Double-crank mechanism engine

A double crank mechanism and engine technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve problems such as low reliability, achieve the effects of reducing friction loss, increasing limit speed, toughness and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

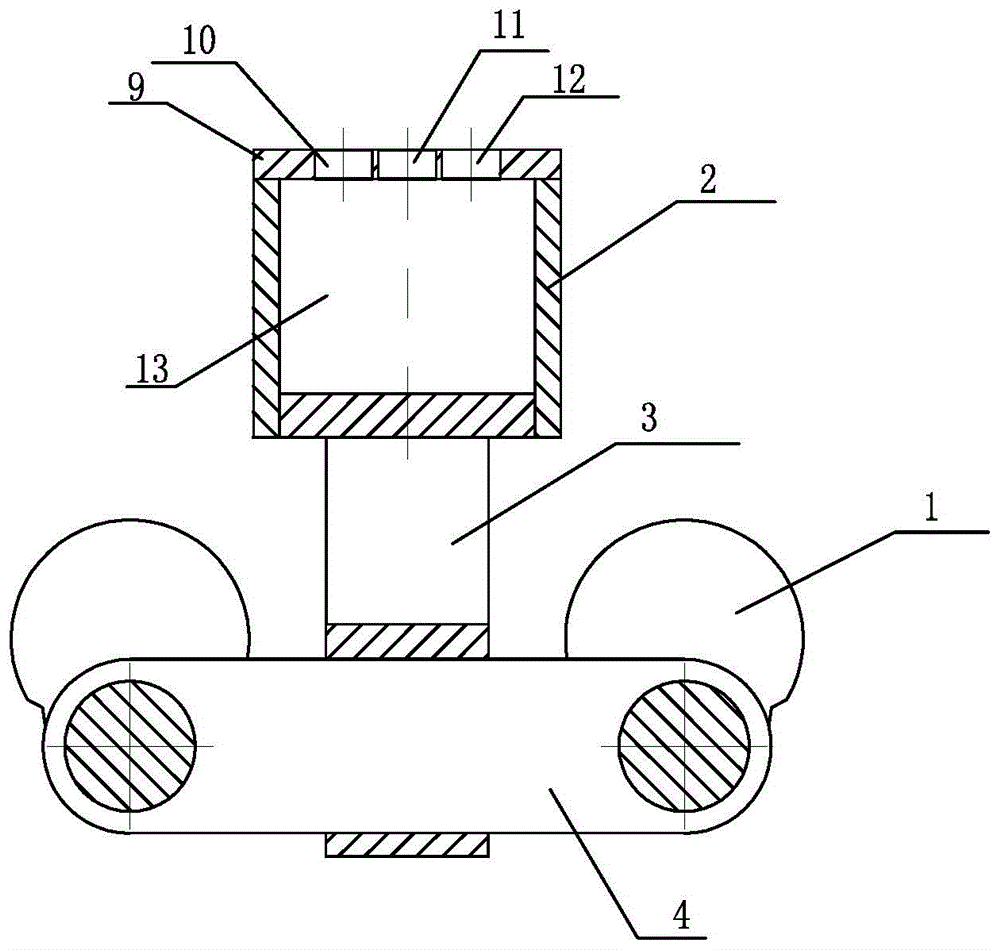

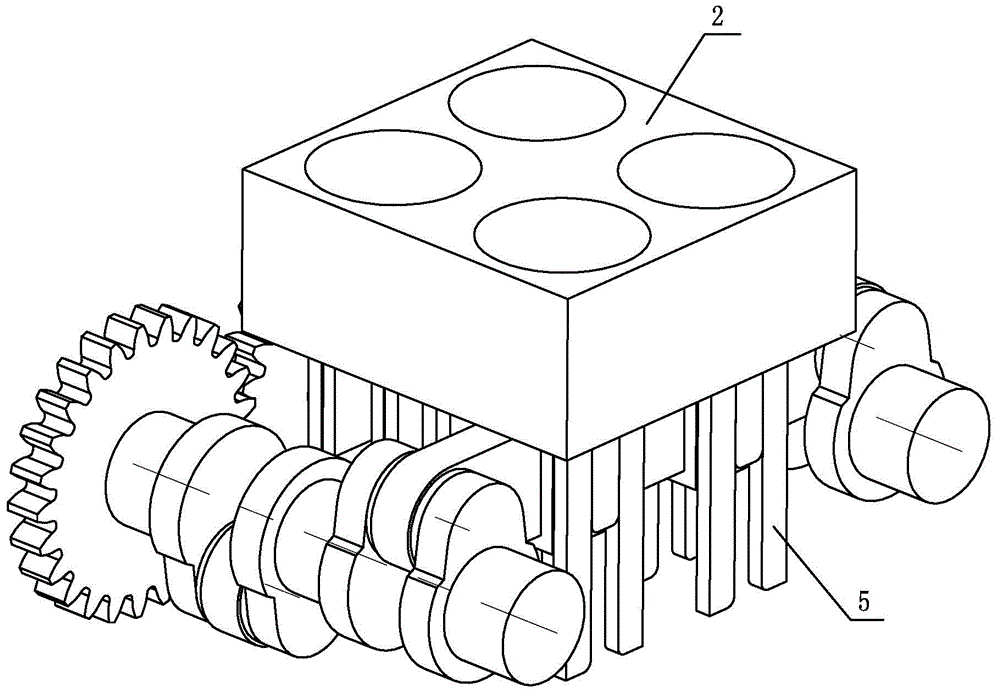

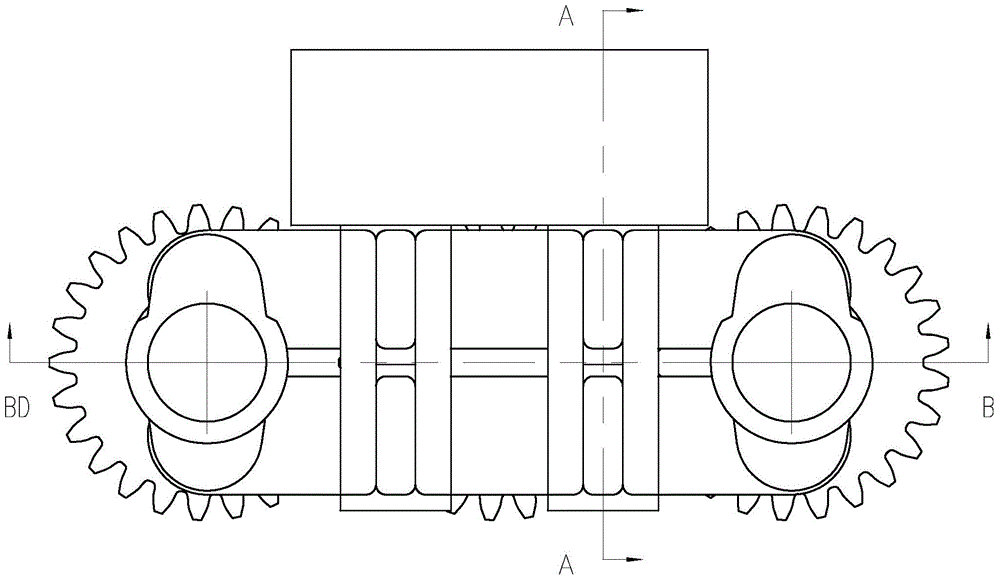

[0061] Embodiment 1, with reference to Figure 2-Figure 9 , said cylinder 2 has four, and four cylinders 2 are arranged in parallel in two rows, and described piston 3, piston rod 3-1 are corresponding to the quantity and the position of cylinder 2; Described connecting rod 4 simultaneously from two The connecting rod slots 3-2 of the two piston rods 3-1 between the crankshafts 1 pass through, and the connecting rods 4 and the crank pins on each crankshaft 1 correspond to the number and position of the single-row cylinders 2 .

Embodiment 2

[0062] Embodiment 2, with reference to Figure 10-Figure 15 , there are four cylinders 2, and the four cylinders 2 are arranged in a straight line, the number and position of the piston 3, the connecting rod 4, the piston rod 3-1 and the crank pin on each crankshaft 1 and the cylinder 2 Corresponding.

[0063] When the piston does work, the linear reciprocating motion of the piston is converted into the rotation of the connecting rod and the crankshaft. The guide block bears the lateral force, and the force-bearing area is transferred to the low-temperature and easy-to-lubricate area outside the cylinder. The rotation of the crankshaft is transmitted to the output shaft 7 by the gear transmission pair. To do work externally. Four cylinders correspond to four strokes to ensure continuous output.

Embodiment 3

[0064] Embodiment 3, with reference to Figure 16-Figure 25 , the piston 3 is a double-headed piston, that is, a piston 3 is provided at both ends of the piston rod 3-1, and a cylinder 2 is arranged at each end of the piston 3 . As an improvement, each of the two ends of the piston rod 3-1 has a row or double exhaust cylinder 2, and the crank pin on the piston 3, connecting rod 4, piston rod 3-1 and each crankshaft 1 is connected with the The number and position of the cylinders 2 are adapted.

[0065] In the double crank mechanism, the friction between the piston and the connecting rod causes the lateral force of the piston, the piston slides reciprocally along the guide block, and the lateral force of the piston is completely borne by the guide block so as not to cause the impact friction between the piston and the cylinder liner. Whether it is the friction between the piston and the connecting rod or the friction between the piston and the guide block, they are all in a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com