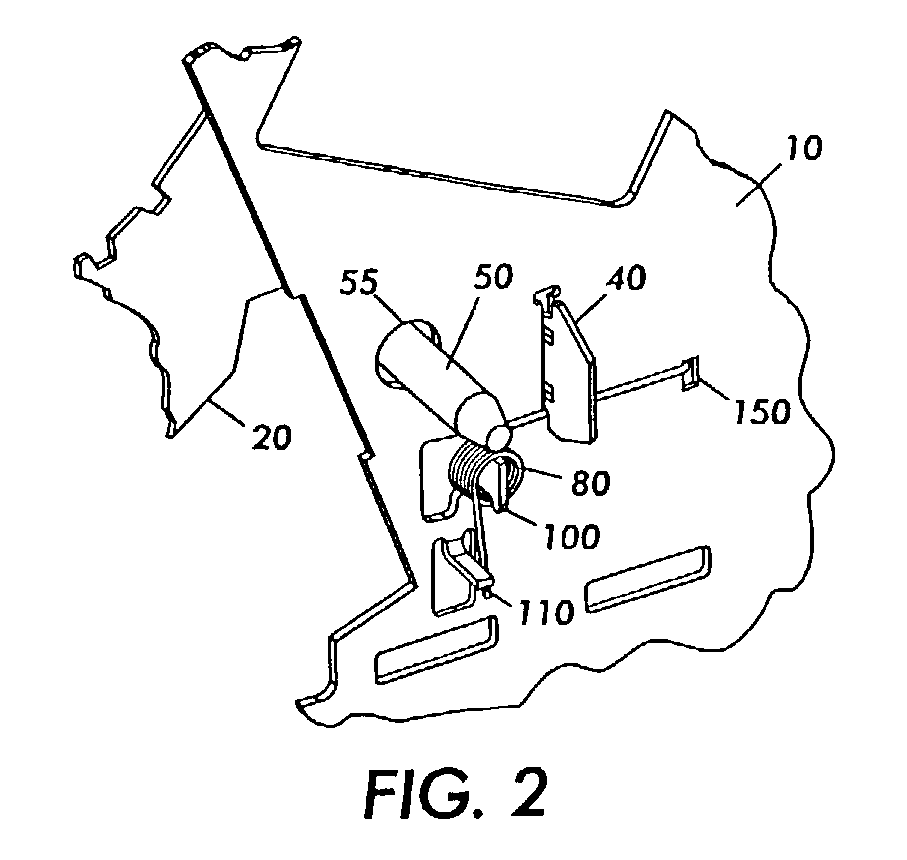

Belleville spring guide system

ActiveUS7854425B2Reduce frictionReduce lateral forceBelleville-type springsRing springsFriction effectMechanical engineering

Owner:HALLIBURTON ENERGY SERVICES INC

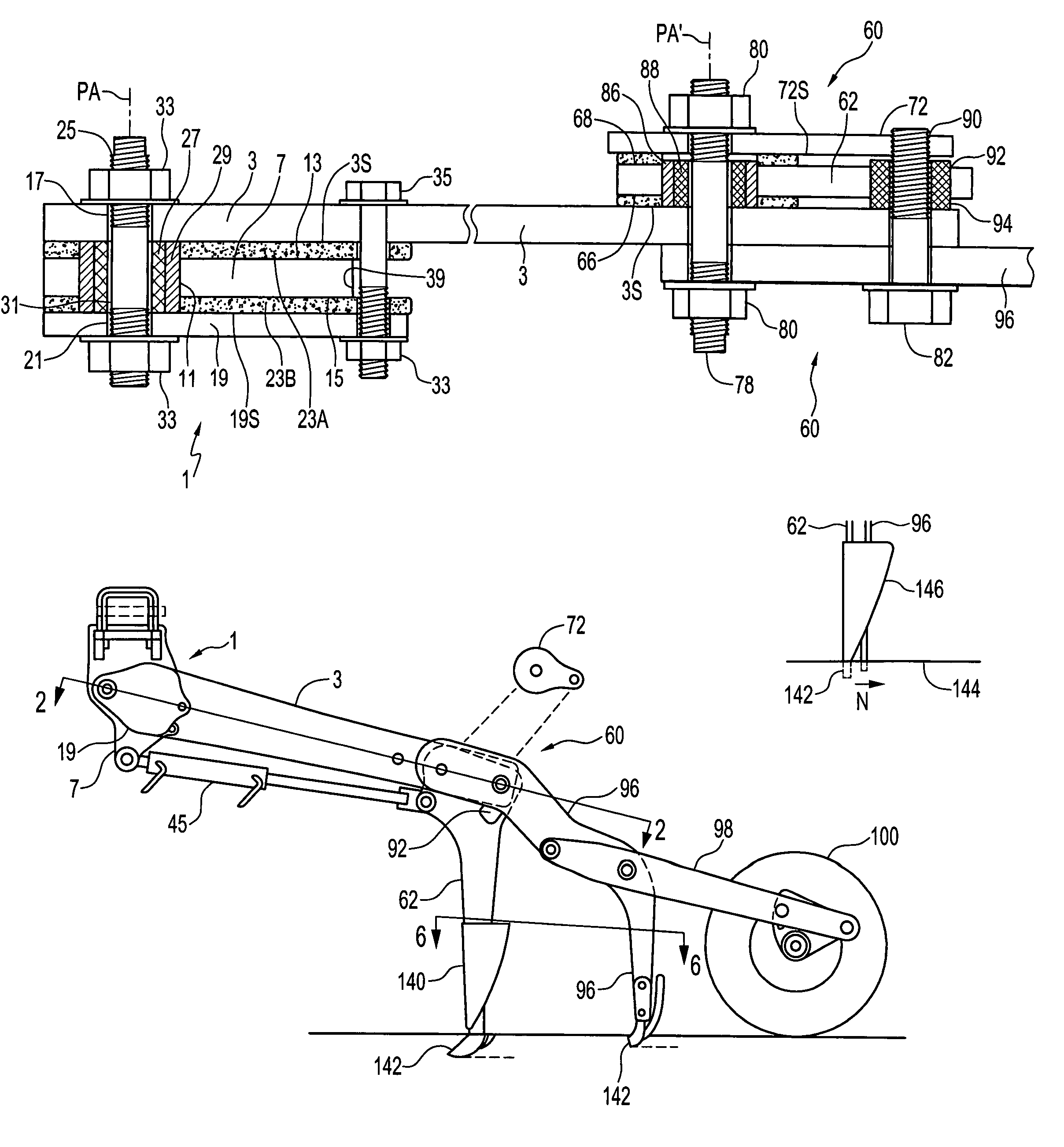

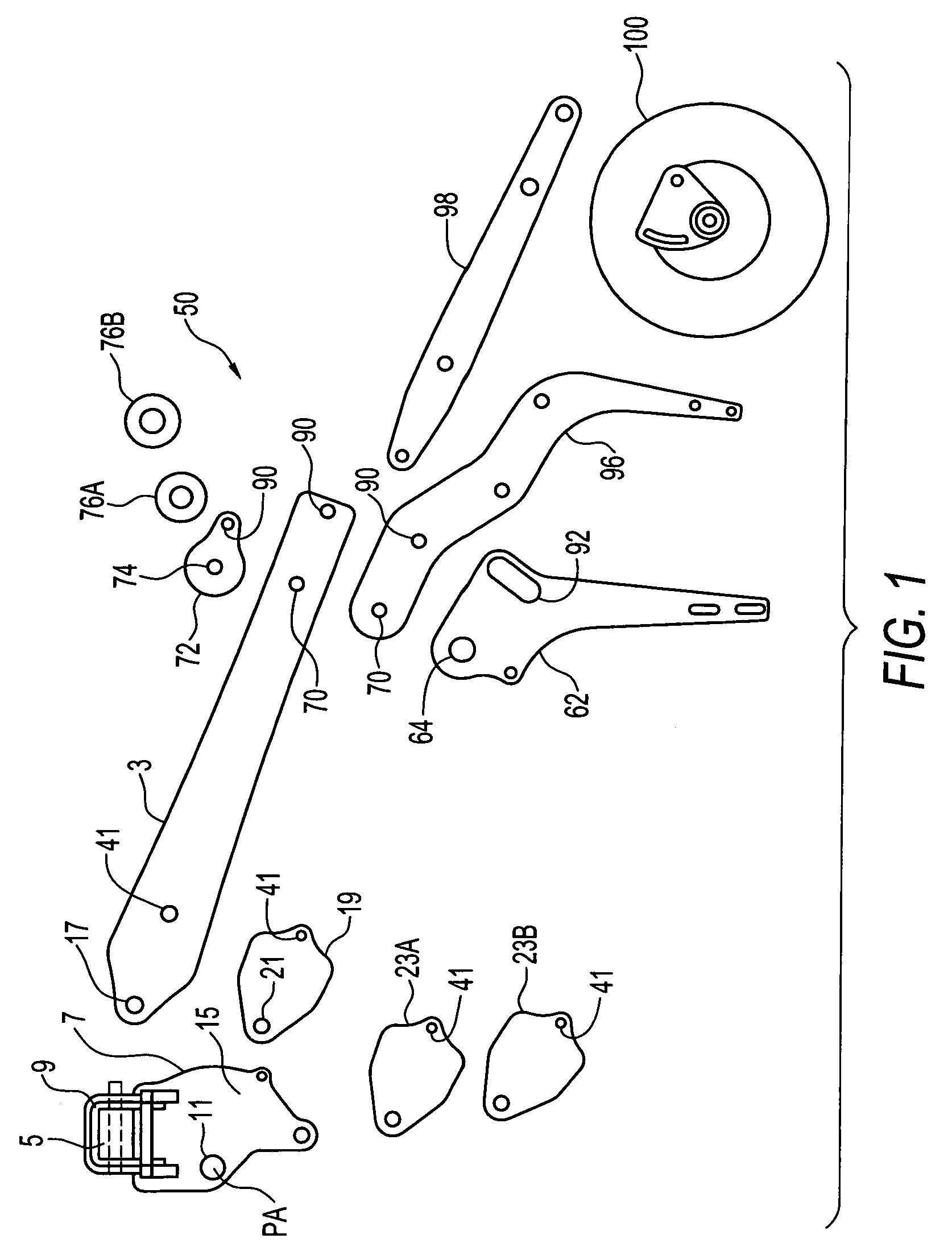

Pivoting arm for seeders

A pivot mechanism for pivotally attaching two members about a pivot axis comprises a first member defining a first pivot hole, and having first and second bearing surfaces oriented perpendicular to the pivot axis. A second member defines a second pivot hole aligned with the first pivot hole, and a pivot plate defines a plate pivot hole aligned with the first and second pivot holes such that inner surfaces of the second member and pivot plate are parallel to the bearing surfaces. Wear pads are located between the inner and bearing surfaces. A pivot pin extends through the pivot holes. The pivot plate and second member are squeezed against the wear pads, and the second member and the pivot plate rotate together with respect to the first member. A residue deflector deflects residue clumps falling off a front seeder leg away from the path of a rear seeder leg.

Owner:SEEDMASTER MFG

Rollover protecting system for vehicle

InactiveUS20050006166A1Improve steering stabilityReduce contact surfacePedestrian/occupant safety arrangementInterconnection systemsRolloverRoad surface

A rollover protecting system for a vehicle comprising an actuator for pushing out an upper arm to an external direction of the vehicle by pivoting a pivot arm such that a tire produces a positive camber in relation to the road surface. Protruding ends are formed on a shoulder part of the tire for reducing a contact surface of the tire to the road, thereby reducing the lateral force applied to the tire and preventing an occurrence of rollover.

