Patents

Literature

269results about How to "Compensation for wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

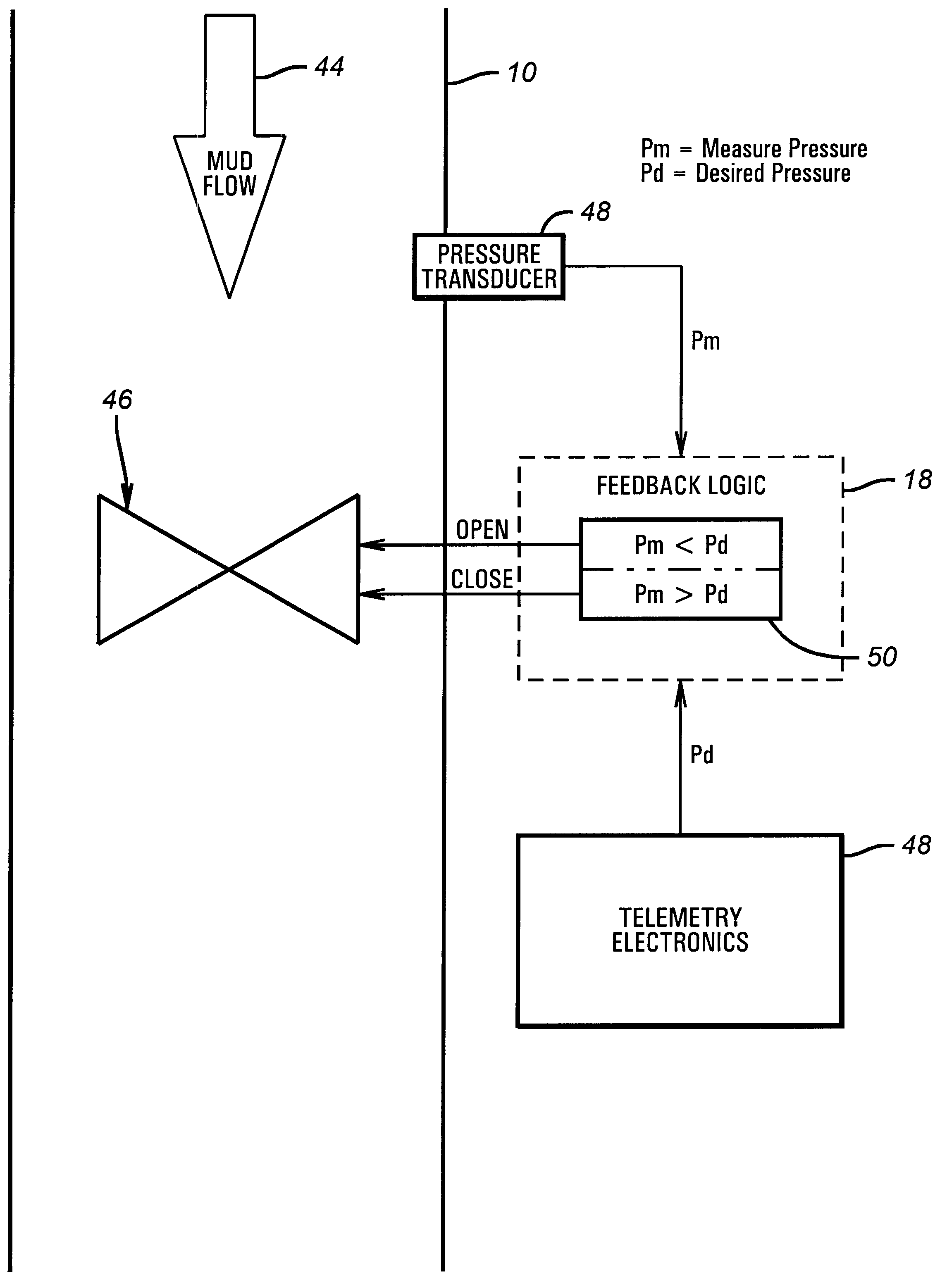

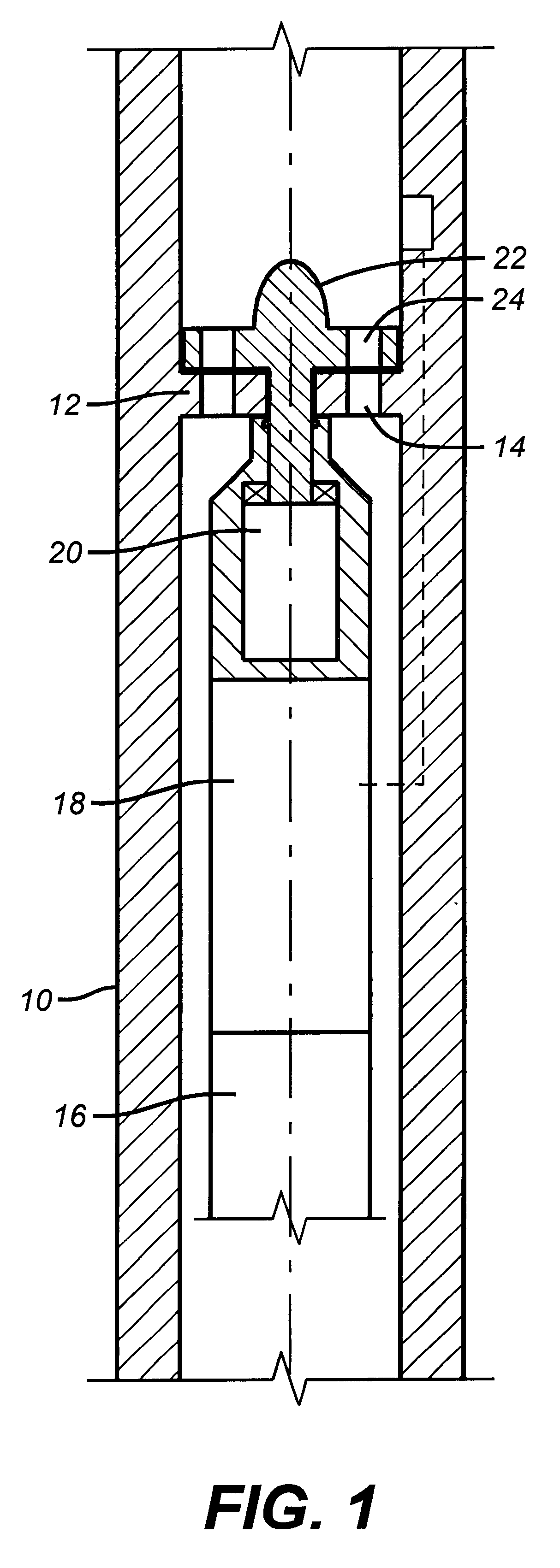

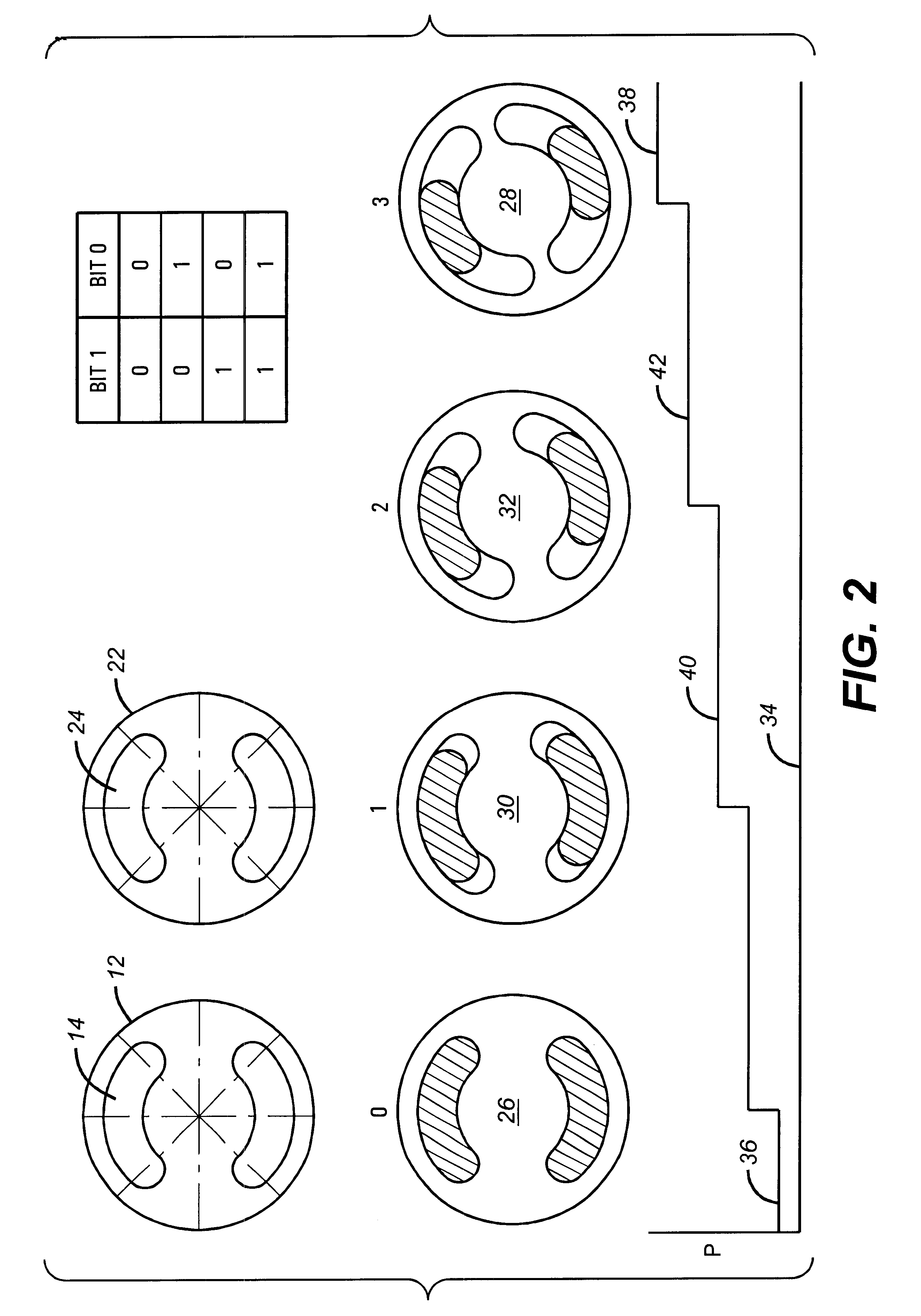

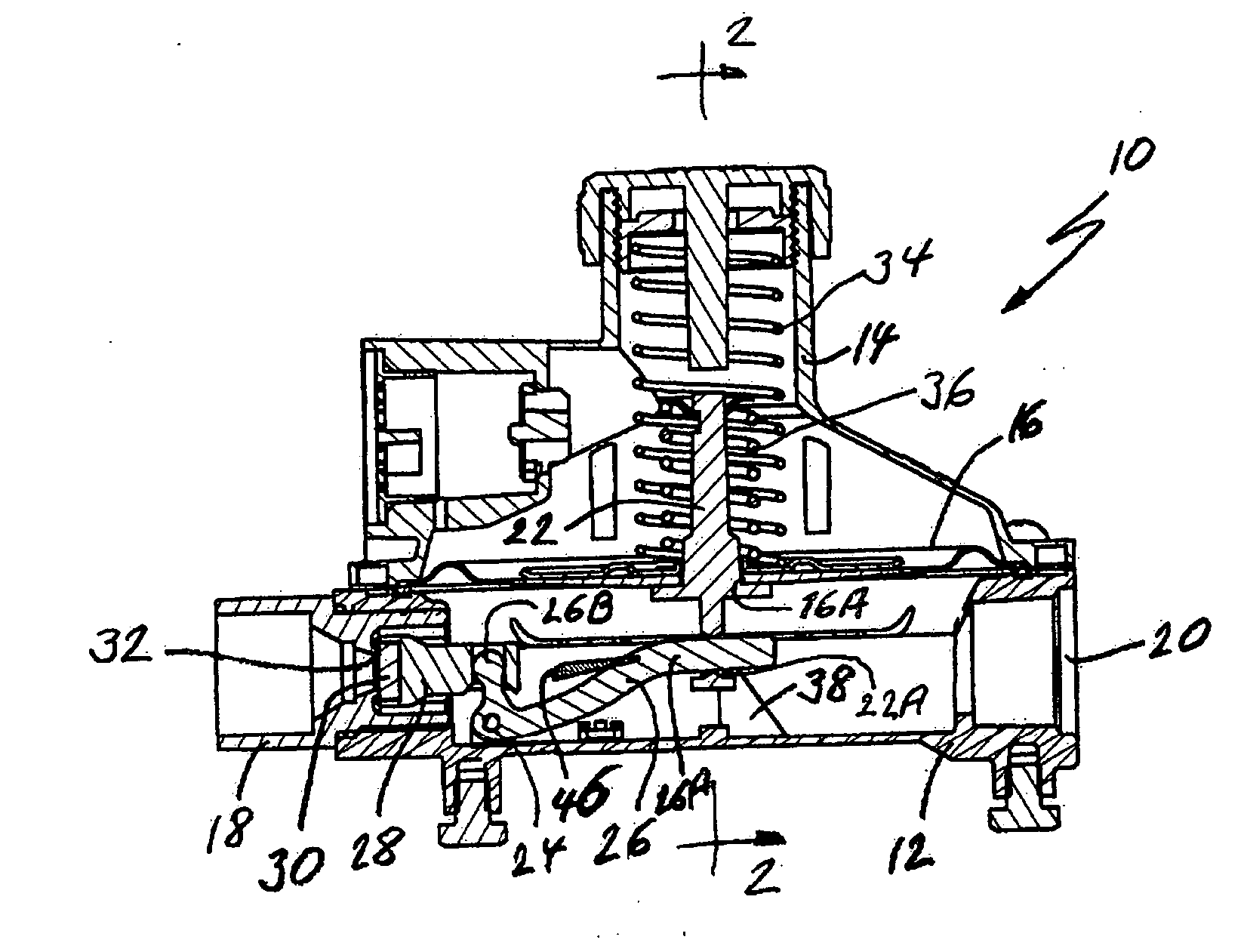

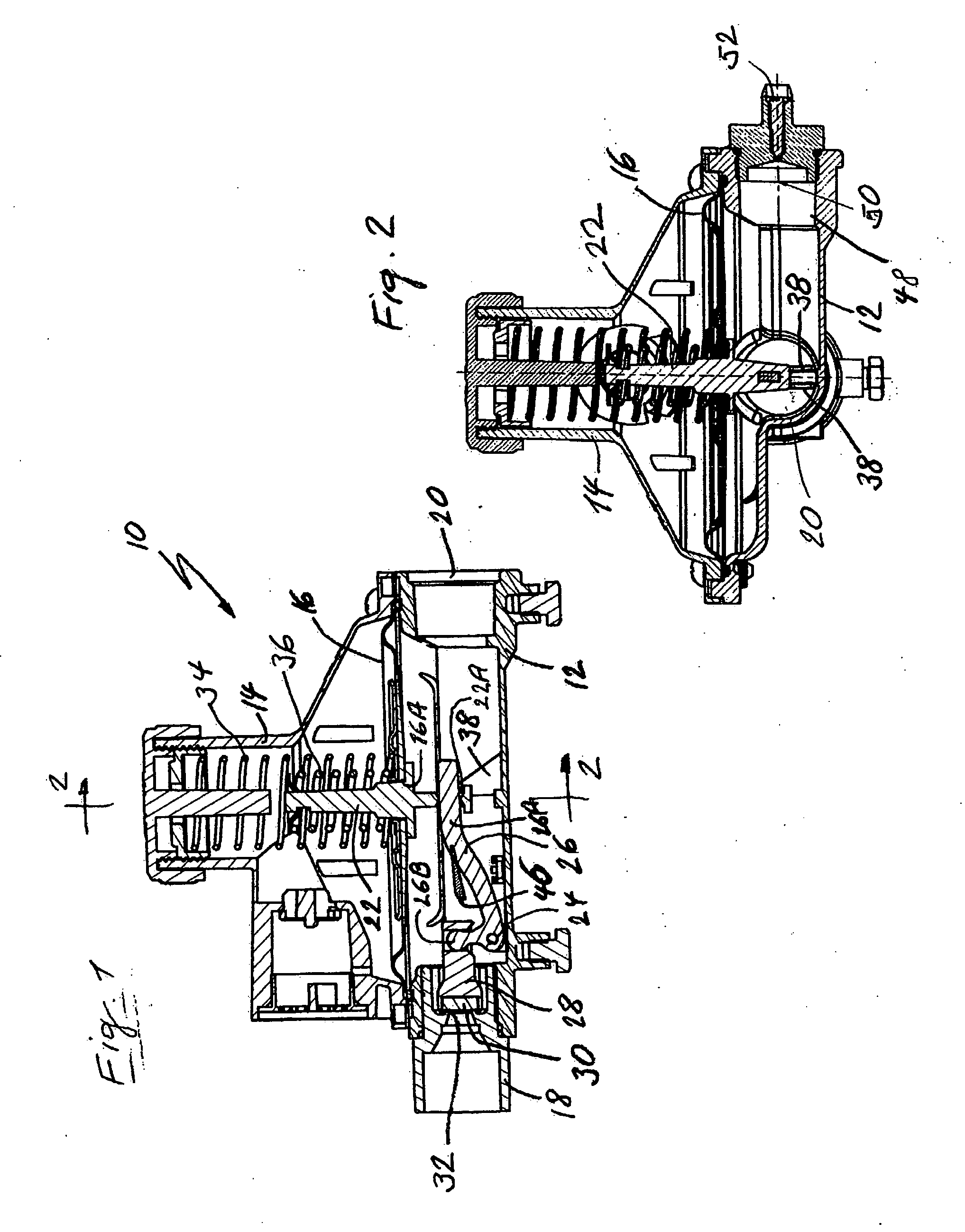

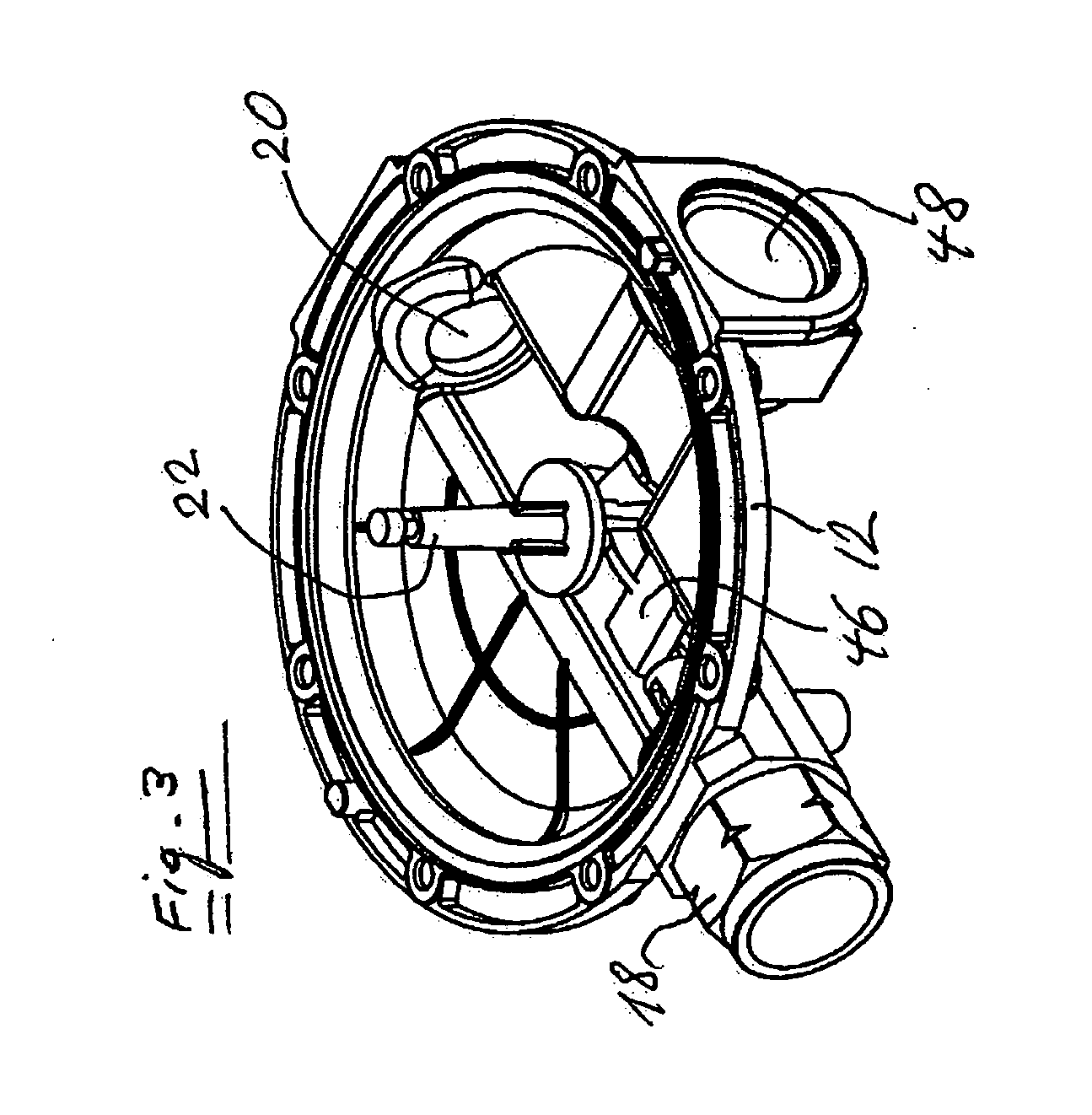

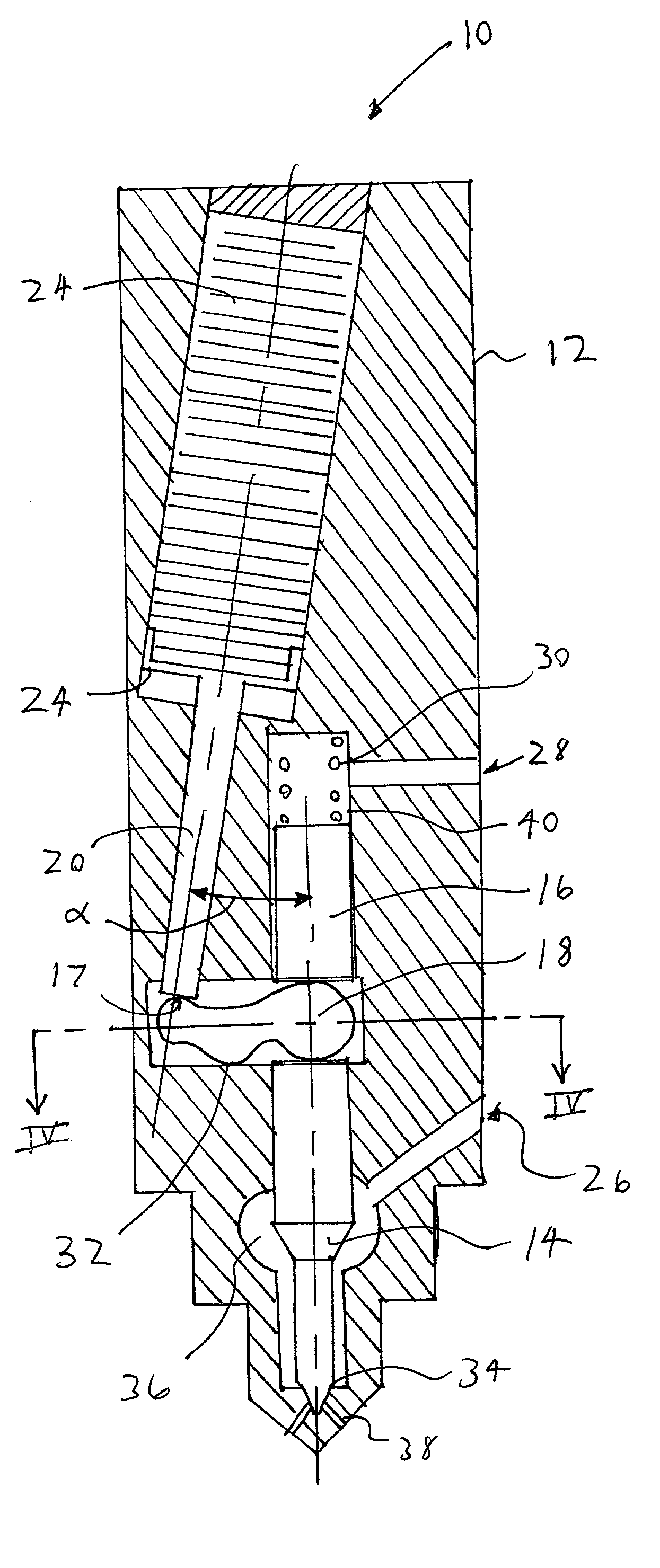

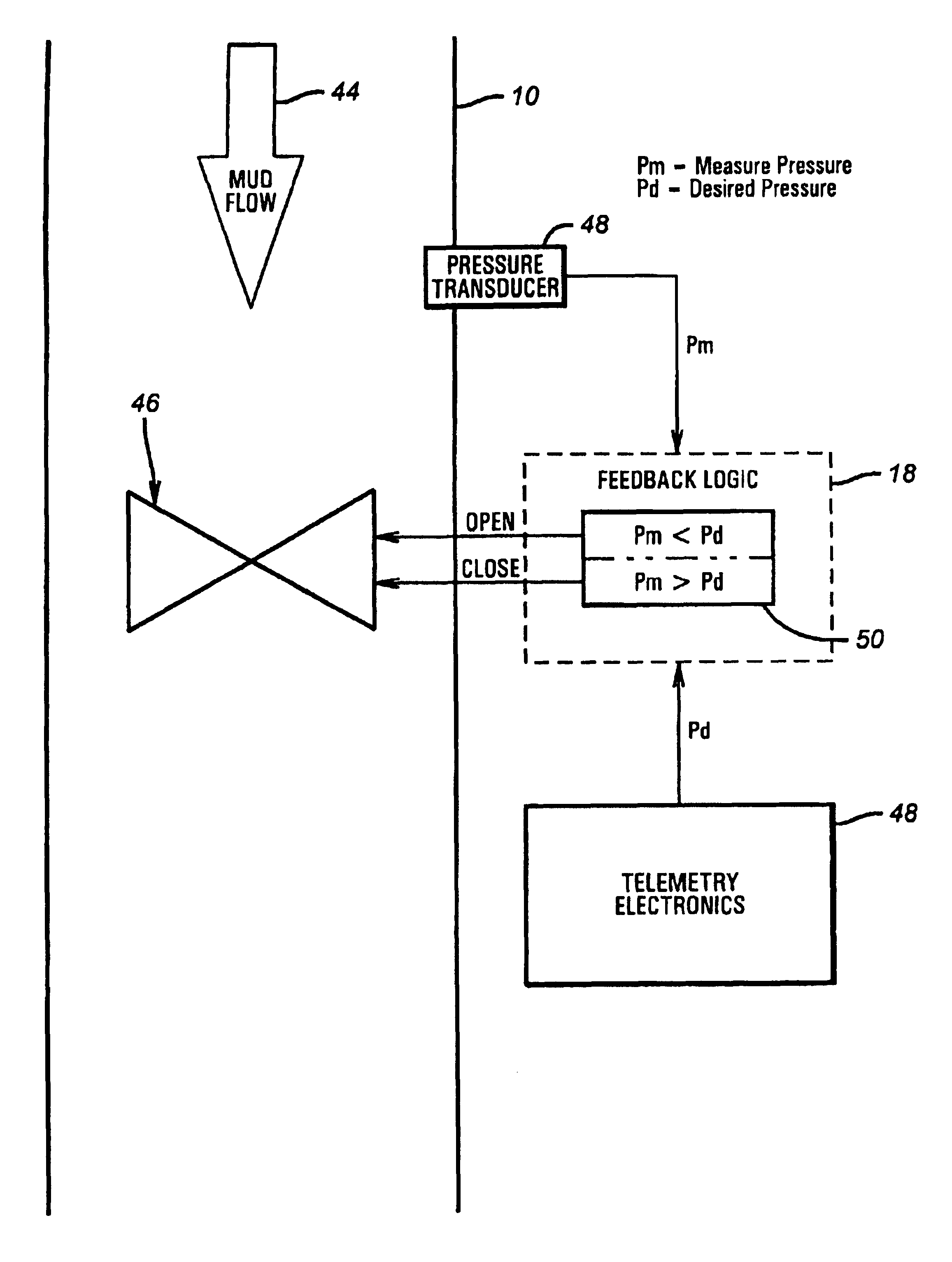

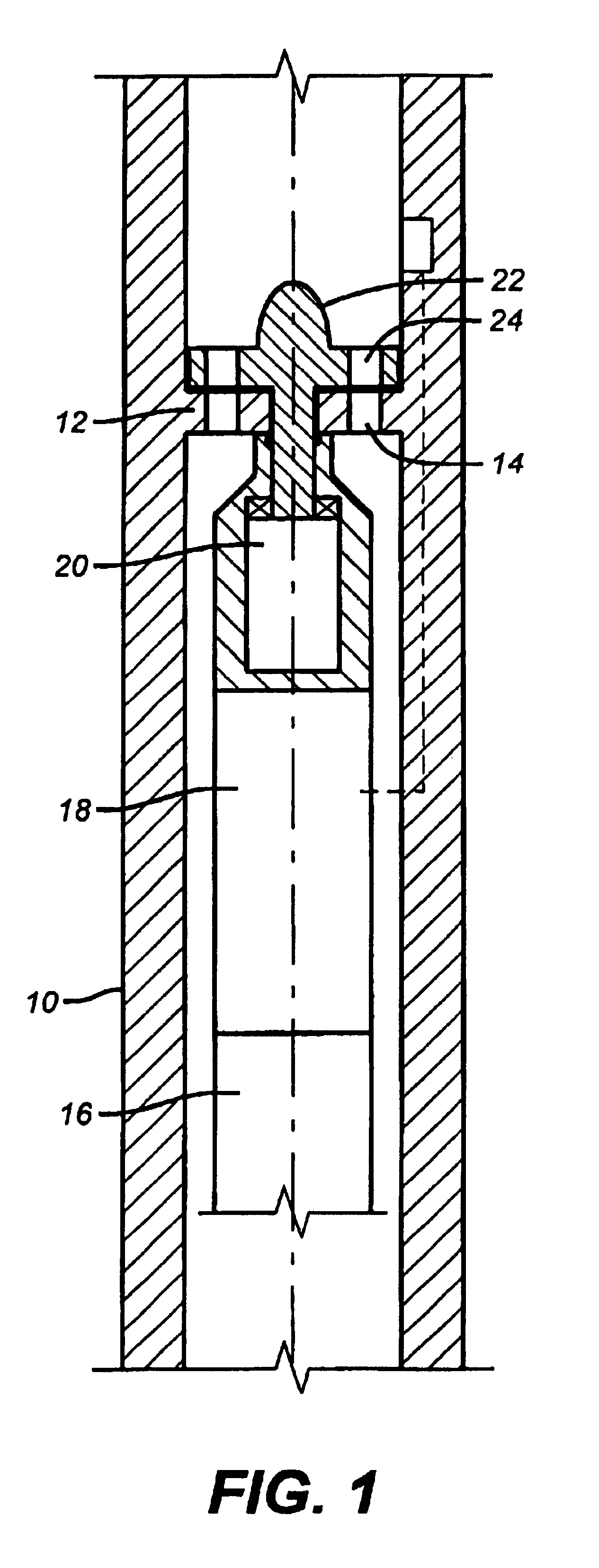

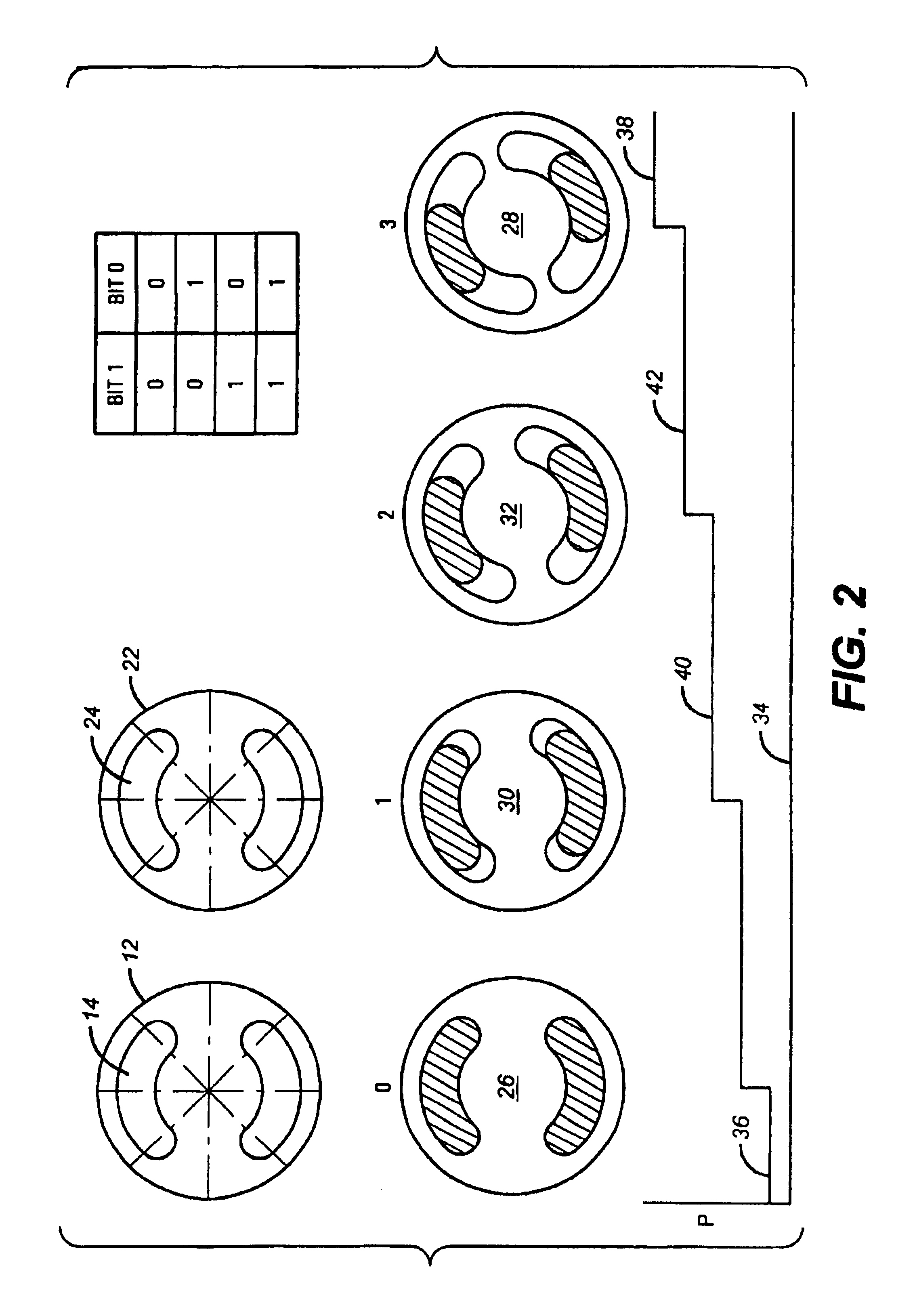

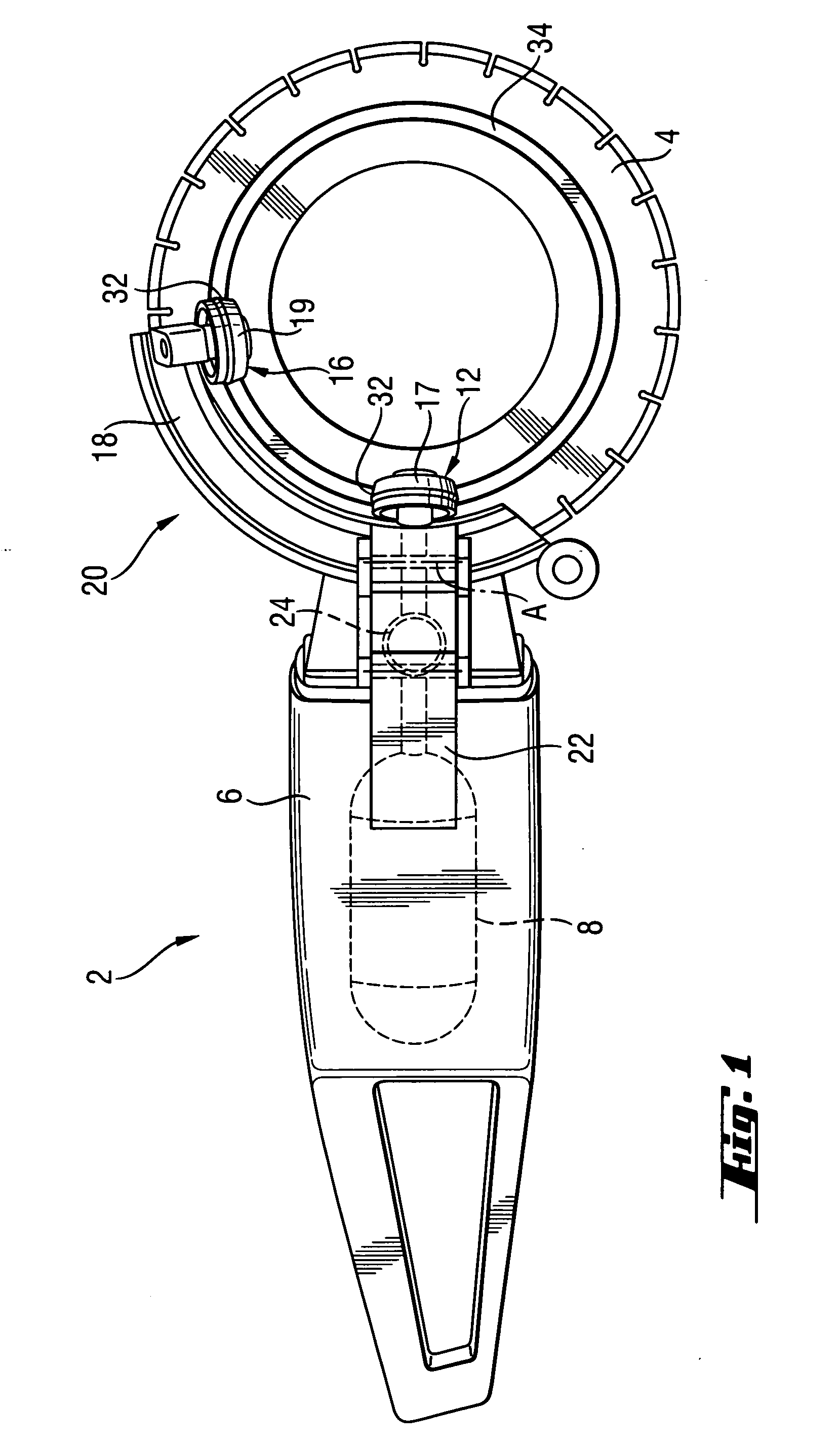

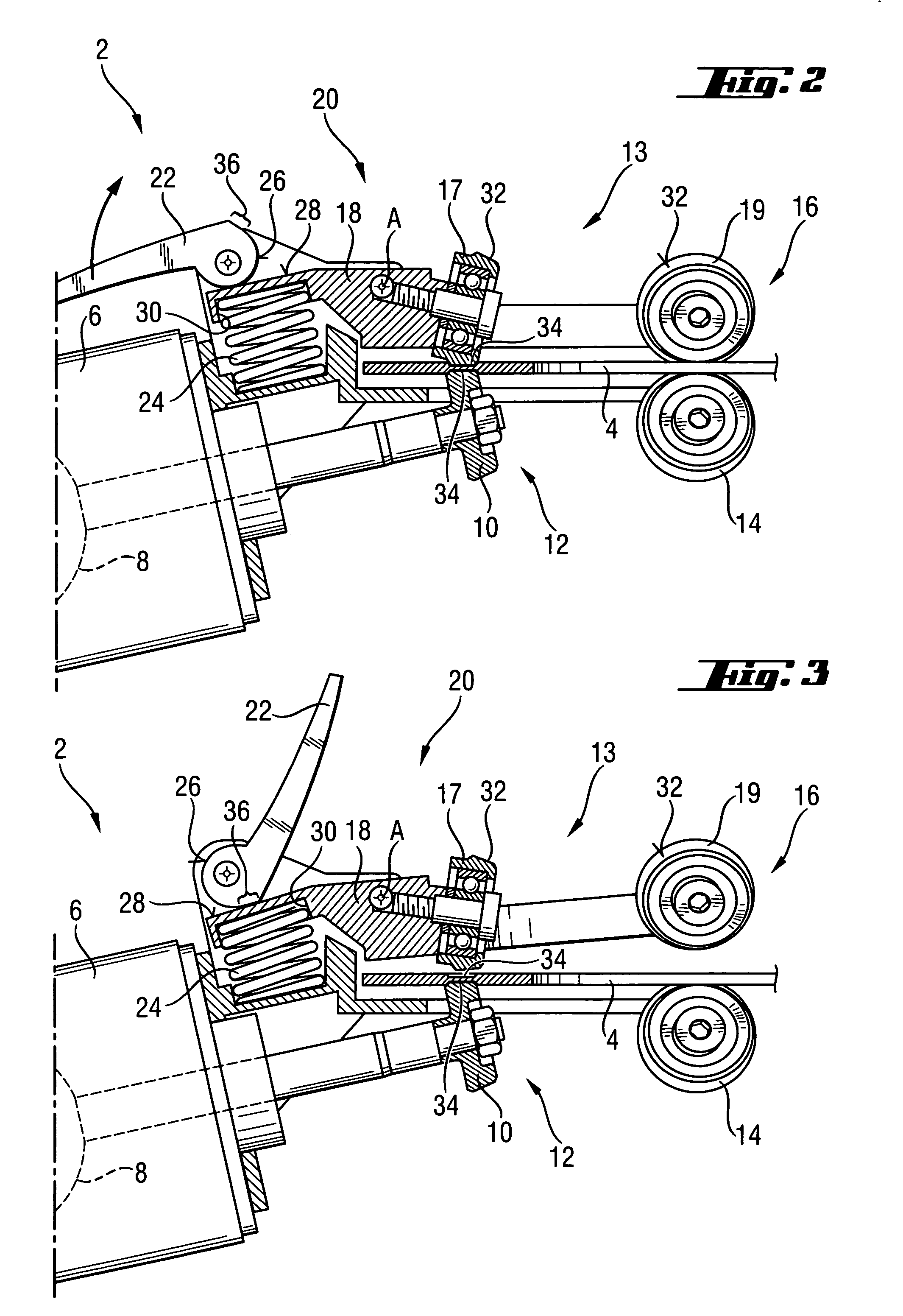

Adjustable shear valve mud pulser and controls therefor

InactiveUS6469637B1Enhanced data transmissionCompensation for wearSurveyConstructionsControl systemEngineering

