Patents

Literature

78results about How to "Stable polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

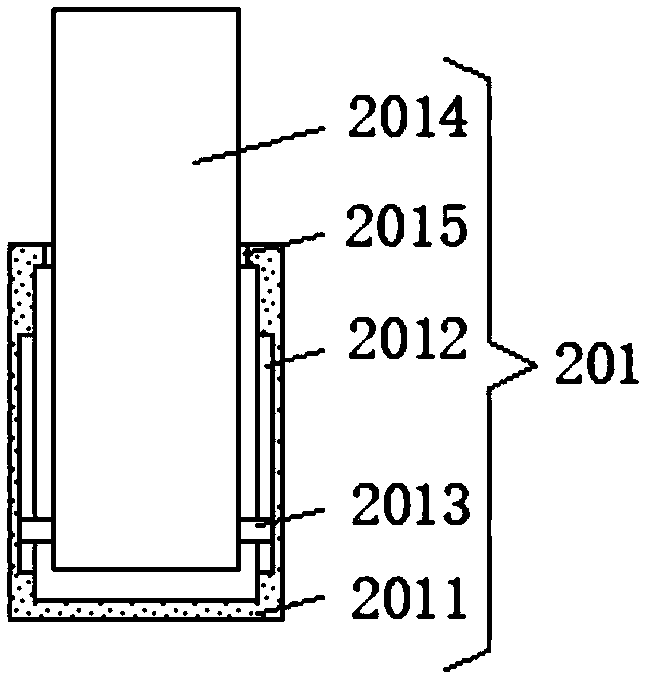

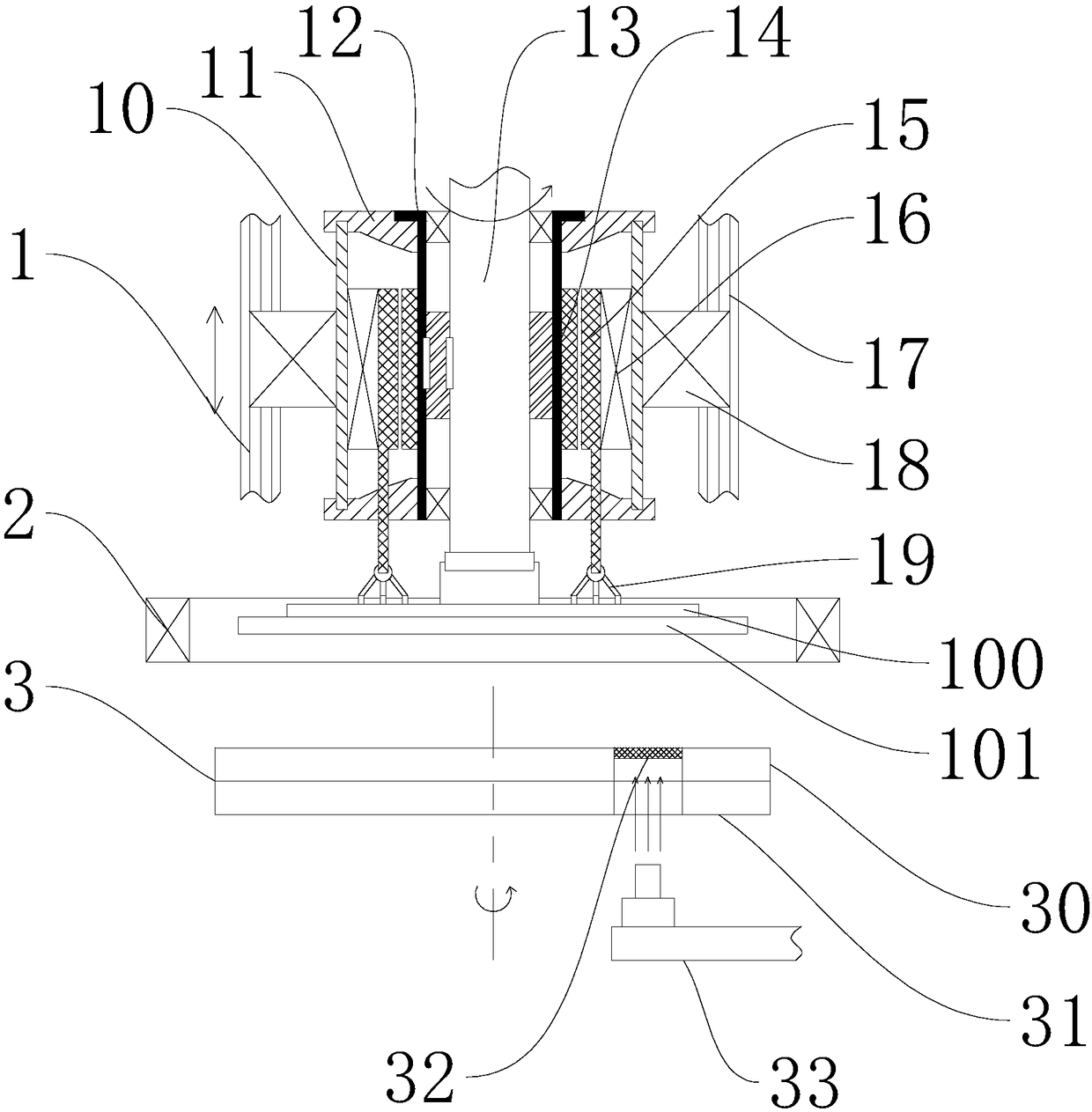

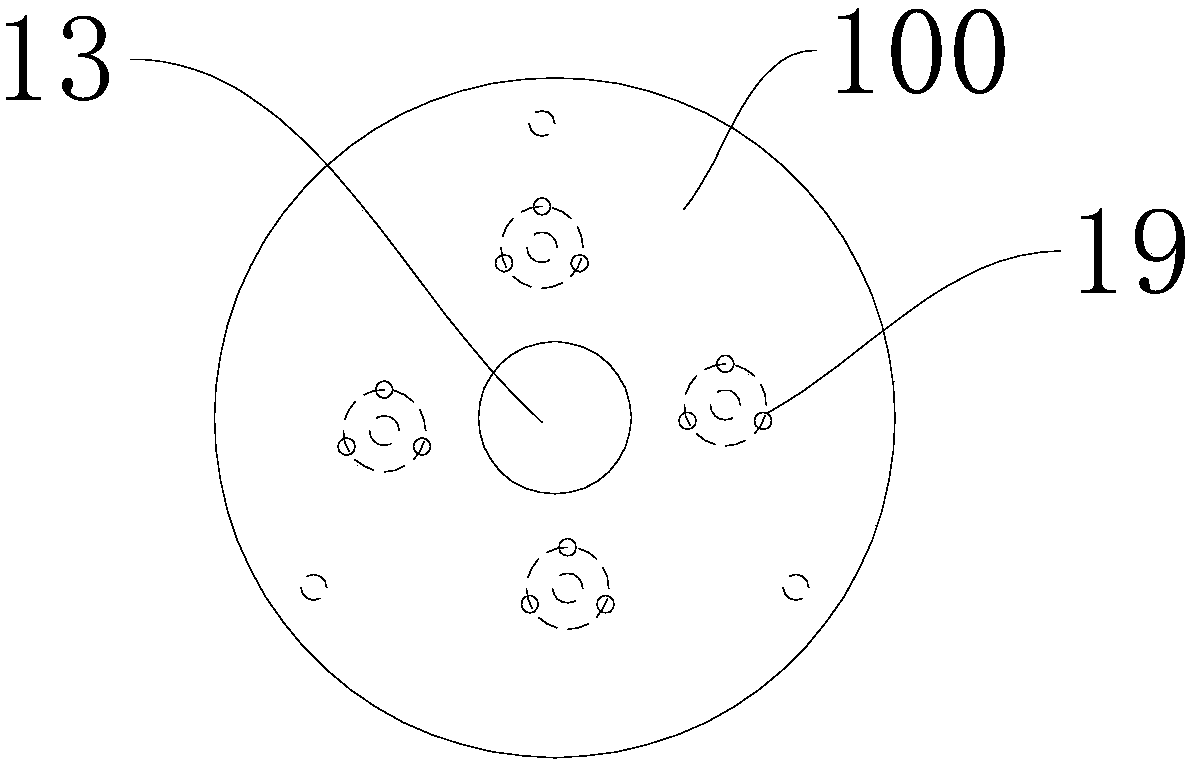

Double side polishing device for wafer and double side polishing method

InactiveUS20050124264A1High precision without deteriorating wafer shapeGood precisionEdge grinding machinesPolishing machinesEngineeringSlurry

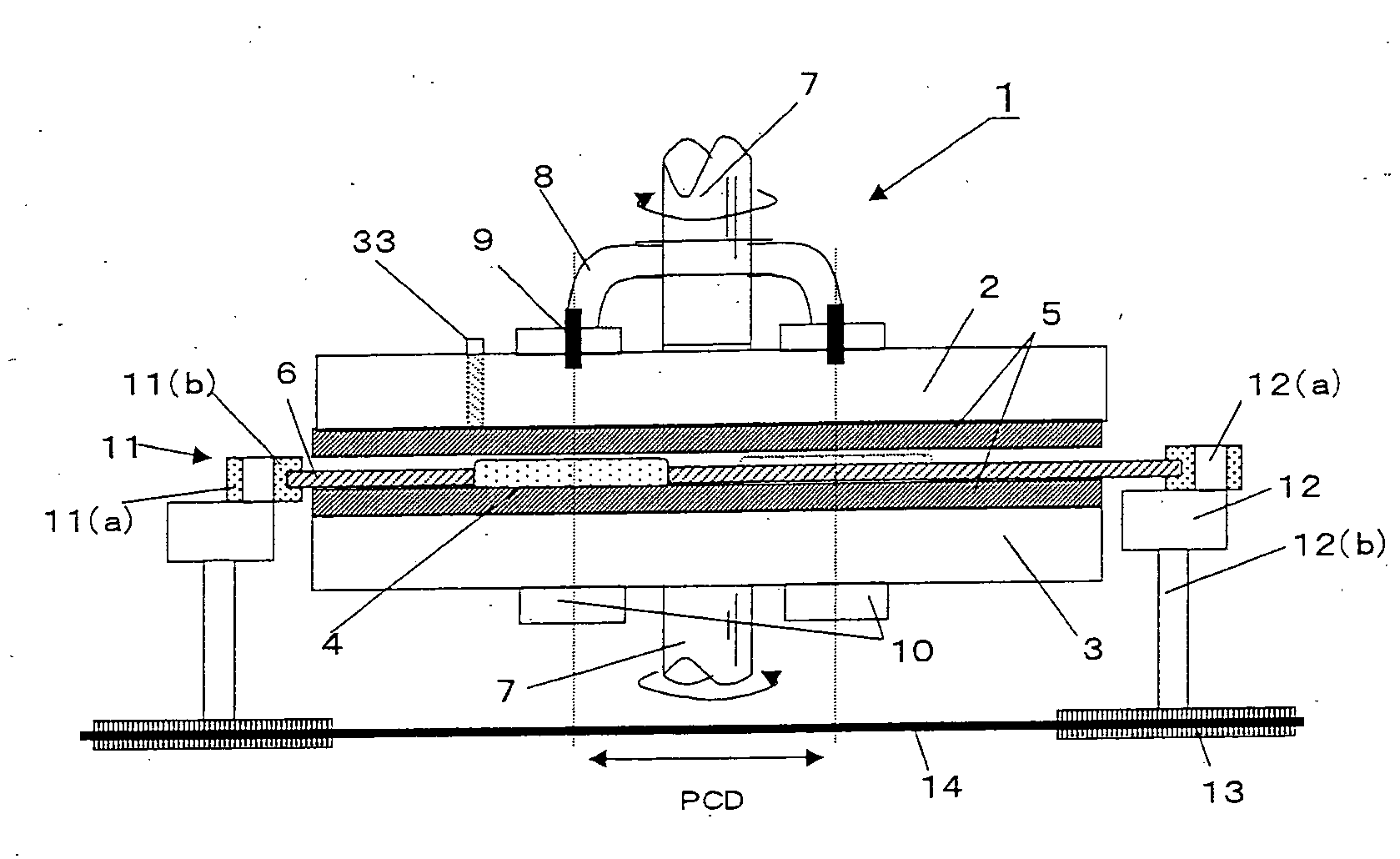

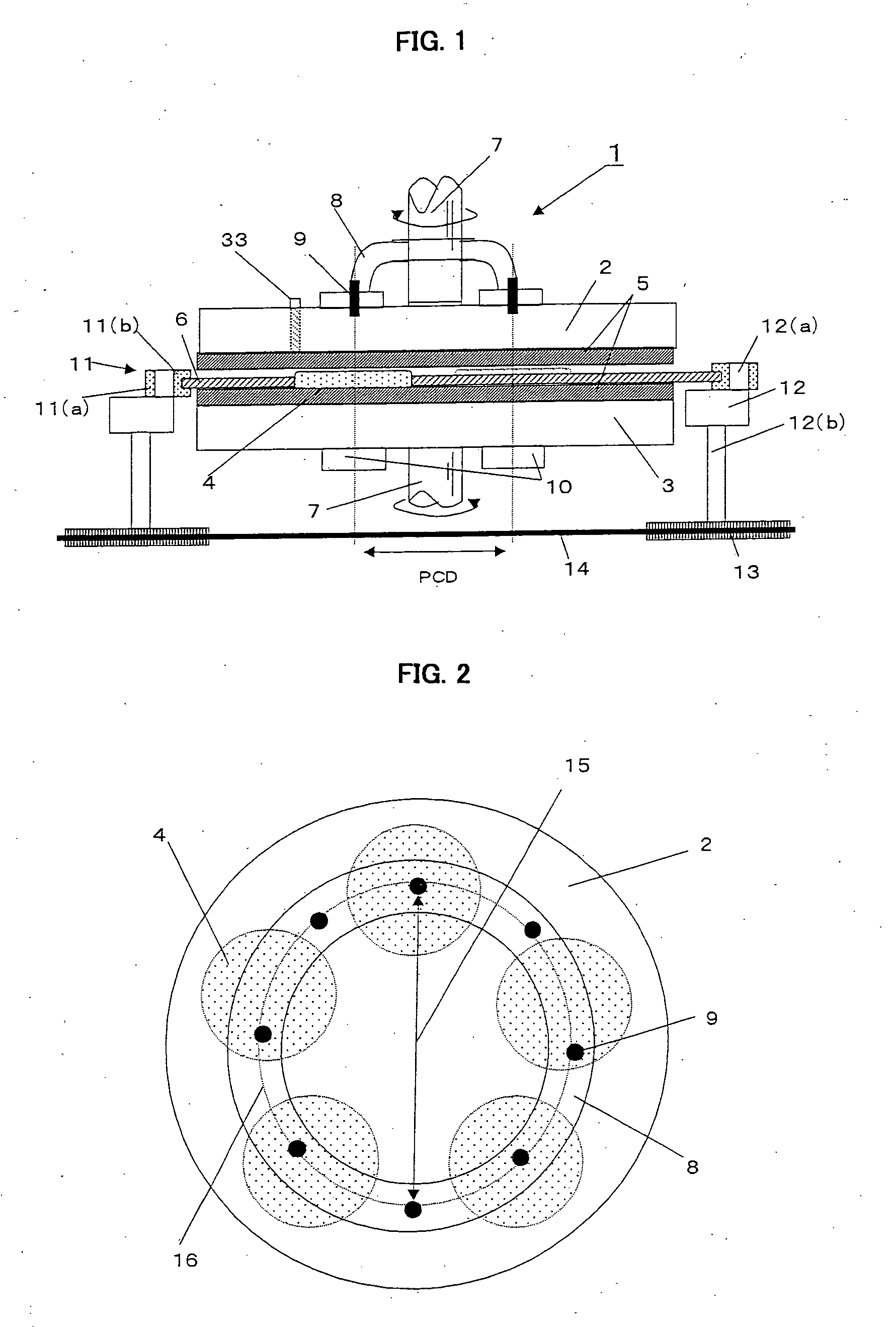

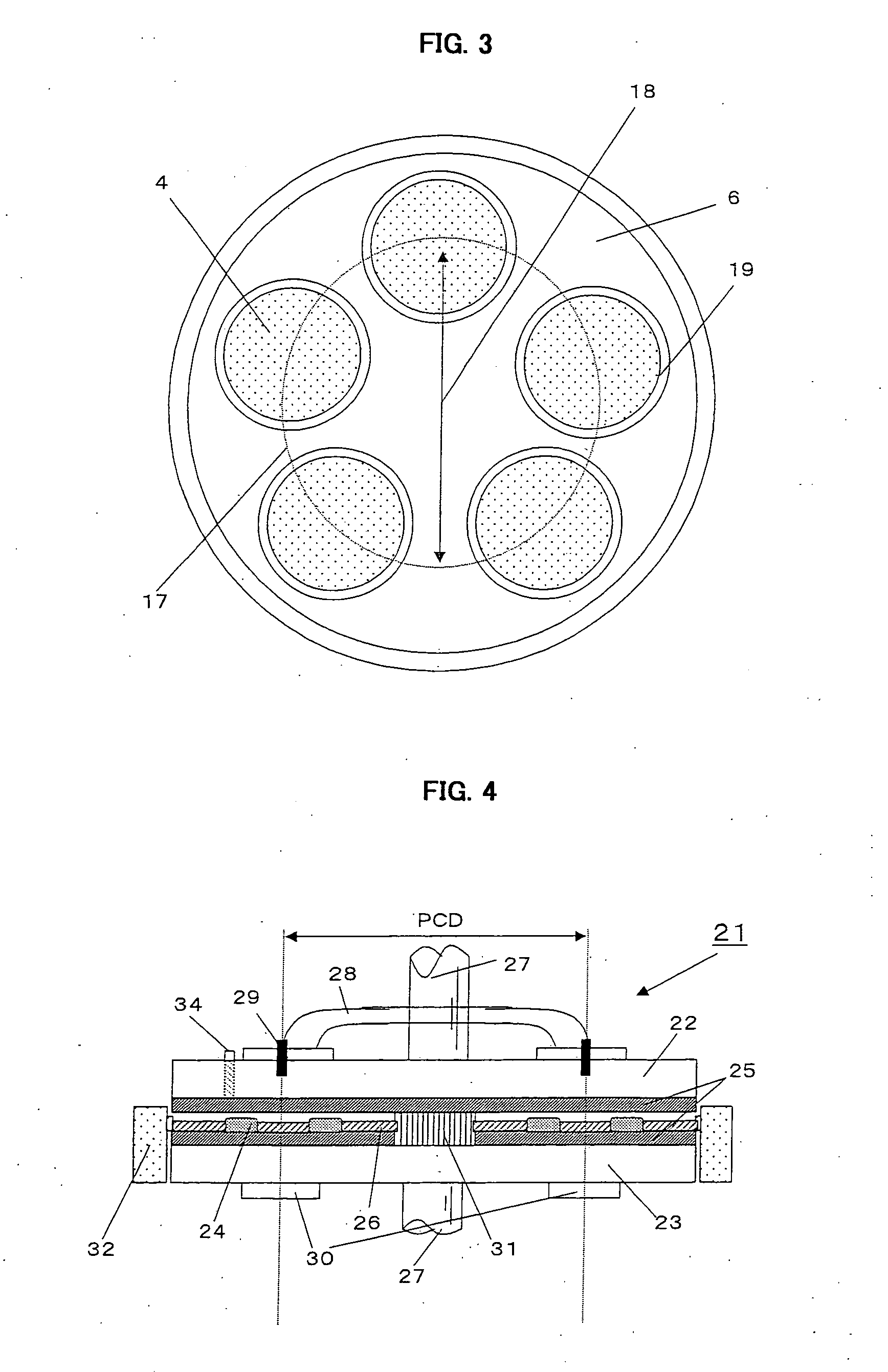

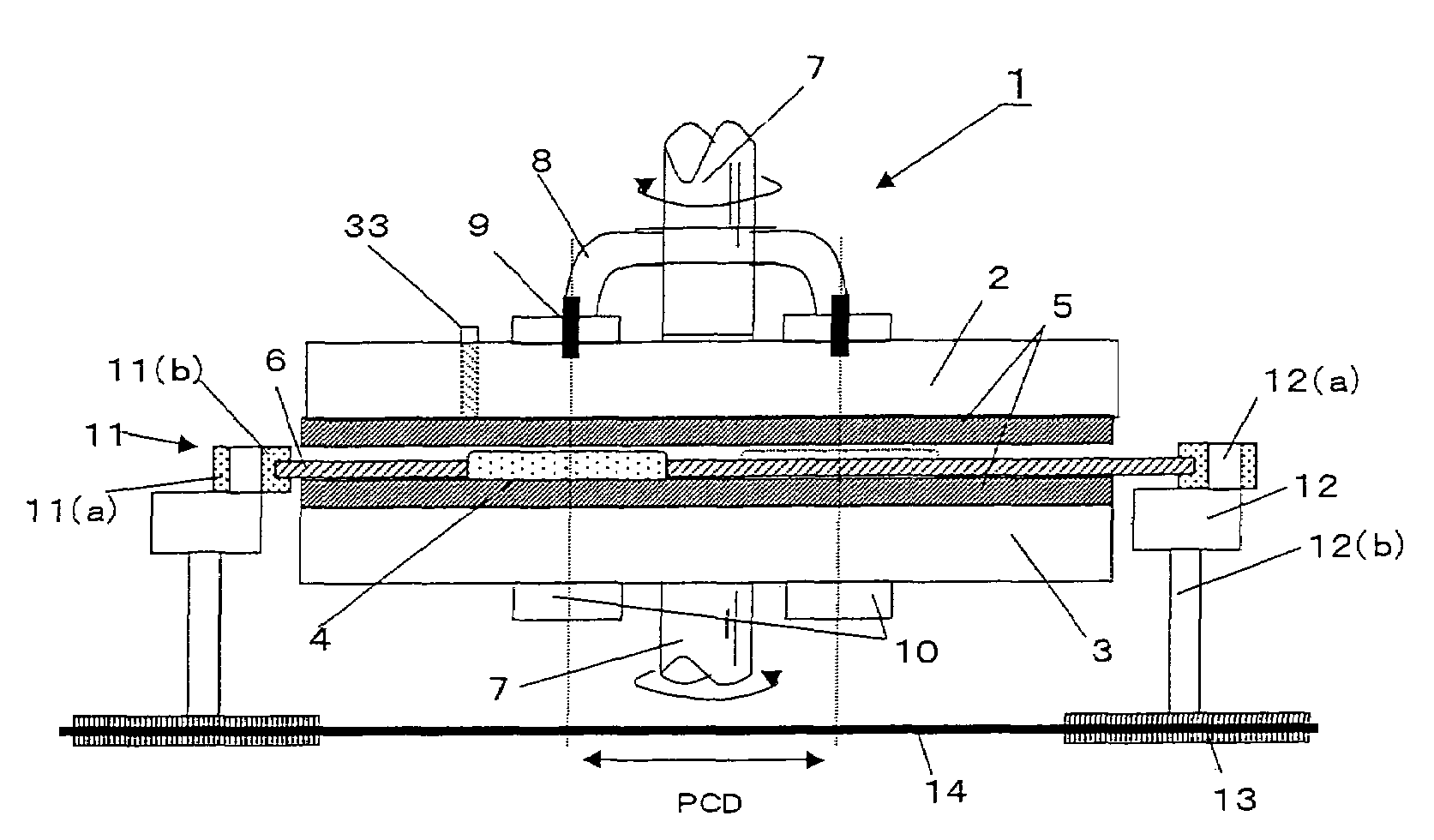

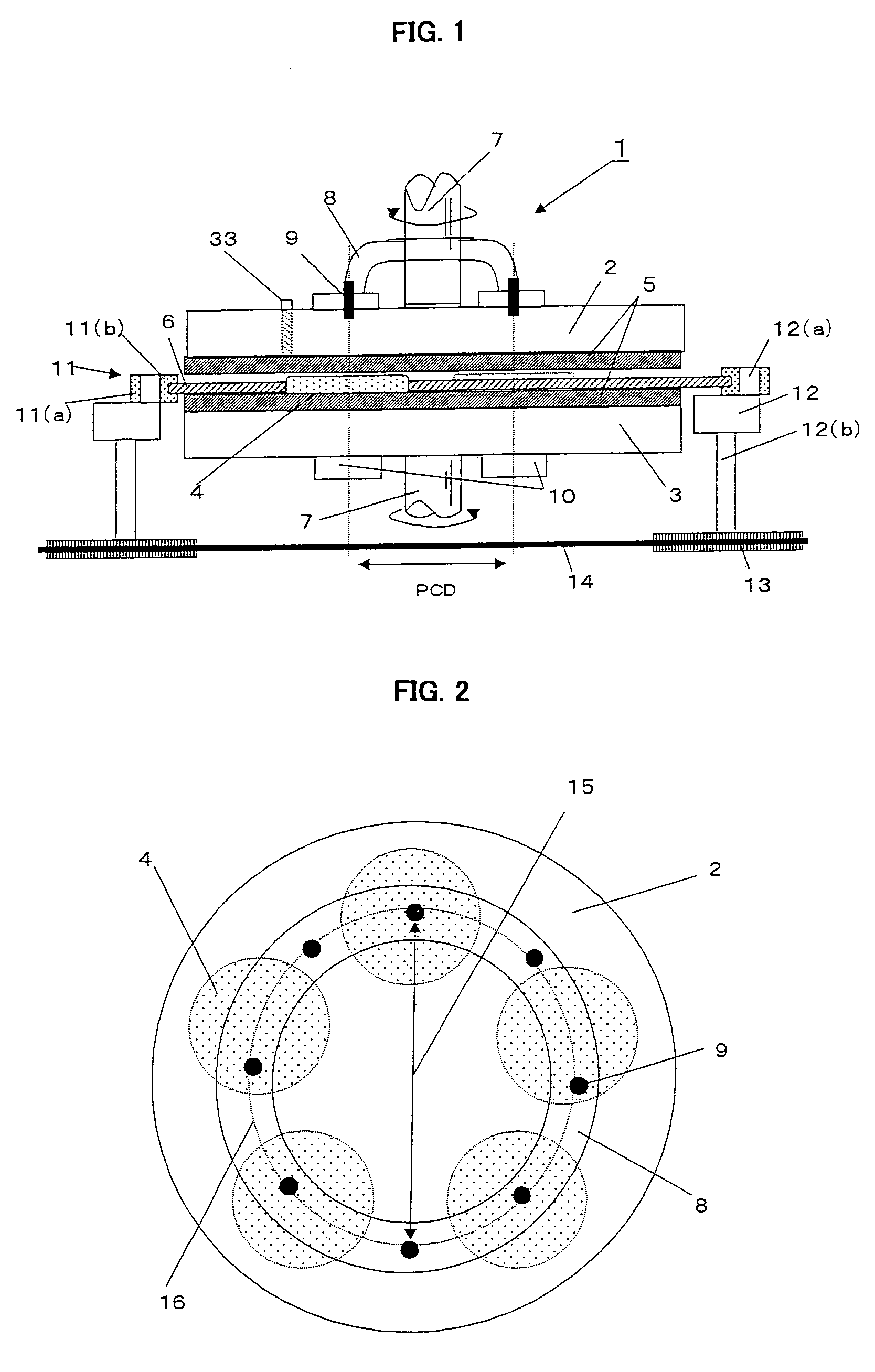

The present invention provides a wafer double-side polishing apparatus comprising at least a carrier plate having wafer holding holes; upper and lower turn tables to which polishing pads are attached; and a slurry supply means; with wafers held in the wafer holding holes, the carrier plate being moved between the upper and lower turn tables while supplying slurry, to simultaneously polish both front and back surfaces of wafers, wherein a PCD of upper turn table load supporting points that is a diameter of a circle joining load supporting points of the upper turn table coincides with a PCD of centers of the wafer holding holes on the carrier plate that is a diameter of a circle joining each center of the wafer holding holes on the carrier plate. Thereby, there can be provided a wafer double-side polishing apparatus and method in which it is possible to control wafer shape by deforming turn tables with excellent responsiveness, and to polish the wafers stably with high precision without deteriorating wafer shape.

