Patents

Literature

30results about How to "Avoid over polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

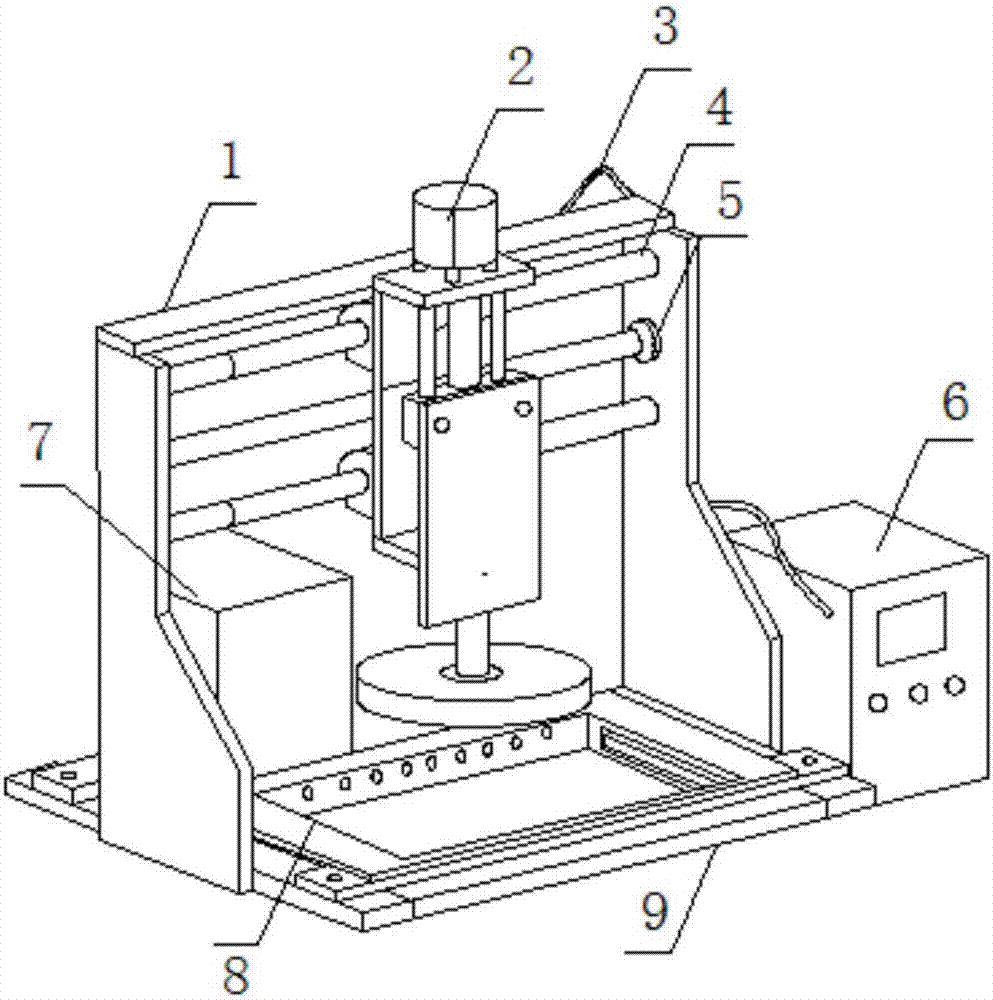

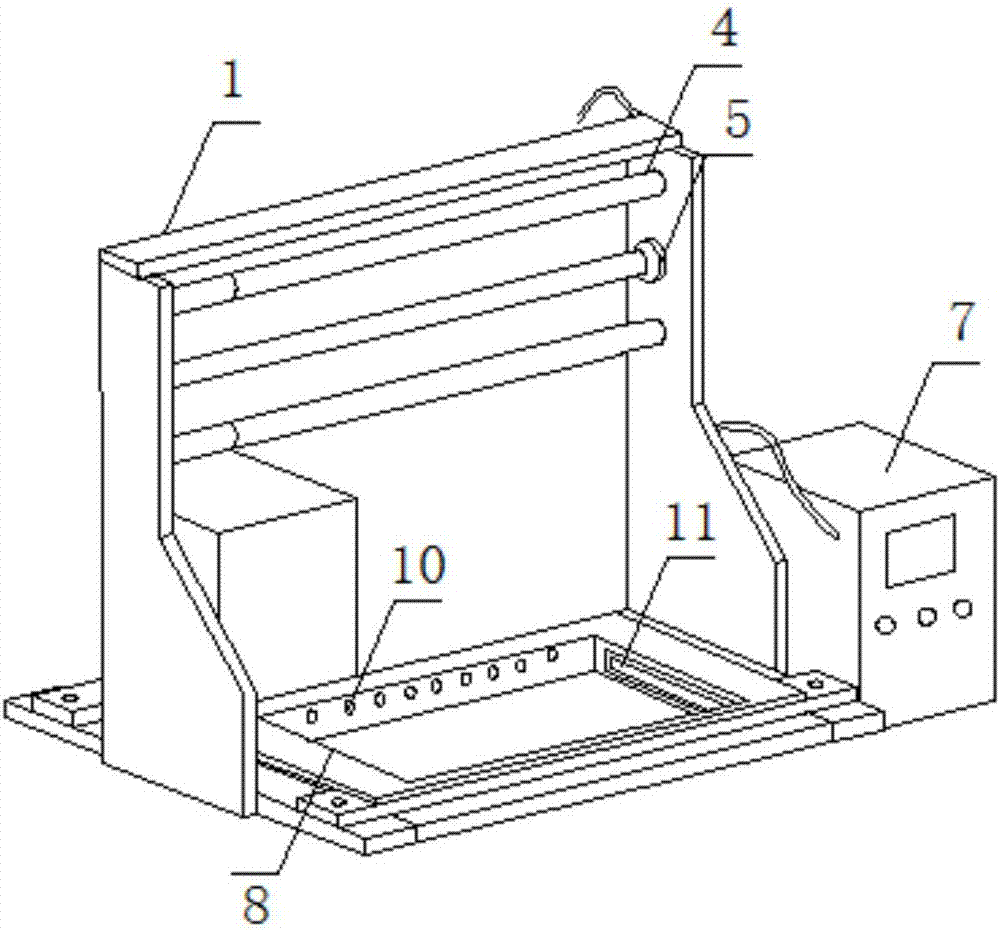

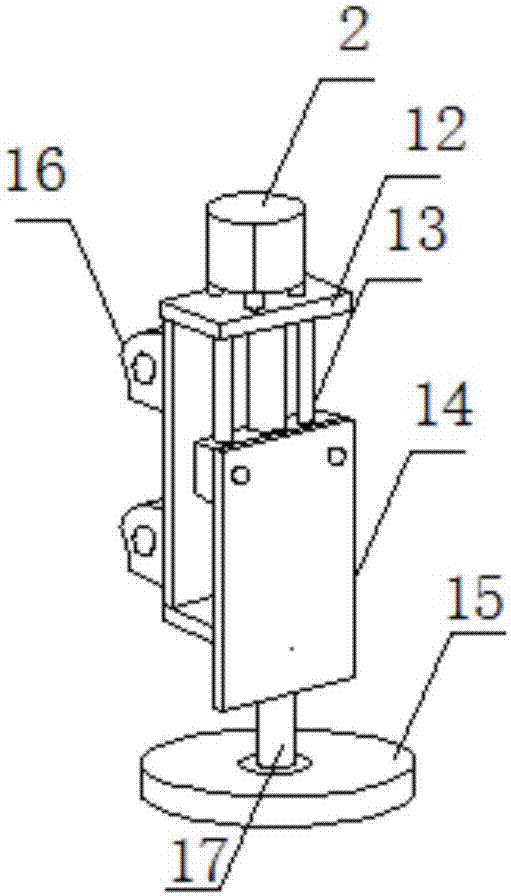

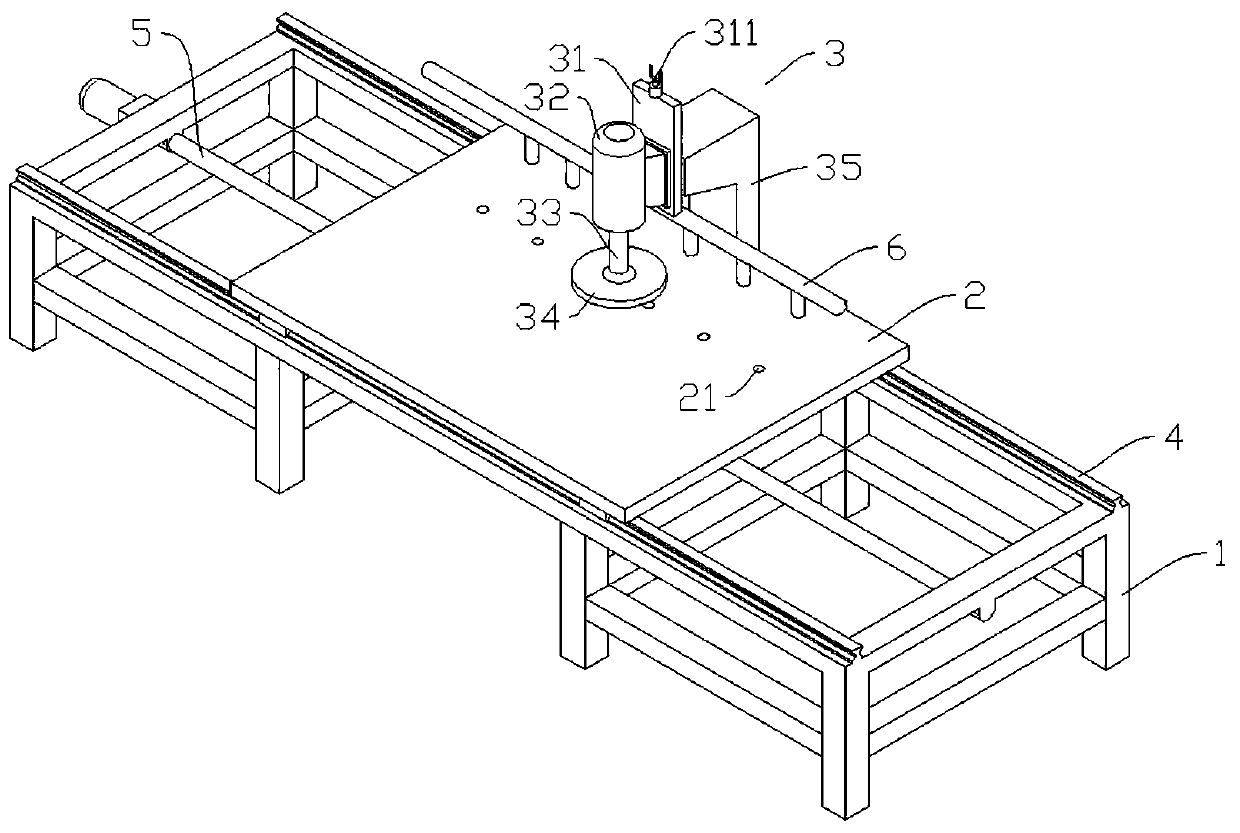

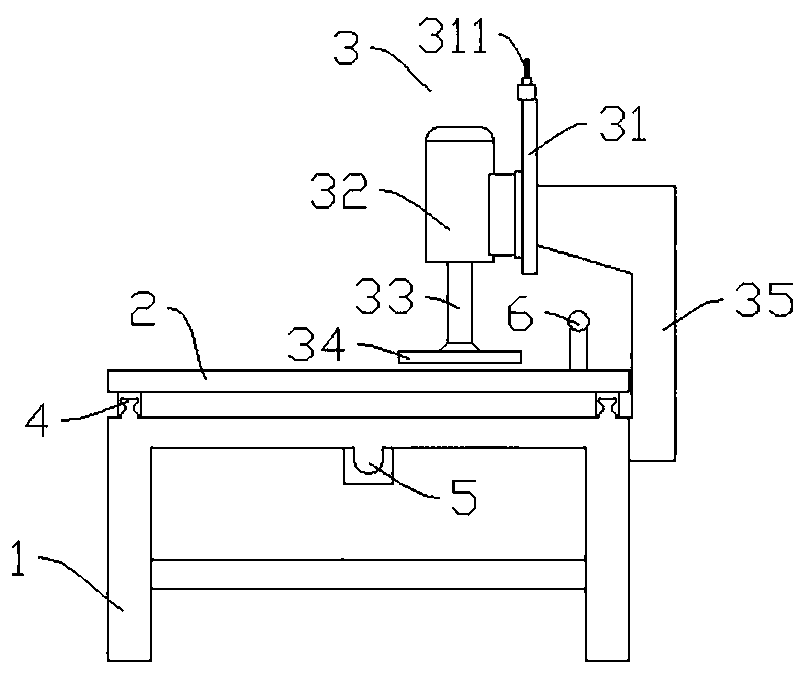

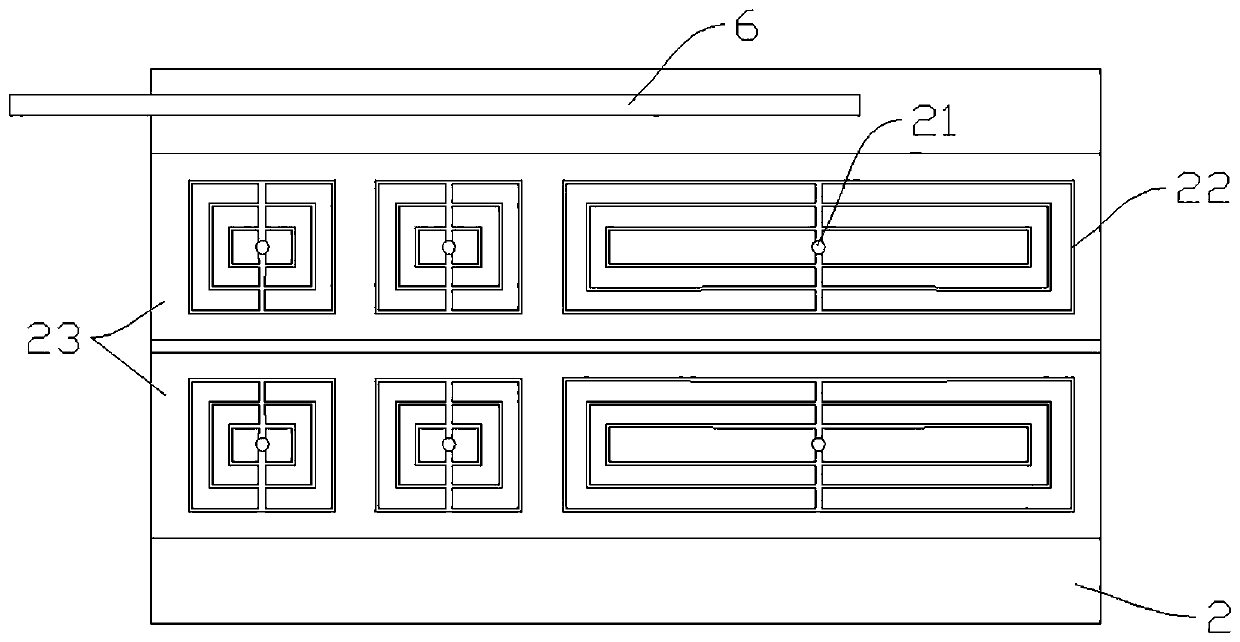

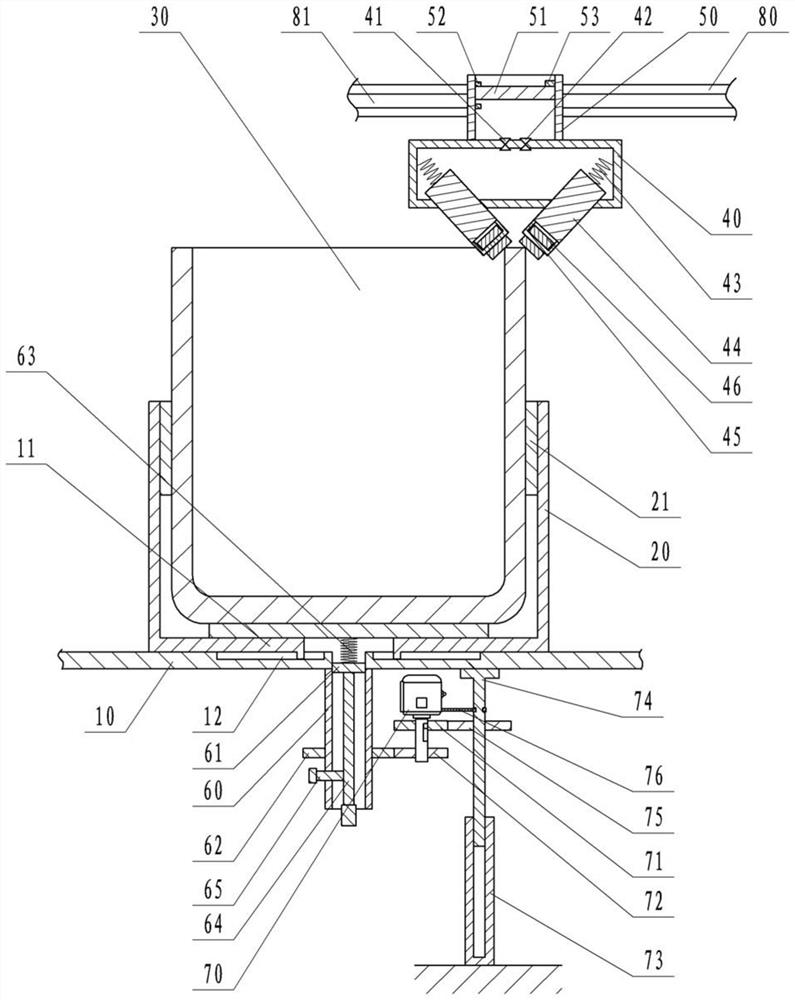

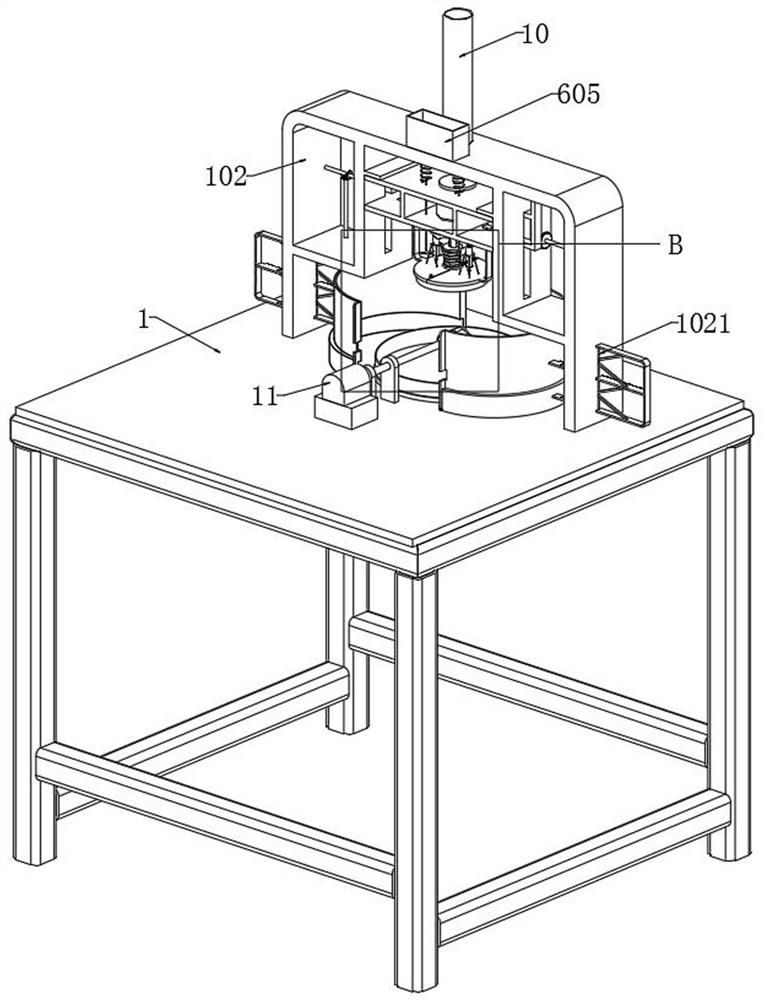

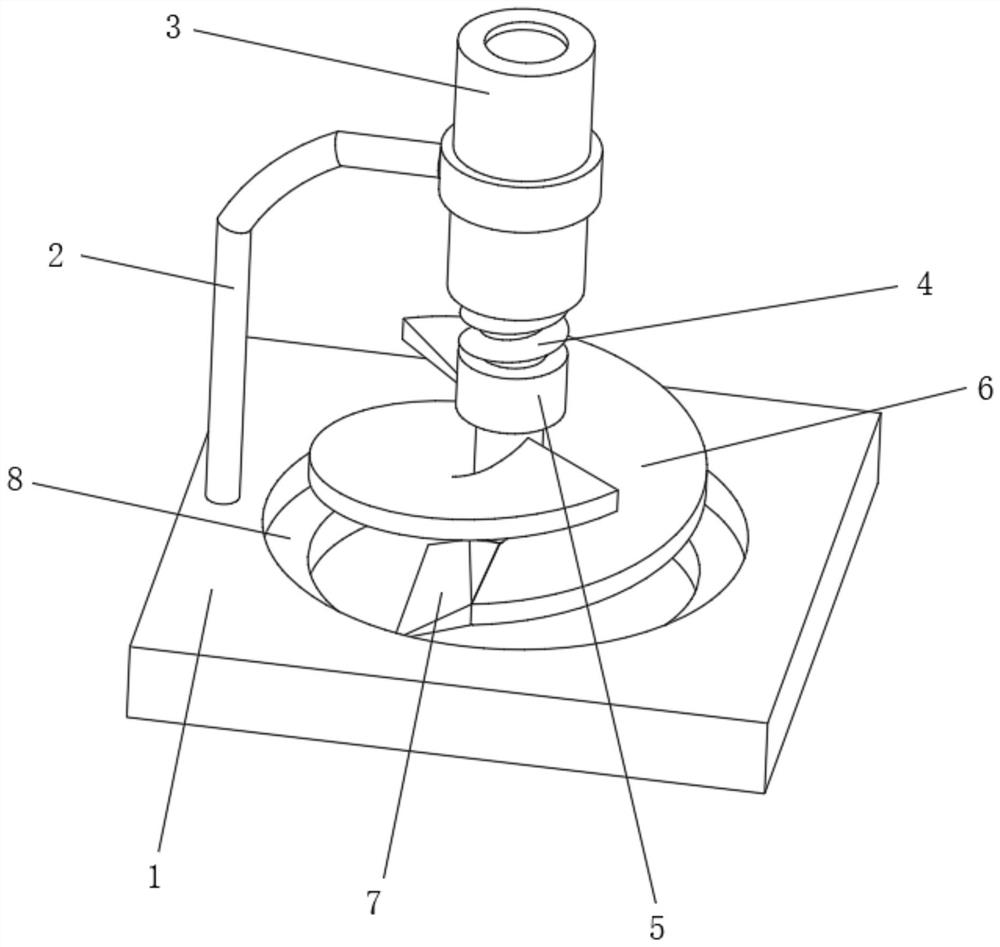

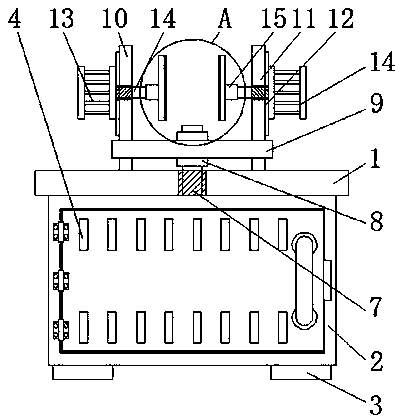

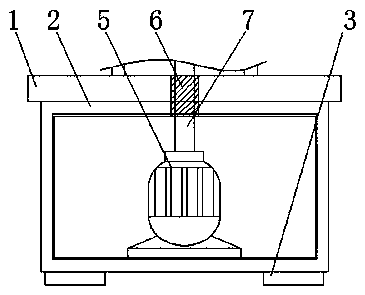

Polishing device for surfaces of building boards

InactiveCN107097142AWon't shakeAvoid affecting the polishing effectGrinding carriagesPolishing machinesEngineeringMechanical engineering

The invention discloses a polishing device for surfaces of building boards. The polishing device comprises a support, a polishing device body, a wire, sliding rods, a fulcrum bar, a control cabinet, a collection box, a fixing groove, a base, suction holes, clamping plates, a bearing frame, extending and retracting rods, a limiting clamping plate, a polishing disk, lantern rings, a rotating rod, an inner rod and a spring. The polishing device has the beneficial effects that the two sliding rods are arranged in the support, the polishing device body is arranged on the sliding rods through the lantern rings, the polishing device body can slide on the sliding rods to adjust the polishing position in the polishing process, and therefore uniform polishing is achieved. The suction holes are formed in the inner wall of one side of the fixing groove and communicate with a draught fan in the collection box, chippings produced in the polishing process can be absorbed into the collection box through the suction holes, and the situation that the chippings produced in the polishing process affect the polishing effect is avoided. By arranging the clamping plates which can extend and retract are arranged on the inner walls of the two sides of the fixing groove, the building boards are fixed through the extending and retracting clamping plates, and therefore it is ensured that the boards cannot shake in polishing.

