Method for improving surface quality of inner and outer rings and edge parts of oriented silicon steel and annular furnace

A surface quality, oriented silicon steel technology, applied in furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of the influence of the lower end panel type, unfavorable steel coil support, and too many deflectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

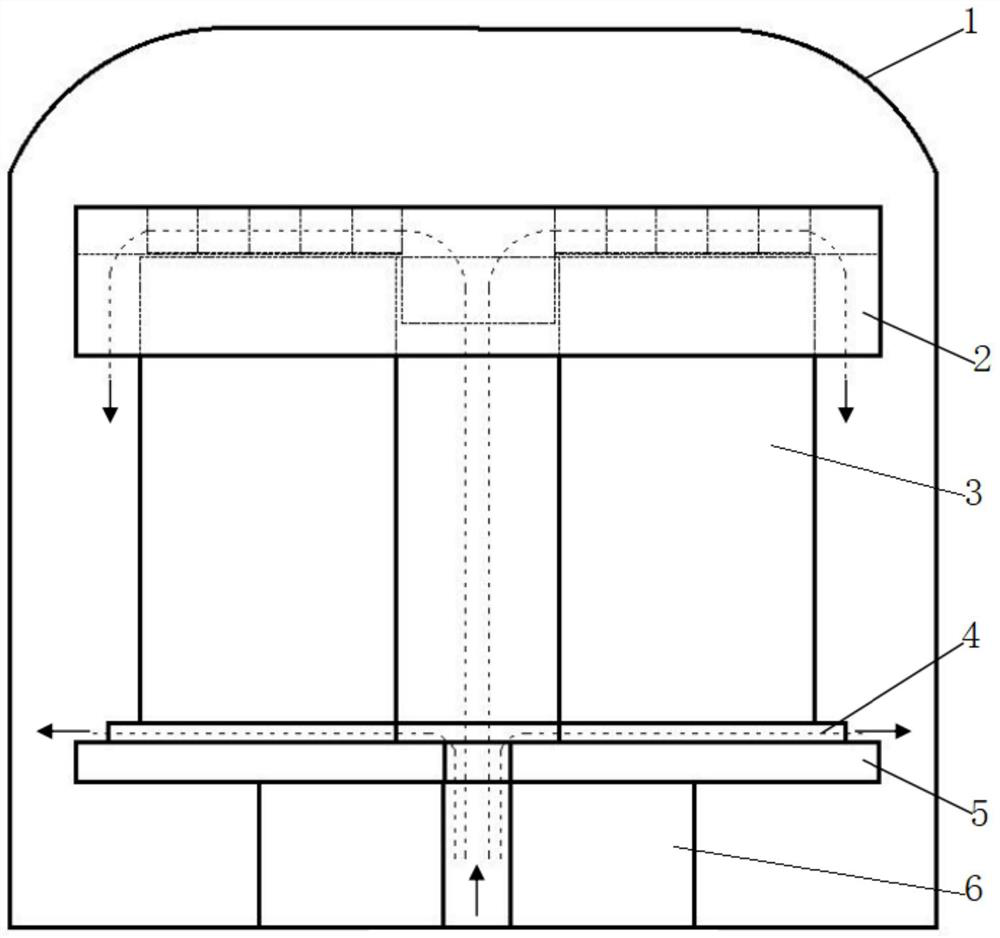

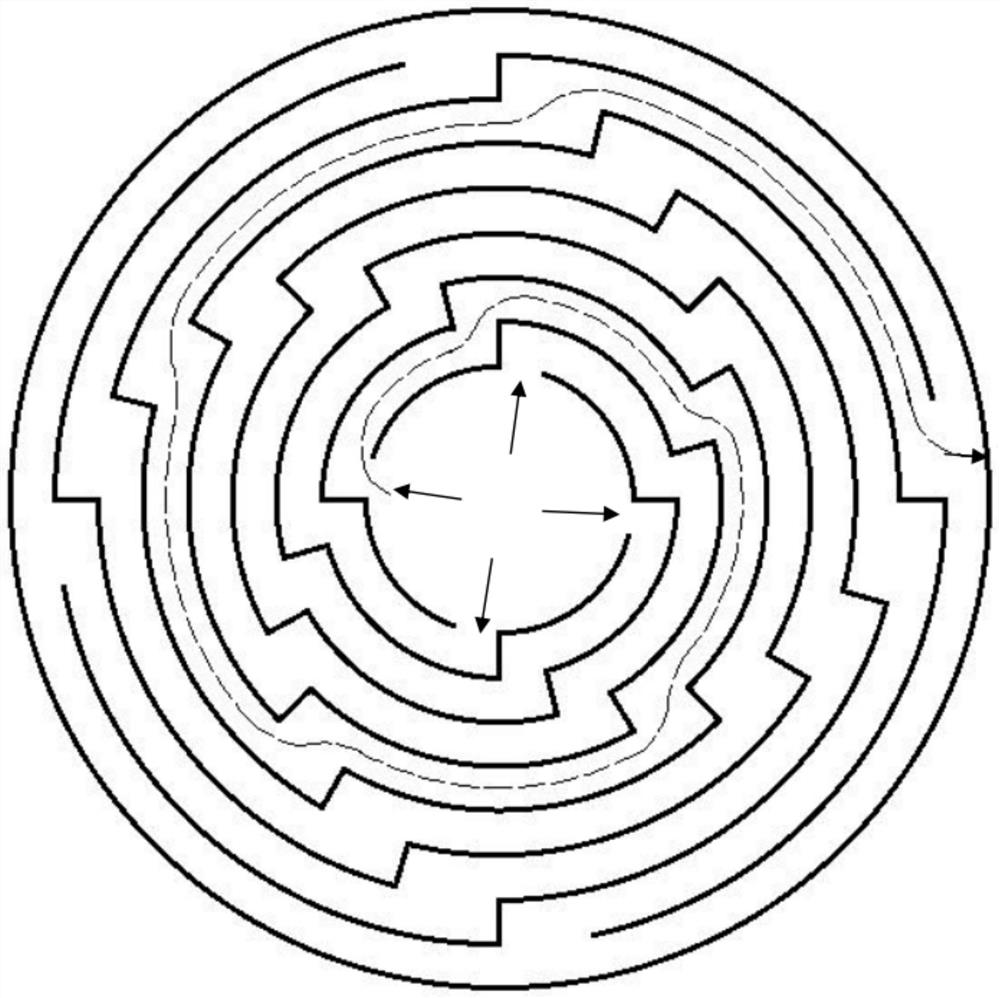

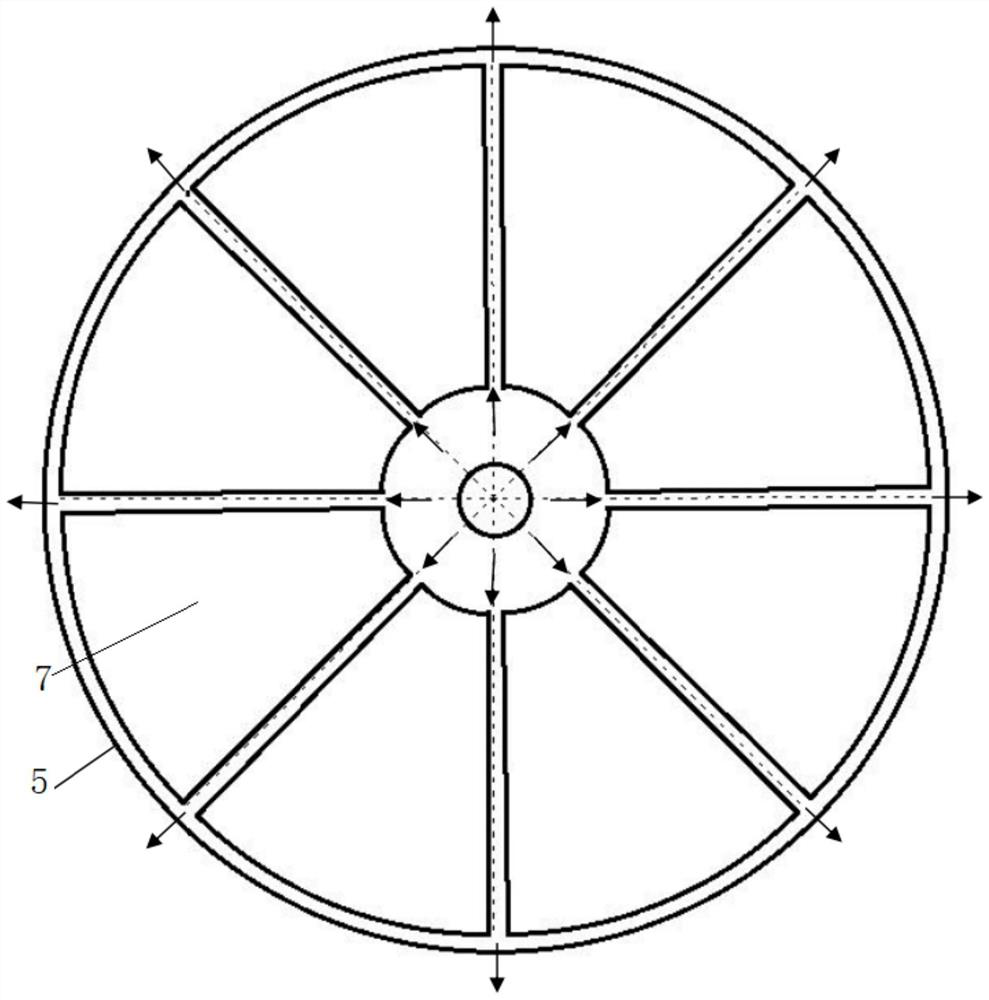

[0035] In one cold rolling process, the amount of misalignment is 1cm, and the misalignment is performed every 5cm until the curling is completed. The MgO coating amount of the head 2000m and tail 1000m is 1g / m less than that of the middle 3 ~2g / m 3 ; In the high-temperature annealing process, adopt 8 fan-shaped blocks 7, the height of the fan-shaped blocks 7 is 3cm, there is a gap of 50mm between the adjacent fan-shaped blocks 7, the width of the diversion groove is 8cm, the height is 10cm, and the middle of the bottom surface of the