Owner:SHIN-ETSU HANDOTAI CO LTD

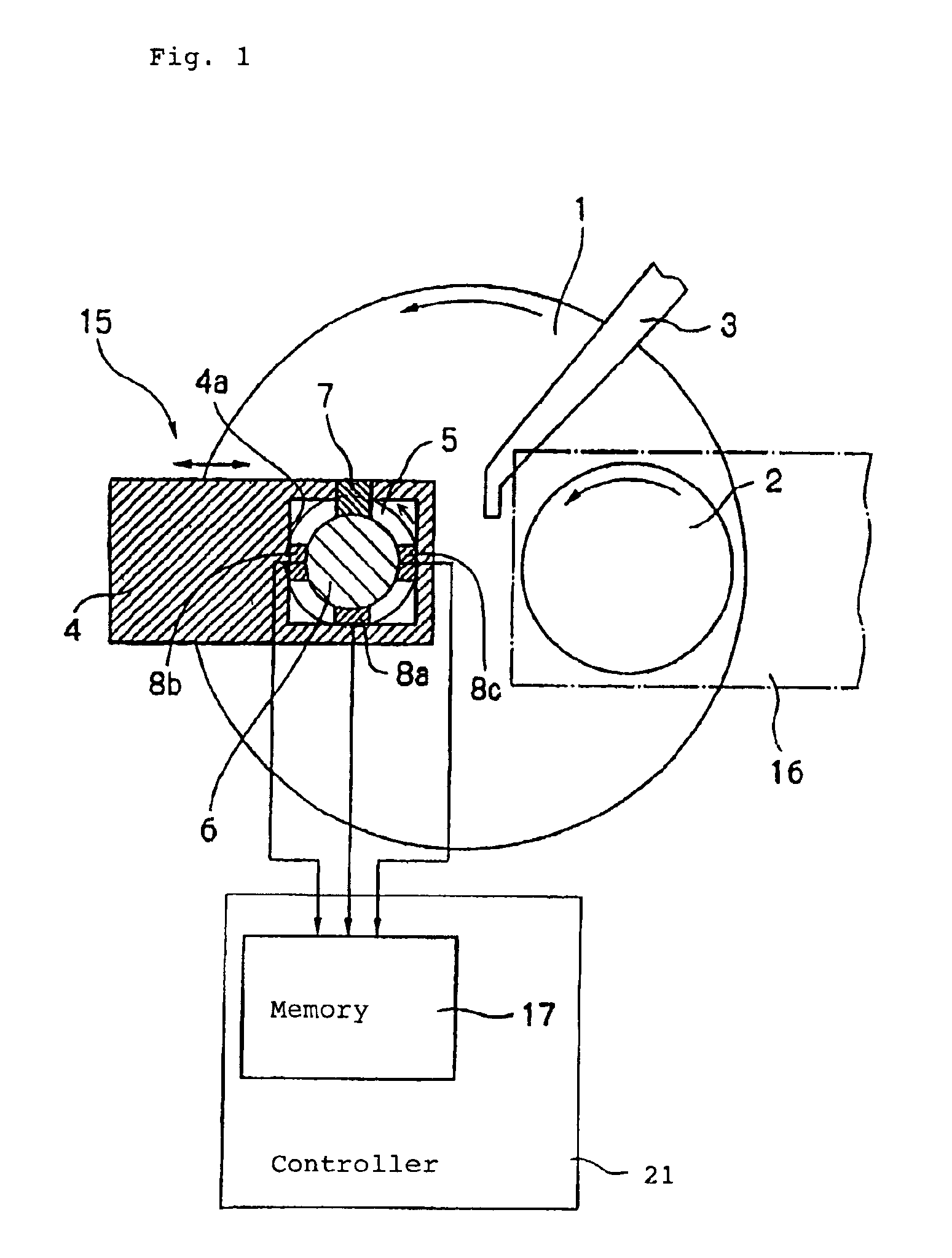

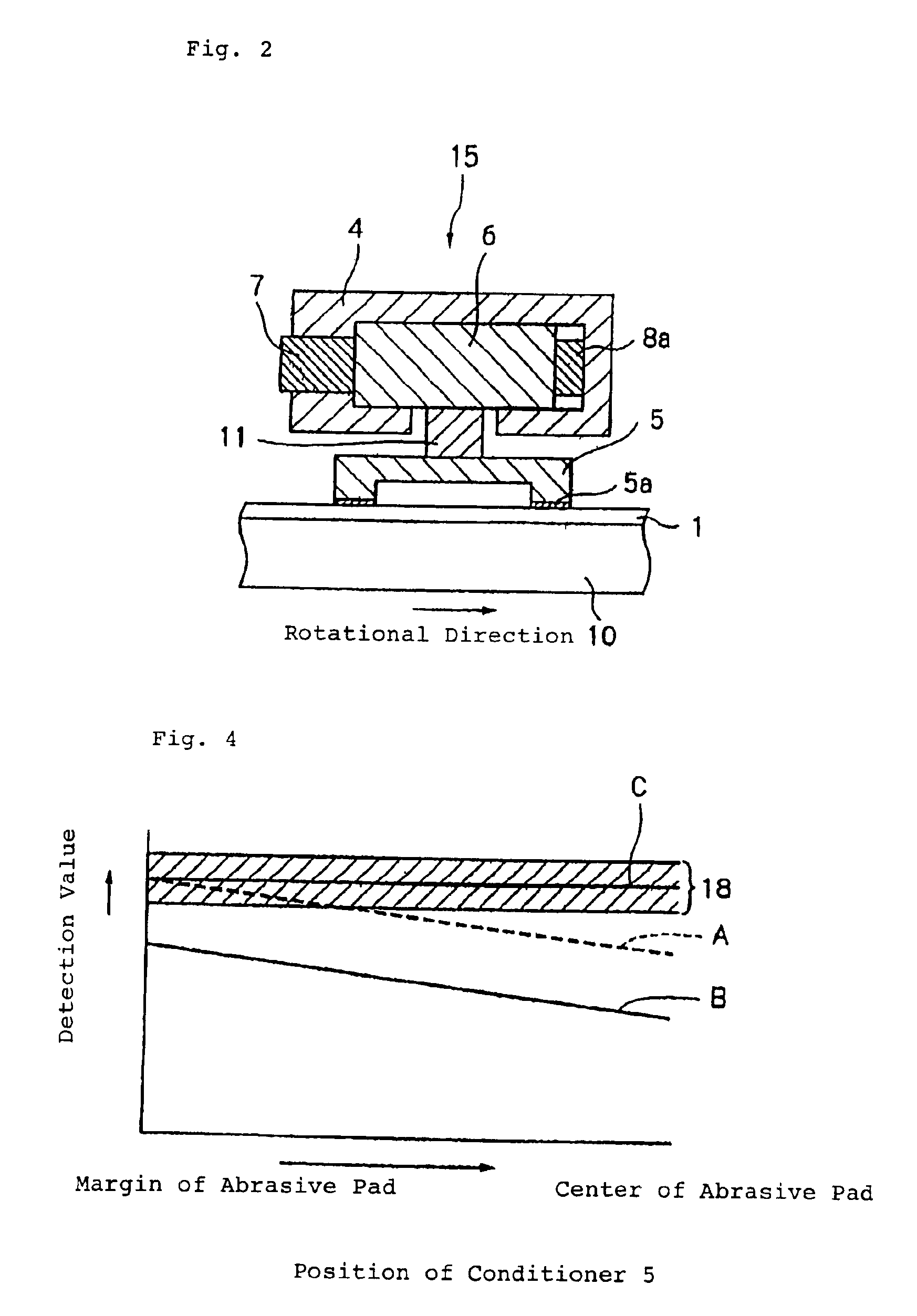

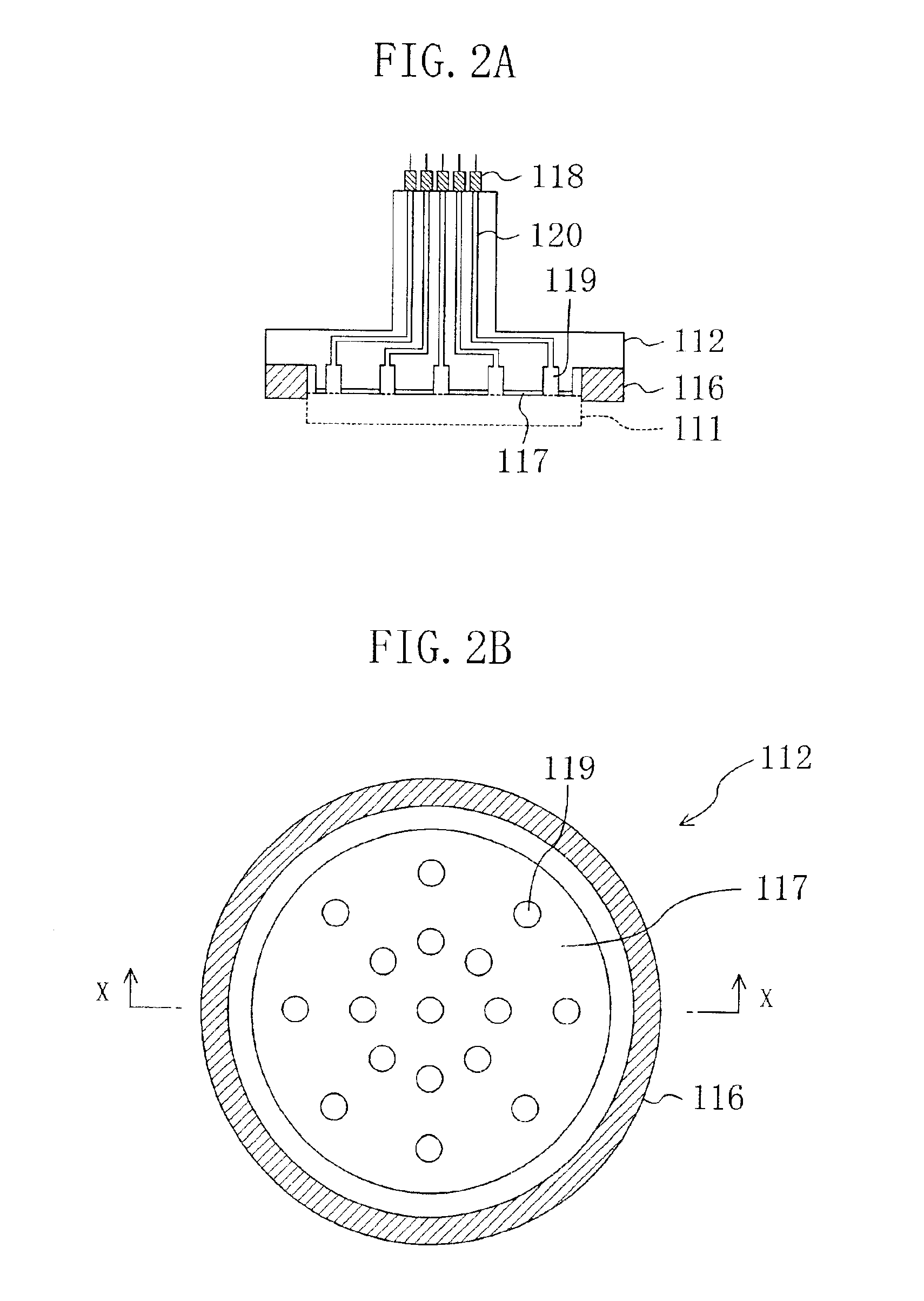

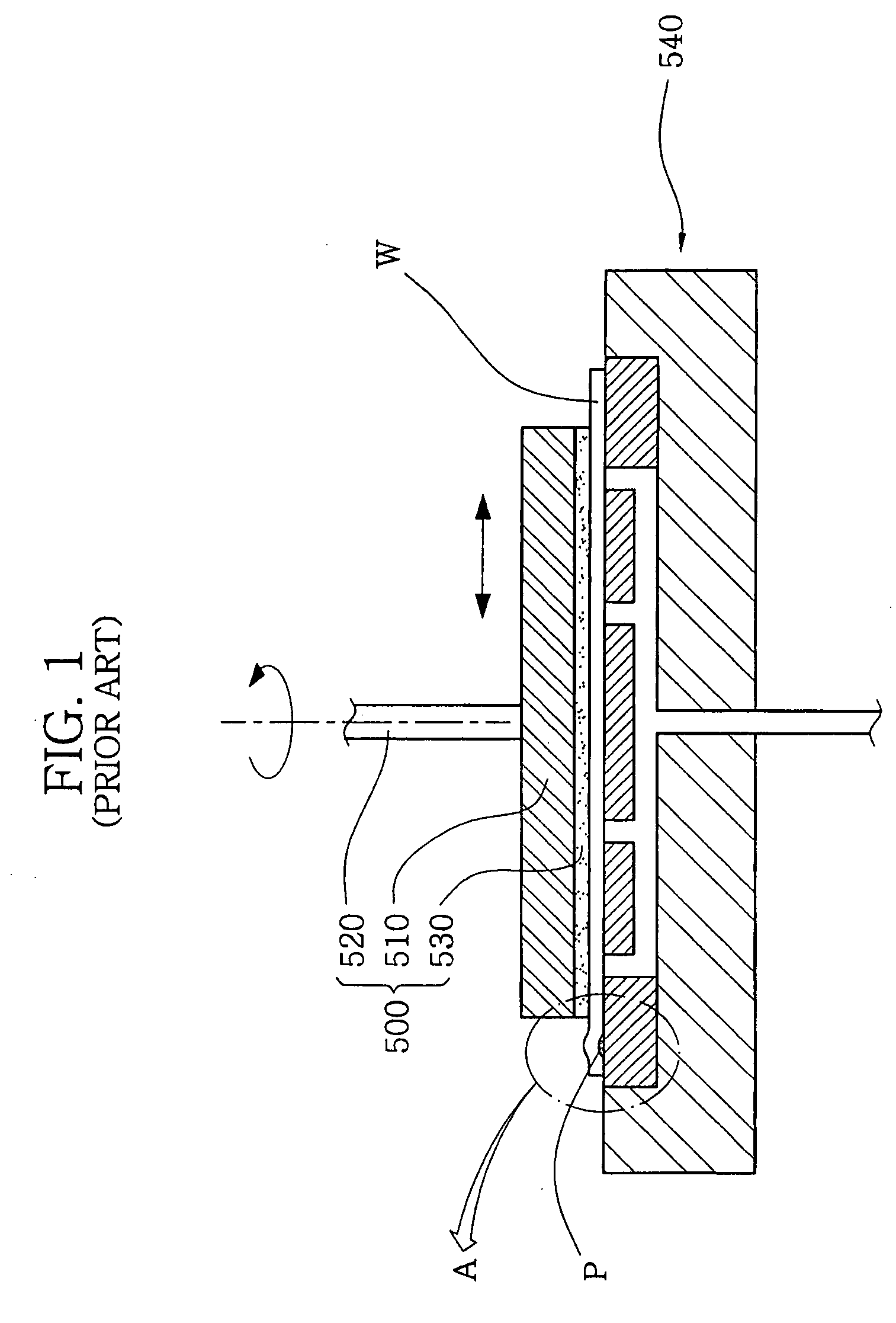

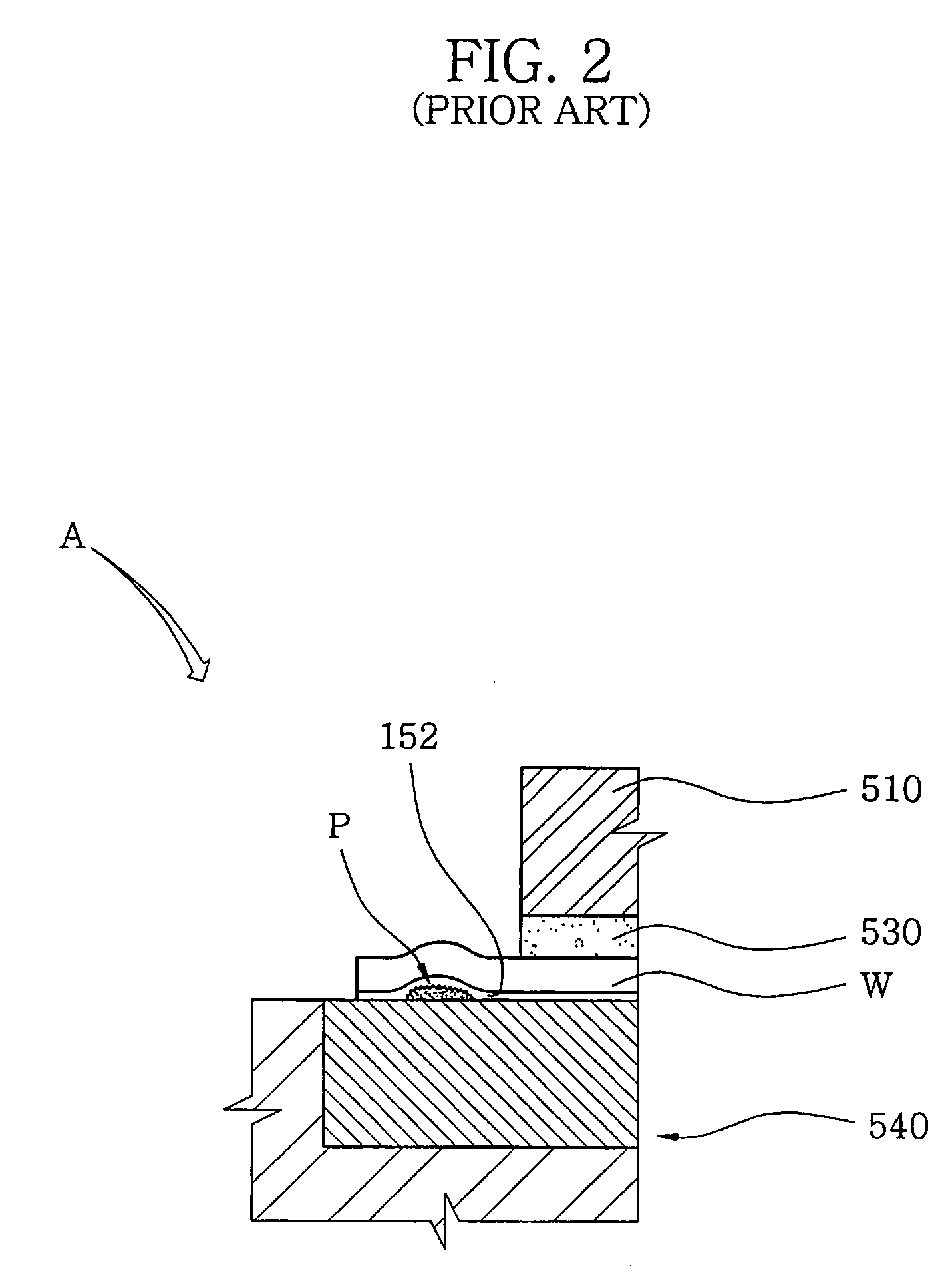

Wafer polishing method and wafer polishing apparatus in semiconductor fabrication equipment

InactiveUS6905571B2Accurately detectAccurate detectionEdge grinding machinesSemiconductor/solid-state device manufacturingSemiconductor

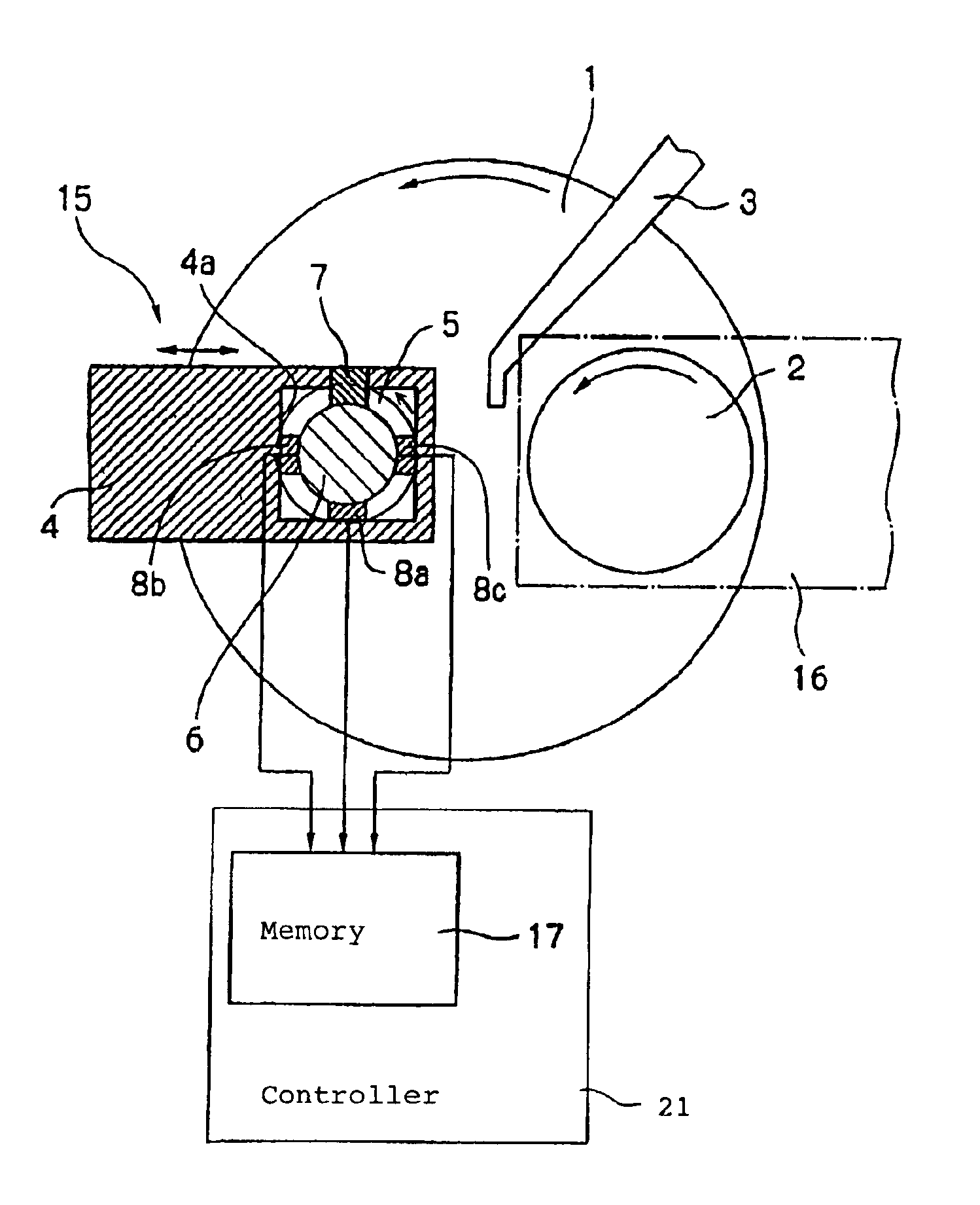

When honing an abrasive pad for polishing a wafer by rotating while closely contacting the wafer by bringing a conditioner into contact with the abrasive pad, forces applied from the abrasive pad to the conditioner are detected by a plurality of pressure detectors through a conditioner driving unit for holding the conditioner. The pressure detectors are respectively able to detect forces in two directions such as rotational direction and radial direction. A memory stores correlations between detection values and wafer polishing quantities under various conditioning terms. Therefore, it is determined whether the detection values are kept within acceptable limits stored in the memory. When the values are out of the acceptable limits, a controller controls the values so that they fall within the acceptable limits by properly changing conditioning terms.

Owner:LONGITUDE SEMICON S A R L

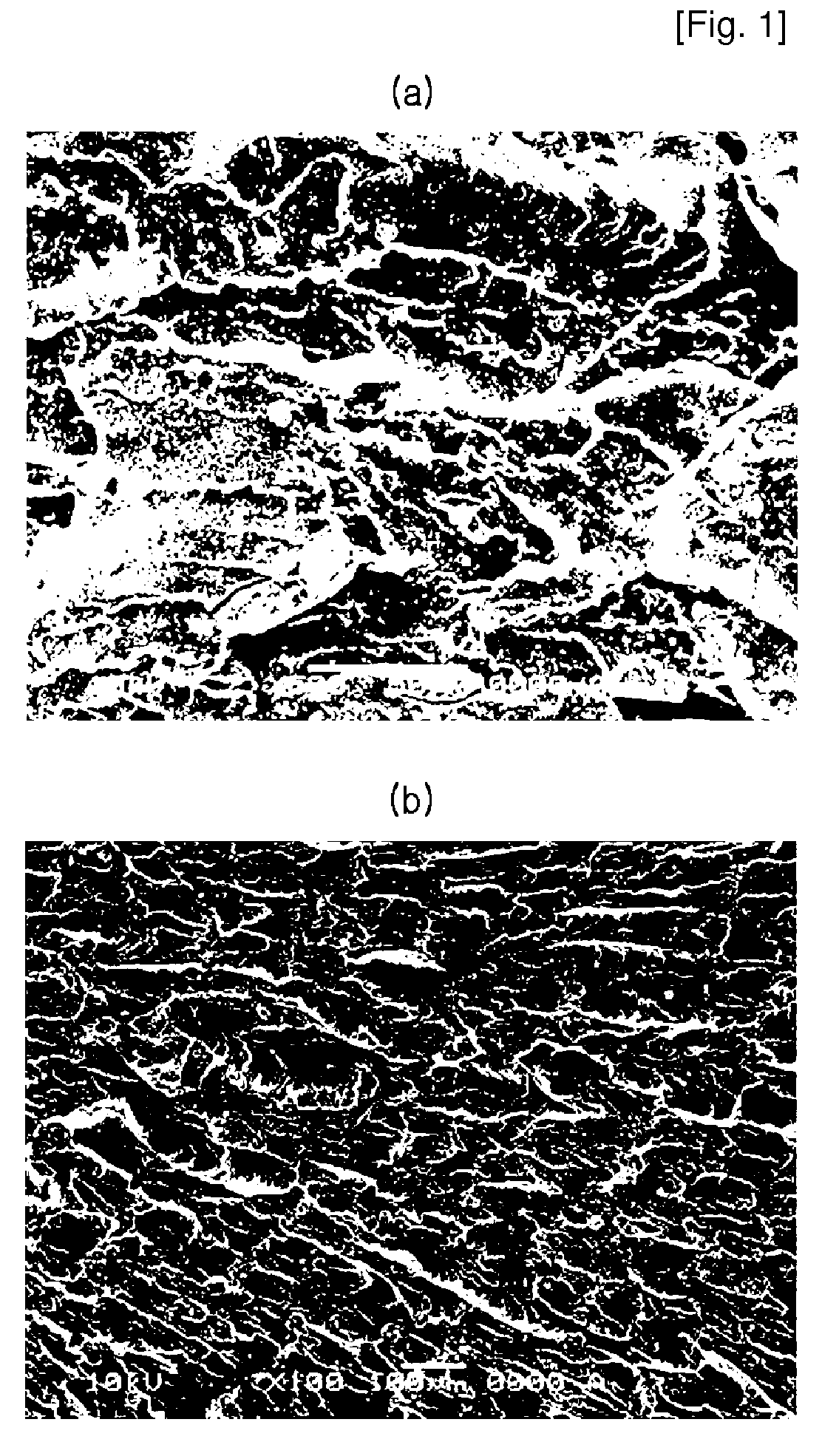

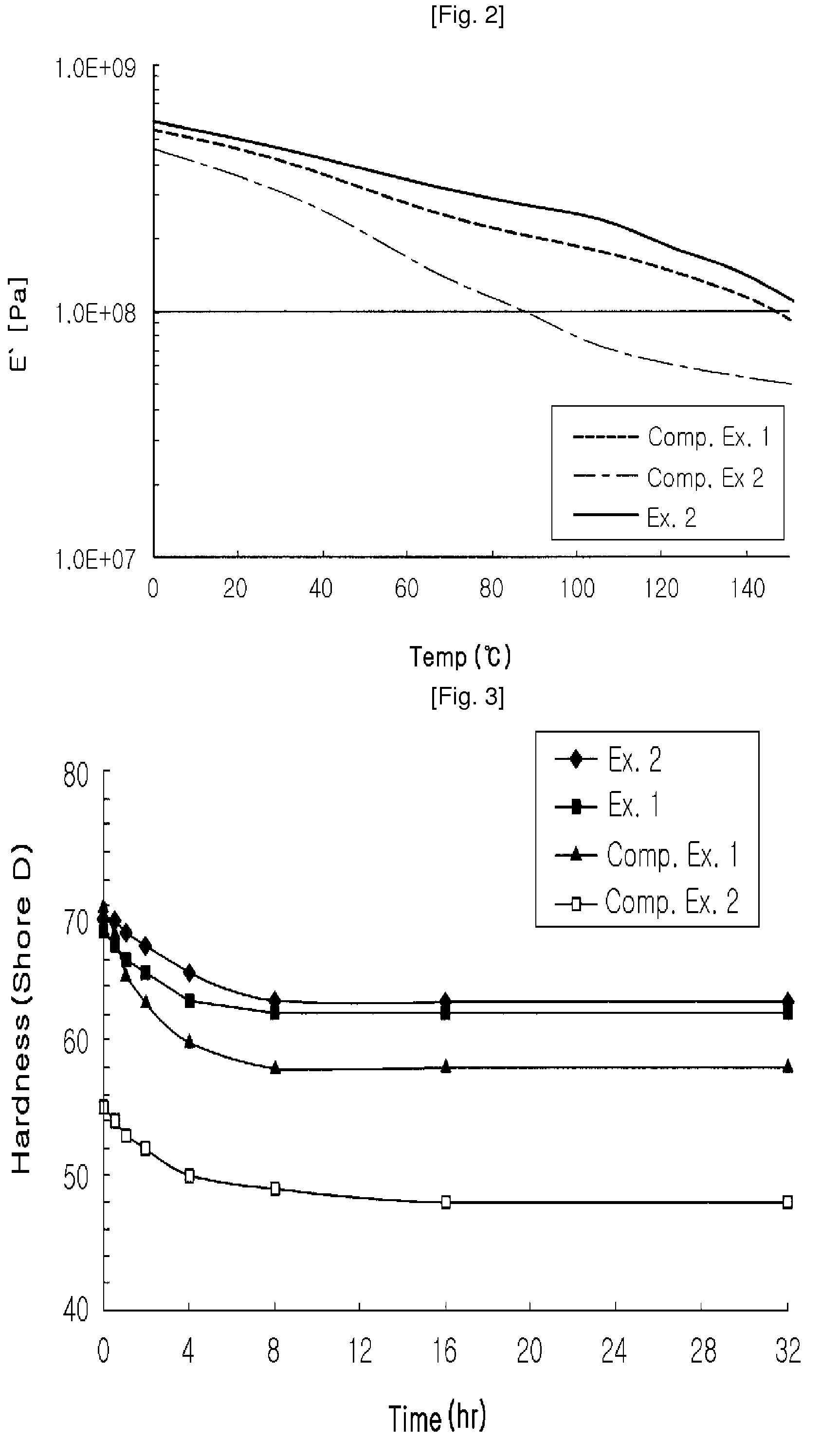

Composition for polishing pad and polishing pad therewith

InactiveUS20040063391A1Stable polishingAbrasion apparatusLapping toolsWater insolubleYoung's modulus

An objective of the present invention is to provide a composition for polishing pad that is excellent in formability, abrasion resistance and small in temperature dependence of Young's modulus and a polishing pad therewith. The composition for polishing pad of the present invention comprises a water-insoluble matrix and a water-soluble particle dispersed in the water-insoluble matrix. The water-insoluble matrix contains a crosslinked ethylene-vinyl acetate copolymer and / or a crosslinked 1,2-polybutadiene and each of these is contained by a prescribed amount against the total of the water-insoluble matrix.

