Patents

Literature

45results about How to "Reduced ease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

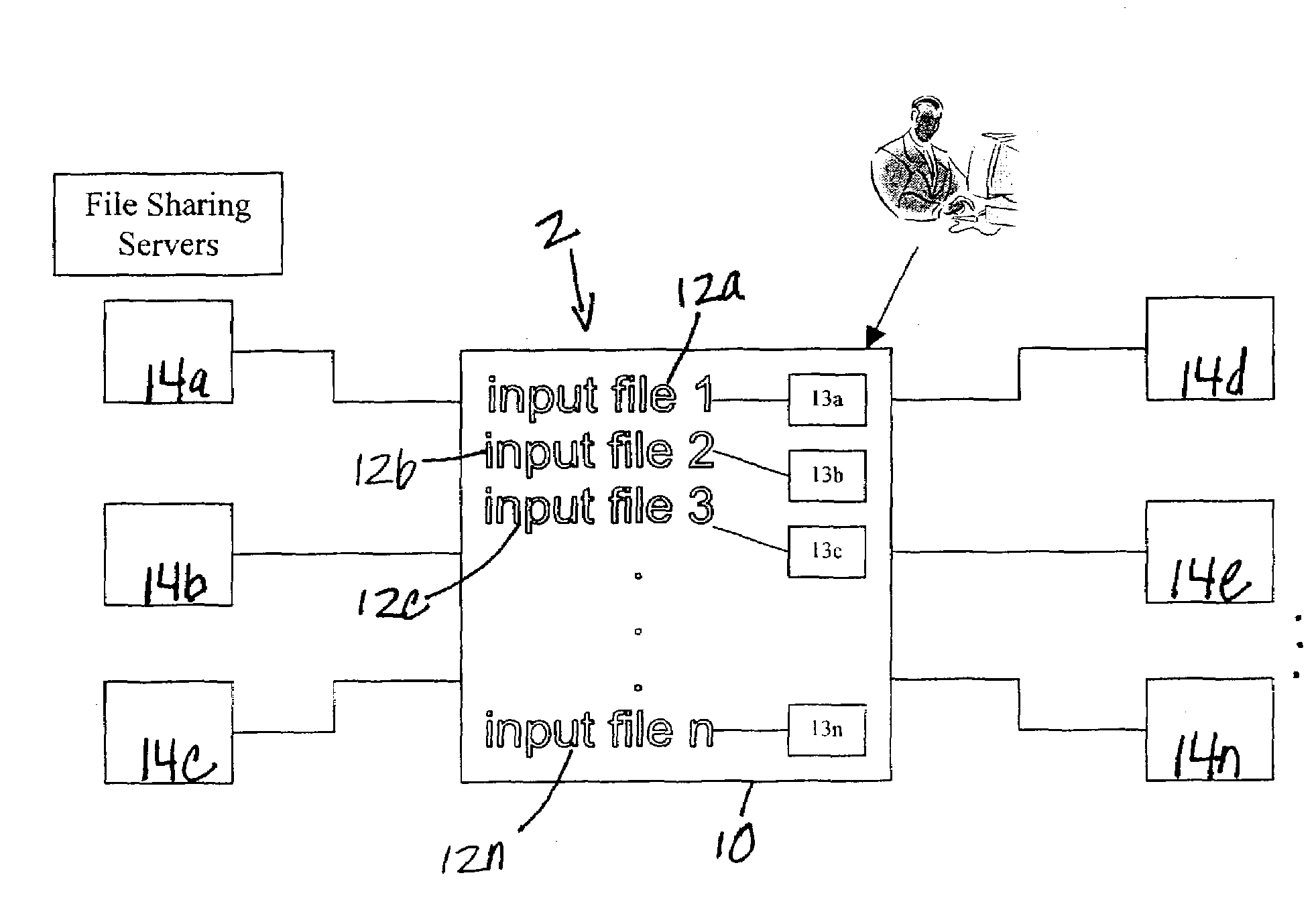

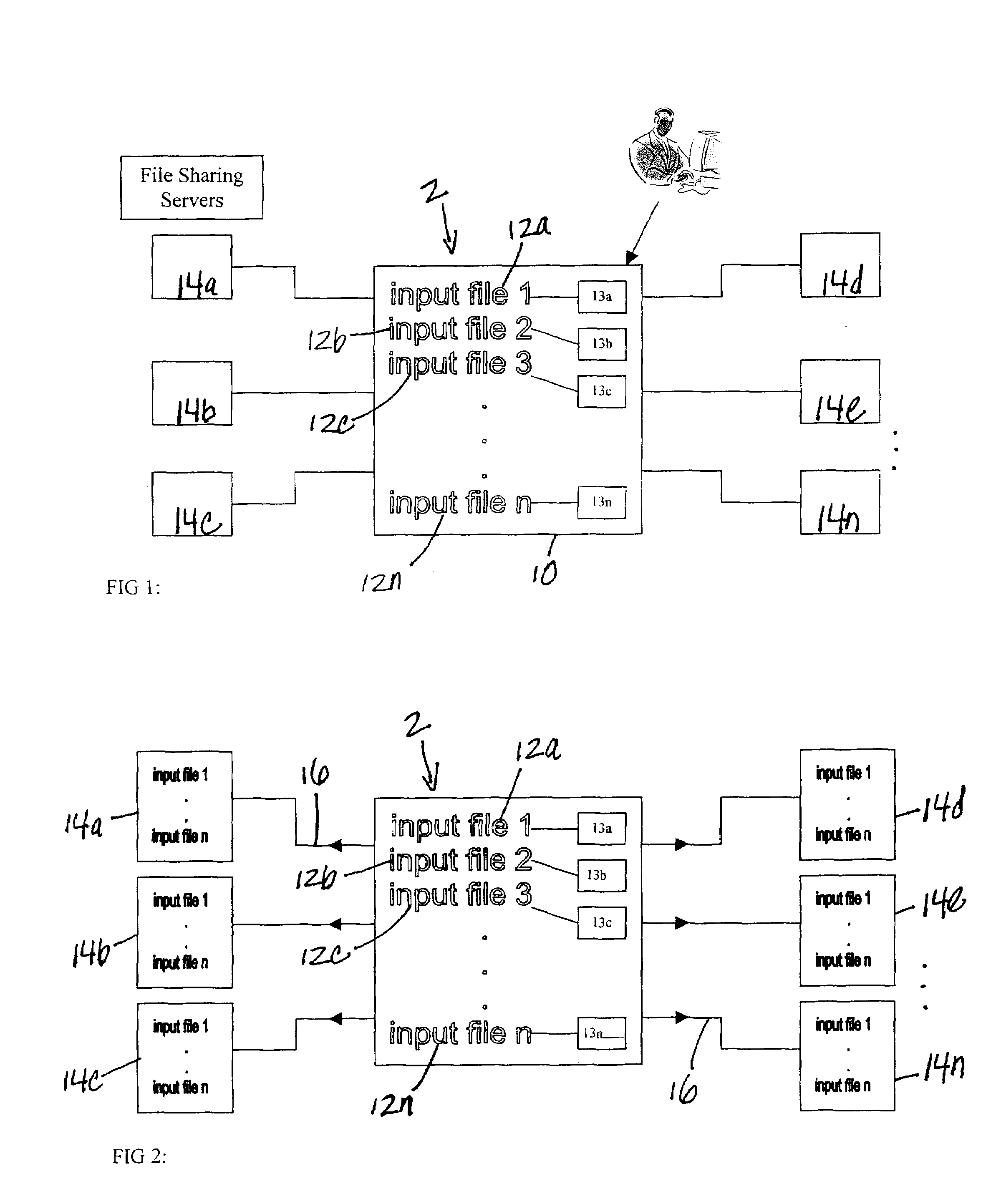

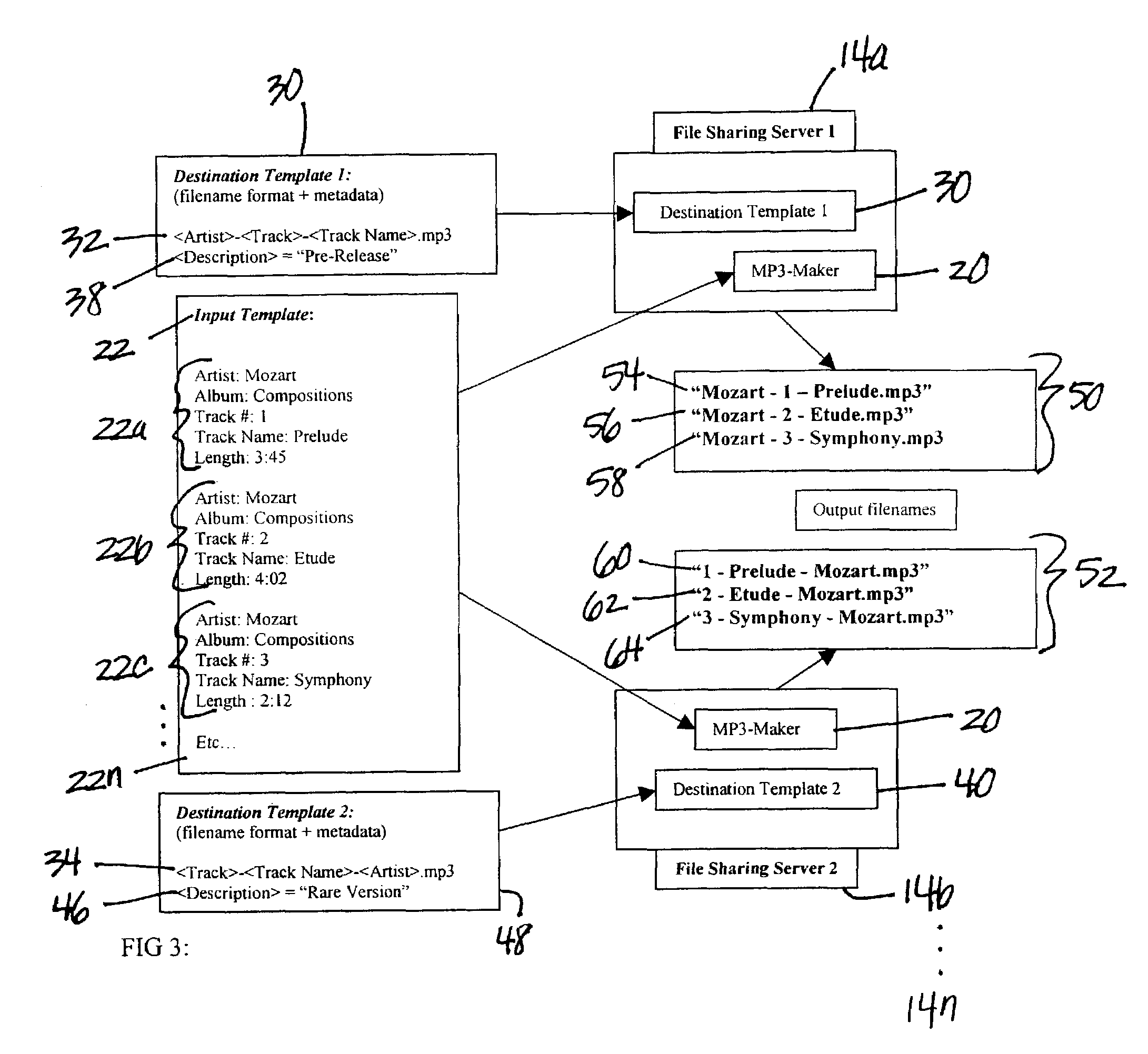

Computer network file synchronization system and method

InactiveUS7441180B1Efficient and effective managementReduce the amount requiredDigital data information retrievalTransmissionFile synchronizationApplication software

A system and method for distribution, replication, and management of files and their metadata across a network of file sharing servers for both preventative and promotion purposes relating to the particular content of the files. The system and method employ a process for dynamically distributing and replicating files across multiple file sharing computer servers using one or more synchronizing computer servers. Once distributed and replicated on a plurality of the file sharing servers, individual, or groups of replicated files are processed using a file modification application, a file input template containing metadata for each replicated file, and preset file destination template information present on each file sharing server. By using different destination template information on each file sharing server in the network, various protective and promotional aspects related to the files may be realized when used in a P2P or similar file sharing network environment.

Owner:MEDIADEFENDER

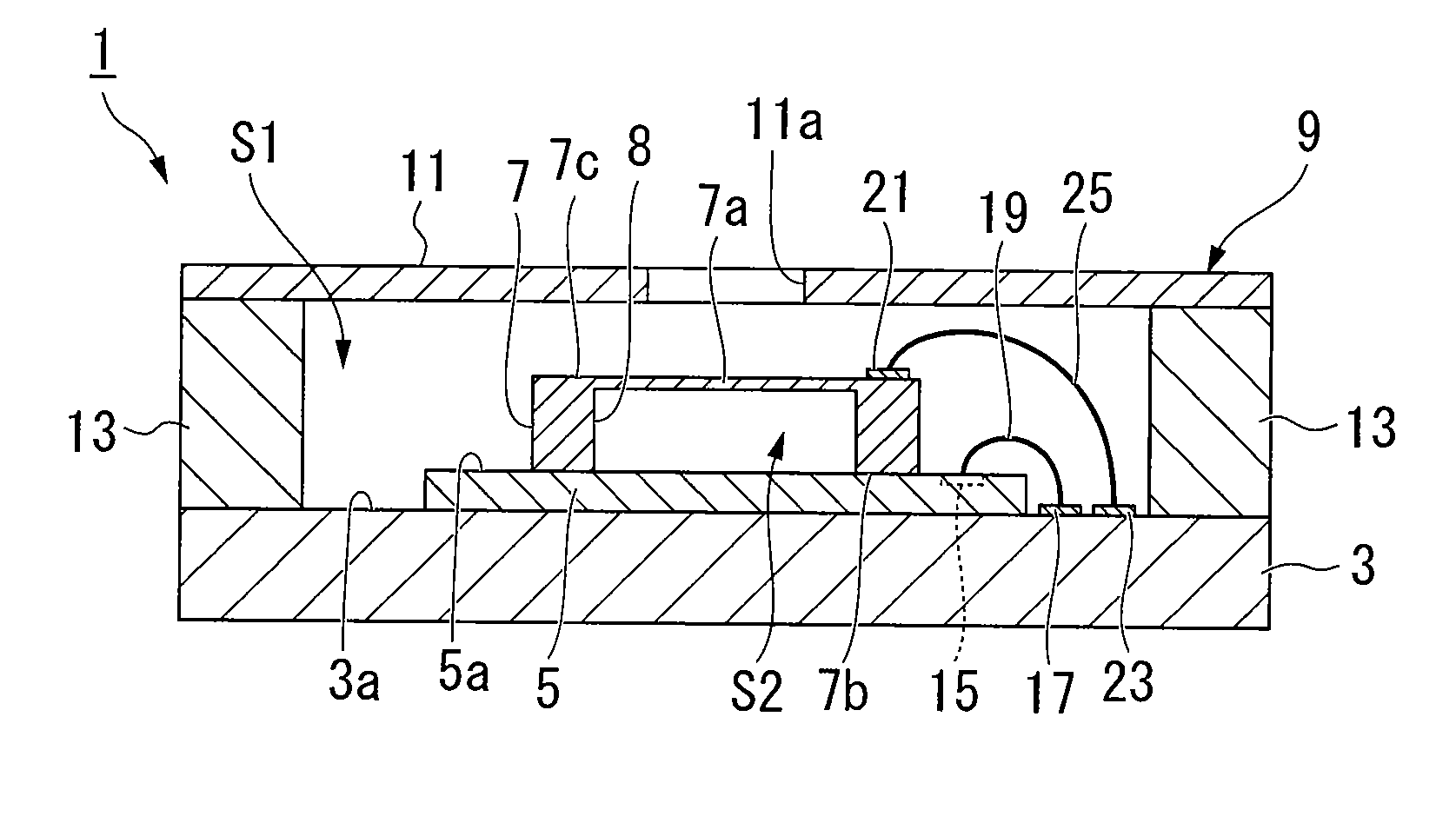

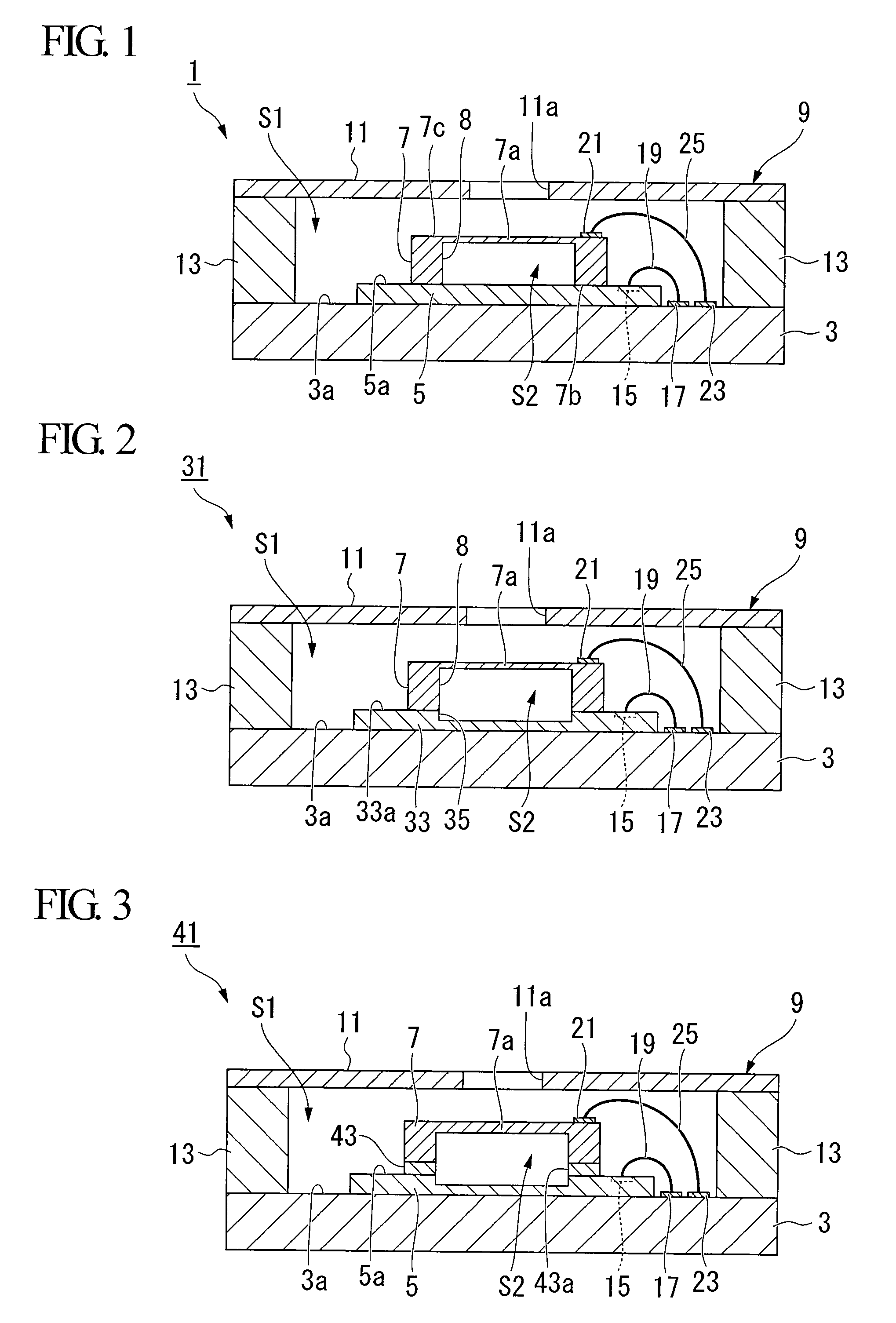

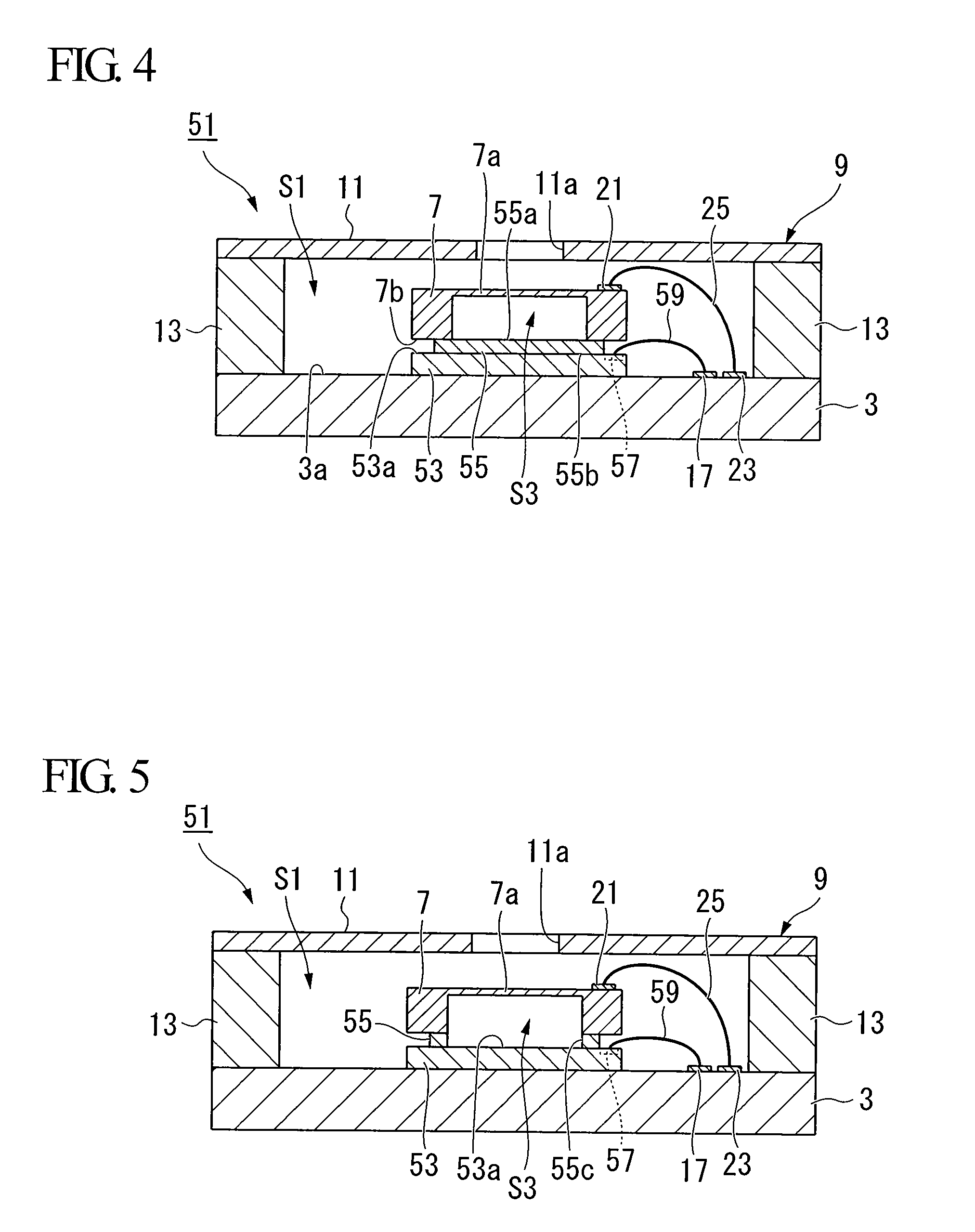

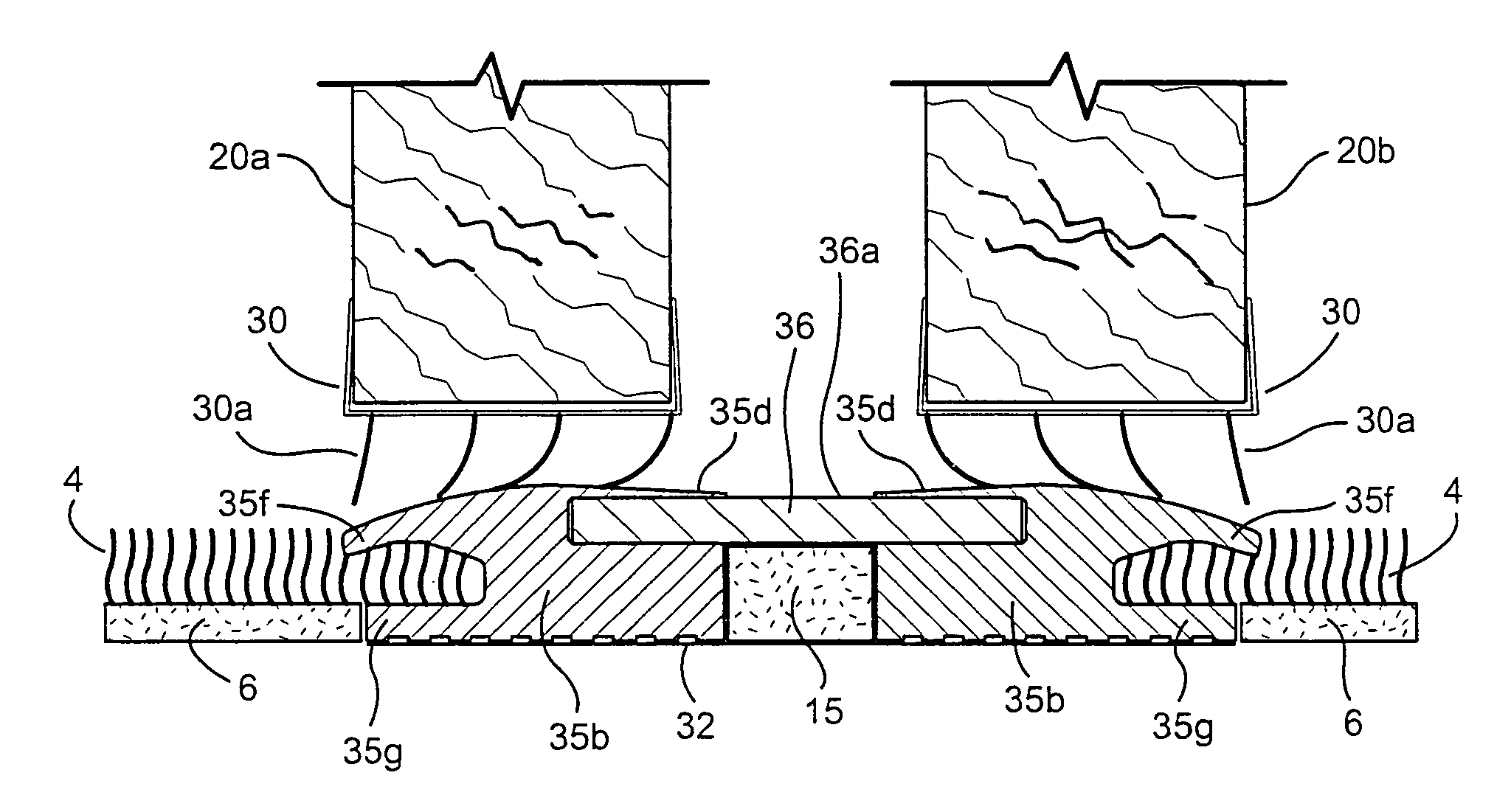

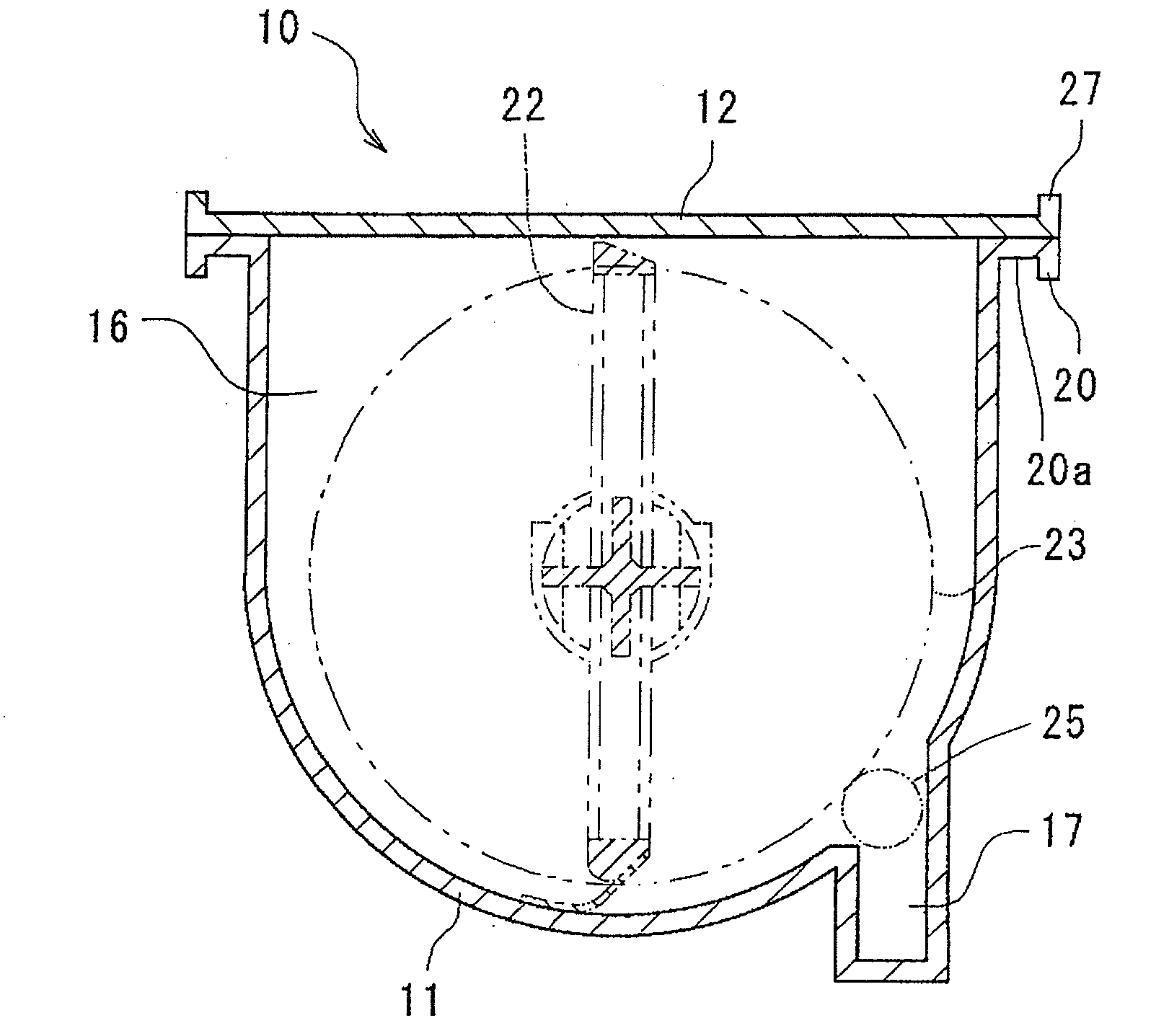

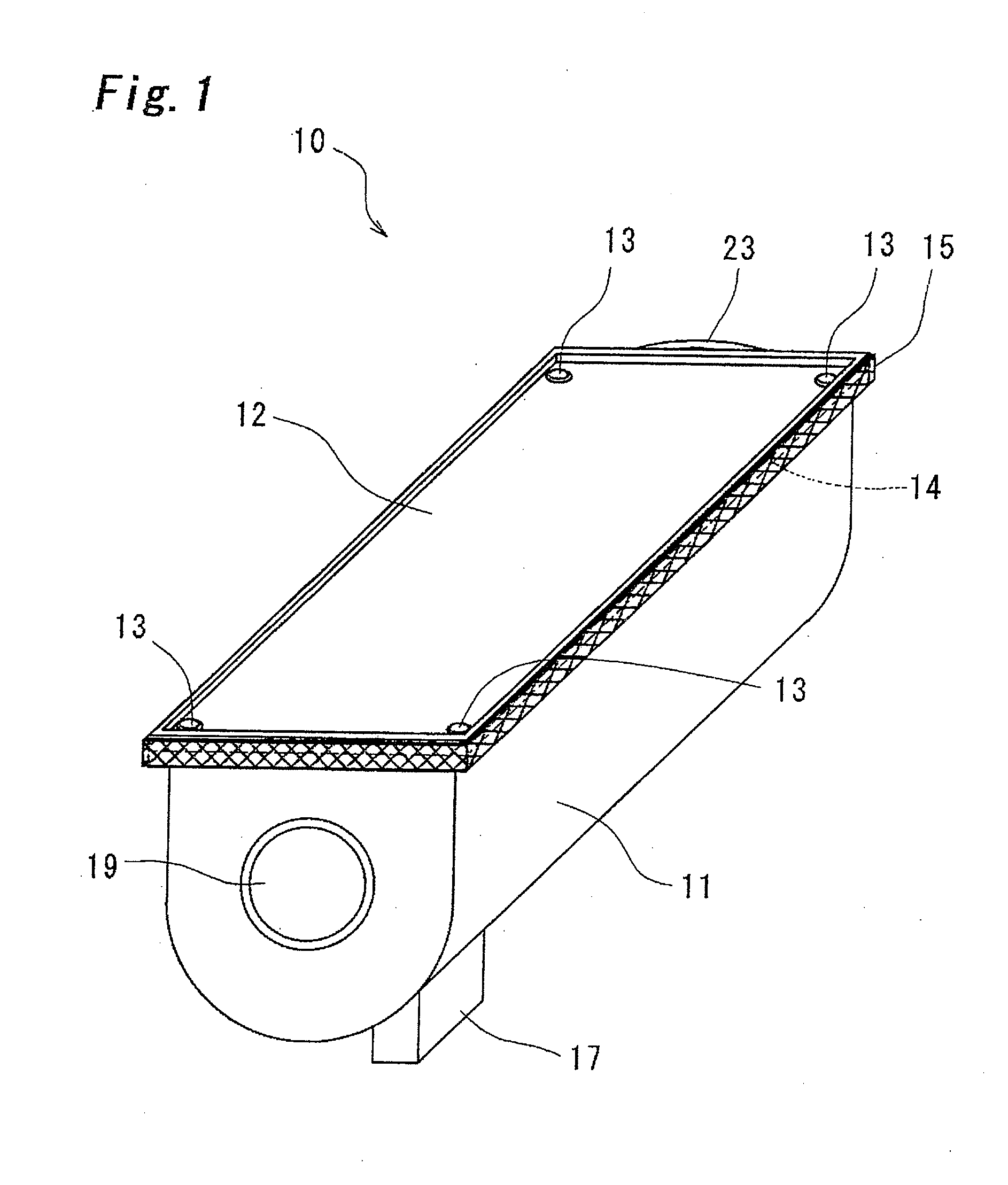

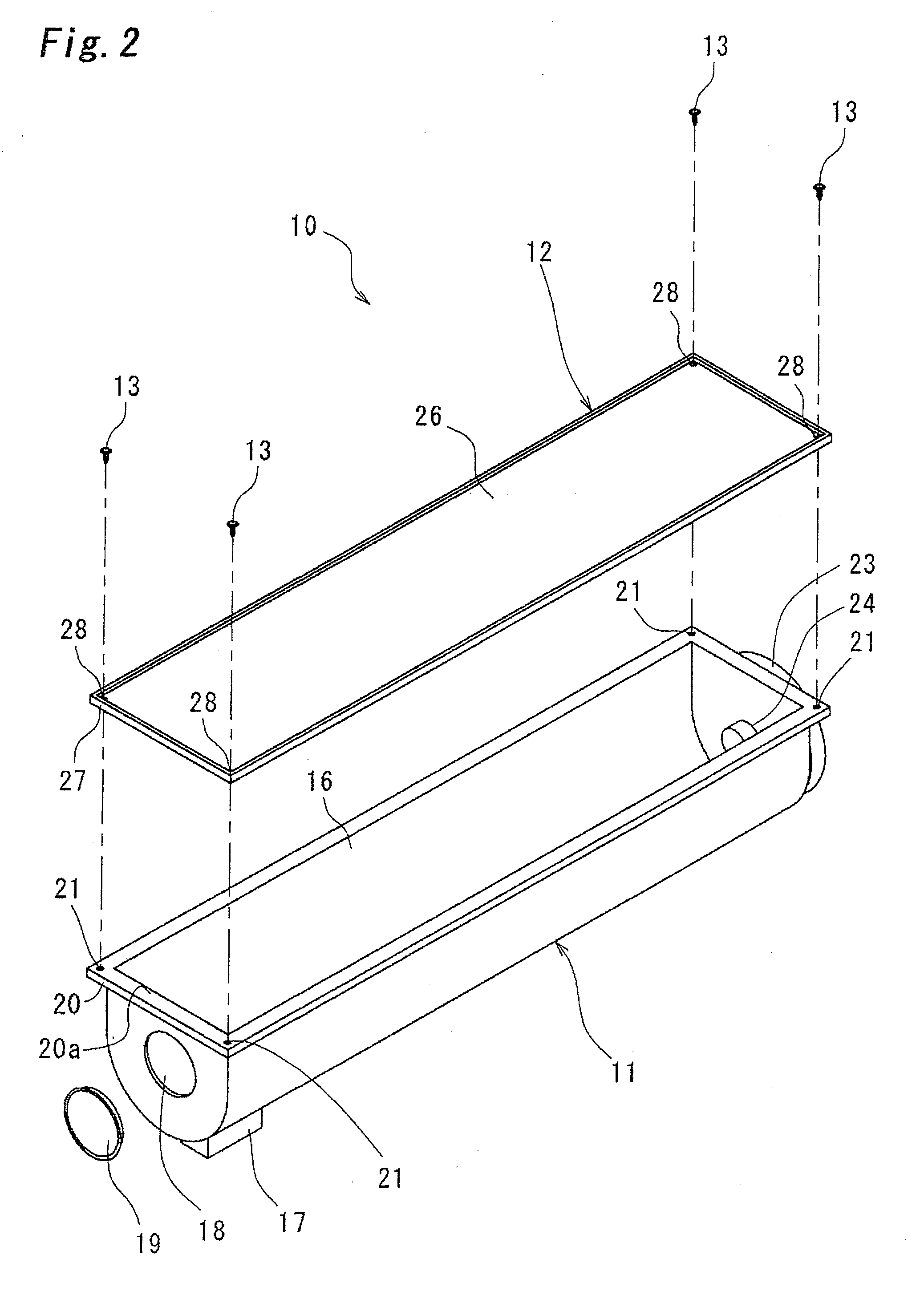

Semiconductor device

InactiveUS20070158826A1Reduced easeFormed with easeMicrophonesLoudspeakersDevice materialSemiconductor chip

A semiconductor device includes a substrate, a semiconductor chip having a diaphragm, which vibrates in response to sound pressure variations, and a circuit chip that is electrically connected to the semiconductor chip so as to control the semiconductor chip, wherein the semiconductor chip is fixed to the surface of the circuit chip whose backside is mounted on the surface of the substrate. Herein, a plurality of connection terminals formed on the backside of the semiconductor chip are electrically connected to a plurality of electrodes running through the circuit chip. A ring-shaped resin sheet is inserted between the semiconductor chip and the circuit chip. The semiconductor chip and the circuit chip vertically joined together are stored in a shield case having a mount member (e.g., a stage) and a cover member, wherein connection terminals of the circuit chip are exposed to the exterior via through holes of the stage.

