Electrochemical polishing device and polishing method for vascular stent

A vascular stent and polishing device technology, applied in the polishing field, can solve the problems of low degree of automation, complicated procedures, uneven contact of vascular stents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

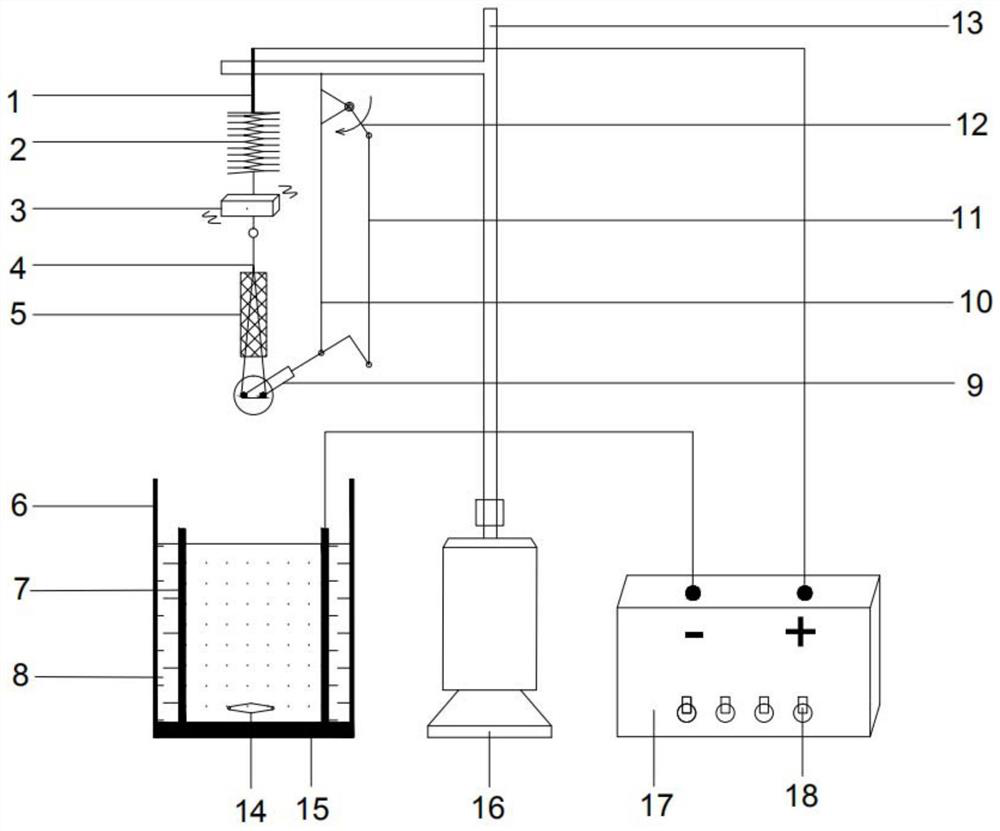

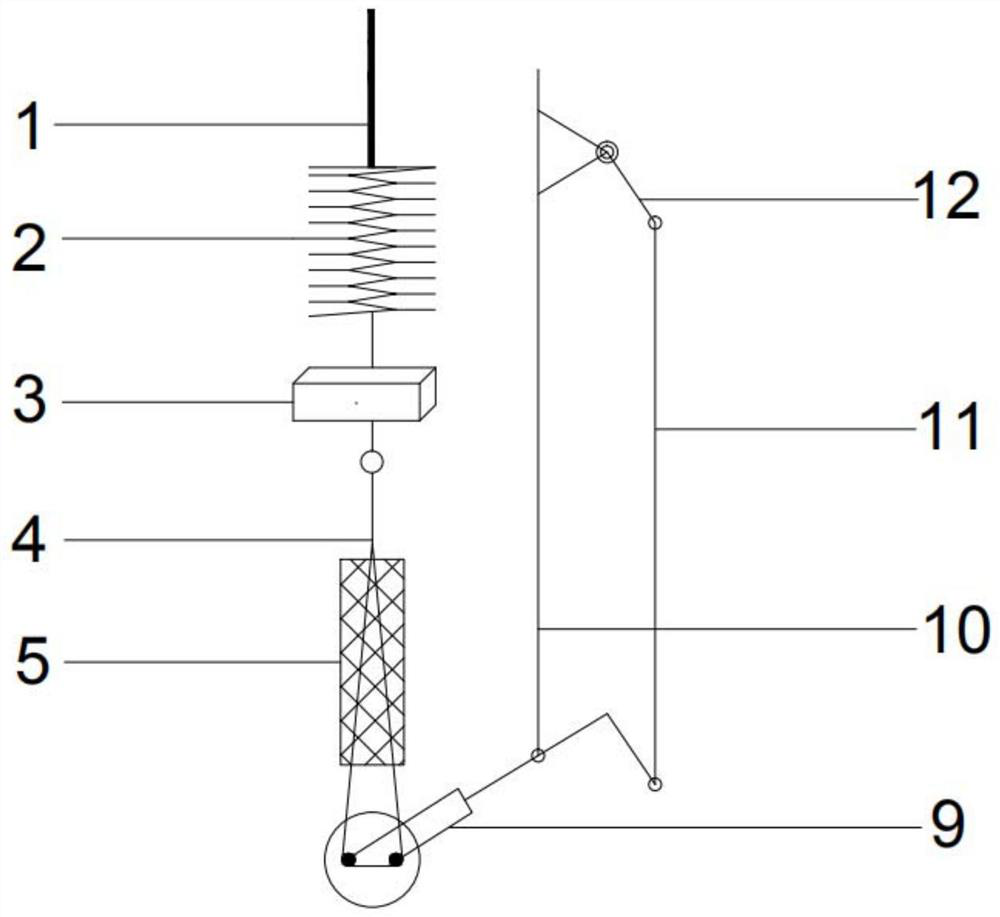

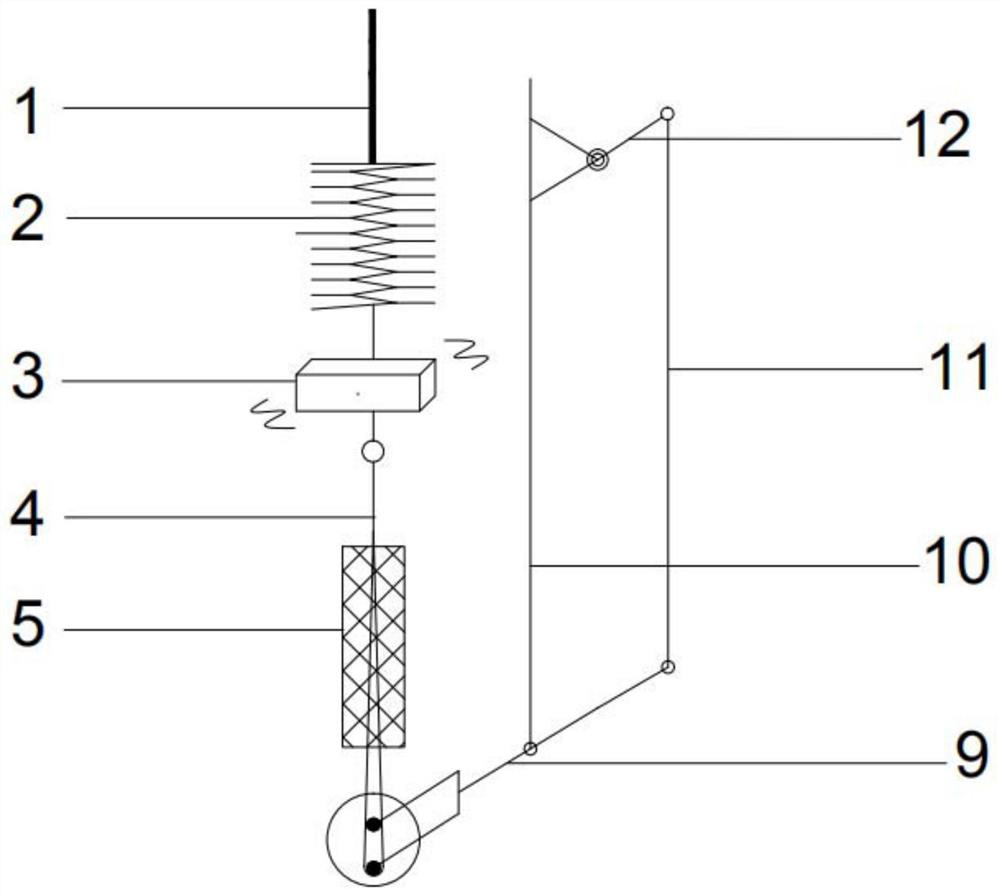

[0046] figure 1 It is a structural schematic diagram of the electrochemical polishing device for the vascular stent provided in this embodiment. figure 2 It is a schematic diagram of the local structure of the electrochemical polishing device for the vascular stent provided in this embodiment Figure 1 (the first support frame is in a horizontal position). image 3 It is a schematic diagram of the local structure of the electrochemical polishing device for the vascular stent provided in this embodiment Figure II (the first support frame is in a vertical position). Figure 4 It is a structural schematic diagram of the first support frame 9 involved in this embodiment. Figure 5 It is a structural schematic diagram of the cathode 7 involved in this embodiment. Such as Figure 1-Figure 5 As shown, this embodiment provides an electrochemical polishing device for a vascular stent, which is used for electrochemically polishing the surface of the vascular stent 5, especially f...

Embodiment 2

[0057] Image 6 It is a process schematic diagram of the vascular stent polishing process involved in this embodiment. Such as Image 6 As shown, this embodiment provides a polishing method for a vascular stent, which is applied to the electrochemical polishing device for a vascular stent in Embodiment 1. This polishing method specifically comprises the steps:

[0058]S1. First, prepare the required polishing solution 8 in the polishing cylinder 6 in proportion. In this embodiment, preferably, the polishing liquid 8 includes: sulfuric acid: 10-20%, methanol: 80-90%, the polishing liquid 8 can effectively polish the molten fragments on the surface of the vascular stent 5, and improve the quality of the vascular stent. 5 surface smoothness. Of course, in other embodiments, a suitable polishing liquid 8 can also be flexibly selected according to needs, which is not limited to this embodiment. After the polishing liquid 8 is prepared, the polishing temperature is set, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com