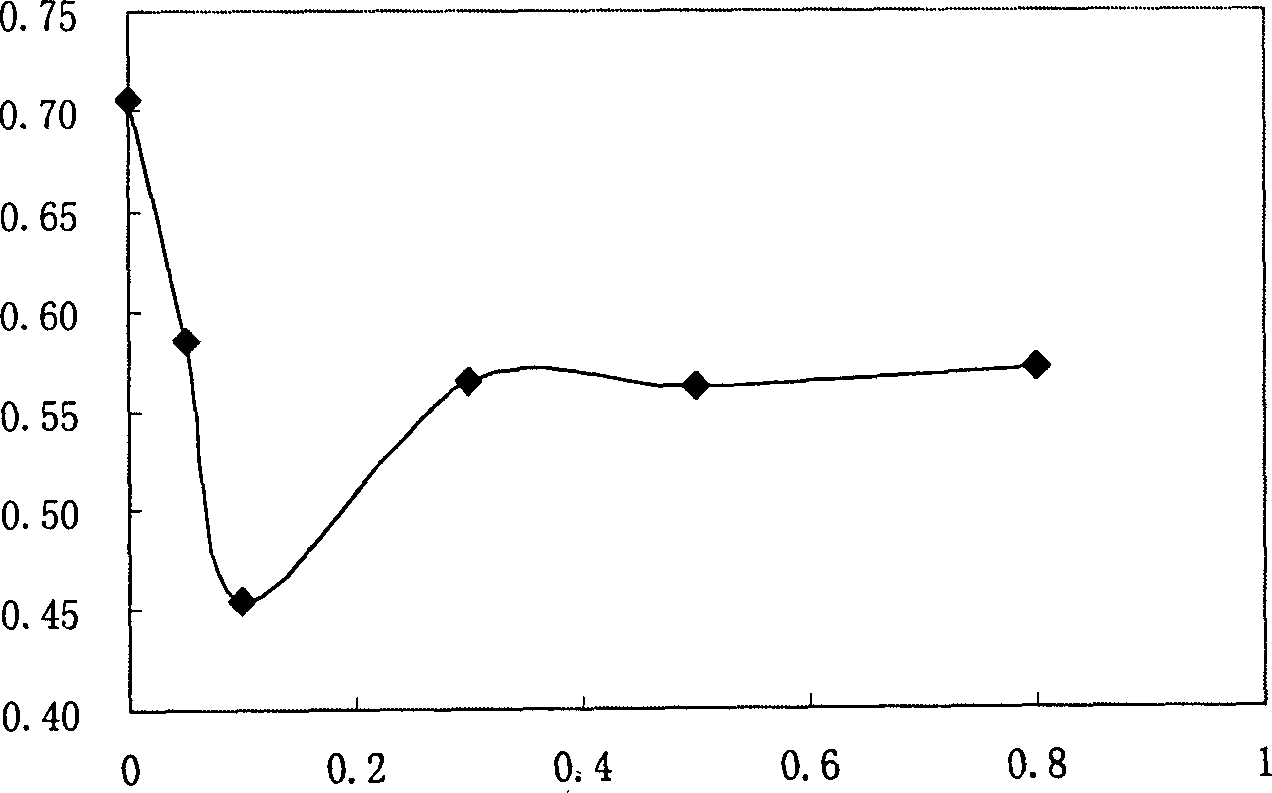

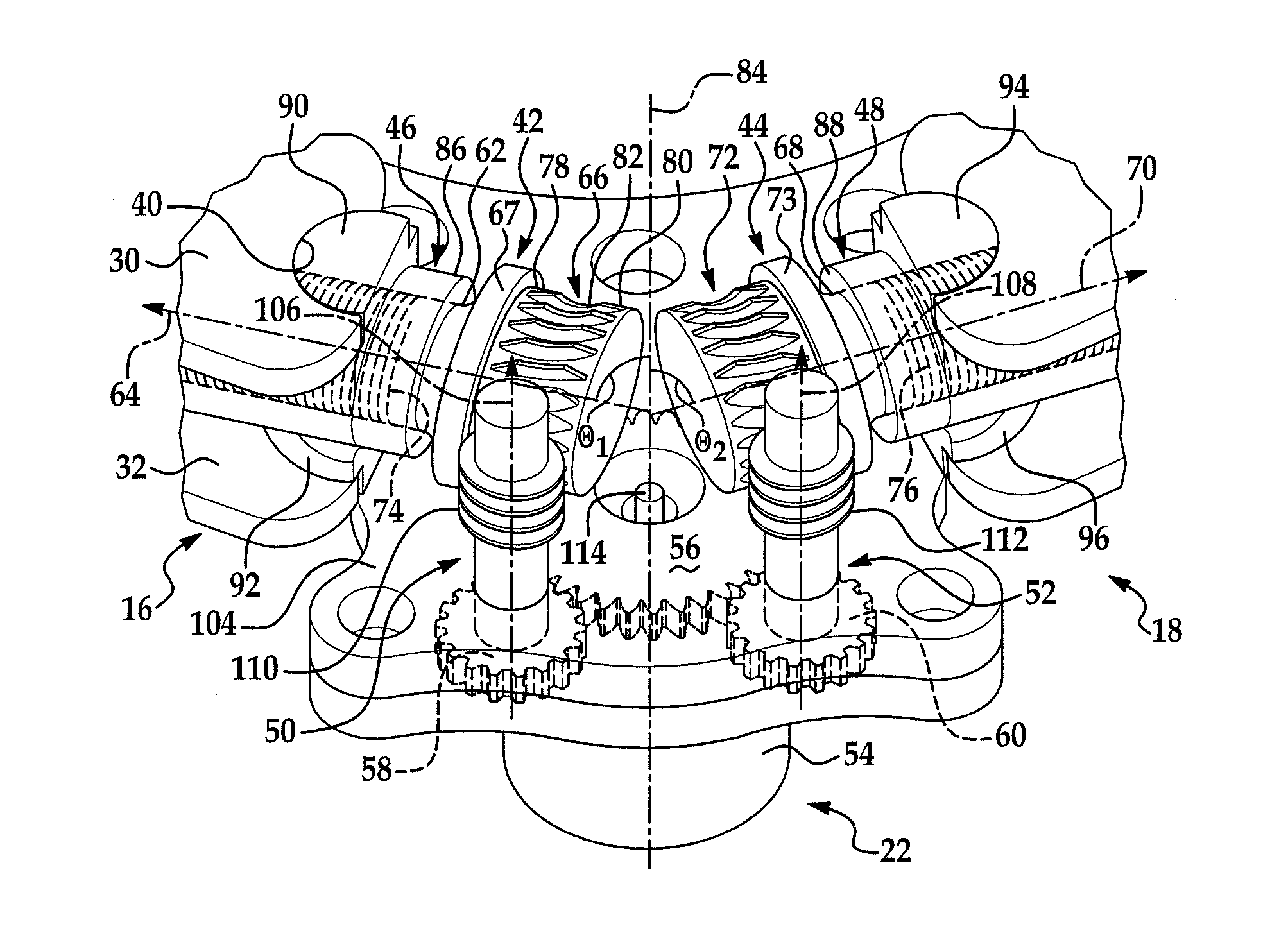

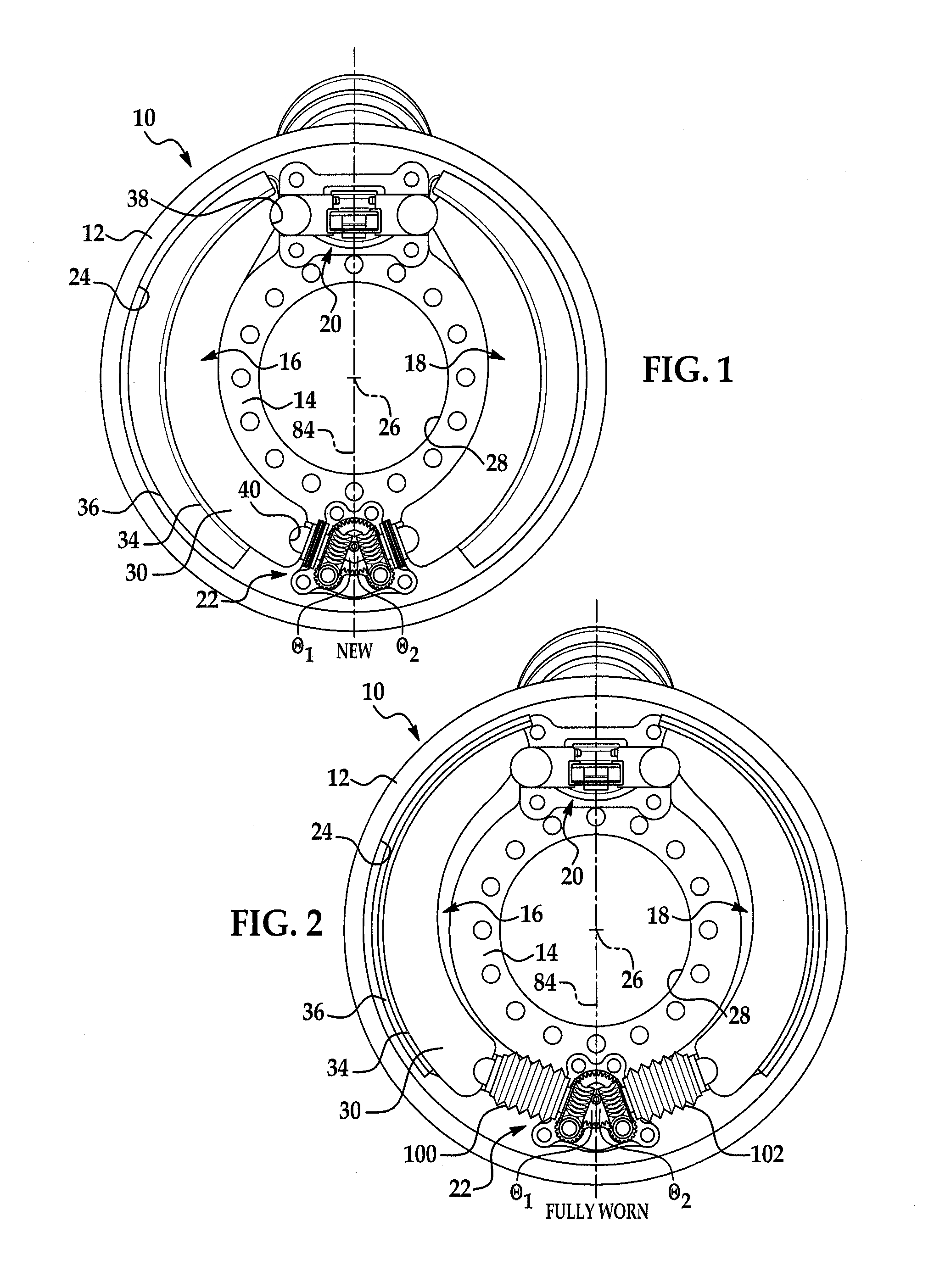

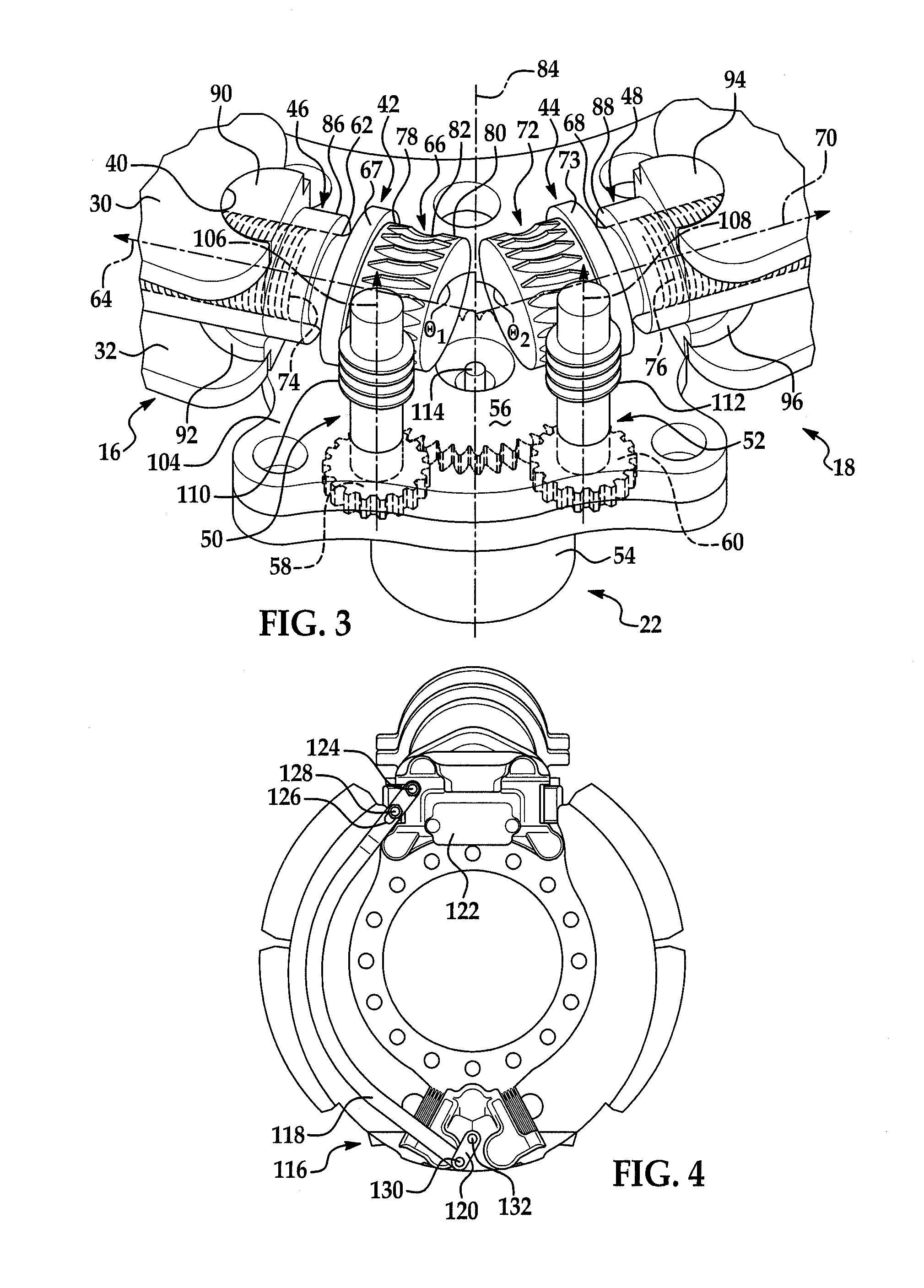

A telemetry system involving a shear-type mud pulser valve as the preferred embodiment is described. The control system includes a motor driver for the mud pulser which, in essence, moves one movable plate with respect to a stationary plate to create openings of various sizes. Pressure is sensed uphole of the pulser valve and is compared in real time to the desired pressure pulse amplitude. By allowing different relative rotational positions of the rotatable plate with respect to the stationary plate, different amplitudes can be achieved to further enhance the transmission of data to the surface. The control system compensates for wear in the mud pulser valve itself as well as drastic changes in mud flow and pressure. The configuration is simple and not prone to fouling from grit or other particles in the mud. The system is capable of creating an initial baseline array of a variety of pulse amplitudes, and thereafter providing the required relative rotation between the stationary and rotatable plates so as to be able to duplicate the baseline pulse amplitudes despite changes in the valve condition or in the flowing conditions of the mud.

Owner:BAKER HUGHES INC

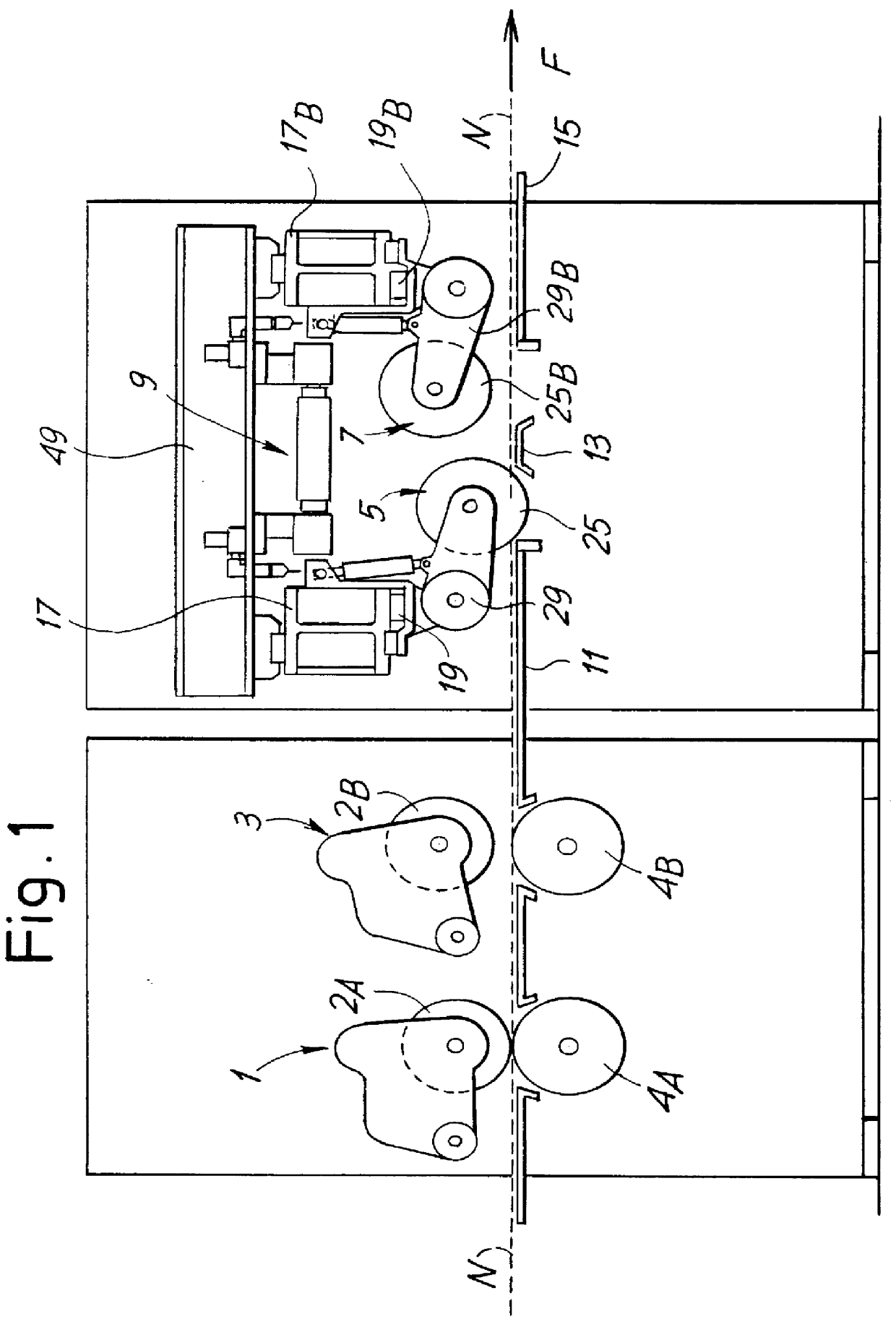

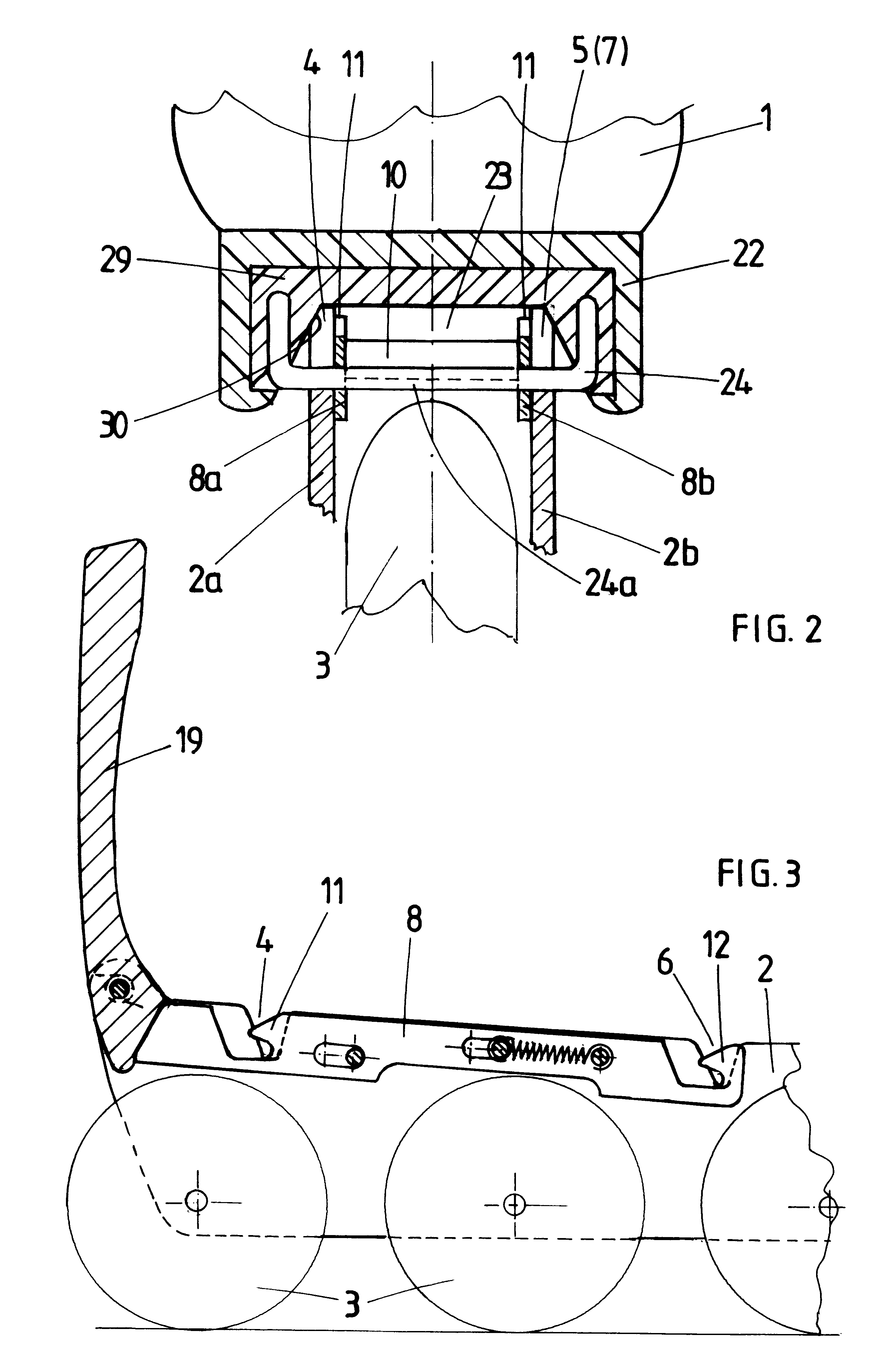

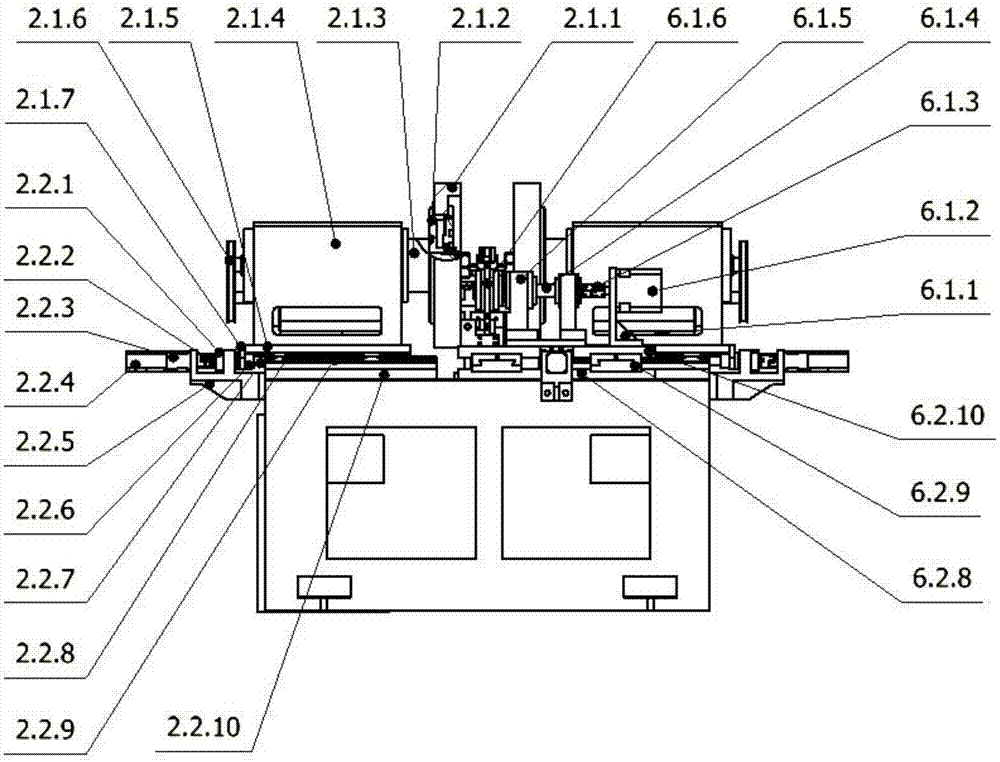

Device and method for the slitting of a web and slitter/scorer machine incorporating said device

InactiveUS6165117AUniform materialEasy to replaceMechanical working/deformationSteering linkagesEngineering

Owner:FOSBER

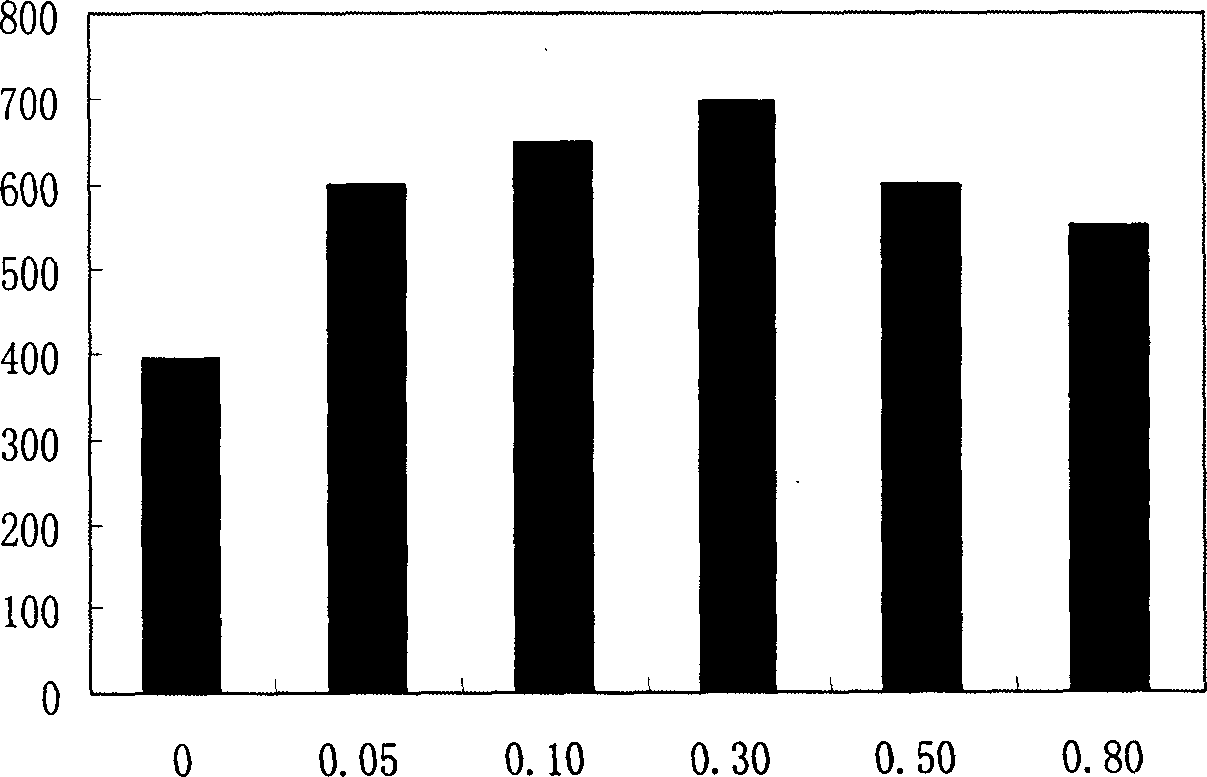

Metal/ ceramic nano composite additive of self-rehabilitation and its preparation method

The invention relates to a metal / ceramic nano complex self-repairing additive, which comprises metal nano micropowder and nano natural ore powder as main material, detergent, catalyst, antioxidant, and solvent, and can be used in lube, grease and ultrasonic medium. The advantages of this invention include: it can form rapidly high-hardness self-repairing protection layer on a plurality of metal friction surfaces with thickness adjustable to optimize gap and improve surface physical and chemical property, and has wide application in friction dual parts.

Owner:JIANGSU MOLEDN PETROCHEM

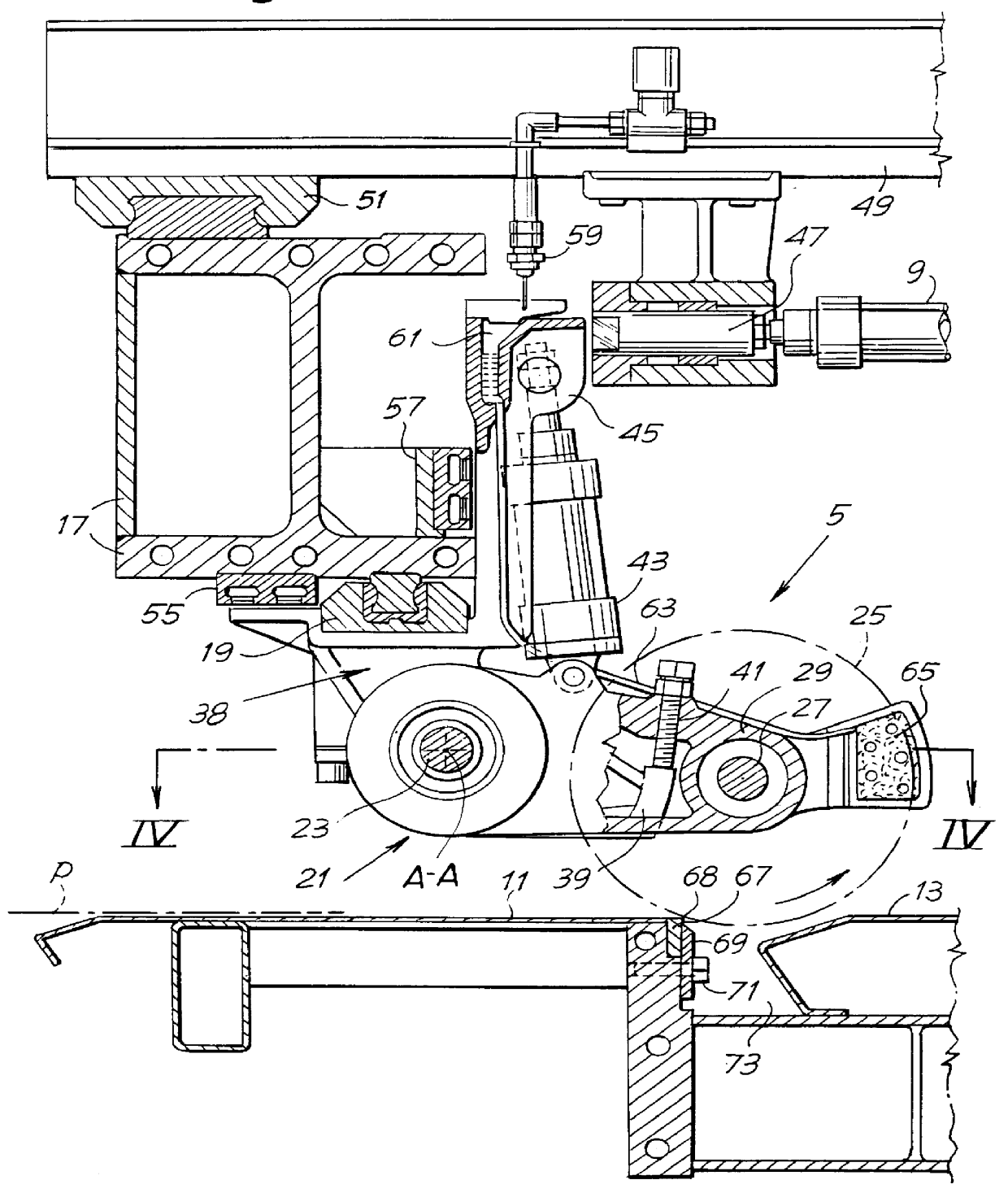

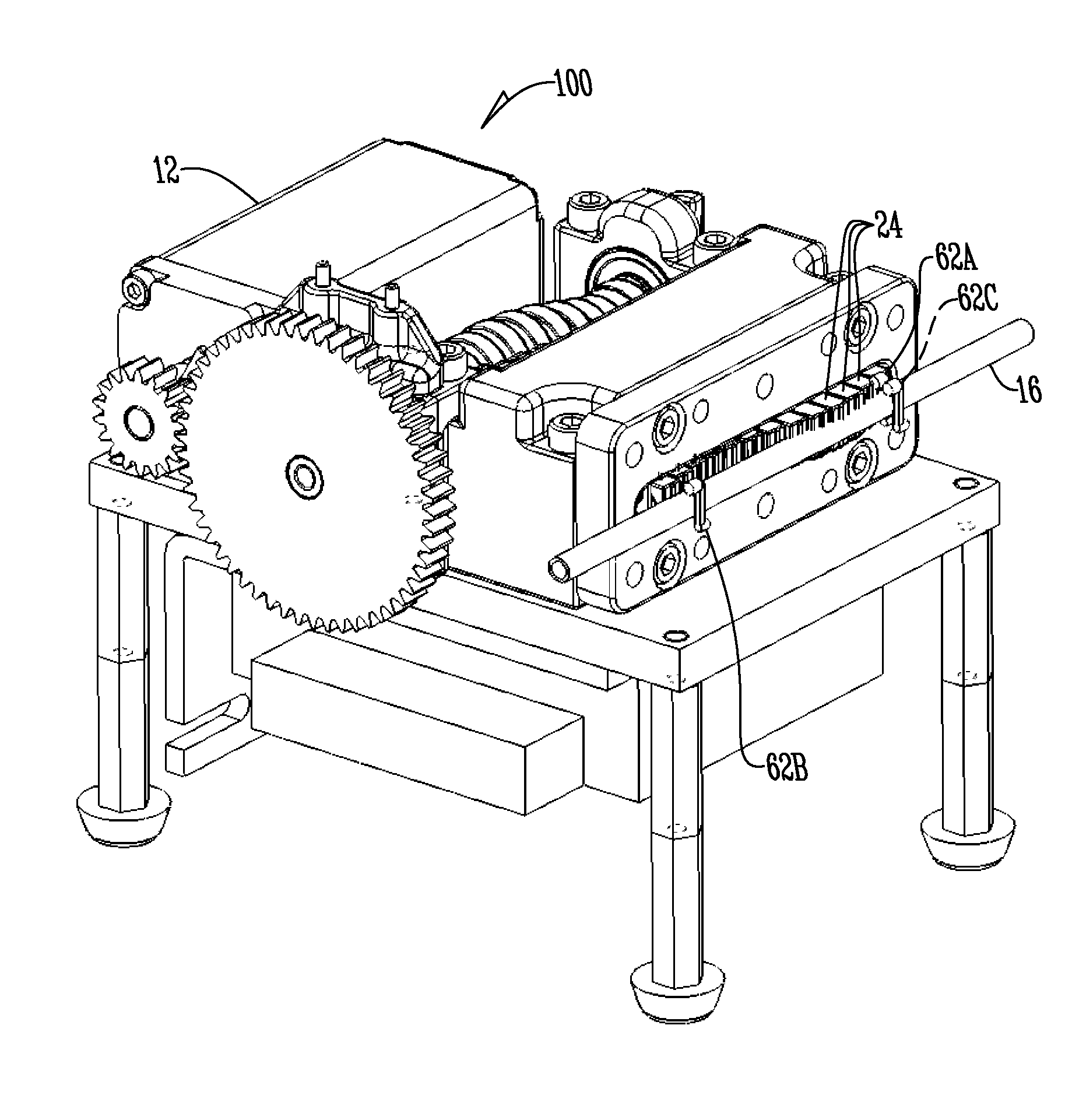

Plunge slitter with clam style anvil rollers

InactiveUS6837135B2Compensation for wearGuide fencesCross-cut reciprocating sawsOrder formPaperboard

An apparatus for slitting a running paperboard web includes a thin high speed rotary slitting blade that is plunged through the moving web and into a slot between a pair of anvil rollers supporting the web on the opposite side. Because the slitting blade and the anvil rollers are vertically separated and pre-positioned before order change, an adjustment apparatus is provided to spread the anvil rollers axially apart to provide an open gap with a large target for blade edge when it is plunged through the web and into the slot. The anvil rollers are then closed against the opposite faces of the blade for running operation. Preferably, the anvil rollers are mounted on brackets hinged together below the rollers to move the opposite upper edges of the rollers between the opened and closed position in the manner of a clam shell. The anvil roller assembly is also adjustable in the machine direction to compensate for reduction in rotary slitting blade diameter with blade wear.

Owner:BARRY WEHMILLER PAPERSYST INC

Nanomer vibration-reducing noise-reducing self-repairing material and its prepn process

InactiveCN1740290AAutomatically adjust thicknessOptimizing friction pair clearanceBase-materialsMachine partsRepair material

The nanometer vibration-reducing and noise-reducing self repairing material is prepared with nanometer level metal powder and natural ore powder as main material and through adding several kinds of supplementary material and certain technological process, and is added into lubricating oil or ultrasonic medium as high performance repair material. The present invention features that the high performance repair material can create high hardness self-repairing lubricating film fast on the surface of metal friction pairs to regulate the interval of the friction pair, reduce friction coefficient, raise bearing capacity, leveling the friction surface, reduce vibration and noise caused by the unbalance, friction and damage of the moving machine parts, and prolong the service life of the machine parts. The present invention may be used widely in improving performance of mechanical friction parts.