Owner:YAMAHA CORP

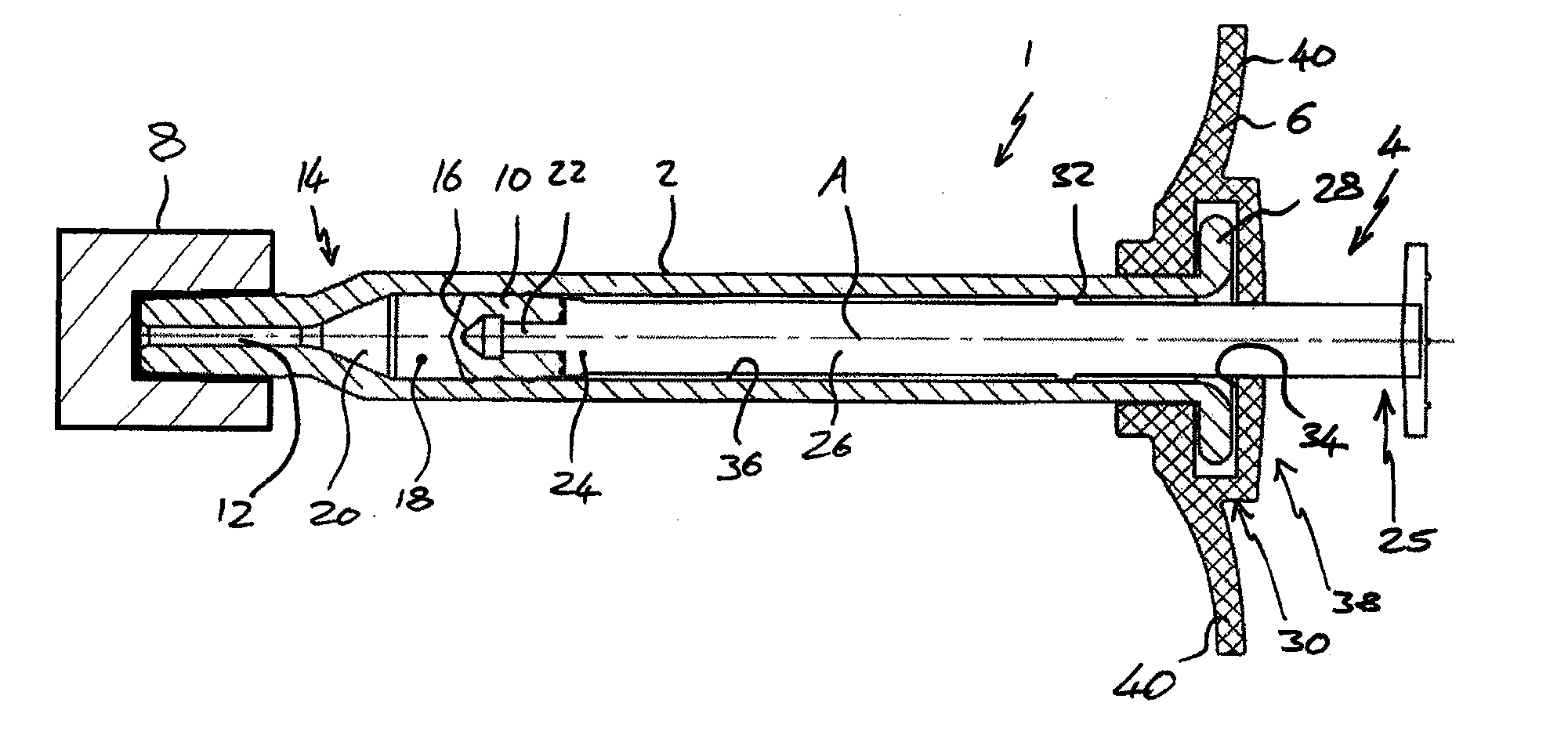

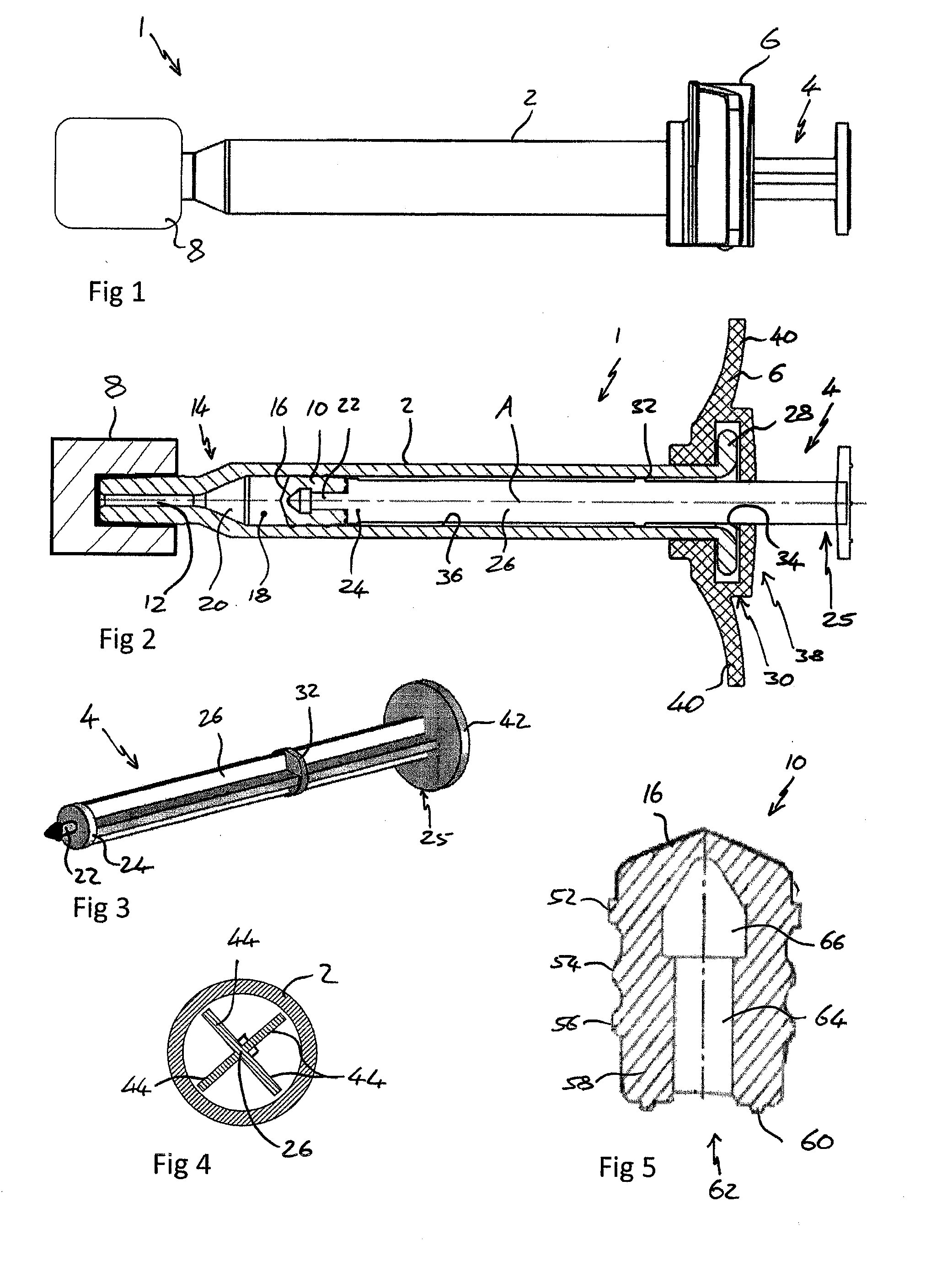

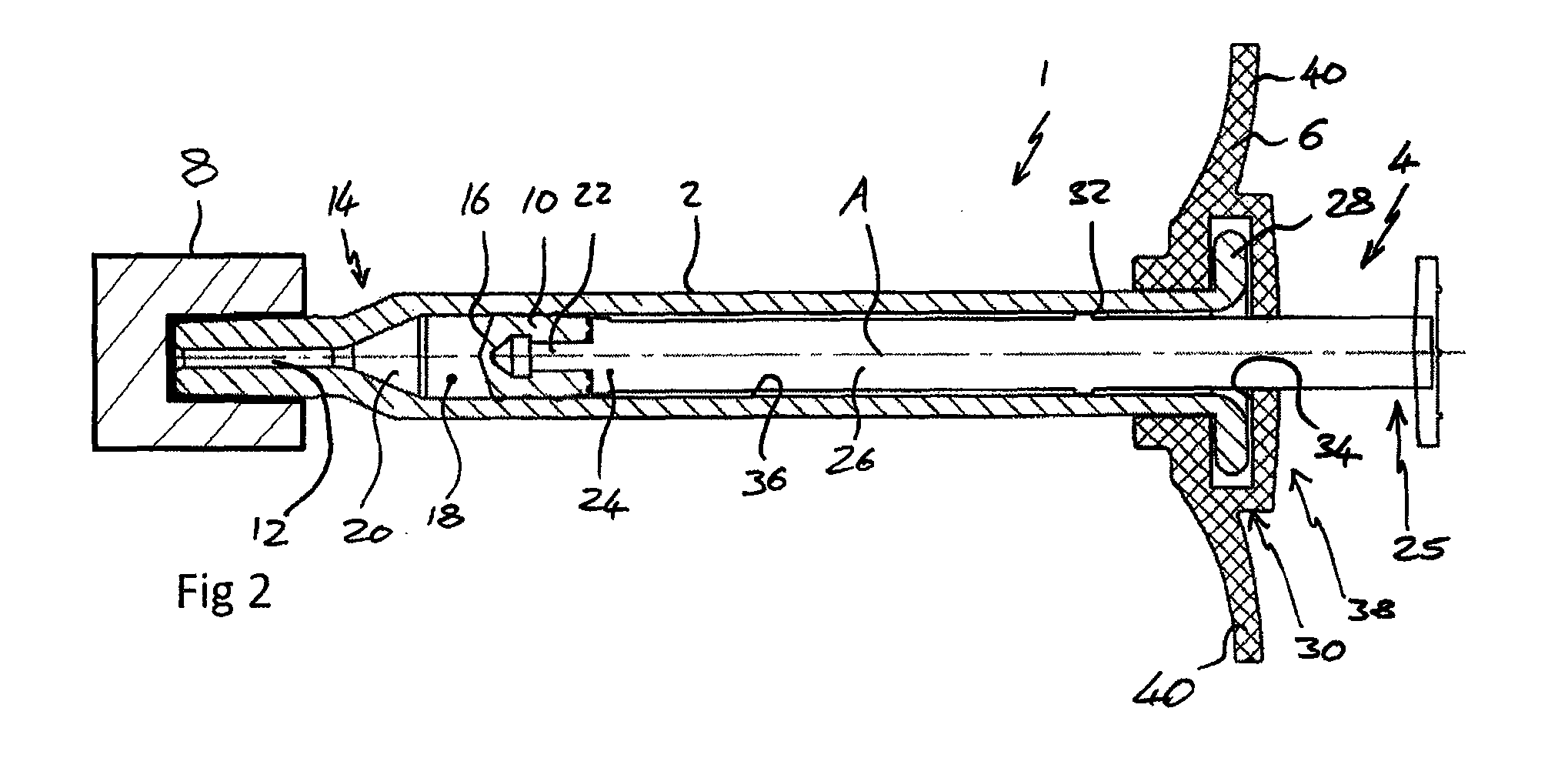

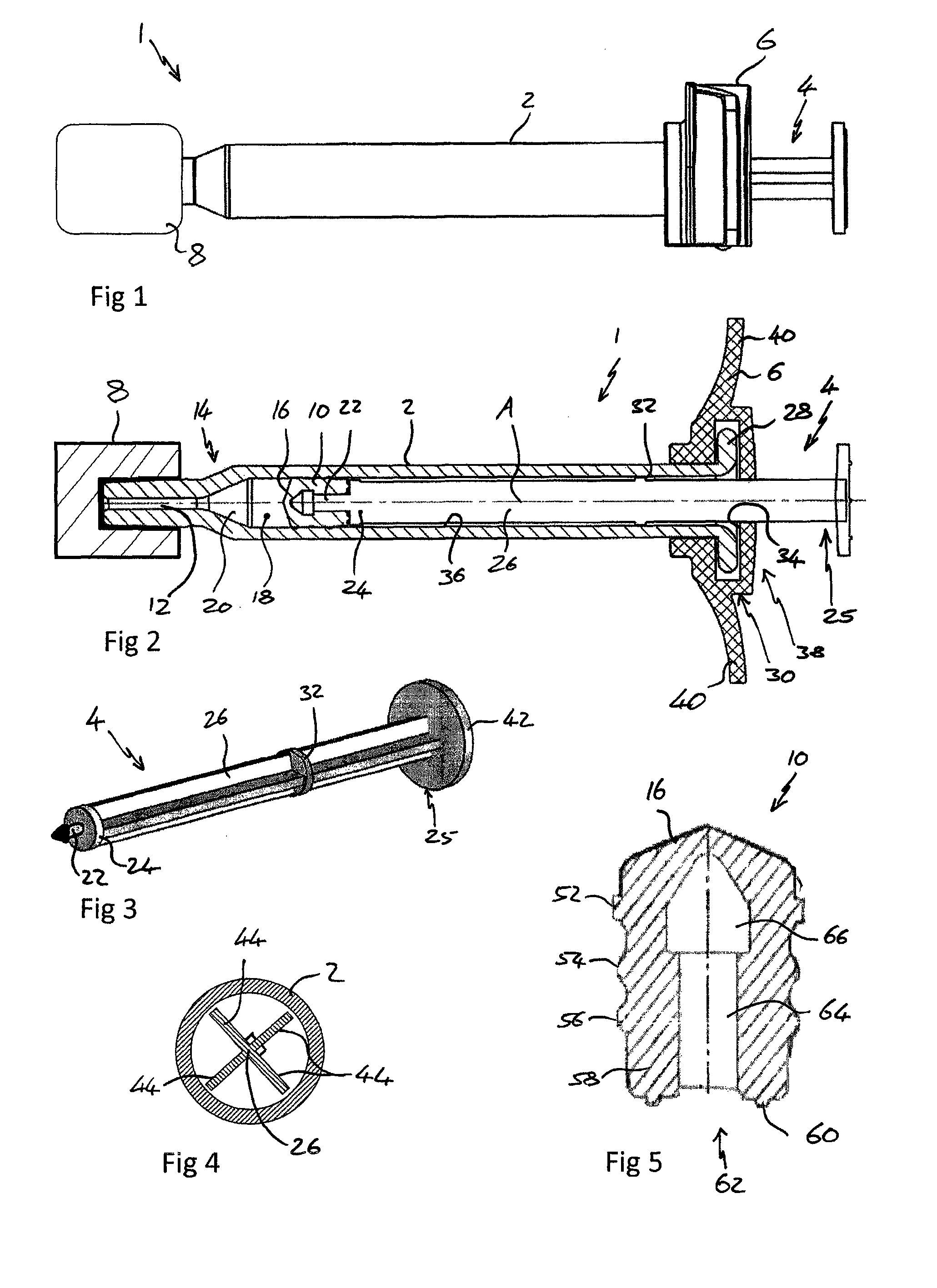

Syringe

ActiveUS20140012227A1Lower tolerances in the component sizesLess flexibilitySenses disorderAmpoule syringesOphthalmologySurgery

Owner:NOVARTIS PHARM CORP +2

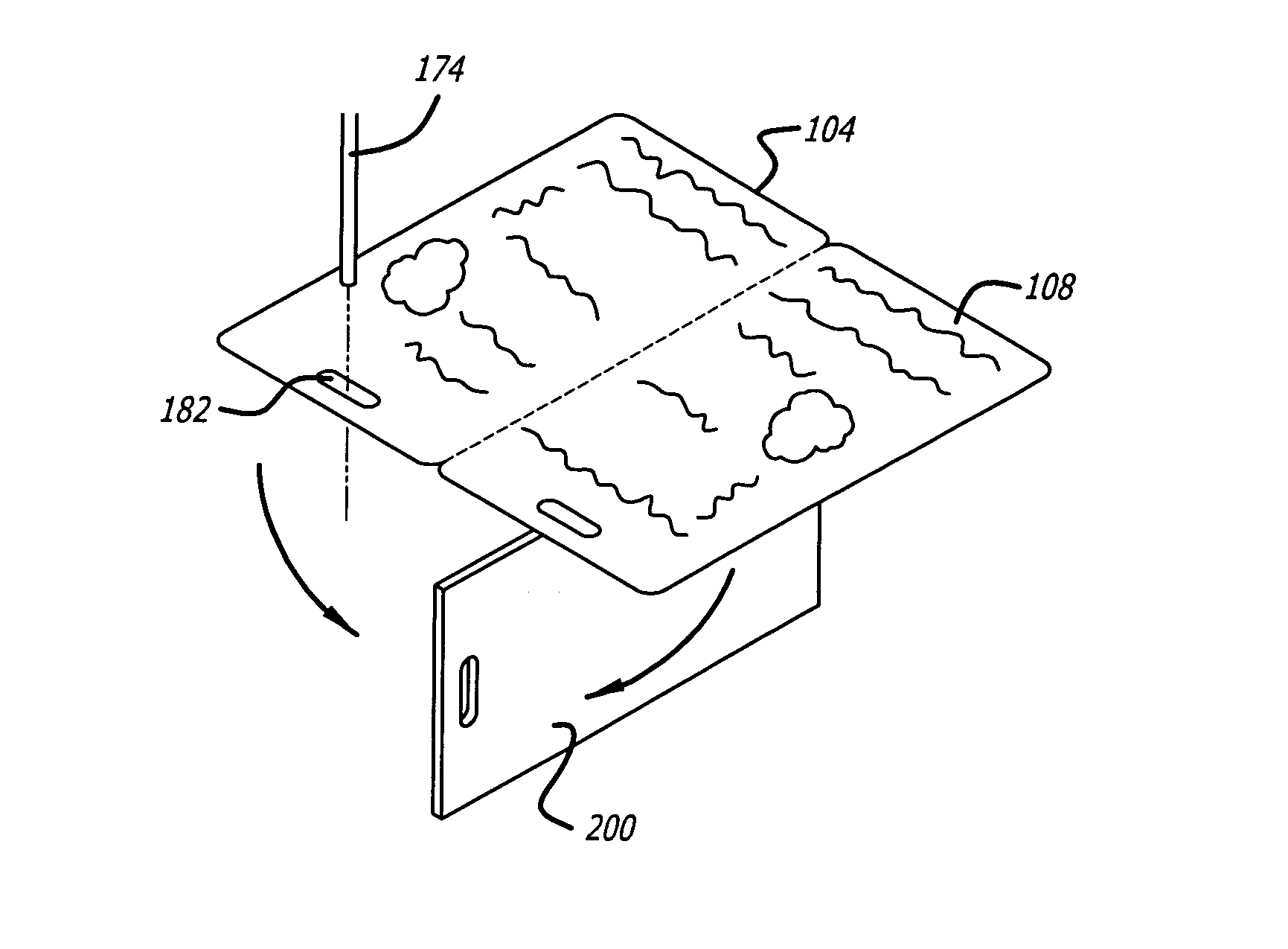

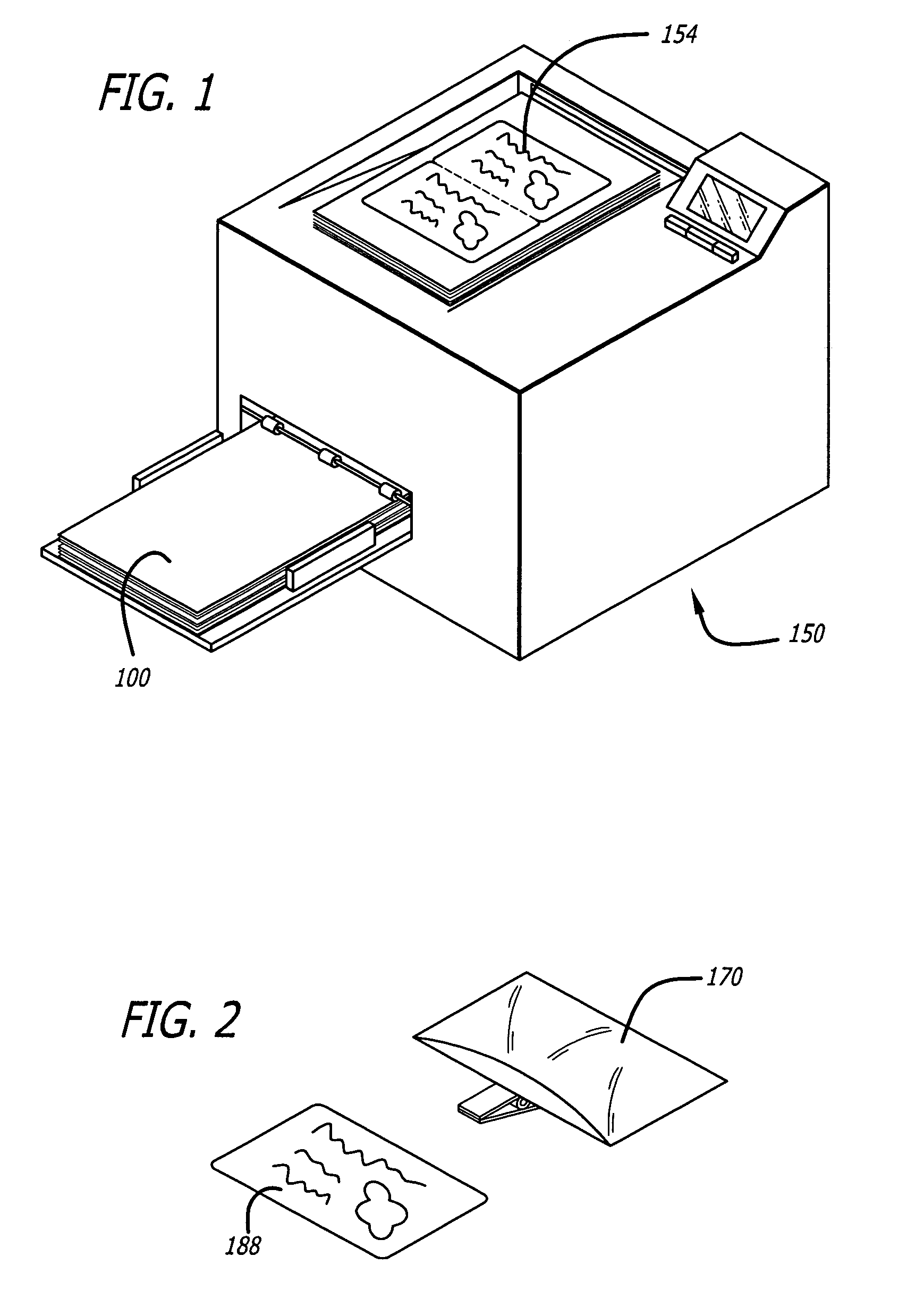

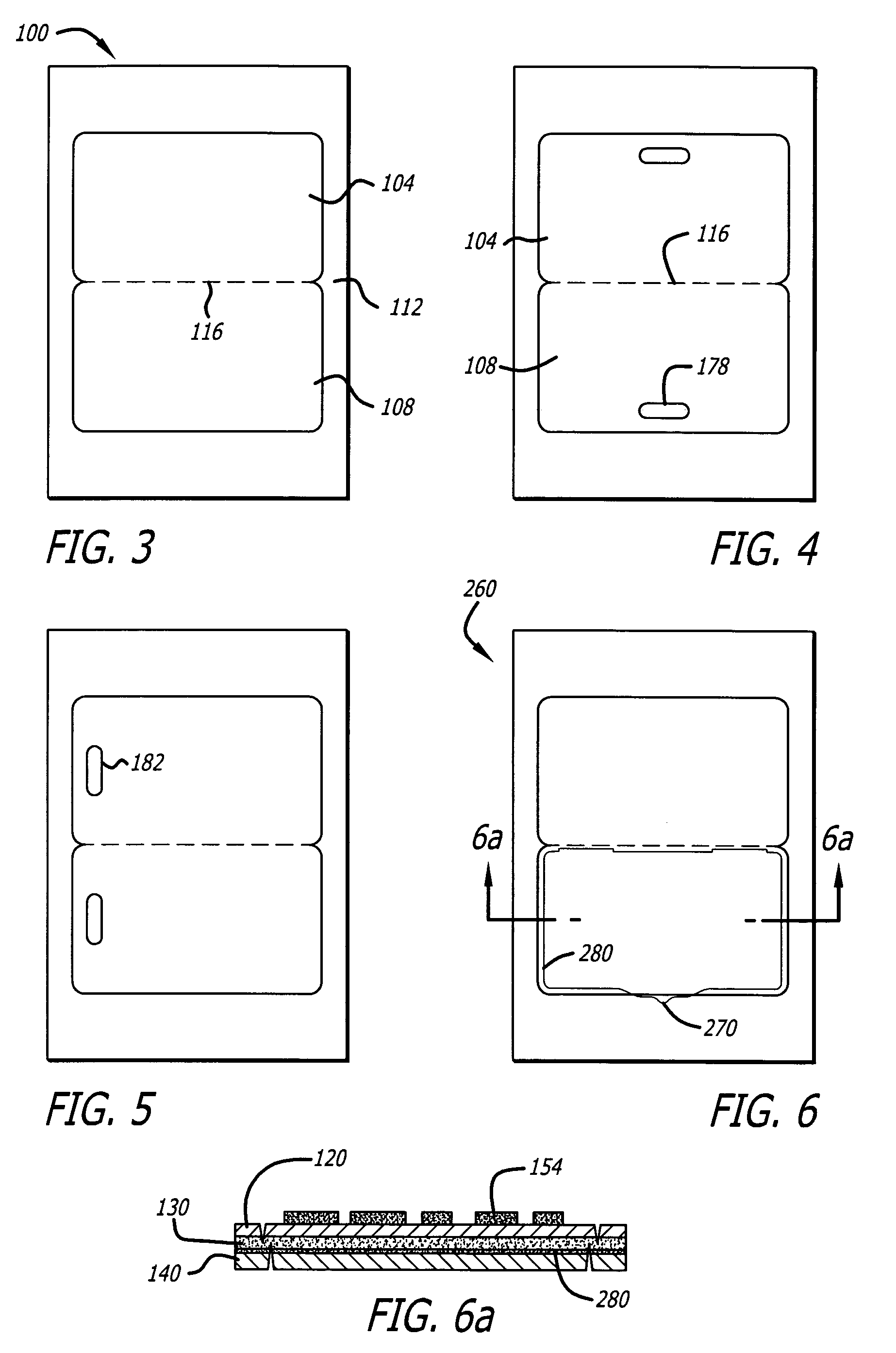

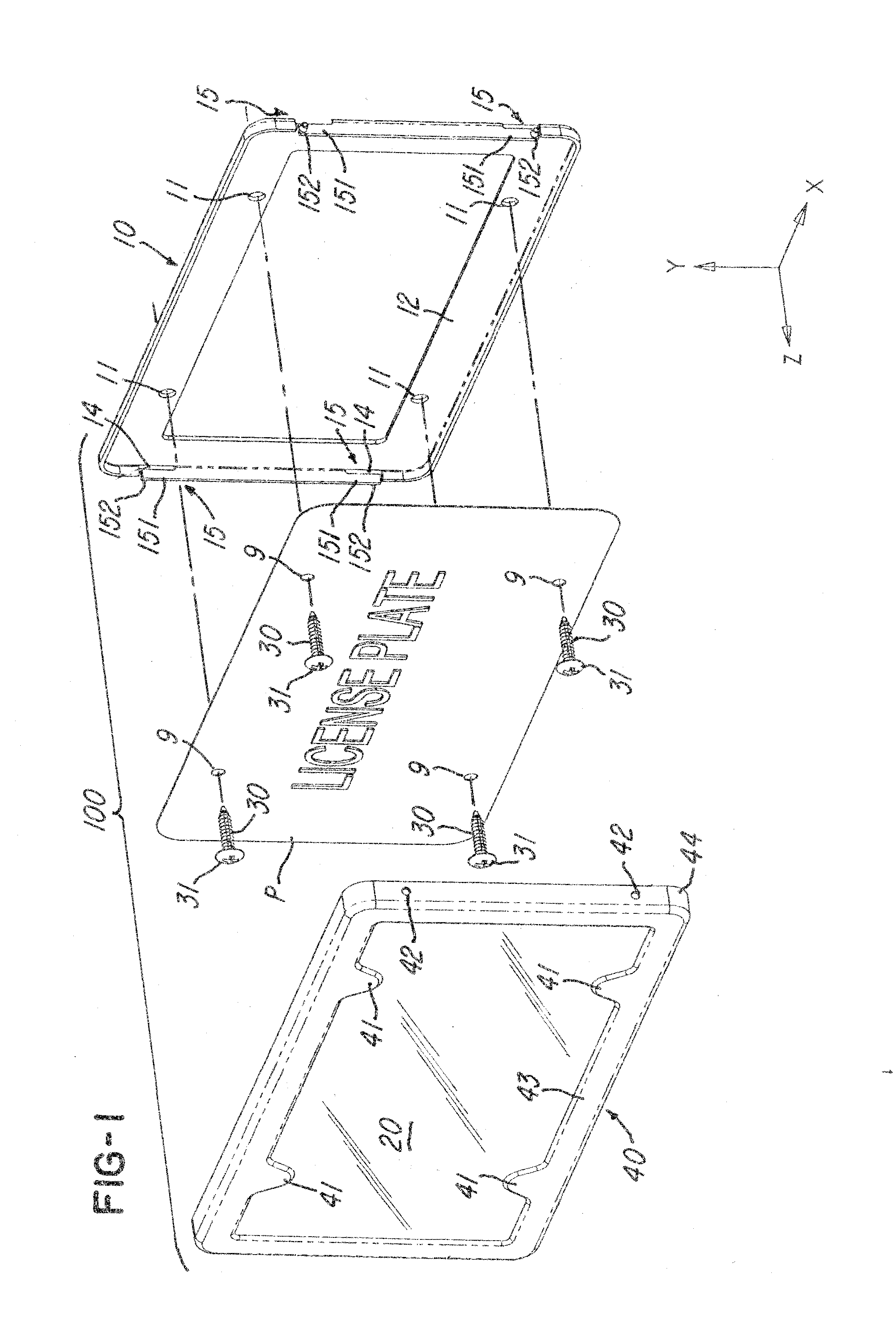

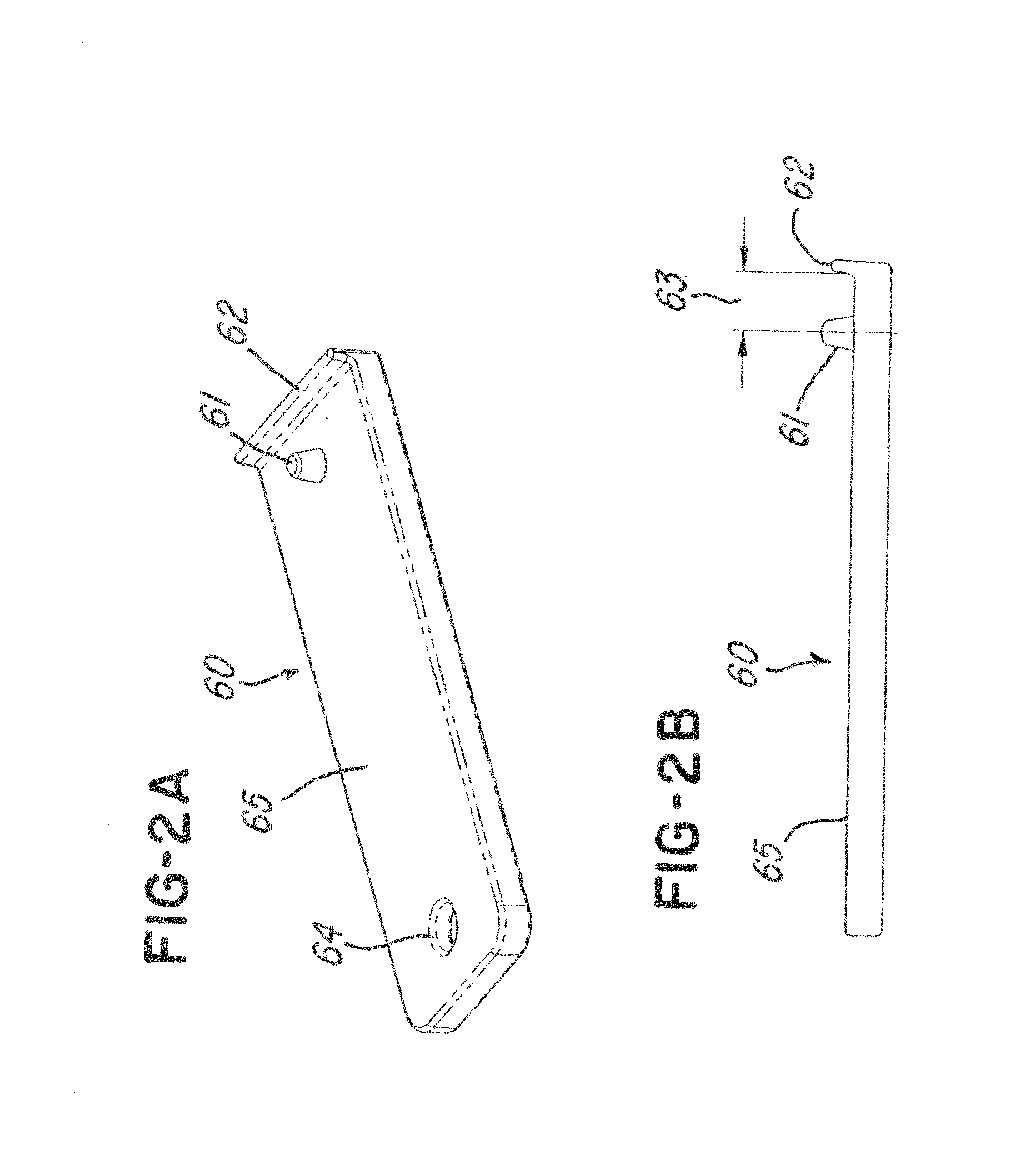

Identification badge construction

A label badge sheet construction including a facestock sheet releasably adhered to a liner sheet. A weakened separation line in the facestock sheet defines at least one label. After the sheet construction has been passed through a printer or copier and desired indicia printed on the at least one label the printed label can be removed to be used as a visitor's badge or the like. Preferably, first and second labels are formed with a fold line separating them, and a weakened separation line through the liner sheet forms a liner panel which is adhered to the back of the first label. With the first and second labels and the liner panel removed as a label assembly and the labels folded on the fold line, through-holes through the first and second labels and the liner panel are aligned. A lanyard or clip can be passed through the aligned through-holes. The liner panel thereby reinforces the through-holes. The invention further includes the assembled label badge, the method of forming same, the method for manufacturing the sheets and the kit which includes sheets, software, hardware, etc.