cover plate 2 passes through Four diversion grooves are evenly distributed around the center, and the inner ring of the bottom surface of the cover plate 2 is 10 cm higher than the diversion groove, and the outer ring is 20 cm higher than the diversion groove.

Embodiment 2

[0037] In one cold rolling process, the amount of misalignment is 0.5cm, and misalignment is performed every 2cm until the curling is completed. The amount of MgO coating at the head 3000m and tail 2000m is 1g / m less than that at the middle 3 ~2g / m 3 ; In the high-temperature annealing process, adopt 4 fan-shaped blocks 7, the height of the fan-shaped blocks 7 is 3cm, there is a gap of 100mm between the adjacent fan-shaped blocks 7, the width of the diversion groove is 12cm, the height is 15cm, and the middle of the cover plate 2 bottom surface passes There are two diversion grooves evenly distributed around the center, the inner ring of the bottom surface of the cover plate 2 is 10cm higher than the diversion groove, and the outer ring is 30cm higher than the diversion groove.

Embodiment 3

[0039] In one cold rolling process, the amount of misalignment is 0.8cm, and the misalignment is performed every 4cm until the curling is completed. The MgO coating amount of the head 2000m and tail 1000m is 1g / m less than that of the middle 3 ~2g / m 3 ; In the high-temperature annealing process, adopt 6 fan-shaped blocks 7, the height of the fan-shaped blocks 7 is 4cm, there is a gap of 50mm between the adjacent fan-shaped blocks 7, the width of the diversion groove is 10cm, the height is 10cm, and the middle of the bottom surface of the cover plate 2 passes There are three diversion grooves evenly distributed around the center, the inner ring of the bottom surface of the cover plate 2 is slightly higher than the diversion grooves, and the outer ring is 20cm higher than the diversion grooves.

[0040] For comparative examples 1, 2, 3, and 4, the conventional CA coiling method and the conventional annular furnace charging method were adopted, and the implementation effects are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com