Owner:JIANGSU MOLEDN PETROCHEM

Variable position anchor assembly for adjusting brake shoes in a drum brake

InactiveUS20120031716A1Fine adjustment rangeReduce operating costsDrum brakesBrake actuating mechanismsEngineeringMechanical engineering

An anchor assembly is provided that permits adjustment of the brake shoes in a drum brake to account for wear. The assembly includes first and second adjuster shafts each having a plurality of threads and first and second pilot connectors. The pilot connectors each have a plurality of threads in engagement with the threads of a corresponding adjuster shaft. The pilot connectors each engage one end of a corresponding brake shoe. Rotation of each adjuster shaft causes longitudinal movement of a corresponding pilot connector in engagement with a corresponding brake shoe along an axis to adjust a position of the brake shoe.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

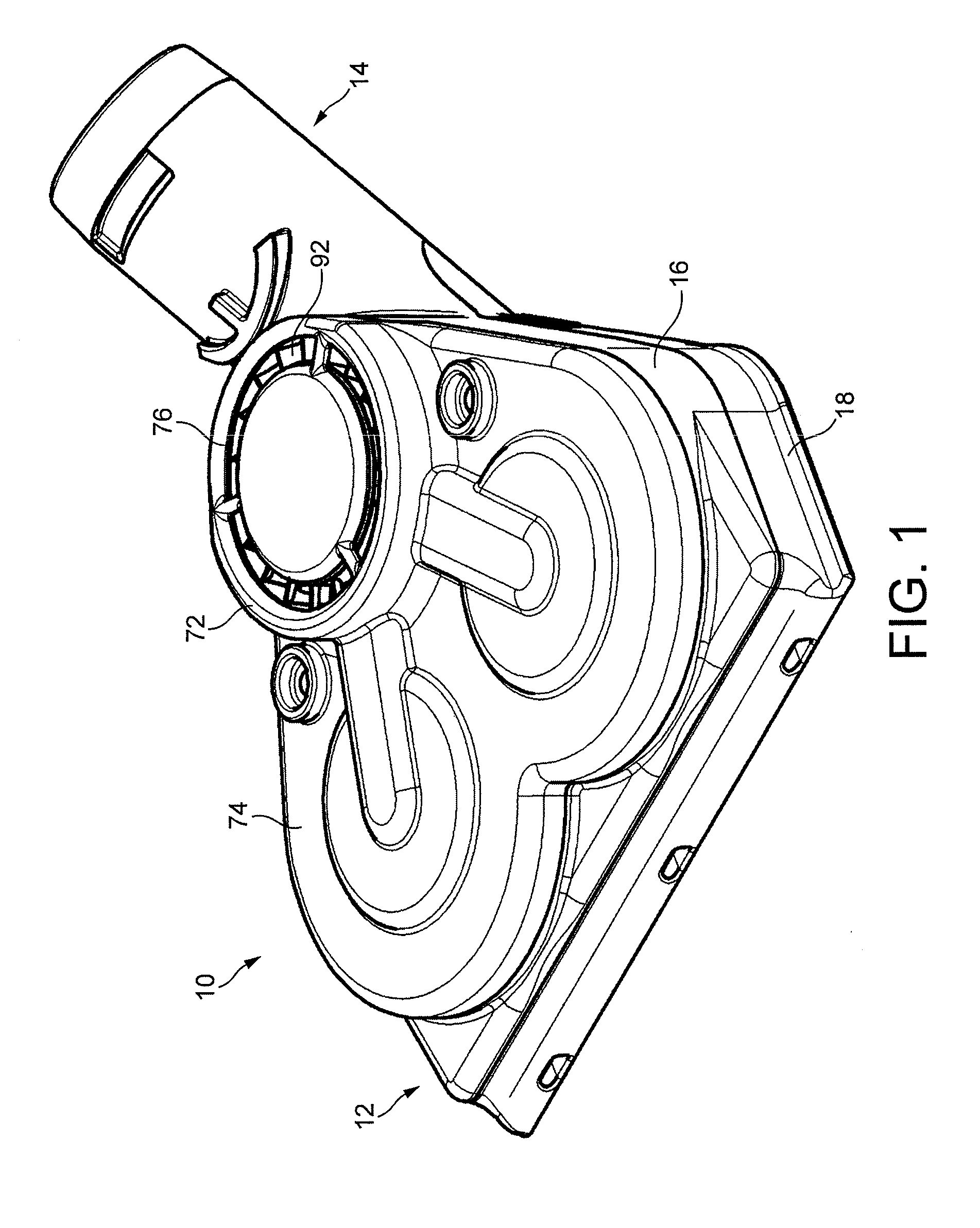

Cleaner head

ActiveUS20120144621A1Easy to useMaximize likelihoodBrush bodiesSuction nozzlesDrive shaftEngineering

A cleaner head for a cleaning appliance includes a rotatable agitator and an agitator chamber housing the agitator. The agitator includes a drive shaft, a flexible body connected to the drive shaft and surface engaging members mounted on the flexible body. The agitator chamber includes a downwardly-directed opening through which debris energized by the surface engaging members enters the cleaner head. The opening is located in a plane relative to which the flexible body is inclined so that, with rotation of the agitator, the surface engaging members protrude through the opening, preferably towards the front of the opening.

Owner:DYSON TECH LTD

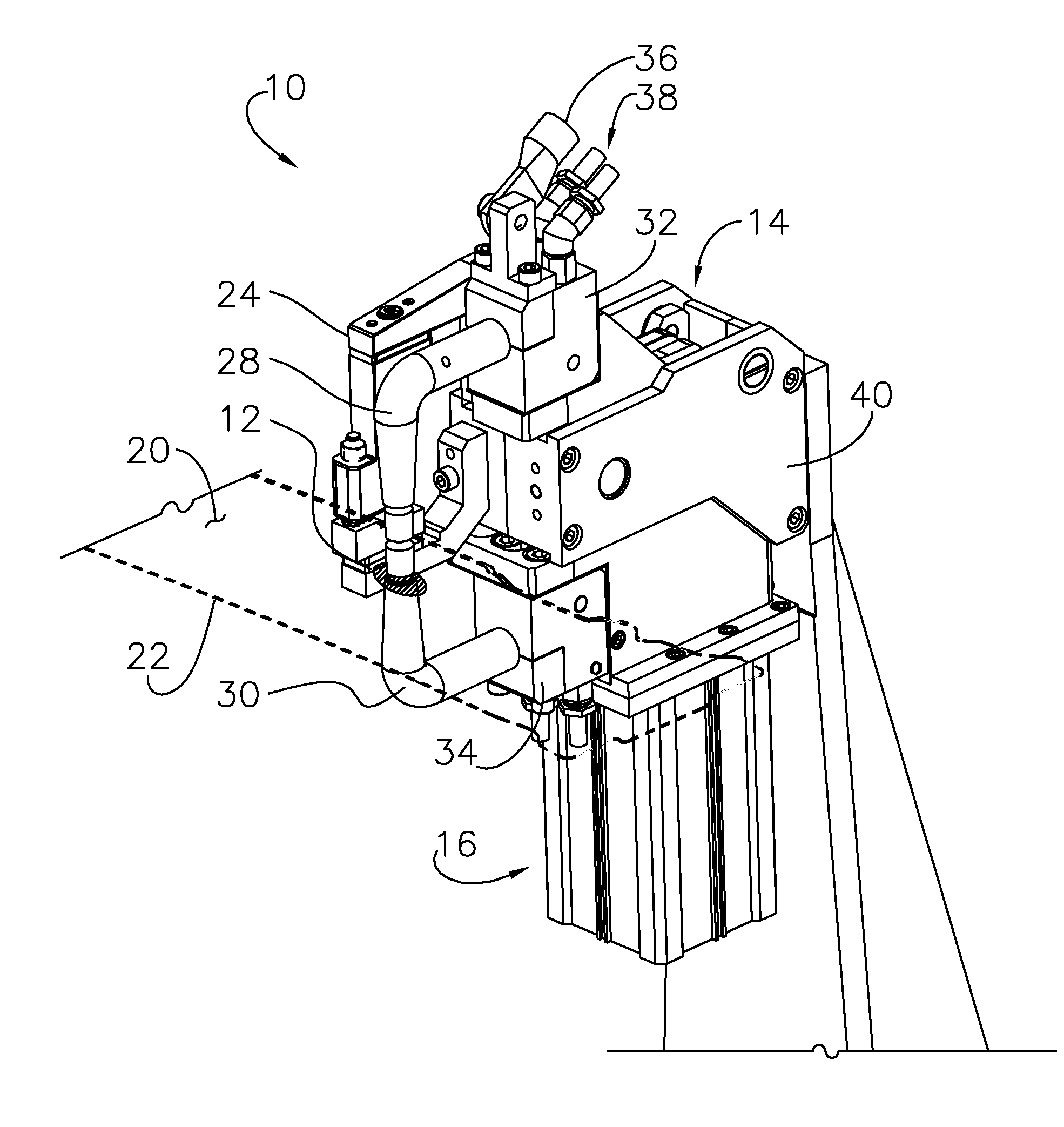

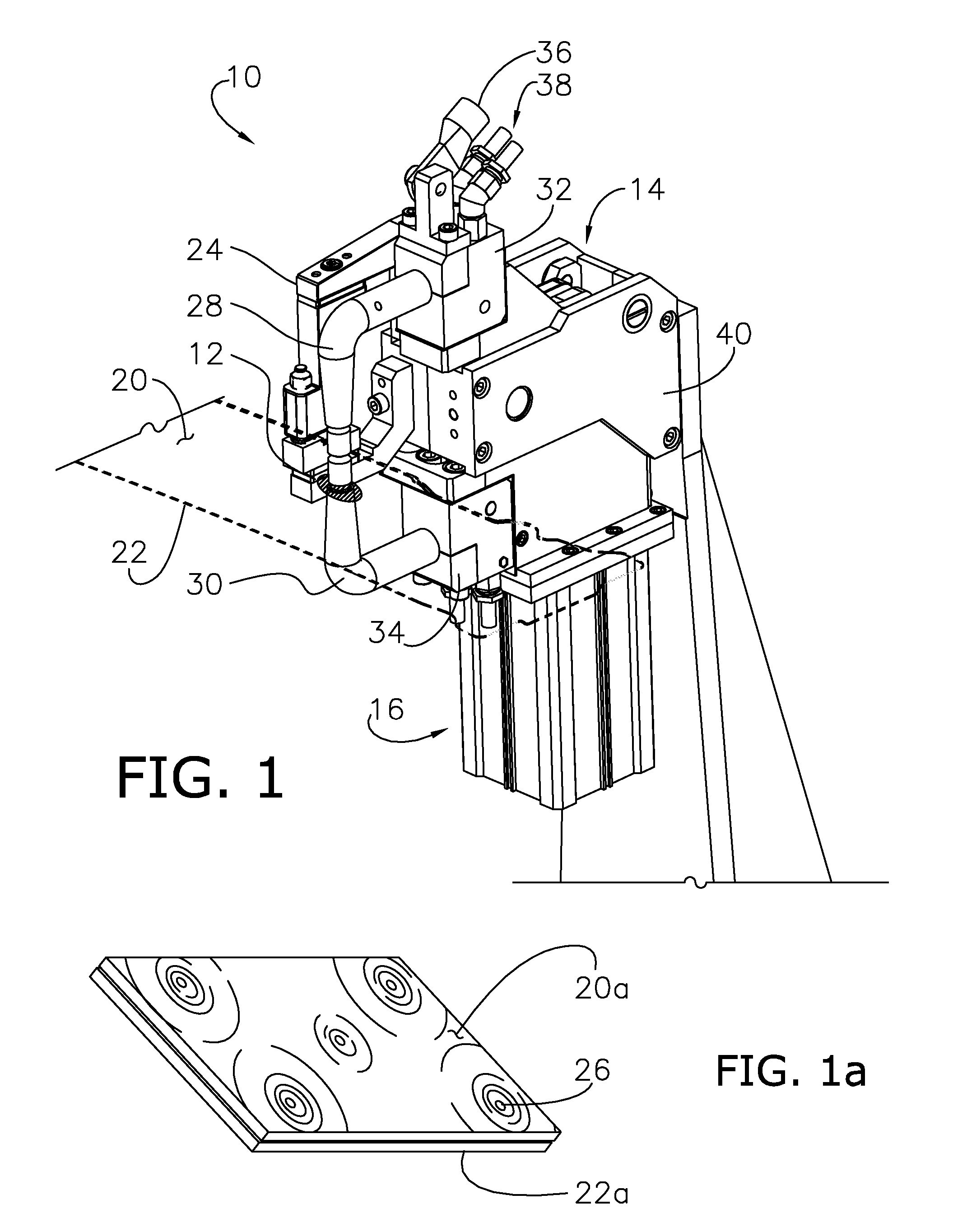

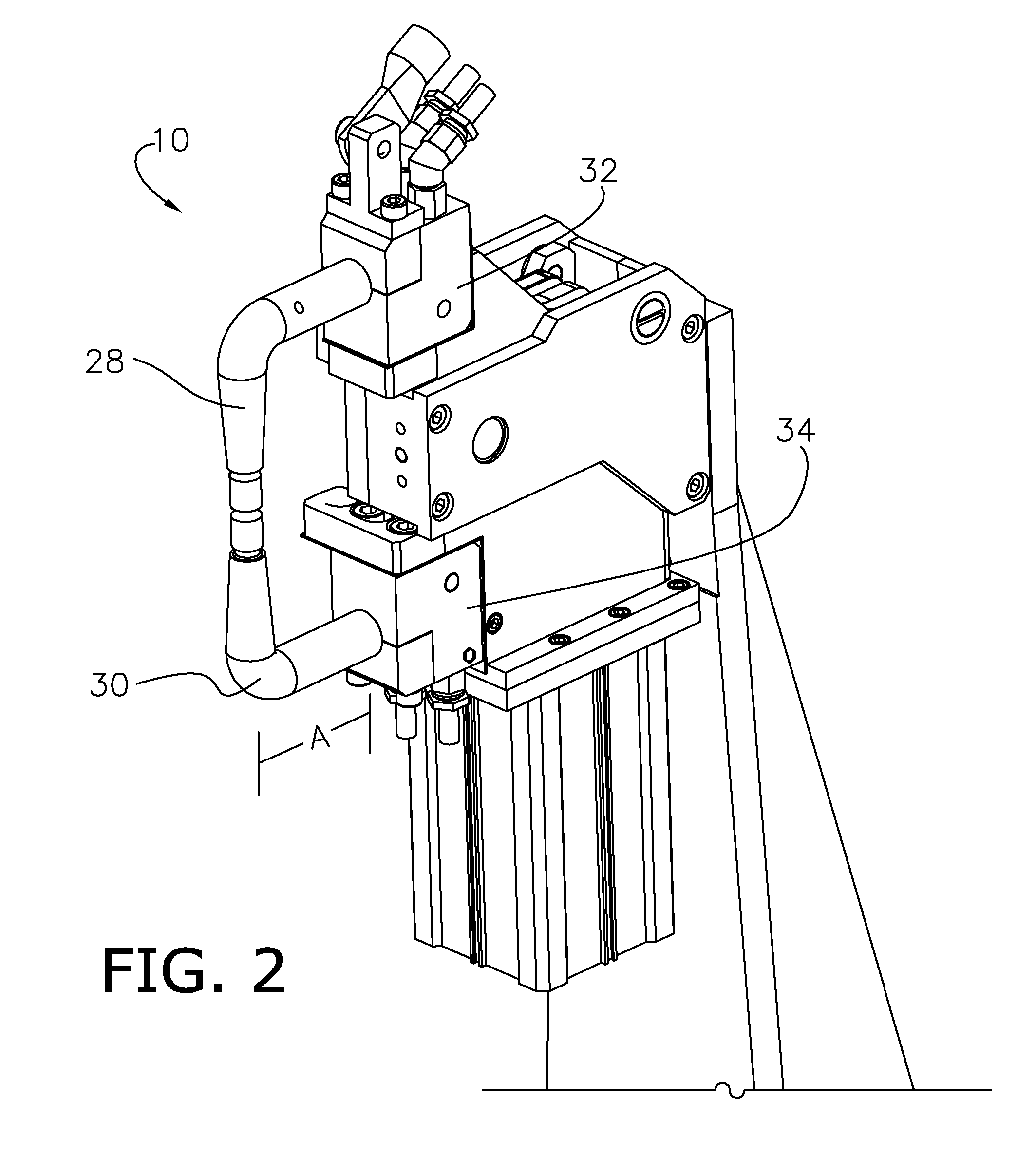

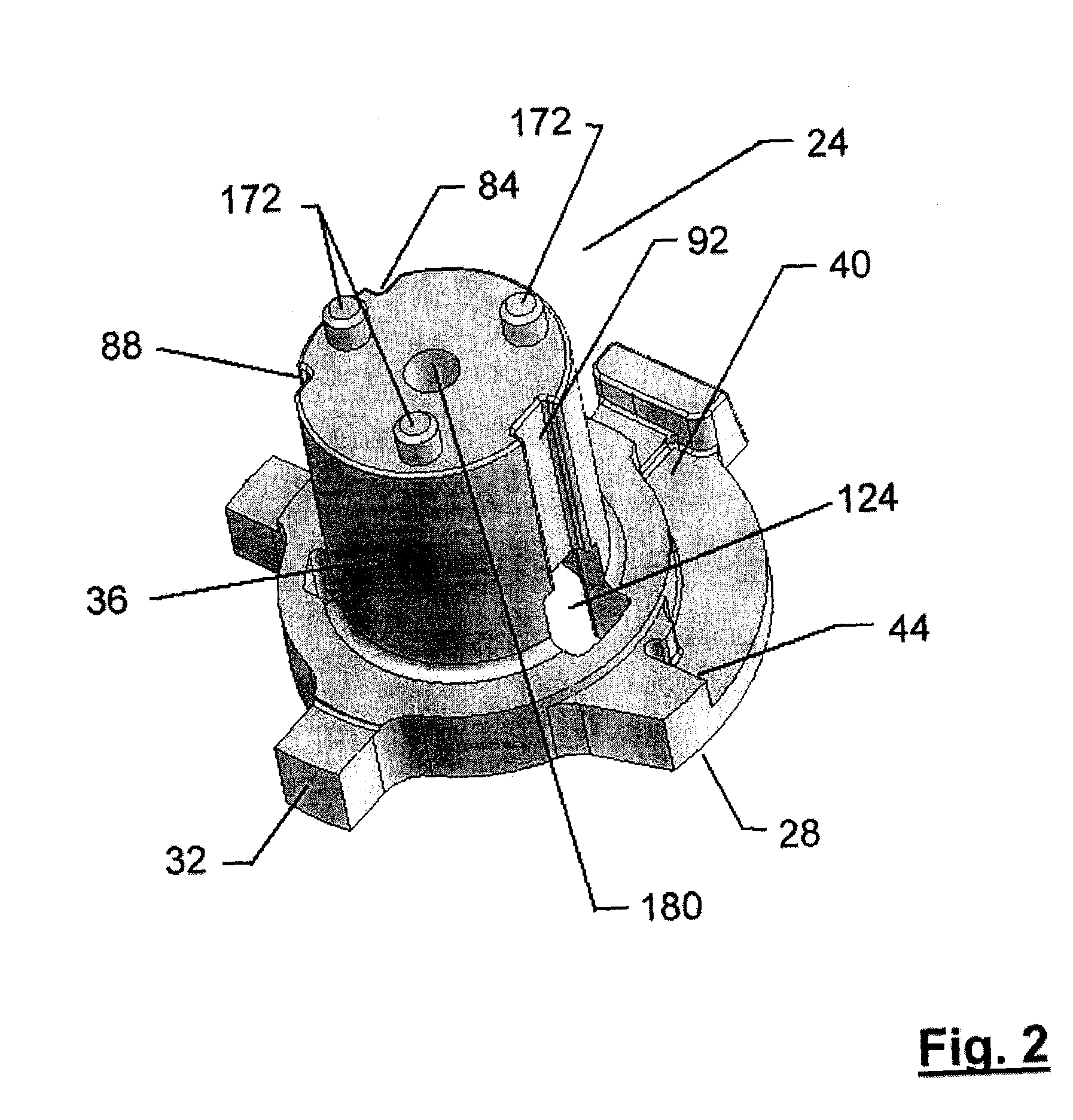

Single drive and source for adjacently clamping and resistance welding

InactiveUS20070175868A1Deformation MinimizationReduce assemblyResistance electrode holdersWelding accessoriesCamEngineering

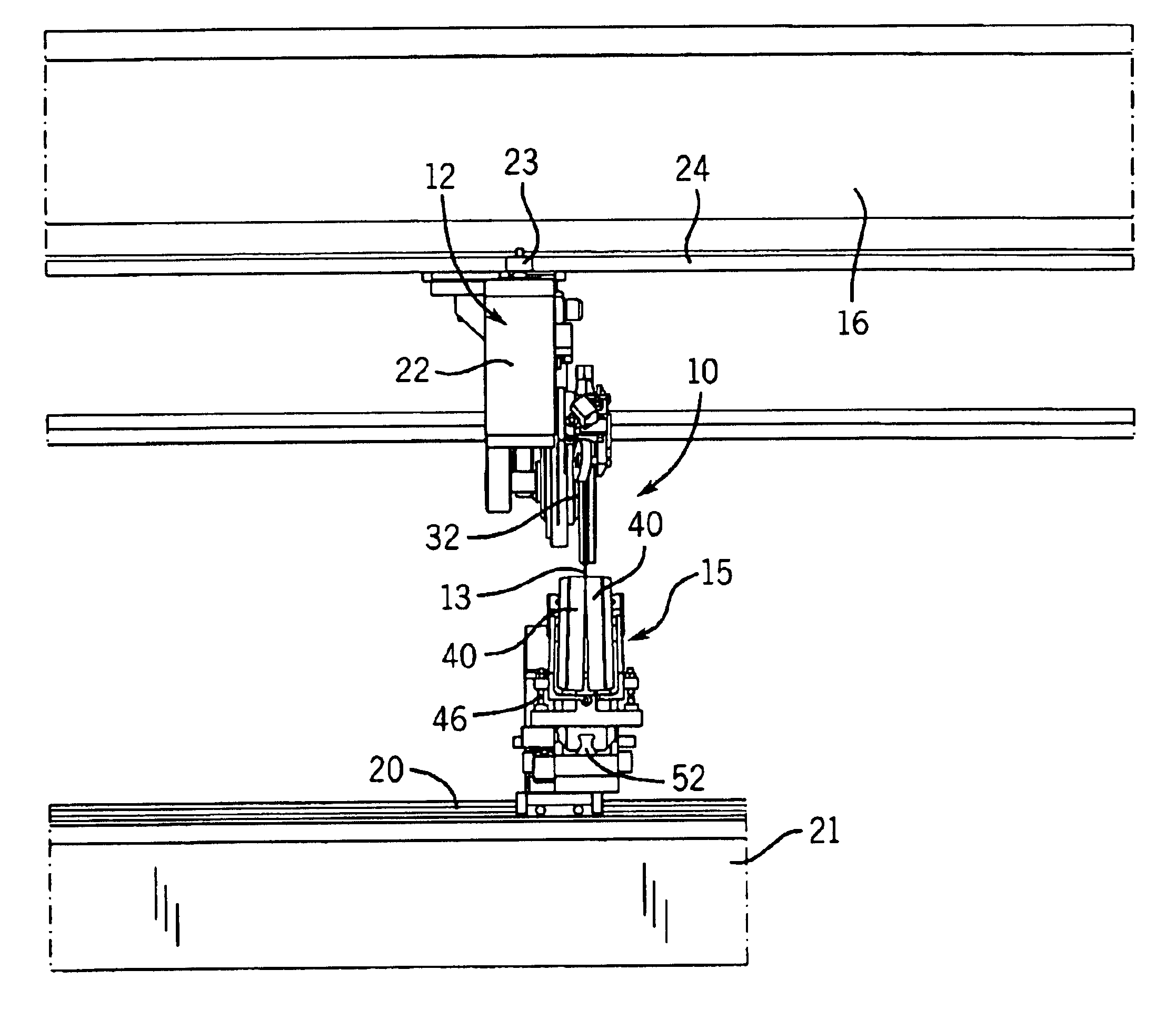

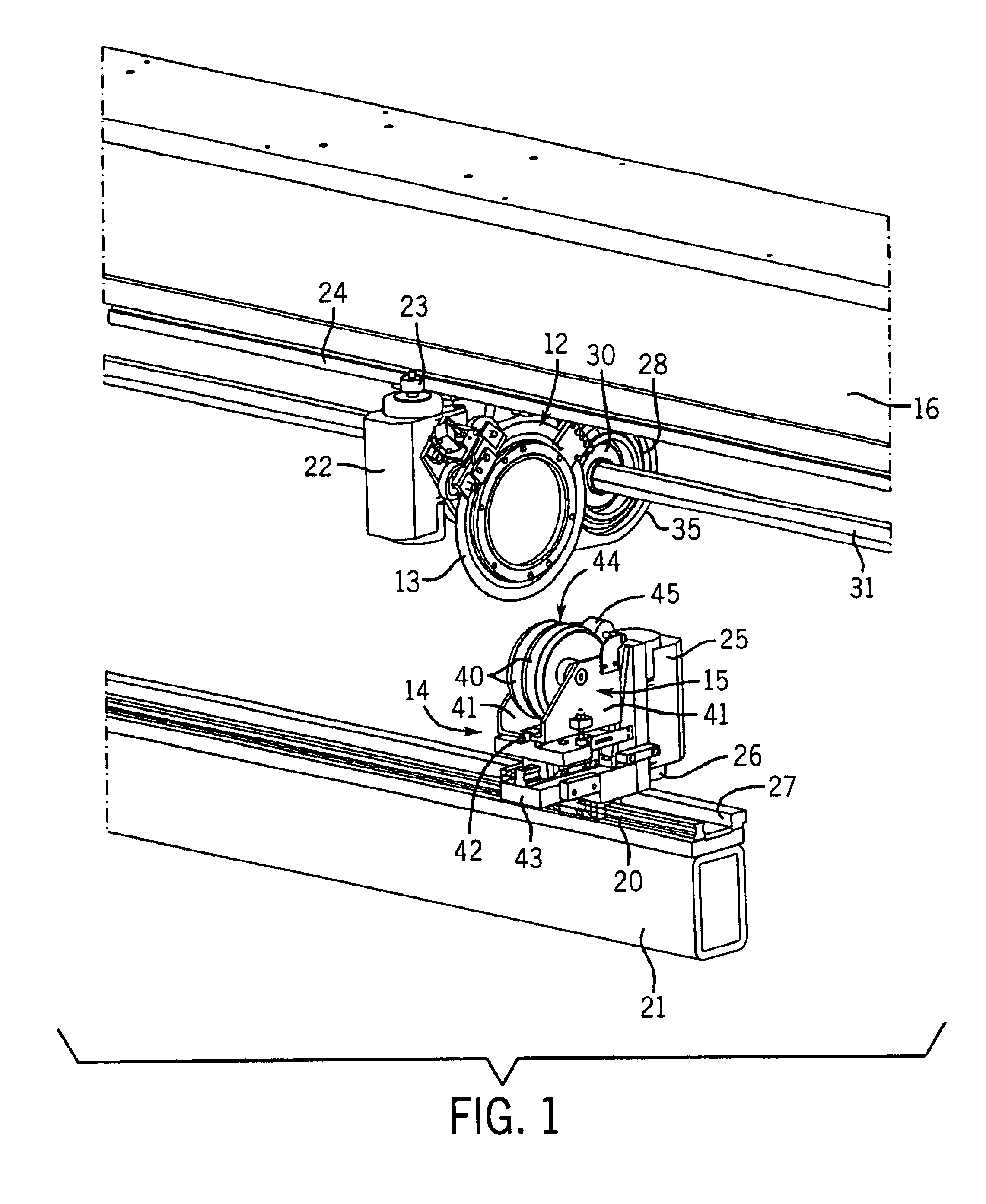

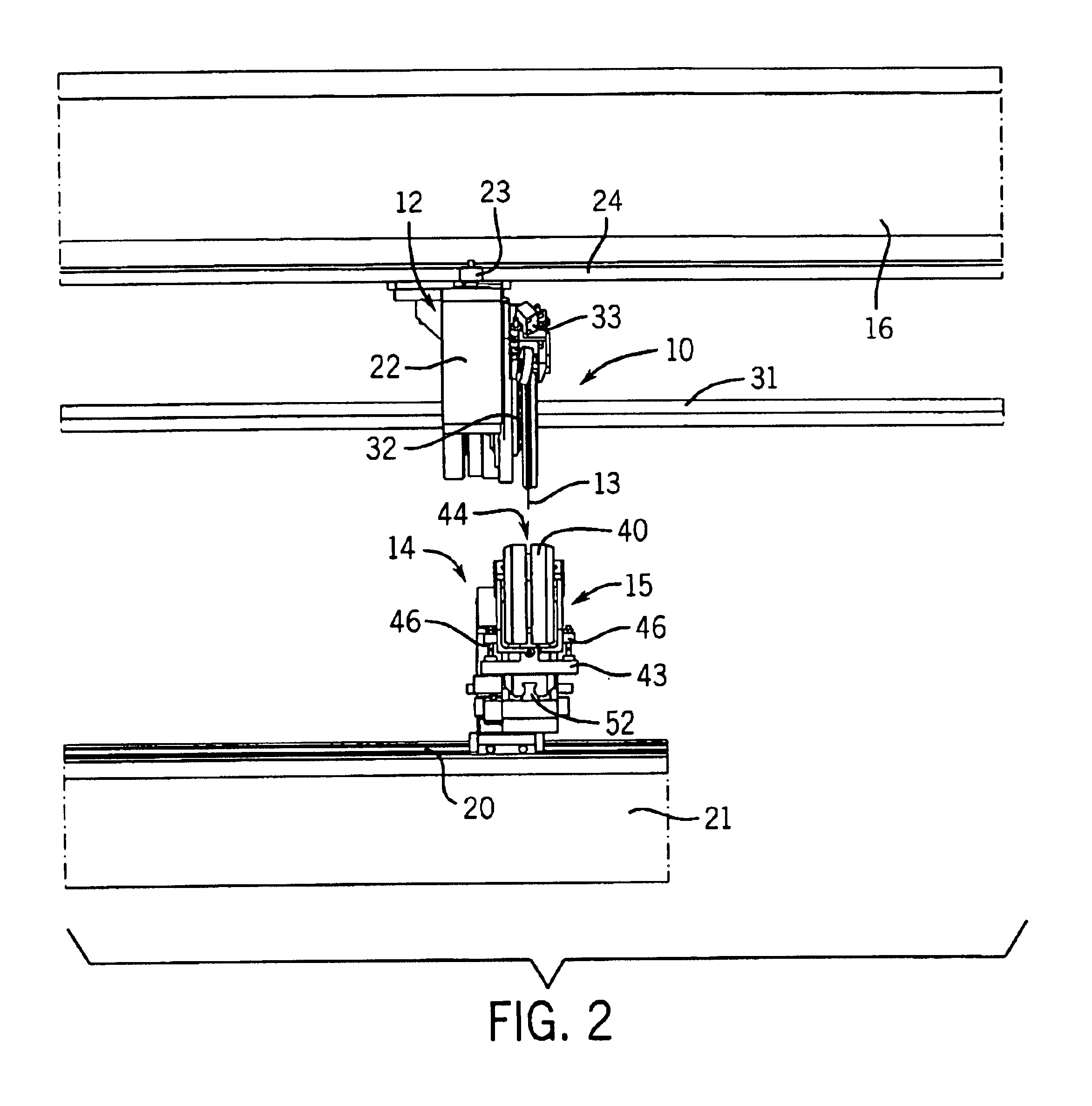

A resistance spot welding system (10) for sequentially clamping a plurality of workpieces (20,22) at predetermined locations and welding the workpieces (20,22) substantially adjacent the locations, including a clamping element (24) able to be locked in a workpiece engaged position, at least one set of equalizing welding electrodes (28,30) for oppositely engaging the workpieces (20,22) so as to produce the weld (12) without deformation, a singular drive mechanism (14) including a cam coupled to the clamping element (24) and electrodes (28,30), and a singular source (16) for actuating the mechanism (14) and generating the welding and clamping forces.

Owner:GM GLOBAL TECH OPERATIONS LLC

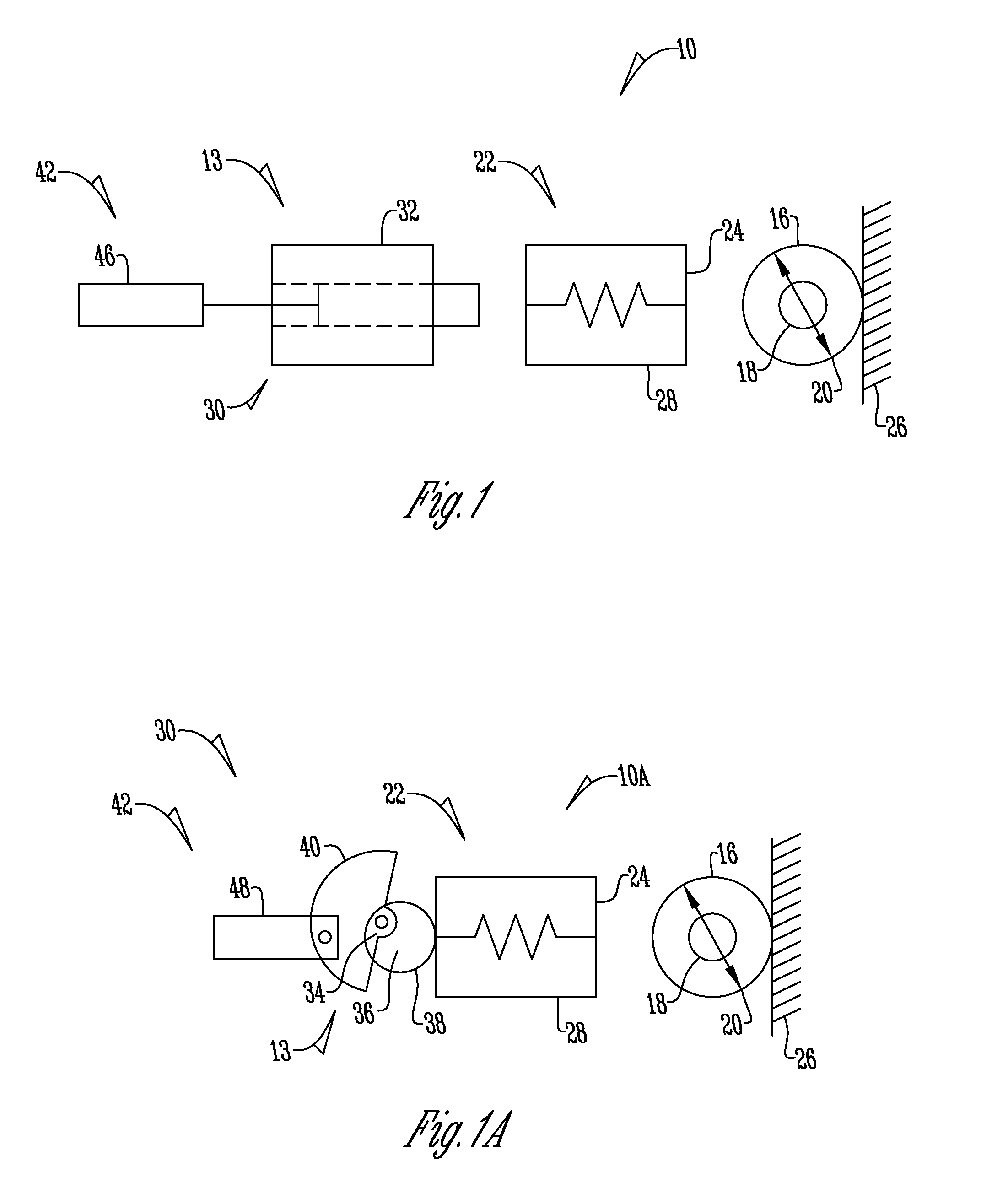

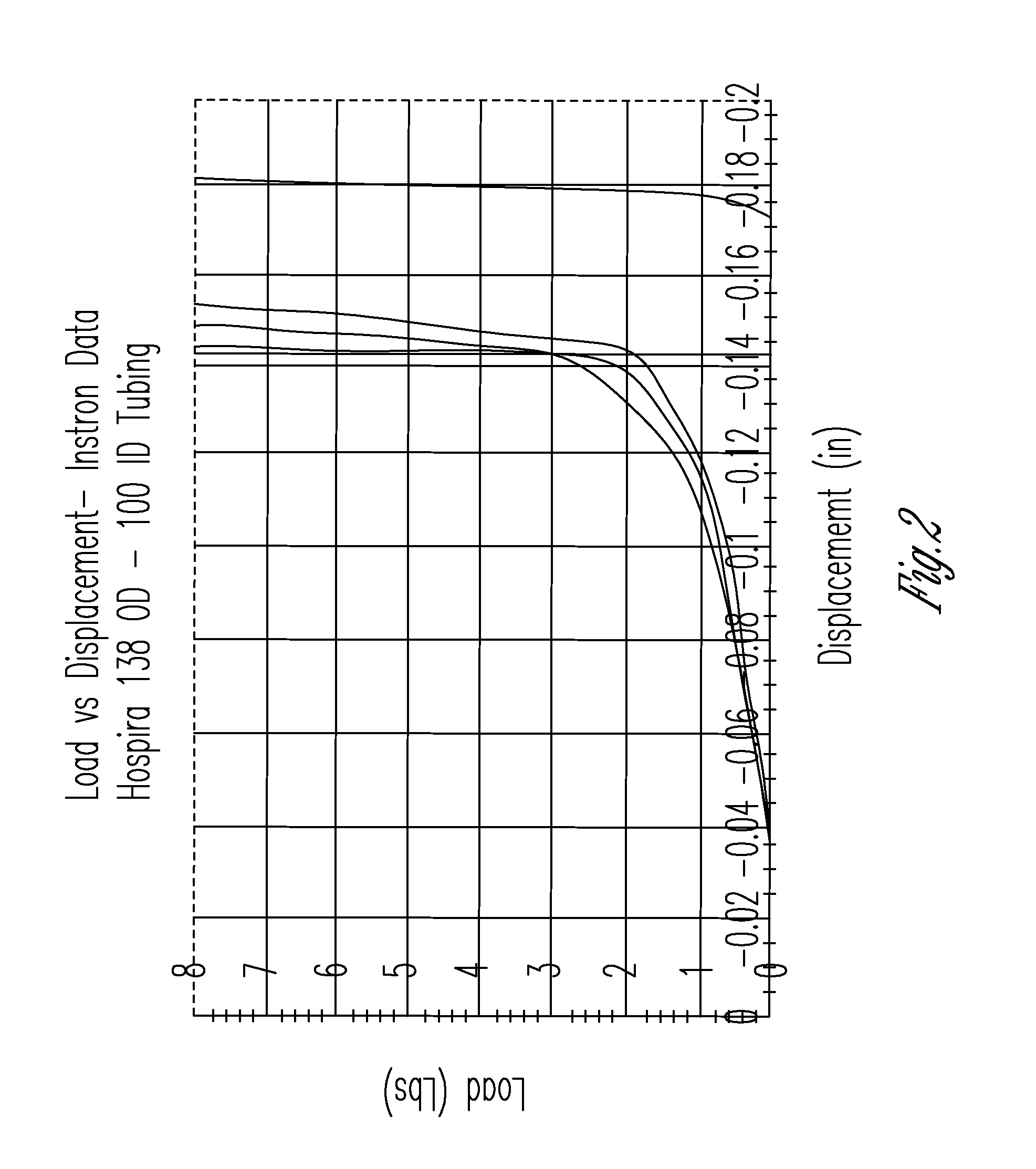

Fluid flow rate compensation system using an integrated conductivity sensor to monitor tubing changes

ActiveUS8858185B2Consistent rateCompensate degradationFlexible member pumpsIntravenous devicesElectricityElectric signal

An infusion system and method for controlling the fluid flow from a pump includes a pump system that has a controller that utilizes an algorithm to control the flow rate of fluid through tubing. A plurality of electrodes operatively contacts an electrically conductive portion of the tubing that is also acted upon by the pump system. The electrodes monitor electrical properties of the tubing and provide an electric signal indicative thereof to the controller, which varies the flow rate of the fluid through the tubing as a result of the electric signal.