Owner:HYUNDAI MOTOR CO LTD

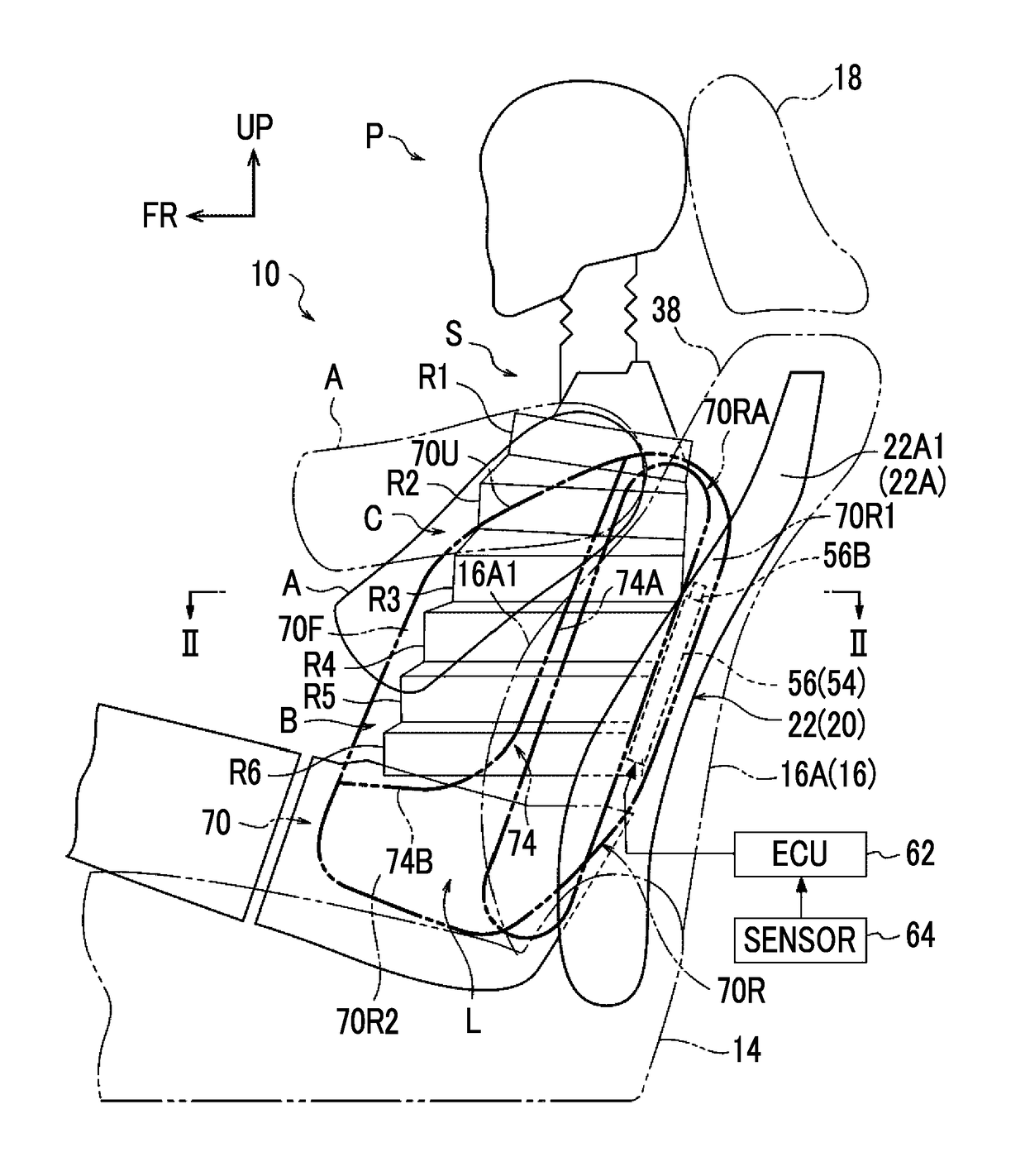

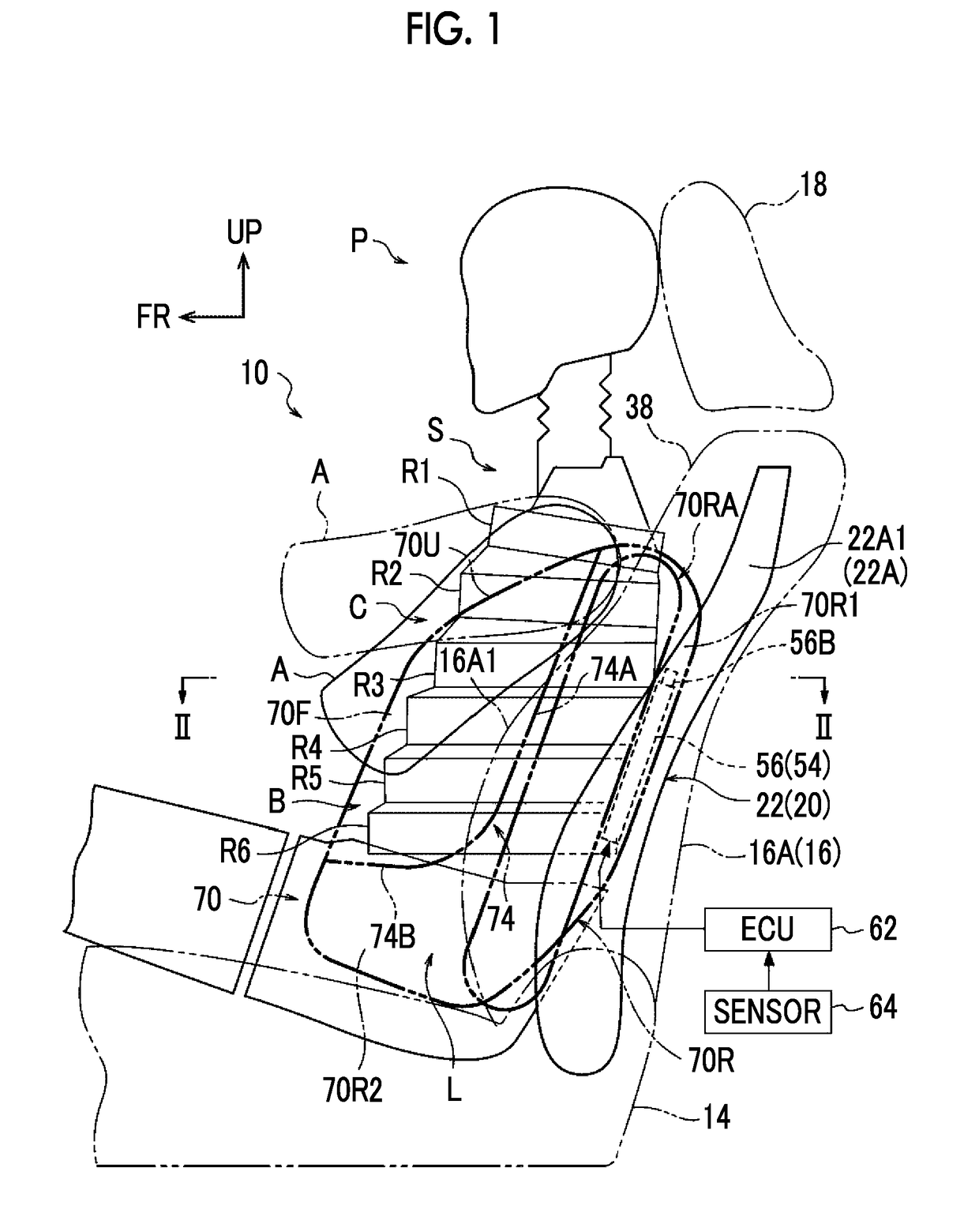

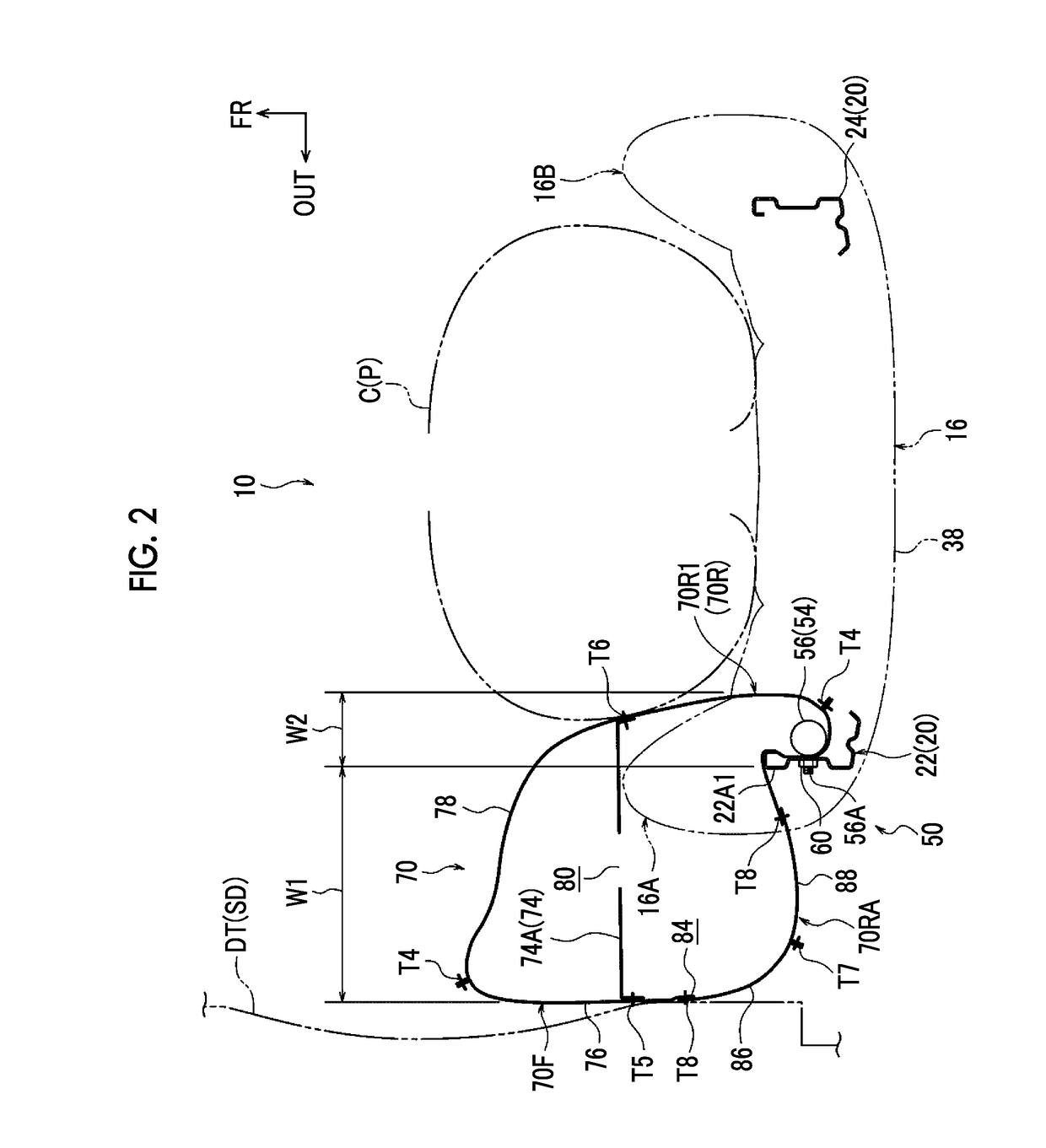

Vehicle seat with side airbag device

ActiveUS20180222435A1Improving initial occupant restraint performanceReduce lateral forceVehicle seatsPedestrian/occupant safety arrangementLateral airbagEngineering

A vehicle seat with a side airbag device includes: a gas generating device attached to an inner side of an outer side frame in a vehicle-width direction, which is disposed in a side portion on an outside of a seat back in the vehicle-width direction; a side airbag which inflates and deploys to expand over the outer side frame from a vehicle front side of the outer side frame in the vehicle-width direction by receiving gas from the gas generating device accommodated in the side airbag; and an inflation width expansion portion which is provided in the side airbag and causes an inflation width of the side airbag in the vehicle-width direction to be greater outside a side surface provided on an outside of the outer side frame in the vehicle-width direction than inside the side surface.

Owner:TOYOTA JIDOSHA KK

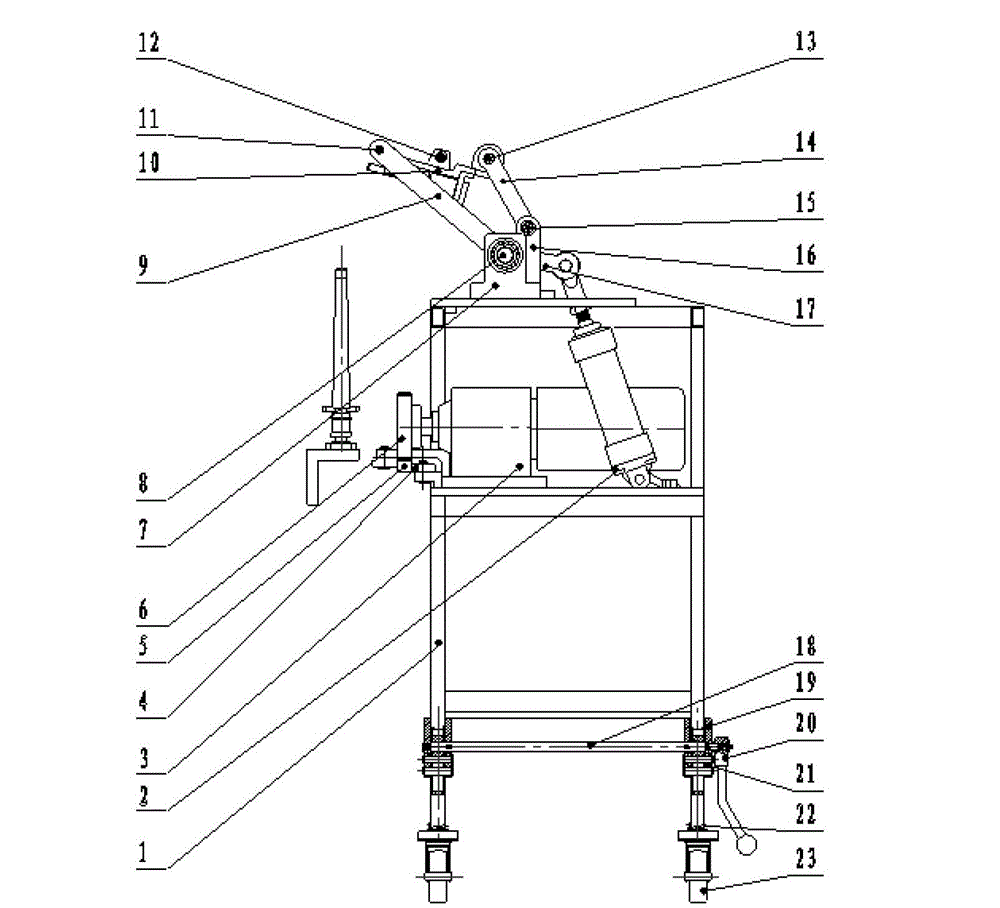

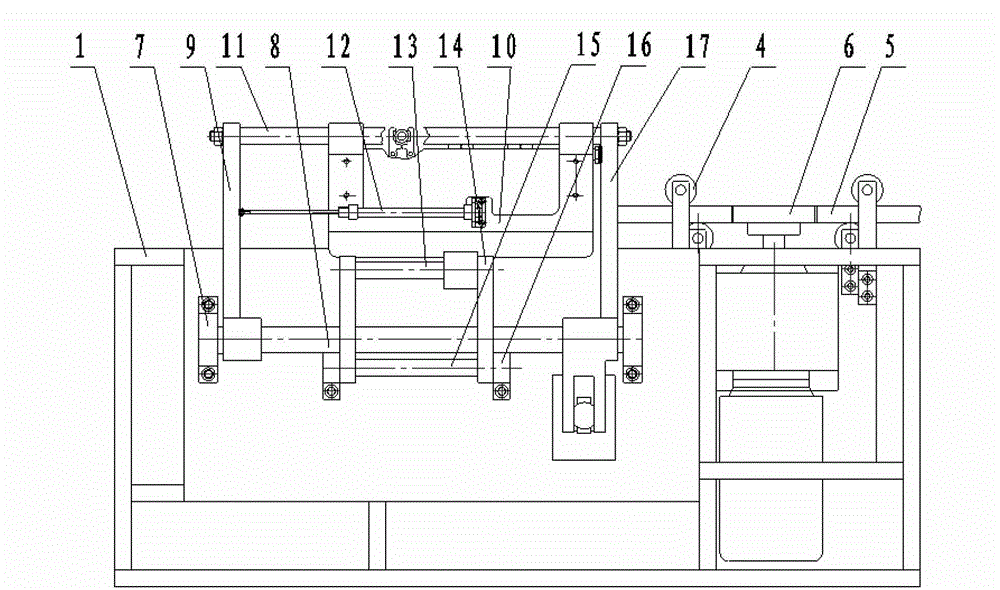

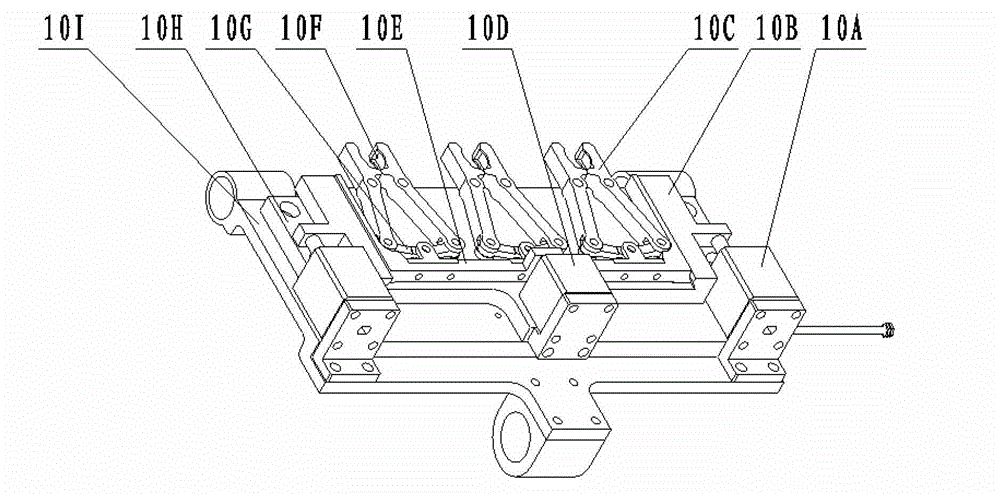

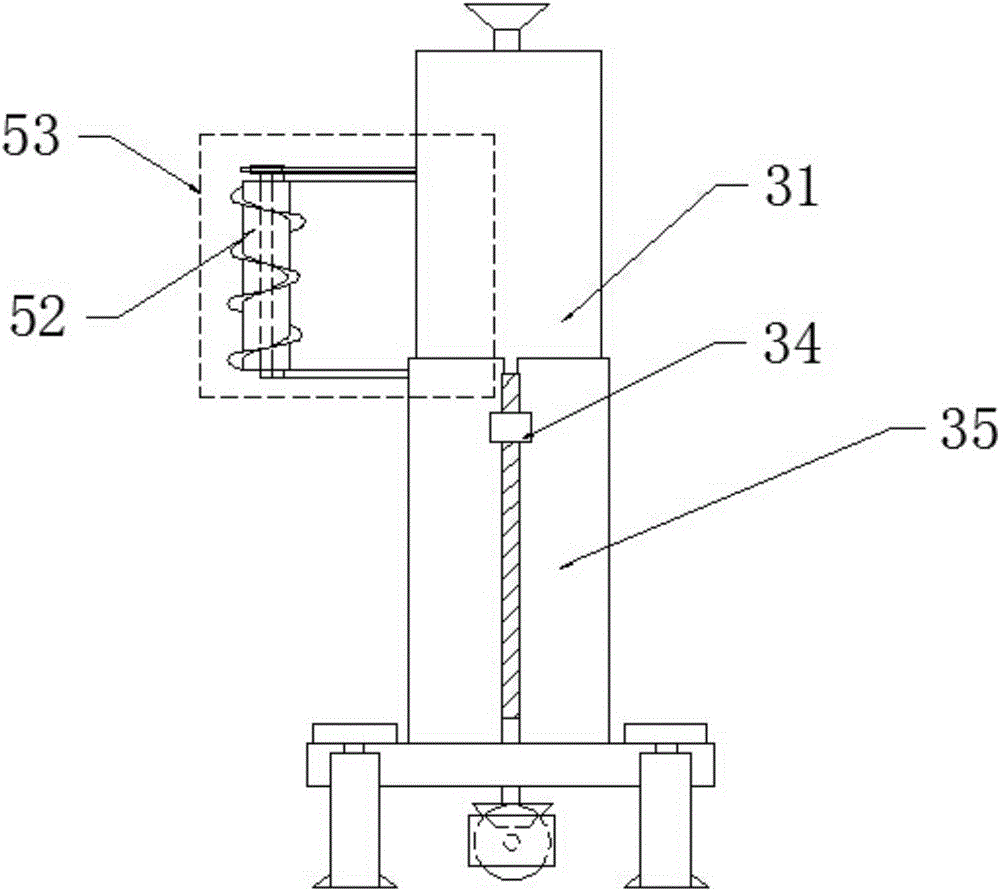

Automatic tube drawing device of doffer

The invention belongs to the technical field of textile equipment, and relates to an automatic tube drawing device of a doffer. A main air cylinder component and a reducing motor are connected onto a doffer frame respectively; a bracket for mounting a guiding wheel is fixed on the doffer frame; a gear is meshed with racks fixed on the doffer; a driving shaft is mounted in a bearing pedestal of a driving rocker arm and is supported through a rolling bearing; a front driving rocker arm and a rear driving rocker arm are in key joint with and fixedly mounted onto the driving shaft respectively; a driving rocker arm guiding shaft is fixedly mounted in holes corresponding to the front driving rocker arm and the rear driving rocker arm; a driven rocker arm is supported through a sliding bearing mounted in a driven rocker arm bracket and is mounted on a pin shaft for a driven rocker arm in an interference fit manner; a driven rocker arm guiding shaft is mounted in a hole corresponding to the driven rocker arm; and a connecting rod is mounted on the driving rocker arm guiding shaft and the driven rocker arm guiding shaft, and performs reciprocating motion along the two guiding shafts. The automatic tube drawing device has reliable principle, simple structure, high tube drawing effective rate and friendly production environment, is safe in operation and running, and saves human resources.