Owner:柳州市文宇科技服务有限公司

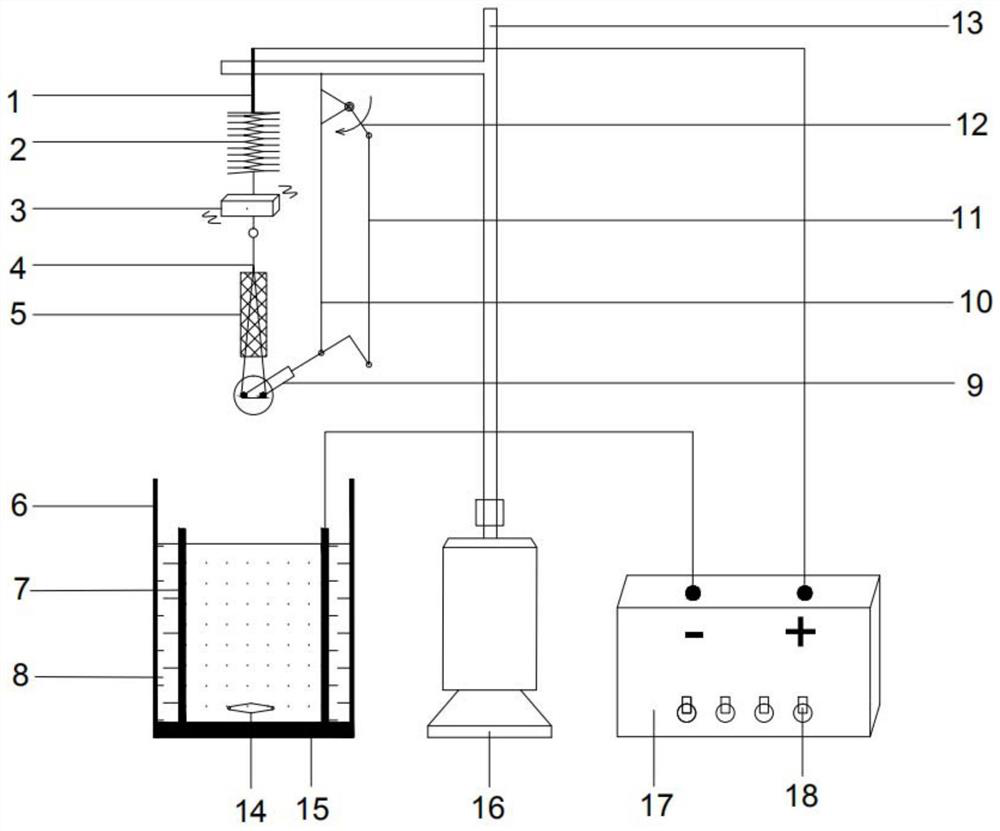

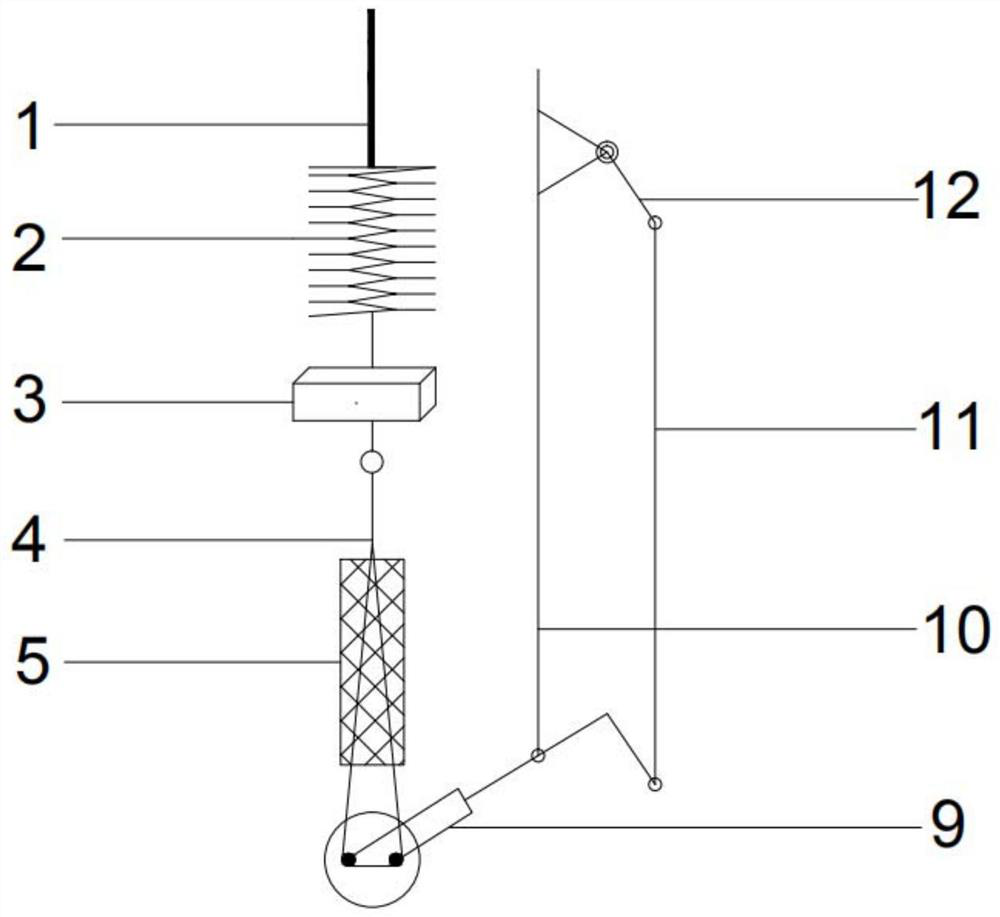

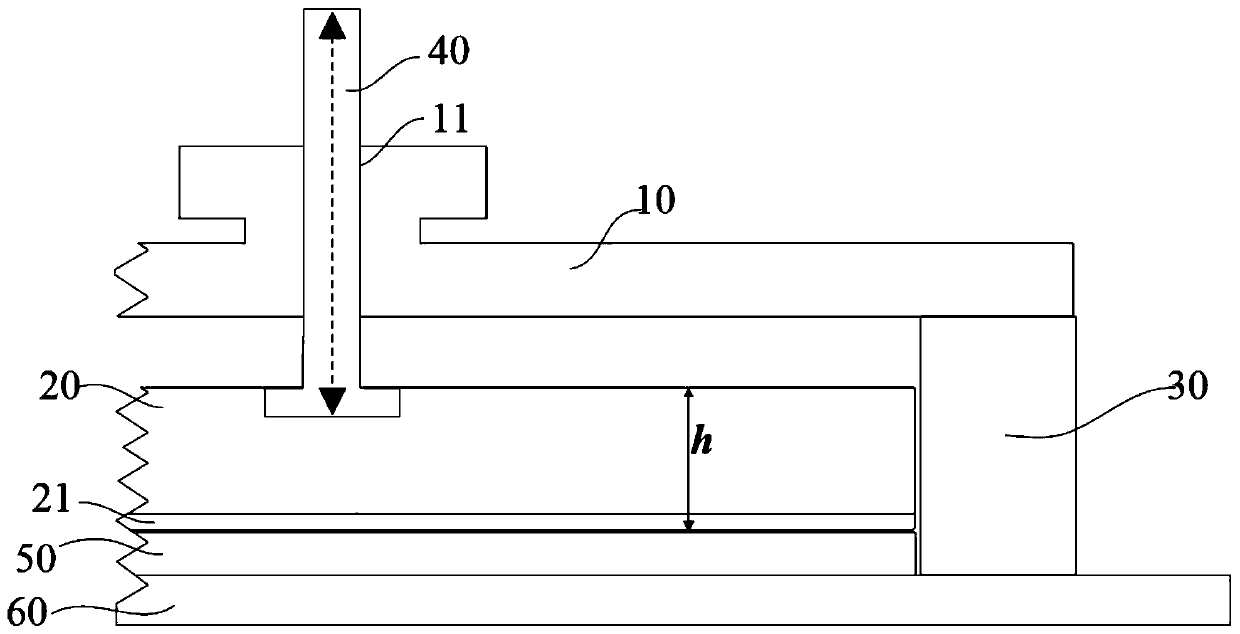

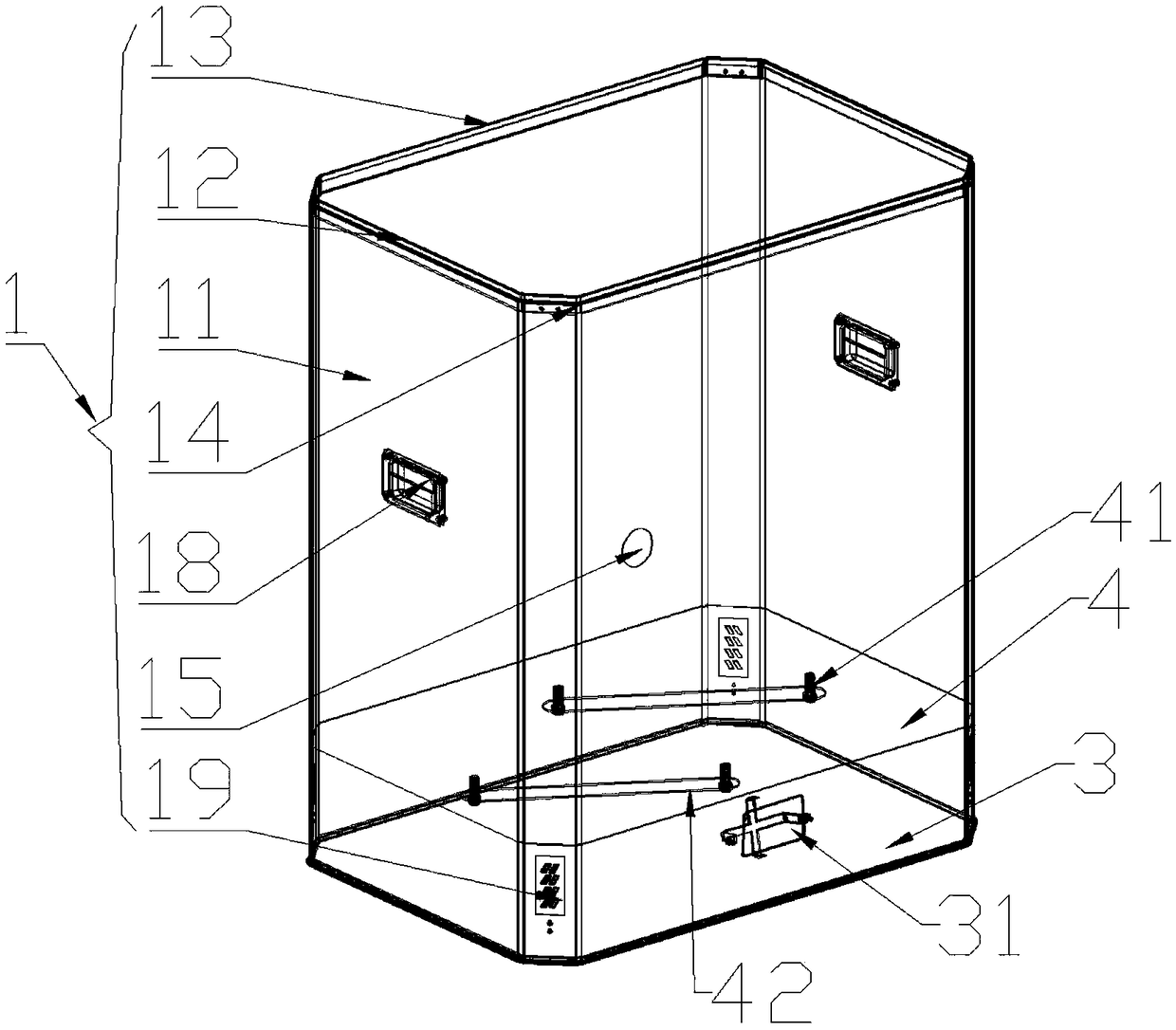

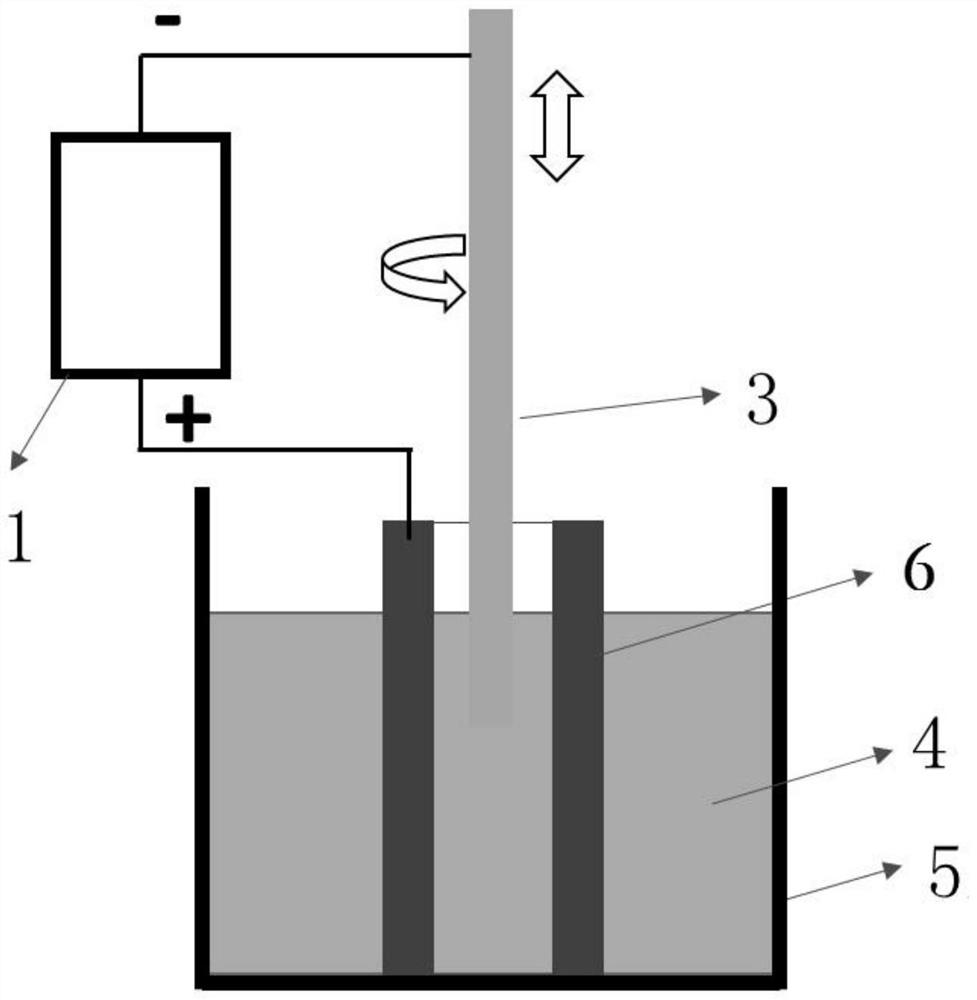

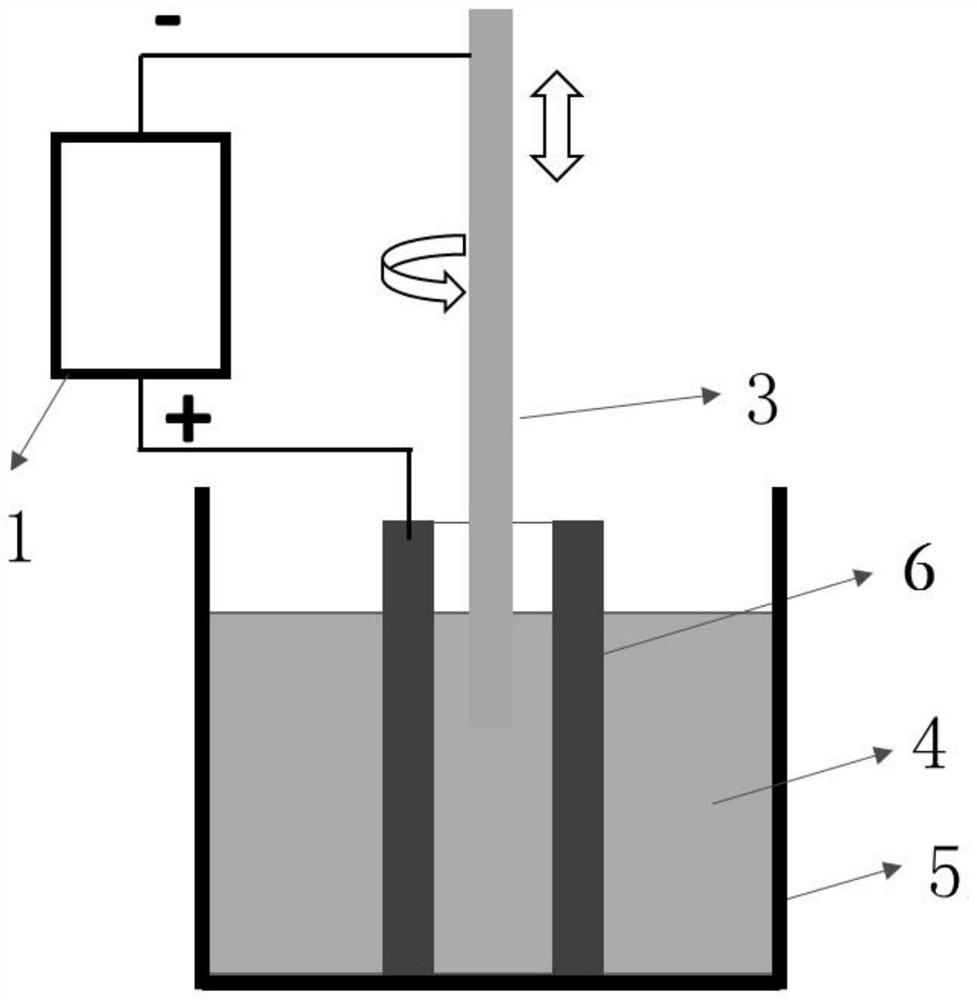

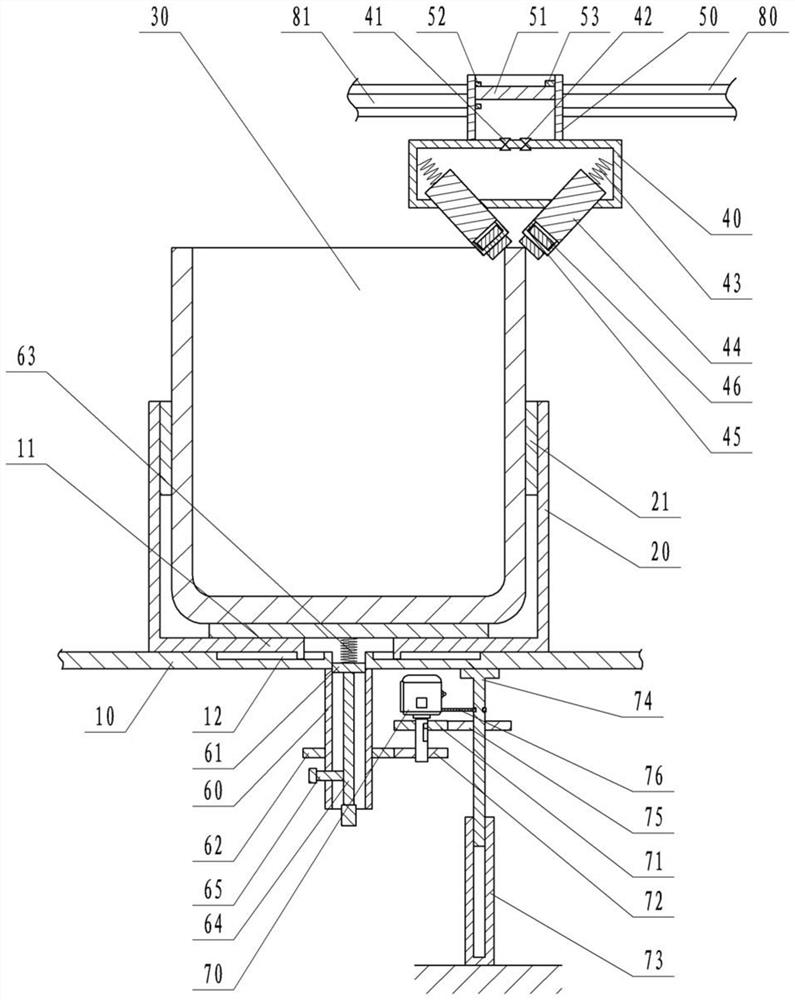

Electrochemical polishing device and polishing method for vascular stent

PendingCN111850669AQuality improvementAchieve conversionElectrolysis componentsEngineeringStructural engineering

The invention relates to the technical field of polishing, and discloses an electrochemical polishing device and polishing method for a vascular stent. The polishing device comprises a lifting assembly, an anode assembly, an adjusting assembly and a cathode assembly; the lifting assembly comprises a lifting frame and a first driving mechanism; the anode assembly comprises an anode, an elastic piece, a vibration source and a metal wire which are connected in sequence; the metal wire is used for mounting the vascular stent and has a contracted state and an expanded state, wherein in the contacted state, the metal wire is movably connected with the vascular stent, and in the expanded state, the metal can be fixedly connected with the vascular stent; the adjusting assembly comprises a first supporting frame and a second driving mechanism, and the first supporting frame is connected with the metal wire and provided with a vertical position where the metal wire can be in the contracted stateand a horizontal position where the metal wire can be in the expanded state; and the cathode assembly is arranged below the anode assembly and comprises a polishing barrel containing a polishing solution and a cathode arranged in the polishing barrel. The electrochemical polishing device is simple and compact in structure, convenient to operate, uniform in polishing, good in polishing effect andhigh in efficiency.

