Large-specification bar hole pattern design method

A pass design, large-scale technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as the accuracy of pass design cannot be guaranteed, and the applicability has not been studied, so as to achieve convenient computer holes. Type design, improve flexibility and finished product accuracy, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

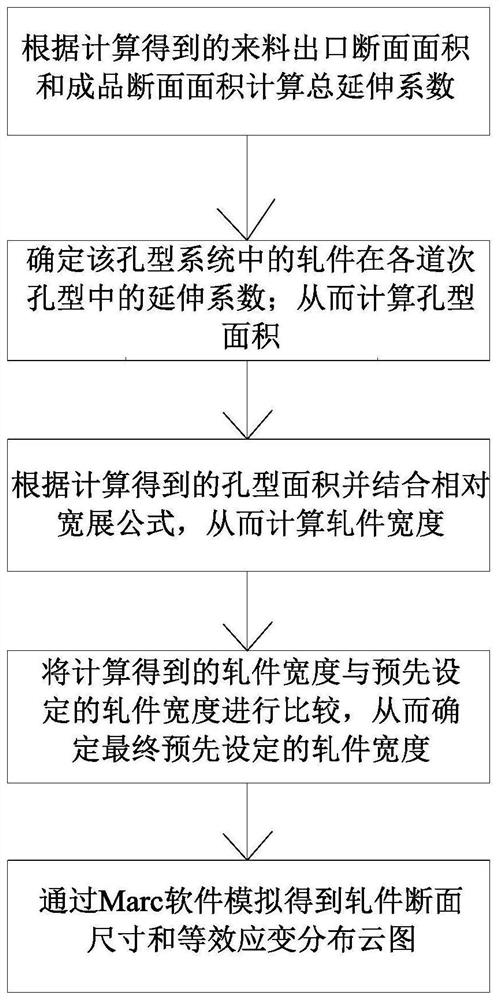

Method used

Image

Examples

example 1

[0052] The relative spread formula is: b=B×β, where b is the width of the rolled piece, B is the preset width of the rolled piece, and β is the relative spread coefficient; where K 1 Influence coefficient of steel type, K 2 is the temperature influence coefficient, λ is the reduction coefficient, and δ is the section shape coefficient; among them, λ reflects the parameter of reduction influence, λ=h c / H c , h c is the height of rolled piece after rolling, H c is the height of the rolled piece before rolling;

[0053] δreflects the parameter affected by the shape of the rolled piece, δ=B / H c ;

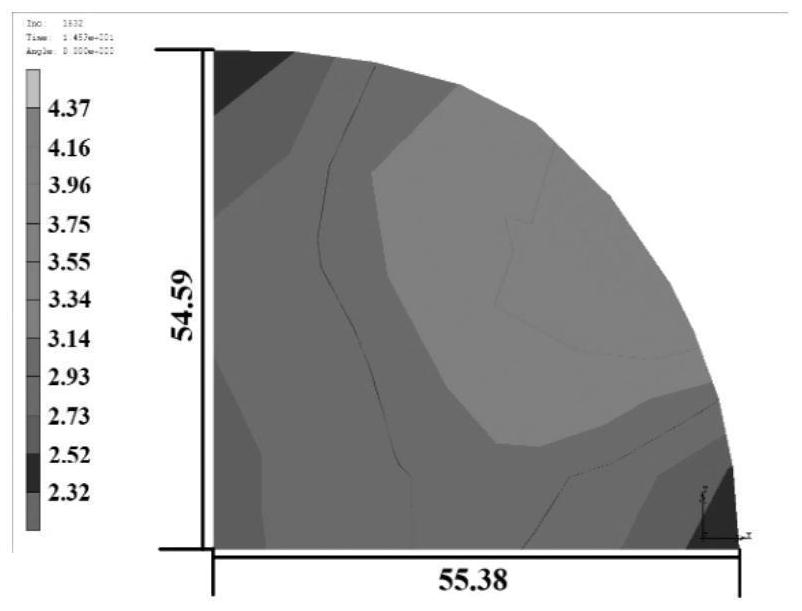

[0054] Now given the following data: Pass area F after rolling 1 =9293, pass area F before rolling 2 =10604, the width of the rolled piece after rolling b 1 =95.19, preset rolling width b 2 =100; wherein, the above-mentioned pass area after rolling and the width of the rolled piece after rolling are substituted into the formula h c1 =F 1 / b 1 Calculate the height h of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com