Owner:QINGDAO UNIV

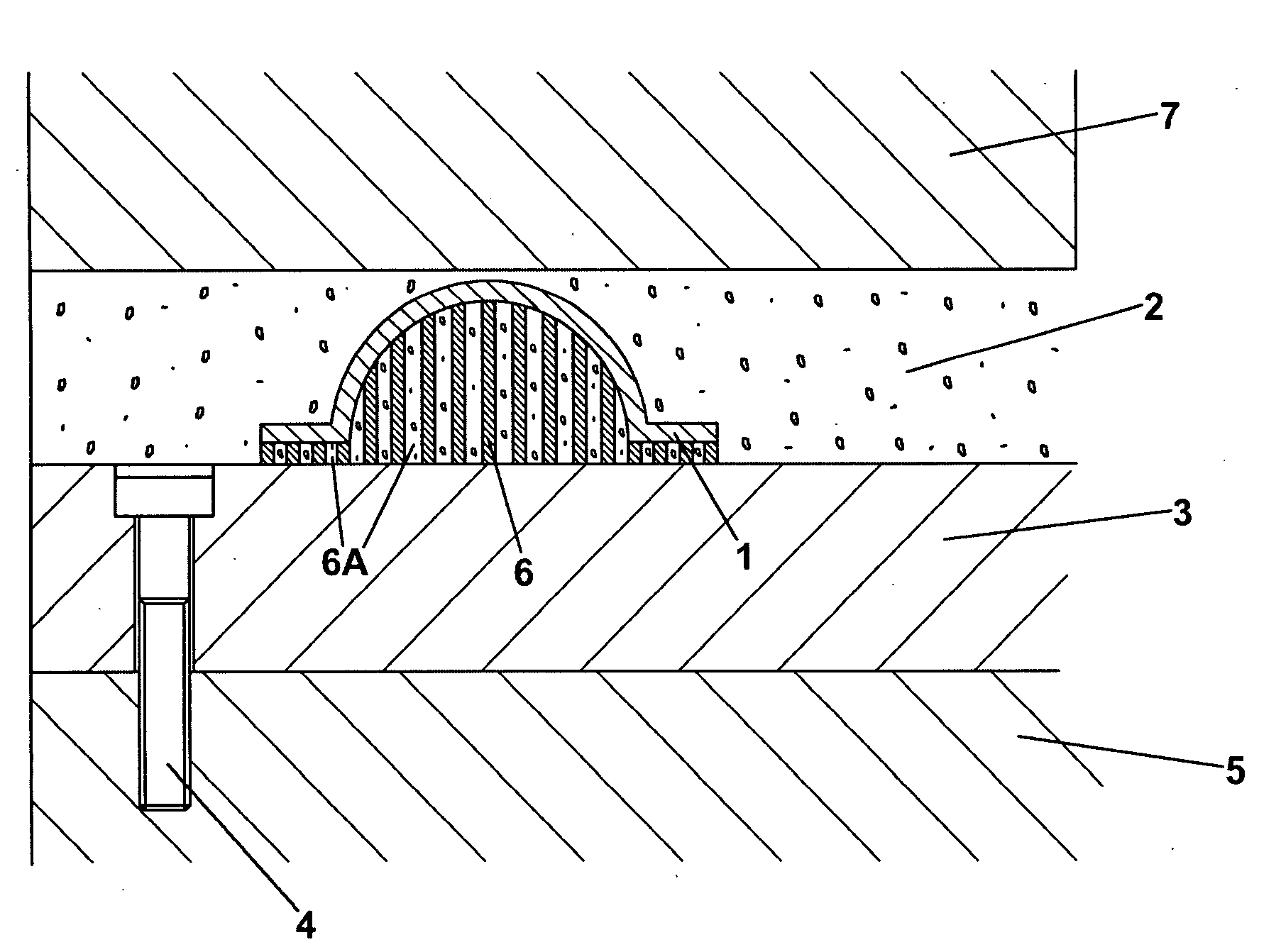

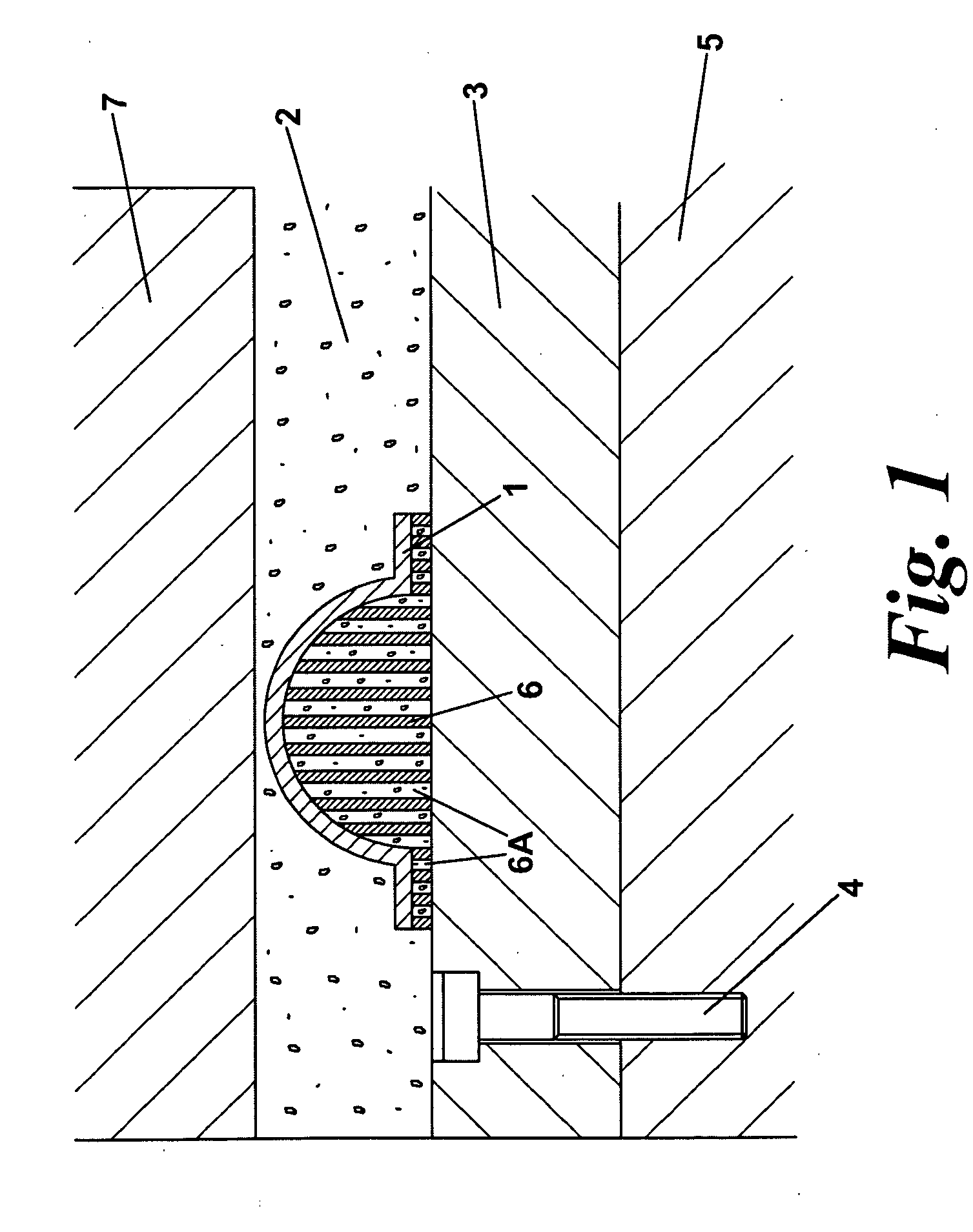

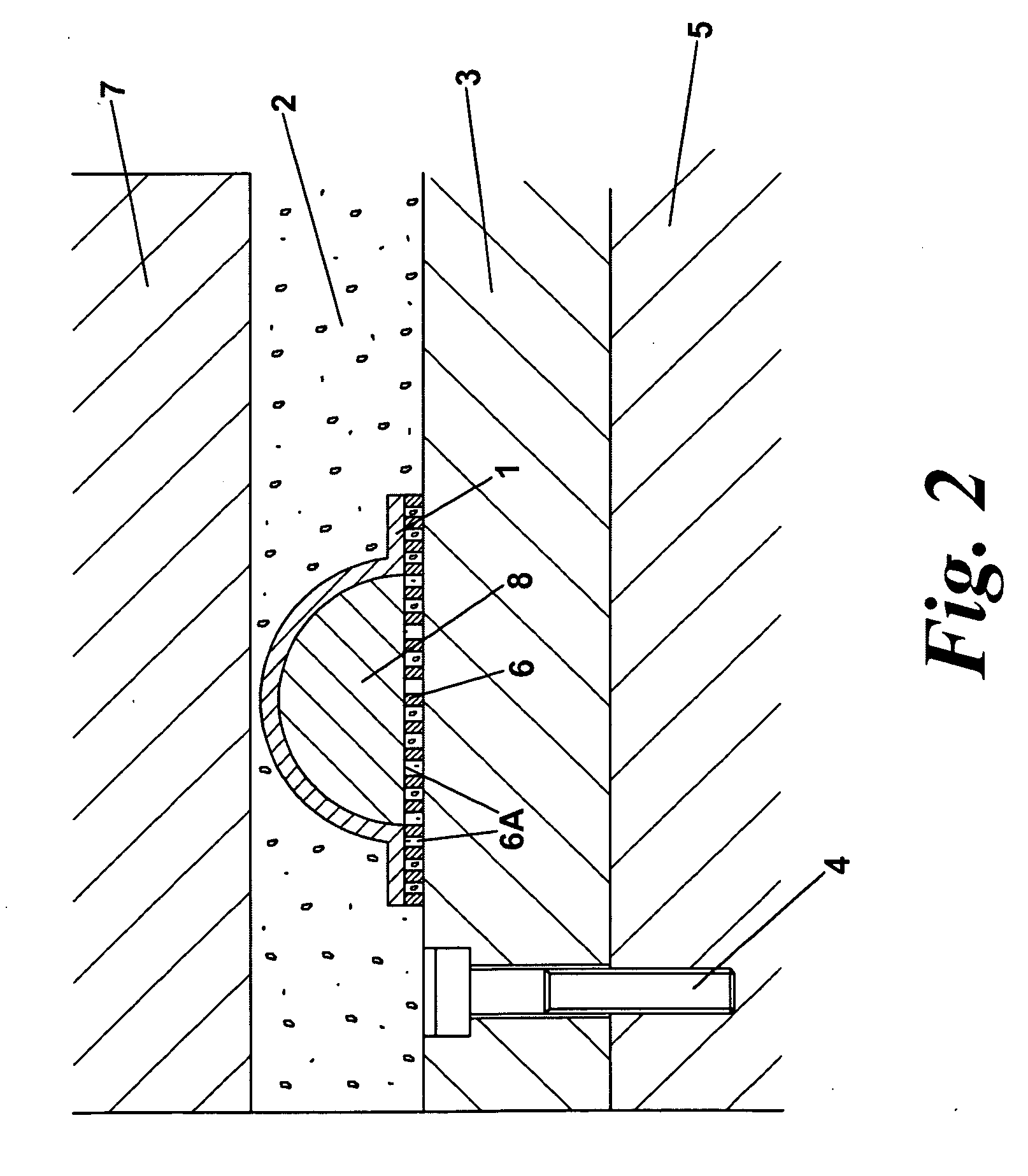

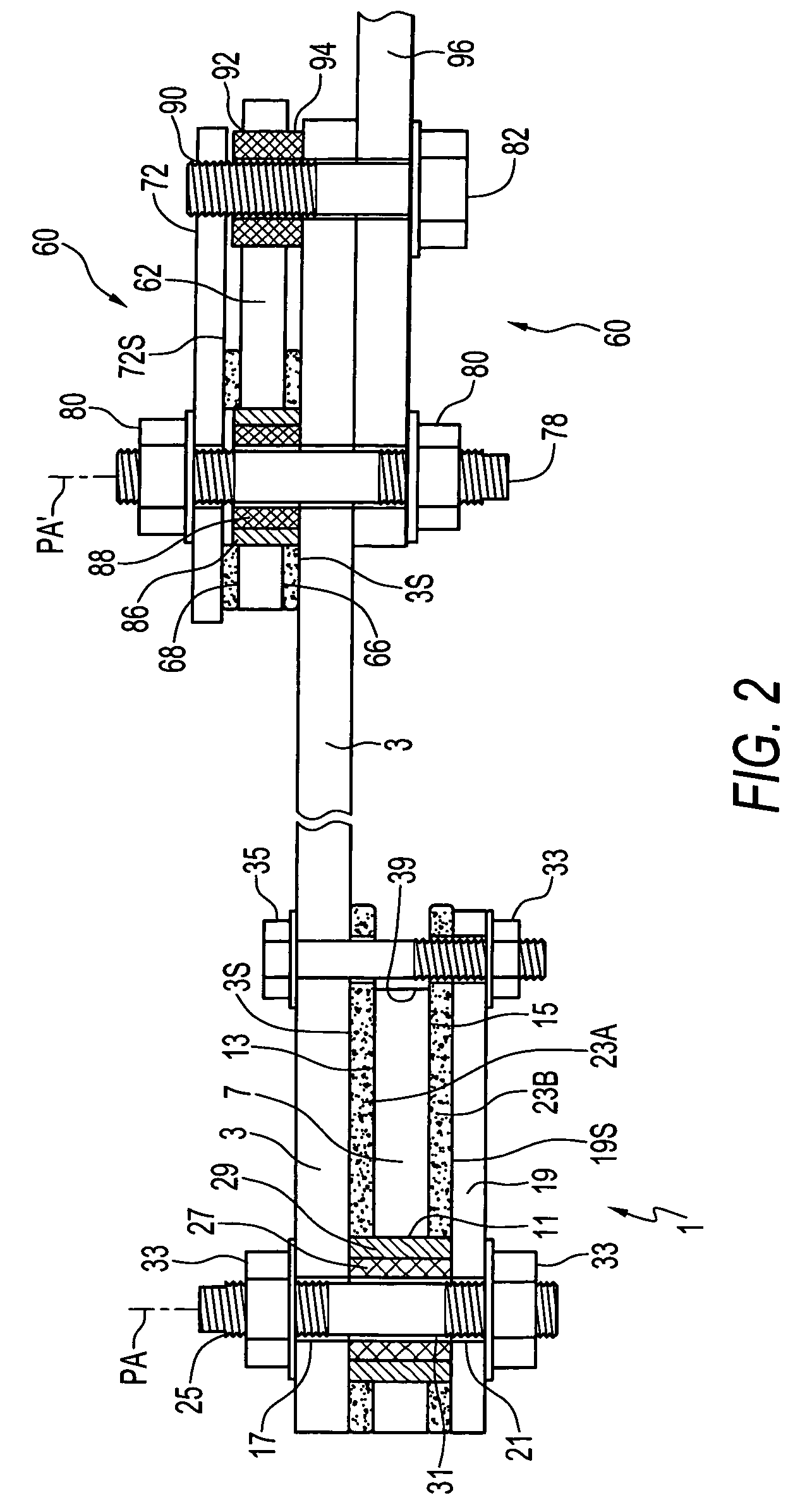

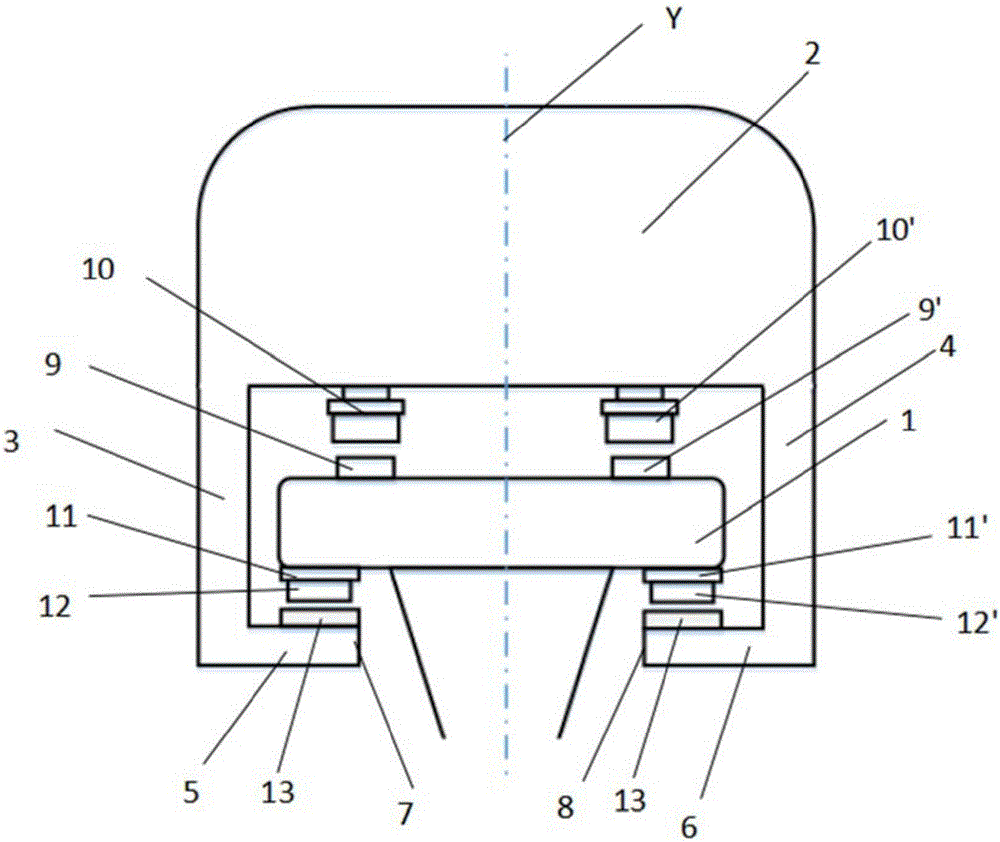

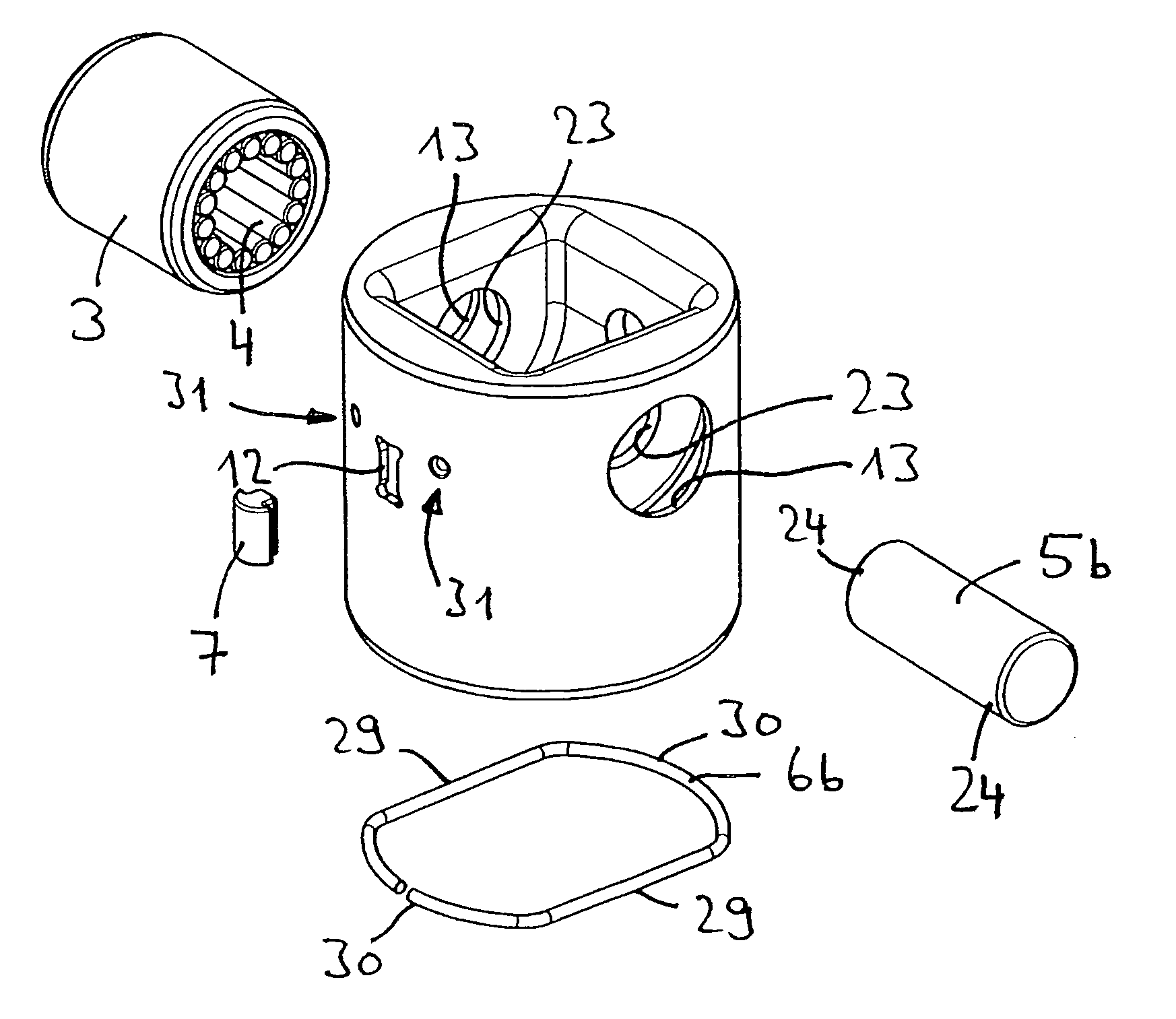

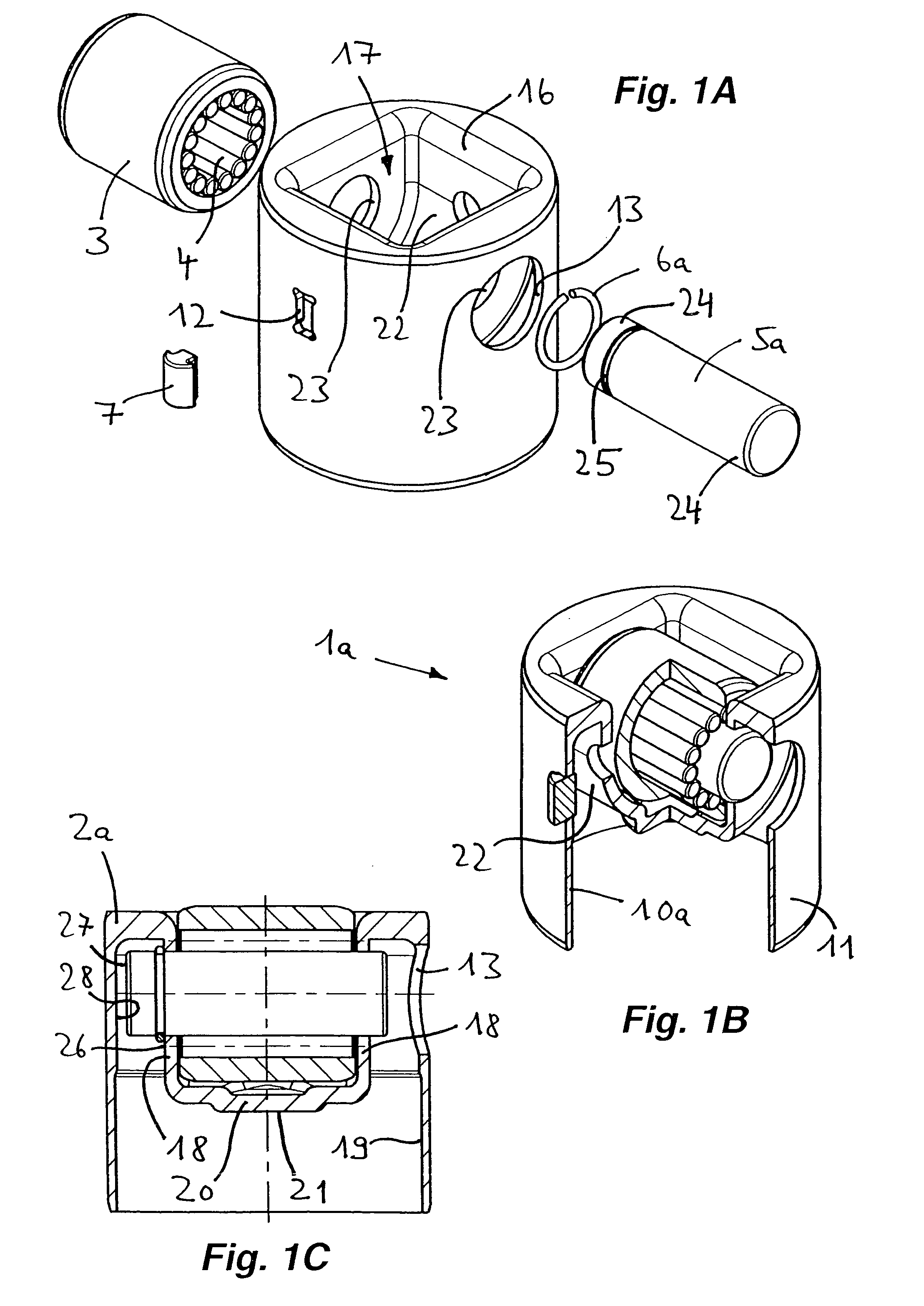

Electromagnetic reciprocating compressor with spring assembly mounted around piston

InactiveUS6015273AShorten the lengthReduce lateral forceEngine sealsPiston pumpsReciprocating motionPiston Guide

PCT No. PCT / GB95 / 02901 Sec. 371 Date Jul. 10, 1997 Sec. 102(e) Date Jul. 10, 1997 PCT Filed Dec. 8, 1995 PCT Pub. No. WO96 / 18037 PCT Pub. Date Jun. 13, 1996An electromagnetic reciprocating compressor has a body (1, 2), a piston (10) reciprocating in the body, and an electromagnetic drive (22, 23, 24) for the piston. The piston has a piston head (11) which slides in a cylinder (12) in the body to effect compression of fluid in the cylinder during operation of the compressor and, axially spaced from the piston head, a piston guide member (13) slidingly movable on a guide surface (14) provided by the body. The compressor has a compression spring arrangement (20) comprising at least one helical compression spring (20a, b) acting to drive the piston axially. The spring (20a, b) is mounted around the piston and is at least partly located within the cylinder during at least part of the piston stroke but is outside the working volume of fluid undergoing compression.

Owner:PEGASUS

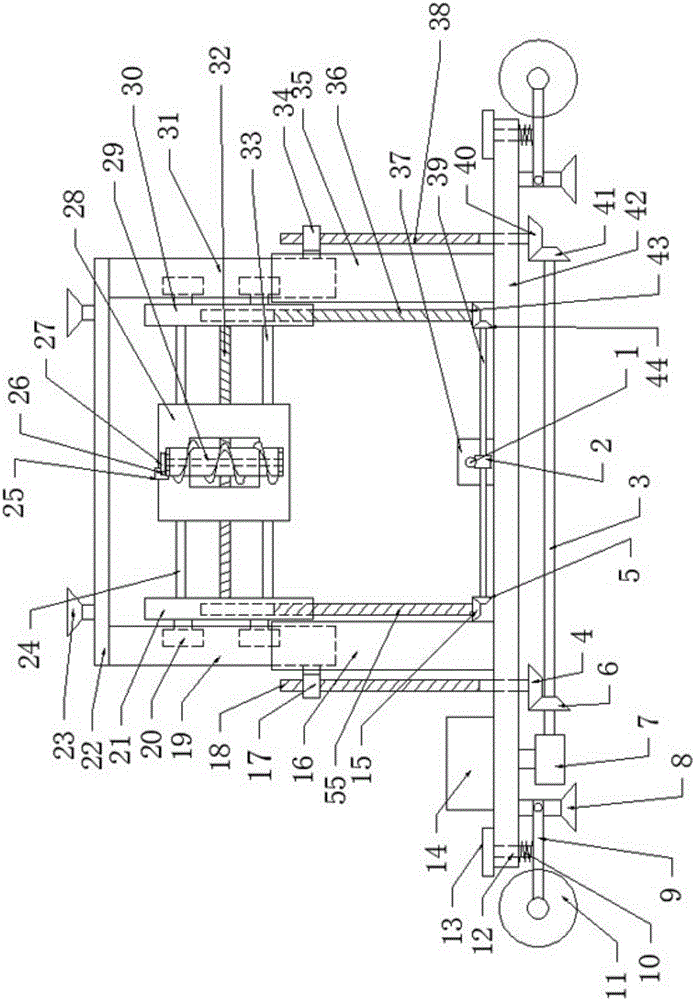

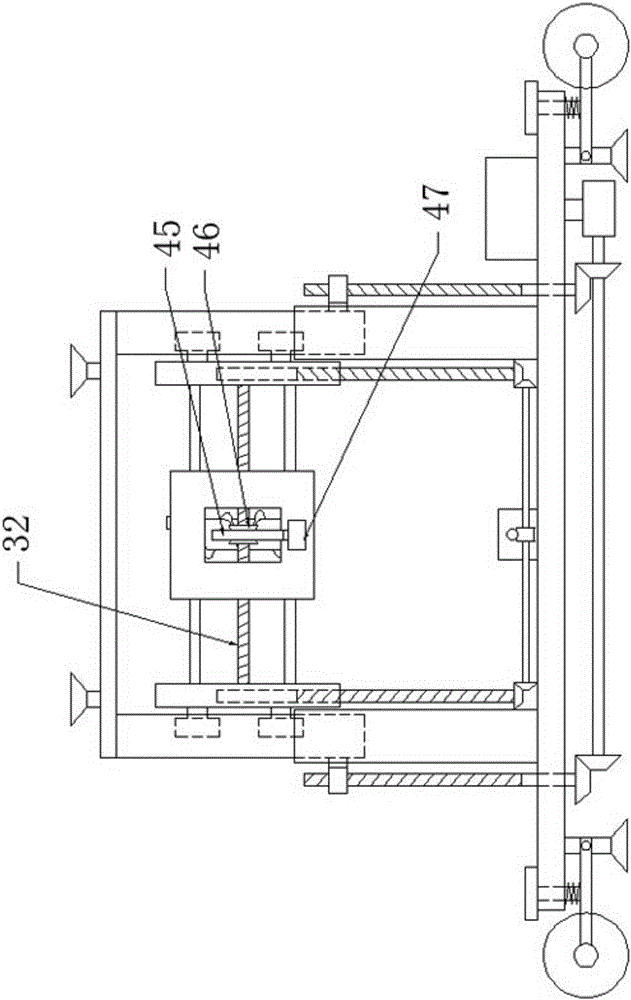

Equipment with functions of cleaning and full-automatic wall outer layer removal

The invention relates to equipment with functions of cleaning and full-automatic wall outer layer removal. The equipment comprises a bottom plate and a top plate, wherein support seats are arranged on the bottom plate and the top plate, a telescopic device is mounted between the bottom plate and the top plate and comprises telescopic rods I mounted on the bottom plate, and telescopic rods II capable of moving up and down relative to the telescopic rods I are mounted on the telescopic rods I and connected with a power drive device I; connecting pillars capable of sliding relative to the telescopic rods II are arranged on the telescopic rods II and connected with a power drive device II, a screw rod I and guide rods are fixedly mounted on the connecting pillars, the screw rod I is connected with a power drive device III, a fixing support plate is arranged on the guide rods, a concentric shaft is mounted on the fixing support plate and connected with a power drive device IV, and a blade or a cleaning material is mounted on the concentric shaft. The equipment has multiple functions and can vertically move up and down and can horizontally move, and the work effect is greatly improved.

