Patents

Literature

838results about How to "Reduce surface defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

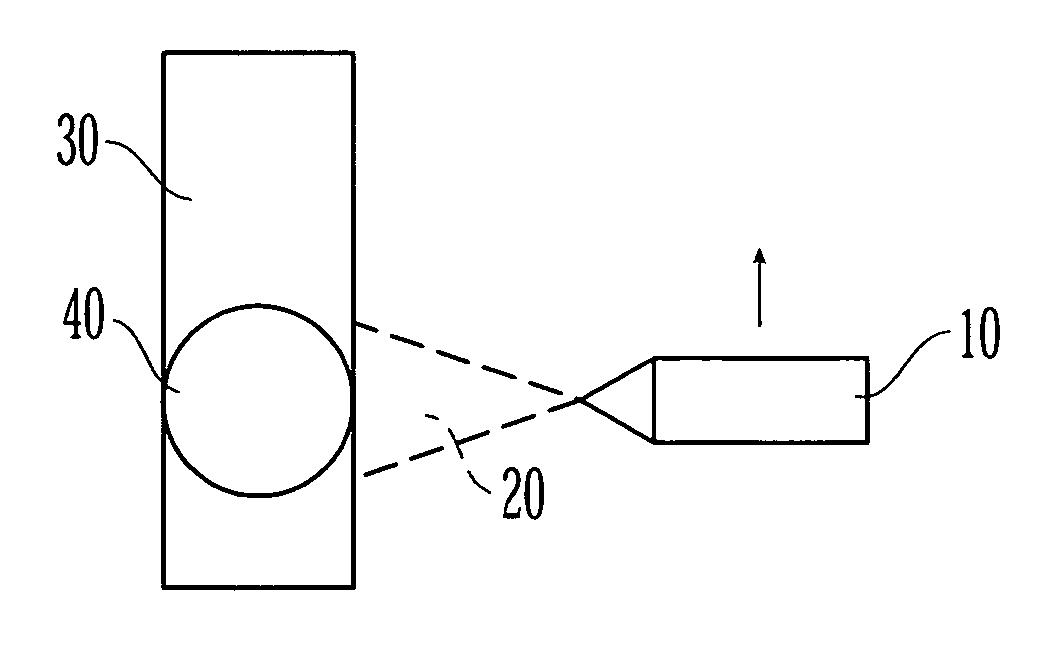

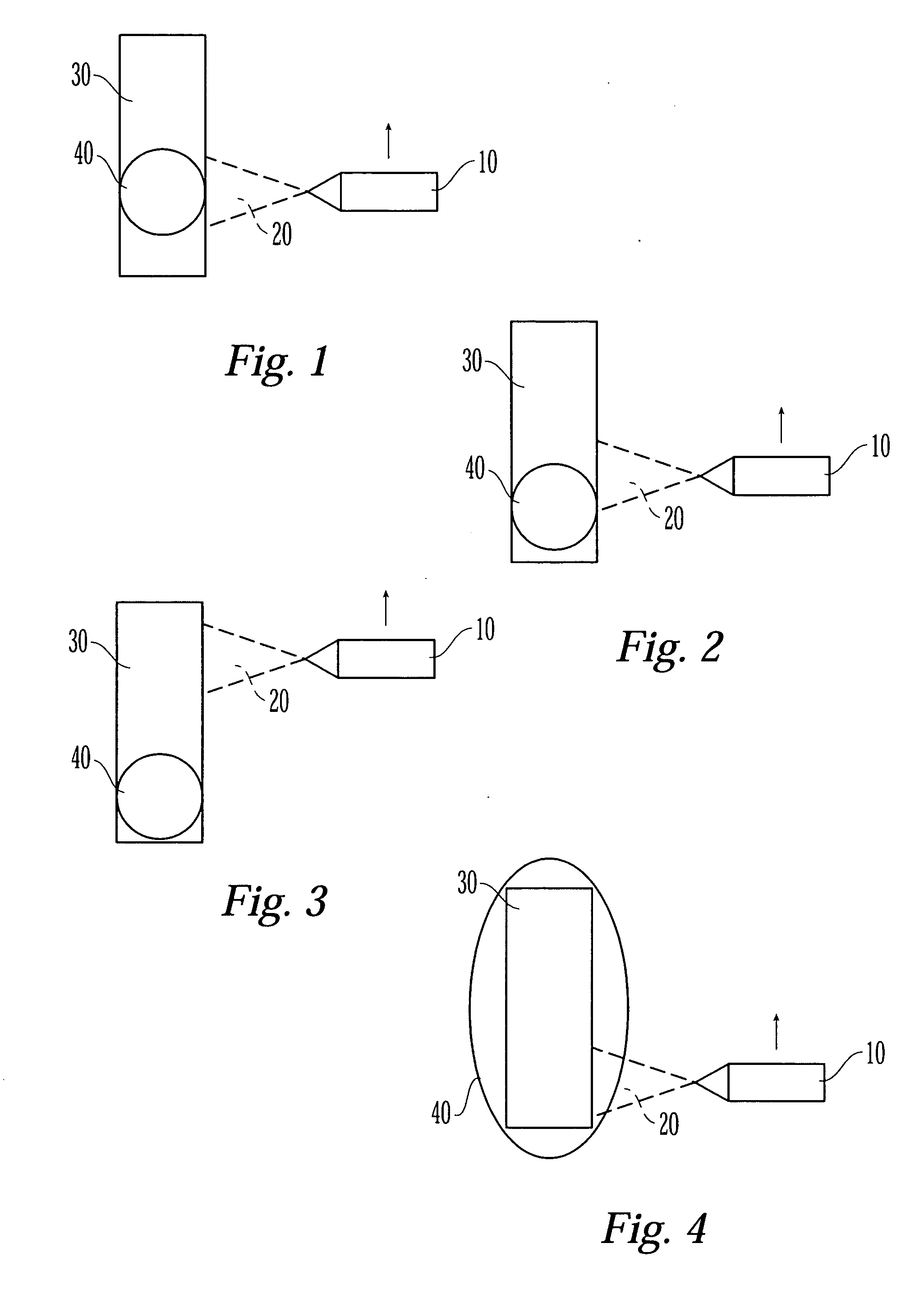

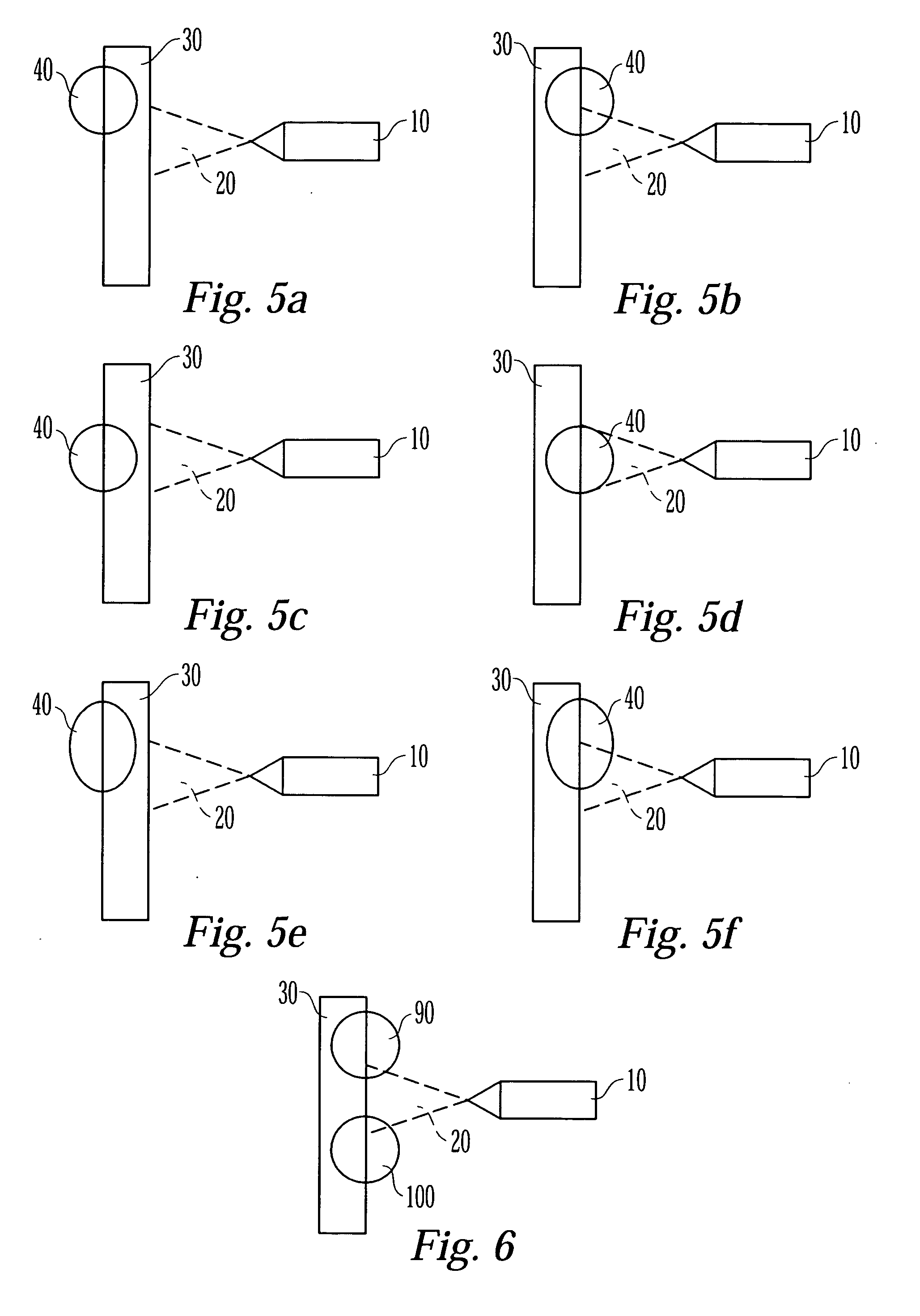

Method and system for making a coated medical device

InactiveUS20050196518A1Increase flow rateShorten production timeConfectionerySurgeryInsertion stentMedical device

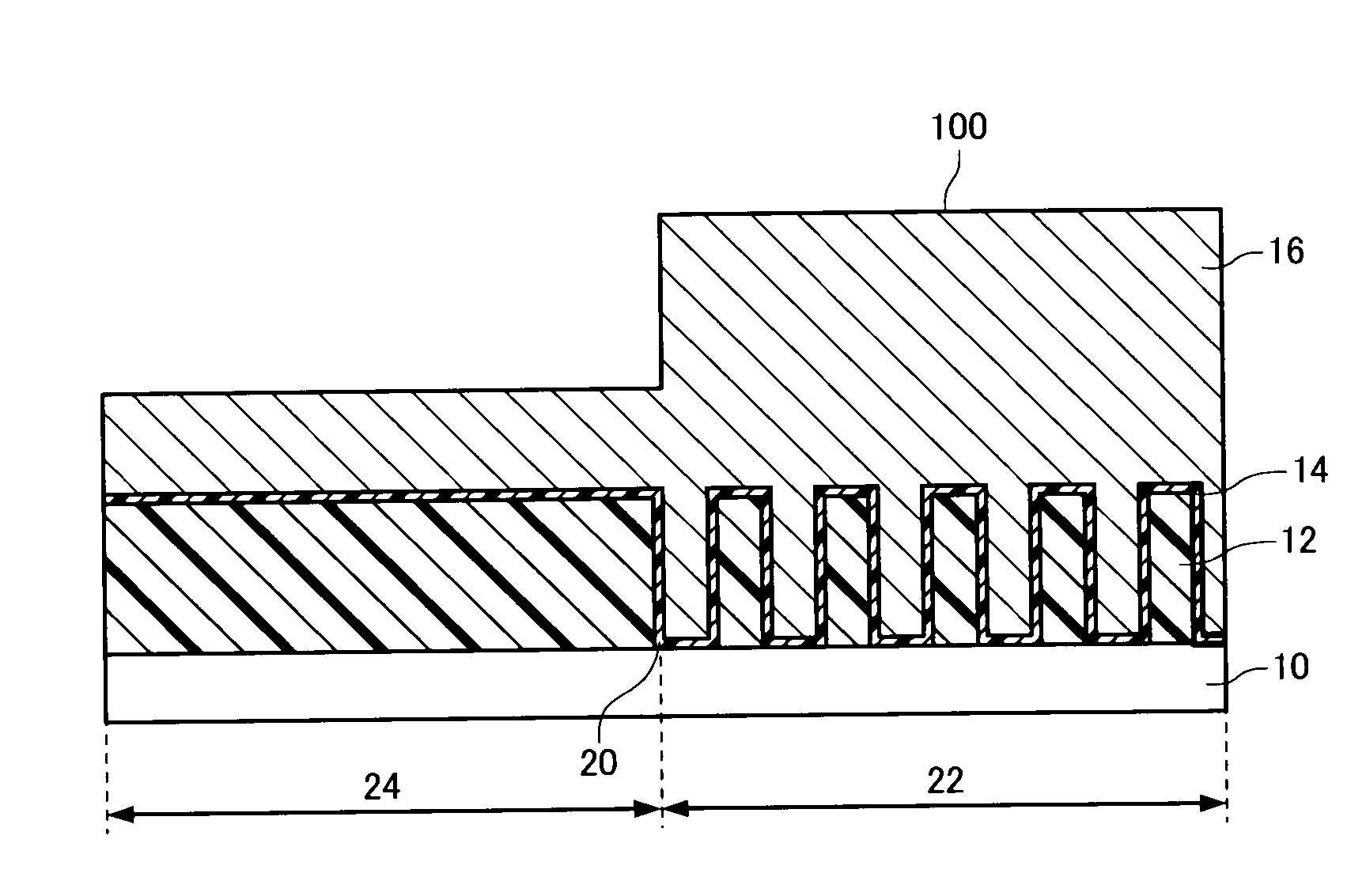

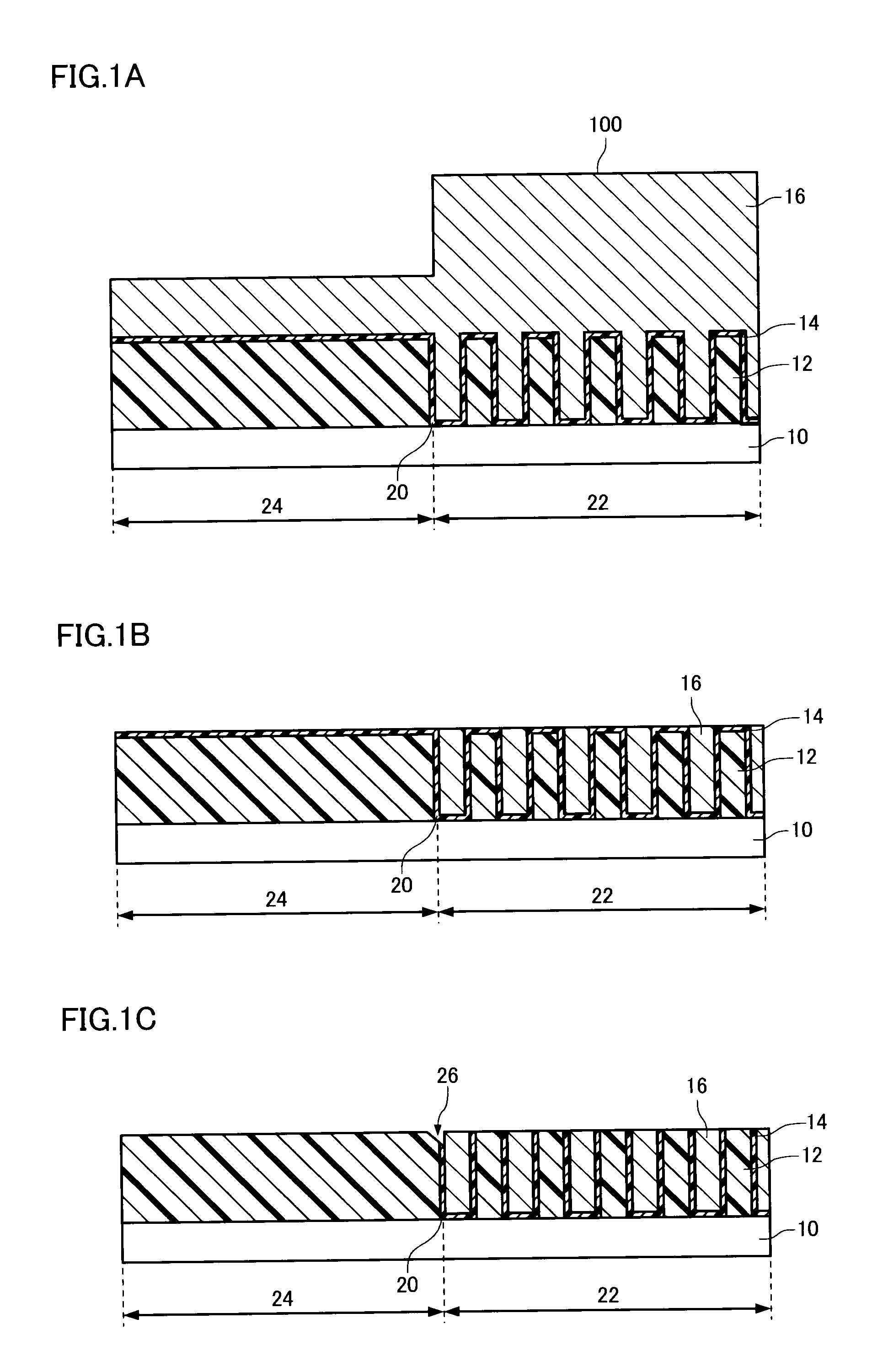

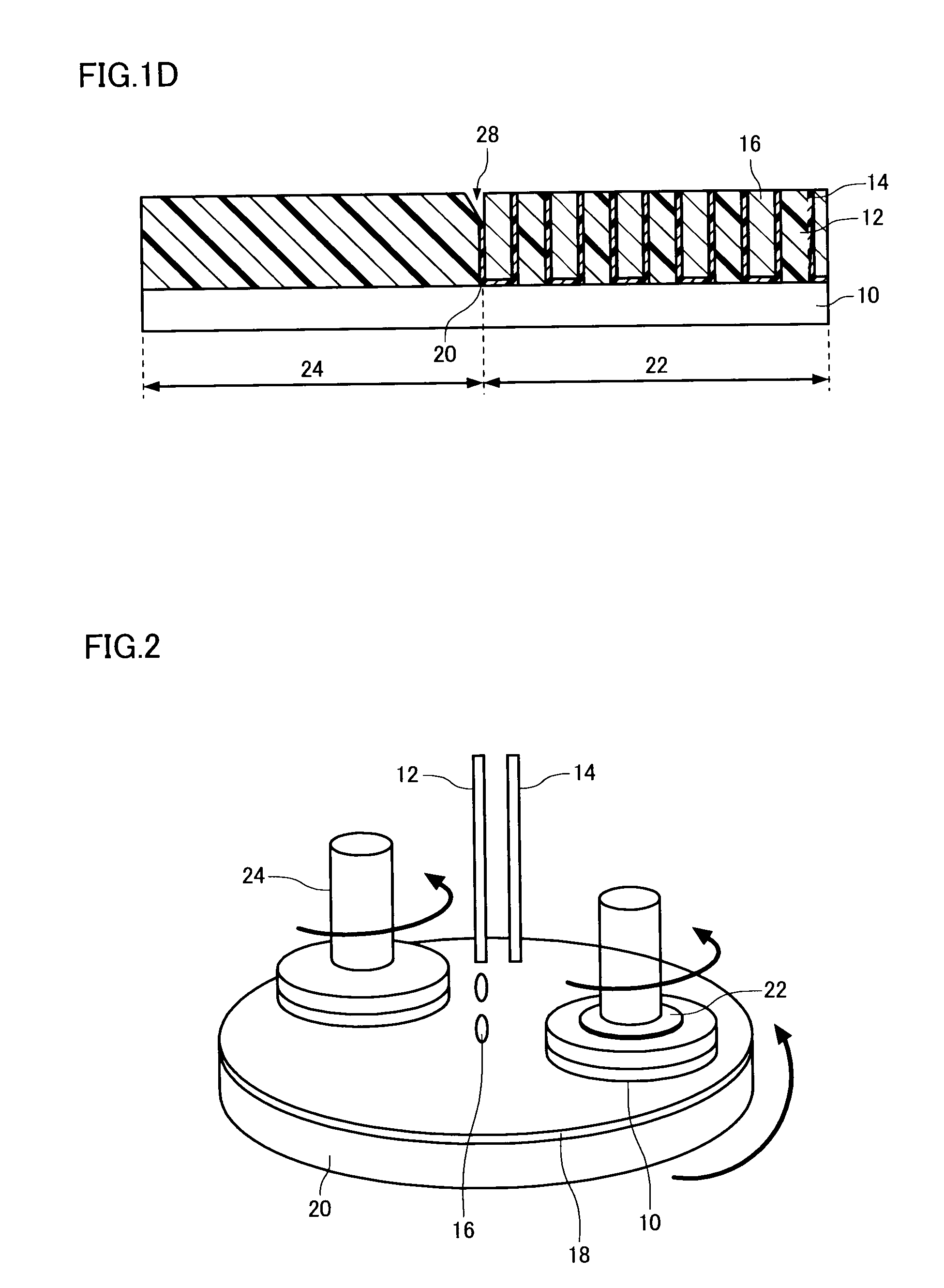

Methods of making medical devices, such as stents, having a surface and a coating layer disposed on a portion of the surface are described herein. The coating is formed by applying a coating composition to a portion of the surface of the medical device and then at least partially drying the coating composition substantially simultaneously with the application of the coating composition. The process may be repeated until a desired amount of the coating composition is applied to the surface of the medical device. This method allows for a more efficient and effective method of applying a coating composition to a medical device such as a stent. Also disclosed is a system for making a coated medical device.

