Method for utilizing self-made grinding machine to grind two end faces of aligning roller simultaneously

A self-aligning roller and two-end surface technology, which is applied in the field of bearing processing, can solve the problems of bumping and scratching on the grinding surface, low processing accuracy, and low production efficiency, achieve high surface accuracy and quality, improve grinding quality, and improve The effect of finished product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention is a method for simultaneously grinding both ends of self-aligning rollers with a self-made grinding machine. It has the characteristics of high automation, high processing efficiency, stable and reliable quality, good processing accuracy and consistency, and is very convenient for adjustment, installation and maintenance. .

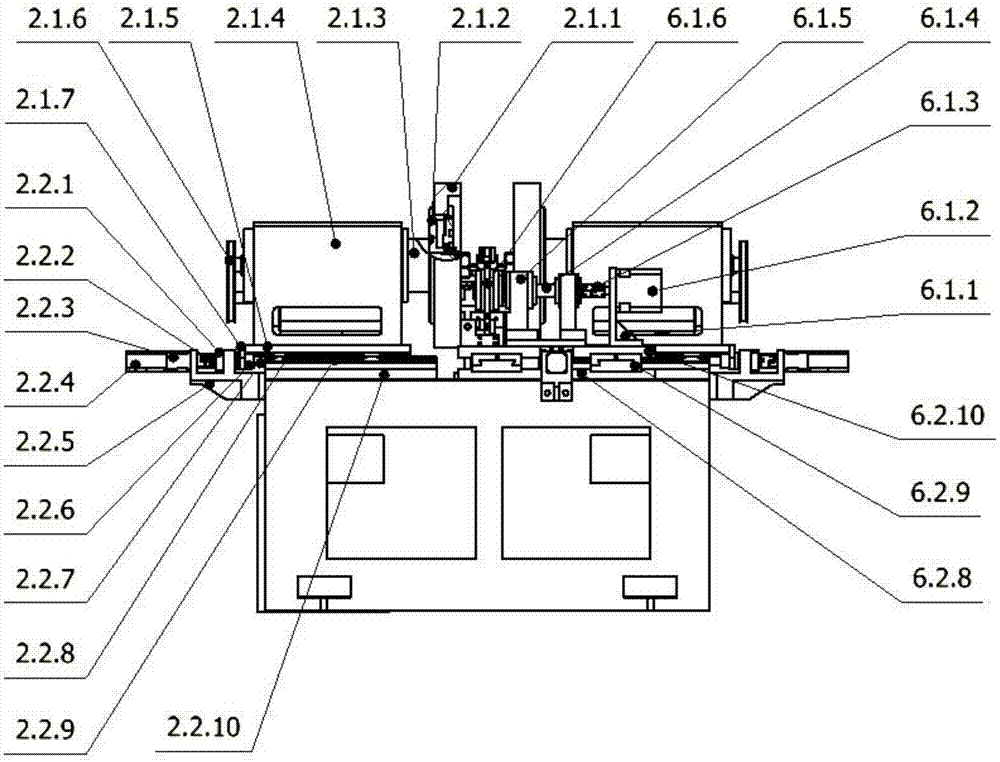

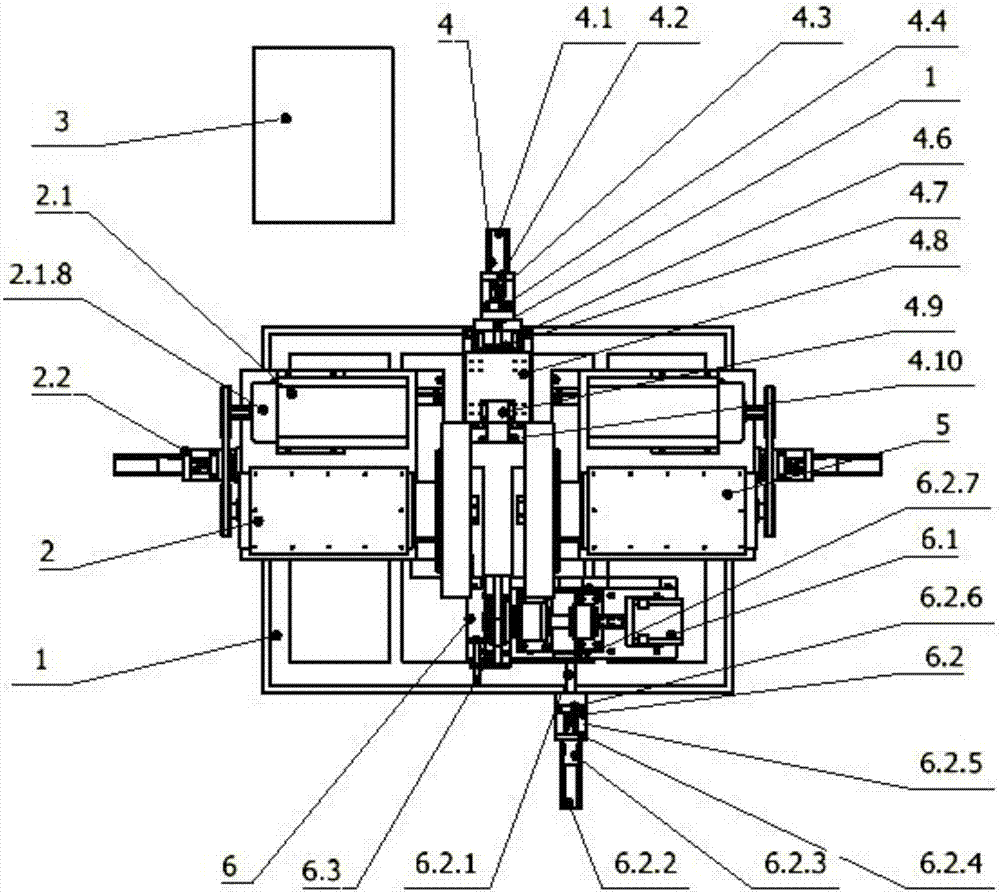

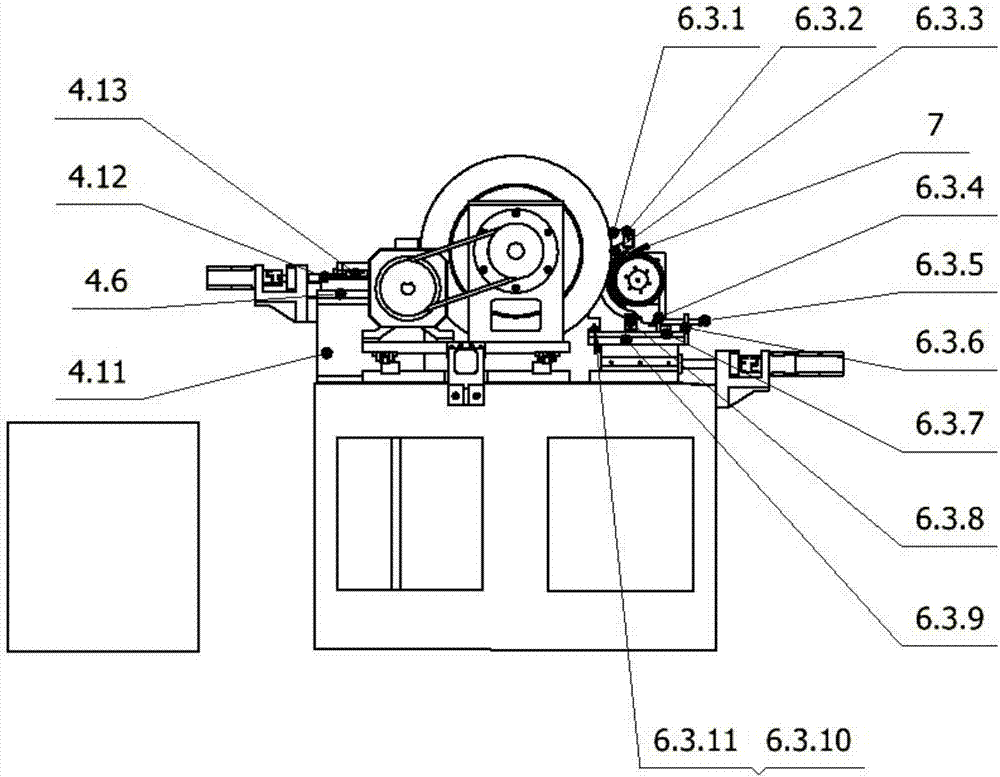

[0031] combine Figure 1-3 , the self-made grinding machine of the present invention comprises a bed 1, a left grinding wheel device 2, a right grinding wheel device 5, a mold rotary disc device 6, a grinding wheel dressing device 4 and an electric control box 3, and the left grinding wheel device 2 or the right grinding wheel The condition that the device 5 can reciprocate left and right is referred to as lateral movement for short, and the condition that the mold turntable device 4 or the grinding wheel dressing device 5 can reciprocate forward and backward is referred to as longitudinal movement, and the longitudinal movement is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com