Owner:袁宁婧

High temperature superconducting magnetic suspension vehicle driven by permanent magnet linear synchronous motor without gear grooves

PendingCN106828184ASmall normal magnetic attractionPrecise control of dq axis currentElectric devicesRailway vehiclesSuction forceIn vehicle

The invention relates to a high temperature superconducting magnetic suspension vehicle driven by a permanent magnet linear synchronous motor without gear grooves. The high temperature superconducting magnetic suspension vehicle comprises a vehicle body, a high temperature superconducting suspension system and a linear motor propulsion system. The linear motor propulsion system is arranged at the two sides at the lower portion of guiding rail beam or the middle upper portion of the guiding rail beam. A winding of the permanent magnet synchronous motor is fixed by non-ferromagnetic materials and the like, which has the advantages of good heat conduction performance, convenient installation and the like; a vehicle permanent magnet secondary does not need vehicle power supply, the secondary is light in weight and the vehicle effective loading is large; when a single-side permanent magnet linear synchronous motor without the gear grooves is used, the magnetic attraction between the permanent magnet and a back iron of a long stator can be used as suspension force for the magnetic suspension vehicle system, and the overall suspension capacity of the magnetic suspension vehicle is improved; when a double-side permanent magnet linear synchronous motor without the gear grooves is used, the vehicle permanent magnet is subjected to small lateral force and no vertical force; the linear motor propulsion system has little disturbance to the vehicle suspension system, and the system runs dynamically and has good stability.

Owner:SOUTHWEST JIAOTONG UNIV

Roll stability control using four-wheel drive

ActiveUS7640081B2Improve the level ofLow levelHand manipulated computer devicesDigital data processing detailsRolloverMobile vehicle

A control system (18) and method for controlling an automotive vehicle (10) includes a number of sensors that are used to generate a potential rollover signal. In response to the potential rollover, active differentials (112, 114, 116) may be used alone or in addition to braking to prevent the vehicle from rolling over.