Owner:INNER MONGOLIA UNIV OF TECH

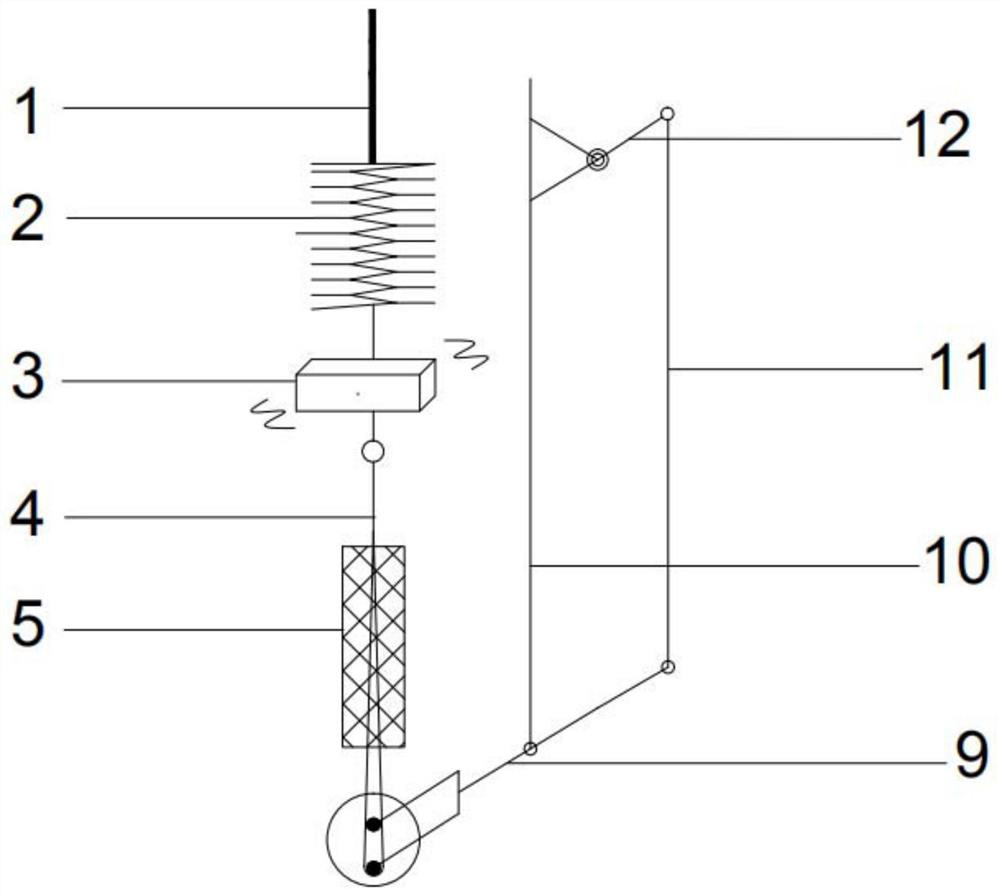

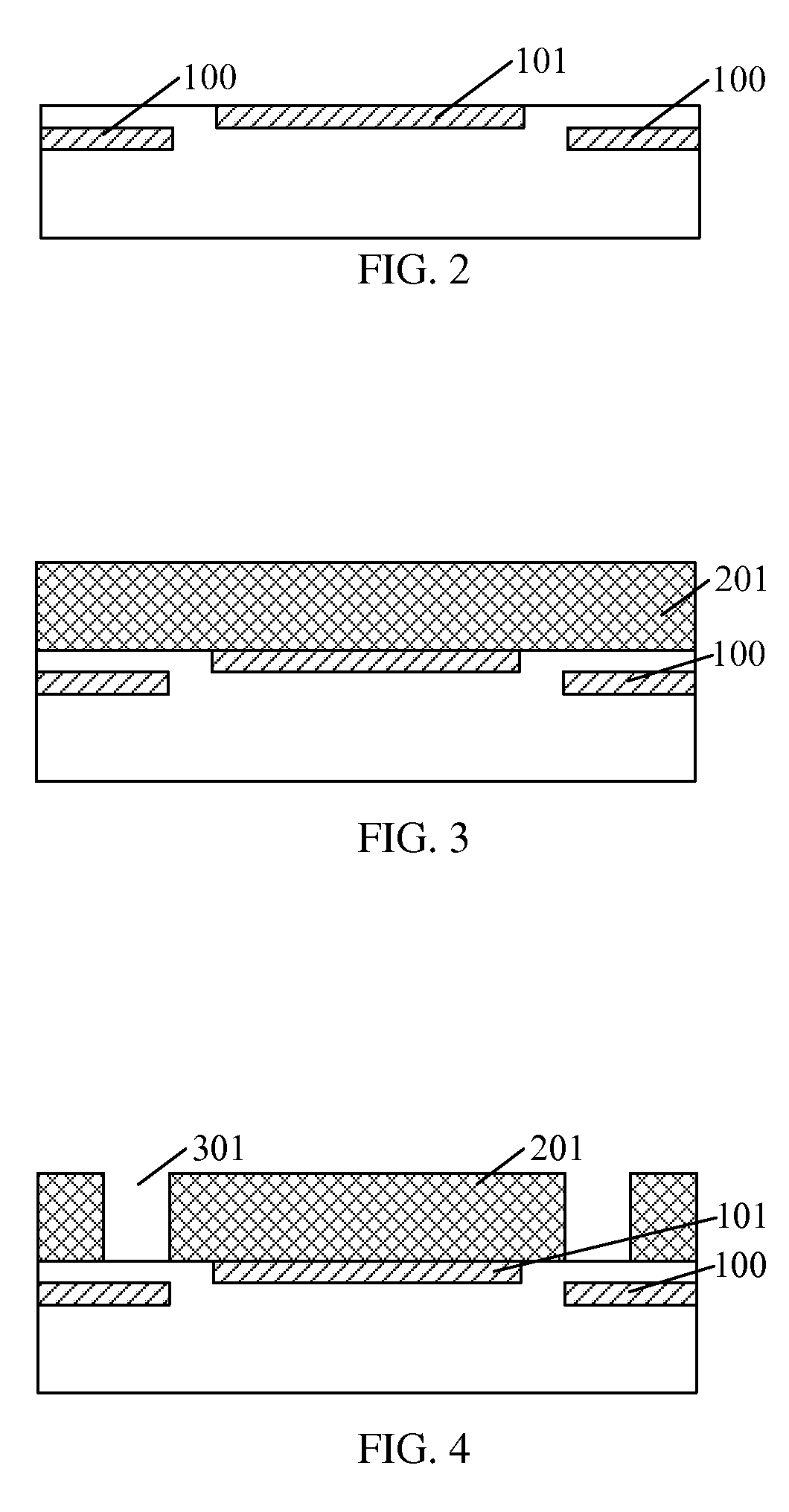

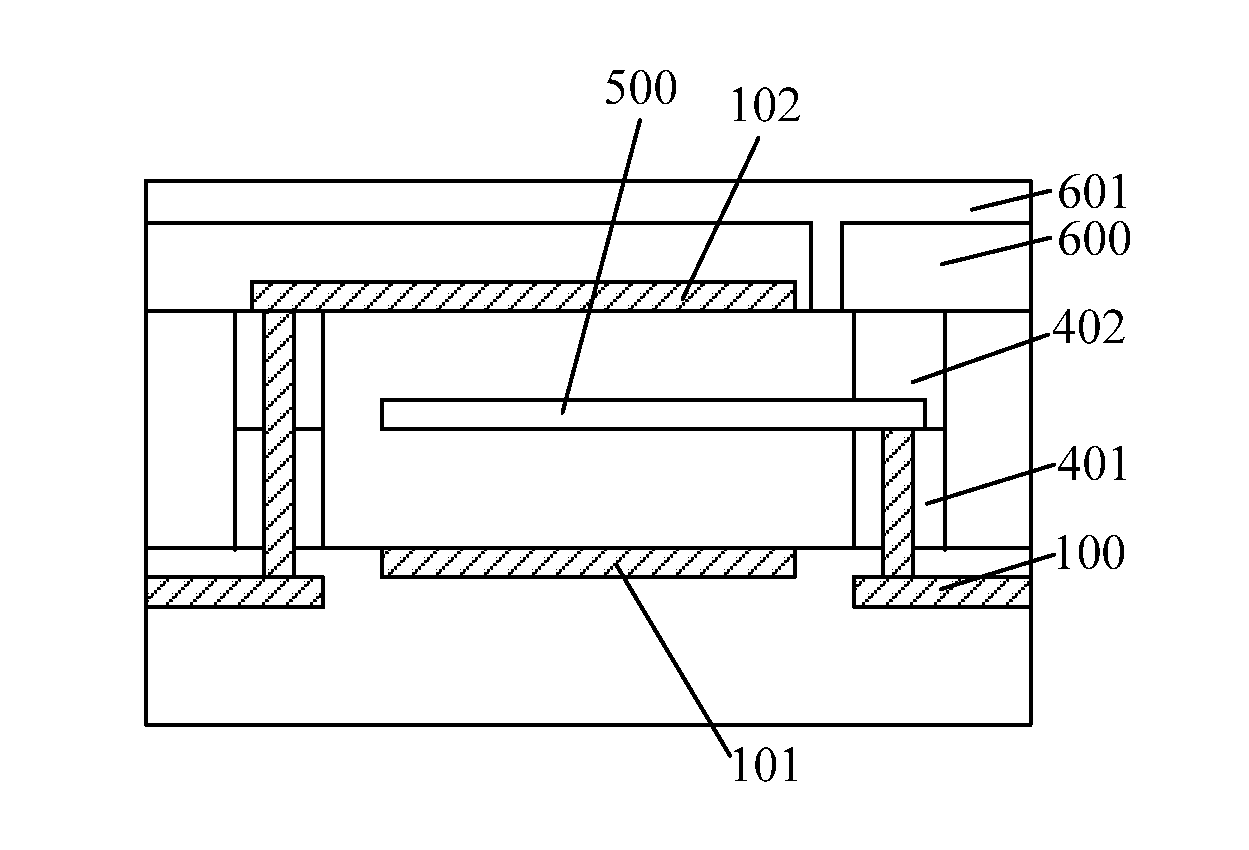

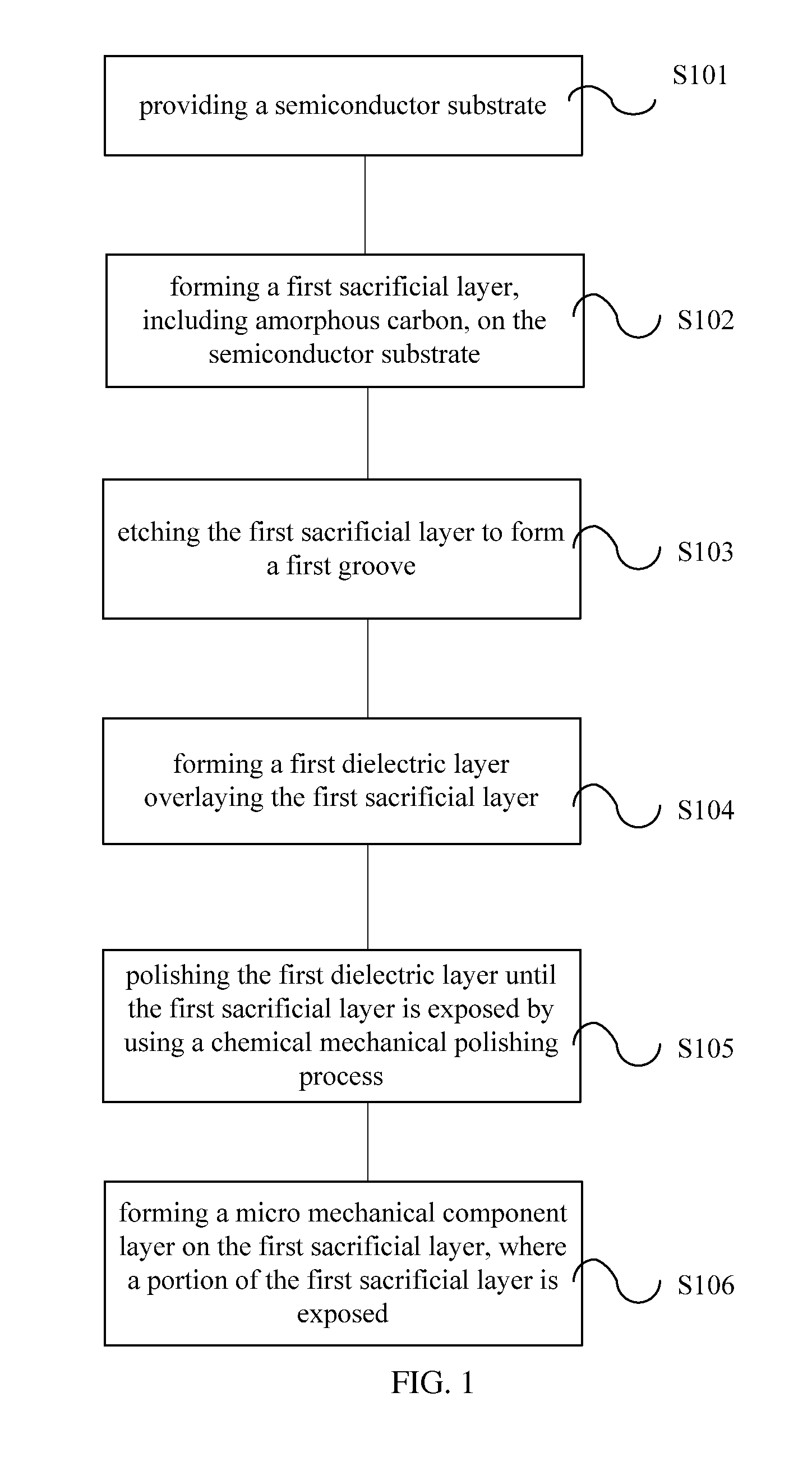

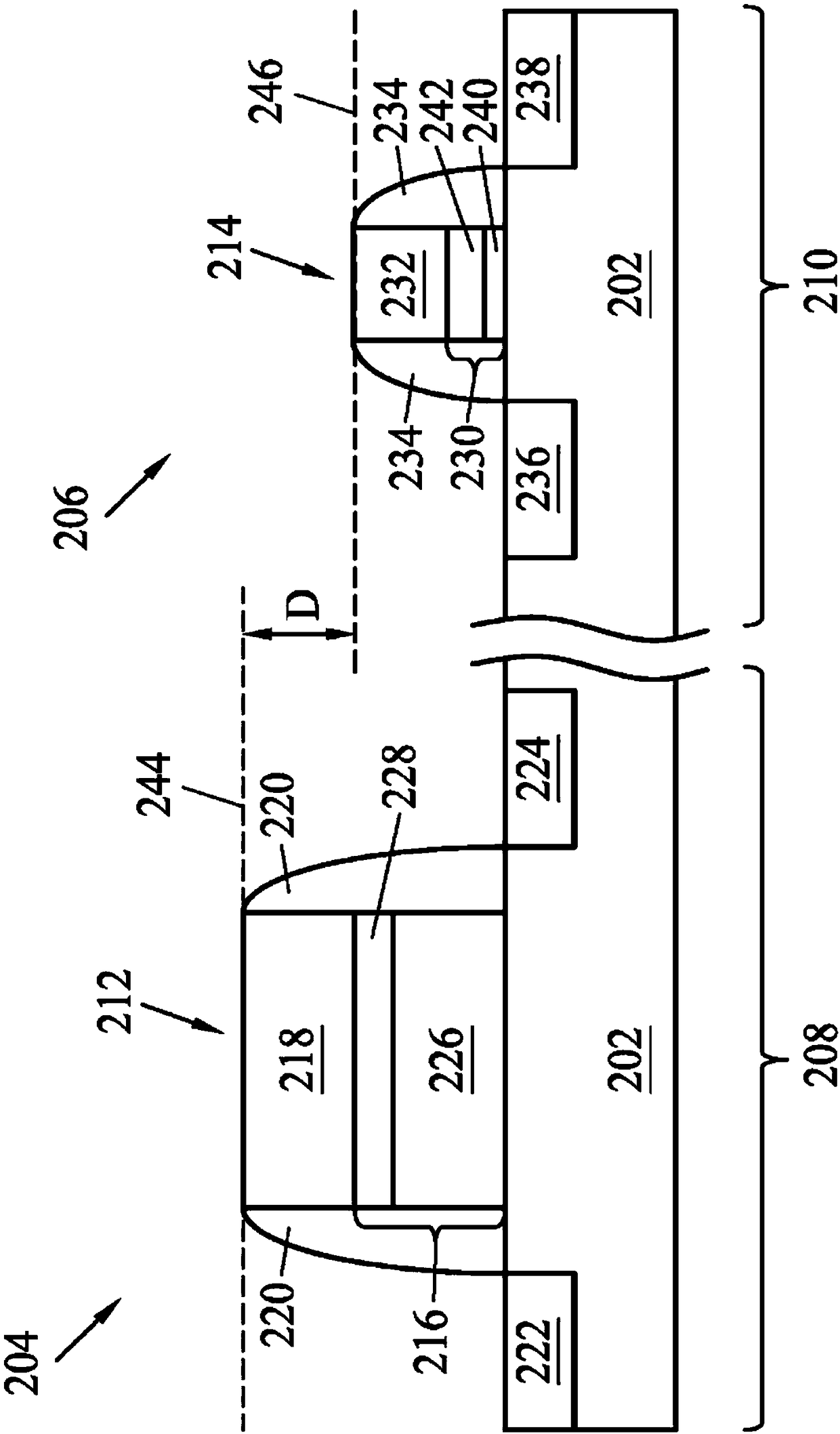

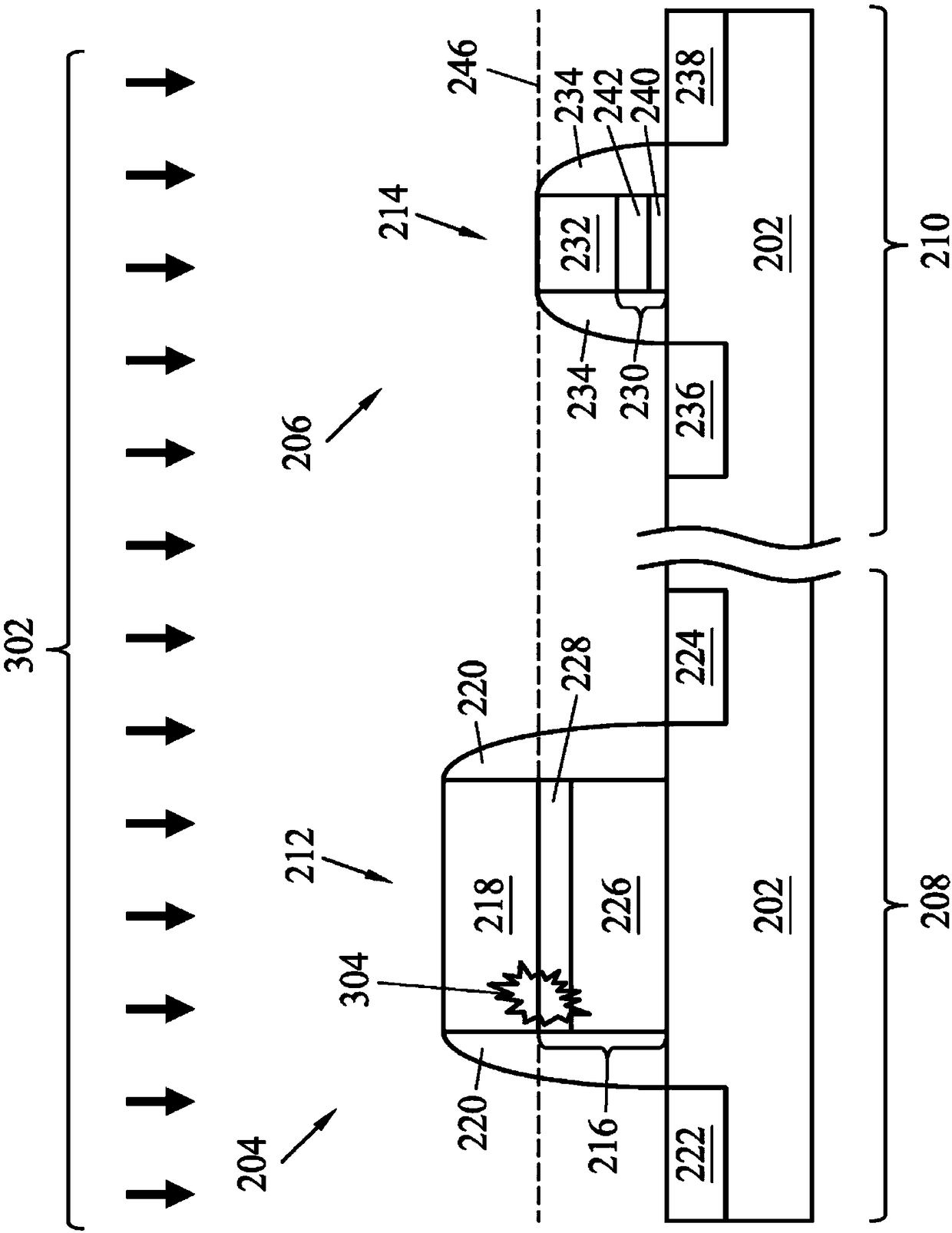

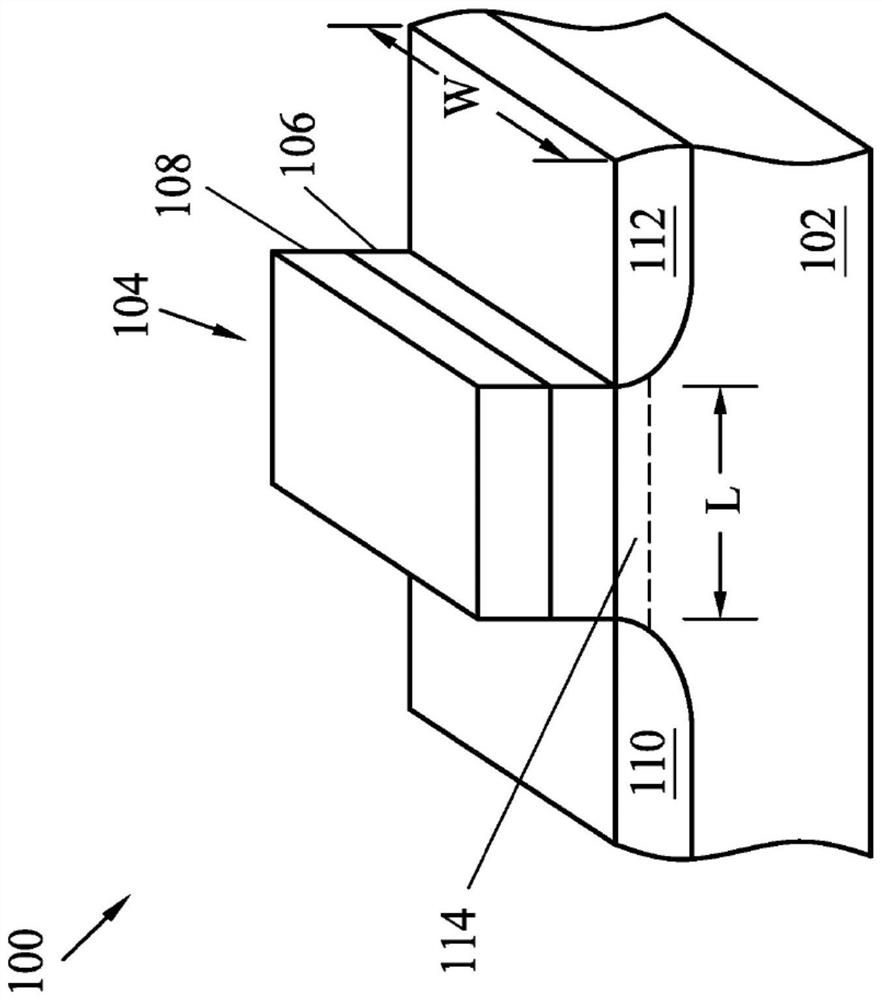

Method for manufacturing MEMS device

ActiveUS8877537B2Increase polishing speedAvoid over polishingAcceleration measurement using interia forcesImpedence networksInterconnectionDielectric layer