Owner:JSR CORPORATIOON

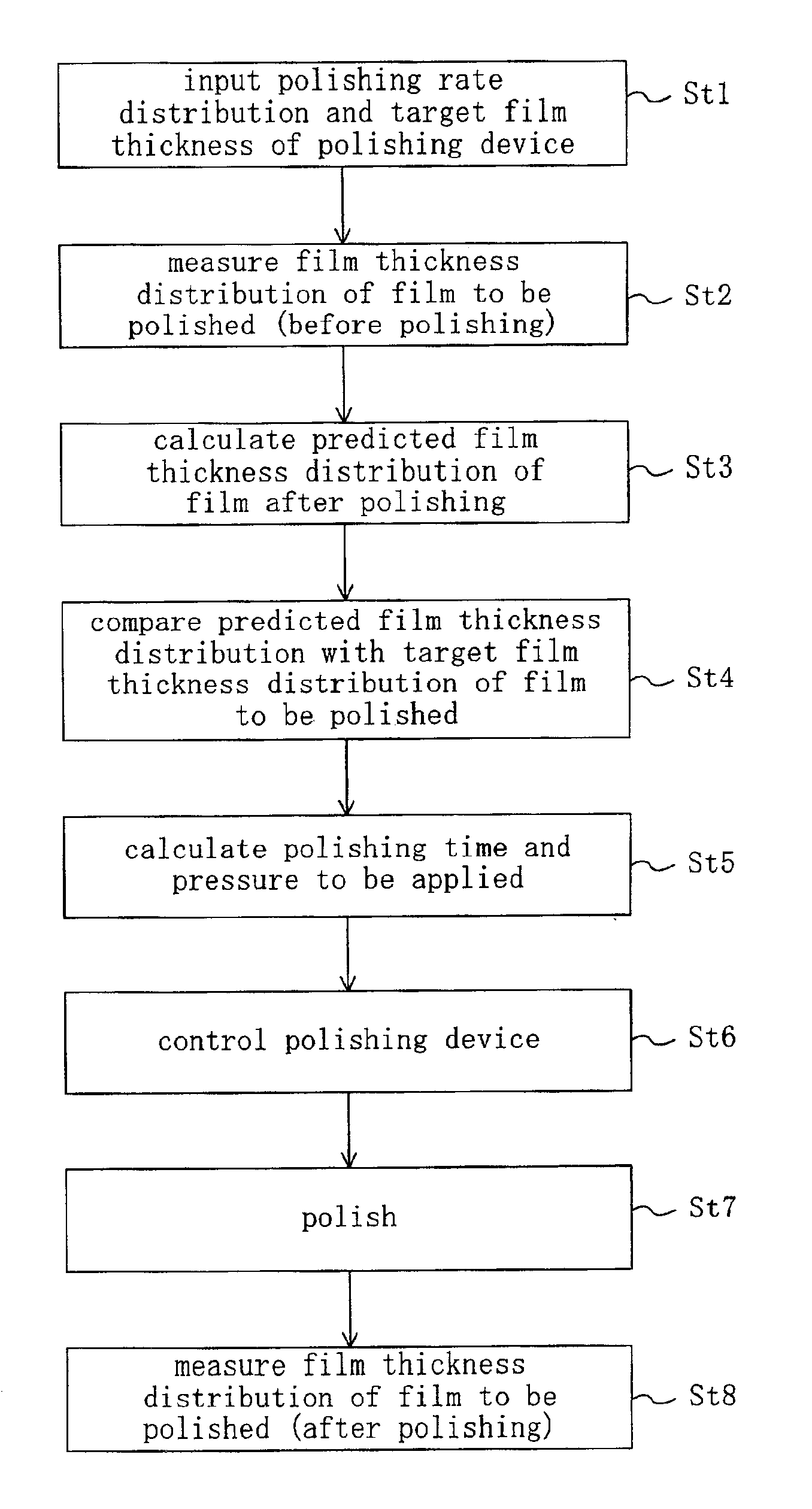

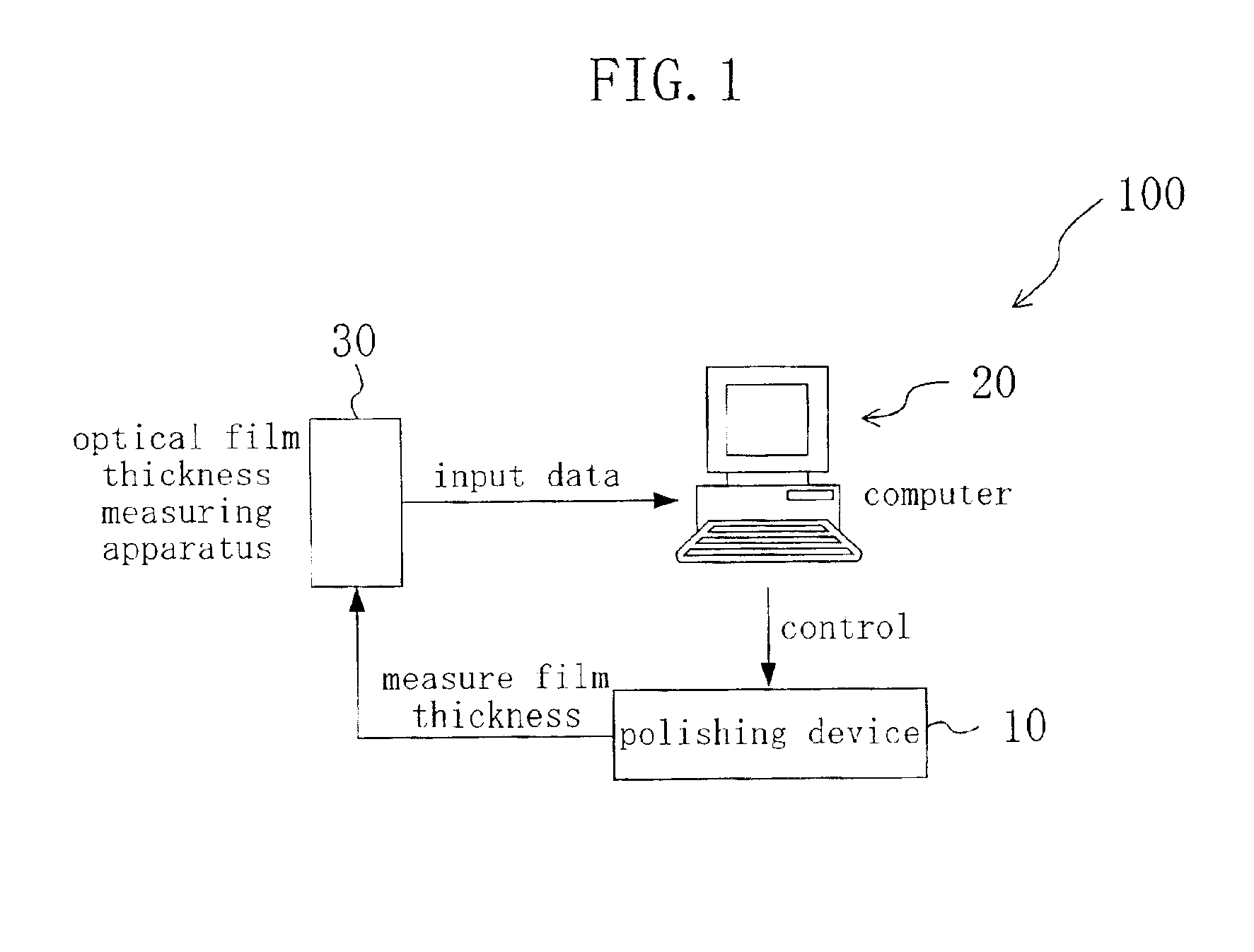

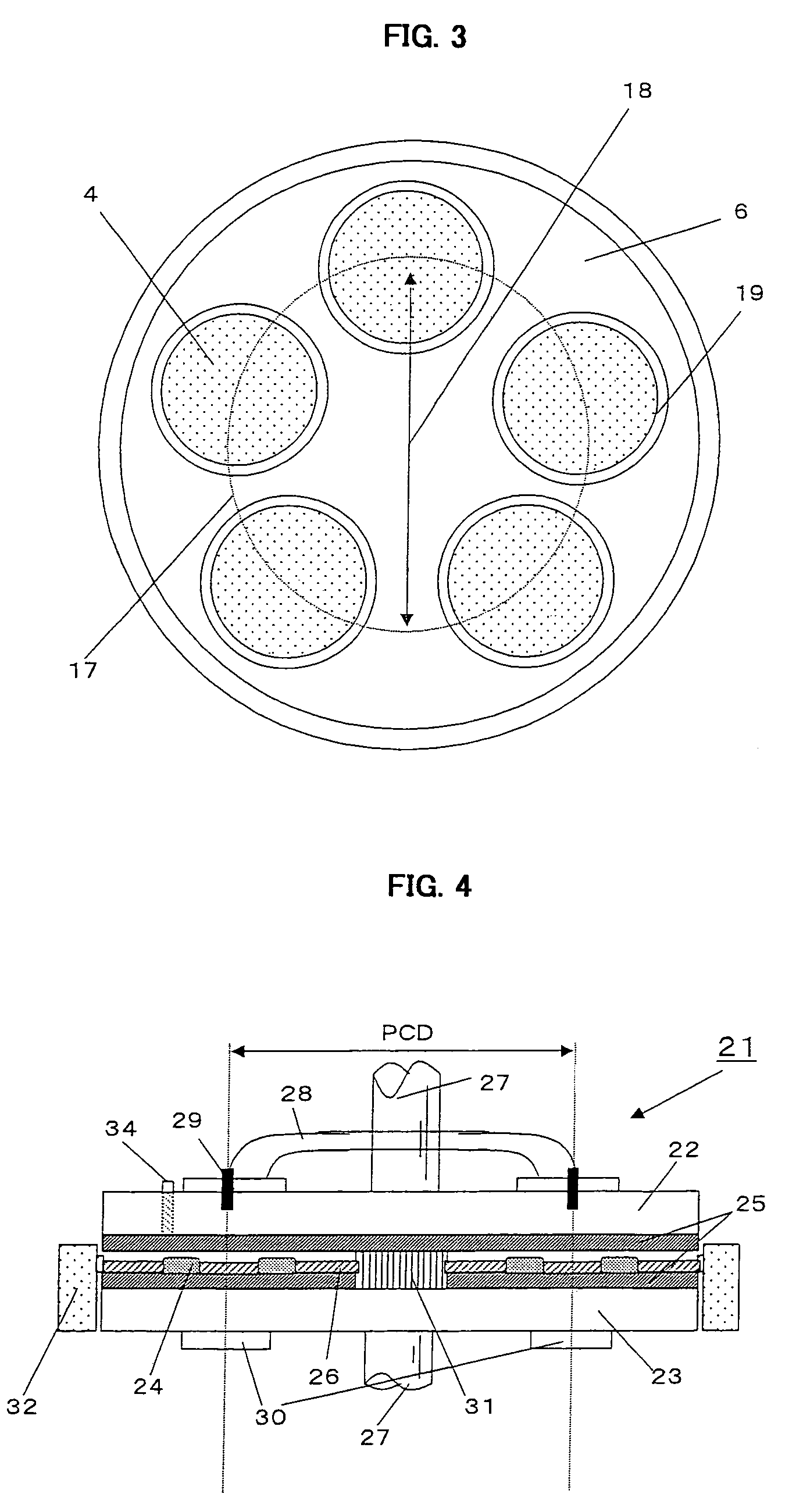

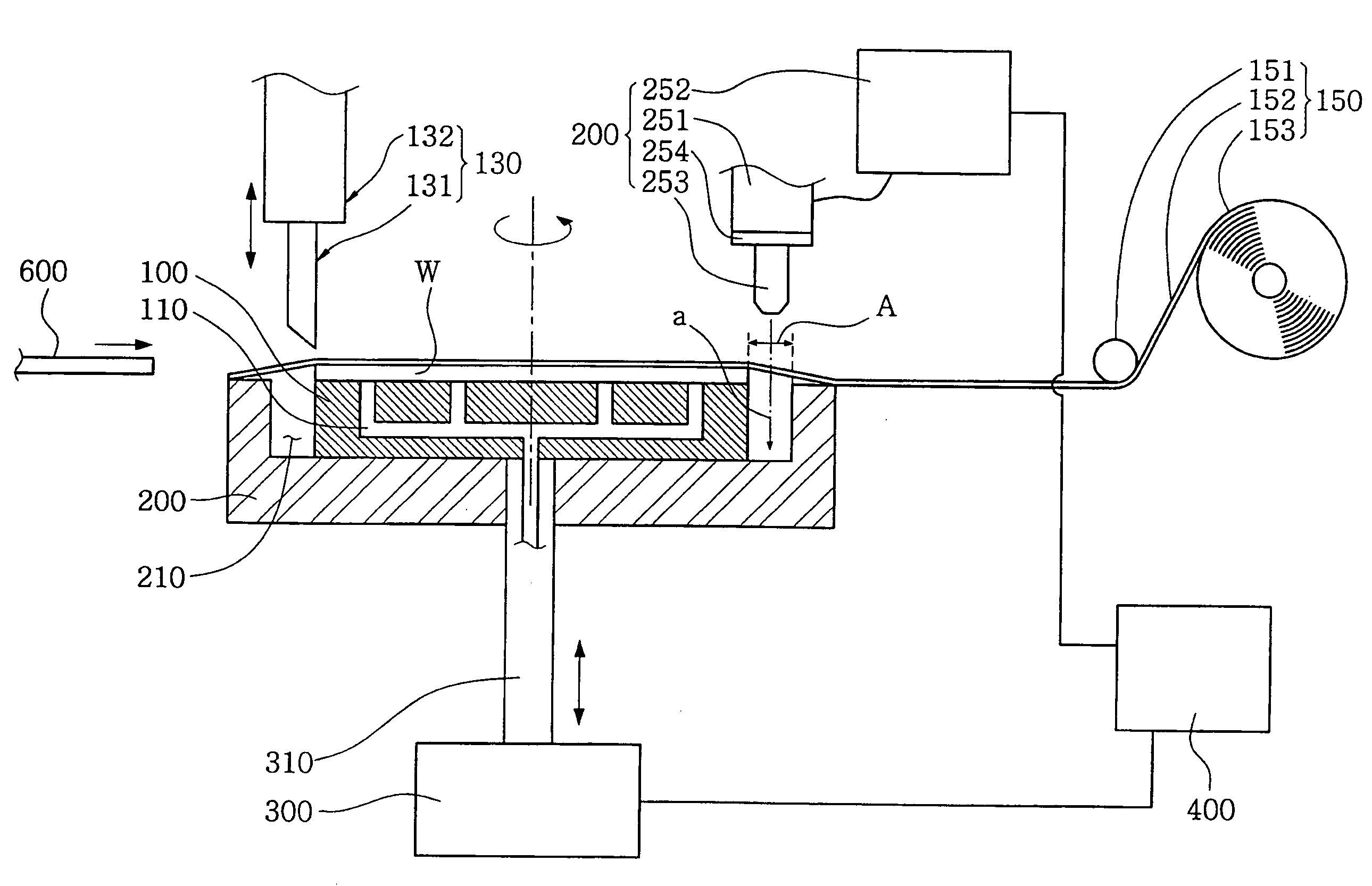

Polishing method, polishing system and process-managing system

InactiveUS6914000B2Stable polishingAccurate estimateSemiconductor/solid-state device manufacturingLapping machinesEngineeringManagement system

A polishing method of the present invention is a polishing method for planarizing a film to be polished that is deposited on a wafer, and includes a step (a) of establishing a polishing rate distribution of the film to be polished that is deposited on the wafer and a target film thickness distribution after polishing of the film to be polished, a step (b) of measuring a film thickness distribution before polishing of the film to be polished, a step (c) of calculating a predicted film thickness distribution after polishing of the film to be polished from the film thickness distribution before polishing and the polishing rate distribution, a step (d) of calculating a pressure against a polishing pad for each of a plurality of regions of the film to be polished and a polishing time from the predicted film thickness distribution and the target film thickness distribution, and a step (e) of polishing while applying the pressure against the film to be polished during the polishing time.

Owner:PANASONIC CORP

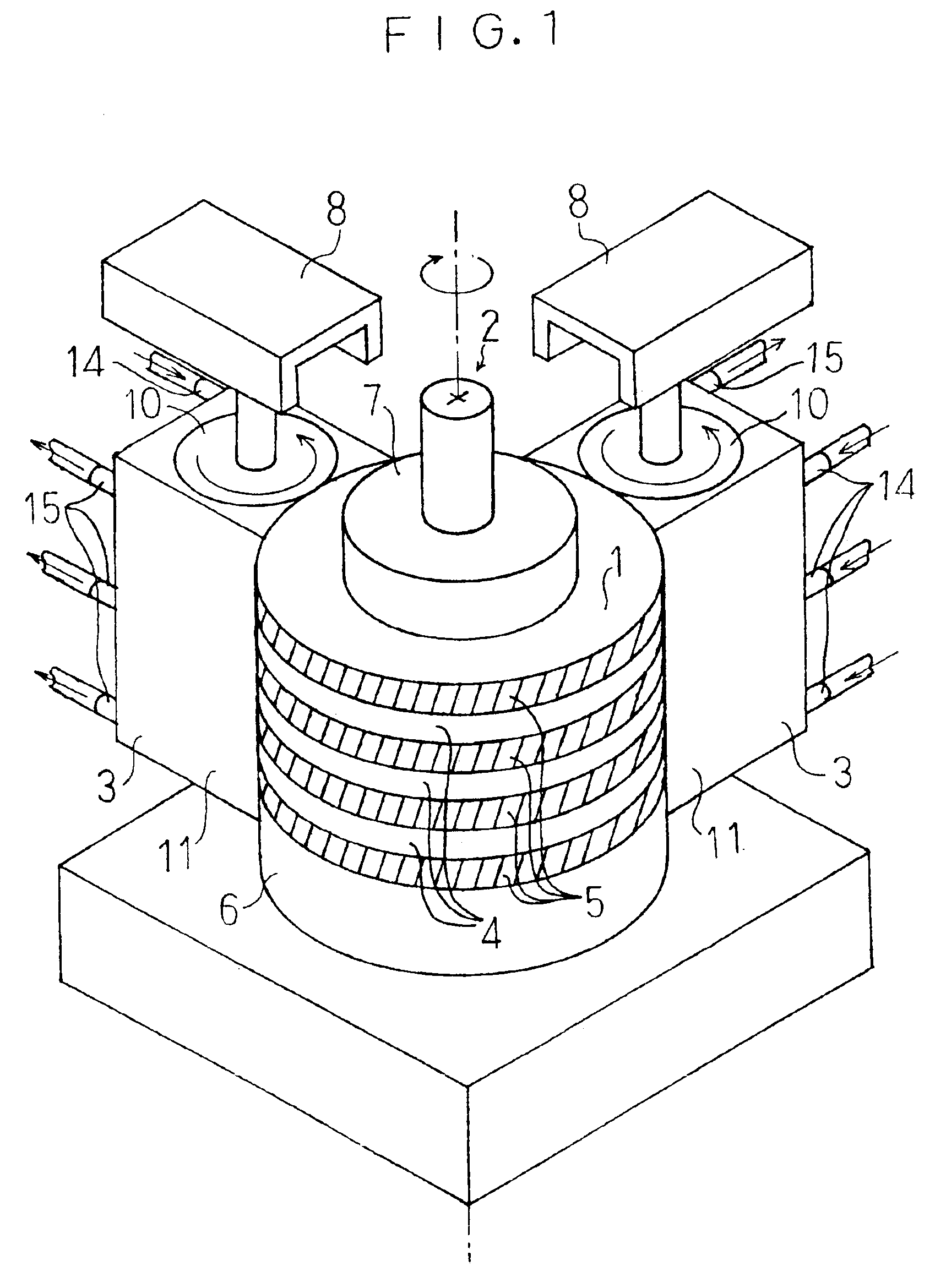

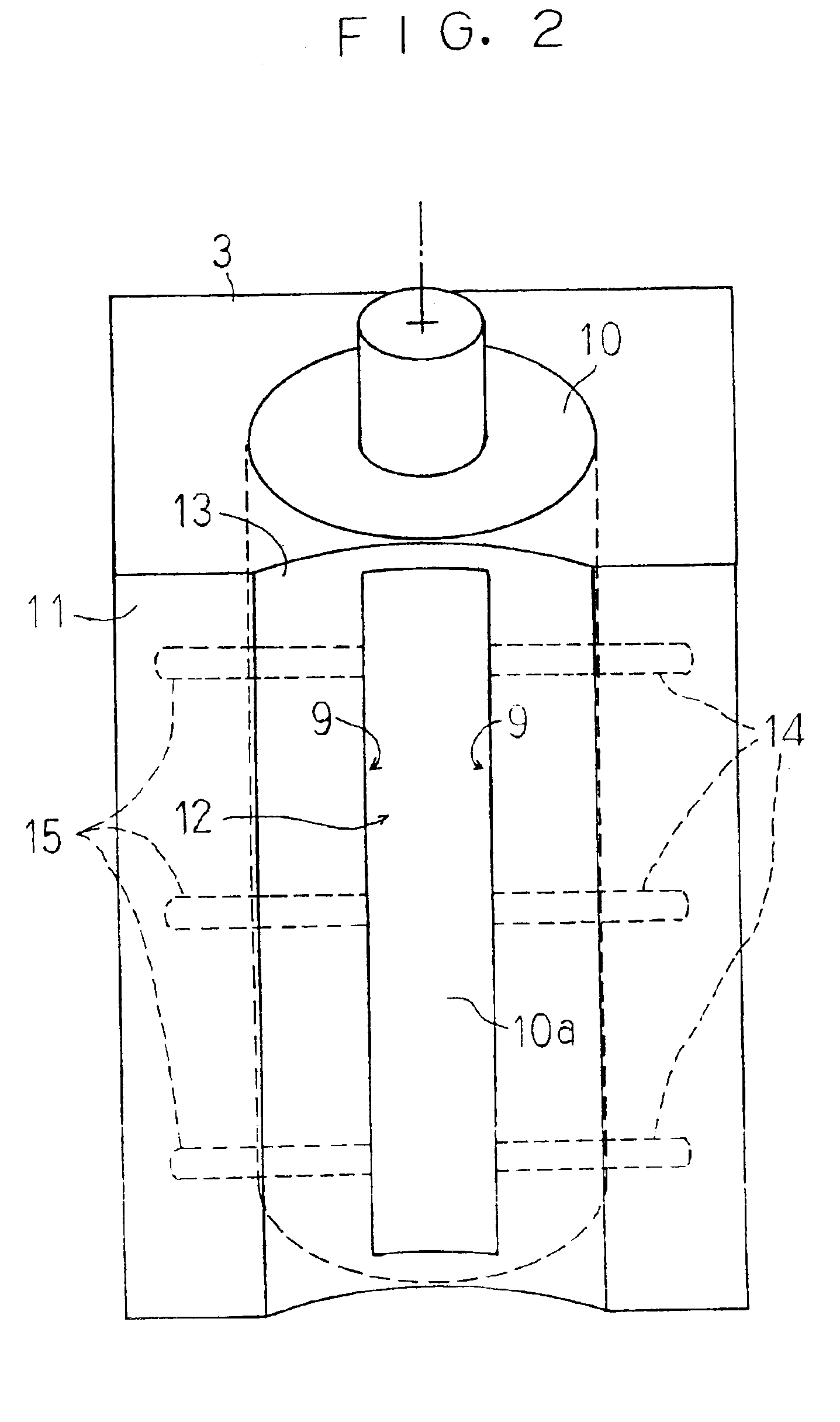

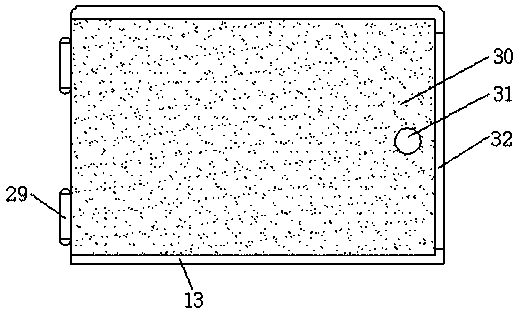

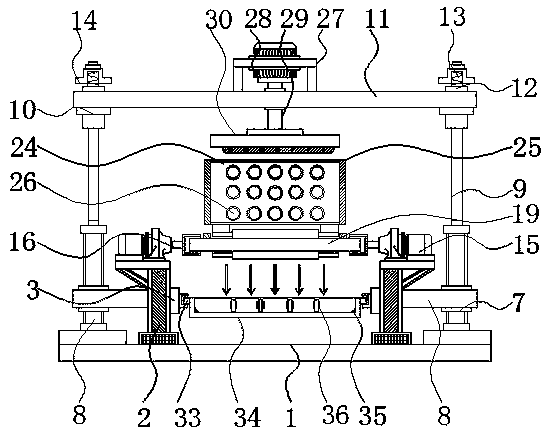

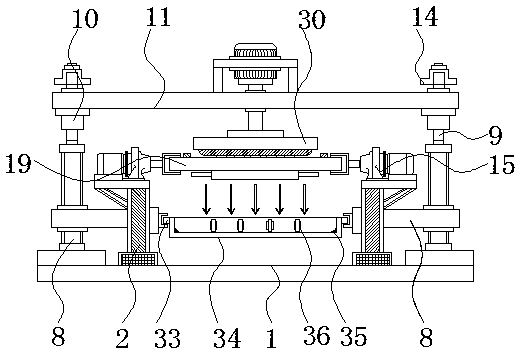

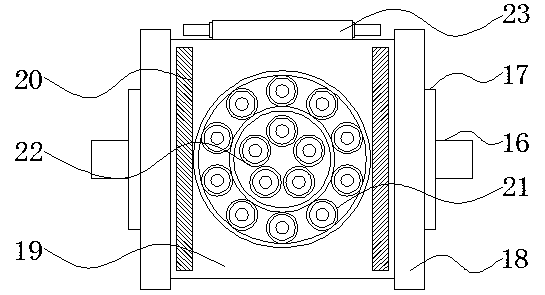

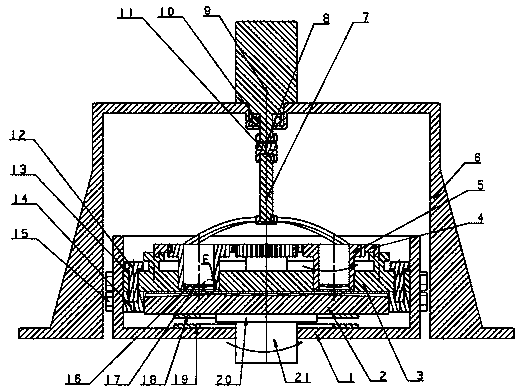

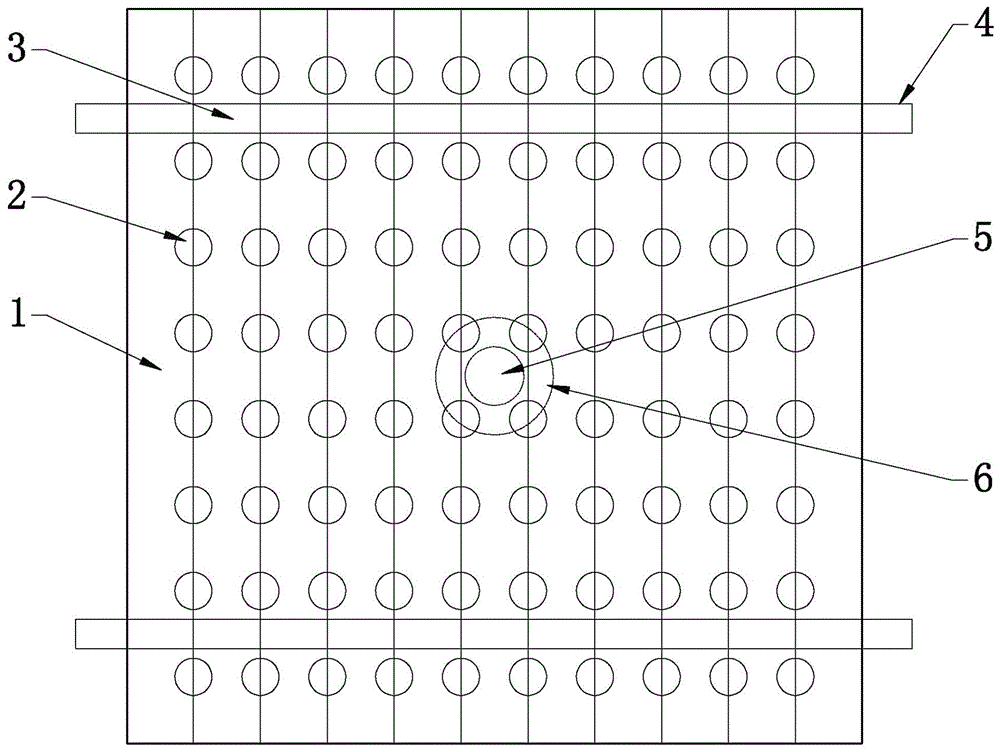

Wafer double-side polishing apparatus and double-side polishing method

InactiveUS7364495B2High precision without deteriorating wafer shapeGood precisionPolishing machinesRevolution surface grinding machinesSlurryEngineering

The present invention provides a wafer double-side polishing apparatus comprising at least a carrier plate having wafer holding holes; upper and lower turn tables to which polishing pads are attached; and a slurry supply means; with wafers held in the wafer holding holes, the carrier plate being moved between the upper and lower turn tables while supplying slurry, to simultaneously polish both front and back surfaces of wafers, wherein a PCD of upper turn table load supporting points that is a diameter of a circle joining load supporting points of the upper turn table coincides with a PCD of centers of the wafer holding holes on the carrier plate that is a diameter of a circle joining each center of the wafer holding holes on the carrier plate. Thereby, there can be provided a wafer double-side polishing apparatus and method in which it is possible to control wafer shape by deforming turn tables with excellent responsiveness, and to polish the wafers stably with high precision without deteriorating wafer shape.