Owner:FORD GLOBAL TECH LLC

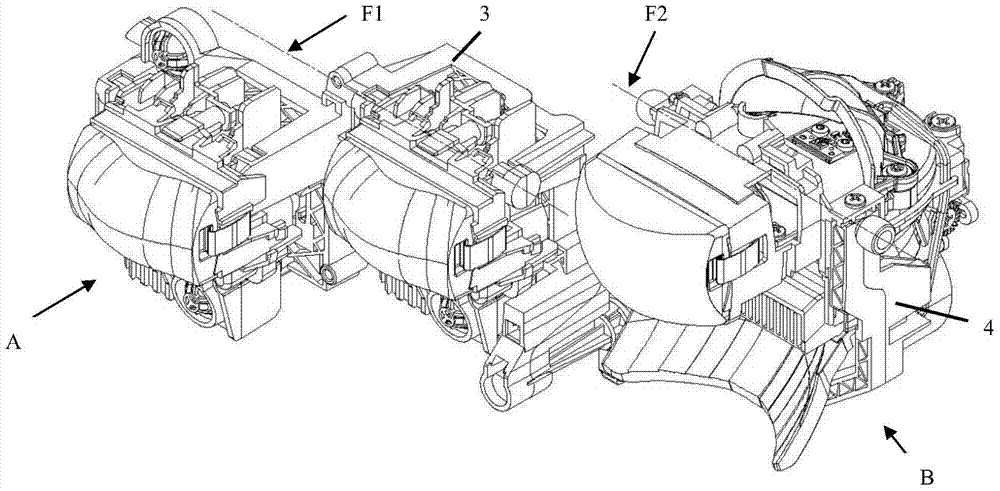

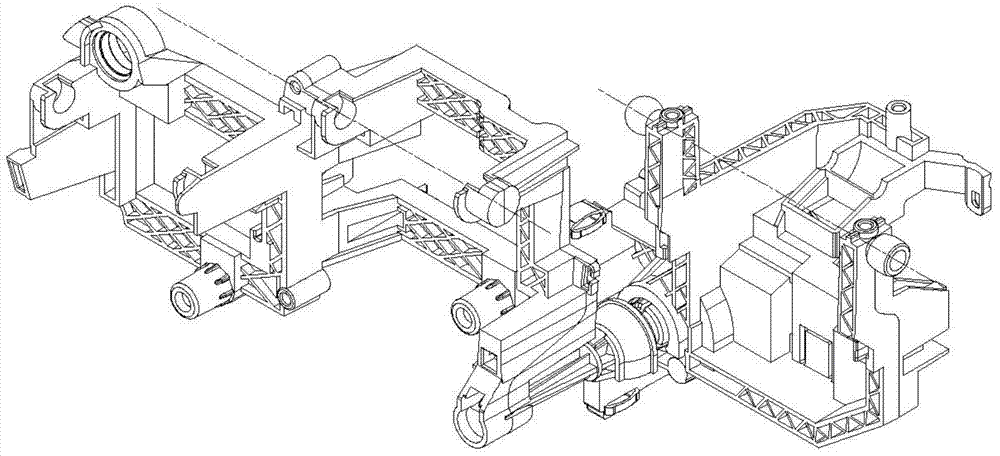

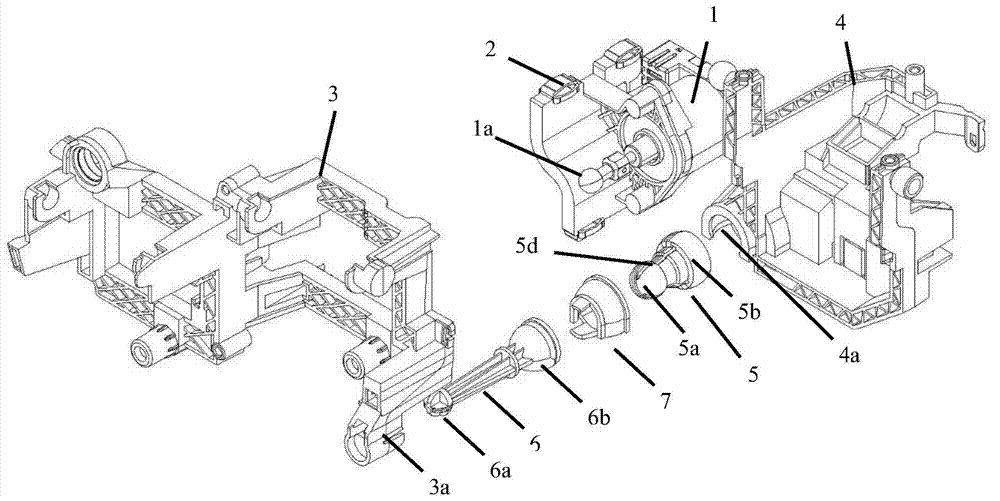

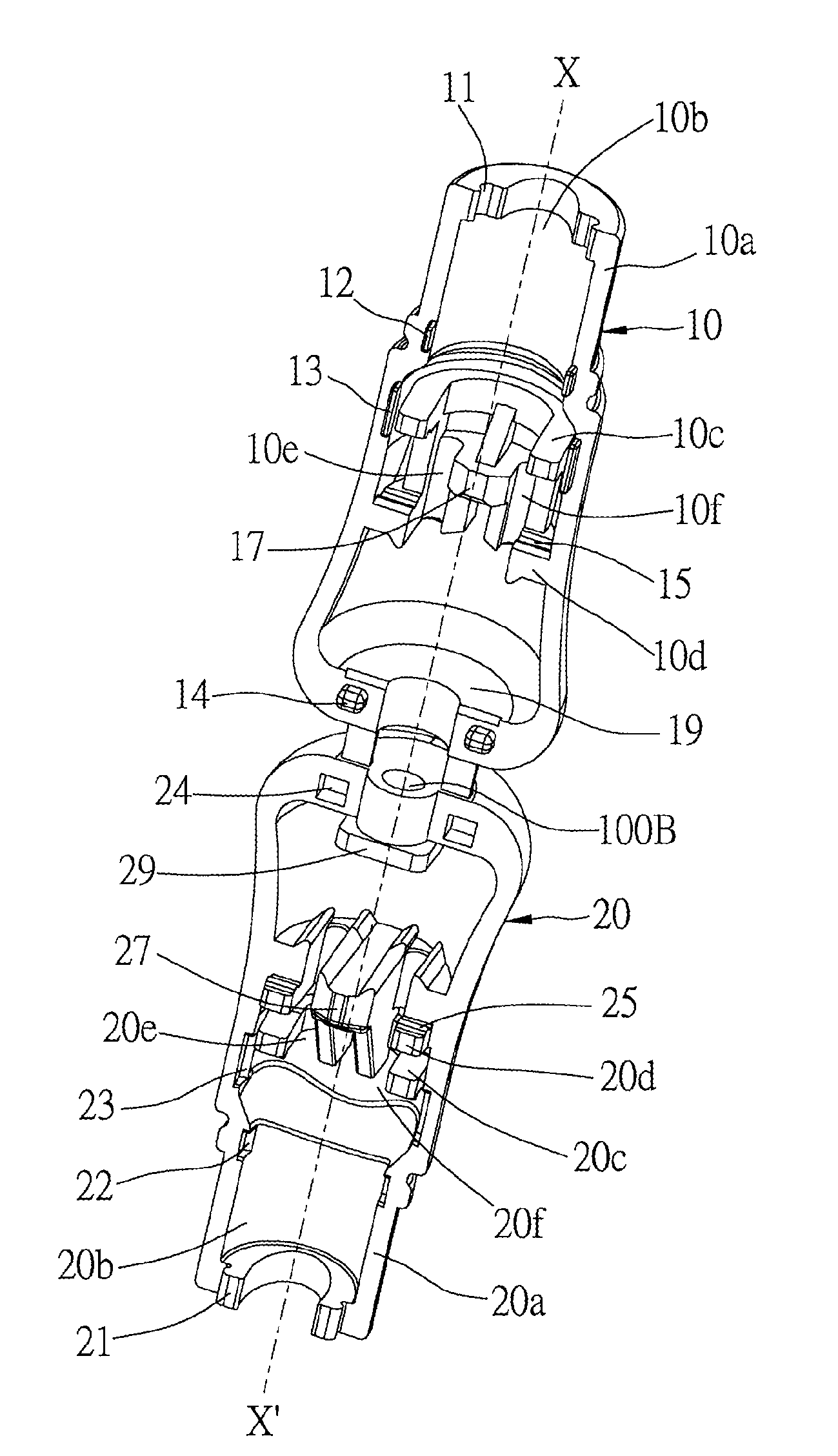

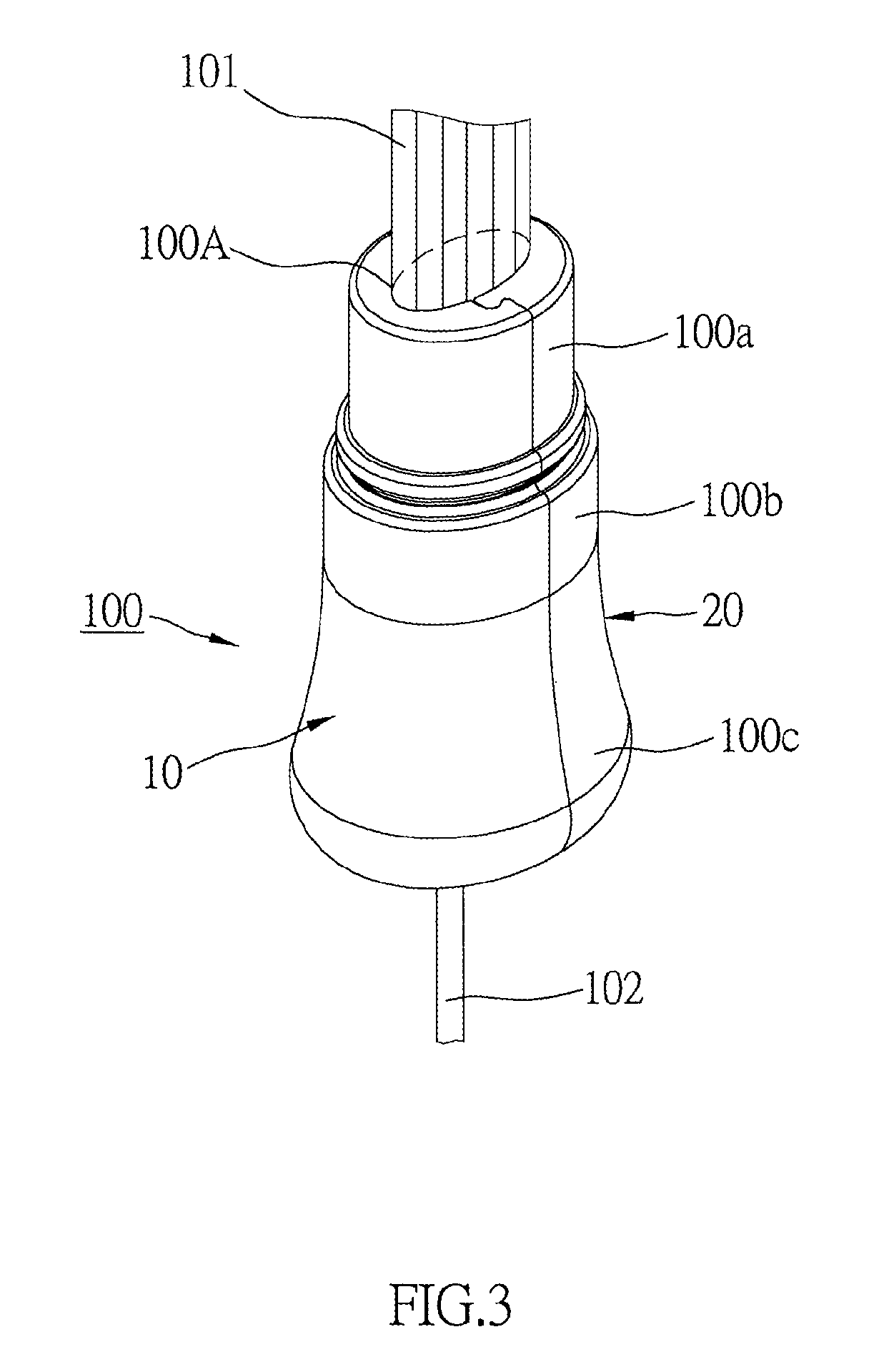

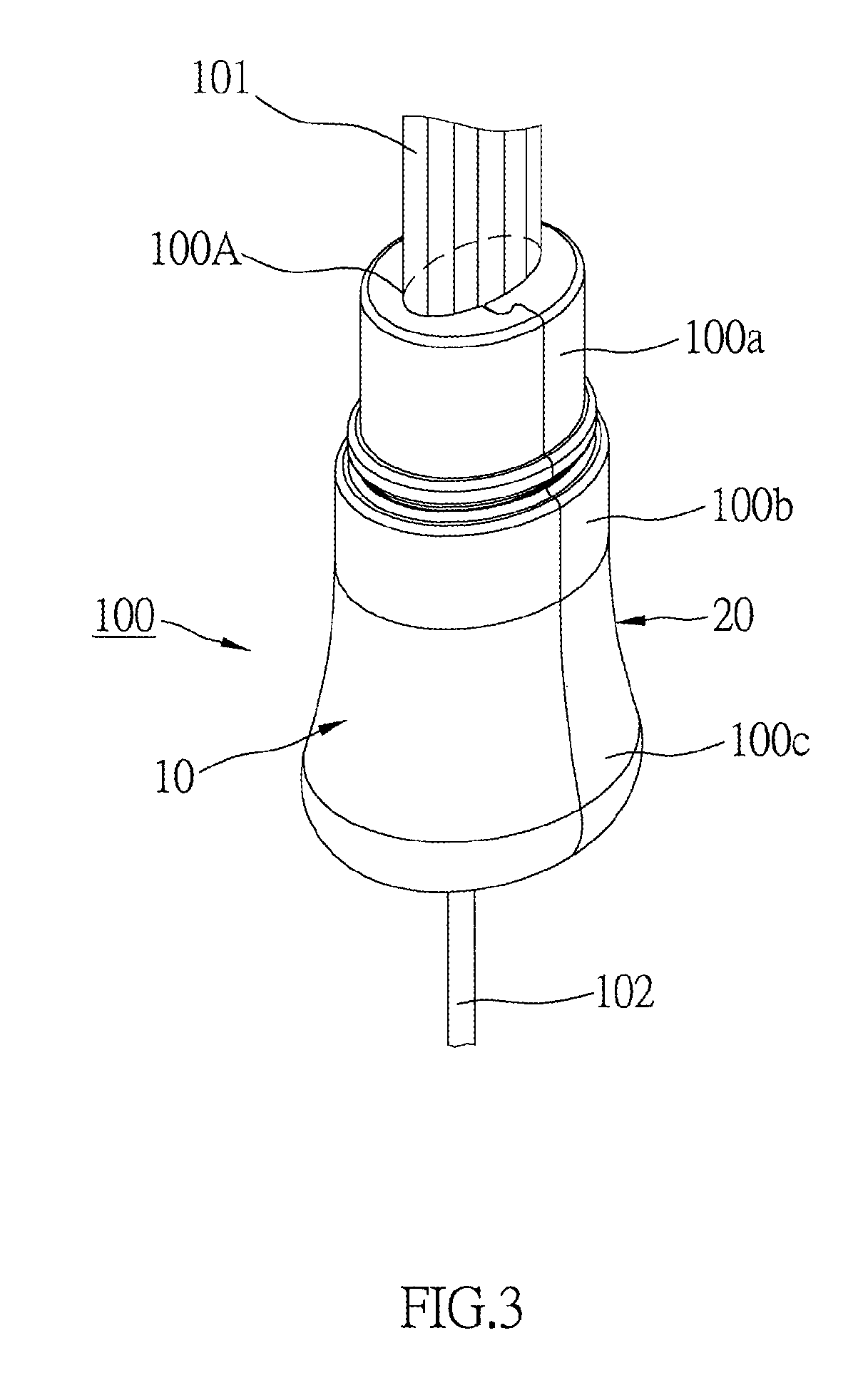

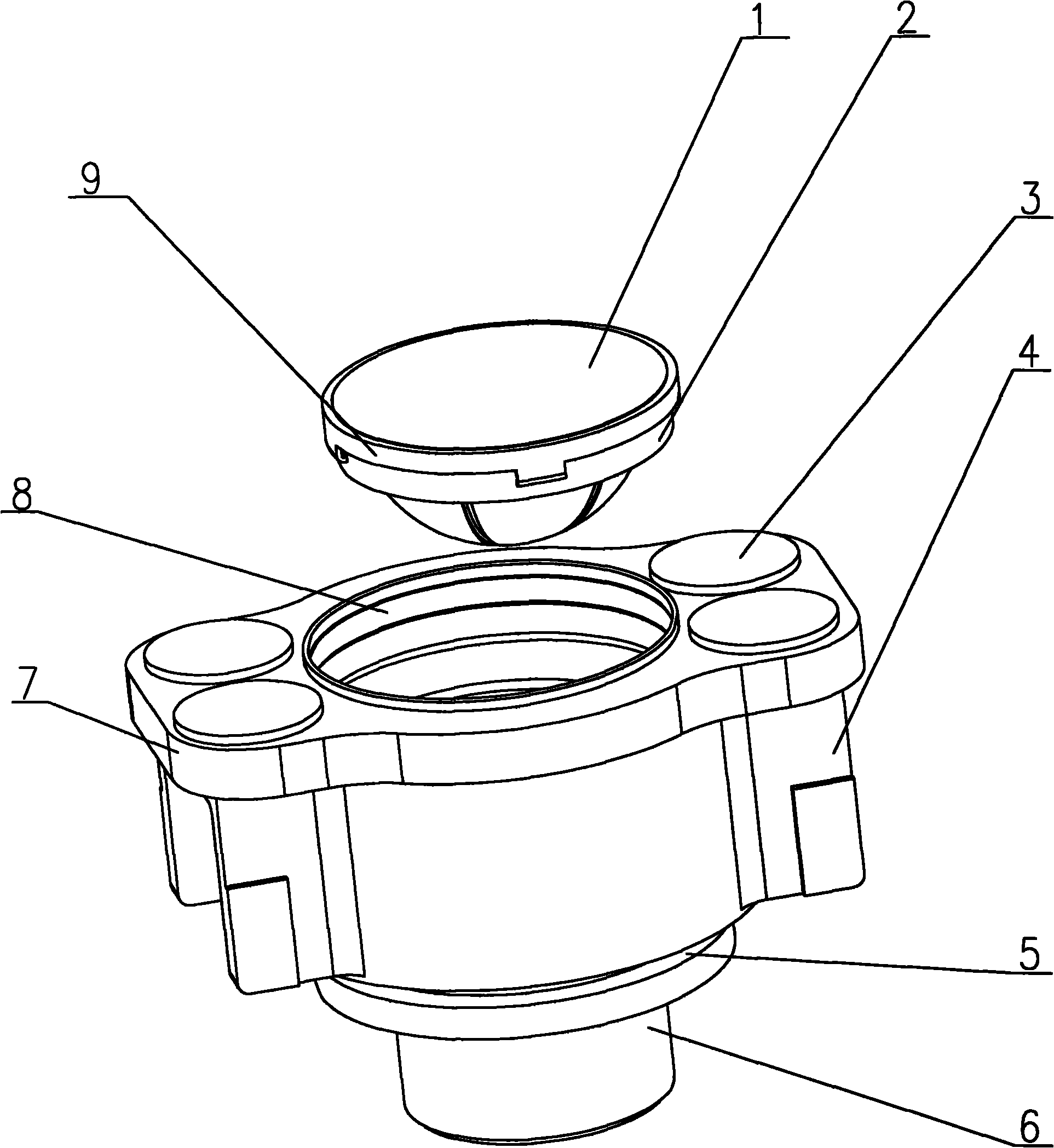

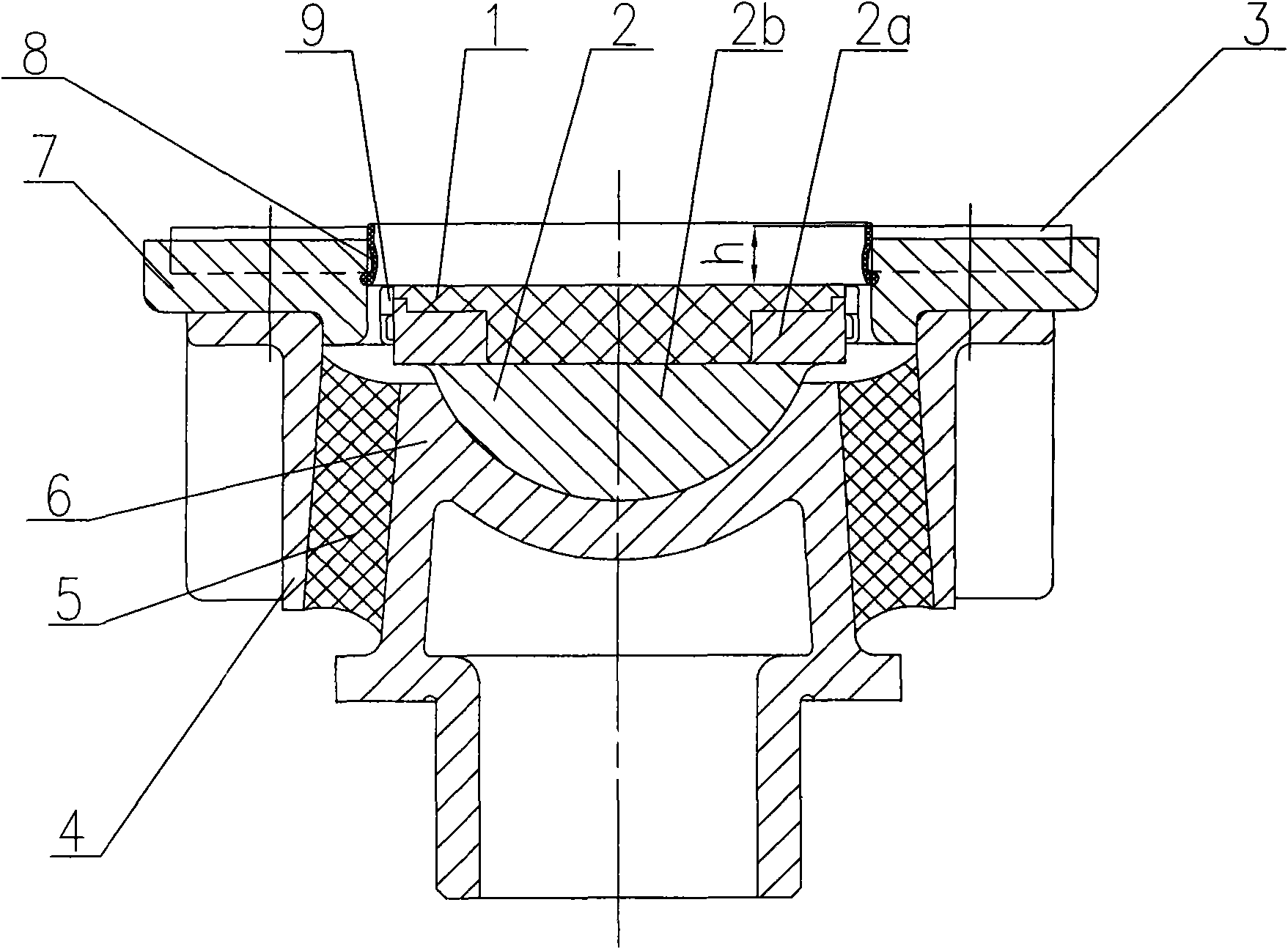

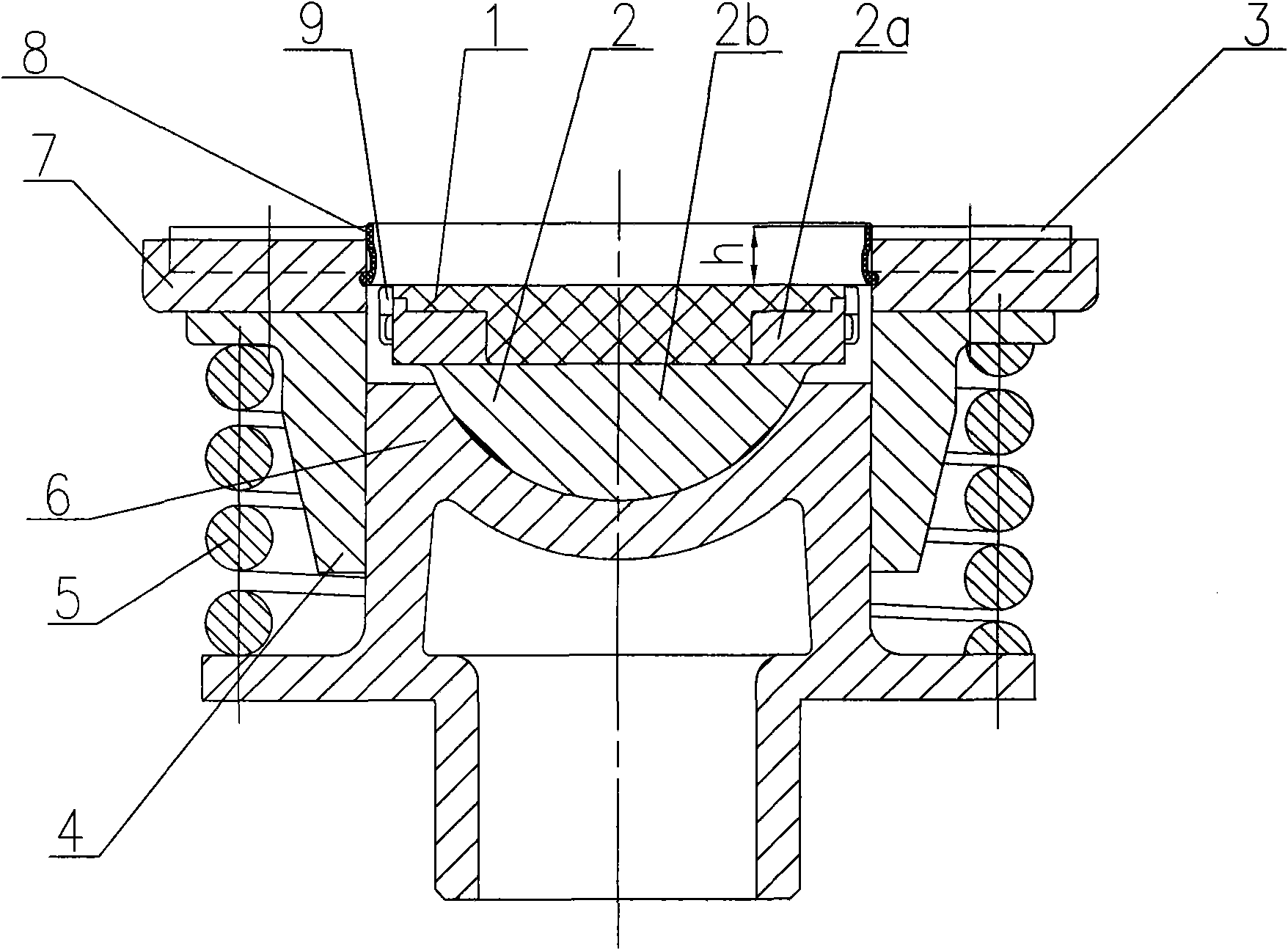

Double-ball connecting rod connection device used for vehicle lamp adjustable support connection

ActiveCN104296093ASmall volumeReduce lateral forceVehicle headlampsLighting support devicesEngineeringElectrical and Electronics engineering

Owner:HASCO VISION TECHNOLOGY CO LTD

Mechanical roller tappet for an internal combustion engine

InactiveUS20100012065A1High shape stabilityEliminate drawbackValve drivesMachines/enginesEngineeringCam

