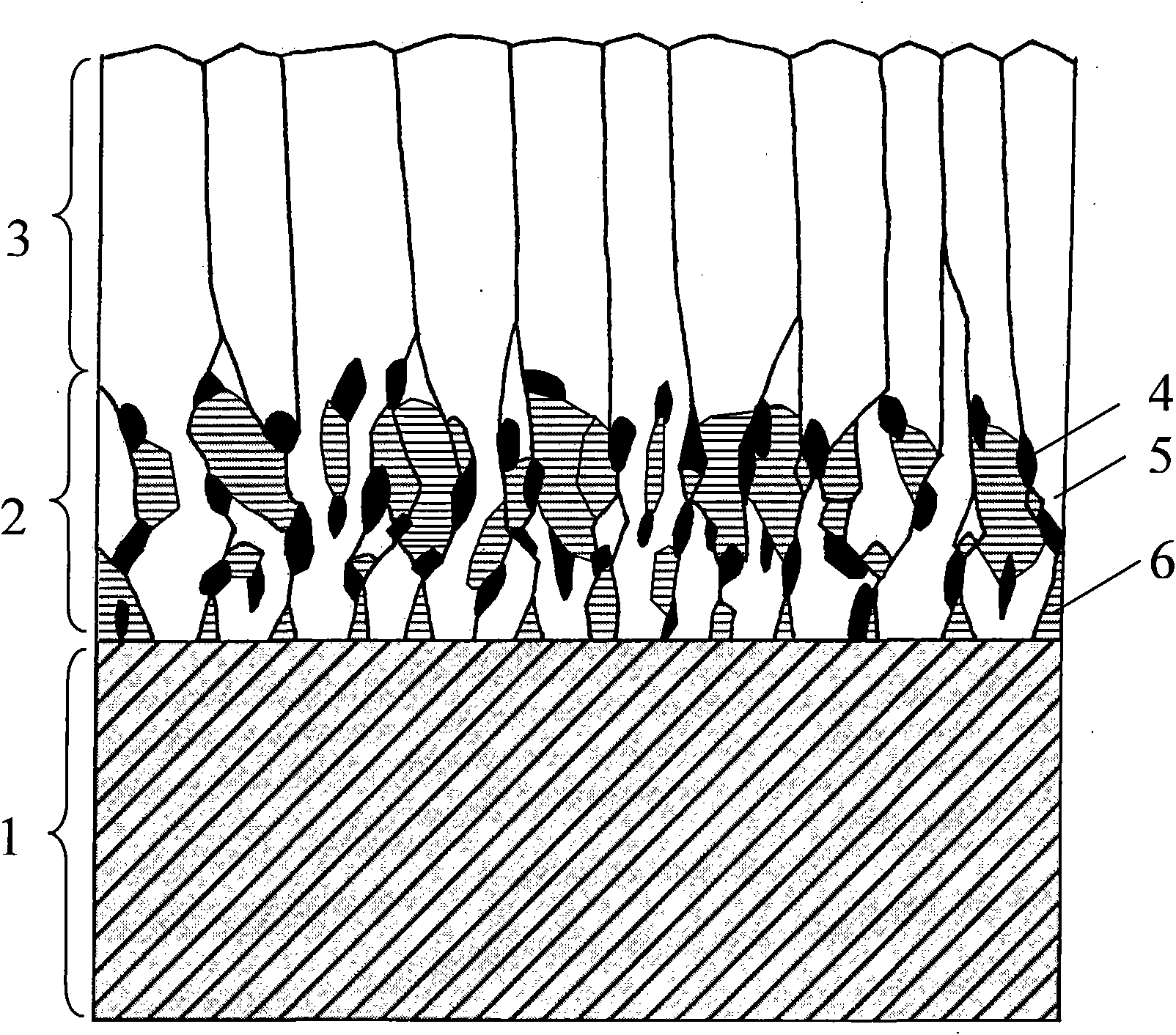

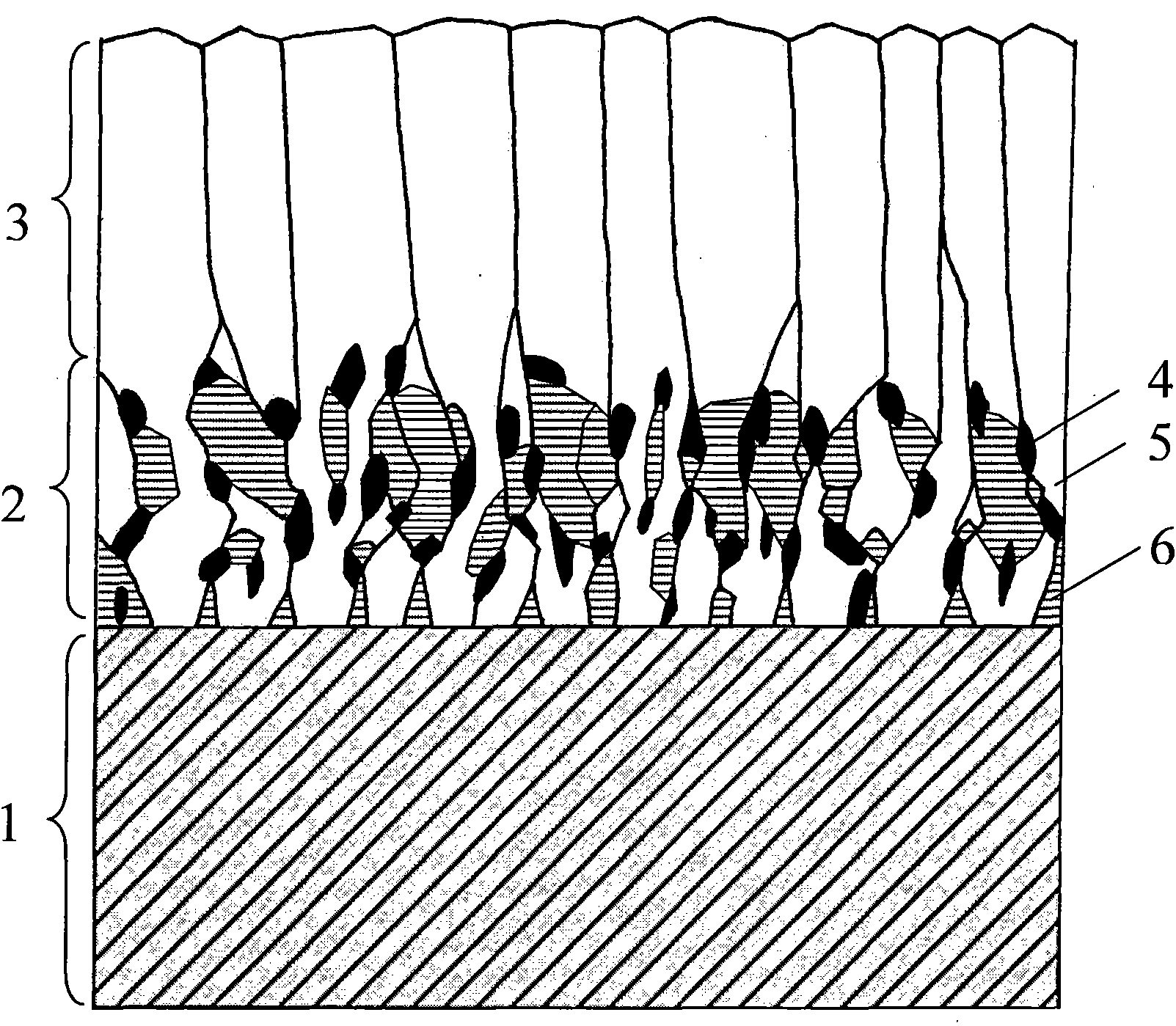

Method for preparing diamond-silicon carbide-cobalt disilicide composite interlayer of diamond coating on hard alloy

A technology of composite intermediate layer and diamond coating, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problem of insufficient adhesion between CVD diamond coating and cemented carbide substrate, and cannot effectively reduce the diamond coating. The peak shear stress of the film, the inability to further reduce micro pores and other problems, achieve broad industrialization prospects, easy control of process parameters, and enhanced toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Use the YG6X (WC-6% Co) cemented carbide blade sold on the domestic market as the substrate, and prepare the diamond-silicon carbide-cobalt silicide composite intermediate layer and the top layer of diamond coating on it, and its specific implementation steps are as follows:

[0033] The first step: perform conventional pretreatment on the substrate, ultrasonically clean the cemented carbide in alcohol for 10 minutes, and then immerse it in a KOH:K 3 [Fe(CN) 6 ]: H 2 In the solution of O=1:1:10 (mass ratio) for 10 minutes, then immersed in the H 2 SO 4 :H 2 o 2 =1:10 (volume ratio) solution for 1 minute to etch the cobalt on the surface of the cemented carbide.

[0034] Step 2: Sonicate the cemented carbide for 60 minutes in an alcohol suspension containing diamond micropowder and nanopowder to pre-nucleate, and then ultrasonically clean it with alcohol for 10 minutes.

[0035] The third step: Put the pretreated cemented carbide substrate into the vacuum chamber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com