Owner:SHIN-ETSU HANDOTAI CO LTD

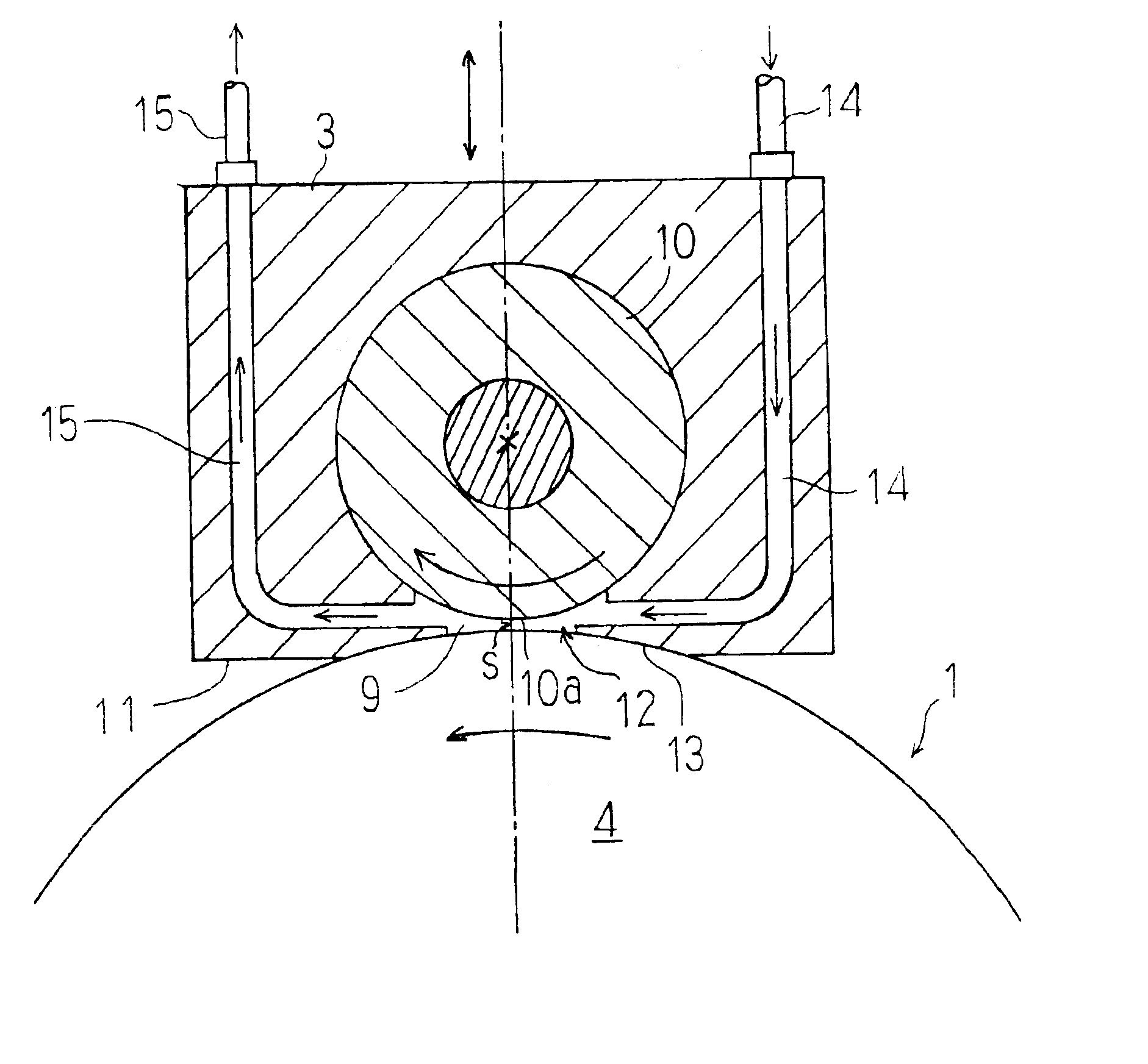

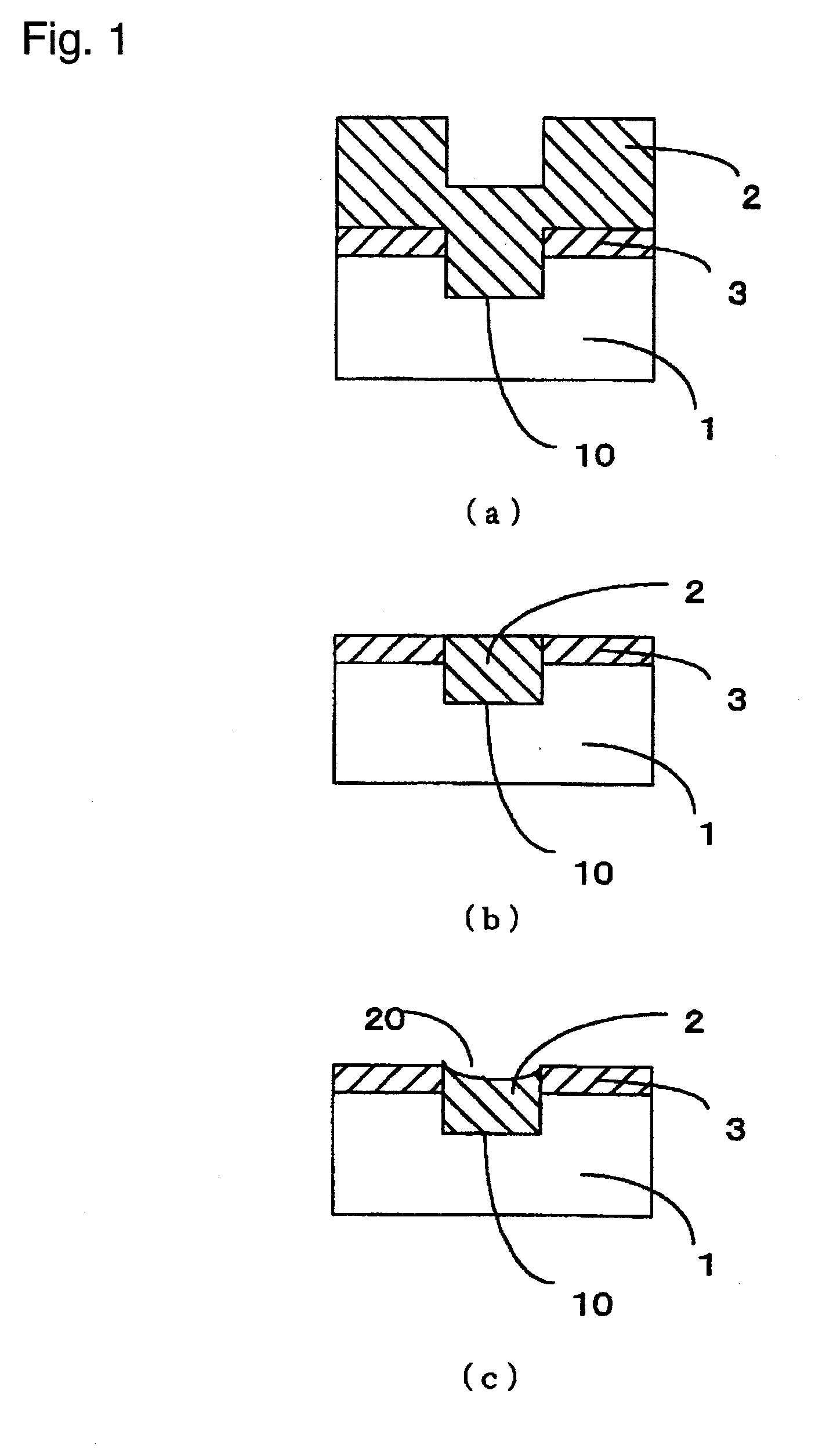

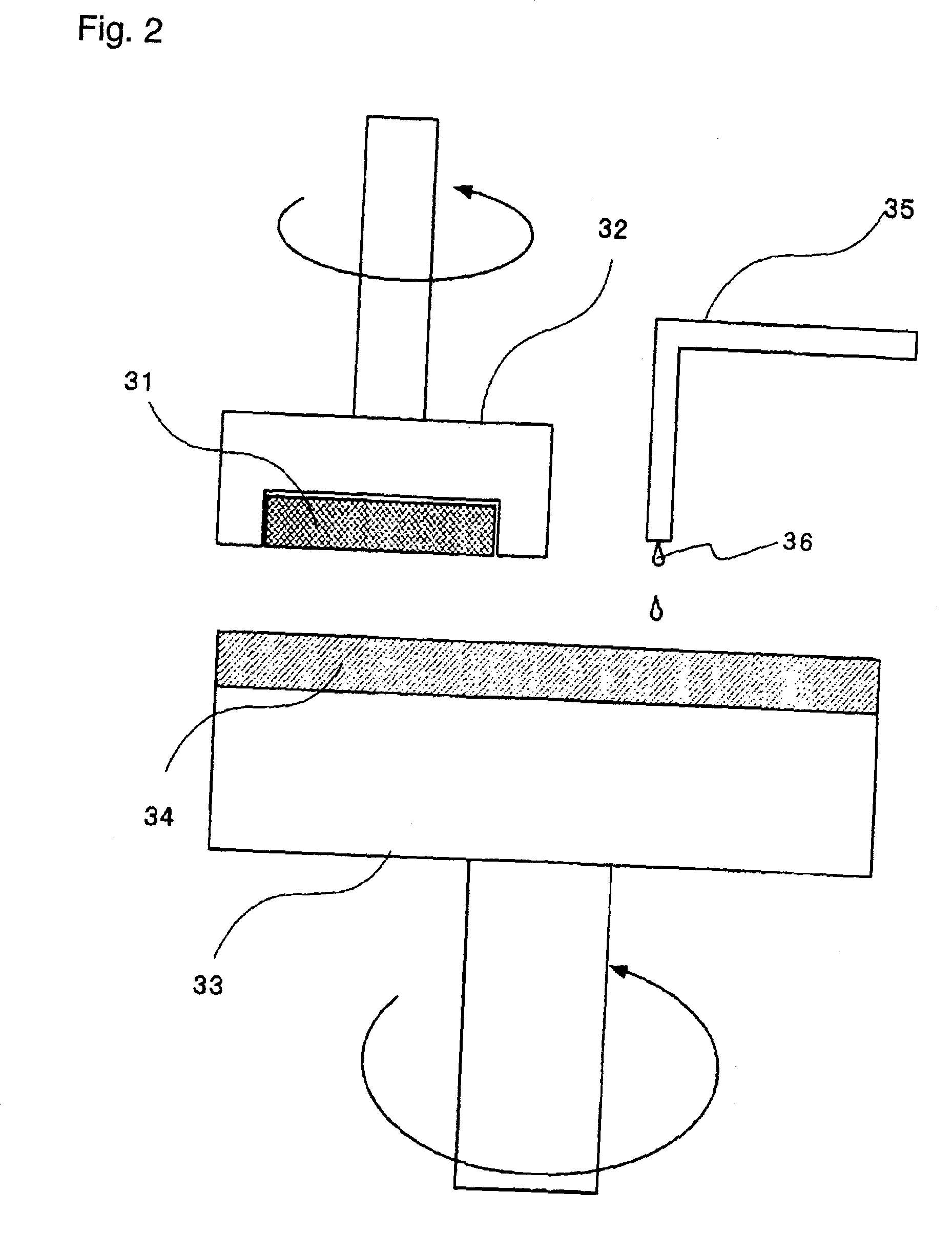

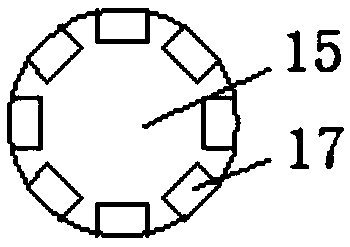

Device for polishing outer peripheral edge of semiconductor wafer

InactiveUS6921455B1High precisionImprove uniformityEdge grinding machinesPolishing machinesEngineeringSemiconductor

A polishing machine for a peripheral edge of a semiconductor wafer comprises a rotary mechanism 2 which rotates a stack 1 of semiconductor wafers 4 mounted thereon, and a polishing mechanism 3 which is arranged to be movable in the radial direction of the rotary mechanism 2 and polishes the peripheral edges of the rotating semiconductor wafers 4 by means of contactless polishing. Minute gaps s are formed between the rotary column 10 of the polishing mechanism 3 and the stack 1 of semiconductor wafers 4, and polishing solution is drawn into these minute gaps s. The peripheral edges of the semiconductor wafers 4 are polished by means of contactless polishing, using polishing abrasive particles included in polishing solution.