Owner:CCL LABEL INC

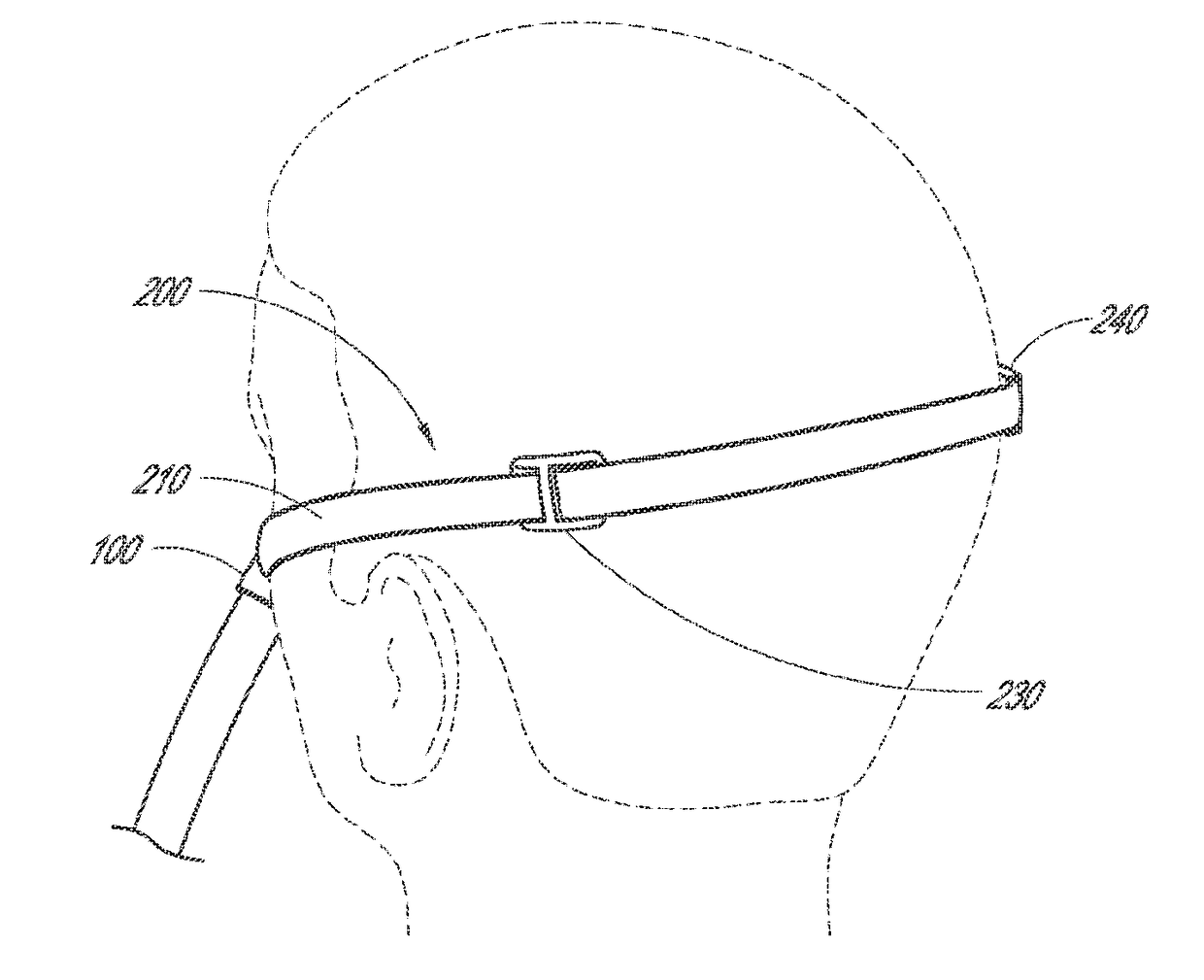

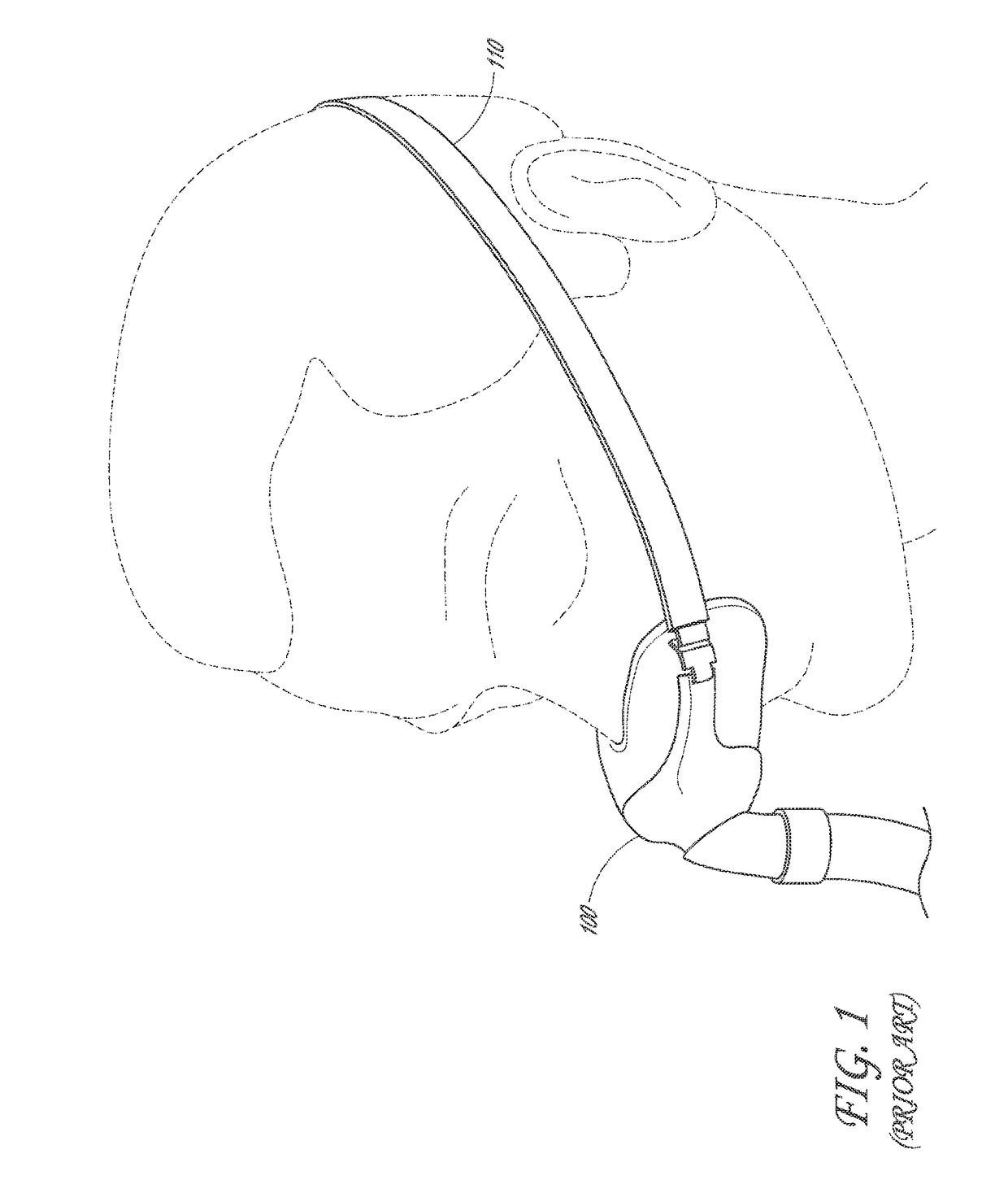

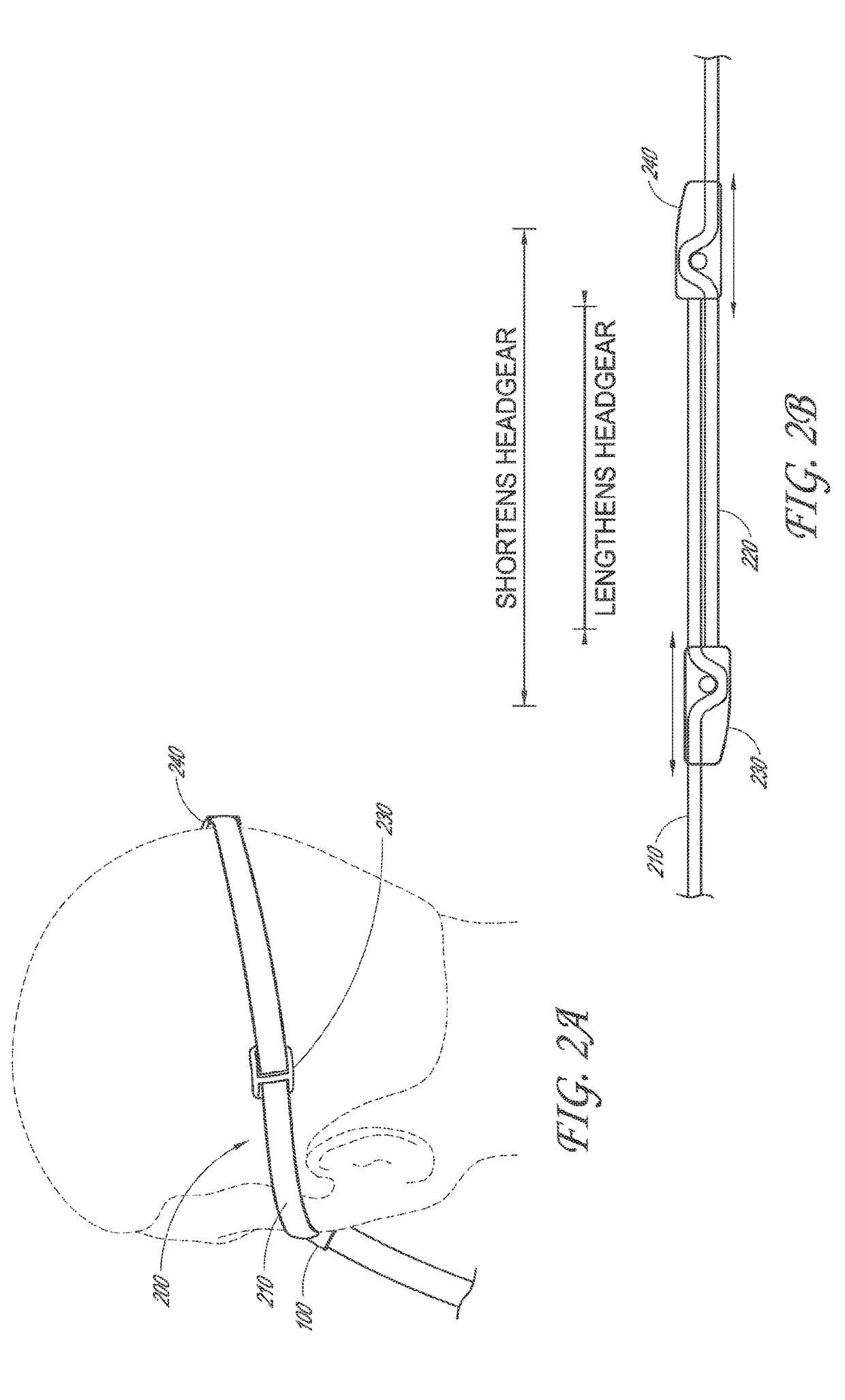

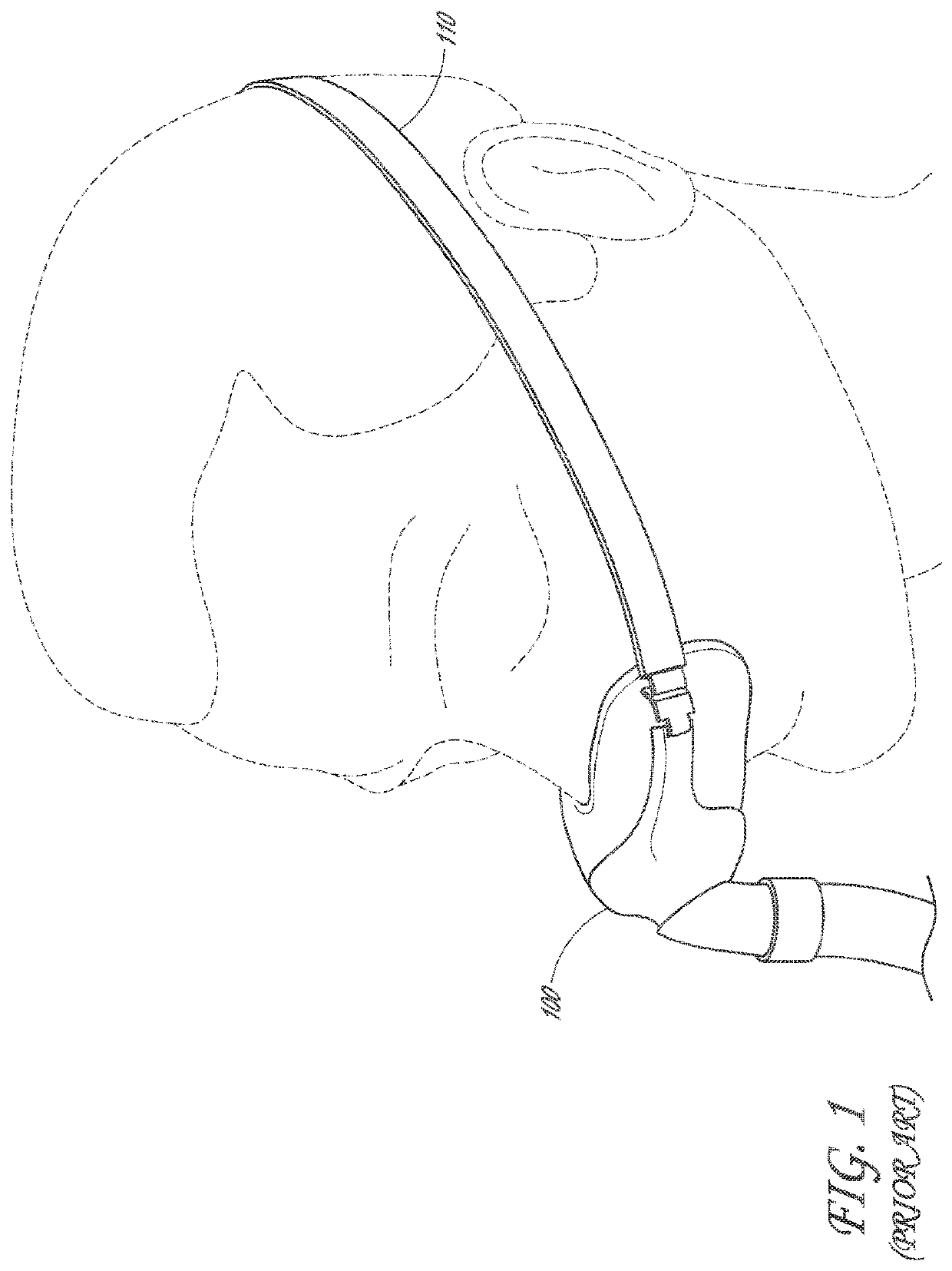

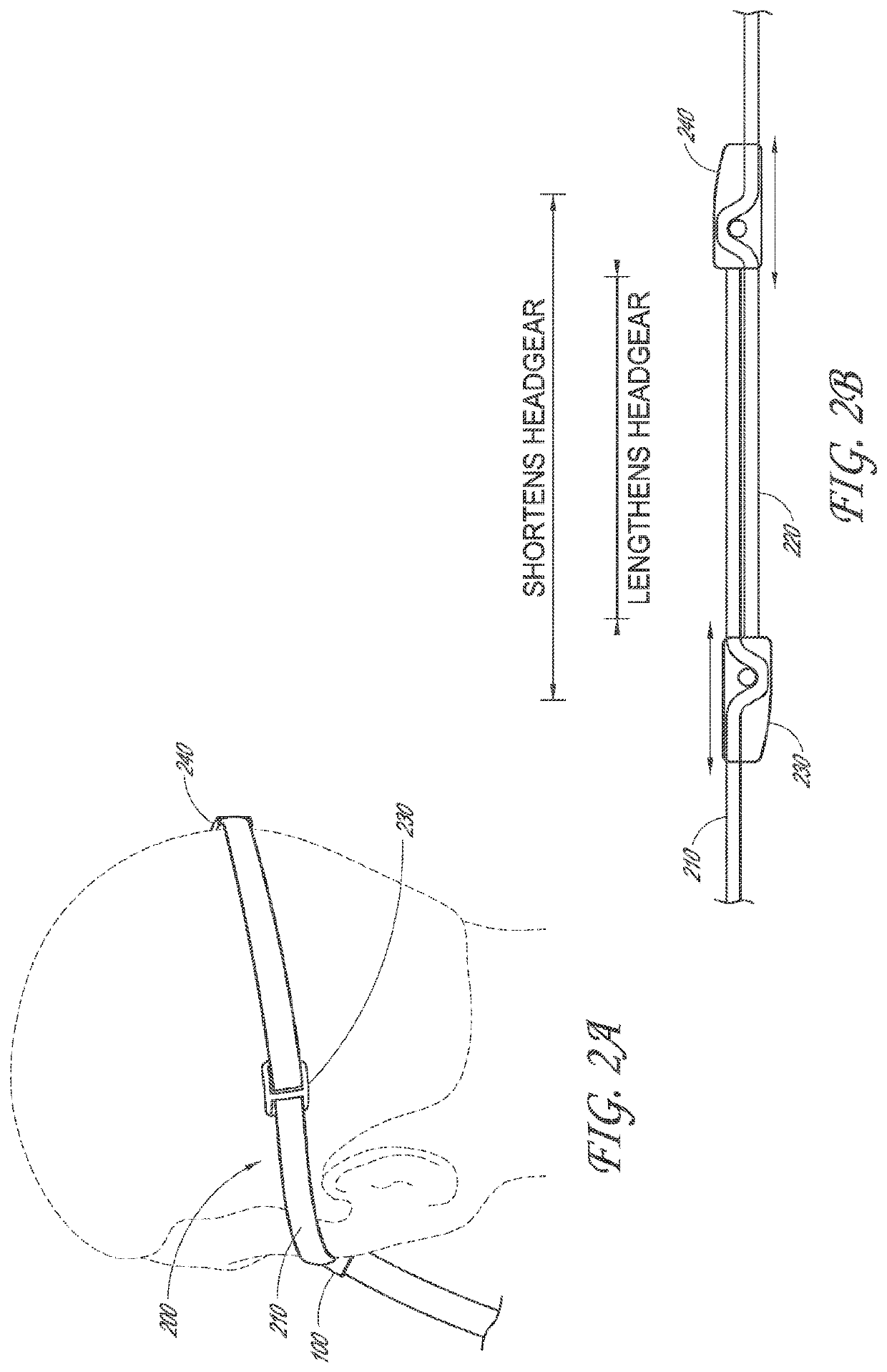

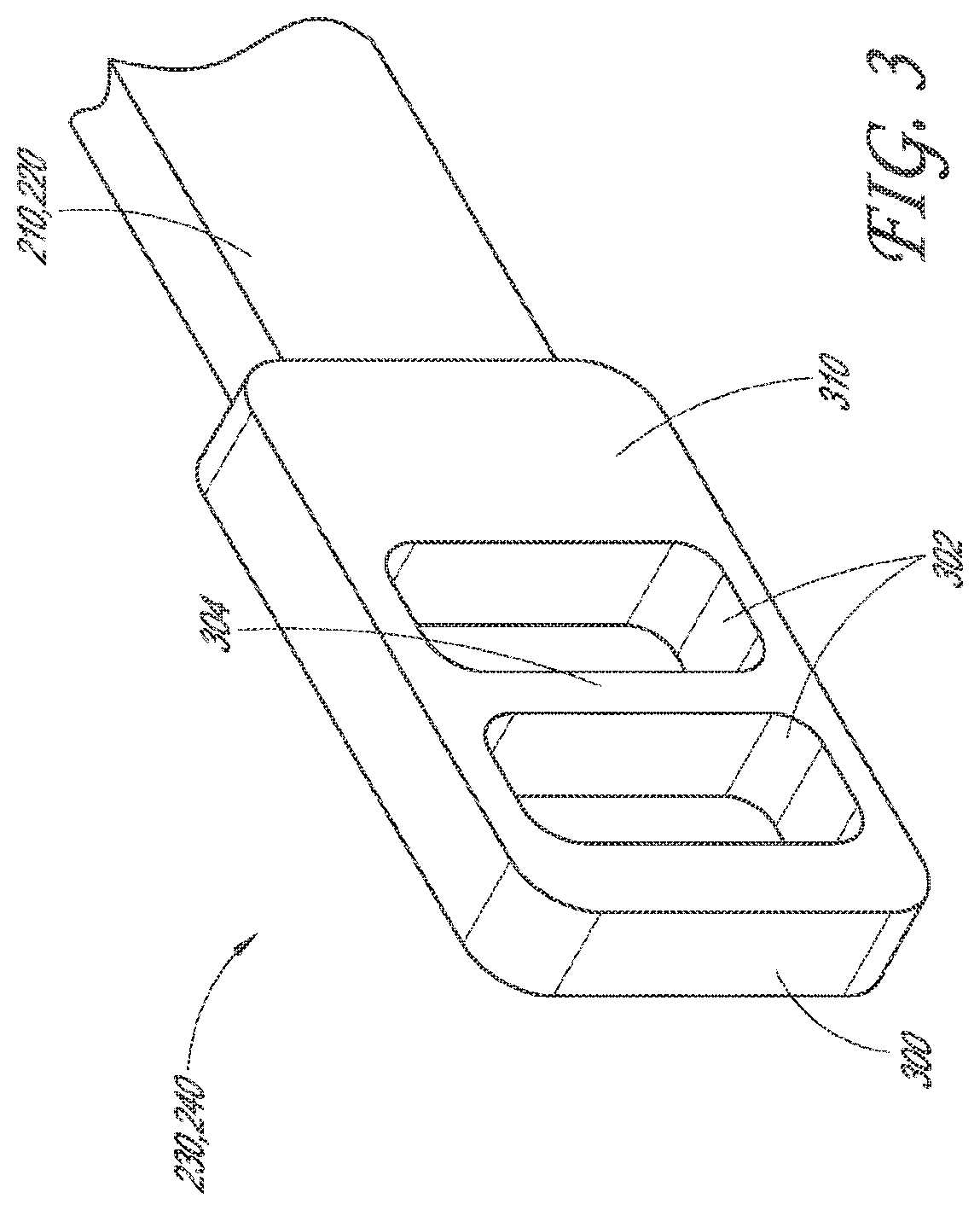

Headgear for a respiratory mask

ActiveUS20170281894A1Improve stabilityIncrease frictionRespiratory masksMedical devicesEngineeringRespiratory mask

A headgear for a respiratory mask has first and second straps configured to be connected to each other by first and second buckles. The straps are configured to overlap in a region that contacts the rear of a user's head. The overlapping regions of the first and second straps can be positioned in a bifurcated configuration to improve stability on a user's head. The first and second buckles can feature a glider end through which one of the first and second straps can slide and a strap attachment end to which the other strap is permanently connected. In some embodiments, the first and second buckles have two components that are pivotally connected to allow adjustment of the headgear size whilst in a bifurcated configuration.

Owner:FISHER & PAYKEL HEALTHCARE LTD

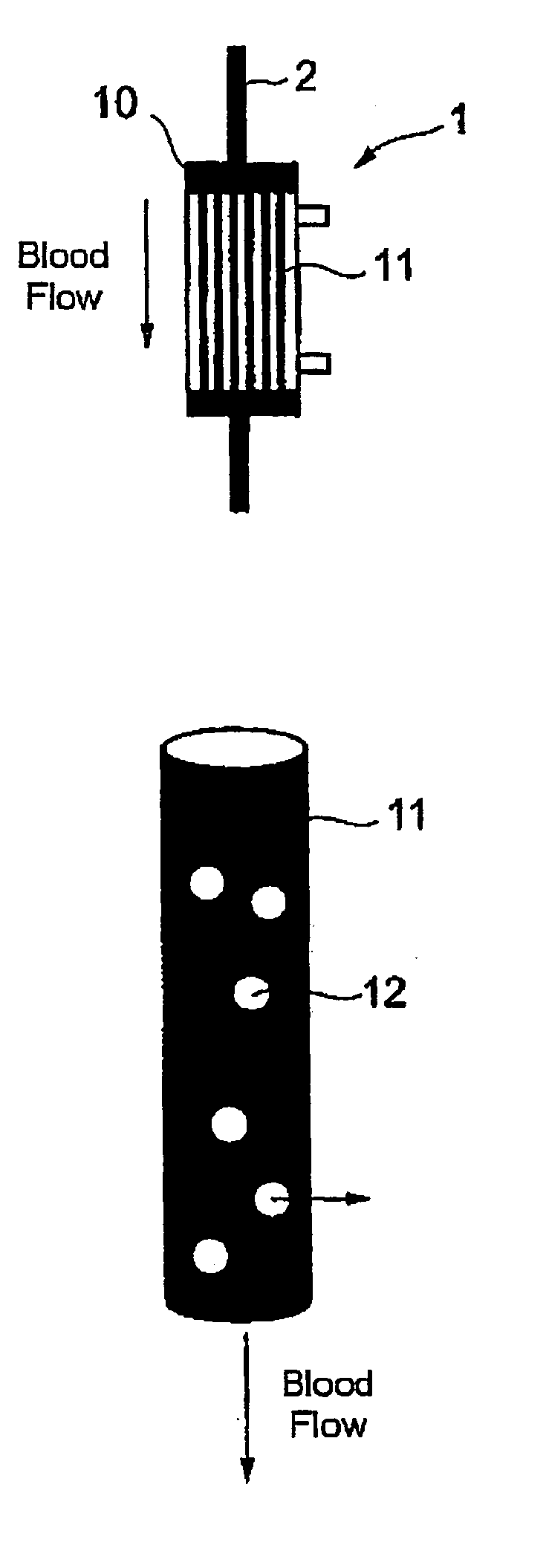

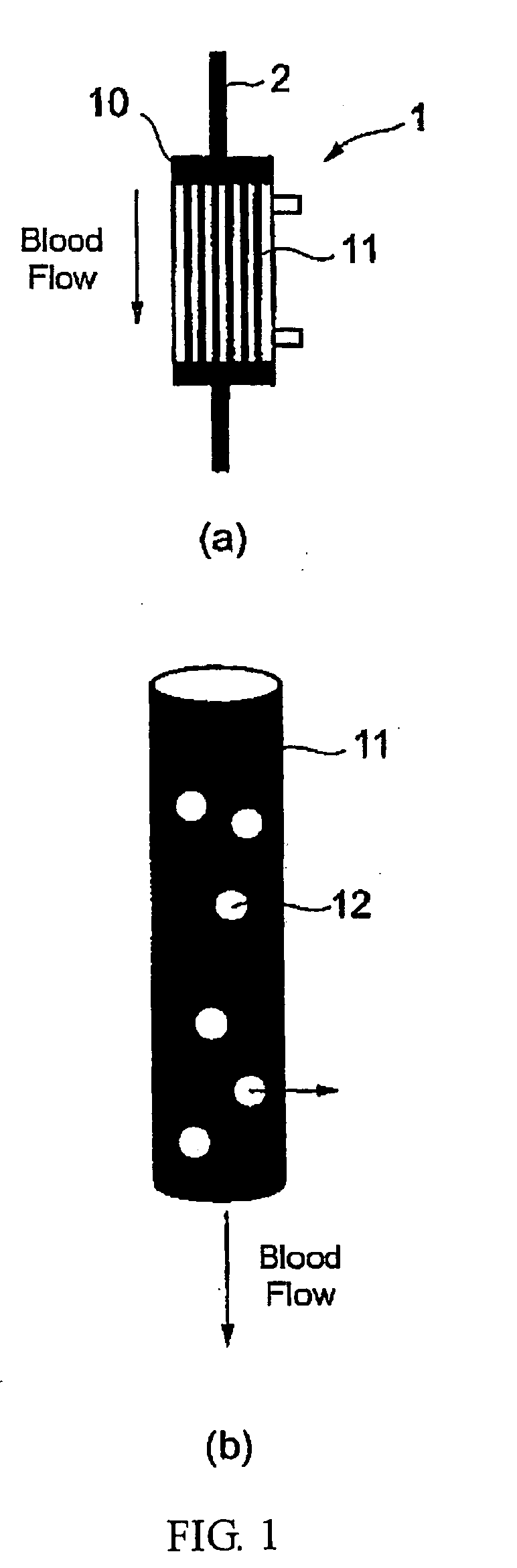

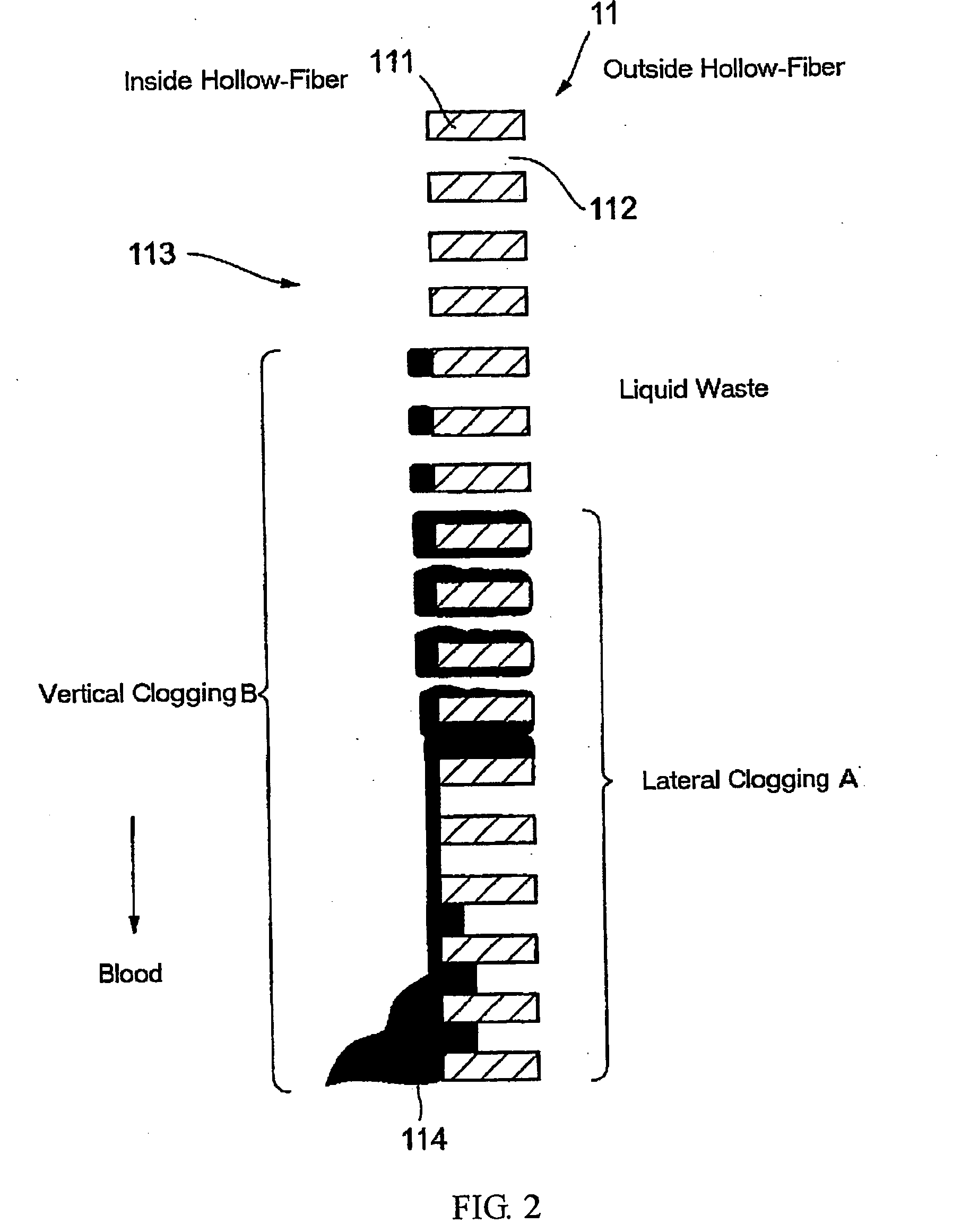

Method for calculating filter clogging factor and bed-side system

InactiveUS20050203493A1Inhibit progressEasy to adjustOther blood circulation devicesHaemofiltrationMedicineBlood inflow

Method for calculating a clogging factor of a filter composed of hollow-fiber membrane, which has a blood inflow portion 32a and a blood outflow portion 32b, by passing a blood, the method including the steps of measuring at least two pressure selected from the group consisting of a pressure (Pa) in said blood inflow portion, a pressure (Pv) in said blood outflow portion, a filtering pressure (Pf1) in said blood inflow portion, and a filtering pressure (Pf2) in said blood outflow portion and calculating a filter clogging factor in vertical direction and / or a filter clogging factor in lateral direction using at least two of the measured pressures, flow rate information, biometric information (viscosity information and so on), and structure information.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Syringe

ActiveUS9220631B2Lower tolerances in the component sizesLess flexibilityAmpoule syringesSenses disorderOphthalmologySurgery

Owner:NOVARTIS PHARM CORP +2

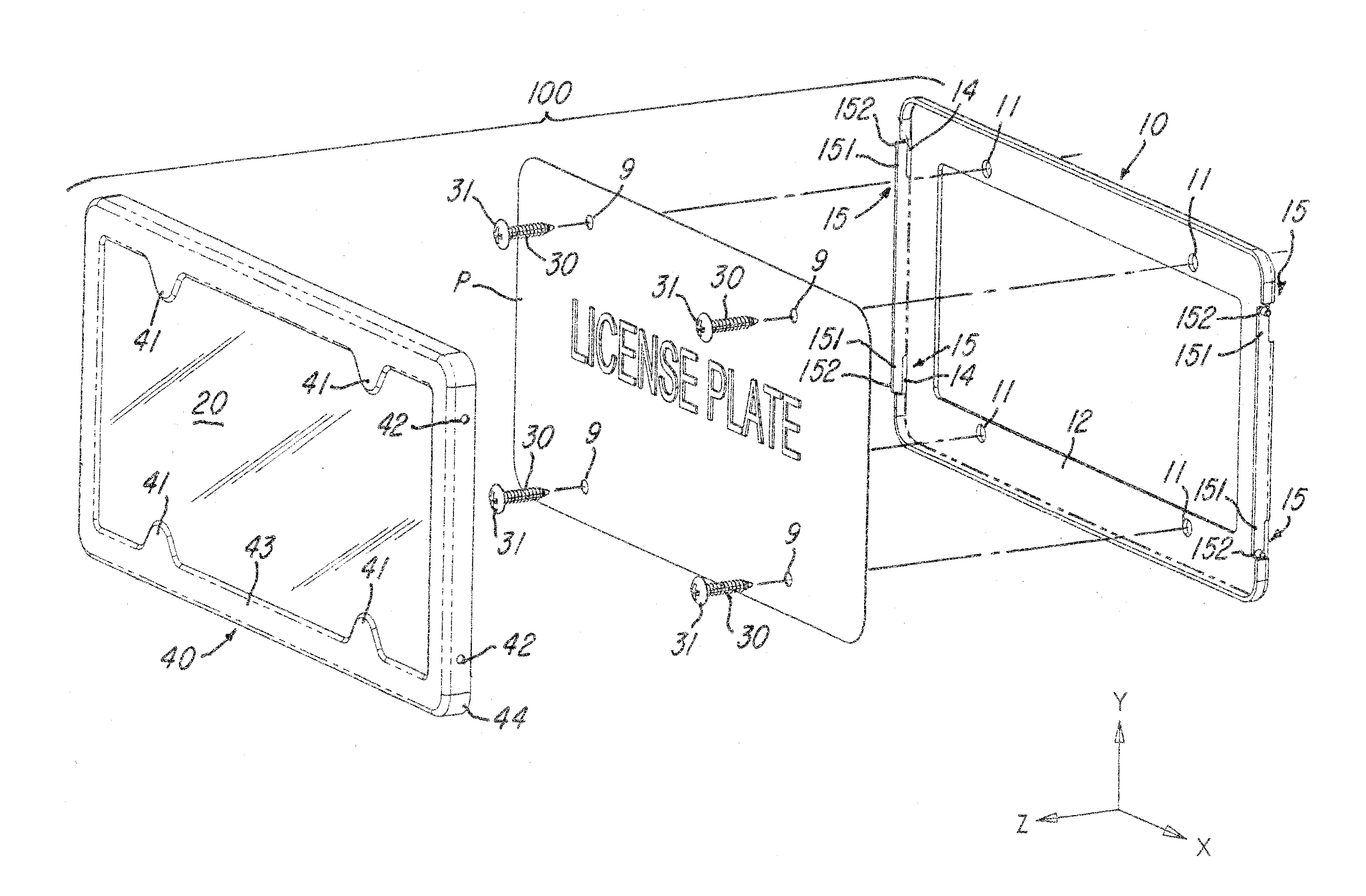

Semi-locking license plate holder

InactiveUS20080098629A1Accessibility reducedImprove visibilityBuilding locksVehicle componentsBiomedical engineeringLicense

A semi-locking license plate holder for an automobile including a rear frame, a frame cover and optionally a transparent plate. The rear frame has at least one fastener attach point for insertion of at least one fastener such that the fastener head abuts the rear frame securing it to the automobile. The frame further includes an assembly mechanism having at least one pin arm. The pin arm has at least one pin for attachment to the frame cover. The frame cover has at least one pin hole designed to align with at least one pin on the pin arm such that the pins may be inserted into the pin hole or holes. The frame cover has at least one fastener head cover for covering at least one and preferably all of the fastener heads such that the fastener heads cannot be used to remove the license plate without first removing the frame cover.

Owner:REAL CARBON FIBER LLC D B A ZERO 261 DESIGN GRP

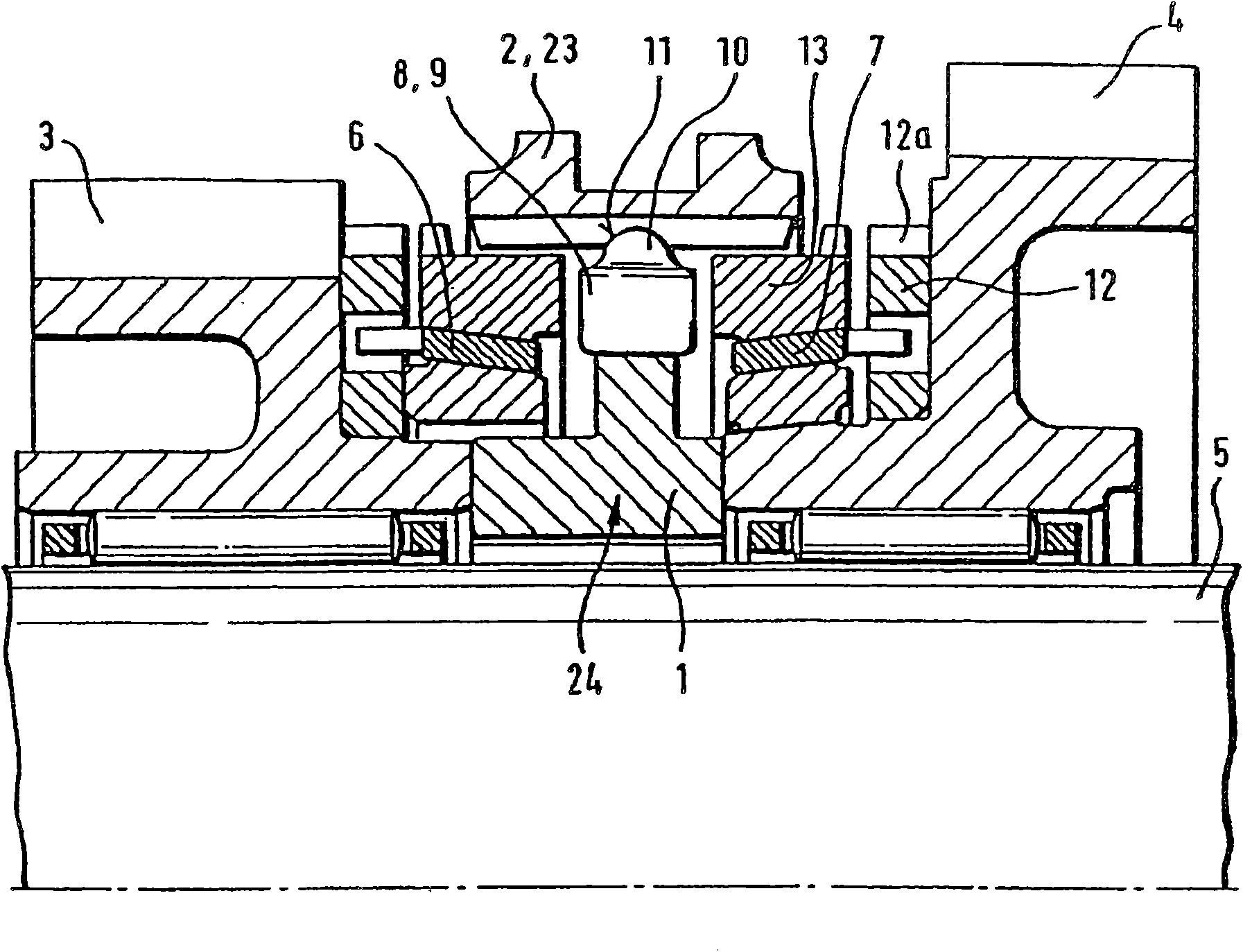

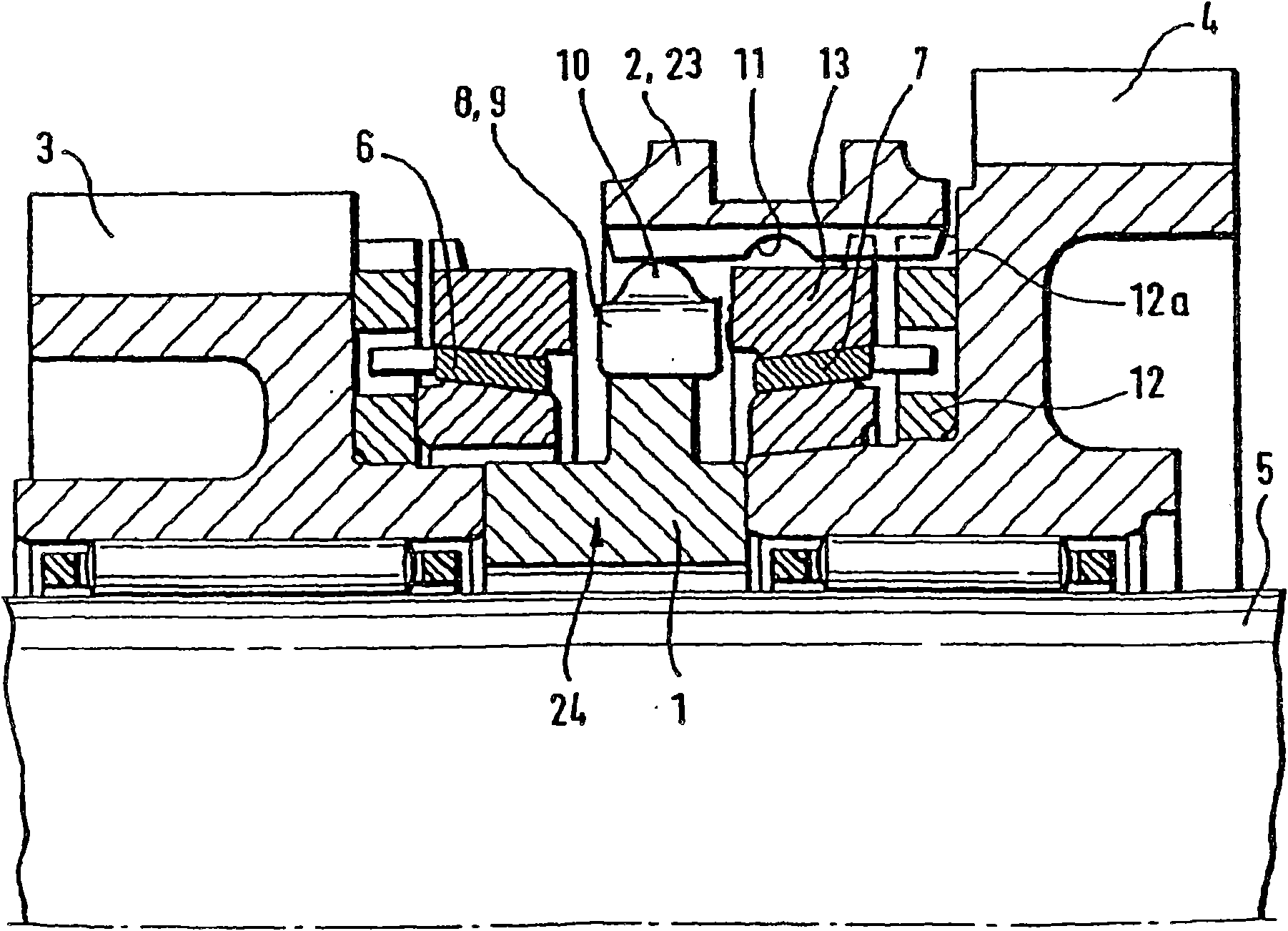

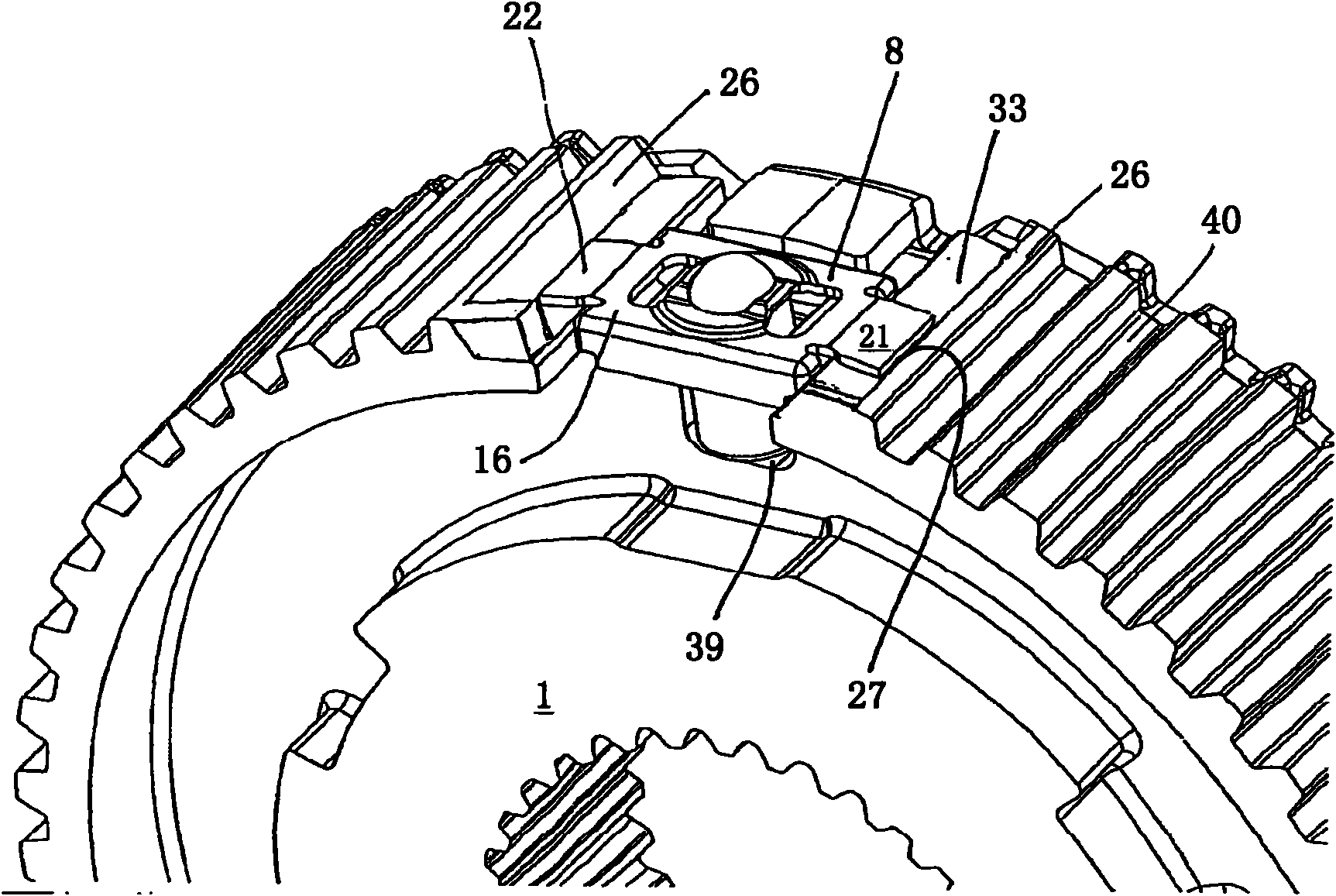

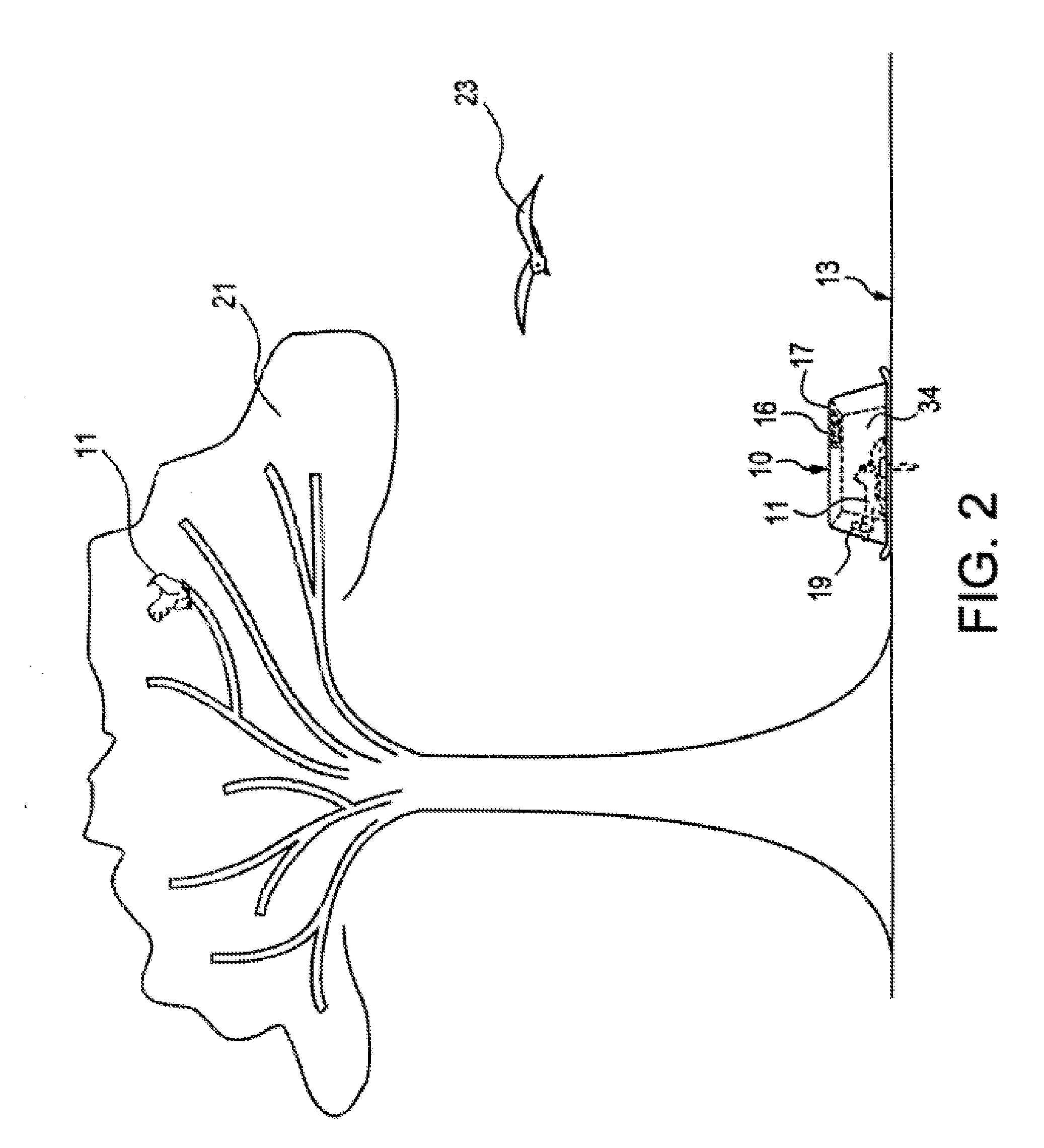

Catch

ActiveCN101965462AIncrease the number ofAchieve preparationMechanical actuated clutchesRest positionEngineering

The invention relates to a catch (6) of a synchronization device (27) that can be axially displaced in the installed state with regard to a synchronous body (1) comprising teeth at the outer circumference thereof, wherein the catch (6) comprises a catch element (8) acted on by an engagement element (15) for engaging in a rest position and a housing (14) having an approximately rectangular radial surface (16) having axial edges (17, 18) aligned outward and side edges (19, 20) oriented in the circumferential direction, wherein the catch element (8) is disposed in the interior of the radial surface (16), the wings (21, 22) being formed flush with the radial surface (16) as seen in the radial direction, and the axial width of the wings (21, 22) being smaller than the minimal axial width of the radial surface (16), and a method for producing the same.

