Semiconductor polishing compound

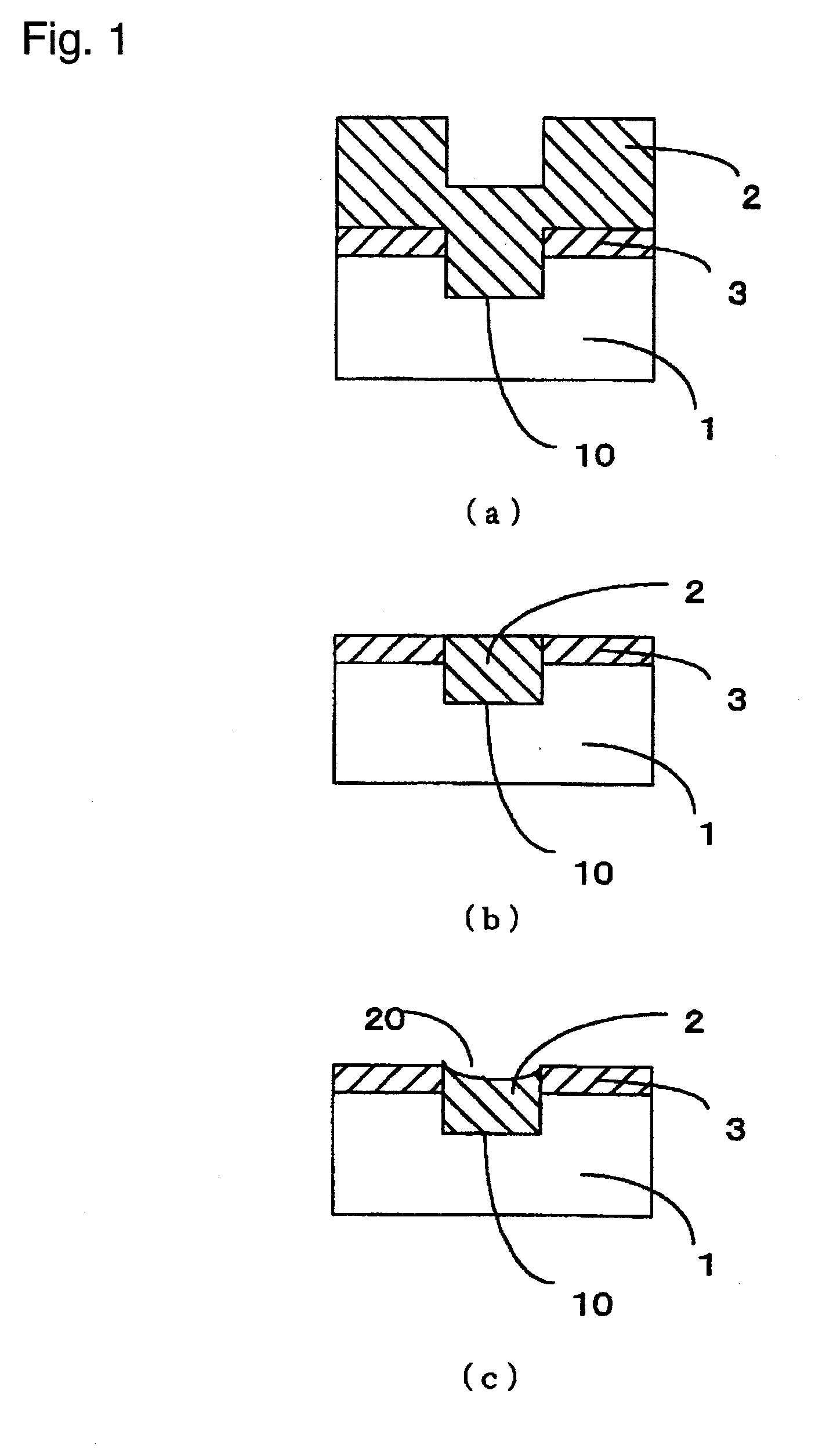

a technology of semiconductors and polishing compounds, applied in lapping machines, other chemical processes, manufacturing tools, etc., can solve the problems of uneven surface (difference in level) in each layer of the production process, inability to planarize properly, and electrical performance tend to deteriorate, so as to achieve excellent dispersion stability and removal rate, and less susceptible to influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