Owner:ISHII HYOKI

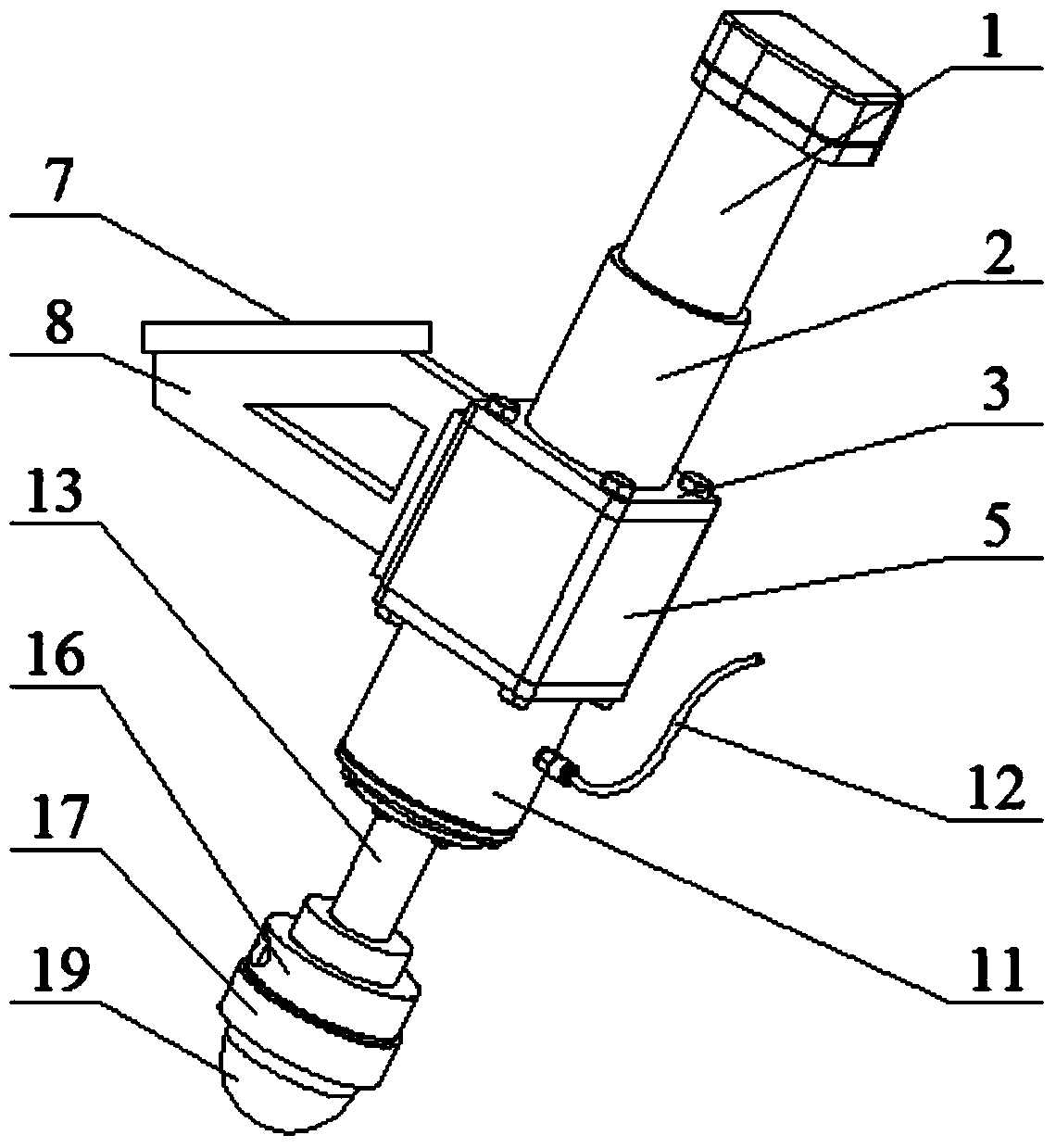

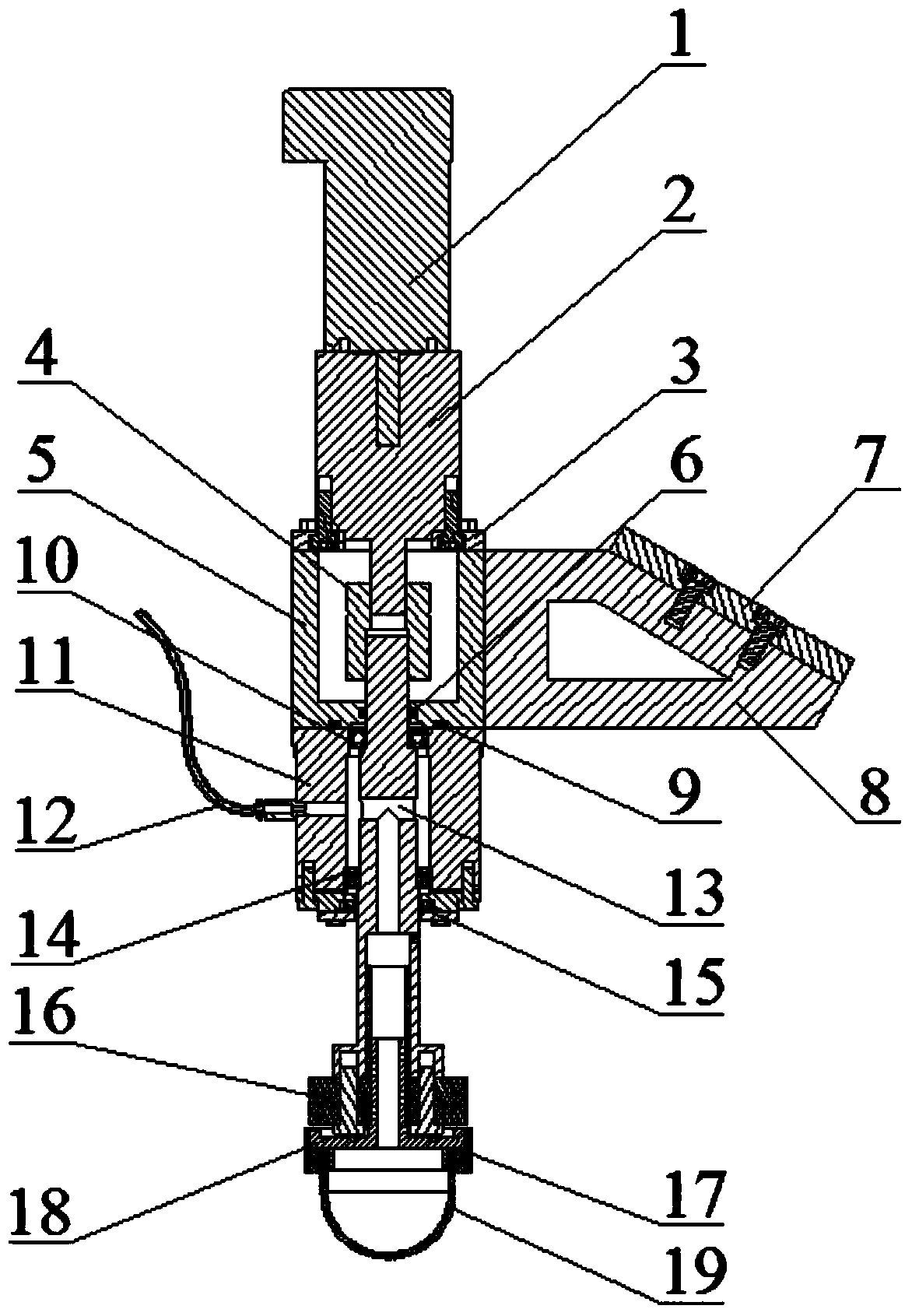

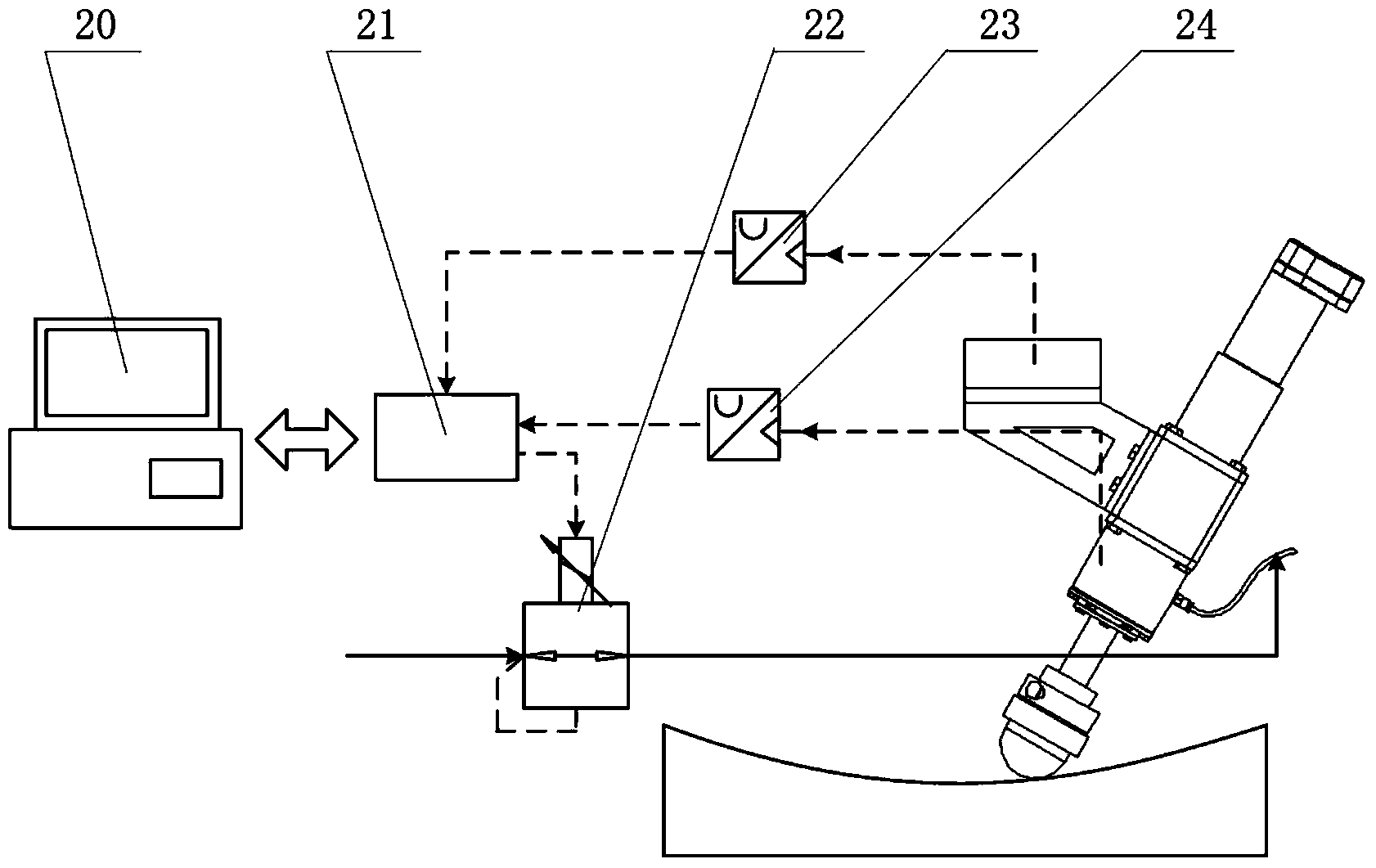

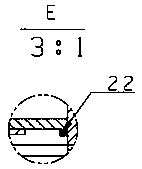

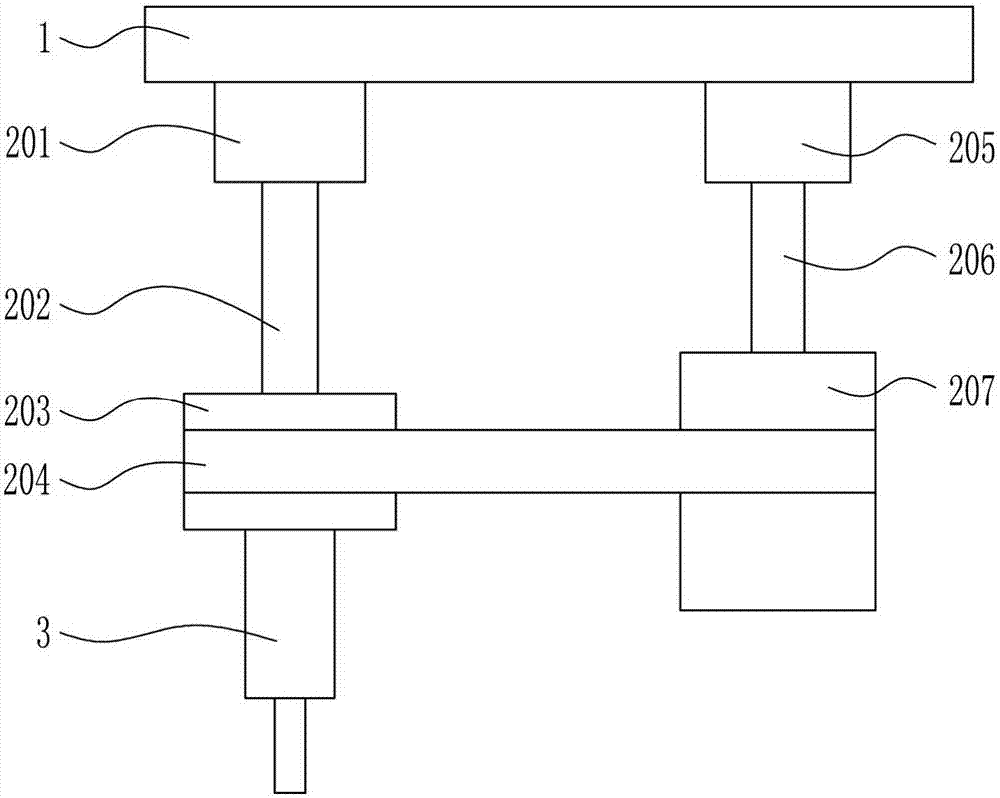

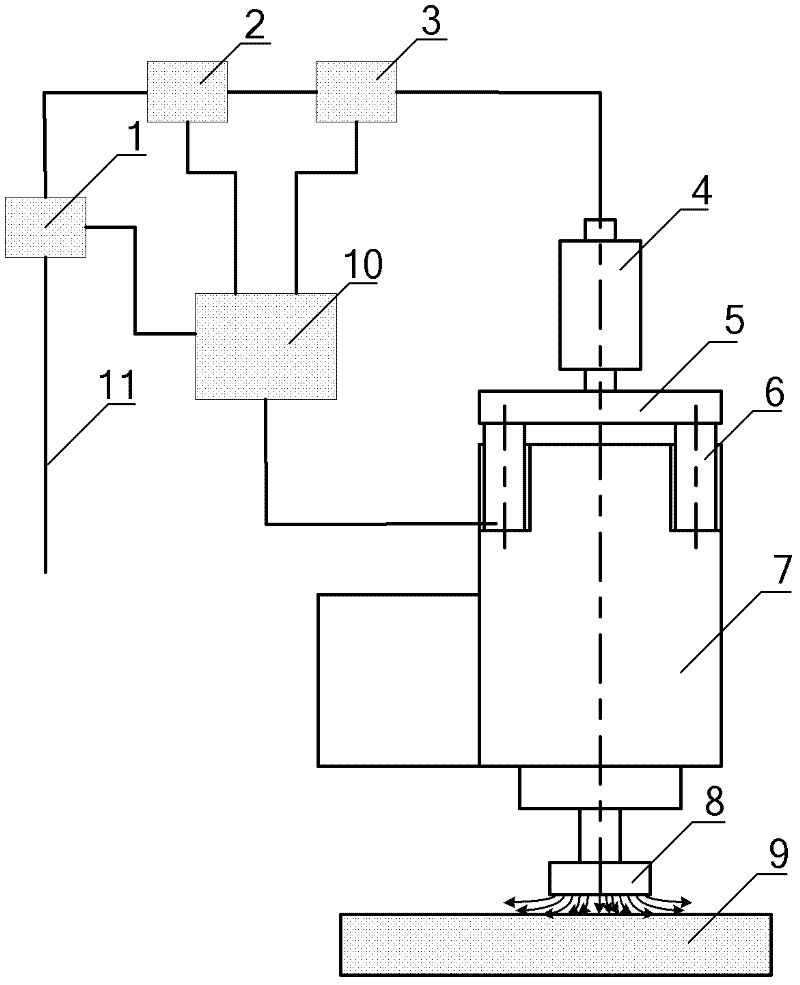

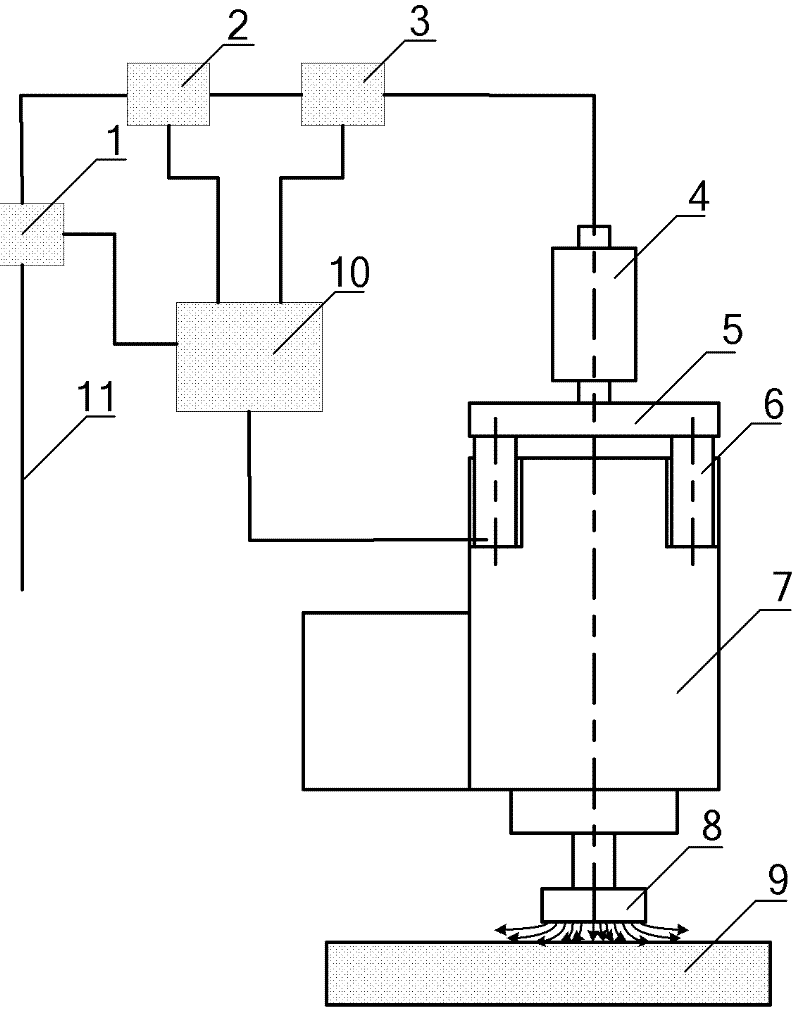

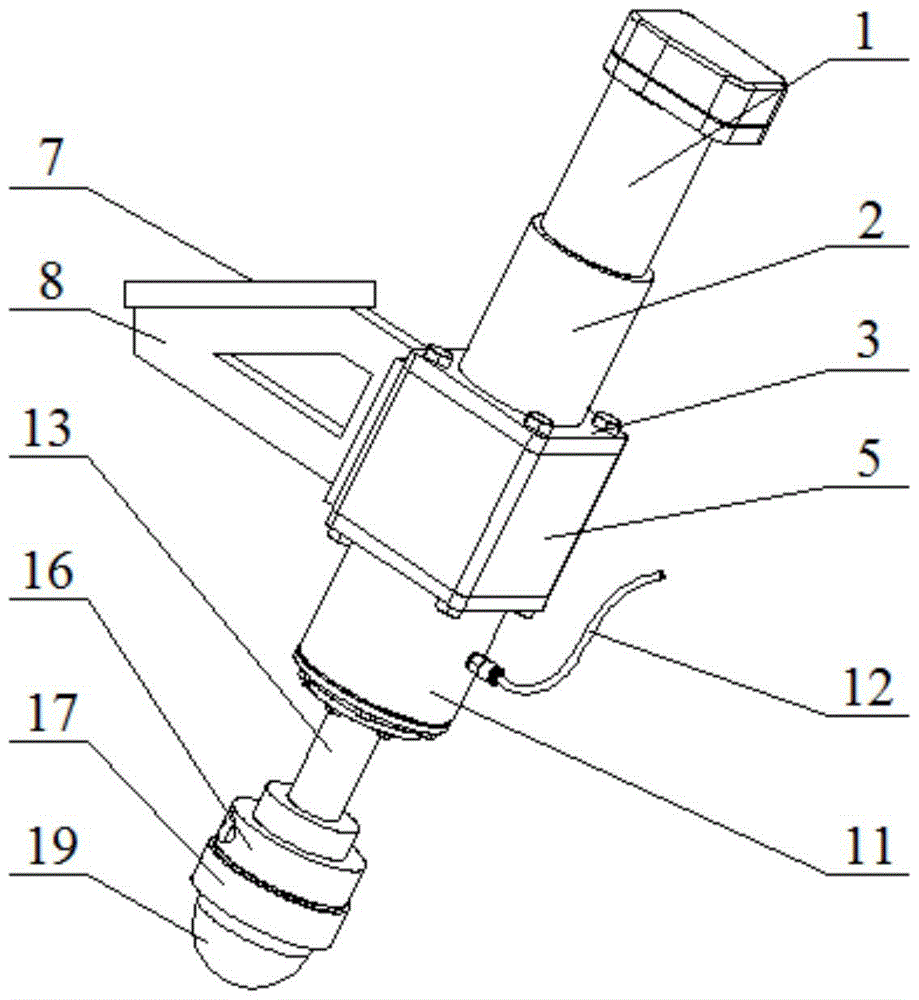

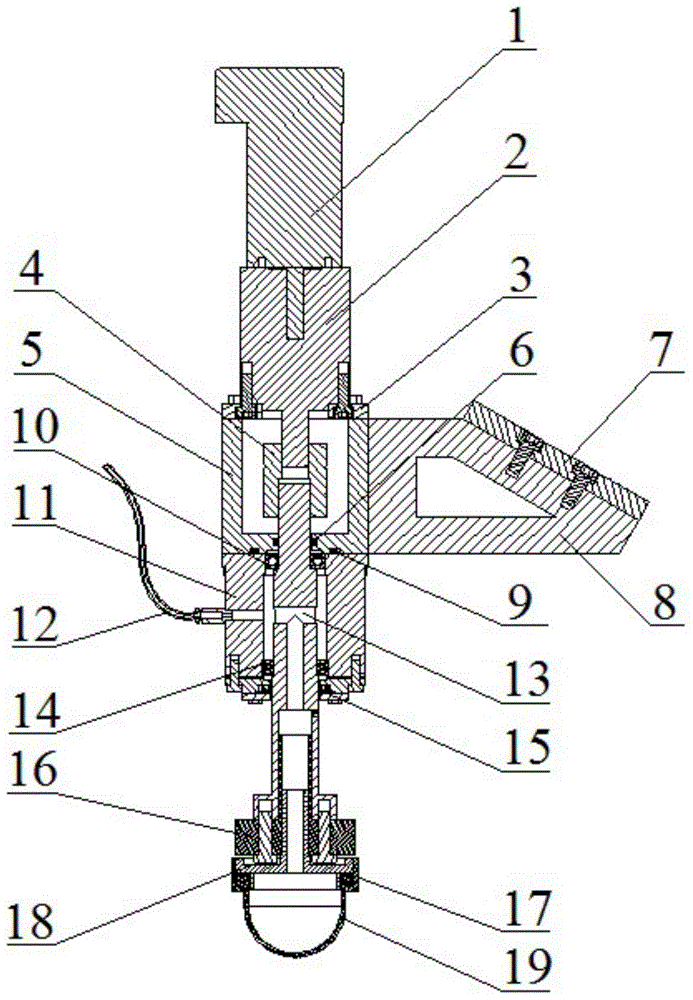

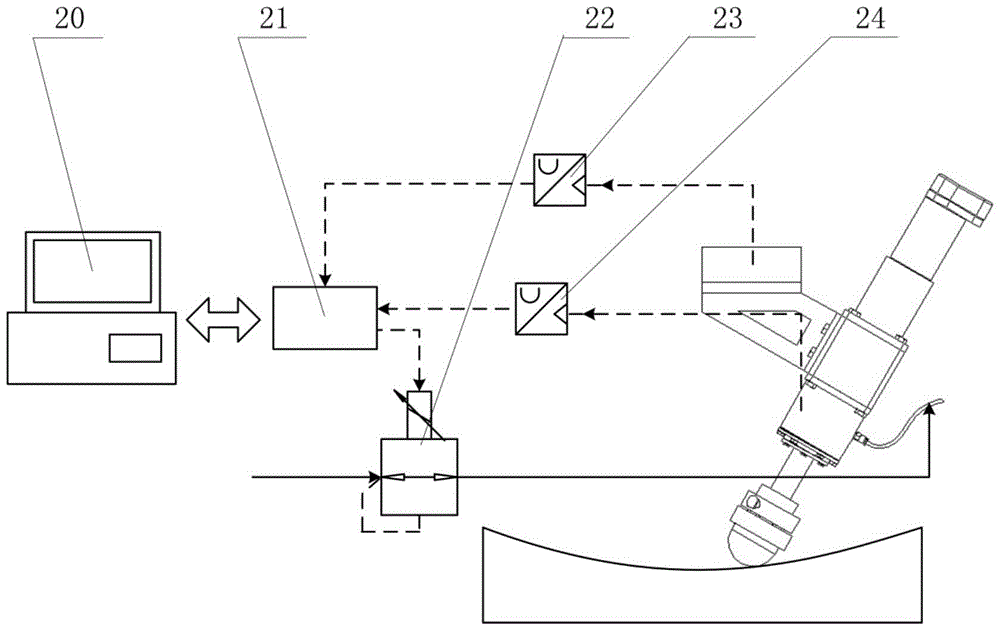

Air bag polishing tool and system and method

ActiveCN104369064AFulfill process requirementsStable polishingPolishing machinesOptical surface grinding machinesContact pressurePositive pressure

The invention discloses an air bag polishing tool and system and method. The air bag polishing tool comprises a motor, a speed reducer, a hollow rotating shaft and an air bag, wherein the motor, the speed reducer, the hollow rotating shaft and the air bag are sequentially connected. The hollow rotating shaft is provided with a hollow cavity, the two ends of the hollow cavity are communicated to the air bag and a ventilation guide pipe respectively, and an electrical proportional valve is arranged on the ventilation guide pipe. The air bag polishing tool further comprises a pressure intensity sensor for detecting the pressure intensity of air in the air bag and a pressure sensor for detecting the positive pressure of the tool. By means of the air bag polishing tool, based on the electrical proportional valve, the contact pressure and the contact pressure intensity of a polished surface can be controlled in real time, the air bag polishing tool can meet the requirements of different machined surfaces for different machining pressures, the machining accuracy can be improved, the polishing process can be simplified, the machining cost can be reduced, and the air bag polishing tool is simple in structure and easy to control.

Owner:江苏拓域智能装备有限公司

Cushioning Material for a Polishing Pad

ActiveUS20090011221A1Low water absorptionHigh suppression characteristicsSynthetic resin layered productsSemiconductor/solid-state device manufacturingCushioningPolyol

Disclosed is a cushioning material for a polishing pad, which hardly suffers swelling deformation caused by water because it is extremely low in water-absorbing characteristics and water-swelling characteristics. The cushioning material for a polishing pad includes a polyurethane foam capable of polishing even a semiconductor wafer having an undulated surface or a wafer having a local step that is formed during circuit forming process so that the undulation or step becomes smaller by uniformly polishing an entire surface of the wafer along the undulation or step. The cushioning material for a polishing pad is characterized by including a polyurethane foam obtained by reacting polyol and polyisocyanate with each other, the polyurethane foam having a contact angle with water of 90° or more. The polyurethane foam is preferably made by using hydrophobic polyol, and preferably has a self-skin layer formed thereon.

Owner:NHK SPRING CO LTD

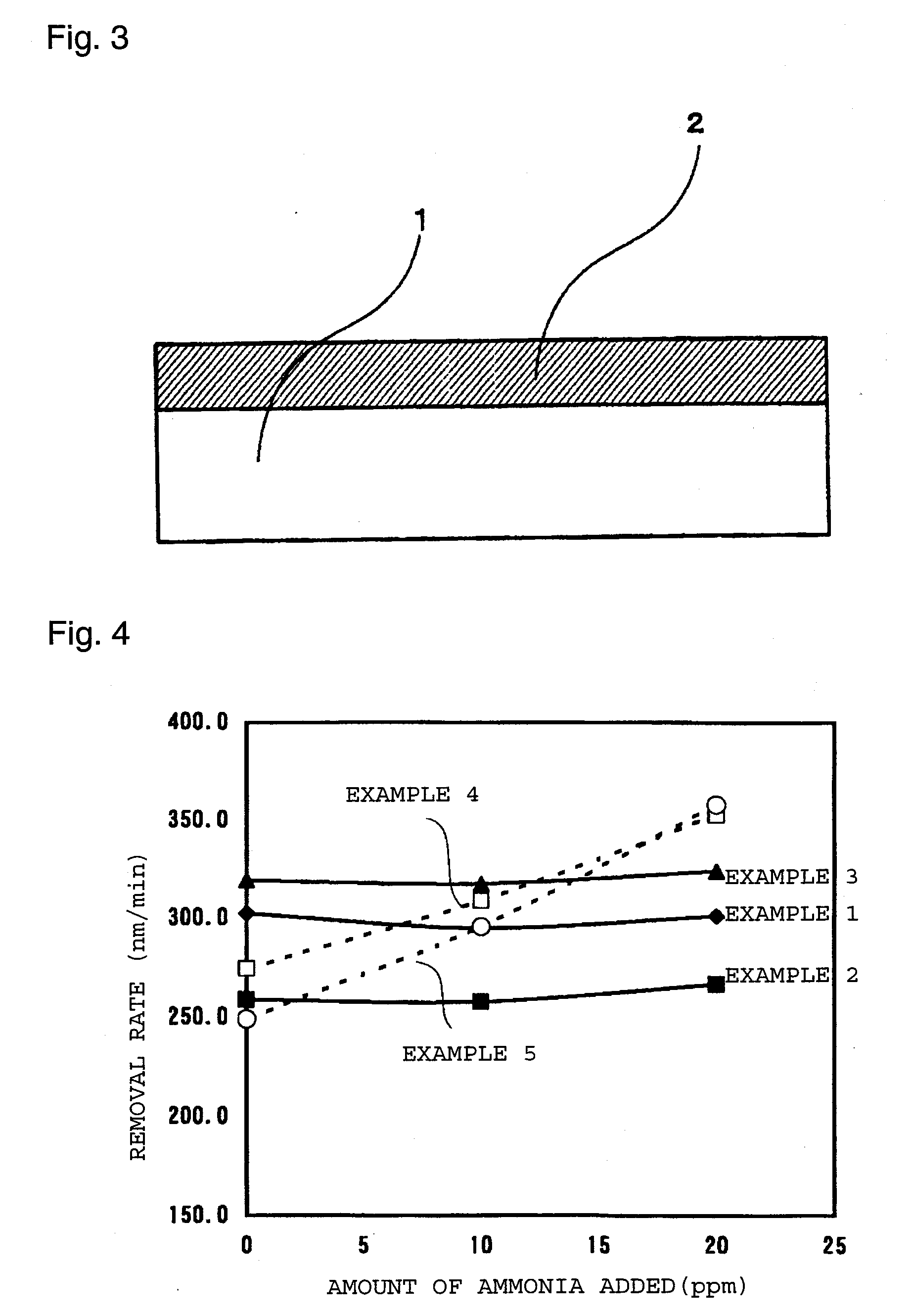

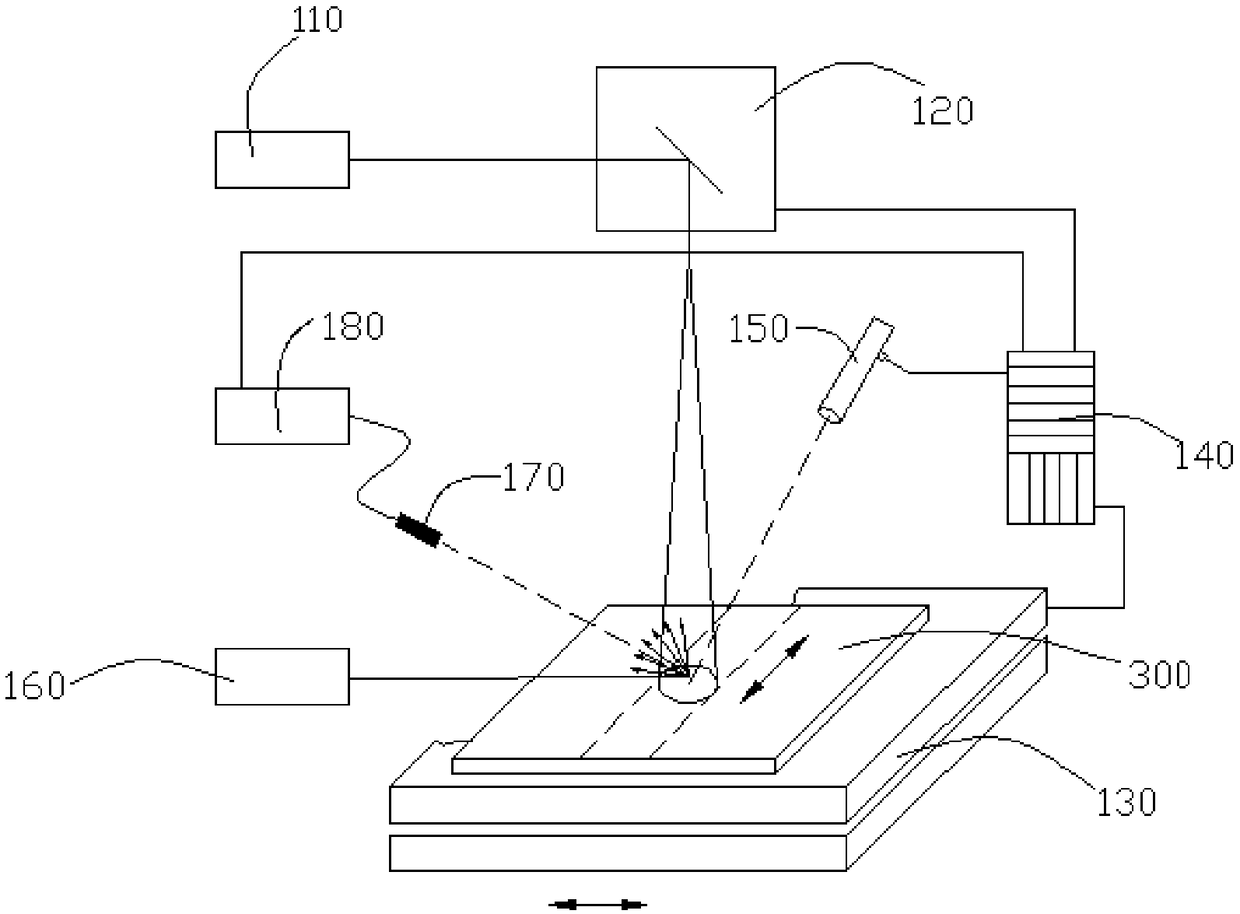

Semiconductor polishing compound

InactiveUS20080086950A1Excellent in dispersion stabilityHigh removal rateOther chemical processesAbrasion apparatusDispersion stabilityCompound (substance)

To provide a semiconductor polishing compound which is excellent in dispersion stability and removal rate and which has a stabilized polishing property, as it is less susceptible to an influence even when contacted with an alkaline polishing compound during its application to CMP comprising a multistage process. A polishing compound for chemical mechanical polishing to polish a surface to be polished in the production of a semiconductor circuit device, said polishing compound comprising cerium oxide abrasive particles, water and a dicarboxylic acid represented by the formula 1: HOOC(CH2)nCOOH Formula 1 wherein n is an integer of from 1 to 4, and the pH of said polishing compound at 25° C. being within a range of from 3.5 to 6.

Owner:ASAHI GLASS CO LTD +1

Method for preparing infrared cut-off filter

ActiveCN104977638ANot suitable for chippingIncrease productivityOptical filtersRejection rateInfrared cut-off filter

The invention relates to a method for preparing an infrared cut-off filter, specifically comprising the steps of cutting, shaping, slicing, chamfering, grinding, double-sided chemical polishing, coating, and the like. An infrared cut-off filter prepared by the method has high quality. The rejection rate is low. The production efficiency is high.

Owner:中山市飞科光学科技有限公司

Method for preparing infrared cut-off filter

InactiveCN104977639ANot suitable for chippingIncrease productivityOptical filtersInfrared cut-off filterRejection rate

The invention relates to a method for preparing an infrared cut-off filter, specifically comprising the steps of cutting, shaping, slicing, chamfering, grinding, double-sided chemical polishing, coating, and the like. An infrared cut-off filter prepared by the method has high quality. The rejection rate is low. The production efficiency is high.

Owner:江苏苏创光学器材有限公司

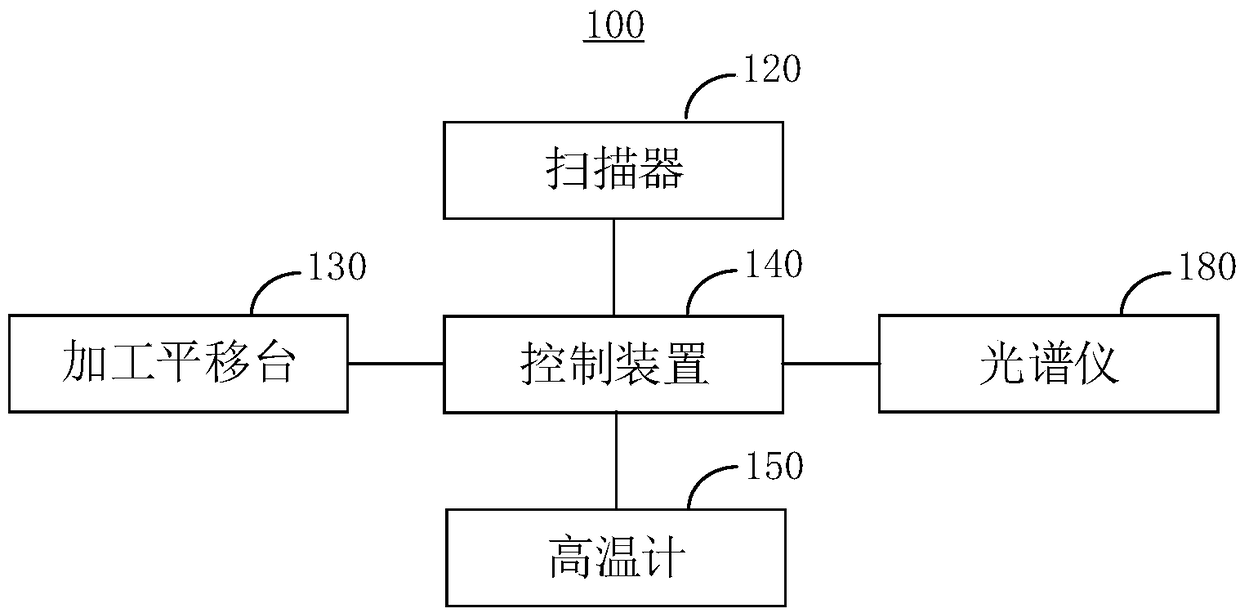

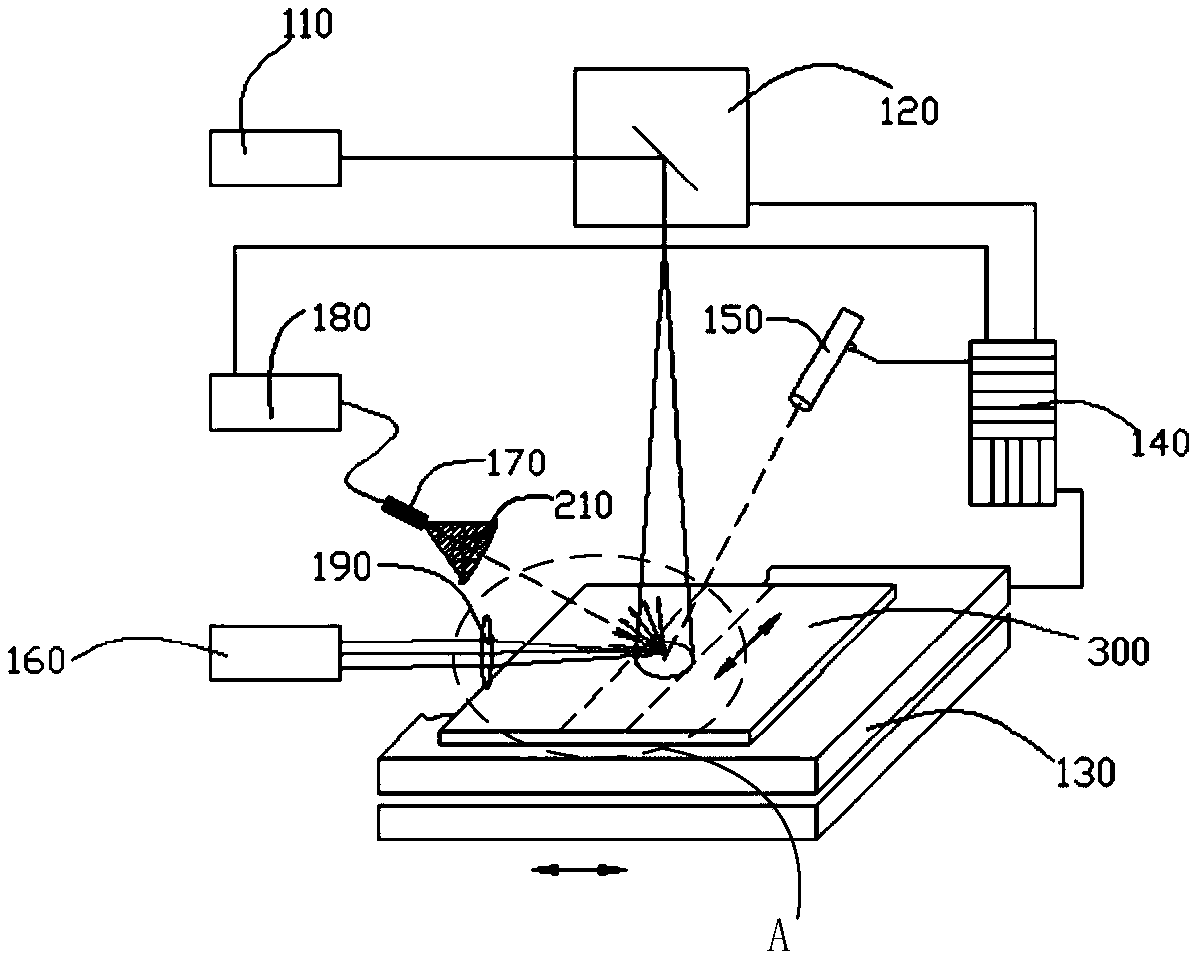

Laser polishing equipment and method

ActiveCN109079313AStable polishingAvoid the problem of poor processing stabilityLaser beam welding apparatusPyrometerMoving speed

The invention relates to the technical field of laser polishing and in particular relates to laser polishing equipment and method. The equipment comprises a first laser emitter, a pyrometer, a secondlaser emitter, a detector and a spectrograph, wherein the first laser emitter is used for emitting a first laser beam which is projected to a workpiece to be processed on a processing translation platform through a scanner to form a processing zone; the pyrometer is used for acquiring temperature data of the processing zone; the second laser emitter is used for transmitting a second laser beam toa detection focus; the detector is used for detecting a light signal at the detection focus under the action of the second laser beam; the spectrograph is used for acquiring spectrum information according to the light signal; a control device is used for controlling movement speeds of the processing translation platform and scanning speeds of the scanner in a scanning direction according to the spectrum information and the temperature data. Due to the arrangement, scanning speeds and moving speeds of the platform can be fed back and controlled according to the temperature data and the spectruminformation, and the problem that the size of a laser spot is affected as laser power is changed, and poor processing stability is caused, can be avoided.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

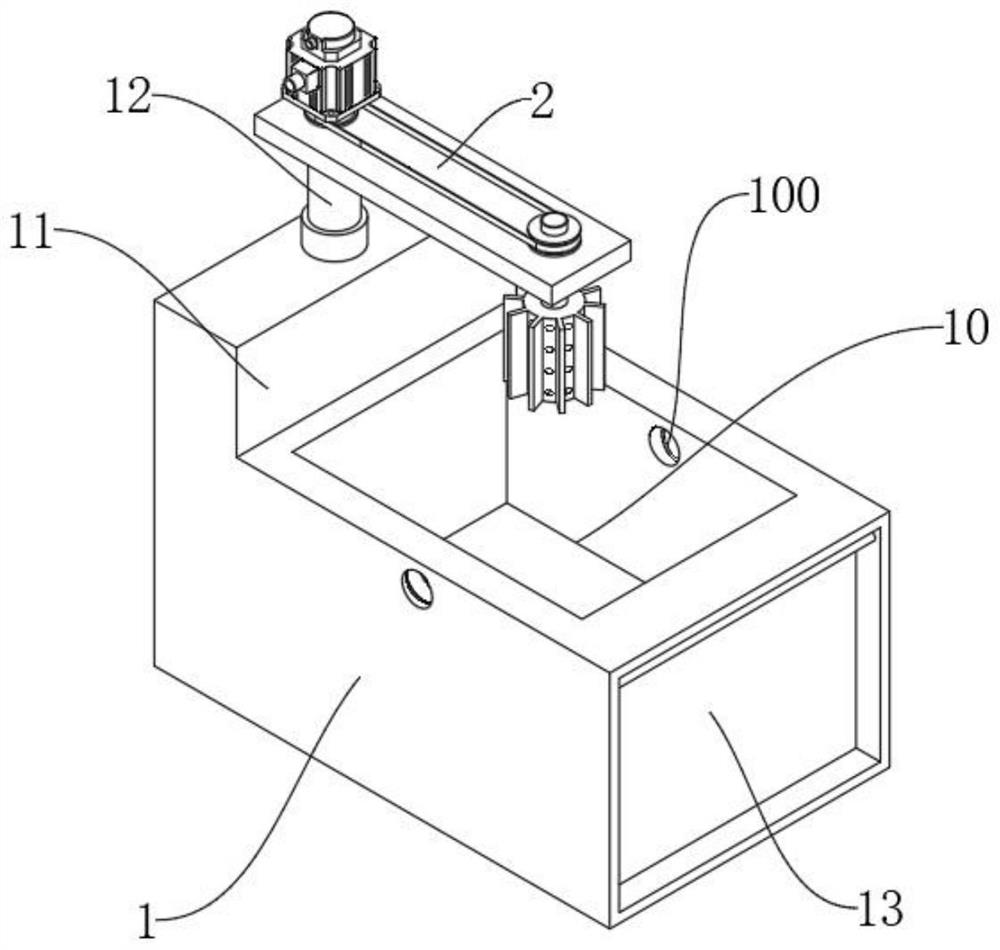

Planar polishing equipment for mobile phone shell

InactiveCN109590879AReduce pollutionEasy to cleanPolishing machinesGrinding drivesWater vaporSpray nozzle

The invention discloses planar polishing equipment for a mobile phone shell, and relates to the technical field of polishing. The planar polishing equipment comprises a bottom plate, wherein the uppersurface of the bottom plate is fixedly connected with the lower surface of the base; the upper surface of the base is provided with a groove; and the right side face of the inner wall of the groove is fixedly connected with a first pressing plate. According to the planar polishing equipment for the mobile phone shell, a dust collection air blower, a connecting tube, a box body, a filter plate, awater pump, a first water pipe, a second water pipe and spray nozzles, water ejected from the spray nozzles can remove water vapor in the gas and some toxic and harmful gas pollutants while dust-containing dust gas particles can be removed at the same time, so that gas in a box body can pass through the filter plate and can be discharged; and crumbs produced by polishing the mobile phone shell body through a polishing wheel can be fallen into a collection box through a through hole, so that the crumbs and the dust can be effectively treated, pollution to an environment is reduced, and moreover, the crumbs and the dust can be effectively collected and also can be conveniently cleared up by the working personnel.