Owner:ICU MEDICAL INC

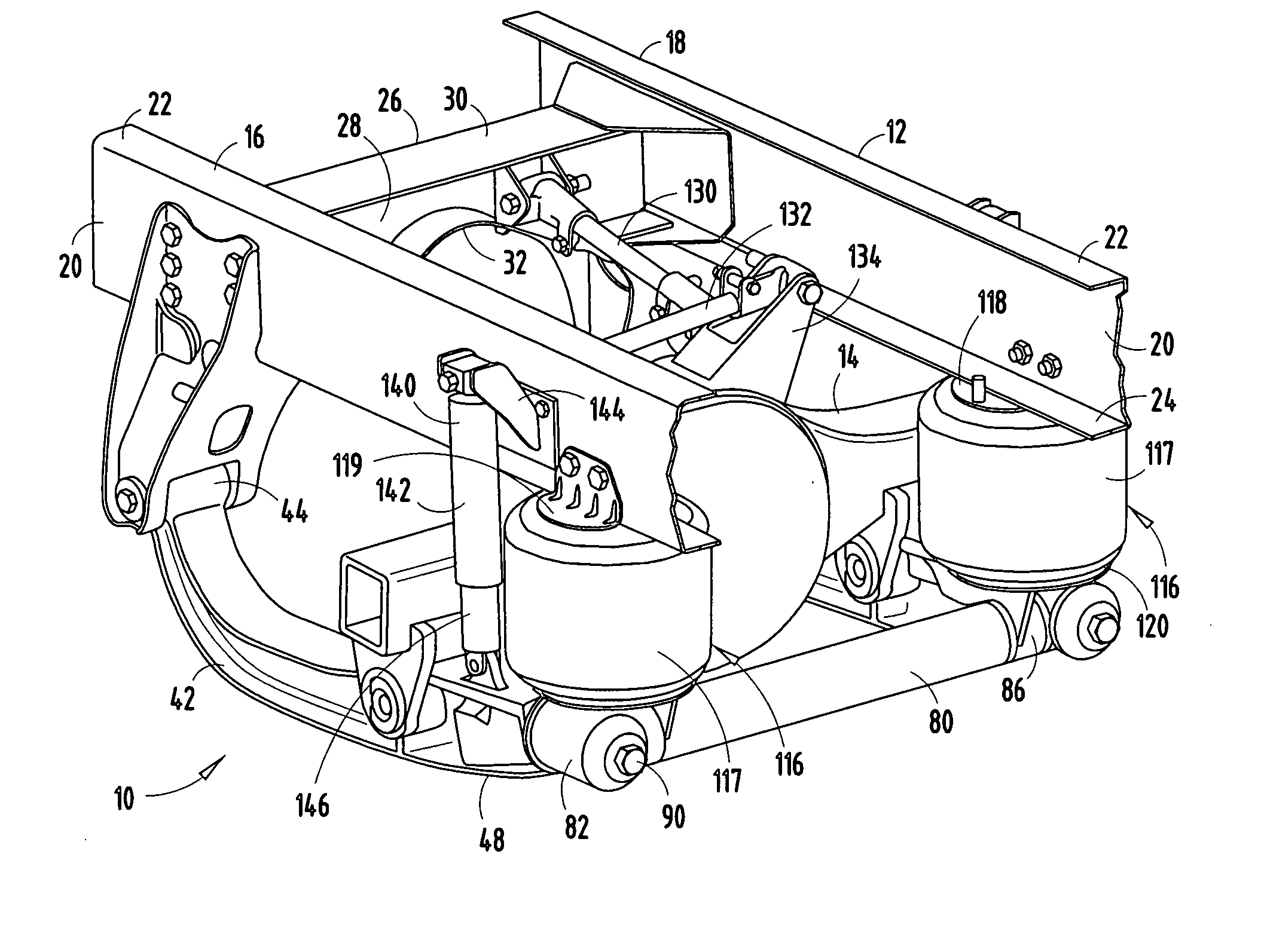

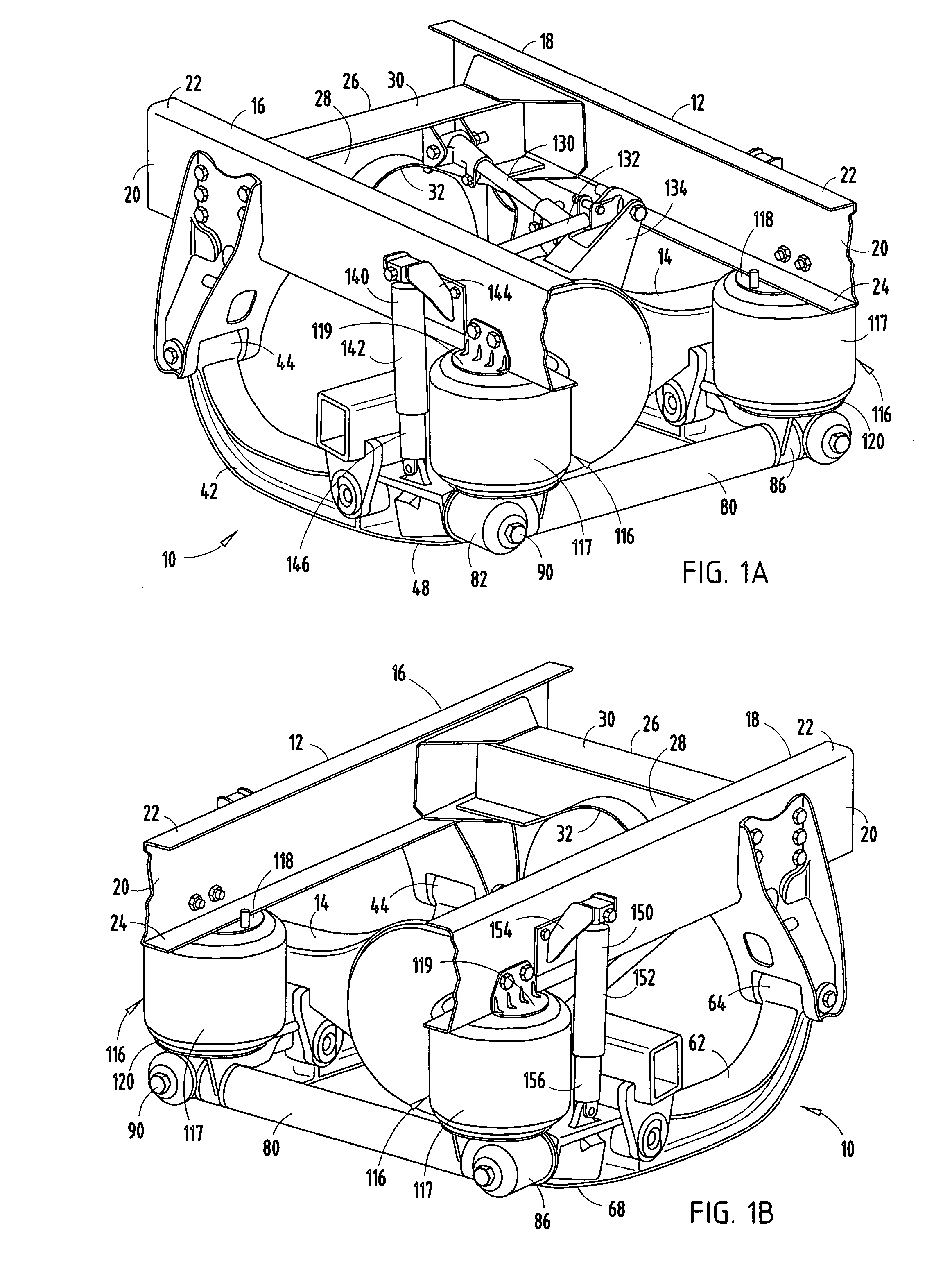

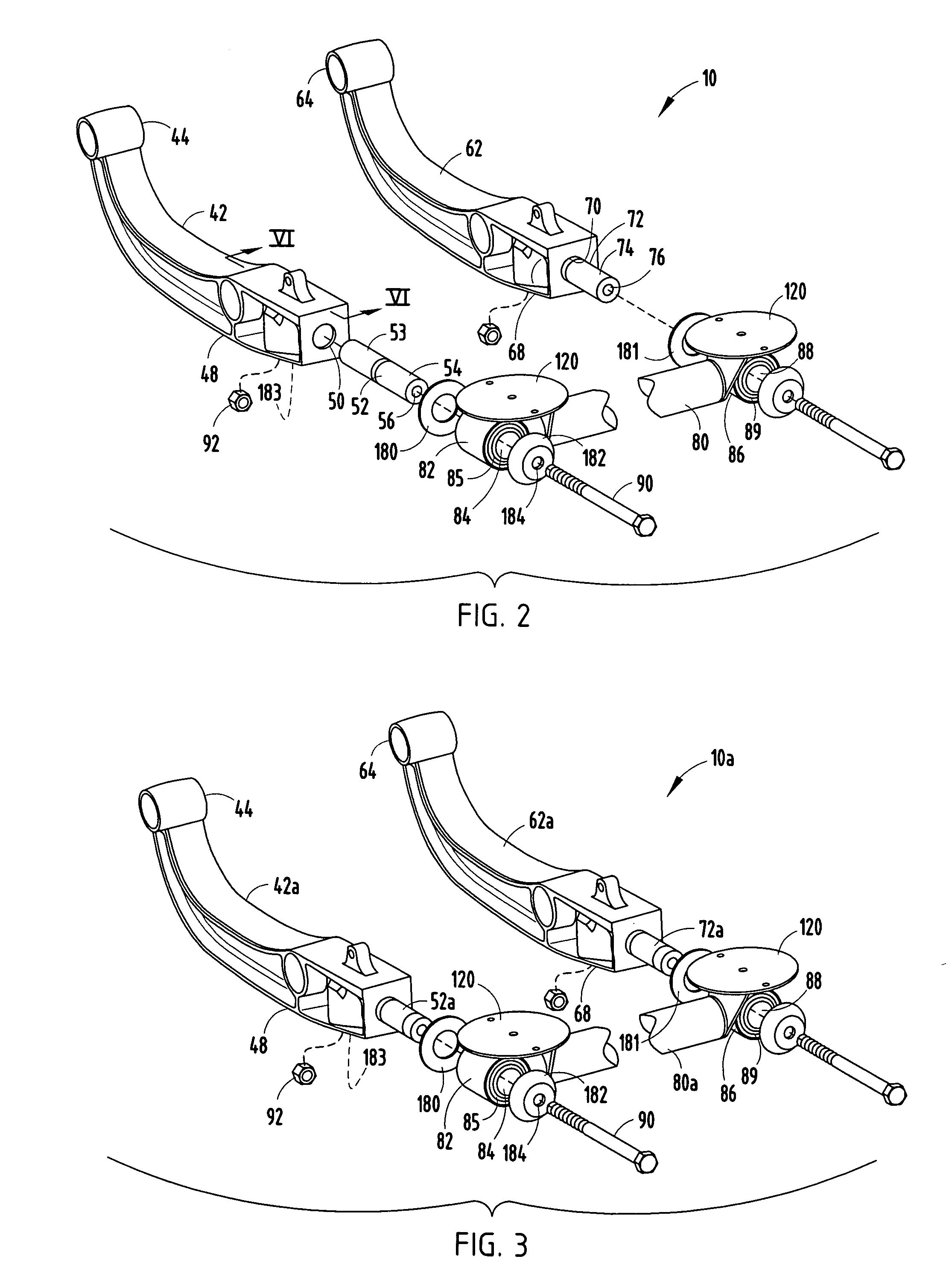

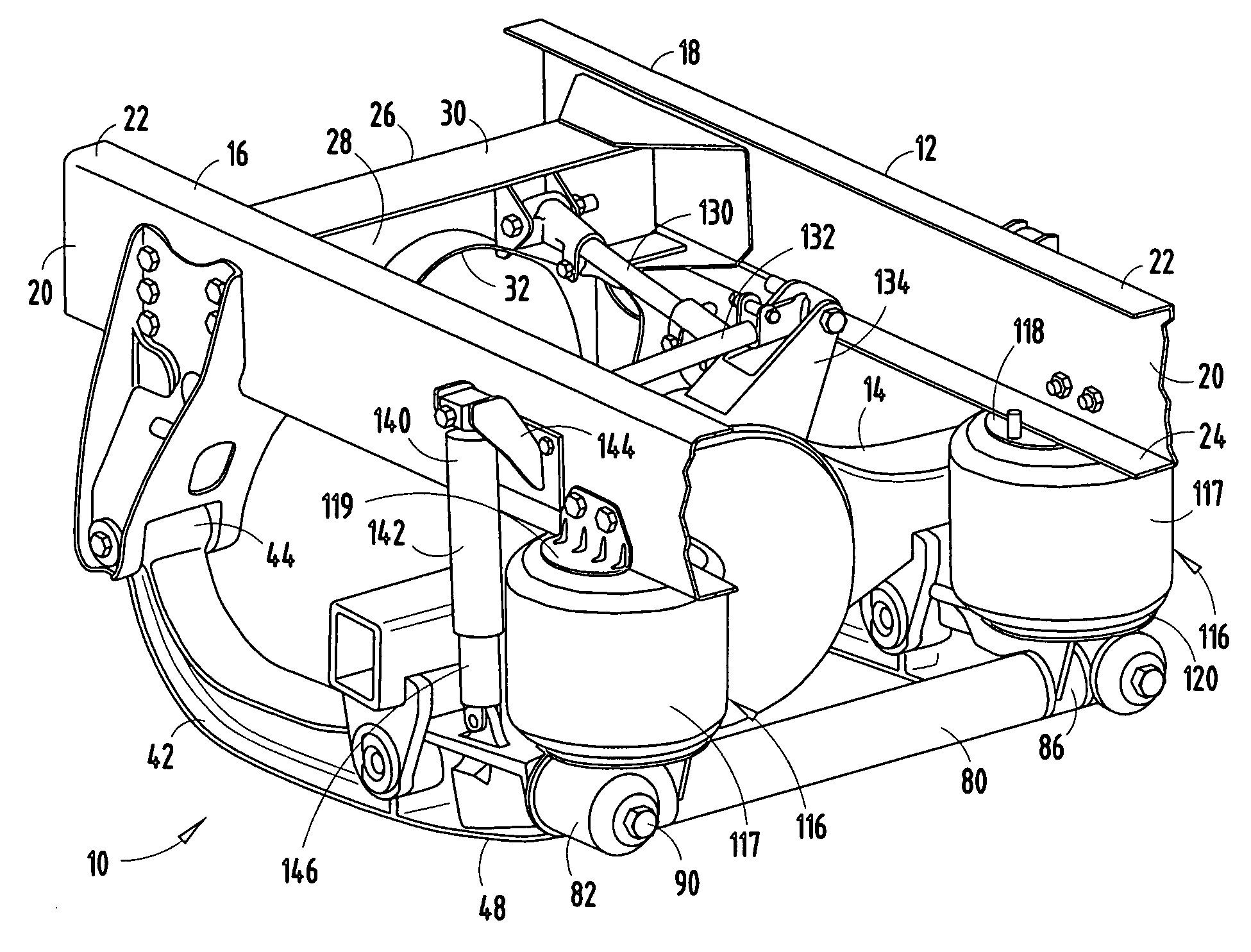

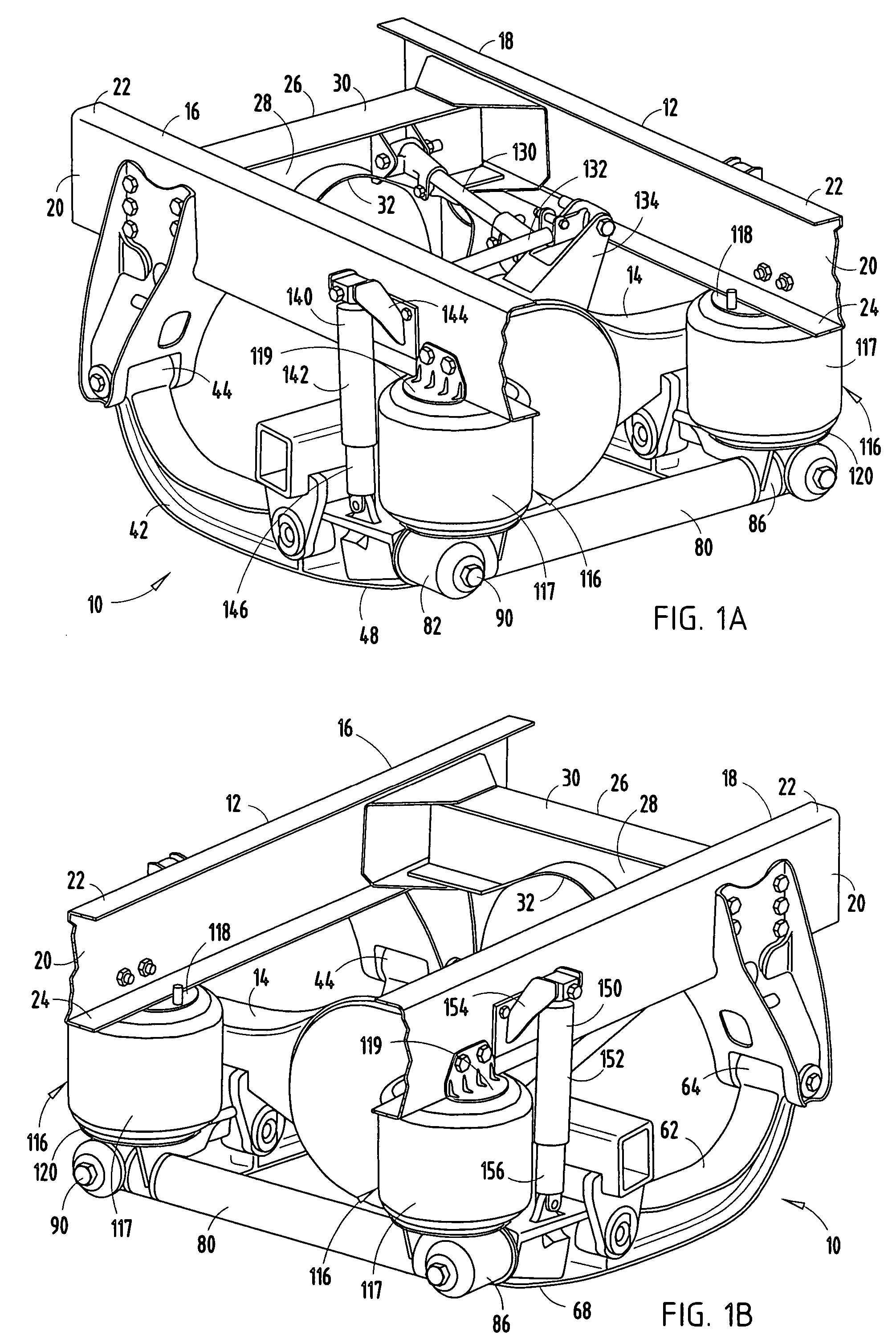

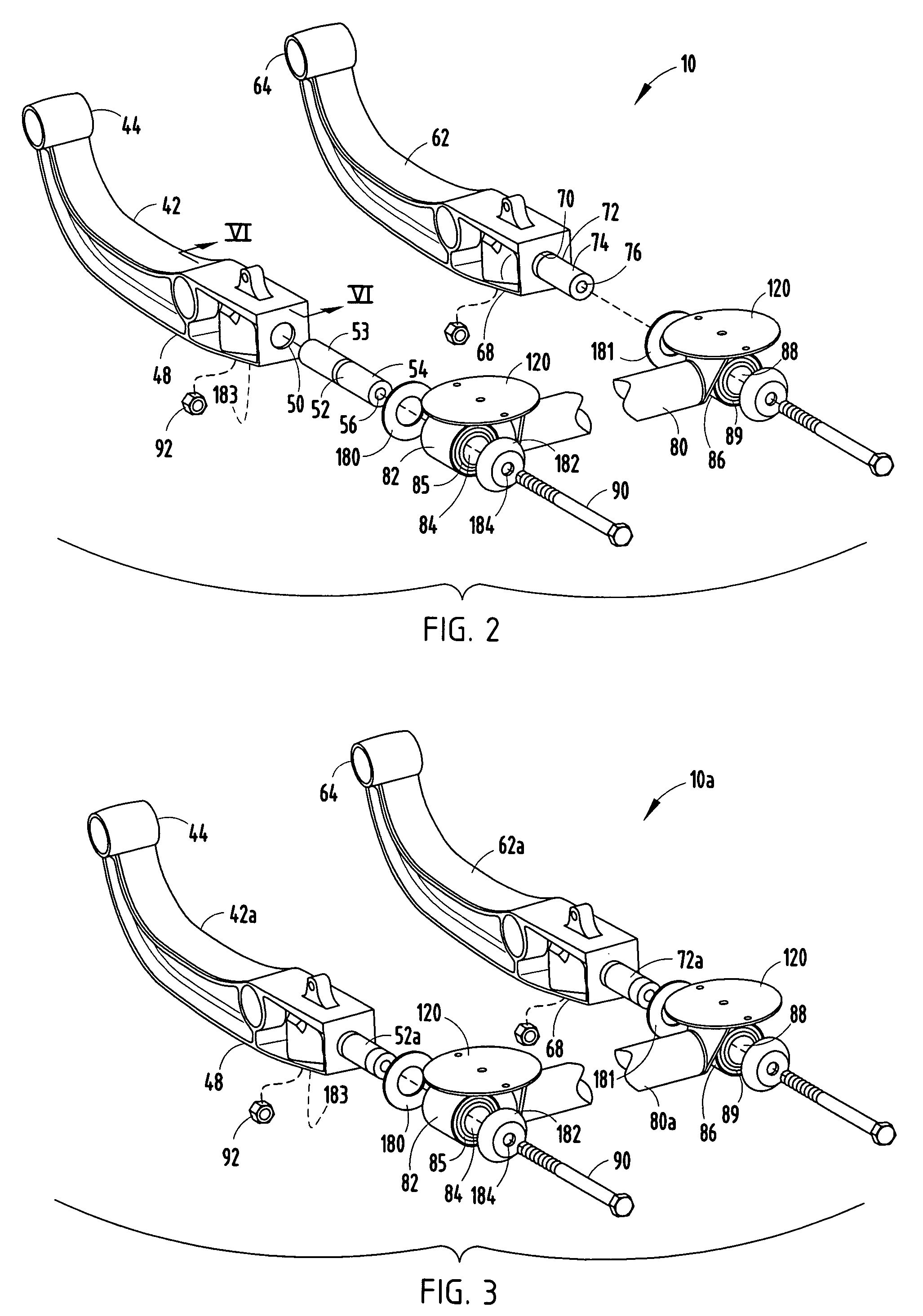

Vehicle suspension assembly

ActiveUS20060255557A1Increase resistanceMinimize assemblyRigid suspensionsInterconnection systemsInterference fitVehicle frame

A vehicle suspension assembly that includes first and second main beams each having a first end operably coupled to a vehicle frame, and a second end having a cavity formed therein, and first and second extension members each having an aperture extending therethrough, wherein the first and second extensions are interference-fit within and extend outwardly from the cavity of the first and second main beams, respectively. The assembly further including a torsion member having apertured first and second ends that receive the first and second extension members therein, and threaded mechanical fasteners extending through the apertures of the first and second extension members and engage nuts that are frictionally engaged by the first and second main beams.

Owner:THE HOLLAND GROUP

Gas pressure regulator having a vibration damping abutment

InactiveUS20060065307A1Improve damping performanceIncrease coefficient of frictionOperating means/releasing devices for valvesFluid pressure controlAbutmentControl theory

A gas pressure regulator has in the regulator housing (12) a damping abutment (38) adapted to be engaged, in open position of the regulator, by an actuating shaft (22) fixed to a regulator diaphragm (16) for damping vibrations of the regulator mechanism.

Owner:LUXEMBOURG PATENT CO SA

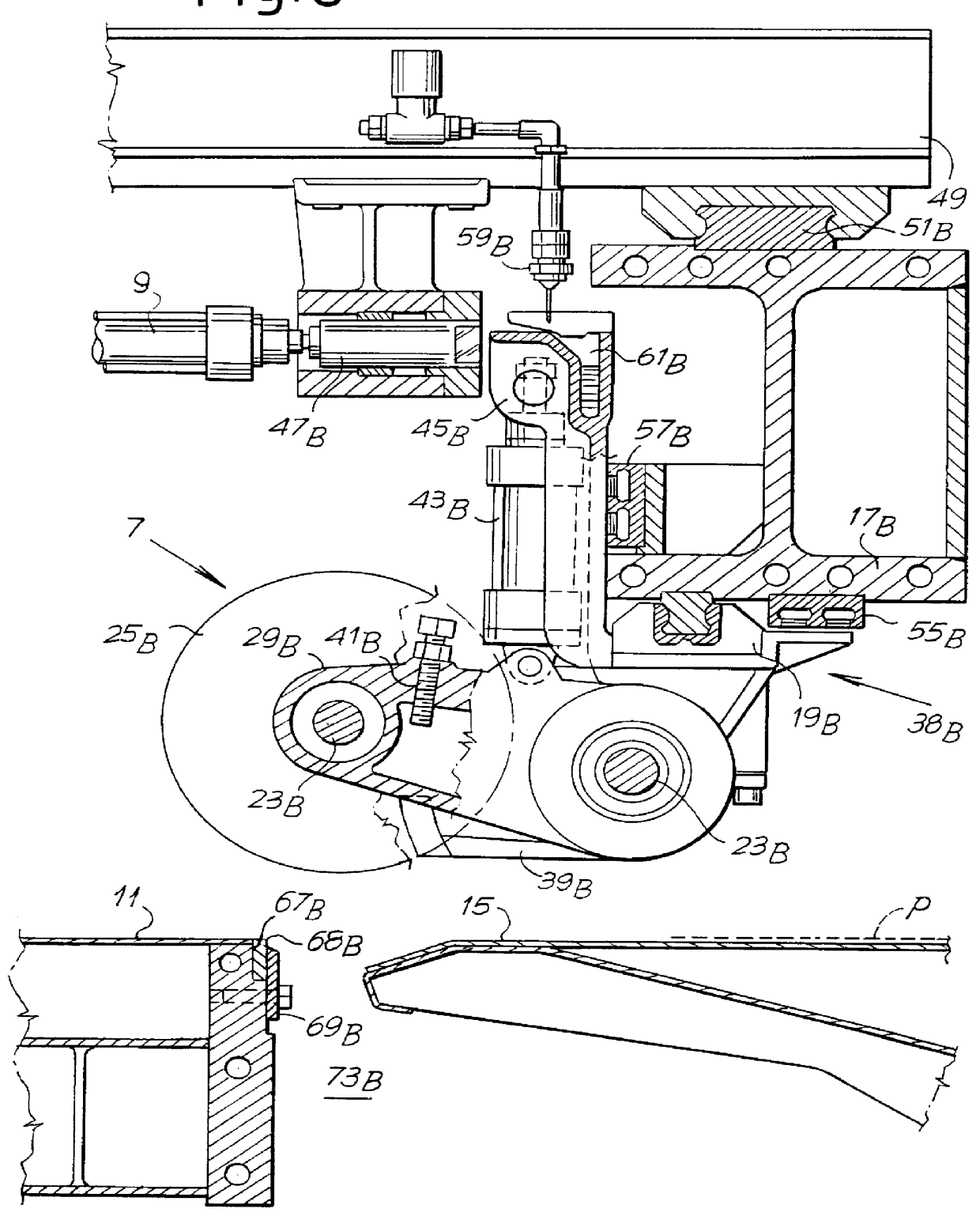

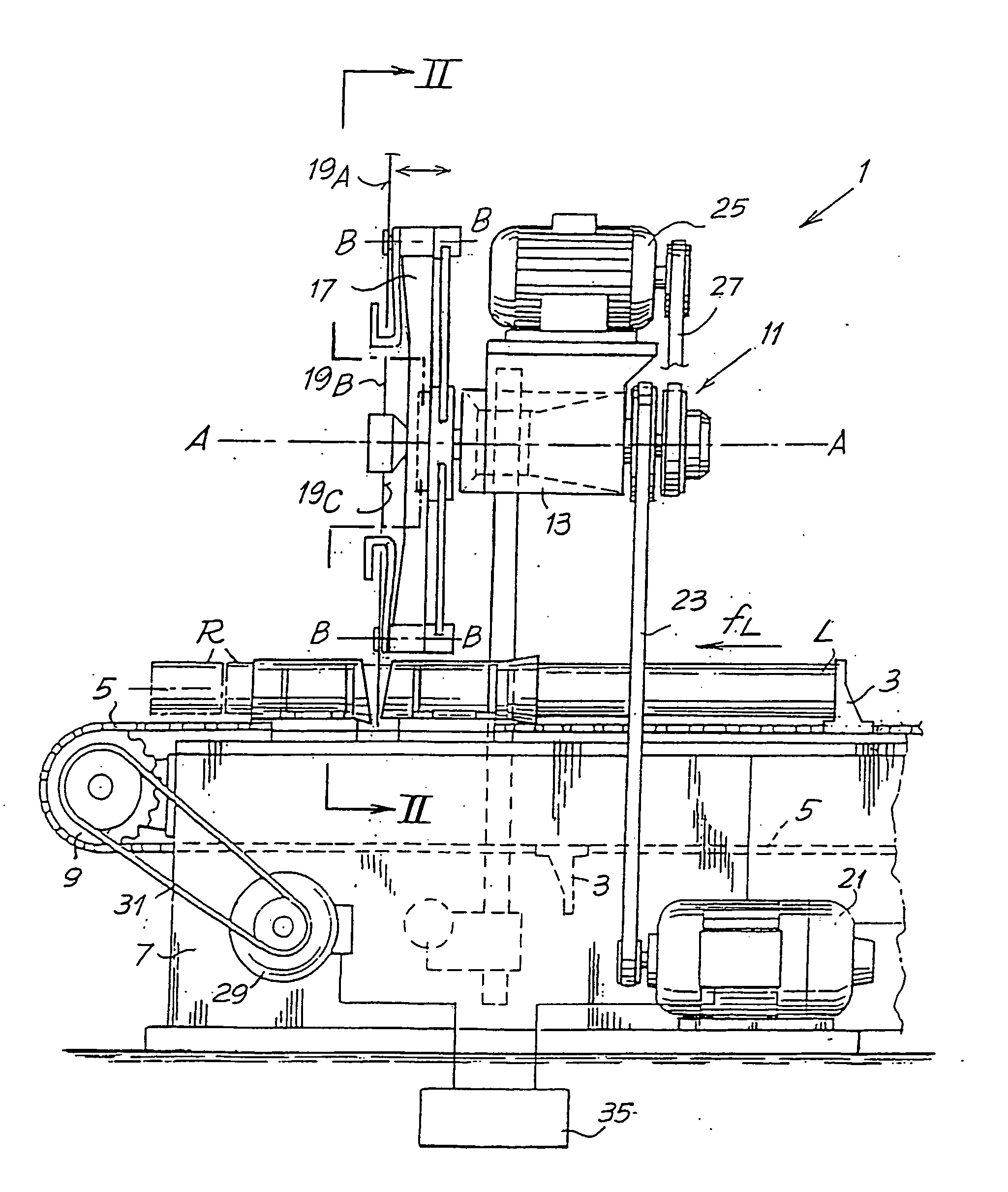

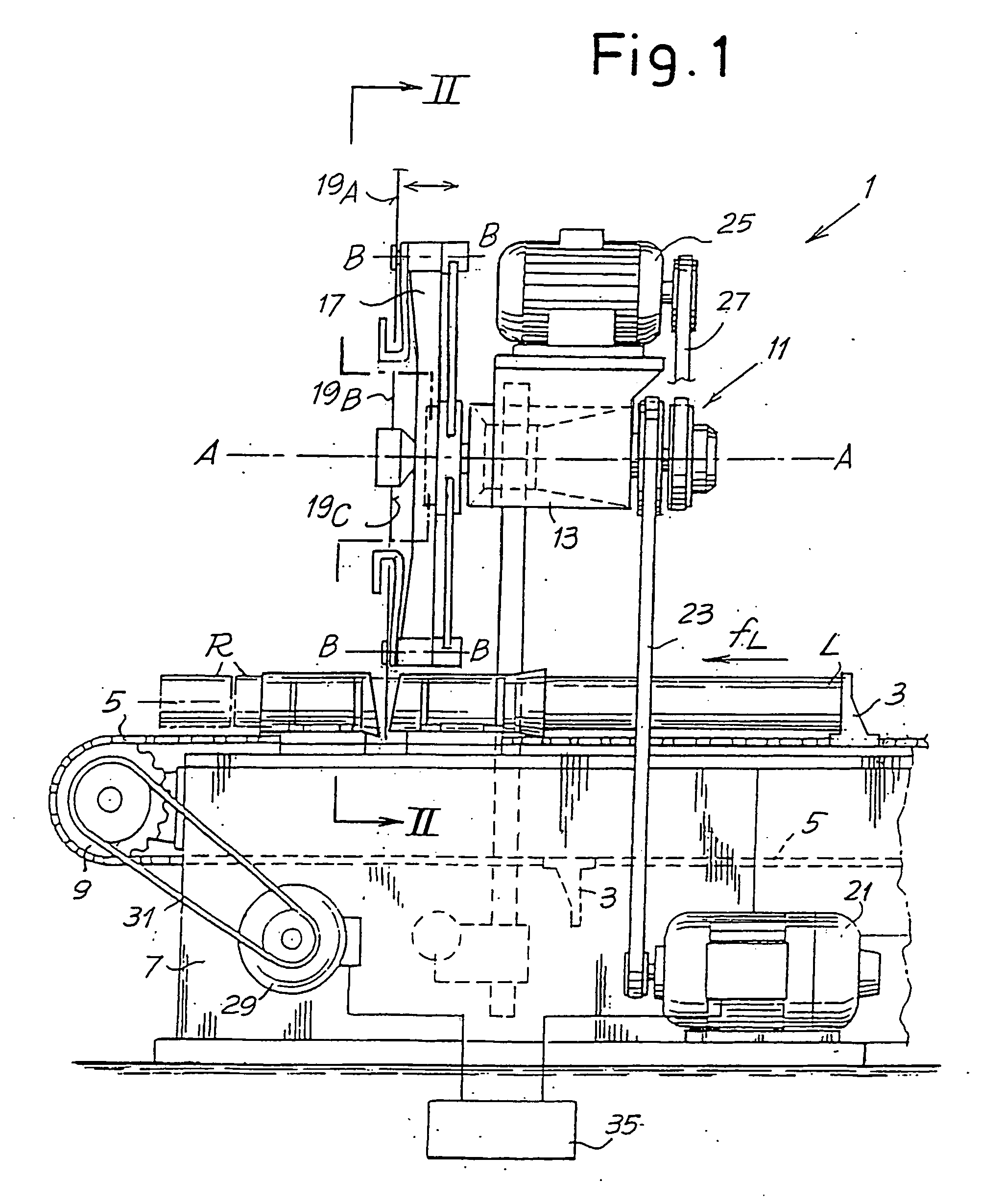

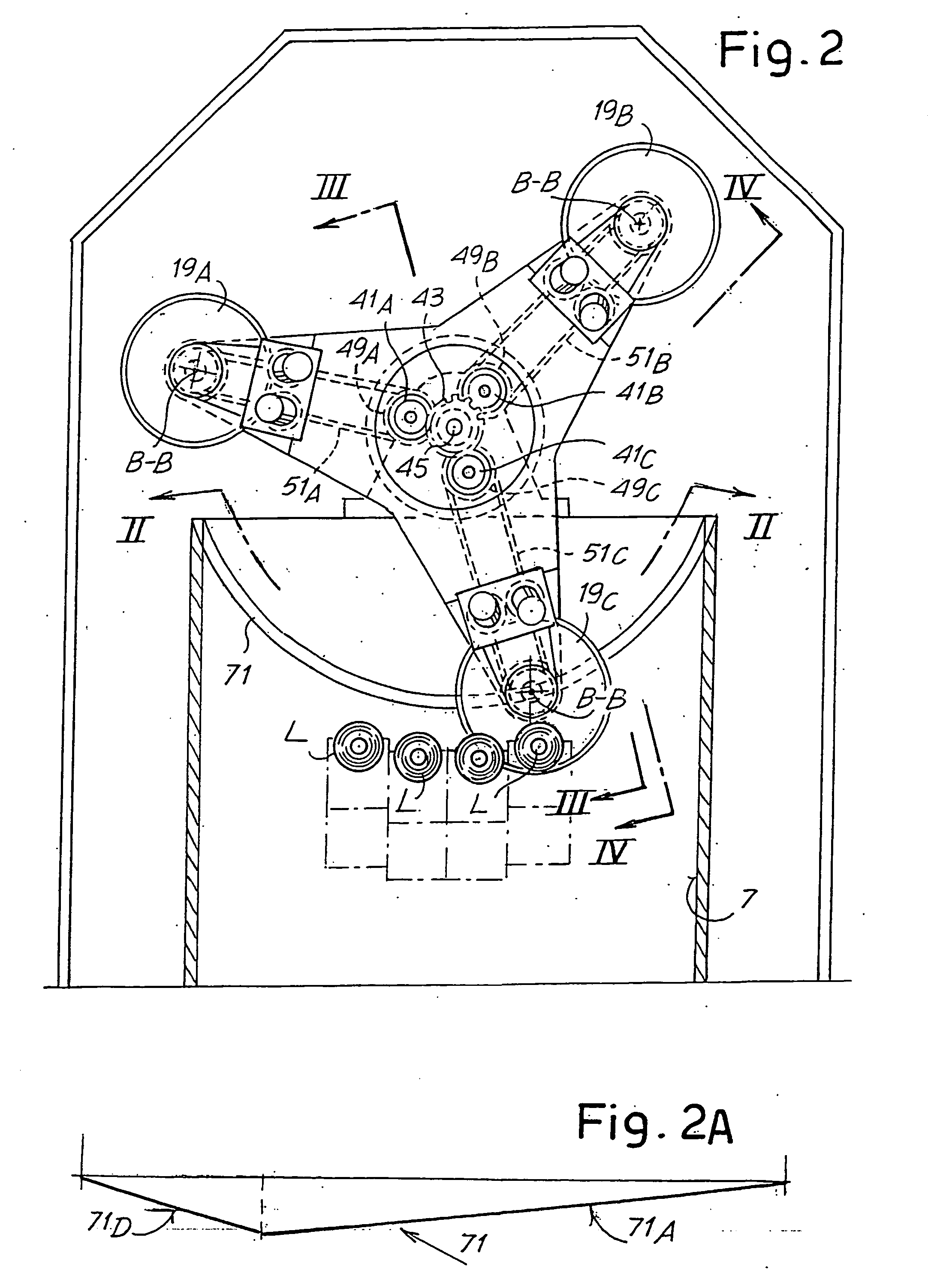

Cutting machine for cutting elongated products

InactiveUS20060162522A1Convenient ArrangementSimple structureCigarette manufactureShearing machinesEngineeringTranslatory motion

The cutting machine comprises at least one path for the products to be cut (L); at least one device (3, 5, 9) for feed of the products along said path, according to a direction of feed (fL); an element (17) rotating around a main axis of rotation (A-A); on said rotating element, at least one disk-shaped blade (19A, 19B, 19C) rotating around its own axis of rotation (B-B), said blade being provided with alternate translatory motion, substantially parallel to the direction of feed. The disk-shaped blades moves axially in relation to the rotating element during rotation of said rotating element. Moreover, the translatory movement of the disk-shaped blade is controlled so that it moves in the same direction as the direction of feed of the products to be cut when the blade is engaged in said products to follow the feed of the products during cutting. Motion in the opposite direction to the direction of feed of the products is imparted on the blade in a period of time in which the blade is disengaged from said products.

