Beneficiation method of micro-fine particle dissemination type lead-zinc sulphide ore containing marmatite and pyrrhotite

A technology of pyrrhotite and ore dressing method, which is applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of poor comprehensive index of ore dressing, low sorting efficiency, and difficult sorting of ore dressing process, and achieves Solve the effect of low sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]Embodiment 1, with 100 gram potassium permanganate, 300 gram sodium humate (molecular weight 10 4 ~10 6 ), 30 grams of hydroxyalkyldithiocarbamate, mixed with a beaker at normal temperature and pressure, and stirred with a magnetic stirrer for 40 to 60 minutes to obtain XKY-12.

Embodiment 2

[0026] Embodiment 2, with 100 gram potassium permanganate, 300 gram sodium humate (molecular weight 10 4 ~10 6 ), 50 grams of hydroxyalkyldithiocarbamate, mixed with a beaker at normal temperature and pressure, and stirred with a magnetic stirrer for 40 to 60 minutes to obtain XKY-12.

Embodiment 3

[0027] Embodiment 3, with 100 gram potassium permanganate, 300 gram sodium humate (molecular weight 10 4 ~10 6 ), 40 grams of hydroxyalkyldithiocarbamate, mixed with a beaker at normal temperature and pressure, and stirred with a magnetic stirrer for 40 to 60 minutes to obtain XKY-12.

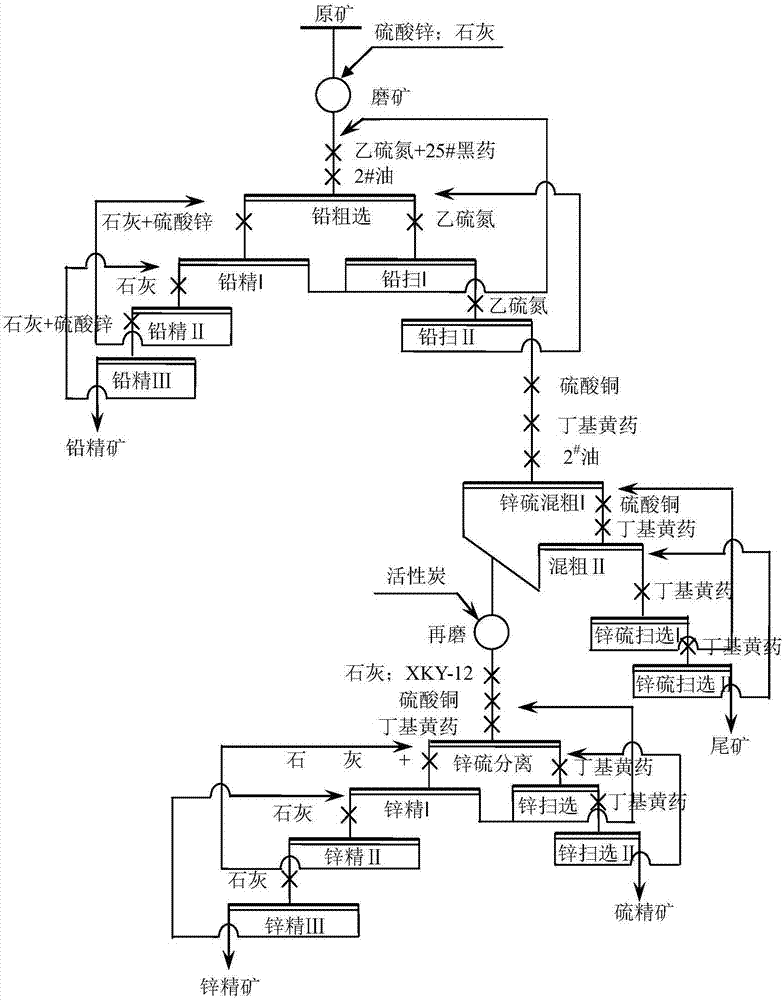

[0028] Second, the sorting process

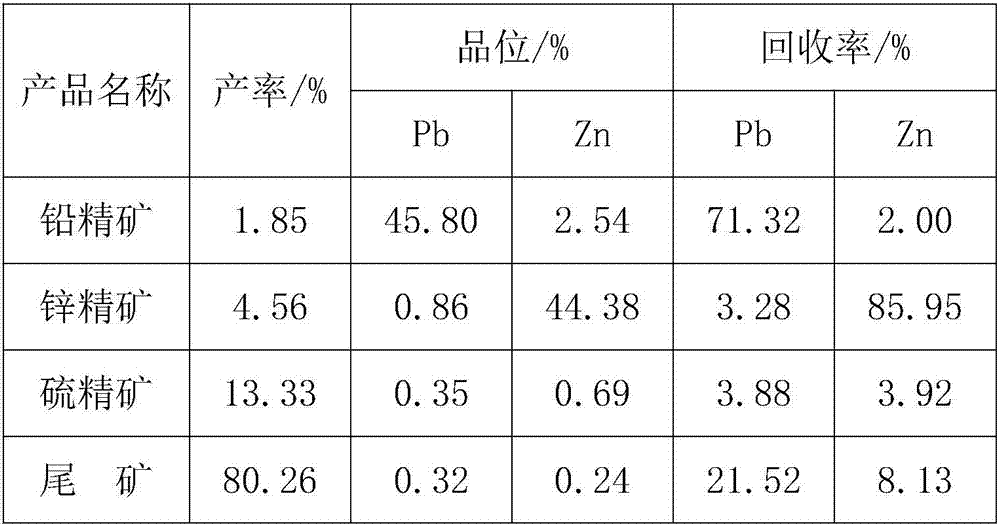

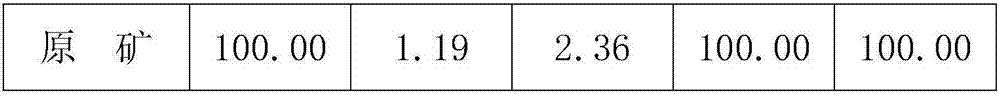

[0029] Embodiment 1. The selected ore is a certain iron-containing sphalerite and high pyrrhotite fine-grained complex lead-zinc sulfide ore in Inner Mongolia. The raw ore contains 1.19% lead, 2.36% zinc, 14.13% sulfur, and Iron 20.23%; the main metal mineral is pyrrhotite, followed by pyrite, sphalerite, galena, limonite, a small amount of hematite, magnetite, chalcopyrite, smithsonite etc.; the main gangue minerals are quartz, calcite, sericite, kaolinite, etc.; the intercalation relationship of the main metal minerals is complex, the intercalation particle size is fine, and it is difficult to dissociate the monomer. The ore was processed by the traditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com