Titration device for coating materials

A titration device and coating solution technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large influence of accuracy errors, time-consuming and labor costs, etc., to improve the precision of finished products , Improve efficiency and reduce the time of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

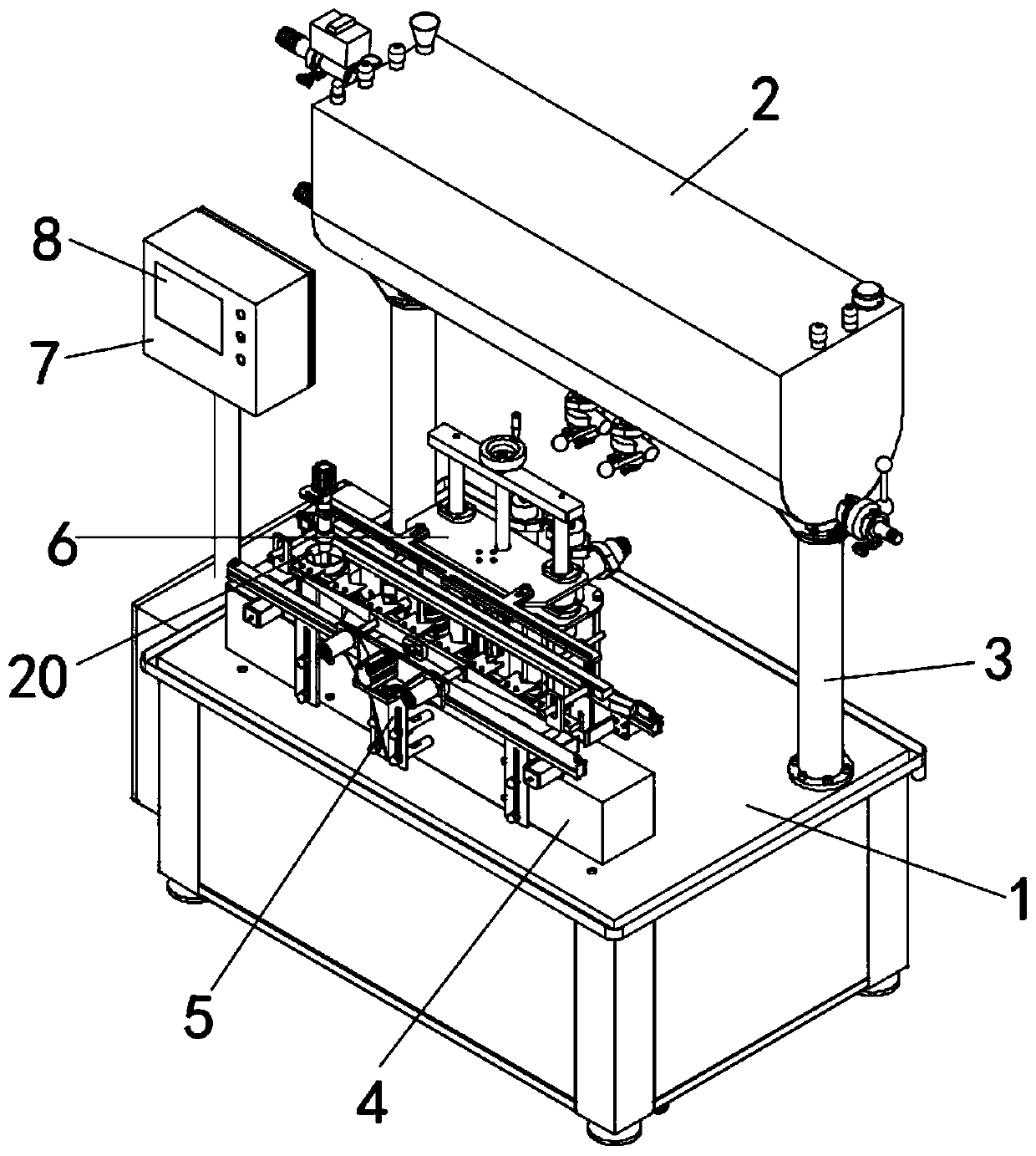

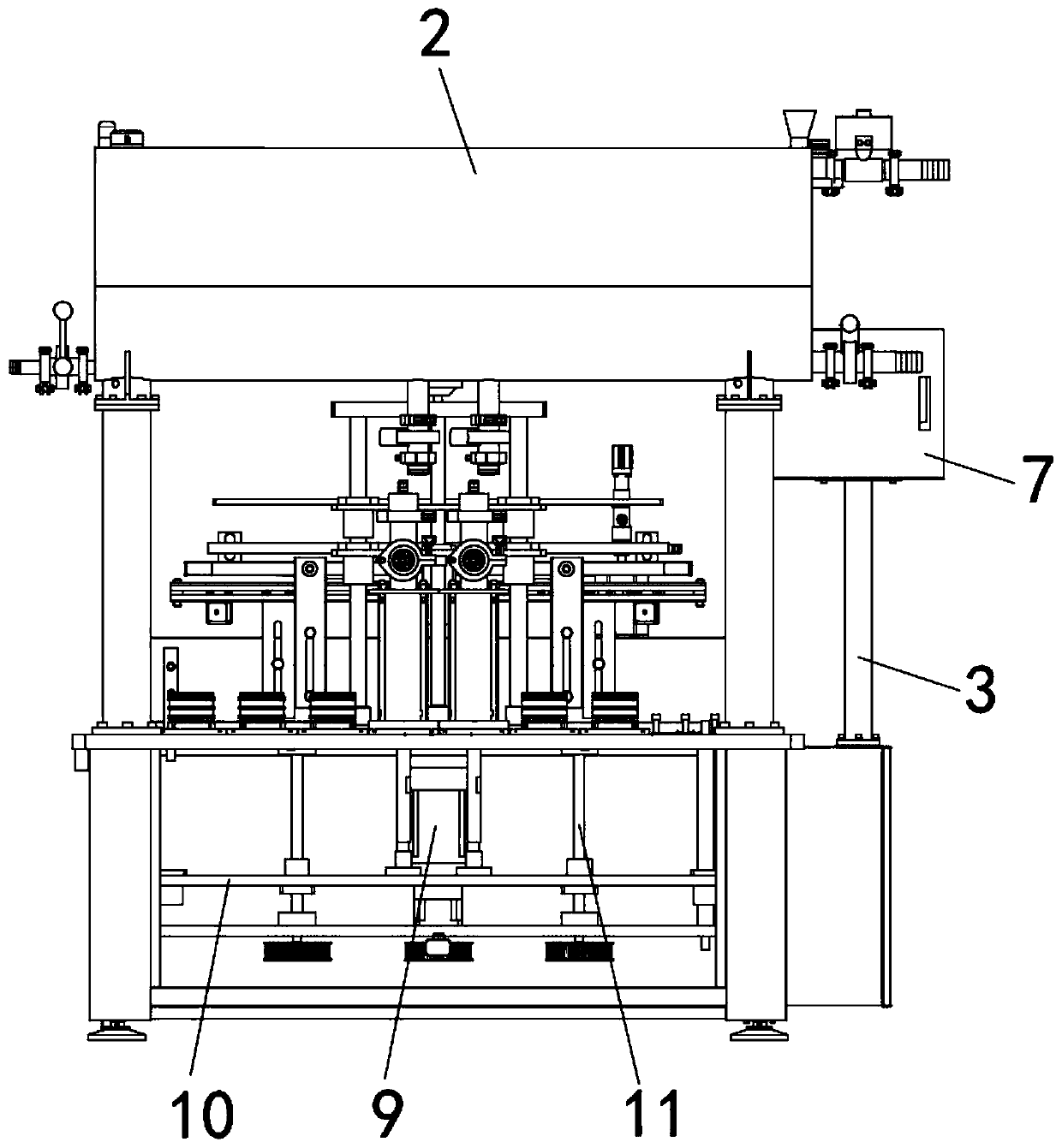

