Edge grinding machine for plate rolling motor casing

An edge grinding machine and casing technology, applied in the direction of grinding machine, grinding frame, grinding bed, etc., can solve the problems of scratching employees' hands, unstable installation, and high power, so as to improve quality and avoid problems. Scratch, enhanced stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

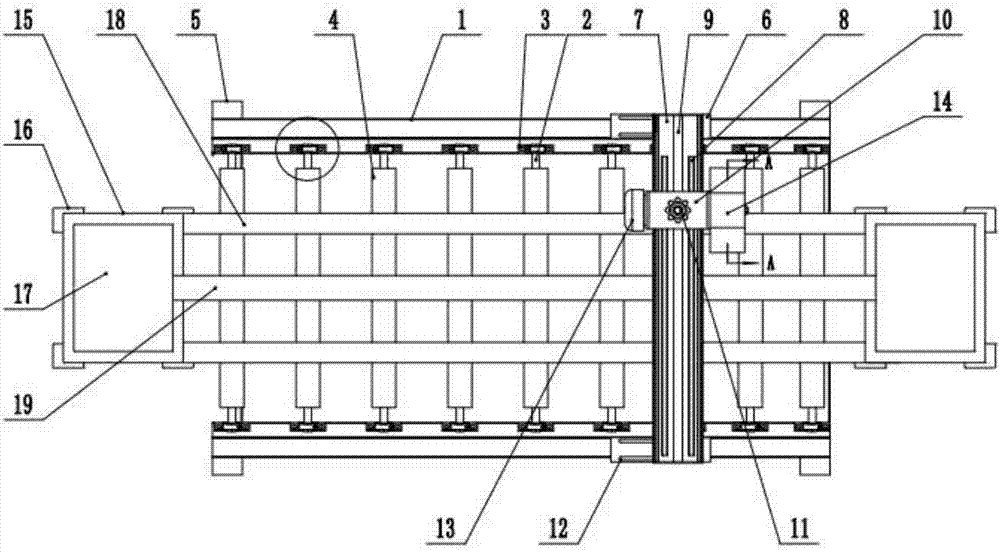

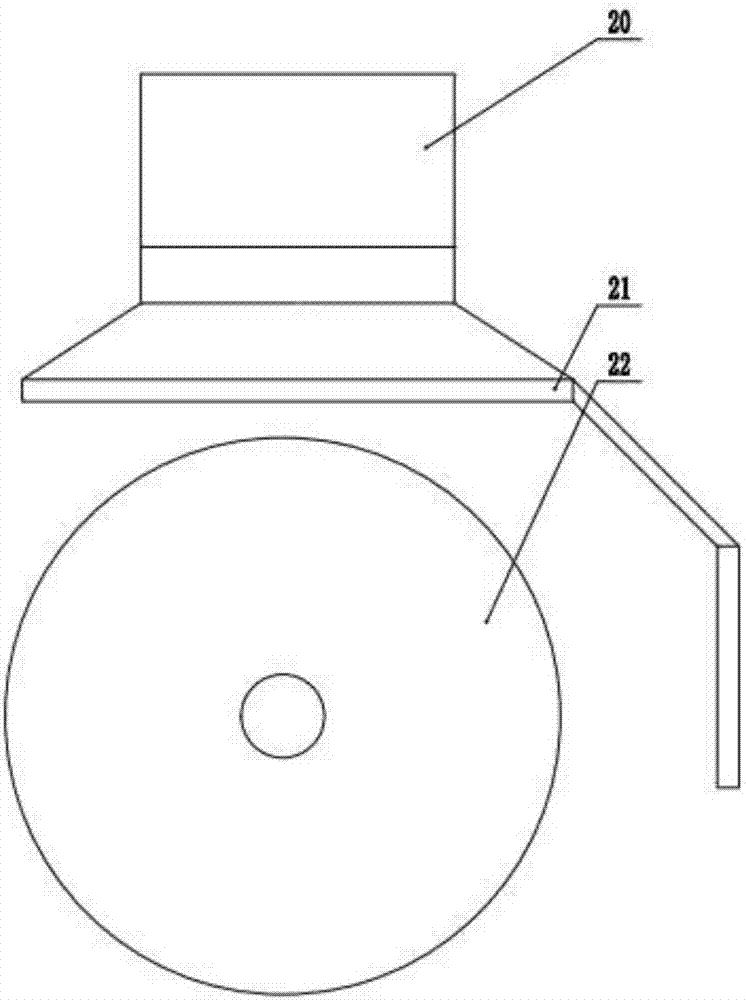

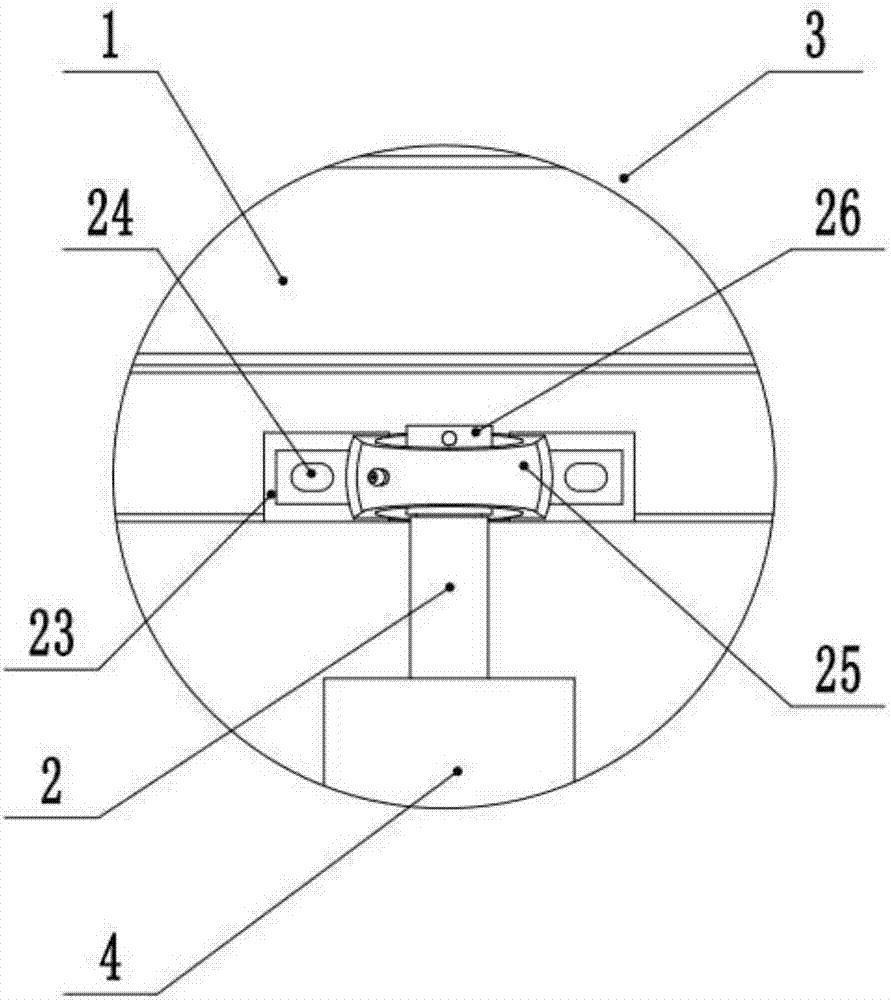

[0022] see figure 1 , a kind of edging machine for rolling plate motor casing, comprising edging machine body, described edging machine body is provided with frame 1, and described frame 1 is made of steel structure material, and the four corners of described frame 1 A fixed support frame A5 is set, and the fixed support frame A5 is fixedly connected to the frame 1 by welding. The inner side of the frame 1 is provided with a roller shaft rotating shaft 2, and the roller shaft rotating shaft 2 is connected to the frame 1. They are rotationally connected by the function of the fixed mounting frame 3, the roller shaft 4 is arranged on the roller shaft rotating shaft 2, the roller shaft 4 is fixedly connected with the roller shaft rotating shaft 2, and the frame 1 is fixedly installed plate 6, the fixed mounting plate 6 and the frame 1 are fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com