Owner:ZHEJIANG JUEXIN MICROELECTRONICS CO LTD

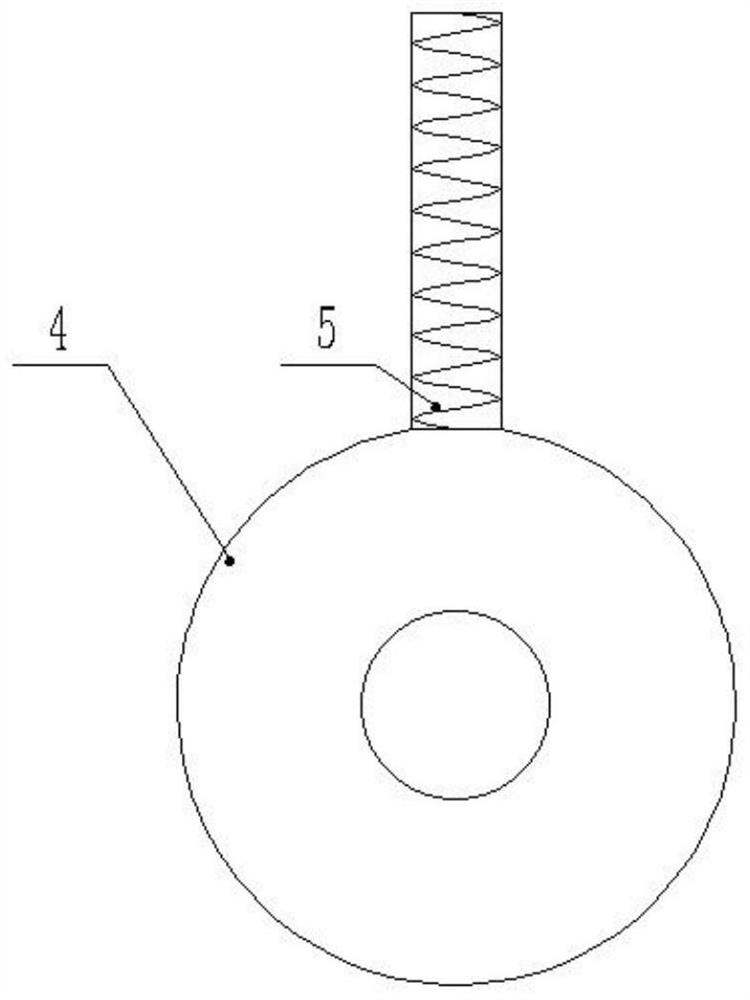

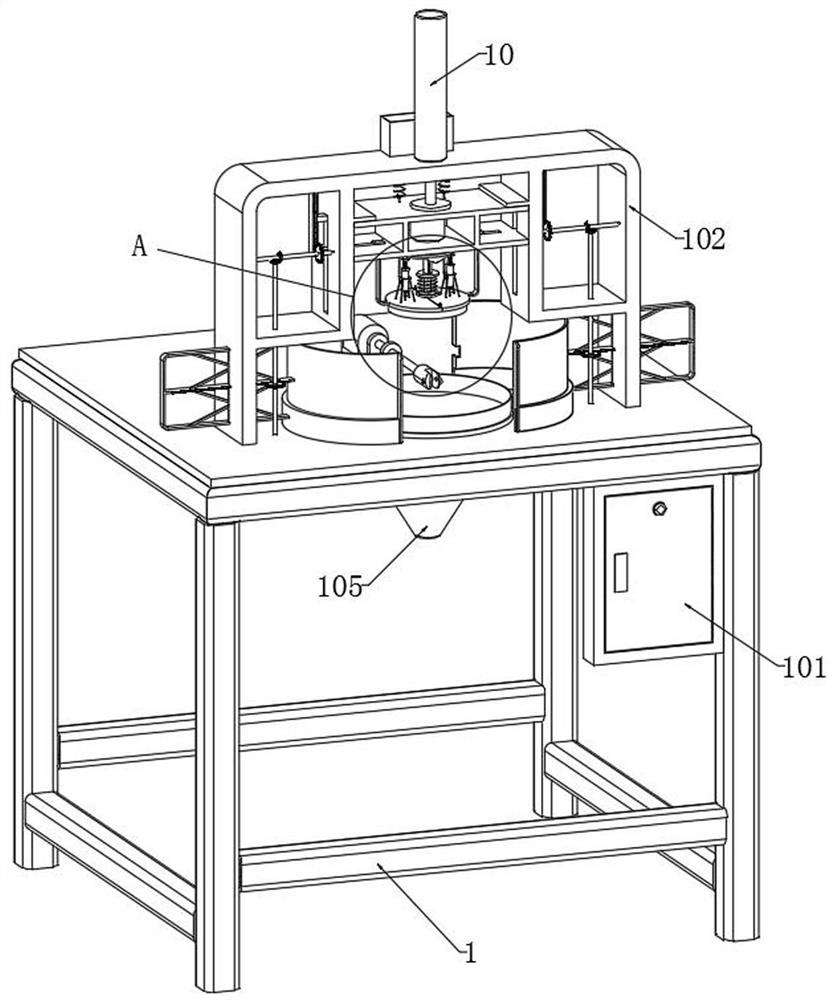

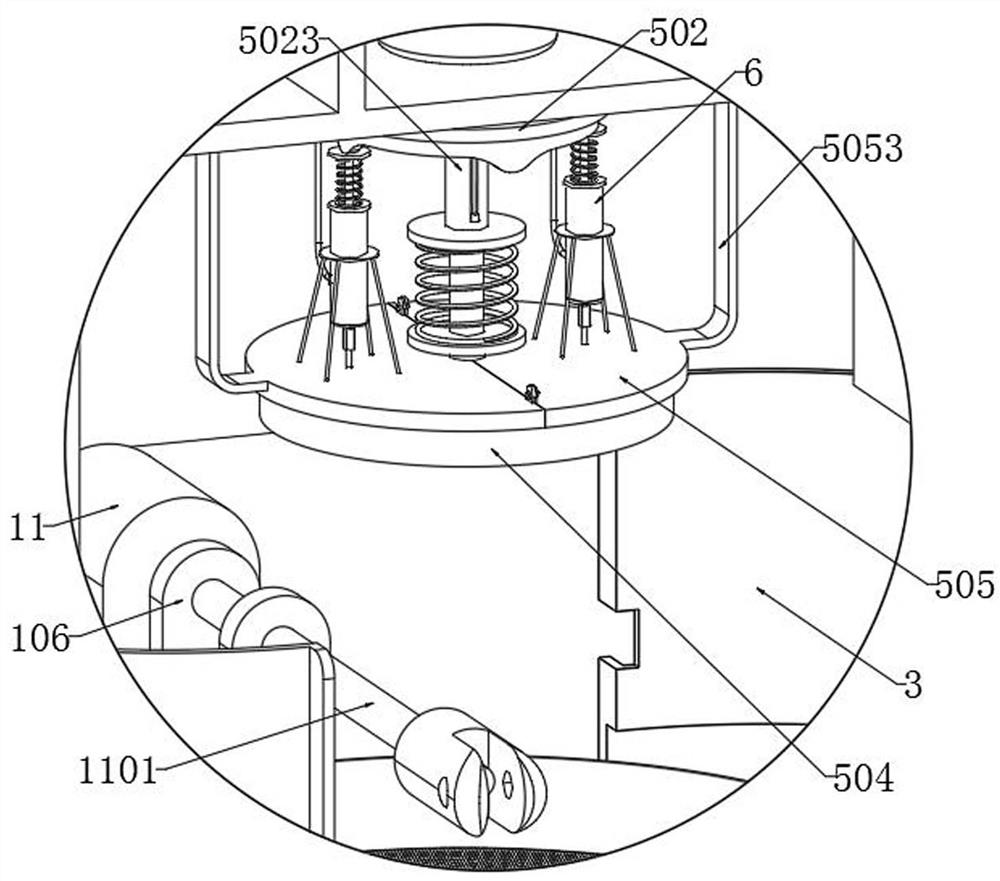

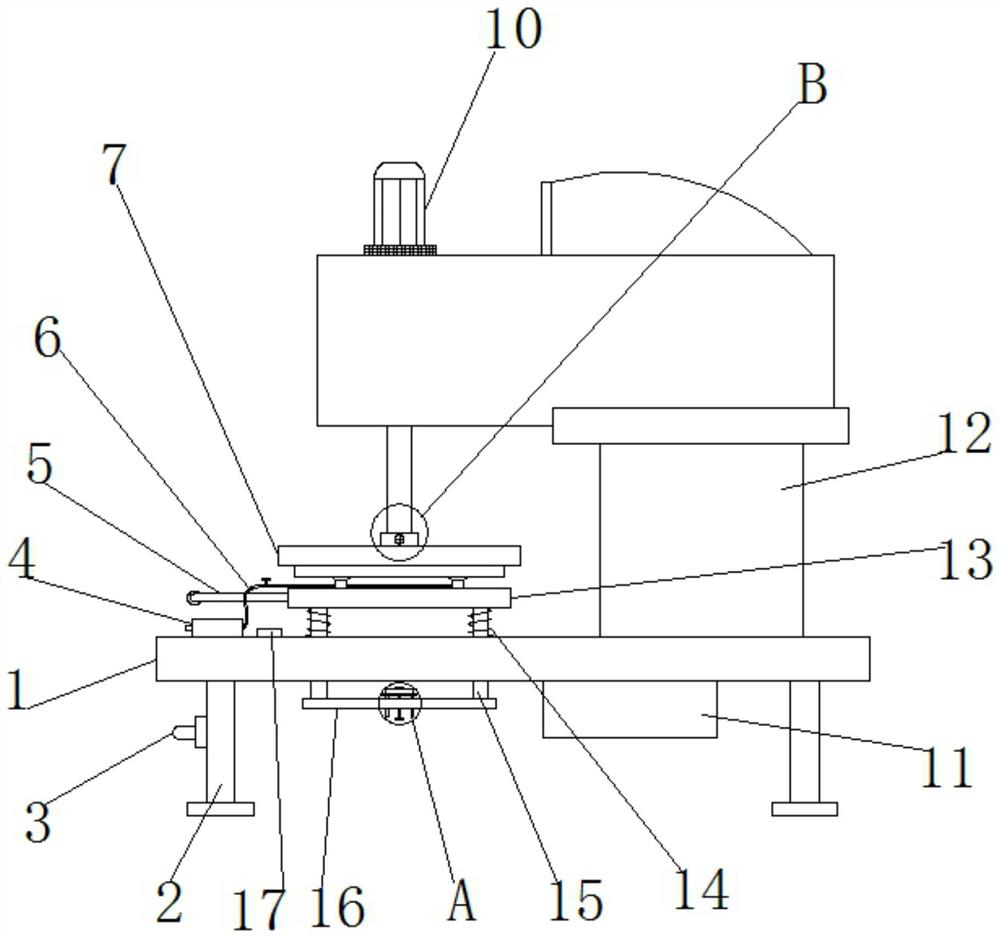

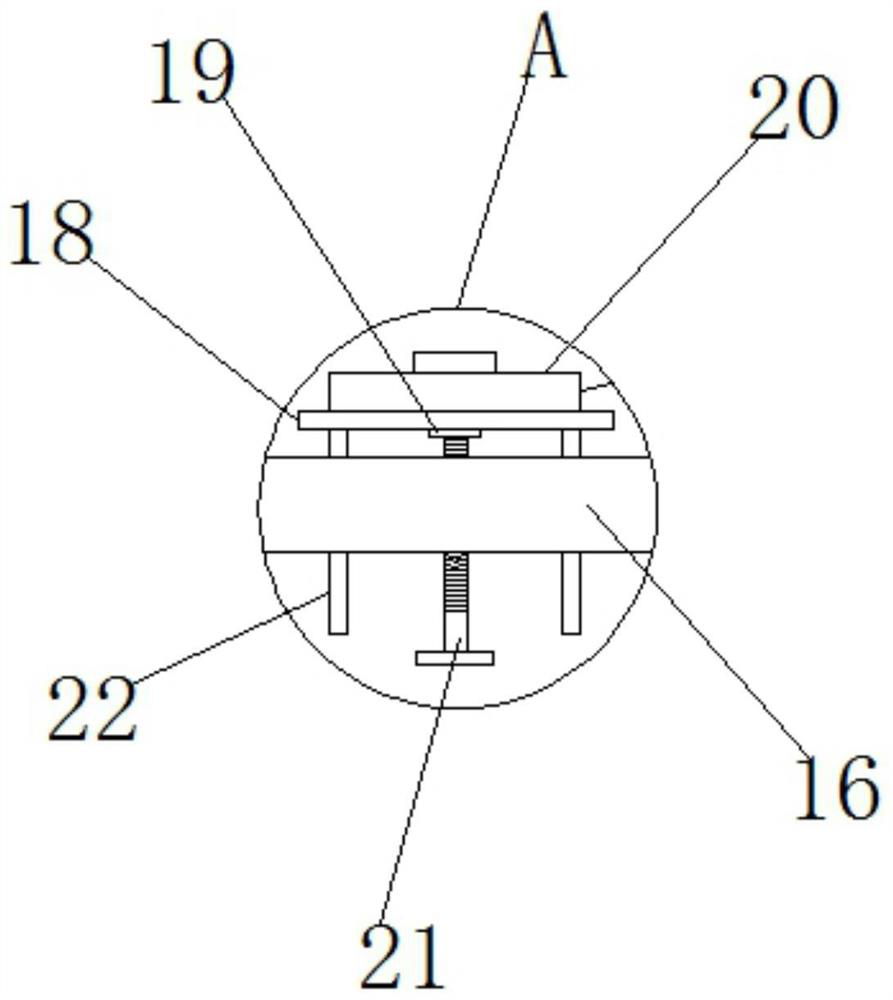

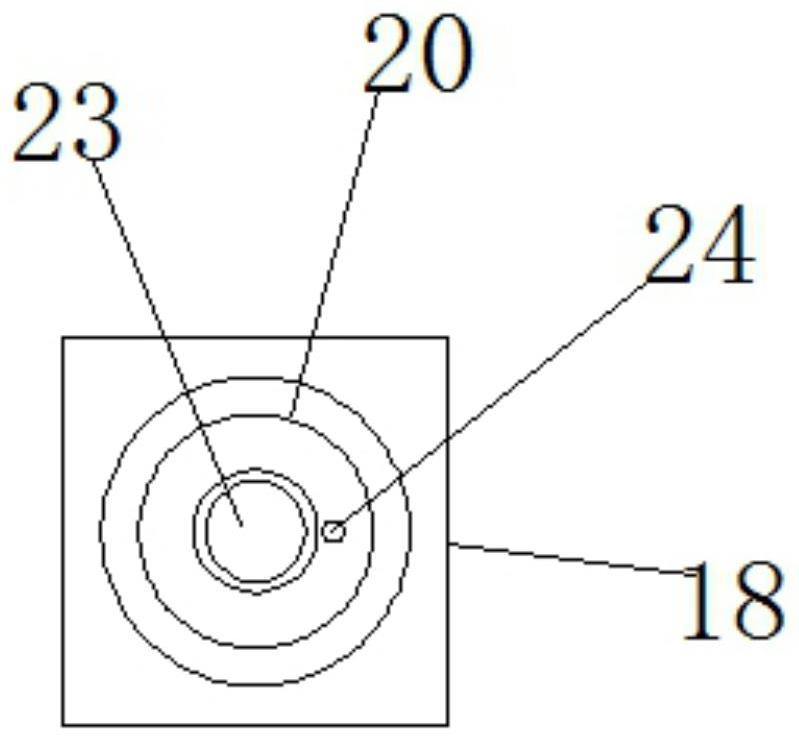

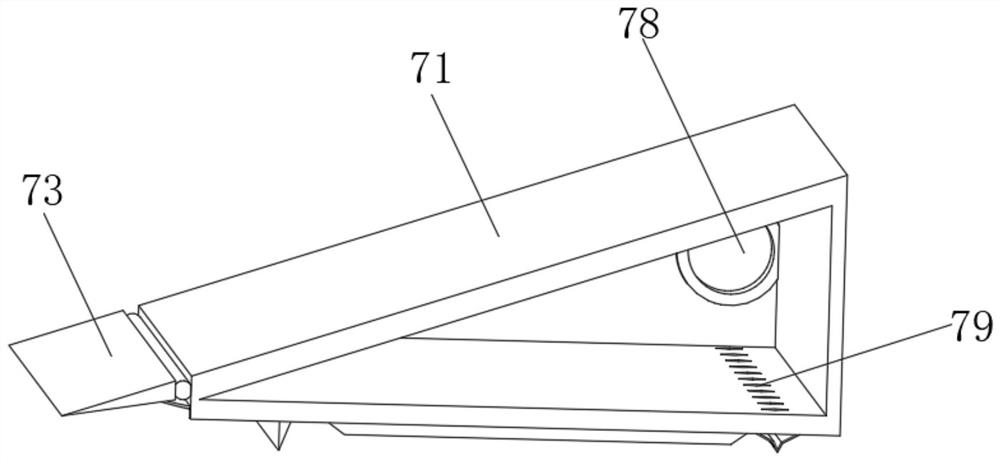

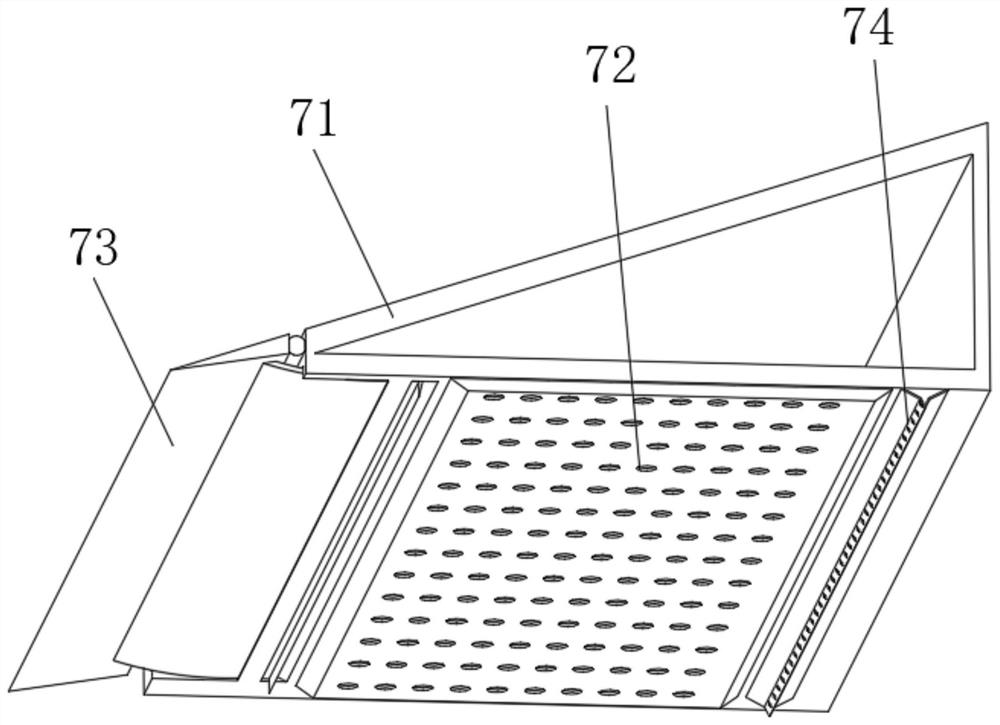

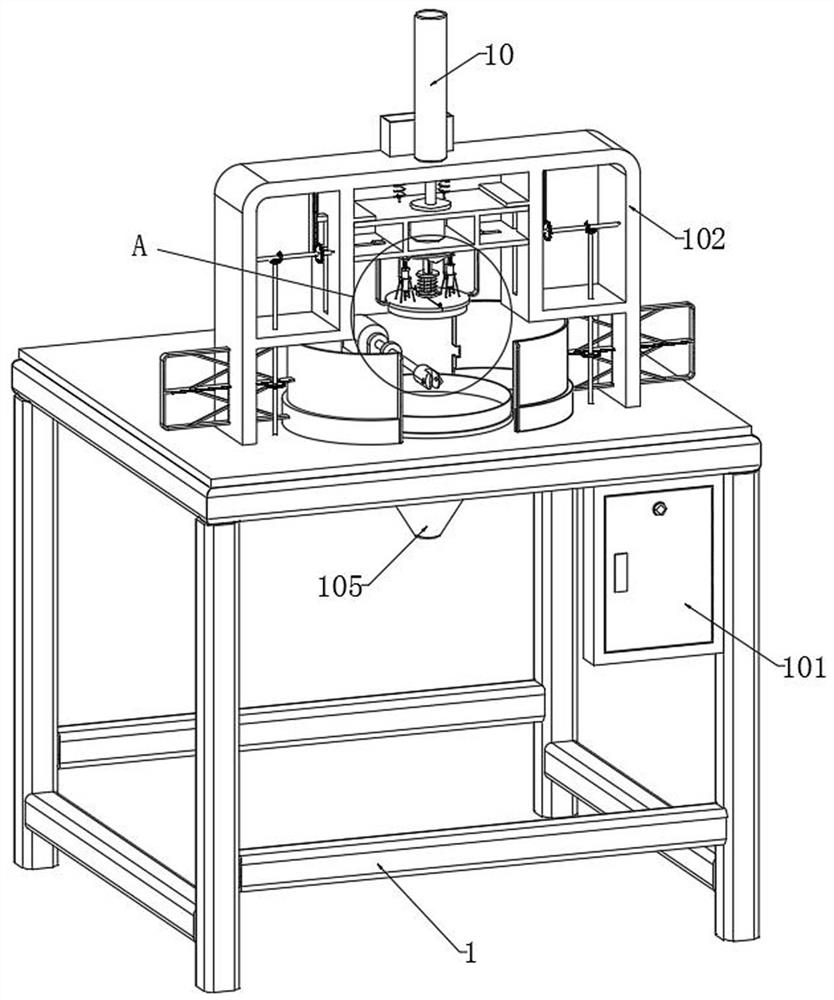

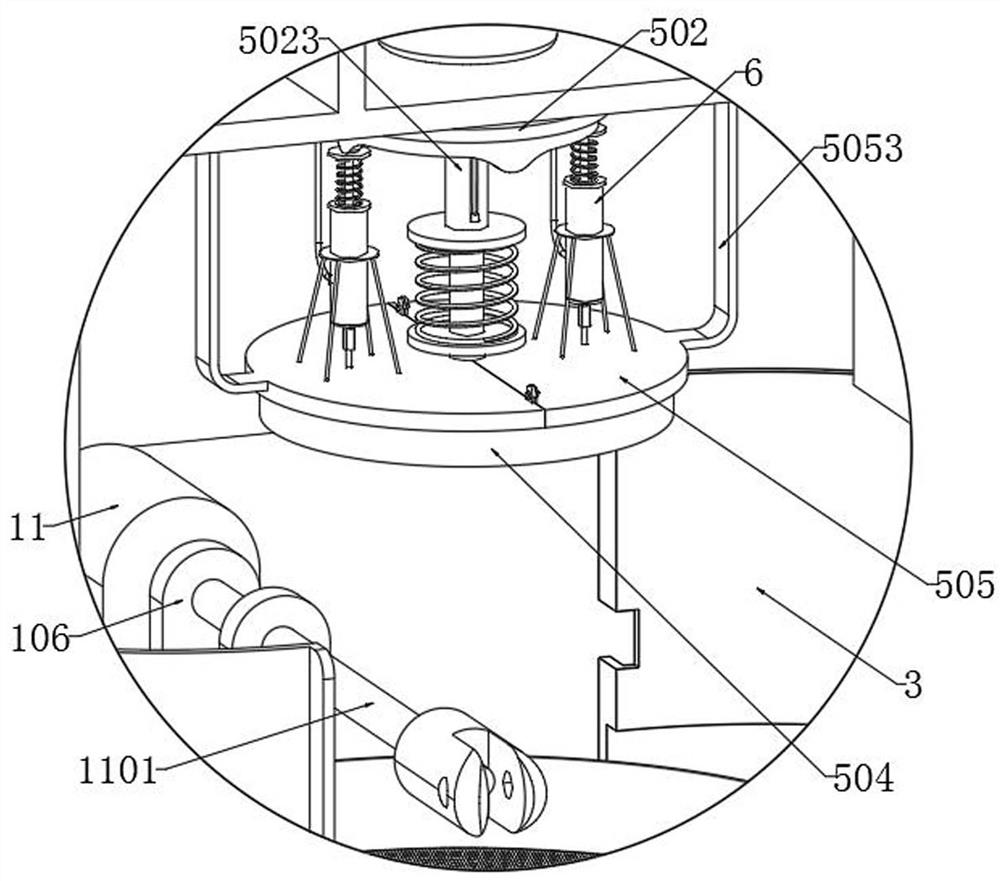

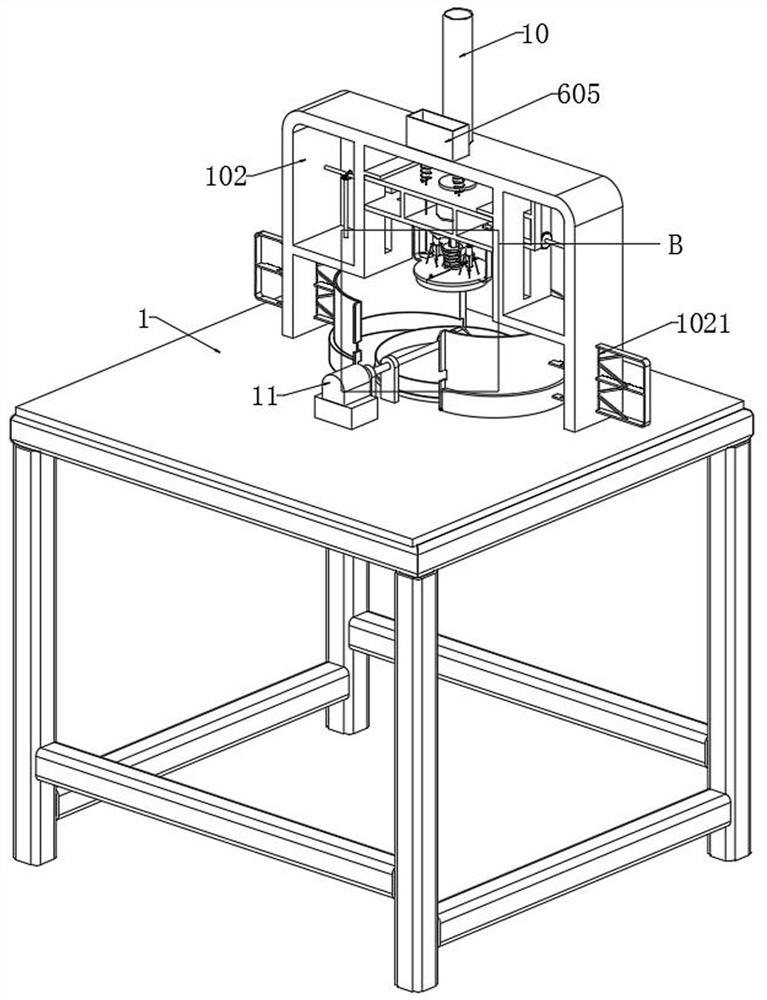

High-precision polishing equipment for graphite slices

PendingCN111531452AAchieve level adjustmentHigh polishing precisionGrinding carriagesPolishing machinesPolishingEngineering

The invention belongs to the technical field of graphite product machining equipment, and particularly discloses high-precision polishing equipment for graphite slices. The high-precision polishing equipment for the graphite slices comprises a rack, a workbench and a grinding assembly. Small holes are formed in the surface of the workbench for vacuumizing to adsorb and fix the graphite slices, double sliding rails and the grinding assembly are arranged on the rack for adjustment of polishing positions, and the relatively high polishing precision is obtained preliminarily; annular channels communicating with the small holes are formed in the peripheries of the small holes to enhance the vacuum adsorption effect, with the arrangement of a concave area of the workbench combined, it is guaranteed that the graphite slices cannot deviate in position in the polishing process, and the polishing precision is improved; and through the three-layer structural design of a metal layer, a rubber layer and a polishing layer of a polishing disc, the stability of the grinding assembly is improved, and the polishing precision is further improved; in addition, the high-precision polishing equipment for the graphite slices also has the characteristics that the operation is easy, the safety is high, the polishing layer can be easily replaced, and the polishing efficiency is high.