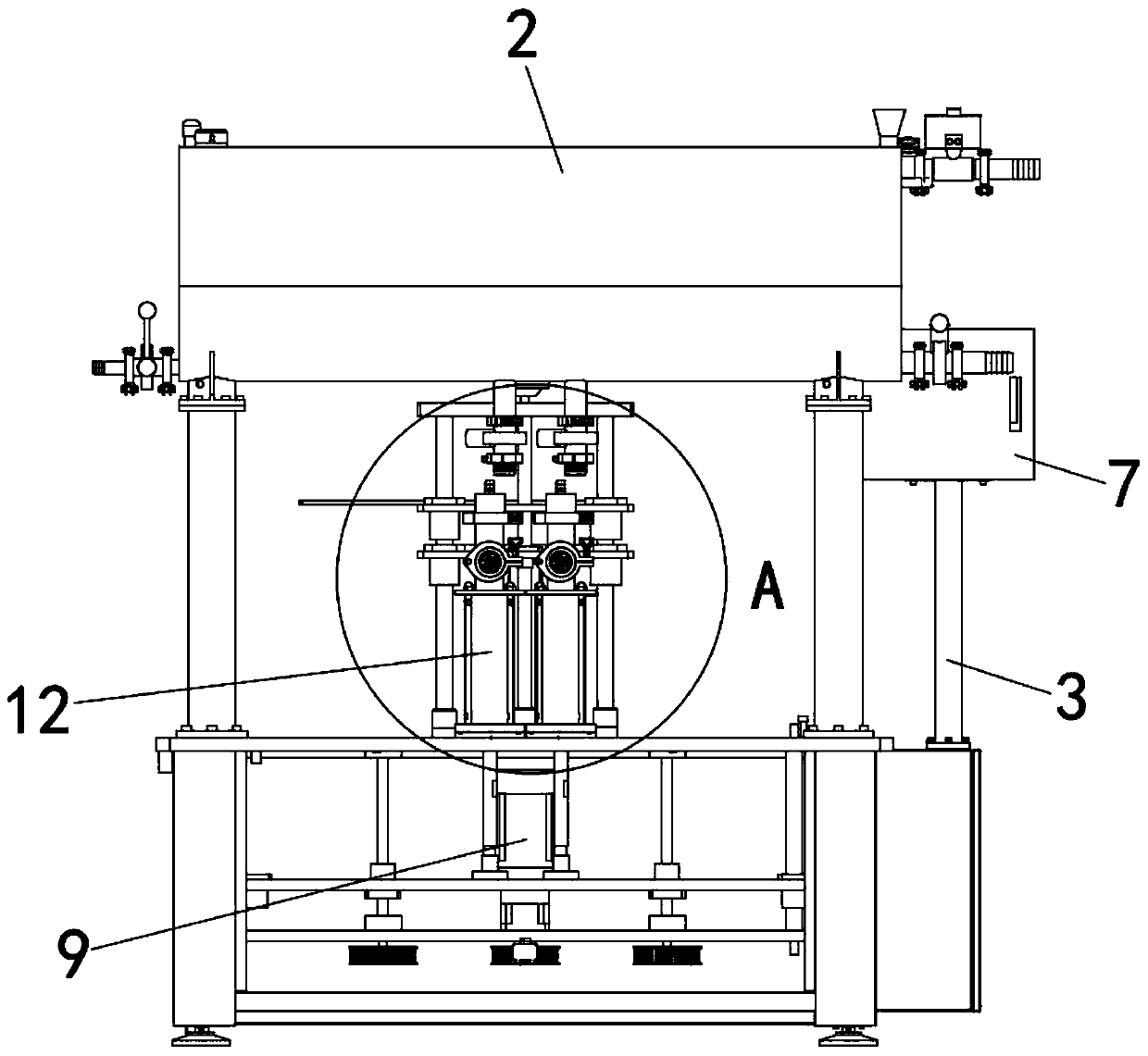

[0025] Such as Figure 1 to Figure 5 As shown, the present invention provides a titration device for a coating material, comprising: an additive liquid storage tank 2, a coating fluid tank 4, a flow measuring barrel 12 for measuring the flow of the additive fluid, a limiting mechanism 5 for limiting the burette 20, a driving The burette 20 moves up and down to titrate the elevating plate 6 for the coating solution tank 4 and the motor 9 for driving the elevating plate 6 to move up and down.

[0026] The upper surface of the workbench 1 is symmetrically installed with a support column 3 with bolts, the top of the support column 3 is fixed with an additional liquid storage tank 2 by bolts, and the bottom end of the additional liquid storage tank 2 is connected with a second out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com