Owner:BOSTON SCI SCIMED INC

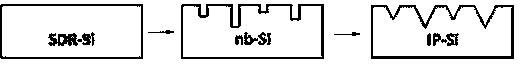

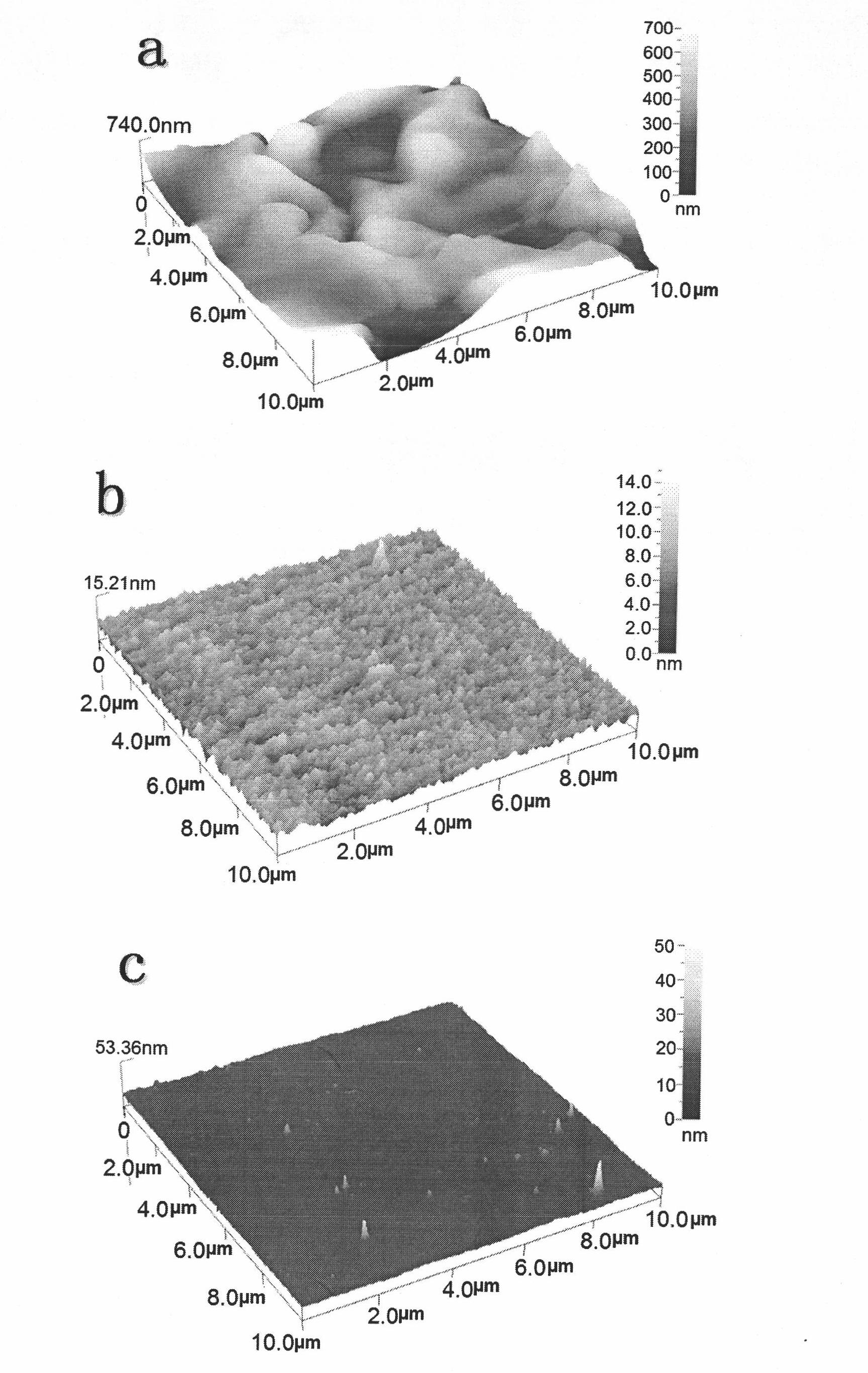

Method for forming inverted-pyramid porous surface nanometer texture on polycrystalline silicon and method for manufacturing short-wave reinforcing solar cell

InactiveCN103456804AExtend your lifeUniform and smooth microstructureFinal product manufacturePhotovoltaic energy generationCharge carrierSolar cell

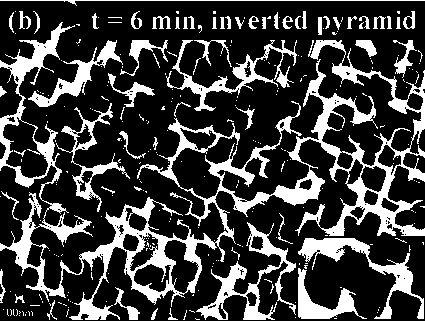

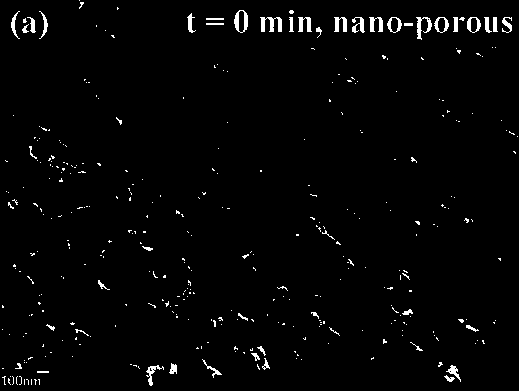

The invention discloses a method for forming an inverted-pyramid porous surface nanometer texture on polycrystalline silicon and a method for manufacturing a short-wave reinforcing solar cell. The method for forming the inverted-pyramid porous surface nanometer texture on the polycrystalline silicon and the method for manufacturing the short-wave reinforcing solar cell are suitable for the technical field of solar photovoltaic batteries. By means of a metal catalytic chemical corrosion method, a nanometer porous surface structure is formed on the polycrystalline silicon through HF, AgNO3, H2O2, HNO3 and other solutions, then partial samples are placed in a NaOH corrosive liquid with the concentration of 0.1-1% for surface modification of a nanometer inverted pyramid, a nanometer inverted pyramid silicon structure is formed, and the micro structure appearance of the nanometer inverted pyramid silicon structure is even and smooth, so that service life of a few effective charge carriers is greatly prolonged, and ultimately, in the nanometer texture surface structure, by means of changes of the thickness of a silicon nitride layer in the solar cell manufacturing process, a nanometer inverted pyramid silicon solar photovoltaic cell which is low in surface reflection rate and high in short wave spectrum response is prepared. The method for forming the inverted-pyramid porous surface nanometer texture on the polycrystalline silicon and the method for manufacturing the short-wave reinforcing solar cell are simple in process, convenient to operate, low in cost and suitable for industrial production.

Owner:SHANGHAI UNIV

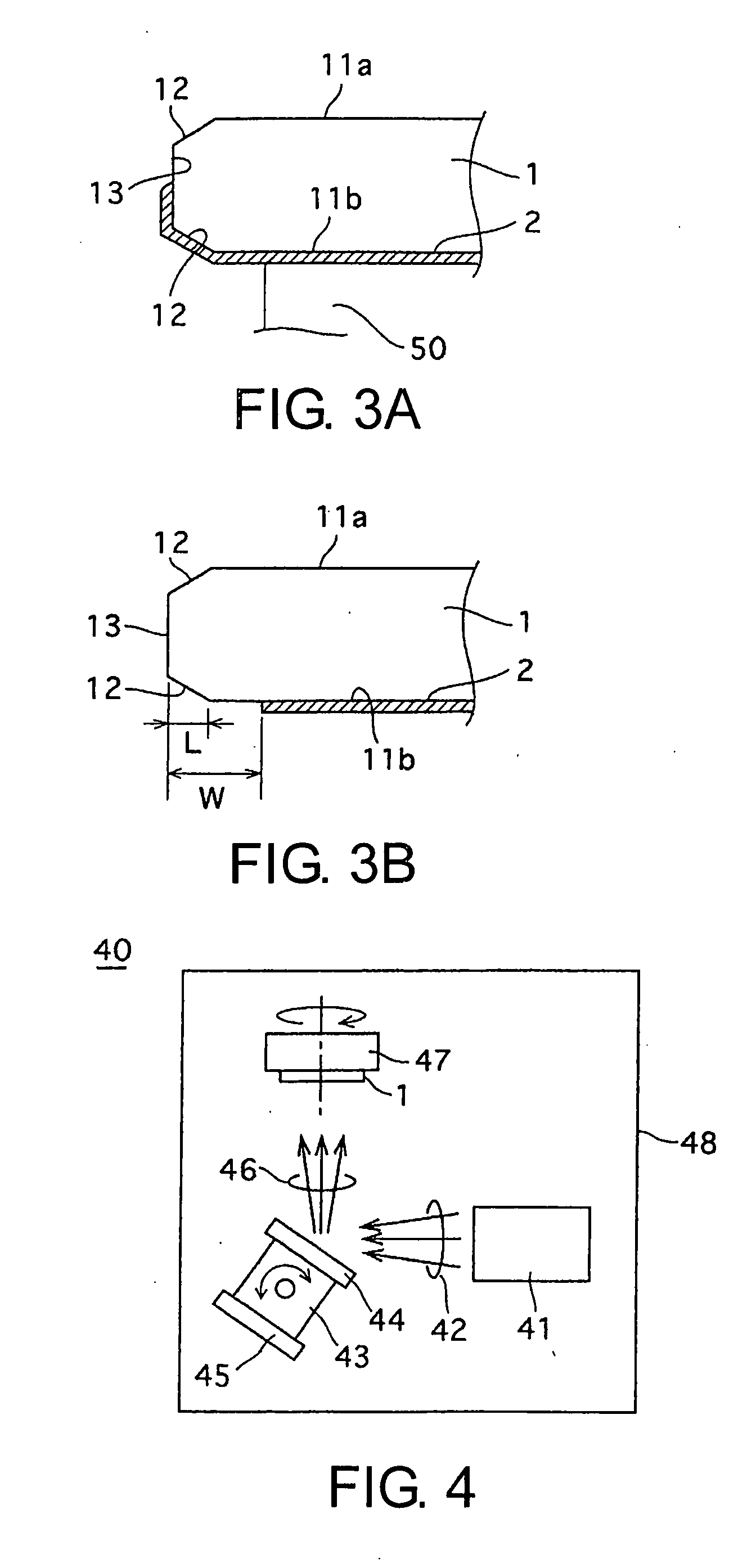

Substrate with a multilayer reflection film, reflection type mask blank for exposure, reflection type mask for exposure and methods of manufacturing them

InactiveUS20050238922A1Avoid it happening againMinimizing surface defectRadiation/particle handlingNanoinformaticsNitrogenOptoelectronics

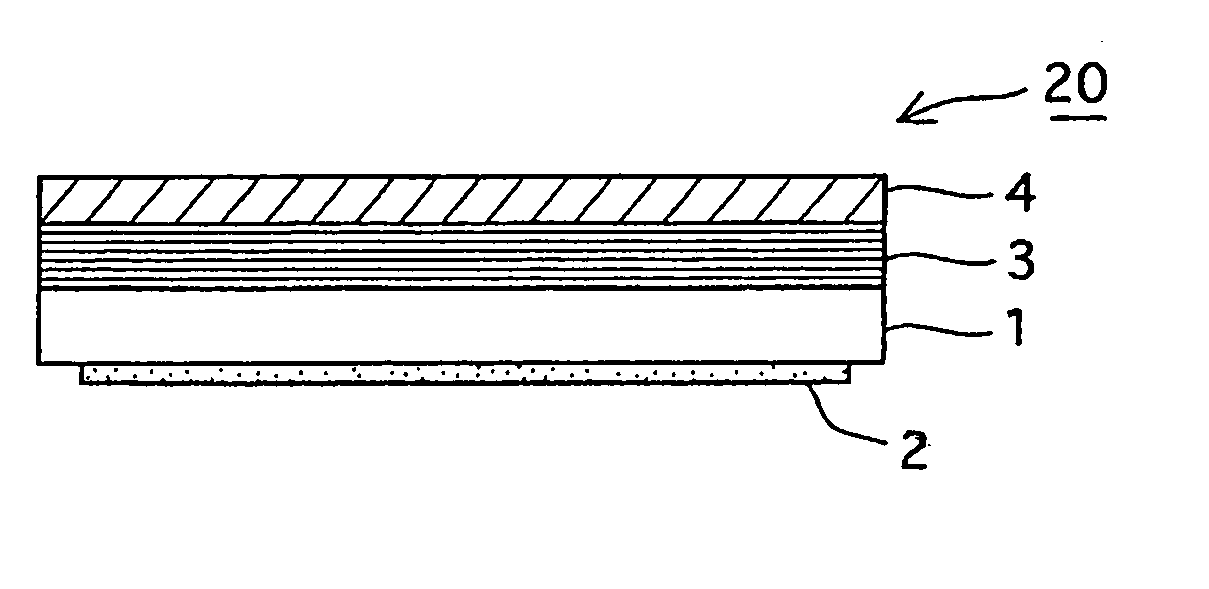

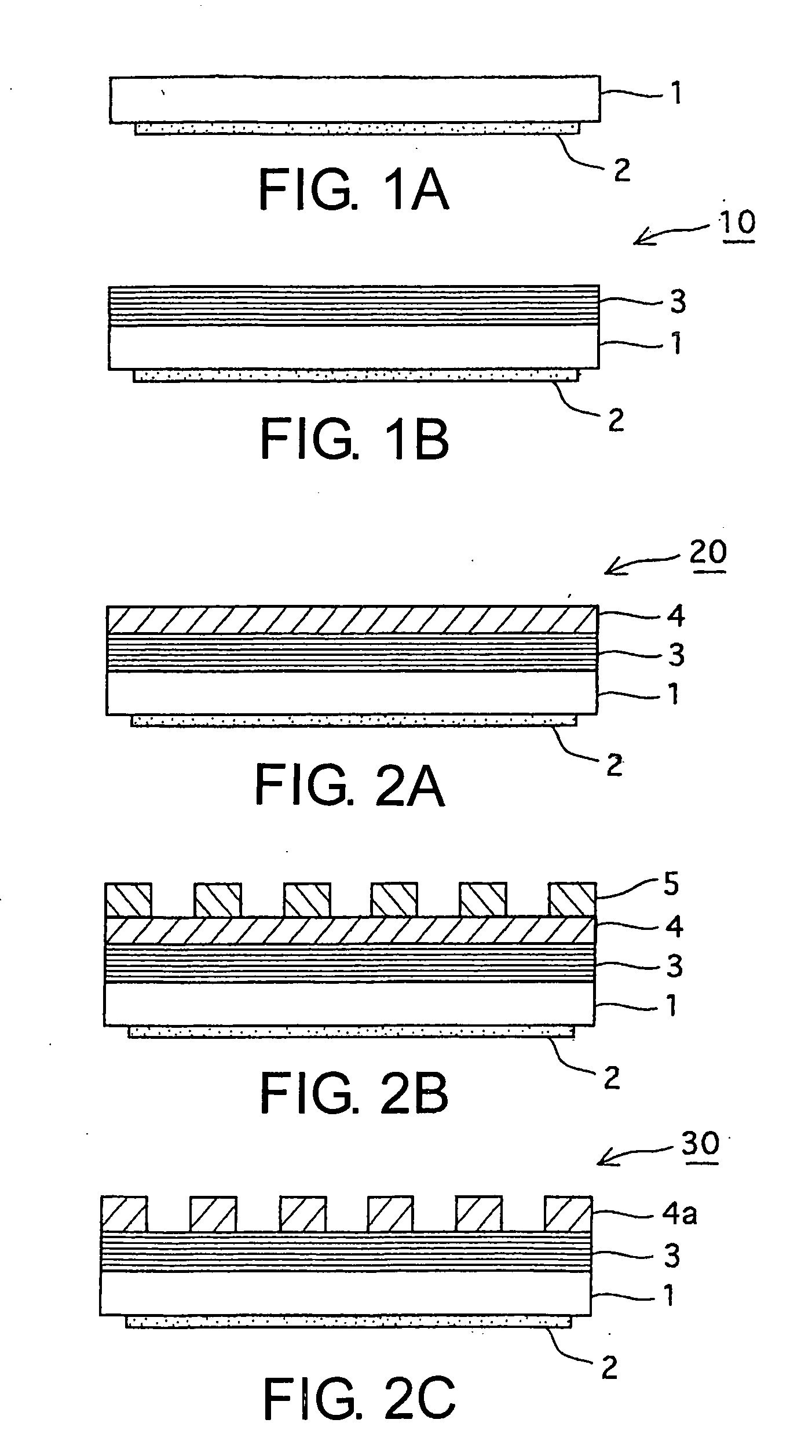

A multilayer-reflection-film-coated substrate includes a substrate, a multilayer reflection film formed on the substrate and reflecting an exposure light, and a conductive film formed on an opposite side of the substrate from the multilayer reflection film in a region excluding at least a peripheral portion of the substrate. The conductive film is made of a material containing chromium (Cr). The conductive film contains nitrogen (N) on a substrate side and at least one of oxygen (O) and carbon (C) on a surface side. A reflection type mask blank for exposure is obtained by forming an absorber film for absorbing the exposure light on the multilayer reflection film of the multilayer-reflection-film-coated substrate. A reflection type mask is obtained by forming a pattern on the absorber film of the reflection type mask blank for exposure.