Owner:ZHEJIANG HAROG TECH CO LTD

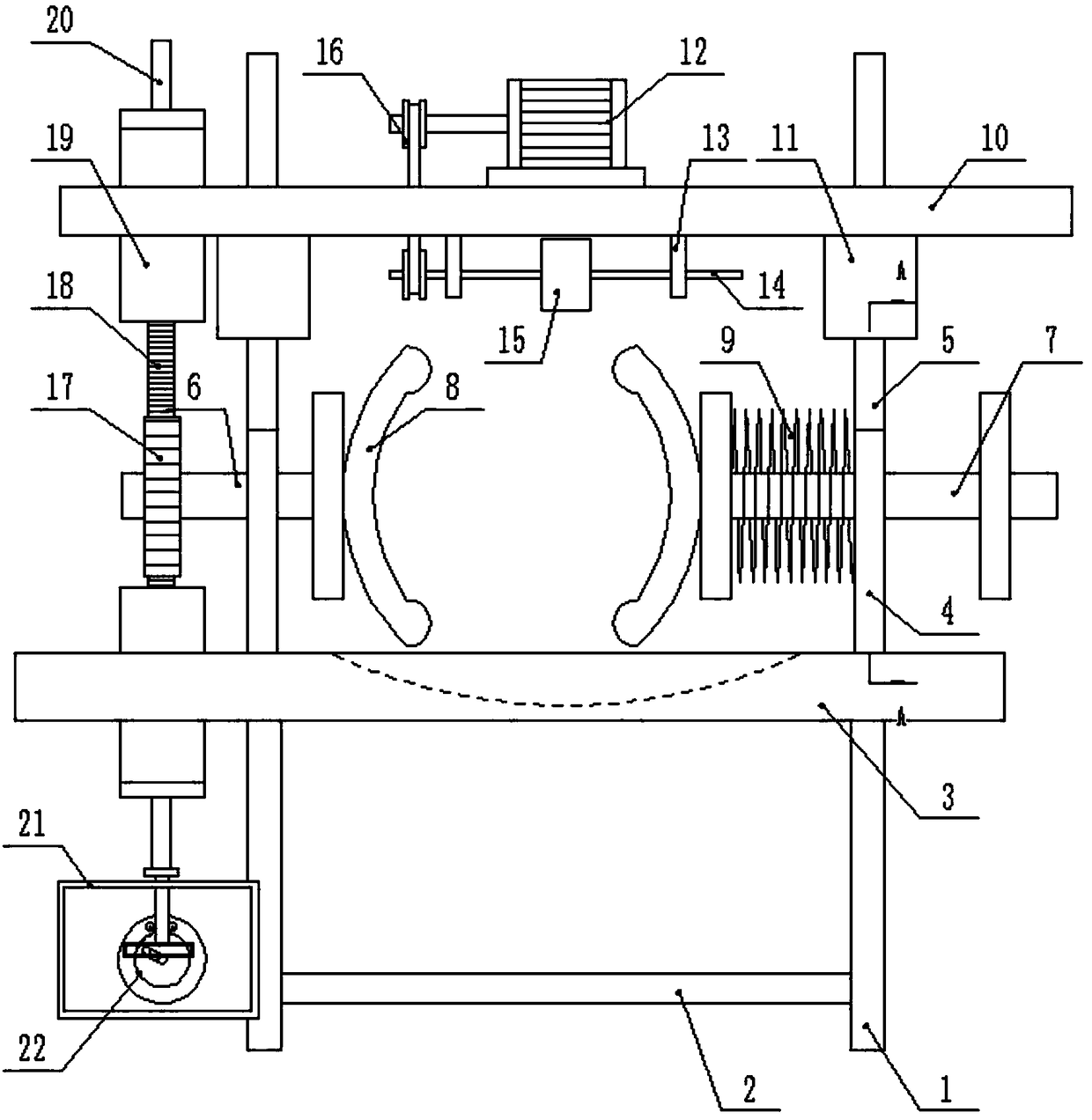

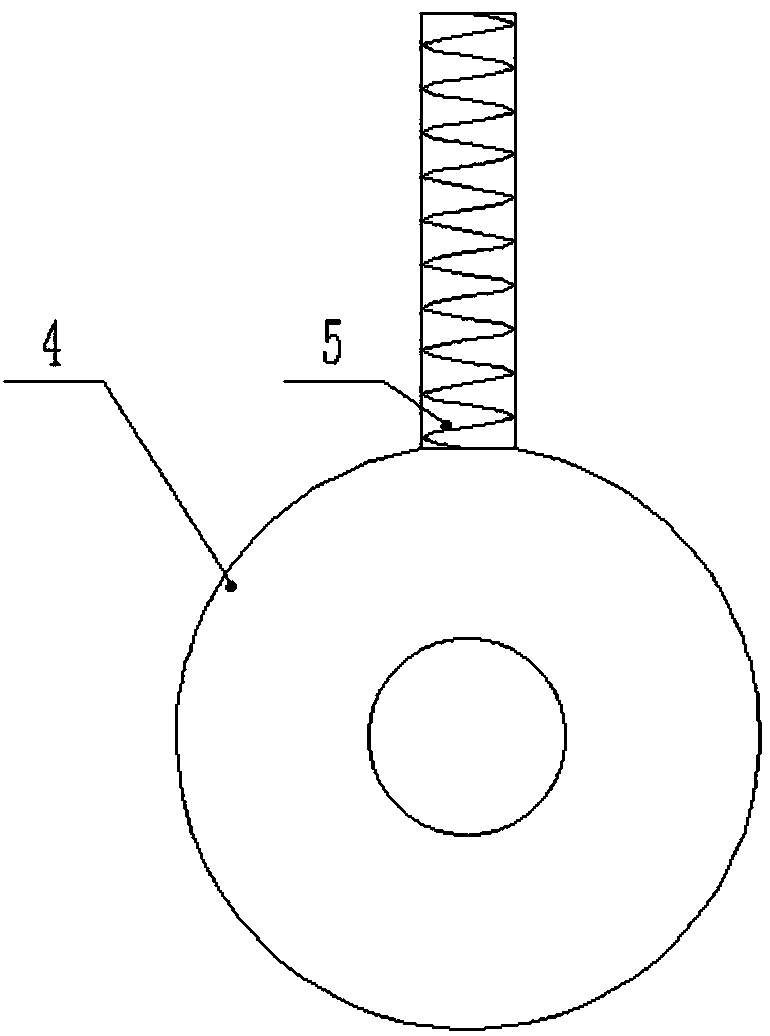

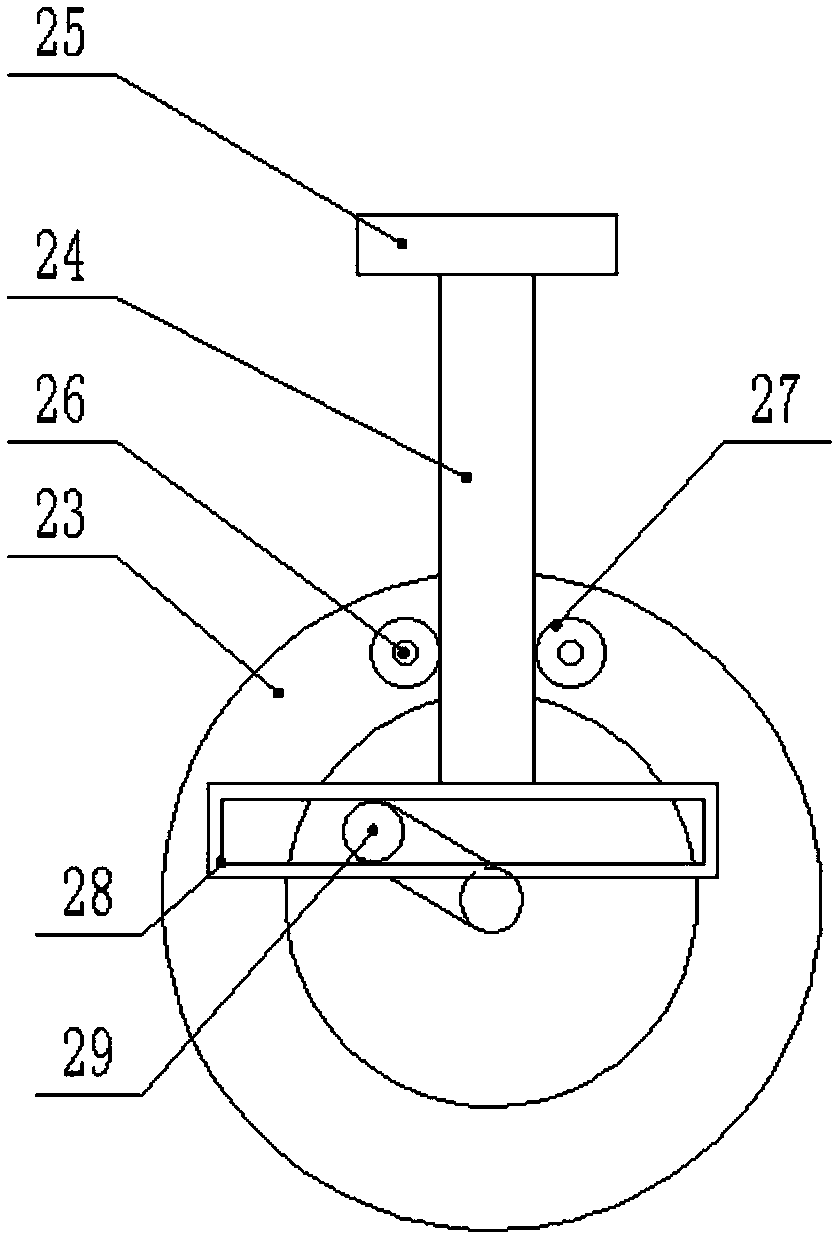

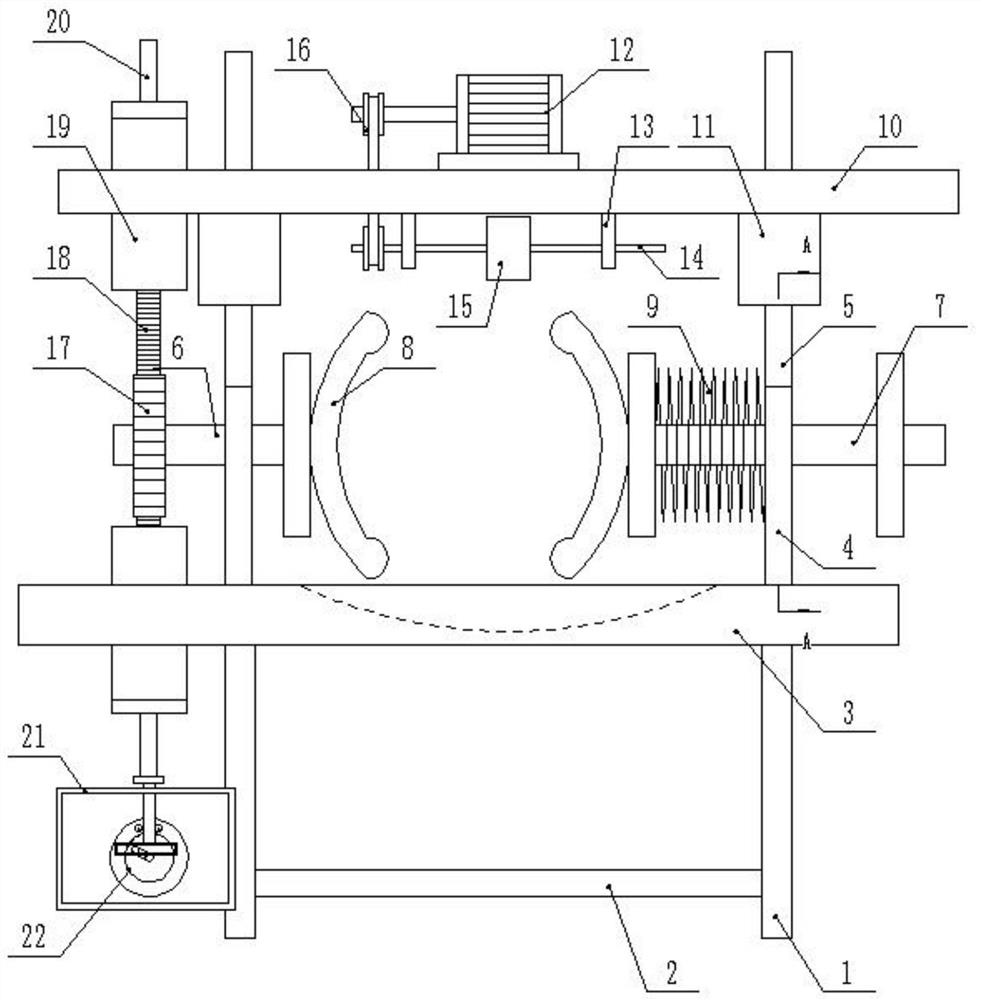

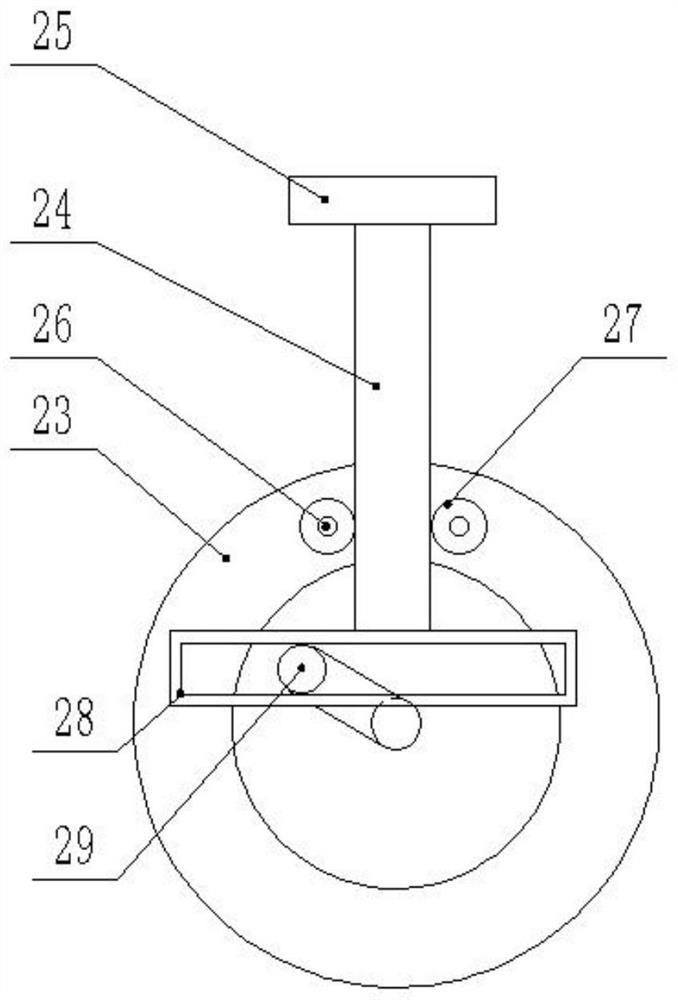

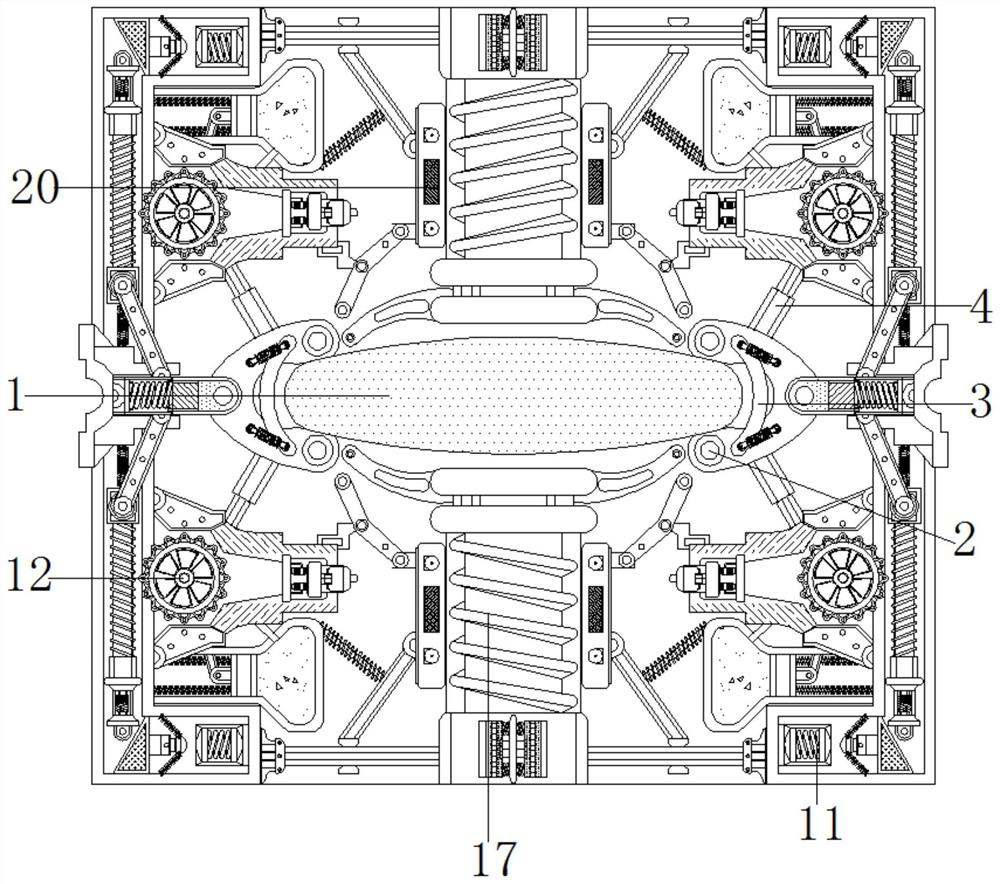

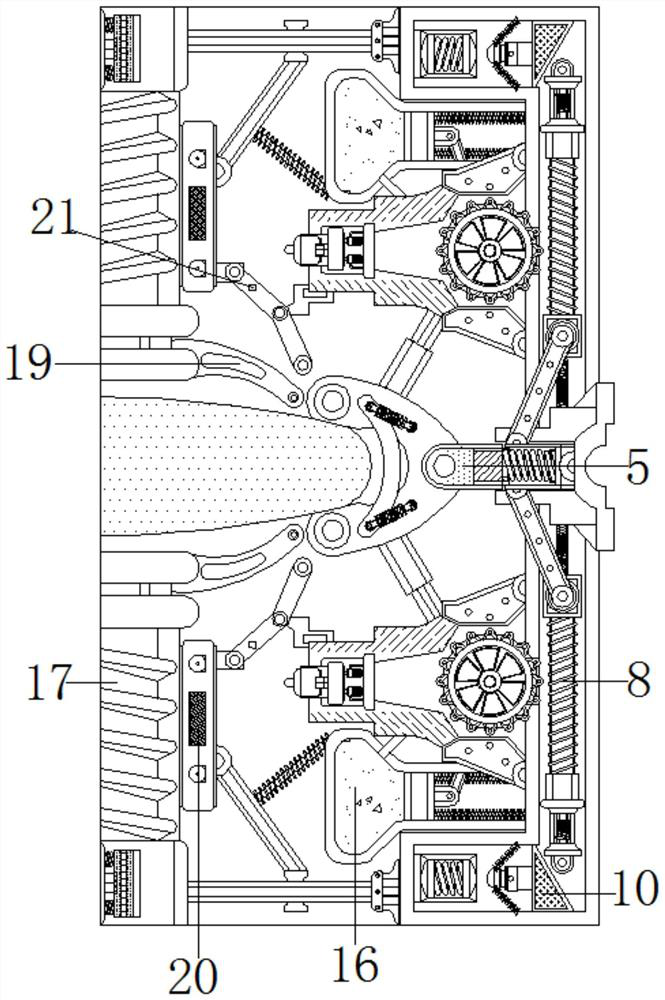

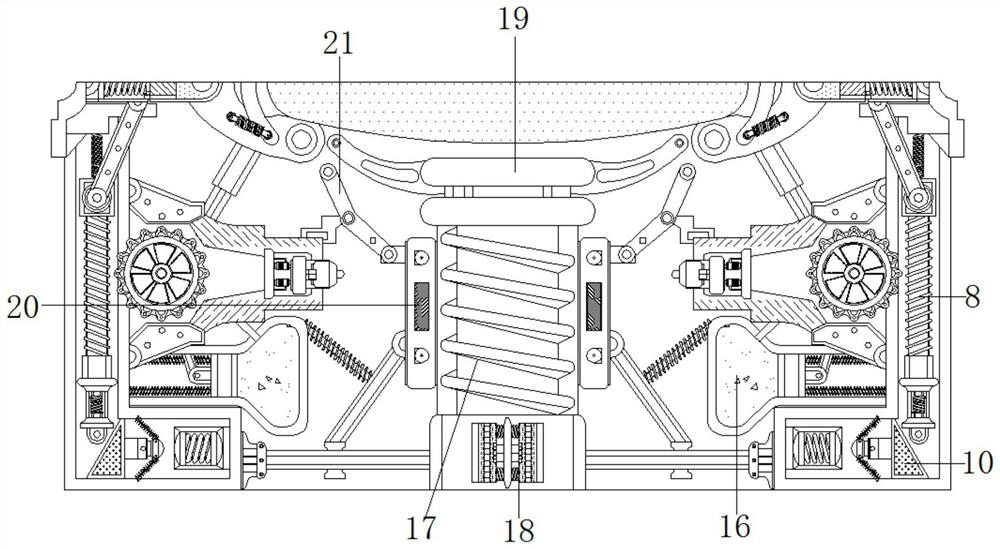

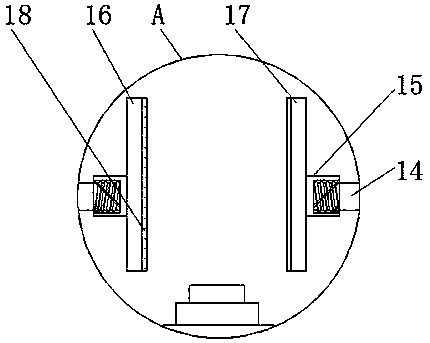

Spherical loudspeaker box shell joint polishing device of disc sliding type structure

ActiveCN108515412AGuaranteed polishing effectEasy to handleGrinding machinesCircular discFixed frame

The invention discloses a spherical loudspeaker box shell joint polishing device of a disc sliding type structure. The spherical loudspeaker box shell joint polishing device comprises a device body, supporting frames are arranged on the device body, a supporting plate is arranged at the tops of the supporting frames, fixing frames are arranged on the supporting plate, threaded columns are arrangedat the tops of the fixing frames, a rotating rod A and a rotating rod B are arranged on the fixing frames, the device body is provided with a supporting top plate, a polishing motor is arranged on the supporting top plate, a driven gear is arranged at the end part, arranged at the outer side of the left fixing frame, of the rotating rod A, the device body is provided with a power box, and a powerassembly is arranged in the power box. The spherical loudspeaker box shell joint polishing device has the advantages that the structure is simple, through the circulating type vertical movement, a spherical loudspeaker box shell clamped in clamping plates is driven to rotate, so that a joint of the spherical loudspeaker box shell can be effectively processed, protruding burrs can be avoided, in addition, through a circulation type power structure, the effect of polishing the joint of the spherical loudspeaker box shell can be guaranteed, the processing effect can be better, the use is convenient, and the practicability is high.

Owner:嵊州市格瑞特电子有限公司

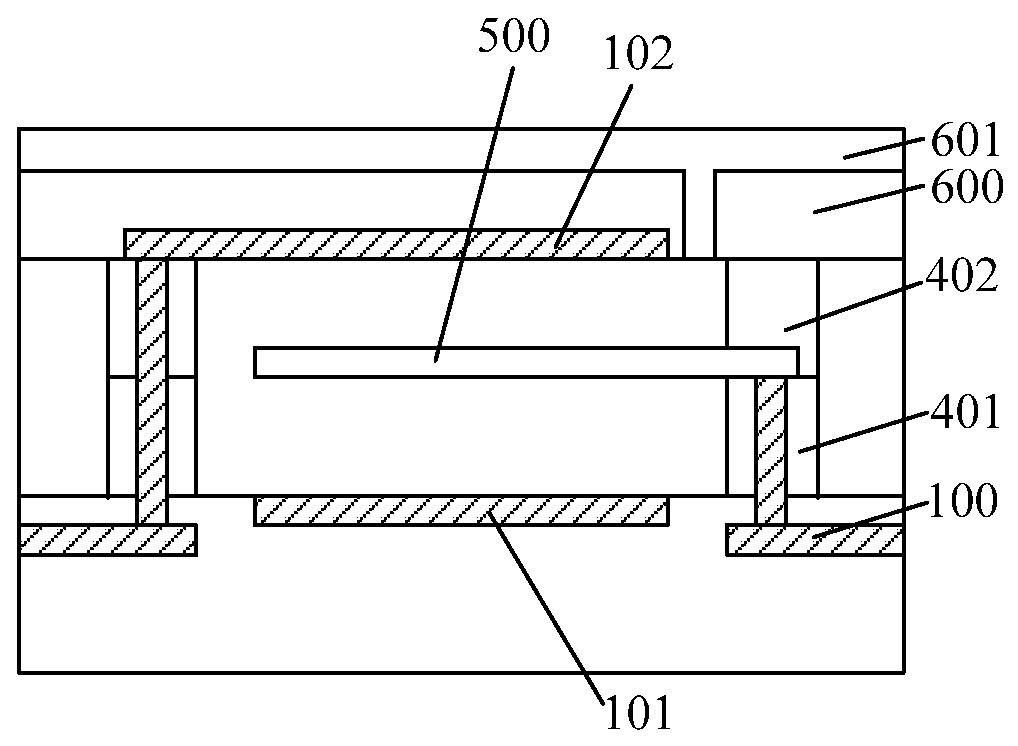

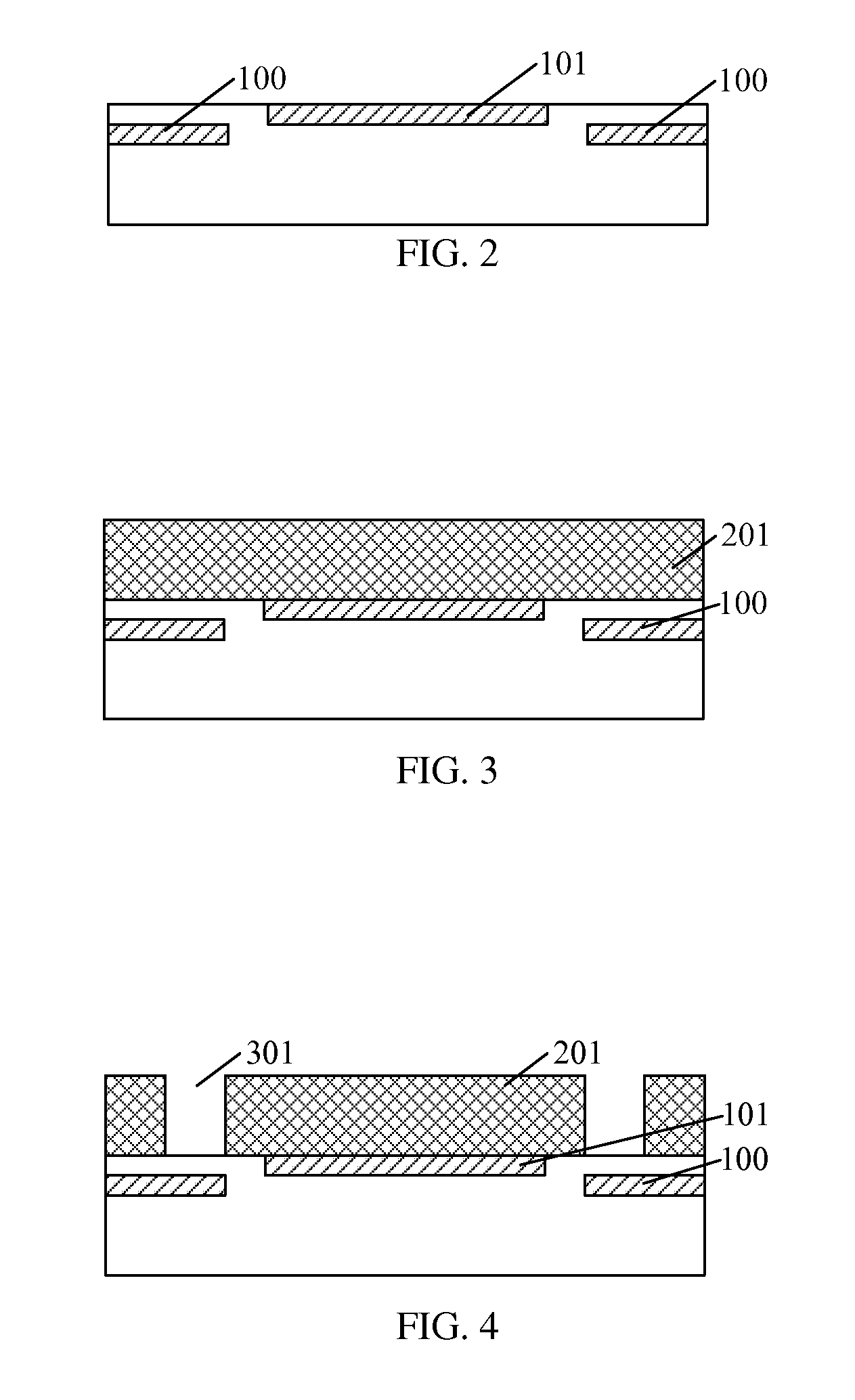

Method for manufacturing MEMS device

ActiveUS20130309797A1Avoid polishingShorten the production cycleImpedence networksDecorative surface effectsInterconnectionDielectric layer

A method for manufacturing a micro-electro-mechanical system (MEMS) device is provided. The method comprises: providing a semiconductor substrate, the semiconductor substrate having a metal interconnection structure (100) formed therein; forming a first sacrificial layer (201) on the surface of the semiconductor substrate, the material of the first sacrificial layer is amorphous carbon; etching the first sacrificial layer to form a first recess (301); covering and forming a first dielectric layer (401) on the surface of the first sacrificial layer; thinning the first dielectric layer by a chemical mechanical polishing (CMP) process, until exposing the first sacrificial layer; forming a micromechanical structure layer (500) on the surface of the first sacrificial layer and exposing the first sacrificial layer, wherein a part of the micromechanical structure layer is connected to the first dielectric layer. The method avoids polishing the amorphous carbon, shortens the period of production, and improves the production efficiency

Owner:ZHEJIANG JUEXIN MICROELECTRONICS CO LTD

Glass product polishing device

ActiveCN113070804AReduce pressureControl lengthPolishing machinesGrinding work supportsPolishingEngineering

The invention belongs to the technical field of glass processing, and particularly relates to a glass product polishing device which comprises a workbench, a rotary clamping mechanism, a polishing mechanism and a lifting mechanism. The rotary clamping mechanism comprises a sleeve, a power part and an L-shaped clamping plate, a piston and a reset piece are slidably connected in the sleeve, and a piston rod is arranged on the piston; the polishing mechanism comprises a mounting block, a cavity is formed in the mounting block, two polishing blocks are slidably connected to the side wall of the mounting block, and an elastic part is arranged in the cavity; an adjusting cylinder is fixed on the mounting block, and an adjusting plate is slidably connected in the adjusting cylinder; a one-way inflow valve and a one-way outflow valve are arranged on the side wall of the mounting block; the sleeve, the sliding groove, the adjusting cylinder and the cavity are all filled with transmission media; a limiting block is arranged on the inner wall of the adjusting cylinder; and the lifting mechanism is used for controlling lifting of the workbench. By the adoption of the scheme, the bottle opening of a glass product can be specifically and rapidly polished, meanwhile, the polishing degree can be effectively controlled, and excessive polishing is avoided.

Owner:CHONGQING XINGYUAN GLASSWARE CO LTD

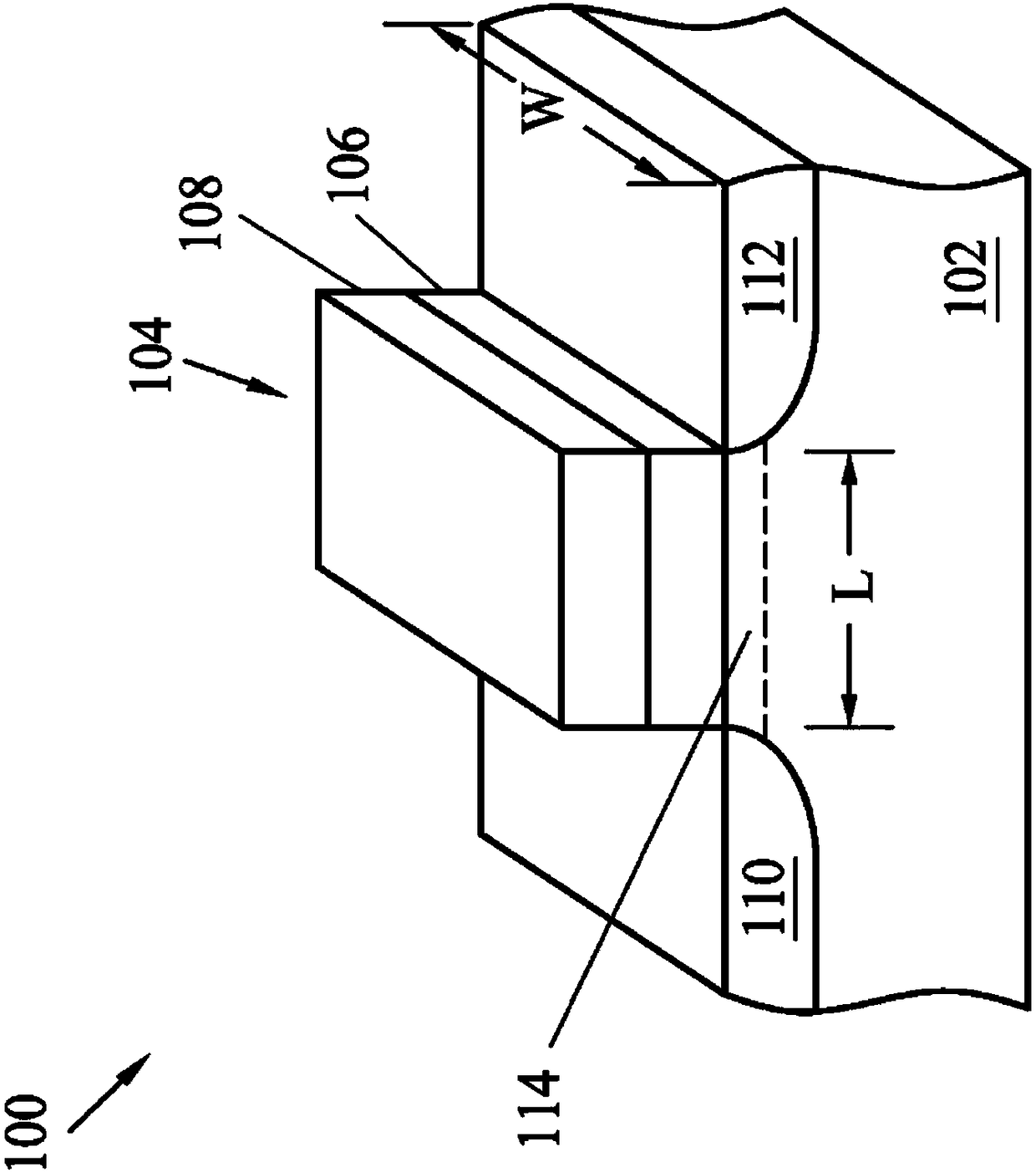

Gate structure and methods thereof

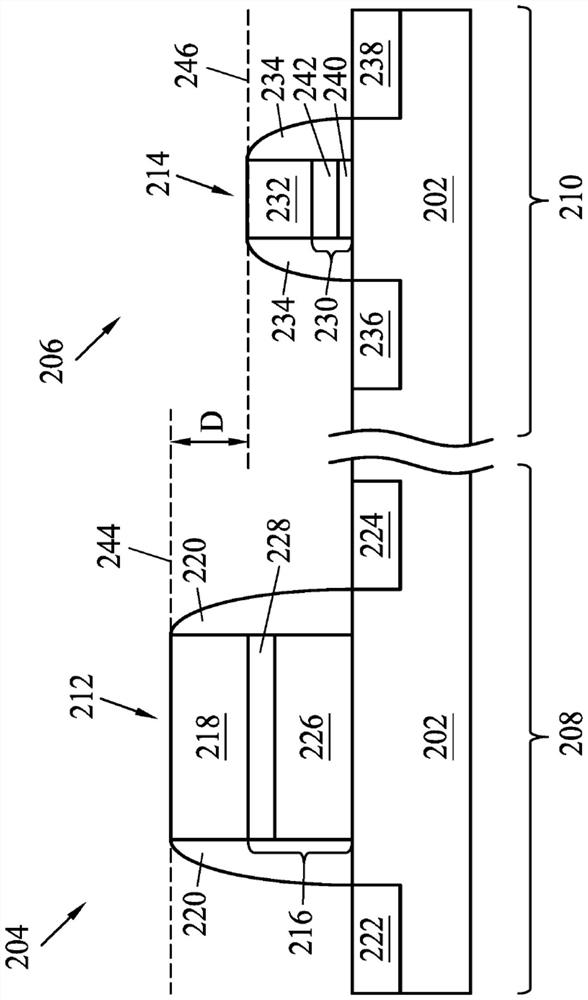

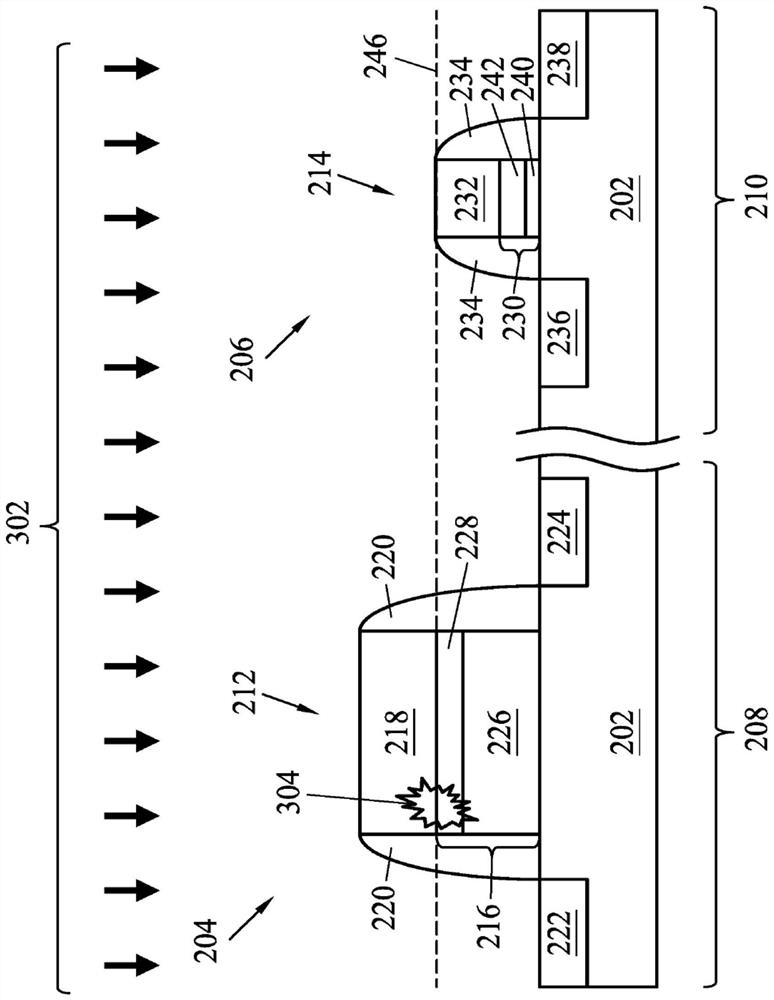

ActiveCN109216177AAvoid over polishingSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricHigh voltage transistors

The embodiment of the invention relates to a method and structure that provide a high-voltage transistor (HVT) including a gate dielectric, where at least part of the gate dielectric is provided within a trench disposed within a substrate. In some aspects, a gate oxide thickness may be controlled by way of a trench depth. By providing the HVT with a gate dielectric formed within a trench, embodiments of the present disclosure provide for the top gate stack surface of the HVT and the top gate stack surface of a low-voltage transistor (LVT), formed on the same substrate, to be substantially co-planar with each other, while providing a thick gate oxide for the HVTs. Further, because the top gate stack surface of HVT and the top gate stack surface of the LVT are substantially co-planar with each other, over polishing of the HVT gate stack can be avoided.