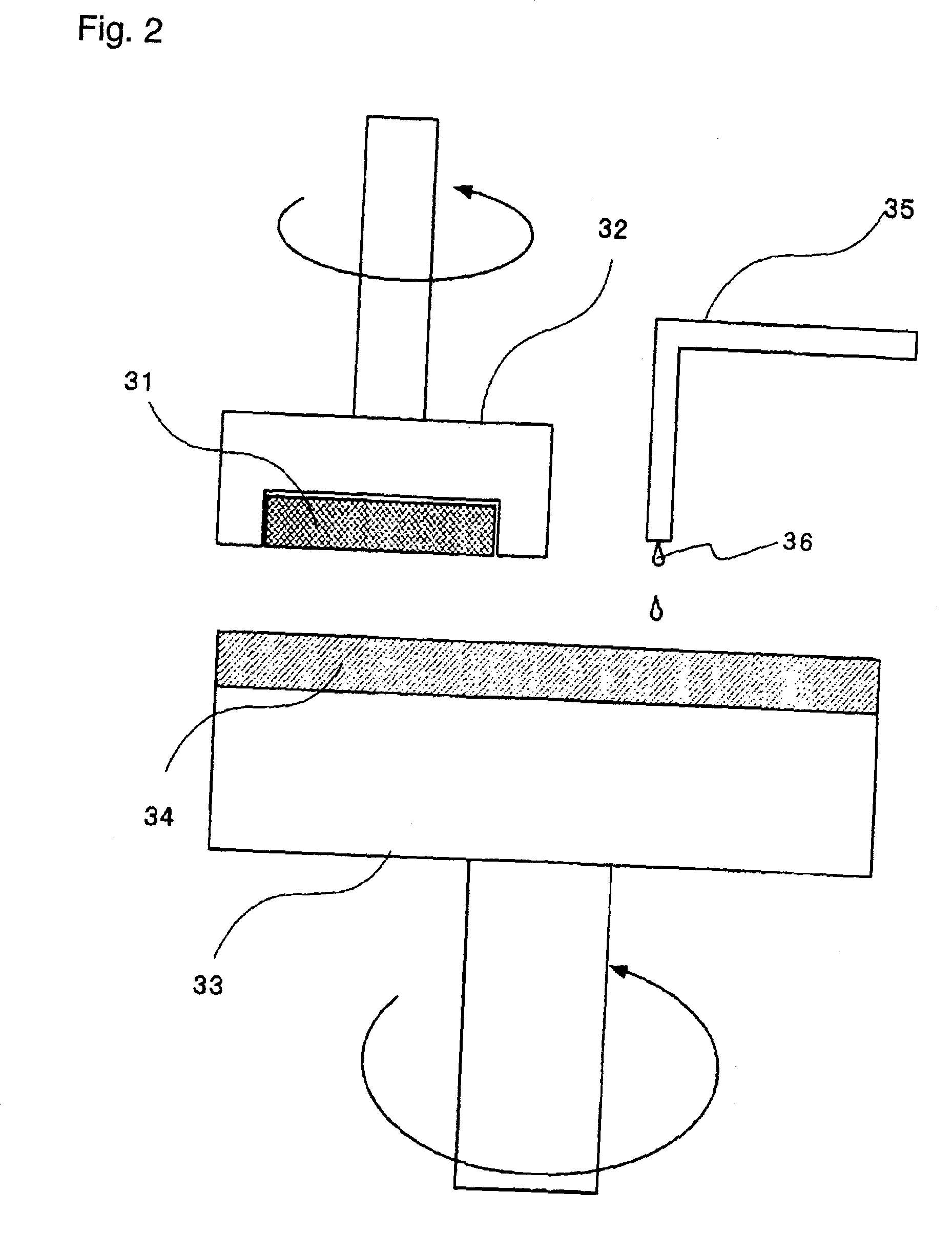

Method used

Image

Examples

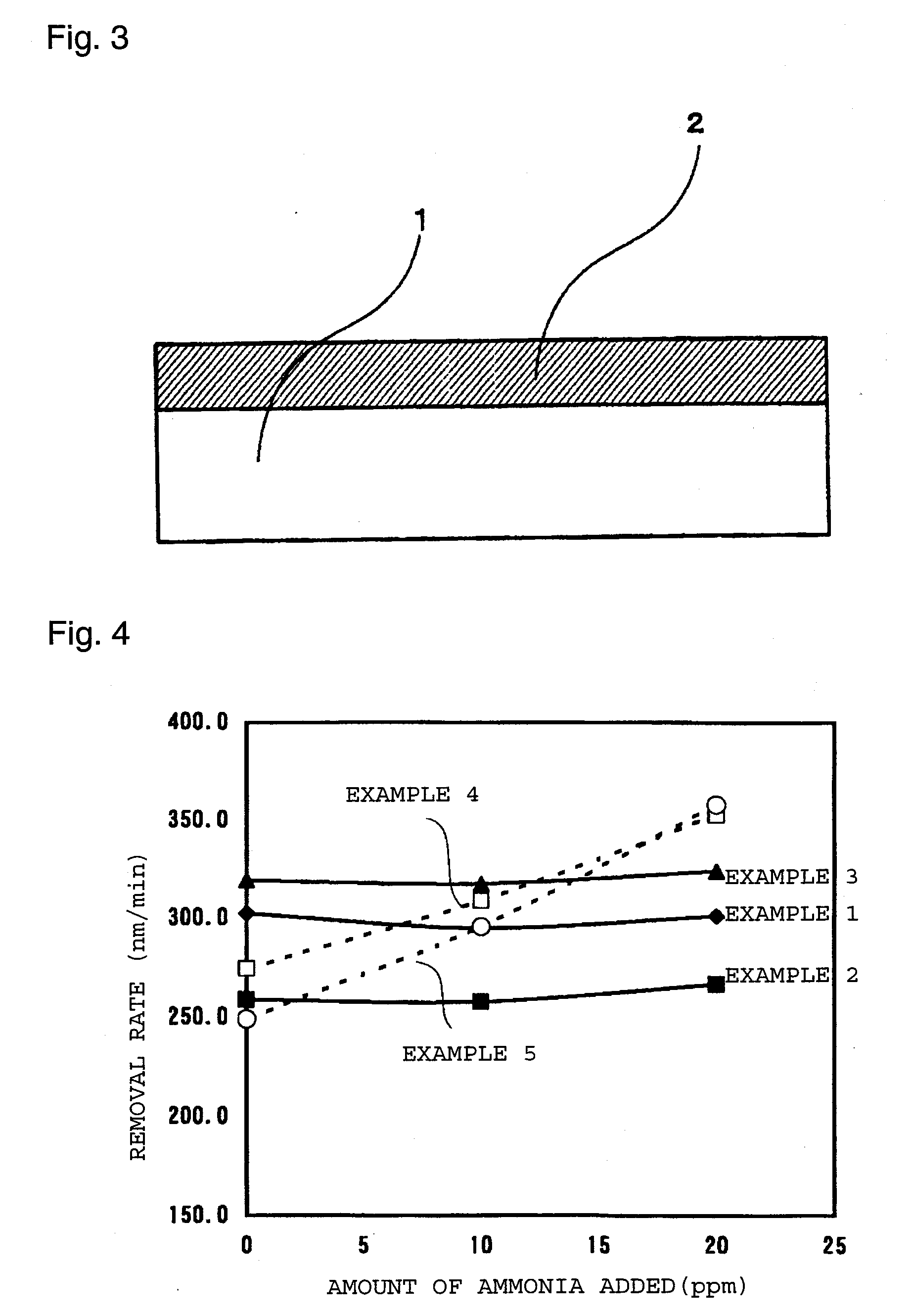

example 1

[0087] Cerium oxide abrasive particles and, as an additive, an ammonium polyacrylate having a molecular weight of 5,000 were mixed in a mass ratio of 100:0.7 in deionized water with stirring, and subjected to ultrasonic dispersion and filtering to obtain a mixture having a concentration of abrasive particles of 10% by mass ratio and a concentration of the additive of 0.07%. This mixture was diluted five times with deionized water to prepare an abrasive particle mixed liquid A having an abrasive particle concentration of 2% and an additive concentration of 0.014%. The abrasive particle mixed liquid A had a pH of 7.6 and an average particle diameter of 0.18 μm.

[0088] Then, an ammonium polyacrylate having a molecular weight of 5,000 was dissolved in deionized water, and the pH adjustment was carried out by adding malonic acid (pKa2=5.28) to bring the pH to from 4.7 to 5.0, to prepare an additive liquid B having an ammonium polyacrylate concentration of 0.289% and a malonic acid concen...

example 2

[0090] An additive liquid C was prepared in the same manner as the preparation of the additive liquid B in Example 1 except that instead of malonic acid, adipic acid (pKa2=5.03) was used, and the concentration of adipic acid was adjusted to be 0.272%. This additive liquid C and the abrasive particle mixed liquid A prepared in the same manner as in Example 1 were mixed in a mass ratio of 1:1 with stirring to prepare a polishing compound having an abrasive particle concentration of 1%, an adipic acid concentration of 0.136% and a pH of 4.90.

example 3

[0091] An additive liquid D was prepared in the same manner as the preparation of the additive liquid B in Example 1 except that instead of malonic acid, succinic acid (pKa2=5.24) was used, and the concentration of succinic acid was adjusted to be 0.198%. This additive liquid D and the abrasive particle mixed liquid A prepared in the is same manner as in Example 1 were mixed in a mass ratio of 1:1 with stirring to obtain a polishing compound having an abrasive particle concentration of 1%, a succinic acid concentration of 0.099% and a pH of 5.06.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com