Sealing device of vacuum moving element

A technology of moving parts and sealing devices, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as gas leakage, equipment performance decline, affecting sealing effect, etc., to reduce motion resistance, excellent sealing characteristics, prolong The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

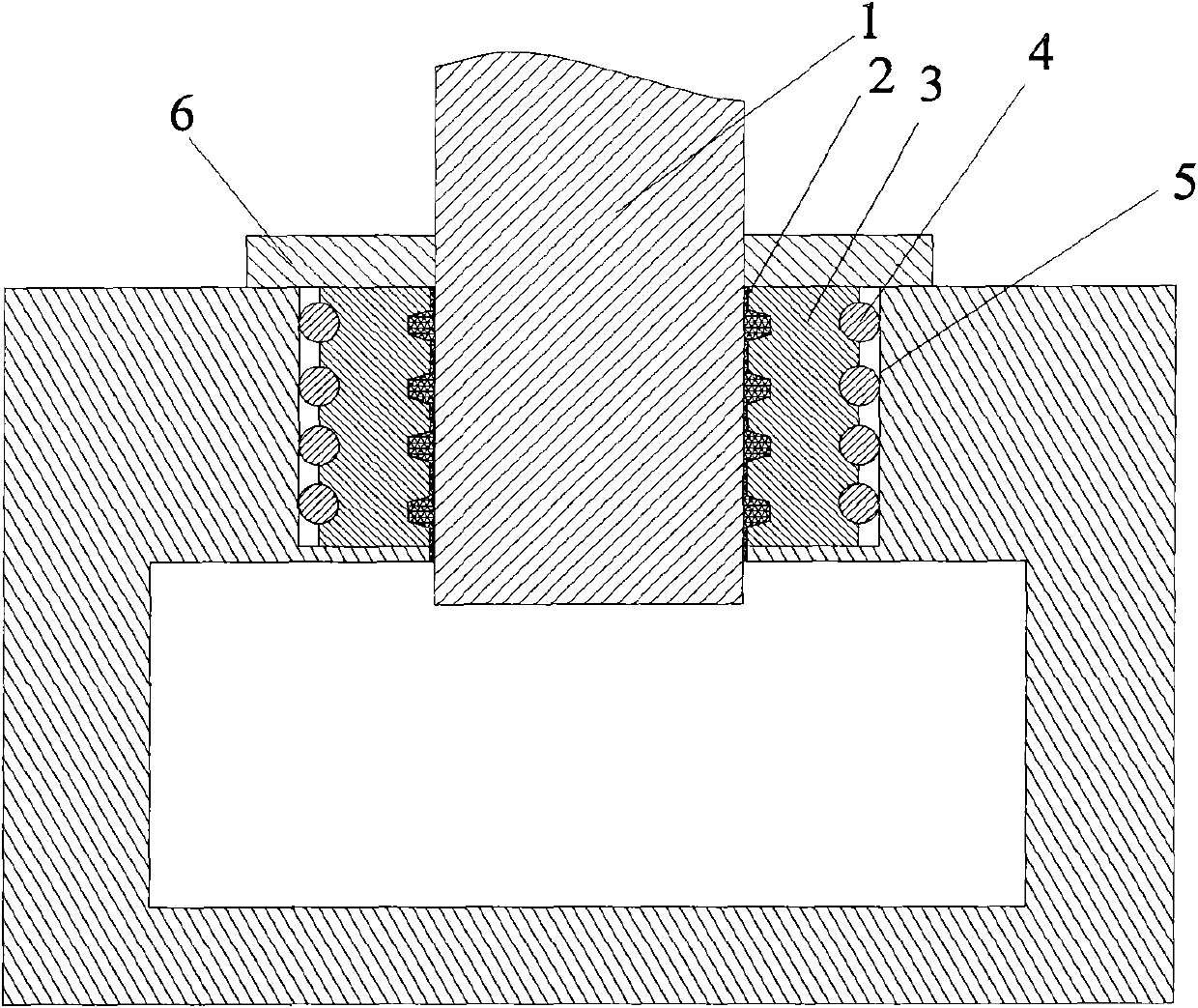

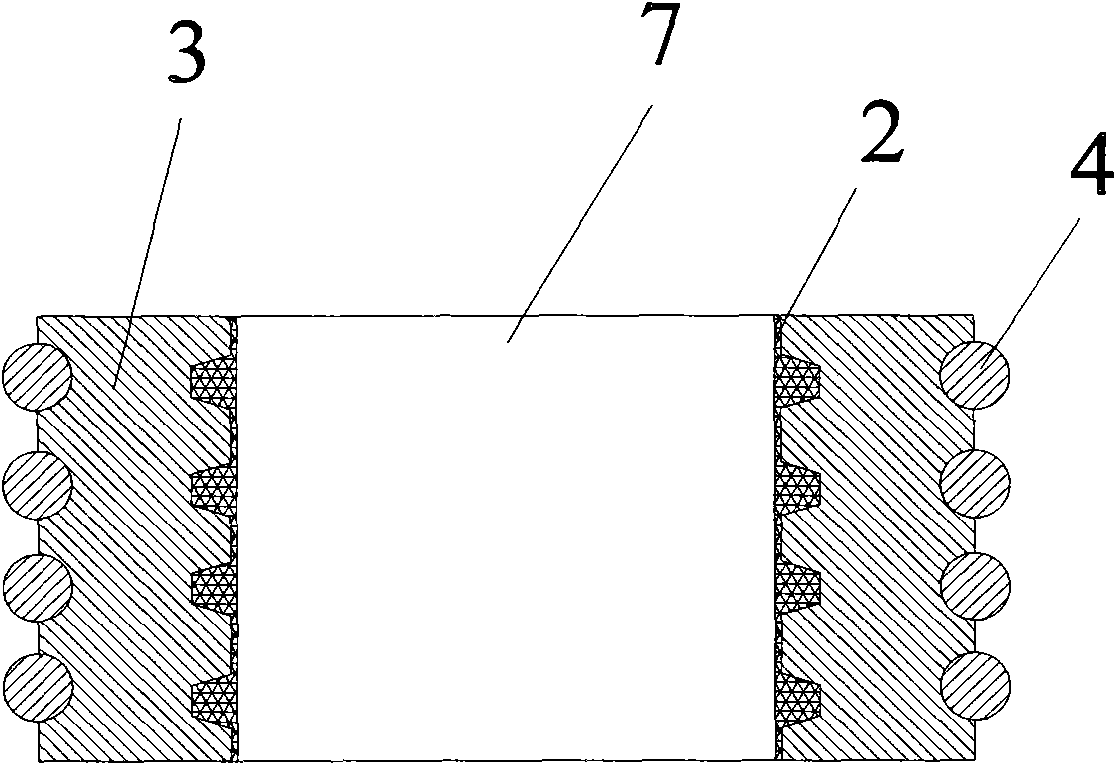

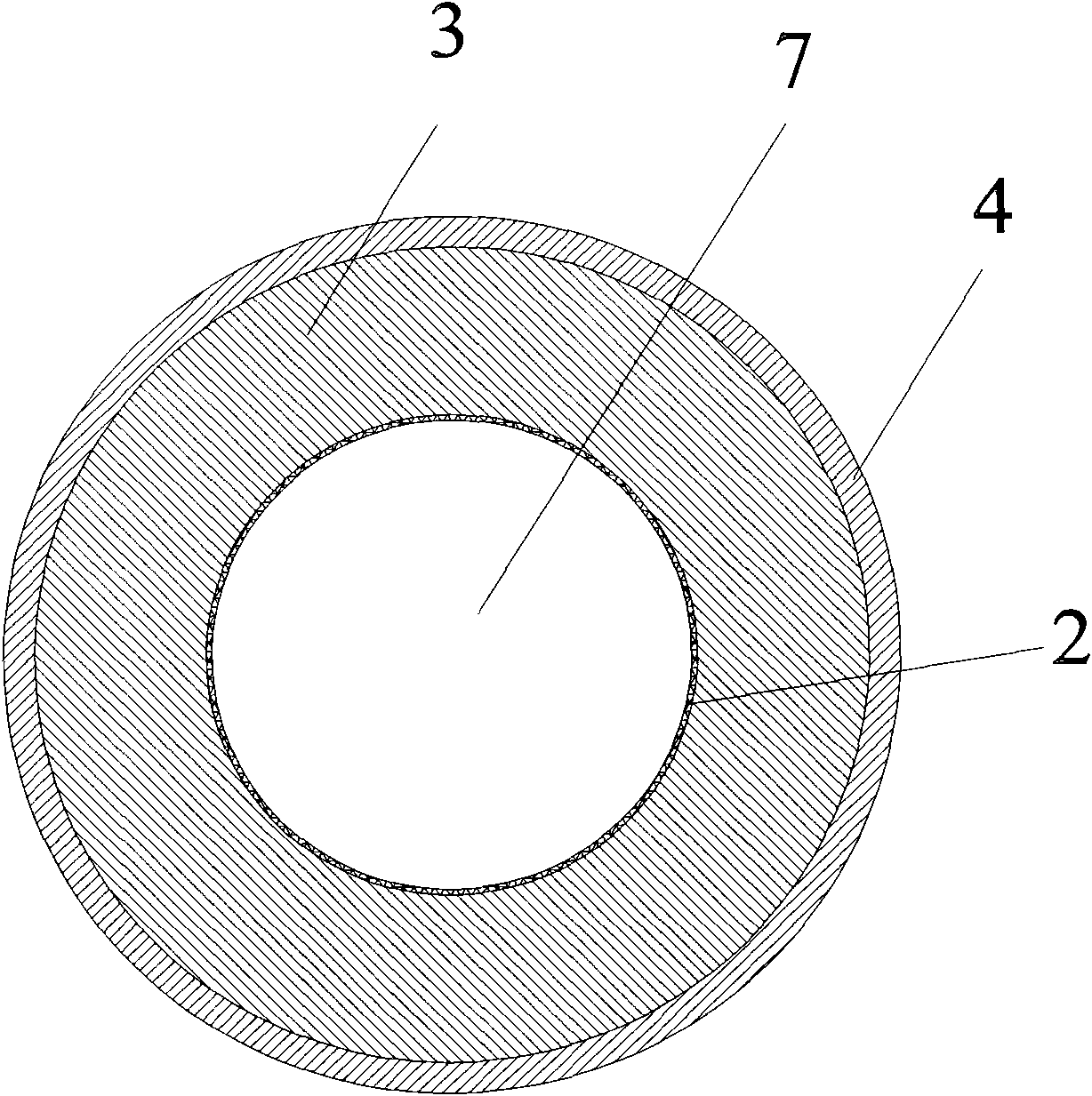

[0040] Figure 1 to Figure 5 Shows the specific structural diagram of this embodiment, such as figure 1 As shown, this vacuum moving part sealing device includes a moving part 1 and a sealing ring 3 matched with it, and the inner hole wall of the inner hole 7 of the sealing ring 3 matching with the moving part 1 is provided with four ring-shaped storage grooves 8. Both the inner hole wall and the storage tank 8 have a sealing grease layer 2; the outer wall of the sealing