Owner:HOYA CORP

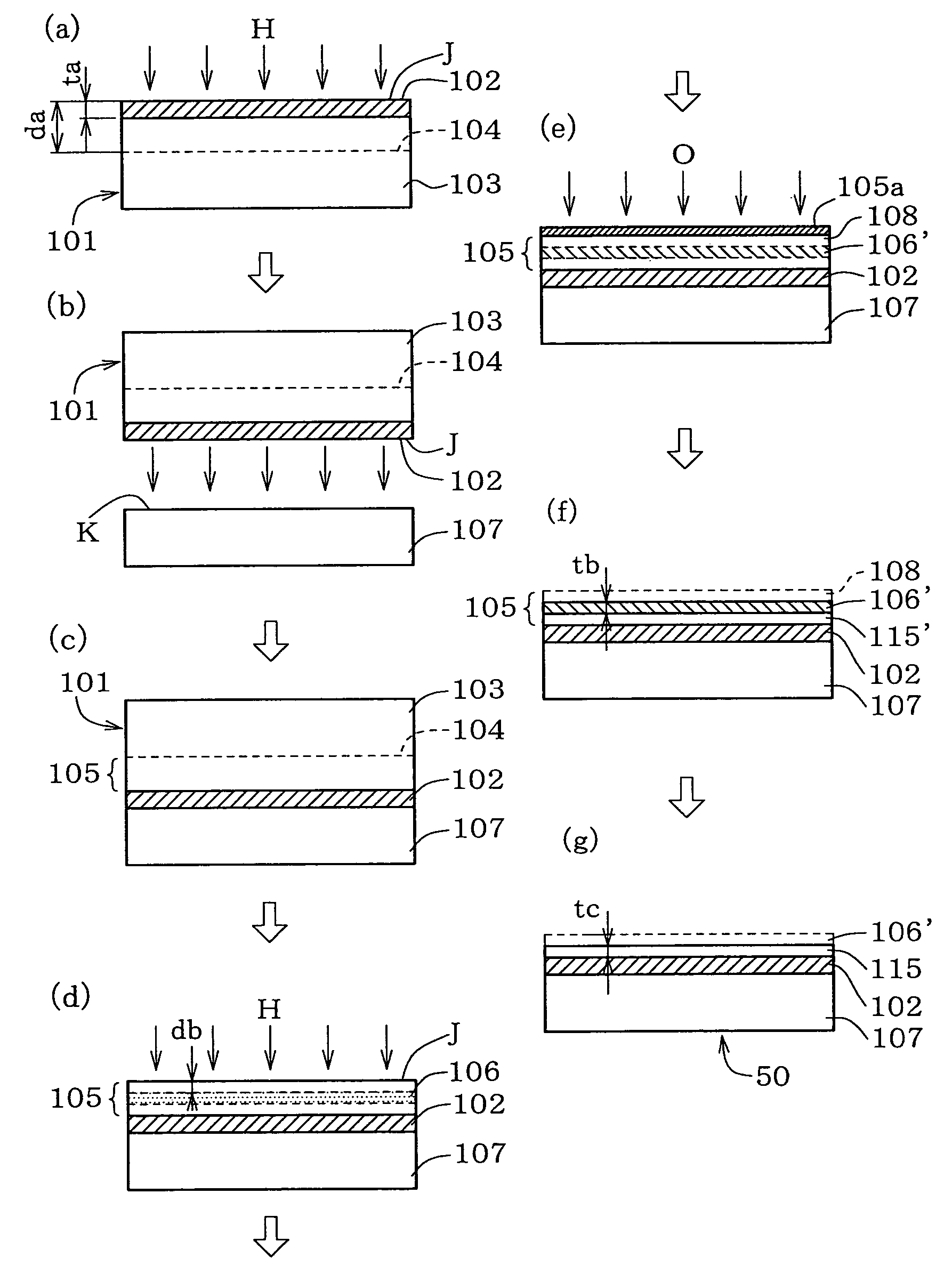

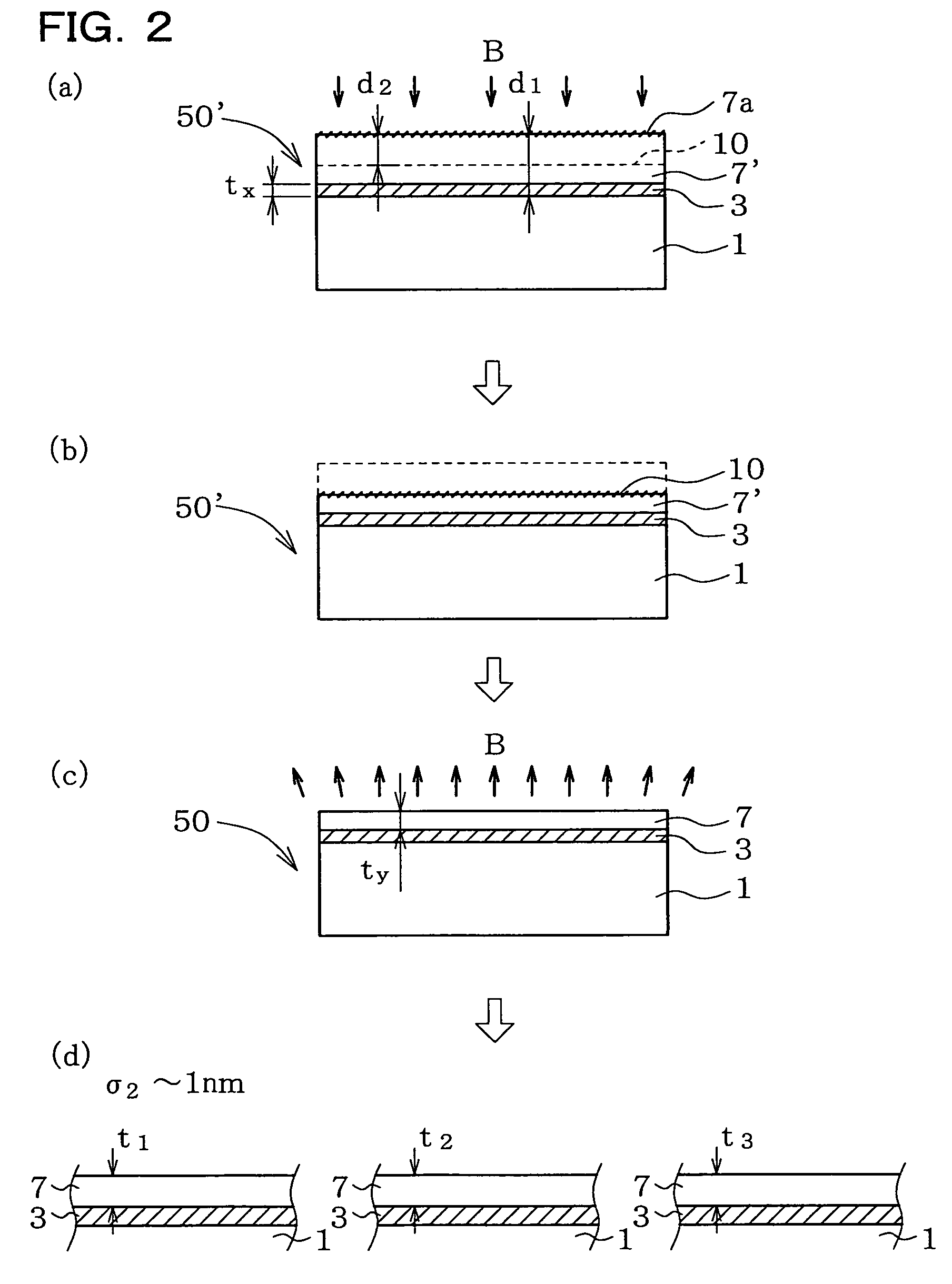

Method of fabricating SOI wafer

InactiveUS7084046B2Sharp concentration profileImprove concentrationSolid-state devicesSemiconductor/solid-state device manufacturingEtchingThinning

After completion of annealing for bonding of the base wafer 1 and bond wafer 2, the bond wafer 2 is thinned to a first thickness suitable for ion implantation, and boron is ion-implanted to thereby form a high-boron-concentration layer 10. A second thinning step based on selective etching is then carried out while using the high-boron-concentration layer 10 as an etch stop layer. This is successful in providing a method of fabricating an SOI wafer which is suppressed both in intra-wafer uniformity of the firm thickness and in inter-wafer uniformity of the film thickness even when a required level for the thickness of the SOI layer is extremely small.

Owner:SHIN-ETSU HANDOTAI CO LTD

Master batch with light scattering function, and preparation method and application thereof

The invention discloses a master batch with a light scattering function, and a preparation method and application thereof. The master batch with a light scattering function comprises 20-99.5% of transparent thermoplastic resin, 0.1-40% of small-particle-size light scattering agent, 0.1-10% of large-particle-size light scattering agent, 0.01-10% of antioxidant and 0.01-20% of light stabilizer. By compounding the light scattering agents with two particle sizes, the optical properties of the light scattering material can be obviously enhanced. Under the condition of the same content of light scattering agent, since the light scattering agents with two particle sizes are compounded, the light scattering material not only can achieve the same light scattering effect, but also has better light transmittance. The light scattering agents, antioxidant, light stabilizer and other functional assistants are mixed with the matrix resin to prepare the functional master batch, so that the concentration of the assistants in the master batch is increased; and the functional master batch is blended with the matrix resin to prepare the light scattering material. The invention has the advantages of low consumption of light scattering agents, uniform distribution, excellent optical properties, fewer surface defects, lower cost and the like. The master batch with a light scattering function is suitable for producing high-quality optical components, lamp shells, diffuser plates in backlight modules, advertisement signboards, display windows and the like.

Owner:KINGFA SCI & TECH CO LTD +1

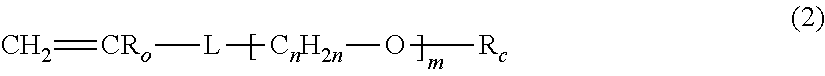

Polishing composite for silicon wafer polishing

InactiveCN101451046AFast polishing rateReduce surface defectsSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesIonEther

The invention discloses a silicon wafer polishing composition in the field of chemical mechanical polishing (CMP). The polishing composition comprises silica, a polishing interface control agent, a surfactant, a chelating agent, an alkaline compound and water, wherein the particle diameter of the silica in the polishing composition is between 1 and 200 nm; the content of the silica is between 0.05 and 50 weight percent; the polishing interface control agent is polyhydroxy cellulose ether; the content of the polishing interface control agent is between 0.001 and 10 weight percent; the content of the surfactant is between 0.001 and 1 weight percent; the content of the chelating agent is between 0.001 and 1 weight percent; the content of the alkaline compound is between 0.001 and 10 weight percent; the balance being water; and the PH value is between 8.5 and 12. The polishing interface control agent can control a polishing interface between abrasive particles and a polishing object in the chemical mechanical polishing process in order that the surface of the polished silicon wafer is more perfect. The polishing composition is in particular suitable for polishing the silicon wafer and has the advantages of rapid polishing speed, little surface defect and high planeness; and the polished silicon wafer has few metal ion contaminants and is easy to clean.

Owner:TSINGHUA UNIV +1

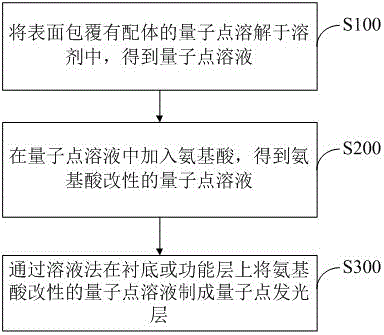

Quantum dot luminescent layer and preparation method thereof, and quantum dot light-emitting diode (QLED) and preparation method thereof

ActiveCN106601925AReduce surface defectsClosely connectedSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionQuantum dot

The invention discloses a quantum dot luminescent layer and a preparation method thereof, and a quantum dot light-emitting diode (QLED) and a preparation method thereof. The preparation method of the quantum dot luminescent layer comprises the following steps: dissolving a quantum dot whose surface is clad with a ligand in a solvent so as to obtain a quantum dot solution; adding amino acid in the quantum dot solution to obtain an amino modified quantum dot solution; and through a solution method, preparing the amino modified quantum dot solution into the quantum dot luminescent layer on a substrate or a function layer. According to the invention, the amino acid is added to the quantum dot solution, on one hand, the formed quantum dot luminescent layer is totally uniformly covered and is compact and flat; and on the other hand, through introduction of the amino acid, the quantum dot luminescent layer can be closely anchored on the substrate or the function layer below or above the quantum dot luminescent layer, the quantum dot luminescent layer is enabled to be closely connected with the substrate or the function layer, the interface stability and the interface property are maintained, surface defects of the quantum dot are passivated, the electron injection efficiency is effectively improved, the life of a QLED device is prolonged, and the stability of the QLED device is improved.

Owner:TCL CORPORATION

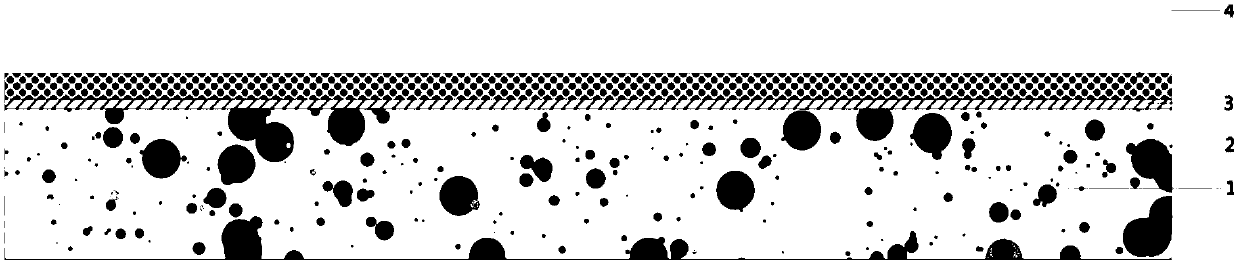

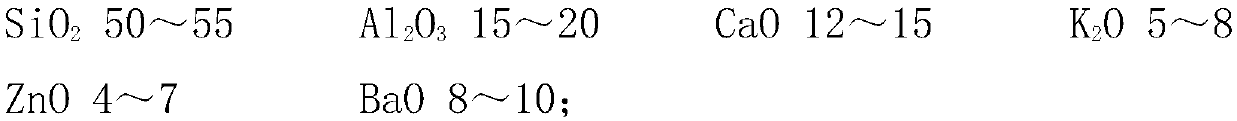

Full-body anti-slip ceramic brick and production method thereof

The invention relates to a full-body anti-slip ceramic brick and a production method thereof. According to the full-body anti-slip ceramic brick, a compound layer brick body is composed of a colored spot green body layer, large-particle colored spots mixed into the colored spot green body layer, a pattern decoration layer on the surface of the green body layer and a dry-particle glaze layer attached to the pattern decoration layer; the production method comprises the following steps: (1) pressing a green body, wherein green body powder is composed of conventional powder and large-particle powder; (2) drying under the conditions that the drying temperature is 80 to 100 DEG C and the drying time is 60 to 80 min; (3) decorating a pattern: before decorating the pattern, not applying any glazelayer or other protection layers on the surface of the blank body, so as to directly realize inkjet printing decoration on the surface of the blank body; (4) applying dry-particle glaze: spraying theglaze through a bell jar; (5) firing under the conditions that the temperature is 1150 to 1160 DEG C and the time is 50 to 60 min.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Chemical mechanical polishing aqueous dispersion preparation set, method of preparing chemical mechanical polishing aqueous dispersion, chemical mechanical polishing aqueous dispersion, and chemical mechanical polishing method

InactiveUS20080318427A1Long-term storage stability be excellentExcellent long-term storage stabilityOther chemical processesNanoinformaticsColloidal silicaOrganic acid

A chemical mechanical polishing aqueous dispersion preparation set including: a first composition which includes colloidal silica having an average primary particle diameter of 15 to 40 nm and a basic compound and has a pH of 8.0 to 11.0; and a second composition which includes poly(meth)acrylic acid and an organic acid having two or more carbonyl groups other than the poly(meth)acrylic acid and has a pH of 1.0 to 5.0.

Owner:JSR CORPORATIOON

Method of manufacturing Anti-reflection film, Anti-reflection film and coating composition

ActiveUS20130084442A1Improve anti-reflection efficiencyLower surface energyGroup 4/14 element organic compoundsLayered productsRefractive indexSolvent

A method of manufacturing an anti-reflection film, the method forming a multi-layer structure with different refractive indices from a coating composition in which the following (A) to (F) components are mixed. (A) Fluorine-containing polymer including a fluorine-containing hydrocarbon structure and a constituent unit derived from a compound having at least one group selected from a polyalkylene oxide group and a basic functional group, (B) Low refractive index inorganic fine particles which are not surface-modified or low refractive index inorganic fine particles which are surface-treated with a silane coupling agent having the molecular weight of 600 or less, (C) A curable binder containing no fluorine atoms in the molecule, (D) A solvent, (E) A polyfunctional fluorine-containing curable compound, and (F) High refractive index inorganic fine particles treated with a specific surface modifying agent.

