Metal/ ceramic nano composite additive of self-rehabilitation and its preparation method

A self-healing additive and nano-composite technology, which is applied in the development and application of new nano-materials, can solve problems such as increased recovery, poor lubricating oil, and low dry friction coefficient, and achieve the effect of compensating for wear of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

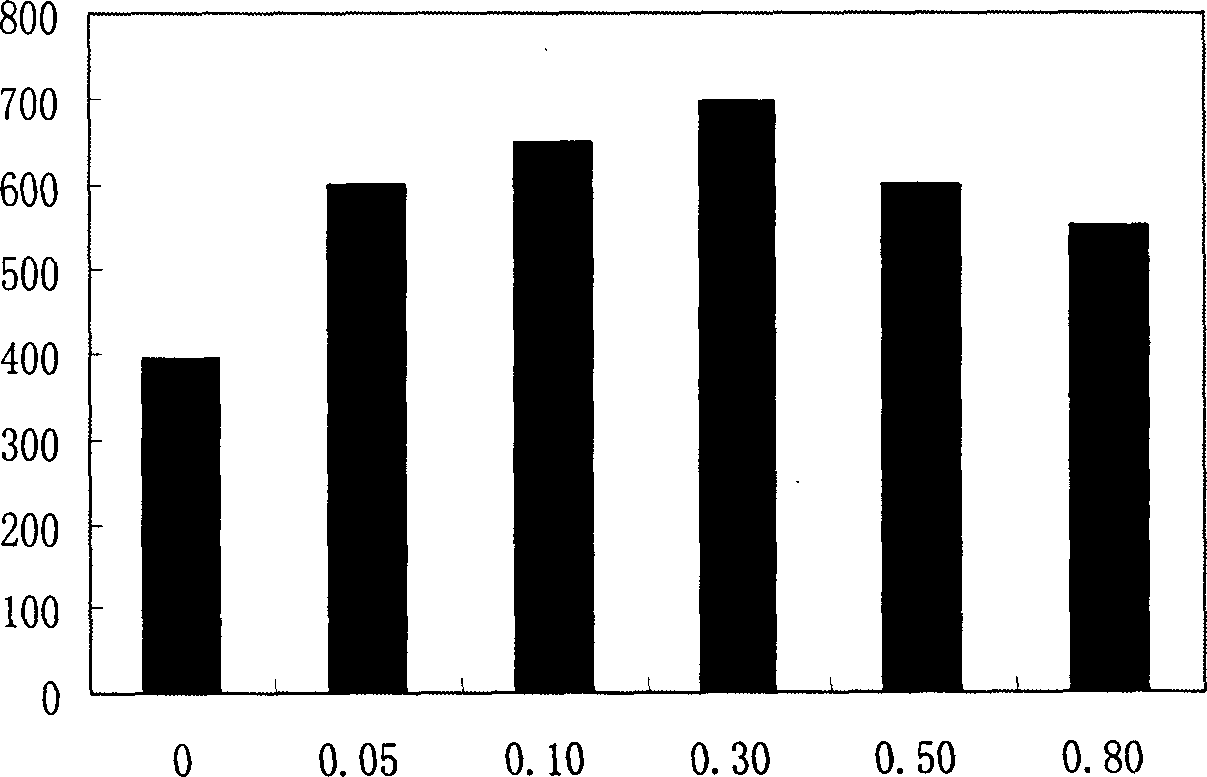

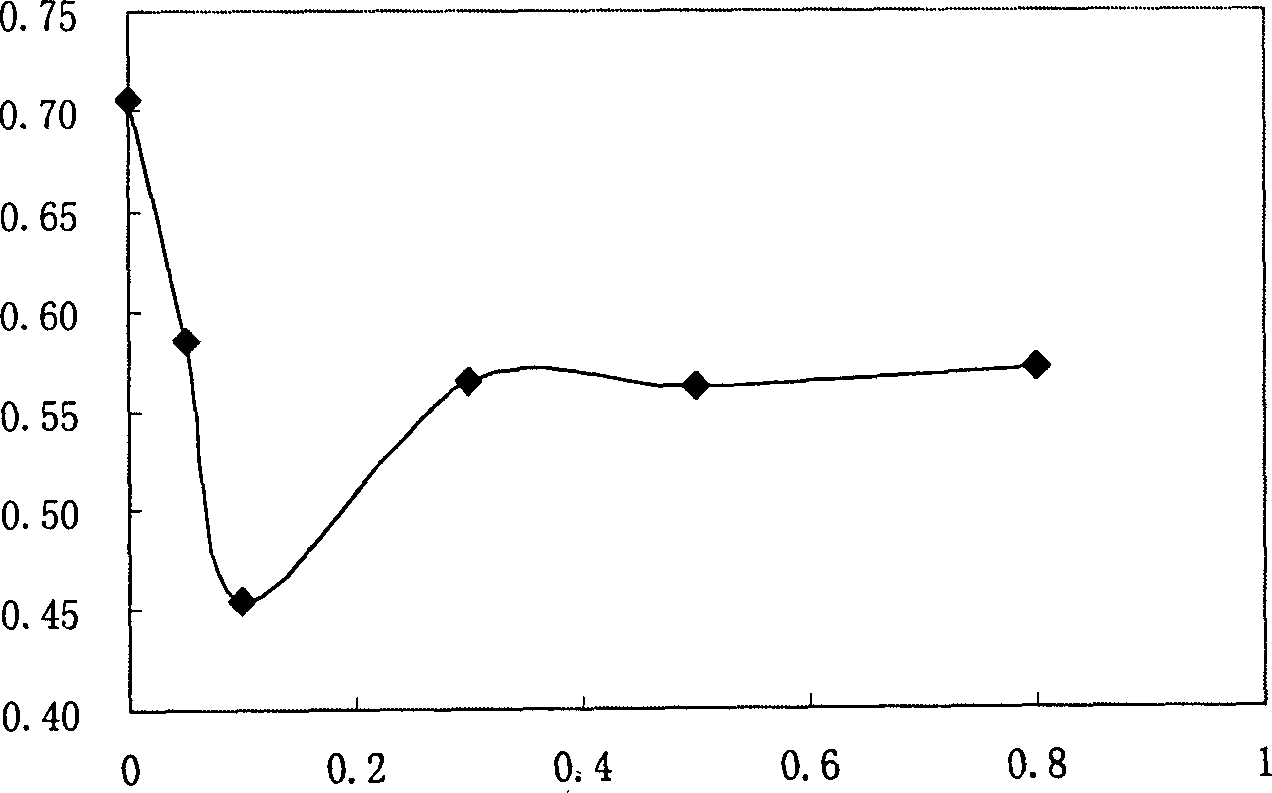

[0054] Example 1: Weigh 8.1g of metal nano-copper powder and 0.9g of nickel powder, and adopt the multi-gun DC arc plasma evaporation method to prepare metal nano-copper-nickel composite powder with an average particle size of 54nm, weigh 2.5g of oleic acid and add 84g of 15W base oil Add metal nano-copper-nickel composite powder, disperse for 15-60 minutes with a high-speed disperser at a speed of 600-3000 rpm, add 3g of castor oil, 0.5g of MoDDP, and 0.5g of T154 to the obtained metal nano-dispersion, Grind T2020.5g in a ball mill for 20 minutes to 2 hours to obtain Additive B. Measure 2 grams of metal nano-powder per liter of lubricating oil and add it to Kia commercial vehicle lubricating oil for testing. The vehicle has driven 60,000 kilometers before the test. The original long-term addition of conventional lubricating additives, the engine noise, vibration, and lubricating oil has turned black. About 20 minutes after injecting the additive, the engine noise and vibratio...

example 2