Owner:SCHAEFFLER TECH AG & CO KG

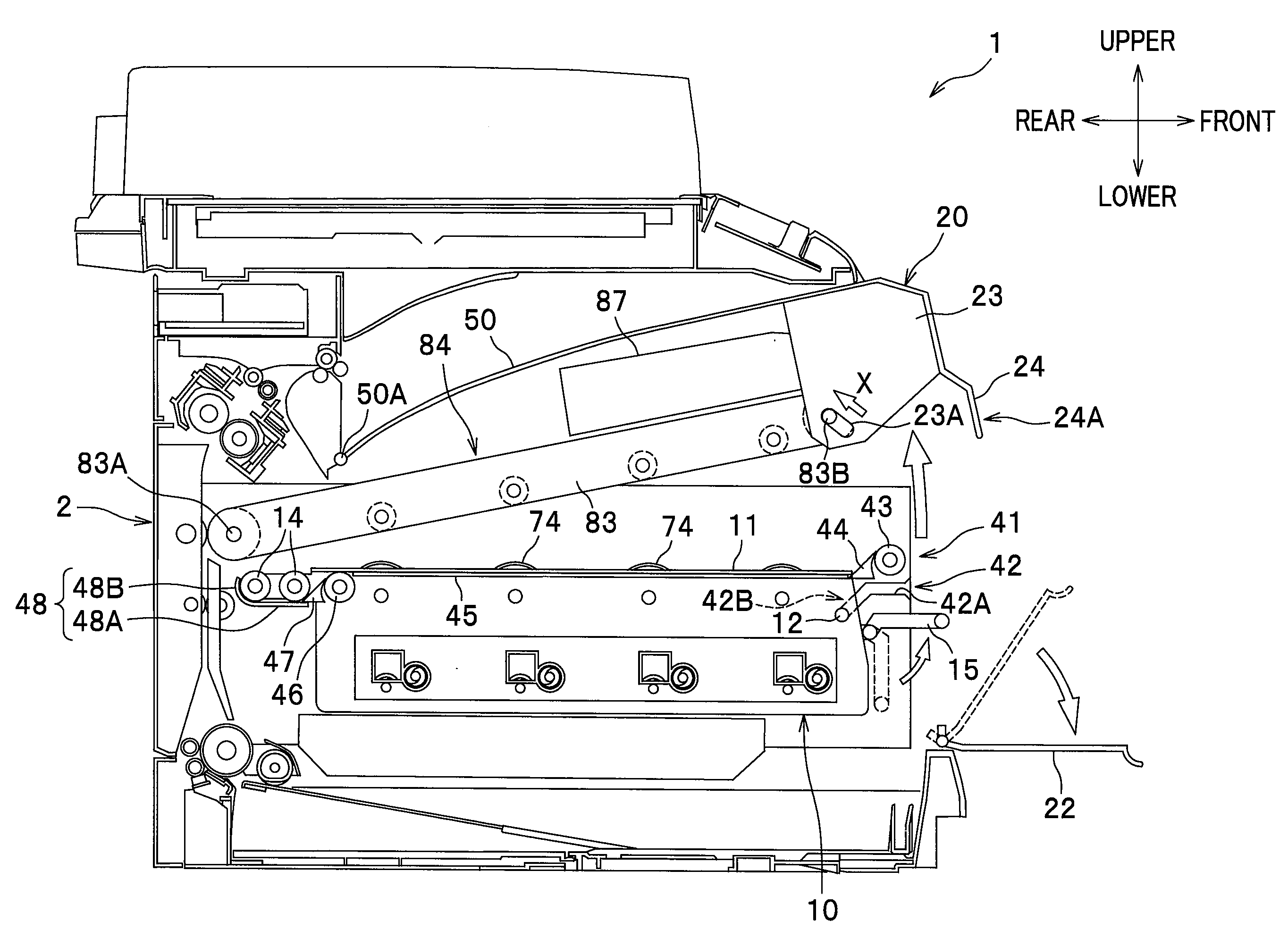

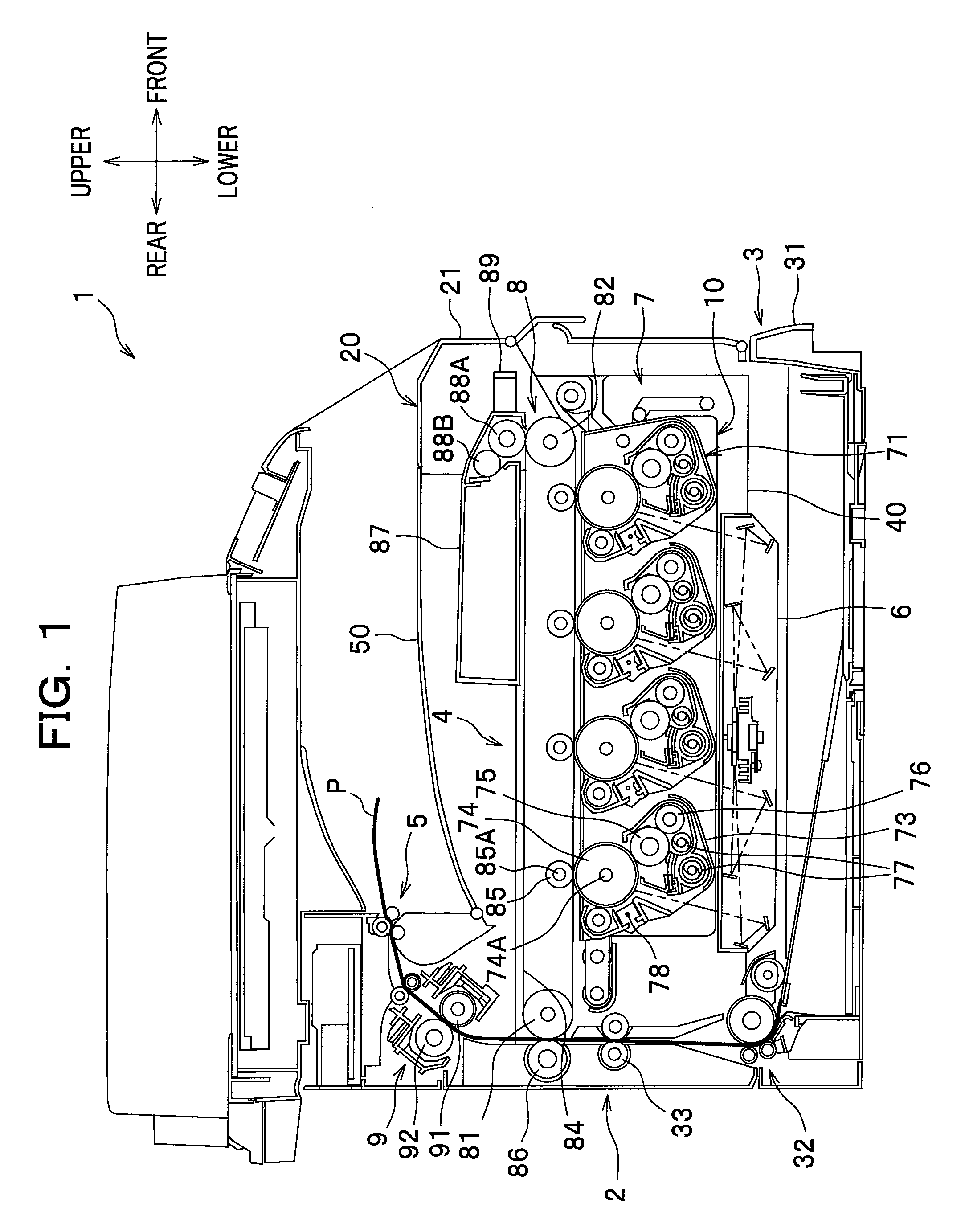

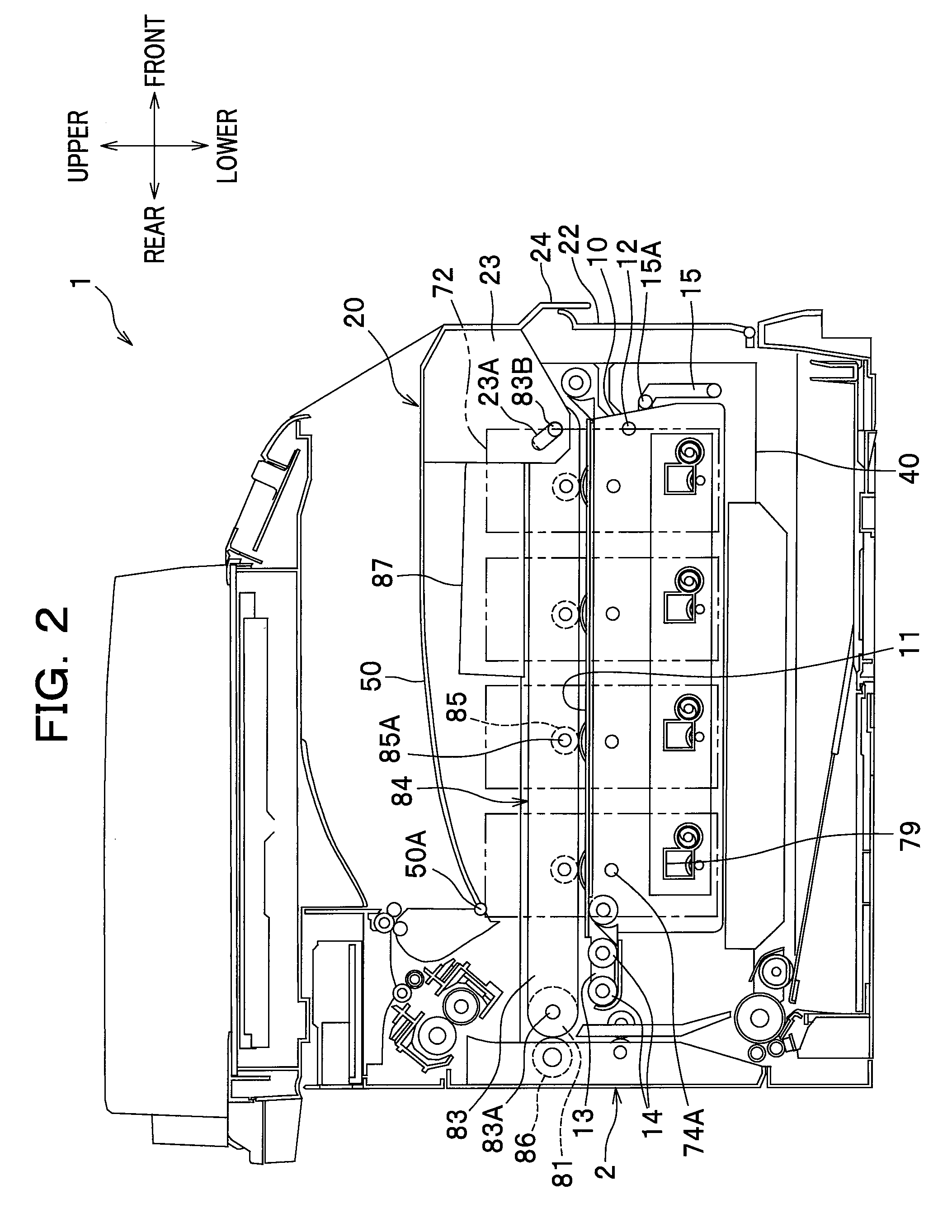

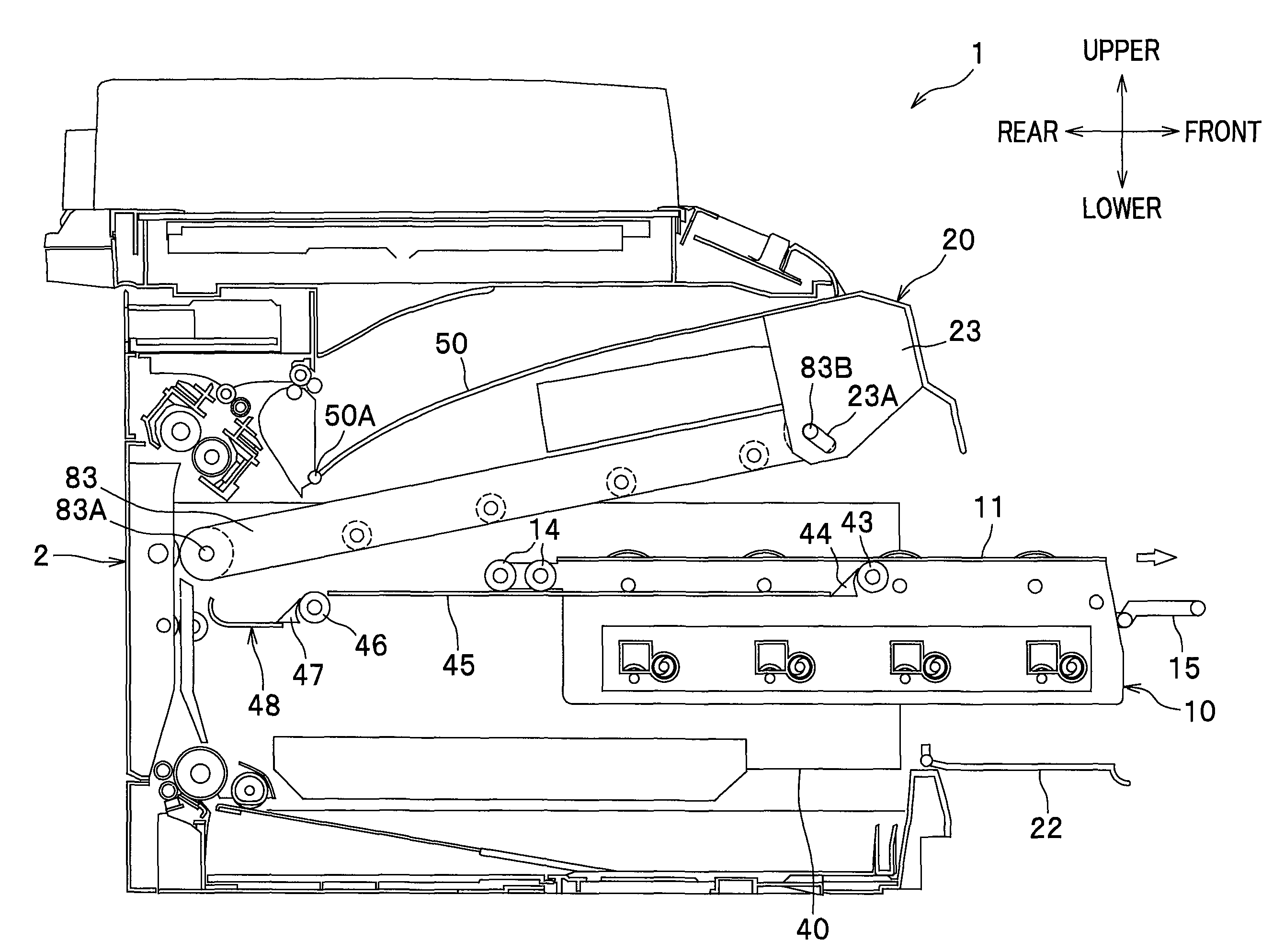

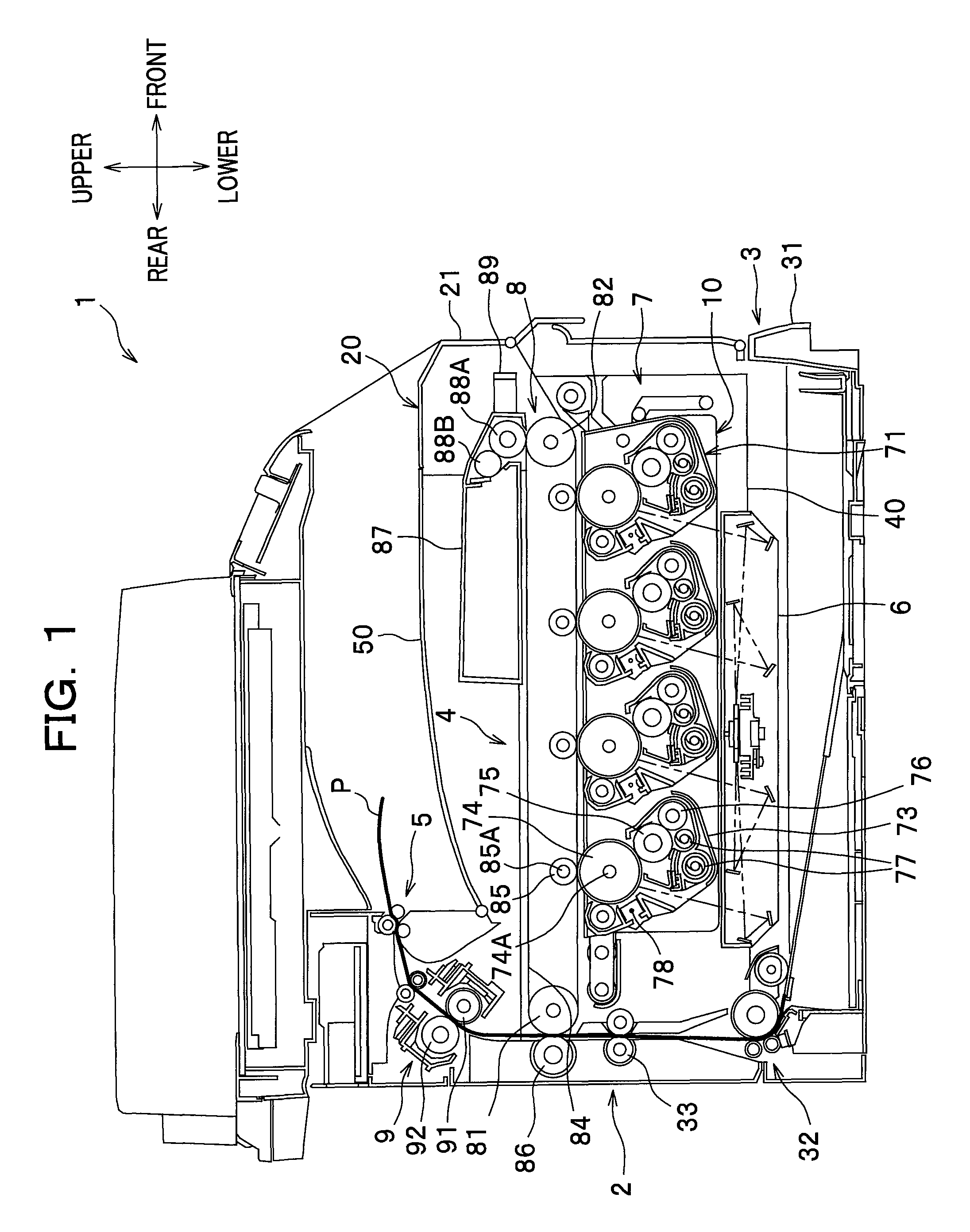

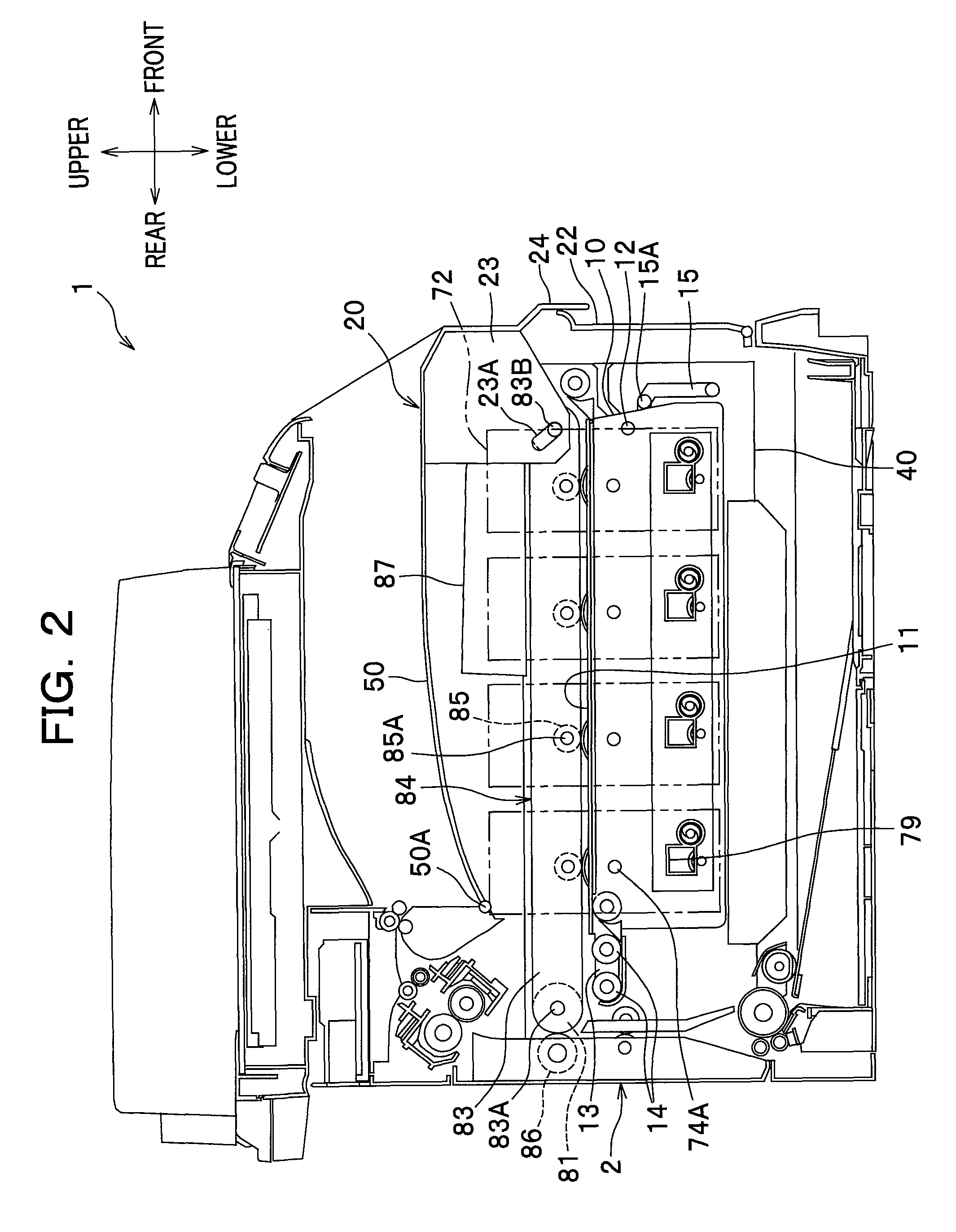

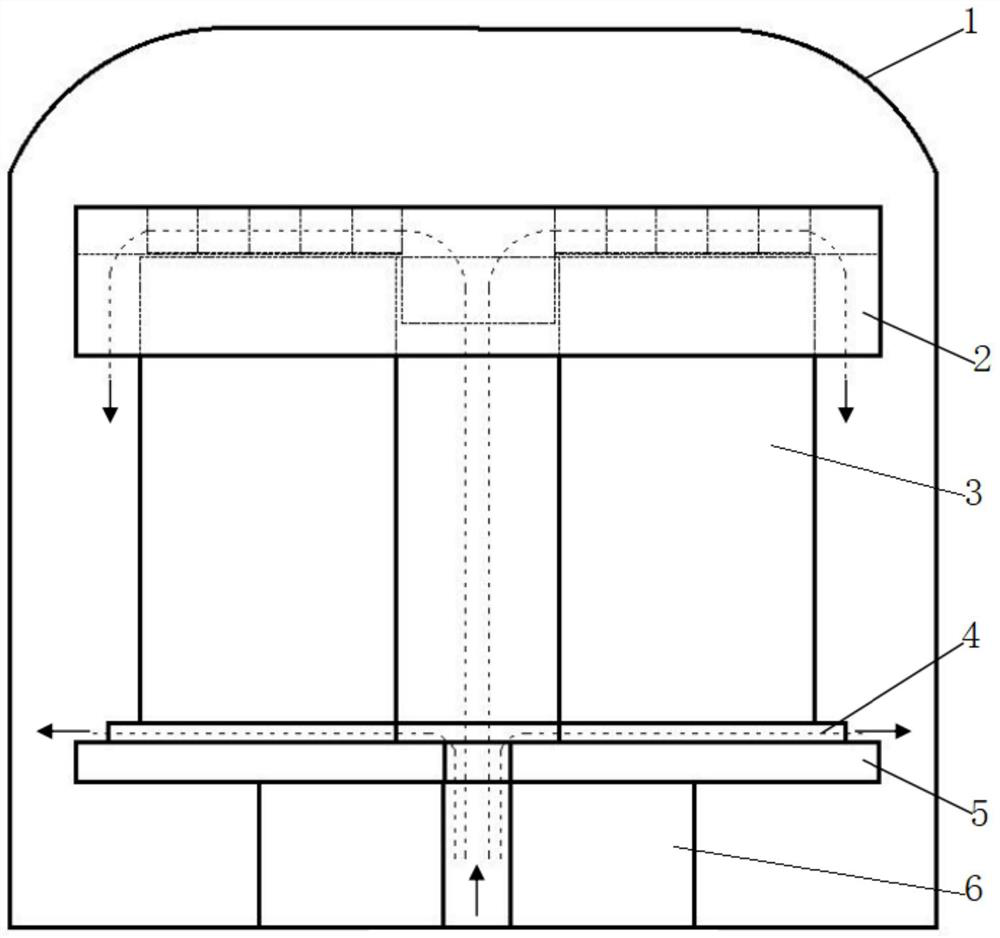

Image Forming Apparatus

ActiveUS20090169252A1Reduced easeImprove image qualityElectrographic process apparatusCorona dischargeElectrical conductorImage formation

In an image forming apparatus, a support frame is configured to support a plurality of photoconductors arranged in the apparatus, the support frame being allowed to be pulled out from a casing of the apparatus, and an intermediate transfer belt is disposed above the plurality of photoconductors and configured to be movable between a contact position in which the intermediate transfer belt is in contact with each of the plurality of photoconductors and a separate position in which the intermediate transfer belt is separate from the each of the plurality of photoconductors. A predetermined amount of upward movement of the support frame made when the intermediate transfer belt is or comes in the separate position renders the support frame operable to be pulled out in a direction of arrangement of the plurality of photoconductors.