Owner:FABIO PERINI SPA

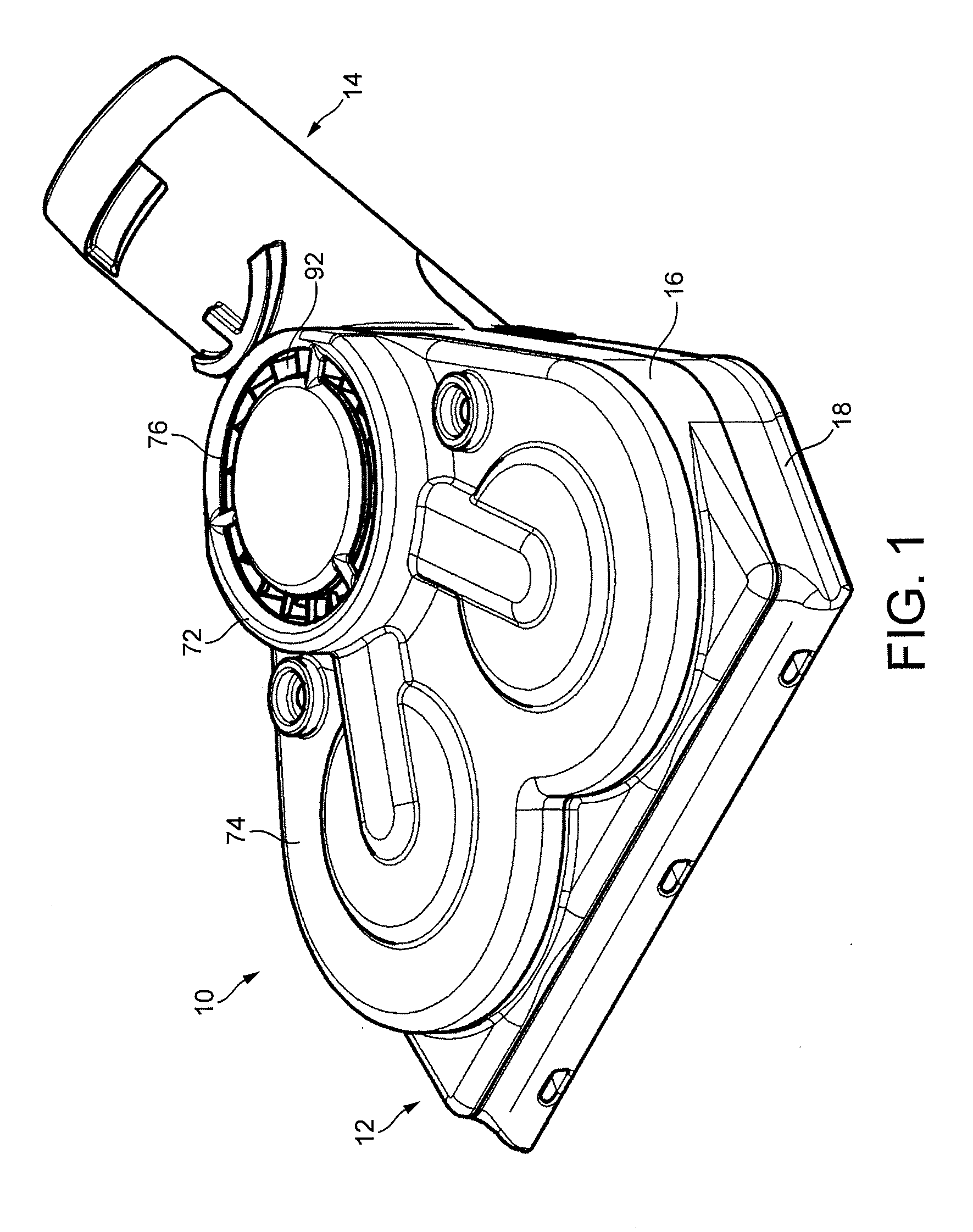

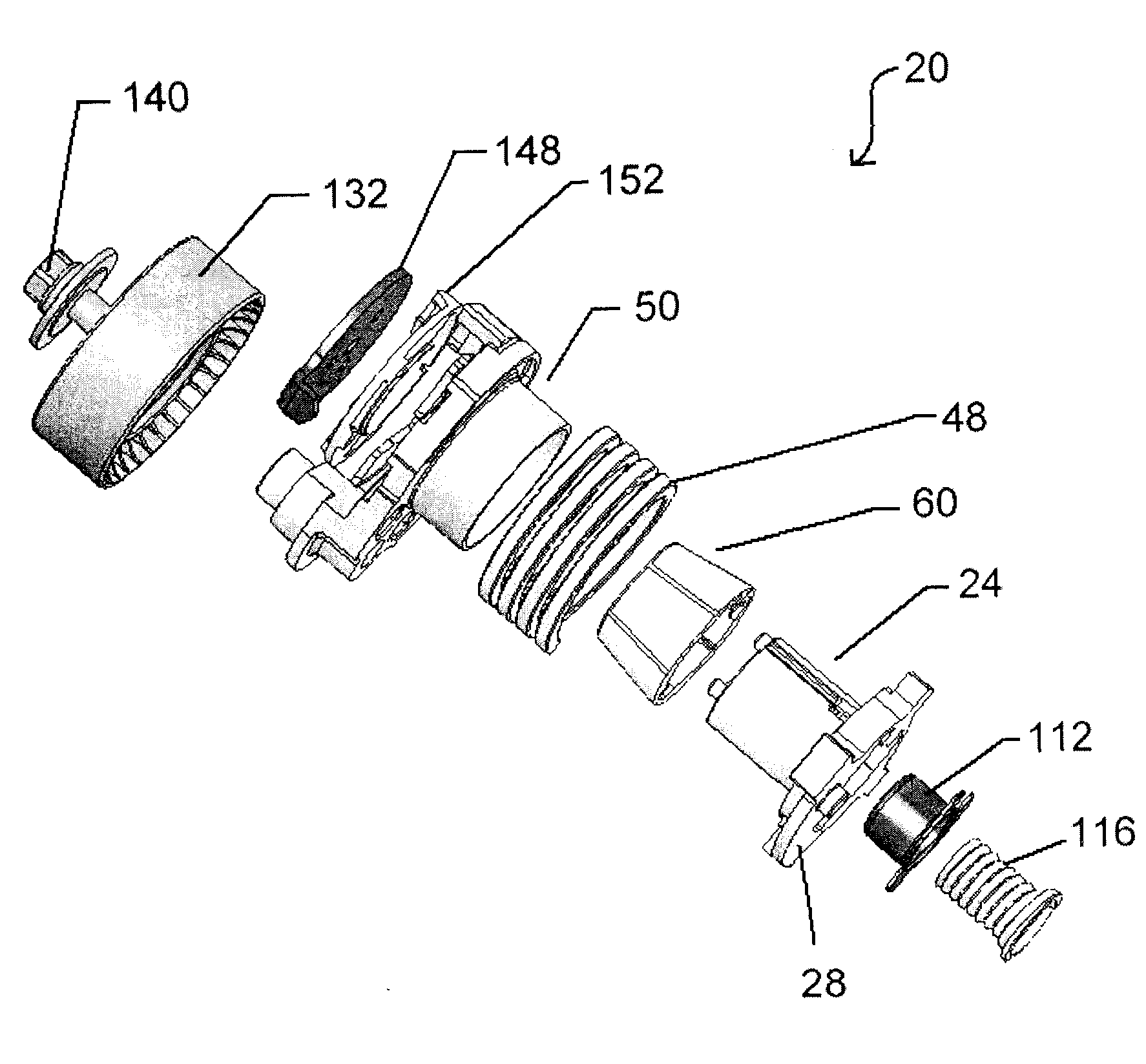

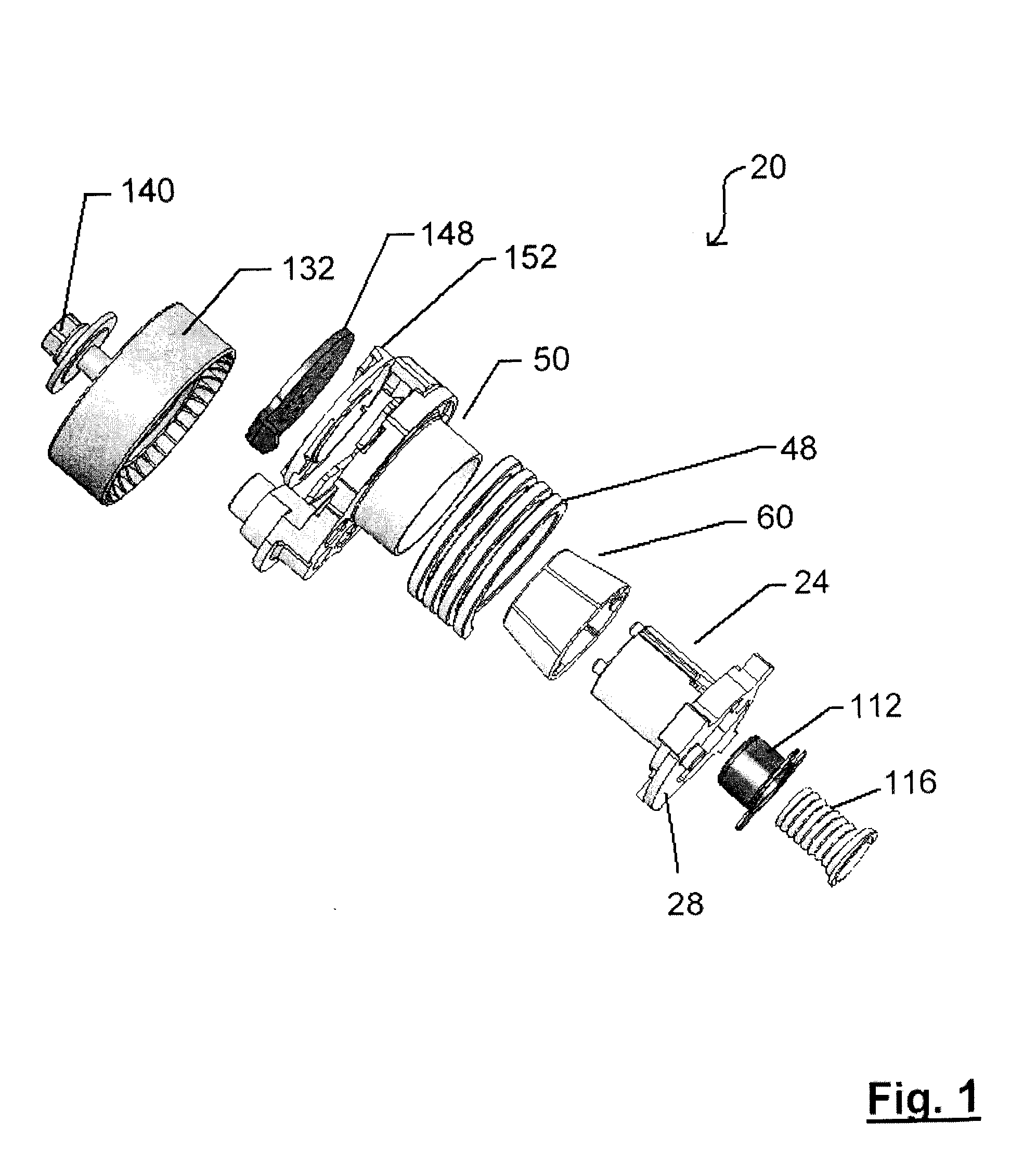

Belt Tensioner with Wear Compensation

A novel tensioner for use with flexible drives, such as serpentine accessory belts on automobiles includes a tensioner arm to spindle pivot design which employs a frustoconical bushing between an inner pivot surface of the tensioner arm and a spindle shaft. The frustoconical design of the bushing resists off axis movement of the tensioner arm and a wear take up mechanism biases the bushing into contact with the inner pivot surface to compensate for normal wear of the bushing and / or pivot surface. A thrust plate is mounted to the end of the spindle shaft and rides in a thrust washer, the thrust plate and thrust washer being held captive in the tensioner arm such that the tensioner arm can pivot about the bushing and the spindle and the thrust plate and thrust washer assist in inhibiting off-axis movement of the tensioner arm. In one embodiment, the biasing force which biases the bushing against the inner pivot surface of the tensioner arm can be varied to change the amount of dampening of the tensioner.

Owner:LITENS AUTOMOTIVE INC

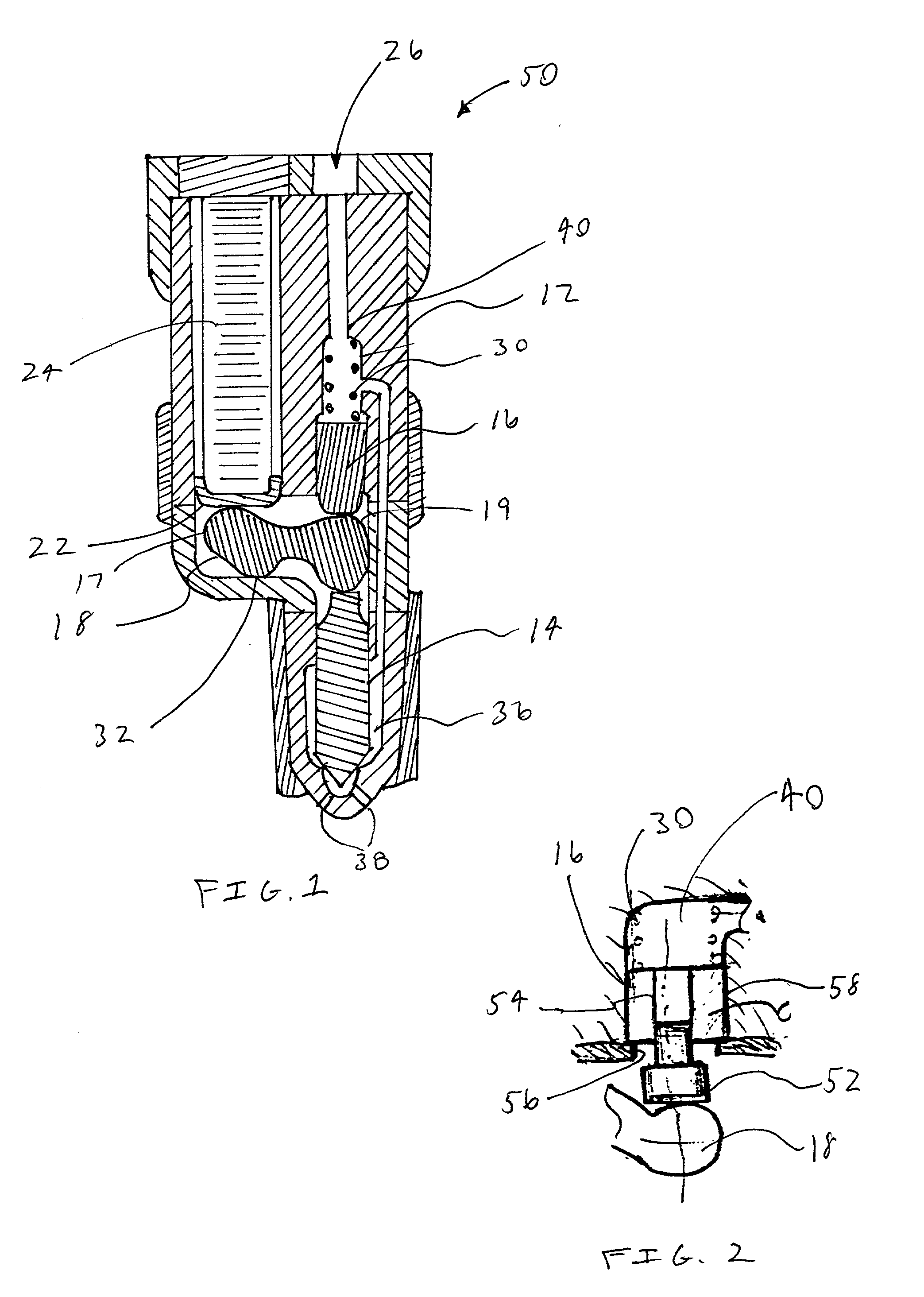

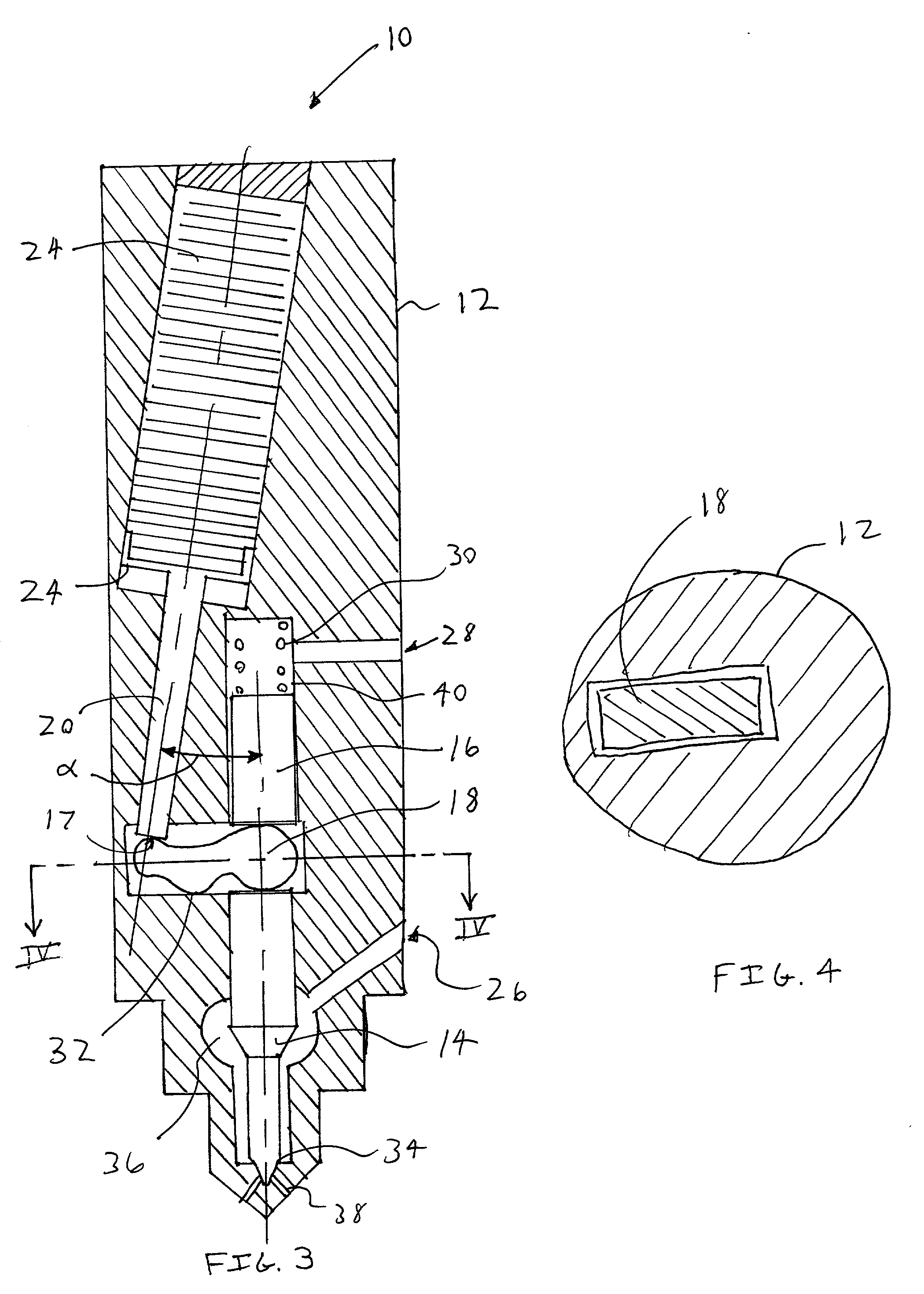

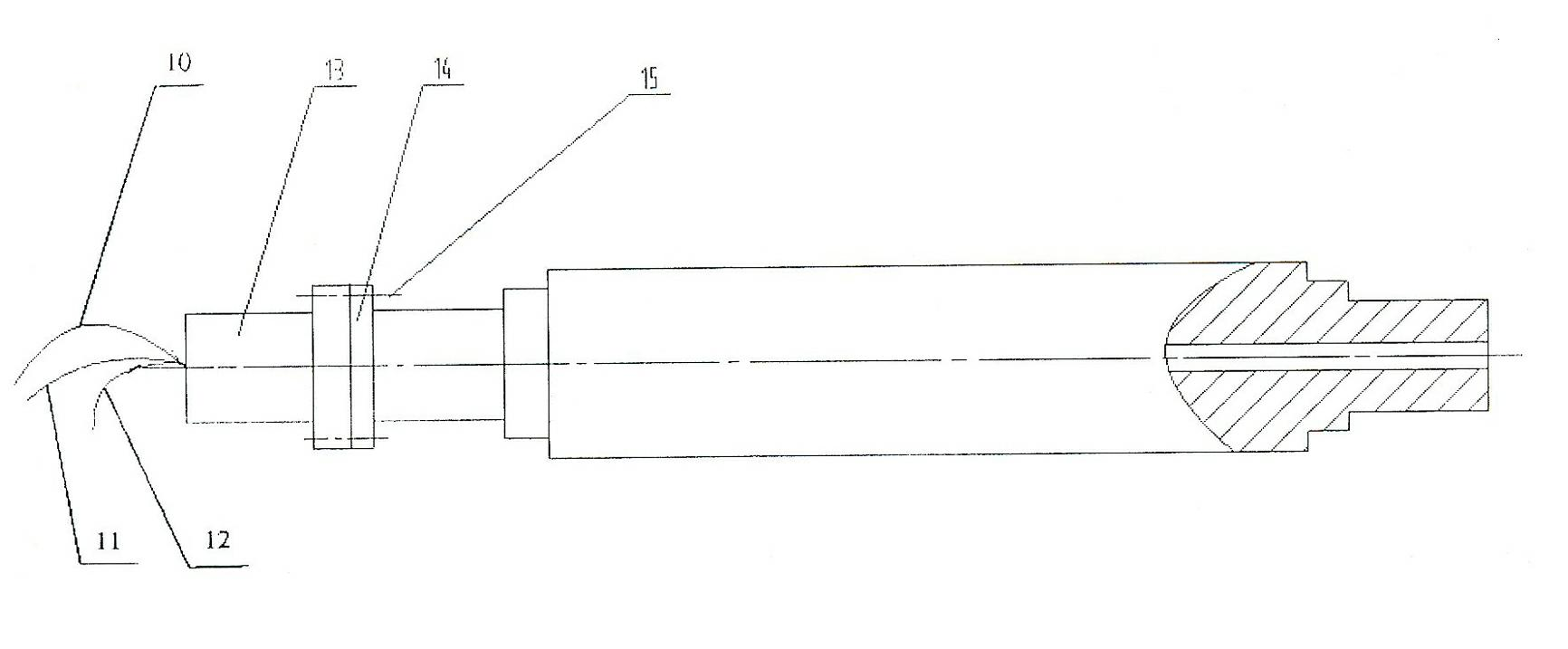

Proportional needle control injector

InactiveUS20020166542A1Compensation changesCompensation for wearOperating means/releasing devices for valvesMovable spraying apparatusActuatorControl theory

The fuel injector includes a solid state actuator that operates through an actuator motion amplifying lever to directly control the needle valve motion. Hydraulic forces, which act along the axes of the needle valve and the motion amplifying lever, are compensated by using a control piston, or other biasing means, to reduce the required amplitude of the control current / voltage and to reduce the required strength of the spring biasing the needle valve closed. The fuel injector may also include a control fuel inlet that is separate from the injection fuel inlet port.

Owner:CUMMINS INC

Vehicle suspension assembly

ActiveUS7416200B2Increase resistanceMinimize assemblyRigid suspensionsInterconnection systemsInterference fitVehicle frame

A vehicle suspension assembly that includes first and second main beams each having a first end operably coupled to a vehicle frame, and a second end having a cavity formed therein, and first and second extension members each having an aperture extending therethrough, wherein the first and second extensions are interference-fit within and extend outwardly from the cavity of the first and second main beams, respectively. The assembly further including a torsion member having apertured first and second ends that receive the first and second extension members therein, and threaded mechanical fasteners extending through the apertures of the first and second extension members and engage nuts that are frictionally engaged by the first and second main beams.

Owner:THE HOLLAND GROUP

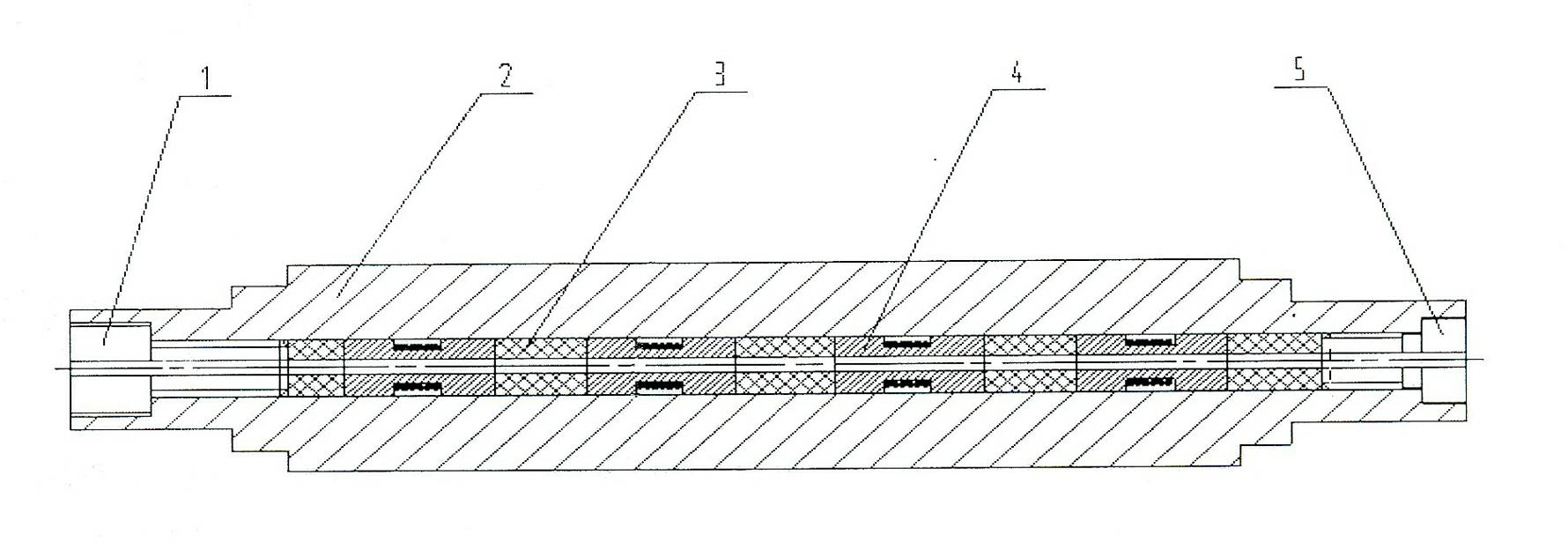

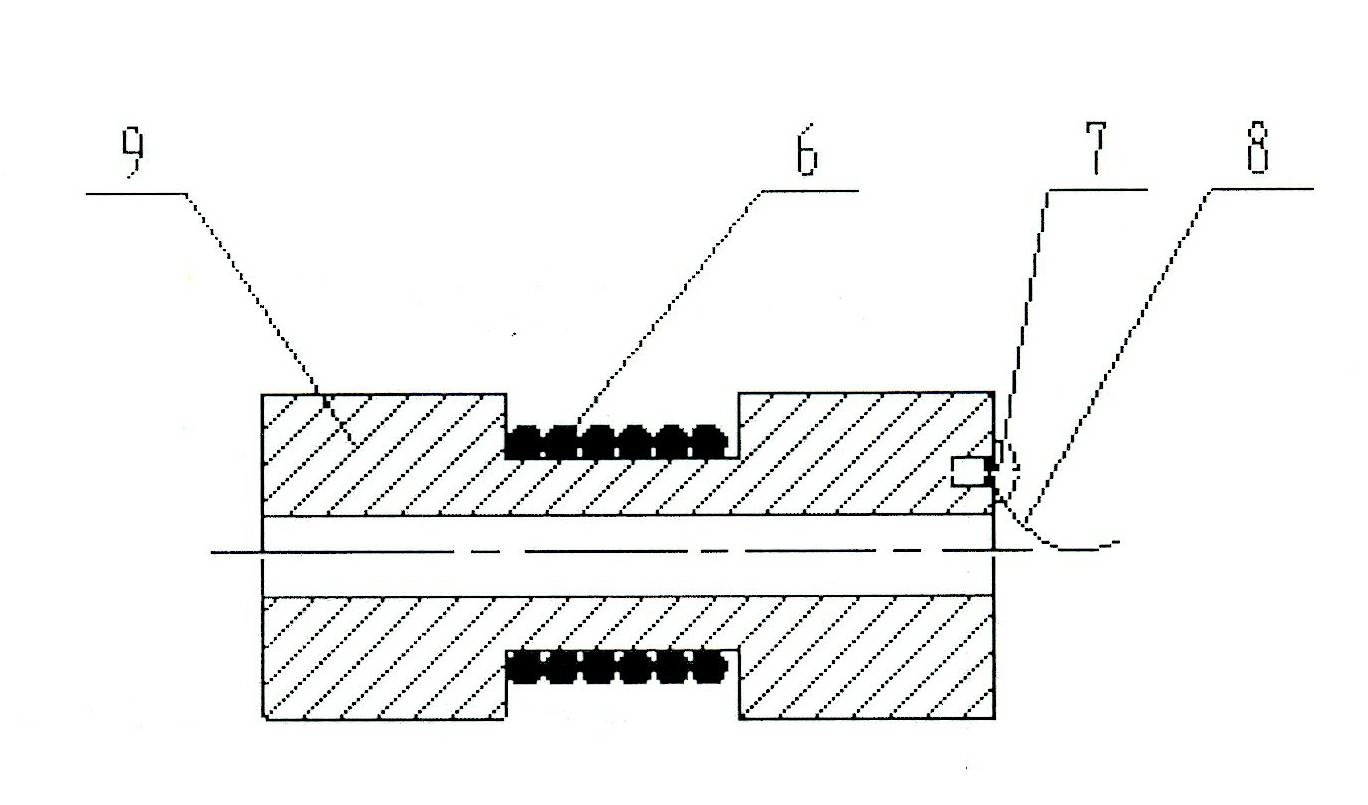

Roller with flexibly adjustable roller type curves

InactiveCN102527727AOptimal shape controlOptimum Gap Shape ControlRollsMetal rolling arrangementsElectrical resistance and conductanceTemperature control

The invention discloses a roller with flexibly adjustable roller type curves. A plurality of groups of electric heating temperature control expansion rods are mounted inside a through hole of a roller body by means of stationary fit, and the electric heating temperature control expansion rods generate radial expansion deformation and form internal expansion driving force by directly using inductance heat (or resistance heat), so that the roller body is driven to radially deform. A heat-insulation distance ring is mounted between each two electric heating temperature control expansion rods, so that heat flow is directionally and radially conducted, and the expansion rods drive the roller body to radially deform. When different current is supplied to the groups of electric heating temperature control expansion rods respectively, a roller profile can be segmentally adjusted. Therefore, various continuously variable high-level roller type curves can be generated to flexibly adjust strip shapes. The roller has the effects of compensating roller wear and eliminating local high shape waves.

Owner:YANSHAN UNIV +1

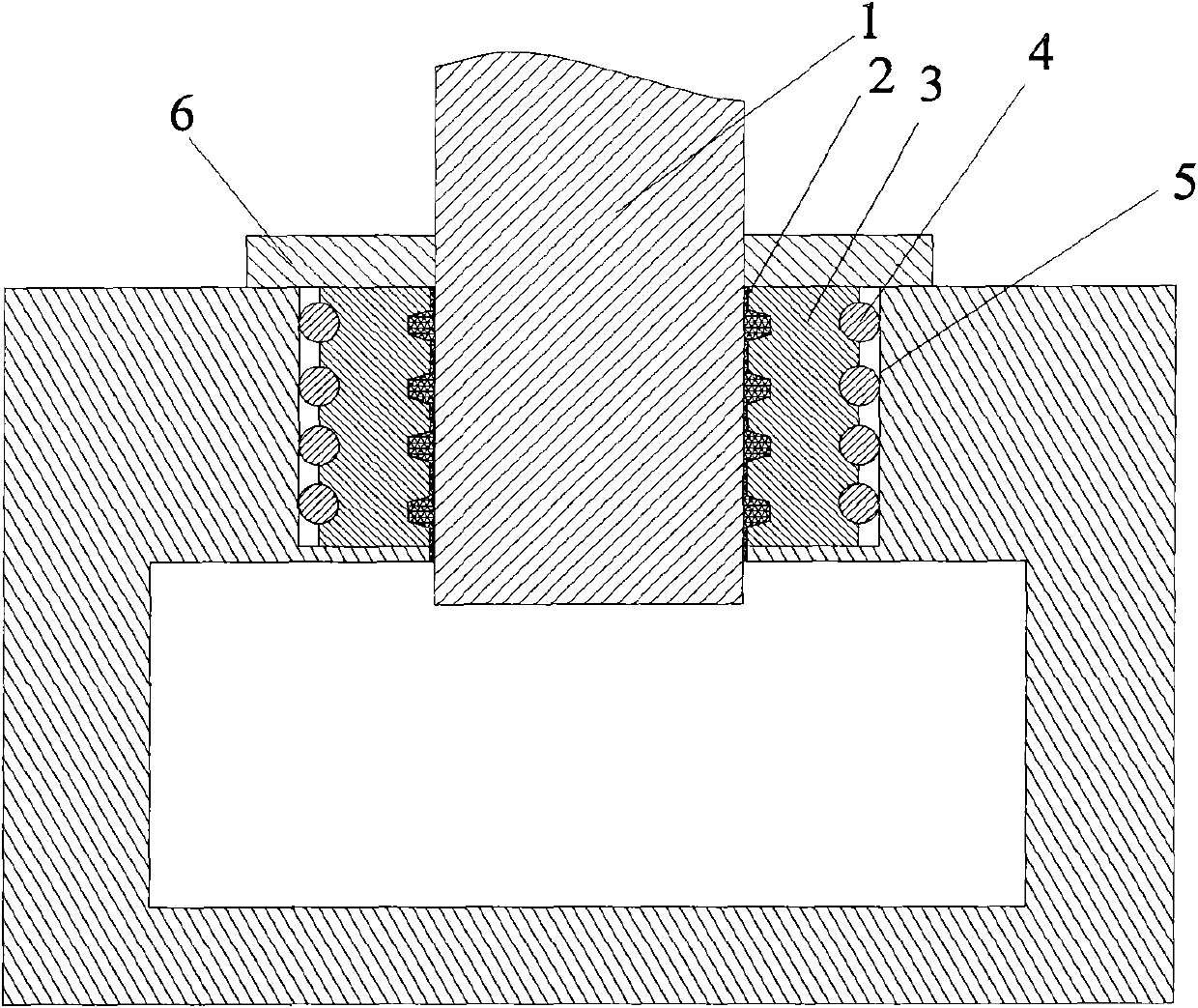

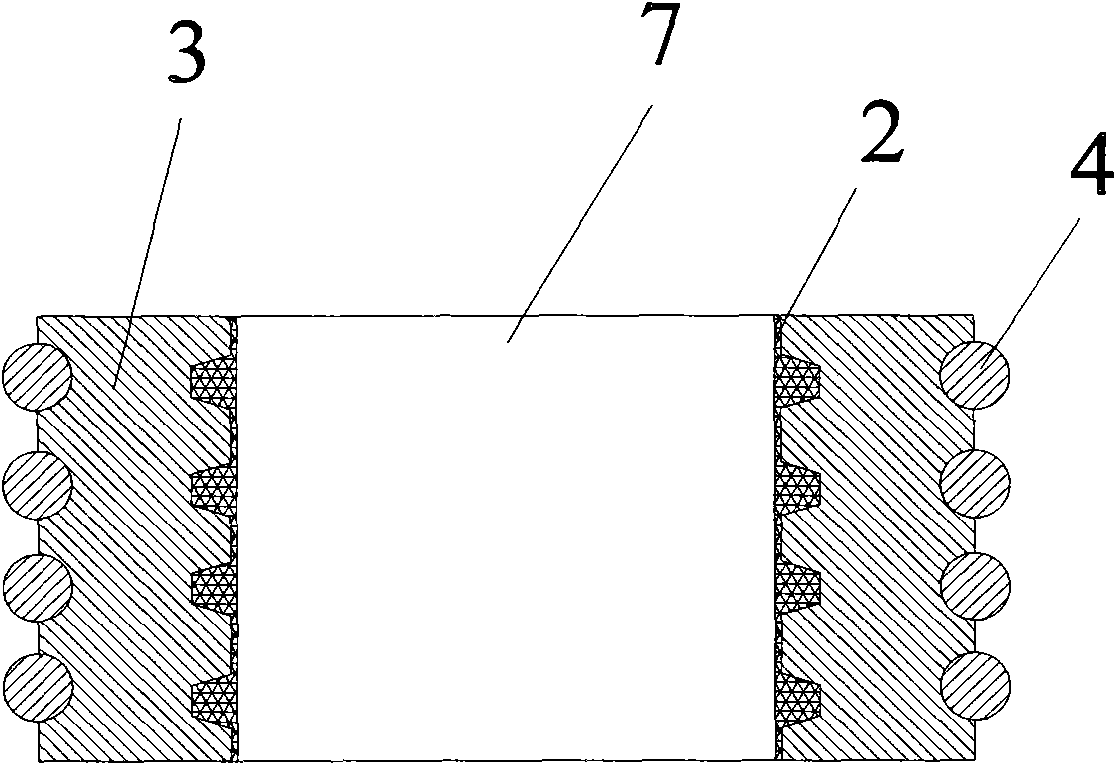

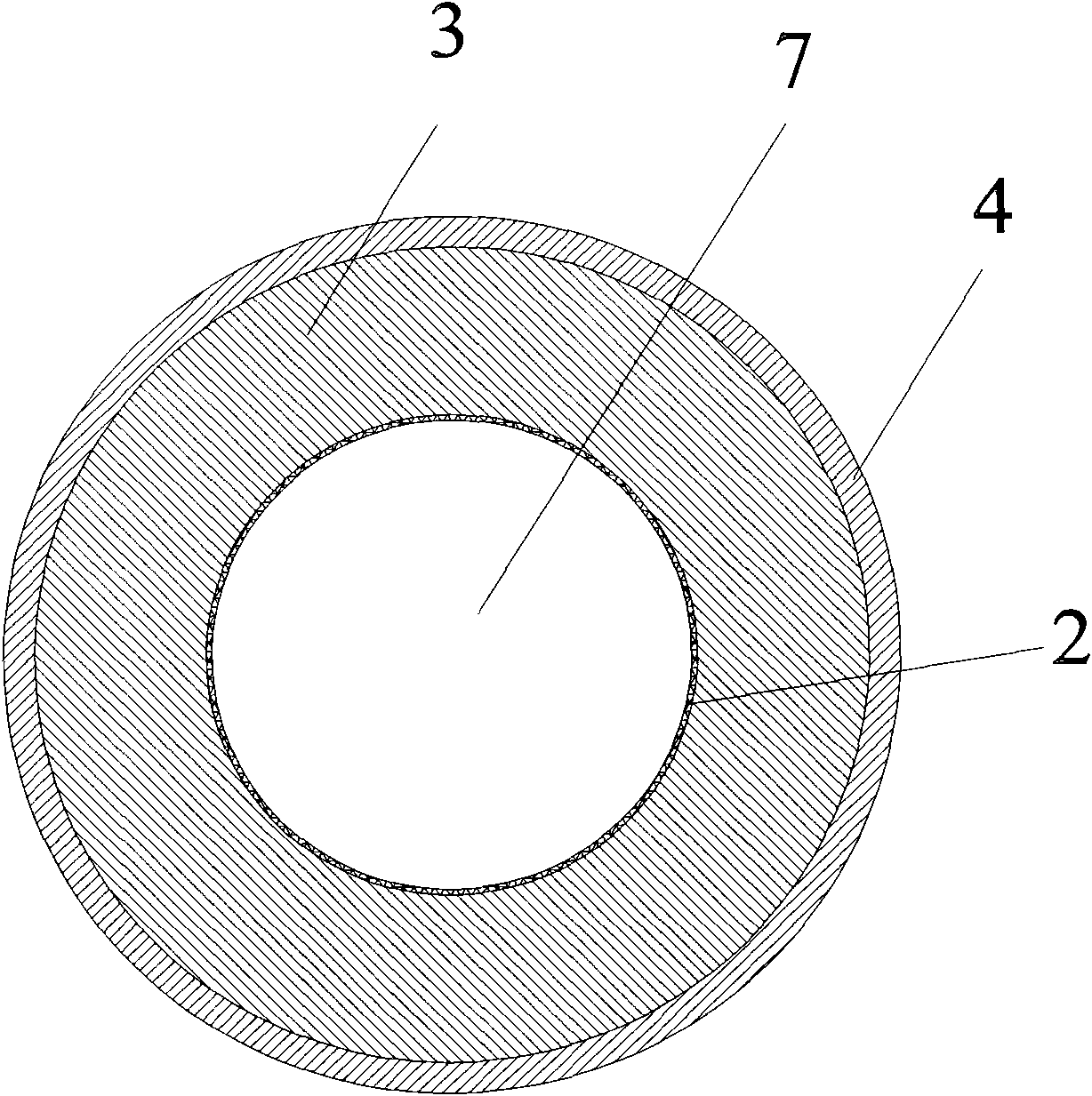

Pressure-compensated rotary joint

The invention relates to a pressure-compensated rotary joint, which belongs to the technical field of compensators. The rotary joint mainly comprises an outer sleeve, an inner tube and a gland flange, wherein a thrust ring and a connection baffle ring are fixed in the outer sleeve; a first baffle ring and a second baffle ring are fixed on the periphery of the inner tube, and the wall of the inner tube is provided with a through hole; the gland flange is provided with an extension ring; the end face of the first baffle ring is contacted with the thrust ring, and a rolling piece is installed between the end face of the second baffle ring and the opposite end face of the connection baffle ring; a seal ring is filled between the end face of the extension ring and the connection baffle ring, and a backing ring is installed in the extension ring; a sealing ring, of which the inner circle is provided with a groove, is installed between the first baffle ring and the second baffle ring; and the groove is communicated with the through hole in the wall of the inner tube. In the invention, a reliable double seal is formed by the seal ring and the sealing ring between the outer sleeve and the inner tube, and the abrasion of the sealing ring can be compensated, thereby effectively avoiding leakage at the movable joint of the pipeline for a long time.