[0055] Example 2: First, after crushing 10.5g of serpentine and ball milling to about 30 microns, weigh and prepare serpentine powder, 4.5g of magnesium oxide, 3g of sodium hexametaphosphate, and 70.8g of 15W base oil, and then use a planetary ball mill to After the ore powder is ball-milled to 80 nanometers, add nano-Ca(OH) 2 5g, nanometer graphite powder 3g, nanometer Fe 2 o 3 2g, Nano Ce 2 o 30.2g, T501 1g was further ball milled for 120min to obtain the additive A. According to the amount of 0.08 grams of nano ore powder per liter of lubricating oil, add it to the motorcycle lubricating oil for the test. The car has driven 25,000 kilometers before the test. The engine noise is loud, the vibration is big, and the power is insufficient. About 20 minutes after the additive is injected, the engine noise, The vibration is obviously reduced, the engine is obviously increased in about 30 minutes, and the fuel saving effect reaches an average of 12.6%. After traveling 500 k...

example 3

[0056] Example 3: After compounding 10 g of additive B in Example 1 and 40 g of additive A powder in Example (2), ball milling and mixing for 80 minutes prepared additive C, which was added to the lubricating oil of trucks used in mines for testing. Before the test, it had traveled about 150,000 kilometers, and the engine was noisy, vibrating, and lacking in power. About 40 minutes after the injection of the additive, the noise and vibration of the engine are significantly reduced, the power is increased, the blue smoke in the exhaust gas is significantly reduced, and the average fuel saving effect reaches 15.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com