Owner:BROTHER KOGYO KK

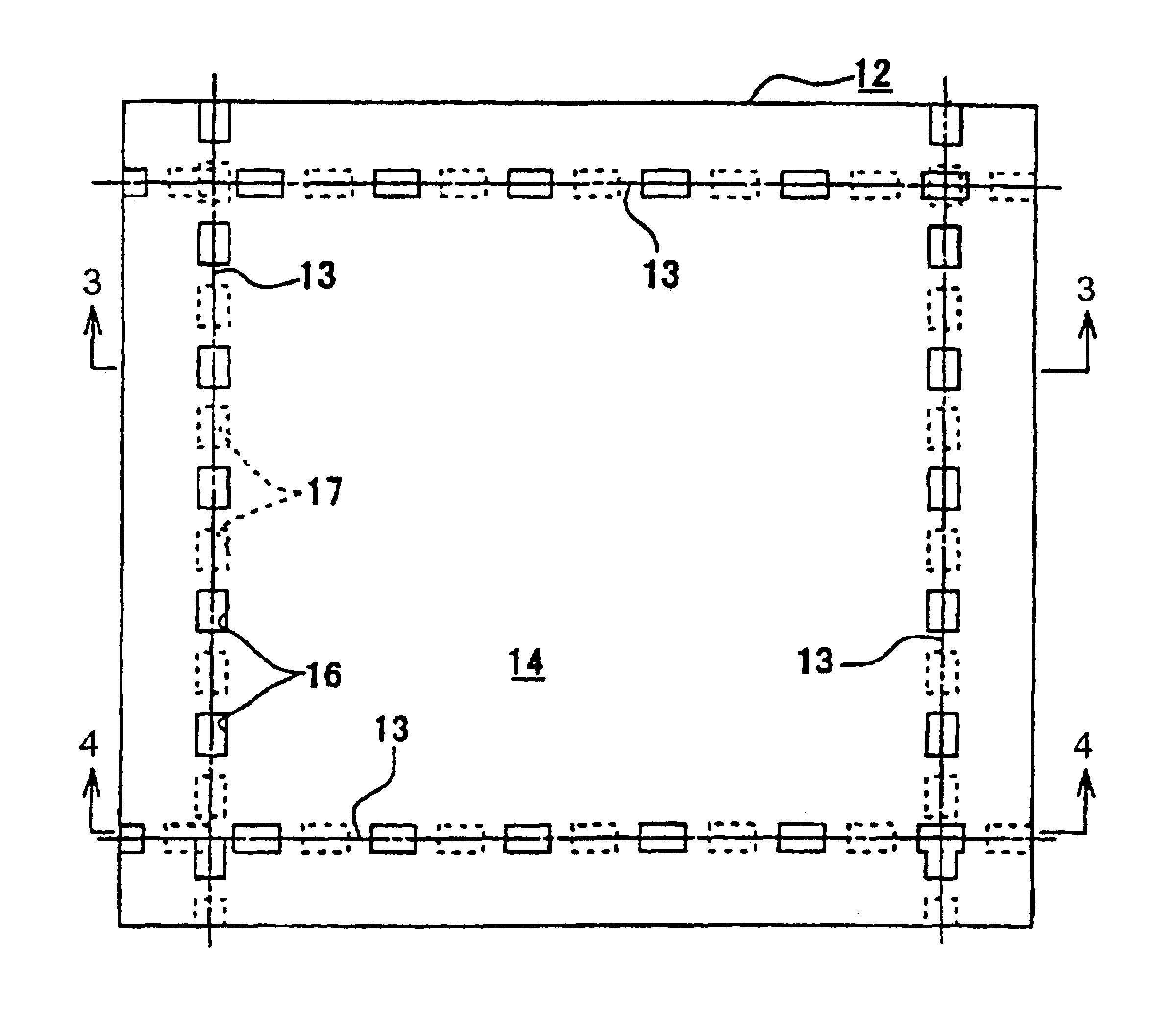

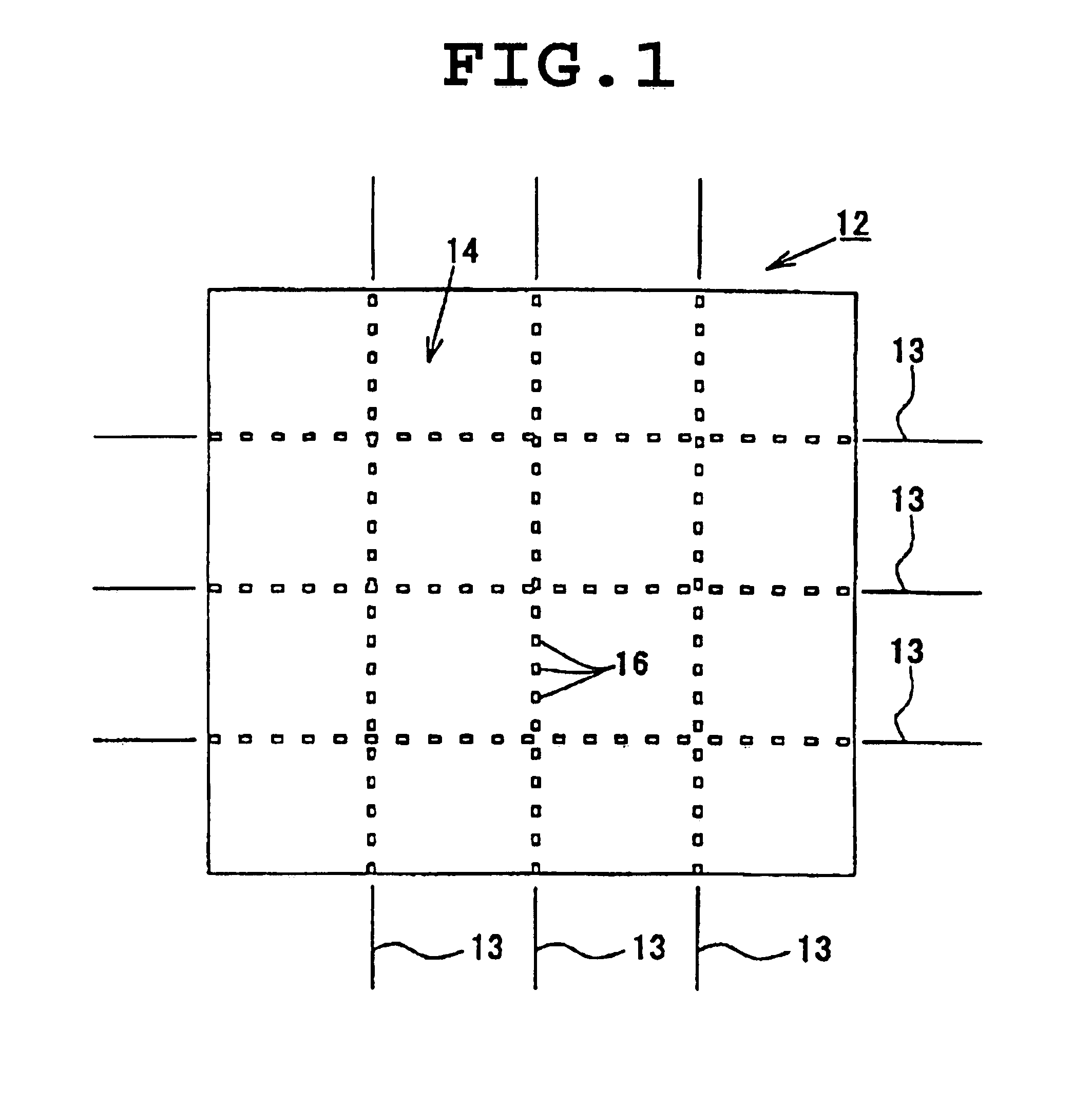

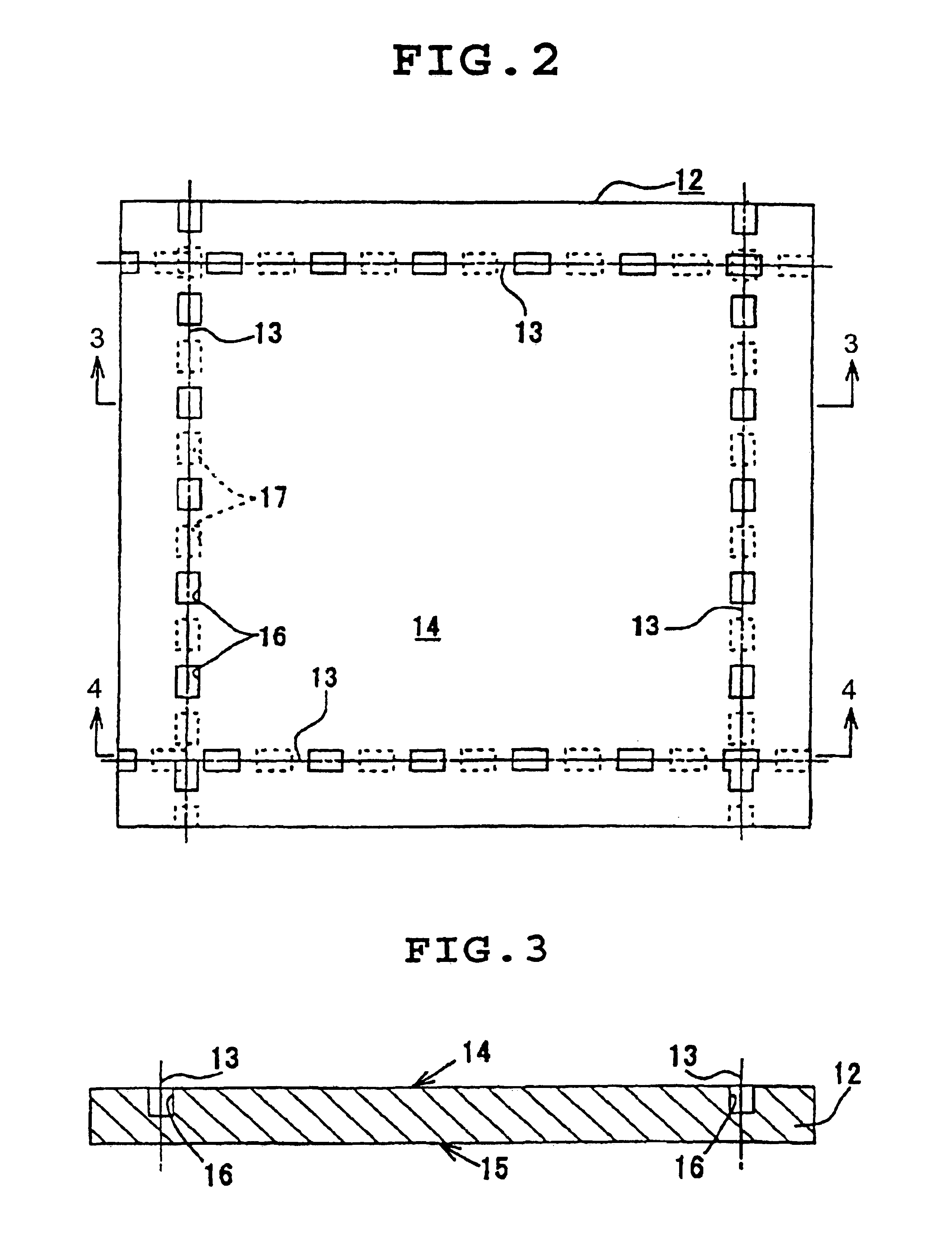

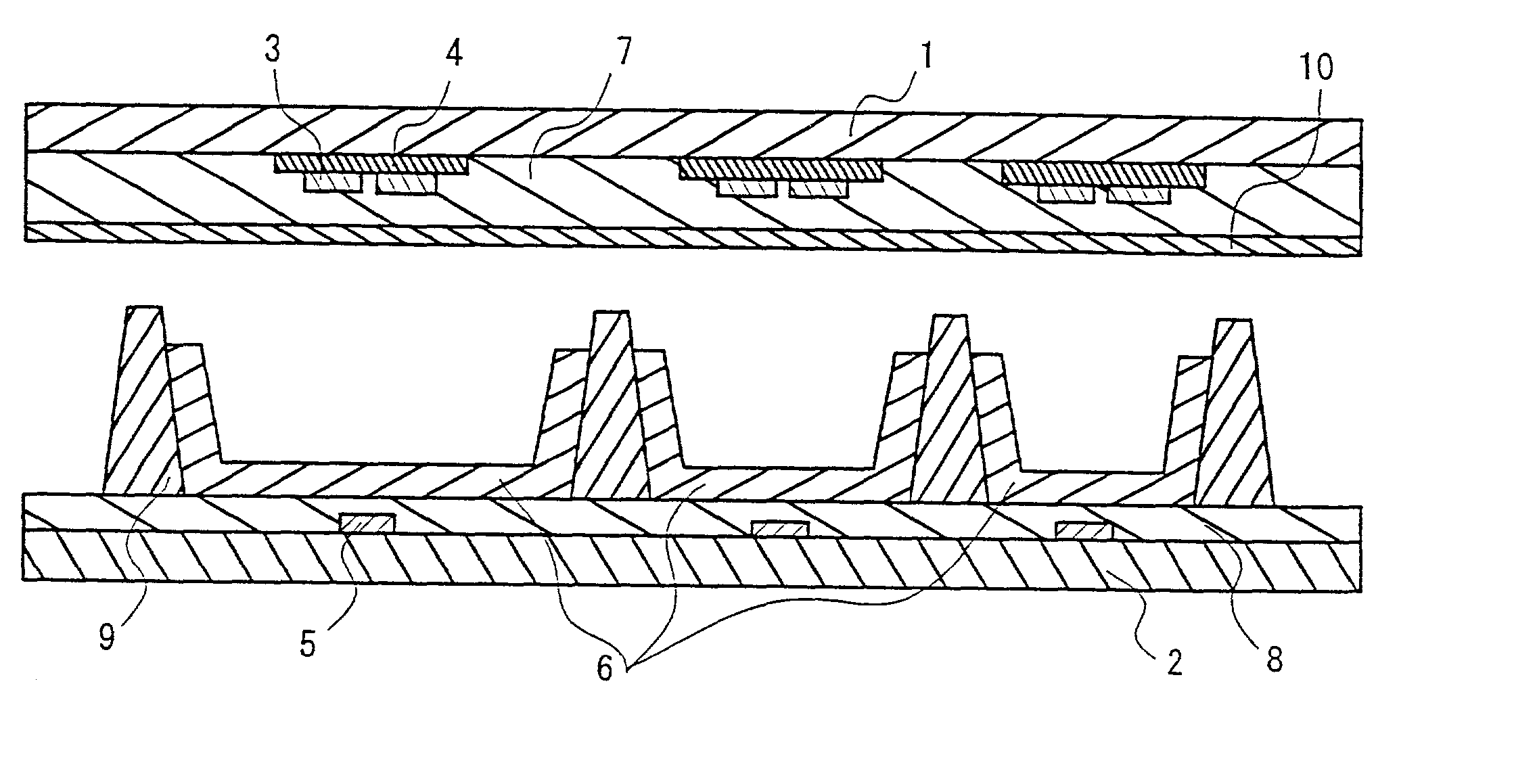

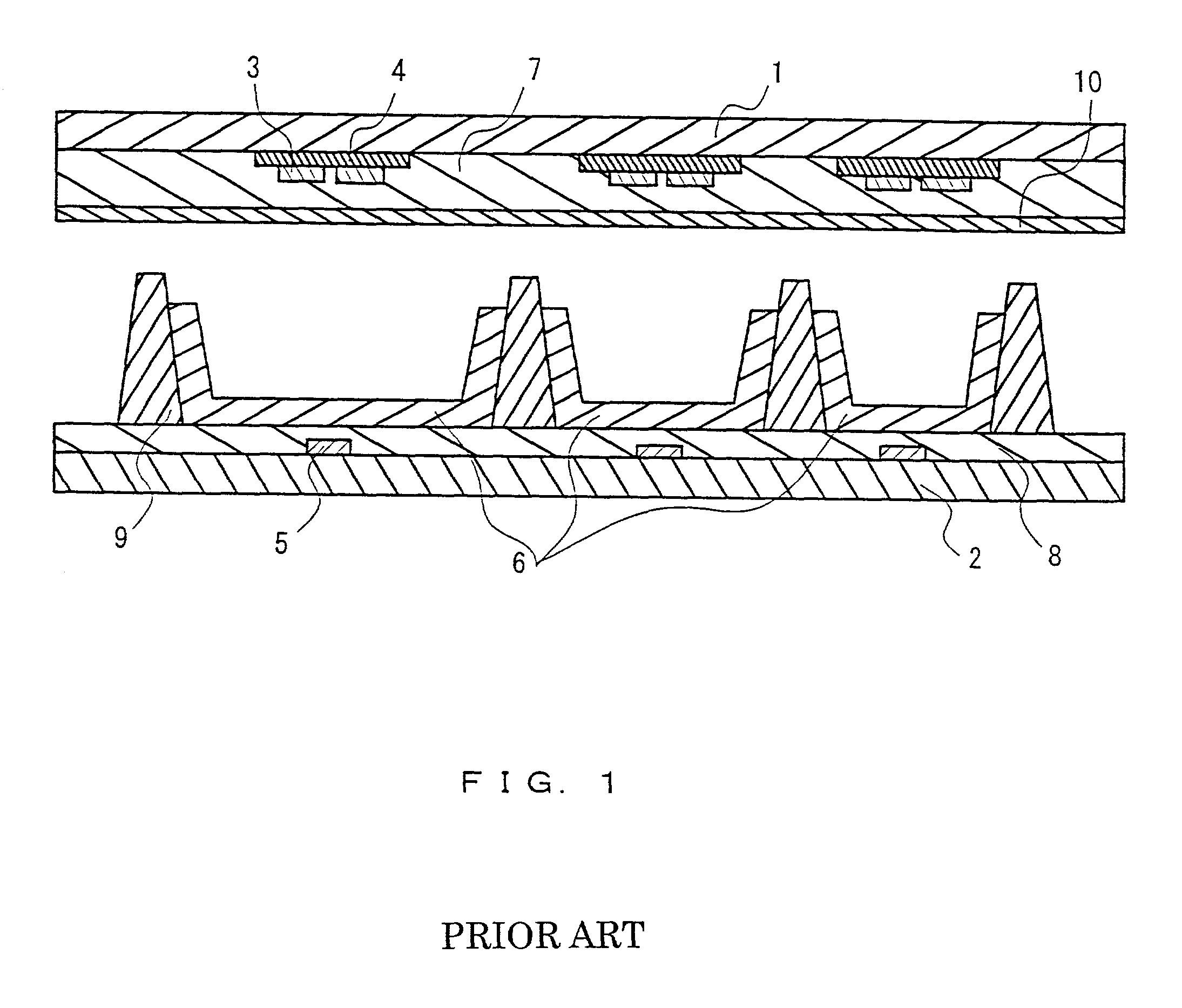

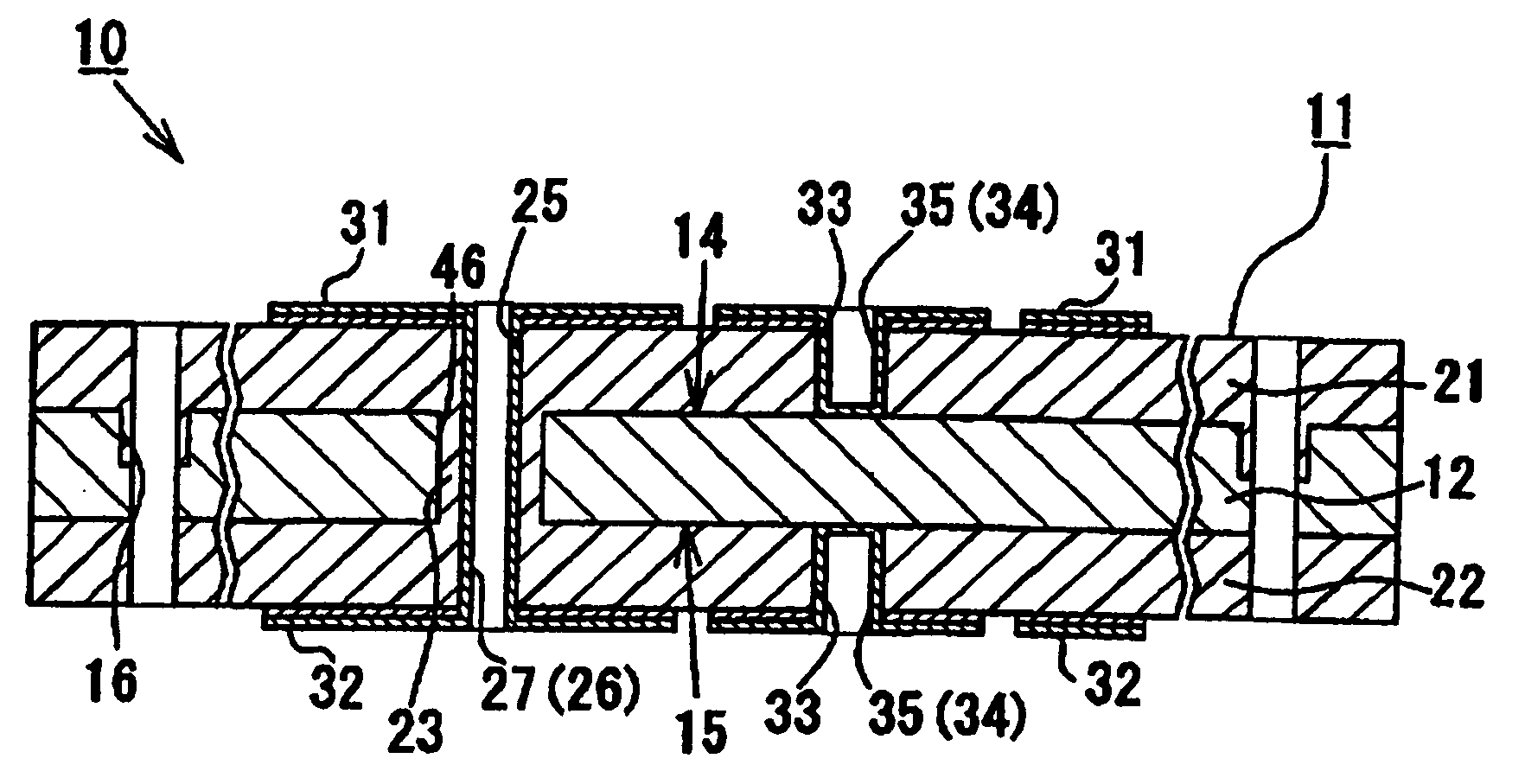

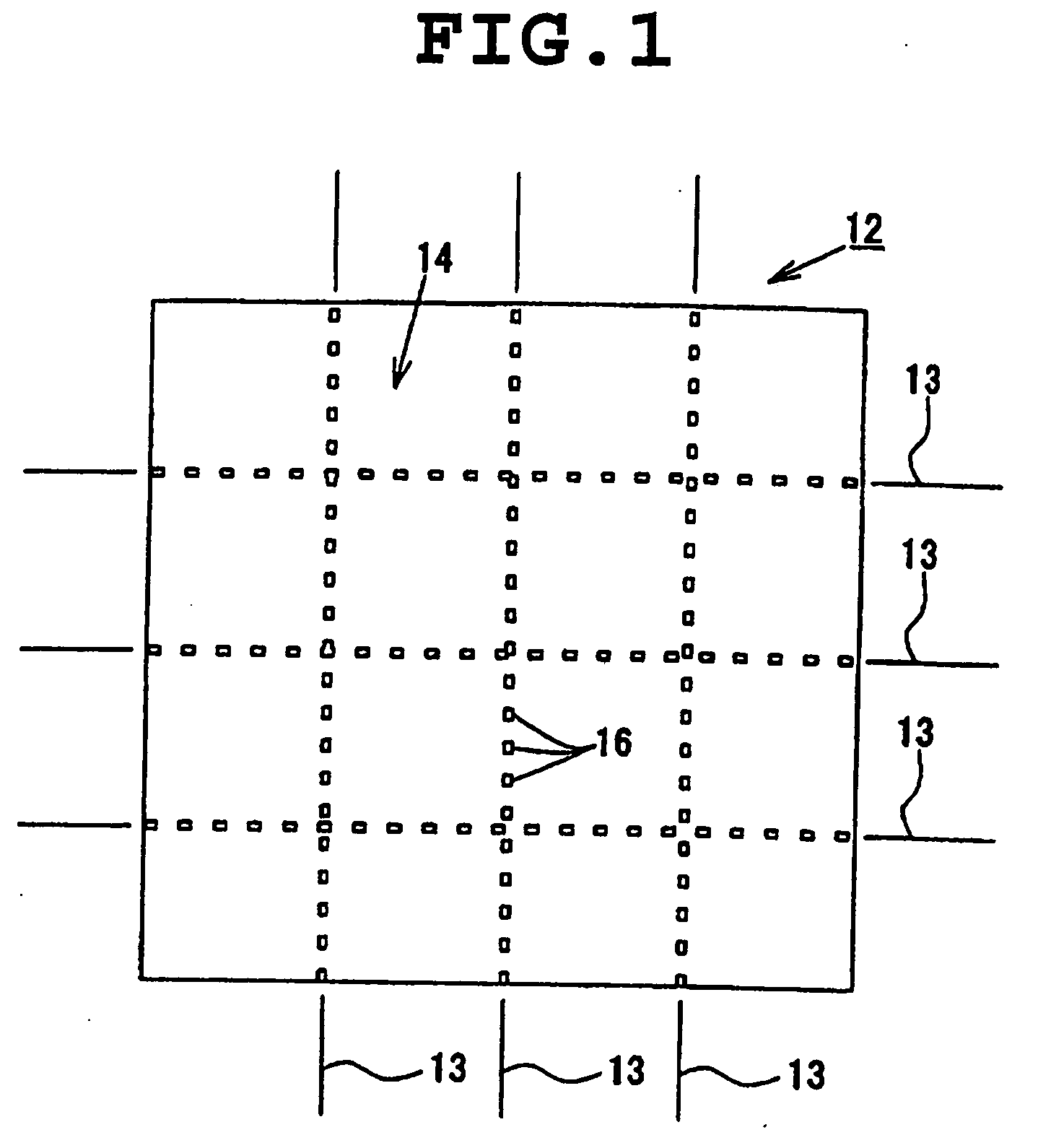

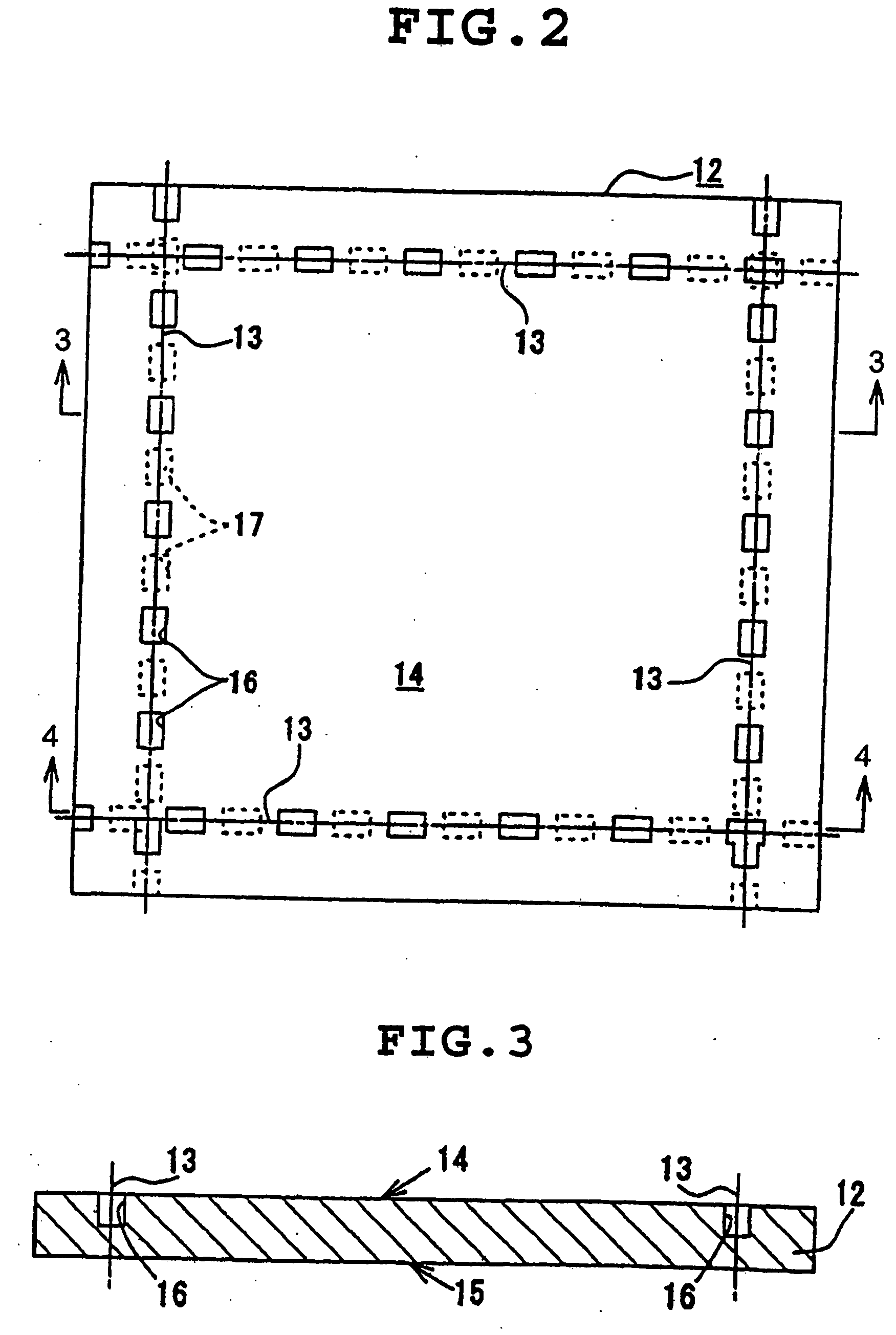

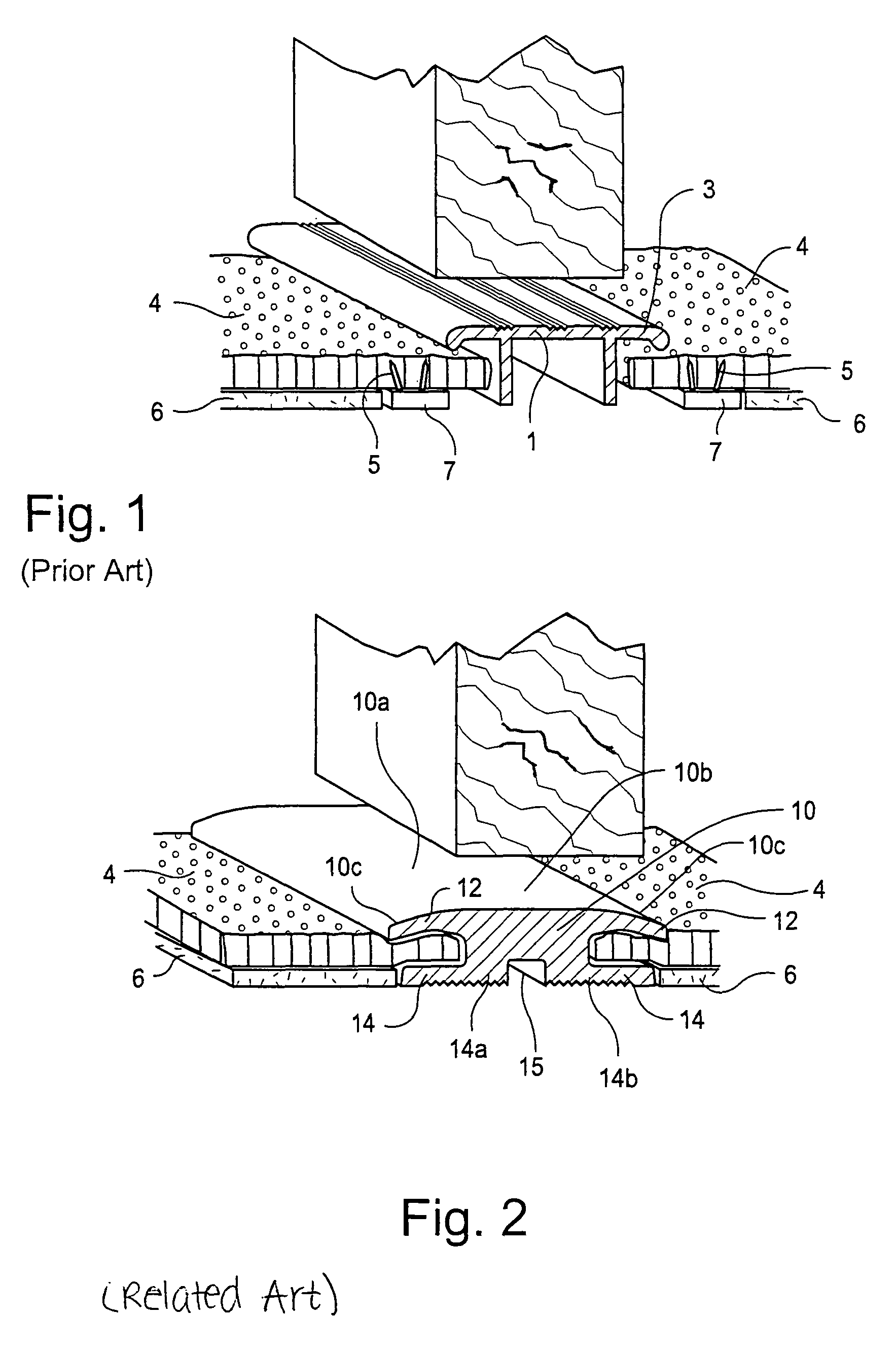

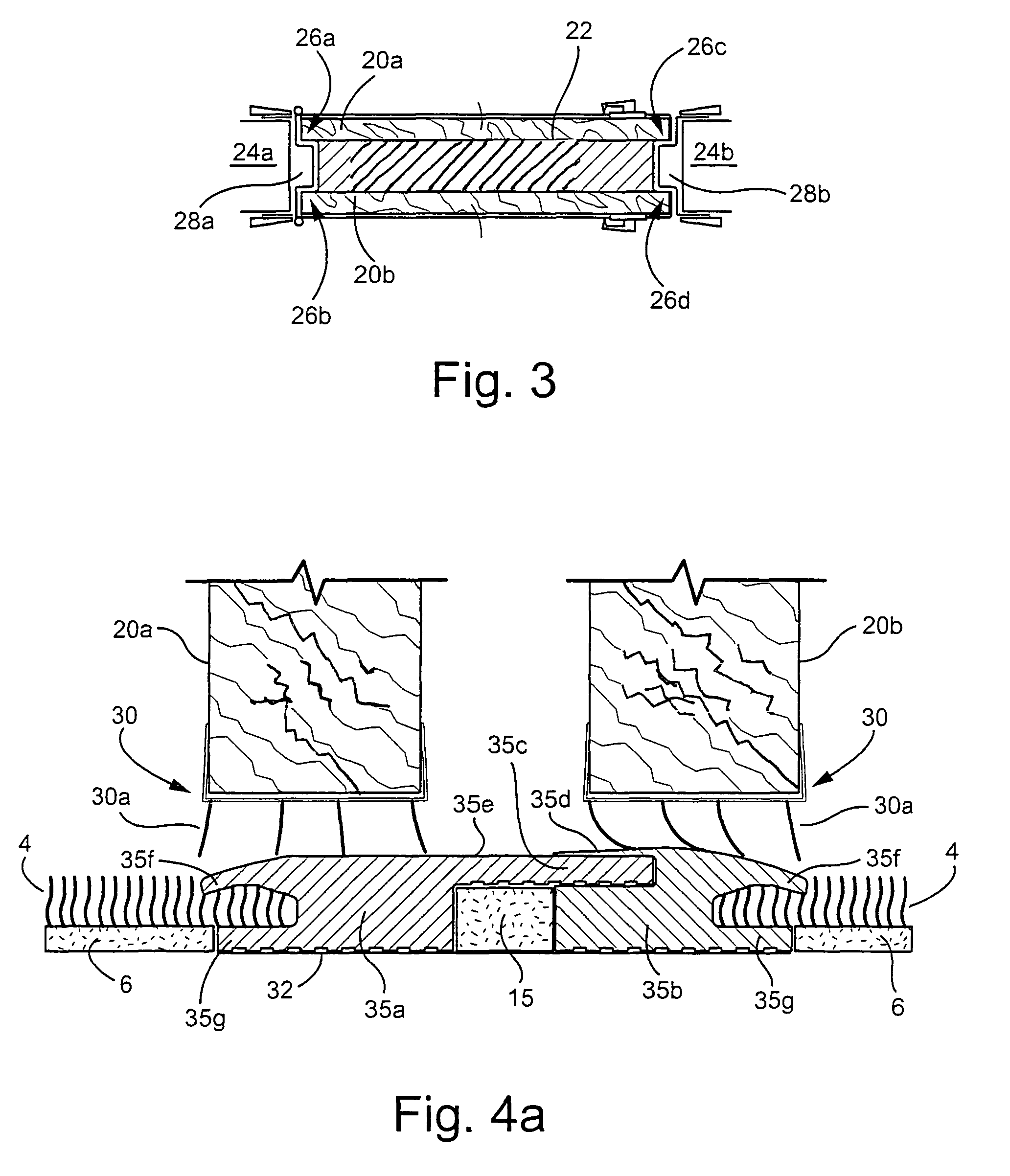

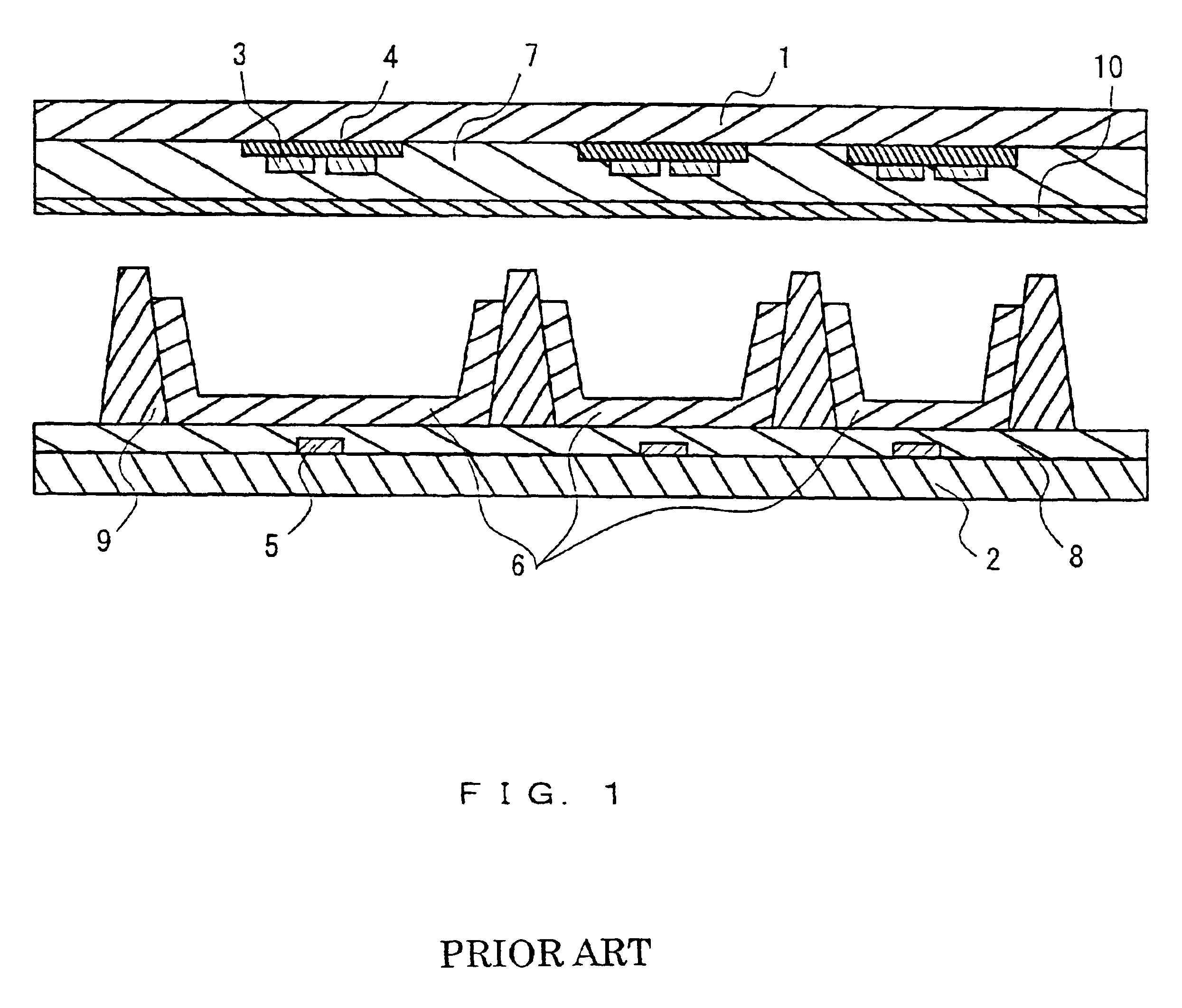

Method for manufacturing printed wiring substrates, metal plate for use in manufacturing printed wiring substrates, and multi-printed wiring-substrate panel

InactiveUS6872436B2Improve readinessAvoiding great increase amountWrappersExtrusion containersEngineeringSurface plate

The invention provides a method for manufacturing printed wiring substrates which can manufacture printed wiring substrates each having resin dielectric layers of uniform thickness and excellent surface flatness while maintaining favorable cutting performance in a dicing step. A multi-printed wiring-substrate panel is manufactured which includes a metal plate having a first main surface and a second main surface, and resin dielectric layers disposed on the first and second main surfaces. The metal plate has first depression portions and second depression portions. The first depression portions are opened at the first main surface and arranged discontinuously along predetermined cutting lines. The second depression portions are opened at the second main surface and arranged discontinuously along the predetermined cutting lines. The multi-printed wiring-substrate panel is cut along the predetermined cutting lines into a plurality of printed wiring substrates.

Owner:NGK SPARK PLUG CO LTD

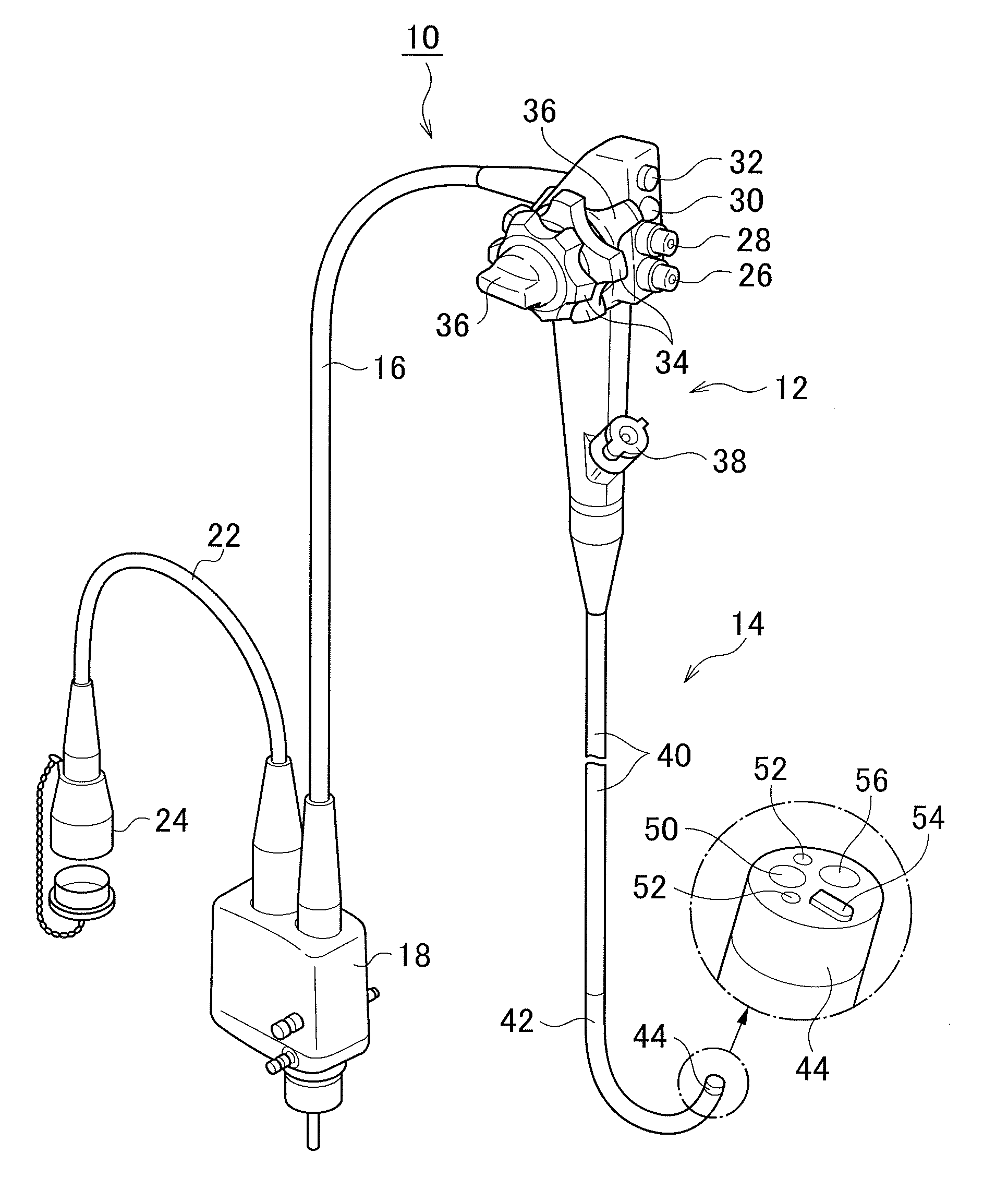

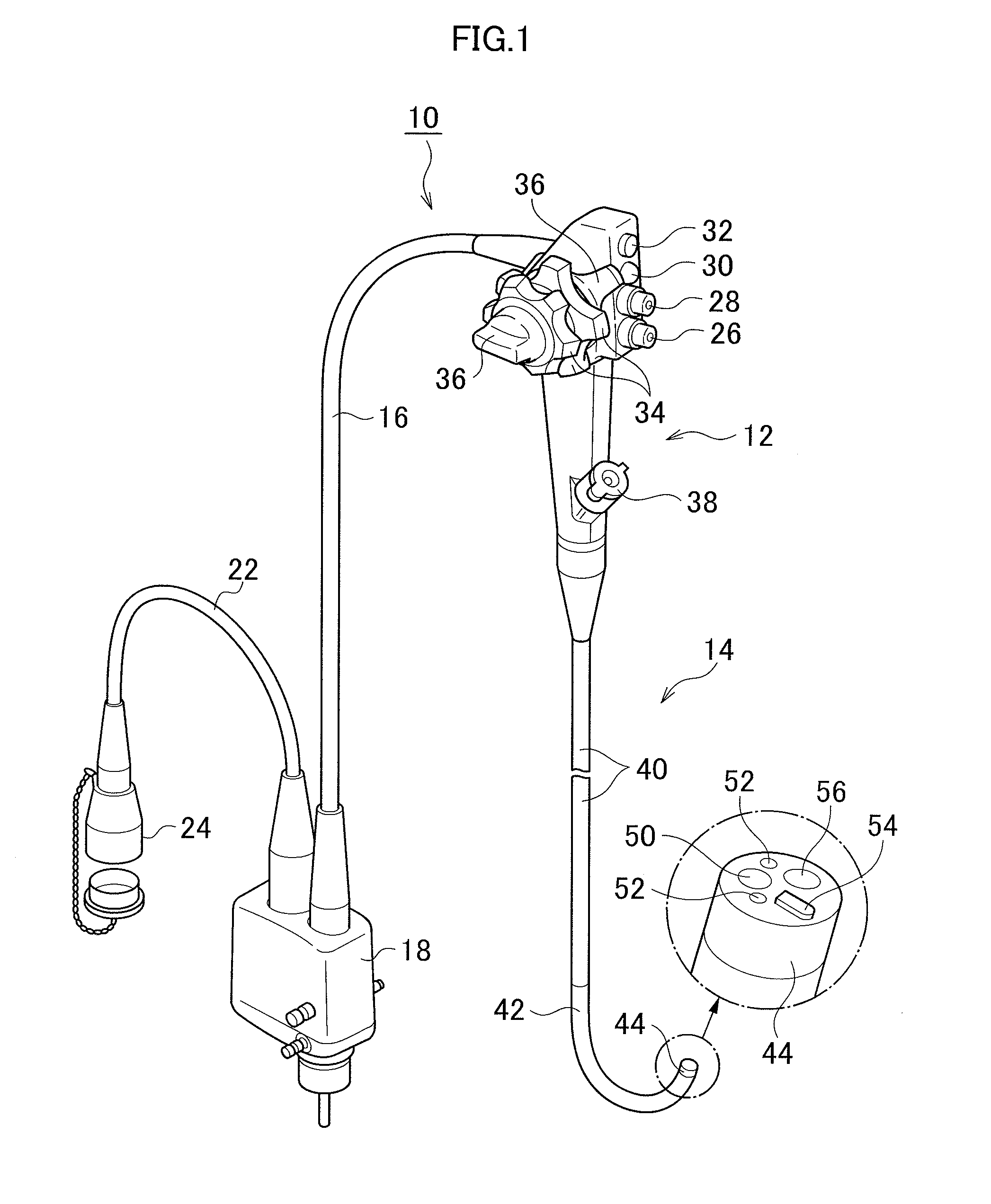

Image pickup device and endoscope

An image pickup device includes: an image pickup element; a spacer surrounding a light receiving surface of the image pickup element; a cover glass attached to the spacer, the cover glass being disposed opposing to the light receiving surface; and an insulative resin configured to thermally couple the image pickup element with the cover glass, and to have a thermal conductivity of not less than 8 W / mK. An endoscope includes: the image pickup device; an image pickup optical system; a drive circuit; a light guide configured to radiate light from a illumination light source; a tubular body configured to accommodate the image pickup device, the image pickup optical system, the drive circuit, the light guide, and a forceps opening; and a first insulative resin having a thermal conductivity of not less than 8 W / mK, and adapted to thermally couple the image pickup device with the drive circuit.