Owner:FUJIFILM CORP

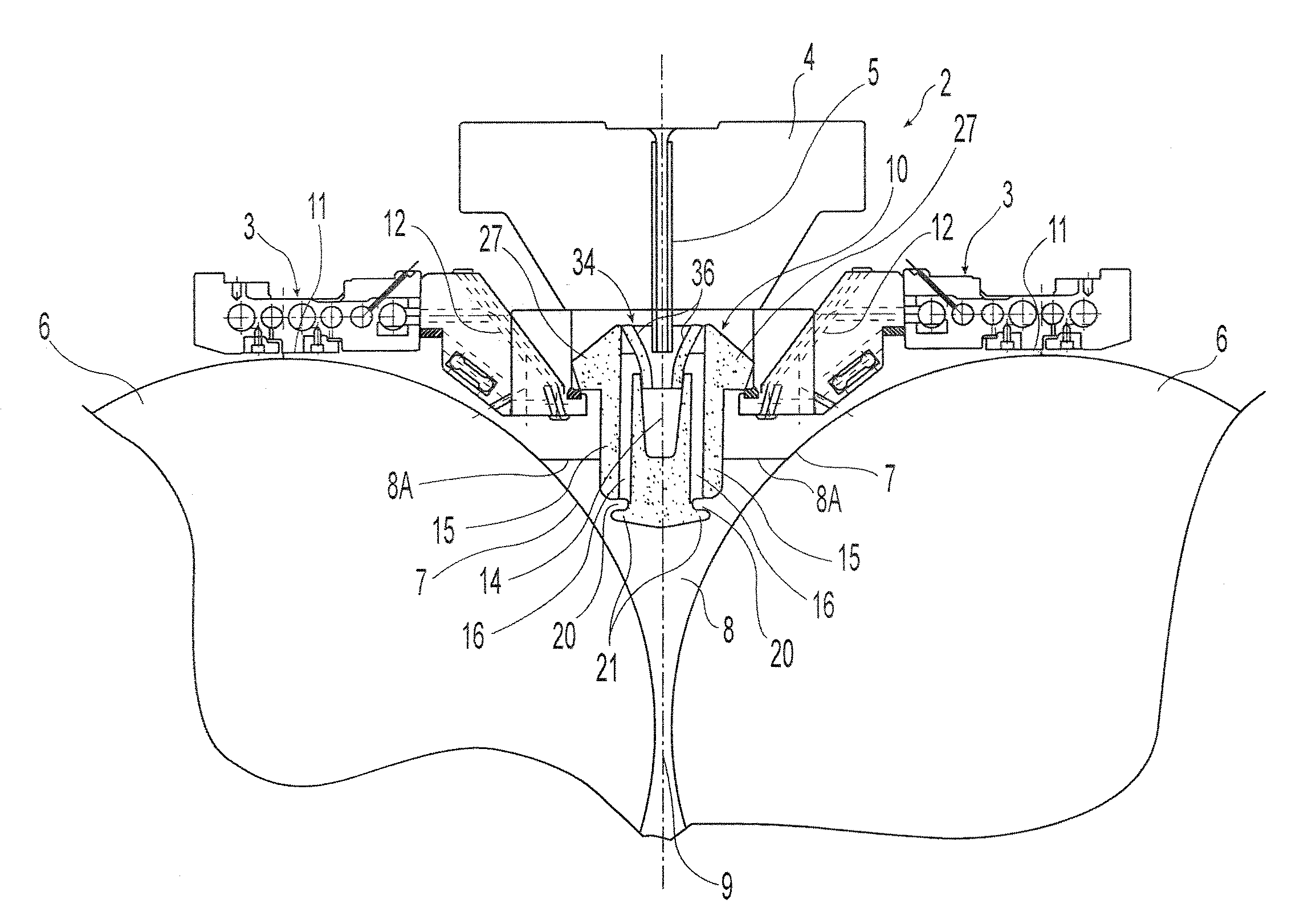

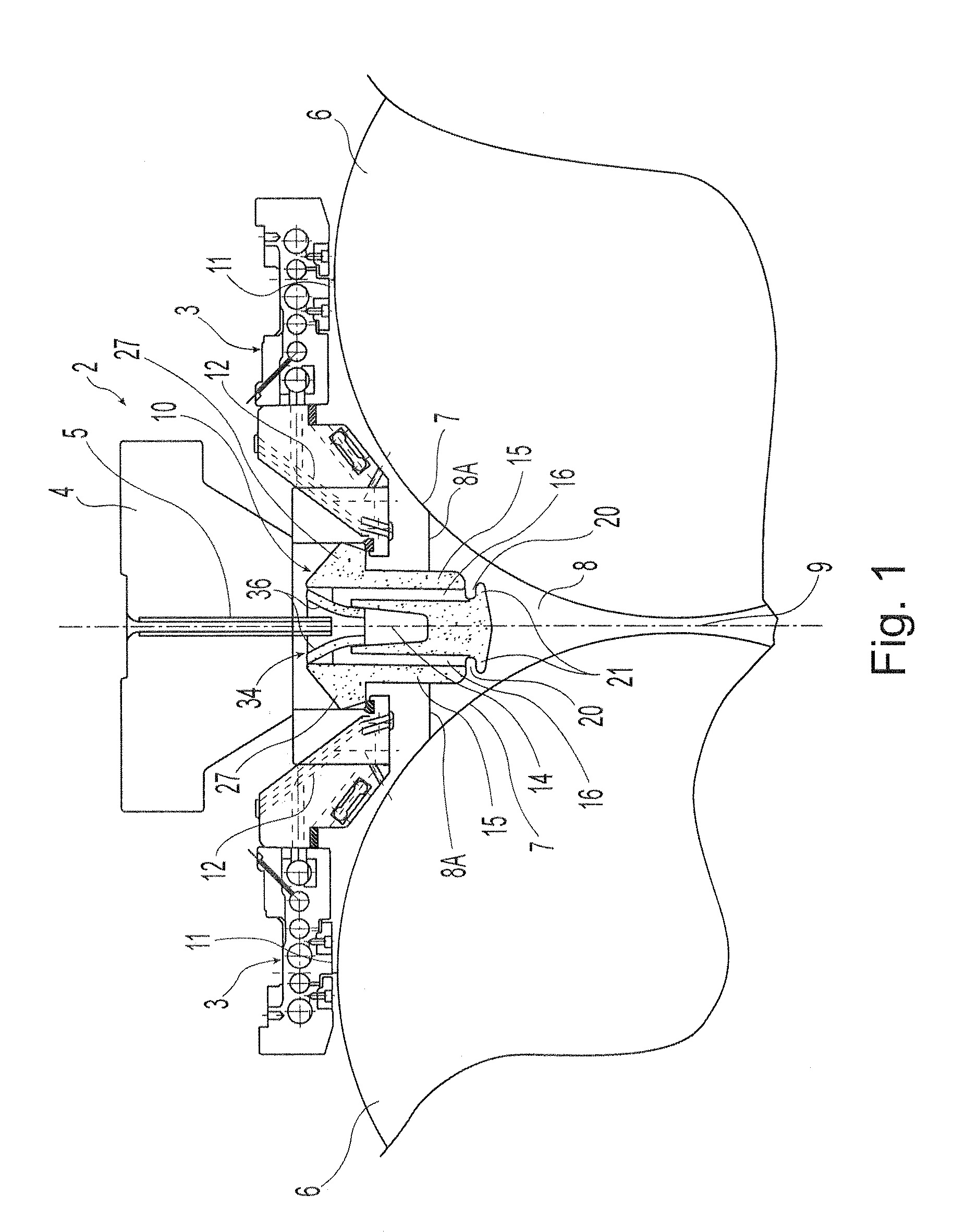

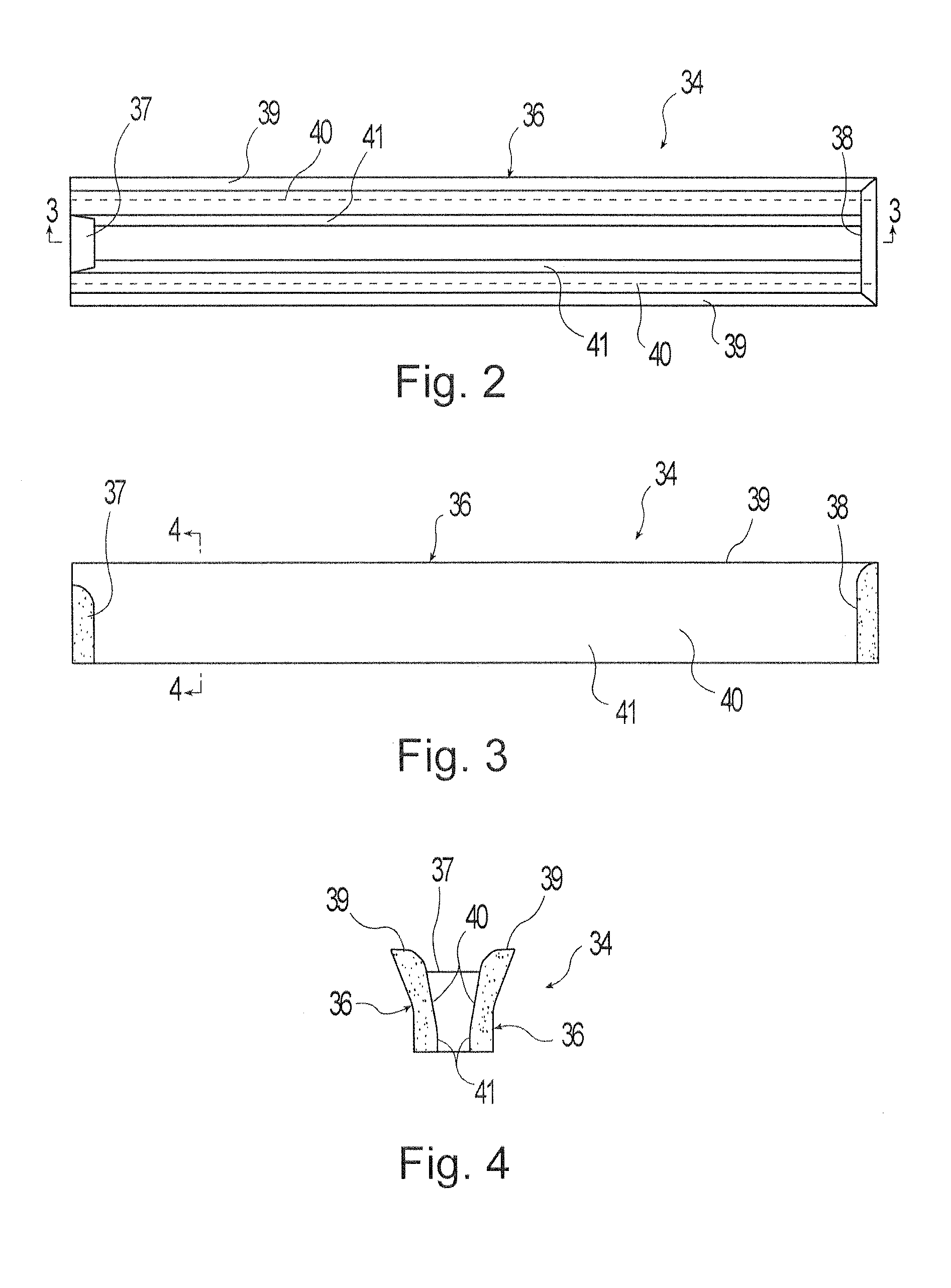

Casting delivery nozzle with insert

InactiveUS20080264599A1Easy to replaceReduces turbulence in flowMolten metal pouring equipmentsMolten metal supplying equipmentsMolten metalNozzle

A metal strip casting apparatus and a method of casting continuous metal strip includes assembling a pair of counter-rotatable casting rolls having casting surfaces positioned laterally forming a nip between for casting, and delivering molten metal through a delivery nozzle disposed above the nip capable to form a casting pool supported on the casting rolls. The delivery nozzle comprises segments each having elongate nozzle body with longitudinally extending side walls, end walls and a bottom part to form an inner trough, a nozzle insert disposed above bottom portions of the inner trough of each segment and supported relative to the nozzle body through which incoming molten metal may be delivered to the inner trough of each segment of the delivery nozzle, and the elongate nozzle body of each segment having passageways in fluid communication with the inner trough and outlet openings capable of discharging molten metal from the nozzle body outwardly into the casting pool.

Owner:NUCOR CORP

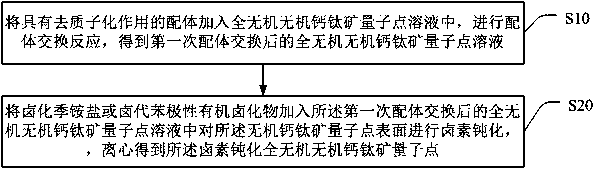

A halogen passivated perovskite quantum dot, a preparation method thereof and a QLED device are provided

ActiveCN109256495AHigh fluorescence intensityHigh fluorescence efficiencySolid-state devicesSemiconductor/solid-state device manufacturingHalogenCentrifugation

The invention discloses a halogen passivated perovskite quantum dot, a preparation method thereof and a QLED device, wherein, the preparation method comprises the following steps: adding a ligand withdeprotonation effect into an inorganic perovskite quantum dot solution, carrying out ligand exchange reaction to obtain an inorganic perovskite quantum dot solution after the first ligand exchange; Then, the polar organic halide is added into the inorganic perovskite quantum dot solution after the first ligand exchange to perform halogen passivation on the surface of the inorganic perovskite quantum dot, and the halogen passivated inorganic perovskite quantum dot is obtained by centrifugation. The invention can effectively passivate the metal and non-metal elements on the surface of the inorganic perovskite quantum dot, reduce the surface defects of the inorganic perovskite quantum dot, thereby improving the fluorescence intensity and the charge transmission efficiency of the inorganic perovskite quantum dot.

Owner:TCL CORPORATION

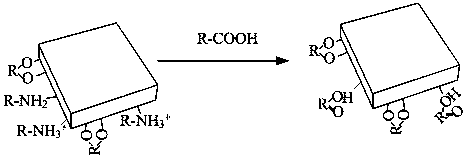

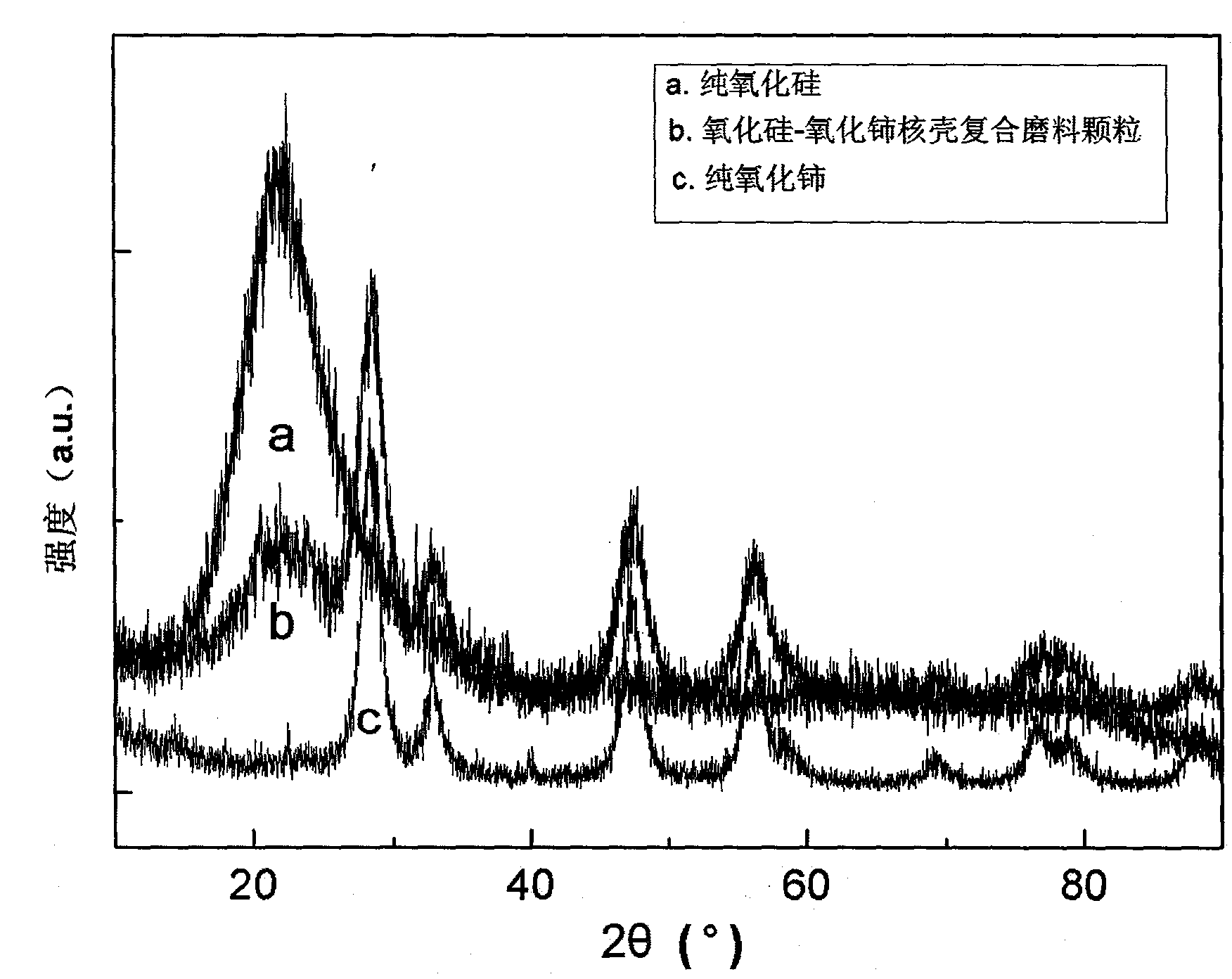

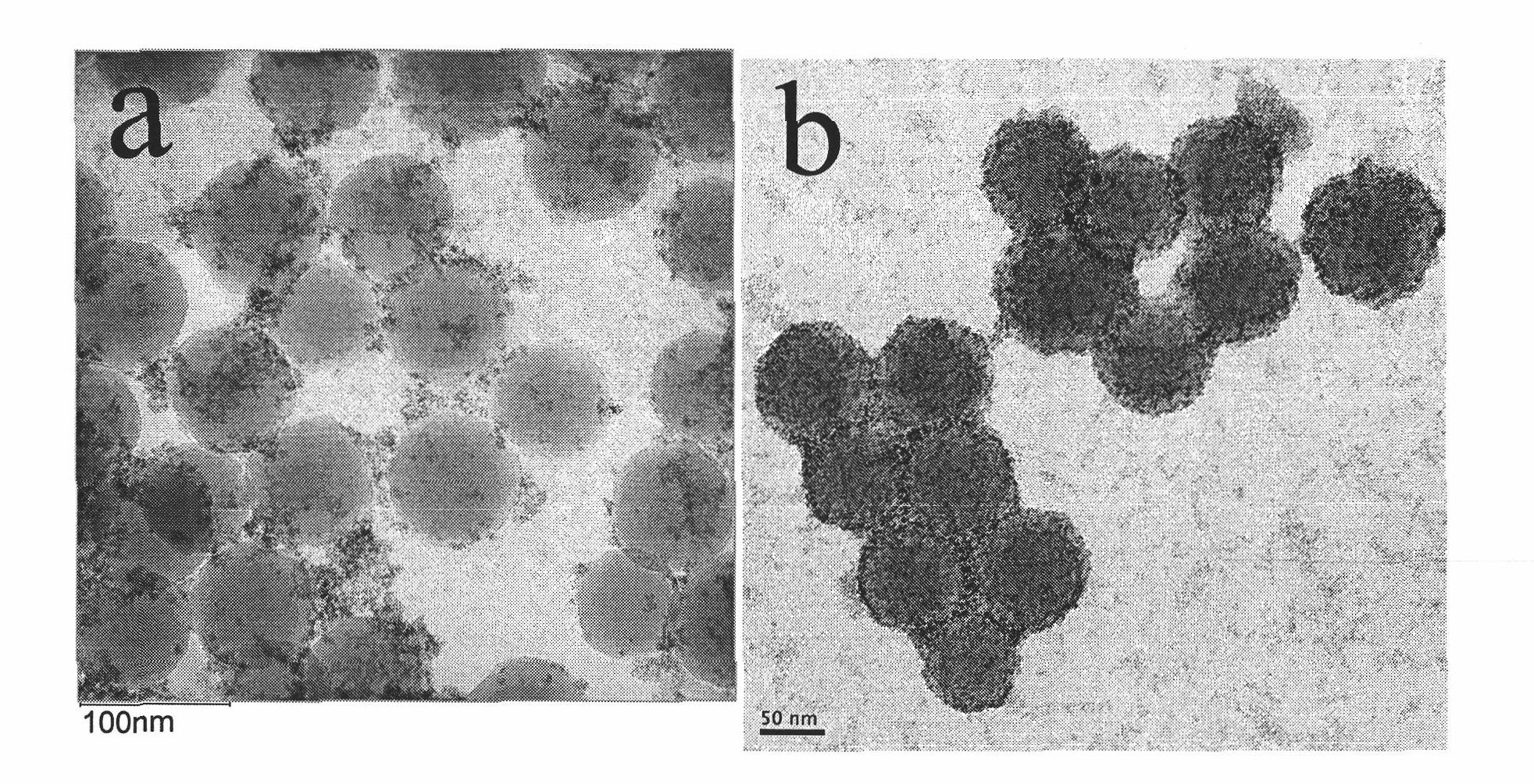

Silicon oxide-cerium oxide nuclear shell compounded abrasive granules, and preparation and application thereof

ActiveCN101818047AHigh polish removal rate and polish selectivityReduce surface defectsOther chemical processesSemiconductor/solid-state device manufacturingCerium oxideDielectric

The invention belongs to the field of polishing solution of chemical machinery in microelectronic processing, and particularly relates to silicon oxide-cerium oxide nuclear shell compounded abrasive granules, and a preparation and application thereof. The silicon oxide-cerium oxide nuclear shell compounded abrasive granules comprise silicon oxide and cerium oxide, the inner core of each compounded abrasive granule is spherical silicon oxide, and the shell is a cerium oxide coating layer. When being used for polishing very large-scale integrated circuit glass, silicon dioxide dielectric layersand STI, the polishing solution prepared from the silicon oxide-cerium oxide nuclear shell compounded abrasive granules can increase the polishing removal rate and polishing selection ratio and reduce the polishing defects.