Owner:AEROSUN CORP

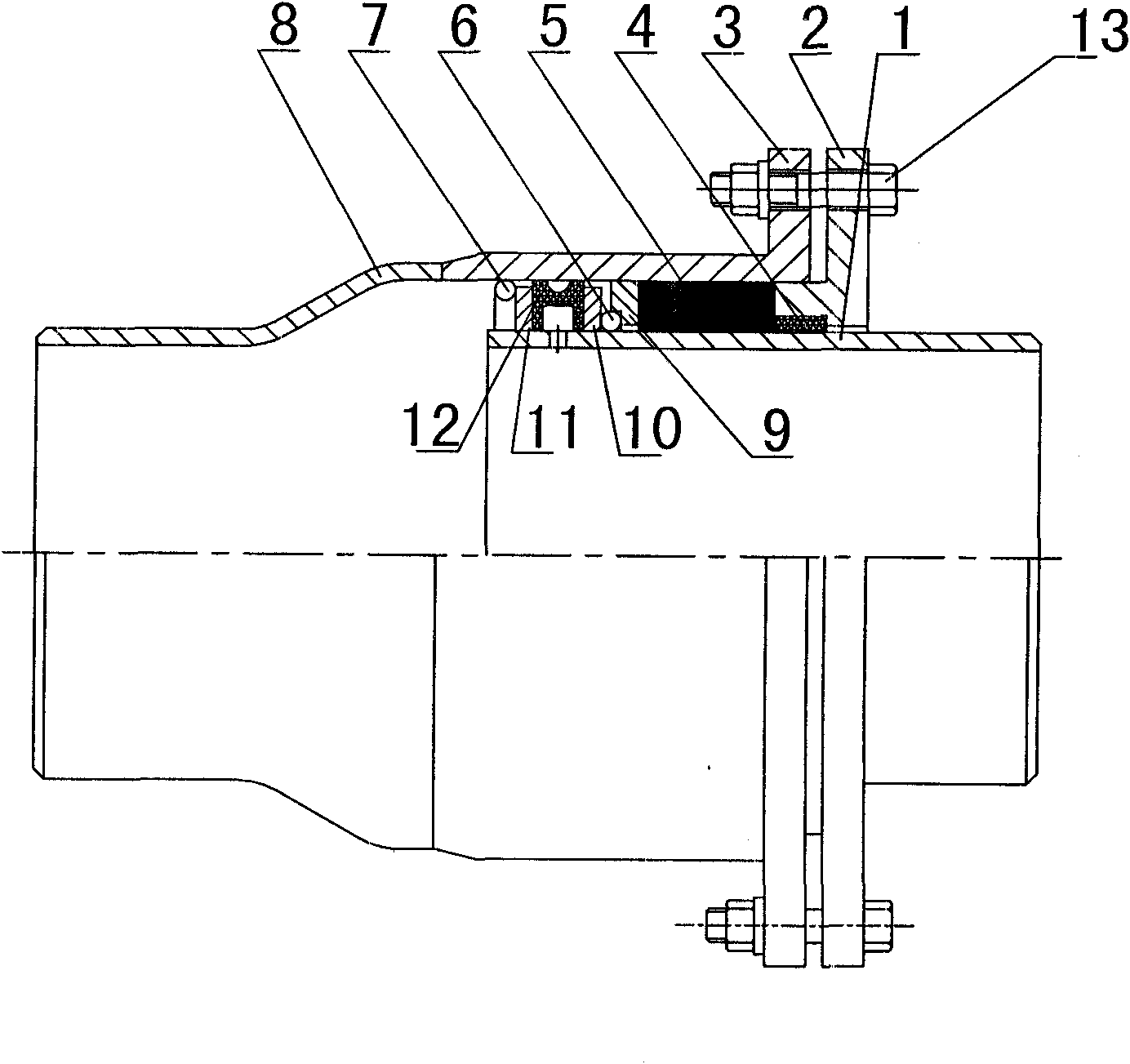

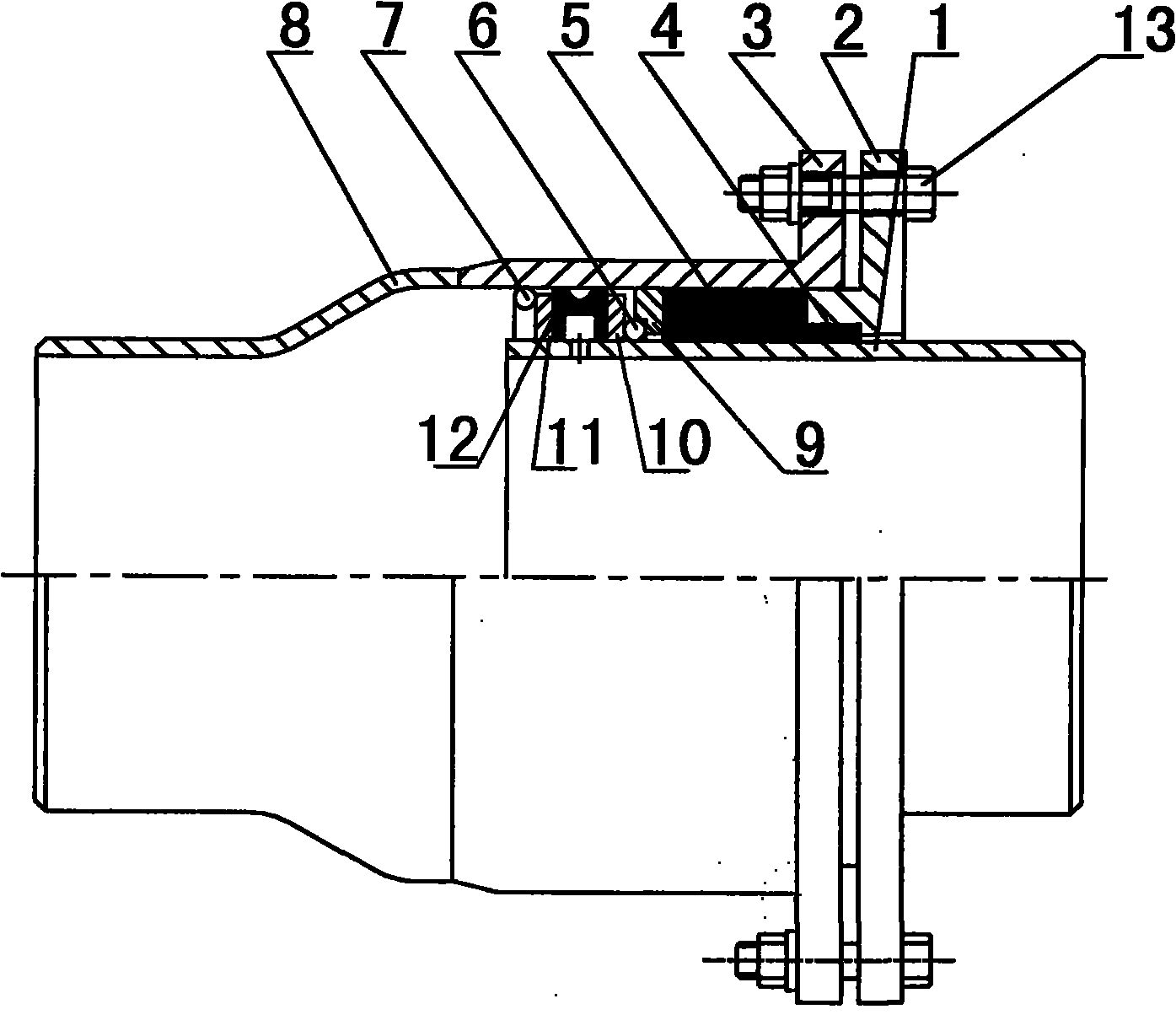

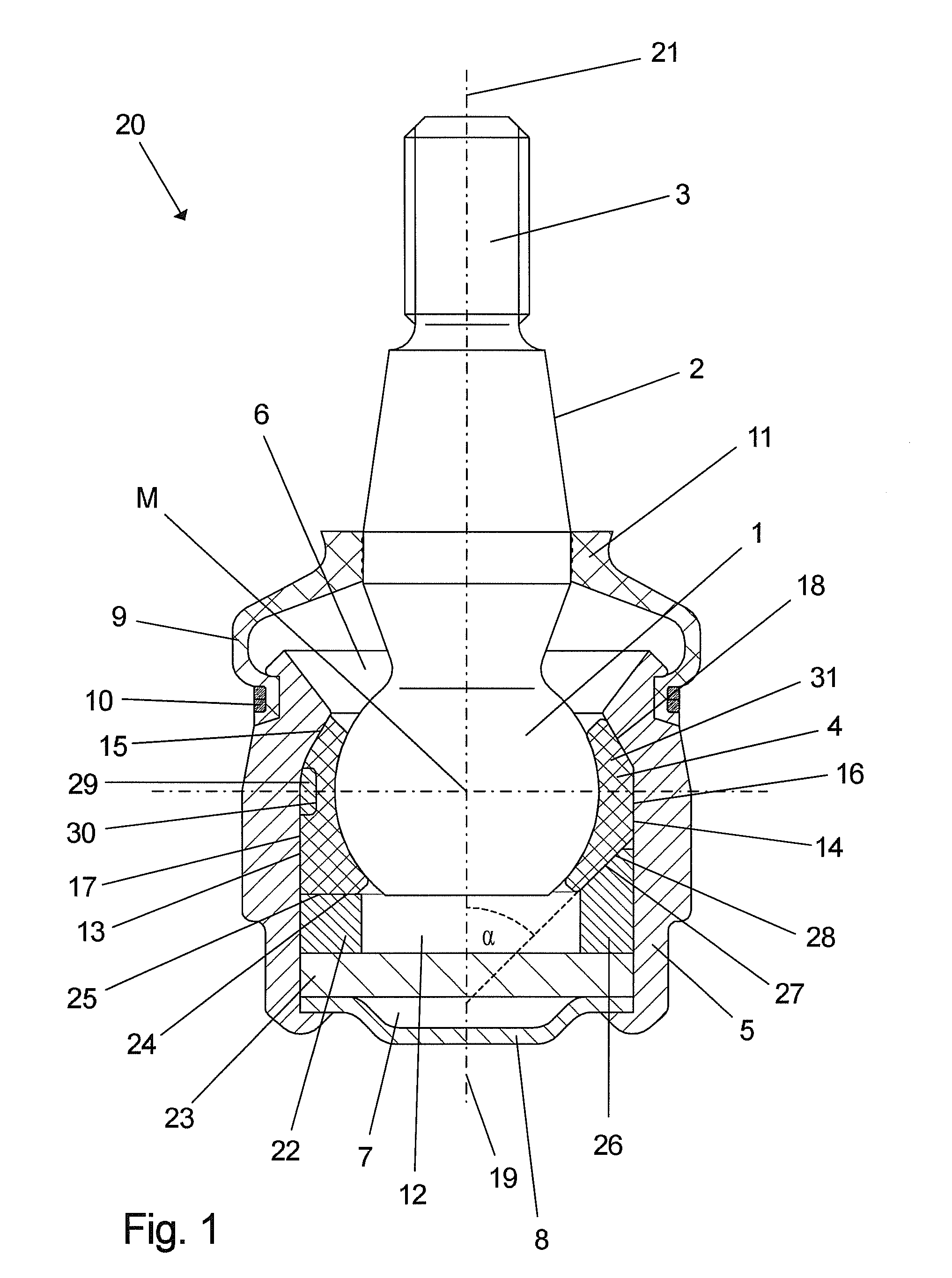

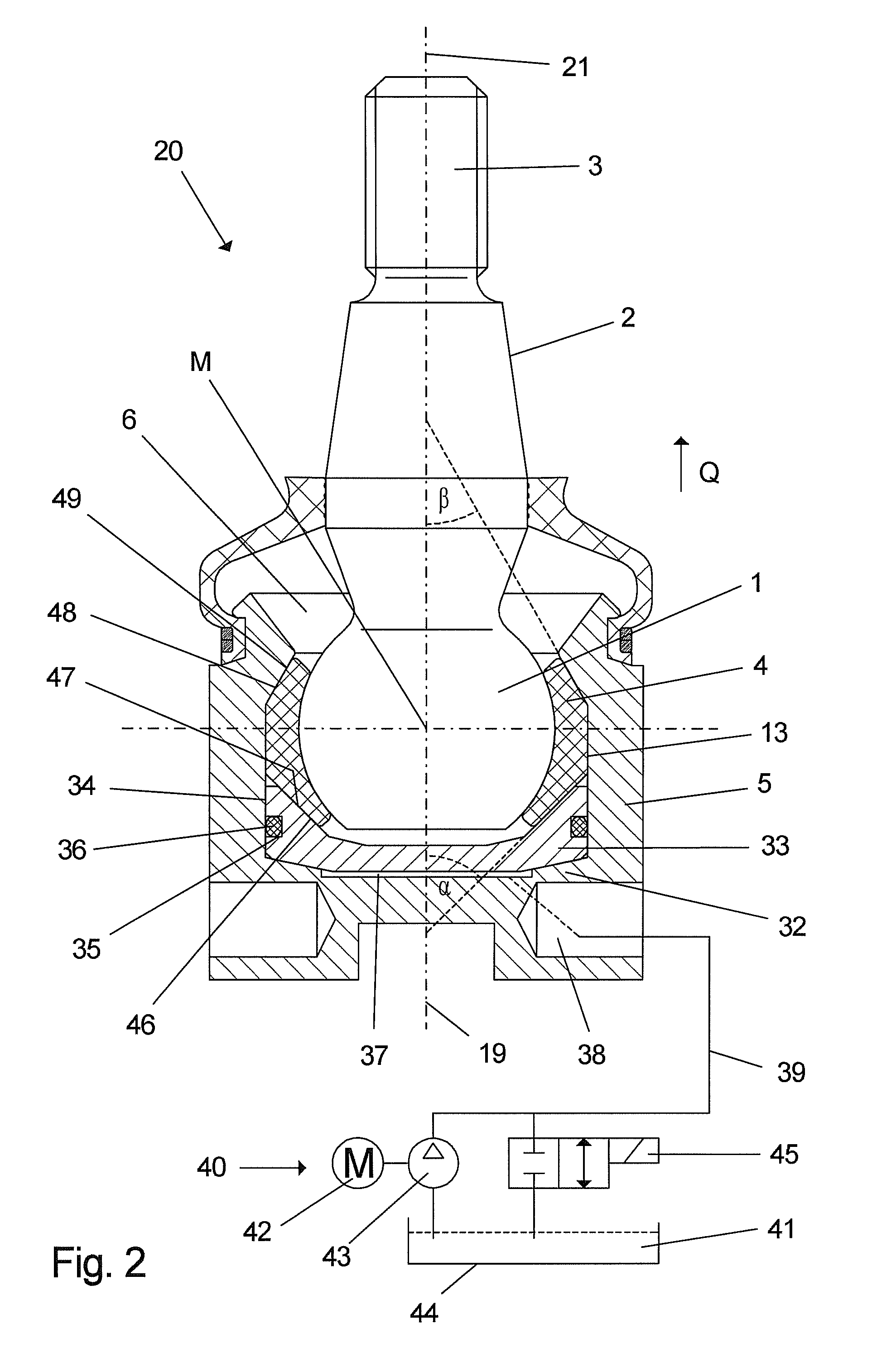

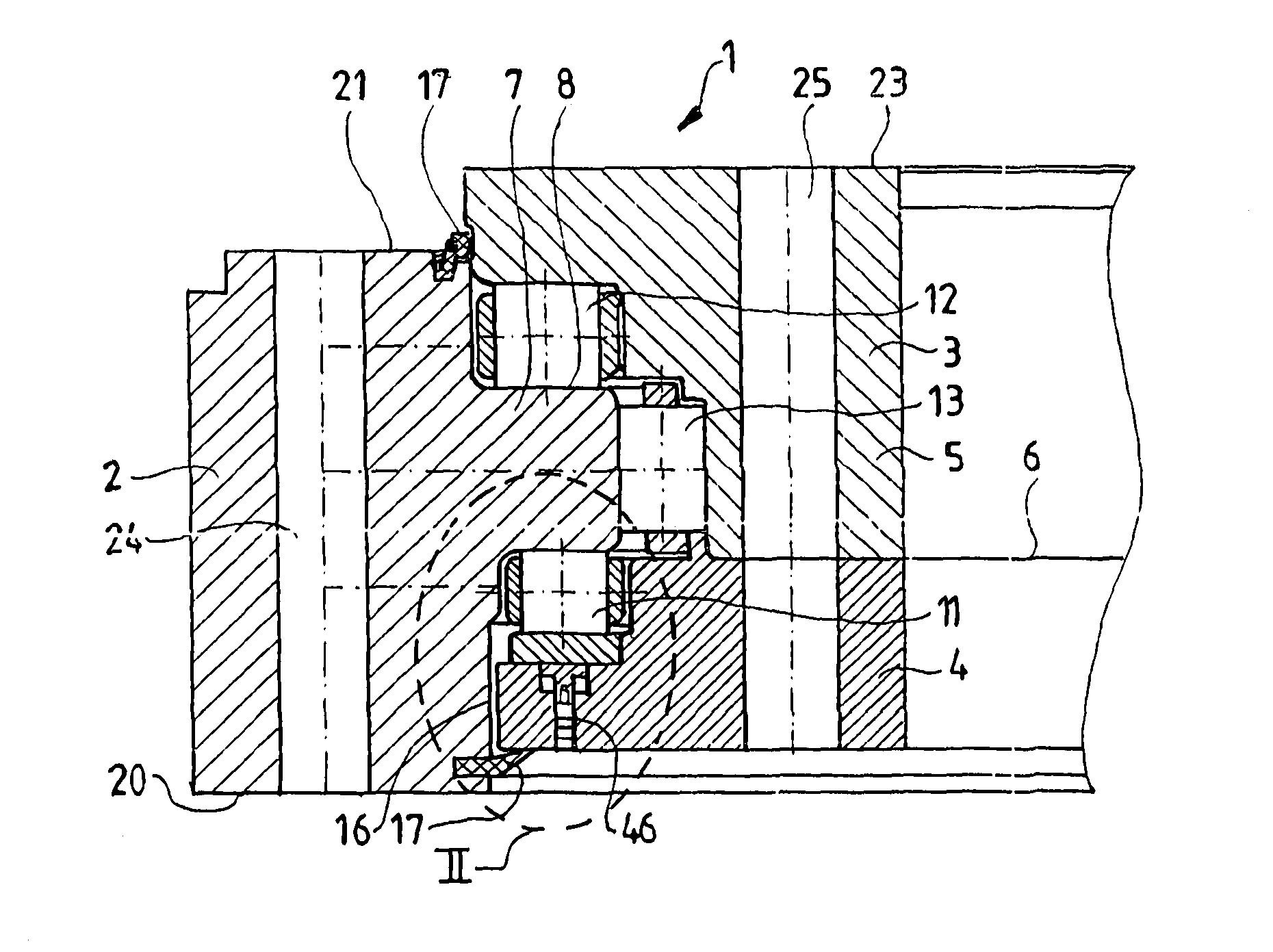

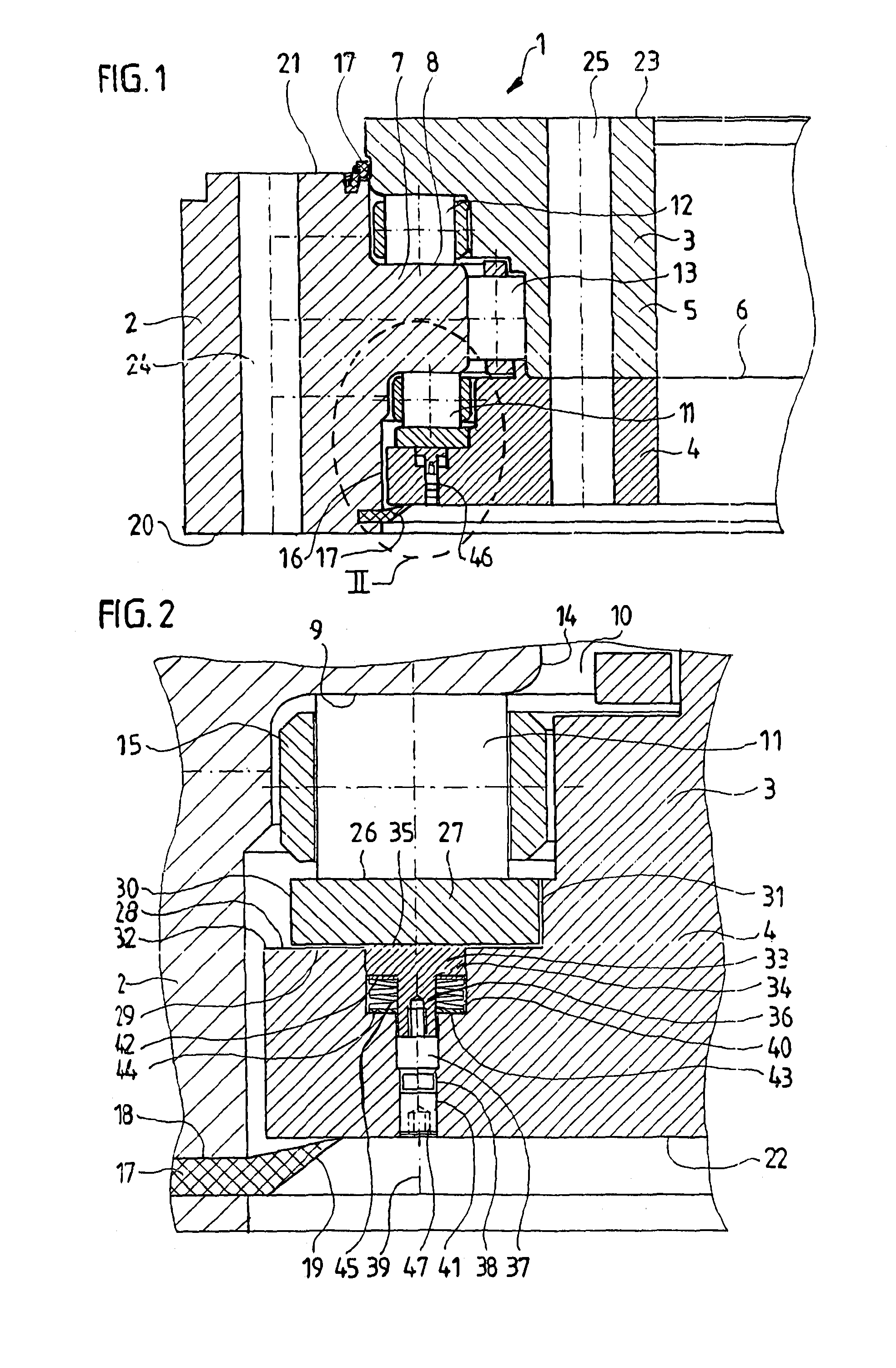

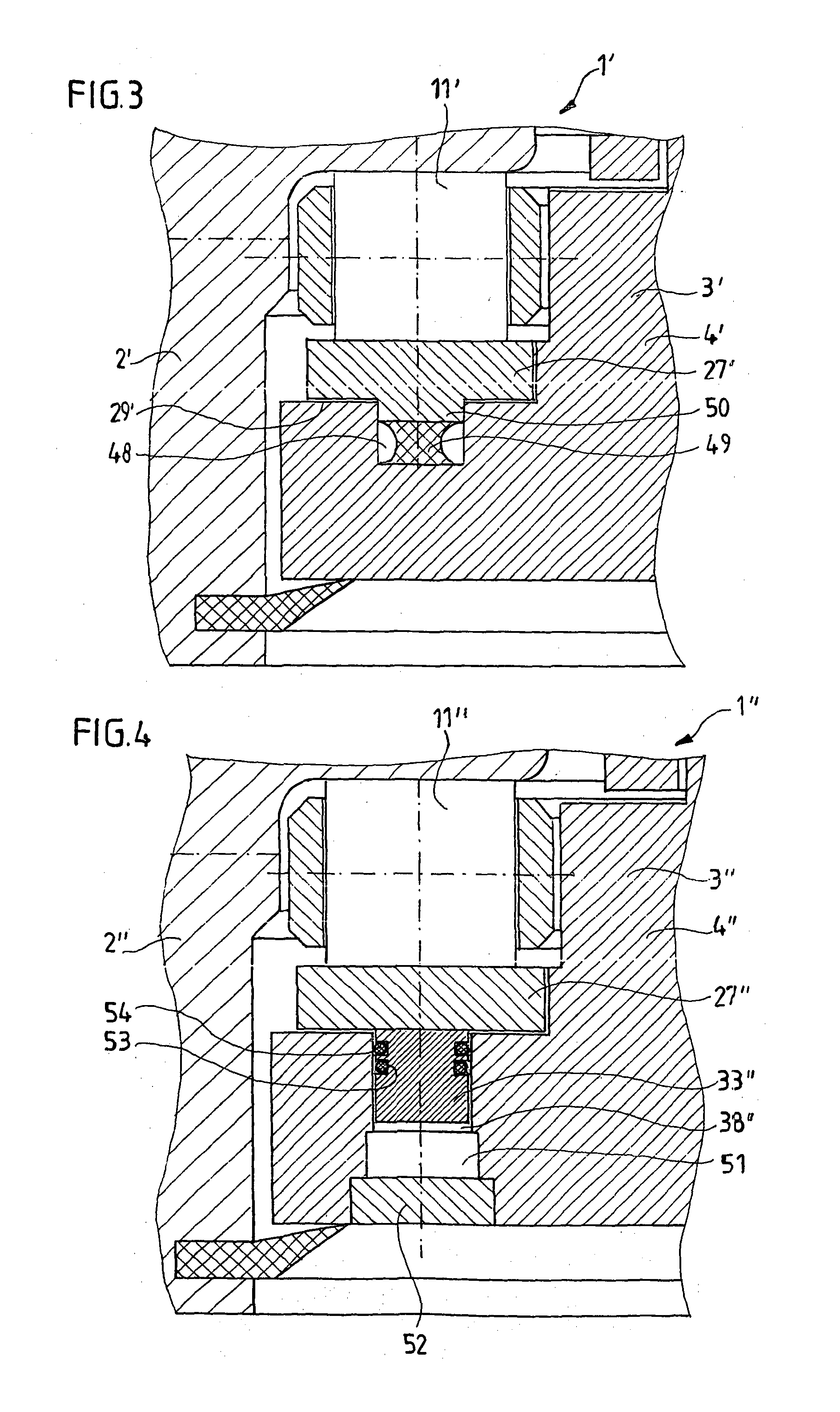

Joint for a motor vehicle

InactiveUS20090232590A1Easy to set upEasy constructionBearing assemblyShaftsEngineeringMotorized vehicle

A joint for a motor vehicle is provided with a housing (5), a bearing shell (4) arranged in the housing (5), a bearing journal (3), which has a bearing area (1) and a pivot area (2) and which is mounted pivotably and / or rotatably in the bearing shell (4) with the bearing area (1). The joint has at least one tensioning device (33), which is arranged in the housing 5, is designed as a solid body and by which a mechanical stress exerted by the bearing shell 4 on the bearing area 1 can be changed. The bearing shell 4 is springy at least in some areas and is deformable by the tensioning means 33 in a springy manner.

Owner:ZF FRIEDRICHSHAFEN AG

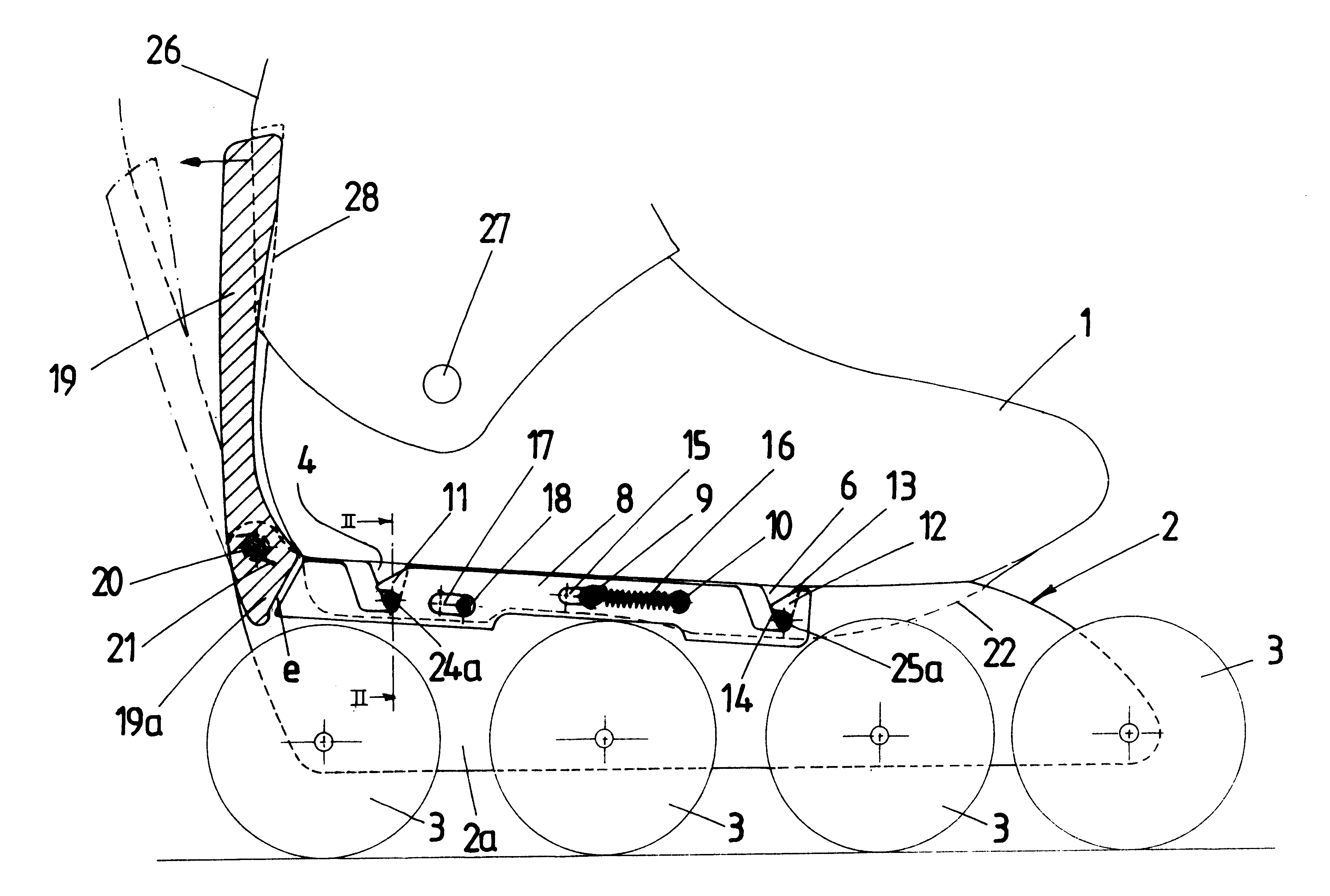

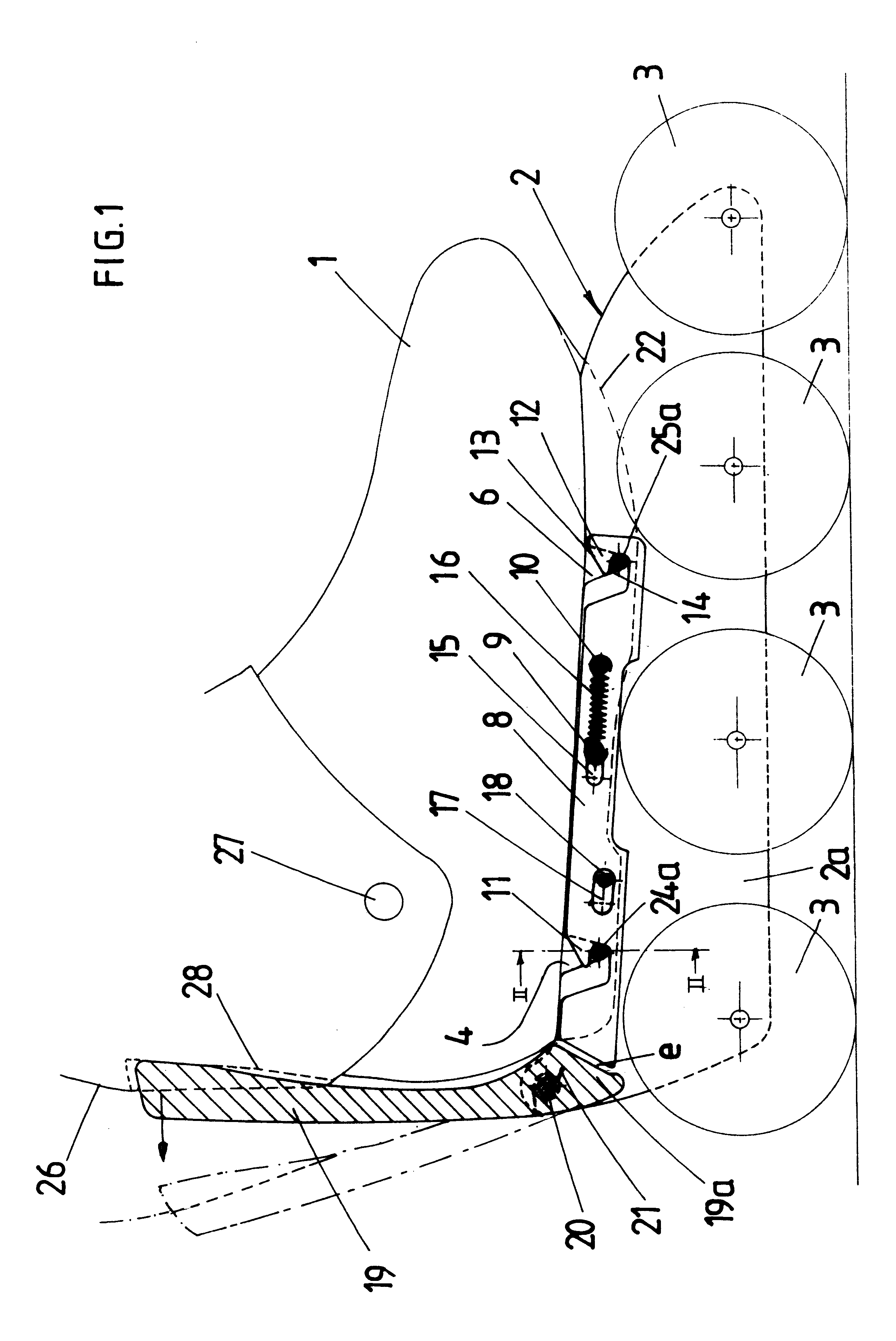

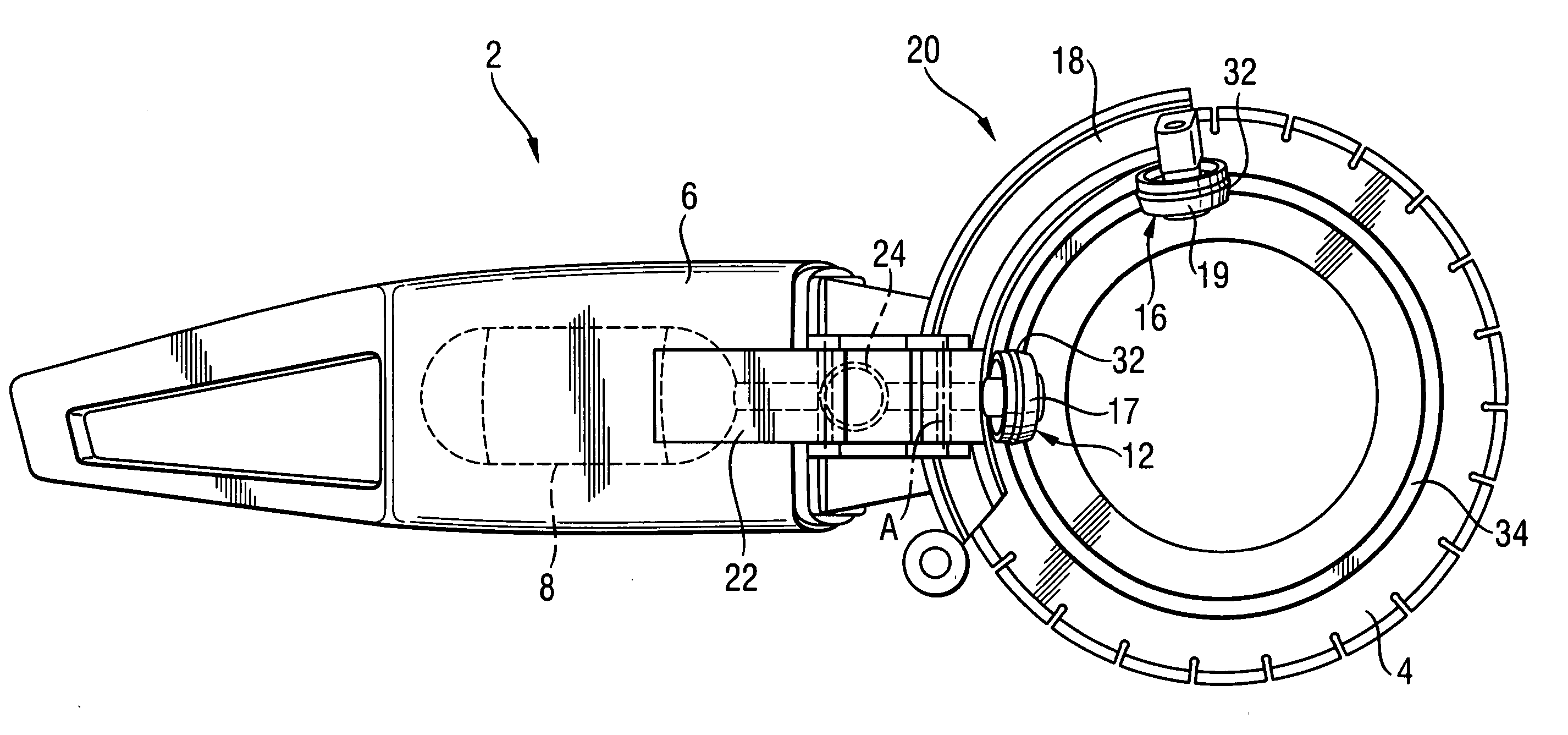

Roller skate with removable boot

Roller skate comprising a chassis (2) equipped with rollers (3) and a boot (1) attached removably to the chassis at four points by catching and locking. Catching and locking are achieved automatically and simultaneously at all of the attachment points using a common element (8) subject to the action of an elastic means (16). Unlocking is achieved using a lever (19) articulated to the rear of the chassis and which can be used as a handle when putting the chassis on.

Owner:SKIS ROSSIGNOL

Sealing device of vacuum moving element

InactiveCN101994836ALow movement resistanceGood sealing performanceEngine sealsMotion resistanceEngineering

The invention provides a sealing device of a vacuum moving element, which comprises a moving element and a sealing ring matched with the moving element, wherein the inner hole wall of the sealing ring, matched with the moving element, is provided with a plurality of annular storing slots; the inner hole wall and the storing slots are all provided with sealing grease layers or lubricant layers; the outer wall of the sealing ring is provided with a plurality of outer ring slots; a sealing circle is embedded into each outer ring slot; and the sealing circles are matched with the sealing inner wall of a cavity body. The sealing device has the bidirectional sealing property, in particular the sealing of excellent sealing property in the frequent large-travel reciprocating motion for a long time under the vacuum or high pressure difference conditions; the inner hole wall of the sealing ring is provided with the storing slots capable of storing a certain amount of sealing grease or lubricant to effectively supplement the sealing grease or the lubricant taken way by the motion of the moving element so as to maintain the excellent sealing property at the same time of reducing motion resistance; and the pretightening force is supplied through the deformation of the sealing circle, the sealing circle can supplement the abrasion of the sealing ring, and thus, the service life of the sealing ring is prolonged.