Owner:SCHAEFFLER TECH AG & CO KG

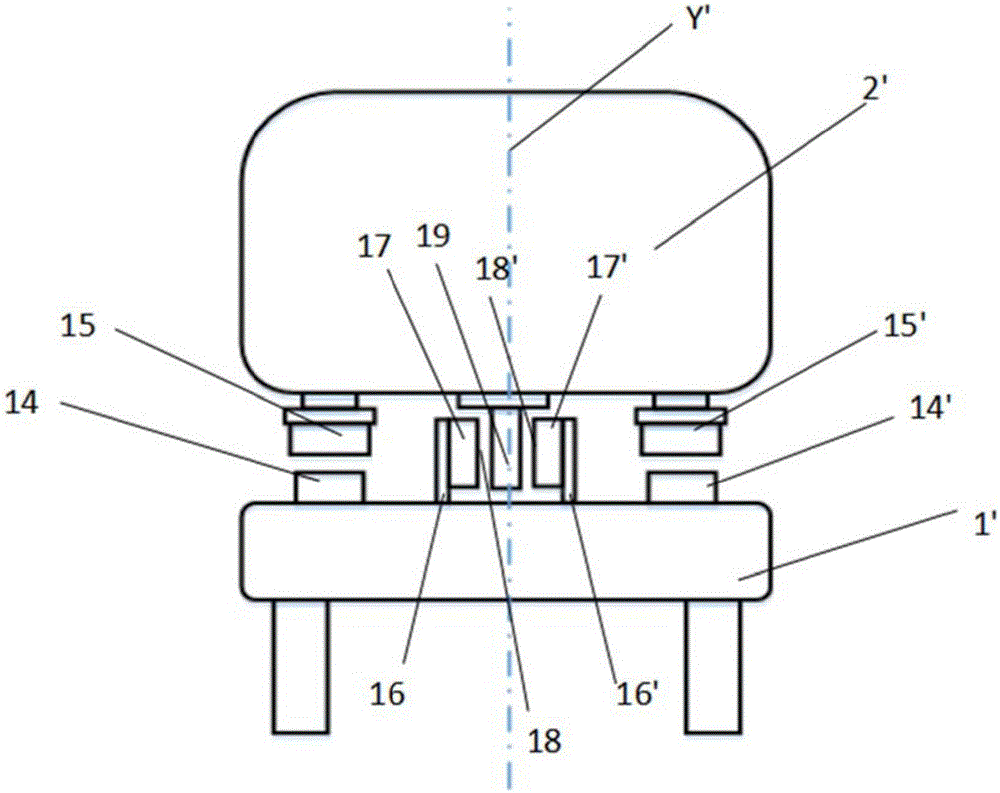

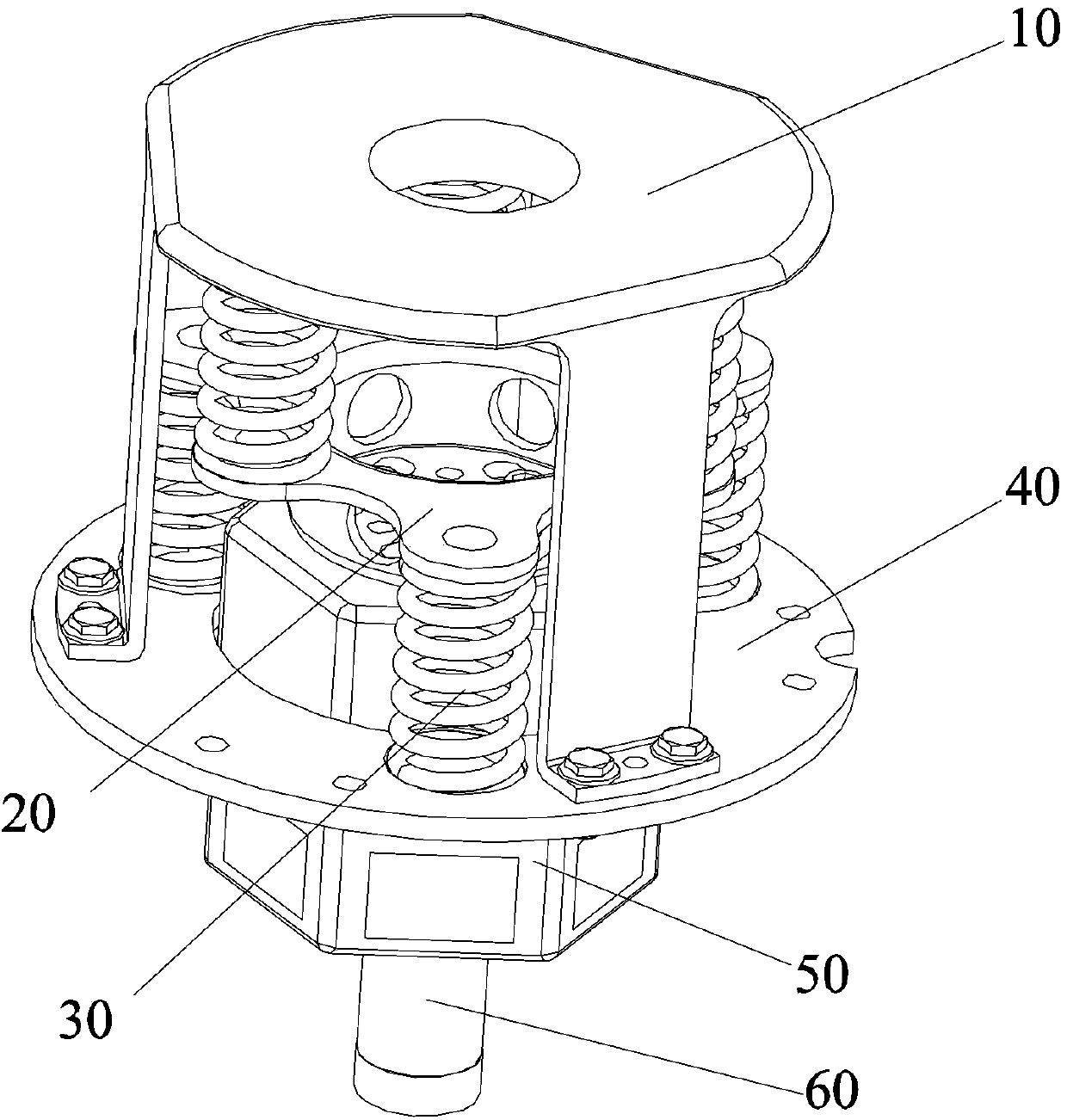

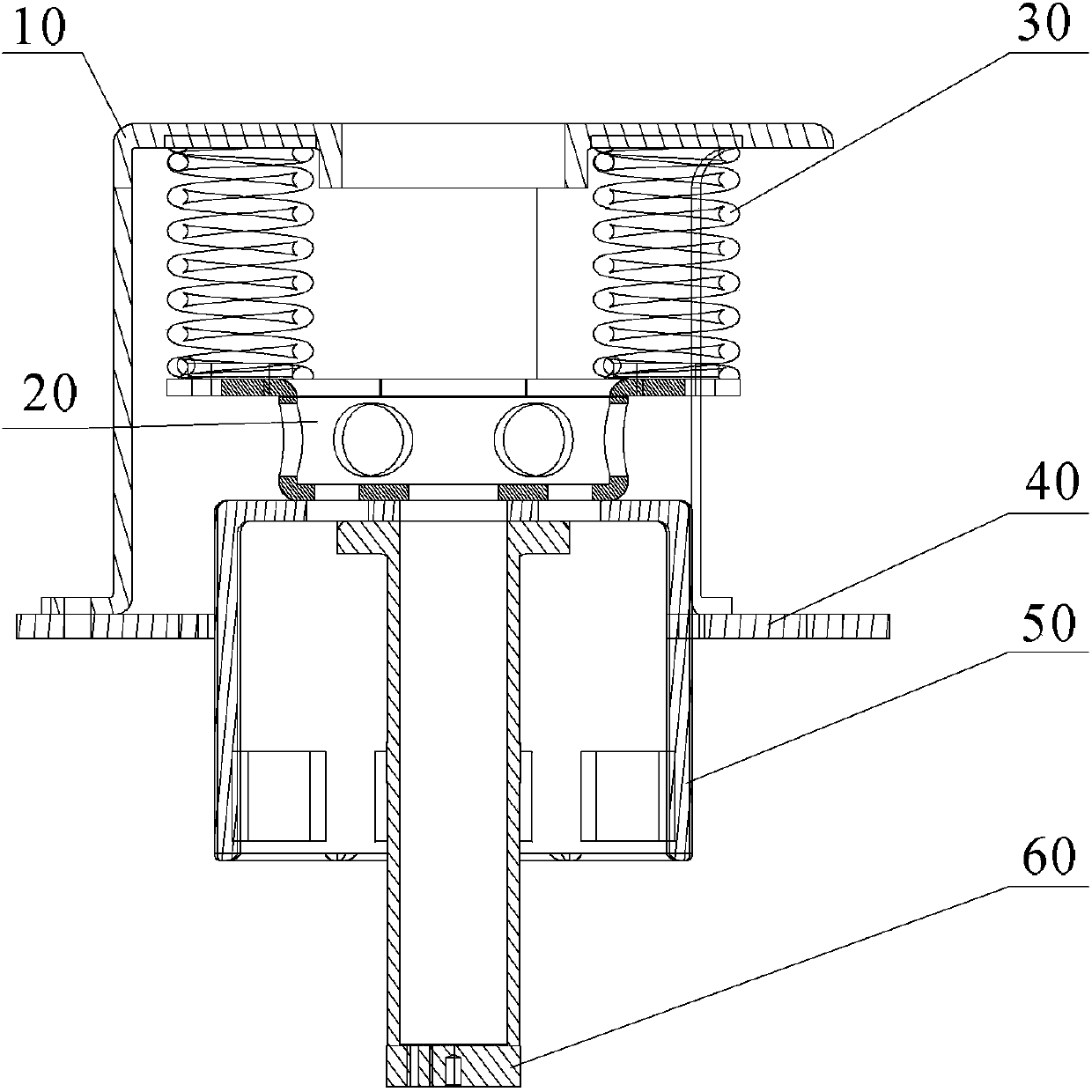

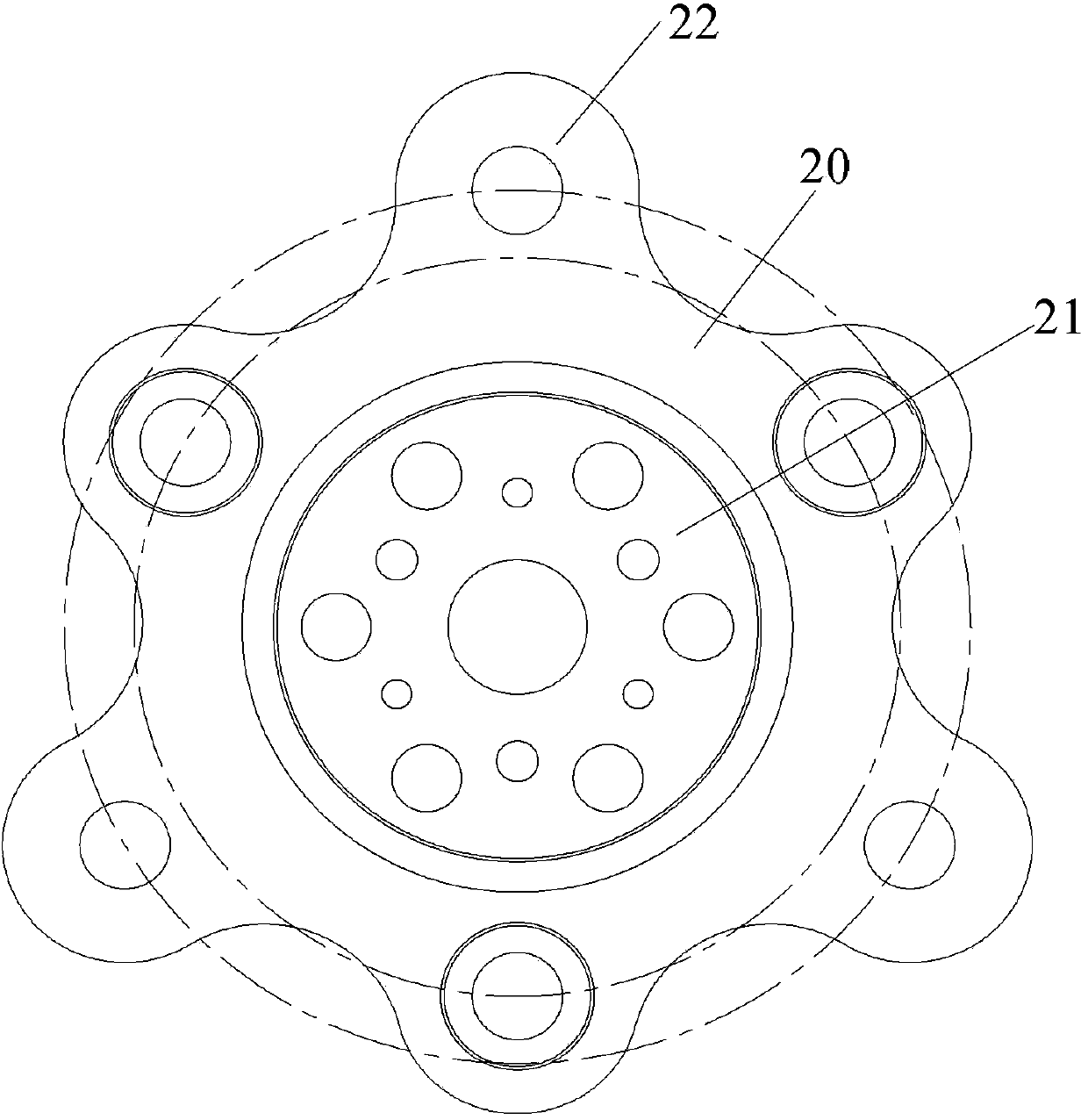

Resonance system

InactiveCN103629075AReduce lateral forcePositive displacement pump componentsPositive-displacement liquid enginesResonanceEngineering

The invention provides a resonance system which comprises a spring rear cover, a stator end plate connected with the spring rear cover, a spring supporting part arranged between the spring rear cover and the stator end plate, and two sets of springs, wherein the first set of springs are evenly arranged between the spring supporting part and the spring rear cover in the circumferential direction, and the second set of springs are evenly arranged between the spring supporting part and the stator end plate in the circumferential direction. According to the resonance system, the springs are evenly arranged in the circumferential direction on both sides of the spring supporting part, the diffuse force of the springs can be counteracted to the maximum degree, and then lateral force is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Apparatus and methods for connecting a movable subsystem to a frame

InactiveUS6968606B2Function increaseReduce forceAssembly machinesElectrographic processVertical loadMechanical engineering

An assembly has a frame that defines at least one opening and a subsystem that is movable relative to the frame. At least one slide connects the subsystem to the frame such that the weight of the subsystem transmits a force to the slide. The slide includes at least one projection that extends through the at least one opening in the frame. At least one urging member biases the projection to at least partially counter the force transmitted to the slide by the weight of the subsystem. At least one docketing pin slides into at least one docking hole with minimal vertical load on the docking hole.

Owner:XEROX CORP

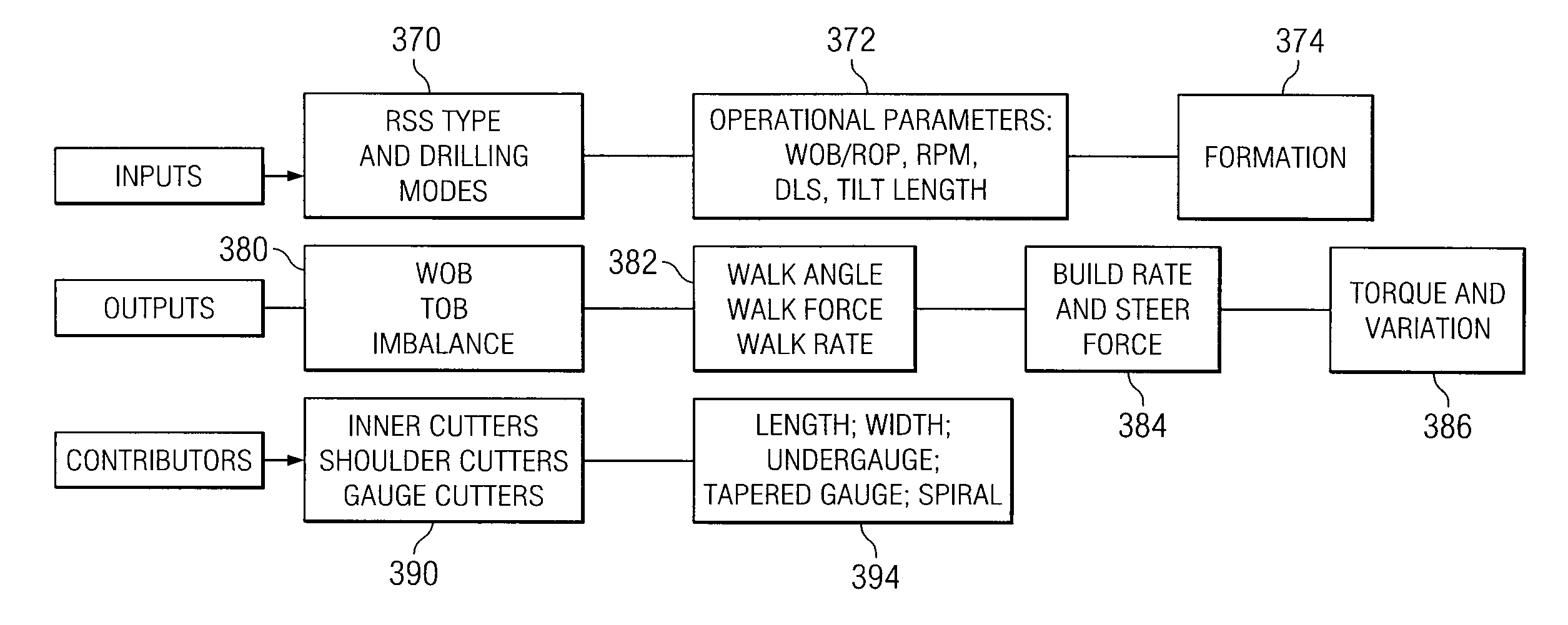

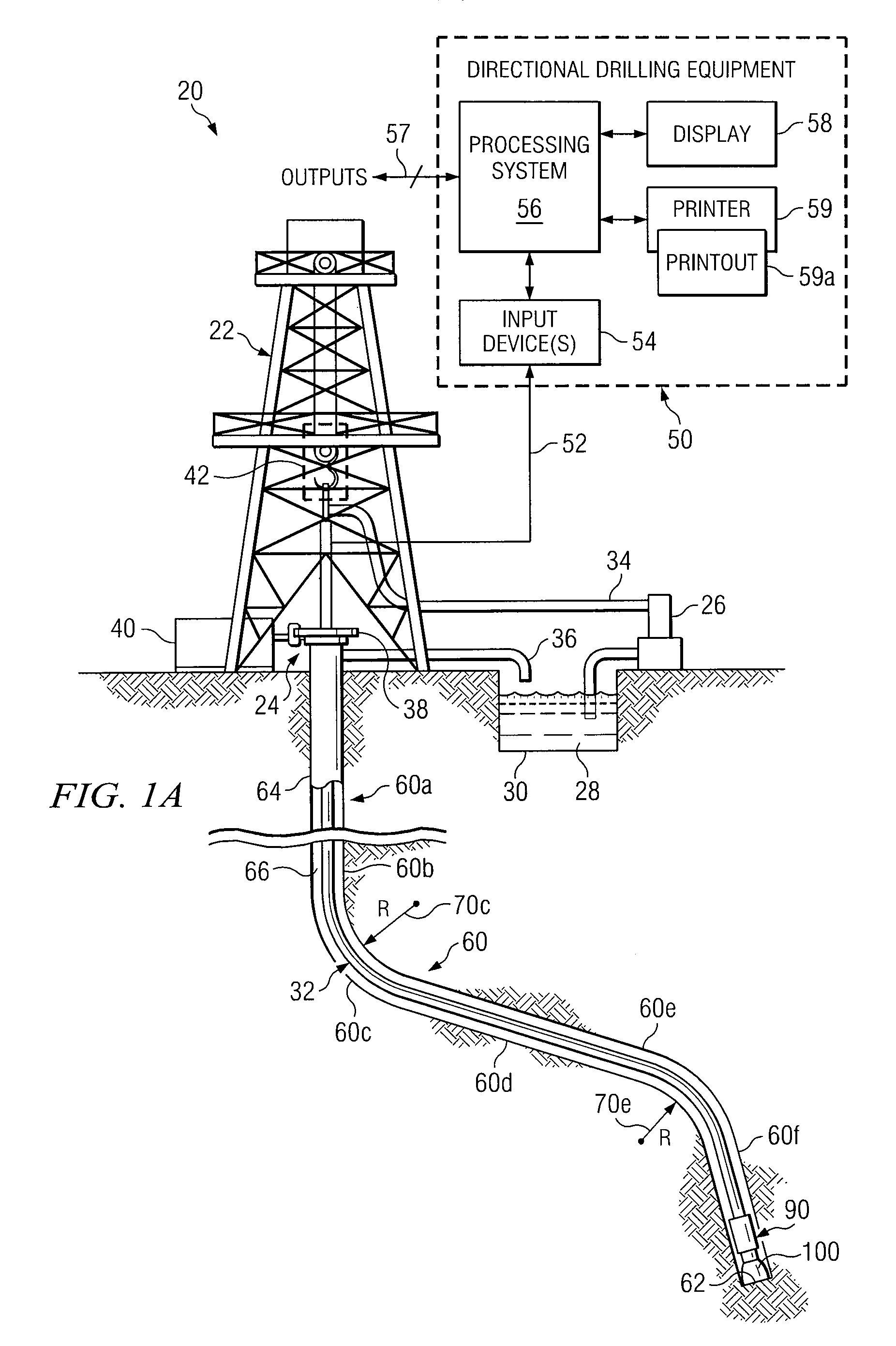

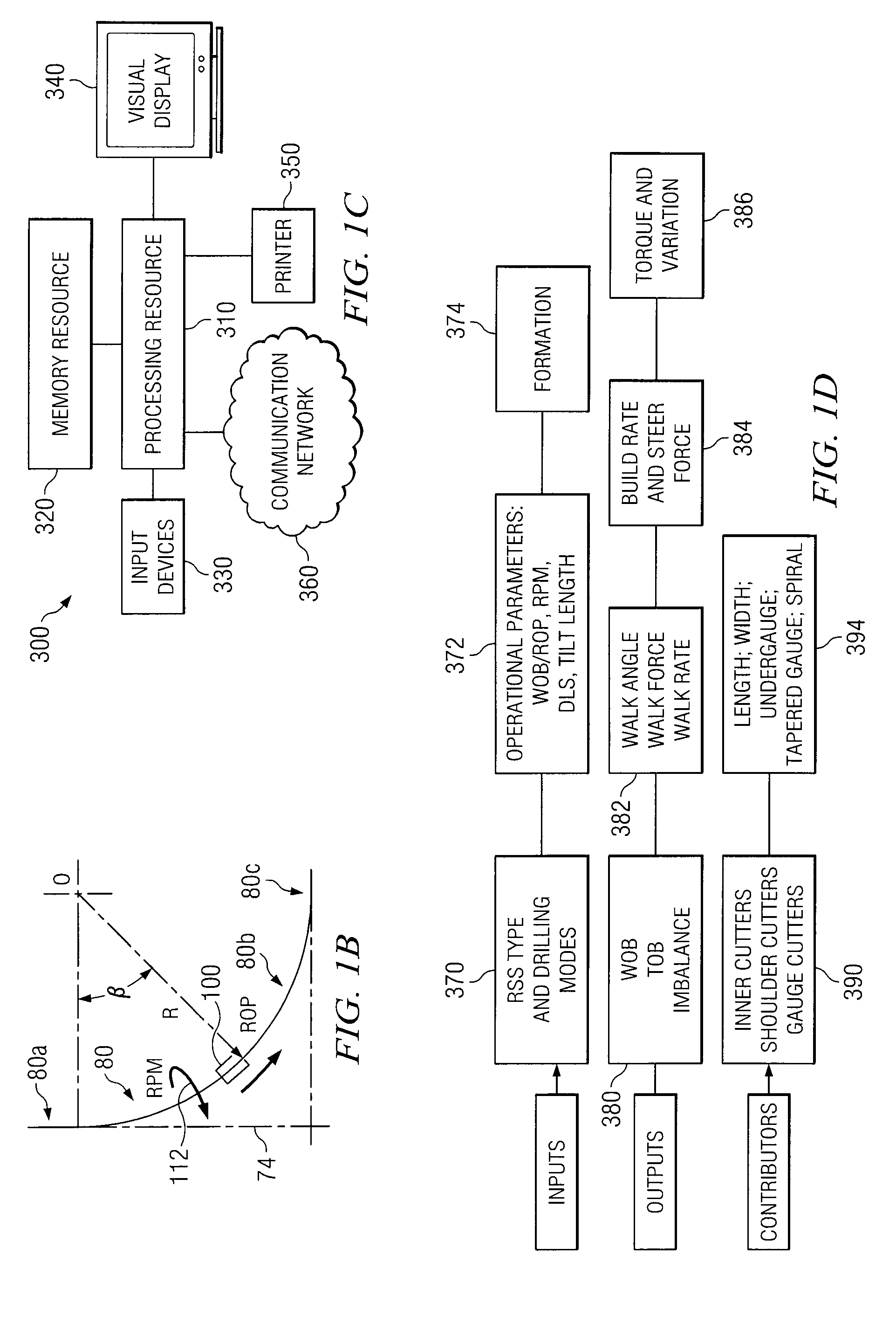

Methods and systems to predict rotary drill bit walk and to design rotary drill bits and other downhole tools

ActiveUS7860696B2Reduce or avoid undesired right walk forcesReduce lateral forceDrill bitsDirectional drillingEngineeringMultiple layer