Owner:SHANGHAI XINANNA ELECTRONICS TECH

Method for preparing continuous silicon carbide fiber by PCS fiber

InactiveCN101787588AAvoid damageReduces the generation of internal and surface defectsFibre chemical featuresOptoelectronicsSic fiber

The invention relates to a method for preparing continuous silicon carbide fiber by a PCS fiber. In the method, after the PCS melting spinning, a screen roller wound with the continuous PCS fiber is treated by the infusible process, is pre-sintered at the intermediate temperature of 1,000 DEG C and then is unwound; finally, the treated continuous PCS fiber is continuously sintered at the high temperature of 1,200-1,900 DEG C after the concentration of beam and the stranding. The method avoids that the PCS fiber is damaged in the unwinding or in the process the contact of the PCS fiber and a guide roller and other machines, ensures the continuity and the uniform performance of a SiC fiber and can be used for preparing the SiC fibers in different types.

Owner:NAT UNIV OF DEFENSE TECH

Method for controlling impurity in ultra low carbon IF steel

The invention provides a method for controlling impurity in ultra low carbon IF steel, including the following steps: (1) control ranges of converter finishing point C, T and a[0] are determined, converter finishing point C is controlled to be 0.02-0.06%, T is controlled to be 1685-1700 DEG C, and a[0] is controlled to be 400-800ppm; (2) steel ladle top residue modification treatment is carried out, namely lime and fluorite are added in converter tapping process, steel ladle top residue modifier is added at argon flushing station, ratio of CaO / Al2O3 in residue after modification is ensured tobe controlled to be 1.2-1.8, and TFe content in residue is less than 8%; (3) RH finishing point molten steel T.O is reduced, namely net cycle time after RH deoxidation alloying is controlled to be more than 6 minutes, and RH finishing point T.O content is ensured to be less than 40ppm; (4) double layer covering agent is adopted for pouring protection in continuous casting of middle ladle; (5) a stopper rod is adopted for argon blowing technology.

Owner:MAANSHAN IRON & STEEL CO LTD

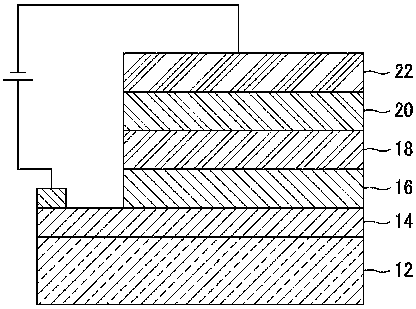

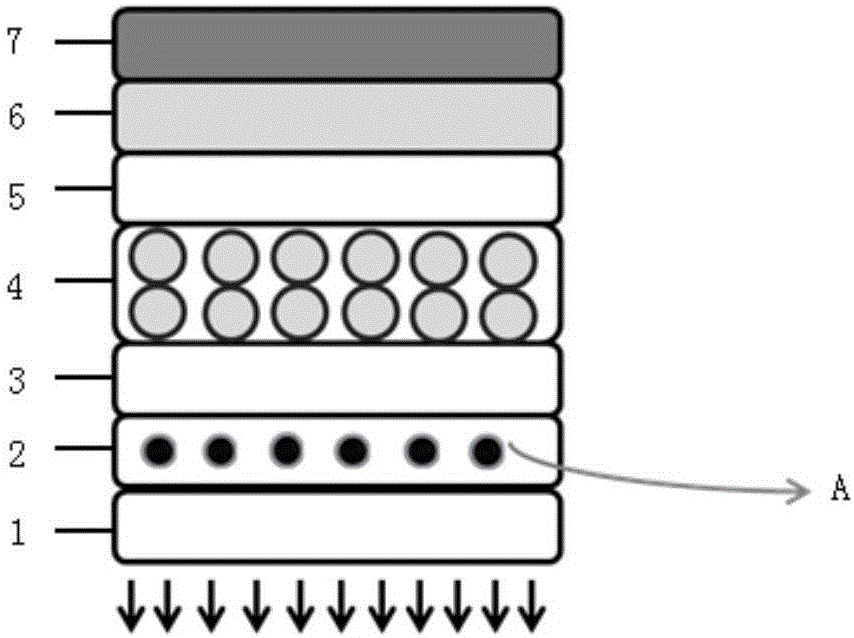

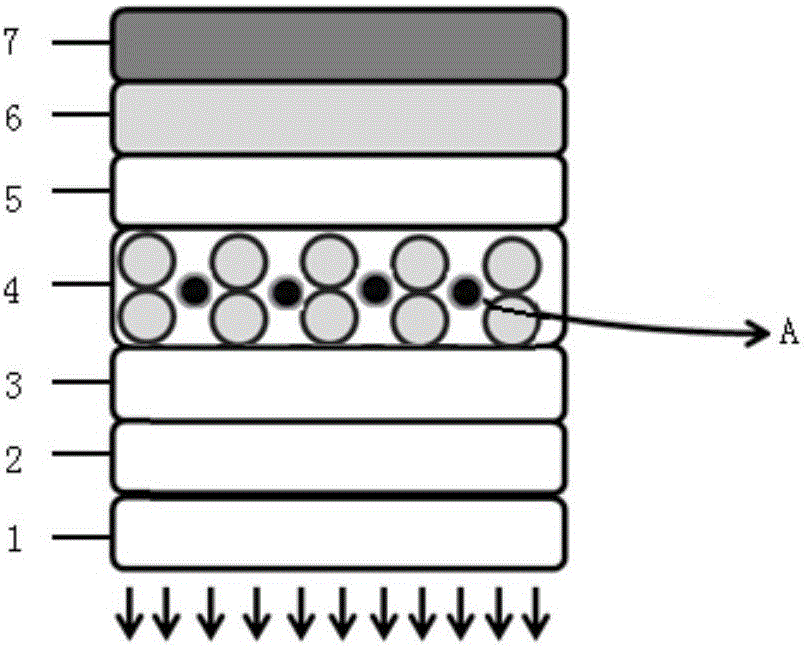

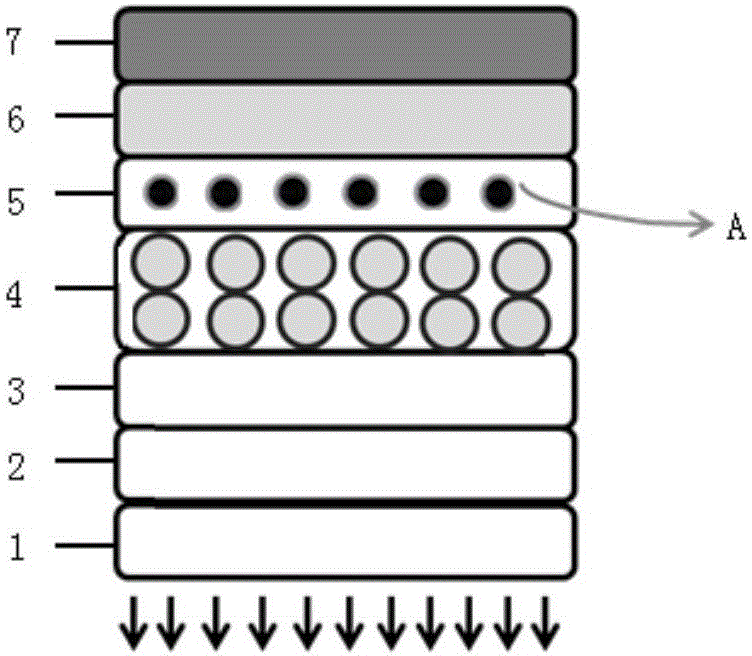

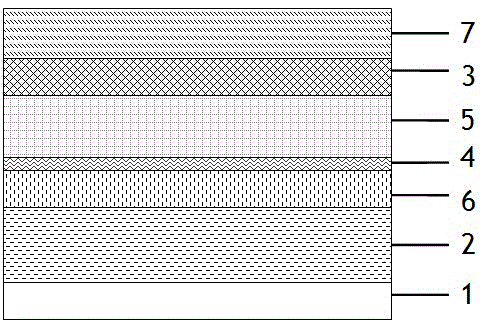

QLED containing noble metal nanomaterial and preparation method of QLED

InactiveCN106784348AEffectively adjust the spacingEffectively exert the reinforcement effectSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerQuantum dot

The invention provides a QLED containing a noble metal nanomaterial. The QLED comprises an anode, a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, an electron injection layer and a cathode which are sequentially stacked, wherein the QLED contains the noble metal nanomaterial; the noble metal nanomaterial is a nano noble metal core-shell structure composite material and comprises a noble metal core and a shell layer structure coating the noble metal core; and at least one of the hole injection layer, the hole transport layer, the quantum dot light-emitting layer, the electron transport layer and the electron injection layer is doped with the nano noble metal core-shell structure composite material; or the nano noble metal core-shell structure composite material is arranged between any two adjacent layers of structures of the hole injection layer, the hole transport layer, the quantum dot light-emitting layer, the electron transport layer and the electron injection layer as a nano noble metal core-shell layer.

Owner:TCL CORPORATION

Titanium alloy seamless tube and manufacturing method thereof

The present invention belongs to the technical field of titanium alloy and the manufacturing method thereof and discloses a titanium alloy seamless tube and the manufacturing method thereof. The invention is mainly characterized by comprising a tube body. The tube body comprises the following components by weight: 90 parts of Ti, 3.5-4.5 parts of V, 5.5-6.5 parts of Al, 0.08-0.12 parts of Ru, 0.28 or fewer parts of Fe, 0.13 or fewer parts of O, 0.07 or fewer parts of C, 0.03 or fewer parts of N, and 0.015 or fewer parts of H. An anti-oxidation coating layer is repeatedly and uniformly coated on the blank material, and then is subjected to the operations of heating, skew-rolling, perforating, deforming, heating, tube-rolling and deforming at the temperature of 850-780 DEG C. Meanwhile, the multi-pass reducing and sizing deformation is conducted at the temperature of 850-780 DEG C, and then the straightening and shot-blasting treatment is finally conducted to obtain the finished products of titanium alloy tubes. The titanium alloy seamless tube and the manufacturing method are simple in process, more environmentally-friendly in manufacturing process, and wider in the dimension range of manufactured titanium alloy tubes. Manufactured products are good in microstructure and mechanical properties, and manufactured titanium alloy tubes have fewer surface defects. Manufactured titanium alloy seamless tubes are good in machining performance, such as low cost, easy forging and corrosion resistance, thus being widely applicable to complex corrosion environments.

Owner:HEBEI HENGXIANG TITANIUM ALLOY PROD CO LTD

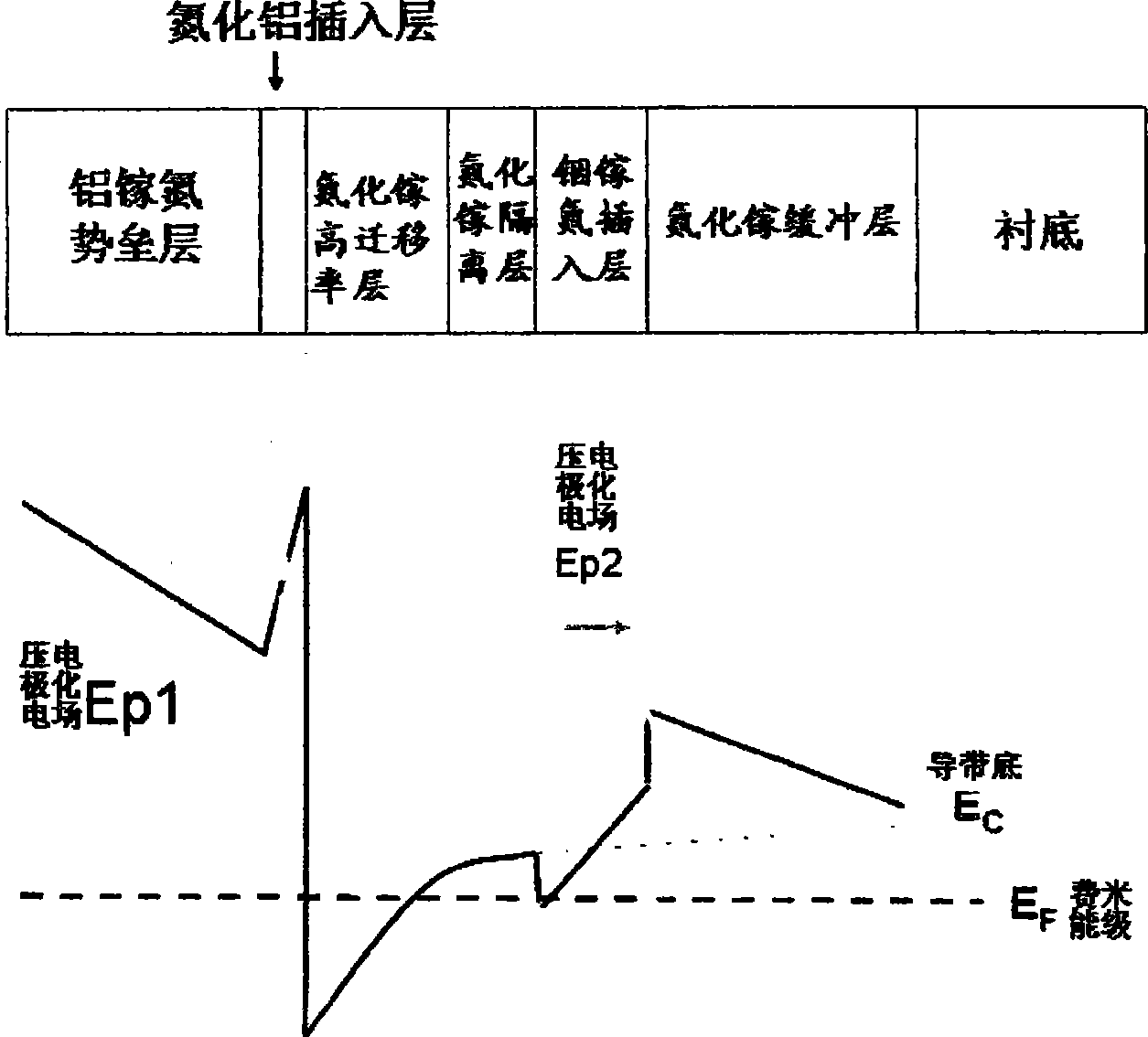

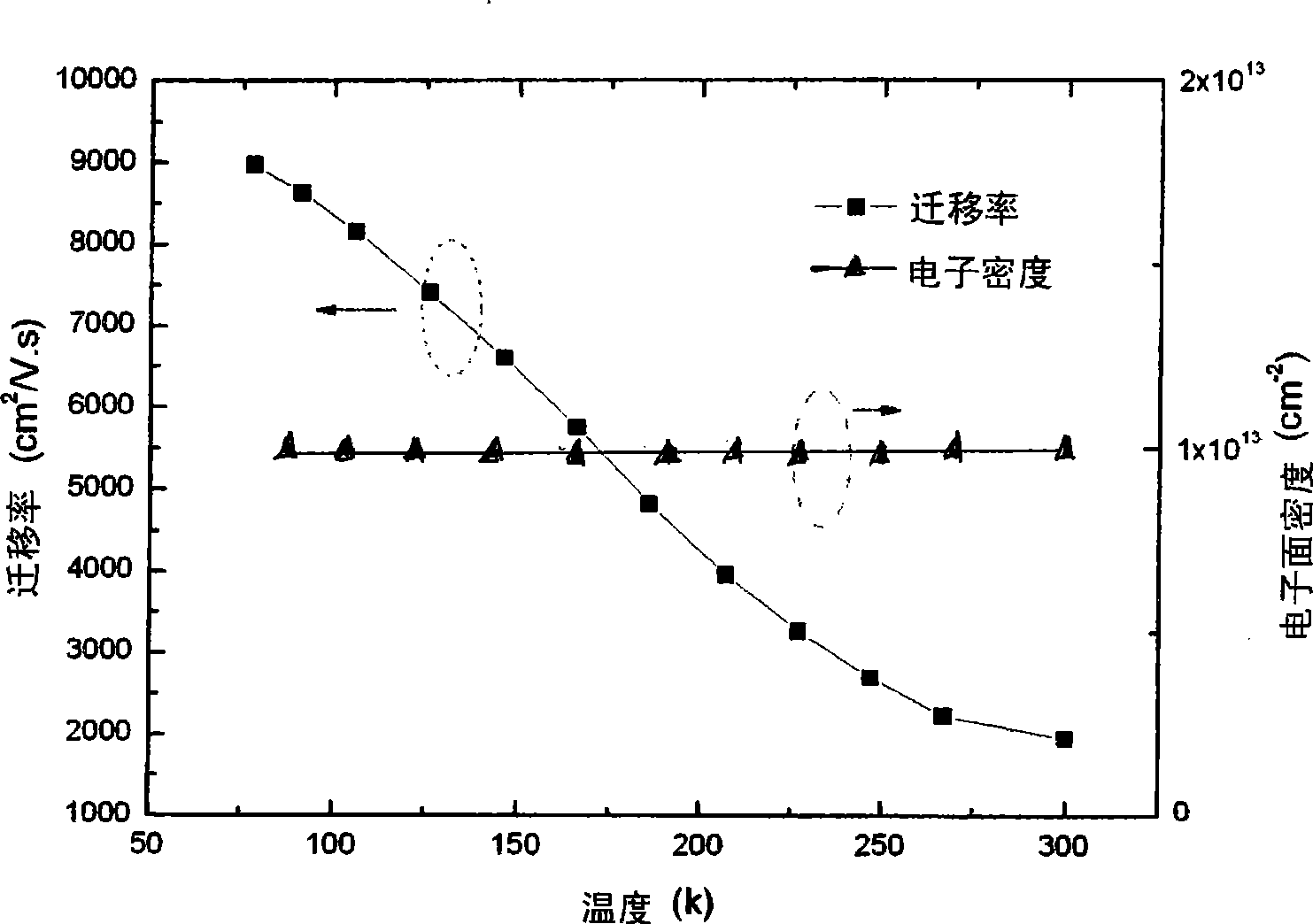

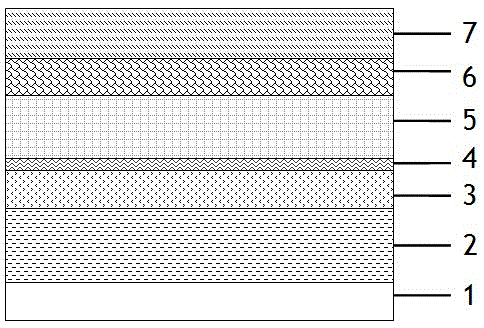

Gallium nitride based transistor structure with high electron mobility

InactiveCN101399284APrevent segregation and spreadHigh conduction band discontinuitySemiconductor devicesIndiumIsolation layer

