Bare weight two-stage friction-type lower side bearing

A friction-type, empty-weight technology, applied in the direction of railway car body parts, bogies, devices for lateral relative movement between the underframe and the bogie, etc. It can achieve the effect of improving the ability to pass the curve, improving the critical speed, and increasing the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

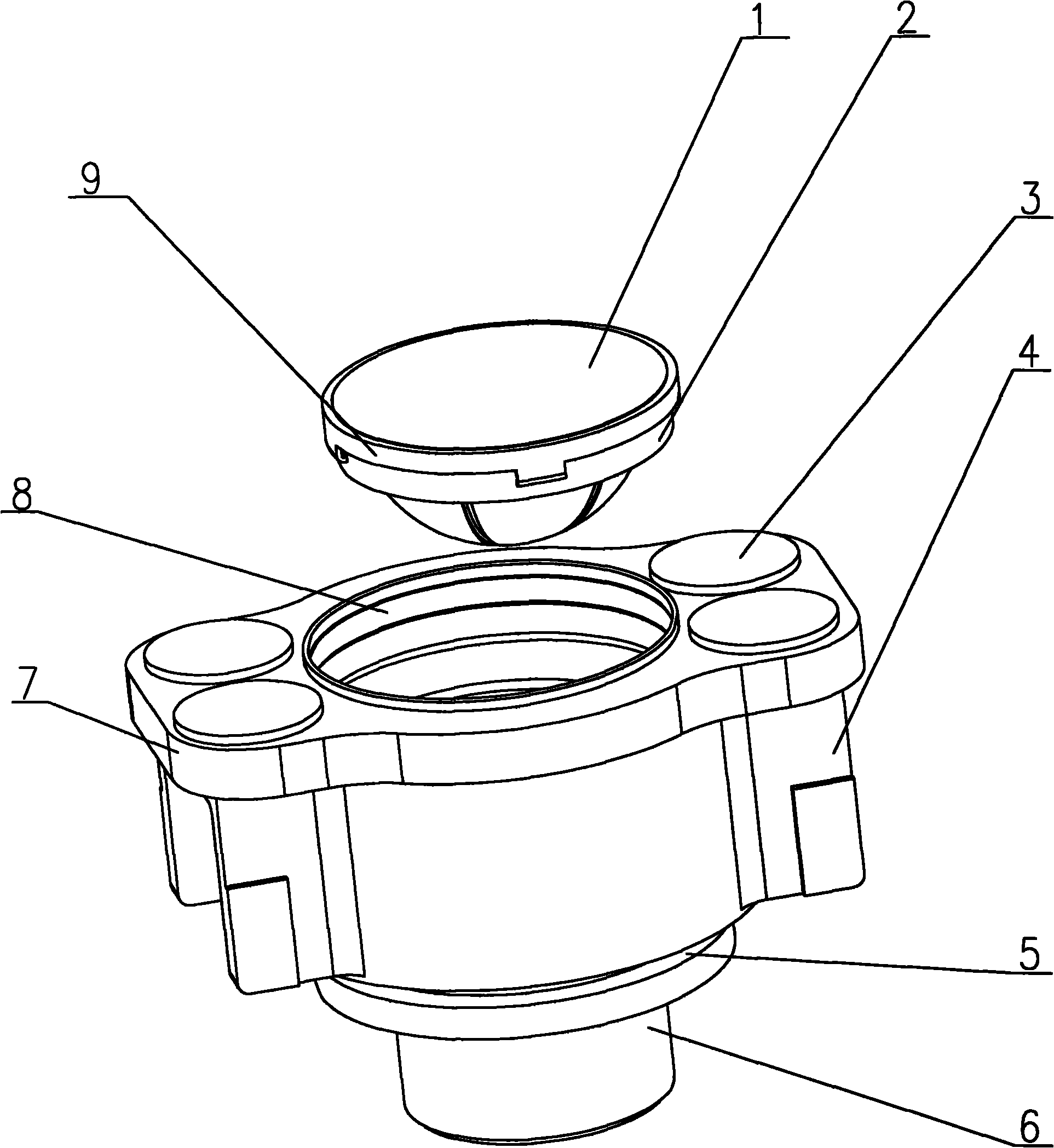

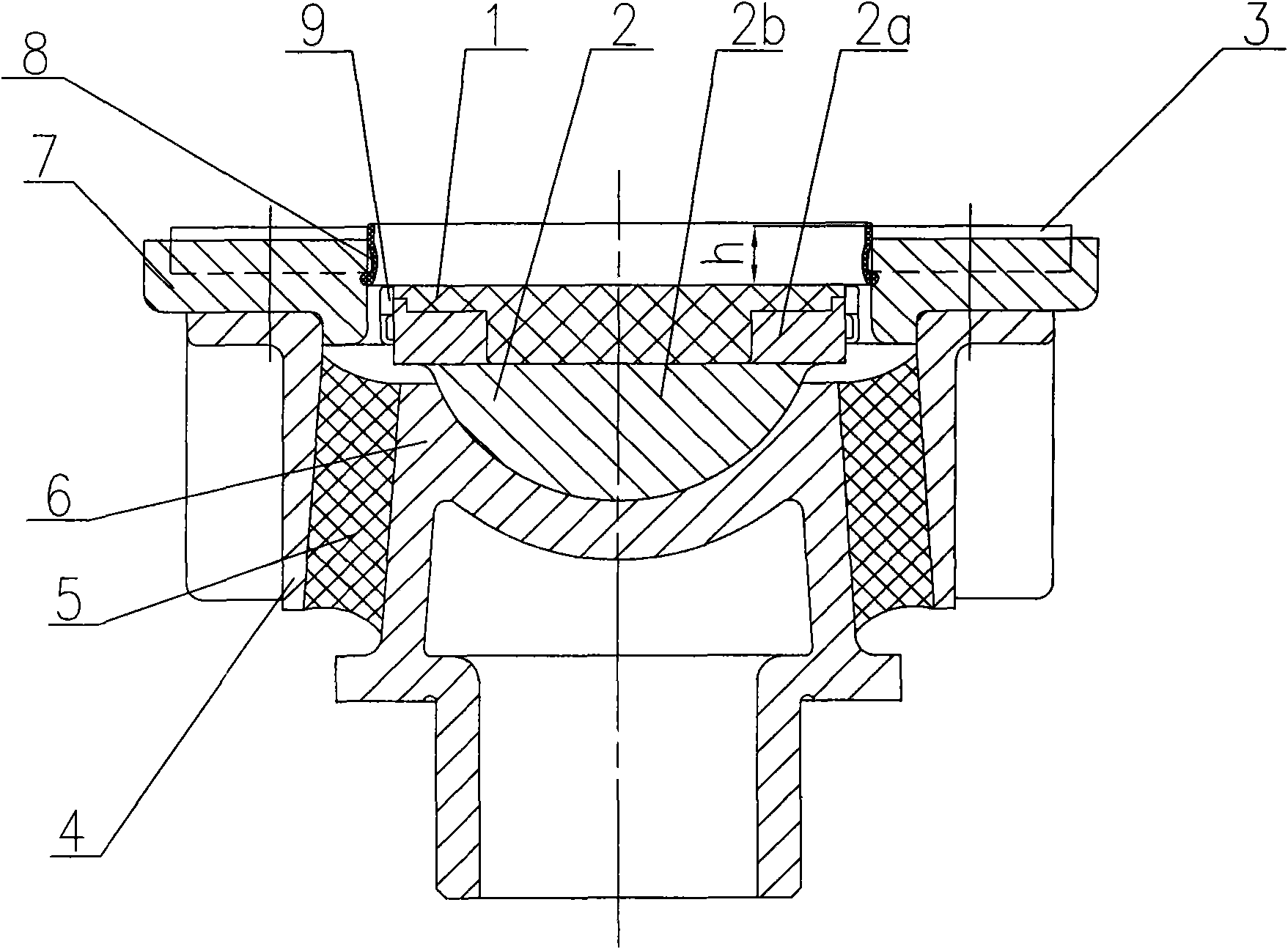