Owner:FUJIFILM CORP

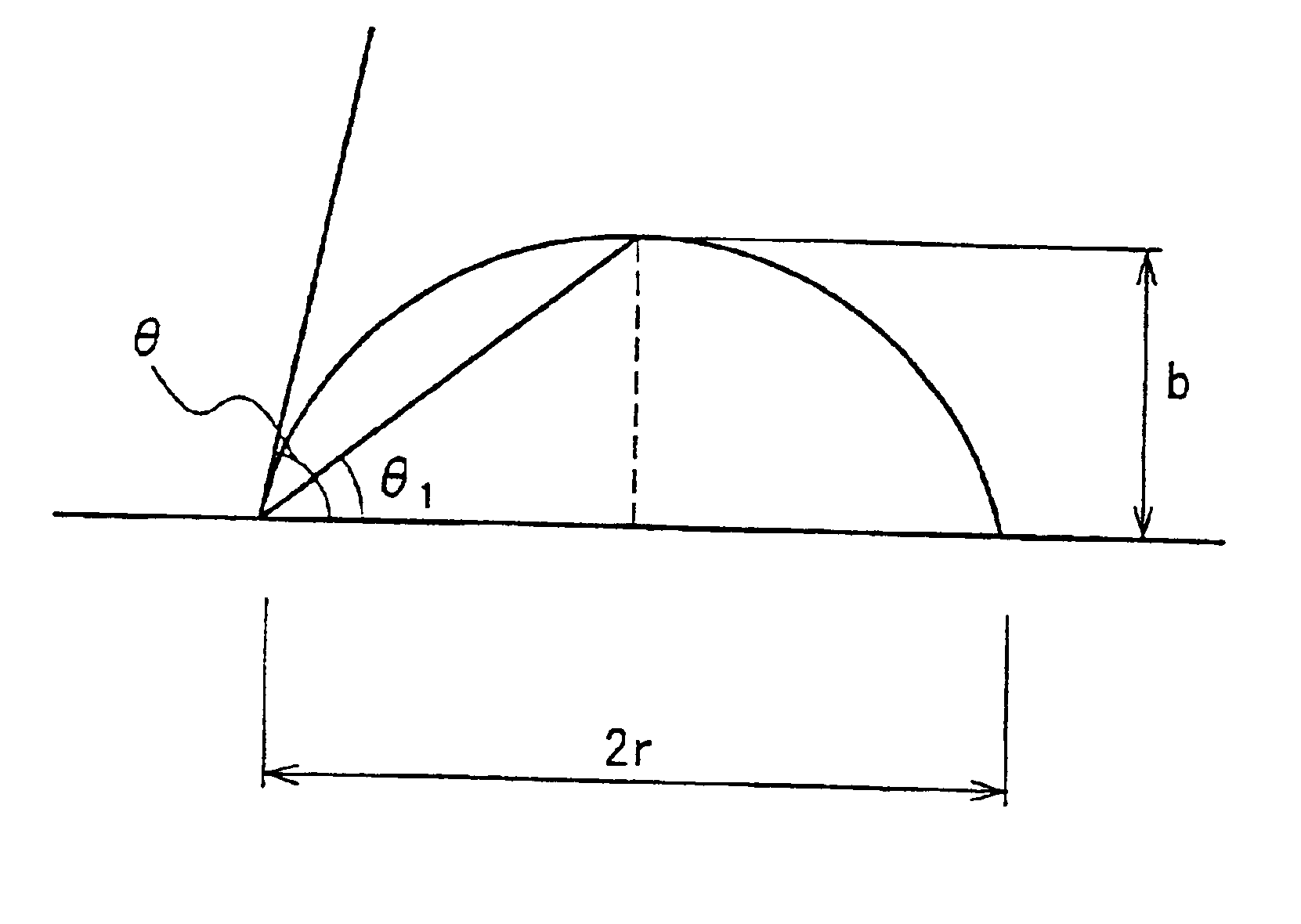

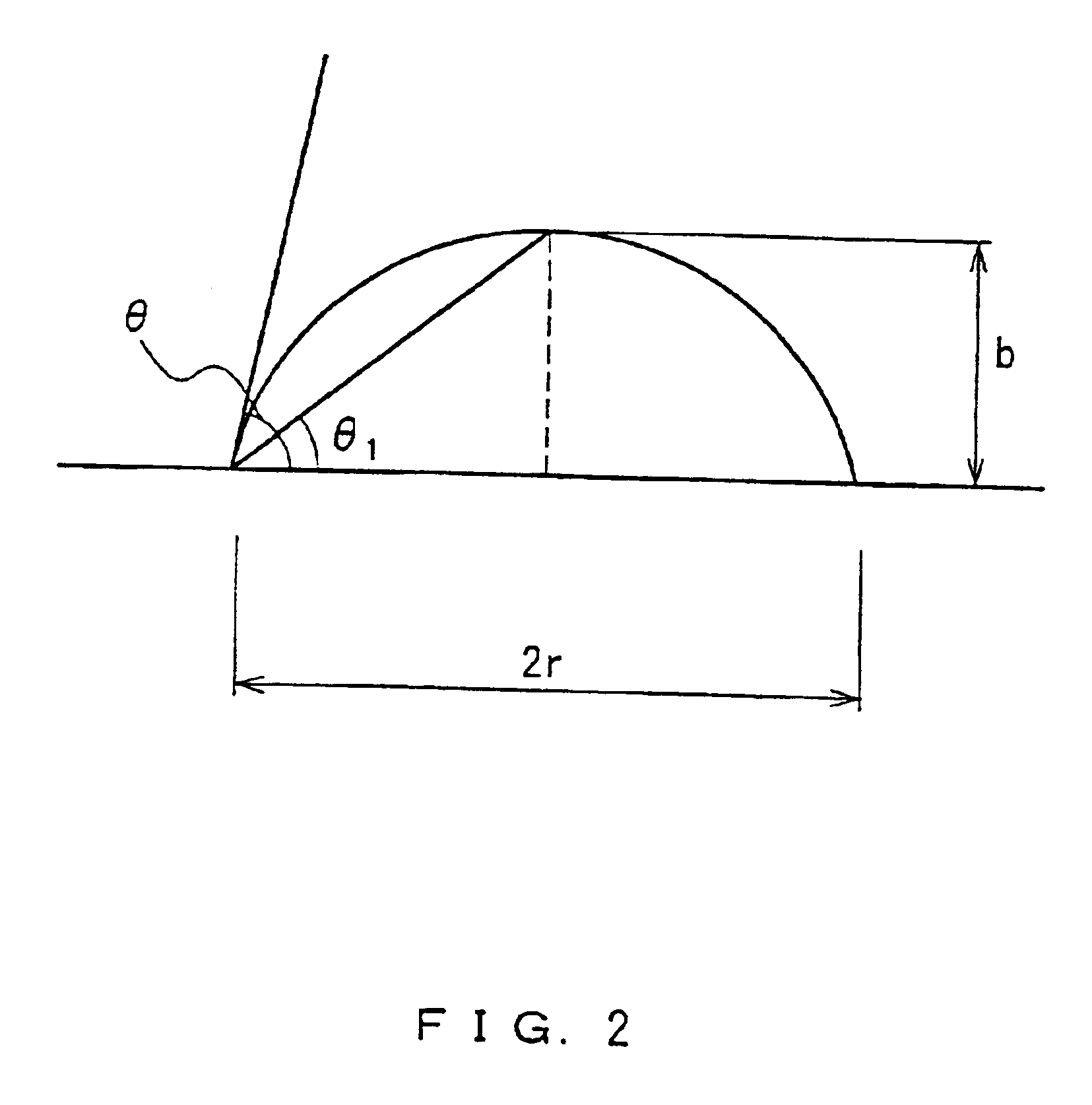

Paint for forming insulating film, and plasma display panel using the paint and method of manufacturing the same

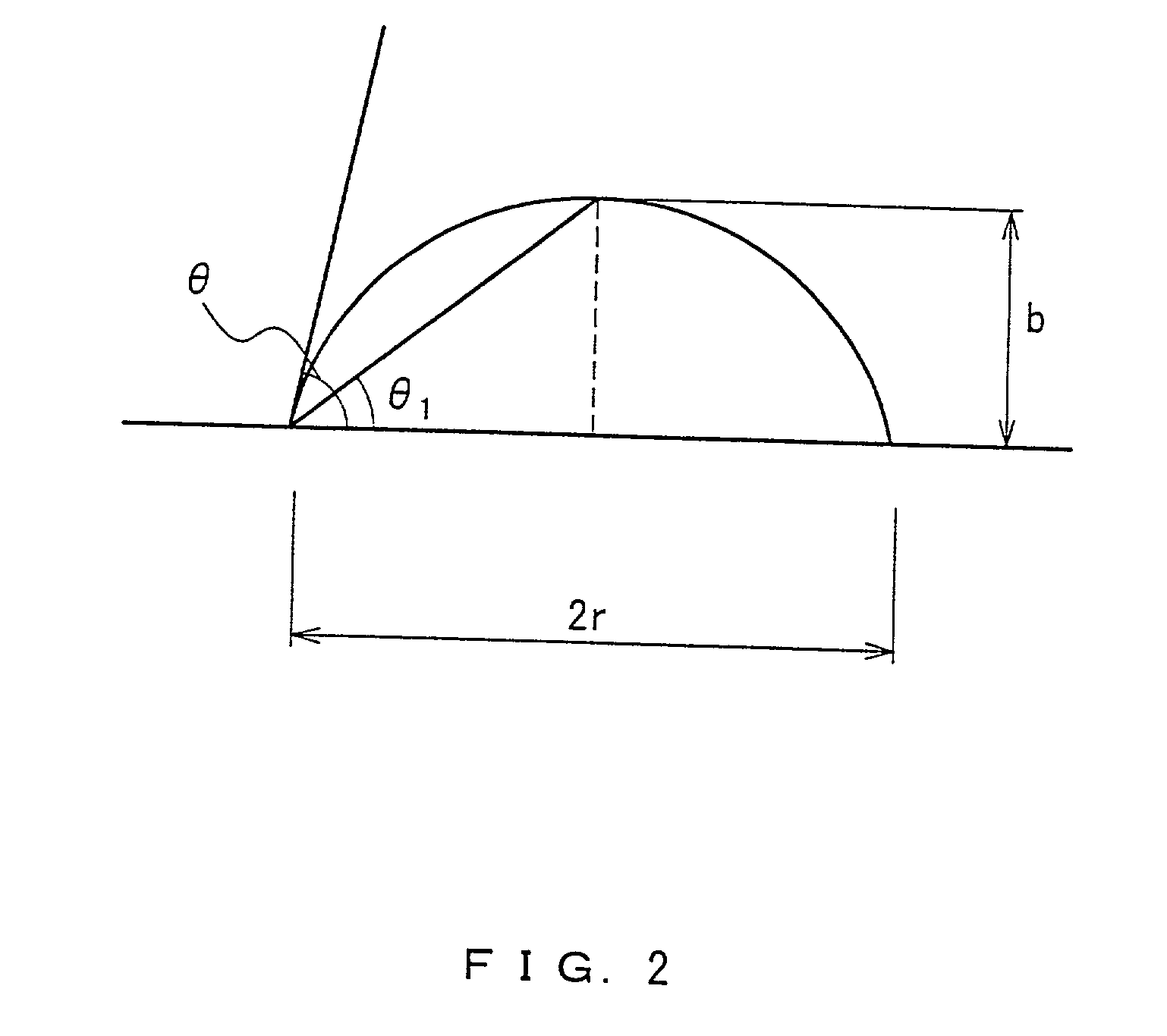

InactiveUS20020063527A1Improve wettabilityLow costSynthetic resin layered productsAlternating current plasma display panelsOrganic solventInorganic materials

The present invention provides a paint for forming an insulating film, which has a good wettability to a surface to be coated with the paint and has no voids or pin-holes after being fired; a plasma display panel including a dielectric layer formed using the paint; and a method of manufacturing the plasma display panel. The paint contains inorganic fine particles, a binder resin, and an organic solvent that has a good wettability to glass such as a glass substrate, ceramic as an Ag electrode, and a metal compound such as an ITO film and forms a contact angle of less than 5° with these inorganic materials. Accordingly, the paint has a good wettability to a glass substrate, an Ag electrode, and an ITO film and the resultant insulating film thus has no voids or pin-holes.

Owner:PANASONIC CORP

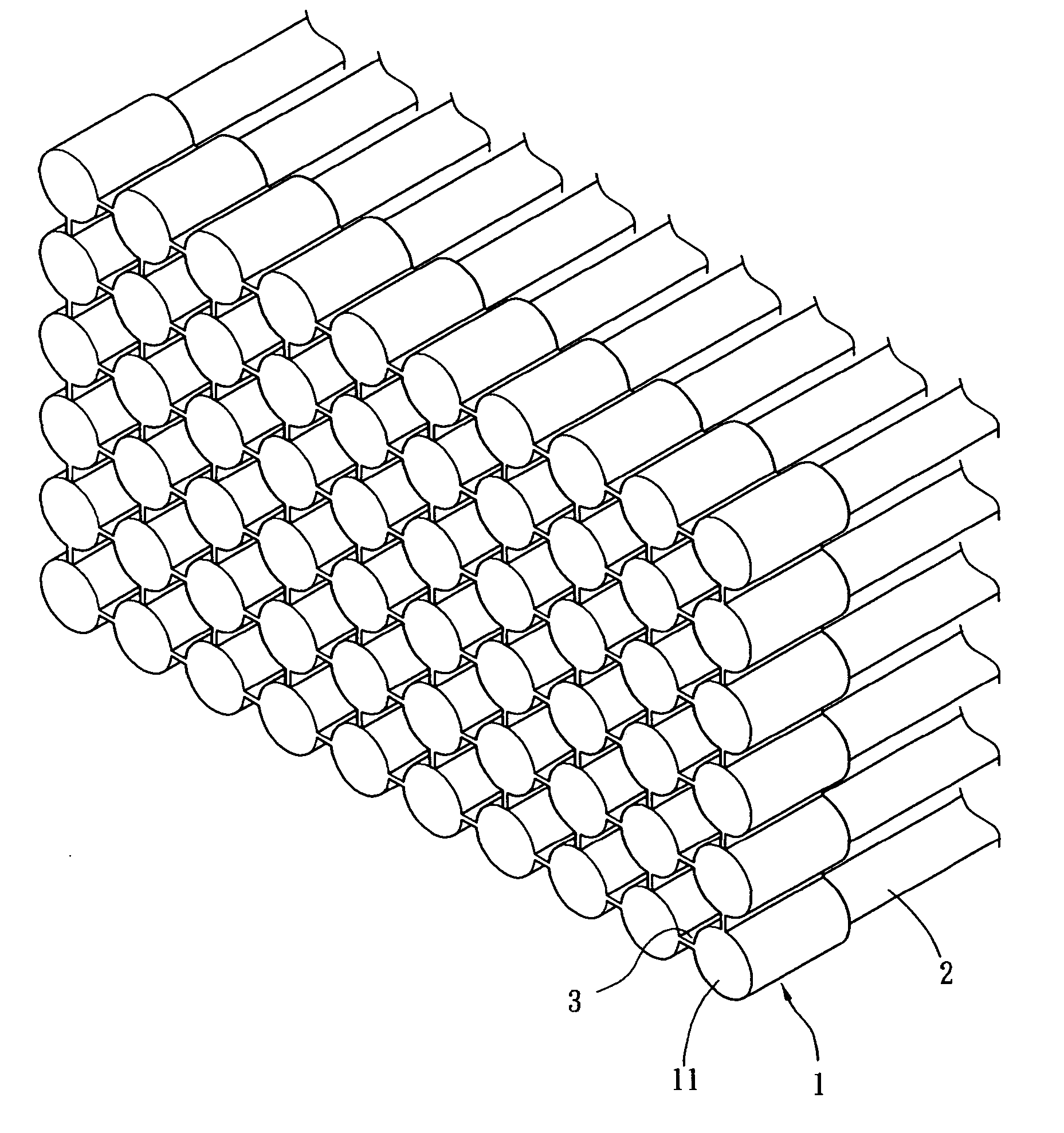

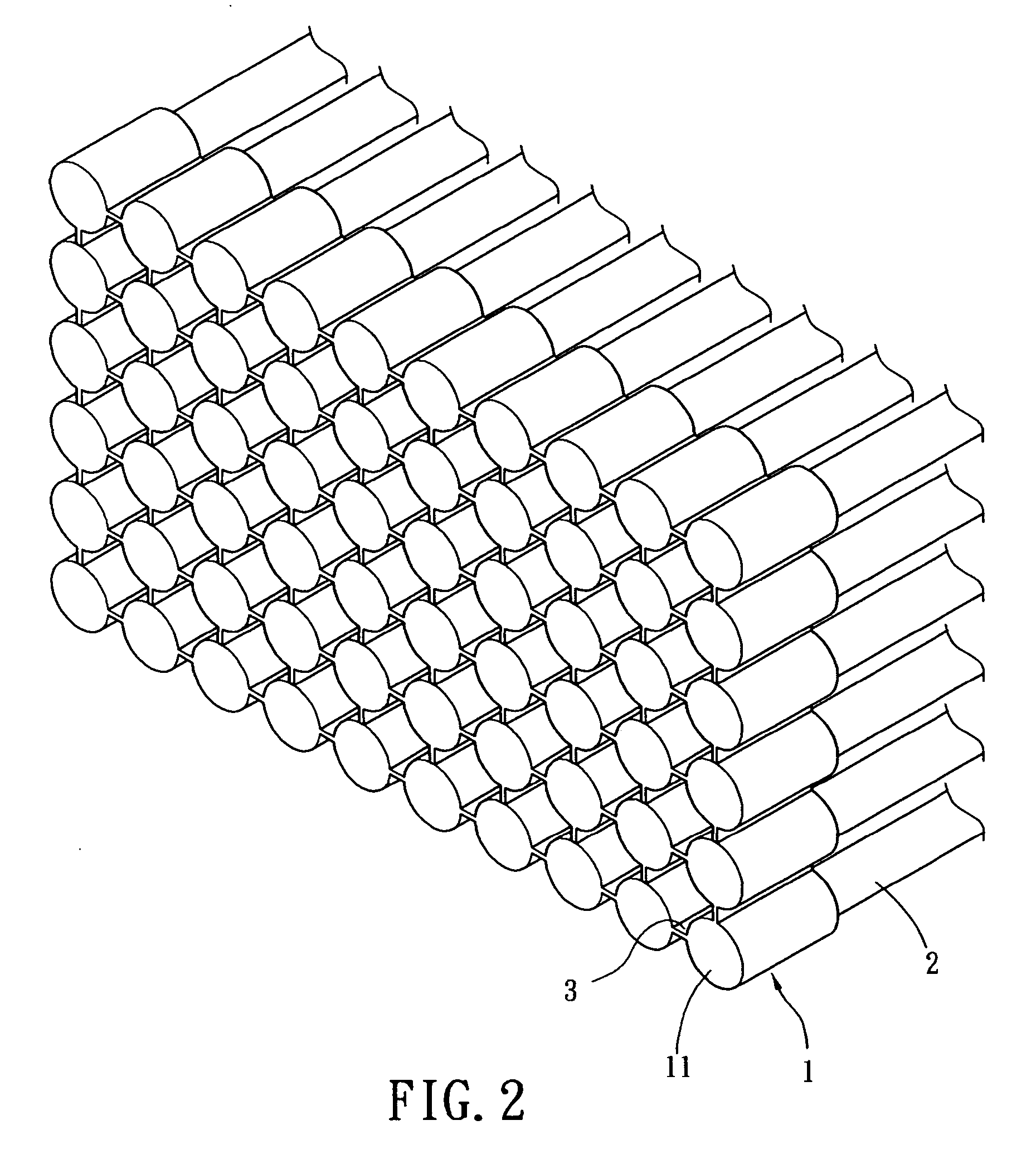

Optical fiber array

InactiveUS20070086700A1Easy to cutDesirable shapeCoupling light guidesFiber arrayElectrical and Electronics engineering

An optical fiber array includes two more glass containers each with a cylindrical shape. Each container contains an optical fiber, including a convex face on outer side thereof to provide light focusing effect. Four straight bridging sections are extended symmetrically from the container and one bridging section is connected to another container to form an array-type base. Moreover, the bridging section can be an assembling and locking structure to form base with flexible shape.

Owner:WENG ALLEN

Method for manufacturing printed wiring substrates, metal plate for use in manufacturing printed wiring substrates, and multi-printed wiring-substrate panel

InactiveUS20050155789A1Reduce the amount requiredImprove flatnessPrinted circuit assemblingSynthetic resin layered productsEngineeringDielectric layer

The invention provides a method for manufacturing printed wiring substrates which can manufacture printed wiring substrates each having resin dielectric layers of uniform thickness and excellent surface flatness while maintaining favorable cutting performance in a dicing step. A multi-printed wiring-substrate panel is manufactured which includes a metal plate having a first main surface and a second main surface, and resin dielectric layers disposed on the first and second main surfaces. The metal plate has first depression portions and second depression portions. The first depression portions are opened at the first main surface and arranged discontinuously along predetermined cutting lines. The second depression portions are opened at the second main surface and arranged discontinuously along the predetermined cutting lines. The multi-printed wiring-substrate panel is cut along the predetermined cutting lines into a plurality of printed wiring substrates.

Owner:NGK SPARK PLUG CO LTD

Adjustable door threshold

A door threshold may comprise a main body formed from two feet. In certain example embodiments, a male-female connection between the feet may be used to adjust the depth of the door threshold. In certain other example embodiments, a center bridge insert to be used in connection with two female feet to adjust the depth of the door threshold. In still further example embodiments, one or more center layers may be disposed between two feet, with the size of the center layer(s) determining the depth of the door threshold. Also, the door threshold may include upper and lower members for sandwiching carpet and / or carpet padding therebetween which, in certain example embodiments, may grip the carpet to reduce the ease with which it may be pulled out from between the upper and lower members. Thus, certain example embodiments may reduce and / or eliminate the need for tacks proximate to the threshold.

Owner:RISSONE ROBERT

Image forming apparatus having an intermediate transfer belt disposed above a plurality of photoconductors

ActiveUS8200120B2Easy to disassemblePrecise positioningElectrographic process apparatusCorona dischargeElectrical conductorImage formation