Owner:TAIWAN SEMICON MFG CO LTD

Polishing paste for modifying and processing plastic product

ActiveCN105219275AHigh dimensional accuracyImprove polishing effectPolishing compositionsMicrocrystalline waxVaseline

The invention discloses a polishing paste for modifying and processing a plastic product, and relates to the technical field of processing a plastic product. The polishing paste is prepared from the following raw materials, by weight: 80-90 parts of modified bentonite, 30-35 parts of soap powder, 25-30 parts of zeolite powder, 15-20 parts of fly ash, 15-20 parts of rape seed cake powder, 13-18 parts of tea seed powder, 12-16 parts of tung oil, 10-15 parts of modified microcrystalline wax, 8-12 parts of active carbon, 8-12 parts of silica powder, 6-10 parts of vaseline, 5-8 parts of tallow, 50-60 parts of ethanol, and 300-350 parts of water. According to the invention, the polishing paste for modifying and processing a plastic product is prepared by taking modified bentonite as a main raw material, and can be directly coat the surface of the plastic product. The polishing effect can be effectively improved; the dimension accuracy of the plastic product can be furthest protected; and over polishing is prevented.

Owner:YINGSHANG LONGYUYANG IND & TRADE

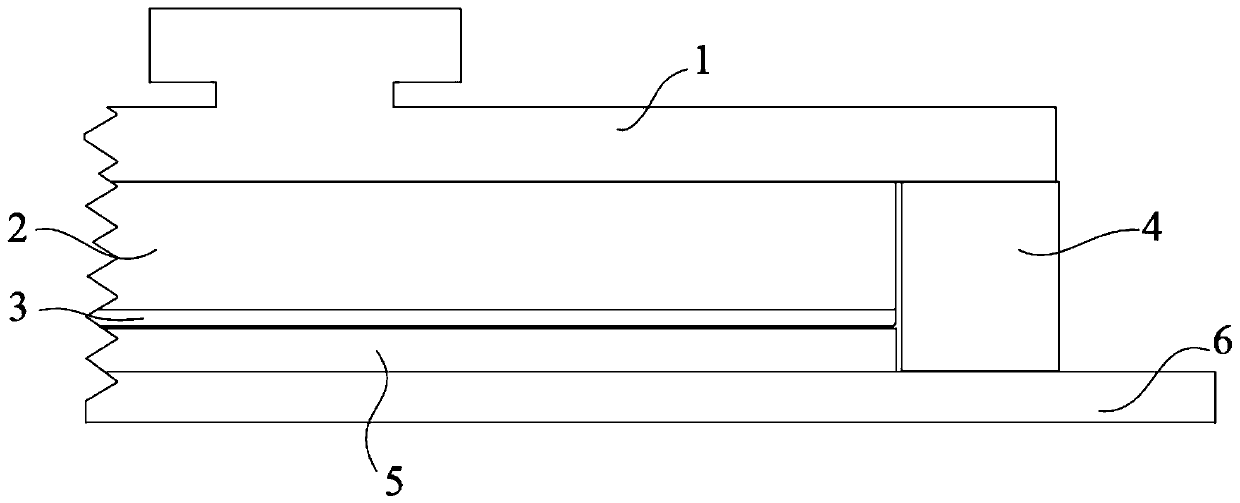

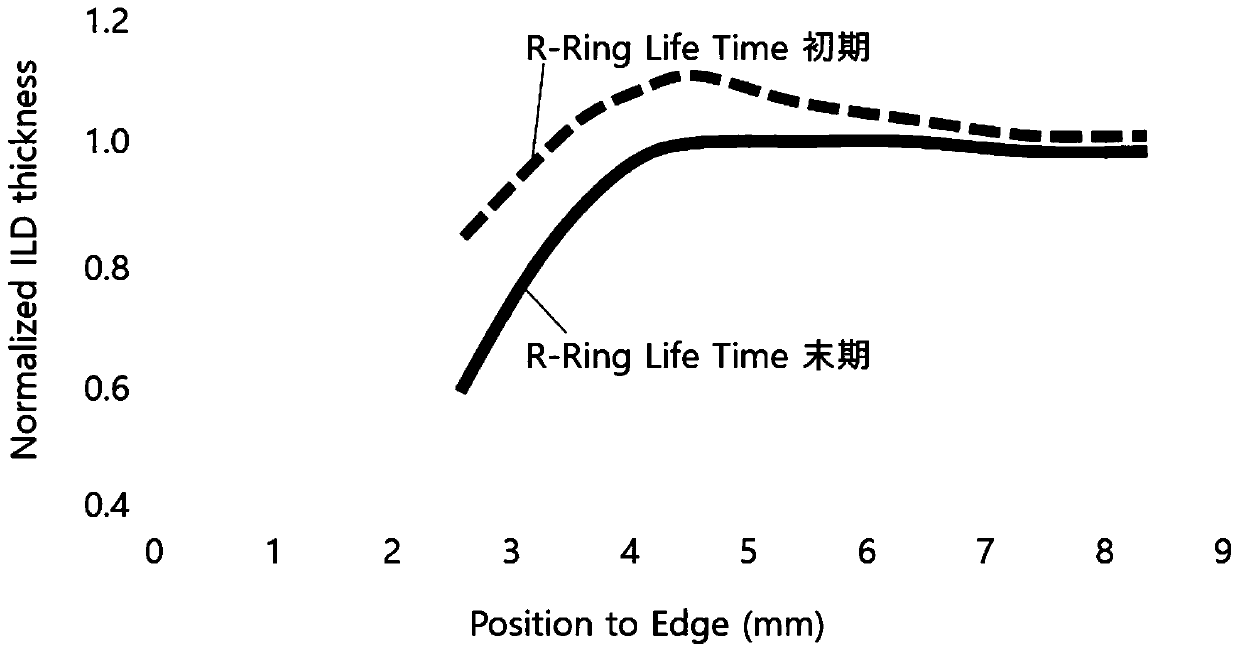

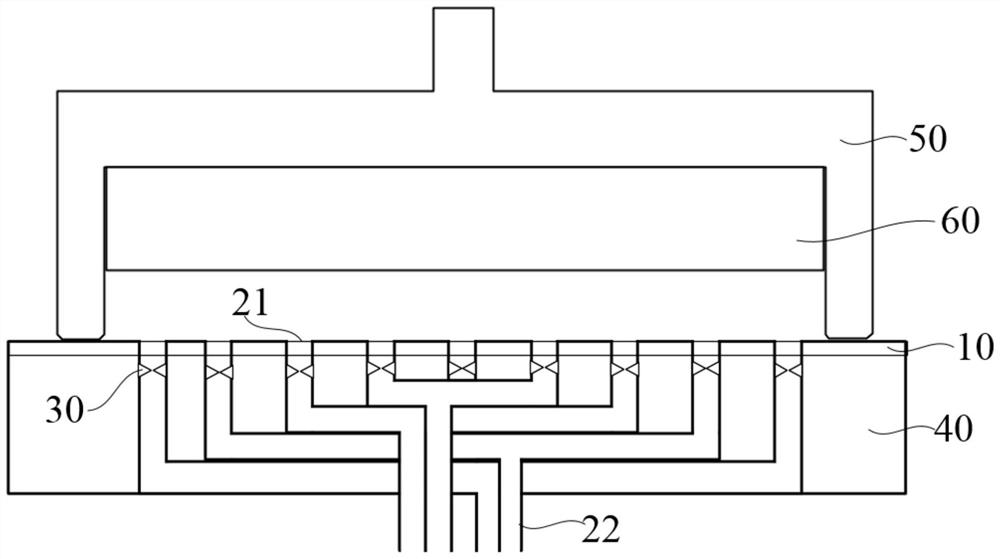

Polishing head and polishing device

The invention provides a polishing head and a polishing device. The polishing head is used for keeping a wafer on a polishing platform. The polishing head comprises a shell and a limiting ring connected to the shell. The limiting ring surrounds the wafer to limit the wafer. The polishing head further comprises a bracket located in the limiting ring. A back film leaning against the surface of the wafer is arranged on the bracket. The bracket is slidably assembled on the shell along a first direction. The polishing head further comprises a driving device which drives the bracket to slide relative to the shell along the first direction. By way of slidably assembling the bracket on the shell along a direction parallel to the axis of the limiting ring and arranging the driving device to drive the bracket to slide along the axis direction of the limiting ring relative to the shell, the bracket can be driven by the driving device to move along a direction far away from the wafer when the limiting ring is relatively worn severely and the separation distance between the bracket and the surface of the wafer is kept in a reasonable range, so that the separation distance between the wafer andthe bracket is not reduced as a result of wear of the limiting ring, and therefore, the edge of the wafer is prevented from being polished excessively.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

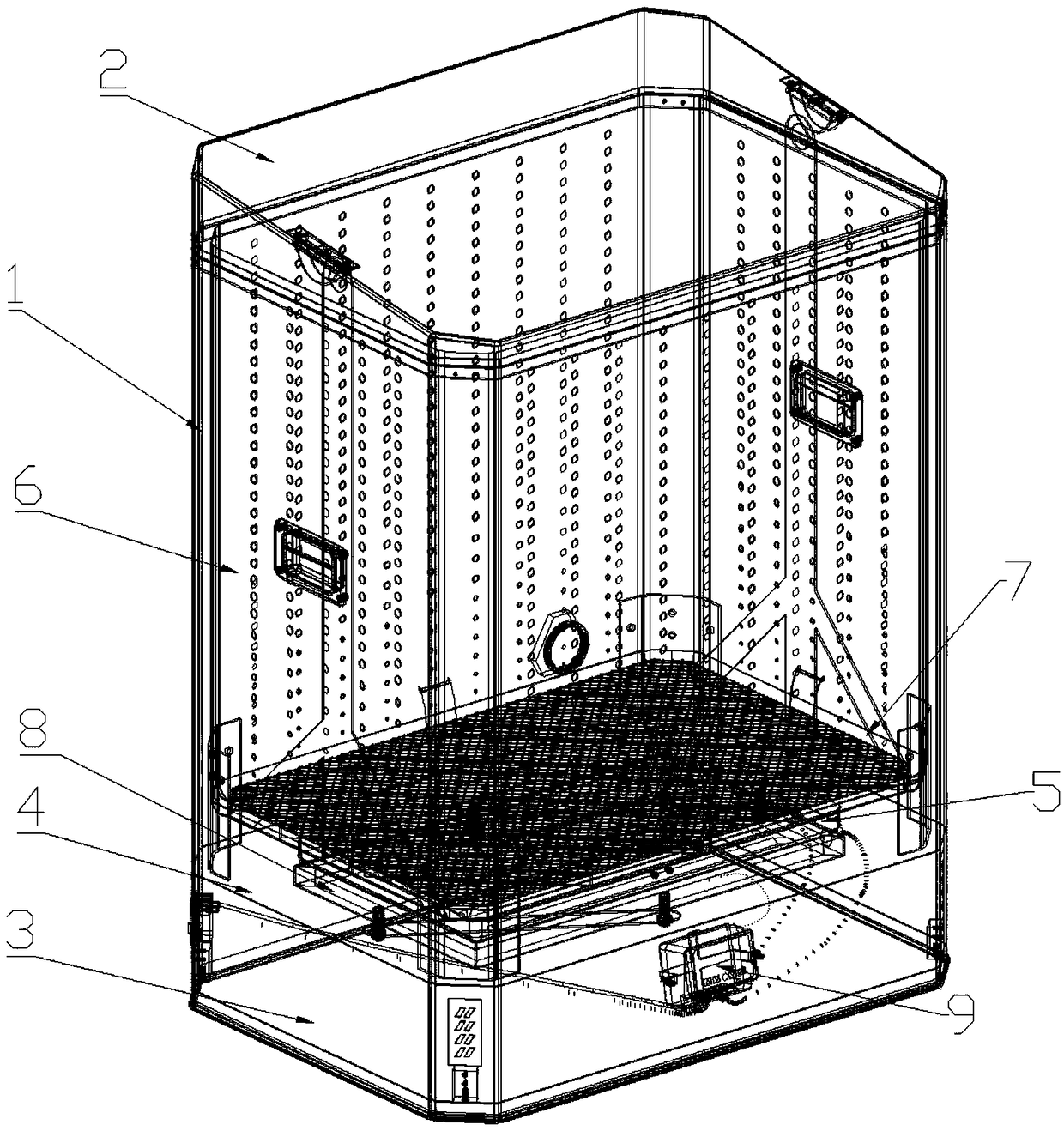

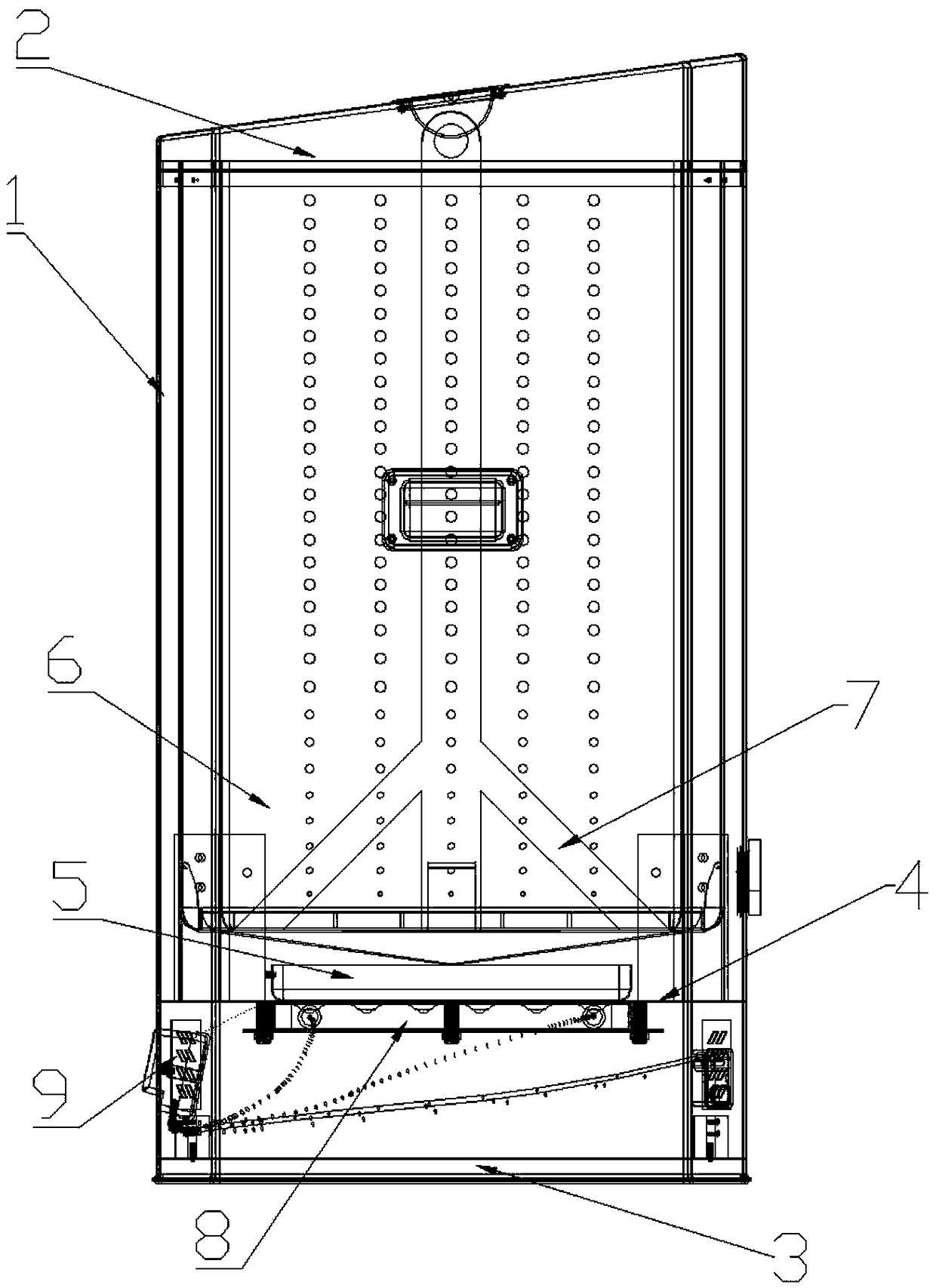

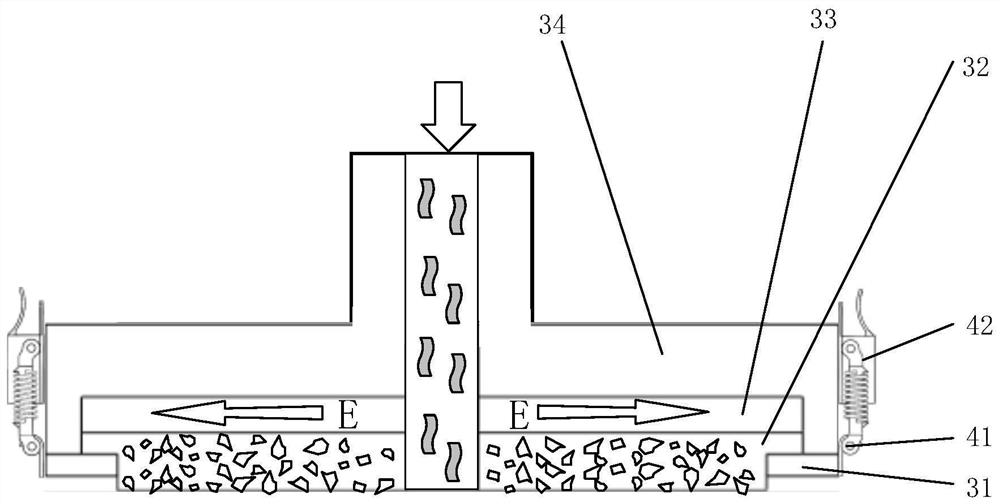

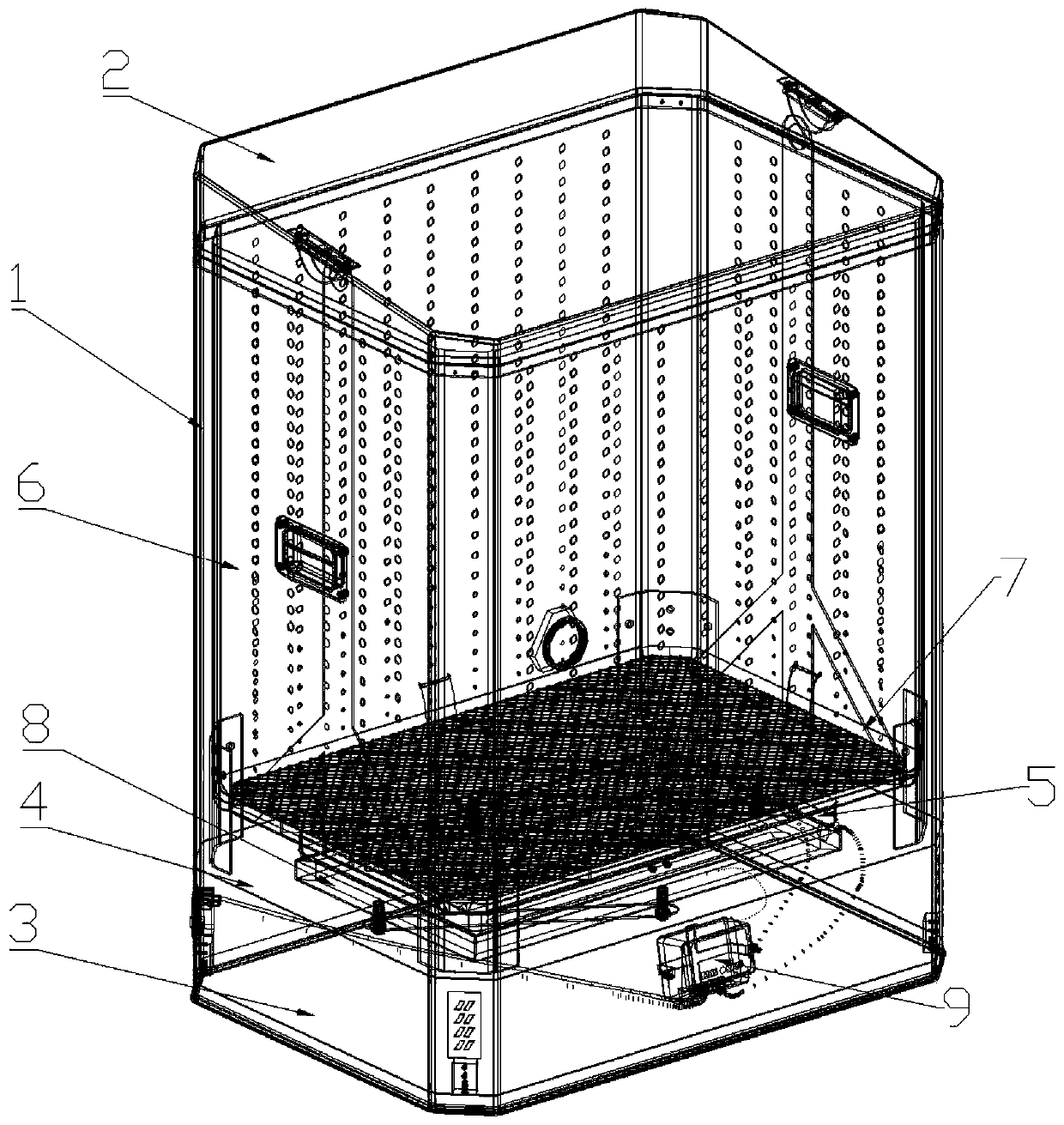

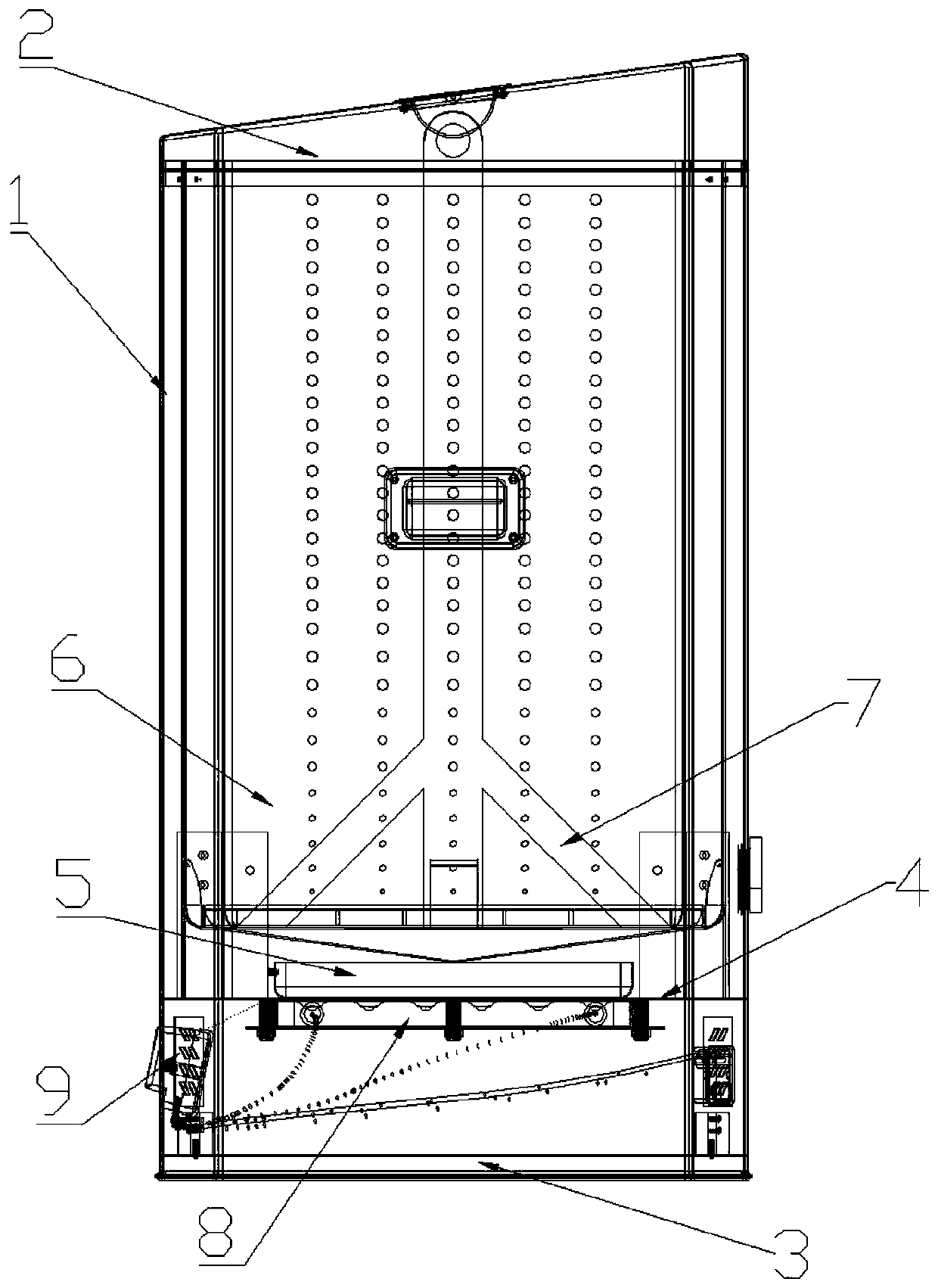

3D printing object surface polishing and strengthening device

ActiveCN108790175AReduce restrictionsHigh strengthAdditive manufacturing apparatus3D object support structuresEngineeringHolding tank

The invention discloses a 3D printing object surface polishing and strengthening device. The device comprises an outer shell, a top cover arranged at the top of the outer shell, a bottom cover arranged at the bottom of the outer shell, a separation plate arranged in the outer shell, a polishing liquid holding tank formed above the separation plate, a liner arranged above the polishing liquid holding tank, a tray arranged in the liner, an electric heating plate arranged under the separation plate, and an electronic relay arranged on the bottom cover. The 3D printing object surface polishing andstrengthening device can hold polished objects made of multiple materials and multiple types of polishing liquid, is uniform in polishing, high in polishing efficiency and excellent in polishing effect, improves the rupture strength and the toughness of the polished objects, recycles the polishing liquid, is safe in operation, protects the environment, and saves the cost; and the polishing devicecan be zoomed according to equal proportion, and the capacity can be increased or reduced according to special polishing demands, so that the size application range of the polished objects is more free.

