An abrasive belt grinding and polishing combined machine tool and its application method

A combined machine tool and abrasive belt grinding technology, which is applied in the direction of abrasive belt grinders, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of low efficiency, equipment that cannot handle workpieces with surface flatness, and affects the work process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

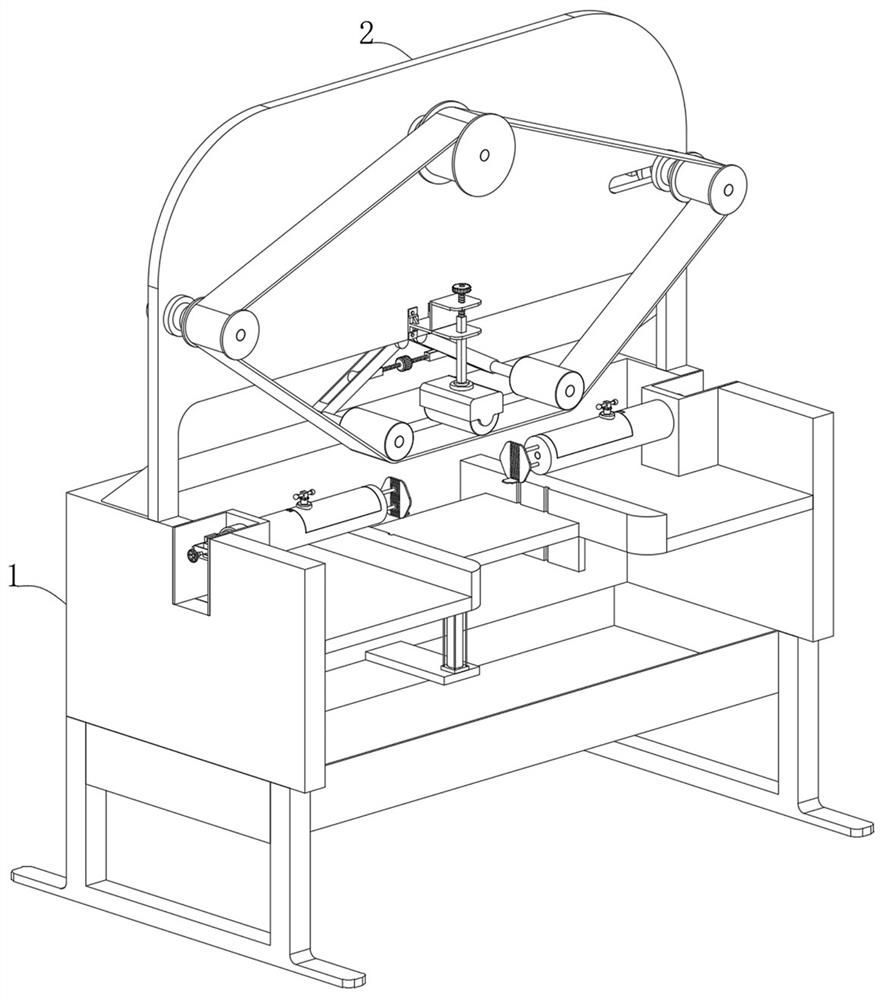

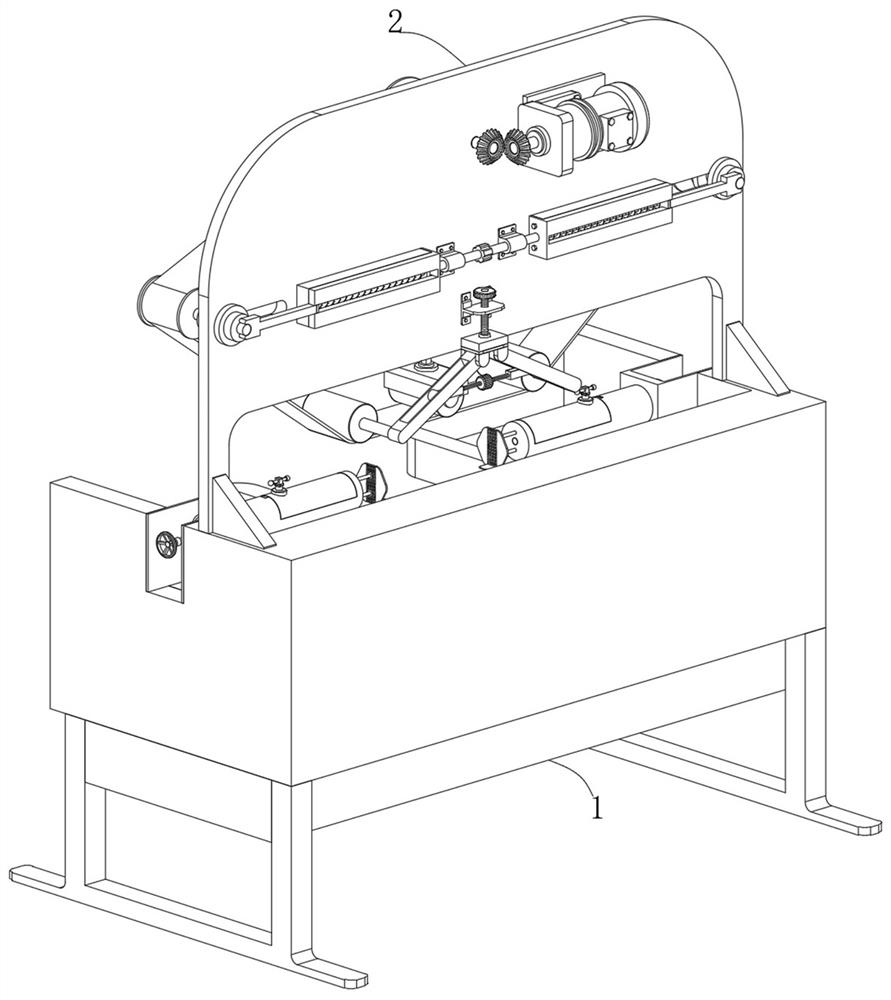

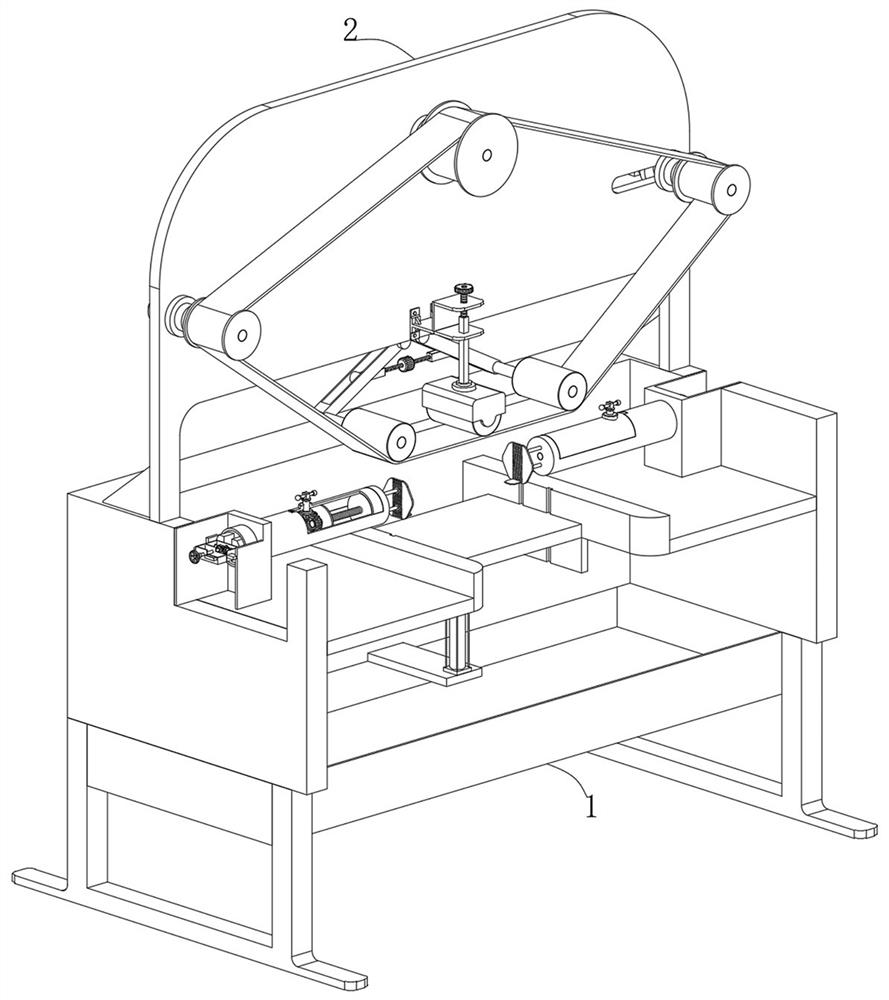

[0037] refer to Figure 1-Figure 10 : A combination abrasive belt grinding and polishing machine tool, comprising: a support mechanism 1 and a functional mechanism 2; the support mechanism 1 includes a base 101, a support component and a clamping component, and the establishment of the base 101 provides an installation basis for other functional components of the equipment to be set At the same time, it is convenient to install and set other functional components of the equipment. There are installation grooves at the bottom of the base 101 close to the center of the edges on both sides. The installation grooves are set up to facilitate the installation and setting of the installation frame 102. 101, the clamping part includes two installation frames 102, the installation frame 102 is set up to facilitate the installation and setting of other functional parts of the equipment, the two installation frames 102 are fixedly connected to the inside of the corresponding installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com