Gallium nitride based transistor structure with high electron mobility

A high electron mobility, gallium nitride-based technology, applied in the structural field of gallium nitride-based high electron mobility transistors, can solve the problem that the performance of the corresponding device with electron mobility is difficult to be further improved, and the uneven scattering effect of alloy composition , device performance deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

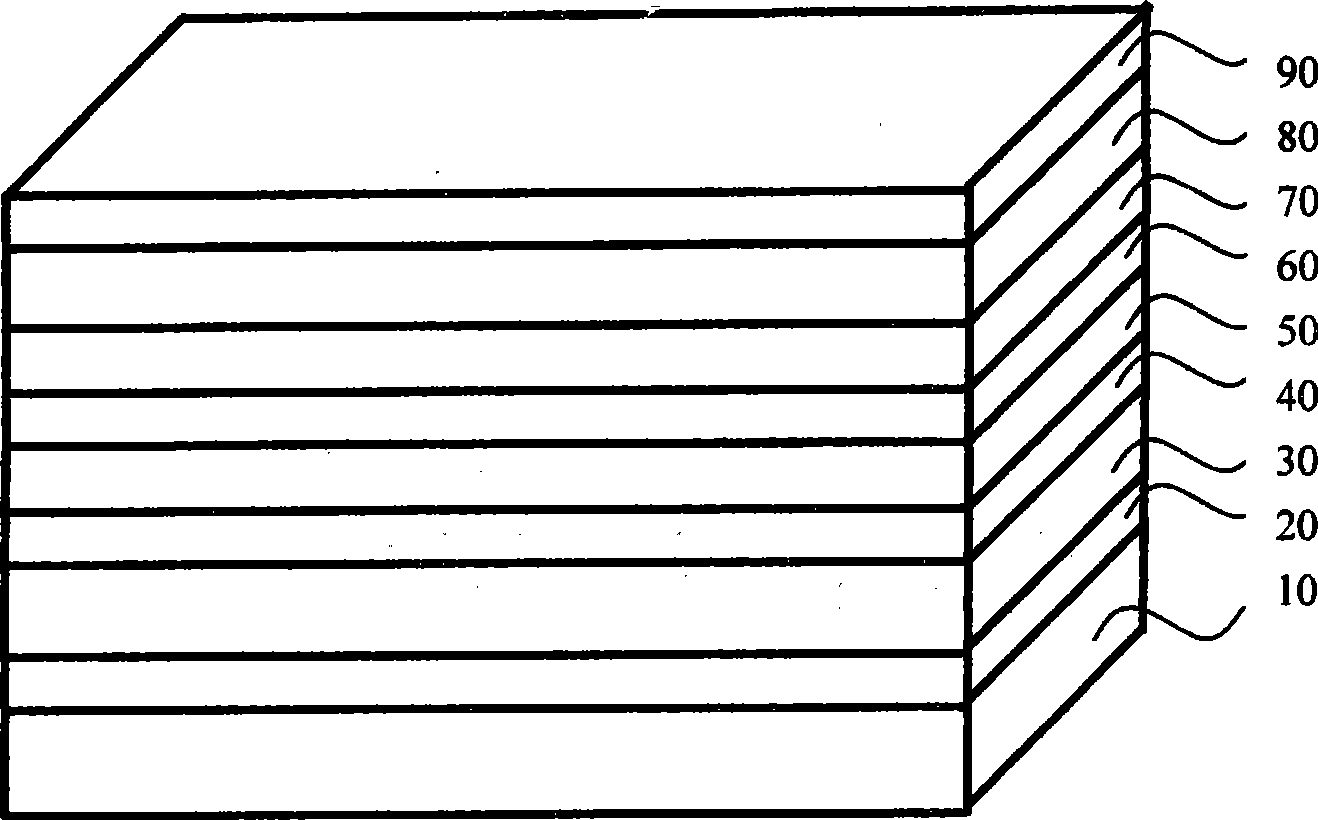

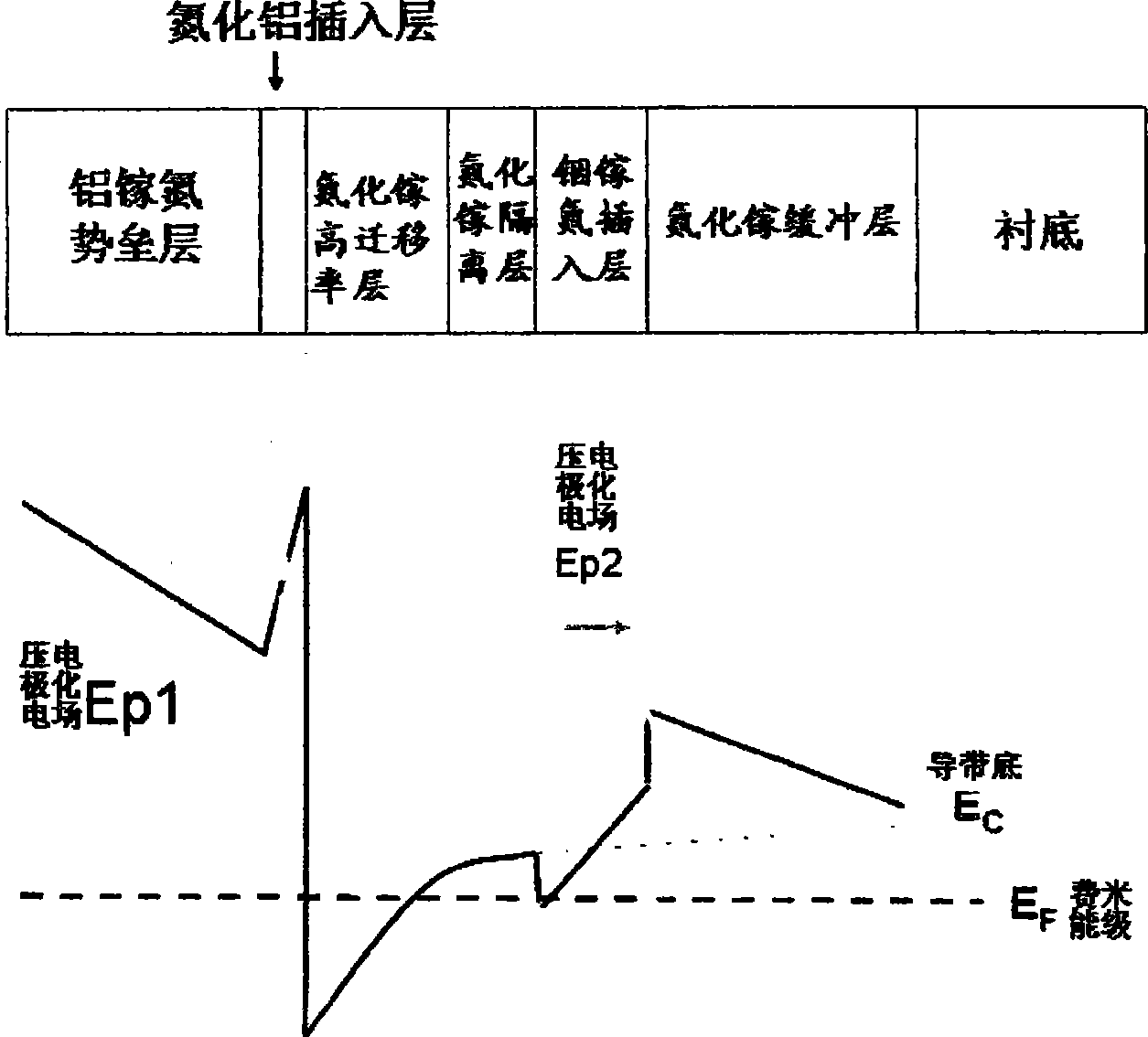

[0029] see figure 1 As shown, the present invention has invented a GaN-based high electron mobility transistor structure, which includes:

[0030] (1) substrate 10, the material of the substrate 10 is sapphire or silicon or silicon carbide or gallium nitride or aluminum nitride or ZnO;

[0031] (2) low temperature nucleation layer 20, this low temperature nucleation layer 20 is gallium nitride or aluminum nitride or AlGaN, is made on the substrate 10, and the effect of low temperature nucleation layer 20 is to provide effective for the growth of epitaxial layer Nucleation center, and because a large number of dislocations generated release most of the stress of the epitaxial layer, effectively reducing the dislocation density of the epitaxial layer, improving the crystal quality of the material and the performance of the device;

[0032] (3) gallium nitride high resistance layer 30, the gallium nitride high resistance layer 30 is fabricated on the low-temperature nucleation l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com