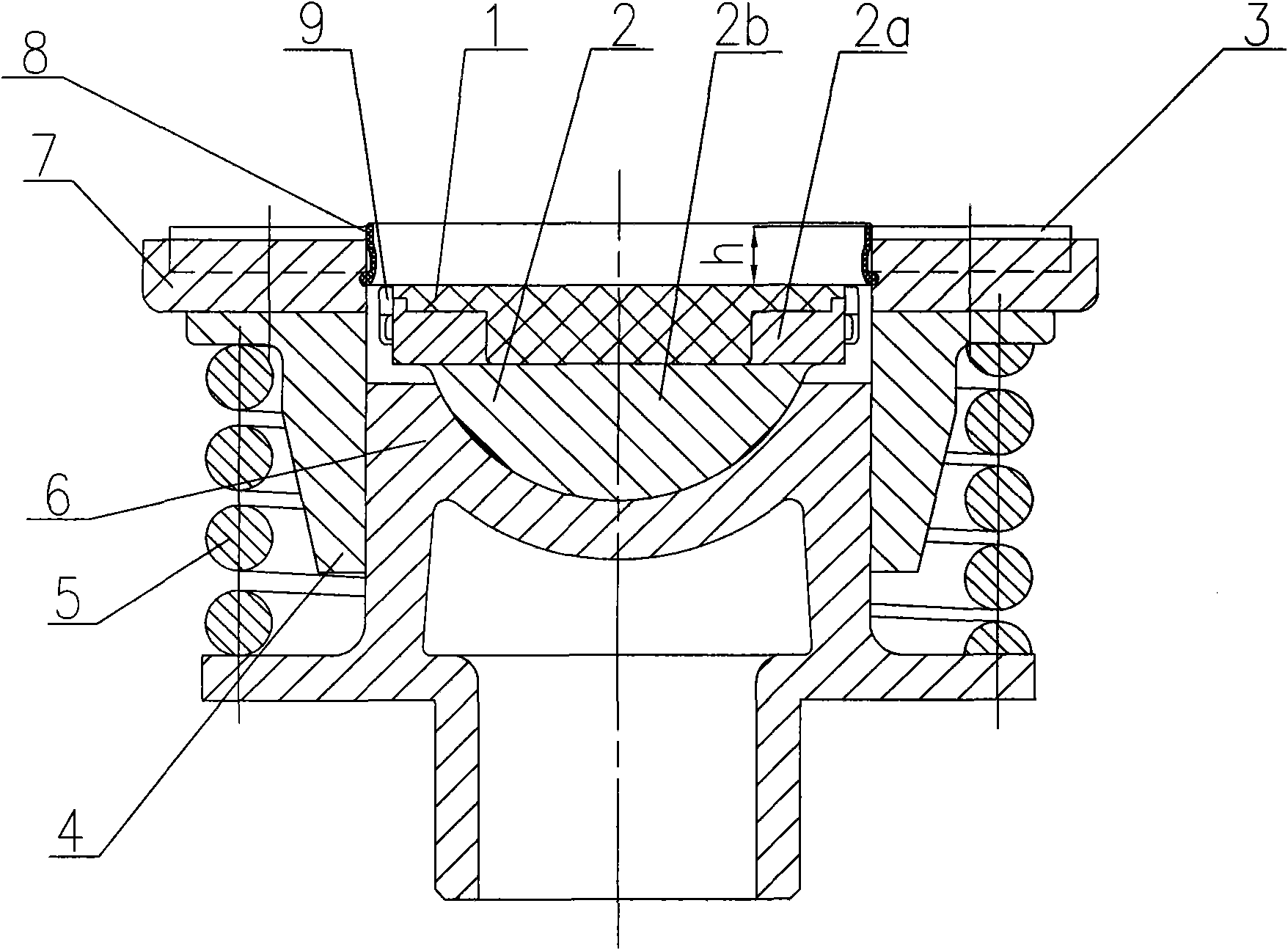

[0015] like Figure 1~3 As shown, the empty-weight two-stage friction lower side bearing of the present invention has a side bearing inner seat 6 located in the middle and a side bearing outer cover 4 that is fitted on the outer periphery of the side bearing inner seat 6 and can move up and down. A side bearing inner seat pressing block 2 is installed on the top of the side bearing inner seat 6, and a heavy-duty friction plate 1 is installed on the top of the side bearing inner seat pressing block 2. The top of the side bearing jacket 4 is equipped with a side bearing jacket pressing plate 7, and the top of the side bearing jacket pressing plate 7 is equipped with an unloaded friction plate 3. An elastic element 5 for controlling the upper and lower positional relationship between the side bearing inner seat 6 and the side bearing outer casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com