ring 3 is provided with four outer ring grooves 9, each outer ring groove 9 is embedded with a sealing ring 4, and the sealing ring 4 is in contact with the cavity The sealing inner wall 5 cooperates.

[0041] Such as figure 2 and Figure 4 As shown, the cross-sectional shape of the storage tank 8 is trapezoidal.

[0042] The cross-sectional shape of the outer ring groove 9 is a semicircle.

[0043] Each outer ring groove 9 is embedded with a sealing ring 4 .

[0044] The distance between the peripheral...

Embodiment 2

[0056] Present embodiment except following feature other structures are with embodiment 1: as Figure 6 As shown, the inner hole wall and the surface of the storage tank 8 are also provided with a polytetrafluoroethylene coating 10 .

[0057] The sealing ring 3 is made of perfluororubber, and the sealing ring 4 is made of silicon rubber.

Embodiment 3

[0059] The structure of this embodiment is the same as that of Embodiment 1 except for the following features: the inner hole wall of the inner hole 7 of the sealing ring 3 cooperating with the moving part 1 is provided with seven annular storage grooves 8, the inner hole wall and the storage groove 8 have a sealing grease layer 2; the outer wall of the sealing ring 3 is provided with four outer ring grooves 9, and each outer ring groove 9 is embedded with a sealing ring 4, and the sealing ring 4 cooperates with the cavity sealing inner wall 5.

[0060] Such as Figure 7 As shown, the cross-sectional shape of the storage tank 8 is a rectangle with a side length of 5 mm.

[0061] The cross-sectional shape of the outer ring groove 9 is a semicircle.

[0062] The distance between the peripheral edges of every two adjacent storage grooves is 2mm, and the distance between the peripheral edges of every two adjacent outer ring grooves is also 2mm.

[0063] The cross-sectional shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com