A gallium nitride-based high electron mobility transistor structure comprises: a substrate; a low temperature nucleating layer is produced on the substrate; a gallium nitride-based high resistivity layer is produced on the low temperature nucleation layer; an indium gallium nitride insertion layer is produced on the gallium nitride-based high resistivity layer; a low temperature gallium nitride isolation layer is produced on the indium gallium nitride insertion layer; a high mobility gallium nitride layer is produced on the low temperature gallium nitride isolation layer; an aluminum nitride insertion layer is produced on the high mobility gallium nitride layer; an aluminium gallium nitride barrier layer is produced on the aluminum nitride insertion layer; a gallium nitride cap layer is produced on the aluminium gallium nitride barrier layer, and the gallium nitride cap layer effectively inhibit the current collapse effect.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

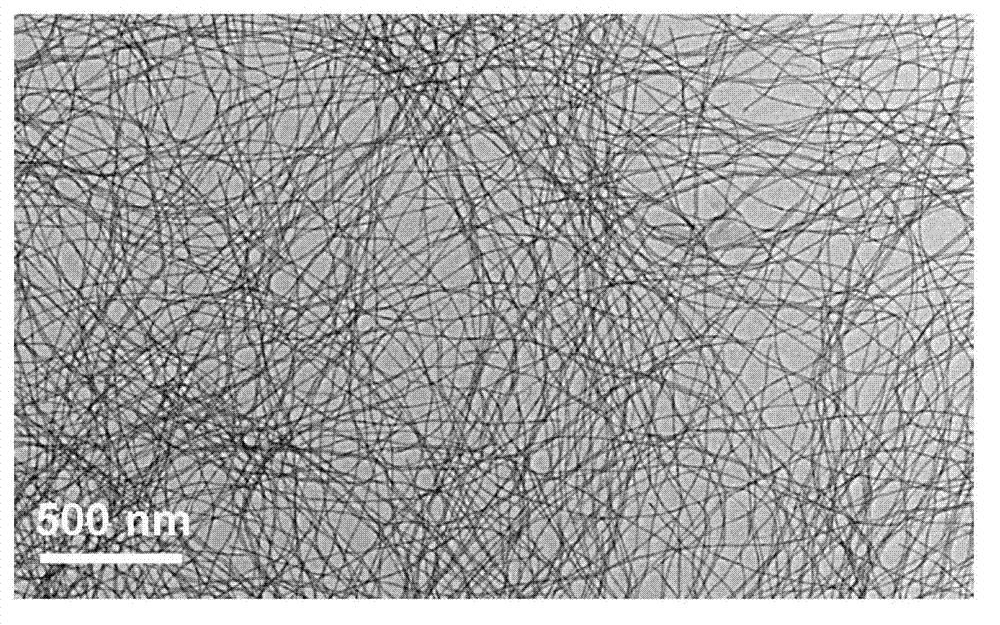

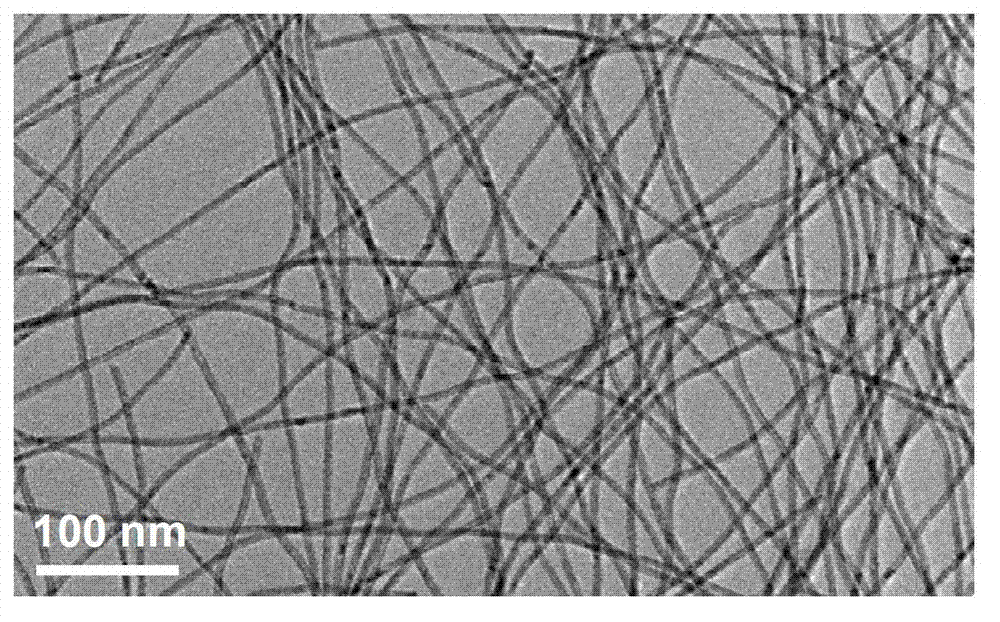

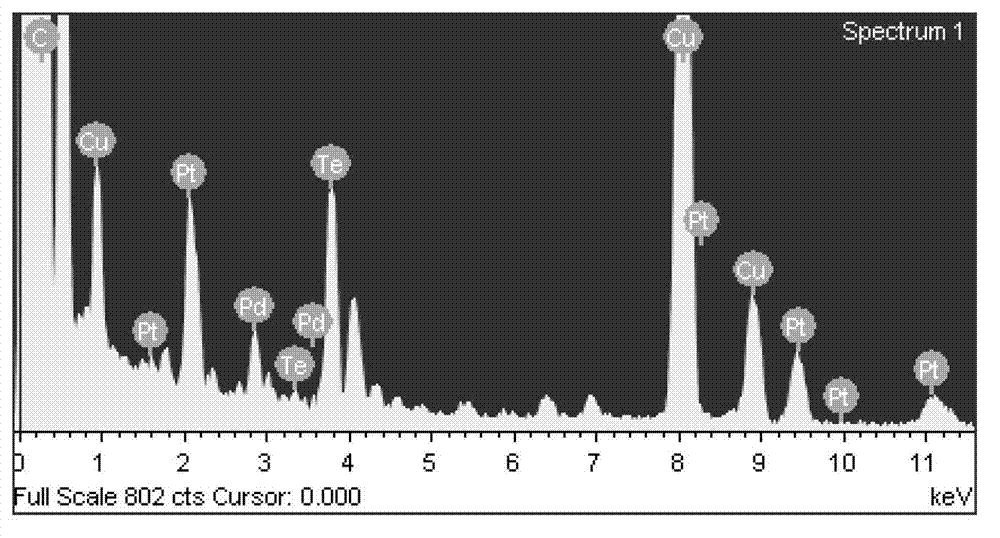

Preparation method and application of tellurium-based precious metal alloy nanowire catalyst

InactiveCN102872886ALow costReduce the amount of precious metalsMaterial nanotechnologyPhysical/chemical process catalystsSolventActive carbon

The invention discloses an active template method for preparing a tellurium-based precious metal alloy nanowire catalyst. The active template method comprises the following steps of: (a) dispersing tellurium nanowires in a solvent in a ratio to obtain a tellurium nanowire dispersion liquid, and dissolving a precious metal precursor in the solvent to obtain a precious metal precursor solution; (b) adding the precious metal precursor solution obtained in the step (a) into the tellurium nanowire dispersion liquid obtained in the step (a) in a ratio with stirring to obtain a mixed solution of the precious metal precursor solution and the tellurium nanowire dispersion liquid; and (c) performing replacement reaction on the mixed solution obtained in the step (b) to obtain the tellurium-based precious metal alloy nanowire catalyst. The one-dimensional catalyst prepared by the method can serve as a self-support catalyst, effectively avoids defects of particle catalyst agglomeration and Ostwald curing, and avoids a defect of Pt loss caused by corrosion of an active carbon supported carrier. Meanwhile, by the method, the catalyst can be synthesized massively and the industrialization is realized.

Owner:UNIV OF SCI & TECH OF CHINA

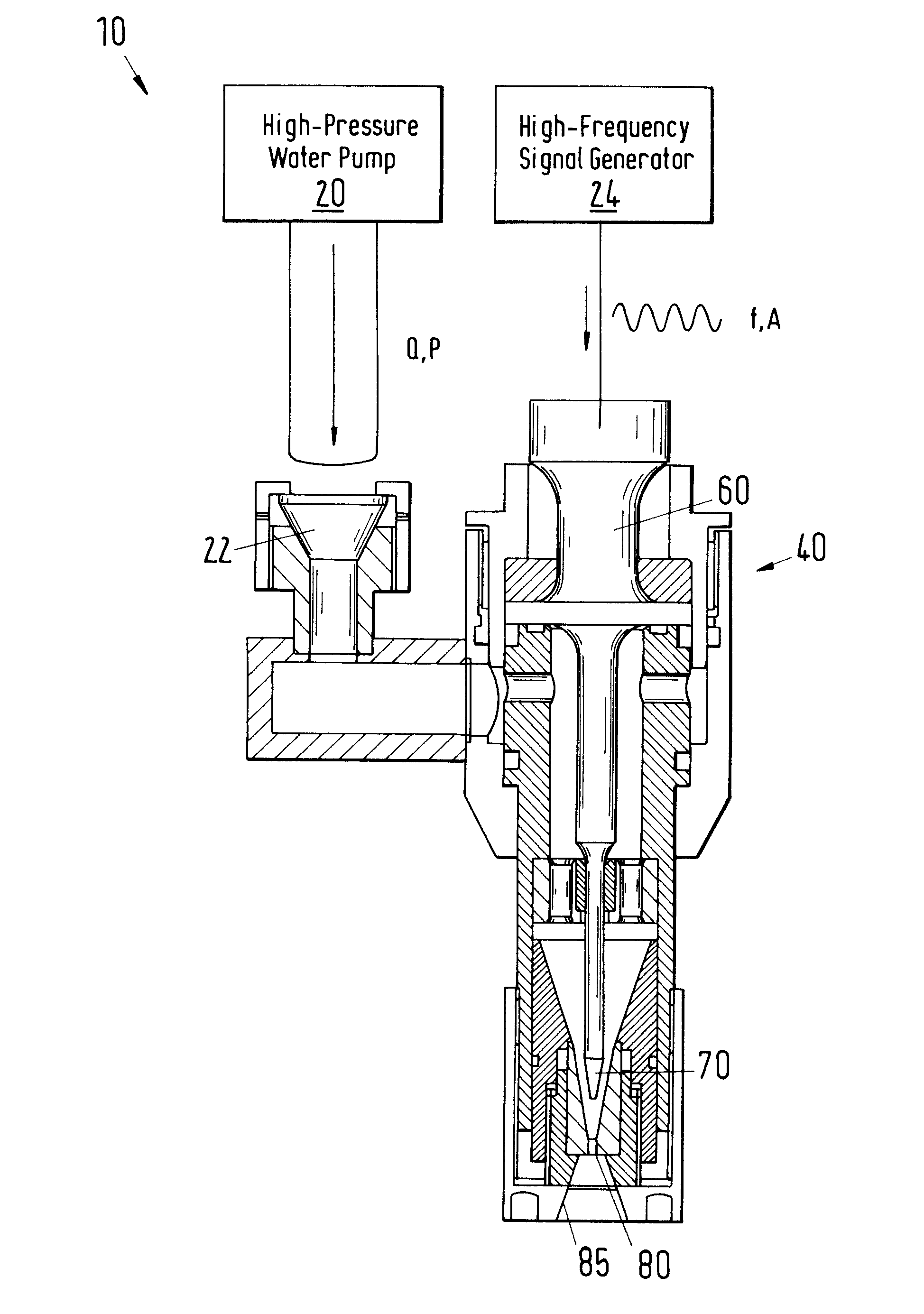

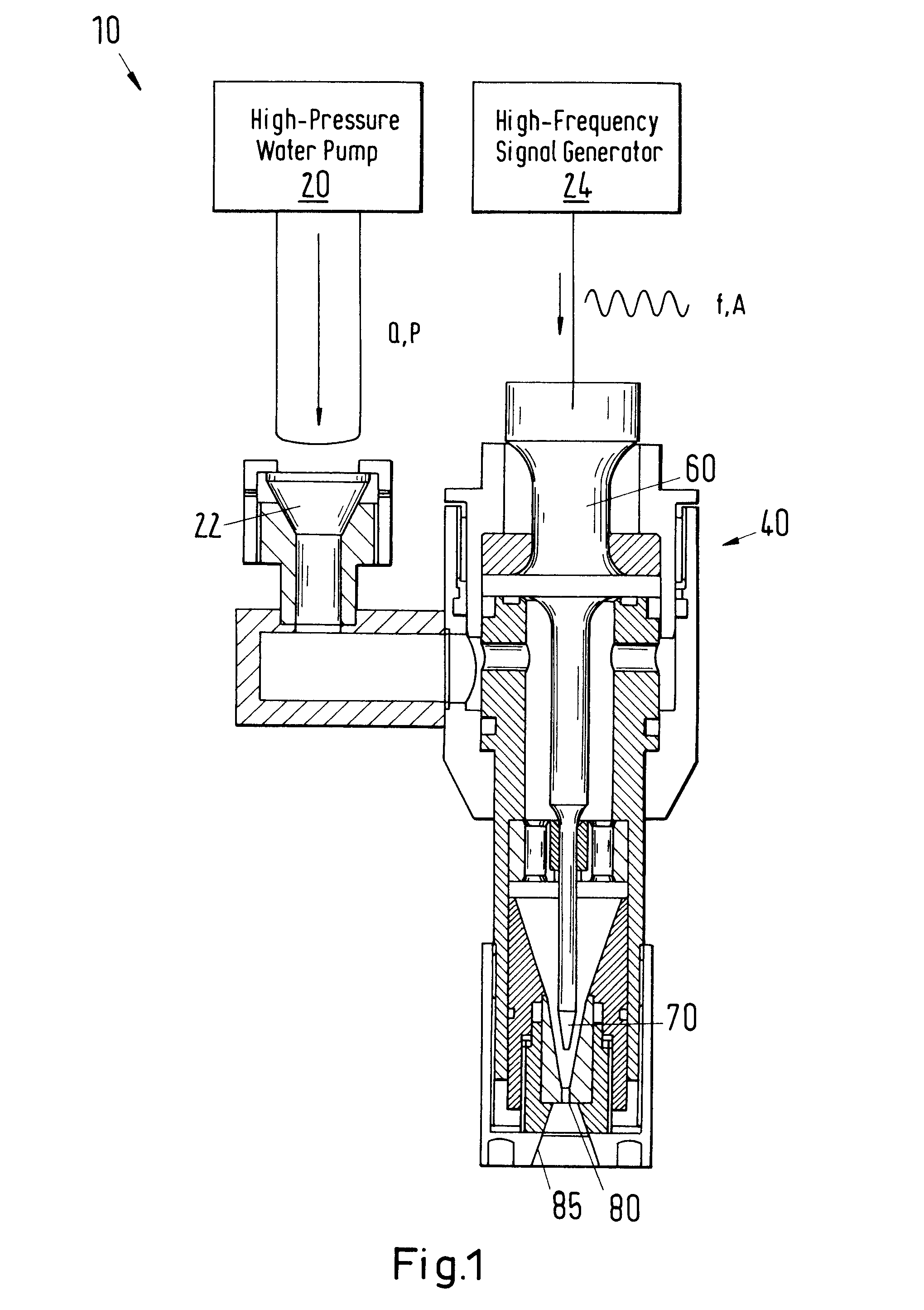

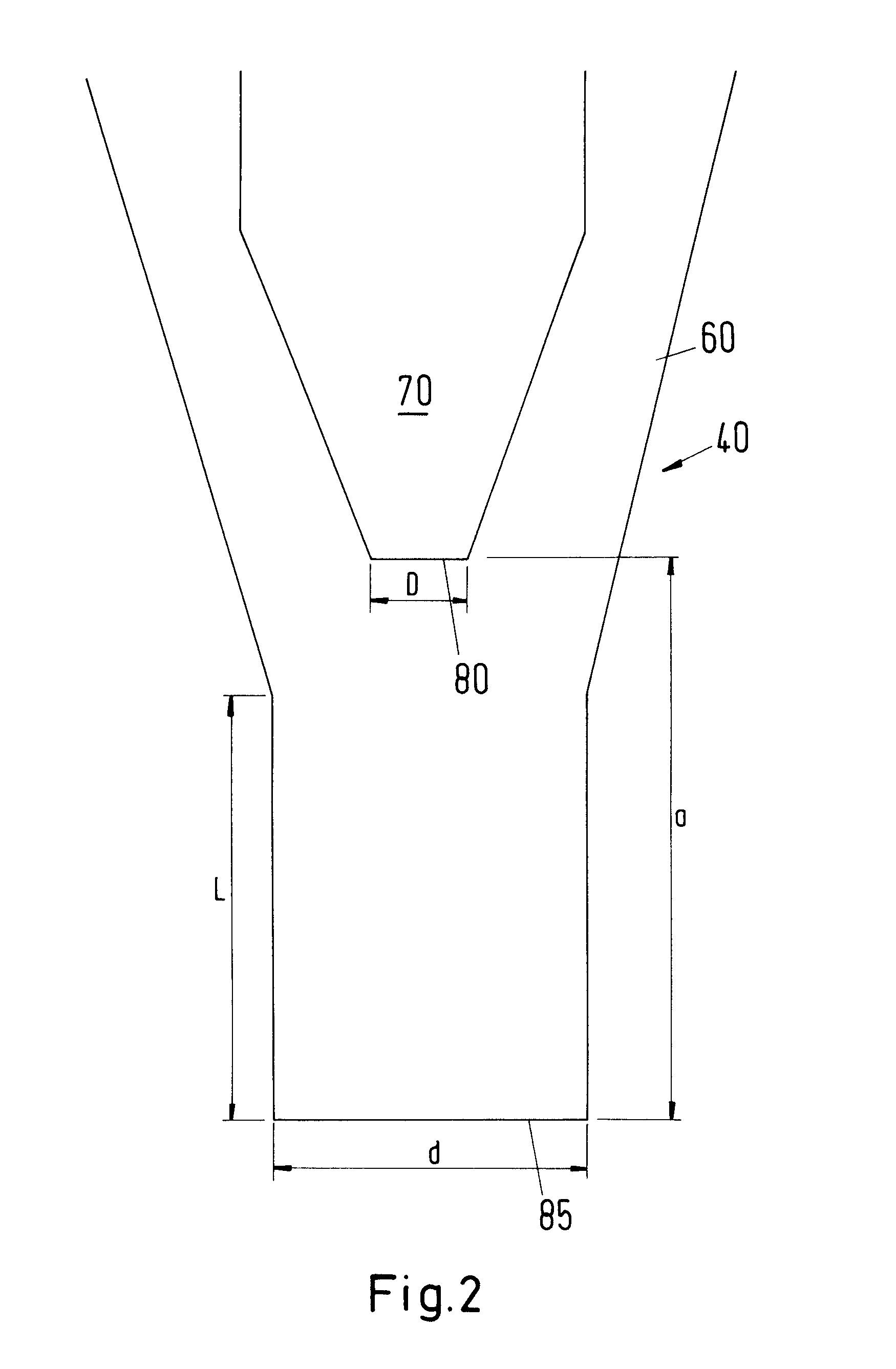

Method and apparatus for preparation of cylinder bore surfaces with a pulsed waterjet

InactiveUS20120322347A1Exact and highly uniform surface roughness characteristicHighly predictableBlast gunsMolten spray coatingSpray nozzleWater flow

An apparatus for and a method of prepping a surface of a cylinder bore using a pulsed waterjet entails generating a signal having a frequency f using a signal generator, applying the signal to generate a pulsed waterjet through an exit orifice of a nozzle having an exit orifice diameter d and a length L. The pulsed waterjet prepares the surface to within a predetermined range of surface roughness. The surface roughness is determined by selecting operating parameters comprising a standoff distance (SD), a traverse velocity VTR of the nozzle, a water pressure P, a water flow rate Q, a length-to-diameter (L / d) ratio, the frequency f, and an amplitude A of the signal.

