QLED containing noble metal nanomaterial and preparation method of QLED

A nanomaterial and precious metal technology, applied in the fields of organic semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as affecting luminous efficiency, non-radiative recombination of electrons and holes, affecting LSRP enhancement effect, etc., and the method is simple. easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] And, an embodiment of the present invention provides a method for preparing a QLED containing noble metal nanomaterials, comprising the following steps:

[0048] S01. Preparation of nano-noble metal core-shell composite materials;

[0049] S02. Adding the nano-noble metal core-shell structure composite material to at least one of hole injection material, hole transport material, quantum dot luminescent material, electron transport material, and electron injection material to prepare a corresponding functional layer material;

[0050] S03. Provide an anode, and sequentially deposit hole injection materials, hole transport materials, quantum dot luminescent materials, electron transport materials, and electron injection materials to obtain the corresponding hole injection layer, hole transport layer, quantum dot light emitting layer, and electron transport layer, an electron injection layer, and a cathode is formed on the electron injection layer.

[0051] Specifically, ...

Embodiment 1

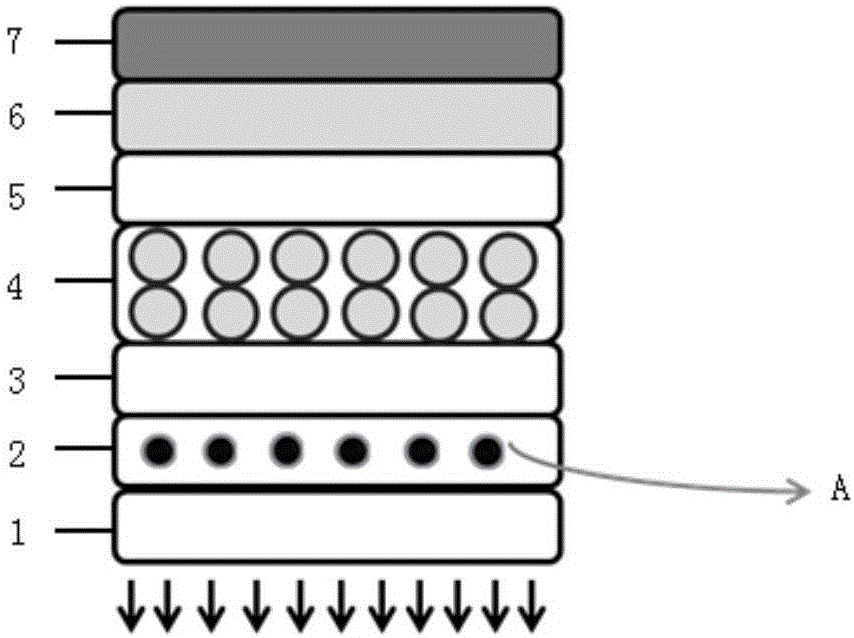

[0089] A kind of Ag@SiO 2 QLEDs with core-shell composite materials, such as figure 1 As shown, it includes an anode 1, a hole injection layer 2, a hole transport layer 3, a quantum dot light-emitting layer 4, an electron transport layer 5, an electron injection layer 6 and a cathode 7 that are stacked in sequence, wherein the hole injection layer 2 is doped with a nano-noble metal core-shell structure composite material A, the nano-noble metal core-shell structure composite material A is an Ag@SiO2 core-shell structure composite material, and the total weight of the hole injection layer 2 is 100% , the doping weight percentage of the nano-noble metal core-shell structure composite material A is 0.1%.

[0090] The above-mentioned QLED containing noble metal nanomaterials comprises the following steps:

[0091] S11. Ag@SiO 2 Synthesis of core-shell nanoparticles

[0092] S111. Preparation of silver nanoparticles: Pour 200 mL of ethylene glycol into a 250 mL three-necked rou...

Embodiment 2

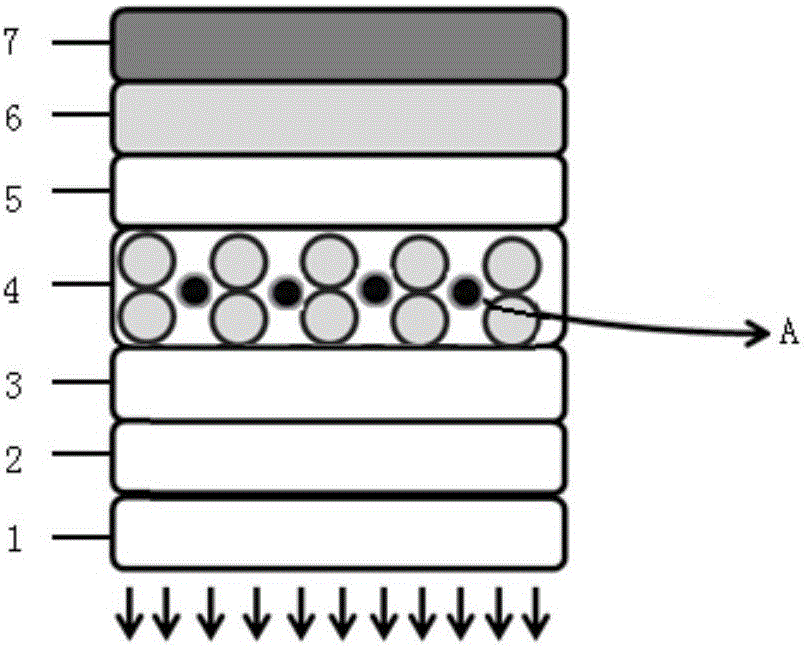

[0103] A QLED of Ag@C core-shell composite material, such as figure 2 As shown, it includes an anode 1, a hole injection layer 2, a hole transport layer 3, a quantum dot light-emitting layer 4, an electron transport layer 5, an electron injection layer 6 and a cathode 7 that are stacked in sequence, wherein the quantum dot light-emitting layer 4 doped with nano-noble metal core-shell structure composite material A, the nano-noble metal core-shell structure composite material is Ag@C core-shell structure composite material, and based on the total weight of the quantum dot light-emitting layer 4 as 100%, the The doping weight percentage of the nano-noble metal core-shell composite material A is 0.1%.

[0104] The above-mentioned QLED containing noble metal nanomaterials comprises the following steps:

[0105] S21. Synthesis of Ag@C core-shell nanoparticles:

[0106] Weigh 1.0g of glucose, put it into a beaker, then add 20ml of deionized water, stir magnetically, add 0.5ml of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com