Methods and systems may be provided to simulate forming a wide variety of directional wellbores including wellbores with variable tilt rates, relatively constant tilt rates, wellbores with uniform generally circular cross-sections and wellbores with non-circular cross-sections. The methods and systems may also be used to simulate forming a wellbore in subterranean formations having a combination of soft, medium and hard formation materials, multiple layers of formation materials, relatively hard stringers disposed throughout one or more layers of formation material, and / or concretions (very hard stones) disposed in one or more layers of formation material. Values of bit walk rate from such simulations may be used to design and / or select drilling equipment for use in forming a directional wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

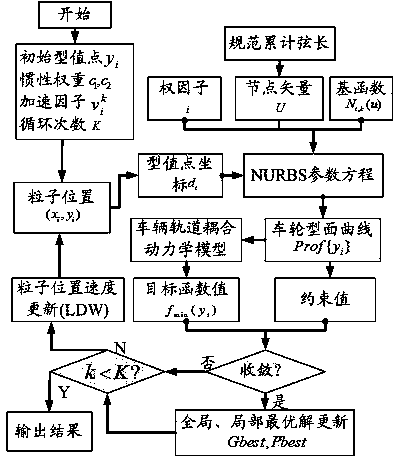

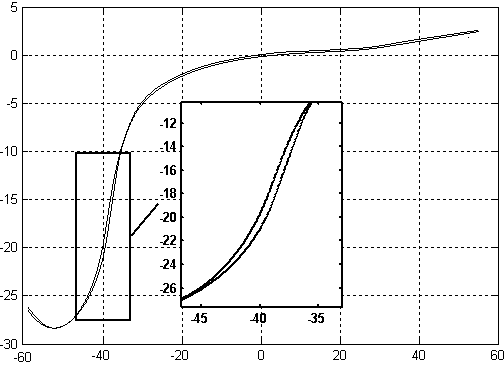

Optimal design method of low-wear high-speed train wheel profile

InactiveCN104036089AReduce lateral forceReduce touch pointsSpecial data processing applicationsTransverse forceEngineering

An optimal design method of a low-wear high-speed train wheel profile is characterized in that a curve of the high-speed train wheel profile is divided via equal arc length, N discrete coordinate points are used as data points, and a wheel profile curve is reconfigured; vertical coordinates of N data apexes are used as design variables, a circuit average for reducing wheel wear consumption and wheel track transverse force are used as target functions, wheel profile wear statistics and concavity and continuity of the profile curve are used as geometric constraints, a high-speed train wheel profile multi-target optimization model is established, and the model is subjected to multi-target optimizing calculation. Results show that contact points of a rim portion of the profile and the side of a track are significantly reduced, and line average of each single wheel for low wear consumption is 26.8% lower than that of the original standard profile; the wheel track transverse force of the wheel is reduced; root-mean-square values of the wheel track transverse forces of left and right wheels are decreased by 17.6% and 18.3% respectively; root-mean-square values of maximum contact stresses of the left and right wheels are decreased by 21.6% and 19.8% respectively; root-mean-square values of derailment coefficients of the left and right wheels are decreased by 9.5% and 6.2% respectively.