Owner:SULZER METCO (US) INC

Environment-friendly insulating paint for non-oriented silicon steel and preparation method of coating thereof

The invention relates to an environment-friendly insulating paint for non-oriented silicon steel and a preparation method of a coating thereof. The paint is prepared from the following components by weight percent: 10-30% of aluminium dihydrogen phosphate, 1-10% of coating color-developing agent, 0-10% of manganese dihydrogen phosphate, 0.5-1.5% of zinc oxide, 0.1-1% of magnesium oxide, 1-5% of silica sol, 1-5% of boric acid, 0.5-5% of titanate coupling agent, 0.1-0.4% of bismuth nitrate, 2-6% of organic solvent, 0.1-0.5% of other auxiliary agent and the balance of water, wherein the sum of all components is 100%. The environment-friendly insulating paint disclosed by the invention has the advantages that the coating is an environment-friendly coating free of chromate and the high-temperature treatment temperature can be up to 850 DEG C.

Owner:江阴市诺科科技有限公司 +1

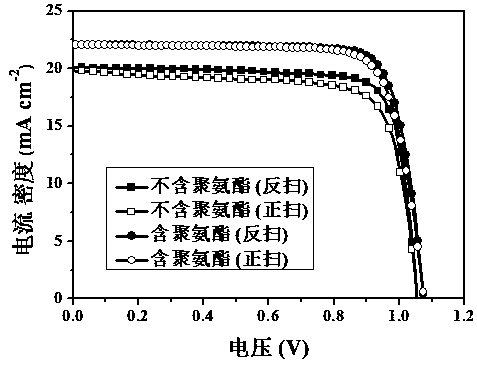

Bend-resistant perovskite solar cell and preparation method thereof

InactiveCN107611190ASlow crystallization rateRefine the grain sizeFinal product manufactureSemiconductor devicesPerovskite solar cellHole transport layer

The invention discloses a bend-resistant perovskite solar cell, comprising a transparent substrate, an anode, an electron transport layer, a perovskite active layer, a hole transport layer and a cathode. The perovskite active layer is composed of a perovskite material and an additive. The additive is polyurethane. The perovskite material is CH<3>NH<3>PbI<3>, CH<3>NH<3>PbI<3>-xClx or (FAPbI<3>)l-x(MAPbBr<3>)x. The additive polyurethane is added to perovskite precursor solution according to mass concentration of 0.01wt%-5wt%. According to the bend-resistant perovskite solar cell, the polyurethane is introduced into perovskite precursor solution, perovskite crystals are controlled to nucleate, a crystallization rate is reduced, the bend-resistance of perovskite film is improved, a new thoughtfor preparing high performance flexible perovskite solar cell is provided, and the flexible roll-to-roll commercialized production of the perovskite solar cell is realized.

Owner:NANCHANG UNIV

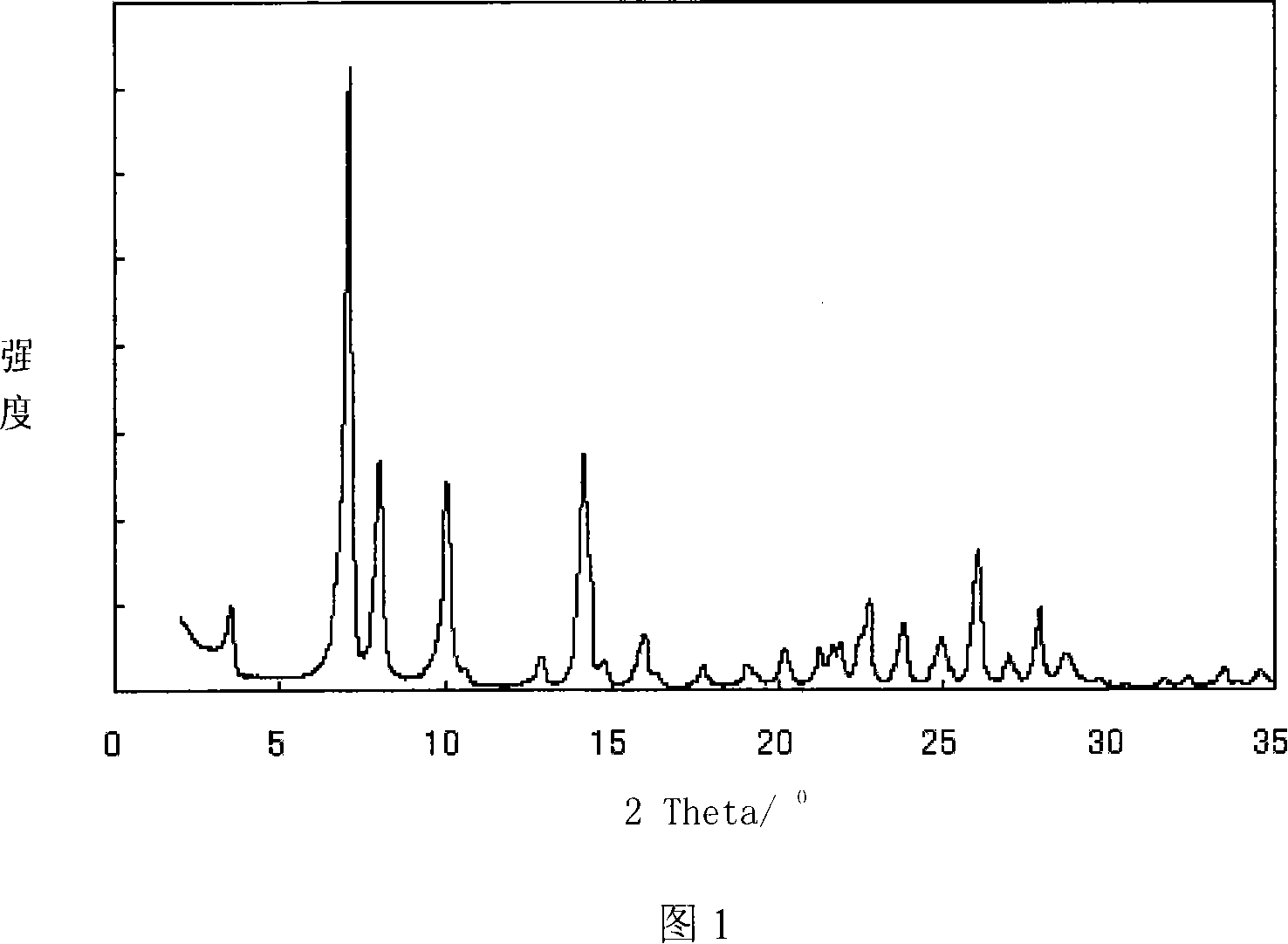

Titanium-silicon molecular screen with MWW structure and its synthesis and application

InactiveCN101148260AReduce surface defectsImprove catalytic performanceMolecular sieve catalystsOximes preparationMolecular sieveInorganic Chemical

The present invention is one kind of Ti-Si molecular sieve in MWW structure and its synthesis and application, and belongs to the field of inorganic chemical technology. The Ti-Si molecular sieve in MWW structure with Ti, Si and O as the skeleton elements and without B adverse to selective catalytic oxidation is prepared through synthesizing intermediate crystal material and roasting directly or after acid treatment. It is suitable for use as the catalytic oxidation catalyst, and has less surface faults, great specific surface area up to 450 sq m / g, high catalytic oxidation performance and other advantages.

Owner:EAST CHINA NORMAL UNIV

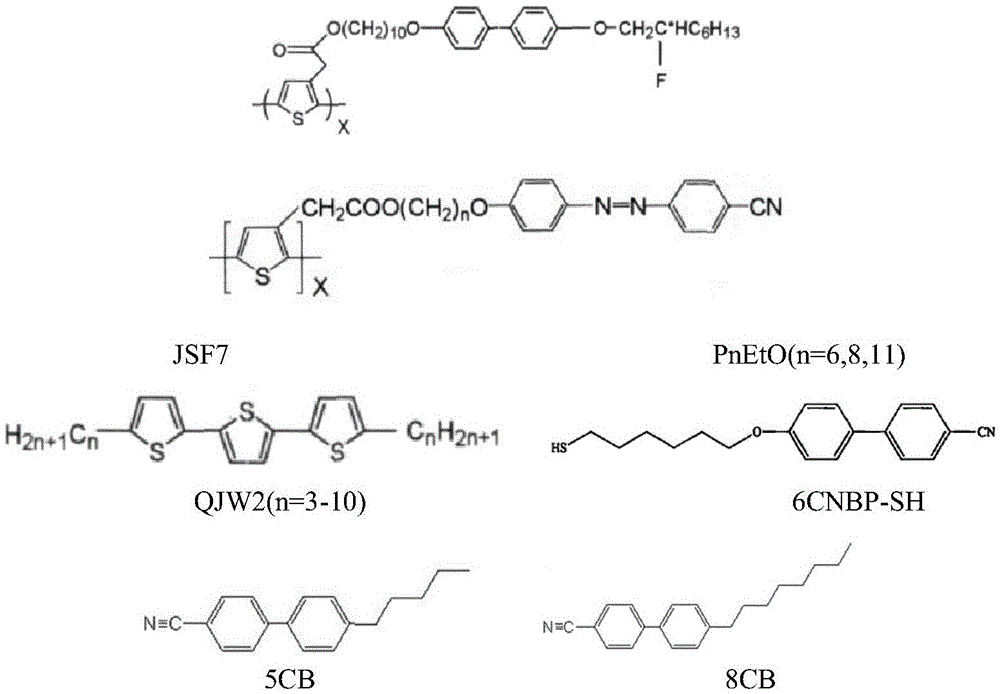

Perovskite solar cell and preparation method thereof

ActiveCN105609641AImprove film morphologyReduce surface defectsFinal product manufactureSolid-state devicesThin film morphologyLiquid-crystal display

The invention relates to a perovskite solar cell and a preparation method thereof. By arranging a liquid crystal layer on the surface of an electron transmission layer or a hole transmission layer, the thin film morphology of the electron transmission layer or the hole transmission layer is improved, the defect on the surface of the electron transmission layer or the hole transmission layer is passivated, the transmission of reverse current carriers is effectively blocked, the electric leakage generation is prevented, the combination probability of electrons and holes which are generated in a perovskite light absorption layer is reduced, and the photoelectric conversion efficiency and the stability of the cell are improved; and meanwhile, the liquid crystal layer is prepared by a low-temperature solution method, and the preparation method is suitably used for roll-to-roll industrial production of the perovskite photovoltaic cell, and is simple in process and low in fabrication cost.

Owner:CHINA LUCKY FILM CORP

Acid-washing hot-rolled low-carbon steel without line defects on surface and production method thereof

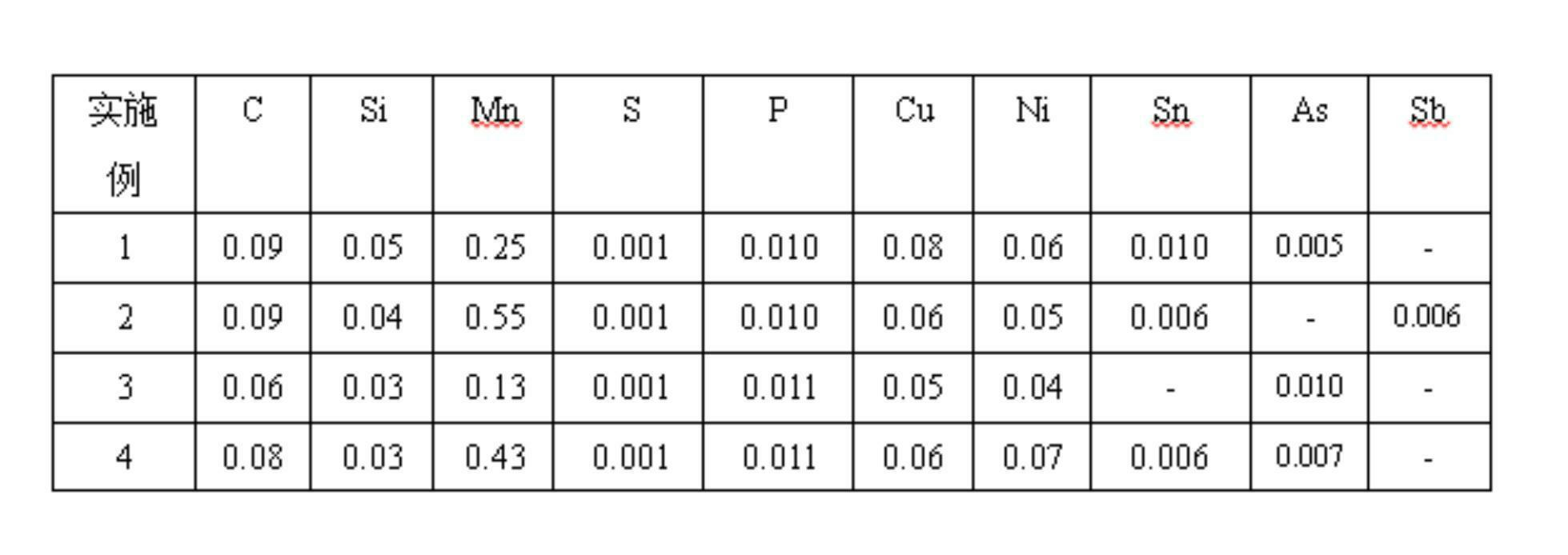

The invention discloses an acid-washing hot-rolled low-carbon steel without line defects on the surface and a production method thereof. The hot-rolled low-carbon steel consists of the following components in percentage by weight: 0.02 to 0.12 percent of C, 0.05 percent or less of Si, 0.10 to 0.60 percent of Mn, 0.015 percent or less of P, 0.010 percent or less of S, 0.10 percent or less of Cu, 0.10 percent or less of Ni, 0.05 percent or less of Cr, 0.010 to 0.070 percent of Als, 0.010 percent or less of Sn, 0.010 percent or less of As, 0.010 percent or less of Sb and the balance of iron; moreover, As plus Sn plus Sb are less than or equal to 0.015 percent, and the ratio of Ni to Cu is greater than or equal to 0.5. The production method of the hot-rolled low-carbon steel includes the following steps: after molten iron desulfurization and converter blowing, a raw sheet billet of the hot-rolled low-carbon steel is obtained, and the raw sheet billet of the hot-rolled low-carbon steel sequentially is subjected to continuous casting, heating, scale removal before rough rolling, rough rolling, finish rolling, laminar flow cooling, rolling, fan cooling and acid-washing. While the mechanical property of the steel is guaranteed by the components of the raw steel, the surface defects of the acid-washinghot-rolled low-carbon steel are reduced, consequently, the surface quality of the steel is greatly increased, and economic loss is reduced.

Owner:武汉钢铁有限公司

Wet-spinning preparation method for polyacrylonitrile-based carbon fiber precursor

InactiveCN105755581AImprove performanceImprove splittingFibre chemical featuresWet spinning methodsYarnCarbon fibers

The invention relates to a preparation method of a carbon fiber precursor, and in particular to a wet-spinning preparation method for a polyacrylonitrile-based carbon fiber precursor. The preparation method comprises the following steps: 1) metering a spinning solution of polyacrylonitrile-based carbon fiber by using a metering pump, ejecting from a 12000 spinning nozzle to form fine yarns, and feeding the yarns into a coagulating bath, wherein the coagulating bath is a dimethyl sulfoxide solution of which the temperature is 60-80 DEG C, the concentration is 30-50% and the pH value is 7.0-9.0; 2) performing wet-spinning at minus drafting of minus 80% to minus 25% and coagulating bath circulation volume of 1000-2000L / h, and performing water washing, water holding, oiling, drying, steaming drafting, thermal molding, and winding, thereby obtaining the polyacrylonitrile-based carbon fiber precursor, wherein the final spinning speed is up to 120-150m / min. According to the preparation method, in the wet-spinning process, curing molding conditions of wet-spinning are improved, and a high-temperature and low-concentration coagulating bath molding method is provided, so that surface defects of the polyacrylonitrile-based carbon fiber can be reduced, and the spinning speed of the wet-spinning method can be increased.