Owner:神匠(深圳)新技术有限公司

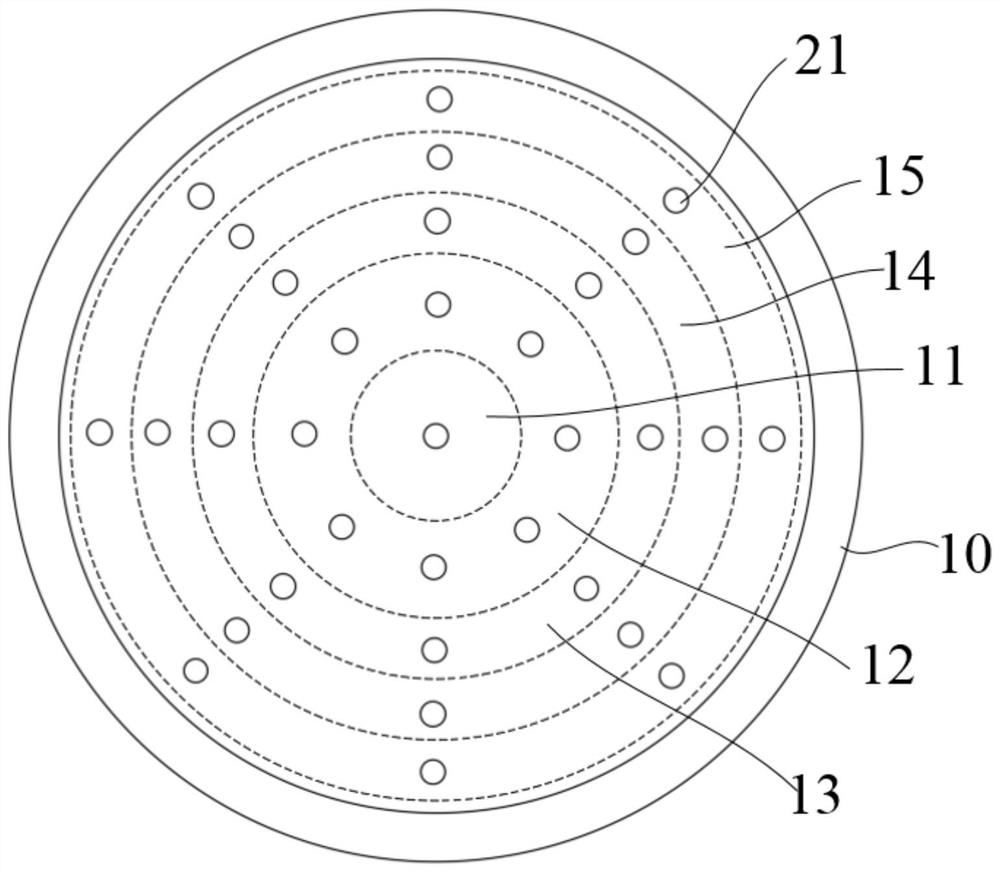

Polishing device and polishing assembly

InactiveCN111805396AAvoid over polishingControl UniformityPolishing machinesGrinding drivesWaferSprayer

The invention provides a polishing device and a polishing assembly. The polishing device is used for polishing a wafer. The polishing device comprises a rotary plate capable of rotating, a polishing pad with a polishing surface, and a sprayer on the upper side of the polishing pad, wherein the polishing pad is arranged on the rotary plate, and the sprayer is used for spraying a polishing solutionto the polishing surface. The polishing surface is divided into a plurality of polishing areas, and solution discharging holes are formed in the polishing areas respectively and used for discharging the polishing solution in the polishing areas. The polishing device further comprises control valves for controlling whether the polishing solution is discharged from the solution discharging holes ornot respectively. By dividing the polishing surface into the polishing areas, forming the solution discharging holes in the polishing areas respectively and arranging the control valves for controlling whether the polishing solution is discharged from the solution discharging holes or not, the amount of the polishing solution at different positions of the wafer is easily controlled. In use, for the high-polishing area on the wafer, a certain amount of the polishing solution on the corresponding polishing area can be correspondingly discharged, and accordingly, the wafer is prevented from beingover polished to control the uniformity of film-forming patterns on the wafer.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

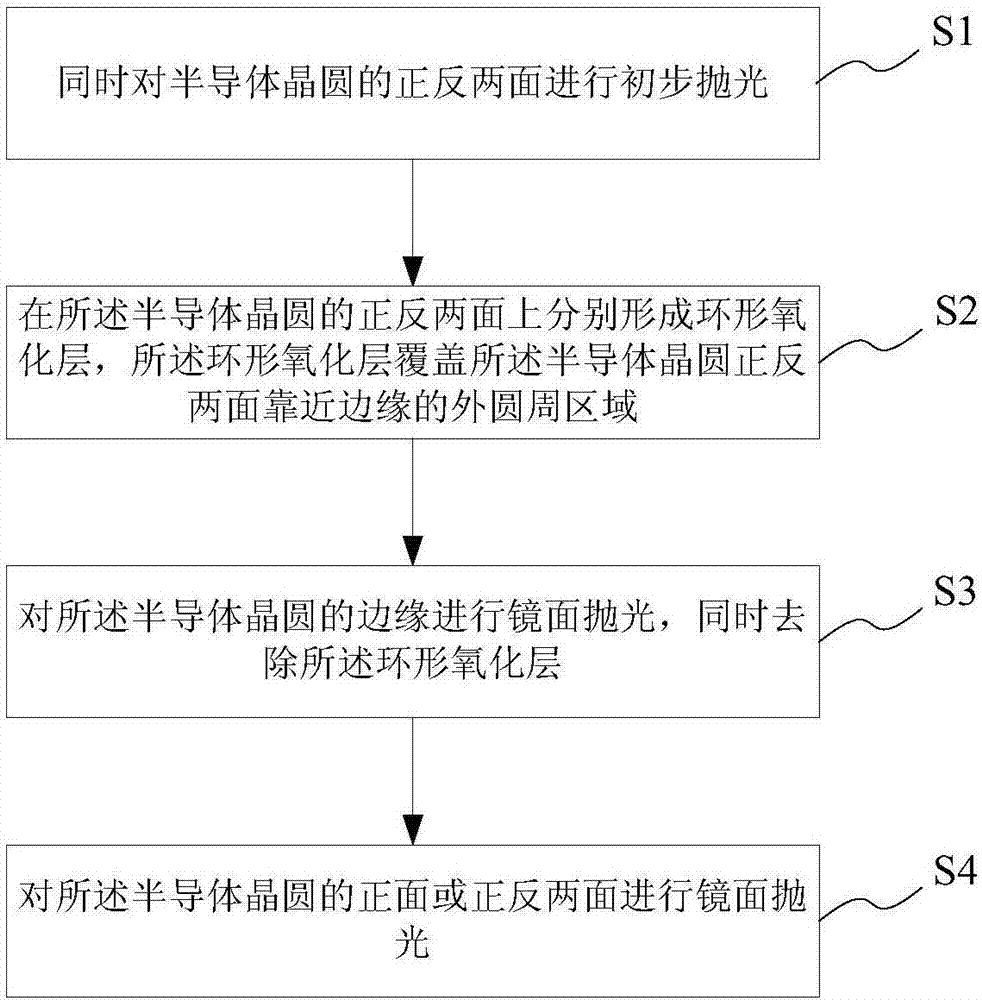

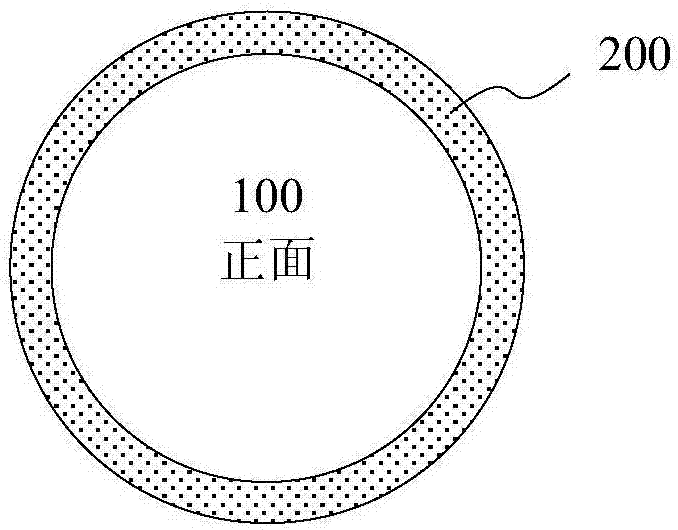

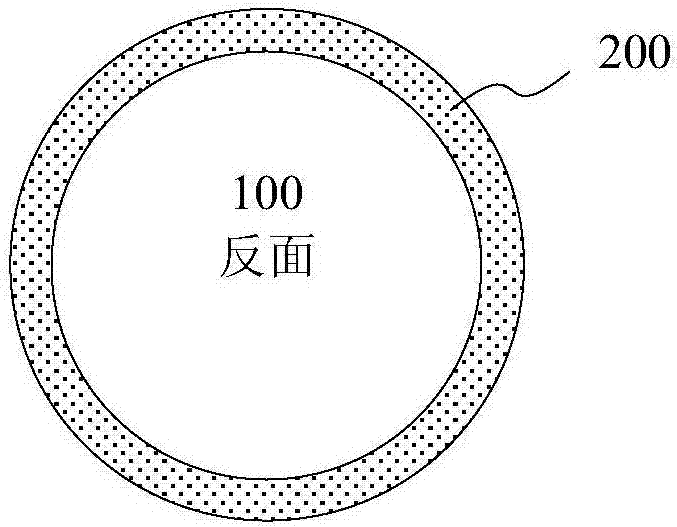

Polishing method of semiconductor wafer

InactiveCN107953225ANot affected by polishing stepsAvoid over polishingEdge grinding machinesPolishing machinesEngineeringSemiconductor

The invention provides a polishing method of a semiconductor wafer. The polishing method of the semiconductor wafer sequentially comprises the following steps: S1, primarily polishing the front side and the reverse side of the semiconductor wafer simultaneously; S2, forming an annular oxidation layer on each of the front side and the reverse side of the semiconductor wafer, wherein the annular oxidation layers cover the outer circumferential areas, near the edge, of the front side and the reverse side of the semiconductor wafer; S3, performing mirror polishing on the edge of the semiconductorwafer and removing the annular oxidation layers; and S4, performing mirror polishing on the front side or the front side and the reverse side of the semiconductor wafer. By the polishing method of thesemiconductor wafer, excessive polishing of the area, near the edge, of the surface of the semiconductor wafer in the edge polishing step can be avoided; furthermore, after the edge of the semiconductor wafer is polished, the annular oxidation layers are completely removed and influence on the subsequent polishing step is avoided, so the method is simple, economic and practical.

Owner:ZING SEMICON CORP

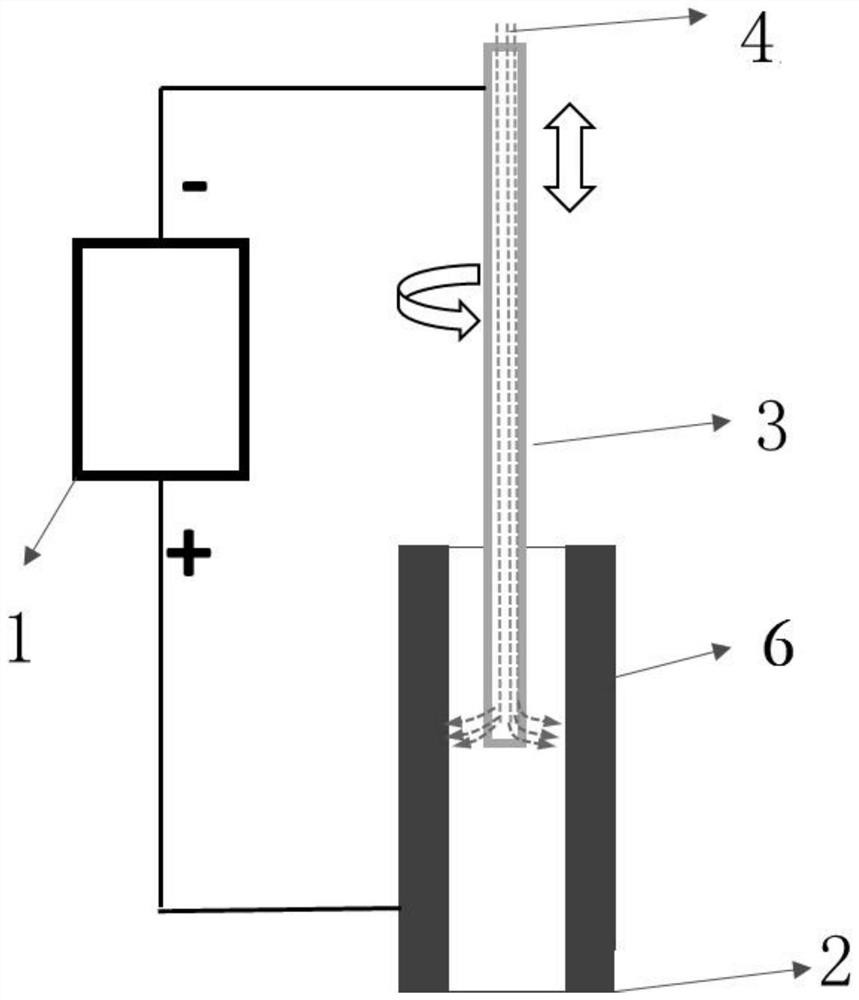

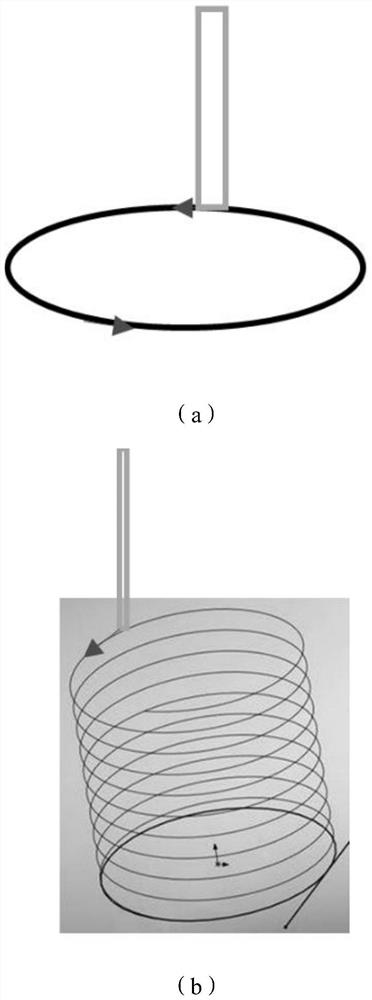

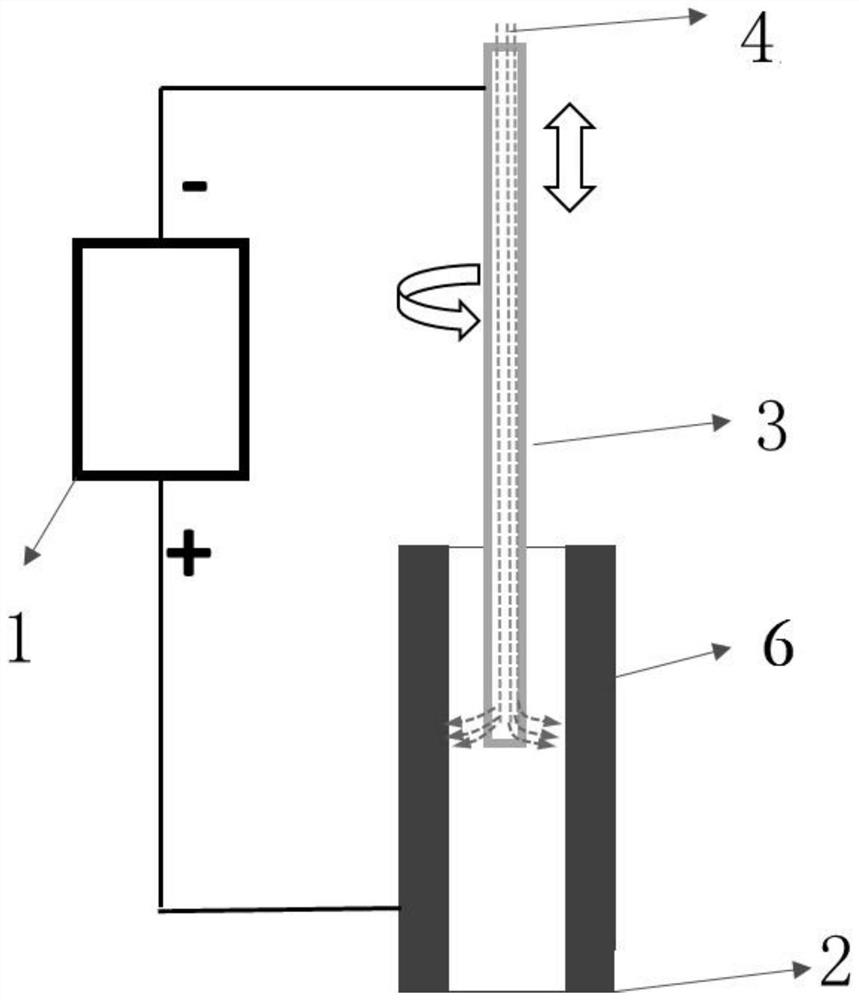

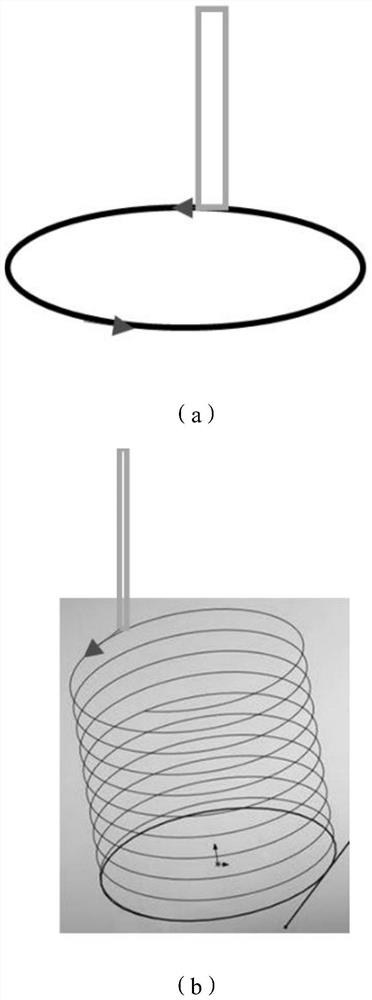

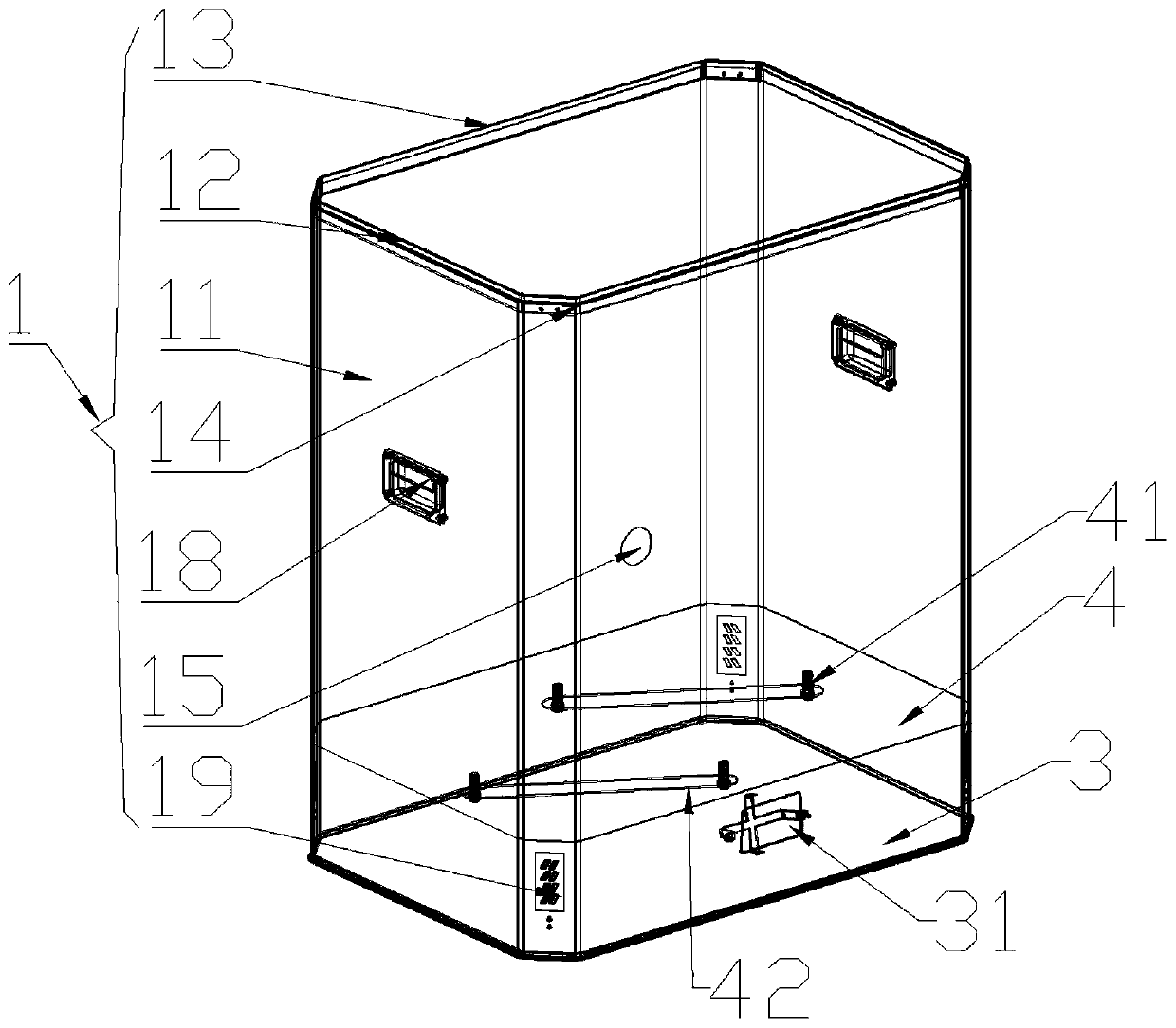

Electrochemical layer-by-layer polishing device for additive manufacturing metal tubular part

ActiveCN111636095AAvoid over polishingHigh polishing precisionElectrolysis componentsAnodic dissolutionMetallurgy

The invention discloses an electrochemical layer-by-layer polishing device for an additive manufacturing metal tubular part, and relates to the technical field of precision surface treatment. The electrochemical layer-by-layer polishing device mainly comprises a control driving part, a power supply, an electrode and a working solution; during working, an additive manufacturing metal tubular part to be polished is placed at a set position, the electrode extends to the inner part of the additive manufacturing metal tubular part; the anode of the power supply is connected with the additive manufacturing metal tubular part, the cathode of the power supply is connected with the electrode; and the control driving part is connected with the electrode and / or the additive manufacturing metal tubular part, the control driving part is used for controlling the fact that relative movement of the electrode and the additive manufacturing metal tubular part is carried out so that the electrode, the additive manufacturing metal tubular part and the working solution form an electric loop, and then anodic dissolution occurs between the inner surface of the additive manufacturing metal tubular part and the electrode. According to the electrochemical layer-by-layer polishing device for the additive manufacturing metal tubular part, the inner hole wall surface of the additive manufacturing part canbe effectively smoothened, and adhesive particles are removed, so that the inner hole wall surface of the additive manufacturing part meets the machining standard.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Polishing slurry composition for sti process

InactiveCN113195658AFast polishingExcellent polishing inhibition performanceOther chemical processesAqueous dispersionsMetallurgySlurry

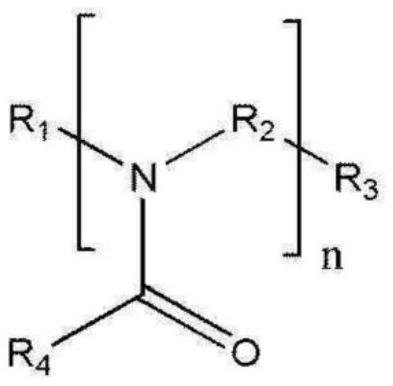

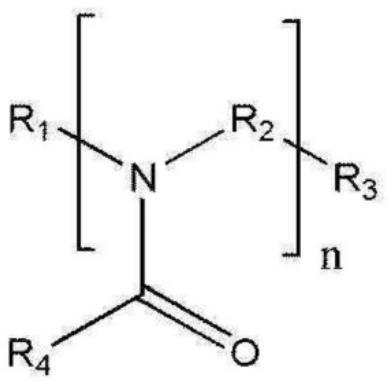

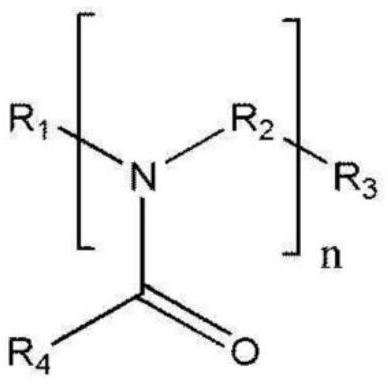

The present invention relates to a polishing slurry composition for an STI process and, more specifically, to a polishing slurry composition for an STI process, the polishing slurry composition comprising: a polishing solution including polishing particles; and an additive solution containing a polymer having an amide bond, and a polysilicon film polishing barrier inclusive of a monomer having three or more chains linked to one or more atoms.