Owner:湖南融灏实业有限公司

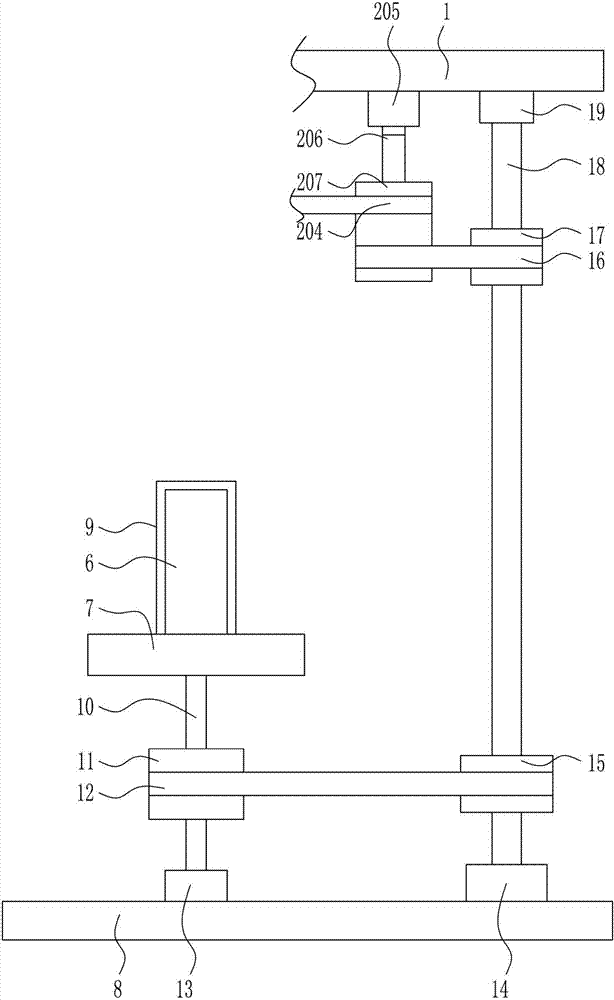

Polishing device of fixing clamp with rotating mechanism for machining bearing washer

InactiveCN110315414AIncrease flexibilityEasy to installGrinding carriagesGrinding feedersDrive shaftEngineering

The invention discloses a polishing device of a fixing clamp with a rotating mechanism for machining a bearing washer, and relates to the technical field of bearing washer production. The polishing device comprises a supporting seat mechanism, a clamping mechanism and a waste material collecting box, wherein a supporting rod is welded above the supporting seat mechanism, a sliding rail is arrangedin a transverse plate, a first motor is fixedly arranged at the upper end of the supporting rod, the other end of a first transmission shaft is connected with an expansion plate, the clamping mechanism is positioned on the inner side of the expansion plate, and the left side surface and the right side surface of the waste collecting box are integrally connected with a sliding block. According tothe polishing device, through mutual cooperation among a sleeve, a limiting groove, a limiting column and a screw cap, an upper-layer plate can be combined and fixed at the upper end of a hydraulic rod, so that the overall structure of the device is high in flexibility and convenient to mount and dismount; the device is arranged with a storage plate through the clamping mechanism, the bearing washers can be overturned at the same time, and the device can be used for carrying out double-sided polishing on the bearing washers.

Owner:东莞市史雷帝三维数控科技有限公司

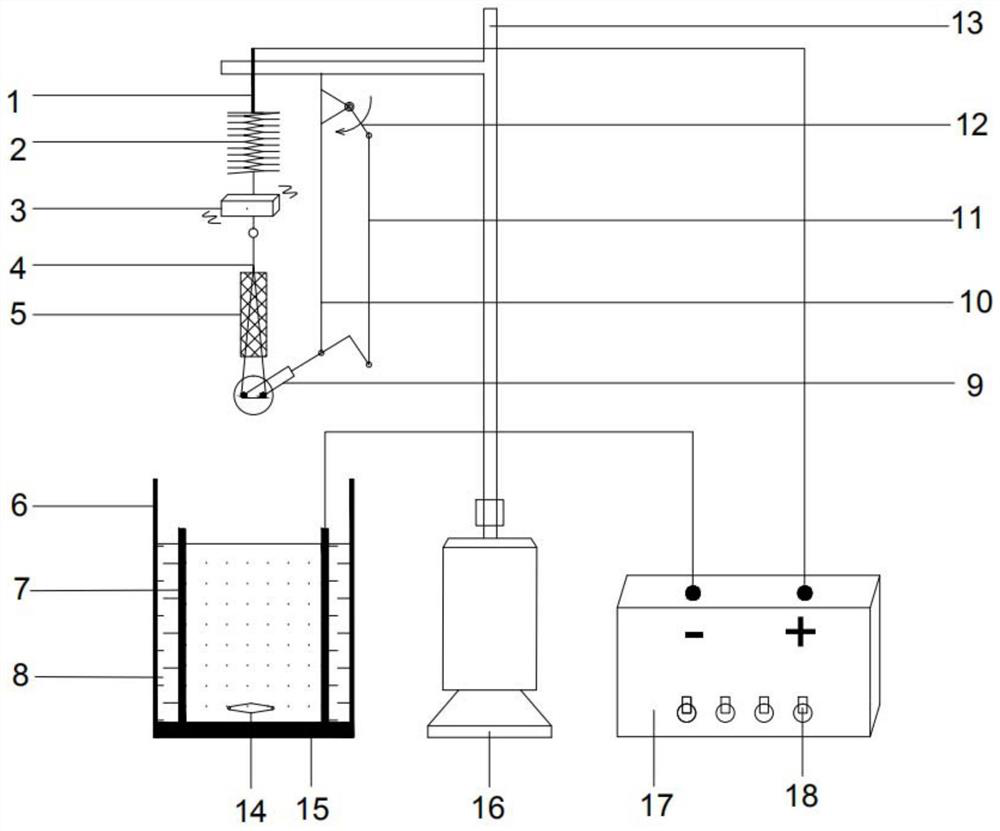

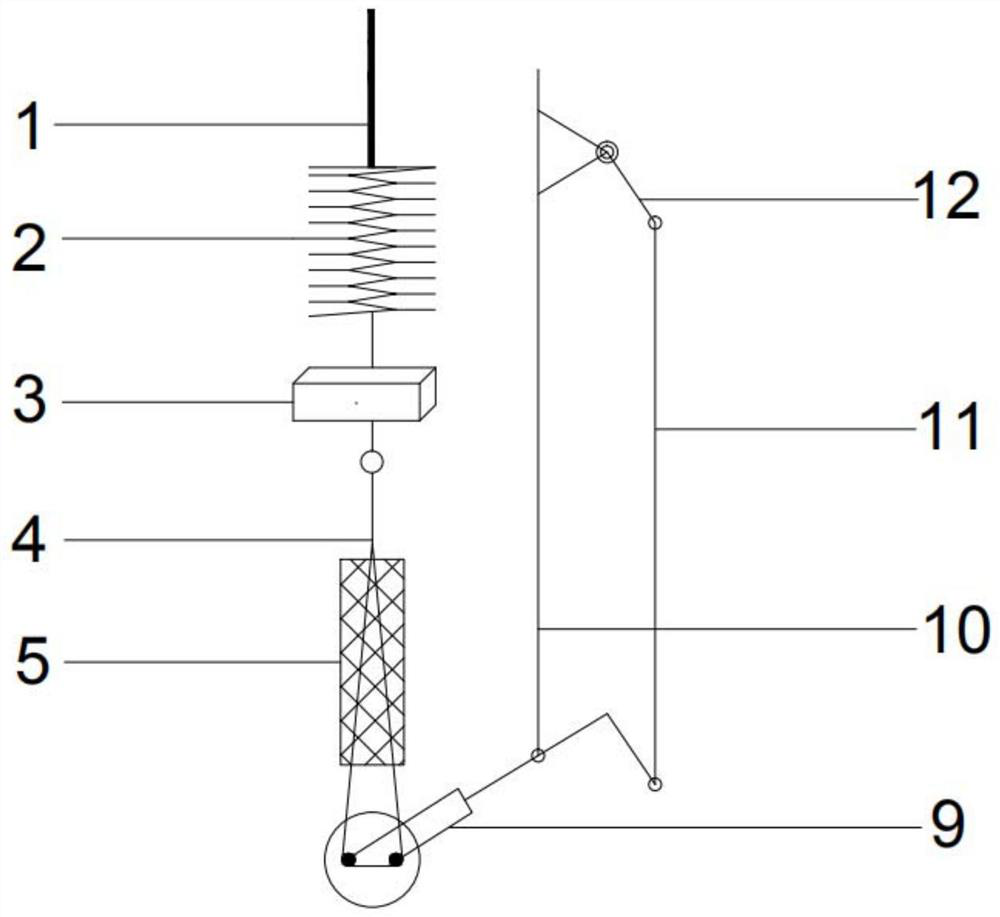

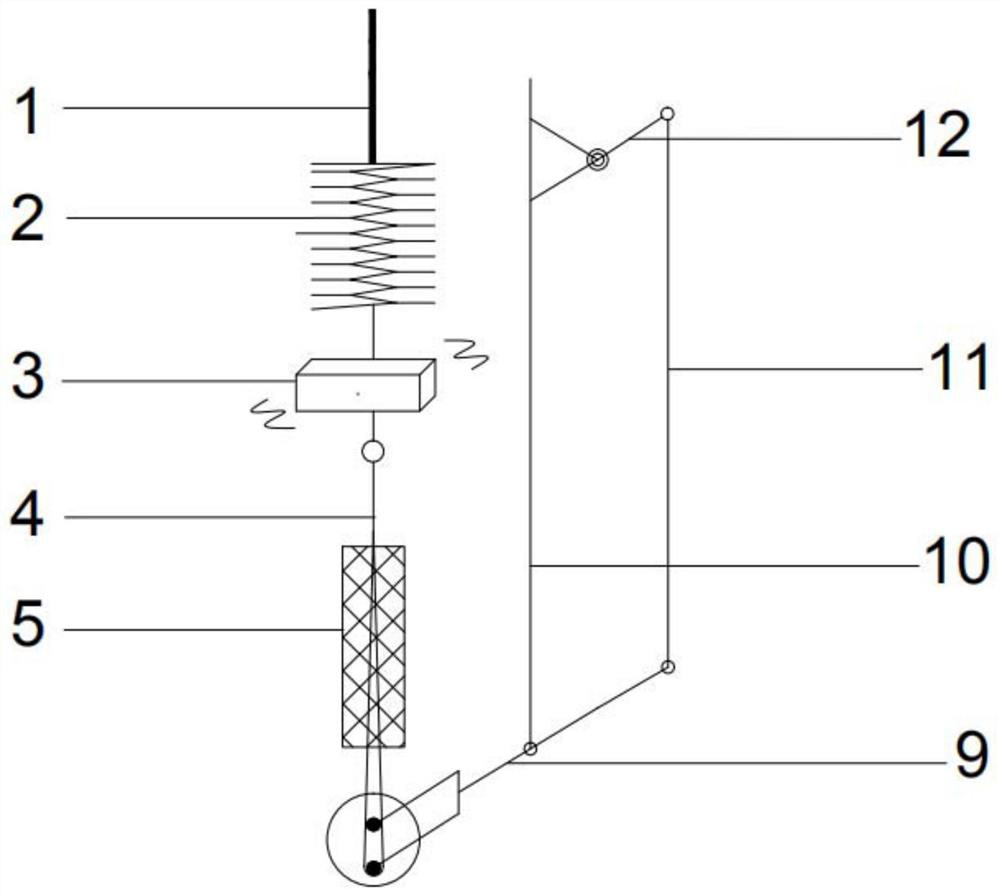

Electrochemical polishing device and polishing method for vascular stent

PendingCN111850669AQuality improvementAchieve conversionElectrolysis componentsEngineeringStructural engineering

The invention relates to the technical field of polishing, and discloses an electrochemical polishing device and polishing method for a vascular stent. The polishing device comprises a lifting assembly, an anode assembly, an adjusting assembly and a cathode assembly; the lifting assembly comprises a lifting frame and a first driving mechanism; the anode assembly comprises an anode, an elastic piece, a vibration source and a metal wire which are connected in sequence; the metal wire is used for mounting the vascular stent and has a contracted state and an expanded state, wherein in the contacted state, the metal wire is movably connected with the vascular stent, and in the expanded state, the metal can be fixedly connected with the vascular stent; the adjusting assembly comprises a first supporting frame and a second driving mechanism, and the first supporting frame is connected with the metal wire and provided with a vertical position where the metal wire can be in the contracted stateand a horizontal position where the metal wire can be in the expanded state; and the cathode assembly is arranged below the anode assembly and comprises a polishing barrel containing a polishing solution and a cathode arranged in the polishing barrel. The electrochemical polishing device is simple and compact in structure, convenient to operate, uniform in polishing, good in polishing effect andhigh in efficiency.

Owner:INNER MONGOLIA UNIV OF TECH

Fixture facilitating polishing of circular-arc-shaped part

InactiveCN108838882AEasy to polishShorten the timePolishing machinesGrinding work supportsEngineeringElectric drive

The invention discloses a fixture facilitating polishing of a circular-arc-shaped part. The fixture comprises a placement plate, wherein the upper surface of the placement plate is fixedly connected with the lower surface of a first support plate, the left side surface of the first support plate is fixedly connected with the right end of an electric drive pusher; the left end of the electric drivepusher is fixedly connected with the right side surface of a first connecting plate, the right side surface of the first connecting plate is fixedly connected with the left end of a sliding device, and the sliding device is clamped to the right side surface of the first support plate. According to the fixture facilitating polishing of the circular-arc-shaped part, under cooperation of the electric drive pusher, a sliding rod, a sliding sleeve, the first connecting plate and a first clamping plate, a handle is rotated, so that a second clamp plate and an arc-shaped workpiece are enabled to rotate, after the arc-shaped workpiece rotates to the appropriate position, the next surface of the arc-shaped workpiece can be polished, the arc-shaped workpiece is not required to be polished after being taken down for angle adjustment and fixation, time is saved, and work efficiency is guaranteed.

Owner:柳州市钜嘉机械有限公司

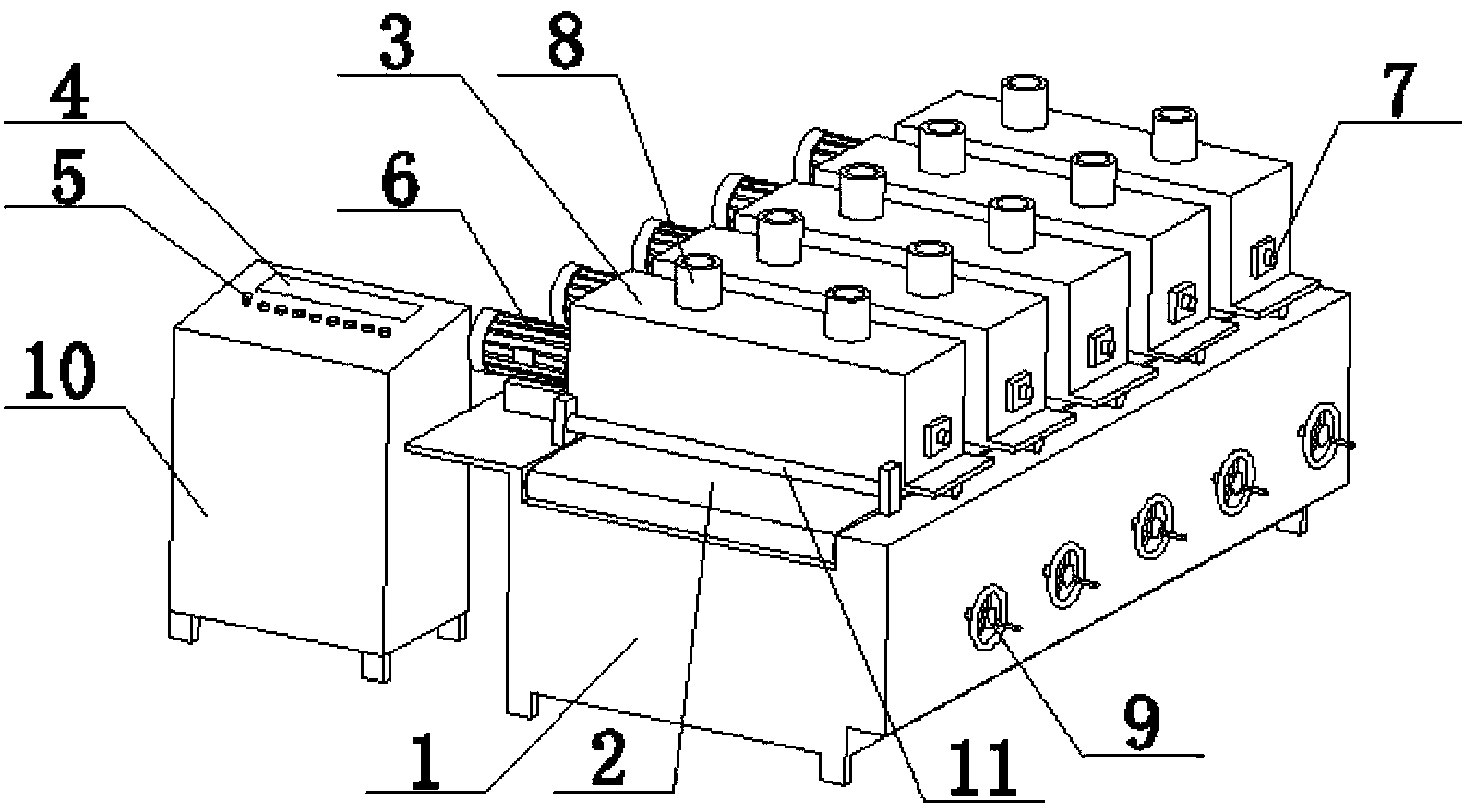

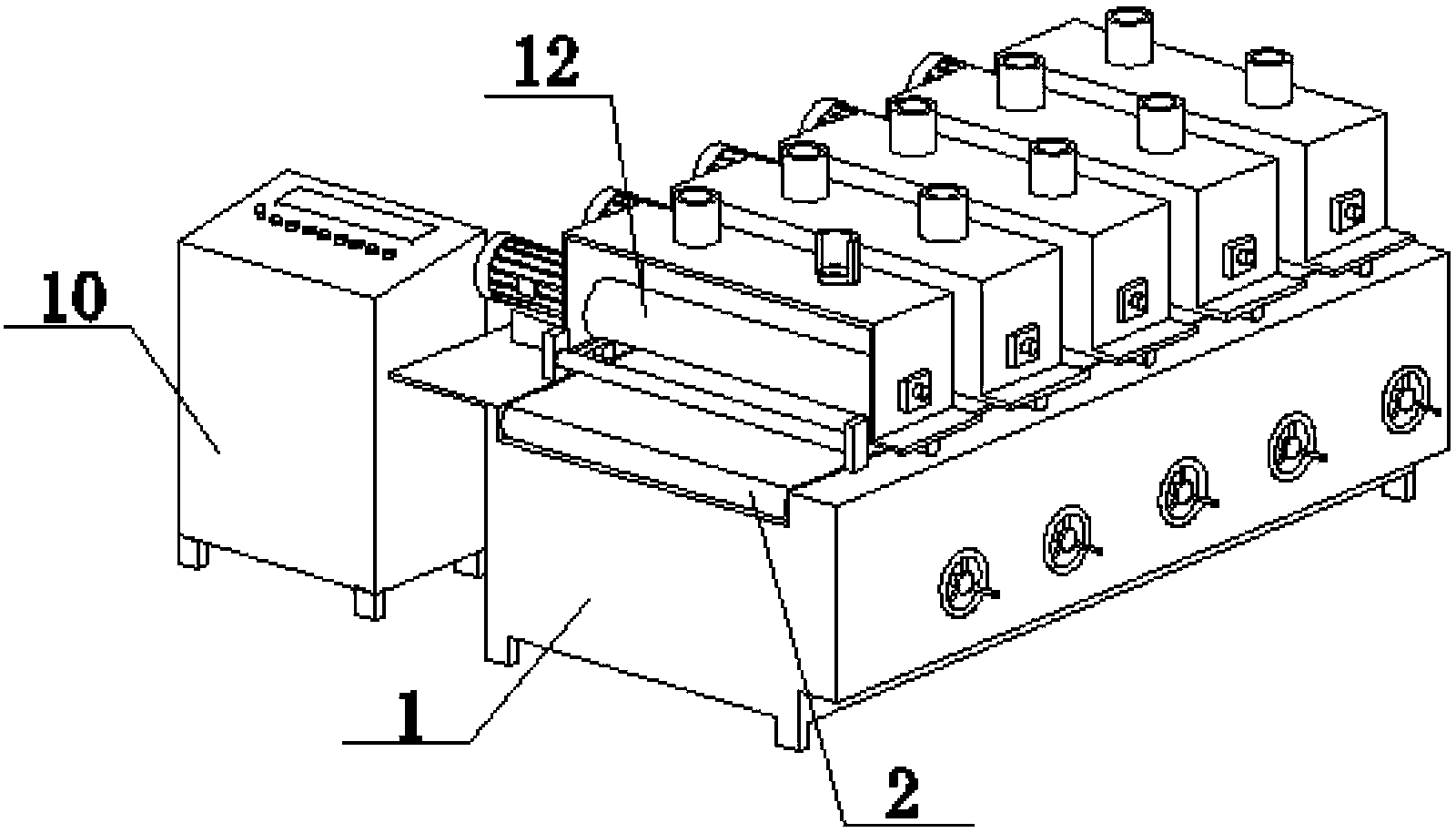

Plate polishing machine

InactiveCN104290015AEasy to replaceAvoid liftingGrinding machine componentsPolishing machinesEngineeringUltimate tensile strength

The invention discloses a plate polishing machine which comprises a rack 1, a conveying tabletop 2, polishing rooms 3 and motors 6. The conveying tabletop 2 is arranged on the rack 1, the polishing rooms are arranged at the upper end of the conveying tabletop 2, the position, on one side of each polishing room 3, of the rack 1 is provided with the corresponding independent motor 6, and the other side of each polishing room 3 is provided with an installation shaft 7. Polishing rollers 12 are arranged in the polishing rooms 3, and the polishing rollers 12 are connected between the motors 6 and the installation shafts 7. The width of the conveying tabletop 2 is 600 mm to 700 mm, any side of the rack 1 is provided with a power distribution cabinet 10, and a digital display 4 is arranged on the power distribution cabinet 10. According to the plate polishing machine, the polishing width is increased, the higher machining efficiency is obtained at the same machining speed, a release bearing is used for control, replacing of the polishing rollers is facilitated, meanwhile, the digital display is arranged, and the polishing intensity can be mastered more conveniently.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