Owner:EAST CHINA JIAOTONG UNIVERSITY +1

Apparatus and methods for connecting a movable subsystem to a frame

InactiveUS20050044713A1Function increaseReduce forceAssembly machinesElectrographic processEngineeringVertical load

An assembly has a frame that defines at least one opening and a subsystem that is movable relative to the frame. At least one slide connects the subsystem to the frame such that the weight of the subsystem transmits a force to the slide. The slide includes at least one projection that extends through the at least one opening in the frame. At least one urging member biases the projection to at least partially counter the force transmitted to the slide by the weight of the subsystem. At least one docketing pin slides into at least one docking hole with minimal vertical load on the docking hole.

Owner:XEROX CORP

Safety cord release of window covering

InactiveUS20120000036A1Reduce lateral forceDoor/window protective devicesRopes and cables for vehicles/pulleyWindow coveringEngineering

A safety cord release for a window covering has a top section, a middle section, and a bottom section from a top to a bottom thereof. The safety cord release has a right case and a left case combined with the right case. There are several pairs of couplers on the right case and the left case located at the top section, the middle section and the bottom section respectively for engagement to reduce a transverse force from cords and to separate the right case and the left case immediately to release the cords for safety.

Owner:NIEN MADE ENTERPRISE CO LTD

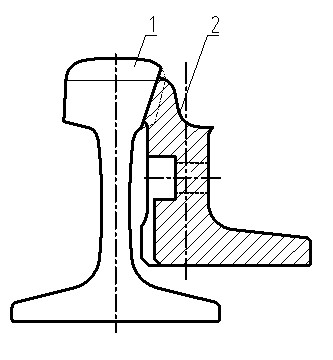

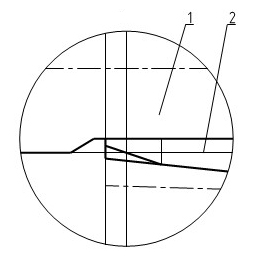

Horizontal deeply-concealed wear-resistant tongue rail and stock rail structure

The invention relates to a horizontal deeply-concealed wear-resistant tongue rail and stock rail structure. The structure can effectively prolong the service life of a tongue rail and comprises the tongue rail and a stock rail, wherein the horizontal slicing depth of the working edge of a tightly attaching section of the stock rail is 6mm; and with respect to the tongue rail which does not adopt the technology, the width of a rail head of the tongue rail is increased by 6mm at positions which have the same distance away from the tip of the tongue rail, the working edge of the tongue rail has a gradient of 1:5, and the non-working edge has a gradient of 1:3. The horizontal deeply-concealed wear-resistant tongue rail and stock rail structure has the advantages that: the horizontal slicing depth of the working edge of the tightly attaching section of the stock rail is 6mm, so that on the one hand, the robustness of the tongue rail can be improved, and on the other hand, the length of a front-end weak cross section can be shortened, and the service life of the tongue rail is effectively prolonged.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Safety cord release of window covering

InactiveUS8104146B2Reduce lateral forceSnap fastenersDoor/window protective devicesTransverse forceWindow covering

A safety cord release for a window covering has a top section, a middle section, and a bottom section from a top to a bottom thereof. The safety cord release has a right case and a left case combined with the right case. There are several pairs of couplers on the right case and the left case located at the top section, the middle section and the bottom section respectively for engagement to reduce a transverse force from cords and to separate the right case and the left case immediately to release the cords for safety.

Owner:NIEN MADE ENTERPRISE CO LTD

Bare weight two-stage friction-type lower side bearing

ActiveCN101830235AIncrease contactFit closelyBogiesBogie-underframe connectionsFrictional coefficientTruck

The invention relates to a bare weight two-stage friction-type lower side bearing which comprises an inner seat of the side bearing and an outer sleeve of the side bearing which are sleeved and matched with each other, wherein a pressing block of the inner seat of the side bearing is arranged at the upper part of the inner seat of the side bearing; a heavy-load friction plate is arranged at the top part of the pressing block of the inner seat of the side bearing; a pressing plate of the outer sleeve of the side bearing is arranged at the upper part of the outer sleeve of the side bearing; a non-load friction plate is arranged at the top part of the pressing plate of the outer sleeve of the side bearing; the friction factor muk of the non-load friction plate is greater than the friction factor muz of the heavy-load friction plate; an elastic element for controlling the vertical position relation between the inner seat of the side bearing and the outer sleeve of the side bearing is arranged between the inner seat of the side bearing and the outer sleeve of the side bearing; and the mechanical property of the elastic element enables the non-load friction plate and the heavy-load friction plate to meet the following position relation: in an empty car state, the horizontal position of the non-load friction plate is higher than the that of the heavy-load friction plate, and in a heavy car state, the horizontal position of the non-load friction plate is flush with that of the heavy-load friction plate. A railway freight car bogie assembled with the lower side bearing has higher critical speed in the no-load state and better curve negotiation capacity in the heavy-load state.

Owner:CRRC YANGTZE CO LTD

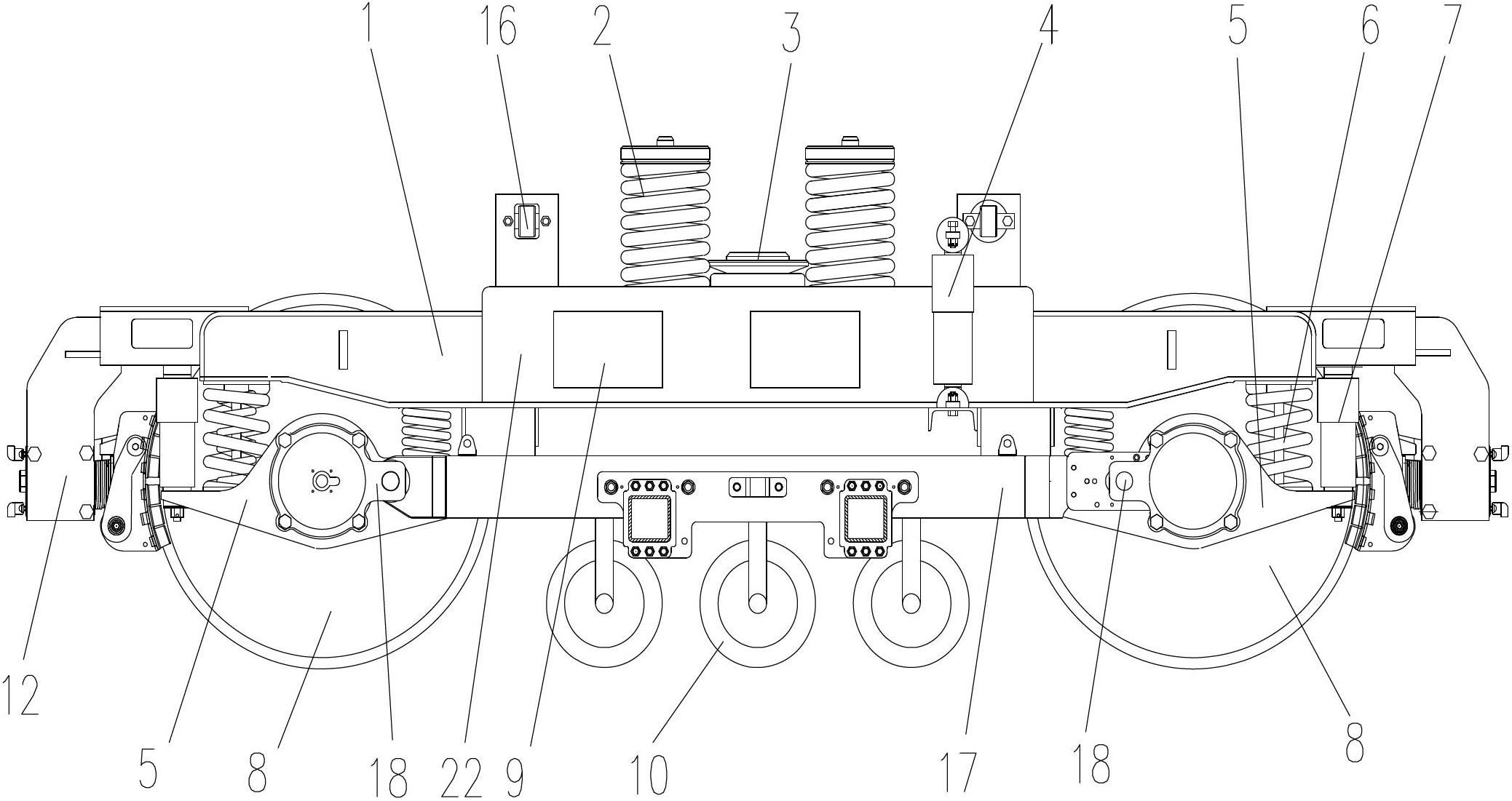

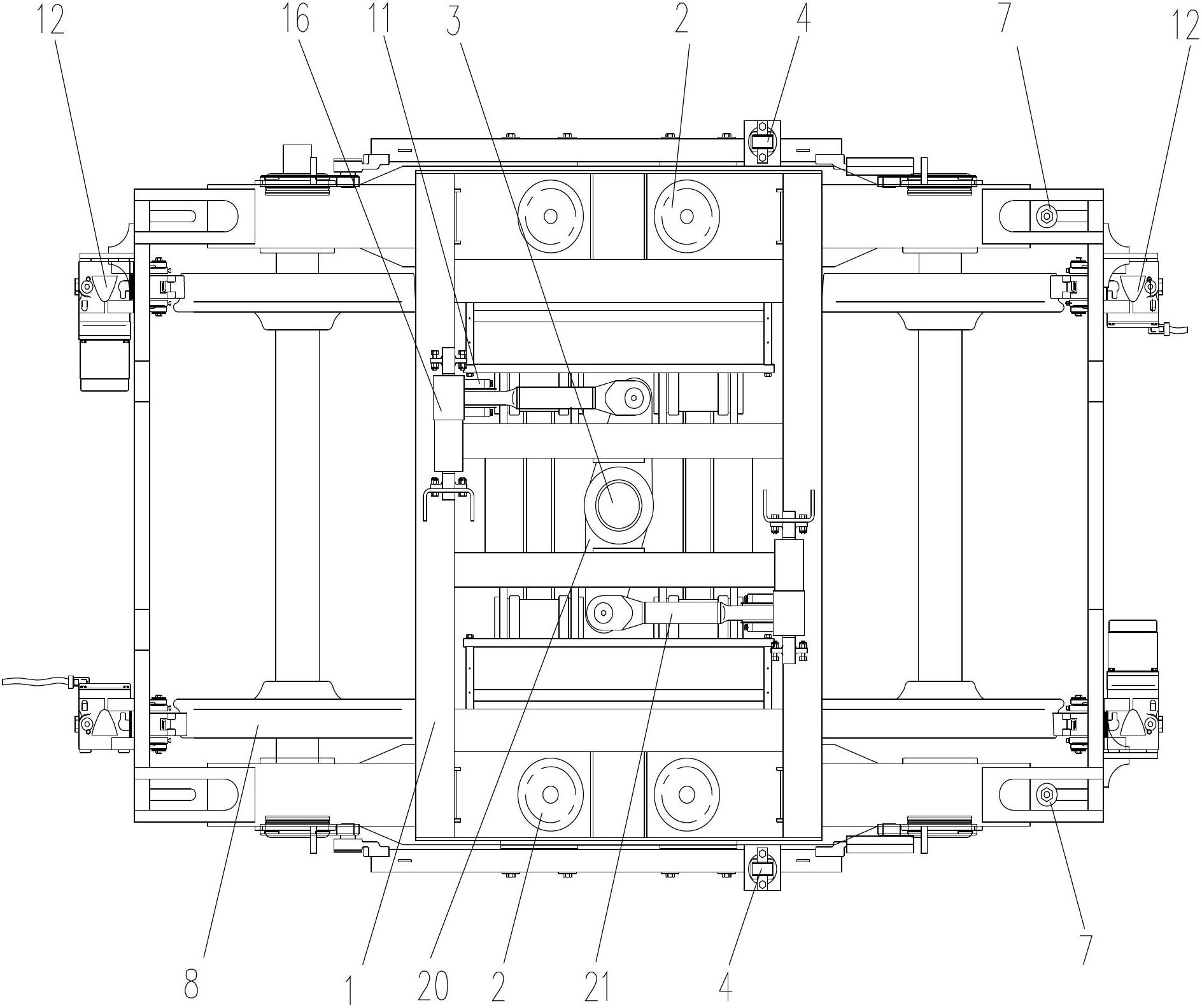

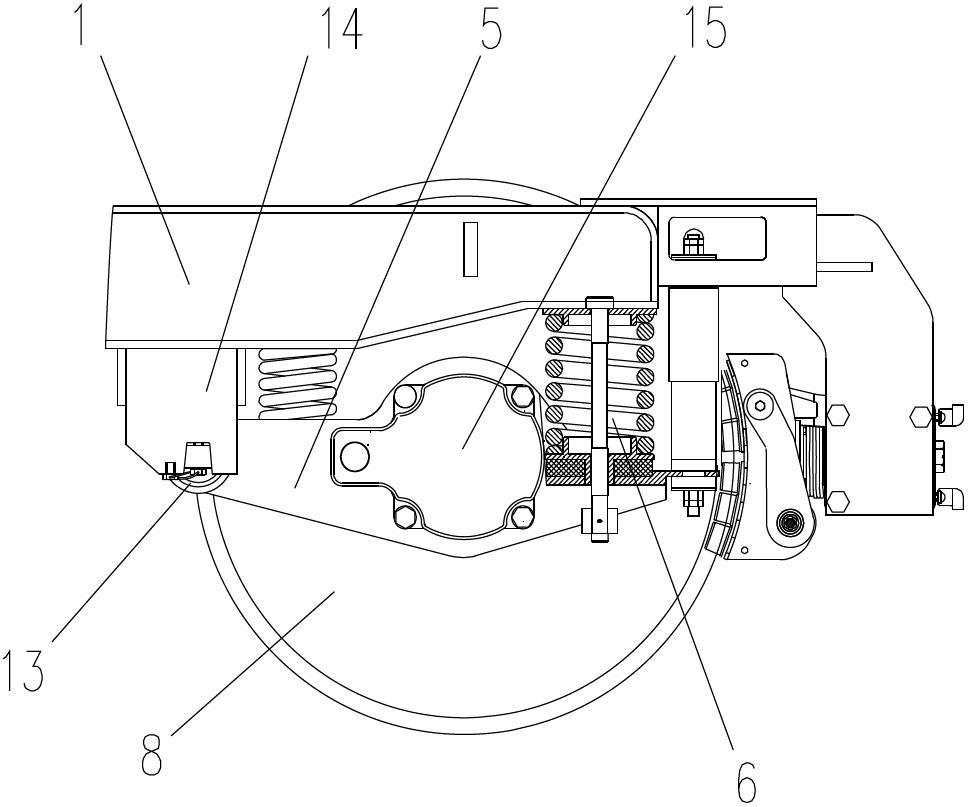

Steering frame of railway track car with flaw detection devices

InactiveCN102673607ASolve the problem of low accuracy of flaw detectionReduce manufacturing costBogiesRailway auxillary equipmentBogieHorizontal force

The invention discloses a steering frame of a railway track car with flaw detection devices, which comprises a framework, the upper part of the framework is provided with a traction seat connected with a car body through a traction device; the lower part of the framework is provided with an elastic node seat which is connected with a shaft box body through an elastic node; the shaft box body is connected with wheel pairs; a support spring arranged on the framework, a horizontal shock absorber and a two-system vertical shock absorber form a two-system suspension system of the car body; a shaft box spring with one end supported at the upper part of the shaft box body and the other end supported at the lower end of the framework and a one-system vertical shock absorber arranged on the framework form a one-system suspension system of the car body; the end part of the framework is provided with a unit brake; the shaft box body is provided with flaw detection devices arrange at intervals along the direction of steel tracks; and detection wheels of the flaw detection devices are in direct contact with steel tracks between the wheel pairs. According to the invention, the manufacturing cost is lowered, the shock of the detection wheels is reduced, the flaw detection accuracy rate is improved; moreover, the steering frame has the advantages of good operation quality is good, high pass curve performance, small horizontal force of wheel tracks, reliable braking performance and great convenience in maintenance and can completely meet the requirement of steel track flaw detection with high flaw detection speed.

Owner:BAOJI CSR TIMES ENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com