Owner:BROTHER KOGYO KK

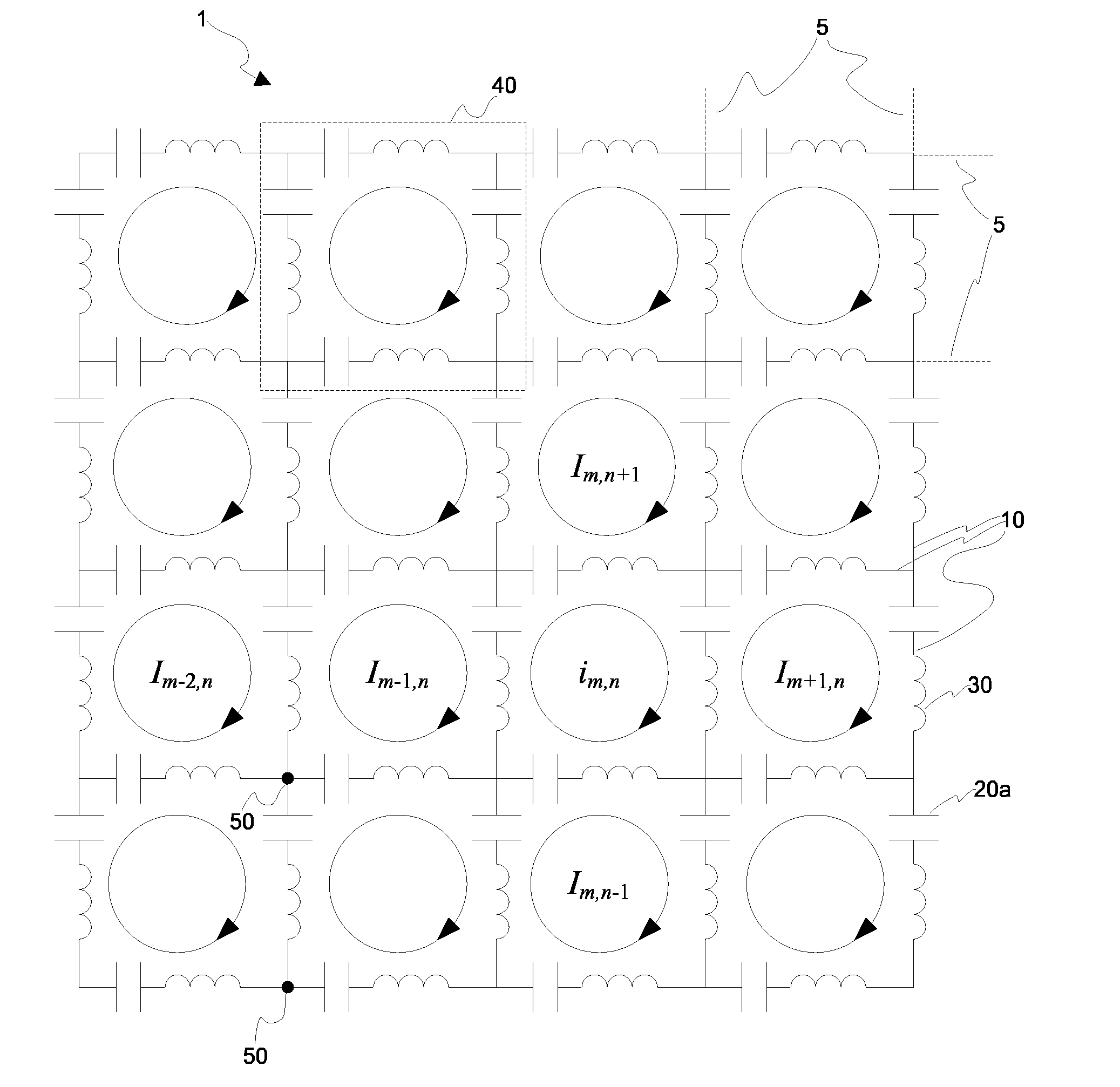

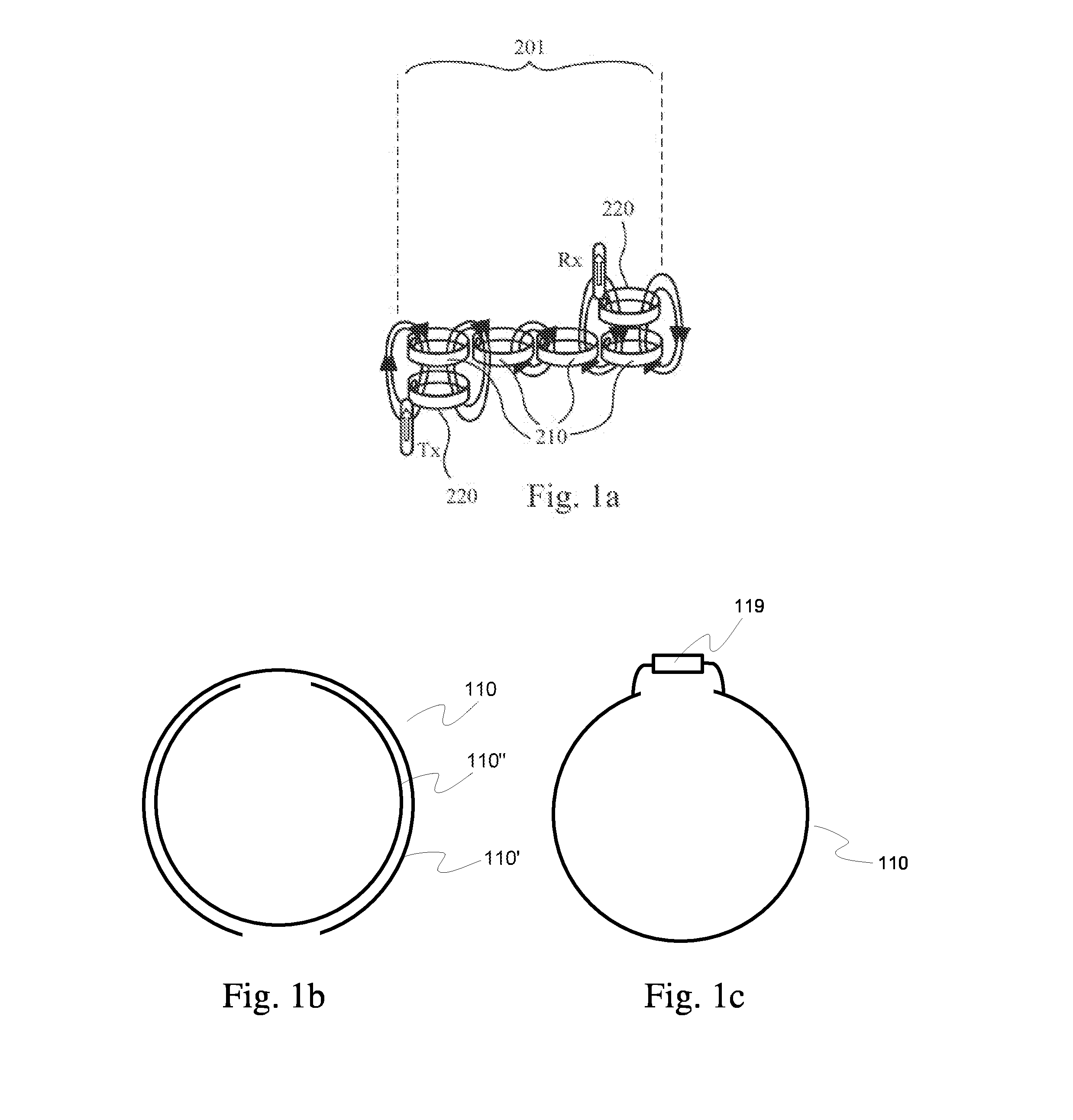

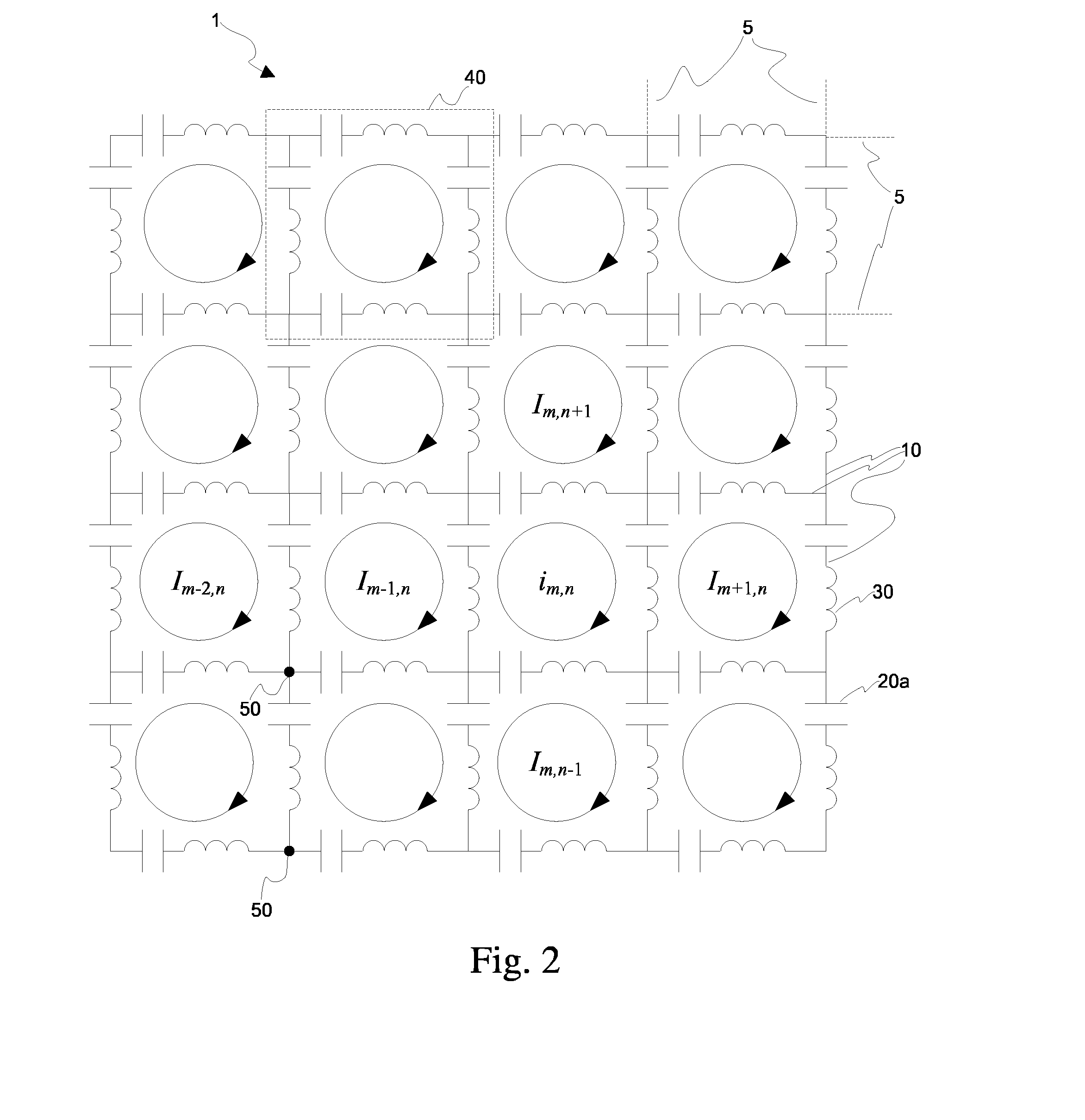

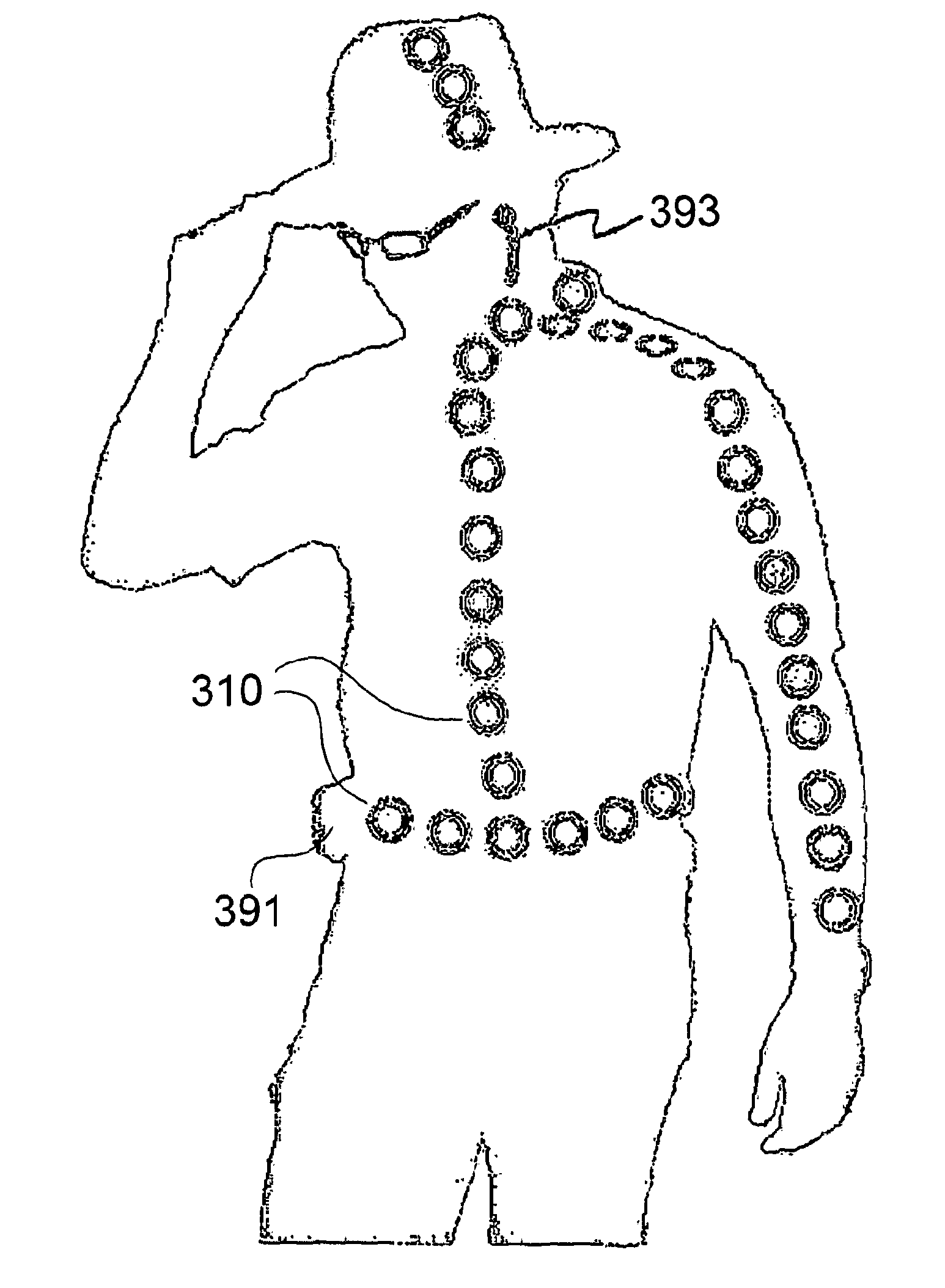

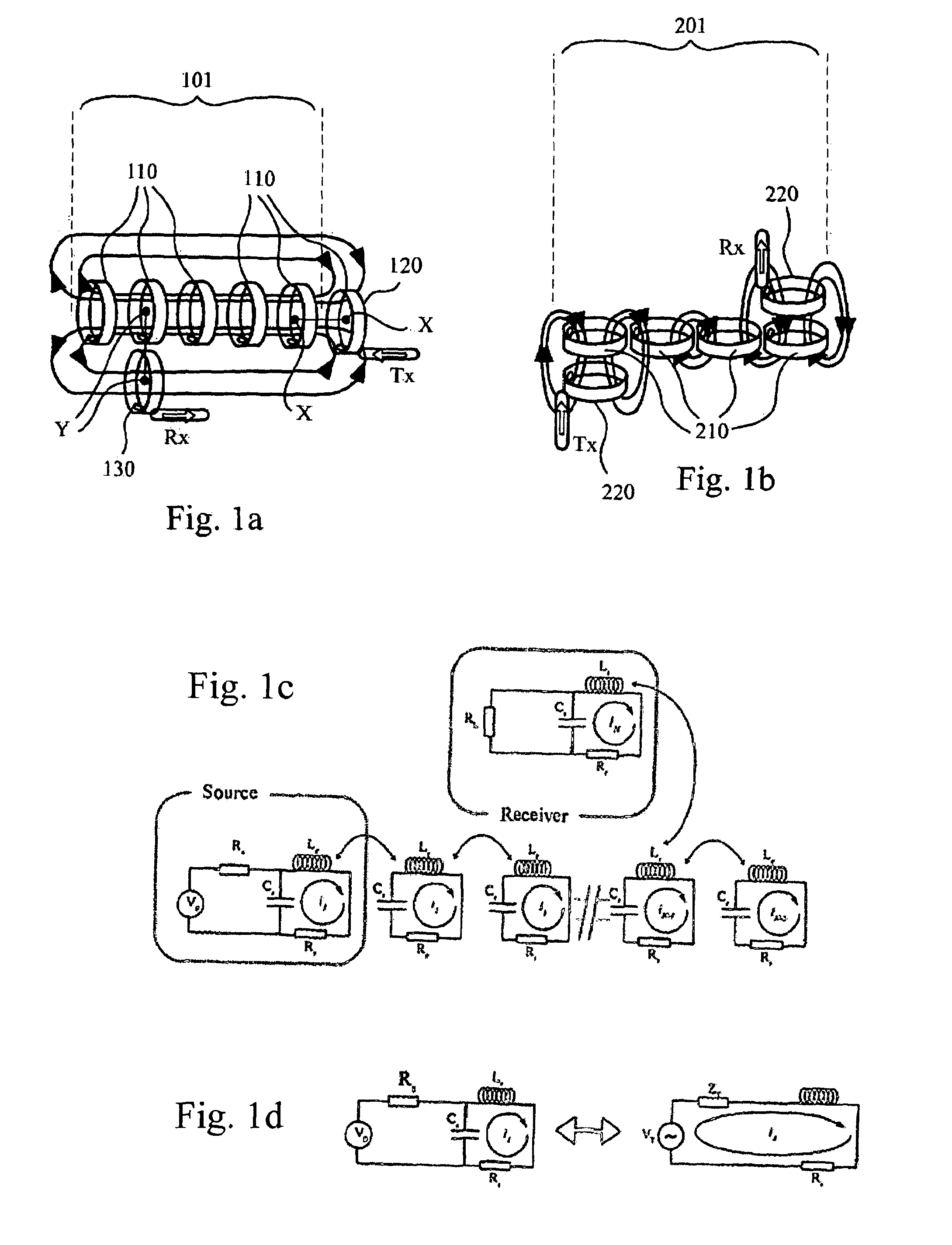

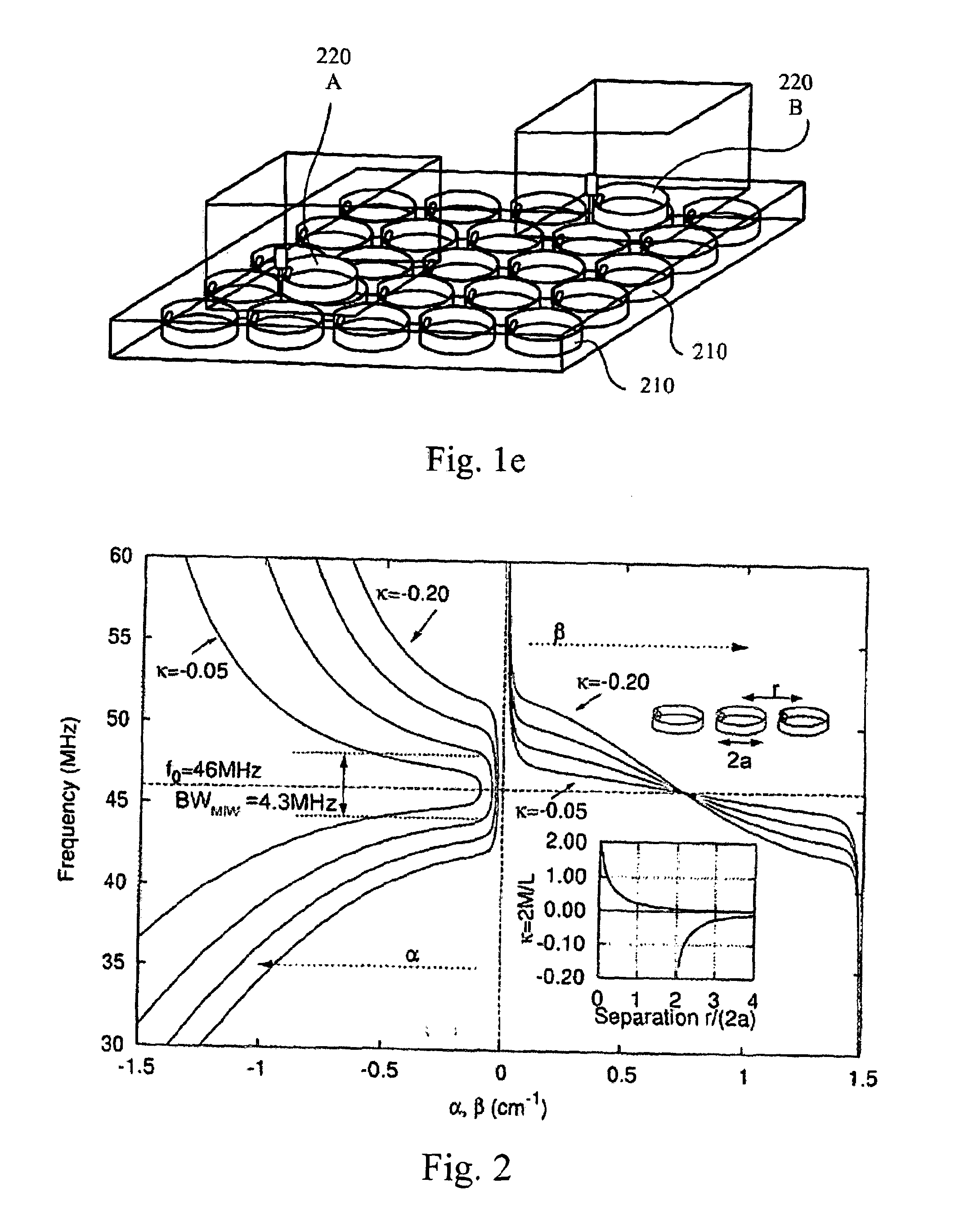

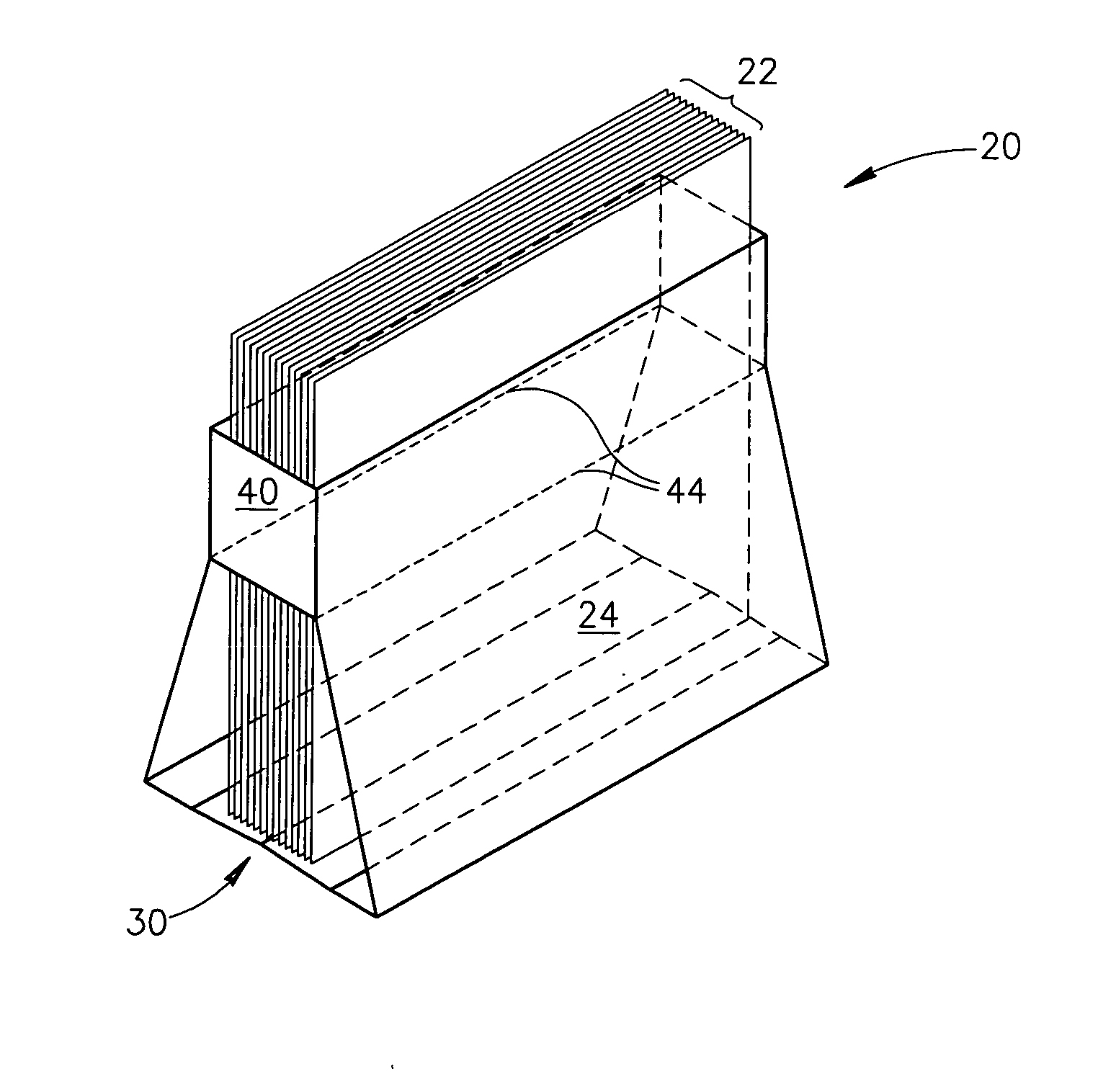

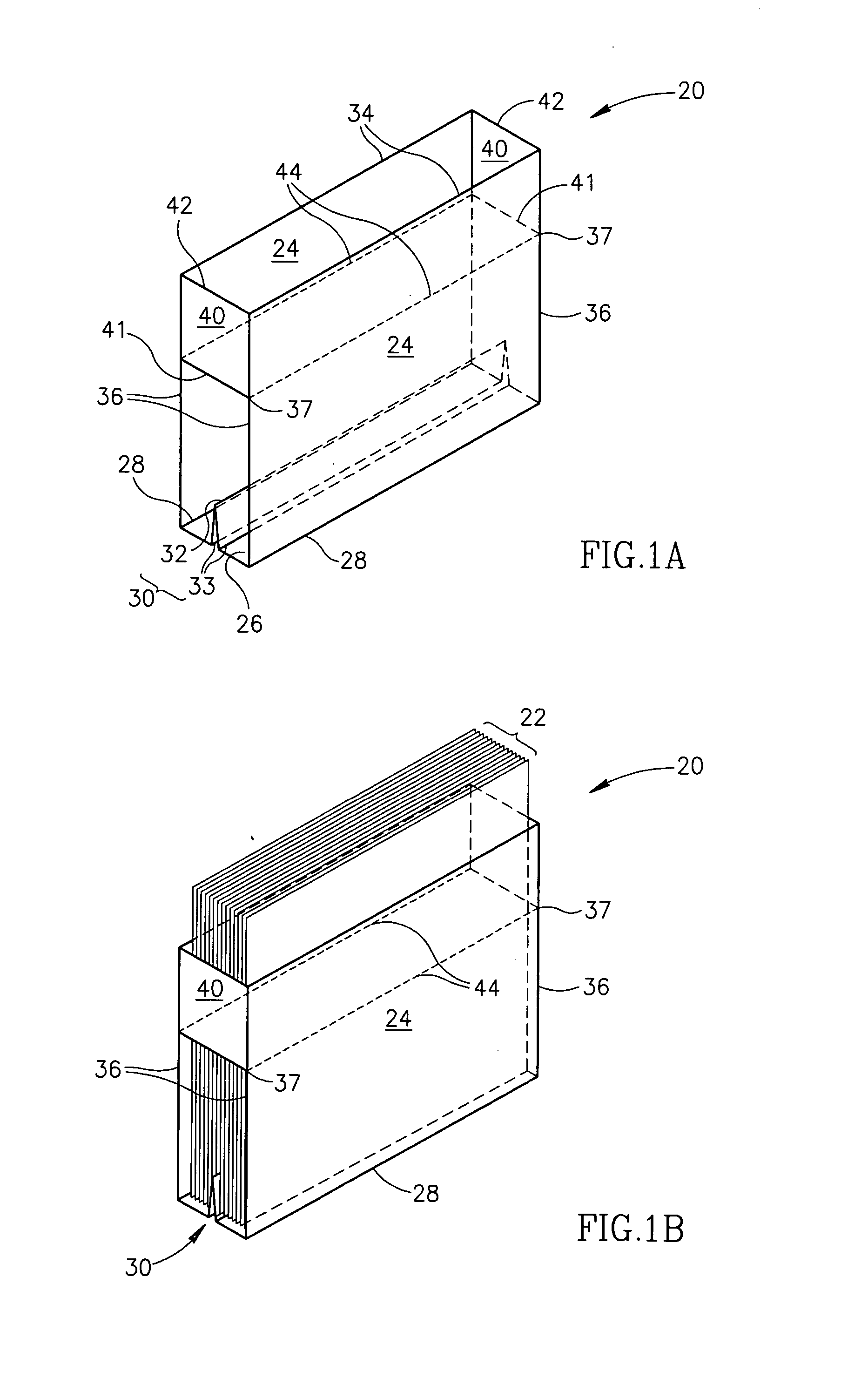

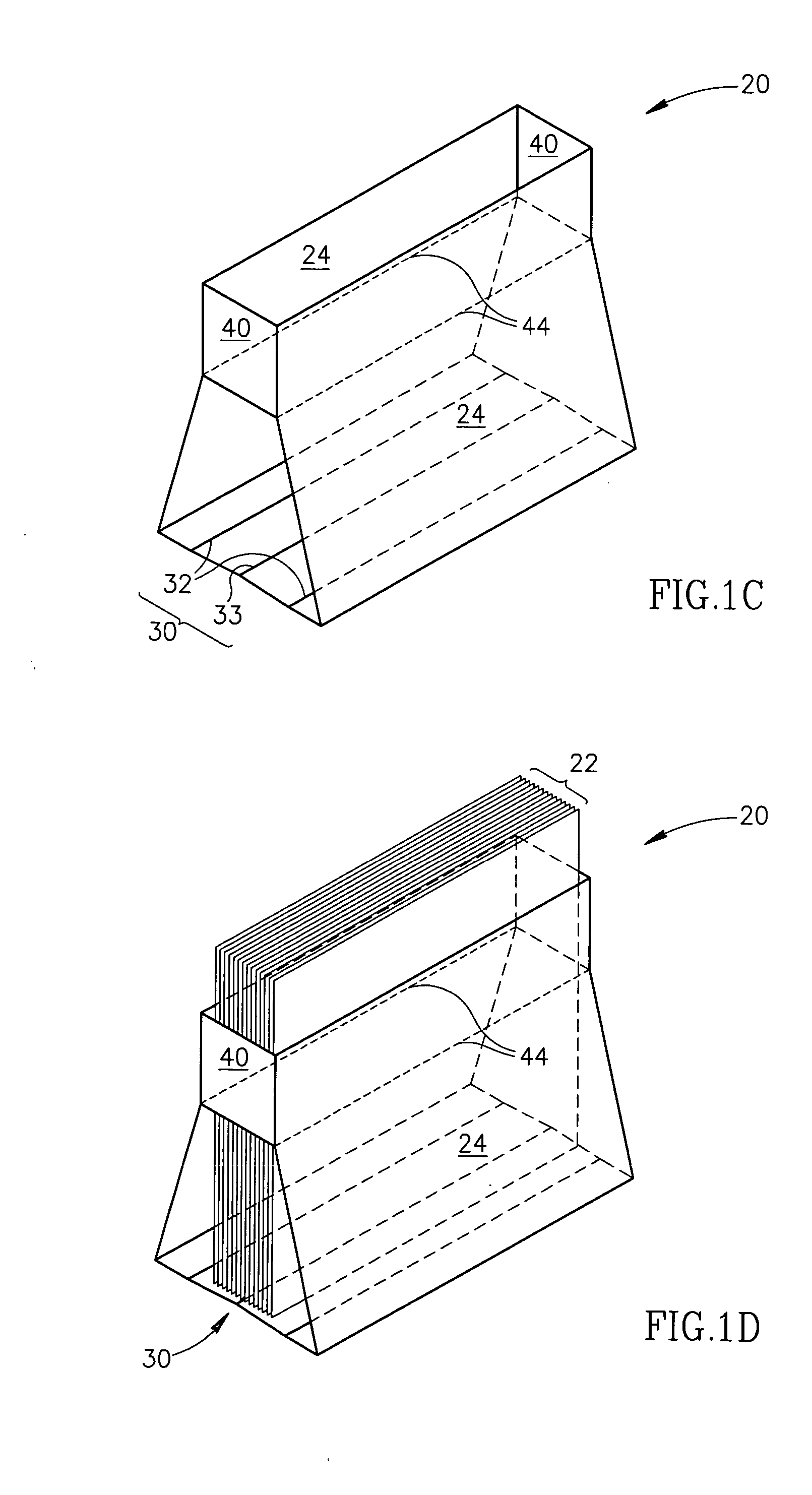

Magneto-inductive waveguide

ActiveUS20140111290A1Eliminate requirementsImprove shielding effectImpedence networksWaveguidesCapacitanceWaveguide

A magneto-inductive waveguide comprising a plurality of resonant elements, the plurality of resonant elements including a first resonant element comprising a conductive loop broken by at least one capacitive gap, and a second resonant element comprising a conductive loop broken by at least one capacitive gap, the second resonant element for magneto-inductively coupling with the first resonant element; wherein the first resonant element and second resonant element are conductively coupled.

Owner:OXFORD UNIV INNOVATION LTD

Common communications device

ActiveUS20120309316A1Eliminate requirementsImprove shielding effectAntenna arraysCharging stationsEngineeringData transmission

A common communications device comprising an array of near-field coupled resonant elements, the elements each comprising a coupling portion comprising a loop portion with free ends, the device being provided in combination with a data transmission unit and a data reception unit, each unit having a coupling portion, the units being arranged to communicate with one another by means of the coupling portion of each unit and the common communications device, the coupling portion of the data transmission unit comprising a resonant element comprising a loop portion arranged to be near-field coupled to the loop portion of a first resonant element of the device, the coupling portion of the data reception unit comprising a resonant element comprising a loop portion arranged to be near-field coupled to the loop portion of a second resonant element of the device not being the first resonant element.

Owner:OXFORD UNIV INNOVATION LTD

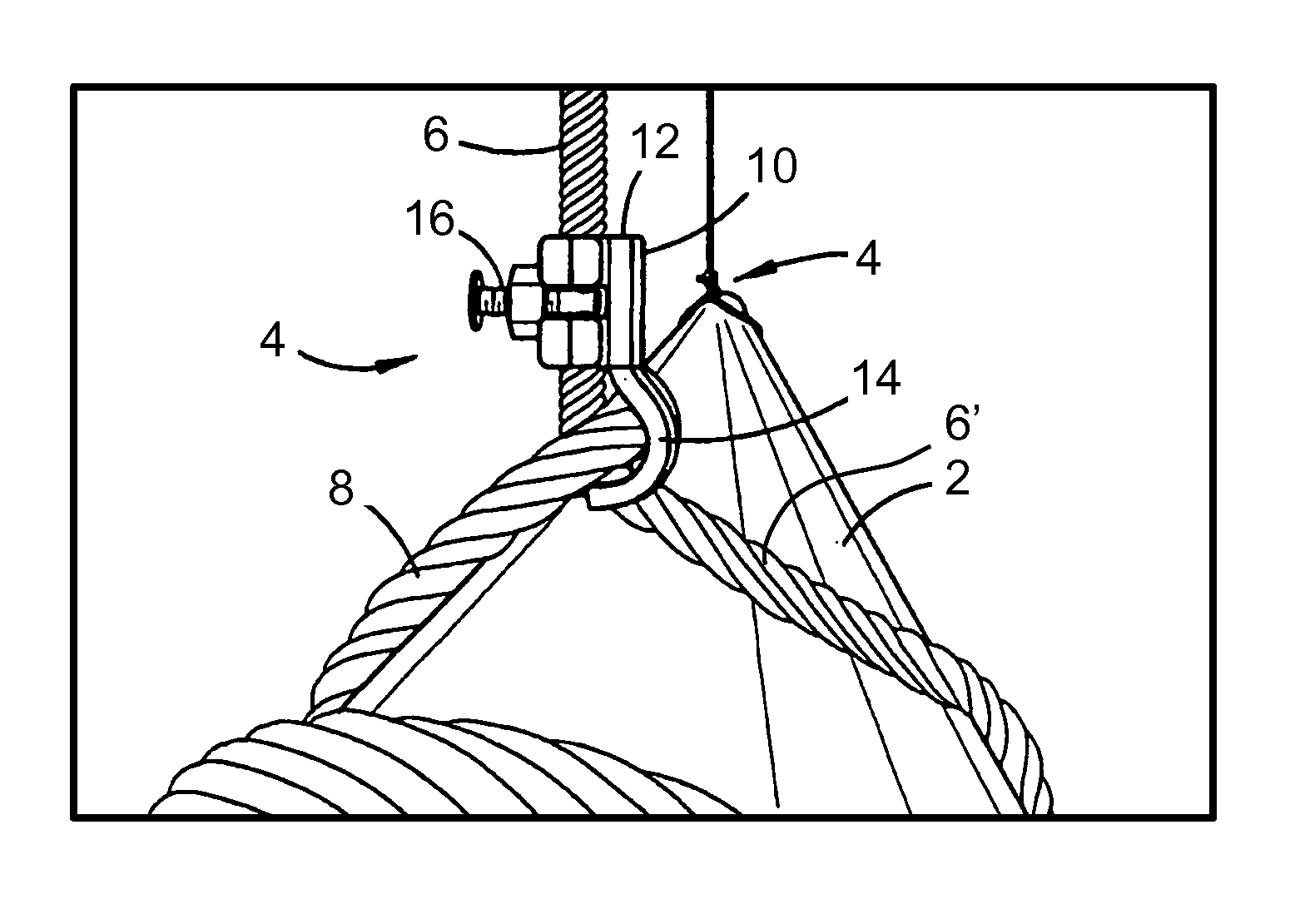

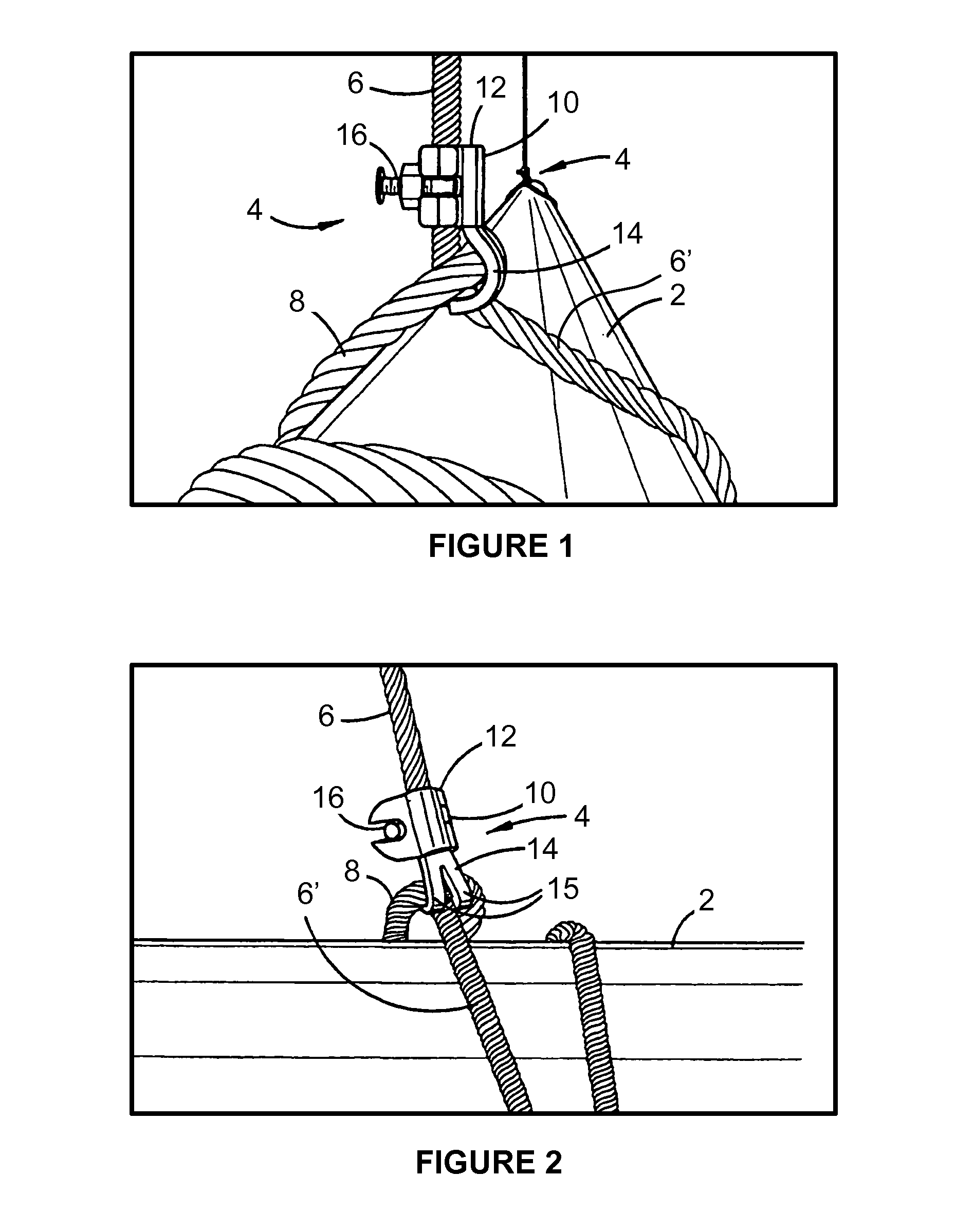

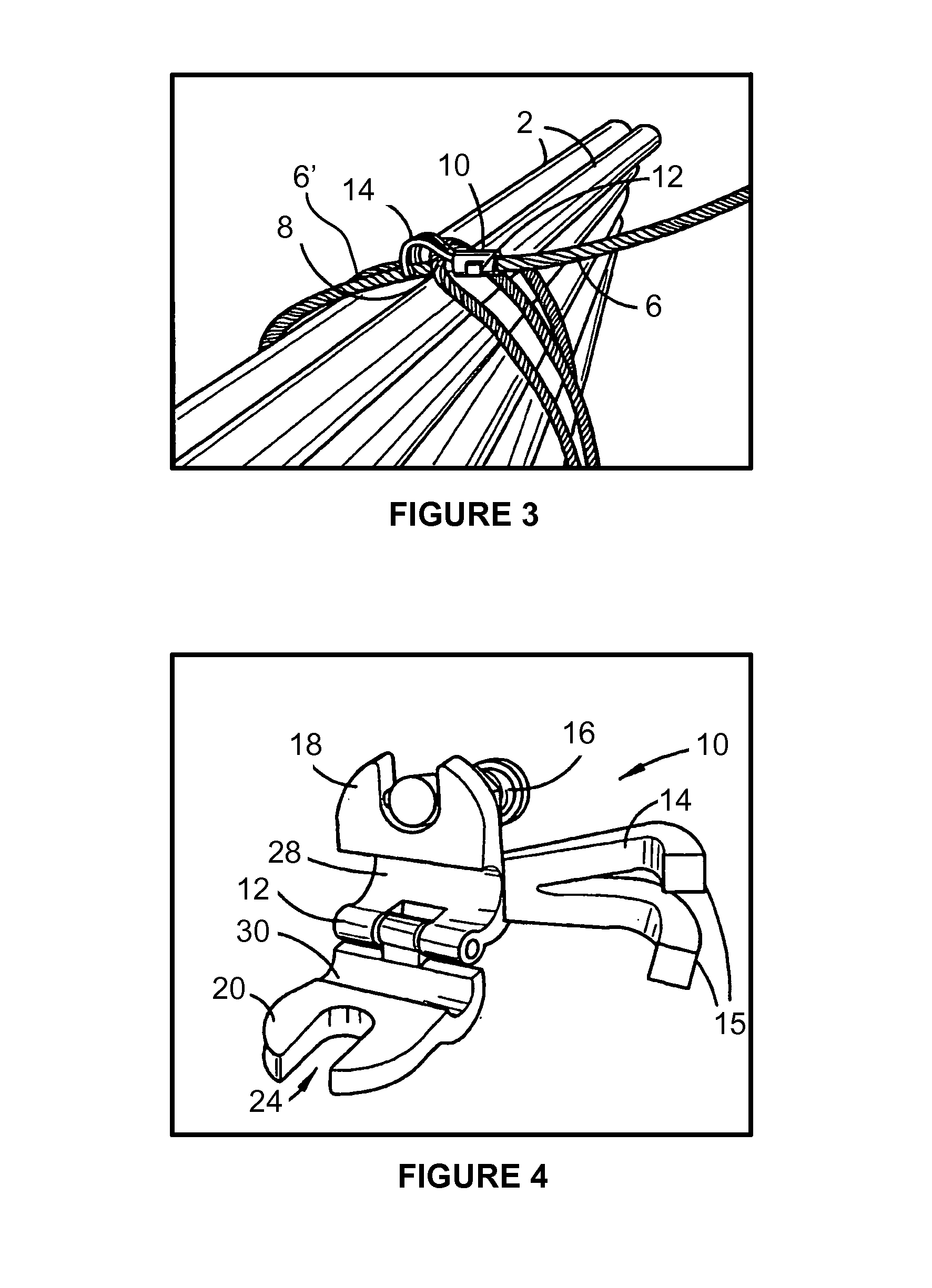

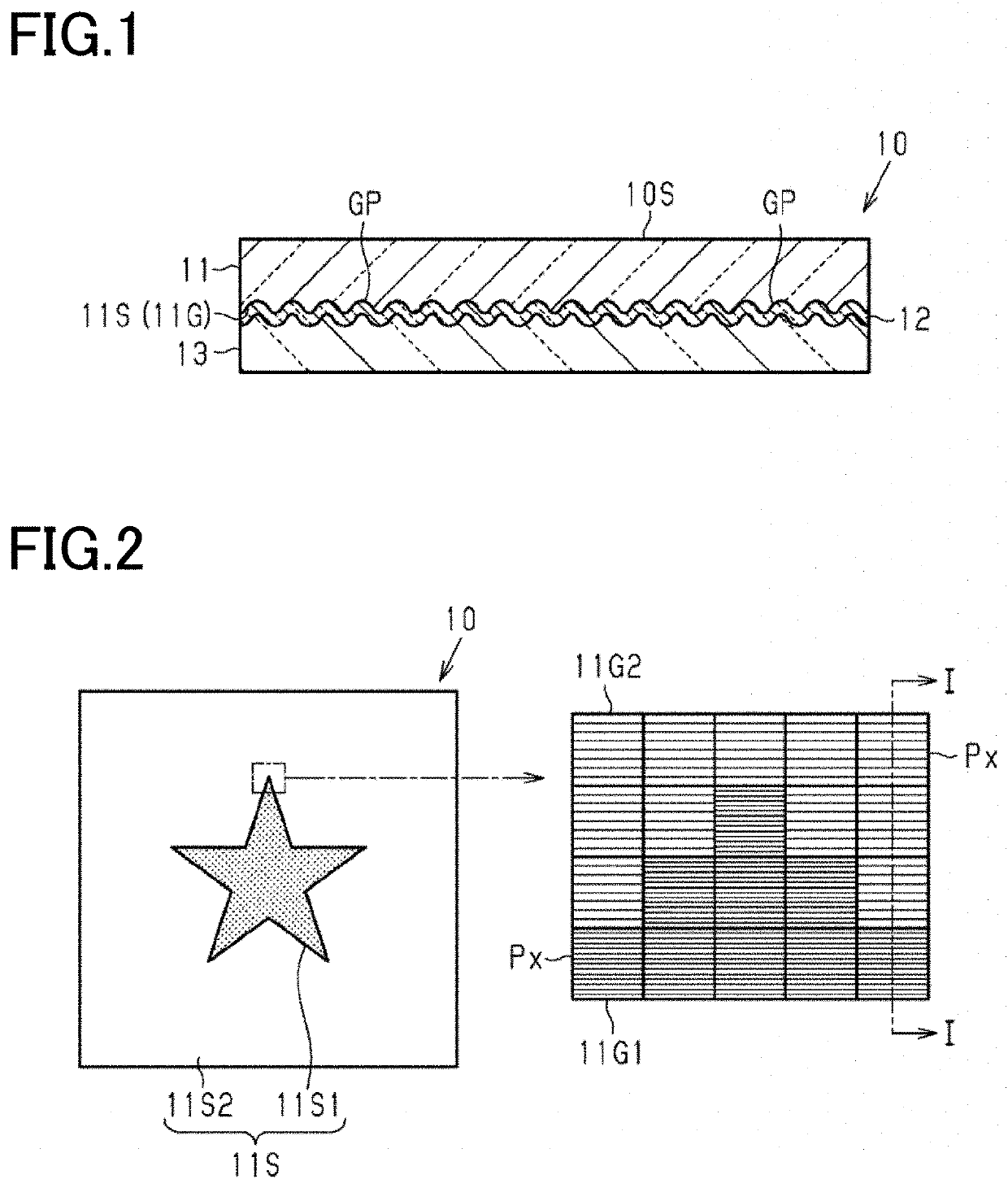

Clamping device

ActiveUS8801062B2Reduce harmReduce wearCeramic shaping apparatusHaberdasheryMechanical engineeringEngineering

A safety clamping device for clamping onto a first rope portion and retaining a second rope portion. The clamping device comprises a clamping portion and a retaining portion. The clamping portion clamps onto the first rope portion, and comprises first and second clamping members in use hingedly coupled to one another such that the clamping portion is movable between an open configuration suitable for receiving the first rope portion and a clamping configuration suitable for clamping onto the first rope portion. The retaining portion retains the second rope portion relative to the position of the first rope portion, and is coupled to the clamping portion.

Owner:CLAMPSAFE INT

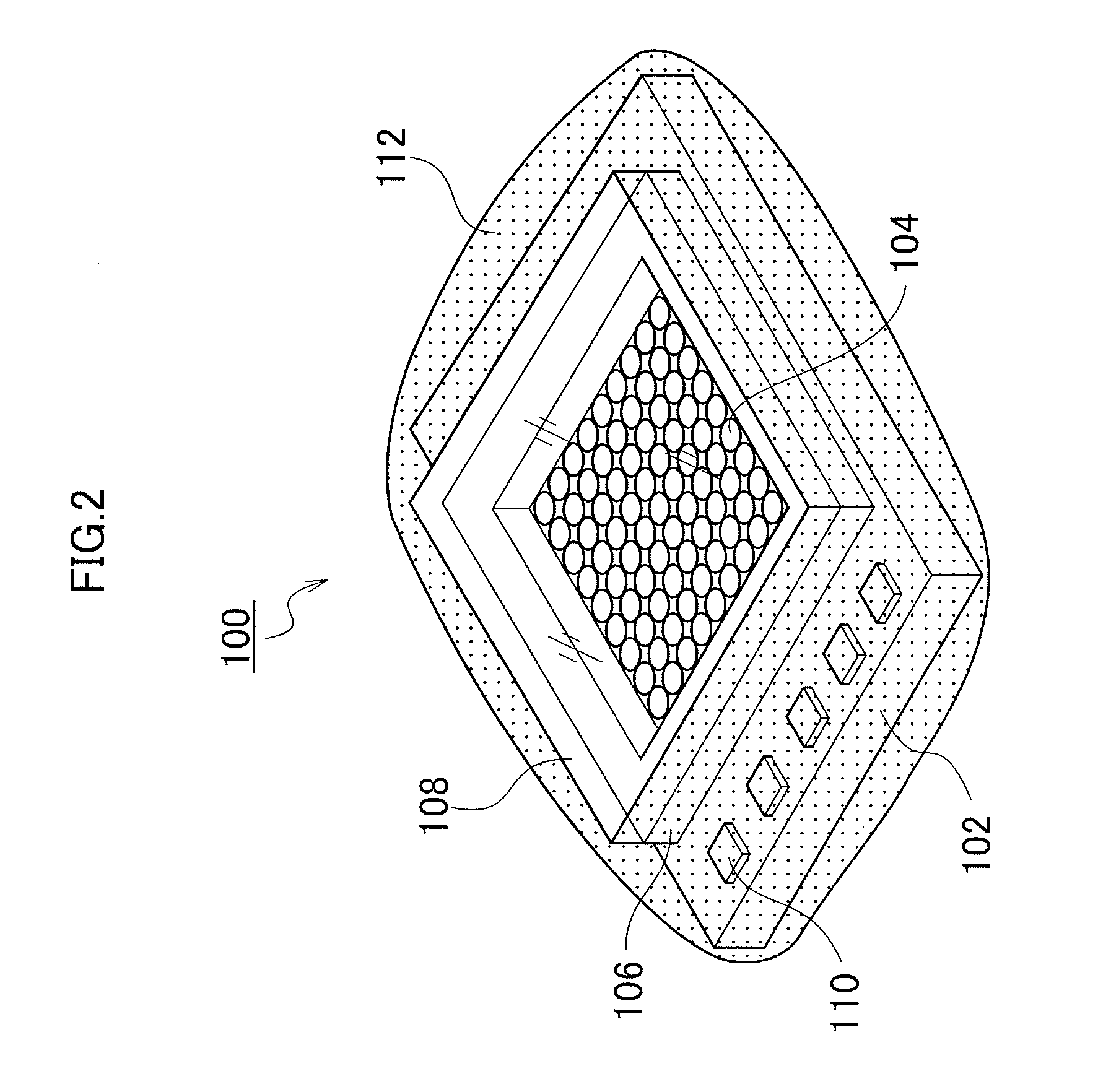

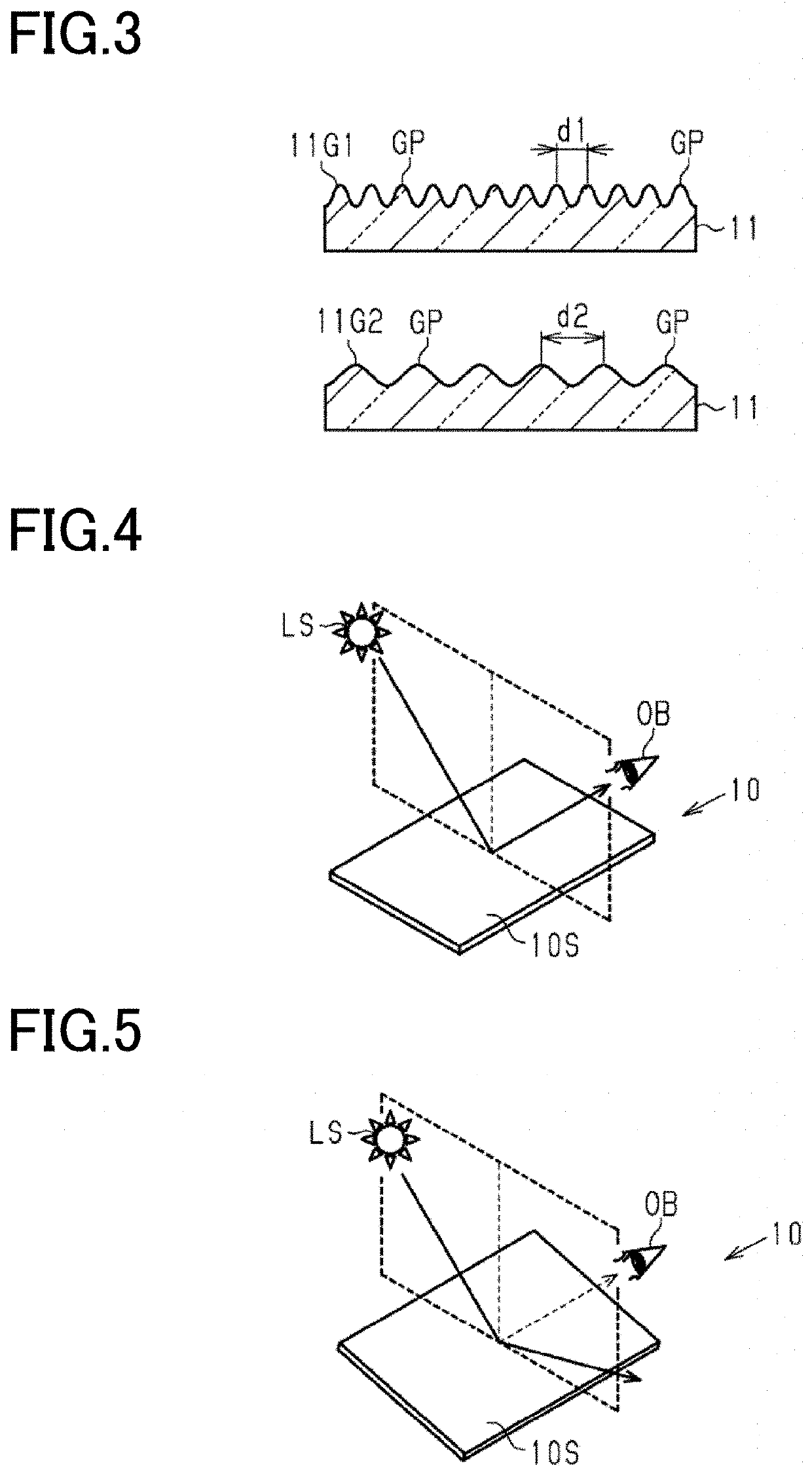

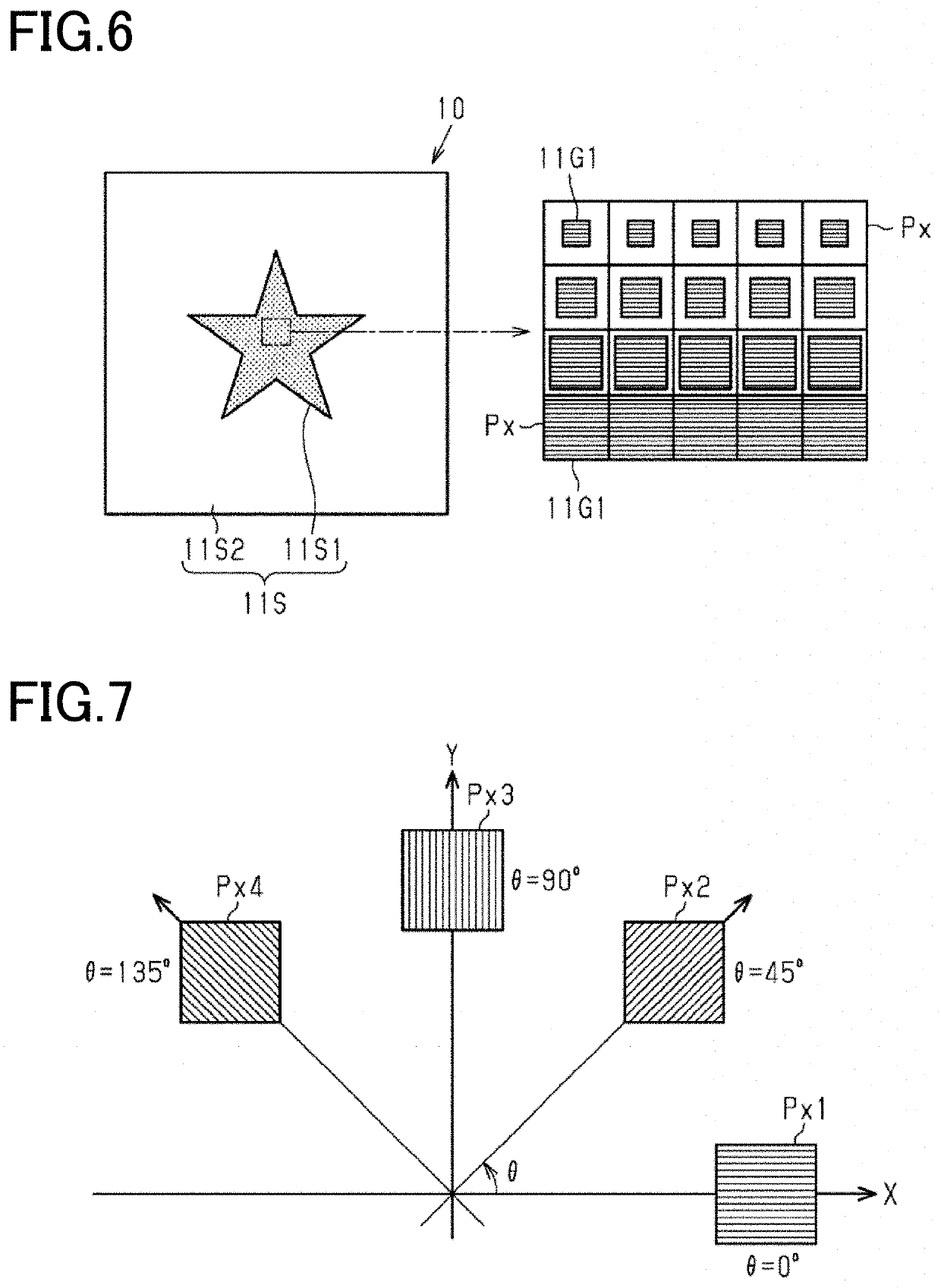

Optical element, transfer foil, authentication medium, and method of verifying authentication medium

ActiveUS20210001659A1Convenient verificationSimple definitionPaper-money testing devicesInformation cardsSurface displayGrating

A subwavelength grating displaying a colored image exhibiting a color corresponding to a grating period of a subwavelength grating in reflection directions including a specular reflection direction. A relief surface displaying a reflection image in monochromatic reflected light in reflection directions including a direction different from the specular reflection direction. An optical element has a first state in which neither a colored image nor a reflection image is displayed, a second state in which the colored image is mainly displayed, and a third state in which the reflection image is mainly displayed. A plane in which the optical element is disposed and a plane including a line of sight of an observer form an observation angle therebetween. The optical element is observed in any of the first, second and third states according to the observation angle.