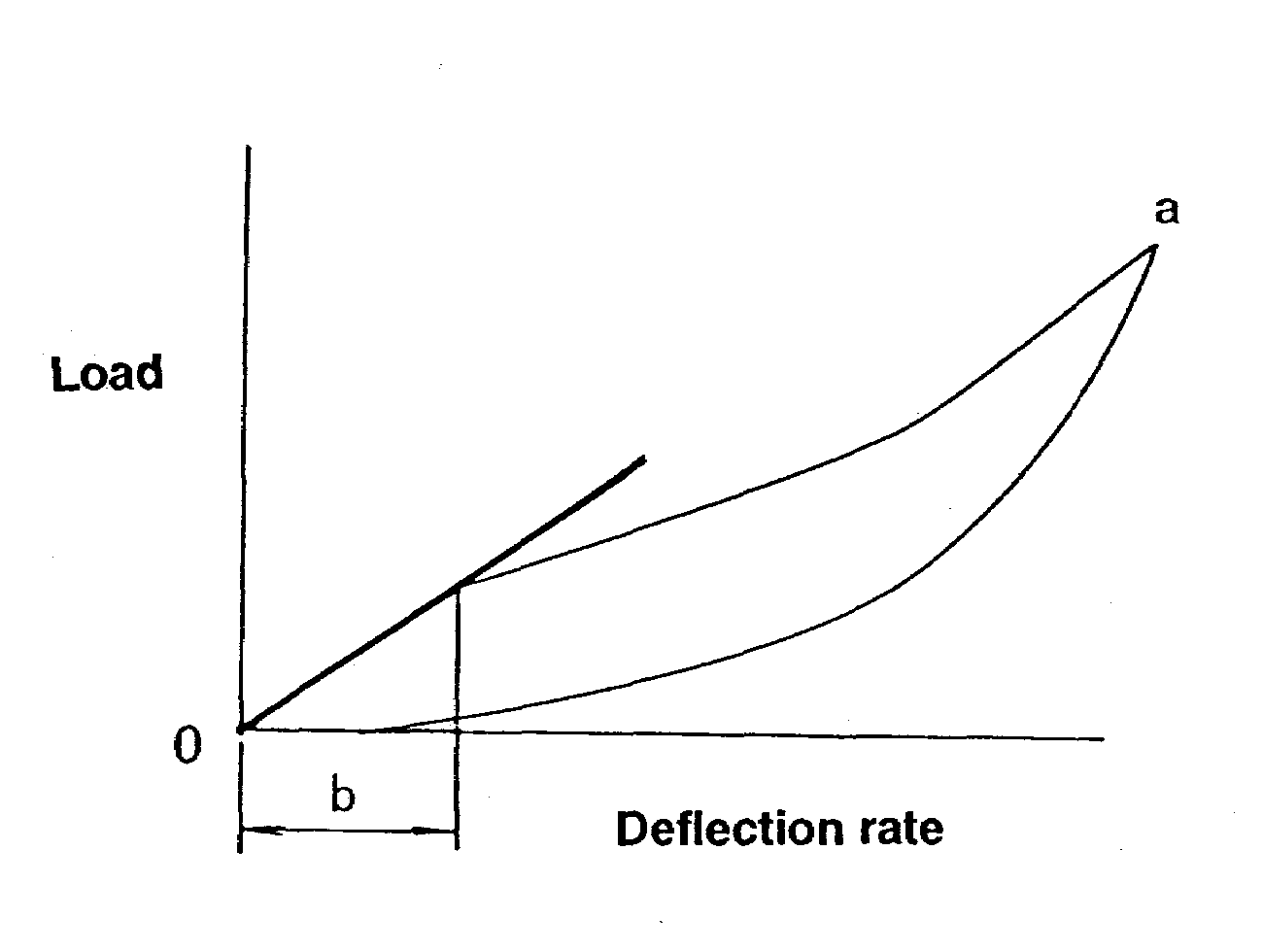

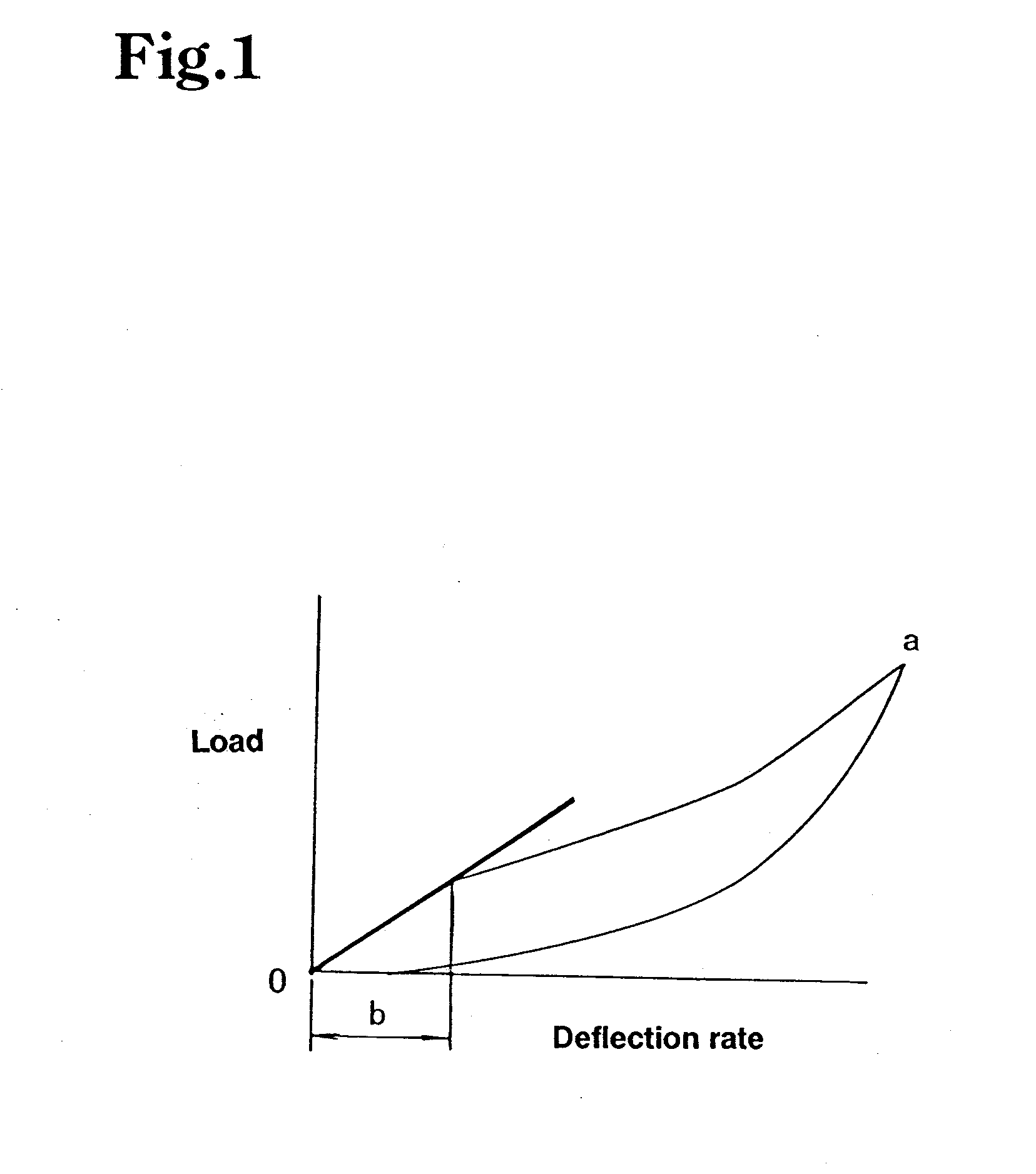

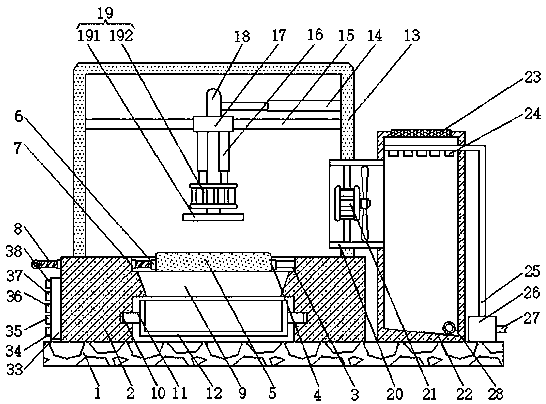

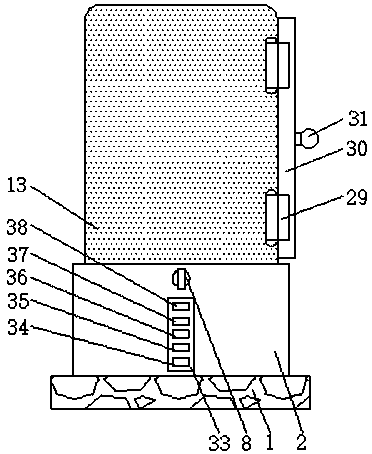

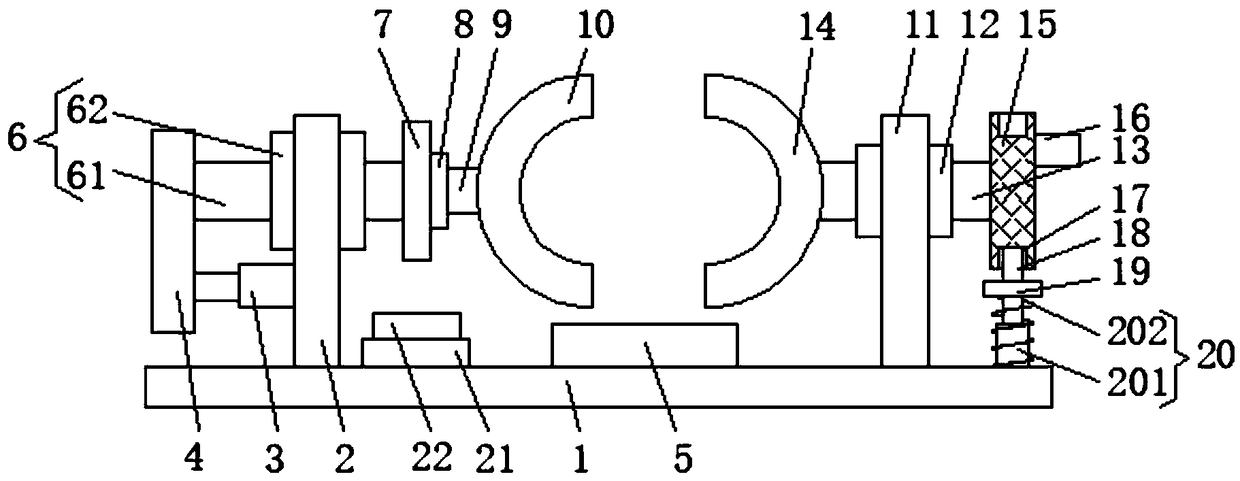

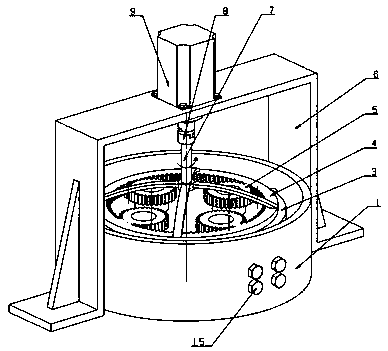

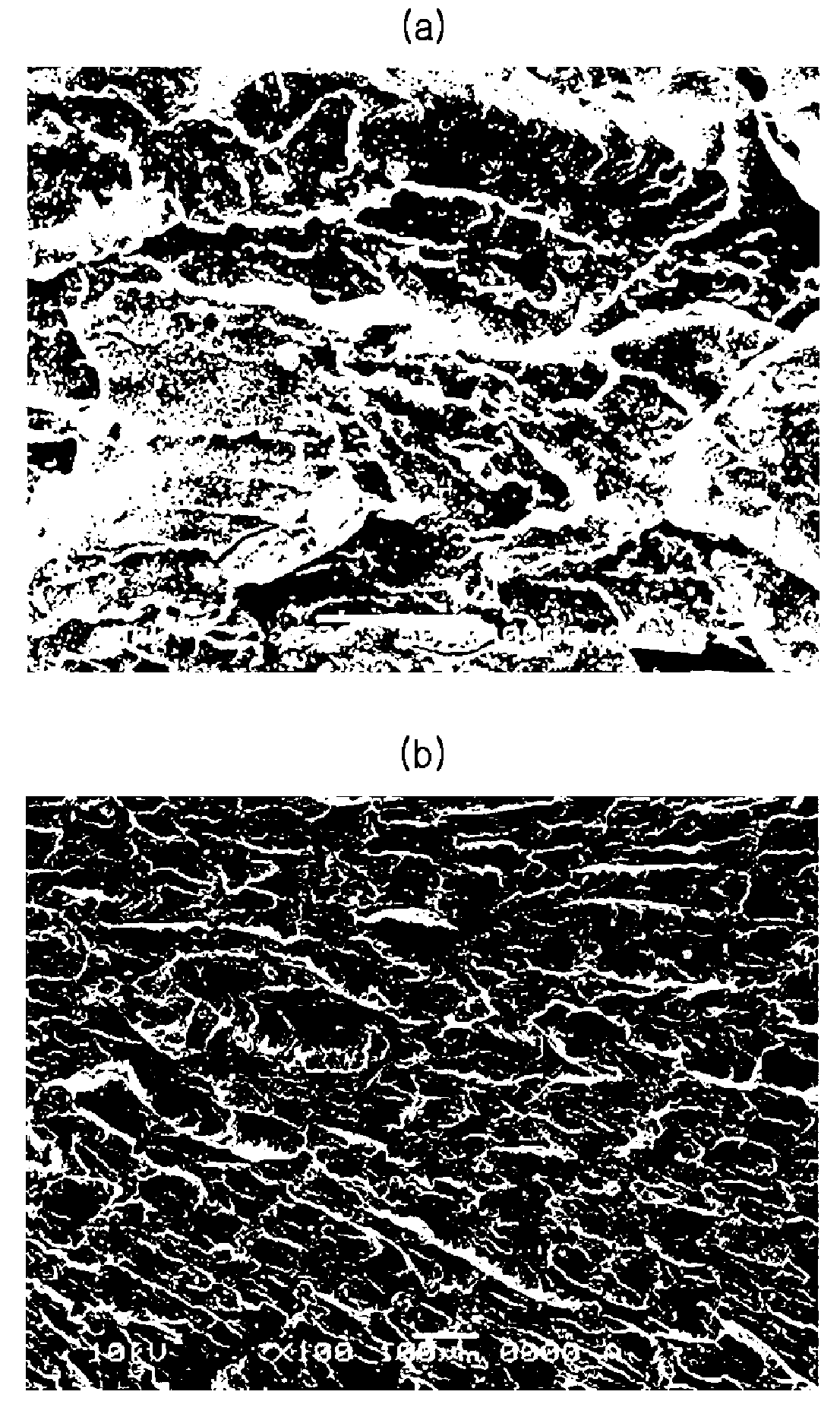

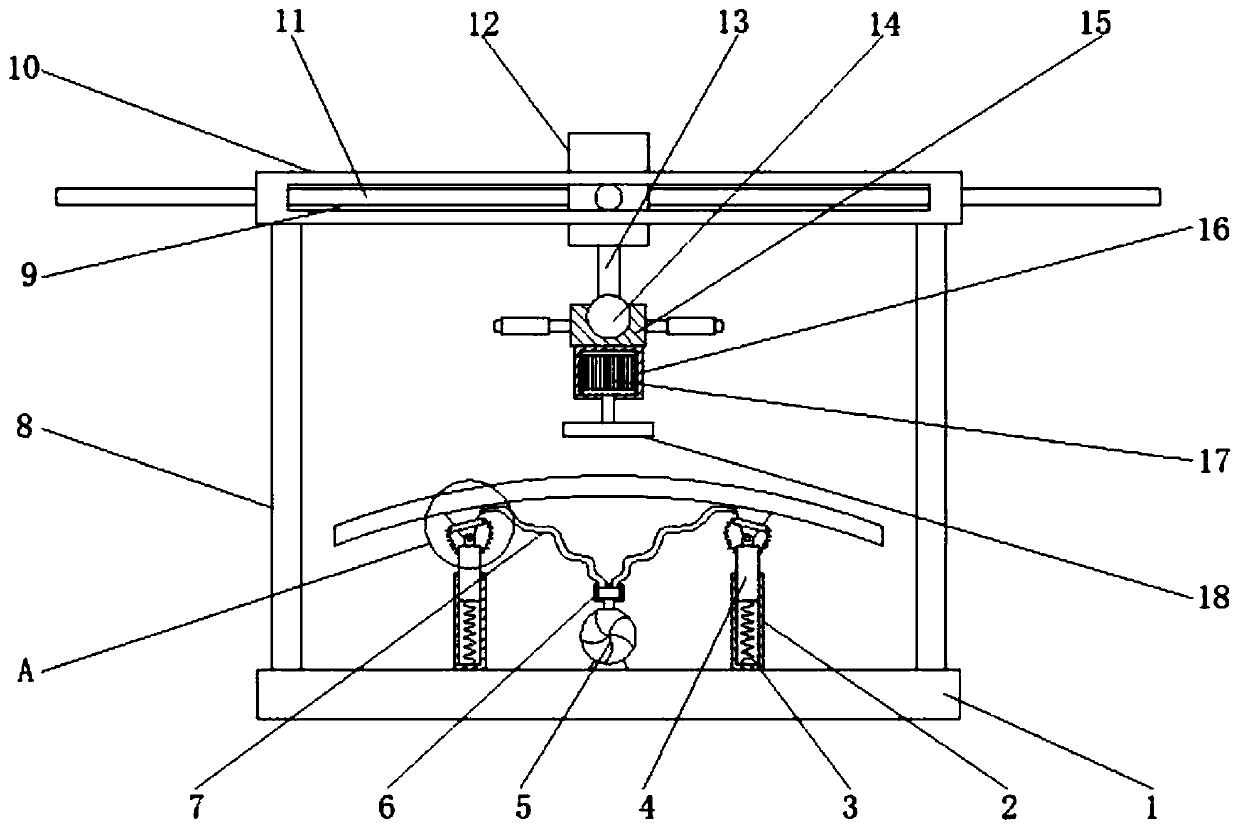

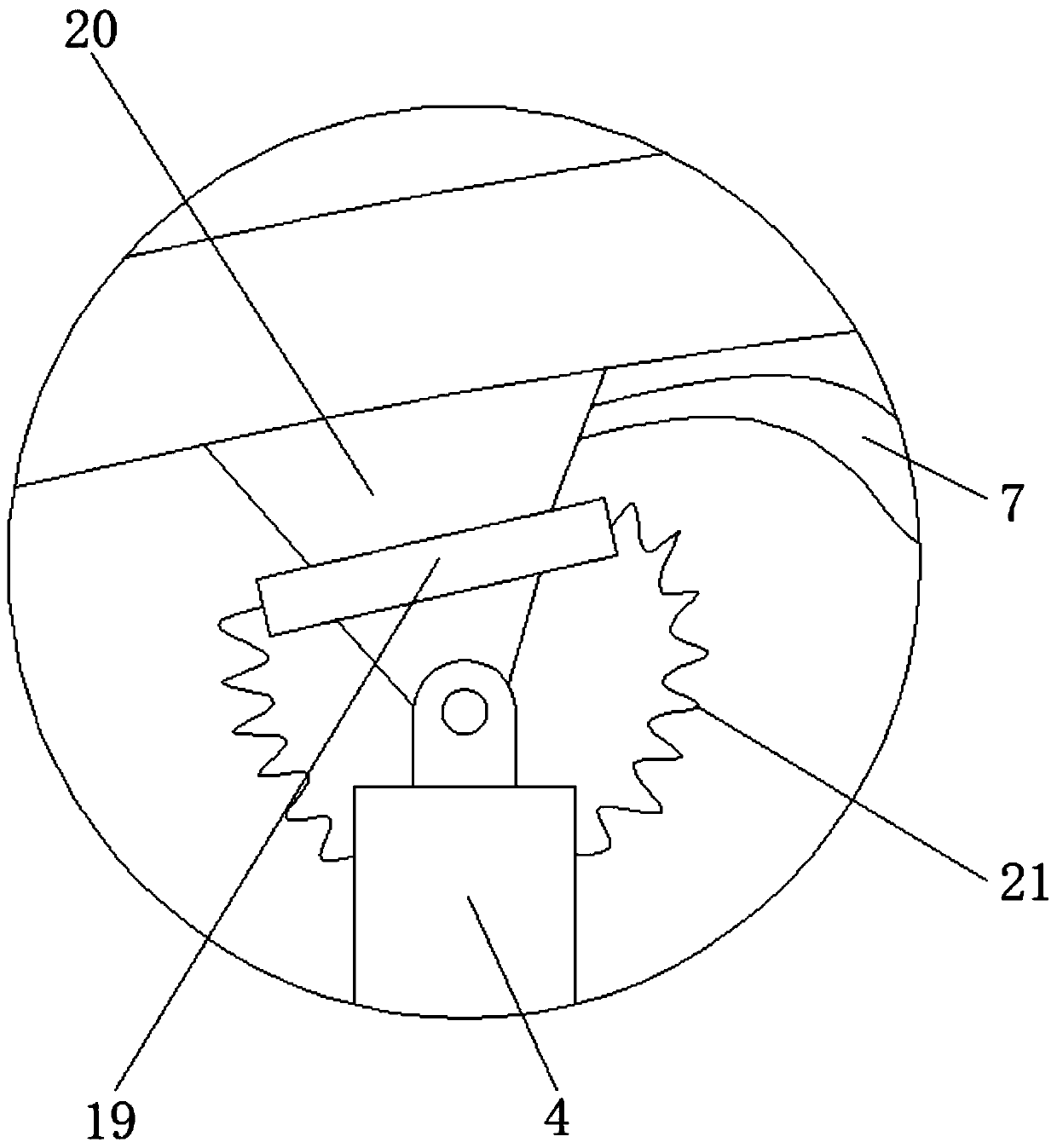

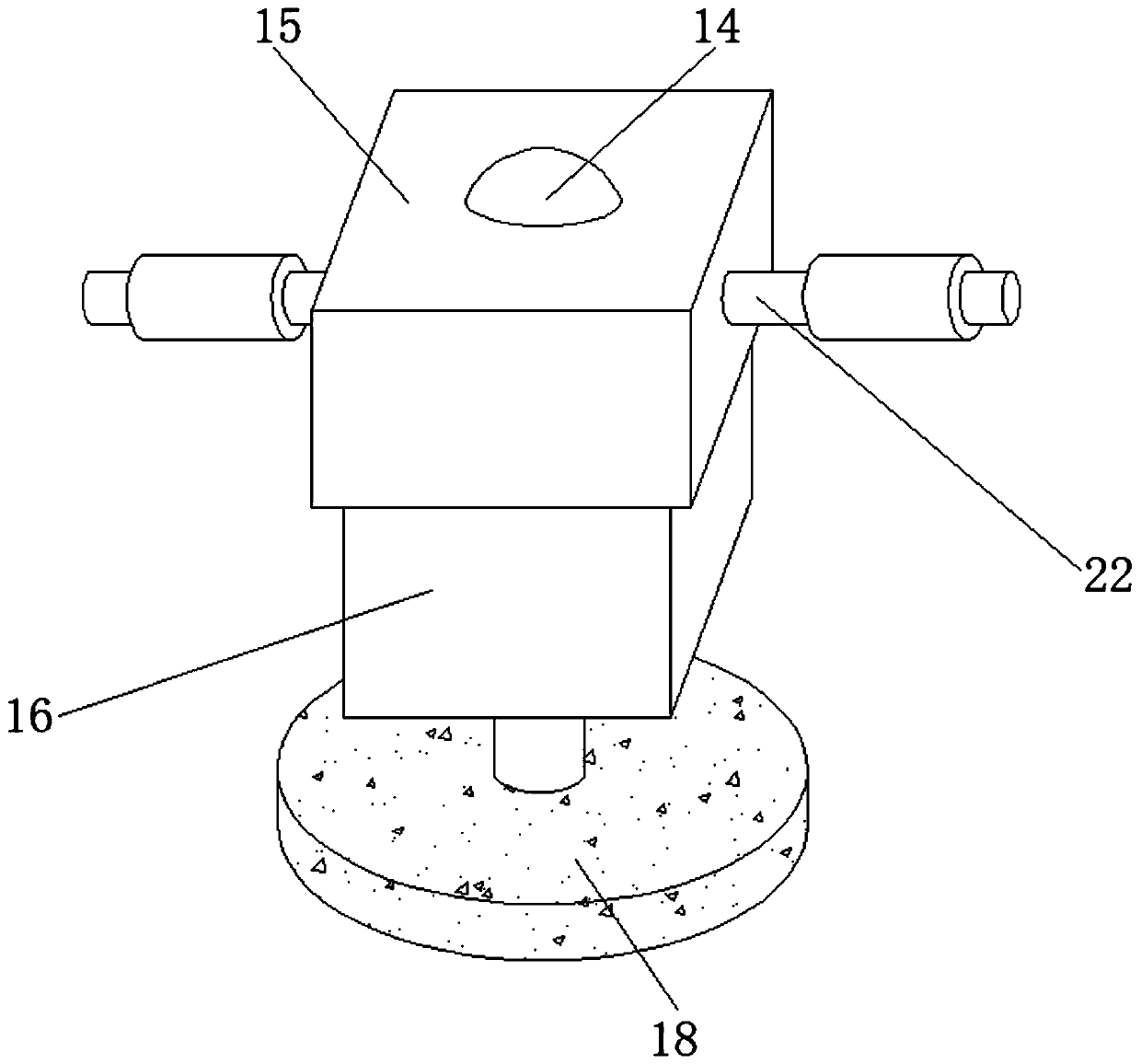

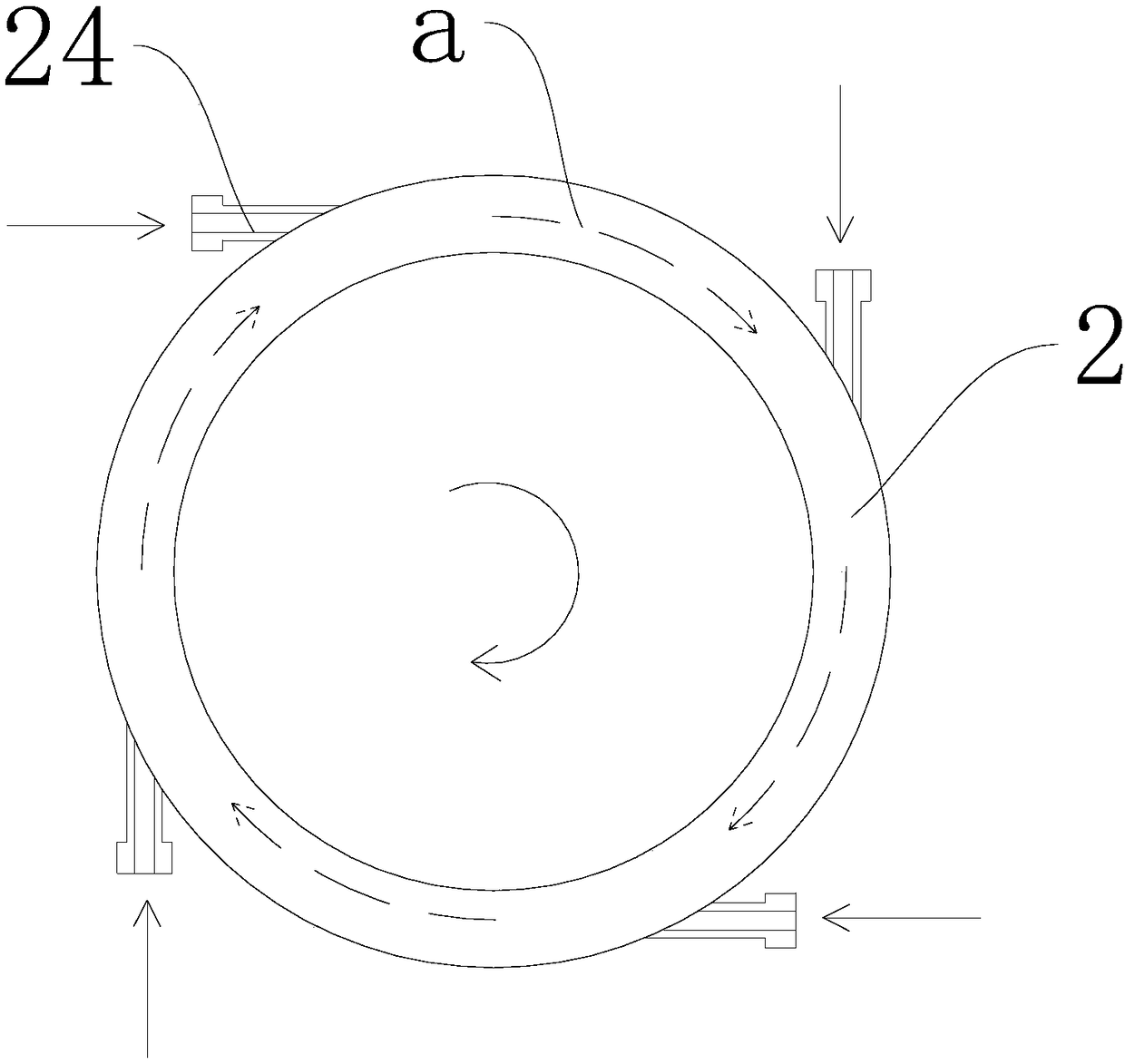

Suspension polishing device with adjustable pressure

PendingCN108705411ASolve the problem of unstable surface pressureStable polishingOptical surface grinding machinesGrinding drivesGear transmissionMotor shaft

The invention relates to a suspension polishing device with the adjustable pressure, and belongs to the field of ultra-precision polishing. The suspension polishing device comprises a magnetic-suspension micro-displacement mechanism, a polishing plate mechanism, a fixture maintenance platform mechanism and a motor transmission mechanism; a first electromagnet and a second electromagnet are mountedat the bottoms of a polishing plate and a polishing container, the polishing plate is fixed at the upper end of a polishing tray, and a second spindle is fixed at the lower end of the polishing tray;the fixture maintenance platform is fixed on the wall of the polishing container through a fixing piece, a rotating fixture is placed on the bottom platform in a hole in the fixture maintenance platform, a workpiece maintenance plate is clamped in the rotating fixture, a pressure sensor is arranged at the bottom of the workpiece maintenance platform, and a sliding block of a gear transmission part is connected with a groove of the fixture maintenance platform and meshed with the gear teeth of the rotating fixture; and a motor is mounted on a supporting frame, and a motor shaft penetrates through a rolling bearing and is connected with a gear tooth rotating part through a coupling, a flat key and a first spindle. The suspension polishing device effectively solves the problem of poor quality of the polishing surface due to the pressure instability and improves the polishing quality.

Owner:KUNMING UNIV OF SCI & TECH

Manufacturing method for sapphire fingerprint recognition panel

ActiveCN105128157ANot suitable for chippingIncrease productivityPolycrystalline material growthAfter-treatment detailsAgricultural engineeringRejection rate

The invention relates to a manufacturing method for a sapphire fingerprint recognition panel. The manufacturing method comprises the specific steps of crystal growth, crystal bar drawing, crystal cutting, laser wafer taking, grinding, chamfering, annealing, double-face polishing, film plating, ink smearing, hot drying and the like. According to the manufacturing method for the sapphire fingerprint recognition panel, the quality of finished wafers is high, the rejection rate is low, and the production efficiency is high.

Owner:清远惠晶科技有限公司

Polishing pad containing interpenetrating liquified vinyl monomer network with polyurethane matrix therein

ActiveUS7833297B2Stable polishingNot susceptibleOther chemical processesAbrasion apparatusSolubilityNetwork structure

Provided is a polyurethane polishing pad. More specifically, the present invention provides a polyurethane polishing pad having an interpenetrating network structure of a vinyl polymer with a polyurethane matrix via radical polymerization and having no pores and gas bubbles. The polyurethane polishing pad having an interpenetrating network structure of a vinyl polymer exhibits uniform dispersibility and reduced changes in hardness of the urethane pad due to heat and slurry, thereby resulting in no deterioration of polishing efficiency due to abrasion heat and solubility in the slurry upon polishing, and also enables a high-temperature polishing operation. Further, according to the present invention, the interpenetrating network structure leads to an improved polishing rate and abrasion performance, thereby significantly increasing the service life of the polishing pad.