Owner:FOSHAN JUSHITAI POWDER METALLURGY CO LTD

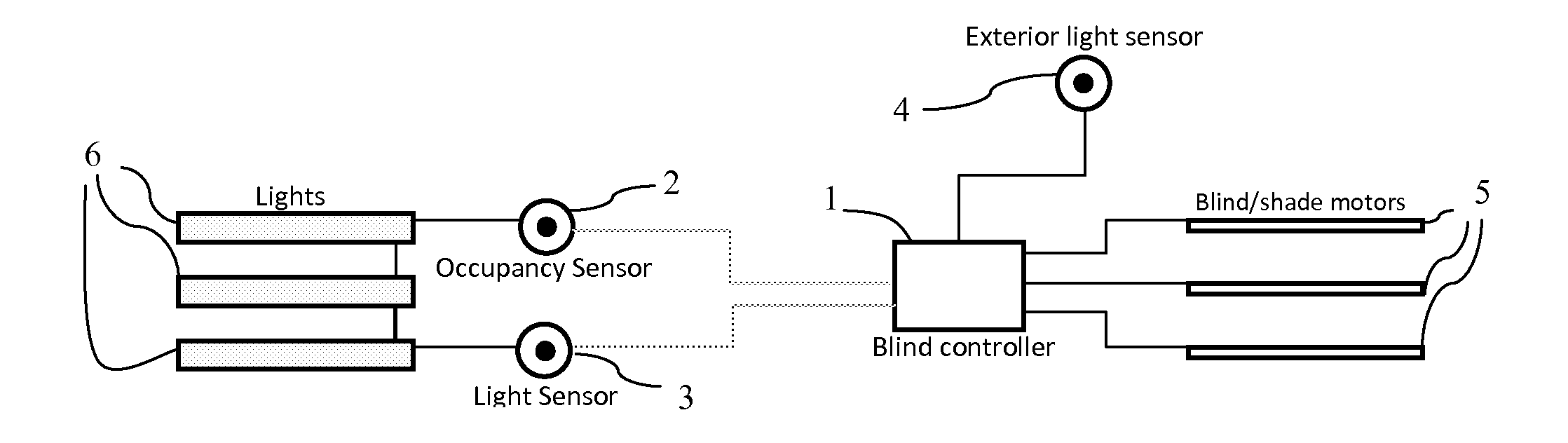

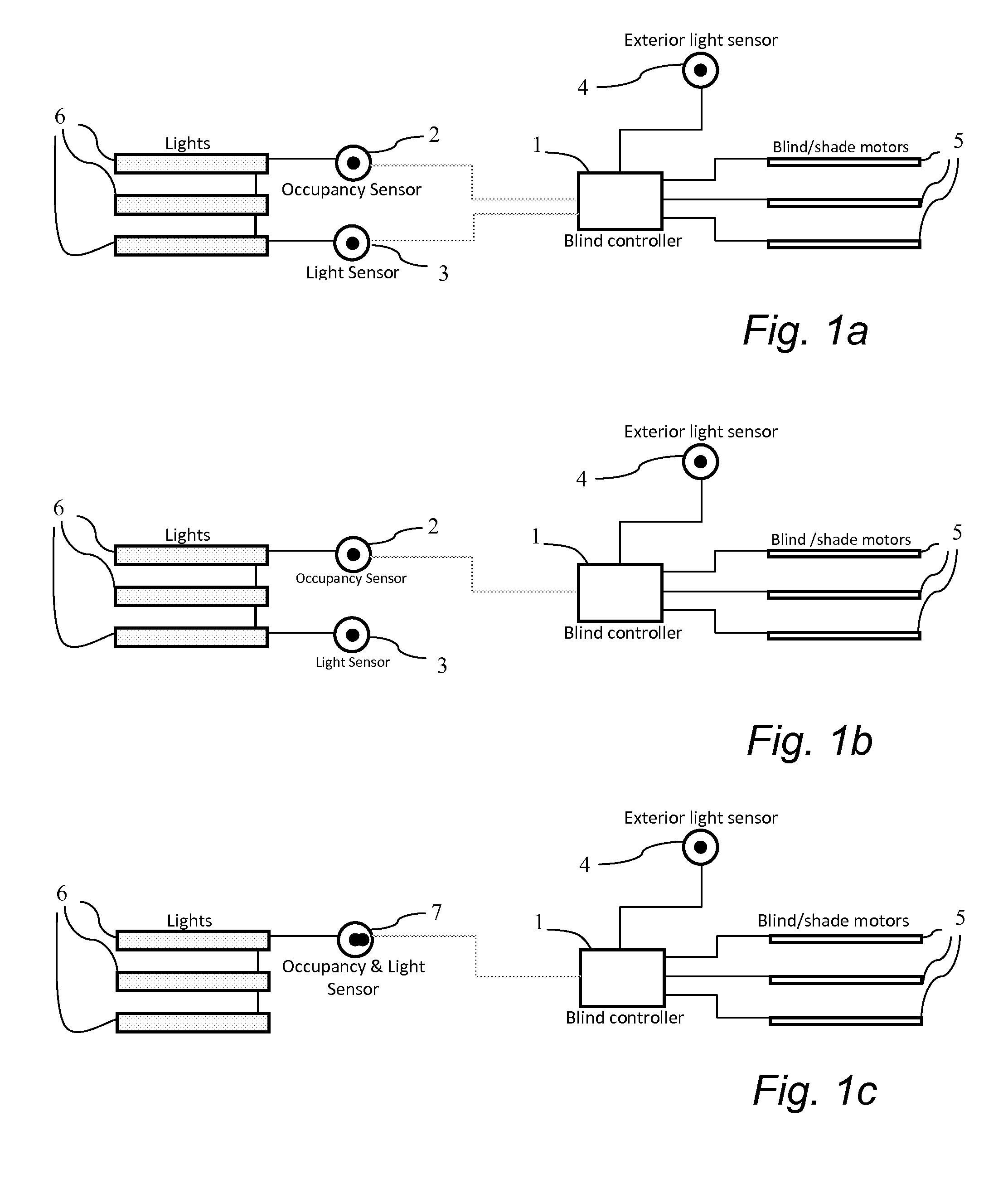

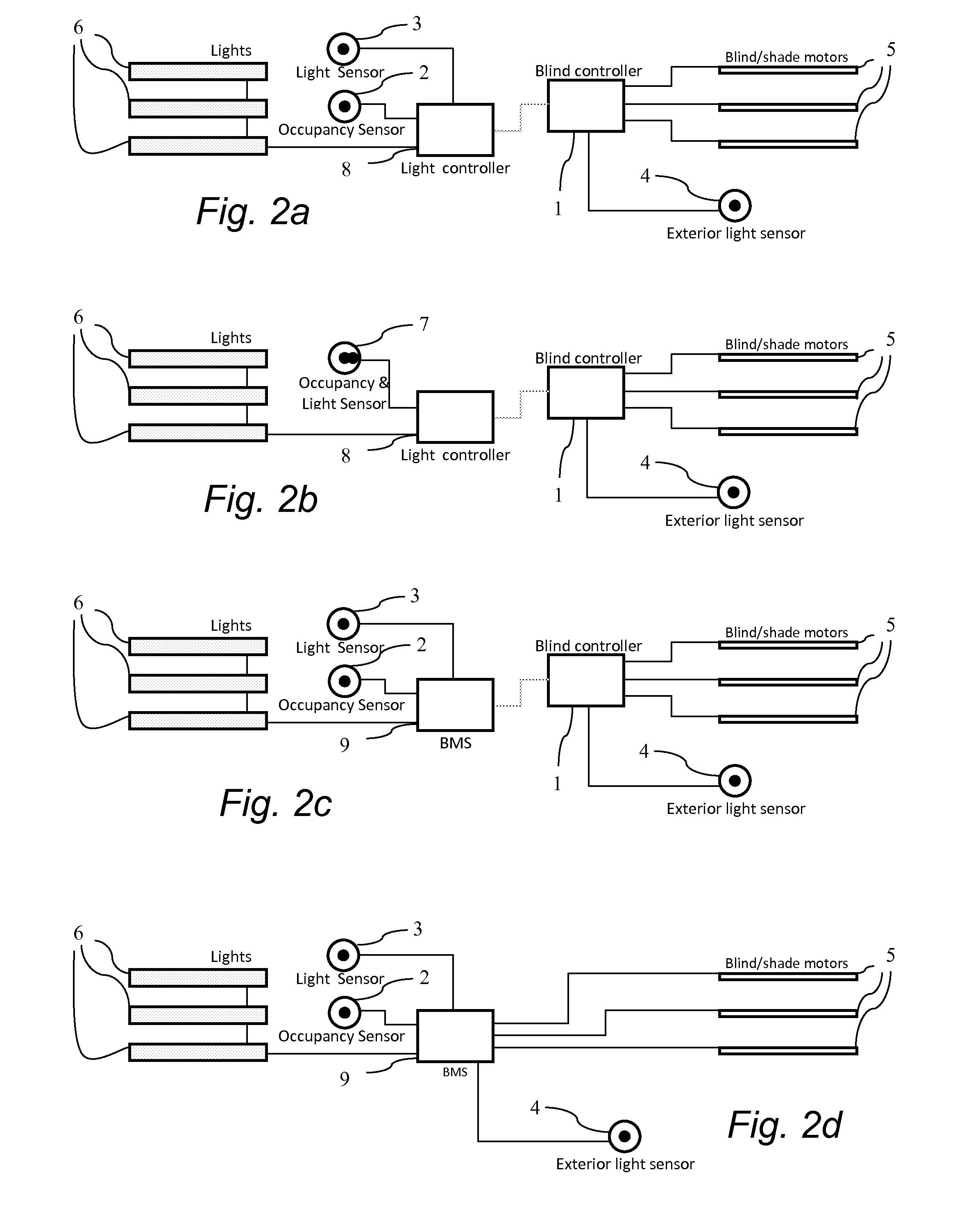

Auto-calibration of blinds systems in buildings

ActiveUS20140338844A1Assure maximum comfort and energy saving over longer periods of timeCompensation for wearCurtain accessoriesClimate change adaptationControl systemEmbedded system

The present invention relates to a control system for automatic calibration of a blinds system installed in a room, comprising: a controller (1, 8, 9) having a memory, a clock and a processor, an occupancy sensor (2, 7), an interior light sensor (3, 7), an exterior light sensor (4). The control system is characterised in that the control system is arranged to run an automated calibration of the blinds system when the exterior light sensor indicates an outside light level above a predetermined threshold, the occupancy sensor indicates that no person is present in the room, and a predetermined time has passed since the last calibration. The invention further relates to a method for automatic calibration of a blinds system installed in a room using a control system comprising a controller (1, 8, 9) having a memory, a clock and a processor, an occupancy sensor (2, 7), an interior light sensor (3, 7), an exterior light sensor (4), the method comprising the step of: running an automated calibration of the blinds system when the exterior light sensor (4) indicates an outside light level above a predetermined threshold, the occupancy sensor (2, 7) indicates that no person is present in the room, and a predetermined time has passed since the last calibration.

Owner:SIGNIFY HLDG BV

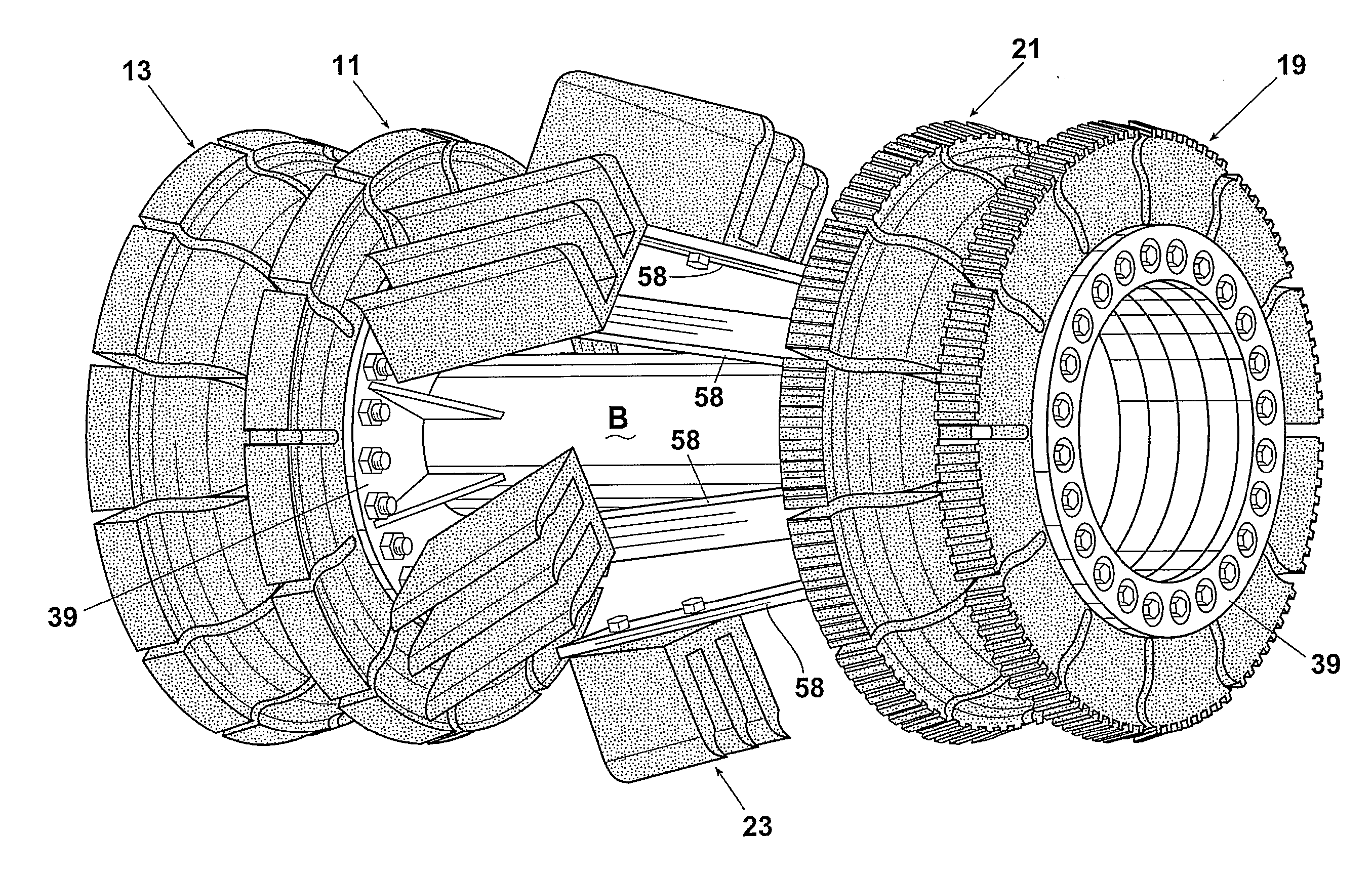

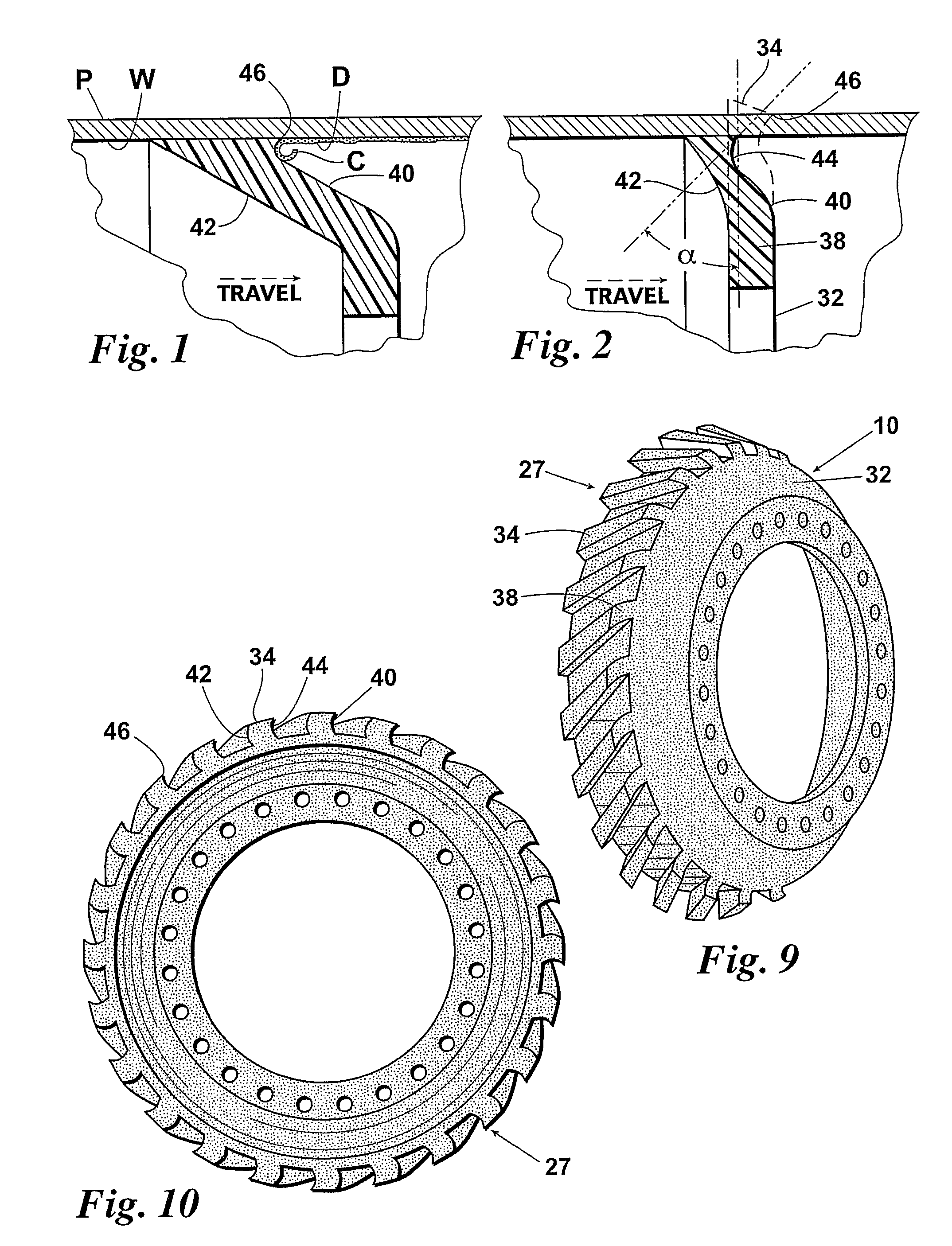

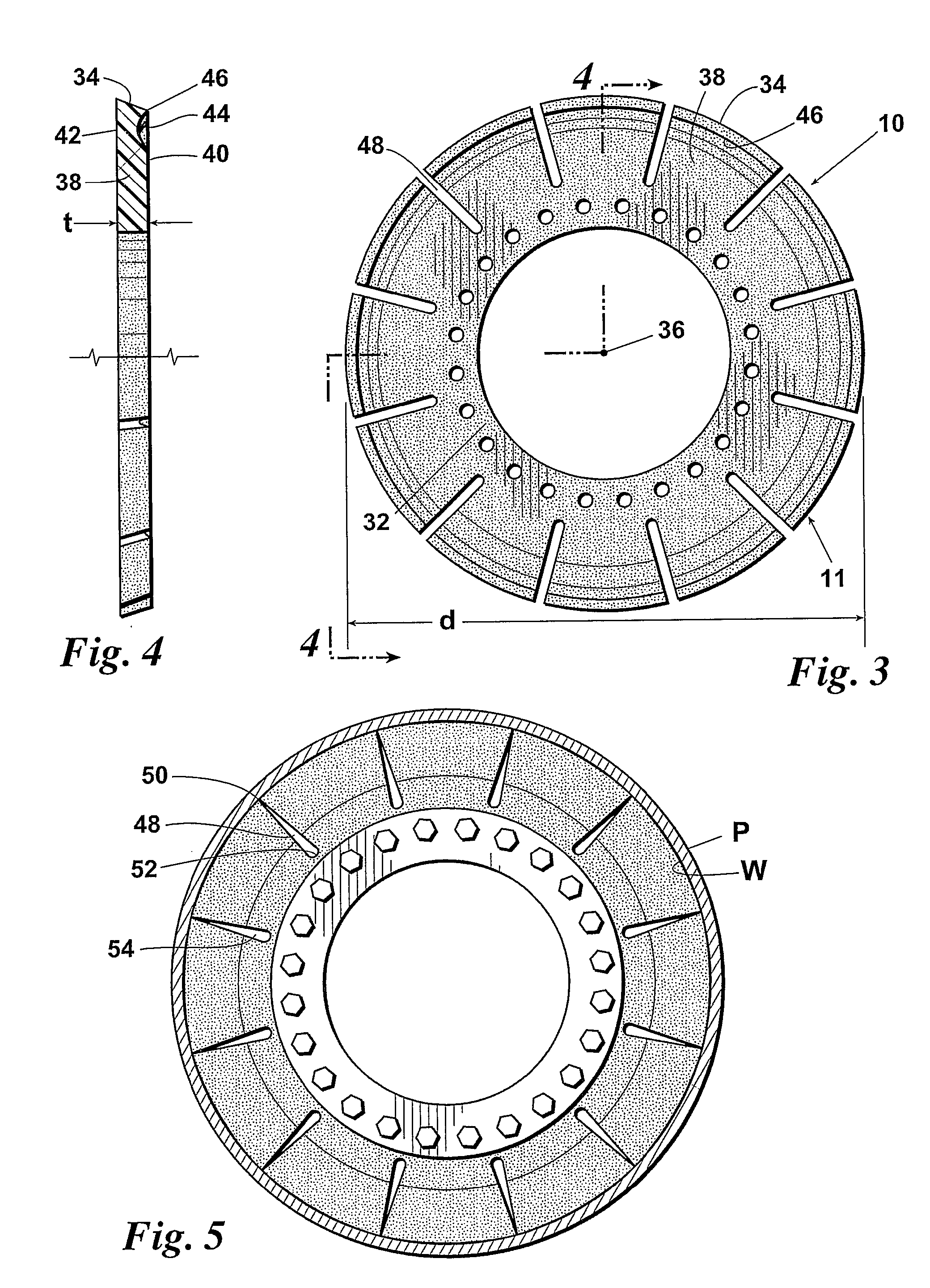

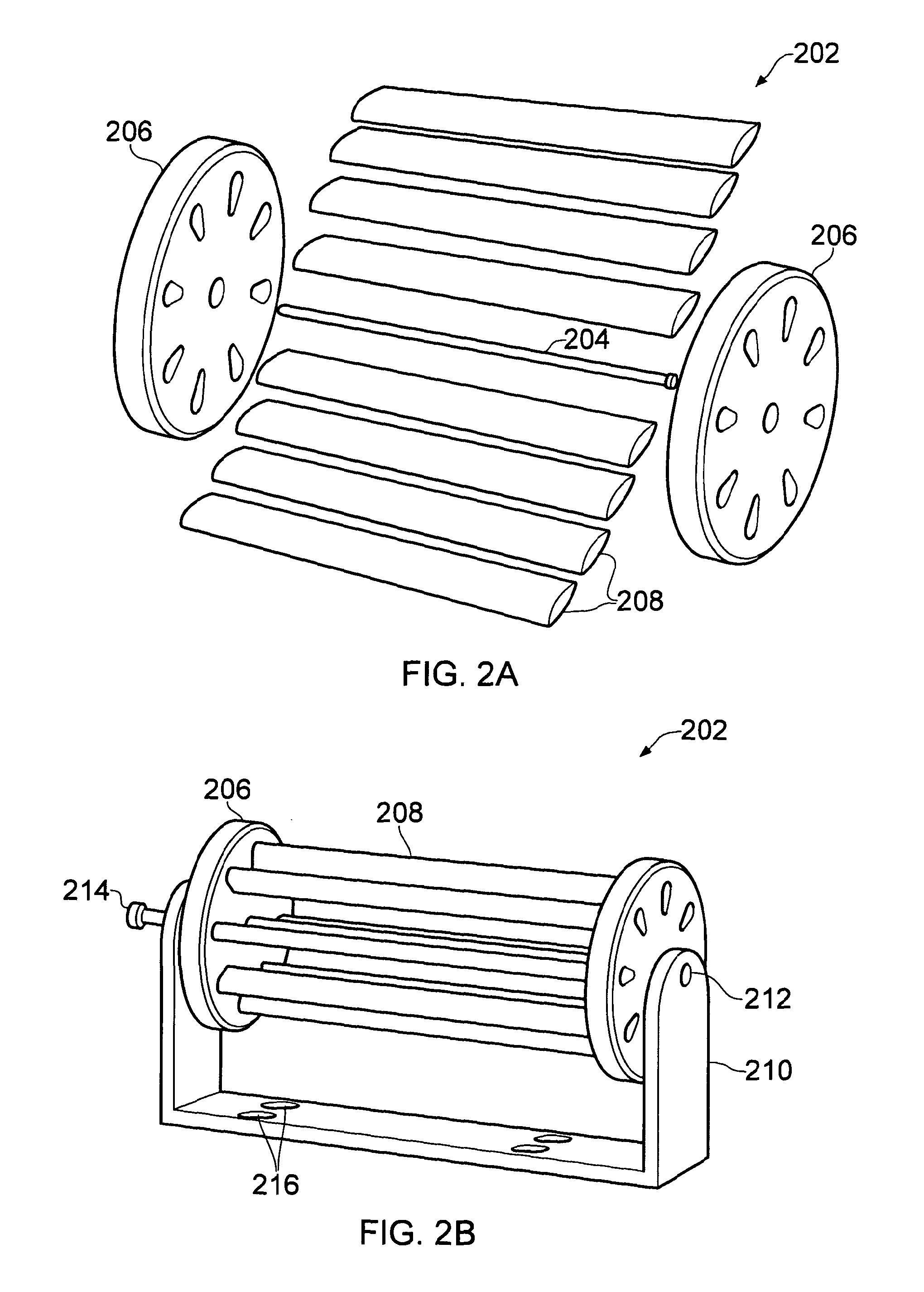

Pipeline Debris Shearing Device

ActiveUS20120017386A1Avoid progressive build upCompensation for wearHollow article cleaningCleaning using toolsMechanical engineeringElastomer

A pipeline debris shearing device includes a forwardly positioned, self sharpening, wear compensating, diameter conforming elastomeric member that forms a peeling edge having a negative rake angle to peel away debris from the internal wall of a pipeline. The peeling edge is formed at the point of meeting between a concave-shaped, curved forward face surface and a substantially straight outer peripheral surface. Radial slots may be provided to lessen the force being exerted on the peeling edge and provide for bypass flow to carry away debris removed by the peeling edge. Spaced-apart narrow stripper teeth may be added to help in removing harder deposits of debris. The peeling edge may be arranged substantially perpendicular the central longitudinal axis of the pipeline pig or arranged oblique to it. Further, the peeling edge may spiral about at least a portion of the pipeline pig.

Owner:TDW DELAWARE INC

generator

ActiveUS20120175879A1Reduce riskCompensation for wearPump componentsEngine fuctionsEngineeringTurbine

A wind turbine assembly comprising, an elongate generally cylindrical rotor operable to rotate about an axis, an elongate rotor housing that houses the rotor and which is adapted to be secured to a roof, and a flow regulator adapted to regulate wind flow to the rotor, wherein the flow regulator is orientatable in an open orientation, a closed orientation and a partially open orientation.

Owner:THE POWER COLLECTIVE INC

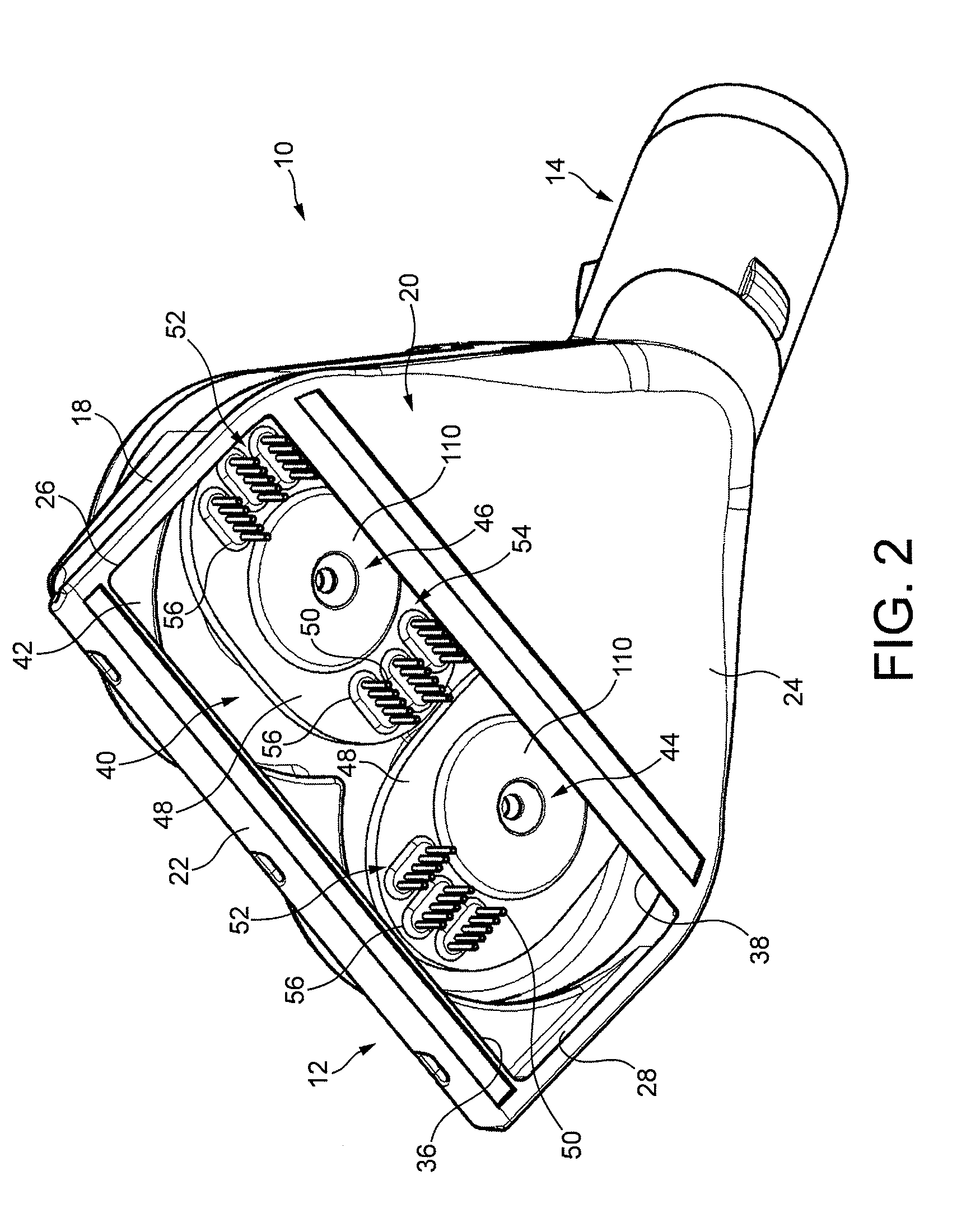

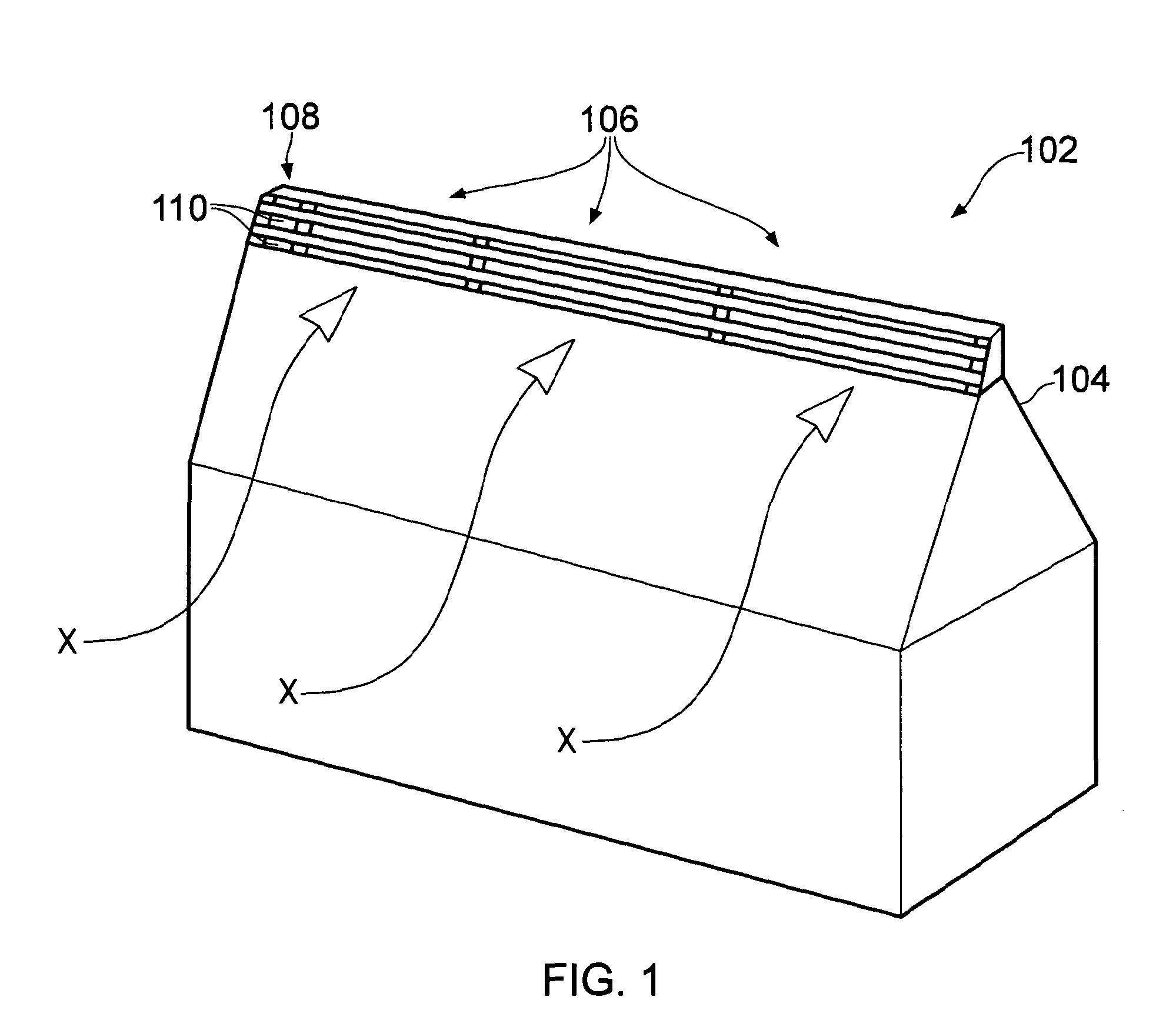

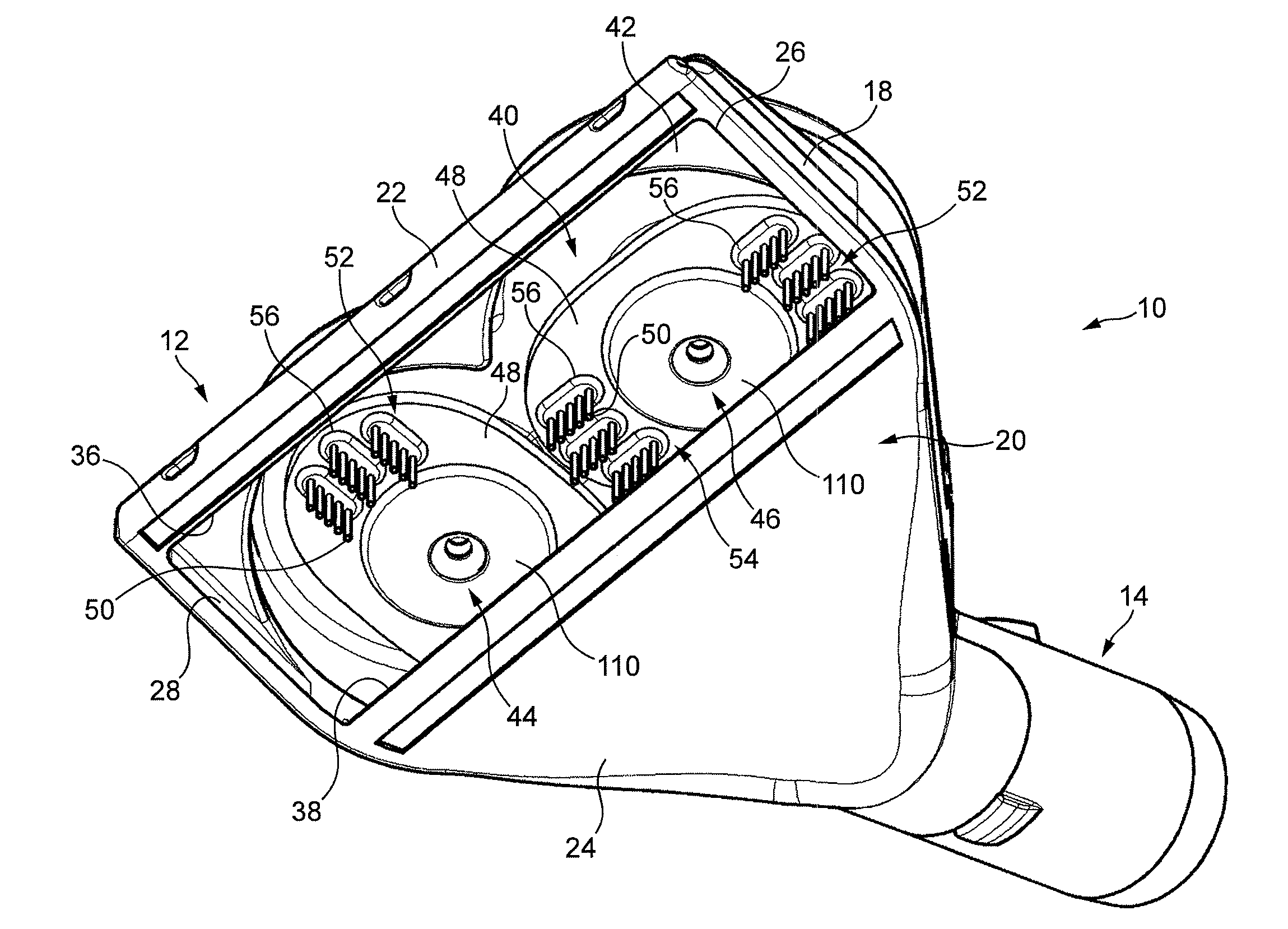

Cleaner head

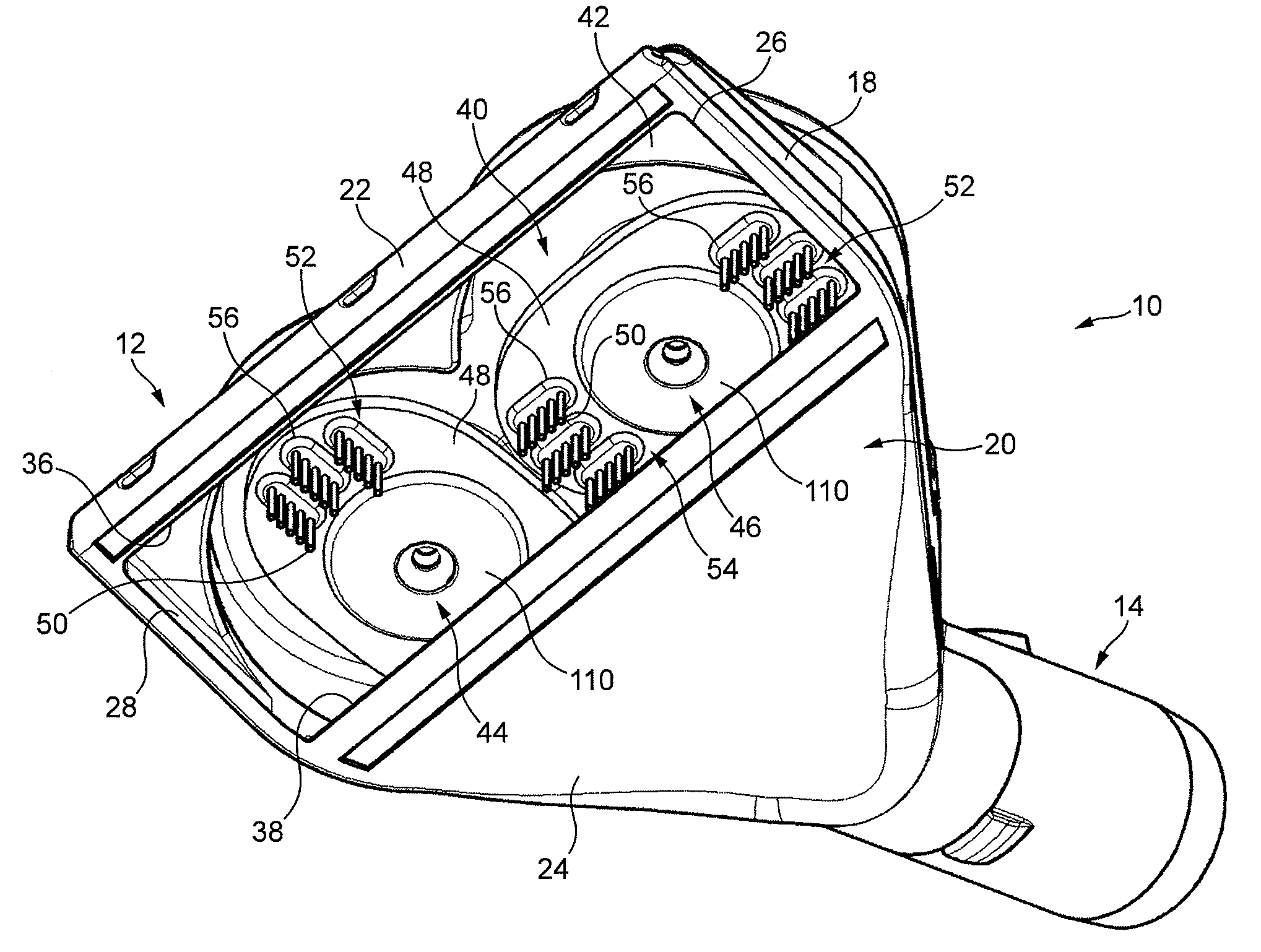

InactiveUS20120144619A1Easy to useMaximize likelihoodCarpet cleanersFloor cleanersBristleEngineering

A cleaner head for a vacuum cleaning appliance includes a first rotatable agitator and a second rotatable agitator for sweeping debris from a surface, each agitator comprising a disc-shaped body and a plurality of resilient members, preferably in the form of bristles, mounted on the body for engaging the surface. The agitators are housed within an agitator chamber which includes a downwardly-directed opening through which debris energized by the bristles enters the cleaner head. The opening is located in a plane, and each body is inclined relative to the plane of the opening so that, with rotation of the agitator, the bristles protrude through the opening. The bristles of the first agitator are angularly offset from the bristles of the second agitator.