Owner:K C TECH

Polishing paste for plastic product modification

ActiveCN105219275BHigh dimensional accuracyImprove polishing effectAlkali/ammonium soap compositionsSodium BentoniteMicrocrystalline wax

The invention discloses a polishing paste for modifying and processing a plastic product, and relates to the technical field of processing a plastic product. The polishing paste is prepared from the following raw materials, by weight: 80-90 parts of modified bentonite, 30-35 parts of soap powder, 25-30 parts of zeolite powder, 15-20 parts of fly ash, 15-20 parts of rape seed cake powder, 13-18 parts of tea seed powder, 12-16 parts of tung oil, 10-15 parts of modified microcrystalline wax, 8-12 parts of active carbon, 8-12 parts of silica powder, 6-10 parts of vaseline, 5-8 parts of tallow, 50-60 parts of ethanol, and 300-350 parts of water. According to the invention, the polishing paste for modifying and processing a plastic product is prepared by taking modified bentonite as a main raw material, and can be directly coat the surface of the plastic product. The polishing effect can be effectively improved; the dimension accuracy of the plastic product can be furthest protected; and over polishing is prevented.

Owner:YINGSHANG LONGYUYANG IND & TRADE

Method for manufacturing MEMS device

ActiveUS8841155B2Increase polishing speedAvoid over polishingAcceleration measurement using interia forcesImpedence networksInterconnectionDielectric layer

Owner:ZHEJIANG JUEXIN MICROELECTRONICS CO LTD

A polishing device for the joint of a spherical sound box shell with a disc sliding structure

The invention discloses a polishing device for the joint of a spherical sound box shell with a disc sliding structure, comprising a device body, a support frame is arranged on the device body, a support plate is arranged on the top of the support frame, a fixing frame is arranged above the support plate, and a fixing frame is arranged on the top of the fixing frame A threaded column is set, a rotating rod A and a rotating rod B are arranged on the fixed frame, a supporting top plate is arranged on the device body, a polishing motor is arranged above the supporting top plate, a driven gear is arranged on the end of the rotating rod A arranged on the outside of the fixed frame, and a driven gear is arranged on the device body The power box is equipped with power components inside the power box. The present invention is simple in structure, drives the spherical speaker housing clamped inside the clamping plate to rotate through the circular up and down movement, effectively processes the joints of the spherical speaker housing, avoids burrs protruding, and through the circular power The structure ensures the polishing effect of the joint of the spherical speaker shell, which makes the treatment effect better, easy to use, and strong in practicability.

Owner:嵊州市格瑞特电子有限公司

Omnidirectional Rotary Polishing Mechanism for Metal Tools

ActiveCN113547439BEasy to replaceAvoid over polishingGrinding carriagesPolishing machinesPolishingElectric machinery

The invention provides an all-round rotary polishing mechanism for metal tools, relates to the field of tool polishing, and solves the problem of uneven polishing on the surface of the sleeve caused by hand-held sleeve polishing, and uneven oil staining on the surface will also affect the polishing effect, including The installation frame, the installation frame is slidably installed between the two sets of L-shaped structures inside the upper bracket, and the two ends are respectively equipped with an inverted F frame, which is slid and interspersed in the vertical chute, and the front side is provided with a rack B , there are two sets of horizontal grooves on the bottom side of the installation frame; the polishing part, the polishing part is installed on the installation frame; the electric push rod drives the installation frame and the polishing part to move downward synchronously, and is driven The two sets of semi-cylinders move closer to the middle, and the polishing motor drives the sponge sand block on the bottom side of the polishing plate to polish the sleeve. The connecting shaft can be adjusted up and down by itself. With polishing oil, there will be no uneven polishing oil.

Owner:南通嘉伦汽车科技有限公司

Polishing self-adaptive polishing pressure self-cleaning intelligent device for optical lens

InactiveCN112757097AReduce curvatureReduce extrusion pressureOptical surface grinding machinesGrinding drivesOptic lensMechanical engineering

The invention relates to the technical field of optics, and discloses a polishing self-adaptive polishing pressure self-cleaning intelligent device for an optical lens. The intelligent device comprises the lens, a clamping plate is movably connected to the surface of the lens, a threaded rod is movably connected to the inner wall of a sliding groove, a piezoresistor is movably connected to the side surface of an inclined plate, a gear is movably connected to the surface of the threaded rod, the surface of the gear is movably connected with an air bin, the surface of the gear is movably connected with a piston rod, the other end of the piston rod is movably connected with a piston plate, the surface of the lens is movably connected with a polishing disc, and the bottom end of the rotating rod is fixedly connected with an electromagnet. In the lens polishing process, the thickness is reduced, the magnetism of the electromagnet is increased, the pressure of the polishing disc and the lens is gradually reduced, excessive polishing is prevented, the threaded rod moves downwards to drive the gear to rotate, scraps diffused during lens polishing are sucked into the air bin, and the piston rod and the piston plate reciprocate in the horizontal direction, so that the chippings in the piston plate are compacted.

Owner:王永凤

Polishing device with alarm function

InactiveCN113977393AAvoid over polishingTimely replacementOptical surface grinding machinesAlarmsPolishingDrive shaft

The invention relates to the technical field of optical lens processing equipment, and discloses a polishing device with an alarm function, the polishing device comprises a carrier plate, a machine body is fixedly mounted on the right side of the top of the carrier plate, a motor is fixedly mounted on the left side of the top of the machine body, and a rotating rod is in transmission connection with the bottom of a transmission shaft of the motor and extends into a sleeve. A bolt penetrates through the middle of the front wall of the sleeve, the rear end of the bolt is rotationally connected with a screw hole preset in the rotating rod through threads, a polishing rotating disc is fixedly installed at the bottom of the sleeve, and a lens body is placed on the right lower side of the polishing rotating disc. By arranging a spring and a limiting block, when the polishing rotary disc is used for polishing and thinning the lower side lens, acting force can be applied to the supporting plate through the spring, the lens moves upwards in a self-adaptive mode under the acting force of the spring, when the limiting block abuts against the carrying plate, a workpiece stops moving upwards, excessive polishing of the workpiece is avoided, meanwhile the carrying plate can extrude the touch switch and the alarm to be powered on and run; the device is used for reminding workers to replace workpieces in time.

Owner:江苏华兮网络科技工程有限公司

Automobile injection molding part surface polishing device

InactiveCN113021707AAvoid over-polishingReduce wearPolishing machinesGrinding headsFan bladeThreaded rod

The invention discloses an automobile injection molding part surface polishing device. The automobile injection molding part surface polishing device comprises a supporting bottom plate and an installation frame at the top of the supporting bottom plate, wherein a pressing driving rod is arranged in a corresponding position above the middle of the installation frame and the supporting bottom plate, a transmission threaded rod is arranged at the lower end of the interior of the pressing driving rod, a walking liquid storage part is arranged at the axis of the lower portion of the transmission threaded rod, a guiding fan blade is evenly arranged on the outer portion surface of the walking liquid storage part, and a polishing contact part is arranged in the position, at the lower end of the guiding fan blade, of the outer portion of the walking liquid storage part. The invention relates to the technical field of automobile injection molding parts. According to the automobile injection molding part surface polishing device, surface pretreatment is achieved, the polishing quality is guaranteed, and meanwhile, a polishing period is shortened.

Owner:杨向东

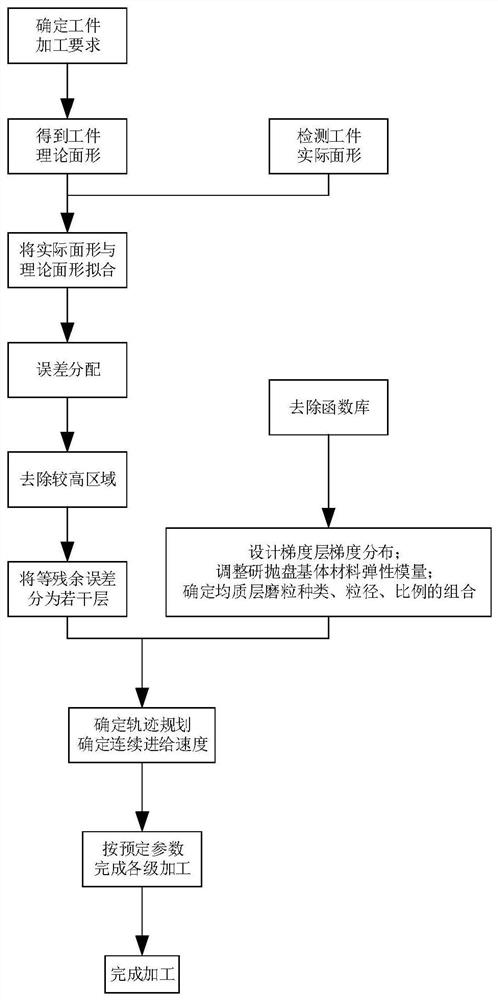

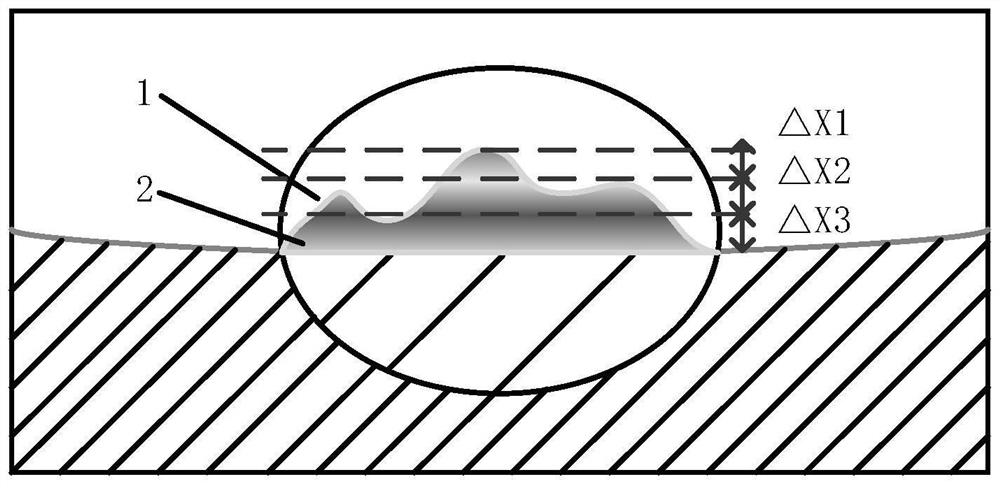

A Gradient Correction Method of Surface Shape Error Based on Gradient Elastic Polishing Tool

ActiveCN110405621BAvoid over-polishingQuick automatic replacementLapping machinesGrinding feed controlMaterial removalPolishing

The invention discloses a surface shape error classification correction method based on a gradient elastic polishing tool, comprising the following steps: (1) determining the theoretical surface shape of the workpiece according to the processing requirements of the workpiece; (2) detecting the actual surface shape characteristics of the workpiece; (3) Fit the actual surface shape of the workpiece with the theoretical surface shape to determine the surface error of the workpiece, use the contour line processing method to obtain the residual error and grade the residual error; (4) select the appropriate one according to the material removal distribution A polishing tool with a combination of parameters; (5) According to the determined removal depth, select the appropriate process parameters from the removal function library, plan the appropriate path and the appropriate feed speed to achieve uniform removal of each single layer. The processing method of the present invention can better realize the quantitative removal on demand, and the material removal is predictable, so the processing efficiency and processing quality can be improved.

Owner:ZHEJIANG UNIV OF TECH

All-dimensional rotary polishing mechanism for metal tool

ActiveCN113547439AEasy to replaceAvoid over polishingGrinding carriagesPolishing machinesOil canElectric machine

The invention provides an all-dimensional rotary polishing mechanism for a metal tool, and relates to the field of tool polishing. The all-dimensional rotary polishing mechanism aims to solve the problems that the polishing effect is influenced by non-uniform polishing of the surface of a sleeve and non-uniform oil on the surface of the sleeve due to handheld sleeve polishing. The all-dimensional rotary polishing mechanism comprises a mounting frame and a polishing part, wherein the mounting frame is slidably mounted between two sets of L-shaped structures on the inner side of an upper supporting frame, inverted-F-shaped frames are arranged at the two ends of the mounting frame correspondingly and slidably penetrate through vertical sliding grooves, racks B are arranged on the front side faces of the inverted-F-shaped frames, and two sets of transverse grooves are further formed in the bottom side of the mounting frame; the polishing part is mounted on the mounting frame; and an electric push rod drives the mounting frame and the polishing part to synchronously move downwards, the racks B on the two sides of the mounting frame are used for driving two sets of semicircular cylinders to get close to the middle, a polishing motor drives a sponge sand block on the bottom side of a polishing disc to polish the sleeve, and a connecting shaft can be automatically adjusted up and down; and an oil filling cylinder is arranged, in the polishing process, polishing oil can always exist on the sponge sand block, and the phenomenon that the polishing oil is not uniform is avoided.

Owner:南通嘉伦汽车科技有限公司

Polishing device for glass decoration product production

InactiveCN109590882AAchieve fixationMeet processing needsGrinding carriagesPolishing machinesEngineeringMachining

The invention discloses a polishing device for glass decoration product production. An operation table is included, and a machine cabinet is fixedly installed on the lower surface of the operation table; a cabinet door is movably installed on the front wall of the machine cabinet; the front side position of the bottom of the inner wall of the machine cabinet is provided with a motor; a first fixedcolumn and a second fixed column are perpendicularly and fixedly installed at the rear side position of the upper surface, close to a polishing disk, of the operation table; connection plates are arranged at the outer wall positions of the sides, away from each other, of the first fixed column and the second fixed column; the first fixed column is fixedly provided with a cylinder through the corresponding connection plate; the middle positions of the outer walls of the sides, close to each other, of the two cylinders are each movably connected with a piston rod; and the ends, close to each other, of the two piston rods are each in threaded connection with a screw sleeve. In the polishing device for glass decoration product production, the polishing device can be used for limiting the depth of polishing, excessive polishing is avoided, meanwhile, clamping plate replacing is convenient, and the machining requirement of glass decoration products in different types can be met.

Owner:阜宁长鑫工艺品有限公司

Gate structure and method thereof

ActiveCN109216177BAvoid over polishingSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricHigh voltage transistors

Embodiments of the invention relate to methods and structures for providing a high voltage transistor (HVT) including a gate dielectric, wherein at least a portion of the gate dielectric is disposed within a trench disposed within a substrate. In some aspects, gate oxide thickness can be controlled by trench depth. By providing the HVT with the gate dielectric formed within the trench, embodiments of the present invention provide the top gate stack surface of the HVT and the low voltage transistor (LVT) being formed on the same substrate approximately coplanar with each other. The top gate stack surface while providing a thick gate oxide for HVT. Furthermore, because the top gate stack surface of the HVT and the top gate stack surface of the LVT are substantially coplanar with each other, over-polishing the HVT gate stack can be avoided.

Owner:TAIWAN SEMICON MFG CO LTD

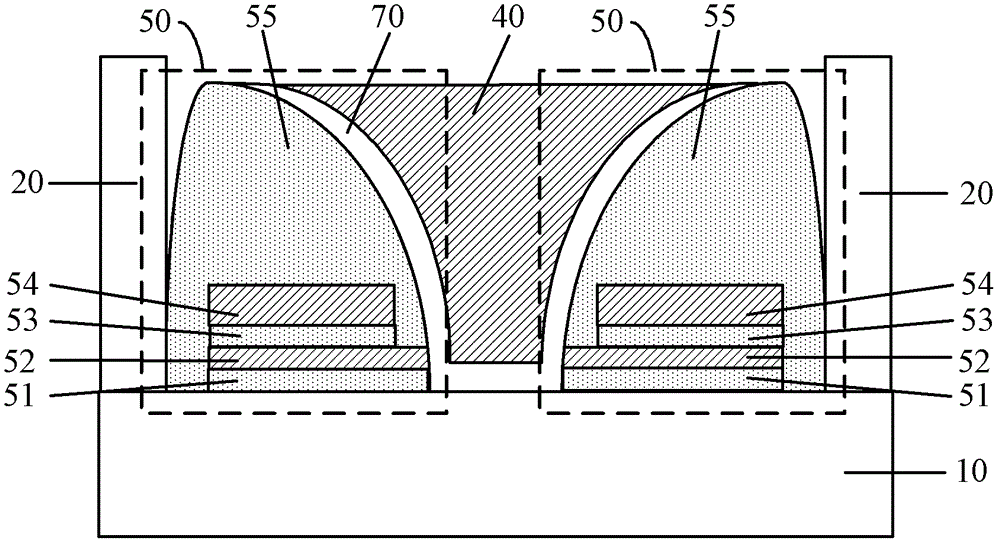

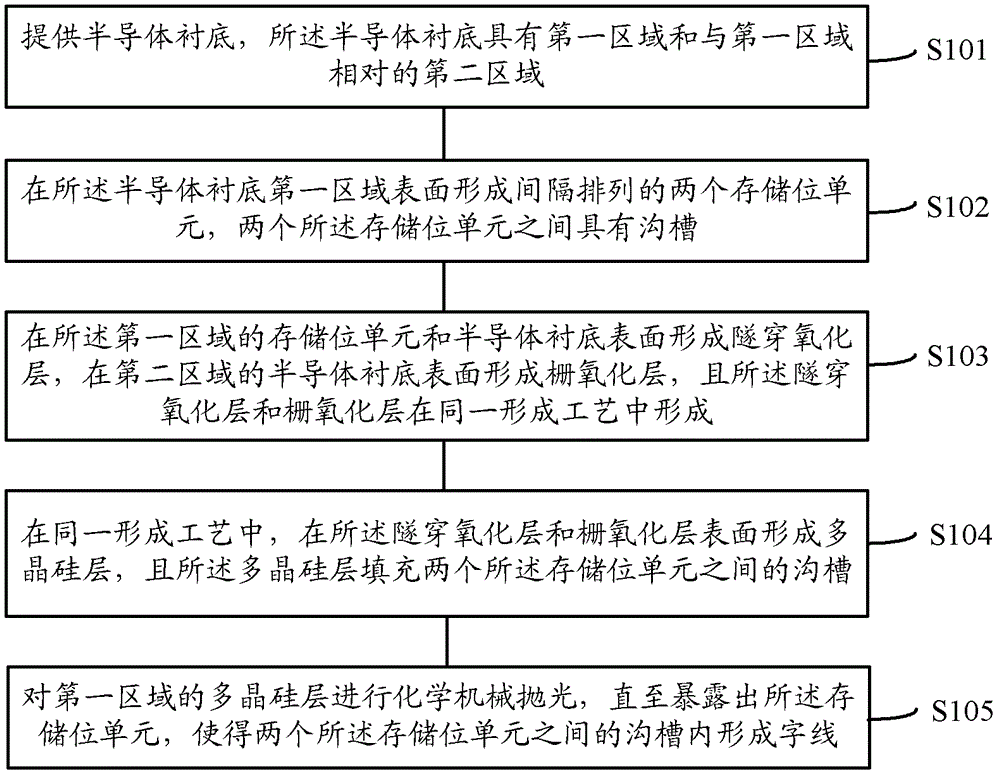

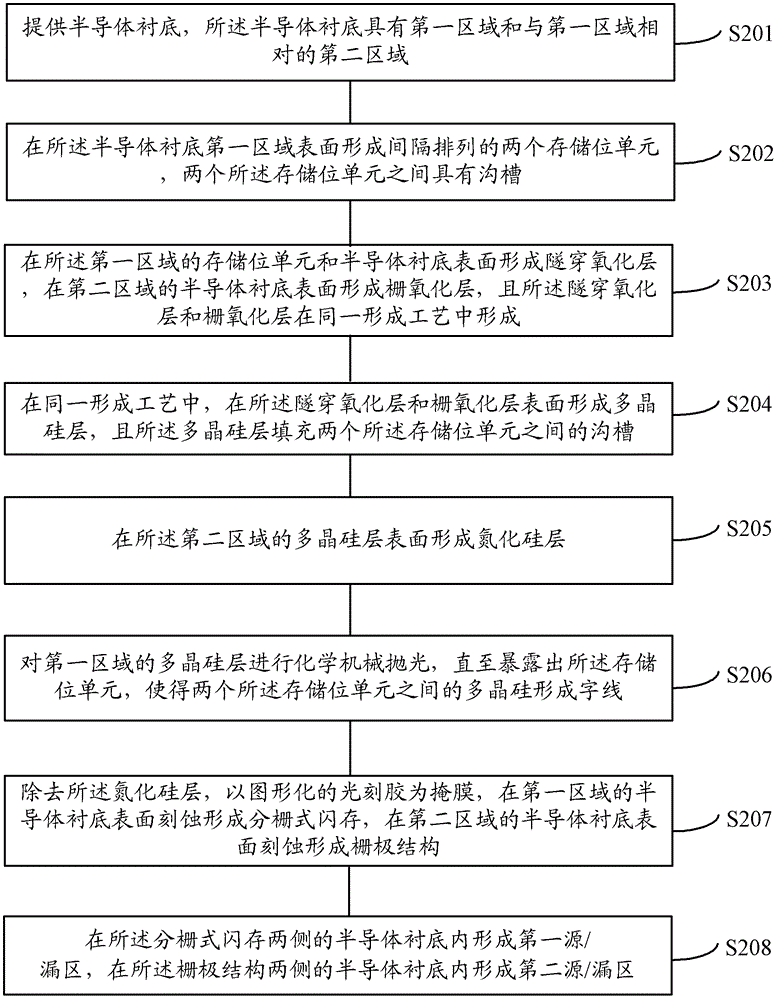

Method for manufacturing semiconductor integrated device

ActiveCN102332432BReduce consumptionReduce process stepsSemiconductor/solid-state device manufacturingMaterial consumptionEngineering

The invention provides a method for manufacturing a semiconductor integrated device, comprising the following steps of: providing a semiconductor substrate; forming two storage bit units on the surface of a first area of the semiconductor substrate in a spaced mode; forming tunneling oxide layers on the two storage bit units in the first area and the surface of the semiconductor substrate and forming gate oxide layers on the surface of the semiconductor substrate in a second area by using the same formation technology; forming polycrystalline silicon layers on surfaces of the tunneling oxide layers and gate oxide layers by using the same formation technology, and filling the polycrystalline silicon layers in the groove between the two storage bit units; and carrying out chemically mechanical polishing on the polycrystalline silicon layer in the first area until the storage bit units are exposed, so that polycrystalline silicon between the two storage bit units forms word lines. In the method, the polycrystalline silicon layers of the polycrystalline silicon word lines formed in a split gate type flash memory are utilized to manufacture other devices with the polycrystalline silicon layers, thus saving the processing steps and the material consumption and improving the processing integrated level.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

An electrochemical layer-by-layer polishing device for additively manufactured metal tubular parts

ActiveCN111636095BSmooth bore wall surfaceLayer-by-layer polishingElectrolysis componentsMechanical engineeringMaterials science

The invention discloses an electrochemical layer-by-layer polishing device for additively manufacturing metal tubular parts, which relates to the technical field of precision surface treatment, and mainly includes a control driving part, a power supply, electrodes and a working fluid; when working, the additively manufactured metal to be polished The tubular part is placed at the set position, and the electrode extends into the interior of the additively manufactured metal tubular part; the positive pole of the power supply is connected to the additively manufactured metal tubular part, and the negative pole of the power supply is connected to the electrode; the control drive part is connected to the electrode and / or the additive manufacturing To manufacture metal tubular parts, the control drive part is used to control the relative movement between the electrode and the additively manufactured metal tubular part, so that the electrode, the additively manufactured metal tubular part and the working fluid form an electrical circuit, and then the inner part of the additively manufactured metal tubular part Anodic dissolution occurs between the surface and the electrode. The invention can effectively smooth the surface of the inner hole wall of the additively manufactured parts, remove the adhered particles, and make it reach the processing standard.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Glass product polishing device

ActiveCN113070804BReduce pressureControl lengthPolishing machinesGrinding work supportsBottlePiston rod

The invention belongs to the technical field of glass processing, and in particular relates to a glass product polishing device, comprising a worktable, a rotating clamping mechanism, a polishing mechanism and a lifting mechanism; the rotating clamping mechanism includes a sleeve, a power part and an L-shaped clamping plate, and the sleeve A piston is slidably connected in the cylinder and a reset piece is provided, and a piston rod is arranged on the piston; the polishing mechanism includes an installation block, a cavity is opened in the installation block, and two grinding blocks are slidably connected on the side wall of the installation block, and the cavity is An elastic part is provided; an adjustment cylinder is fixed on the installation block, and an adjustment plate is slidably connected in the adjustment cylinder; a one-way inflow valve and a one-way outflow valve are arranged on the side wall of the installation block; a sleeve, a sliding groove, an adjustment cylinder and an empty The cavity is filled with transmission medium; the inner wall of the adjusting cylinder is provided with a limit block; the lifting mechanism is used to control the lifting and lowering of the worktable. Using this solution, the bottle mouth of glass products can be polished quickly and in a targeted manner, and at the same time, the degree of polishing can be effectively controlled to avoid excessive polishing.

Owner:CHONGQING XINGYUAN GLASSWARE CO LTD

A 3D printed article surface polishing and strengthening device

ActiveCN108790175BReduce restrictionsHigh strengthAdditive manufacturing apparatus3D object support structuresEngineeringHolding tank

The invention discloses a 3D printing object surface polishing and strengthening device. The device comprises an outer shell, a top cover arranged at the top of the outer shell, a bottom cover arranged at the bottom of the outer shell, a separation plate arranged in the outer shell, a polishing liquid holding tank formed above the separation plate, a liner arranged above the polishing liquid holding tank, a tray arranged in the liner, an electric heating plate arranged under the separation plate, and an electronic relay arranged on the bottom cover. The 3D printing object surface polishing andstrengthening device can hold polished objects made of multiple materials and multiple types of polishing liquid, is uniform in polishing, high in polishing efficiency and excellent in polishing effect, improves the rupture strength and the toughness of the polished objects, recycles the polishing liquid, is safe in operation, protects the environment, and saves the cost; and the polishing devicecan be zoomed according to equal proportion, and the capacity can be increased or reduced according to special polishing demands, so that the size application range of the polished objects is more free.

Owner:神匠(深圳)新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com