Owner:RION SMI

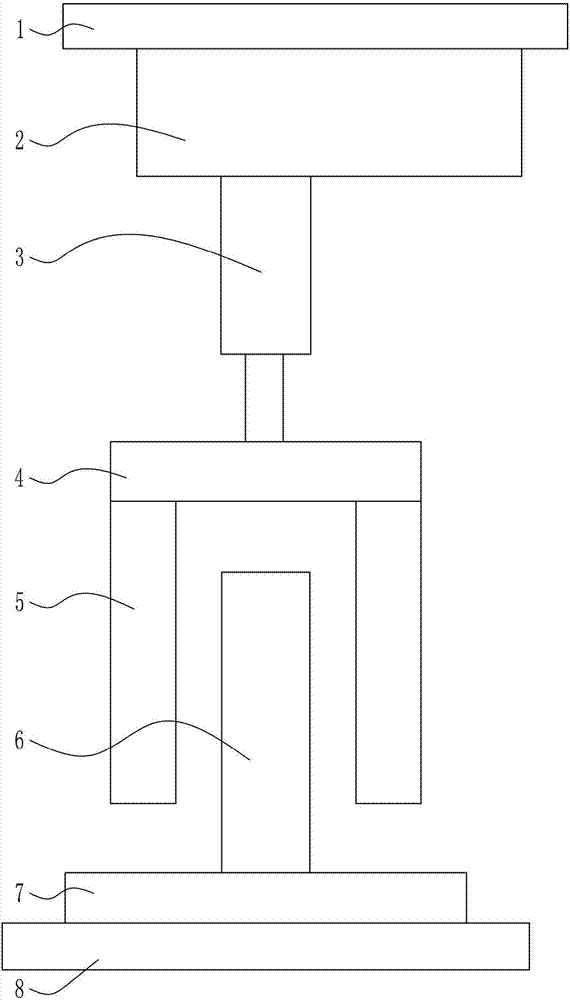

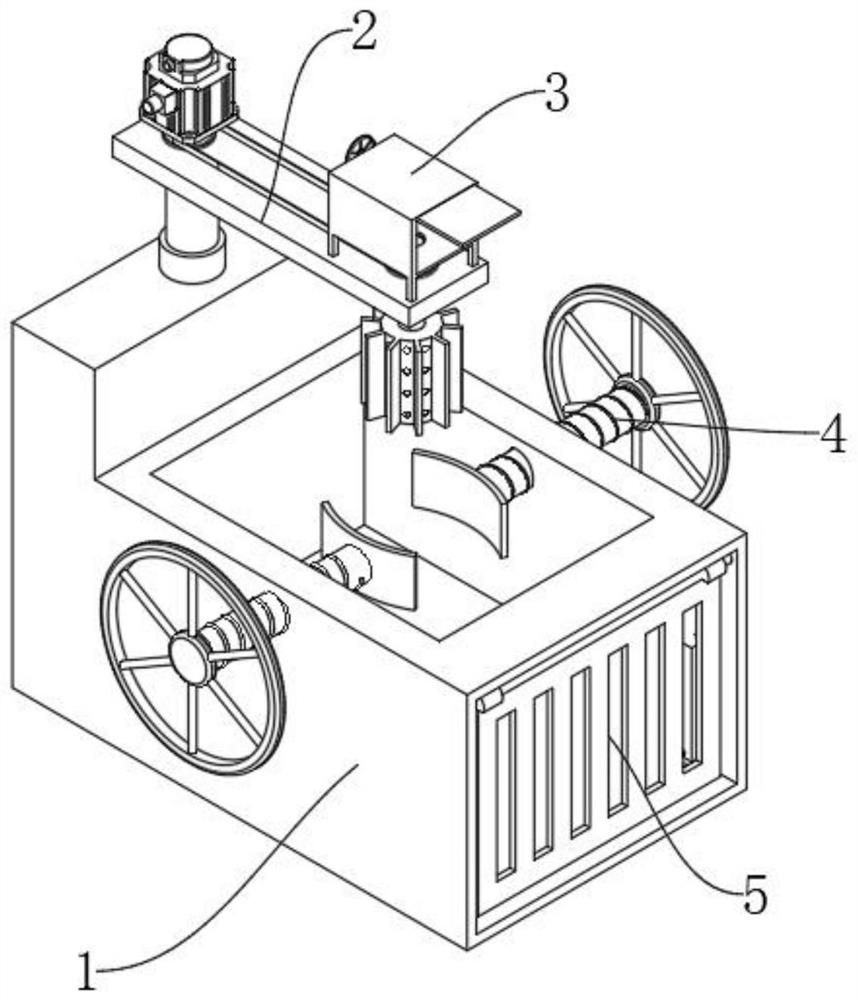

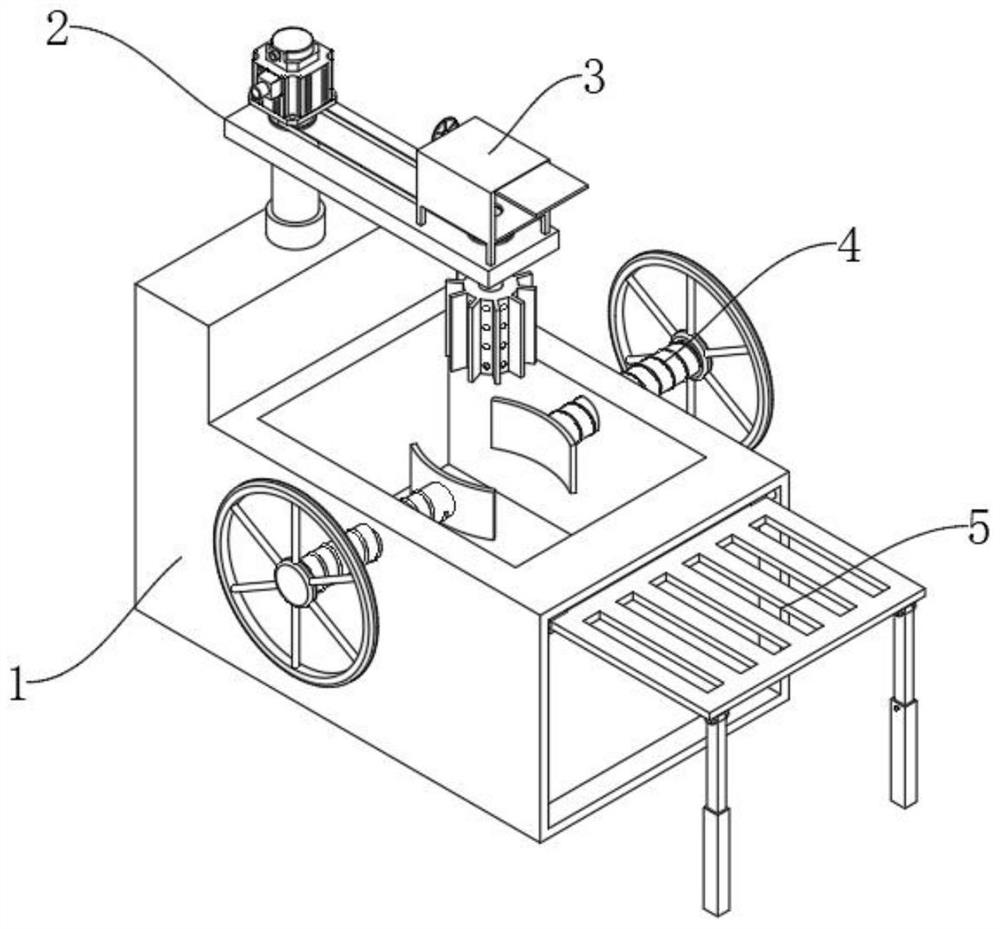

Barrel polishing device for production of water purifiers

PendingCN106956206ANot easy to moveSo as not to damageGrinding carriagesPolishing machinesEngineeringMechanical engineering

The invention relates to a polishing device, particularly to a barrel polishing device for production of water purifiers. The invention aims to provide a polishing device for production of the water purifiers, and the polishing device can be used for polishing a barrel comprehensively, and has the advantages of good polishing effect and easy polishing. In order to achieve the technical effects, the invention provides a barrel polishing device for production of the water purifiers. The barrel polishing device comprises a top plate, a rotating mechanism, a cylinder, a first fixed plate, polishing plates, a fixed barrel, etc.; the bottom of the top plate is provided with the rotating mechanism of which the bottom is provided with the cylinder, and the bottom of the cylinder is provided with the first fixed plate; the left and right sides of the bottom of the first fixed plate are provided with the polishing plates, and a base plate is arranged below the top plate; and the top of the base plate is provided with a second fixed plate. According to the barrel polishing device provided by the invention, the surface of the barrel can be polished evenly and completely, without damage, so that the polishing effect is good; first polishing cloth at the periphery of the fixed barrel plays a certain role in polishing the inner side of the barrel.

Owner:施亮

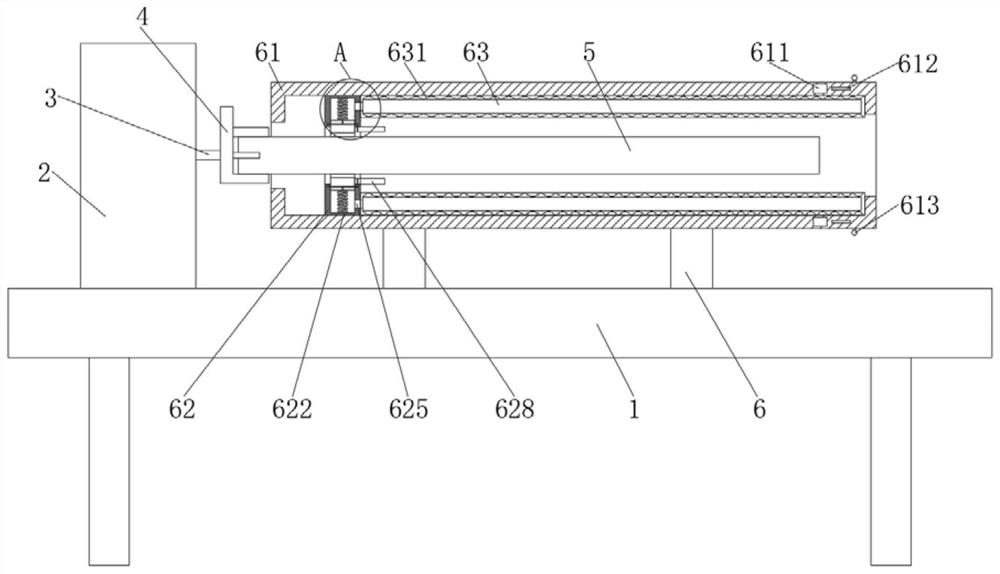

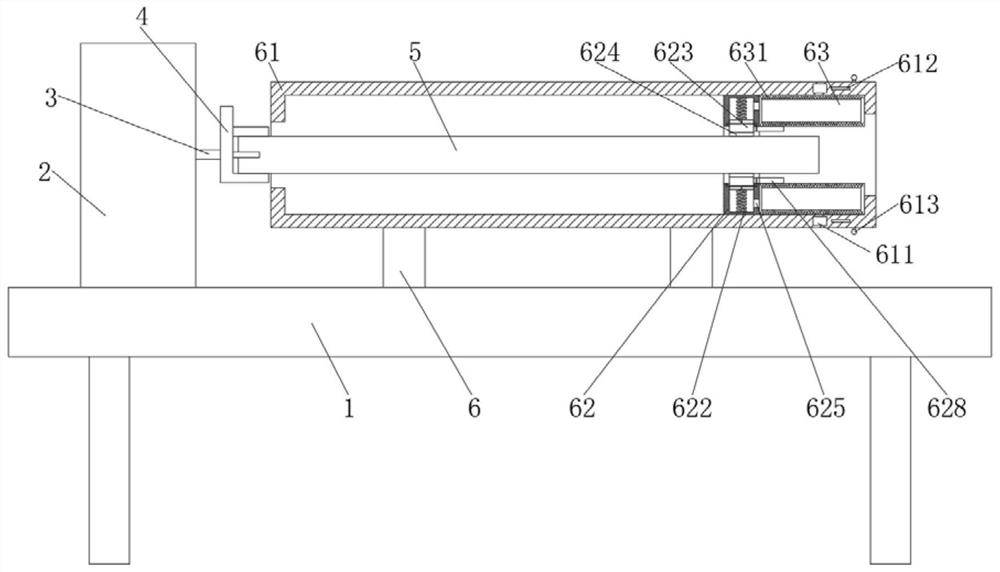

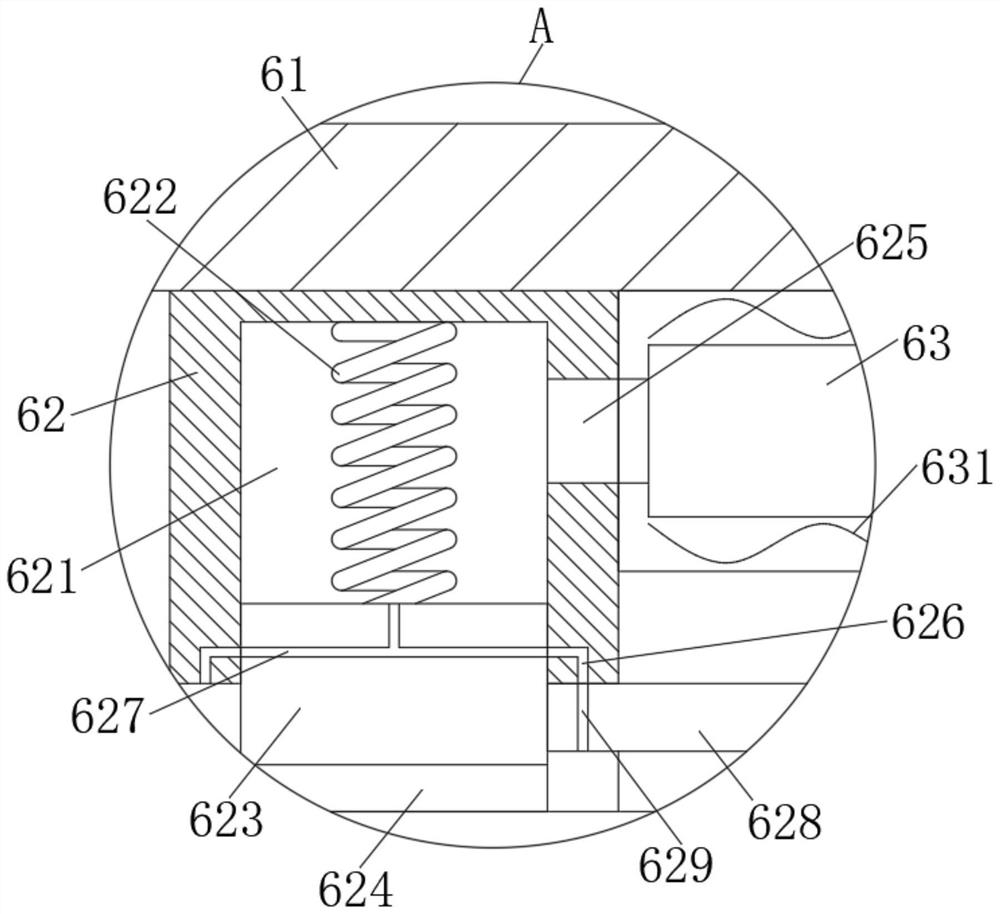

A stable gap device for long-distance polishing

InactiveCN102284911AStable polishing processImprove polishing qualityOptical surface grinding machinesGrinding/polishing safety devicesEngineeringPressure sensor

The invention discloses a long-range polishing stable-clearance device, which belongs to the technical field of optical cold machining. The device comprises a control valve, a flow sensor, a pressure sensor, a rotary connector, a main shaft, a piezoceramic stack, a frame, a liquid-spraying grinding head and a controller. Adverse influence on a polishing process because of low precision of a machine tool, clamping and a workpiece surface is avoided by keeping distance between the liquid-spraying grinding head and the workpiece surface in the device; the polishing process is more stable; and the polishing quality is improved. At the same time, under the condition of not changing a process, the requirement on the precision of the machine tool and clamping is reduced.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Steel pipe polishing equipment with scrap removing and reminding functions

InactiveCN114406888AAvoid scratchesIncrease gas pressureGrinding carriagesPolishing machinesPolishingPipe

The invention relates to the technical field of steel pipe machining, and discloses scrap-removing and reminding steel pipe polishing equipment which comprises a rack, a clamping mechanism, a steel pipe and a supporting rod, and a polishing barrel is fixedly connected to the top of the supporting rod. By designing the polishing barrel, the moving block, the sliding cavity, the sliding block, the polishing block and the air bag, when a steel pipe is polished, the telescopic rod is used for controlling the moving block to slide to extrude the air bag, so that air in the air bag enters the sliding cavity, and the sliding block is promoted to drive the polishing block to move downwards; meanwhile, heat generated by friction between the steel pipe and the polishing block during polishing is used for promoting the gas pressure in the sliding cavity to be increased, the sliding block is promoted to drive the polishing block to be attached to the steel pipe more tightly, and the steel pipe is polished; and high-pressure gas in the sliding cavity is exhausted, powder and chippings generated when the steel pipe is polished are blown away, and the polished outer surface is prevented from being scratched.

Owner:冯星星

Cambered surface burnishing device for machining inner wall of crane hydraulic oil cylinder body

InactiveCN112025522AHealth hazardEasy to fixOffice stoolsPolishing machinesHydraulic ramCylinder block

The invention relates to the technical field of burnishing devices, in particular to a cambered surface burnishing device for machining the inner wall of a crane hydraulic oil cylinder body. The burnishing device comprises a burnishing frame. A side plate is arranged at the top of the burnishing frame, an electric push rod is arranged at the top of the side plate, a movable plate is arranged on apiston rod of the electric push rod, a rotating rod is rotationally arranged on the surface of the movable plate, a dust collecting box is rotationally arranged at the top of the rotating rod, the bottom of the rotating rod communicates with a burnishing roll, a plurality of burnishing plates are arranged on the outer wall of the burnishing roll, a plurality of through holes are formed in the outer wall of the burnishing roll and communicate with the interior of the dust collecting box, a fixed slot is formed in the top of the burnishing frame, both sides of the fixed slot are in threaded connection with fixing devices, the fixing devices are located right under the burnishing roll, a cambered plate is rotationally arranged at the end part of a corresponding screw, and a folding stool is rotationally arranged in a folding groove in the outer wall of the burnishing frame. According to the burnishing device, dust can be conveniently collected, hydraulic oil cylinder bodies of different sizes can be fixed, and workers can have a rest on the burnishing device.

Owner:铁美珍

High-precision polishing equipment for automobile parts

InactiveCN111002204AFlexible angle adjustmentMove up and down to save effortGrinding carriagesPolishing machinesElectric machineryBolt connection

The invention discloses high-precision polishing equipment for automobile parts. The equipment comprises a bottom plate; fixing rods are welded to the four corners of the outer wall of the top of thebottom plate correspondingly; a fixed frame is welded to the outer walls of the tops of the fixing rods; slide grooves are formed in the outer walls of the periphery of the fixed frame; the inner walls of the slide grooves are slidably connected with a sliding rod; a movable box is welded to the outer wall of one end of the sliding rod; a third spring is welded to the inner wall of the top of themovable box; a lifting plate is welded to the outer wall of the bottom of the third spring; a connecting rod is welded to the outer wall of the bottom of the lifting plate; a universal ball is weldedto the outer wall of the bottom of the connecting rod; a movable base is rotatably connected to the outer wall of the universal ball; a motor cover is welded to the outer wall of the bottom of the movable base; and a motor is connected to the inner wall of the motor cover through bolts. With the equipment of the invention adopted, automobile parts with different radians can be polished, and the automobile parts can be firmly adsorbed to suction cups. The equipment has the advantages of higher flexibility in use, higher stability in polishing and better polishing effect.

Owner:王菊

Chemical-mechanical polishing equipment for semiconductor wafers

ActiveCN108098564AVibration isolationEasy to monitorSemiconductor/solid-state device manufacturingLapping machinesDevice formEngineering

The invention relates to chemical-mechanical polishing equipment for semiconductor wafers. The equipment comprises a wafer clamping assembly, a grinding pulp control device and a CMP device arranged in sequence from top to bottom. The equipment is simple in structure, discards a traditional grinding machine structure, and dose not directly control lifting of a main shaft of a motor which controlsrotation of the wafers; a mounting cylinder is provided; a wafer levelness checking device and the main shaft of the motor are linked and arranged in the mounting cylinder together; a single linear drive of the mounting cylinder is directly lifted, so that the precision is higher, the vibration problem of the motor is isolated, and the engagement problem at the contact moment can be solved; and meanwhile, the grinding pulp control device forms homogenous annular water film layers between the wafers and polishing plates, so that the air gap problem can be prevented, the polishing process can bestabilized, the laser interference monitoring is convenient, and the polishing precision is improved.

Owner:汉斯半导体(江苏)有限公司

Wafer protection tape cutting apparatus, back lapping equipment, and wafer protection tape cutting method using the same

InactiveUS20080121347A1Avoid it happening againAvoid breakingLamination ancillary operationsLaminationLight irradiationElectrical and Electronics engineering

A wafer protection tape cutting apparatus comprises: a chuck on which a wafer is held, the chuck being rotatable at a predetermined speed and being movable up and down; a protection tape supply unit for supplying a protection tape to be attached onto a top side of the wafer and to cover an upper part of the chuck; a light irradiation unit for irradiating light to harden a bonding agent of the protection tape, along an outer circumference part of the wafer; and a tape cutting unit for cutting the protection tape positioned at the outer circumference part of the wafer. The present invention also provides back lapping equipment having the wafer protection tape, and a wafer protection tape cutting method using the wafer protection tape cutting apparatus.

Owner:SAMSUNG ELECTRONICS CO LTD

Adjustable circular optical device positioning fixture

InactiveCN106346390AProcessing quality meetsReach the processing quality to meet the requirementsWork holdersGrinding work supportsMachining processEngineering

The invention discloses an adjustable circular optical device positioning fixture. The adjustable circular optical device positioning fixture comprises adjustable clamping blocks (1), wherein a single side or dual sides of the adjustable clamping block (1) are provided with semicircular holes which are distributed uniformly; the plurality of adjustable clamping blocks (1) are assembled together, so that corresponding semicircular holes in adjacent adjustable clamping blocks (1) are combined into workpiece holes (2); the positioning fixture constructed by the plurality of adjustable clamping blocks (1) is provided with a mandrel hole (3); a mandrel (4) is inserted into the mandrel hole to fix the plurality of adjustable clamping blocks (1) in order to construct the positioning fixture; the workpiece holes (2) can accommodate workpieces of different apertures by adjusting the tightness of the mandrel (4). In the positioning fixture, the workpiece holes (2) can accommodate the workpieces of different apertures by adjusting the tightness of the mandrel (4), workpieces to be machined are prevented from moving and deviating in a machining process, and ports of protruding ends of the workpieces can be ground or polished stably, so that the requirement on machining quality of the workpieces to be machined is met.

Owner:YIXING JINGKE OPTICAL INSTR

Airbag polishing tool, system and method

ActiveCN104369064BFulfill process requirementsStable polishingPolishing machinesOptical surface grinding machinesContact pressurePositive pressure

The invention discloses an air bag polishing tool and system and method. The air bag polishing tool comprises a motor, a speed reducer, a hollow rotating shaft and an air bag, wherein the motor, the speed reducer, the hollow rotating shaft and the air bag are sequentially connected. The hollow rotating shaft is provided with a hollow cavity, the two ends of the hollow cavity are communicated to the air bag and a ventilation guide pipe respectively, and an electrical proportional valve is arranged on the ventilation guide pipe. The air bag polishing tool further comprises a pressure intensity sensor for detecting the pressure intensity of air in the air bag and a pressure sensor for detecting the positive pressure of the tool. By means of the air bag polishing tool, based on the electrical proportional valve, the contact pressure and the contact pressure intensity of a polished surface can be controlled in real time, the air bag polishing tool can meet the requirements of different machined surfaces for different machining pressures, the machining accuracy can be improved, the polishing process can be simplified, the machining cost can be reduced, and the air bag polishing tool is simple in structure and easy to control.

Owner:江苏拓域智能装备有限公司

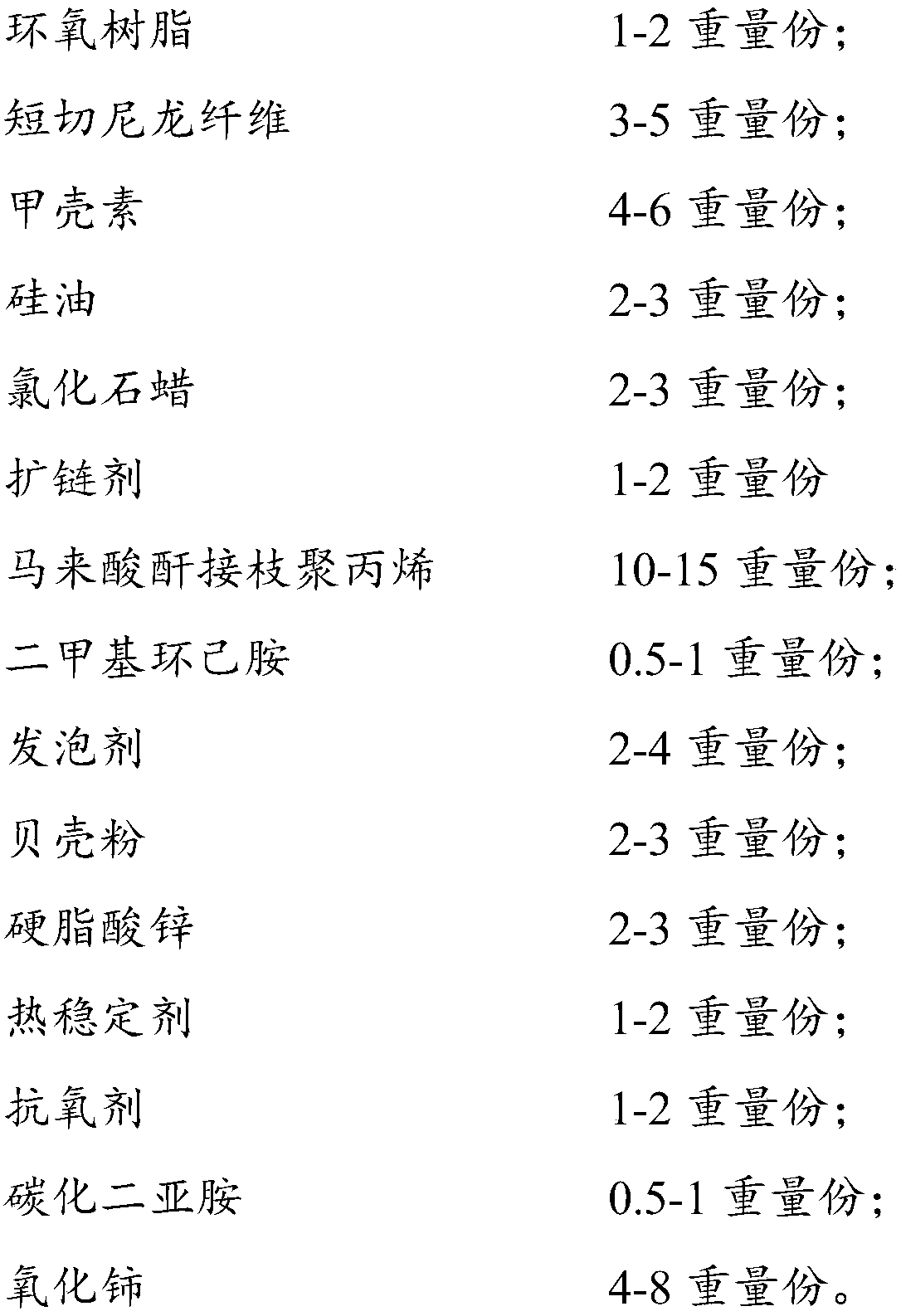

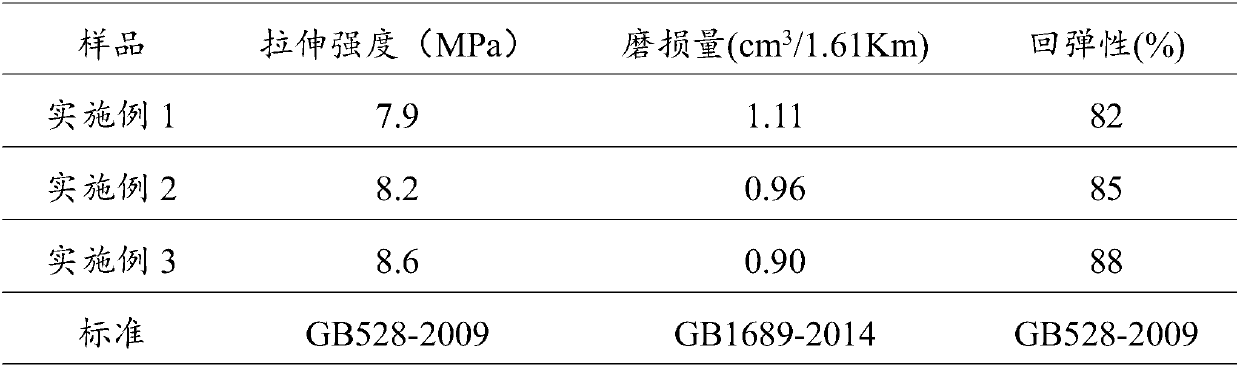

Optical polishing material

The invention relates to an optical polishing material, belongs to the technical field of polishing materials and solves the technical problem that a polyurethane polishing pad is hard and brittle andis lack of toughness and elasticity in the prior art. The optical polishing material is prepared from components in parts by weight as follows: 100 parts of polyether polyol, 100 parts of diisocyanate, 1-2 parts of bisphenol A epoxy resin, 3-5 parts of chopped nylon fiber, 4-6 parts of chitin, 2-3 parts of silicone oil, -3 parts of chlorinated paraffin, 1-2 parts of ethylene glycol, 10-15 parts of maleic anhydride grafted polypropylene, 0.5-1 part of dimethylcyclohexylamine, 2-4 parts of acetone, 2-3 parts of shell powder, 2-3 parts of zinc stearate, 1-2 parts of tris(2,4-ditert-butylphenyl)phosphite, 1-2 parts of antioxidant 1010, 0.5-1 part of carbodiimide and 4-8 parts of cerium oxide. The optical polishing material has high tensile strength and good rebound resilience, wear resistance and die assembly performance, and is not prone to passivation.

Owner:CHANGCHUN A&Z SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com