Glass product polishing device

A technology for glass products and polishing devices, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., and can solve the problems that the open end of glass products is difficult to be polished, and the degree of polishing and polishing is difficult to control precisely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is further described in detail by specific embodiments:

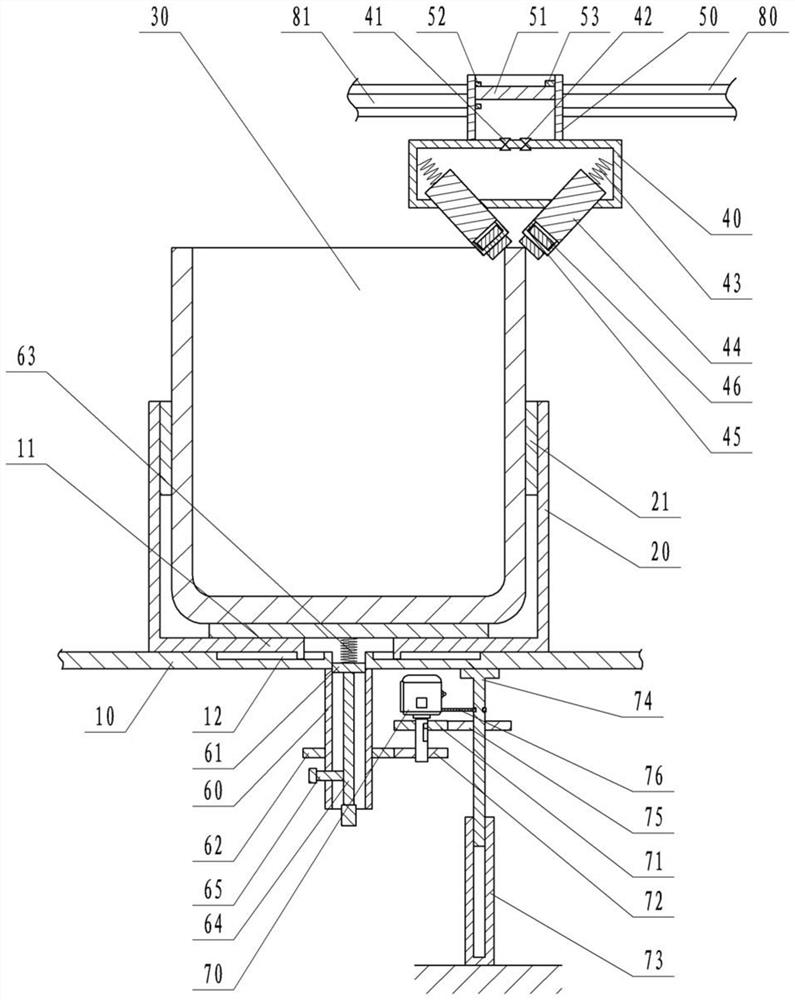

[0018] Reference numerals in the drawings include: workbench 10, sliding groove 11, L-shaped clamping plate 20, rubber pad 21, glass product 30, mounting block 40, one-way inflow valve 41, one-way outflow valve 42, elastic 43, grinding block 44, mounting frame 45, grinding roller 46, adjusting cylinder 50, adjusting plate 51, limit block 52, sleeve 60, piston 61, driven gear 62, reset piece 63, piston rod 64, threaded rod 65. Motor 70, first gear 71, driving gear 72, threaded barrel 73, screw 74, second gear 75, connecting rod 76, frame 80, guide rail 81.

[0019] This embodiment is basically as figure 1 Shown: a glass product polishing device, including a frame 80, a worktable 10, a rotating clamping mechanism, a polishing mechanism and a lifting mechanism. The side wall of the worktable 10 is provided with four sliding grooves 11, one end of the four sliding grooves is connected with each other,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com