Owner:TOPPAN PRINTING CO LTD

Napkin holder

InactiveUS20050061702A1Easy to stackReduced easeOther accessoriesTray containersEngineeringBackplane

Owner:BRAUN ORI J +1

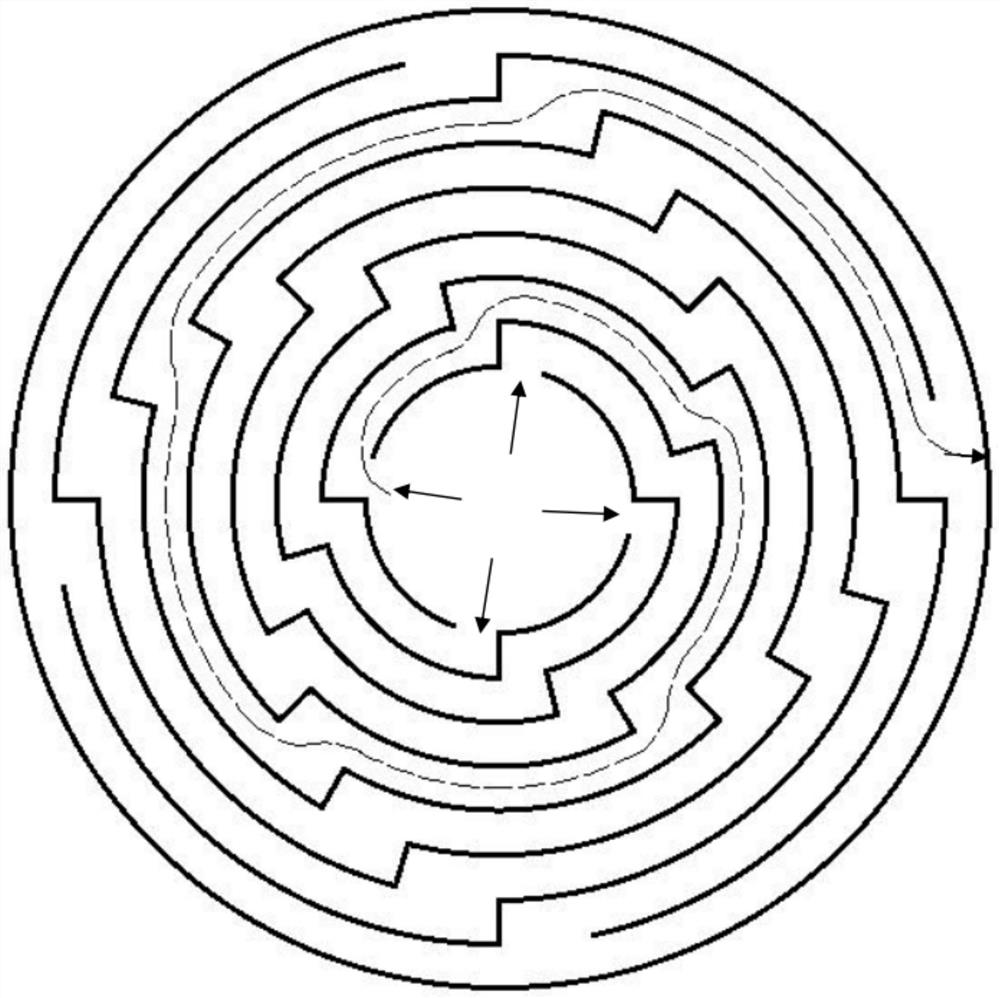

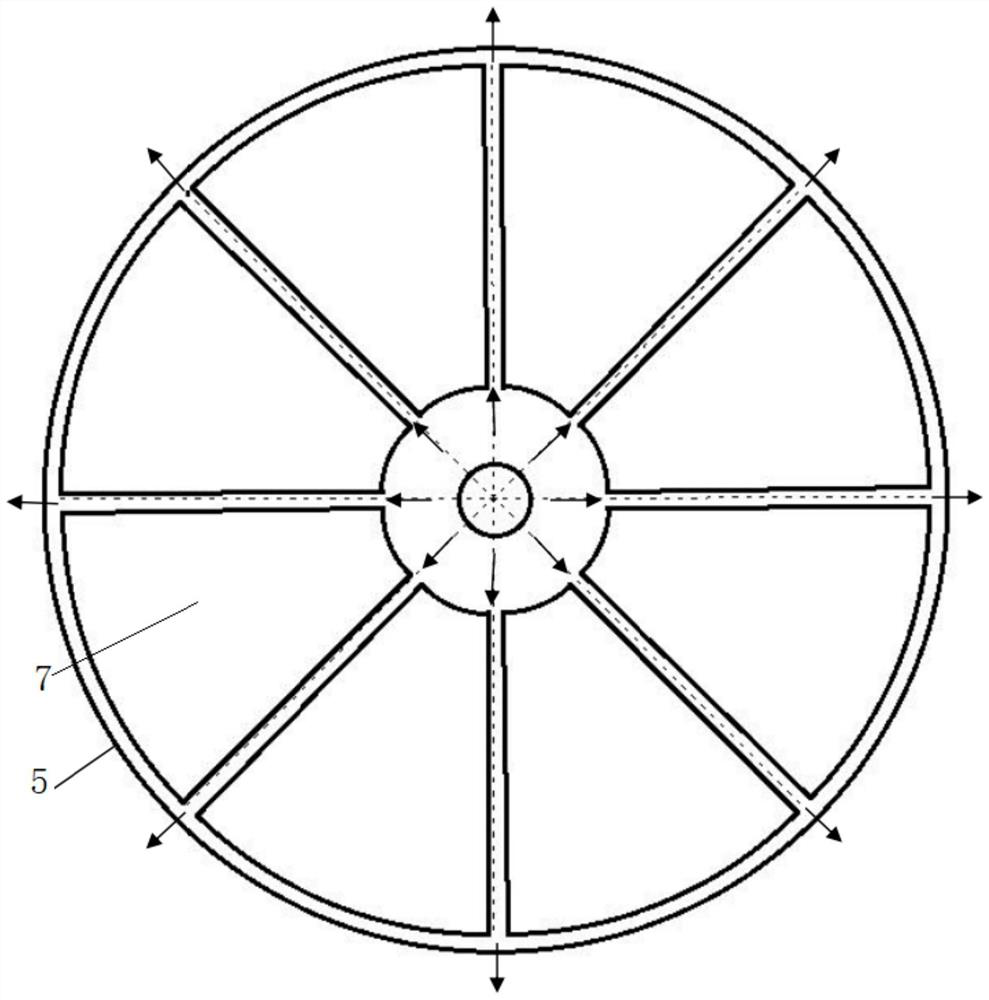

Method for improving surface quality of inner and outer rings and edge parts of oriented silicon steel and annular furnace

ActiveCN114085973ASolve quality problemsReduce interlayer gapFurnace typesProcess efficiency improvementStructural engineeringMechanical engineering

The invention discloses a method for improving the surface quality of inner and outer rings and edge parts of oriented silicon steel and an annular furnace. In a primary cold rolling process, misalignment crimping is adopted, crimping tension is controlled according to gradual change tension, the crimping tension at the head and the tail is large, and the crimping tension at the middle part is small; the coating amount of MgO and the curling tension change synchronously, the coating amount of the head and the tail is small, and the coating amount of the middle part is large; in the high-temperature annealing process, a cushion layer formed by evenly distributing a plurality of fan-shaped blocks around the center is additionally arranged on a bottom plate of the annular furnace, gaps exist between the adjacent fan-shaped blocks, and the upper end of a steel coil in an inner cover of the annular furnace is covered with a ventilated cover plate. An inner ring gap of the bottom surface of the cover plate extends into a steel coil hole, an outer ring gap sleeves a steel coil, the middle of the cover plate is supported on the end surface of the steel coil through diversion trenches uniformly distributed around the center, the diversion trenches are spiral, inlets of the diversion trenches are communicated with openings in the inner ring of the cover plate in a one-to-one correspondence manner, and outlets of the diversion trenches extend to the inner side of the outer ring of the bottom surface of the cover plate. The method can obviously reduce surface defects, obviously improve surface quality and magnetism, and is easy to operate.

Owner:武汉钢铁有限公司

Aqueous dispersion of poly(acetal-polyether) and its use in protective coatings

An aqueous dispersion includes an associative thickener based on a hydrophobically modified poly(acetal- or ketal-polyether) (HM-PAPE) and at least one viscosity reducing agent selected from ethoxylated alcohols, ethoxylated acetyleneic diols, phosphate esters, dialkyl sulfosuccinates, and mixtures thereof. This aqueous dispersion improves the incorporation of the HM-PAPEs into aqueous based protective coatings. This dispersion also improves water-borne coating compositions that optionally contain latex.

Owner:HERCULES INC

Headgear for a respiratory mask

ActiveUS11154680B2Improve stabilityAdjustable lengthRespiratory masksMedical devicesPhysical medicine and rehabilitationEngineering

A headgear for a respiratory mask has first and second straps configured to be connected to each other by first and second buckles. The straps are configured to overlap in a region that contacts the rear of a user's head. The overlapping regions of the first and second straps can be positioned in a bifurcated configuration to improve stability on a user's head. The first and second buckles can feature a glider end through which one of the first and second straps can slide and a strap attachment end to which the other strap is permanently connected. In some embodiments, the first and second buckles have two components that are pivotally connected to allow adjustment of the headgear size whilst in a bifurcated configuration.

Owner:FISHER & PAYKEL HEALTHCARE LTD

Paint for forming insulating film, and plasma display panel using the paint and method of manufacturing the same

InactiveUS6808435B2Improve wettabilityDecrease in flowabilitySynthetic resin layered productsAlternating current plasma display panelsOrganic solventInorganic materials

The present invention provides a paint for forming an insulating film, which has a good wettability to a surface to be coated with the paint and has no voids or pin-holes after being fired; a plasma display panel including a dielectric layer formed using the paint; and a method of manufacturing the plasma display panel. The paint contains inorganic fine particles, a binder resin, and an organic solvent that has a good wettability to glass such as a glass substrate, ceramic as an Ag electrode, and a metal compound such as an ITO film and forms a contact angle of less than 5° with these inorganic materials. Accordingly, the paint has a good wettability to a glass substrate, an Ag electrode, and an ITO film and the resultant insulating film thus has no voids or pin-holes.

Owner:PANASONIC CORP

TONER CARTRIDGE AND ITS RECYCLING METHOD (as amended)

InactiveUS20110170912A1Reliable leakEasy to recycleElectrographic process apparatusRecovery methodEngineering

The present invention provides a toner cartridge and its recycling method in which a clearance due to stack of the housing and the lid can reliably be sealed so that toner leakage can be prevented. A toner cartridge which is set in an image forming apparatus to feed toner to the image forming apparatus includes a housing having a toner containing portion for containing toner therein, and a lid for covering the toner containing portion of the housing. A stack portion where the housing and the lid are stacked on each other is sealed by a sealing member having first and second adhesive materials provided on both-side surfaces of a base material with the first adhesive material stuck on an outer peripheral surface of the stack portion and with a release paper stuck on the second adhesive material.

Owner:KONICA MINOLTA BUSINESS TECH INC

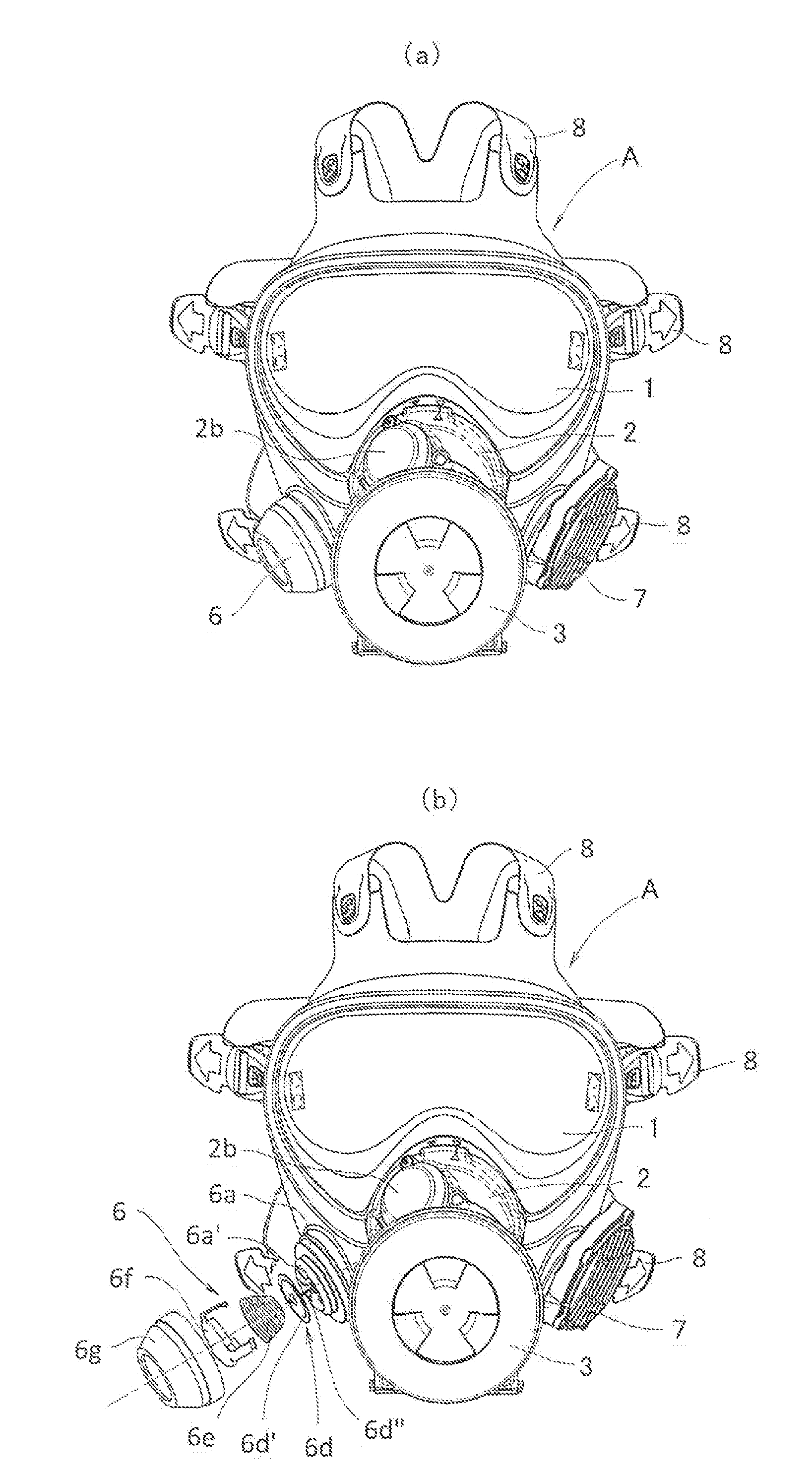

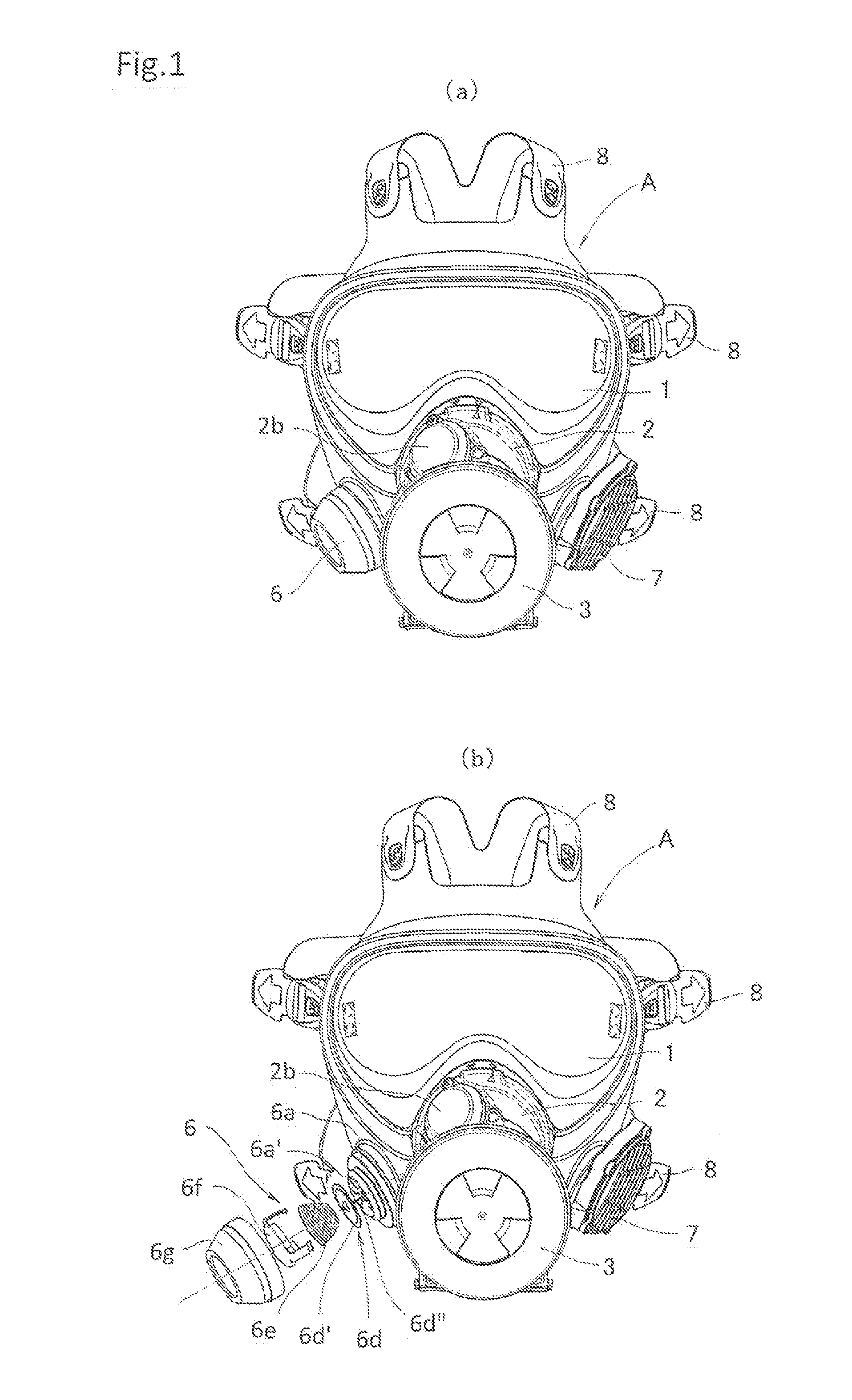

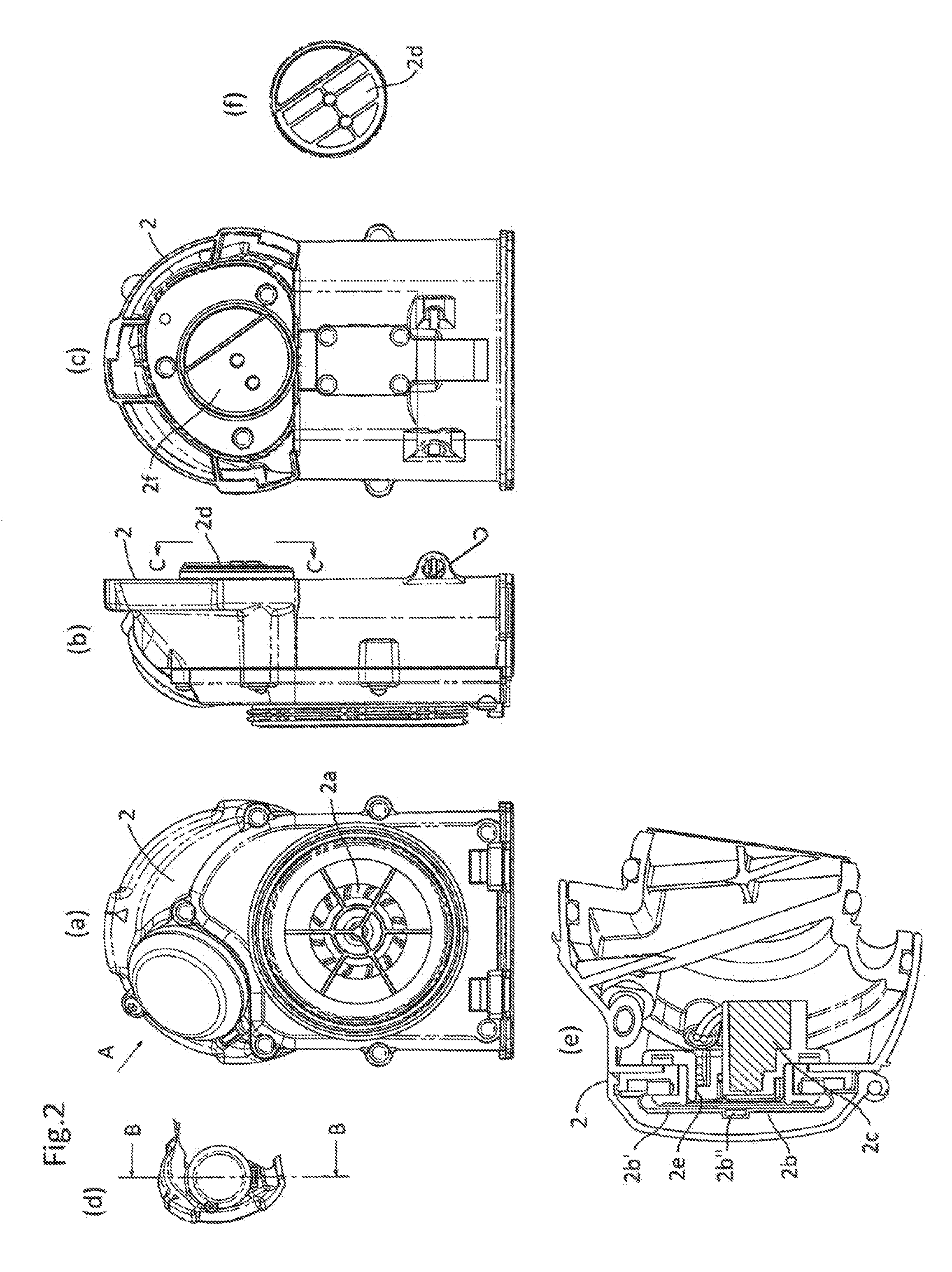

Breathing apparatus

InactiveUS20160236016A1Reduced easeSpeed of motorBreathing filtersBreathing masksInternal pressureElectrical conductor

[Object of the Invention] An object of the present invention is to provide a breathing apparatus comprising a face piece for covering the whole face or part of the face provided with a hole at each side portion, a motor fan for supplying the face piece with external air, a pressure sensor for monitoring internal pressure of the face piece, a controller for controlling the operation of the motor fan based on a detection signal from the pressure sensor, a filter for purifying the external air supplied to the face piece, and an inhale valve and an exhale valve, wherein filter consumption is minimized.[Disclosure of the Invention] A breathing apparatus comprises a face piece for covering the whole face or part of the face provided with a hole at each side portion, a motor fan for supplying the face piece with external air, a pressure sensor for monitoring internal pressure of the face piece, a controller for controlling the operation of the motor fan based on a detection signal from the pressure sensor, a filter for purifying the external air supplied to the face piece, and an inhale valve and an exhale valve, wherein a positive pressure exhale valve is attached to one of the holes at the side portions of the face piece and a positive pressure exhale valve or a voice conductor is attached to the other of the holes at the side portions of the face piece.

Owner:SHIGEMATSU WORKS CO LTD

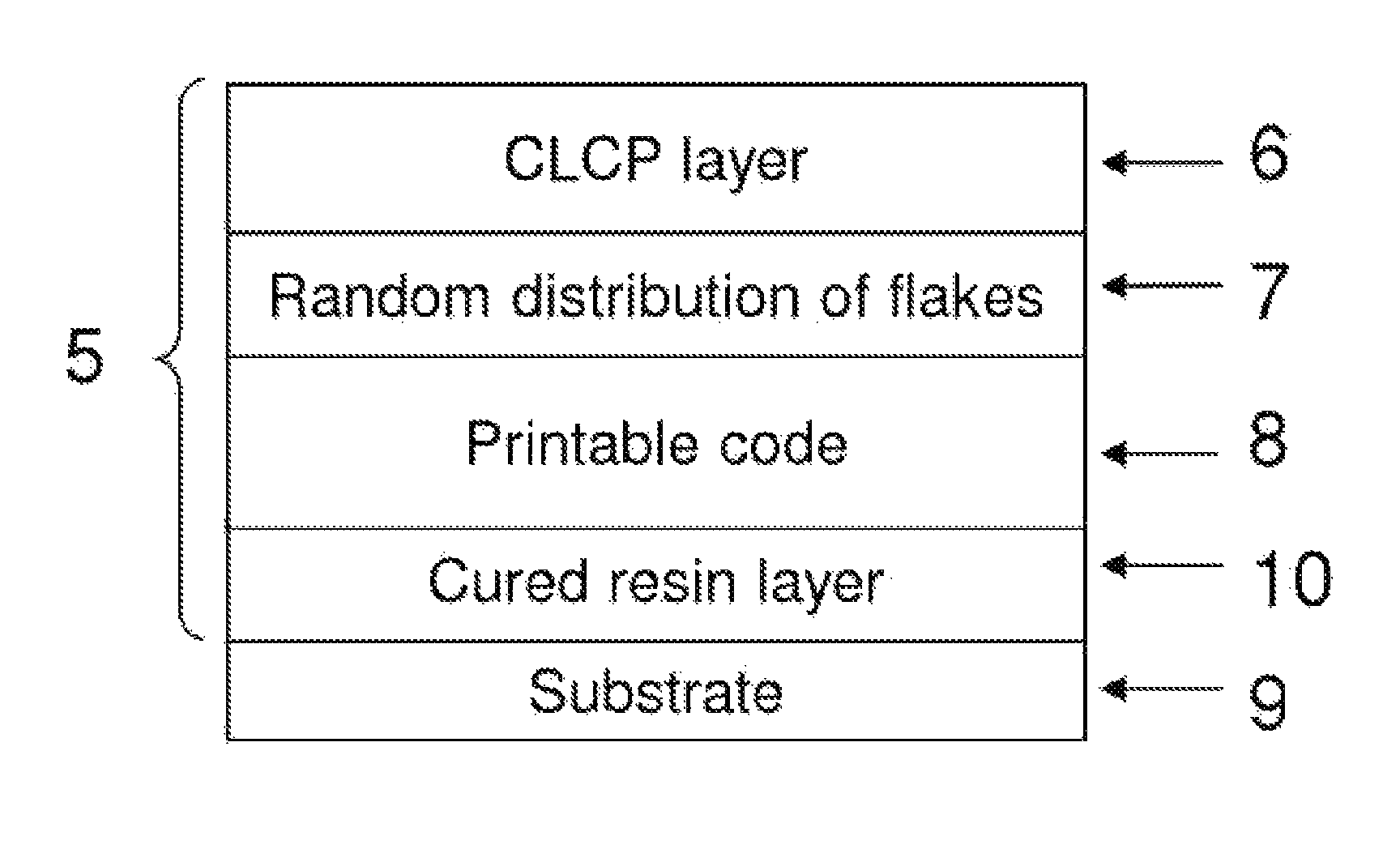

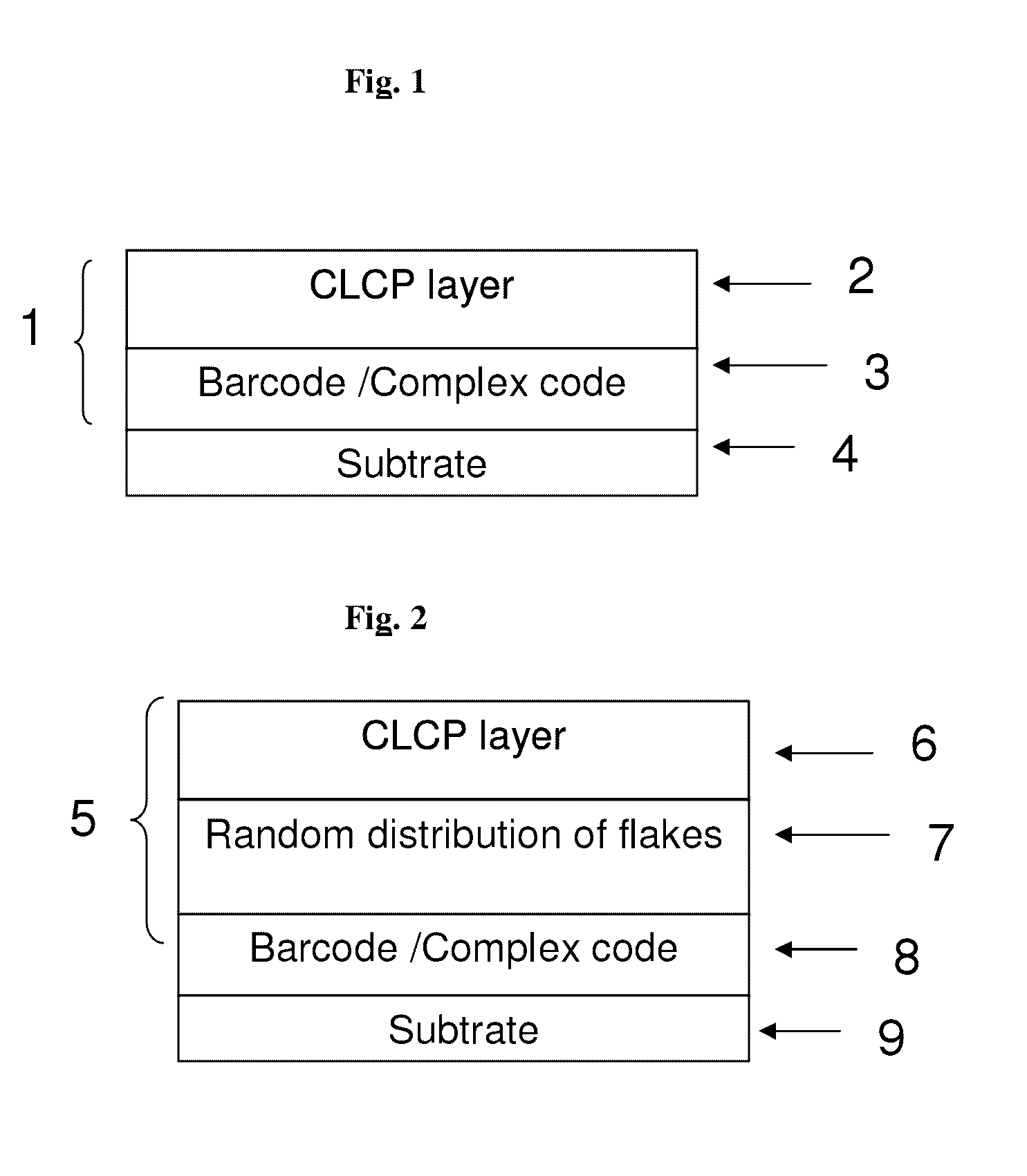

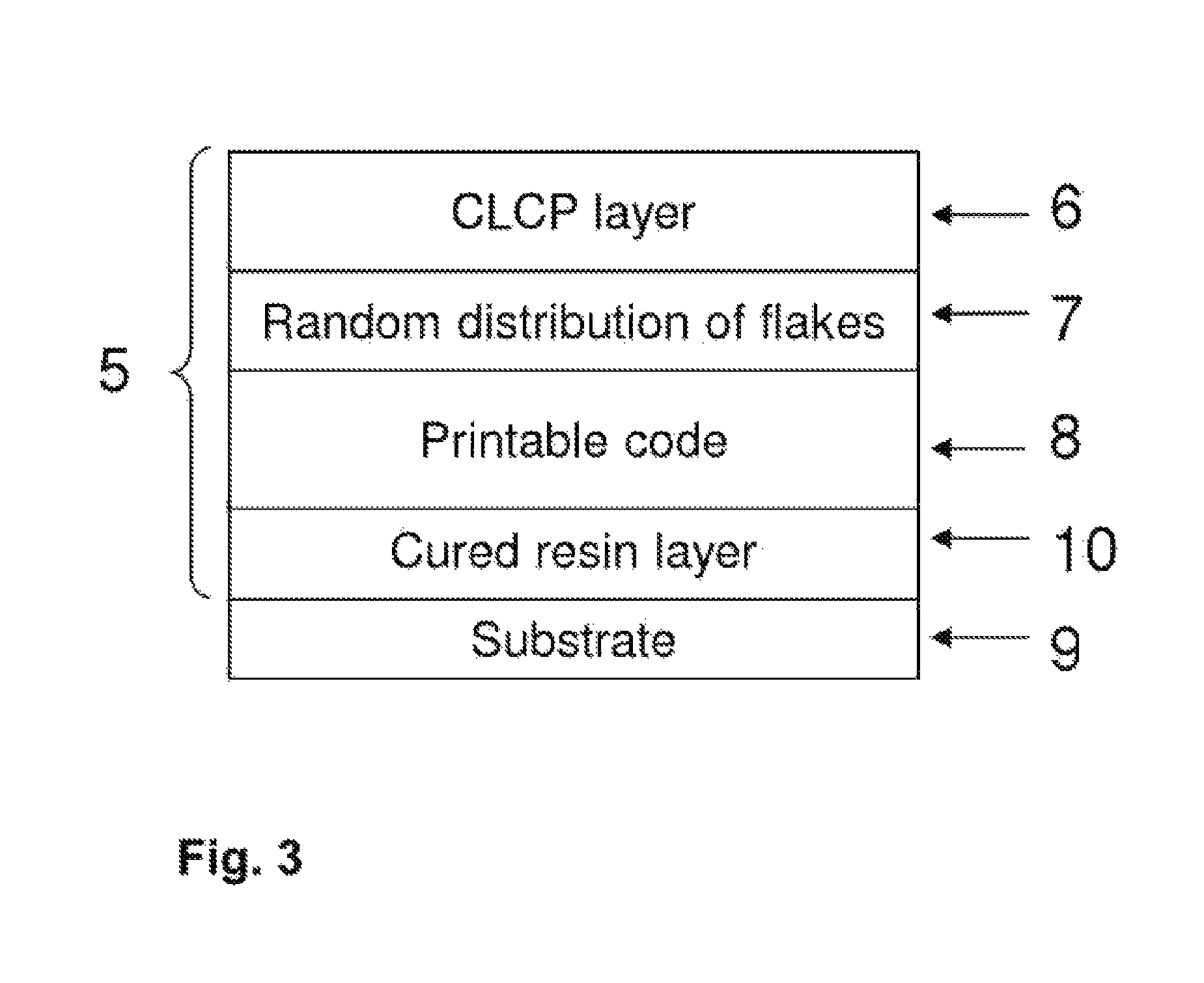

Marking comprising a printable code and a chiral liquid crystal polymer layer

ActiveUS9579922B2Increased complexityReduced easeLiquid crystal compositionsStampsPolymer sciencePolymer

Disclosed is a marking for an article, item or substrate. The marking comprises a printable code, at least a part of which is covered by a chiral liquid crystal polymer (CLCP) layer, and further preferably including an intermediate layer including a distribution of flakes, to provide readable information of at least two different types on the article.

Owner:SICPA HLDG SA

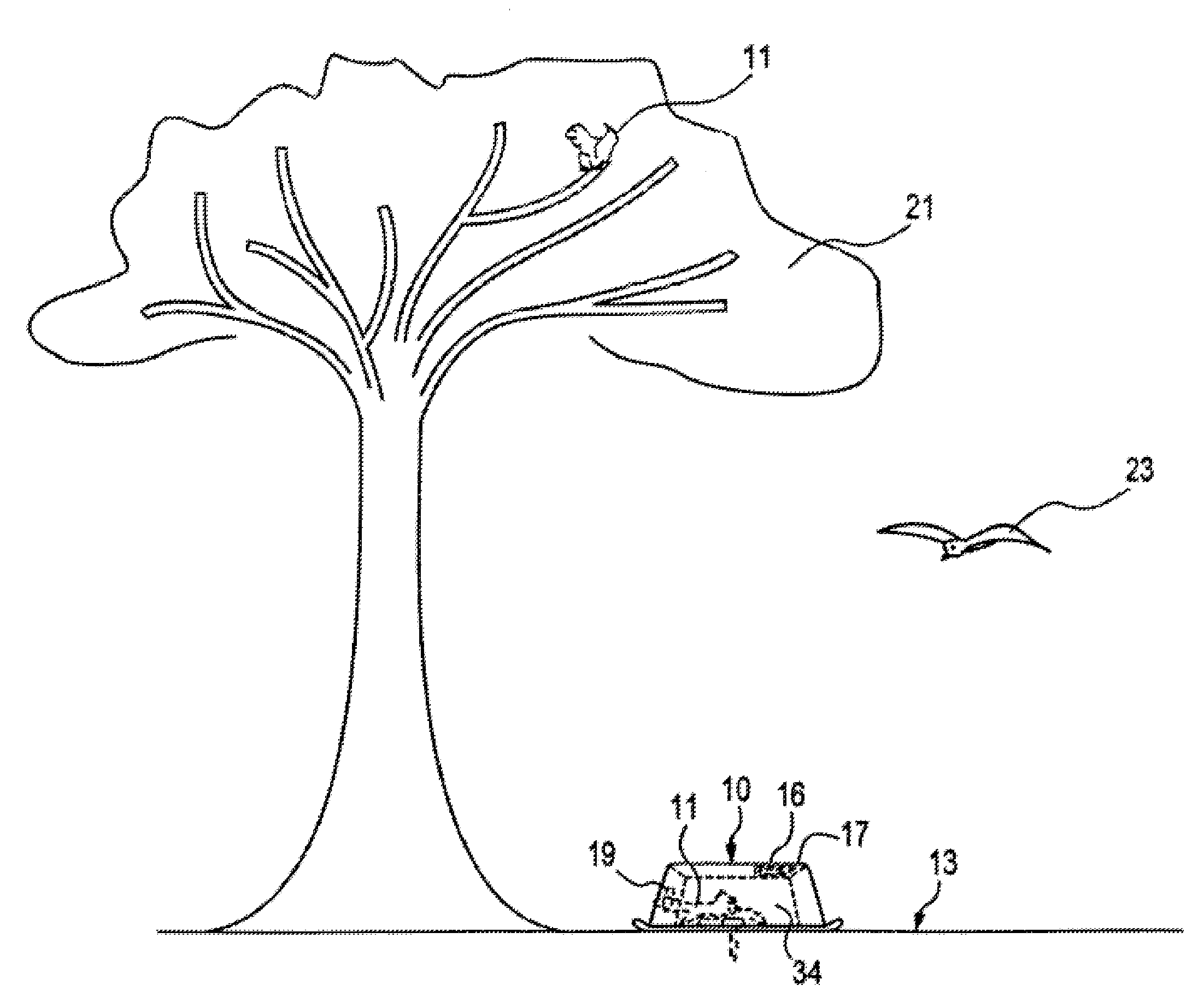

Protected Squirrel Feeder

InactiveUS20110061597A1Quick exitAvoid viewingAnimal feeding devicesPisciculture and aquariaEngineeringHigh calcium

A protected feeder is provided for squirrels which comprises a feeder having a self supporting enclosure for predator protection from hawks or foxes to be positioned adjacent a tree for providing a protected perch with access openings in the cover and a selected portion of ground therein is covered with food. The enclosure member is substantially impervious and protects the squirrels while feeding and protects the squirrel from weather. This invention provides various designs for the protected squirrel feeder adapted to protect the food, one using a tray which is smaller than the self supporting enclosure and a second feeder uses small high-calcium loaded rocks as a ground layer.

Owner:EHRREICH JOHN E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com