Owner:DYSON TECH LTD

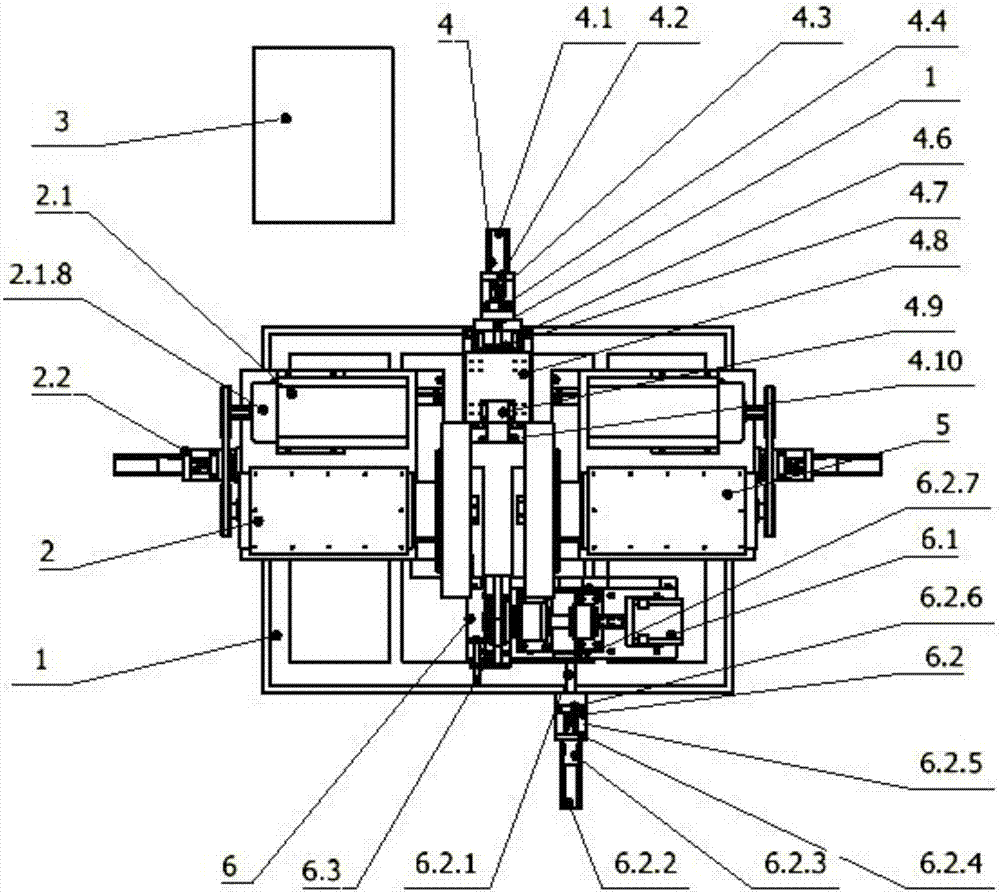

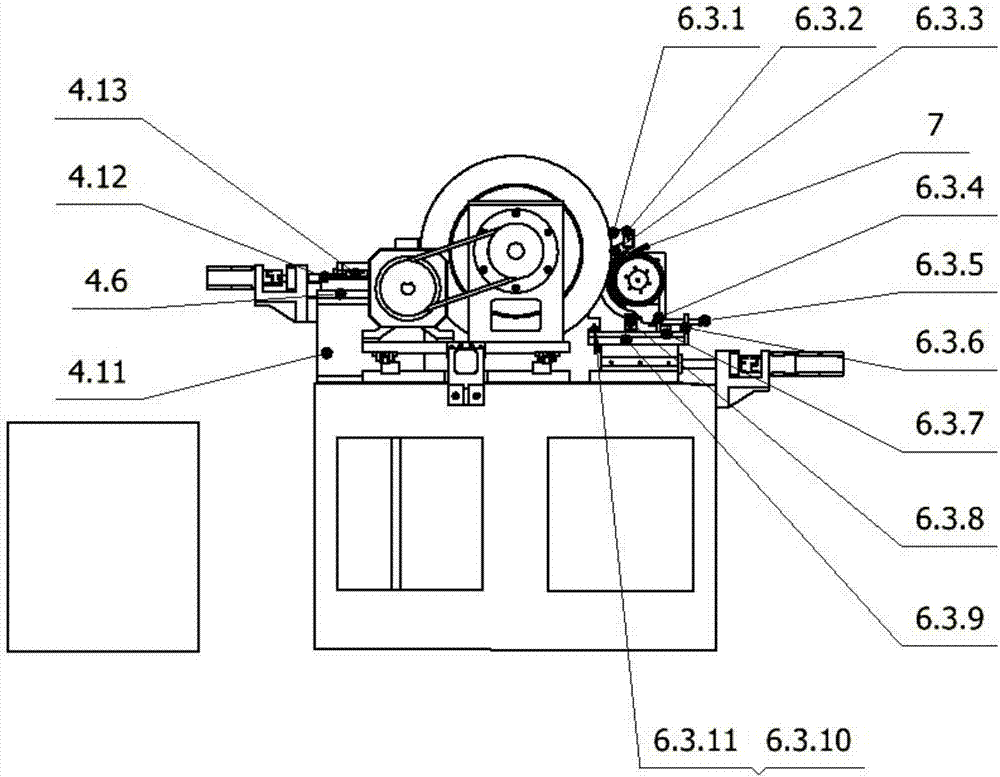

Method for utilizing self-made grinding machine to grind two end faces of aligning roller simultaneously

ActiveCN107363691AHigh precision of finished productImprove grinding qualityGrinding carriagesAbrasive surface conditioning devicesNumerical controlElectrical control

The invention provides a method for utilizing a self-made grinding machine to grind the two end faces of an aligning roller simultaneously. The self-made grinding machine comprises a lathe bed, a left grinding wheel device, a right grinding wheel device, a die rotary disc device, a grinding wheel dressing device and an electrical control box. The electrical control box implements control and enables the self-made grinding machine to achieve numerical control. The self-made grinding machine can grind the two end faces of the aligning roller simultaneously, abrasion to two grinding wheels is corrected by means of the grinding wheel dressing device assembled on the self-made grinding machine, and the self-made grinding machine is integrated and has multiple functions. By means of the self-made grinding machine, the condition of grinding the two end faces of the aligning roller simultaneously is improved, the self-made grinding machine operates stably, the deviation of the length of the finished product aligning roller is reduced, the finished product precision of the aligning roller is improved, the quality of grinding the two end faces of the aligning roller is improved, and the precision of the two end faces of the aligning roller obtained after grinding can be up to over the national standard level II through detection.

Owner:LUOYANG LIBO NUMERICAL CONTROL TECH CO LTD

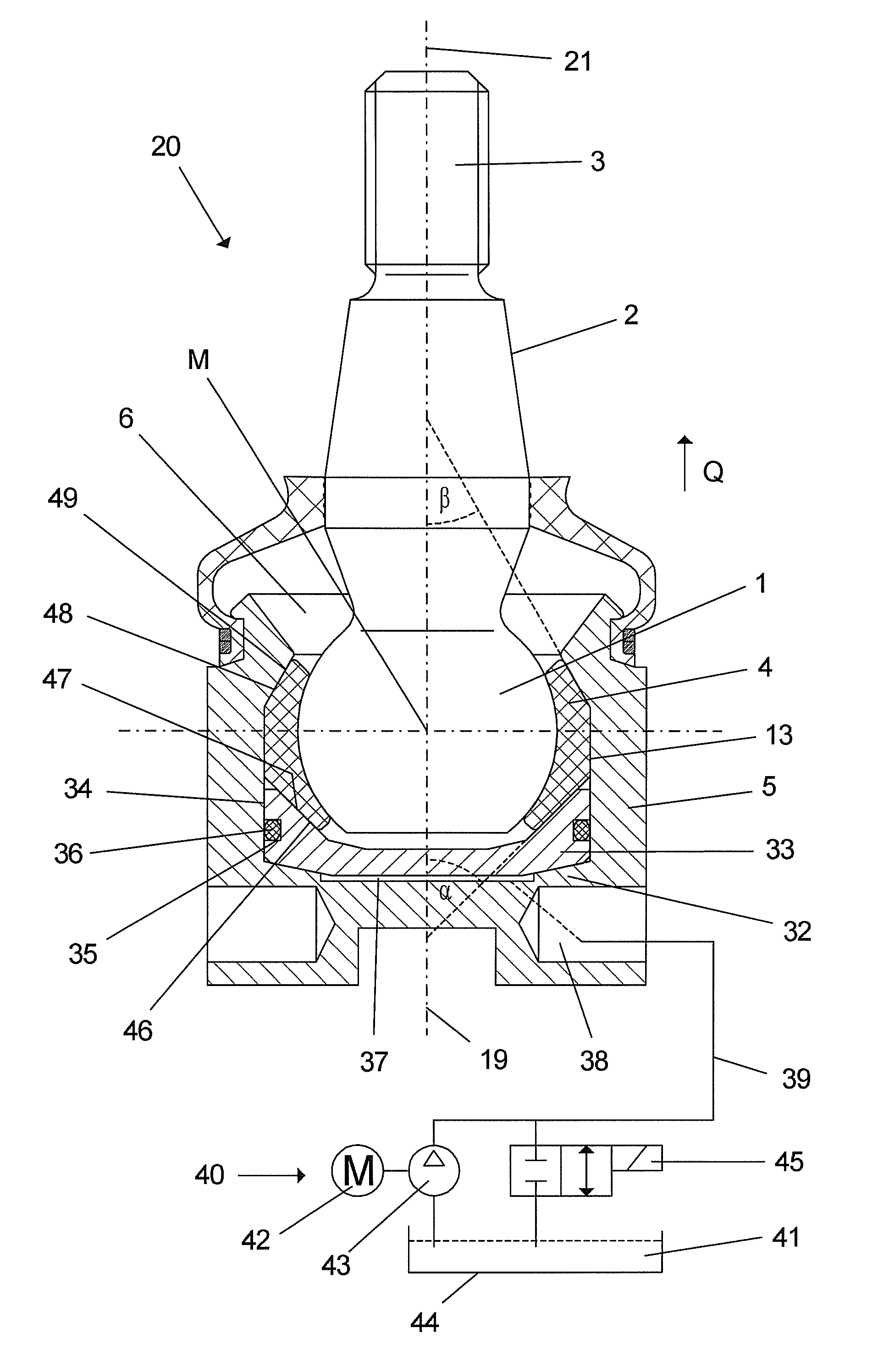

Rotor bearing for a wind power generating plant

ActiveUS20140023305A1Advantageous effect smoothnessReduce gapRolling contact bearingsShaftsPower stationRolling-element bearing

A rolling bearing, particularly a rotor bearing, or main bearing, for a wind power generating plant, the bearing having at least two mutually concentric rings separated from each other by a gap in which one or more rows of rolling elements roll along raceways on both rings, such that the two rings are rotatable in mutually opposite directions about their common axis, wherein each ring has at least one connection surface for connection to a foundation, wherein the connection surfaces extend parallel to one another and are passed through approximately perpendicularly by a plurality of fastening bores for receiving fastening bolts extending through them or screwed into them, wherein the raceway of at least one rolling-element row is formed on a part separate from the ring concerned and is pushed away from the ring concerned in a direction perpendicular to the connection surfaces, by at least one resilient element.

Owner:IMO HOLDING GMBH

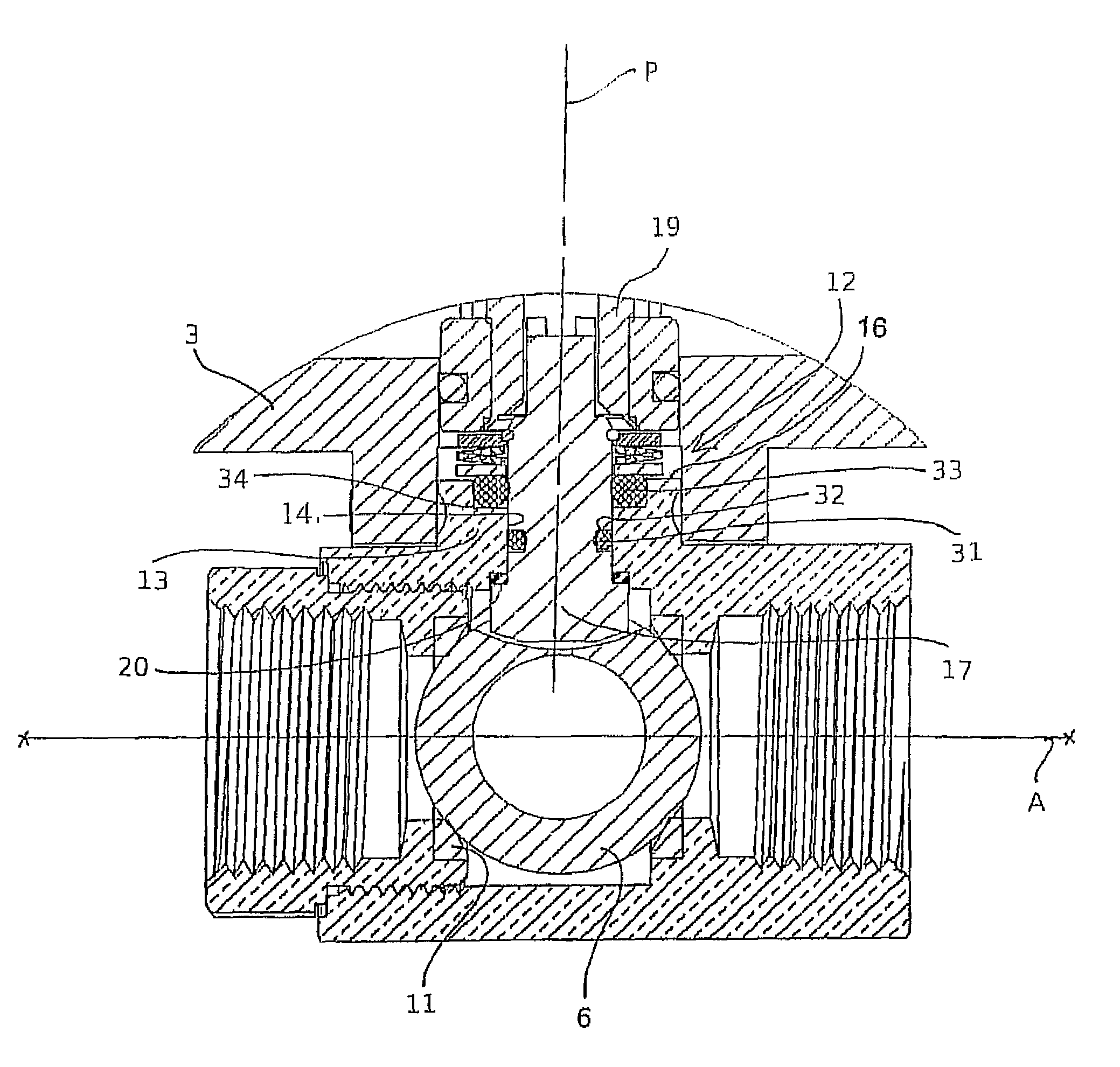

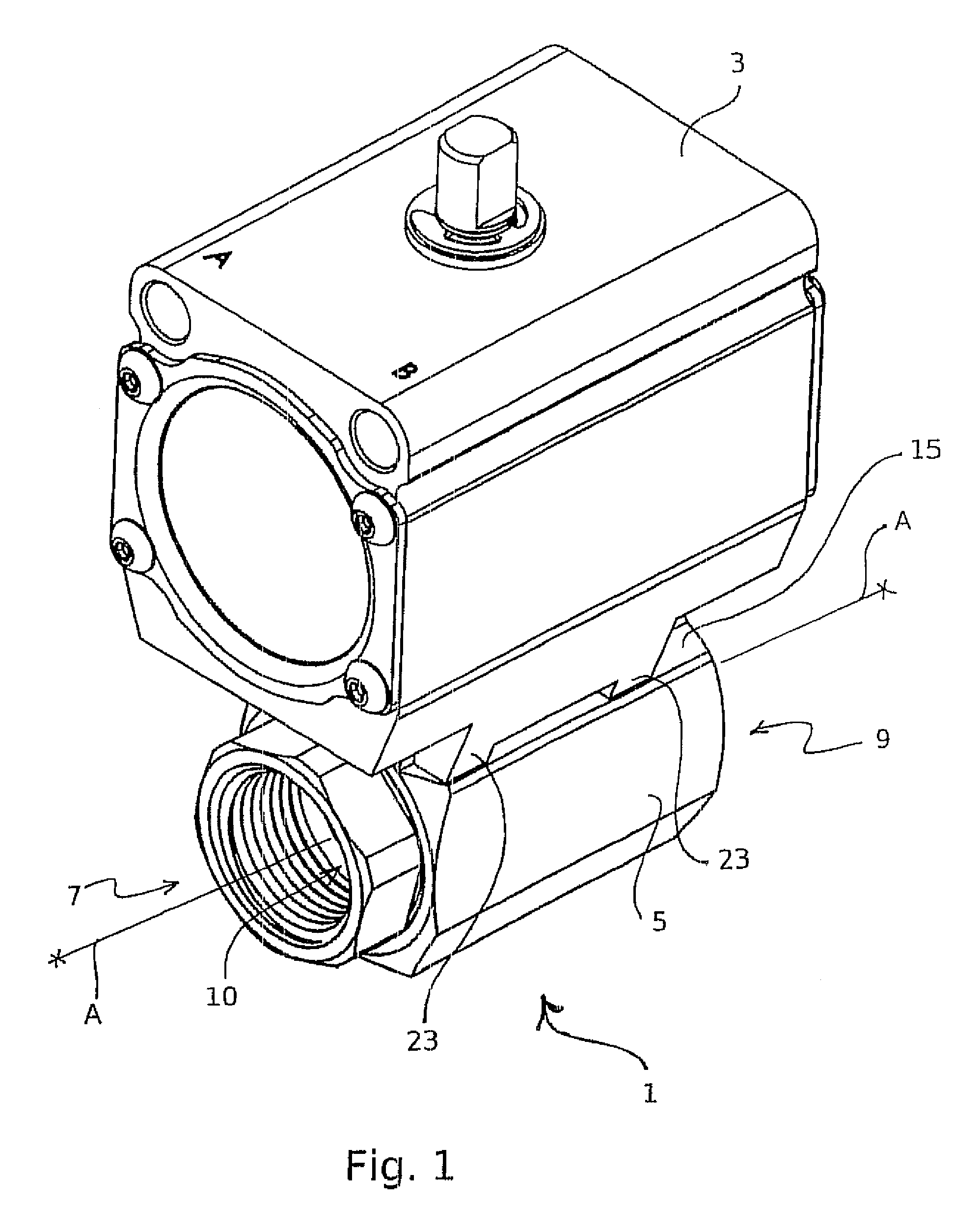

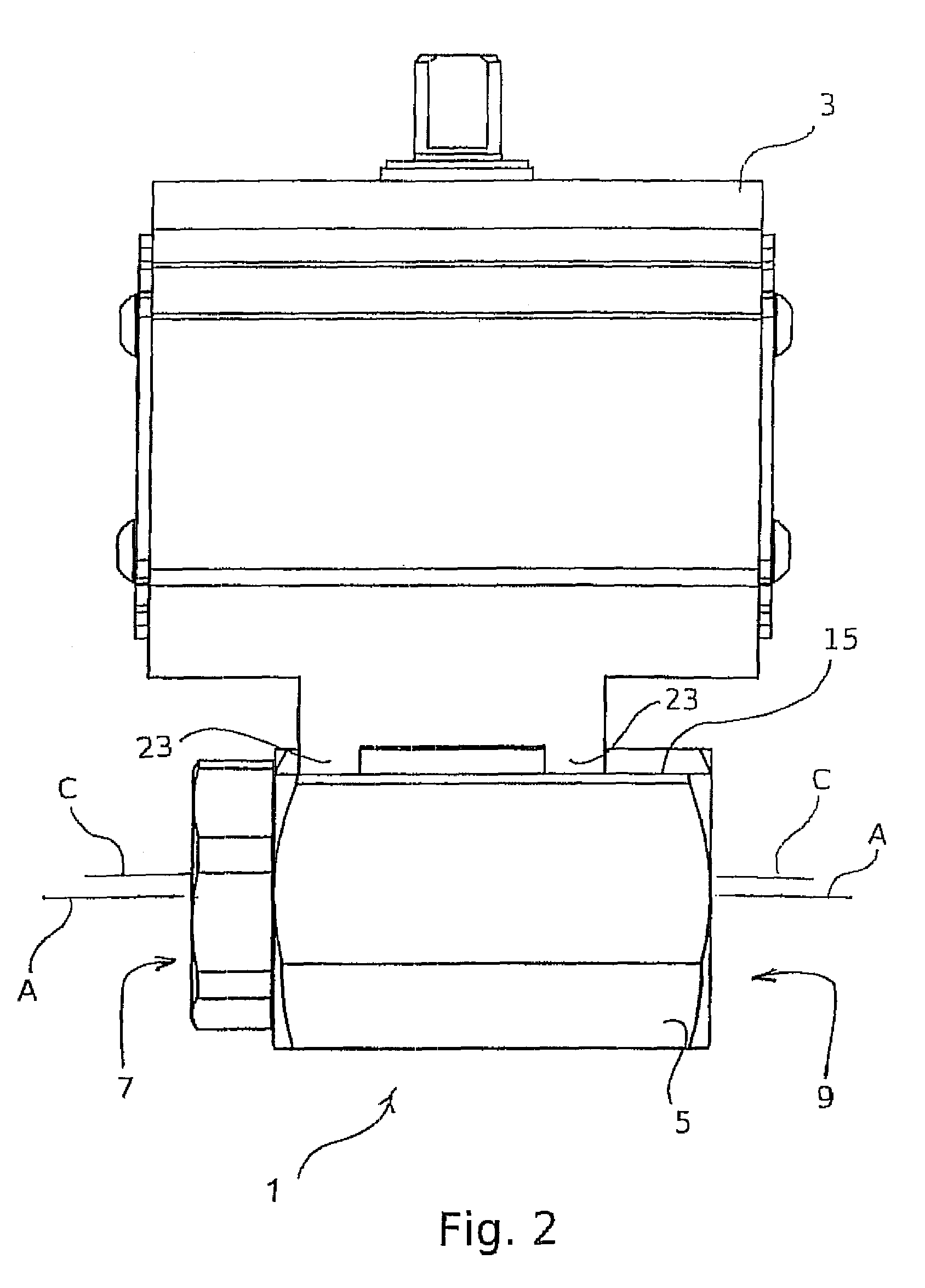

Automated ball valve and actuator

A ball valve and ball valve actuator including a unique valve stem seal and mounting connection between the ball valve and actuator. The stem seal design reduces leakage issues and significantly lengthens the life span of the ball valve and actuator and the mounting connection between the actuator. The ball valve maintains the centrality of the valve stem in connection with the actuator pinion and minimizes torque and shear forces transferred to the valve stem and hence the stem seal itself.

Owner:GEMINI VALVE

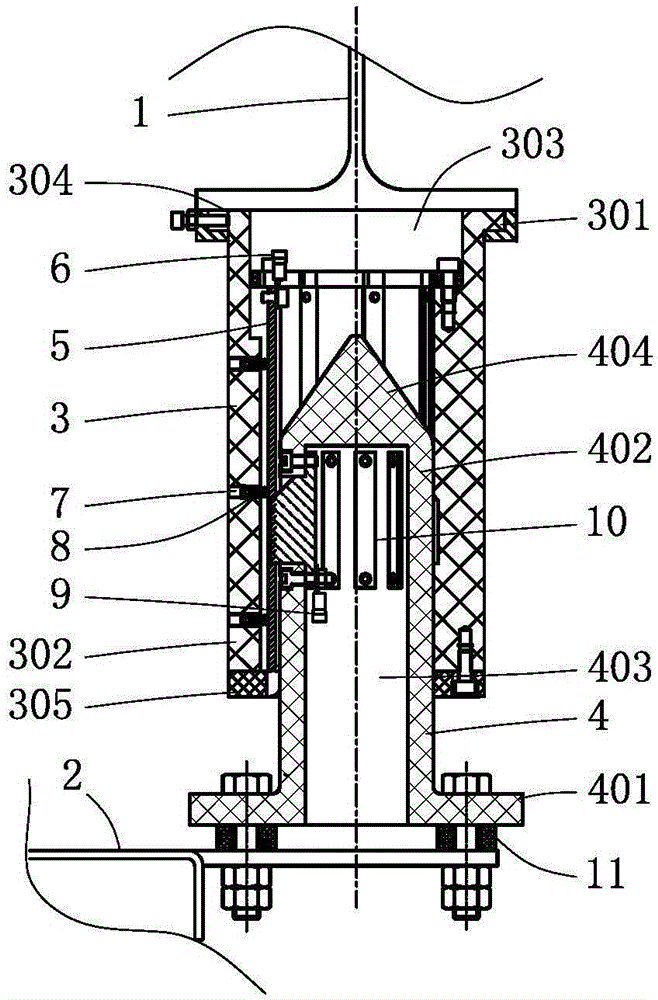

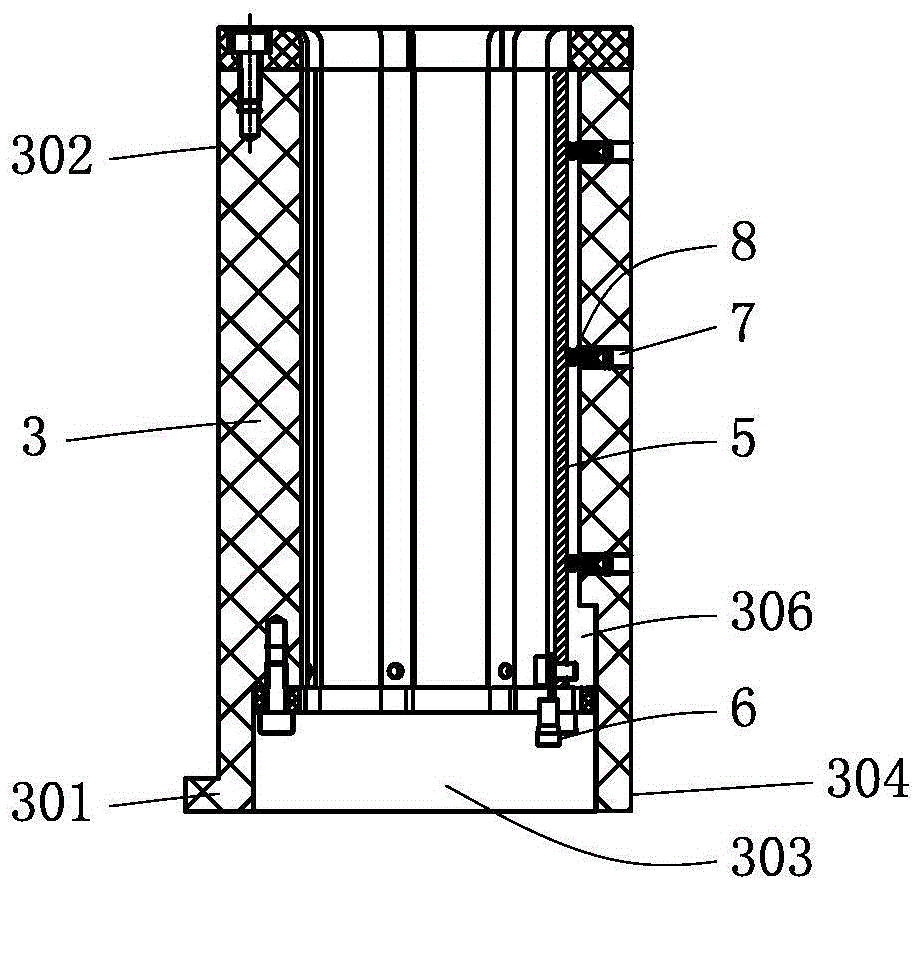

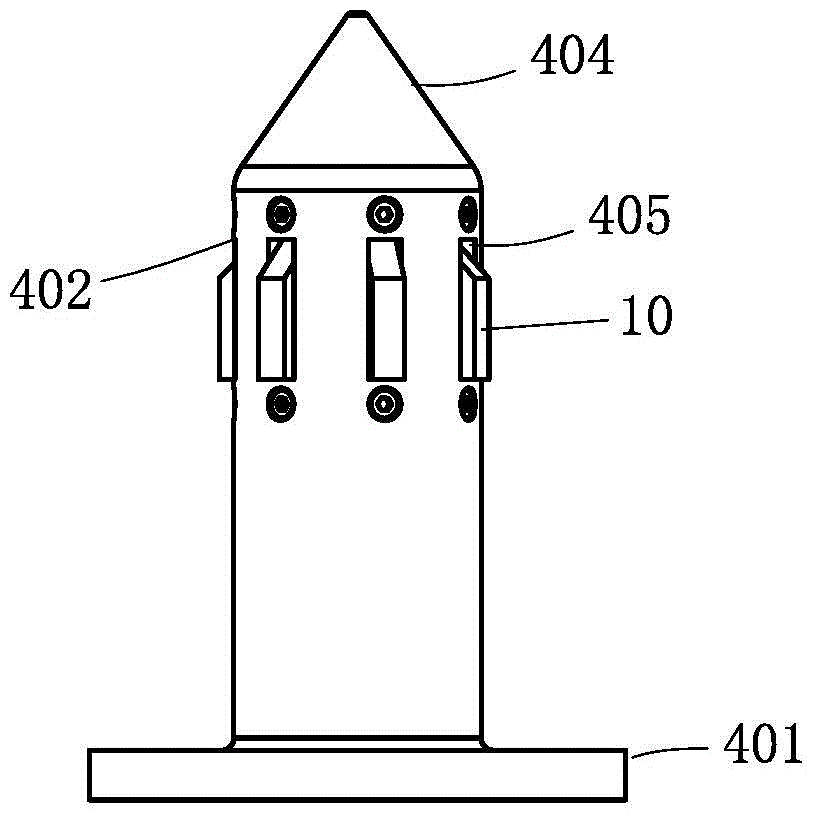

Charging plug and charging garage

ActiveCN104966963AImplement aligned importsPrecise positioningBatteries circuit arrangementsCoupling contact membersEngineeringElectrical and Electronics engineering

The invention discloses a charging plug, which belongs to the technical field of garage charging. The charging plug comprises a socket and a plug; the socket comprises a socket body; the socket body is provided with a mounting part arranged on a longitudinal beam and a reaching-out extending part; a hollow part is arranged in the socket body; a plurality of socket conductors are arranged on the socket body in the hollow part; the socket conductors are connected with a charging joint connected with a charging power supply; the plug comprises a plug body; the plug body is provided with a fixing end arranged on a car contained panel and an insertion end matched with the hollow part; the insertion end is provided with a plurality of plug conductors corresponding to the socket conductors; and the plug conductor is connected with a transition joint connected with a car charging end. The invention also provides a charging garage. The structure is simple, the performance is stable, the technical problem that the current lifting and transferring stereo garage can not realize parking charging can be solved, and the charging plug can be widely applied to the charging garage.

Owner:DAYANG PARKING CO LTD

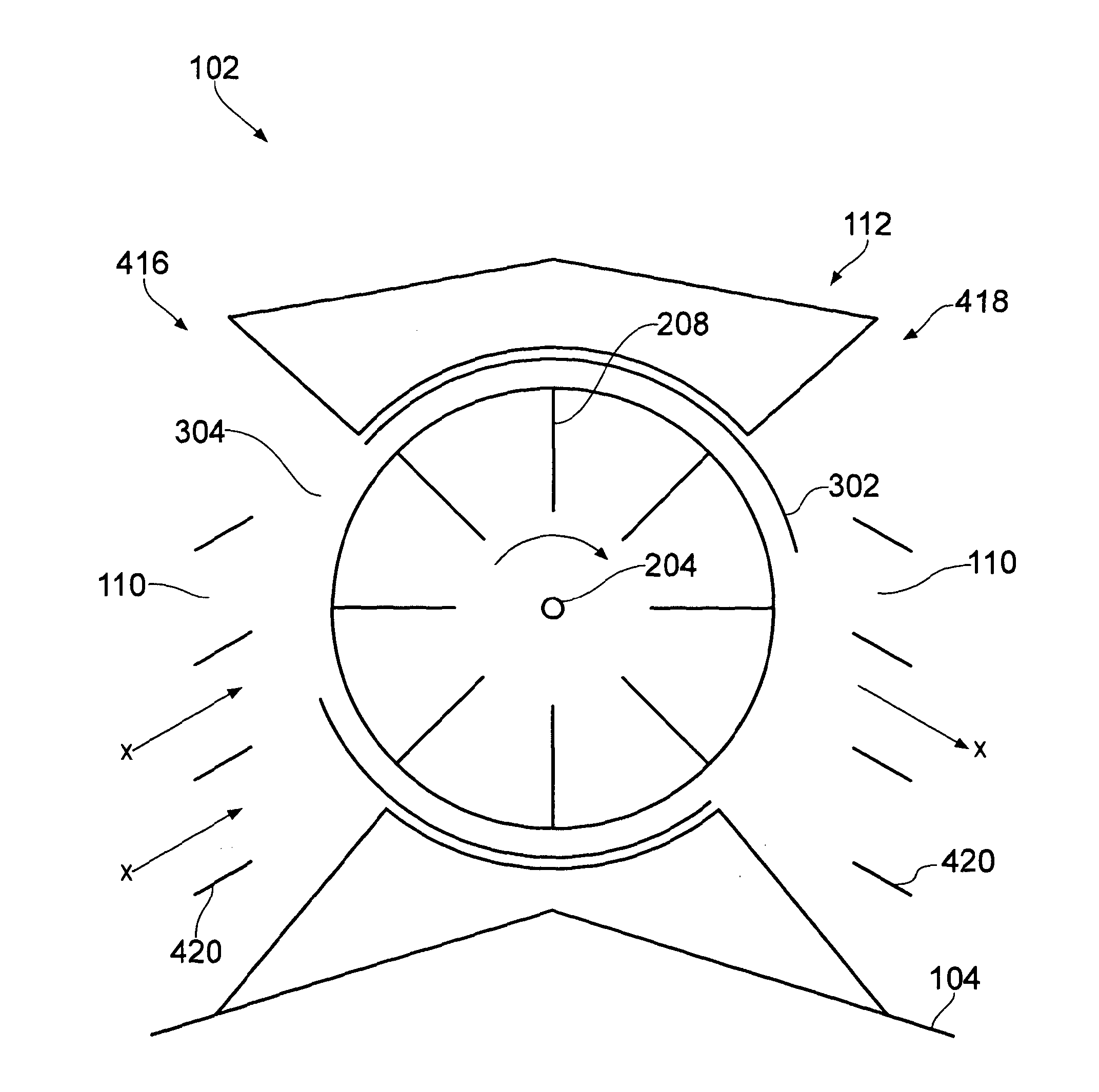

Adjustable shear valve mud pulser and controls therefor

InactiveUSRE40944E1Facilitate transmissionCompensation for wearSurveyConstructionsControl systemEngineering

A telemetry system involving a shear-type mud pulser valve as the preferred embodiment is described. The control system includes a motor driver for the mud pulser which, in essence, moves one movable plate with respect to a stationary plate to create openings of various sizes. Pressure is sensed uphole of the pulser valve and is compared in real time to the desired pressure pulse amplitude. By allowing different relative rotational positions of the rotatable plate with respect to the stationary plate, different amplitudes can be achieved to further enhance the transmission of data to the surface. The control system compensates for wear in the mud pulser valve itself as well as drastic changes in mud flow and pressure. The configuration is simple and not prone to fouling from grit or other particles in the mud. The system is capable of creating an initial baseline array of a variety of pulse amplitudes, and thereafter providing the required relative rotation between the stationary and rotatable plates so as to be able to duplicate the baseline pulse amplitudes despite changes in the valve condition or in the flowing conditions of the mud.

Owner:BAKER HUGHES INC

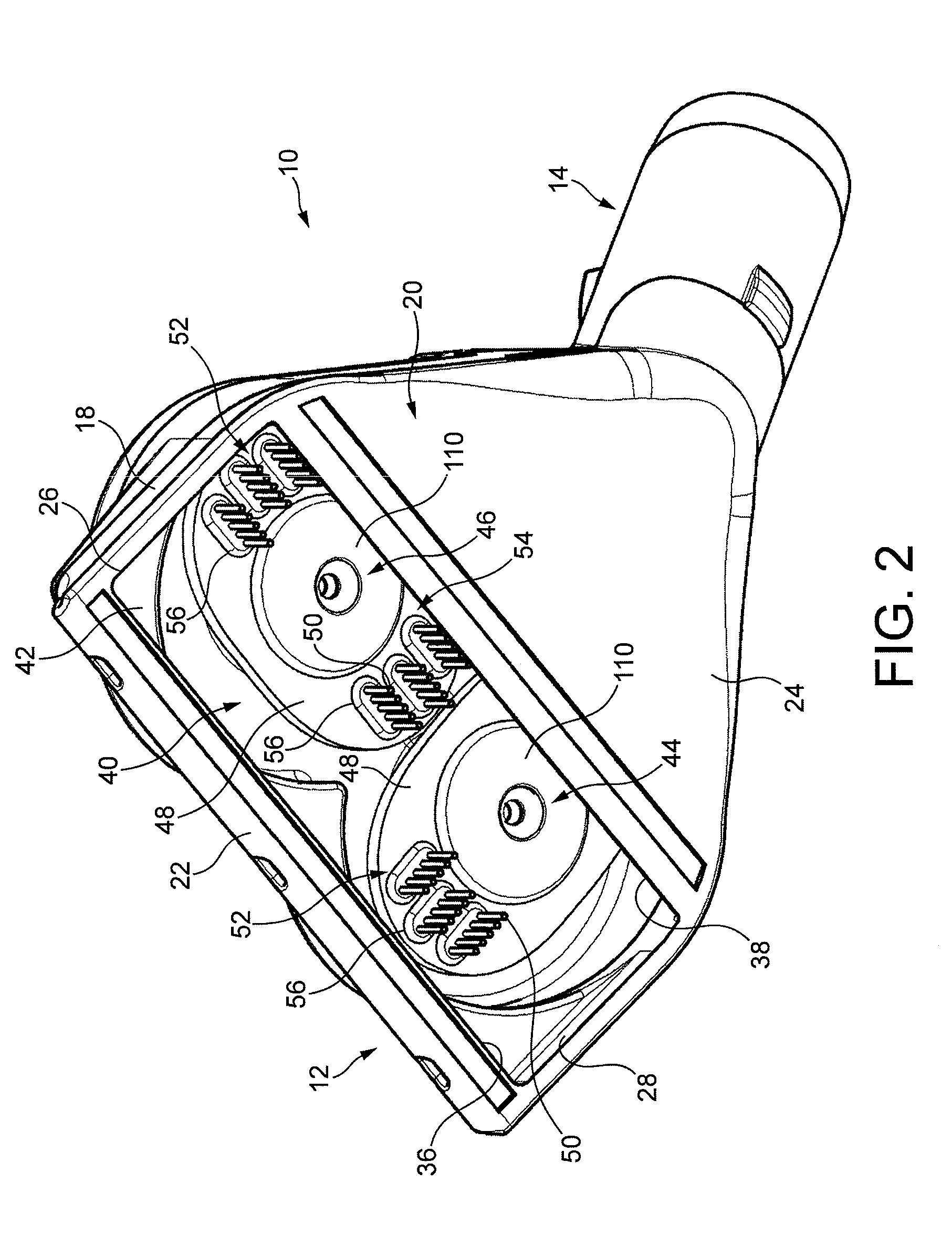

Power tool with an eccentrically driven working tool

ActiveUS20060064881A1Less additional mounting spaceCompensation for wearMetal sawing devicesPortable power driven sawsPower toolEngineering

A power tool, in particular a circular saw, for eccentrically a rotatable working tool and, in particular, a circular saw blade, includes a roller device (13) supported on a tool housing (6) and having at least two roller pairs (12, 16) each having a first roller (10, 14) and a second roller (17, 19) engageable with opposite sides of the working tool (4), with at least one of the rollers (10, 14, 17, 19) of at least one roller pair (12, 16) being rotatable by a tool motor (8) which is located in the housing (6), for driving the working tool (4), and a pivot device (20) for pivoting the first rollers (10, 14) together relative to the second rollers (17, 19) between a release position in which the working tool (4) is brought in or removed from the roller device (13), and a drive position in which a forcelocking connection between the at least one of the rollers (10) of the at least one roller pair (12, 16) and the working tool (4) is established.

Owner:HILTI AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com