Owner:ZHONGFU SHENYING CARBON FIBER

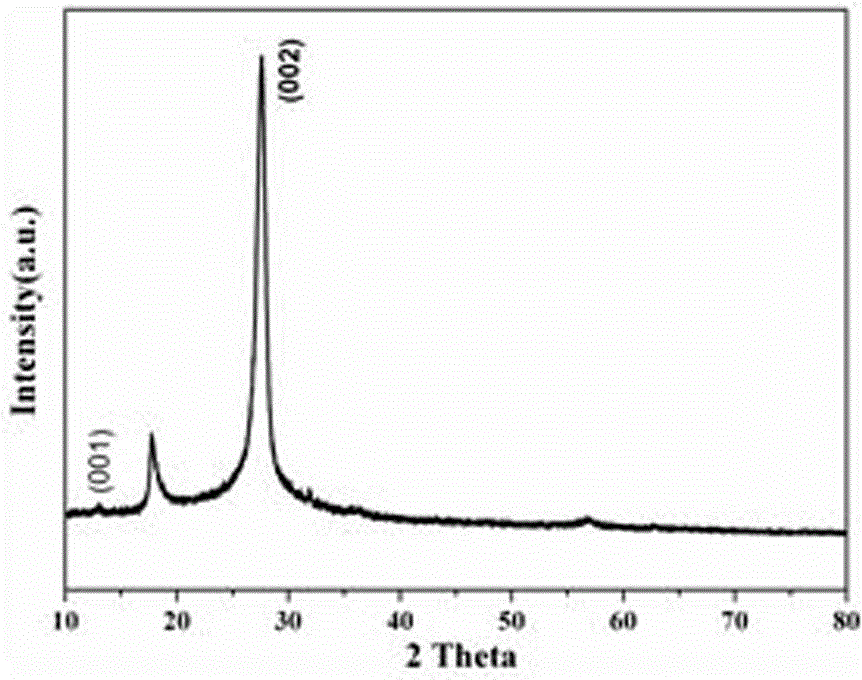

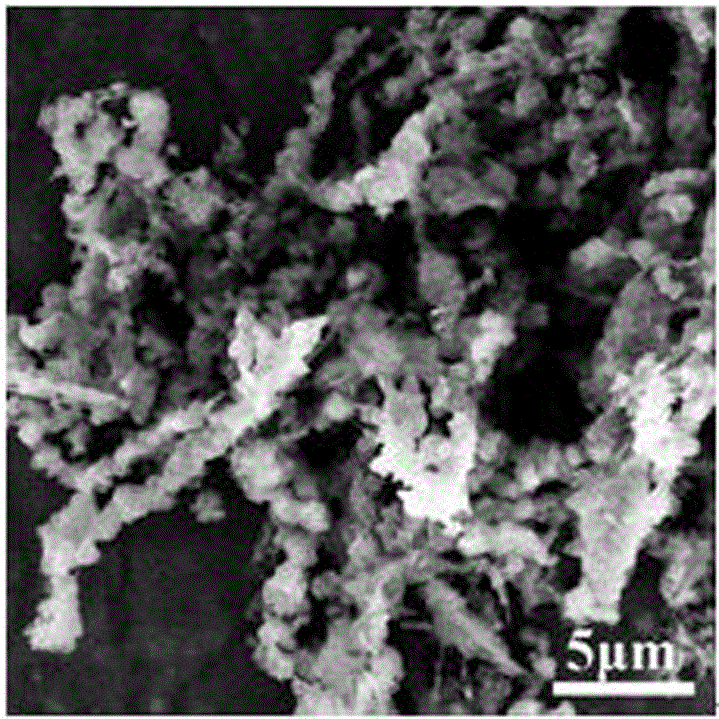

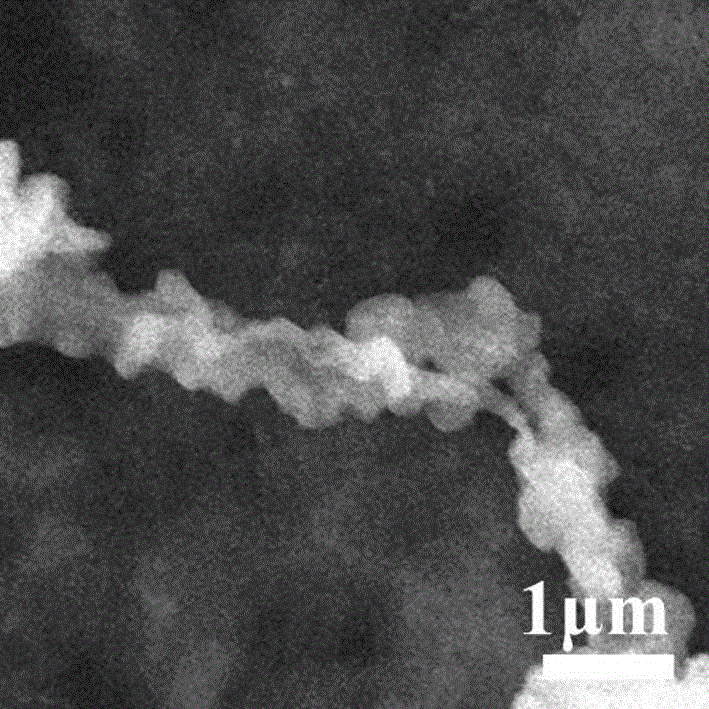

Bead-chain-like graphitized carbon nitride nano material and preparation method thereof

InactiveCN104986742AGood crystallinityReduce surface defectsMaterial nanotechnologyPhysical/chemical process catalystsSmooth surfaceNoble metal

The invention relates to a bead-chain-like graphitized carbon nitride nano material and a preparation method thereof and belongs to the technical field of semi-conductor material preparation. The bead-chain-like graphitized carbon nitride nano material adopts a bead-chain-like structure formed by arranging raised bead-like objects on the surfaces of graphitized carbon nitride nano-rods, wherein the diameter of the bead-like objects is 200-800 nm; the space between the bead-like objects is 200-800 nm; the nano-rods connected with the bead-like objects are 80-500 nm in diameter, and 5-13.6 [mu]m in chain length. The preparation method comprises the following steps: dissolving melamine into an alcohol solution to obtain an initial solution; then adding a nitric acid solution, stirring and precipitating to produce carbon nitride precursor solid powder; after that, forging to obtain the bead-chain-like graphitized carbon nitride nano material. The preparation process is simple, and the obtained product has the advantages of smooth surface, uniform size, relatively good dispersity and the like, and can serve as a template for preparing other materials or as carriers of noble metal nano-particles.

Owner:UNIV OF JINAN

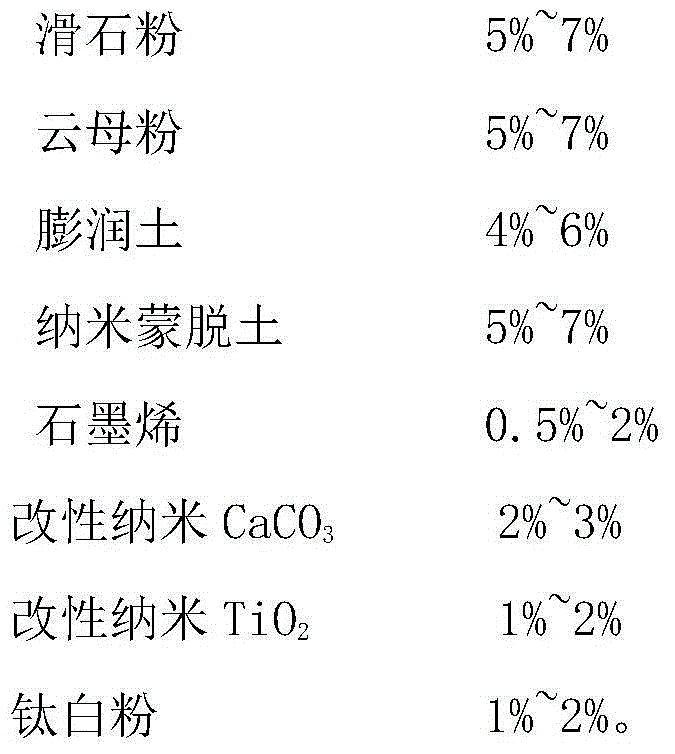

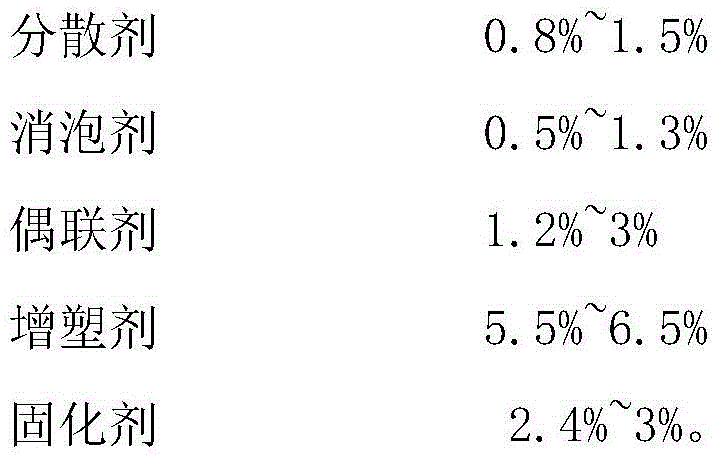

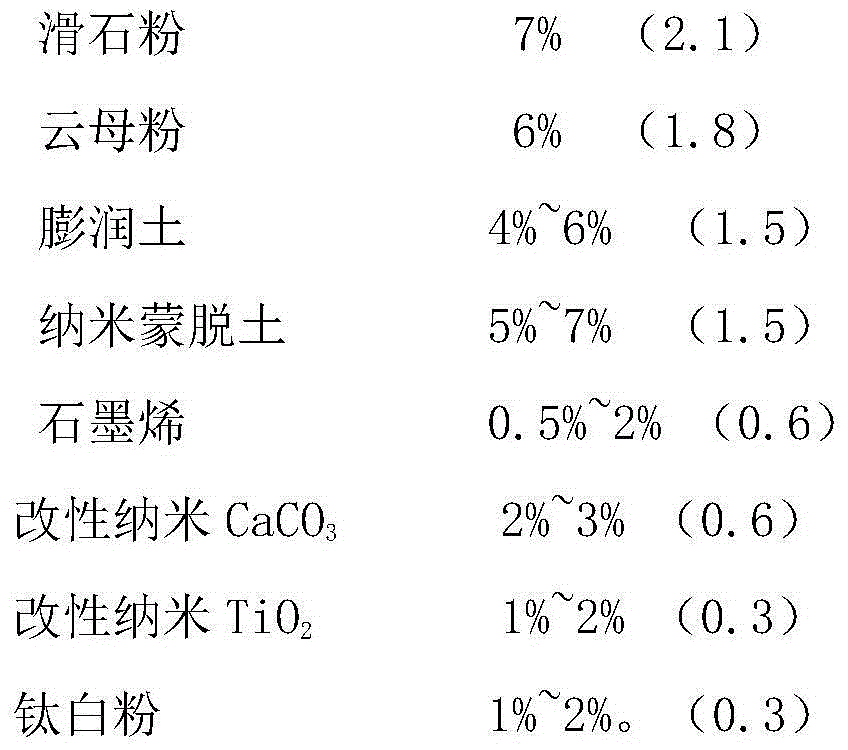

Epoxy resin coating in marine steel pipe 3PE anticorrosive coating and preparation method thereof

InactiveCN104449249AReduce dosageAvoid crackingAnti-corrosive paintsEpoxy resin coatingsEpoxyShrinkage rate

The invention discloses an epoxy resin coating in a marine steel pipe 3PE anticorrosive coating and a preparation method thereof. The epoxy resin anticorrosive coating comprises the following components in percentage by weight: 55-65 percent of epoxy resin, 23.5-36 percent of filler and pigments and 10.4-15.3 percent of aids, wherein the epoxy resin comprises the following components in percentage by weight: 39-47 percent of E-12 epoxy resin and 16-23 percent of novolac epoxy resin. Talcum powder, mica powder, bentonite and titanium dioxide are properly added into the epoxy resin to serve as partial fillers. The use amount of the resin can be relatively reduced, the cost is reduced, the physical and mechanical properties can be improved; particularly, the elasticity modulus is increased, the cure shrinkage rate is reduced, the seawater impact resistance is increased, and the seawater resistance is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

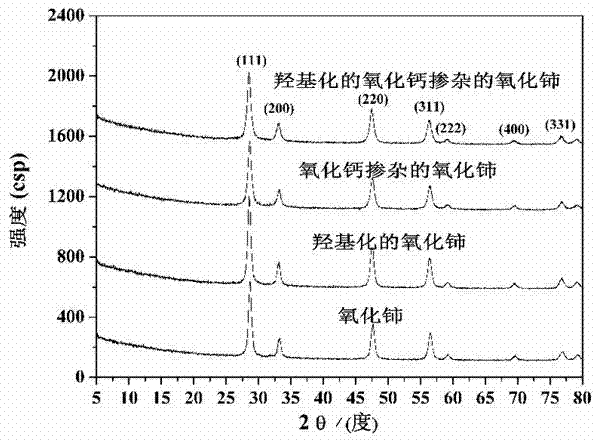

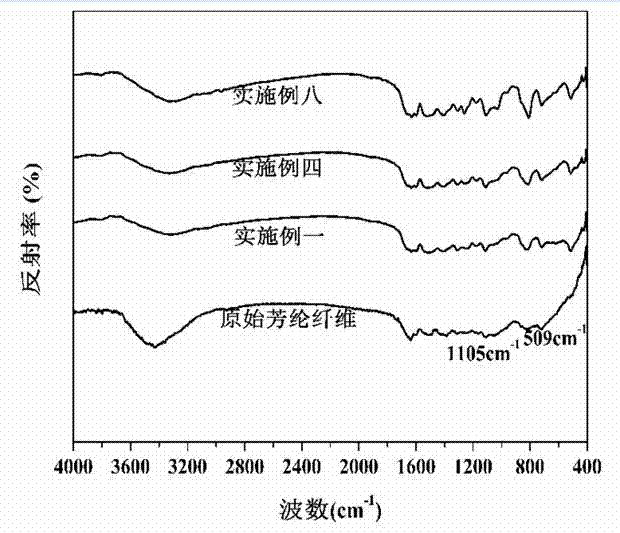

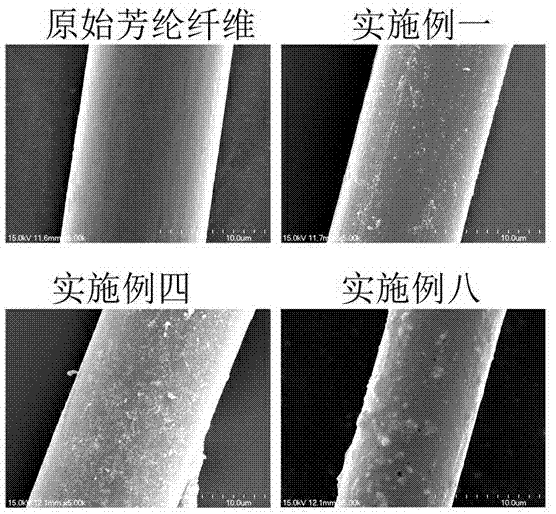

Aramid fiber coated with inorganic nanoparticles on surface and preparation method thereof

InactiveCN103572583AGood long-term usabilityWide UV absorption rangeFibre typesRare earth metal compoundsInorganic nanoparticlesUltraviolet

The invention relates to aramid fiber coated with inorganic nanoparticles on the surface and a preparation method thereof. The preparation method comprises the following steps: functionalizing the surface of the aramid fiber to enable the surface of the fiber to contain methoxy groups; hydroxylating calcium-oxide-doped cerium oxide and reacting the cerium oxide with the fiber to obtain the aramid fiber coated with the inorganic nanoparticles on the surface. According to the invention, the hydroxylated calcium-oxide-doped cerium oxide is an inorganic particle with the photocatalytic activity much lower than that of ultraviolet absorbents such as TiO2 and zinc oxide; the inorganic particles can absorb ultraviolet rays to protect the fiber from damage caused by the ultraviolet rays, and the damage caused by a photocatalytic action of the inorganic particles to the fiber during ultraviolet radiation can be avoided, so that the hydroxylated calcium-oxide-doped cerium oxide is a safe, effective and long-lasting ultraviolet absorber. The surface of the modified aramid fiber is provided with a large number of reactive groups, so that adhesion of the modified aramid fiber to a lot of substrates can be improved, and thus the application field of the fiber is widened; the nanoparticles with high heat resistance are coated on the surface of the fiber, so that the thermal property of the fiber can be effectively improved.

Owner:SUZHOU UNIV

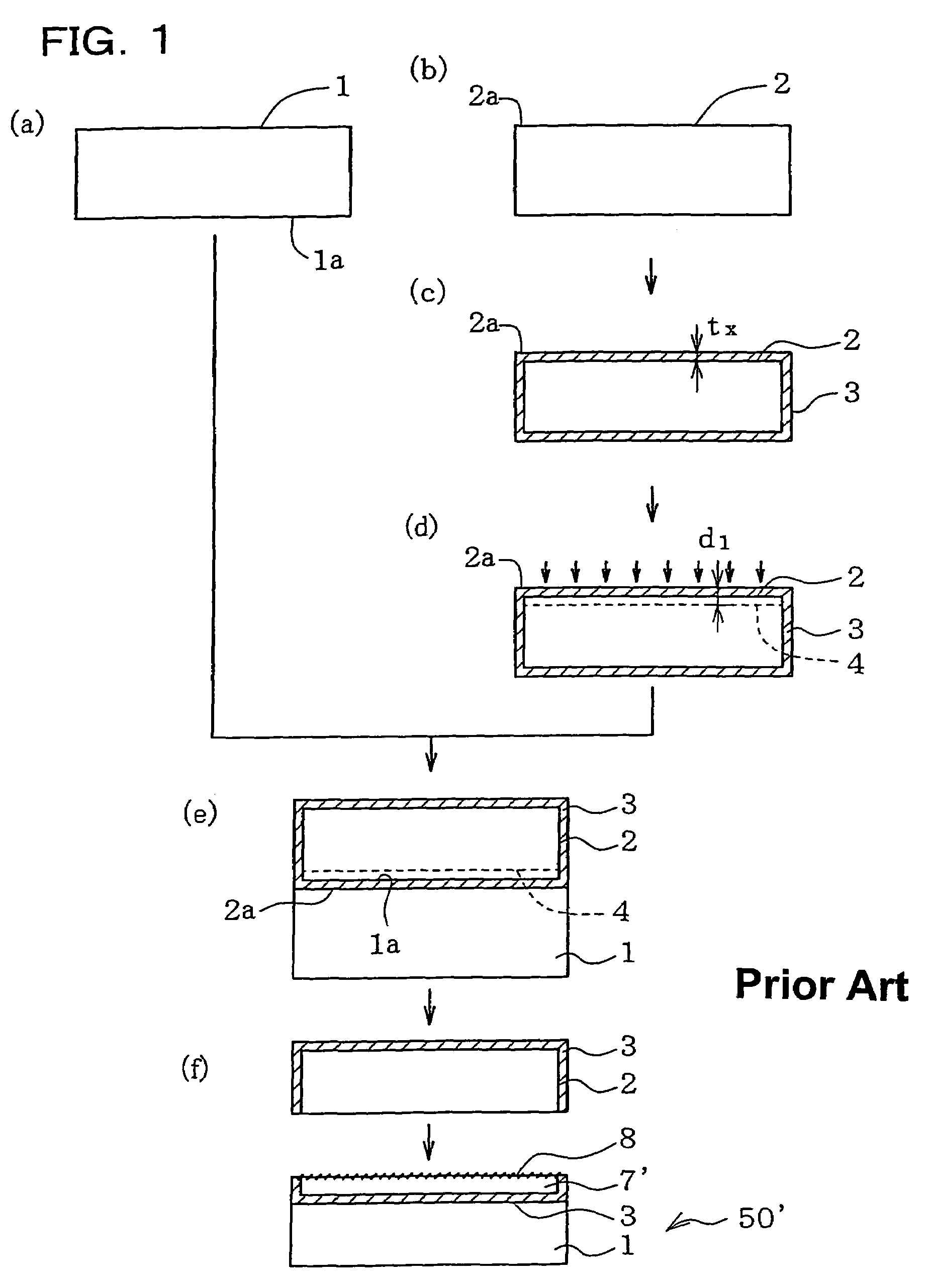

Polyester film and a production method thereof

InactiveUS20030148131A1Improve productivityQuality improvementSynthetic resin layered productsRecord information storagePolyesterEngineering

The object of the present invention is to provide a method for producing a polyester film excellent in rigidity, toughness, dimensional stability, electric properties, etc. and less in thickness fluctuation and surface defects, hence very suitable as a film for various industrial materials such as magnetic recording media, capacitors, heat transfer ribbons and thermal mimeographic stencil paper. The first method of the present invention is a method for producing a polyester film, in which a film made of a resin mainly composed of a polyester is simultaneously biaxially stretched by a simultaneously biaxially stretching tenter oven, comprising the step of effecting small-ratio stretching at an area stretching ratio of 1.0005 to 3.0 times three times or more, to achieve a total area stretching ratio of 25 to 150 times, and the second method of the present invention is a method for producing a polyester film, in which a film made of a resin mainly composed of a polyester is stretched using a simultaneously biaxially stretching tenter oven, comprising the step of effecting a series of operation consisting of stretching and subsequent relaxation twice to less than 10000 times, to achieve a total area stretching ratio of 25 to 150 times.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com